Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Increase the degree of splitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

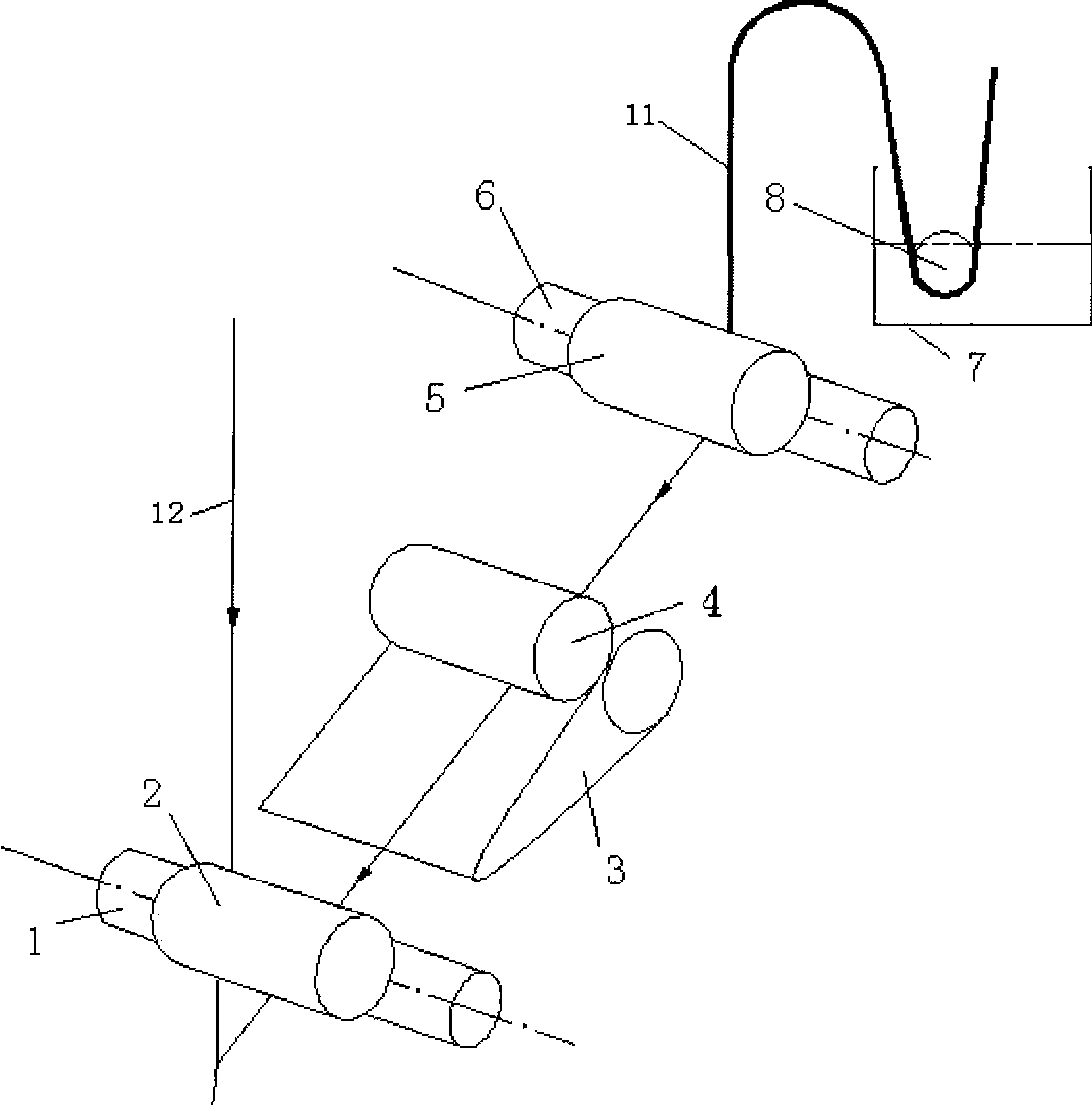

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

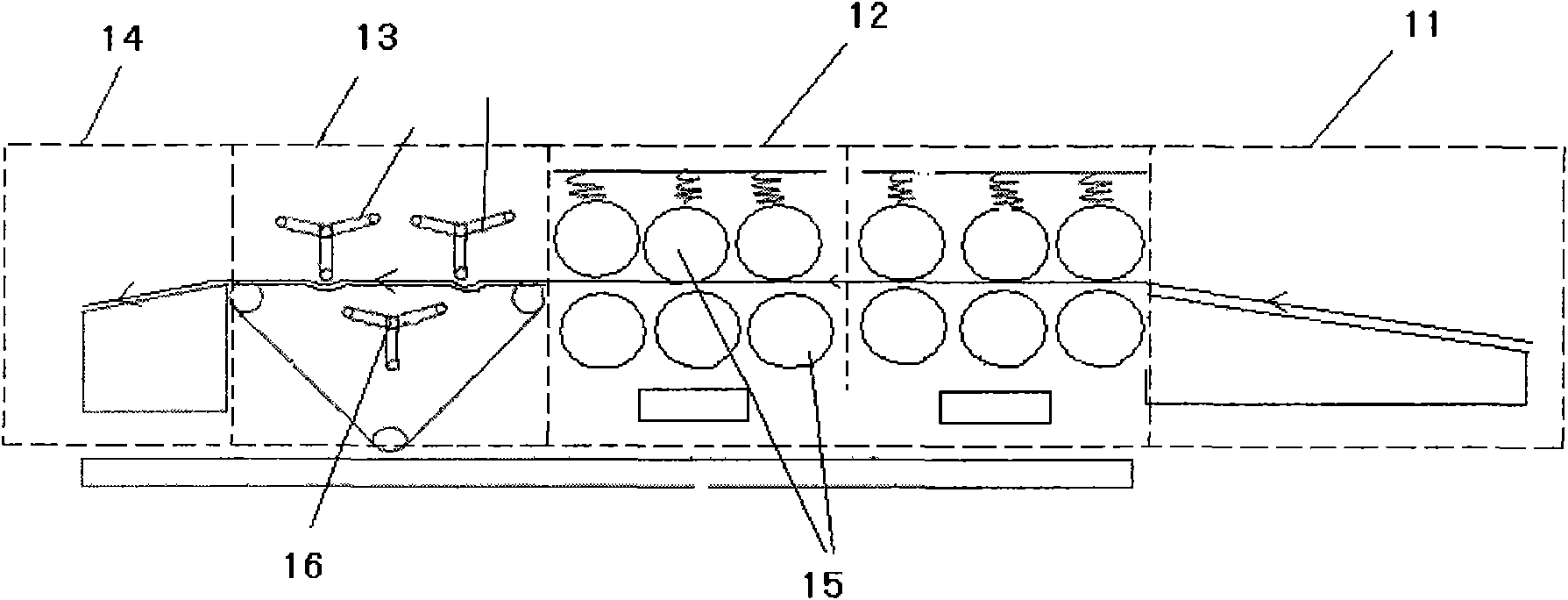

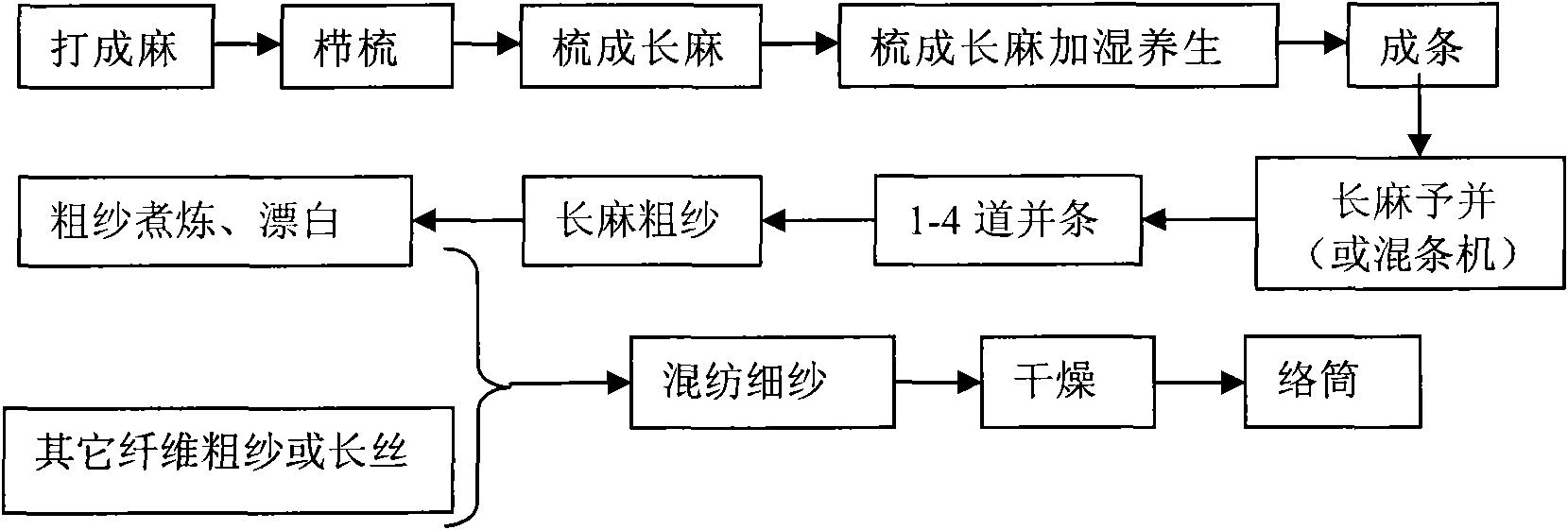

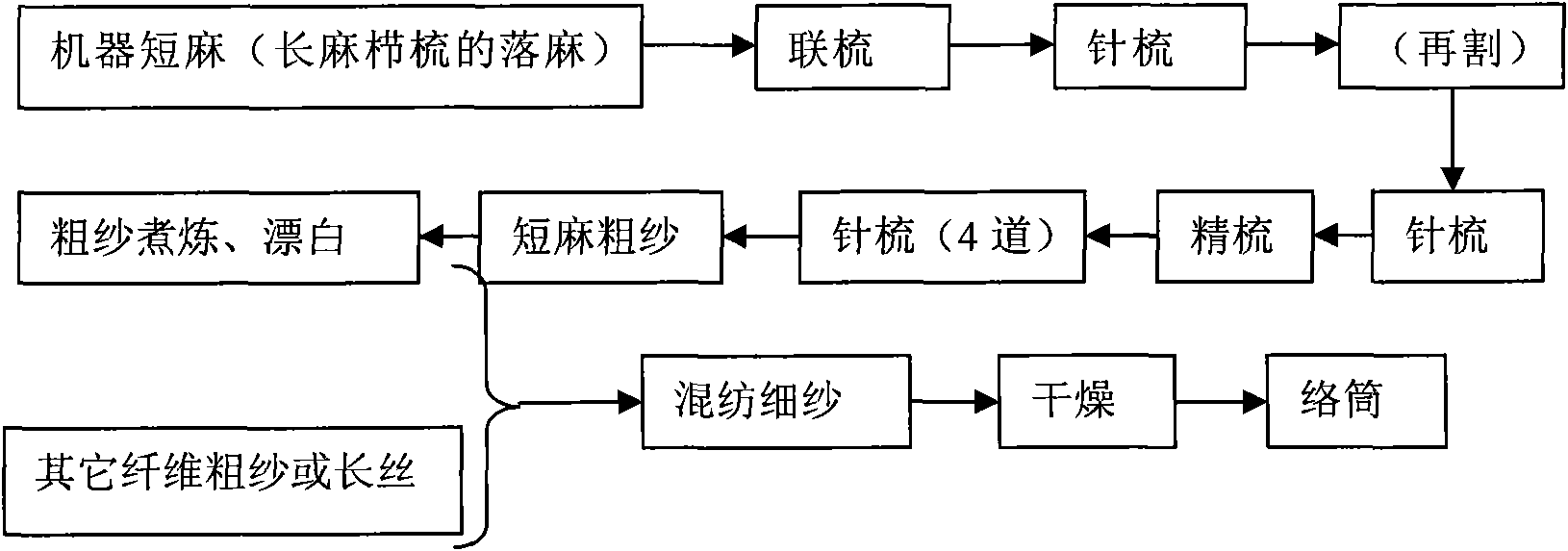

Blending method using hemp fiber as main material

InactiveCN101871147AIncrease the degree of splittingImprove impurity removalHackling machinesBleaching apparatusImpurityMaterials science

The invention relates to a blending method using a hemp fiber as a main material. The method comprises the following steps of: firstly, processing the hemp fiber into rovings; secondly, mixing the roving yarns of the hemp fiber with the rovings or filaments of other fibers in proportion to form bunch yarns; and finally, spinning the mixed bunch yarns in the second step into spun yarns. The blending method has the advantages of improving the disintegration degree of the hemp fiber and removing impurity without damaging the performance of the blended fibers, ensuring a high spinning yam count and quality of the blended yarns and greatly improving the quality of the blended yarns of the hemp fiber along with simple process.

Owner:肇融亚麻纺织有限公司

Short-flow environmentally-friendly production method for jute fibers

ActiveCN102031568AShort production processEfficient removalYarnFibre treatment to obtain bast fibreChemical oxygen demandImpurity

The invention relates to a short-flow environmentally-friendly production method for jute fibers. The method is characterized in that: the principle of deep oxidation is adopted, and jute bast is subjected to identical bath degumming and bleaching. The method comprises the following steps of: 1) performing impurity removal and washing on the jute bast; 2) performing first identical bath degumming and bleaching by using 5 to 6 g / l of nano argil preparation, 6 to 7 g / l of caustic soda, 1 to 3 g / l of soda ash and 8 to 10 g / l of hydrogen peroxide; 3) performing second identical bath degumming and bleaching by using 4 to 5 g / l of nano argil preparation, 4 to 6 g / l of caustic soda, 1 to 3 g / l of soda ash and 8 to 12 g / l of hydrogen peroxide; 4) washing after degumming and bleaching; and 5) dehydrating, shaking, softening and drying the washed jute fibers. Compared with the prior art, the method has the advantages that: 1) the production process flow is shortened by adopting a deep oxidation method; 2) the produced jute fibers have good softness and high whiteness; and 3) the process wastewater is little and has low chromaticity, and the discharge of wastewater chemical oxygen demand (COD) is greatly reduced.

Owner:郑州银泰企业管理咨询有限公司

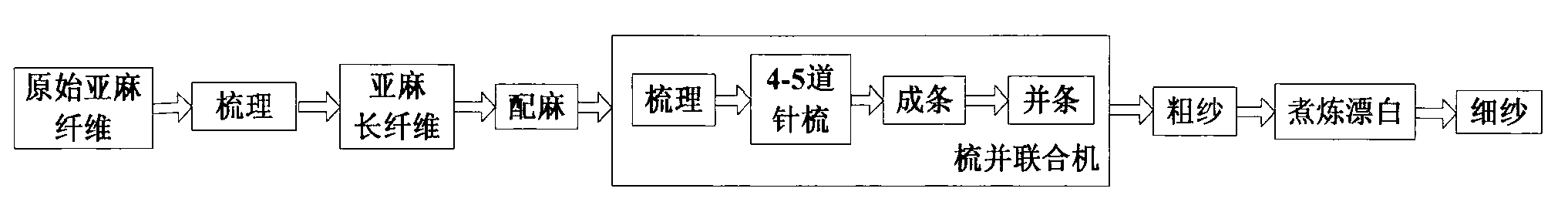

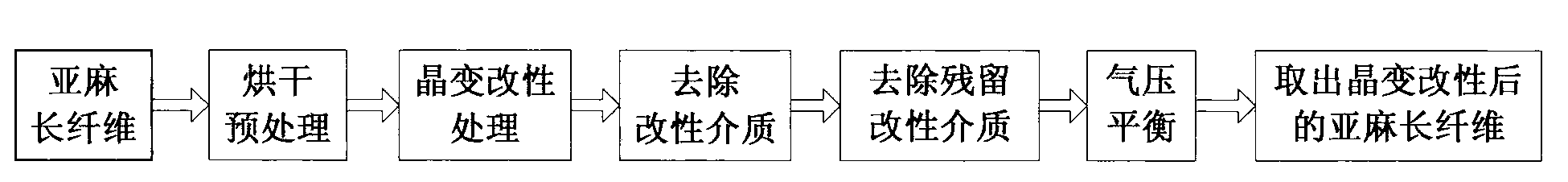

Wet spinning method of low-proportion high-spun flax macrofiber

The invention provides a wet spinning method of low-proportion high-spun flax macrofiber, which comprises the steps of: a first step, combing original flax fiber to obtain flax macrofiber; a third step, carrying out hemp proportioning on the flax macrofiber obtained after crystal transition modification in a former step, gilling, paralleling and spinning by a roving process to obtain flax roving; and a fifth step, carrying out wet spinning on the flax roving obtained after water blanching in a former step by a wet spinning frame to obtain the flax yarn. The wet spinning method is characterized in that a second step of carrying out crystal transition modification treatment on the flax macrofiber is performed between the first step and the third step, and a fourth step of carrying out water blanching on the flax roving is performed between the third step and the fifth step. The method has the advantages that the utilization ratio of the flax macrofiber is greatly improved and reaches more than 70%, and the material resources are saved; high-count linen yarn can be spun according to the fiber proportion of the traditional wet spinning method; and the water blanching replaces the scouring blanching in the traditional wet spinning method, so that the process is simplified, the energy sources are saved and the cost is lowered.

Owner:DONGHUA UNIV +1

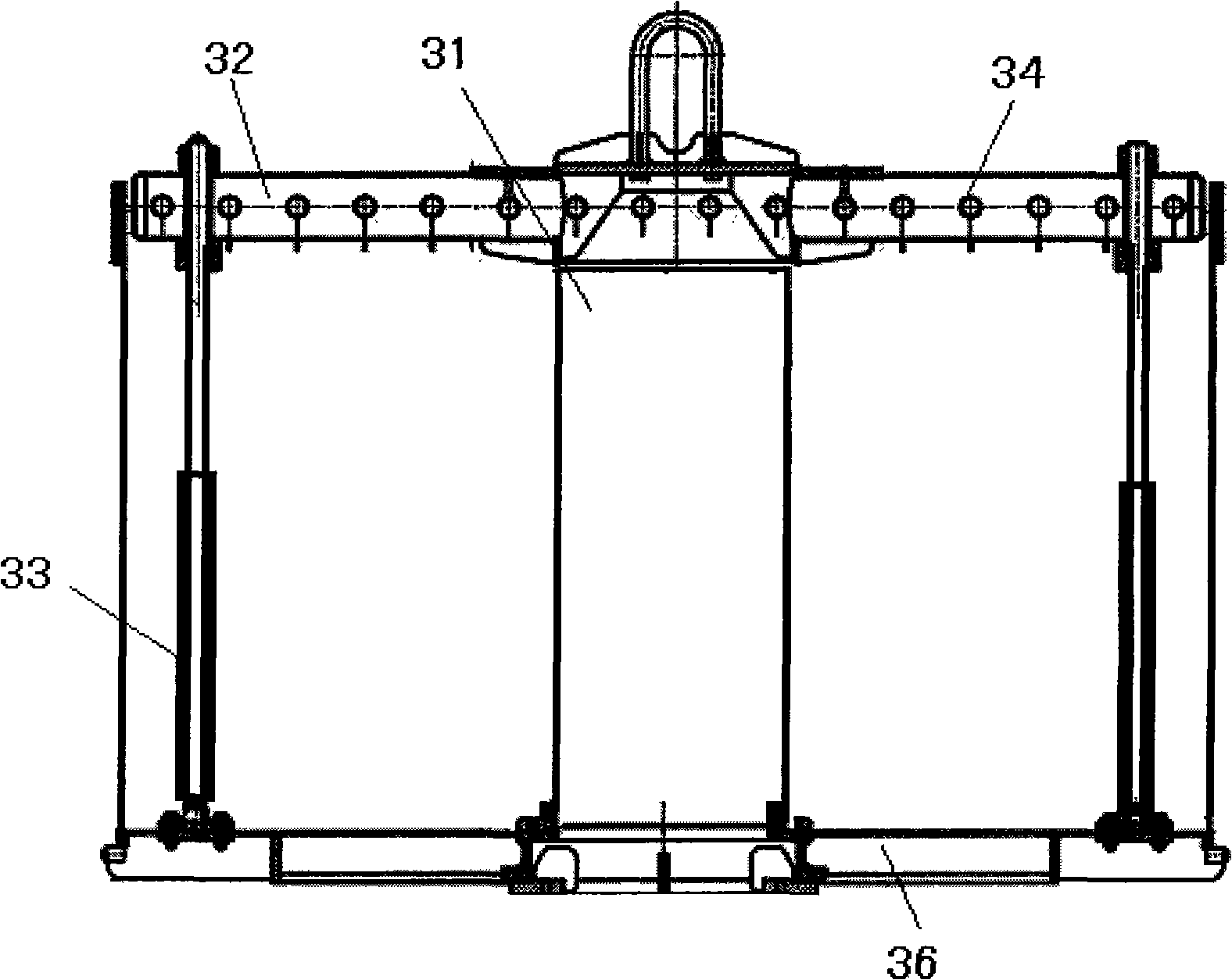

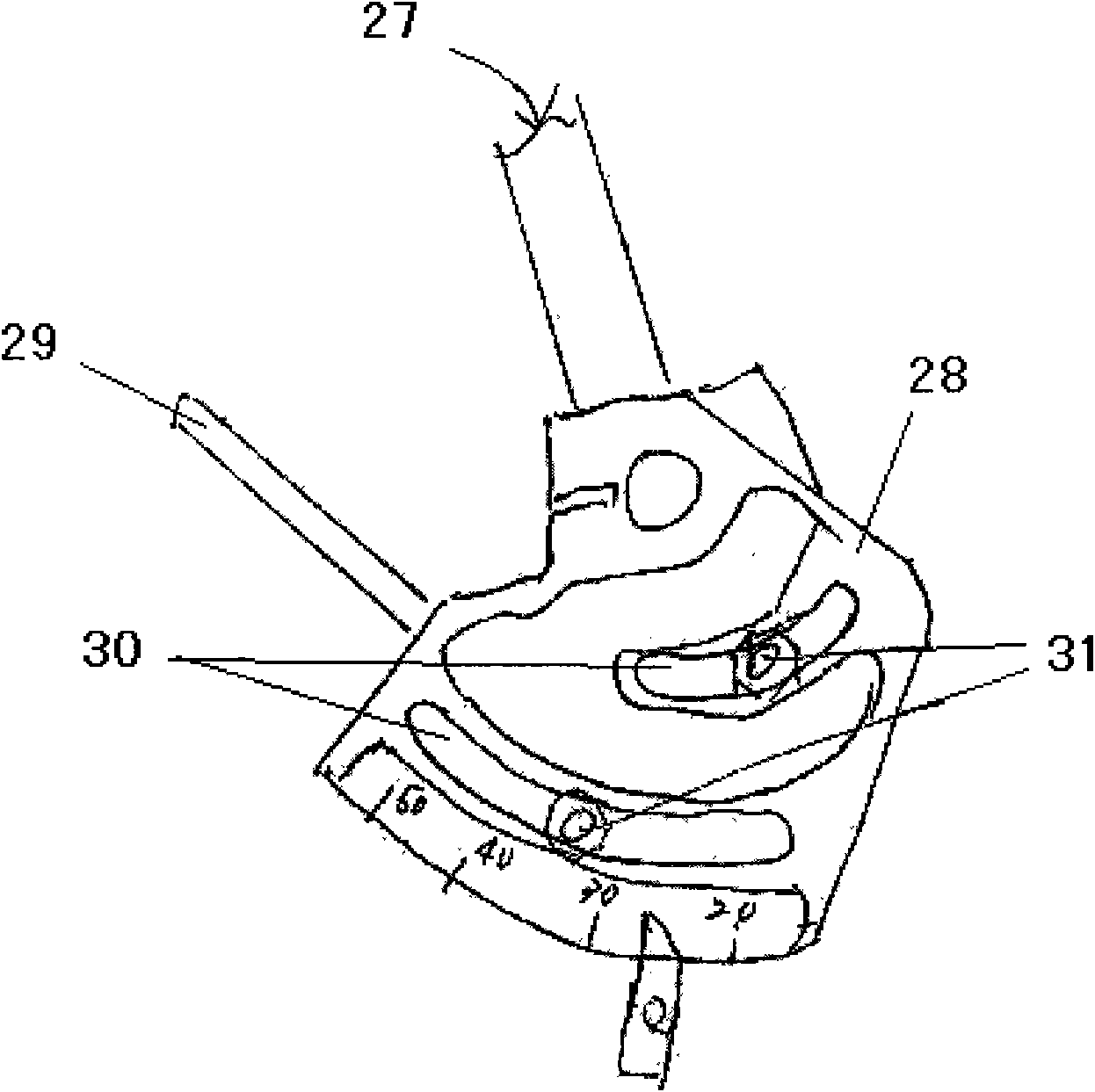

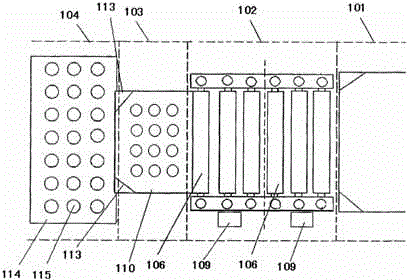

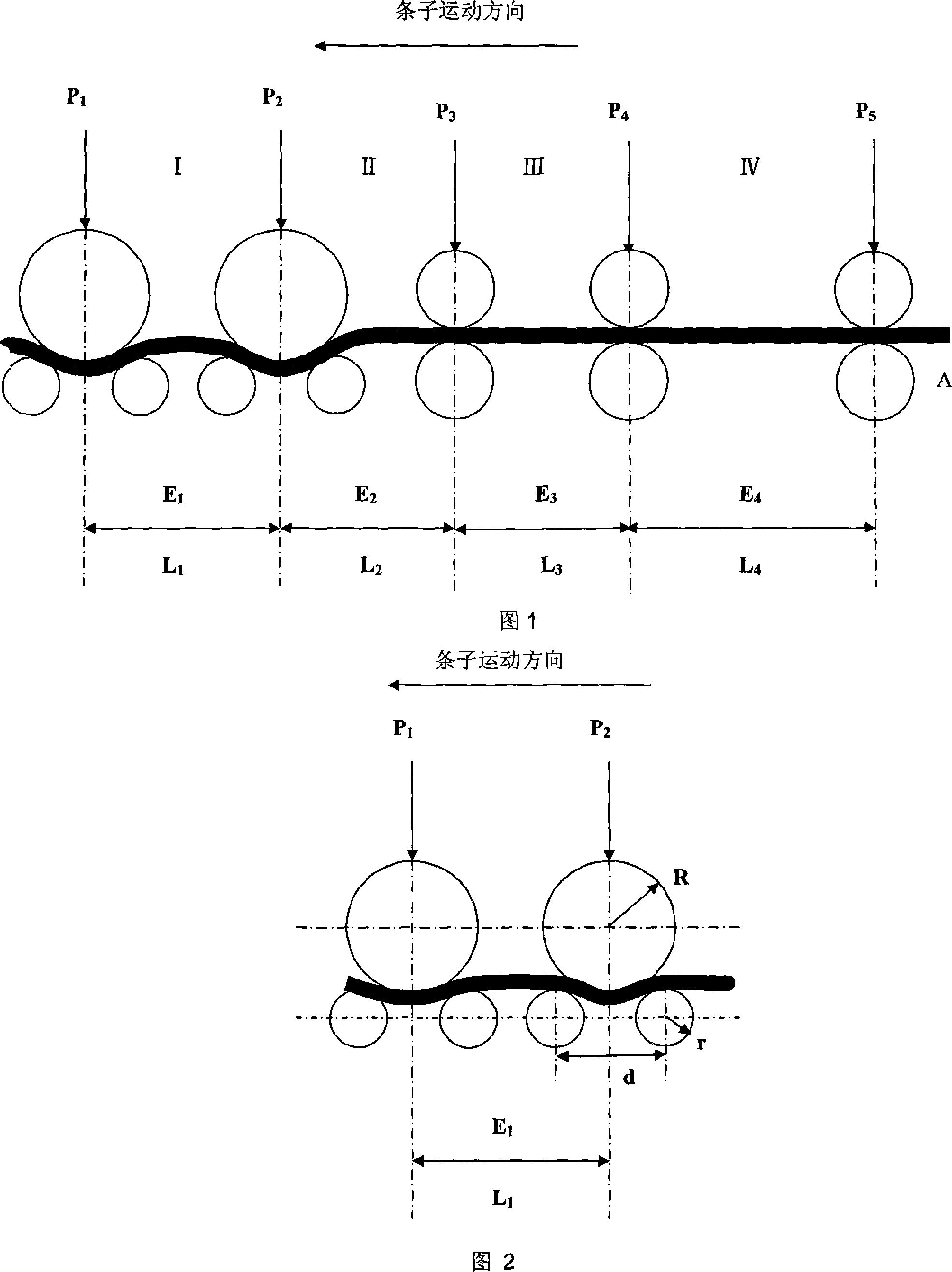

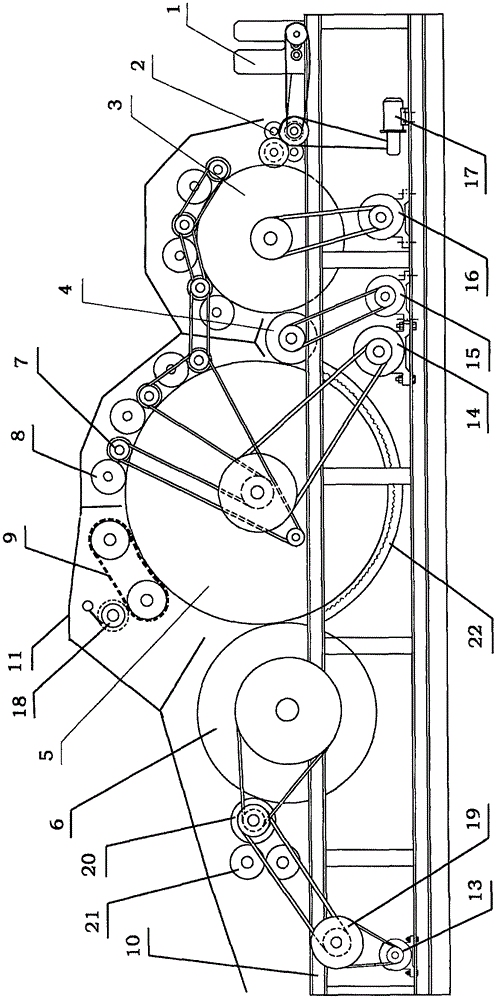

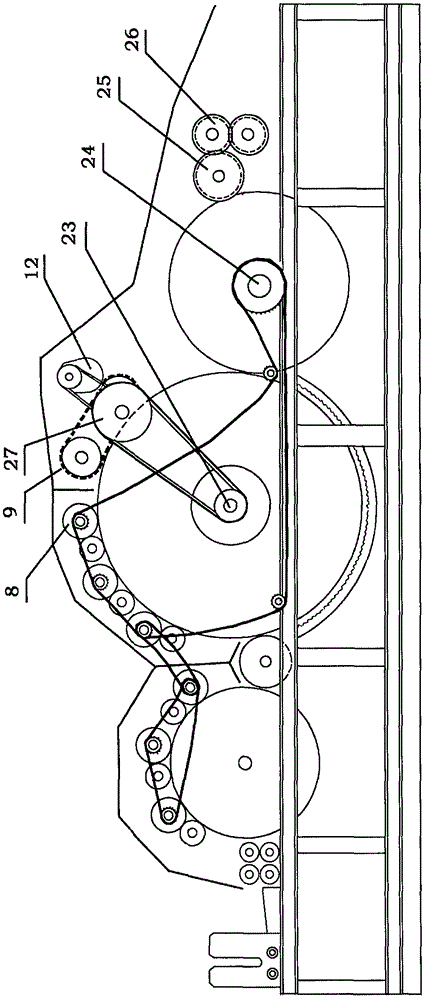

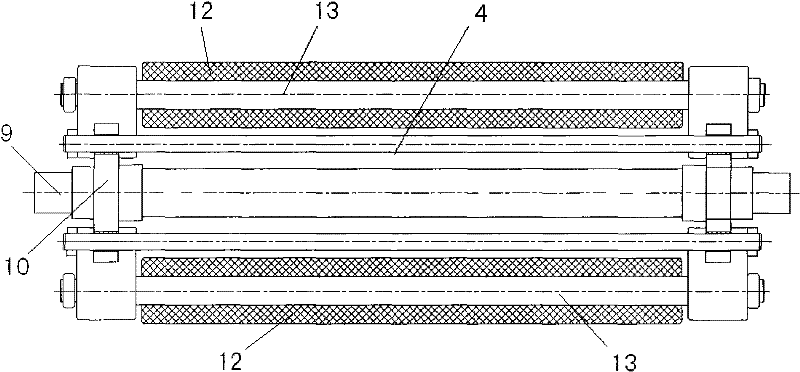

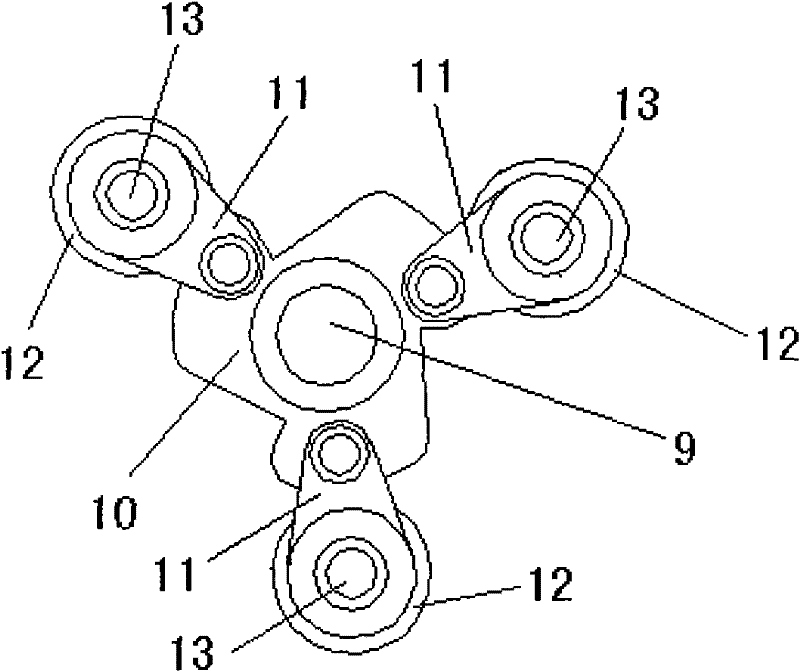

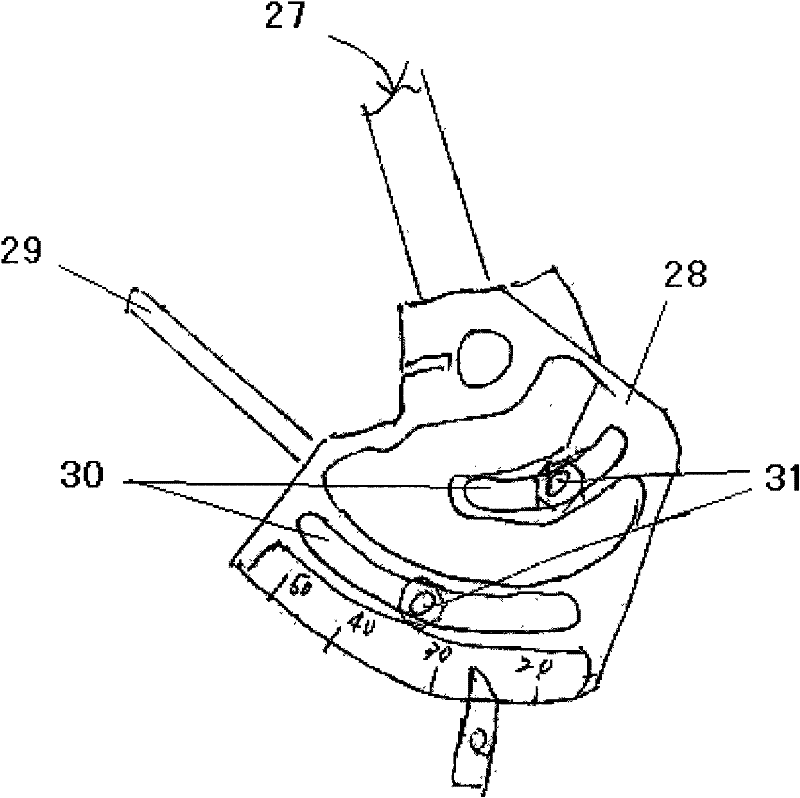

Sesaron combing and sorting method and device

ActiveCN101824676AEfficient removalIncrease the degree of splittingSafety devices for fibre treatmentCombing machinesCombingEngineering

The invention relates to a sesaron combing and sorting method and a device; combed ramie stripes with different specifications and lengths are obtained through a plurality of layers of combing; the split degree of the ramie stripes is decided by comb needle models used in all the layers of combing; and the lengths of the ramie stripes are changed by adjusting a pulling vehicle. In a combing and sorting mechanism of the device, circular comb needle strips are lined in a circumference of 0 to 270 degrees respectively through a rack method and a rack and needle row combined method, and top combs are in a single row or a plurality of rows. A pulling separation mechanism comprises the pulling vehicle, the pulling vehicle is arranged on a regulation frame, the regulation frame is provided with a rod and a circular arc-shaped chute, a bolt is inserted into the circular arc-shaped chute, the bolt is fastened on a frame, the bolt is loosened, and the regulation frame can slide along the circular arc-shaped chute by triggering the rod. At least two pairs of curl rollers are arranged in a strip discharge mechanism. The ramie stripe fibers processed by the method and the device are even and uniform, have short fiber rate, uniform fiber length and low ultra-long length fiber content, so that the fibers are more parallel and straighter, the operation is convenient, the efficiency is high, and the labor intensity is low.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

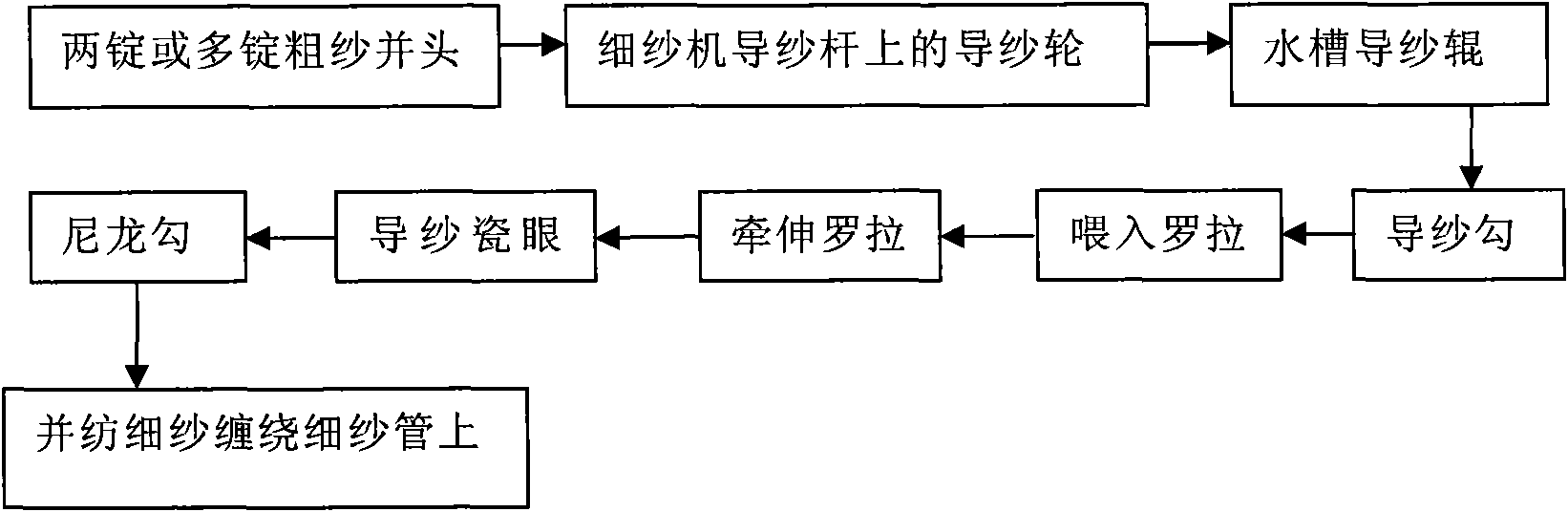

Blended spinning method of long spinning and damp spinning for bast fibers

The invention provides a method integrated with long spinning, wet spinning and blended spinning for bast fibers. The method comprises the following steps: the bast fibers are scotched into flax; the flax is humidified and soaked for a period of time; the flax is carded into long flax; and the long flax is subjected to matching, silvering, drawing, roving, scouring, bleaching, spinning, drying and winding. The method is characterized in that after the bast fibers are bleached, the obtained rove of the bast fibers and rove or filaments of other fibers are blended on a spinning machine. With the method, blended fibers are not bleached and scoured together with the bast fibers, so the defect that the performance of blended yarn is affected due to the damage of bleaching and scouring agents to the blended fibers in the prior wet spinning and blended spinning is overcome, and the obtained blended yarn has the characteristics of bright and clean yarn body, less hairness, evenness and good wear resistance. In addition, the method can fully play a role in respective advantages of the bast fibers and the blended fibers, complement respective disadvantages of the bast fibers and the blended fibers, has simple process, is favorable for improving the quality of blended yarn of the bast fibers, and realizes the high count, high grade and diversification of varieties of the bast fibers.

Owner:DONGHUA UNIV

Mechanical rolling-exploding-carding for edulcorating combined degumming method for hemp

ActiveCN103436969ANo damageNo pollution in the processMechanical fibre separationFibre treatment to obtain bast fibreHemp fiberPre treatment

The invention relates to a mechanical rolling-exploding-carding for edulcorating combined degumming method for hemp, belonging to the technical field of textile fiber processing. A product hemp fiber with original color is obtained through pre-treatment, explosion, chlorine bleaching, drying, edulcorating and post-treatment. The hemp fiber produced by the method provided by the invention is fluffy and flexible, and shows the original color of the hemp. The lignin content can be reduced to below 1%, the fiber fineness ranges from 200 to 600 Nm, and the process fiber is 25mm-50mm long. According to the degumming method provided by the invention, except for a spinning lubricant agent which has a softening effect, a penetrant, sodium hypochlorite and crude oil, any other chemical reagent is not used in the whole degumming process, so that the environment-friendly physical degumming method is free from environmental pollution and damage to fibers.

Owner:无锡恒隆纺织品有限公司

Pretreatment method combining biological enzyme with chemical degumming for rough linen yarn

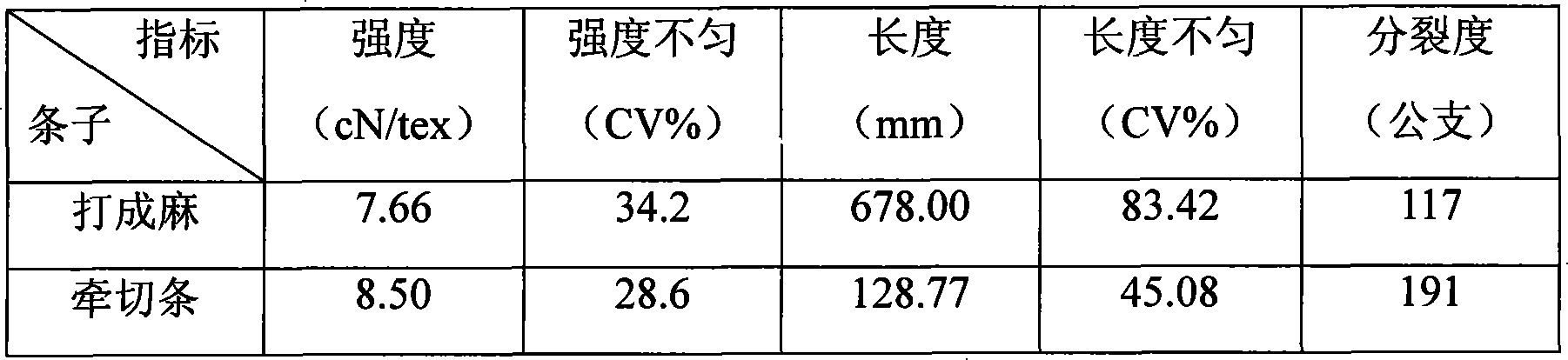

InactiveCN107503158AIncrease the degree of splittingAverage length longBiochemical treatment with enzymes/microorganismsVegetal fibresYarnPretreatment method

The invention provides a pretreatment method combining biological enzyme with chemical degumming for rough linen yarn, and belongs to the technical field of textile industry production. The rough linen yarn is treated by using a crude enzyme liquid, under the synergistic action of enzymes in the crude enzyme liquid and with addition of hydrogen peroxide and catalase, the removal effect of lignin and hemicellulose in the rough linen yarn is enhanced, a proper amount of pectin is reserved, the splitting degree of fibers is increased, and spinnability of the linen process fibers, quality of the spun yarn and spinnability of high-count yarn are further improved. Besides, decolorization of the rough linen yarn can be effectively realized in a bleaching process of hydrogen peroxide, whiteness is ensured, and the impurity removal effect is also enhanced. With adoption of the process, damage to the linen fibers and environmental pollution can be reduced to the greatest extent, and clean processing is realized.

Owner:JIANGSU LIANFA TEXTILE +1

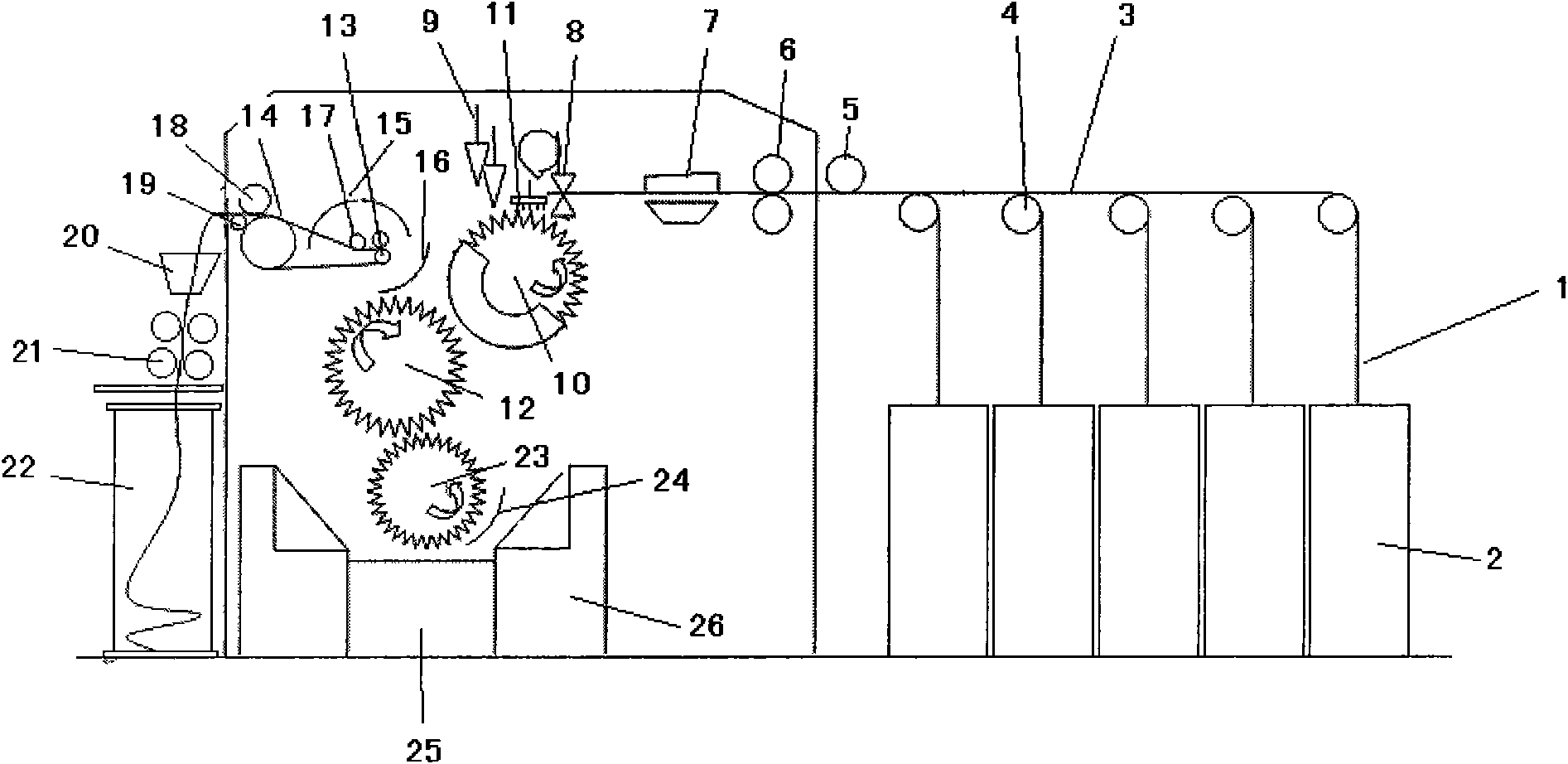

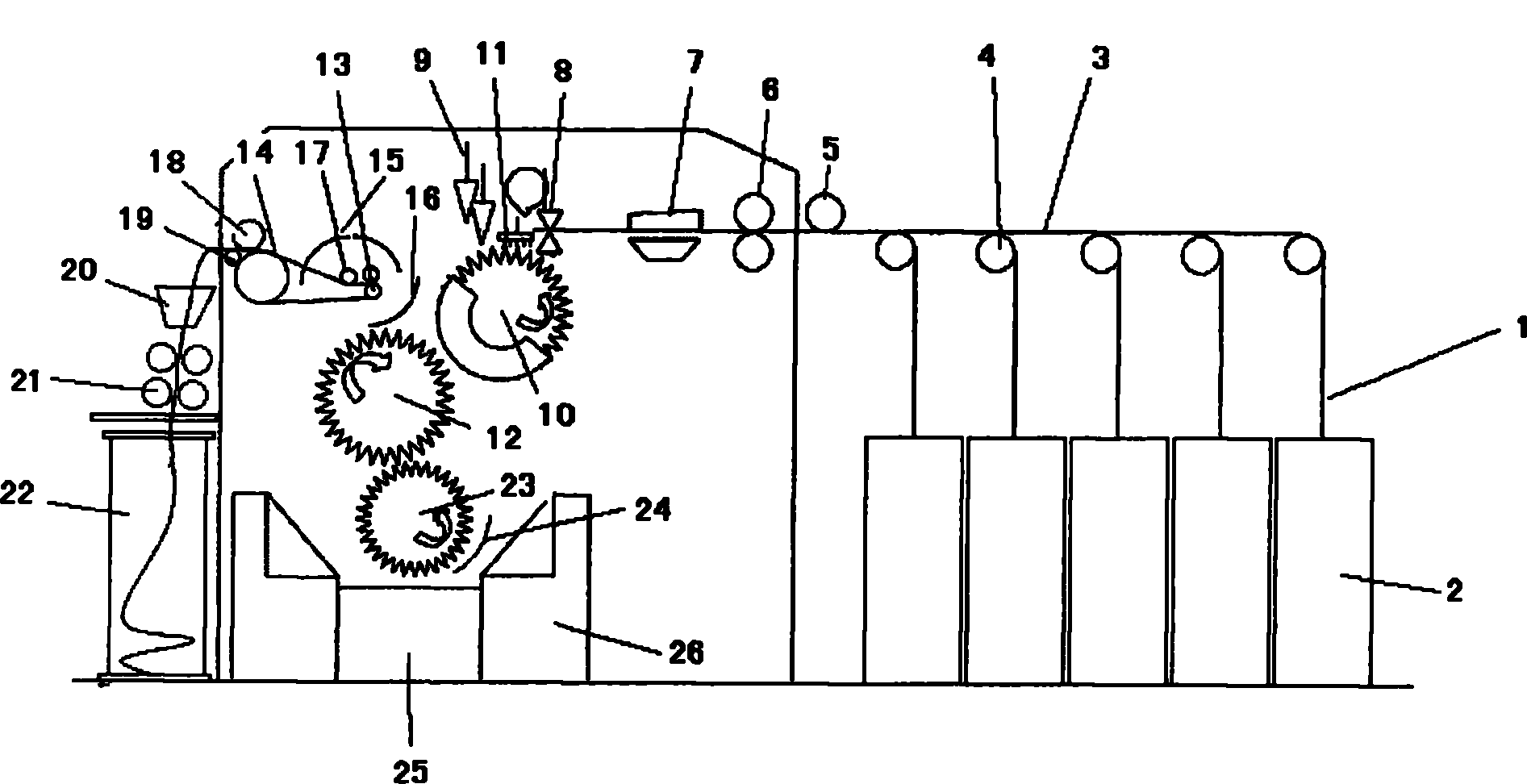

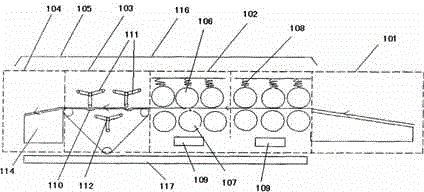

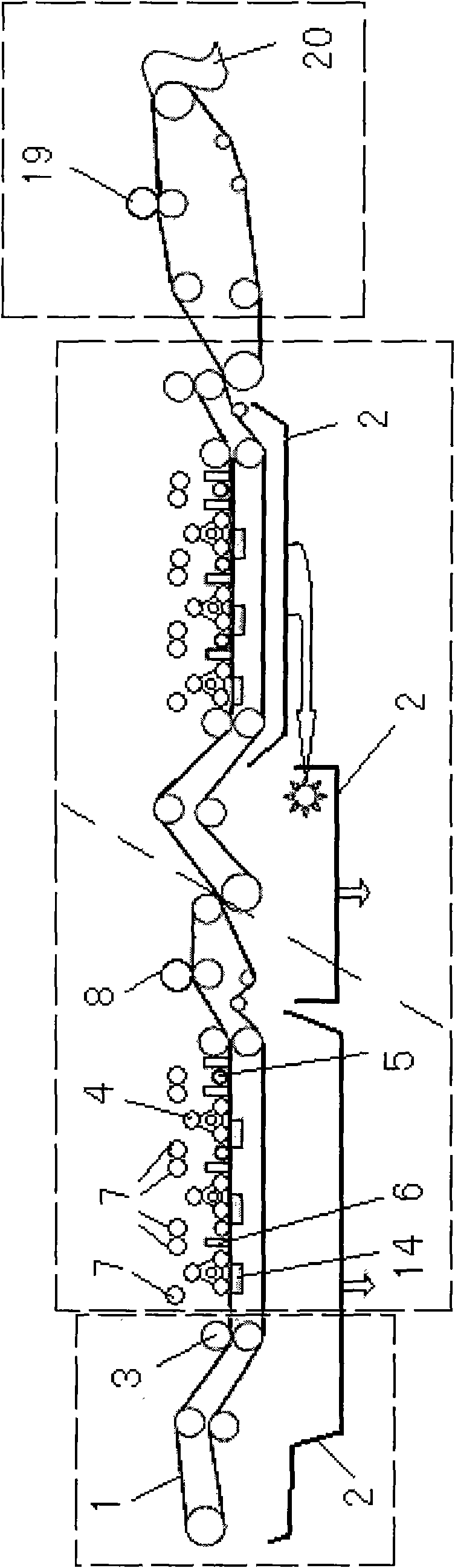

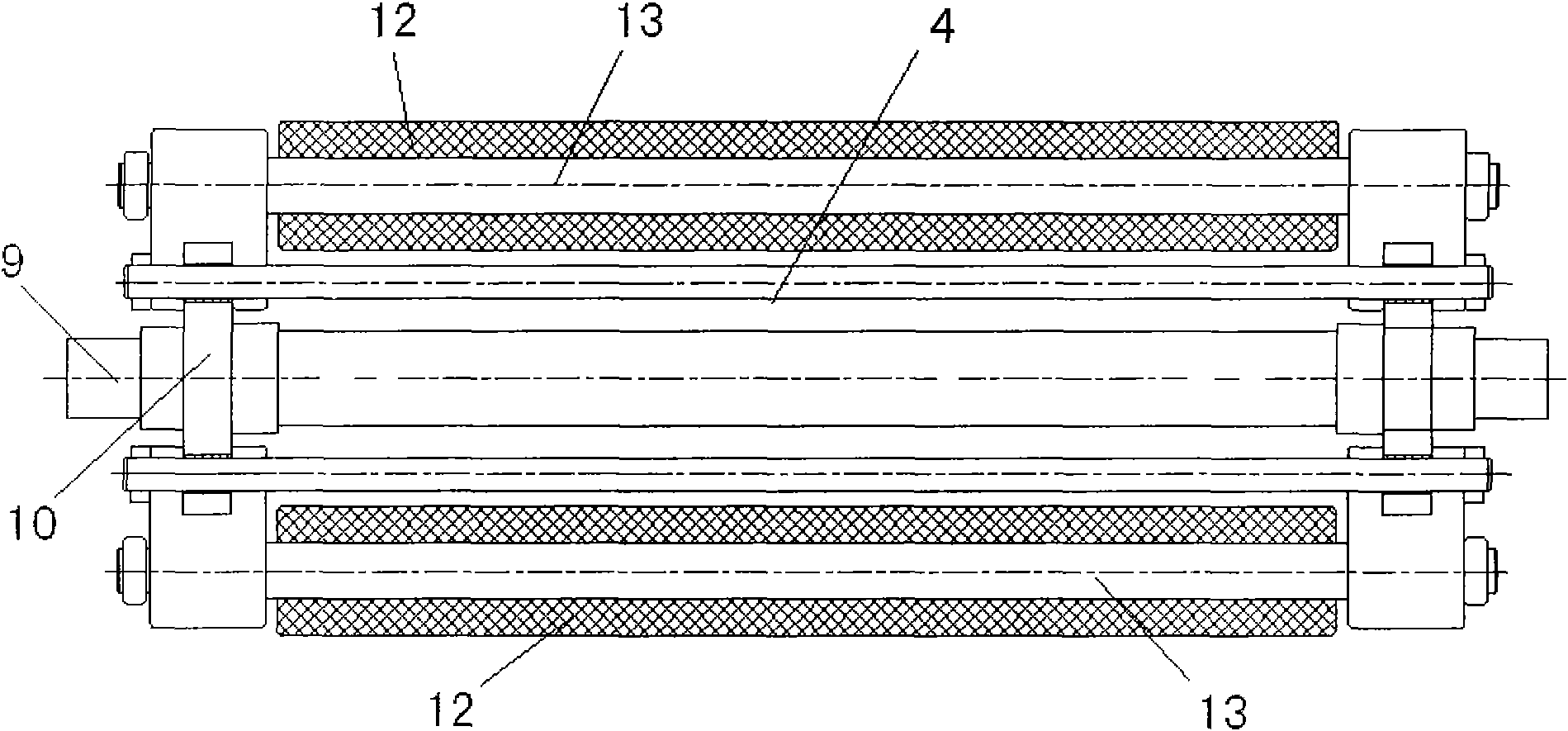

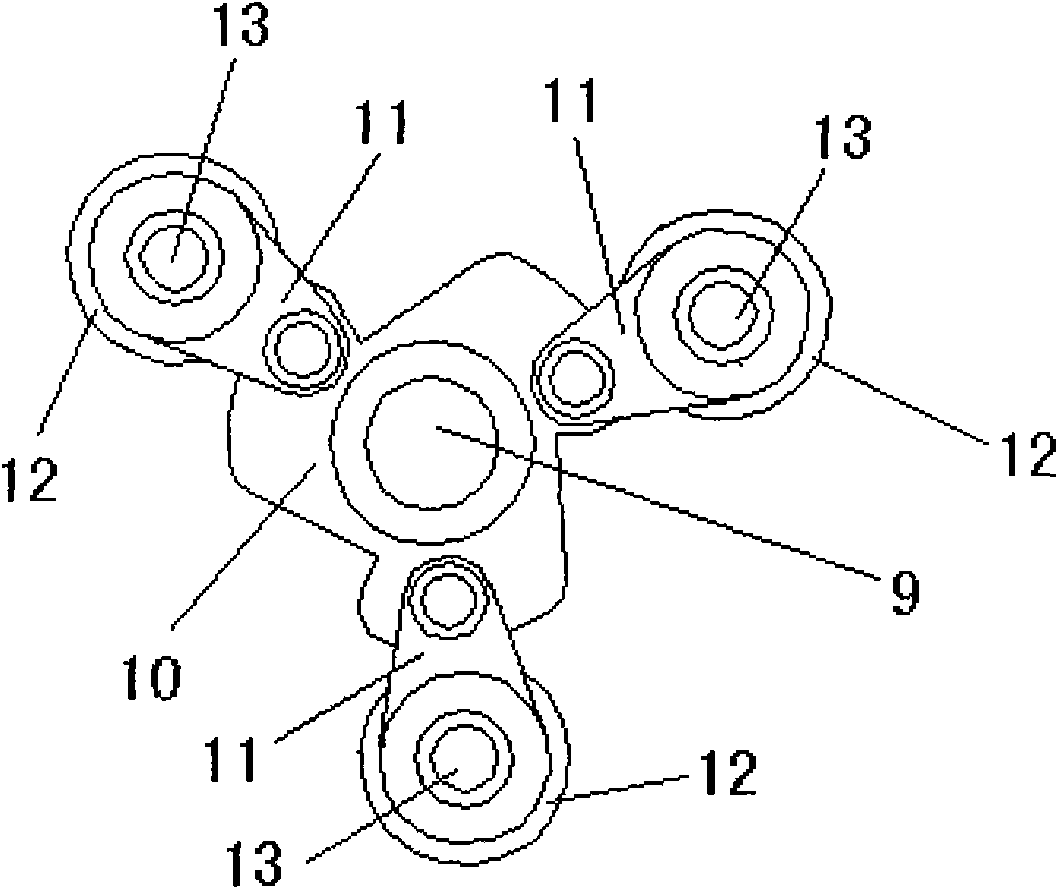

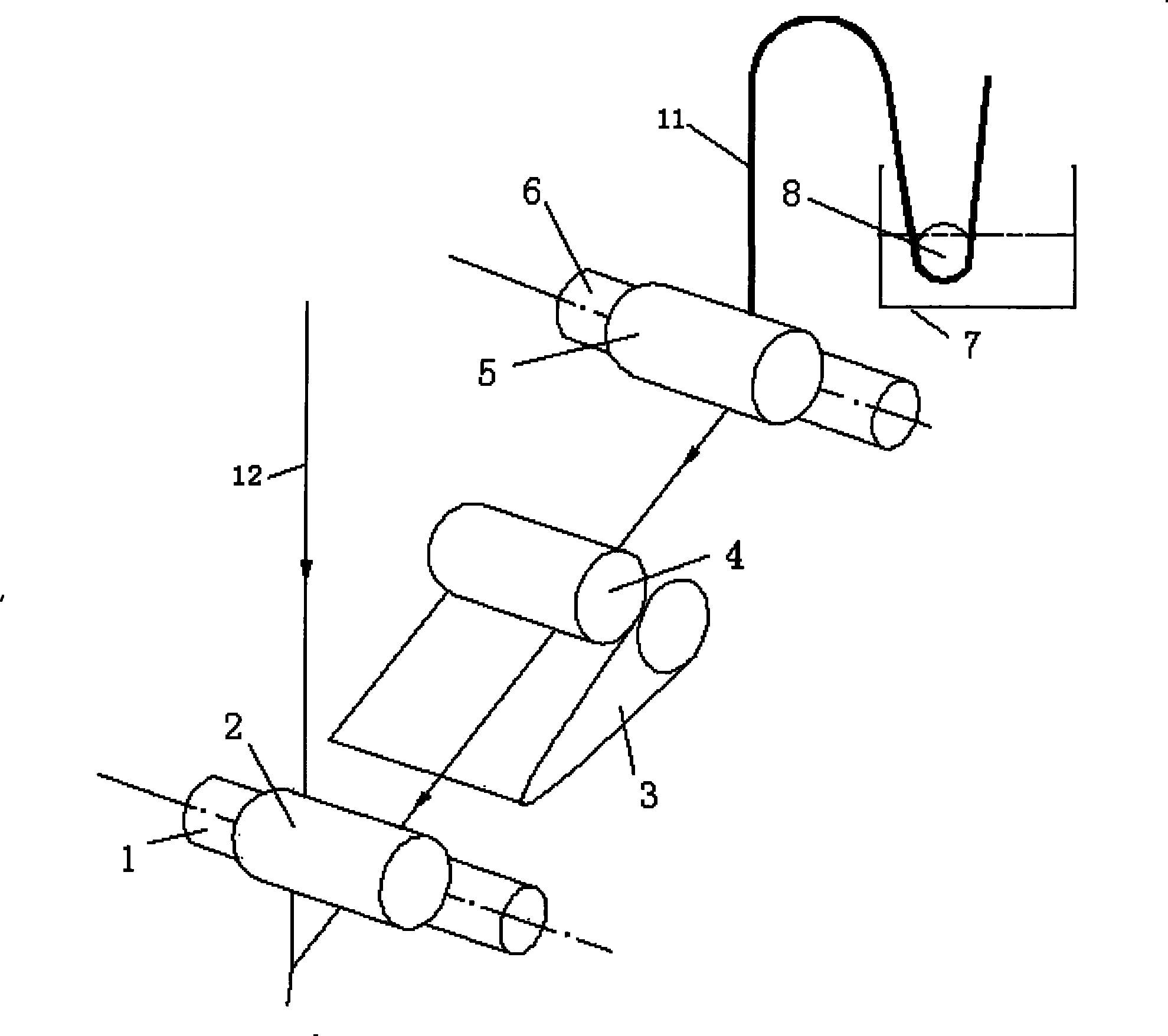

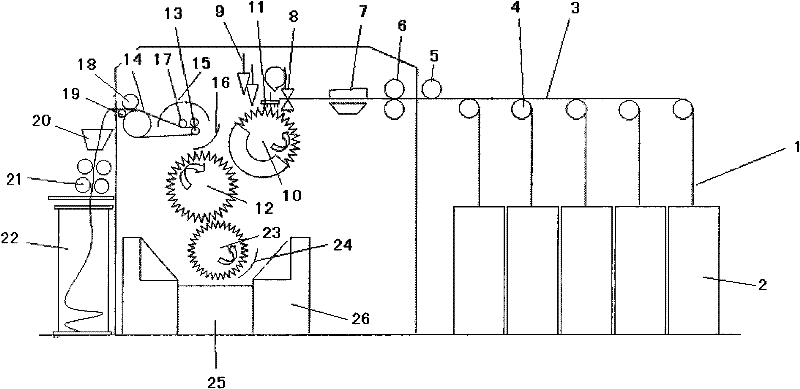

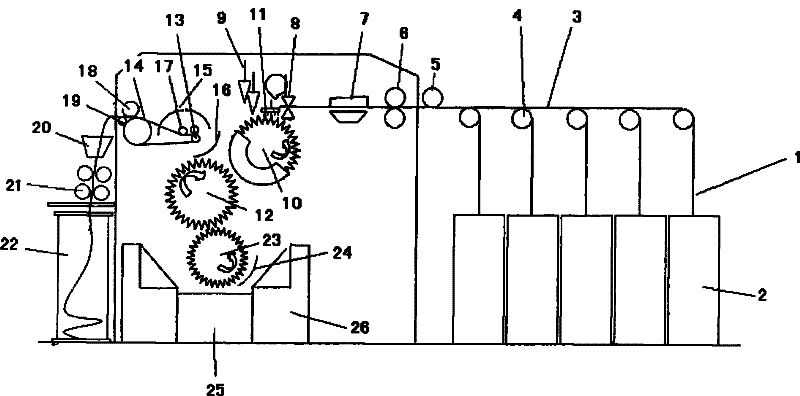

Processing system for processing hemp into hemp fiber

InactiveCN104562217AReduce stress and difficultyReduce processing timeMechanical impurity removalTextile/flexible product manufactureHemp fiberFineness

The invention relates to a hemp fiber manufacturing production line, in particular to a processing system for processing hemp into hemp fiber. The processing system for processing the hemp into the hemp fiber comprises devices for arranging hemp, degumming, dividing fiber and water washing, rinsing and softening, drying, softening and oiling, permeating and health maintaining, crush cutting and teasing, and combing and arranging; a degumming device comprises a mechanical degumming device, a biological degumming device and a high-temperature scouring-bleaching degumming device, and the device is special; a yarn hanging rack is composed of a hollow post and a plurality of hollow beams in a connecting mode, the hollow beams are provided with a plurality of hanging rods, and a plurality of holes are formed in the sides of the hanging rods; the crush cutting and teasing use a drafting roller set and a snapping roller set, and the drafting roller set and snapping roller set run in differential speeds and pressurize simultaneously. The combing and arranging use a round comb and a top comb to comb and a pulling vehicle to pull, along the rotating direction, the density of gill bars is increased gradually, and the fineness is reduced gradually. The processing system for processing the hemp into the hemp fiber changes a traditional hemp processing device, improves the long hemp yield and facilitates subsequent processing, and the produced hemp fiber is stable in quality.

Owner:王学钢

Method for preparing flax fiber in high cleavage degree

InactiveCN1687491ANo change in propertiesIncrease the degree of splittingVegetable materialYarnBleach

Preparation method of linen fiber of high fission belongs to the domain of weave. The stuff is come unglued by enzyme first, then oxygen bleach it in common pressure, acid and alkali neutralization, drying it and make linen fiber in wet condition. It improves the fission of the fiber and doesn't change its characteristic. The fission increases from 400 - 600 to more than 2000. The cohesion performance and spinnability of the fiber is improved. Blended yarn is high, can reach more than 160N.

Owner:无锡鼎球绢丝纺有限公司

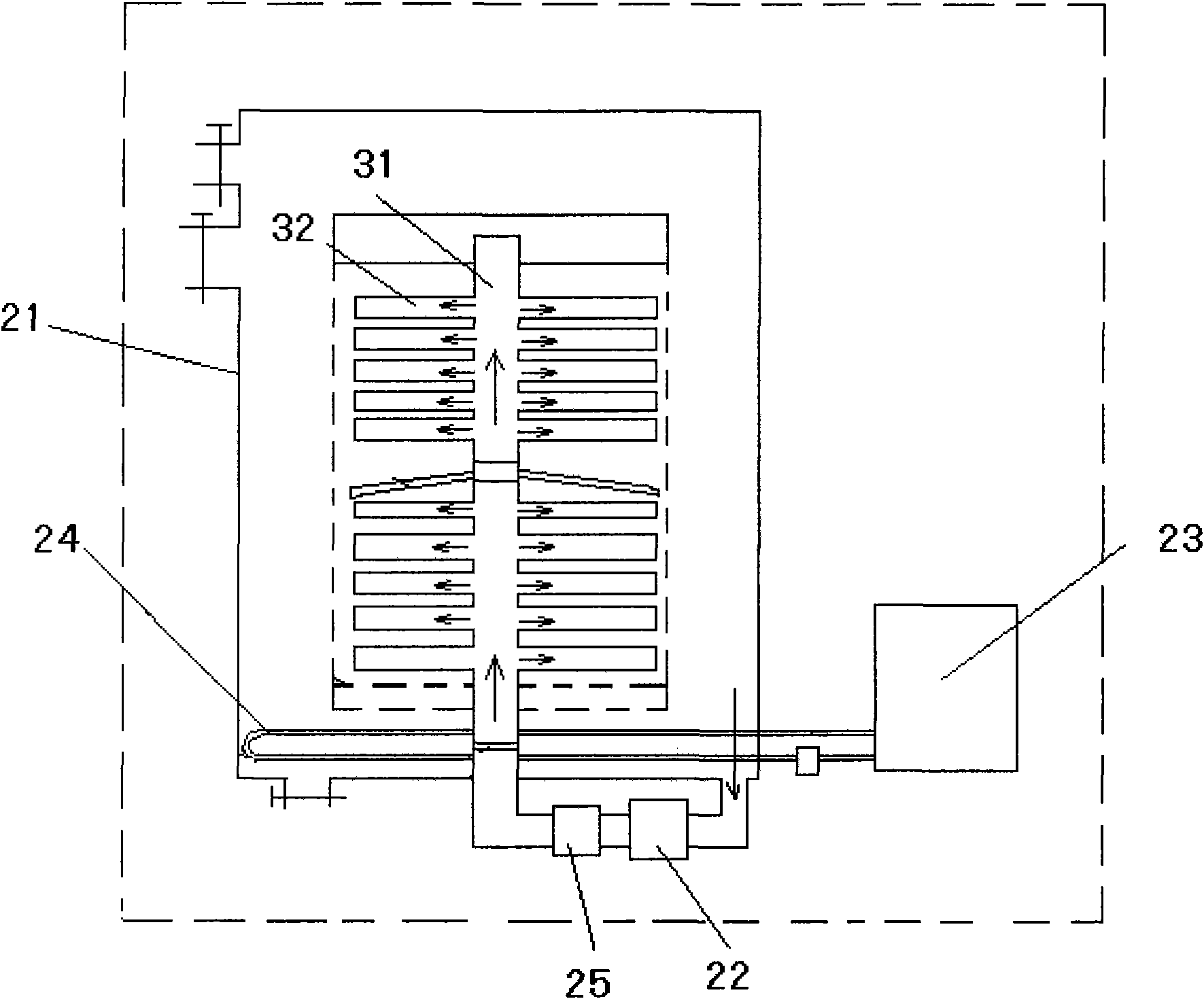

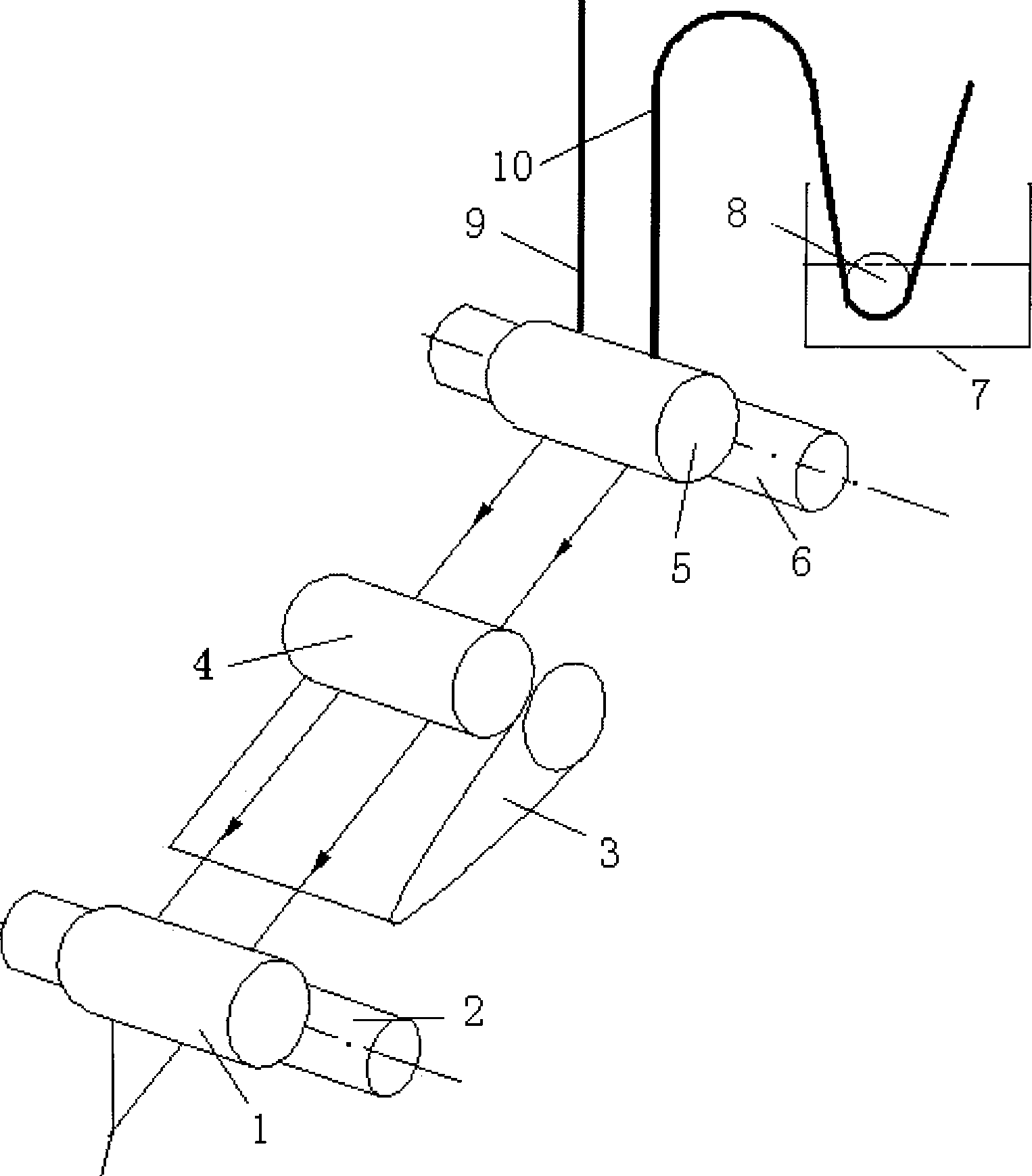

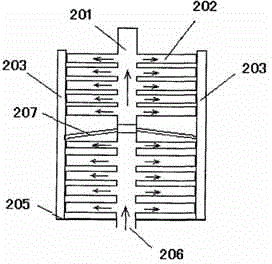

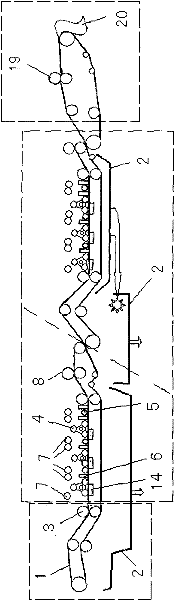

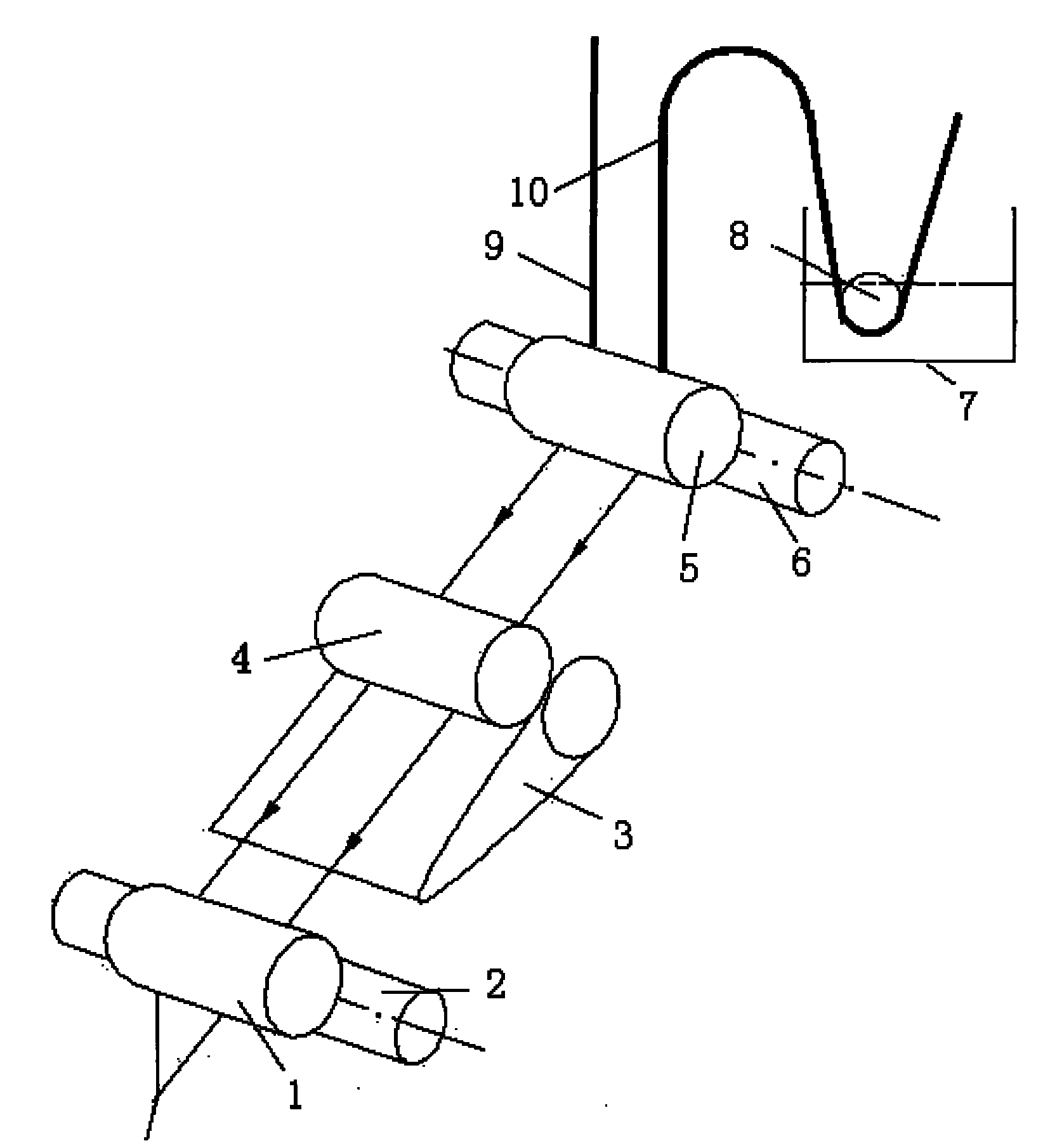

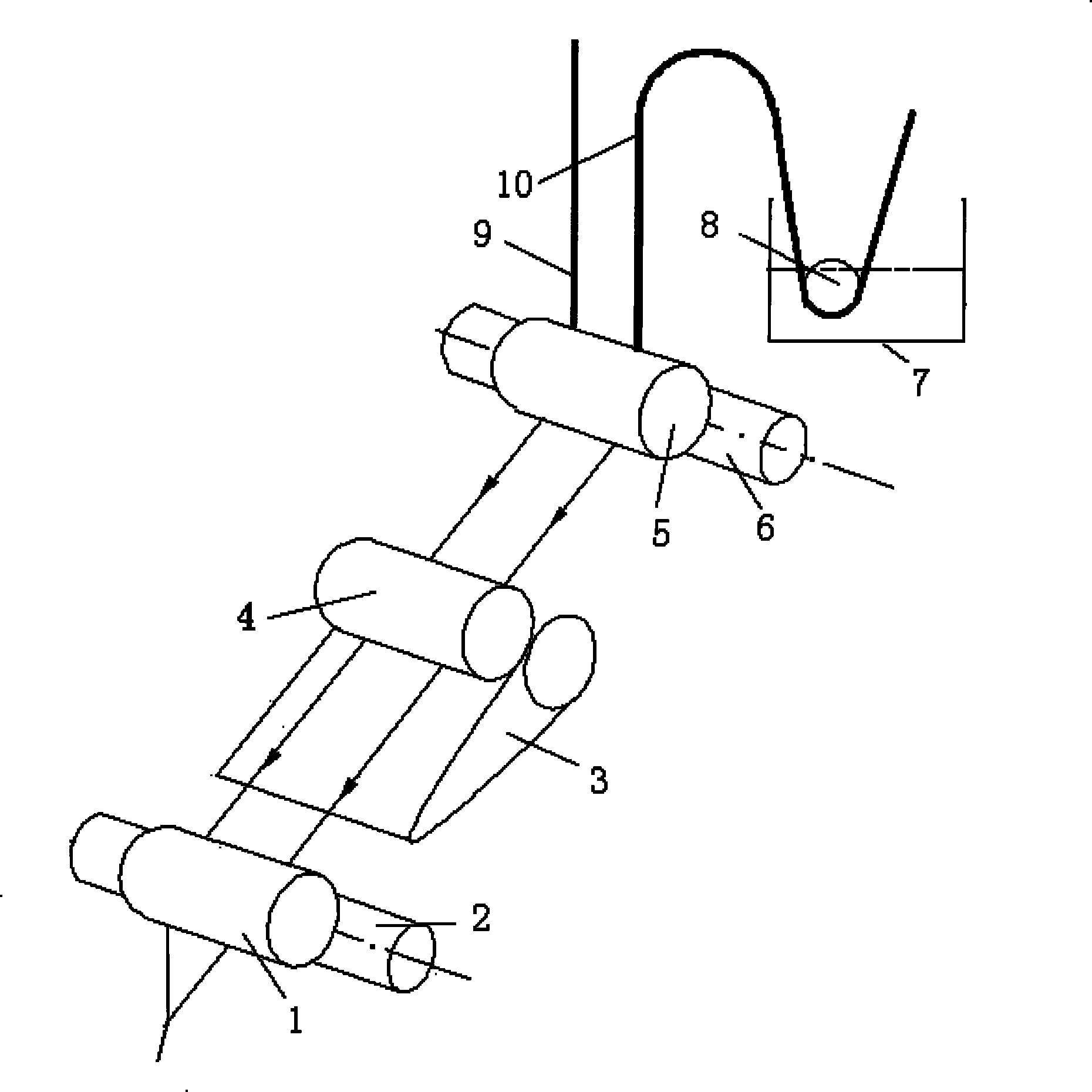

Fiber bundle dividing and washing method and device

ActiveCN101851789AGuaranteed cleanlinessHit evenlyMechanical treatmentFibre treatment to obtain bast fibreCardingFiber bundle

The invention relates to a fiber bundle dividing and washing method and a fiber bundle dividing and washing device. The method comprises the following steps of: 1) arranging a plurality of groups of fiber dividing and washing units and a fiber output unit on a frame, wherein each unit is provided with a running rotating crawler; 2) passing a feeding roller through a crawler input end of each fiber dividing and washing unit so as to convey the fiber bundle forward, making the fiber bundle enter a fiber dividing and washing area which is provided with a beater and a fiber dividing roller at intervals, simultaneously opening a high pressure water pipe which is arranged above the beater and the fiber dividing roller, and performing washing soaking, beating, carding and fiber dividing on the fiber bundle edges; 3) feeding the fiber treated by the previous fiber dividing and washing unit to the next fiber dividing and washing unit for continuous fiber dividing and washing; and 4) feeding the fiber treated by the last fiber dividing and washing unit into a fiber dividing input area, performing water squeezing operation through a squeezing roll, feeding the fiber into a cloth arrangement mechanism, arranging and folding the strip-shaped fiber through the cloth arrangement mechanism, and feeding the fiber into a fiber storage box. The fiber bundle dividing and washing method and the fiber bundle dividing and washing device can be widely applied to fiber dividing and washing treatment for various bast fibers, leaf fibers, and grass family fibers.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

High counts high blending ratio silk/flax scribbled and its preparation

InactiveCN1670279AIncrease the degree of splittingNo change in propertiesBiochemical fibre treatmentBleaching apparatusYarnEngineering

The invention relates to a high branch high mixed weaving ratio silk / flax blending yarn that belongs to weaving field. The blending yarn is made up from flax fiber that the splitting degree is over 2000 and silk by the method of dry mixed weaving technology. The ratio of silk and flax is 40-90:60-10. The key point of the blending yarn is the preprocessing to the flax material that improves the splitting degree but does not change the feature of it, and the splitting degree improves from 400-600 to 2000, the holding capacity is enhanced, and the spinnability is improved as well. The dry spinning method is adopted, the silk content is high in the blending yarn and the comfort of the cloth is sharply increased.

Owner:无锡鼎球绢丝纺有限公司

Short-flow environment-friendly degumming and bleaching method for hemp fibers

ActiveCN102146589ALow lignin contentEfficient removalVegetable materialFibre treatment to obtain bast fibreState of artChemical oxygen demand

The invention relates to a short-flow environment-friendly degumming and bleaching method for hemp fibers. The method is characterized by performing one-bath degumming and bleaching on hemp bast by adopting a deep oxidation principle and utilizing materials such as a nano-clay preparation, hydrogen peroxide and the like. The method comprises the following steps of: 1) performing impurity-removing washing on the hemp bast for 1 to 3 times by using recycled washing water; 2) performing temperature-rising washing on the hemp bast for 1 to 3 times by using the recycled water again; 3) performing the one-bath degumming and bleaching on the hemp bast by using 3 to 4 g / l nano-clay preparation, 3 to 4 g / l sodium hudroxide, 1 to 2 g / l sodium carbonate and 5 to 10 g / l hydrogen peroxide; 4) washing with water after performing the one-bath degumming and bleaching; and 5) processing the hemp bast into ramie cotton blended yarns after shaking hemp, curing and drying. Compared with the prior art, the method has the advantages that: the processes of embossing the hemp and beating the hemp are saved by adopting a deep oxidation method; the production flow is shortened; and the water dosage is greatly reduced; 2) the whiteness and the softness are high; and 3) the chemical oxygen demand (COD) value of the process waste water is low.

Owner:郑州银泰企业管理咨询有限公司

Flax converter spinning process

The invention relates to flax tow-to-yarn direct spinning method. It includes the following steps: combing, gilling, roving, boiling off, bleaching, spinning, and tow-to yarn direct spinning. The invention has the advantages of little fiber damage, high regularity, increasing flax yarn quality, simplifying original spinning system, shorting process scheme.

Owner:DONGHUA UNIV

Pretreatment processing method of short flax fibers

InactiveCN104452263AIncrease the degree of splittingImprove spinnabilityDry-cleaning apparatus for textilesBleaching apparatusYarnEcological environment

The invention discloses a pretreatment processing method of short flax fibers. The pretreatment processing method comprises the following steps: with the short flax fibers as a raw material, carrying out procedures of peracetic acid pretreatment, warm washing, sodium percarbonate-peracetic acid scouring, hot washing, cold washing, dehydration and drying. The pretreatment processing method has the beneficial effects that most impurities such as pectin and lignin in the short flax fibers are removed by virtue of an ecological environment-friendly aid, so that wastewater pollution is avoided; processing conditions are relatively mild, so that the problem that the fiber strength is greatly damaged due to strong base and high temperature in a traditional process is remedied; the procedures of scouring and bleaching are simultaneously finished, so that impurity removal and bleaching are finished, the processing process is shortened, and the production efficiency is improved; original auxiliary projects and facilities can be utilized, so that the operation is easy, and the cost is low; the processed short fibers are pure white, soft, high in splitting degree and good in spinnability, so that the quality of finished yarns is beneficially improved, the technical requirements of the production of flax yarns for circular machine weft knitted single jersey are well met, and the grade of application range is promoted.

Owner:QIQIHAR UNIVERSITY

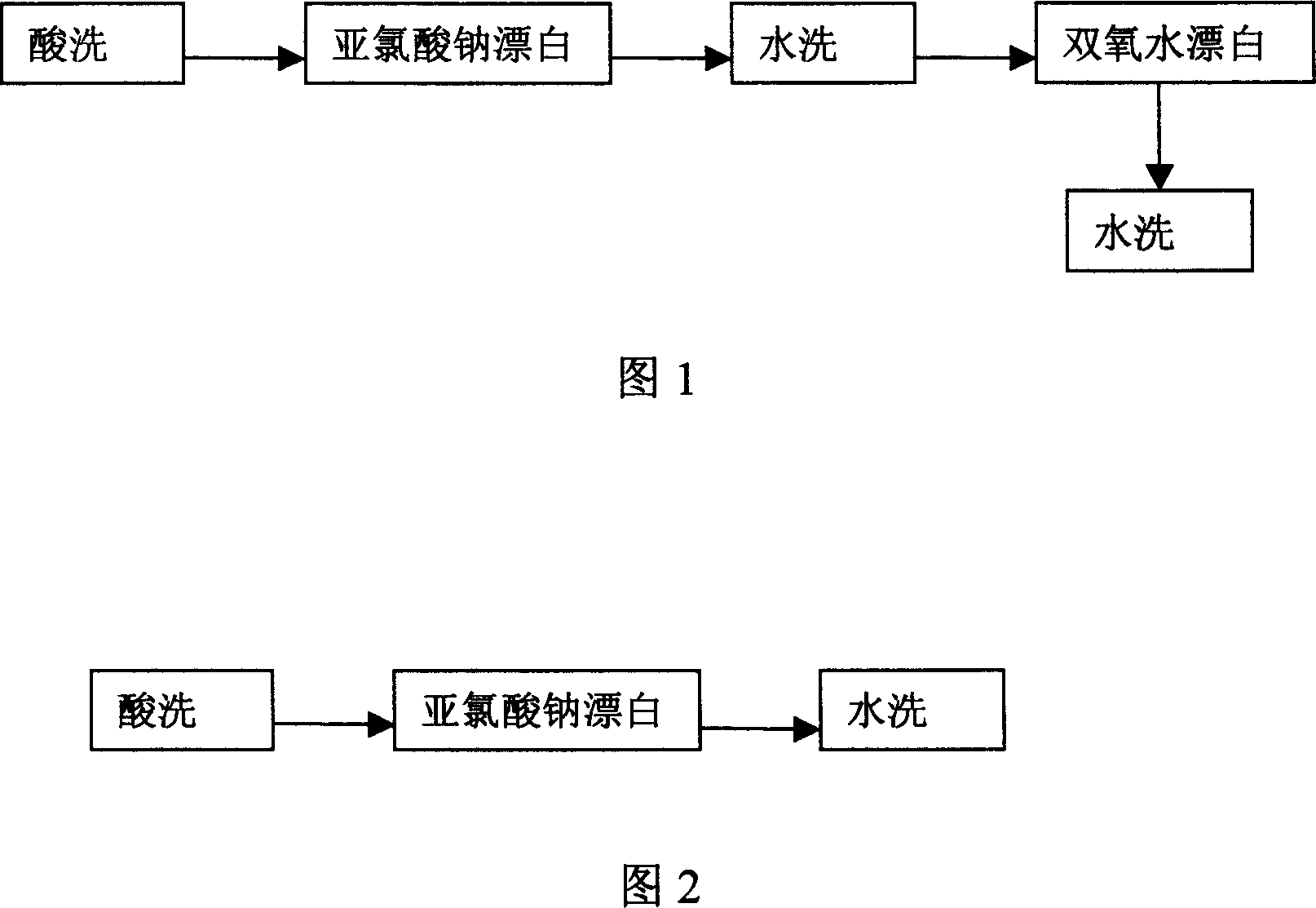

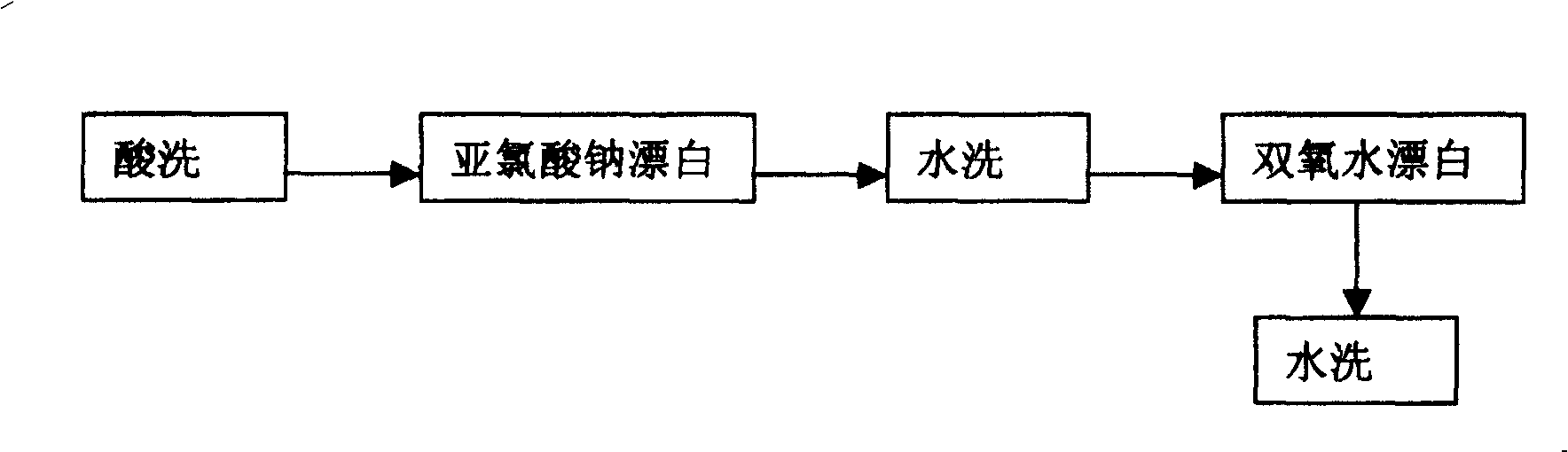

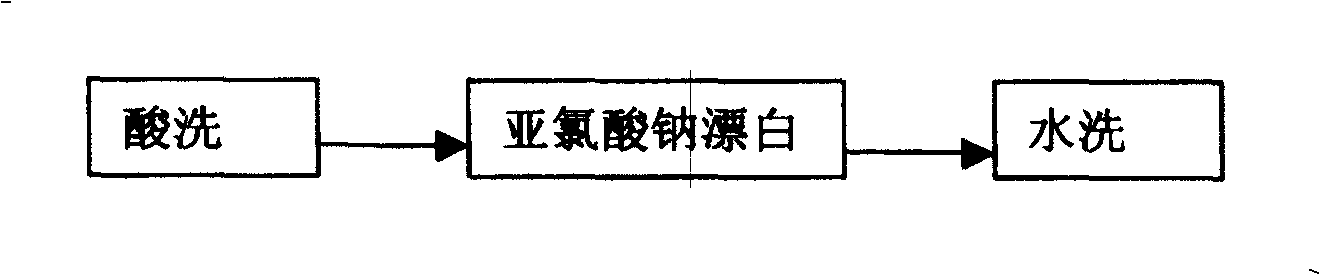

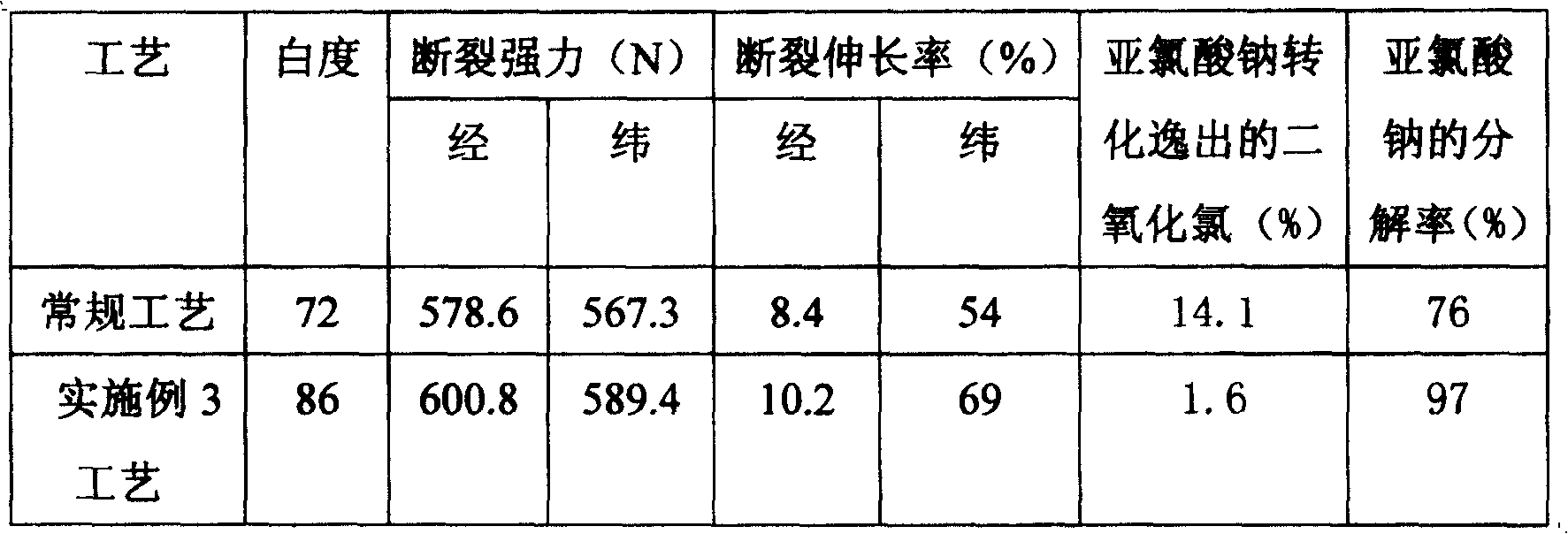

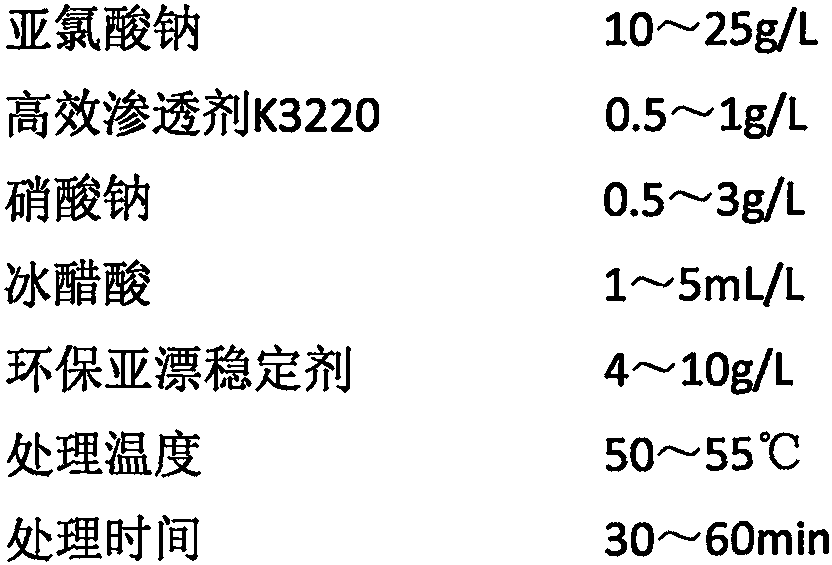

Stabilizer for use in sodium chlorite degumming and bleaching of flax and its preparation method and application

InactiveCN1970852AFast decomposition rateReduce dosageBleaching apparatusVegetal fibresYarnGreen environment

The invention relates to a stabilizer for sodium chlorite degumming and bleaching of linen rove and the textile and the new technology of degumming and bleaching for green environment protection. The stabilizer is a saturated solution of salt mixture, which comprises 3-13% by wt of six methylene amine, 1-6% by wt of diamine sulfate, 2-10% by wt of triethanolamine, 1-8% by wt of ammonium persulfate and water. In the process of degumming and bleaching, the stabilizer is joined to restrain generation and dissipation of chlorine dioxide so that not only bleaching conditions are satisfied and the quality of yarn is improved but also the health of operating workers is protected and the equipment is maintained. It is no-pollution so as to decrease the consumption of sodium chlorite and improve the utilization ratio of sodium chlorite is improved. The degumming and bleaching technology for linen rove can improve yarn evenness evidently, decrease hemp particle greatly, and improve the spinning number and the loom efficiency greatly. Especially it is provided with notable effect for primary color yarn with difficult spinning performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

China hemp fiber one-step fiber forming and carding machine

The invention relates to a China hemp fiber one-step fiber forming and carding machine and belongs to the technical field of design and manufacturing of China hemp combined fiber forming and carding machines. Equipment is composed of a vehicle wallboard and an equipment body. The equipment body is composed of a feeding part, a carding region I, a carding region II and a net strip forming part. A transferring licker-in roller is arranged between a cylinder A and a cylinder B, and a doffer is arranged at the front part of the cylinder B. Transferring rollers above the cylinder A and the cylinder B are respectively provided with a small chain wheel. During operation, a hemp roll is unwound and fed to a roller to be held and then is fed into the cylinder A, a hemp layer is stripped and carded step by step in the cylinder A, then the hemp layer subjected to carding enters the cylinder B, carding treatment is carried out on the hemp raw material by virtue a working roller and a transferring roller, and finally the net strip is output. The machine provided by the invention has the characteristics of simple equipment structure, short operational process, one-step carding, less wet dissipation, optimum degree of carding strength, improvement of the split degree and increase of fiber length, thereby solving the problems of the existing equipment.

Owner:YINGKOU XINYI TEXTILE

Biotreatment method for flax short-fibre

InactiveCN1752337AImprove spinnabilityImprove dyeing effectBiochemical fibre treatmentVegetal fibresFiberWastewater

A biological treatment method of flax staple fibre relates to a method for preparing flax staple fibre. Said method includes the following steps: a). enzyme catalysis degradation; (b). dissolution by using hot water; (c). extraction; (d). dissolution by hot water; (e). dewatering; (f). softening; (g). dewatering; (h). oven-drying; and (i). mechanically-splitting fibre.

Owner:黑龙江圆宝纺织股份有限公司

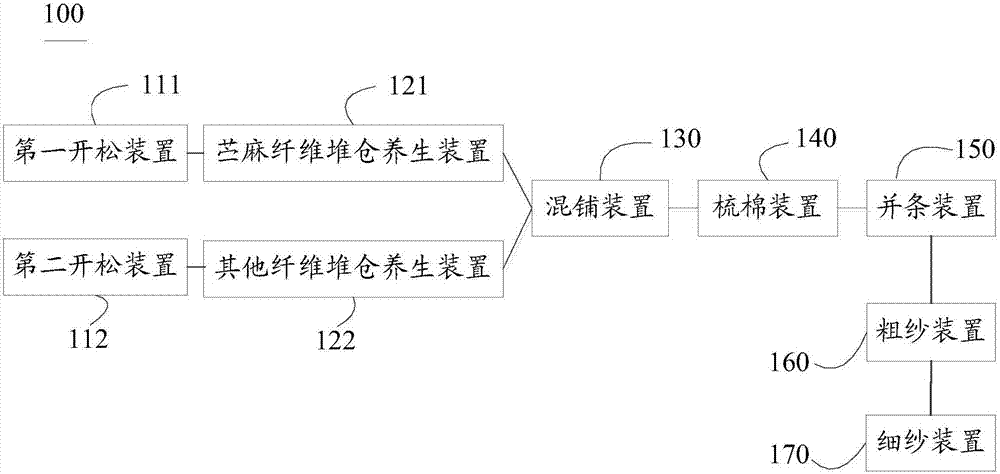

Ramie blended yarn and processing method, system and application of ramie blended yarn

InactiveCN107142578AIncrease the degree of splittingAvoid problems with poor yarn qualityYarnYarnCarding

A ramie blended yarn processing method includes the following steps: opening is conducted on ramie fiber and other fiber besides the ramie fiber respectively; stowing and preserving are conducted on the ramie fiber obtained after the opening treatment so as to soften the ramie fiber, and refined ramie fiber is obtained; the refined ramie fiber and the other fiber obtained after the opening treatment are mixed and spread to be fiber web, cotton carding is conducted on the fiber web, and blended card slivers are obtained; drawing, roving, and spinning are sequentially conducted on the blended card silvers, and the ramie blended yarn is obtained. The ramie blended yarn processing method is used for ramie blended yarn, the quality of formed yarn is improved, the ramie blended yarn with a higher ramie blending proportion can be obtained, and the technological process is shortened.

Owner:湖南莎丽袜业股份有限公司

Chemical modification method of short flax fibers

InactiveCN106555334AMake up for the problem of strong damageReduce crystallinityGrip property fibresVegetal fibresYarnBreaking strength

The invention discloses a chemical modification method of short flax fibers. Short flax fibers are used as a raw material. The method comprises the following steps: carrying out pretreatment by an alkali waste circulatory reboiling method, carrying out selective oxidation by the use of sodium periodate, immersing with a glycerol solution, washing with deionized water, dehydrating, and drying. By the method, split degree, whiteness and spinnability of short flax fibers can be enhanced, short fibers become soft, and anti-crease property is improved. Aldehyde content of modified short flax fibers is 216.67-233.58 umol / g; infrared crystallization index of O' KI is 0.8285-0.8374; split degree is 1225-1262 Nm; breaking strength is 7.64-8.40 cN.tex<-1>; elongation is 4.97-5.46%; whiteness is 72.11-75.03%. The method meets the technical requirements of flax yarn production for circular knitting machine for weft knitting of single jersey. Processing range of short flax fibers is broadened.

Owner:QIQIHAR UNIVERSITY

Short-flow environment-friendly degumming and bleaching method for hemp fibers

ActiveCN102146589BLow lignin contentEfficient removalVegetable materialFibre treatment to obtain bast fibreChemical oxygen demandImpurity

Owner:郑州银泰企业管理咨询有限公司

Stabilizer for use in sodium chlorite degumming and bleaching of flax and its preparation method and application

InactiveCN100439573CFast decomposition rateReduce dosageBleaching apparatusVegetal fibresYarnGreen environment

The invention relates to a stabilizer for sodium chlorite degumming and bleaching of linen rove and the textile and the new technology of degumming and bleaching for green environment protection. The stabilizer is a saturated solution of salt mixture, which comprises 3-13% by wt of six methylene amine, 1-6% by wt of diamine sulfate, 2-10% by wt of triethanolamine, 1-8% by wt of ammonium persulfate and water. In the process of degumming and bleaching, the stabilizer is joined to restrain generation and dissipation of chlorine dioxide so that not only bleaching conditions are satisfied and the quality of yarn is improved but also the health of operating workers is protected and the equipment is maintained. It is no-pollution so as to decrease the consumption of sodium chlorite and improve the utilization ratio of sodium chlorite is improved. The degumming and bleaching technology for linen rove can improve yarn evenness evidently, decrease hemp particle greatly, and improve the spinning number and the loom efficiency greatly. Especially it is provided with notable effect for primary color yarn with difficult spinning performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Hemp fiber woven product and application thereof

InactiveCN110685053AImprove spinnabilityHigh mechanical strengthDispersed particle filtrationWoven fabricsPolymer scienceCotton fibre

The invention relates to a hemp fiber woven product and an application thereof, and aims to solve the problems that the existing hemp fiber woven product is low in quality and difficult to impart highcount so that the application thereof is limited. The hemp woven product is formed by blending and weaving hemp fibers and other fibers, wherein the other fibers include ES (ethylene-propylene side by side) fibers, Visil fibers and cotton fibers; the hemp fiber woven product manufactured by the invention is used for manufacturing a filter screen. The hemp woven product disclosed by the inventionallows the hemp fibers to be blended with the ES fibers, the Visil fibers and the cotton fibers, and the hemp woven product is treated by a special process, so that the hemp woven product is soft to touch, smooth and stiff, natural and comfortable, high in processing and production efficiency, high in splitting degree, low in product loss and good in quality, and the high count degree of the hempfibers can be produced is increased. The hemp fiber woven product is applied to the field of hemp fiber manufacture.

Owner:黑龙江壹善汉麻生物科技有限公司

Process for decompressing and debonding cannabis

InactiveCN100460574CIncrease the degree of splittingQuality improvementVegetable materialDiseaseCarding

A method for cannabis decompression degumming includes: (1) Pick out the useless thing such as impurities, dead Ma, Ma disease classes in the original Ma, immerse the original Ma in the alkali solution of low concentration with the temperature between 60 to 90 centigrade, lower to room temperature, keep it for 10 to 12 hours, and then dry it to get the dry original Ma Soaked by alkali solution; (2) put the original Ma into pressure cookers to get the expanded cannabis after the treatment of decompression Expanded. (3) Put the expanded cannabis into centrifuge to releases the concentrated glue of cannabis and collect the glue, Dry cleaning bleach the hemp fiber after dry. (4) Produce the production of expanded cannabis ball and strips after the loose carding. The expanded cannabis ball and strips produced by this method has the characters: the high split rates of the hemp fiber, high quality, easily recover the hashish with high value and pollution avoided.

Owner:冯海金

Cellulomonas fimi DA 8 bacterial strain as well as acquiring method and application thereof

InactiveCN102010836BIncrease the lengthGrain reductionBacteriaBiochemical fibre treatmentBiotechnologyPectinase

Owner:DONGHUA UNIV

Fiber bundle dividing and washing method and device

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

A kind of pretreatment processing method of flax short fiber

InactiveCN104452263BIncrease the degree of splittingImprove spinnabilityDry-cleaning apparatus for textilesBleaching apparatusYarnEcological environment

The invention discloses a pretreatment processing method of short flax fibers. The pretreatment processing method comprises the following steps: with the short flax fibers as a raw material, carrying out procedures of peracetic acid pretreatment, warm washing, sodium percarbonate-peracetic acid scouring, hot washing, cold washing, dehydration and drying. The pretreatment processing method has the beneficial effects that most impurities such as pectin and lignin in the short flax fibers are removed by virtue of an ecological environment-friendly aid, so that wastewater pollution is avoided; processing conditions are relatively mild, so that the problem that the fiber strength is greatly damaged due to strong base and high temperature in a traditional process is remedied; the procedures of scouring and bleaching are simultaneously finished, so that impurity removal and bleaching are finished, the processing process is shortened, and the production efficiency is improved; original auxiliary projects and facilities can be utilized, so that the operation is easy, and the cost is low; the processed short fibers are pure white, soft, high in splitting degree and good in spinnability, so that the quality of finished yarns is beneficially improved, the technical requirements of the production of flax yarns for circular machine weft knitted single jersey are well met, and the grade of application range is promoted.

Owner:QIQIHAR UNIVERSITY

Blended spinning method of long spinning and damp spinning for bast fibers

The invention provides a method integrated with long spinning, wet spinning and blended spinning for bast fibers. The method comprises the following steps: the bast fibers are scotched into flax; the flax is humidified and soaked for a period of time; the flax is carded into long flax; and the long flax is subjected to matching, silvering, drawing, roving, scouring, bleaching, spinning, drying and winding. The method is characterized in that after the bast fibers are bleached, the obtained rove of the bast fibers and rove or filaments of other fibers are blended on a spinning machine. With the method, blended fibers are not bleached and scoured together with the bast fibers, so the defect that the performance of blended yarn is affected due to the damage of bleaching and scouring agents to the blended fibers in the prior wet spinning and blended spinning is overcome, and the obtained blended yarn has the characteristics of bright and clean yarn body, less hairness, evenness and good wear resistance. In addition, the method can fully play a role in respective advantages of the bast fibers and the blended fibers, complement respective disadvantages of the bast fibers and the blendedfibers, has simple process, is favorable for improving the quality of blended yarn of the bast fibers, and realizes the high count, high grade and diversification of varieties of the bast fibers.

Owner:DONGHUA UNIV

A method and device for combing and sorting hemp fibers

ActiveCN101824676BEfficient removalIncrease the degree of splittingSafety devices for fibre treatmentCombing machinesDecision modelCombing

The invention relates to a method and device for combing and sorting hemp fibers. Combed hemp slivers of different specifications and lengths are obtained through multi-passes of combing. The length can be changed by adjusting the pulley. In the carding mechanism of the device of the present invention, the circular combs are arranged in the range of 0 to 270°, and are divided into a rack type and a combined rack and needle row type, and the top combs are divided into a single-row type and a multi-row type. The pulling and separating mechanism includes a pulling car, which is installed on an adjusting frame, and the adjusting frame is provided with a lever and an arc-shaped chute, and bolts are inserted in the arc-shaped chute, and the bolts are fastened to the frame. Loosen the bolt and pull the lever to make the adjustment frame slide along the arc-shaped chute. At least two pairs of crimping rollers are arranged in the delivery mechanism. The hemp sliver processed by the method and device of the invention has uniform dryness, low short-lint rate, uniform fiber length, low ultra-long fiber content, more parallel and straight fibers, convenient operation, high efficiency and low labor intensity.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

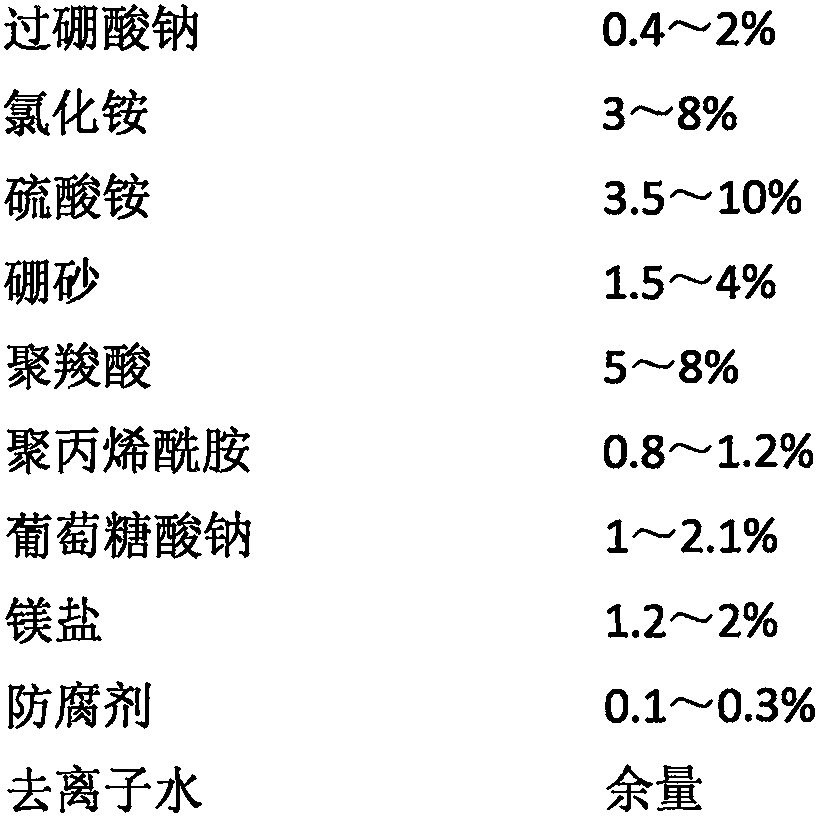

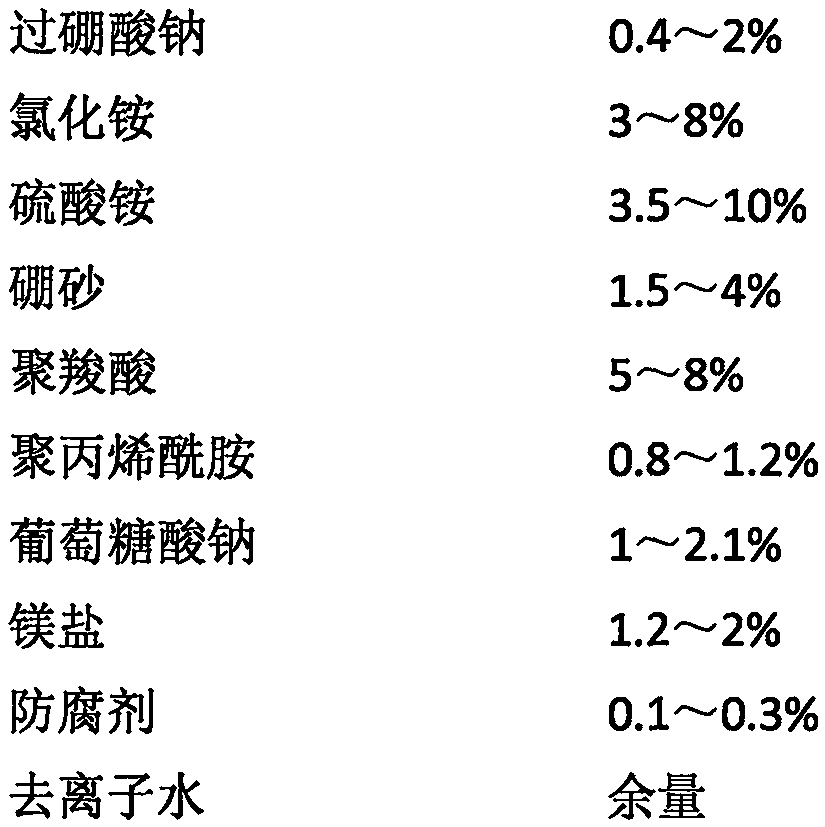

Environment-friendly chlorite bleaching stabilizer as well as preparation method and application thereof

InactiveCN111101370AStrong pH buffering capacityEffective control of pH buffer rangeTextiles and paperFiberYarn

The invention relates to an environment-friendly chlorite bleaching stabilizer as well as a preparation method and application thereof. The stabilizer comprises the following components in percentageby mass: 0.4-2% of sodium perborate, 3-8% of ammonium chloride, 3.5-10% of ammonium sulfate, 1.5-4% of borax, 5-8% of polycarboxylic acid, 0.8-1.2% of polyacrylamide, 1-2.1% of sodium gluconate, 1.2-2% of magnesium salt, 0.1-0.3% of preservative and the balance of deionized water. The magnesium salt is sulfate or chloride of magnesium, and the preservative is Proxel LV or Proxel GXL. The stabilizer is used for a linen sodium chlorite degumming bleaching process and has strong pH buffering capacity, the use amount of sodium chlorite is effectively reduced, the escape of chlorine dioxide gas isreduced, the corrosion degree of the equipment is reduced, the bleaching effect is good, the fiber splitting degree is improved, the yarn forming quality and utilization rate of linen staple fibers are improved, and the stabilizer is economical and environment-friendly.

Owner:葛江波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com