Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1104 results about "Combing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combing is a method for preparing carded fibre for spinning. Combing is divided into linear and circular combing. The Noble comb is an example of circular combing. The French comb is an example of linear combing. The process of combing is accompanied by gilling, a process of evening out carded or combed top making it suitable for spinning. Combing separates out short fibres by means of a rotating ring or rectilinear row of steel pins. The fibres in the 'top' it produces have been straightened and lie parallel to each other. When combing wool, the discarded short fibres are called noils, and are ground up into shoddy.

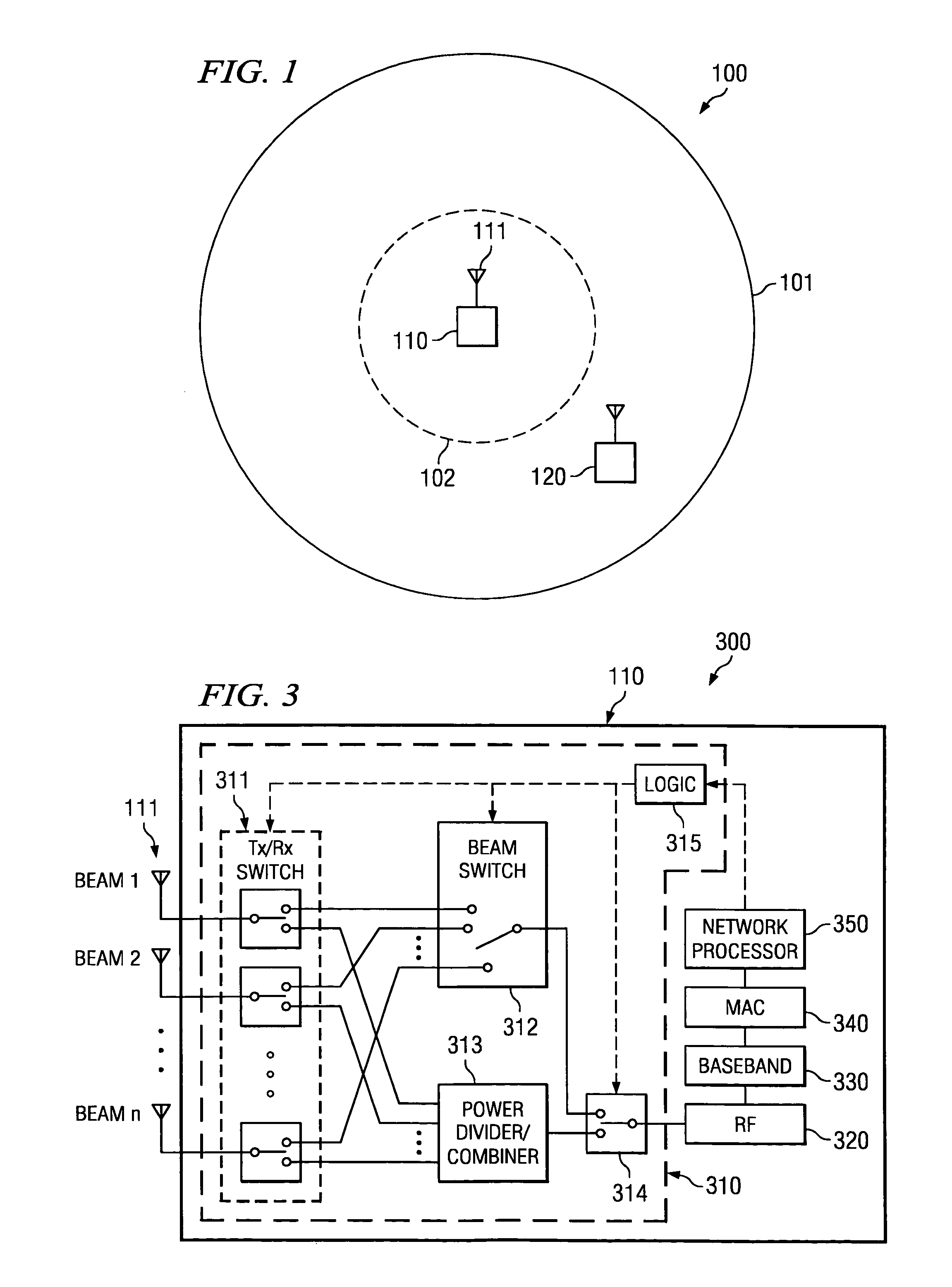

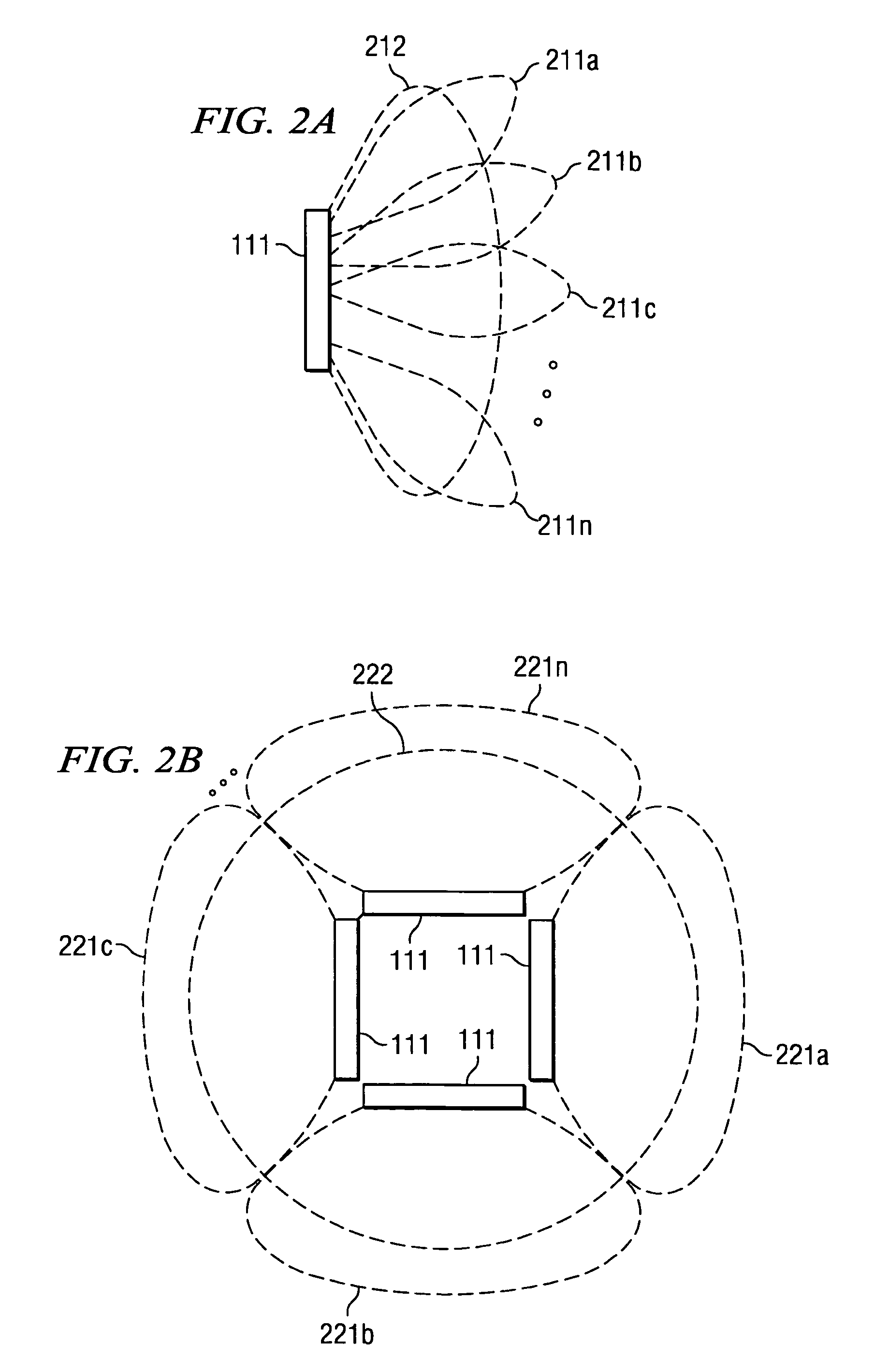

WLAN access point with extended coverage area

ActiveUS20060025178A1Reduce bitrateImprove link qualityNetwork topologiesSubstation equipmentExtended coverageHigh bandwidth

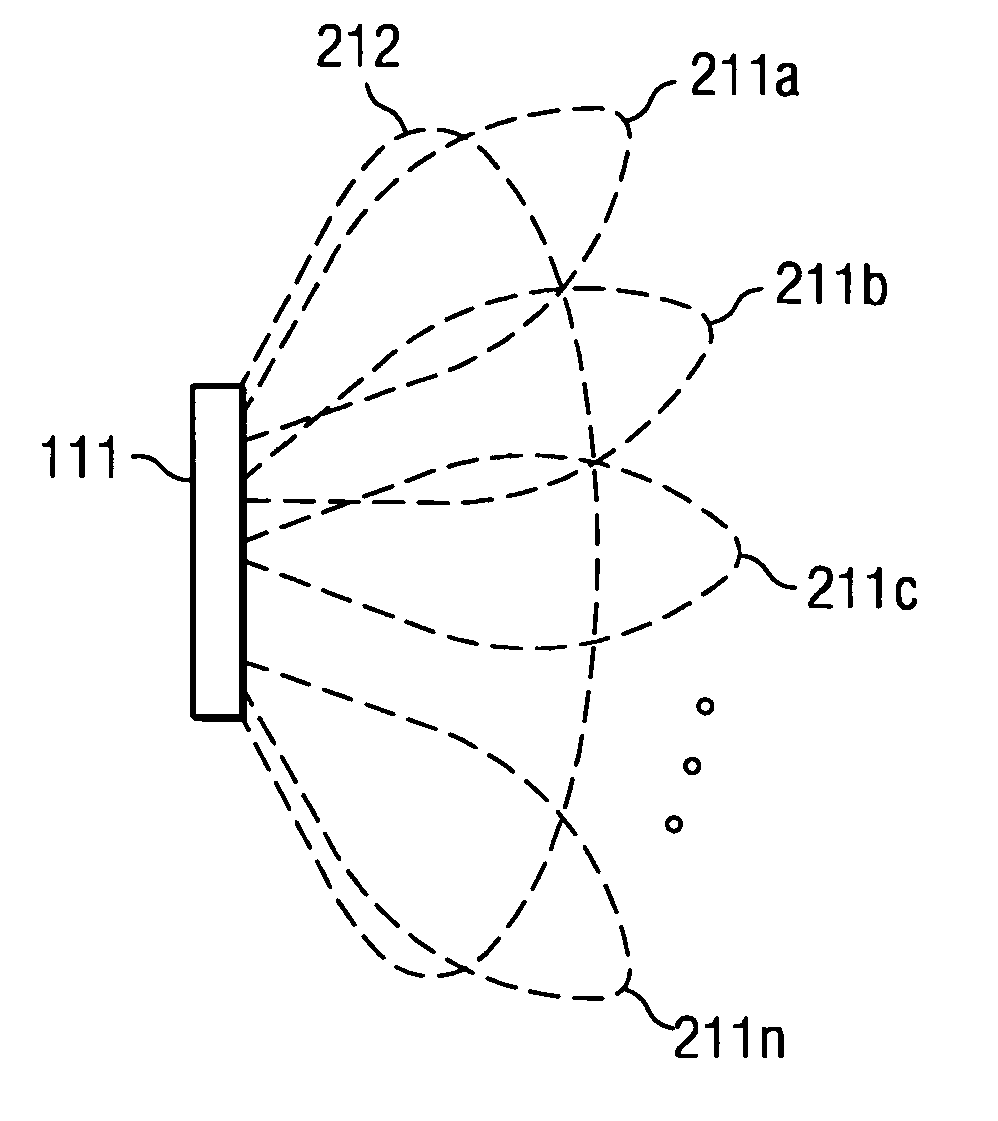

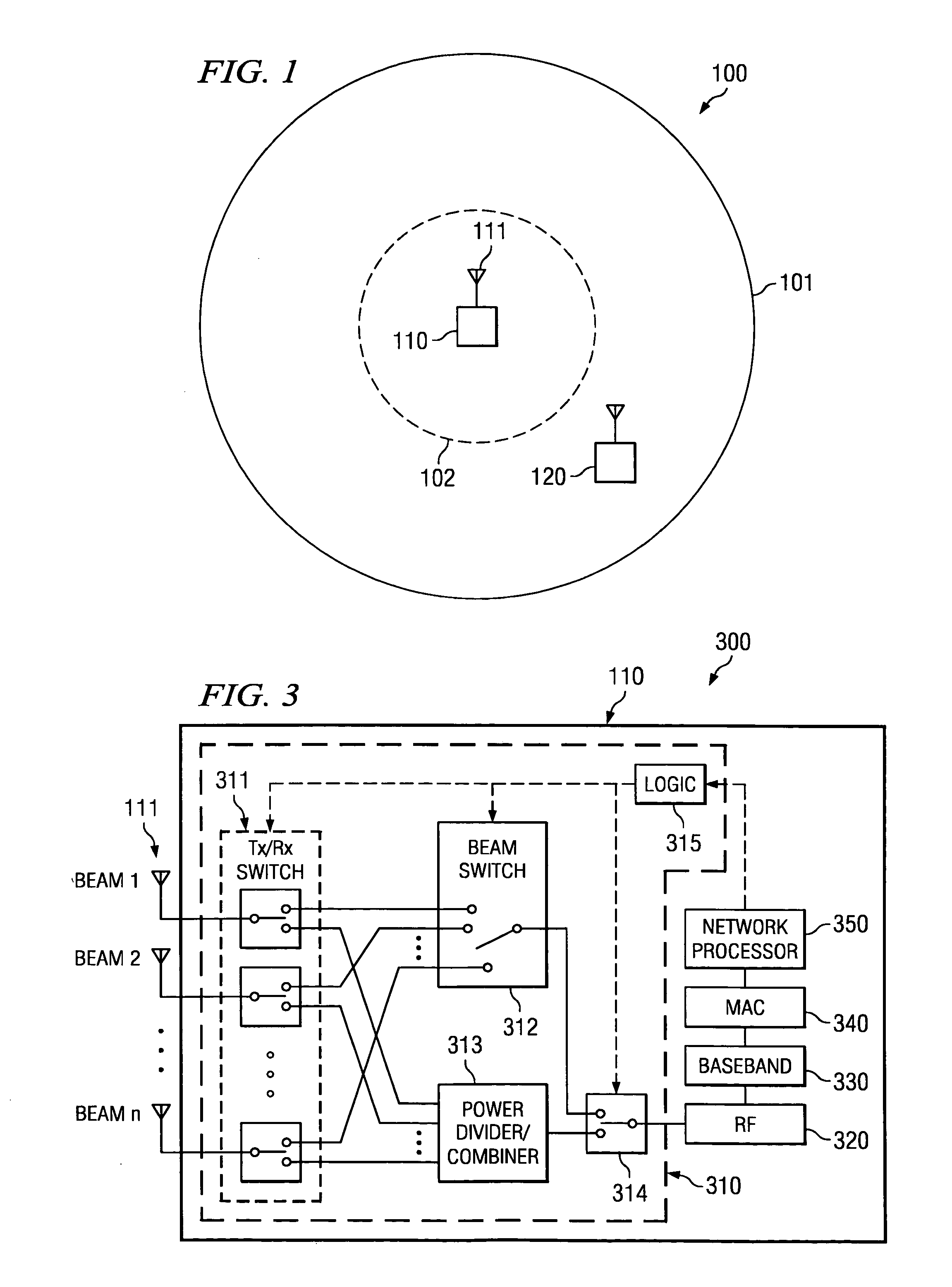

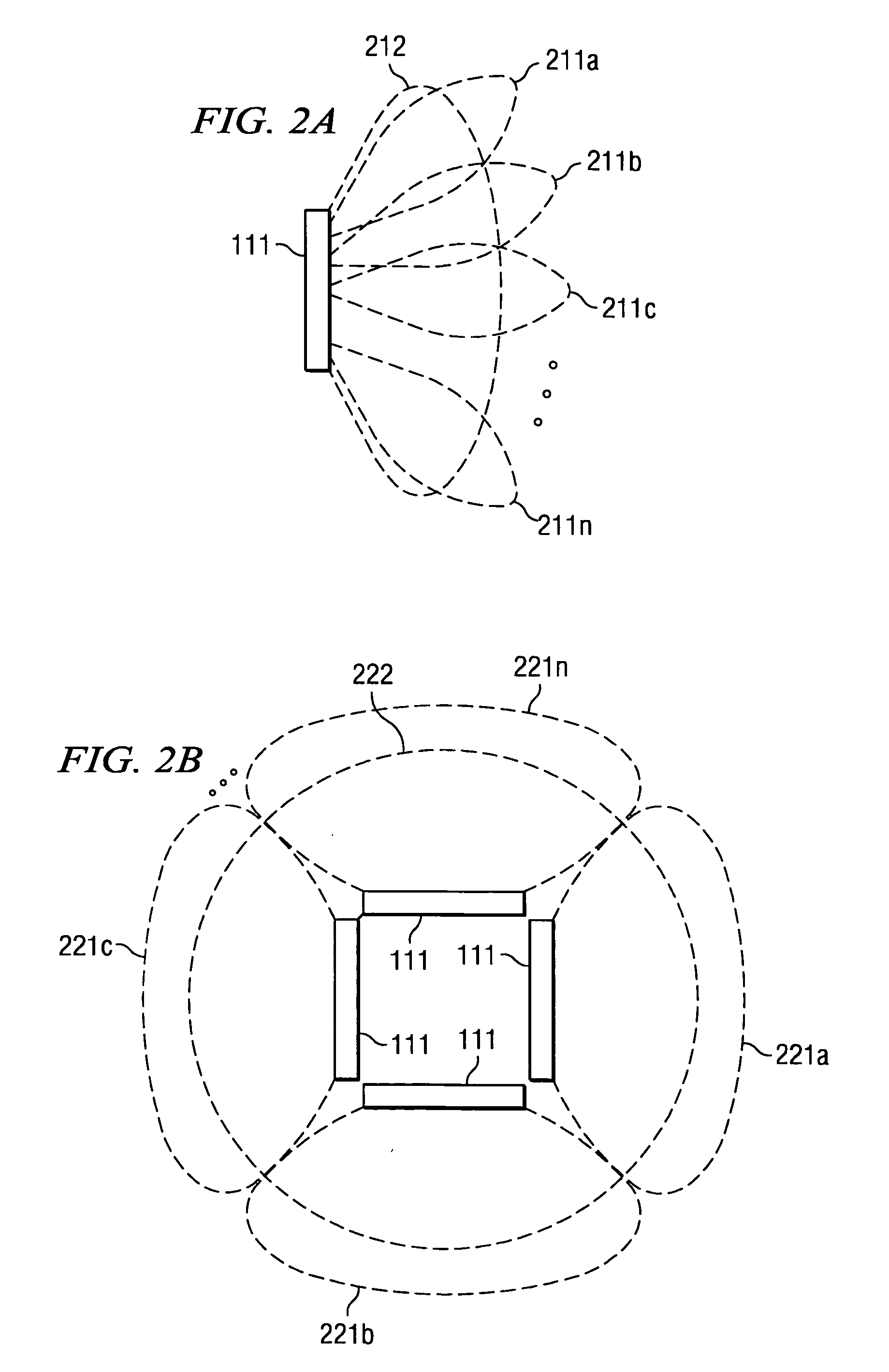

Disclosed are systems and methods which provide high bandwidth data communication with respect to a large coverage area using smart antenna and / or directional antenna (referred to herein as multi-beam antenna) technology. Circuitry may be provided at a WLAN AP to provide selection of particular antenna beams used in the downlink and / or uplink, control of multicast transmission, control of unicast transmission, and to provide antenna pattern shaping techniques. Embodiments implement multi-beam antenna technology with little or no hardware modifications to AP circuitry. Other embodiments implement multi-beam technology using radio front-end and / or radio hardware modifications to AP circuitry. Various diversity techniques may be implemented, such as selection diversity, maximum ratio combining, and equal gain combing. To provide desired antenna pattern shaping, phase offsets with respect to a signal as transmitted in each antenna beam may be employed.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

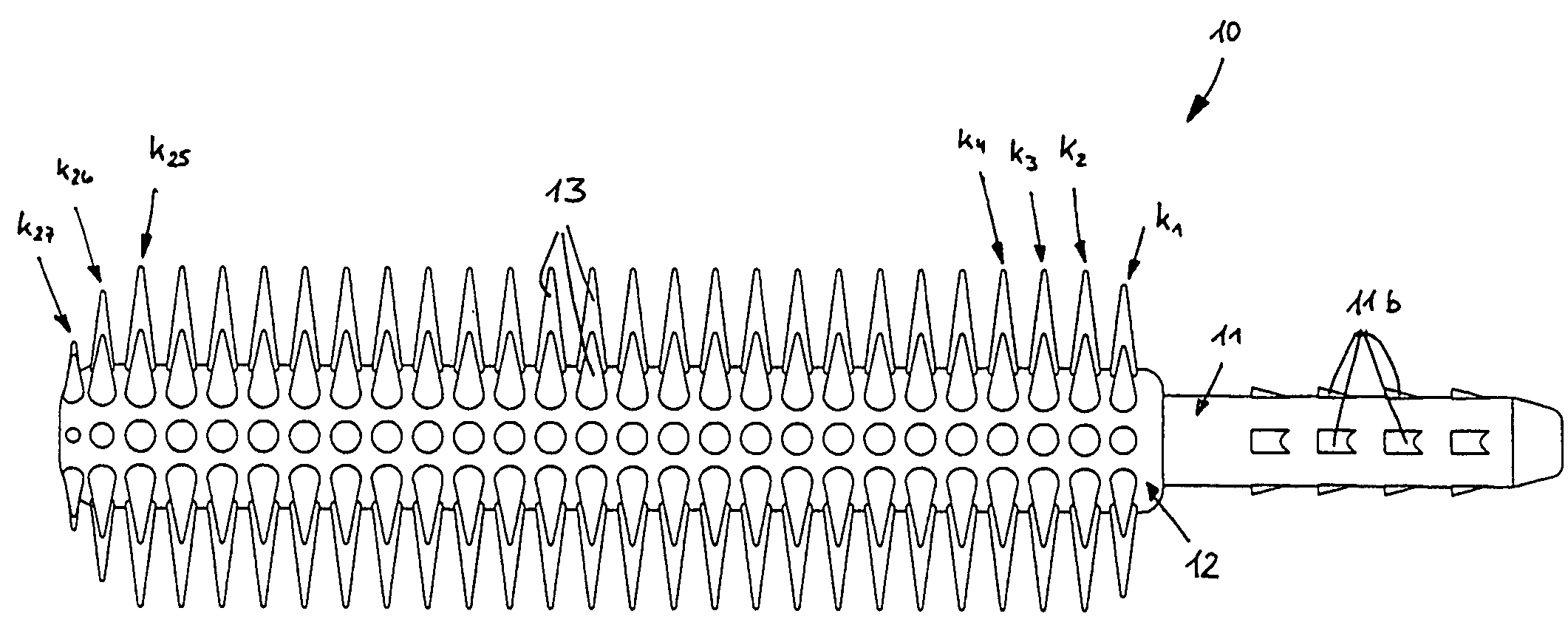

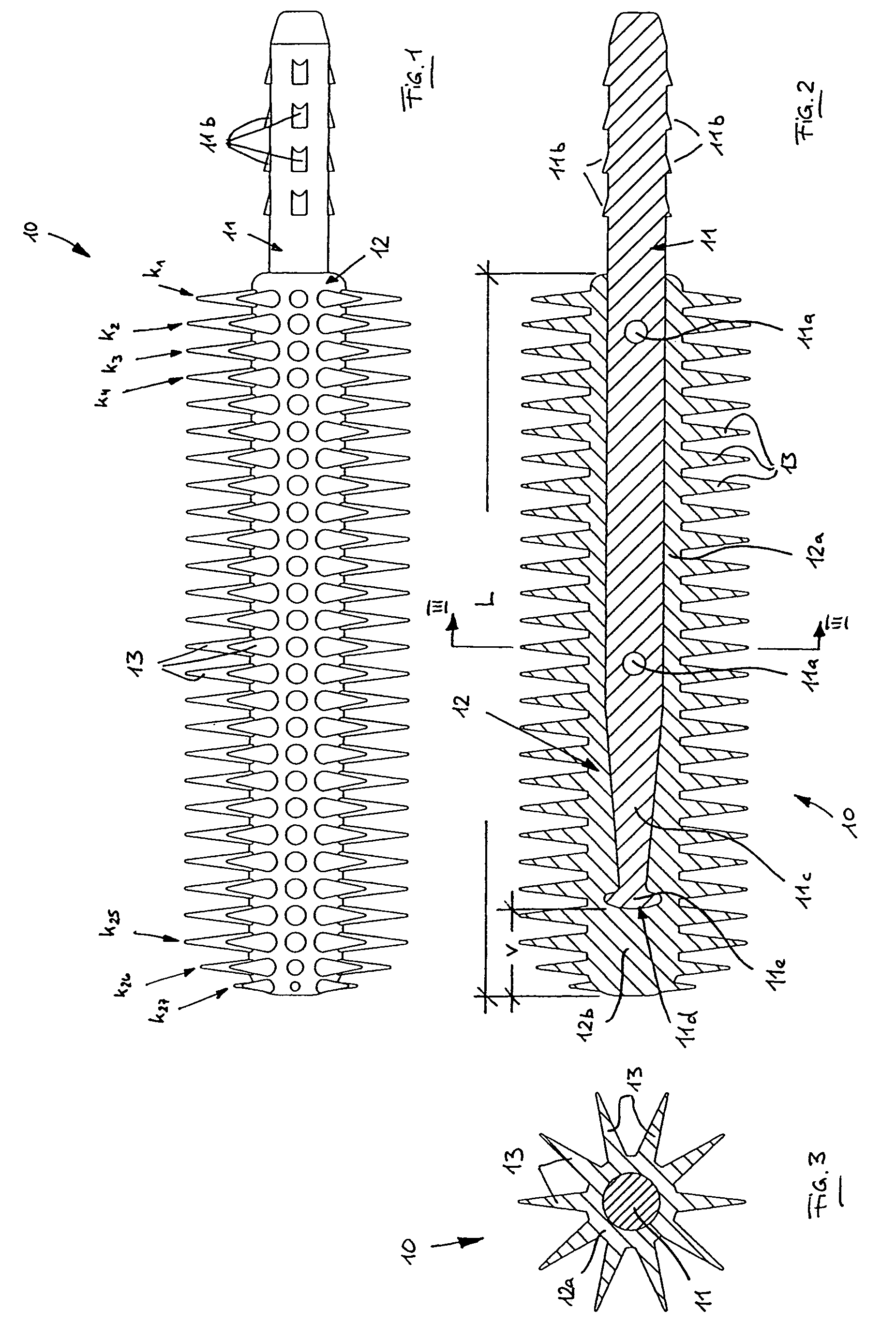

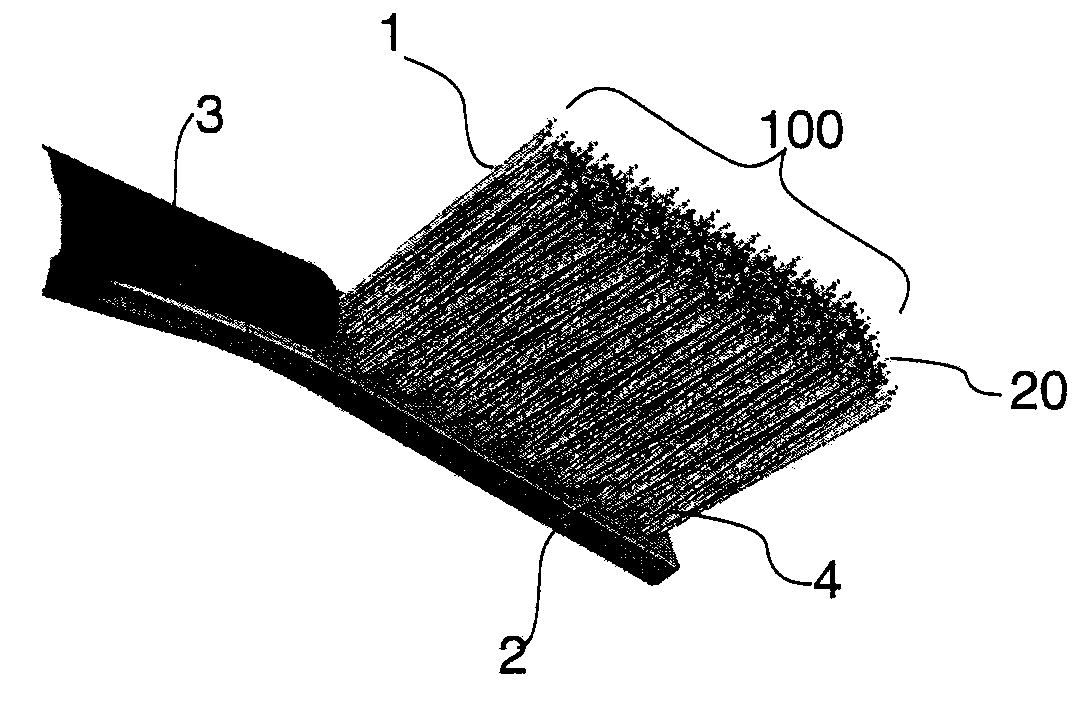

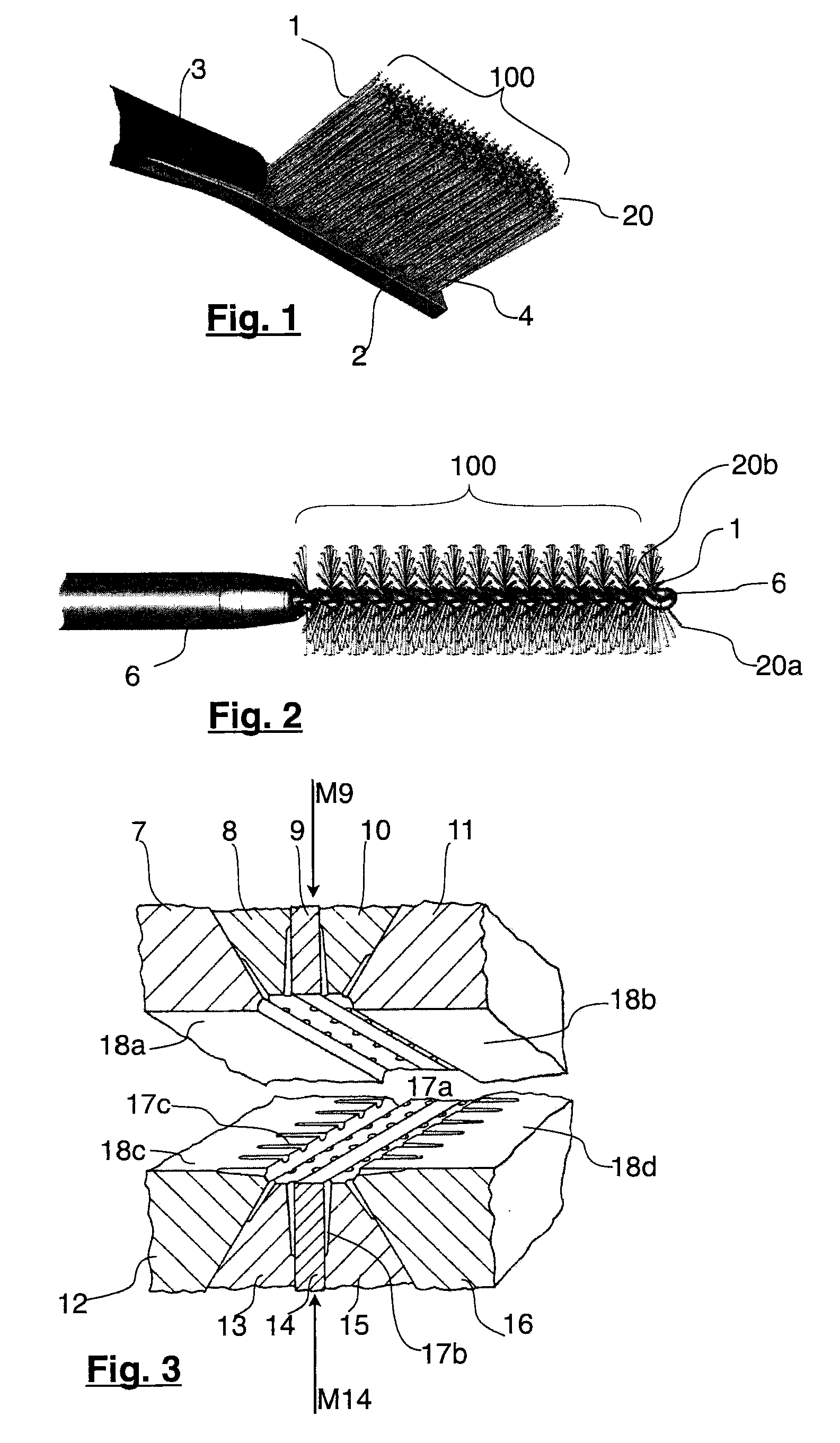

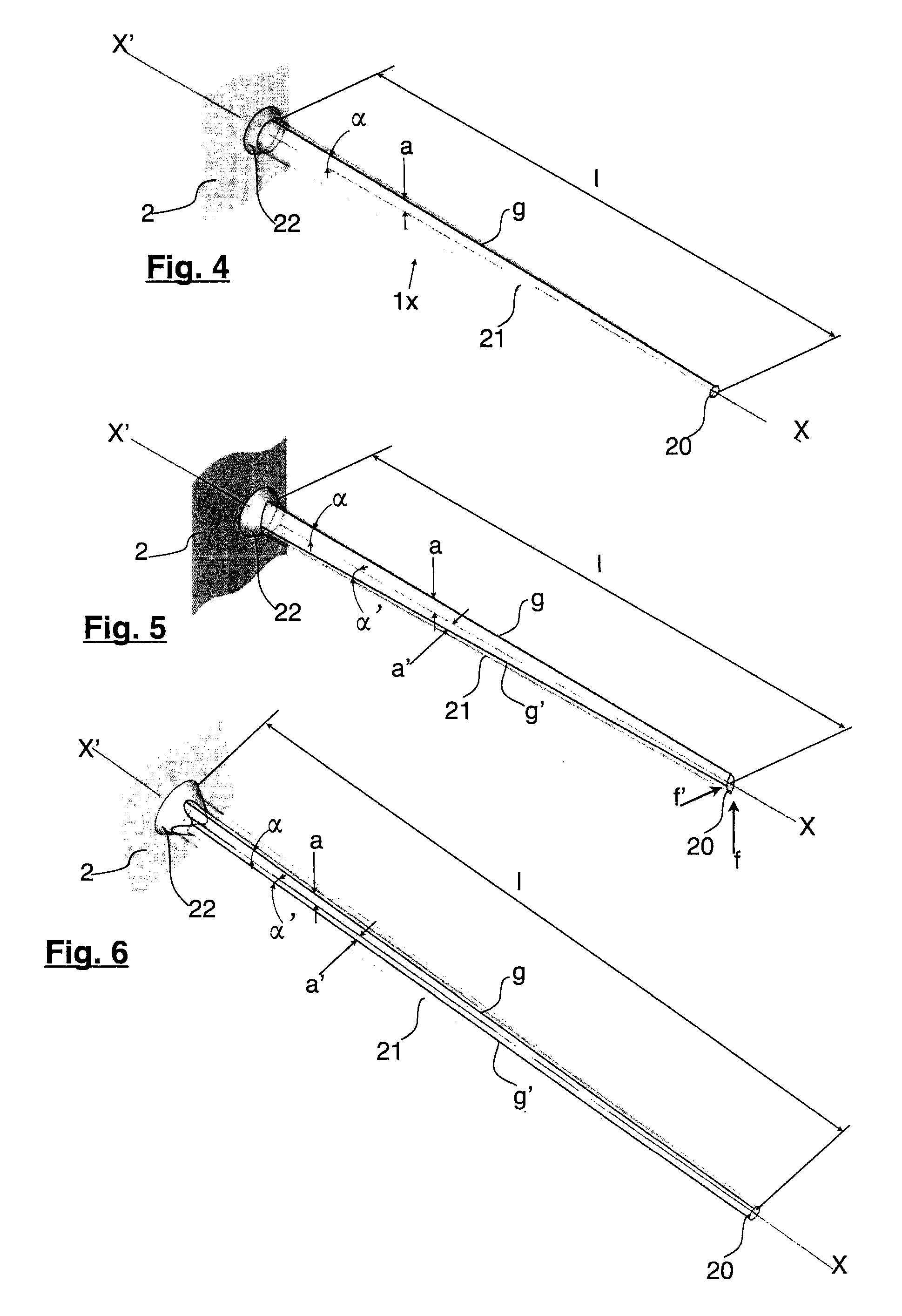

Applicator for liquid or paste-like media, in particular decorative cosmetics such as mascara

InactiveUS7325550B2Increase flexibilityEasy to operateBristlePackaging toiletriesBristlePlastic materials

An applicator for liquid or pasty media, in particular for decorative cosmetics such as mascara has a rod-shaped reinforcing core of a first plastic material which is surrounded at least in the region of its front end by a support sleeve of a second plastic material. The support sleeve has a plurality of radially outwardly projecting fingers which are integrally formed on the support sleeve and also consist of the second plastic material. Several fingers which are distributed over the periphery of the support sleeve form a finger collar and a plurality of finger collars with identical finger number are disposed one behind the other in the longitudinal direction of the support sleeve. A particular combination of parameters for the bristles leads to improved combing and application properties.

Owner:GEKA

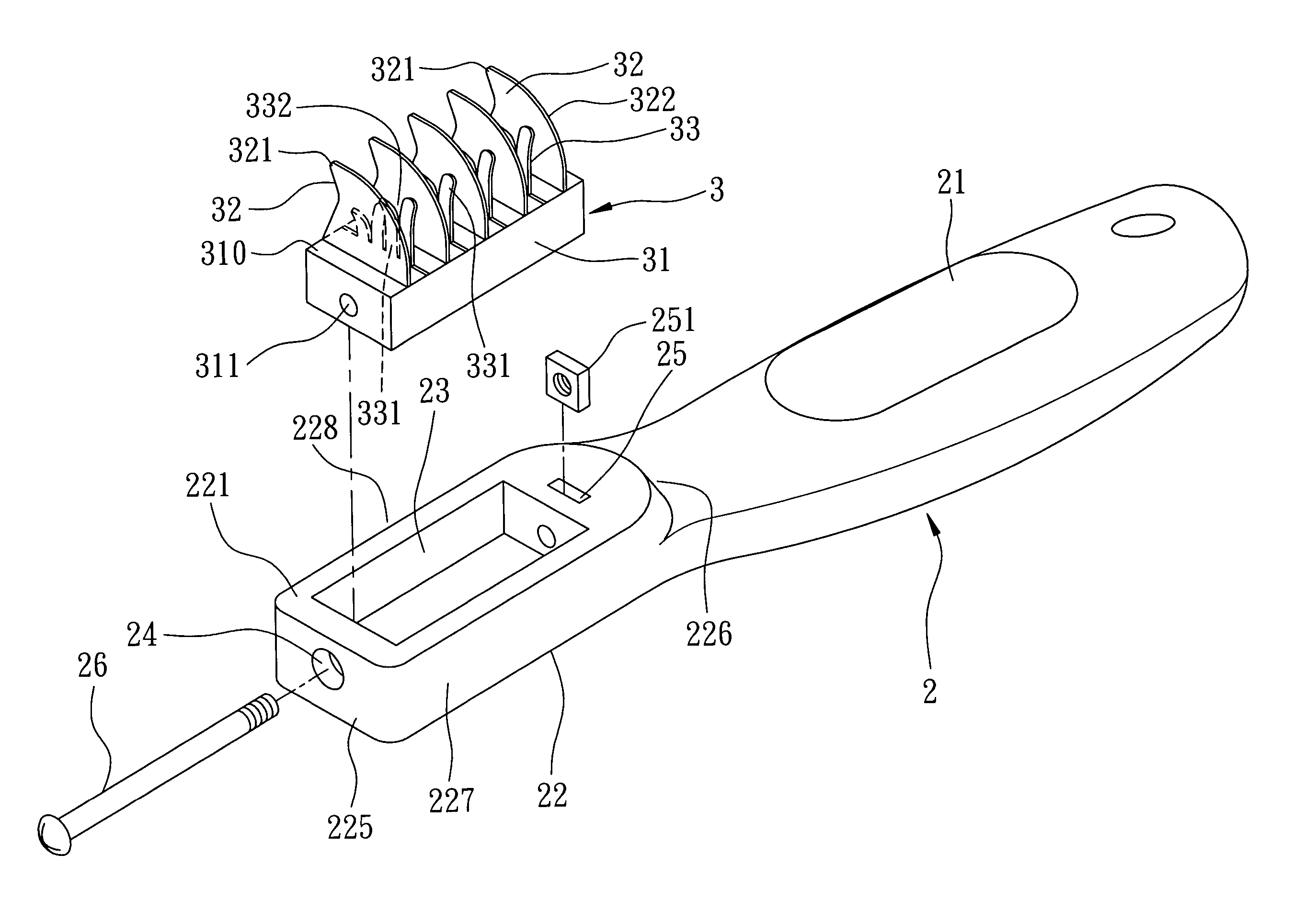

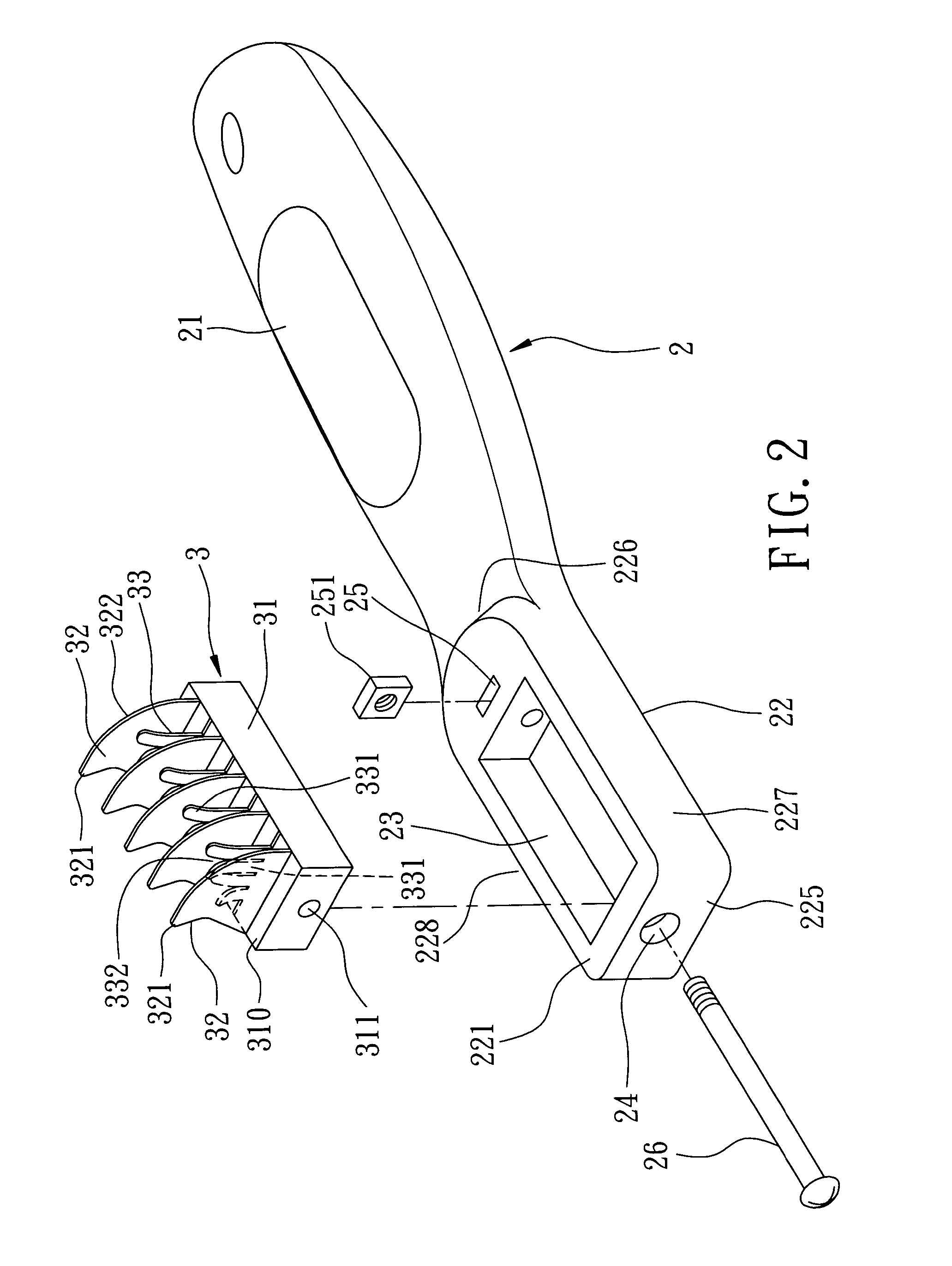

Device and packaging for precision brushing and combing and method and tool for obtaining same

The invention proposes a precision brushing and combing device, allowing a top-quality, consistent, faultless and industrial implementation. To do this, the invention provides a geometrical bristle structure adjusted with precision distance-wise and angle-wise with respect to a reference, as well as dimension-wise, with mold implementation by wire spark erosion.In an example embodiment, the plastic-injection tool comprises at least one block assembly consisting of several steel plates, at least one row of cavities each intended to form the main portion of a bristle, machined either side of the surface separating two adjacent plates, and a closing-up element, disposed at the end of at least one row of cavities, in order to form the free end surface of the bristles. A space of calibrated thickness is made between the plates forming the main portion of the bristle and the plate or bar forming the free end surface of the bristle, so as to allow the air to escape at the time of the injection whilst avoiding leakage of plastic. An ejection mechanism is provided for extracting the device from the cavity after solidification of the plastic.

Owner:CINQPATS

Finishing Comb

Owner:GOODY PRODS

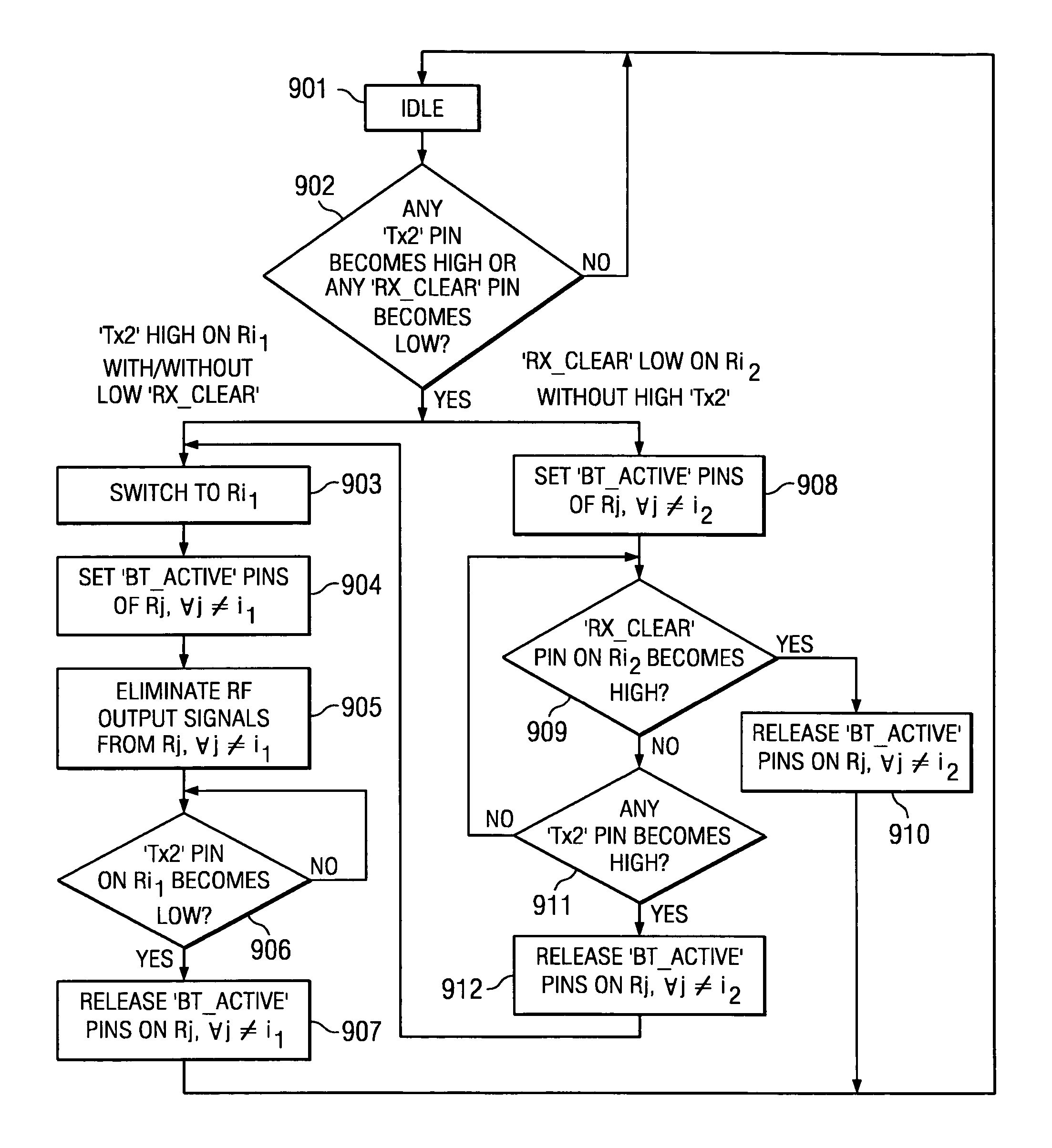

WLAN access point with extended coverage area

ActiveUS8280443B2Consume capacityReduce bitrateNetwork topologiesSubstation equipmentExtended coverageHigh bandwidth

Disclosed are systems and methods which provide high bandwidth data communication with respect to a large coverage area using smart antenna and / or directional antenna (referred to herein as multi-beam antenna) technology. Circuitry may be provided at a WLAN AP to provide selection of particular antenna beams used in the downlink and / or uplink, control of multicast transmission, control of unicast transmission, and to provide antenna pattern shaping techniques. Embodiments implement multi-beam antenna technology with little or no hardware modifications to AP circuitry. Other embodiments implement multi-beam technology using radio front-end and / or radio hardware modifications to AP circuitry. Various diversity techniques may be implemented, such as selection diversity, maximum ratio combining, and equal gain combing. To provide desired antenna pattern shaping, phase offsets with respect to a signal as transmitted in each antenna beam may be employed.

Owner:HONG KONG APPLIED SCI & TECH RES INST

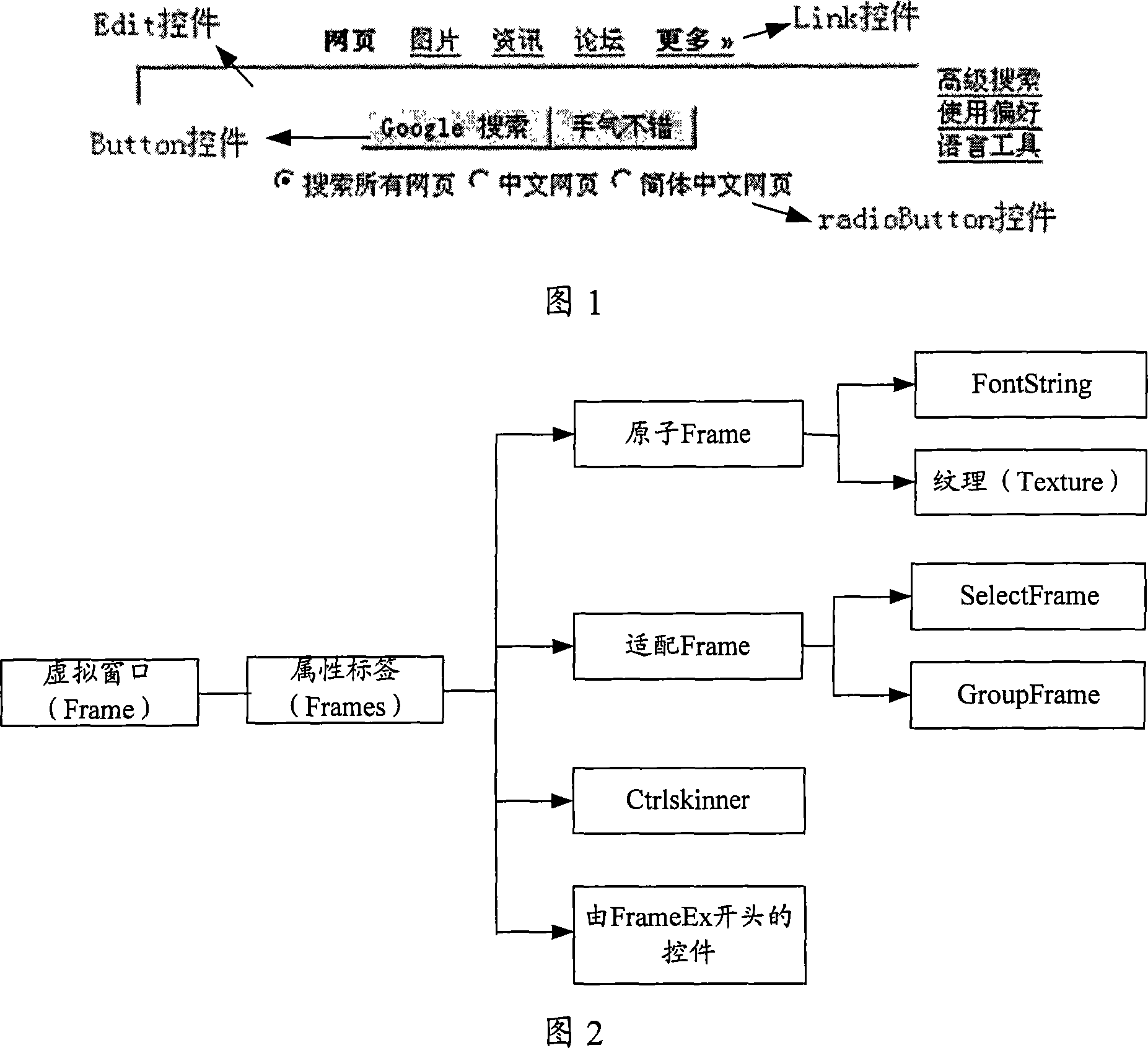

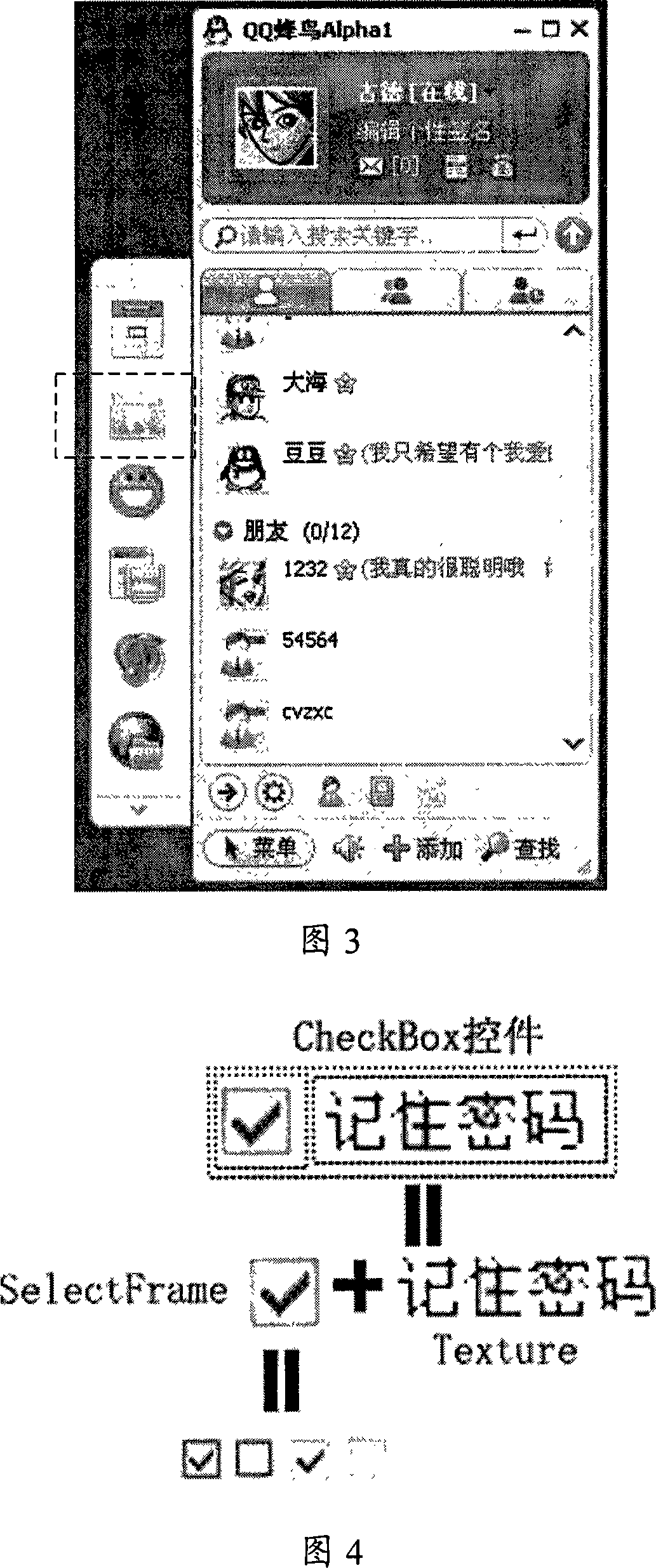

Interface development system and control combing method

InactiveCN101071375AEasy splicingSplicing shortcutSpecific program execution arrangementsScripting languageRelationship - Father

The invention applied to the field of computer graphics interface design provides a combination of the interface development system and the control methods. The system's basic interface elements as virtual window, which covers the virtual window attributes, including: size, compared to his father virtual window position for the virtual window marked by the other virtual window contains the attributes and labels used to produce the script callback events. Implementation of this invention virtual window through the use of the unique attributes, use scripting language description of the father and son relationship between virtual window, space and function call location, convenient, speedy realization of the existence of multiple virtual window splicing into a new, more functional powerful virtual window, thus enhancing the control of the expansion and reuse, an increase of the types of controls, making the development of the interface flexibility and development efficiency has been greatly increased.

Owner:TENCENT TECH (SHENZHEN) CO LTD

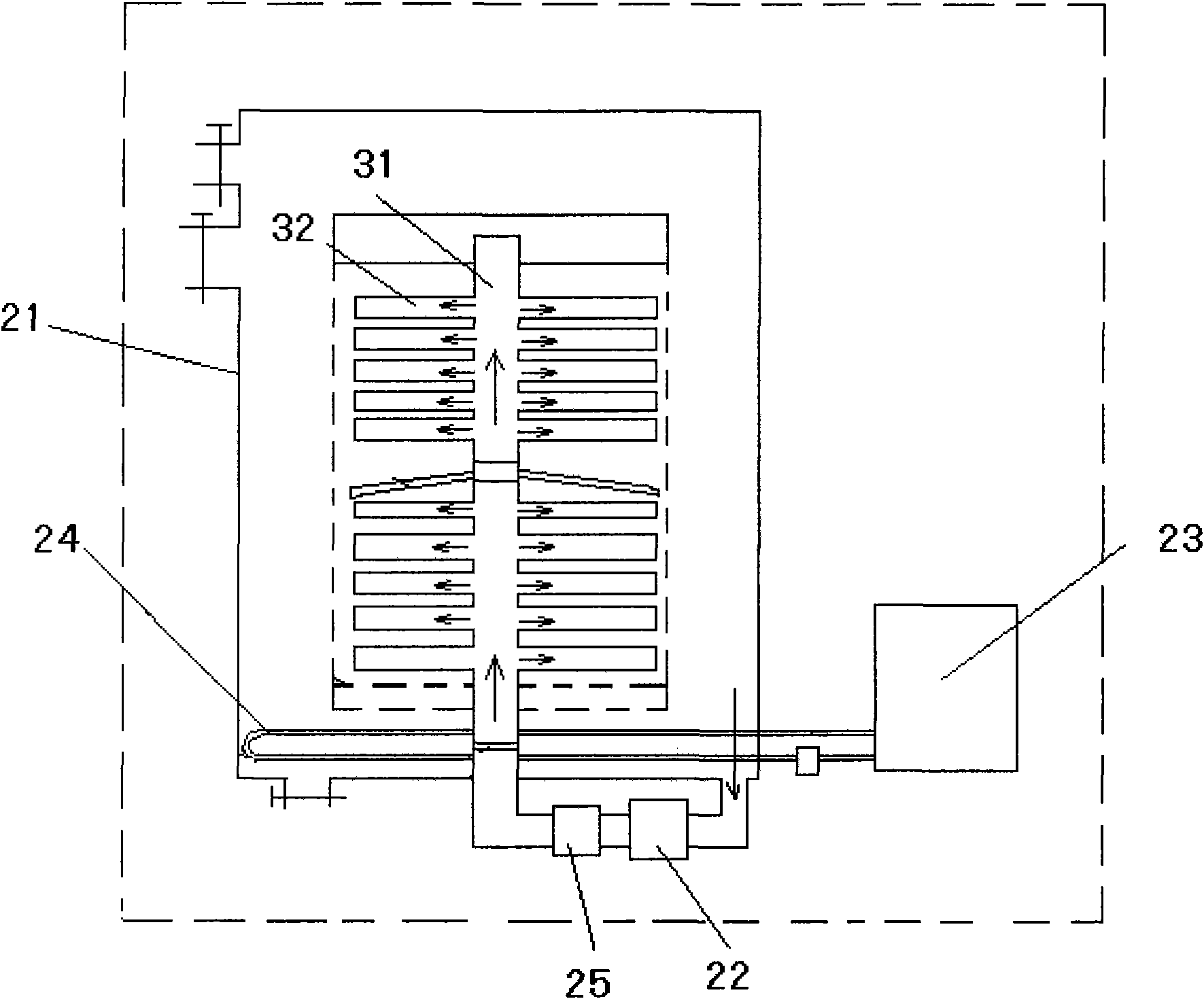

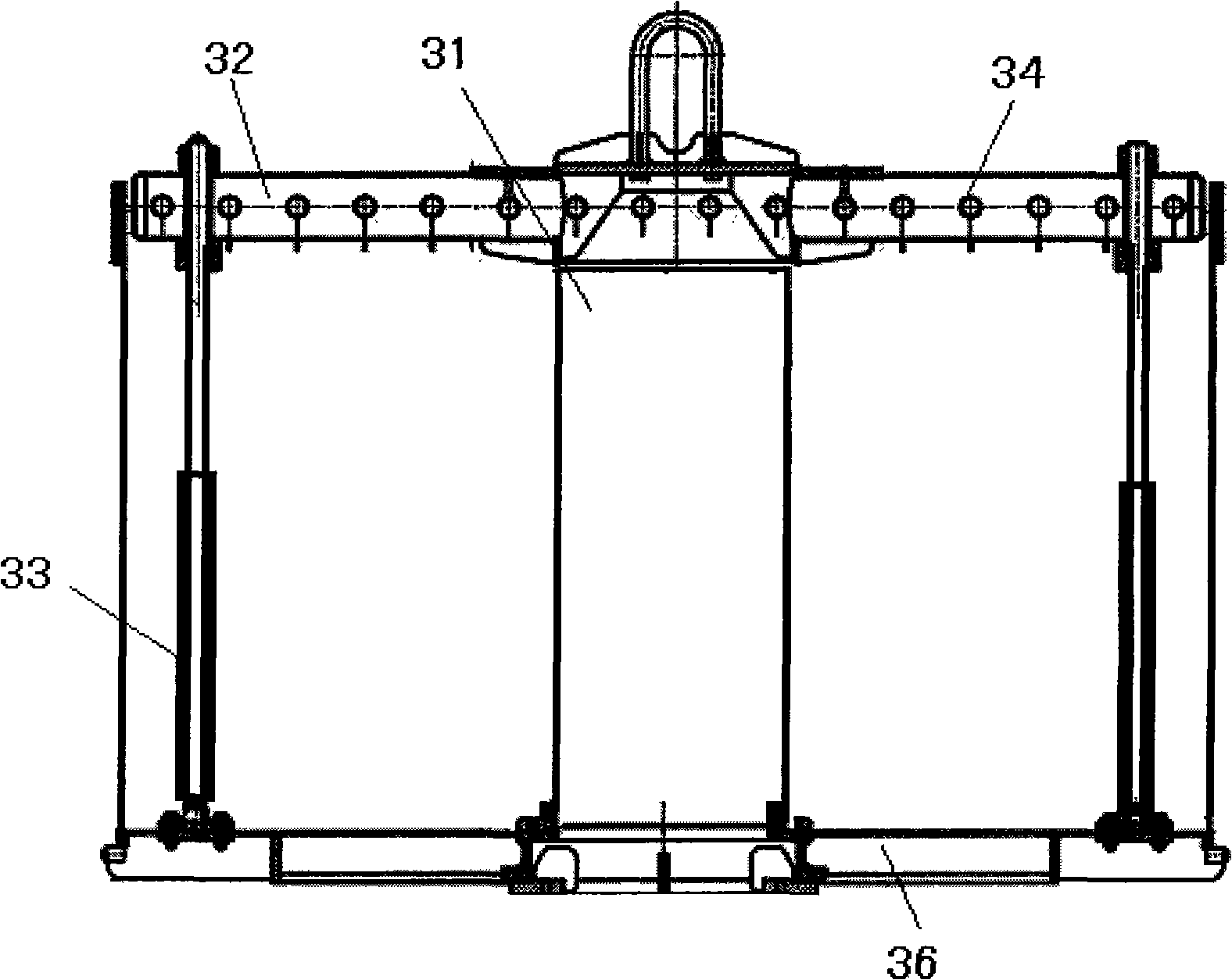

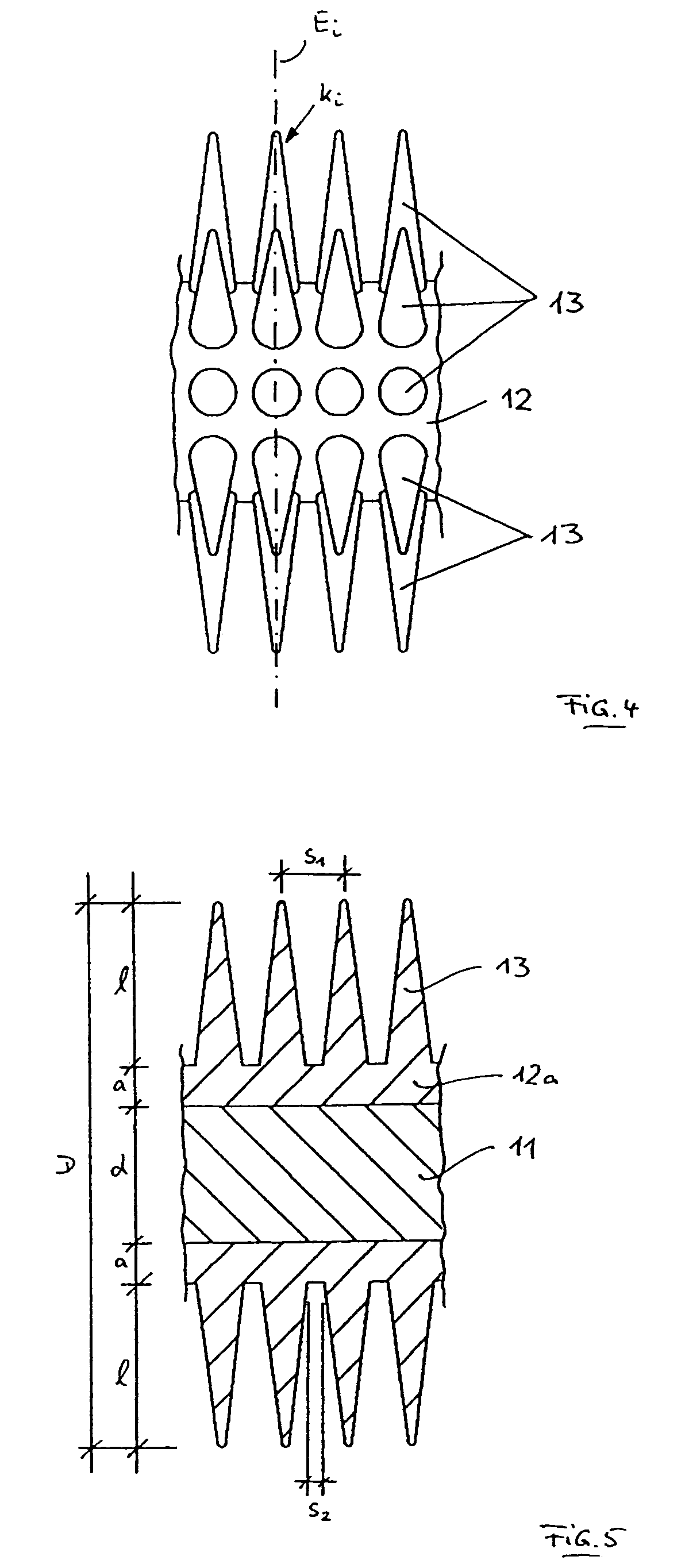

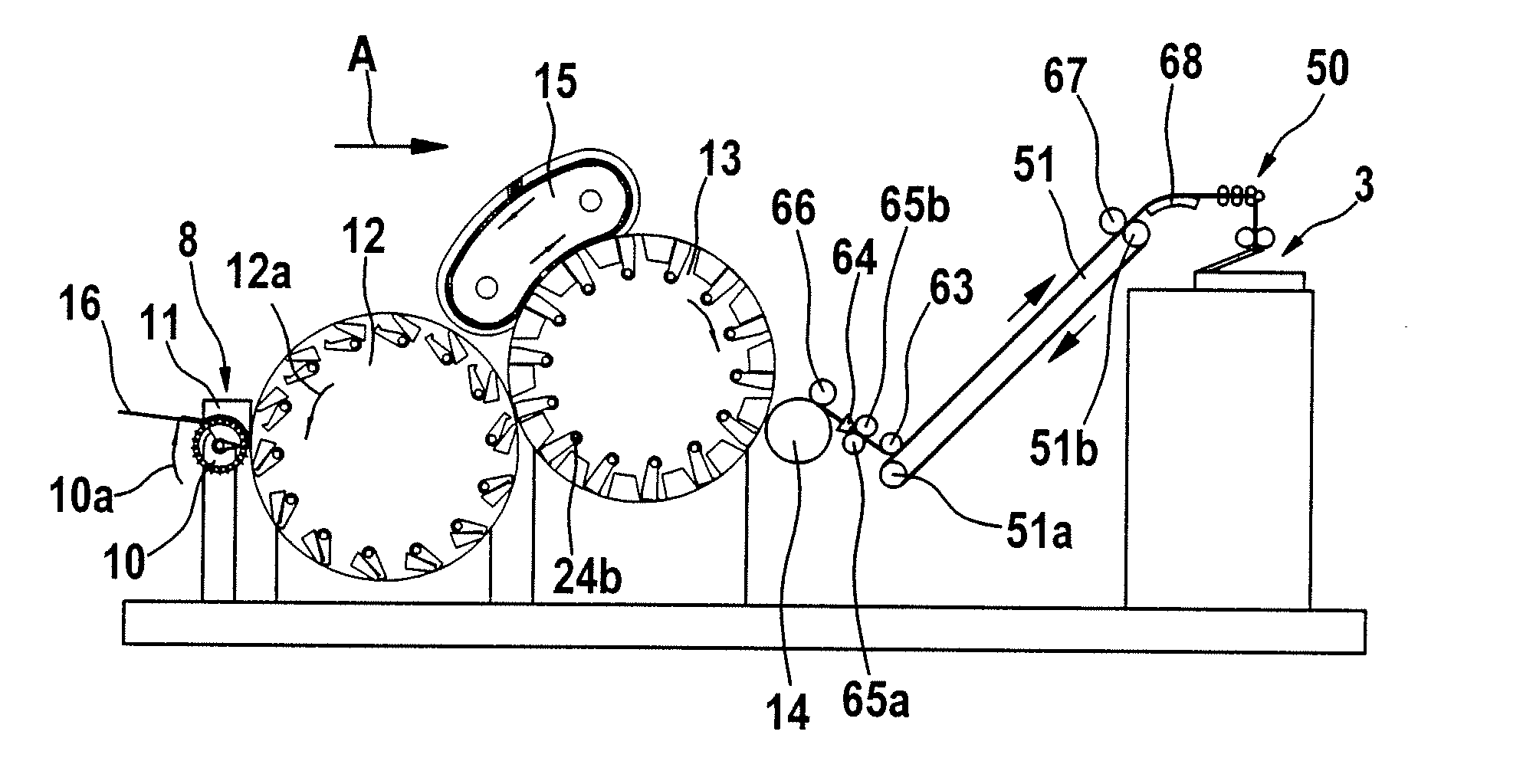

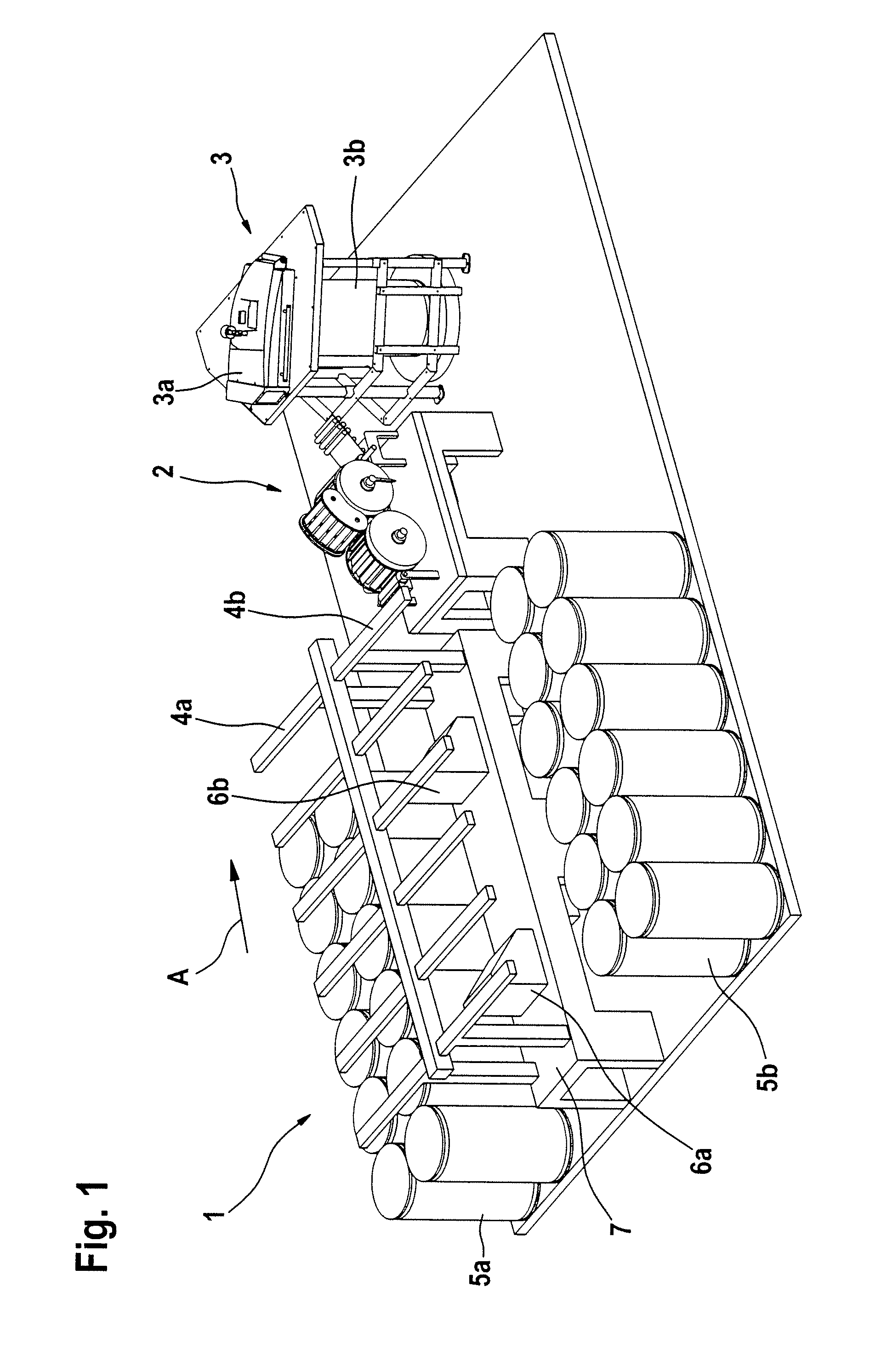

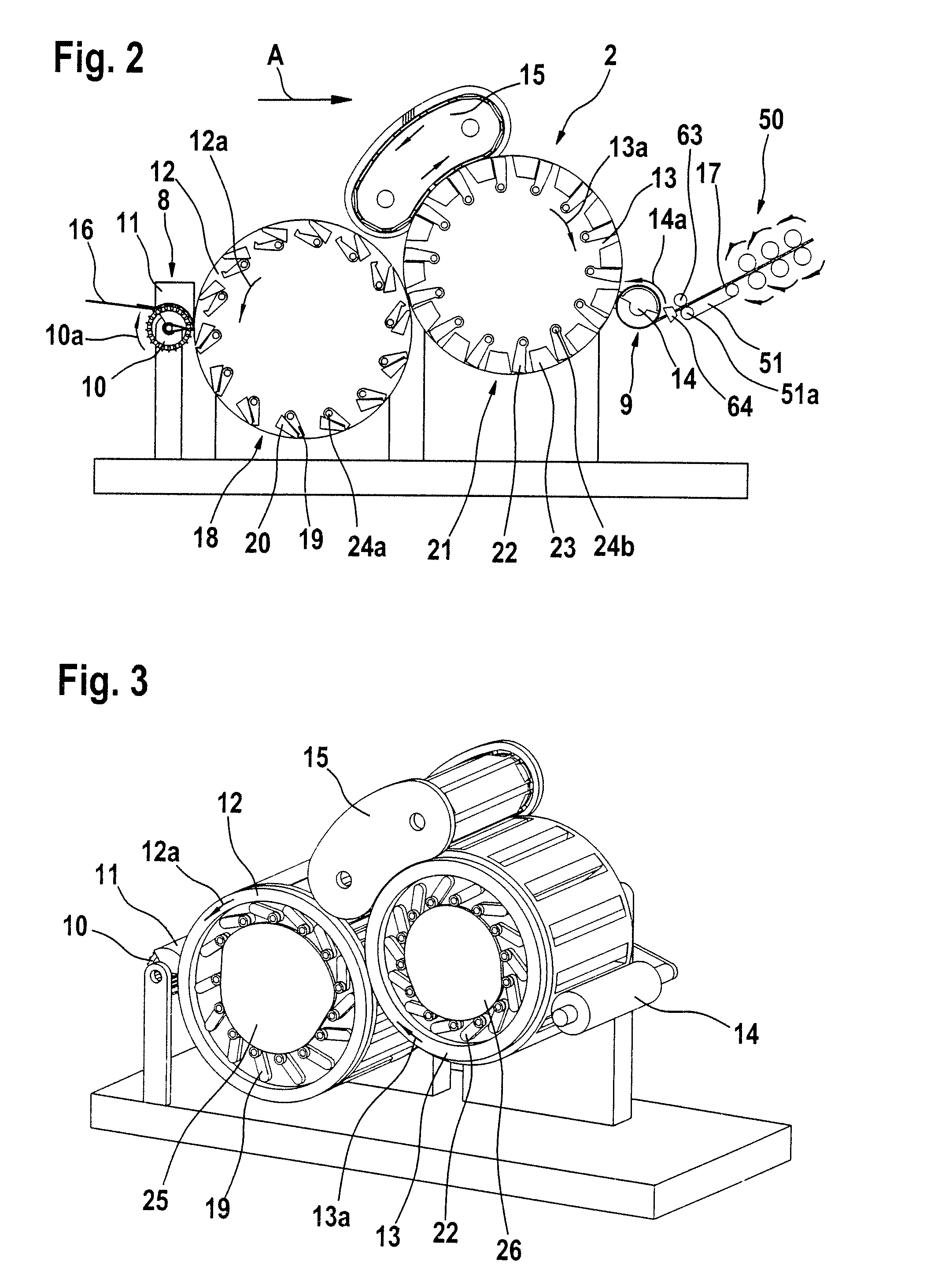

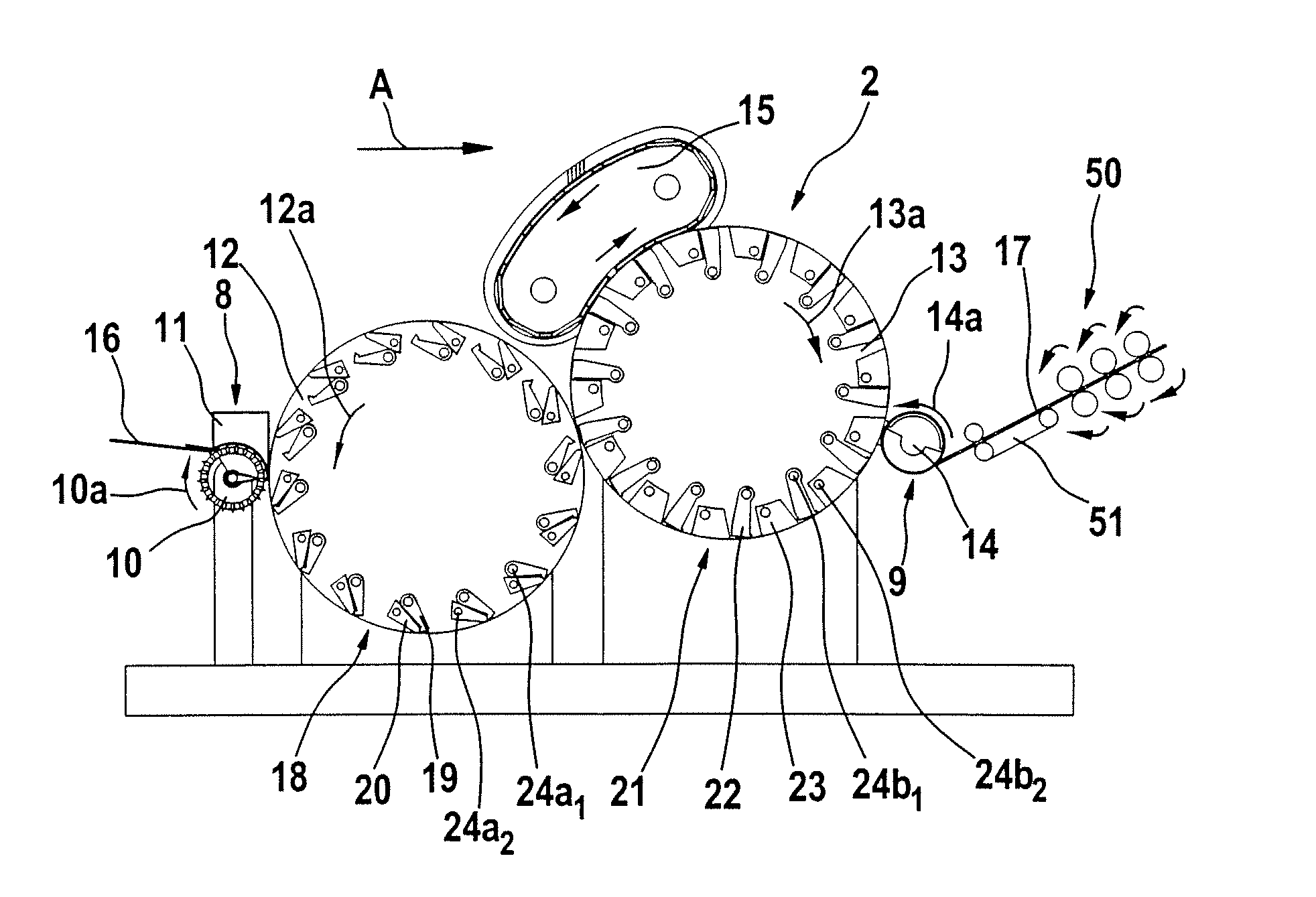

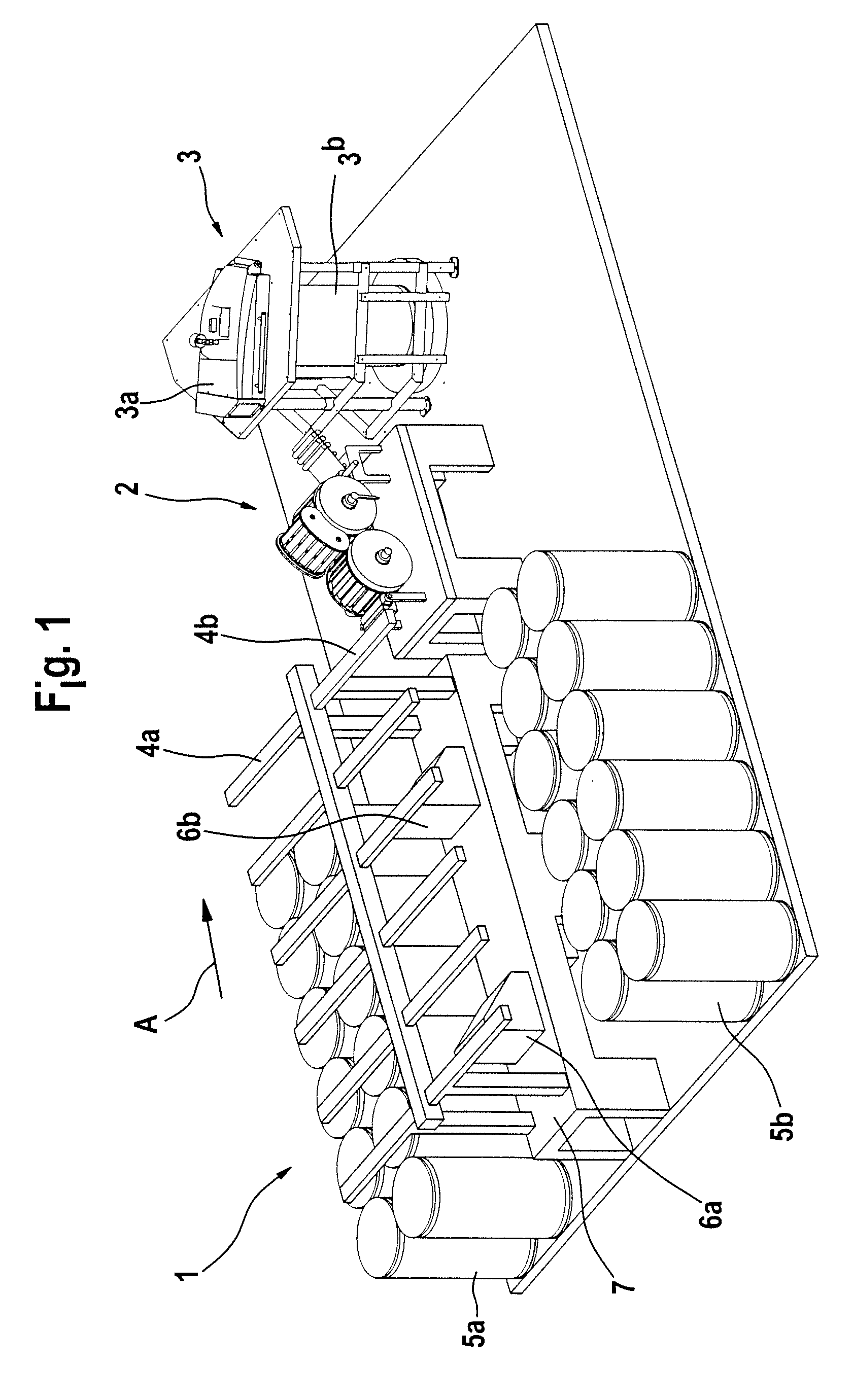

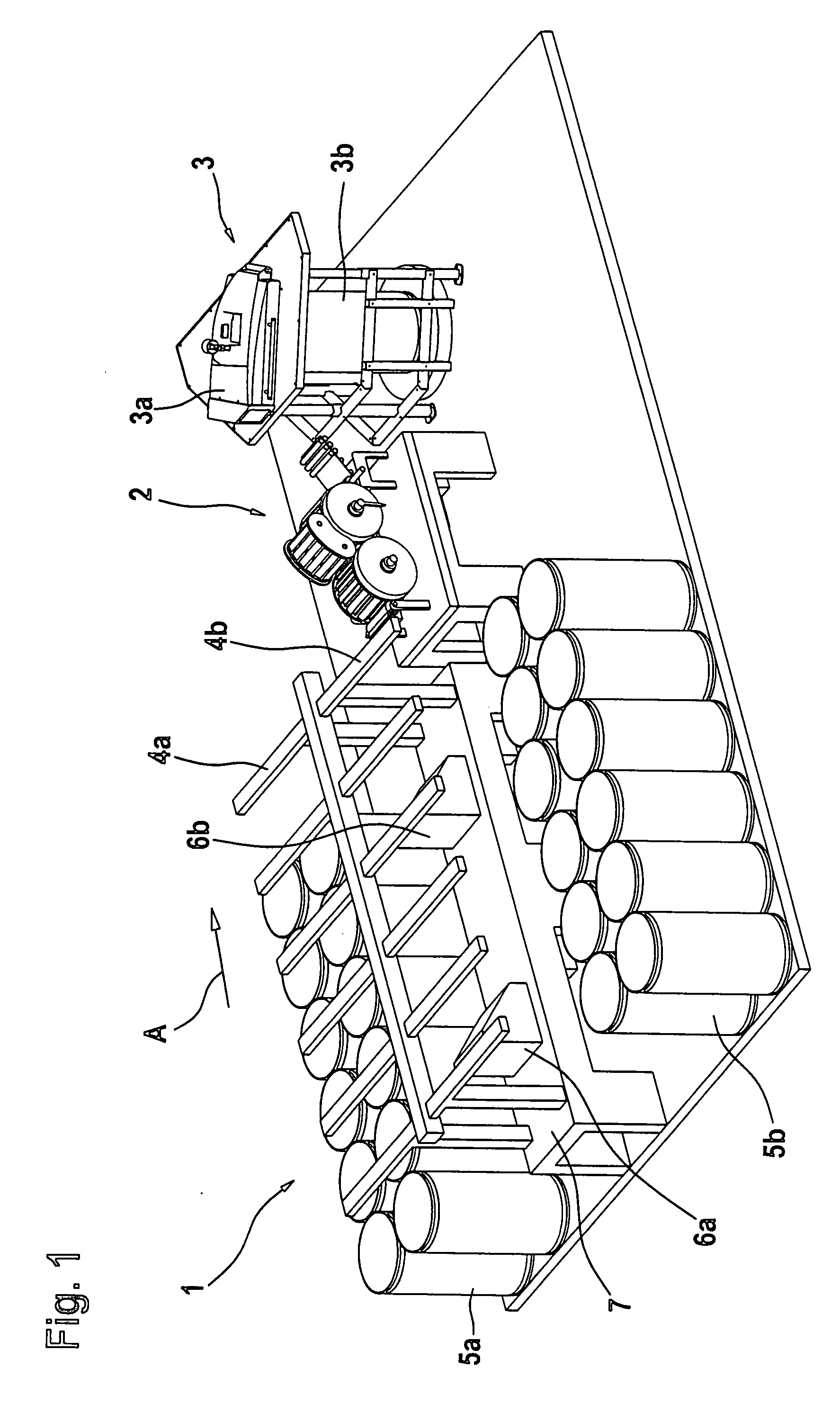

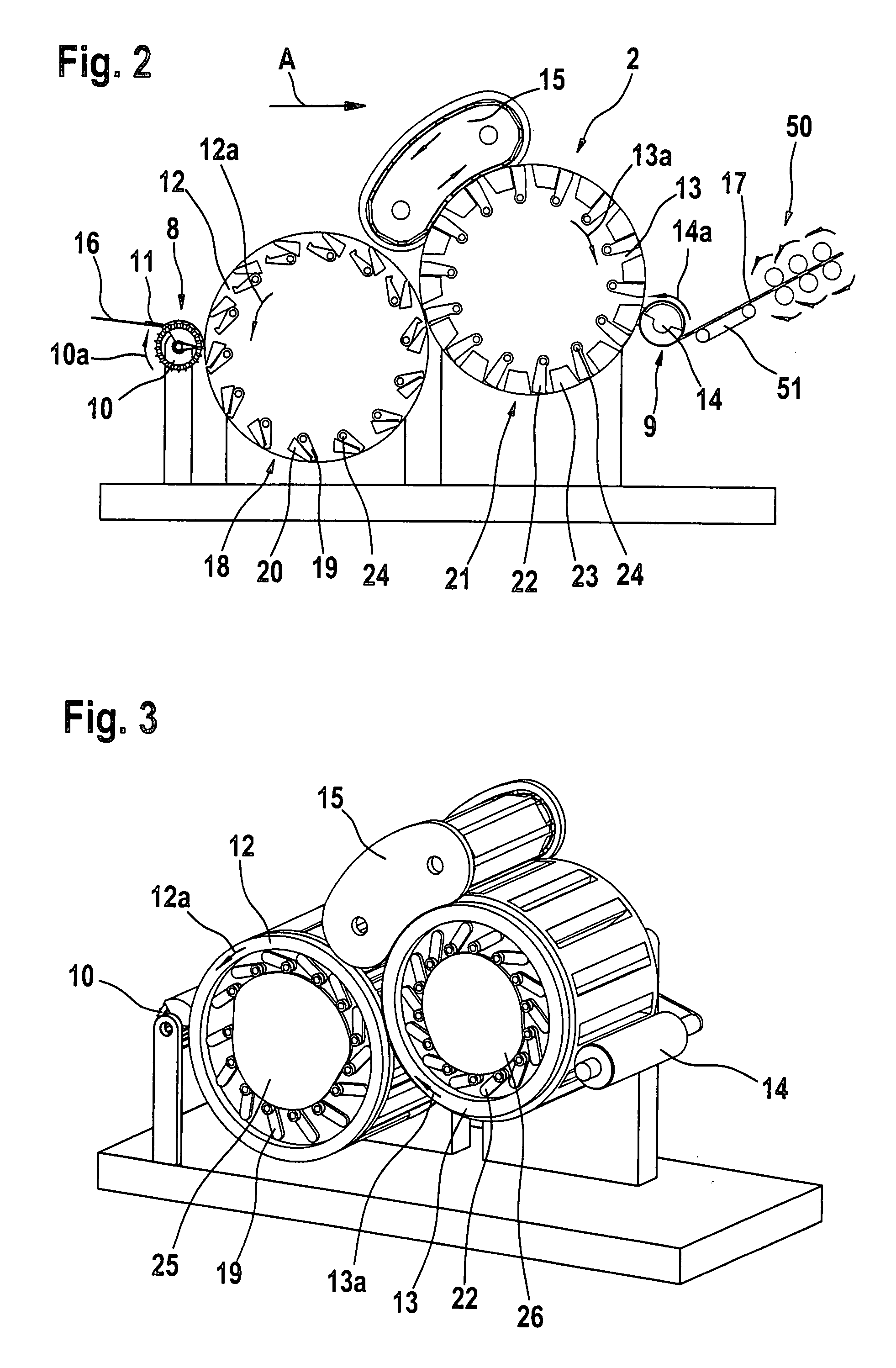

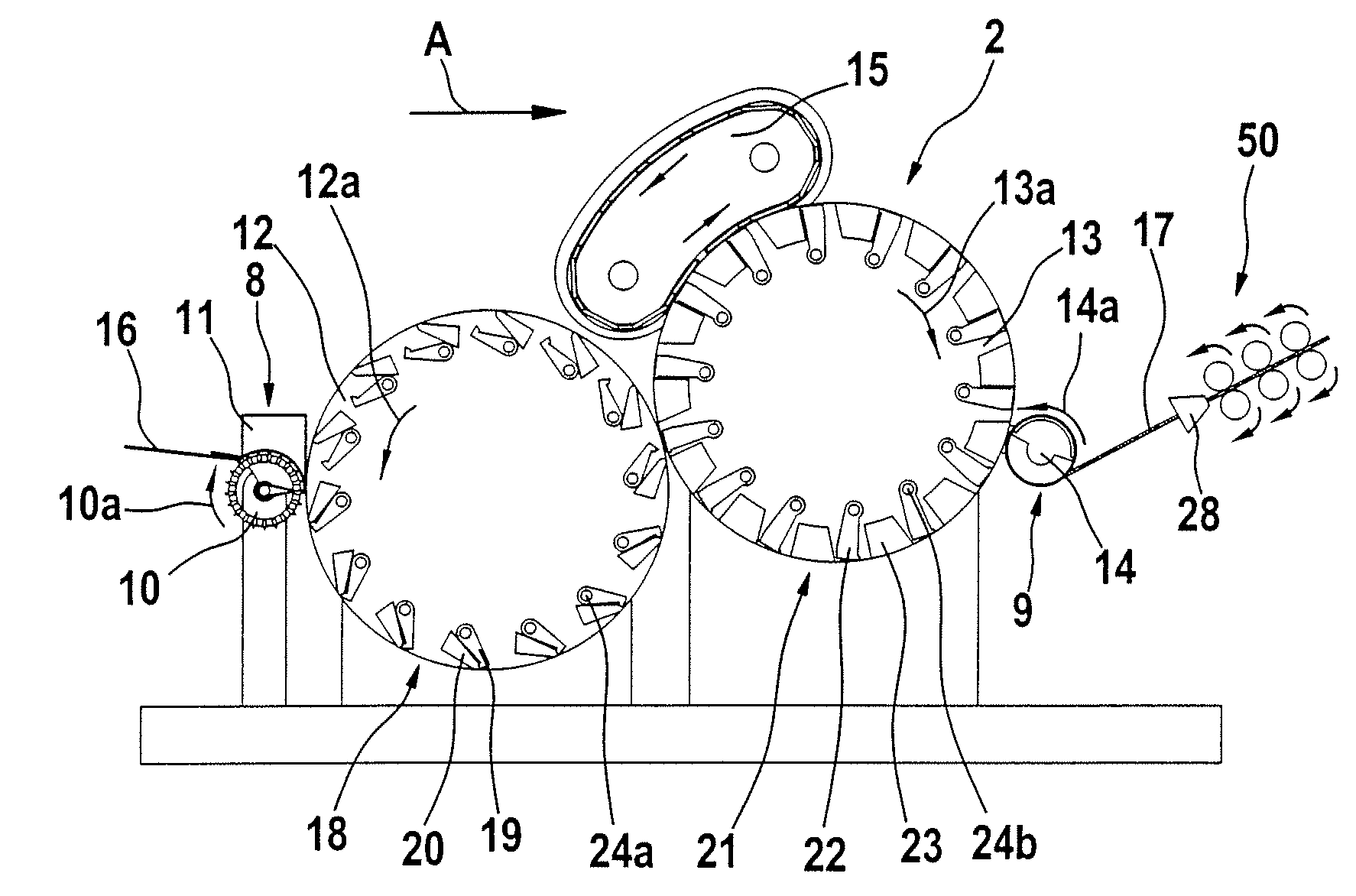

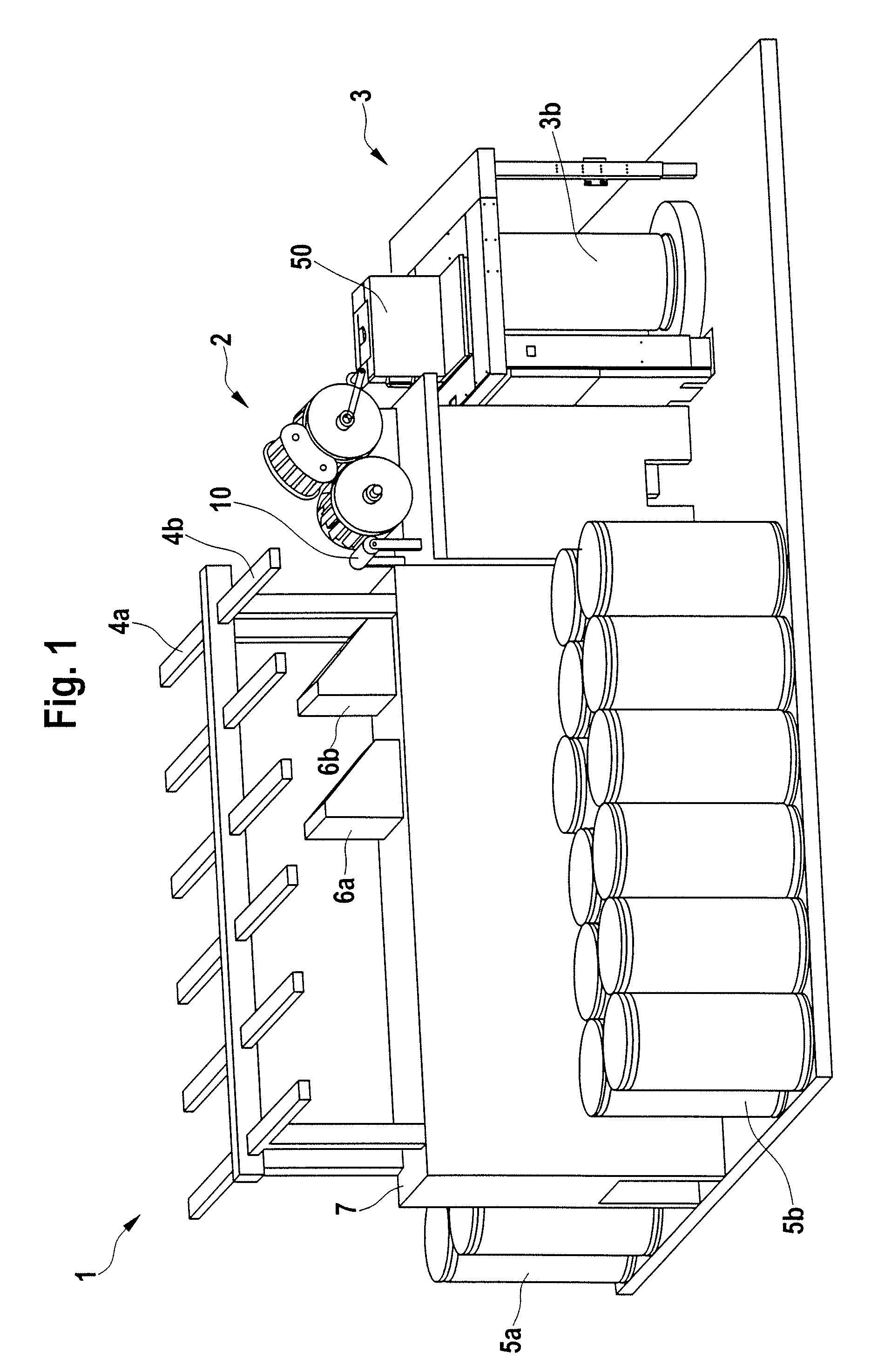

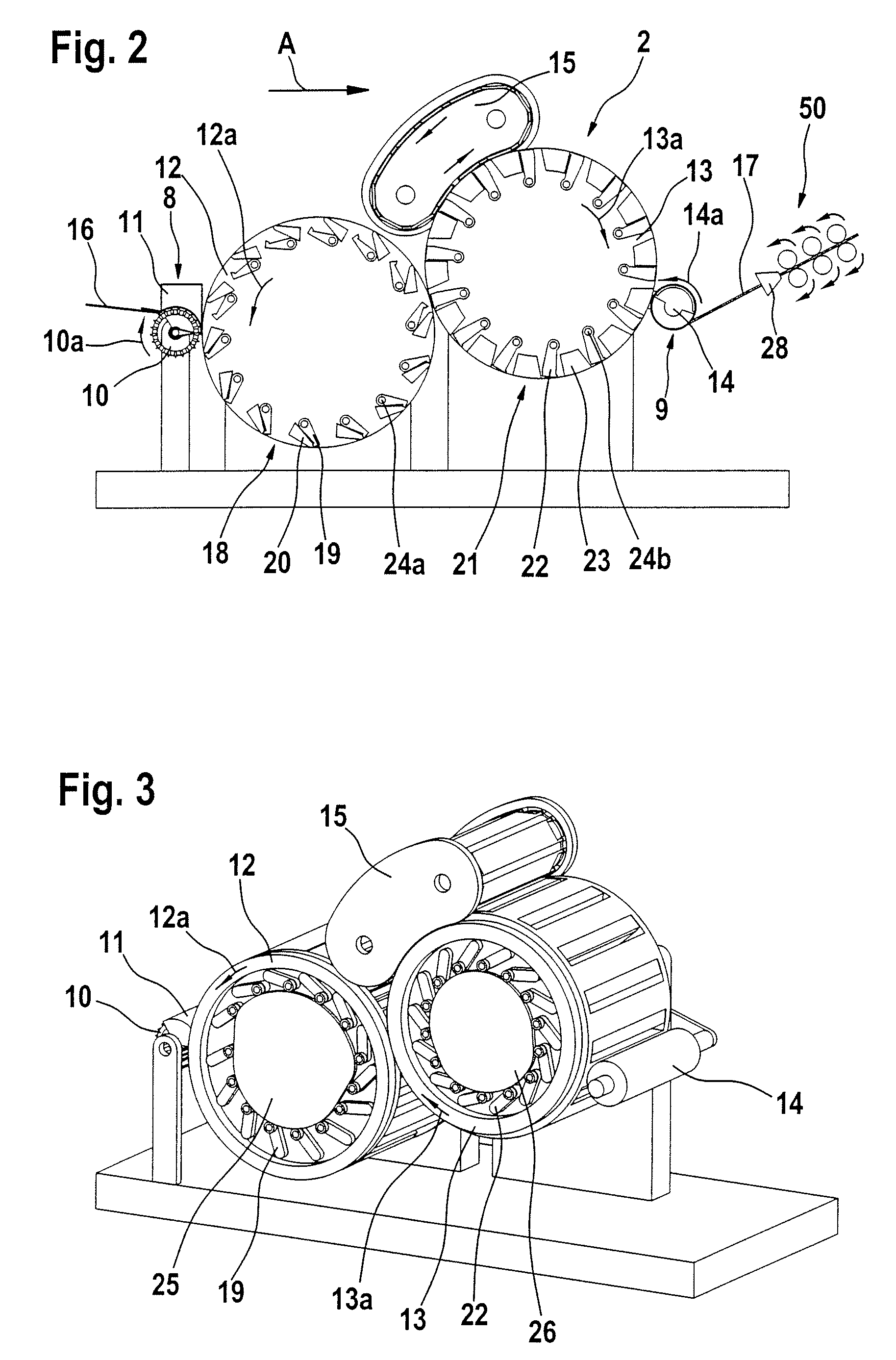

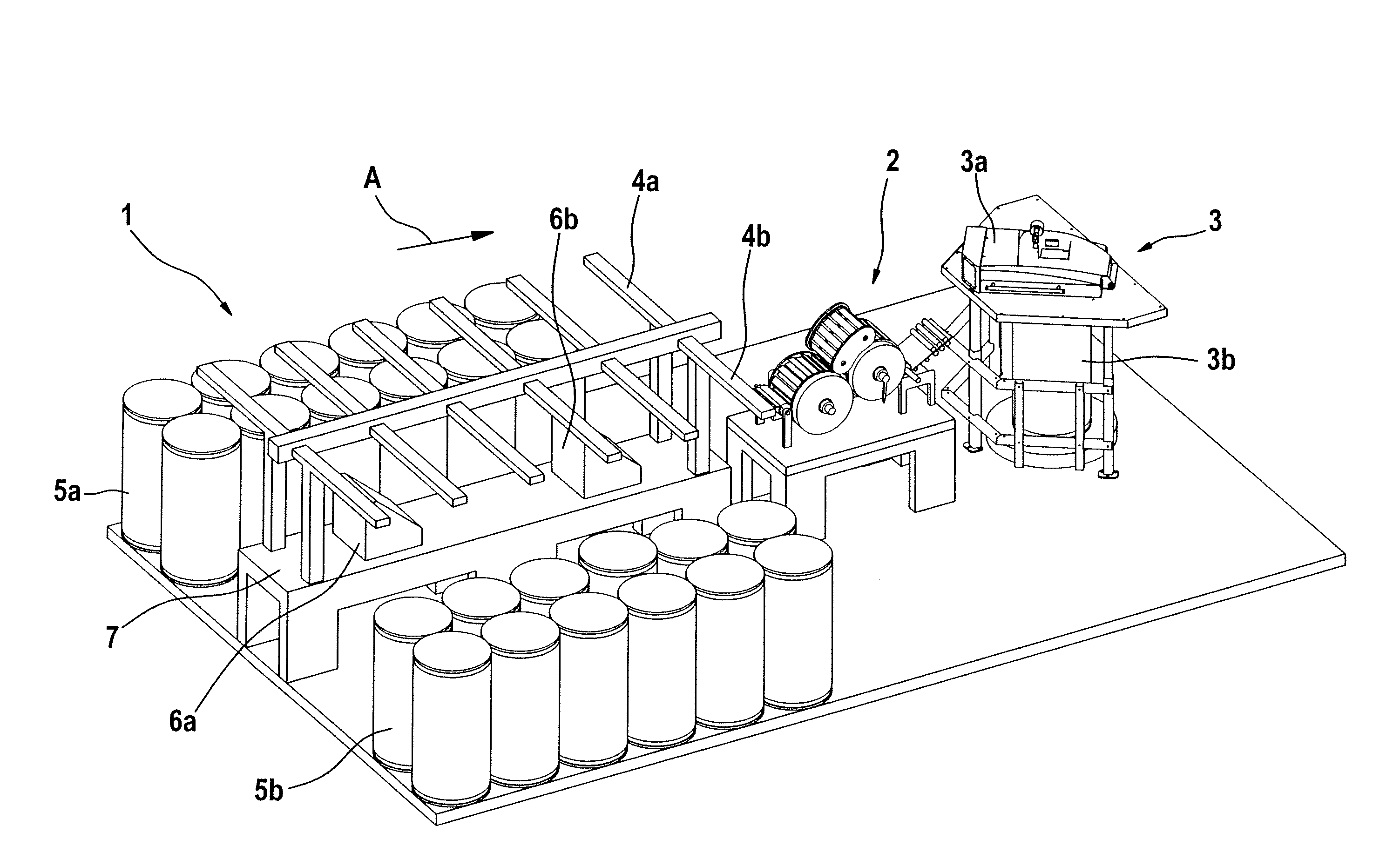

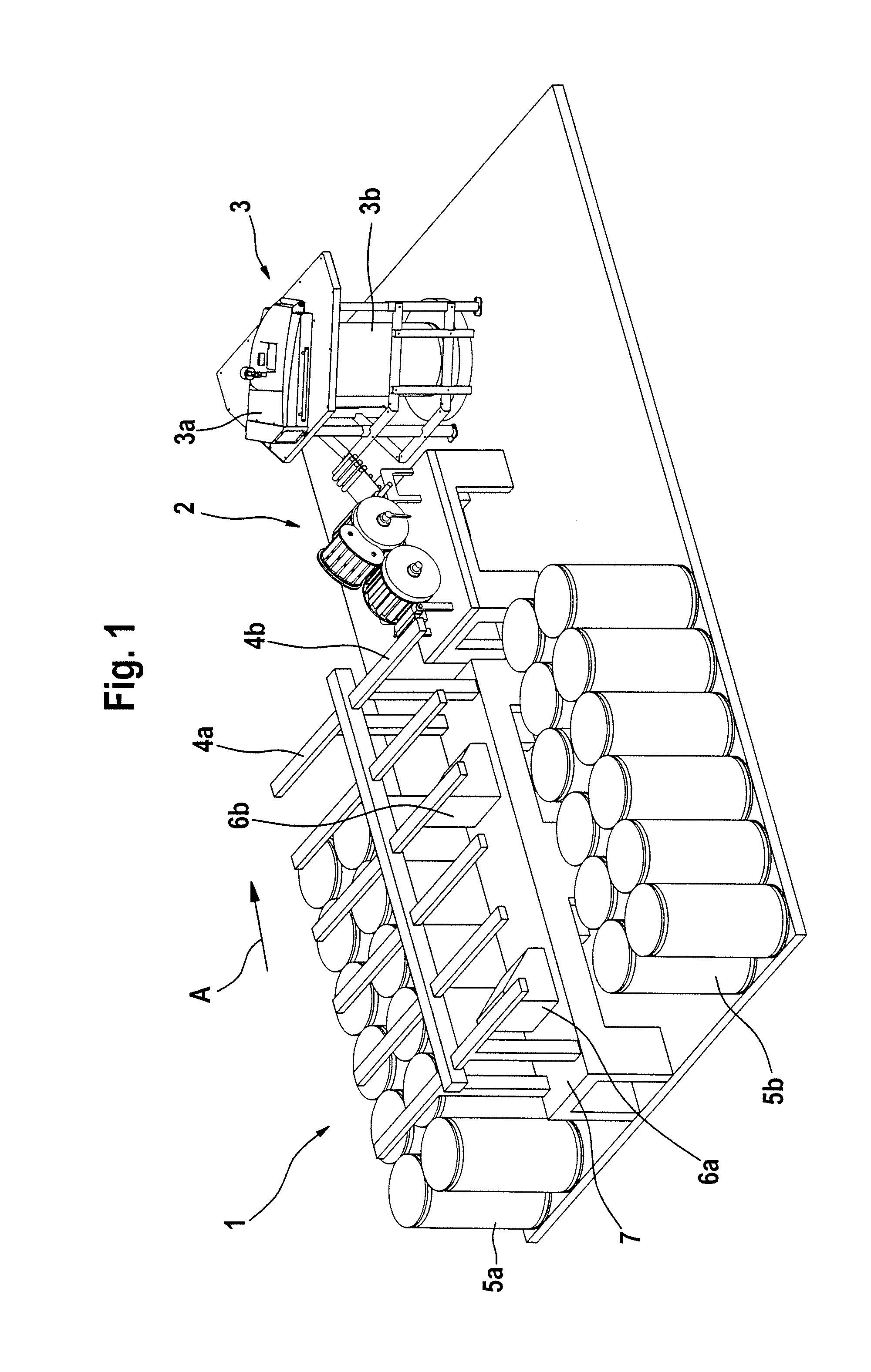

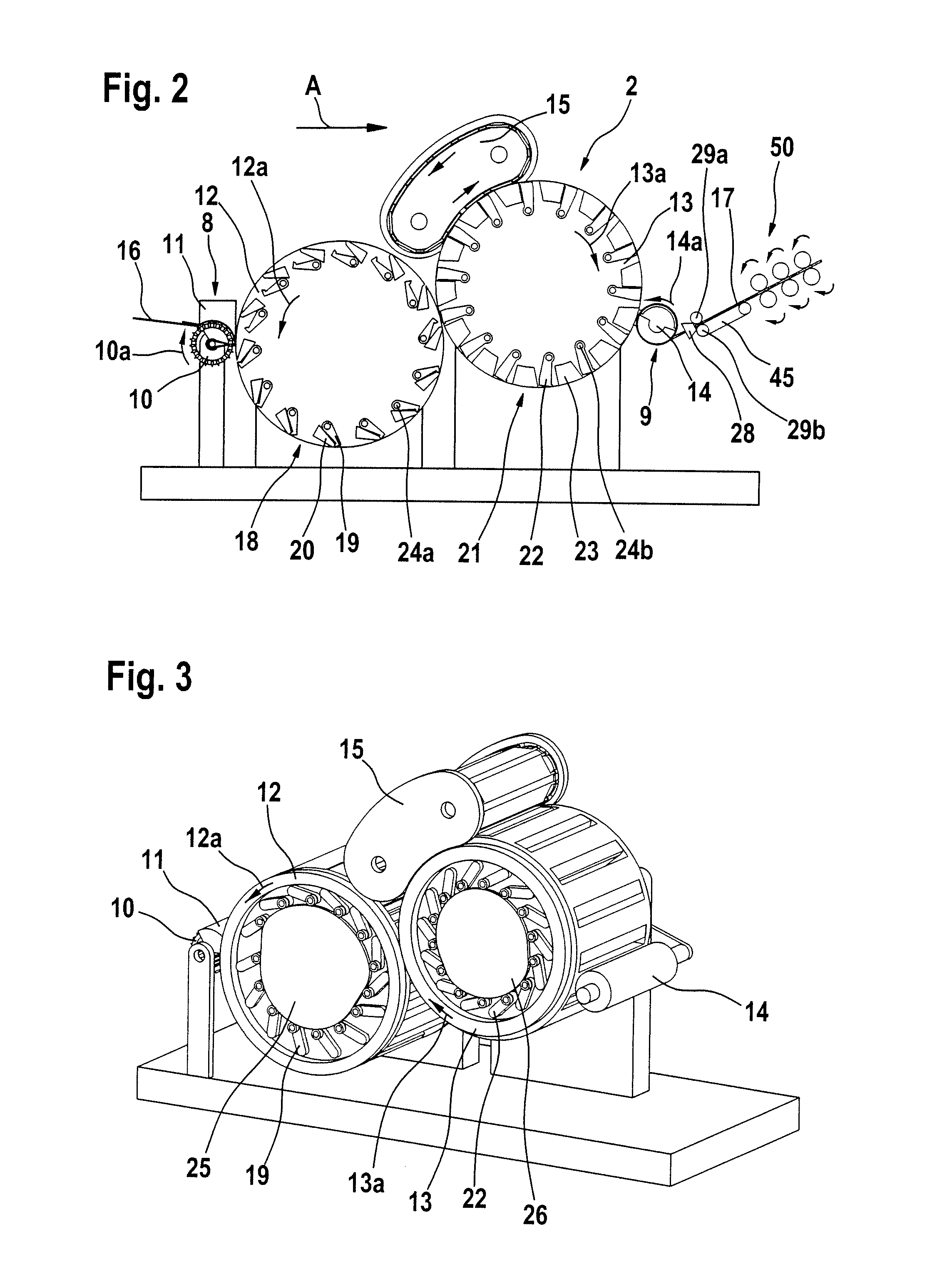

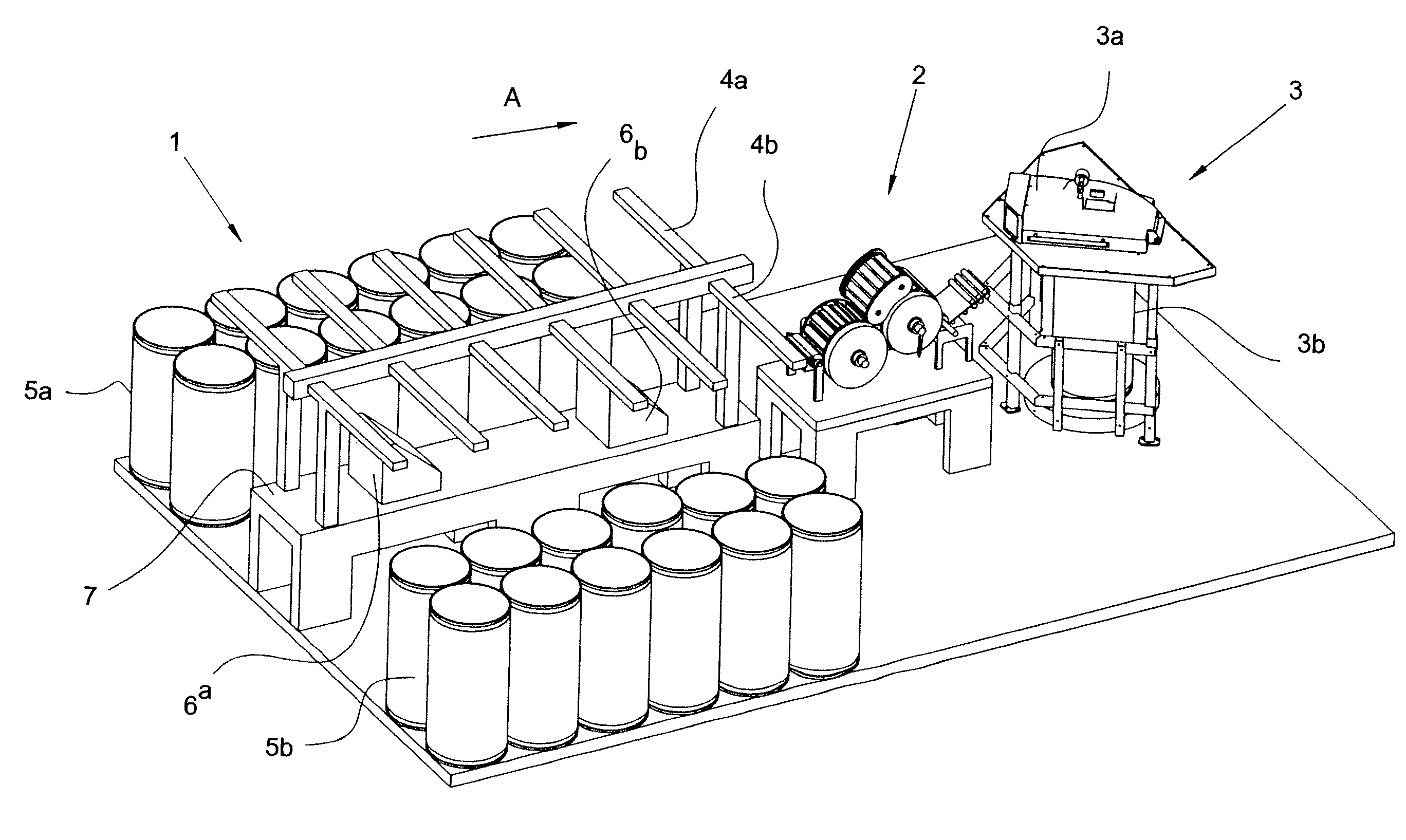

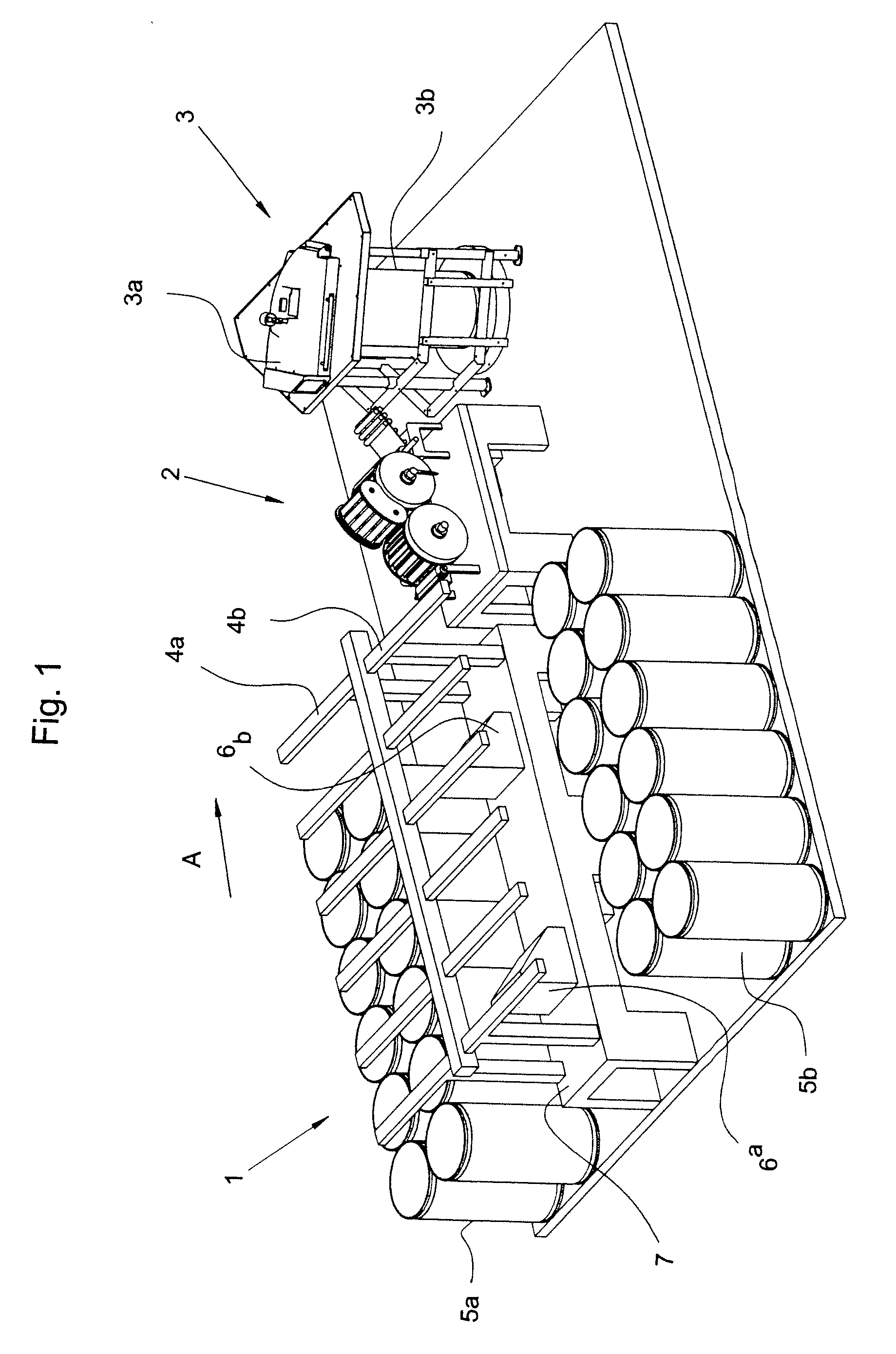

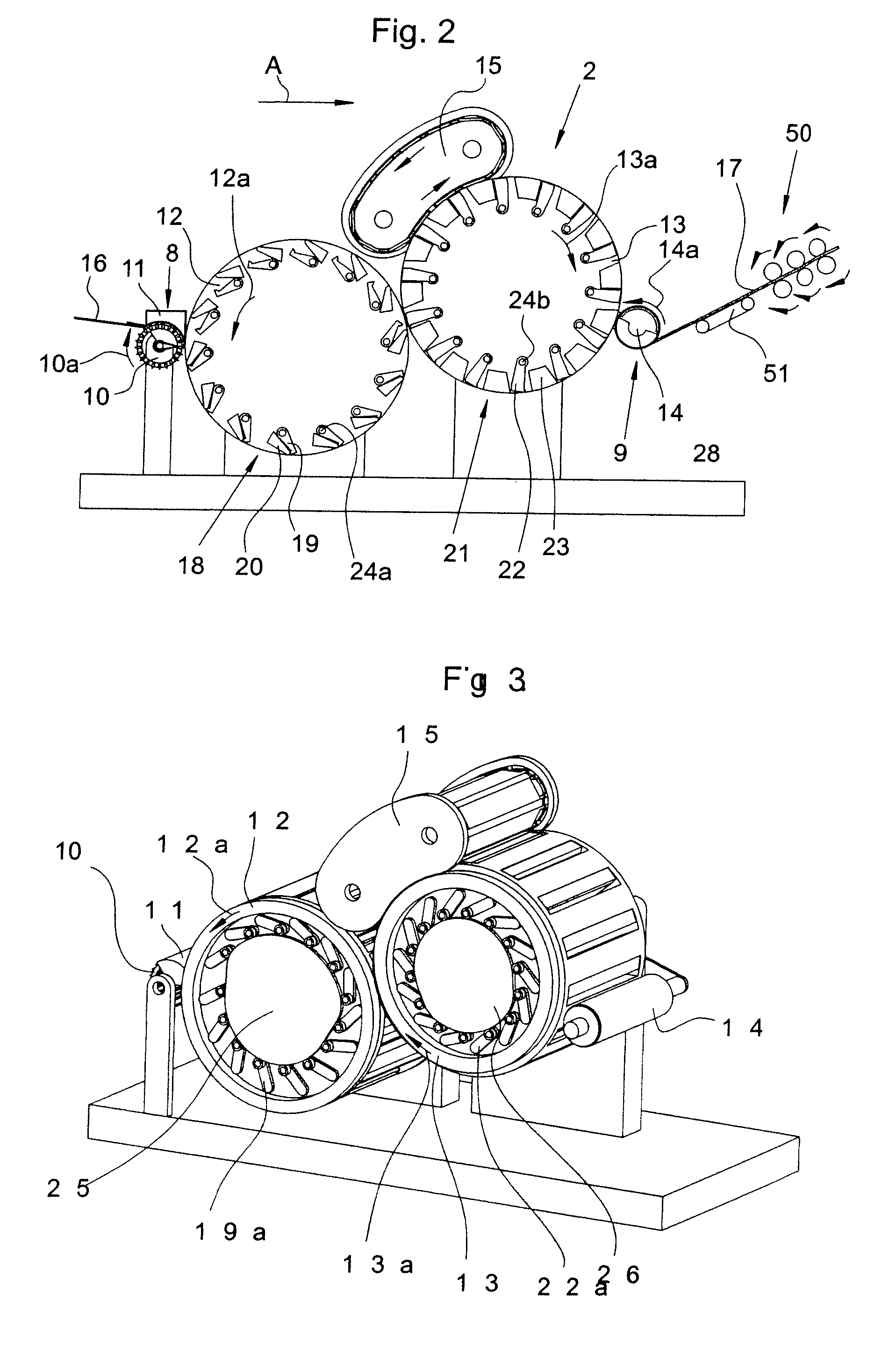

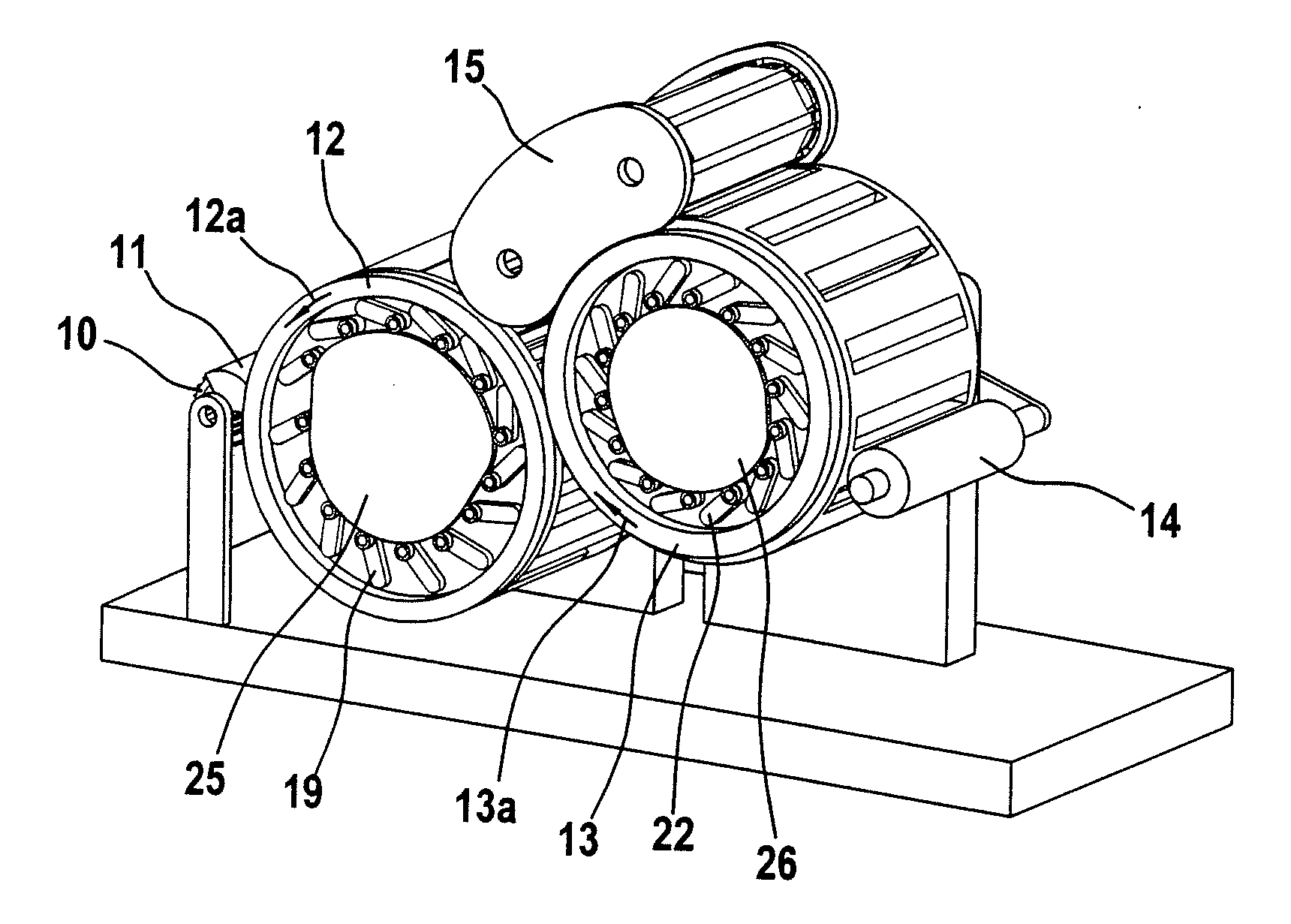

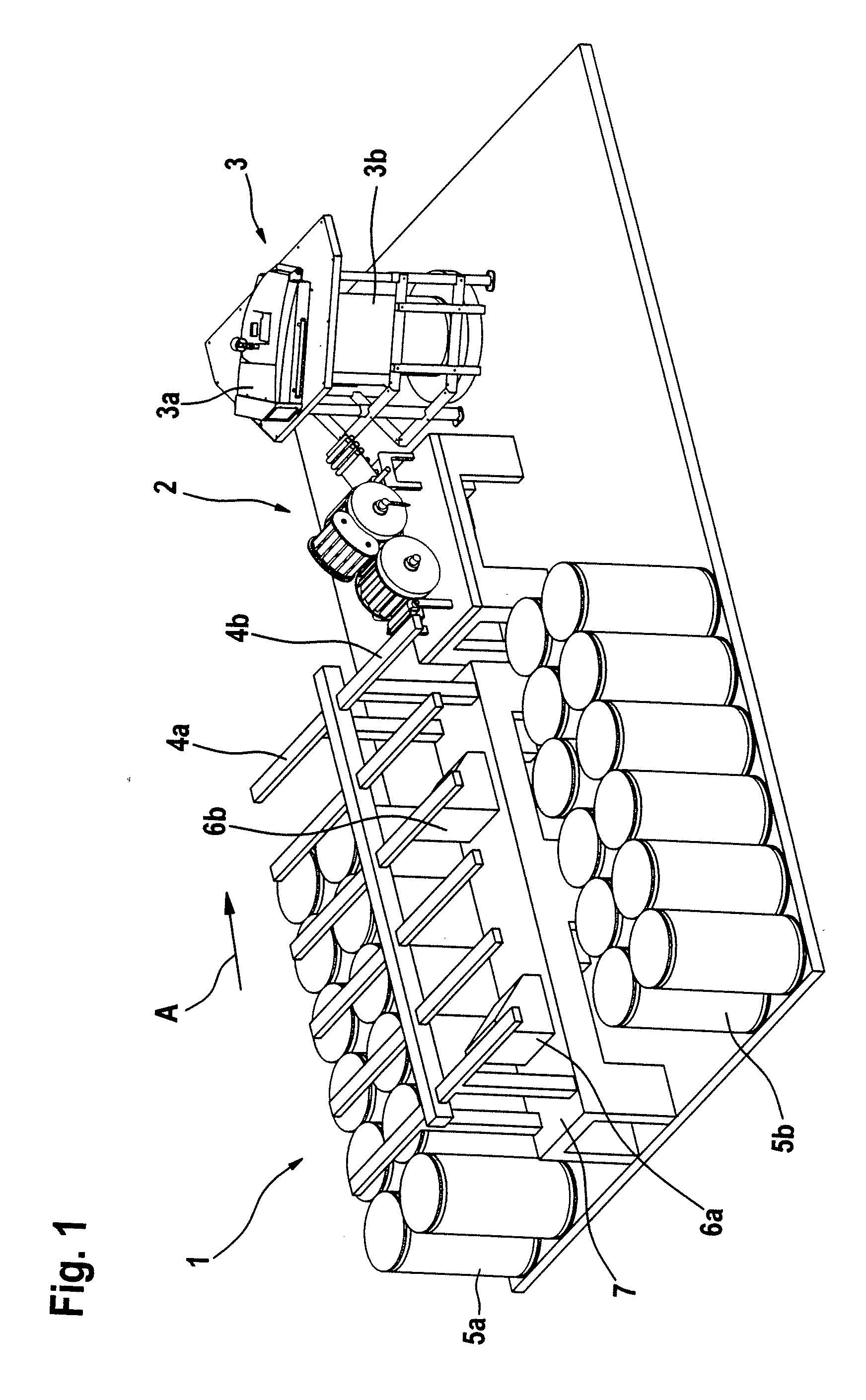

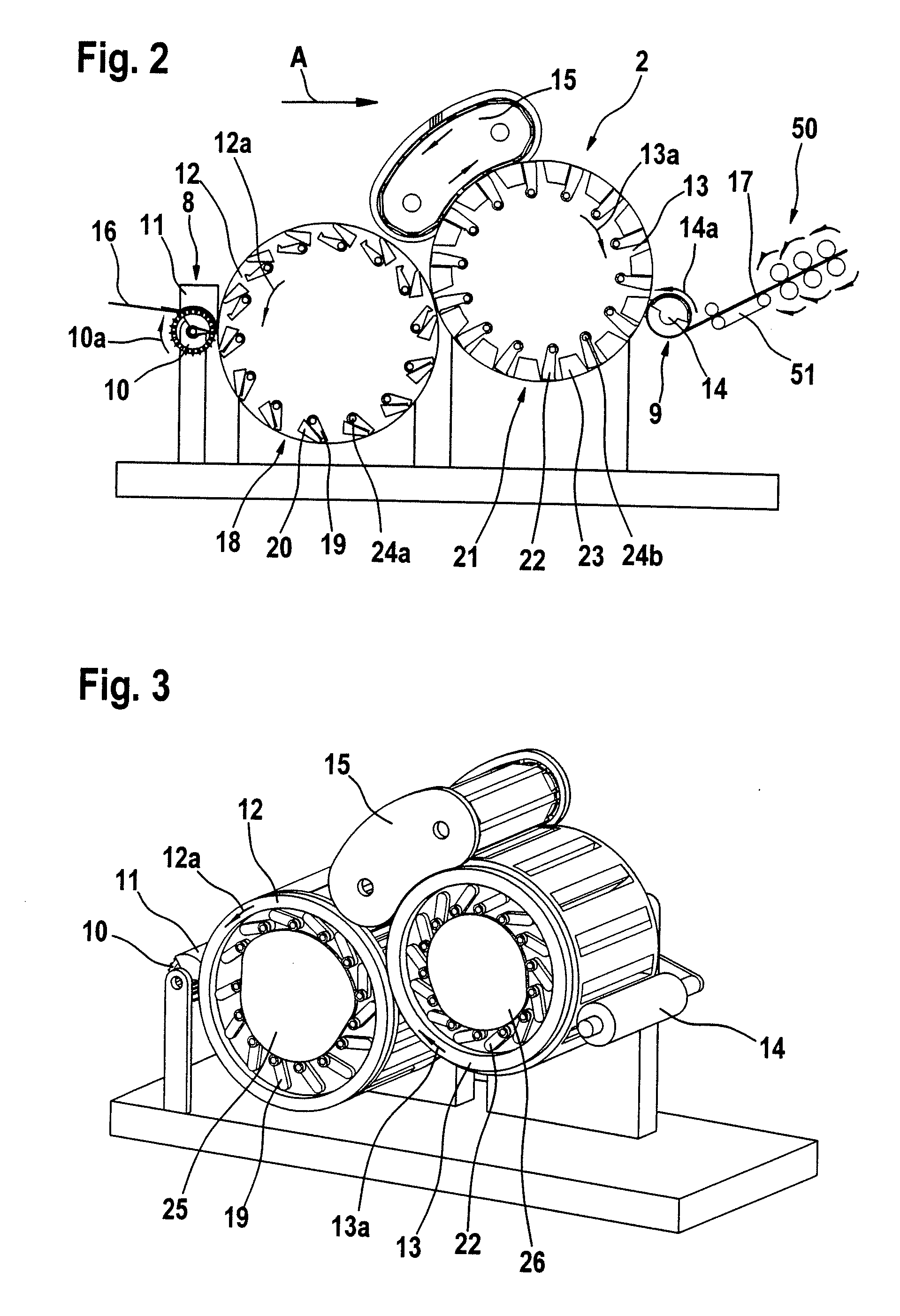

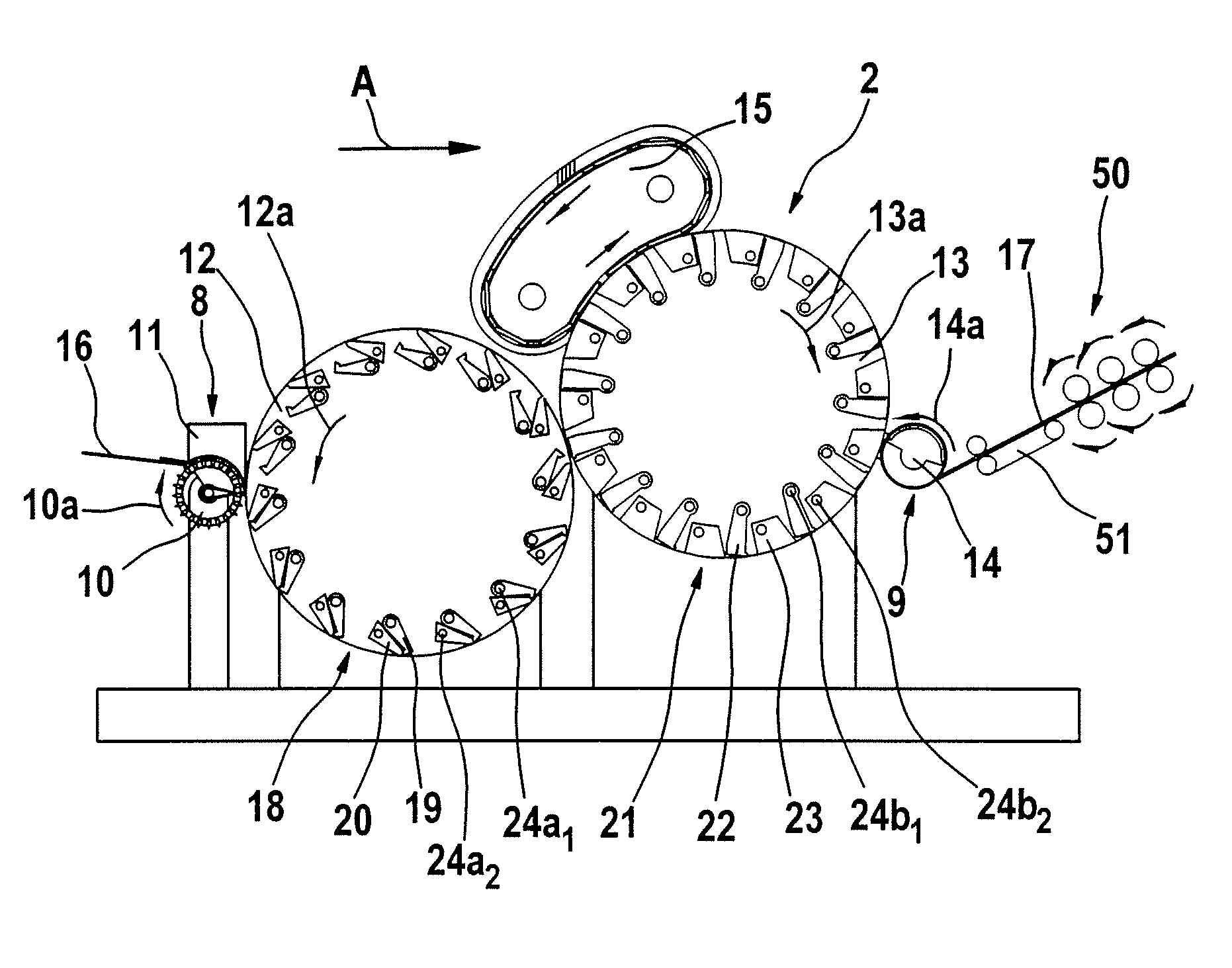

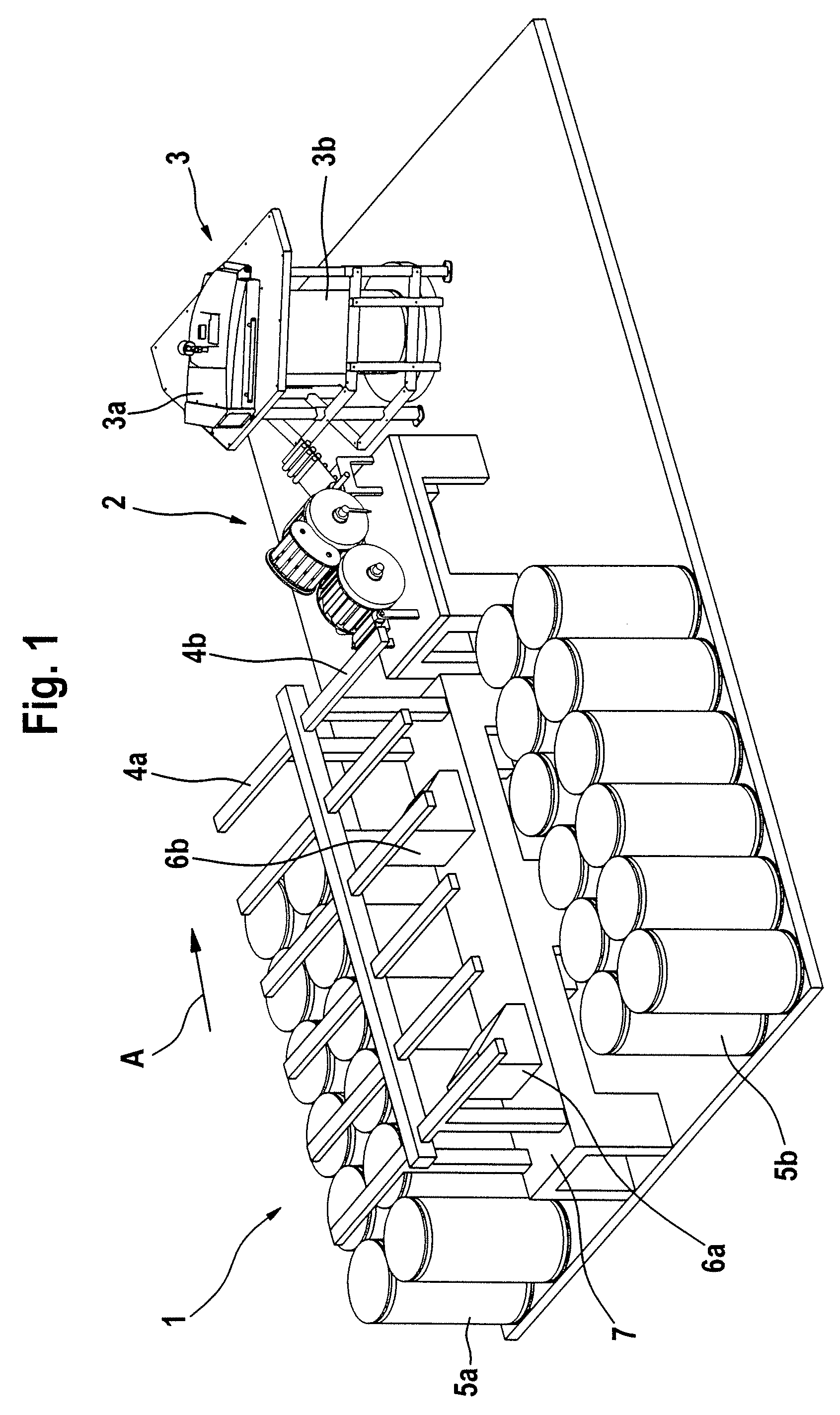

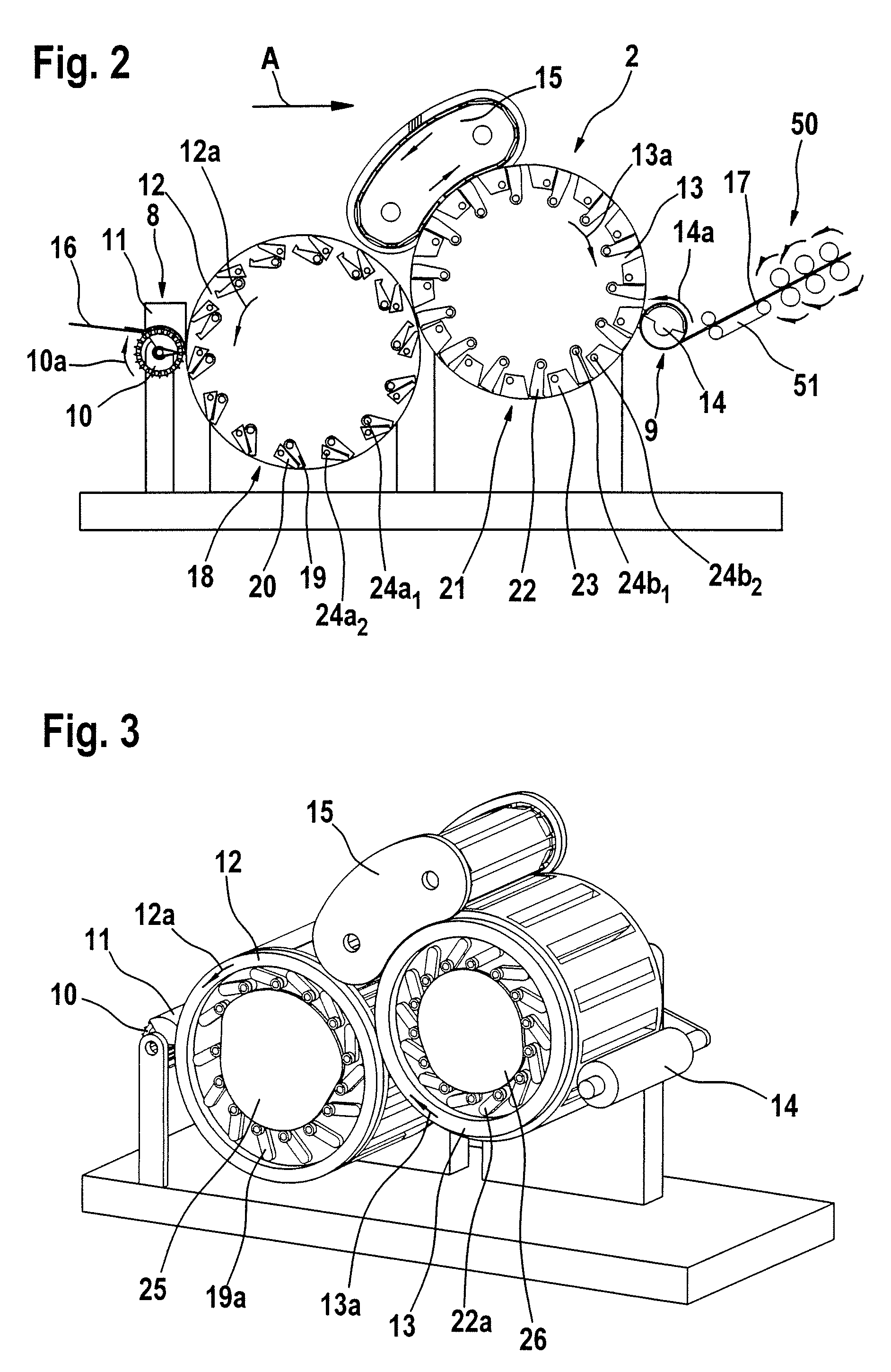

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000067A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

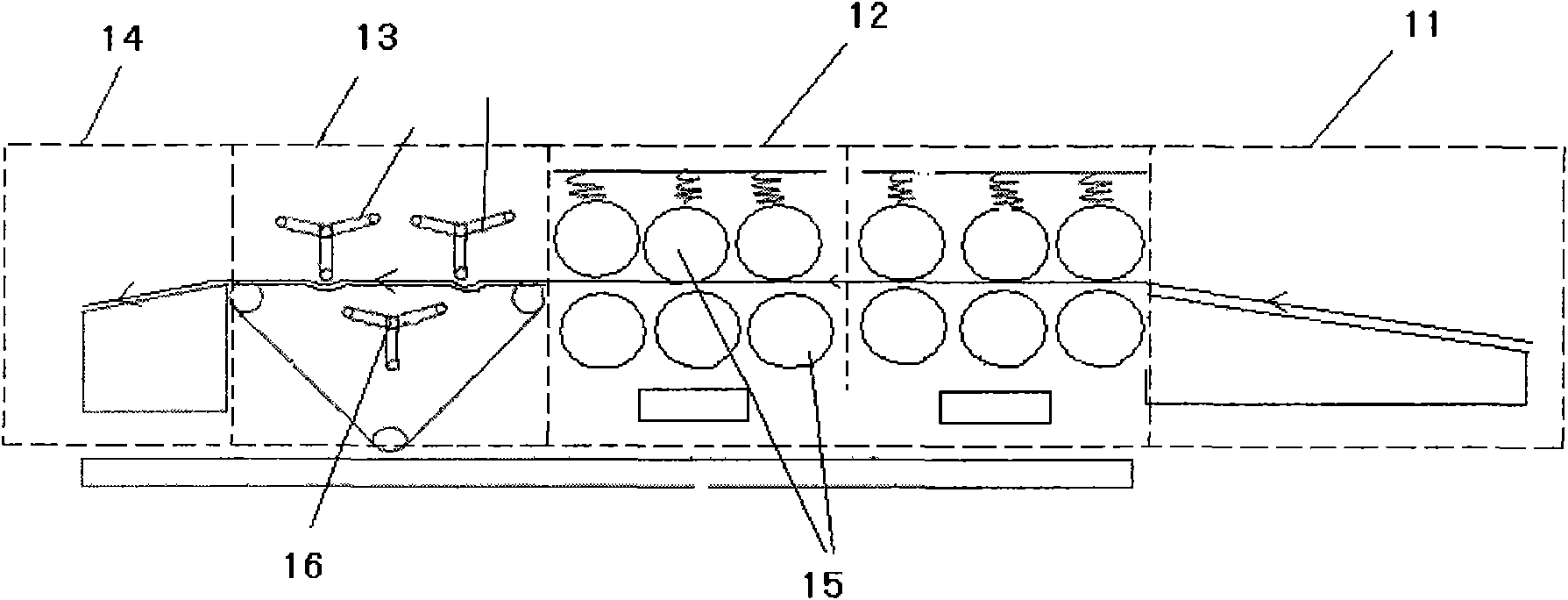

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of a supply device to a fibre-sorting device, especially a combing device, for removal of the combed fibre material at least one take-off device with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices for the fibre bundle, and between the sliver-forming element and the drafting system at least one conveyor element for a formed combed sliver is present.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000077A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part at least partially of a lightweight material. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the sorting or selection of a fibre sliver comprising textile fibres, especially for combing

An apparatus for the sorting or selection of fibre, especially for combing, is supplied by supply device to a sorting device. Clamping devices are provided which clamp the fibre sliver at a distance from its free end, for combing in order to loosen and remove non-clamped constituents, such as, for example, short fibres, neps, dust and the like from the free end. To enable productivity to be increased and an improved combed sliver to be obtained, downstream of the supply there is arranged at least one rotatably mounted roller which is provided with clamping devices for the fibre sliver, which clamping devices are distributed spaced apart around the periphery of the roller, and combing elements are associated with the periphery of the roller.

Owner:TRUETZSCHLER GMBH & CO KG

Preparation method of moisture-absorbing, sweat-permeable and anti-crease fabric

ActiveCN101949092AComfortable and breathableImprove wrinkle resistanceDyeing processWoven fabricsFiberColour fastness

The invention relates to a preparation method of a moisture-absorbing, sweat-permeable and anti-crease fabric, which comprises the following steps: weaving combed long stapled cotton and terylen fibers with grooves of a special shape into a base fabric by warp and weft interwaving based on a certain ratio, and enduing the fabric with the soft and air-permeable natural texture and permanent moisture-absorbing, sweat-permeable and anti-crease functions based on the physical structures of the raw materials; and dyeing the base fabric at high pressure and high temperature, carrying out a post-treatment on the fabric with a finishing liquid mixed according to a ratio of a special formula, and chemically finishing to enable the fabric to have high color fastness and feel soft and comfortable while having the moisture-absorbing, sweat-permeable and anti-crease functions. Thus, the invention meets the requirements for the moisture-absorbing, sweat-permeable and anti-crease fabric in the market, especially the requirements for outdoor clothes such as police uniforms, sports wears and the like.

Owner:江苏恒润盛鑫纺织实业有限公司

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000065A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device for removal of the combed fibre material at least one take-off means with a sliver-forming element is present, downstream of which is a drafting system to enable productivity to be substantially increased and an improved combed sliver to be obtained, downstream of the supply device there is arranged at least one rotatably mounted roller rotating rapidly without interruption, which is provided with clamping devices for the fibre bundle, which clamping devices are distributed spaced apart in the region of the periphery of the roller and the combed sliver formed is arranged to be supplied directly to the drafting system.

Owner:TRUETZSCHLER GMBH & CO KG

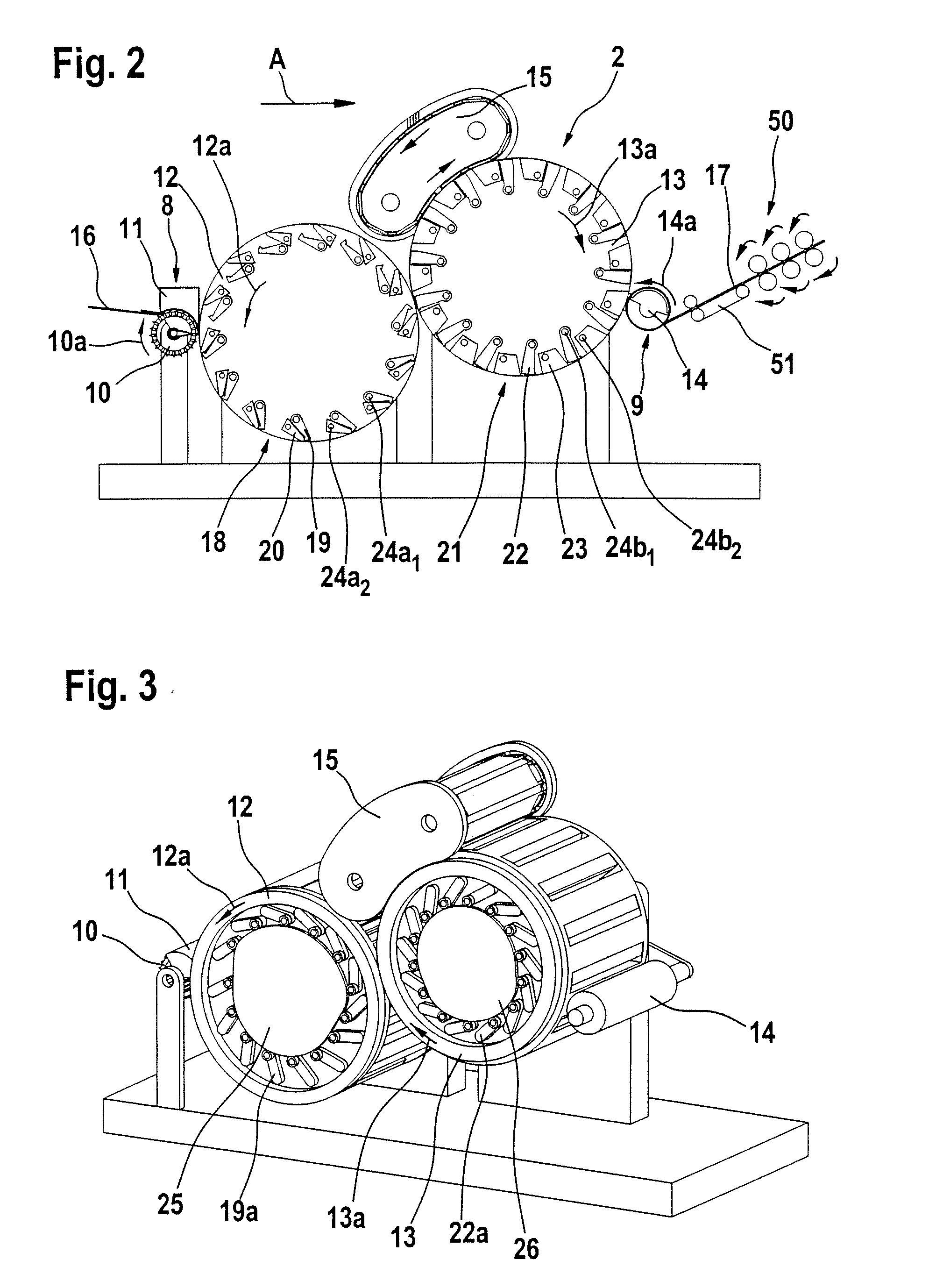

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000075A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by a supply device to a fibre-sorting device, especially a combing device, having clamping devices, which clamp the fibre bundle at a distance from its free end, for combing to remove non-clamped constituents, at least one take-off device 14 with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and improve the combed sliver, the fibre-sorting device has at least two rotatably mounted rollers rotating rapidly without interruption, having the clamping devices and between the sliver-forming element and the drafting system the at least one fibre sliver is present in the form of a fibre structure having a width greater than its height, for example, following spreading by a web-spreader.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000064A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part which is at least partially resilient. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

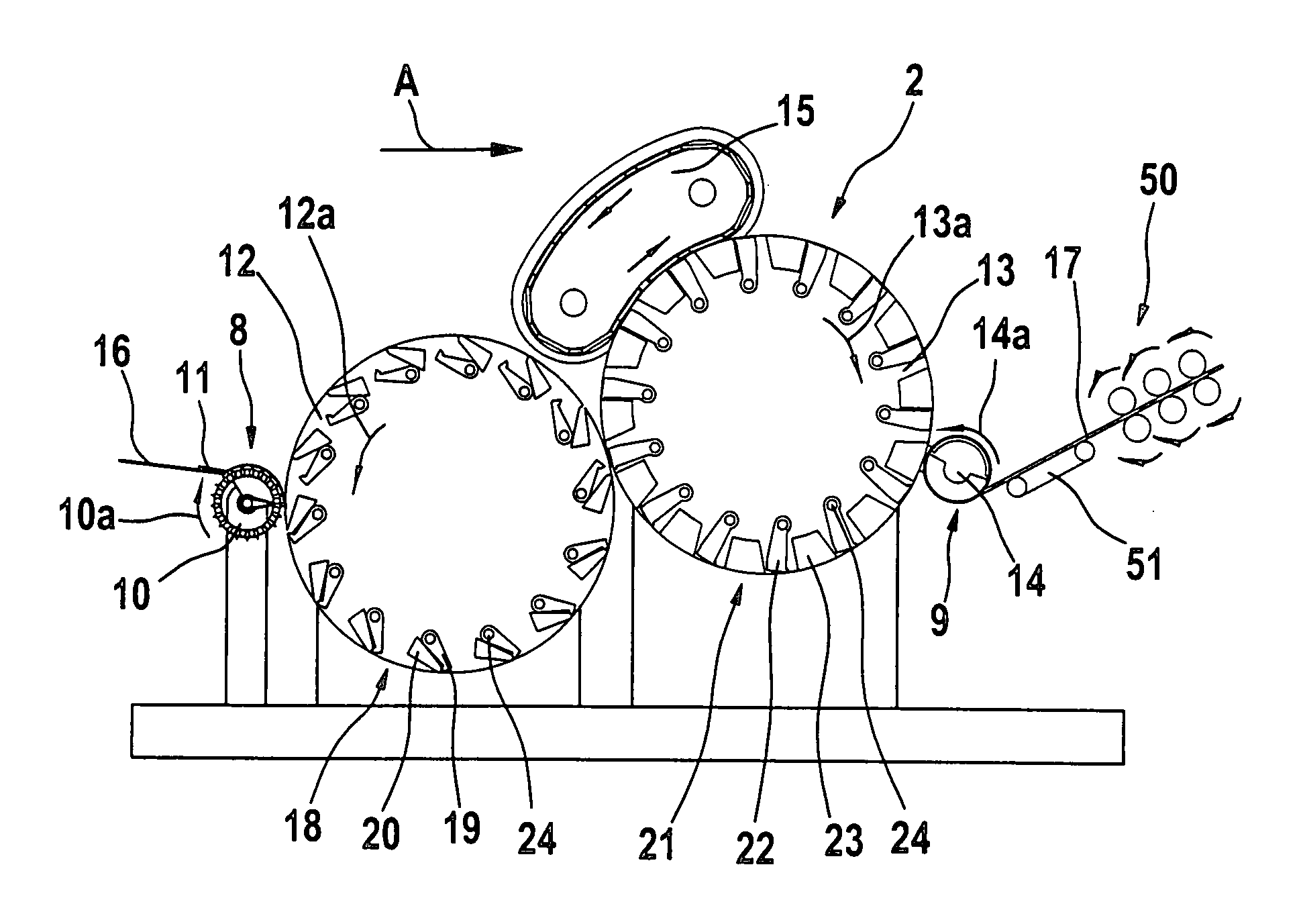

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000068A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, fibre is supplied by a supply device to a fibre-sorting device, especially a combing device. Clamping devices clamp the fibre bundle at a distance from its free end, and a mechanical device combs the free end to loosen and remove non-clamped constituents, for example, short fibres, neps, dust and the like. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices, and measured value sensors for detecting values relating to the fibres or machine settings are connected to a control and regulation device, which is arranged to effect actions in dependence on the measured values.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000069A1Increase volumeImproved combed sliverCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is suppled by a supply device to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and the clamping jaws of the each clamping device are arranged to be movable in relation to one another and separately drivable.

Owner:TRUETZSCHLER GMBH & CO KG

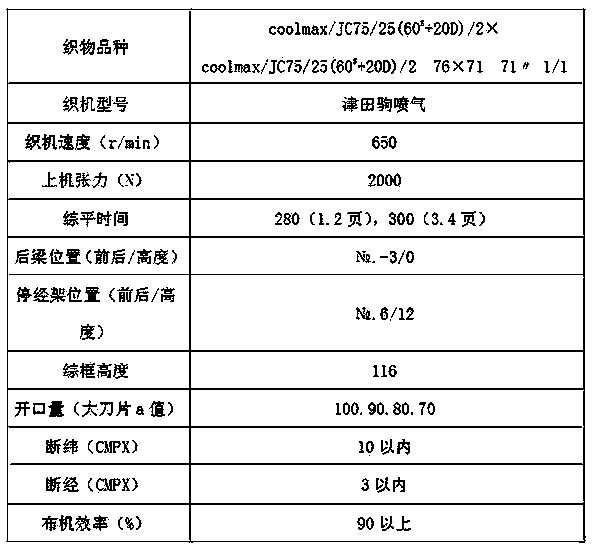

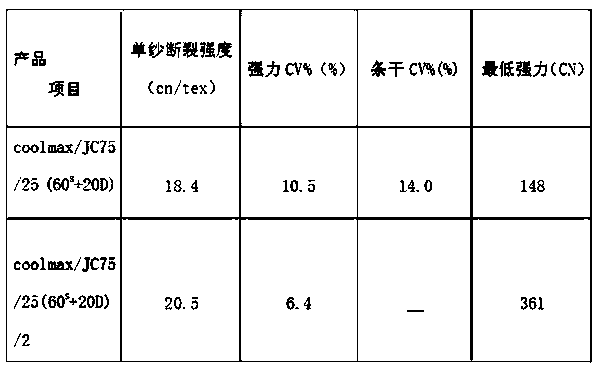

Moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and production method thereof

The invention provides moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and a production method of the moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and belongs to the technical field of textile. 75% of coolmax moisture-absorbing and sweat-releasing modified polyester fibers and 25% of cotton fibers are used as coated fibers, and 20D common polyester filament yarn is composed of covering yarn. Cotton opening and picking, cotton carding and pre-drawing are performed on the coolmax moisture-absorbing and sweat-releasing modified polyester fibers, and primary drawing, secondary drawing, roving, spinning, single yarn winding, yarn twisting and plied yarn winding are performed on the cotton fibers undergoing cotton opening and picking, cotton carding and combing to generate coolmax / JC75 / 25(60S+20D) single yarn and coolmax / JC75 / 25(60S+20D) / 2 plied yarn; the moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric is produced through beaming, slashing, denting, weaving and weave repairing. By means of reasonable scotching and cotton carding processes, two-time drawing mixing and appropriate slashing and weaving processes, the fabric has good moisture-absorbing, sweat-releasing, washable and quick-drying effects and good boney feel.

Owner:JIHUA 3542 TEXTILE CO LTD

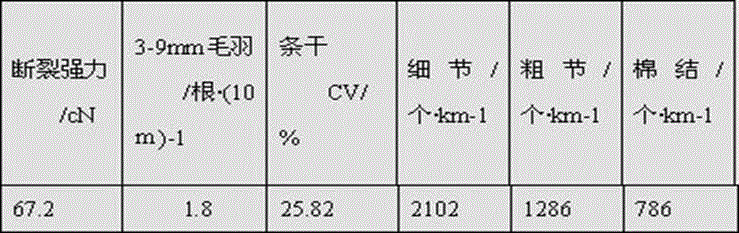

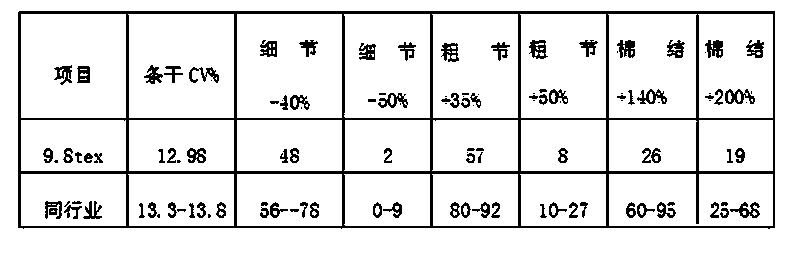

Ultra-high-count pure cotton combing yarn and spinning technology of ultra-high-count pure cotton combing yarn

ActiveCN103334190APromote maturityAmerican cotton has high strengthContinuous processingCombing machinesYarnFiber

The invention discloses ultra-high-count pure cotton combing yarn and a spinning technology of the ultra-high-count pure cotton combing yarn. Raw cotton comprises, by weight, 15%-25% of Egypt cotton, 25%-35% of American cotton and 40%-50% of Xinjiang long stapled cotton, wherein the Egypt cotton, the American cotton and the Xinjiang long stapled cotton are blended to spin 200S to 300S pure cotton yarn. The spinning technology includes the following steps that the first procedure of blowing-carding, the second procedure of combing, the third procedure of drawing, the fourth procedure of roving yarn, the fifth procedure of spun yarn and the sixth procedure of spooling. With the blending scheme, the raw cotton can integrate the advantages of high fineness and good maturity of the Egypt cotton, the advantages of high strength and non-existing abnormal fibers of the American cotton, the advantage of large length of the Xinjiang long stapled cotton and the like. The raw cotton reaches the requirements for the fiber length, the length CV value, the Micronaire value, the fineness, the strength and other performance indexes of raw cotton in producing ultra-high-count yarn. According to the spinning technology of the ultra-high-count pure cotton combing yarn, the ultra-high-count yarn can be produced under a large ration of roving yarn, the spinning efficiency is improved and meanwhile, quality of resultant yarn is ensured.

Owner:傲丝生态(中国)有限公司

Production method of under-twisted yarn towel

The invention discloses a towel manufacturing process, which relates to the textile field. The towel manufacturing process comprises the steps: combed long-staple cotton yarns are woven into a piece of grey cloth by a high speed weaving machine; the grey cloth is soaked into a solution of a continuous washing and bleaching range to remove the impurities and slurries in the cotton yarns; the grey cloth is deoxidized, dyed, enzyme-washed, softened, dried by vibration and sewn into towels. Through adopting the long-staple cotton, shorter fibers are eliminated through fine combing, and the long-staple cotton is spun into yarns through twisting, the fibers are parallel and smooth, the gloss is better, and the hairiness is less. Without the water soluble yarn working procedure, the product woven through soft twist yarns reaches the effect of the non-twisted yarn, the labor intensity of workers is reduced, the sewage treatment pressure is relieved, the problem of the environmental pollution is reduced, and the product service life is prolonged.

Owner:孙日贵

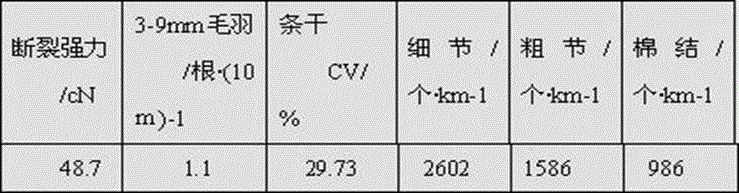

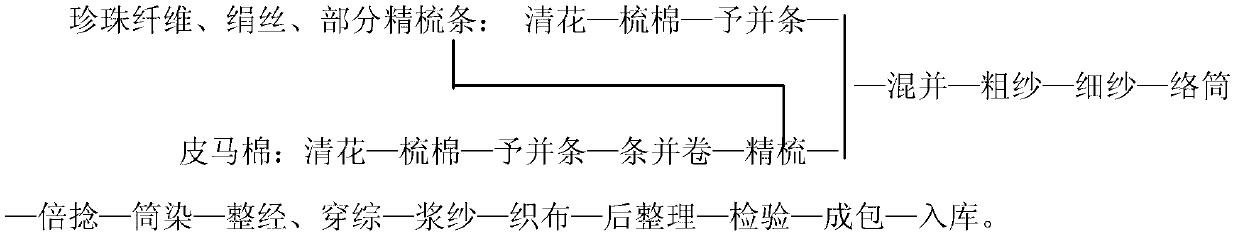

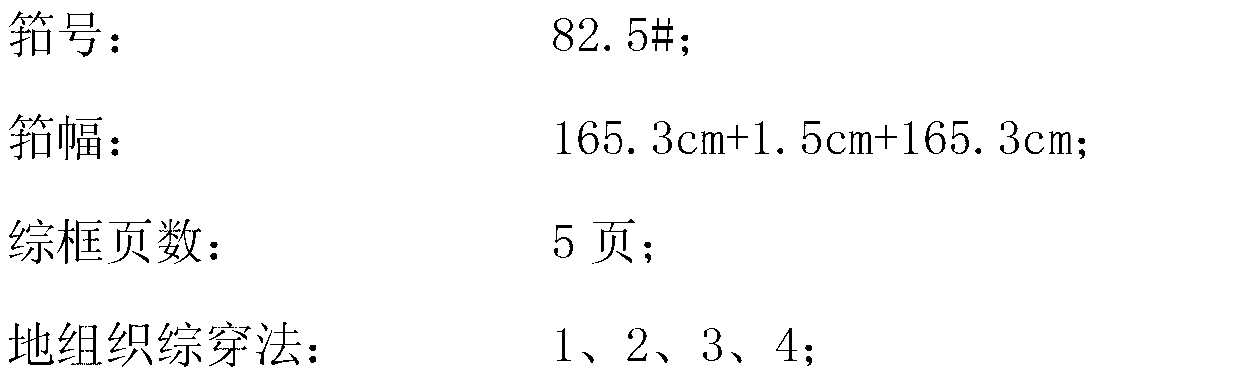

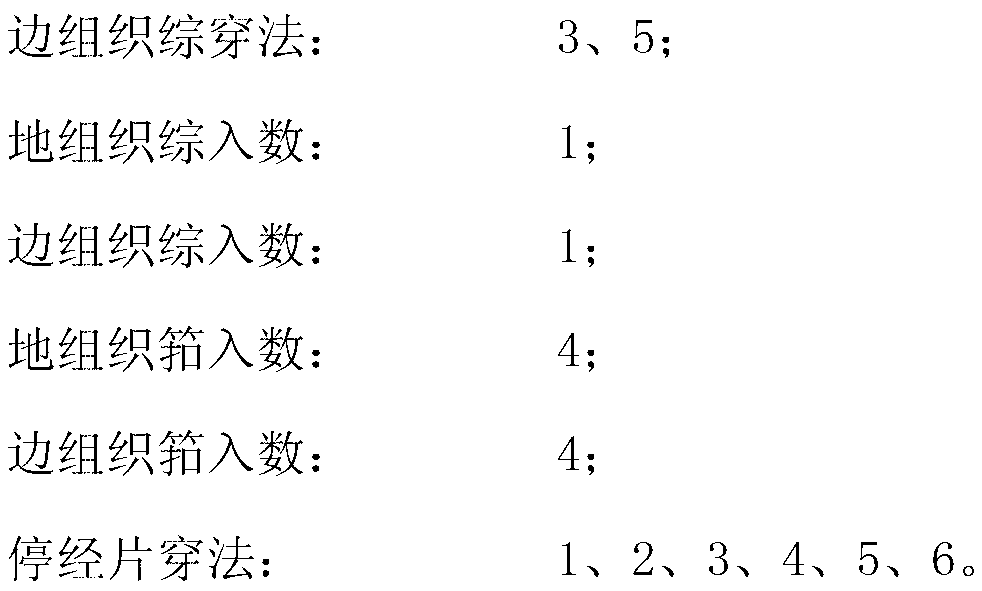

Pearl fiber shirt fabric and preparation method thereof

The invention provides a pearl fiber shirt fabric which has silky luster and is less in hairiness and anti-pilling. Warps and weft yarns of the pearl fiber shirt fabric are all 120 Ne two-fold yarns which are formed by compact spinning of 30% pearl fibers, 20% spun silks and 50% long stapled cottons. The invention further provides a preparation method of the pearl fiber shirt fabric. The preparation method of the pearl fiber shirt fabric includes the following steps: a, spinning; enabling part of combing long stapled cottons to be mixed with the spun silks and the pearl fibers and rolled in the process of opening picking, then drawing after cotton carding, mixing with other combing long stapled cottons and then through the processes of roving, fine spinning, spooling and two-for-one twisting; b, cheese dyeing; including the steps of cheese loosing, preprocessing, dyeing, hot washing, acid-washing, soaping, hot washing, cold washing, color fixing, softening, cylinder discharging, drying and cheese fastening, the preprocessing includes bleaching and enzyme treatment; c, weaving; including the steps of beaming, drafting, slashing and weaving; and d; post-processing, including the steps of desizing, softening, sizing and preshrinking.

Owner:JIANGSU YDTEX GRP LTD

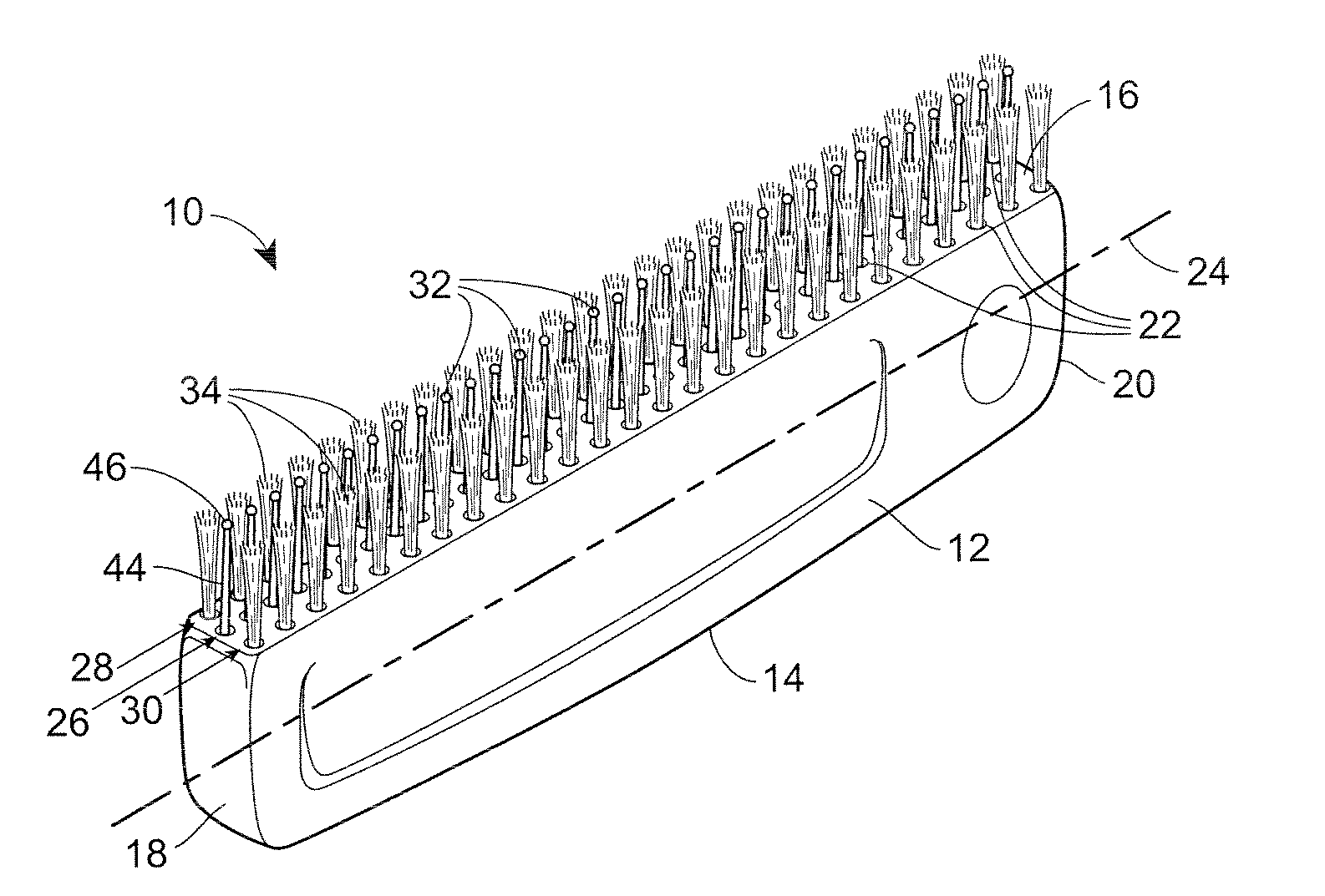

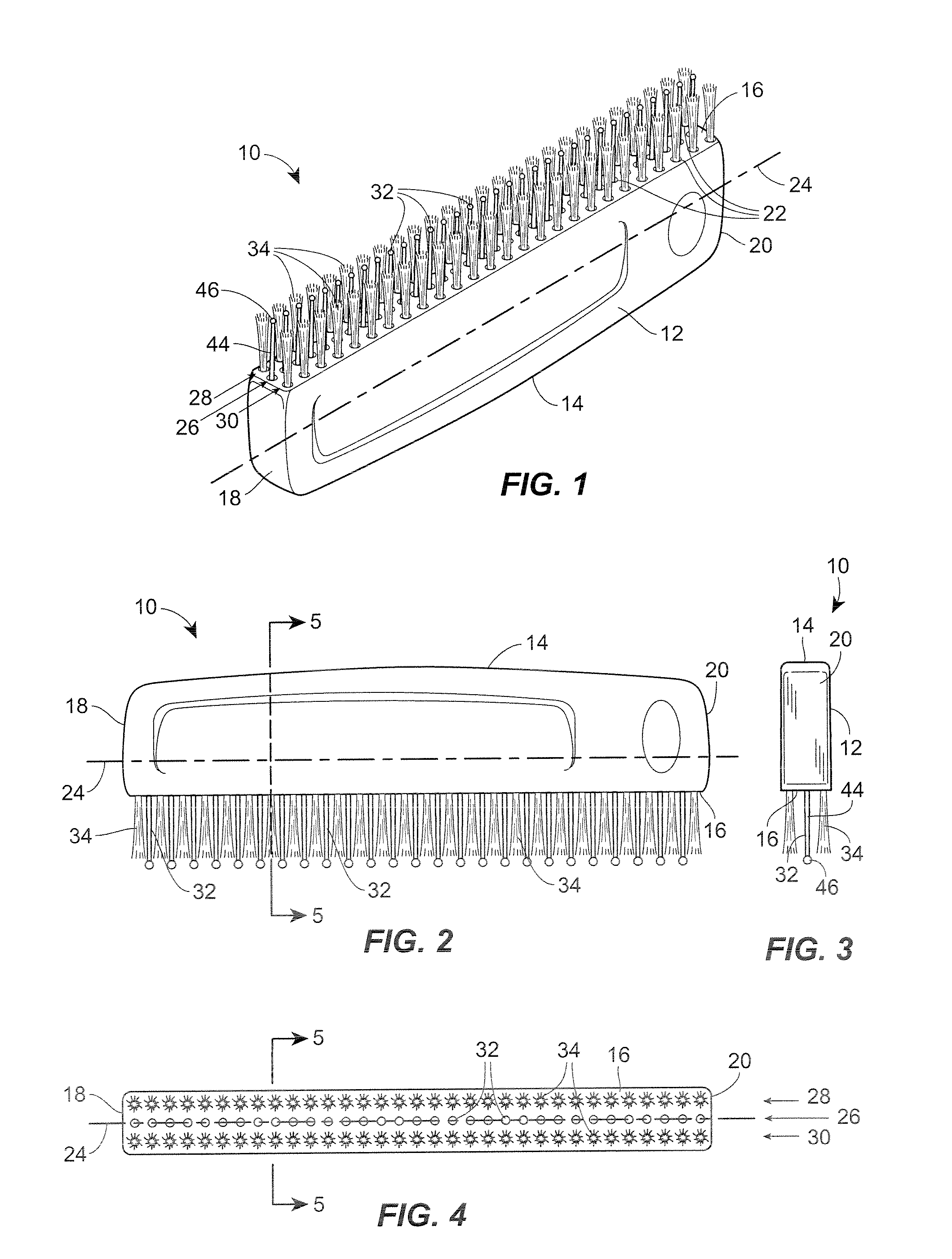

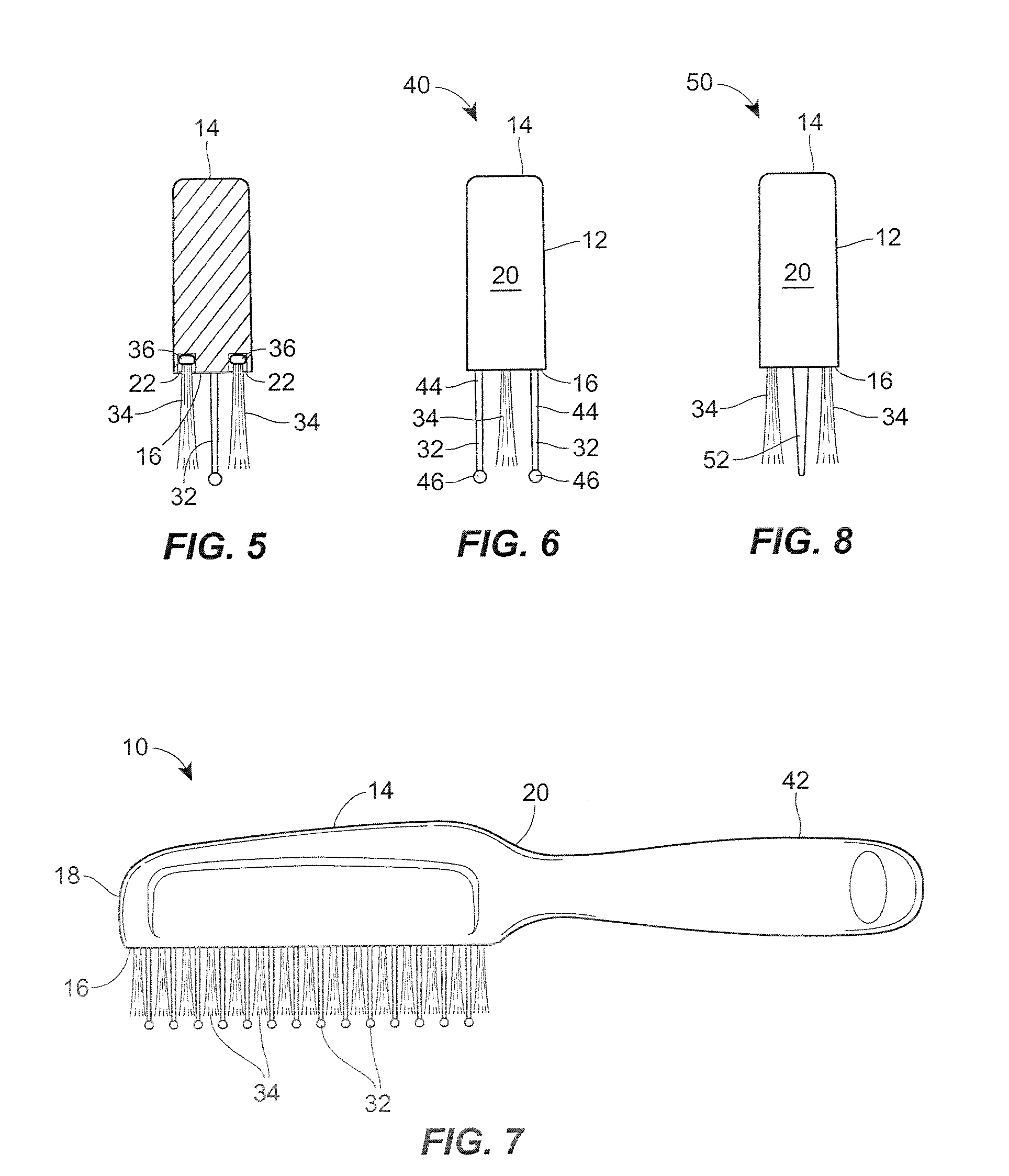

Brush with combing members having ribs to facilitate combing of tangled hair strands

InactiveUS20050081875A1Easy to combFacilitate disentanglingBristle carriersBristleCombingEngineering

A brush includes a combing unit that projects outwardly from a mounting portion of a brush body, and that includes a plurality of spaced apart combing plates and a plurality of auxiliary combing members. Each of the auxiliary combing members is disposed between an adjacent pair of the combing plates, and has a plurality of ribs. Each of the ribs has a top portion. The top portions of each adjacent pair of the ribs angle away from each other to define a V-shaped groove therebetween.

Owner:WANG HUO PIA

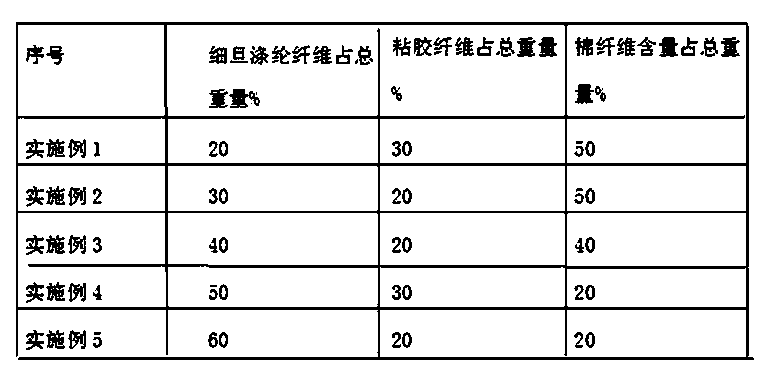

Dacron, viscose rayon and cotton blending compact siro spinning yarn and manufacturing technology thereof

A dacron, viscose rayon and cotton blending compact siro spinning yarn comprises 20%-60% of fine-denier dacron, 20%-60% of viscose rayon fibers and 20%-60% of cotton fibers. A manufacturing technology of the dacron, viscose rayon and cotton blending compact siro spinning yarn comprises the steps that the dacron, viscose rayon and cotton are subjected to the cotton blowing and carding processes, the cotton fibers are made into rough slivers through the fine carding and drawing processes, the fine-denier dacron and viscose rayon fibers are compounded in the drawing process according to the blending ratio and then are subjected to the roving process to be made into rough slivers, two rough slivers are fed into two horn mouths of a refine yarn rear area in sequence in the fine yarning process, a high-power fan is selected to make the compact siro spinning yarn, yarn faults and single yarns are cleaned by a winder, the dacron, viscose rayon and cotton blending compact siro spinning yarn is manufactured, and the relative humidity of the production environment of all processes is 56-60% of humidity. The dacron, viscose rayon and cotton blending compact siro spinning yarn is compact in structure, few in yarn hairiness, high in strength, and capable of being made into fabrics of top-grade textile garments, and a pure-natural and comfortable textile product is provided for the textile field.

Owner:JIHUA 3542 TEXTILE CO LTD

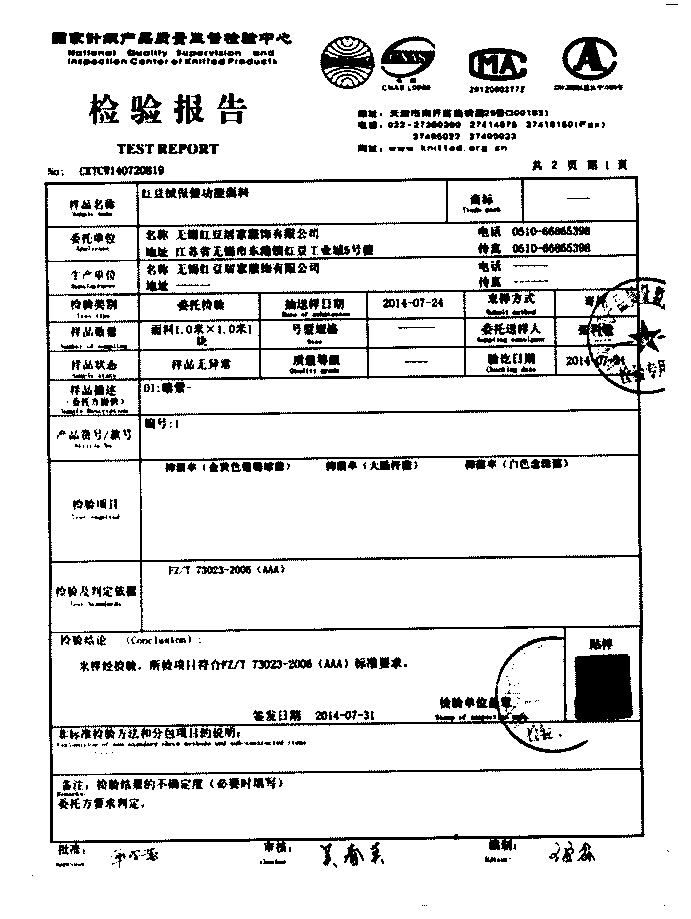

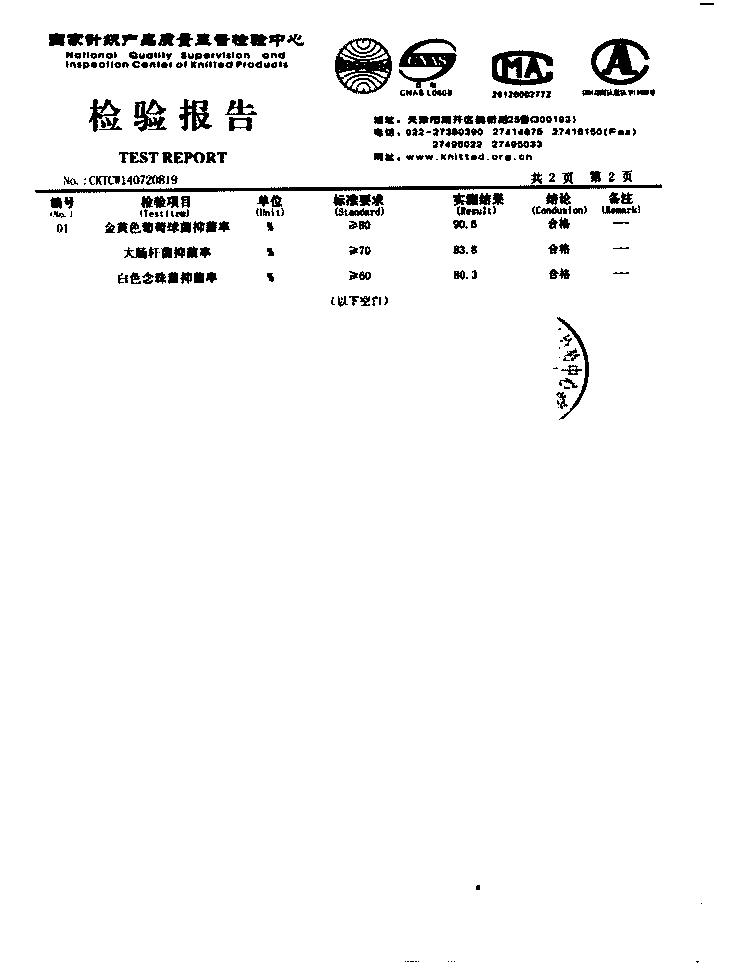

Red bean velvet healthcare functional fabric

ActiveCN104305541AImprove antibacterial propertiesGood washing stabilityWeft knittingHeating/cooling textile fabricsYarnColor changes

The invention relates to a red bean velvet healthcare functional fabric. The red bean velvet healthcare functional fabric is characterized by adopting the following technology (1) weaving into the fabric through all cotton combing yarns, processing through weak positive ion softening agent S200 after refining, bleaching and dying, performing napping processing on the front side and rear side through a sanding machine after preprocessing open width drying before napping and enabling the fabric speed to be 16 to 18 meters per minute and the rotary speed of a carbon brush hair roller to be 1800 to 2000 turns per minute; (2) sorting the red beam fabric in antibacterial agent, wherein the antibacterial agent comprises components of 1.5 to 5 % o.w.f (On weight the fabric) of nano-modification titanium dioxide, 2 to 5 % o.w.f of penetrating agent and 1 to 3 % of dispersing agent; (3) performing tentering sizing sorting; (4) performing organic silicon and organic fluorine sorting. The red bean velvet healthcare functional fabric has the advantages of not needing to adding extra chemical crosslinking agent, having an anti-bacterial function, being good in antibacterial performance, high in washing fastness, free of color change and fluffy and soft.

Owner:无锡红豆织造有限公司

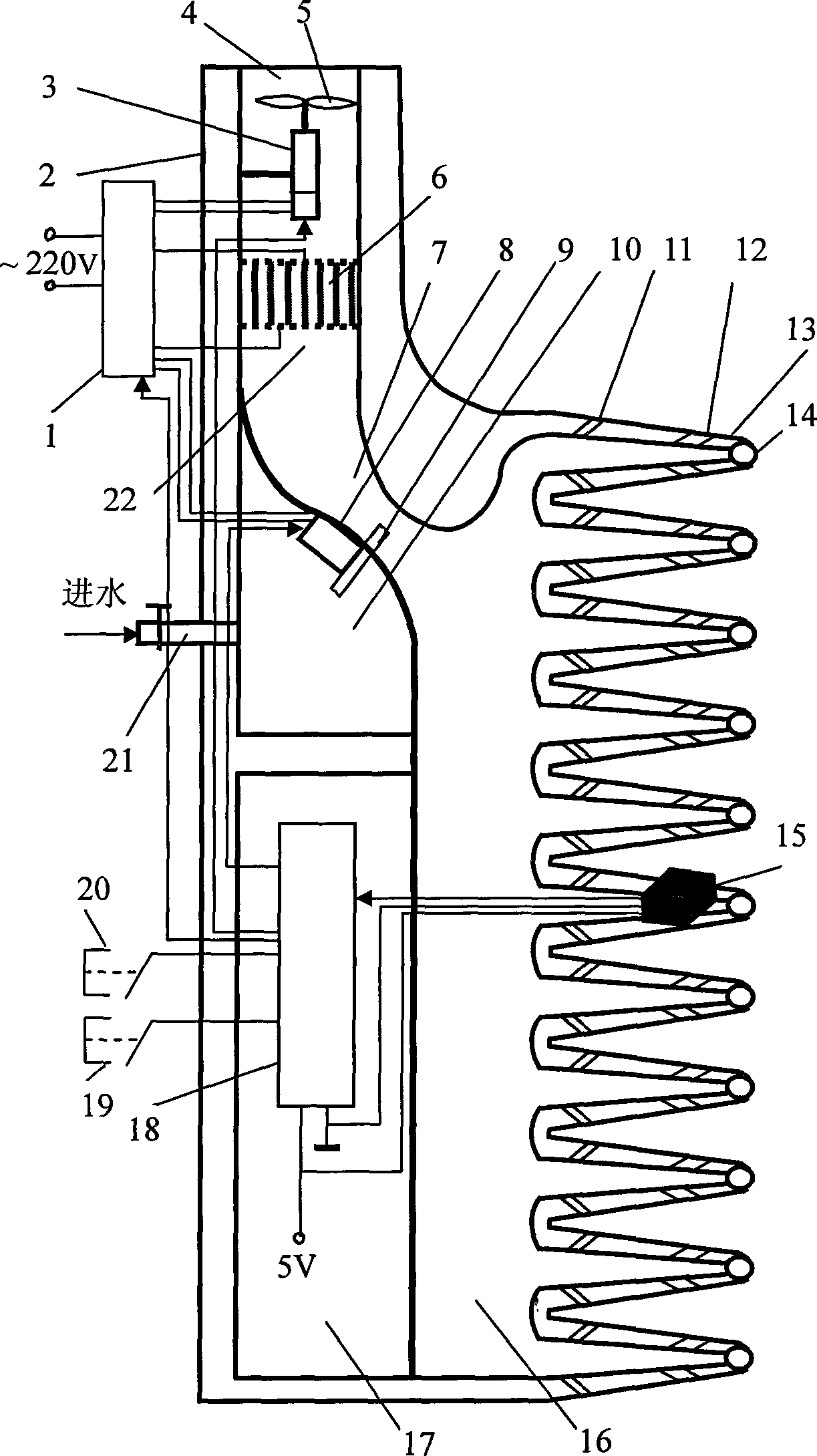

Intelligent comb with functions of blow-drying, combing and healthcare

ActiveCN103251199AAchieve health functionImprove energy efficiencyHair combsHair dryingAutomatic controlCombing

An intelligent comb with functions of blow-drying, combing and healthcare comprises a blower motor, a fan, a PTC heating element, an air inlet throat port, a water spraying electromagnetic switch, a water spraying nozzle, a water cavity, small air spraying holes, big air spraying holes, comb teeth, massaging balls, a temperature and humidity sensor, a single-chip microcomputer, a blow-drying function button, a combing function button, a water inlet switch and an air inlet channel. The small air spraying holes are formed in the root portions of the comb teeth, the big air spraying holes are formed in the end portions of the comb teeth, the massaging balls are located at the tooth ends of the comb teeth, and the temperature and humidity sensor is located on the end portion of the comb teeth. By means of the intelligent comb, the hair can be combed and blown dried at a time, the wet hair can be blown dried fast, blow-drying time is shortened, energy utilizing efficiency is improved, blow-drying temperature and air output can be automatically controlled to protect the hairlines and the scalp, mist is sprayed to the dry hair, so that the dry hair is molded conveniently, and massage can be carried out on the head to play a role of healthcare.

Owner:深圳市麦戈科技有限公司

Natural cotton fiber spunlaced nonwoven fabric for medical health and production method thereof

ActiveCN104313795AImprove removal efficiencyImprove pass rateCarding machinesHeating/cooling textile fabricsEngineeringMoisture absorption

The invention relates to a natural cotton fiber spunlaced nonwoven fabric for medical health and a production method thereof. The method is performed according to the following steps: preprocessing fibers; preliminarily combing cotton fibers; performing fine mixing; performing fine combing; forming a fiber net and performing drafting; performing hydraulic entanglement on the fiber net to form a cotton fiber spunlaced nonwoven fabric, and squeezing a bleaching solution into the fabric; performing cold pad-batch; removing cotton wax and pectin substances through a one-step method; performing cloth cover modification or jacquard treatment on a jacquard spunlaced device; drying the cotton fiber spunlaced nonwoven fabric on a tentering and setting machine; cutting the natural cotton fiber spunlaced nonwoven fabric, packaging the cut cotton fiber spunlaced nonwoven fabric, and warehousing the packaged cotton fiber spunlaced nonwoven fabric. According to the natural cotton fiber spunlaced nonwoven fabric for medical health, the gram weight deviation of the unit area does not exceed the range of minus 7% to plus 7%, the whiteness is greater than and equal to 85, the water absorption time is smaller than or equal to 5 s, the pH value is 6-8, the water-soluble matters are less than or equal to 0.5%, the soluble matters in ether are less than or equal to 0.5%, and the surface active substances are smaller than or equal to 2 mm. The natural cotton fiber spunlaced nonwoven fabric for medical health, provided by the invention, has the advantages of good hand feeling, good moisture absorption, good air permeability and no irritation to skins, the nonwoven fabric can be naturally degraded after being used, and the nonwoven fabric completely meets the requirement of environmental protection. The nonwoven fabric can be widely applied to the fields of medical care, hygiene, cosmetology, daily life, industrial cleaning, clean rooms and the like.

Owner:XINLONG HLDG GROUP +1

Natural colour cotton spinning treatment process

InactiveCN1405373AQuality improvementMeet design and production requirementsFibre treatmentYarnYarnCombing

The invention is a spinning technique of natural colour cotton, especially a blending technique of natural colour cotton and white cotton. First respectively make said colour and white cotton into cotton roll in clean-cotton opening procedure and respectively make the roll into crude strips in cotton-combining procedure; then make the color-cotton crude strips carry through one-step pre-combination and make the white-cotton crude ones into combining ones; then make pre-combining strips and combing ones into mixed wrough ones in strip-combining procedure; make the wrought strips into finished yarn product through the procedure of rough yarn, spun yarn and so on.

Owner:刘小珍

Production method of cotton bamboo silk towel

InactiveCN101343809AFeel goodHigh glossBiochemical fibre treatmentDry-cleaning apparatus for textilesYarnFiber

The invention relates to a towel manufacturing process, which belongs to the textile field. The towel manufacturing process comprises the steps: silk yarns, bamboo fibers and long-staple cotton are mixed in proportion, and are manufactured into 12 cone yarns through cotton combing, strip drawing, rough spinning and fine spinning; the yarns are woven into a piece of grey cloth through normal starching and weaving; water soluble yarns are washed off at the high temperature from the grey cloth through a continuous washing and bleaching range, the natural impurities and slurries on the cotton yarns are removed through boiling and rinsing with an overflow dyeing machine, and the grey cloth is deoxidized, dyed, enzyme-washed, softened, dried by vibration and sewn into towels. Compared with the common cotton towel, the towel manufactured through the towel manufacturing process has the advantages that the hand feeling and the gloss are good, the towel is very smooth, the drapability is better, and the towel is not easy to be creased. And meanwhile the problem that the pure cotton towel becomes hard after being washed for a plurality of times is solved, and the process is simple.

Owner:孙日贵

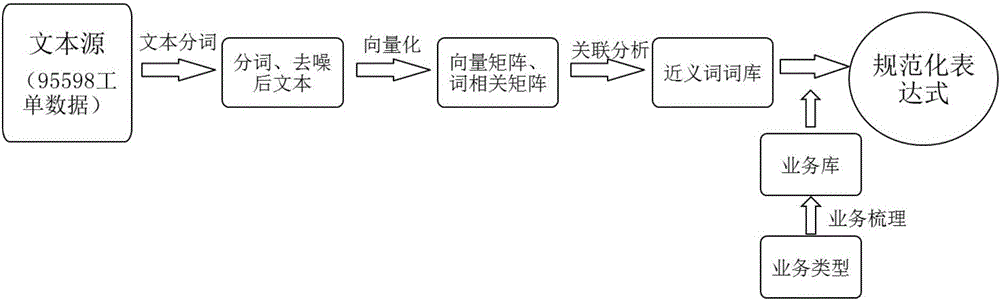

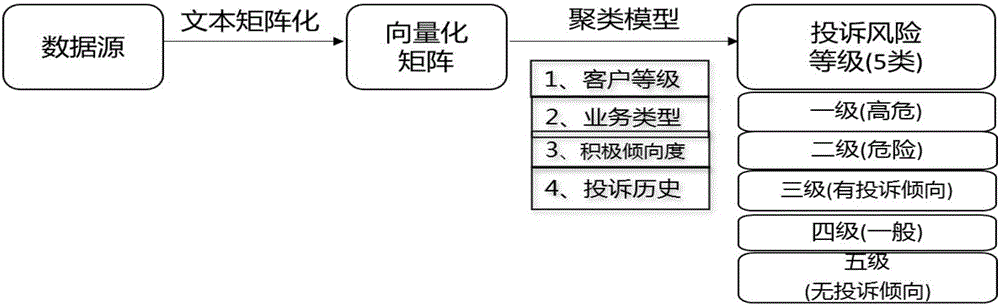

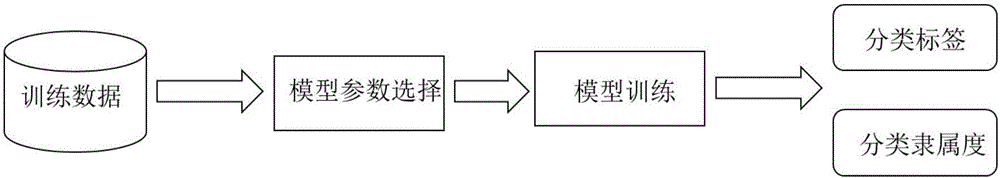

Complaint early warning and monitoring analysis system based on text mining

The invention discloses a complaint early warning and monitoring analysis system based on text mining. The complaint early warning and monitoring analysis system comprises a text data standardization module for converting input text data into a unified regular standardized data mode; and a standardized data analysis and early warning module for analyzing the standardized data mode by establishing a complaint level clustering model, classifying complaint risk levels according to a clustering result, and giving an early warning according to the level of risk. The complaint early warning and monitoring analysis system, on the premise of ensuring highest customer satisfaction, greatly reduces the workload of manual combing and sampling observation, and effectively improves a passive post-tracing management mode so as to facilitate proactive service in advance and to achieve professional management requirements for timely response to customer appeals.

Owner:JIANGSU ELECTRIC POWER CO +2

Wool semi-worsted spinning technique

InactiveCN101469470AWell mixedWide adaptabilityHeating/cooling textile fabricsCarding machinesCombingWinding machine

The invention relates to a wool semi-worsted spinning process, including fearnaughting, feeding by a FB001 automatic feeding bucket, carding by a FB201 carding machine, drawing by a A272 drawing machine, treating by a A456G fly frame machine, spinning by a A513W spinning machine, cheese winding by an automatic winding machine, twisting by a twisting machine, two-for-one twisting by a two-for-one twisting machine or the like. The manufacturing apparatus is composed by combining a wool spinning apparatus with a cotton spinning apparatus. The process has advantages of: (1) creatively reconfiguring and modifying by introducing cotton spinning apparatus and process, so as to spin woolen short fiber into high count semi-worsted yarn; (2) the spinning process is comparative to ordinary cotton carding, but simplified in process, and lower in cost; (3) drawing process spinning is adopted, cotton material mixing, carding and combined drawing of cotton spinning are introduced, so that spun yarns are uniform in color, mixed uniformly, bright and clean on surface, loose in hand feeling, and soft; feature of the product is between the worsted spinning and the woollen spinning; (4) the process is relatively adaptive to raw material, flexible in yarn number, easy for technology diffusion, low in equipment investment, small in occupation.

Owner:TIANJIN TEXTILE ENG RES INST

Blended stain color yarn and method for making same

The present invention essentially provides a novel blended fiber segment-color yarn. The technical proposal is that a blended segment-color yarn is composed of colorful fiber and natural fiber, wherein the color fiber is any one or any combination of terylene, acrylon, regenerated cellulose fiber, natural color cotton, artificial dyed cotton and bamboo charcoal fiber; the natural fiber is pure cotton fiber or mixed fiber of cotton fiber and any other fiber; the colorful fiber and the natural fiber are blended and twisted after cotton cleaning, cotton combing and drawing. The yarn has the advantages of rational structure, simple processing, moderate fiber fracture strength, high extensibility, fine spinning and weaving property, etc. With the excellent moisture absorption of natural fiber and the good moisture conductivity of synthesized fiber, clothes made of the yarns feel soft and are gas-permeable.

Owner:浙江云山纺织印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com