Method for exploiting natural gas hydrates and device thereof

A technology for hydrate and natural gas, which is applied in the mining of minerals, mining fluids, and earth-moving drilling, etc., can solve the problems of increased mining cost, slow replacement reaction speed, and complicated mining equipment, and achieves energy saving in transportation and fast decomposition rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

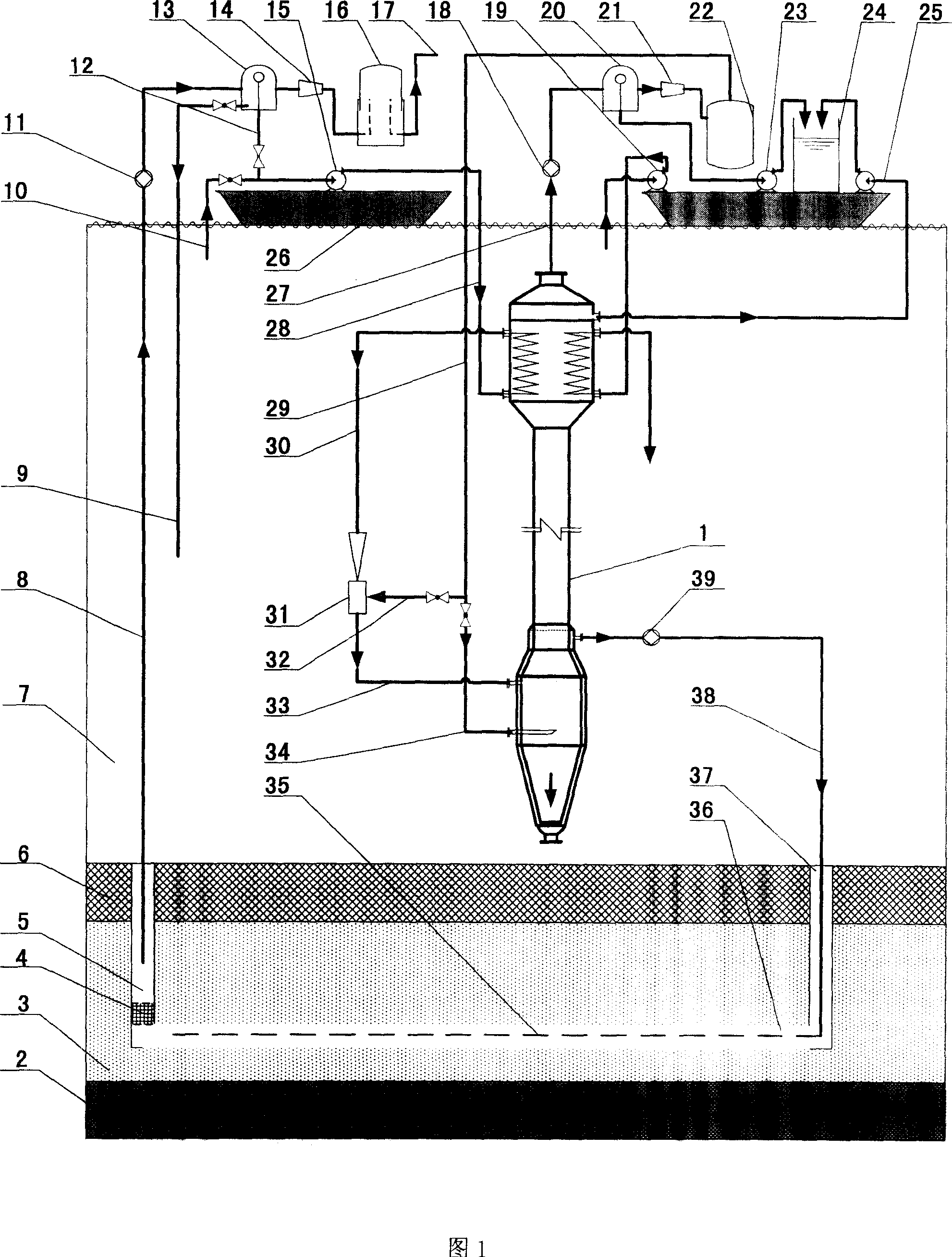

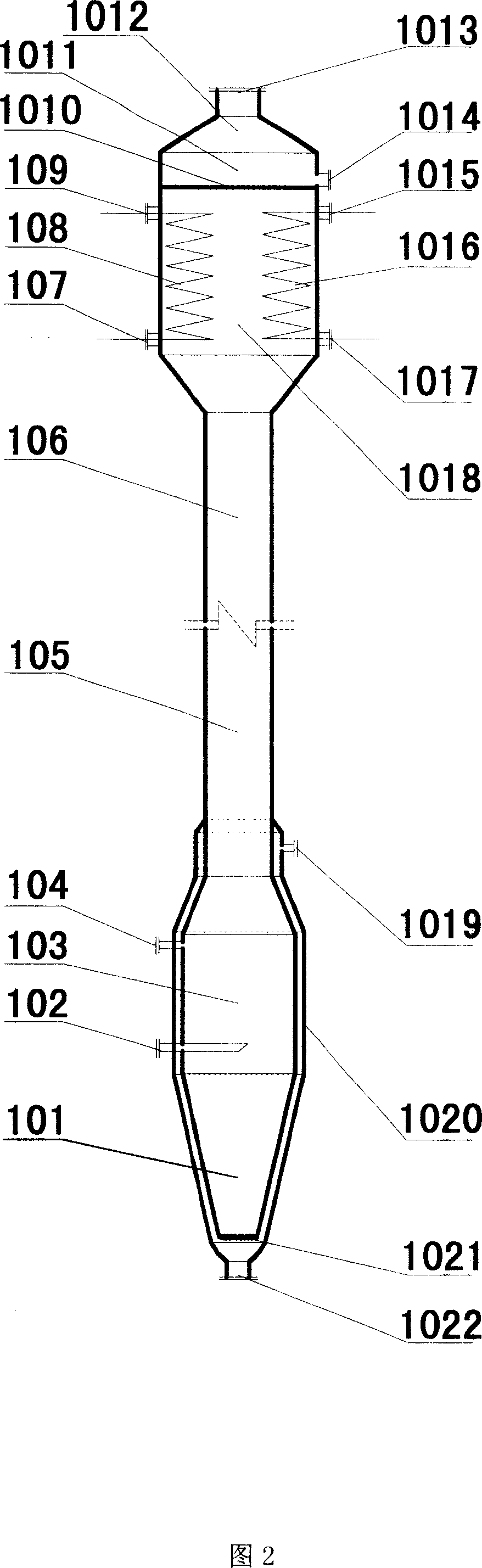

[0056] As shown in Figures 1 and 2, firstly, on the seabed rock layer 2, the hydrate production well 37, the gas collection well 5 and the connection between the production well 37 and the gas hydrate reservoir 3 are constructed on the seabed rock layer 2. The horizontal well 36 is located in the natural gas hydrate reservoir 3, the sand filter device 4 is installed in the gas gathering well, and the seawater concentration heating device 1, hot brine delivery pump 39, gas-liquid mixing device 1 are installed at a certain depth in the seawater layer 7 A gas-liquid separator 13, a natural gas compressor 14, a natural gas storage tank 16, a seawater concentration heating device feed water pump 15, a hydrate formation recovery pump 18, and a hydrate formation separator 20 are installed on the offshore floating platform 26 , seawater heater inlet pump 19, hydrate forming gas compressor 21, hydrate forming product storage tank 22, centrifugal pump 23, fresh water storage tank 24, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com