Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3650 results about "Electric arc furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electric arc furnace (EAF) is a furnace that heats charged material by means of an electric arc. Industrial arc furnaces range in size from small units of approximately one ton capacity (used in foundries for producing cast iron products) up to about 400 ton units used for secondary steelmaking. Arc furnaces used in research laboratories and by dentists may have a capacity of only a few dozen grams. Industrial electric arc furnace temperatures can be up to 1,800 °C (3,272 °F), while laboratory units can exceed 3,000 °C (5,432 °F).

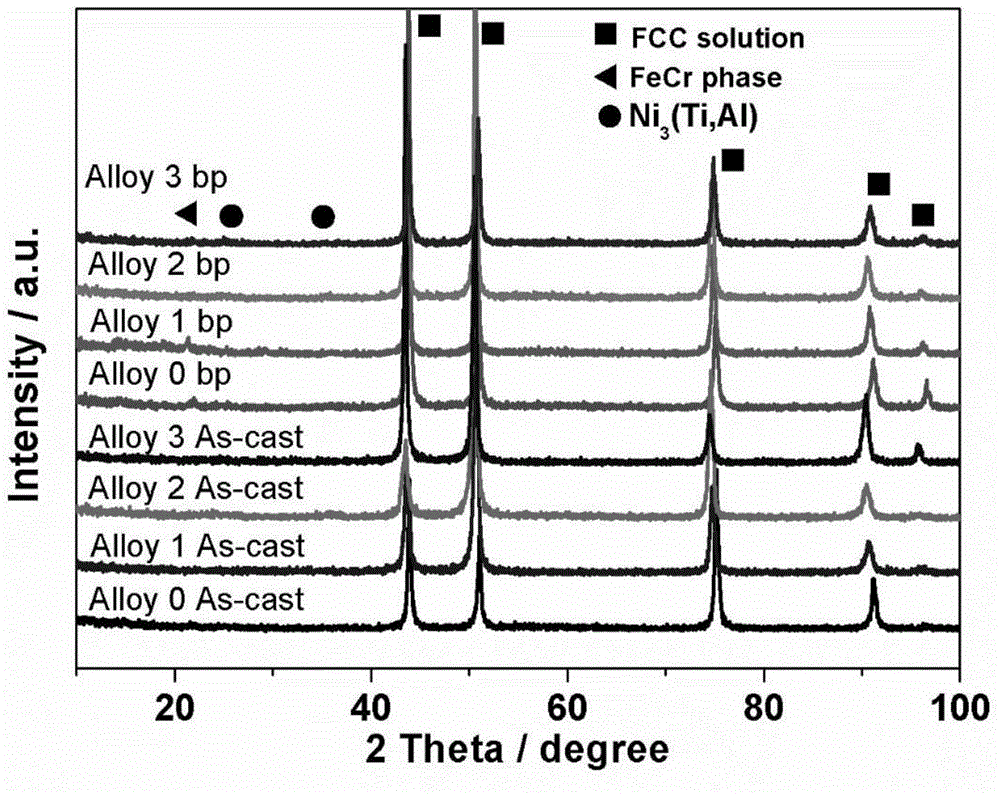

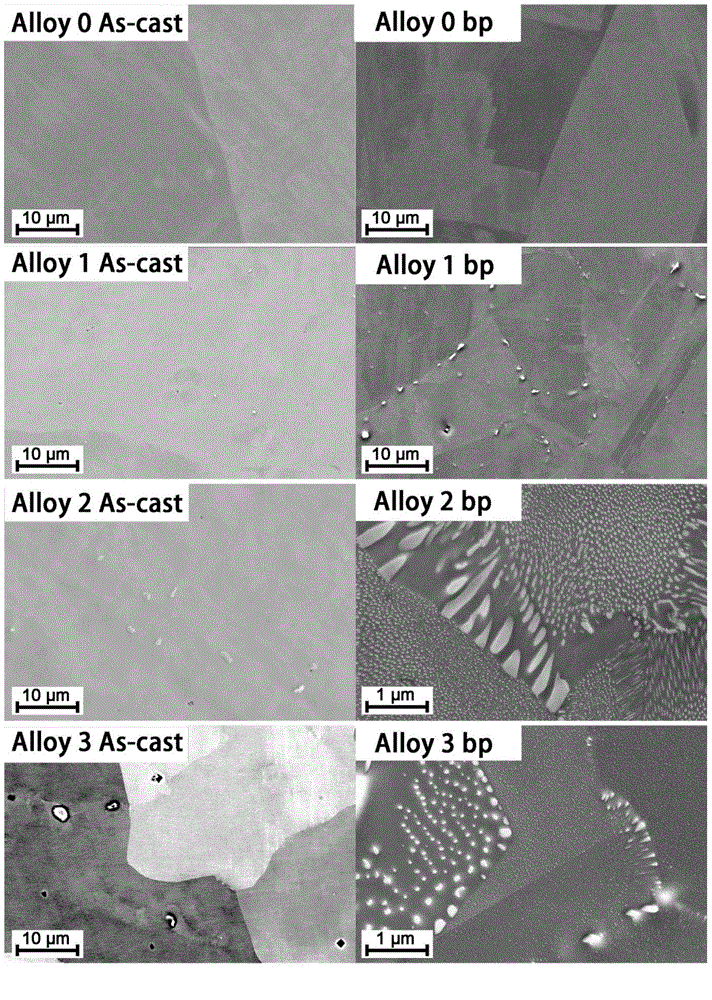

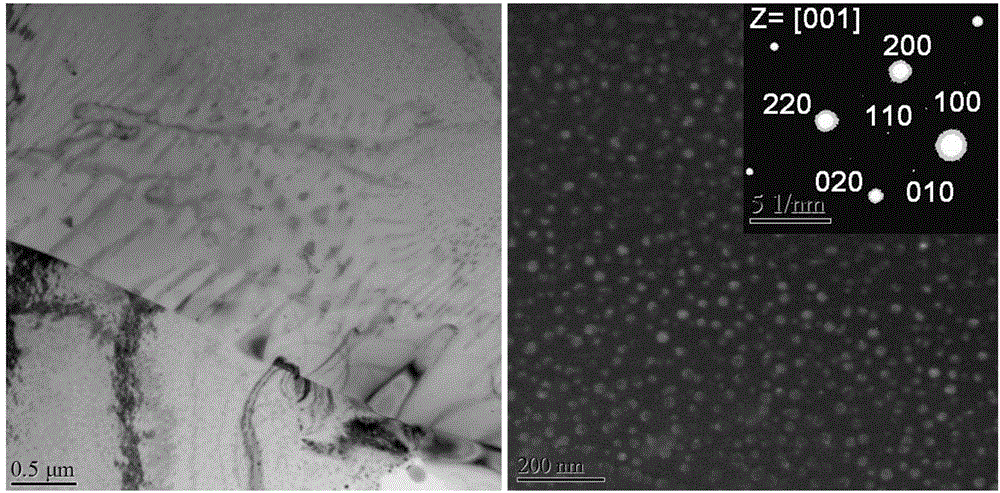

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

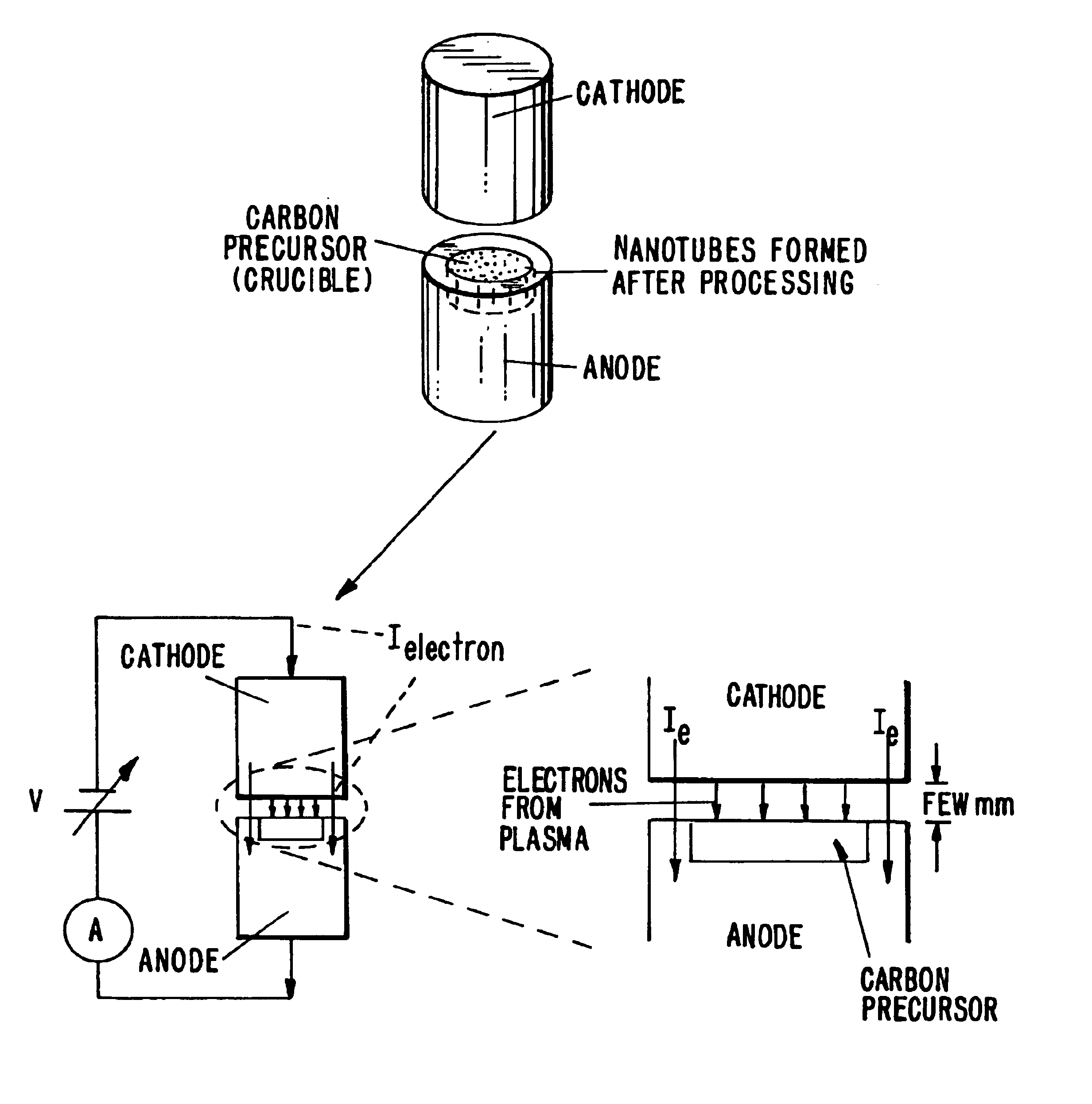

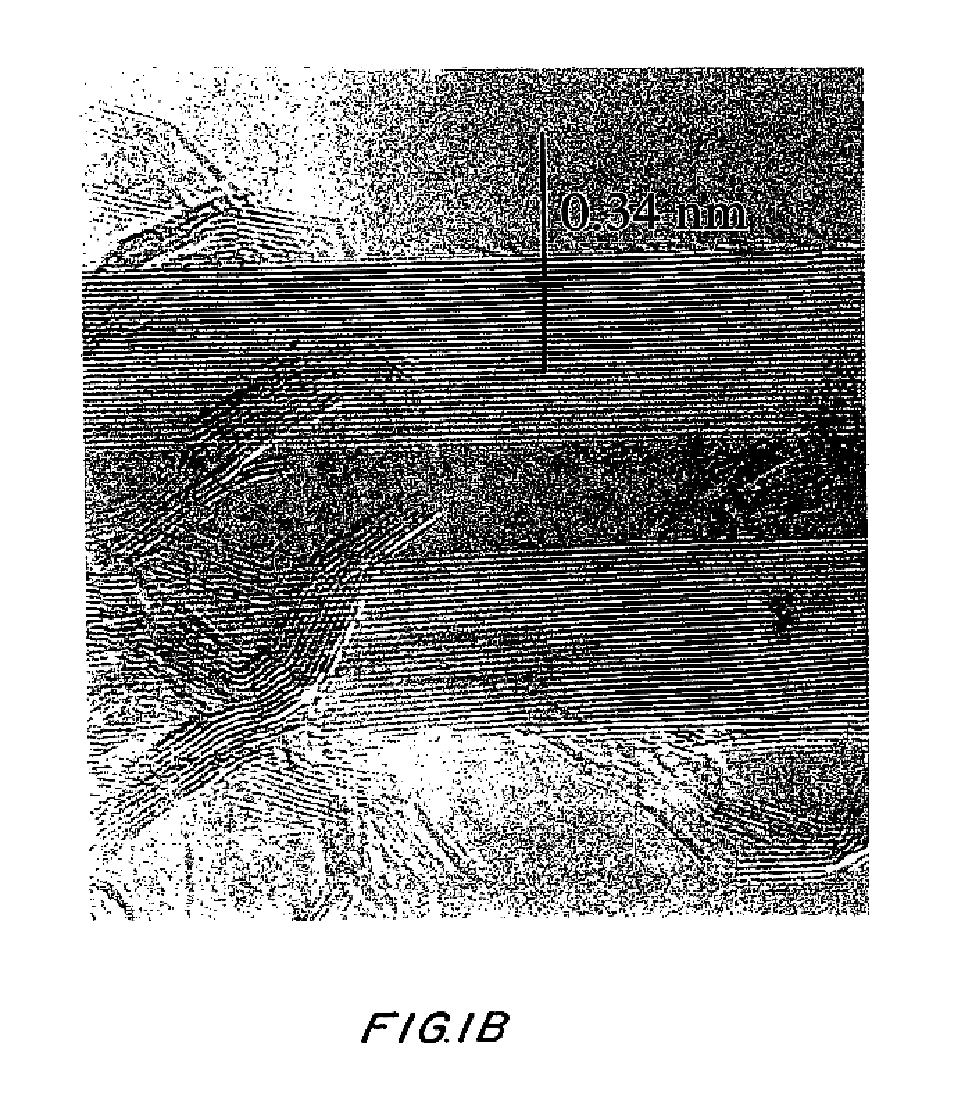

Carbon nanostructures and methods of preparation

InactiveUS6765949B2Enhanced and superior structural and mechanical propertyImprove processing efficiencyMaterial nanotechnologyElectric discharge heatingSufficient timeElectric arc furnace

An electric arc furnace and method for forming tubular carbon nanostructures comprising a first electrode (cathode) and an a second electrode (anode) opposite the first electrode, sources of voltage (V) and current (A) to create charged particles (Ie) and produce an arch between the electrodes, a source of a gas to surround the arc, and a source of carbon precursor positioned adjacent the anode and within the arc, wherein the arc is maintained at a pressure and high temperature for a time sufficient to heat the carbon precursor to form carbon nonotubes upon the anode.

Owner:CHANG ROBERT P H

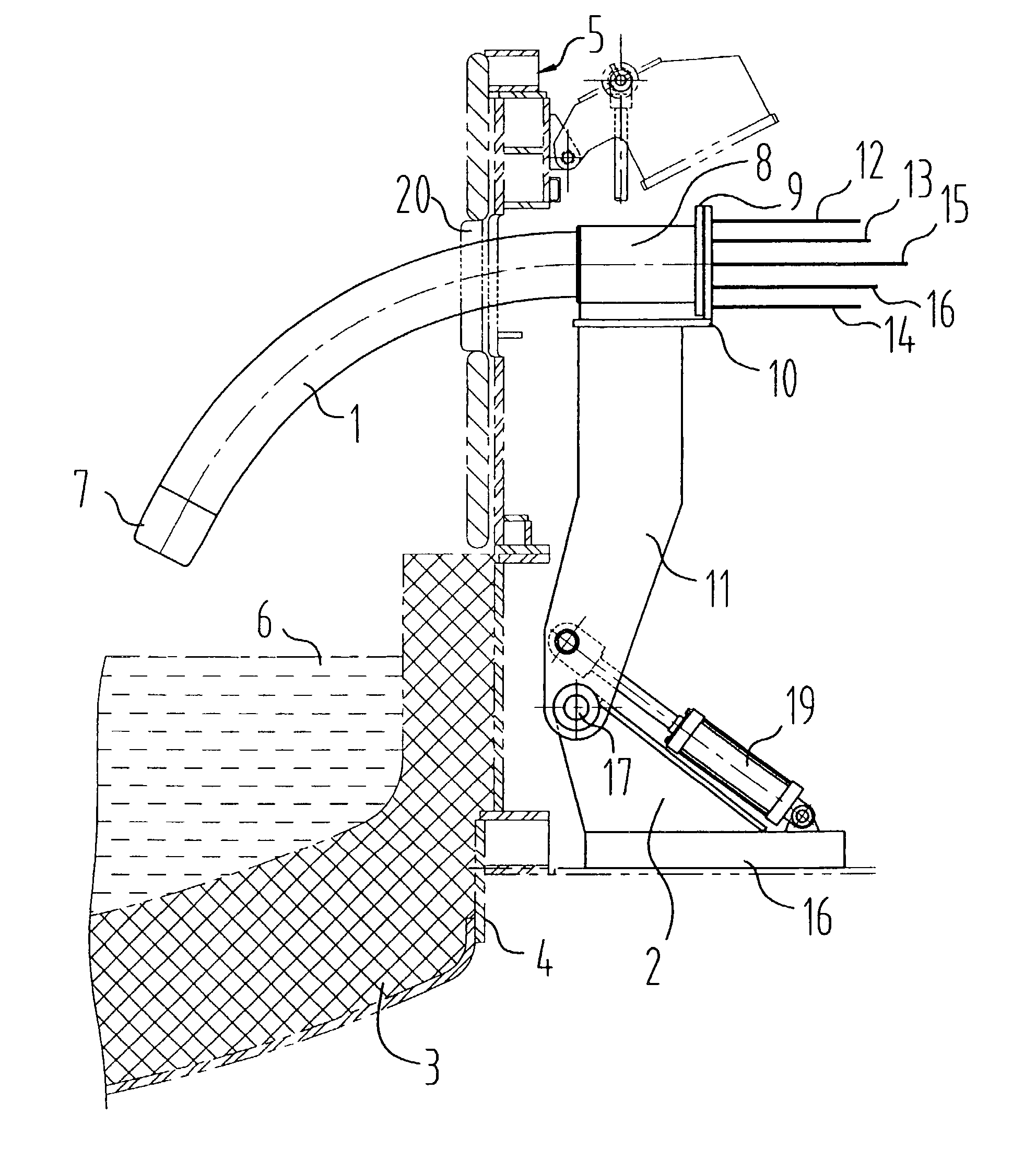

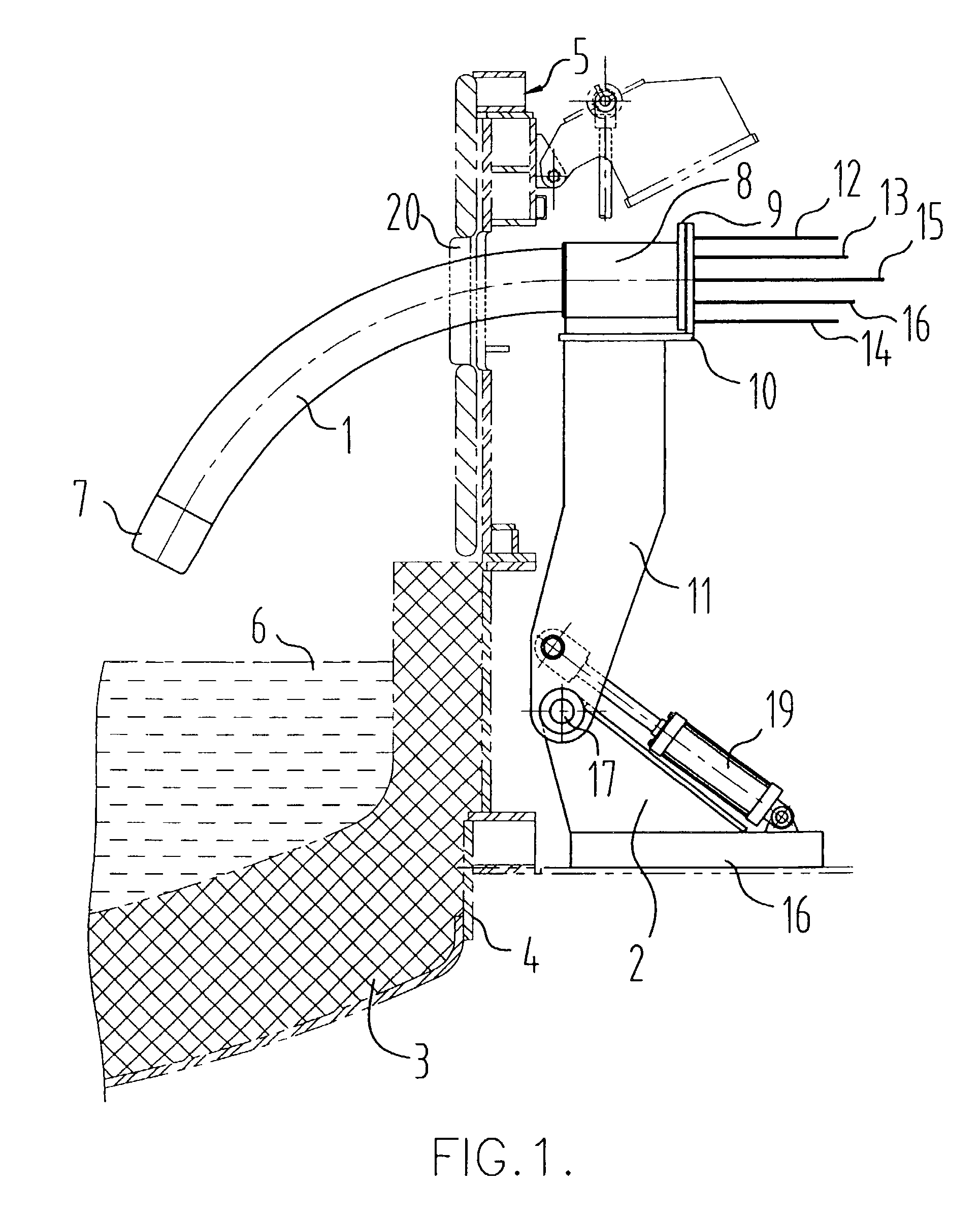

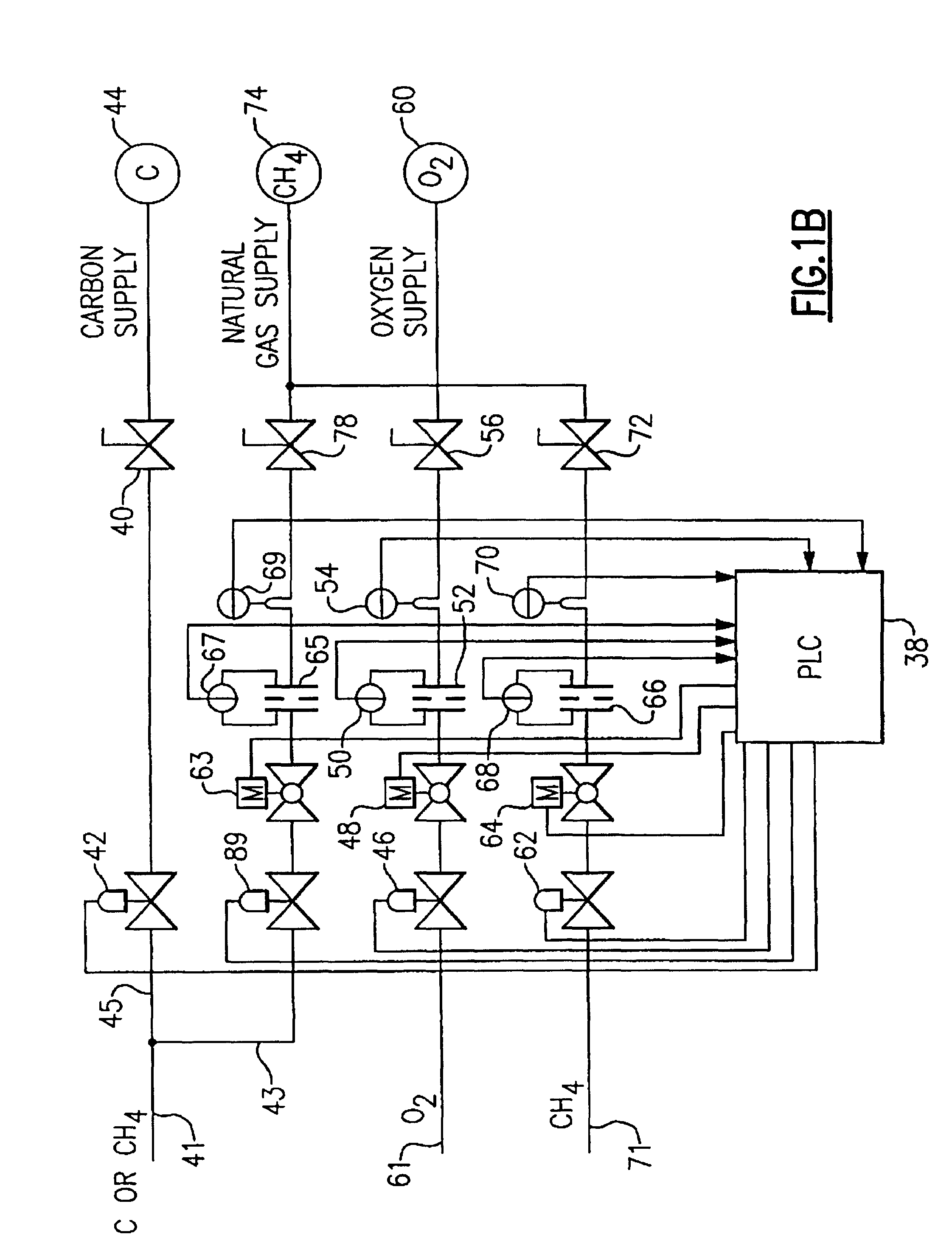

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

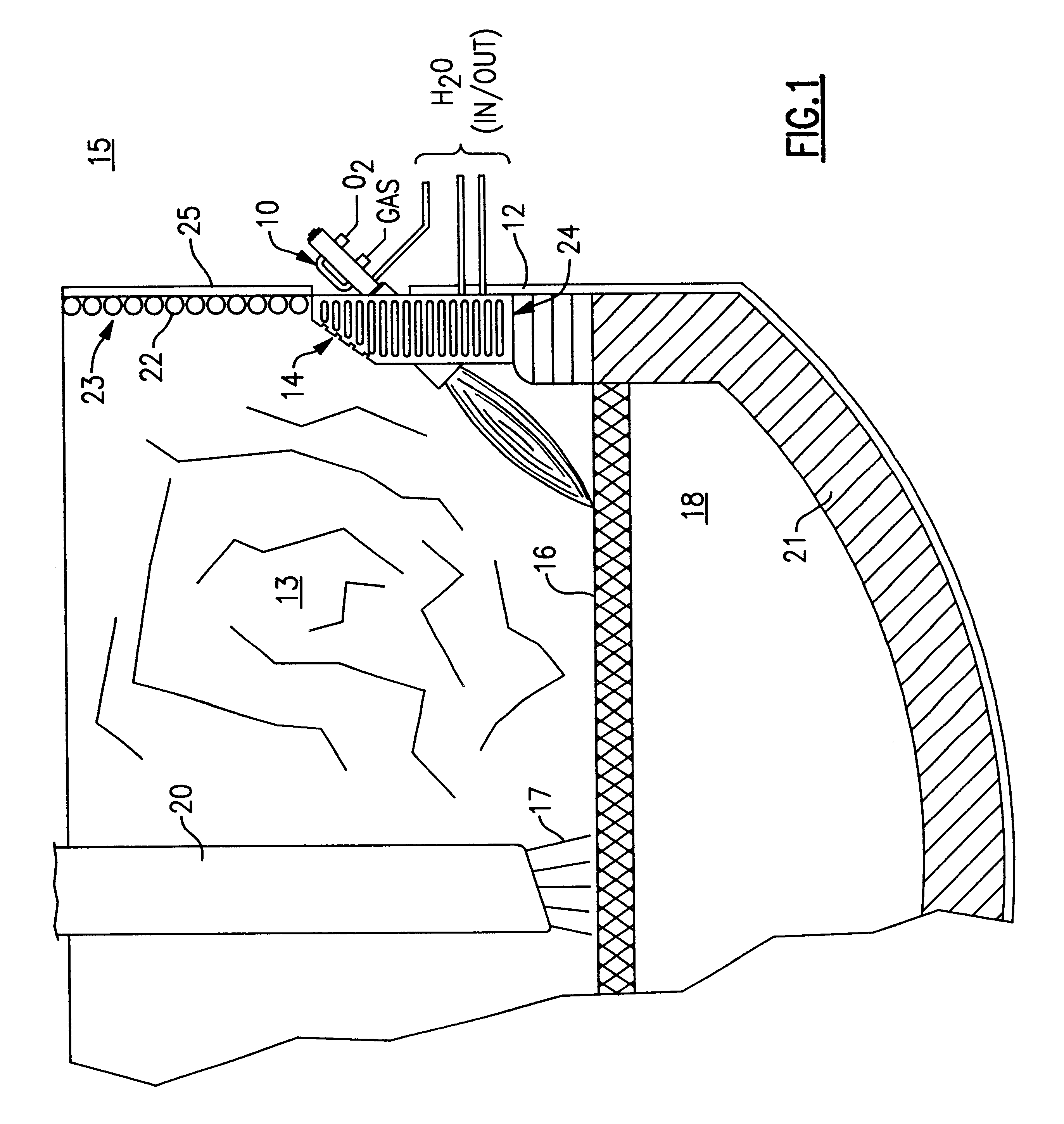

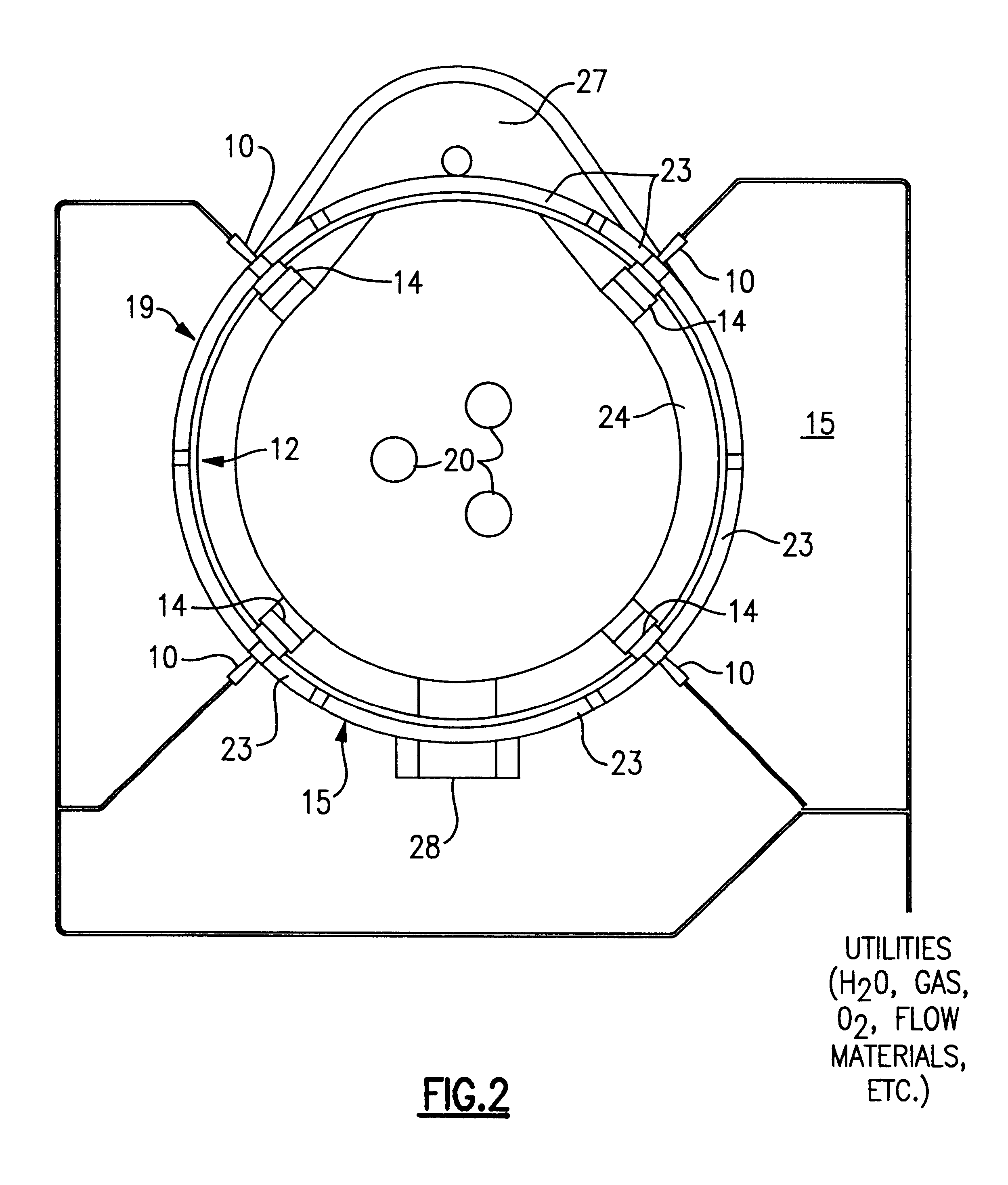

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

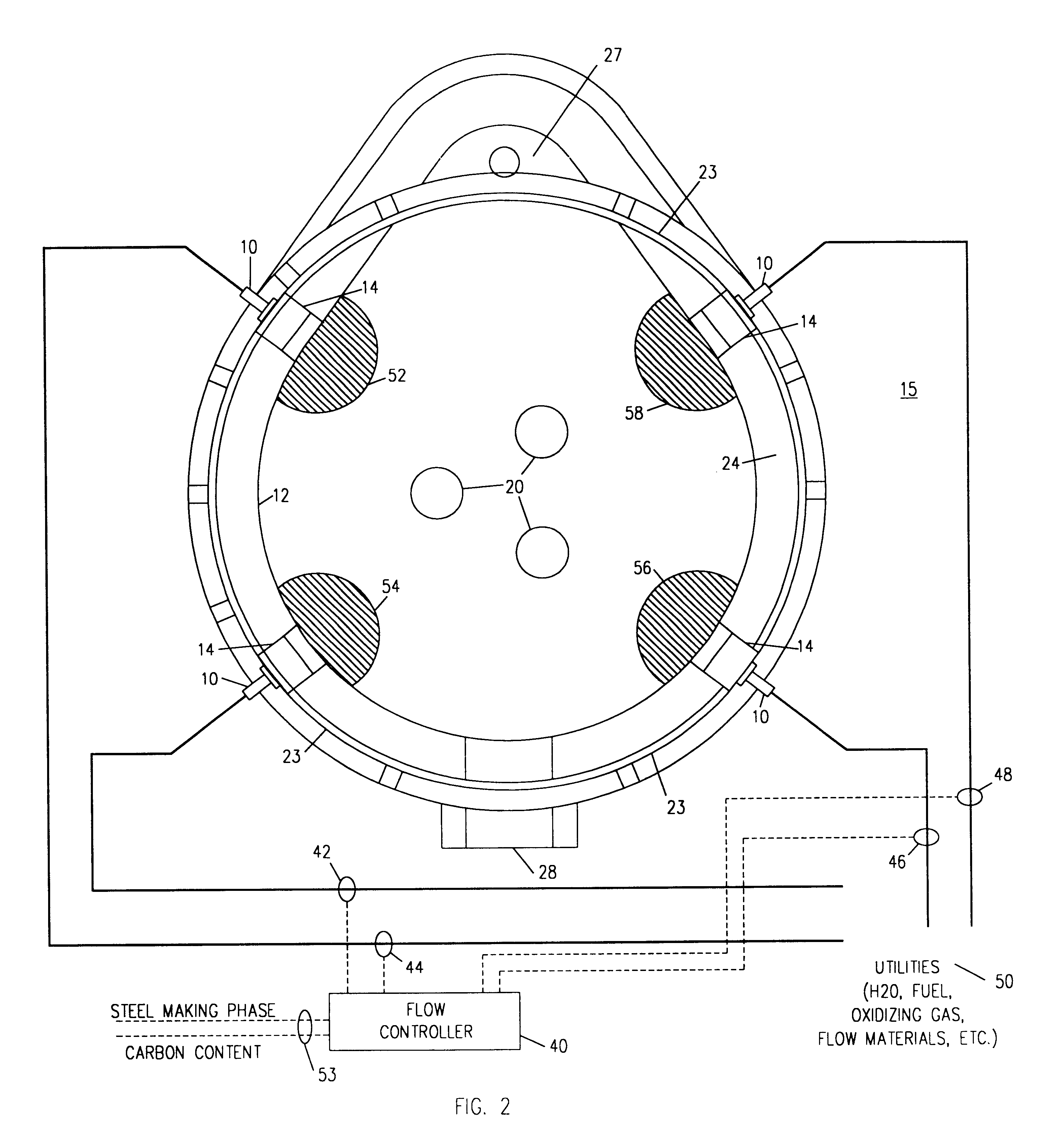

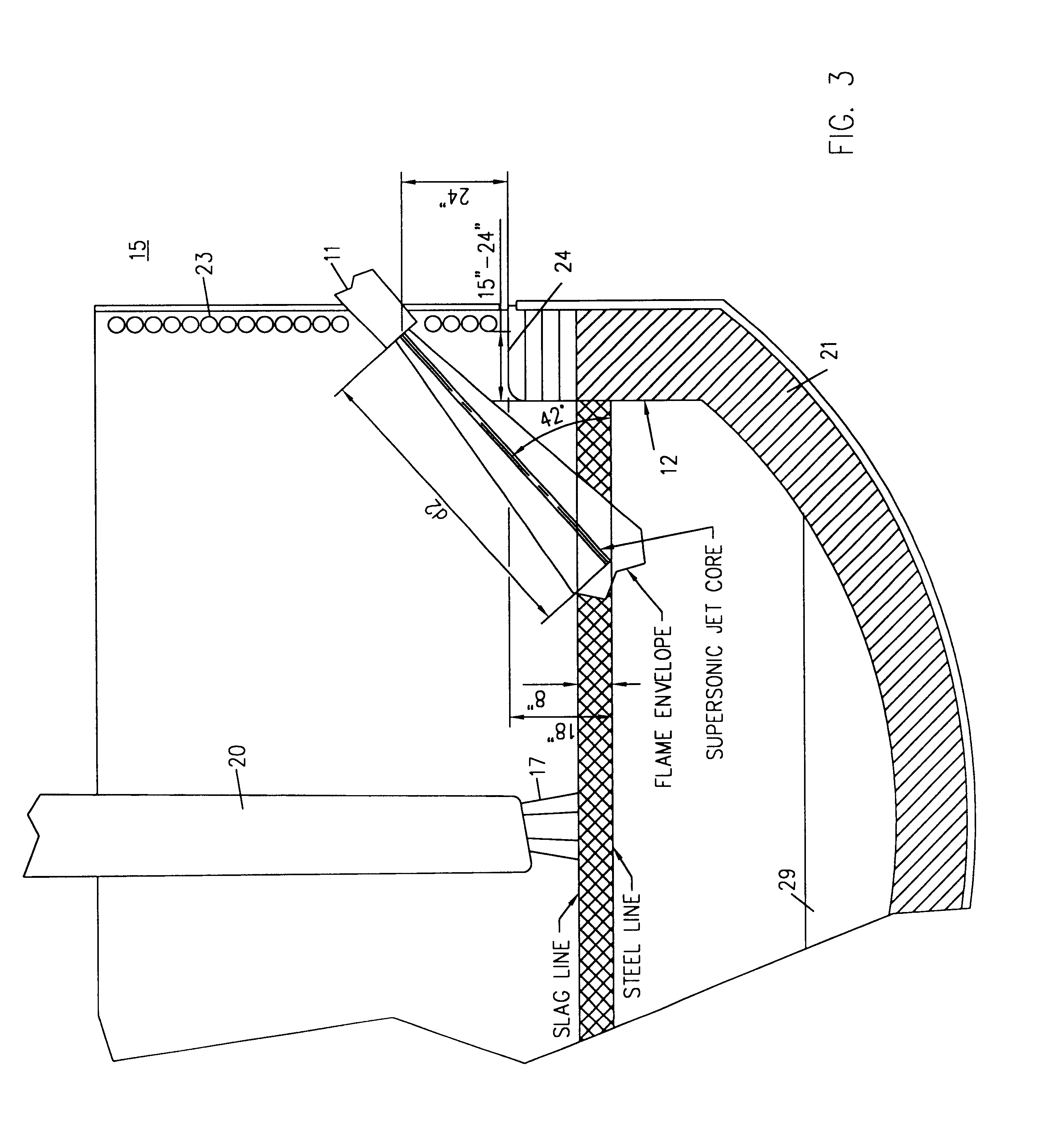

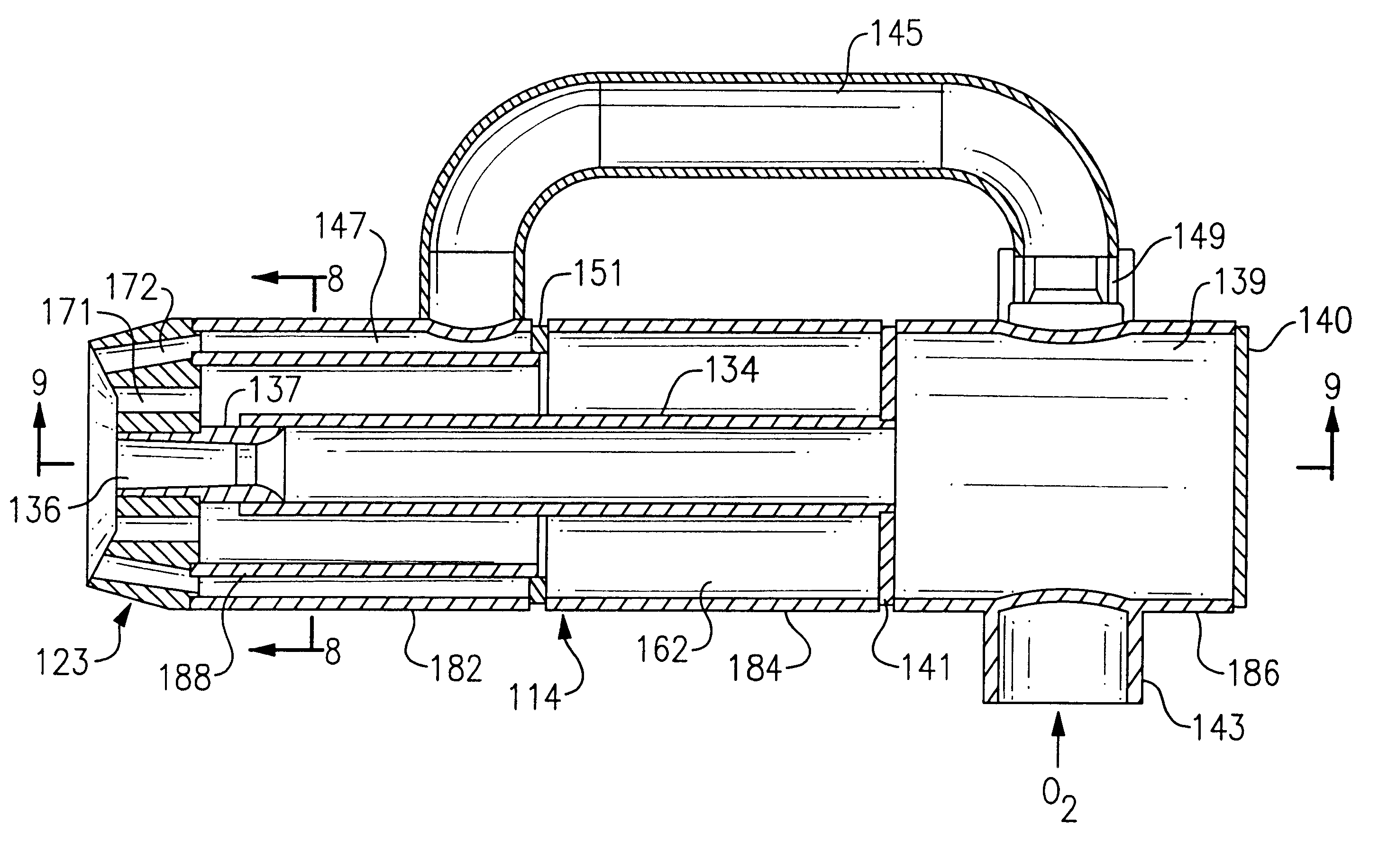

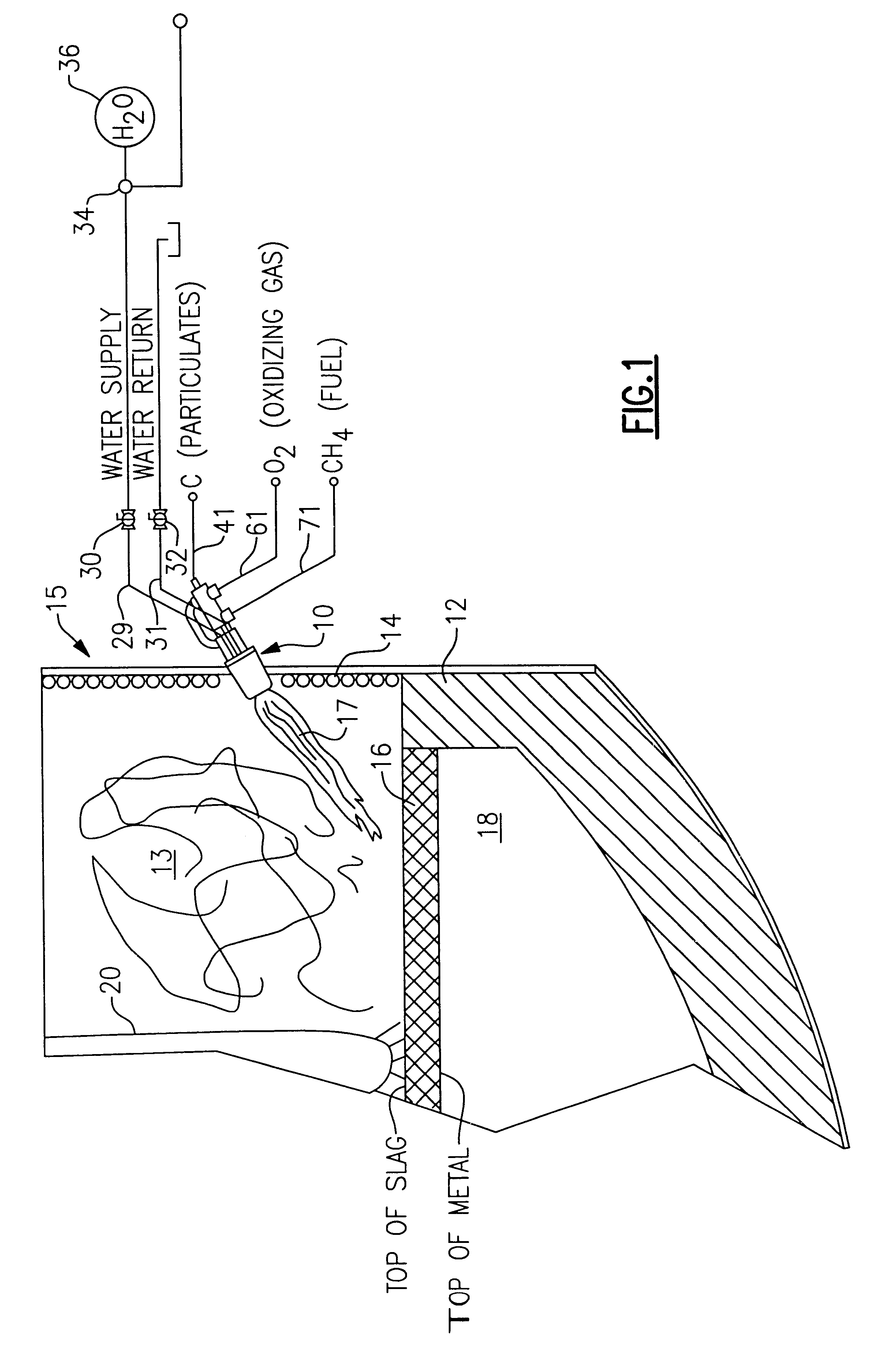

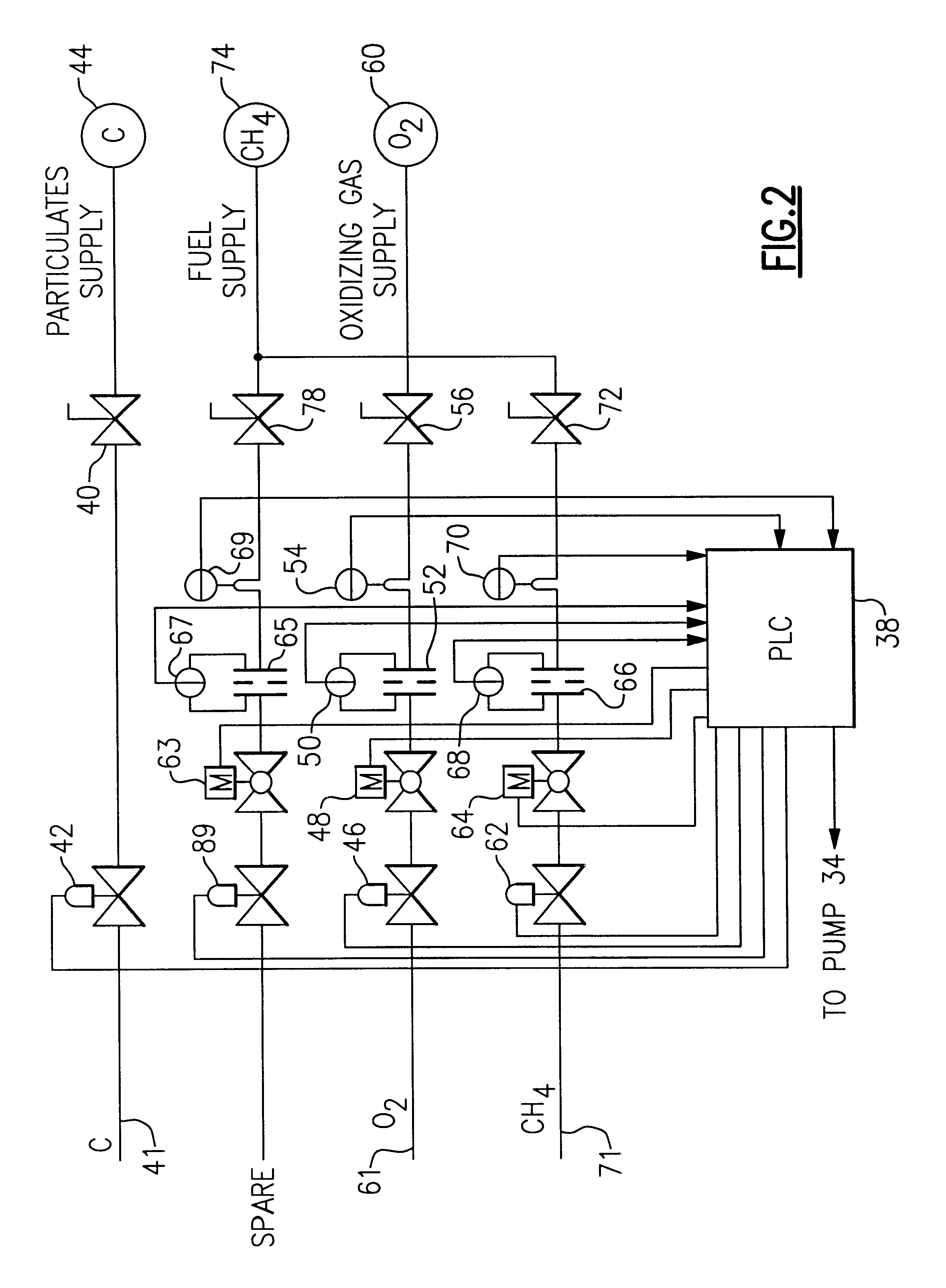

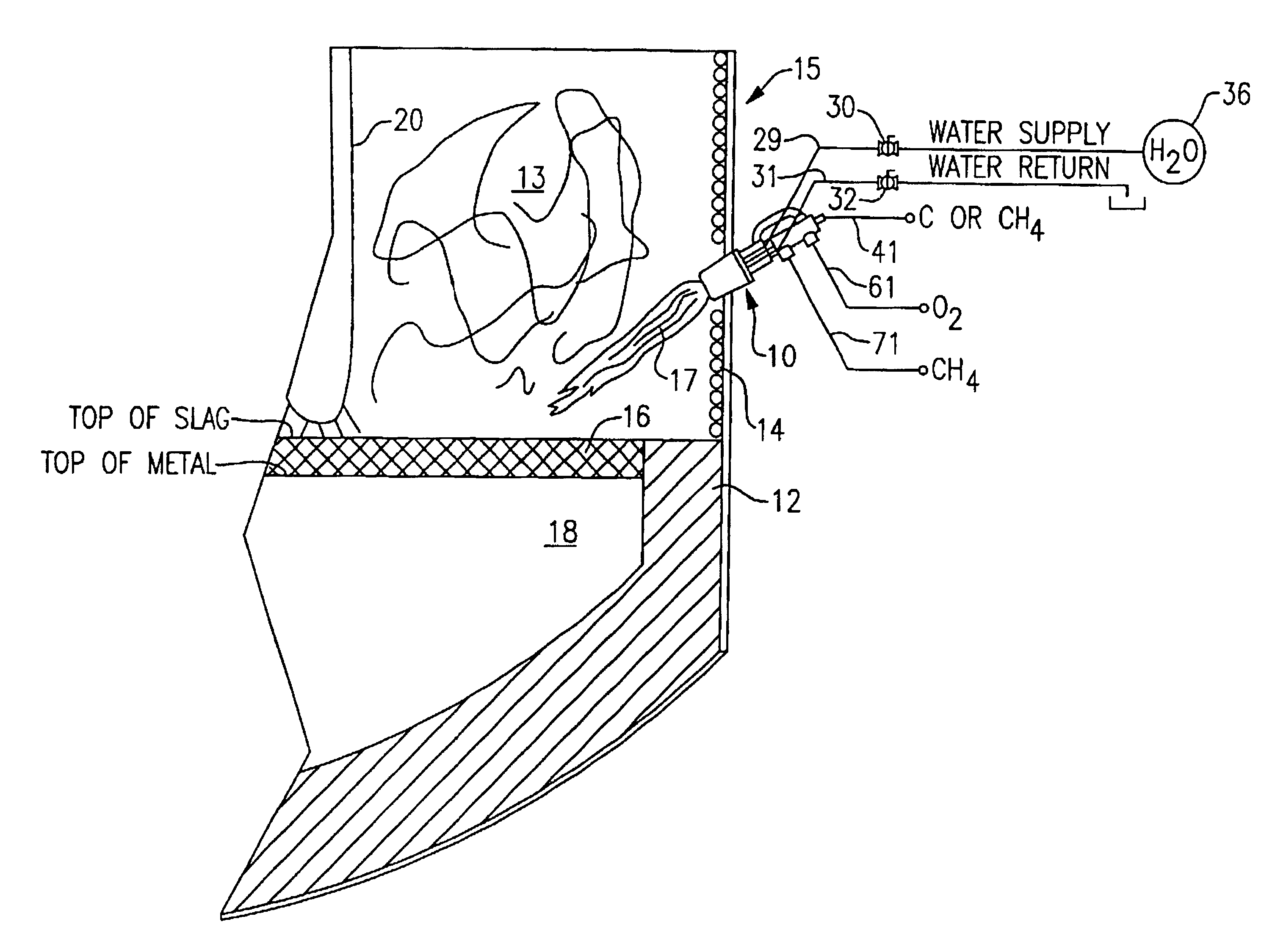

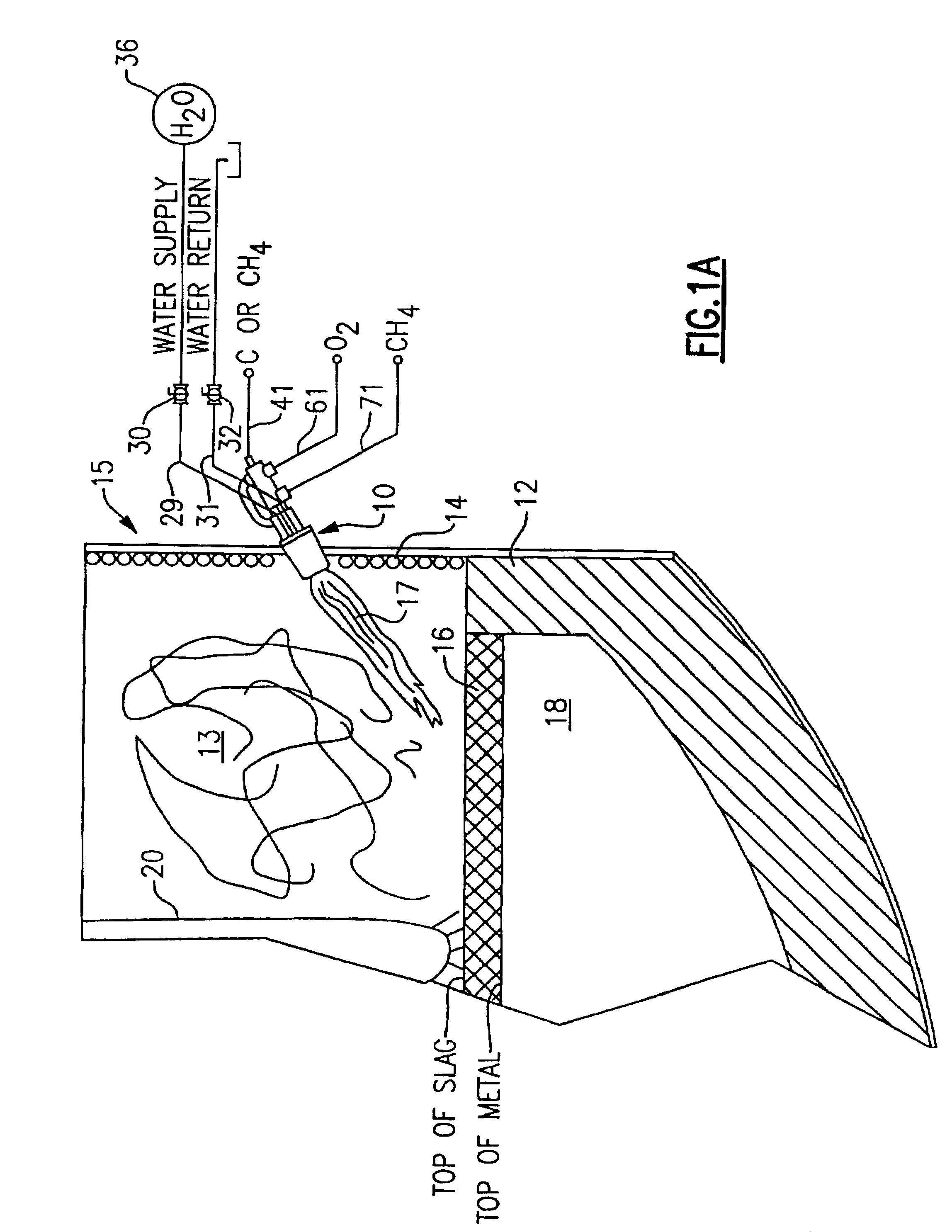

Method for metal melting, refining and processing

An improved method and apparatus for metal melting, refining and processing, particularly adapted to steel making in an electric arc furnace. The method provides auxiliary thermal energy to the steel making process, particulate injection for the formation of slag and foamy slag, and oxygen injection for the decarburization of the melt, for the formation of foamy slag and for post combustion burning of carbon monoxide. The burner includes two injection barrels for providing finely pulverized particles and for providing either a supersonic or a subsonic primary flow of an oxidizing gas. The barrels are positioned side by side in a nozzle at the entrance of a flame shaping chamber of a fluid cooled combustion chamber. The nozzle also contains a plurality of fuel orifices for the providing pressurized fuel to the combustion chamber and a plurality of oxidizing gas orifices for providing a secondary flow of an oxidizing gas around the periphery of the nozzle. Because all of the flows of fuel, oxidizing gas and particulates pass through the flame shaping chamber, they are all substantially directed to the same location in the electric arc furnace. The directionality of the flows allows the burner to heat a localized spot of the slag with thermal energy from the oxidation of the fuel, from the oxidation of oxidizable components in the slag or the melt by the lancing of supersonic oxidizing gas, or from any combination of these. Once a spot in the slag is sufficiently heated, a flow of carbon is directed to the localized hot spot in the slag to reduce the FeO, and other oxides, in the slag to carbon monoxide and produce foamy slag. The particulate carbon introduction can be accompanied by further oxidizing gas injection before, during or after the carbon injection.

Owner:PROCESS TECH INT

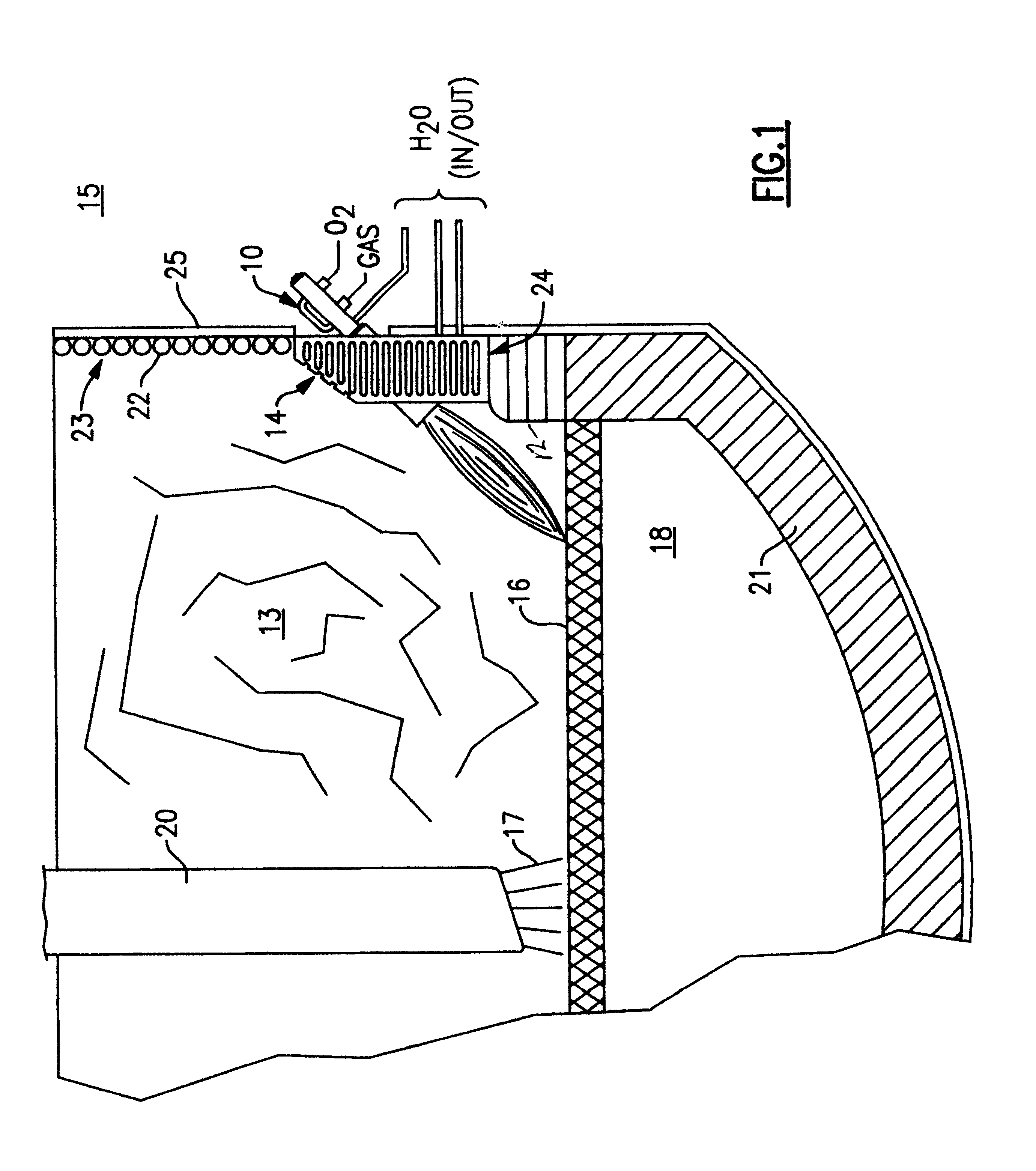

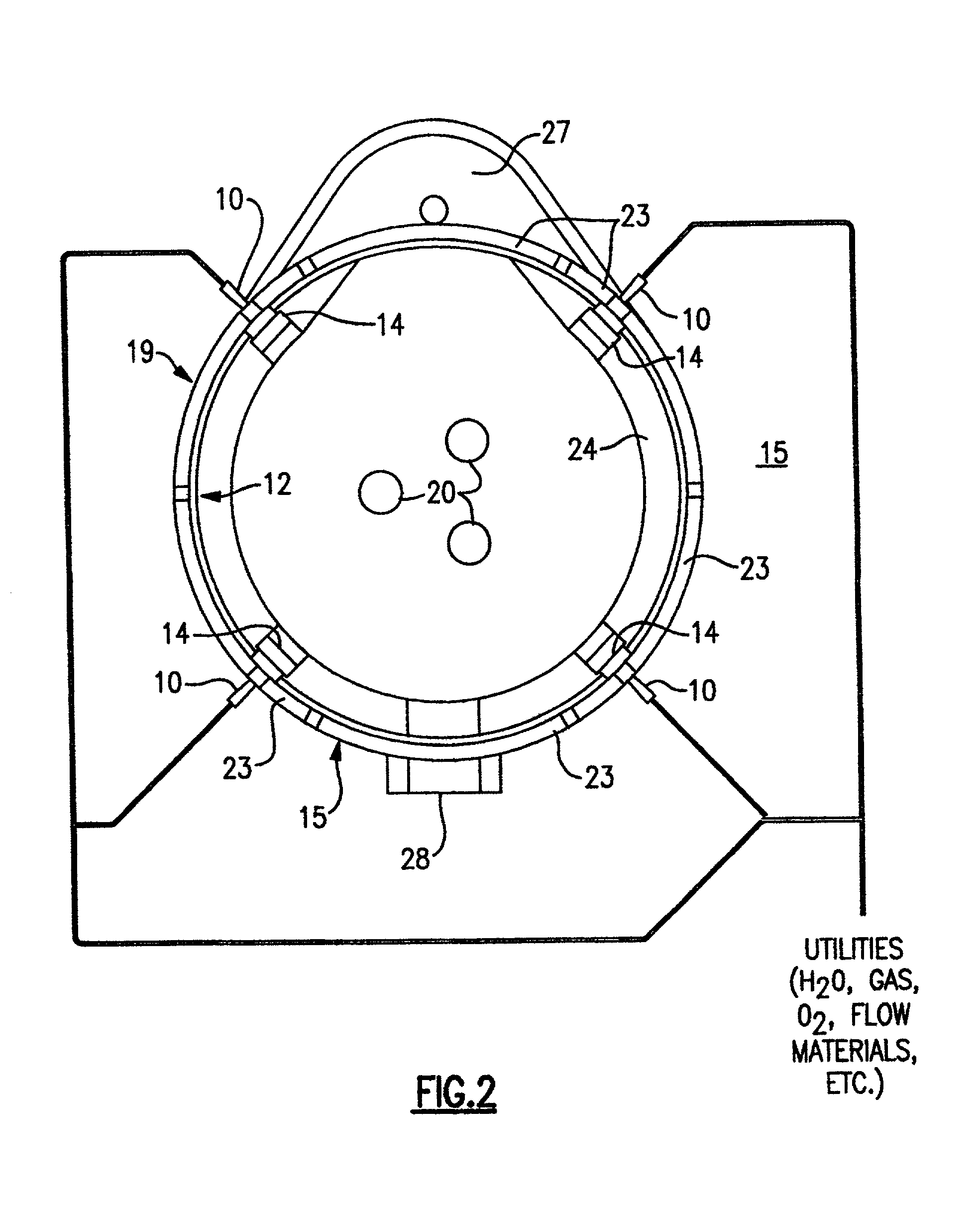

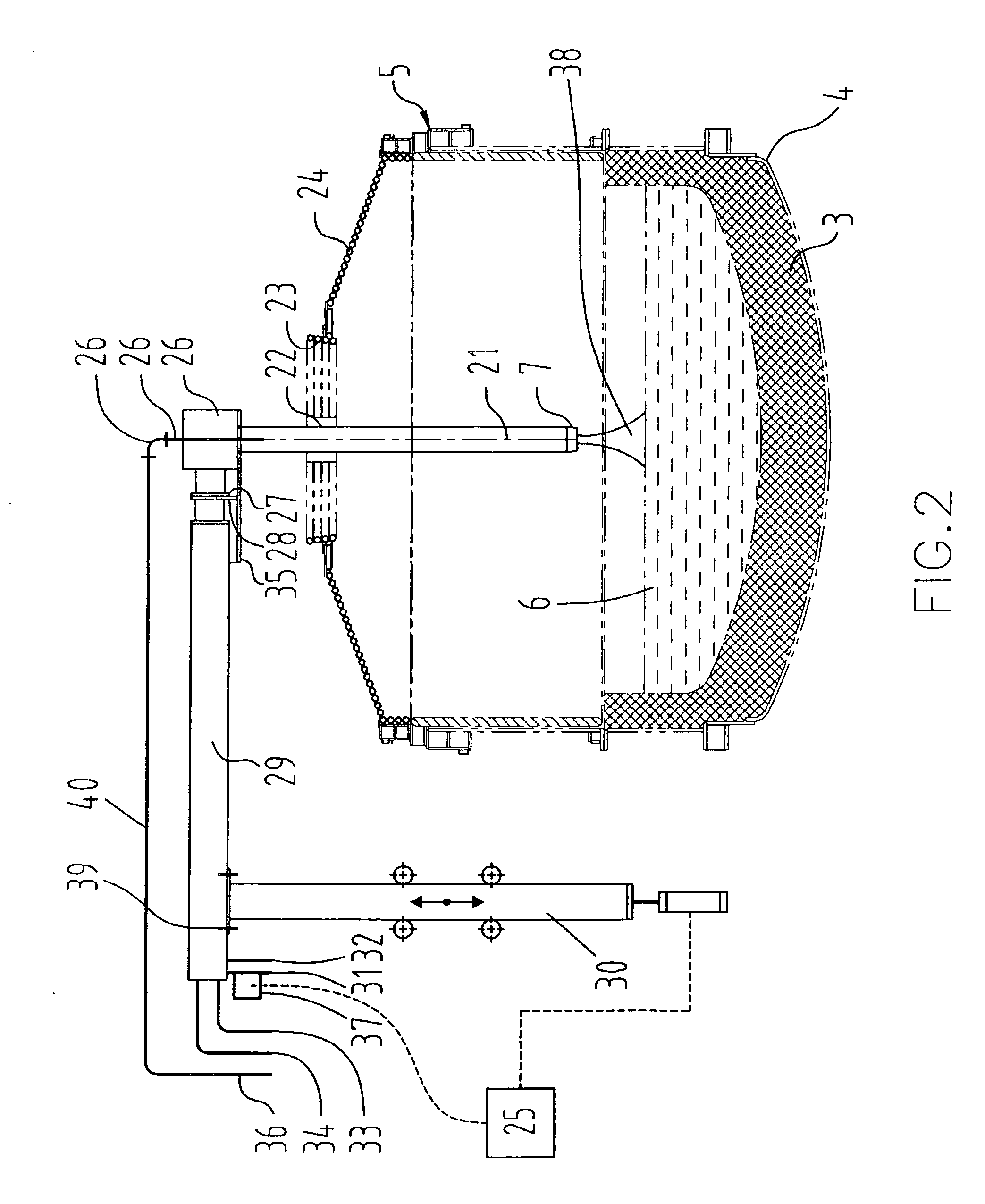

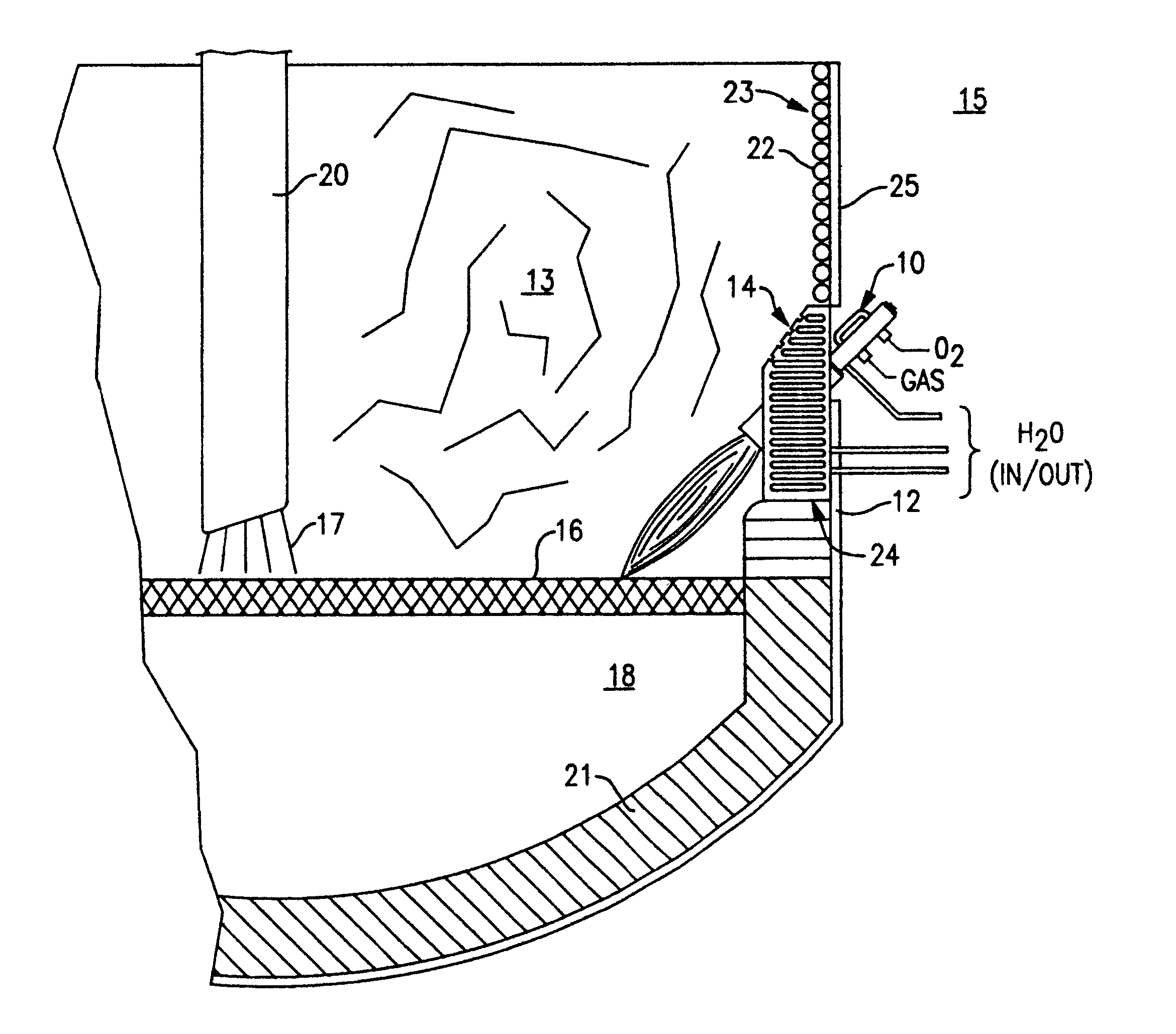

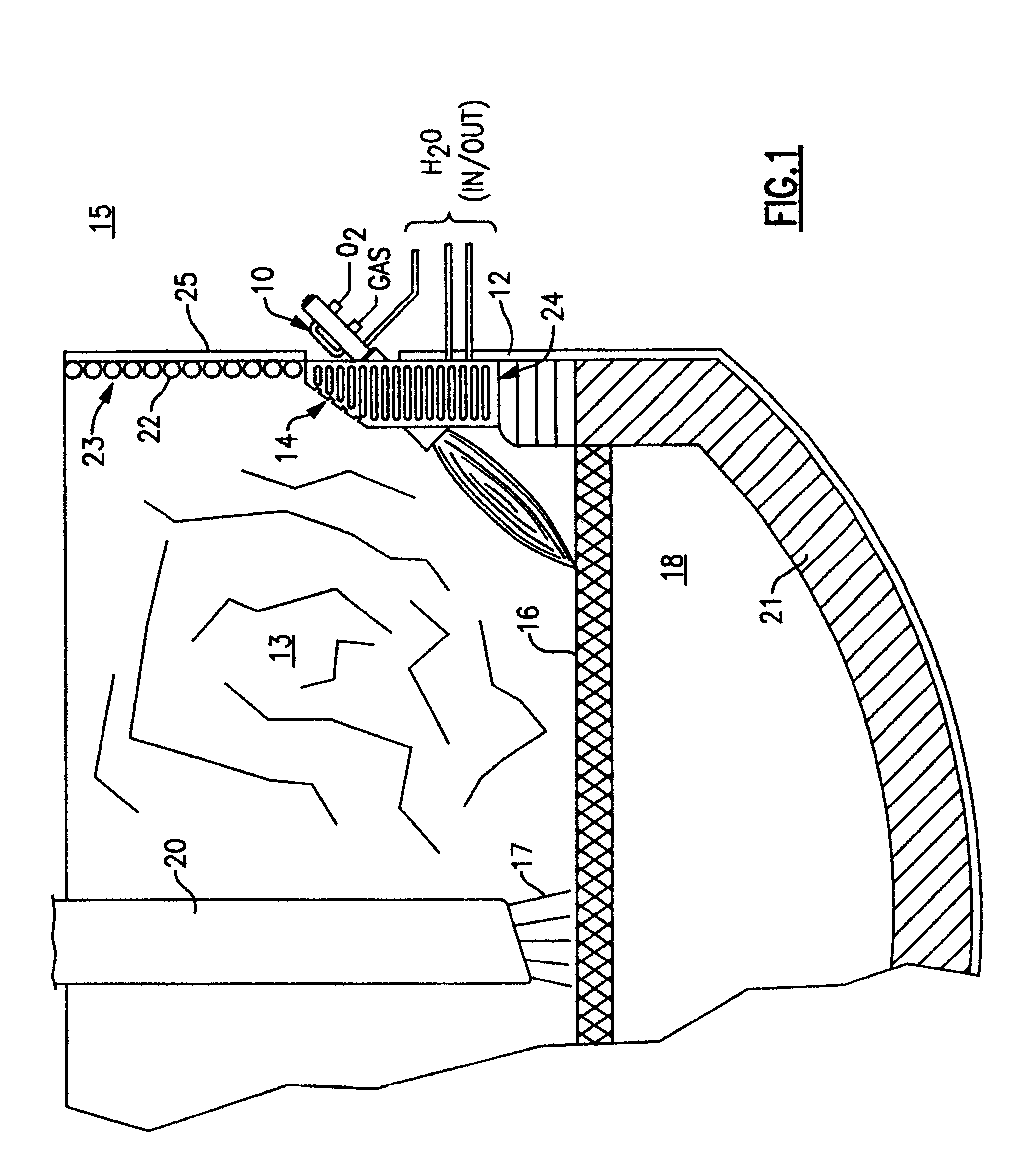

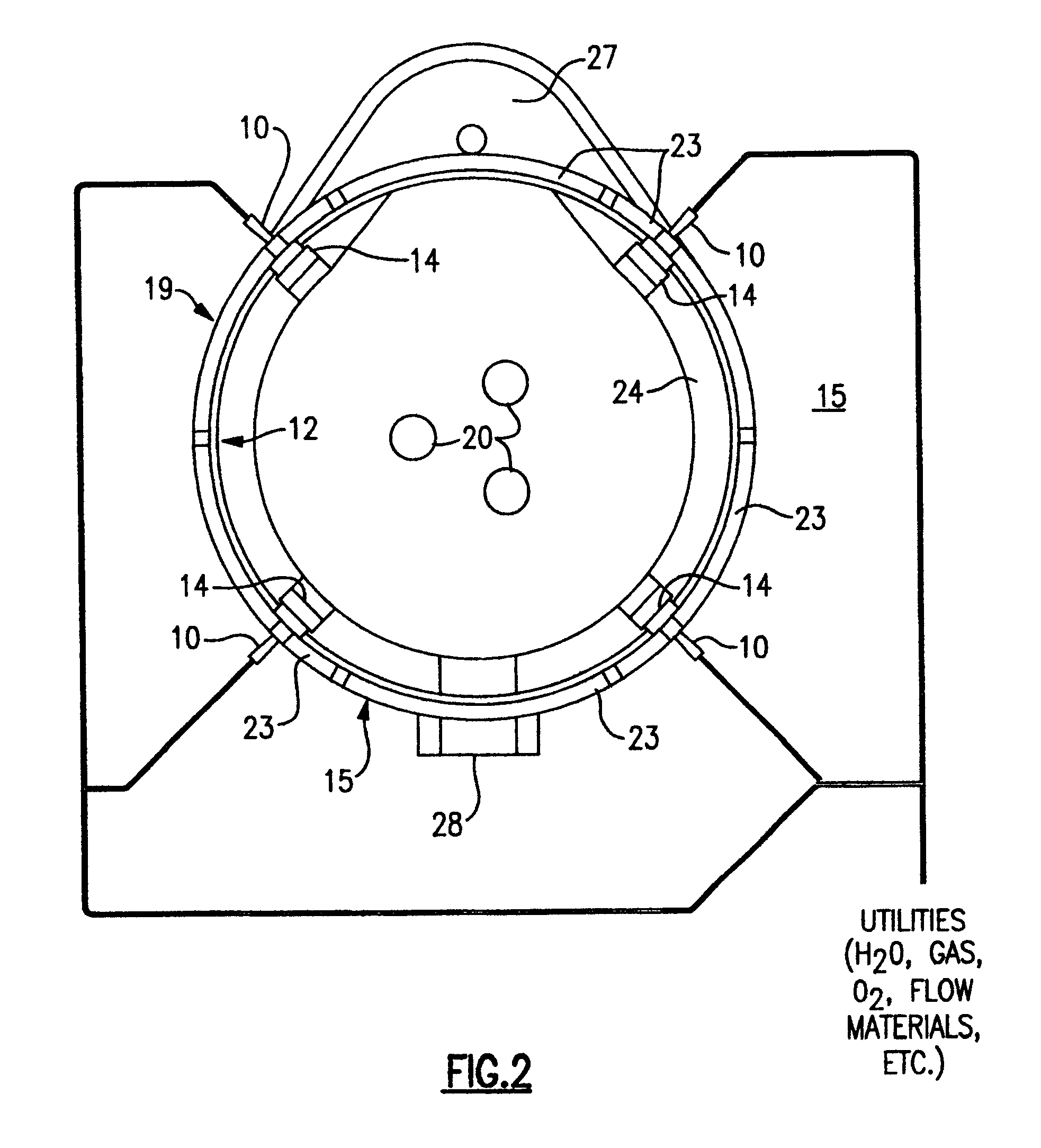

Mounting arrangement for auxiliary burner or lance

InactiveUS6614831B2Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

Mounting arrangement for auxiliary burner or lance

InactiveUS6289035B1Easy to produceImprove thermal conductivityElectric discharge heatingStirring devicesElectric arc furnaceCombustor

A mounting block and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted to steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability. The mounting block is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to rest on the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting block comprises a plurality of fluid cooling conduits surrounding an aperture which is formed through the block and adapted to mount the apparatus. The mounting arrangement includes utilizing the mounting block to mount an apparatus with supersonic oxidizing gas or lancing capability in an electric arc furnace. The apparatus is mounted by passing it through an aperture in a water cooled side panel aligned with the mounting aperture in the mounting block. Because the mounting block is approximately the width of the step, the discharge opening of the apparatus is moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge opening will now also extend past the inner edge of the step so that the oxidizing gas flow pattern does not degrade the hearth material and other furnace equipment mounted nearby.

Owner:PROCESS TECH INT

Method and apparatus for improved EAF steelmaking

An improved method and apparatus for EAF steelmaking wherein the method provides additional thermal energy to the steel making process, carbon injection for the formation of foamy slag, and oxygen injection for the decarburization of the melt, the formation of foamy slag and post combustion burning of carbon monoxide. The apparatus comprises a unique burner configuration which has a central conduit for alternatively supplying fluid hydrocarbon fuel or particulate carbon with a carrier gas which are discharged through a exit opening. The fuel or carbon is mixed with a high speed, preferably supersonic, stream of oxidizing gas. The high speed stream of oxidizing gas is provided by an annular supersonic nozzle which causes the oxidizing gas to surround the fuel or the particulates with an annular flow. The annular nozzle design can be adjusted to direct the flows of particulates and oxidizing gases in the areas and shapes desired for efficient management of the steelmaking process. Optionally, the burner can have another conduit for the secondary supply of a pressurized flow of hydrocarbon fluid fuel to a series of apertures which surround the annular flow. Further, optionally, the burner can have another conduit for the supply of a pressurized flow of a secondary oxidizing gas to a series of apertures which surround the annular flow.

Owner:PROCESS TECH INT

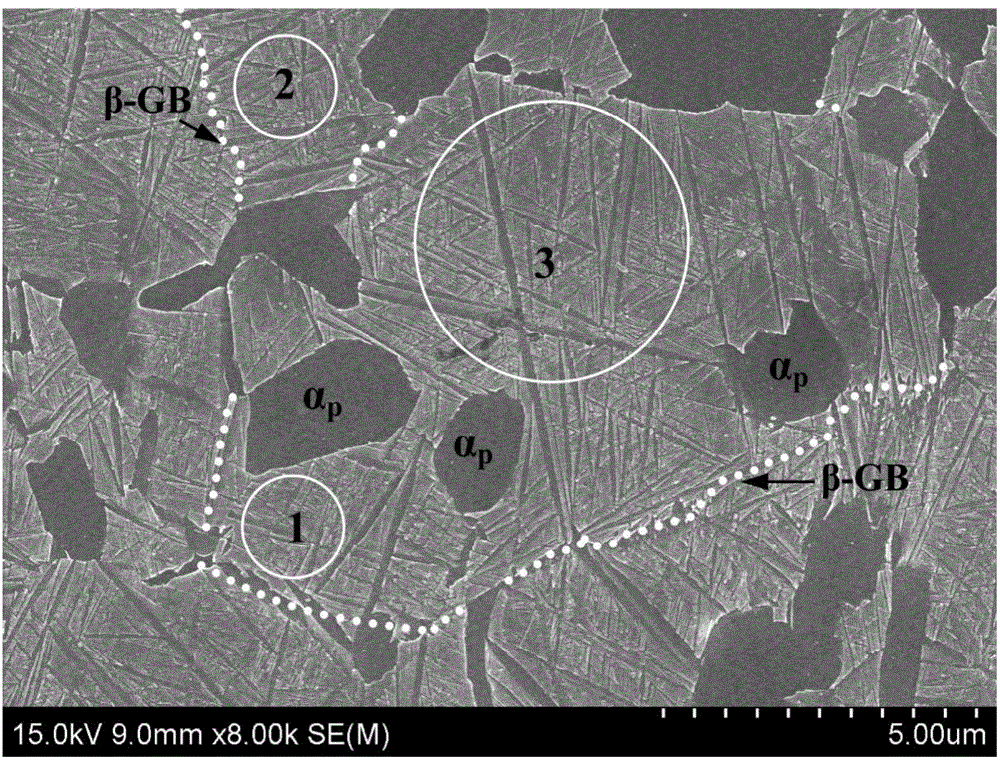

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

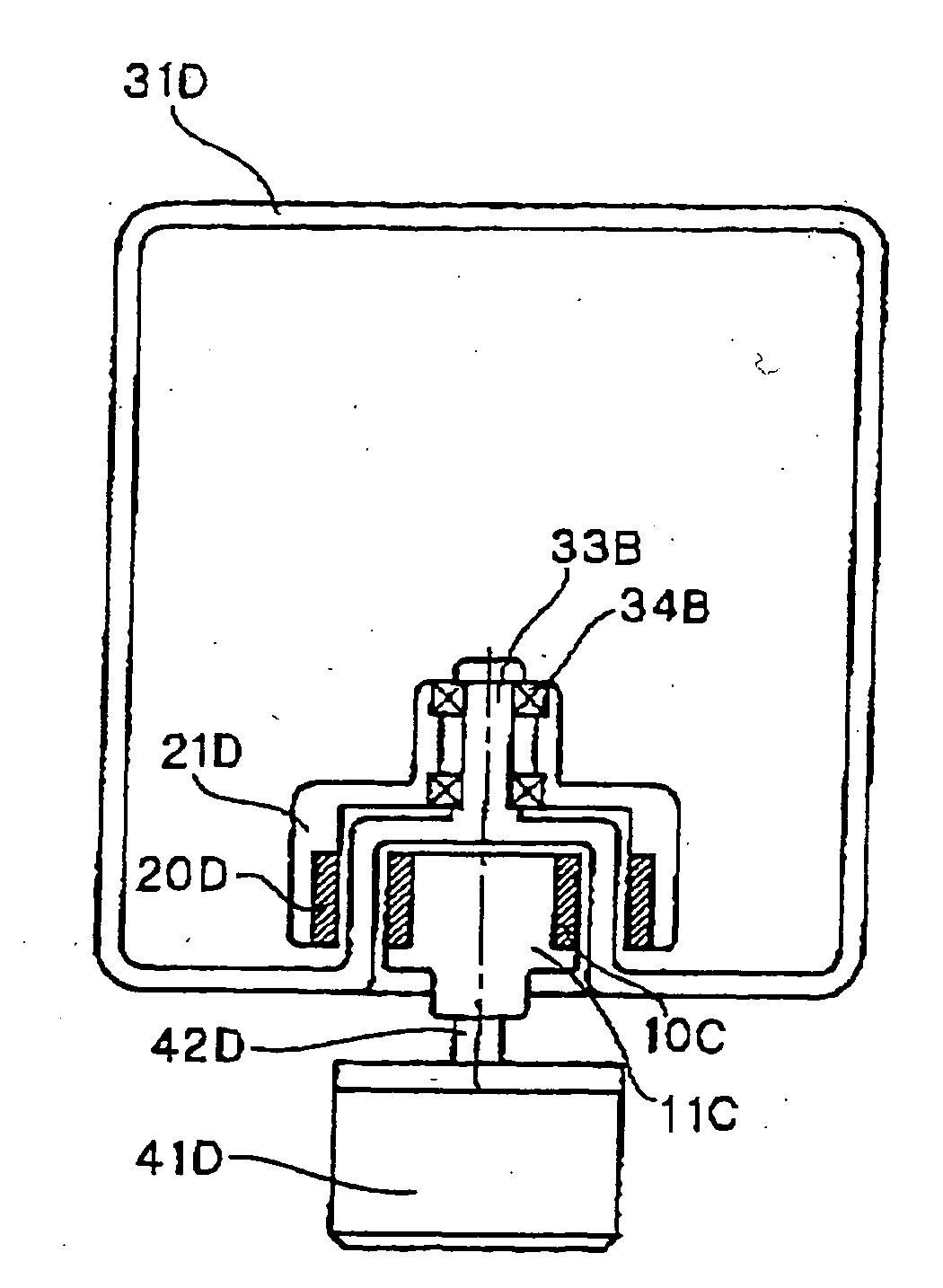

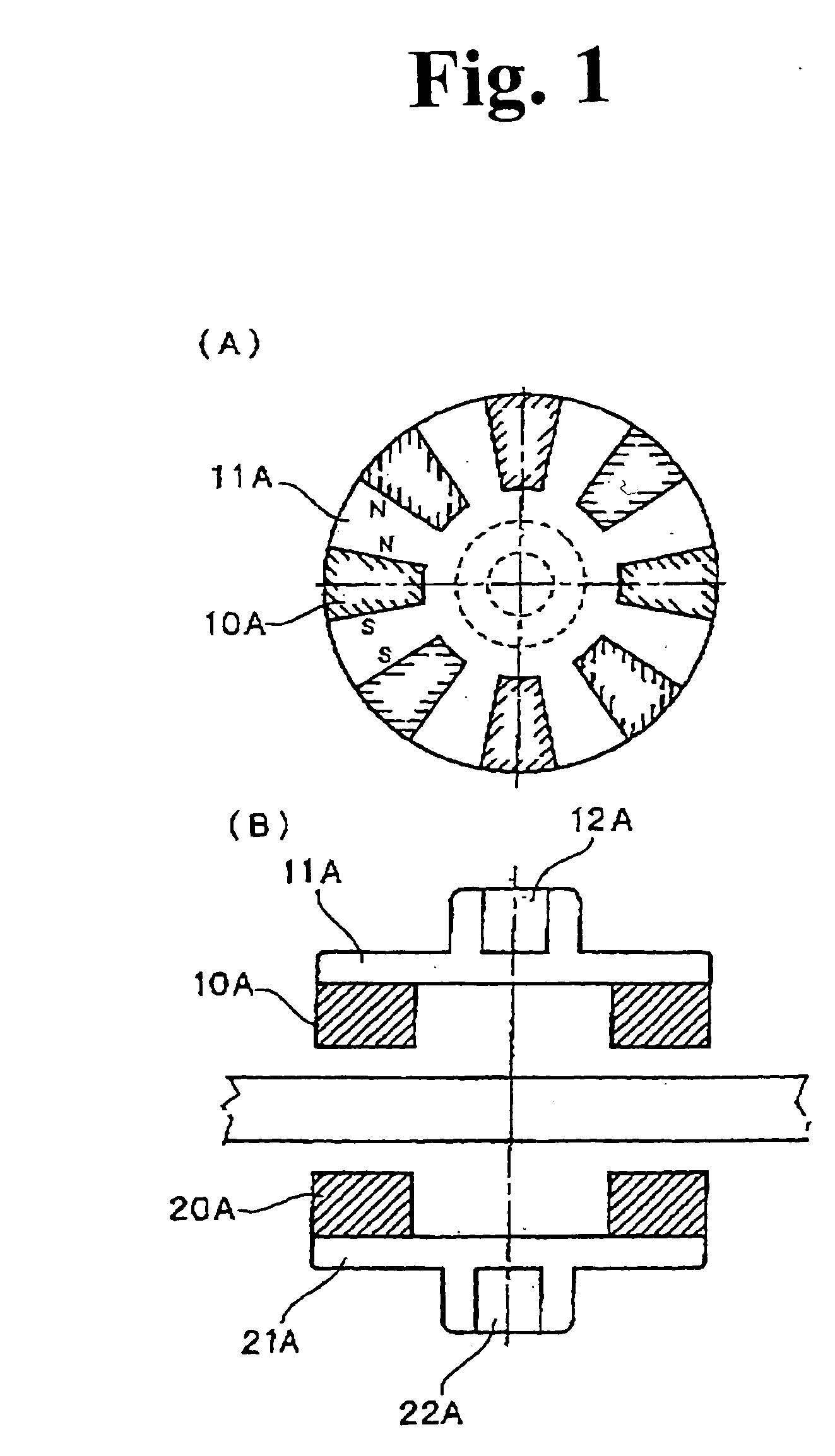

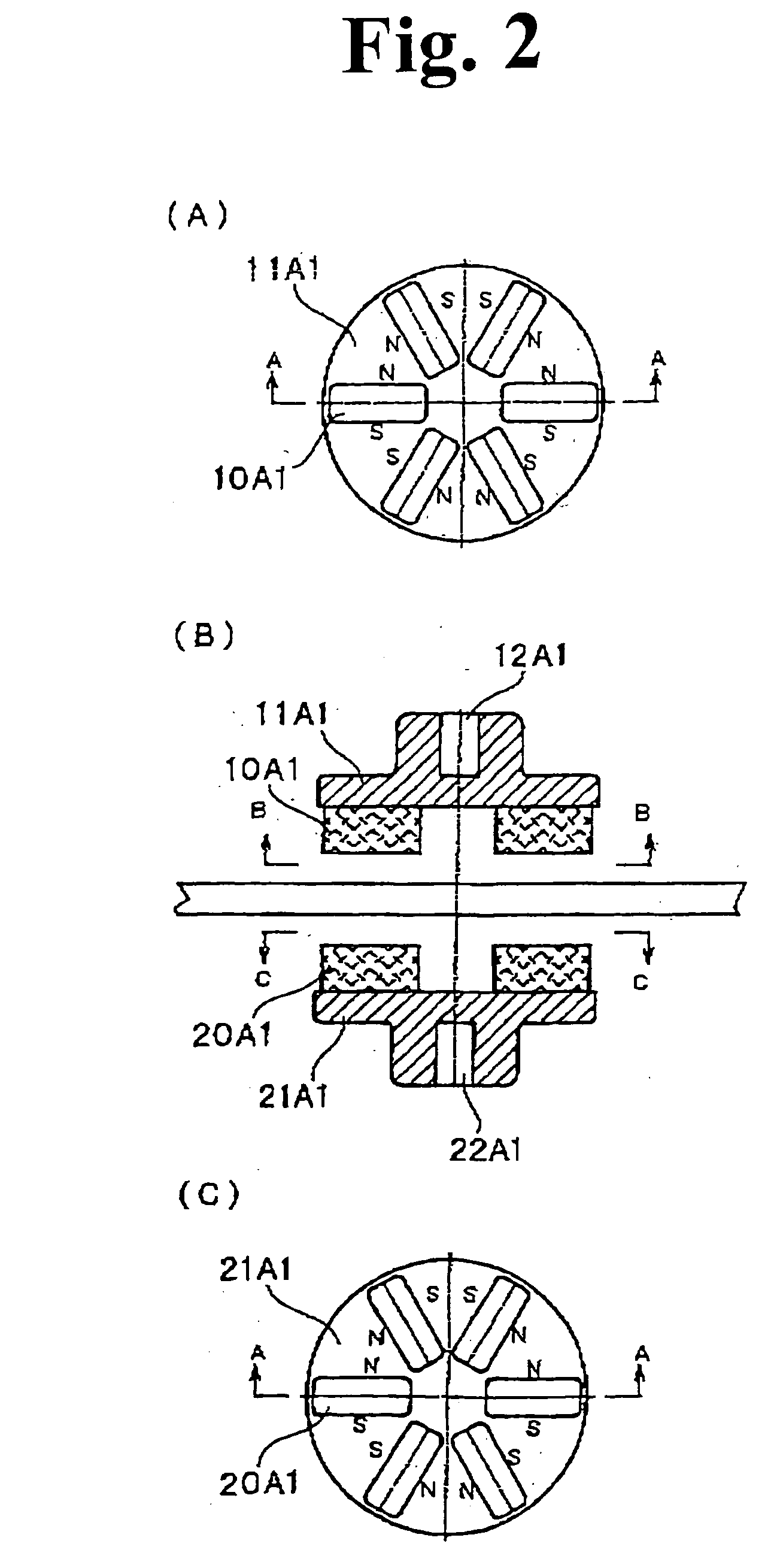

Magnetic rotation transmitting device, hermetic stirring unit, and electric furnace

InactiveUS20050206260A1Dynamo-electric brakes/clutchesRotary stirring mixersElectric arc furnaceMagnetic rotation

In order to provide a magnetic rotation transmitting device capable of obtaining a large transmitting torque without using a large-sized permanent magnet, in an axial-type magnetic rotation transmitting device, which includes a driving rotation body having one or plural magnetic line(s) in which plural first magnets (10A) are disposed in a circumferential direction on a first disk (11A) at almost equal intervals, a drive source rotationally driving a drive shaft of the driving rotation body, and a driven rotation body having one or plural magnet line(s) in which second magnets (20A) of the same number as the first magnets (10A) are disposed in the circumferential direction on a second disk (21A) at almost equal intervals, symmetrically disposed to, and magnetically coupled with the driving rotation body with a magnetic coupling gap and, which utilizes a magnetic operation and which allows the driven rotation body to rotate by rotationally driving the drive shaft by means of the drive source, the first magnet (10A) has a N-magnetic pole portion and a S-magnetic pole portion, and an extended surface of a boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driving center line as being a rotation center line of the driving rotation body, the second magnet (20A) has the N-magnetic pole portion and the S-magnetic pole portion, and the extended surface of the boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driven center line as being the rotation center line of the driven rotation body, adjacent and facing surfaces of the first magnets (10A) adjacent to each other on the first disk (11A) are disposed so that magnetic pole faces having the same polarity make pairs, and adjacent and facing surfaces of the second magnets (20A) adjacent to each other on the second disk (21A) are disposed so that the magnetic pole faces having the same polarity make pairs.

Owner:MAGUNEO

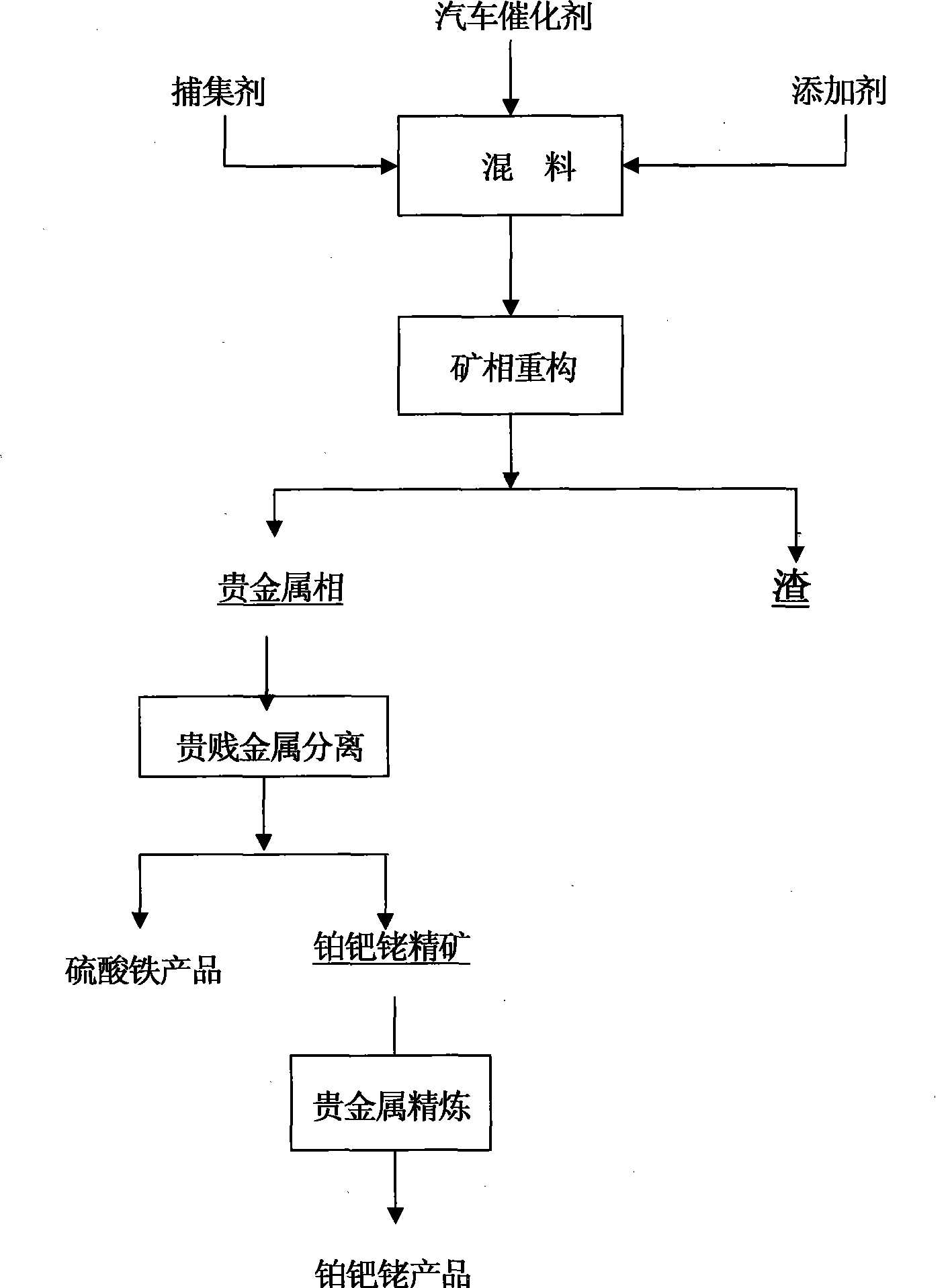

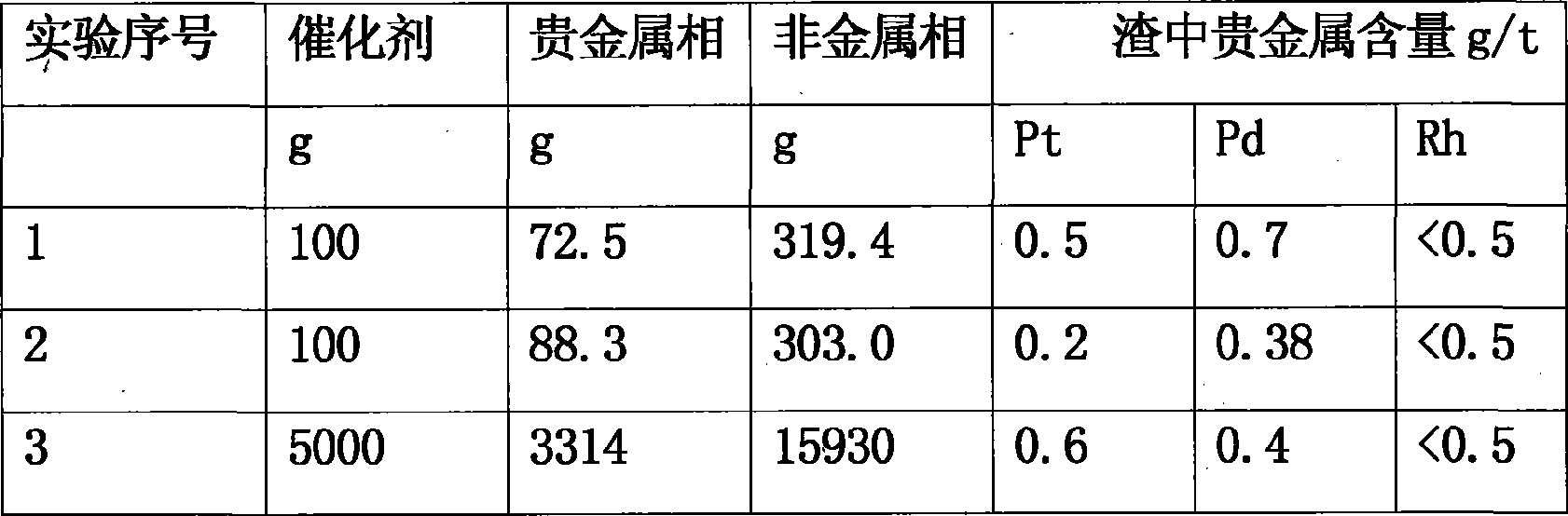

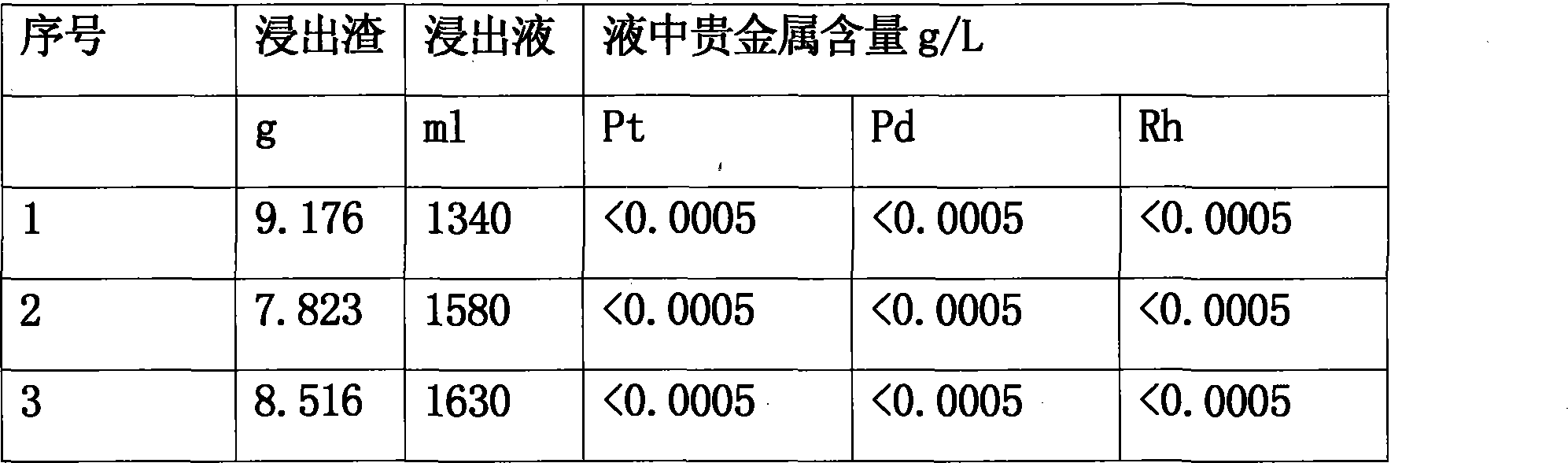

Method for extracting platinum, palladium, rhodium from automotive catalyst of ore phase reconstruction

InactiveCN101509077AEfficient captureReduce corrosionProcess efficiency improvementElectric arc furnaceSlag

The invention relates to a method for recovering noble metals from spent automotive exhaust catalysts, comprising the following processes: 1. mixing the spent automotive exhaust catalyst with a reducing agent, an additive and a trapping agent; 2. putting the mixed materials into a clay graphite crucible, and putting the clay graphite crucible into an electric furnace or an electric arc furnace for smelting, thus obtaining a noble metal phase; 3. selectively leaching base metals from the noble metal phase, thus obtaining the enrichment of the noble metal, refining the enrichment of the noble metal to produce platinum, palladium and rhodium products. The method is characterized by simple process flow and high recovery rates of noble metals. The platinum, palladium and rhodium in the waste slag are less than 1g / t and the product purity is 99.95%.

Owner:KUNMING INST OF PRECIOUS METALS

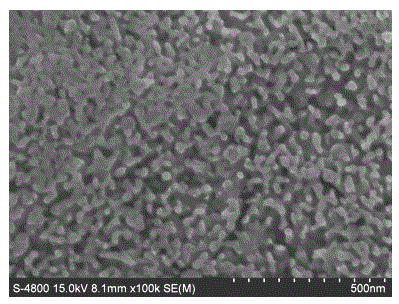

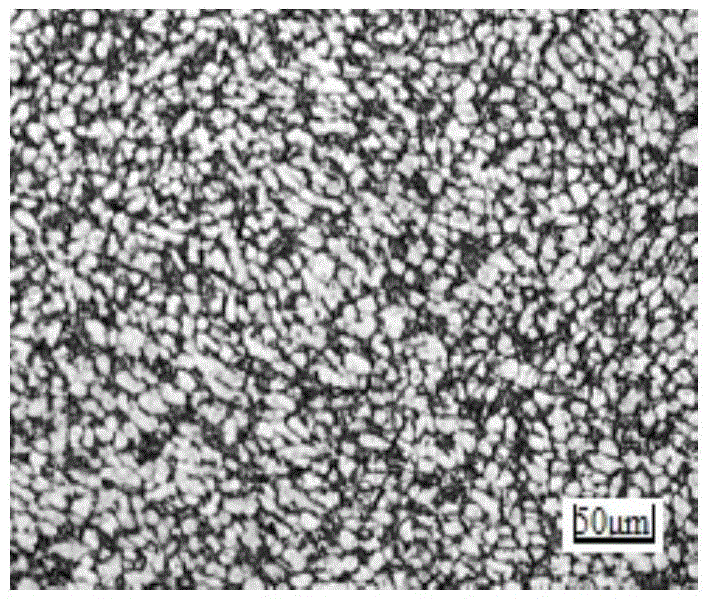

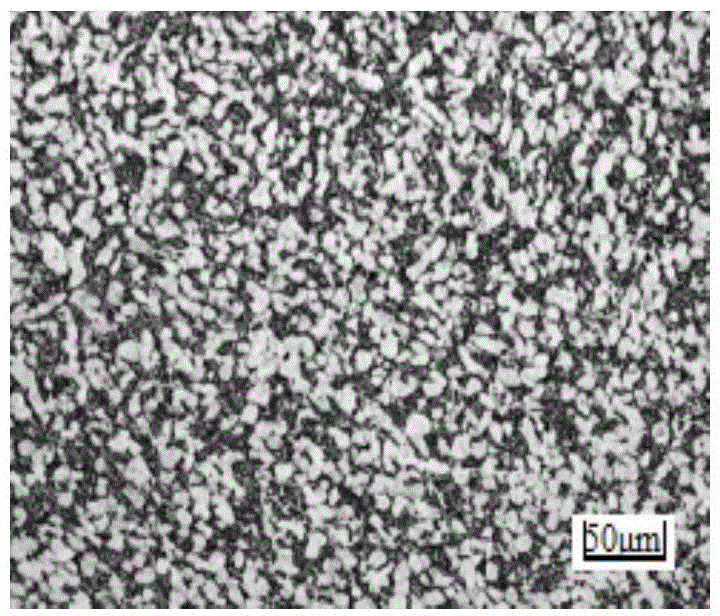

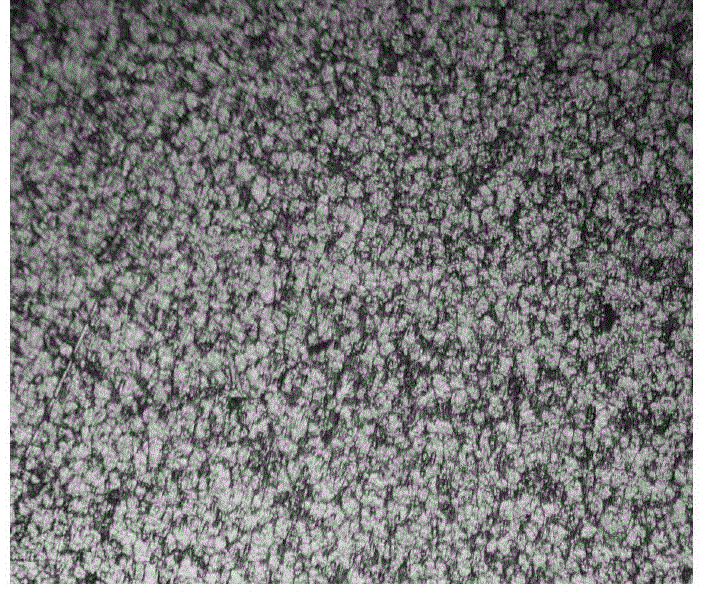

TiZrNbVMo[x] high entropy alloy and preparation method thereof

The invention relates to a high entropy alloy material and a preparation method thereof, the high entropy alloy composition is TiZrNbVMo[x], wherein x is the molar ratio with a value range of x = 0 ~ 1.0. The preparation method comprises the following steps: using a mechanical method to remove oxide skin of metallurgical raw materials of Ti, Zr, Nb, V and Mo elements, then accurately weighing according to the molar ratio; respectively melting intermediate alloys of MoTi and TiZrNbV in a non self-consumable vacuum electric-arc furnace or a cold crucible suspension furnace, finally putting the intermediate alloys together to melt into target alloys, melting each alloy for more than 3 times to ensure uniformity of the composition; taking a specific mass of a master alloy to preparing a rod or plate sample by use of vacuum suction casting or pouring equipment. Compared with traditional crystal materials, the high entropy alloy disclosed by the invention exhibits high hardness, yield strength and fracture strength, and compared with other high-strength body-core-structure high entropy alloys, the high entropy alloy disclosed by the invention has better plastic deformation ability.

Owner:UNIV OF SCI & TECH BEIJING

Method for processing dust with zinc of electric furnace

InactiveCN101092664ARealize comprehensive utilizationRealize secondary useProcess efficiency improvementElectric arc furnaceCooling chamber

This invention discloses a method for treating zinc-containing dust generated in electric furnace. The method comprises: mixing zinc-containing dust with carbon, balling, oven-drying to obtain carbon-containing balls, adding into a converter, calcining at a high temperature to reduce into zinc vapor, introducing into an oxidation chamber, introducing air to oxidize zinc vapor into zinc oxide vapor, introducing into a cooling chamber, cooling to obtain zinc oxide powder, introducing into a dust collection chamber, collecting zinc oxide powder, introducing the carbon-containing balls into a cooler, and cooling to obtain semi-metallized balls. The zinc oxide powder has purity above 90%; the semi-metallized balls have metallization rate above 60%, TFe content above 50%, and zinc content below 2%. The method has such advantages as high utility of zinc-containing dust, low cost and no pollution.

Owner:NANJING NANGANG IND DEV CO LTD

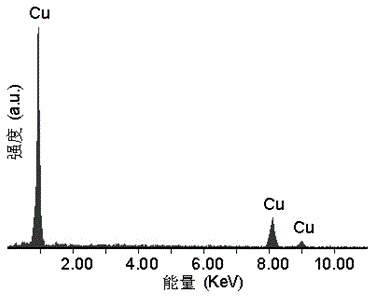

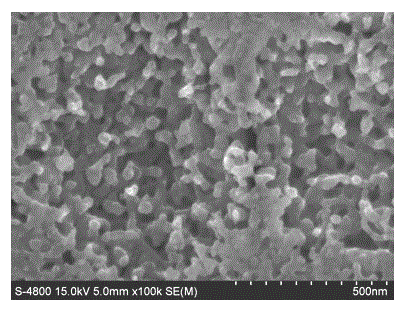

Method for preparing nano-porous copper

ActiveCN103343253AUniform and continuous nanoporous structureReduce complexityElectric arc furnaceIngot

The invention discloses a method for preparing nano-porous copper, which relates to manufacturing for metals with nanoscale porosity. The method comprises the following steps of: calculating the masses of the needed raw materials according to the atomic percent at. % of each element in a target alloy Cu (having an atomic percent of 50.00%)-Zr (having an atomic percent of 42.50-50.00%)(-Al (having the remainder atomic percent)), weighing copper sheets, zirconium grains and aluminium blocks, and mixing to obtain a mother alloy raw material; then smelting the mother alloy raw material in a vacuum arc furnace to prepare a Cu-Zr(-Al) alloy ingot; then preparing a Cu-Zr(-Al) amorphous alloy strip by smelting-spinning equipment; and then preparing a nano-porous metallic copper strip by one-step dealloying, cleaning, and then storing the cleaned nano-porous metallic copper strip in a vacuum chamber having a vacuum degree of 0.1 MPa for the later use, so as to avoid oxidation. With the adoption of the method, the defects of complex preparation process, high cost and inconvenience for industrialized large-scale production of the prior art are overcome.

Owner:HEBEI UNIV OF TECH

Method for preparing ferrovanadium by rollover furnace through electro-aluminothermic process

The invention belongs to the field of metallurgy and particularly relates to a method for preparing ferrovanadium by a rollover furnace through the electro-aluminothermic process. The method for preparing the ferrovanadium by the rollover furnace through the electro-aluminothermic process comprises the steps that raw materials of vanadium oxide, aluminum, iron and lime which meet the production requirement are evenly mixed and then added into the rollover type electric-arc furnace, the method combining multi-phase smelting and stepping aluminum distribution is adopted, most slag is removed after the content of vanadium in the slag is reduced to a certain level, the repeated operation of multiple phases of feeding and slag discharging is conducted, the slag and iron are discharged together when the last phase of smelting is conducted and poured into an ingot mould, and ferrovanadium alloy can be obtained after cooling is conducted. The method for preparing the ferrovanadium by the rollover furnace through the electro-aluminothermic process is convenient to operate, capable of lowering aluminum consumption and obvious in economic benefit; meanwhile, the smelting yield of the ferrovanadium is increased, and the obtained ferrovanadium product is low in content of aluminum.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Low-alloy high-strength cast steel, and smelting and heat treatment method thereof

The invention discloses low-alloy high-strength cast steel, and a smelting and heat treatment method thereof. The cast steel comprises the following chemical components in percentage by weight: 0.17-0.22% of carbon, 0.20-0.60% of silicon, 0.80-1.20% of manganese, less than or equal to 0.020% of phosphorus, less than or equal to 0.015% of sulfur, 0.45-1.05% of chromium, 0.4-0.9% of nickel, 0.4-0.95% of molybdenum and less than or equal to 0.30% of copper, and the balance of iron and inevitable impurities. An electric arc furnace oxidation-reduction method or a medium-frequency induction furnace is used for smelting. After a wind power planet carrier casting poured by the low-alloy cast steel disclosed by the invention is heated, the mechanical properties can be stably achieved, the strength of extension is greater than or equal to 830Mpa, the yield strength is greater than or equal to 790MPa, the extension rate is greater than or equal to 12%, and the impact absorption power with a lower temperature of minus 40 DEG C is greater than or equal to 27J.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-entropy alloy brazing filler metal for welding TA2 and 0Cr18Ni9Ti and preparation method thereof

InactiveCN101590574AHigh strengthImprove toughnessWelding/cutting media/materialsSoldering mediaElectric arc furnaceHigh entropy alloys

The invention discloses a high-entropy alloy brazing filler metal for welding TA2 and 0Cr18Ni9Ti. The brazing filler metal comprises the following compositions according to atomic percentage: 20 to 25 percent of Ti, 25 to 30 percent of Cu, 20 to 25 percent of Ni, 15 to 20 percent of Fe, 10 to 13 percent of Cr, 0.5 to 5 percent of Sn, 0.01 to 2 percent of In, and 0.01 to 2 percent of Ga. The invention also discloses a method for preparing a high-entropy alloy brazing filler metal foil, which comprises the following steps: smelting the compositions to obtain high-entropy master alloy in steps by a super-high vacuum arc furnace; and controlling the linear speed of a roller at 5 to 40m / s by a single roller rapid setting device to obtain the high-entropy alloy brazing filler metal foil. The high-entropy alloy brazing filler metal has good flexibility, and is convenient for processing and assembling; and in welding, the high-entropy alloy brazing filler metal has good matching property with welded metal and alloy, brazing seams have excellent corrosion resistance and are single-phase fcc solid solution tissues, and joints have high comprehensive mechanical performance.

Owner:XIAN UNIV OF TECH

Manufactring method for smelting stainless steel containing N biphase

InactiveCN1563463AGood decarburization effectCarbon content is not limitedElectric arc furnaceDouble phase

A method for smelting double-phase with N stain less steel characterizes 1. carrying out the primary smelting according to the return oxygen blowing wethod 2. smelting qualified double stainless steel with N in composition and purity (1) blown temperature is higher than or equal to 1540deg,c (2) carbon elimination: blowing N2, O2 mixed gas for decarbonization and increasing N2 and process the increased temperature O2 / N2=4, sampling to regulated the components: when c=0.10%, stop blowing O2 but Ar instead, adding prerecovered stags for 7min, total sample analysis including all stags and adding recovery stags (3) recovery: blowing Ar and forcing to eliminate O, blowing N to increase N, sample analysis, fine adjustment to the composition to get the cast ingot.

Owner:宝钢特钢有限公司

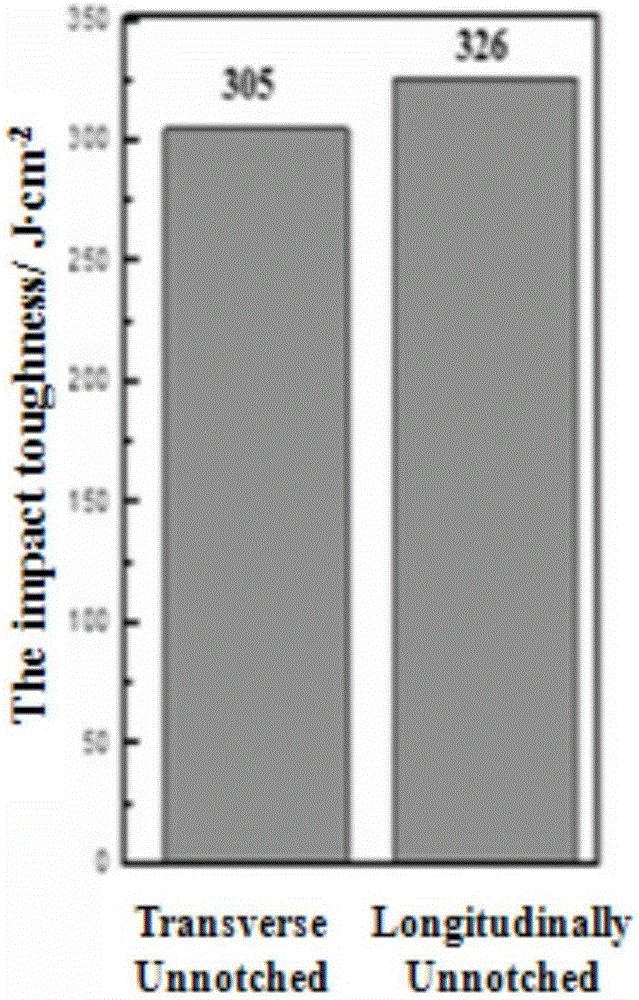

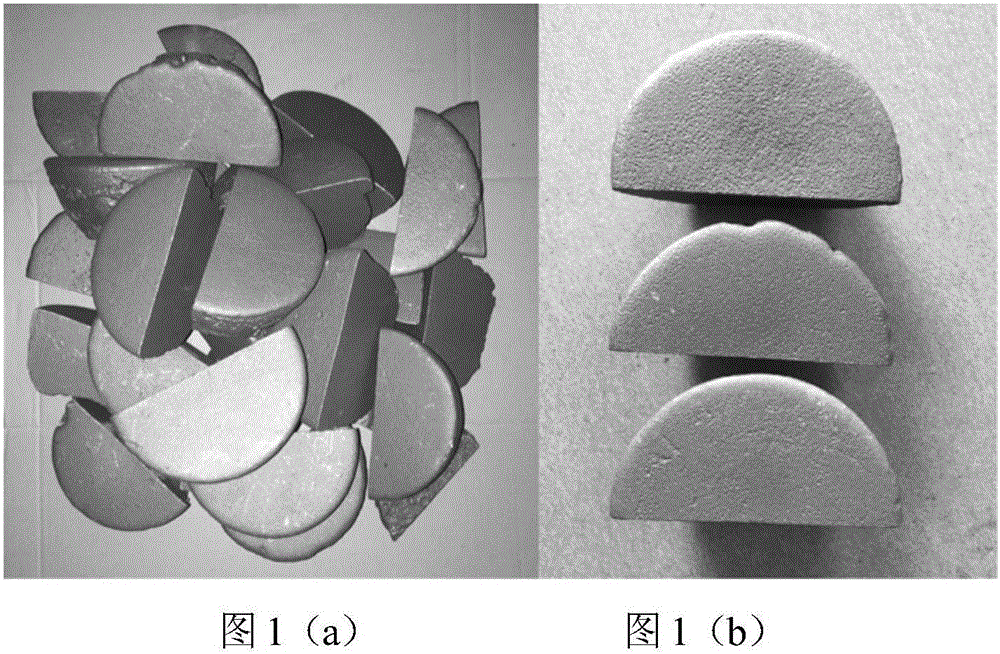

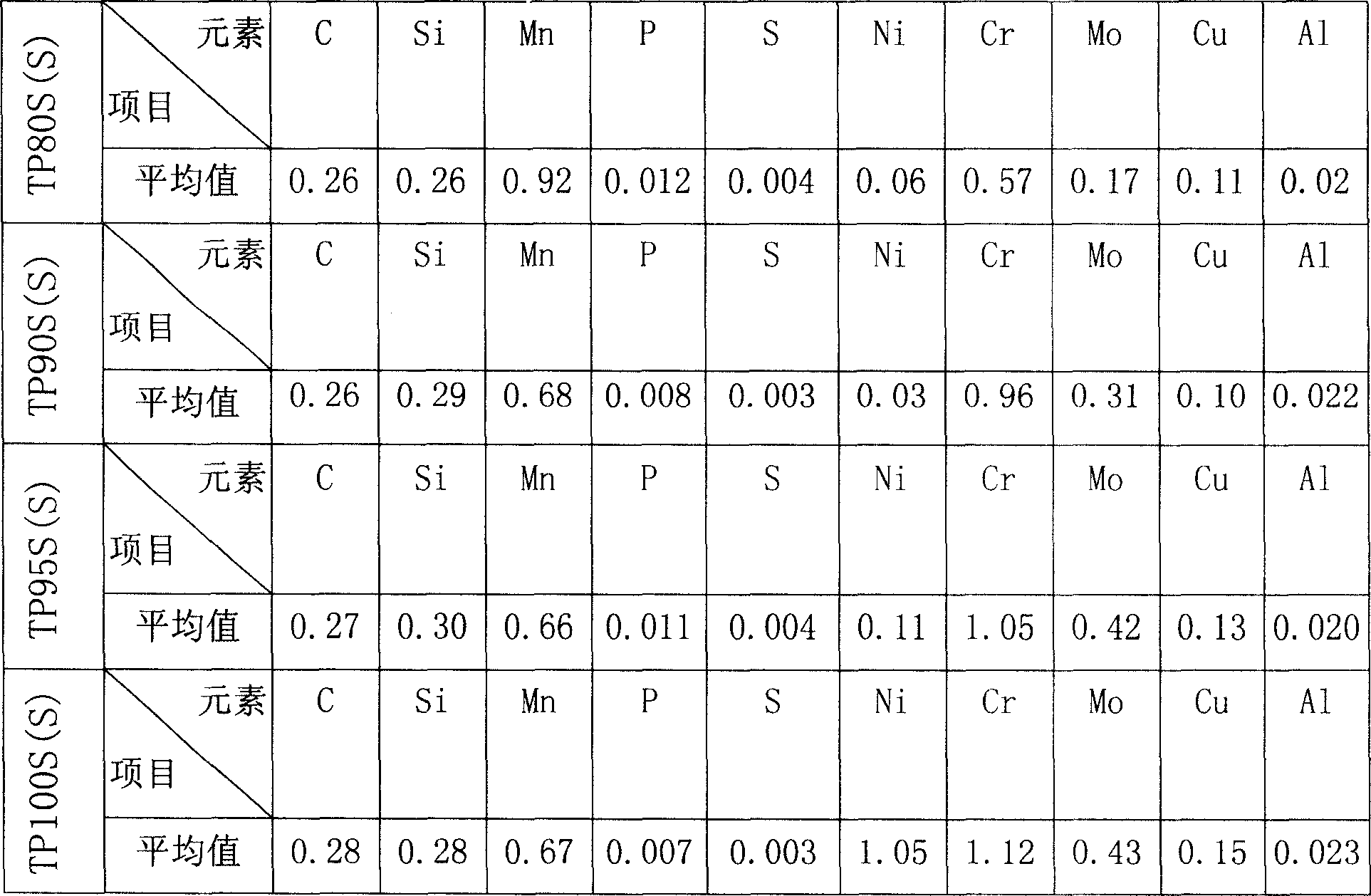

Petroleum steel tube capable of anti hydrogen sulfide stress corrosion and its manufacturing method

ActiveCN1948538AExcellent physical and chemical propertiesEasy to useDrilling rodsFurnace typesElectric arc furnaceArc melting

The invention offers oil steel pipes which can resist stress corrosion by hydrogen sulfide. Weight proportion of their compound is: C 0.25-0.32%,Si 0.10-0.40%,Mn 0.60-1.20%, P<=0.020%,S<=0.010%,Ni<=0.25%,Cr 0.55-1.20%,Mo 0.10- 0.50%,Cu<=0.30%,Al 0.010-0.040% and the allowances are Fe. Scrap steel and spongy iron or melted iron is taken as melting materials. After arc melting, external refinement and vacuum deaeration, they are cast continuously to get round billiets. Then, they are hot rolled to seamless steel pipes and finally to bushing and oil pipes by heat processing of quench and temper. The steel pipes have good physicochemical property and their indexes all reach or exceed API standard. Threshold value of resisting stress corrosion by hydrogen sulfide reaches 90%SMYS, which precedes the standard request and can be extensively applied in oil-gas field with hydrogen sulfide.

Owner:TIANJIN PIPE GROUP CORP

Preparation method of nano porous copper

The invention discloses a preparation method of nano porous copper, and relates to manufacture of alloy with pores, in particular to a method for preparing the nano porous copper by adopting a free dealloying technology. The preparation method comprises the following steps of: firstly according to the atomic percent of all elements in target alloy: 50.00-55.00% of Cu, 40.00-45.00% of Hf and the balance of Al, weighing copper pieces with the mass percent purity being 99.99%, hafnium particles with the mass percent purity being 99.99% and aluminium blocks with the mass percent purity being 99.99%; putting raw materials of master alloy in a vacuum electric-arc furnace, smelting to prepare Cu-Hf-Al master-alloy casting ingot; then preparing a Cu-Hf-Al amorphous alloy strip by using the master-alloy casting ingot; and finally carrying out dealloying treatment with low-concentration hydrofluoric acid solution to prepare the nano porous copper belt. The preparation method disclosed by the invention has the advantages that the defects of complex operation, high cost, long production period and inapplicability for large-scale industrial production in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

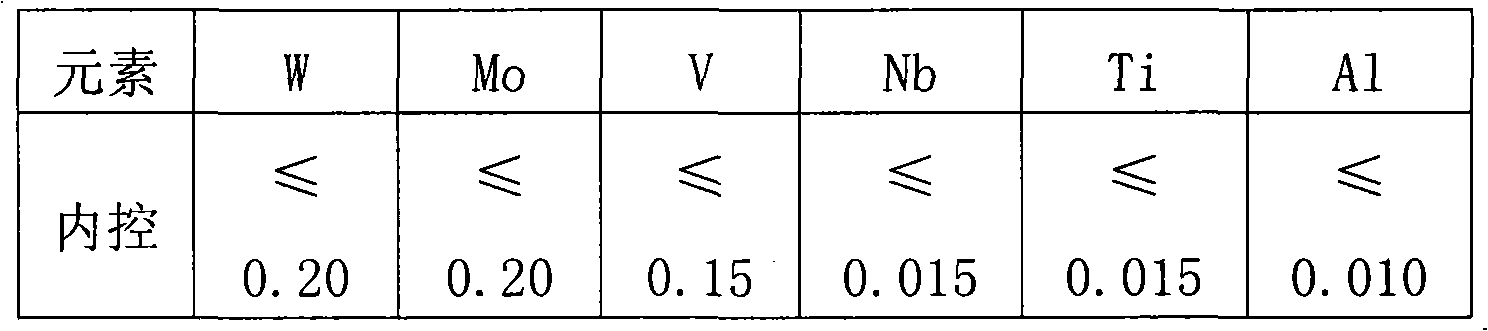

High carbon high silicon martensite stainless steel billet and preparation method thereof

InactiveCN101967610AGuaranteed performanceSmall temperature fluctuationsProcess efficiency improvementElectric furnaceStress concentrationElectric arc furnace

The invention provides a high carbon high silicon martensite stainless steel billet. The steel billet is characterized by comprising the following components by weight percent: 0.41-0.47% of C, 2.80-3.20% of Si, 0.50-0.80% of Mn, 8.50-9.20% of Cr, 0.30% or less of Ni, 0.028% or less of P, 0.005% or less of S, 0.20% or less of W, 0.20% or less of Mo, 0.15% or less of V, 0.015% or less of Nb, 0.015% or less of Ti, 0.010% or less of Al and the balance Fe and inevitable impurities. The invention also provides a preparation method of the high carbon high silicon martensite stainless steel billet. The method comprises the following steps: performing primary smelting with an electric arc furnace (EAF), performing argon-oxygen decarburization (AOD) smelting, refining with a low frequency (LF) furnace, performing continuous casting, annealing and rolling. The method of the invention has simple operation, can stably control the quality of the continuous casting billet, completely suppresse cracks, overcome the defect of concentration of stress and increase the casting yield and quality stability of the martensite stainless steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Cast steel for bearing parts in mechanical lifting system and its making process

The present invention relates to one kind of cast steel for bearing parts in mechanical lifting system and its making process. The cast steel of Cr-Ni-Mo line consists of C 0.15-0.30 wt%, Mn 0.60-1.10 wt%, Si 0.3-0.8 wt%, Ni 0.4-1.1 wt%, Cr 0.4-1.1 wt%, Mo 0.15-0.40 wt%, S less than 0.025 wt%, P less than 0.025 wt%, and residual elements including Cu, W and V less than 0.60 wt%. The making process of the cast steel includes the following technological steps: making steel in MF furnace or electric arc furnace; casting in sand mold with equivalent circular kiel test rod; normalizing, quenching and tempering of both cast part and test rod in the same furnace; and non-destructive detection of the cast part.

Owner:河南石油勘探局南阳石油机械厂

Method for melting and decarburization of iron carbon melts

InactiveUS6749661B2Shorten the construction periodHigh energyElectric discharge heatingStirring devicesElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame and a high velocity oxidizing gas into a furnace for metal melting, refining and processing, particularly steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase and introducing an effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal. In one implementation of an apparatus, improved efficiency is obtained by mounting a fixed burner / lance closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through the scrap to clear a path to the molten metal and shortens the distance the high velocity oxygen from the lance travels to the slag-metal interface thereby increasing its penetrating power. The method additionally includes supplying a plurality of reaction zones with the high velocity oxidizing gas to decarburize the melted metal. The plurality of reaction zones increases the surface area available for the reaction thereby allowing a more rapid rate of decarburization and a more homogenous metal bath. The reaction zones are supplied with the high velocity oxidizing gas according to an oxygen supply profile which is related to the carbon content of the metal bath. In this manner an optimal amount of oxygen can be introduced into the metal bath to shorten the decarburization process without producing excessive oxidation of the metal bath and excessive free oxygen in the furnace.

Owner:PROCESS TECH INT

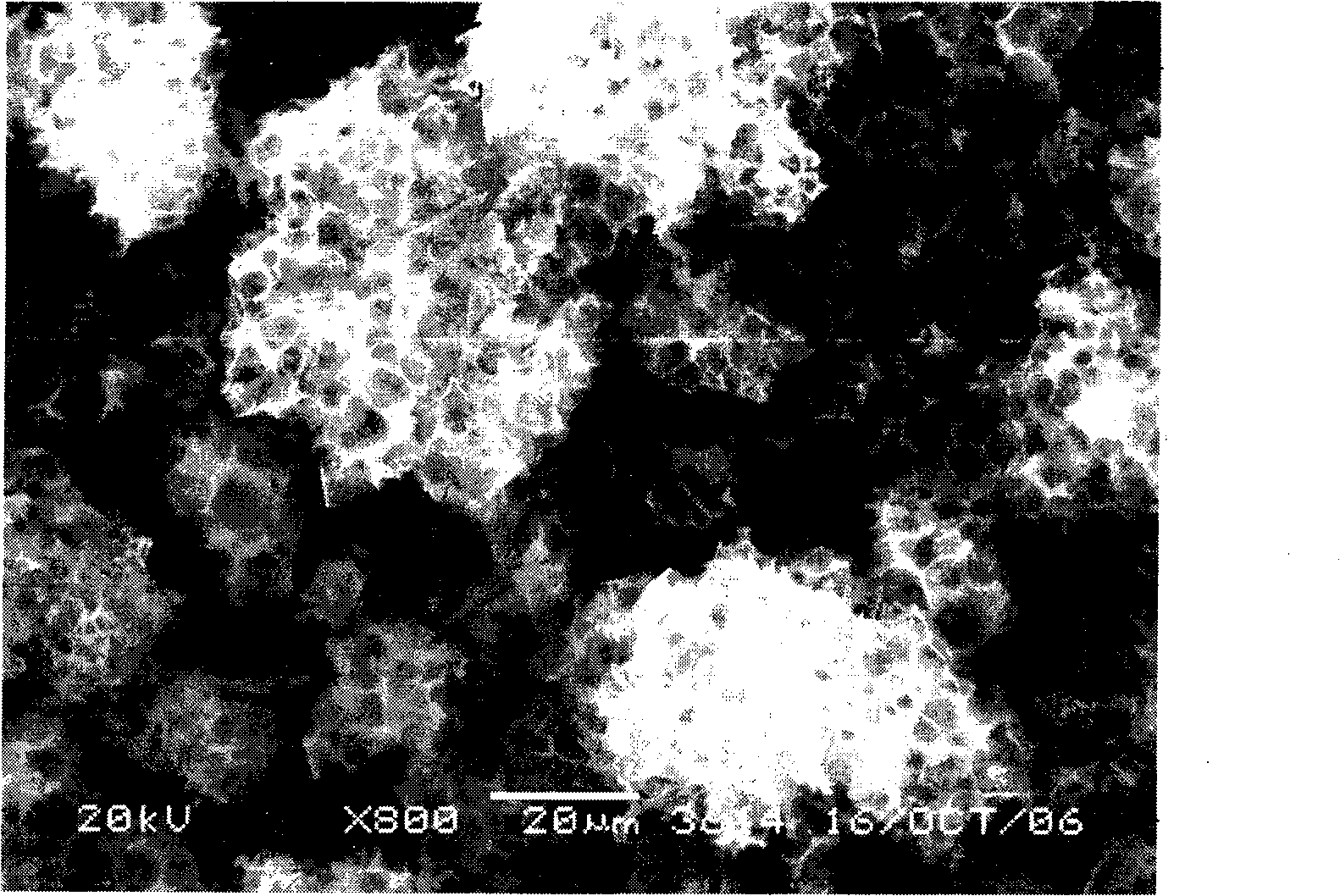

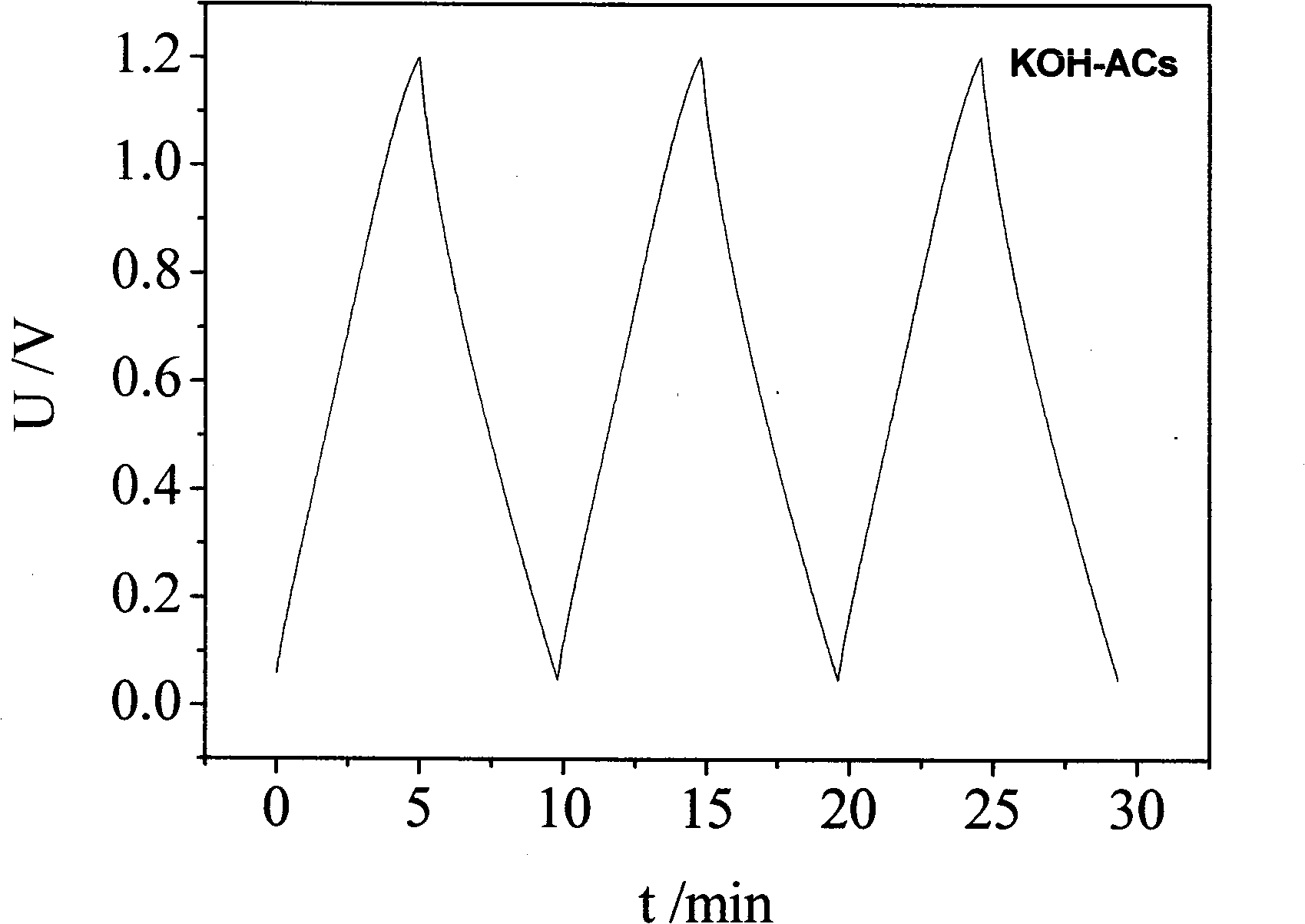

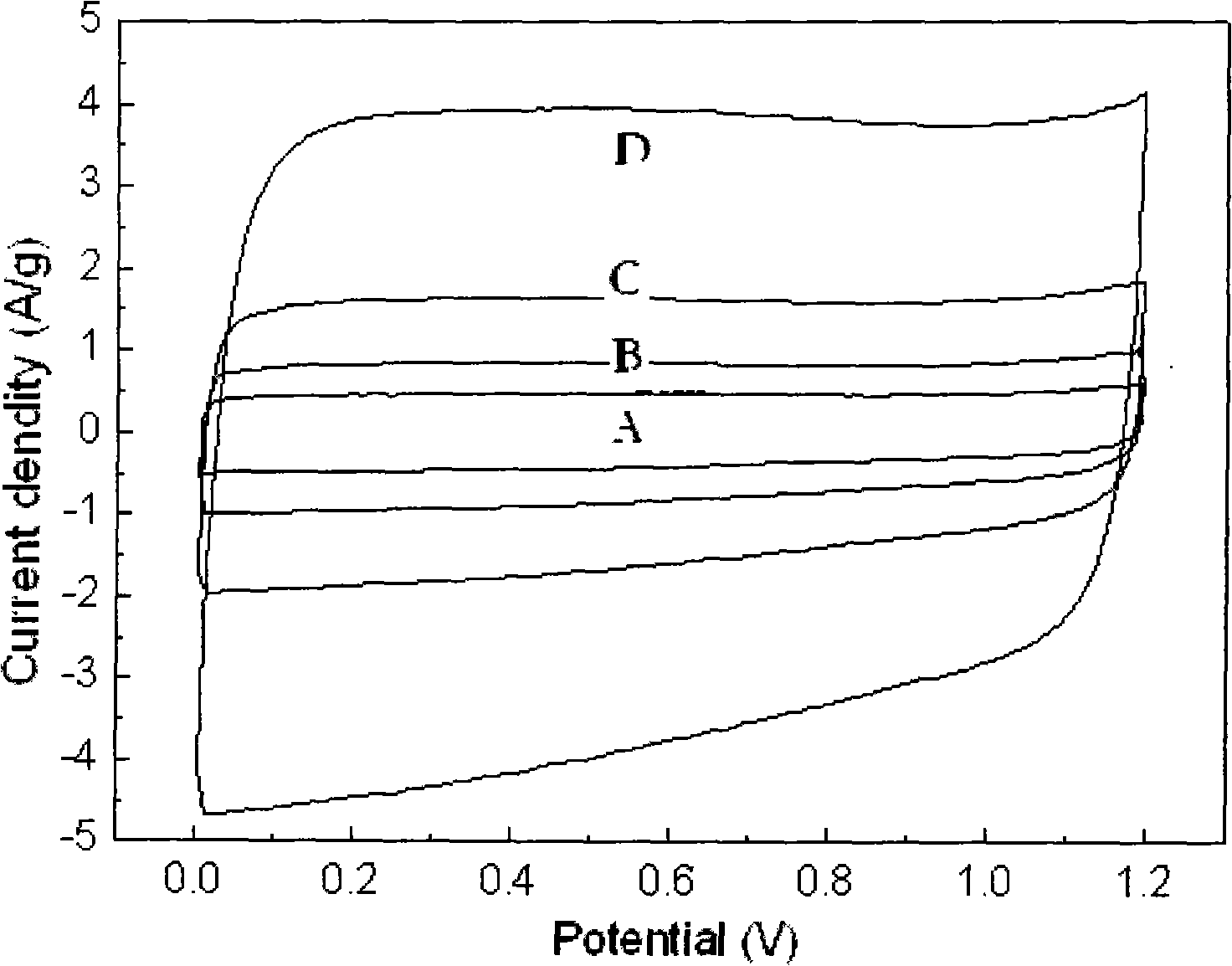

Active carbon for super capacitor and a preparation method thereof

InactiveCN101525132ANo pollution in the processRich varietyLight-sensitive devicesHybrid capacitor electrodesElectric arc furnacePotassium hydroxide

The invention relates to an electrode material for an electrochemical super capacitor, more particularly to an active carbon for the super capacitor and a preparation method thereof. The inventive active carbon for the super capacitor is obtained by the steps of drying, carbonizing and activating starch that is taken as raw material. The preparation method thereof comprises the following steps of: 1) drying moisture in the starch; 2) putting the dried starch in an electric resistance furnace to be heated up to 350-550 DEG C under the protection of an inert gas, keeping constant temperature for 1-4 hours, and taking out after cooling to obtain a carbonizing material; 3) grinding and mixing the carbonizing material with potassium hydroxide saturated solution uniformly, drying the moisture and putting the mixture in the electric resistance furnace to be heated up to 750-850 DEG C under the protection of the inert gas, keeping constant temperature for 1-4 hours, and taking out the mixture after cooling to be ground, washing to a neutral state and drying to obtain the active carbon; the proportion by weight of the carbonizing material to potassium hydroxide solid is 1:4-8. The invention has extensive source of the raw materials, high specific surface area of the prepared active carbon and low production cost.

Owner:GUANGXI NORMAL UNIV

Preparation method of titanium zirconium base alloy

InactiveCN103602840AHigh strengthElongation at failure retentionElectric arc furnaceTitanium zirconium

The invention relates to a preparation method of a titanium zirconium base alloy. The titanium zirconium base alloy comprises the following components in percentage by weight: 41-62% of Ti, 30-51% of Zr, 5% of Al and 3% of V. The preparation method comprises the following steps: adding the raw materials into a nonconsumable electric-arc furnace and melting the raw materials to obtain an alloy ingot; after coating a high-temperature antioxidant on the surface of the alloy ingot, heating and insulating in the furnace, and cogging and forging to obtain a platy alloy; after removing the antioxidant on the surface, heating in a thermal treatment furnace at 850-870 DEG C, insulating for 1 hour and performing water quenching and cooling; cutting the alloy plate to thin plates which are 3-4mm long for rolling and forming at room temperature, wherein the rolling strain rate is 2.2-3.1<-s> and the total deformation is over 80%; then, annealing, wherein the vacuum degree is 10<-4>-10<-5>Pa, the temperature is 740-760 DEG C; insulating for 1 hour; performing air cooling to room temperature. According to the preparation method provided by the invention, the titanium zirconium base alloy with the microstructure which is a special duplex microstructure is obtained, and the alloy strength is effectively improved while the plasticity of the alloy is maintained.

Owner:YANSHAN UNIV

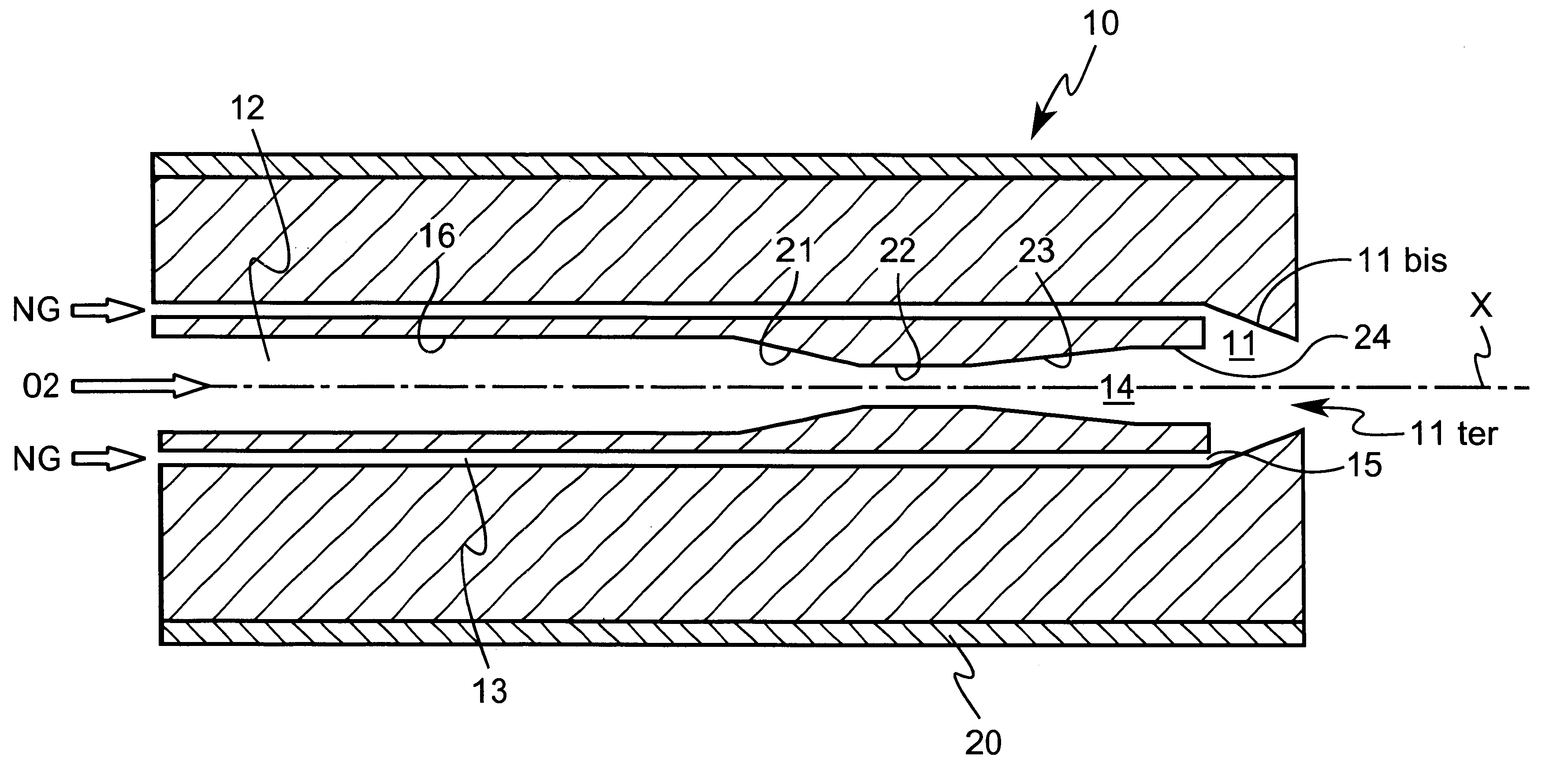

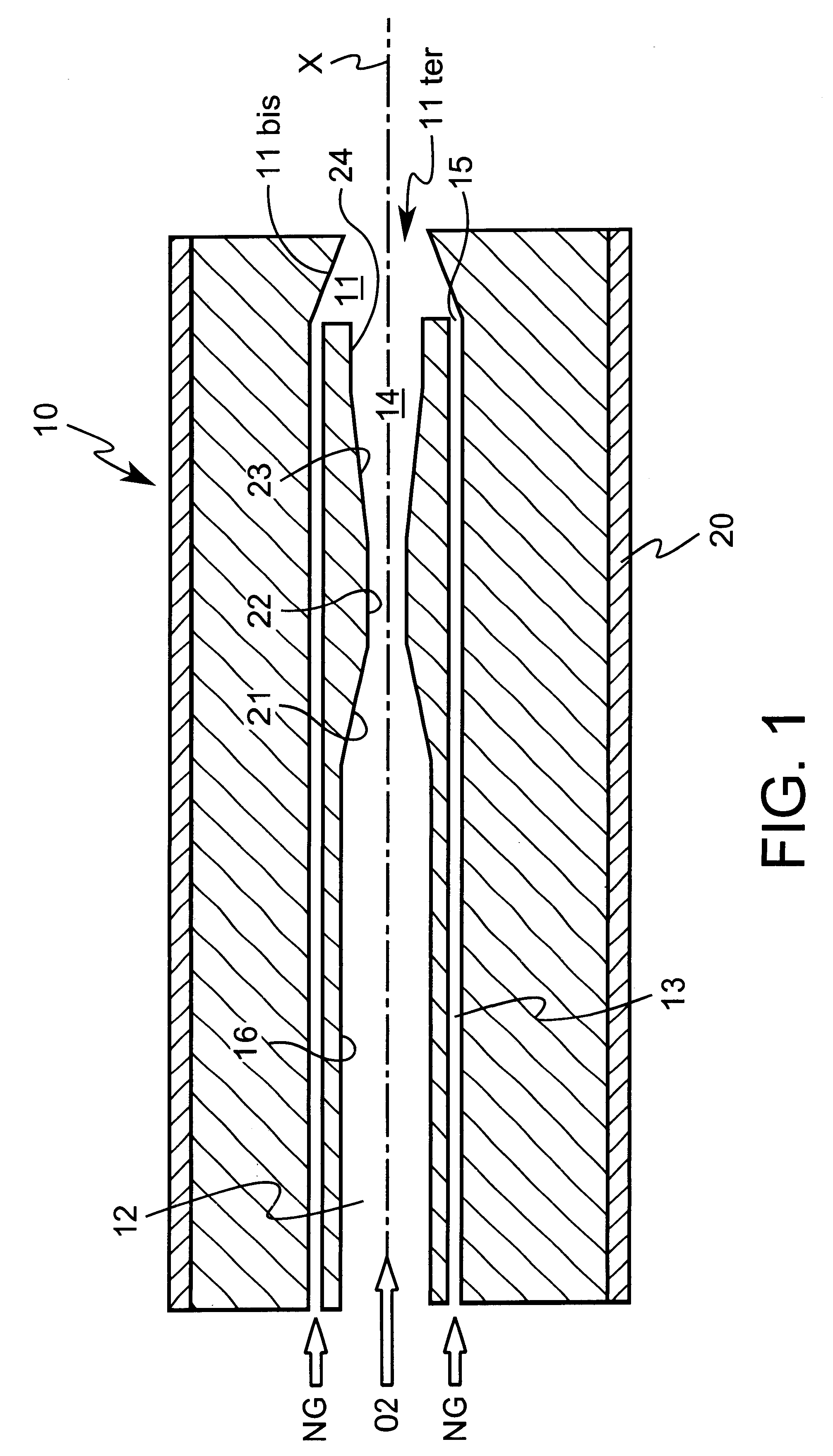

Process for injection of a gas with the aid of a nozzle

The electric arc furnace is equipped with a supersonic injector comprising a so-called Laval nozzle arranged at a certain distance above the bath. The dimensions of the nozzle are calculated as a function of the desired flow rate of oxygen and the desired velocity of the jet, and the pressure of the oxygen at the intake of the nozzle is such that the static pressure of the jet at the exit of the injector is substantially equal to the pressure of the surrounding atmosphere. Preferably, the injector comprises an annular channel for injection of natural gas, and can be used in burner mode at the start of the melting of scrap iron. The velocity of the oxygen is then subsonic.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Beta titanium alloy and preparation method thereof

The invention discloses a beta titanium alloy and a preparation method thereof, relates to a titanium alloy, and provides a beta titanium alloy with excellent combination property and a preparation method thereof. The beta titanium alloy comprises the following components by mass percent: 6-10% of vanadium, 2-4% of aluminum, 2-4% of chromium, 0-13% of niobium, 0-3% of tin, 0-5% of zirconium, 0-4% of molybdenum, 0-0.05% of boron and the balance titanium. The preparation method comprises the following steps: putting the titanium and zirconium in a sponge state into an arc furnace; vacuumizing and then charging argon for smelting; smelting the smelted titanium and zirconium with vanadium, aluminum, chromium, niobium, tin, molybdenum and boron to obtain a beta titanium alloy pig material; carrying out homogenizing heat treatment on the beta titanium alloy pig material, and cooling along with the furnace; rolling the beta titanium alloy pig material after the heat treatment into a schistose alloy material; slicing the obtained schistose alloy material into a sample; and quenching with icy water after the solution treatment, and then carrying out aging to obtain the beta titanium alloy.

Owner:XIAMEN UNIV

Hazardous waste stabilization methods, products and testing procedures

InactiveUS6991593B2Protect environmentFacilitate methodSludge treatmentSolid waste disposalElectric arc furnaceEnvironmental engineering

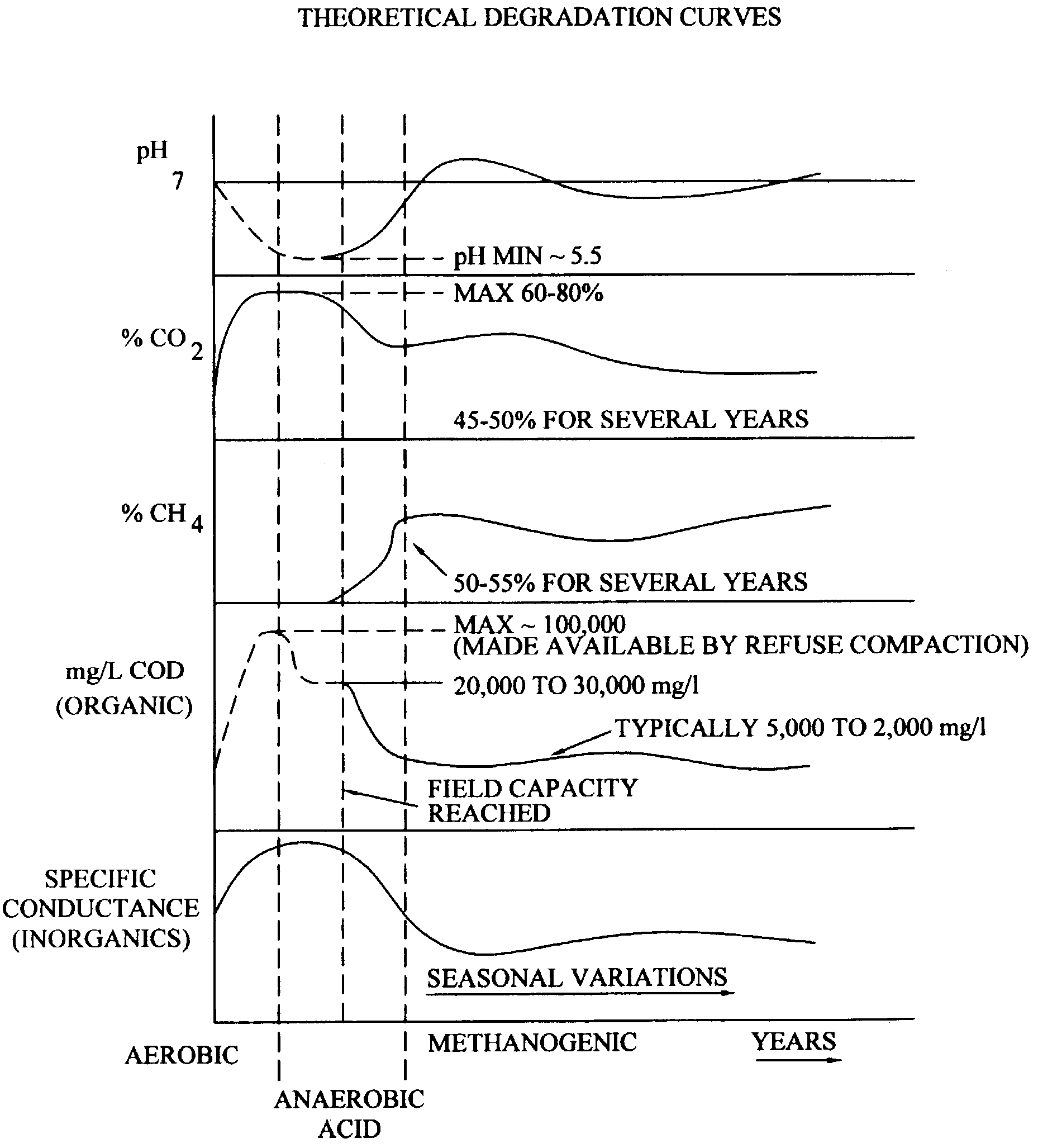

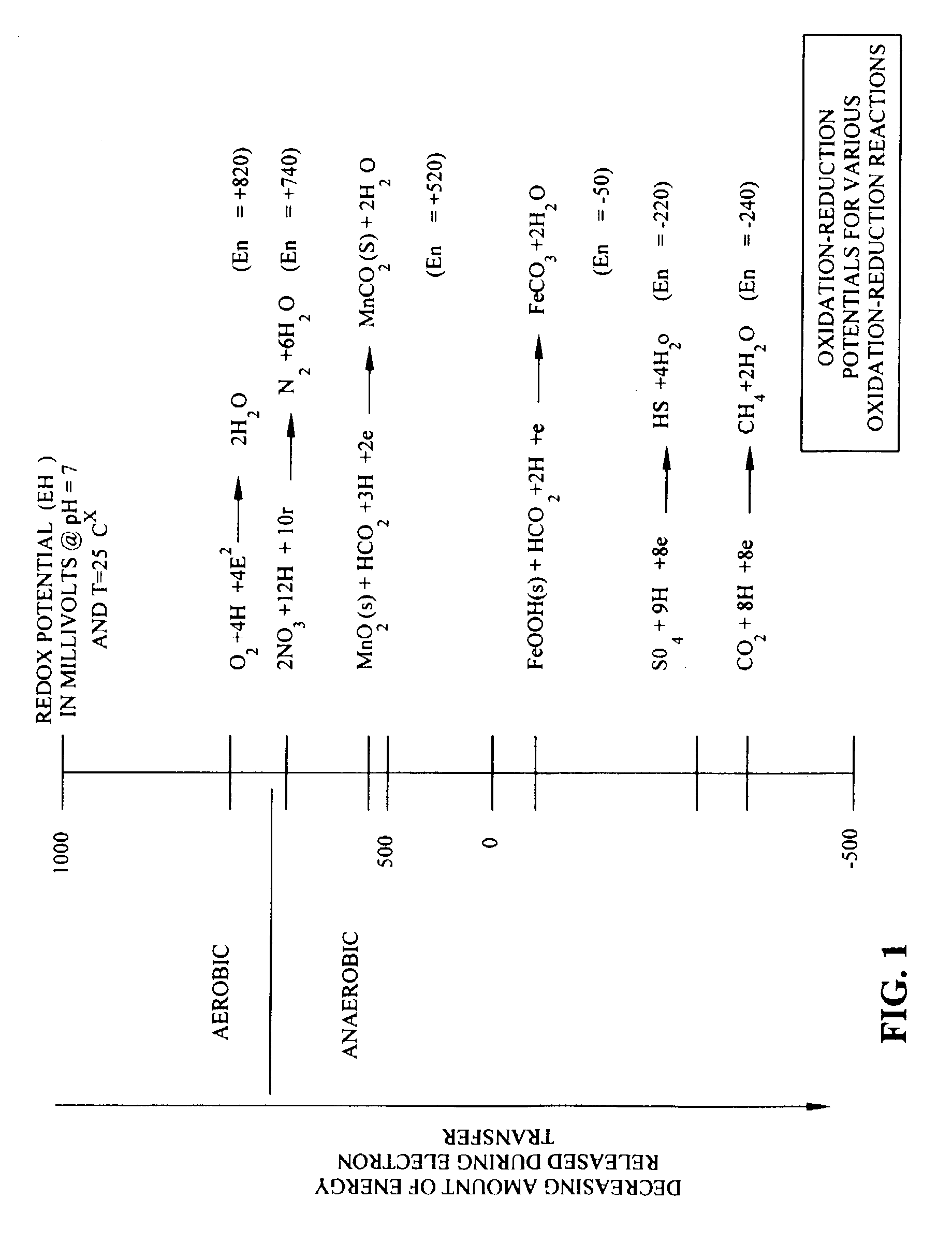

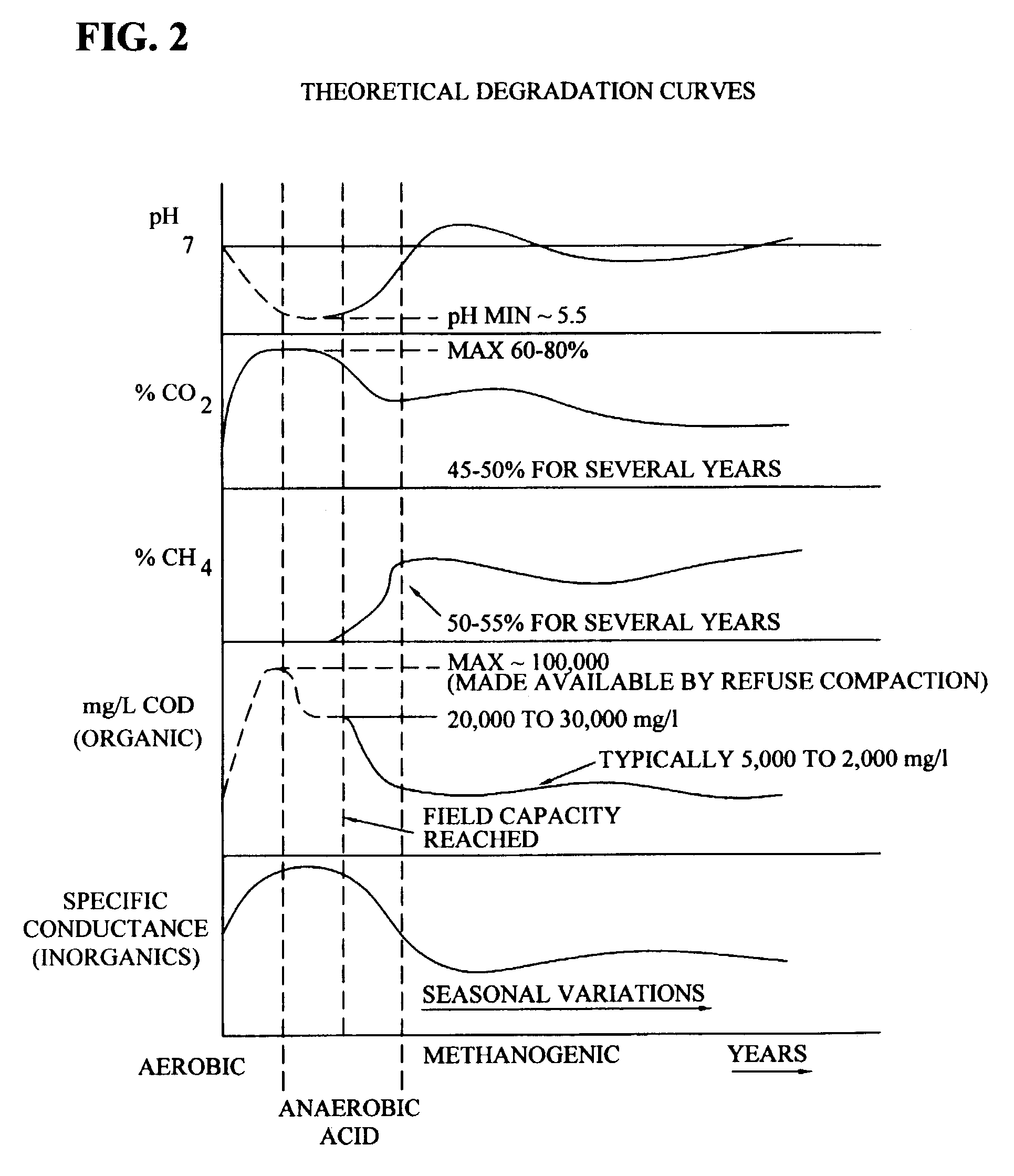

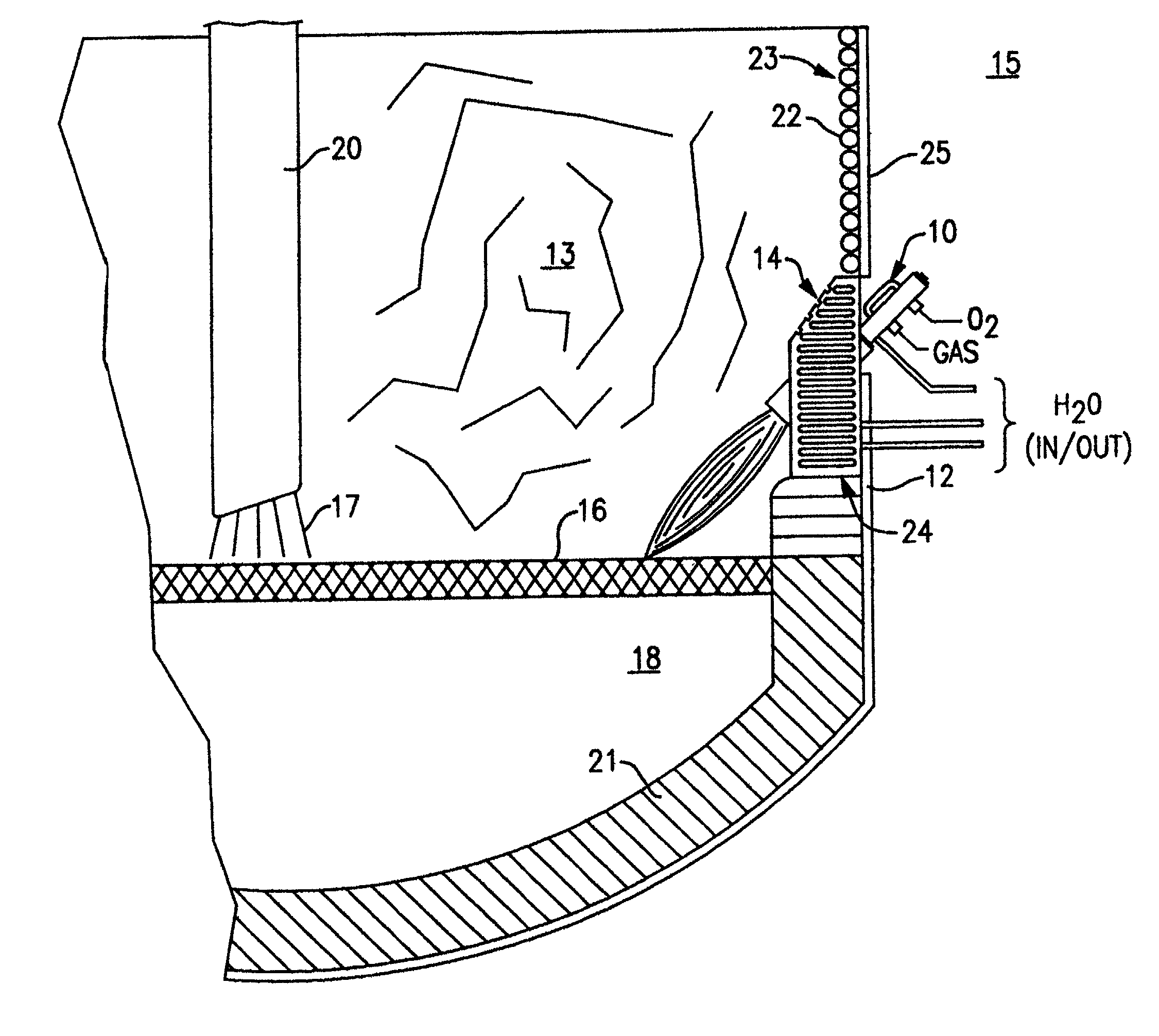

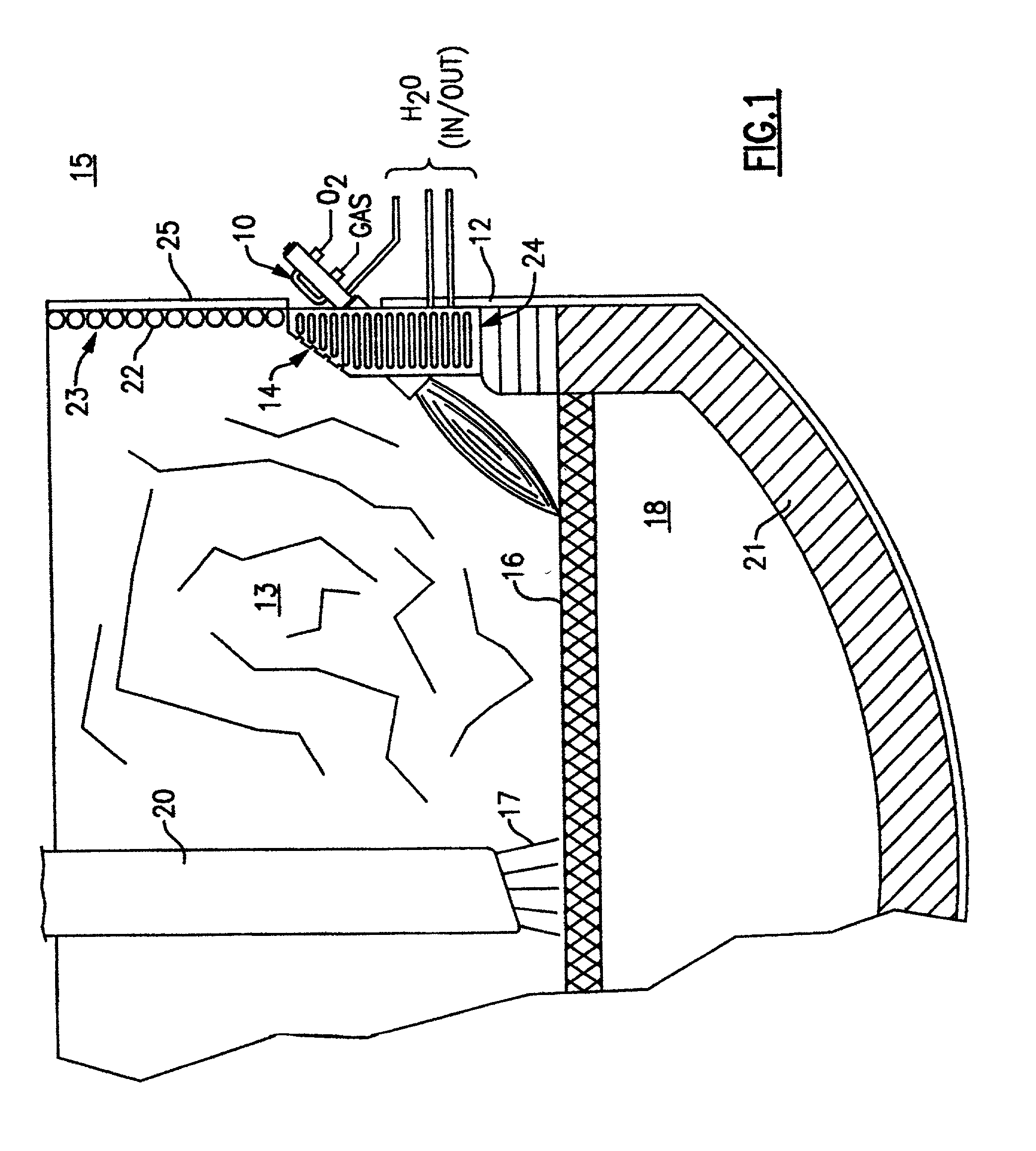

A process for the stabilization of metal bearing waste is provided that is based upon the discovery that landfills have anaerobic environments. This process includes adjusting the pH of the waste and adding a sulfide containing reducing agent to the waste to achieve a reducing environment. In one embodiment, electric arc furnace dust is stabilized for landfill disposal. Also provided is a method for a determination of landfilled waste leachability. This method is performed under conditions that simulate the chemical characteristics of landfills. In one embodiment, stabilized metal bearing waste is deoxygenated and a simulated leachate is prepared under anaerobic conditions.

Owner:HERITAGE ENVIRONMENTAL SERVICES

Mounting arrangement for auxiliary burner or lance

InactiveUS20020001332A1Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

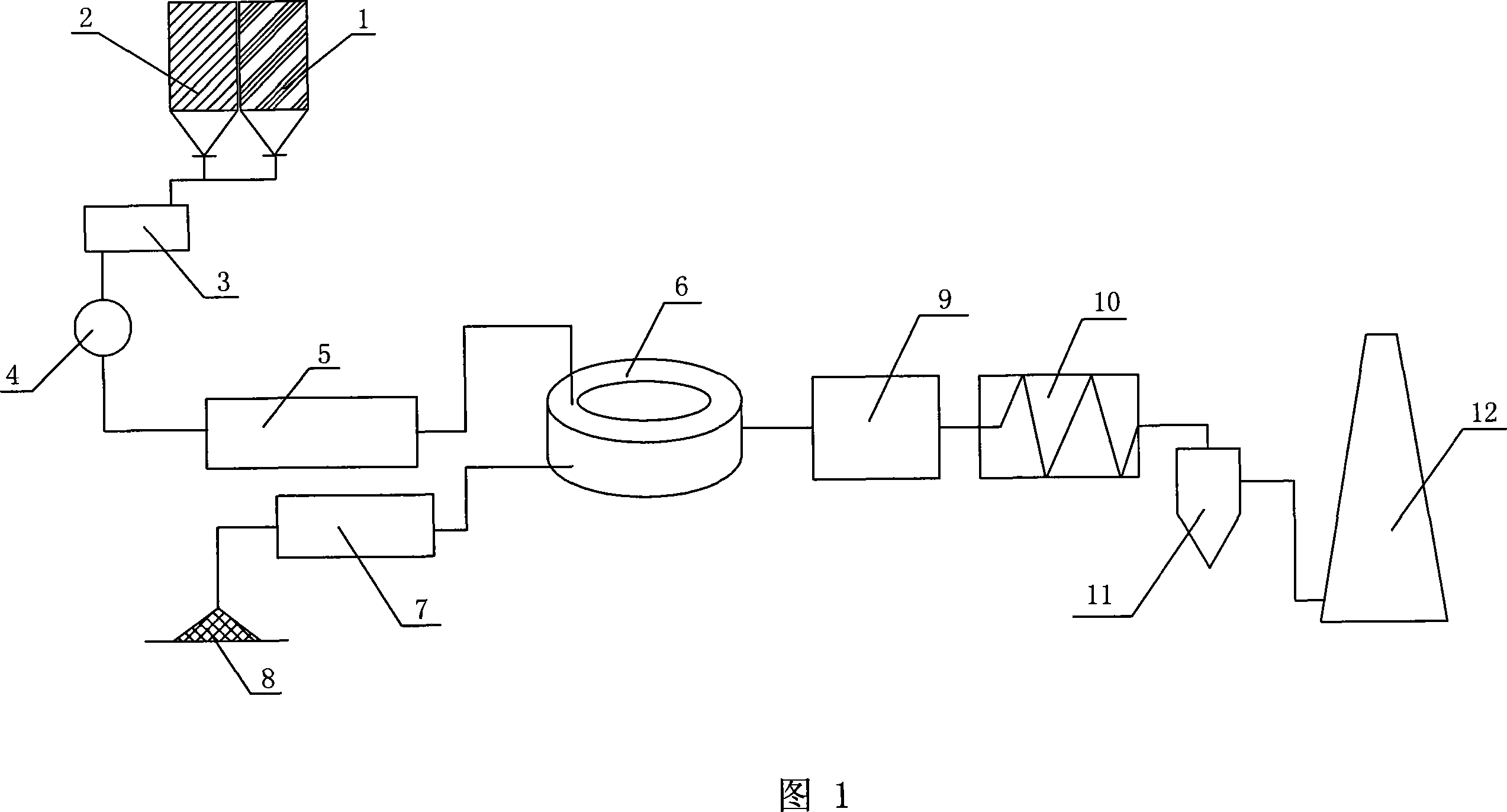

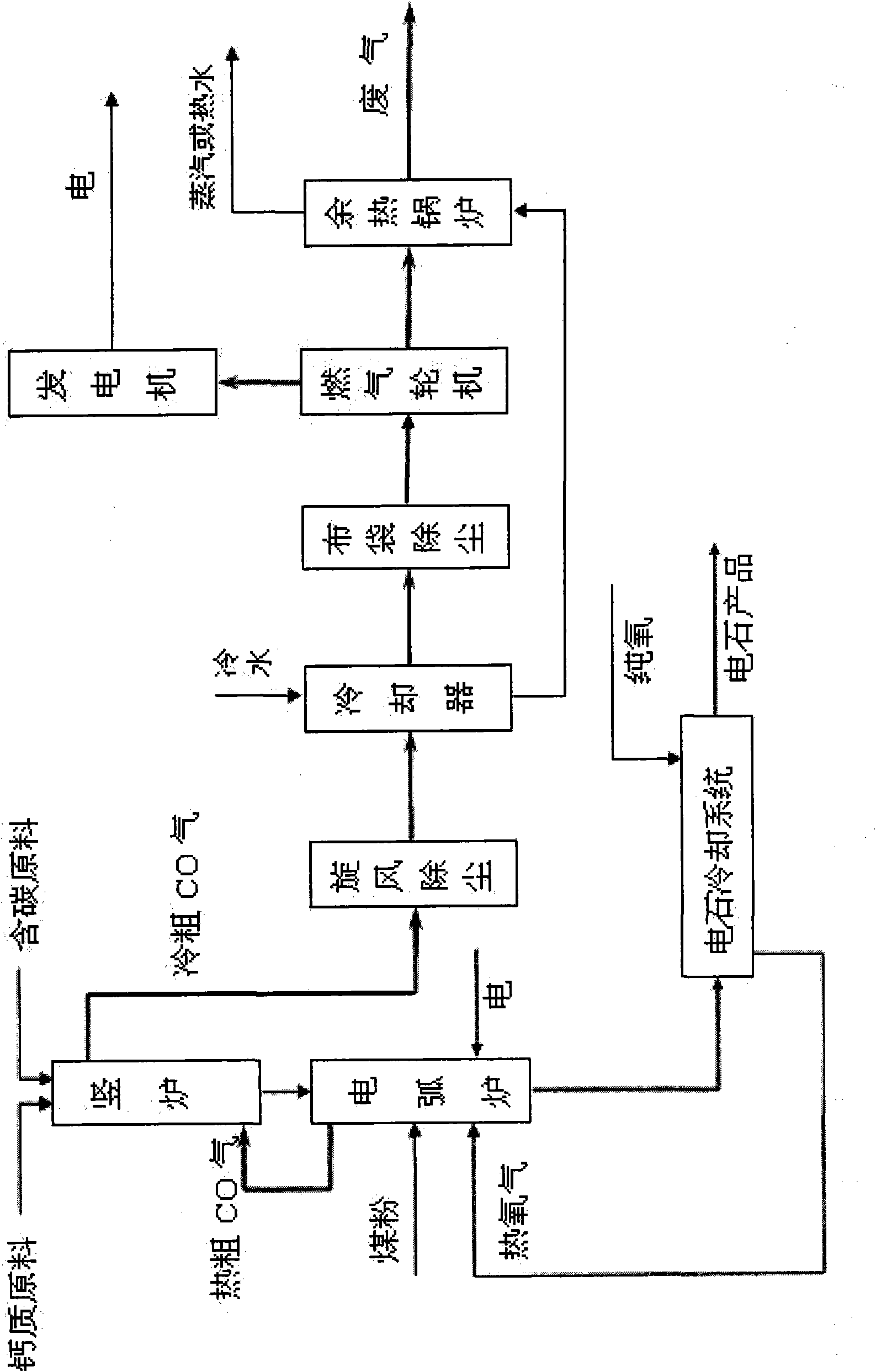

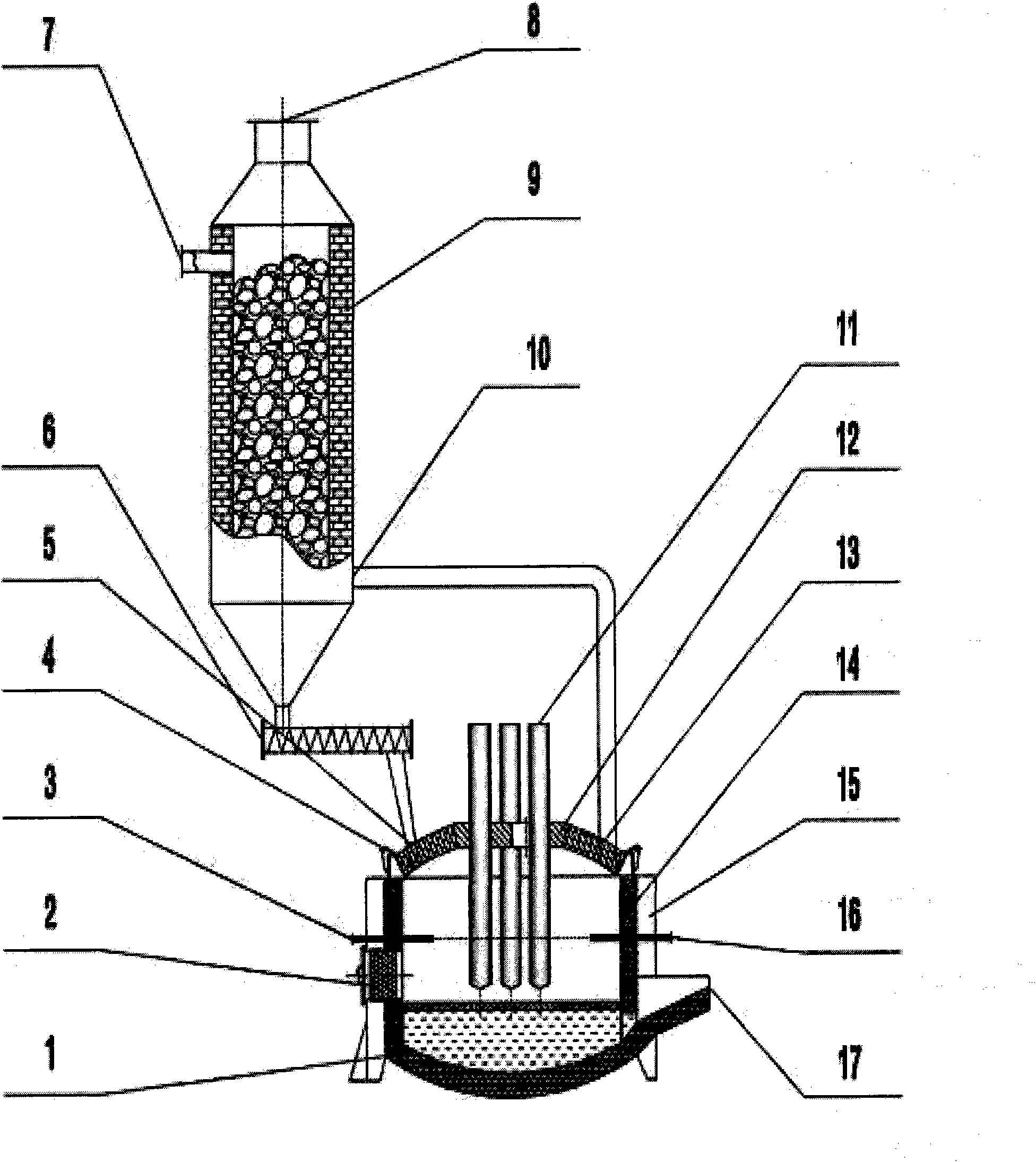

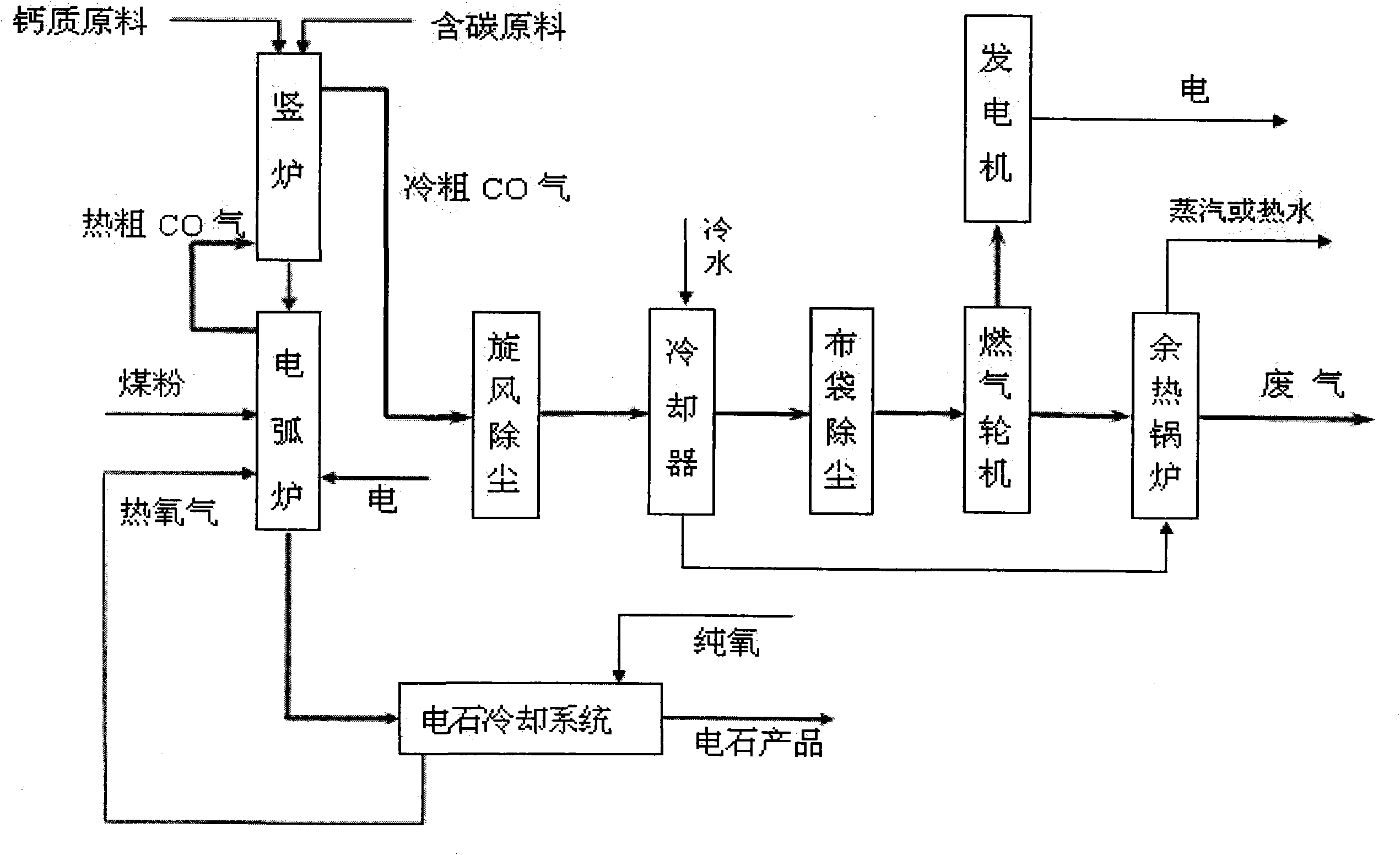

Technique for producing calcium carbide and cogeneration by two-stage method and device thereof

InactiveCN101830464AQuality assuranceReduce consumptionEnergy inputCalcium carbideElectric arc furnaceCogeneration

The invention relates to a technique for producing calcium carbide and cogeneration by a two-stage method and a device thereof. The technique comprises the following steps: after being preheated at a shaft furnace at the upper section, massive carbonous raw material and massive calcic raw material enter an arc furnace at the lower section; while blowing oxygen and coal powder and supplying heat by the electrode in the arc furnace, the raw materials react to produce calcium carbide; and the produced calcium carbide furnace gas is dedusted and combusted by a gas turbine so as to drive the generator to generate power, and sensible heat of exhaust gas is recycled by an exhaust-heat boiler, thereby centrally supplying heat to cities and towns. The invention has the advantages of capability of continuous production, high yield, low investment, low energy consumption, high calcium carbide grade, energy saving, high efficiency and investment saving, and realizes coordinated development of economy, environment and energy sources.

Owner:山西亿众公用事业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

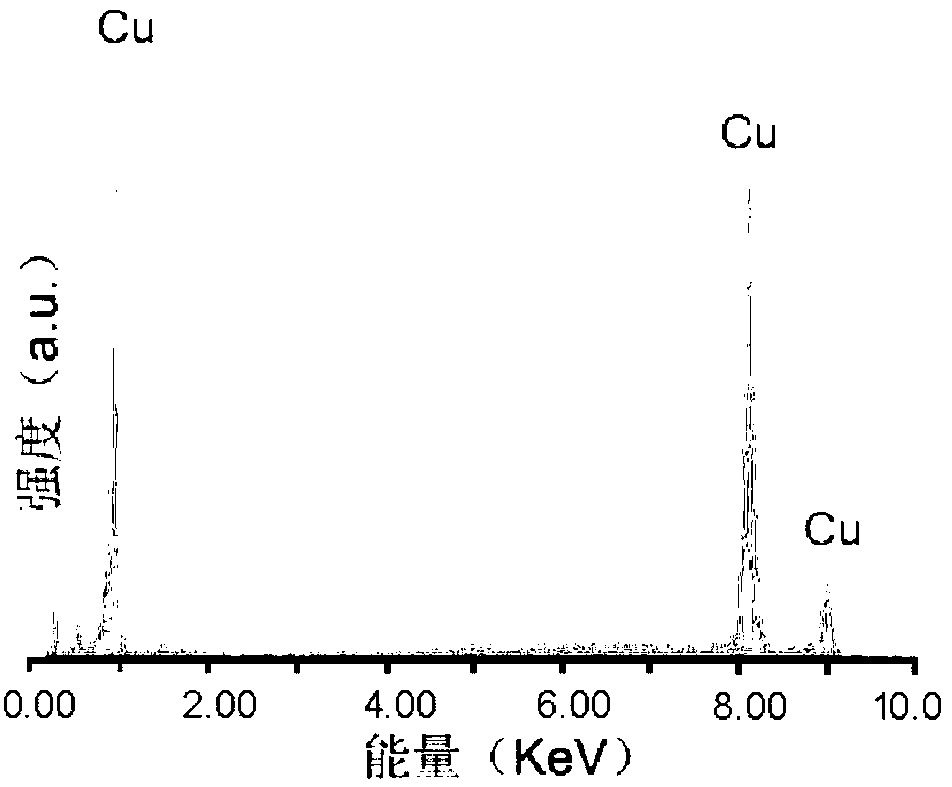

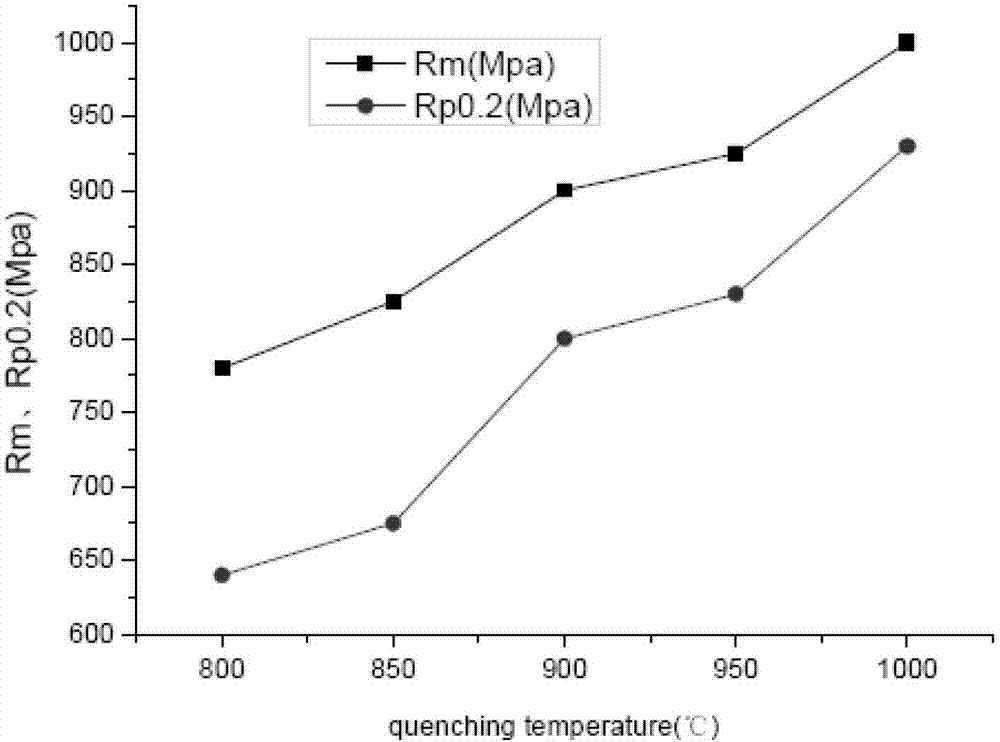

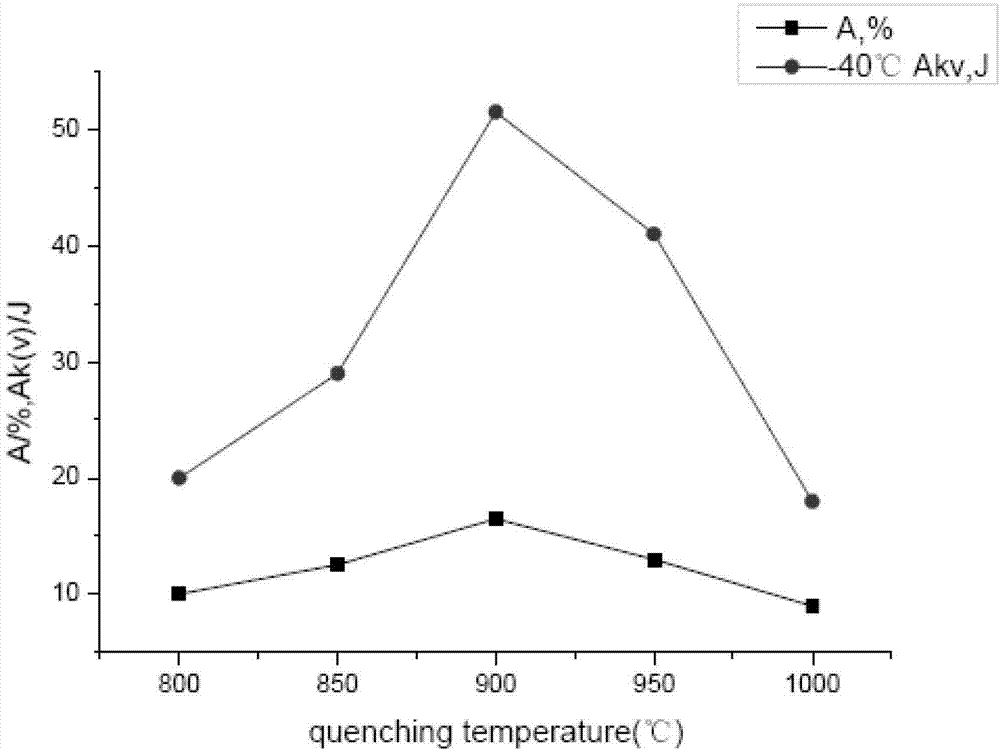

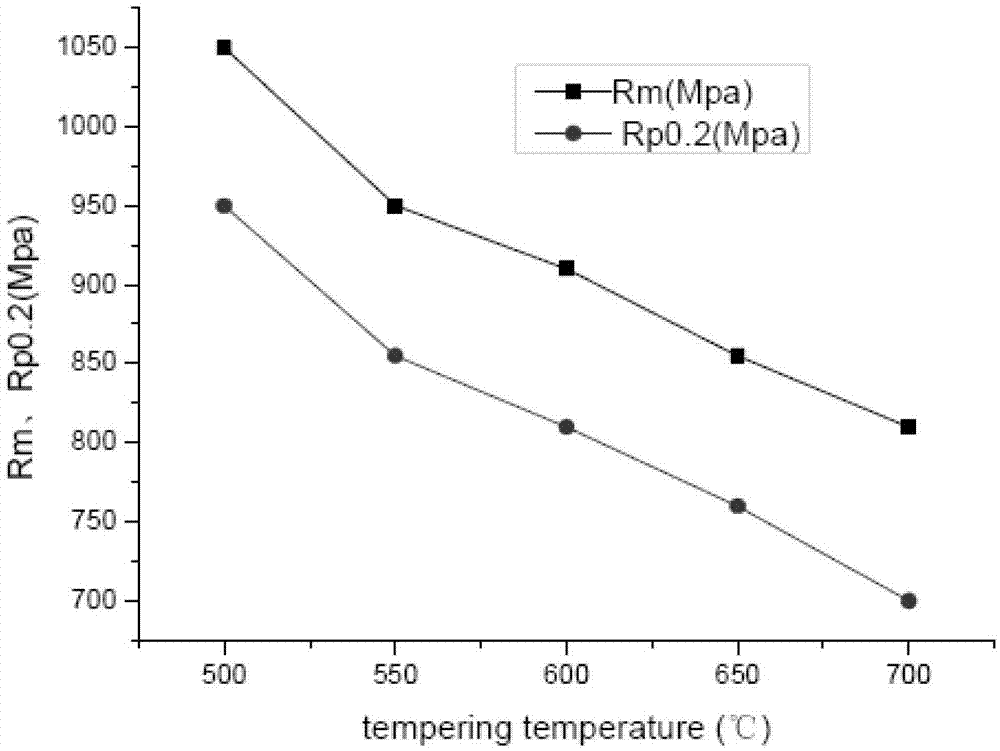

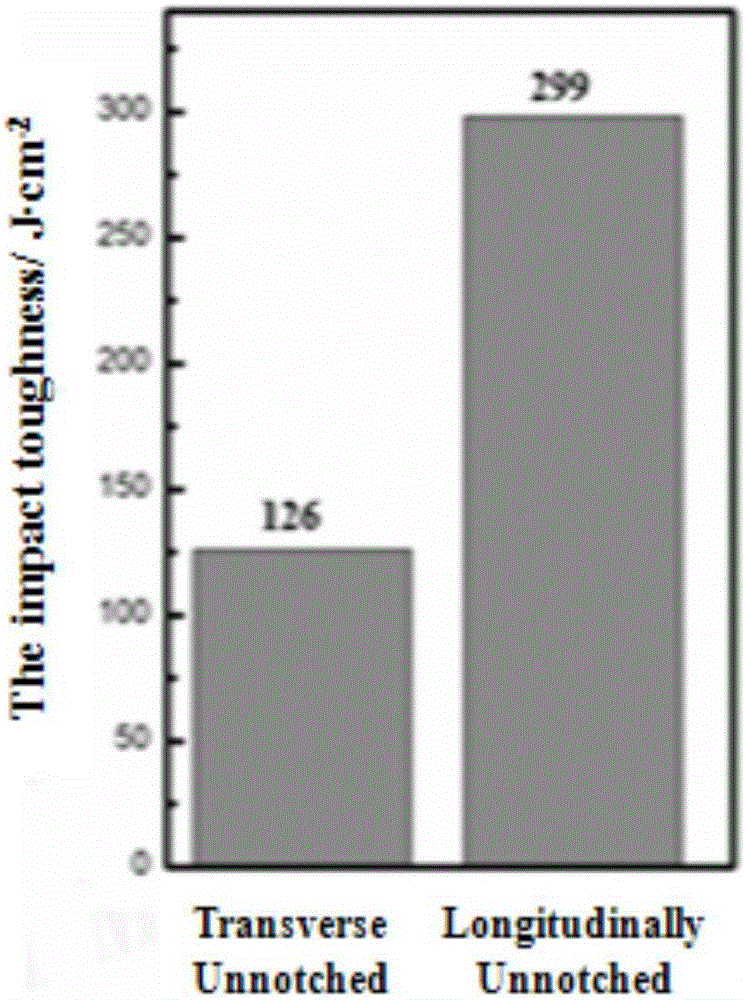

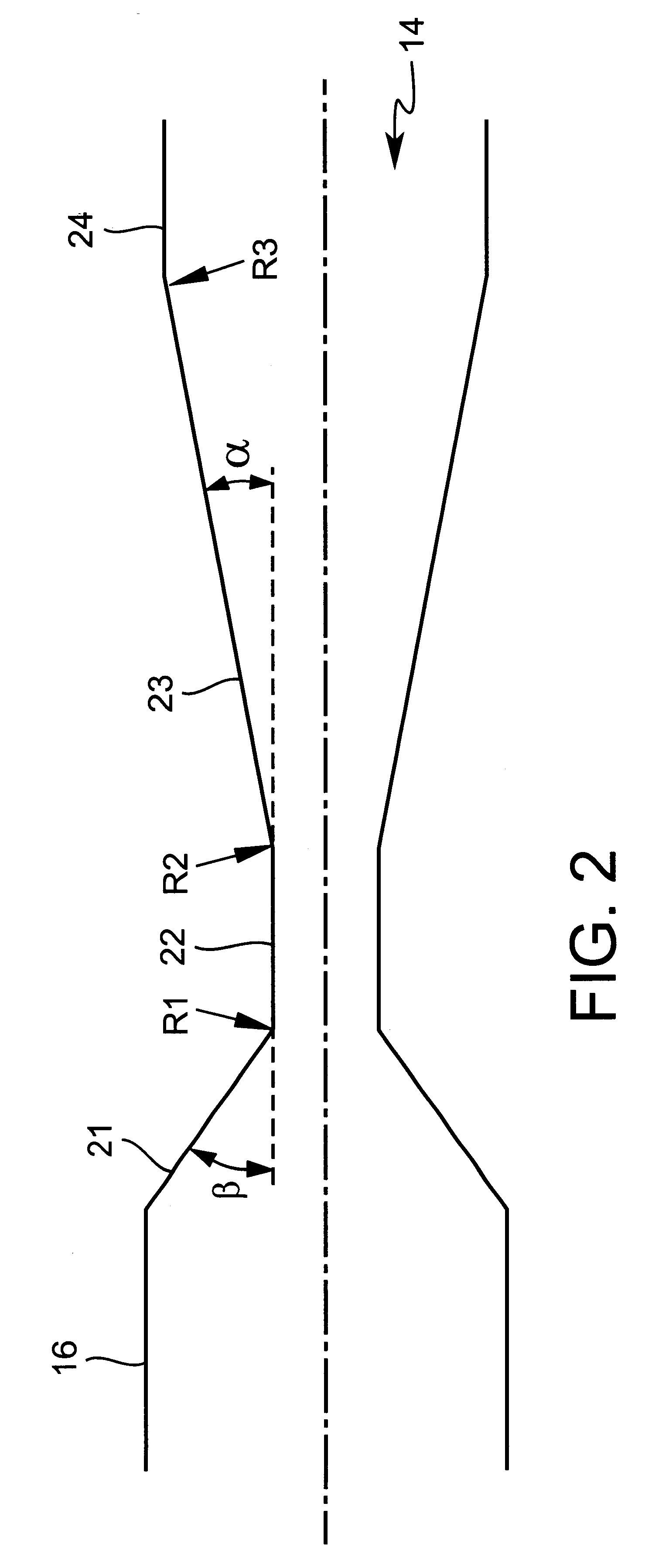

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000011.PNG)

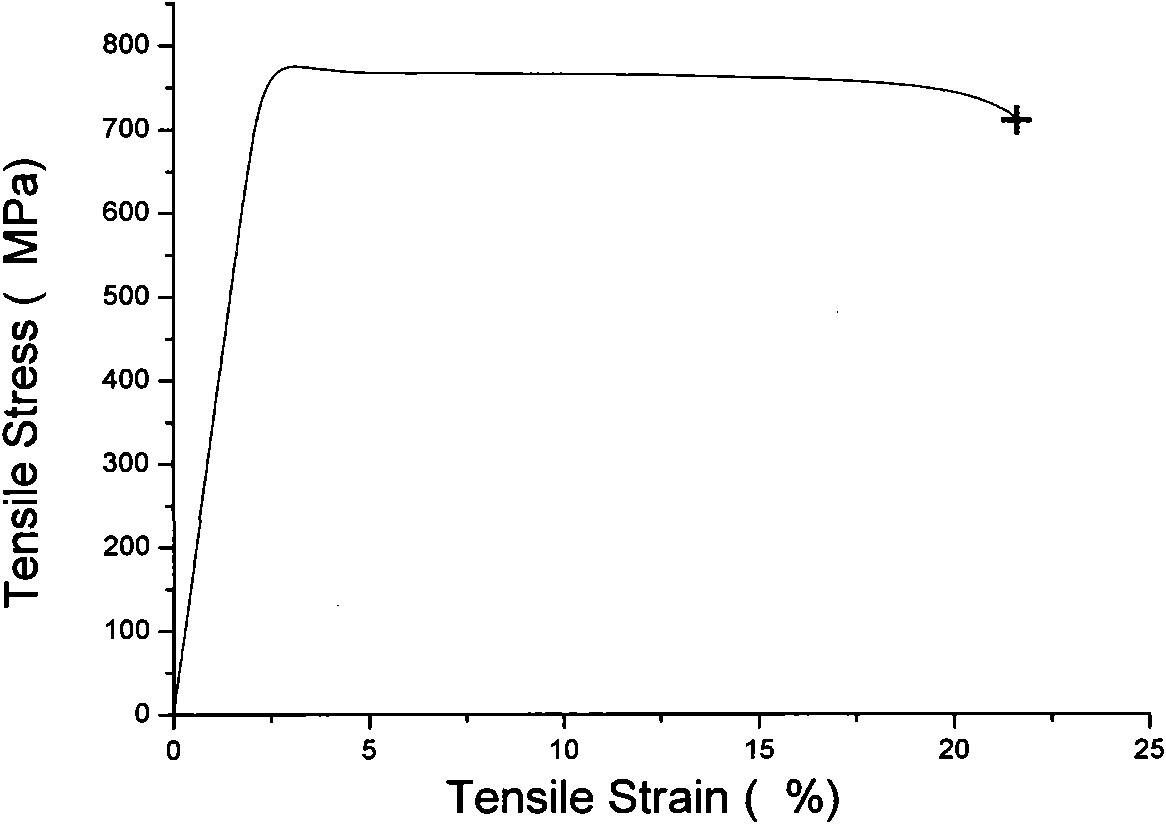

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000021.PNG)

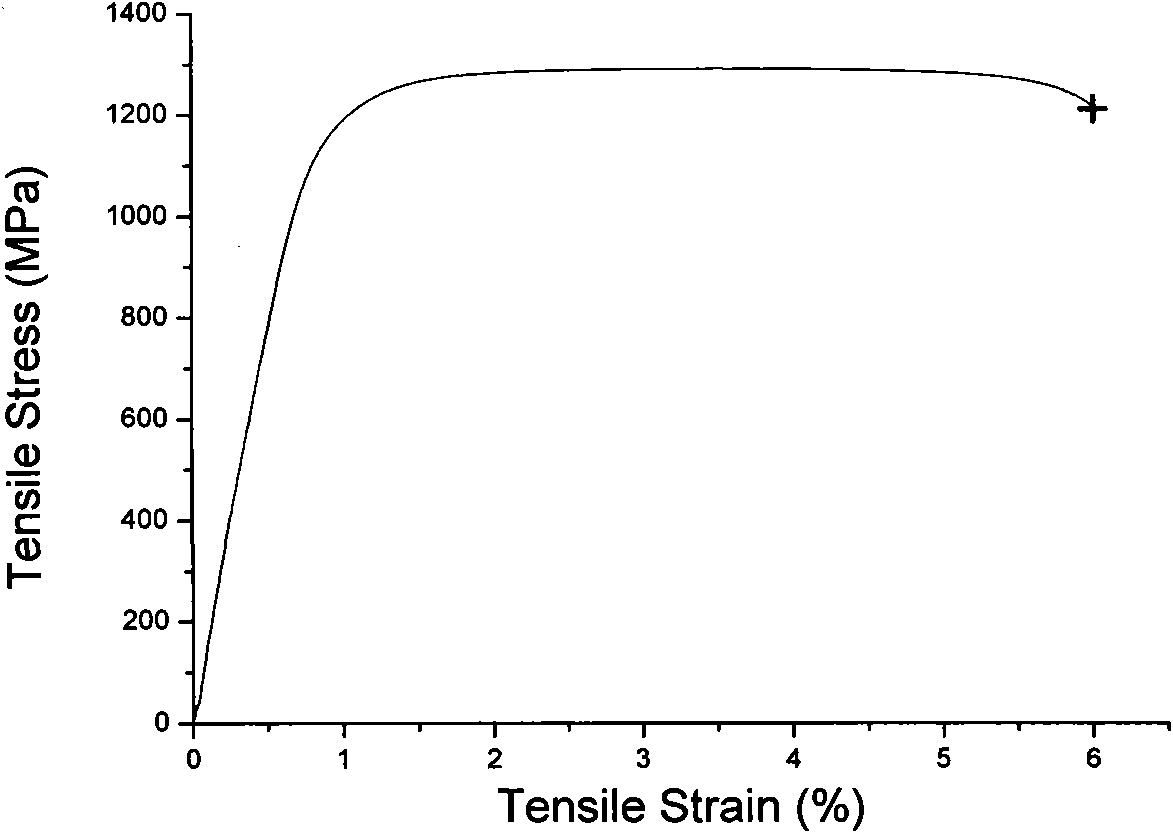

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000031.PNG)