Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Strong moisture wicking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional comfort fiber with functions of phase transition temperature regulation, moisture absorption and moisture wicking

InactiveCN102443878AStrong moisture wickingGood heat resistanceMelt spinning methodsConjugated synthetic polymer artificial filamentsMultiple functionPolymer

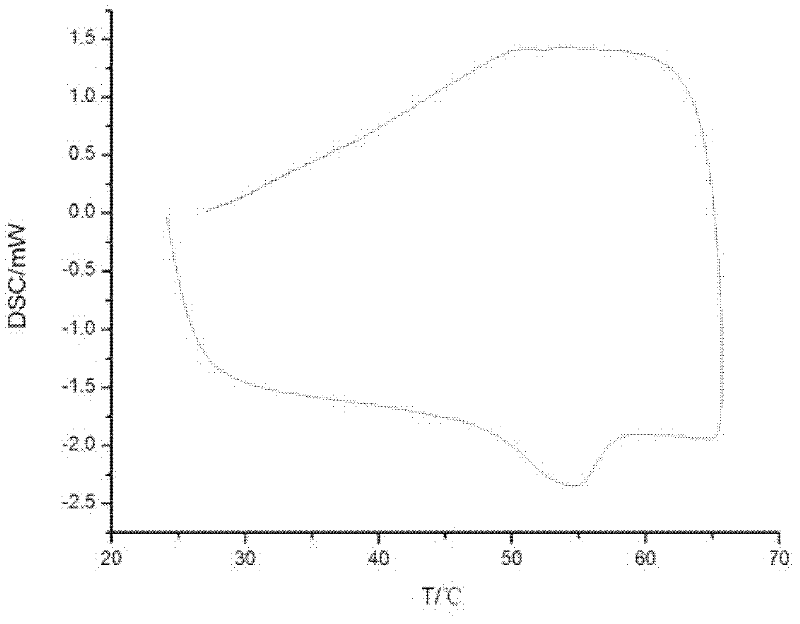

The invention relates to multifunctional comfort fiber with functions of phase transition temperature regulation, moisture absorption and moisture wicking. According to the fiber, an interpenetrating network composite phase transition material is adopted as a heat storage and temperature regulation material, a fiber-forming polymer is adopted as a matrix, a pore-forming agent and a compatibilizer are added to prepare a spinning raw material, and a melt spinning process is adopted to prepare the multifunctional comfort fiber. The spinning raw material preparation method comprises: mixing the interpenetrating network composite phase transition material and the fiber-forming polymer according to a mass ratio of (95-60):(5-40), then adding the pore-forming agent and the compatibilizer, and uniformly mixing, wherein the mass of the pore-forming agent is 0-10% of the total mass of the interpenetrating network composite phase transition material and the fiber-forming polymer, the mass of the compatibilizer is 1-5% of the total mass of the interpenetrating network composite phase transition material and the fiber-forming polymer, the pore-forming agent is the PEG with the molecular weight of 1000-2000, the compatibilizer is one or a plurality of materials selected from PP-g-PEGA, PP-g-PEG, PET-g-PEGA, PEGA, montmorillonite, and the like. The phase transition temperature range of the multifunctional comfort fiber is 30-55 DEG C, the melting phase transition enthalpy is 5.24-29.12 J / g, the breaking strength is 3.0-3.5 cN / dex, and the thermal decomposition temperature is more than 400 DEG C.

Owner:DALIAN POLYTECHNIC UNIVERSITY

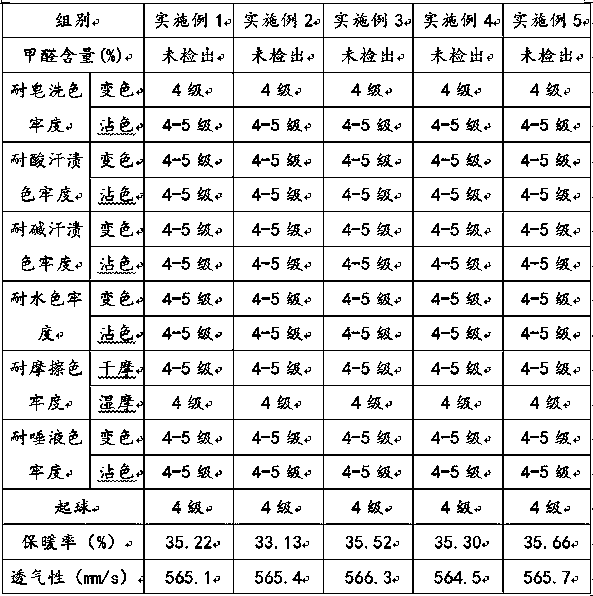

Manufacturing method of anti-microbial satin fabric

ActiveCN105862225AGood hygroscopicityStrong moisture wickingSucessive textile treatmentsLiquid/gas/vapor removalPolyesterFiber

The invention discloses a preparation method of an anti-microbial satin fabric. The fabric is manufactured from superfine polyester fiber, thereby having better hygroscopicity, moisture absorption and sweat releasing performance, gas permeability and drapability compared with a conventional imitation silk fabric. Appropriate twisting is adopted, the polyester fiber produces the diffuse reflection phenomenon for light, the gloss is approximate to gloss of real silk, and drapability of the fabric is increased; cattail fiber is added for blending, and the anti-microbial performance of the fabric is increased; the cattail fiber is pretreated, so that it is ensured that anti-microbial effective ingredients are not damaged to the greatest degree.

Owner:江西求学纺织科技有限公司

Preparation method of three-component composite fiber with special-shaped cross section

ActiveCN102691119AImprove stabilityStrong moisture wickingNew-spun product collectionStretch-spinning methodsPolyesterFiber

The invention relates to the technical field of fiber preparation. The invention provides a preparation method of a three-component composite fiber with a special-shaped cross section, to solve problems that chemical fiber products have no good moisture conductivity or moisture permeability, and that single-component fibers with special-shaped cross sections are high in modulus, bad in fabric handles, difficult in dyeing, and not good in comprehensive properties. The preparation method comprises the following steps: three types of polyester slices are fused and extruded from a metering pump respectively, entera special-shaped spinneret, and are stretched and wound, thereby obtaining the multi-component composite fiber with the special-shaped cross section. Of the composite fiber prepared in the invention, the caking property between two components is greatly improved to ensure that two components are not separated. The composite fiber is a special, novel, and special-shaped fiber, which is endowed with better stability and maintains excellent functions of ordinary special-shaped fibers such as a moisture absorbable and breathable function.

Owner:浙江双兔新材料有限公司

Process for processing bamboo charcoal fibers

InactiveCN103556307AInnovativeStrong deodorizationArtifical filament manufactureWater basedUltraviolet

The invention relates to a process for processing bamboo charcoal fibers. The process is characterized by comprising the following steps: (1) preparing bamboo charcoal powder, namely drying mao bamboos which grows for more than 5 years at the temperature of 100-120 DEG C for 4-5 days; heating to 400-450 DEG C and carbonizing for 3-4 days; heating to 800-860 DEG C for 2-3 days to obtain block-shaped bamboo charcoal, carrying out jet milling on the block-shaped bamboo charcoal, and collecting particles less than 0.30 micron for later use; (2) adding the bamboo charcoal powder into a water solution containing a polyacrylate dispersant, and carrying out wet grinding to obtain a nano bamboo charcoal water-based dispersion solution; (3) adding extracts of honeysuckle, eupatorium and rhizoma corydalis into the nano bamboo charcoal water-based dispersion solution, and heating for boiling for 5-6 hours to obtain a modified nano bamboo charcoal water-based dispersion solution; (4) preparing the modified bamboo charcoal fibers by using a dry spinning method. The bamboo charcoal powder prepared by using the method has good effects on removing the odor, absorbing the moisture, removing the sweat, storing heat, preserving the heat, resisting bacteria and preventing the mildew, and has good functions of far-infrared and negative ion emission, ultraviolet resistance and the like.

Owner:衢州净力竹炭科技有限公司

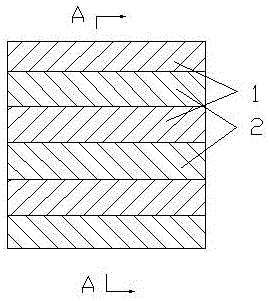

Multi-component weft triple fabric and weaving process thereof

InactiveCN105568473AStrong moisture wickingImprove antistatic performanceLoomsWarping machinesWear resistantEngineering

Provided are a multi-component weft triple fabric and a weaving process thereof. The fabric is formed y five components of cotton, Coolmax modified polyester fibers, China-hemp, conductive fibers, and polyester filament yarns. Four kinds of yarns are used, and warps are combed cotton / Coolmax modified polyester fibers, and weft yarns are combed cotton / Coolmax modified polyester fibers, terylene low-elastic interlaced yarns, combed cotton / China-hemp and terylene, and conductive fibers. Fabric weave structure is a weft triple structure. The front surface is combed cotton / Coolmax modified polyester fiber warps and wefts, the middle layer is the terylene low-elastic interlaced yarns, and the back surface is the combed cotton / China-hemp blended yarns. The face weave is cross grain, the intermediate weave is cross grain, and the inner weave is cross grain. The fabric is cool and crisp in hand feeling, novel in style, and is firm and wear-resistant. The fabric has good moisture absorption and sweat releasing property, and is comfortable in wearing. The fabric has good healthcare and functionality, and is especially suitable for professional uniform in spring and autumn.

Owner:JIHUA 3542 TEXTILE CO LTD

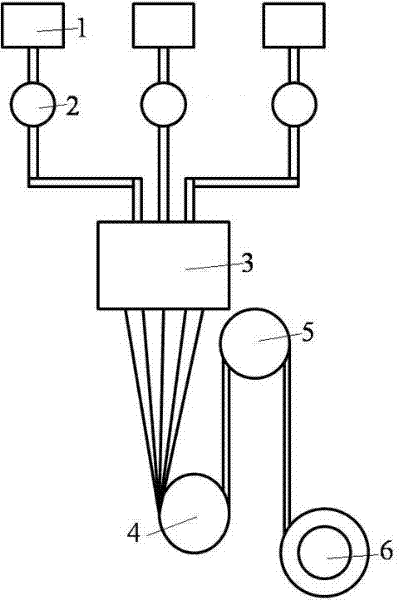

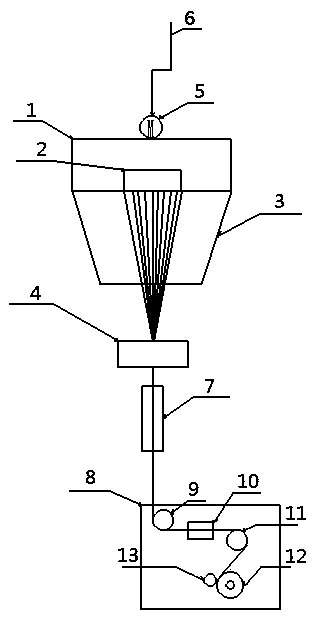

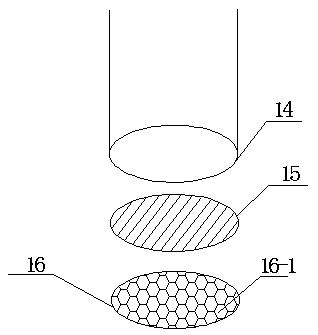

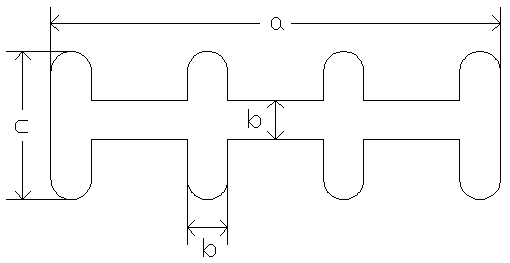

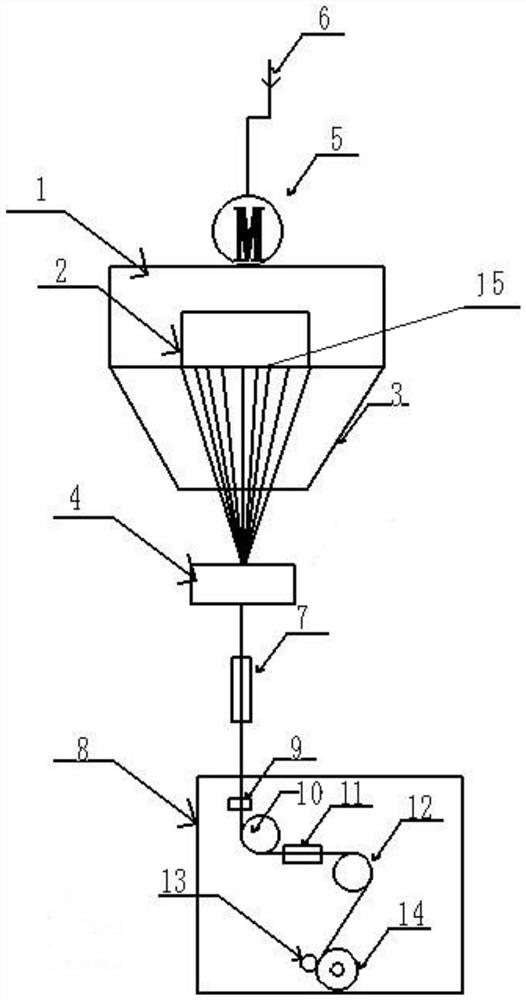

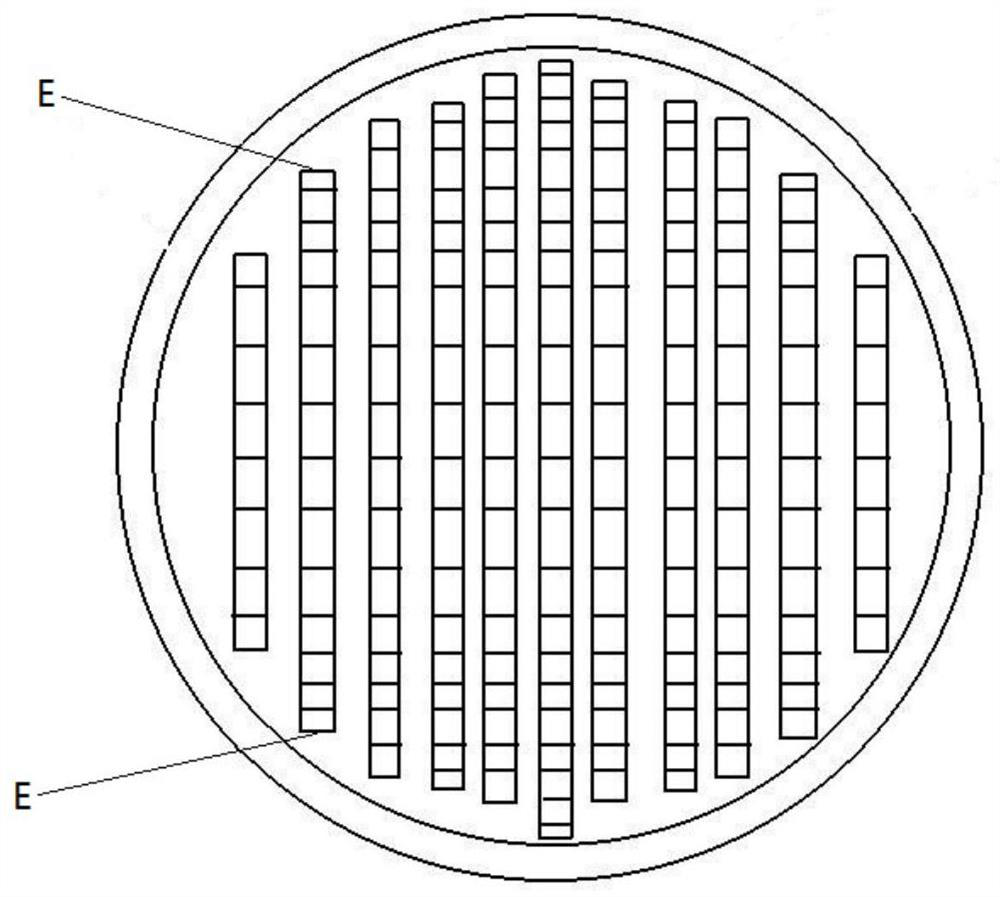

Production equipment of multi-H-shaped coarse-denier porous POY filament and manufacturing method thereof

InactiveCN109137109ANovel structural designReduce unevennessSpinning head liquid feederArtificial thread manufacturing machinesPolyesterWinding machine

The invention discloses the production equipment of a multi-H-shaped coarse-denier porous POY filament and a manufacturing method thereof. The production equipment comprises spinning box bodies, a ring blowing cooling device, an oiling device, a spinning channel, a winding machine and a plurality of heating medium pipeline system devices used for melt conveying in a spinning process, wherein the spinning box bodies, the ring blowing cooling device, the oiling device, the spinning channel and the winding machine are successively arranged from top to bottom. The manufacturing method comprises the following steps of using the above production equipment to produce; making molten polyester melt pass through the melt pipes of the heating medium pipeline system devices to enter into each spinningbox body; after passing through a metering pump and a spinning component, extruding a nascent fiber; and passing through the ring blowing cooling device, the oiling device and the spinning channel, finally winding into a spinning cake. A temperature in the spinning box bodies can be rapidly increased, and the temperature can be accurately controlled, balanced and uniformed, product quality is ensured, energy consumption is reduced, and production efficiency and the abnormity degree of products are increased, which is good for rear channel processing.

Owner:JIANGSU DELI CHEM FIBER CO LTD

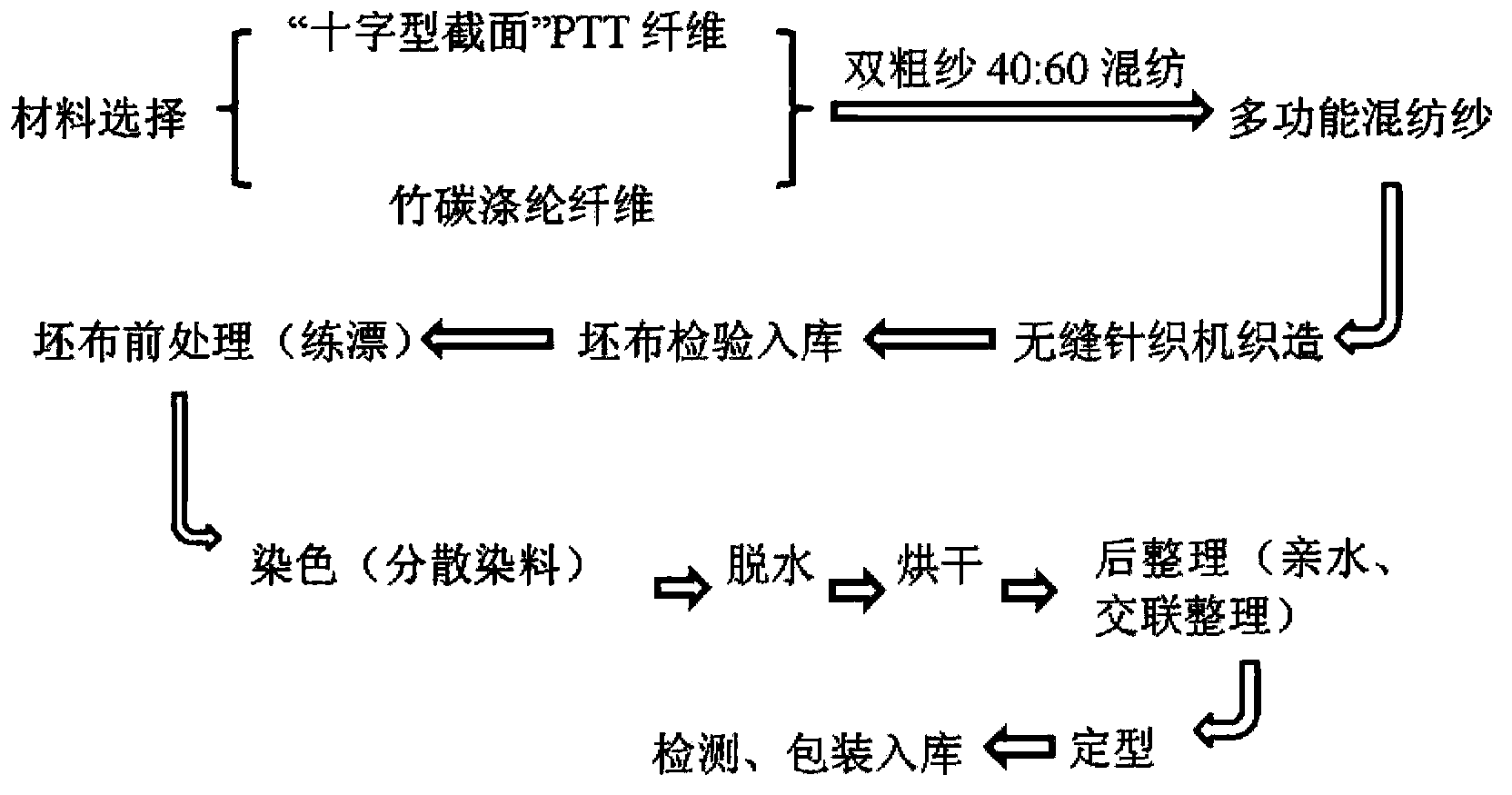

Production technology of PTT fiber seamless knitted underwear with high wicking function

ActiveCN103361867AHigh moisture permeabilityStrong moisture wickingWeft knittingDyeing processYarnPolytrimethylene terephthalate

The invention belongs to the field of functional knitted product production, and relates to a production technology of PTT (Polytrimethylene Terephthalate) fiber knitted seamless underwear with a high wicking function. The production technology comprises the steps that a PTT fiber with the crossed cross section and a bamboo carbon polyester fiber are taken as raw materials; two rough yarns and a double rough yarn feeding technology are adopted to manufacture a blended yarn; the blended yarn is knitted by a seamless knitting machine to form seamless knitted underwear grey cloth; and the seamless knitted underwear grey cloth is subjected to scouring and bleaching pretreatment, then dyeing treatment, and dehydration, drying, afterfinish and shaping treatment to from a PTT fiber seamless knitted underwear product with the high wicking function. The PTT fiber seamless knitted underwear with the high wicking function has the significant characteristics of moisture absorption, wicking, easiness in curing, bacteriostasis and the like; particularly, a wicking speed, the fastness to washing, the dimensional stability and the like of the product reach design requirements very well; and the design rationality of the product, the practicability of the product, the scientific rationality of the production technology and the significance of economic and social benefits are reflected.

Owner:浙江芬雪琳针织服饰有限公司

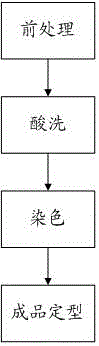

Preparation technology of copper fiber knitted double faced fabric

InactiveCN105133400ASolve the shortcomings of rough hand feeling and poor dyeing performanceFeel comfortableSucessive textile treatmentsFibre treatmentAcid washingCopper

The invention discloses a preparation technology of copper fiber knitted double face fabric. The preparation technology comprises steps of pretreatment, acid washing, dyeing, and finished product moulding. According to the provided preparation technology, special fiber slices are made into colorless low-elasticity filaments; during the dyeing process, heating, cooling, and temperature-maintaining time directly influence the hand feeling of fabric; in the moulding step, a nylon softening agent and an additive, which can help sweat discharging and moisture absorbing, are added, thus the fabric has a good hand feeling and a strong performance on discharging sweat and absorbing moisture; and moreover, a special post-treatment technology is adopted to overcome the cooper fiber's shortages of roughness and bad dyeing performance.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Soybean protein fiber graphene fiber blended knitted fabric

The invention discloses a soybean protein fiber graphene fiber blended knitted fabric, which comprises the following components in parts by weight: 30-60 parts of graphene viscose composite fiber, 30-50 parts of soybean protein fiber, 10-30 parts of organic cotton and 3-10 parts of spandex; according to the fabric, the graphene, the soybean protein, the organic cotton and the spandex are matched and blended according to a proper ratio, so that the fabric is soft and comfortable, good in skin affinity, good in wrinkle resistance and smoothness, and good in elasticity and shaping effect. The fabric has the functions of ultra-strong far infrared, sterilization and bacteriostasis, moisture absorption and perspiration, and ultraviolet-proof and antistatic function, the function of the fabric isnot weakened due to wearing time, the material used by the fabric is green and environment-friendly, and the fabric is a green and environment-friendly inner heating material with a health-care function.

Owner:FOSHAN YUANCHENGSHUN ECOLOGICAL TEXTILE SCI & TECH CO LTD

Method for manufacturing bottle piece spinning return material recycled polyester moisture-absorbing sweat-releasing POY filament

InactiveCN103668511AGood moisture absorption characteristicsGood moisture wicking functionFilament forming substance formingArtificial thread manufacturing machinesEngineeringContinuous production

The invention discloses a method for manufacturing a bottle piece spinning return material recycled polyester moisture-absorbing sweat-releasing POY filament. The method includes the following steps that (1) pre-crystallization is carried out on materials, wherein the materials are PET bottle piece return materials, and dried hot air is adopted for pre-crystallization; (2) the materials are fed in a screw mode, the PET bottle piece return materials are dried through hot air, and then the dried PET bottle piece return materials are fed into a screw extruding machine; (3) filtering, homopolymerization and pressurizing are carried out, wherein filtering, homopolymerization and pressurizing are carried out on melts generated through extruding of the extruding machine so as to guarantee continuous production of spun yarn and stability of melt pressure; (4) spinning is carried out, wherein the melts output from a pressurizing pump enter a spinning assembly, and are ejected from a spinneret plate through the spinning assembly and coiled and formed. The bottle piece spinning return material recycled polyester moisture-absorbing sweat-releasing POY filament manufactured in the method is good in moisture-absorbing and sweat-releasing characteristic, size stability and air permeability, and stability of fabrics is not influenced by any environment.

Owner:仪征市仲兴环保科技有限公司

Non-ironing shirt fabric and method for manufacturing same

ActiveCN105887279AGuaranteed finishing effectDecreased finishing effectPhysical treatmentBiochemical fibre treatmentMetallurgyPolytrimethylene terephthalate

The invention discloses a non-ironing shirt fabric and a method for manufacturing the same. The non-ironing shirt fabric and the method have the advantages that PTT (polytrimethylene terephthalate) fibers, Coolplus fibers and cashmere fibers are blended without finishing, so that the non-ironing shirt fabric which is excellent in thermal, moisture absorption, sweat releasing, elasticity, antibacterial and drape performance can be obtained; blended fibers have non-ironing performance, and the non-ironing shirt fabric is good in appearance and high in grade; pearl powder is ultrasonically treated for the Coolplus fibers, accordingly, nano-particles of the pearl powder can be fed in small grooves in the fibers, and beautifying, skin protection and ultraviolet resistance effects and the like can be realized by the ultimately woven blended fibers; the blended fibers do not need to be subjected to sterilization and anion finishing after the Coolplus fibers are subjected to sterilization and anion finishing, accordingly, finishing effects can be guaranteed, and the cost can be reduced.

Owner:CHANGXING BAOFU WEAVING

Blended yarn of viscose fibre and microporous fibre, preparation method and applications of blended yarn in home textiles

The invention relates to blended yarn of viscose fibre and microporous fibre, a preparation method and applications of the blended yarn in home textiles. The blended yarn comprises the components in percentage by weight: 60-80 percent of viscose fibre and 20-40 percent of microporous fibre, and the yarn counts of the yarn is 14-18tex cheese. The preparation method of the blended yarn comprises the following steps: preparation of raw materials, short process of blowing, a cotton combing machine, a drawing frame, a roving frame, a spinning frame and a bobbin winder. The blended yarn blends two types of viscose fibre and microporous fibre with different performances, makes the best of the two types of viscose fibre and micoporous fibre, and not only maintains the stiff and smooth performances of the microporous fibre and makes up the deficiencies such as no body skeleton and poor size stability and the like of the viscose fibre, but also enables the excellent performances such as moisture absorption and ventilation of the microporous fibre to be fully played. The home textile manufactured by adopting the yarn has the performances such as natural touch, soft gloss, good moisture absorption and perspiration, wrinkle resistance and pilling resistance, and also has the functions of ultraviolet resistance and antistatic property.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Knitting method for ultrathin high-grade sports underwear knitted fabric

InactiveCN104264350ADelicate and smooth to the touchReduce quality problemsWeft knittingUndergarmentsYarnPolyester

The invention discloses a knitting method for an ultrathin high-grade sports underwear knitted fabric. Fine denier polyester yarns serve as surface yarns, and polyurethane yarns serve as ground yarns. The ultrathin high-grade sports underwear knitted fabric is woven according to the processes that a machine is a single-face open-width circular knitting machine; the machine number is 48 stitches / 24.8mm; the cylinder diameter is 748mm; the route number is 92F; the revolving speed is 15r / min; the total number of stitches is 4,684. The hand feeling of the ultrathin high-grade sports underwear knitted fabric woven by using the knitting method is fine and smooth, the weight is reduced by 15-50 percent, the fabric has good moisture absorption and sweat releasing functions and is comfortable to wear, a finished product is convenient to carry, the demands of people for outdoor exercises are met, and the market prospect is wide.

Owner:常熟市华尔达制衣有限公司

Double-thick double-wire six-into-one antivirus and antibacterial compound yarn and preparing method thereof

The invention relates to healthcare yarn, in particular to a producing method and application of double-thick double-wire six-into-one anti-ultraviolet antivirus and antibacterial comfortable skincarehealthcare compound yarn. The blended yarn is prepared from, by weight, 15-85% of long staples, 15-85% of Outlast air conditioning fiber, 15-75% of white bamboo charcoal fiber and 25-85% of moistureabsorption and sweat releasing Topocool fiber. The compound functional knitted yarn is good in moisture absorption property and breathability, good in dyeing property, elasticity and plump performance, soft in hand feel, bright in color, rich in color and luster, free of adverse reaction when making contact with a human body, not prone to worm damage or corrosion and unique in appearance, has healthcare functions of bacterial resistance, inflammation elimination, skincare and bodybuilding, skin beautifying, skin moisturizing and good skincare property, and is good in draping, excellent in comfort, good in wear resistance, natural in color and luster and wide in application range.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Novel cutting-preventive wear-resistant garment

InactiveCN103040159AStrong wear resistanceAnti-cutProtective garmentSpecial outerwear garmentsFiberWear resistant

The invention discloses a novel cutting-preventive wear-resistant garment which comprises a garment body and a garment cutting-preventive layer. The garment body comprises an inner garment layer and a garment wear-resistant layer, the inner garment layer is made of breathable fibers, the garment wear-resistant layer is made of high-wear-resistant fibers, the garment cutting-preventive layer is made of bulletproof fibers and Kevlar fibers, the garment wear-resistant layer is connected with and arranged outside the inner garment layer, and the garment cutting-preventive layer is connected with and arranged outside the garment body in a crossed manner. By the mode, the novel cutting-preventive wear-resistant garment has the advantages of high wear resistance, cutting prevention and good stab resistance and provides safety guarantee and convenience for people executing or implementing dangerous works.

Owner:WUJIANG JIESHENG TEXTILE FINISHER

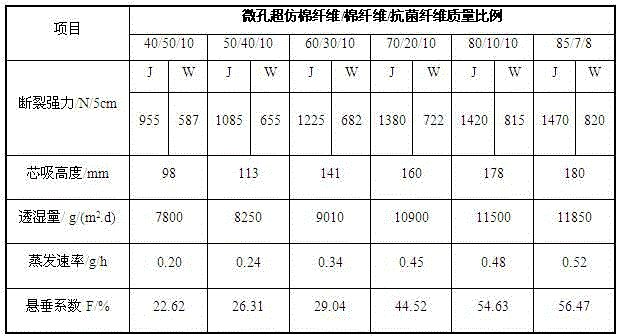

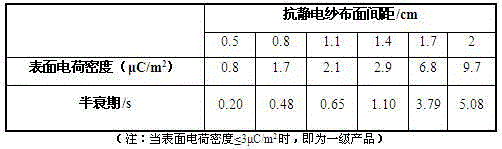

Antistatic, antibacterial and heat-moisture comfortable summer uniform fabric and preparation process for same

ActiveCN104473362AStrong moisture wickingImproves UV protectionGarment special featuresDyeing processPolyesterPolymer science

The invention belongs to the field of spinning of summer uniform fabrics, and particularly relates to an antistatic, antibacterial and heat-moisture comfortable summer uniform fabric and a preparation process for the same. The antistatic, antibacterial and heat-moisture comfortable summer uniform fabric is prepared by blending lamellar nano-silver-based antibacterial polyester fibers, microporous cotton-like polyester fibers and cotton fibers, which are taken as raw materials, embedding antistatic fibers during weaving and carrying out an improved and optimized slashing process and an improved and optimized fabric dyeing and finishing process, wherein the mass ratio of the microporous cotton-like polyester fibers to the cotton fibers to the lamellar nano-silver-based antibacterial polyester fibers is (60-80):(30-10):10; the embedding spacing distance of the antistatic fibers in the fabric is controlled to be 0.8 to 1.4cm. The summer uniform fabric has antistatic and antibacterial effects, and has high comfort under heat and moisture conditions.

Owner:FUJIAN CHANGLE CITY CHANGYUAN TEXTILE

Water absorption and diversion fabric for hollowed flower stripy socks

InactiveCN105671766AFast water absorptionAdd dimensionWeft knittingSynthetic resin layered productsPolyesterYarn

The invention relates to a water-absorbing and water-conducting fabric for hollow pattern-striped socks. The water-absorbing and water-conducting fabric for the hollow pattern-striped socks comprises a hollow pattern part and a colored strip part. , the hollow flower part and the colored stripe part are on the same plane, interlaced and connected in parallel to form a concave-convex structure. The hollow flower part is made of fabric, and the fabric is a polyester-cotton interwoven fabric composed of polyester yarn and nylon yarn The wheel yarn is on the front side of the fabric, and the nylon yarn is on the back side of the fabric. The concave-convex structure of the water-absorbing and water-conducting fabric of the hollow flower-striped socks enhances the three-dimensional effect of the water-absorbing and water-conducting fabric of the hollow flower striped socks. The present invention absorbs water and conducts water.

Owner:JIANGYIN YIFAN IND & TRADE

Fabric with cotton handfeel, woolen appearance and linen coolness and production process of fabric

InactiveCN106037100AComfortable texture and touchIncrease elasticityDry-cleaning apparatus for textilesWrinkle resistant fibresPolyesterWool fiber

The invention discloses a fabric with cotton handfeel, woolen appearance and linen coolness and a production process of the fabric. The fabric is prepared from microporous polyester fibers, wool fibers and polyester based conductive fibers, wherein the microporous polyester fibers is (1.5-1.8)dtex*(30-45)mm in specification and 80-85% in weight percentage; the wool fibers are (1.7-1.9)dtex*(35-50)mm in specification and 13-18% in weight percentage; the polyester based conductive fibers are (2-2.3)dtex*(30-45)mm in specification and 1-2% in weight percentage. The fabric has comprehensive functions and styles of cotton handfeel, woolen appearance and linen coolness.

Owner:HAIXI NEW TEXTILE MATERIAL OF JINJIANG IND TECH ACAD +1

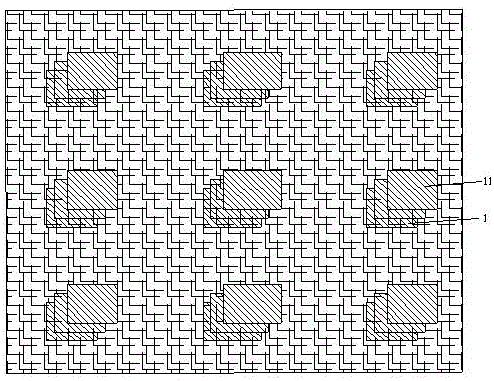

Composite mesh absorbent water-conductive fabric with composite fabric layer

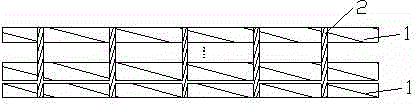

InactiveCN104921375ARich layersStrong moisture wickingLayered productsTextile decorationYarnPolyester

The invention relates to a composite mesh absorbent water-conductive fabric with a composite fabric layer. The composite mesh absorbent water-conductive fabric comprises a plurality of mesh layers (1) which are made of mesh fabric; each mesh layer (1) provided with a plurality of non-mesh fabric layers (11); the mesh layers (1) are adjacently staggered and are connected through bright yarns (2); the mesh fabric is made of cloth which is polyester / cotton interwoven cloth, made of polyester yarns and polyamide yarns; the polyester yarns are located on the front of the cloth, and the polyamide yarns are located on the back of the cloth. The composite mesh absorbent water-conductive fabric is brighter in color, water absorbent and water conductive.

Owner:JIANGSU HEJIA TEXTILE

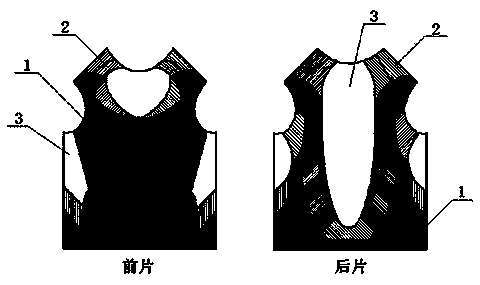

Novel warp-knitted sport suit

InactiveCN103462238AStrong moisture wickingBroad market application prospectsWarp knittingProtective garmentBiomedical engineeringWhite area

The invention discloses a novel warp-knitted sport suit. The novel warp-knitted sport suit consists of a dark area, a light-colored area and a white area, and is made of a warp-knitted fabric which is woven by a Jacquard warp knitting machine and has moisture-absorbing and sweat-releasing functions, wherein the warp-knitted fabric comprises a mesh Jacquard tissue structure, a thin Jacquard tissue structure and a thick Jacquard tissue structure; the dark area is made of a thick Jacquard tissue fabric; the light-colored area is made of a thin Jacquard tissue fabric; the white area is made of a mesh Jacquard tissue fabric. By the adoption of different fabric tissue structures, the novel warp-knitted sport suit disclosed by the invention has good moisture-absorbing and sweat-releasing functions, has uniquely styled patterns, is a high-performance sport suit with integrated properties of comfort, functionality and fashion, and has a wide market application prospect.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

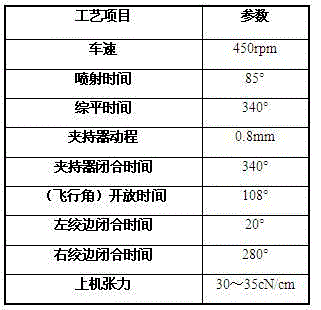

Product design and production process of anti-static moisture absorption and sweat releasing color weaving fabric

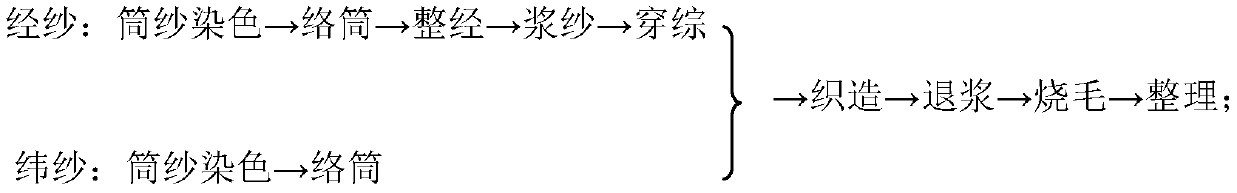

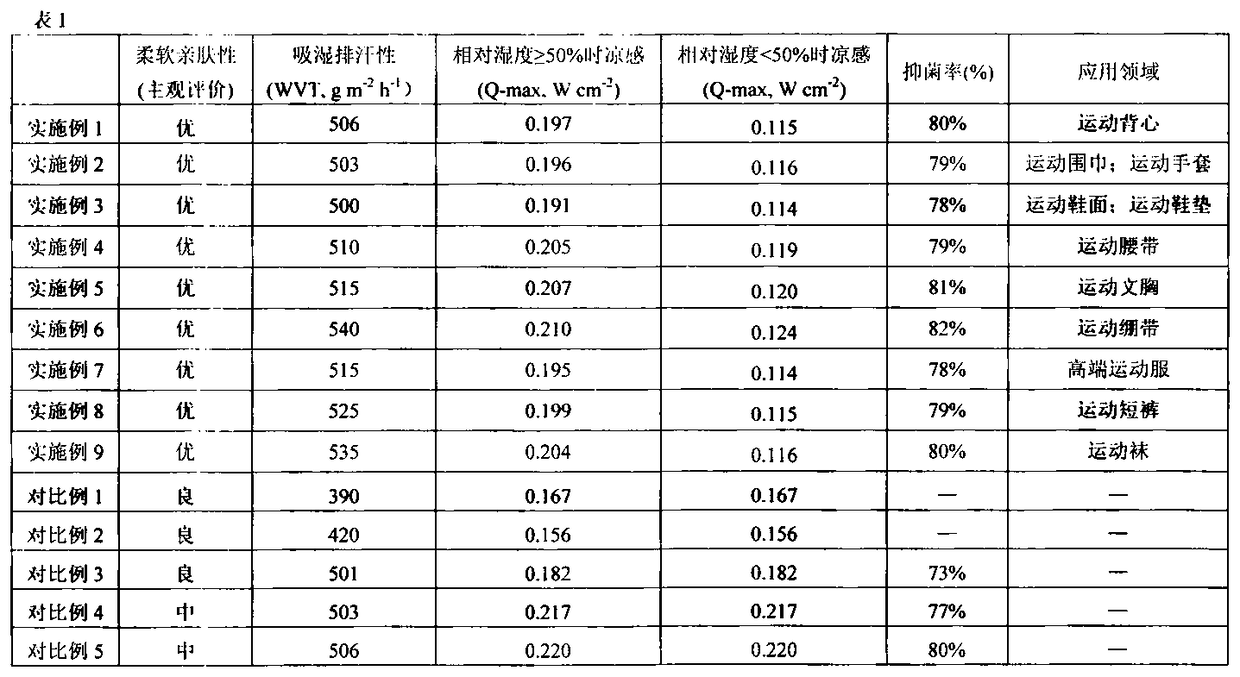

InactiveCN110295444AReduce coefficient of frictionFlat surfaceBiochemical fibre treatmentSingeingSizingWeft yarn

The invention discloses product design and a production process of a soft color weaving fabric with various functions of resisting static electricity, absorbing moisture, releasing sweat, achieving soft texture and good shape-preserving property and the like. PLA (polylactic acid) / Modal fiber blended warp yarns and vinylon / copper ammonia fiber blended weft yarns are interwoven to form the weavingfabric, and performance advantages among various fibers are complemented with each other. The production process of the weaving fabric includes the steps: cheese dyeing; spooling; warping; warp sizing; drafting; weaving; desizing; singeing; finishing. The process meets the ecological processing requirement that 'problems are chemically looked at and solved by a physical method'. The weaving fabricprepared by the process has excellent antistatic property, moisture absorbing and sweat releasing capability, soft texture, good shape-preserving property, size stability and the like.

Owner:义乌市润朵服装有限公司

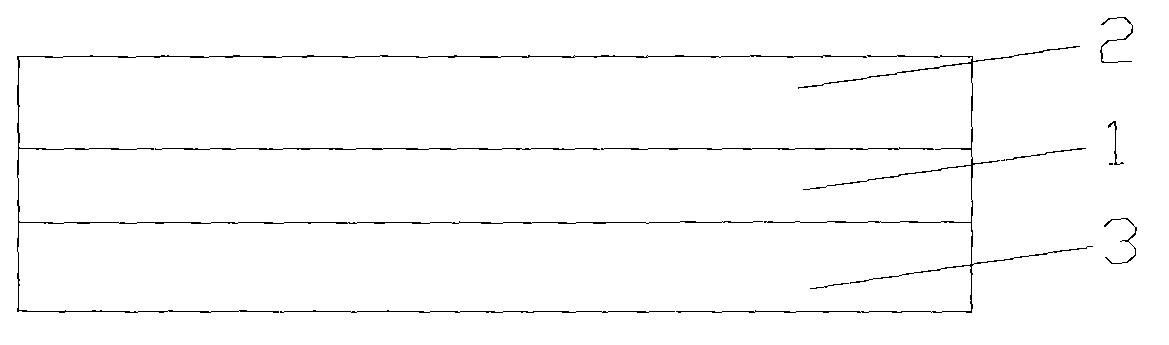

Multifunctional fabric

ActiveCN109049899AAdjustable coolingExcellent soft skinSynthetic resin layered productsCellulosic plastic layered productsComposite functionCooling effect

The invention provides a multifunctional fabric, and belongs to the technical field of textiles. The multifunctional fabric comprises an inner layer made of a component A, a middle layer made of a component B and an outer layer made of a component C; the inner layer, the middle layer and the outer layer are mutually attached, wherein the component A accounts for 3-15%, in percentage by mass, of the total mass of the whole multifunctional fabric, the component A comprises heavy denier ultrahigh weight polyethylene fiber and fine denier ultrahigh weight polyethylene fiber, the heavy denier ultrahigh weight polyethylene fiber accounts for 91-99% of the total mass of the component A, the component B is highly moisture-absorbing fiber, the component C is lowly moisture-absorbing fiber, the moisture regain difference value of the component B and the component C is higher or equal to 2.5% under the condition that the relative humidity is higher than or equal to 50%. Compared with the prior art, the multifunctional fabric has the superior functions of being soft, skin-friendly, hygroscopic and sweat releasing, cool and bacteriostatic, can have different levels of cooling effects along withthe difference of the relative humidity of the inner layer contact face, and meanwhile, the cost of the multifunctional fabric is remarkably lowered.

Owner:宁波凯丽安科技股份有限公司

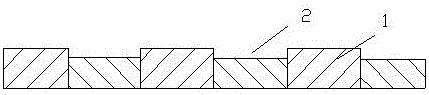

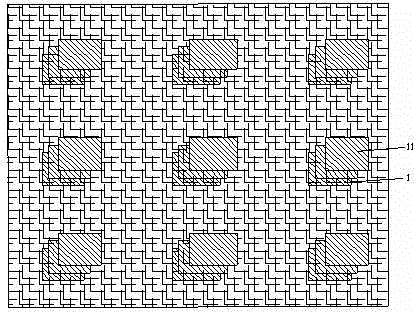

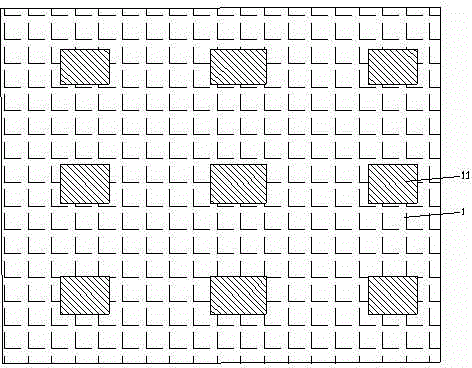

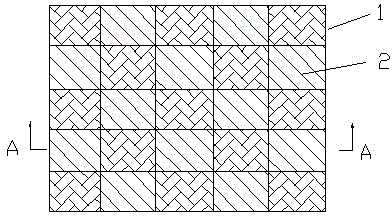

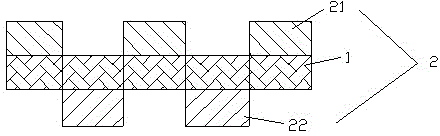

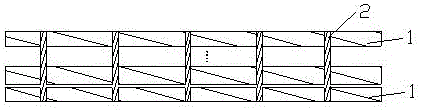

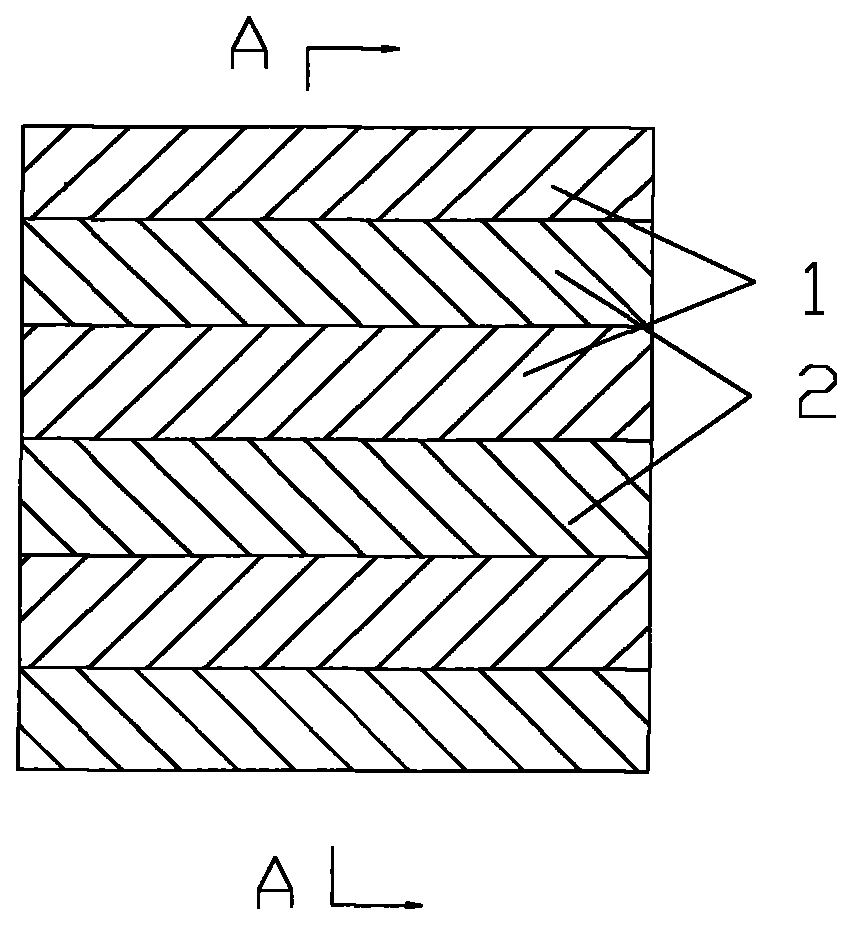

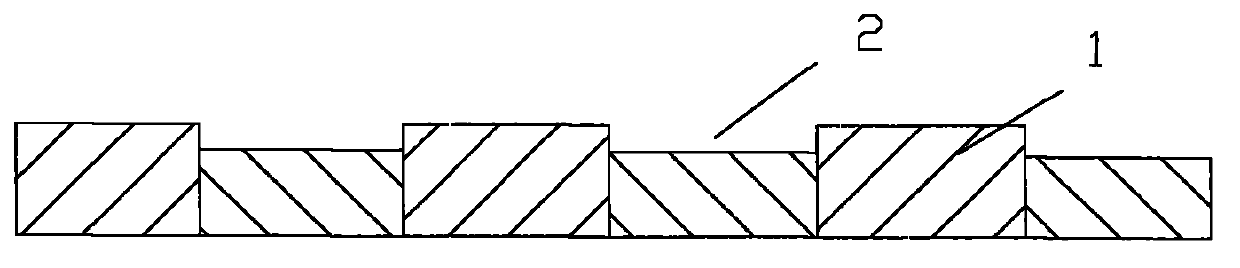

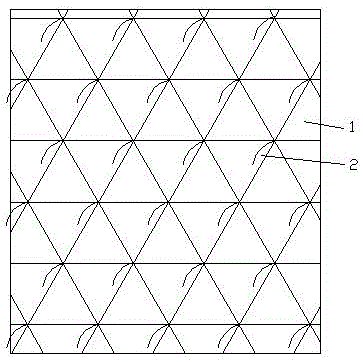

Front-back-staggered-jacquard-woven water-absorption water-diversion fabric

InactiveCN105082680AEnhance layeringStrong water absorptionSynthetic resin layered productsYarnEngineering

The invention relates to a front-back-staggered-jacquard-woven water-absorption water-diversion fabric. The front-back-staggered-jacquard-woven water-absorption water-diversion fabric comprises a base fabric (1), wherein jacquard-woven layers (2) are respectively arranged on the front and back faces of the base fabric (1), each jacquard-woven layer (2) comprises a plurality of jacquard-woven areas (21) and non-jacquard-woven areas (22), the jacquard-woven areas (21) and the non-jacquard-woven areas (22) are block-shaped and are of staggered arrangement, the base fabric (1) is made from a fabric material, the fabric material is polyester fiber-cotton intertexture and consists of polyester fiber yarns and polyamide fiber yarns, the polyester fiber yarns are located on the front face of the fabric material, the polyamide fiber yarns are located on the back face of the fabric material, and antibacterial layers are arranged between the base fabric and the jacquard-woven layers. The jacquard-woven areas and the non-jacquard-woven areas which are of staggered distribution are respectively arranged on the front and back faces of the front-back-staggered-jacquard-woven water-absorption water-diversion fabric, so that the layered feeling of the fabric is enhanced.

Owner:黄文平

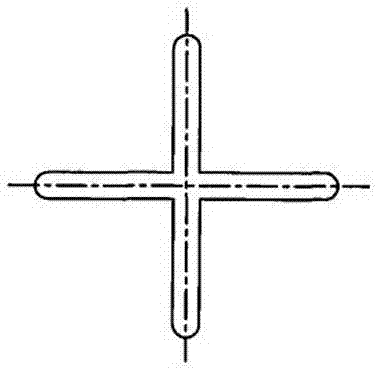

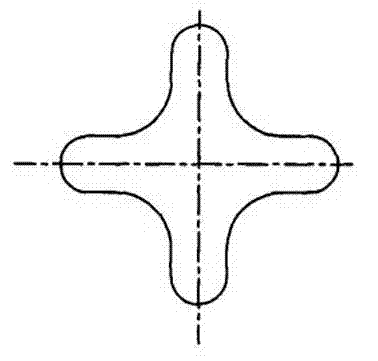

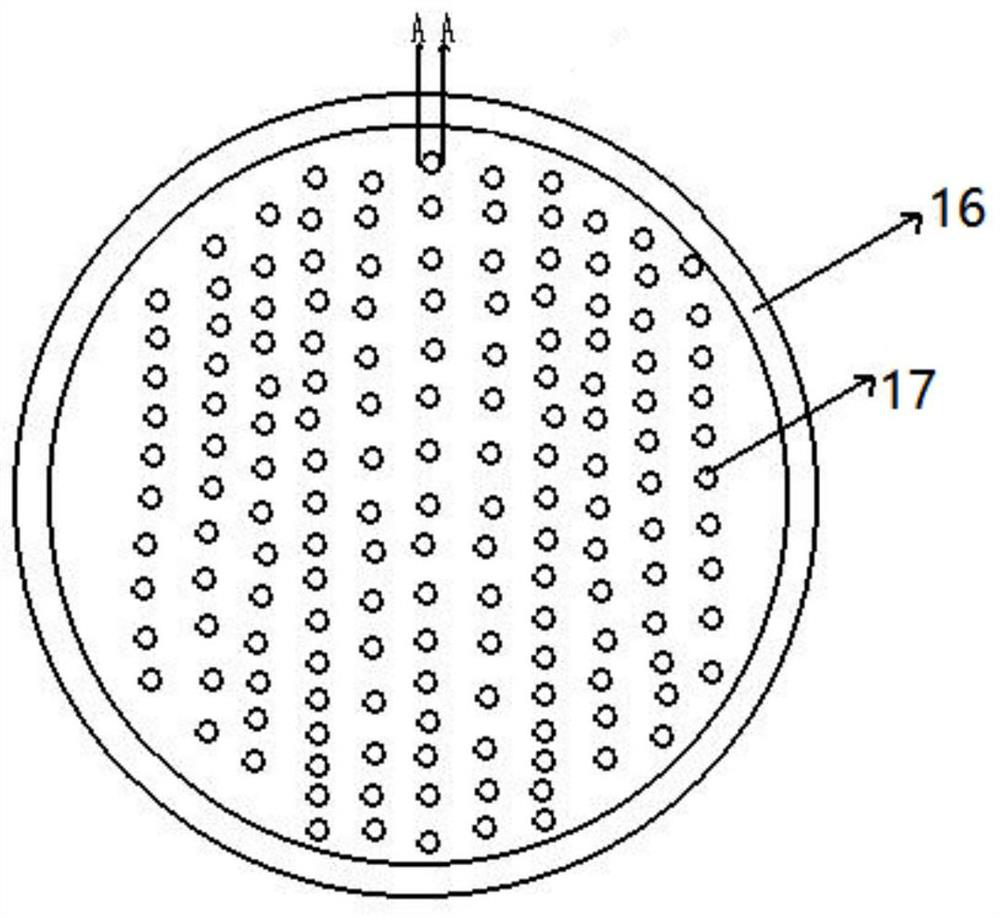

Manufacturing method of moisture-conducting and temperature-conducting wicking polyester fibers

InactiveCN112593299ABig spaceDry and moisture-conducting and temperature-conducting propertiesNew-spun product collectionFilament manufacturePolyesterFiber

The invention relates to a manufacturing method of moisture-conducting and temperature-conducting wicking polyester fibers. The manufacturing method comprises the following steps that multi-arc cross-shaped spinneret orifices are adopted; wherein the multi-arc cross shape comprises four leaves, namely a leaf I, a leaf II, a leaf III and a leaf IV; the leaf I is defined by two line segments and a major arc; the two line segments are parallel to each other, the two ends of each line segment are flush, one end of each line segment is an m end, the other end of each line segment is an n end, and the m ends of the two line segments are connected through the major arc; a straight line, which passes through the circle center of the circle corresponding to the major arc and is simultaneously arranged at equal intervals with the two line segments, is taken as a line L, wherein one point, which is positioned outside the leaf I and is close to the n end, on the line L is a point O; the leaf II, the leaf III and the leaf IV are correspondingly formed by rotating the leaf I around the point O by 90 degrees, 180 degrees and 270 degrees respectively; and the technological process comprises a winding procedure. A comb-shaped filament separator is arranged in a winding machine, and the comb-shaped filament separator porcelain piece is shaped like a formula as shown in the specification. The problems that in the prior art, a large number of broken filaments and filament burrs are generated in the spinning process, and tows are prone to jumping out when passing through a comb-shaped filamentseparator porcelain piece are effectively solved.

Owner:JIANGSU DELI CHEM FIBER CO LTD

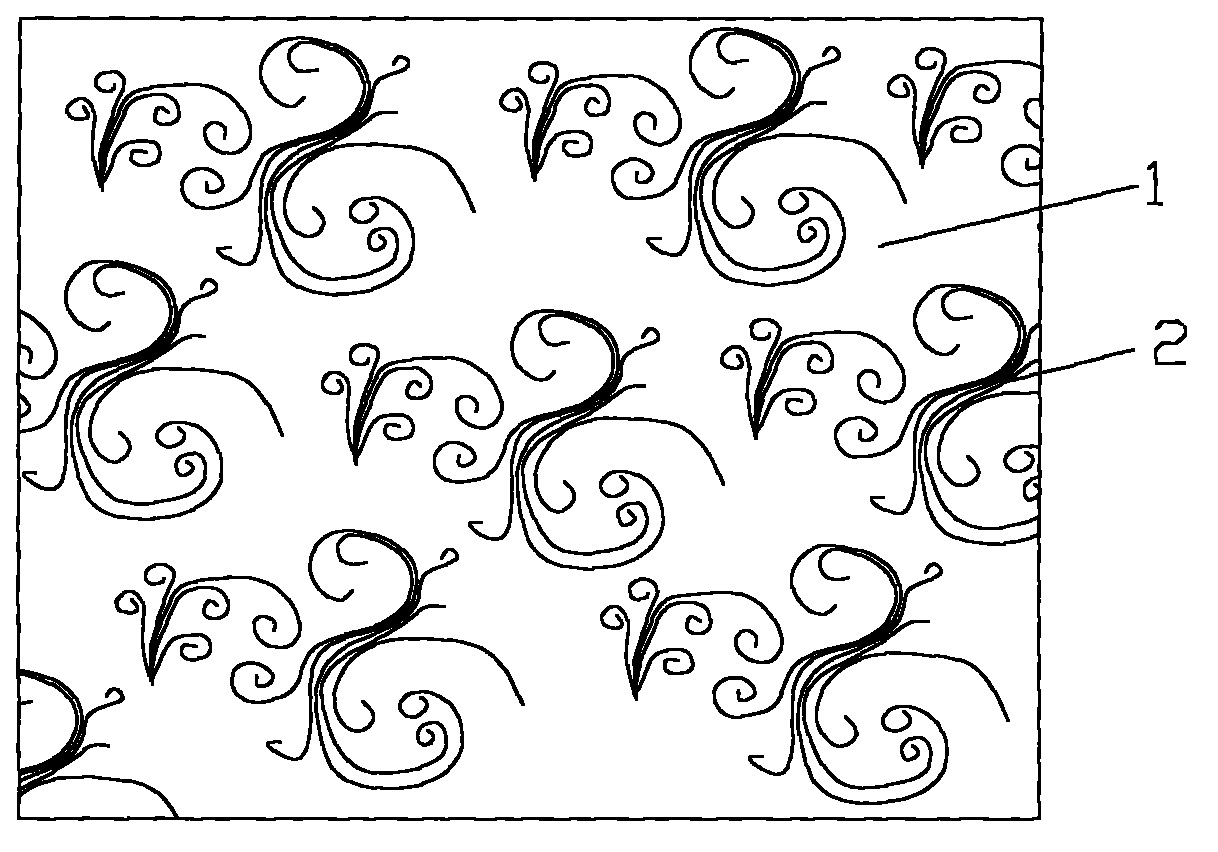

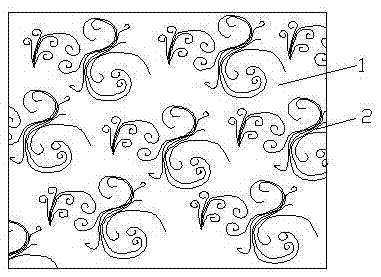

Spiral flower flocking water-absorbing and water diversion fabric

InactiveCN103818032AFast water absorptionEnhance layeringLayered productsTextile decorationPolyesterYarn

The invention relates to a spiral flower flocking water-absorbing and water diversion fabric which comprises a fabric body (1), wherein the fabric body (1) is net-shaped; a spiral layer (2) is arranged on the upper surface of the fabric body (1); a flocking layer (3) is arranged on the lower surface of the fabric body (1); spiral flowers are arranged on the spiral flower layer (2); flocking flowers are arranged on the flocking layer (3); the fabric body (1) is made of a textile; the textile is a polyester / cotton intertexture which consists of polyester yarns and polyamide staple fiber spun yarns; the polyester yarns are arranged on the front side of the textile; the polyamide staple fiber spun yarns are arranged on the back side of the textile. Due to the convex spiral flowers and the flocking flowers, the layering feeling of the spiral flower flocking water-absorbing and water diversion fabric is improved, and the fabric is soft and comfortable in hand feeling. The fabric can absorb and diverse water.

Owner:徐立生

Water absorbing and guiding fabric with discoid flower layer and flocking layer

InactiveCN107031159AFast water absorptionEnhance layeringSynthetic resin layered productsYarnPolyester

The present invention relates to a coil flocked water-absorbing and water-conducting fabric, comprising a fabric body, the fabric body is in the shape of a net, a coil layer is provided on the upper surface of the fabric body, and a flocking layer is provided on the lower surface. The disc flower layer is provided with disc flowers, and the flocking layer is provided with velvet flowers. The fabric body is made of fabric, and the fabric is a polyester-cotton interwoven fabric composed of polyester yarn and nylon yarn. On the front side of the fabric, the nylon yarn is on the back side of the fabric. The raised discs and velvet enhance the layering of the disc flocked water-absorbing and water-conducting fabric, and it feels soft and comfortable. The present invention absorbs water and conducts water.

Owner:郭亚娟

Compound net layer water absorption and guide fabric

InactiveCN105711204ARich layersStrong moisture wickingSynthetic resin layered productsTextile decorationPolyesterYarn

The invention relates to a compound net layer water absorption and guide fabric which comprises a plurality of net face layers which are net face fabrics.A plurality of non-net-face fabrics are arranged on the net face layers.Every two adjacent net face layers are sequentially arrayed in a staggered mode and vertically connected through bright silks.The net face fabrics are made of fabric which is polyester-cotton interwoven fabric formed by polyester yarn and nylon yarn, the polyester yarn is located on the front face of the fabric, and the nylon yarn is located on the back face of the fabric.The bright color is added, and the compound net layer water absorption and guide fabric absorbs and guides water.

Owner:JIANGYIN YASHUN GARMENT

Water-absorbing and water-guiding fabric for hollow striped sock

InactiveCN103859616AStrong water absorptionStrong moisture wickingTextile decorationWoven fabricsPolyamidePolyester

The invention relates to a water-absorbing and water-guiding fabric for a hollow striped sock. The Water-absorbing and water-guiding fabric for the hollow striped sock comprises a hollow part (1) and a color stripped part (2), wherein both the hollow part (1) and the color stripped part (2) are stripped and are equal in widths; the hollow part (1) and the color stripped part (2) are on the same plane, and are connected in parallel in a crossing way, so that a concave-convex structure is formed; the hollow part (1) is made of a textile fabric which is a polyester intertexture consisting of polyester yarns and polyamide yarns; the polyester yarns are positioned on the front face of the textile fabric; the polyamide yarns are positioned on the back face of the textile fabric. Through the concave-convex structure of the water-absorbing and water-guiding fabric for the hollow striped sock, the three-dimensional sensation of the water-absorbing and water-guiding fabric for the hollow striped sock is enhanced. The fabric can be used for absorbing and guiding water.

Owner:卞平芳

Vertical-tassel knitted water absorption and diversion fabric with compound fabric layer

InactiveCN105054430AAdd dimensionImprove agilitySynthetic resin layered productsTextile decorationPolyesterYarn

The present invention relates to a vertical-tassel knitted water absorption and diversion fabric with a compound fabric layer, which belongs to the field of textile fabrics. The fabric comprises a fabric body (1), and is characterized in that the outer surface of the fabric body (1) is provided with vertical tassels (2) which are color knitted lines 0.1-5 cm in length, one end of each vertical tassel (2) is fixed into the fabric body (1) while the other end naturally falls, the vertical tassels (2) are evenly distributed, the fabric body (1) is made from a textile fabric which is a polyester-cotton interwoven fabric formed by polyester yarns and polyamide staple fiber spun yarns, and the polyester yarns are disposed at the front side of the textile fabric while the polyamide staple fiber spun yarns are disposed at the back side of the textile fabric. The color knitted lines on the vertical-tassel knitted water absorption and diversion fabric with the compound fabric layer swing along with the wind, so that stereoscopic impression and dynamism of the fabric are enhanced.

Owner:JIANGYIN HULIAN DYEING & FINISHING

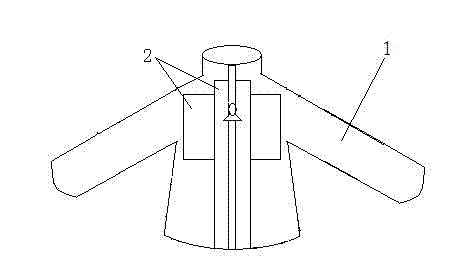

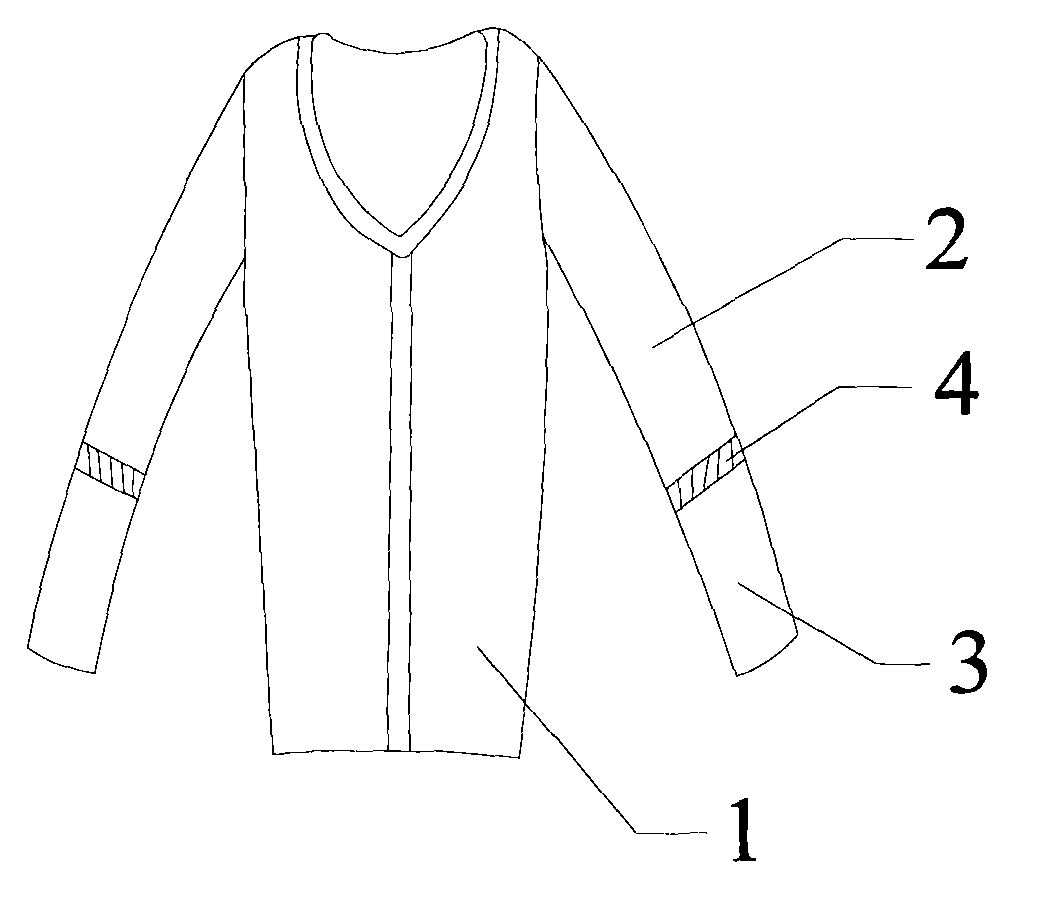

Detachable water absorption and guide coat

The invention relates to a detachable water absorption and guide coat. The detachable water absorption and guide coat comprises a coat body (1). Sleeves (2) are arranged on the coat body (1), wherein cuffs (3) are arranged on the bottom portions of the sleeves (2), and a zipper (4) is arranged between each sleeve (2) and the corresponding cuff (3). The cuffs (3) are made of dacron materials. The coat body (1) is formed by fabric. The fabric is a polyester and cotton interwoven fabric and composed of polyester yarn and chinlon yarn, wherein the polyester yarn is located on the front face of the fabric, and the chinlon yarn is located on the back face of the fabric. The detachable water absorption and guide coat is quite convenient to wash and can absorb and guide water.

Owner:沈卫军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com