Blended spinning method of long spinning and damp spinning for bast fibers

A kind of fiber and bast technology, which is applied in the field of bast fiber long-spinning wet spinning blending, can solve the problems of not developing a variety of flax products, the function of blended fibers cannot be fully exerted, and the performance damage of blended fibers such as elongation , to achieve the effect of improving spinnability and product quality, alleviating the shortage of raw materials, and smoothing the yarn body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The 22tex flax long linen 55 / polyester 45 blended yarn is spun by the present invention. The process is as follows: before spinning, in order to improve the softness and strength of the flax fiber, the flax is sprayed with emulsion, humidified and maintained for 18-24 hours, and then combed into long flax by combing machine. Comb long hemp through physical experiments to determine various technical indicators, blend hemp on the sliver machine, and initially form hemp sliver, the hemp sliver is made into roving on the long hemp roving frame after five draws, after the roving is boiled and bleached Mix with polyester filaments and nylon filaments on the short linen wet spinning frame, dry, and wind to make blended yarns.

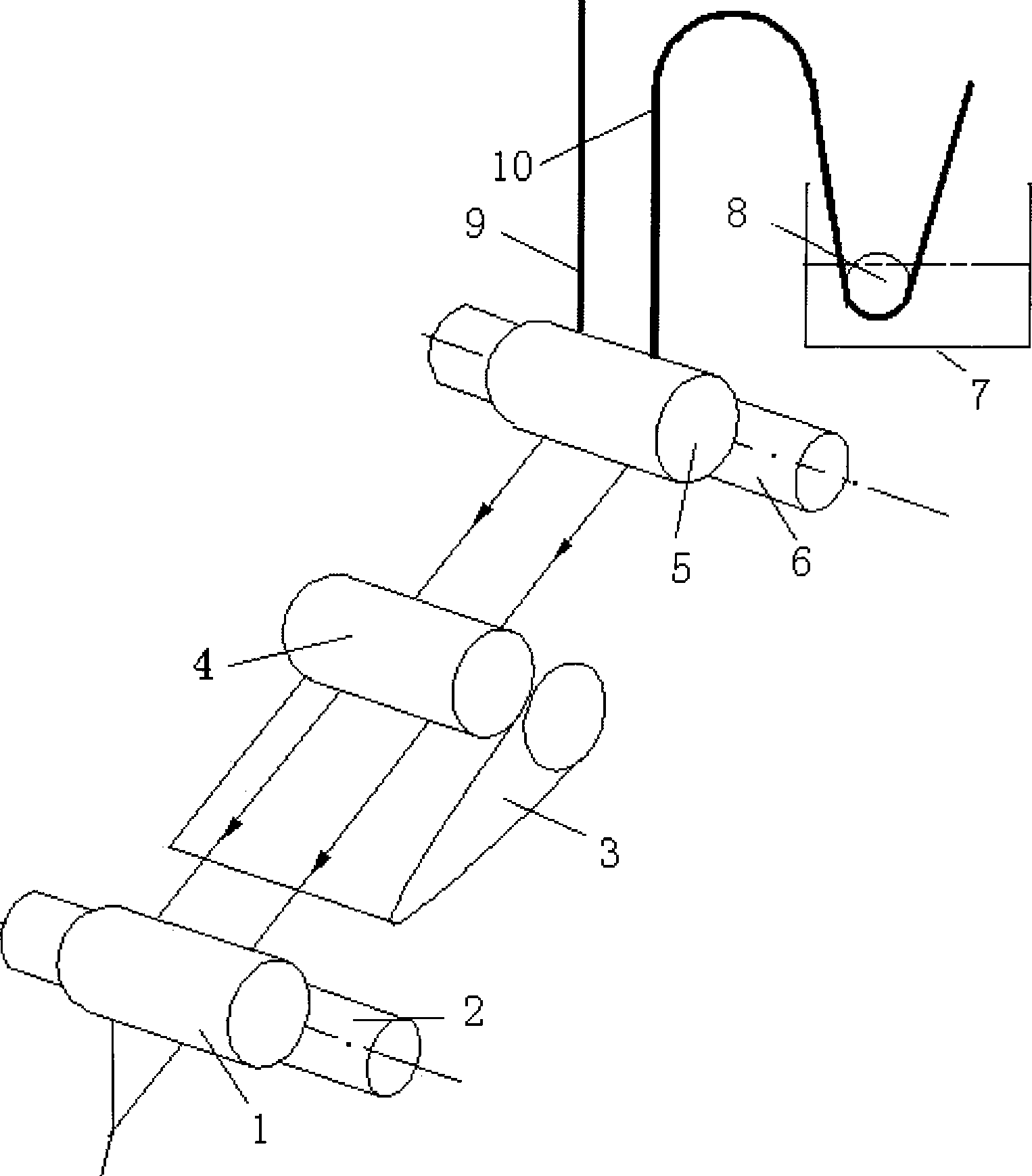

[0023] like figure 1 As shown, it is a schematic diagram of the blending of flax roving and polyester roving. The mixing method of flax roving and polyester roving is: after the flax roving 9 is boiled and bleached, it enters the spinning frame togethe...

Embodiment 2

[0027] Adopt the present invention to spin 30tex linen 60 / viscose 40 blended yarns. The process is as follows: before spinning, in order to improve the softness and strength of the hemp fiber, the hemp is sprayed with emulsion, humidified and maintained for 18-24 hours, and then combed into a long hemp by combing machine. The combed long flax is determined through physical experiments to determine various technical indicators, and the flax is blended on the sliver machine to initially form a flax sliver. The back roller 6 is fed together with the viscose roving on the spinning frame, wherein the viscose roving does not pass through the water tank, and the method in Example 1 is used for drafting on the spinning frame, drying, and winding to obtain a flax / viscose blend Yarn, its quality is shown in the table below:

[0028]

Embodiment 3

[0030] Using the present invention to spin 25tex flax 50 / polyester 50 blended yarn, the process is as follows: before spinning, in order to improve the softness and strength of the flax fiber, spray the emulsified emulsion for 18-24 hours, and then use the comb The carding machine is combed into combed long flax, and the combed long flax combed by the combing machine is determined through physical experiments. The technical indicators are determined on the sliver machine, and the flax is initially formed. The roving is made on the long hemp roving frame, and then mixed with polyester filaments on the long hemp wet spinning frame, dried and wound to make a blended yarn.

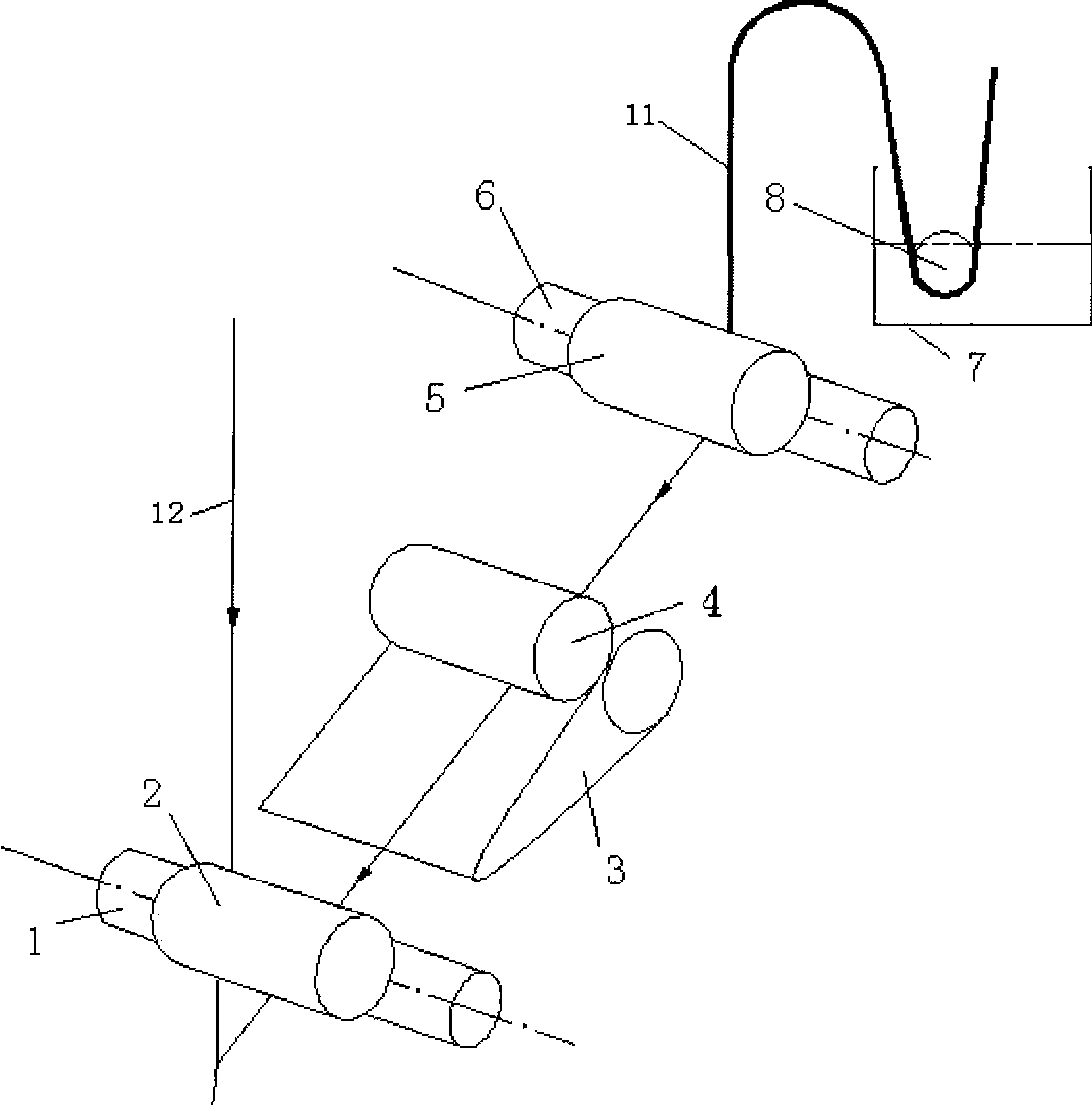

[0031] like figure 2 As shown, it is a schematic diagram of flax roving and polyester filament blending. The mixing method of flax roving and polyester filament is: the flax roving 11 passes through the water tank 7 (which is provided with a guide roller 8) after the boiling and bleaching process, and then pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com