Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

372results about How to "Increase response rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

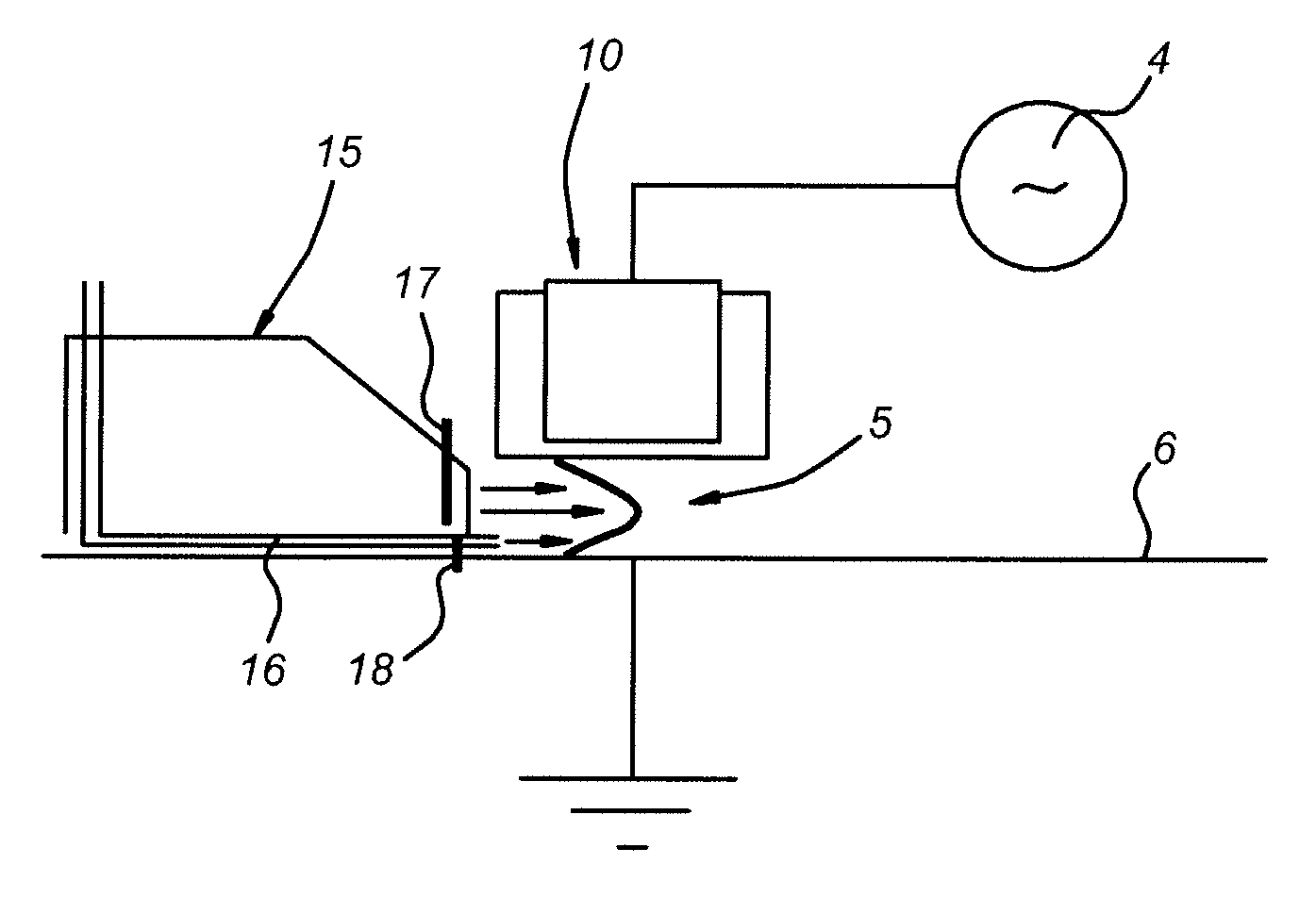

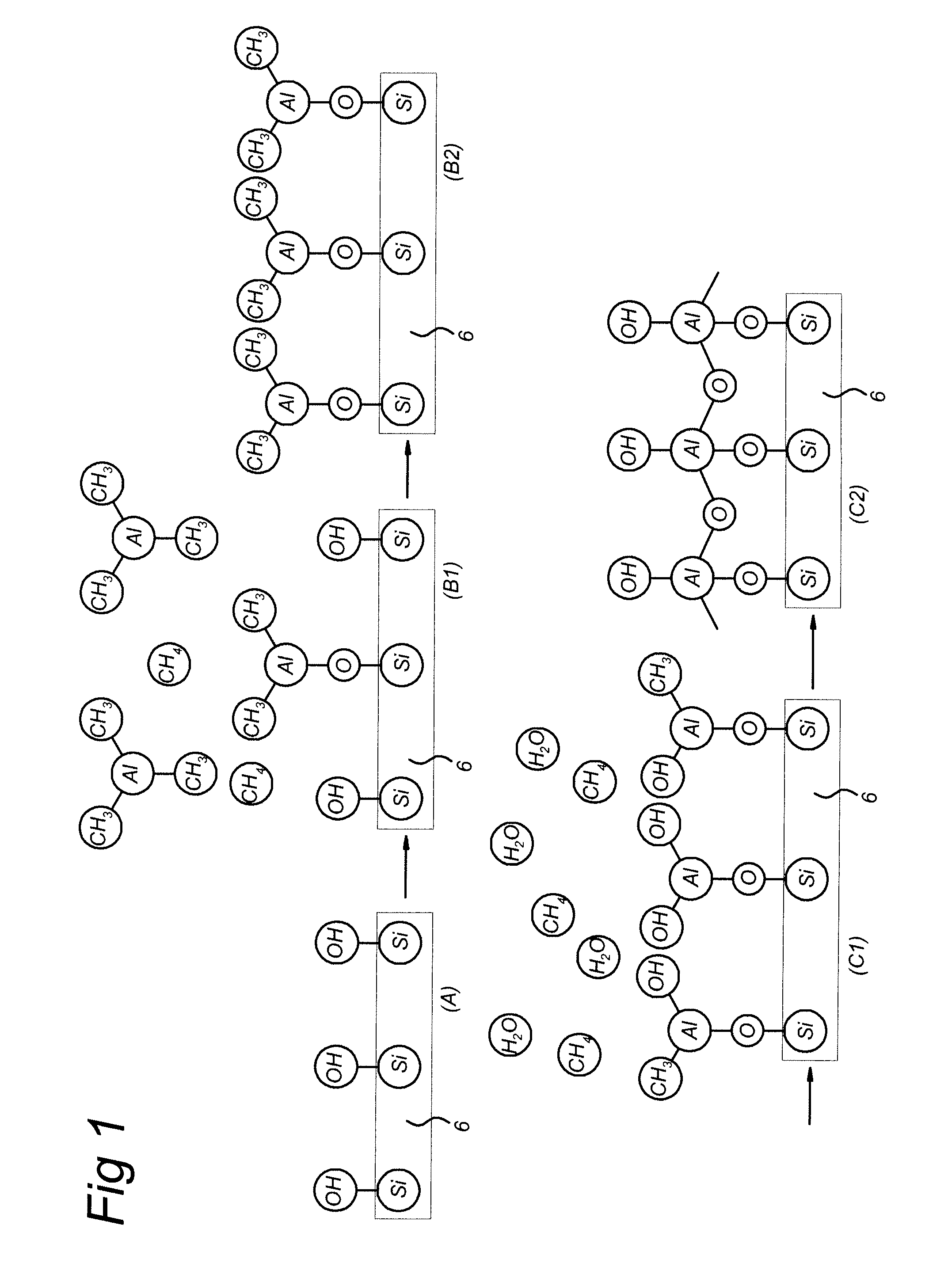

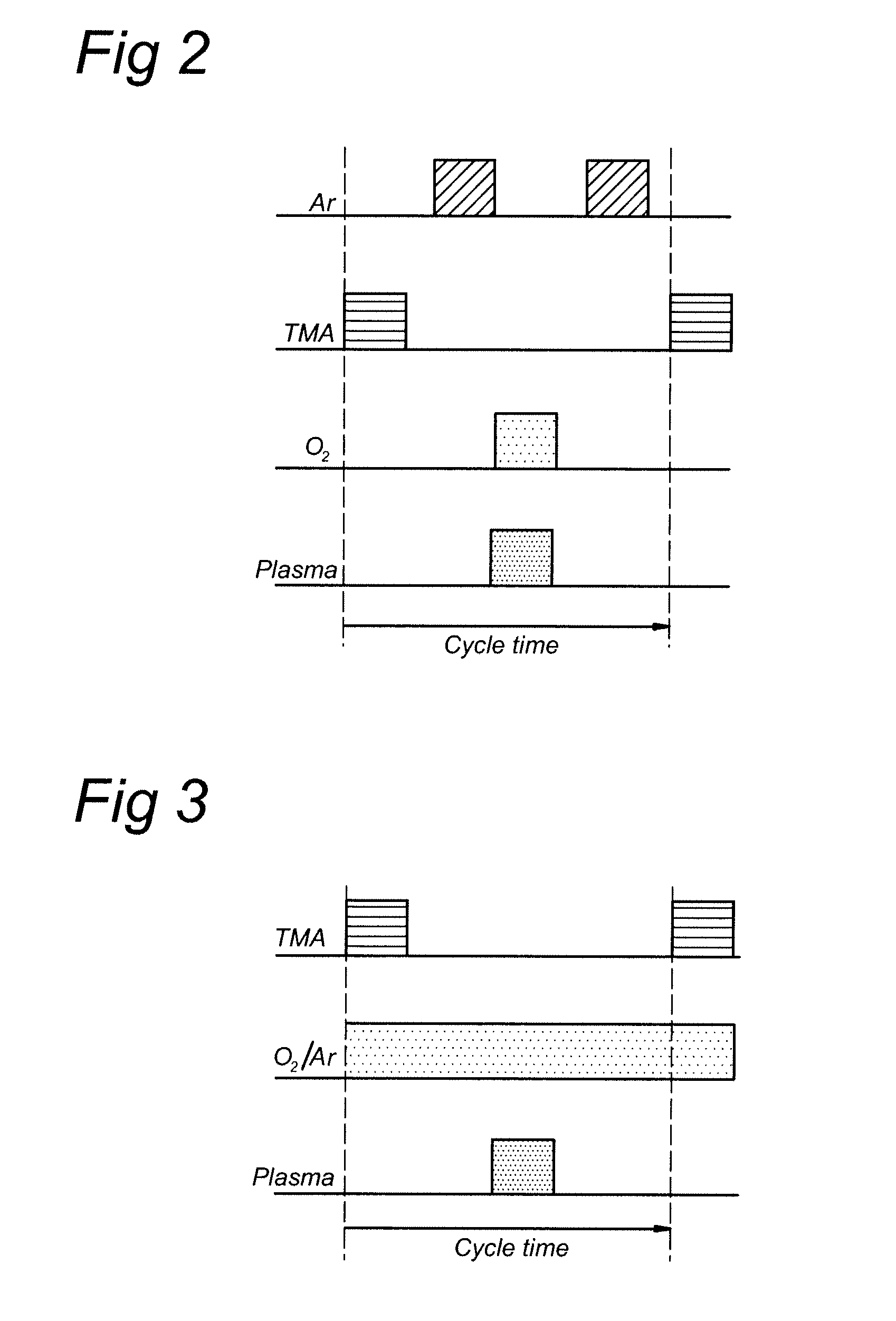

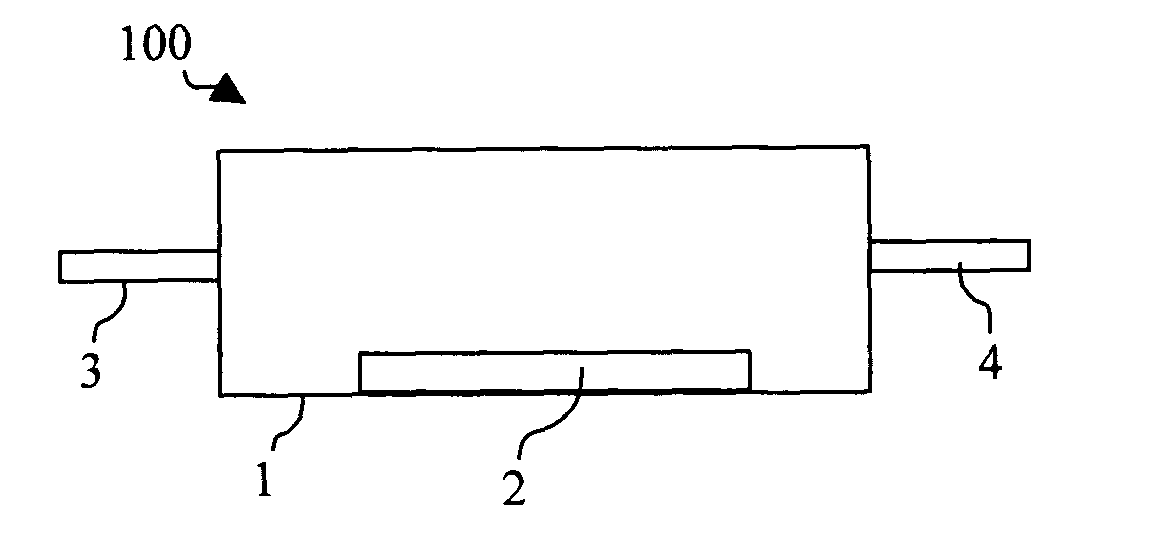

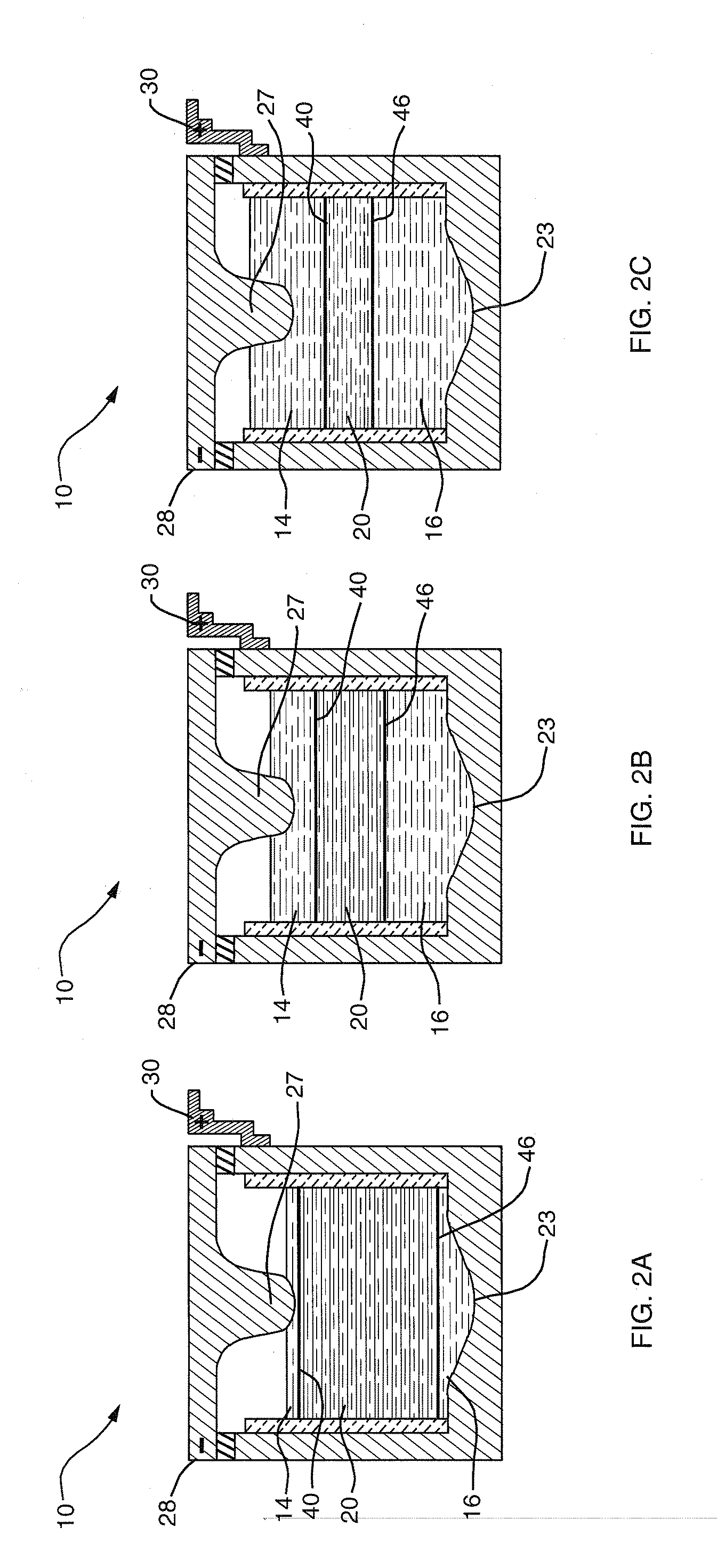

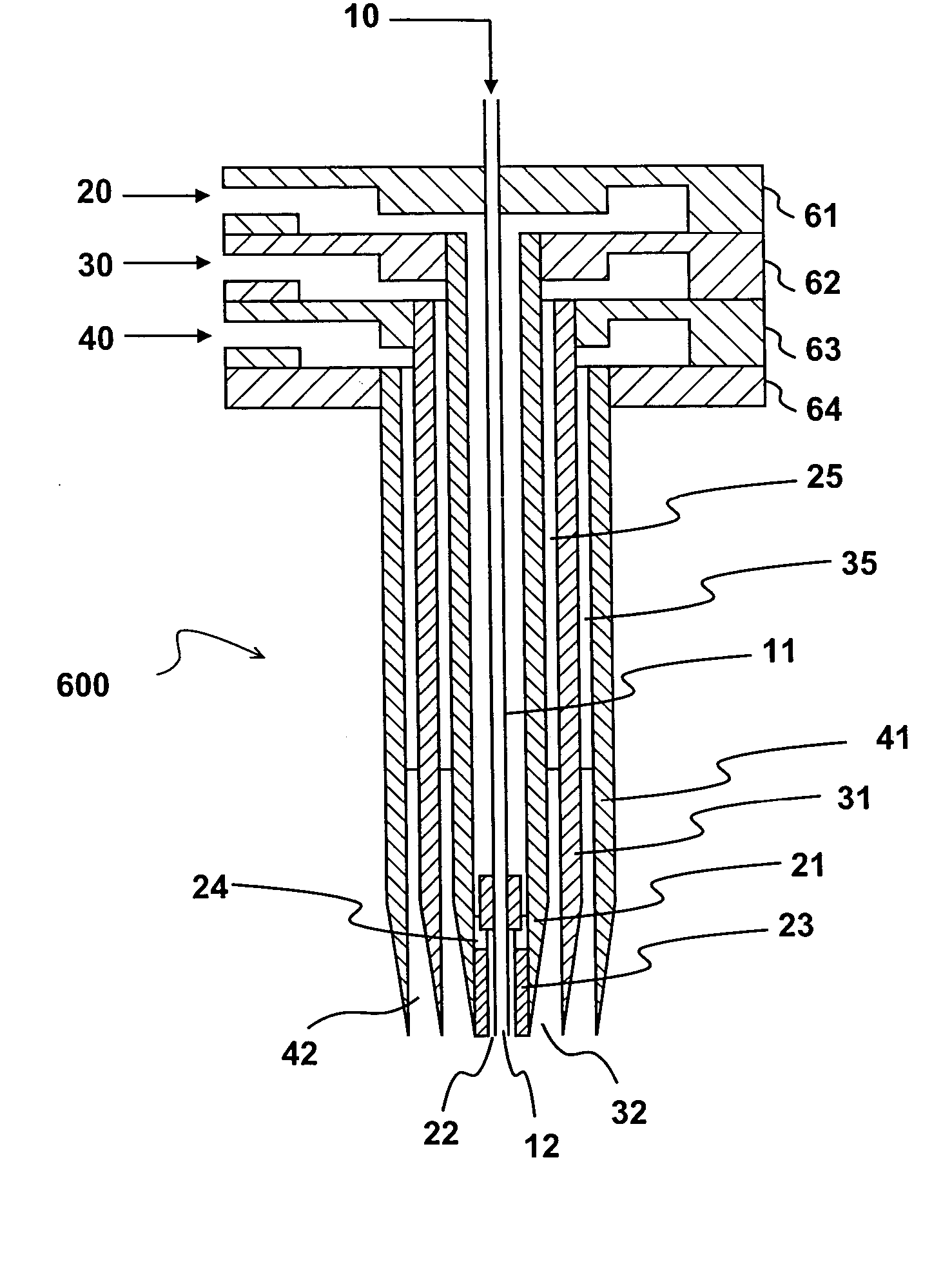

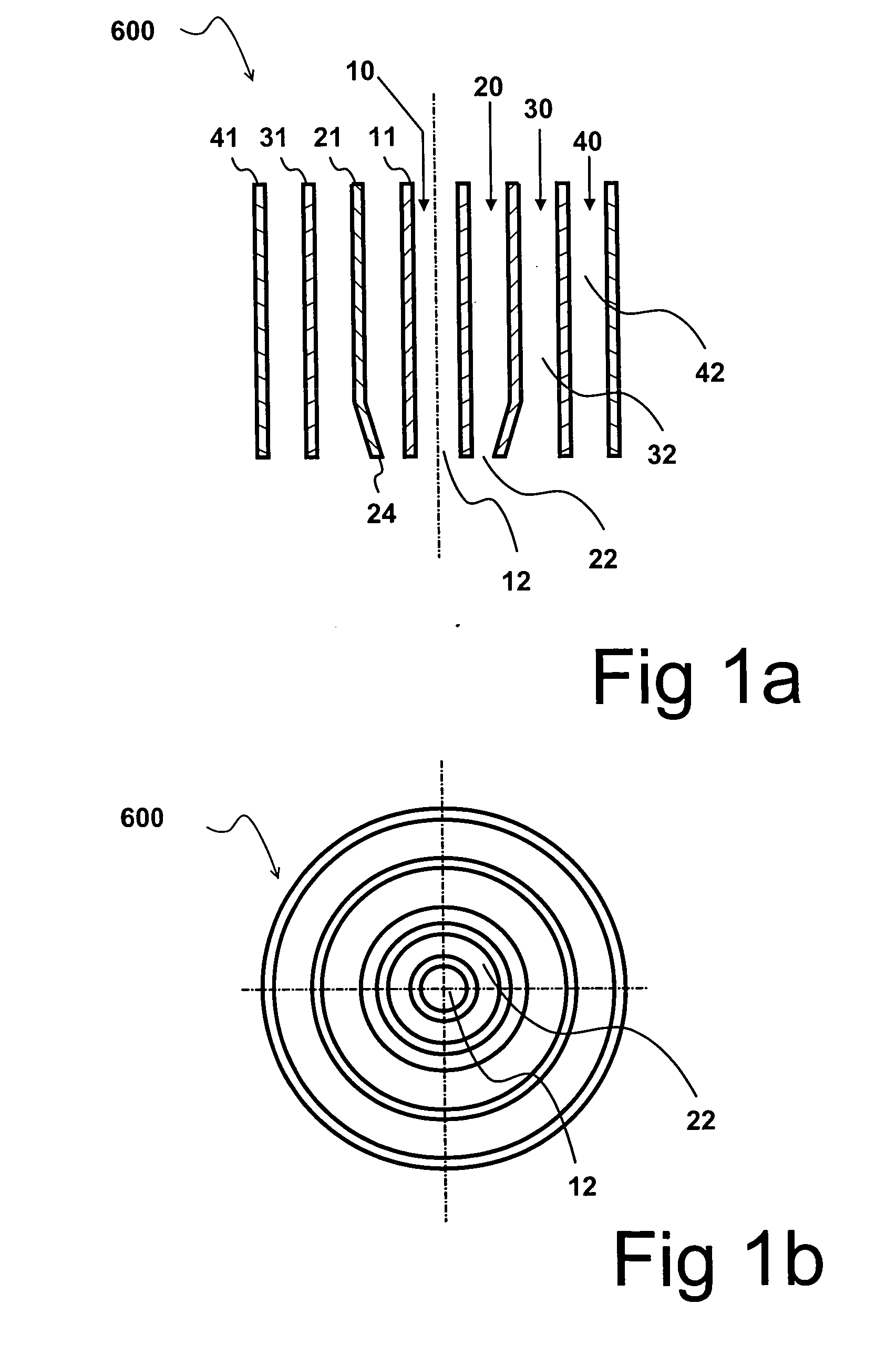

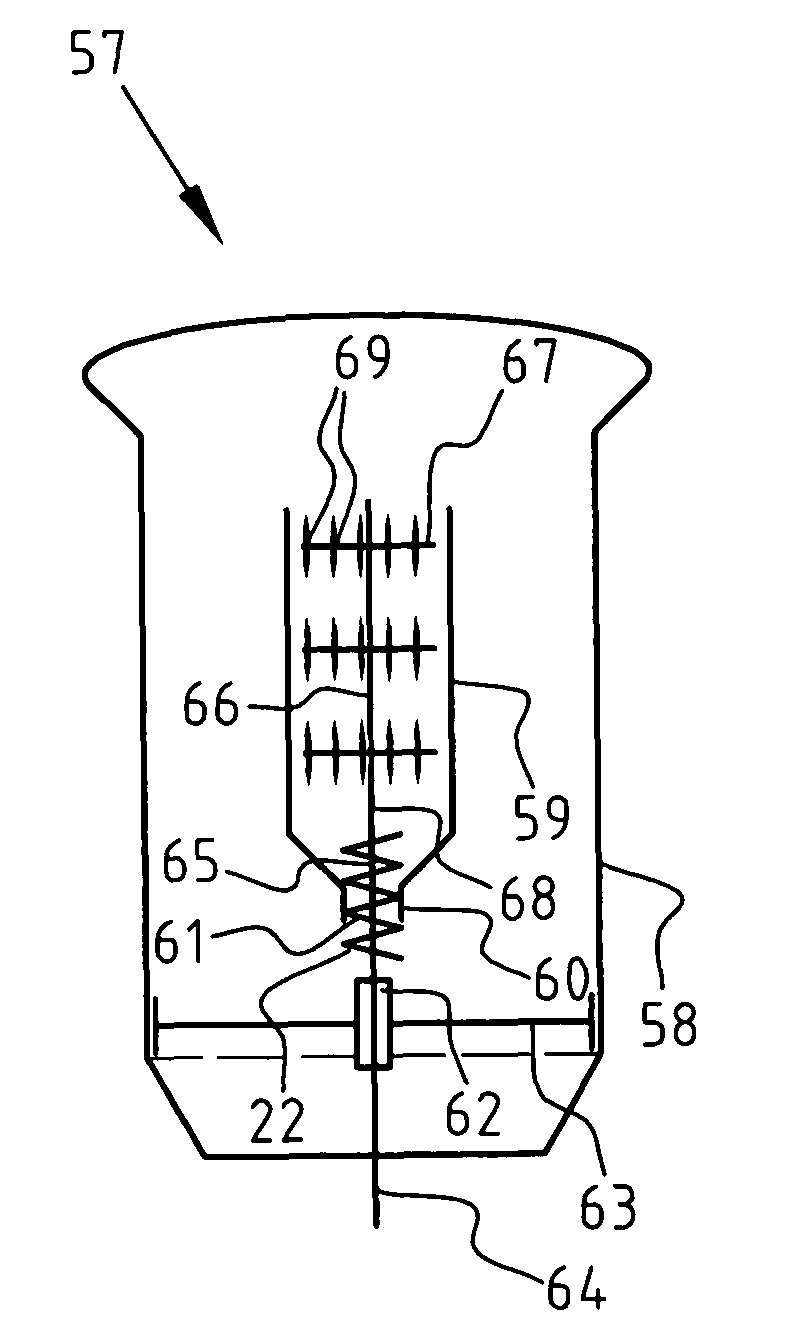

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20090324971A1Increase response rateImprove productivitySynthetic resin layered productsChemical vapor deposition coatingPlasma generatorProduct gas

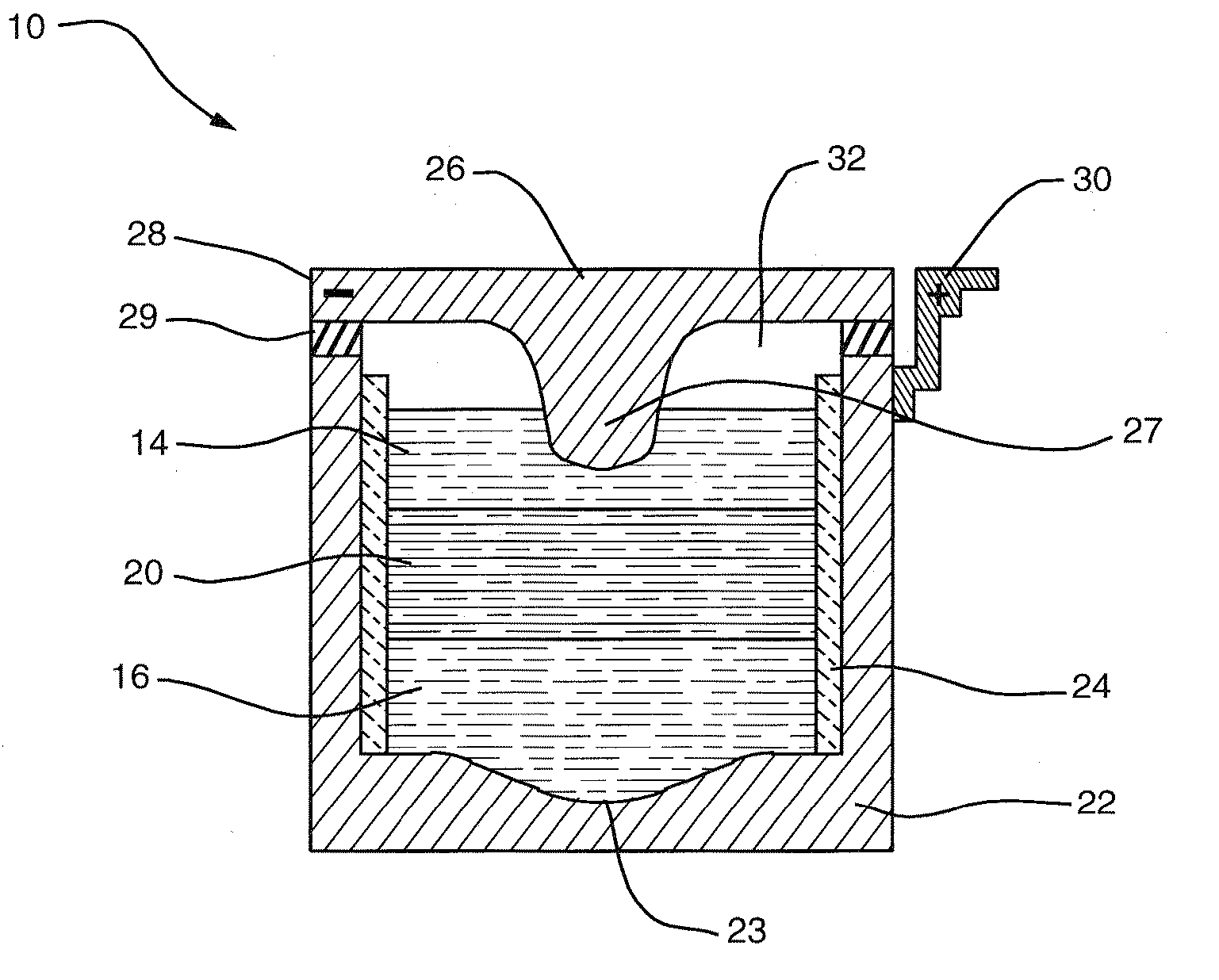

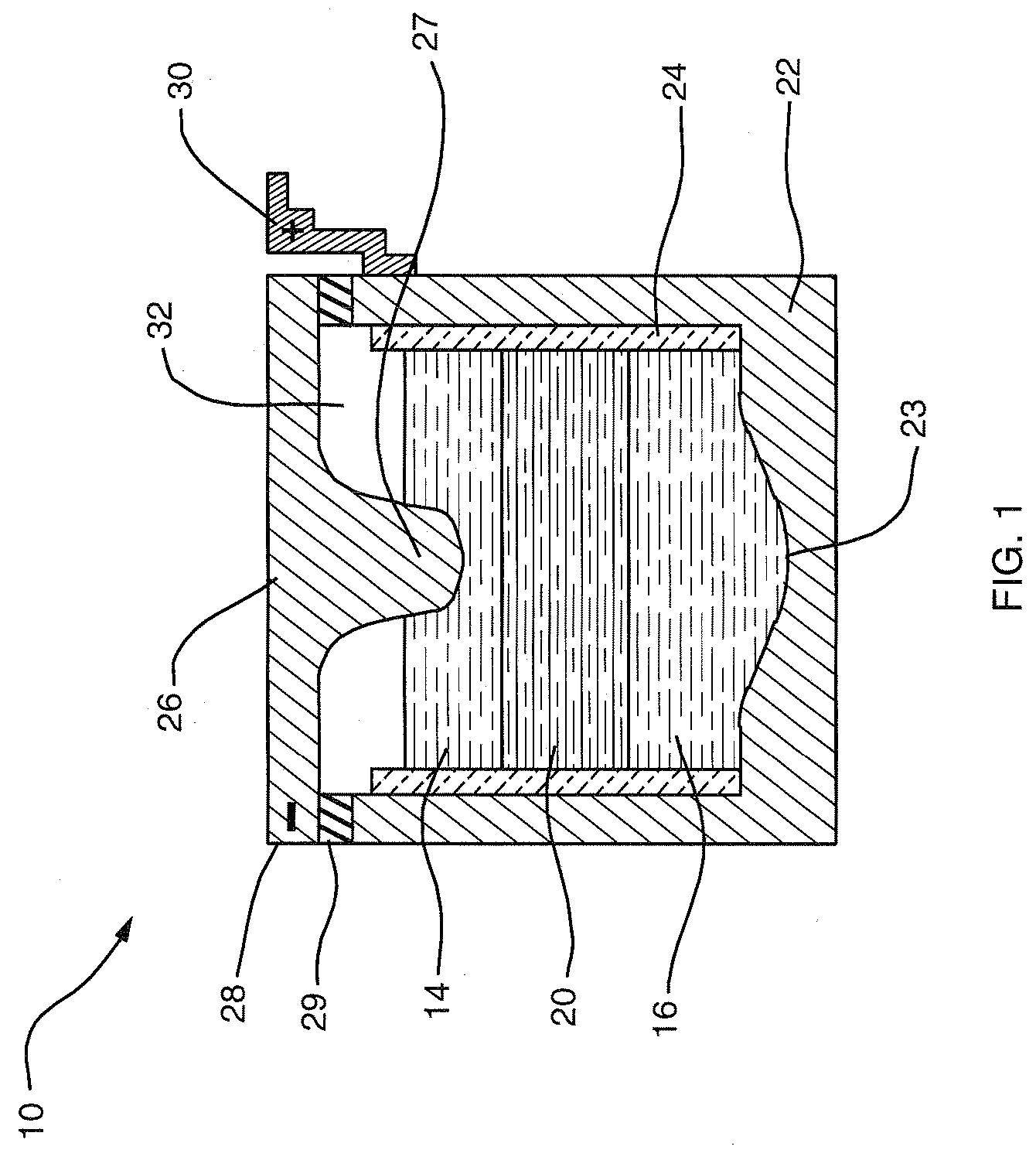

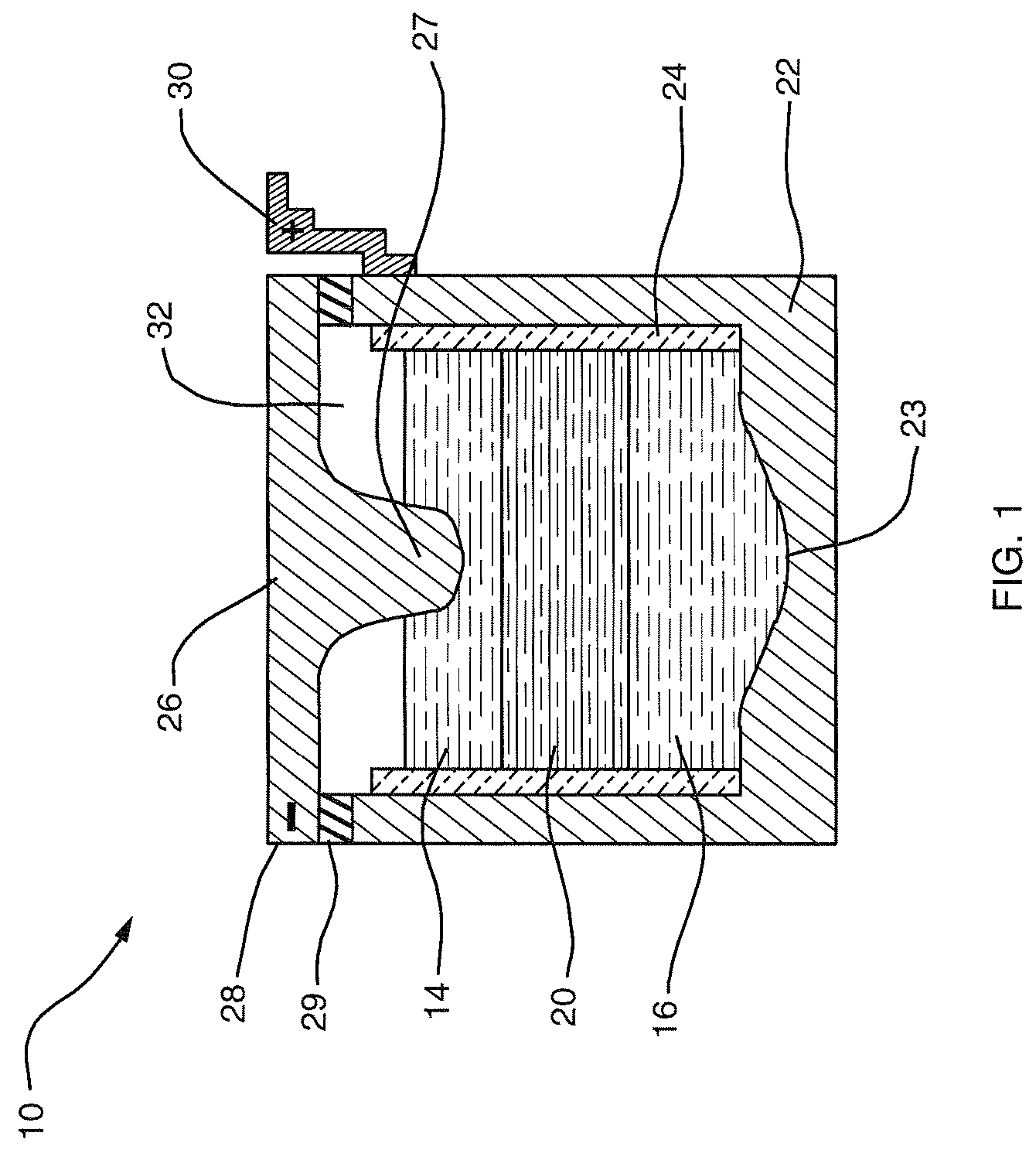

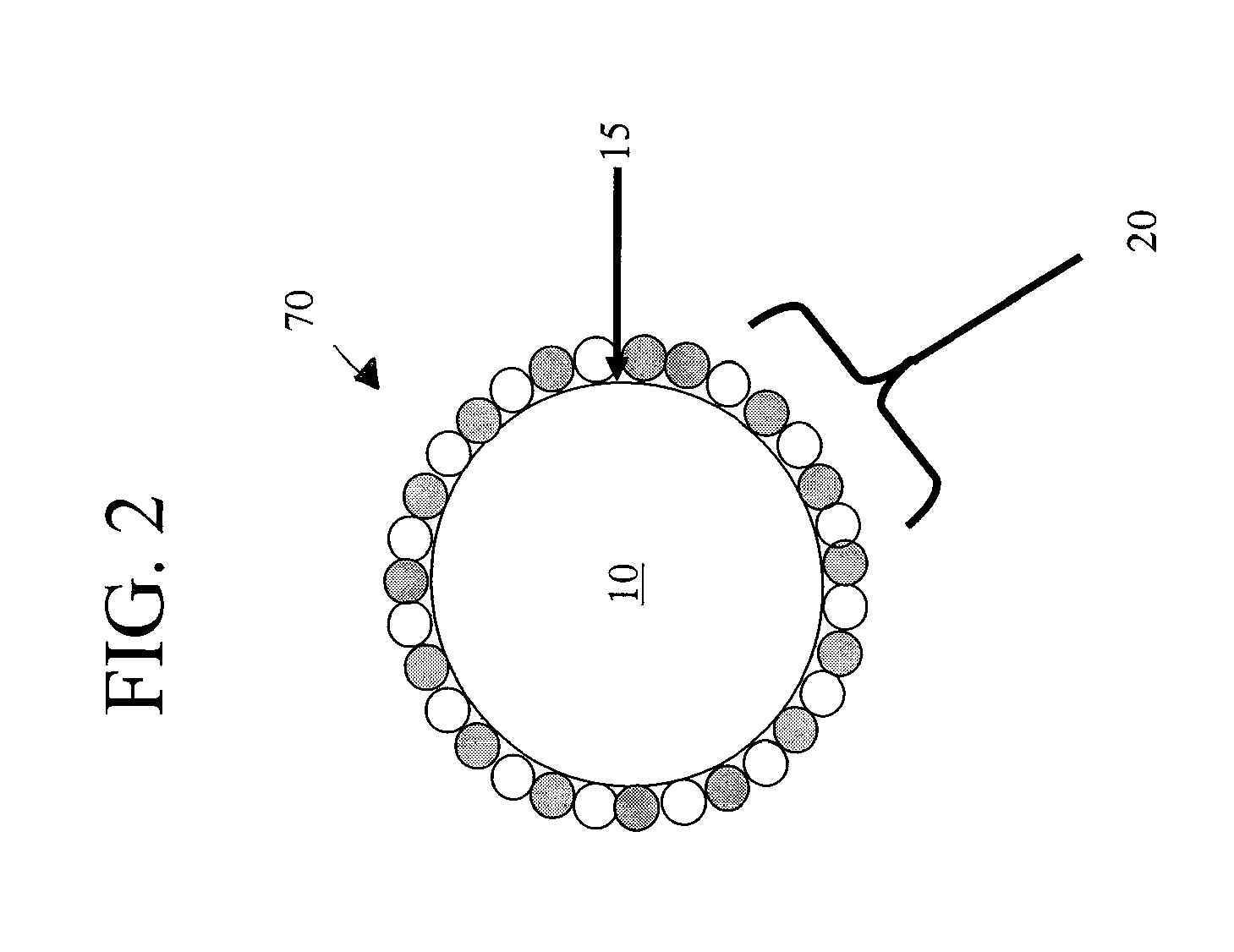

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space. The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent.

Owner:FUJIFILM MFG EURO

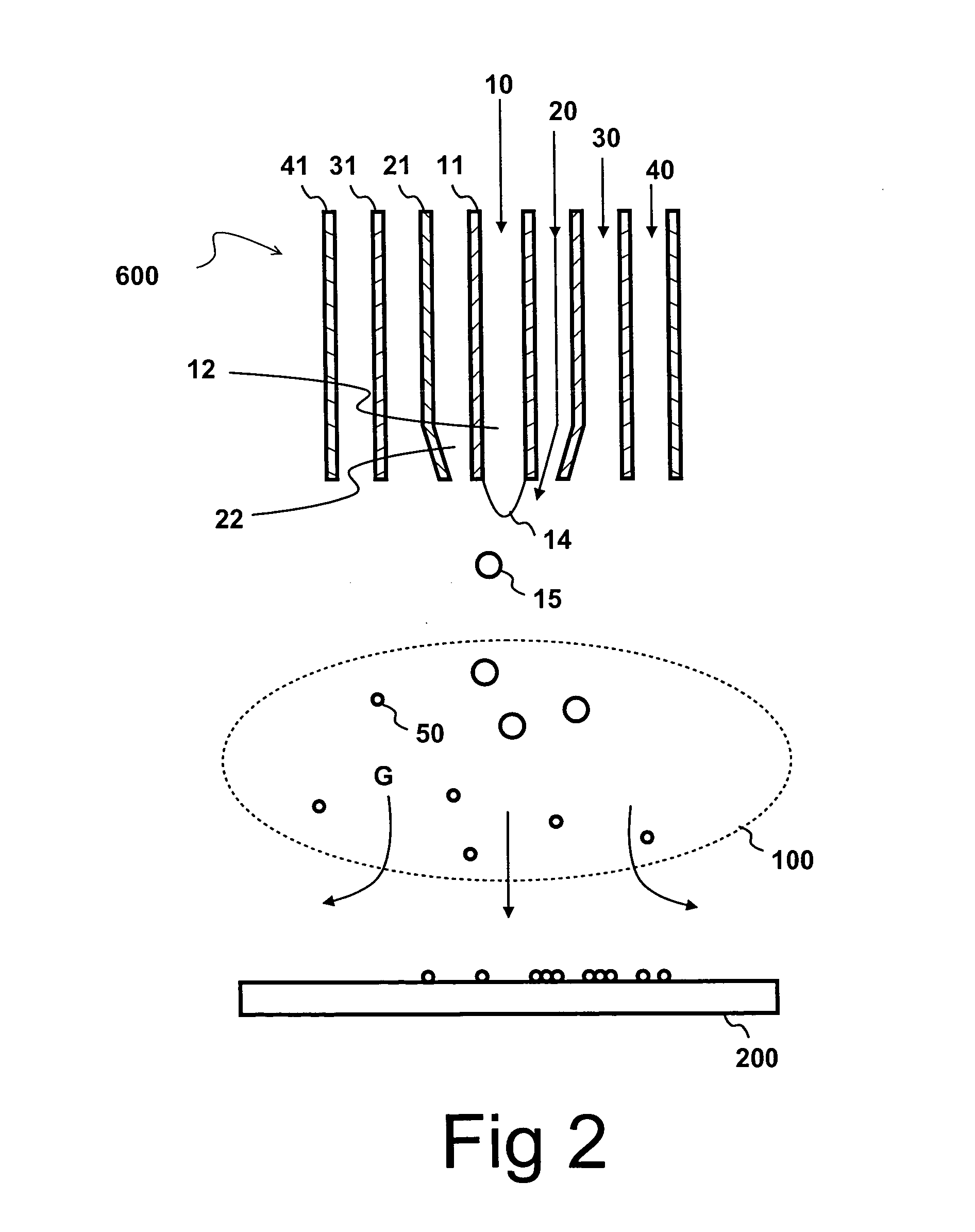

Atmospheric pressure molecular layer CVD

InactiveUS20050084610A1Reducing physisorptionHigh purityChemical vapor deposition coatingChemical physicsControl system

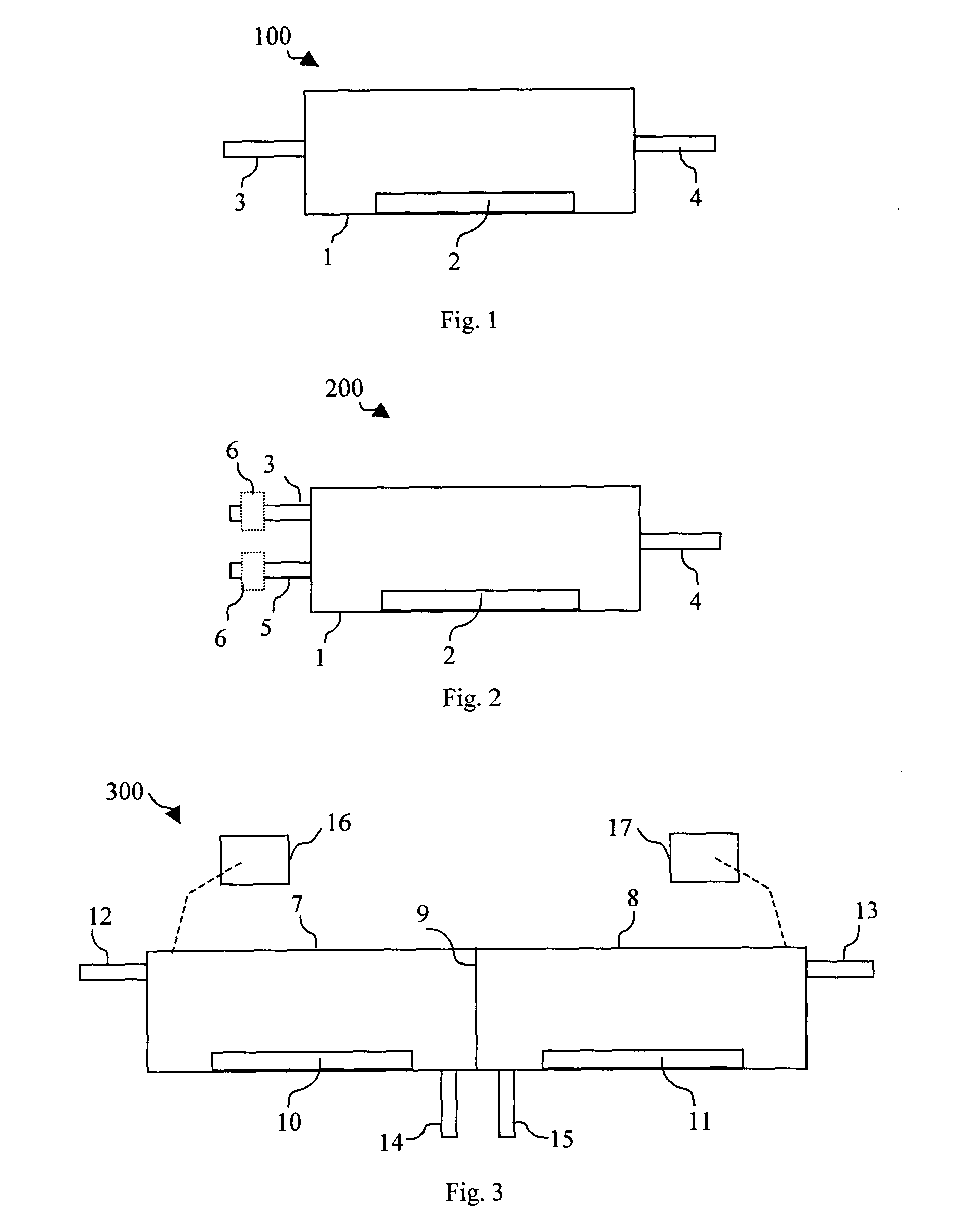

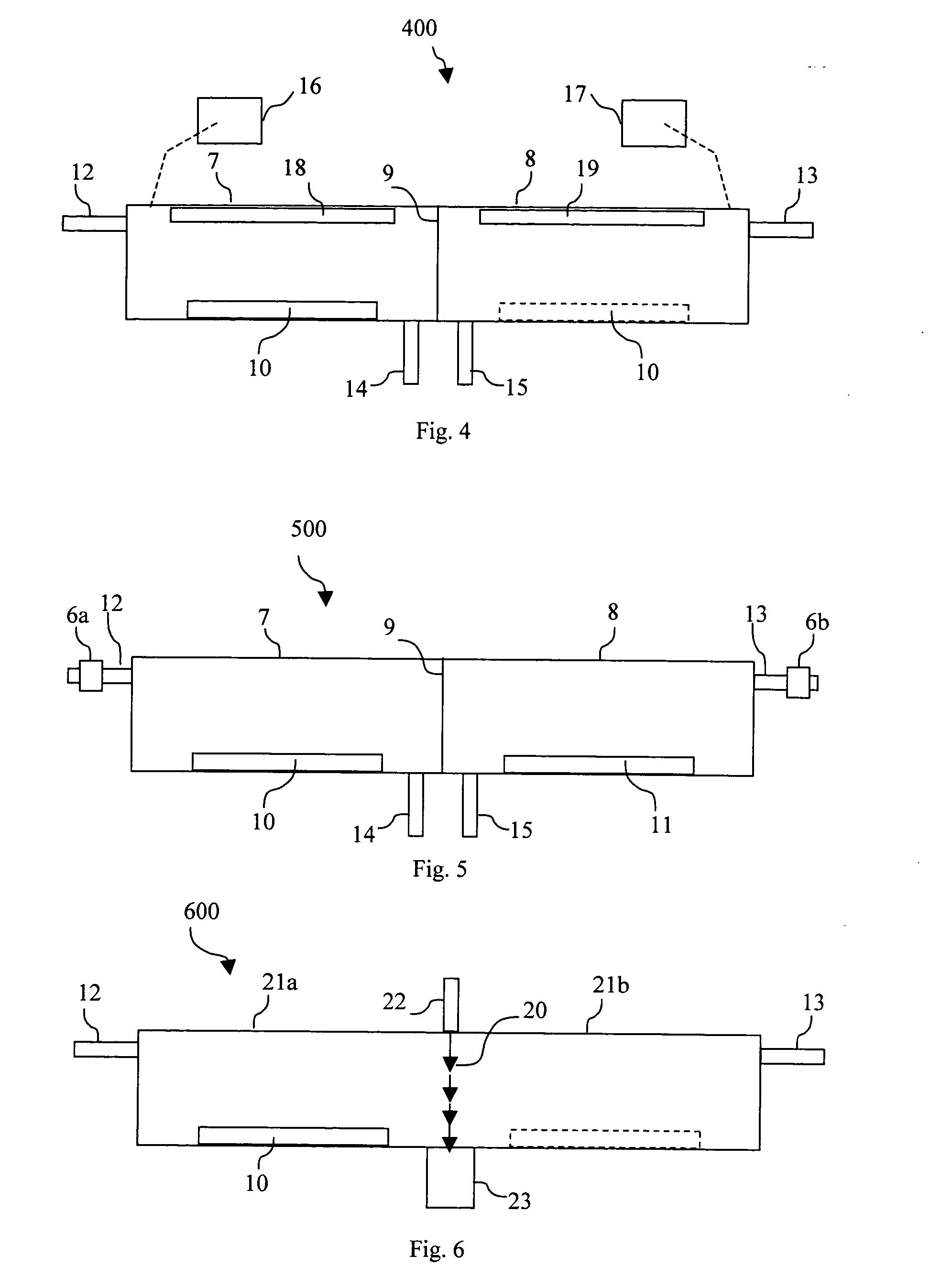

An Atomic Layer CVD process and apparatus deposits single and or multiple minelayers of material sequentially at atmospheric pressure. Sequential monolayer depositions are separated in time and in space by combinations of physical barriers and / or gas curtains and / or by physical movement of substrates from one deposition chamber or location to another Pulse and / or continuous flows of reactant and purge gases are used in alternate embodiments of the present invention. Reactant injection, purge gas flow and exhaust flows at separated deposition chambers or locations are controlled by coordination of dedicated gas manifolds and control systems for each spatially or temporally separated deposition process or location.

Owner:SELITSER SIMON I

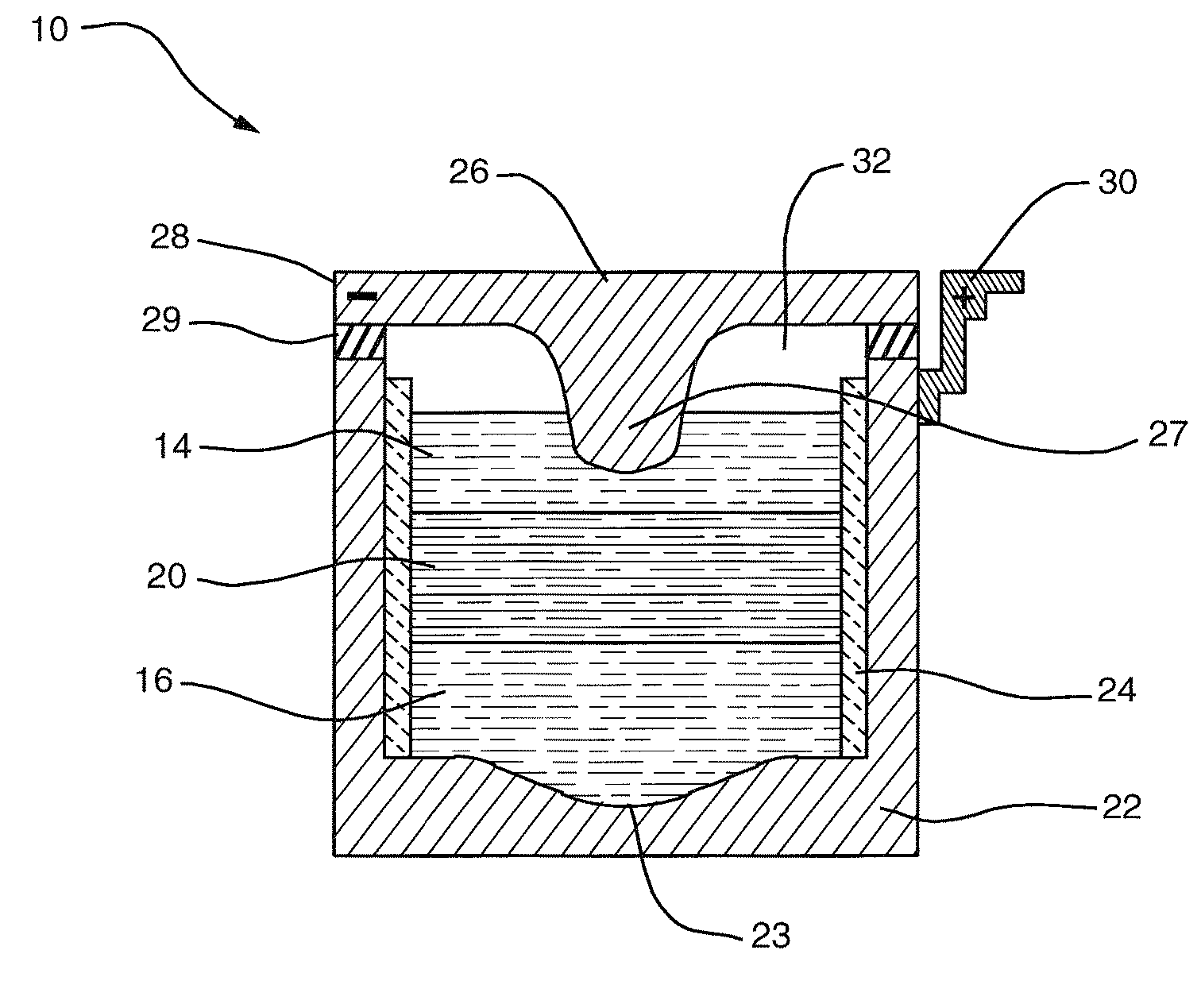

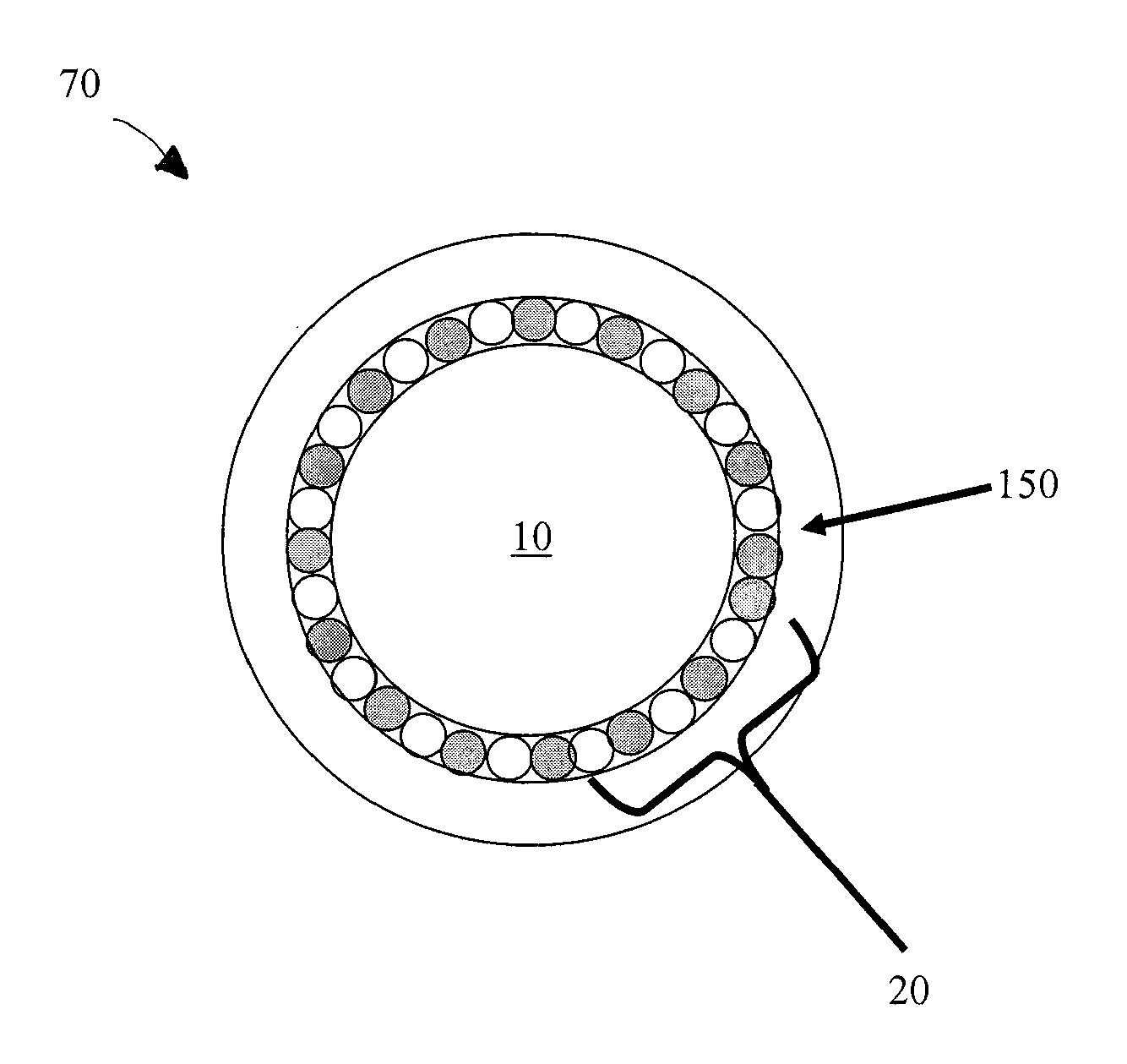

High-amperage energy storage device and method

ActiveUS20080044725A1Power capacity is large and scalableImprove ionic conductivityPrimary cell to battery groupingCell electrodesElectrical energy storageElectric energy

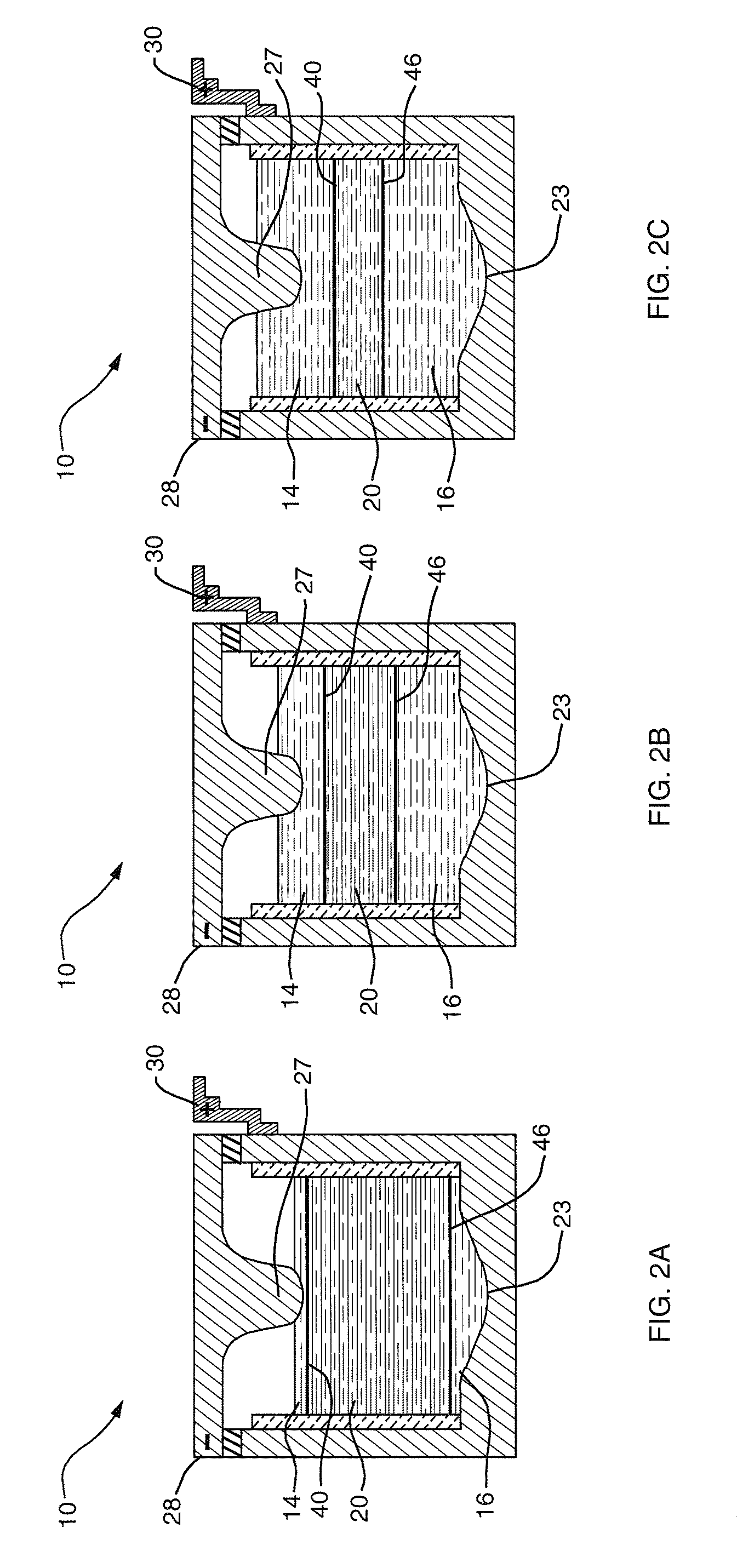

An electrochemical method and apparatus for high-amperage electrical energy storage features a high-temperature, all-liquid chemistry. The reaction products created during charging remain part of the electrodes during storage for discharge on demand. In a simultaneous ambipolar electrodeposition cell, a reaction compound is electrolyzed to effect transfer from an external power source; the electrode elements are electrodissolved during discharge.

Owner:MASSACHUSETTS INST OF TECH

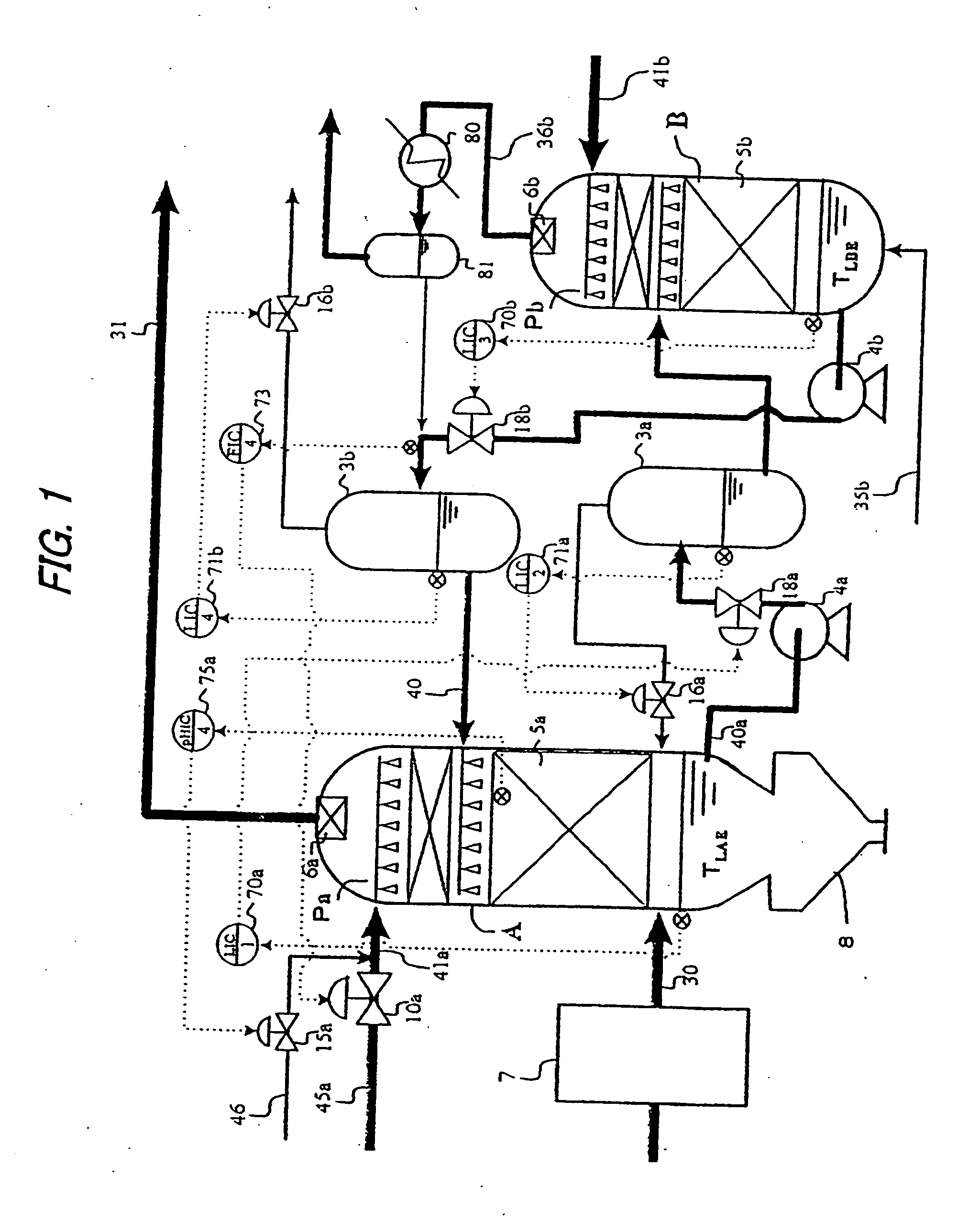

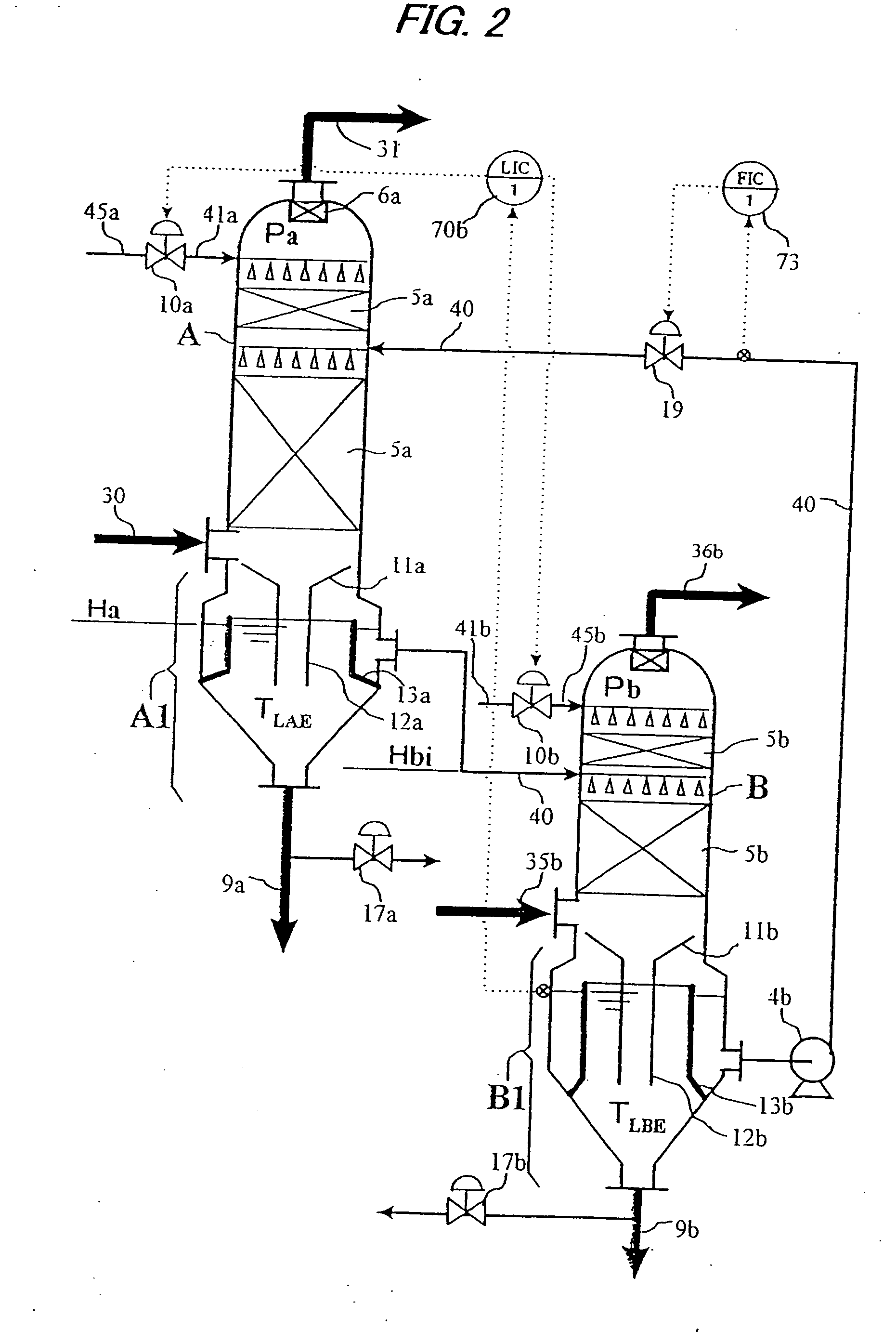

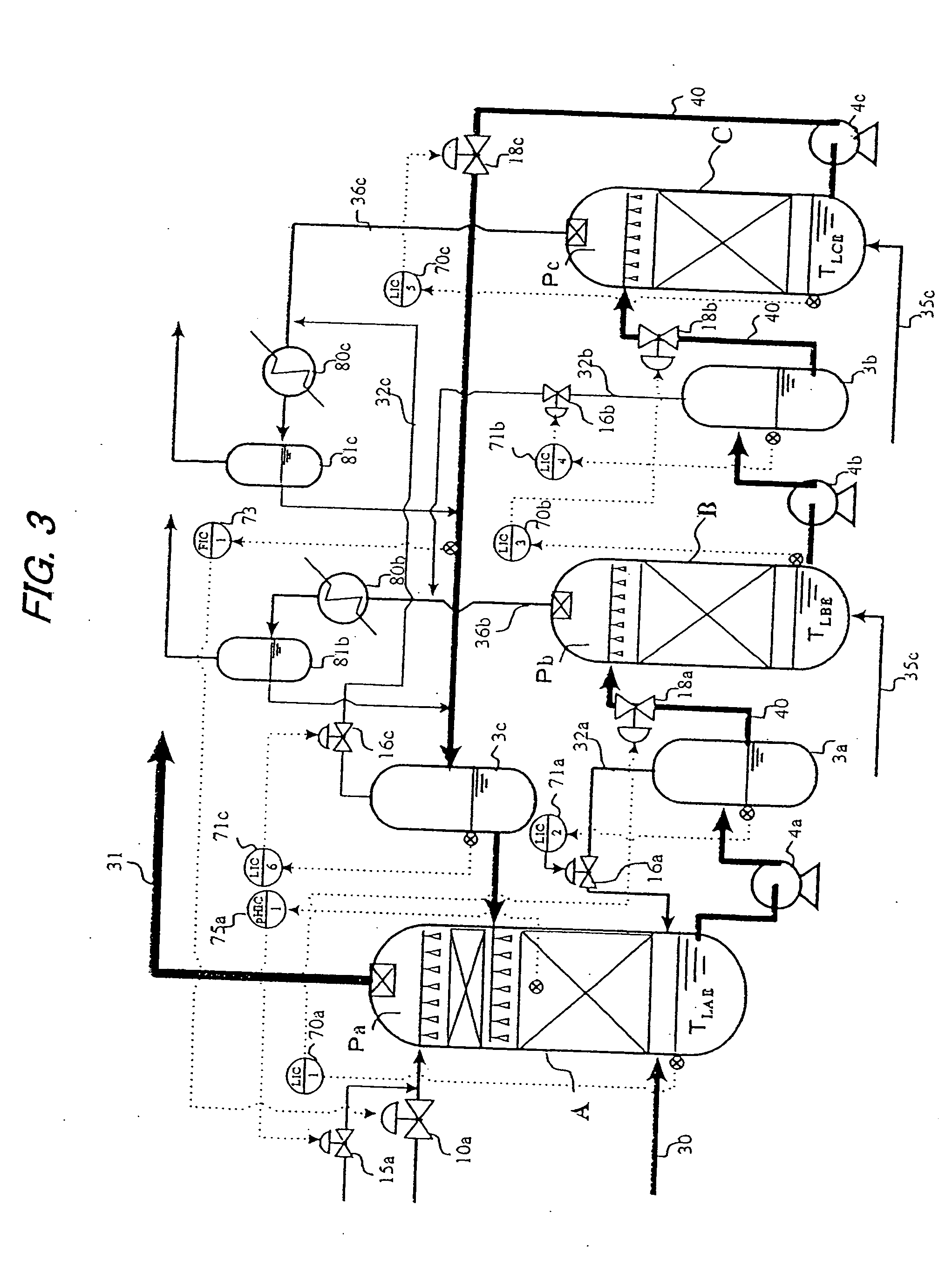

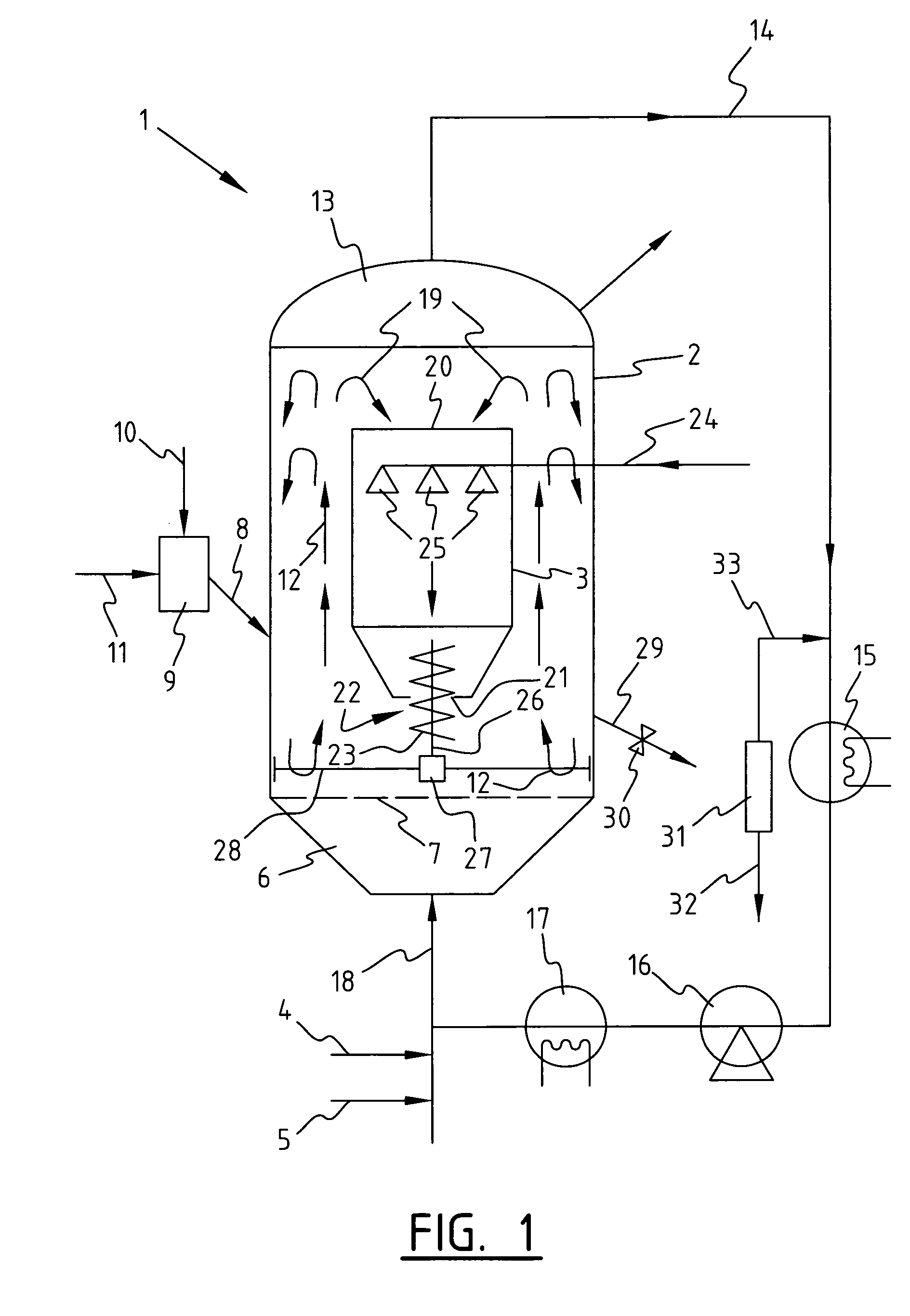

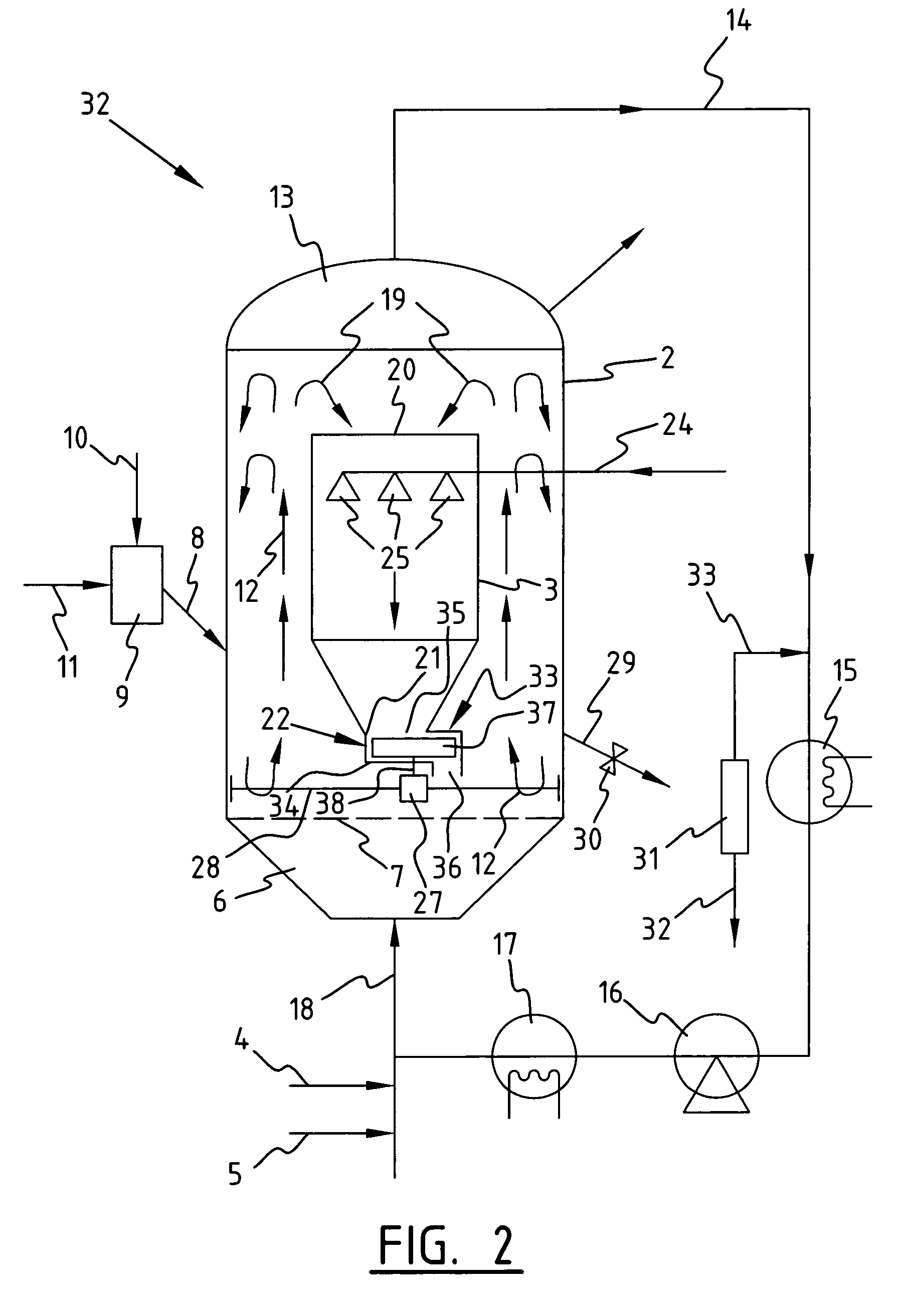

Acid gas scrubbing apparatus and method

InactiveUS20050132883A1Improve energy efficiencyImprove acid gas removal capabilityUsing liquid separation agentCombustible gas catalytic treatmentScrubberCarbon dioxide

An acid gas scrubbing apparatus and method brings a gas, to be scrubbed, containing carbon dioxide into contact with a gas scrubbing liquid containing alkaline agent and cooled, and acid gases in the gas are removed. A gas scrubber removes acid gases in a gas, to be scrubbed, containing carbon dioxide by bringing the gas to be scrubbed into contact with a gas scrubbing liquid containing alkaline agent. A scrubbing liquid regenerator regenerates and cools the gas scrubbing liquid by bringing the gas scrubbing liquid into contact with a regenerating gas having components different from the gas scrubbing liquid and the gas to be scrubbed. A circulating device is provided between the gas scrubber and the scrubbing liquid regenerator for circulating the scrubbing liquid.

Owner:SU QINGQUAN +4

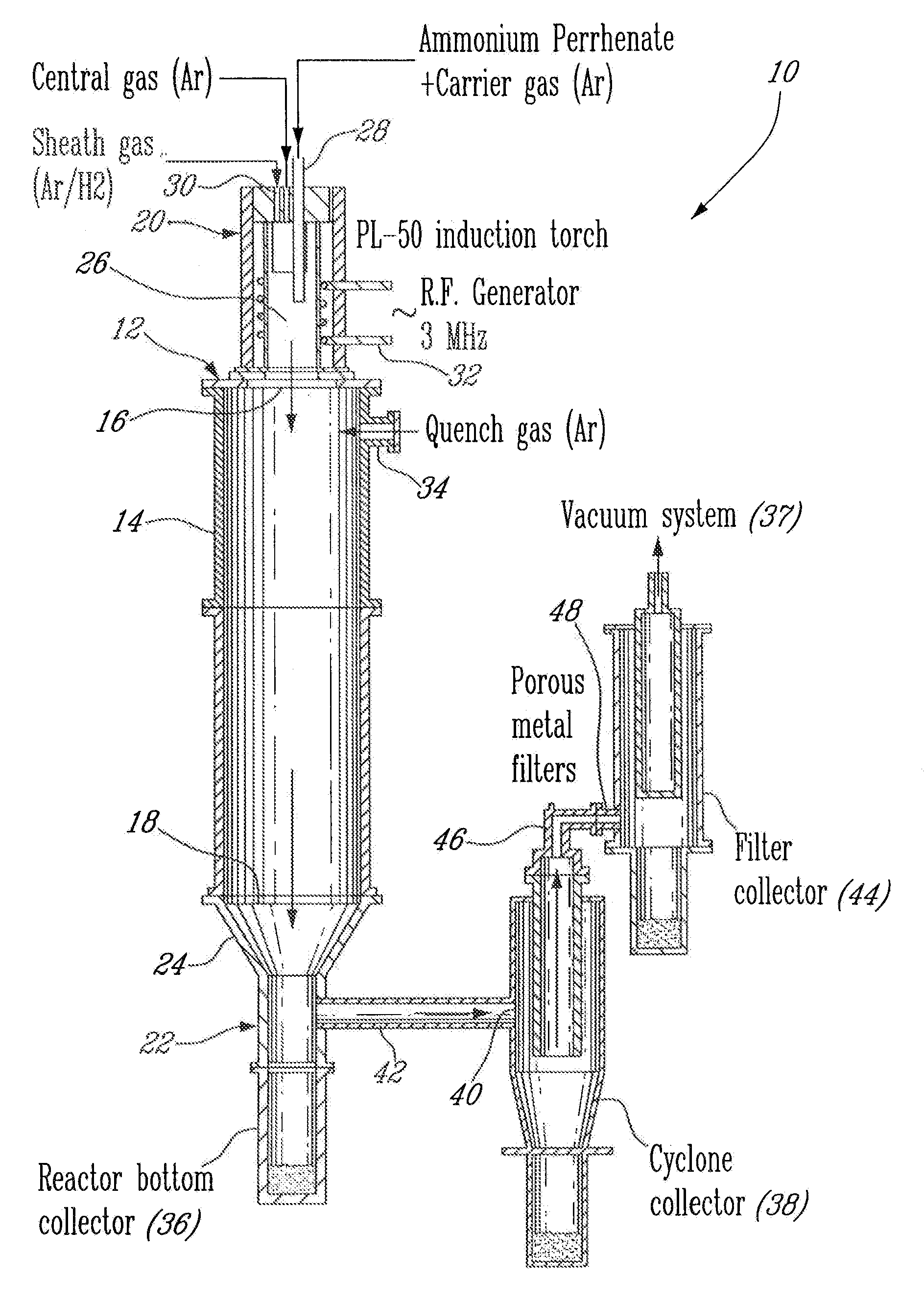

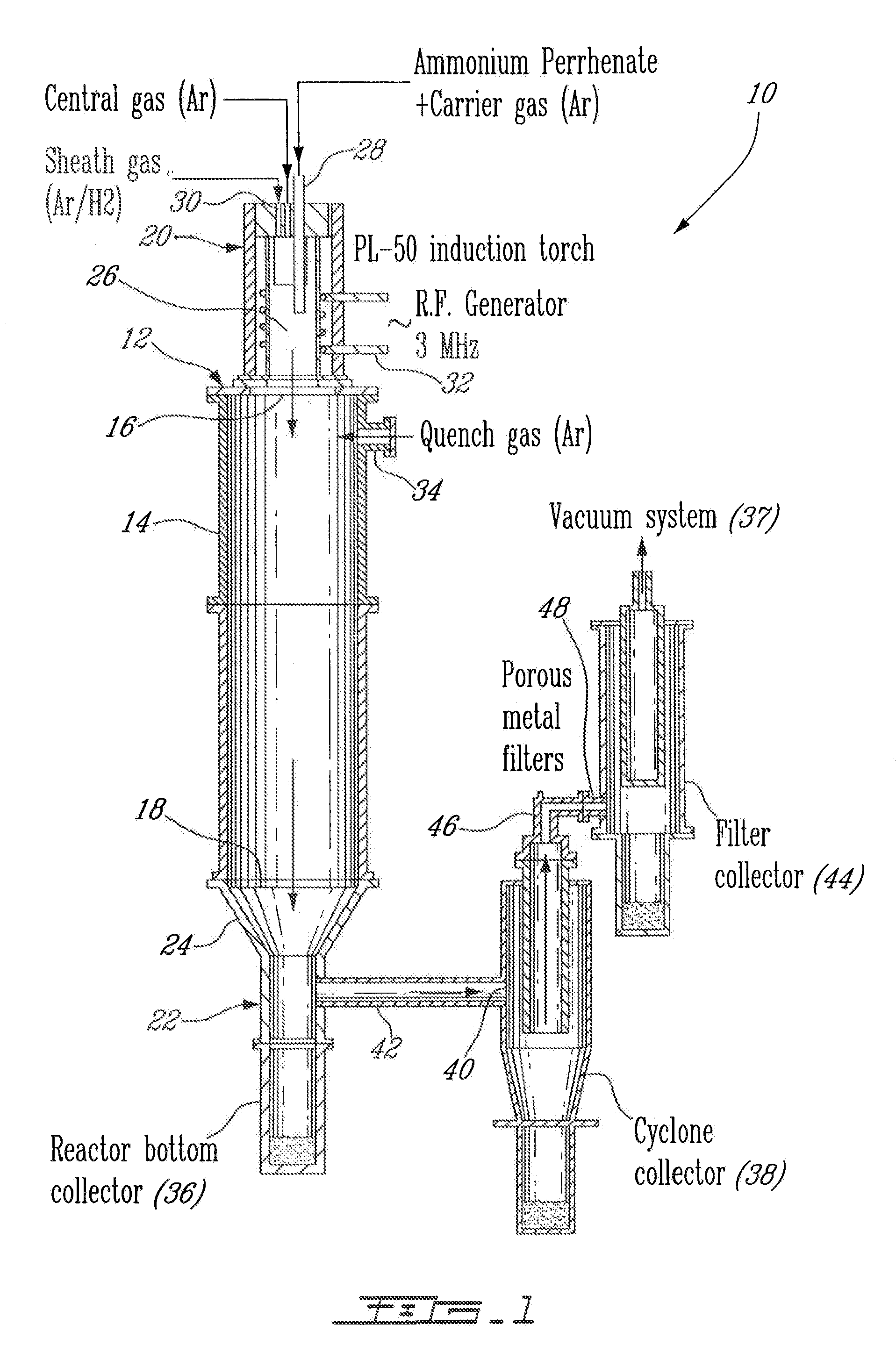

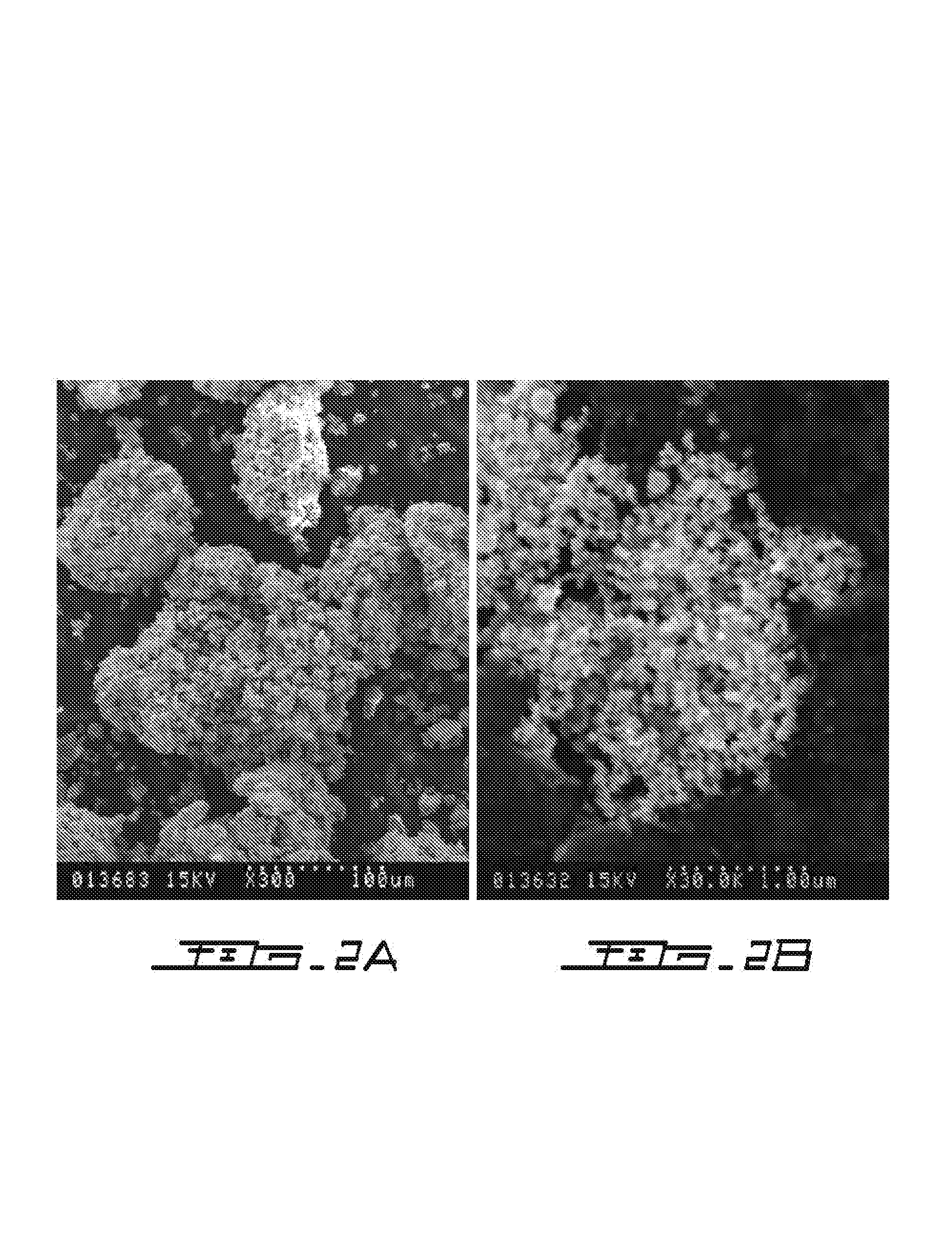

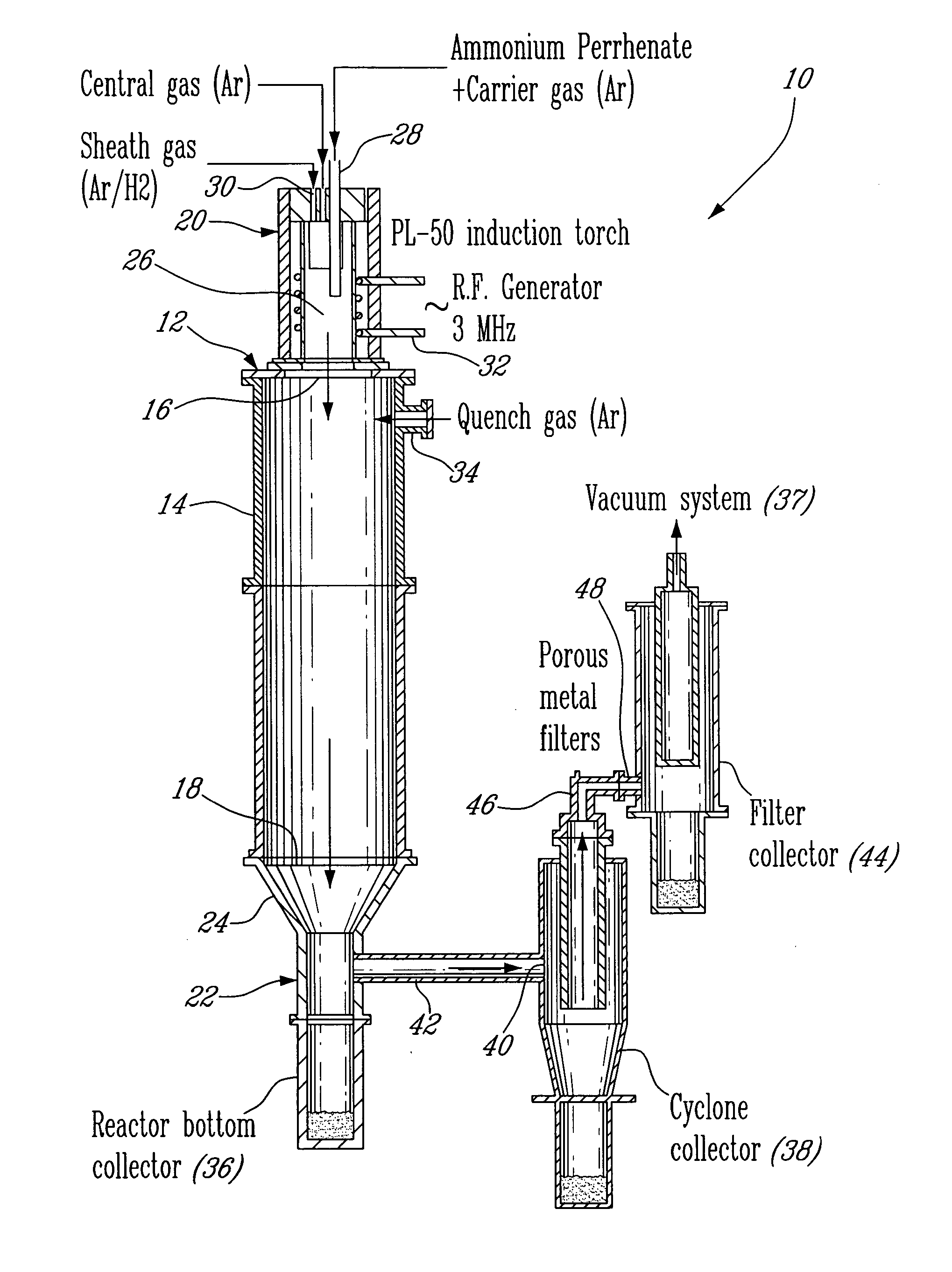

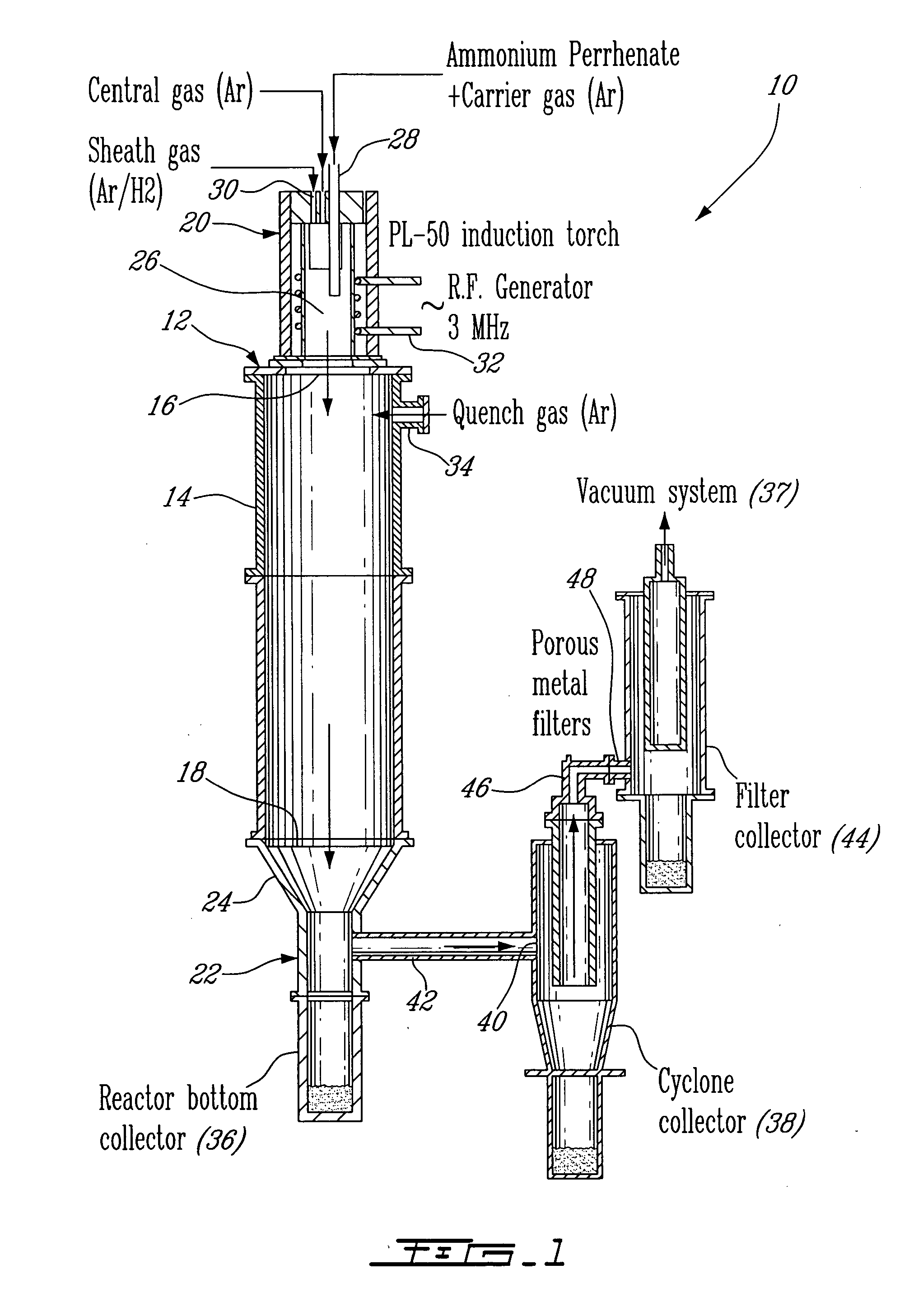

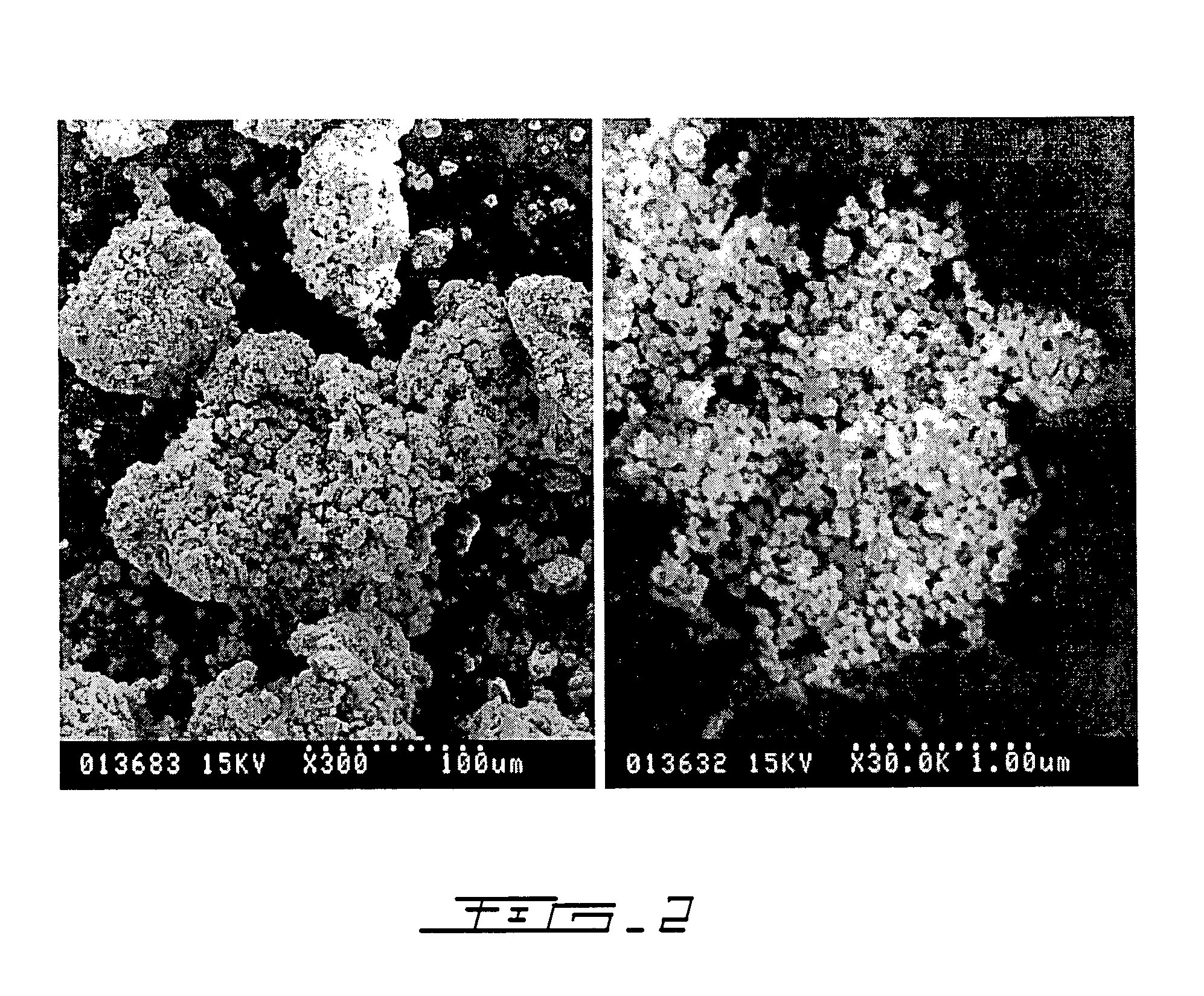

Process for plasma synthesis of rhenium nano and micro powders, and for coatings and near net shape deposits thereof and apparatus therefor

Owner:TEKNA PLASMA SYST INC

Process for plasma synthesis of rhenium nano and micro powders, and for coatings and near net shape deposits thereof and apparatus therefor

The process for the synthesis of rhenium powders comprises the injection of ammonium perrhenate powder through a carrier gas in a plasma torch of a plasma reactor operated using a mixture including hydrogen as the plasma gas, yielding metallic rhenium under the following chemical reaction: 2 NH4ReO4+4 H2→2 Re+N2↑+8 H2O↑. The reactor is provided with a quench zone for cooling the metallic rhenium so as to yield rhenium nano and micro powders.

Owner:TEKNA PLASMA SYST INC

Continuous carbonylation process

InactiveUS6916951B2Improve heat removal efficiencyStable catalyst environmentOrganic compound preparationOrganic chemistry methodsAcetic acidGas phase

Disclosed is a continuous process wherein carbon monoxide, a carbonylatable reactant, and a halide in the gas phase are contacted with a non-volatile catalyst solution comprising an ionic liquid and a Group VIII metal to produce a carbonylation product in the gas phase. The process is useful for the continuous preparation of acetic acid by the carbonylation of methanol.

Owner:EASTMAN CHEM CO

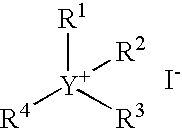

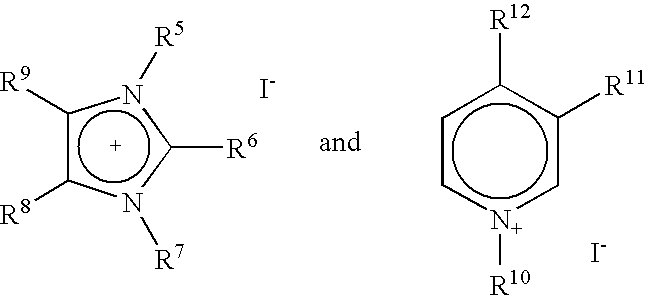

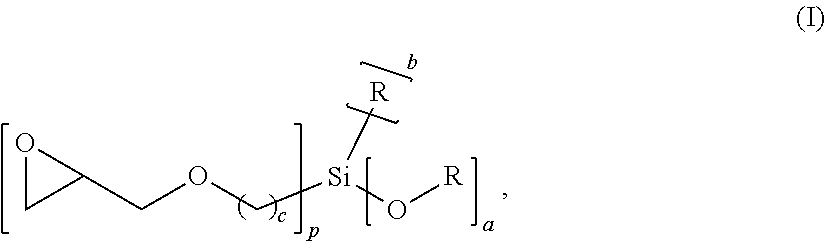

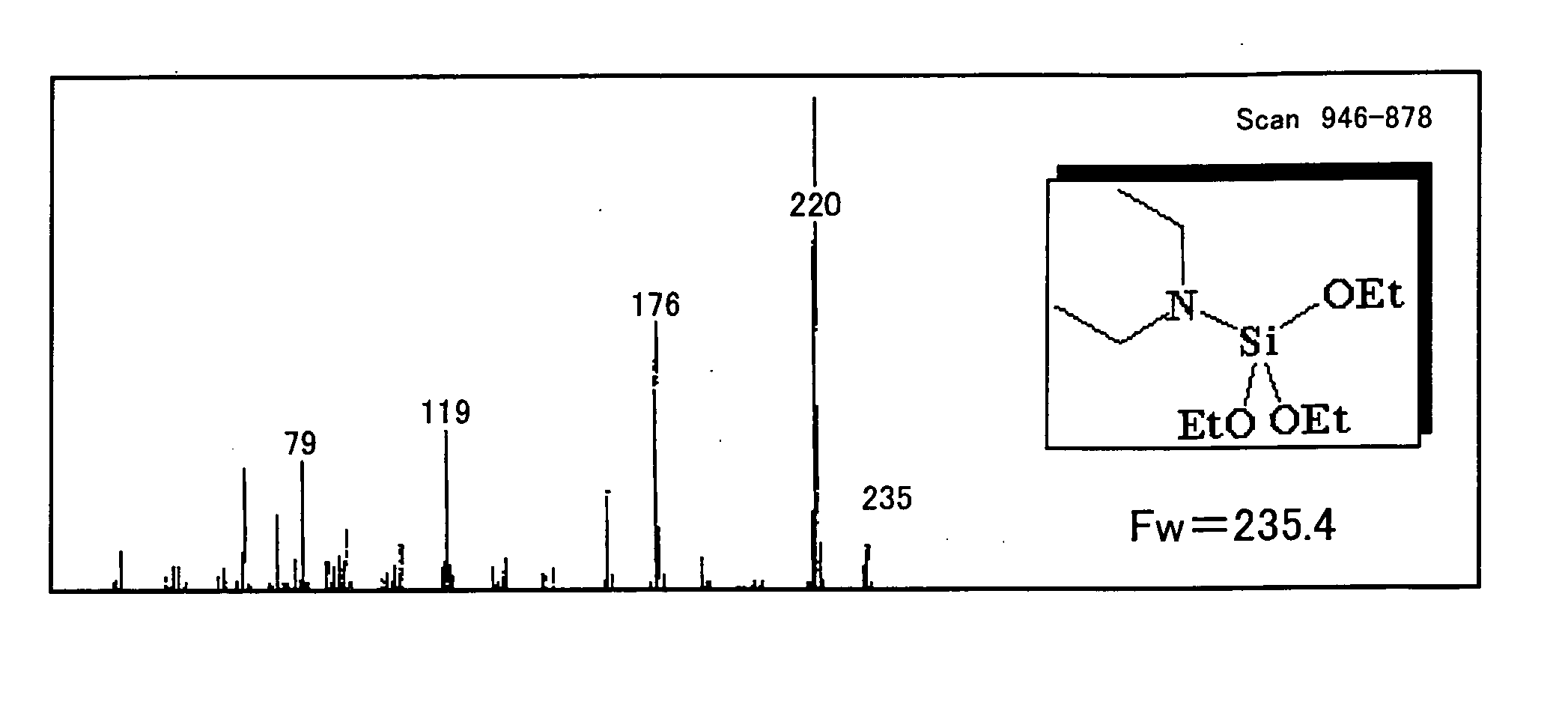

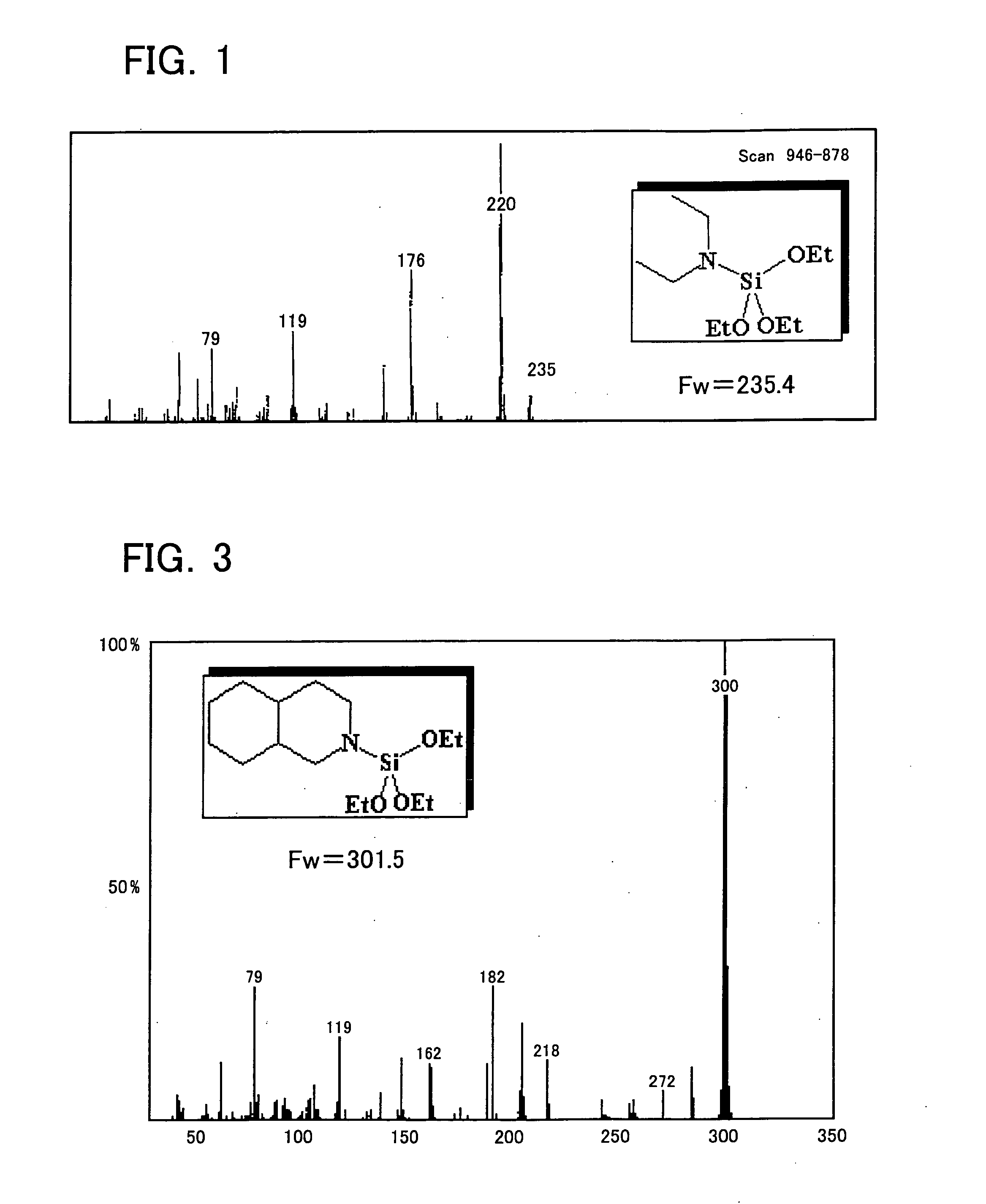

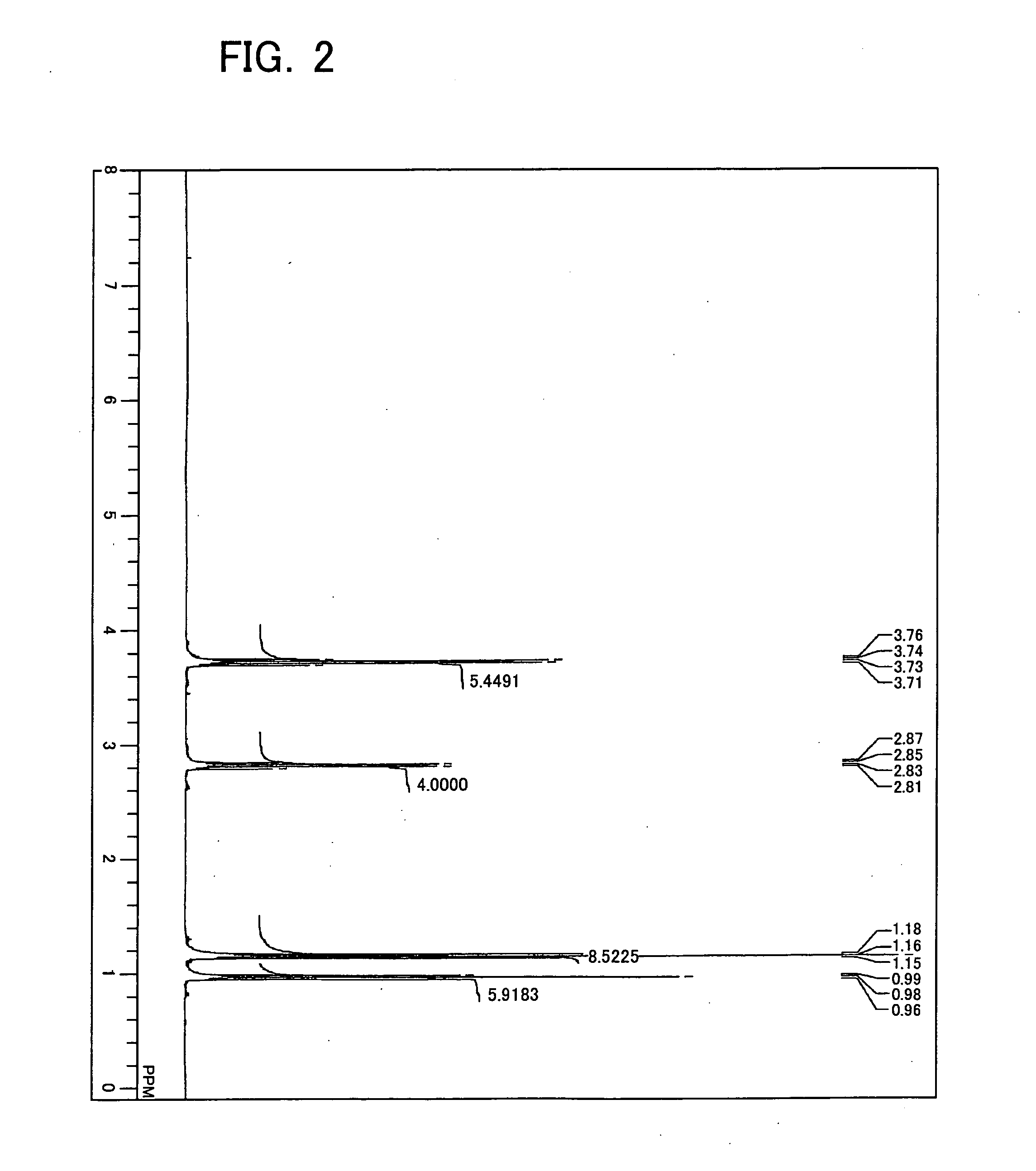

Catalysts for polymerization or copolymerization of α-olefins, catalyst components thereof, and processes for polymerization of α-olefins with the catalysts

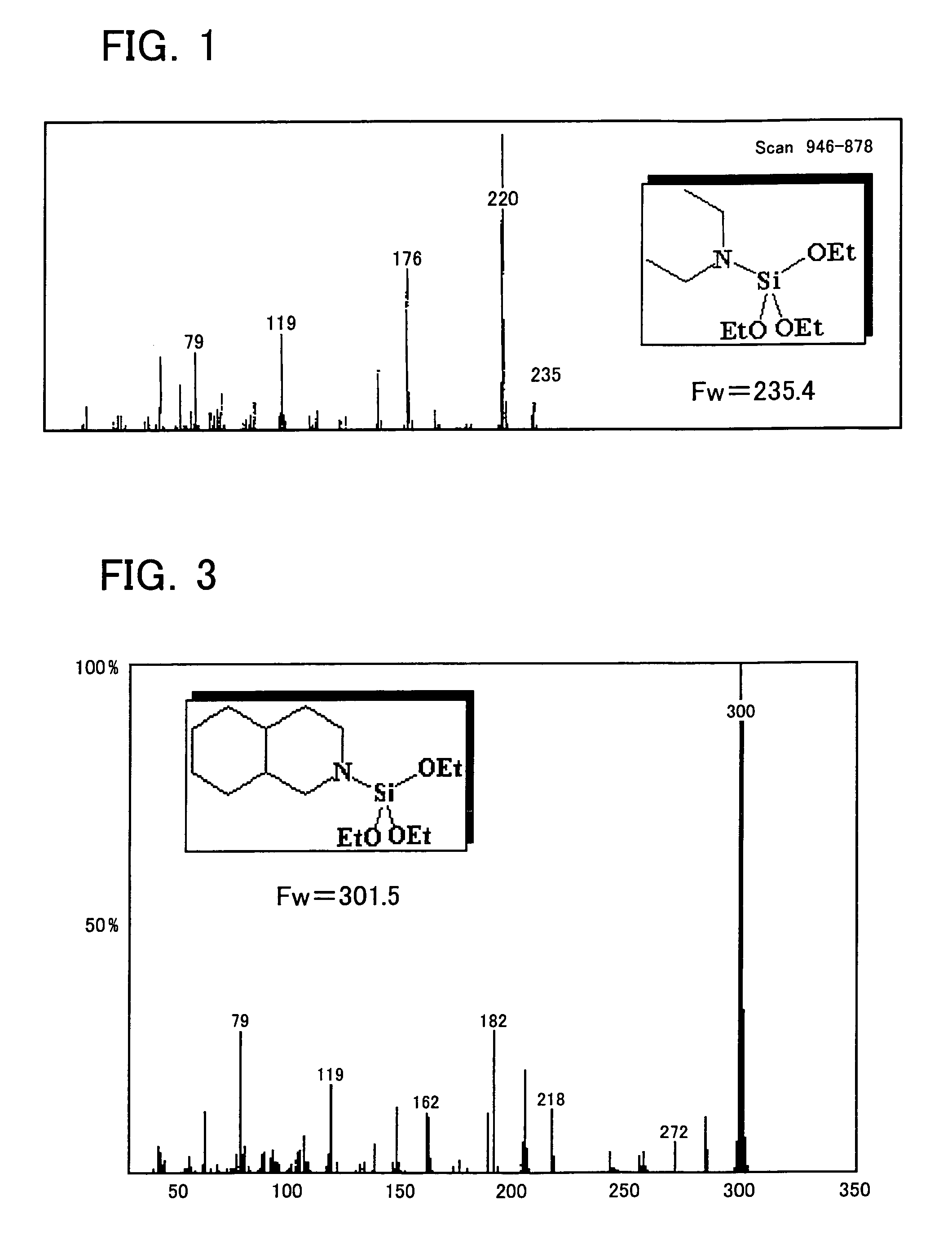

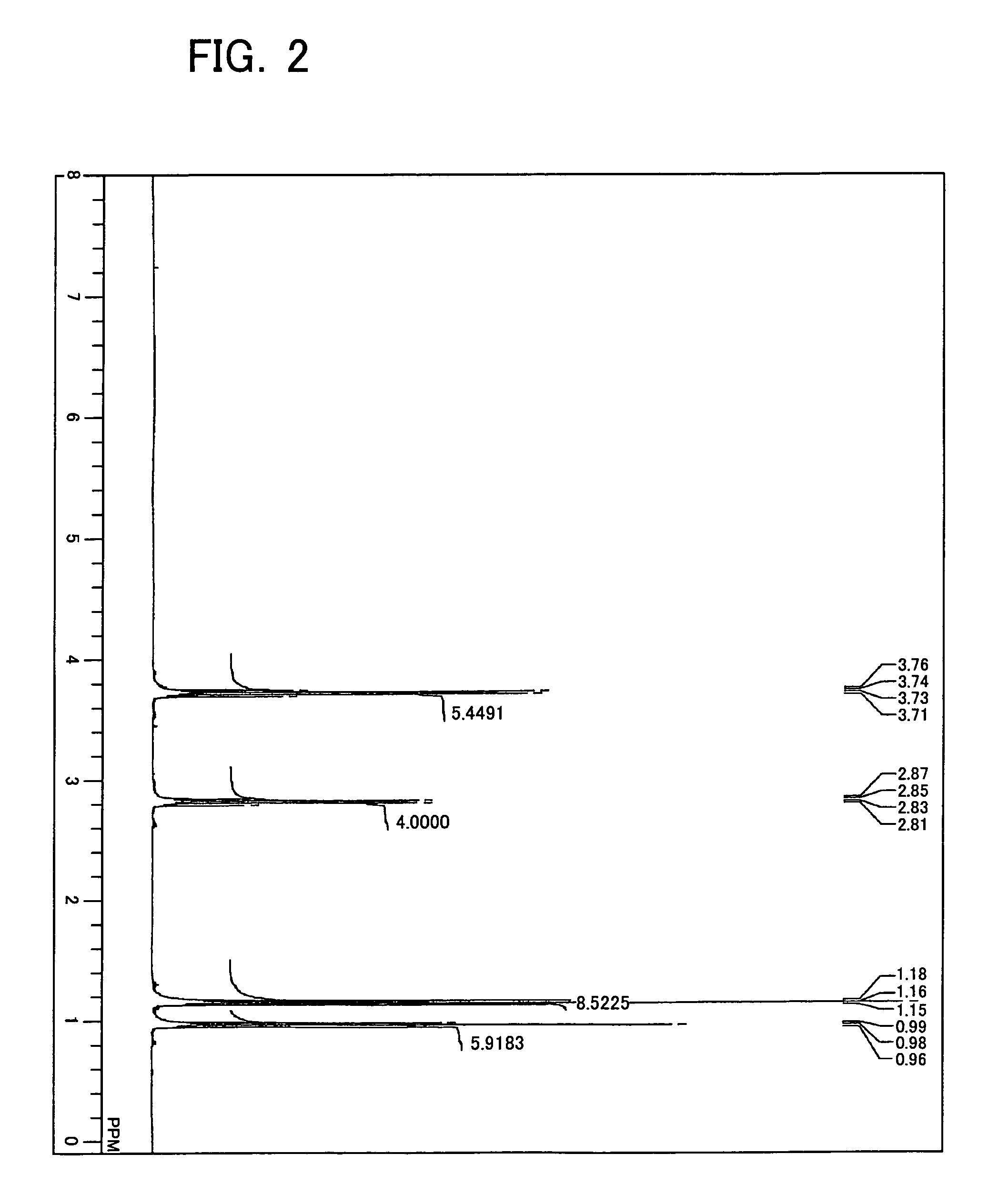

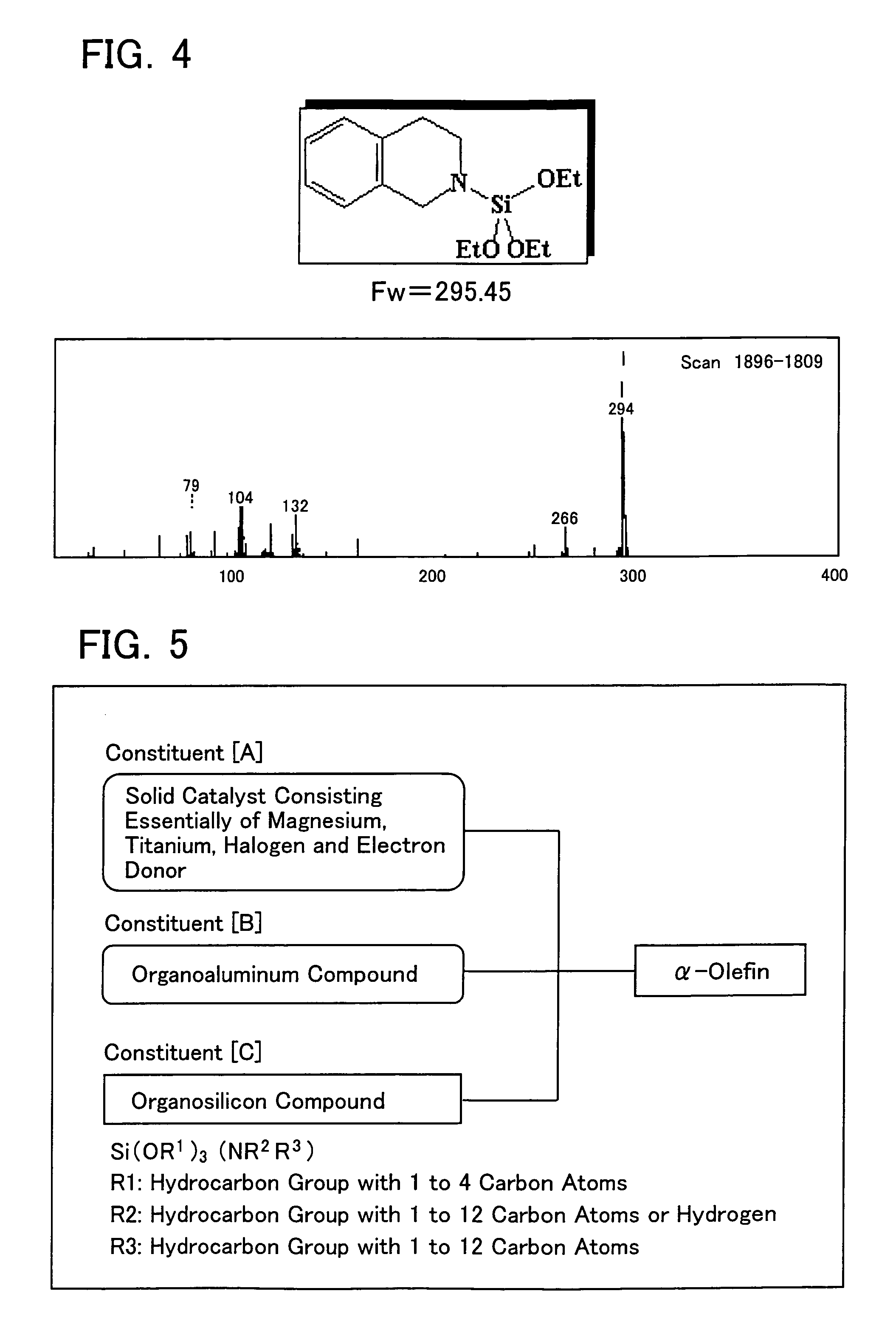

InactiveUS7238758B2Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenReaction rate

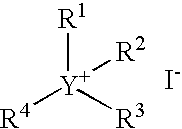

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38:Si(OR1)3(NR2R3)Formula 37(where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms)RNSi(OR1)3Formula 38(where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Stabilization of a hydroformylation process

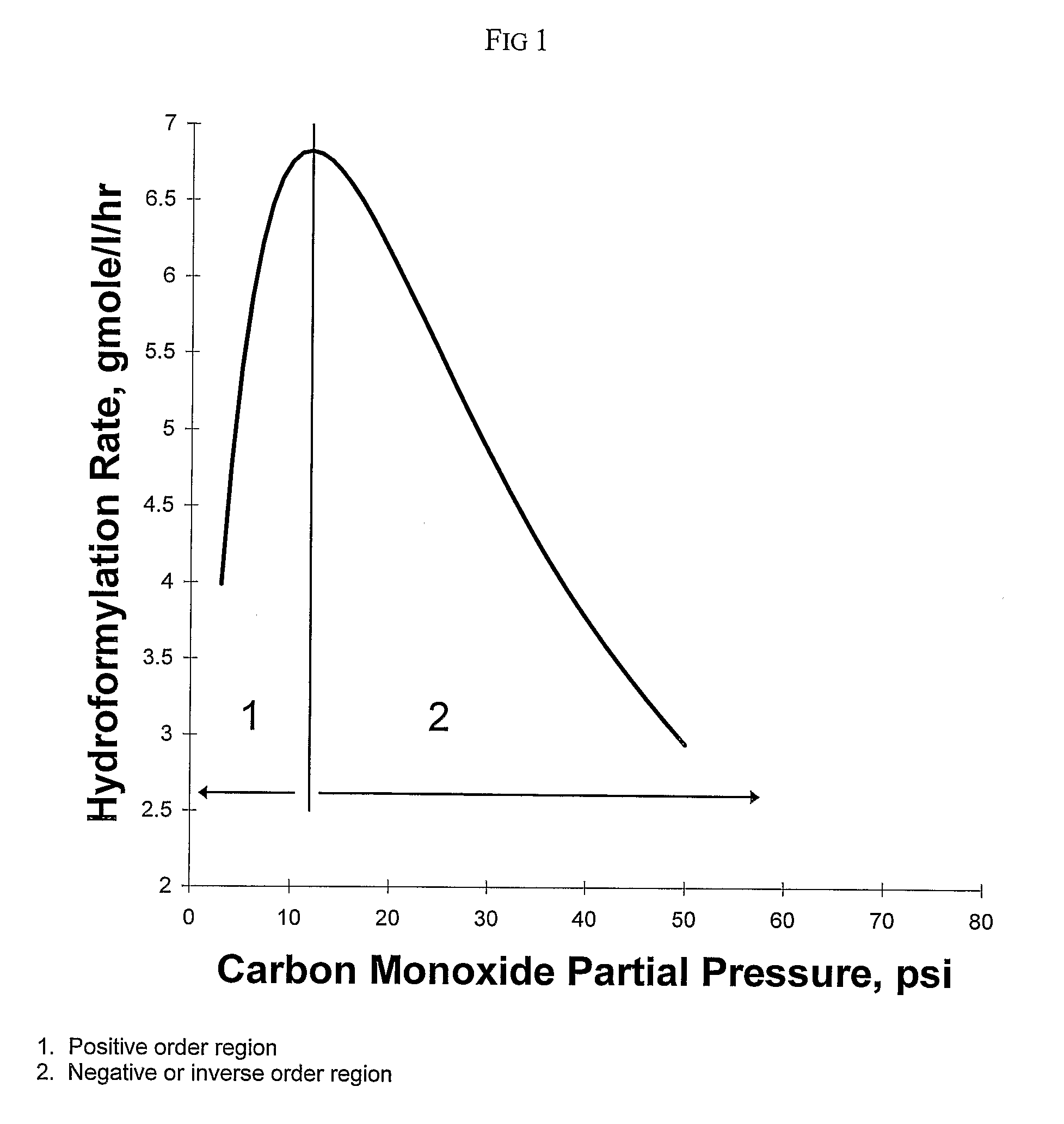

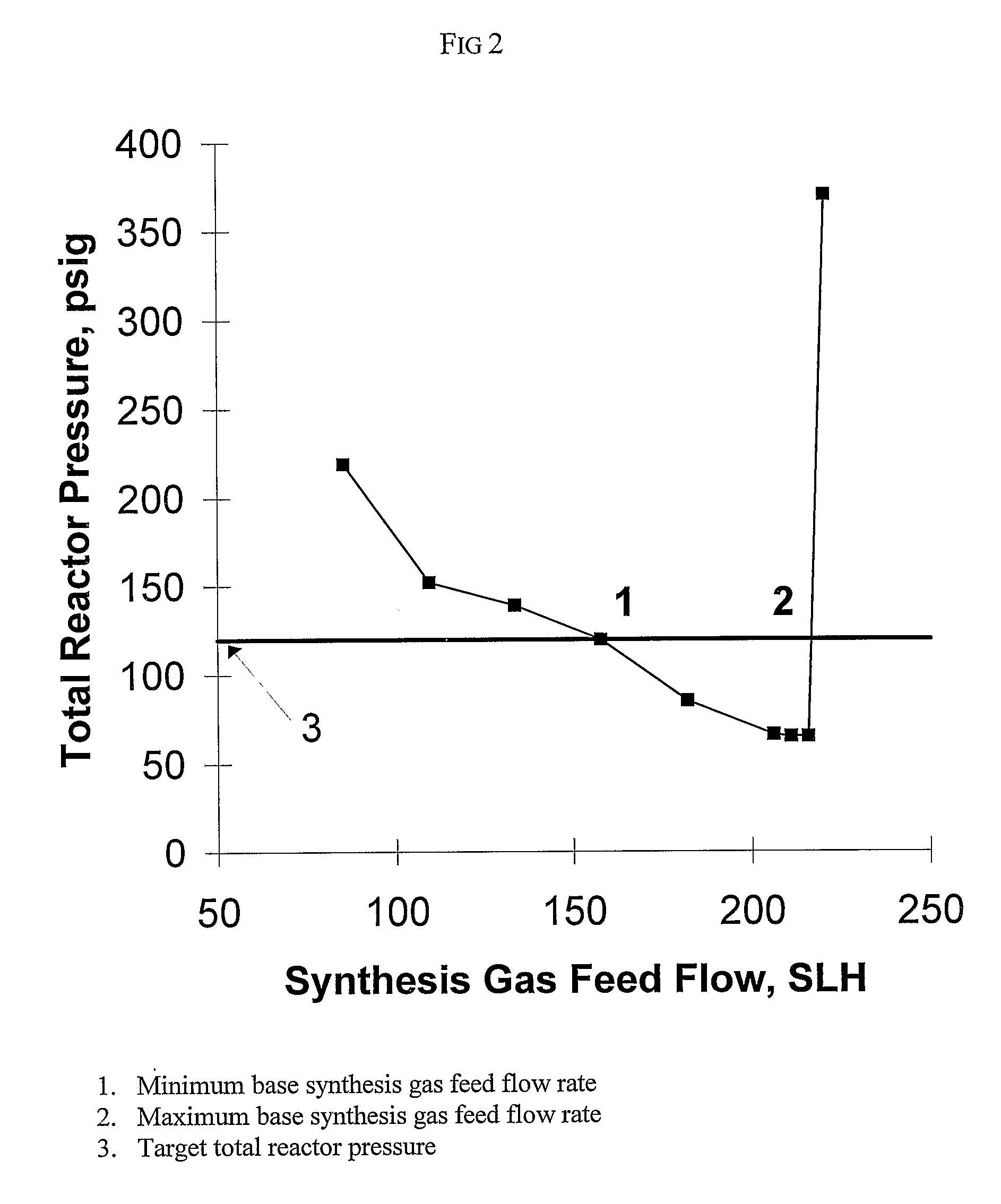

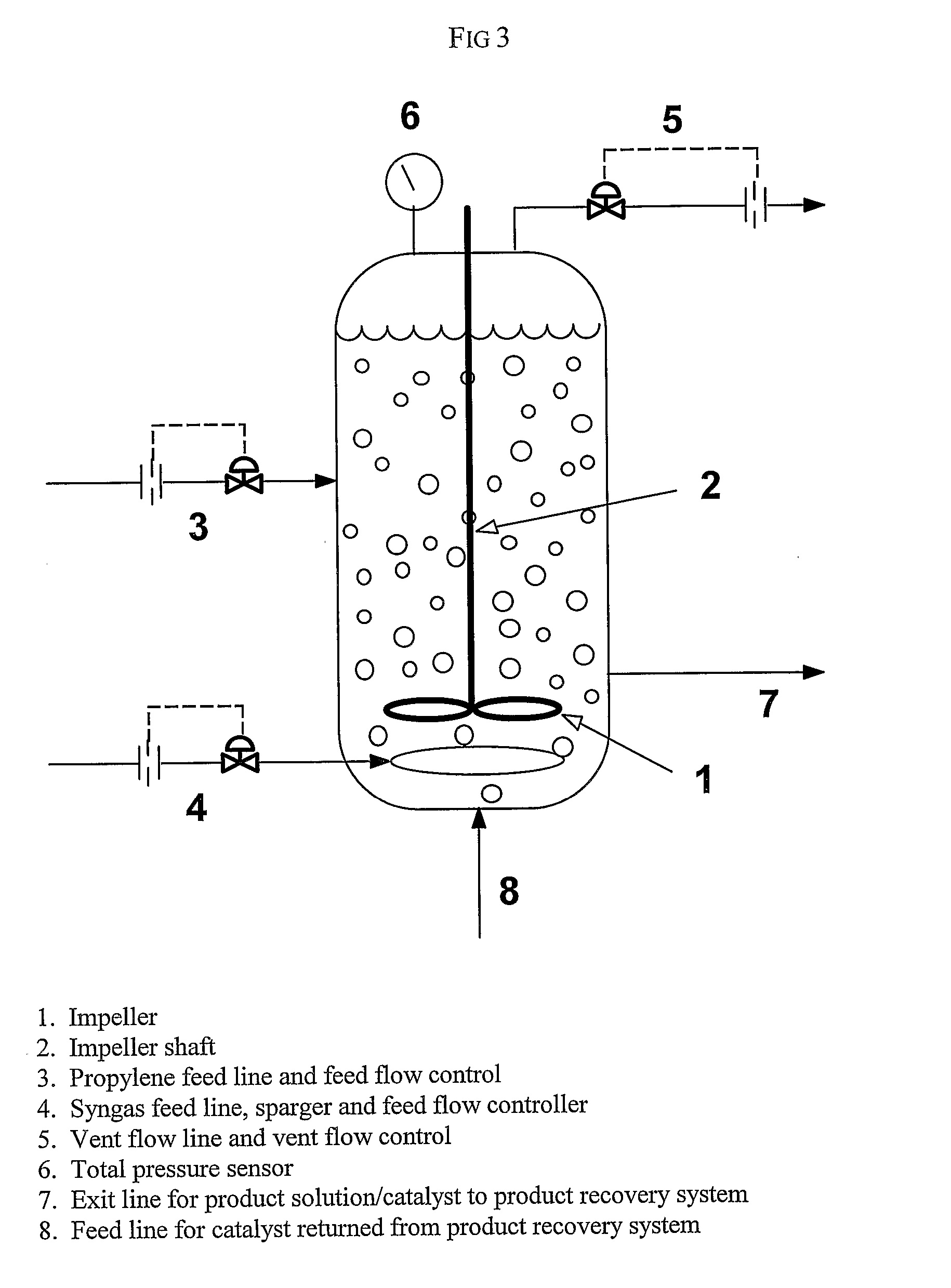

ActiveUS7446231B2Improve efficiencyProcess stabilityLiquid degasificationOrganic compound preparationReaction rateRate curve

An improved hydroformylation process involving reacting one or more reactants, such as an olefin, with carbon monoxide and hydrogen in the presence of a hydroformylation catalyst, to produce a reaction product fluid comprising one or more products, preferably aldehydes; wherein said process is conducted in a region of the hydroformylation rate curve that is negative or inverse order in carbon monoxide, which is sufficient to prevent and / or lessen deactivation of the hydroformylation catalyst; and wherein total pressure is controlled at a predetermined target value and / or vent flow rate is controlled at a predetermined target value, by adjusting a flow of a carbon-monoxide containing inlet gas, so as to prevent and / or lessen cycling of process parameters, e.g., reaction rate, total pressure, vent flow rate, and / or temperature.

Owner:DOW TECH INVESTMENTS

High-amperage energy storage device with liquid metal negative electrode and methods

ActiveUS8268471B2Improve ionic conductivityIncrease response ratePrimary cell to battery groupingCell electrodesElectrolysisEngineering

Owner:MASSACHUSETTS INST OF TECH

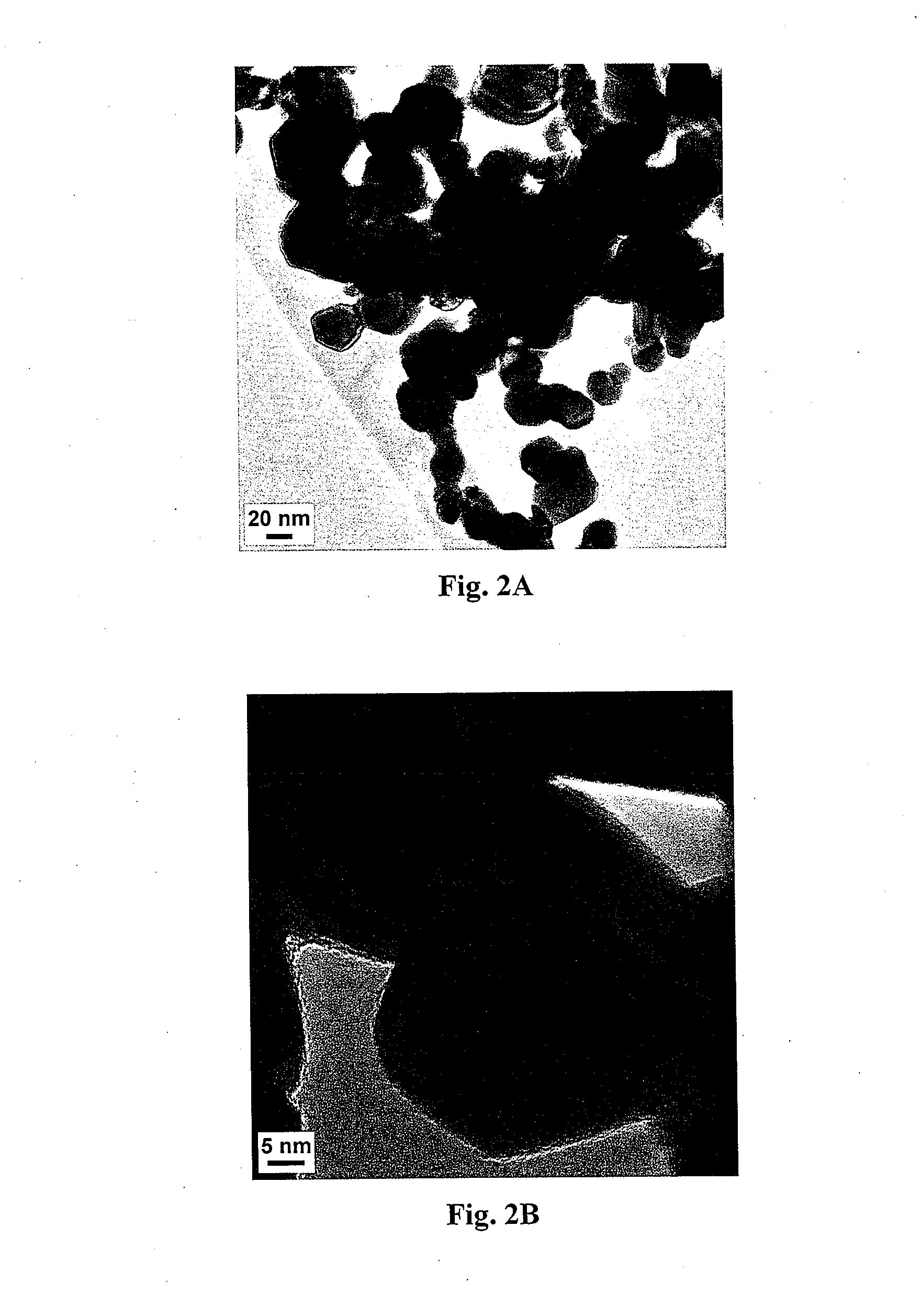

Electrocatalyst Synthesized by Depositing a Contiguous Metal Adlayer on Transition Metal Nanostructures

InactiveUS20100099012A1Minimizes Pt loadingMaximizingActive material electrodesSolid electrolyte fuel cellsNanowireSheet film

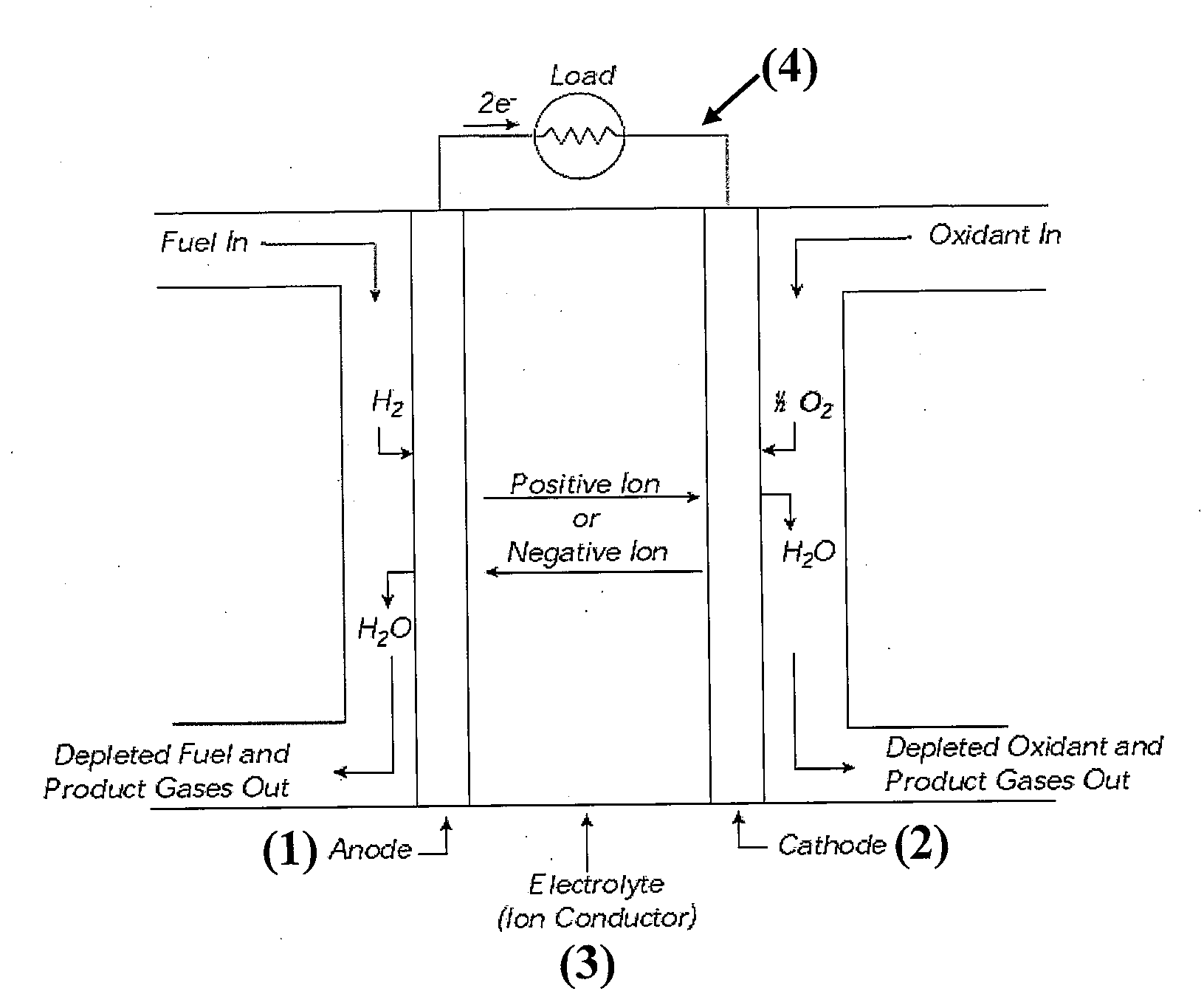

Transition metal nanostructures coated with a contiguous, conformal submonolayer-to-multilayer noble metal film and their method of manufacture are described. The manufacturing process involves the initial formation of suitably sized transition metal or alloy nanostructures which may be nanorods, nanobars, or nanowires. A monolayer of a non-noble metal is deposited onto the surface of the nanostructures by underpotential deposition. This is followed by the galvanic displacement of the non-noble metal by a second metal to yield a conformal coating of a monolayer of the second metal on the surface of the nanostructures. The replacement of atoms of the first metal by atoms of the second metal is an irreversible and spontaneous redox reaction which involves the replacement of a non noble metal by a more noble metal. The process can be controlled and repeated to obtain the desired film coverage. The resulting coated nanostructures provide heightened catalytic activity and can be used as high-performance electrodes in fuel cells.

Owner:BROOKHAVEN NAT LAB +1

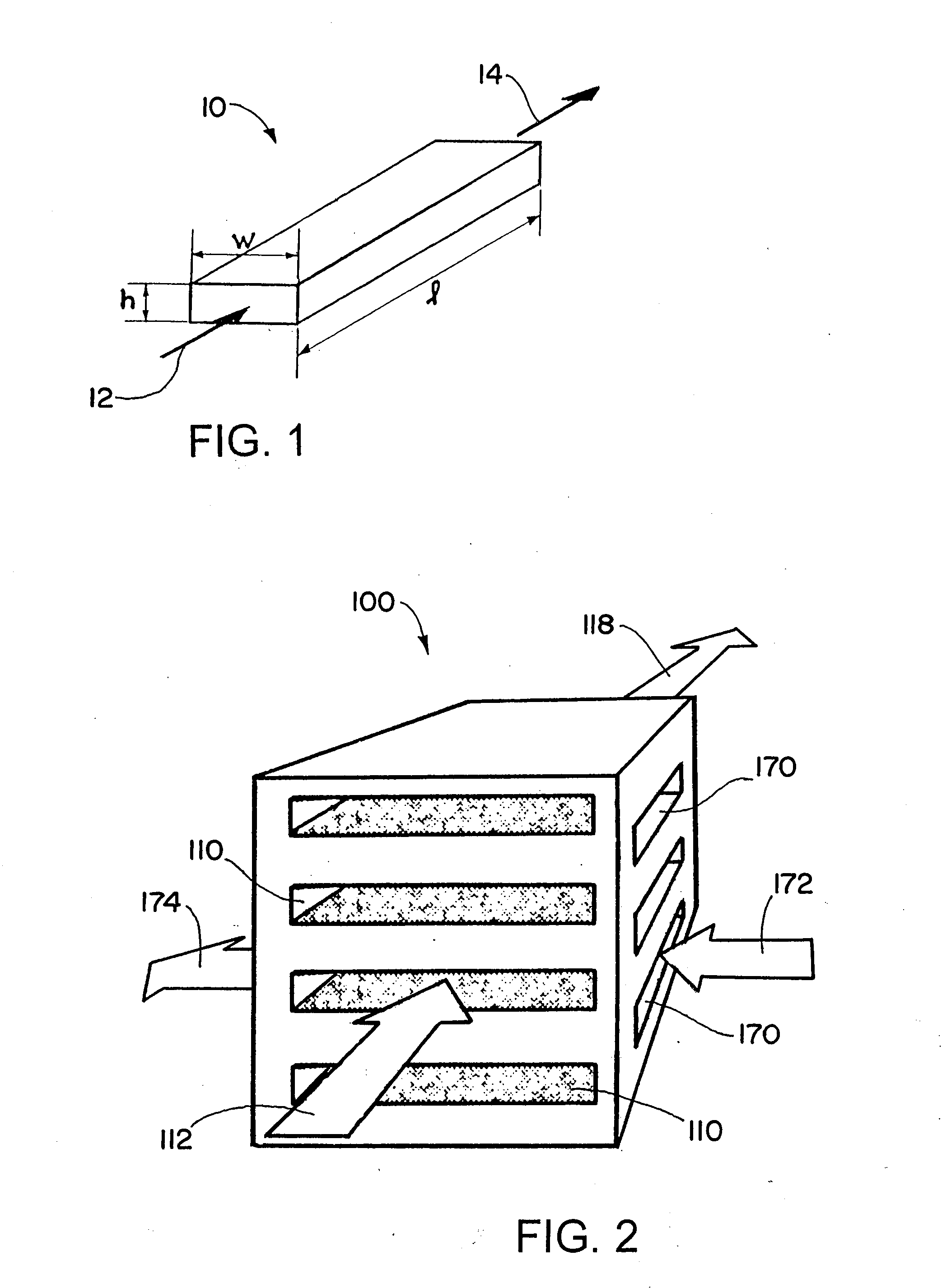

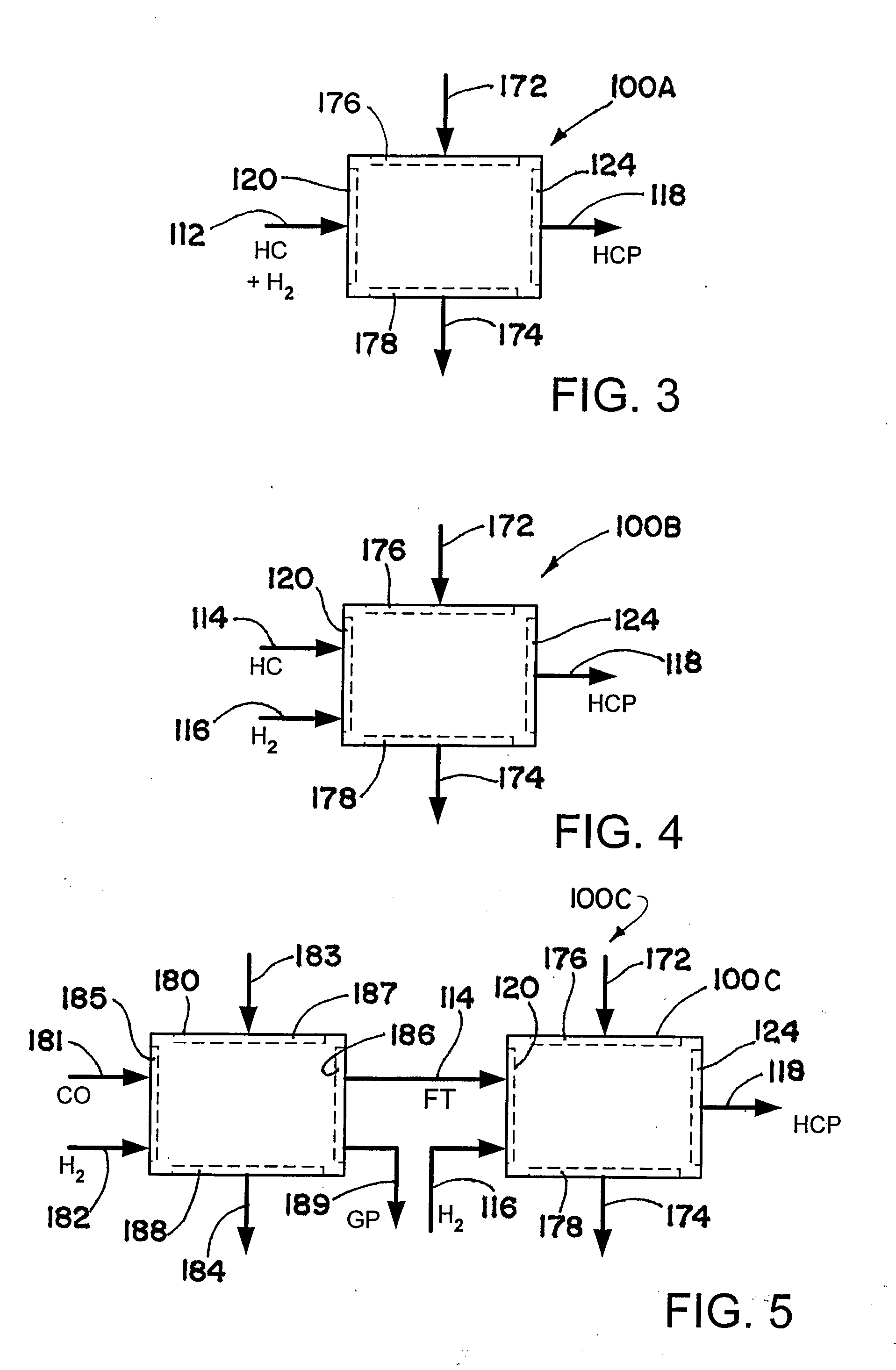

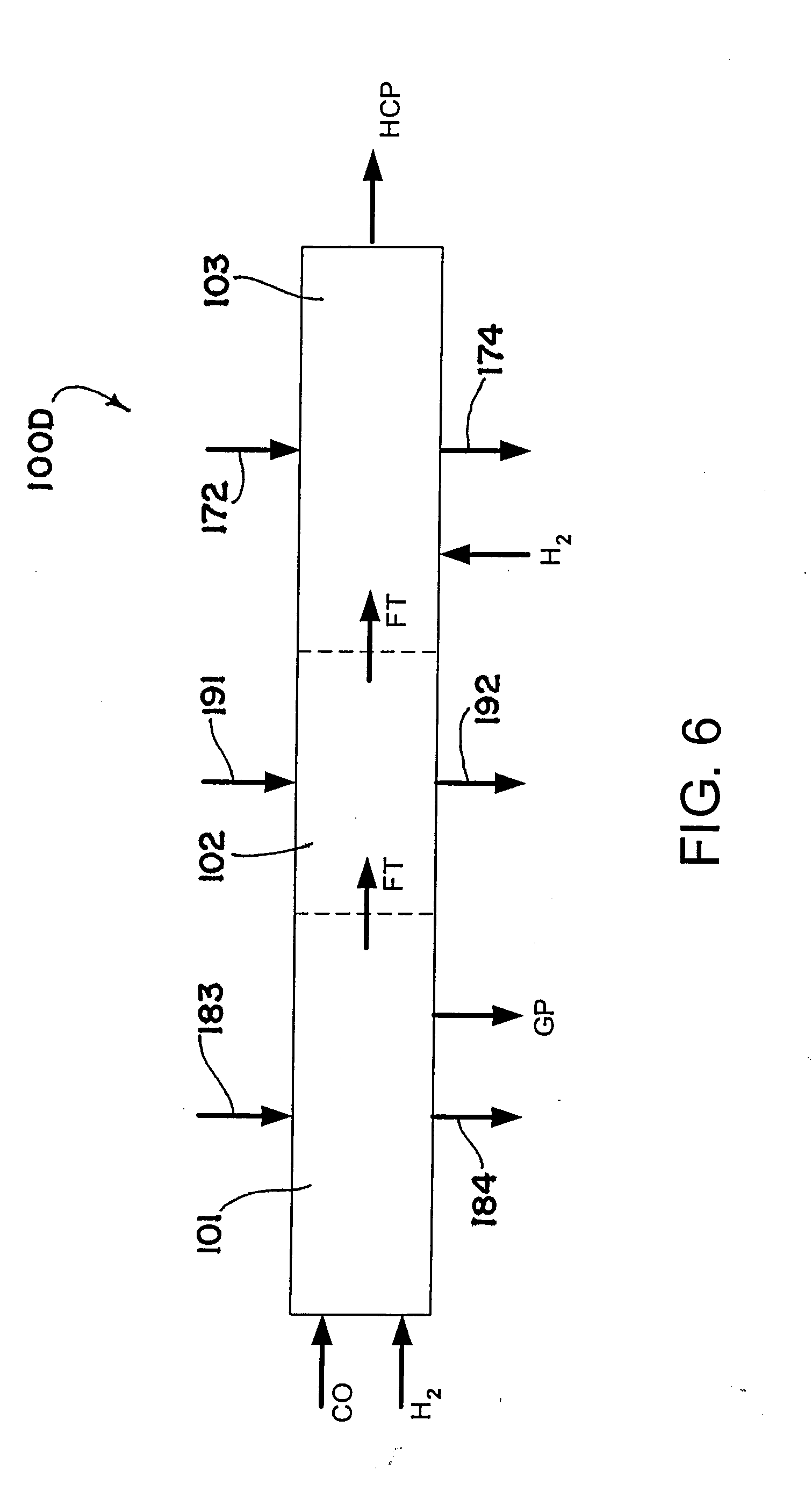

Process and apparatus employing microchannel process technology

InactiveUS20100174124A1High selectivityAlleviate cokingOrganic compound preparationChemical/physical/physico-chemical microreactorsChemistry

This invention relates to a process for conducting a hydrocracking or a hydrotreating process in a microchannel reactor. This invention also relates to a process and apparatus for flowing a vapor and liquid into a plurality of microchannels in a microchannel processing unit.

Owner:VELOCYS CORPORATION

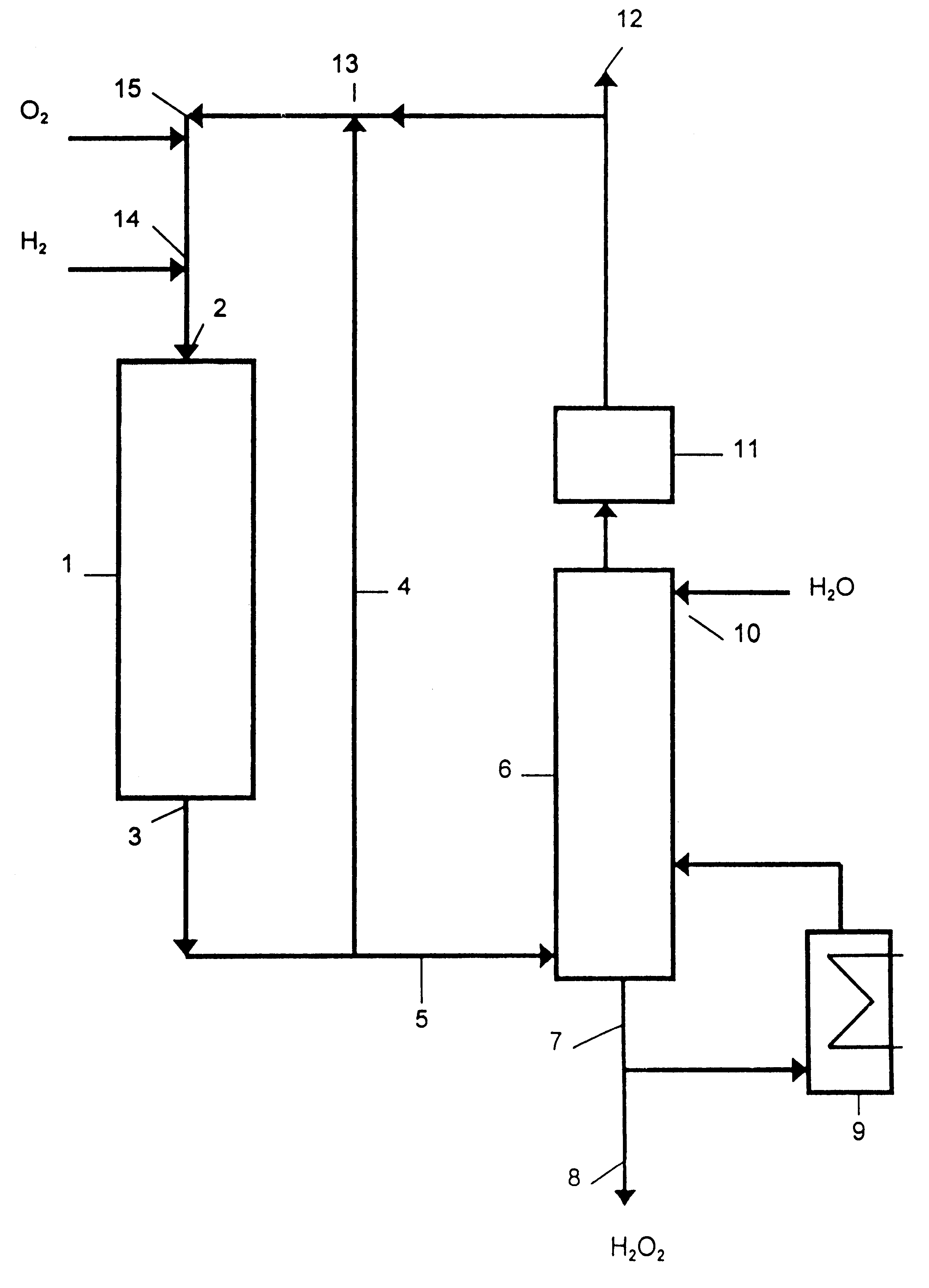

Process for producing hydrogen peroxide

InactiveUS6210651B1Increase response rateHigh selectivityHydrogen peroxideCatalyst carriersStationary phaseHydrogen

The invention relates to a process for continuously producing hydrogen peroxide comprising the steps of feeding hydrogen and oxygen containing gas to a reactor provided with a catalyst; contacting the hydrogen and oxygen gas with the catalyst and thereby forming hydrogen peroxide, and; withdrawing hydrogen peroxide containing gas from the reactor; wherein the catalyst comprises a solid catalytically active material at least partially covered with a layer of a stationary phase different from the catalytically active material.

Owner:AKZO NOBEL NV

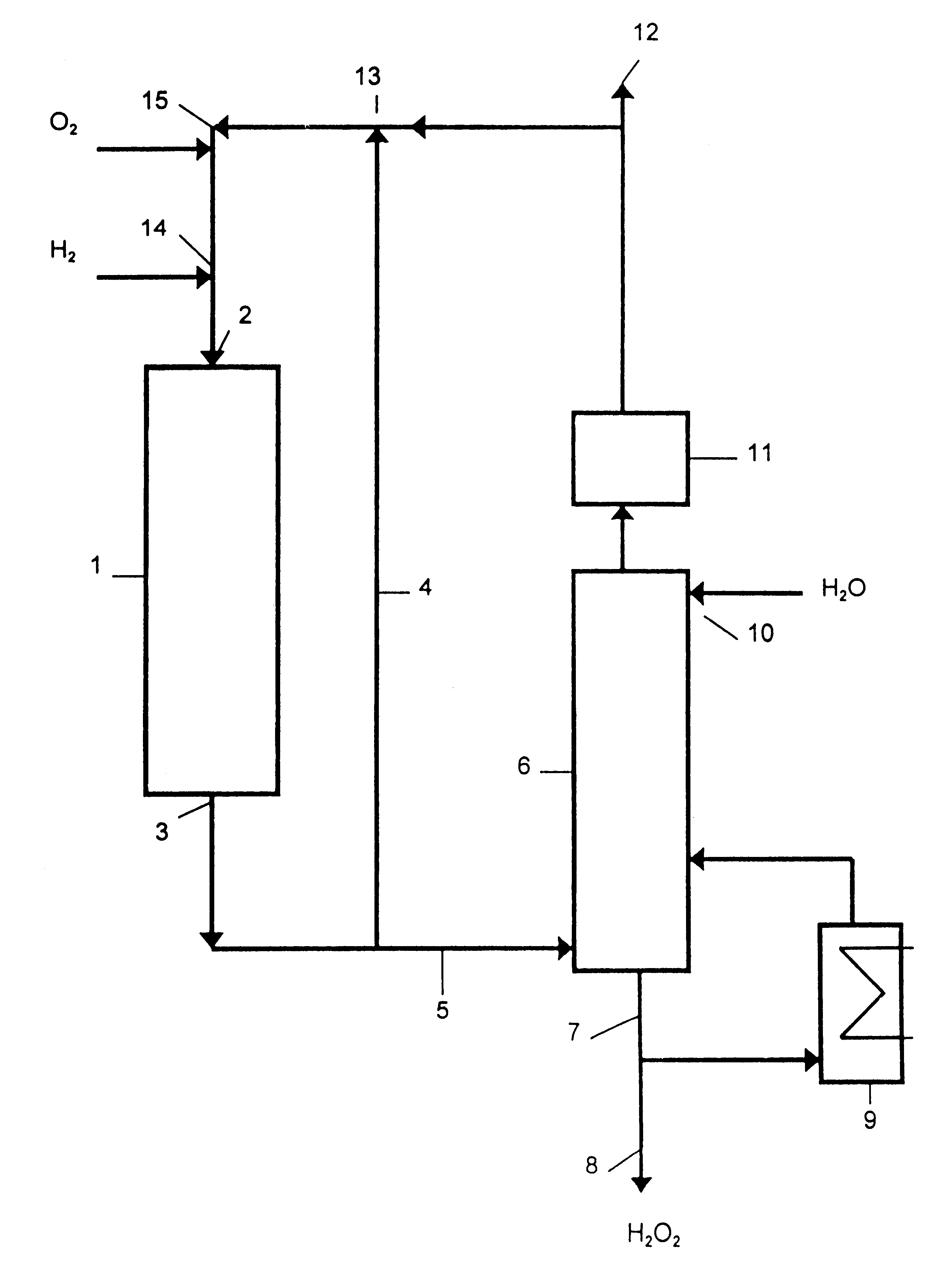

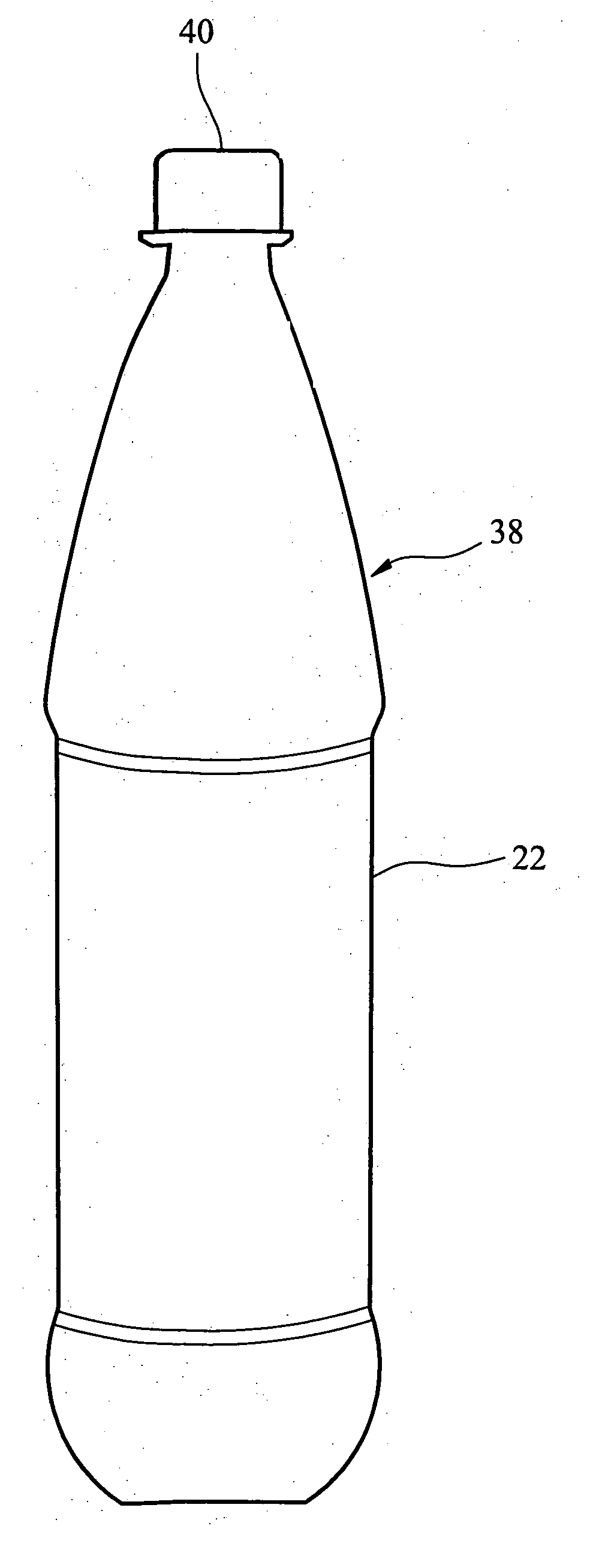

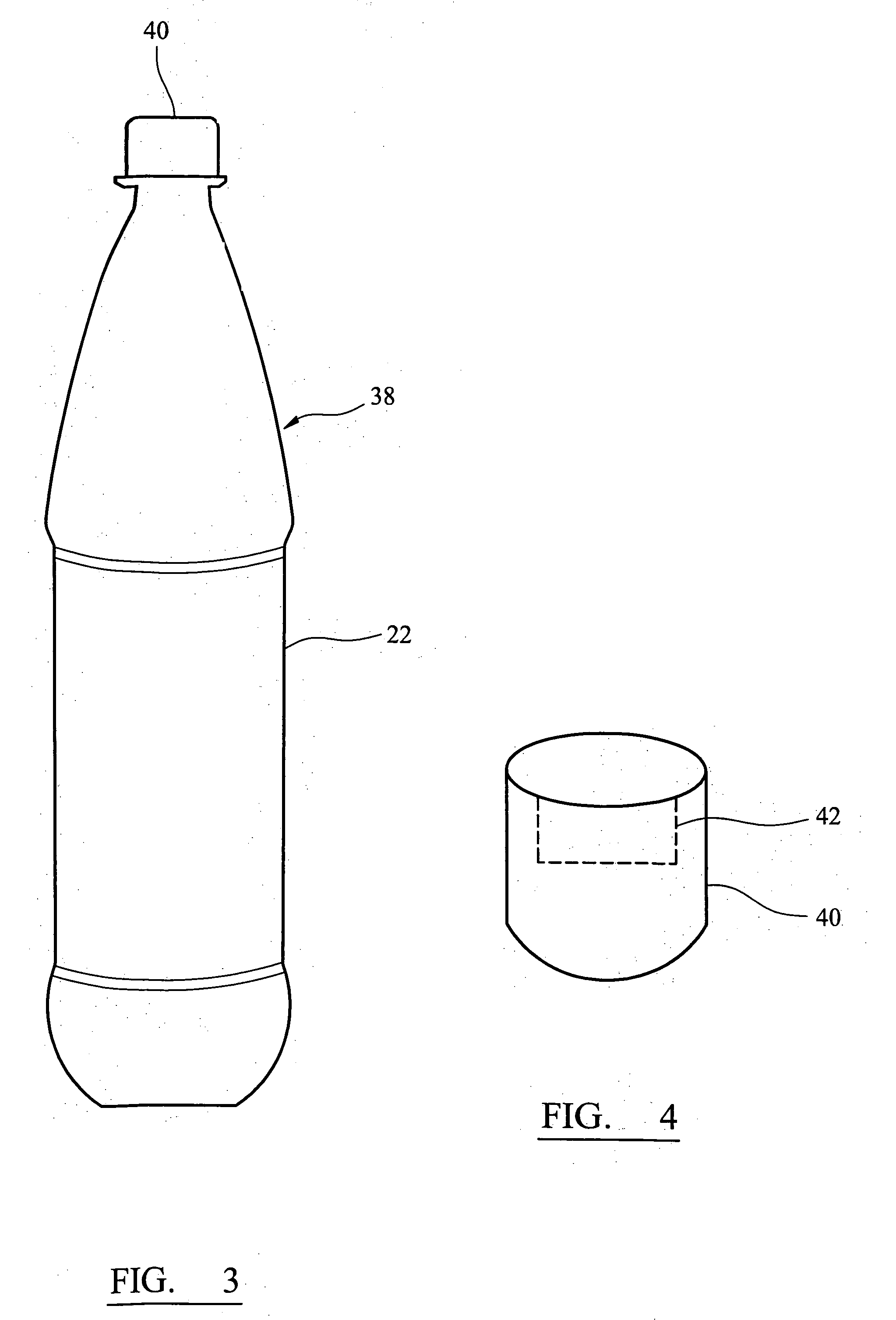

Scavenging oxygen

InactiveUS20100028499A1Increase response rateSmall amountClosures with oxygen absorbersFruit and vegetables preservationWater vaporPalladium catalyst

A container (22) includes a shell (24) made from a polymer, for example PET, and incorporating a catalyst, for example a palladium catalyst. A closure (40) incorporates a plug which includes a source of hydrogen, for example a hydride. In use, with container (22) including a beverage and closure (40) in position, the headspace in the container will be saturated with water vapor. This vapor contacts the hydride associated with plug (42) and as a result the hydride produces molecular hydrogen which migrates into the polymer matrix of shell (24) and combines with oxygen which may have entered the container through its permeable walls. A reaction between the hydrogen and oxygen takes place, catalysed by the catalyst, and water is produced. Thus, oxygen which may ingress the container is scavenged and the contents of the container are protected from oxidation.

Owner:COLORMATRIX HLDG

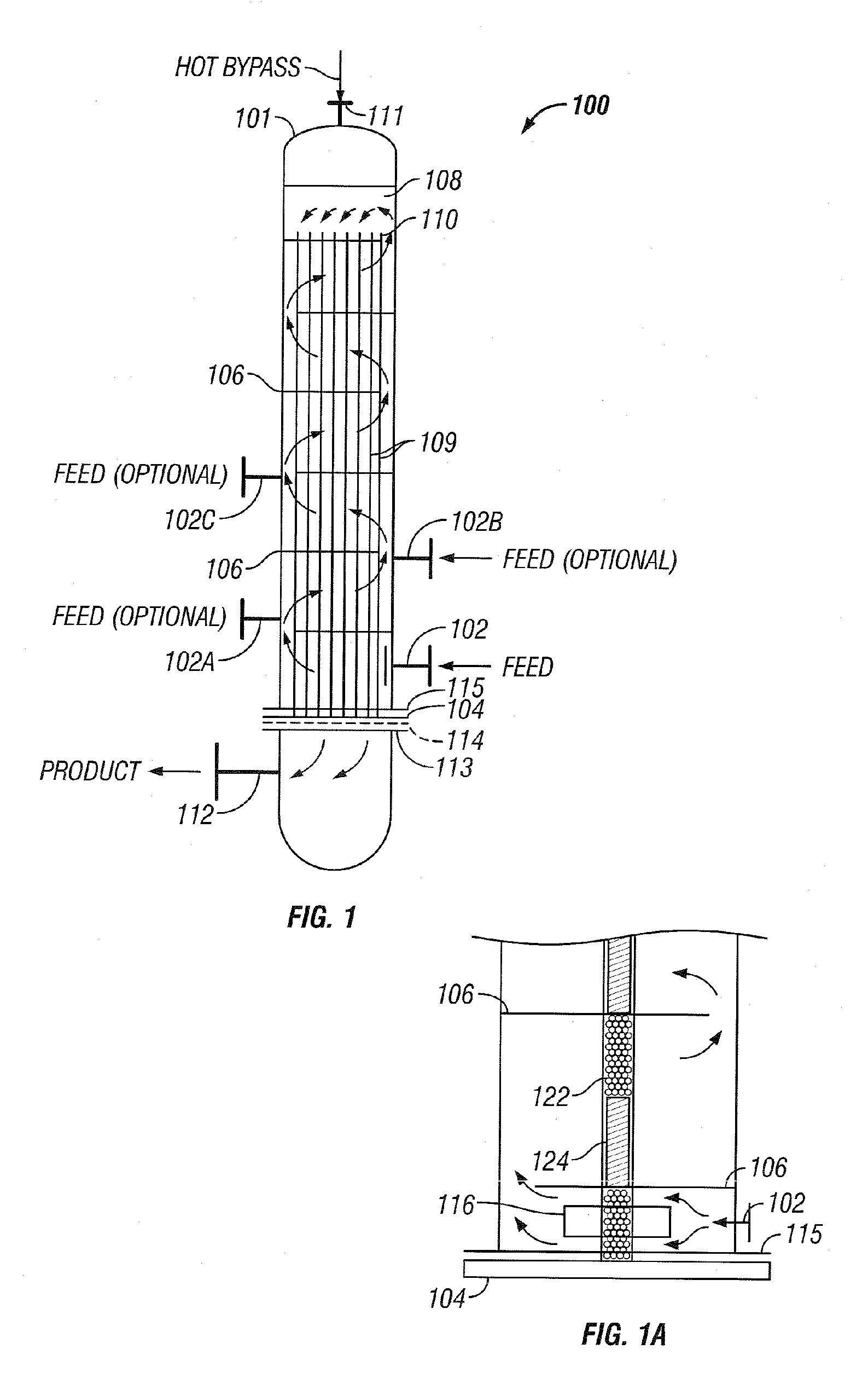

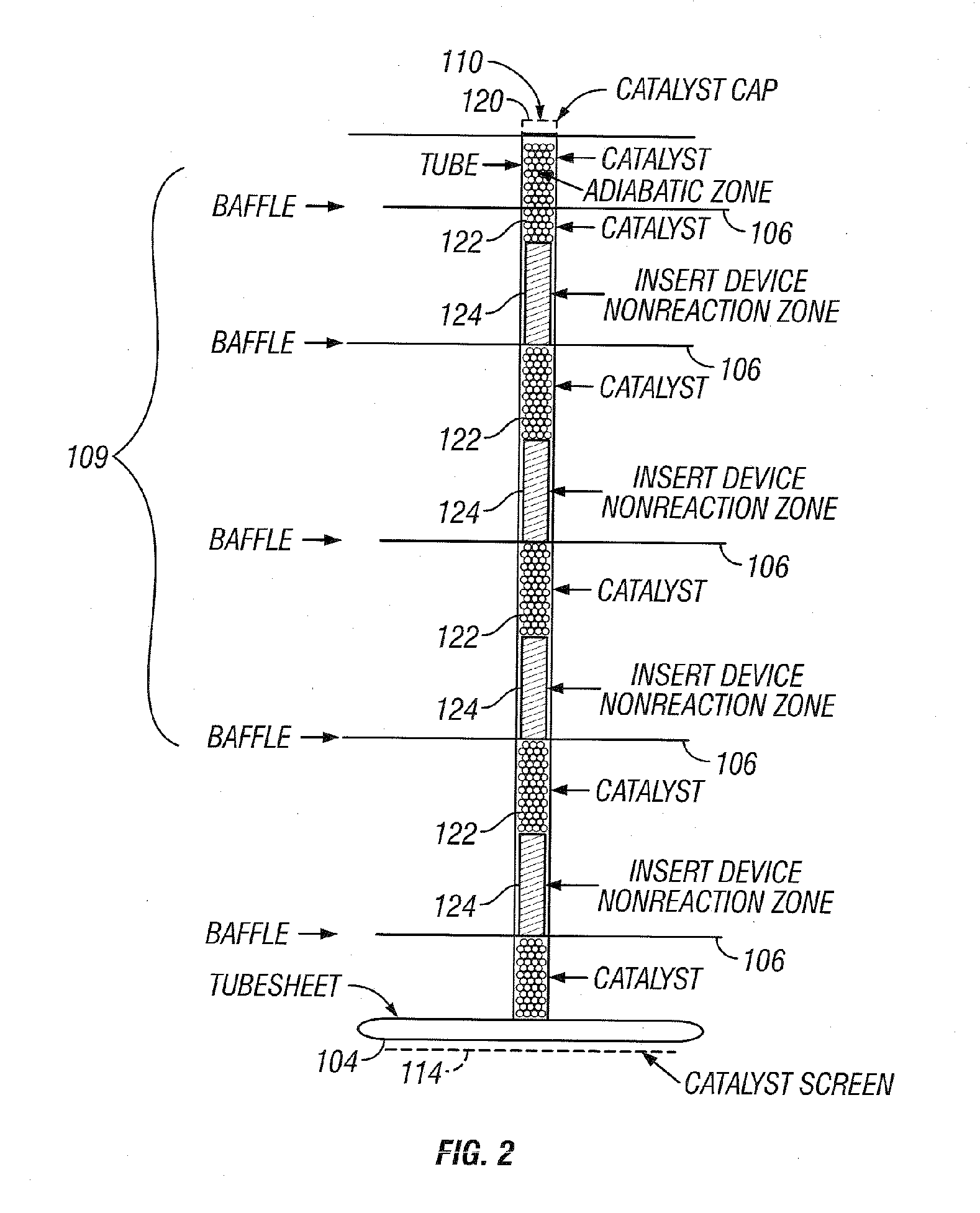

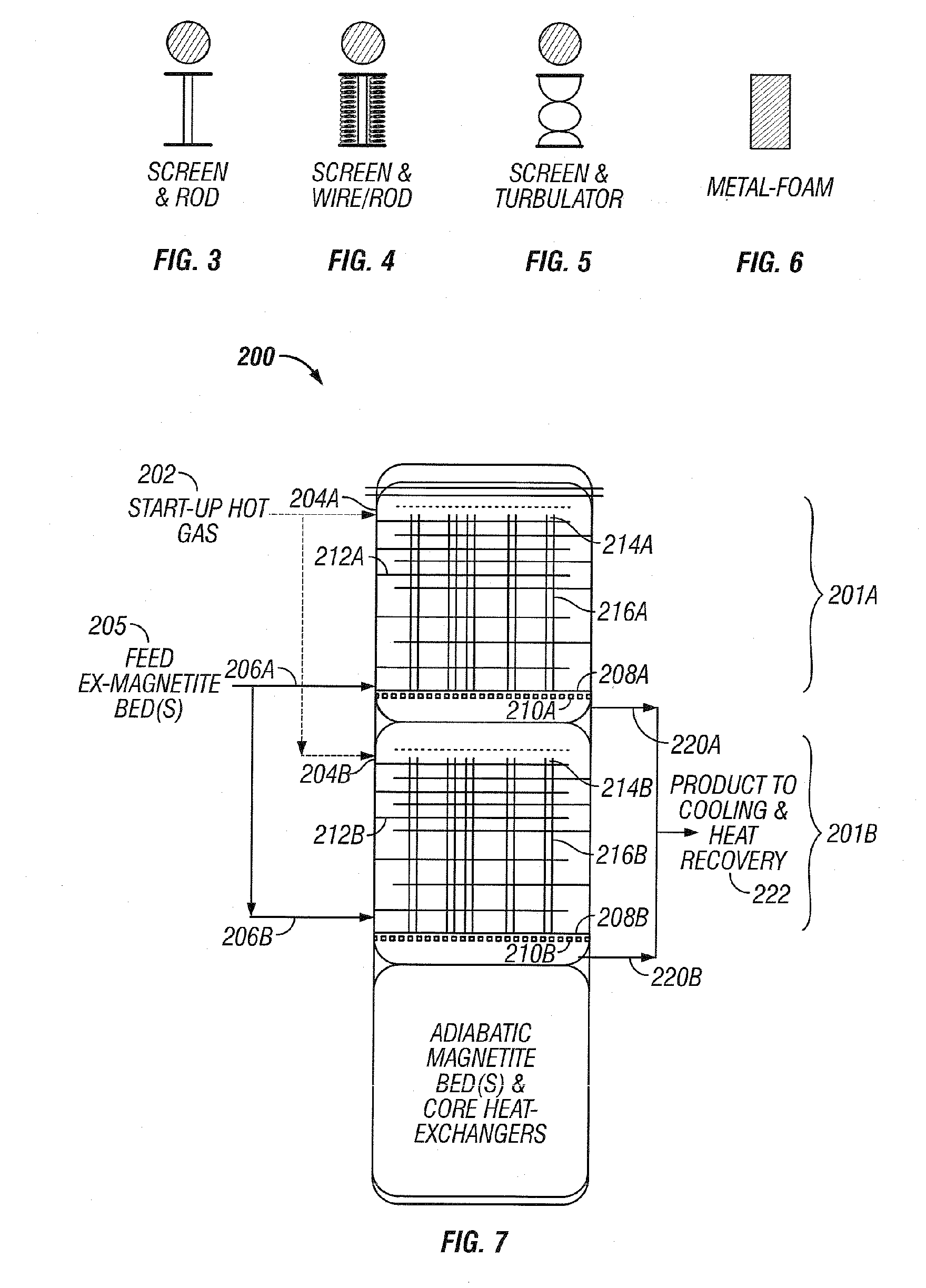

Maximum reaction rate converter system for exothermic reactions

ActiveUS20060099131A1Reduction in catalyst volumeSpeed up the conversion processMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionReaction temperatureEquilibrium curve

An ammonia converter system and method are disclosed. The reactor can alter the conversion of ammonia by controlling the reaction temperature of the exothermic reaction along the length of the reactor to parallel the equilibrium curve for the desired product. The reactor 100 can comprise a shell 101 and internal catalyst tubes 109. The feed gas stream enters the reactor, flows through the shell 101, and is heated by indirect heat exchange with the catalyst tubes 109. The catalyst tubes 109 comprise reactive zones 122 having catalyst and reaction limited zones 124 that can comprise inert devices that function to both separate the reactive zones, increase heat transfer area, and reduce the temperature of the reaction mixture as the effluent passes through the catalyst tube 109.

Owner:KELLOGG BROWN & ROOT LLC

Production method of ultrafine cell level ferric orthophosphate

InactiveCN101462704AIncrease response rateHigh purity of finished productPhosphatesCell electrodesChemistryPhosphate

The invention relates to a method for producing ultrafine battery-level positive ferric phosphate. The method comprises the following steps that: a ferrite solution is added into a catalytic reaction kettle, added with sulphuric acid to adjust the pH value and slowly added with hydrogen peroxide while stirring to perform oxidation reaction; the dissolved phosphate solution is added to the catalytic reaction kettle, added with soda ash or ammonia to control the pH value and strongly stirred to obtain slurry of the positive ferric phosphate; the slurry is water-washed, press-filtered and separated to obtain a positive ferric phosphate filter cake; a conversion reaction kettle is added with an aqueous solution of phosphoric acid and added with the filter cake, the pH value and the temperature of the obtained mixing solution are adjusted, and the mixing solution is stirred; the mixing solution is placed in a thermal insulation reaction kettle, heated and stirred for a few hours until the mixing solution becomes pink, and the slurry of the positive ferric phosphate is obtained; and the slurry is water-washed, press-filtered, dried and crushed to obtain a finished product of the positive ferric phosphate. The method has the advantages of complete reaction and high reaction ratio, 28 to 29 percent of the total iron content Fe<3+> of the obtained products and even and thin grain diameter, and the D50 is less than or equal to 2um, the P is more than or equal to 16 percent, the grain is ultrafine and high in purity, and has even grain diameter; and because waste slag discharged in the production of a titanium pigment or industrial acid pickling waste liquid is used as a raw material, the environment is protected, and the product cost is lowered.

Owner:刘世琦

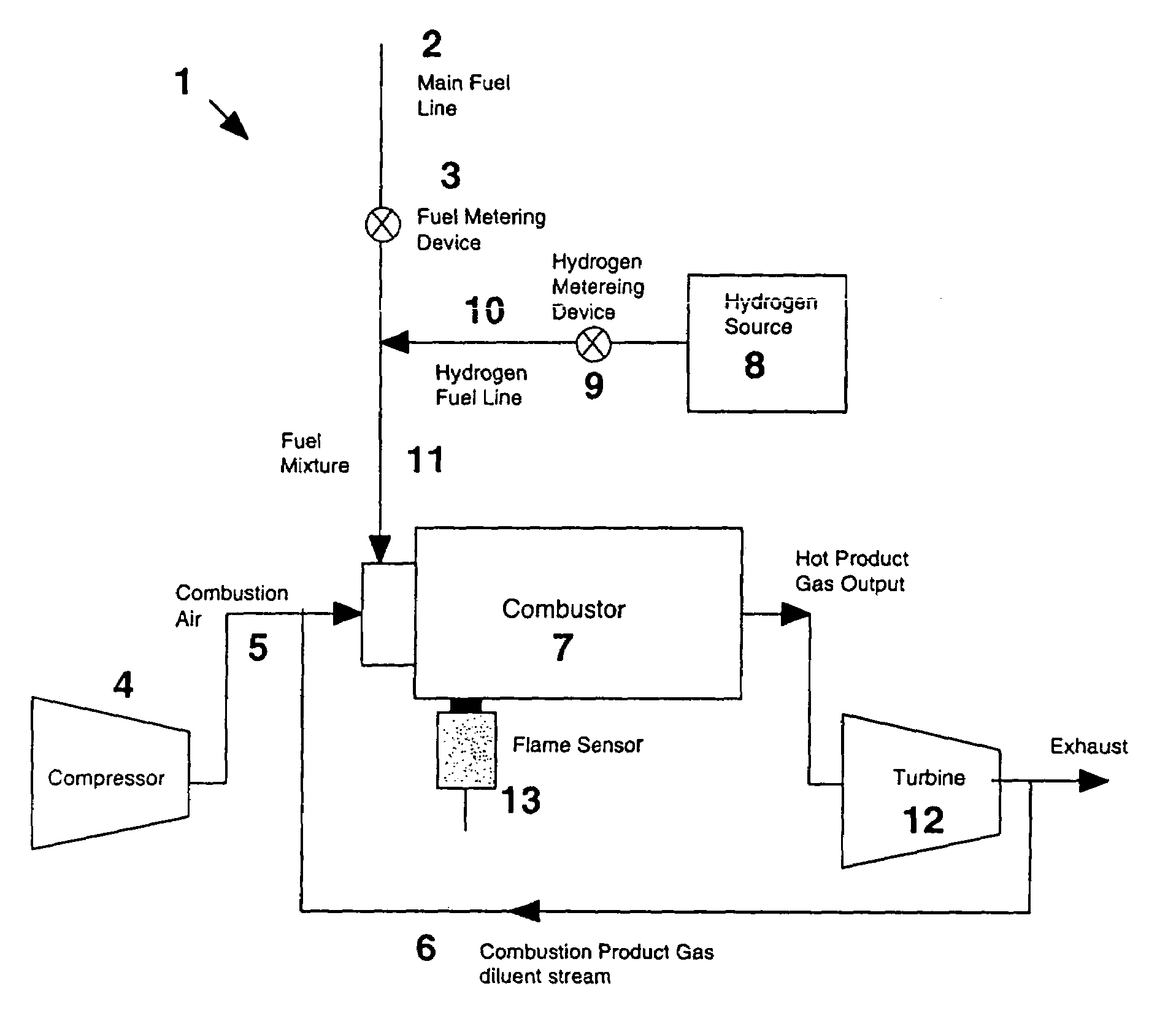

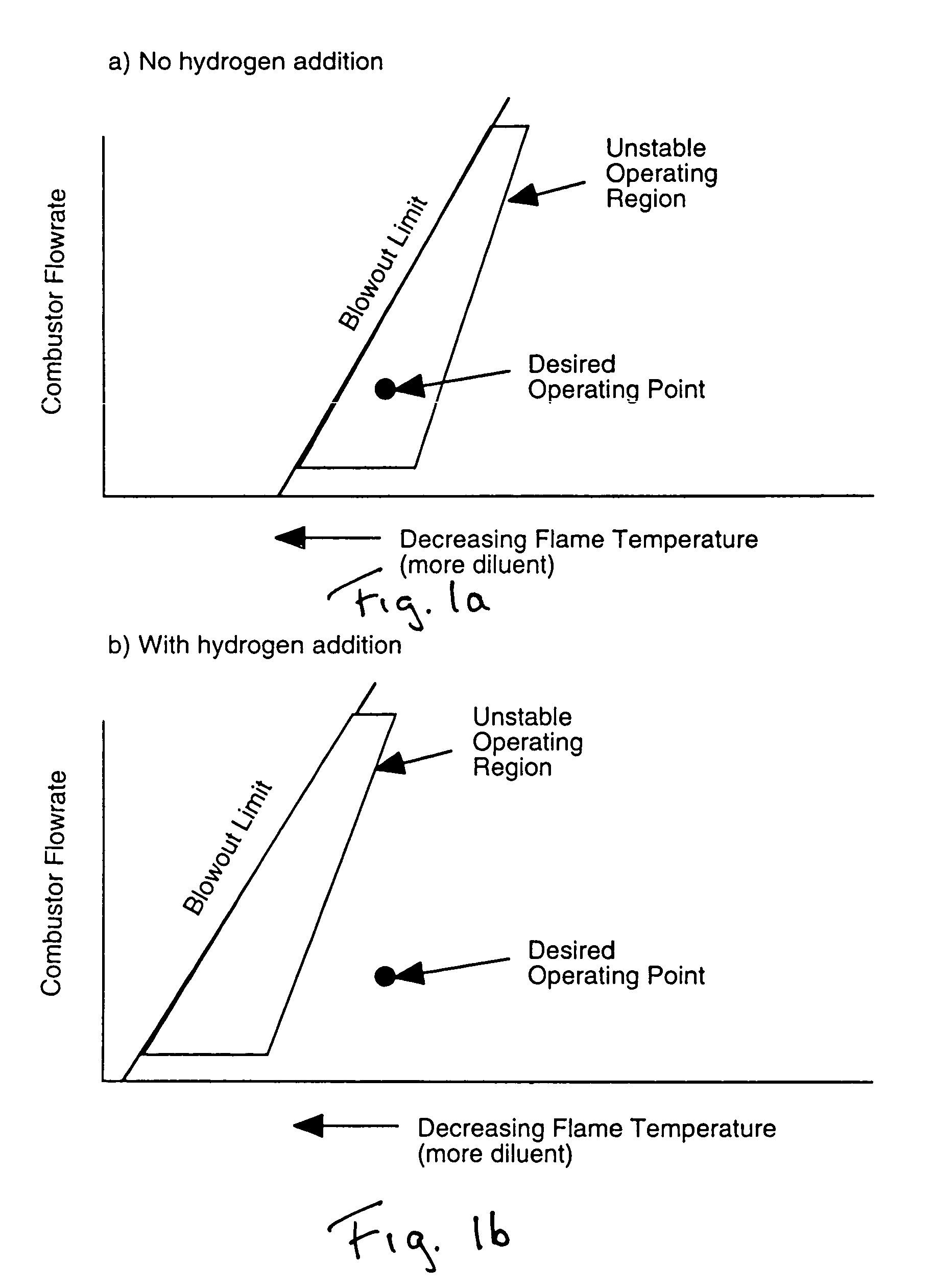

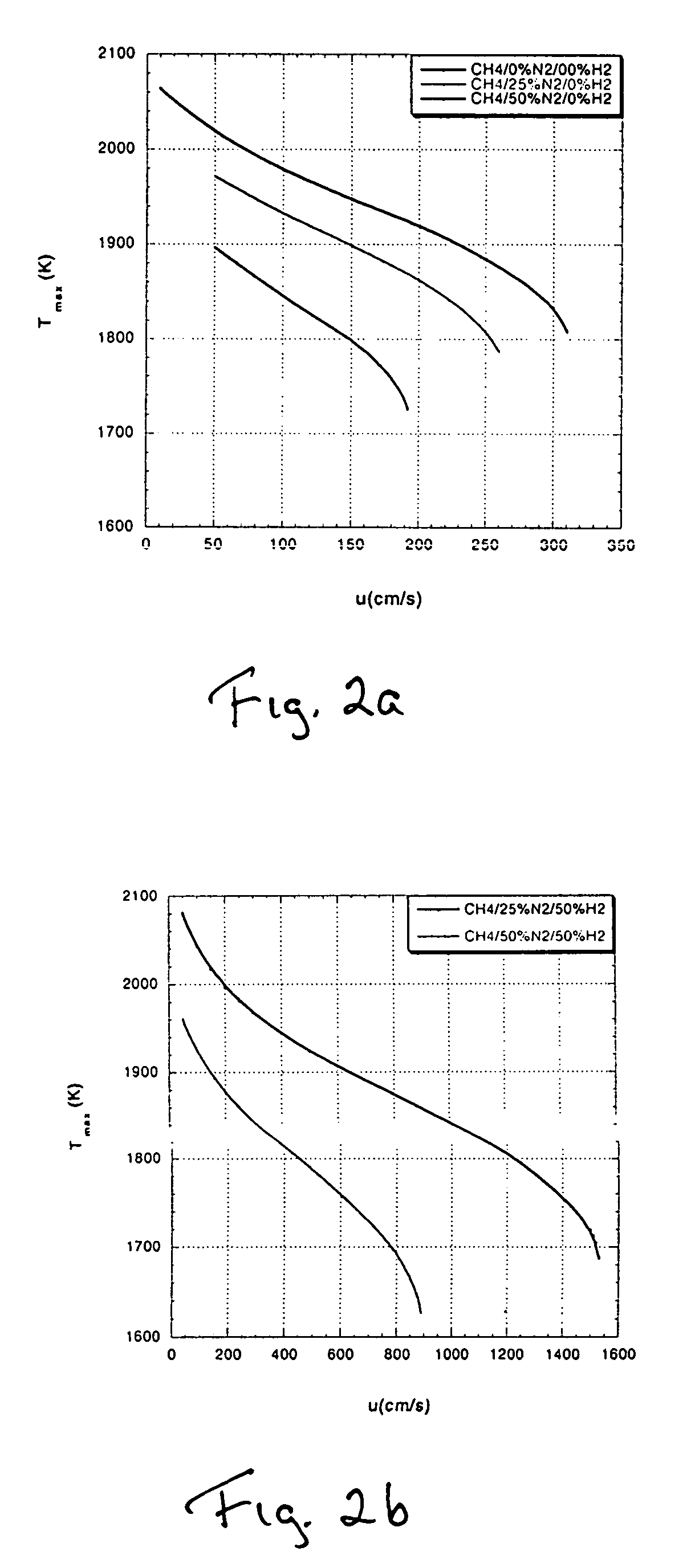

Method for control of NOx emission from combustors using fuel dilution

ActiveUS7162864B1Fast reaction timeLower temperatureInternal combustion piston enginesExhaust apparatusBiomassGas turbines

A method of controlling NOx emission from combustors. The method involves the controlled addition of a diluent such as nitrogen or water vapor, to a base fuel to reduce the flame temperature, thereby reducing NOx production. At the same time, a gas capable of enhancing flame stability and improving low temperature combustion characteristics, such as hydrogen, is added to the fuel mixture. The base fuel can be natural gas for use in industrial and power generation gas turbines and other burners. However, the method described herein is equally applicable to other common fuels such as coal gas, biomass-derived fuels and other common hydrocarbon fuels. The unique combustion characteristics associated with the use of hydrogen, particularly faster flame speed, higher reaction rates, and increased resistance to fluid-mechanical strain, alter the burner combustion characteristics sufficiently to allow operation at the desired lower temperature conditions resulting from diluent addition, without the onset of unstable combustion that can arise at lower combustor operating temperatures.

Owner:SANDIA NATIOANL LAB

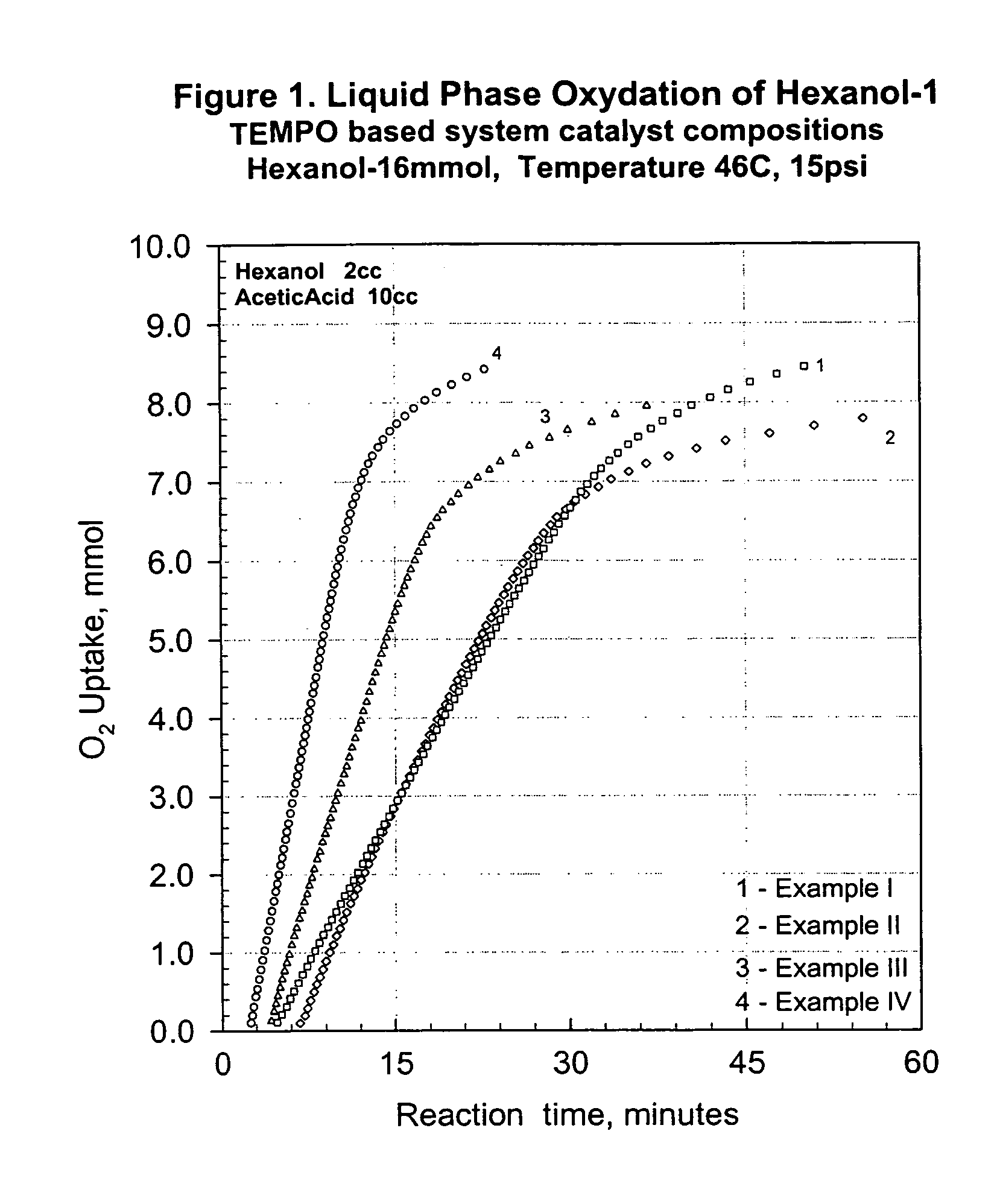

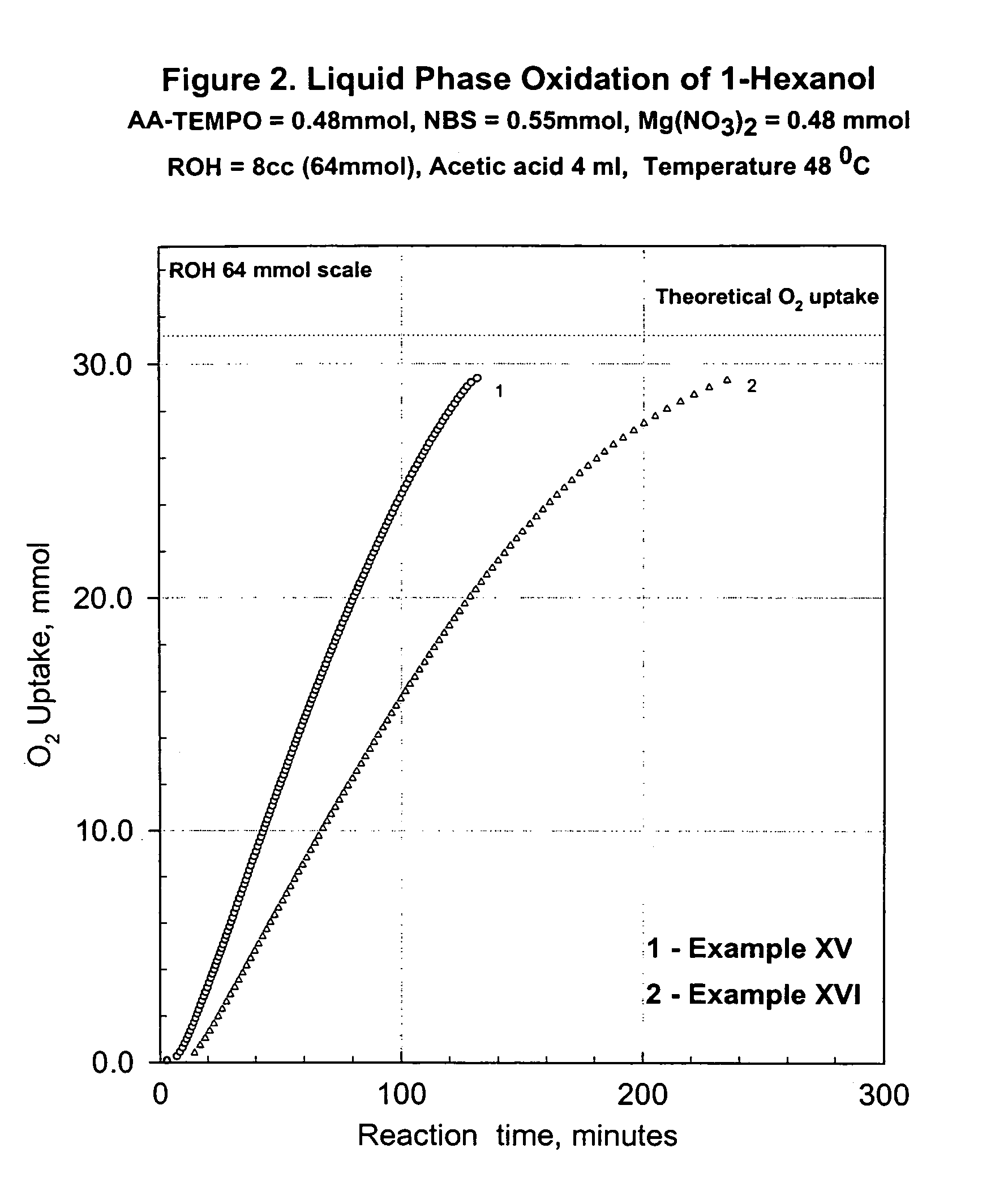

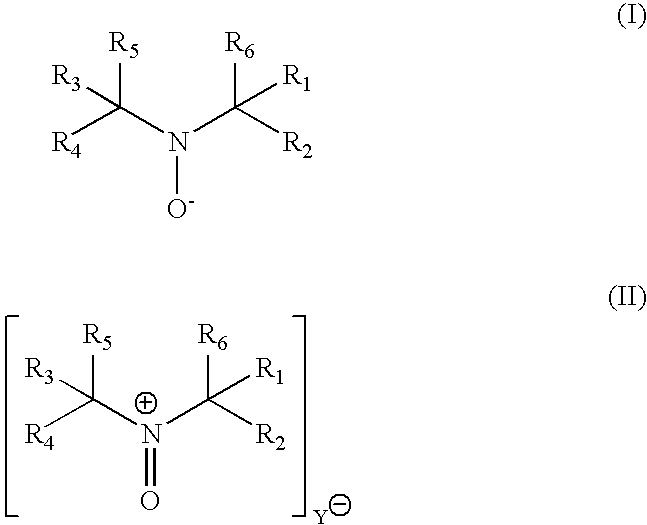

Process for transition metal free catalytic aerobic oxidation of alcohols under mild conditions using stable free nitroxyl radicals

InactiveUS7030279B1High selectivityHigh reaction rateOrganic compound preparationCarbonyl compound preparation by oxidationKetoneAldehyde

An alcohol can be oxidized by a process in which a primary or secondary alcohol are reacted with an oxygen-containing gas in the presence of a catalyst composition containing (i) a stable free nitroxyl radical derivative, (ii) a nitrate source, (iii) a bromide source, and (iiii) a carboxylic acid, thereby obtaining an aldehyde or a ketone.

Owner:EVONIK DEGUSSA GMBH

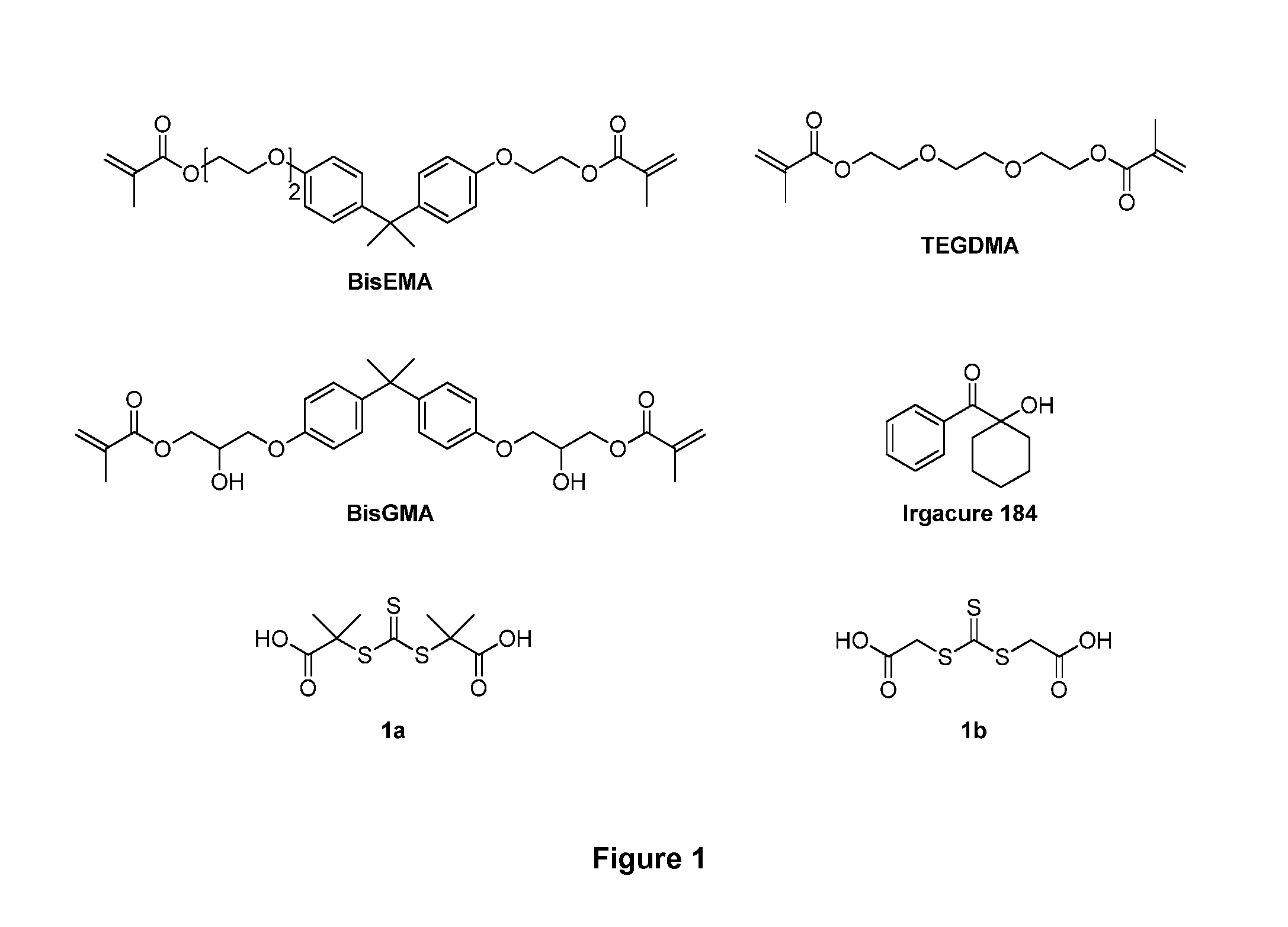

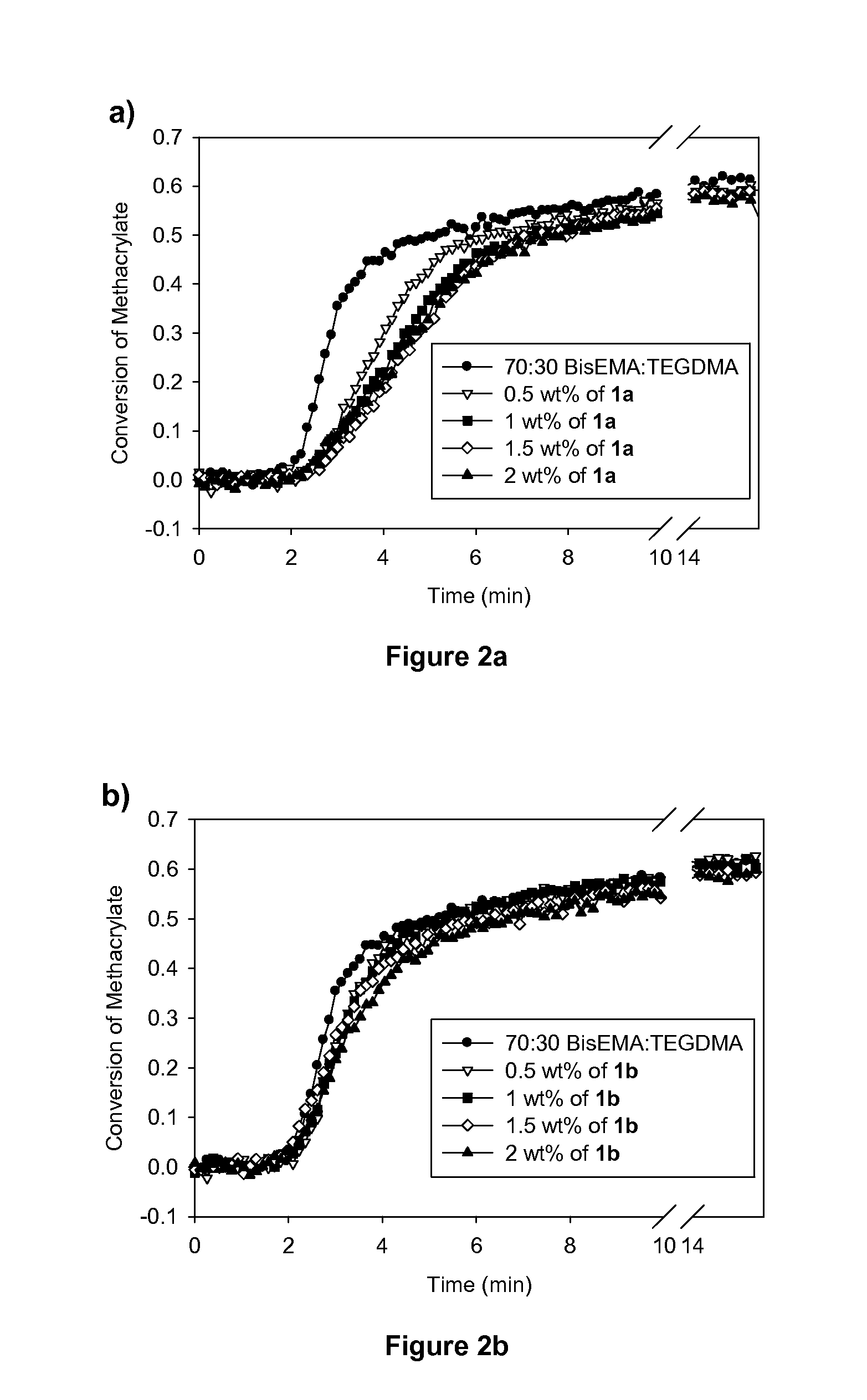

Reducing polymerization-induced shrinkage stress by reversible addition-fragmentation chain transfer

ActiveUS20130096219A1Prevent premature gelationReduce shrinkage stressCross-linkCrosslinked polymers

The invention provides methods of reducing shrinkage stress in cross-linked polymerized materials by combining an addition-fragmentation chain transfer additive with a resin system prior to polymerization. The methods of the invention can improve the performance of conventional resin systems by reducing the shrinkage stress without significantly degrading the mechanical properties of the polymerized material. The shrinkage stress in the crosslinked polymeric materials produced by the methods of the invention may be from 25% to 75% of that of a control material produced by polymerization of the resin system alone to the same conversion.

Owner:UNIV OF COLORADO THE REGENTS OF

Method and device for producing optical material, and an optical waveguide

InactiveUS20060001952A1Improve abilitiesImprove homogeneityLaser detailsMolten spray coatingReaction rateErbium doping

The invention relates to the production of light-amplifying optical material. Liquid reactant is atomized into droplets using a high velocity gas. The droplets are subsequently introduced into a flame. Reactants are oxidized in the flame and condensed by forming small particles. At least a fraction of said particles is collected and fused to form optical waveguide material, which is subsequently drawn to form an optical waveguide. According to the invention, the velocity of the atomizing gas stream is in the order of the velocity of sound. The high velocity enhances atomization and increases reaction rates in the flame. The residence times are reduced to such a degree that unwanted phase transformations in the produced particles are substantially minimized. Consequently, very homogeneous material is produced. Especially, in the production of erbium-doped silica, low percentage of clustered erbium ions is achieved.

Owner:LIEKKI OY

Reactor system and process for the catalytic polymerization of olefins, and the use of such reactor system in catalytic polymerization of olefins

InactiveUS8354483B2Easy to controlReduce gas velocityChemical/physical/physico-chemical stationary reactorsFluidised-bed furnacesReactor systemFluidized bed

The invention relates to a reactor system and process for the catalytic polymerization of olefin monomer and optionally comonomer(s), having one or more inlets for olefin monomer, catalyst, optionally for comonomer, chain growth controllers or chain transfer agents, and / or inert gas, an outlet for gas and an outlet for polymerized particles. The reactor system has at least one fluidized bed unit and at least one moving bed unit, wherein the fluidized bed unit has means for maintaining a fluidized bed in the fluidized bed unit and wherein the moving bed unit is provided with an inlet and an outlet which are connected to the fluidized bed unit, wherein the outlet of the moving bed unit is provided with means for displacing metered quantities of polymerized particles from the moving bed unit into the fluidized bed unit, and to the use of such reactor system.

Owner:BOREALIS TECH OY

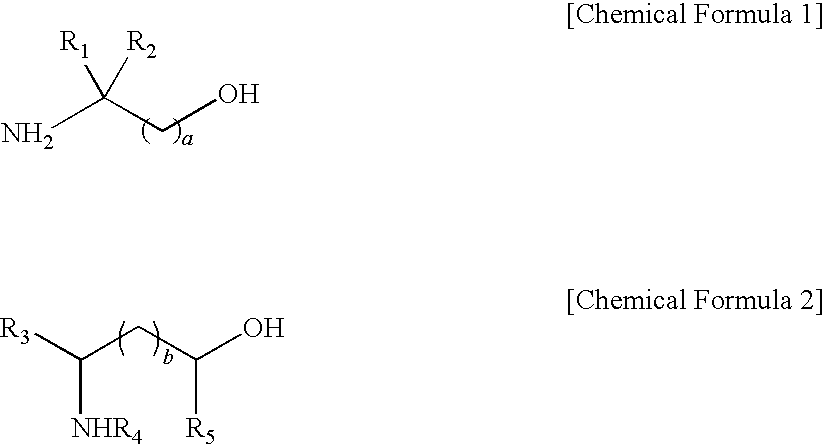

Absorbents for separating acidic gases

ActiveUS20100105551A1Increase response ratePromote absorptionGas treatmentOrganic chemistryDesorptionProduct gas

An absorbent for separating acidic gases is disclosed. The absorbent or an absorbent composition for separating acidic gases has more than 3 kinds of compounds along with Chemical Formula 1 and 2, and has ability of rapid carbon dioxide elimination, excellent absorption ability, and less energy consumption for regenerating an absorbent due to easy desorption of carbon dioxide.

Owner:KOREA ELECTRIC POWER CORP

Metal oxide product suitable for use in dehydrated gas

InactiveUS6126911AIncrease response rateReduce the amount of waterGas treatmentOther chemical processesSystems designSulfur

The present invention relates to the use of metal oxide particles held on carrier particles and moistened with a hygroscopic moistening agent, preferably glycol, with the moistened metal oxide particles used in a system designed to remove sulfur from dehydrated and water under-saturated gas compounds.

Owner:MI

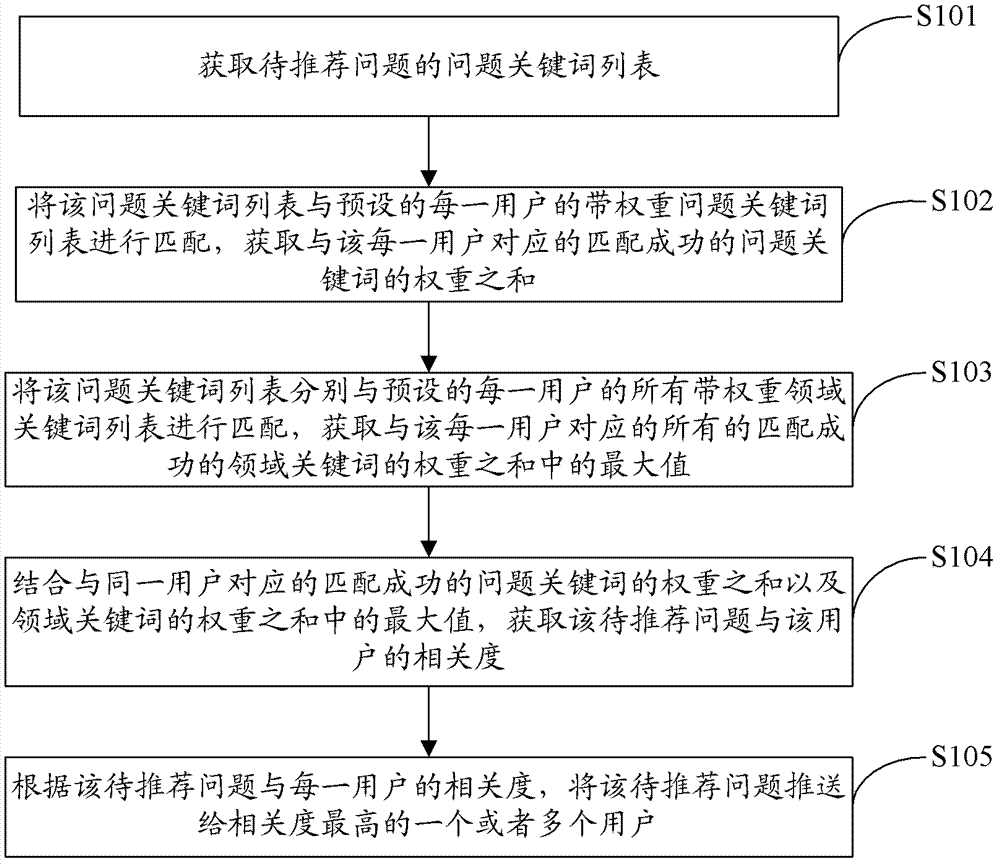

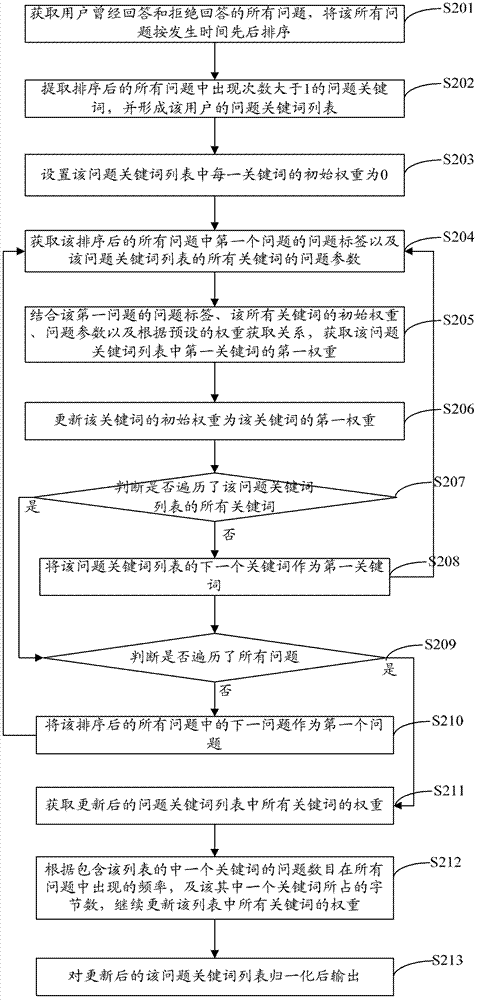

Question recommending method and question recommending system both in questions-and-answers community

ActiveCN103365899AIncrease response rateImprove experienceTransmissionSpecial data processing applicationsMatched fieldQuestions and answers

The invention is applicable to the technical field of internet technology, provides a question recommending method and a question recommending system both in a questions-and-answers community. The method includes the following steps: matching a question keyword list of a to-be-recommended question with a preset weighted question keyword list of each user to acquire a weight sum of successfully-matched question keywords corresponding to each user, matching the question keyword list with preset weighted field keyword lists of each user to acquire a maximum value of a weight sum of successfully-matched field question keywords corresponding to each user, combining the weight sum of the successfully-matched question keywords corresponding to each user and the maximum value of the weight sum of the field question keywords to acquire relevancy of the to-be-recommended question and a user, and pushing the to-be-recommended question to one or more users with highest relevancy to improve answering rate of the users to the questions in the questions-and-answers community and improve user experience effect.

Owner:SHENZHEN SHI JI GUANG SU INFORMATION TECH

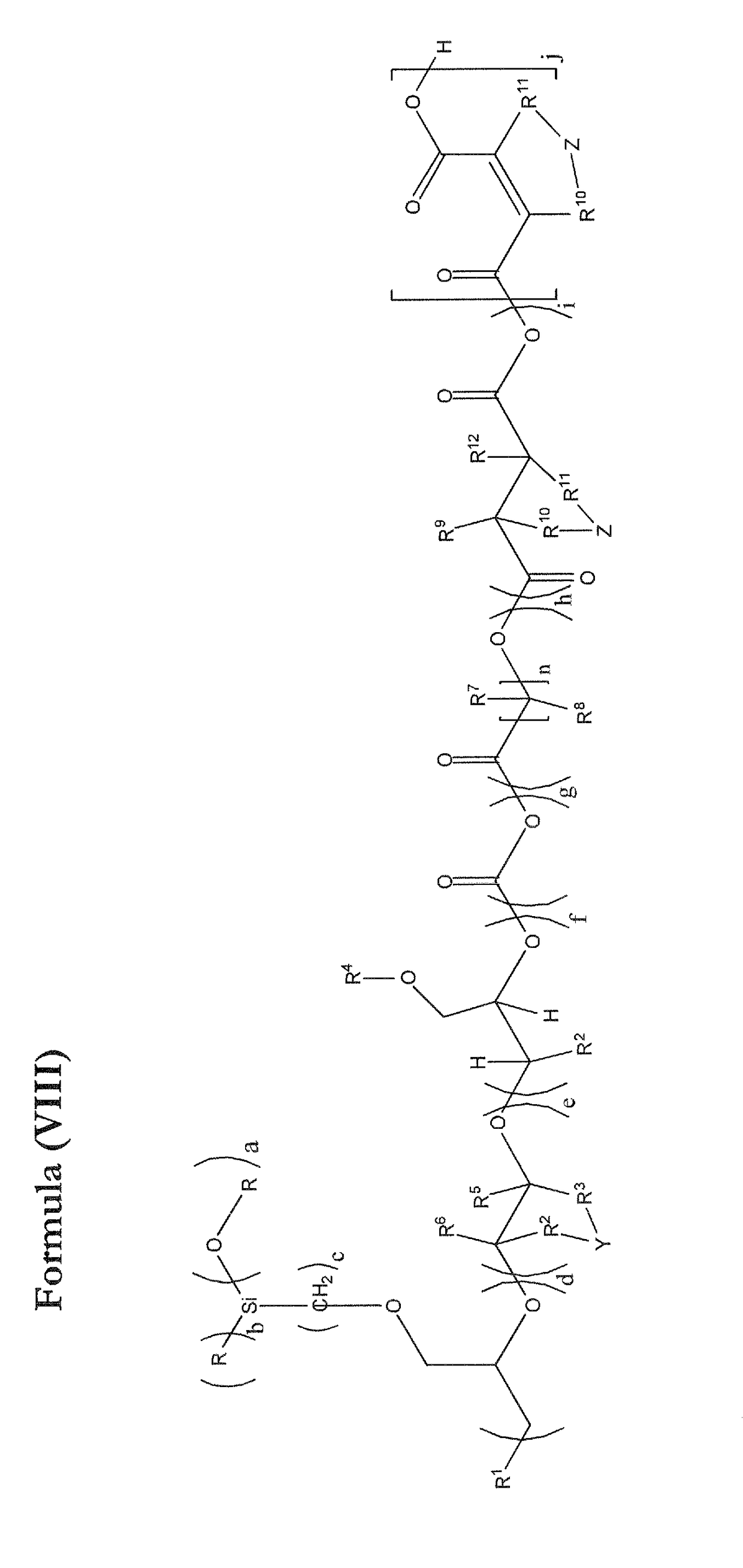

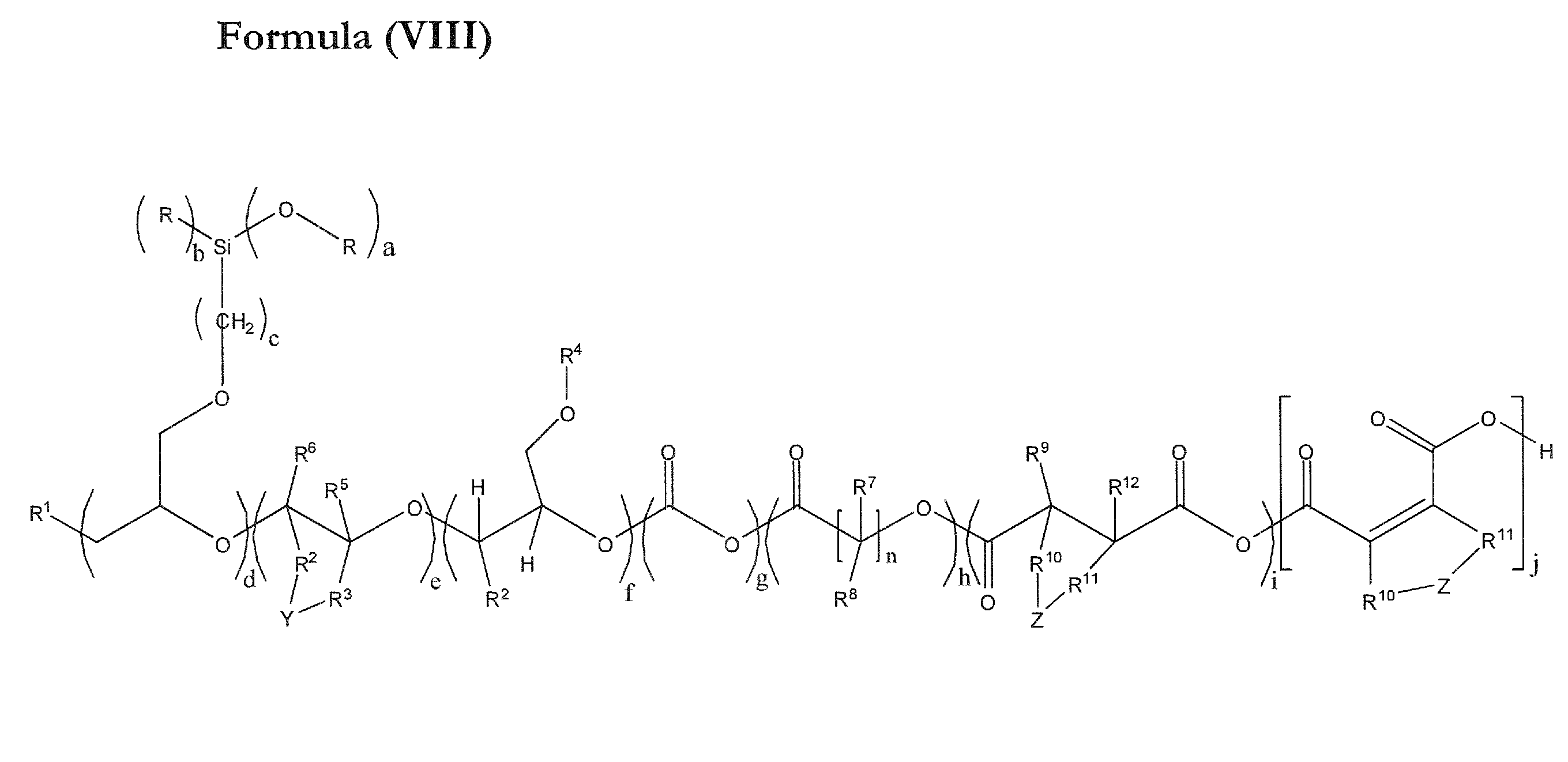

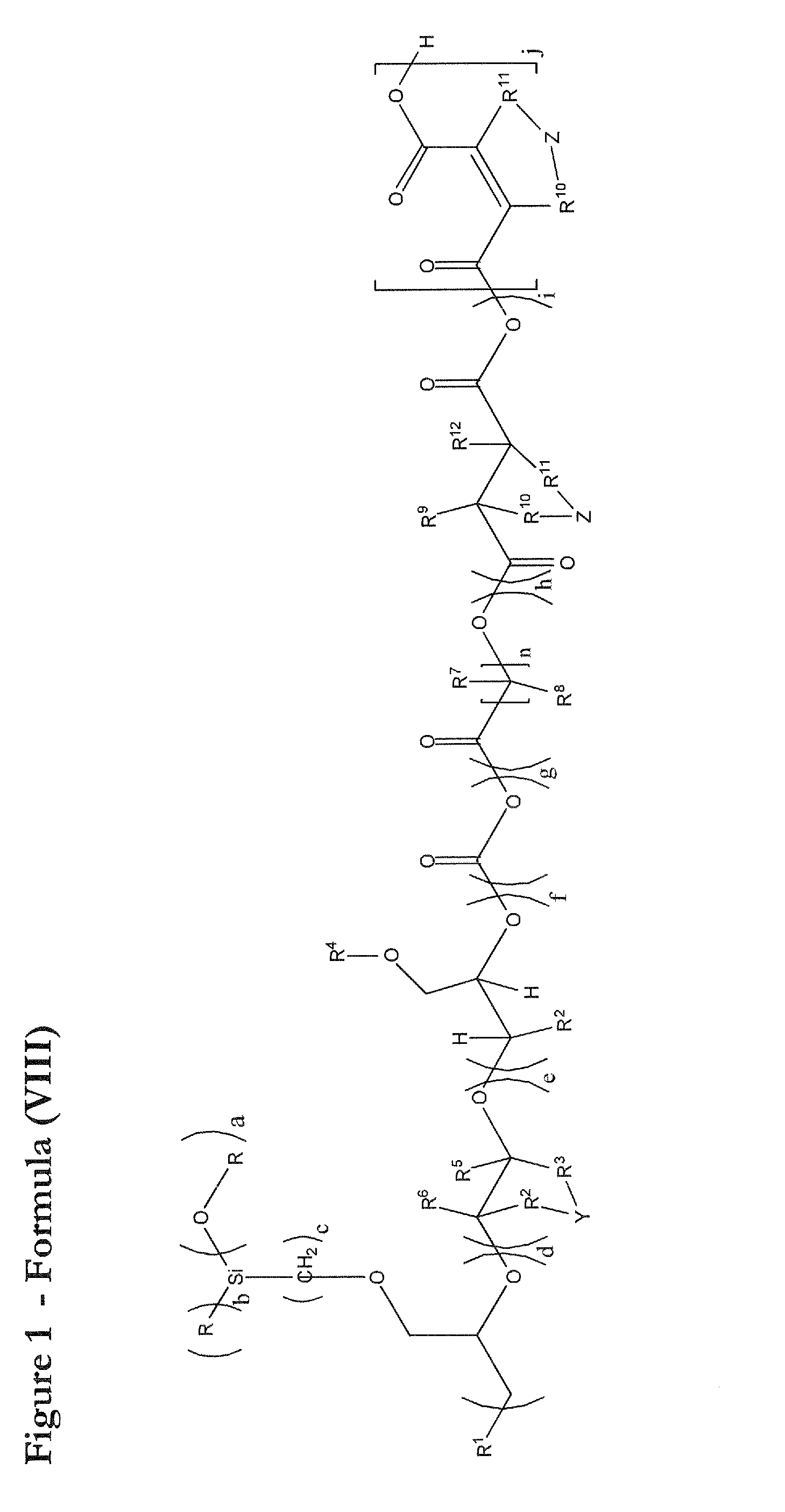

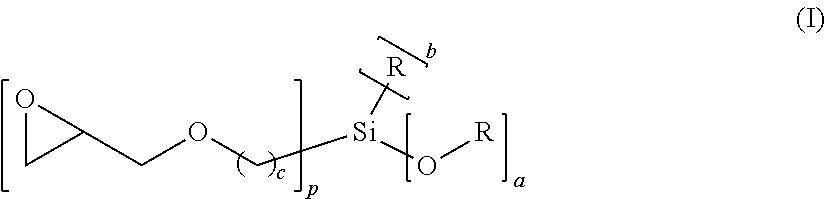

Polyether alcohols bearing alkoxysilyl groups by alkoxylation of epoxy-functional alkoxysilanes over double metal cyanide (DMC) catalysts, and processes for preparation thereof

Owner:EVONIK OPERATIONS GMBH

Novel polyether alcohols bearing alkoxysilyl groups by alkoxylation of epoxy-functional alkoxysilances over double metal cyanide (DMC) catalysts, and processes for preparation thereof

Polyether alcohols having alkoxysilyl groups, the use thereof and a process for their preparation by means of DMC catalysis, characterized in that one or more epoxy-functional alkoxysilanes are added individually or in a mixture with further epoxide compounds and optionally further comonomers, either in block form or in random distribution, onto a chain starter of the formula (VII):R1—H (VII);having at least one reactive hydroxyl group, where R1 is a saturated or unsaturated, optionally branched radical, or a polyether radical of the alkoxy-, arylalkoxy or alkylarylalkoxy group type, in which the carbon chain may be interrupted by oxygen atoms or corresponds to a polyetheralkoxy radical or to a singularly or multiply fused phenolic group.

Owner:EVONIK OPERATIONS GMBH

Method of preparing semiconductor nanocrystal compositions

InactiveUS7850777B2High quantum yieldMore and cheapMaterial nanotechnologyFrom normal temperature solutionsSemiconductor materialsSemiconductor nanocrystals

A semiconductor nanocrystal composition comprising a Group V to VI semiconductor material and a method of making same. The method includes synthesizing a semiconductor nanocrystal core, where the synthesizing includes dissolving a Group V to VI anion gas in a first solvent to produce a Group V to VI anion precursor, preparing a cation precursor, and reacting the Group V to VI anion precursor with the cation precursor in the presence of a second solvent. The reacting may occur in a high pressure vessel.

Owner:EVIDENT TECH

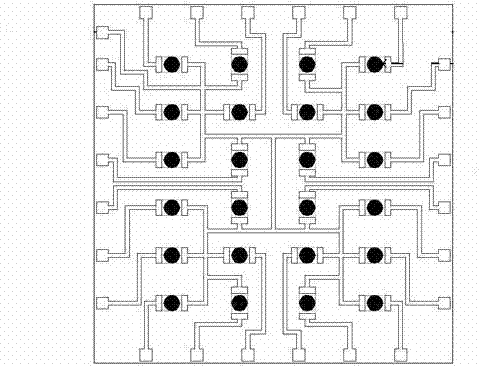

Dielectric Al/CuO composite film energetic electric ignition bridge and ignition bridge array

The invention discloses a dielectric Al / CuO composite film energetic electric ignition bridge and an ignition bridge array. The bridge body of the ignition bridge is formed by overlapping an upper electrode, a lower electrode and a dielectric layer; two layers of metal films with the same size and different directions serve as the upper electrode and the lower electrode; an Al / CuO composite film layer with the same size and direction as the upper electrode metal film is sandwiched between the two layers of metal films to serve as the dielectric layer; partial Al / CuO composite film layer is coated and overlapped on the lower electrode metal film; and the upper electrode metal film is completely coated and overlapped on the Al / CuO composite film layer. In the ignition array taking the dielectric Al / CuO composite film energetic electric ignition bridge as a basic unit, a plurality of dielectric Al / CuO composite film energetic electric ignition bridges are connected through leads preparedfrom Au metal films or Cu metal films to form the ignition array. The invention has the advantages of high safety, high ignition capacity and good compatibility.

Owner:NANJING UNIV OF SCI & TECH

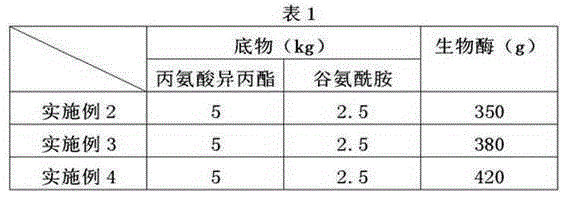

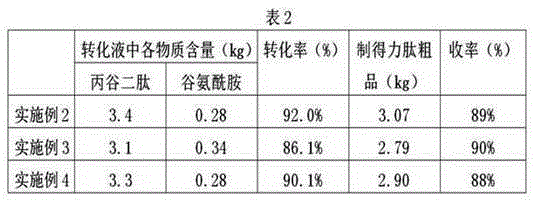

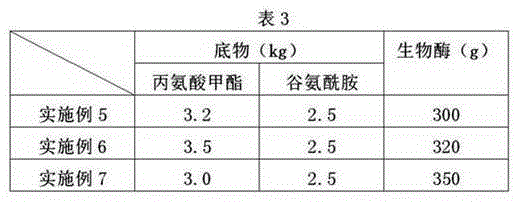

Method for preparing alanyl-glutamine dipeptide through biological enzyme conversion

InactiveCN105274174AHigh activityImprove catalytic conversion effectFermentationTemperature controlReaction rate

The invention relates to the technical field of the preparation for alanyl-glutamine dipeptide and particularly discloses a method for preparing alanyl-glutamine dipeptide through biological enzyme conversion. The method comprises the following steps: 1) preparing a biological enzyme liquid: dissolving the biological enzyme in a buffered liquid, controlling pH value within the scope of 7.0+ / -2.0, controlling the temperature at 5-10 DEG C, thereby acquiring the biological enzyme liquid, wherein the mass fraction of the ester acyl-containing transferring biological enzyme is 5%-20%; 2) dissolving the ester derivates of substrate L-alanine and glutamine in pure water, and then uniformly dropping the biological enzyme liquid into a reaction liquor, and meanwhile, adding acid liquor or alkali liquor, controlling the pH of the reaction liquor at 5-10, reacting under the temperature controlled at 15-25 DEG C, sampling and detecting the production of the alanyl-glutamine dipeptide during the reaction process, stopping reaction when the content of the alanyl-glutamine dipeptide is highest, and separating the acquired converted liquid, thereby acquiring the alanyl-glutamine dipeptide. According to the method provided by the invention, the enzyme activity is high, the reaction rate of the materials is higher, the method has the advantages of simple technique control, easy control on quality index and low cost, and the method is more fit for industrial production.

Owner:JING JING PHARMA

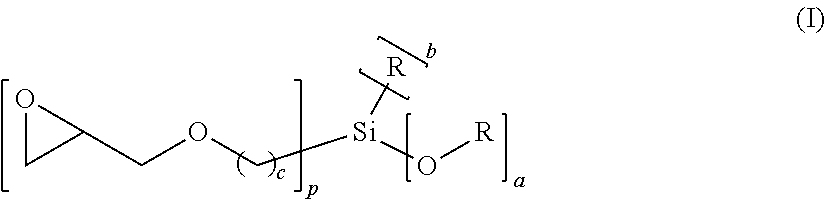

Catalysts for polymerization or copolymerization of alpha-olefins, catalyst components thereof, and processes for polymerization of alpha-olefins with the catalysts

InactiveUS20050202958A1Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenOlefin polymerization

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38: Si(OR1)3(NR2R3) Formula 37 (where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms) RNSi(OR1)3 Formula 38 (where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com