Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

266 results about "Low temperature combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature combustion. Low temperature combustion (LTC) is a flameless, staged burning of the fuel (gasoline, diesel, or biofuel) in an engine's combustion chamber at temperatures that are lower than what occurs during conventional engine combustion.

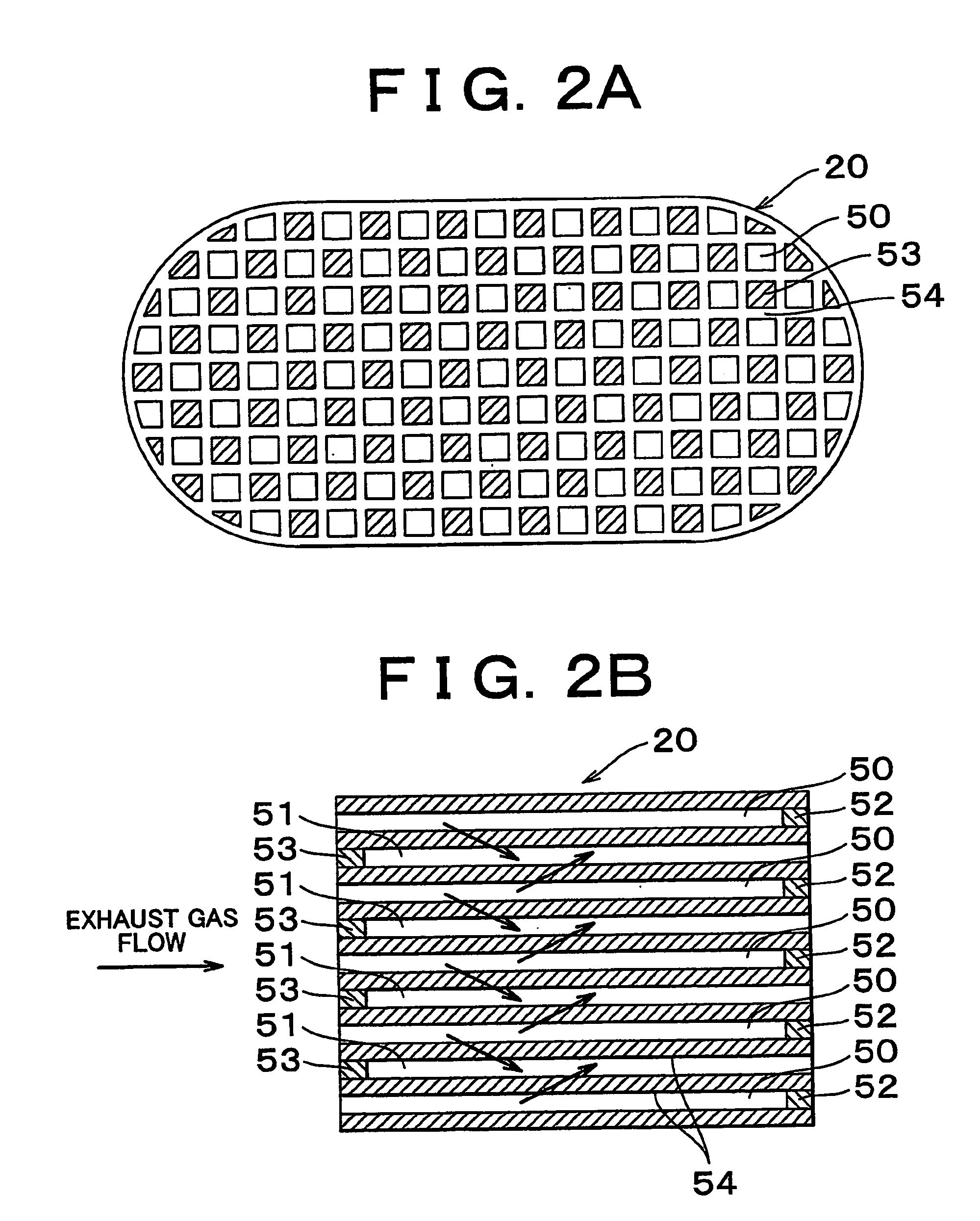

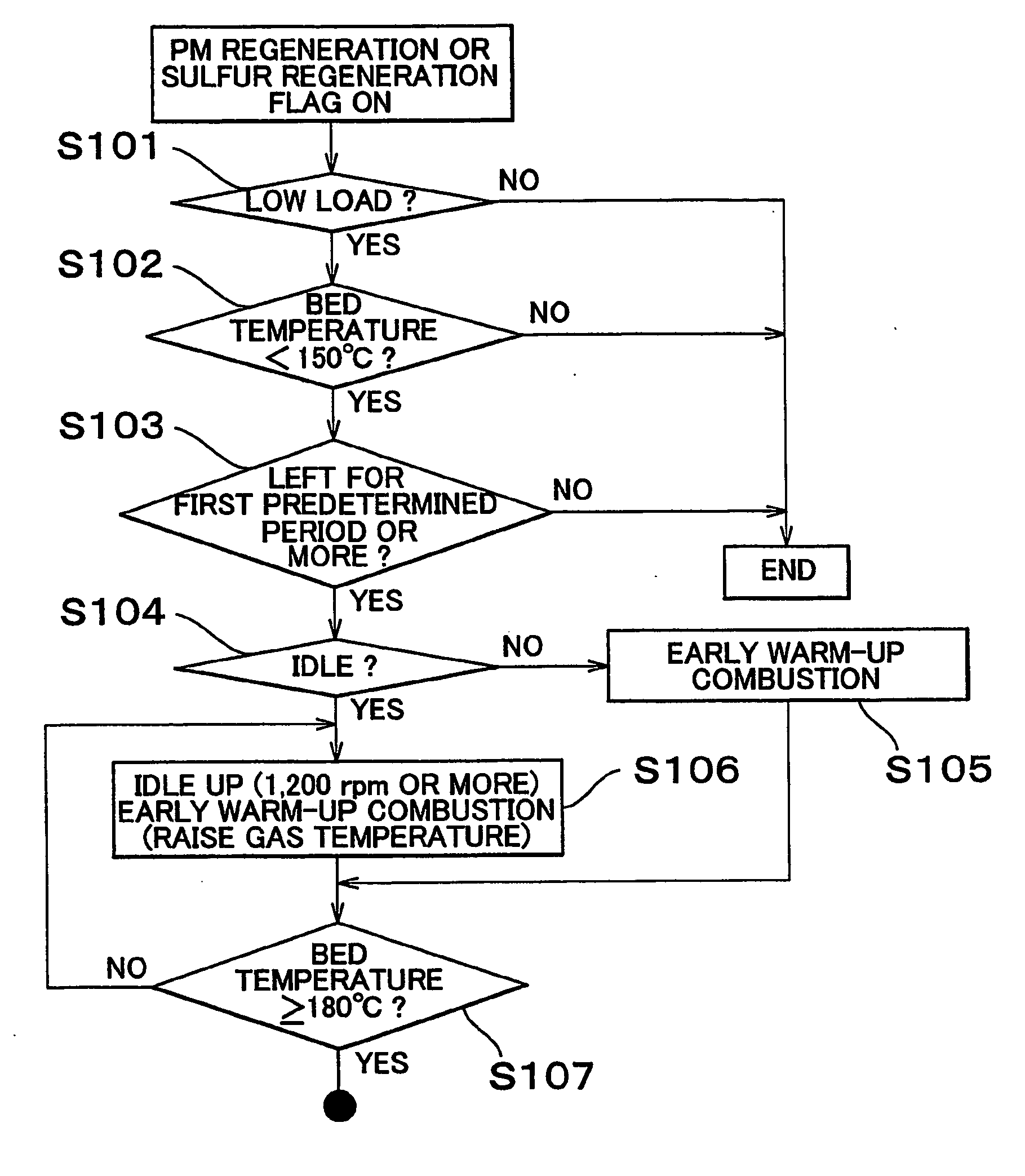

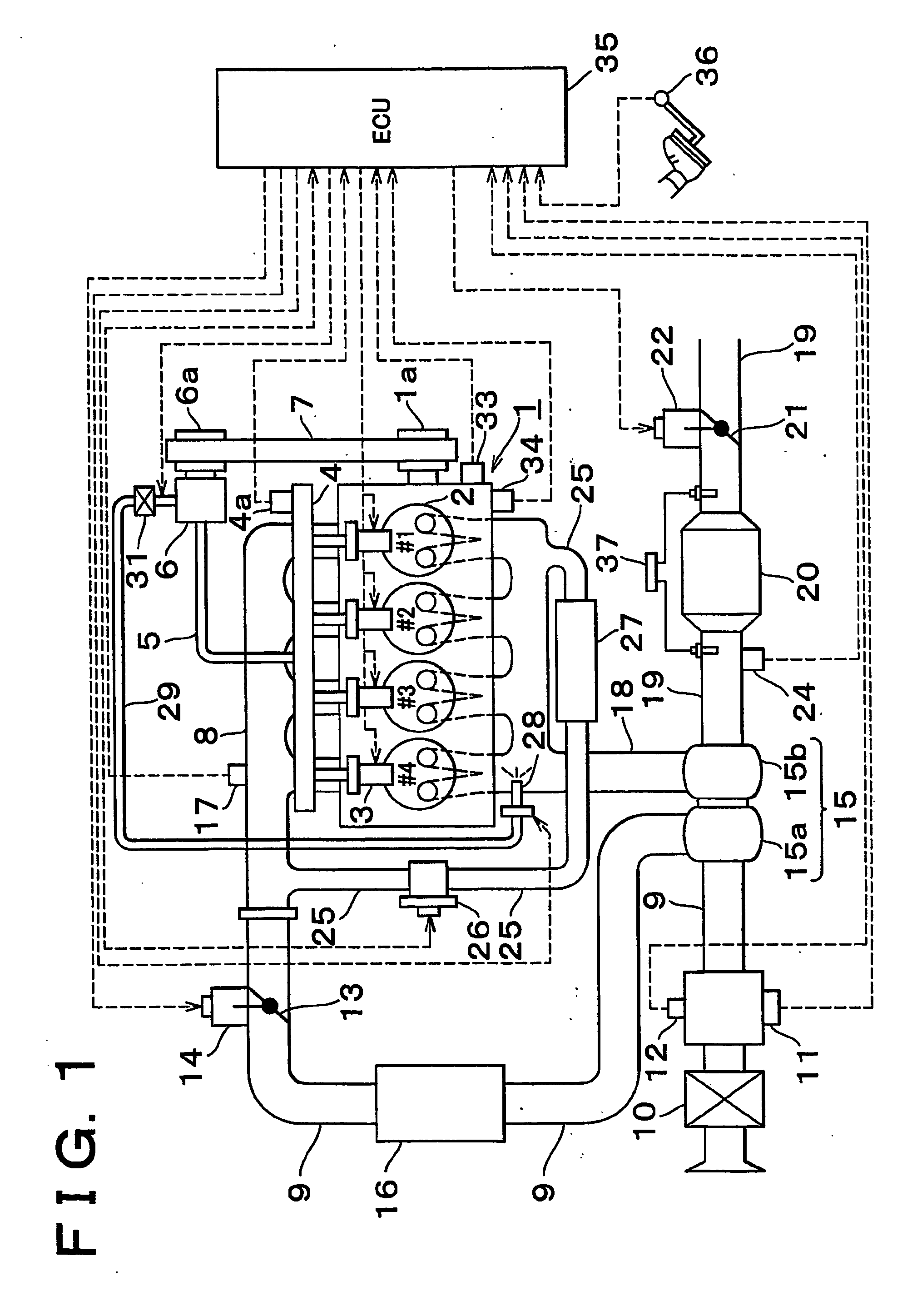

Exhaust gas purifying device and method for internal combustion engine

Removal of fine particles by oxidation or / and sulfur poisoning recovery control may be required when an internal combustion engine has been in an extremely low load state for a predetermined period or more. In this case, the engine speed of the internal combustion engine (1) is adjusted to a range where the temperature of a filter (20) can be raised by heat-up control. The heat-up control is then executed by a filter temperature control means to raise the temperature of the filter (20) to a predetermined value. When the filter (20) reaches the predetermined temperature by means of low-temperature combustion, post-injection, VIGOM-injection, addition of 10 fuel to an exhaust system and the like, removal of fine particles by oxidation or / and sulfur poisoning recovery control for eliminating sulfur poisoning of a NOx absorbent are conducted. Removal of PMs captured by the filter and sulfur poisoning recovery control of the NOx absorbent can thus be conducted even if the internal combustion engine is left in an extremely low load operational state.

Owner:TOYOTA JIDOSHA KK

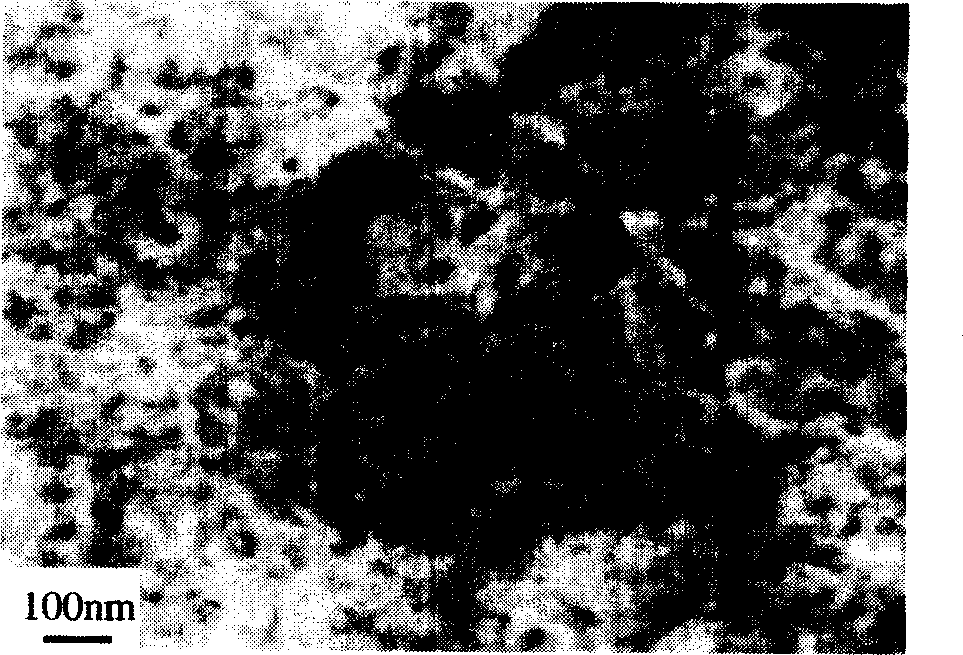

Catalytic filter for removing soot particulates from diesel engine exhaust and method of preparing the same

Owner:SK ENERGY CO LTD (KR)

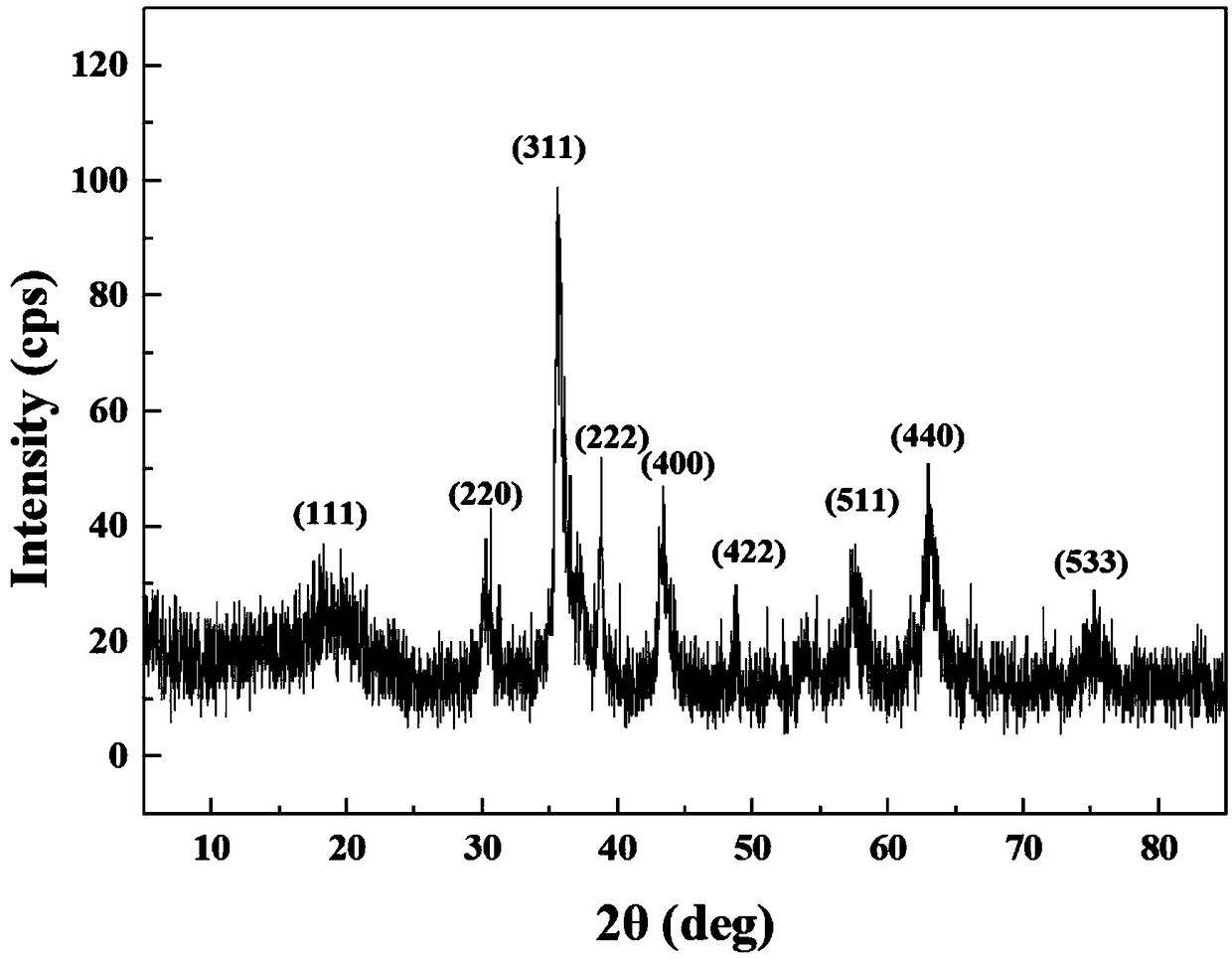

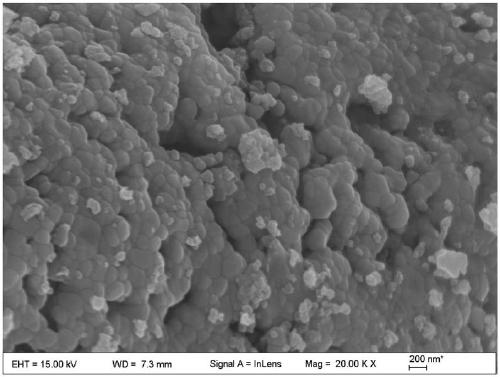

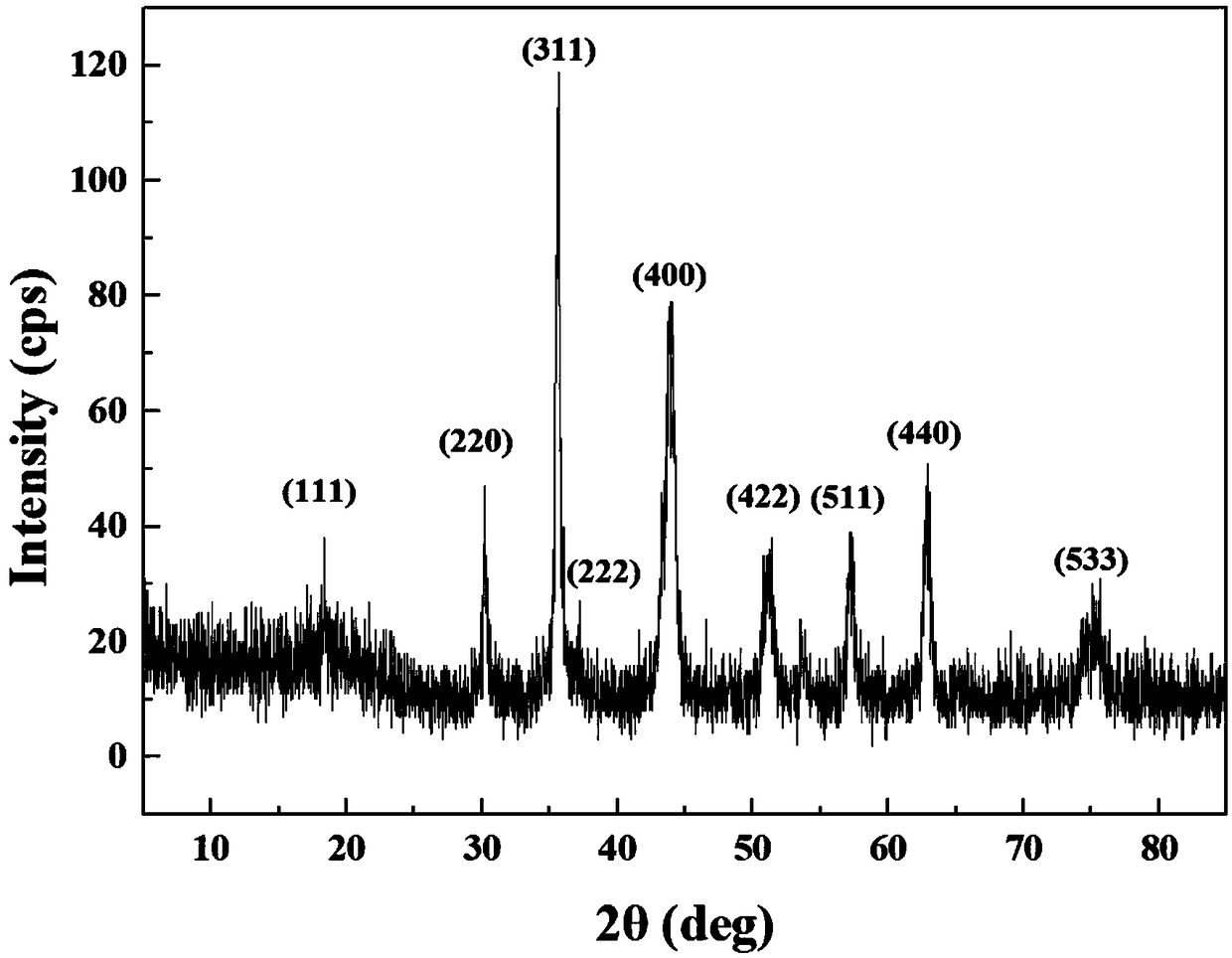

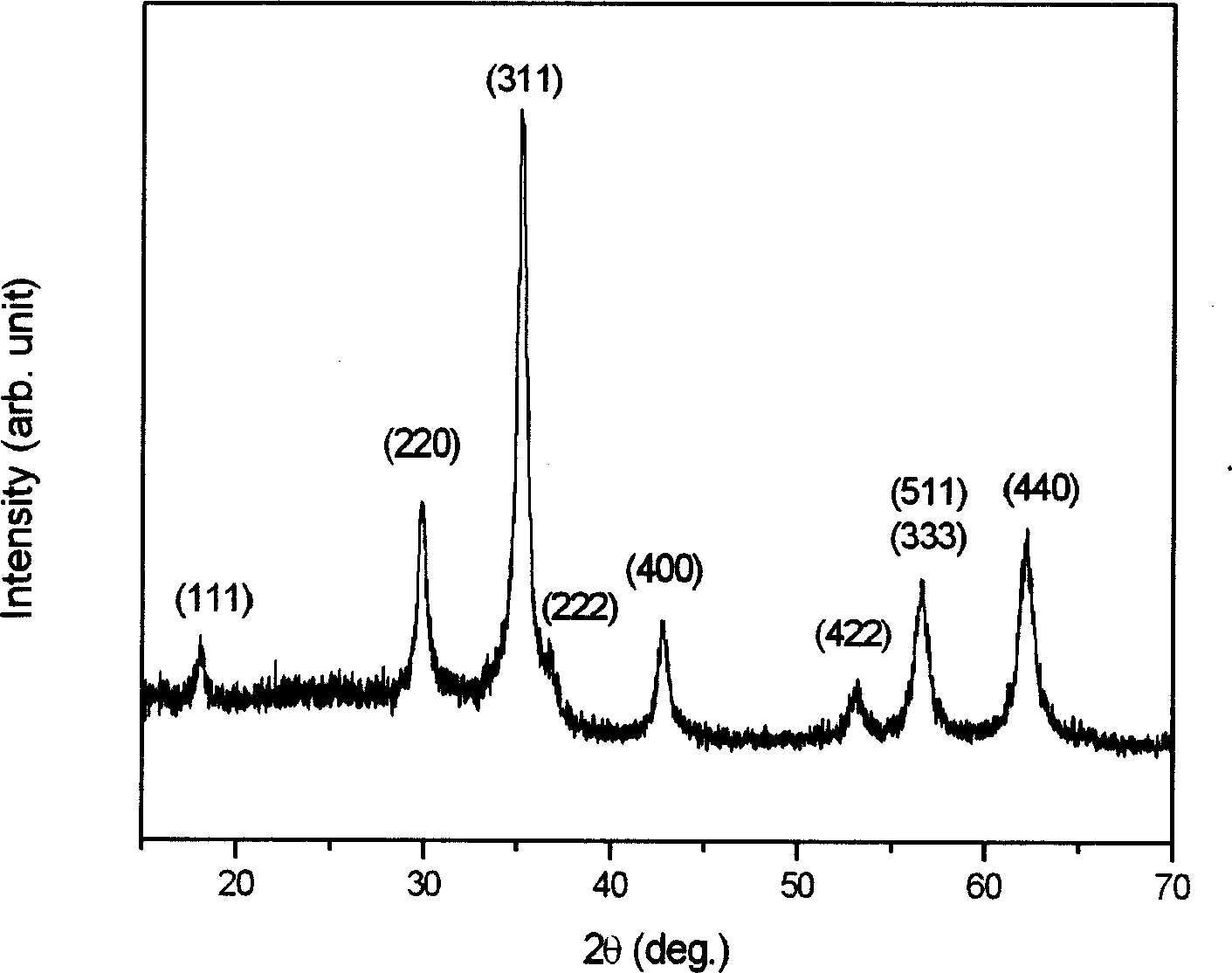

Preparation method of lithium ion battery negative electrode material spinel porous high-entropy oxide material

ActiveCN109052491AGood dispersionGood chemical uniformityChemical industryNegative electrodesAdditive ingredientSynthesis methods

The invention discloses a preparation method of a lithium ion battery negative electrode material spinel porous high-entropy oxide material, and belongs to the field of inorganic oxide powder materials. The method is a low-temperature combustion synthesis method, and specifically includes the steps that metal nitrate is adopted as a metal source, one or a mixture of several of tartaric acid, citric acid, glucose, hexamine and ethylenediaminetetraacetic acid is used as a fuel, and by controlling the concentration of the metal salt raw material, the kind and the amount of the fuel, the kind andthe amount of a combustion improver and an ignition mode, characteristics of the grain size, the shape and the like of spinel ransition metal high-entropy oxide nano-powder are adjusted and controlled. According to the preparation method of the lithium ion battery negative electrode material spinel porous high-entropy oxide material, liquid-phase ingredients are adopted, molecular-level even mixing of the raw materials is ensured, and a stoichiometric ratio of the product is achieved; meanwhile the preparation method of the lithium ion battery negative electrode material spinel porous high-entropy oxide material has the advantages of being energy-saving, high in production efficiency, environmentally friendly, free from complex post-treatment and the like, and the prepared high-entropy oxide powder is high in purity, small in grain size and even in distribution, and has high initial discharge capacity and good cycle performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

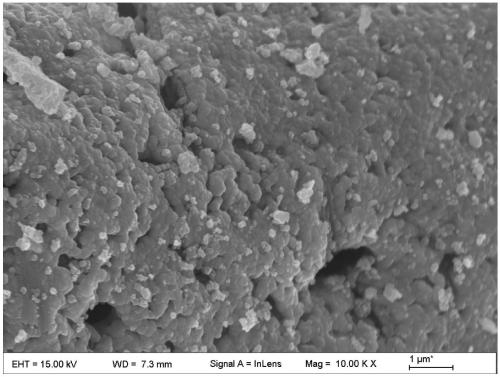

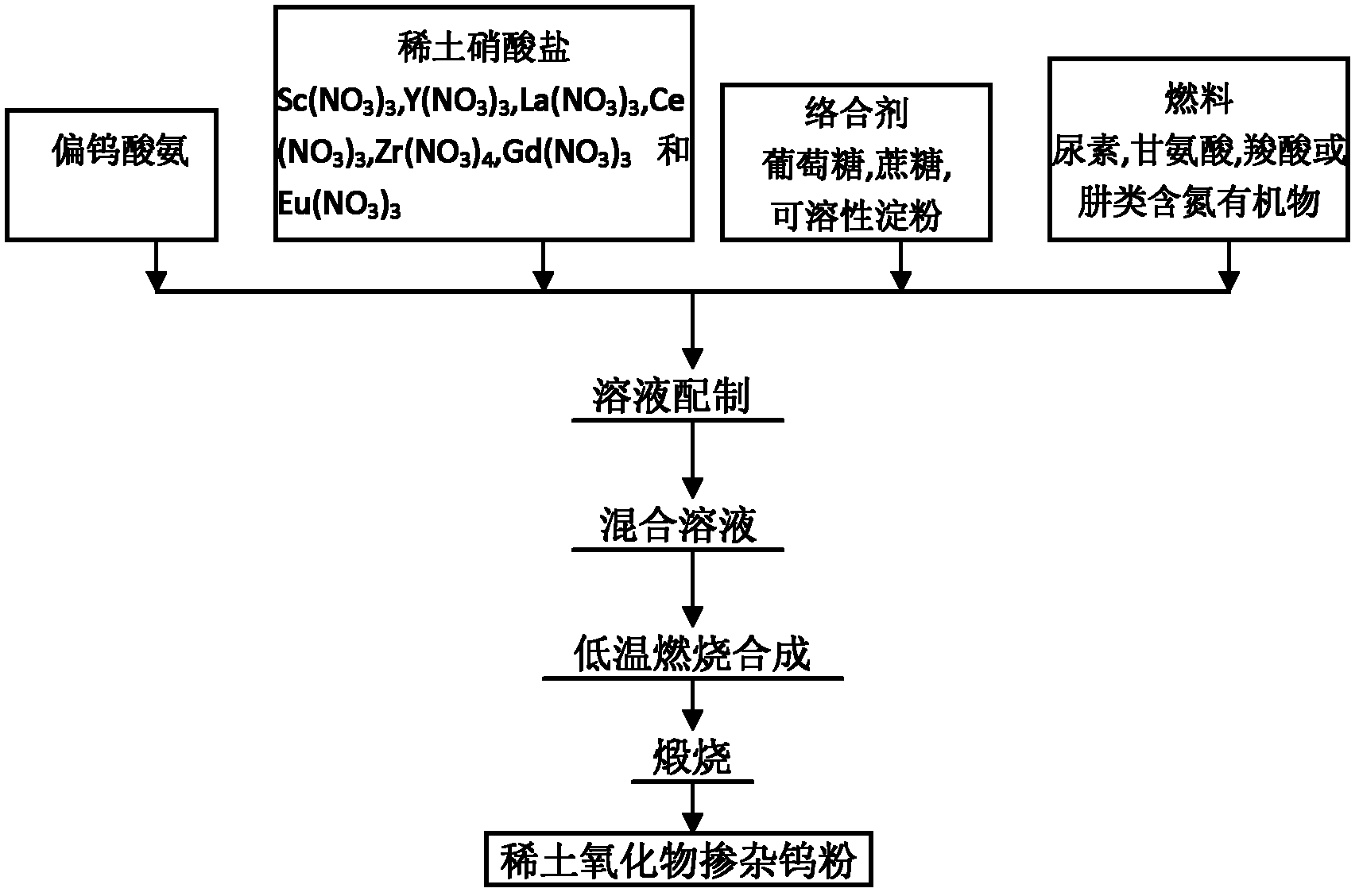

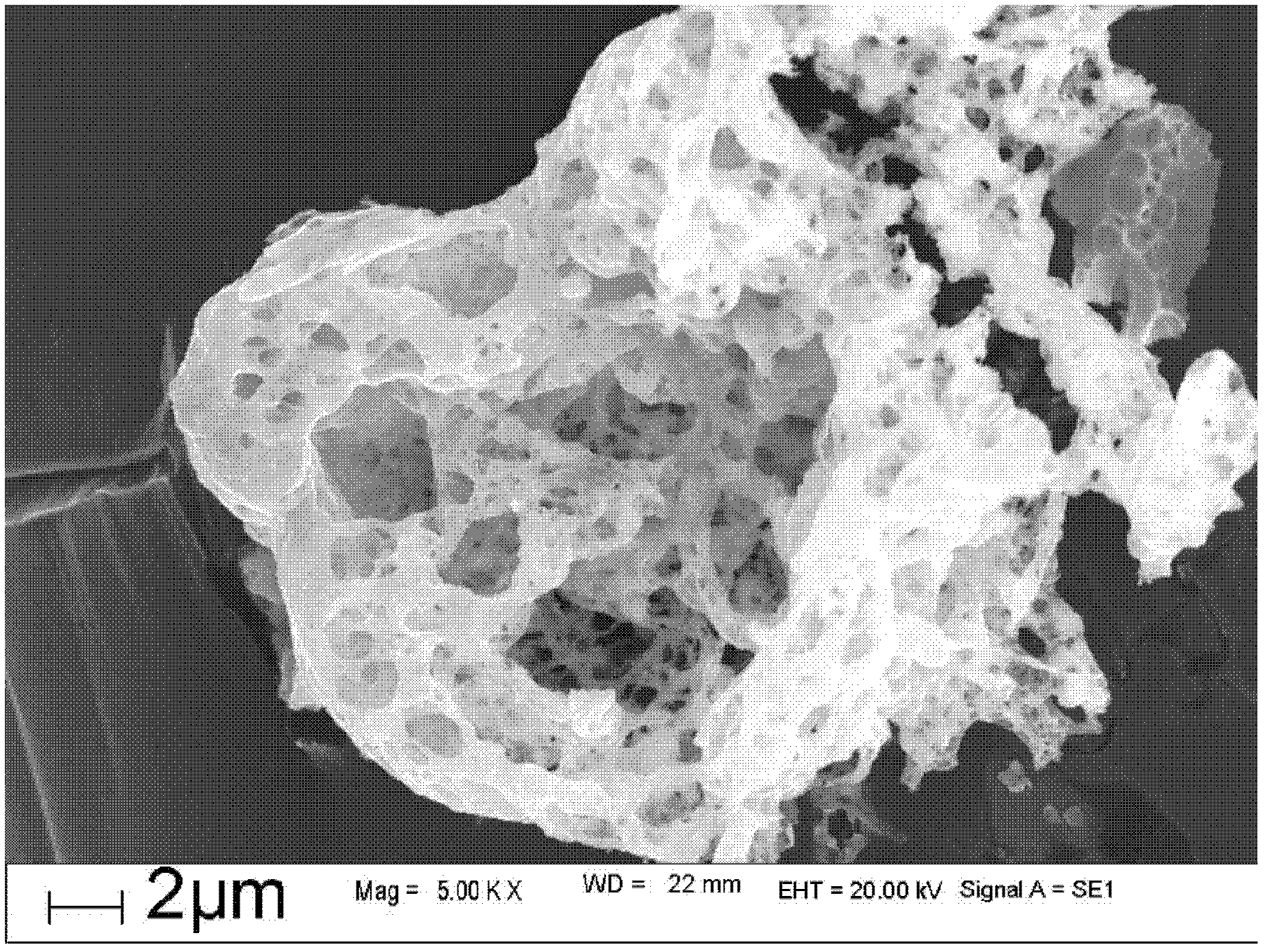

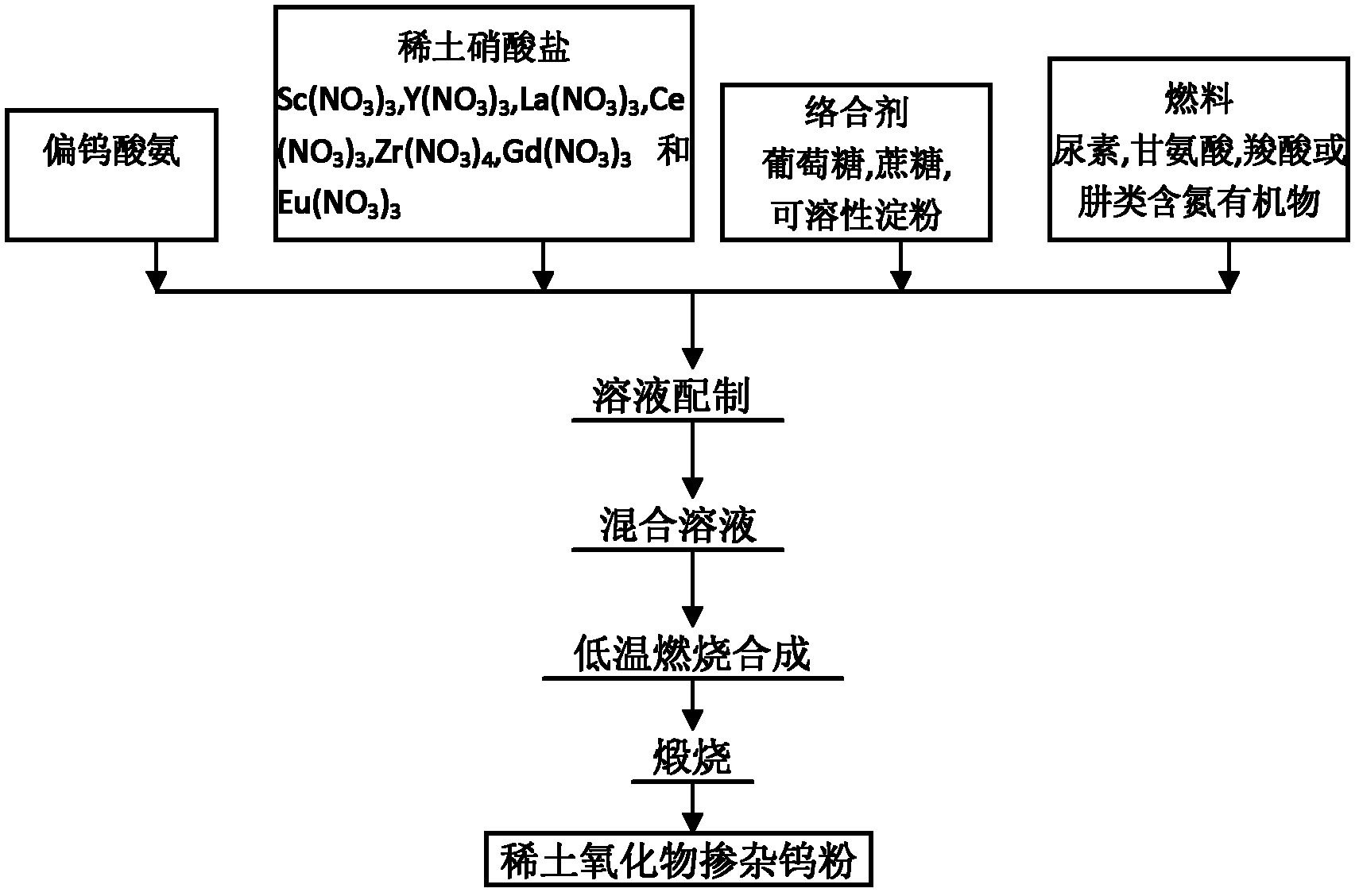

Preparation method for rare earth oxide doped tungsten powder

The invention provides a preparation method of rare earth oxide doped tungsten powder, belonging to a technical field of rare earth refractory metal material. The process flow is that: firstly, a precursor powder is obtained by adopting low-temperature combustion synthesis, wherein the precursor powder is a uniform mixture of rare earth oxide (at least one of Sc2O3, Y2O3, La2O3, CeO2, ZrO2, Gd2O3and Eu2O3) and tungsten oxide; secondly, the precursor powder undergoes calcination in a muffle furnace; lastly, two-step reduction is carried out in the atmosphere of hydrogen or dissociated ammonia. Easy-reduction tungsten oxide is reduced to tungsten matrix powder, and the rare earth oxide that can not be reduced is reserved, thereby the rare earth oxide doped tungsten powder is obtained. The content of the rare earth oxide in the rare earth oxide doped tungsten powder is 0.05-35 wt%. The advantage of the invention is that target element and organic carbon source are capable of forming a highly dispersed system, and particle sizes of the obtained oxide are uniform and fine. The method is suitable for industrialization production because of low cost of raw materials, quick reaction speed, low energy consumption and simple technology.

Owner:UNIV OF SCI & TECH BEIJING

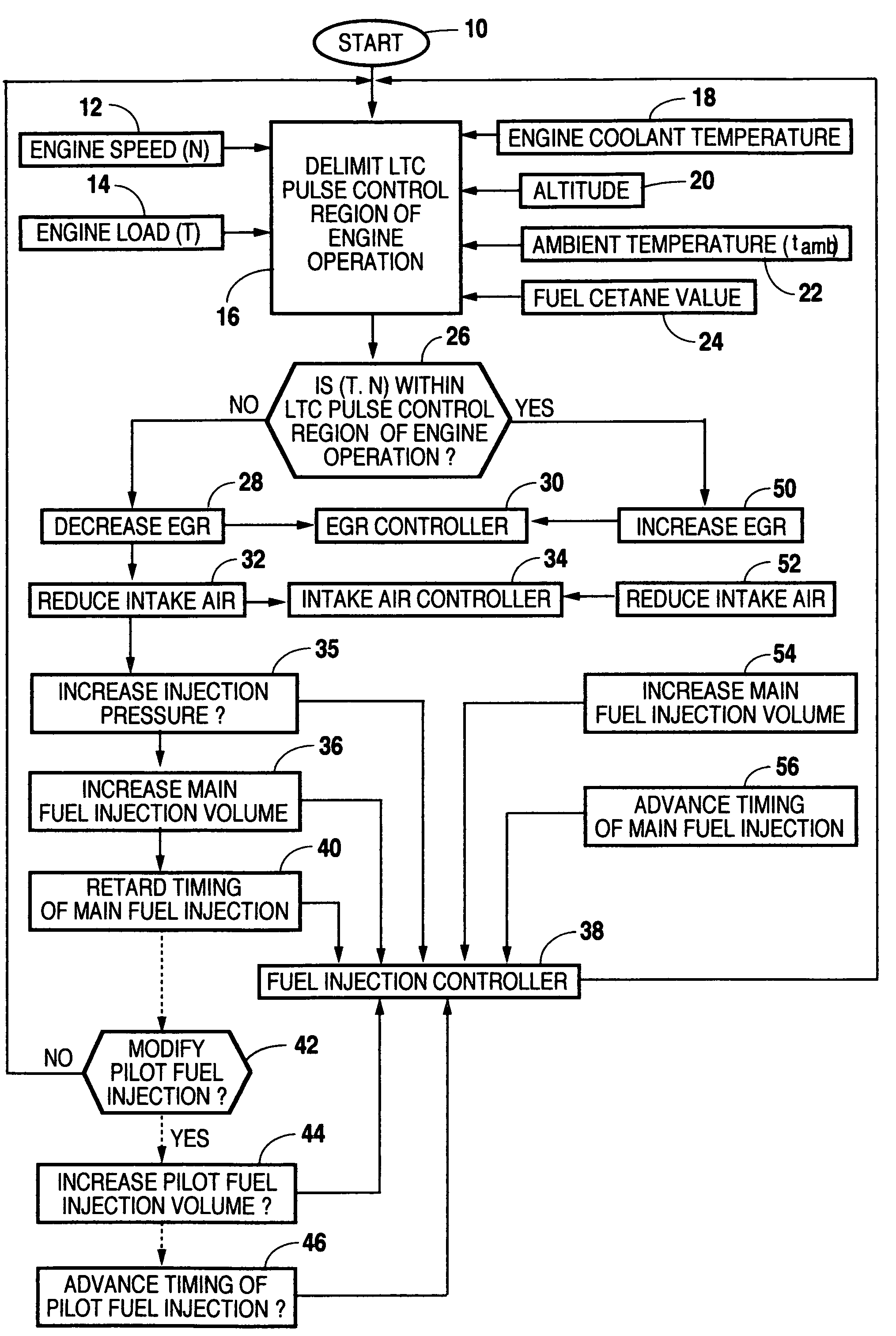

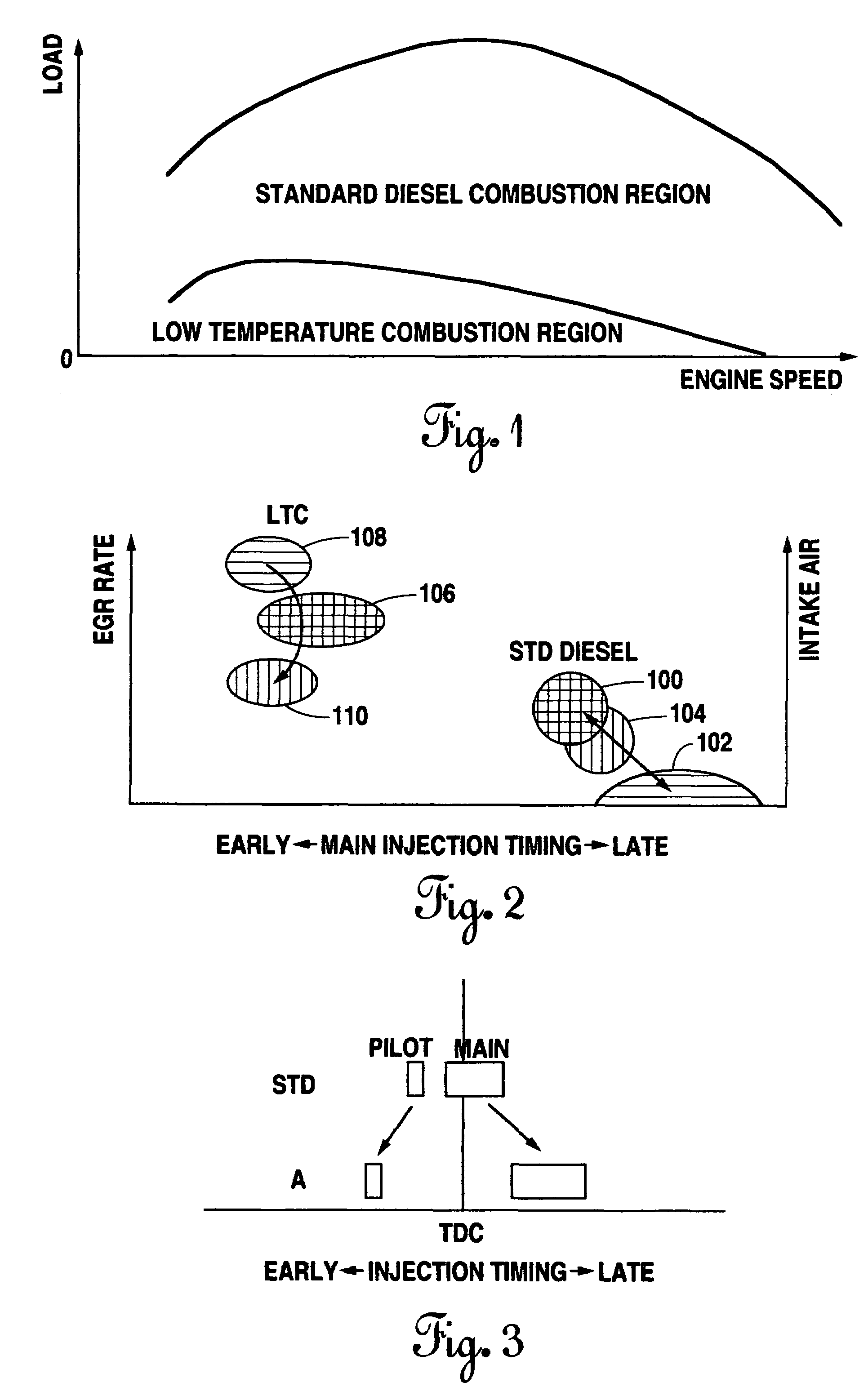

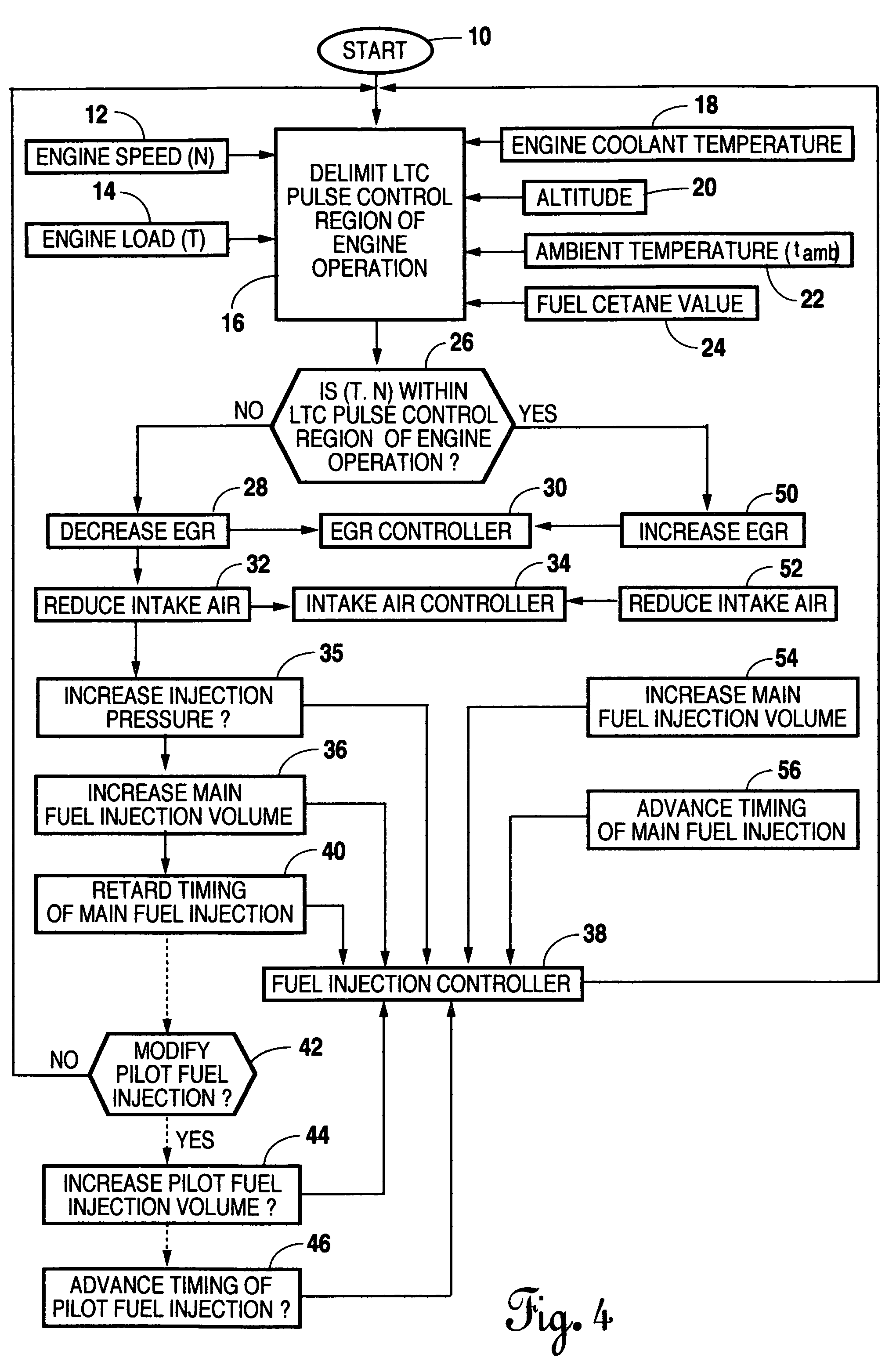

Method for rich pulse control of diesel engines

ActiveUS7137379B2Increased recirculationIntake air is reducedElectrical controlInternal combustion piston enginesPulse controlLow load

A combustion control method for the rich pulse control of Diesel engines with Lean NOX Trap systems includes identifying areas within a Diesel engine operating regime in which reduced recirculated exhaust gas and air with increased pre-mixed combustion is effective in providing fuel rich combustion, and a second, lower load, region in which low temperature combustion is particularly desirable.

Owner:SOUTHWEST RES INST

Preparation method of spinel-type porous high entropy oxide material

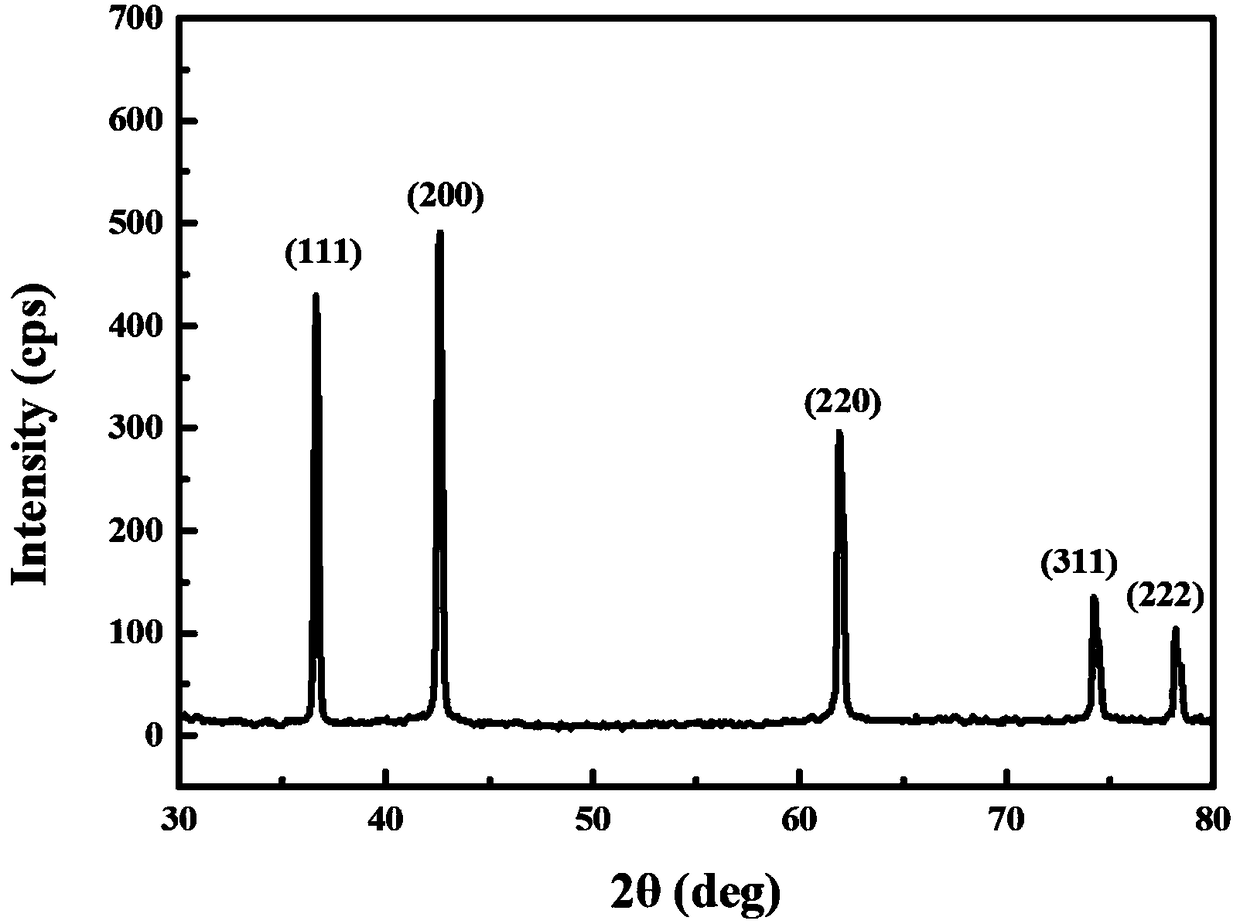

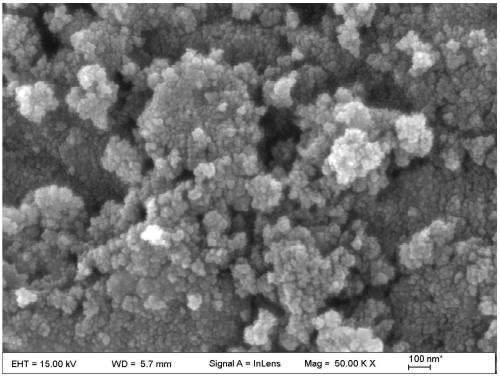

ActiveCN108821351AAchieving a stoichiometric ratioReduce energy consumptionMaterial nanotechnologyNickel compoundsHexamethylenetetramineSynthesis methods

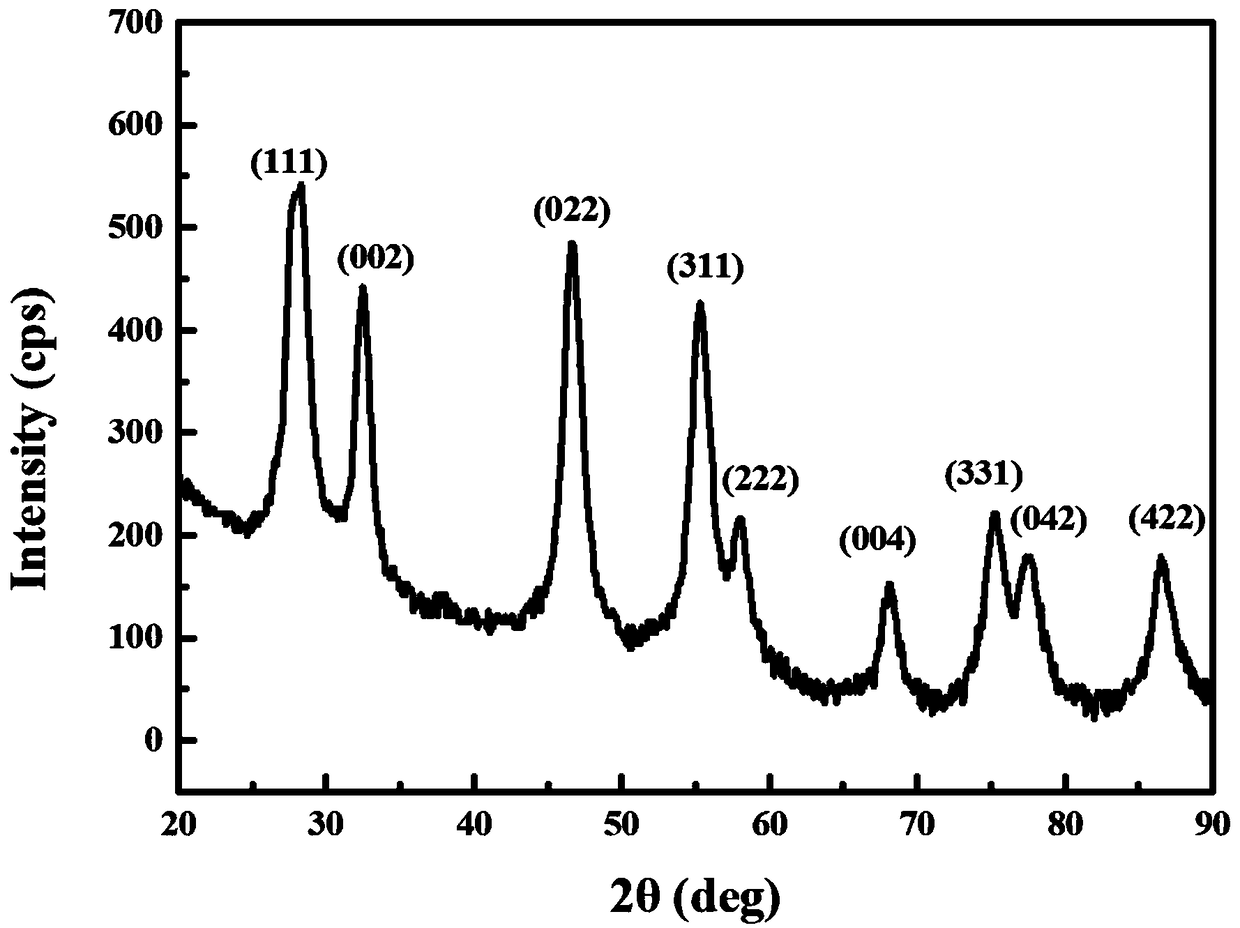

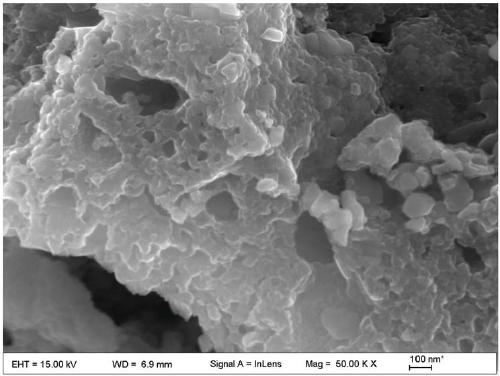

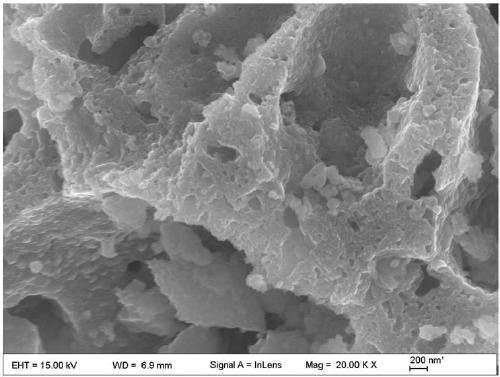

Belonging to the field of inorganic oxide powder materials, the invention discloses a preparation method of a spinel-type porous high entropy oxide material. The method is low temperature combustion synthesis method. Specifically, a metal nitrate is adopted as the metal source, one of or a mixture of several of citric acid, ethylenediamine tetraacetic acid, hexamethylenetetramine and glucose is adopted as the fuel, by controlling the concentration of the metal salt raw materials, the fuel type and adding amount, the combustion improver type and adding amount, and the ignition way, the granularity, morphology and other characteristics of the spinel-type transition metal high entropy oxide (CoCrFeMnNi)3O4 nanopowder can be regulated. The preparation method adopts liquid phase compounding toensure molecular level uniform mixing of the raw materials, and the product achieves stoichiometric ratio. At the same time, the method has the advantages of energy saving, high production efficiency,green and environmental protection, no need for complicated post-treatment and the like. The high entropy oxide powder prepared by the method provided by the invention has high purity and uniform particle size distribution.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Exhaust gas purifying device and method for internal combustion engine

InactiveUS20040261401A1Electrical controlNon-fuel substance addition to fuelTemperature controlLow load

Removal of fine particles by oxidation or / and sulfur poisoning recovery control may be required when an internal combustion engine has been in an extremely low load state for a predetermined period or more. In this case, the engine speed of the internal combustion engine (1) is adjusted to a range where the temperature of a filter (20) can be raised by heat-up control. The heat-up control is then executed by a filter temperature control means to raise the temperature of the filter (20) to a predetermined value. When the filter (20) reaches the predetermined temperature by means of low-temperature combustion, post-injection, VIGOM-injection, addition of 10 fuel to an exhaust system and the like, removal of fine particles by oxidation or / and sulfur poisoning recovery control for eliminating sulfur poisoning of a NOx absorbent are conducted. Removal of PMs captured by the filter and sulfur poisoning recovery control of the NOx absorbent can thus be conducted even if the internal combustion engine is left in an extremely low load operational state.

Owner:TOYOTA JIDOSHA KK

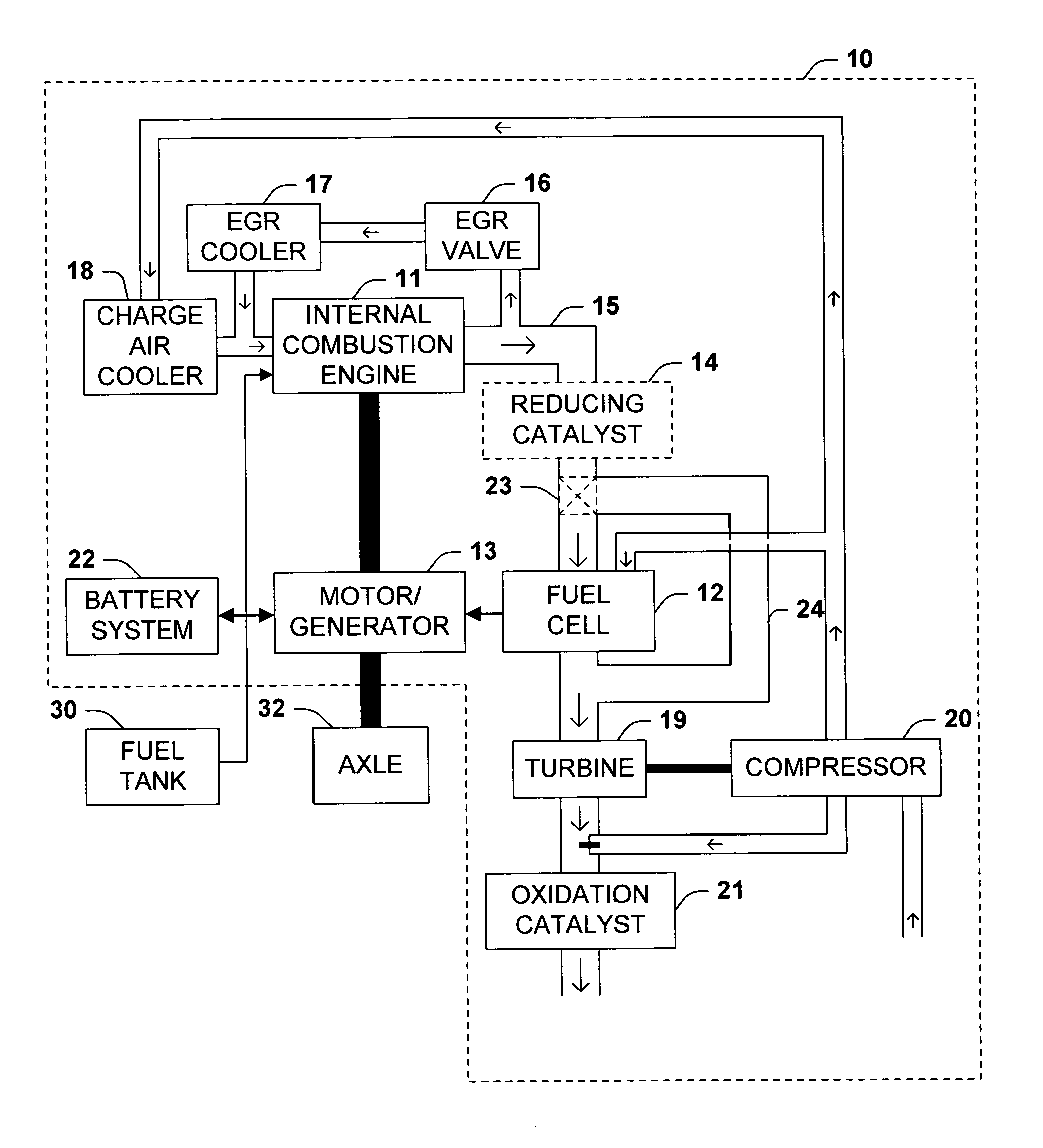

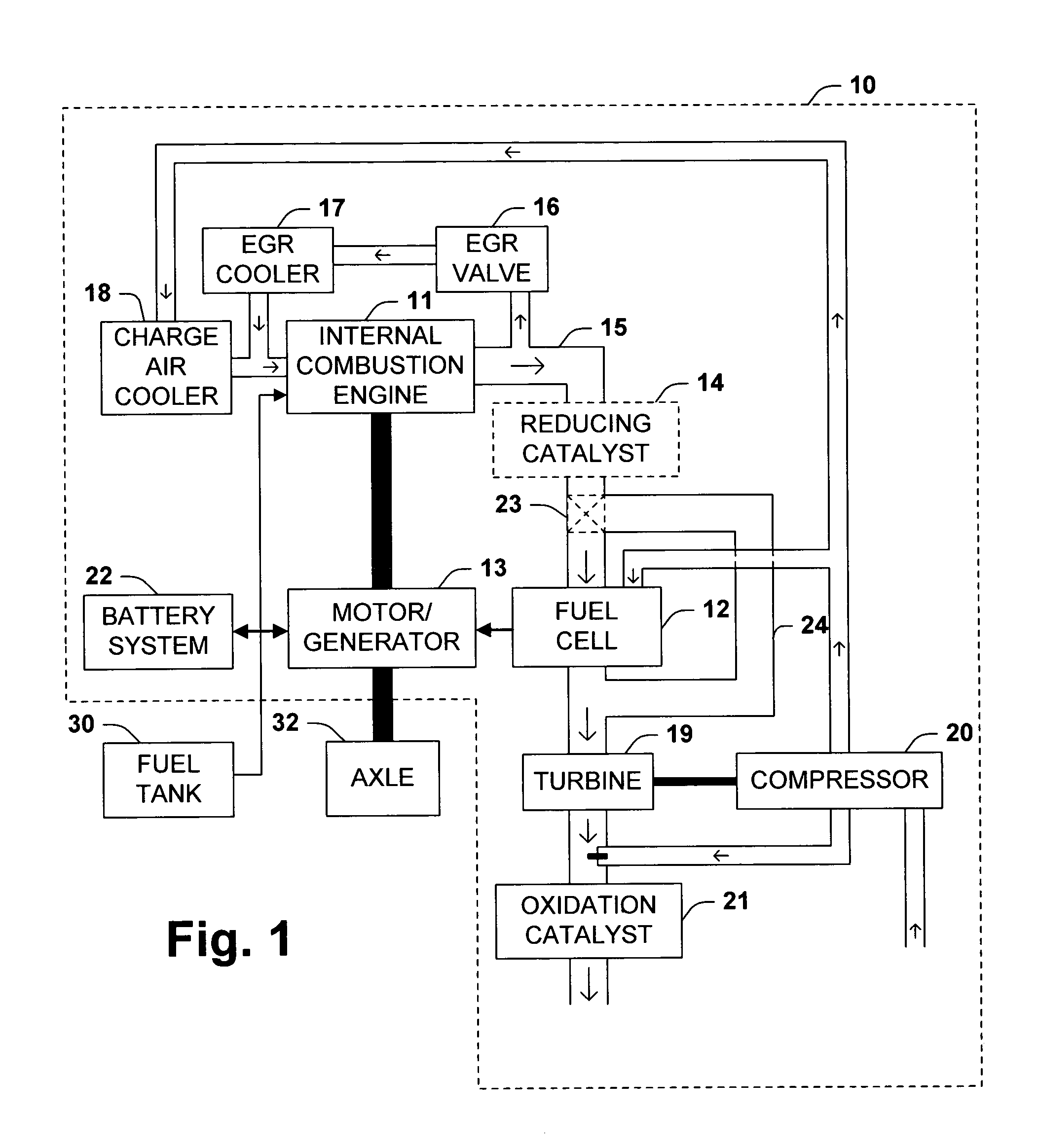

Clean power system

ActiveUS7818959B2Exhaust apparatusFinal product manufactureSimple Organic CompoundsElectric power system

One aspect of the invention relates to a power generation system that has an internal combustion engine that operates in a low temperature combustion mode to produce an engine exhaust that is low in NOx and particulate matter. The exhaust is treated by a fuel cell to remove organic compounds and CO while producing useful power. Another aspect of the invention relates to controlling the adiabatic flame temperature by EGR drawing from upstream of the fuel cell. A further aspect of the invention relates to treating engine exhaust with a reducing catalyst and then with a fuel cell. A still further aspect of the invention relates to treating exhaust with an intermediate temperature solid oxide fuel cell. A further aspect of the invention relates to a system equipped with a valve allowing exhaust to selectively bypass a fuel cell.

Owner:EATON INTELLIGENT POWER LTD

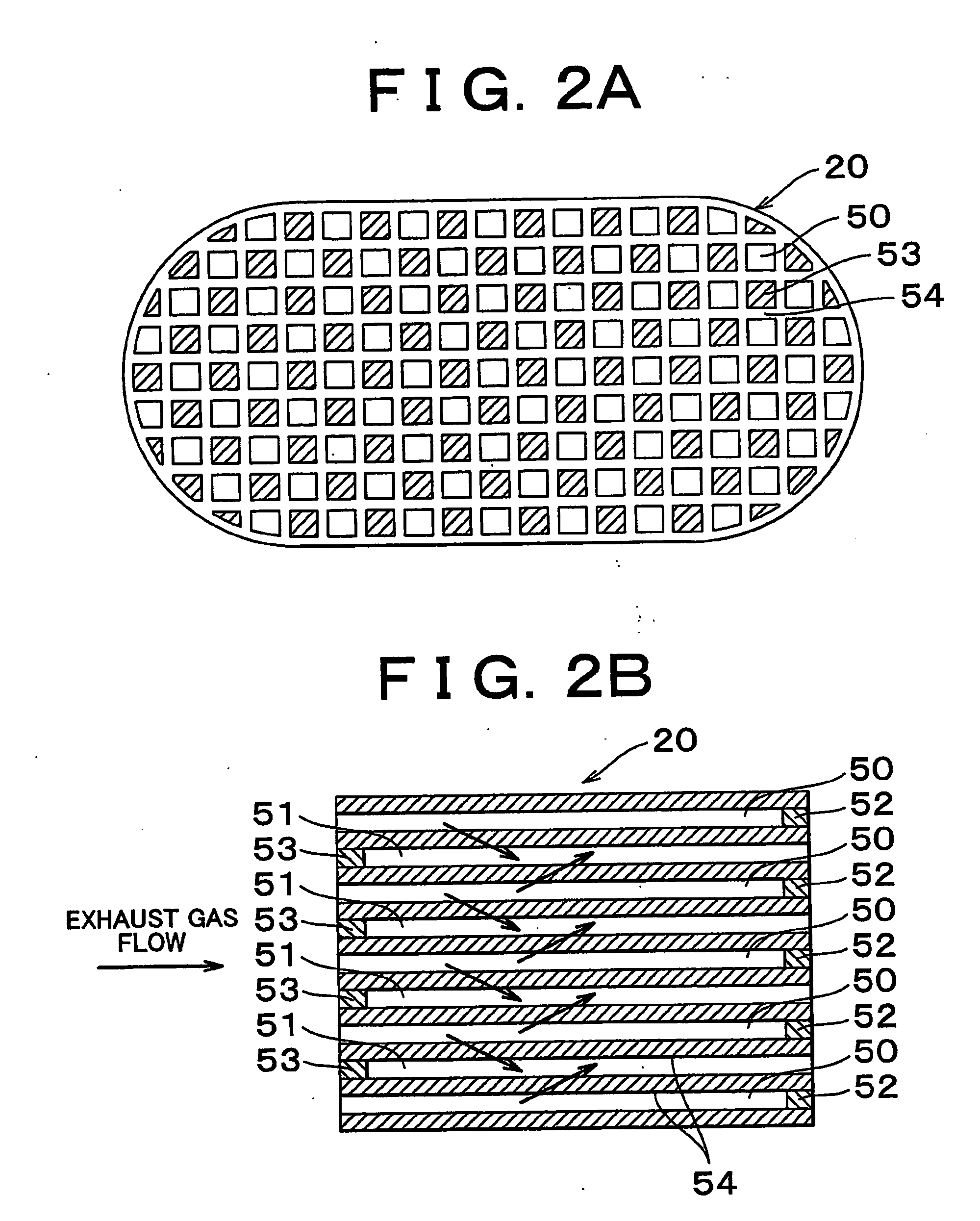

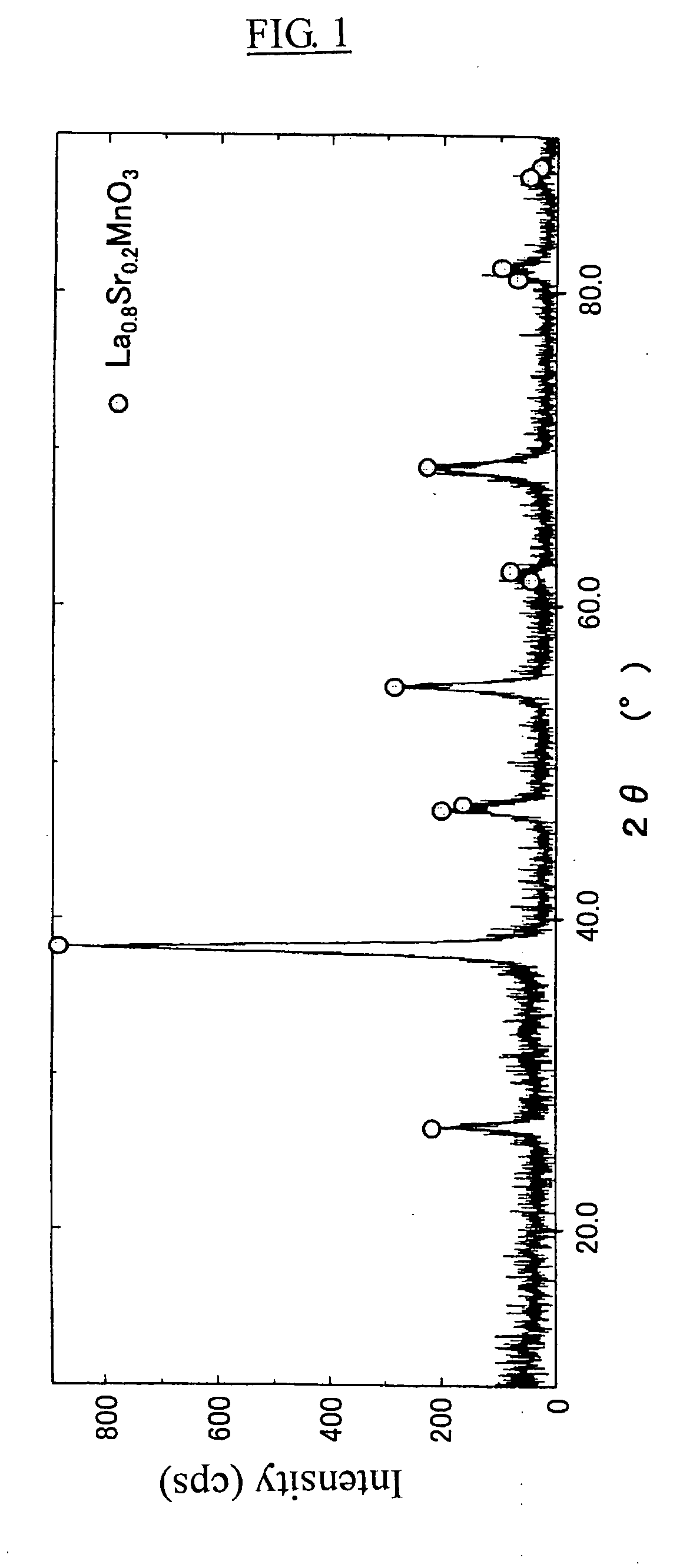

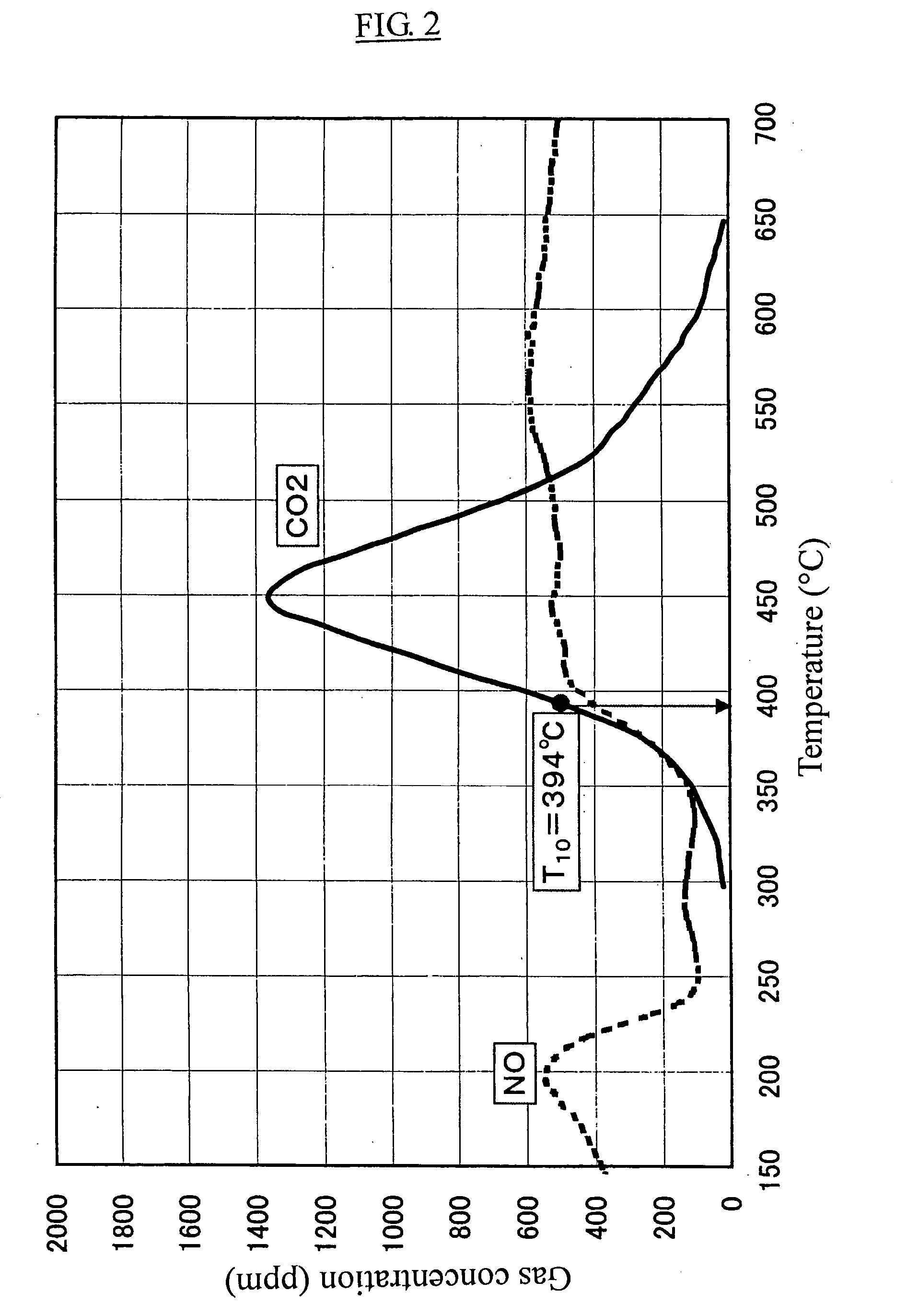

Particulate matter oxidation catalyst and filter

InactiveUS20070105715A1Increased durabilityReduce the amount requiredCombination devicesGas treatmentStructural formulaDiesel particulate filter

This is a catalyst suitable for a diesel particulate filter (DPF) that traps particulate matter (PM) present in diesel engine exhaust, being a diesel engine exhaust gas particulate matter oxidation catalyst using a perovskite-type composite oxide that has an NO adsorption domain over the range of 200-450° C. This catalyst induces low-temperature combustion of PM but does not use noble metals so it is inexpensive and its constituent materials are not volatile at exhaust gas temperatures so it has superior durability. The perovskite-type composite oxide contains essentially no Na and is represented by the structural formula RTO3, where R comprises one or more elements selected from a group made up of La, Sr, Ba, Ca and Li, and T comprises one or more elements selected from a group made up of Mn, Fe, Co, Cu, Zn, Ga, Zr, Mo, Mg, Al and Si.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Combustion diagnostic for active engine feedback control

InactiveUS7277790B1Good sense and control combustionEmission reductionAnalogue computers for vehiclesValve arrangementsDiffusionFeedback control

This invention detects the crank angle location where combustion switches from premixed to diffusion, referred to as the transition index, and uses that location to define integration limits that measure the portions of heat released during the combustion process that occur during the premixed and diffusion phases. Those integrated premixed and diffusion values are used to develop a metric referred to as the combustion index. The combustion index is defined as the integrated diffusion contribution divided by the integrated premixed contribution. As the EGR rate is increased enough to enter the low temperature combustion regime, PM emissions decrease because more of the combustion process is occurring over the premixed portion of the heat release rate profile and the diffusion portion has been significantly reduced. This information is used to detect when the engine is or is not operating in a low temperature combustion mode and provides that feedback to an engine control algorithm.

Owner:UT BATTELLE LLC

Preparation method of rock salt type (MgCoCuNiZn)O high entropy oxide powder material

ActiveCN109019701AAchieving a stoichiometric ratioIncrease productivityCobalt compoundsSynthesis methodsMolecular level

Belonging to the field of high entropy oxide powder materials, the invention discloses a preparation method of a (MgCoCuNiZn)O high entropy oxide powder material with a rock salt type structure. The method is low-temperature combustion synthesis method, uses a metal nitrate as the metal source, and takes one or more of citric acid, tartaric acid and glucose with an appropriate carbon content as the fuel. The concentration of the metal salt raw material, the fuel variety and adding amount, the combustion improver variety and adding amount, and the ignition way are controlled to regulate the granularity, morphology and other characteristics of the high entropy oxide (MgCoCuNiZn)O nanopowder. According to the invention, the reactants exist in a solution, so that the raw materials in the solution can easily reach molecular level blending, and the product realizes a stoichiometric ratio. At the same time, the method provided by the invention has the advantages of energy saving, high production efficiency, simple and feasible process, green and environmental protection, no need for complex post-treatment, etc., and the prepared high entropy oxide powder has high purity and fine particlesize, and is uniformly distributed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

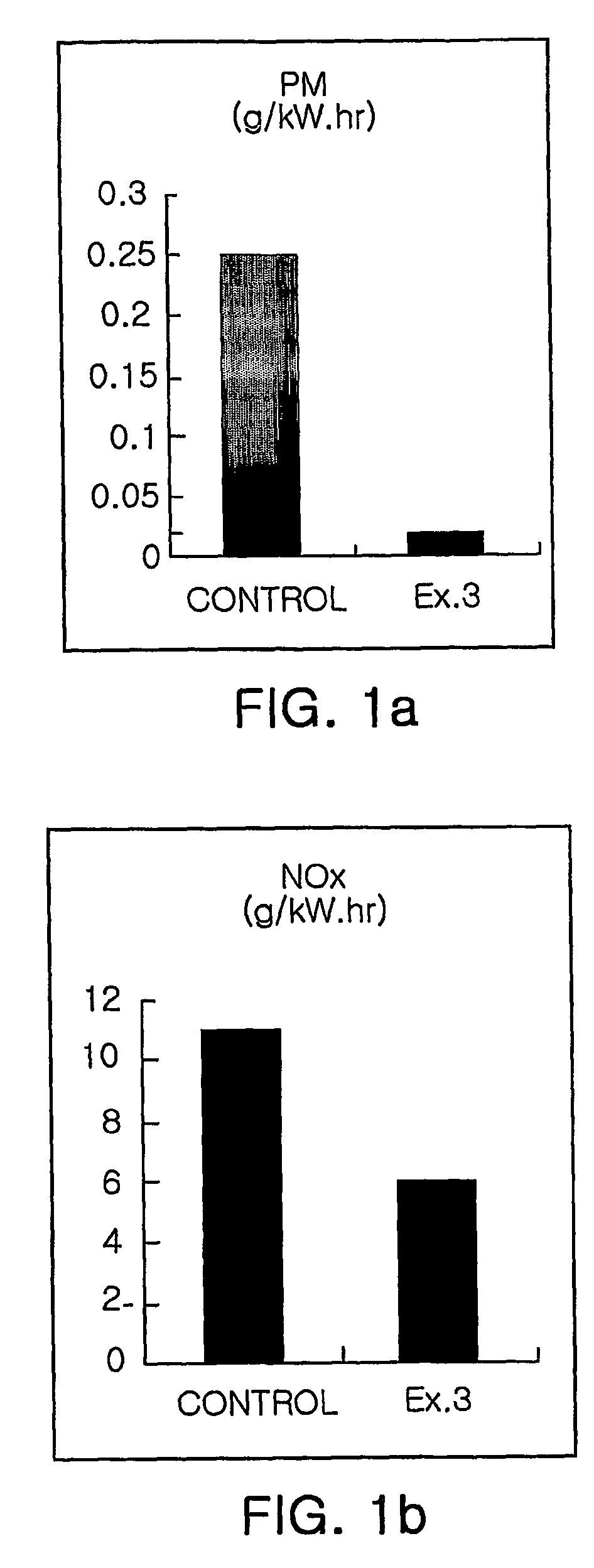

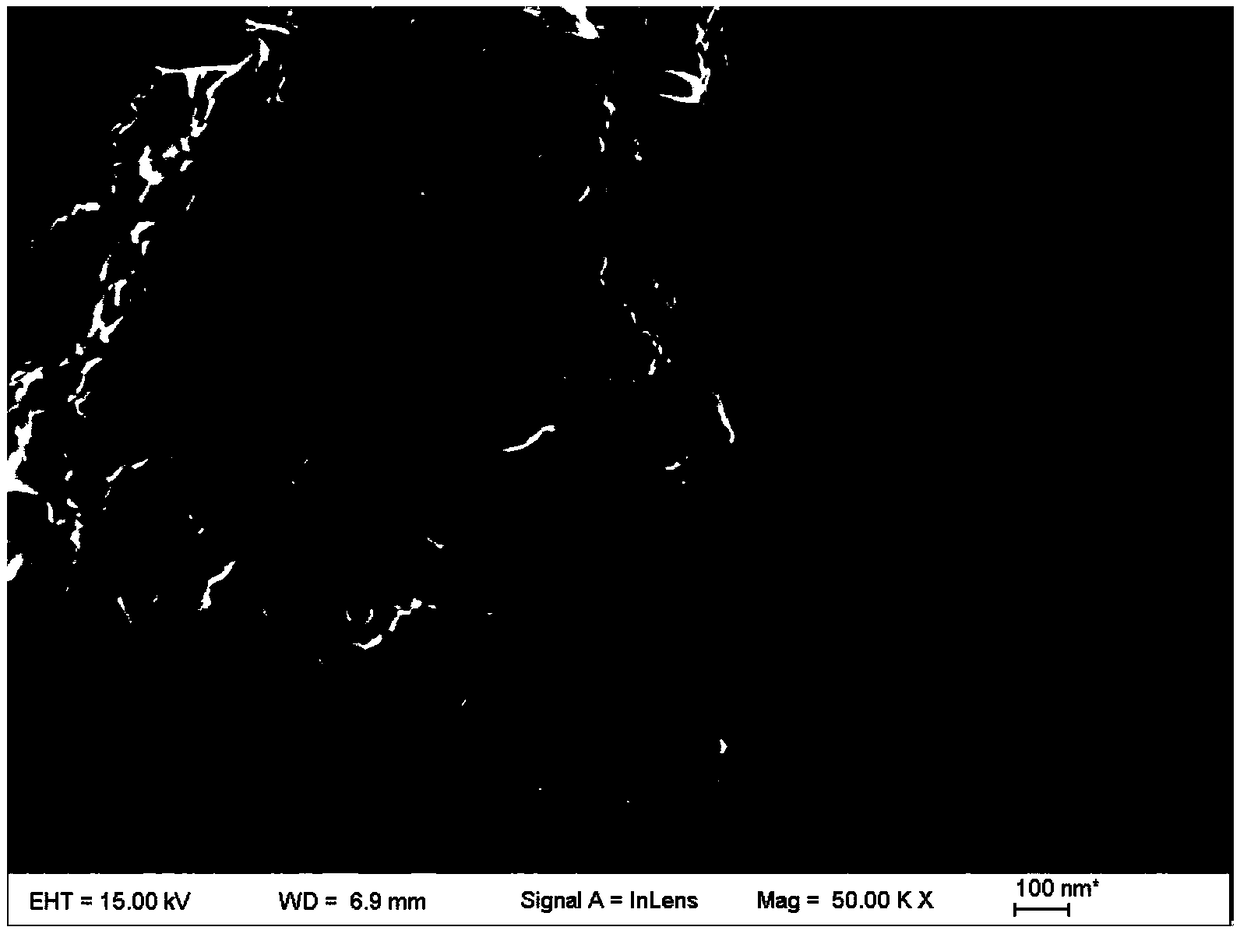

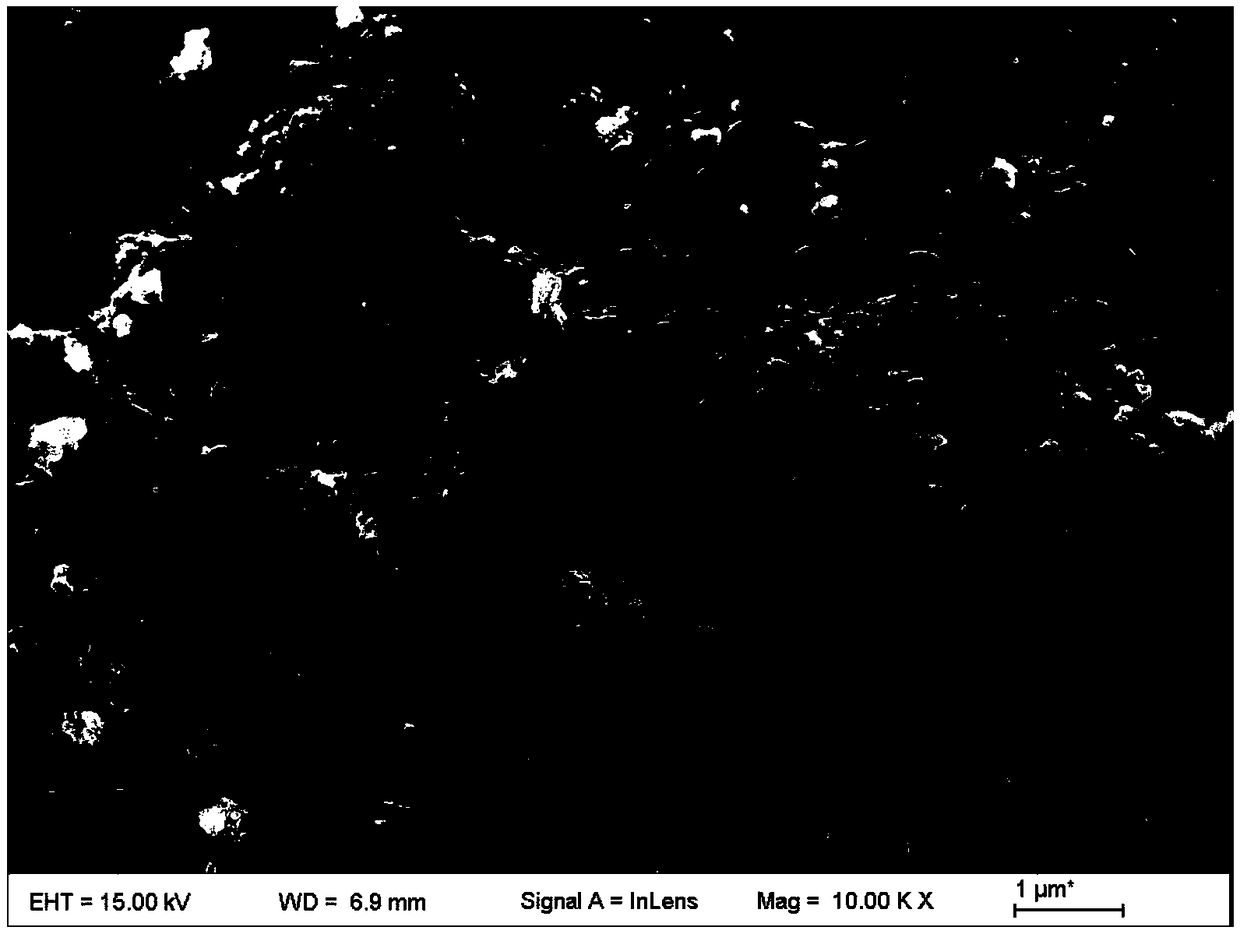

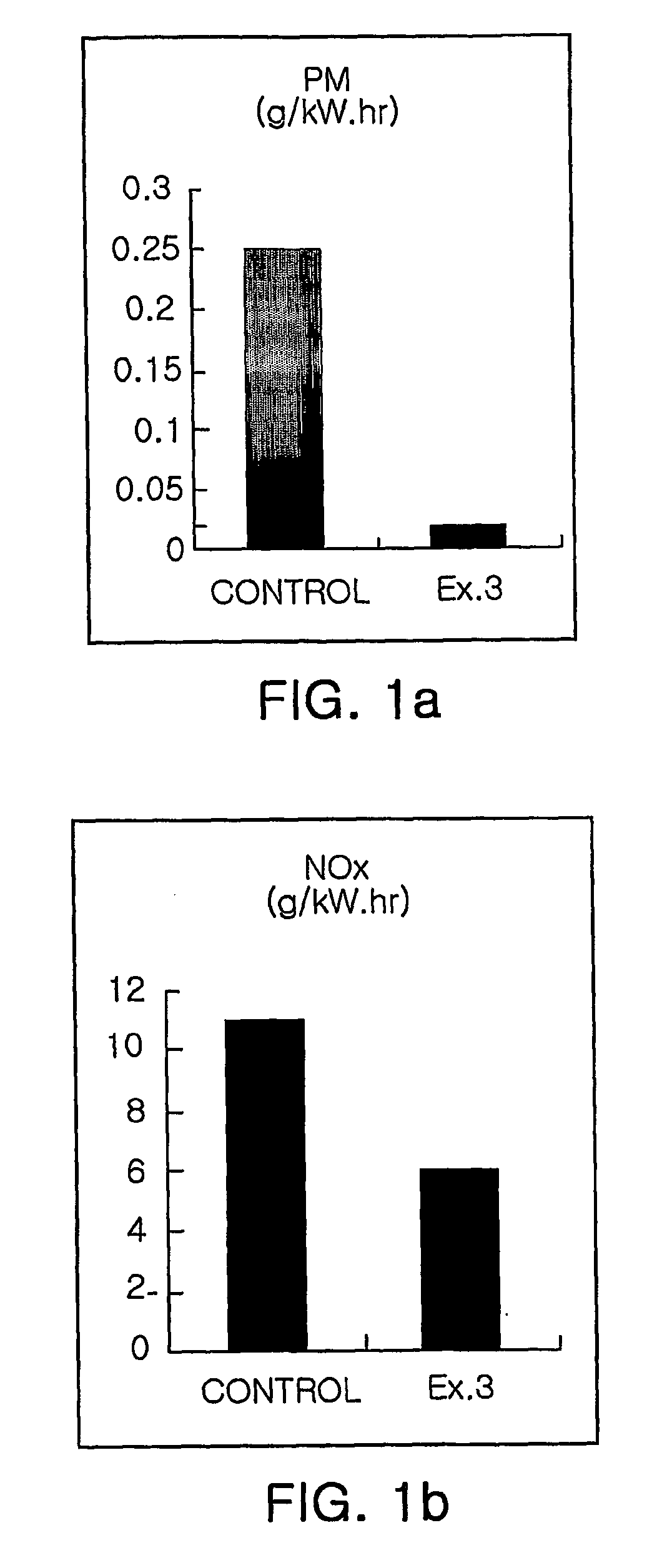

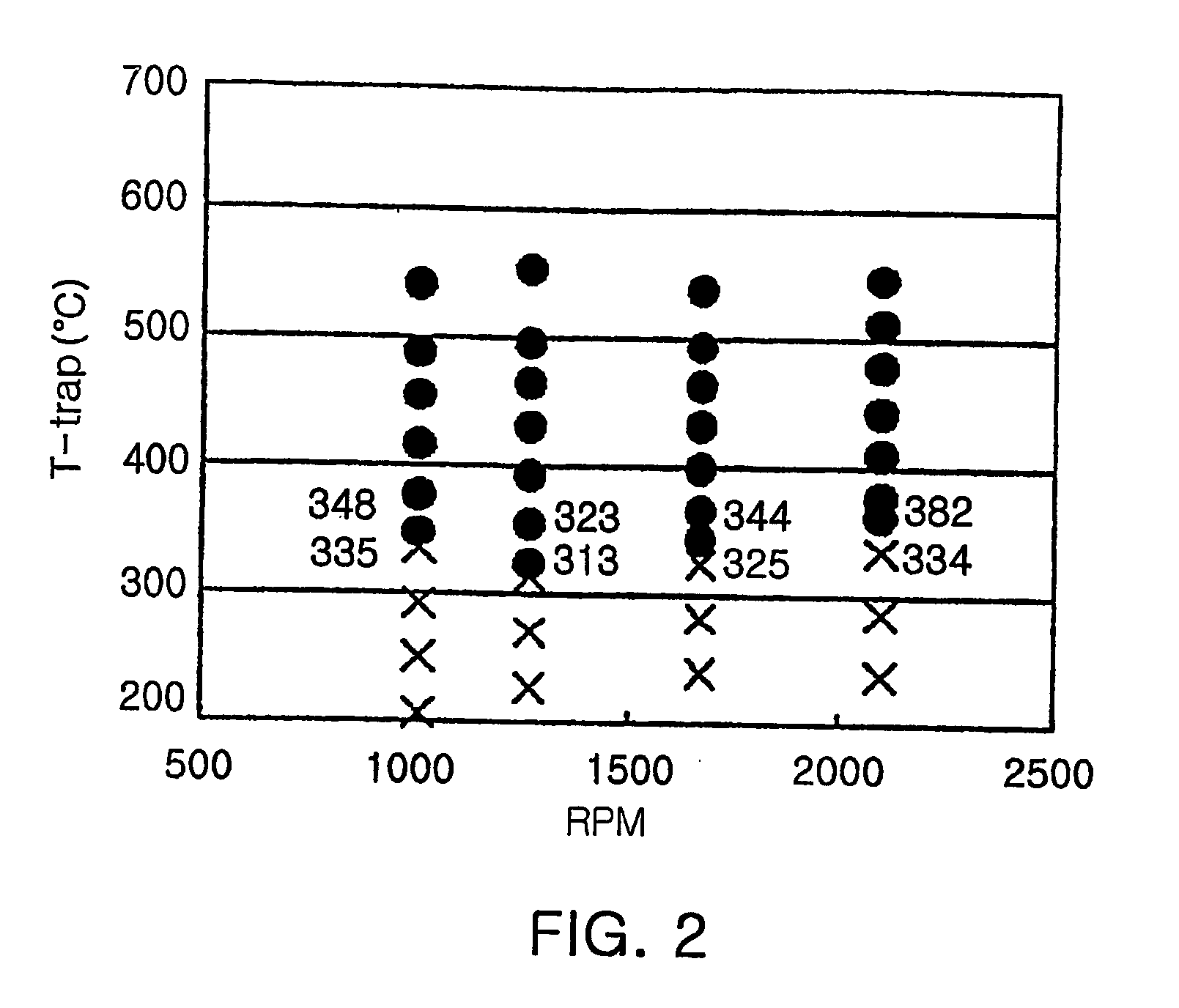

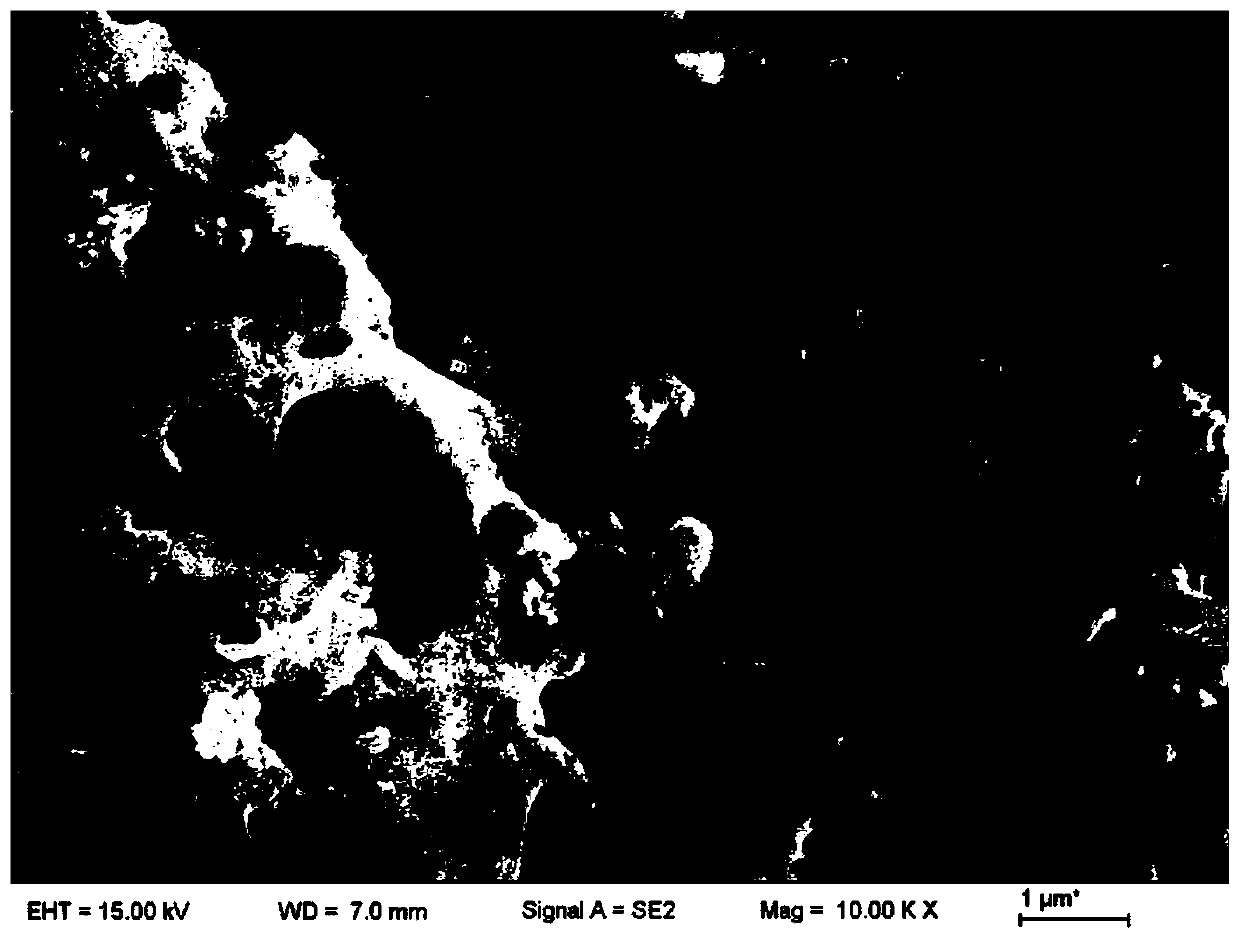

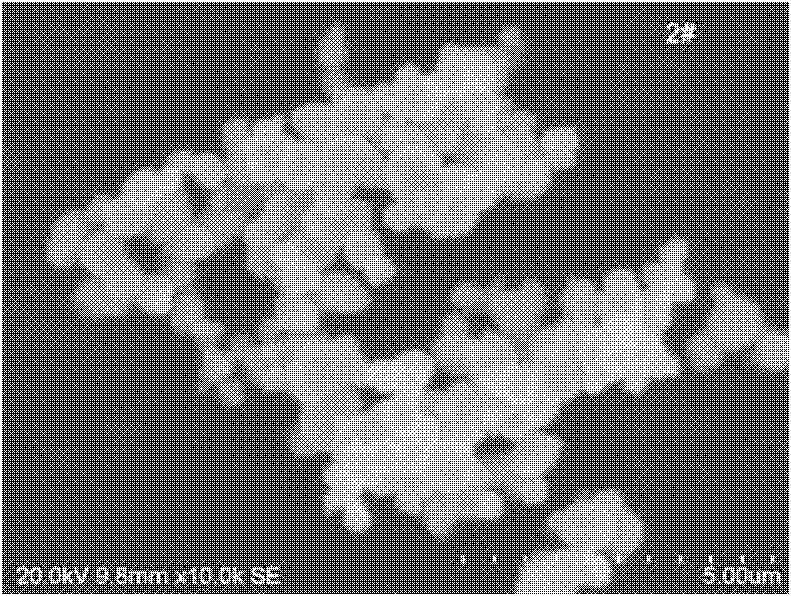

Catalytic filter for removing soot particulates from diesel engine exhaust and method of preparing the same

ActiveUS20050239642A1Efficiently oxidizedCombination devicesAuxillary pretreatmentReducing agentMetal salts

Disclosed is a catalytic filter for removing soot particulates from diesel engine exhaust, which is comprised of monolithic oxidation catalyst upstream of the catalytic filter, which effectively oxidize gaseous pollutants and volatile organic fractions, and a catalyzed wall-flow filter downstream serving to low temperature combustion of soot particulates collected on the filter. Also, the preparation method of the catalytic filter is provided, including the colloidal mixture solution of platinum group metal salts and other metal salts with a water-soluble polymer and a reducing agent, which is then impregnated on a catalyst support, followed by calcining at high temperatures. In the present invention, use of the catalytic filter provides effective means of abating diesel exhaust pollutant emissions, that is, particulate matter (PM) and gaseous pollutants (HC, CO, NOx).

Owner:SK ENERGY CO LTD (KR)

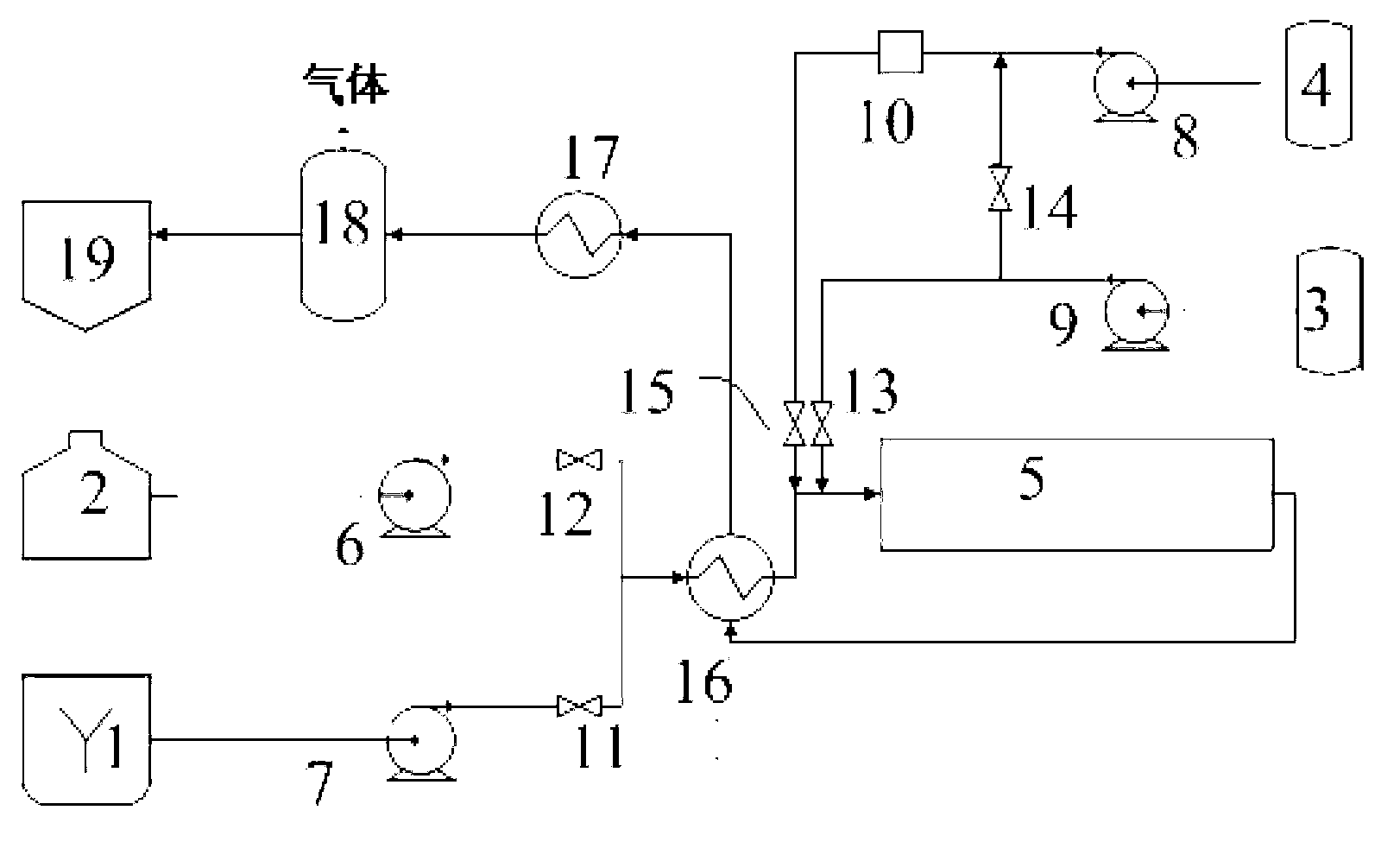

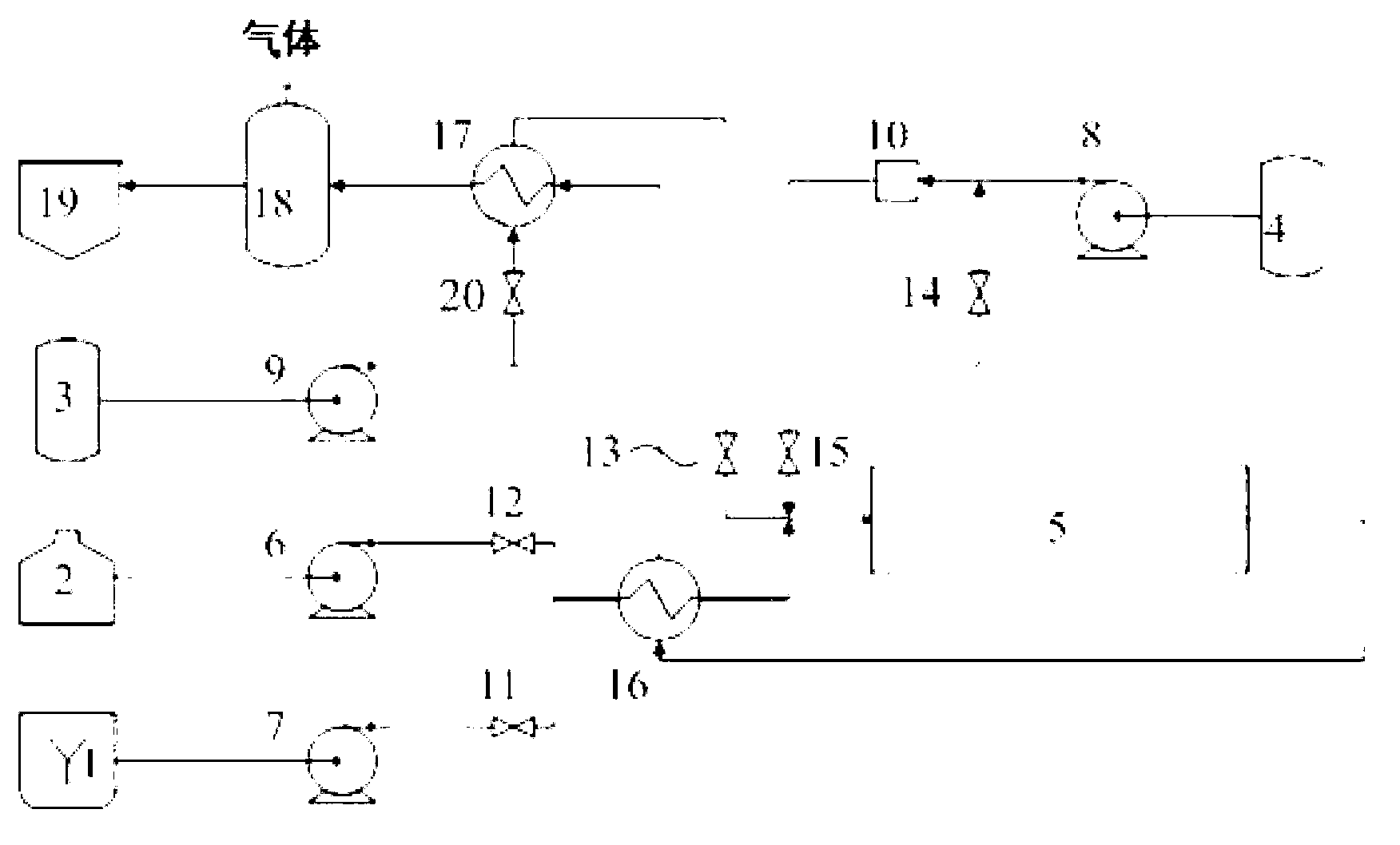

Method for treating carbon-containing organic matter by supercritical water oxidation

ActiveCN103073103AAchieve self-sufficiencyStart raw material without heatingWater/sewage treatment by oxidationDecompositionSupercritical water oxidation

The invention relates to a method for treating carbon-containing organic matter by supercritical water oxidation. The method comprises the step of obtaining oxidative decomposition product by oxidizing the carbon-containing organic matter in the supercritical state of water and under the effect of oxidant; heat released by the supercritical water oxidation treatment of the carbon-containing organic matter at least can satisfy the heat required by warming the carbon-containing organic matter to the supercritical state of the water, thereby energy is not required to be provided by the outside in the stable operation process, and the self-supply of reaction energy is completely achieved; and the cold start of the reaction is achieved by the cold start mode of low-temperature combustion catalysis.

Owner:ENN SCI & TECH DEV

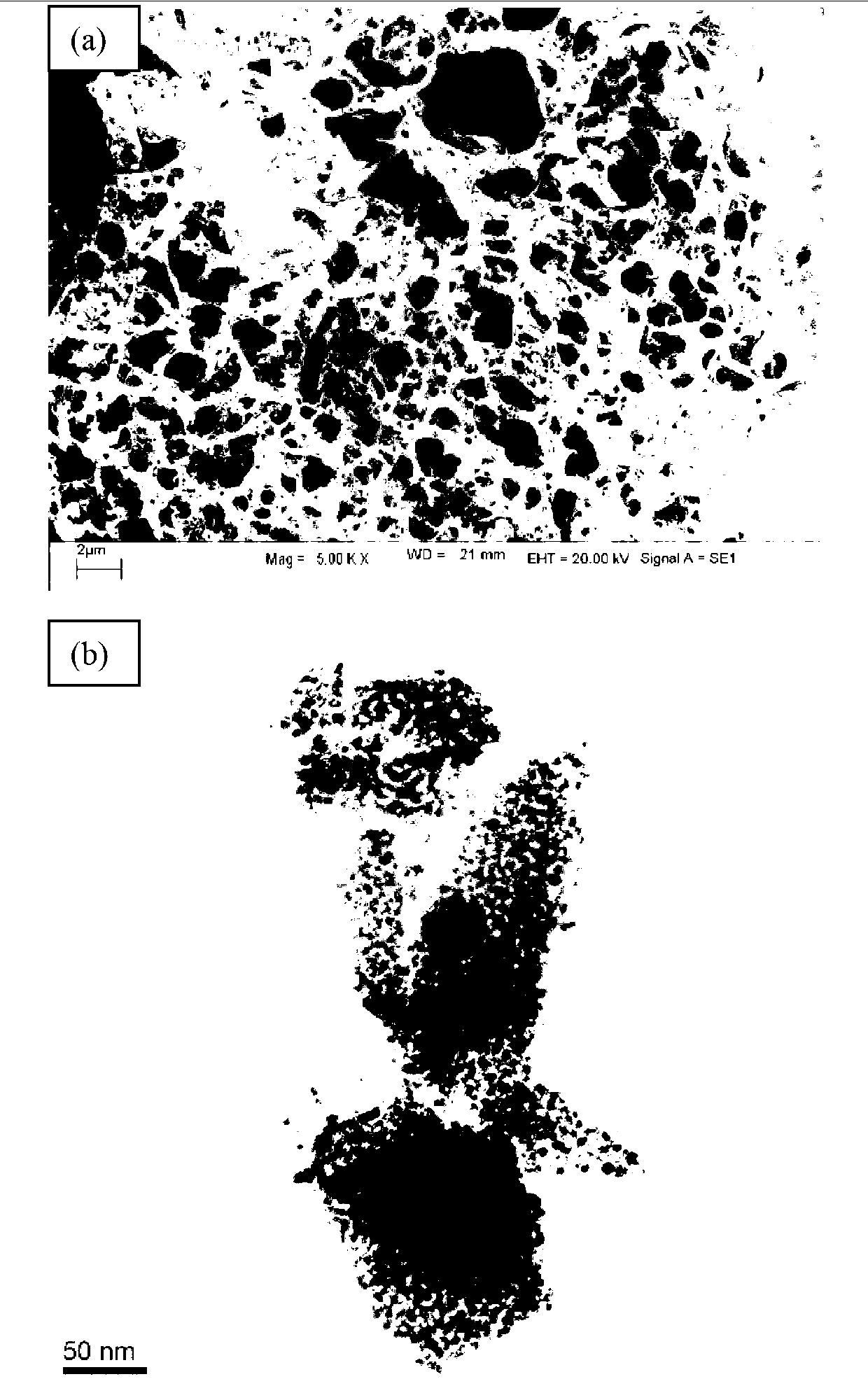

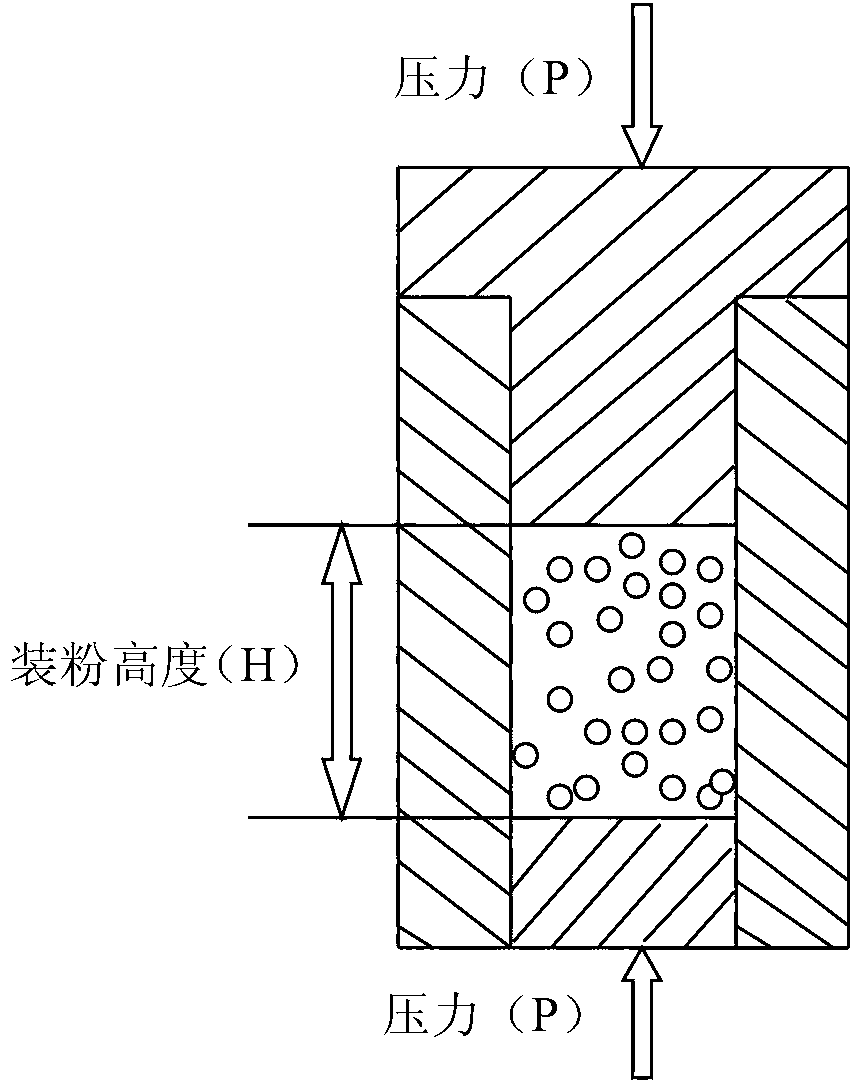

Preparation method of prealloying powder for dispersion strengthening metal by low-temperature combustion synthesis method

InactiveCN101956119ARaw materials are cheap and easy to getSimple methodSynthesis methodsMuffle furnace

The invention provides a preparation method of prealloying powder for dispersion strengthening metal by a low-temperature combustion synthesis method, comprising the following steps of: adding a mixture of base metal nitrate and second phase nitrate to an aqueous solution of ethanol with a solved dispersant, and then adding an organic combustion improver to the mixing solution to mix evenly so as to form a highly dispersed reaction system, heating the reaction system to fast generate auto-combustion, and obtaining ultrafine precursor powder after the product is combusted by a muffle furnace, and then placing the precursor powder under the atmosphere of hydrogen for carrying out selective reduction to obtain the prealloying powder for the dispersion strengthening metal with ultrafine and evenly distributed second phase particles. The invention has the advantages that: in the prepared prealloying powder, the second phases are ultrafine in size and evenly distributed, and the final product has excellent property; the cost is low, the method is simple, the operation is easy, the reaction condition is gentle, the period is short, and the energy consumption and the pollution can be greatly reduced.

Owner:UNIV OF SCI & TECH BEIJING

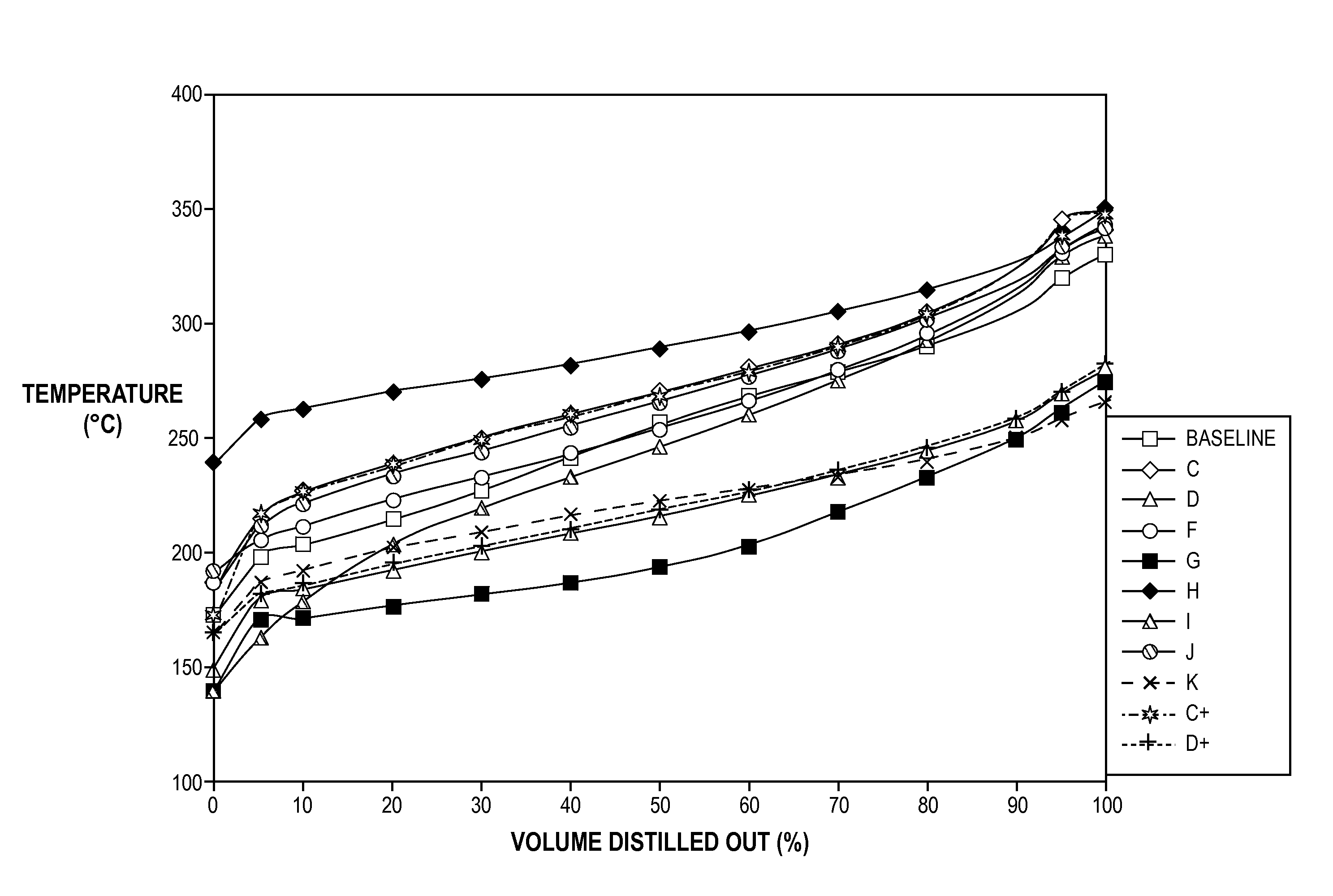

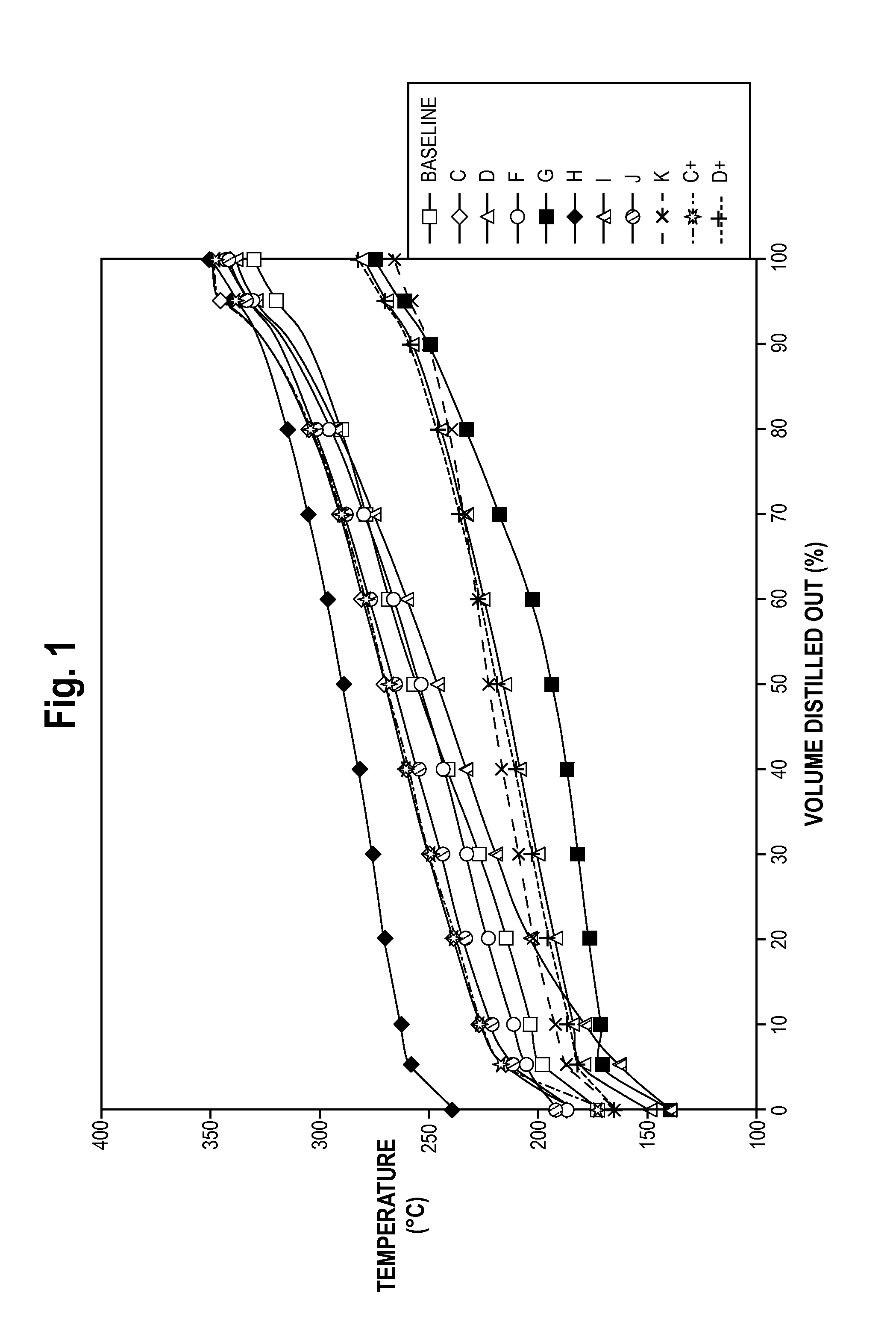

Composition and Method for Reducing NOx Emissions From Diesel Engines at Minimum Fuel Consumption

InactiveUS20110099979A1Reduce nitrogen oxide emissionsReduce the amount requiredExhaust apparatusSilencing apparatusNitrogenNitrogen oxide

A diesel fuel composition is disclosed, as well as a method for reducing NOx emissions from a diesel engine at minimum fuel consumption wherein the diesel engine operates in a low temperature combustion mode, comprising the step of adding to the diesel engine at least one diesel fuel or blending component for a diesel fuel having a combination of a low T50 in the range of from 190° C. to 280° C., a high cetane number in the range of from 31 to 60, and an effective emissions reducing amount of a nitrogen-free cetane improver.

Owner:BP CORP NORTH AMERICA INC

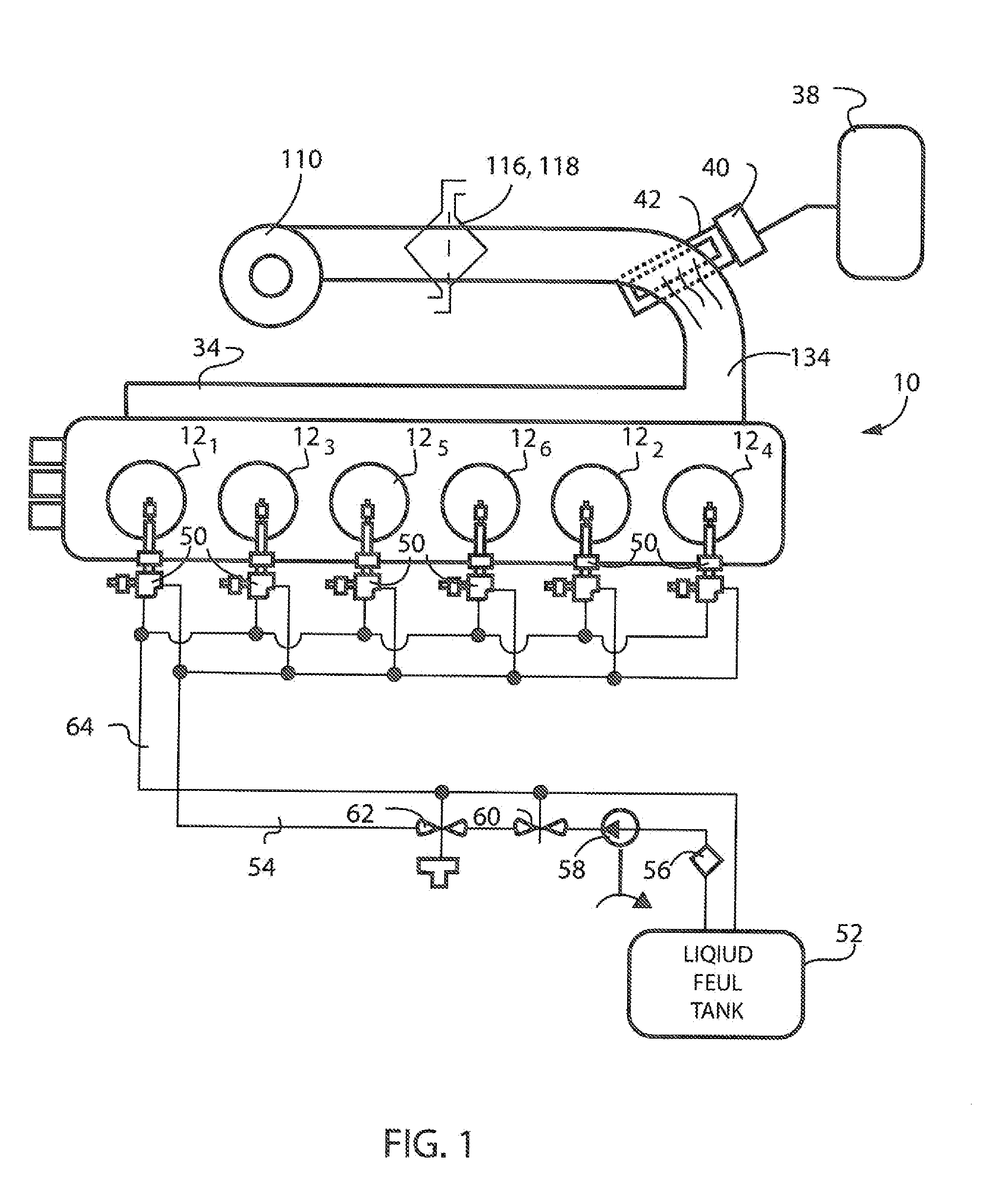

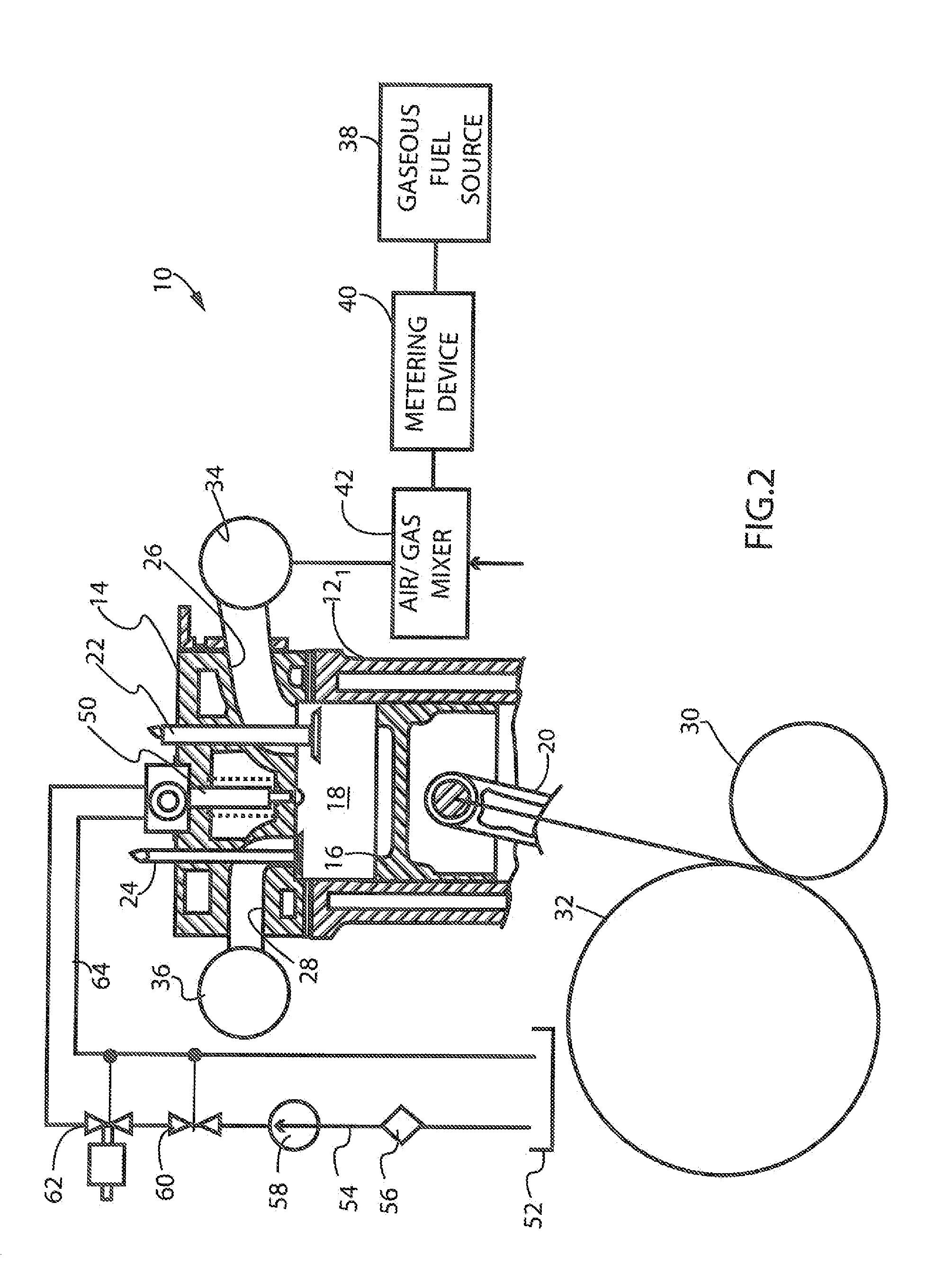

Method and apparatus for controlling premixed combustion in a multimode engine

InactiveUS20140076291A1Reduce the temperatureElectrical controlInternal combustion piston enginesLiquid fuelEngineering

A method of fueling an internal combustion engine including operating the internal combustion engine in a dual-fuel mode in which the engine is fueled by a pre-mixed charge of fresh air, recirculated exhaust gases, gaseous fuel as primary fuel and early injected liquid fuel as a secondary fuel, ignited by a late injected pilot fuel to provide low temperature combustion. The method further includes adjusting EGR and / or fresh airflow to the engine to maintain peak in-cylinder temperature in a desired range, preferably between 1500 K and 2000 K. EGR preferably is controlled to obtain a desired in-cylinder O2 mole fraction, and fresh airflow preferably is controlled to obtain a desired fresh air lambda.

Owner:CLEAN AIR POWER

Preparation method of WC-Co nano powder added with grain growth inhibitor

The invention provides a preparation method of WC-Co nano powder added with a grain growth inhibitor, and belongs to the technical field of powder metallurgy and powder preparation. The preparation method comprises the following steps: ammonium metatungstate, cobalt nitrate, fuel, ammonium nitrate, metal salt with a needed amount of the added grain growth inhibitor and an organic carbon source are used as raw materials, and oxide / carbon composite powder is prepared by adopting a low-temperature combustion synthesis method; and then carbonization is carried out under atmosphere protection or vacuum to obtain the WC-Co nano powder mixed with the grain growth inhibitor. According to the preparation method, the low-temperature combustion synthesis method belongs to a liquid-phase synthesis method, molecular-level mixing is achieved, so that diffusion range of the carbon in the carbonization process is short, and the requirements for the reaction temperature requirement and the reaction time requirement are low; and in addition, the raw materials are simple to obtain, the equipment is simple, the process is fast, and large-scale production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

Six-element high-entropy oxide material for lithium ion battery and preparation method

ActiveCN110556536AGuaranteed stabilityImprove cycle stabilityCell electrodesSodium-ion batteryChromium nitrate

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing ultrafine tungsten copper composite powder by low-temperature combustion method

The invention discloses a method for preparing ultrafine tungsten copper composite powder by a low-temperature combustion method, which comprises the following steps: using ammonium para-tungstate (APT) or ammonium meta-tungstate (AMT), a copper salt, citric acid and polyethylene glycol as raw materials; mixing the raw materials and adding water to prepare a transparent citric acid sol system; putting the sol system in a spray tower, and obtaining precursor powder by means of spraying and low-temperature combustion; and finally, carrying out reduction on the precursor powder to obtain ultrafine tungsten copper composite powder. The method has the advantages of energy consumption conservation, being simple in process, large in yield ratio, and being suitable for large-scale industrialization production. By using the methods of sol spraying and low-temperature combustion, the speed of crystallization is improved and the phase separation of tungsten and copper is reduced. Particularly, the composite powder is ignited in a reaction kettle to carry out low-temperature combustion, so that the energy can be saved and the subsequent calcining procedure can be canceled through the low-temperature combustion of the composite powder on one hand, and the yield ratio can be improved to a larger extent on the other hand.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Preparation method of rare-earth-based fluorite type high-entropy oxide powder material

ActiveCN108946787AAchieving a stoichiometric ratioReduce energy consumptionRare earth metal oxides/hydroxidesMaterial nanotechnologySynthesis methodsRare earth

The invention discloses a preparation method of a rare-earth-based fluorite type high-entropy oxide powder material and belongs to the field of rare earth oxide powder materials. The method is a low-temperature combustion synthesis method and specifically comprises the following steps: taking rare earth nitride as a metal source and one or a mixture of more of urea, acetic acid, ammonium acetate,oxalic acid and glycine as fuel; and controlling the concentration of metal salt raw materials, types and adding amounts of the fuel, types and adding amounts of a combustion improver and an ignitionmanner to regulate and control properties including granularity, shapes and the like of rare-earth-based fluorite type high-entropy oxide powder. According to the preparation method disclosed by the invention, liquid-phase ingredients are adopted to ensure that a molecular level of the raw materials is uniform and a stoichiometric proportion of a product is realized; meanwhile, the preparation method has the advantages of energy source saving, high production efficiency, greenness and environment protection, no need of complicated post-treatment and the like; and the prepared rare earth oxidepowder has the advantages of high purity, small granularity and uniformity in distribution.

Owner:内蒙古广禾元纳米高科技有限公司

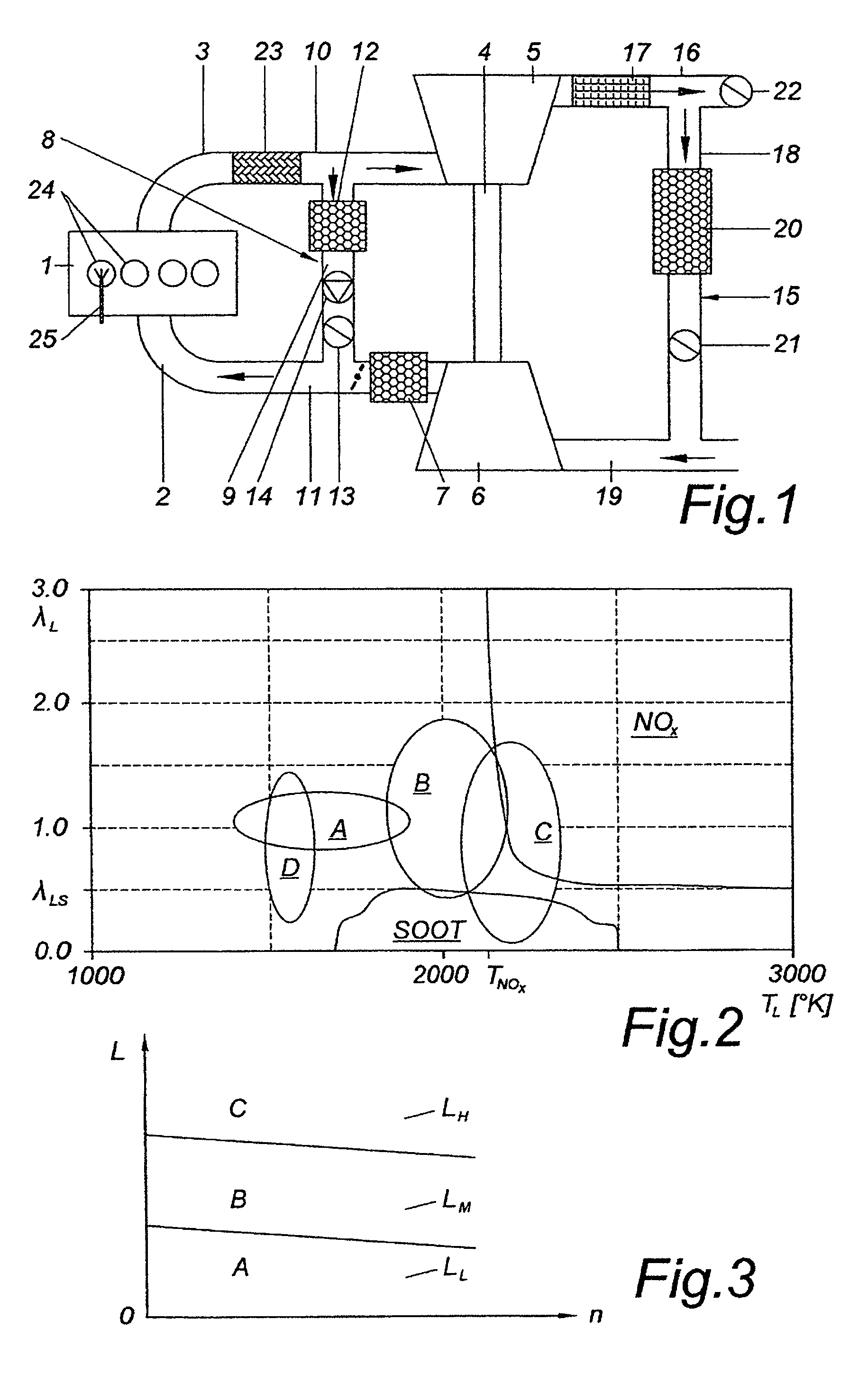

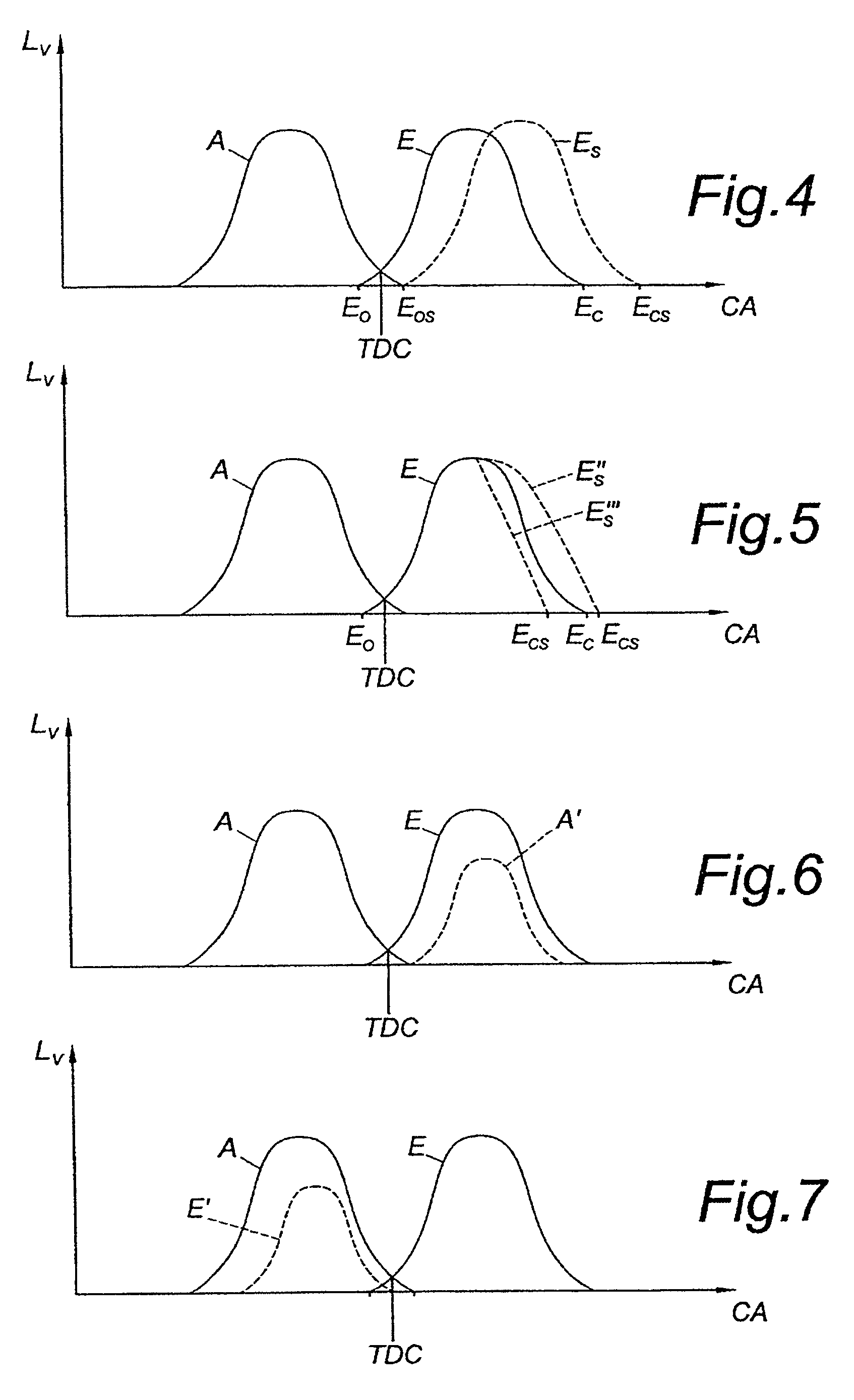

Method for operating an internal combustion engine

InactiveUS7415963B2Shorten injection timeEasy to igniteElectrical controlInternal combustion piston enginesNitrogen oxidesInternal combustion engine

The invention relates to a direct-injection internal combustion engine that is operated in a first operating range associated with the low part load, with largely homogeneous combustion of the mixture and subsequent injection. Said internal combustion engine is operated in a second operating range associated with the middle part load, with low-temperature combustion of the mixture. In this way, minimum nitrogen oxide and soot emissions and a high degree of efficiency can be achieved both in the lower part load region and up to the full load region.

Owner:AVL LIST GMBH

Prepn process of spinel type nanometer composite ferrite material

The preparation process of spinel type nanometer composite ferrite material is the organic combination of sol-gel process and low temperature combustion synthesis and is intense oxidation-reduction practically. During forming sol, fuel or oxidant, such as citric acid, is introduced, the sol is dewatered and ignited in air, and oxidant and nitrate react to produce high temperature to promote the formation of spinel type ferrite. The present invention has the demerits of traditional method overcome and obtains spinel type nanometer composite ferrite AFe2o4 / SiO2 material directly through combustion in a fast simple process with low power consumption.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing porous nickel-based ODS ( Oxide Dispersion Strengthened) alloy

The invention relates to a method for preparing a porous nickel-based ODS (Oxide Dispersion Strengthened) alloy, and belongs to the technical field of porous high temperature alloy preparation. The method comprises the following steps of: preparing nano mixed oxide powder by a low temperature combustion synthesis method; then, selectively reducing the oxide powder in hydrogen to obtain ODS alloy powder; then, obtaining a porous blank by pressing, injection moulding and degreasing the powder; and then sintering to obtain the final porous nickel-based ODS alloy or directly performing SPS (Spark Plasma Sintering) to obtain the final porous nickel-based ODS alloy. The method provided by the invention solves the problem that porous nickel-based ODS alloy which is complex in shape is hard to form and the pore structure is hard to control. The method has the advantages of strong designability of porosity and aperture, low cost, high utilization ratio of raw material powder and high strength at a high temperature, and is suitable for high temperature resisting, corrosion resisting and oxidization resisting conditions.

Owner:UNIV OF SCI & TECH BEIJING

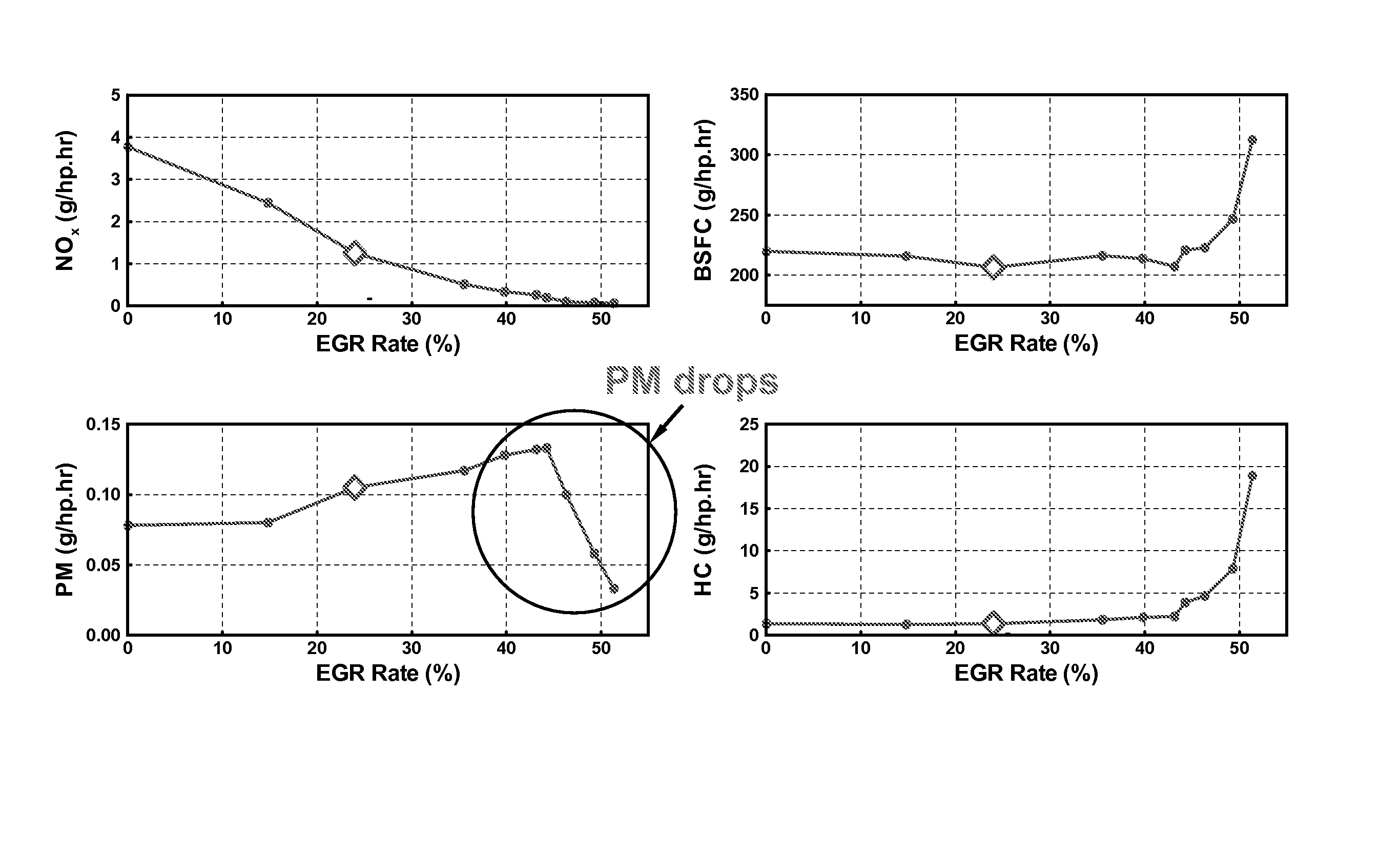

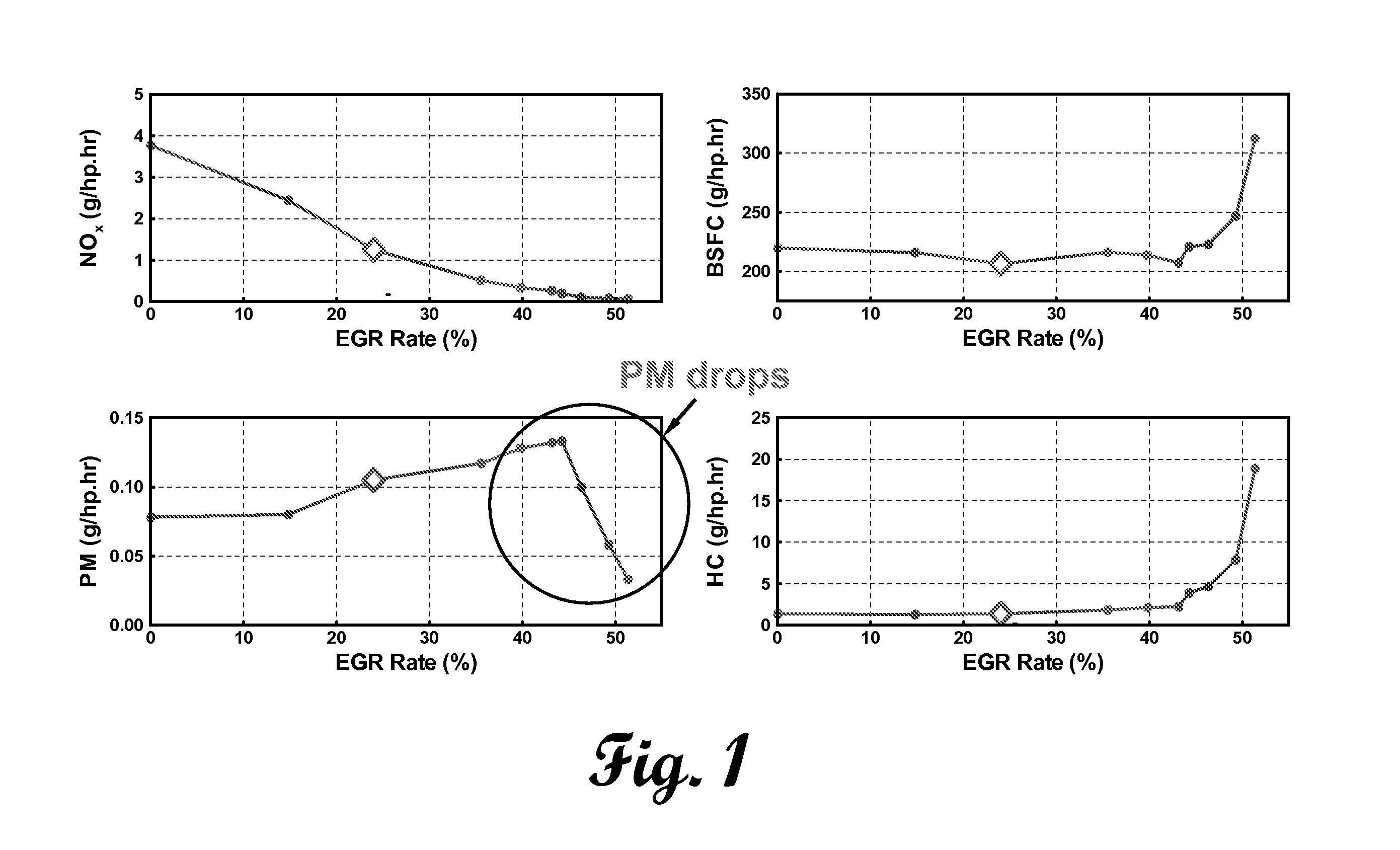

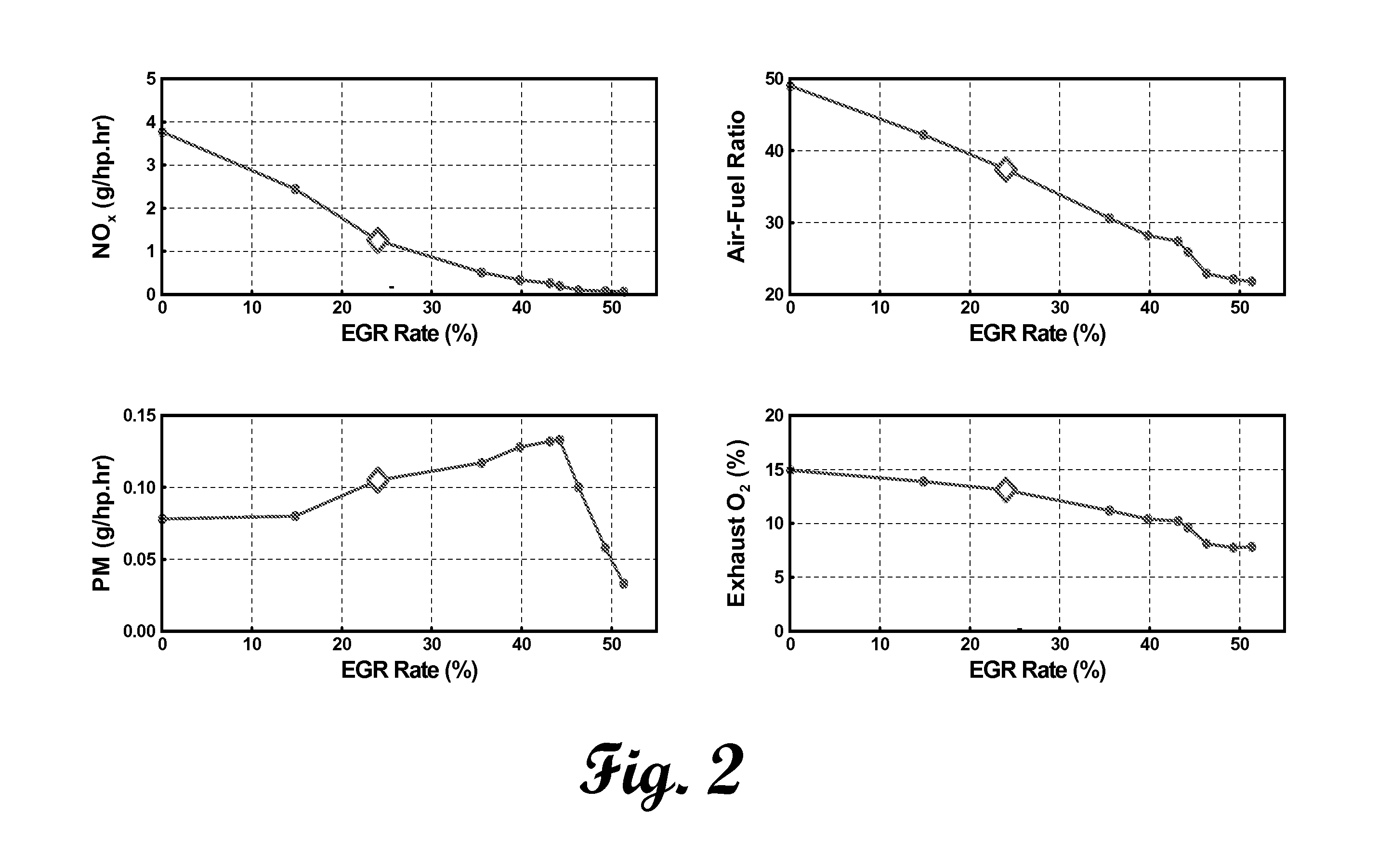

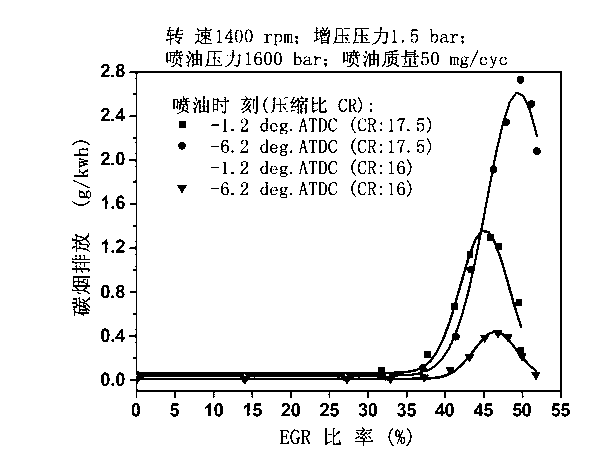

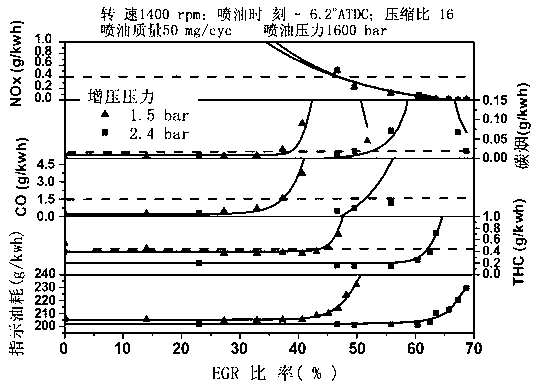

Method for improving low-temperature combustion soot emission and fuel economy of diesel engine

InactiveCN103061909AEmission peak reductionIncrease EGR rateElectrical controlMachines/enginesControl signalPeak value

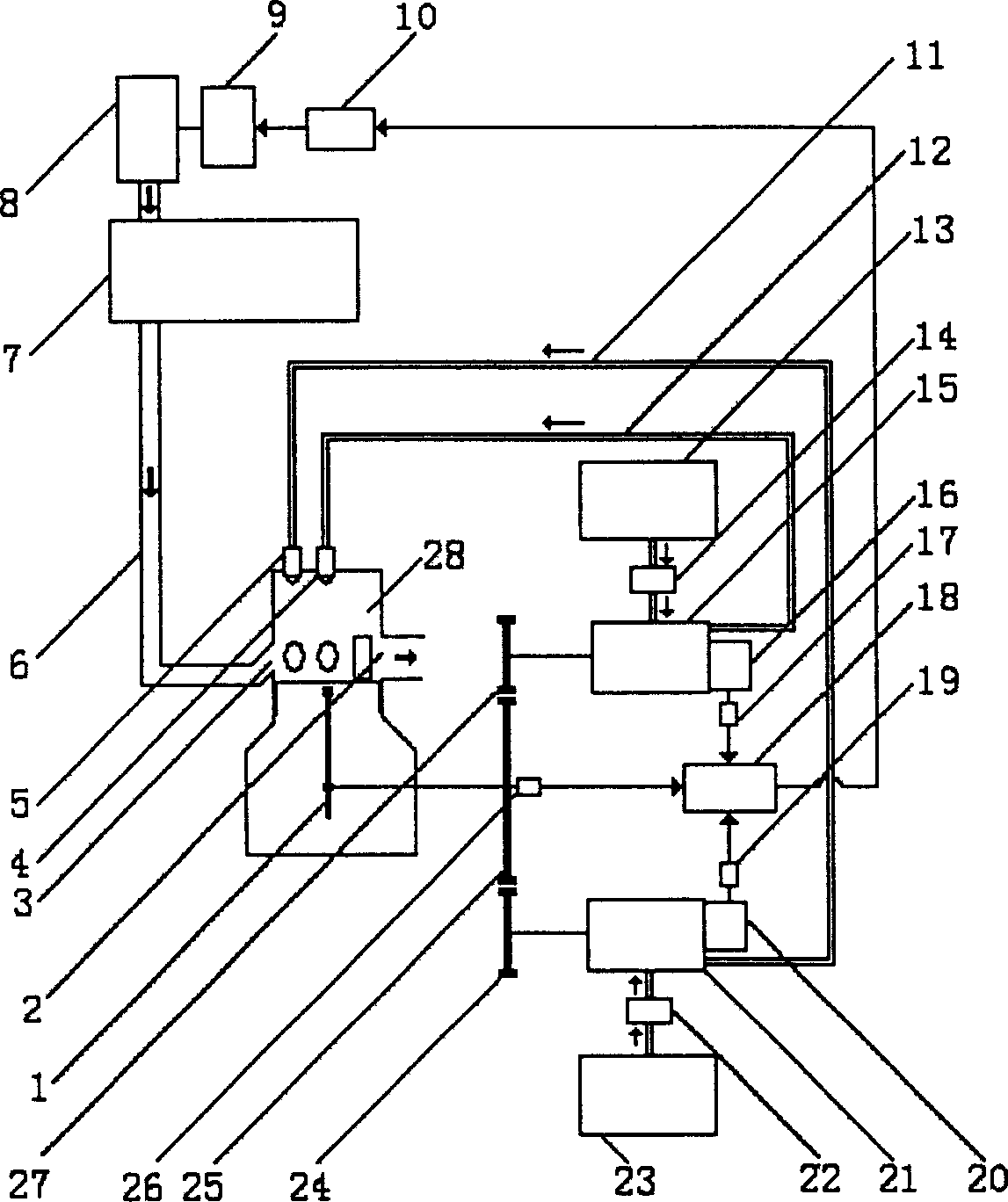

The invention discloses a method for improving low-temperature combustion soot emission and fuel economy of a diesel engine. The method includes the steps of firstly, a control unit reads a rotation speed signal of a sensor mounted on a crankshaft of the engine and an engine load signal of a sensor mounted at an accelerator pedal, and judges operation load and rotation speed of the engine according to the engine load signal and the rotation speed signal; and secondly, a control signal is output according to the judging result obtained in the first step. EGR (exhaust gas recirculation) rate when low-temperature combustion soot emission increases evidently is delayed effectively by the method, EGR tolerance is increased from 35% to above 55%, and soot emission peak is lowered effectively.

Owner:TIANJIN UNIV

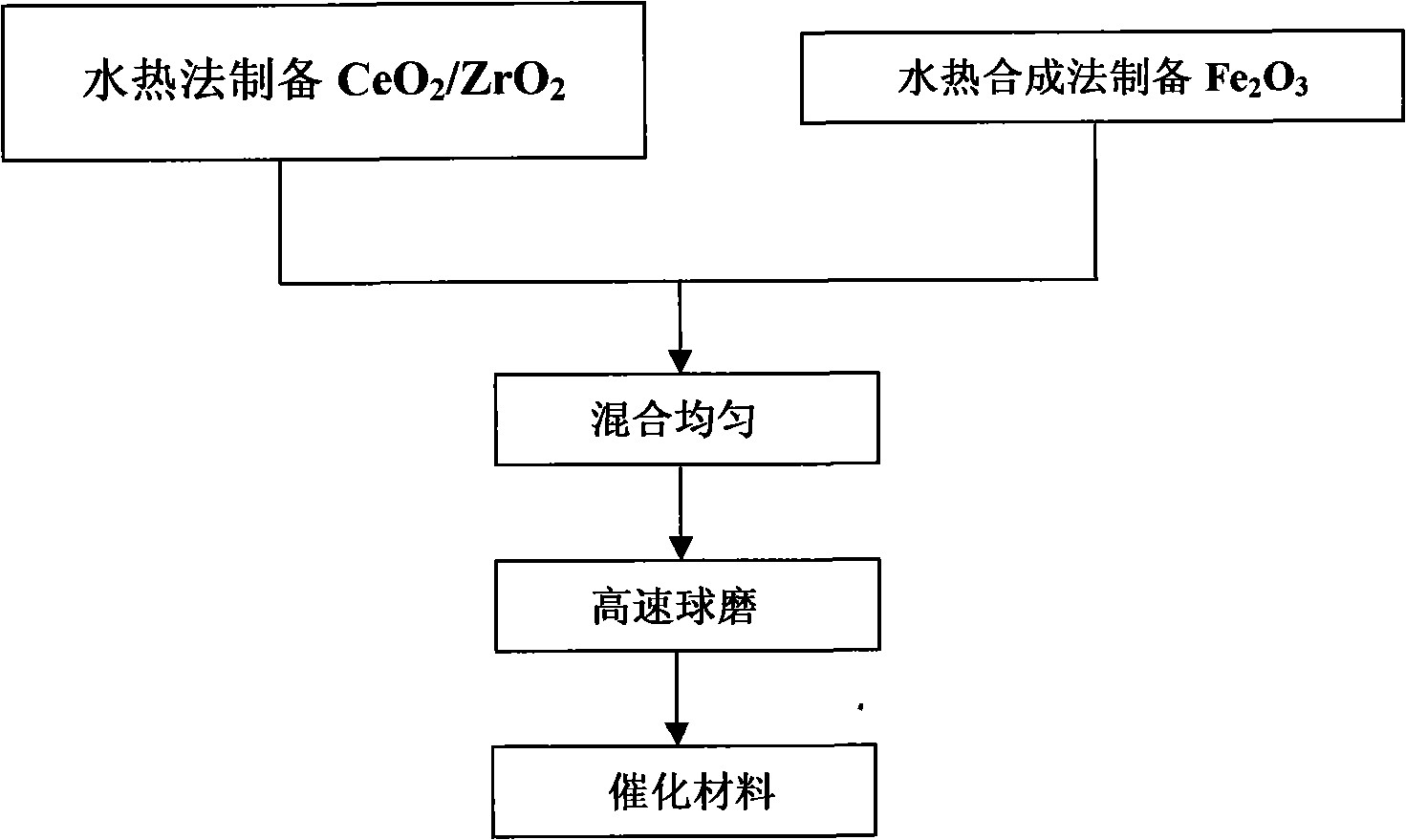

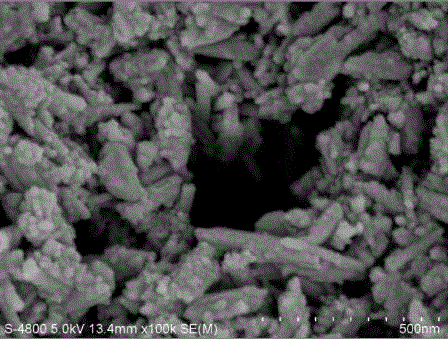

Low-temperature combustion catalyst for eliminating diesel engine carbon black

InactiveCN101767012ALow costNo secondary pollutionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumHigh pressure

The invention discloses a low-temperature combustion catalyst for eliminating diesel engine carbon black, the low-temperature combustion catalyst does not contain alkali metal and precious metal and is ferro-cerium-zirconium composite oxide; wherein the mole percentage composition of CeO2 is 50 percent, the mole percentage composition of Fe2O3 is 5-50 percent, and the mole percentage composition of ZrO2 is 45-0 percent; two preparation methods are included, the method I is coprecipitation hydrothermal synthesis method, the method II is mechanical mixing method; the method I comprises the following steps: Ce, Fe and Zr nitrates are prepared into saline solution with 0.1-0.5mol / L of total concentration according to stoichiometric ratio, and then H2O2 with proper amount is added, the mixture is fully stirred and mixed uniformly; under the strong stirring condition, the mixing solution is dropped in 3-8mol / L of ammonia water at 2-10mL / mim speed, so as to obtain precipitate; after the precipitating is completely carried out, the solution is continuously stirred for 30-120min. after aging is carried out for 30-180min, partial supernatant liquid is removed, the precipitate is transferred to a high pressure reactor (50-70 percent of filling degree) with 160-240 DEG C for 24-72 hours. The obtained product is washed respectively by deionized water and ethanol, and is dried 6-24h at 80-120 DEG C, so as to obtain the target catalyst. The material has high catalytic activity and heat stability, and has no pollution to environment.

Owner:KUNMING UNIV OF SCI & TECH

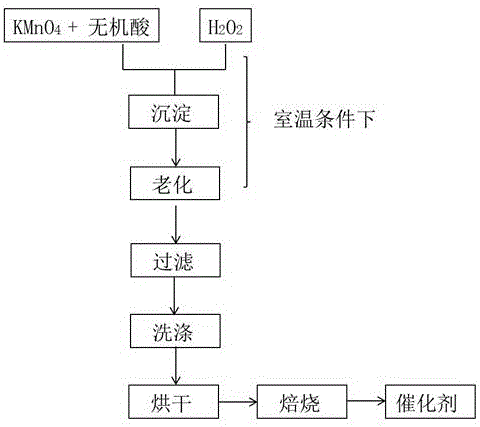

Preparation of Mn-base metal oxide catalyst through H2O2 quick reduction method and application of Mn-base metal oxide catalyst to volatile organic chemicals (VOCs) low-temperature catalytic combustion

ActiveCN105921146AGood dispersionImprove adsorption capacityCatalyst activation/preparationIncinerator apparatusPrecipitationHigh heat

The invention discloses a novel preparation method of a Mn-base metal oxide (MnOx) catalyst and application of the MnOx catalyst to the field of volatile organic chemicals (VOCs) low-temperature catalytic combustion. The method comprises the steps that KMnO4 and inorganic liquid acid are dissolved to a certain volume of deionized water to form a solution 1; a certain amount of H2O2 is diluted by deionized water to form a solution 2; on the room temperature condition, the solution 2 is added into the solution 1 dropwise; generated sediment is filtered, washed, dried and roasted at the high temperature after being aged and passing the night, and then the needed MnOx catalyst can be obtained. The method has the advantages that simpleness and quickness are achieved; the problems that the synthetic temperature is high, time is long and the amount of waste water and the number of waste residues are large in a hydrothermal synthesis method and a direct precipitation method can be avoided; a MnOx material of a multilevel structure can be synthesized, and the large comparison area is beneficial for a VOCs catalytic combustion reaction on the surface of the MnOx catalyst. In methylbenzene and methanol low-temperature combustion, the synthesized MnOx has an ideal catalyzing effect.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Low emission combustion system of flexible fuel engine

InactiveCN1558101AEmission reductionEasy to adjustElectrical controlInternal combustion piston enginesElectric controlMixed gas

The low exhaust combustion system for flexible fuel engine includes main gear, rotation speed sensor, two oil pumps with speed regulator, throttle valve position sensor, electric control unit, frequency variator, motor, compressor, pressure stabilizer, scavenging port, exhaust port, oil ejector and cylinder. The present invention consists of engine scavenging and exhausting system and diesel oil and fuel substitute double ejecting system. The present invention has double ejecting system and flexibly selected fuel substitute to lower the exhaust of the engine, two oil pumps for convenient regulation of oil supplying ahead angle and sectional ejecting, homogeneous mixed gas obtained before ignition, fast low temperature combustion, greatly lowered NOx and grain exhaust and raised heat efficiency.

Owner:SHANGHAI JIAO TONG UNIV

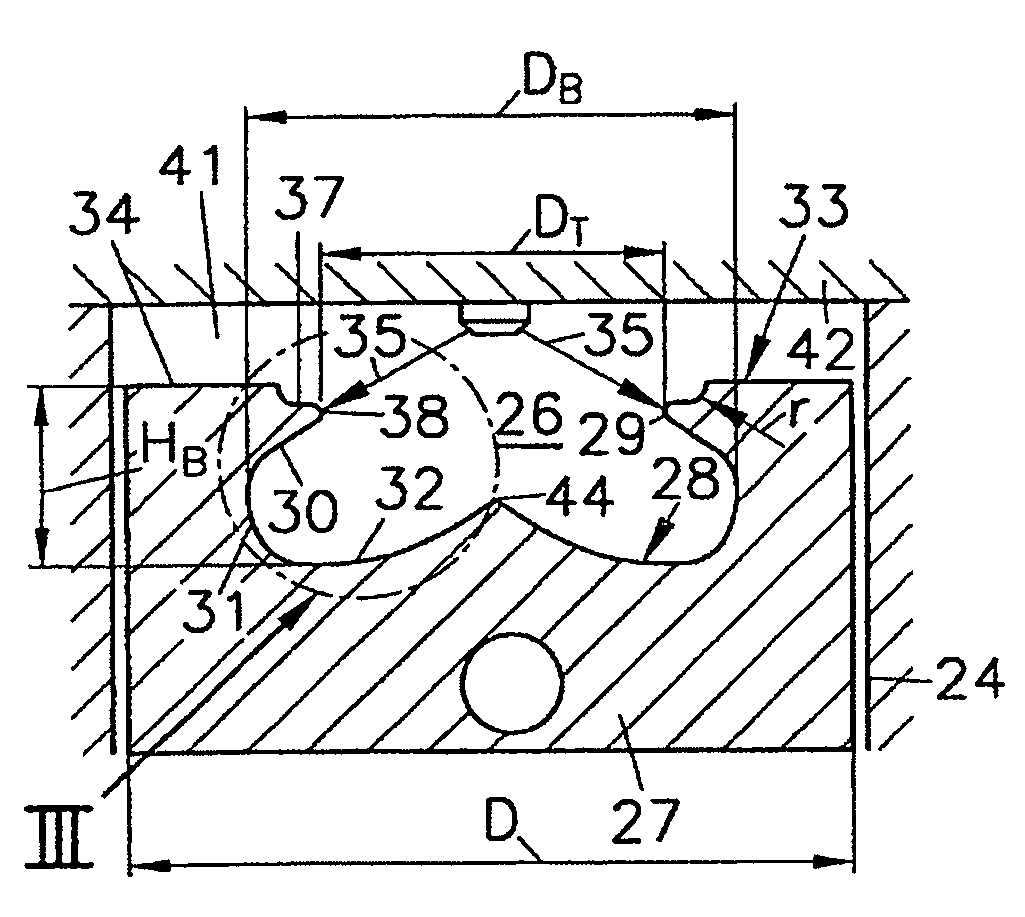

Rotary valve in an internal combustion engine

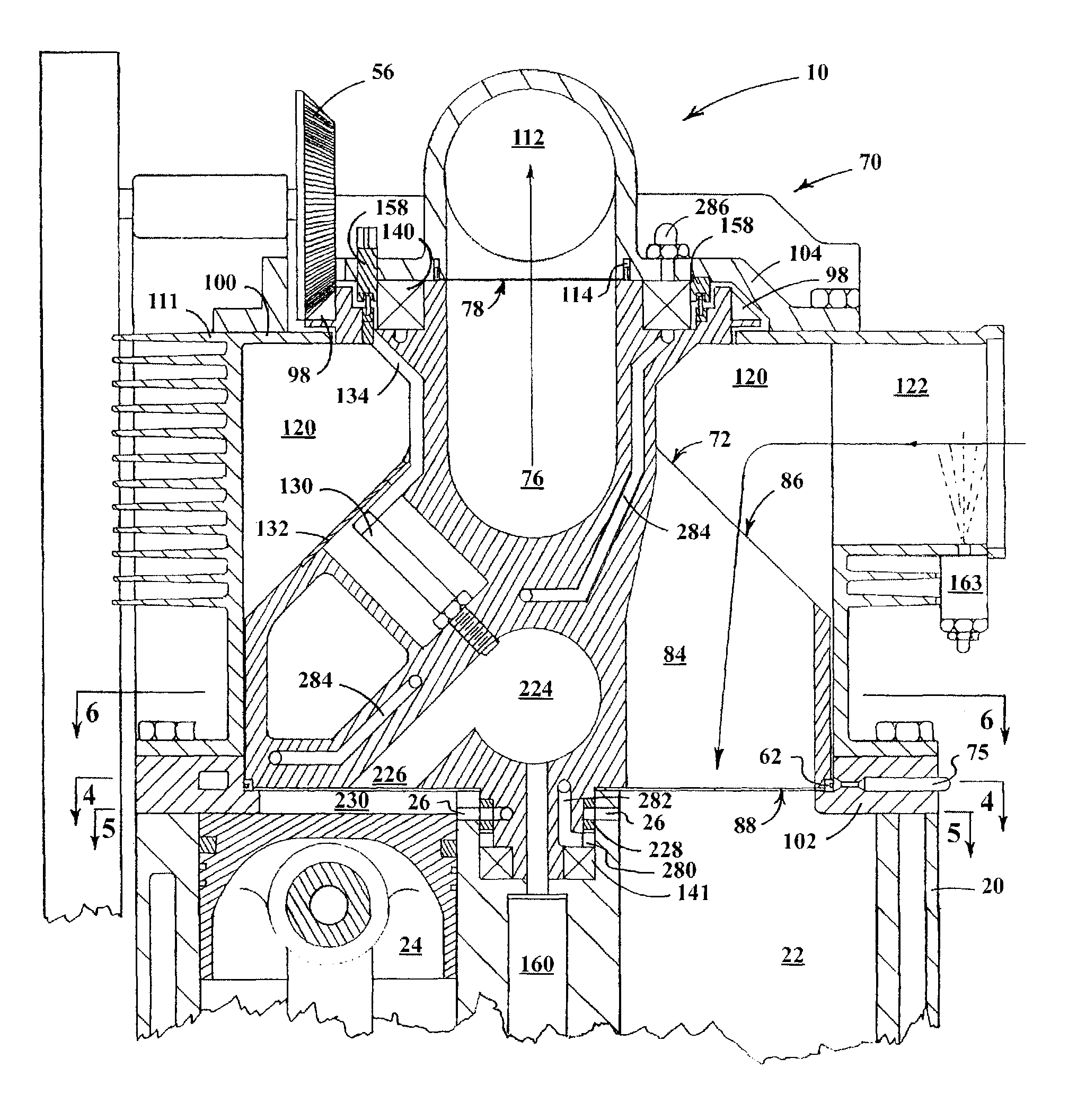

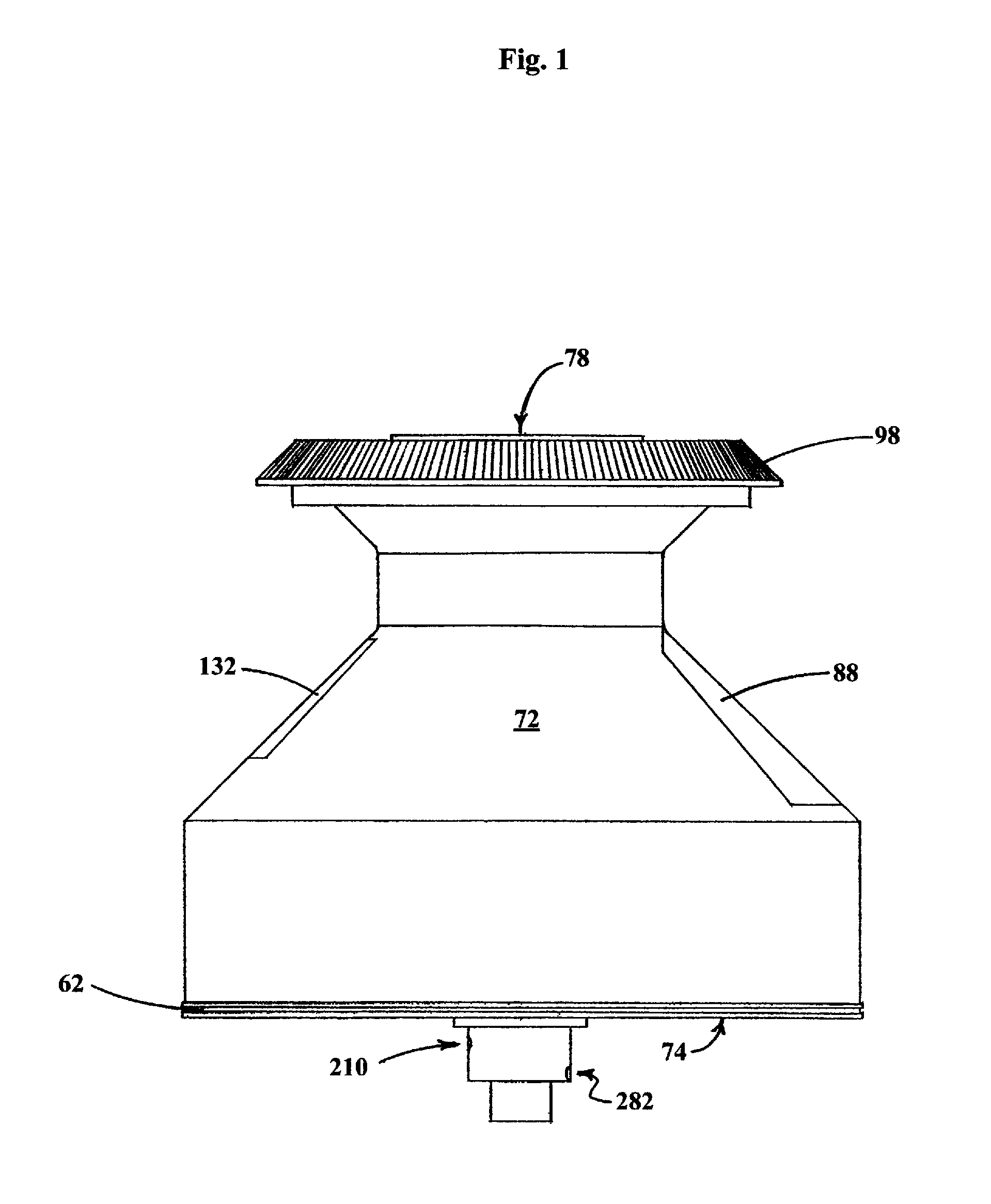

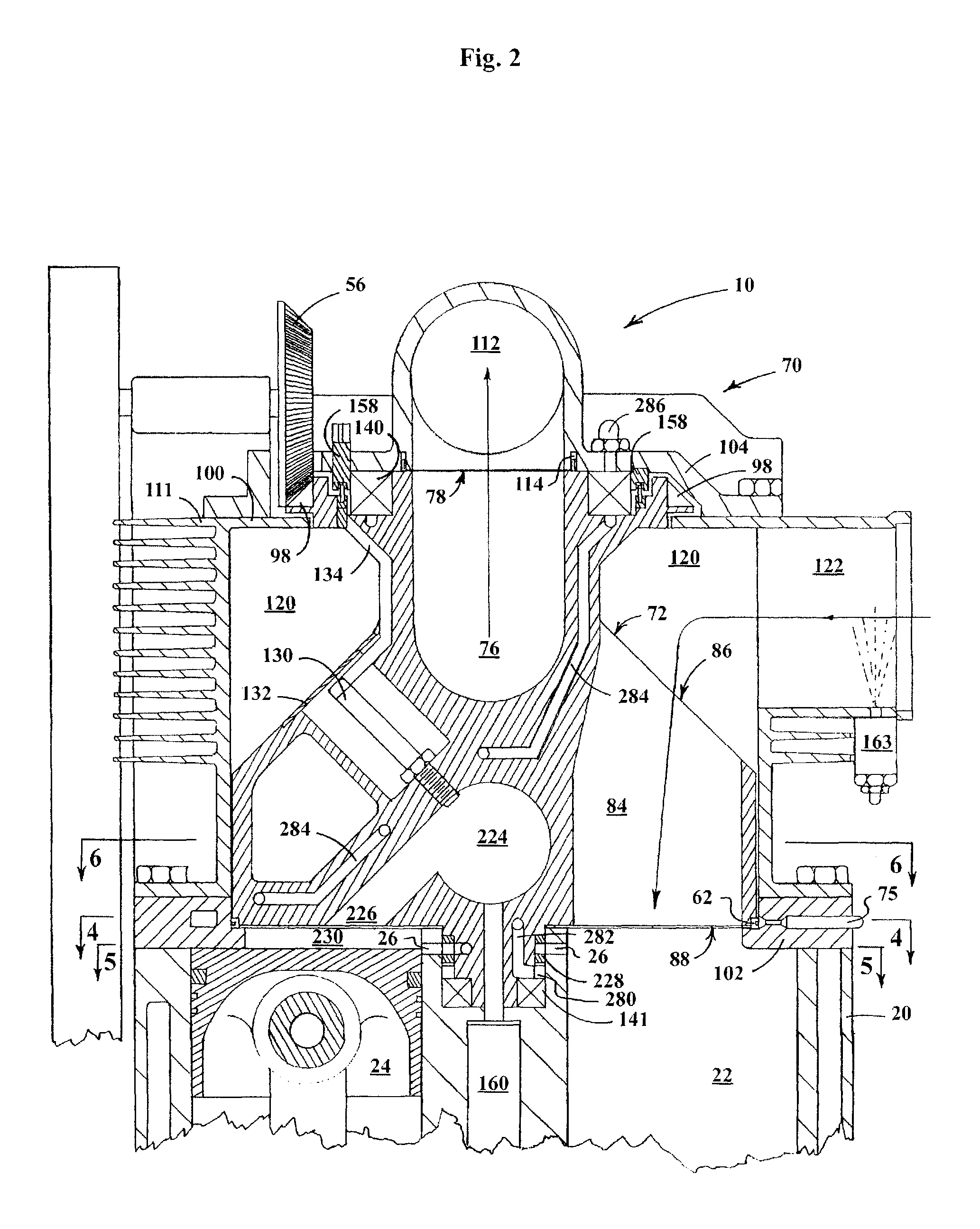

InactiveUS7841308B1Increase volumeImprove fuel economyNon-fuel substance addition to fuelEngine operationsThermal energyCombustion chamber

A rotary valve engine using a single rotary valve serving multiple cylinders significantly increases both volumetric and thermodynamic efficiencies. A novel stratified three stage low temperature combustion system reduces both heat transfer loss and combustion process irreversibility. Using large intake and exhaust valves and passages to reduce throttling losses, the rotary valve also contains a combustion valve and passage connected to a central combustion chamber. Combustion is initiated for all cylinders by a fuel injector in this central chamber which then sequentially ignites a second combustion chamber charge located in each cylinder head. A passage in the rotary valve shaft transfers gas from the combustion cycle to the compression cycle varying the compression ratio of the engine, producing EGR, and transferring radical species for combustion to the next cycle. A compounding element on the rotary valve extracts additional thermal energy derived from reduced heat transfer loss and increased energy.

Owner:MUTH BARRY A

Method for exploiting heavy oil reservoir by strengthening in-situ oil combustion

The invention provides a method for exploiting a heavy oil reservoir by strengthening in-situ oil combustion. The method includes: arranging a vertical injection-production well pattern including an injection well and a production well in an exploiting area of the heavy oil reservoir; lighting oil layers by means of chemical ignition or electric ignition; continuously injecting air from the vertical injection well to maintain combustion; continuously exploiting through the production well; injecting 1-3m<3> of hydrogen peroxide slug 30-50% in mass concentration when every 100000-150000Nm<3> of air is injected in the injection well, and alternately injecting in this way; and closely monitoring oxygen content and temperature of gas produced by the production well, and timely adjusting slug injection parameters. Hydrogen peroxide rapidly decomposes at high temperature in the oil layers, so that a large amount of heat and oxygen is provided for oil layer combustion, strengthened combustion is achieved, heavy oil combustion rapidly and favorably crosses a low-heat area to enter a high-temperature combustion area, and continuous oil combustion exploiting is achieved.

Owner:PETROCHINA CO LTD

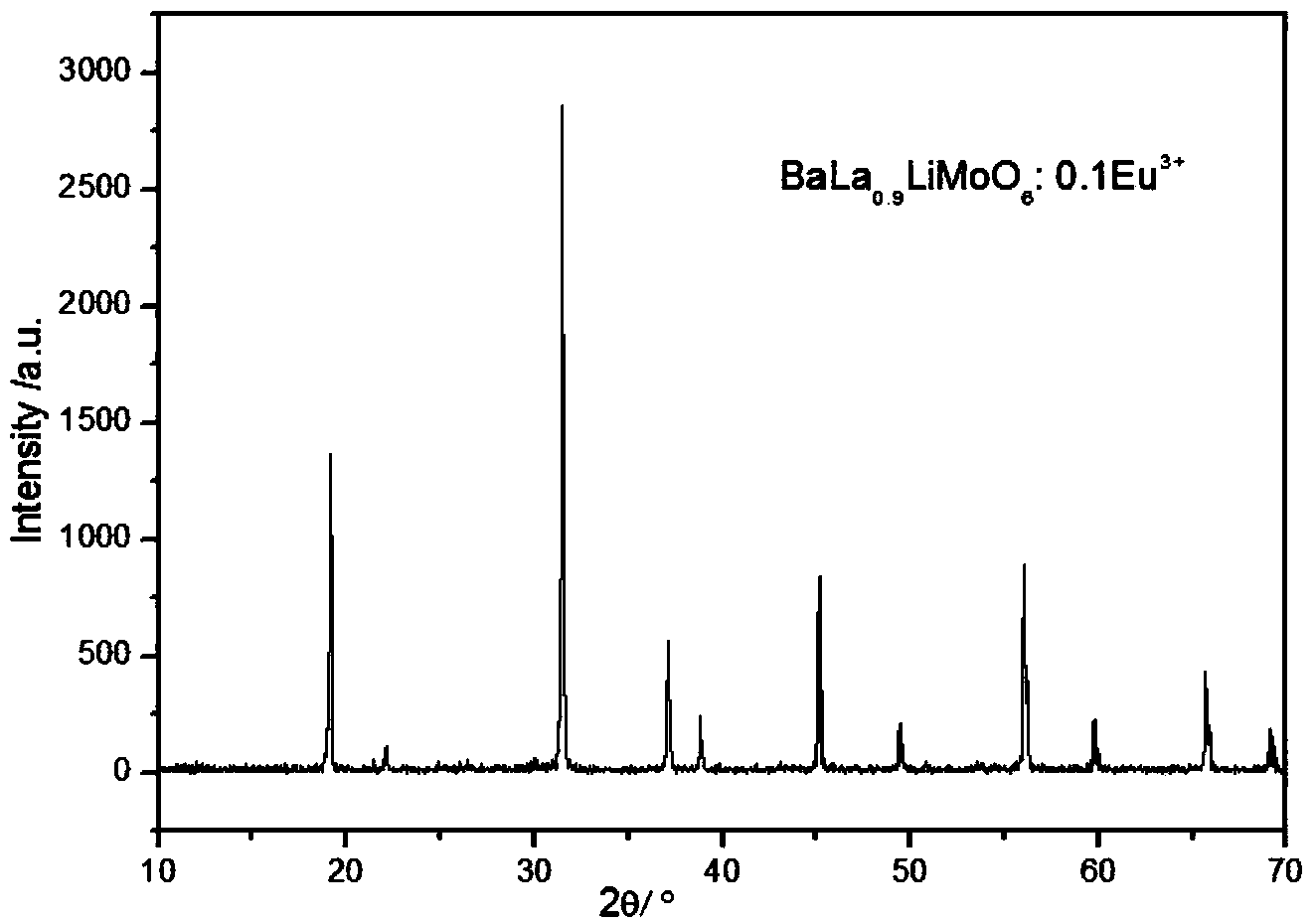

Double-perovskite tungsten molybdate red fluorescent powder for white light LED and preparation method of double-perovskite tungsten molybdate red fluorescent powder

ActiveCN104371719AEfficient excitationHigh luminous intensityEnergy efficient lightingLuminescent compositionsAlkaline earth metalMolybdate

The invention relates to double-perovskite tungsten molybdate red fluorescent powder for a white light LED and a preparation method of the double-perovskite tungsten molybdate red fluorescent powder. The chemical expression of the red fluorescent powder is AA<II>1-xLi<+>B<II>O6:xEu<3+>, wherein Eu<3+> is an active ion doped to an A<II> site, and the doping amount x is more than or equal to 0.01 and less than or equal to 0.6; A is any one of or a combination of more of divalent alkaline earth metal ions Ca<2+>, Sr<2+> and Ba<2+>; A<II> is any one of or a combination of more of trivalent rare-earth ions La<3+>, Gd<3+>, Y<3+> and Sc<3+>; B<II> is any one of or a combination of W<6+> and Mo<6+>; and the red fluorescent powder is prepared by adopting a low-temperature combustion method. The double-perovskite tungsten molybdate red fluorescent powder disclosed by the invention can be efficiently excited by near ultraviolet and blue light chips, the luminous efficiency is improved, the preparation process is simple, and the synthesis temperature is low, so that the double-perovskite tungsten molybdate red fluorescent powder is ideal red fluorescent powder suitable for the white light LED.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com