Multifunctional fabric

A composite function and fabric technology, applied in synthetic resin layered products, cellulose plastic material layered products, clothing, etc., can solve the problem that the durability of the functional layer needs to be improved, achieve cooling sensation and antibacterial function, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

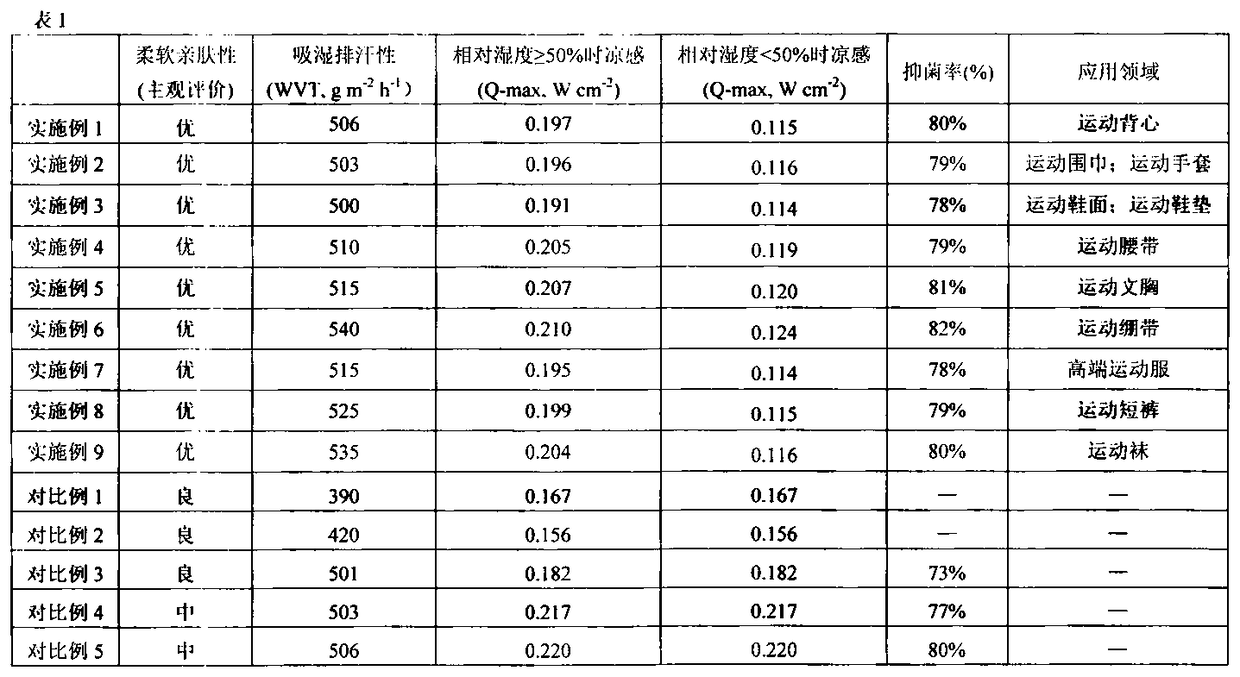

Examples

Embodiment 1

[0026] Embodiment 1, a kind of composite function fabric, comprises the A component of inner layer, the B component of middle layer and the C component of outer layer, and the area density of A component is 10 g / square meter, and its mass accounts for 10% of composite function fabric 4.5% of the total mass, component A is composed of coarse denier ultra-high molecular weight polyethylene fibers (UHMWPE-1) with a mass content of 91% and fine denier ultra-high molecular weight polyethylene fibers (UHMWPE-2) with a mass content of 9%, The monofilament fineness of UHMWPE-1 is 3.0dtex, the total fineness is 45 dtex, the mass crystallinity is 85%, the initial Young's modulus is 1800cN / dtex, and the axial thermal conductivity is 325mWcm -1 k -1 , the elongation at break is 3.5%, the tensile breaking strength is 35cN / dtex; the single filament fineness of UHMWPE-2 is 0.9dtex, the total fineness is 13.5dtex, and the axial thermal conductivity is 248mWcm - 1 k -1 , the initial Young's...

Embodiment 2

[0027] Embodiment 2, a kind of composite function fabric, comprises the A component of inner layer, the B component of middle layer and the C component of outer layer, and the surface density of A component is 50 g / square meter, and its mass accounts for 1% of the composite function fabric 3.75% of the total mass, component A is composed of coarse denier ultra-high molecular weight polyethylene fiber (UHMWPE-1) with a mass content of 95% and fine denier ultra-high molecular weight polyethylene fiber (UHMWPE-2) with a mass content of 5%, The monofilament fineness of UHMWPE-1 is 1.5dtex, the total fineness is 90 dtex, the mass crystallinity is 80%, the initial Young's modulus is 1600cN / dtex, and the axial thermal conductivity is 320mWcm -1 k -1 , the elongation at break is 5.0%, the tensile breaking strength is 30 cN / dtex; the single filament fineness of UHMWPE-2 is 0.75dtex, the total fineness is 45dtex, the mass crystallinity is 65%, and the axial thermal conductivity is 245mW...

Embodiment 3

[0028] Embodiment 3, a kind of composite function fabric, comprises the A component of inner layer, the B component of middle layer and the C component of outer layer, and the area density of A component is 30 grams / square meter, and its mass accounts for 1% of composite function fabric 3% of the total mass, component A is composed of coarse denier ultra-high molecular weight polyethylene fiber (UHMWPE-1) with a mass content of 99% and fine denier ultra-high molecular weight polyethylene fiber (UHMWPE-2) with a mass content of 1%, The monofilament fineness of UHMWPE-1 is 4.5dtex, the total fineness is 135 dtex, the mass crystallinity is 90%, the initial Young's modulus is 2000cN / dtex, and the axial thermal conductivity is 330mWcm -1 k -1 , the elongation at break is 2.0%, and the tensile breaking strength is 33 cN / dtex; the single filament fineness of UHMWPE-2 is 0.45dtex, the total fineness is 13.5dtex, the mass crystallinity is 60%, and the axial thermal conductivity is 240m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com