Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

342results about How to "Reduce soot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

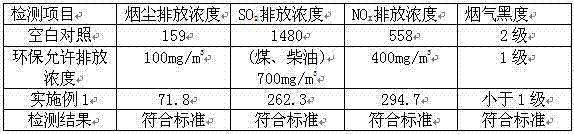

Environment-protecting synergistic agent for fuel coal

InactiveCN101440328AIncreased flammable contentIncreased space gapSolid fuelsFuel additivesSodium bicarbonateFurnace temperature

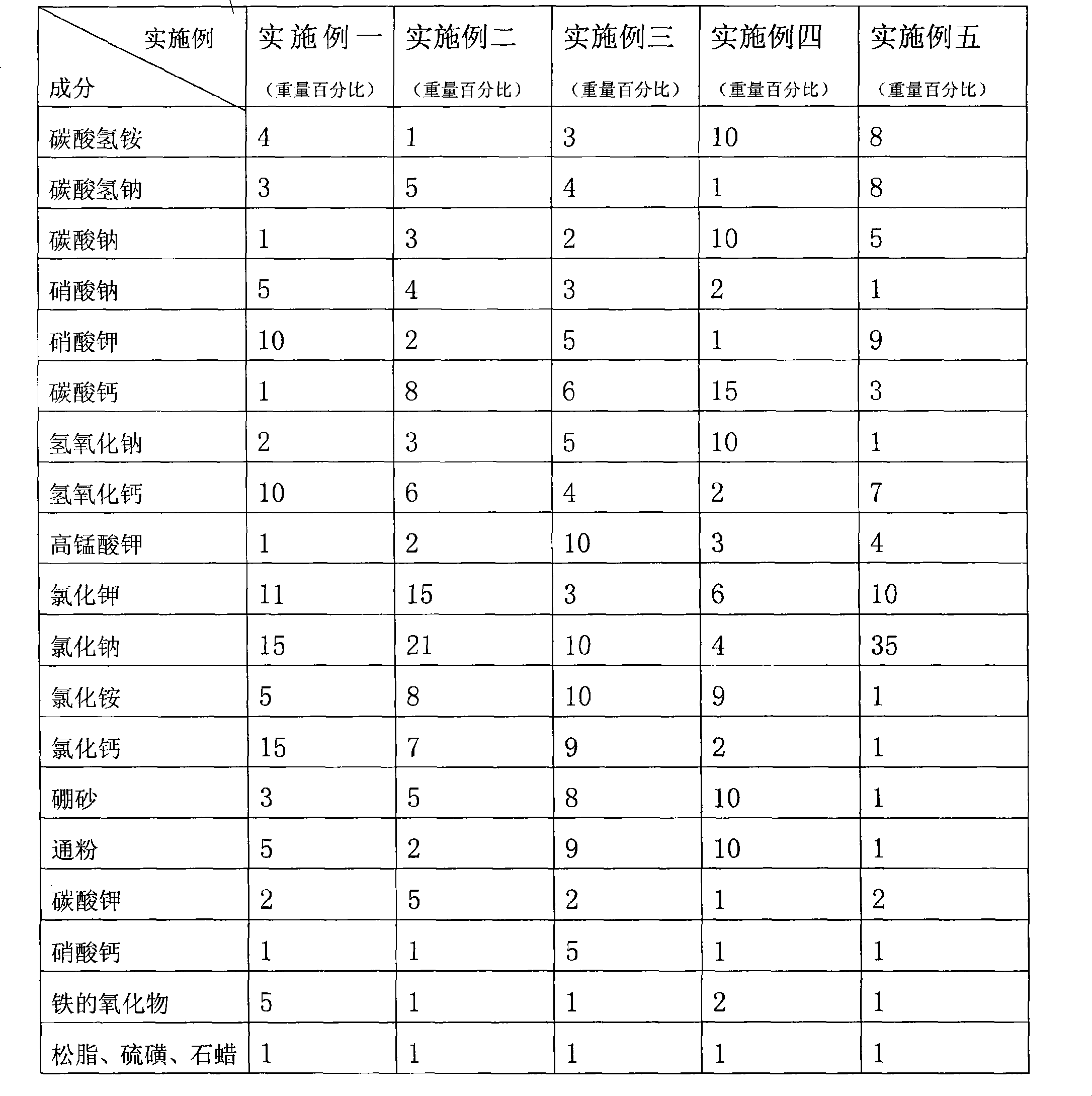

The invention discloses a bunker coal environment-friendly synergist, which comprises the following components by weight percent: 1 to 10 percent of ammonium bicarbonate, 1 to 8 percent of sodium bicarbonate, 1 to 10 percent of sodium carbonate, 1 to 5 percent of sodium nitrate, 1 to 10 percent of potassium nitrate, 1 to 15 percent of calcium carbonate, 1 to 10 percent of sodium hydroxide, 2 to 10 percent of calcium hydroxide, 1 to 10 percent of potassium permanganate, 3 to 15 percent of potassium chloride, 10 to 35 percent of sodium chloride, 1 to 10 percent of ammonium chloride, 1 to 15 percent of calcium chloride, 1 to 10 percent of borax, 1 to 10 percent of macaroni, 1 to 5 percent of potassium carbonate, 1 to 5 percent of calcium nitrate, 1 to 5 percent of iron oxide, and the balance being micro turpentine, sulfur and paraffin wax. The bunker coal environment-friendly synergist makes flame of combustion be more rampant and denser, the furnace temperature rise to a higher level, the hearth be brighter and cleaner and tail gas be cleaner.

Owner:李政 +1

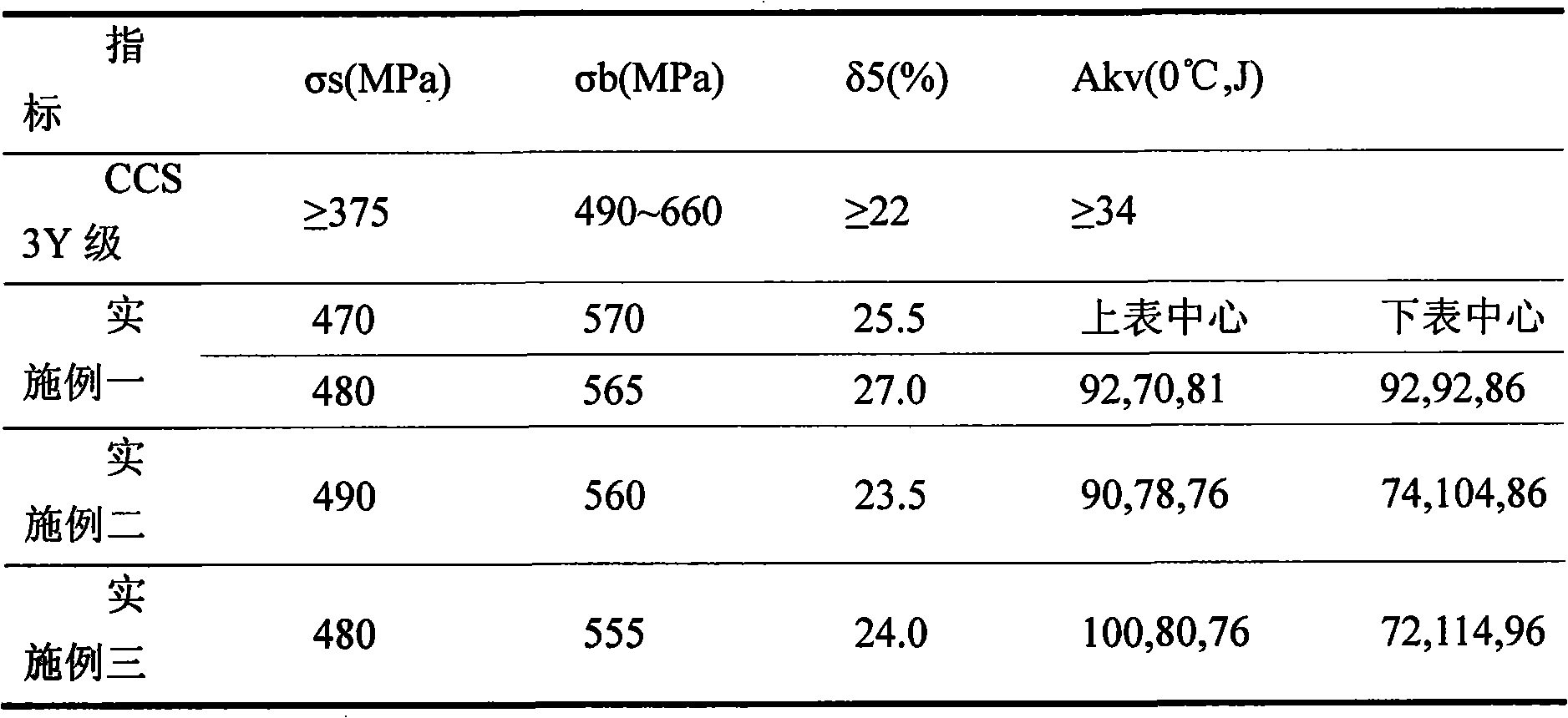

Metal powder-cored type nitrogen austenite stainless steel flux-cored wire and method for manufacturing same

ActiveCN103042321AEffective combinationGood wire qualityWelding/cutting media/materialsSoldering mediaCeriumMechanical property

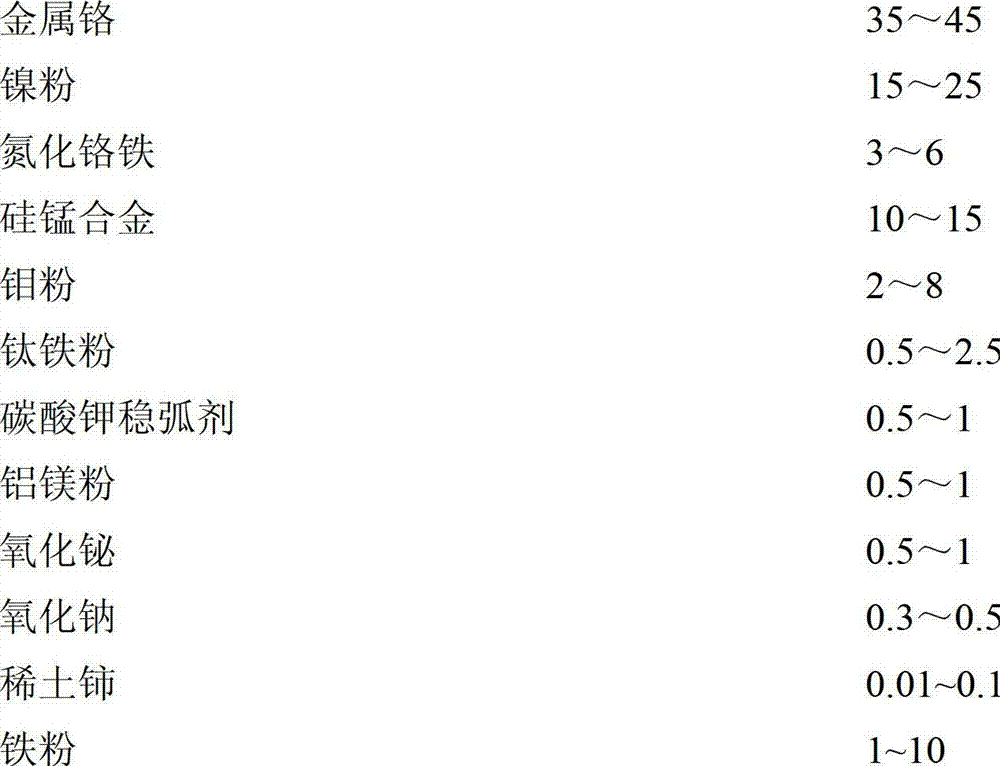

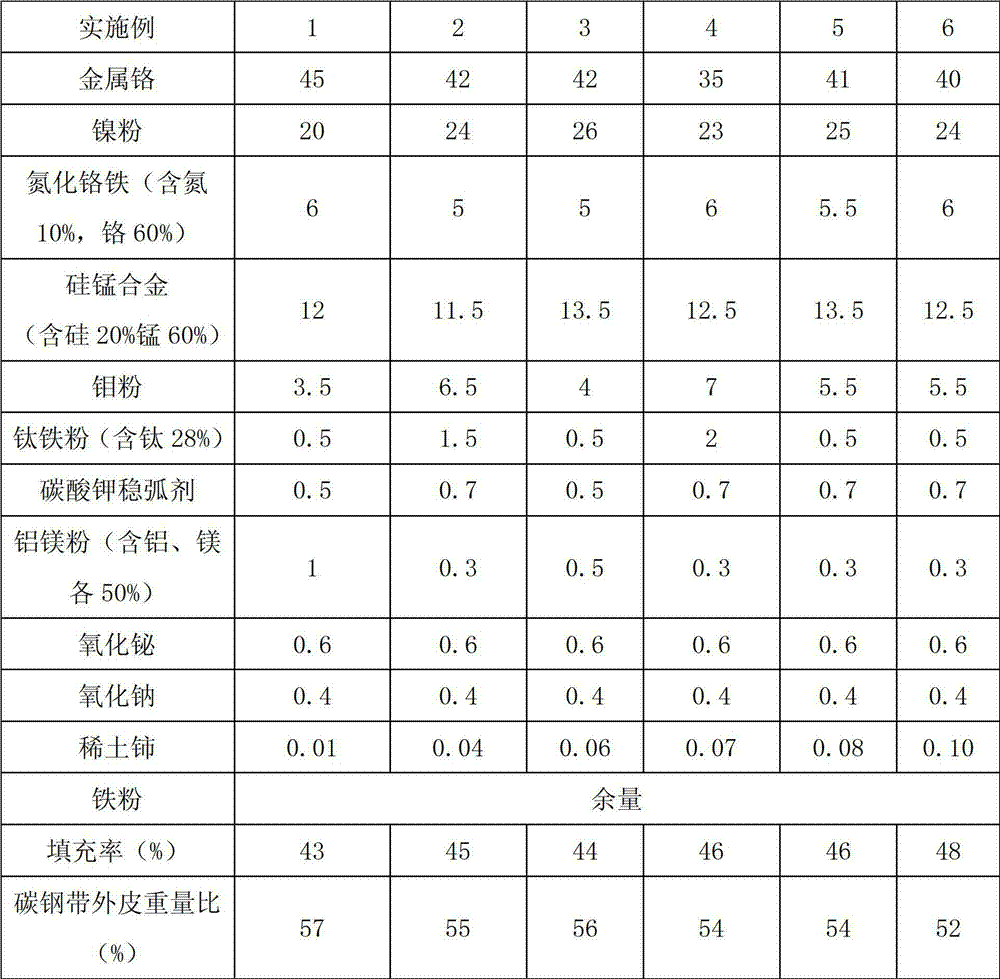

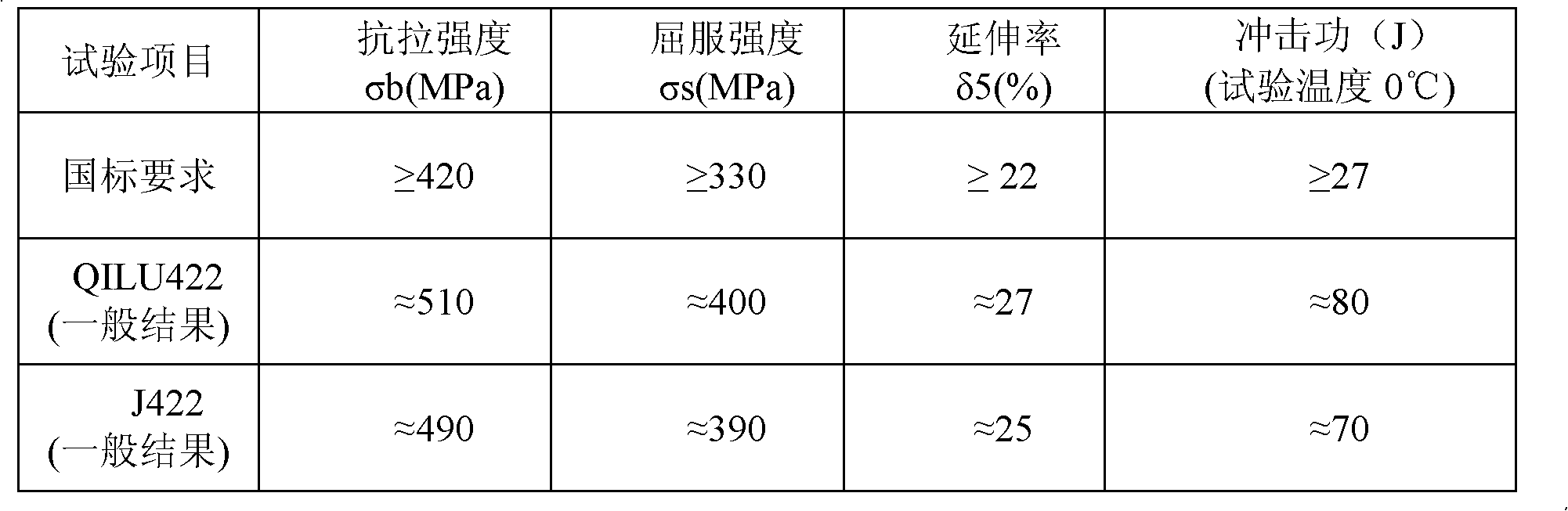

The invention relates to a metal powder-cored type nitrogen austenite stainless steel flux-cored wire and a method for manufacturing the same. The metal powder-cored type nitrogen austenite stainless steel flux-cored wire comprise a carbon steel cored shell and powder filled in the shell, and is characterized in that the powder comprises, by weight, from 35% to 45% of metal chromium, from 15% to 25% of nickel powder, from 3% to 6% of ferrochromium nitride, from 10% to 15% of silicon-magnesium alloy, from 2% to 8% of molybdenum powder, from 0.5% to 2.5% of ferrotitanium powder, from 0.5% to 1% of potassium carbonate arc stabilizers, from 0.5% to 1% of aluminum-magnesium powder, from 0.5% to 1% of bismuth oxide, from 0.3% to 0.5% of sodium oxide, from 0.01% to 0.1% of rare-earth cerium and from 1% to 10% of iron powder, and the weight of the powder ranges from 40% to 50% of the total weight of the wire. Compared with the prior art, the metal powder-cored type nitrogen austenite stainless steel flux-cored wire has the advantages that weld metal has excellent mechanical properties such as good toughness and high strength after the wire is applied to welding high-nitrogen steel, and a corrosion resistant effect is good.

Owner:北方材料科学与工程研究院有限公司 +2

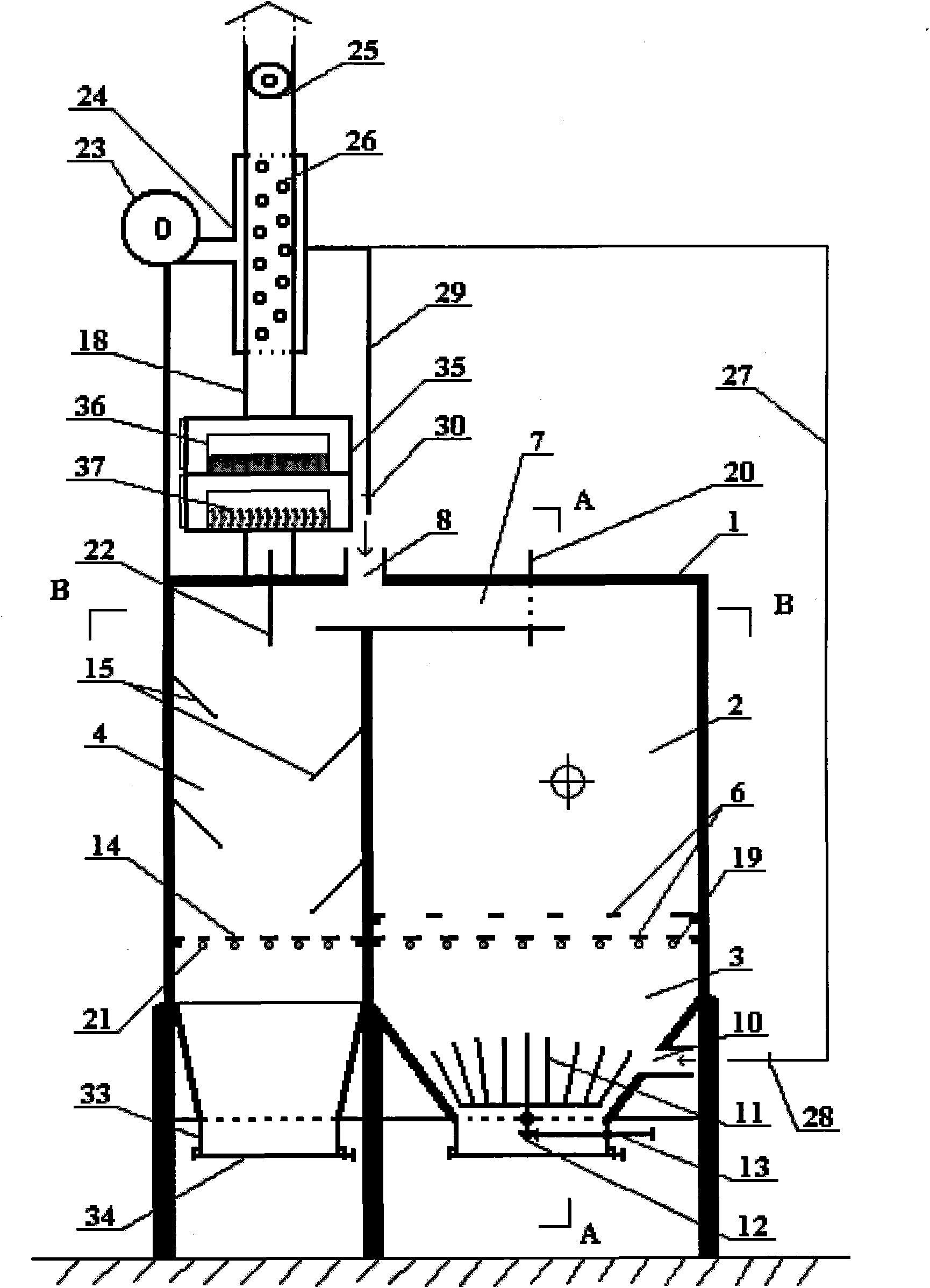

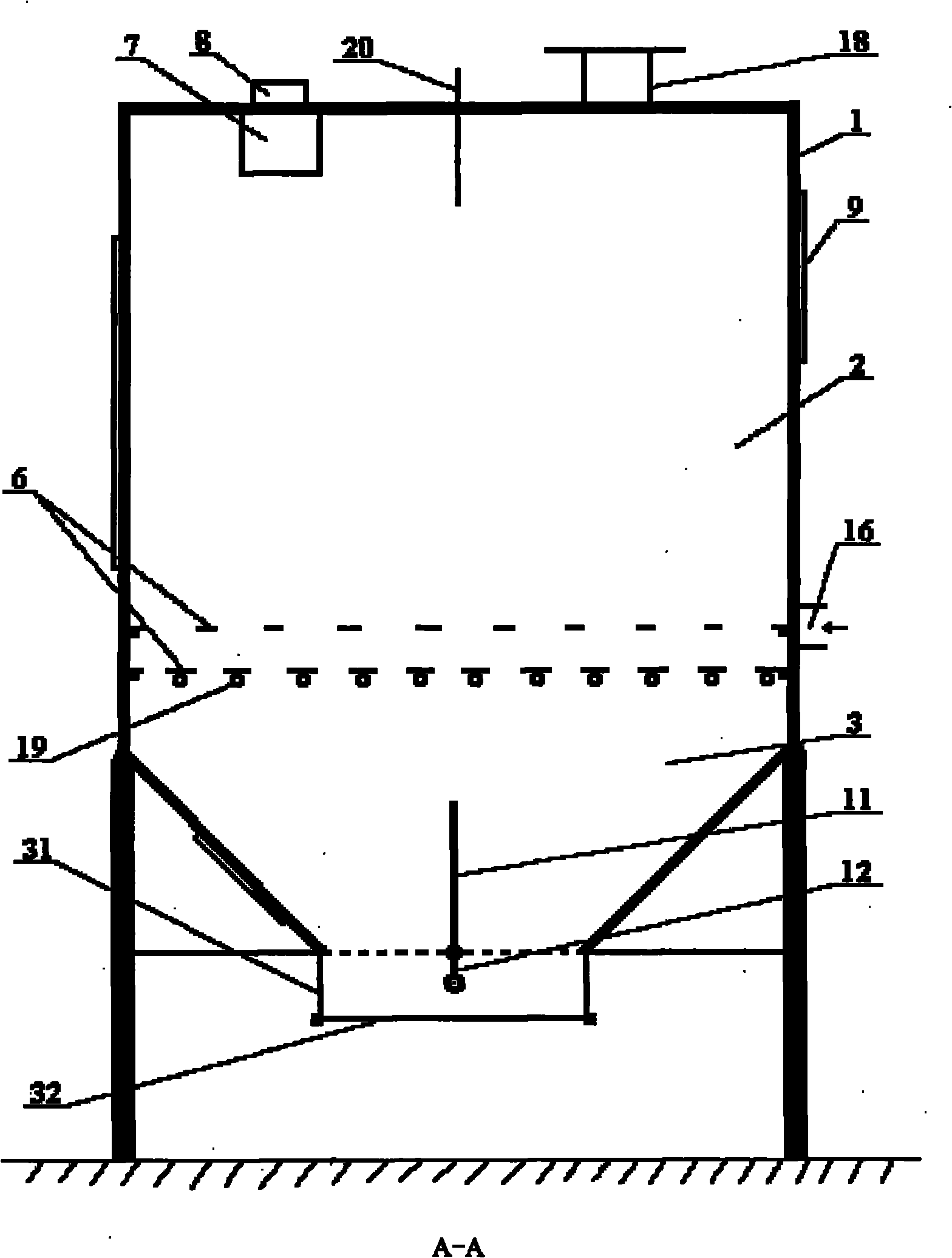

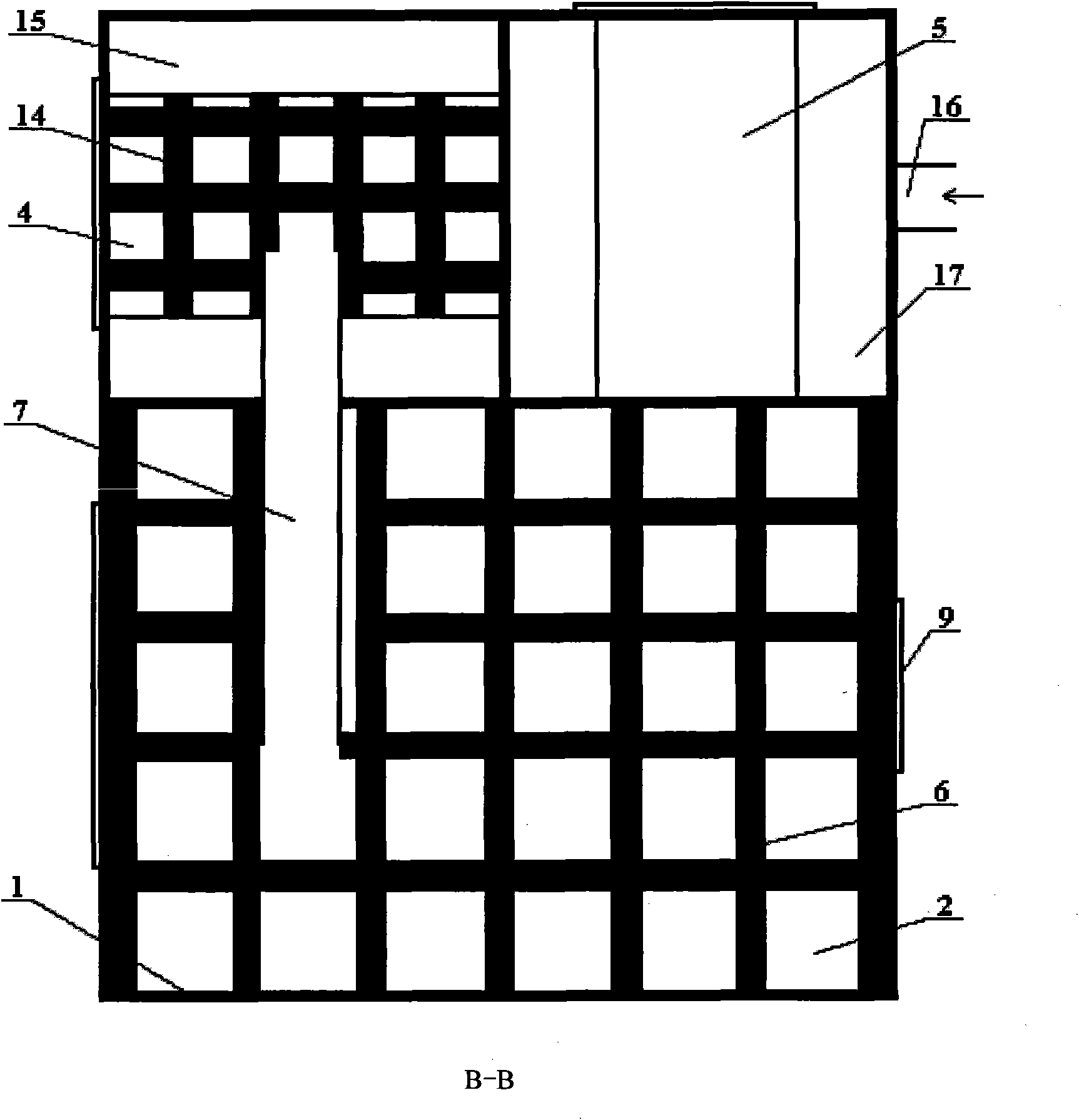

Small efficient medicinal rubbish pyrolysis incinerator

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

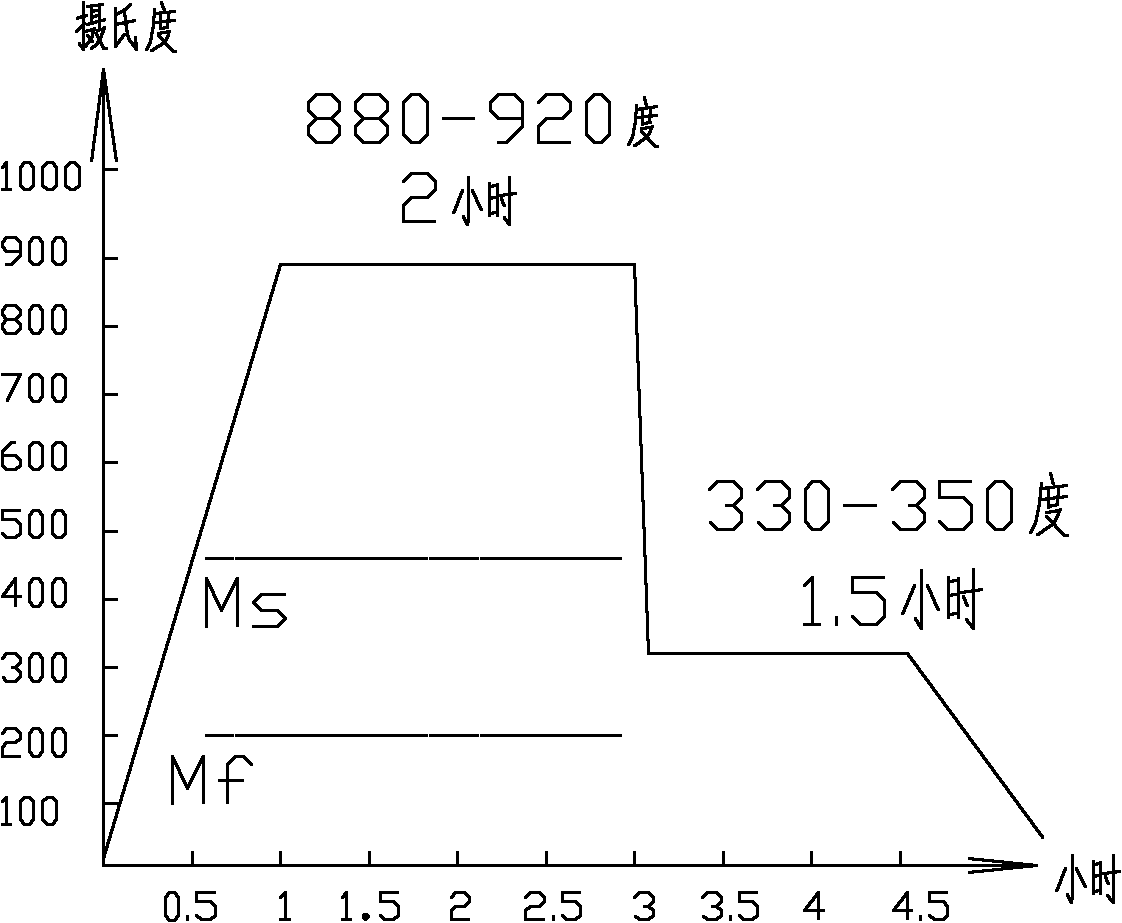

Method for manufacturing austempered ductile iron (ADI) front axle of heavy truck by sand casting

InactiveCN102218504AImprove integrityImprove fatigue lifeFoundry mouldsFurnace typesVolumetric Mass DensityQuenching

The invention discloses a method for manufacturing an austempered ductile iron (ADI) front axle of a heavy truck by sand casting. By the method, nickel molybdenum copper austempered ductile iron (ADI) front axle of the heavy truck is produced by a furane resin sand molding process, and the problems that the internal density and the performance reliability of ADI products are difficult to guarantee and the mechanical properties of the ADI products are low are solved. The method has the following steps of: firstly, casting a blank of the nickel molybdenum copper alloyed spheroidal graphite cast iron front axle by the furane resin sand molding process; secondly, performing the surface shot peening strengthening and isothermal quenching heat treatment; and finally machining the front axle parts. By the method, casting is replaced by forging, and the iron is replaced by steel, the comprehensive mechanical properties are obviously higher than those of common spheroidal graphite cast iron and forged steel, the weight of truck parts is reduced, the investment of heavy forging equipment and dies is saved, the cost is reduced, the production cycle is shortened, energy is saved, the emission is reduced, and the economic benefit and the social benefit are obvious.

Owner:DALIAN XINZHONG GRP +1

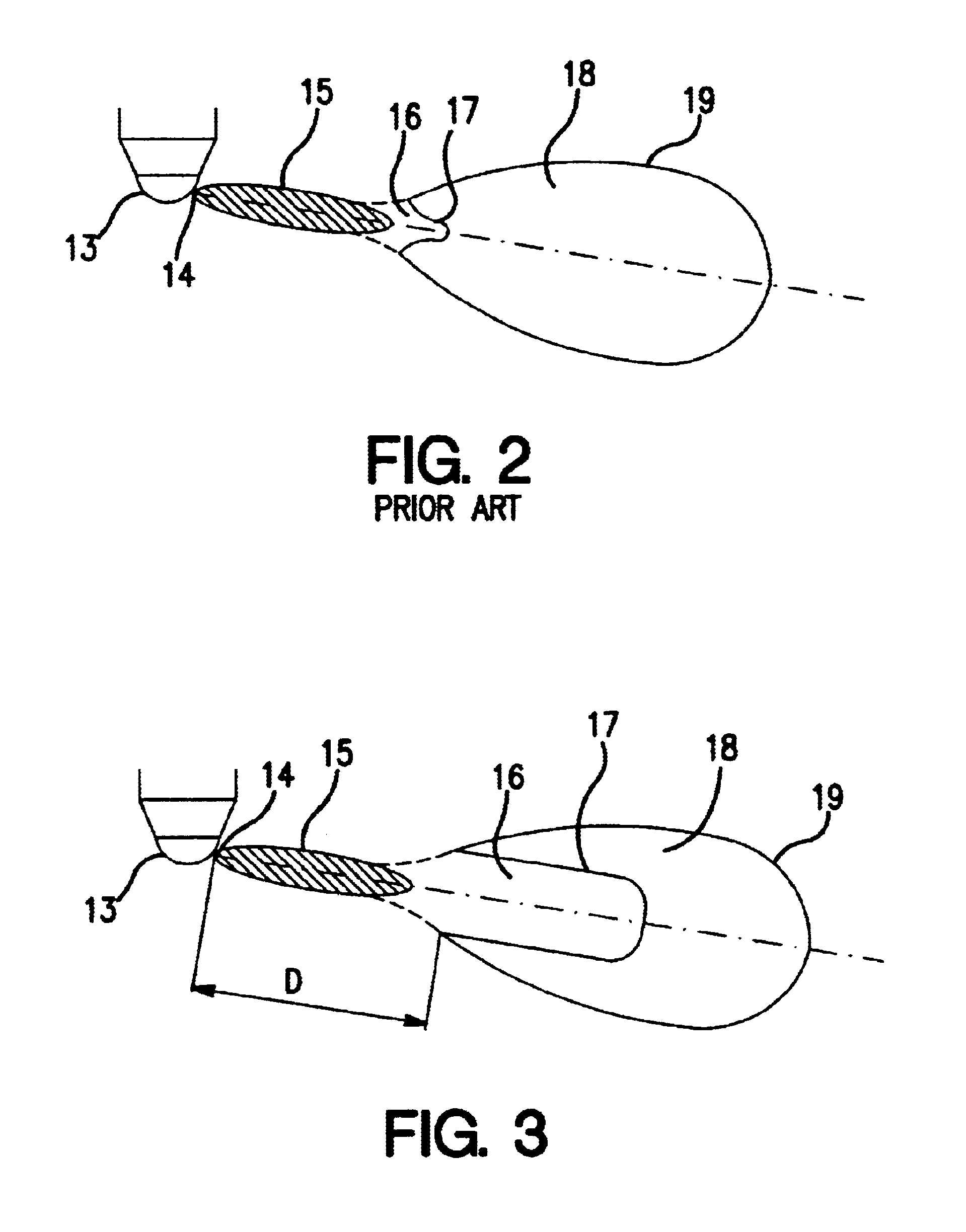

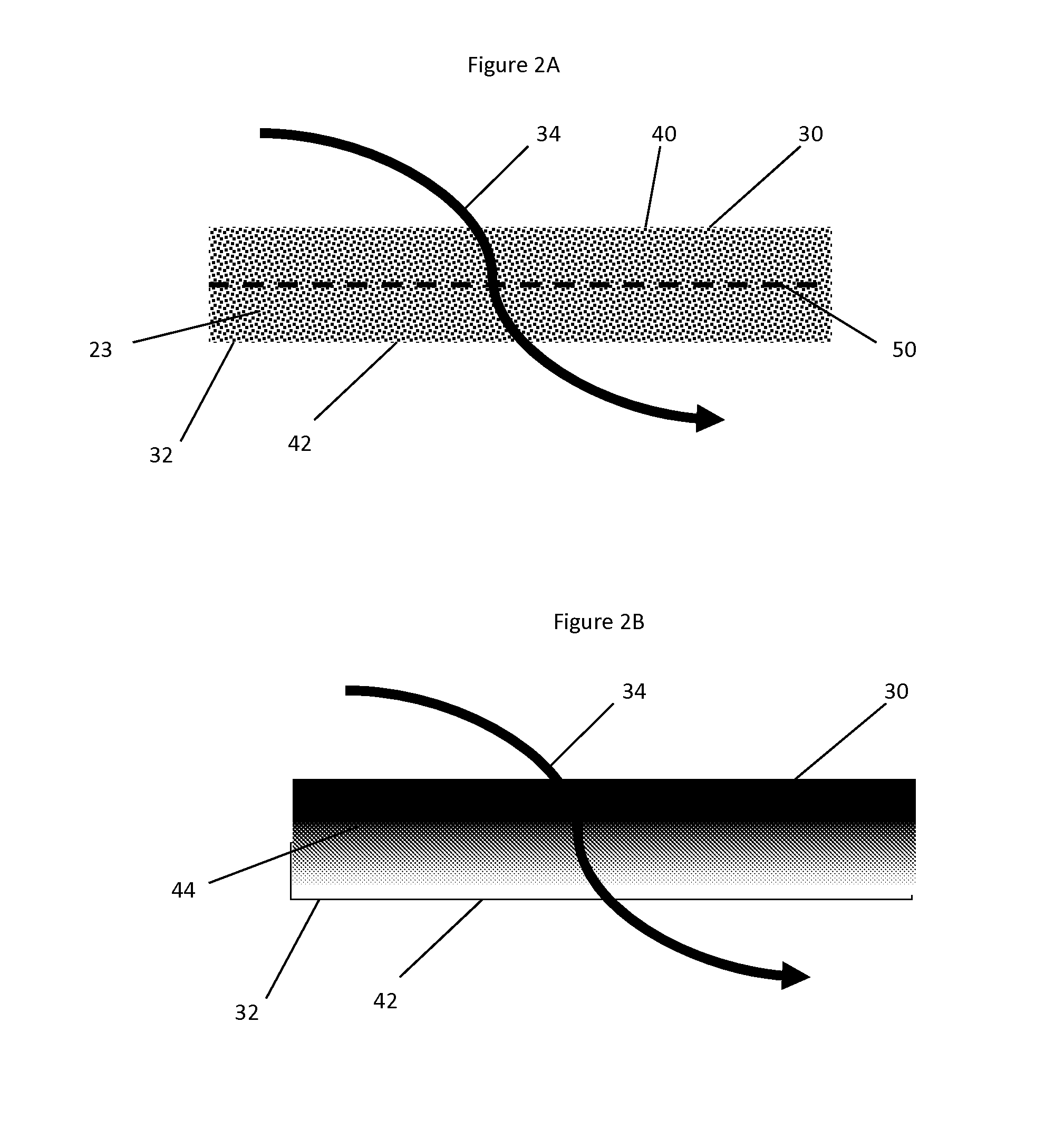

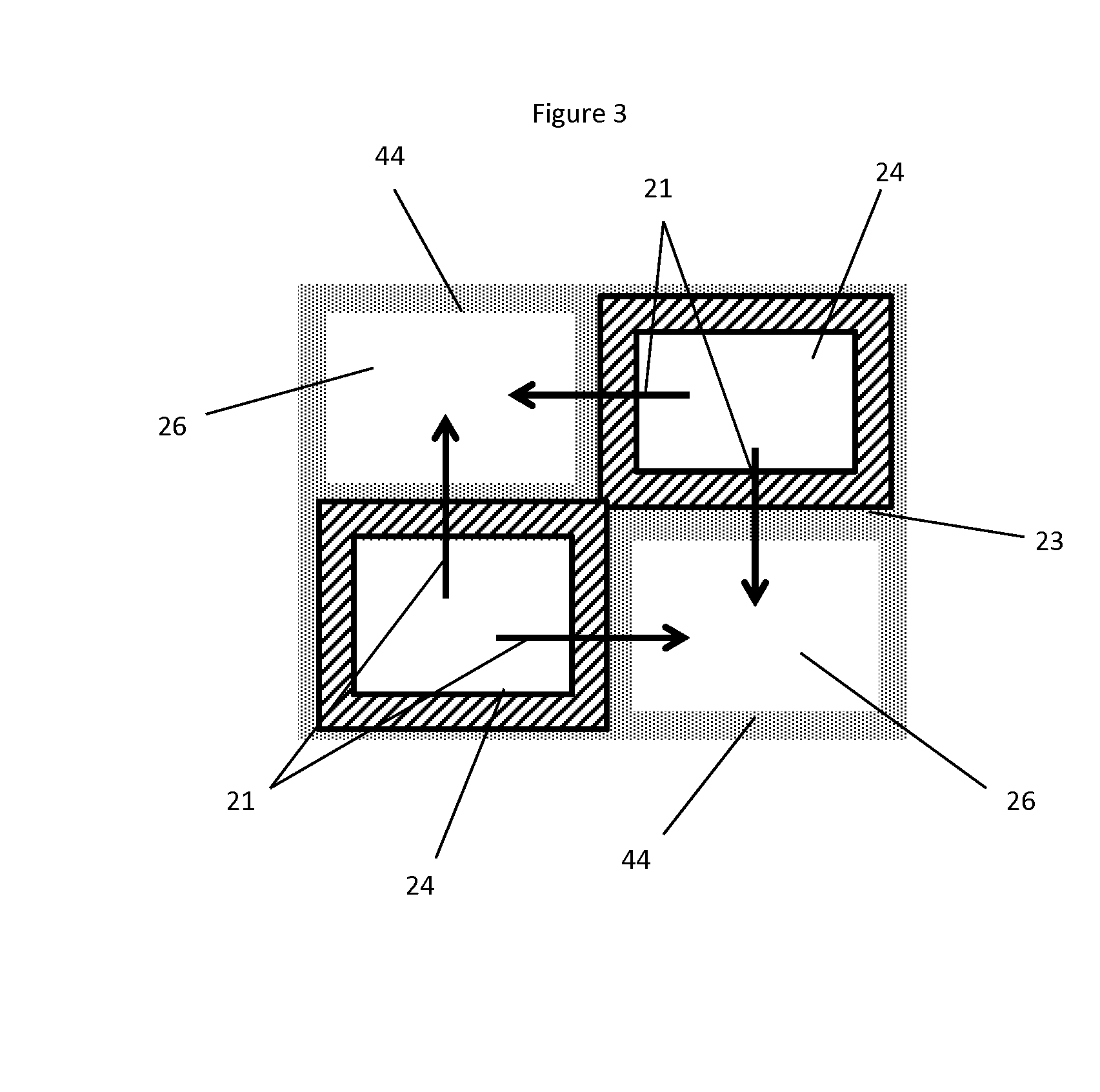

Direct injection combustion chamber geometry

InactiveUS7213564B2Reduce rateReduce sootInternal combustion piston enginesGaseous engine fuelsExternal combustion engineInternal combustion engine

Owner:WESTPORT POWER

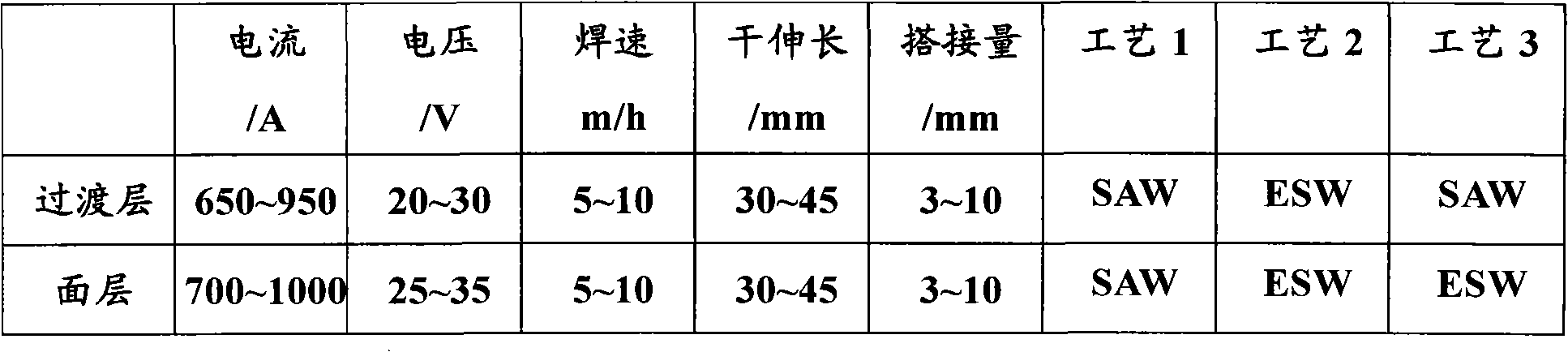

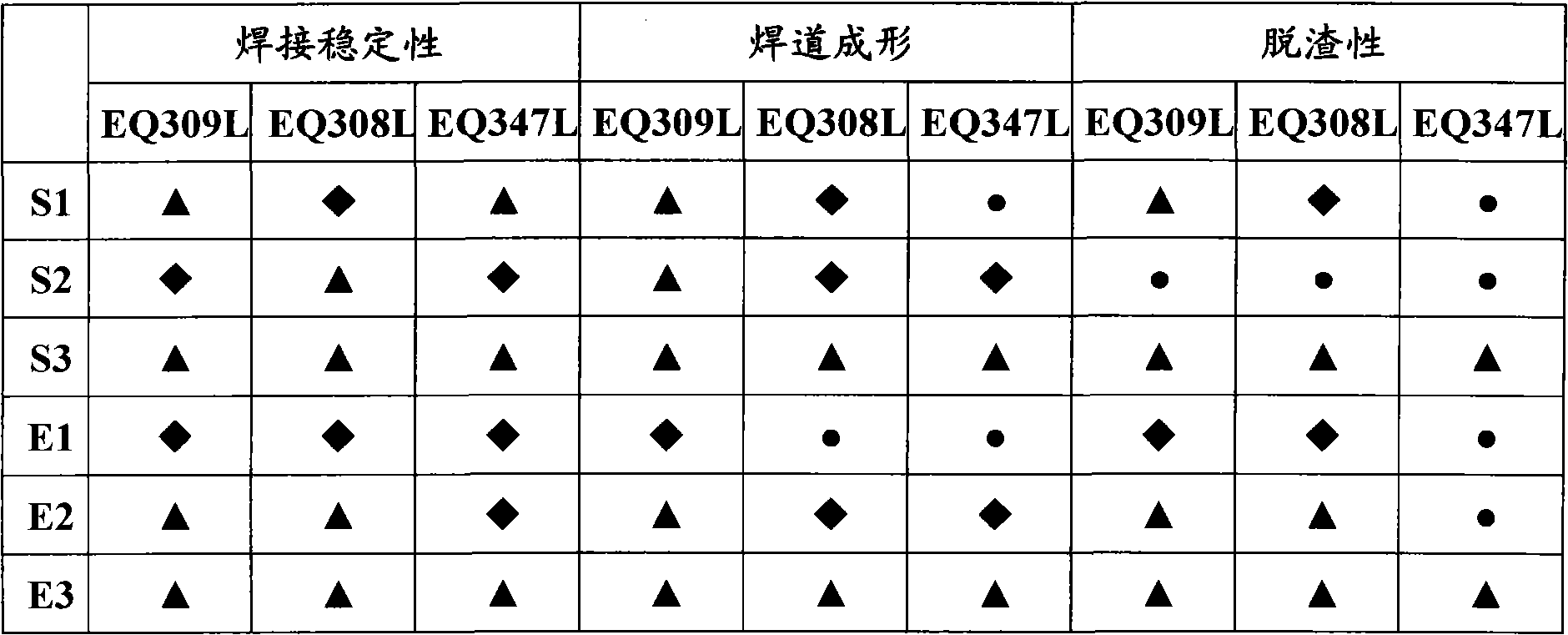

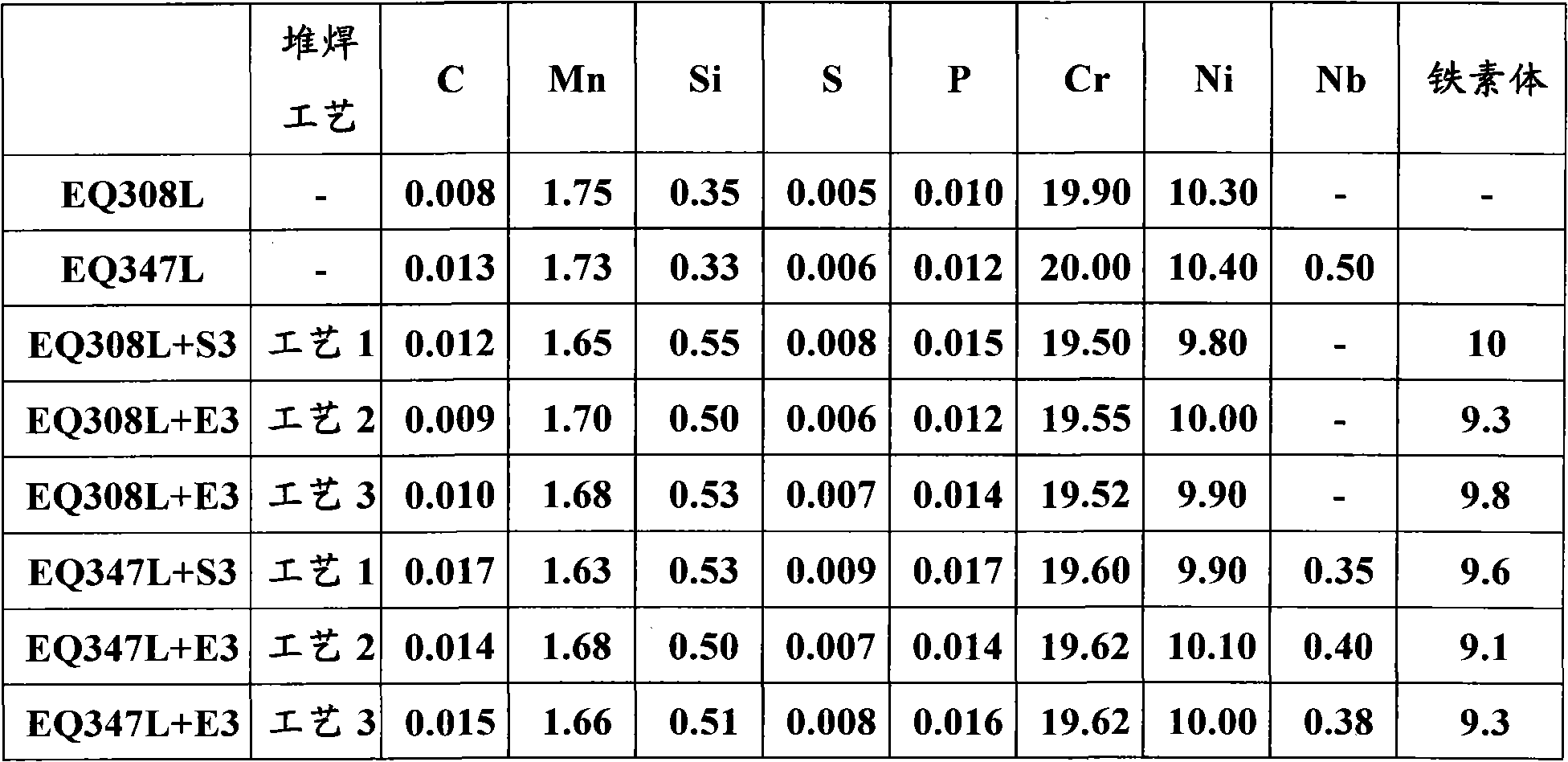

Sintered flux for stainless steel surfacing with band electrode

ActiveCN102581518AAdjustable viscosityWeld firmlyWelding/cutting media/materialsSoldering mediaRaw materialAlloy

The invention relates to a sintered flux for stainless steel surfacing with band electrode. One technical scheme of the sintered flux for stainless steel surfacing with band electrode includes that the sintered flux is formed by sintering the following components and the proportioned raw materials or materials, including 15-30 parts of CaF2, 20-50 parts of MgO, 1-10 parts of Al2O3, 15-30 parts of CaO, 25-50 parts of SiO2, and 1-5 parts of alloy powder. The another technical scheme includes that the sintered flux for stainless steel surfacing with band electrode comprises the following components and the proportioned raw materials or materials including 60-80 parts of CaF2,20-40 parts of Al2O3, 1-5 parts of CaO, 1-5 parts of SiO2, and 1-5 parts of alloy powder. The sintered flux has excellent performance and can meet the service requirements completely.

Owner:BEIJING JINWEI WELDING MATERIAL +1

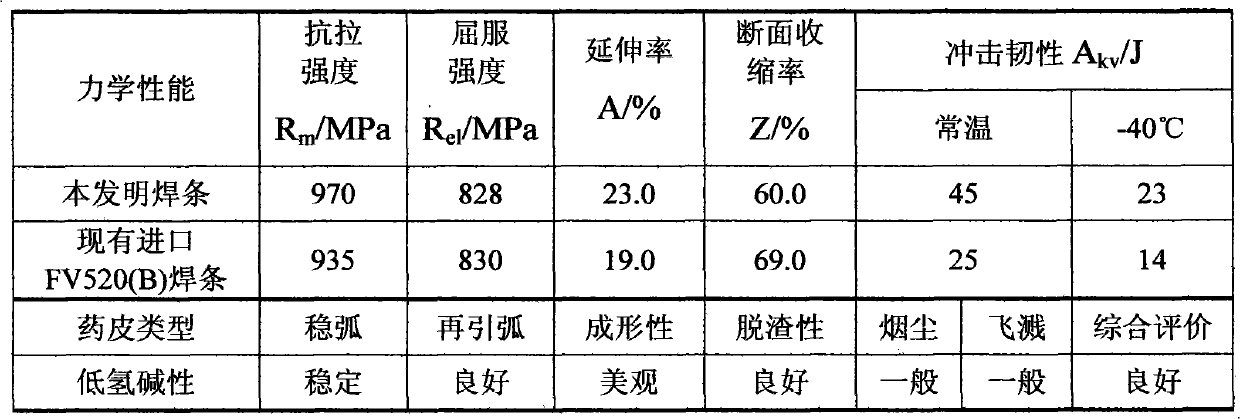

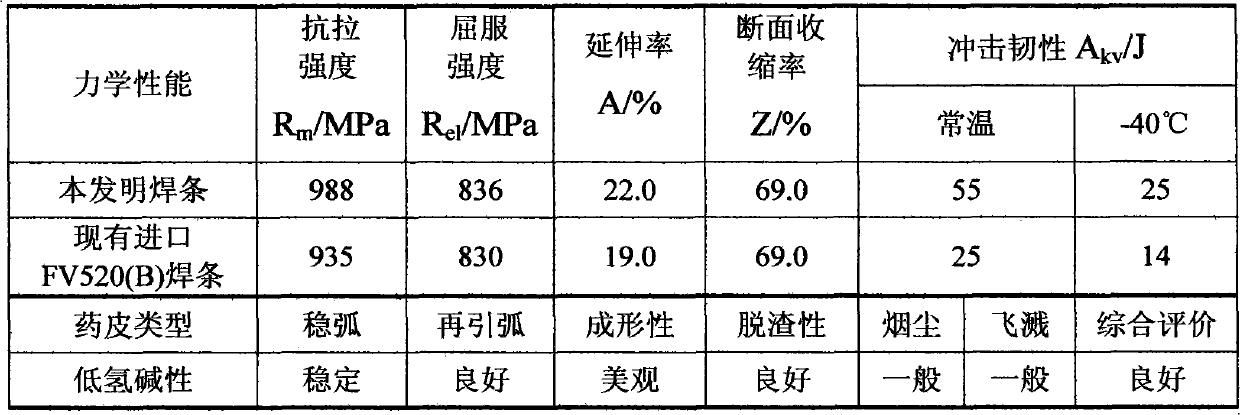

Low-hydrogen basic electrode for welding FV520 (B) stainless steel

ActiveCN101905395AImproved arc stabilityGood fluidity of molten poolWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention discloses a low-hydrogen basic electrode for welding FV520 (B) stainless steel, comprising a core wire and an electrod covering, wherein the electrode covering comprises the following materials in weight percentage: 35%-45% of marble, 18%-26% of fluorite, 6%-9% of quartz, 3%-6% of zircon sand, 6%-12% of rutile, 1%-3% of ferrosilicon, 6%-10% of ferrotitanium, 5%-11% of low-carbon ferromanganese, 1%-3% of rare-earth ferrosilicon and 0.5%-1.5% of sodium carbonate, and the sum of the weight percentages of the components is 100%. Compared with the traditional special imported electrode for the FV520 (B) stainless steel, the electrode made of the electrode covering has the advantages of favorable arc stabilization performance, good fluidity of a molten bath, less splash and dust, easier slag removal after welding, uniform slag coverage, and delicate and attractive welding joint formation. The content of diffusible hydrogen generated by using the developed electrode for depositing metal is effectively controlled and meets the requirements of low-carbon contents.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

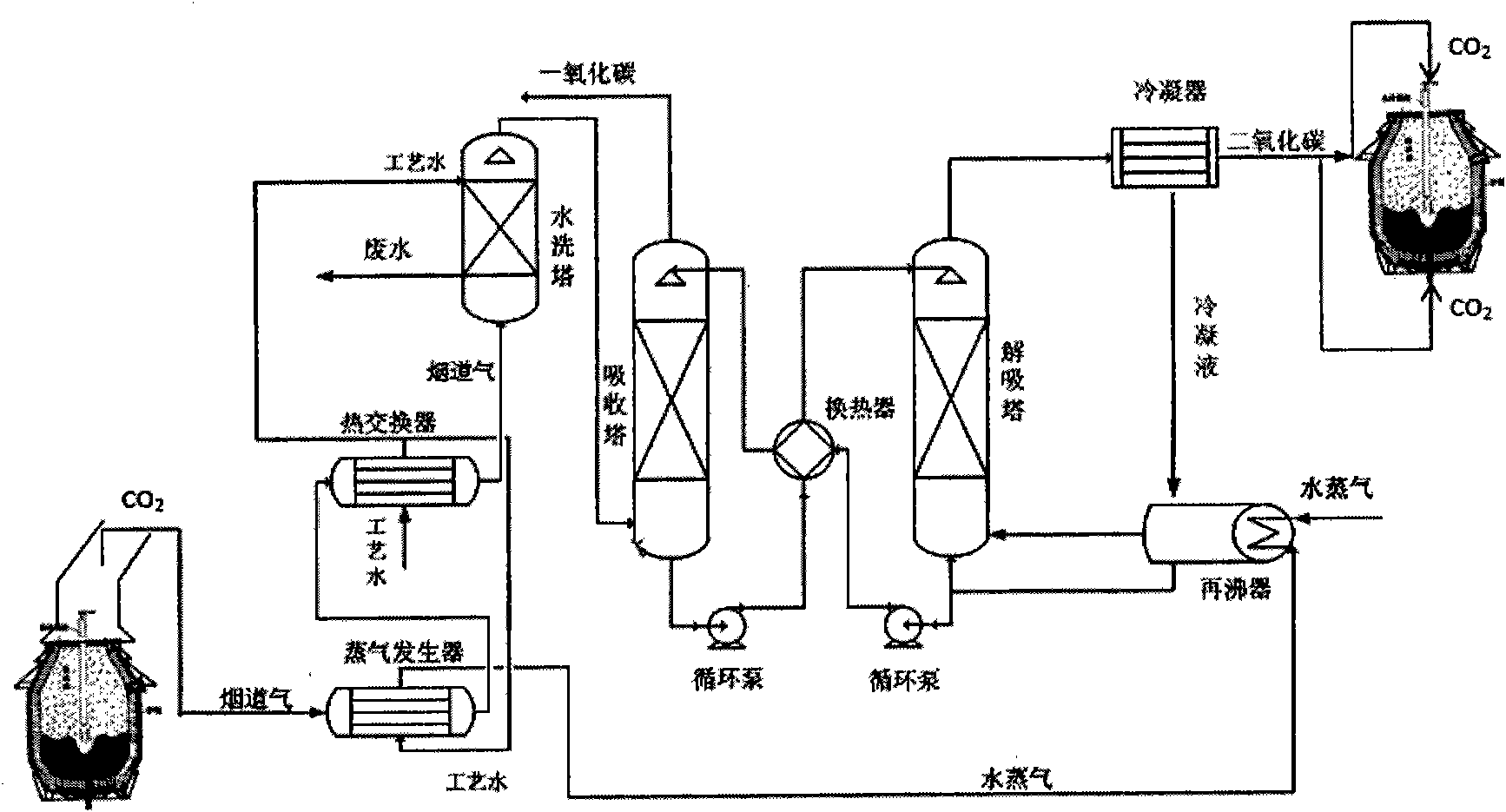

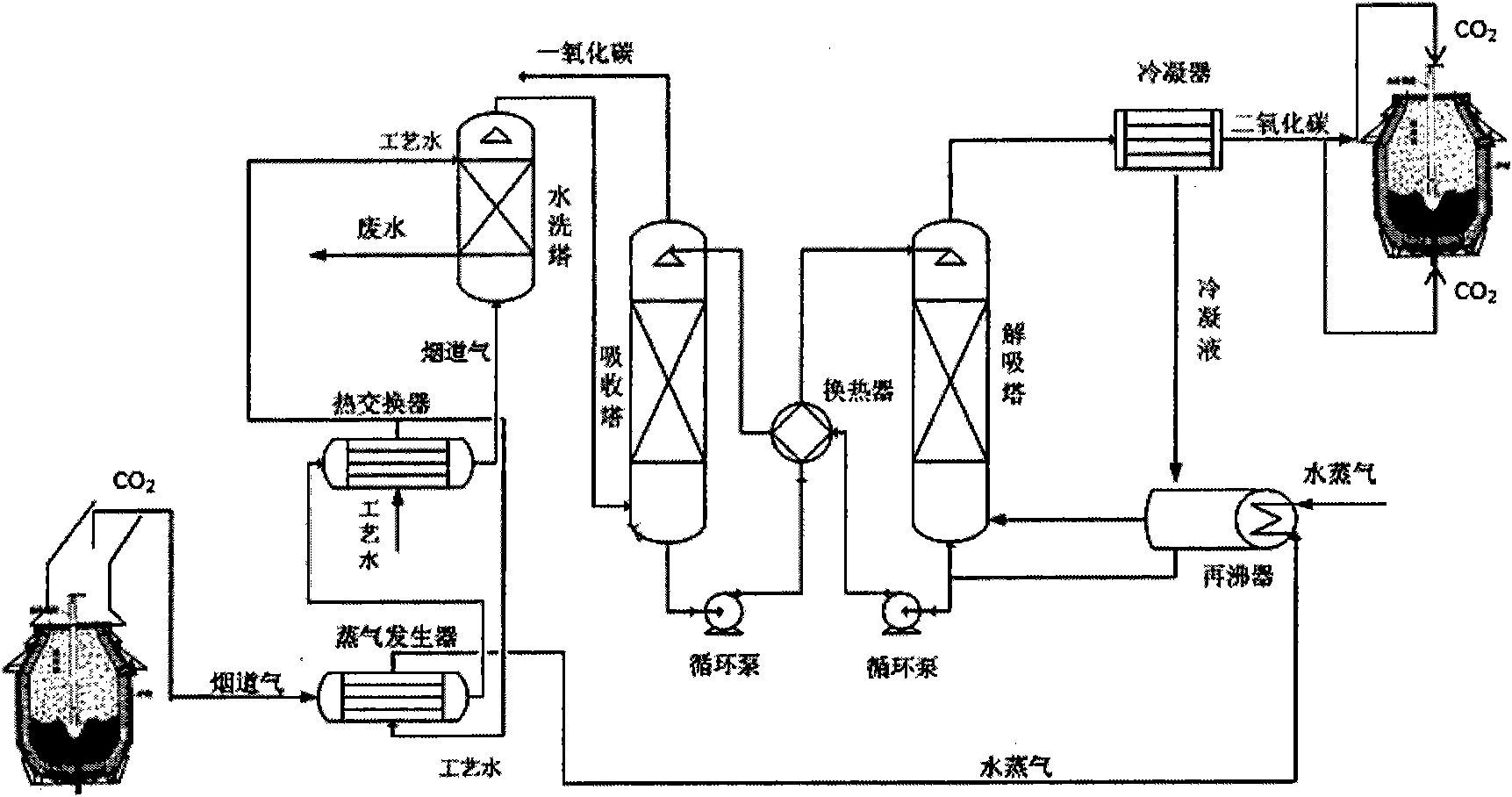

Method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing

InactiveCN101818227AHigh carbon contentControl heating rateManufacturing convertersGas emission reductionProduct gasProcess engineering

The invention discloses a method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing and belongs to the fields of ferrous metallurgy, energy conservation and environment protection. In the invention, the CO2 in the converter steel-making gas is separated and recycled after being cooled and dedusted; the recovery is 100 to 15,000Nm<3> / h; and the concentration of CO in the converter gas is improved by 5 to 20 percent at the same time. The CO2 serves as a gas source for the top blowing and the bottom blowing of a top and bottom combined blown converter. A chemical absorption separation method is adopted to separate the CO2; steam added with rich liquid is generated by using the residual heat of the converter gas; and almost no additional energy is consumed in the process for separating the carbon dioxide. 1 to 30 percent of the CO2 and 99 to 70 percent of O2 are blown from the top part; pure CO2 or a mixture of the CO2 and N2 or Ar or O2 or gas and the like is adopted in the whole process of the bottom blowing; and the amount of the CO2 is 100 to 3,000Nm<3> / h. The method is applicable to a steel-making process for a 30 to 350 ton converter. By adopting the method, for each ton of steel, 1 to 20 m3 of CO2 emission is reduced synthetically; the soot amount is reduced by 1 to 30 percent; and the content of the CO in the gas is improved to more than 2 to 15 percent.

Owner:UNIV OF SCI & TECH BEIJING

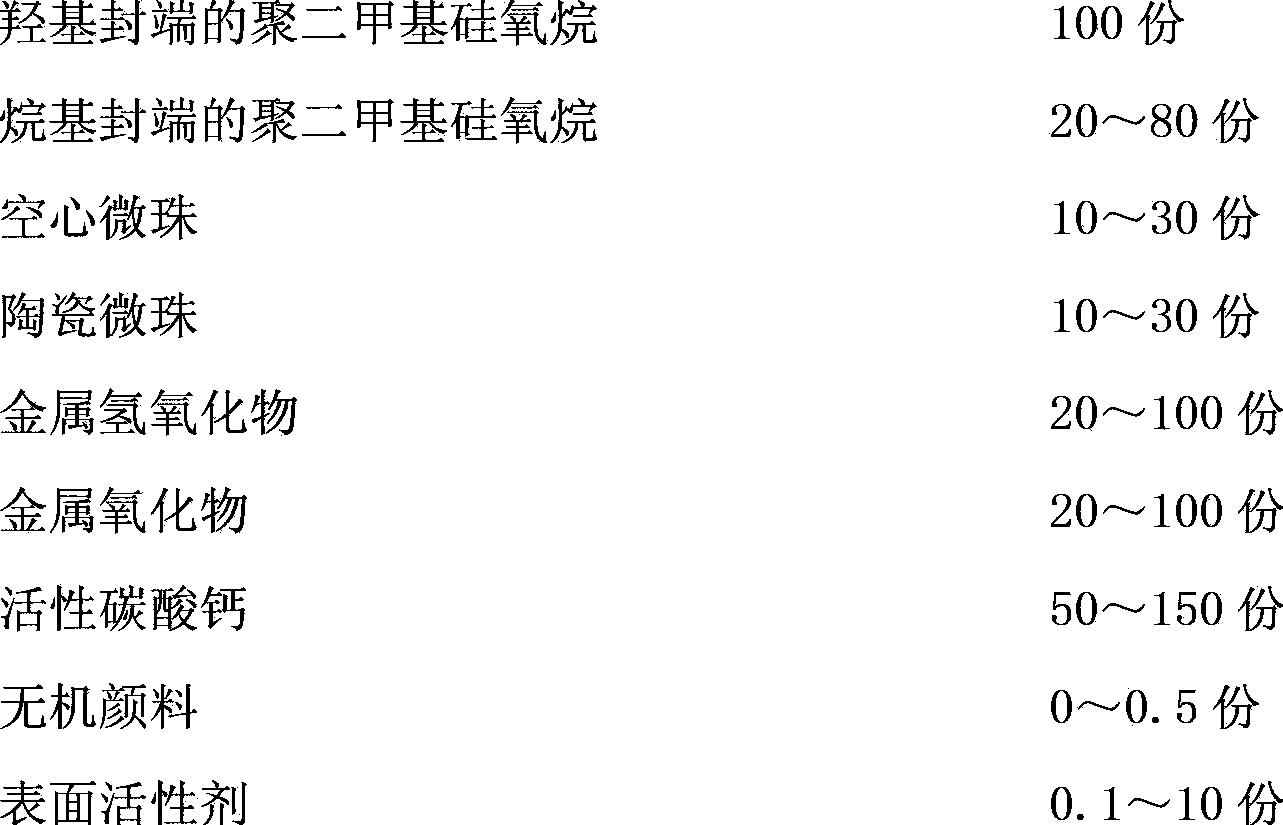

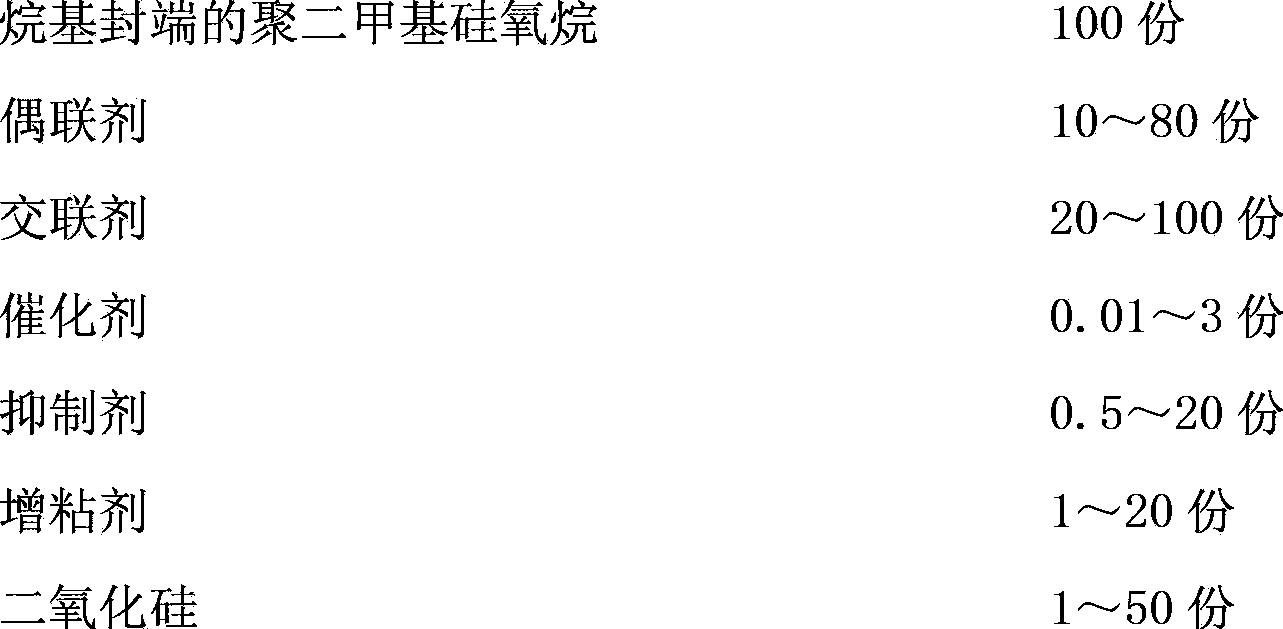

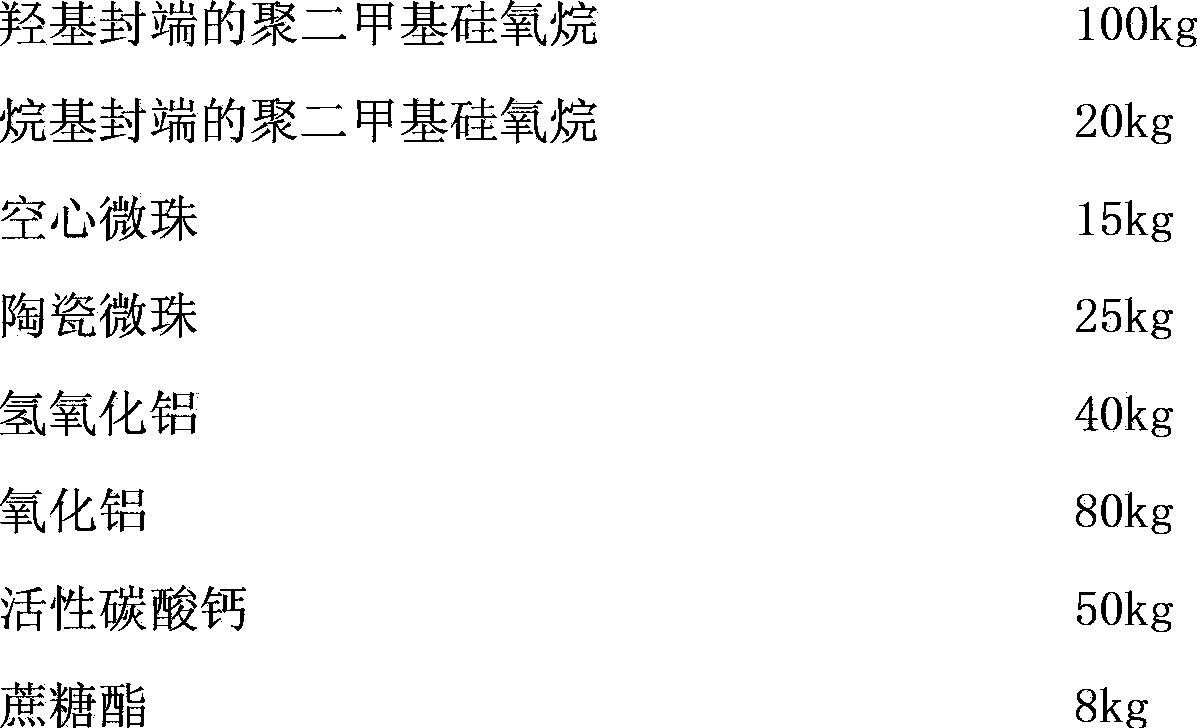

Double-component silicone structural sealant for heat mirror hollow glass and preparation method thereof

ActiveCN103820072AIncreased crosslink depthFast bondingNon-macromolecular adhesive additivesCross-linkMicrosphere

The invention discloses a double-component silicone structural sealant for heat mirror hollow glass and a preparation method of the sealant. The sealant comprises a component A and a component B, wherein the component A comprises hydroxyl-terminated polydimethylsiloxane, alkyl-terminated polydimethylsiloxane, hollow microsphere, ceramic microbead, metal hydroxide, metal oxide, activated calcium carbonate, inorganic pigment and a surfactant; the component B comprises alkyl-terminated polydimethylsiloxane, a coupling agent, a cross-linking agent, a catalyst, an inhibitor, a thickening agent, and silicon dioxide. The preparation method of the sealant comprises the following steps: 1) taking each ingredient in the component A to be mixed uniformly under the vacuum condition; 2) taking each ingredient in the component B to be mixed uniformly under the vacuum condition; 3) mixing the component A and the component B at room temperature according to the weight ratio of (8:1) to (20:1), and at last obtaining the sealant. The double-component silicone structural sealant is good in adhesiveness, high in curing speed, good in sealing performance, high in hardness and modulus, and excellent in thermal barrier effect, and suitable for sealing and bonding of heat mirror film, glass and metal materials etc.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

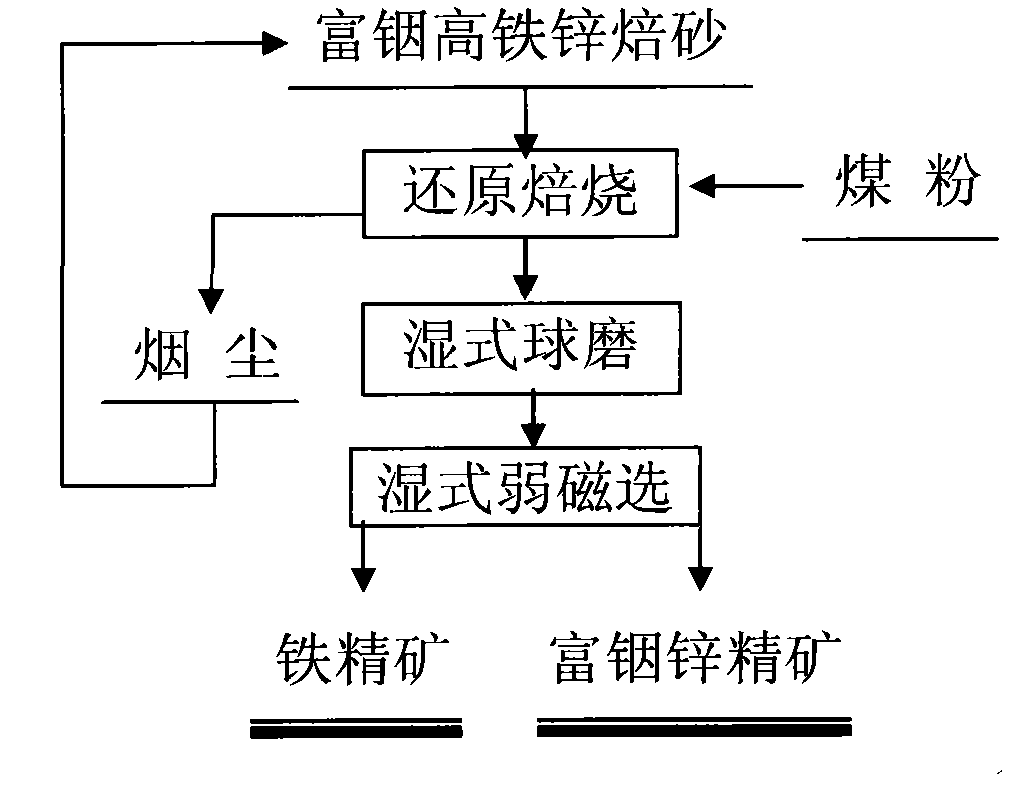

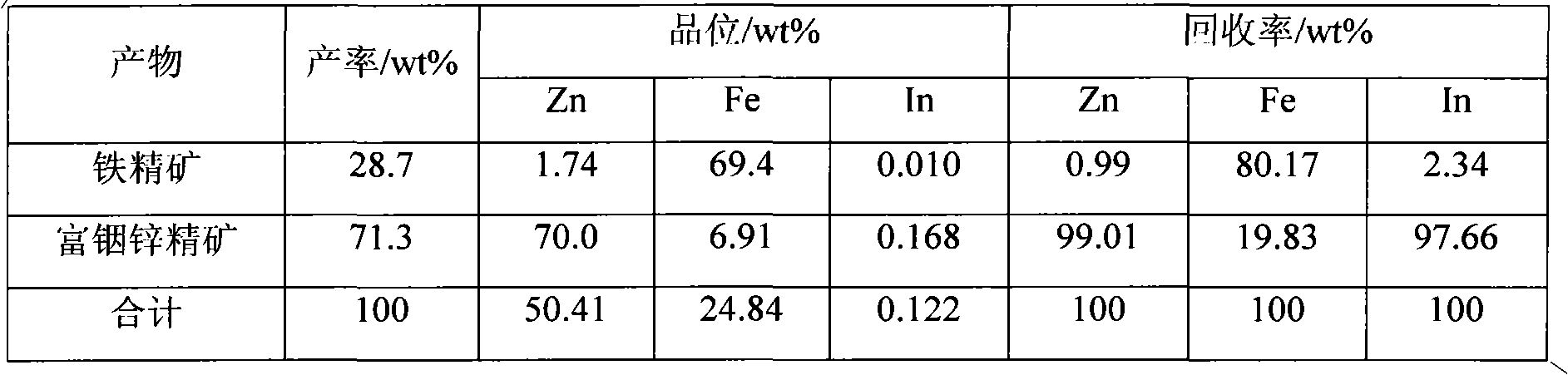

Method for separating zinc and indium and iron from indium-enriched high-iron high-zinc calcine through reduction-magnetic separation

InactiveCN102134655AReduce dosageReduce energy consumptionMagnetic separationReduction treatmentIndium

The invention relates to a method for separating zinc and indium and iron from indium-enriched high-iron high-zinc calcine through reduction-magnetic separation, belonging to the technical field of mineral processing. The invention is characterized in that the method adopts the technical means that mineral dressing is combined with smelting and performs smelting firstly and mineral dressing secondly; and the method is as follows: the waste heat of the indium-enriched high-iron zinc calcine obtained through fluidized roasting is utilized, the indium-enriched high-iron zinc calcine is introduced to perform low-temperature weak reduction treatment at below 570 DEG C and ensure that zinc ferrite is decomposed and reduced to ZnO, Fe3O4 and iron, the reduced calcine is levigated to prepare slurry, and zinc and indium and iron is separated through wet-type magnetic separation to obtain iron ore concentrates and indium-enriched zinc- enriched ore concentrates. The method has low energy consumption and low dosage of a reducing agent, is simple in operation, easy in control and high in metal recovery rate. Therefore, the indium embedded and distributed in zinc ferrite can be released, the loss caused by the high temperature volatilization of indium can be avoided, and the zinc and indium and iron of the indium-enriched high-iron high-zinc calcine can be separated in an ore dressing manner before leaching.

Owner:KUNMING UNIV OF SCI & TECH

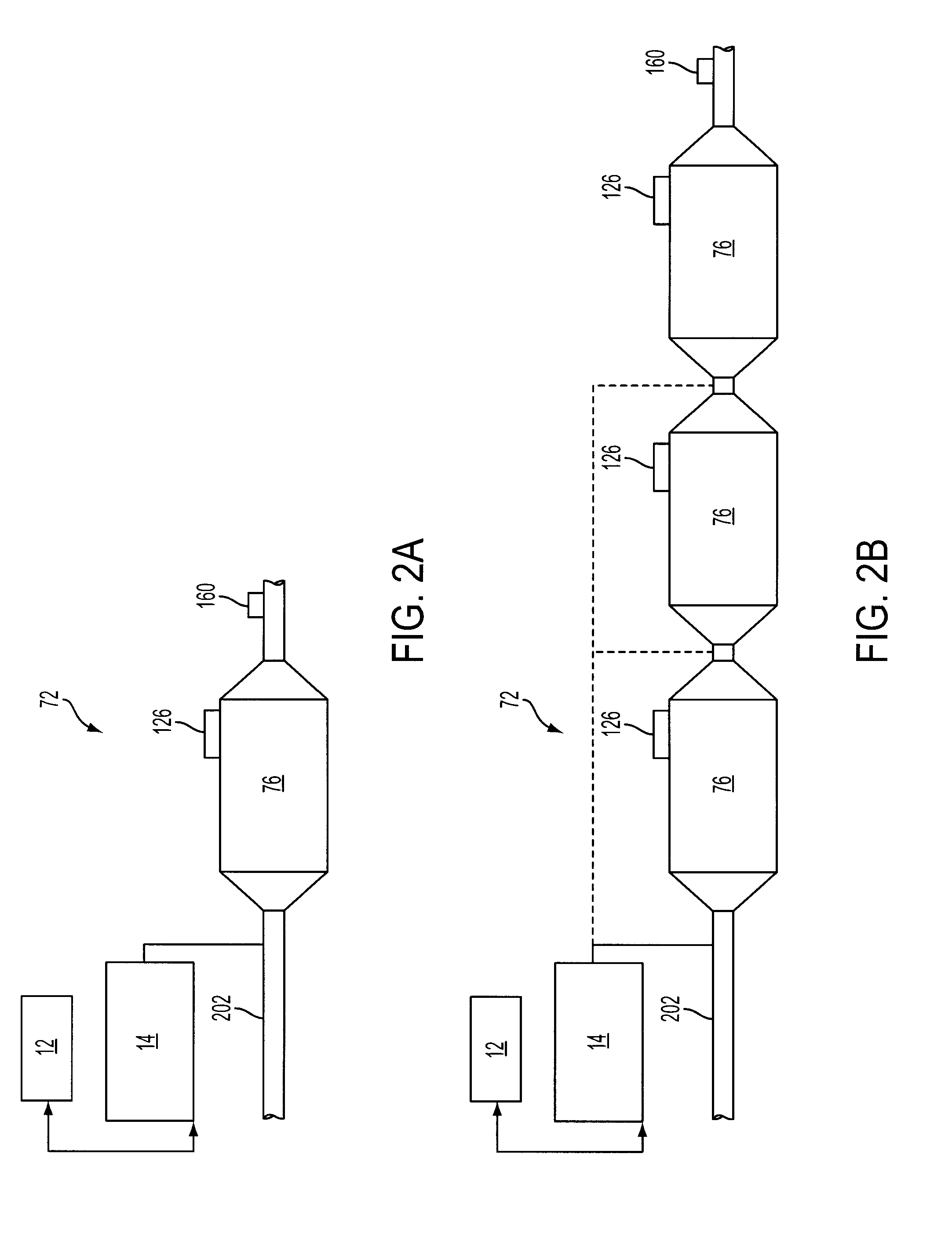

Biomass power plant flue gas purification treatment process and system based on dry-process desulfurization and low-temperature denitration

The invention relates to a biomass power plant flue gas purification treatment process and system based on dry-process desulfurization and low-temperature denitration (low-temperature SCR (Selective Catalytic Reduction)). The biomass power plant flue gas purification treatment process based on the dry-process desulfurization and the low-temperature denitration comprises the following steps: firstly, carrying out primary dust removal on dust-containing flue gas generated by combusting biomasses in a boiler, and keeping temperature of gas which is pre-treated by a cyclone dust collector (1) at about 215 DEG C; secondly, carrying out dry-process desulfurization purification treatment on the flue gas, which is subjected to the primary dust removal, in a desulfurization device (2); thirdly, treating the desulfurized flue gas by adopting a bag type dust collector (3); fourthly, conveying the gas into an SCR system (4) and carrying out denitration reaction to generate harmless nitrogen gas and steam; after recycling residual heat through a heat exchanger (5) and conveying the gas into a chimney (9) through a draught fan (8) and discharging to the atmosphere; fifthly, inputting smoke ash separated from the cyclone dust collector and the bag type dust collector into a concentrated ash silo (7) through a first bin pump pneumatic ash removal device (61) and a second bin pump pneumatic ash removal device (62) and storing.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

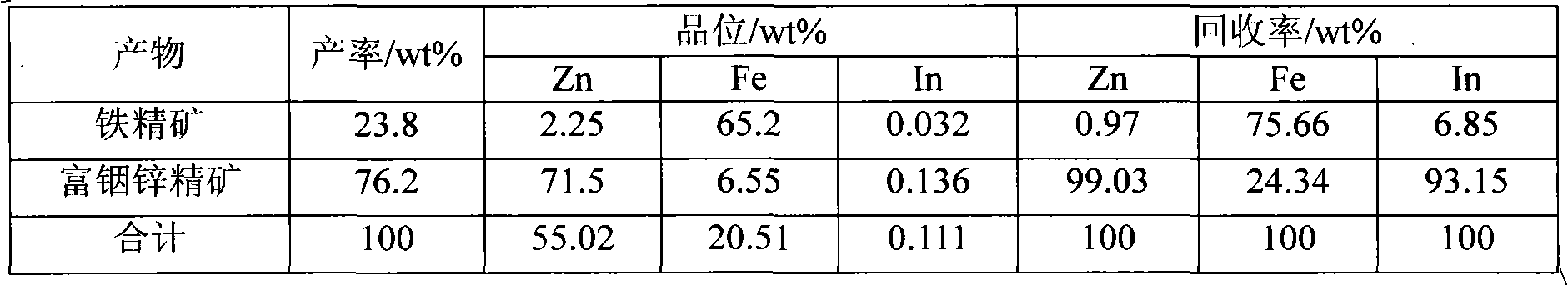

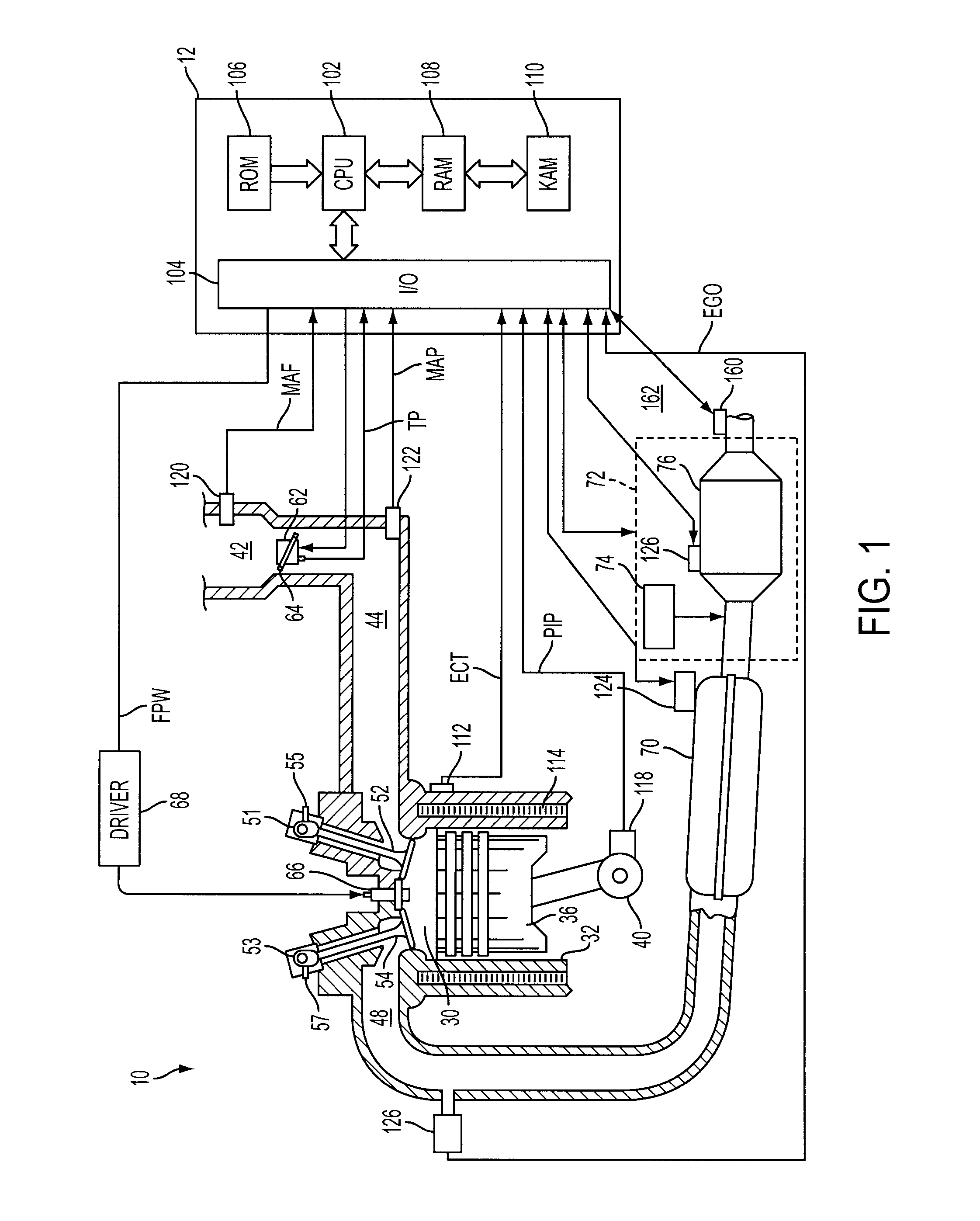

Composition and Method for Controlling Excessive Exhaust Gas Temperatures

ActiveUS20090107118A1Reduce sootDecrease fuel economyInternal combustion piston enginesDispersed particle filtrationExhaust gasExhaust fumes

A method of operating an internal combustion engine having a reductant delivery and storage system in an emission control system is disclosed. The method includes an approach for reducing thermal damage to aftertreatment devices in an exhaust system by reducing excessive exhaust gas temperatures created during particulate filter regeneration.

Owner:FORD GLOBAL TECH LLC

Method for preparing biomass lump coal

The invention discloses a method for preparing lump coal by adopting biomass as raw material and relates to the preparation method for the lump coal. The method comprises the following steps: (1) crushing straws into thick-filament straws, and crushing firewood and twigs into sawdust; (2) mixing the thick-filament straws and the sawdust, then, soaking the mixture with an aqueous alkaline solution, then, fermenting the mixture, and then, continuing to ferment under the condition of high-speed stirring; (3) crushing cattle manure and combustible refuse in municipal domestic waste, then, adding the crushed material into a fermentation softening solution, soaking the crushed material, and then, fermenting for 6 to 10 hours; (4) standing the fermented solution, and filtering out moisture, thereby obtaining viscous biomass slurry; (5) crushing barks, then, adding water to the crushed barks, heating, and then adding starch; and (6) uniformly mixing coal slurry, a binder and the biomass slurry which are in the mass ratio of 1 to (2 to 3) to (40 to 45), and then, carrying out compacting molding at molding pressure, thereby obtaining the finished product. The method disclosed by the invention has the advantages that the method is low in cost and easy to operate, and the product is easy to mold, high in mechanical strength, difficult in slag-bonding and little in smoke dust.

Owner:SHANXI TIANRUNFENG AGRI TECH DEV CO LTD

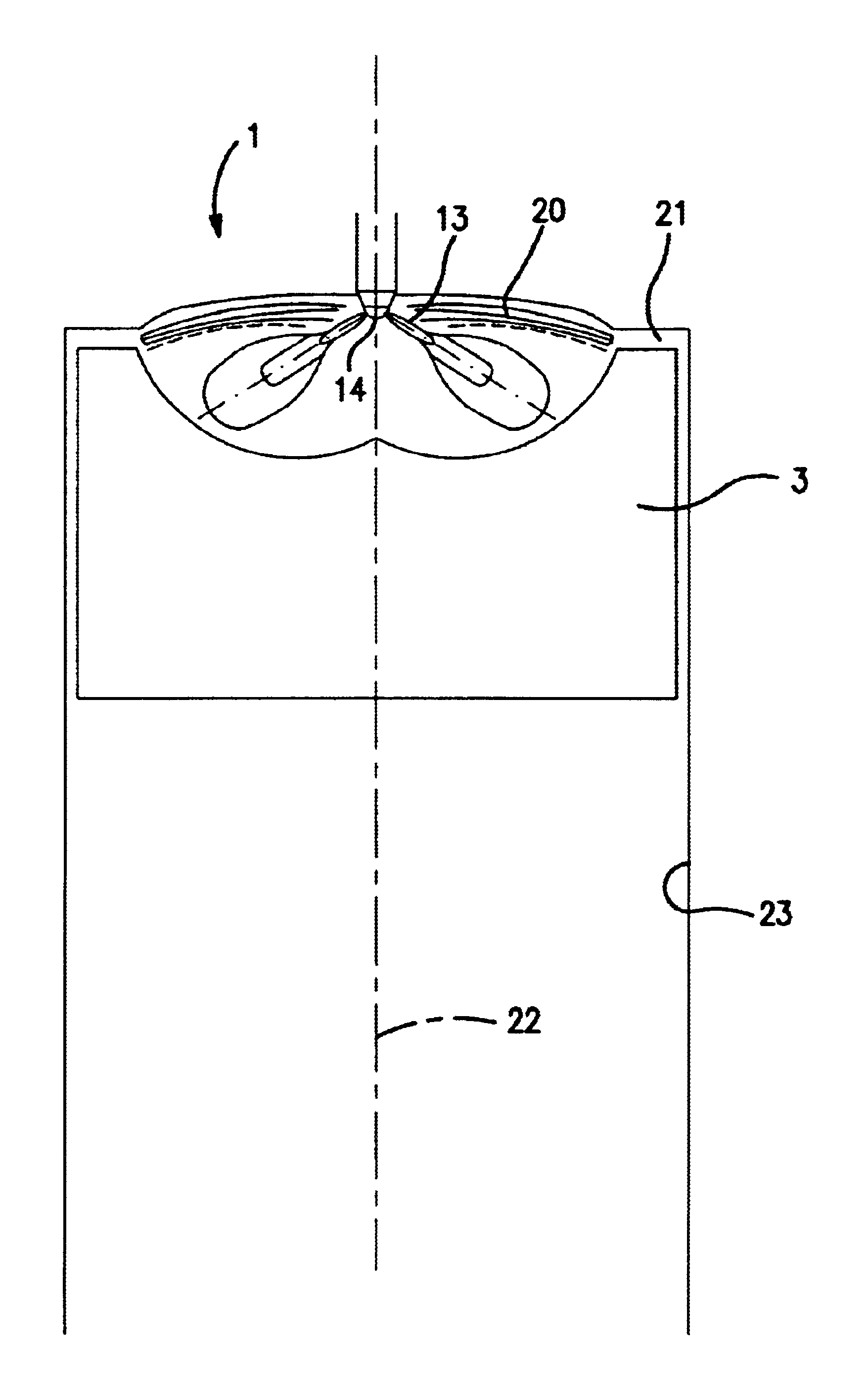

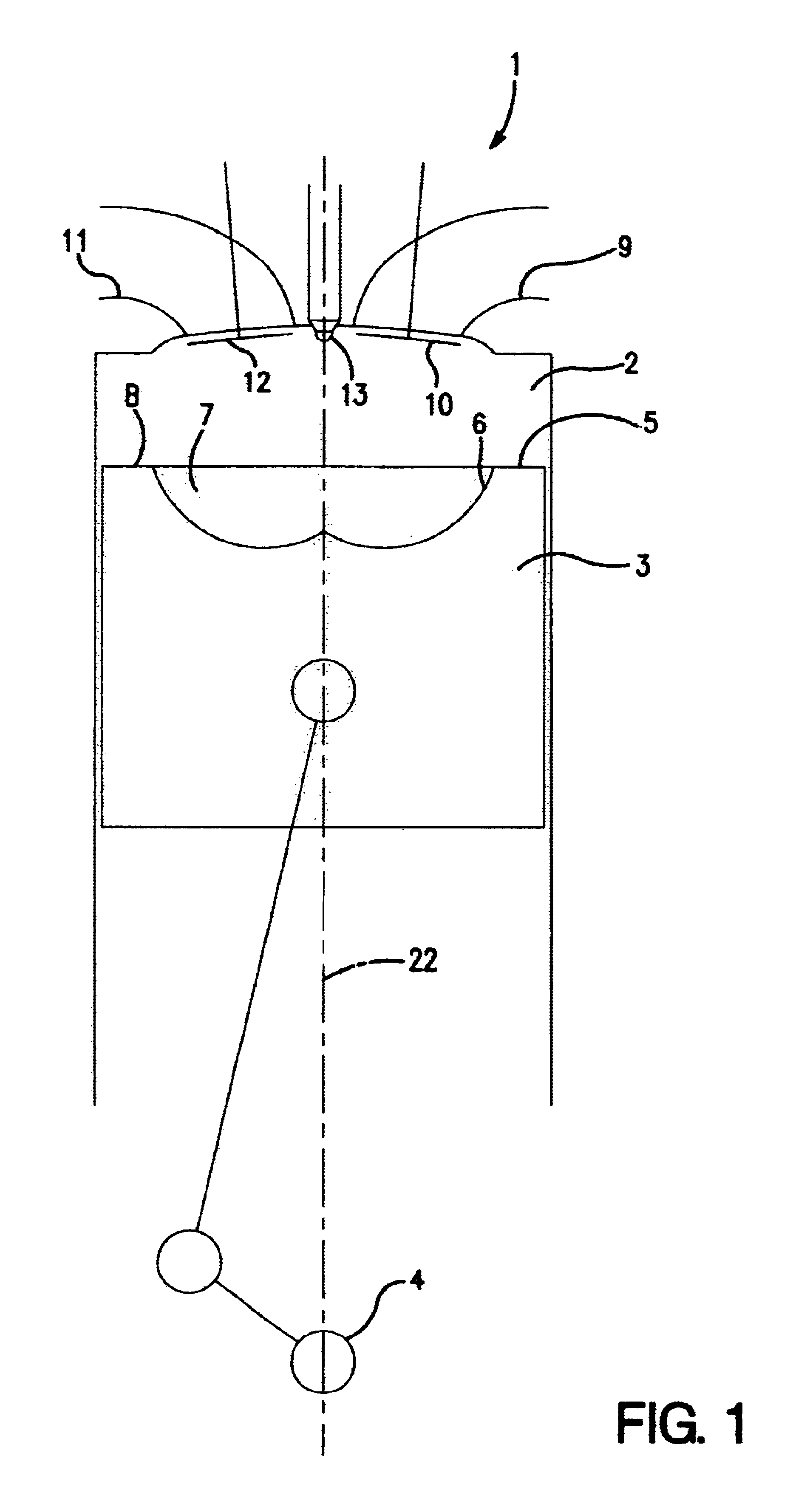

Method for controlling a combustion process in a combustion engine

InactiveUS6820587B1Low sootIncrease in soot emissionElectrical controlNon-fuel substance addition to fuelProcess engineeringNOx

Process which, by spray-controlled, directly injected combustion with the aid of step-by-step technical development of the whole of the combustion system, achieves an intensified mixing process during injection and after-burning, which speeds up soot oxidation during various stages so effectively that the engine can be run with sufficiently high EGR content for desired NOx and soot content down to ultra-low emissions, at the same time as parameters which control the efficiency are decoupled from measures for desired emission level, thereby enabling optimum efficiency to be attained for the process.

Owner:VOLVO LASTVAGNAR AB

Fuel Injection System of Internal Combustion Engine

InactiveUS20080053408A1Improve combustionReduce NOxElectrical controlInternal combustion piston enginesInjection pressureInjection port

A fuel injection system deliberately utilizing after injection so as to improve the engine combustion and reduce soot and NOx, wherein at least one operating valve is provided for operating a first injection port group and second injection port group, after injection is performed consecutively after main injection in a high load region, fuel is injected from the first injection port group and second injection port group at the time of main injection, fuel is injected from the first injection port group at the time of after injection, the actual injection pressure near the first injection port during the after injection period is higher than the actual injection pressure near the first injection port during the main injection period, the operating valve opens the first injection port group to start the injection, then the operating valve opens the second injection port group simultaneously or in a short time as well to perform the main injection, the operating valve closes the second injection port group, then performs the after injection, and the operating valve closes the first injection port group and ends the injection after the elapse of a time longer than simultaneously or a short time from after start of after injection.

Owner:TOYOTA JIDOSHA KK

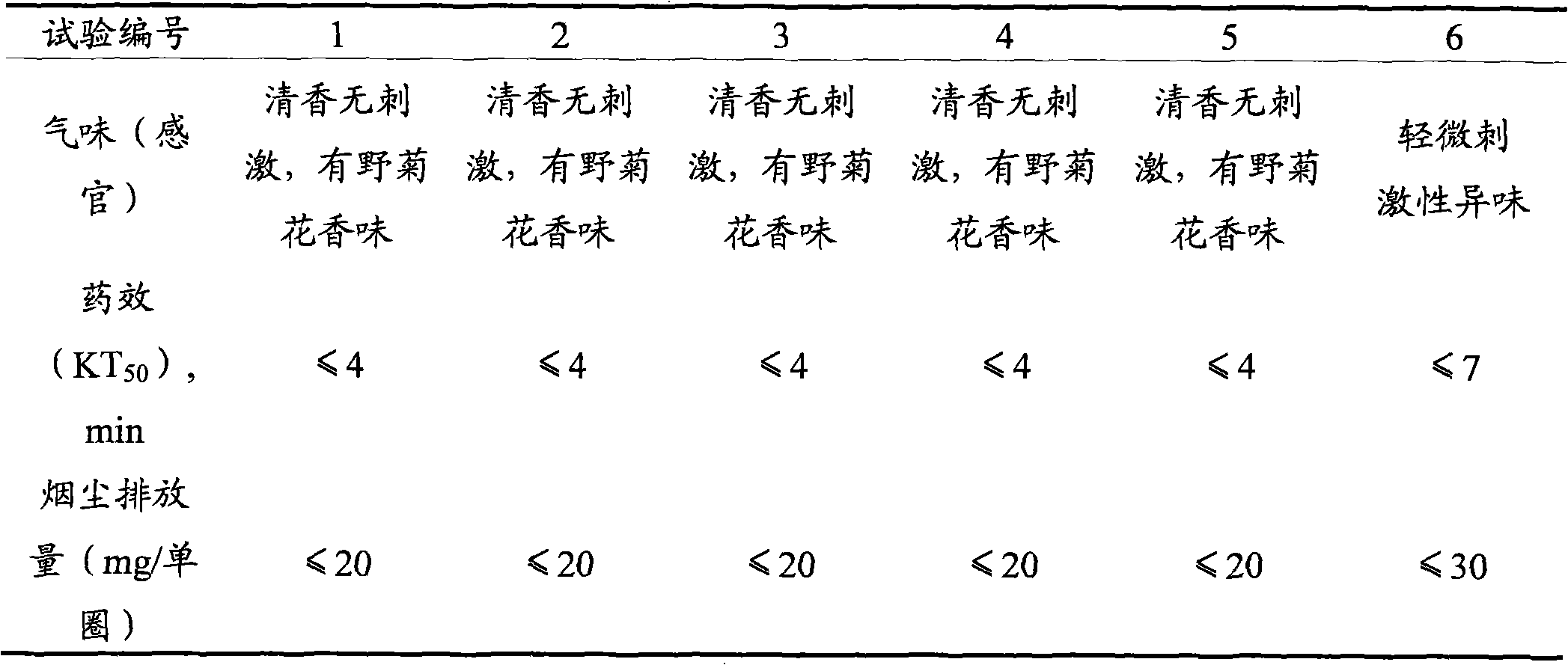

Combustion mosquito coil incense and preparation method thereof

ActiveCN101946806AOvercoming volatileGood for healthBiocidePest repellentsCombustionChrysanthemum Flower

The invention relates to combustion mosquito coil incense and a preparation method thereof. The combustion mosquito coil incense comprises the following components in proportion by weight: 30-60% of carbon powder, 30-60% of vegetable powder, 0.1-0.5% of starch, 0.02-0.5% of pyrethroid and 5-10% of natural wild chrysanthemum flower. The preparation method of the combustion mosquito coil incense comprises the following steps: crushing and fully mixing the carbon powder, the vegetable powder and the natural wild chrysanthemum flower to form a first mixture; adding the starch to the first mixture, and evenly stirring to form a second mixture; extruding the second mixture into slices, and stamping the slices into a spiral billet shape to form spiral billets; drying the spiral billets to obtain dried billets; and attaching the pyrethroid to the dried billets to obtain the combustion mosquito coil incense. The combustion mosquito coil incense of the invention has the advantages of stable combustion, small smoke quantity, fragrant odor and good mosquito repelling effect.

Owner:中山榄菊日化实业有限公司

Welding device for compounding ultrasonic focusing sound field with molten pole arc welding

InactiveCN101947696AStrong penetrating powerEasy to shapeArc welding apparatusNon-electric welding apparatusUltrasonic sensorTransformer

The invention provides a welding device for compounding an ultrasonic focusing sound field with molten pole arc welding for improving the energy density of ultrasonic, changing the arc shape and the energy density and realizing high-efficiency high-quality welding. The welding device comprises a molten pole welding wire, a conductive pole, an ultrasonic transducer, an axle center through hole ultrasonic amplitude transformer, a welding nozzle, a focusing surface, a welding arc, a workpiece to be welded, a welding power supply and an ultrasonic power supply, wherein the molten pole welding wire passes through the conductive pole and is in sliding contact with the conductive pole, the ultrasonic power supply is connected with the ultrasonic transducer through a cable, the ultrasonic transducer is connected with the ultrasonic amplitude transformer through a bolt, and the focusing surface is positioned at the lower end part of the ultrasonic amplitude transformer. The invention ensures that the arc is compressed to improve the arc energy density, increase weld penetration and improve weld formation. The invention can change the arc shape and the heat generation characteristic and the transition form of molten metal, realizes the high-efficiency high-quality welding, and enlarges the application range of the arc welding.

Owner:HARBIN INST OF TECH

Method for extending initiation time of nodulizer, environment-friendly nodulizer and preparation method thereof

The invention discloses a method for extending initiation time of a nodulizer and a nodulizer with long initiation time (the environment-friendly nodulizer ). The method is characterized by coating a layer of heat insulating materials on the surface of the nodulizer. The nodulizer is protected by the layer of heat insulating materials, the temperature cannot be risen promptly, and detonation cannot occur promptly, thus the initiation time of the nodulizer is extended. The heat insulating material powder is coated on the surface of the nodulizer by mixing with the nodulizer with completely stirring, or by using a binder, or by mixing with a binder to form slurry.

Owner:SHENZHEN FORAL TECH

Low emissions diesel piston

ActiveUS7389764B1Well mixedReduce sootInternal combustion piston enginesPistonsPistonThree dimensional shape

Owner:GM GLOBAL TECH OPERATIONS LLC

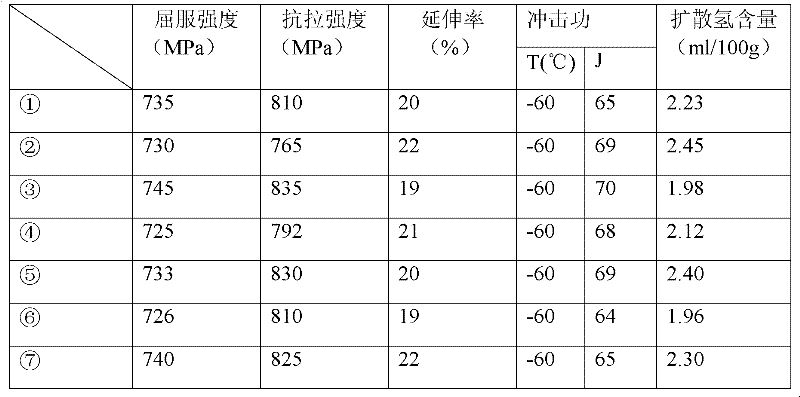

High-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire

ActiveCN102528332AIncrease coverageArc stabilizationWelding/cutting media/materialsSoldering mediaHydrogen contentMetal

The invention discloses a high-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire, which comprises the following components in percentage by mass (based on total mass): 4.5-6.5% of TiO2, 0-0.6% of Al2O3, 0-1% of SiO2, 0-0.5% of ZrO2, 0-0.4% of MgO, 0-0.5% of F, 0-0.15% of C, 0.2-1.5% of Si, 1.0-3.5% of Mn, 0.5-3.5% of Ni, 0.1-1.0% of Mo, 0-0.4% of Ti and 0-0.009% of B. The cold-rolled steel strip for preparing the flux-cored wire comprises the following chemical ingredients by weight content: not more than 0.02% of C, not more than 0.010% of P, and not more than 0.008% of S. The tensile strength of the deposited metal can reach more than 760MPa, the low-temperature impact at -60 DEG C achieves more than 47J, and the diffusible hydrogen content is smaller than 4mL / 100g ( mercury method); and the flux-cored wire has excellent welding operational performance, and is suitable for port machines, ocean platforms, bridges and the like.

Owner:KUSN GINTUNE WELDING

Environment-friendly converter bedding-face repairing material and preparation method thereof

The invention discloses an environment-friendly converter bedding-face repairing material and a preparation method thereof. The repairing material comprises the following ingredients by weight percent: 30 to 65 percent of sintering magnesium sand, 10 to 45 percent of waste magnesite-chrome bricks, 1 to 10 percent of asphalt powder, 5 to 15 percent of tar, 1 to 5 percent of ethanol, 1 to 5 percent of N-methyl-2-pyrrolidinone and 0 to 5 percent of o-xylene. The preparation method comprises the following steps: 1) pre-crushing the sorted sintering magnesium sand and recycled waste magnesite-chrome bricks; 2) uniformly mixing the pre-crushed sintering magnesium sand and waste magnesite-chrome bricks to obtain a mixed coarse material; 3) finely crushing the mixed coarse material to obtain a mixed fine material; 4) uniformly mixing the mixed fine material and asphalt powder in a stirring machine; 5) adding tar, ethernol, N-methyl-2-pyrrolidinone and o-xylene, and stirring the mixture for 10 to 25 minutes. The practices prove that the converter repairing material has good mobility, can be sintered easily, has long service life and generates little smoke when sintered.

Owner:武汉钢铁有限公司

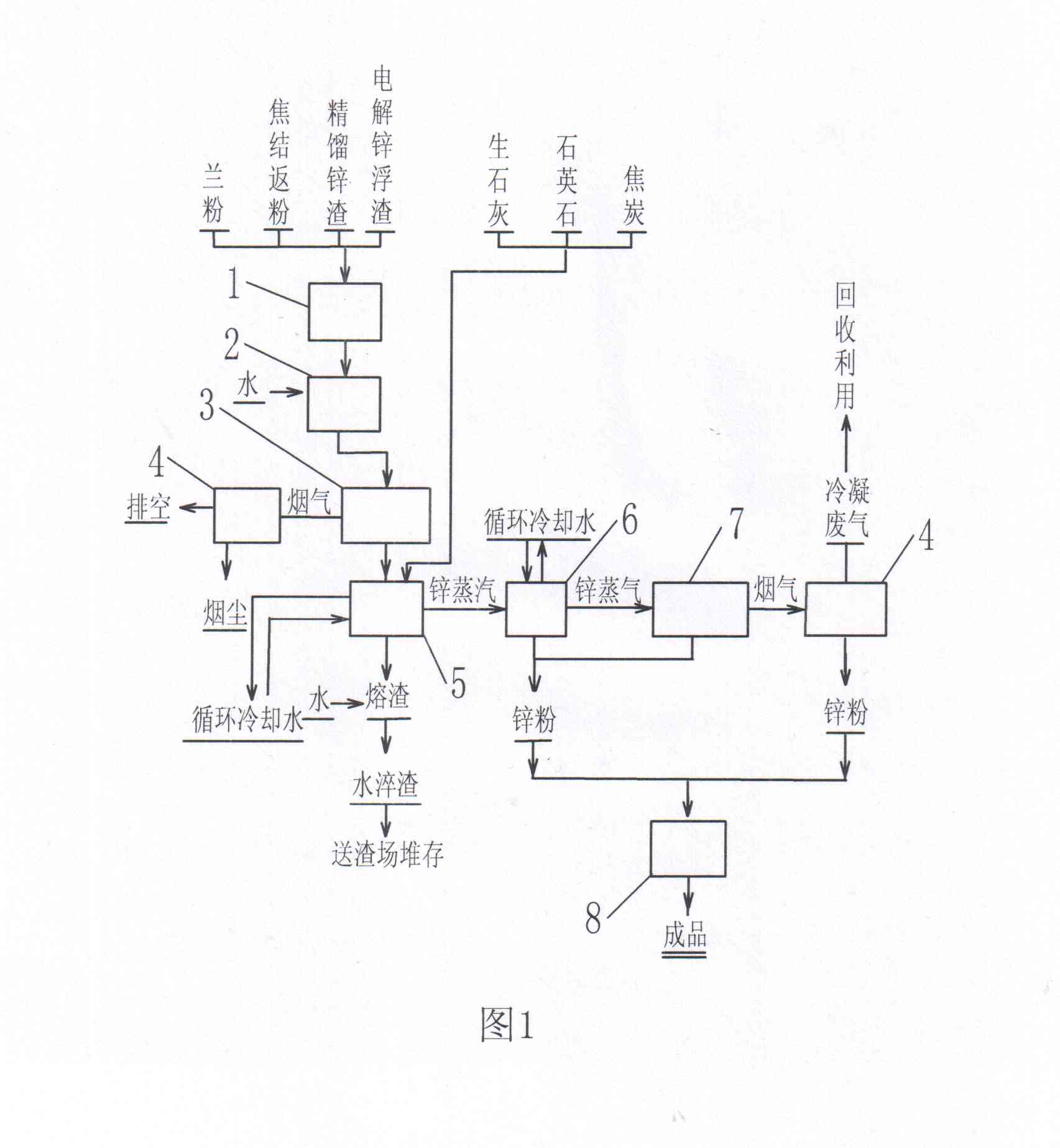

Method for producing zinc powder by treating zinc-containing miscellaneous material through electric furnace

InactiveCN102181663AReduce sootWith defluorinationProcess efficiency improvementElectric arc furnaceHydrometallurgy

The invention relates to a method for producing zinc powder by treating a zinc-containing miscellaneous material through an electric furnace. The zinc powder is prepared by the zinc-containing miscellaneous material through a zinc-containing miscellaneous material quantitatively-batching process, a zinc-containing miscellaneous material mixture pelletizing process, a zinc-containing miscellaneousmaterial particle roasting process, a roasted flue gas dust collection process, an electric furnace smelting process, a zinc powder condensation process and a smelted flue gas dust collection process. In the method, the zinc powder is produced by the zinc-containing miscellaneous material generated by zinc pyrometallurgy or zinc hydrometallurgy, so that useful zinc powder can be extracted and recycled from the zinc-containing miscellaneous material. The zinc-containing miscellaneous material can be completely utilized; and the method has the advantages of removing fluorine and chlorine and completely recycling condensed waste gas, along with extremely low content of impurities such as iron and the like in raw materials and low yield of waste residues of a device, and is suitable to be applied to the production of the zinc powder prepared by recycling the zinc-containing miscellaneous material. The obtained zinc powder can be used for a replacement reduction process of hydrometallurgy.

Owner:HULUDAO ZINC IND CO LTD

Coproduction method of diammonium phosphate and monoammonium phosphate and equipment for neutralizing washing liquid

InactiveCN1442358ARealize capacity expansion and transformationIncrease productionPhosphatesPhosphateDiammonium phosphate

A process for preparing diammonium phosphate and ammonium phosphate features that one part of extracted phosphoric acid is used to prepare diammonium phosphate through concentrating, neutralizing, granulating and drying and the other part is used to prepare ammonium phosphate through washing the tail gas generated in neutralizing-granulating steps, neutralizing the washing liquid, concentrating and spraying drying (or granulating and drying). The neutralizing equipment for washing liquid is composed of flash evaporator, reactino lifting up tube and lowering down tube and forced circulating pump.

Owner:SICHUAN UNIV

Gasoline engine

InactiveUS20100147261A1Increase exhaust temperatureReduce HCElectrical controlInternal combustion piston enginesCombustionGasoline

A gasoline engine is provided that effectively uses two injectors to enhance homogeneity of mixture at the time of high-load for improving output power and to enable stable operation also when stratified or weak stratified combustion is performed.One cylinder is provided with a first injector 122a and a second injector 122b, which directly inject fuel into the cylinder. An ECU 201 uses one or both the injectors to perform fuel injection during one combustion cycle depending on operating conditions.

Owner:HITACHI LTD

Energy-saving and environment-friendly boiler with preheating function

InactiveCN107421116AIncrease the burning areaBurn fullyCombustion processIndirect carbon-dioxide mitigationCombustionBoiler slag

The invention discloses an energy-saving and environment-friendly boiler with a preheating function. The energy-saving and environment-friendly boiler comprises a shell, a grate, a boiler slag collection trough, a circulating pump and a fan. A vertical material uniformization plate is arranged on the upper surface of the grate. A material passing opening penetrating the two sides is formed in the material uniformization plate. A heat absorption pipe is arranged in the boiler slag collection trough and is located at the bottom of the boiler slag collection trough, and the outer end of the heat absorption pipe communicates with a heat exchanger. Multiple heat conduction columns are horizontally inserted into a water jacket. The other end of a smoke discharging pipe communicates with a waste heat collection box. A heat exchange coiled pipe is mounted in the waste heat collection box. The bottom of the waste heat collection box communicates with a purification box. According to the energy-saving and environment-friendly boiler, the arranged material uniformization plate moves to uniformly pave dye, the combustion area of fuel is large, and contact of the fuel and air is sufficient; and heat in smoke is absorbed by the heat exchange coiled pipe and used for preheating inner heating water, the water temperature increase speed is increased, and the heating efficiency of hot water in the boiler is guaranteed.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

Submerged arc sintered flux and production method thereof

InactiveCN101537550AEnsuring grain refinementStable welding arcWelding/cutting media/materialsSoldering mediaFerrosiliconRare earth

The invention relates to a hull building high efficiency welding process, and a welding technique for flux copper liner multi-filament single side automatic submerged arc welding, in particular to an automatic submerged arc welding sintered flux comprising a top surface flux and a liner flux and a production method thereof. The submerged arc sintered flux consists of the top surface flux and the liner flux. The top surface flux comprises the following components: 5 to 10 percent of CaO, 15 to 20 percent of MgO, 7 to 14 percent of Al2O3, 3 to 6 percent of MnO, 10 to 15 percent of SiO2, 5 to 10 percent of TiO2, 34 to 38 percent of Fe2O3, 2 percent of rare earth ferrosilicon, 1 percent of ferrotitanium, 0.5 percent of borax, and 0.5 percent of ferromanganese; and the liner flux comprises the following components: 15 to 20 percent of CaO, 30 to 35 percent of MgO, 5 to 10 percent of Fe2O3, 10 to 15 percent of MnO, 15 to 20 percent of SiO2, 5 to 10 percent of TiO2, and 4 to 5 percent of Na2O.

Owner:上海纪好旺造船科技发展有限公司

Method of lubricating an internal combustion engine

InactiveUS20160326453A1Reduce sootReduce formation of depositAdditivesChemistryInternal combustion engine

The invention provides a method of lubricating a compression-ignition internal combustion engine with a maximum laden mass over 2,700 kg comprising supplying to the engine a lubricating composition comprising: an oil of lubricating viscosity, a 300 TBN or higher alkaline earth metal sulphonate detergent having a metal ratio of 10 to 40, 0.1 wt % to 4 wt % of a borated polyisobutylene succinimide dispersant, wherein the polyisobutylene from which the borated polyisobutylene succinimide is derived has a number average molecular weight of 550 to 1150, and 0.1 wt % to 6 wt % of a polyisobutylene succinimide, wherein the polyisobutylene from which polyisobutylene succinimide is derived has a number average molecular weight of 1550 to 2500, 0 wt % to 0.2 wt % of a phenolic based detergent, wherein the total amount of soap delivered by the alkaline earth metal sulphonate (typically calcium sulphonate) is 0.4 to 1 wt % of the lubricating composition, and wherein the lubricating composition has a sulphated ash content of not more than 1.5 wt %.

Owner:THE LUBRIZOL CORP

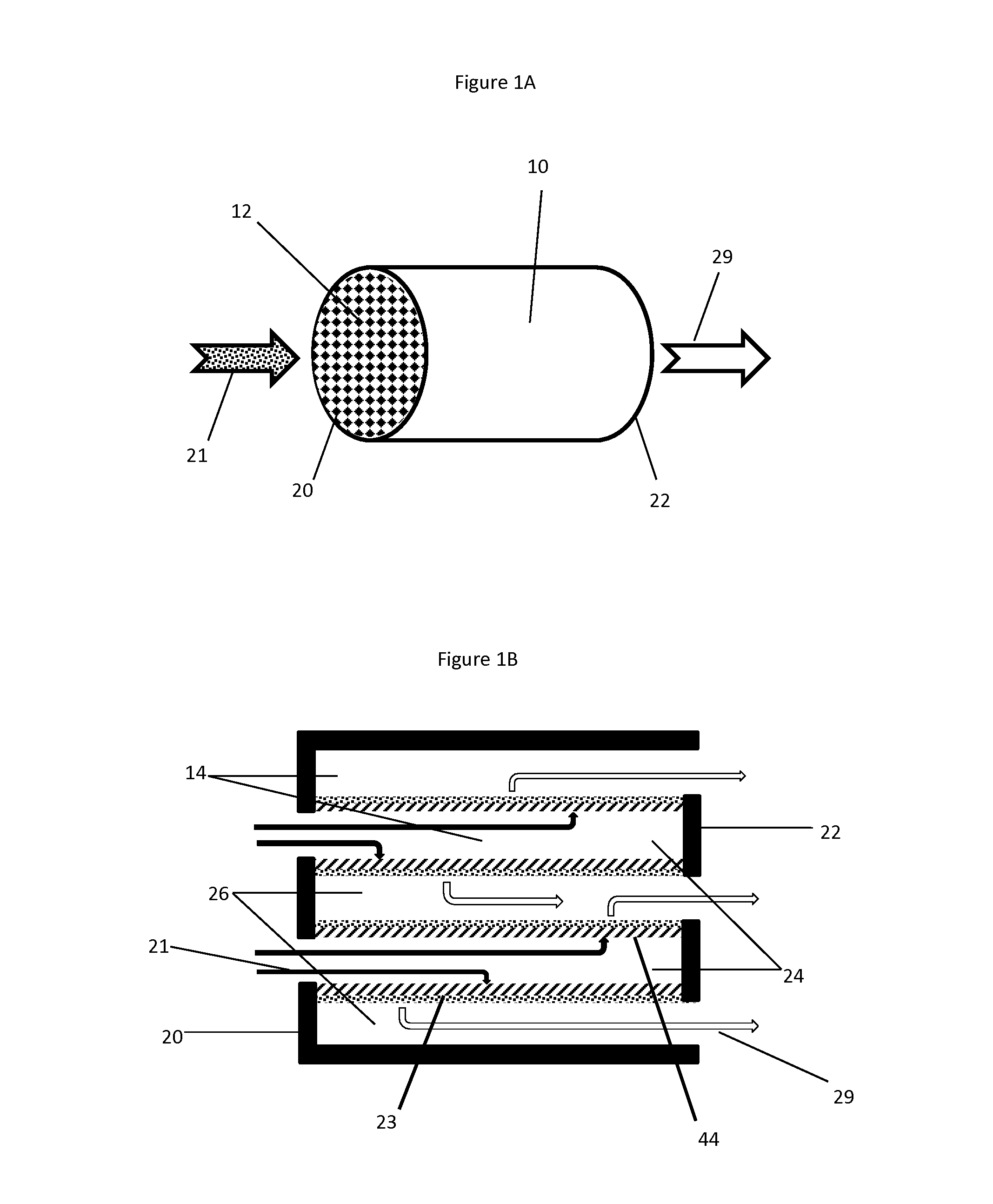

Catalyzed Filter for Treating Exhaust Gas

ActiveUS20140356266A1Reduce the concentration of nitrogen oxidesBackpressure across a wall-flow filter can be reducedCombination devicesInternal combustion piston enginesPore diameterSoot

Provided is a diesel particulate filter capable of removing soot from an exhaust gas while operating at low backpressure, the filter comprising (a) a wall-flow filter substrate having a mean pore size, an inlet side, an outlet side, and a porous interior between the inlet and outlet sides; and (b) a catalyst composition coated from the inlet side of the substrate, wherein the catalyst composition has a d50 particle size distribution, wherein the d50 particle size distribution is less than the mean pore size divided by 4.9, and wherein the outlet side is substantially free of a catalyst coating.

Owner:JOHNSON MATTHEY PLC

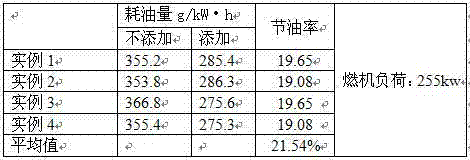

Environmentally-friendly heavy oil additive and preparation method and use method thereof

InactiveCN102559306ALong stable periodImprove performanceLiquid carbonaceous fuelsFuel additivesOil canActive agent

The invention discloses a new environmentally-friendly heavy oil additive and a preparation method and use method thereof. The additive comprises the following components in parts by weight: 10-30 parts of nonionic surfactant, 15-60 parts of combustion improver, 10-30 parts of quality stabilizer, 10-55 parts of purification dispersant, 1-8 parts of corrosion inhibitor and 20-50 parts of water. After the materials are combined according to percentages, the materials can be used with heavy oil mixed with water and the fuel properties of heavy oil are improved. The environmentally-friendly heavy oil additive has the following advantages: the combustion performance of heavy oil can be effectively improved, the liquidity of heavy oil can be increased, the heavy oil fuel oil with the additive has stable performance, long storage time, good atomizing effect, no pollution and high oil-saving efficiency, is easy in ignition and can not coke, the fuel oil does not corrode the equipment, has high combustion value and simple process, is difficult in black smoke generation, is convenient in use and can combust completely, and the equipment loss is reduced furthest.

Owner:山东国弘能源科技有限公司

Energy-saving and environment-protective welding rod

ActiveCN101934442AReduce energy consumptionSmall side effectsWelding/cutting media/materialsSoldering mediaAlternating currentDolomite

The invention relates to an energy-saving environment-friendly welding rod belonging to the field of welding materials. The energy-saving environment-friendly welding rod comprises a coating and a welding core. The energy-saving environment-friendly welding rod is characterized in that the coating comprises the following matters in percentage by weight: 35-50 percent of rutile, 7-12 percent of mid-carbon ferromanganese, 4-14 percent of white slime, 6-12 percent of feldspar, 5-10 percent of mica, 7-13 percent of dolomite, 7-9 percent of ilmenite, 1-3 percent of quartz, 2-4 percent of meerschaum and 9-14 percent of attapulgite powder. For selecting raw materials, the rutile is adopted instead of titanium pigment and reduced titanium, which has low energy consumption and low pollution; and the meerschaum is used instead of organic matters of wood flour, cellulose, and the like, which almost does not generate dust when being used, is environment-friendly and does not damage the health of operating staff. The invention is the carbon steel welding rod with the rutile type coating, has the advantages of excellent welding process property, stable electric arc, beautiful welding seams, low splash, little dust and dual purposes of alternating current and direct current, and can carry out all-position welding.

Owner:淄博齐鲁焊业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com