Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Improve processing uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

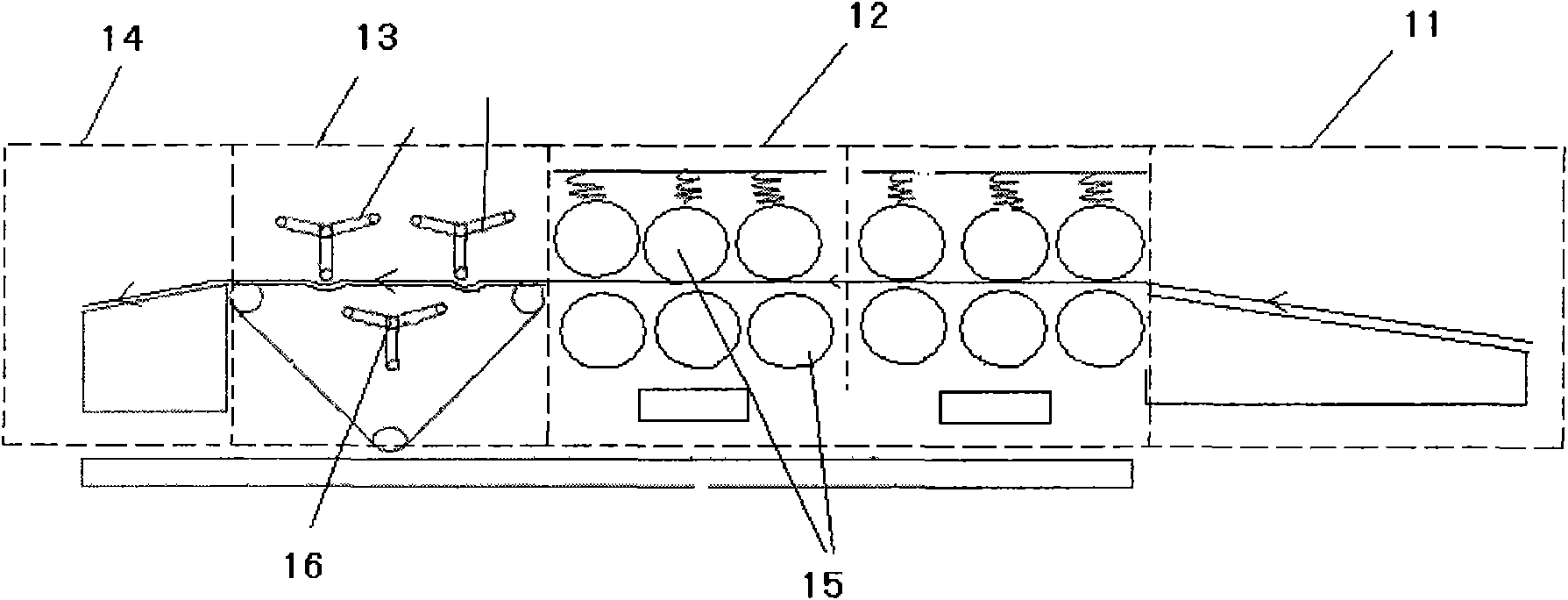

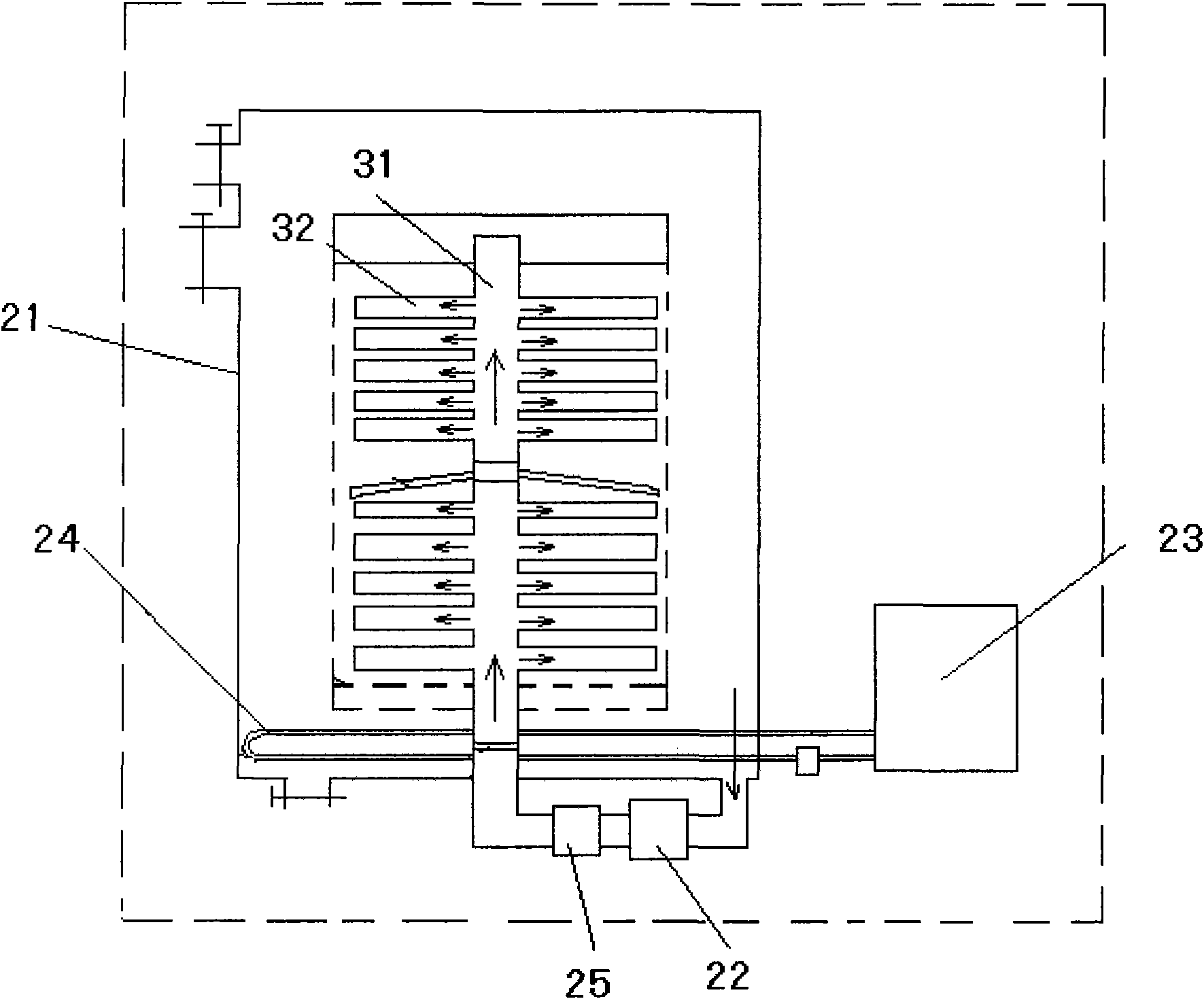

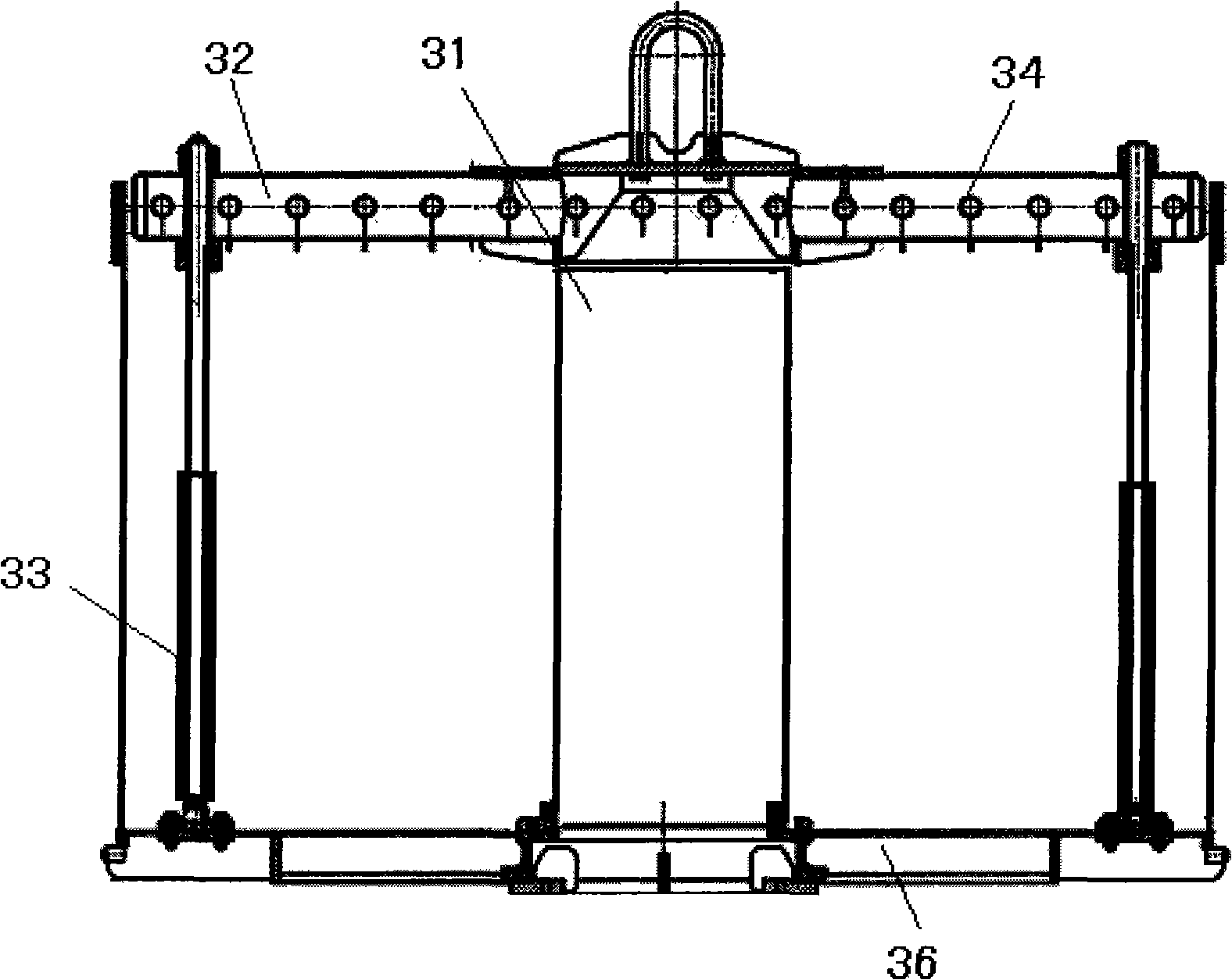

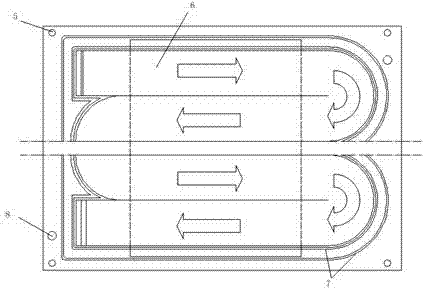

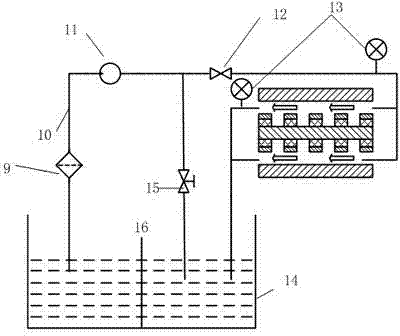

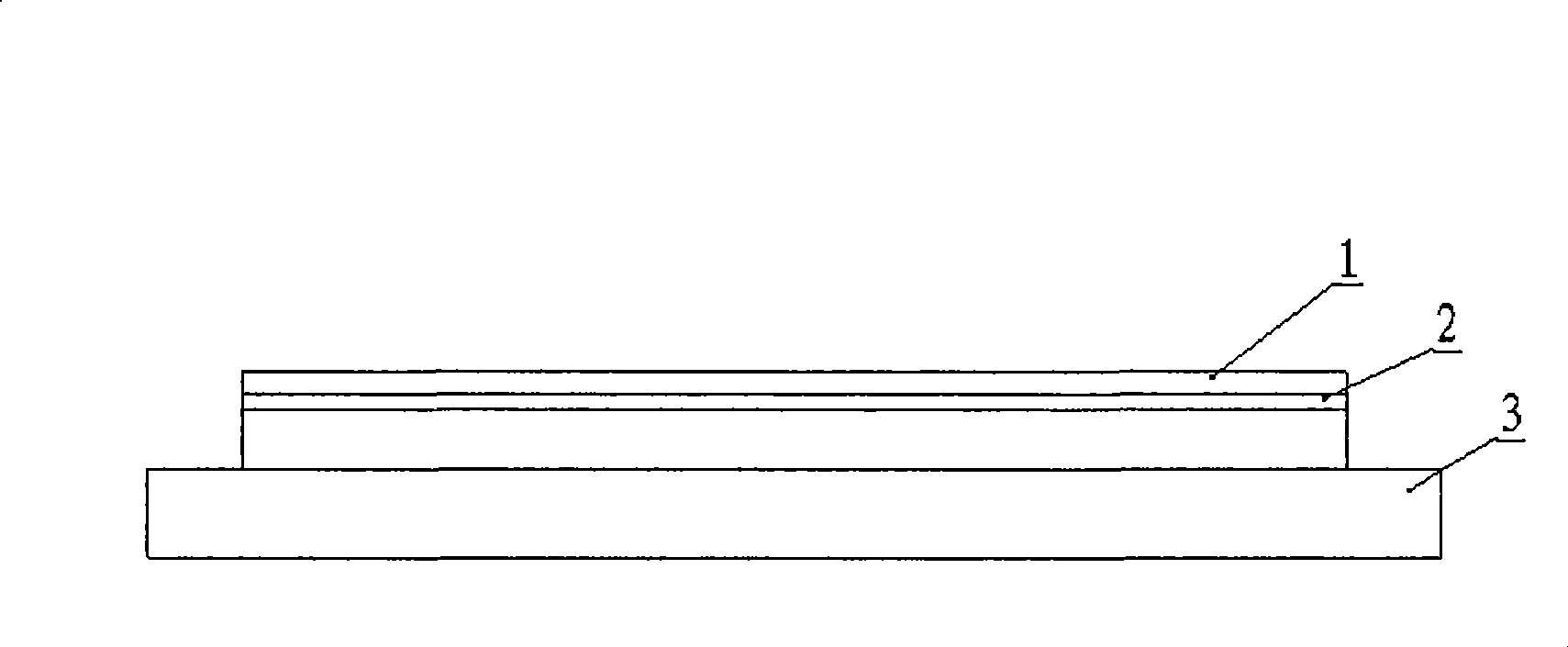

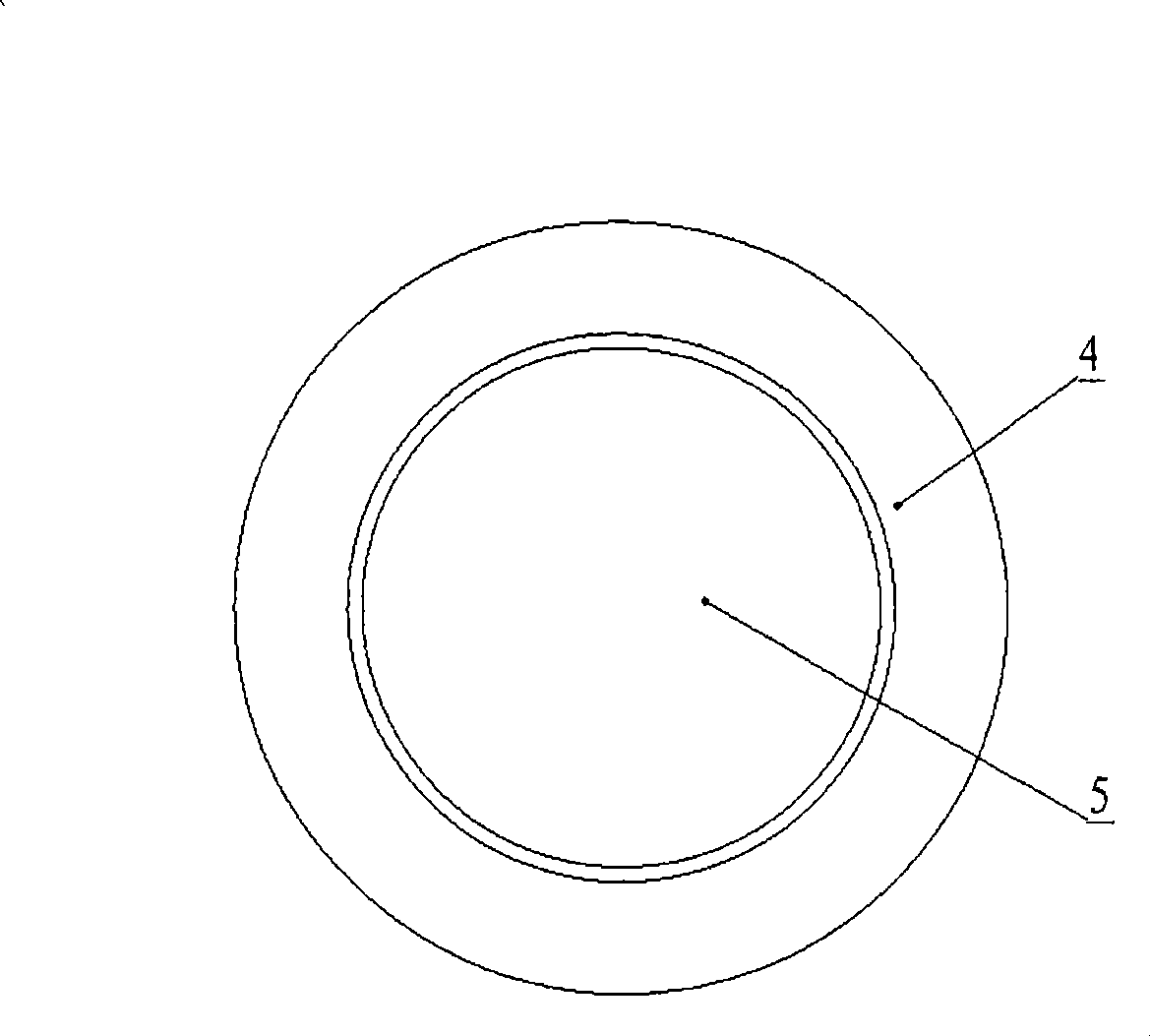

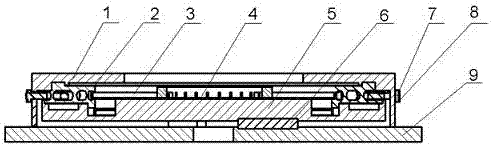

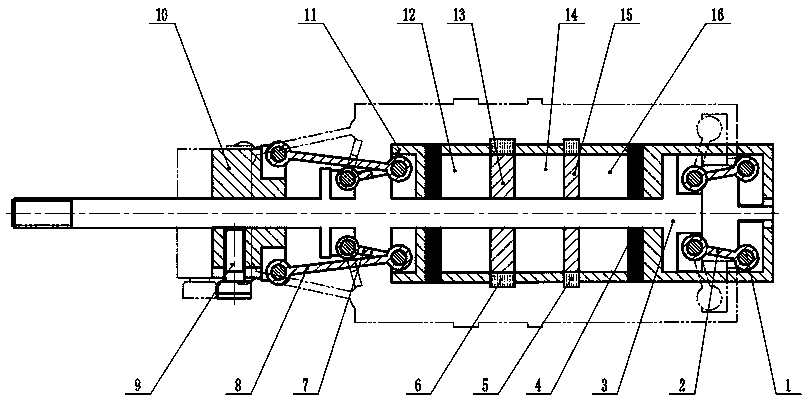

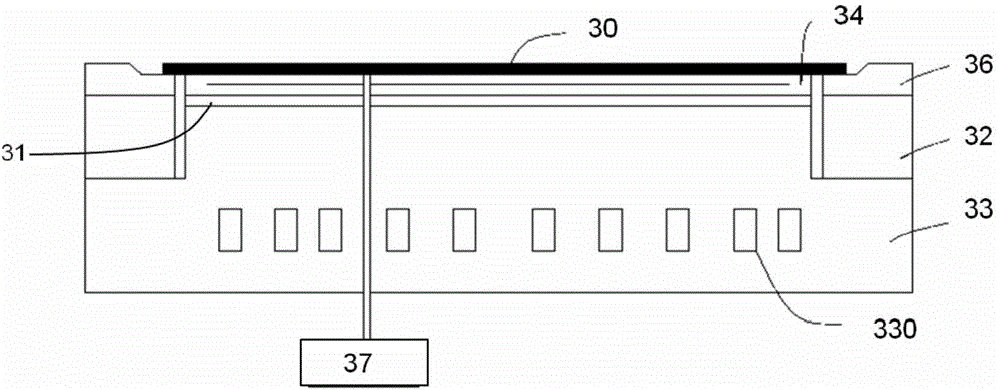

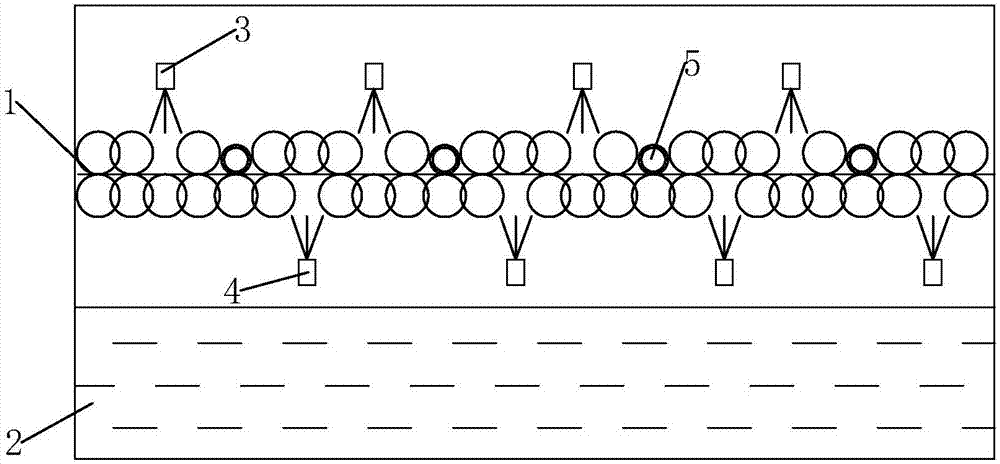

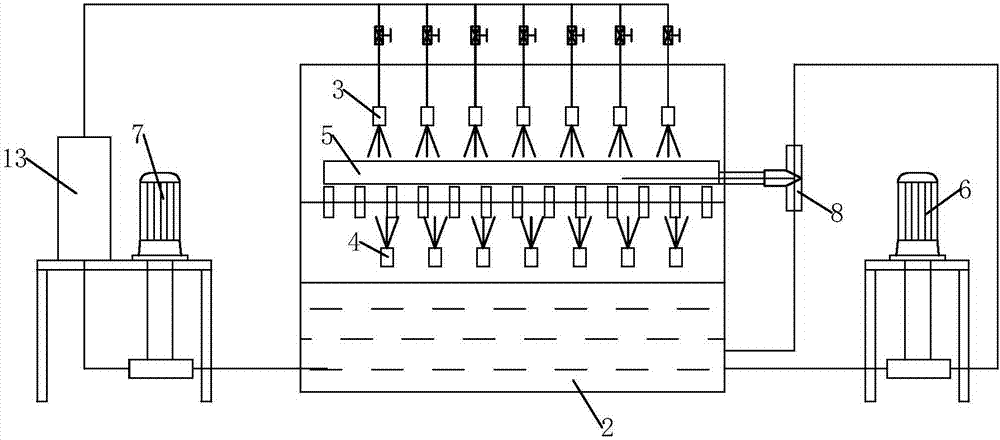

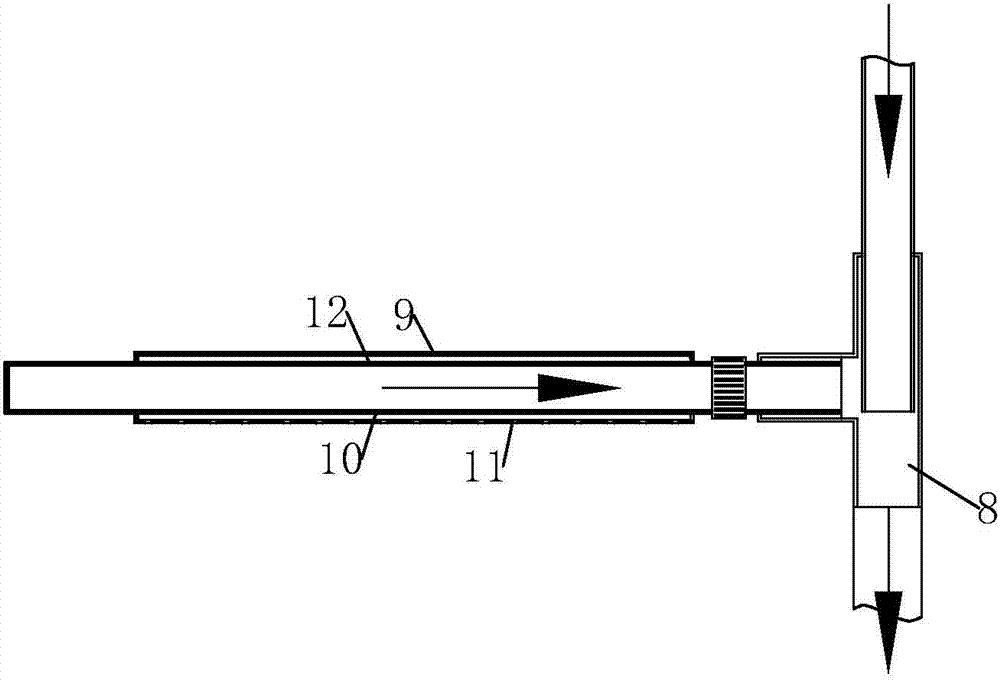

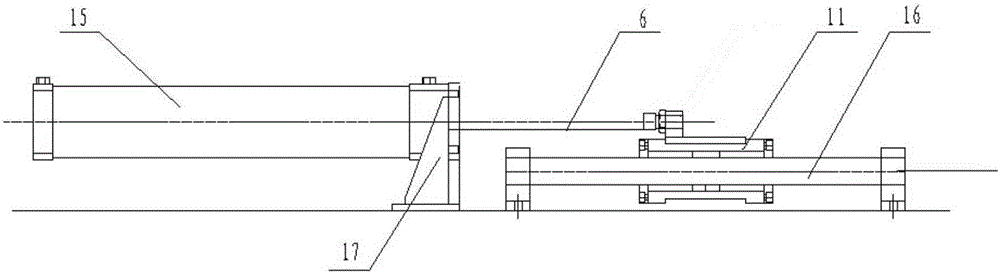

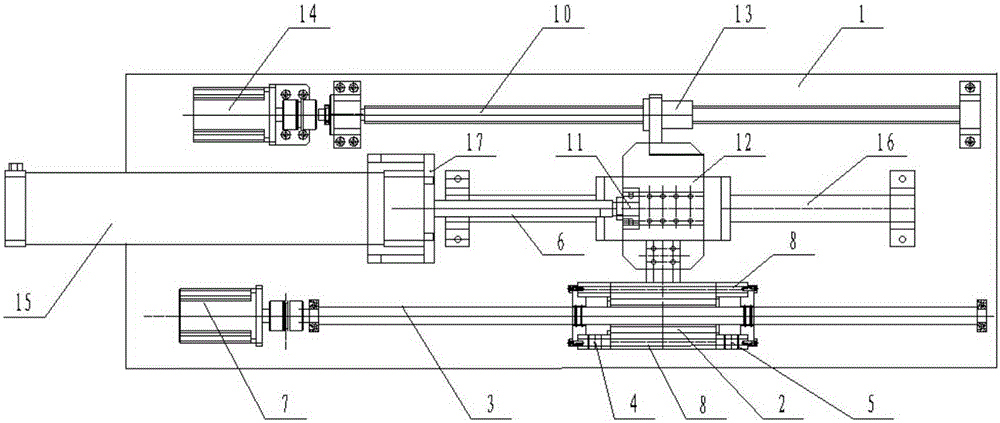

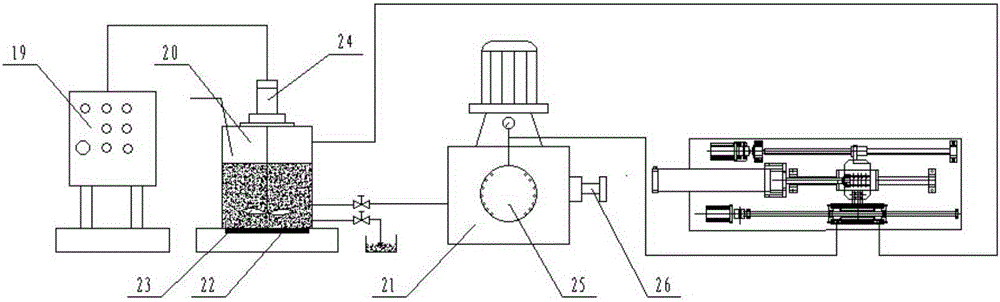

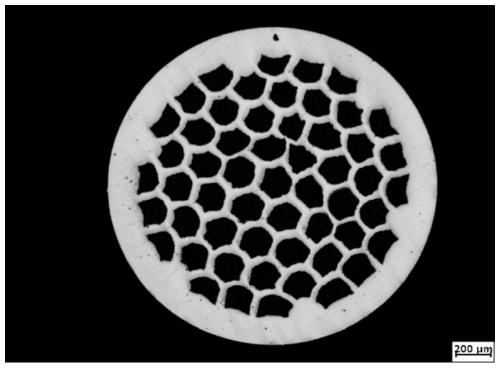

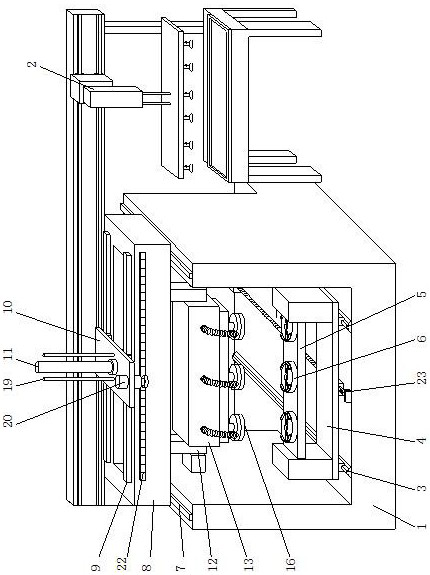

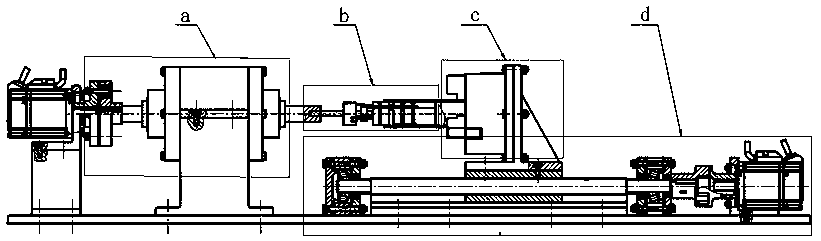

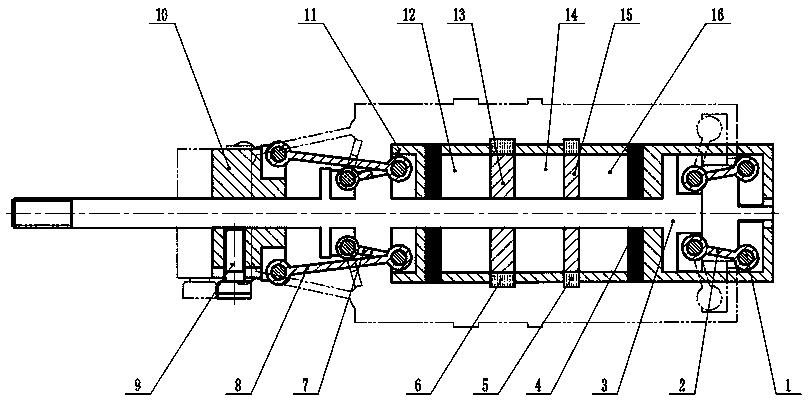

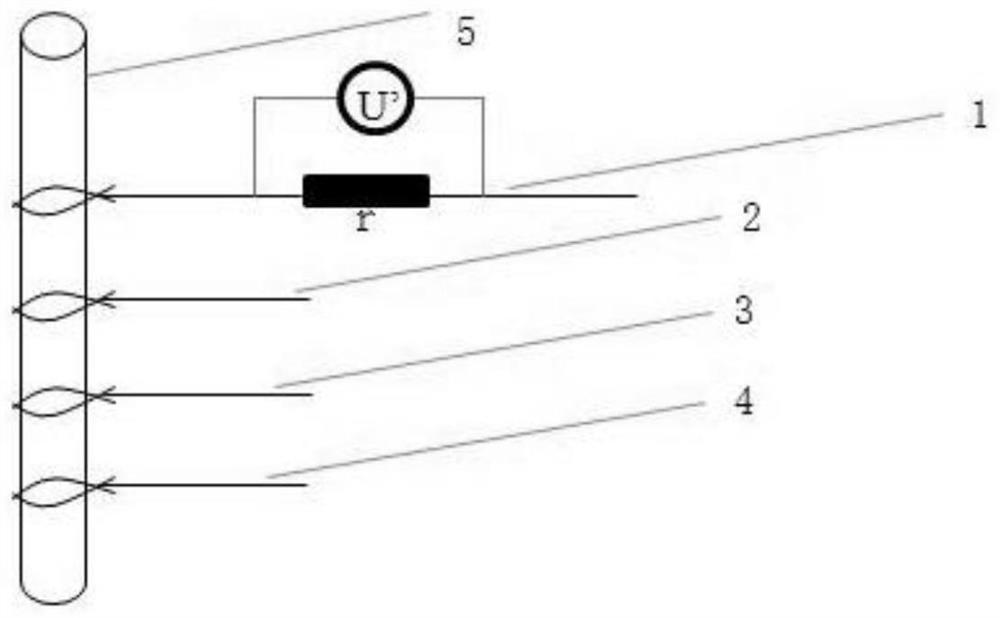

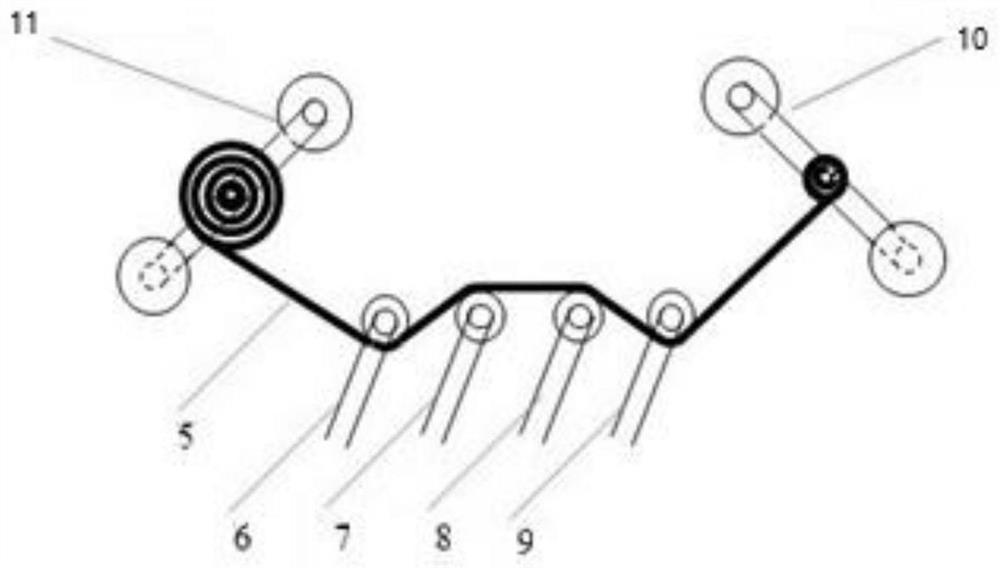

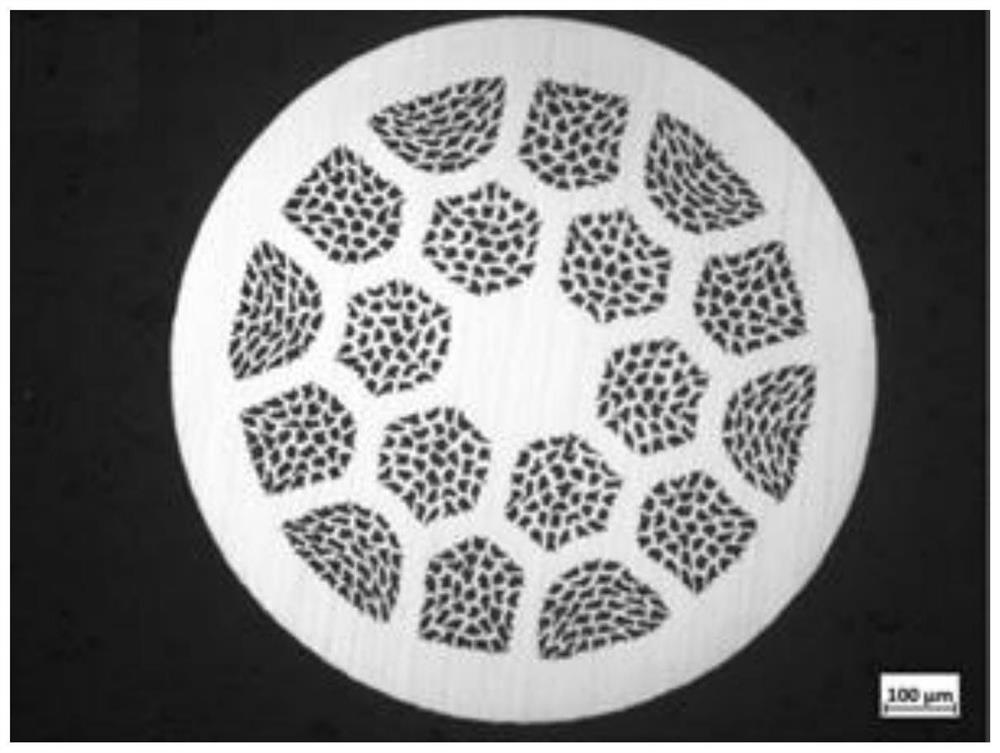

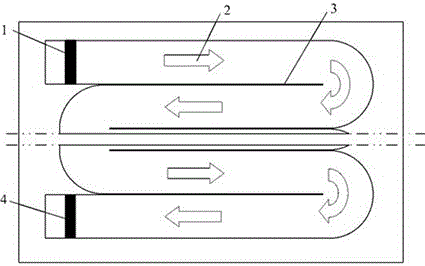

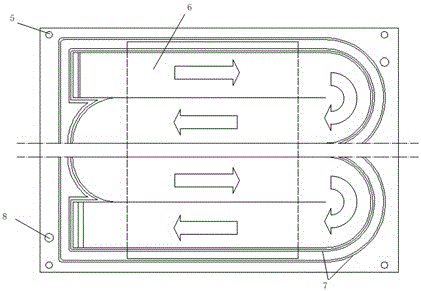

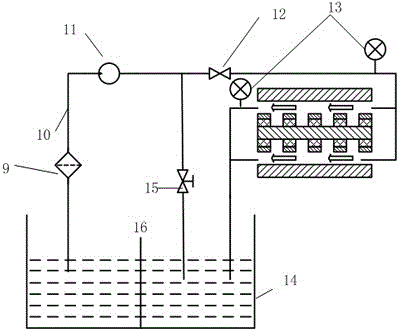

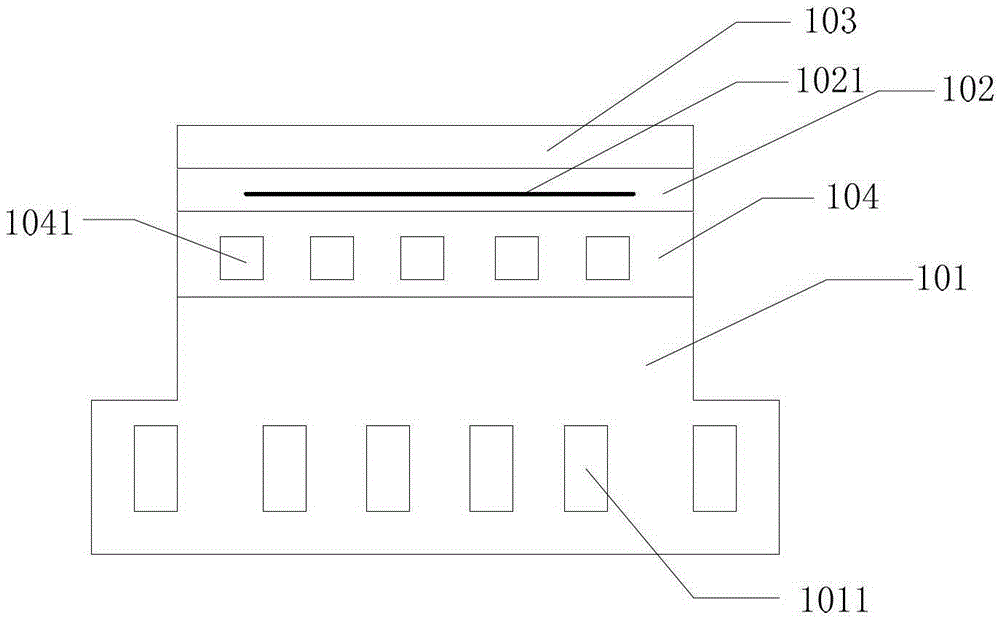

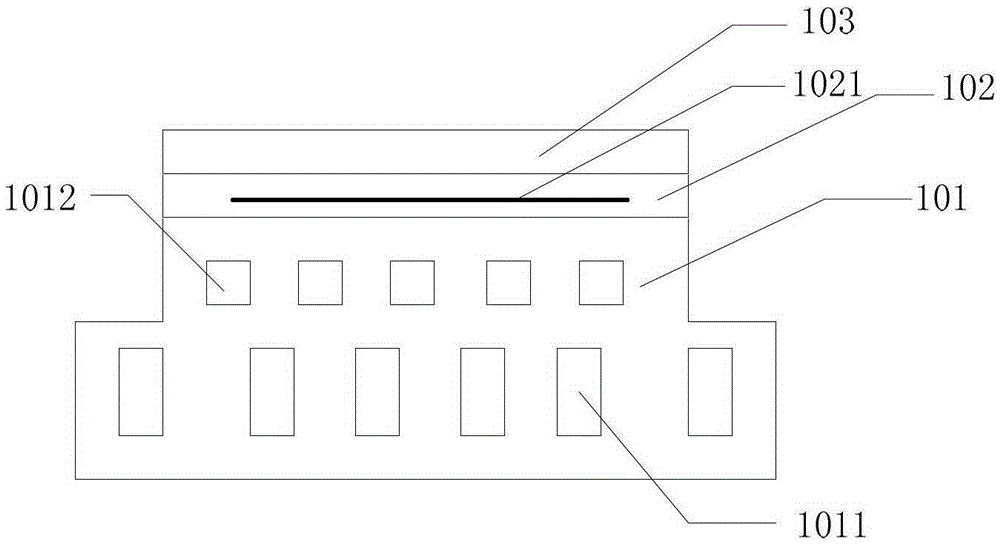

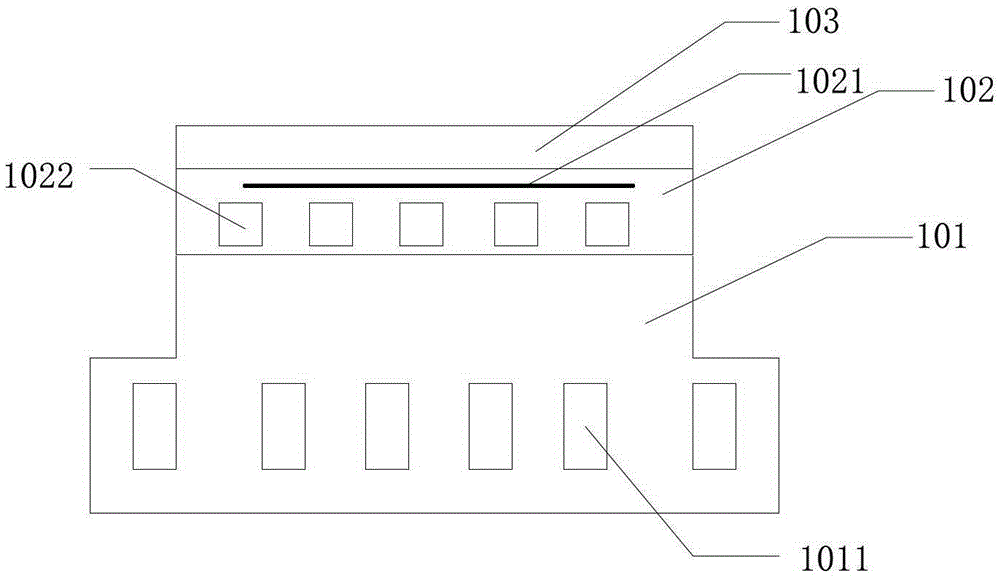

Snakelike runner movable formwork cluster hole electrochemical machining device and machining method

ActiveCN103831497AEasy dischargeImprove processing uniformityElectrochemical machining apparatusEngineeringMachine tool

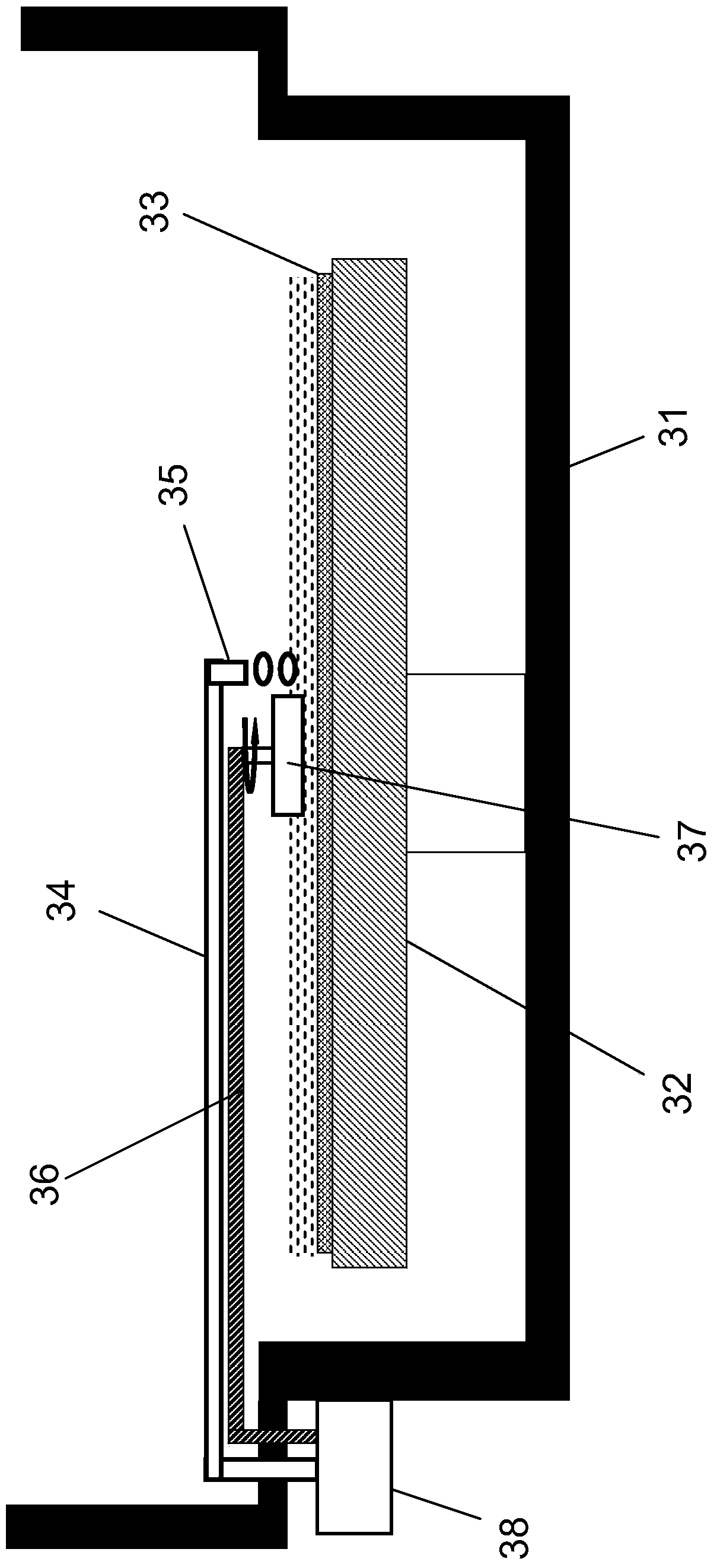

The invention relates to a snakelike runner movable formwork cluster hole electrochemical machining device and a machining method and belongs to the technical field of electrochemical machining. The snakelike runner movable formwork cluster hole electrochemical machine device and machining method are characterized in that a traditional wide runner is changed into a snakelike runner, the runner is narrowed, and flow field distribution evenness on the cross section of the runner in a machining area is improved; the flow velocity of the machining area is relatively improved, machined products can be fast discharged, electric field and flow field parameters are reasonably selected, the flow field state of the machining area can be stable, and machining quality is improved. The machining device comprises a power supply, an electrolyte circulation system, an electrochemical machining machine tool, a mask plate negative electrode and a tool clamp. The snakelike runner movable formwork cluster hole electrochemical machining device and the machining method have important significance in improving the cluster hole electrochemical machining flow field distribution evenness and ensuring that a large-area thin-wall hole plate can be machined at a time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

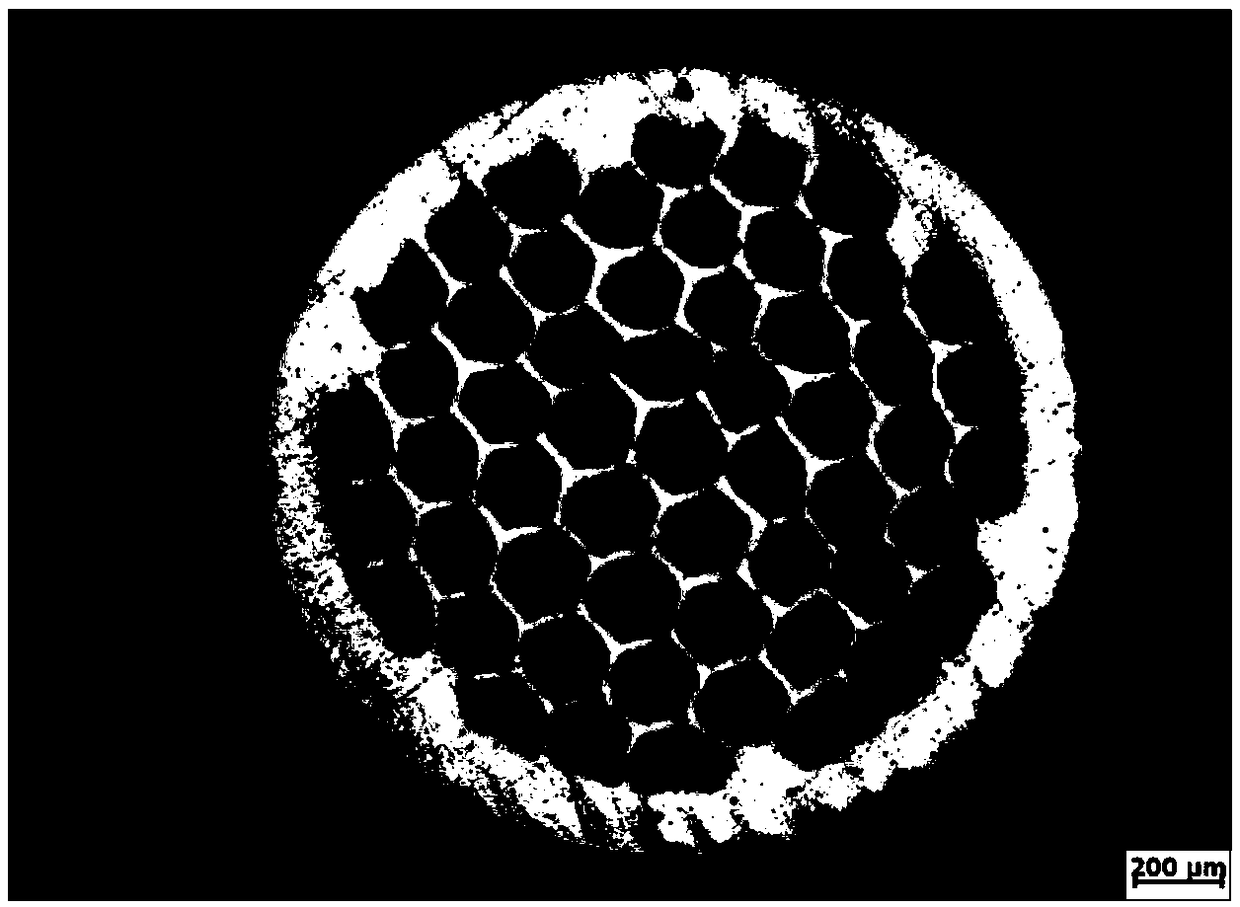

Preparation method of Bi-2212 high-temperature superconductivity wire

ActiveCN102117682ASimple preparation processReasonable designSuperconductors/hyperconductorsSuperconductor devicesHigh-temperature superconductivityAlloy

The invention discloses a preparation method of Bi-2212 high-temperature superconductivity wire, comprising the following steps: firstly, filling superconductivity powder into a pipe; secondly, drawing to process and prepare a secondary compound; thirdly, after drawing the secondary compound, combining the secondary compound with a pure silver rod and a silver alloy rod, and then packing the compound into an AgMn alloy pipe so as to obtain a third compound; fourthly, drawing and processing the third compound into a wire; fifthly, carrying out semi-fused treatment on the wire, and obtaining the Bi-2212 high-temperature superconductivity wire after cooling a furnace. As for the preparation method, the process is simple, the design is reasonable, the manufacturing cost is low, and the application range is wide, and the method can be effectively applied to the preparation process of other relevant superconductivity wires. In the invention, one silver or silver alloy core wire is additionally arranged at the central part of a multi-core wire; therefore, the core wire can be prevented from being broken at the central part of multi-core Bi-2212 wire, the core breakage rate of the wire is obviously reduced, the processing uniformity of the wire is improved, the final uniformity of the wire is improved, and simultaneously the stretching performance of the wire is also improved; and the preparation method is beneficial to the winding of magnet and other applications of superconductivity wire.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

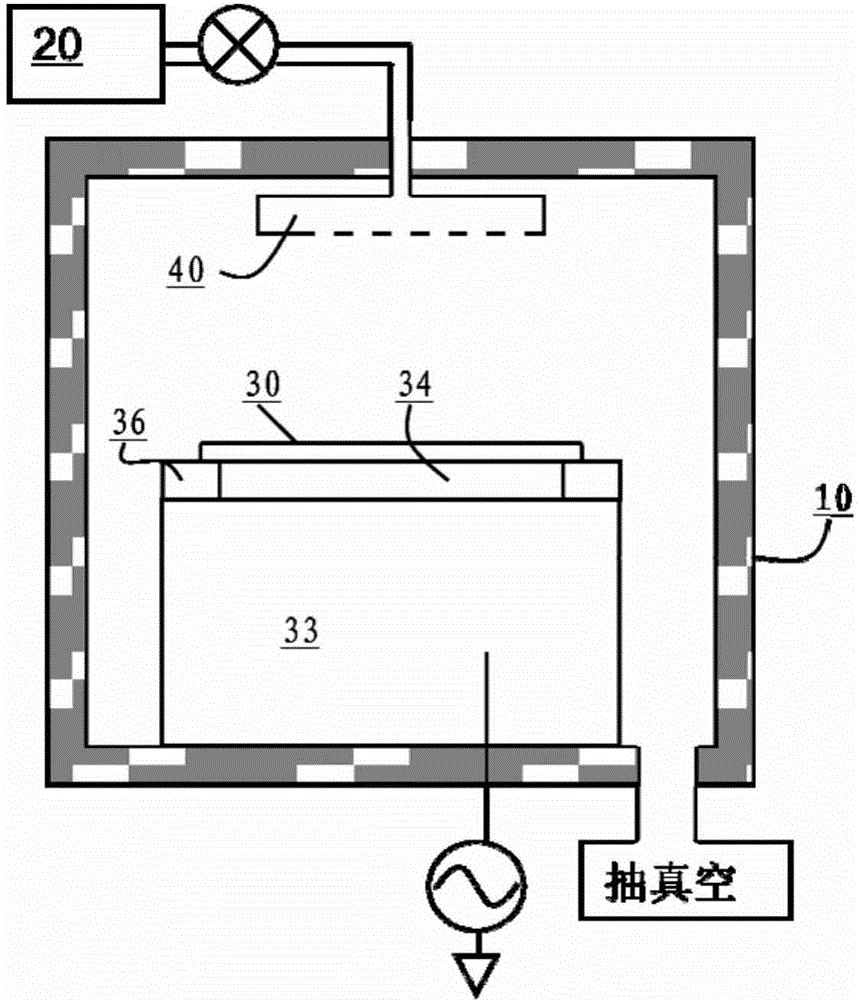

Electrostatic chuck

ActiveCN101378027AIncrease the rate of heatingImprove uniformityVacuum evaporation coatingSputtering coatingElectrostatic attractionSemiconductor package

The invention relates to an electrostatic chuck used for the semiconductor process, and in particular discloses an electrostatic chuck used for fixing parts to be processed in the processing of semiconductor by virtue of electrostatic attraction. The electrostatic chuck comprises an insulated layer, a heater, a base and a thermal insulating layer arranged between the heater and the base. And the parts to be processed are placed on the insulated layer, the base is used for supporting the insulated layer and the heater, and the thermal insulating layer is used for obstructing the conduction of heat generated by the heater to the base. By virtue of the thermal insulating layer, most of heat generated by the heater is only conducted to the insulated layer, thus leading to sufficiently big rate of temperature increase of such parts to be processed as the electrostatic chuck and the wafers on the chuck and causing the parts to be processed of the wafers and the like so as to reach the predetermined temperature in an extremely short time in the processing of semiconductor (especially in a semiconductor etching process), and finally the processing uniformity (for example, etching) of such parts to be processed as wafers is further enhanced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

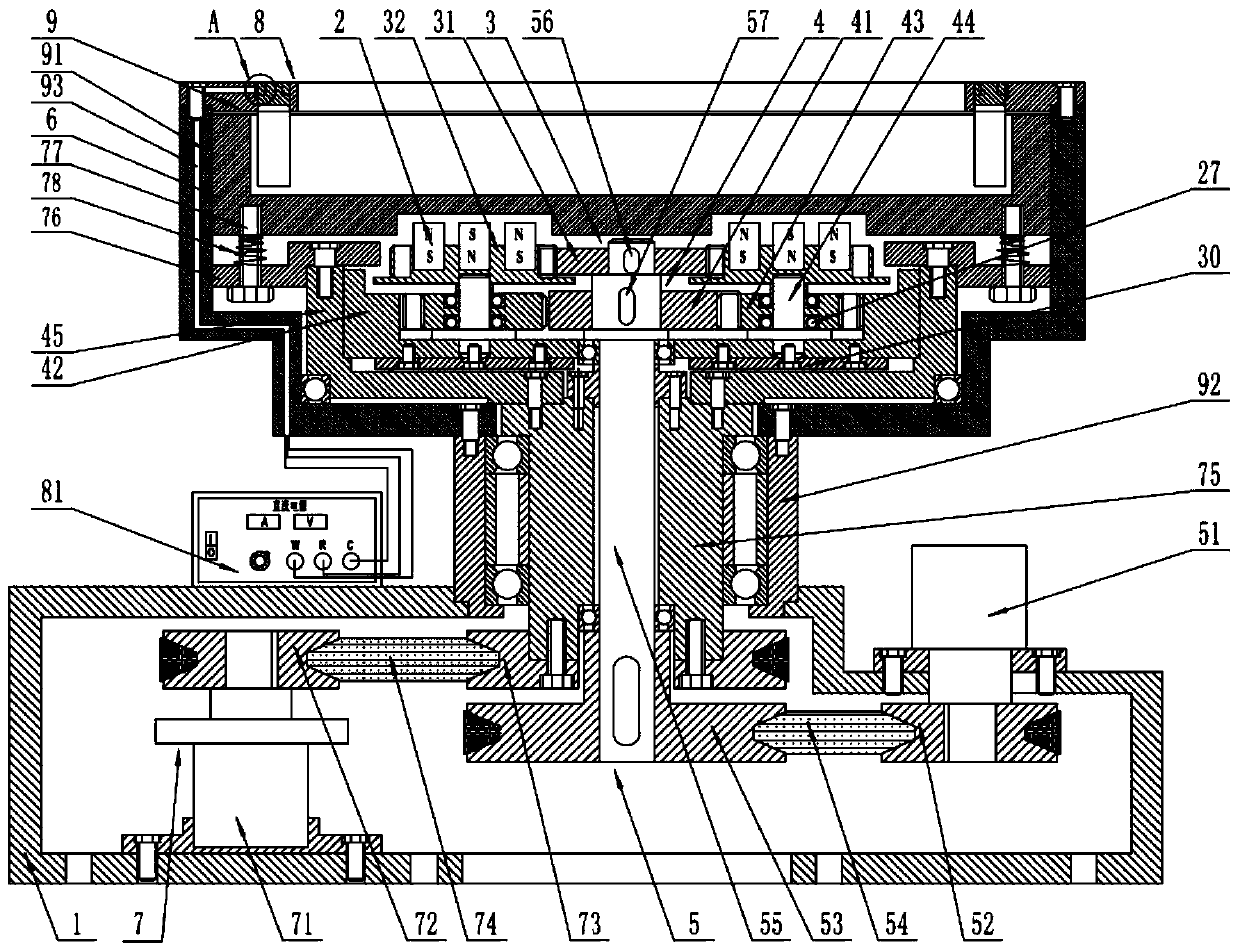

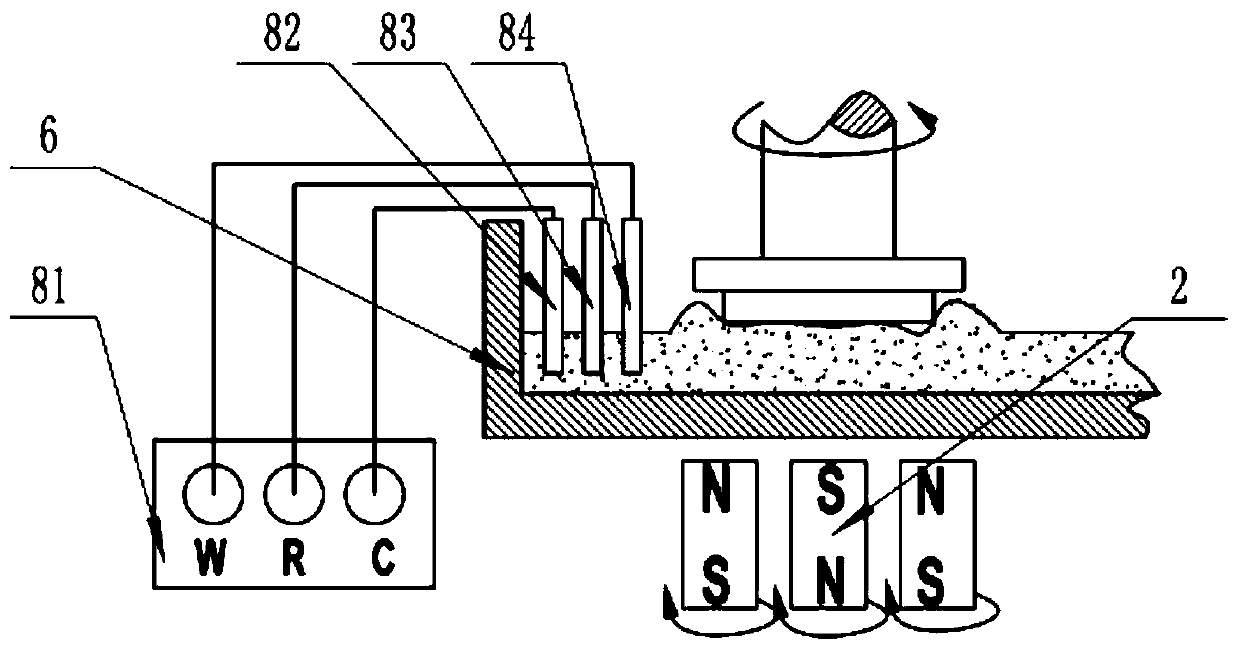

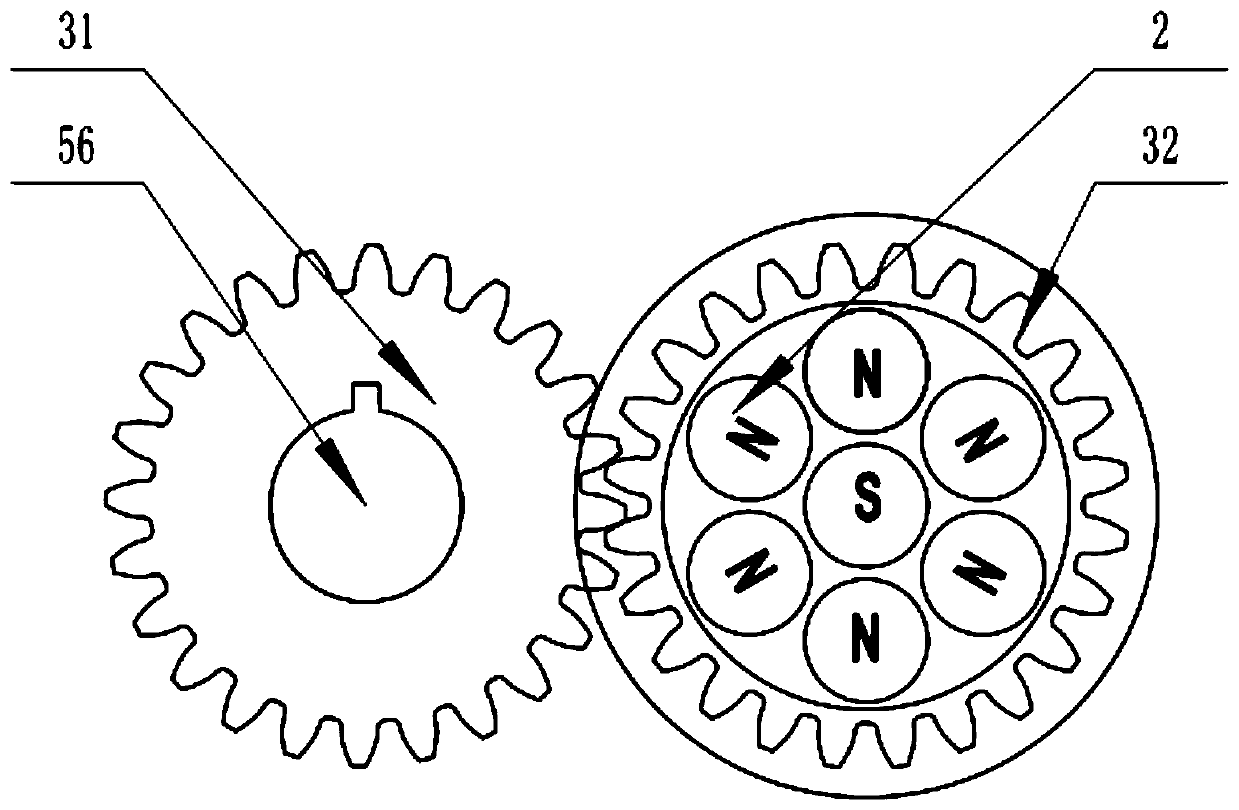

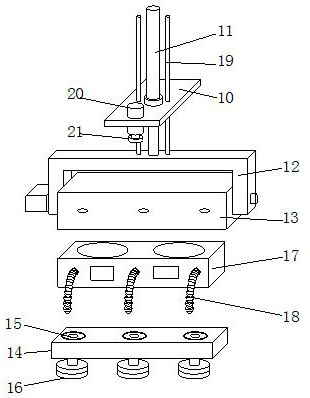

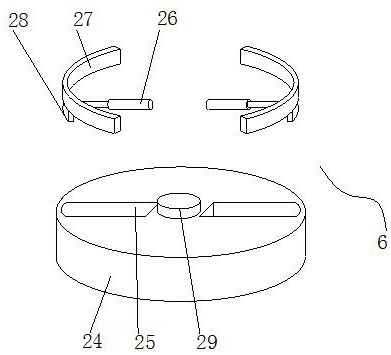

Electro-Fenton cluster magneto-rheological composite grinding and polishing device and method

PendingCN110900322AAchieve reductionQuick updateEdge grinding machinesGrinding carriagesPolishingMagnetorheological fluid

The invention relates to the technical field of ultra-precision machining and particularly relates to an electro-Fenton cluster magneto-rheological composite grinding and polishing device and method.The device comprises a base, a cluster magnet, an autorotation transmission assembly, a revolution transmission assembly, a first driving assembly, a polishing disc containing magnetorheological fluid, a second driving assembly and an electro-Fenton assembly, wherein the cluster magnet is installed on the autorotation transmission assembly, the autorotation transmission assembly is connected between the cluster magnet and the first driving assembly, the revolution transmission assembly is connected between the first driving assembly and the autorotation transmission assembly, the polishing disc is connected with the second driving assembly, and the polishing disc is located above the cluster magnet. The device is advantaged in that an electro-Fenton reaction product OH reacts with a machined workpiece to generate an oxide layer, the cluster magnet rotates and revolves, the polishing disc rotates, the magnetorheological fluid forms a dynamic flexible polishing pad under the action of the cluster magnet, the oxide layer is removed under the action of the dynamic flexible polishing pad, and workpiece machining efficiency and the machining quality can be improved.

Owner:GUANGDONG UNIV OF TECH

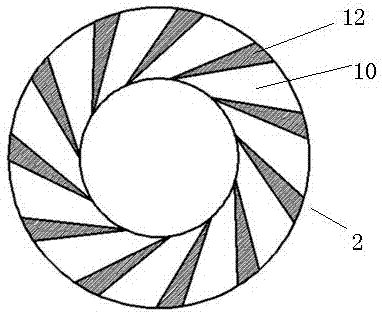

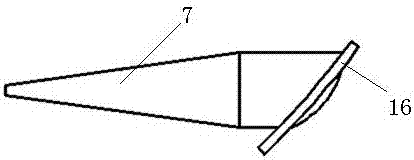

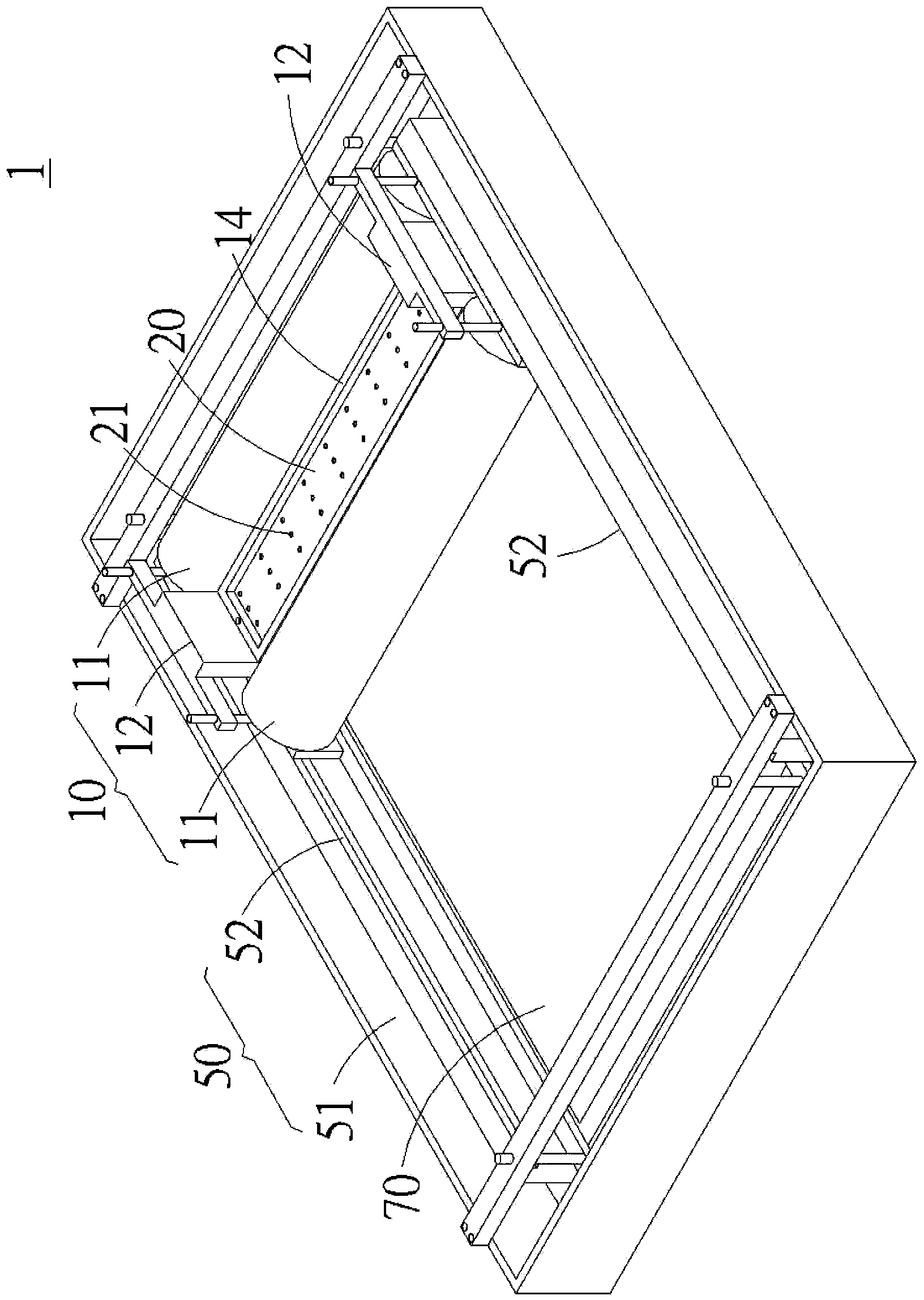

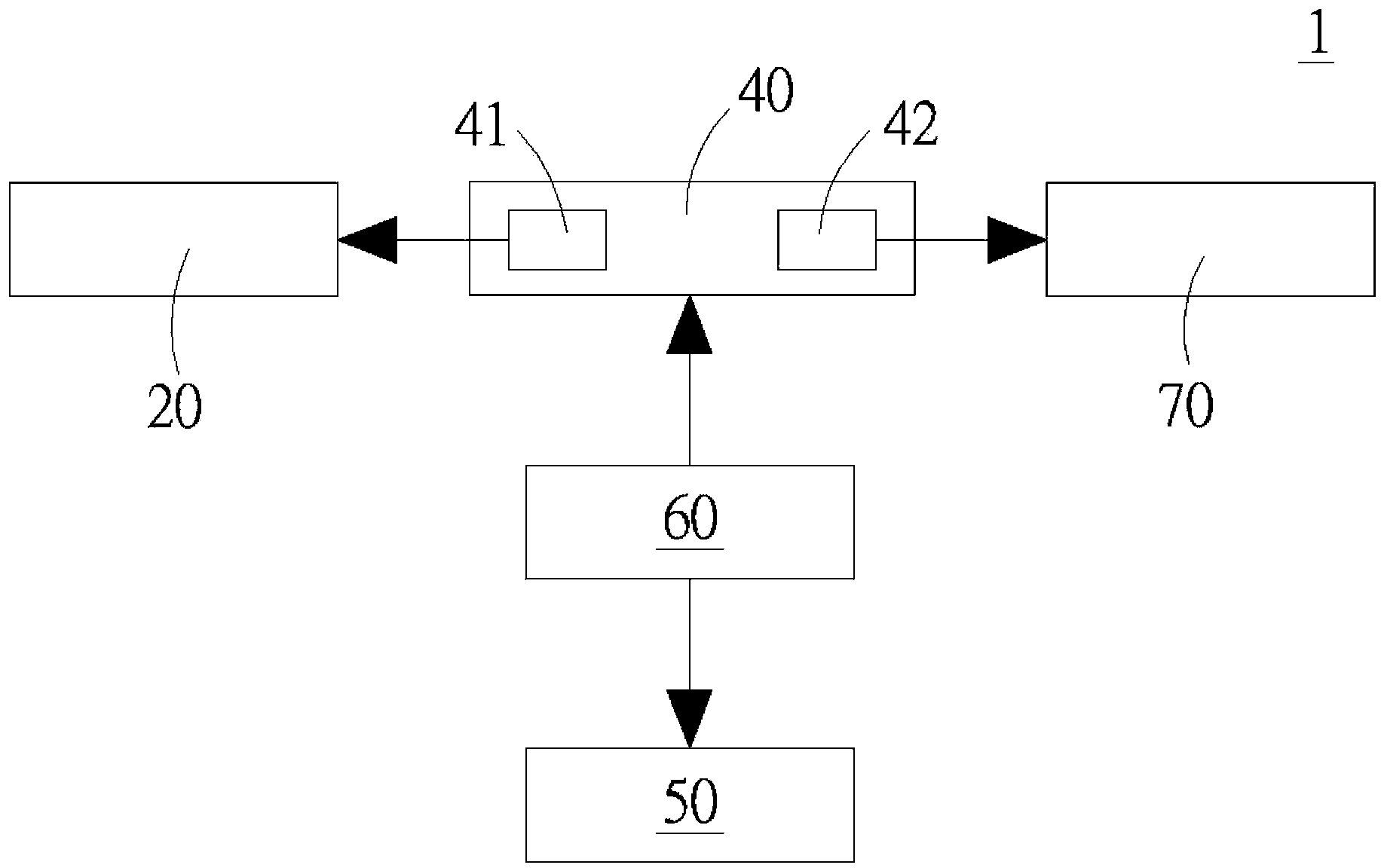

Special clamp for abrasive material flow finishing machining of variable-cross-section specially-shaped channel structure

ActiveCN107127684AAvoid damageImprove surface qualityAbrasive machine appurtenancesAbrasive blasting machinesEngineeringMechanical engineering

The invention provides a special clamp for the abrasive material flow finishing machining of a variable-cross-section specially-shaped channel structure. The special clamp comprises a bottom base plate (9) and a base (5) and is characterized in that the base (5) is arranged in a clamp upper cover (1) in a sleeving manner, the clamp upper cover (1) is fixed to the bottom base plate (9), a workpiece (2) is mounted on the base (5), a fixing ring (4) is mounted on the base (5), and a sharp edge protecting rod (3) is mounted on the fixing ring (4); and an inserting hole is processed in the cylindrical side edge of the clamp upper cover (1), and the main body part of a flow guiding column (7) is inserted into a runner (10) of the workpiece (2). Through the one-time flowing of an abrasive material, the finishing machining of a part comprising the variable-cross-section specially-shaped channel structure is realized. The device is simple, is easy to mount and disassemble, and can realize the high-efficiency and high-precision machining of the part comprising the variable-cross-section specially-shaped channel structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gear shaft forging process

InactiveCN108994247AReduce lossSimple processEngine componentsManufacturing cost reductionMaterials science

The invention mainly discloses a gear shaft forging process. According to the technical field, the gear shaft forging process comprises the steps of material selection, pretreatment, drawing as an initial blank, primary fire forging and upsetting, drawing to a standard specification, heating in a furnace, secondary fire forging and drawing, material separation, drawing of a small end, rounding andfinishing, and cooling and annealing after forging. The product raw material loss is low in the manufacturing process, so that the production cost is reduced; and the product is stable in performance, high in strength and free of damage, so that the production efficiency and the production benefit are greatly improved.

Owner:杭州金越晟重型机械有限公司

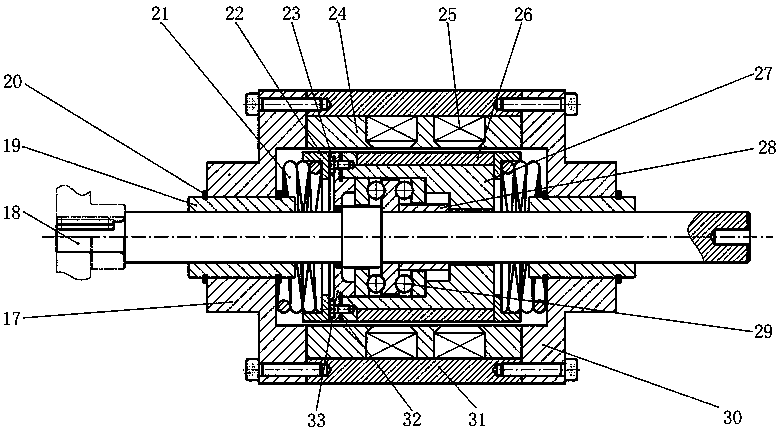

Magnetic grinding tool finishing processing device and method with adjustable magnetic field and self-adaptive aperture

ActiveCN109333164AReduce widthIncrease widthGrinding carriagesGrinding drivesSurface finishMachine parts

The invention belongs to the technical field of surface finishing processing of mechanical parts, in particular to a magnetic grinding tool finishing processing device and method with an adjustable magnetic field and a self-adaptive aperture. The magnetic grinding tool finishing processing device comprises a magnetic field generating device and a self-adaptive aperture mechanism capable of changing the diameter, the self-adaptive aperture mechanism is arranged on the peripheral side of the magnetic field generating device, and the self-adaptive aperture mechanism and the magnetic field generating device are arranged on the inner side of the workpiece to be machined. The magnetic grinding tool finishing processing device can be subjected to finishing processing on the inner hole surface ofthe magnetic material and the non-magnetic material, the whole processing device is simple in structure, simple in process, good in economic benefit and easy to widely apply.

Owner:TAIYUAN UNIV OF TECH

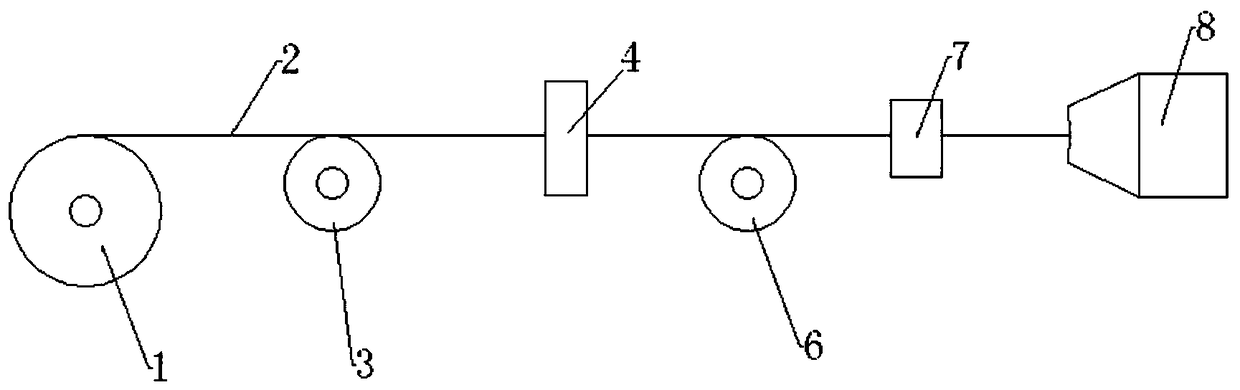

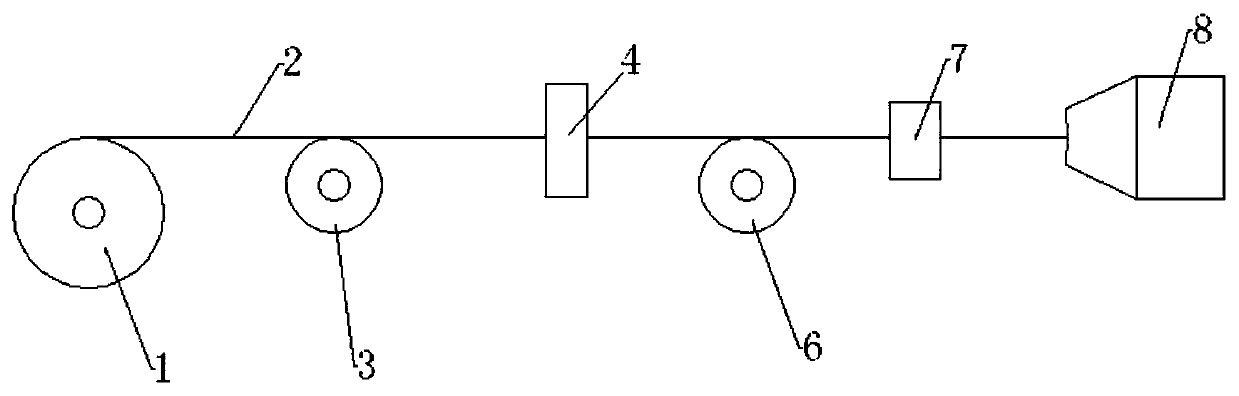

Method for preparing superconducting wire/strip

ActiveCN108878052ASmall temperature changeGuaranteed mechanical propertiesSuperconductors/hyperconductorsFurnace typesMechanical propertyMetal

The invention discloses a method for preparing a superconducting wire / strip. The method for preparing the superconducting wire / strip comprises the following steps that 1, a metal package sheathing / ceramic core wire composite wire is wound on a pay-off reel after the metal package sheathing / ceramic core wire composite wire is cleaned, the metal package sheathing / ceramic core wire composite wire penetrates through a first guide pulley, an induction coil device, a second guide pulley and a drawing die in sequence, and the metal package sheathing / ceramic core wire composite wire is clamped on a wire drawing machine drawing device to complete assembling; 2, the wire drawing machine drawing device is started to drive the metal package sheathing / ceramic core wire composite wire to draw; 3, the drawn metal package sheathing / ceramic core wire composite wire is collected, then the assembling and drawing process are repeated, and then the superconducting wire / strip is obtained through heat treatment; and induction annealing and synchronous drawing are carried out on the metal package sheathing / ceramic core wire composite wire during repeated drawing. According to the method for preparing thesuperconducting wire / strip, induction annealing is introduced into the drawing, so that the metal package sheathing of the metal package sheathing / ceramic core wire composite wire rapidly heats up, induction annealing and synchronous drawing are realized, the mechanical properties of the superconducting wire / strip are guaranteed, the core breaking phenomenon is avoided, and the processing uniformity of the superconducting wire / strip is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

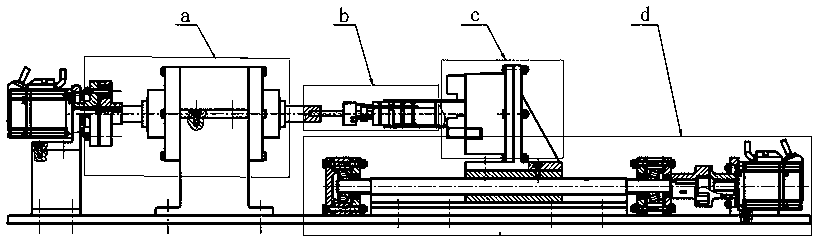

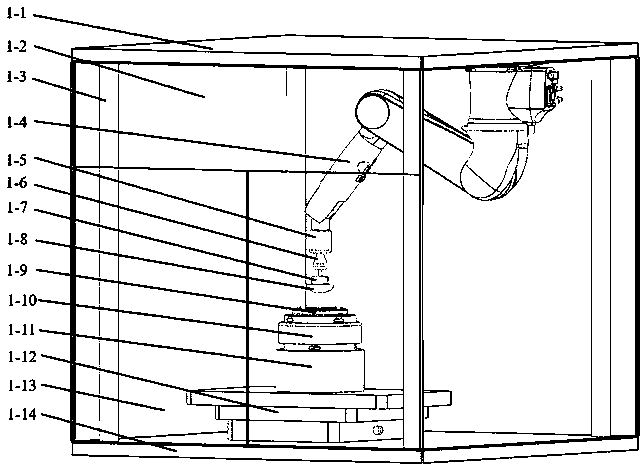

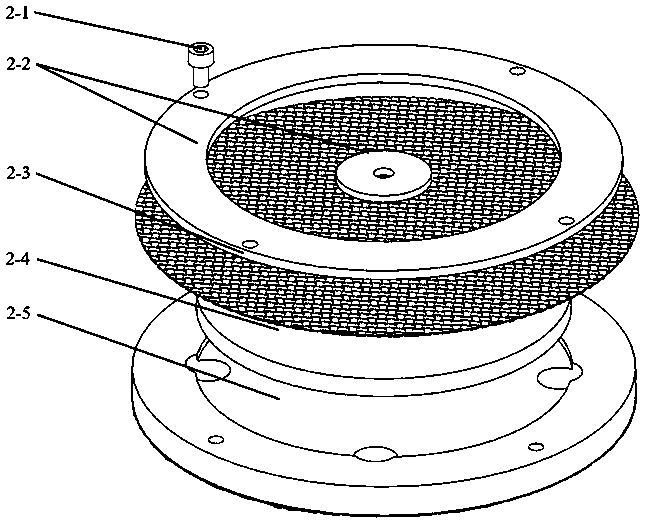

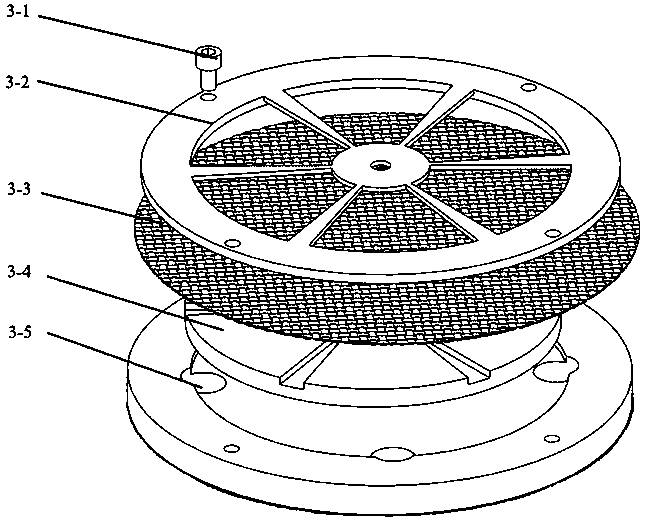

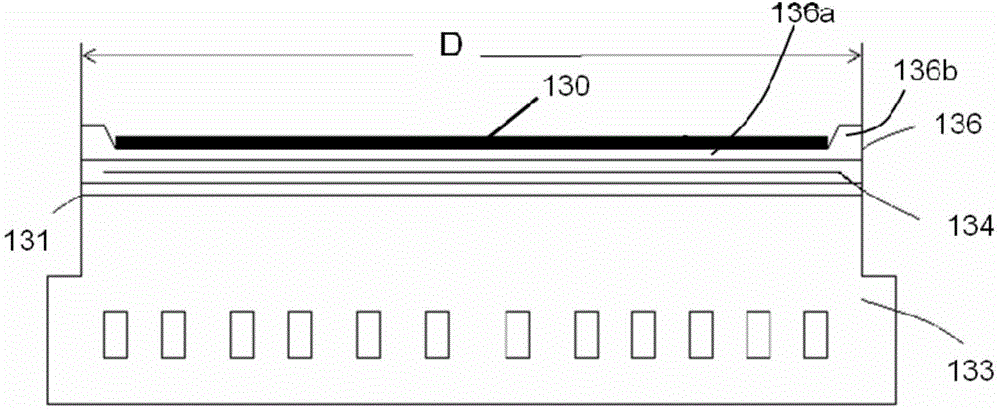

Automatic complex curved surface forced-controlled high shear low pressure grinding device and machining method thereof

ActiveCN110465862AEasy to assemble and disassembleImprove processing uniformityProgramme-controlled manipulatorRevolution surface grinding machinesElectricityControl system

The invention discloses an automatic complex curved surface forced-controlled high shear low pressure grinding device and a machining method thereof, and belongs to the technical field of complex curved surface grinding of difficult-to-machine materials. The grinding device comprises a pedestal, a stand column, an industrial robot, an electric spindle, a force-controlled floating knife handle, a workpiece clamping device, a grinding disc, a six-dimensional force sensor, a rotary workbench, a three-axis precision displacement workbench, a safety shield, a safety door and a base; the grinding disc comprises a grinding disc substrate, a pressure plate, a liner layer and an abrasive layer; and all the modules effective communicate with one another. A control system is used for signal collection and processing and command transmission, and automatic force-controlled grinding of complex curved surfaces is achieved; the shear thickening effect is achieved through the grinding disc abrasive layer, and materials are removed in a high shear low pressure grinding mode; and limitations of traditional machining methods are overcome, and automatic force-controlled precision grinding machining ofthe complex curved surfaces is achieved in the high shear low pressure grinding mode.

Owner:SHANDONG UNIV OF TECH

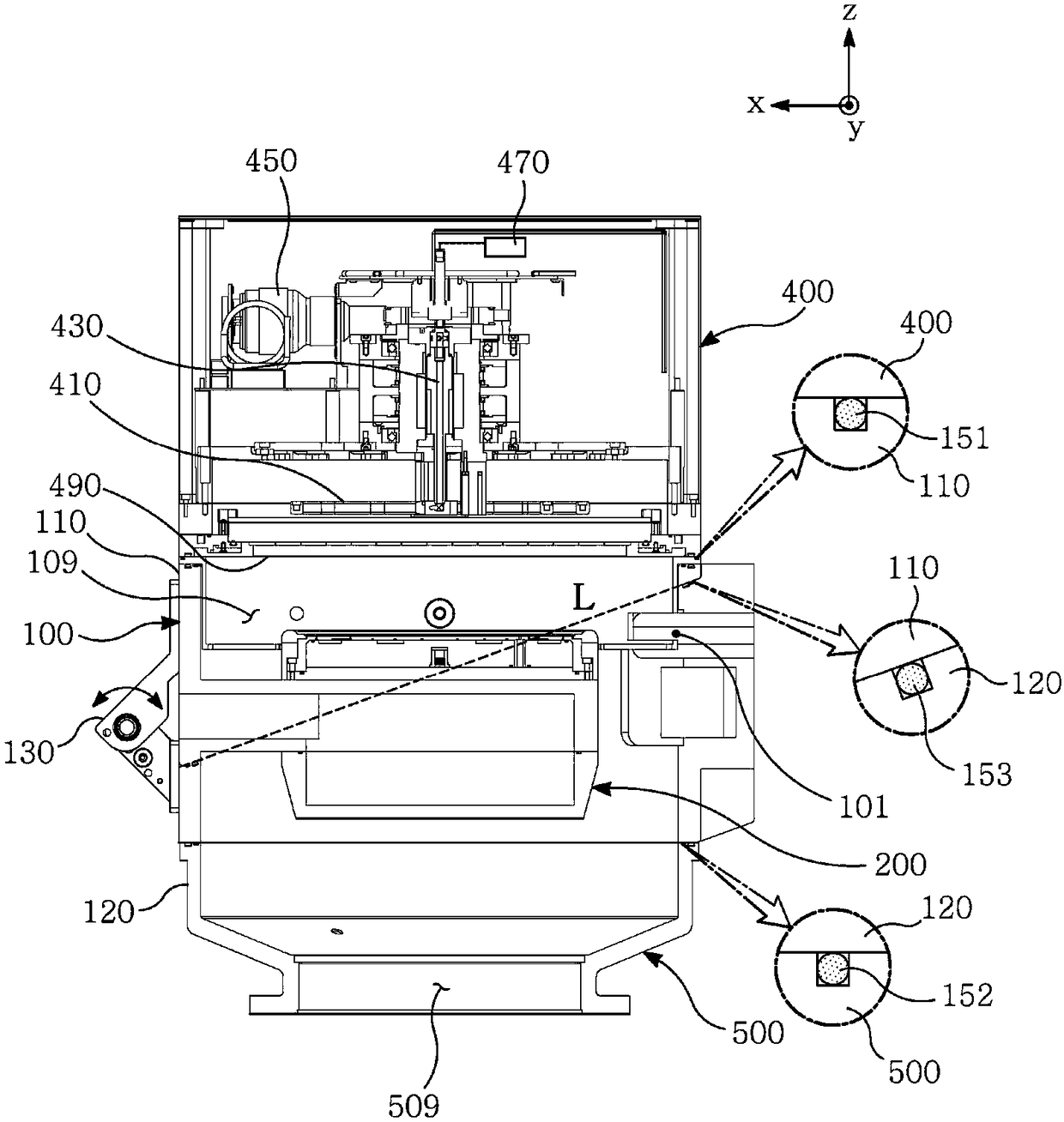

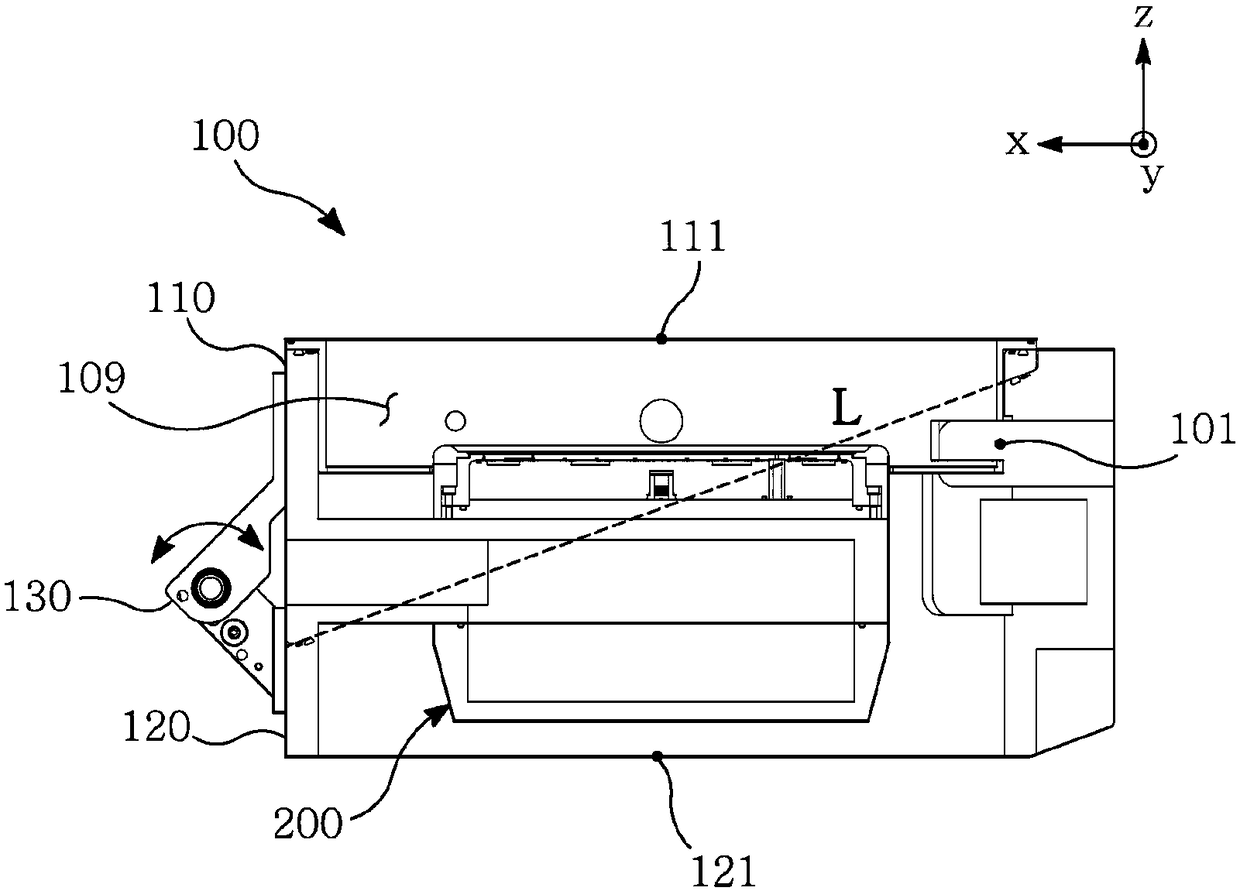

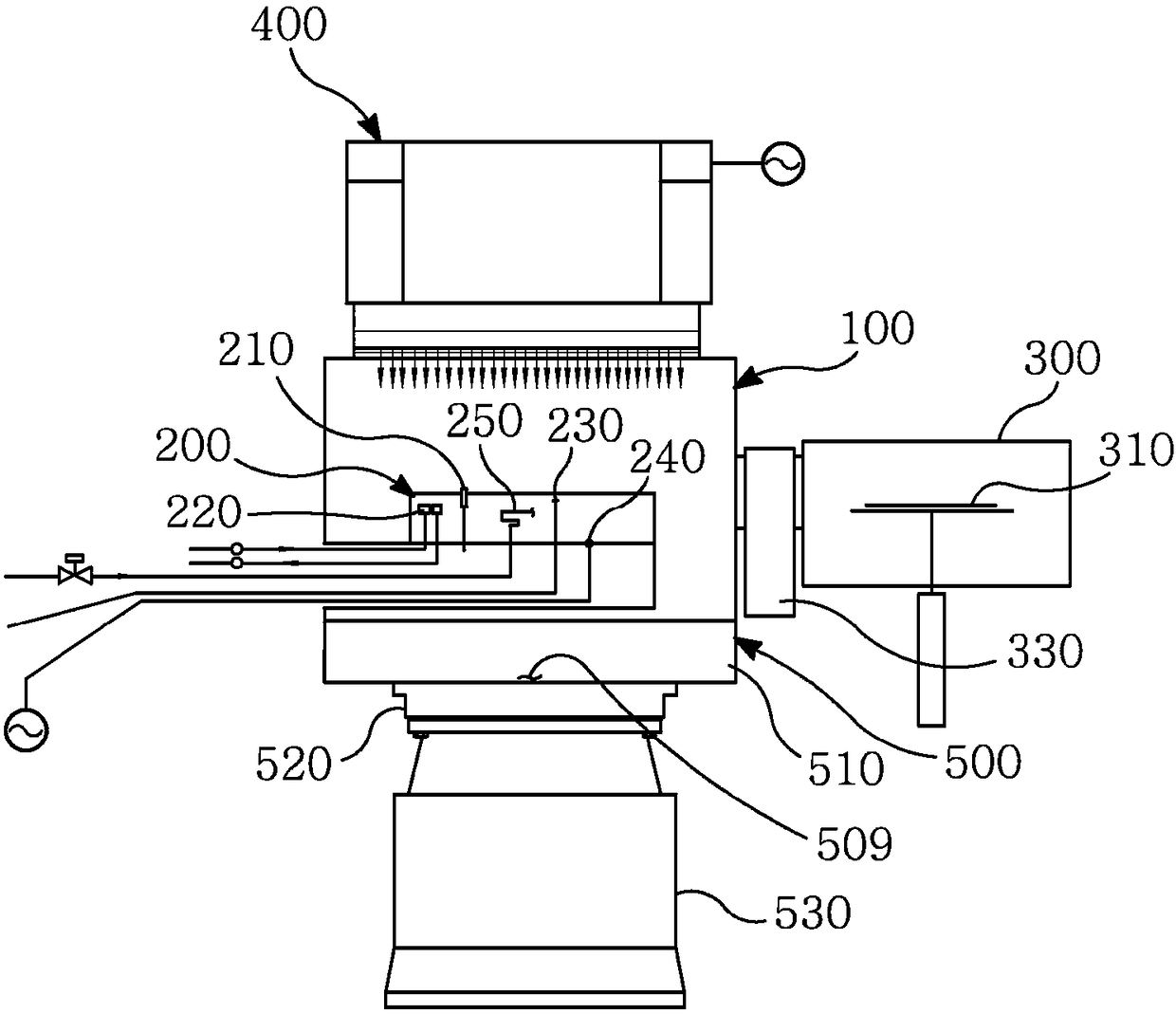

Substrate installation platform, plasma processing device, and operation method for plasma processing device

ActiveCN105448631AImprove processing uniformityExtended service lifeElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma processing

The invention relates to a substrate installation platform, a plasma processing device, and an operation method for the plasma processing device. The device comprises a reaction cavity, and the lower part of the interior of the reaction cavity comprises a conductive substrate, a static chuck, a pallet, and a substrate. The static chuck is fixed on the conductive substrate, and the pallet is placed on the static chuck. The substrate is fixed in the pallet, and the pallet comprises a panel part and an upwards bulged part, wherein the diameter of the upper surface of the panel part is greater than the diameter of the substrate. The bulged part surrounds the panel part and the substrate on the panel part. The diameter of the static chuck is greater than the diameter of the substrate, and is less than or equal to the diameter of the pallet.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

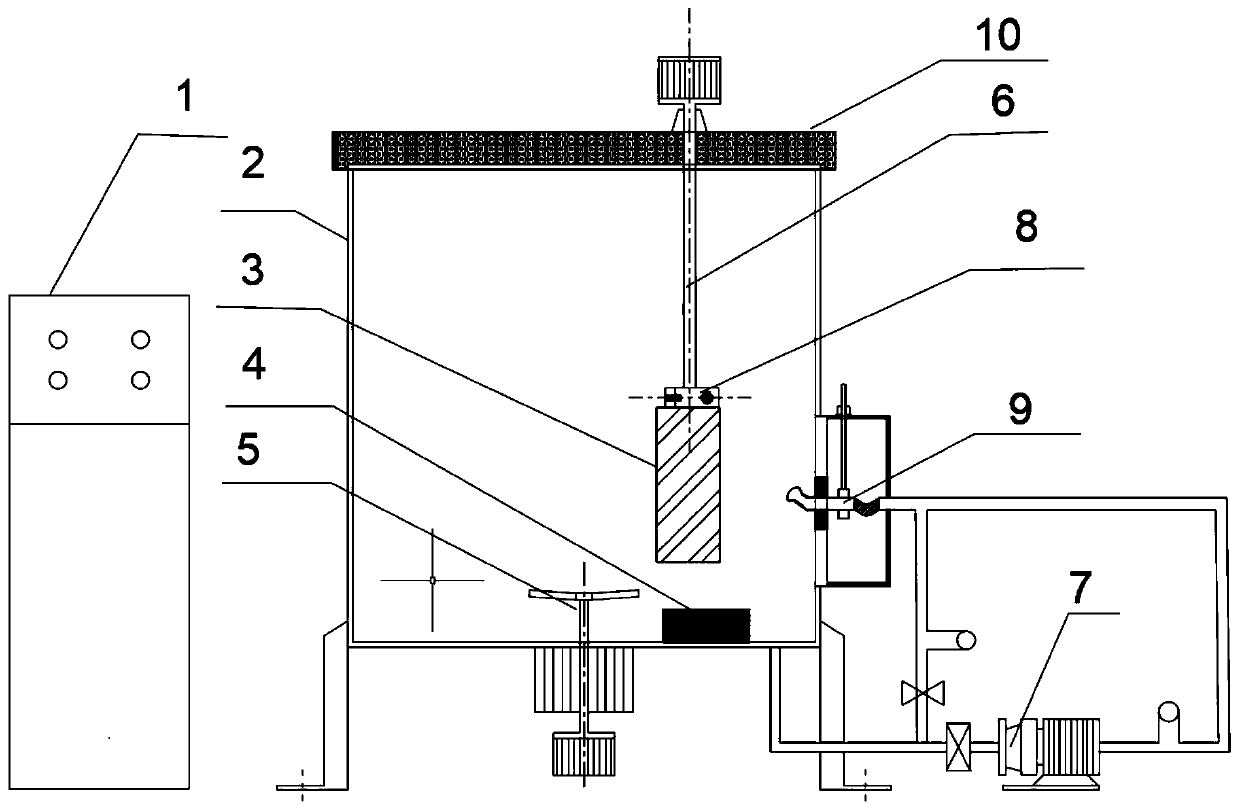

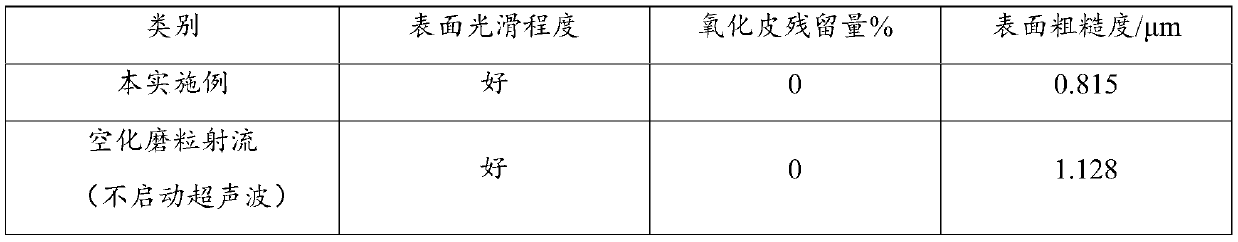

Ultrasonic-assisted cavitation abrasive grain flow finishing method for titanium alloy surface oxide layers

ActiveCN110948398AImprove removal efficiencyRealize integrated enveloping processingAbrasive feedersAbrasive machine appurtenancesMicro nanoUltrasonic assisted

The invention provides an ultrasonic-assisted cavitation abrasive grain flow finishing method for titanium alloy surface oxide layers. The method comprises the following steps: stirring a solid-liquidtwo-phase mixed fluid to form high-speed turbulence vortex; extracting the solid-liquid two-phase mixed fluid, mixing the solid-liquid two-phase mixed fluid with micro-nano bubbles to form a high-speed and high-pressure gas-liquid-solid three-phase abrasive grain flow; spraying the high-speed and high-pressure gas-liquid-solid three-phase abrasive grain flow to a workpiece in a tank body for staged surface treatment; meanwhile, emitting ultrasonic waves by an ultrasonic device configured below the workpiece to form an ultrasonic cavitation effect, and forming a negative fluctuation environment with positive and negative pressure alternating rapidly in the high-speed fluid in the tank body to cause expansion and compression of micro-nano bubbles in the high-speed fluid. Under the comprehensive action of turbulence, jet, cavitaiton and ultrasonic waves, a manner of combining cavitation abrasive grain jet and turbulence integrated surrounding type processing and ultrasonic enhancement isadopted, synchronous stripping of different in-situ defects of oxide scale and derivative and chain stripping of new defect points can be realized, the removal efficiency is high, and the processinguniformity is good.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

Gear shaft forging process

InactiveCN113695500AReduce lossEfficient removalMetal-working apparatusFurnace typesElectric arc furnaceTempering

The invention provides a gear shaft forging process. The gear shaft forging process comprises the steps that S1, raw materials are smelted through an electric arc furnace or a converter, a refining furnace and a vacuum degassing furnace to form steel ingot die casting; S2, earlier stage treatment is carried out; S3, heat treatment is carried out on the steel ingot die casting subjected to earlier stage treatment, and the heat treatment mode is controlled cooling, spheroidizing annealing, annealing, normalizing and high-temperature tempering; S4, forging treatment is carried out on the steel ingot die casting; S5, the forge piece is cooled to 400-450 DEG C, and then annealing treatment is carried out; and S6, rough turning, ultrasonic flaw detection and mechanical property testing are carried out on the forge piece, and finally a finished product is put in storage. The problems that the mechanical performance of a blank is reduced and forging damage of the forge piece is increased due to improper heat treatment after the blank is formed can be solved, the qualified rate of a finished product is high, the service life is long, the technological process is simple, operation is convenient, machining uniformity is good, material loss is small, the obtained product is good in mechanical performance and stable in structure, the manufacturing cost is reduced, and the production efficiency and benefits are improved.

Owner:杭州金越晟重型机械有限公司

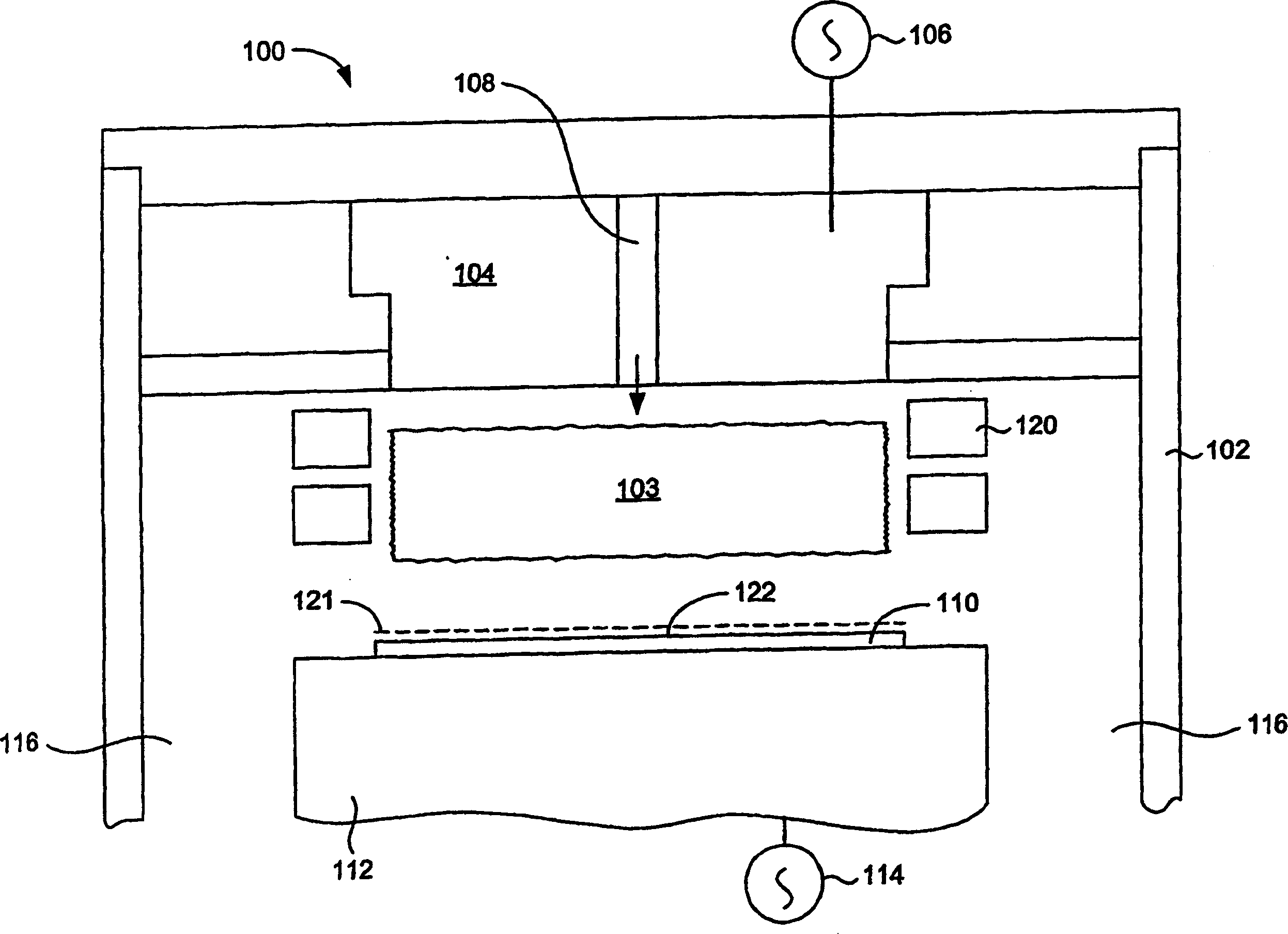

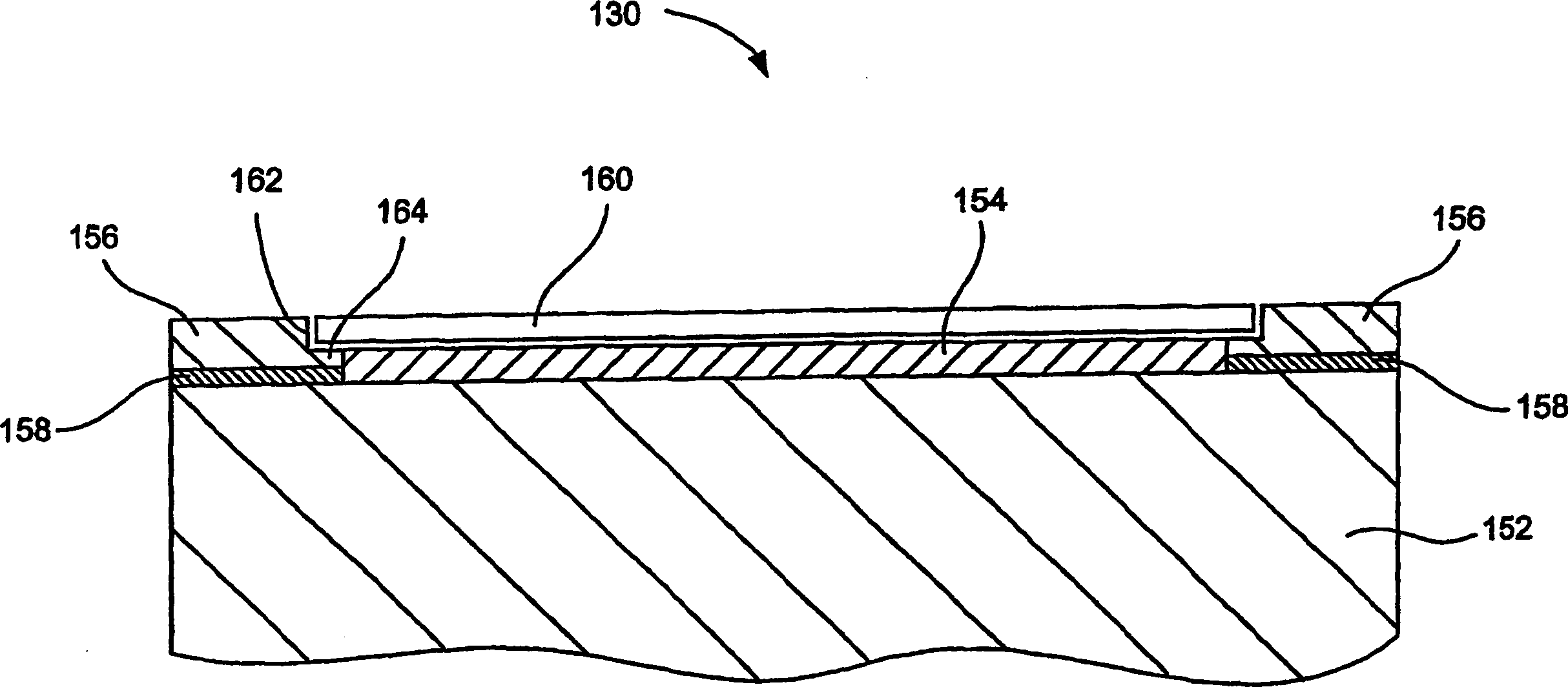

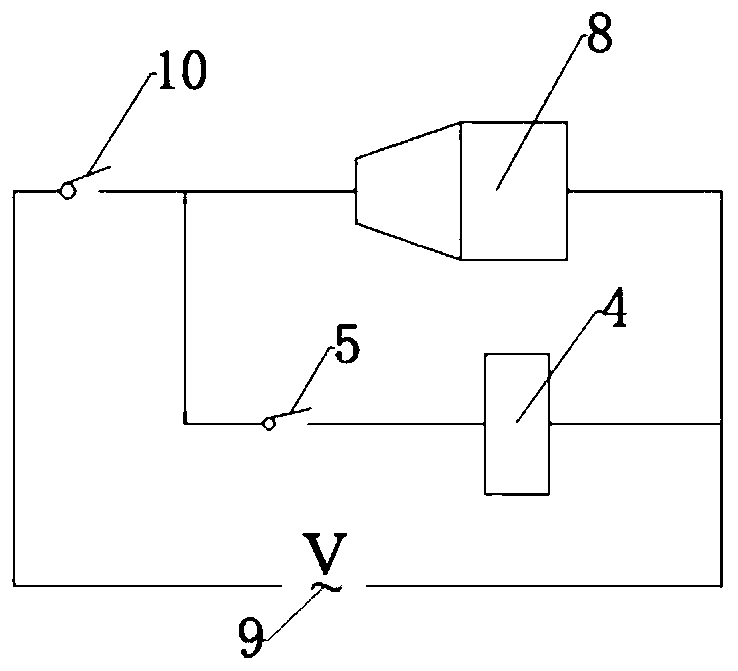

Electrode assembly

InactiveCN1437759AHigh yieldUniform processingElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringElectrical impedance

A plasma processing system for processing a substrate is disclosed. The plasma processing system includes a process chamber within which a plasma is both ignited and sustained for processing. The plasma processing system further includes an electrode (152) disposed at the lower end of the process chamber. The electrode is configured for generating an electric field inside the process chamber. The plasma processing system also includes a component (158) for controlling an impedance between the electrode and the plasma. The impedance is arranged to affect the electric field to improve processing uniformity across the surface of the substrate.

Owner:LAM RES CORP

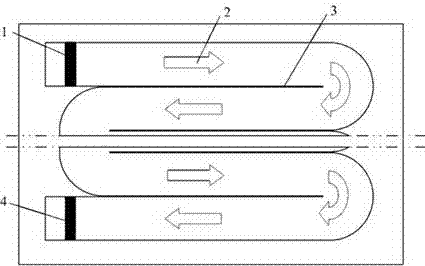

Plate surface machining and liquid guide device

ActiveCN107012459AEliminate the pool effectImprove processing uniformityLiquid/solution decomposition chemical coatingLiquid temperatureSpray nozzle

The invention provides a plate surface machining and liquid guide device which comprises a conveying system, an equipment tank, upper nozzles, lower nozzles, a liquid guide pipe, a circulating pump and a spray pump; the upper nozzles are formed above the conveying system; the lower nozzles are formed below the conveying system; the liquid guide pipe is arranged above a circuit board movement way of the conveying system; the equipment tank is arranged below the conveying system; a first mouth of the equipment tank is connected with the upper nozzles and the lower nozzles through the spray pump; an outlet of the liquid guide pipe is connected with a second mouth of the equipment tank through the circulating pump; and a plurality of suction holes are formed in the liquid guide pipe. The pool effect of an upper plate surface can be eliminated, and the machining uniformity of the upper plate surface is better; the equipment tank can be very small, the equipment capacity is 60% of the original equipment capacity, and a temperature, a PH value, the electric conductivity and the ion concentration of liquid in the equipment tank can be adjusted conveniently; in addition, the circulating pump and the spray pump can use independent external pumps, so that the curing and maintenance are convenient, and the discharge amount of waste liquid can be reduced.

Owner:深圳市华兴四海机械设备有限公司

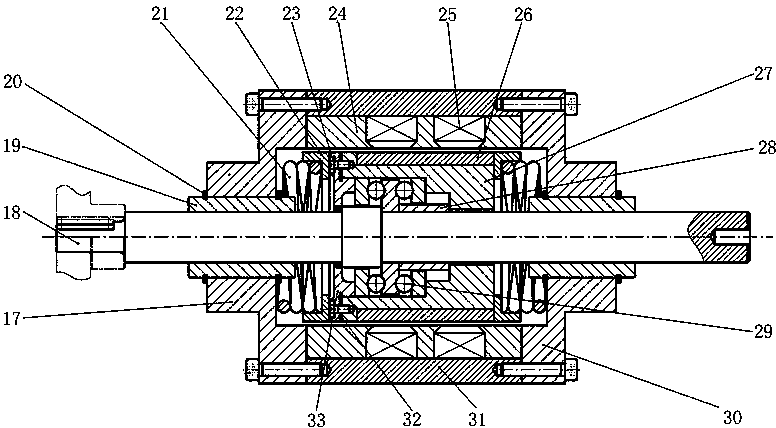

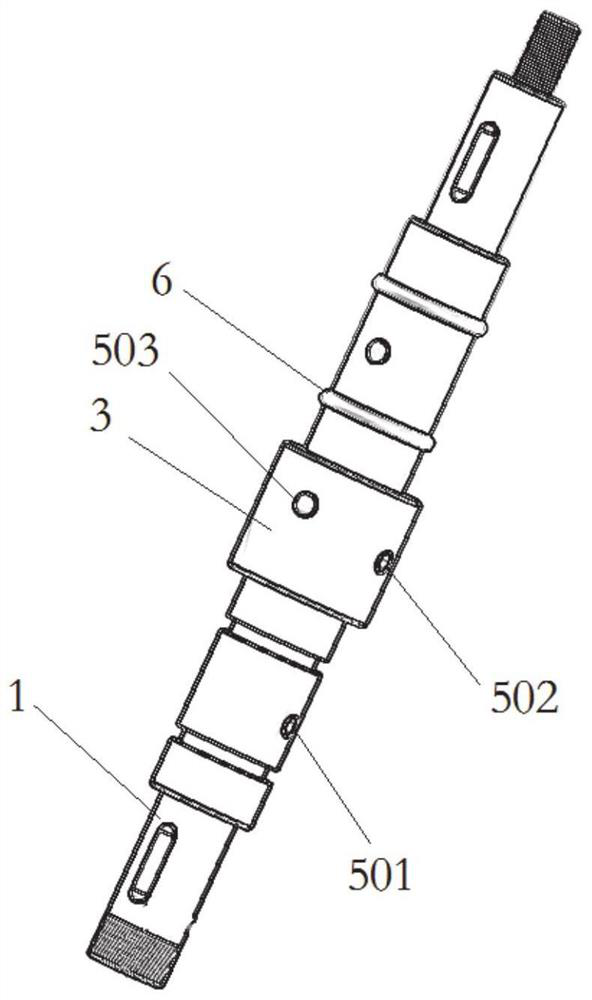

Air-floating shaft rotating soft abrasive flow polishing device

ActiveCN104325412BRealize finishingMeet high speed requirementsAbrasive machine appurtenancesAbrasive blasting machinesCouplingEngineering

The invention discloses an air-floating shaft rotating soft abrasive flow polishing device, which is used for grinding a slender rod to be processed, comprising a fixed plate, a core polishing device for a slender rod, a workpiece feeding device and a buffer device; the slender The rod core polishing device, the workpiece feeding device, and the buffer device are all fixedly installed on the fixed plate; the workpiece feeding device is used for axial feeding of the slender rod core polishing device, and the buffer device is used for buffering the slender rod core polishing device Axial feed; the slender rod core polishing device includes an internal screw type constraint module, a constraint module mounting seat, a sealing cover, a clamping end cover, an O-ring and a screw rod, and the slender rod to be processed passes through one end of the constraint module mounting seat It is connected with the servo motor through a coupling, and the other end is matched with a rolling bearing. The inside of the constraining module mounting seat forms a constrained flow channel through a sealing cover and a clamping end cover. The invention has high polishing efficiency and good polishing effect, and is extremely suitable for ultra-precision machining of the inner wall.

Owner:ZHEJIANG UNIV OF TECH

A kind of preparation method of Bi-based high-temperature superconducting wire/tape

ActiveCN103440932BSimple preparation processReasonable designCable/conductor manufactureHigh-temperature superconductivityManganese

The invention discloses a method for preparing a Bi high temperature superconducting line or strip material. The method comprises the following steps: firstly, preparing a primary composite body; secondly, drawing the primary composite body, and then annealing the drawn primary composite body so as to obtain a line material; thirdly, bundling a plurality of line materials, and then packing into a silver-base alloy pipe so as to prepare a secondary composite body; fourthly, drawing the secondary composite body, and then annealing the drawn secondary composite body so as to obtain a Bi line material; and fifthly, putting the Bi line material into an atmosphere furnace for heat treatment so as to obtain the Bi high temperature superconducting line material; or rolling the Bi line material into a Bi strip material, and then putting into the atmosphere furnace for heat treatment so as to obtain the Bi high temperature superconducting strip material. According to the method, the manufacturing dislocation quantity of silver and silver-manganese alloy is effectively controlled by adopting an unconventional annealing process, so that the phenomenon that a silver super interface is severely rough caused by an excessively soft silver sheath is effectively avoided, and the current-carrying performance of the Bi line or strip material is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of Bi-2212 high-temperature superconductivity wire

ActiveCN102117682BSimple preparation processReasonable designSuperconductors/hyperconductorsSuperconductor devicesHigh-temperature superconductivityAlloy

The invention discloses a preparation method of Bi-2212 high-temperature superconductivity wire, comprising the following steps: firstly, filling superconductivity powder into a pipe; secondly, drawing to process and prepare a secondary compound; thirdly, after drawing the secondary compound, combining the secondary compound with a pure silver rod and a silver alloy rod, and then packing the compound into an AgMn alloy pipe so as to obtain a third compound; fourthly, drawing and processing the third compound into a wire; fifthly, carrying out semi-fused treatment on the wire, and obtaining the Bi-2212 high-temperature superconductivity wire after cooling a furnace. As for the preparation method, the process is simple, the design is reasonable, the manufacturing cost is low, and the application range is wide, and the method can be effectively applied to the preparation process of other relevant superconductivity wires. In the invention, one silver or silver alloy core wire is additionally arranged at the central part of a multi-core wire; therefore, the core wire can be prevented from being broken at the central part of multi-core Bi-2212 wire, the core breakage rate of the wire isobviously reduced, the processing uniformity of the wire is improved, the final uniformity of the wire is improved, and simultaneously the stretching performance of the wire is also improved; and thepreparation method is beneficial to the winding of magnet and other applications of superconductivity wire.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of preparation method of superconducting wire/ribbon

ActiveCN108878052BSmall temperature changeGuaranteed mechanical propertiesSuperconductors/hyperconductorsIncreasing energy efficiencyWire rodHeat treating

The invention discloses a method for preparing a superconducting wire / strip. The method for preparing the superconducting wire / strip comprises the following steps that 1, a metal package sheathing / ceramic core wire composite wire is wound on a pay-off reel after the metal package sheathing / ceramic core wire composite wire is cleaned, the metal package sheathing / ceramic core wire composite wire penetrates through a first guide pulley, an induction coil device, a second guide pulley and a drawing die in sequence, and the metal package sheathing / ceramic core wire composite wire is clamped on a wire drawing machine drawing device to complete assembling; 2, the wire drawing machine drawing device is started to drive the metal package sheathing / ceramic core wire composite wire to draw; 3, the drawn metal package sheathing / ceramic core wire composite wire is collected, then the assembling and drawing process are repeated, and then the superconducting wire / strip is obtained through heat treatment; and induction annealing and synchronous drawing are carried out on the metal package sheathing / ceramic core wire composite wire during repeated drawing. According to the method for preparing thesuperconducting wire / strip, induction annealing is introduced into the drawing, so that the metal package sheathing of the metal package sheathing / ceramic core wire composite wire rapidly heats up, induction annealing and synchronous drawing are realized, the mechanical properties of the superconducting wire / strip are guaranteed, the core breaking phenomenon is avoided, and the processing uniformity of the superconducting wire / strip is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Semiconductor device including chamber unit

InactiveCN108695204APromote conversionAchieve high efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingInterior spaceDevice material

A semiconductor processing device according to the present invention includes a process chamber having an inner space in which plasma is generated and a chuck unit disposed in the inner space and supporting a substrate processed by the plasma. The process chamber includes a first chamber portion and a second chamber portion that are opened from each other, and when the first chamber portion and the second chamber portion are closed together, the process chamber is provided with the inner space in which the plasma is generated. When the first chamber portion and the second chamber portion are opened from each other, the chuck unit is exposed to outside.

Owner:ALLIED TECHFINDERS +1

Surface smoothness treatment method for clutch pressure plate

InactiveCN112318218AEasy to handleAvoid affecting the processing effectPolishing machinesGrinding work supportsElectric machineryEngineering

The invention provides a surface smoothness treatment method for a clutch pressure plate. The surface smoothness treatment method comprises a treatment bin and a storage assembly, wherein the storageassembly is arranged behind the treatment bin; a first guide rail is arranged on the bottom inside the treatment bin; a U-shaped slide plate is movably mounted on the first guide rail; a supporting plate is arranged on the U-shaped slide plate; a clamping assembly is rotatably mounted on the supporting plate; first electromagnetic slide rails are arranged at the two sides of the top of the treatment bin; and slide bins are movably mounted on the first electromagnetic slide rails. According to the surface smoothness treatment method provided by the invention, the clamping assembly is used for clamping and fixing the clutch pressure plate, a first pneumatic cylinder is utilized to put down a U-shaped frame, and a polishing motor drives a polishing disc to rotate for performing smoothness treatment on the surface of the clutch pressure plate clamped on the clamping assembly; a rotary bin rotates to change the angle of the polishing disc to perform multi-angle polishing, so that stubborn rough spots on the surface of the clutch pressure plate are conveniently removed; and the rotation function of the clamping assembly is utilized to drive the clutch pressure plate to rotate to be matched with polishing, so that processing uniformity further can be improved.

Owner:WUHU DAJIE CLUTCH

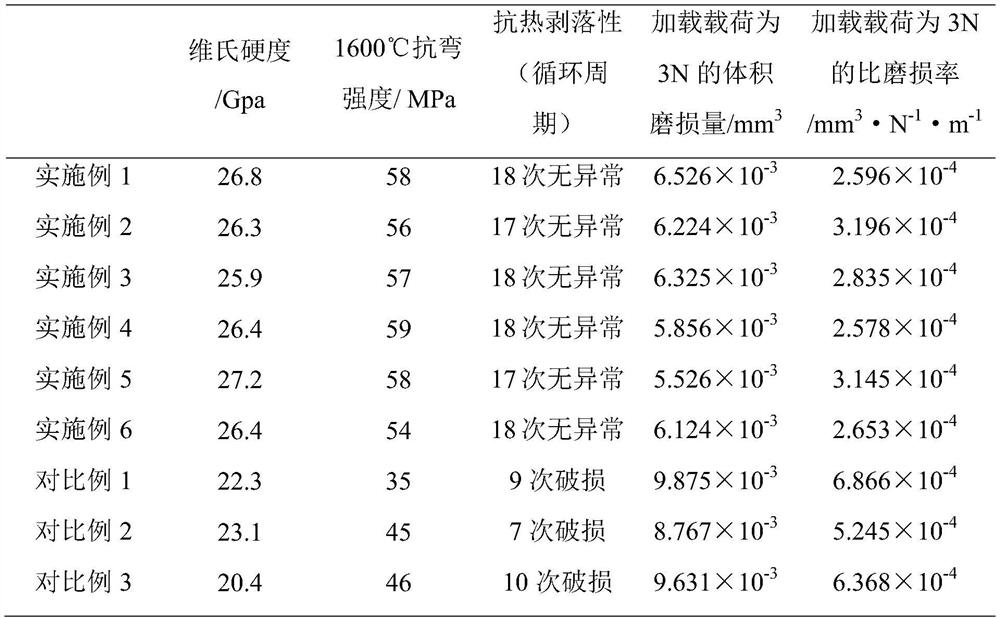

A wear-resistant high-performance ceramic roller rod and its preparation method

ActiveCN113004027BImprove wear resistanceImprove high temperature resistanceCeramic materials productionMulliteUltimate tensile strength

Owner:福建安溪马斯特陶瓷有限公司

Adjustable Magnetic Field and Adaptive Aperture Magnetic Abrasive Finishing Device and Method

ActiveCN109333164BReduce widthIncrease widthGrinding carriagesGrinding drivesSurface finishMechanical components

The invention belongs to the technical field of surface finishing processing of mechanical parts, in particular to a magnetic grinding tool finishing processing device and method with an adjustable magnetic field and a self-adaptive aperture. The magnetic grinding tool finishing processing device comprises a magnetic field generating device and a self-adaptive aperture mechanism capable of changing the diameter, the self-adaptive aperture mechanism is arranged on the peripheral side of the magnetic field generating device, and the self-adaptive aperture mechanism and the magnetic field generating device are arranged on the inner side of the workpiece to be machined. The magnetic grinding tool finishing processing device can be subjected to finishing processing on the inner hole surface ofthe magnetic material and the non-magnetic material, the whole processing device is simple in structure, simple in process, good in economic benefit and easy to widely apply.

Owner:TAIYUAN UNIV OF TECH

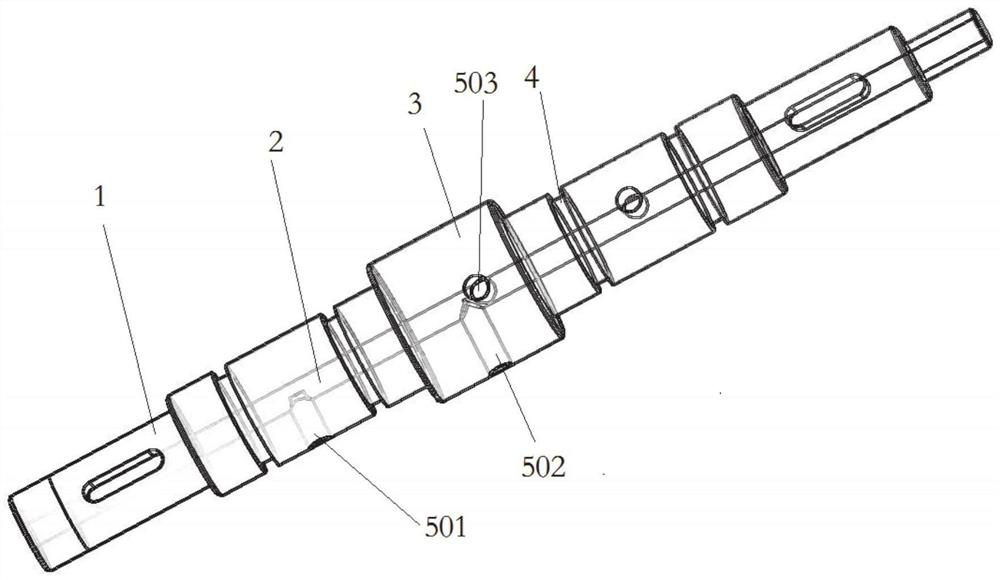

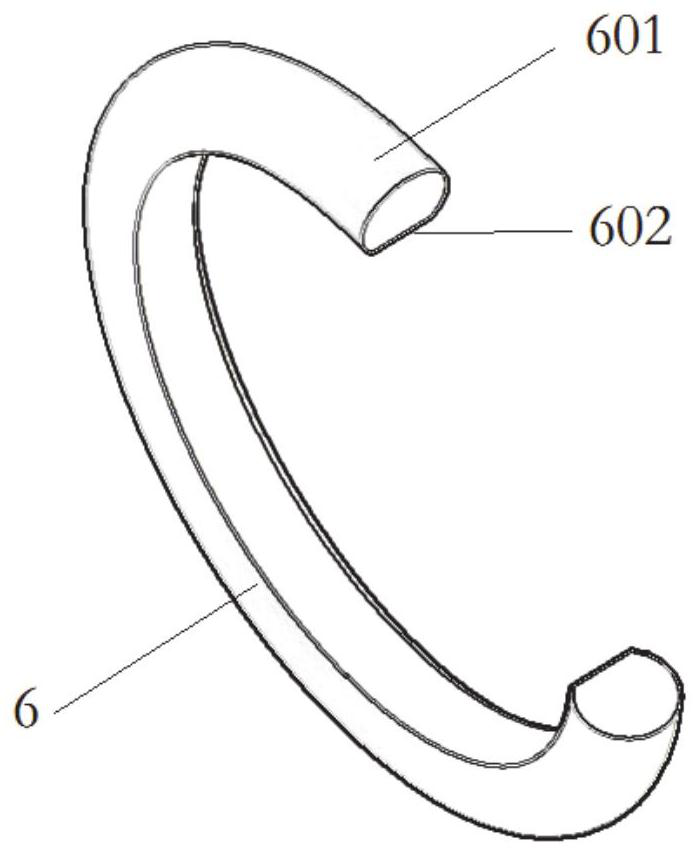

Shockproof pump shaft assembly for magnetic drive pump and magnetic drive pump

PendingCN111911447AImprove shock absorptionImprove processing uniformityPump componentsPumpsPiston ringStructural engineering

The invention relates to a shockproof pump shaft assembly for a magnetic drive pump and the magnetic drive pump. The shockproof pump shaft assembly comprises a pump shaft, the side face of the outer circle of the pump shaft is sleeved with a shaft sleeve, a rubber piston ring is arranged between the shaft sleeve and the side face of the outer circle of the pump shaft, and the side face of the outer circle of the rubber piston ring is formed by combining an inner ring face and an outer arc face, so that the section outline of the rubber piston ring is D-shaped; an annular groove is formed in the side face of the outer circle of the pump shaft, the inner ring face of the rubber piston ring is attached to the ring face of the annular groove, and the outer arc face of the rubber piston ring protrudes out of the annular groove to provide elastic support for the shaft sleeve; and a cooling flow channel is arranged in the pump shaft and penetrates through the pump shaft in the central axis direction of the pump shaft, and an oil hole is formed in the side face of the outer circle of the side face of the pump shaft and can be communicated with the side face of the outer circle of the pumpshaft and the cooling flow channel.

Owner:YANKUANG GRP CO LTD

Electrochemical method and electrochemical device

The invention provides an electrochemical method and an electrochemical device. The electrochemical method and the electrochemical device are applied to electrochemical processing such as electroplating and electro-polishing on the surface of a processed object; in particular when the method and the device are applied to a large-dimension processed object, no large current is needed and continuous batch completion can be realized, and the method and the device have the advantages and effects of effectively saving labor, space and time, and being excellent in processing uniformity; the electrochemical method is mainly characterized in that an electrode plate and an electrolyte are arranged in a plating tank module, the processed object is contacted with the electrolyte by virtue of relative movement generated between the plating tank module and the processed object so that an electrolytic reaction is aroused, and then electrochemical processing on the surface of the processed object is realized.

Owner:BOARDTEK ELECTRONICS CORP +1

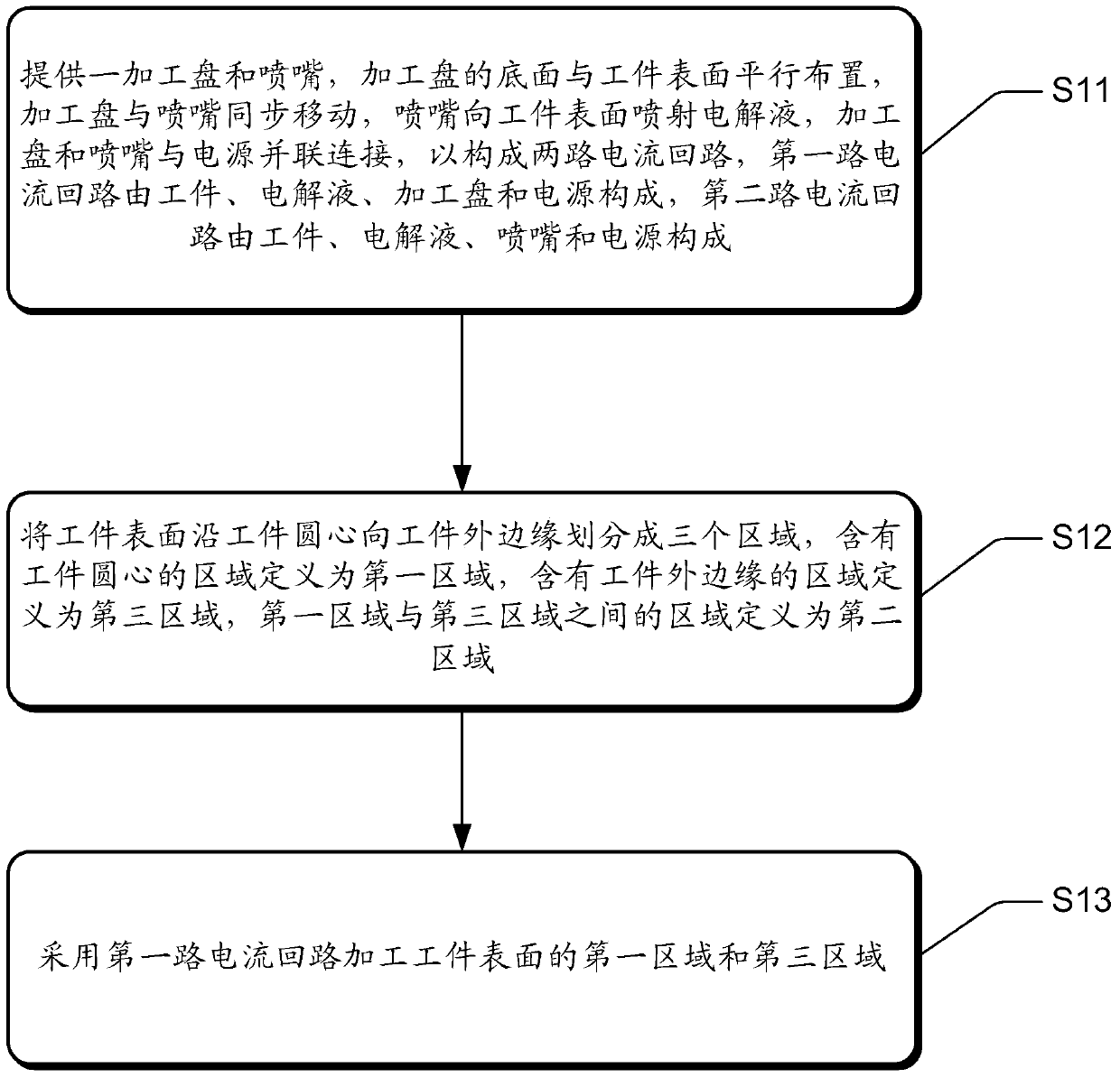

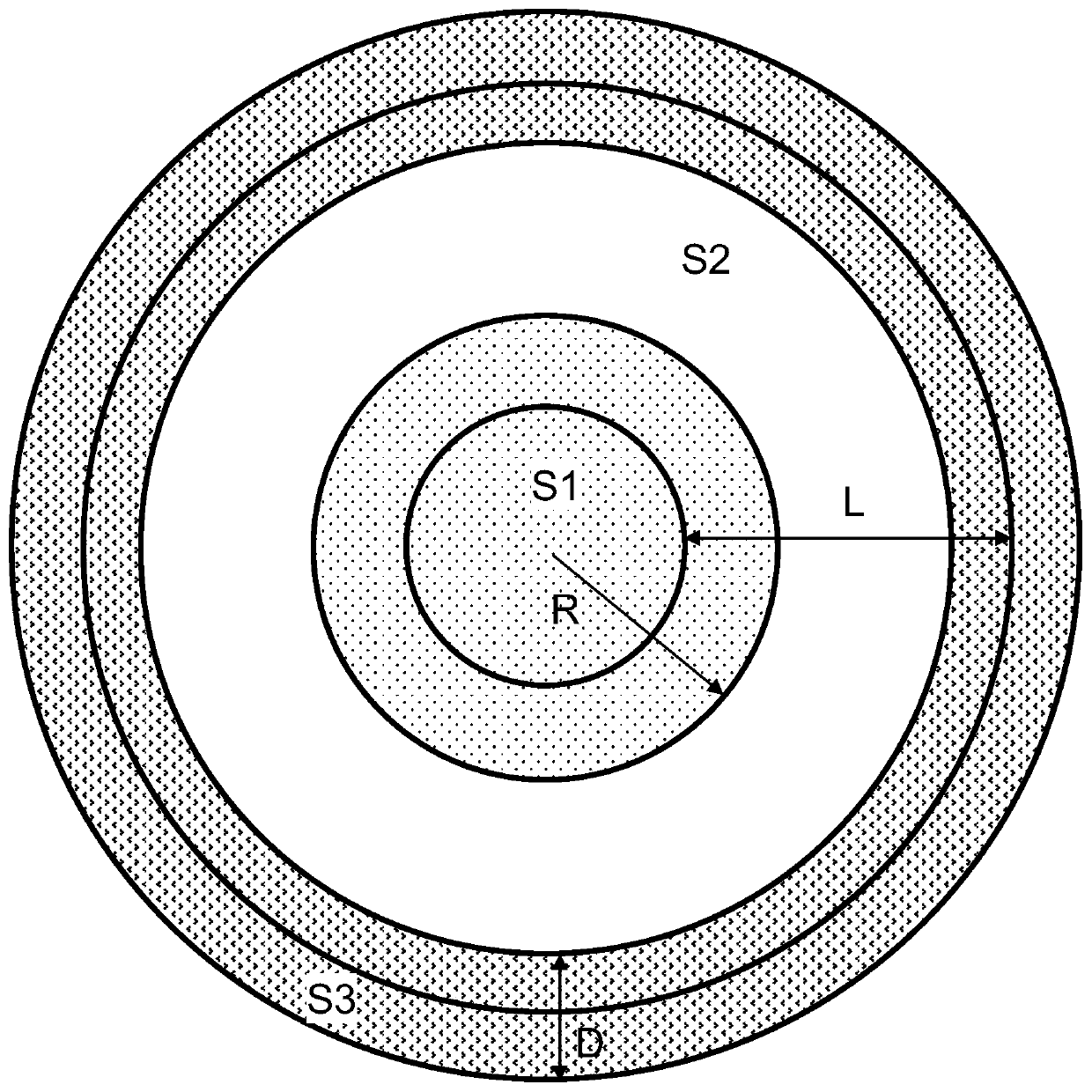

Electrochemical machining process and electrochemical machining device

The invention discloses an electrochemical machining process. The electrochemical machining process includes the steps that a machining disc and a spray nozzle are provided, the bottom surface of the machining disc and the surface of a workpiece are arranged in parallel, the machining disc and the spray nozzle move synchronously, the spray nozzle sprays an electrolyte solution towards the surface of the workpiece, the machining disc and the spray nozzle are in parallel connection with a power supply so as to form two current loops, the first current loop is composed of the workpiece, the electrolyte solution, the machining disc and the power supply, and the second current loop is composed of the workpiece, the electrolyte solution, the spray nozzle and the power supply; the surface of the workpiece is divided into three areas towards the outer edge of the workpiece along the circle center of the workpiece, the first area contains the circle center of the workpiece, the third area contains the outer edge of the workpiece, and the second area is designed between the first area and the third area; and the first current loop is used for machining the first area and the third area of the surface of the workpiece. The center area and the edge area of the surface of the workpiece are machined through the first current loop which comprises the machining disc, a stable electric field is formed, and the machining uniformity of the surface of the workpiece is improved.

Owner:ACM RES SHANGHAI

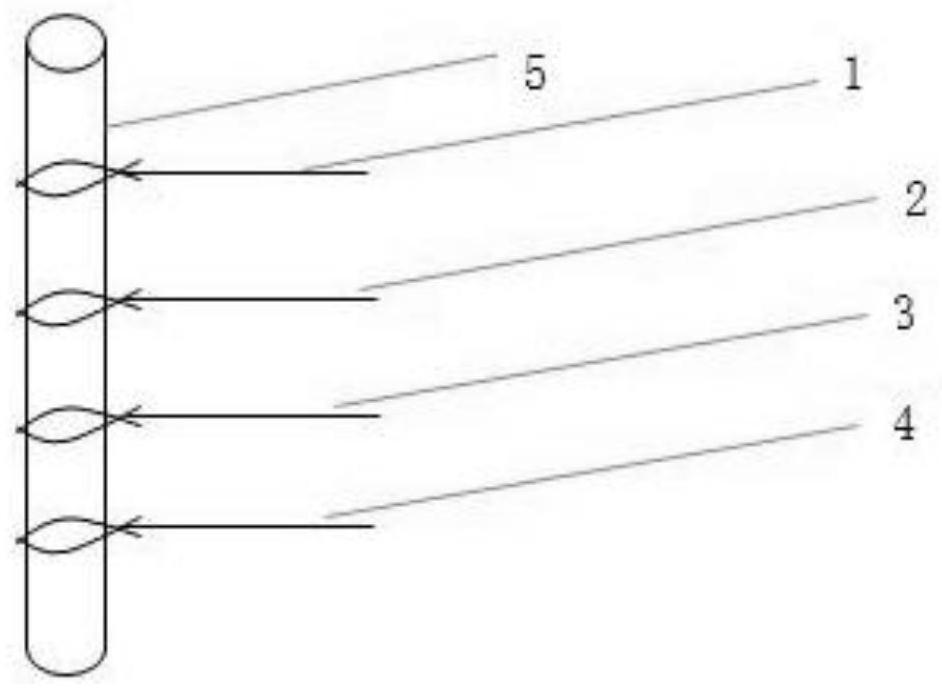

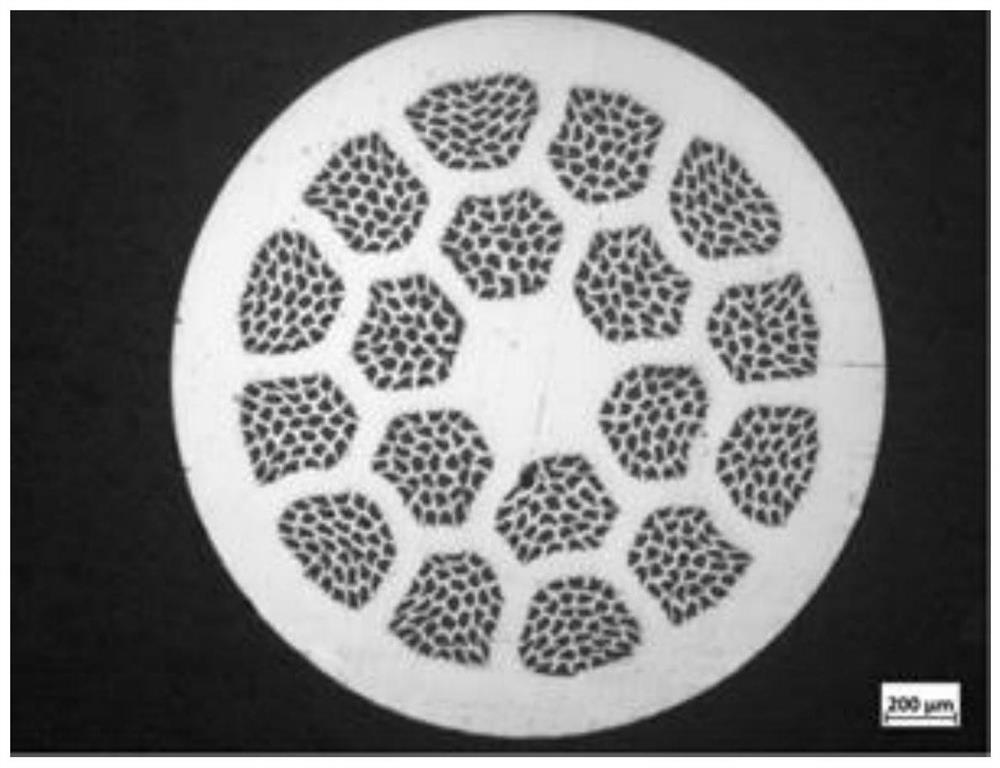

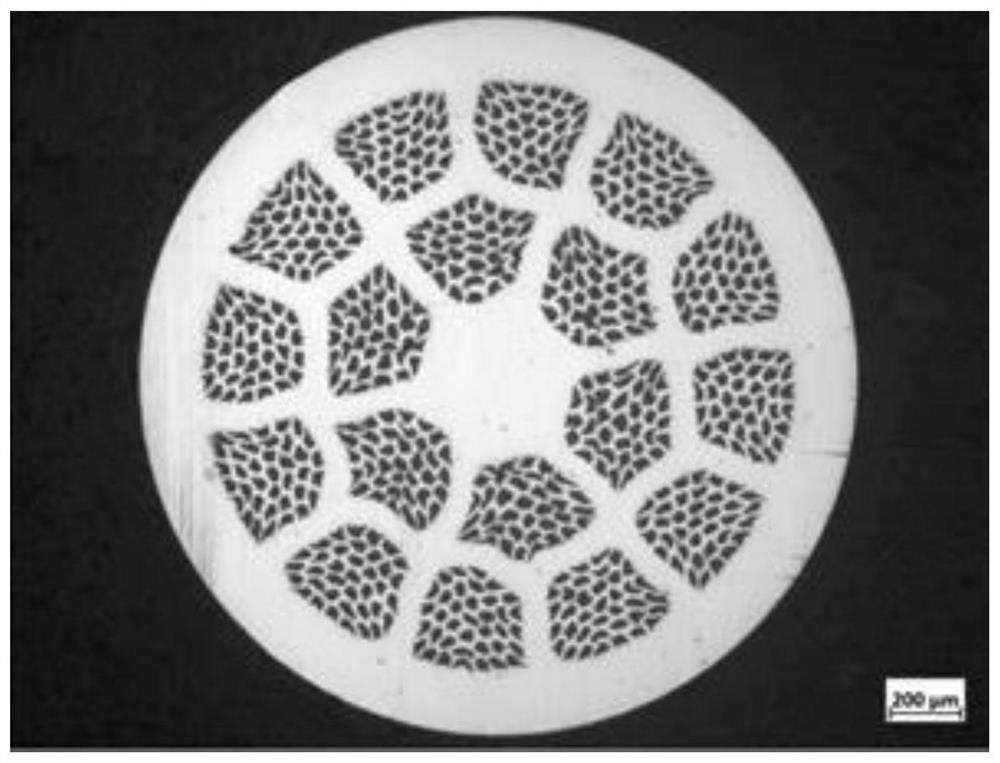

Method for characterizing processing uniformity of Bi-series high-temperature superconducting wire or strip

ActiveCN111768920AReal-time monitoring of processing uniformityImprove processing uniformitySuperconductors/hyperconductorsSuperconductor devicesWire rodElectrical resistance and conductance

The invention discloses a method for characterizing the processing uniformity of a Bi-series high-temperature superconducting wire or strip. According to the method, the resistance at different positions of the Bi-system high-temperature superconducting wire or strip is tested based on the principle of testing the room-temperature resistance through a four-wire method, and then the processing uniformity of the Bi-series high-temperature superconducting wire or strip is represented through the resistance difference at the different positions. According to the method of the invention, the methodfor testing the room temperature resistance based on the four-wire method is adopted; a primary wire, a secondary wire, a composite wire or strip, or a Bi-system high-temperature superconducting composite wire or strip sample in the processing process of the Bi-series high-temperature superconducting wire or strip is detected; the processing uniformity of different processing stages is characterized through the resistance difference at the different positions, real-time monitoring of the processing uniformity in the preparation process of the Bi-series high-temperature superconducting wire orstrip is achieved, and a guidance direction is provided for optimizing processing parameters in the preparation process of the Bi-series high-temperature superconducting wire or strip and improving the processing uniformity of the wire.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for optimizing processing uniformity of Bi2212 wire rod through gradient assembly

PendingCN114695639AAdjust fitImproved co-deformabilitySuperconductor device manufacture/treatmentWire rodStructural engineering

The invention discloses a method for optimizing processing uniformity of a Bi2212 wire rod by gradient assembly, which is characterized in that in a secondary assembly process of a conventional processing technology of the Bi2212 wire rod, a gradient assembly method is adopted, and Bi2212 secondary wires are arranged circle by circle from an inner circle to an outer circle according to a silver super-ratio gradient reduction rule. By designing a gradient assembly process of Bi2212 secondary lines with different silver super ratios, a special gradient structure with a high silver super ratio Bi2212 secondary line on the inner ring and a low silver super ratio Bi2212 secondary line on the outer ring is formed, the plastic deformation of the Bi2212 secondary lines from the inner ring to the outer ring and the matching property of the plastic deformation of the Bi2212 secondary lines from the inner ring to the outer ring and the axial stress of the Bi2212 secondary lines from the inner ring to the outer ring are adjusted, the cooperative deformation of the Bi2212 secondary lines from the inner ring to the outer ring is improved, and the mechanical property of the Bi2212 secondary lines from the inner ring to the outer ring is improved. The processing uniformity of the Bi2212 wire rod is optimized from the intrinsic aspect, and the method has good application advantages and engineering prospects in the processing process of the Bi2212 wire rod.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Serpentine runner movable template group hole electrolytic processing device and processing method

ActiveCN103831497BEasy dischargeImprove processing uniformityElectrochemical machining apparatusElectrolysisMachine tool

The invention relates to a snakelike runner movable formwork cluster hole electrochemical machining device and a machining method and belongs to the technical field of electrochemical machining. The snakelike runner movable formwork cluster hole electrochemical machine device and machining method are characterized in that a traditional wide runner is changed into a snakelike runner, the runner is narrowed, and flow field distribution evenness on the cross section of the runner in a machining area is improved; the flow velocity of the machining area is relatively improved, machined products can be fast discharged, electric field and flow field parameters are reasonably selected, the flow field state of the machining area can be stable, and machining quality is improved. The machining device comprises a power supply, an electrolyte circulation system, an electrochemical machining machine tool, a mask plate negative electrode and a tool clamp. The snakelike runner movable formwork cluster hole electrochemical machining device and the machining method have important significance in improving the cluster hole electrochemical machining flow field distribution evenness and ensuring that a large-area thin-wall hole plate can be machined at a time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Plasma treatment equipment and its electrostatic chuck

ActiveCN103578900BSimple structureLow costElectric discharge tubesSemiconductor/solid-state device manufacturingThermal insulationEngineering

The invention relates to a static chuck used in a reaction chamber of a plasma processing device and used for fixing a piece to be machined. The static chuck comprises a first insulating layer, a second insulating layer and a base body and further comprises a thermal insulation unit, wherein the piece to be machined is placed on the first insulating layer, the second insulating layer is located below the first insulating layer, a heater is arranged in the second insulating layer and used for generating heat and heating the piece to be machined through the first insulating layer, the base body is located below the second insulating layer and used for supporting the first insulating layer and the second insulating layer, the base body comprises at least one cooling liquid passageway which is used for injecting cooling liquid to cool the static chuck, and the thermal insulating unit is arranged below the heater and used for lowering the speed at which the heat generated by the heater is taken away by the cooling liquid. According to the static chuck and the plasma processing device, the utilization rate of the heat generated by the heater is improved, and the temperature of the piece to be machined can be rapidly raised.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com