Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

605results about "Calcium carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

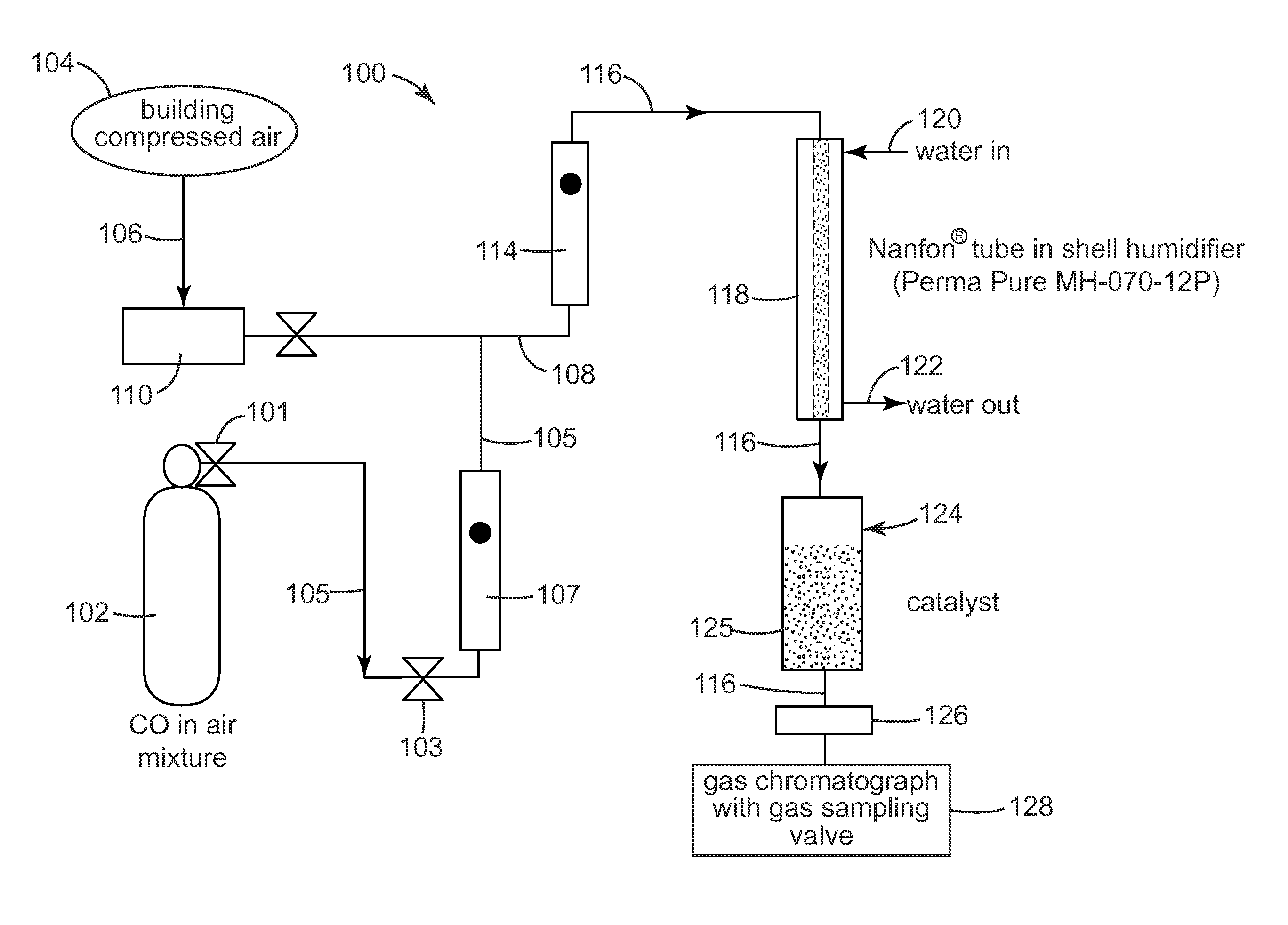

Catalysts, activating agents, support media, and related methodologies useful for making catalyst systems especially when the catalyst is deposited onto the support media using physical vapor deposition

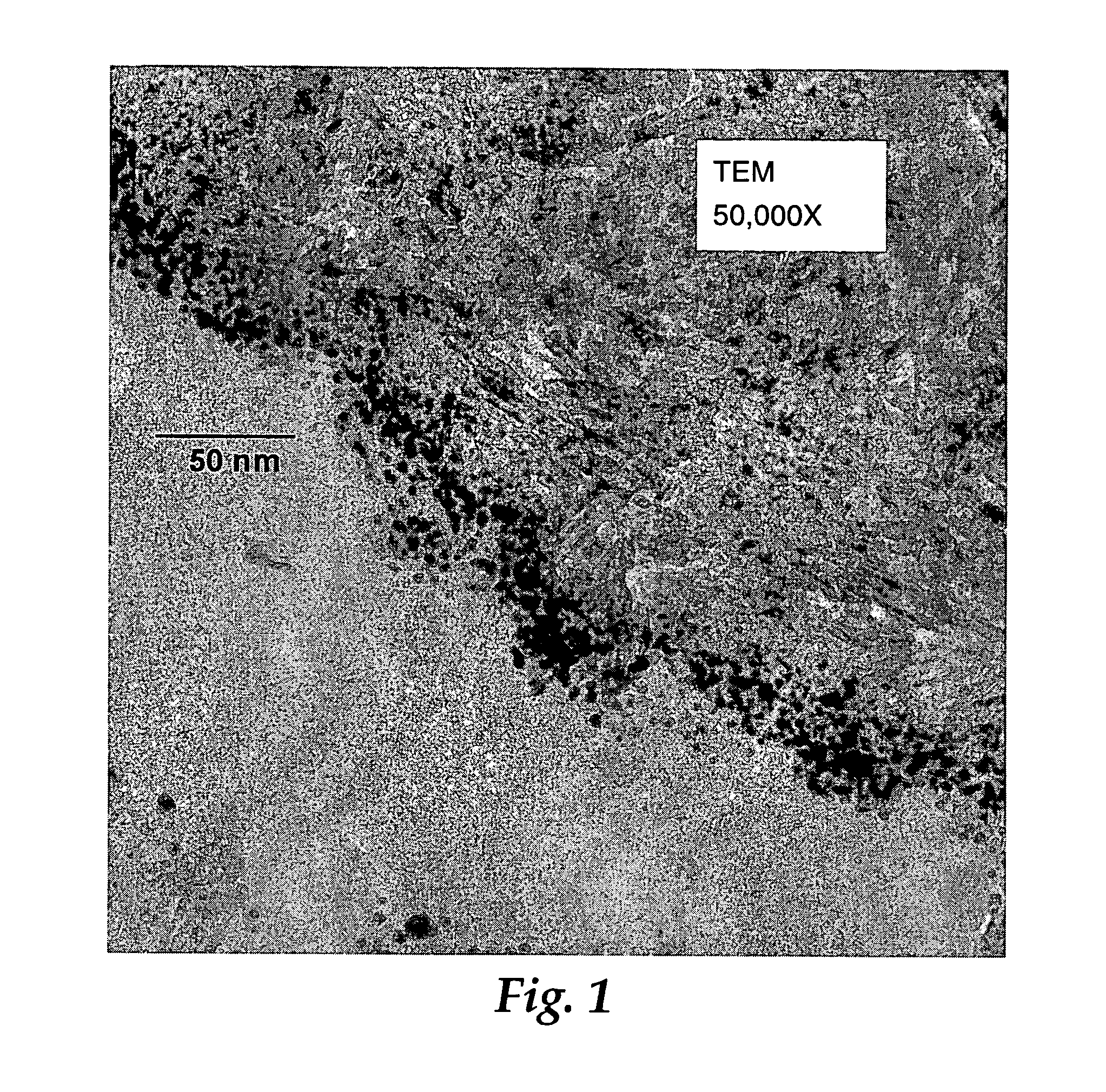

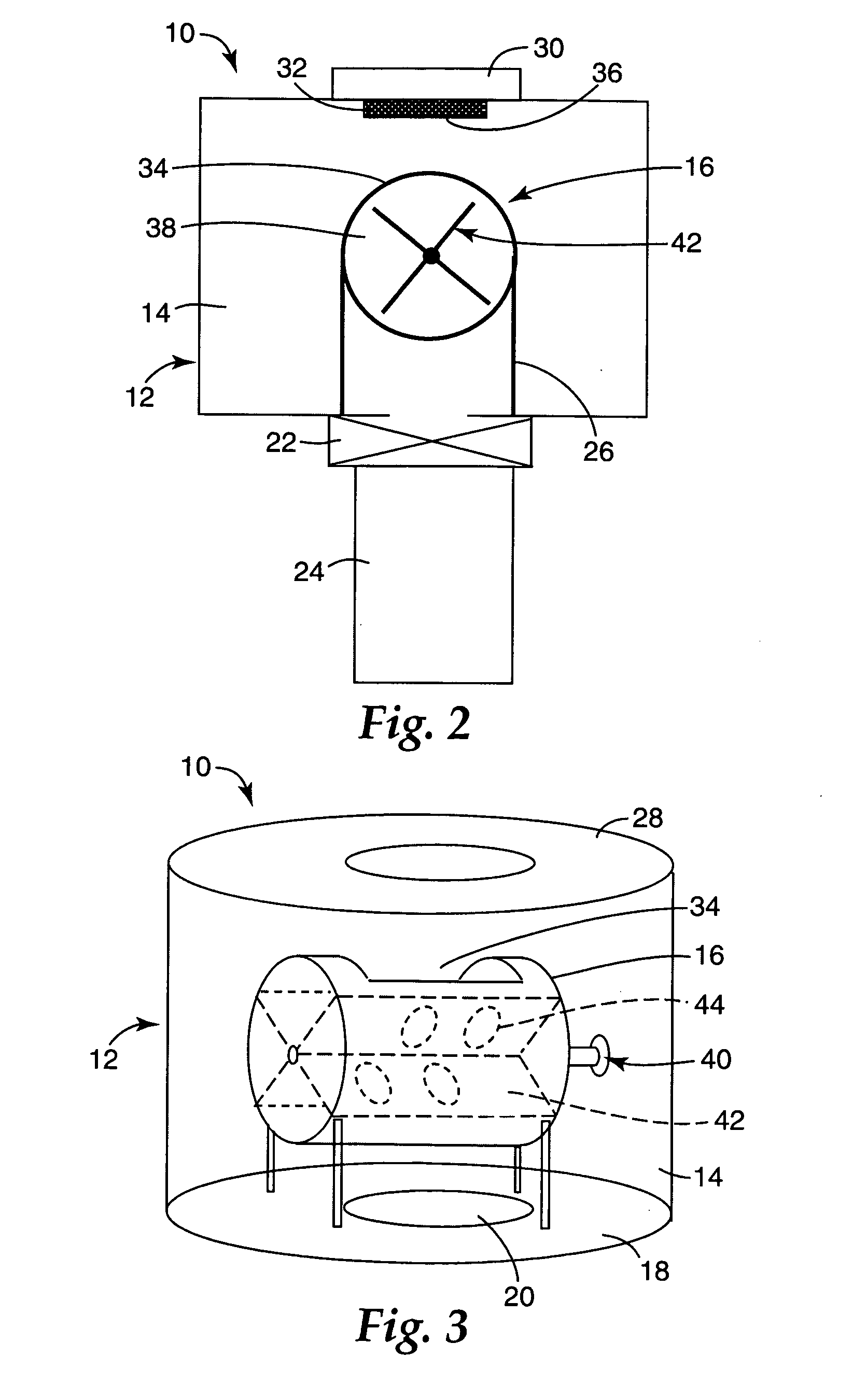

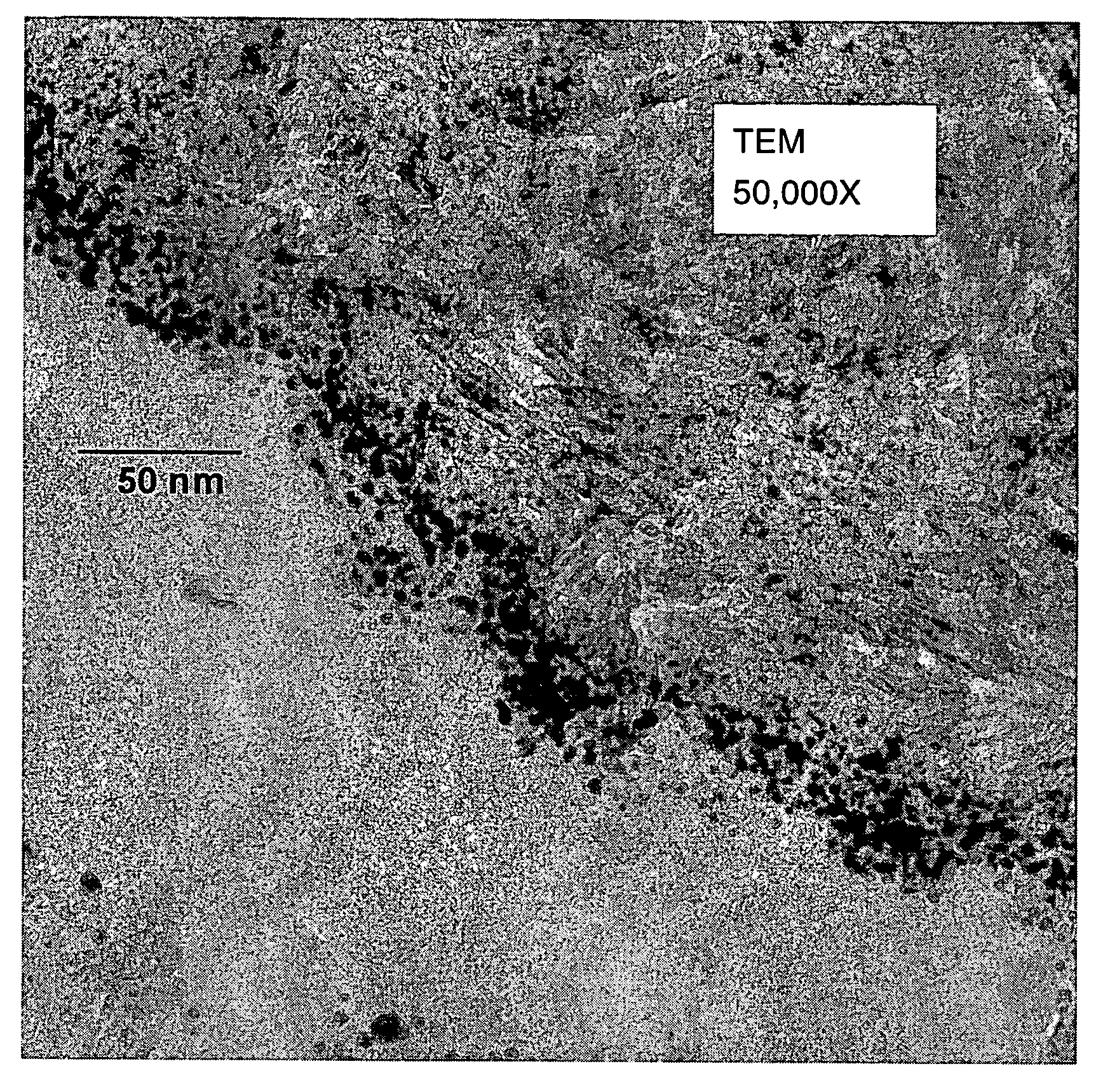

InactiveUS20050095189A1Improve performanceEasy to useMaterial nanotechnologyInternal combustion piston enginesGas phaseAdditive ingredient

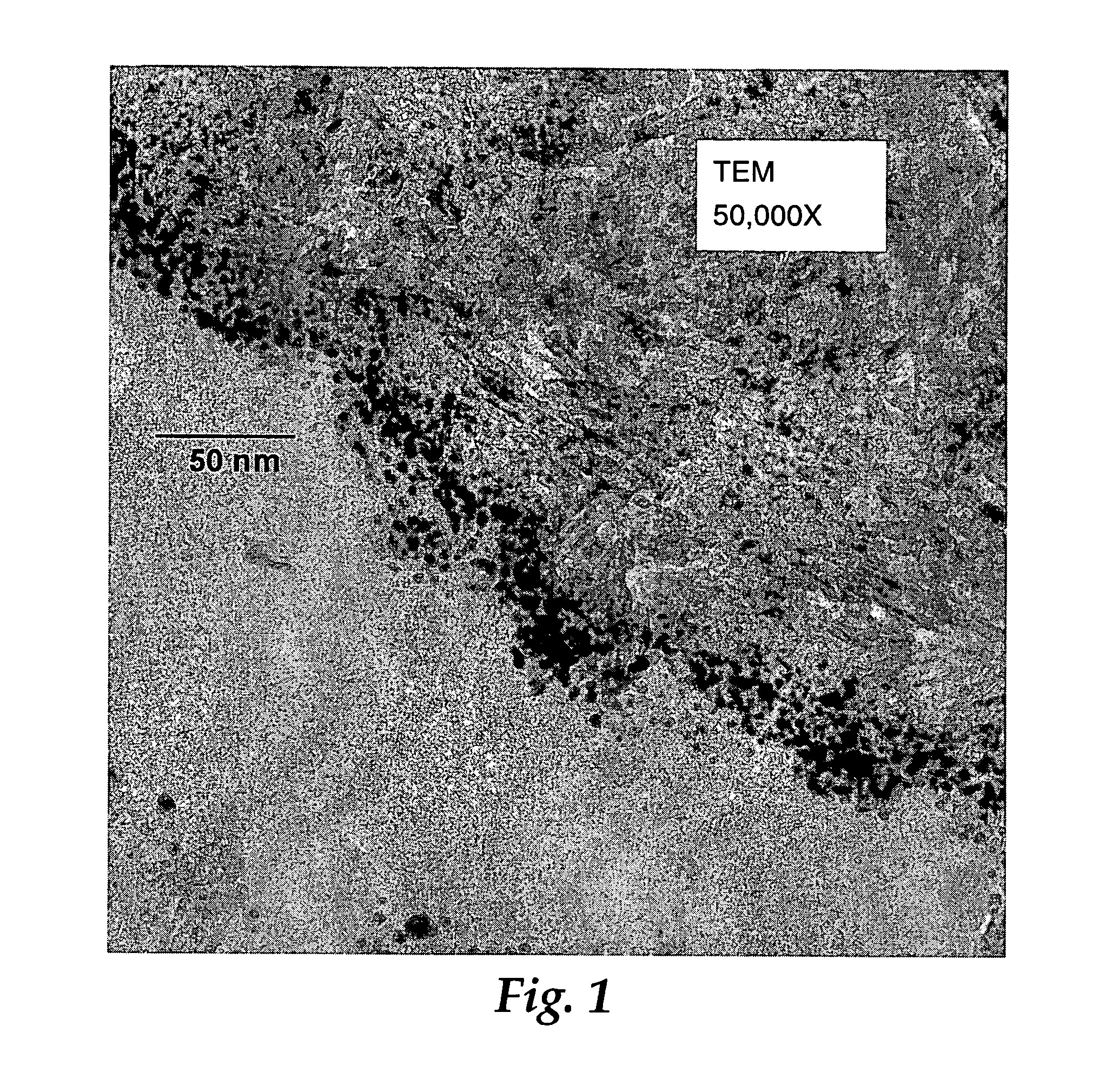

Use of physical vapor deposition methodologies to deposit nanoscale gold on activating support media makes the use of catalytically active gold dramatically easier and opens the door to significant improvements associated with developing, making, and using gold-based, catalytic systems. The present invention, therefore, relates to novel features, ingredients, and formulations of gold-based, heterogeneous catalyst systems generally comprising nanoscale gold deposited onto a nanoporous support.

Owner:3M INNOVATIVE PROPERTIES CO

Catalysts, activating agents, support media, and related methodologies useful for making catalyst systems especially when the catalyst is deposited onto the support media using physical vapor deposition

InactiveUS7727931B2High catalytic activityTendency increaseMaterial nanotechnologyInternal combustion piston enginesGas phasePhysical chemistry

Use of physical vapor deposition methodologies to deposit nanoscale gold on activating support media makes the use of catalytically active gold dramatically easier and opens the door to significant improvements associated with developing, making, and using gold-based, catalytic systems. The present invention, therefore, relates to novel features, ingredients, and formulations of gold-based, heterogeneous catalyst systems generally comprising nanoscale gold deposited onto a nanoporous support.

Owner:3M INNOVATIVE PROPERTIES CO

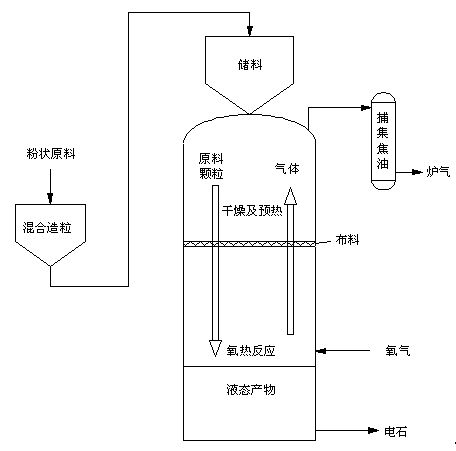

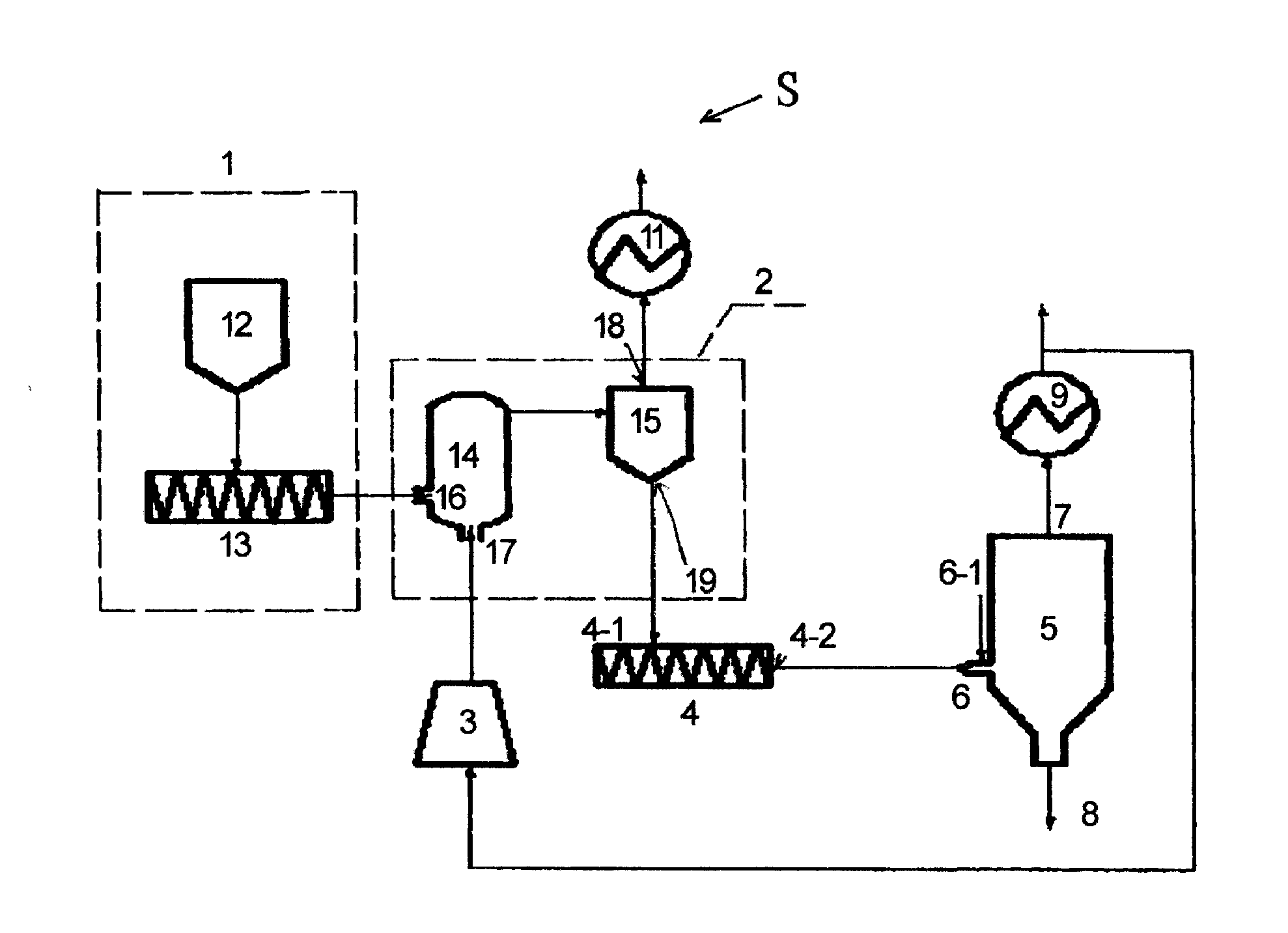

Calcium carbide production method

The invention relates to a carbide preparation method belonging to the field of carbide preparation. The conventional carbide preparation technology adopts block materials and electric arc as a heat-supply, while the preparation method according to the invention adopts powdery carbon-containing materials and powdery calcium-containing materials, and the combustion of partial carbon-containing materials and oxygen-containing gas as a heat-supply at 1700-2300 DEG C to prepare carbide, wherein the carbon-containing materials is coal or coke, calcium-containing materials is calcium carbonate, calcium oxide, calcium hydroxide or carbide slag, the granularity of the carbon-containing materials and calcium-containing materials is less than 1mm, and the quality ratio is 0.5-3:1. The oxygen-containing gas for combustion is oxygen, oxygen-enriched air or air. The method solves the problems of high energy consumption and high pollution of the carbide preparation and has advantages of wide choice scope of materials, high energy utilization rate, continuous operation and large production capacity. The technology also couples with the process of carbon-containing materials coking and calcium-containing materials calcining, preheats the materials to 500-1500 DEG C utilizing the combustion of by-products CO of the carbide preparation and the assistant fuel, thereby further reducing the oxygen and energy consumption of the carbide preparation.

Owner:BEIJING UNIV OF CHEM TECH

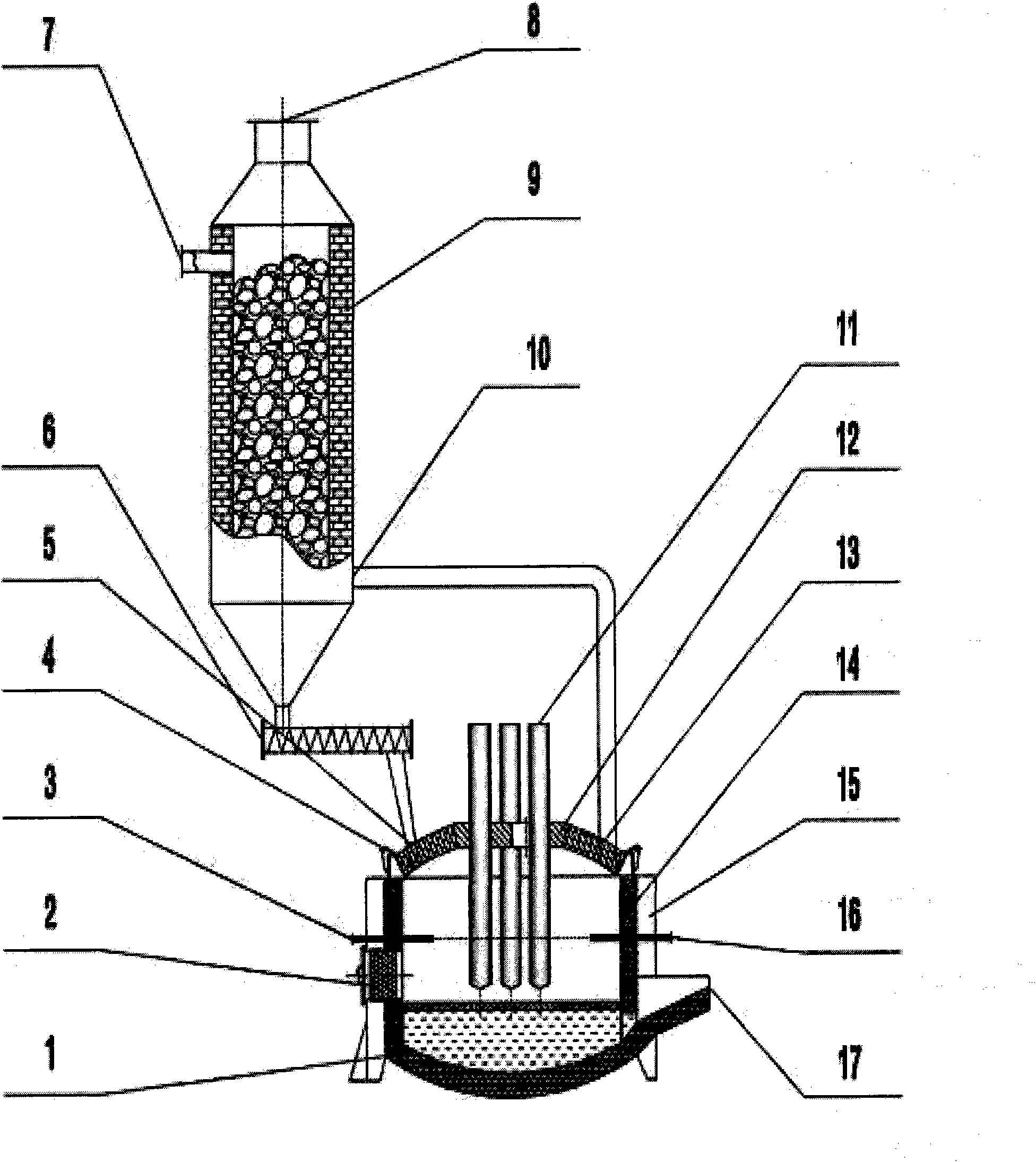

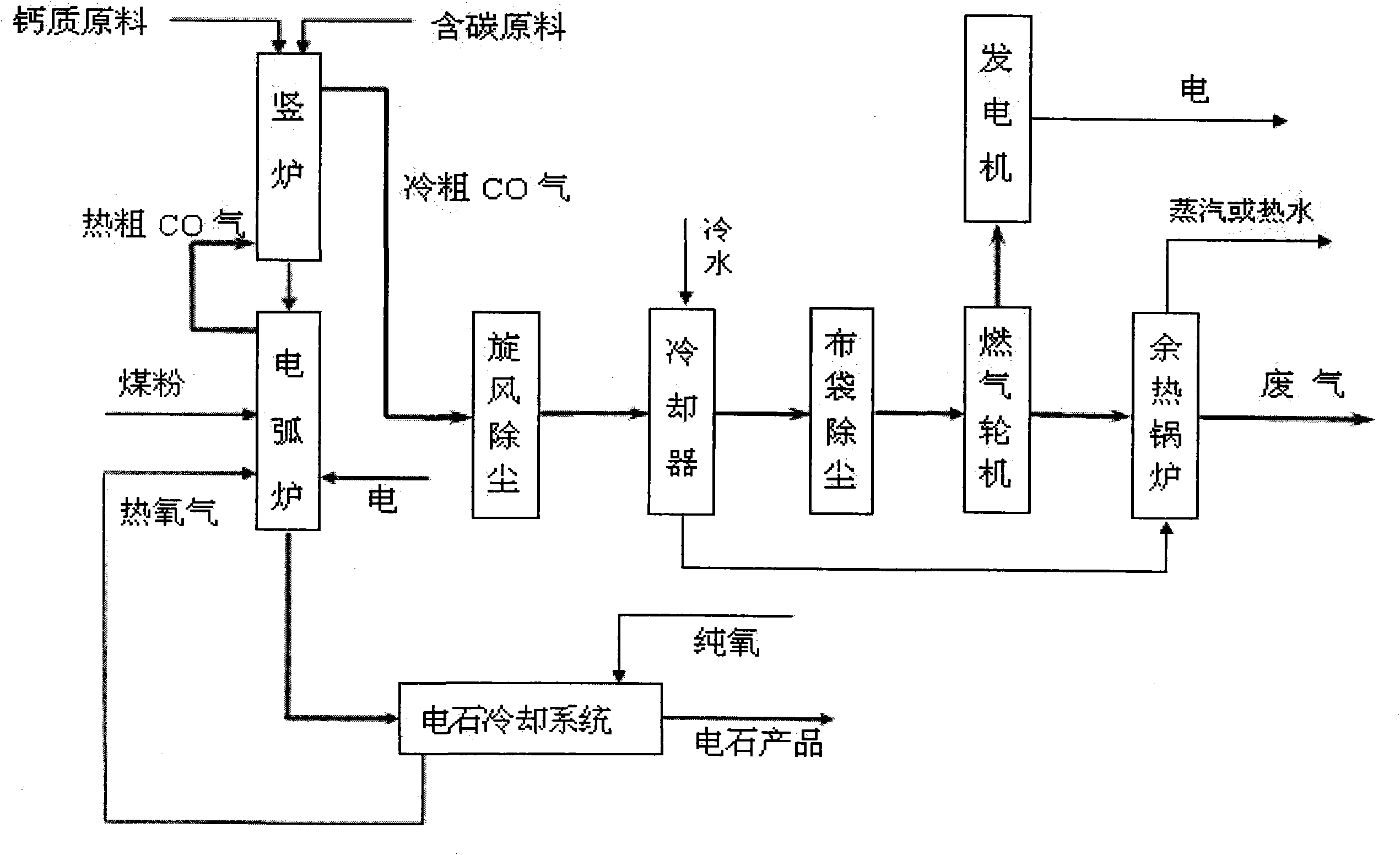

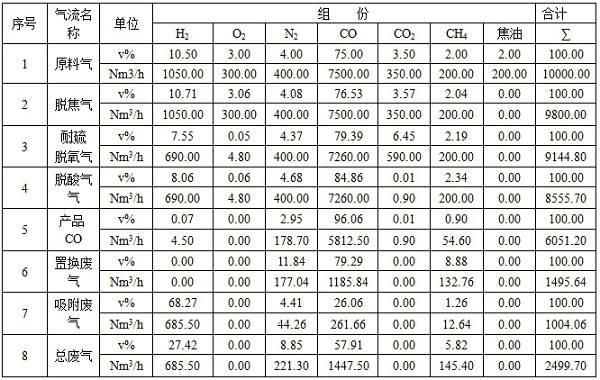

Technique for producing calcium carbide and cogeneration by two-stage method and device thereof

InactiveCN101830464AQuality assuranceReduce consumptionEnergy inputCalcium carbideElectric arc furnaceCogeneration

The invention relates to a technique for producing calcium carbide and cogeneration by a two-stage method and a device thereof. The technique comprises the following steps: after being preheated at a shaft furnace at the upper section, massive carbonous raw material and massive calcic raw material enter an arc furnace at the lower section; while blowing oxygen and coal powder and supplying heat by the electrode in the arc furnace, the raw materials react to produce calcium carbide; and the produced calcium carbide furnace gas is dedusted and combusted by a gas turbine so as to drive the generator to generate power, and sensible heat of exhaust gas is recycled by an exhaust-heat boiler, thereby centrally supplying heat to cities and towns. The invention has the advantages of capability of continuous production, high yield, low investment, low energy consumption, high calcium carbide grade, energy saving, high efficiency and investment saving, and realizes coordinated development of economy, environment and energy sources.

Owner:山西亿众公用事业有限公司

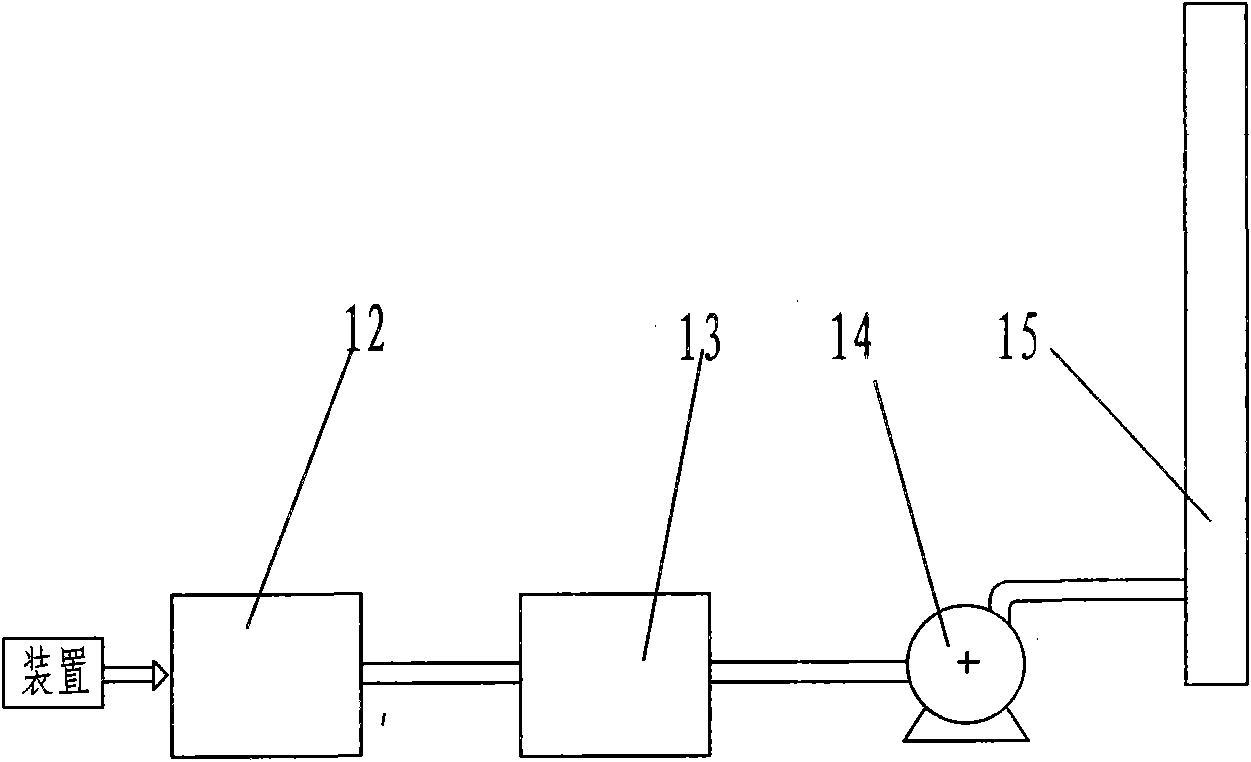

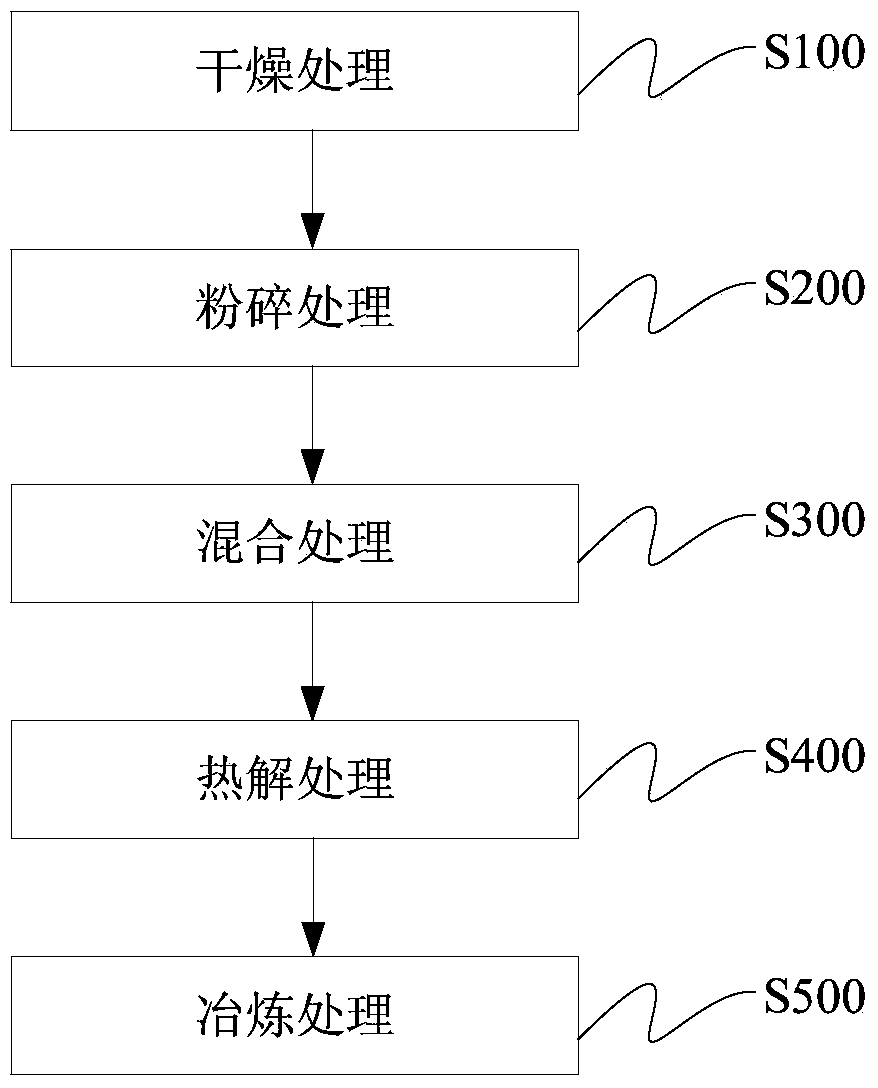

Method for preparing solid calcium carbide

ActiveCN104556036AIncrease productivityReduce manufacturing costCalcium carbideMixed materialsWet grinding

The invention discloses a method for preparing solid calcium carbide. The method comprises the following steps: (1), finely grinding a carbon material and a calcareous material so as to respectively obtain a carbon material powder and a calcareous material powder; (2), mixing and then wet-grinding a mixture containing the carbon material powder and the calcareous material powder, and a bonding agent so as to obtain a mixed material; (3), performing molding on the mixed material so as to obtain material balls; (4), successively distributing the material balls in a rotary hearth furnace, successively pyrolyzing the material balls in a pyrolysis furnace chamber of a radiant tube with the rotation of the bottom of the rotary hearth furnace, and smelting the pyrolyzed material balls in the chamber of a smelting furnace under a temperature of 1200-1380 DEG C, so as to finally obtain solid calcium carbide, coal gas and coal tar. The method disclosed by the invention can be used for preparing solid calcium carbide, the coal gas and the coal tar at the same time, and the production cost of the calcium carbide is obviously lowered.

Owner:SHENWU TECH GRP CO LTD

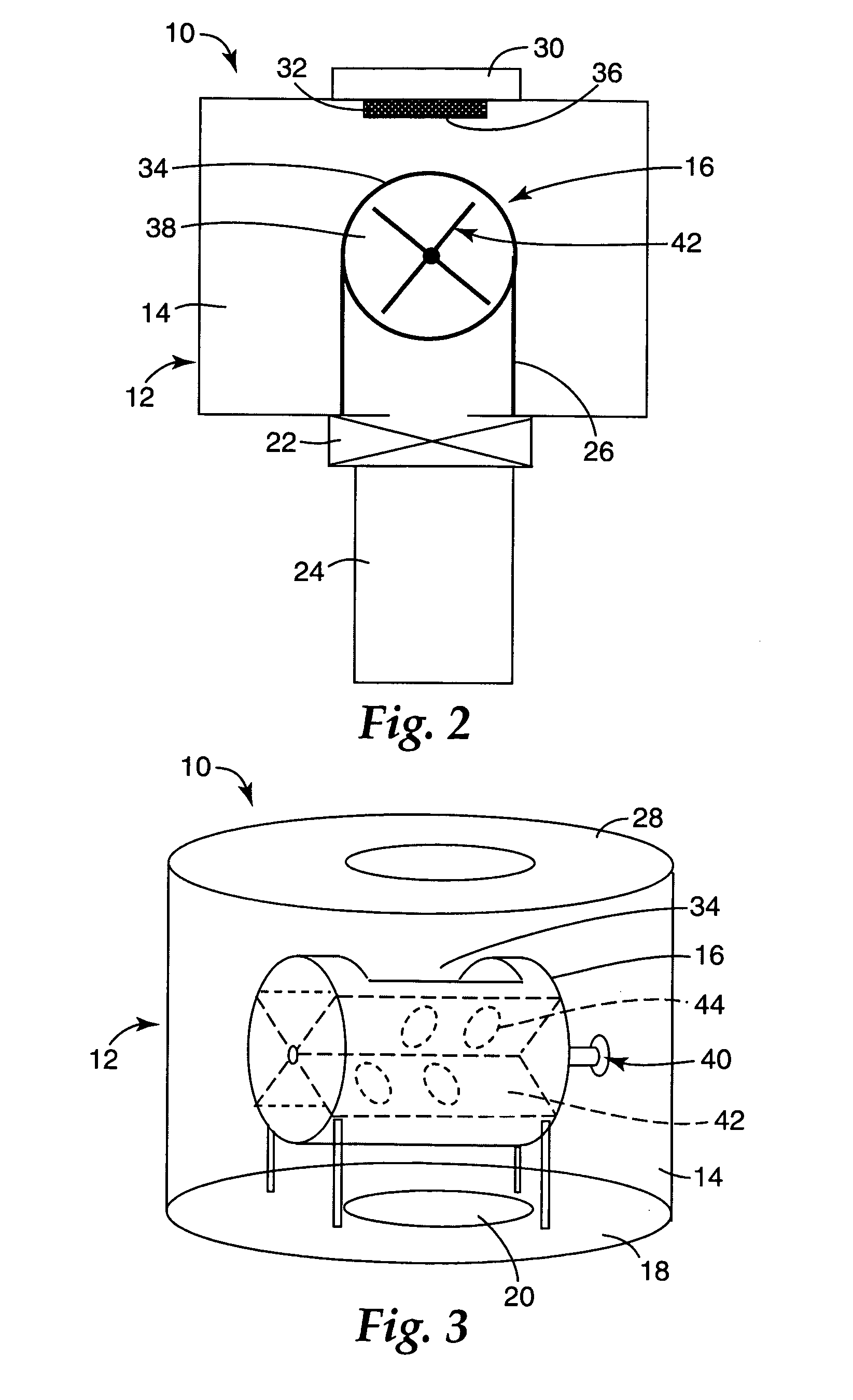

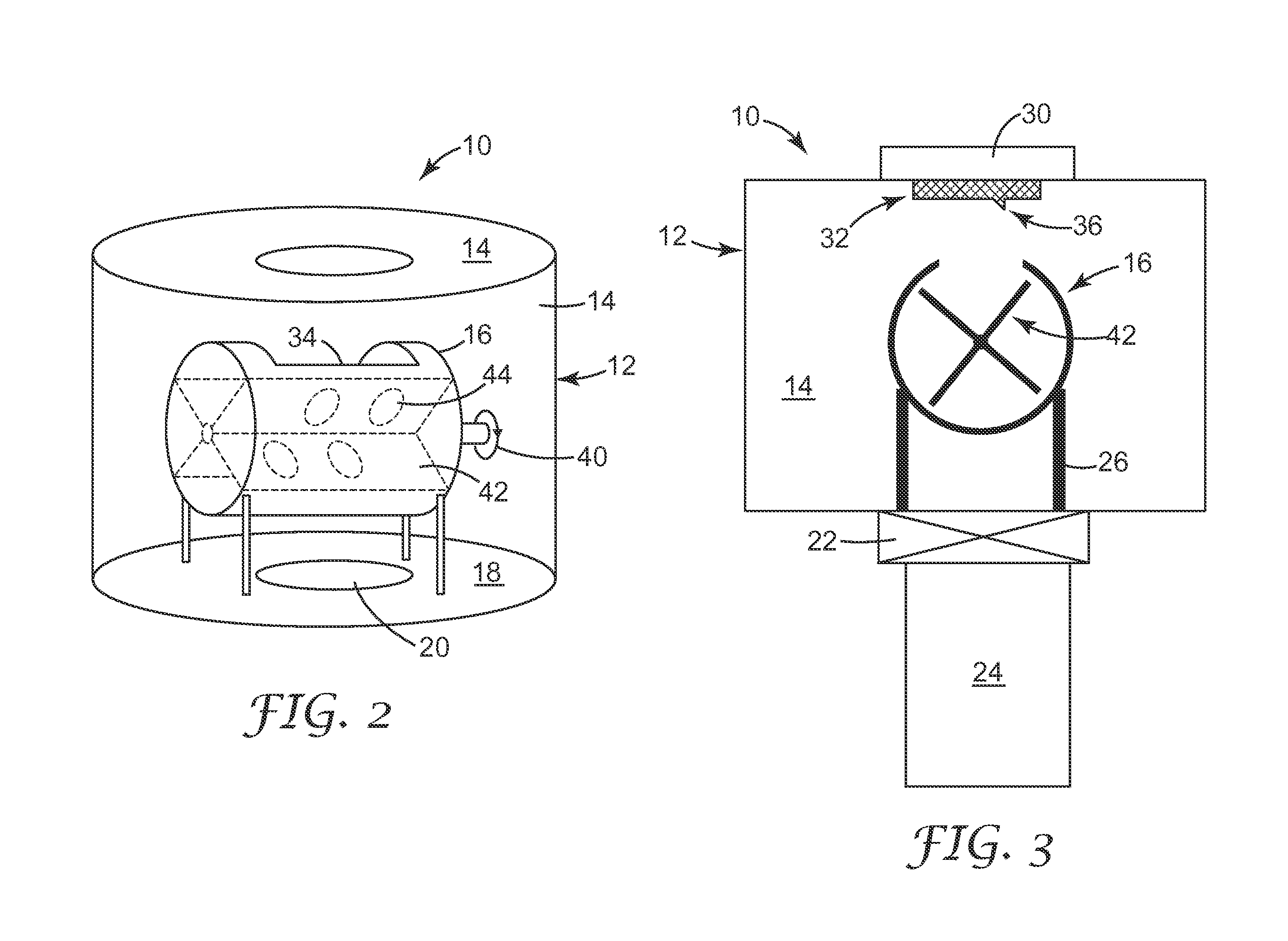

Heterogeneous, composite, carbonaceous catalyst system and methods that use catalytically active gold

ActiveUS20070207079A1Low densityInexpensive materialsMaterial nanotechnologyGas treatmentActivated carbonHost material

Heterogeneous catalyst systems, methods of making these systems, and methods of using these systems, wherein catalytically active gold is deposited onto composite support media. The composite support media is formed by providing nanoporous material on at least a portion of the surfaces of carbonaceous host material. In representative embodiments, relatively fine, nanoporous guest particles are coated or otherwise provided on surfaces of relatively coarser activated carbon particles. Catalytically active gold may be deposited onto one or both of the guest or host materials either before or after the guest and host materials are combined to from the composite host material. PVD is the preferred catalyst system of depositing gold.

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing calcium carbide

The invention discloses a method for preparing calcium carbide, which comprises the following steps: providing carbon-base particles and calcium-base particles, wherein the average particle size of the carbon-base particles and calcium-base particles is not greater than 5 millimeters, and the water content is lower than 5%; mixing the carbon-base particles and calcium-base particles to obtain a mixture; pyrolyzing the mixture to obtain high-quality tar, high heating value gas and a pyrolytic solid product, wherein the pyrolytic solid product contains quicklime and one of coke, semicoke and carbon black; and feeding the pyrolytic solid product into a gas smelting furnace at the temperature of not lower than 450 DEG C to perform smelting in the gas smelting furnace, thereby obtaining the calcium carbide. Thus, the method can further enhance the heat utilization ratio and production efficiency, lower the production cost and reduce the energy consumption and pollution.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

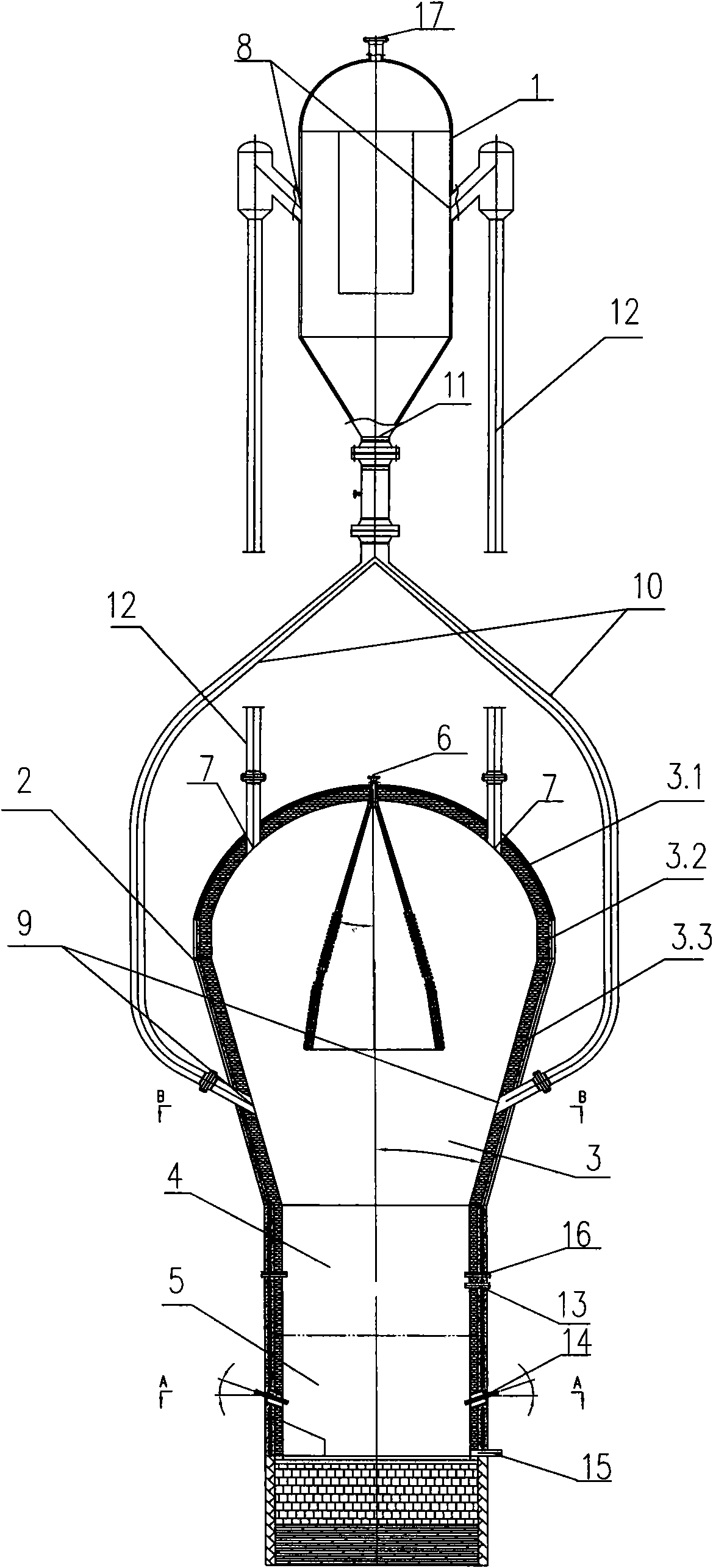

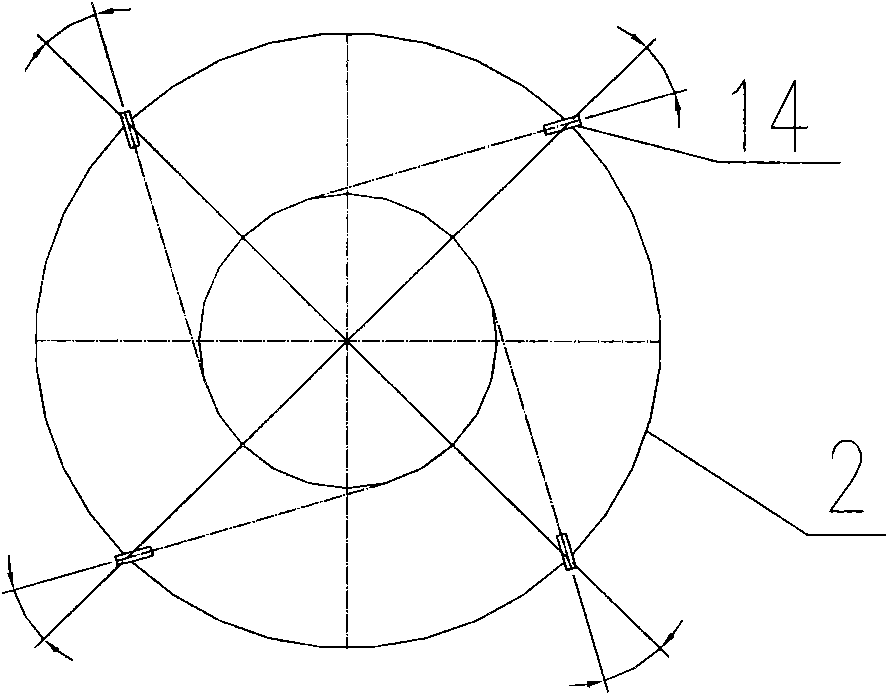

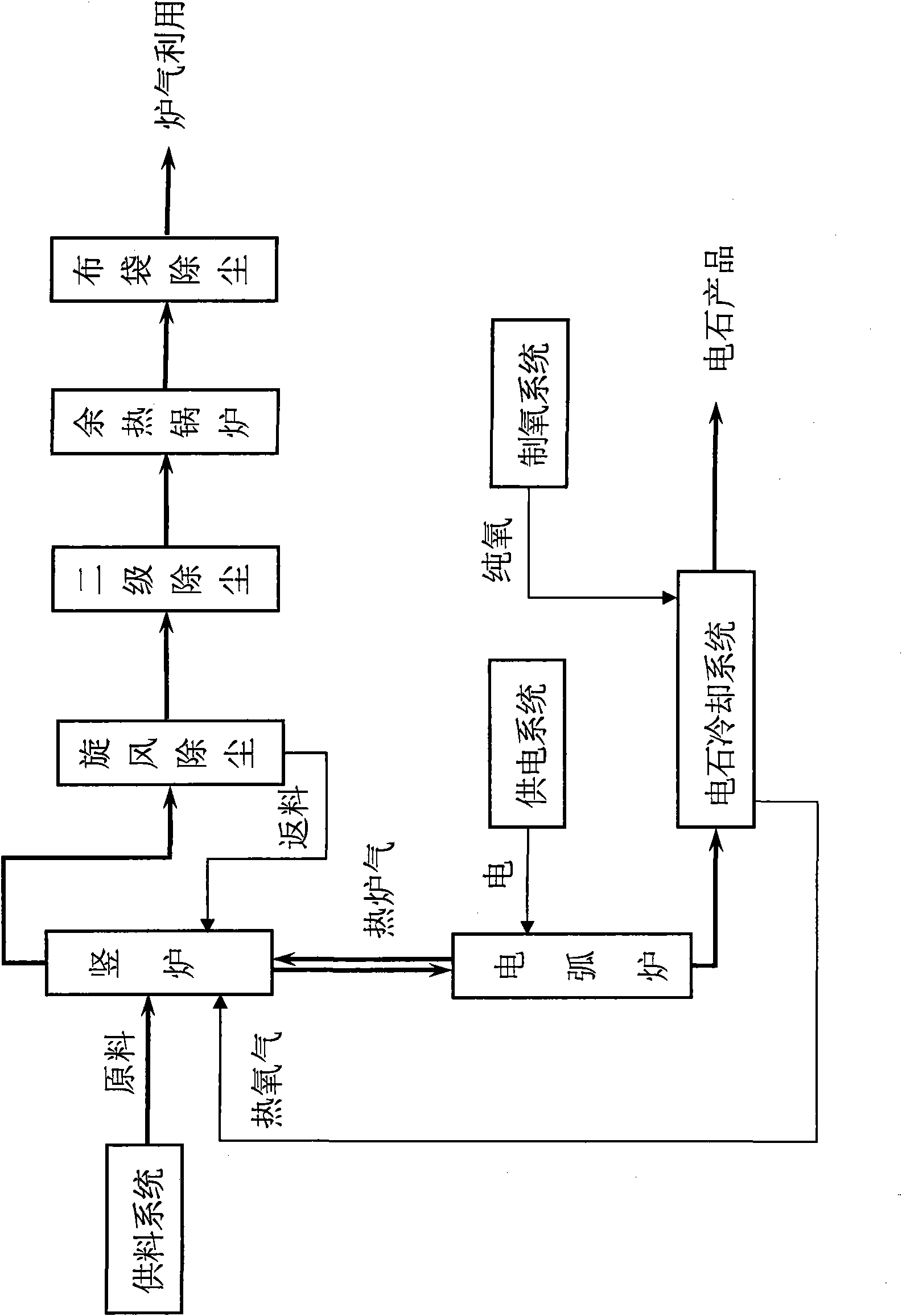

Method for preparing calcium carbide and synthesis gas through thermal oxidation reaction and calcium carbide reactor

ActiveCN102153085ACompact structureLess investmentCalcium carbideGranular/pulverulent flues gasificationGas solidCalcium carbide

The invention discloses a method for preparing calcium carbide and a synthesis gas through a thermal oxidation reaction and a calcium carbide reactor, which solve the problems of great raw material consumption, more equipment, large investment, complex process, less CO byproduct quantity and difficult industrial application of the traditional calcium carbide preparation method. The calcium carbide reactor comprises a gas-solid separator, a closed reacting furnace is arranged below the gas-solid separator, and the closed reacting furnace comprises an upper preheating chamber, a middle vaporizing chamber and a lower reaction chamber. In the method provided by the invention, a special calcium carbide reactor is adopted; when calcium carbide is synthesized, a large amount of produced CO can be industrially applied; and thus, the method has low production and operation costs, low energy consumption, great by-product gas quantity and a broad market prospect.

Owner:WUHUAN ENG +1

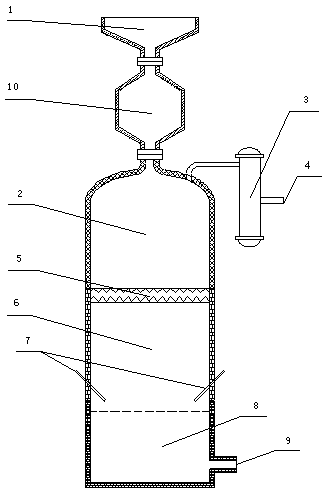

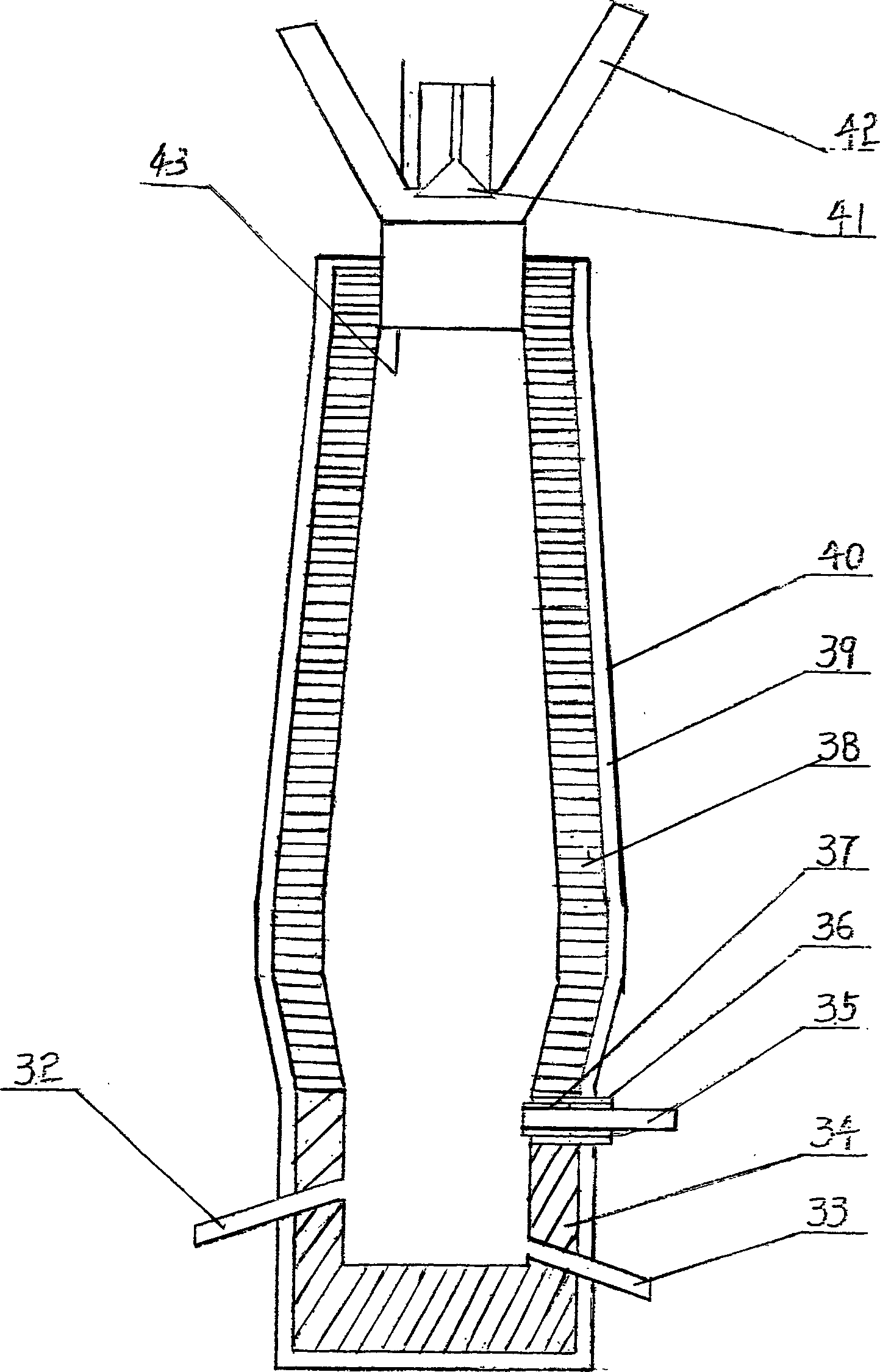

Composite bed reactor and method for combined production of calcium carbide, gas and tar

ActiveCN103272536ATake advantage ofReduce heat lossCalcium carbideSpecial form destructive distillationReaction rateMolten bath

The invention relates to a composite bed reactor and a method for combined production of calcium carbide, gas and tar, and belongs to the field of calcium carbide production. The reactor comprises a hopper, a brake bunker, a moving bed preheating chamber, a tar collector, a gas outlet, a distributing device, an oxygen heat reaction chamber, oxygen spraying burners, a product molten pool and a product outlet, and the hopper is connected with the moving bed preheating chamber by the brake bunker, and the top side surface of the moving bed preheating chamber is provided with the tar collector, and the tar collector is provided with a gas outlet, and the moving bed preheating chamber bottom is provided with a distributing device, and the moving bed preheating chamber is communicated with an oxygen heat reaction chamber by a distributing device, and the oxygen heat reaction chamber bottom is connected with a product molten pool, and the upper portion of the connection between the oxygen heat reaction chamber and the product molten pool is provided with the oxygen spraying burner, and the middle bottom of the product molten pool is provided with a product outlet. The reactor of the invention has the advantages of simple structure and high efficiency, and large scale production is easy to realize, and the raw material is pelleted by powder form carbonaceous raw material and powder form calcium containing raw material, and the contact surface between raw materials is large, the reaction rate is fast, and reactor is convenient for reusing calcium carbide slags.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing calcium carbide

InactiveCN103708456AIncrease profitIncrease productivityCalcium carbideElectric arc furnaceForming gas

The invention discloses a method for preparing calcium carbide, which comprises the following steps: drying a carbon-base raw material to obtain a dried carbon-base raw material; respectively crushing the dried carbon-base raw material and a calcium-base raw material to obtain a carbon-base powder and a calcium-base powder; mixing the carbon-base powder and calcium-base powder to obtain a mixture; forming the mixture to obtain a lump material; pyrolyzing the lump material to obtain high heating value synthetic gas, tar and a pyrolytic solid product, wherein the pyrolytic solid product contains coke, semicoke, carbon black and quicklime; and feeding the pyrolytic solid product into an arc furnace at the temperature of not lower than 450 DEG C to perform smelting in the arc furnace, thereby obtaining the calcium carbide. The method can obviously lower the smelting energy consumption and production cost, and further enhances the preparation efficiency and quality of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

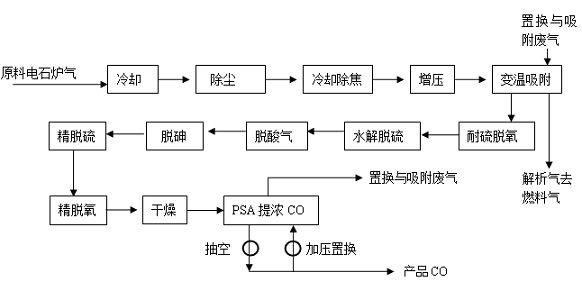

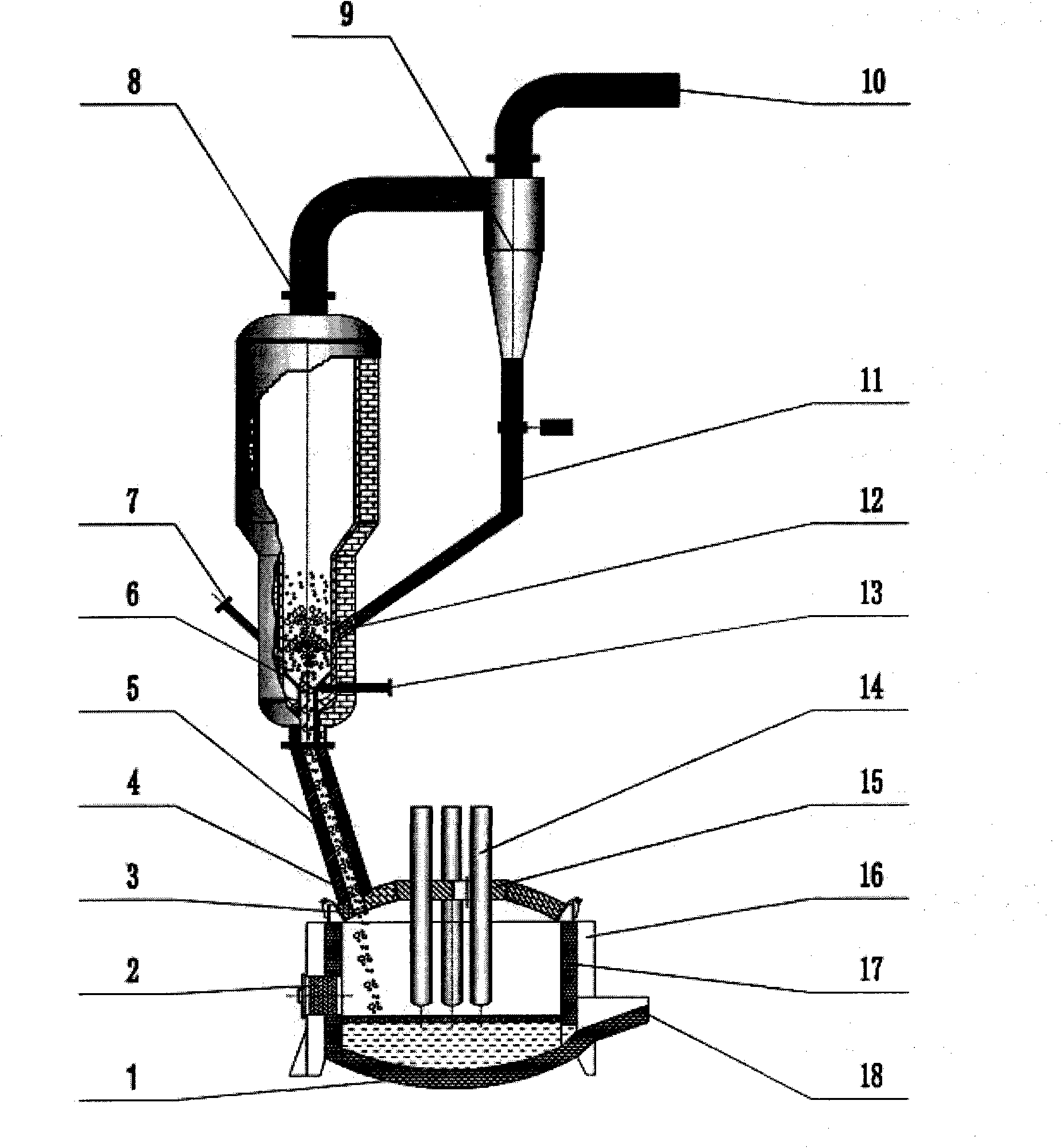

Method for purifying and concentrating CO from calcium carbide furnace gas

ActiveCN102627280AIncrease profitHigh CO yieldCalcium carbideCarbon monoxideDeoxygenationIndustrial scale

The invention discloses a method for purifying and concentrating CO from calcium carbide furnace gas and belongs to a tail gas purification method. The method provided by the invention respectively comprises the following steps of: raw material calcium carbide furnace gas dedusting, cooling and decoking, temperature swing adsorption and precleaning, supercharging, sulphur tolerant catalytic deoxygenation, hydrolysis desulfidation, acid gas removal, arsenic removal, fine desulphurization, fine deoxidation, drying, pressure swing adsorption and concentration of CO. The invention relates to a packaged technology for purifying and concentrating CO from calcium carbide furnace gas. The technology is suitable for industrial scale application and can be adopted to make calcium carbide furnace gas containing various impurities into high-purity CO gas which is suitable for CO raw material for carbonyl synthesis or other chemical production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

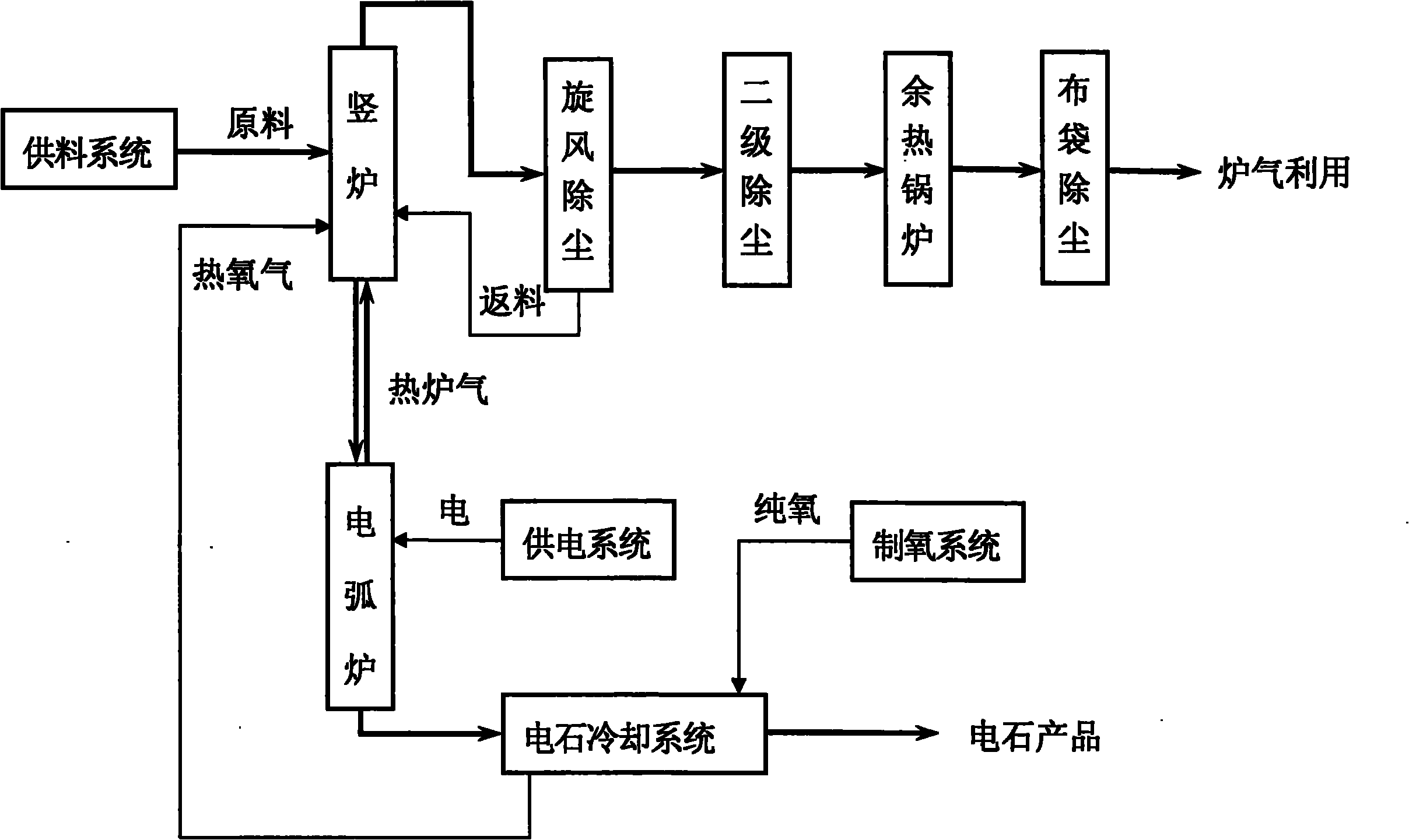

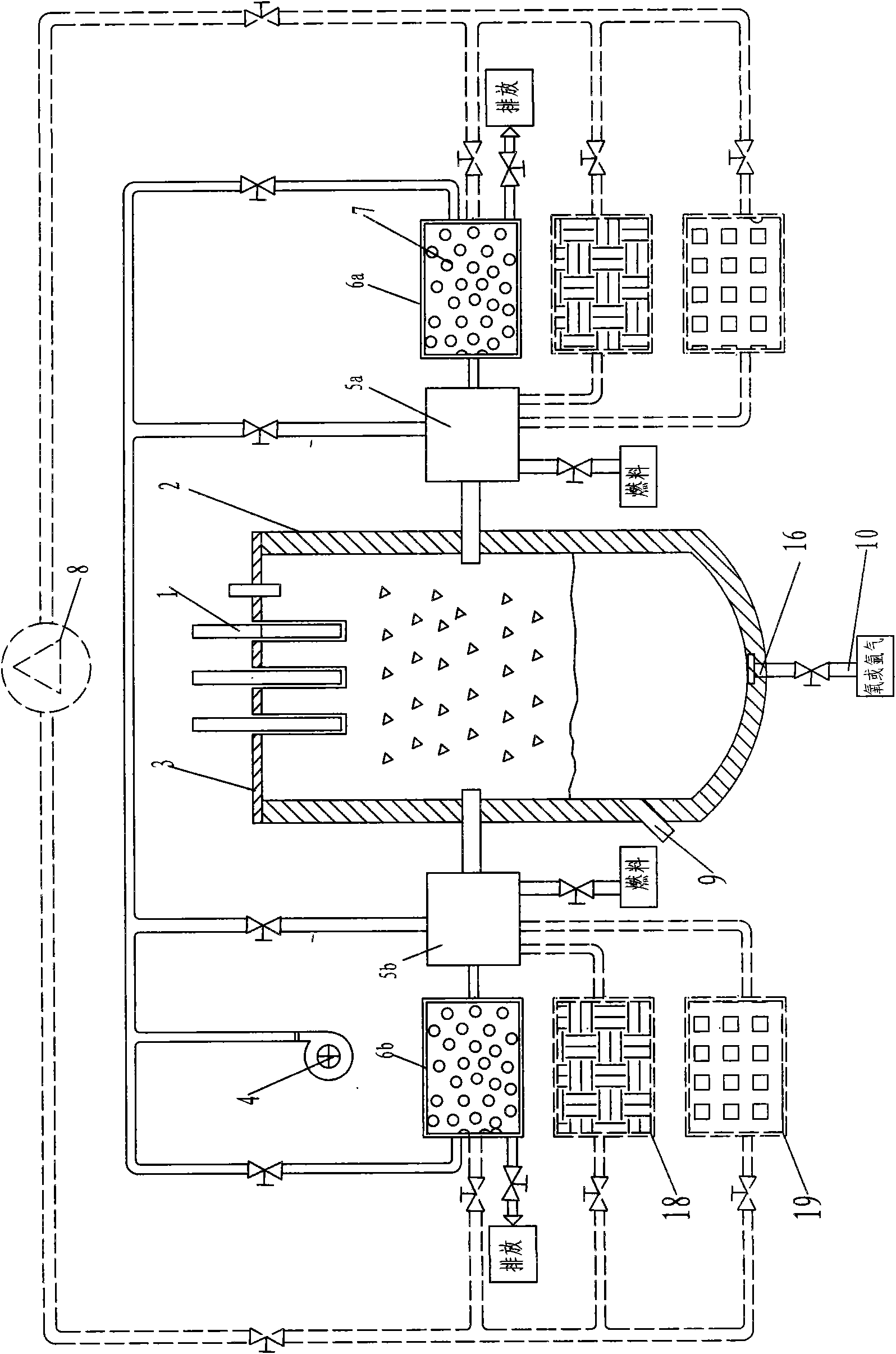

Process and device for producing calcium carbide by using powder raw materials through two-stage method

InactiveCN101817525AWide variety of sourcesIncrease profitEnergy inputCalcium carbideElectric arc furnaceOxygen

The invention relates to a process for producing calcium carbide by using powder raw materials through the two-stage method, which comprises the following steps: leading power carbon-containing material, powder calcium-containing material and oxygen to burn, increasing the temperature of furnace materials in a vertical furnace to above 1300 DEG C, leading the hot furnace materials discharged from the bottom of the vertical furnace to enter into an electric arc furnace, increasing the temperature of the hot furnace materials to 1700-2200 DEG C under the thermal effect of electric arc of an electrode, and carrying out reaction for generating the calcium carbide. Gas containing solids in the vertical furnace is discharged by a furnace gas outlet pipe at the top of the vertical furnace and separated by a cyclone dust collector from, secondary dust collection, residual heat recovery and cloth bag dust collection are carried out on the separated gas to reduce the dust content to below 1-5mg / Nm3, the temperature is reduced to 30-45 DEG C, and then the gas can be recycled as fuel gas or chemical raw material gas. The process has the advantages of powder raw materials, low energy consumption, low cost, continuous production and high grade of the calcium carbide.

Owner:山西亿众公用事业有限公司

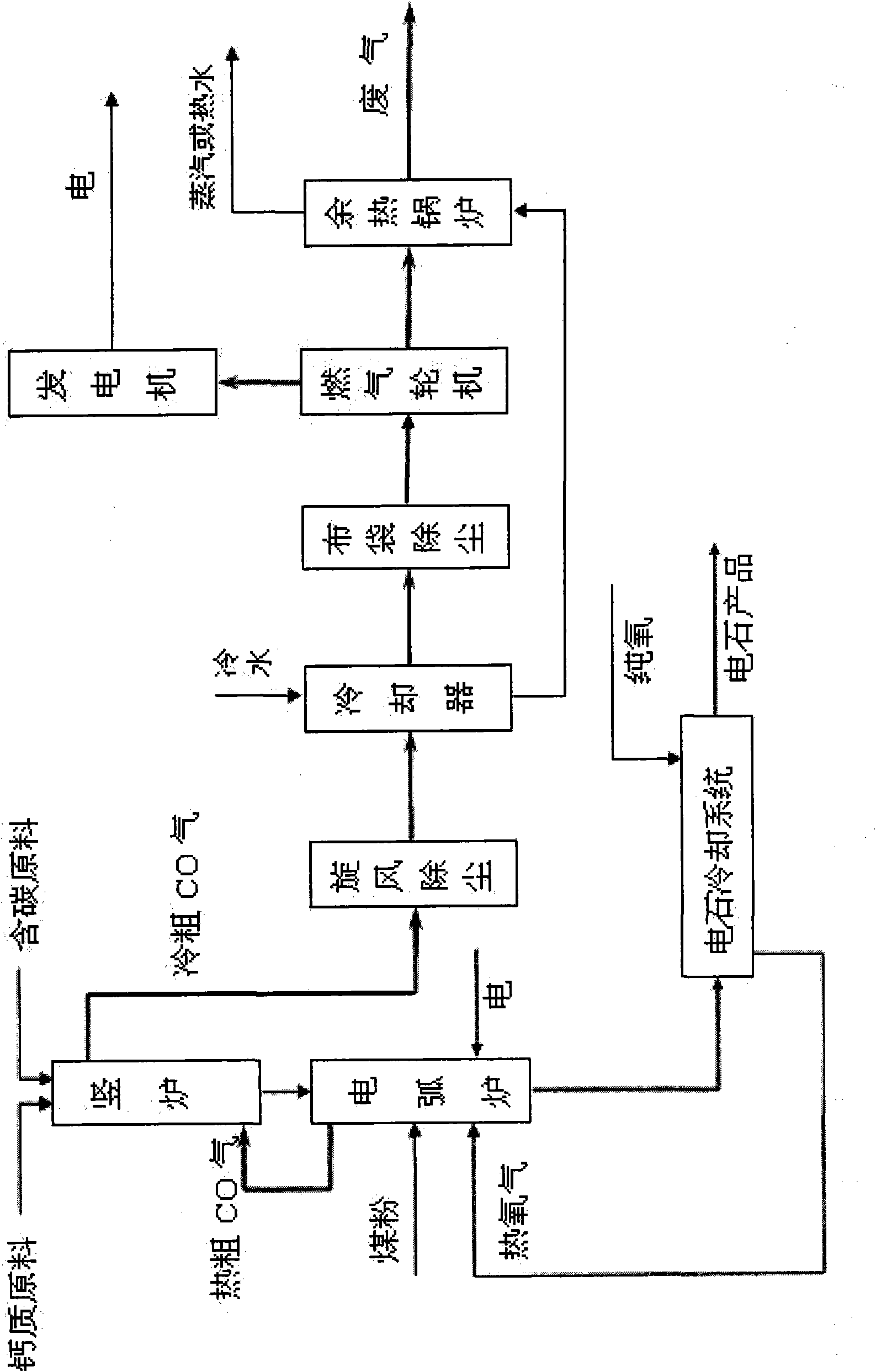

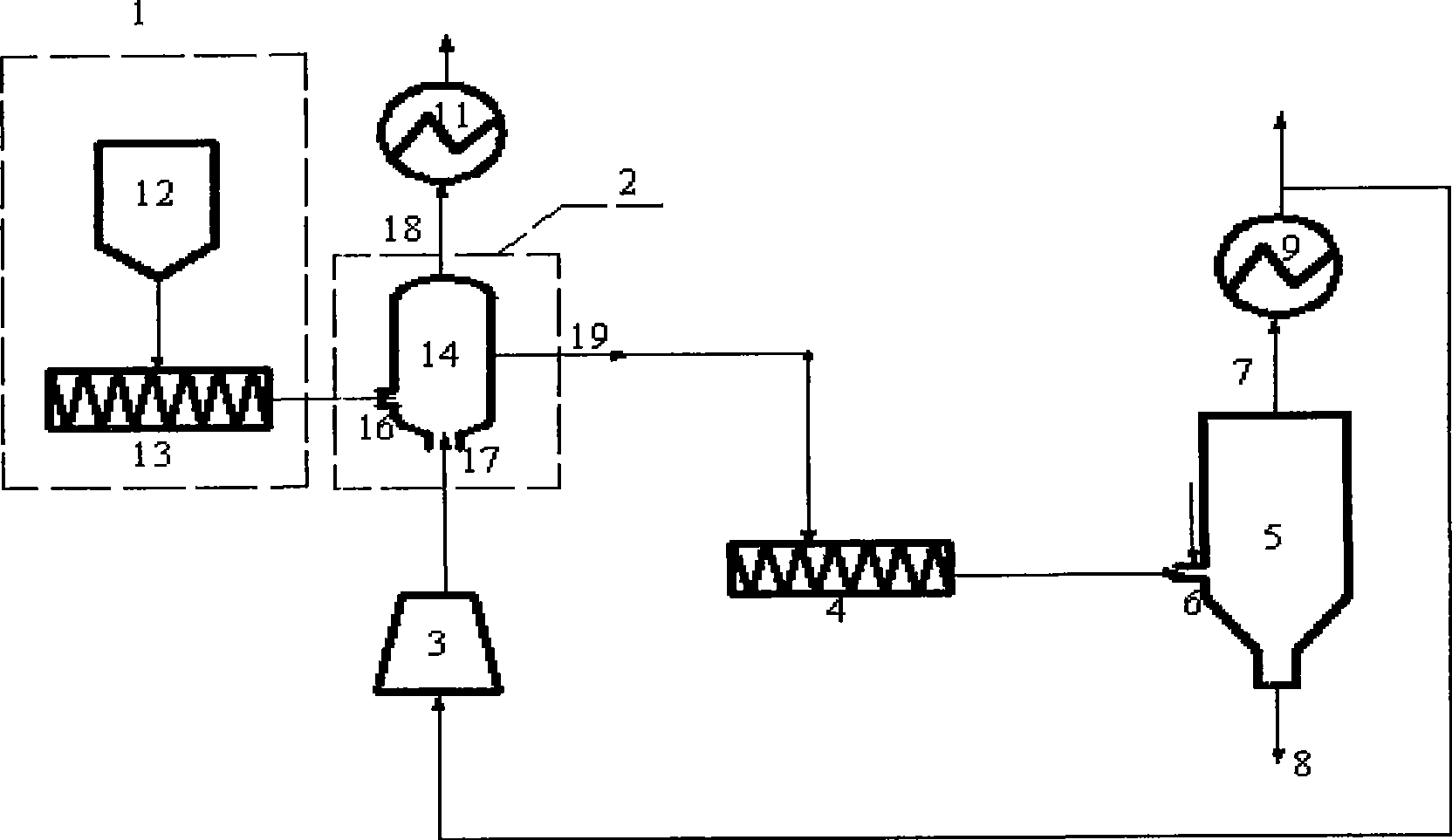

System for producing calcium carbide

InactiveCN101428799AIncrease production capacityEnergy inputCalcium carbideCouplingCompression device

A calcium carbide production system belongs to the field of calcium carbide production. The calcium carbide production system includes a raw material preheating unit and a reaction unit; the raw material preheating unit includes a raw material mixing and feeding device, a preheating device, a gas compression device and a heat exchanger; the raw material mixing and feeding device includes a solid raw material mixer and a feeder; a raw material inlet, a gas inlet, a gas outlet and a solid material outlet are formed on the preheating device; the raw material mixing and feeding device is communicated with the preheating device; the reaction unit includes a feeding device, a reactor and a heat exchanger; a raw material nozzle, a gas outlet and a product outlet are arranged on the reactor; the solid material inlet of the feeding device is communicated with the preheating device; the solid material outlet of the feeding device is communicated with the raw material nozzle on the reactor; the reactor is communicated with the heat exchanger; and the heat exchanger is connected with the gas compression device of the preheating unit. The system realizes the coupling of the process of coal coking and lime calcining and the production of calcium carbide; the capacity usage ratio is high; the powdery material is adopted; the selection range of the raw material is wide; the production capacity is large; and the furnace type is simple.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing calcium carbide

InactiveCN101172605AEasy to crushIncrease surface areaCalcium carbideElectric arc furnaceGranularity

The invention relates to a production method of calcium carbide, which takes coal powder and calcium oxide as raw materials. According to the method, the coal powder is crashed to 120 meshes, and then mixed with the calcium oxide at the weight rate of 1:0.8 to 1. A certain amount of water is added into the mixture which then can be stirred to be even and compressed into cubic honeycomb blocks; and then the cubic honeycomb blocks are sent into an electric-arc furnace for smelting the calcium carbide after airing water. The invention crashes the coal powder into a nanometer particle size, thereby ensuring the cubic honeycomb blocks to have a comparatively large surface area, improving the reaction activation energy and being good for the rapid generation of the calcium carbide. The production method of the calcium carbide of the invention not only reduces reaction temperature and shortens reaction time, but also extends the service life of the electric arc furnace.

Owner:李书堂

Method and apparatus for preparing calcium carbide by oxygen-fuel blowing of high furnace

InactiveCN1843907AReduce manufacturing costRealize the comprehensive utilization of resourcesChemical industryCalcium carbideFerrosiliconHearth

The invention relates to field of preparing calcium carbide with oxygen jetting in tower furnace. The calcium carbonate is heat decomposed into calcium oxide and reduced to calcium carbide by carbon material by jetting with preheating oxygen or oxygen-enriched air. The device comprises: tower furnace and systems of feeding, charging, oxygen producing, heating air, blasting air, oxygen enriching, jetting, cooling, cleaning and recoverying coal gas and recovering calcium carbide and ferrosilicon. The ration between said furnace height and furnace hearth diameter is less than or equal to 3.5, and diameter ratio between furnace hearth and furnace hearth is 0.8-1.1. The invention is to produce calcium carbide of 80%, the proportioning of raw material is lime carbonate: coke: fluorite =(1.2-2.0): (1.5-4.0): (0.039-0.046); jetting material is coal powder, light oil or natural gas; relative oxygen-enriched air amount, the xygen-enriched rate is 9-39%, and prepares side products of calcium carbide of more than 65%, ferrosilicon more than or equal to 54% and carbon monoxide of more than or equal to 54% at high temperature. The invention is characterized by energy saving, high quality and environmental protection.

Owner:岳书才

Method and device for making iron by smelting reduction

ActiveCN101649366ALess investmentReduce pre-restore timeCalcium carbideManufacturing convertersElectric arc furnaceSlag

The invention relates to a method and a device for making iron by smelting reduction. The method for making iron by smelting reduction comprises the following steps: putting raw material forming matters into a smelting ironmaking device; heating and reducing the raw material forming matters into metallic iron; after the reduced metalation rate of various oxides of iron reaches 40-95 percent in rawmaterials, heating and melting products of a reducing furnace; and producing direct reduction molten steel or molten iron produced by the similar blast furnace. The raw materials comprise a breath shell or a half-breath shell or an opening shell or the combination of the raw materials, a coating shells of the breath shell, the half-breath shell and the opening shell is prepared by adding an adhesive in calcium oxide or calcium carbonate or calcium carbide or the combination of the materials. The device for making iron by smelting reduction comprises an arc furnace, a buried arc furnace, a converter, an induction furnace, and the like. After reduction products are heated and melted, and oxygen or inert gas is blown into the arc furnace in order to remove slag. Due to the adoption of a shell coating technology, the method and the device effectively prevent from oxidizing reduced matters in the process, avoid bonding formed matters for contact and are combined with blowing gas and are good for making slag. Slag iron has good separation effect, and the produced iron and steel products have good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Heterogeneous, composite, carbonaceous catalyst system and methods that use catalytically active gold

ActiveUS8058202B2High catalytic activityTendency increaseMaterial nanotechnologyGas treatmentActivated carbonHost material

Heterogeneous catalyst systems, methods of making these systems, and methods of using these systems, wherein catalytically active gold is deposited onto composite support media. The composite support media is formed by providing nanoporous material on at least a portion of the surfaces of carbonaceous host material. In representative embodiments, relatively fine, nanoporous guest particles are coated or otherwise provided on surfaces of relatively coarser activated carbon particles. Catalytically active gold may be deposited onto one or both of the guest or host materials either before or after the guest and host materials are combined to from the composite host material. PVD is the preferred catalyst system of depositing gold.

Owner:3M INNOVATIVE PROPERTIES CO

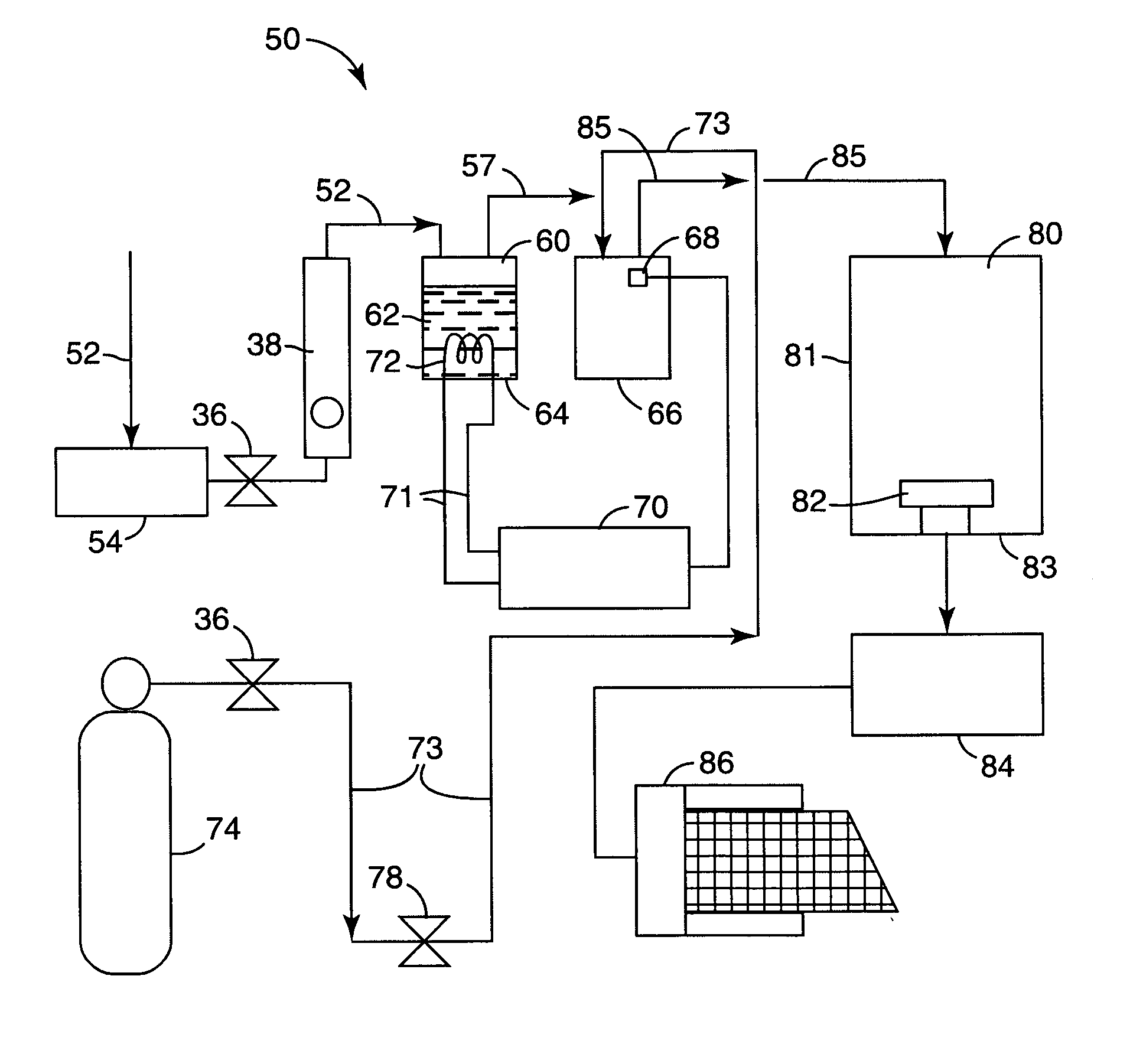

Method and system for producing calcium carbide

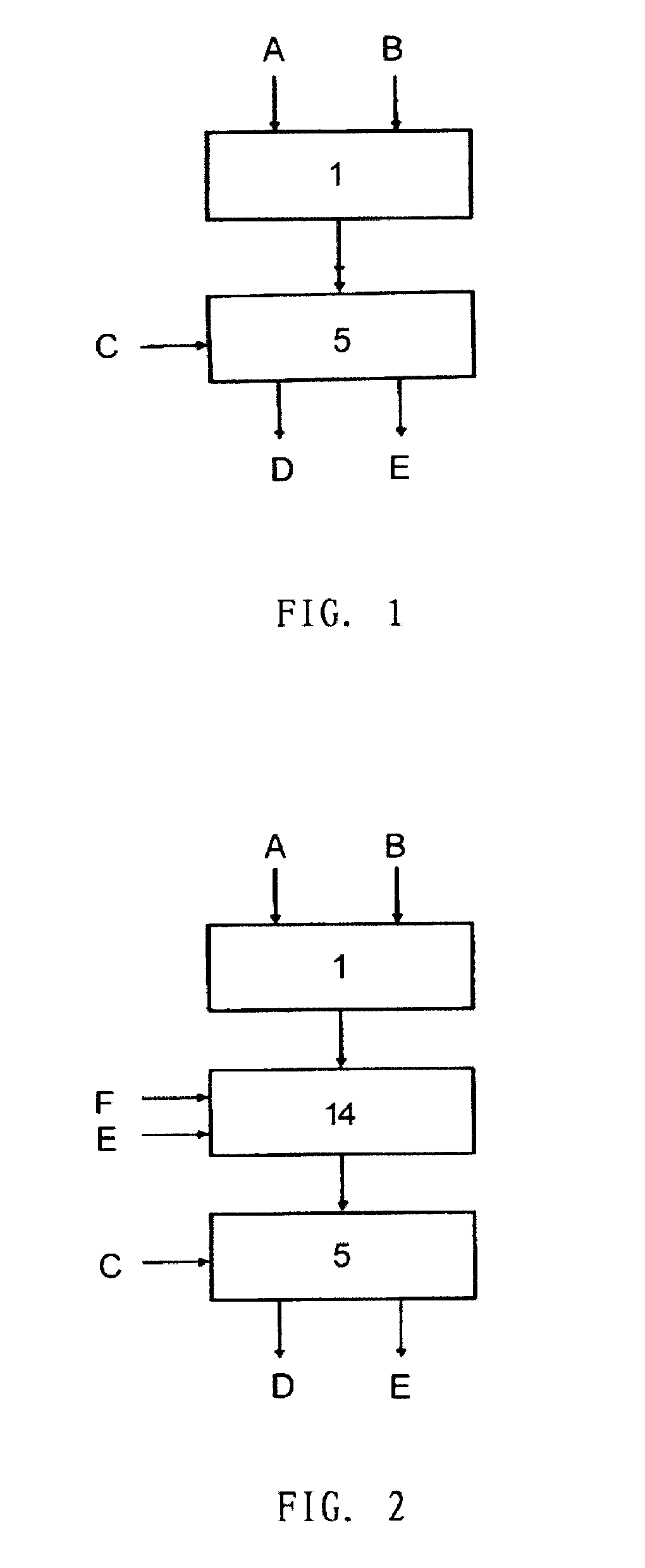

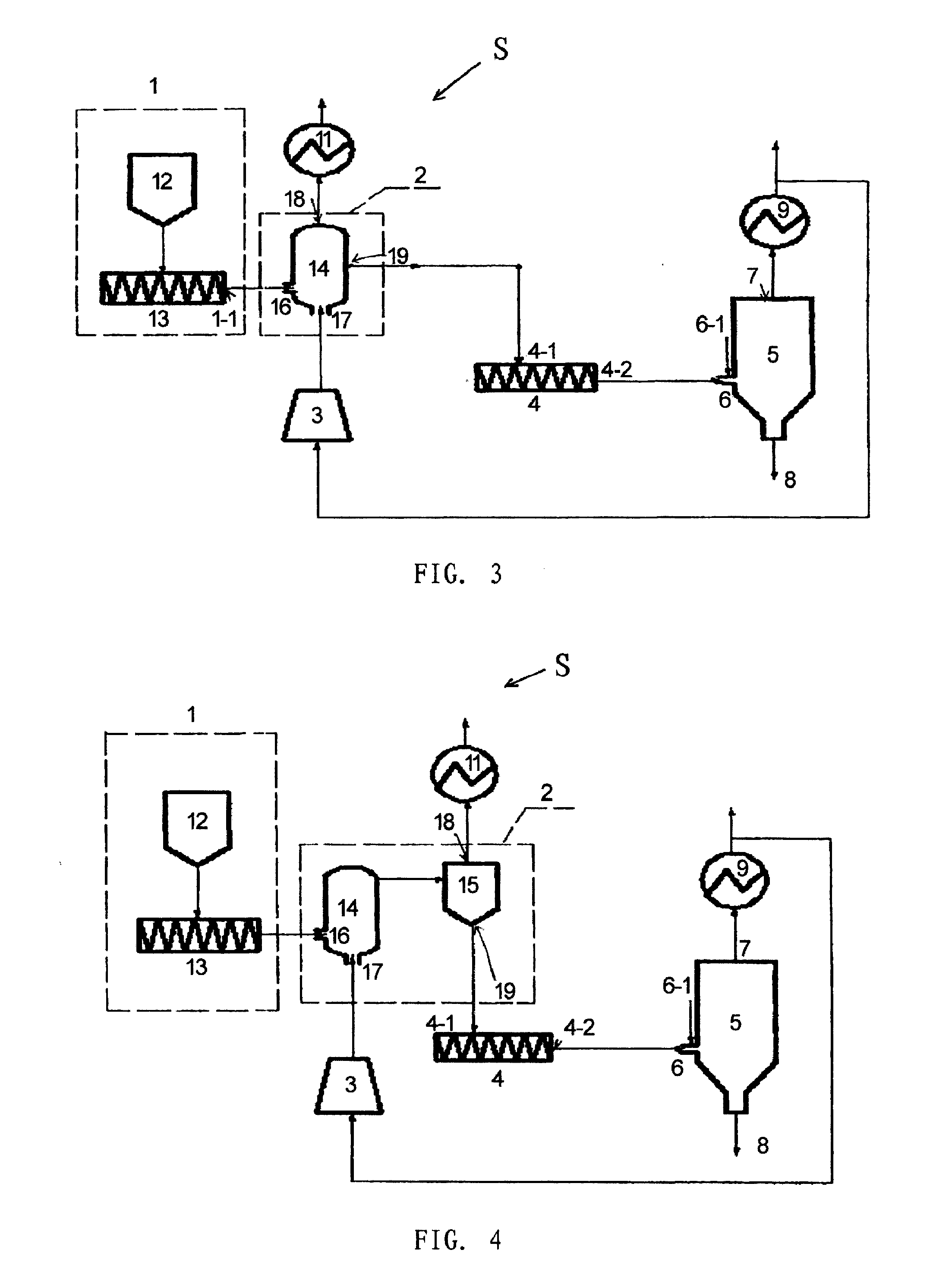

InactiveUS20110123428A1Increase response rateLow reaction temperatureEnergy inputCalcium carbideSlagUranium carbide

A method and a system for producing calcium carbide, the method including mixing powdery carbon-containing raw material with powdery calcium-containing raw material, and directly heating the mixture by combusting a part of carbon-containing raw material in an oxygen-containing atmosphere to produce calcium carbide. The carbon-containing raw material can be coal, semi-coke or coke, the calcium-containing raw material can be calcium carbonate, calcium oxide, calcium hydroxide or carbide slag. The system includes a raw material preheating unit, such as a fluidized bed or an entrained flow bed, and a reaction unit such as an entrained flow bed. By combustion of the by-product CO produced during the production of calcium carbide or auxiliary fuel in the air to preheat the raw materials to 500-1500° C., the carbon consumption and the oxygen consumption for the calcium carbide production can be reduced, and thus process energy consumption is further reduced.

Owner:LIU ZHENYU +2

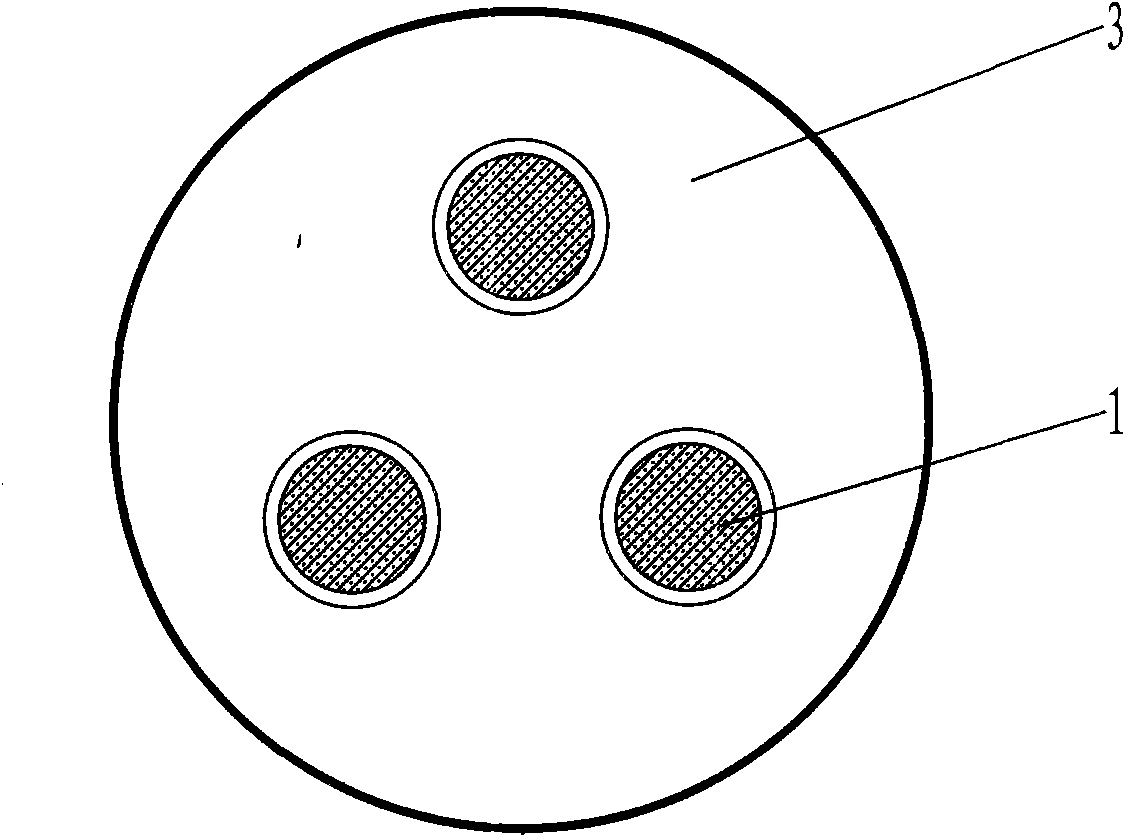

Calcium carbide furnace with combination of oxygen heating method and electric heating method

ActiveCN103408013AReduce power consumptionQuality assuranceCalcium carbideElectric arc furnaceElectric consumption

The invention relates to a calcium carbide furnace with combination of an oxygen heating method and an electric heating method, which adopts the structure of an electric-arc furnace, and comprises a furnace body, a furnace cover, a feed inlet and a calcium carbide furnace gas outlet, wherein 1-5 electrode assemblies are arranged on the calcium carbide furnace and penetrate the furnace cover to be inserted into the furnace body; each electrode assembly is of a sleeve structure, and comprises an inner sleeve and an outer sleeve; an electrode is accommodated in each inner sleeve; a conduction oil jacket is arranged between the inner sleeve and the outer sleeve of each electrode assembly; a fuel spray pipe, an oxygen spray pipe and a calcium carbide extraction pipe are arranged in each electrode; a conduction oil inlet and a conduction oil outlet are arranged on each conduction oil jacket, and are connected with a conduction oil circulation system. According to the calcium carbide furnace, the oxygen heating method and the electric heating method are combined, so that the electric consumption of calcium carbide production is lowered, the cost is saved, the quality of a calcium carbide product is ensured, and the economic efficiency of an enterprise is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Method for preparing calcium carbide

InactiveCN103708462AReduce manufacturing costReduce the temperatureChemical industryCalcium carbideMicrometerEnergy consumption

The invention discloses a method for preparing calcium carbide, which comprises the following steps: respectively crushing a carbon-base raw material and a calcium-base raw material to obtain carbon-base particles and calcium-base particles of which the average particle sizes are not greater than 50 micrometers; mixing the carbon-base particles and calcium-base particles to obtain a mixture; forming the mixture to obtain a massive furnace raw material; and smelting the massive furnace raw material in an arc furnace to obtain the calcium carbide. Since the raw materials are prepared into the ultrafine powders and then mixed and formed, the method disclosed by the embodiment of the invention can effectively lower the smelting temperature and energy consumption of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

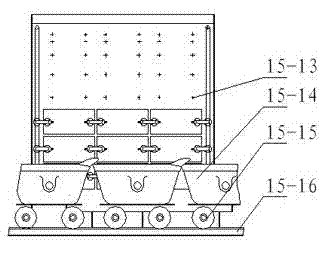

Waste heat collecting and recycling method in solidification course of liquid calcium carbide

InactiveCN102226594ARealization of waste heat collection and reuseRealize cleaner productionOther heat production devicesEnergy inputWater dischargeWater storage tank

The invention relates to a waste heat collecting and recycling method in the solidification course of liquid calcium carbide, which comprises the following steps: the liquid calcium carbide which is emitted from the mouth of a calcium carbide furnace flows into calcium carbide pots which are placed on an annular transportation trolley one by one; the annular transportation trolley loaded with the calcium carbide pots passes through a calcium carbide waste heat collecting box and calcium carbide exchanges heat with water; and the generated hot water is transmitted to a water storage tank through a water discharge pipeline and finally transmitted to a user pipe network through the pipeline. The method provided by the invention realizes recycle of the waste heat in the production course of the calcium carbide and has the obvious effects of saving the energy sources, lowering the production cost, improving the production environment, realizing clean production.

Owner:姚会元

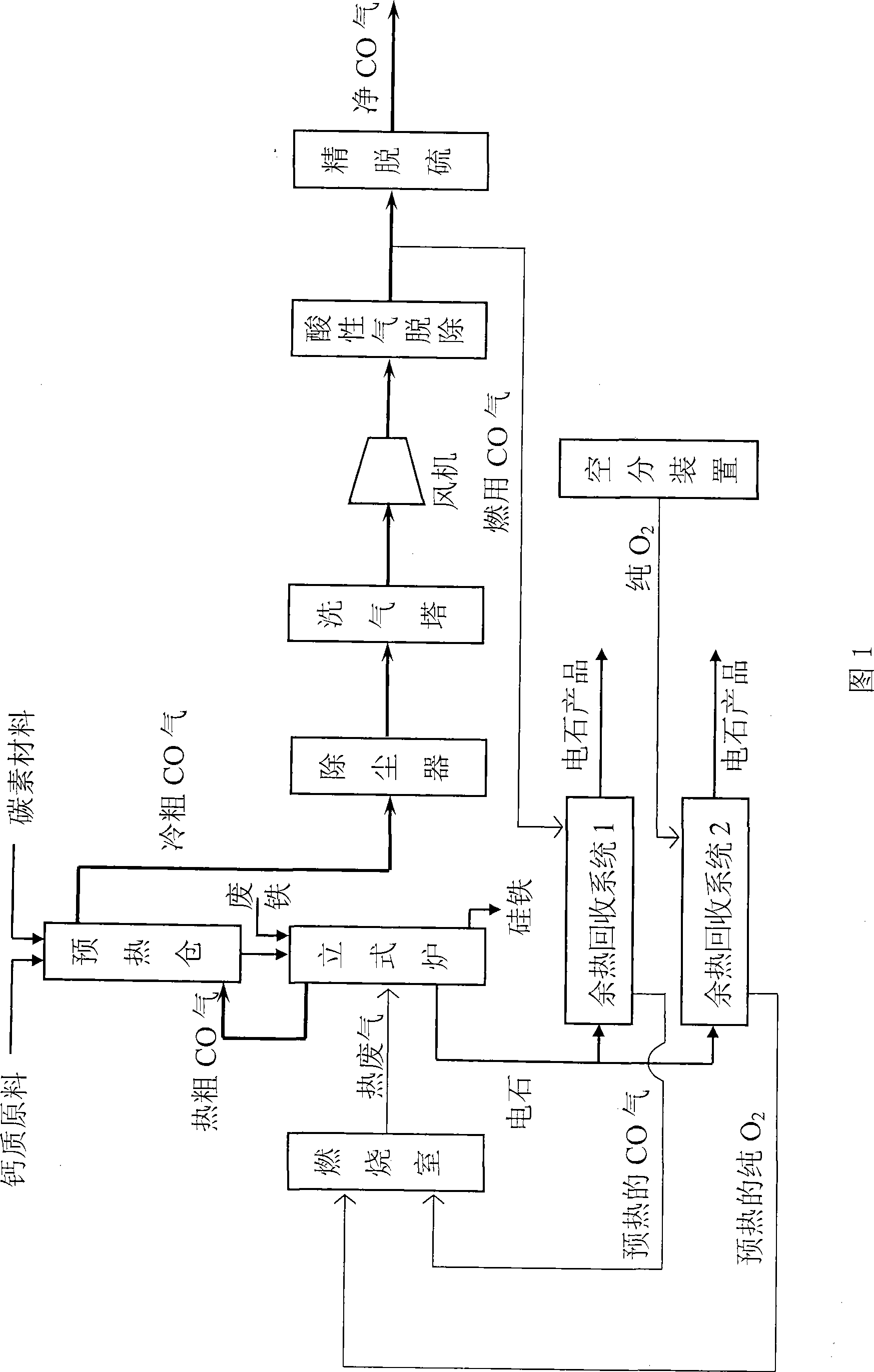

Method for simultaneously producing acetylene stones, ferrosilicium and high-purity CO gas

InactiveCN101362599ATo achieve coordinated developmentReasonable process combinationEnergy inputCalcium carbideGreenhouseFerrosilicon

A method for simultaneously producing calcium carbide, ferrosilicon and high-purity CO gas is characterized in that: an oxygen heating process is adopted, a calcareous material, a carbon material and steel scrap or a ferrous waste are taken as raw materials, self-produced CO gas is taken as a fuel. The method has obvious advantages of no greenhouse gases emission, reasonable process combination, simple process flow, low consumption of energy and water, high efficiency and low cost.

Owner:SHENGHE RESOURCES HLDG CO LTD

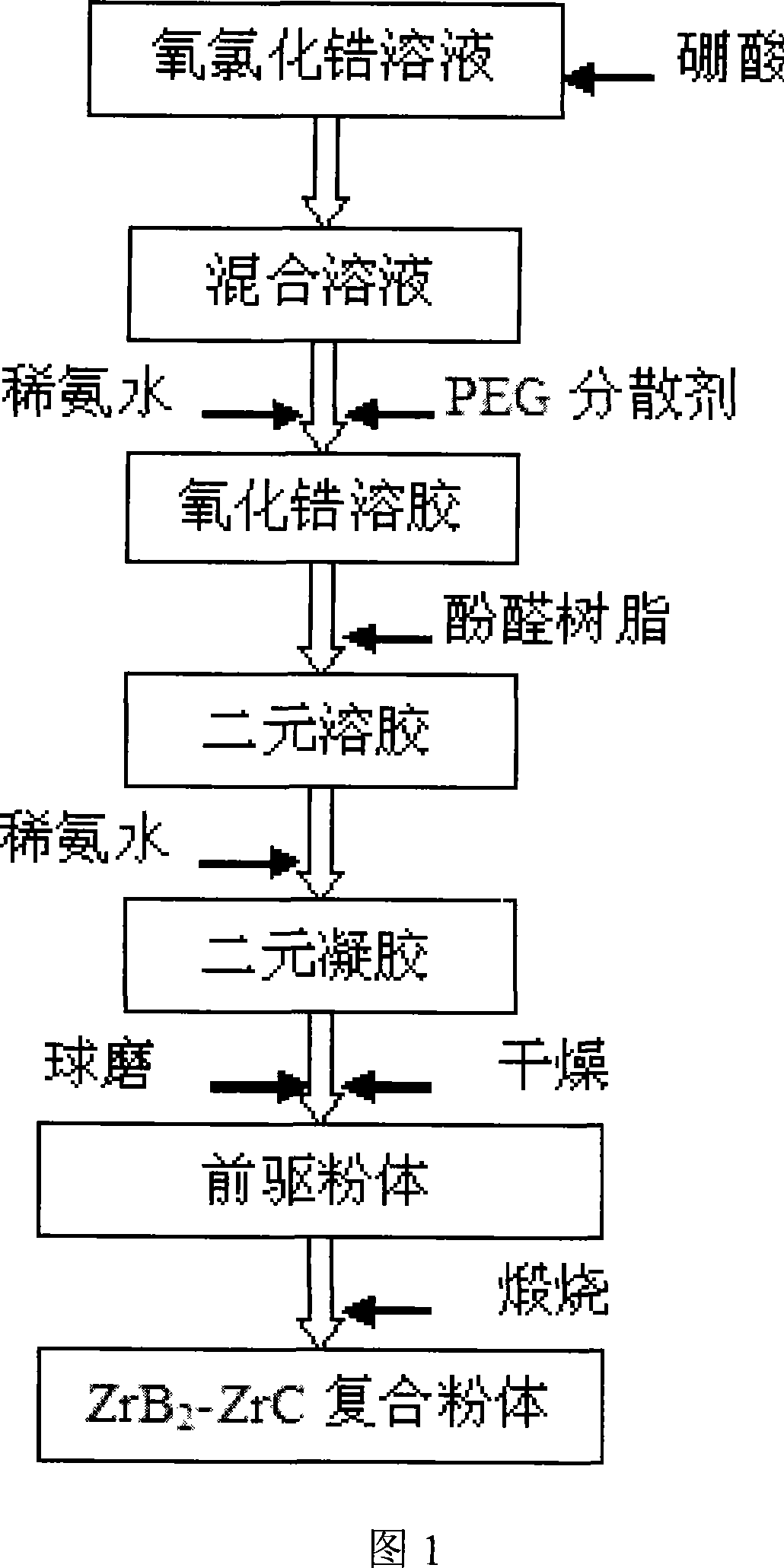

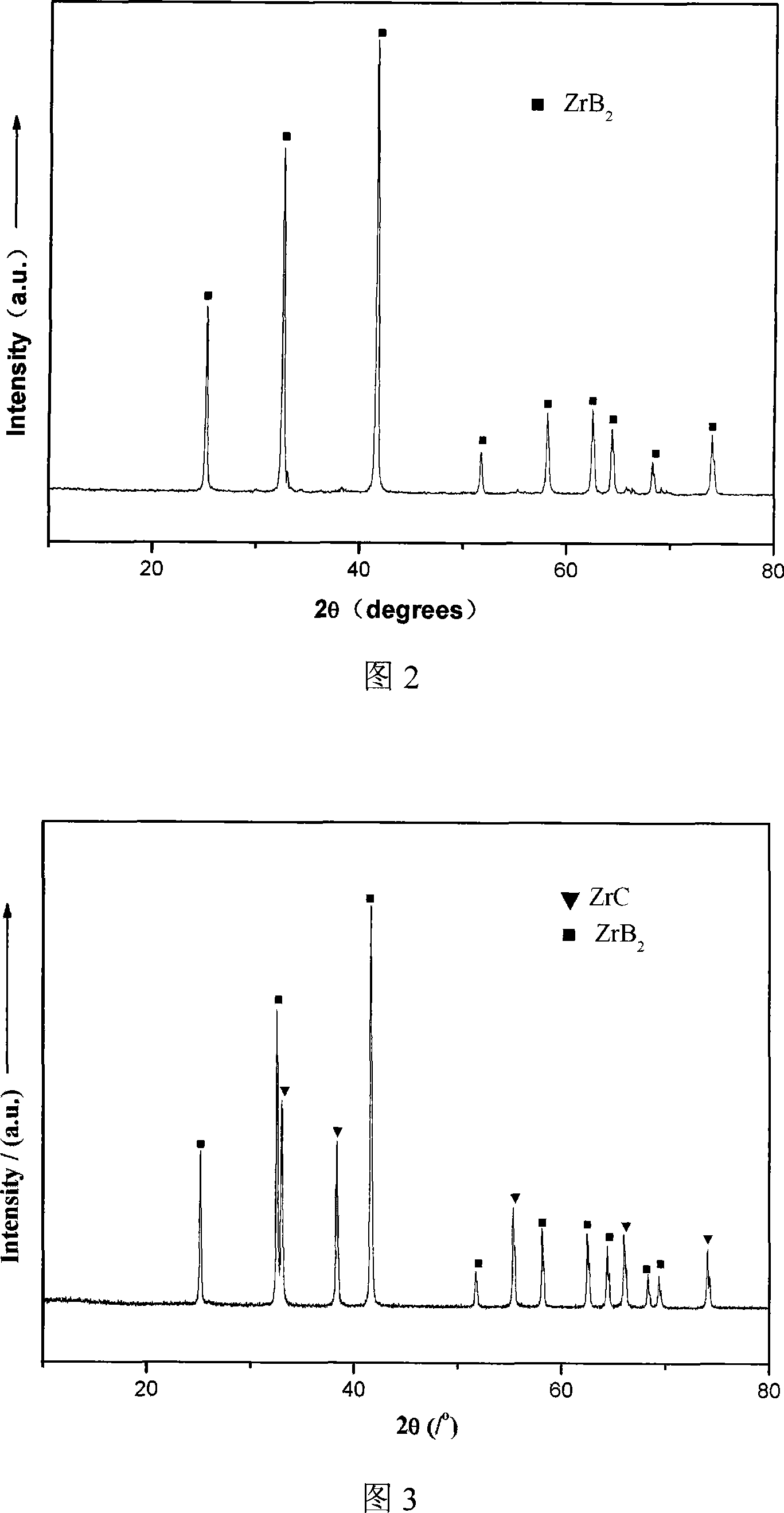

Method for preparing boron-carbon-zirconium material by liquid phase process

InactiveCN101205065AOvercoming is not easy to determine,Overcoming the disadvantages of toxic side effectsCalcium carbideMetal boridesZirconium oxychlorideElectron

The invention relates to a method for preparing boron carbon zirconium materials by liquid phase method, which belongs to the field of structural ceramics. By using carbothermal reduction as the basic principle and adopting zirconium oxychloride, boric acid and phenolic resin as the main materials, the method comprises the steps as follows: the phenolic resin is mixed with zirconia sol which is formed by titration of ammonia; then gel is formed by the titration of the ammonia; finally ball milling is carried out; after drying, screening and heat treatment, the ultrafine boron carbon zirconium materials can be obtained. The boron carbon zirconium materials which are prepared by the invention, with product granularity smaller than 200nm and excellent molding and sintering performance, can be applied to fields such as electron materials and refractory materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing calcium carbide

InactiveCN103708457AReduce manufacturing costReduce the temperatureCalcium carbideEnergy consumptionCalcium carbide

The invention discloses a method for preparing calcium carbide, which comprises the following steps: respectively crushing a carbon-base raw material and a calcium-base raw material to obtain carbon-base particles and calcium-base particles of which the average particle sizes are not greater than 50 micrometers; mixing the carbon-base particles and calcium-base particles to obtain a mixture; and smelting the mixture in a gas smelting furnace to obtain the calcium carbide. Since the raw materials are prepared into the ultrafine powders and then mixed and smelted, the method disclosed by the embodiment of the invention can effectively lower the smelting temperature and energy consumption of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

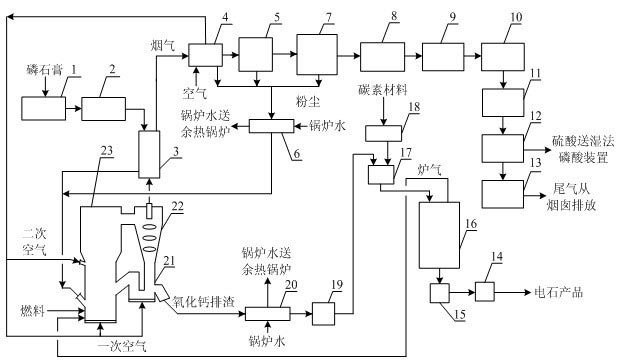

Method for producing sulfuric acid and co-producing calcium carbide by phosphogypsum

ActiveCN102442650ASolve the problem of difficult resource utilizationAchieve recyclingSulfur compoundsEnergy inputCycloneDecomposition

The invention relates to a method for producing sulfuric acid and co-producing calcium carbide by phosphogypsum, and belongs to the technical field of environmental protection. According to the method, phosphogypsum is subjected to a water washing and purification pretreatment by a multi-stage cyclone; then the pretreated phosphogypsum is dried and dewatered; the dewatered phosphogypsum enters a multi-stage suspension heat exchanger to carry out preheating; the hot state gypsum enters a circulating fluidized bed decomposing furnace, then primary air and secondary air are respectively introduced to carry out decompositions; high temperature sulfur dioxide-containing flue gas discharged from the top of the circulating fluidized bed decomposing furnace enters the multi-stage suspension heat exchanger to carry out heat exchanging and cooling with the cold state gypsum; dust in the cooled hot flue gas is removed by a multi-stage dust removing device; the dust-removed flue gas enters an acid washing and purification system to further remove the dust and the gaseous impurities in the flue gas; the purified and cleaned flue gas is conveyed into an acid preparation system to produce the sulfuric acid product; the hot state calcium oxide discharged from the bottom of the circulating fluidized bed decomposing furnace is cooled, and conveyed into a sealed calcium carbide furnace to carry out an electrical arc reaction with a carbon material to generate the calcium carbide product; the high temperature furnace gas discharged from the top of the sealed calcium carbide furnace is directly conveyed into the decomposing furnace, wherein the high temperature furnace gas is adopted as a fuel and a reducing agent. The method of the present invention has good environmental protection benefits and strong economic advantages.

Owner:CHINA PETROCHEMICAL CORP +1

Tail gas treatment and reutilization for calcium carbide stove

InactiveCN1939840AImprove dust removal effectSimple production processHydrogenLighting and heating apparatusSulfateNitrogen

Owner:国能英力特能源化工集团股份有限公司 +1

Method for preparing calcium carbide

The invention discloses a method for preparing calcium carbide, which comprises the following steps: drying a carbon-base raw material to obtain a dried carbon-base raw material; respectively crushing the dried carbon-base raw material and a calcium-base raw material to obtain a carbon-base powder and a calcium-base powder; mixing the carbon-base powder and calcium-base powder to obtain a mixture; pyrolyzing the mixture to obtain high heating value synthetic gas, tar and a pyrolytic solid product, wherein the pyrolytic solid product contains coke, semicoke, carbon black and quicklime; and feeding the pyrolytic solid product into a gas smelting furnace at the temperature of not lower than 450 DEG C to perform smelting in the gas smelting furnace, thereby obtaining the calcium carbide. The method can obviously lower the smelting energy consumption and production cost, and further enhances the preparation efficiency and quality of the calcium carbide.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Method of utilizing microwave energy to prepare calcium carbide at low temperature

The invention discloses a method of utilizing microwave energy to prepare calcium carbide at low temperature. The method comprises the following steps of using coal as a carbon source, using limestone or lime as a calcium source, heating by the microwave energy, and reacting and synthesizing to form the calcium carbide, wherein the reaction temperature of the synthesized calcium carbide is 1300-2000 DEG C, the reaction pressure is 0.3-1.1atm, and the reaction time is 3-120min; primarily grinding the carbon source and the calcium source, mixing according to a ratio, and performing ultrafine treatment to obtain an ultrafine mixed material; heating to react and synthesizing to form the calcium carbide by utilizing the microwave energy. The method has the advantages that the coal and the limestone are directly used as the raw materials, are subjected to ultrafine crushing, and are heated and synthesized to form the calcium carbide by the microwave energy; by utilizing various coal types, two steps of the coking of raw coal and the high-temperature decomposing of the calcium carbonate to prepare the limestone are not needed, the synthesizing temperature of the calcium carbide is lowered, the production efficiency and mechanical degree of the calcium carbide are improved, and a byproduct of carbon monoxide can be used as a chemical raw material to produce other chemical products.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

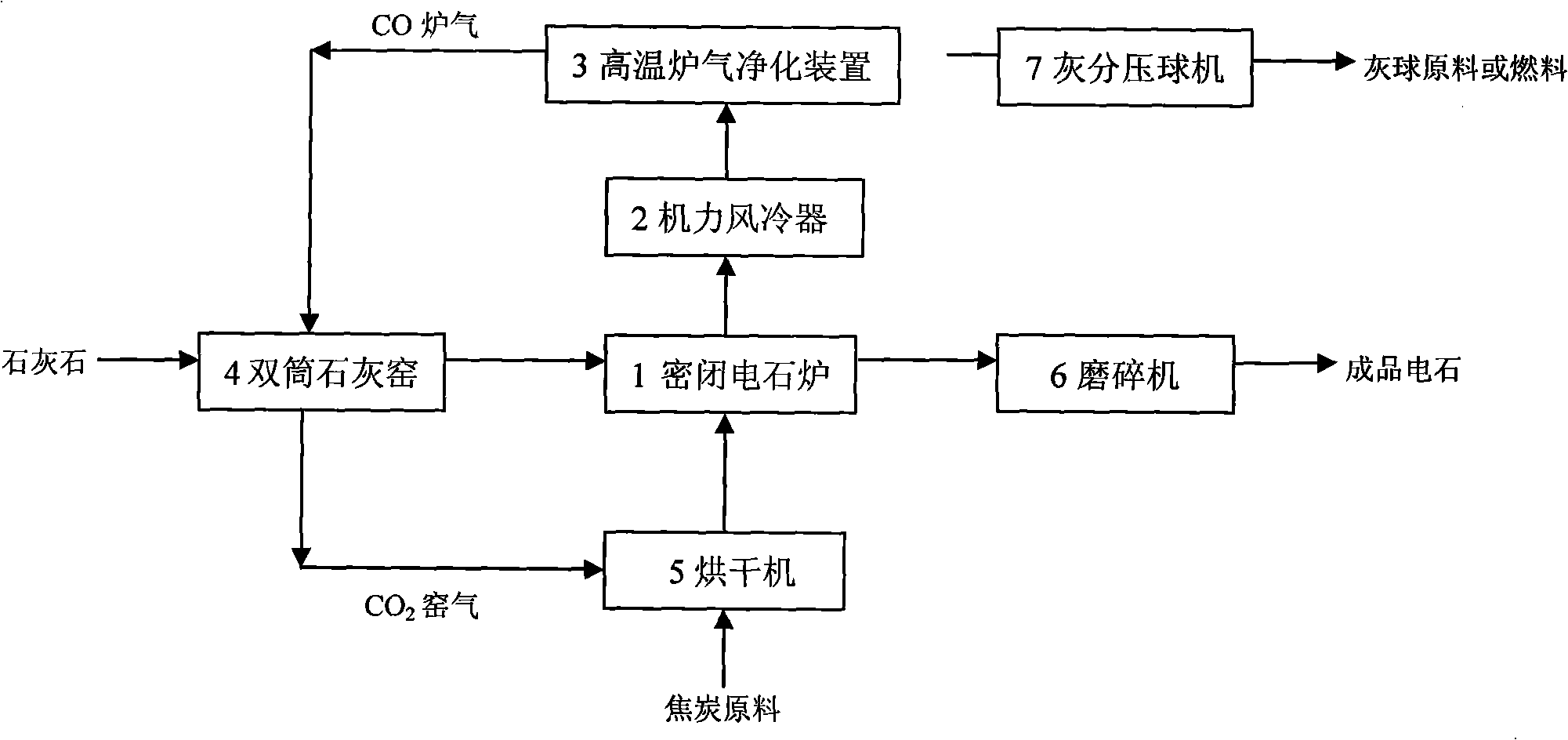

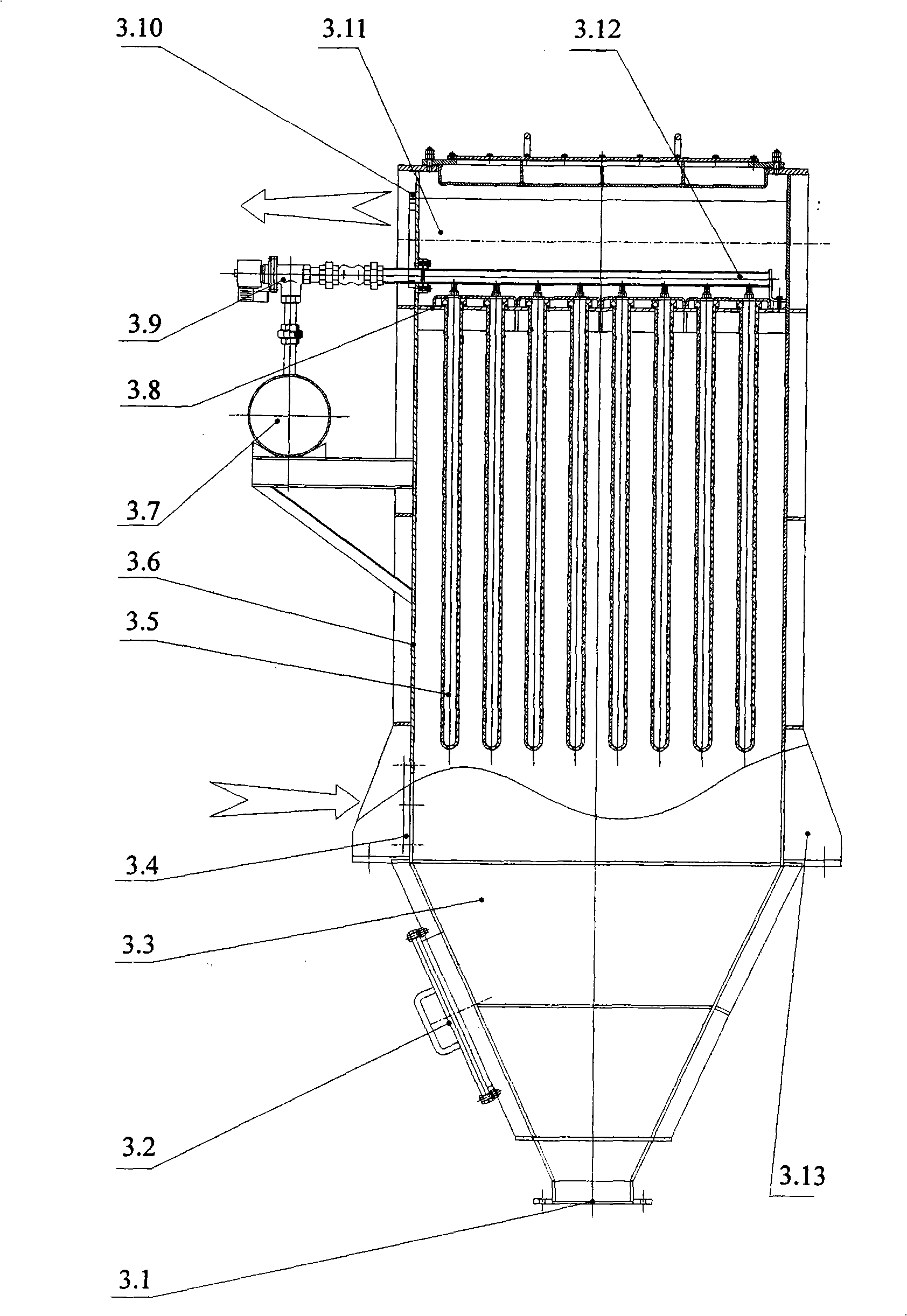

Comprehensive utilization system for high temperature furnace gas of sealed calcium carbide furnace

InactiveCN101284666AImprove separation efficiencyImprove dust removal effectChemical industryCalcium carbideFiberFiltration

The invention discloses a system for comprehensive utilization of the high-temperature furnace gas in a hermetic calcium carbide furnace. Two inlets of the hermetic calcium carbide furnace are respectively connected with a dual-drum limekiln for supplying calcium oxide and a dryer for supplying coke. One outlet of the calcium carbide furnace is connected with a grinding machine used for grinding the calcium carbide; the inlet and the outlet of a mechanical air cooling device are respectively connected with another outlet of the calcium carbide furnace and an inlet of a high-temperature furnace gas purifying device; two outlets of the high-temperature furnace gas purifying device are respectively connected with an inlet of the dual-drum limekiln and an ash content ball press; and the dual-drum limekiln is connected with an inlet of the dryer. The high-temperature furnace gas purifying device in the system takes a foaming aluminum silicate fiber material as a filtration medium which resists high temperature and corrosion and has small resistance and high separative efficiency. The whole system has good energy-saving and environment-friendly characteristics. On the one hand, the recycle of the high-temperature CO furnace gas in the hermetic calcium carbide furnace and the kiln gas of CO2 in the limekiln can satisfy the energy need of the system; on the other hand, the coke consumption and the CO2 emission are reduced.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

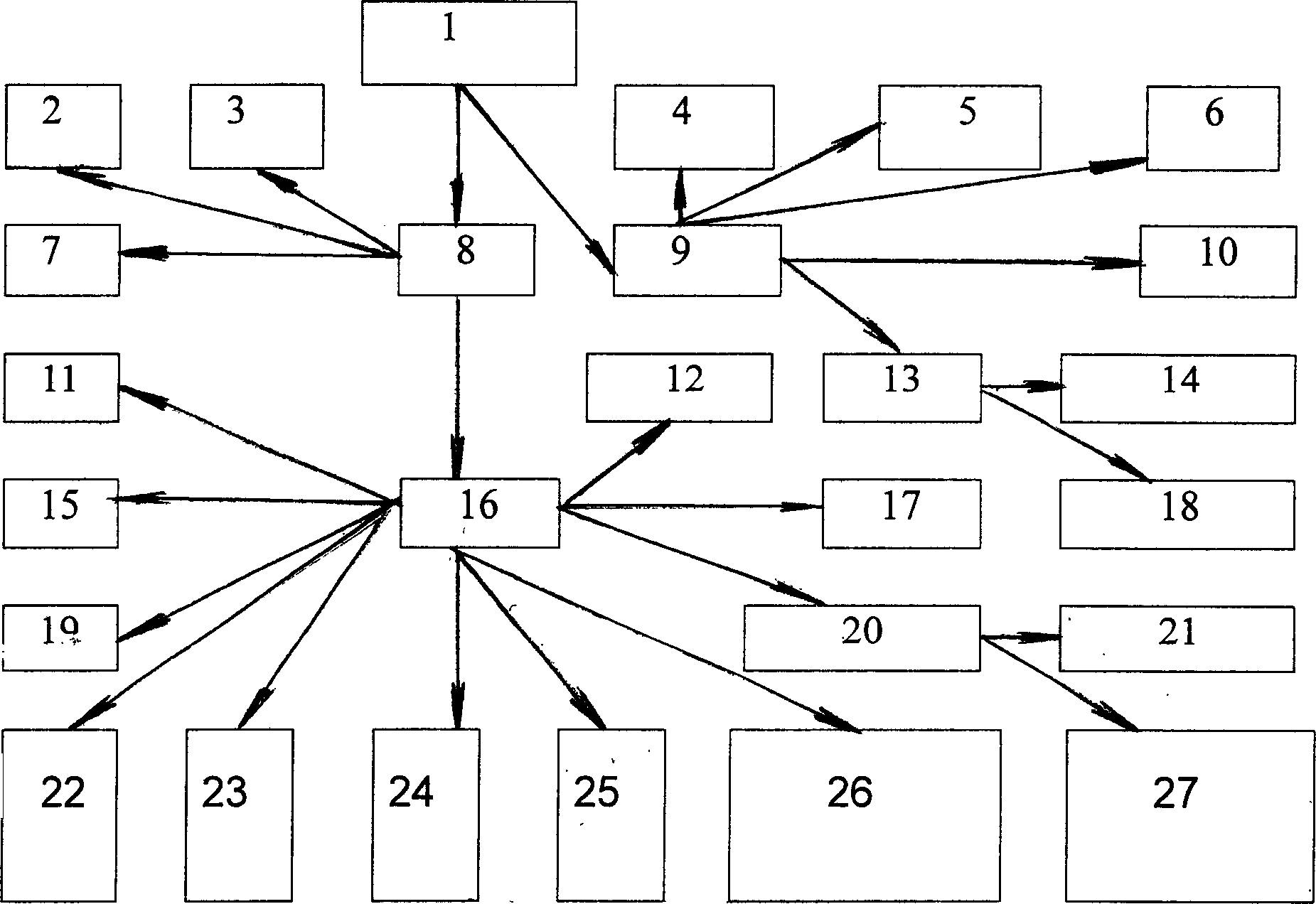

Production device for coproduction of calcium carbide by electrothermal method and oxygen thermal method

The invention relates to a production device for coproduction of calcium carbide by an electrothermal method and an oxygen thermal method. The production device comprises an oxygen thermal method calcium carbide furnace, an electrothermal method calcium carbide furnace, a semi-coke furnace, a lime kiln and a power generation system. A coal briquette preparation system is connected to the semi-coke furnace through a coal briquette preheater, and the semi-coke furnace is connected to the electrothermal method calcium carbide furnace and the oxygen thermal method calcium carbide furnace. A limestone supply device is connected to the lime kiln through a limestone preheater, and the lime kiln is connected to the electrothermal method calcium carbide furnace and the oxygen thermal method calcium carbide furnace. Calcium carbide furnace gas outlets of the calcium carbide furnaces are connected to a fuel inlet of the semi-coke furnace, a semi-coke tail gas outlet of the semi-coke furnace is connected to the fuel inlet of the lime kiln and the fuel inlet of a steam boiler, and a waste heat boiler is connected to a steam turbine. A power generator set is connected to the wiring end of the electrothermal method calcium carbide furnace through a power transmission device. The production device provided by the invention fully utilizes byproducts and waste heat of the calcium carbide furnaces and the semi-coke furnace, reduces the energy consumption and the calcium carbide production cost and improves the comprehensive economic benefits of an enterprise by combining the oxygen thermal method calcium carbide furnace and the electrothermal method calcium carbide furnace with the semi-coke furnace, the lime kiln and the power generation system.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com