Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

347 results about "Post injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

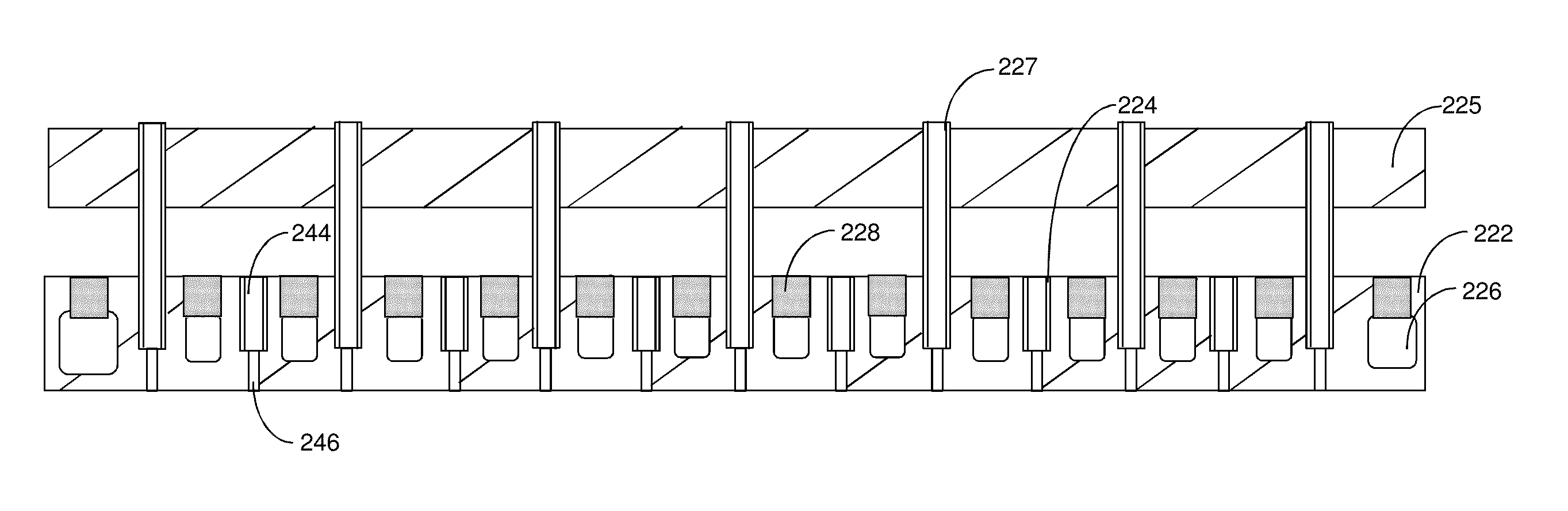

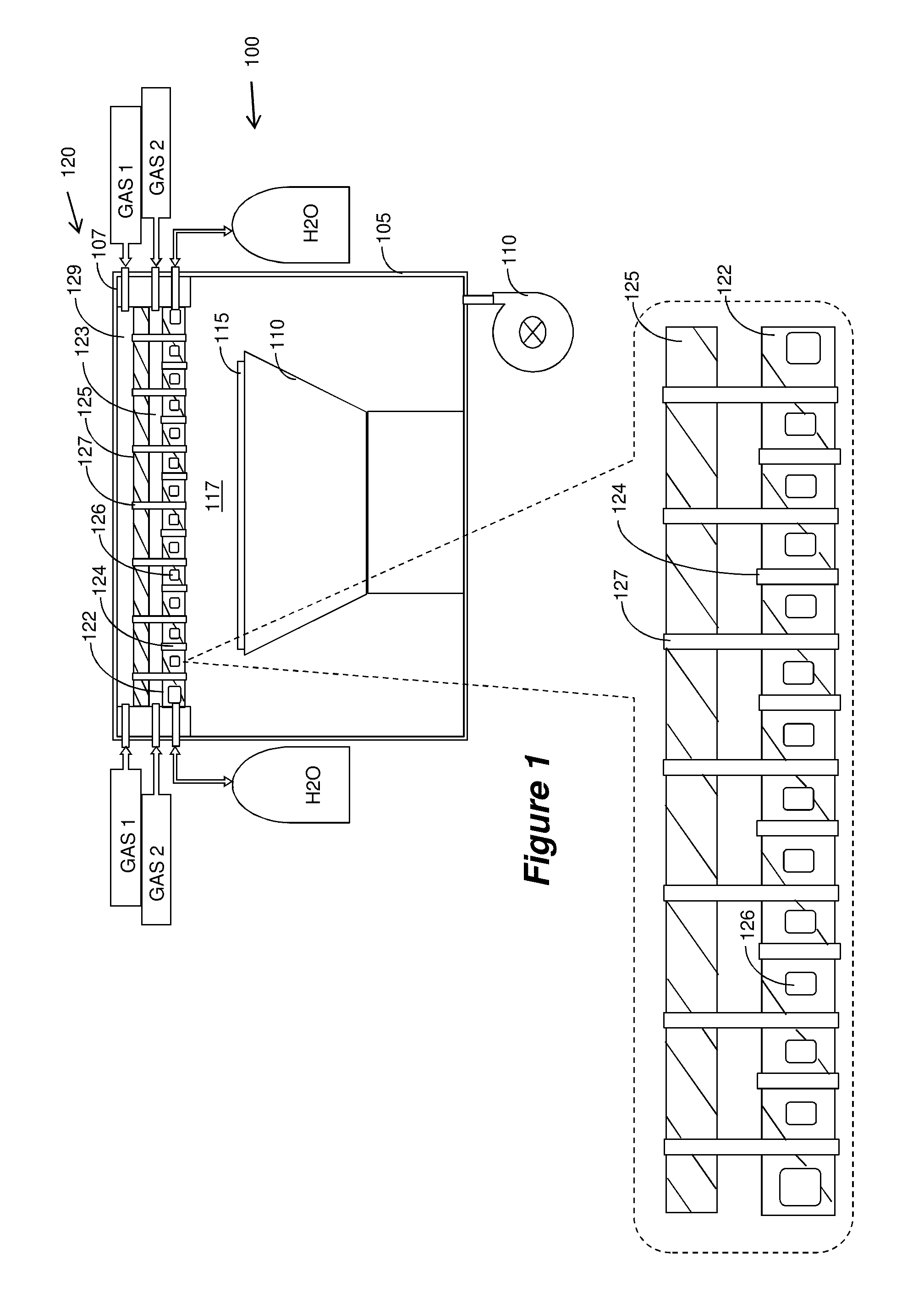

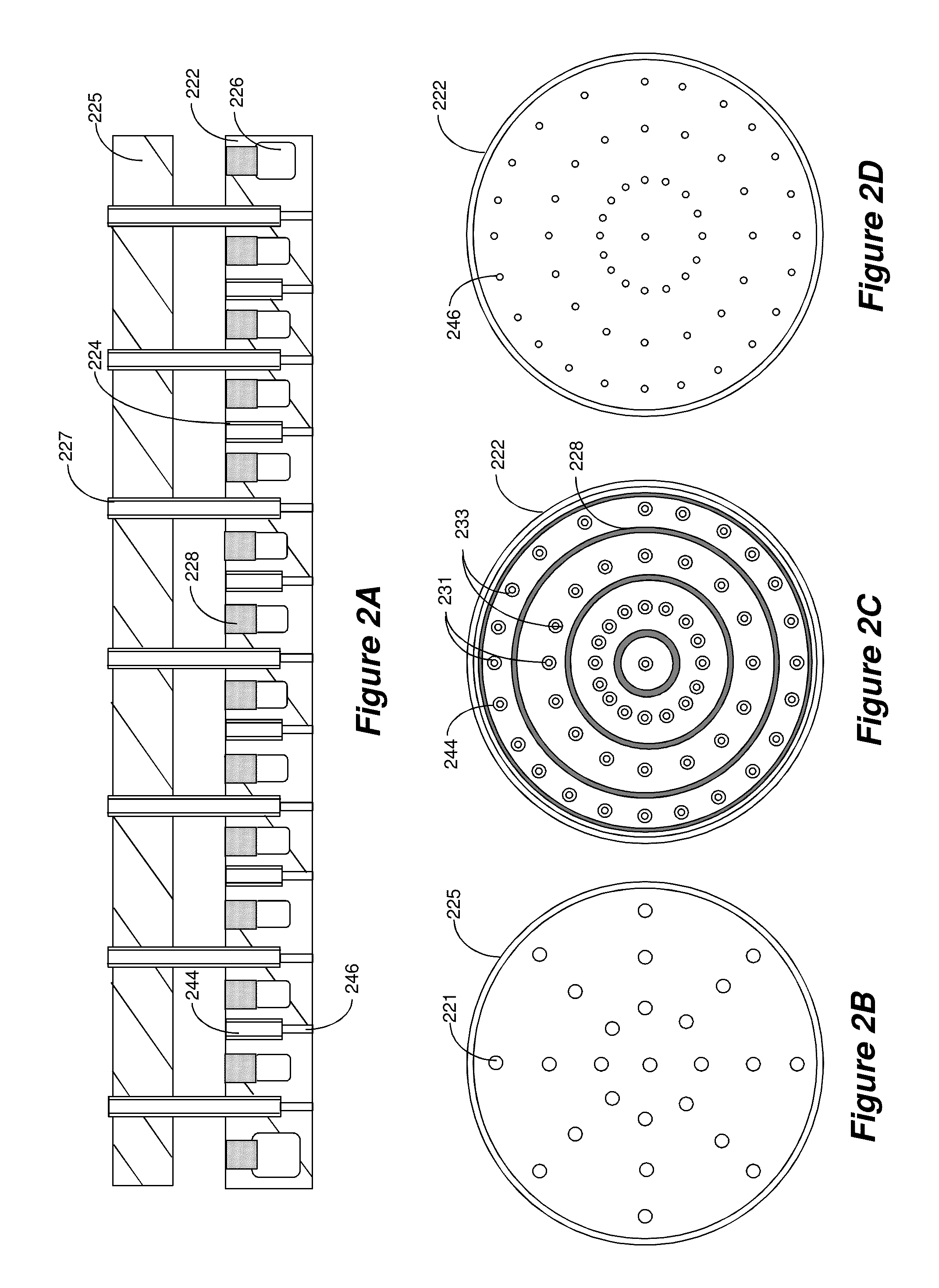

Fluid cooled showerhead with post injection mixing

InactiveUS20130118405A1Easy to manufactureFew partsLiquid spraying apparatusChemical vapor deposition coatingEngineeringMechanical engineering

A showerhead that injects two process gases into the processing chamber via separate sets of holes. The showerhead is constructed of upper plate and lower plate. Upper plate has a first set of holes. The lower plate has two sets of holes: one set is aligned with the holes in the upper plate, while the second set has no corresponding holes in the upper plate. Both sets of holes in the lower plate are made to have two different diameters: a larger diameter extending from the top surface of the lower plate, while a smaller diameter extends from the bottom surface and meets with the larger diameter. A set of pipes are inserted through the holes in the upper plate and the corresponding holes in the lower plate, and are sealingly brazed to both plates. Cooling channels may be provided in the lower plate.

Owner:ADVANCED MICRO-FABRICATION EQUIP INC ASIA

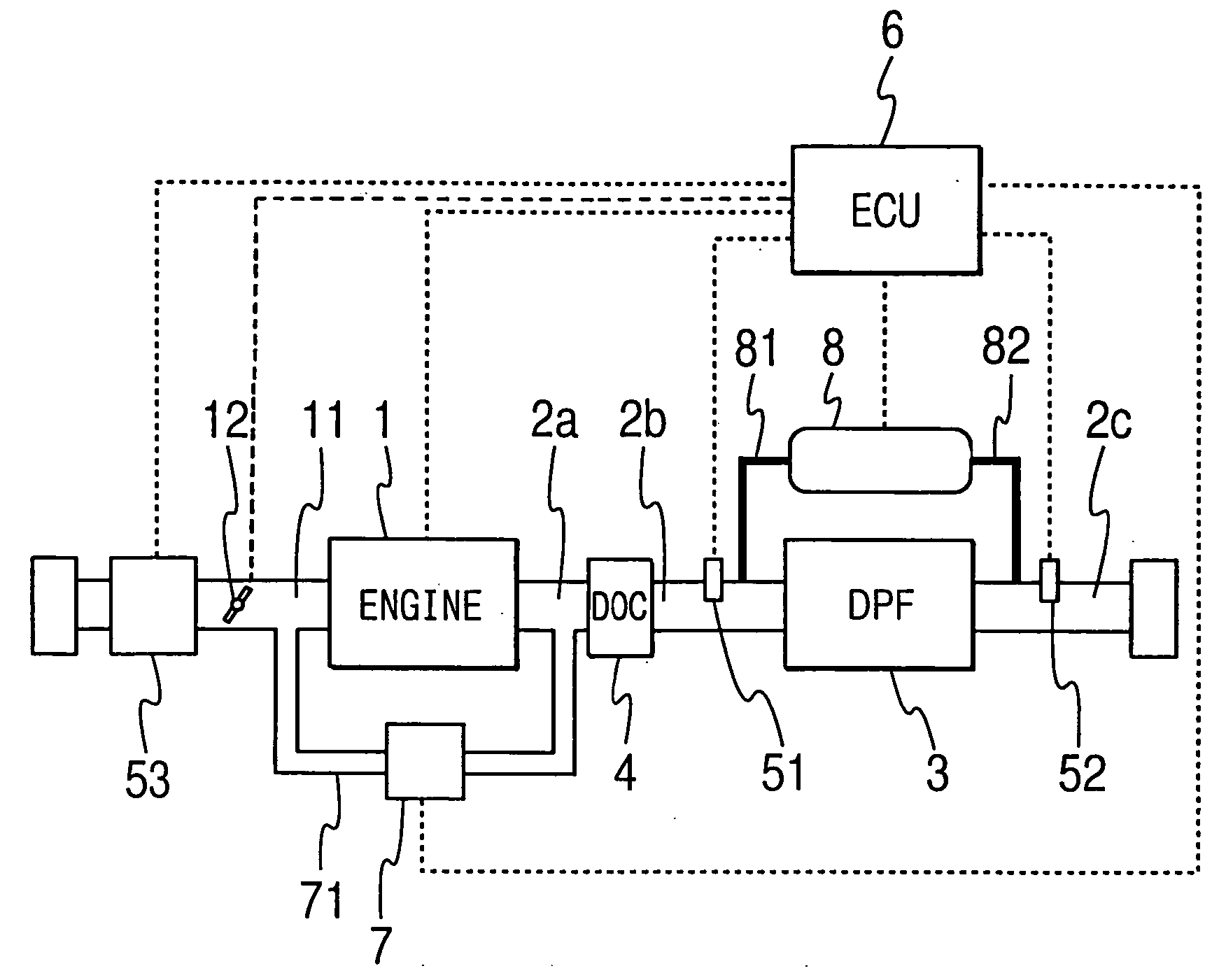

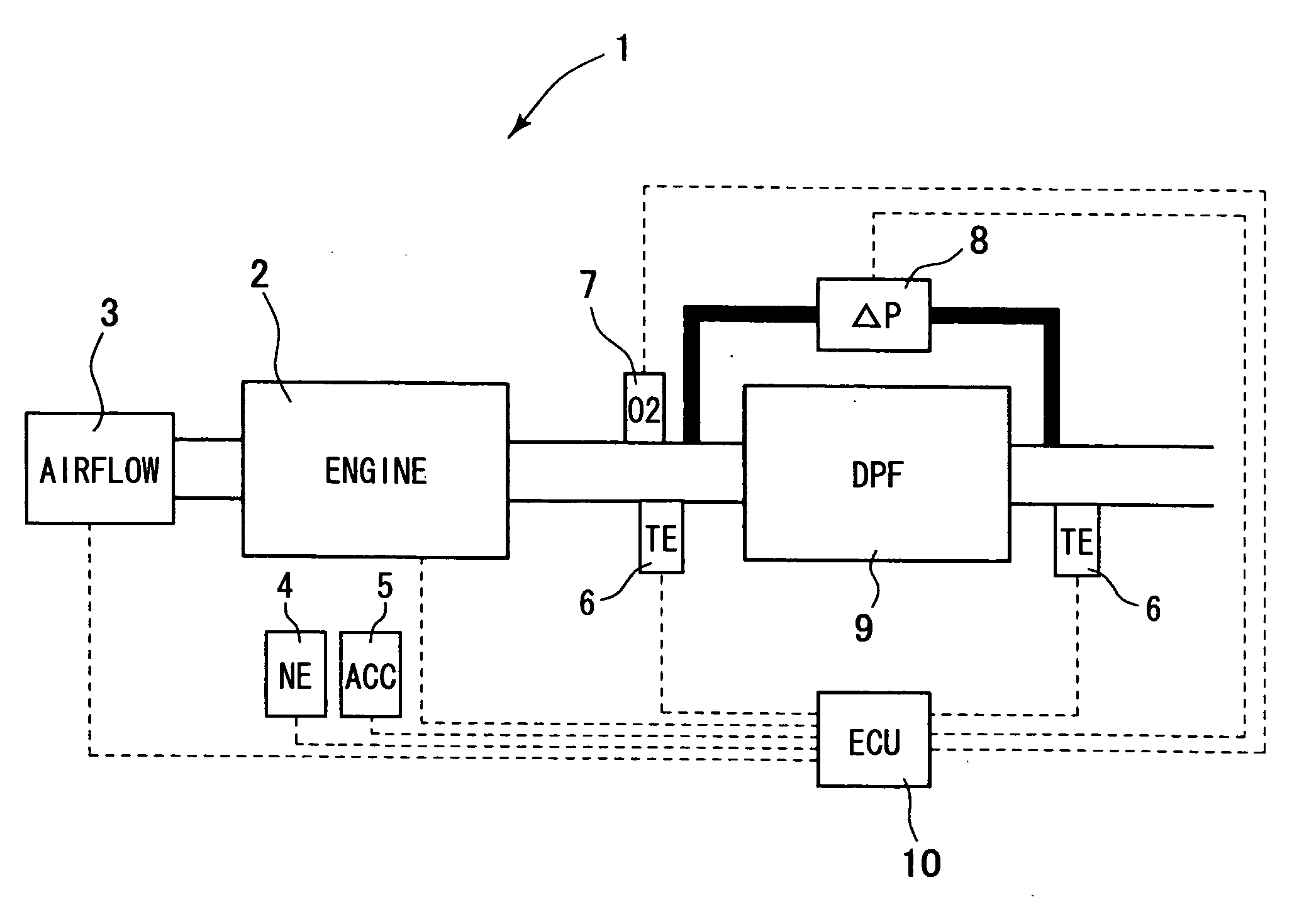

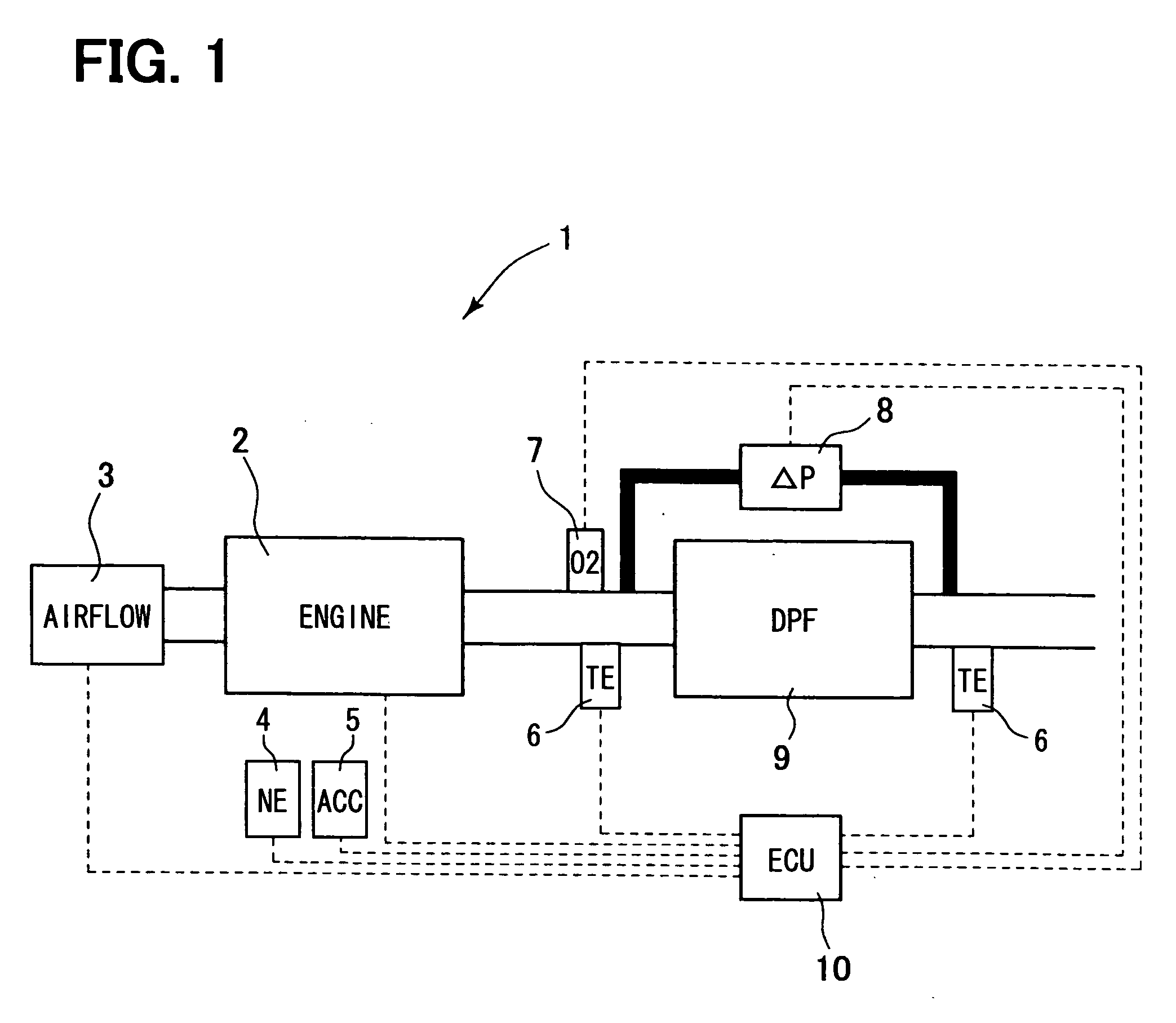

Exhaust gas cleaning system of internal combustion engine

ActiveUS20040187477A1Electrical controlNon-fuel substance addition to fuelPost injectionElectronic control unit

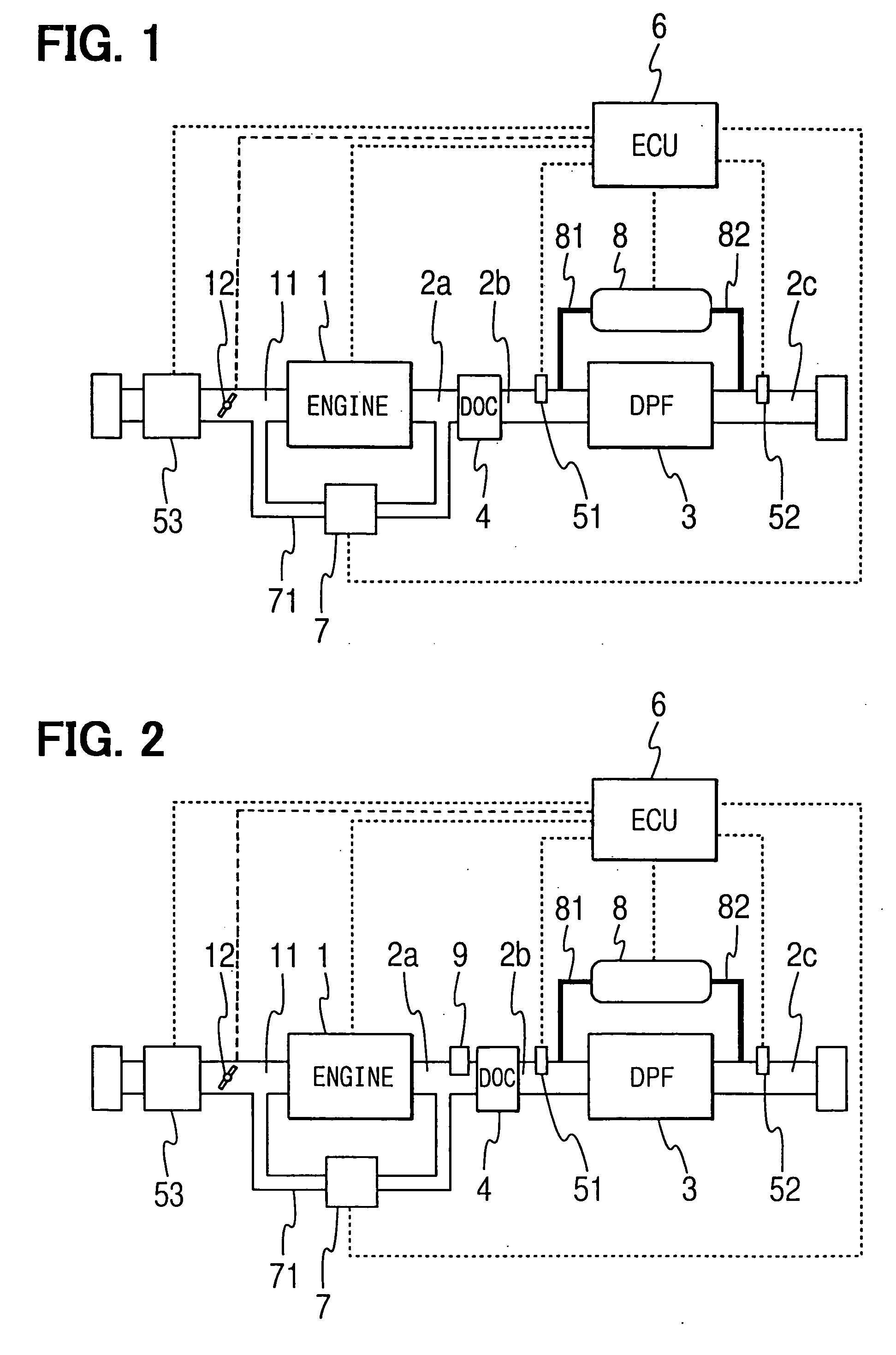

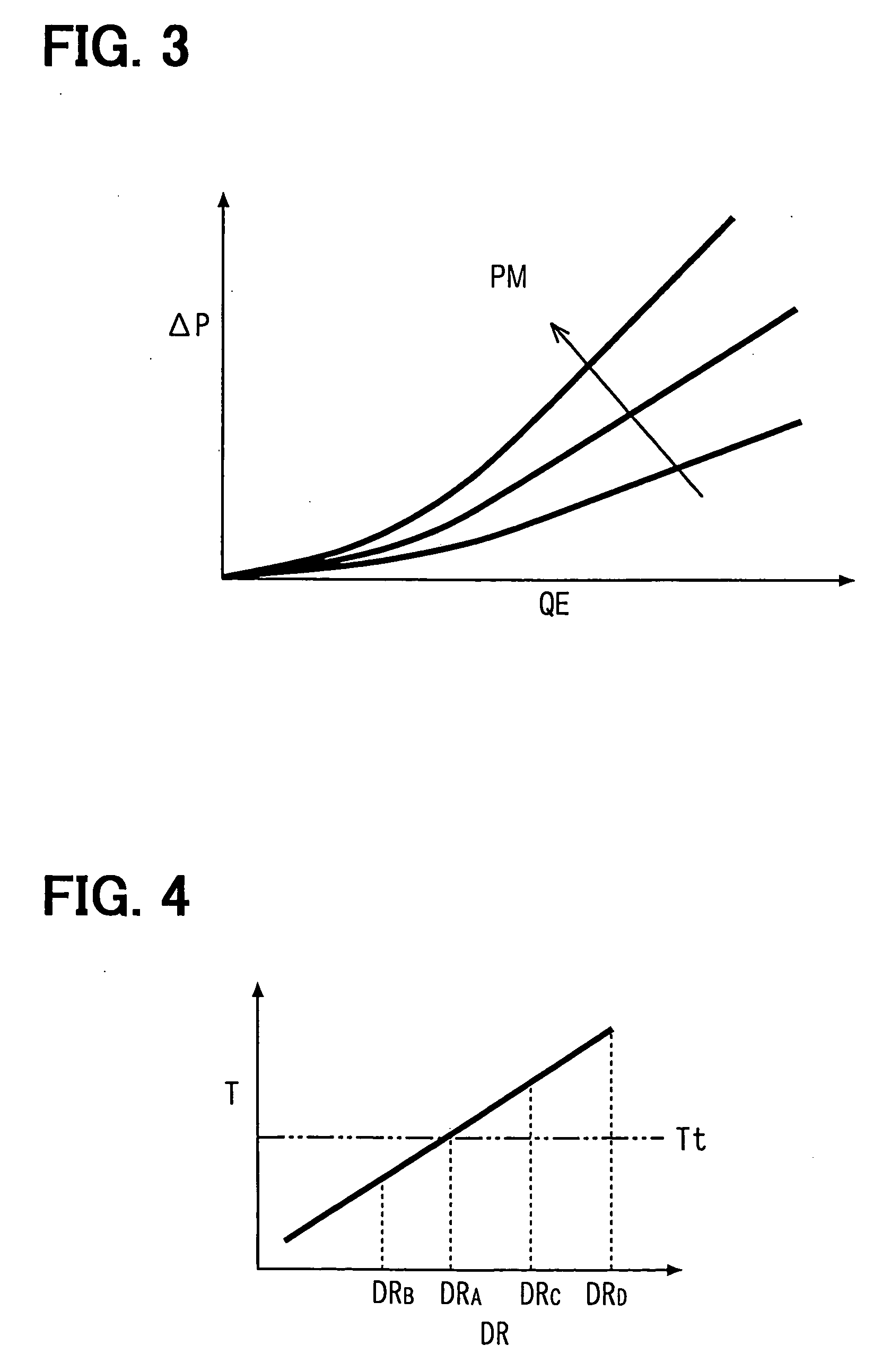

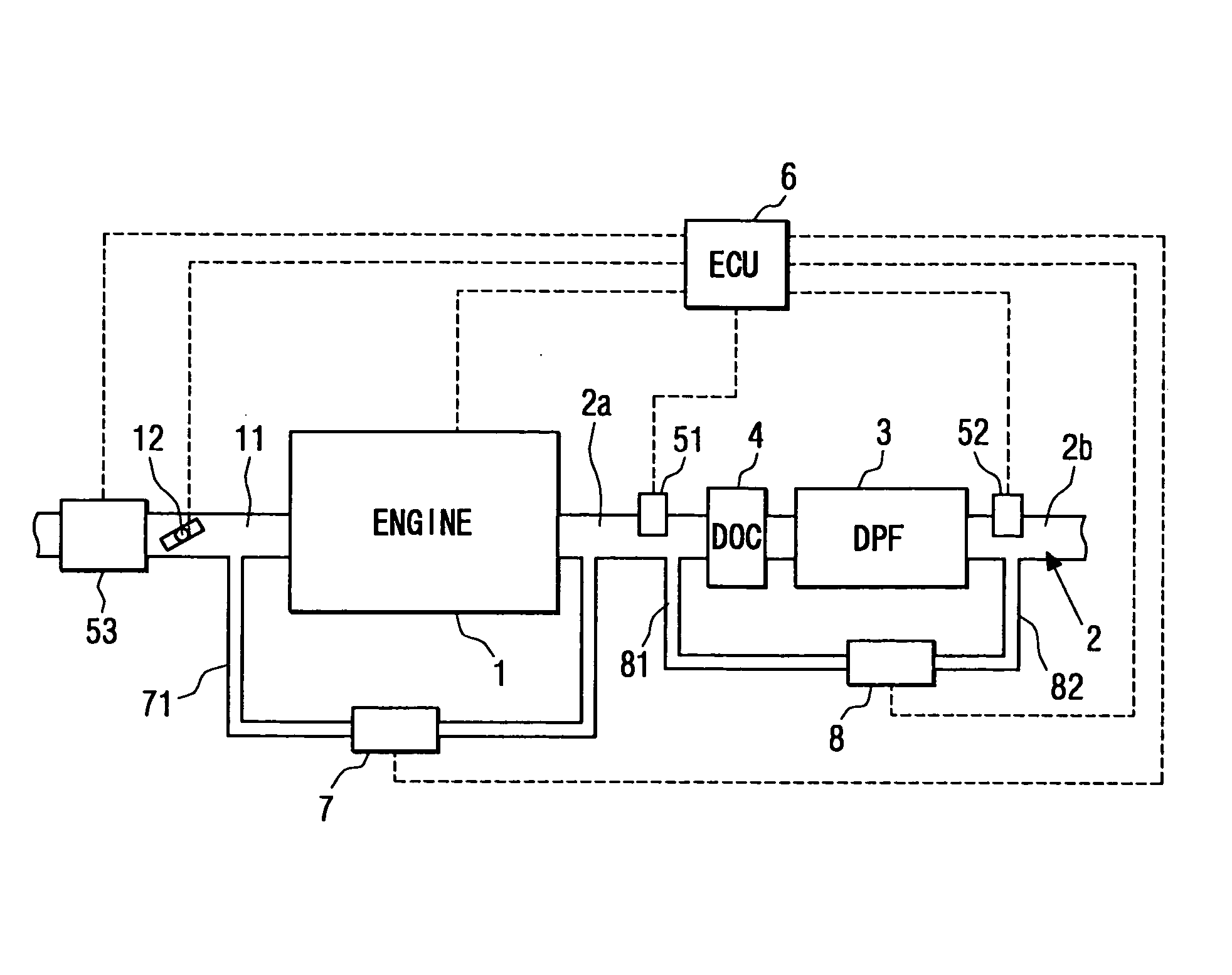

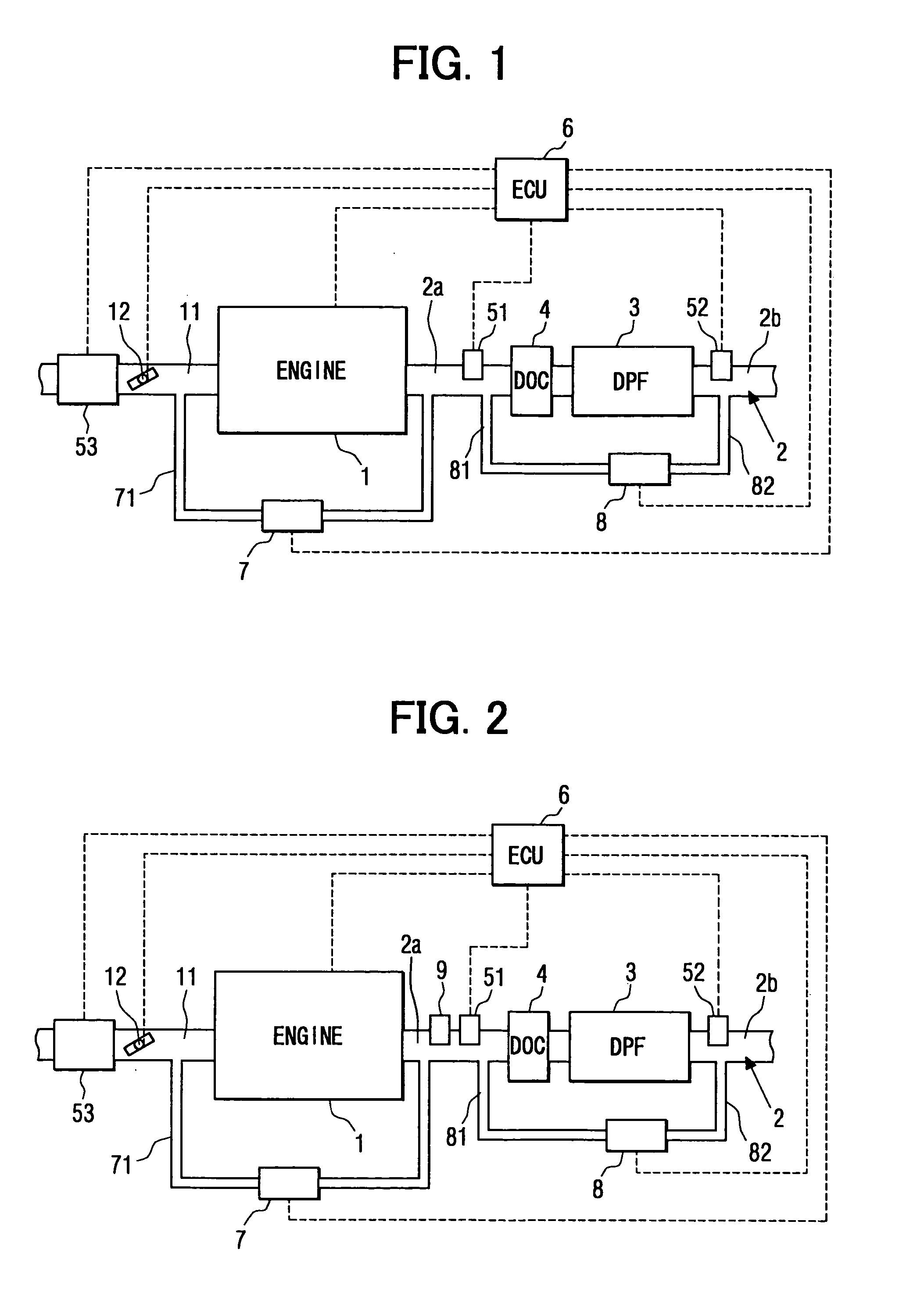

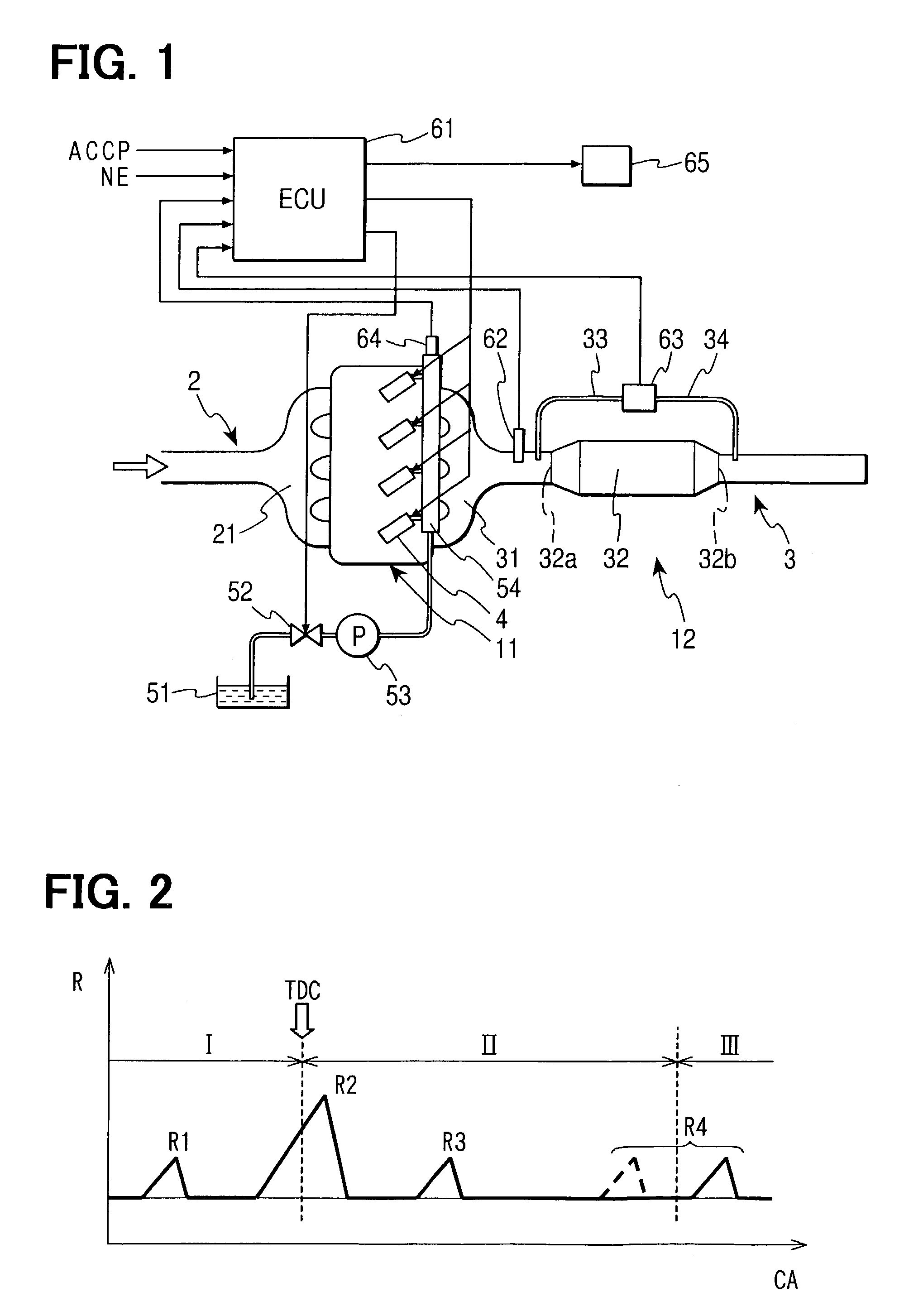

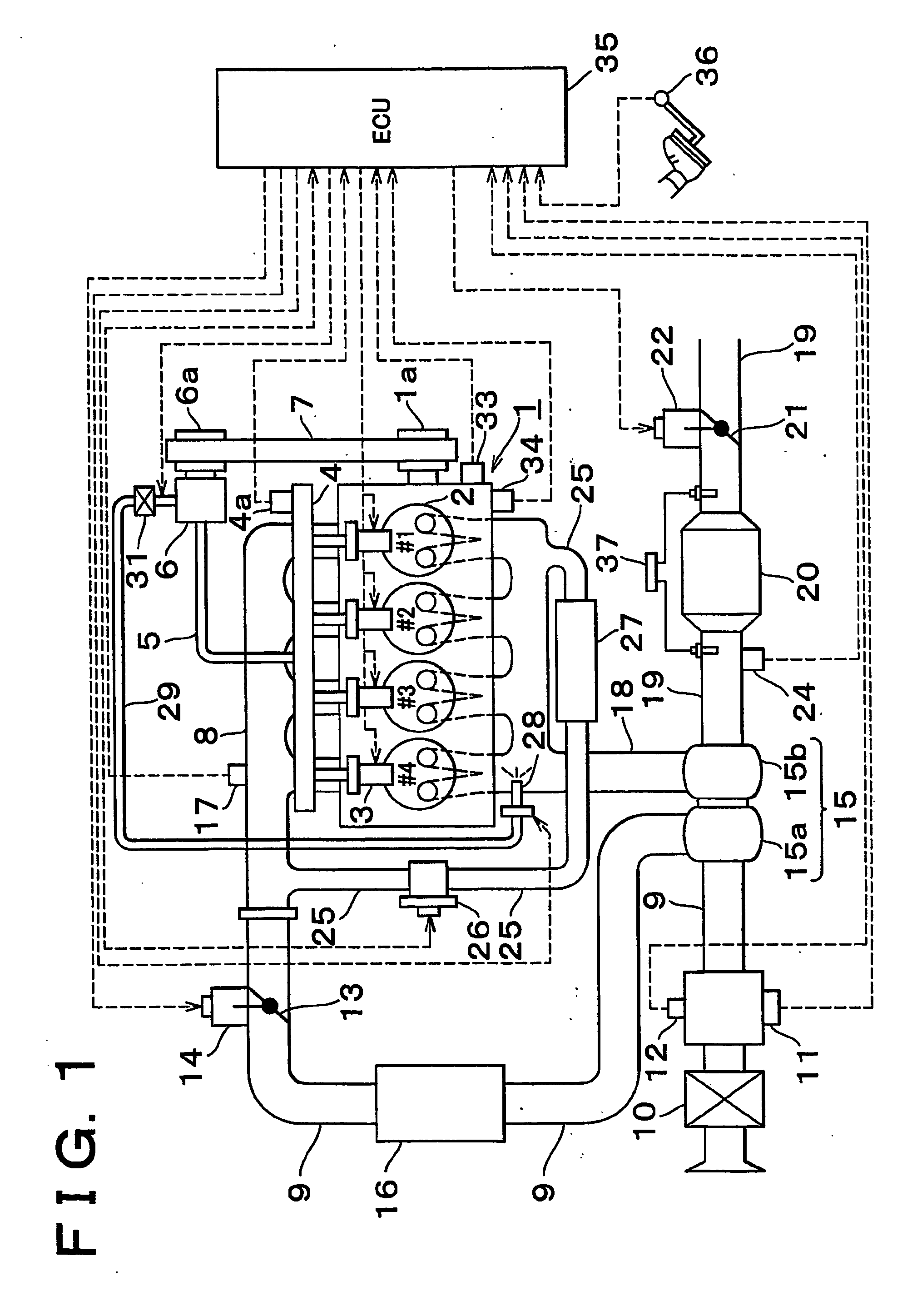

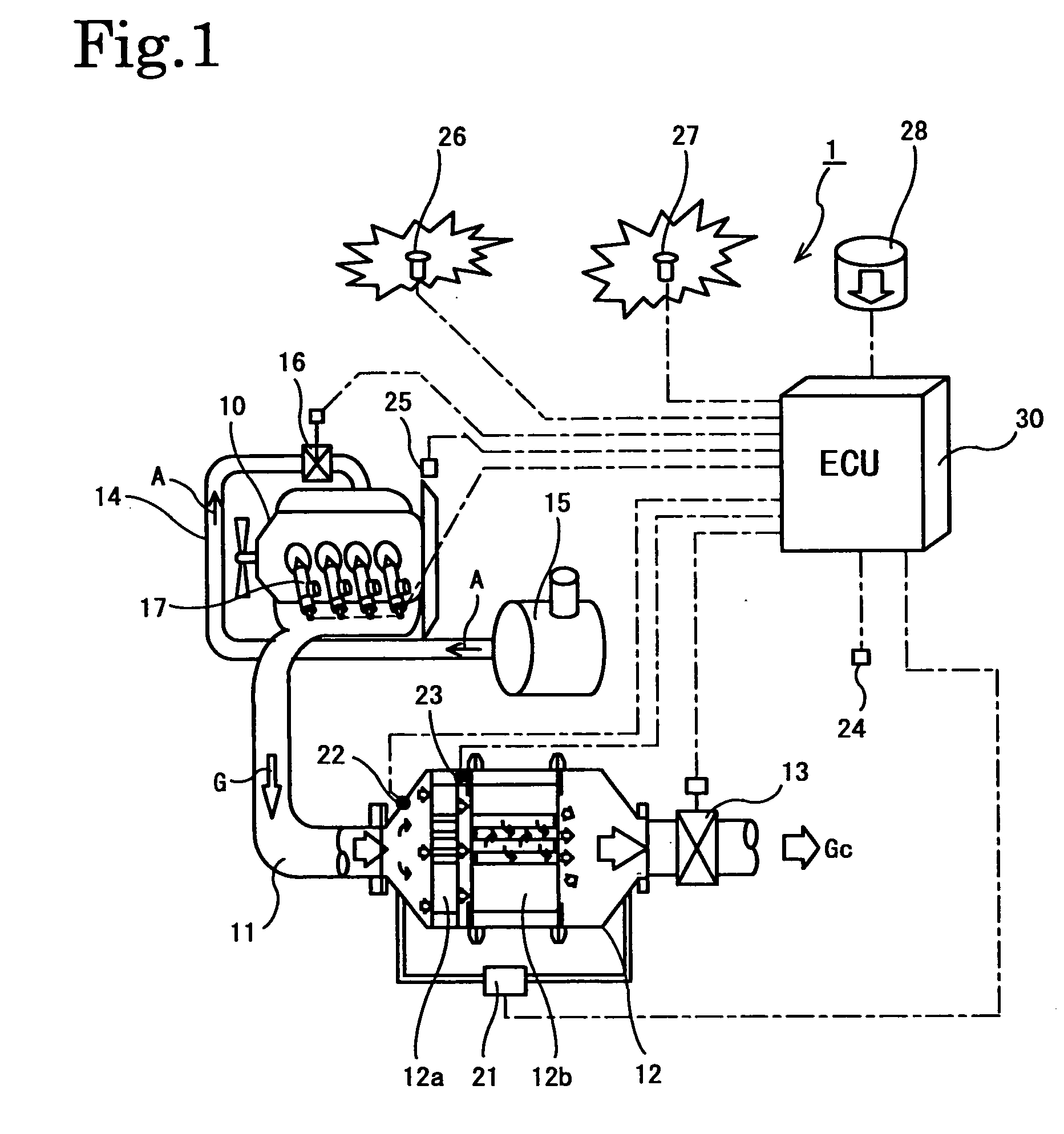

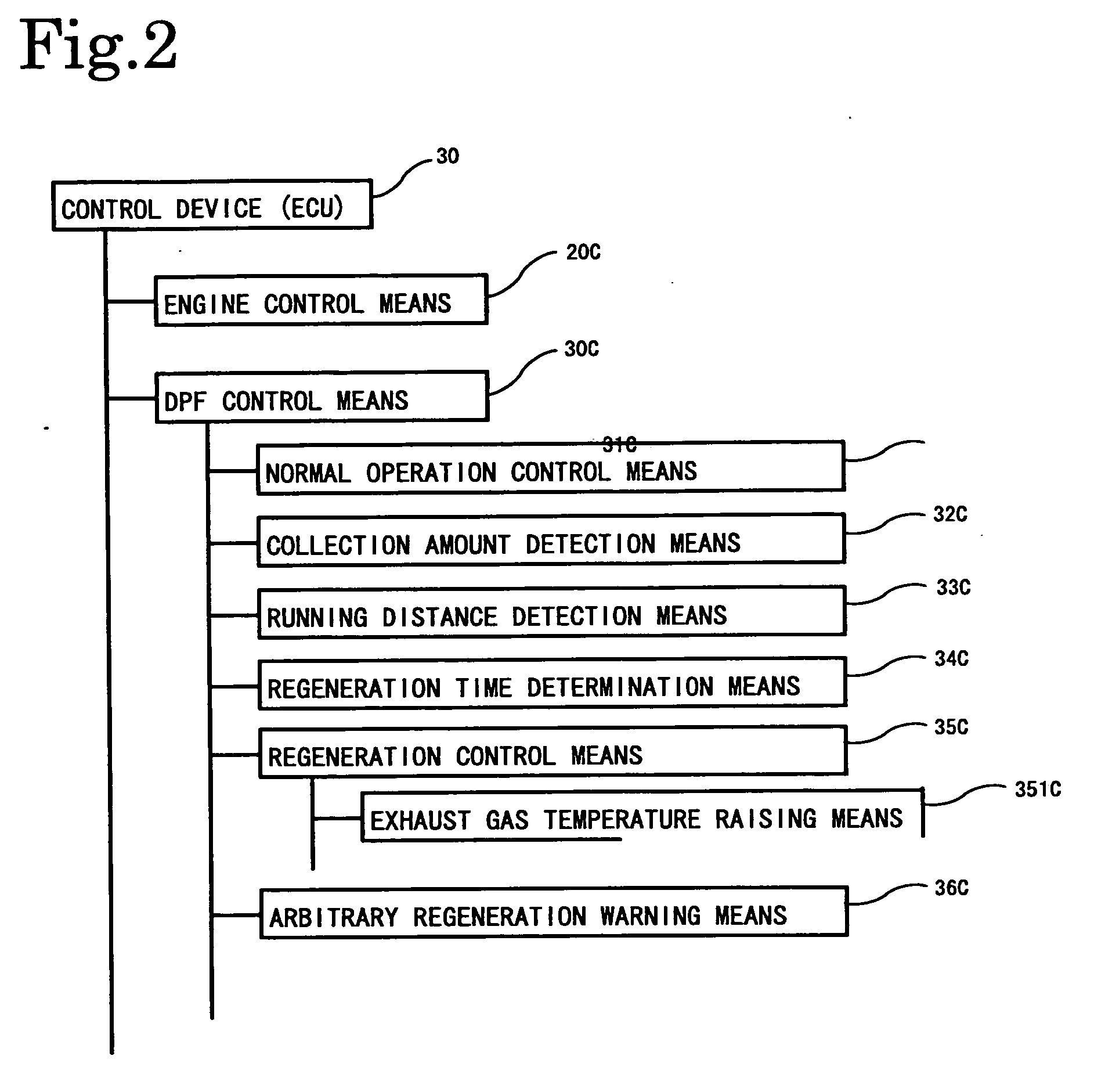

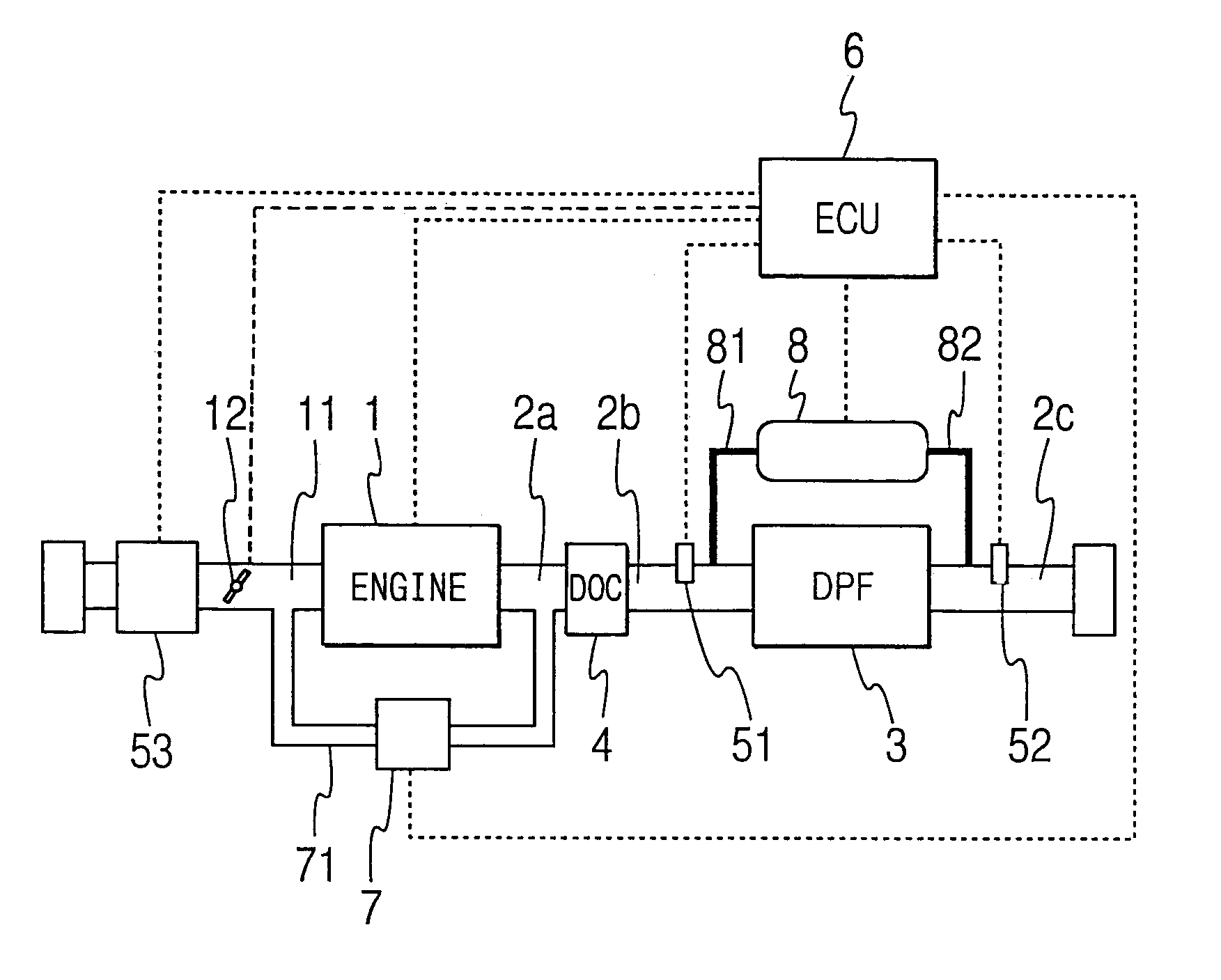

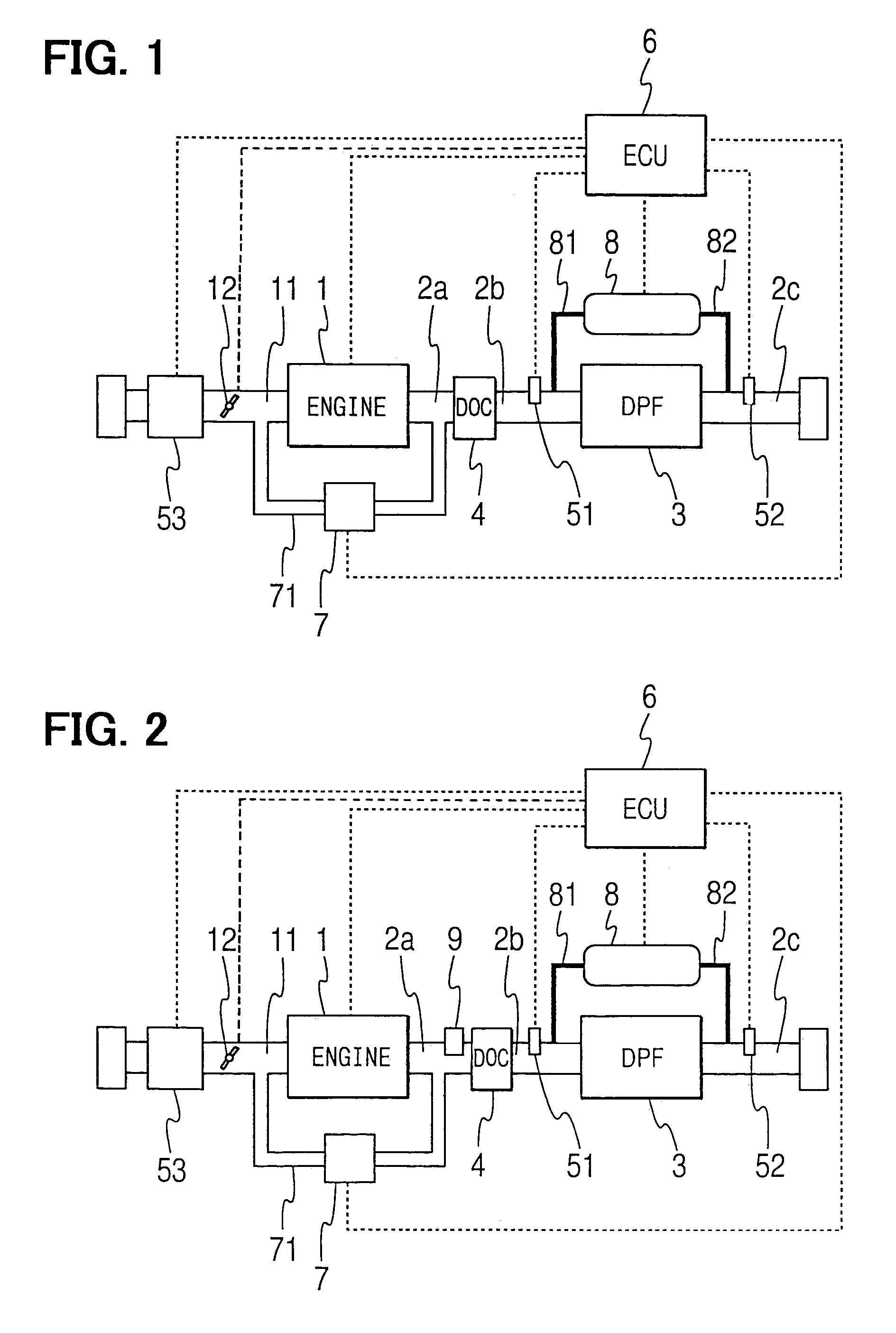

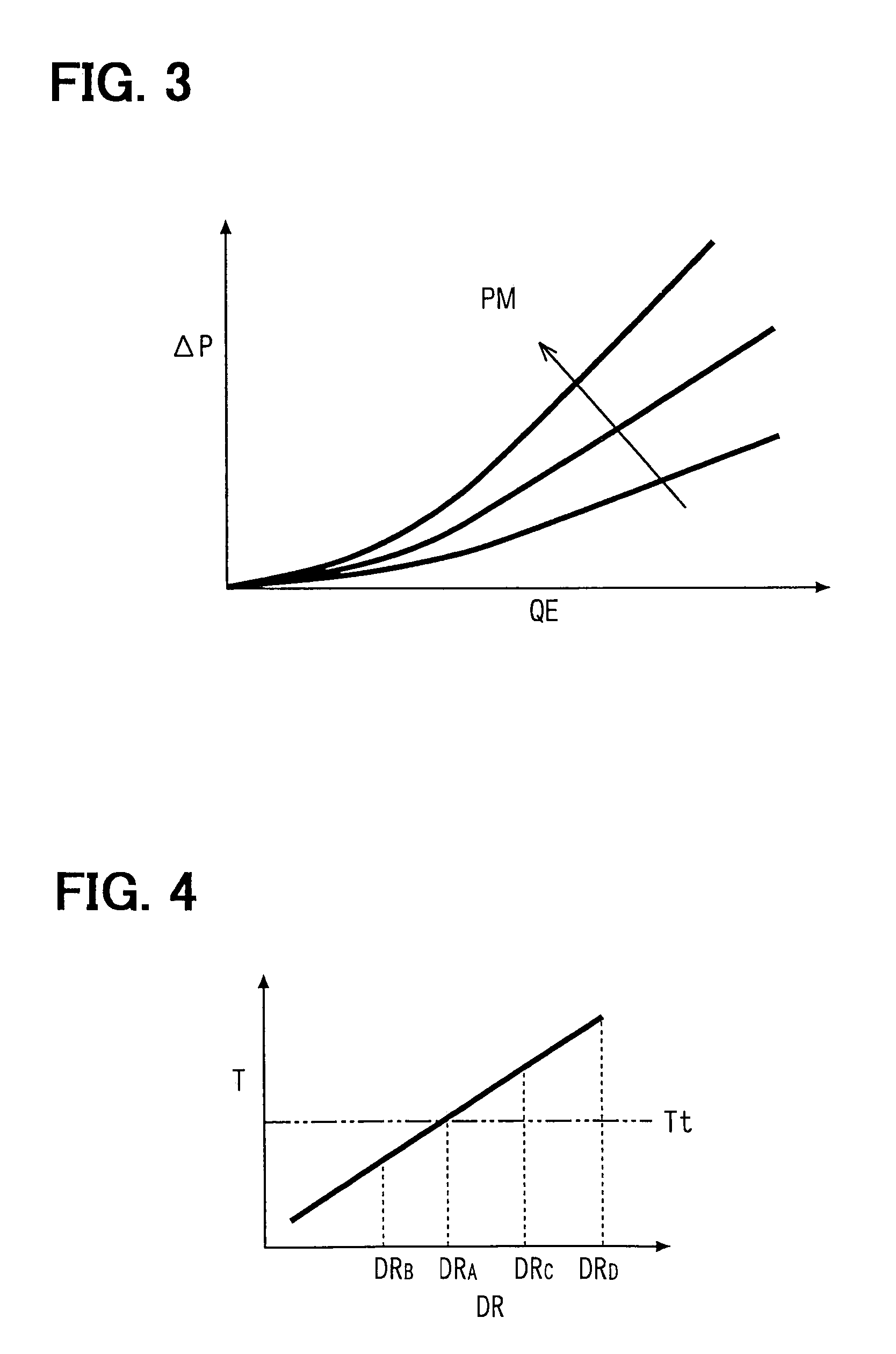

An exhaust gas cleaning system of a diesel engine includes a diesel particulate filter (a DPF) disposed in an exhaust passage, and a diesel oxidation catalyst (a DOC) disposed upstream of the DPF. When an electronic control unit (an ECU) performs a temperature increasing operation such as post-injection to eliminate particulate matters accumulated in the DPF, a ratio (a duty ratio) between a performing period and an interrupting period of the temperature increasing operation is changed in accordance with temperature of the DPF. Thus, a quantity of hydrocarbon supplied to the DOC is controlled stepwise or continuously. Thus, the temperature of the DPF can be increased to target temperature quickly and can be maintained near the target temperature when the regeneration of the DPF is performed.

Owner:DENSO CORP

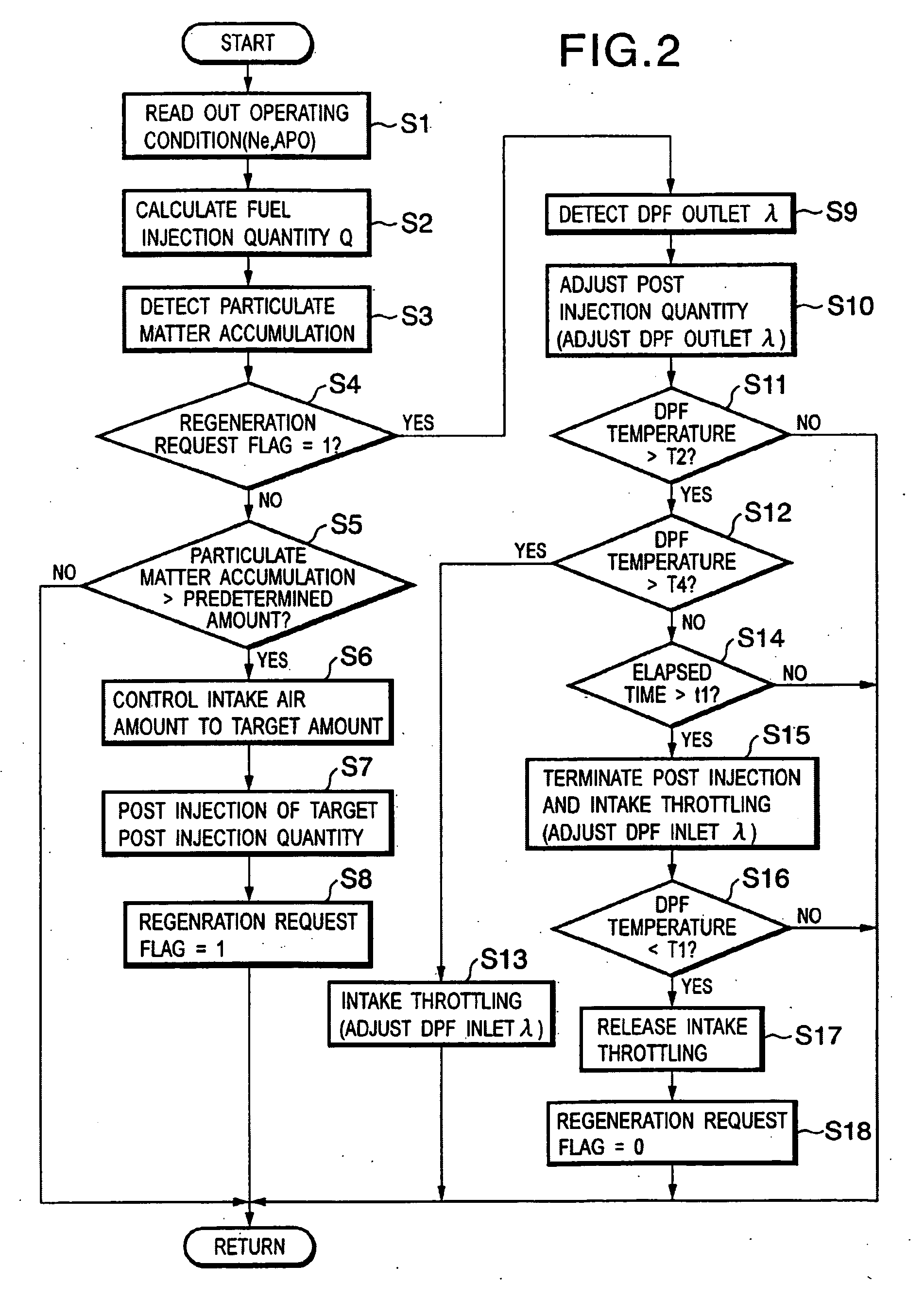

Exhaust gas purification apparatus for internal combustion engine and method thereof

InactiveUS20050072141A1Efficient purificationCombination devicesElectrical controlParticulatesExternal combustion engine

According to the present invention, there is disposed in an exhaust passage of an internal combustion engine a filter that traps particulate matter In an exhaust gas, and a catalyst with a three-way function is carried on the filter. At the filter regeneration, by controlling such as an injection amount of post injection, an air-fuel ratio of the exhaust gas at an outlet of the filter is controlled to a stoichiometric ratio, and also by controlling such as an intake air throttle valve, an oxygen concentration of the exhaust gas at an inlet of the filter is controlled. Hence, at the filter regeneration, the particulate can be reliably burned and removed, and at the same time, NOx in addition to HC and CO can be purified.

Owner:NISSAN MOTOR CO LTD

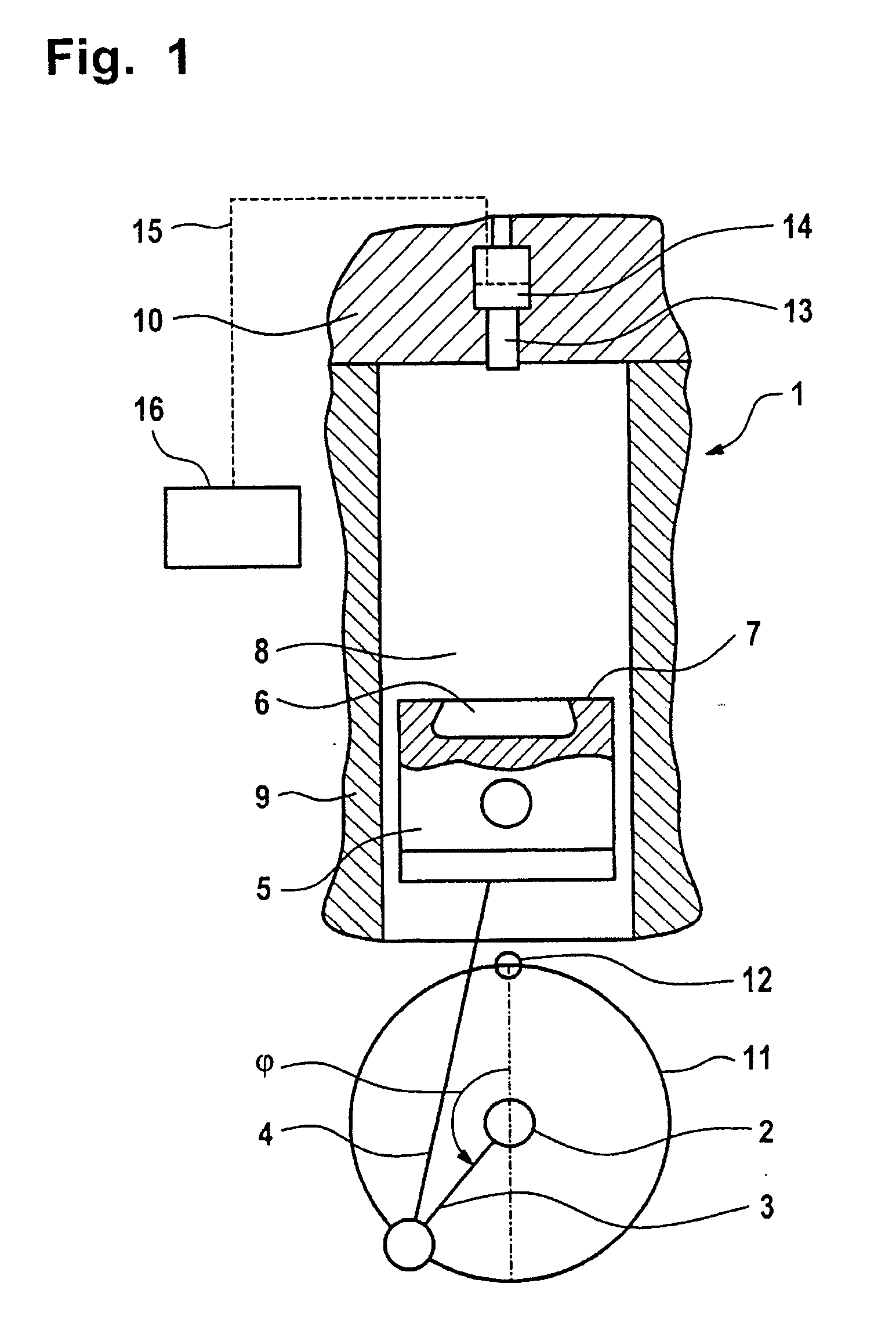

Internal combustion engine with auto ignition

InactiveUS20060037563A1Prevent wettingMinimize wettingElectrical controlNon-fuel substance addition to fuelCombustion chamberInternal combustion engine

In a method for operating an internal combustion engine in which fuel is injected directly into a combustion chamber in a pre-injection and a main fuel injection step, and, if appropriate, also in a post-injection step by means of an injection nozzle with a plurality of injection bores, the injection of fuel takes place in a timed fashion and, to limit pressure and temperature during combustion of the fuel in the combustion chamber, a quantity of water is introduced into the combustion chamber during or after the pre-injection step.

Owner:DAIMLER AG

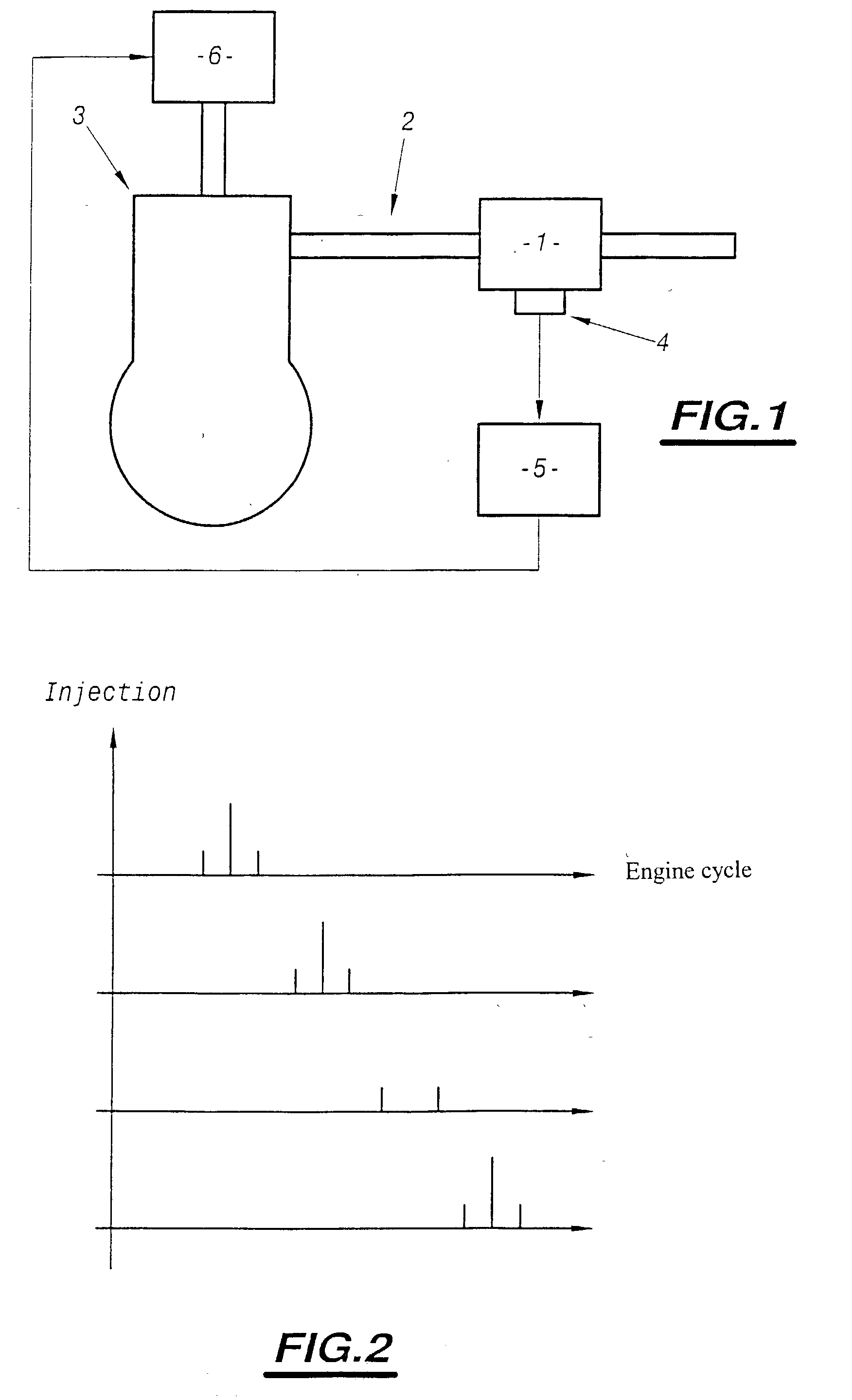

System for aiding the regeneration of pollution-control means that are integrated in an exhaust line of a motor vehicle engine

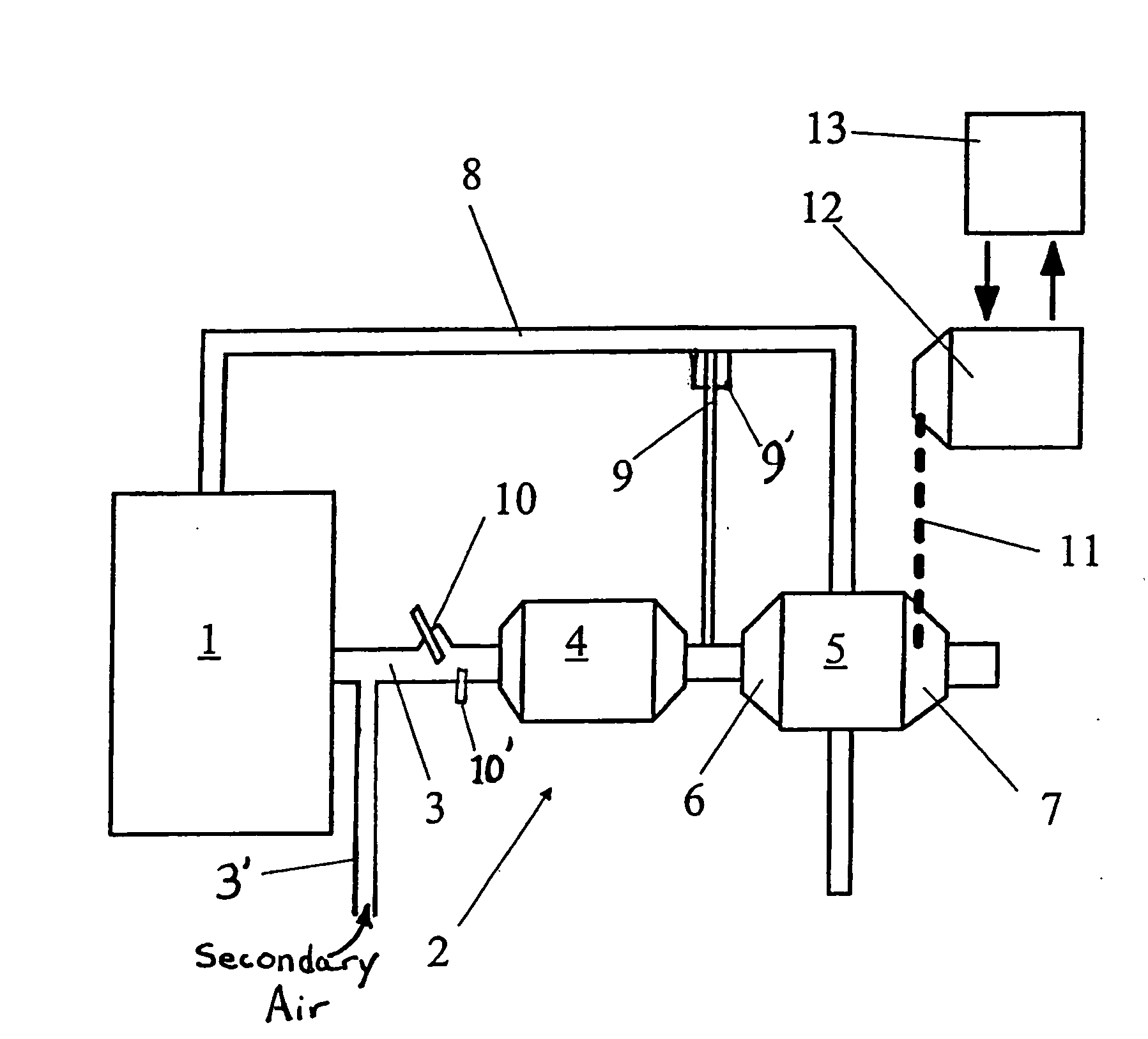

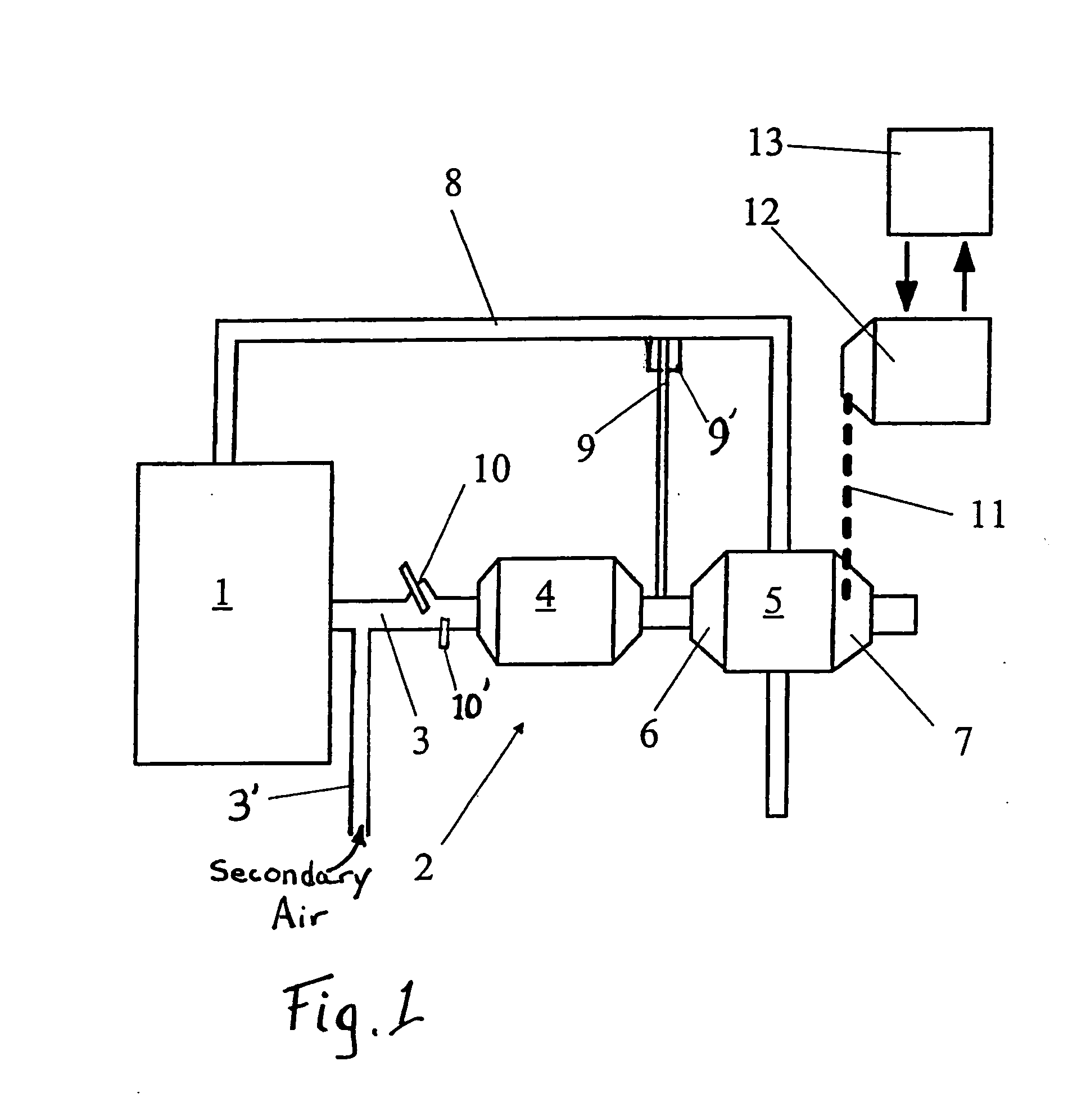

InactiveUS20030089102A1Electrical controlInternal combustion piston enginesExpansion phaseMobile vehicle

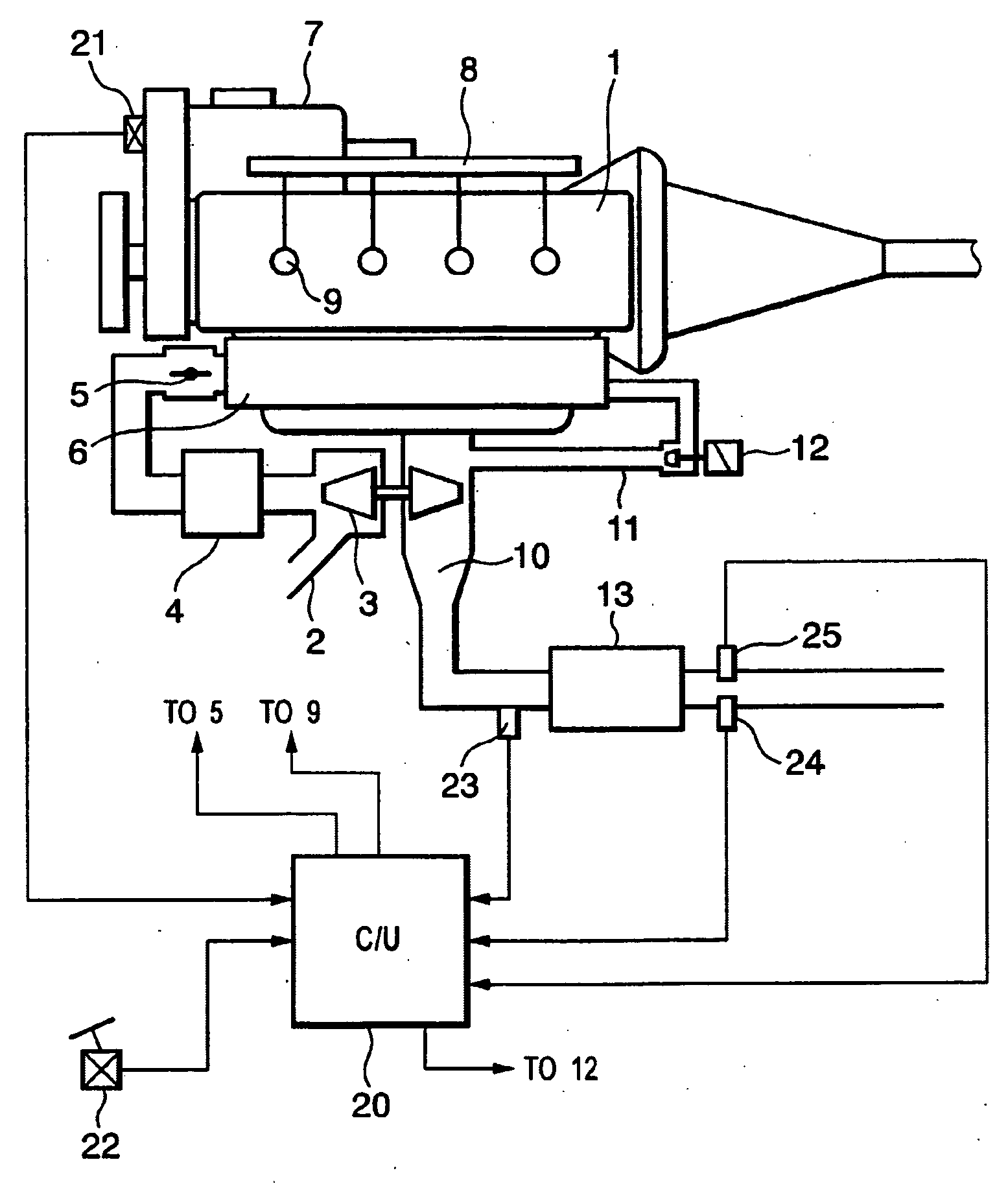

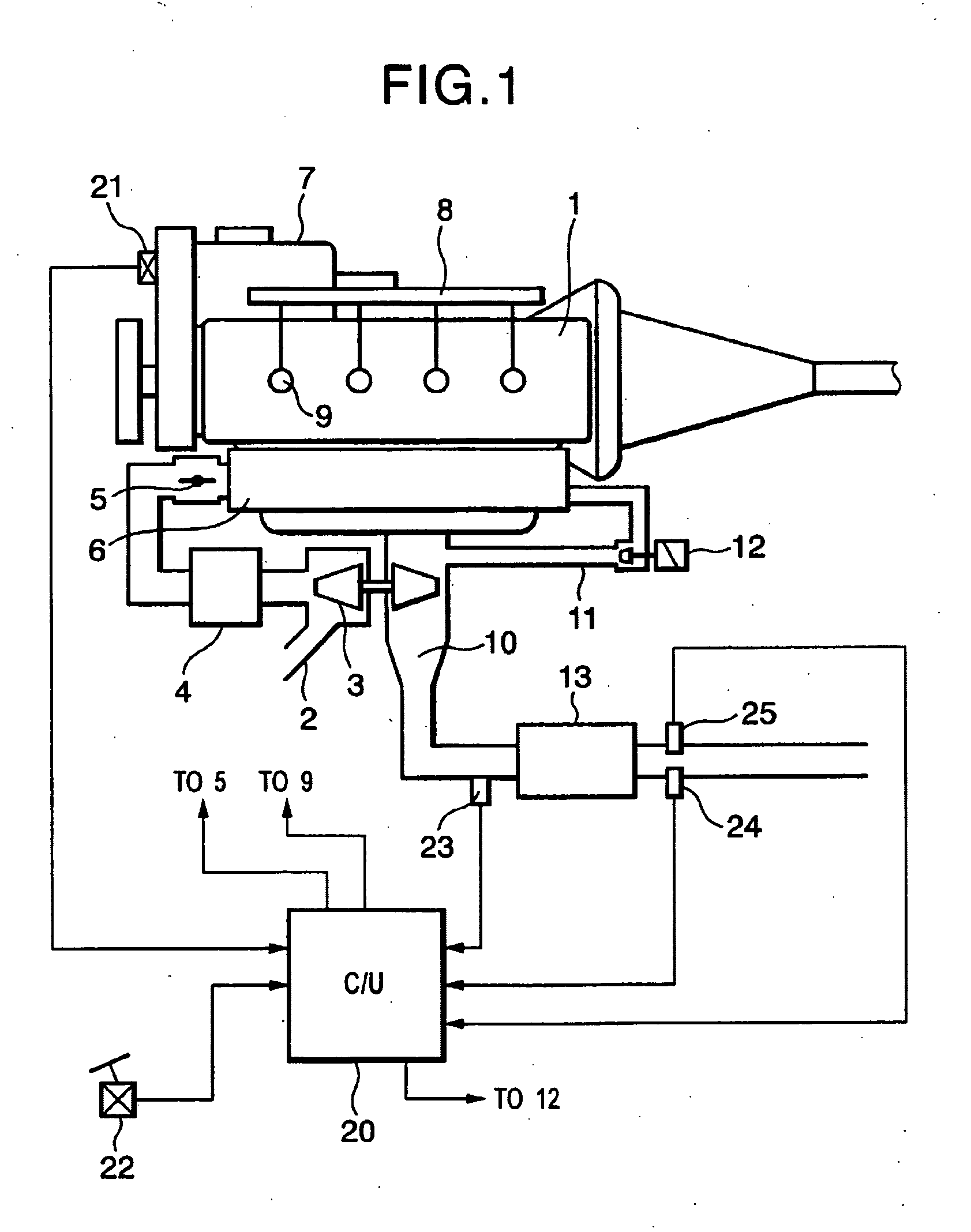

This system for aiding the regeneration of pollution-control means (1) that are integrated in an exhaust line (2) of an engine (3) of a motor vehicle, in which the engine is associated with means (6) for the common supply of the cylinders thereof, which means are in a form suitable for injecting fuel, during regeneration, into each cylinder in the form of at least one principal injection and at least one post-injection during the expansion phase of the cylinder, is characterized in that the supply means (6) are in a form suitable for cutting at least the principal injection of at least one of the cylinders in order to increase the oxygen content of the exhaust gases and to optimise the regeneration of the pollution-control means.

Owner:PEZHO SITROEN AUTOMOBILS SA

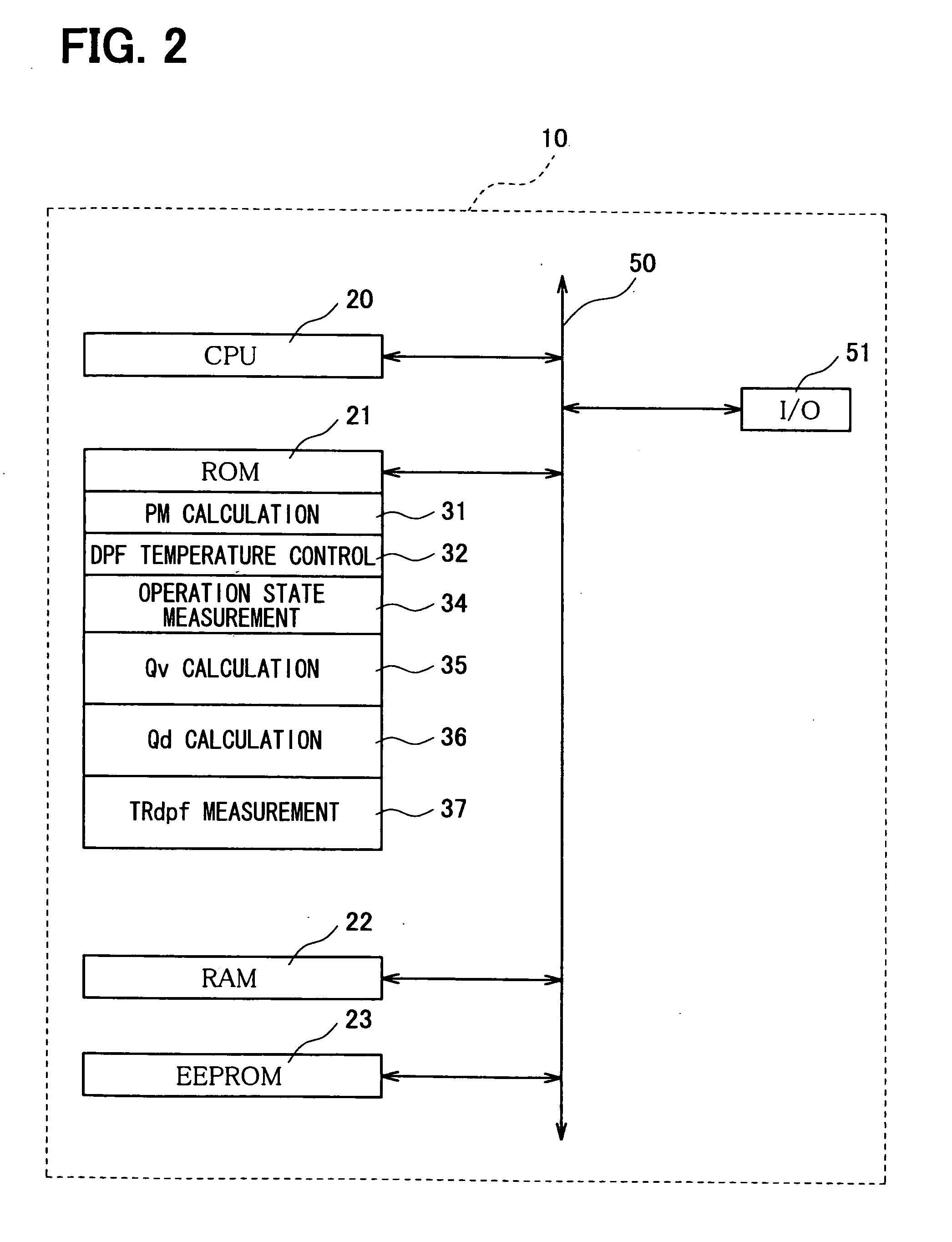

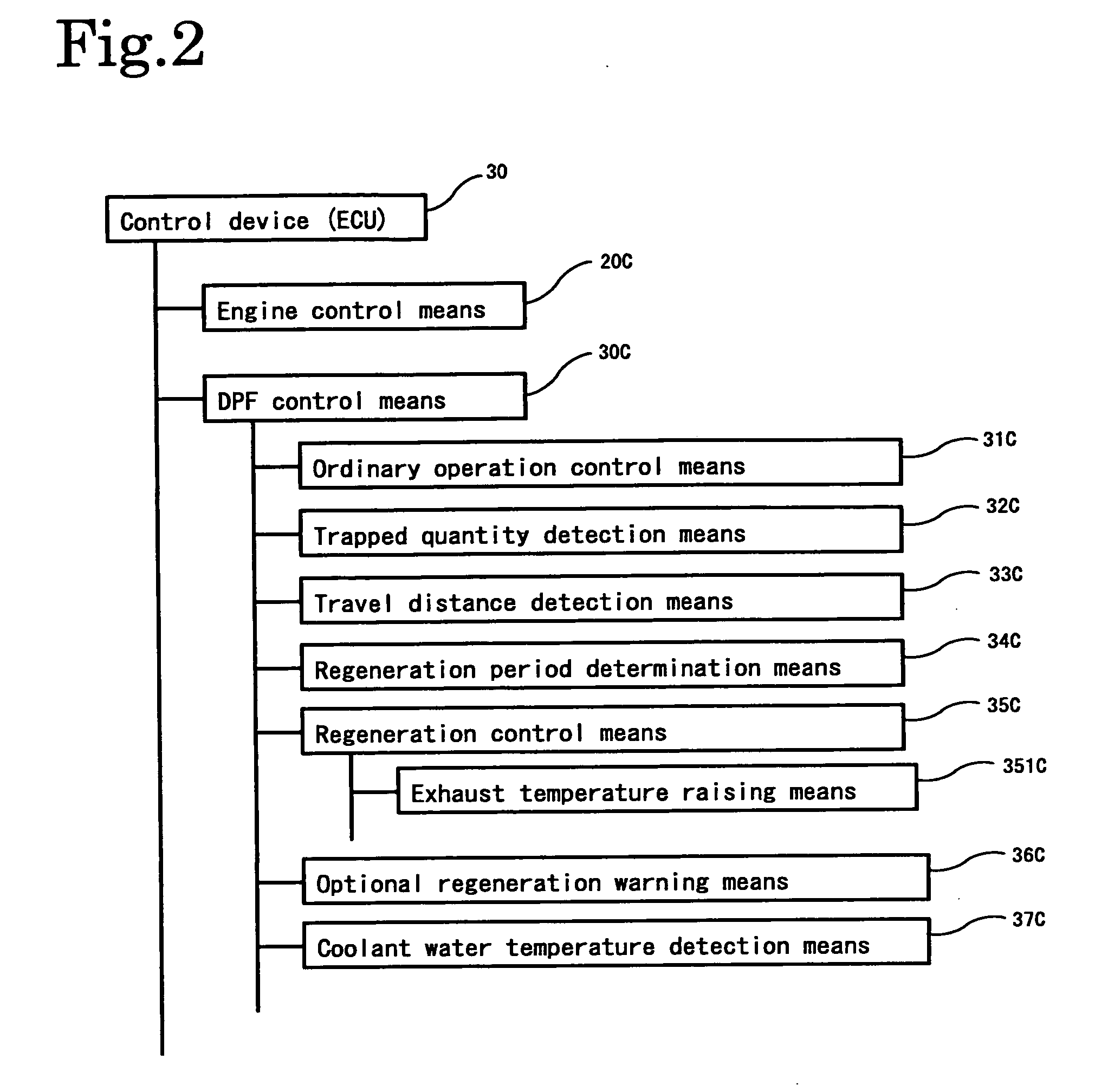

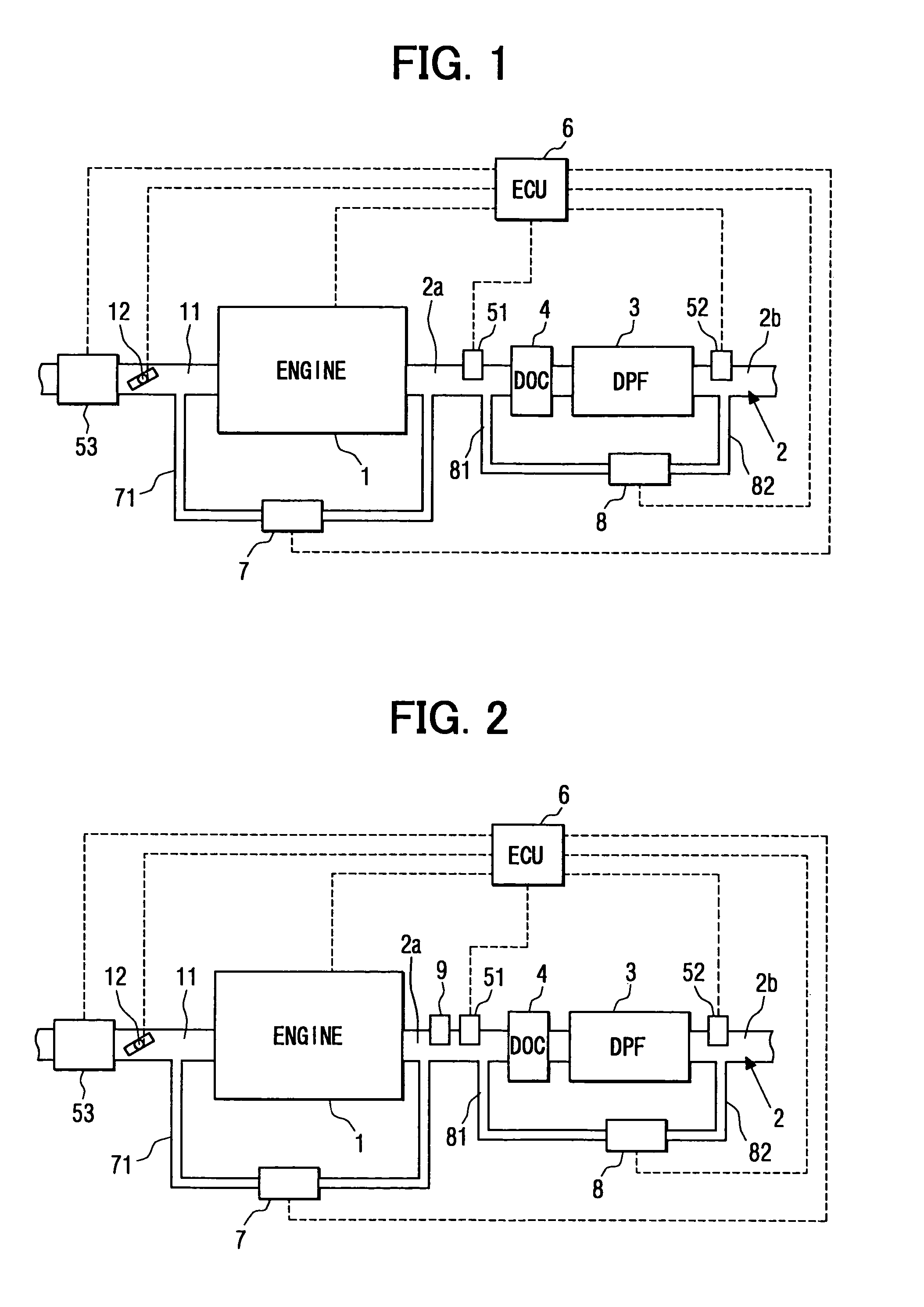

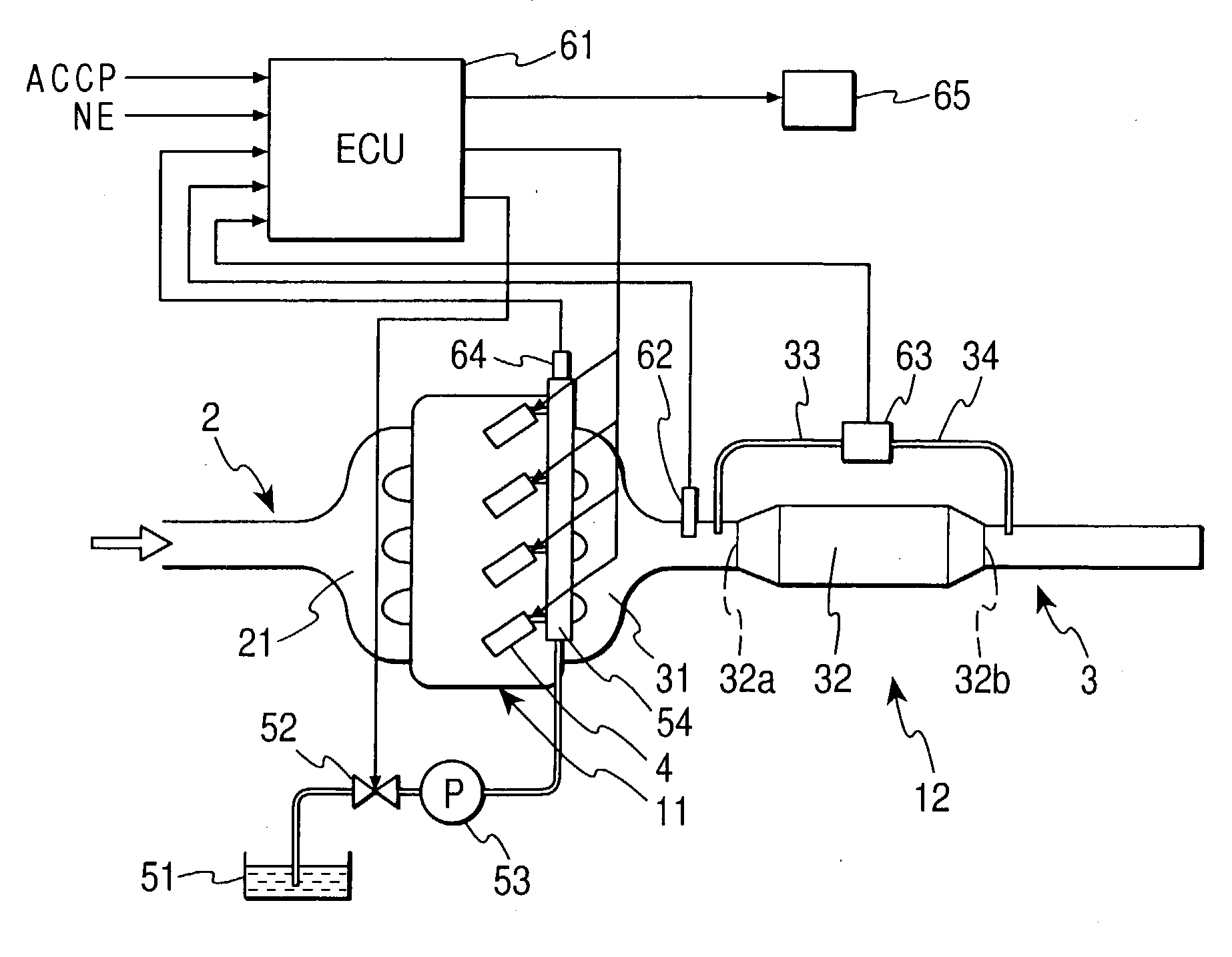

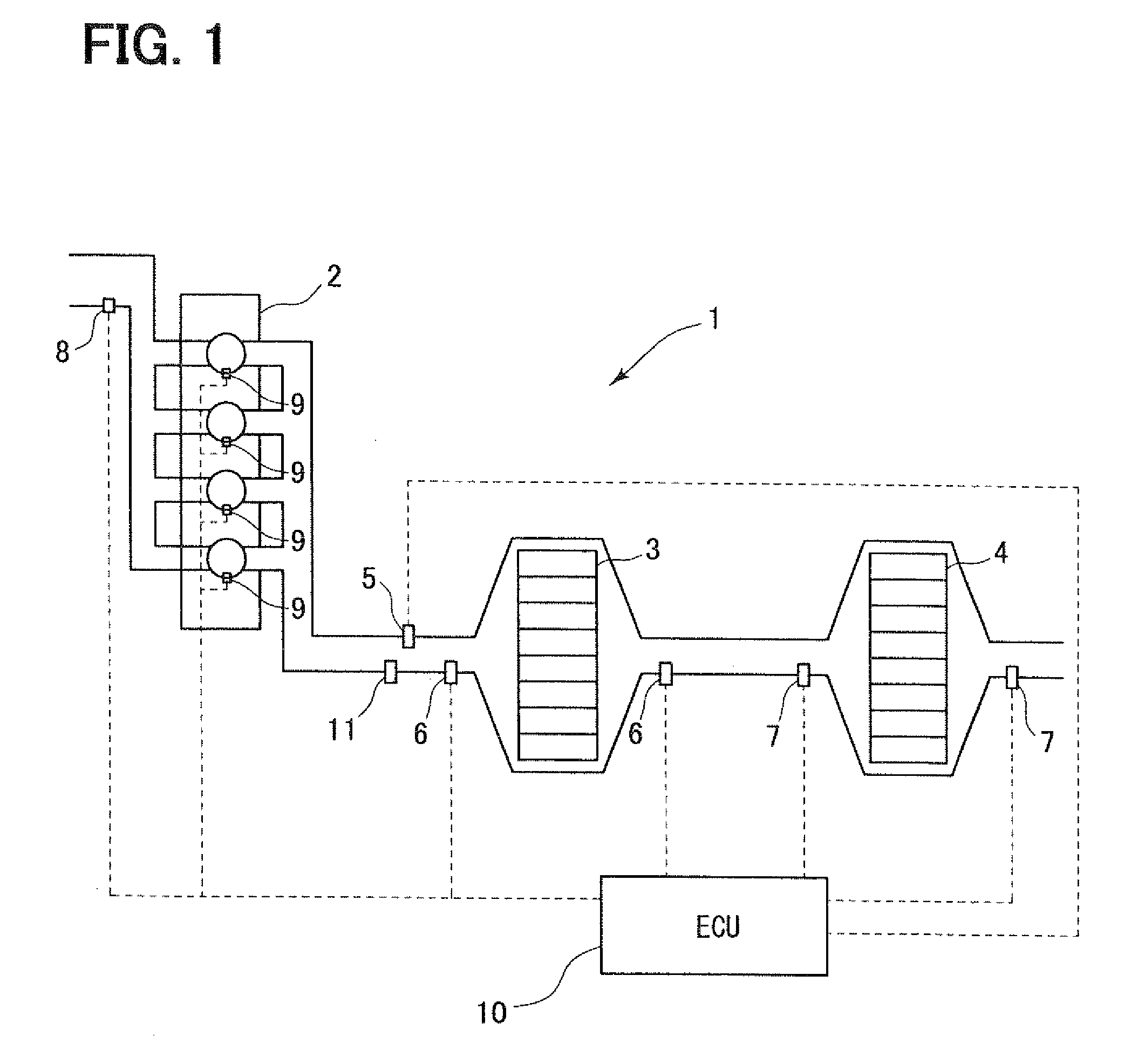

Exhaust gas purification system of internal combustion engine

ActiveUS20040226288A1Electrical controlInternal combustion piston enginesExhaust gas recirculationDiesel particulate filter

A diesel oxidation catalyst is disposed upstream of a diesel particulate filter (a DPF) disposed in an exhaust passage of a diesel engine. An electronic control unit (an ECU) operates temperature increasing means, which performs post-injection, to eliminate particulate matters accumulated in the DPF. The ECU includes first correcting means and second correcting means. The first correcting means corrects a manipulated variable of the temperature increasing means based on a result of comparison between target temperature and temperature of the DPF estimated based on information related to an area upstream of the DPF. The second correcting means corrects the manipulated variable of the temperature increasing means based on a result of comparison between the target temperature and the temperature of the DPF estimated based on information related to an area downstream of the DPF.

Owner:DENSO CORP

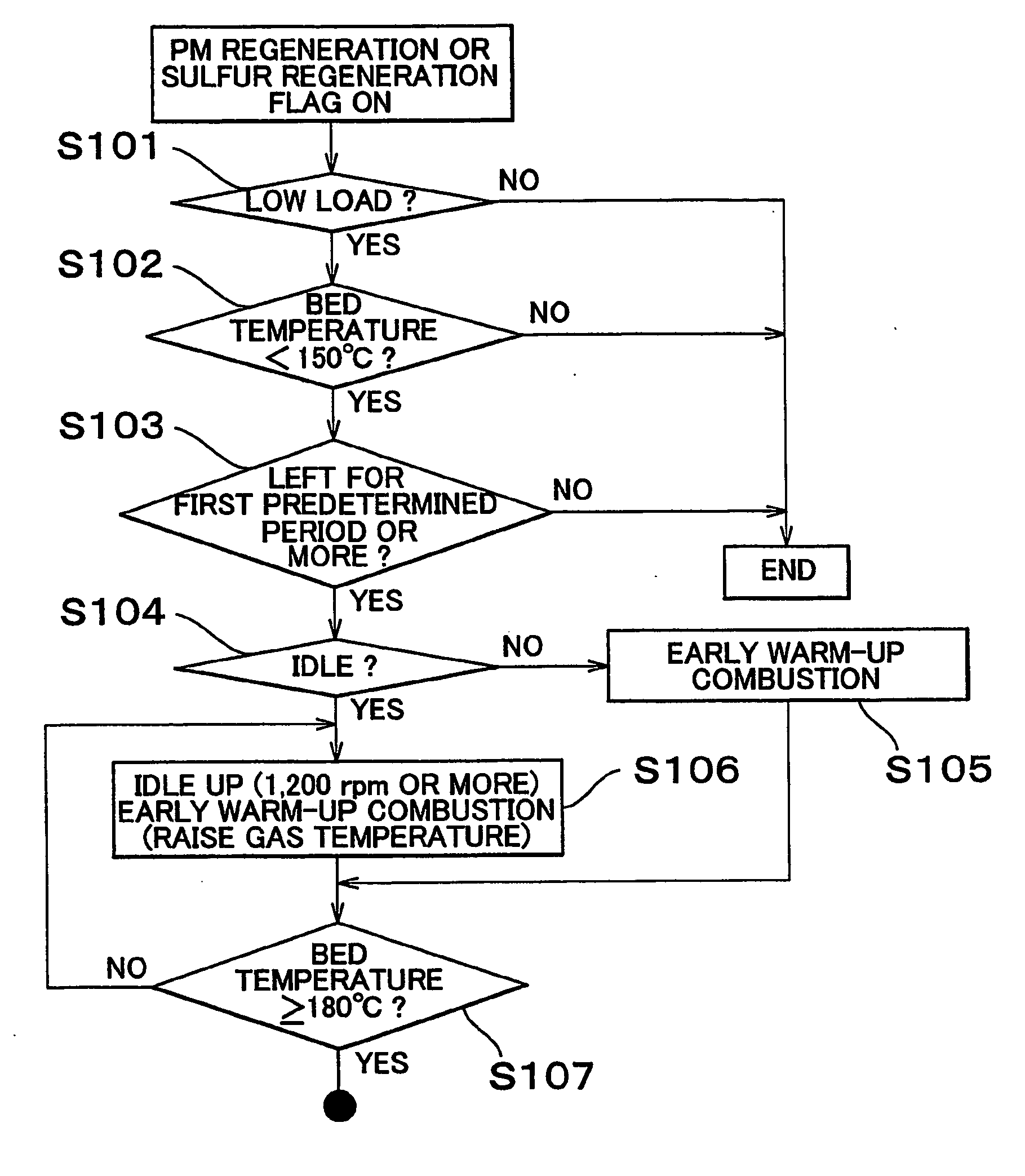

Exhaust gas purifying device and method for internal combustion engine

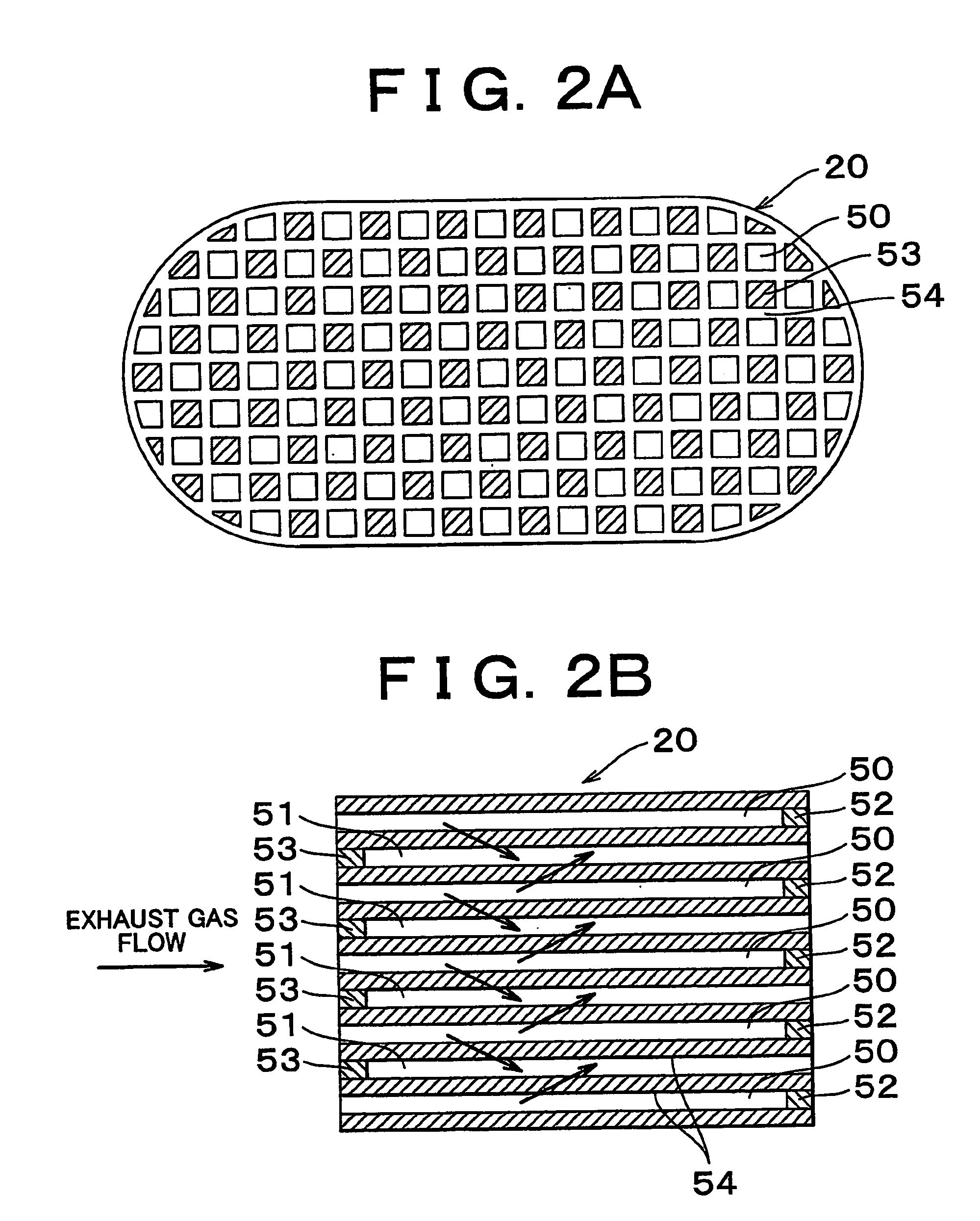

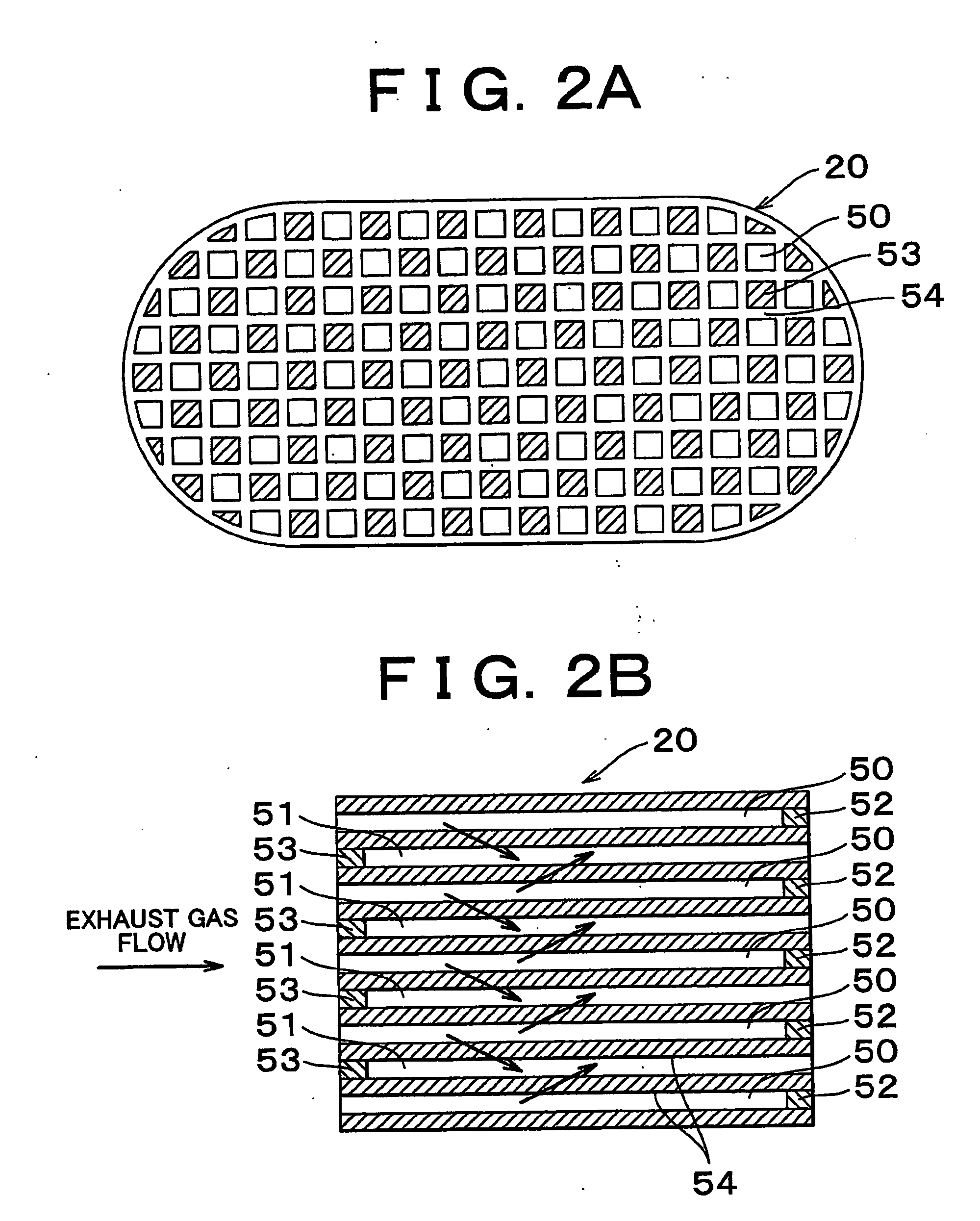

Removal of fine particles by oxidation or / and sulfur poisoning recovery control may be required when an internal combustion engine has been in an extremely low load state for a predetermined period or more. In this case, the engine speed of the internal combustion engine (1) is adjusted to a range where the temperature of a filter (20) can be raised by heat-up control. The heat-up control is then executed by a filter temperature control means to raise the temperature of the filter (20) to a predetermined value. When the filter (20) reaches the predetermined temperature by means of low-temperature combustion, post-injection, VIGOM-injection, addition of 10 fuel to an exhaust system and the like, removal of fine particles by oxidation or / and sulfur poisoning recovery control for eliminating sulfur poisoning of a NOx absorbent are conducted. Removal of PMs captured by the filter and sulfur poisoning recovery control of the NOx absorbent can thus be conducted even if the internal combustion engine is left in an extremely low load operational state.

Owner:TOYOTA JIDOSHA KK

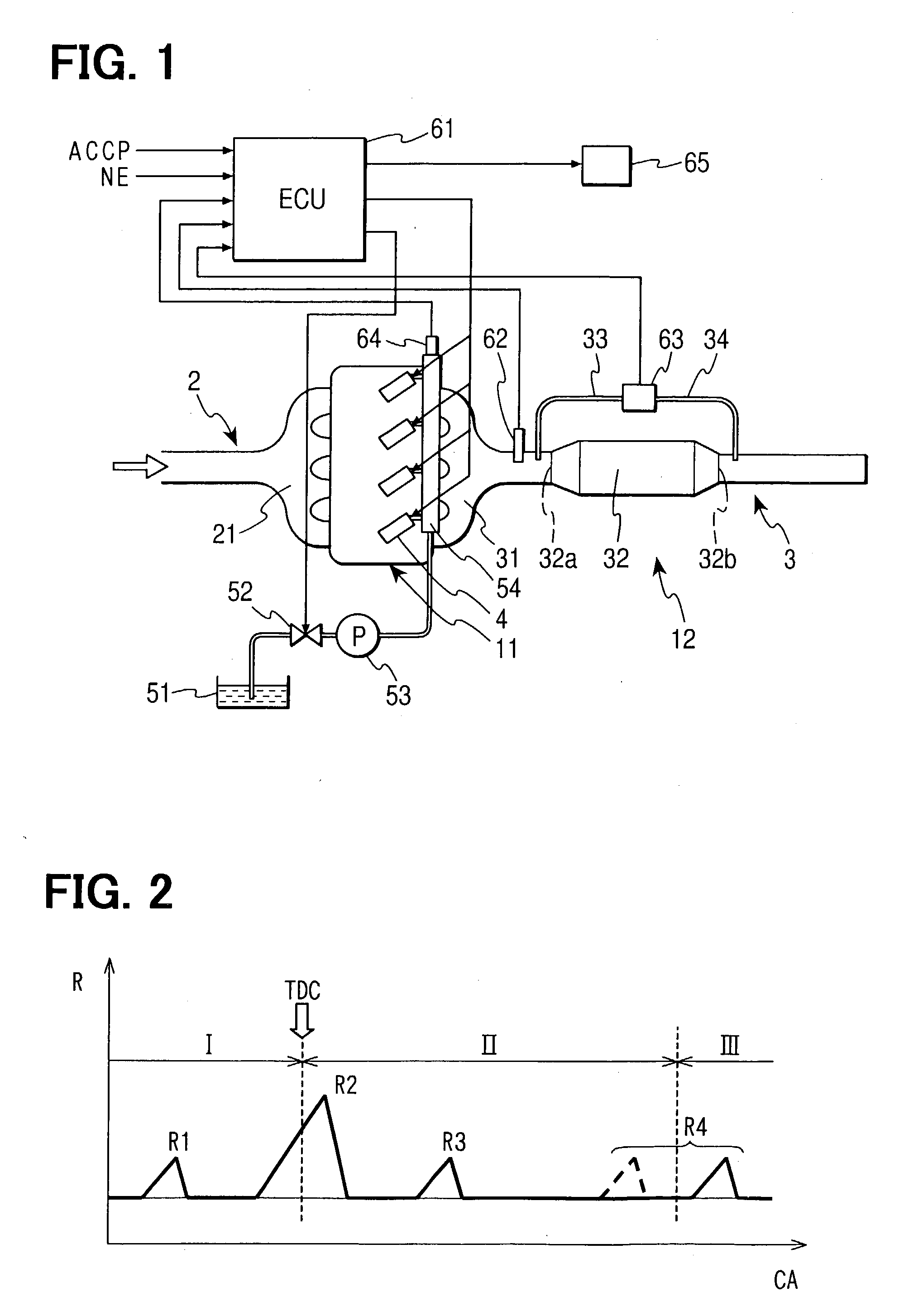

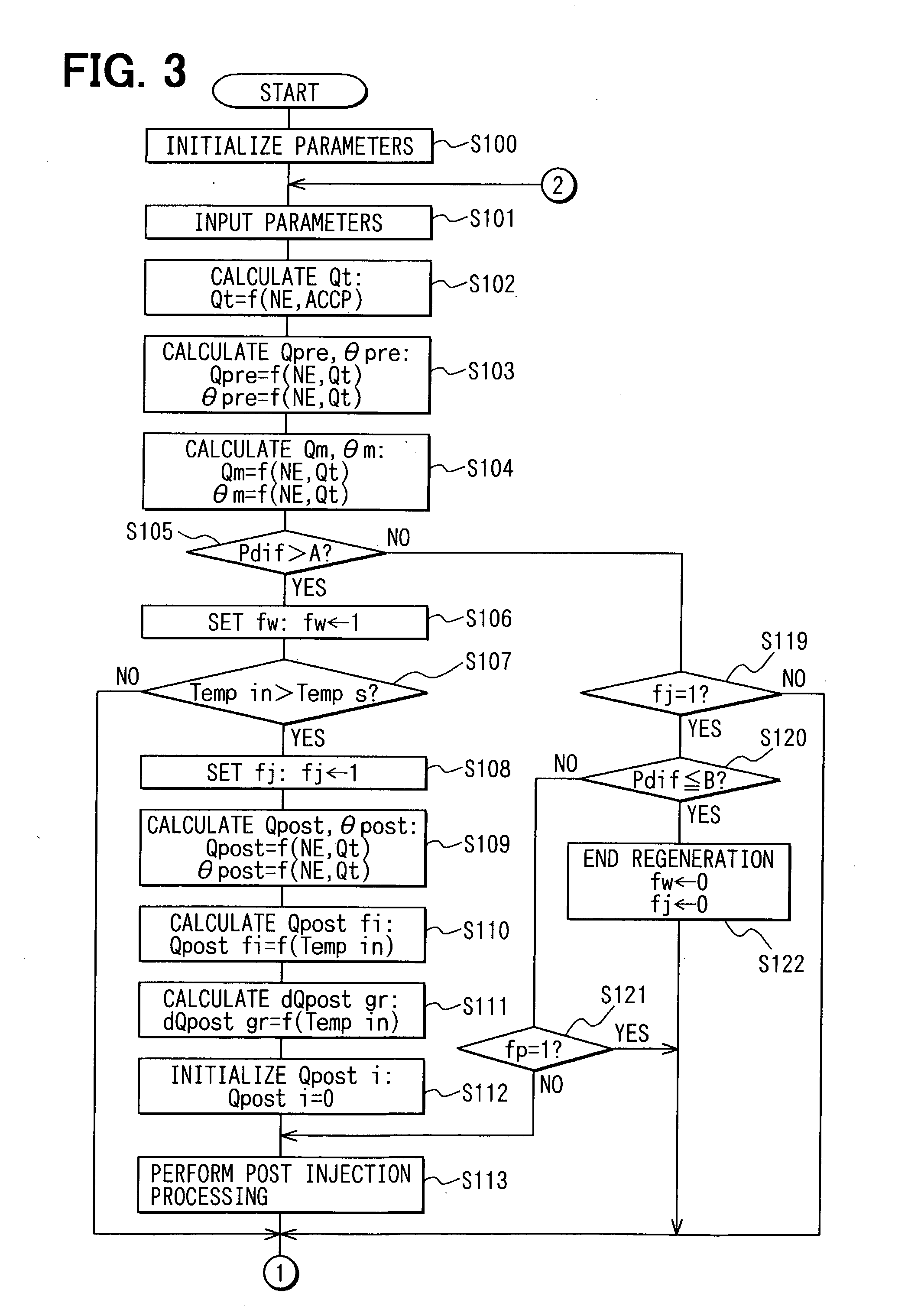

Fuel injection control system for internal combustion engine

InactiveUS6959541B2Avoid emissionsAvoid it happening againElectrical controlInternal combustion piston enginesLower limitParticulates

Owner:DENSO CORP

Vacuum-sealing-type flexible-film primary battery and method of manufacturing the same

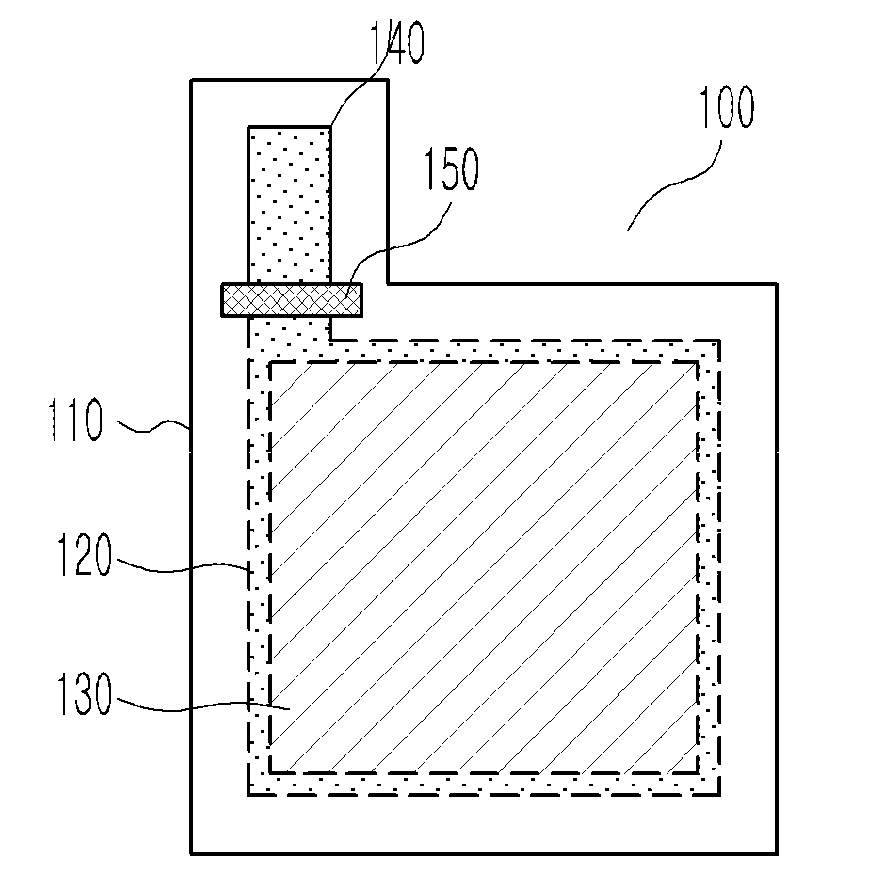

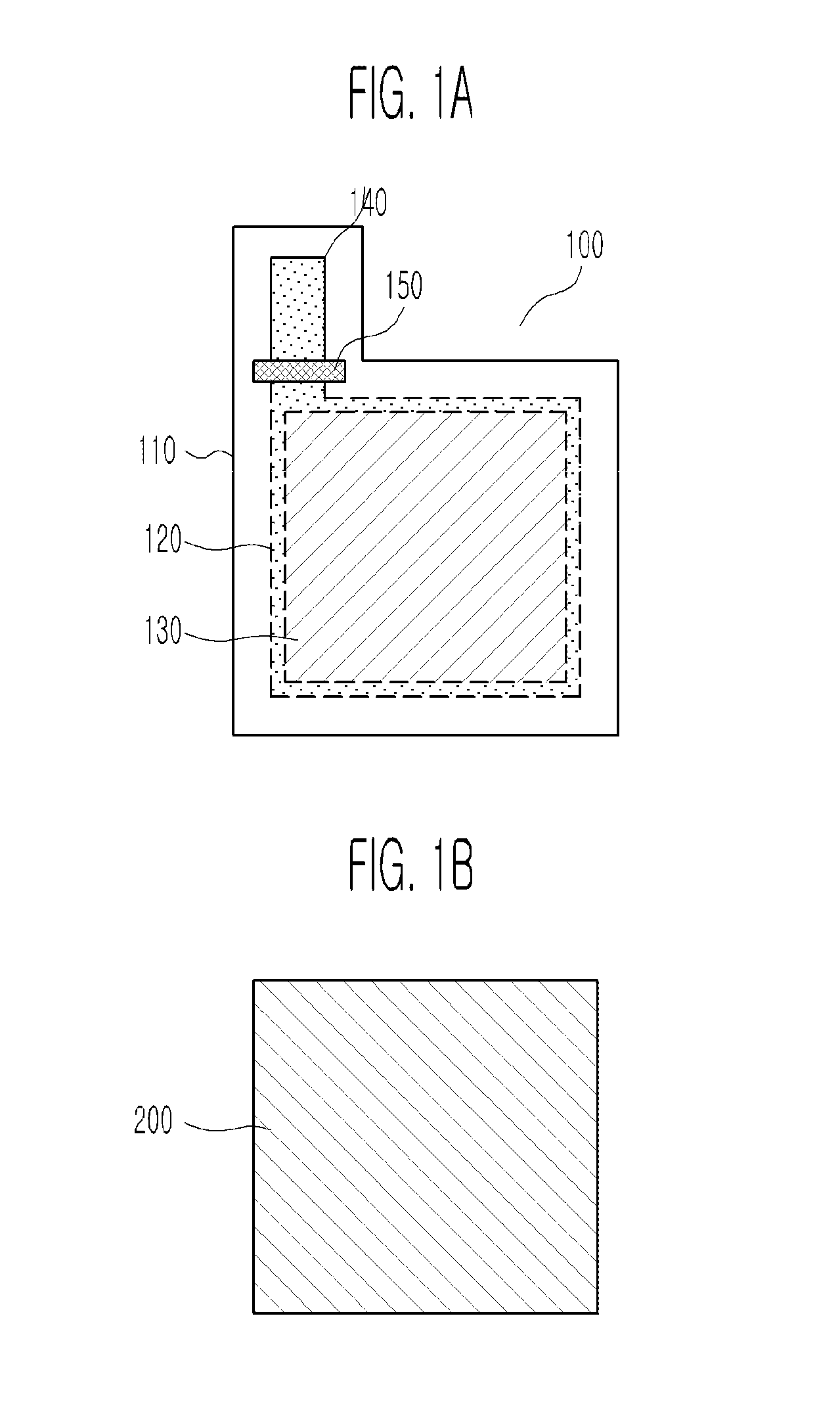

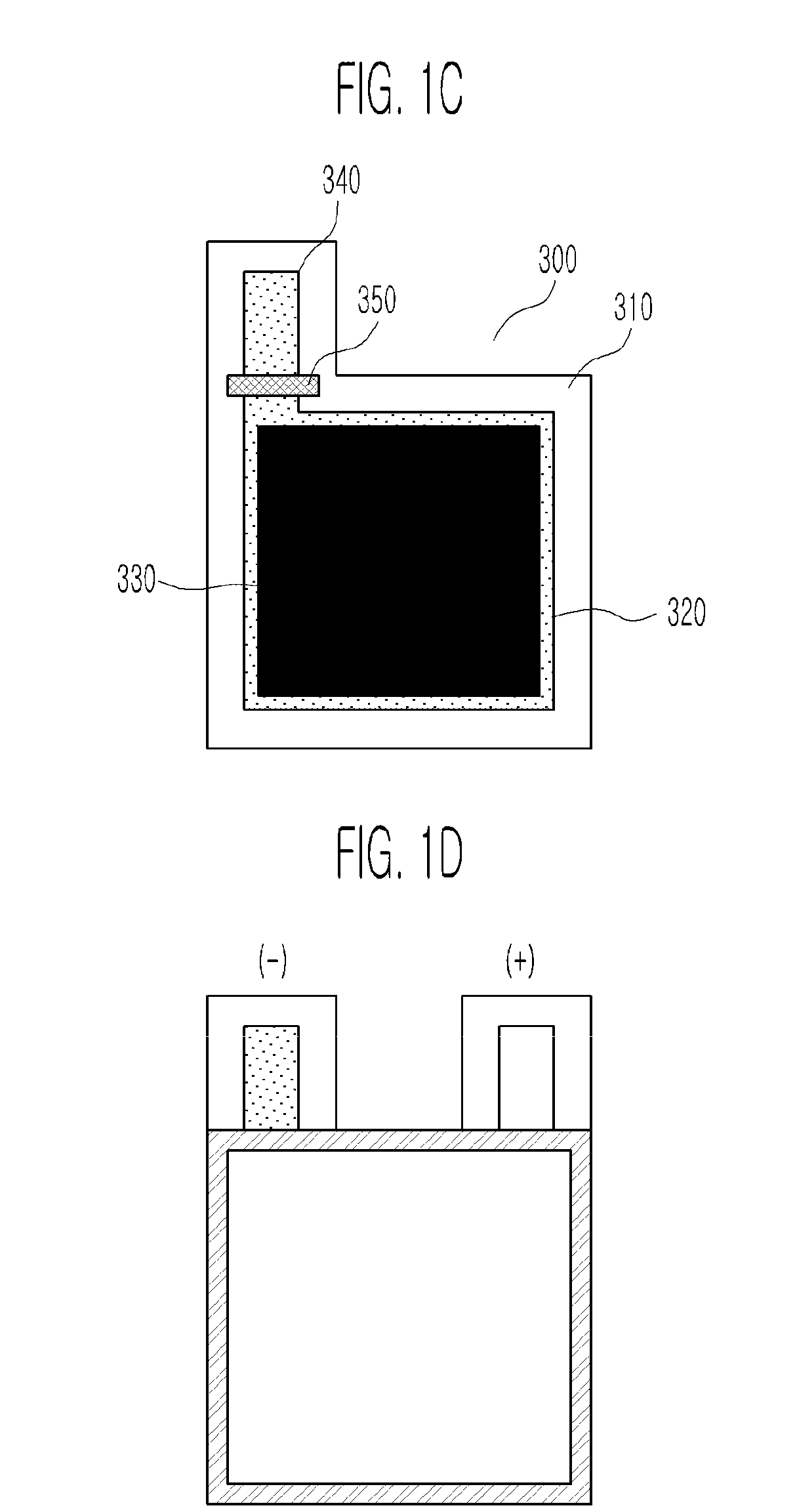

ActiveUS20110045337A1Improve corrosion resistanceElectrode carriers/collectorsPrinted batteriesCarbon layerScreen printing

Provided are a vacuum-sealing-type flexible-film primary battery and a method of manufacturing the same. The primary battery includes a battery assembly comprising a positive electrode plate including a positive electrode collector having a first conductive carbon layer disposed on a surface-treated inner surface of a first pouch and a positive electrode layer disposed on the first conductive carbon layer of the positive electrode collector, a negative electrode plate including a negative electrode collector having a second conductive carbon layer disposed on a surface-treated inner surface of a second pouch and a negative electrode layer disposed on the second conductive carbon layer of the negative electrode collector, and an adhesion / post-injection polymer electrolyte layer interposed between the positive electrode plate and the negative electrode plate, wherein the battery assembly is completely sealed. The flexible-film primary battery may employ the pouch as a collector film to improve flexibility. Also, the flexible-film primary battery may be completely sealed using the pouch to improve a retention period and cell performance. Furthermore, the flexible-film primary battery may be manufactured using a screen printing technique, thereby facilitating a roll-to-roll sequential process.

Owner:ELECTRONICS & TELECOMM RES INST

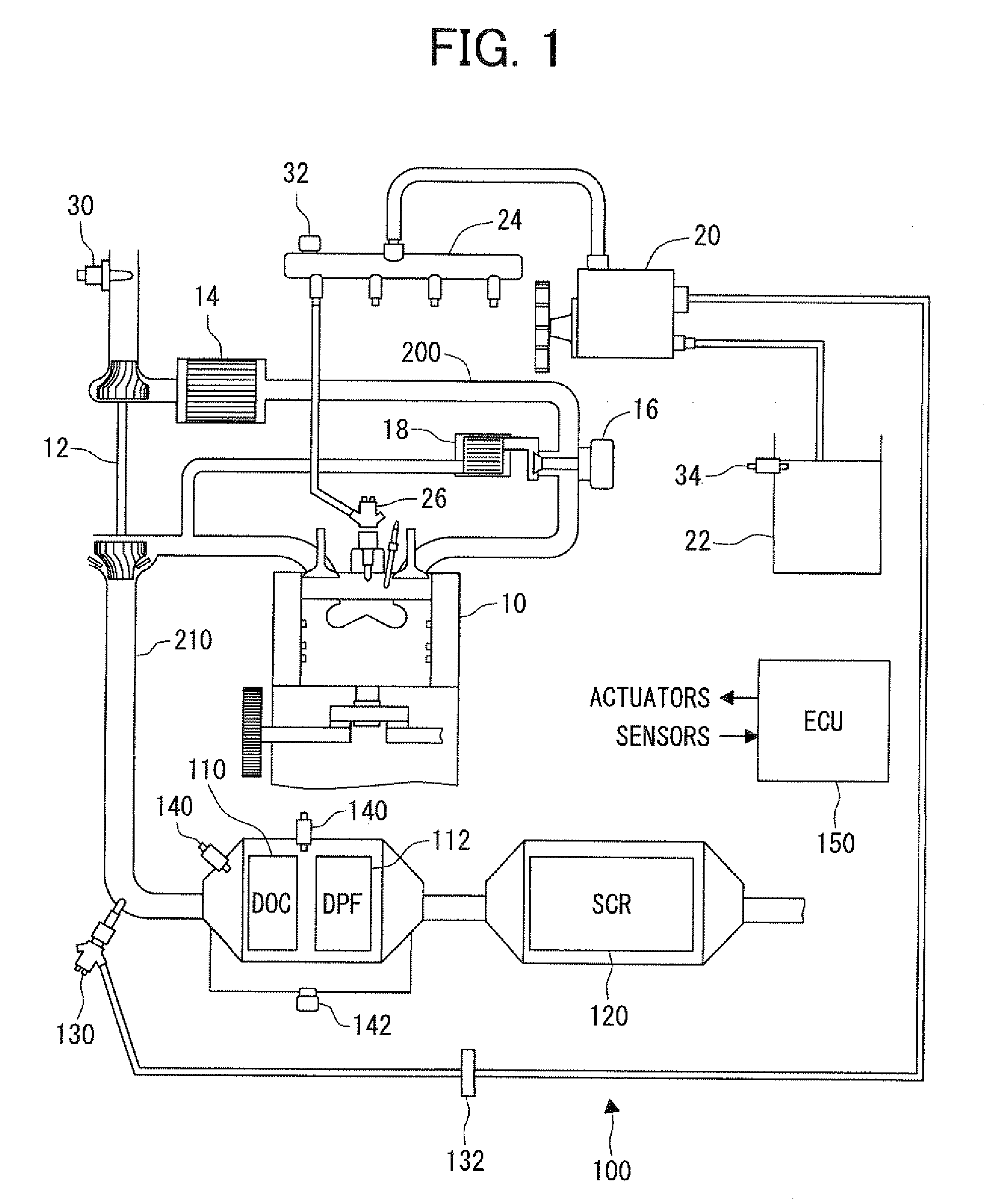

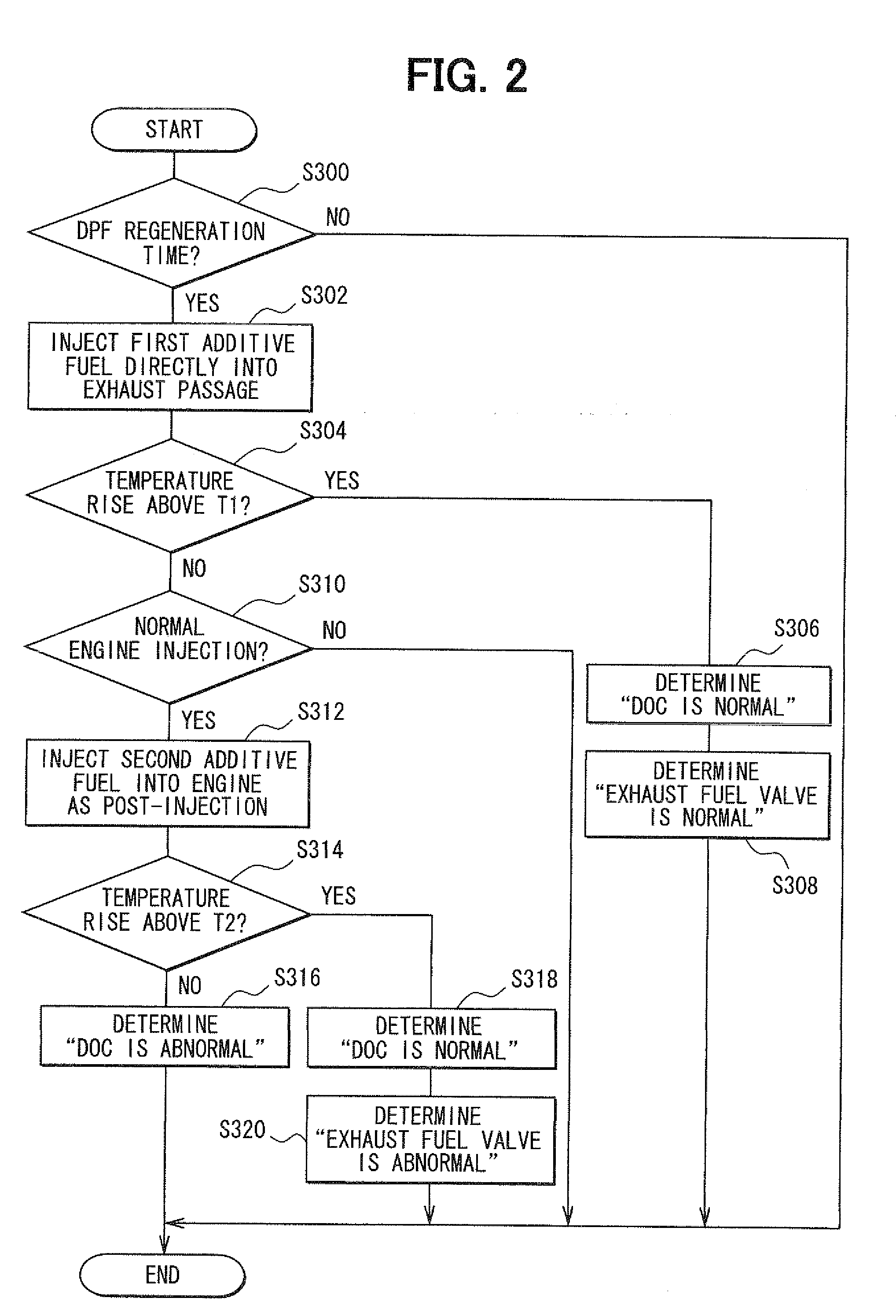

Exhaust purification system, control apparatus and control method therefor

InactiveUS20090235645A1Internal combustion piston enginesExhaust apparatusExhaust valveExternal combustion engine

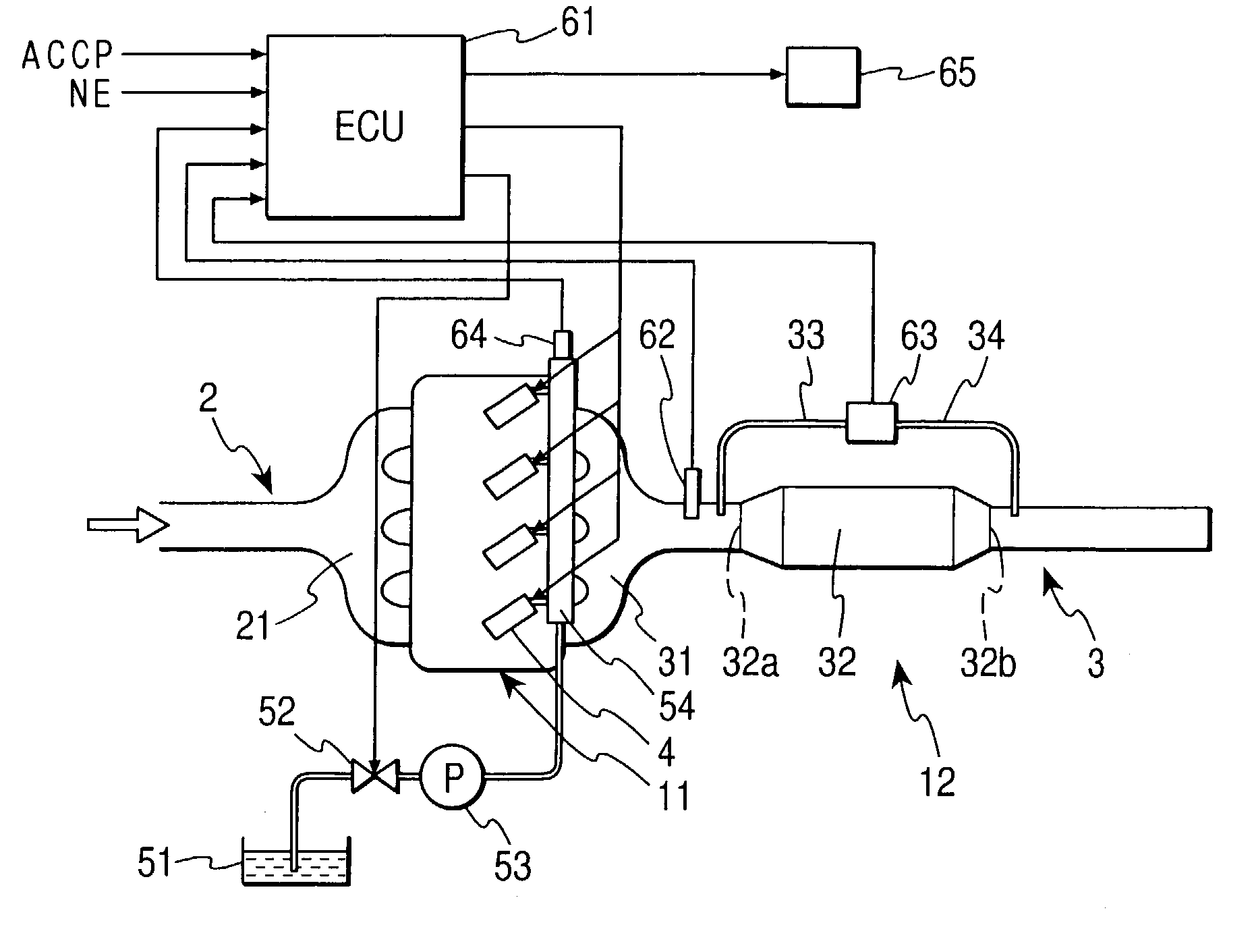

An exhaust gas purification control apparatus for an internal combustion engine instructs an exhaust fuel valve to inject additive fuel when a diesel particulate filter is to be regenerated, and determines that both the exhaust fuel valve and an oxidation catalyst are normal if an exhaust temperature rises. If the exhaust temperature does not rise, the control apparatus instructs an engine fuel valve to inject additive fuel as a post-injection. If the exhaust temperature does not rise, the control apparatus determines that the oxidation catalyst is abnormal. If the exhaust temperature rises, the control apparatus determines that the oxidation catalyst is normal but the exhaust fuel valve is abnormal.

Owner:DENSO CORP

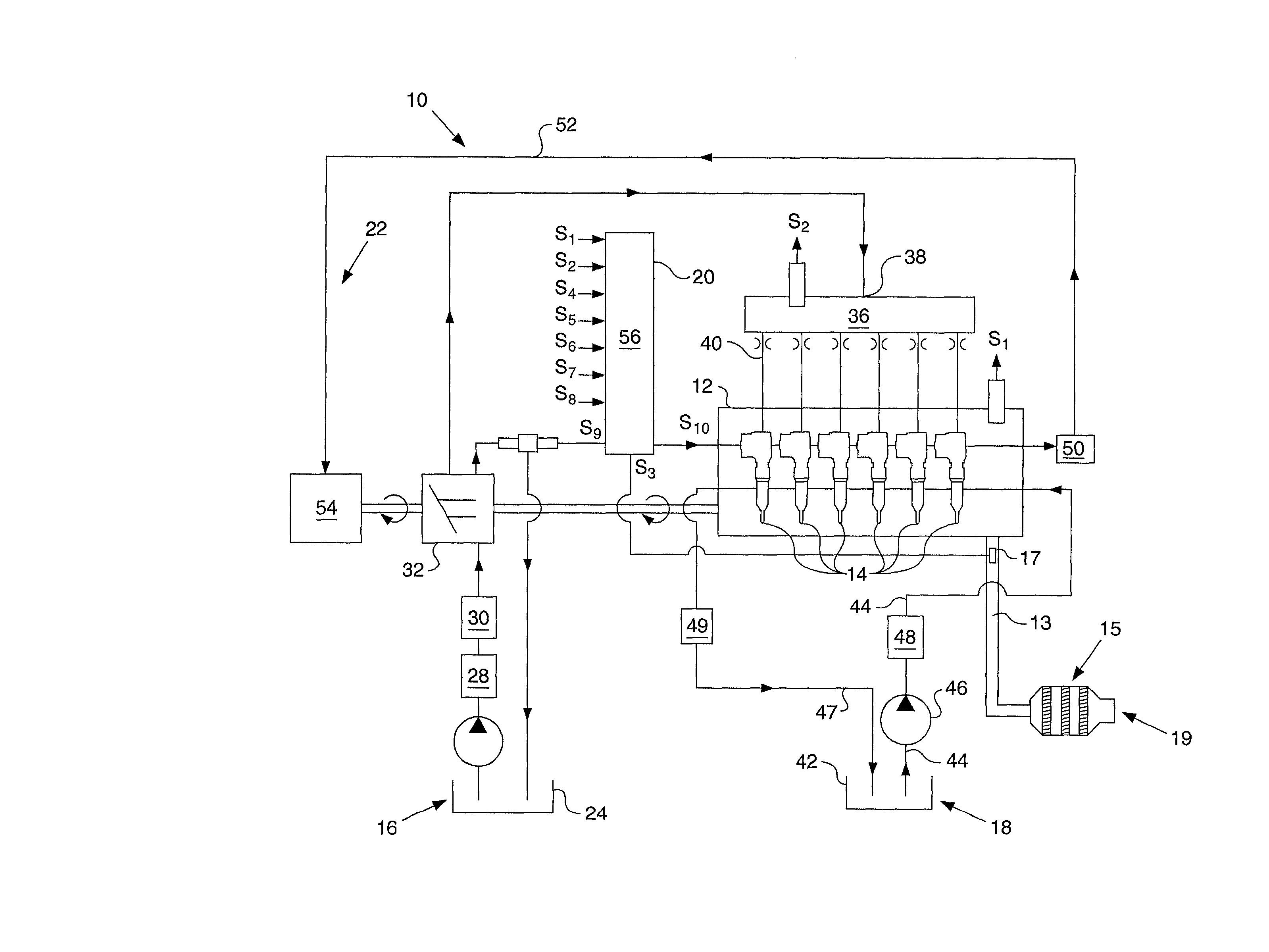

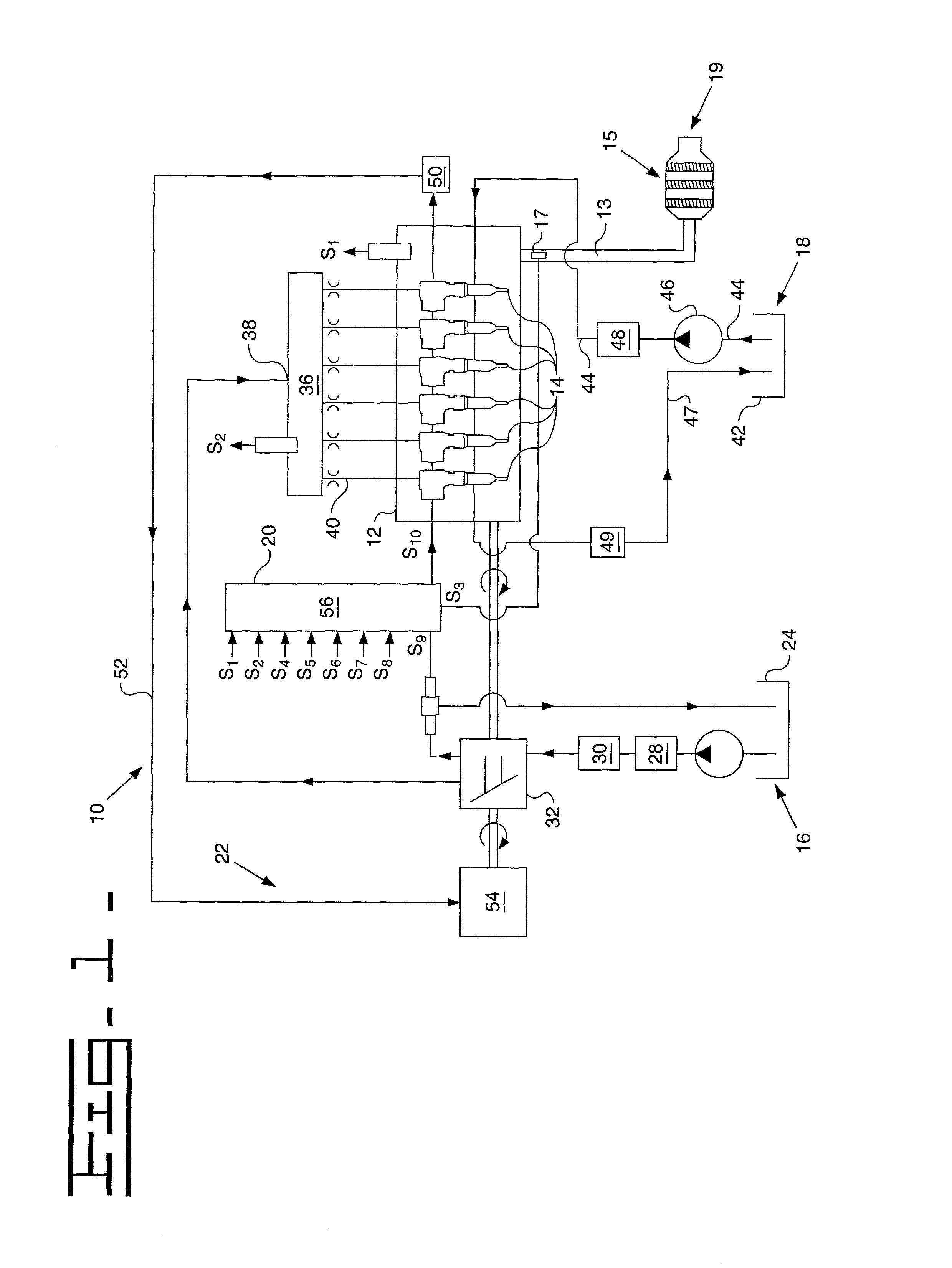

Post injections during cold operation

InactiveUS20020194837A1Electrical controlInternal combustion piston enginesCombustion chamberMechanical energy

An exhaust gas heating system and method of a direct injection compression ignition internal combustion engine which has a plurality of combustion chambers, an exhaust passage, and one or more direct fuel injection devices, each operable to inject fuel directly into a corresponding one of the combustion chambers. The system also includes a fuel injection controller which is operable to provide to at least one of the direct fuel injection devices, a post fuel injection signal during a corresponding cylinder cycle of the corresponding one of the plurality of combustion chambers. The post fuel injection signal is timed so as to provide exhaust gas heating from a resultant post fuel injection, and the fuel injection controller dynamically determines the particular one or more of the plurality of direct fuel injection devices to which the post fuel injection signal will be applied based on a temperature related engine operating parameter such as a desired amount of exhaust gas heating. The post fuel injection may also be timed and / or shaped such that it does not produce a substantial amount of mechanical energy but instead produces heated exhaust gasses.

Owner:FORD MOTOR CO +1

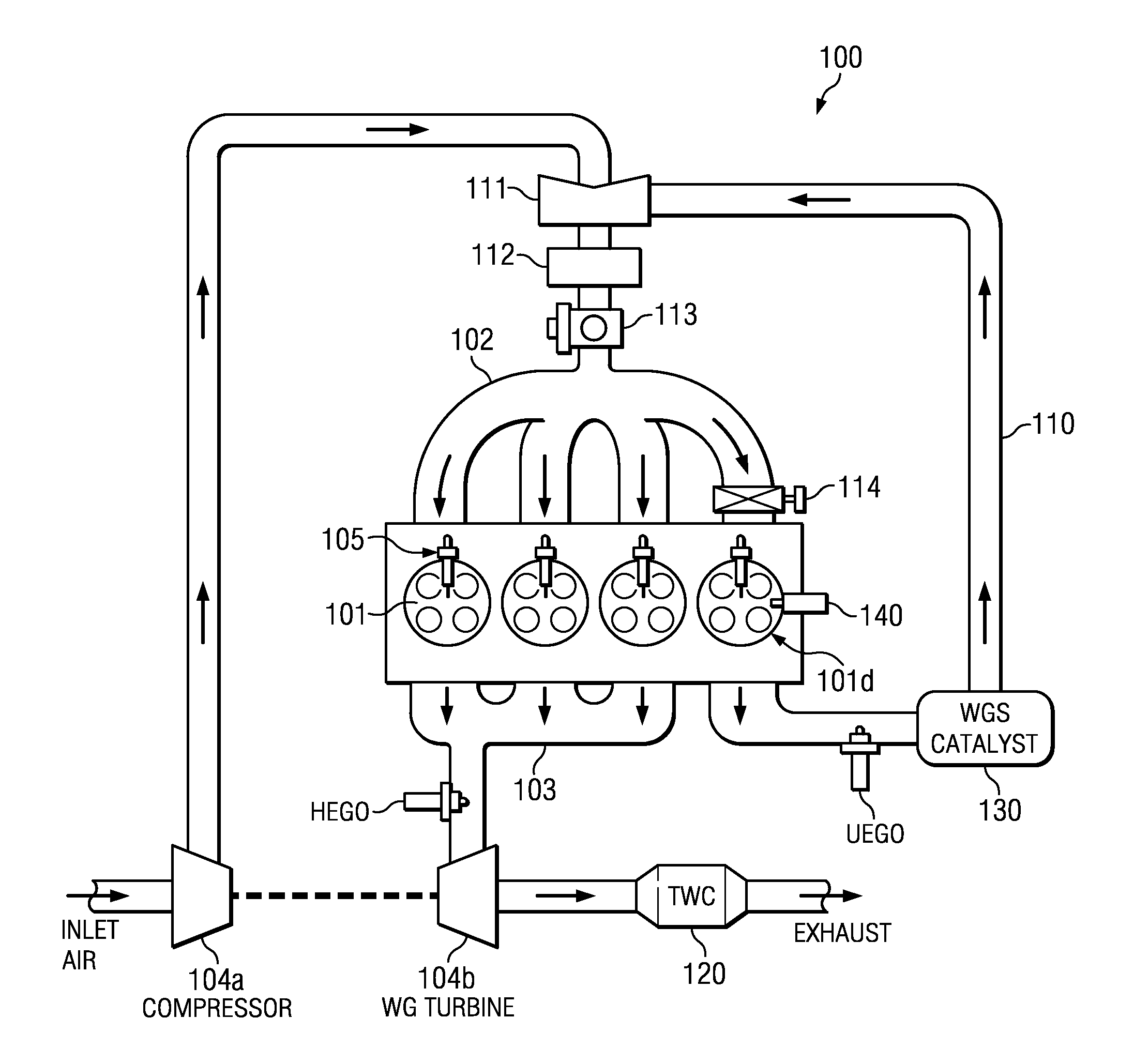

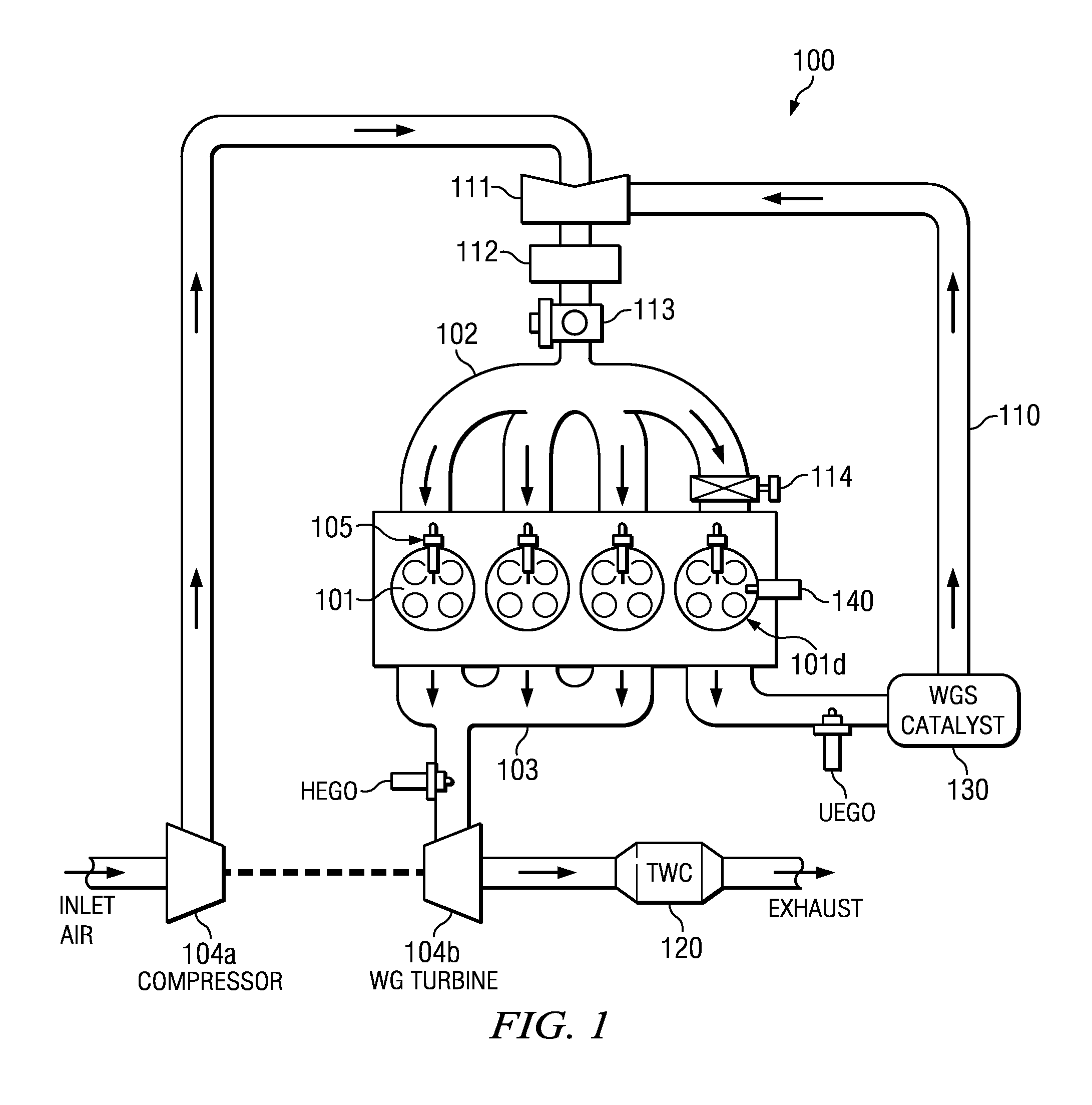

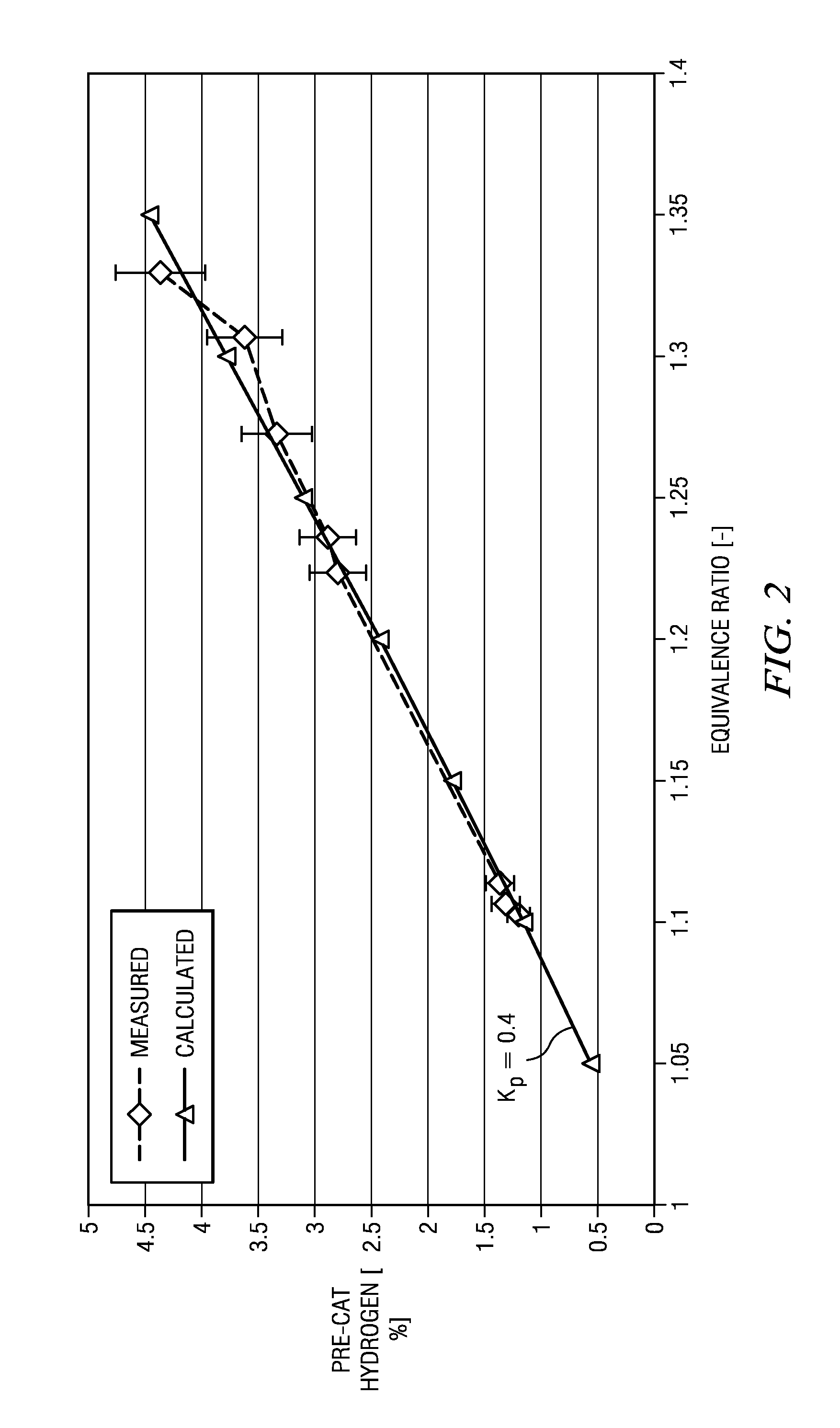

Fuel Injection Strategy for Internal Combustion Engine Having Dedicated EGR Cylinders

ActiveUS20130220286A1Electrical controlNon-fuel substance addition to fuelCombustion chamberFlammability limit

A method using exhaust gas recirculation (EGR) in an internal combustion engine. The engine has at least one “dedicated EGR cylinder”, whose entire exhaust is recirculated back to all the engine cylinders. The dedicated EGR cylinder is operated at a rich air-fuel ratio, and the other cylinders are operated stoichiometrically so that a conventional three way catalyst may be used to treat the exhaust. A fuel injector is used to inject fuel into the combustion chamber of the dedicated EGR cylinder after initiation of the main combustion event. This post injection method overcomes flammability limits of a dedicated EGR cylinder, and increases the hydrogen (H2) and carbon monoxide (CO) in its exhaust.

Owner:SOUTHWEST RES INST

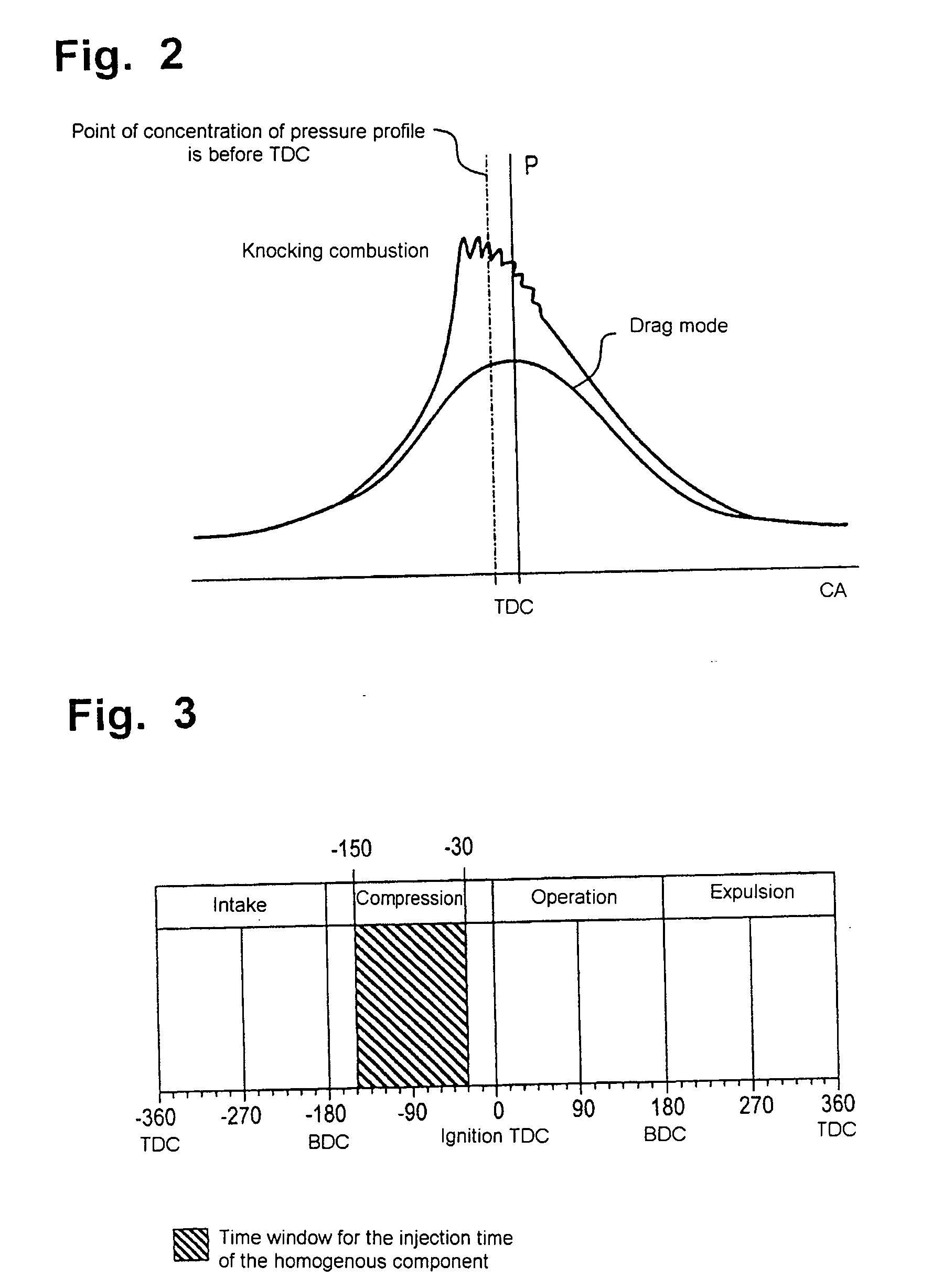

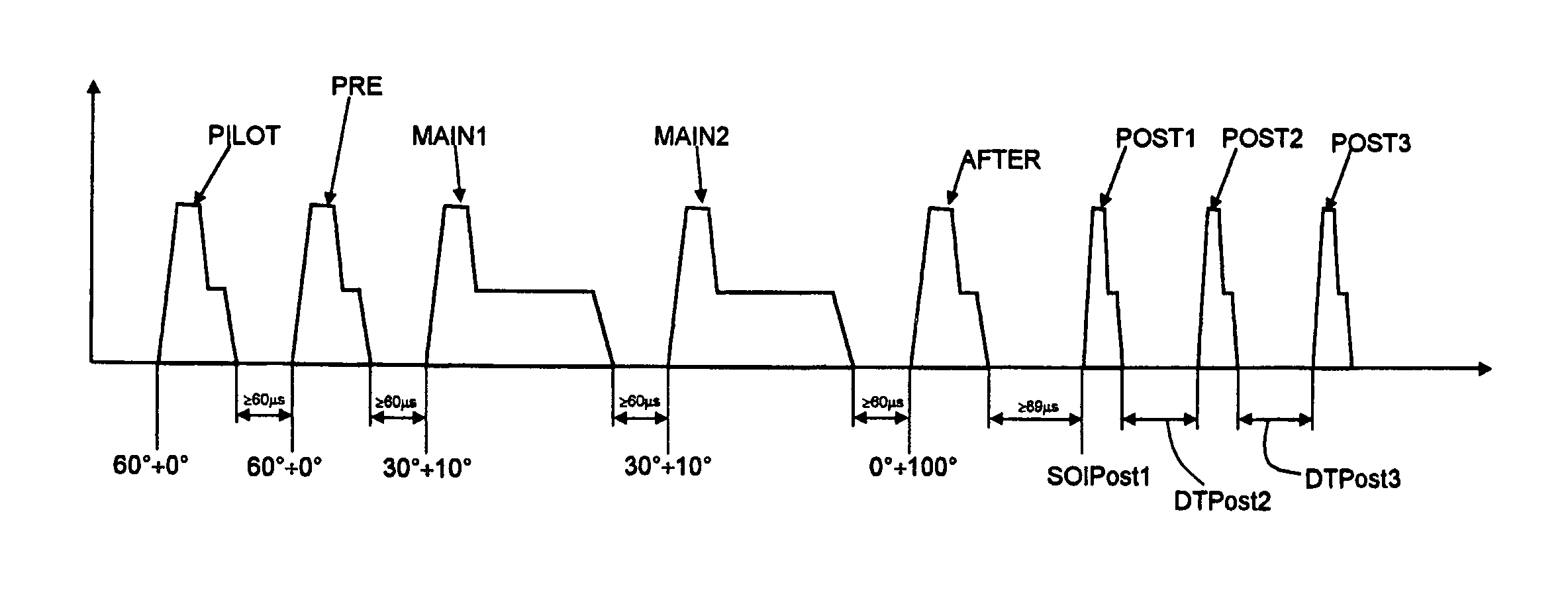

Method for controlling a diesel engine with a common-rail injection system during regeneration of the particulate filter

ActiveUS6948476B2Overcomes drawbackAnalogue computers for vehiclesElectrical controlParticulatesCombustion

Method for controlling a diesel engine with a common-rail injection system and a particulate filter, comprising the steps of performing at least one main injection (PRE, MAIN, AFTER) of fuel into a cylinder of the engine, the fuel being intended to take part in combustion inside the cylinder, and performing a post-injection (POST) in order to inject a predefined total quantity of fuel (QPOST) inside the cylinder, the post-injection being separated from the main injection (PRE, MAIN, AFTER) by means of a time separation interval such that the fuel injected during post-injection does not take part in combustion. The method also comprises the step of dividing the post-injection (POST) into a plurality of separate post-injections (POST1, POST2, POST3).

Owner:CENT RICERCHE FIAT SCPA

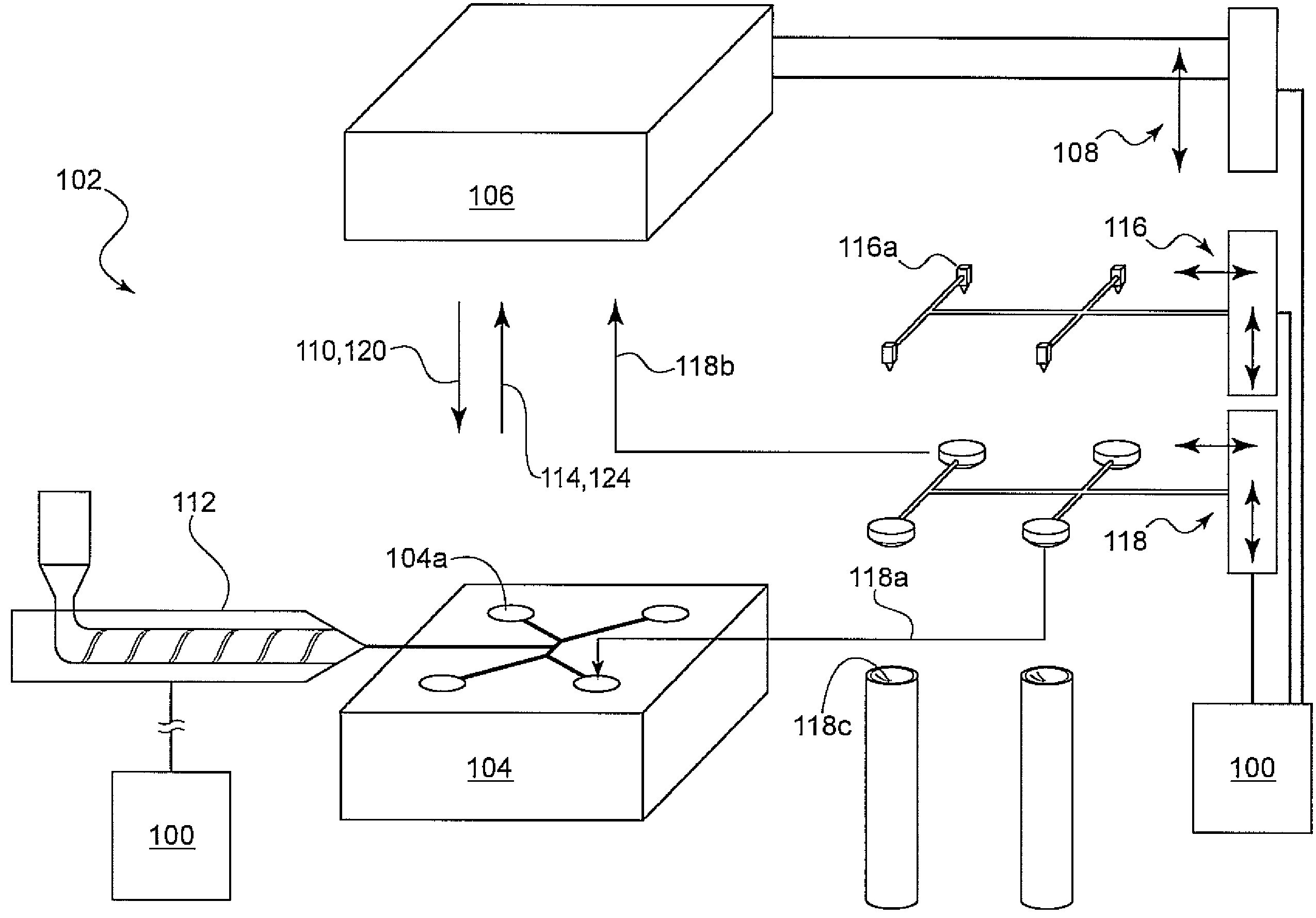

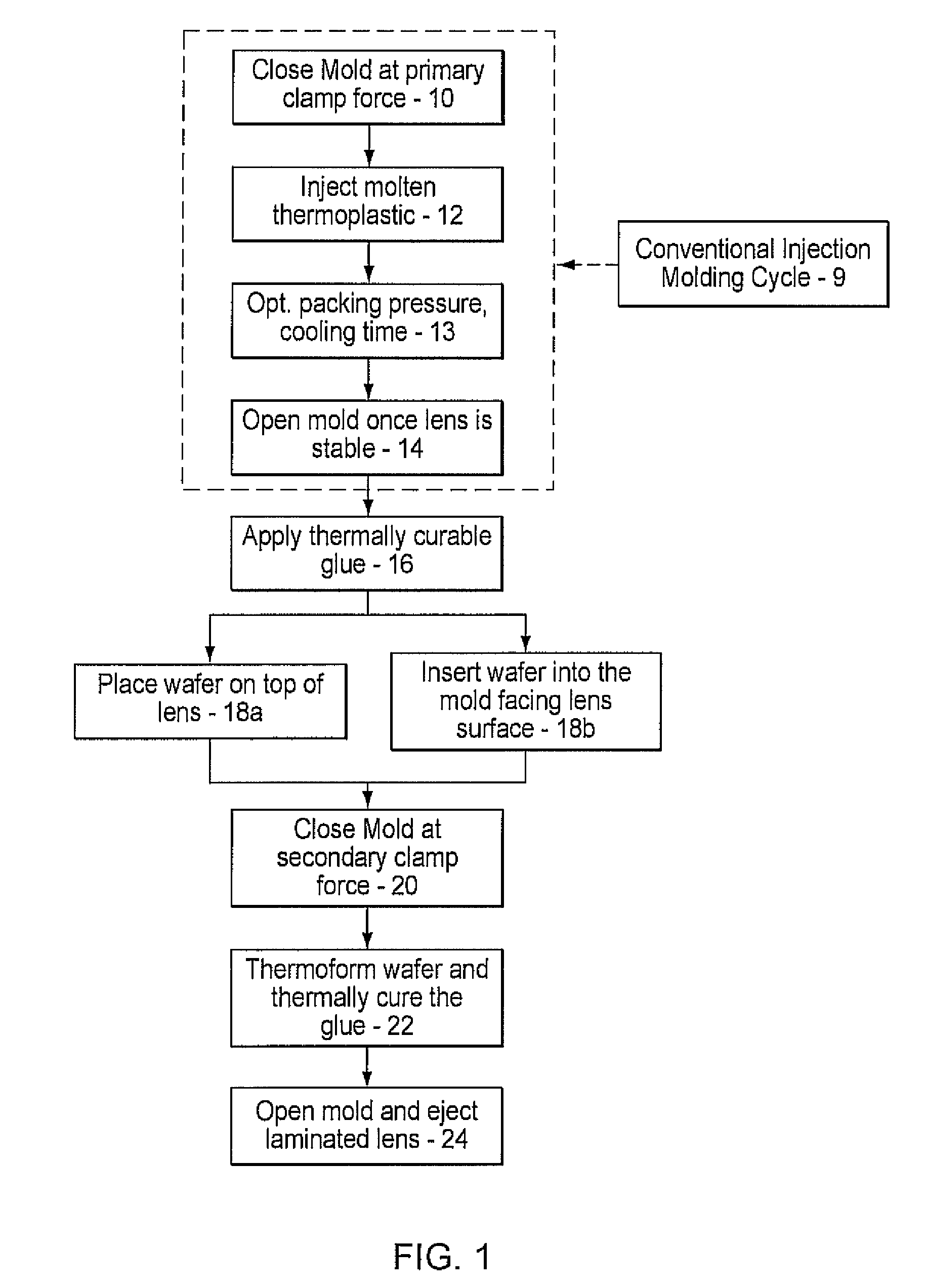

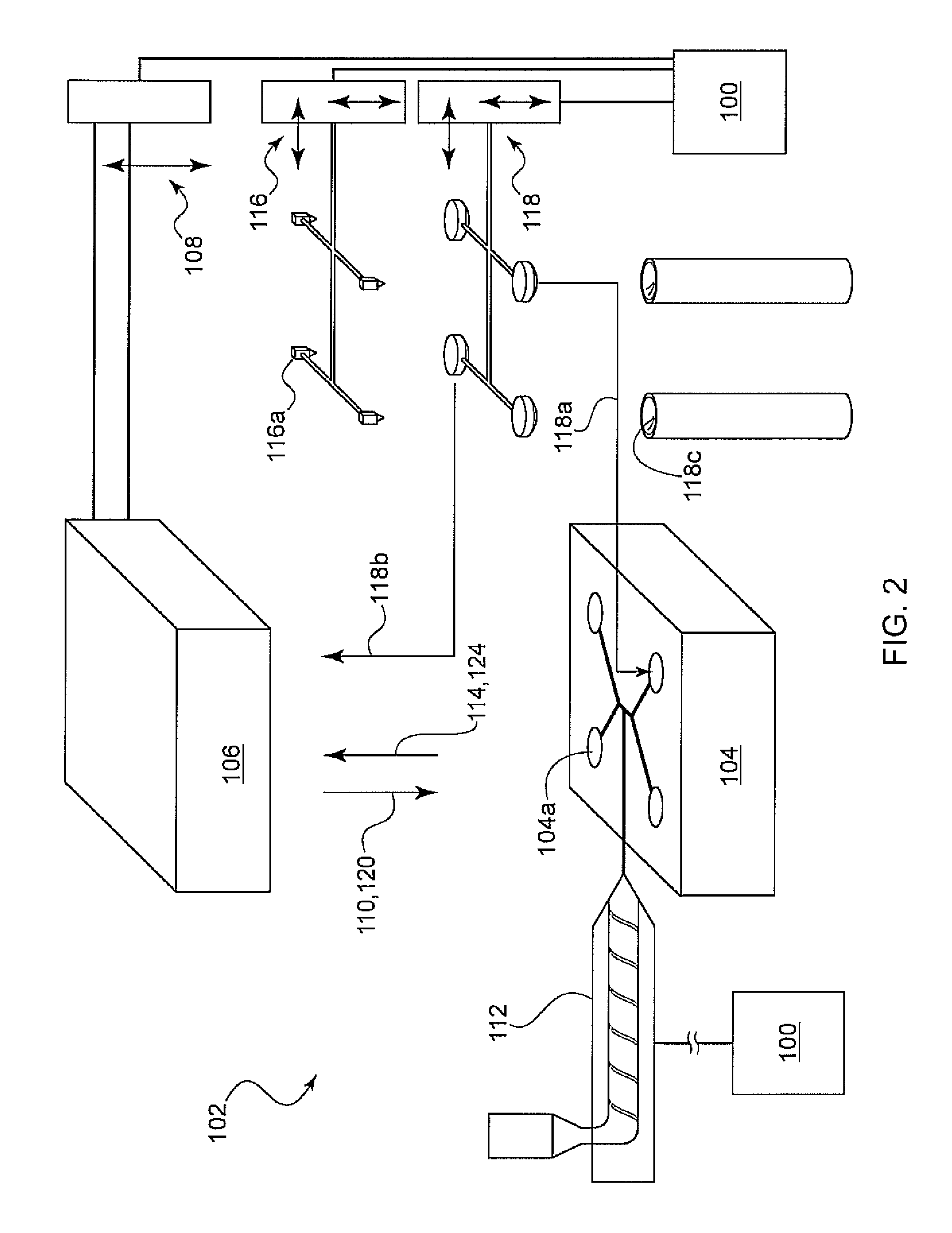

Method for post-injection lamination to add a functional film to an optical lens

ActiveUS7820081B2Easy to combineIncrease rangePolarising elementsOptical articlesAdhesive glueThin membrane

A method for laminating a functional film on to a thermoplastic injection molded lens. A thermally curable glue is deposited on the lens while it is still in the mold. A functional film is introduced and the mold is closed again. The heat from the mold and the clamping pressure thermoform the film and cure the glue, in a lamination process. A functionally enhanced lens having a film intimately laminated on to one side.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Exhaust gas purification device for internal combustion engine

InactiveUS20080295491A1Accurately derivedAchieve inhibitionElectrical controlInternal combustion piston enginesExternal combustion engineExhaust fumes

An exhaust gas purification device of a diesel engine having a DPF (diesel particulate filter) for collecting particulate matters such as soot and unburned components from exhaust gas of the diesel engine calculates an oil dilution quantity as a quantity of fuel diluting engine oil from a regeneration time of the DPF and an operation state. The exhaust gas purification device alleviates an increase in the oil dilution quantity by using a regeneration device that causes the oil dilution quantity less than the oil dilution quantity caused by another regeneration device when the oil dilution quantity exceeds a predetermined value. Thus, both of suppression of the oil dilution quantity and inhibition of deterioration of fuel consumption due to post-injection can be achieved.

Owner:DENSO CORP

Control Method of Exhaust Gas Purification System and Exhaust Gas Purification System

ActiveUS20090082938A1Easy to controlOil dilution can be avoidedElectrical controlInternal combustion piston enginesExhaust fumesEnvironmental engineering

An exhaust gas purification system has an exhaust gas purification device (12) for purifying components in exhaust gas from an internal combustion engine (10) such as a diesel engine. In order to recover the purification ability of the exhaust gas purification device (12), and in order to prevent oil dilution occurring when post injection is conducted as part of an in-cylinder fuel injection control during an exhaust gas temperature raising control that raises the temperature of exhaust gas, the system performs the following. In a regenerative control for recovering purification ability of the exhaust gas purification device (12), injection quantities (Qp) of post injections are calculated based on previously set map data (Mp), accumulated to calculate a post injection accumulated injection amount (ΣQp), and, when the accumulated injection amount (ΣQp) exceeds a predetermined determination value (Cp), the post injection is stopped to cease the regenerative control.

Owner:ISUZU MOTORS LTD

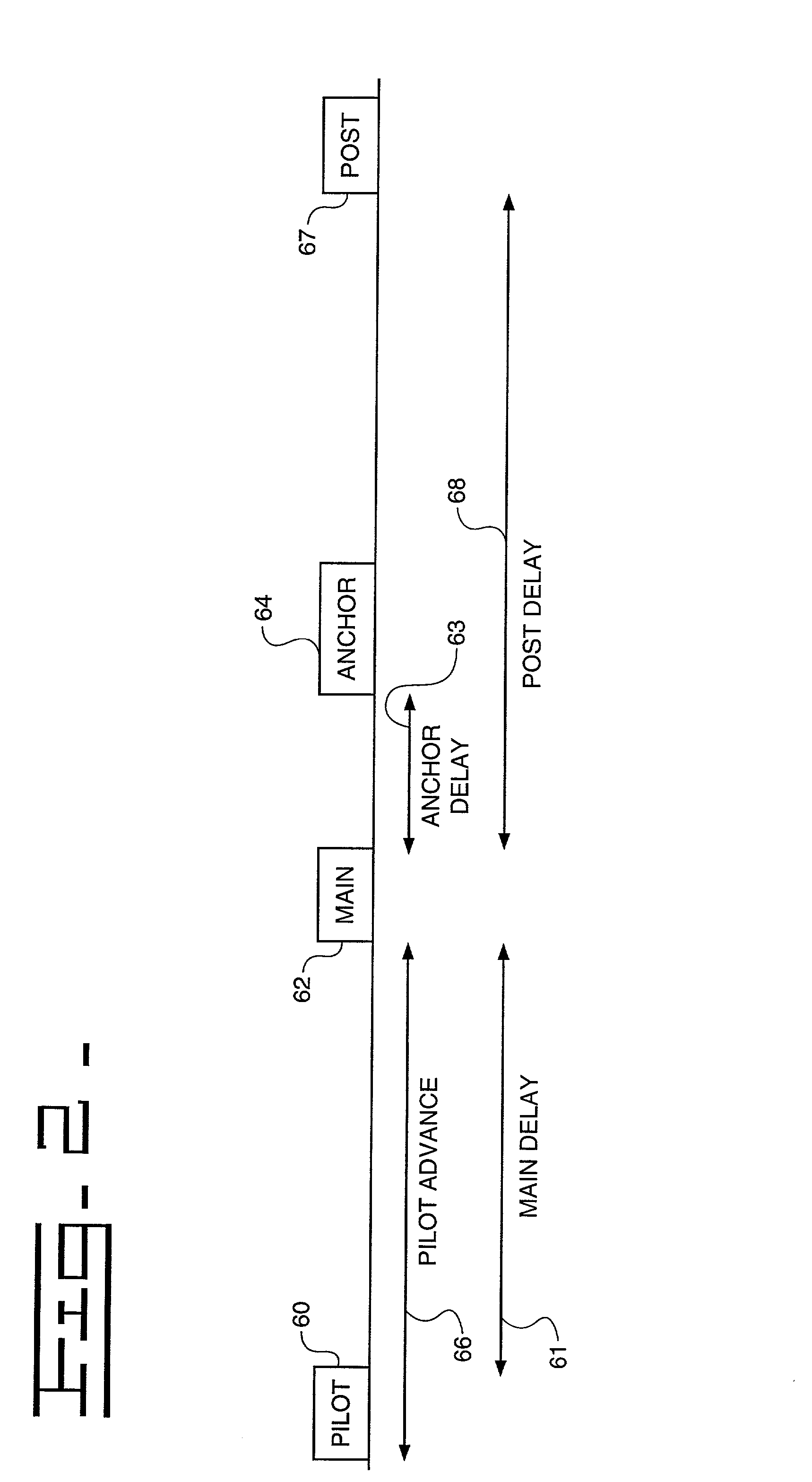

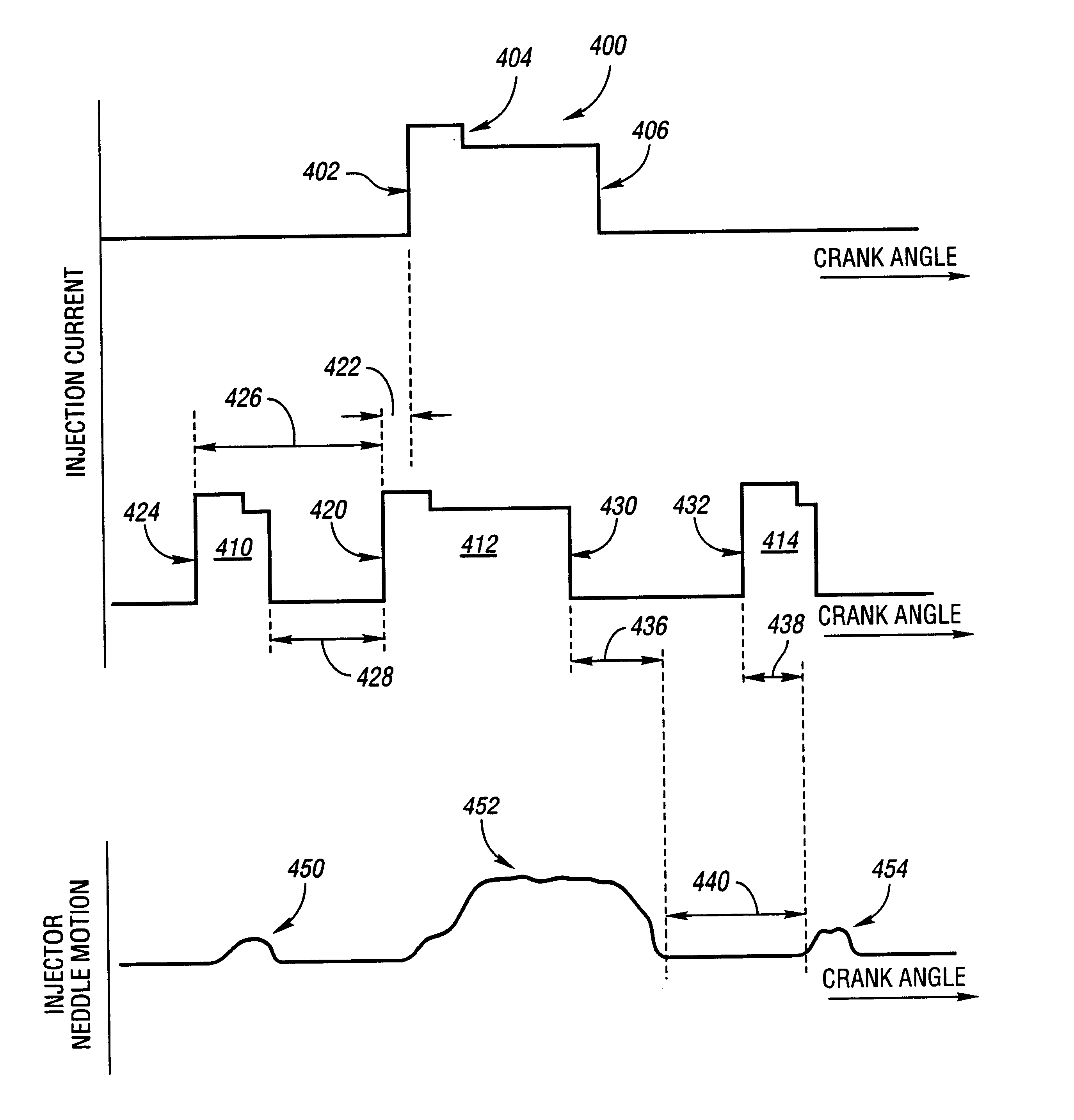

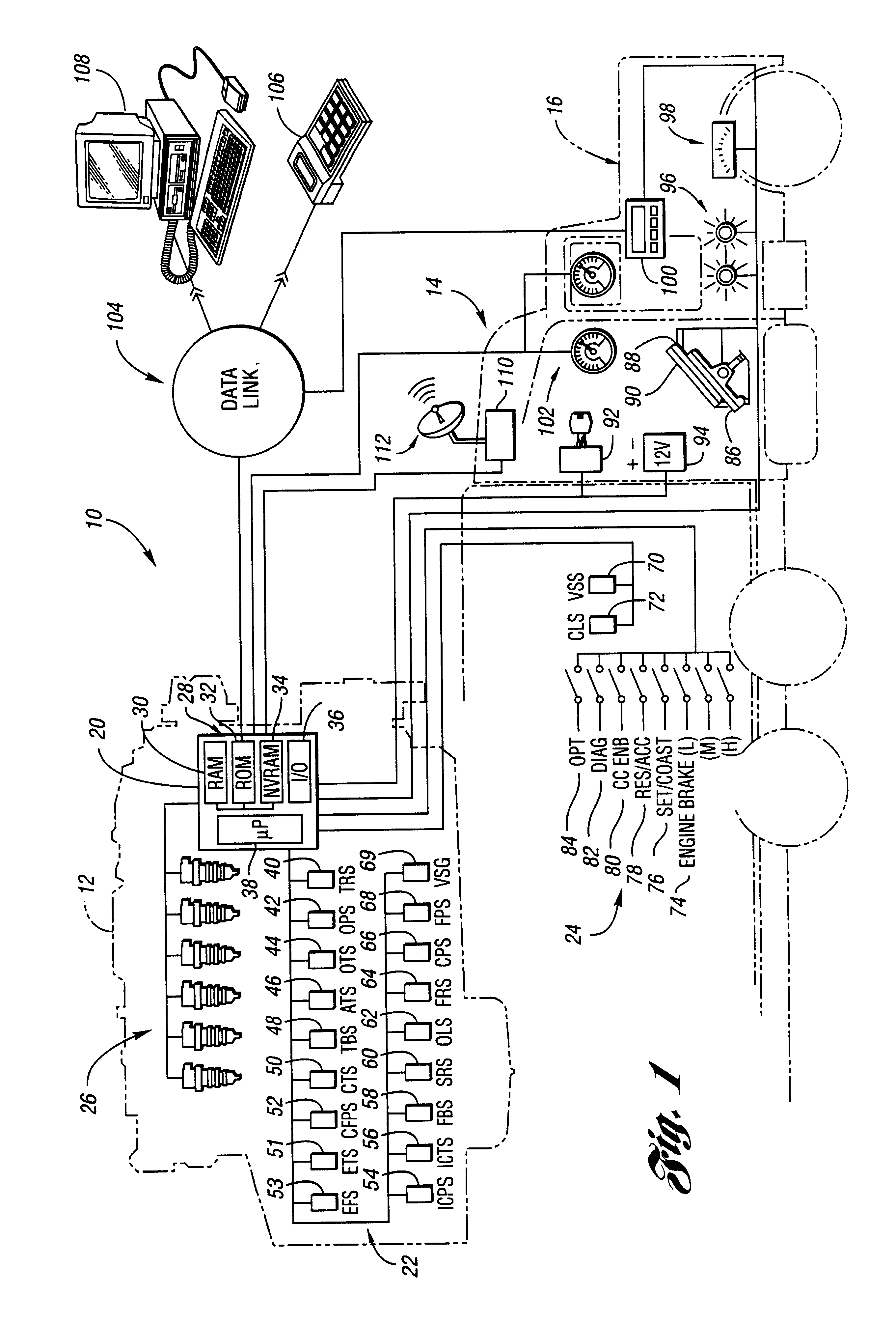

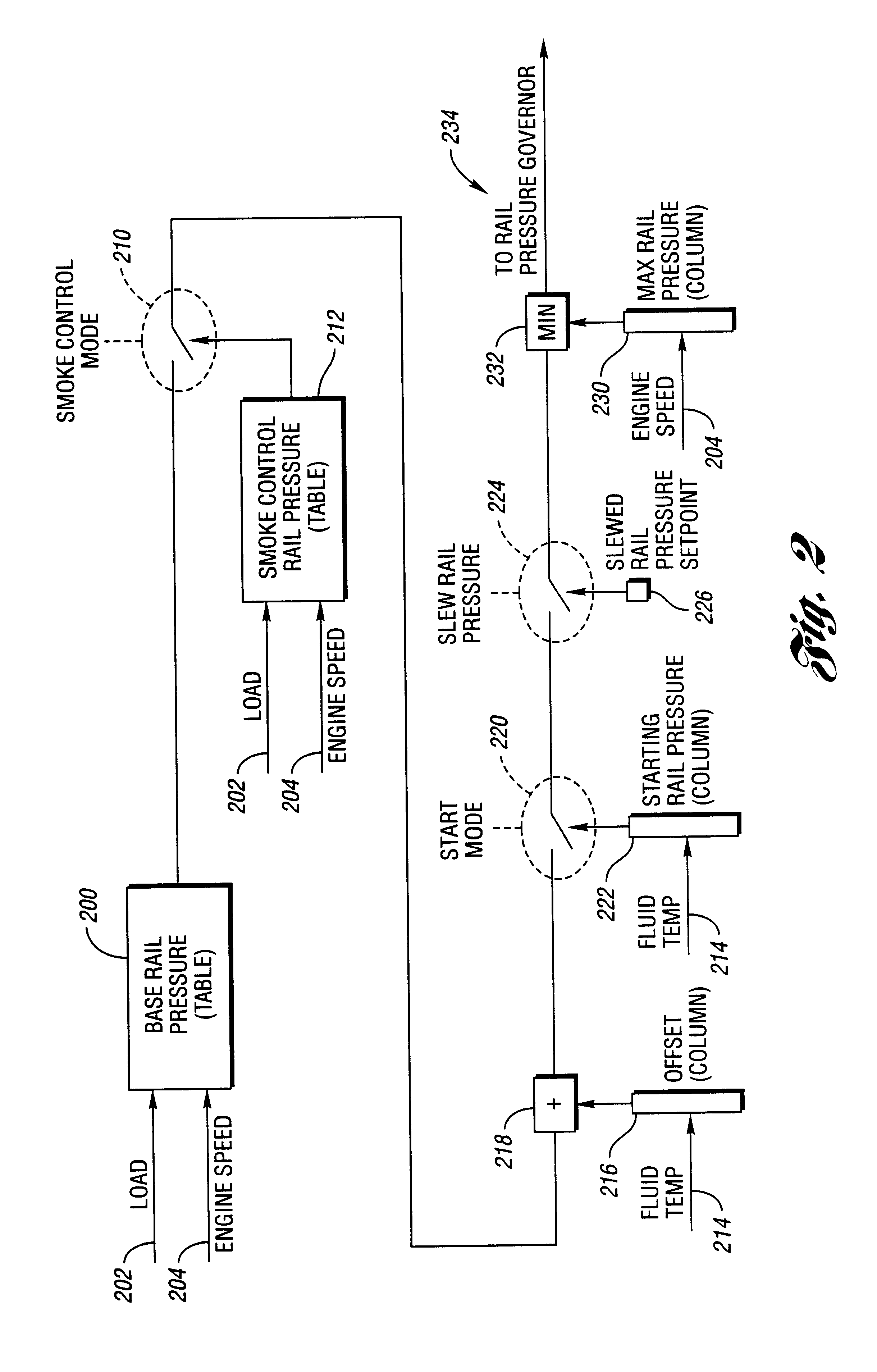

Injection control for a common rail fuel system

InactiveUS6848414B2Accurate injection controlEasy to controlElectrical controlInternal combustion piston enginesRail pressureFuel distribution

A system and method for controlling multiple fuel injections during a single combustion cycle for a multiple cylinder internal combustion engine having a common rail fuel distribution system determine the beginning of injection for the pilot and main injections based on crankshaft position while post injections are based on the main injection timing and an injector turn off delay determined using actual rail pressure. A rail pressure setpoint is determined based on current engine operating conditions including one or more fluid temperatures and current operating mode to provide more accurate injection control.

Owner:DETROIT DIESEL CORP

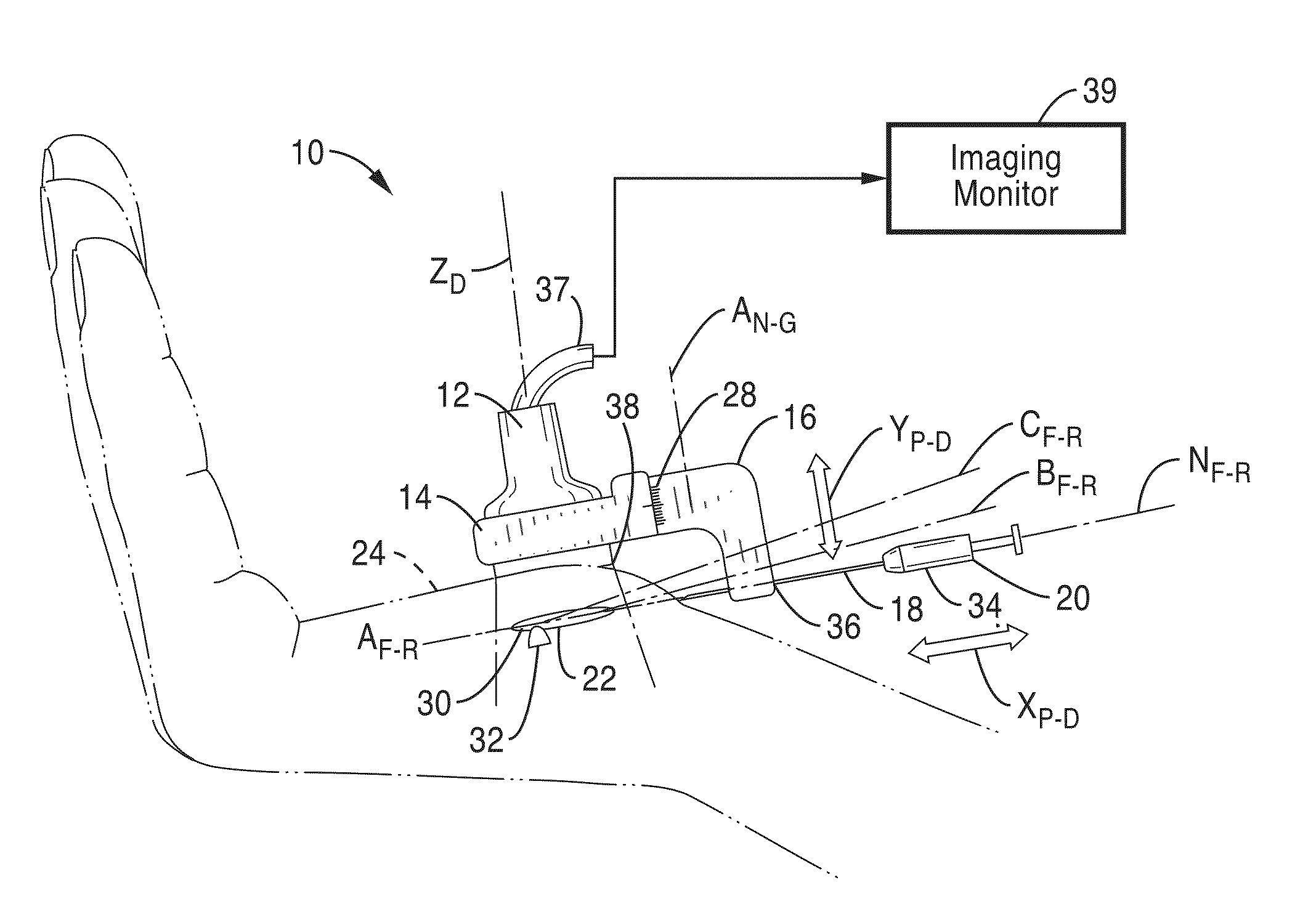

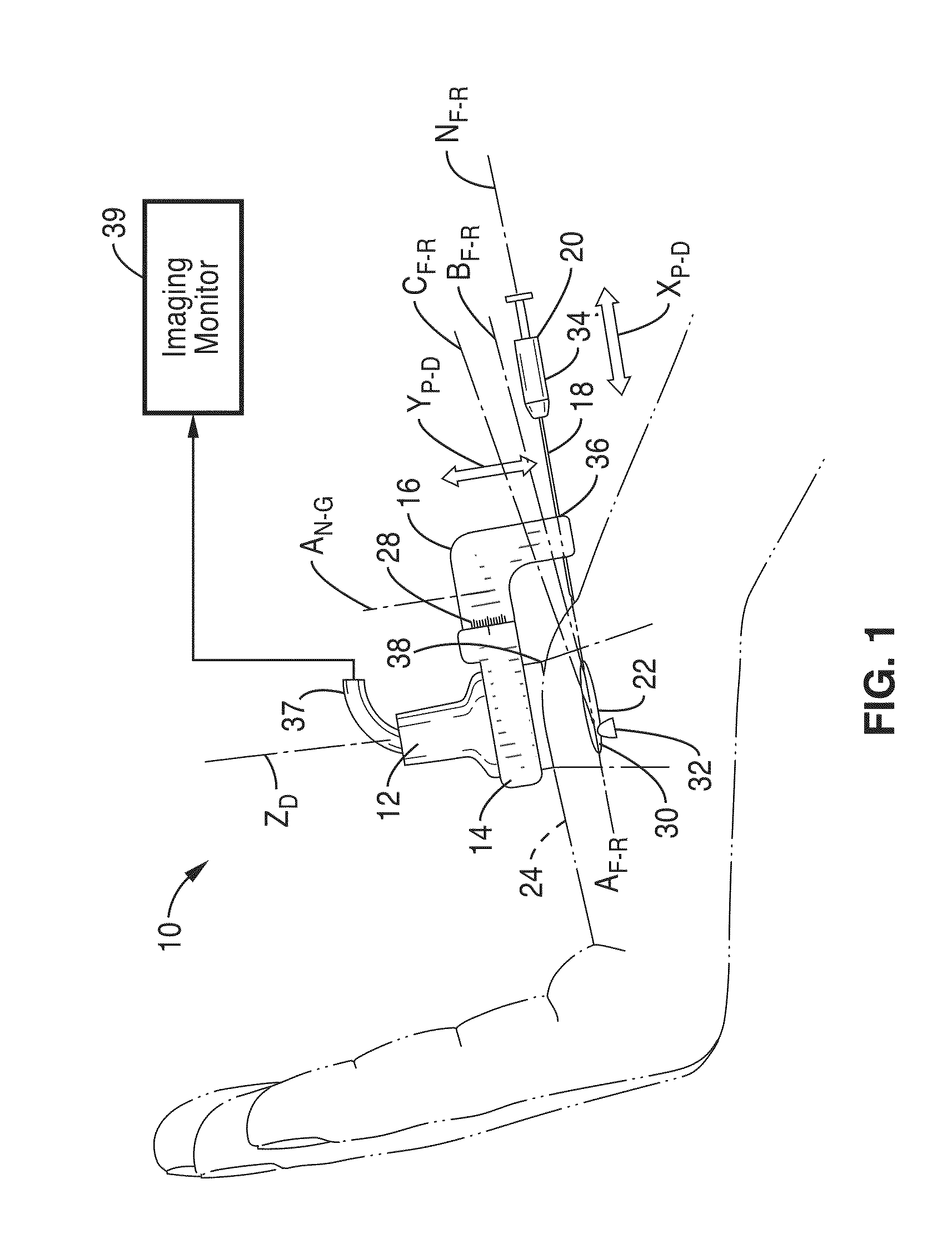

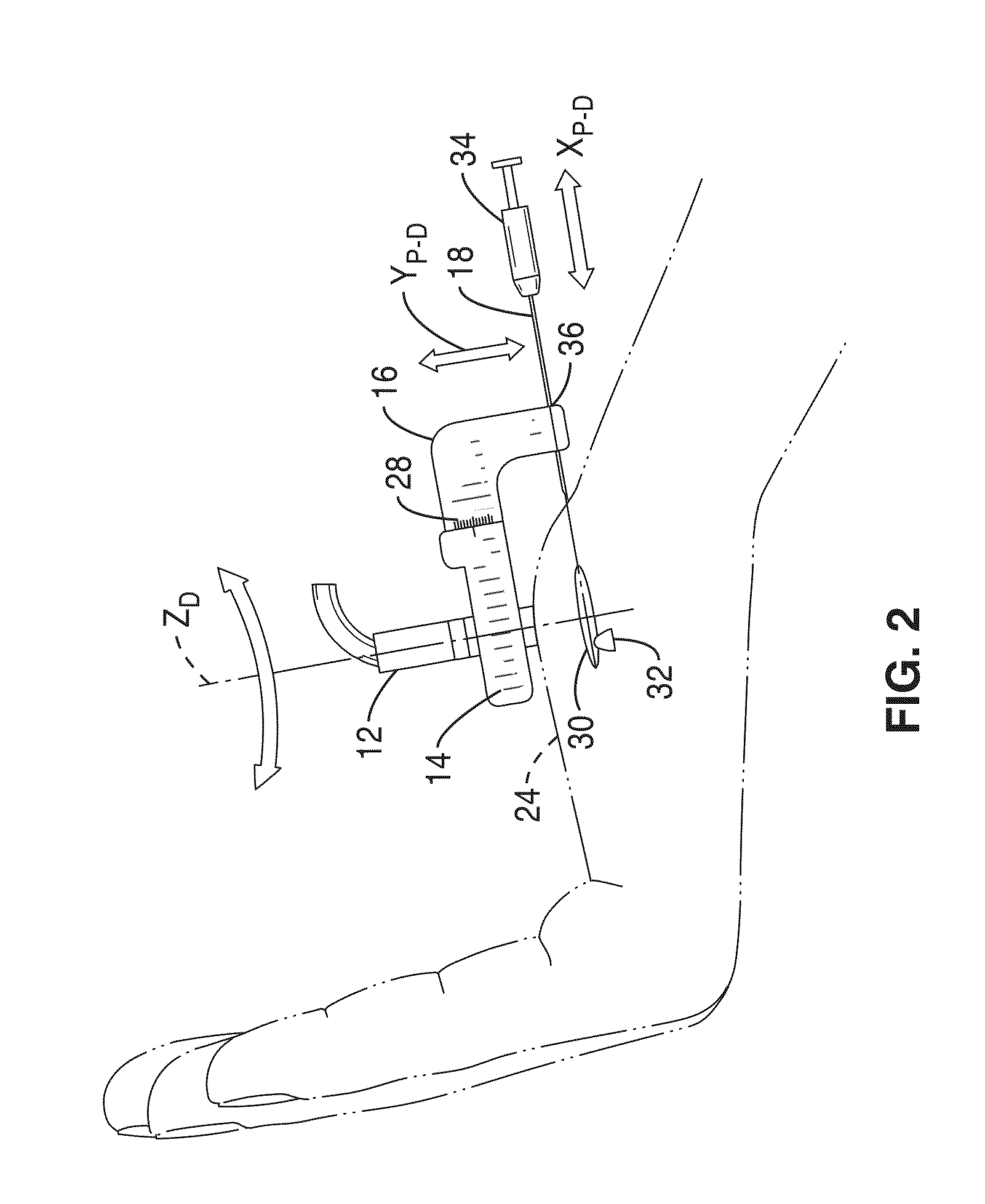

Treatment of carpal tunnel syndrome by injection of the flexor retinaculum

InactiveUS20100247513A1Altered stiffnessReduce pressureOrganic active ingredientsPeptide/protein ingredientsCTS - Carpal tunnel syndromeHand exercises

An apparatus and method for identifying the flexor retinaculum of the carpal tunnel, injecting an effective amount of an agent into at least a portion of flexor retinaculum or tissue adjacent thereto, wherein the agent is configured to weaken the flexor retinaculum. The system may further include means for increasing the tensile stress in the flexor retinaculum post-injection using hand exercises, thereby weakening its structural integrity and decreasing the pressure within the carpal tunnel that impairs median nerve function.

Owner:JOHN M AGEE & KAREN K AGEE TRUSTEES OF THE JOHN M AGEE TRUST

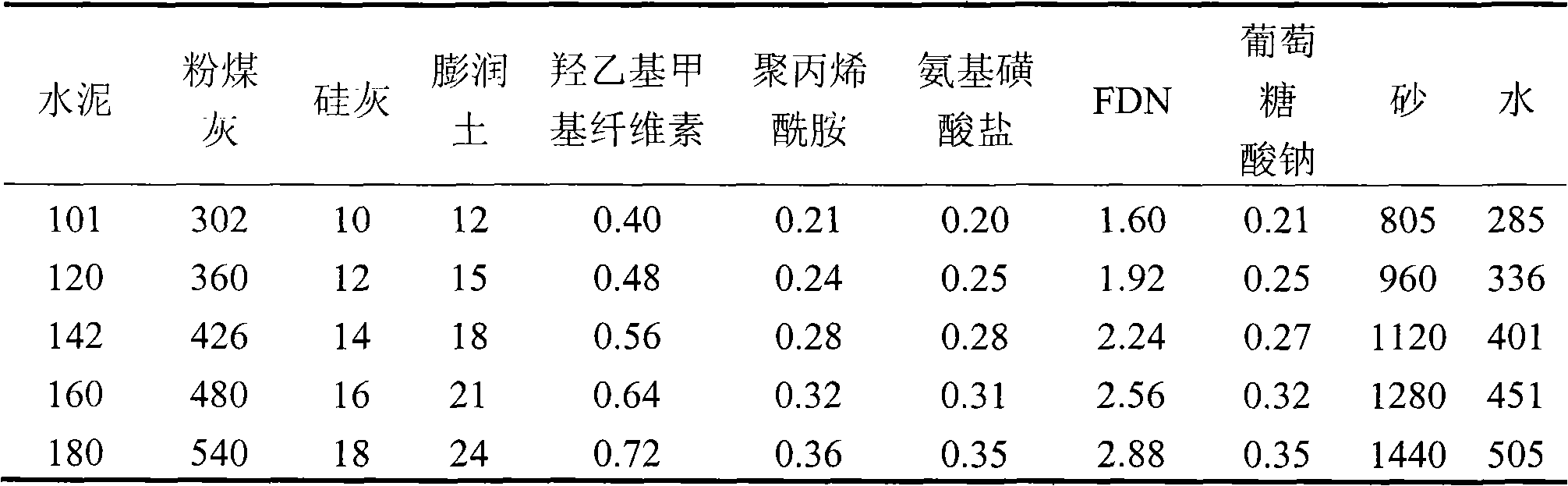

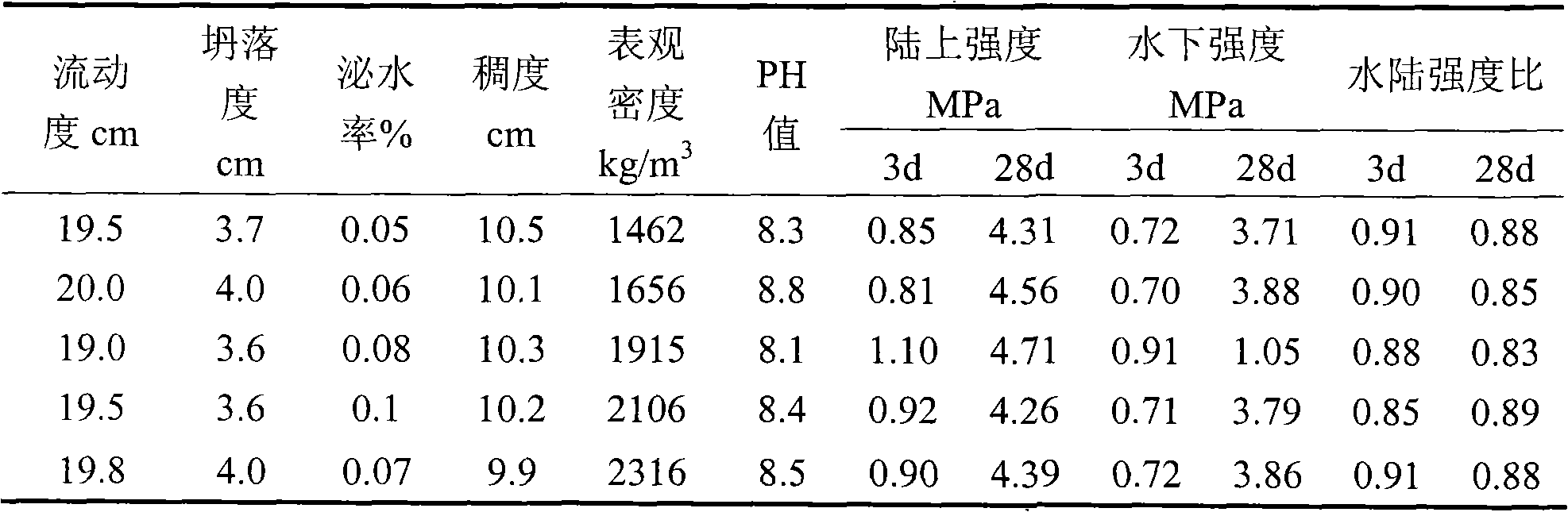

Tunnel backing cloth slip casting material capable of preventing duct piece float upward and preparation method thereof

InactiveCN101269938AAchieve underwater non-dispersionPrevent floatingSolid waste managementPost injectionPolyacrylamide

The present invention relates to tunnel-wall post-injection pulp material and a preparation method of the tunnel-wall post-injection pulp material. Tunnel back-lining pulp-injection material that can prevent the upward-floating of the duct piece is characterized in consisting of a substrate compound A and an additive compound B, wherein, the substrate compound A includes cement, fly ash, sand and water; the additive compound B includes silicone ash, swell soil, droxyethylcellulose, polyacrylamide, sulfamate, naphthaline water-reducing agent and gluconic acid sodium salt; the ratio of the ingredients (kg / m<3>): 100 to 200 portions of cement, 300 to 600 portions of fly ash, 800 to 1600 portions of sand, 280 to 560 portions of water, 10 to 40 portions of silicone ash, 12 to 30 portions of swell soil, 0.4 to 0.8 portions of droxyethylcellulose, 0.2 to 0.4 portions of polyacrylamide, 0.2 to 0.4 portions of sulfamate, 1.6 to 2.9 portions of naphthaline water-reducing agent and 0.2 to 0.4 portions of gluconic acid sodium salt. The present invention can realize the high stability, high water dispersion prevention, high-efficient water-reducing plasticity preservation and adjustable performance of the pulp-injection material the condensation under the conditions of high water pressure and water satuation, thereby greatly improving the working performance and the durance of the pulp-injection material.

Owner:WUHAN UNIV OF TECH +1

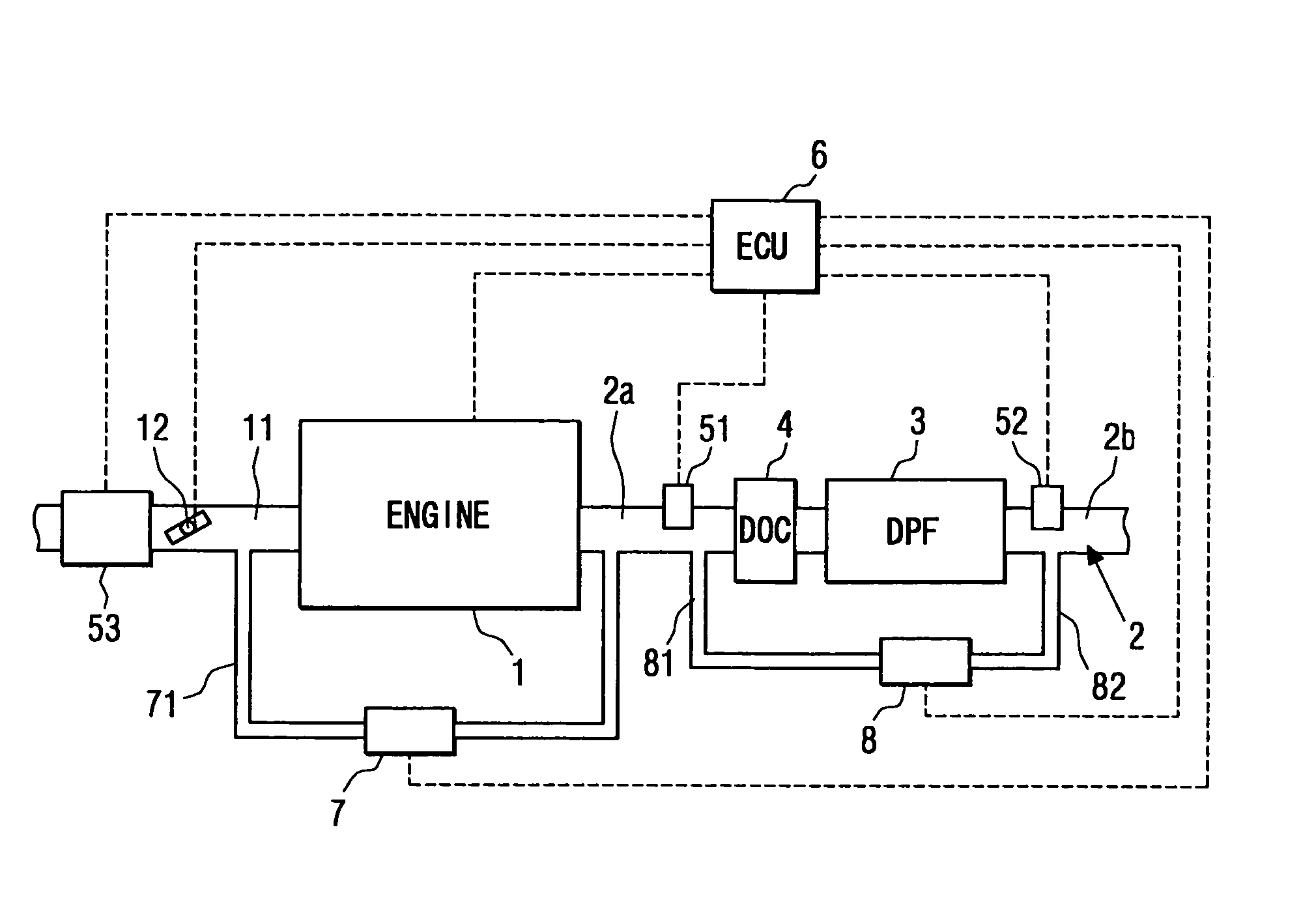

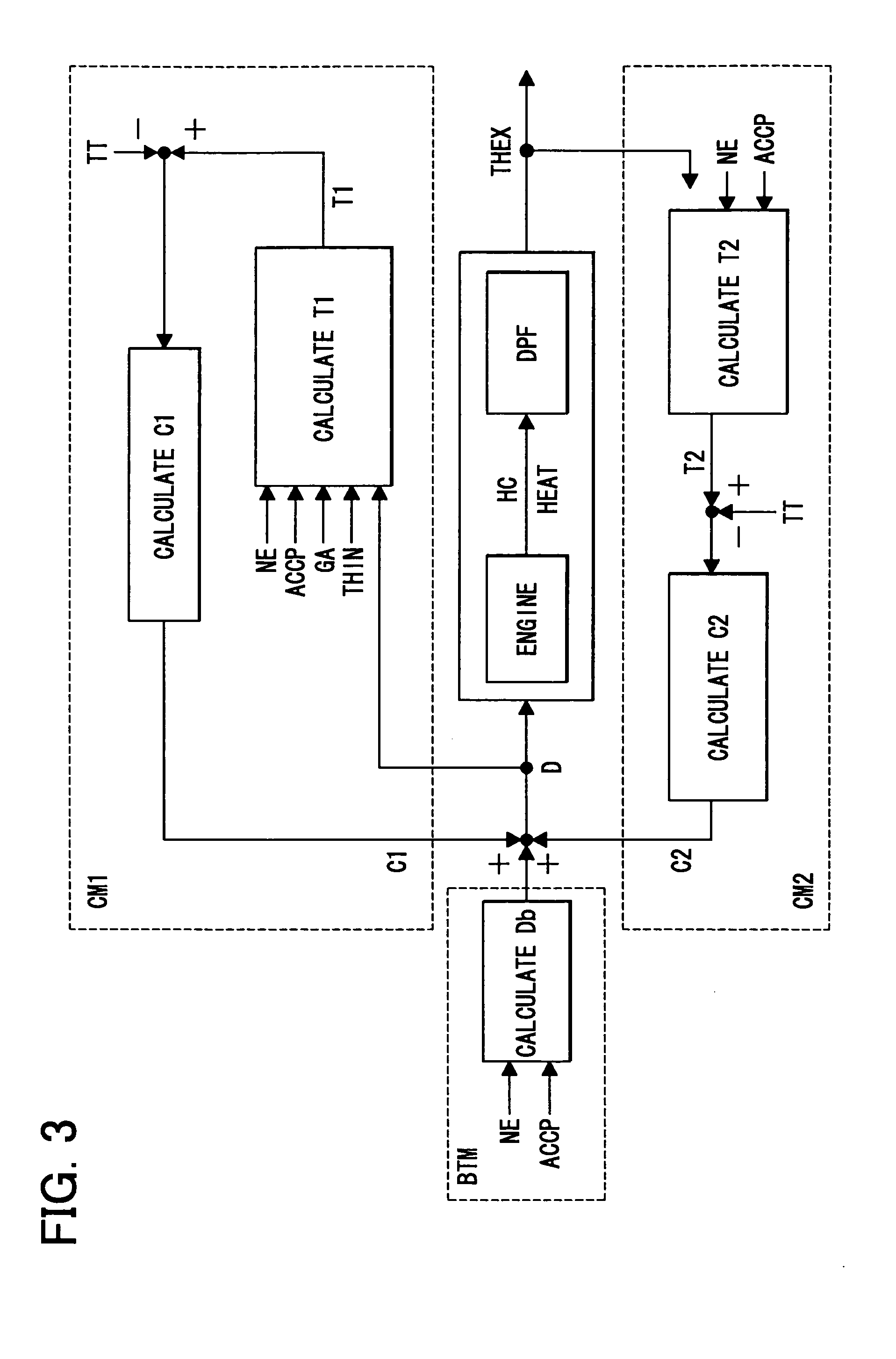

Exhaust gas purification system of internal combustion engine

ActiveUS7243491B2Increase temperatureAvoid damageElectrical controlInternal combustion piston enginesEngineeringExhaust gas recirculation

A diesel oxidation catalyst is disposed upstream of a diesel particulate filter (a DPF) disposed in an exhaust passage of a diesel engine. An electronic control unit (an ECU) operates a temperature increasing circuit, which performs post-injection, to eliminate particulate matters accumulated in the DPF. The ECU includes a first correcting circuit and a second correcting circuit. The first correcting circuit corrects a manipulated variable of the temperature increasing circuit based on a result of comparison between a target temperature and a temperature of the DPF estimated based on information related to an area upstream of the DPF. The second correcting circuit corrects the manipulated variable of the temperature increasing circuit based on a result of comparison between the target temperature and the temperature of the DPF estimated based on information related to an area downstream of the DPF.

Owner:DENSO CORP

Fuel injection control system for internal combustion engine

InactiveUS20030221423A1Avoid it happening againElectrical controlInternal combustion piston enginesLower limitParticulates

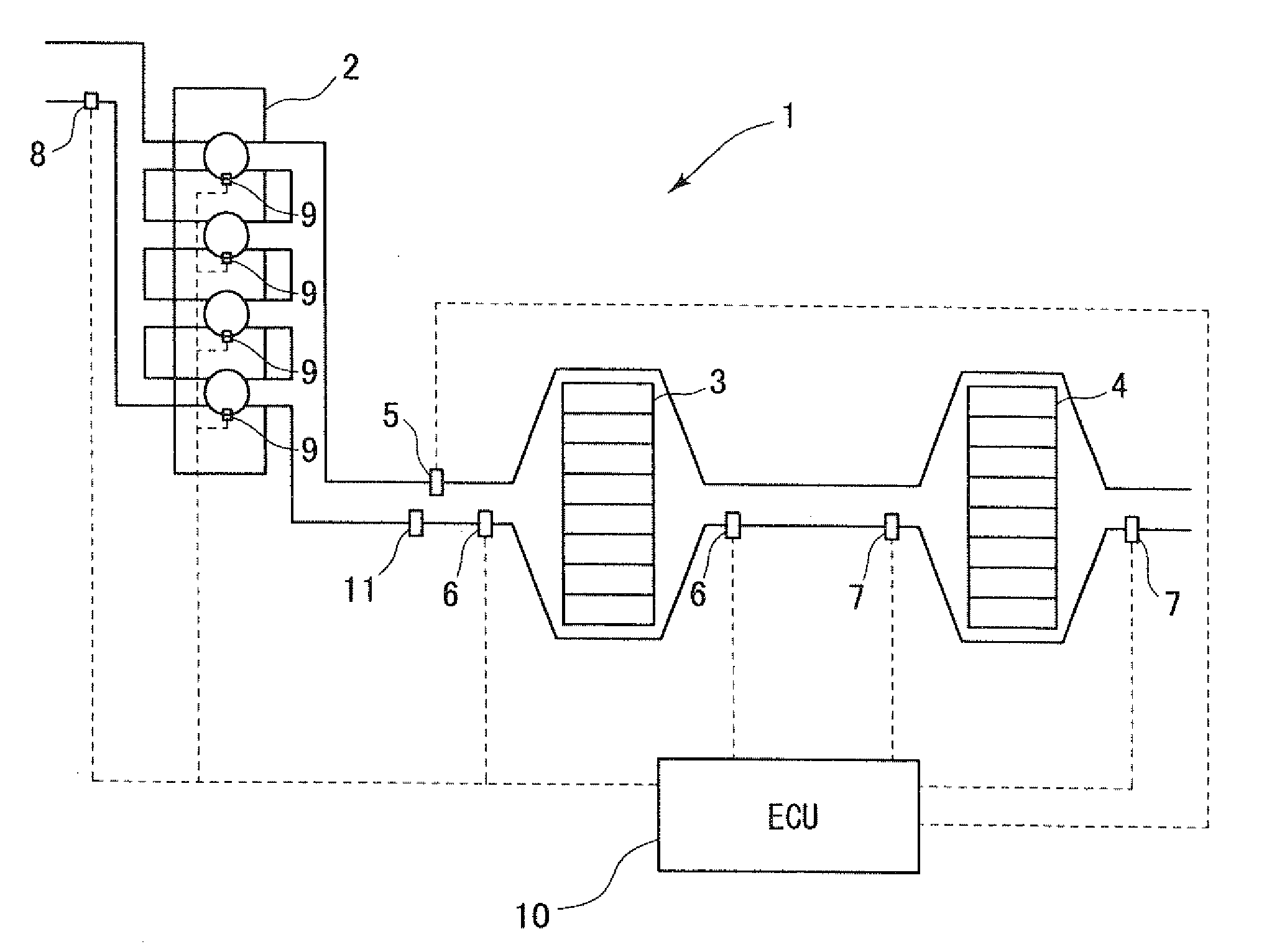

An internal combustion engine has a particulate filter for collecting exhaust particulate matters included in exhaust gas. An oxidization catalyst is supported on the particulate filter. A fuel injection control system for the engine has injection quantity setting means. The injection quantity setting means sets an injection quantity for a post-injection so that the injection quantity is increased toward a basic injection quantity corresponding to a heating value, which is suitable for eliminating exhaust particulate matters collected by a particulate filter. The injection quantity is gradually increased to the basic injection quantity while maintaining temperature of the particulate filter including the oxidization catalyst above a lower limit temperature for inhibiting generation of white smoke. The lower limit temperature is determined in accordance with the injection quantity.

Owner:DENSO CORP

Exhaust gas purifying device and method for internal combustion engine

InactiveUS20040261401A1Electrical controlNon-fuel substance addition to fuelTemperature controlLow load

Removal of fine particles by oxidation or / and sulfur poisoning recovery control may be required when an internal combustion engine has been in an extremely low load state for a predetermined period or more. In this case, the engine speed of the internal combustion engine (1) is adjusted to a range where the temperature of a filter (20) can be raised by heat-up control. The heat-up control is then executed by a filter temperature control means to raise the temperature of the filter (20) to a predetermined value. When the filter (20) reaches the predetermined temperature by means of low-temperature combustion, post-injection, VIGOM-injection, addition of 10 fuel to an exhaust system and the like, removal of fine particles by oxidation or / and sulfur poisoning recovery control for eliminating sulfur poisoning of a NOx absorbent are conducted. Removal of PMs captured by the filter and sulfur poisoning recovery control of the NOx absorbent can thus be conducted even if the internal combustion engine is left in an extremely low load operational state.

Owner:TOYOTA JIDOSHA KK

Method and apparatus for controlling engine operation during regeneration of an exhaust aftertreatment system

InactiveUS20080078167A1Increase fuel consumptionReduction in calibration parameterInternal combustion piston enginesExhaust apparatusCombustion chamberInternal combustion engine

There is provided a method and apparatus for controlling operation of an internal combustion engine, comprising controlling engine torque during regeneration of an exhaust aftertreatment system. This comprises controlling post-injection of fuel into a combustion chamber effective to regenerate an exhaust aftertreatment device. Main fuel injection into each combustion chamber and boost are selectively controlled effective to maintain engine output torque.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method of Controlling Exhaust Gas Purificaiton System, and Exhaust Gas

ActiveUS20090235644A1Regeneration control can be efficientlyExhaust gas temperature is quicklyGas treatmentElectrical controlExhaust fumesEngineering

In an exhaust gas temperature raising control for recovering purification ability of an exhaust gas purification device (12) of an internal combustion engine, the exhaust gas temperature is efficiently raised to a target level with white smoke prevented from being produced. To achieve this, in the exhaust gas temperature raising control in recovery control of the exhaust gas purification device (12), when the temperature (Tg1) of the exhaust gas flowing into the exhaust gas purification device (12) is lower than a predetermined judgment value (Tp), a first exhaust gas temperature raising control that does not include post injection but includes intake air restriction is performed, and when equal to or higher than the predetermined judgment value (Tp), a second exhaust gas temperature raising control that includes both the post injection and the intake air restriction is performed to set an intake air restriction amount (α) in the first exhaust gas temperature raising control greater than an intake air restriction amount (β) in the second exhaust gas temperature raising control.

Owner:ISUZU MOTORS LTD

Method and apparatus for operating an internal combustion engine having exhaust gas turbocharging

InactiveUS20070062189A1Improve system efficiencyImprove responseNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerExhaust fumes

in a method for operating a supercharged internal combustion engine and an internal combustion engine including an exhaust gas treatment system which comprises a catalytic converter arranged close to the engine, an exhaust gas turbocharger which is arranged downstream of the catalytic converter, and a post-injection device for introducing additional fuel into the exhaust gas flow upstream of the catalytic converter, wherein the heat energy of the exhaust gas mass flow which acts on the exhaust gas turbocharger is varied by controlling the fuel quantity which is additionally introduced into the exhaust gas flow by means of the post-injection device resulting in an improvement in the response behavior of the internal combustion engine, excess energy which is generated by the exhaust gas turbocharger by means of a motor generator connected to the exhaust gas turbocharger is stored in a storage device and is returned to the motor generator for rapidly accelerating the turbocharger when an increased power output is demanded from the engine.

Owner:DAIMLER AG

Exhaust gas cleaning system of internal combustion engine

ActiveUS7076944B2Avoid damageAvoid degradationElectrical controlInternal combustion piston enginesExternal combustion engineExhaust fumes

An exhaust gas cleaning system of a diesel engine includes a diesel particulate filter (a DPF) disposed in an exhaust passage, and a diesel oxidation catalyst (a DOC) disposed upstream of the DPF. When an electronic control unit (an ECU) performs a temperature increasing operation such as post-injection to eliminate particulate matters accumulated in the DPF, a ratio (a duty ratio) between a performing period and an interrupting period of the temperature increasing operation is changed in accordance with temperature of the DPF. Thus, a quantity of hydrocarbon supplied to the DOC is controlled stepwise or continuously. Thus, the temperature of the DPF can be increased to target temperature quickly and can be maintained near the target temperature when the regeneration of the DPF is performed.

Owner:DENSO CORP

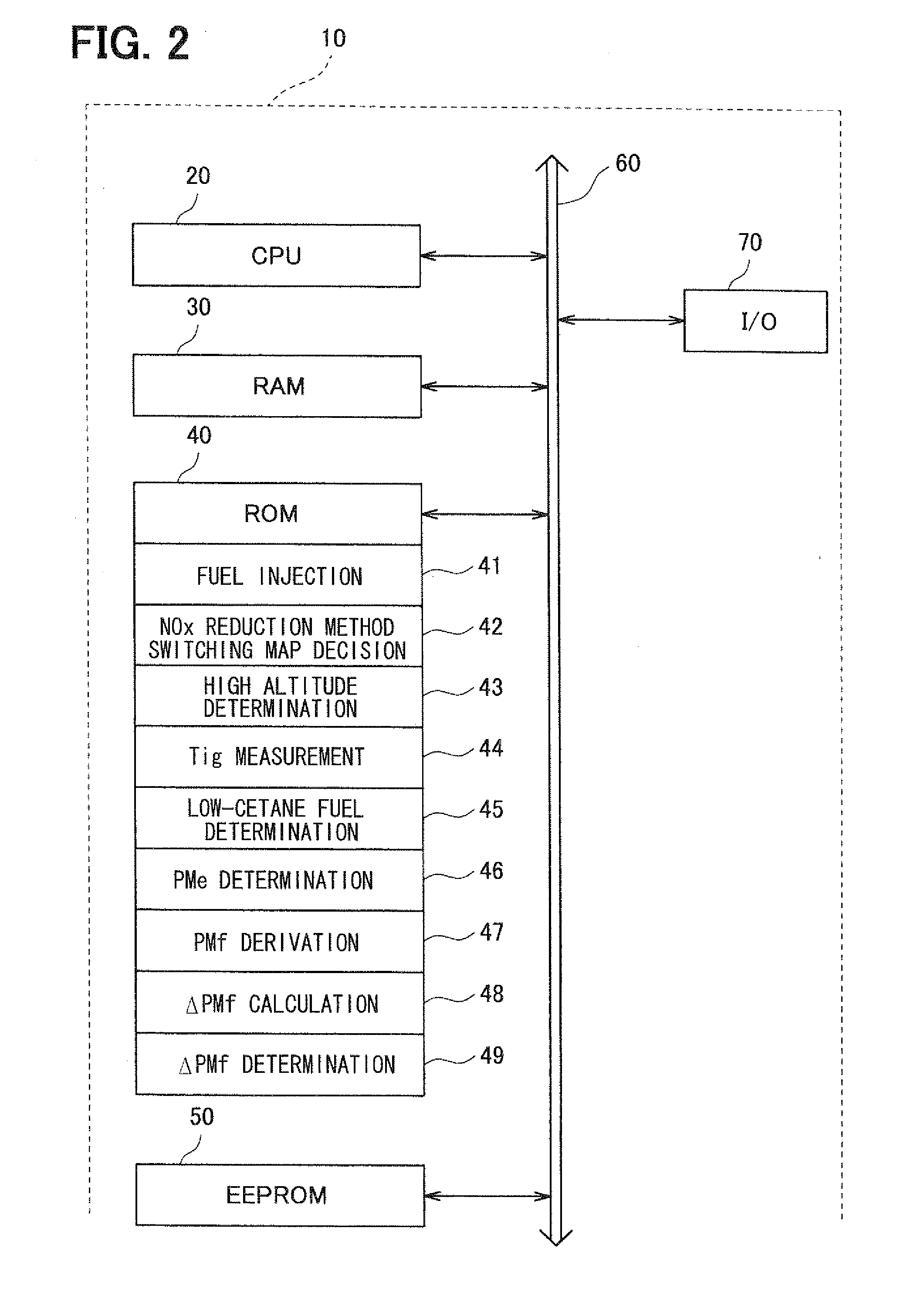

Exhaust purification device for internal combustion engine

InactiveUS20080307772A1Accurate acquisitionReduce catalysisElectrical controlInternal combustion piston enginesExhaust fumesEngineering

When it is determined that fuel in use is low-cetane fuel or a present location point is at a high altitude, a map of rich combustion, exhaust gas fuel addition or a post-injection is rewritten on the occasion of reduction of NOx to inhibit a misfire. Also, deterioration of fuel consumption due to regeneration of a diesel particulate filter is inhibited by suppressing excessive discharge of smoke due to the rich combustion. Thus, an exhaust purification device of an internal combustion engine capable of achieving both of inhibition of the deterioration in the fuel consumption due to the regeneration of the diesel particulate filter and inhibition of torque shock accompanying the misfire during the rich combustion for the NOx reduction is provided.

Owner:DENSO CORP

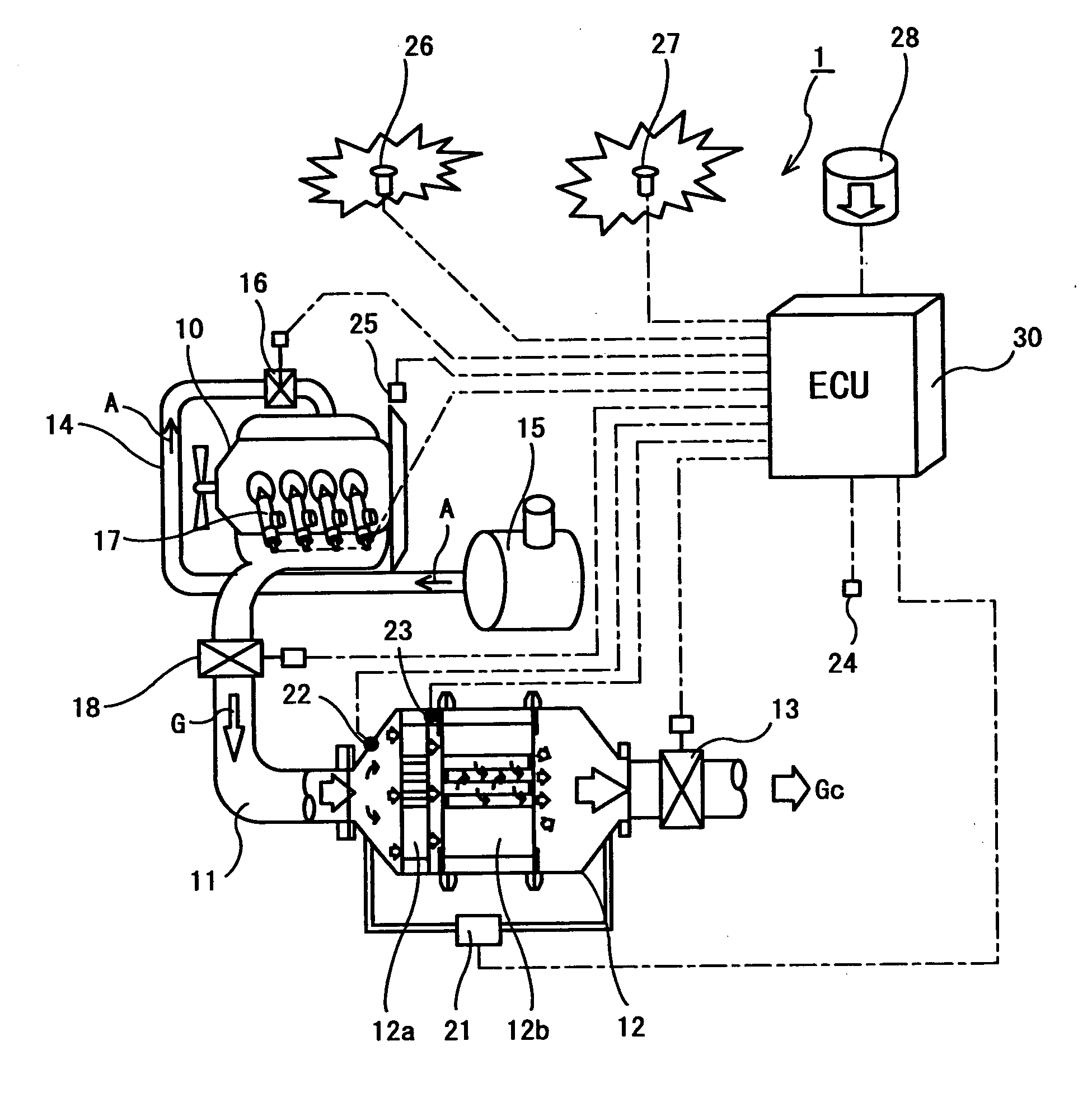

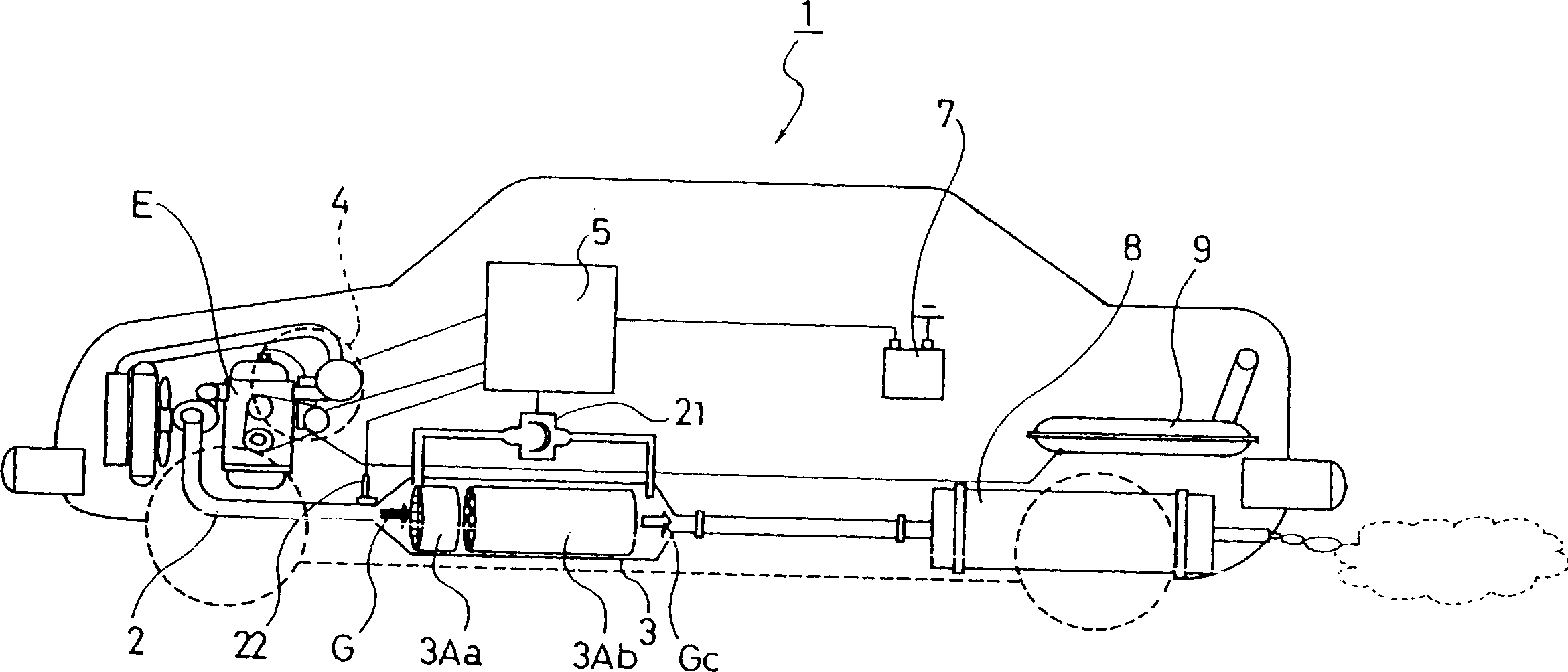

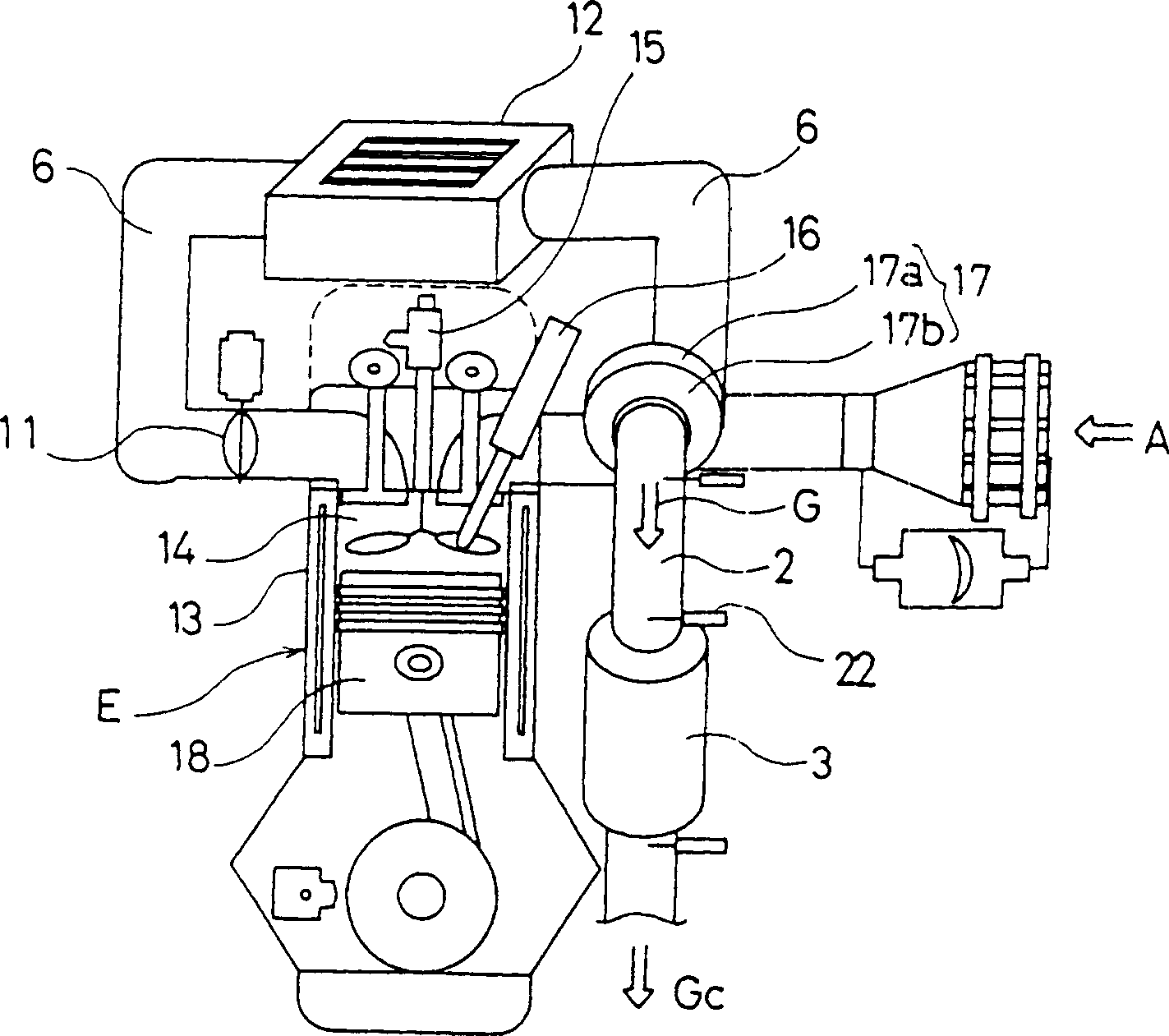

Waste gas purification system

InactiveCN1517526ALarge injection volumeDoes not affect the productionElectrical controlInternal combustion piston enginesExhaust fumesEngineering

An exhaust gas purifying system (1) aving a continuous regeneration DPF (3) installed in the exhaust passage (2) of a diesel engine (E) provided with a glow plug (16) and a regeneration control means for regenerating the continuous regeneration DPF (3), is constituted so that the regeneration control means performs retarded injection or post-injection in the control of fuel injection into a cylinder (13) and heating the inside of the cylinder (13) by the glow plug (16) for regenerating the continuous regeneration DPF (3). Thereby, when raising the temperature of exhaust gas in the regeneration of the continuous regeneration DPF (3), it is possible to prevent the generation of white fumes and misfire and to raise the exhaust gas temperature efficiently and substantially. Therefore, it is possible to prevent the temperature of a catalyst and a DPF from being abnormal high and to prevent the deterioration and the melt down of the catalyst.

Owner:ISUZU MOTORS LTD

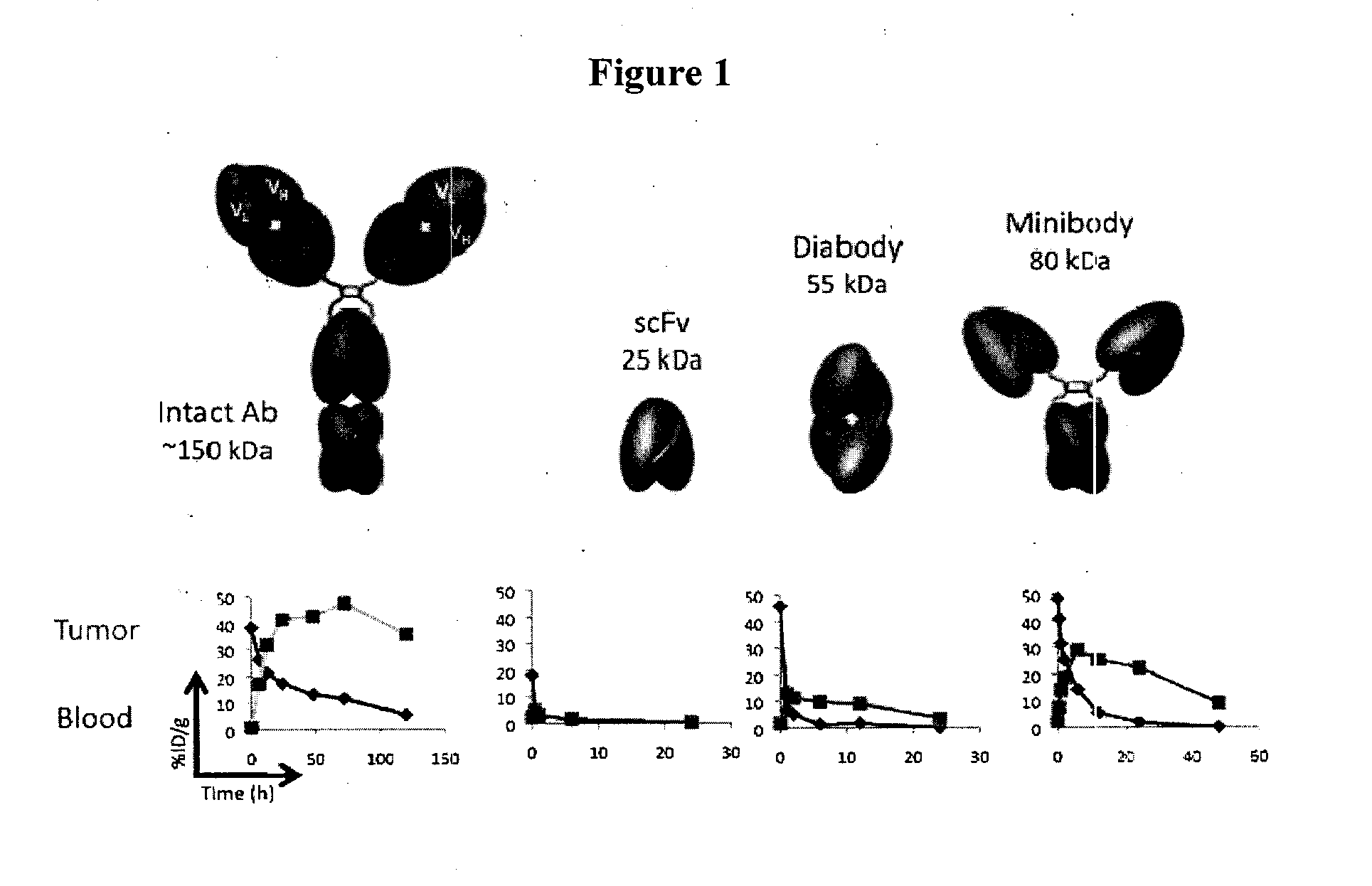

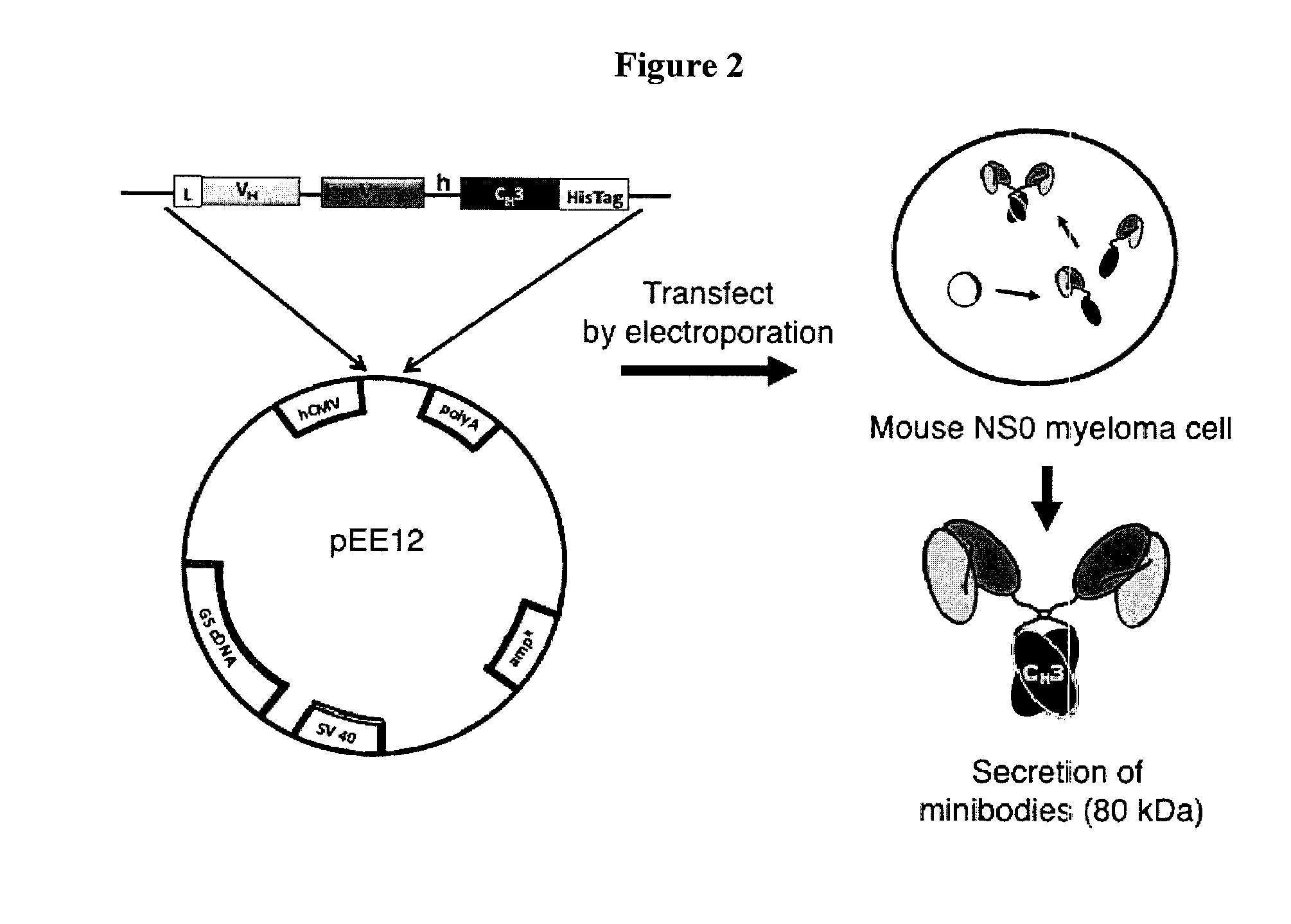

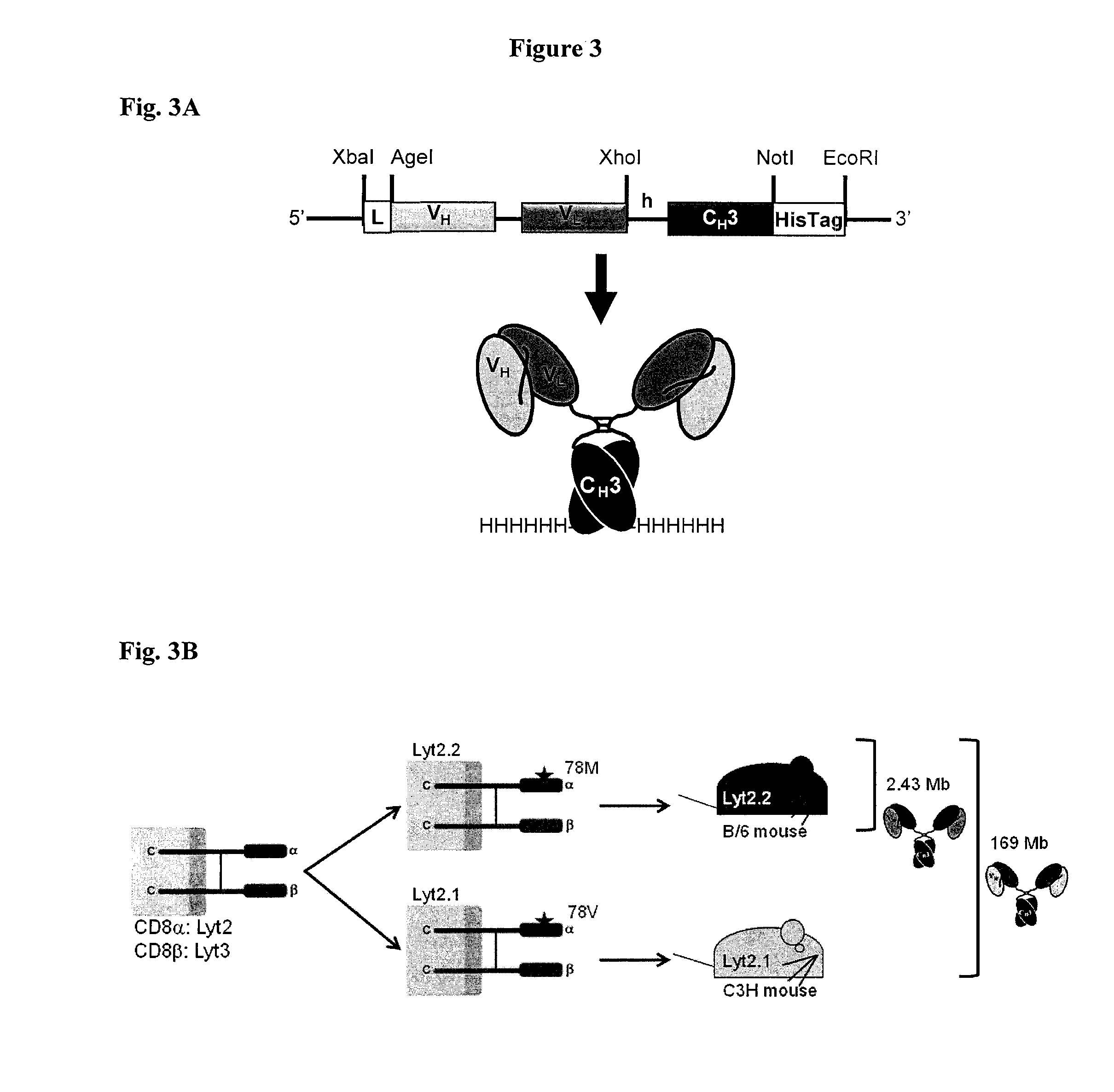

Engineered antibody fragments for targeting and imaging cd8 expression in vivo

InactiveUS20150191543A1X-ray constrast preparationsImmunoglobulins against cell receptors/antigens/surface-determinantsEpitopeAntibody fragments

Disclosed herein, the parental antibodies from the hybridomas YTS 169.4.2.1 (YTS169) and 2.43 were engineered into minibody and diabody fragments. Both the YTS and 2.43 antibodies bind mCD8+. However, they differ in that the YTS 169 antibodies bind both Lyt2.1 and Lyt2.2 while the 2.43 antibodies bind an epitope that is Lyt2.2 specific. These novel minibodies and diabodies retained their antigen specificity as shown by flow cytometry and ImmunoPET imaging. Most importantly, both the 2.43 and YTS169 minibodies and diabodies produced high contrast ImmunoPET images of CD8+ lymphoid organs at only four hours post-injection.

Owner:RGT UNIV OF CALIFORNIA

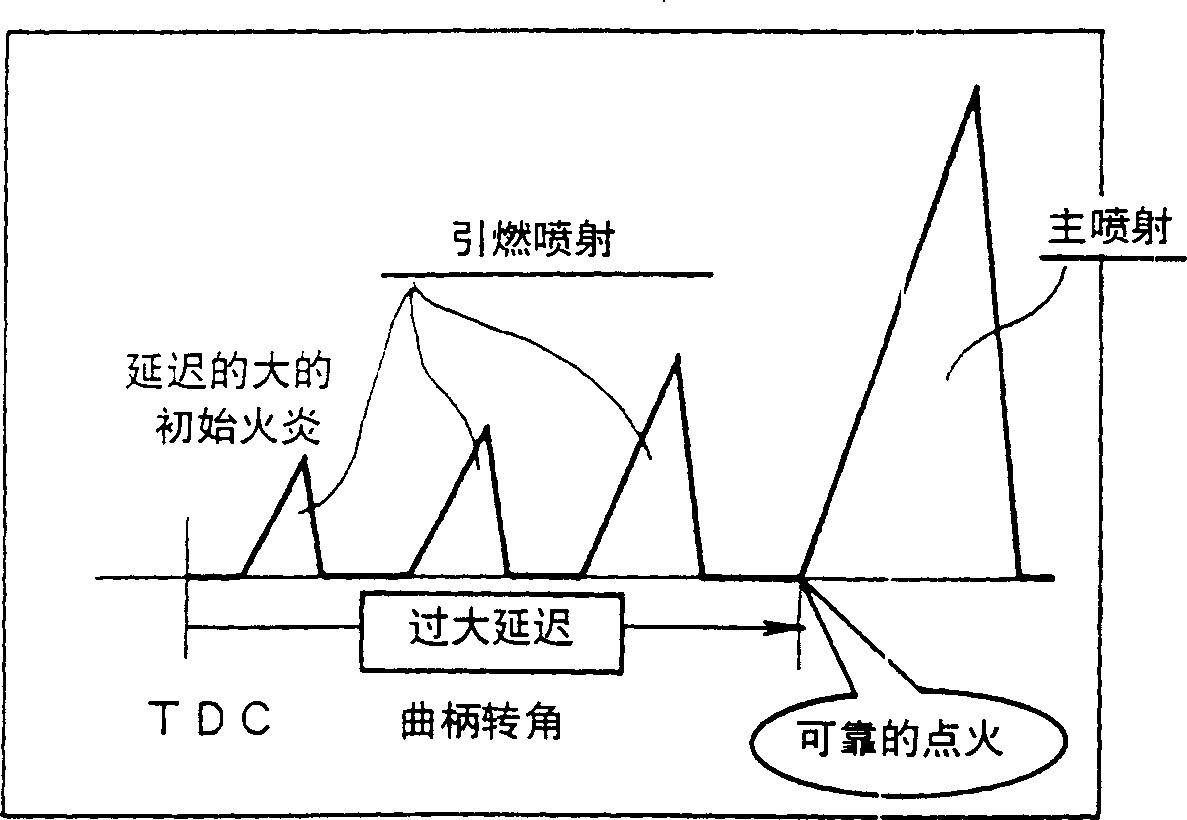

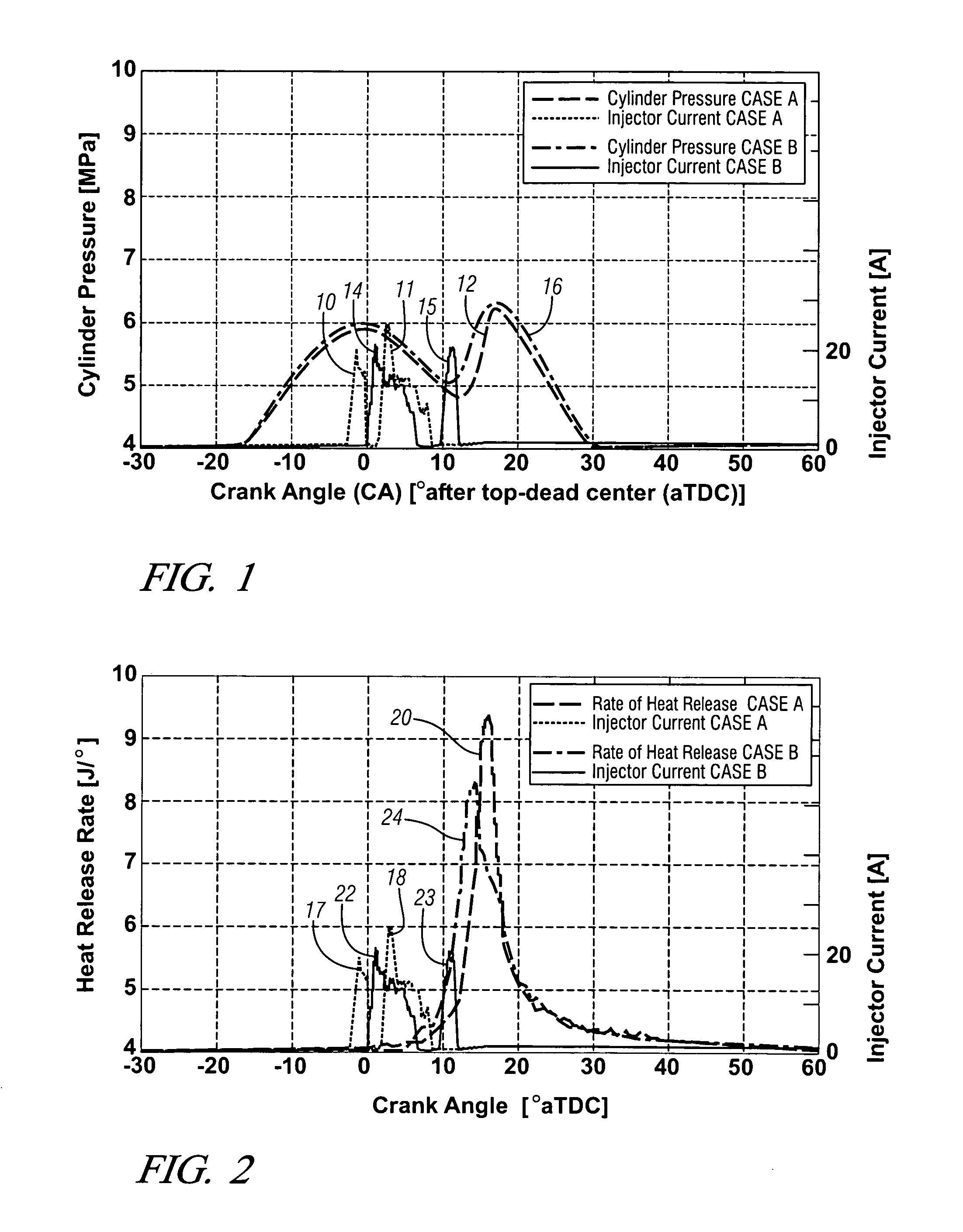

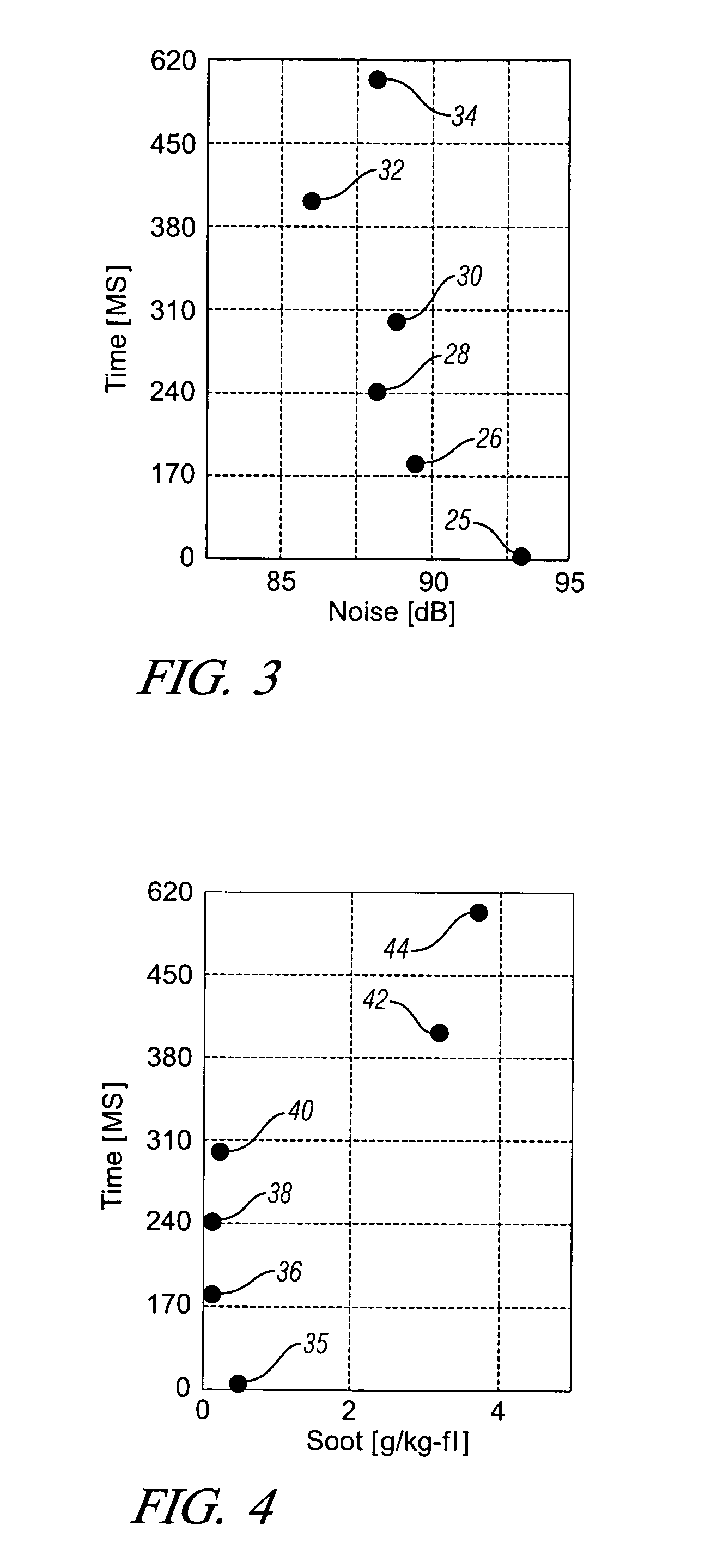

Injection strategy for low noise and soot combustion

InactiveUS20050224044A1Reduce engine noiseReduce sootElectrical controlInternal combustion piston enginesPressure riseLow noise

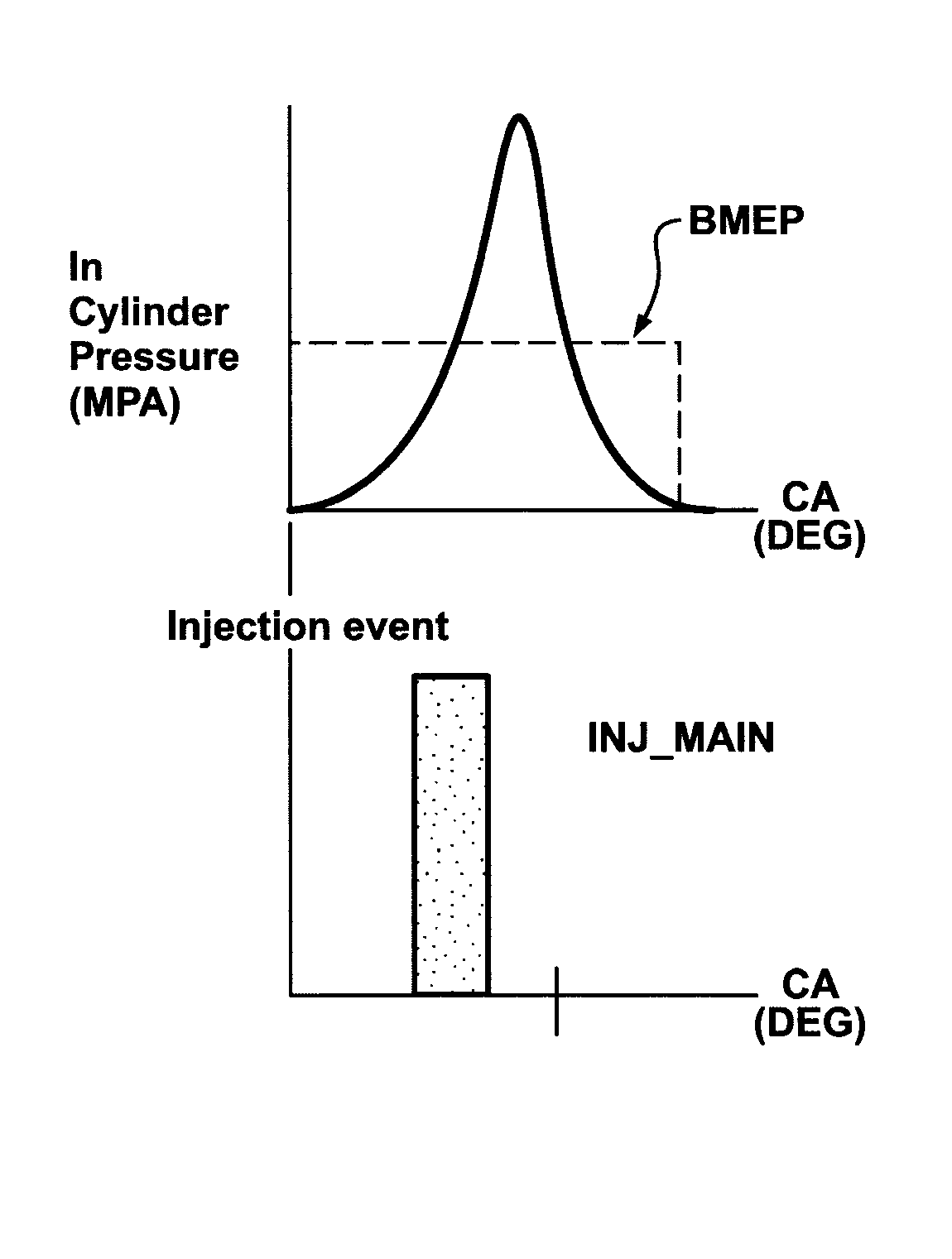

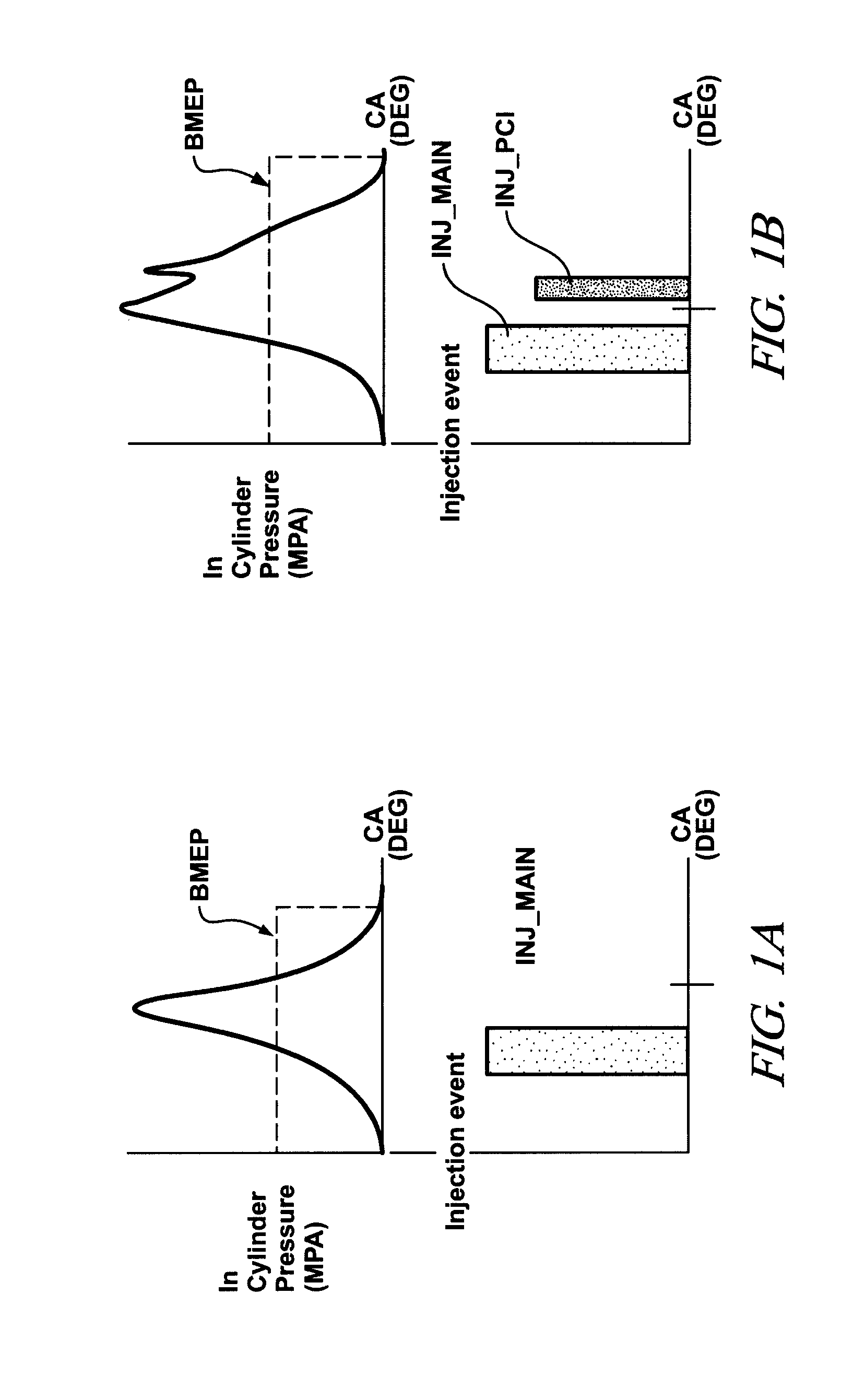

The present invention, provides a strategy or method for injecting fuel in two distinct fuel injection events per engine cycle. The first injection event is main fuel injection, which occurs when the crankshaft is near top-dead center. The main injection event delivers a majority of the fuel needed to provide a majority of the power produced during combustion. The second injection event is post injection, which occurs shortly after the main fuel injection event. The post injection event provides a supplemental amount of fuel to the combustion chamber to reduce the rate of pressure rise while increasing, turbulence, mixing and cylinder pressure within the combustion chamber to reduce the formation of soot. In addition, the combination of the main fuel injection event and the post fuel injection event reduces engine noise by reducing heat release rates and the rate of combustion chamber pressurization.

Owner:GENERAL MOTORS COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com