Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

420results about How to "Improve yarn quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

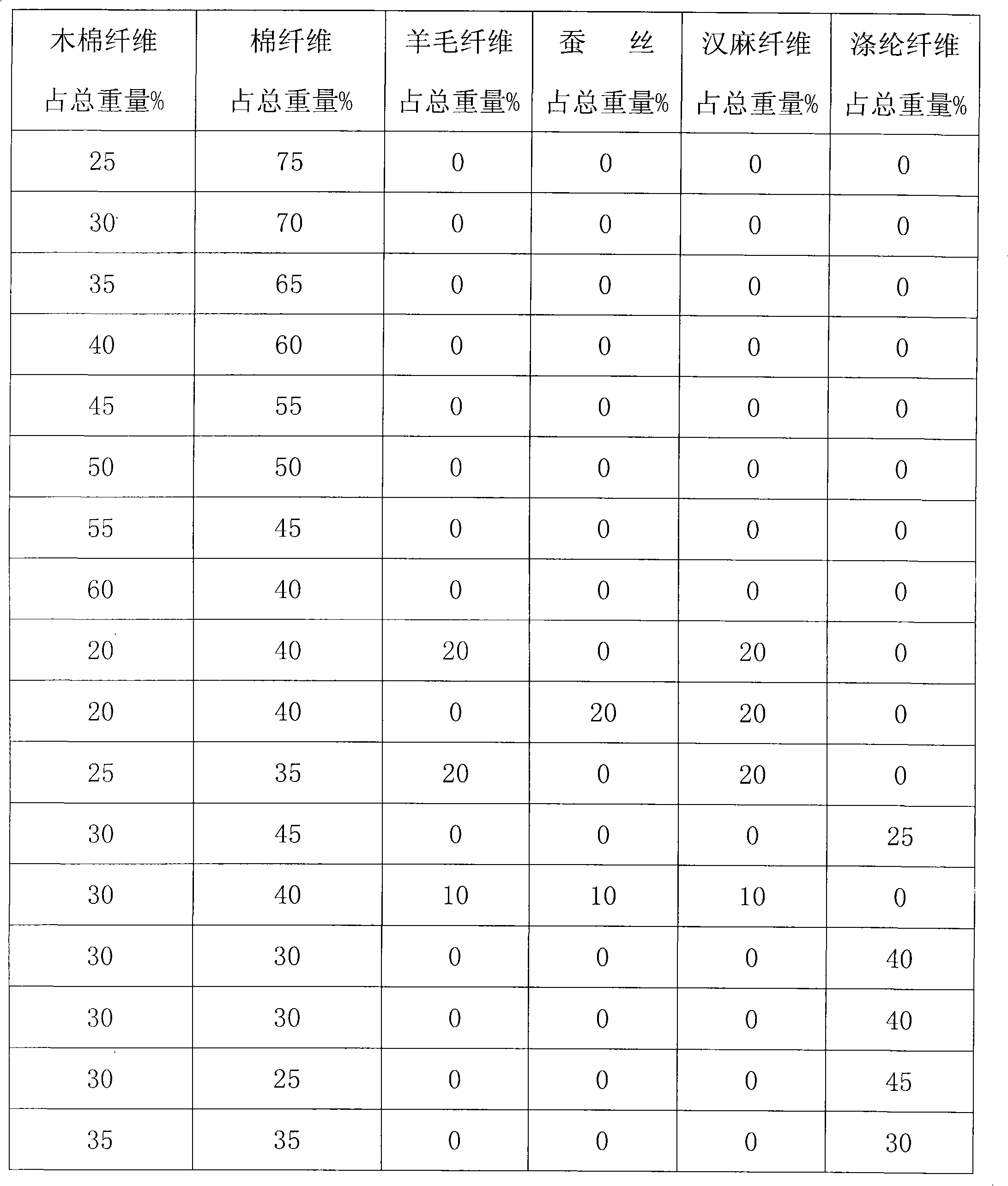

High ratio blended spinning technique for ultrashort low-density fibre based on cotton spinning device

InactiveCN101148797ARaise the ratioReasonable workmanshipFibre cleaning and opening machine combinationsCarding machinesYarnPolymer science

The present invention discloses the process of producing blended cheese yarn with high content of ultra short low density fiber in cotton spinning apparatus. A punching with high homogeneity and great cohesion is first produced through mixing ultra short low density fiber and other fiber in an opening and picking step much loosening and less beating; and then produced into cheese through the steps of combing, drawing, roving, spinning and coning. The blended cheese yarn consists of ultra short low density fiber 51-95 wt%, natural fiber 5-49 wt% and chemical fiber 5-49 wt%. The blended cheese yarn with high content of ultra short low density fiber is light, soft, lofty and high in strength, and its produced fabric has high color fastness.

Owner:DONGHUA UNIV +1

Method for spinning color segment bamboo joint color yarns

ActiveCN103397420AIncrease the added value of yarnImproving Spinnability and Yarn QualityDrafting machinesYarnYarnEngineering

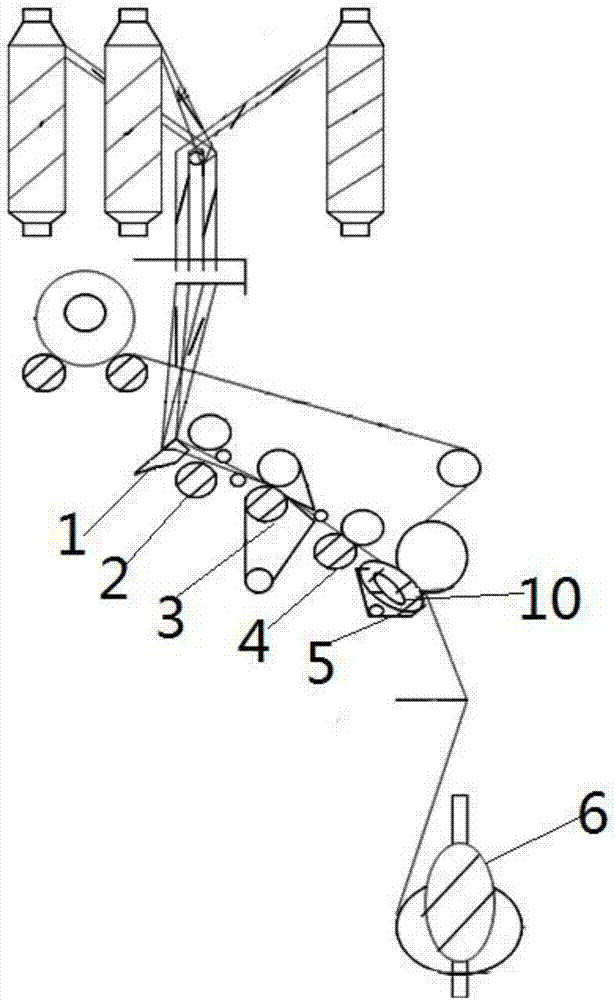

The invention discloses a method for spinning color segment bamboo joint color yarns. In the spun yarn process, four rovings with at least one color are simultaneously fed into a huge drafting spinning frame which is of a four-roller, four-leather-collar and three-area type. In the four rovings, two of the four rovings are fed in from rear rollers through double-horn openings, one roving is fed in from a middle-rear roller through a yarn guiding groove, and one roving is fed in from a middle-front roller through a yarn guiding groove. According to the method, the four-roving feeding scheme is adopted, the segment color effect with four different colors at most can be achieved, and the production of segment color yarns of different styles is achieved. In the part of the spun yarn process, the four-roller, four-leather-collar and three-area type is used so that huge drafting of 30-300 times can be achieved, a foundation is laid for simultaneous feeding of the four rovings, and spinning efficiency is improved. Meanwhile, the rear rollers, the middle-rear roller and the middle-front roller in the four rollers are controlled respectively through an independent servo motor, the draft multiple in the three-area drafting can be adjusted at will, so that the segment color bamboo joint effect of various styles is achieved, and the spinning adaptability and the spinning quality of segment color yarns are improved.

Owner:SUZHOU XINDONGNAN TEXTILE TECH CO LTD

Spinning method of multi-component multi-segment color yarns

The invention discloses a spinning method of multi-component multi-segment color yarns. In the spinning procedure, three roves at least in one color and one material are simultaneously fed into a super-large drafting spinning machine which is formed by four rollers and four aprons and which operates in a three-region drafting mode. The spinning method has the advantages that according to the feeding mode of the three roves, the multi-component segmental color yarns with three different colors can be produced, the color yarns in different styles can be produced, and yarn added value is increased; in the spinning procedure, 30 to 300 times of super-large drafting can be realized through the four rollers and the four aprons in the three-region drafting mode, foundation for simultaneously feeding three roves is established, spinning efficiency is improved effectively, and meanwhile, spinning-compatibility and yarn quality of the color yarns are improved.

Owner:江苏泗水纺织有限公司

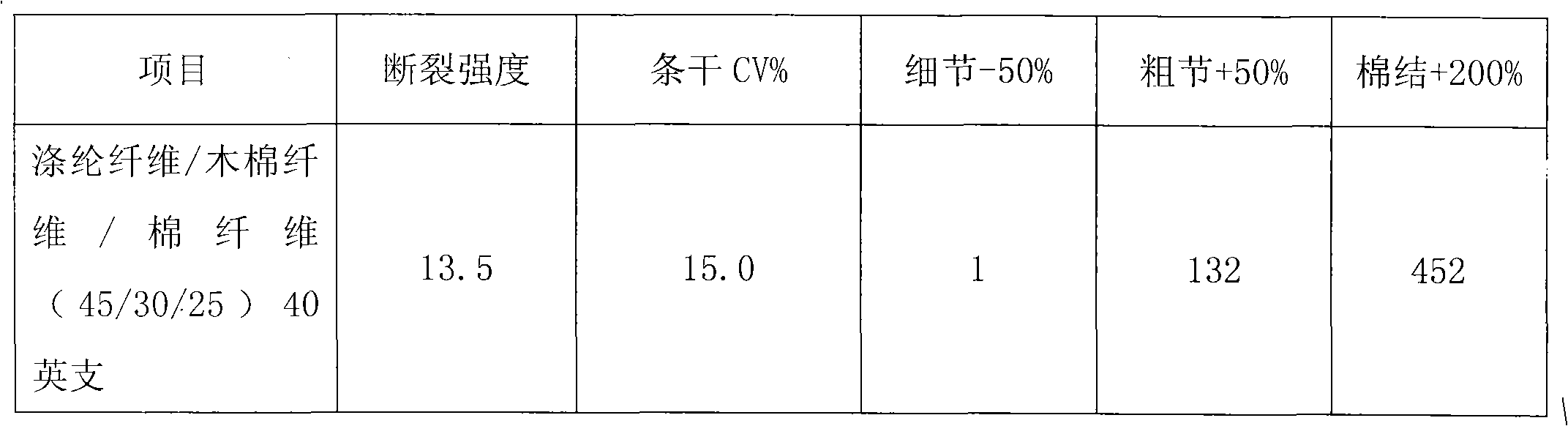

Flame retardant blended yarn and production method thereof

InactiveCN104404671AImprove flame retardant performanceIncrease added valuePhysical treatmentYarnCotton fibreSingle fiber

The invention relates to a flame retardant blended yarn and a production method thereof. According to weight percentage, the flame retardant blended yarn is formed by the following components through blending: 25-30% of flame retardant polyester filament yarns, 20-25% of flame retardant acrylic fibers, 20-30% of hemp fibers and 20-30% of cotton fibers. The production method includes: making hemp fibers and cotton fibers into card slivers respectively and tearing the card slivers into loose fibers, and making the card slivers into hemp / cotton blended combed silvers through second blowing carding in a single fiber type mixing way; making the flame retardant acrylic fibers into flame retardant acrylic card silvers; producing blended rough yarns by use of the hemp / cotton blended combed silvers and the flame retardant acrylic card silvers; producing flame retardant blended yarns by use of spun yarns in a core spun mode; producing the needed flame retardant blended yarns after plasma preprocessing and yarn flame retardant finishing. According to the flame retardant blended yarn and the production method thereof, the hemp fibers, the cotton fibers and two flame retardant fibers are selected for blending, and accordingly the produced yarns have excellent flame retardant performance as well as good antibacterial, moisture absorptive and ventilate wearing performances; the spun yarns are in the core spun mode so the tare effect is eliminated and the flame retardance is improved.

Owner:青岛博徕施纺织有限公司

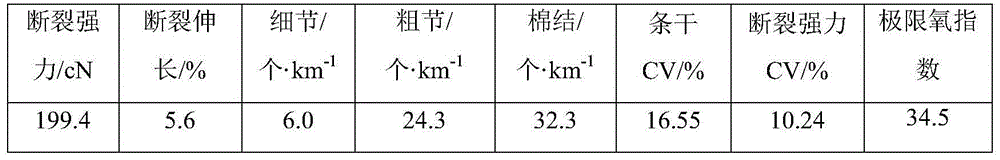

Process for manufacturing kapok fiber blended yarns

The invention discloses a process for manufacturing kapok fiber blended yarns, comprising the steps of selecting a plurality of kapok fibers, cotton fibers, wools, silks, hemp fibers and terylene fibers, wherein the content of the kapok fibers is 25-60% of the total blended yarns; the content of the cotton fibers, wools, silks, hemp fibers and terylene fibers is 40-75% of the total blended yarns; weighing the kapok fibers and other spinning fibers, dividing the fibers into small stacks, and obtaining multi-component blended yarns by mixing, blowing, cotton carding, drawing, roving and spinning, wherein the relative humidity of the production environment of each process is 60-65%; the products produced by the invention can be manufactured to be kinds of blended fabric materials; a fabric product which is pure natural, green, environment-friendly, soft and warming is increased in the spinning field.

Owner:JIHUA 3542 TEXTILE CO LTD

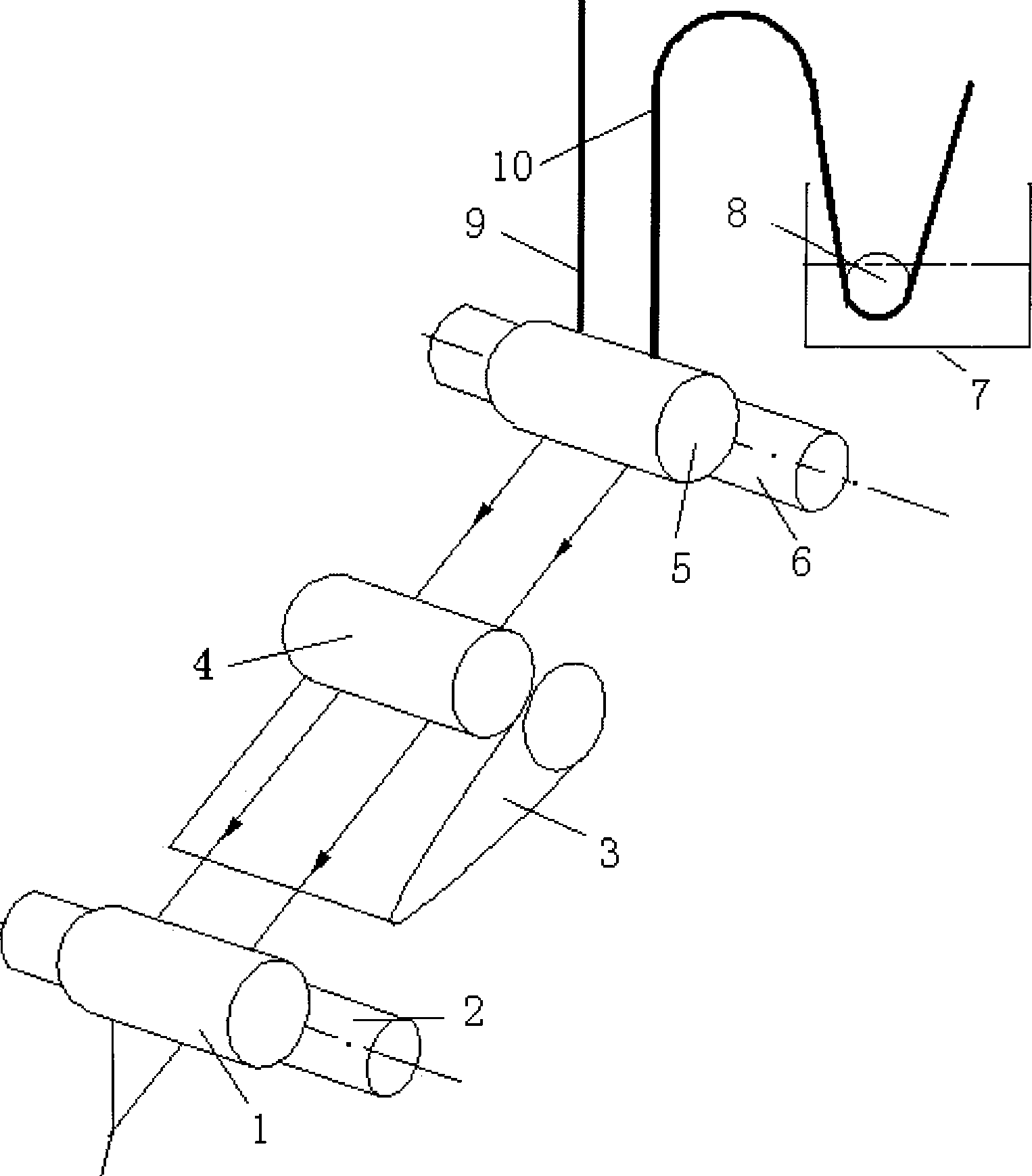

Resilient plate type stereo compact spinning device for spinning machine

The invention relates to a flexible disc solid compact spinner of spinning machine, wherein one flexible yarn disc is arranged under the lower roller, while it has one circle groove; the section of circle groove is in horn shape, with wide top and narrow bottom, while the groove bottom is semi circle with several passive holes; when the yarn bar is outside the lower roller to enter into the circle groove; since the groove is in horn shape, the bars outside the yarn bar can be entered into the yarn, and when the yarn bar translates in the circle groove, and be compressed via the adsorption function of passive holes, it will be flattened and compacted twisted by spindle, to eliminate the triangle twist area of lower roller, to improve the quality of yarn.

Owner:绍兴华裕纺机有限公司

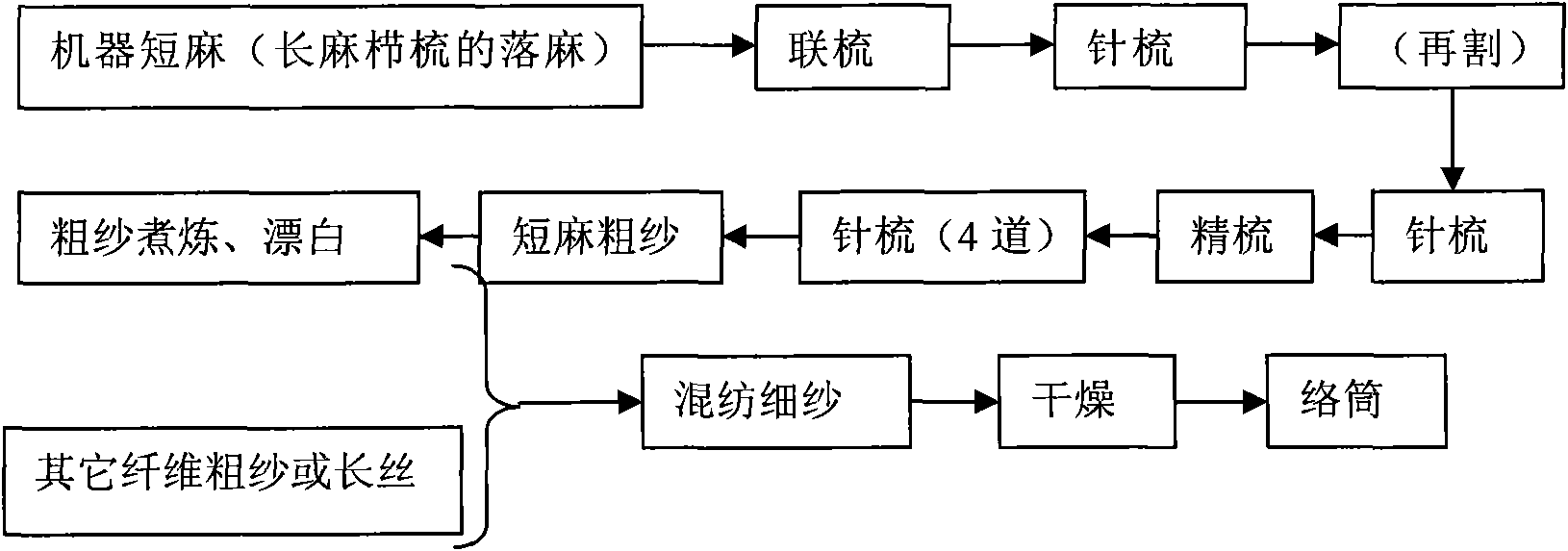

Blending method using hemp fiber as main material

InactiveCN101871147AIncrease the degree of splittingImprove impurity removalHackling machinesBleaching apparatusImpurityMaterials science

The invention relates to a blending method using a hemp fiber as a main material. The method comprises the following steps of: firstly, processing the hemp fiber into rovings; secondly, mixing the roving yarns of the hemp fiber with the rovings or filaments of other fibers in proportion to form bunch yarns; and finally, spinning the mixed bunch yarns in the second step into spun yarns. The blending method has the advantages of improving the disintegration degree of the hemp fiber and removing impurity without damaging the performance of the blended fibers, ensuring a high spinning yam count and quality of the blended yarns and greatly improving the quality of the blended yarns of the hemp fiber along with simple process.

Owner:肇融亚麻纺织有限公司

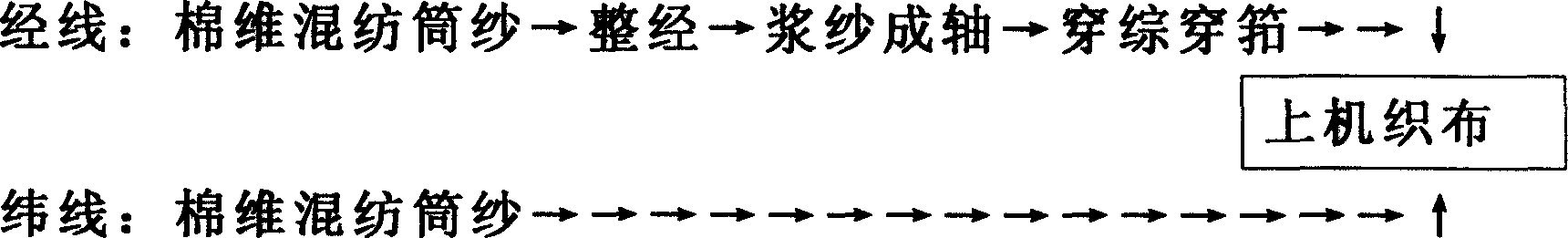

Cotton fiber fabric and manufacture technology thereof

The invention relates to a cotton textile and relative production, wherein it is characterized in that: its transverse line and longitudinal line use the cotton yarn mixed by cotton fiber and soluble vinylon fiber, while the mass between them is 70-85:15-30; and the production comprises: spinning the cotton yarn, warping, sizing, drying, spinning blank cloth, and following treatment. The inventive product is flexible, with wet adsorption, and high yield.

Owner:马伟华

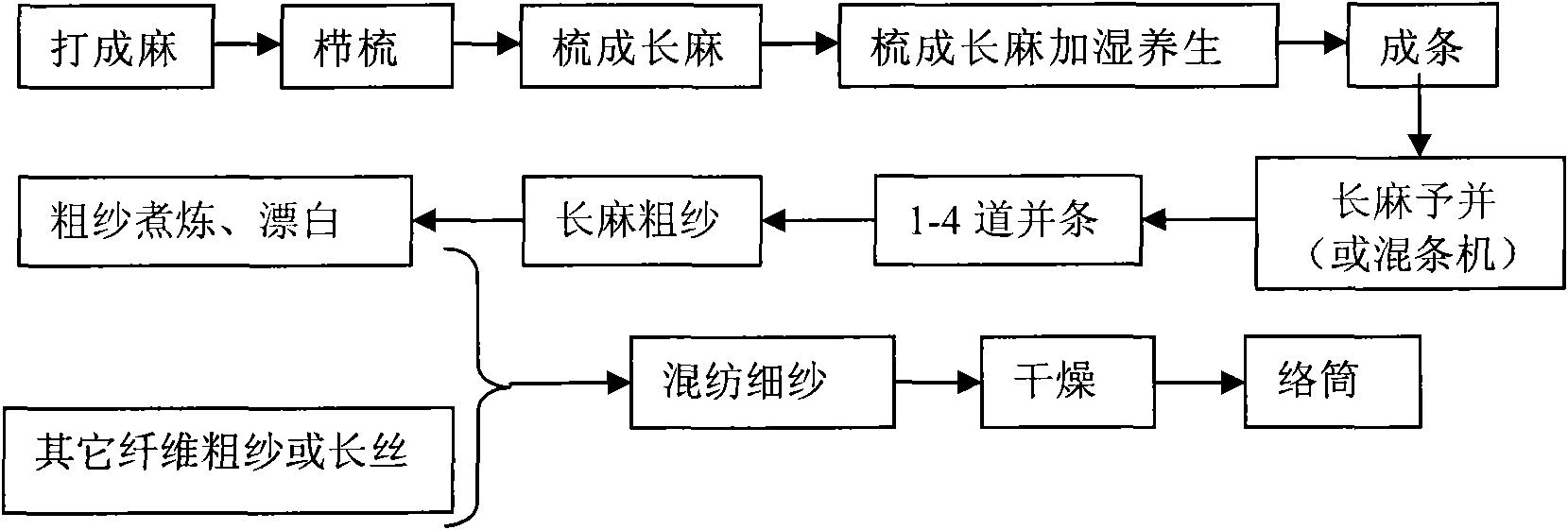

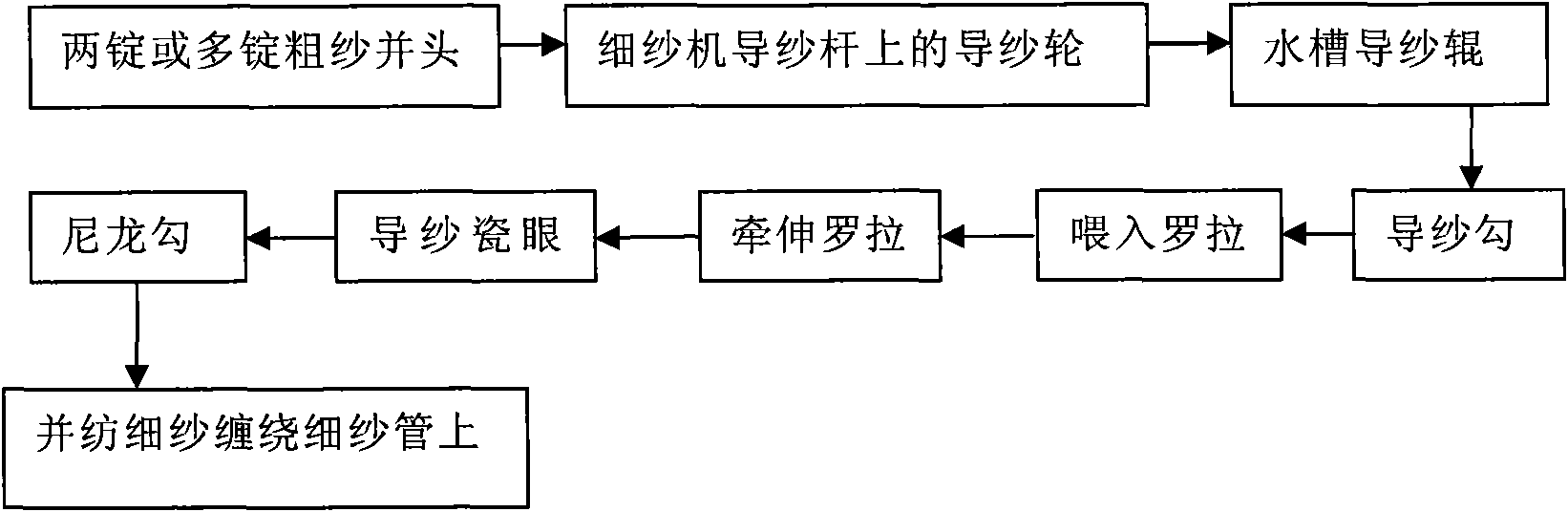

Blended spinning method of long spinning and damp spinning for bast fibers

The invention provides a method integrated with long spinning, wet spinning and blended spinning for bast fibers. The method comprises the following steps: the bast fibers are scotched into flax; the flax is humidified and soaked for a period of time; the flax is carded into long flax; and the long flax is subjected to matching, silvering, drawing, roving, scouring, bleaching, spinning, drying and winding. The method is characterized in that after the bast fibers are bleached, the obtained rove of the bast fibers and rove or filaments of other fibers are blended on a spinning machine. With the method, blended fibers are not bleached and scoured together with the bast fibers, so the defect that the performance of blended yarn is affected due to the damage of bleaching and scouring agents to the blended fibers in the prior wet spinning and blended spinning is overcome, and the obtained blended yarn has the characteristics of bright and clean yarn body, less hairness, evenness and good wear resistance. In addition, the method can fully play a role in respective advantages of the bast fibers and the blended fibers, complement respective disadvantages of the bast fibers and the blended fibers, has simple process, is favorable for improving the quality of blended yarn of the bast fibers, and realizes the high count, high grade and diversification of varieties of the bast fibers.

Owner:DONGHUA UNIV

Composite nozzle device capable of reducing resultant yarn hairiness

InactiveCN102926056ASimple structureImproved anti-pilling propertiesFilament handlingDrafting machinesWinding machineYarn

The invention relates to a device for reducing resultant yarn hairiness by utilizing a composite nozzle, which belongs to the technical field of textile engineering, wherein the composite nozzle substantially comprises a raw head cavity, an intensive cavity and a vortex cavity, the raw head cavity is convenient for yarn joints, the intensive cavity is used to pretreat hairiness which is arranged on the surfaces of resultant yarns, and prevents fibers on the surfaces of the resultant yarns from losing, compressed airflow in the vortex cavity can involve the hairiness on the surfaces of the resultant yarns into a yarn body, and the composite nozzle can conveniently arranged on a spinning frame or a cone winding machine. The device utilizing the composite nozzle to reduce resultant yarn hairiness is simple in structure, convenient to install and low in energy consumption, and is convenient for large-scale promotion and use.

Owner:JIANGNAN UNIV

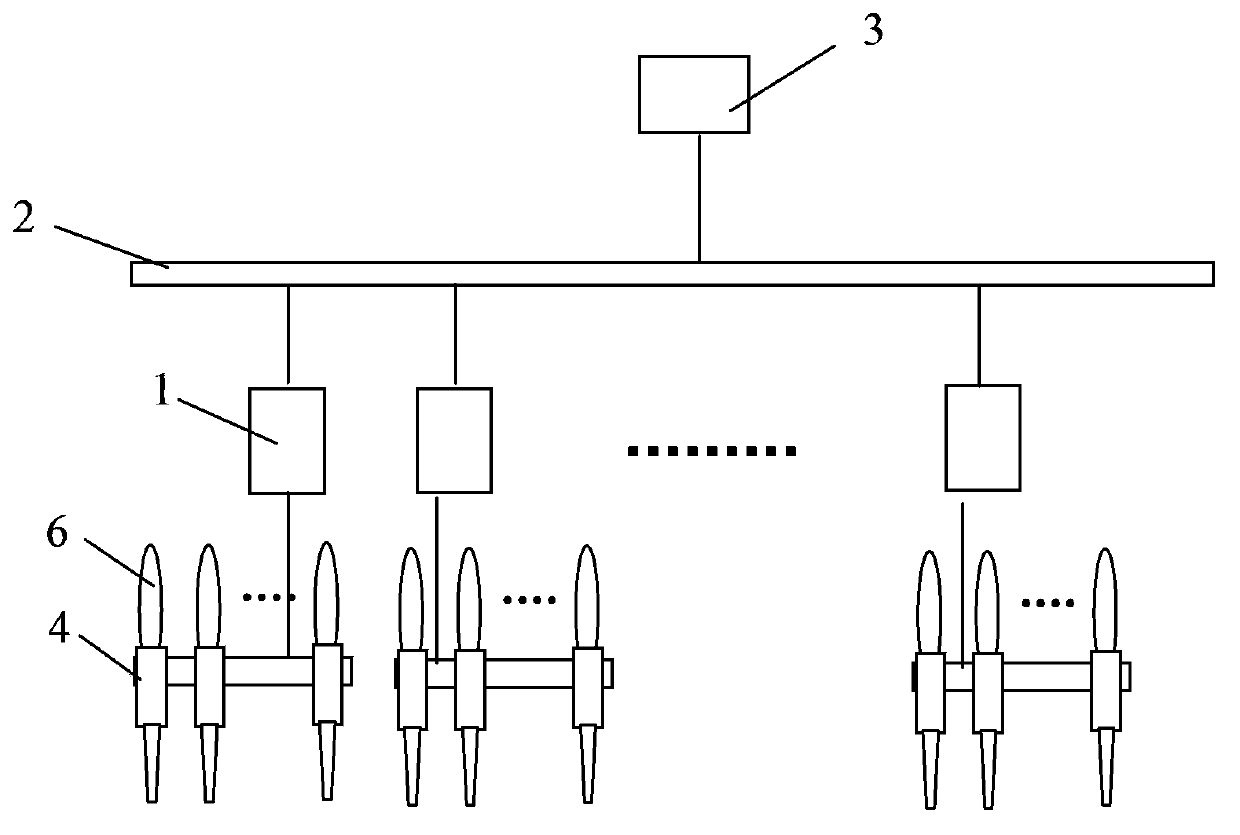

Segment color yarn spinning device and segment color yarn spinning method

ActiveCN105821532ARealize spinningFully stretchedDrafting machinesContinuous wound-up machinesYarnPulp and paper industry

The invention provides a segment color yarn spinning device and a segment color yarn spinning method. The segment color yarn spinning device comprises a front roller, a middle roller and a rear roller, wherein the middle roller comprises a roller shaft; the roller shaft is connected with a first roller sleeve and a second roller sleeve from left to right; the front roller, the middle roller and the rear roller are driven by a first server motor, a second server motor and a third server motor respectively; a first bell mouth, a second bell mouth and a third bell mouth are additionally arranged at the upper parts of the front roller, the middle roller and the rear roller; the first roller sleeve is integrally connected with the roller shaft; the second roller sleeve is connected with the roller shaft through a bearing; and the bearing is connected with an electromagnetic switch. In the production process, main body rough yarns are fed into the rear roller from the first bell mouth, and auxiliary rough yarns are fed into the second roller sleeve of the middle roller from the second bell mouth; and the spinning of white yarn segments and colored yarn segments is realized by switching on / off of the bearing.

Owner:ZHANJIANG ZHONGZHAN TEXTILE

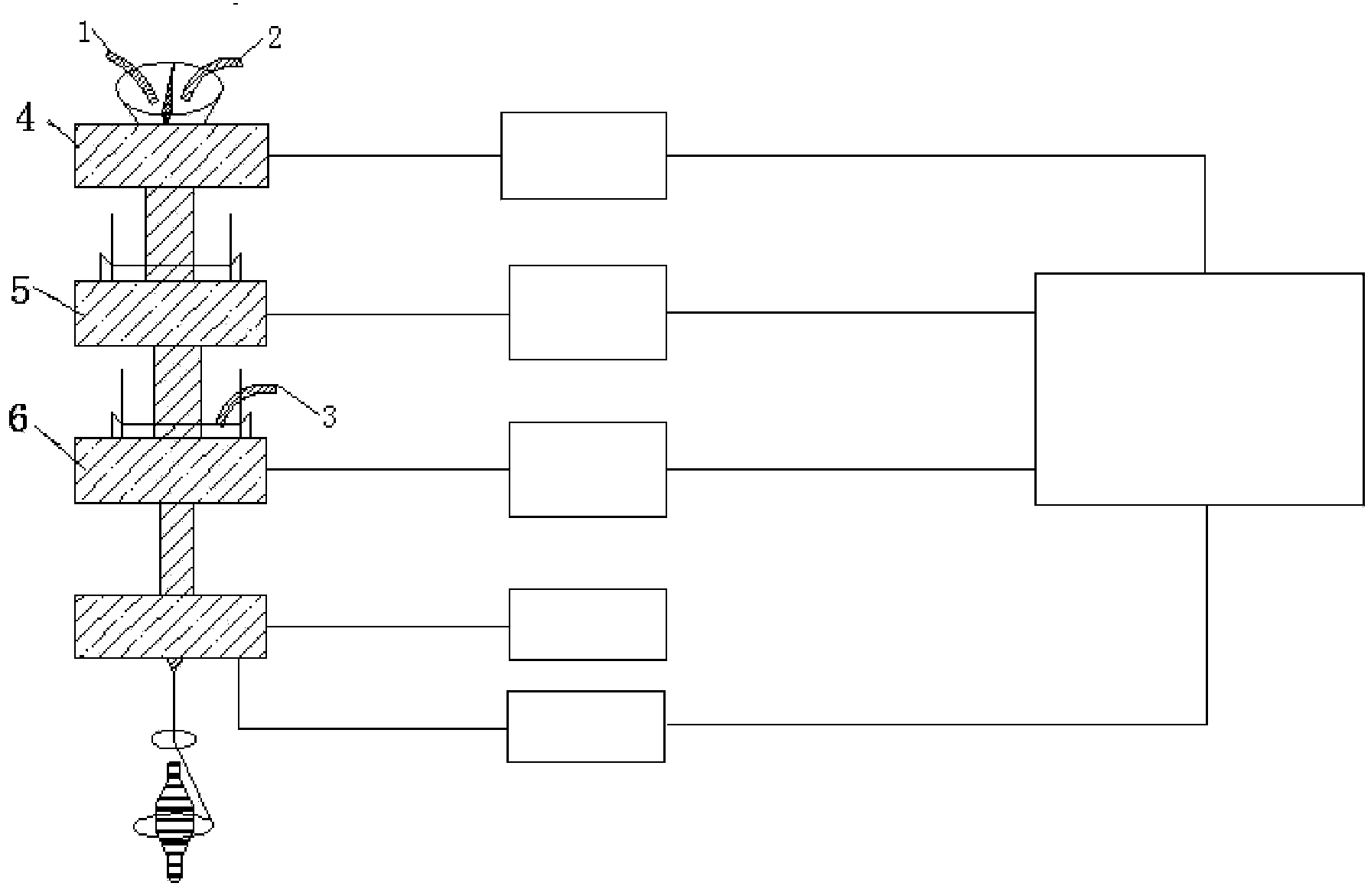

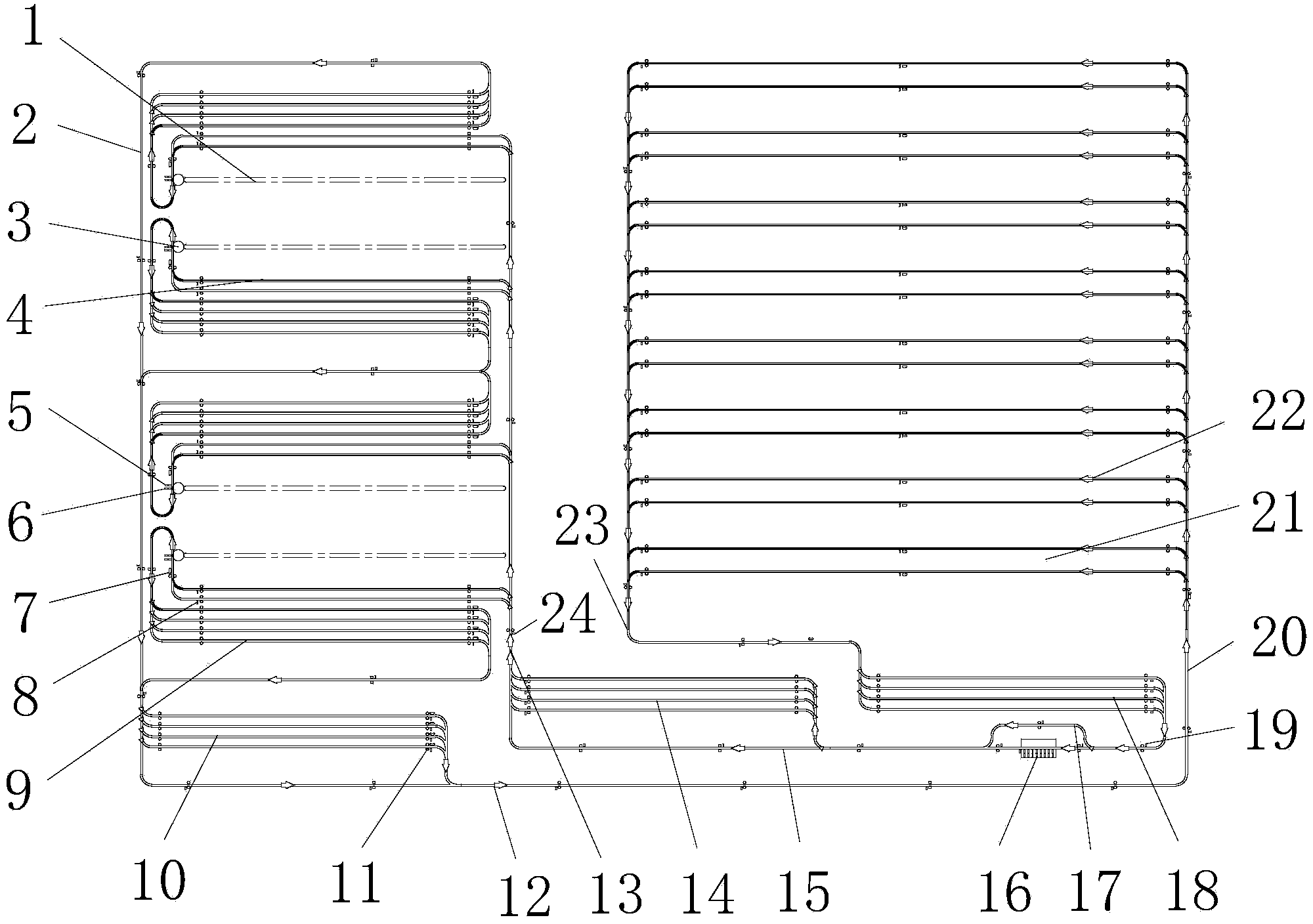

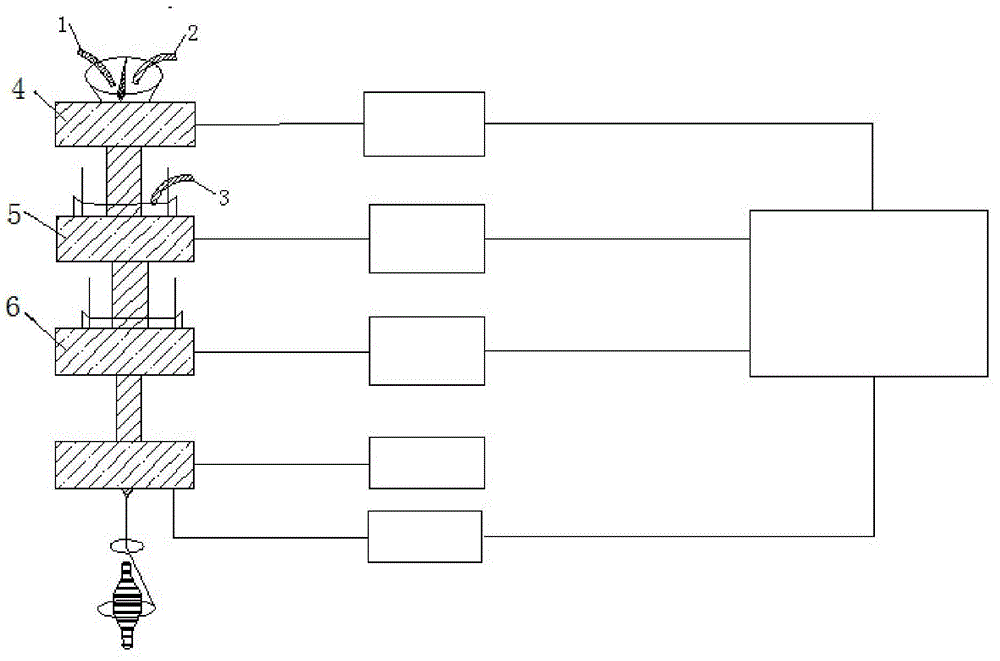

Coarse-fine combined intelligent roving machine control system

ActiveCN103774300AReduce labor costsRealize continuous productionTextiles and paperYarnMachine control

The invention discloses a coarse-fine combined intelligent roving machine control system. The coarse-fine combined intelligent roving machine control system comprises a roving machine doffing area, a spinning machine doffing area, an automatic roving machine doffing control mechanism, a coarse-fine combined conveyor control mechanism, a coarse-fine combined central control mechanism and a closed-loop cycling track which is arranged on the periphery of the roving machine doffing area and the spinning machine doffing area; the roving machine doffing area is provided with a plurality of roving machine yarn lifting platforms, the spinning machine doffing area is provided with a plurality of automatic spinning machine doffing devices, the closed-loop cycling track comprises a blank pipe moving-in track, a full pipe moving-out track and a full-pipe moving-in track, which are sequentially connected with one another to form a closed loop. The coarse-fine combined intelligent roving machine control system is reliable and stable in performance, high in automation degree and intelligence, capable realizing the automatic, intelligent and continuous production for spinning and conveying coarse yarns, the labor cost of a cotton spinning enterprise can be reduced, and the quality of the yarn can be improved.

Owner:QINGDAO TIANYI HONGQI RUN CONTROL TECH +1

Method for improving properties of yarns formed by rotor spinning

InactiveCN102634894AImproved yarn performanceLow bending stiffnessContinuous wound-up machinesOpen-end spinning machinesWoolFlexural rigidity

The invention relates to a method for improving the properties of yarns formed by rotor spinning by reducing fiber modulus and rigidity on line, belonging to the field of textile processing. The method has the following advantages that the fiber modulus and bending rigidity of rotor spun fiber strands are quickly reduced on line by adopting a three-stage parallel softening treatment method, thus improving the fiber combing quality of the combing roller, improving torsion easiness and internal and external transfer properties when the fibers undergo rotor spinning, improving the rotor spun yarn surface twist line clarity and yarn strength and substantially elevating the capability of spinning high count yarns through rotor spinning; the key problems that the rotor spun yarn surface fibers are loose, the twist lines are not clear and the method is not suitable for spinning the high count yarns can be effectively solved; the quality of the yarns formed by rotor spinning of fibers is substantially improved; and the method is especially suitable for high-quality spinning of textile fibers with high rigidity (such as ramie) and high elasticity (such as wool) on the rotor spinning machine.

Owner:WUHAN TEXTILE UNIV

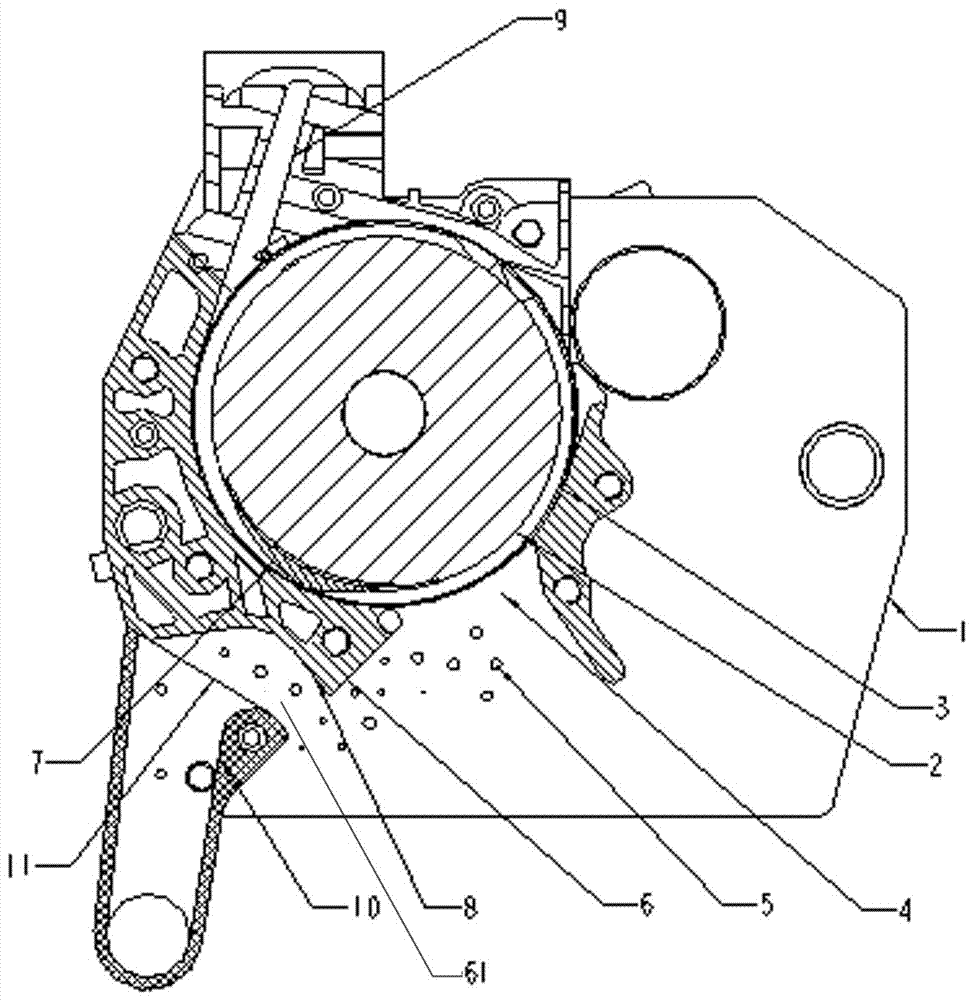

Driving gettering multi-adaption rotor type spinning machine

InactiveCN107366051AReduce distractionsSolve the phenomenon of rolling back into the fiberContinuous wound-up machinesOpen-end spinning machinesFiberEngineering

The invention discloses a driving gettering multi-adaption rotor type spinning machine. The driving gettering multi-adaption rotor type spinning machine comprises a spinning apparatus, wherein the spinning apparatus comprises a carding cavity, a carding roll, a main impurity-removing area and a fiber transferring channel, wherein the carding cavity is used for carding and stripping impurities of silvers, the carding roll is used for rotatably driving the slivers to move in the carding cavity, and works in cooperation with a carding area to card the slivers; the main impurity-removing area is used for conducting falling separation on impurity particles stripped from the slivers; the fiber transferring channel is used for transferring carded sliver fiber; a left impurity-removing area is arranged at the left side surface of the main impurity-removing area, a slot is formed in the left side surface of the left impurity-removing area, a suction nozzle is arranged in the slot, the suction nozzle and the slot enclose a rectangular suction port, and an impurity-removing main air pipe is arranged at the lower rear portion of the spinning apparatus, and is connected with the suction nozzle through a draw.

Owner:苏州多道自动化科技有限公司

Four-roller ultra-large drafting siro spinning AB yarns and production method thereof

The invention discloses four-roller ultra-large drafting siro spinning AB yarns, which are characterized in that A coarse yarns comprise 50% weight percent of Xinjiang long stapled cotton and 50% weight percent of cashmere fibers; and B coarse yarns comprise 55% weight percent of viscose, 20% weight percent of chinlon and 25% weight percent of bamboo fibers. A production method for the four-roller ultra-large drafting siro spinning AB yarns comprises the steps of feeding the A and B coarse yarns, processed and machined according to a ratio, into rear rollers by a dual-horn port, and obtaining the four-roller ultra-large drafting siro spinning AB yarns through four-roller three-area ultra-large drafting. The four-roller ultra-large drafting siro spinning AB yarns and the production method thereof can comprehensively utilize excellent properties of various fibers, realize the excellent comfort and antibacterial function of the blending yarns, realize the multifunctional demands of the yarns, and meet actual demands; and meanwhile, the ultra-large drafting is realized by adopting the four-roller four-leather ring three-area drafting, thus improving the spinning suitability and the finished yarn quality of the yarns.

Owner:DAFENG WANDA TEXTILE

A spinning method of multi-component multi-color segment colored yarn

The invention discloses a spinning method of multi-component multi-segment color yarns. In the spinning procedure, three roves at least in one color and one material are simultaneously fed into a super-large drafting spinning machine which is formed by four rollers and four aprons and which operates in a three-region drafting mode. The spinning method has the advantages that according to the feeding mode of the three roves, the multi-component segmental color yarns with three different colors can be produced, the color yarns in different styles can be produced, and yarn added value is increased; in the spinning procedure, 30 to 300 times of super-large drafting can be realized through the four rollers and the four aprons in the three-region drafting mode, foundation for simultaneously feeding three roves is established, spinning efficiency is improved effectively, and meanwhile, spinning-compatibility and yarn quality of the color yarns are improved.

Owner:江苏泗水纺织有限公司

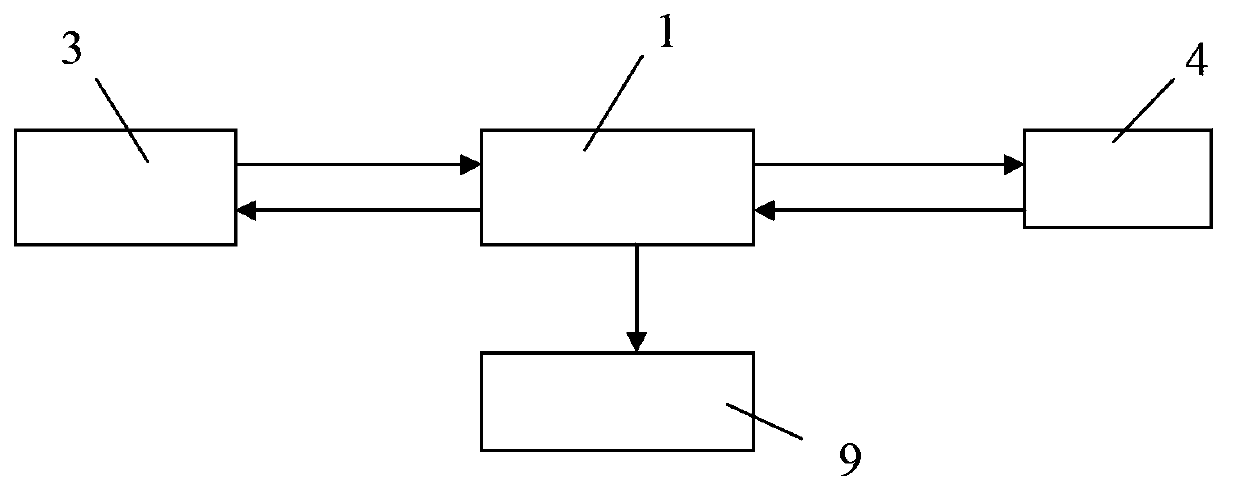

Method and device for detecting electric spindle tension and broken yarn in spinning machine

InactiveCN103966714AReduce lossEasy to shapeTextiles and paperDigital signal processingElectric machinery

The invention discloses a method for detecting electric spindle tension and broken yarn in a spinning machine. The method comprises the following steps: a motor independently drives a spindle, the input end of the motor is connected with a drive circuit; a detection circuit is used for detecting the current value and the speed value passing through the motor in real time, and the change of the tension on a yarn is judged according to the change of the current value or the speed value; during the spindle spinning operation process, the fact that the yarn on the spindle is broken is judged when the current value suddenly decreases or the speed value suddenly increases. The detection circuit and the drive circuit are connected with a control circuit; the control circuit reads the current value and the speed value and outputs a signal or adjusts the output of a control circuit according to the change of the current value or the speed value. The method is implemented through the control circuit. The control circuit comprises a programmable controller and a digital signal processing system. According to the yarn tension, the following commands are outputted including stopping feeding roving in the case of yarn breakage, stopping operation of an electric spindle or decelerating operation, so that cop is formed in an excellent manner, the difference between spindles is reduced, after yarn is broken, feeding of the roving is automatically stopped, and loss of the roving is reduced.

Owner:PACIFIC MECHATRONIC GRP

Millable polyurethane rubber for spinning cot and preparation method thereof

The invention discloses millable polyurethane rubber for a spinning cot, which consists of the millable polyurethane rubber, a reinforcing filler, a plasticizer, an antistatic agent, a protective agent, pigment, a cross linking agent, a cross-linking assistant agent and a processing agent. The millable polyurethane rubber adopts peroxide as a main vulcanizing system and overcomes the defects of large dynamic heat generation and large permanent deformation; the antistatic agent contained in the millable rubber has good conduction and excellent anti-entangling performance; and the spinning cot made of the millable polyurethane rubber is free of surface treatment, is not deformed and durable in use, does not absorb any coating and cleaning agent, can obviously improve yarn quality and keep the stability of the yarn quality, also can adapt to the change of humiture for normal production, has the characteristics of good elasticity, wear resistance, good weather resistance and spinning ability, long service life and the like, has environmental protection and energy conservation, contributes to managing spinning enterprises and reducing cost of a ton of yarns, and lays a good foundation for meeting the technological requirements of heavy ingot, heavy press and high draft.

Owner:广州海丝尔橡塑科技有限公司

Synchronous and anti-clockwise twist spinning device and synchronous and anti-clockwise twist spinning method

ActiveCN106757568AImprove yarn qualityImprove spinning efficiencyDrafting machinesContinuous wound-up machinesYarnFiber

The invention provides a synchronous and anti-clockwise twist spinning device and a synchronous and anti-clockwise twist spinning method. The synchronous and anti-clockwise twist spinning device comprises a drafting mechanism and a winding mechanism, a yarn guiding device is arranged between the drafting mechanism and the winding mechanism, a false twist device is arranged between the drafting mechanism and the yarn guiding device, an upper side band and a lower side band are respectively contacted with fiber strands which are drafted and outputted through a front roller draft pair, a working face of pre-adding twist and a working face of balance twist are respectively formed, the working faces respectively generate twists opposite in twisting direction and identical in size with the fiber strands contacted with the working faces, the drafted double-fed strands are synchronously twisted through the twist generated from speed difference of a bobbin of a bead ring and the reverse twist synchronously generated from upper and lower working faces of the yarn guiding device, the final twist on yarn forming is unaffected by twist effect generated from a yarn forming area by the false twist device, double strands drafted are directed converged and twisted into yarn without changing final twist in yarn forming, quality in yarn forming is improved, and spinning efficiency is improved.

Owner:湖州菱创科技有限公司

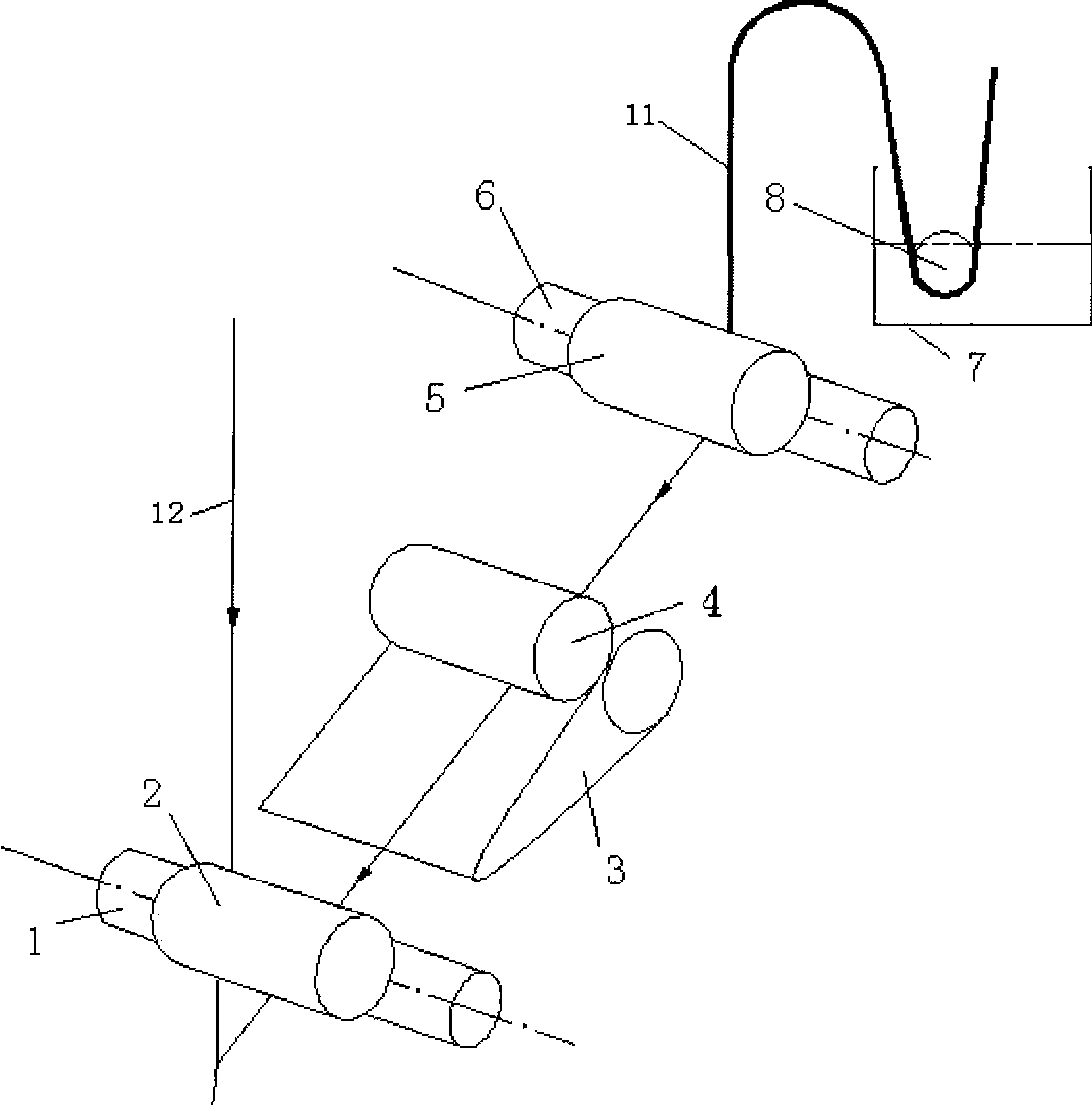

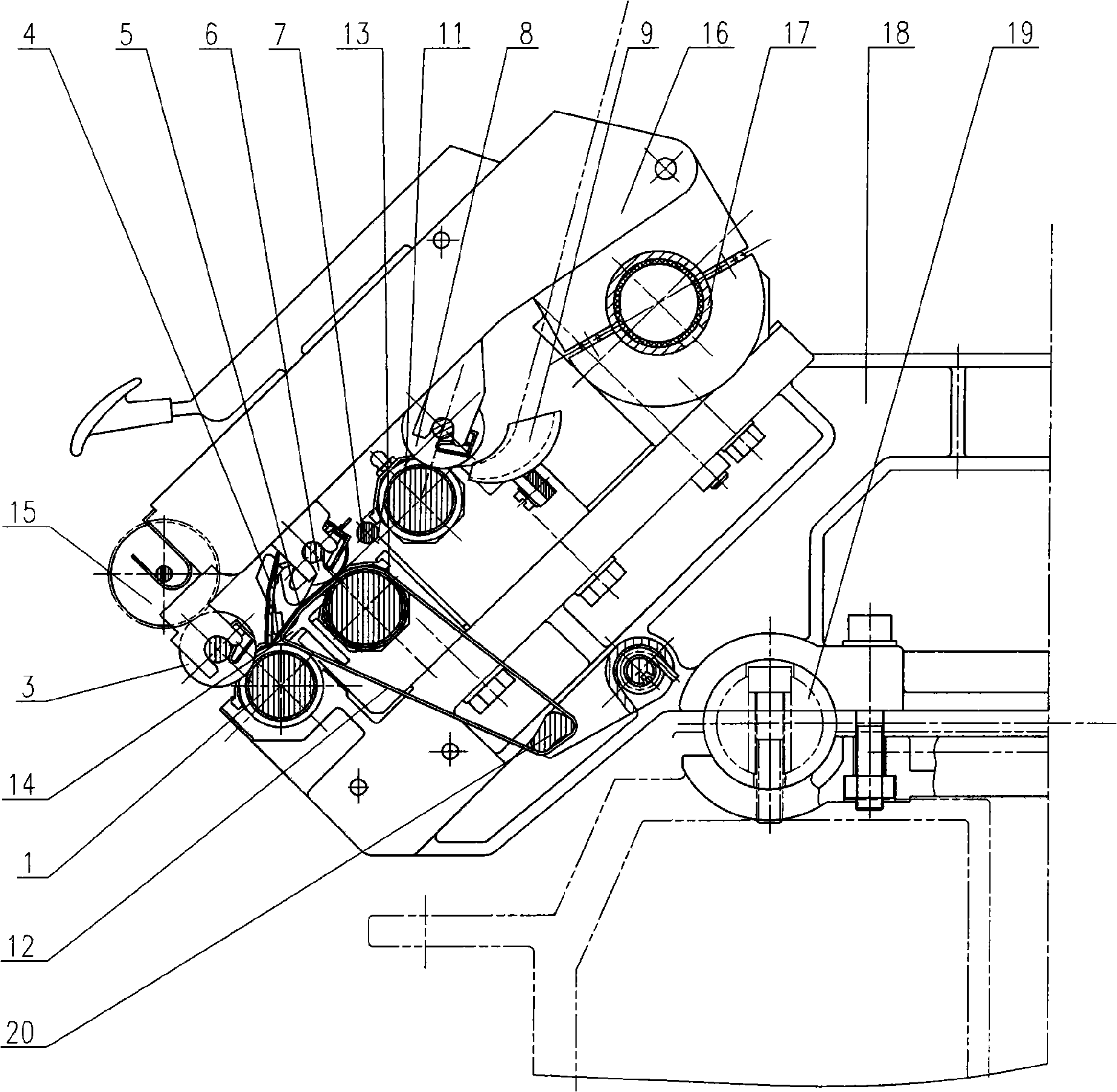

Fiber collecting device for ring spinning frame

The invention discloses a fiber nesting device for ring spinning frame, which comprises a front roller, a front leather roller, a nesting leather roller, and an indraft tube arranged under the nesting leather roller. An indraft groove is arranged on the top of said indraft tube, which slideably muffcouples a conveying belt, said conveying belt is driven by the front roller via belt driving unit or directly muffcoupled on the front roller. The fiber nesting device not only effectively avoids the spinning triangular space, but also ensures matching of the nipper jaws output speed with the conveying belt linear speed, so the resultant yarn quality is further improved.

Owner:DONGTAI TEXTILE MASCH CO LTD

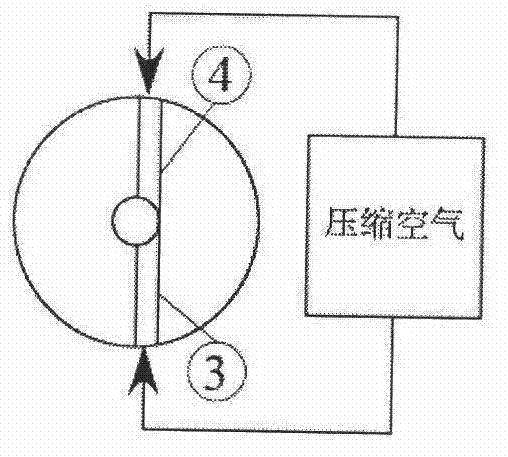

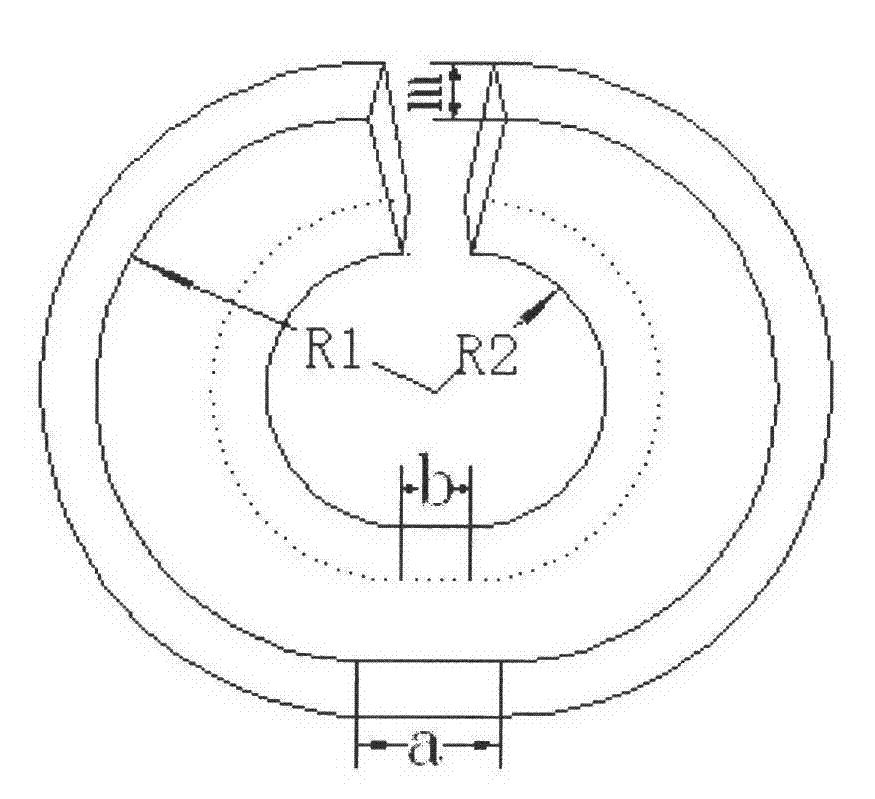

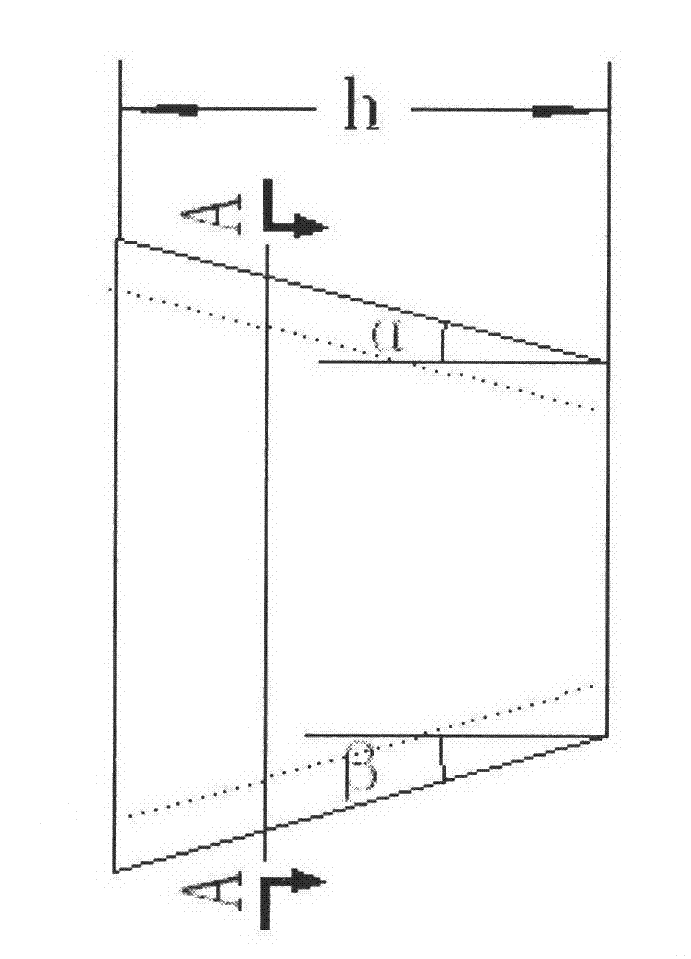

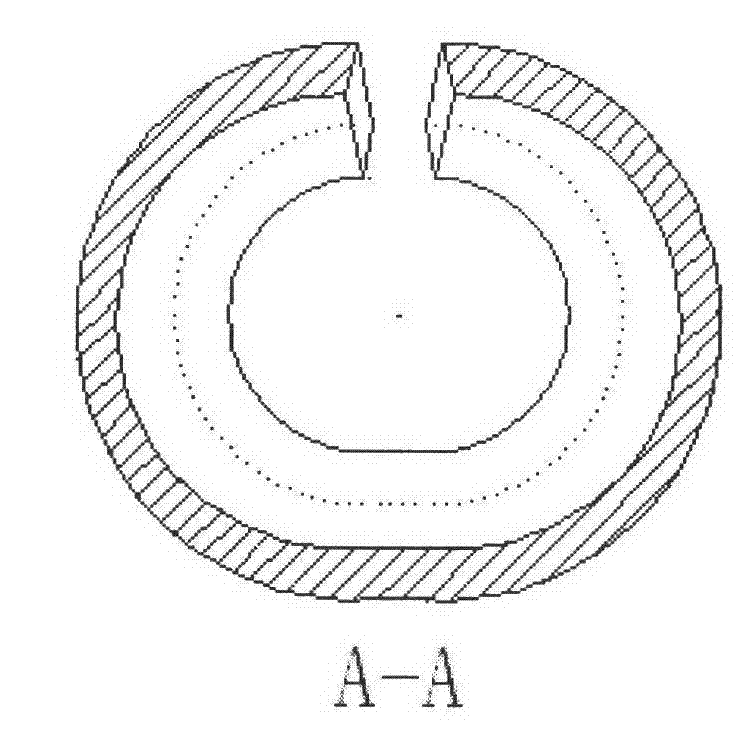

Covering yarn production device and method

The invention relates to the technical field of textile manufacturing and processing, in particular to a covering yarn production device and method. In order to solve the technical problem that an existing compact spinning cotton web is too narrow to benefit filament covering, so that the quality of covering yarn is affected, the covering yarn production device comprises a flare opening, a first roller, a second roller, a third roller, a negative pressure pipe and a ring from top to bottom in sequence. A groove formed in the ring comprises a first end opening and a second end opening, wherein the first end opening is formed above the second end opening, and the width of the first end opening is larger than that of the second end opening. Fiber strands are subjected to drafting, stretching and reducing and then fed into the groove, namely a negative-pressure suction port, a filament volume is subjected to active unwinding and rotation of a loading roller, filaments are drawn forth, the filaments pass through a filament guide wheel and then are fed into a compact spinning leather roller, the compact spinning leather roller applies pressure on the negative-pressure suction port, core yarn covering is facilitated, filament covering cotton is avoided from being exposed to the outside, and the production quality of the covering yarn is improved.

Owner:NINGXIA RUYI SCIENCE & TECHNOLOGY FASHION INDUSTRY CO LTD

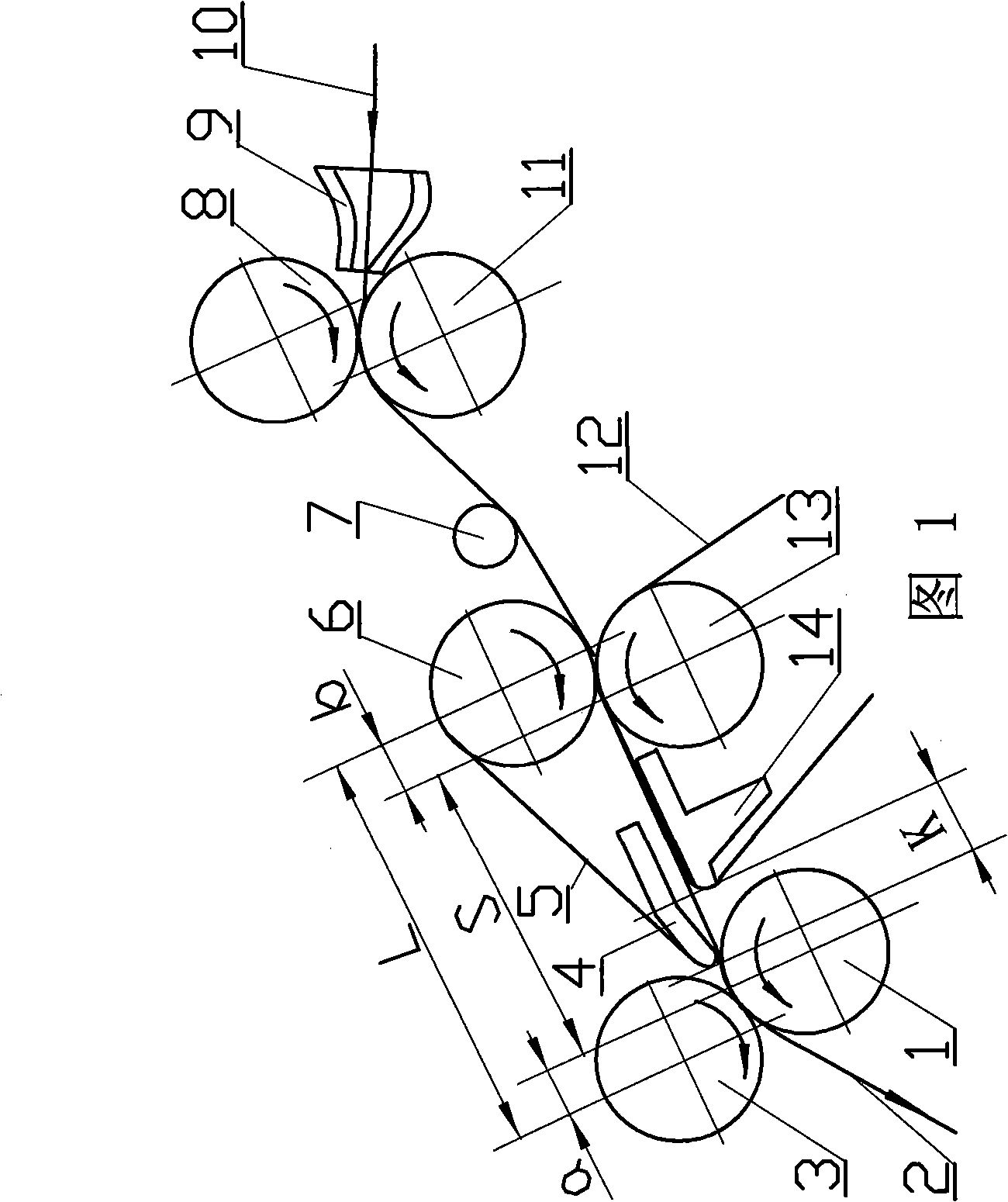

High power drafting device for ring spinning frame

InactiveCN101307515AShorten the lengthExpand the range of the friction fieldDrafting machinesFiberEngineering

The invention discloses a high-power drafting assembly used for a ring spinner, comprising a front drafting roller pair with a front roller and a front belt roller, and a rear drafting roller pair with a rear roller and a rear belt roller, wherein, a middle roller and an upper middle roller are arranged between the front drafting roller pair and the rear drafting roller pair, an upper pin is arranged between the upper middle roller and the front belt roller, while a lower pin is arranged between the middle roller and the front roller, an upper apron is sleeved on the upper middle roller and the upper pin, a lower apron is sleeved on the middle roller and the lower pin, the forward setting distance K between the upper pin front edge and the lower pin front edge is at least 3 millimeters, the ratio of the setting distance L from the upper middle roller to the front belt roller and the setting distance S from the roller to the front roller is between 1.1 and 1.6. The high-power drafting assembly can shorten the freestream flow zone length to the utmost extent, extend the control area of the apron, effectively increase the drafting multiple of the drafting assembly and guarantees the quality of the completed filament.

Owner:DONGTAI TEXTILE MASCH CO LTD

Silver-element fibre spinning technology

The invention relates in particular to a new sliver-element fibre spinning technology, belonging to the spinning engineering field of textile industry production, comprising the following steps: pre-opening silver-element fibre to 80% by an opening machine; maintaining the blowing integrated beater speed in the blowing process of less than 600r / m and the beater frequency of sliver-element fibre per gram of less than 0.55; blocking the noil airdraft opening when carding cotton; using a flatbed drawing frame and a wool-top-proof conducting bar device with the drawing funnel caliber of 5.2mm; keeping the roving cycles of 33-38 cycle / 10cm, spinning frame guide stroke of 3-6mm; maintaining the groove drum speed in spooling less than or equal to 700 meter / minute and using a photoelectric type flaw-cutting device. Compared with the existing technology, the invention has the advantages of effective control of noil rate of blowing and cotton carding, small fibre damage, little nep, removal of belt roller wound by drawing and roving, smooth passage and winding, less broken ends, higher intrinsic quality of semi-manufactured goods, less flaws and better resultant yarn quality.

Owner:SHANGHAI FEILIAN TEXTILE

Tossa short flow chemical degumming method

InactiveCN101144190AShort processStable and reliable process parametersBleaching apparatusFibre treatment to obtain bast fibreChemistryDyeing

The present invention relates to a chemical degumming method of jute fiber in a short process. The technological process is kier boiling,water washing, acid washing, water washing, dehydrating, bleaching, water washing, dehydrating,and drying. The gum content and the lignin content are reduced by using the method, the hand touch is soft, the separation degree is high, the whiteness is good and difficult to turn yellow, and the spinnability and the ability of dyeing and finishing are improved.

Owner:DONGHUA UNIV

Spun yarn collector

InactiveCN103361784ASolve problems affecting yarn qualityImprove yarn qualityDrafting machinesContact modeEngineering

The invention discloses a spun yarn collector. The section of the spun yarn collector is similarly circular, the radius of a contact arc of the collector and the surface of a roller is properly increased, and a double-point contact mode of the original collector is replaced by an arc contact mode, so that the problem of high friction factor due to obvious corner angles of the traditional collector is solved, sliver squeezing frequency of the inner wall of the collector is reduced, the yarn quality is improved, the width of each sliver is effectively reduced, spinning triangular space is reduced, the slivers are compact in structure and smooth in appearance, hairiness is reduced, and the yarn strength is improved. Compared with the traditional collector, the spun yarn collector has the advantages that the width of an outlet of the collector is reduced, and sliver collecting and finishing effects are good on the premise that the yarn quality is guaranteed.

Owner:JIANGNAN UNIV

High-strength ultraviolet-proof antibacterial type textile fabric

InactiveCN106739215AImprove fitImprove breathabilitySynthetic resin layered productsCellulosic plastic layered productsSurface layerCarbon fibers

The invention discloses a high-strength ultraviolet-proof antibacterial type textile fabric and a preparation process thereof, and relates to the field of textile fabrics. The high-strength ultraviolet-proof antibacterial type textile fabric comprises a surface layer, a middle layer and an inner layer, wherein the surface layer is made of ultraviolet-proof fabrics; the middle layer comprises a first fabric layer, a second fabric layer and a third fabric layer; each of the first fabric layer and the second fabric layer is formed by 40 to 60 weight percent of bamboo carbon fiber, 10 to 30 weight percent of Shengma fiber and 10 to 30 weight percent of gossamer through blended spinning and weaving; the second fabric layer is formed by weaving 100 weight percent of bamboo carbon fiber; the inner layer is formed by 30 to 40 weight percent of bamboo charcoal fiber, 20 to 30 weight percent of heating fiber and 40 to 50 weight percent of cotton through blended spinning and weaving. The high-strength ultraviolet-proof antibacterial type textile fabric provided by the invention has the efficacies that the strength is high; the wear resistant performance is good; the ultraviolet-proof effect is achieved; bacteria resistance and bacteriostasis are realized; the hand feeling is comfortable; ventilation and heat insulation are realized, and the like. The preparation process is simple and reasonable; the production efficiency is high.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

Technology for spinning 40<S> high tenacity vortex viscose yarn and vortex viscose yarn

ActiveCN103556315AHigh strengthImprove yarn qualityContinuous wound-up machinesOpen-end spinning machinesViscoseSpray nozzle

The invention provides a technology for spinning a 40<S> high tenacity vortex viscose yarn and the vortex viscose yarn. The technology for spinning the 40<S> high tenacity vortex viscose yarn is characterized in that an 80<S> ring viscose yarn is fed between front rollers of a vortex spinning machine and a vortex spinning spray nozzle; meanwhile, a wrapping viscose rough yarn is fed from rear rollers, drafted by four rows of rollers and converged with the fed 80<S> ring viscose yarn between the front rollers and the vortex spinning spray nozzle so as to be commonly twisted into a 40<S> fine yarn; the technology comprises an opening and cleaning procedure, a cotton carding procedure, a drawing procedure, a rough yarn procedure, a ring spinning procedure, a spooling procedure and a vortex spinning procedure. By the adoption of the technology for spinning the 40<S> high tenacity vortex viscose yarn, the combination of advantages of vortex spinning and ring spinning, i.e. less hair and high strength can be realized; meanwhile, during the vortex spinning procedure, the tension stability control prior to the feeding of a core yarn between the front rollers and the vortex spinning spray nozzle is realized via a mode that a filament tension control device and a filament guide frame in the shape of a circular arc are additionally installed; therefore, the uniformity of mixing the 80<S> ring viscose yarn fed between the front rollers and the vortex spray nozzle and viscose fiber fed from the vortex rear rollers and drafted by the four rows of rollers is improved, so that a finished yarn is perfected.

Owner:WUJIANG JINGYI SPECIAL FIBER

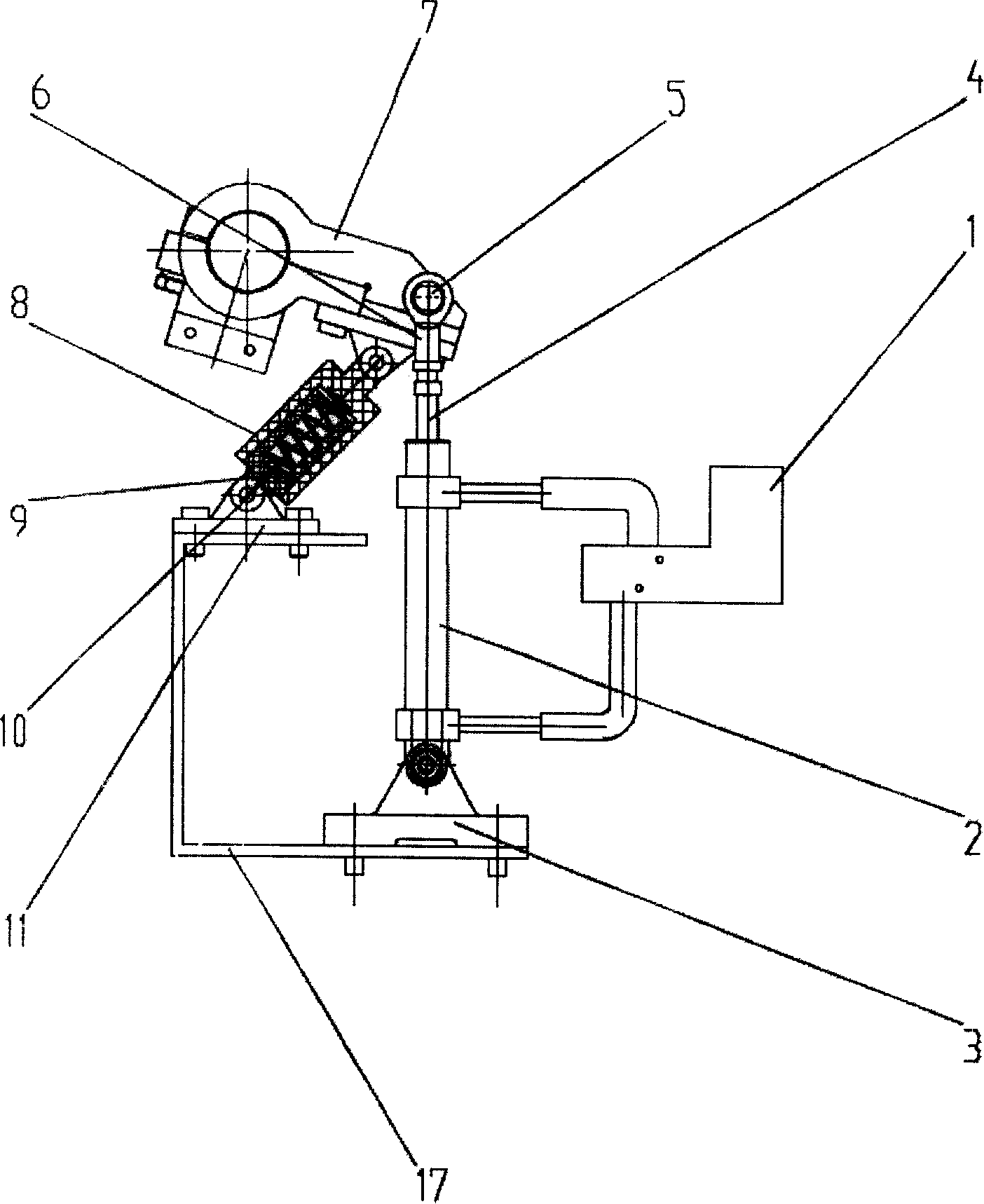

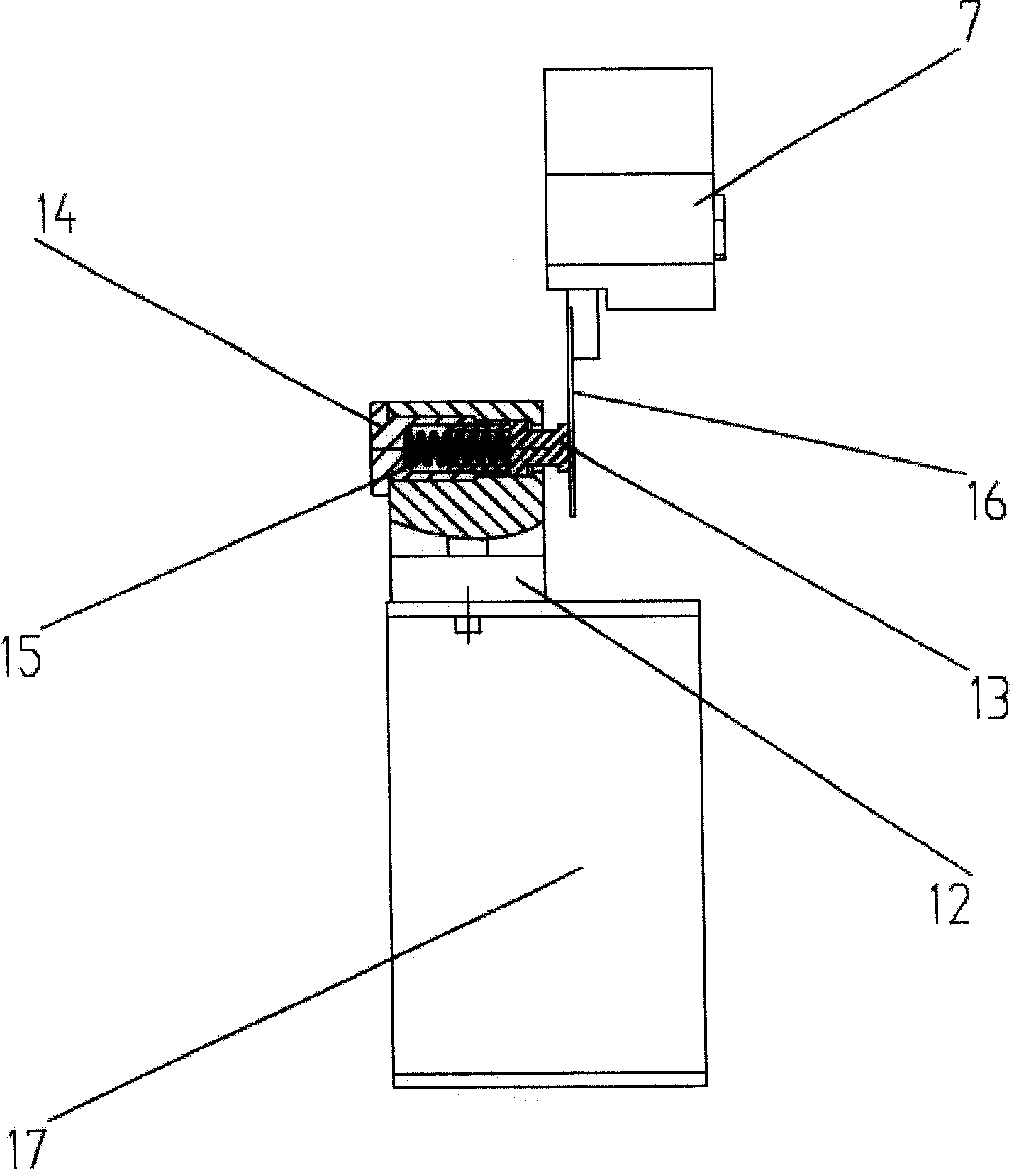

Elevator apparatus of pony roll support

InactiveCN101195452ALift up quickly and smoothlyAvoid left and right offsetFilament handlingCreelsBobbinBiochemical engineering

The invention provides a hoisting device for bobbin creels, which comprises a bobbin creel and a hoisting mechanism. The improvements of the hoisting device are that a fixing hole is arranged on the bobbin creel, one end of a connecting piece is fastened with the fixing hole by a built-in fitting, the other end of the connecting piece is connected with a lifting rod of the hoisting mechanism, and a connecting base of the hoisting mechanism is fixed on a base. A buffering mechanism is arranged between the base and the bobbin creel. The invention has the advantages of reasonable and simple structure, easy processing of main parts, convenient installation, operation and maintenance, improvement of production efficiency and low equipment failure rate. Besides, the invention can avoid oil leak problems, effectively improves yarn quality and has good application effect.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

Single-spindle drive wheel disc false-twist spinning device

The invention provides a single-spindle drive wheel disc false-twist spinning device. A rotation wheel disc serves as a false-twist element, and the outer periphery of the rotation wheel disc drives a sliver in a frication mode to rotate so that false twist is generated. The single-spindle drive wheel disc false-twist spinning device is characterized in that the downstream of a front roller jaw is provided with at least one false-twist wheel disc, the periphery of one of the false-twist wheel disc contacts a front upper roller or a front lower roller in a pressing mode, the surface of the front upper roller or the front lower roller drives the false-twist wheel disc to rotate in a friction mode, the included angle alpha is formed between the axis of the false-twist wheel disc and the axis of the rollers is alpha, a false-twist contacting section exists between the sliver output from the front jaw and the periphery of at least one of the false-twist wheel discs.

Owner:高密市元信纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com