Composite material for automobile interior part and production method thereof

A technology of automotive interior parts and composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

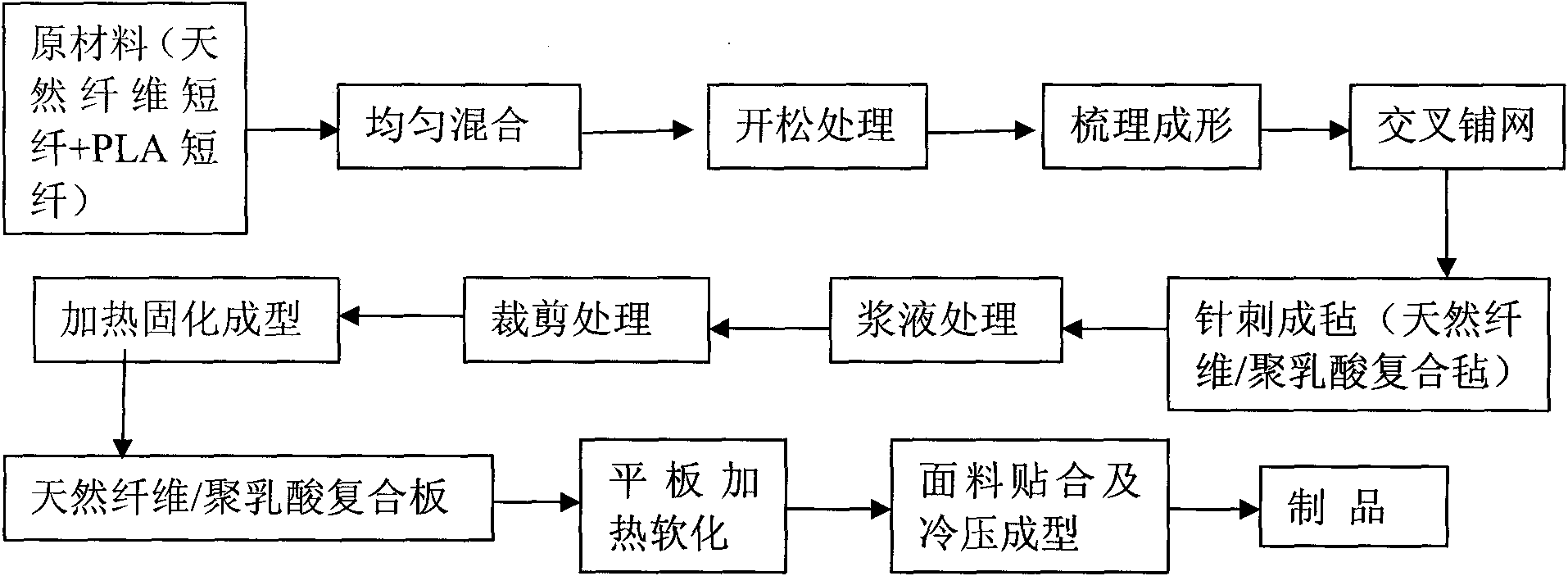

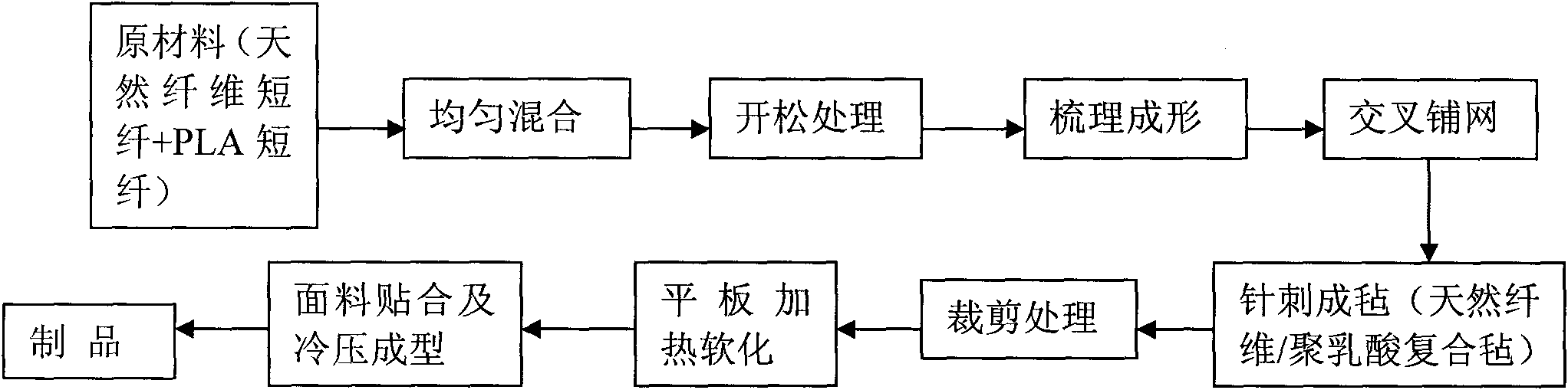

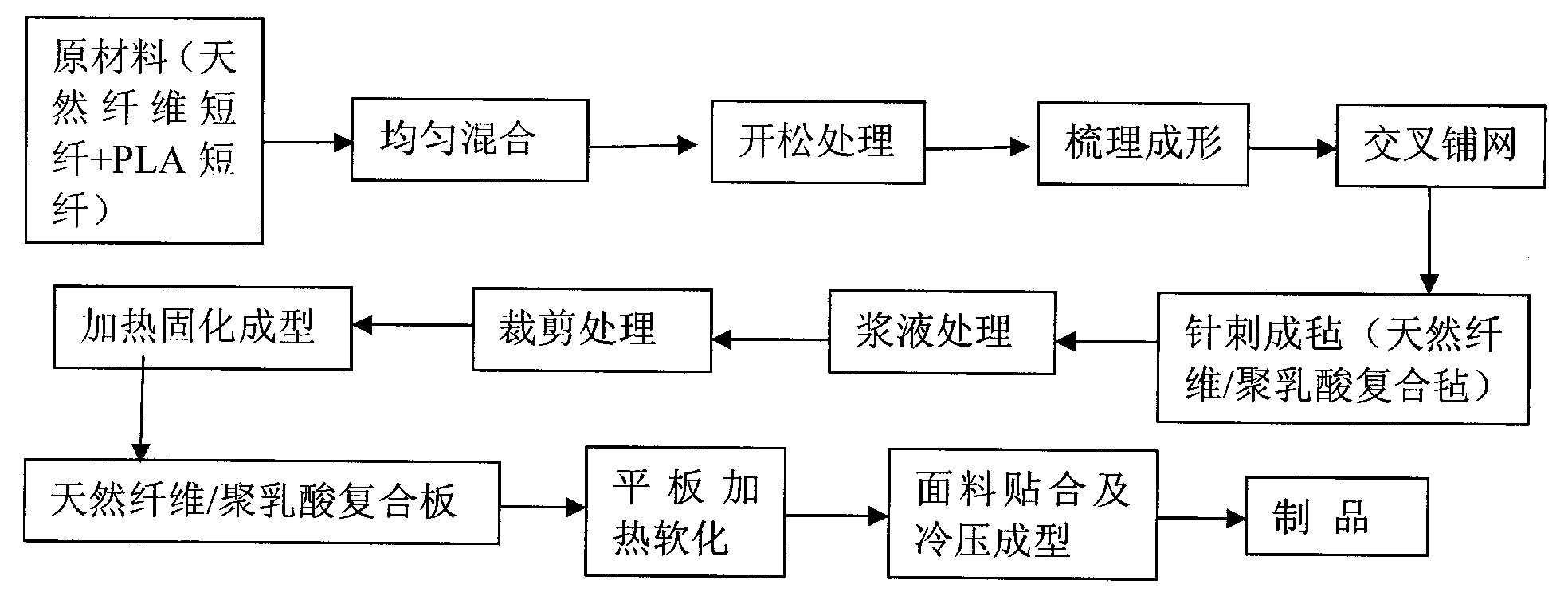

Method used

Image

Examples

Embodiment 1

[0035] Weigh the raw material (kg) according to the following weight:

[0036] Polylactic acid fiber 40, jute fiber 60;

[0037] Methods of producing automotive interior composites:

[0038] (1) the jute fiber of 7-15cm and 40 kilograms of 8-12cm polylactic acid fiber are evenly mixed by 60 kilograms of length;

[0039] (2) Put the mixed fiber into the opener to open and mix, mix for 30s, and then send it into the cotton box;

[0040] (3) The loosened and mixed fibers stored in the cotton box are transported to the carding machine by airflow for carding;

[0041] (4) The fiber after carding is sent to cross-lapping in the web-laying machine;

[0042] (5) After the laid net is folded according to the required requirements, it is sent into the pre-needling machine for pre-needling into felt;

[0043] (6) Send the pre-needled mat to the main needling machine for main needling. After reaching the predetermined gram weight, heat and pre-press it into a coil. The heating tempera...

Embodiment 2

[0048] Weigh the raw material (kg) according to the following weight:

[0049] Polylactic acid fiber 50, hemp fiber 30, flax 20;

[0050] Methods of producing automotive interior composites:

[0051] (1) 30 kilograms of length are the hemp fiber of 7-15cm, the flax fiber of 20 kilograms of length 7-15cm and 50 kilograms of 8-12cm polylactic acid fiber are evenly mixed;

[0052] (2) Put the mixed fiber into the opener to open and mix, mix for 40s, and then send it into the cotton box;

[0053] (3) Transport the loosened and mixed fibers stored in the cotton box to the carding machine for carding;

[0054] (4) The fiber after carding is sent to cross-lapping in the web-laying machine;

[0055] (5) Fold the laid net and send it into the pre-needling machine for pre-needling into felt;

[0056] (6) Send the pre-needled mat to the main needling machine for main needling. After reaching the predetermined gram weight, heat and pre-press it into a coil. The heating temperature is ...

Embodiment 3

[0059] Weigh the raw material (kg) according to the following weight:

[0060] Polylactic acid fiber 60, ramie fiber 20, sisal fiber 10, kenaf fiber 10;

[0061] Methods of producing automotive interior composites:

[0062] (1) the ramie fiber of 7-15cm, the sisal fiber of 7-15cm, the kenaf fiber of 7-15cm and the polylactic acid fiber of 60 kilograms of 8-12cm are evenly mixed in 10 kilograms of lengths by 20 kilograms of lengths;

[0063] (2) Put the mixed fiber into the opener to open and mix, mix for 20s, and then send it into the cotton box;

[0064] (3) The loosened and mixed fibers stored in the cotton box are transported to the carding machine by airflow for carding;

[0065] (4) The fiber after carding is sent to cross-lapping in the web-laying machine;

[0066] (5) After the laid net is folded according to the required requirements, it is sent into the pre-needling machine for pre-needling into felt;

[0067] (6) Send the pre-needled mat to the main needling mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com