Semiconductor device including chamber unit

An engineering device and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, discharge tubes, etc., can solve problems such as low compatibility and difficult maintenance of modules inside the cavity, and achieve convenient maintenance and real-time efficiency. , the effect of the upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Next, embodiments to which the present invention is applied will be described in detail with reference to the accompanying drawings. In this process, the size, shape, etc. of the constituent elements shown in the drawings may be exaggerated for clarity and convenience of description. In addition, the terms specifically defined in consideration of the process and action of the present invention may be different due to the intention of the user or the practice. Therefore, the above-mentioned terms should be defined based on the content in the entire specification.

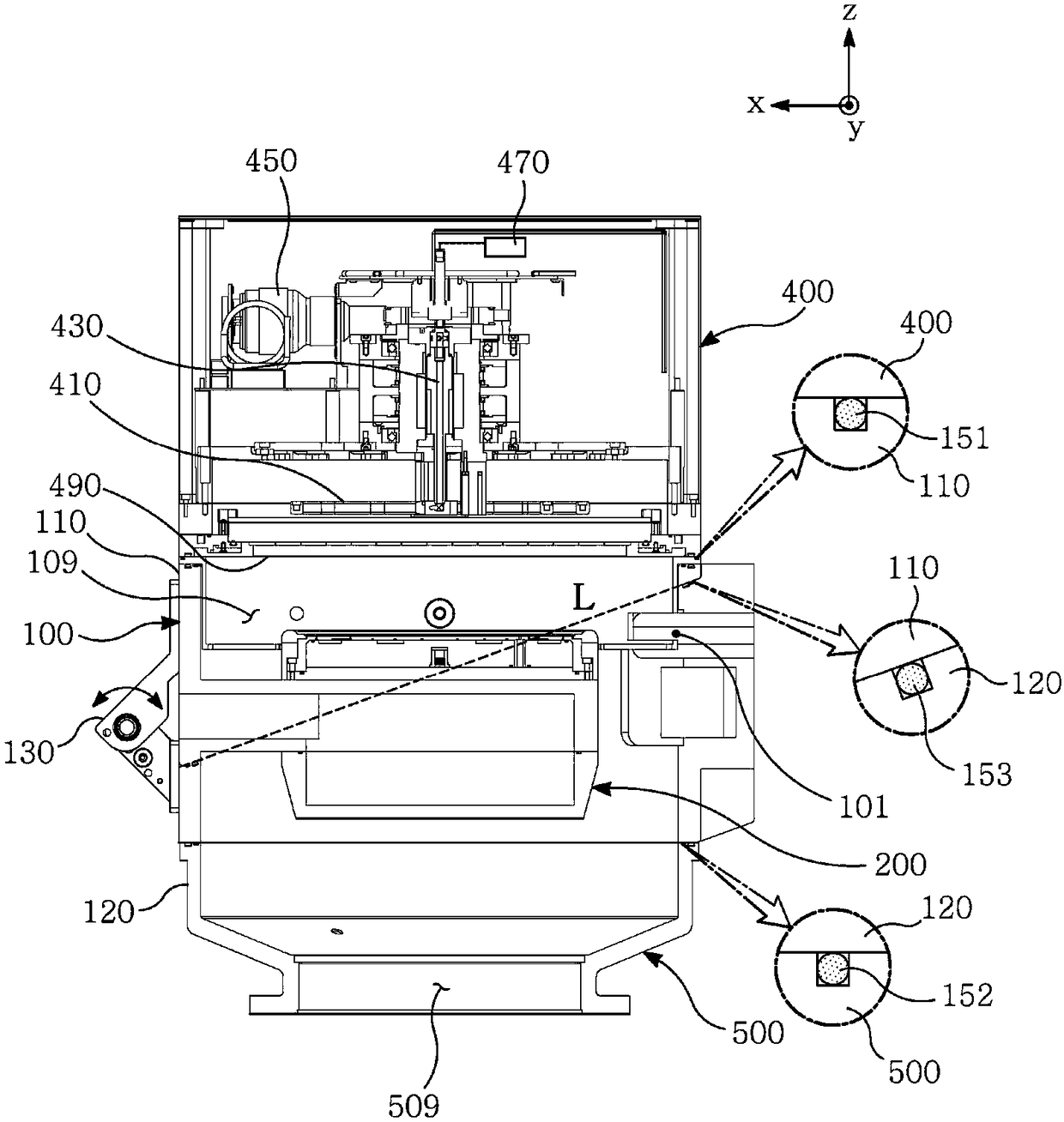

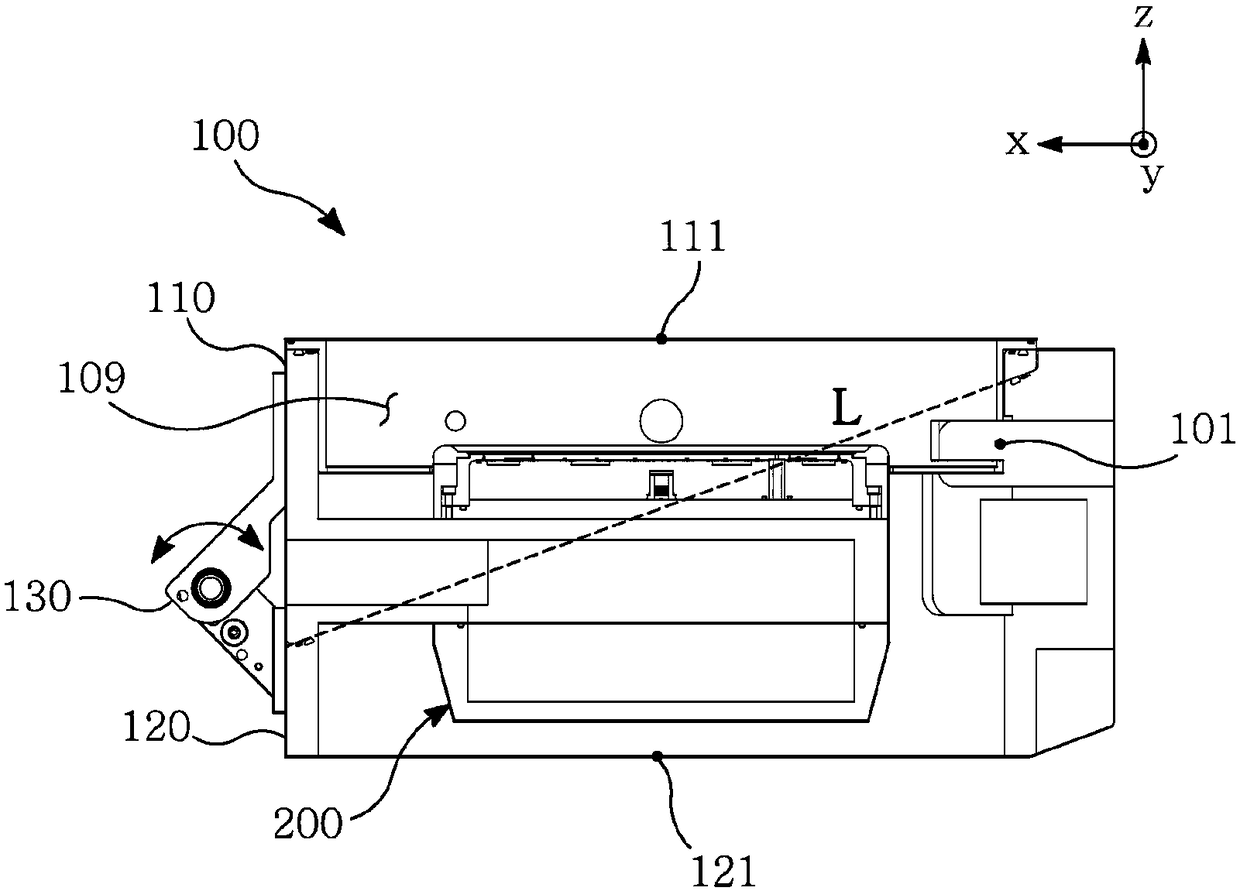

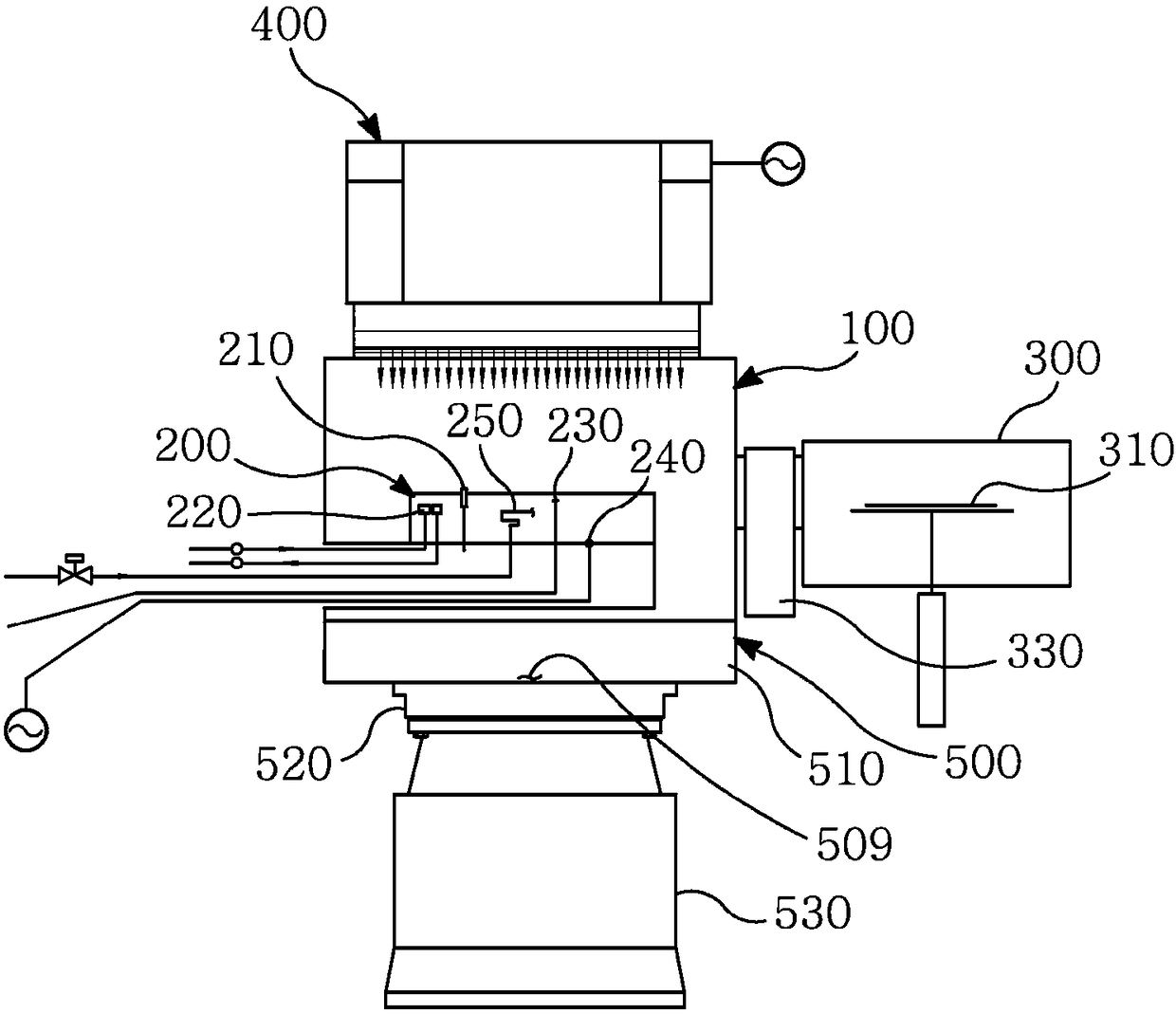

[0040] figure 1 It is a schematic diagram illustrating a semiconductor process device to which the present invention is applied.

[0041] A semiconductor engineering device applicable to the present invention can include a process chamber 100 and a chuck unit 200 .

[0042] The chuck unit 200 can be arranged in the inner space 109 of the cavity unit 100 . The chuck unit 200 can support a substrate processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com