Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

424results about How to "Guaranteed thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

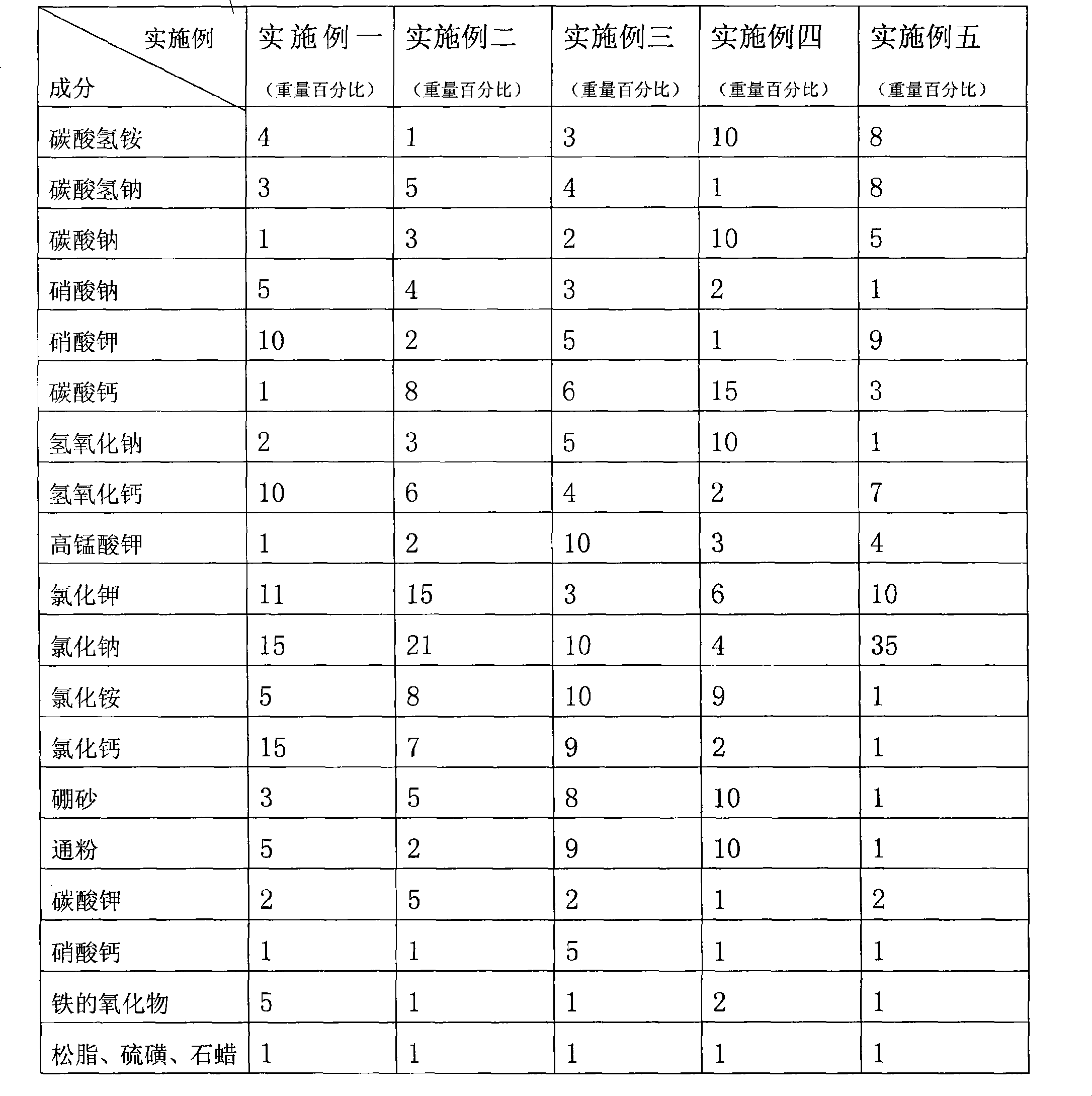

Environment-protecting synergistic agent for fuel coal

InactiveCN101440328AIncreased flammable contentIncreased space gapSolid fuelsFuel additivesSodium bicarbonateFurnace temperature

The invention discloses a bunker coal environment-friendly synergist, which comprises the following components by weight percent: 1 to 10 percent of ammonium bicarbonate, 1 to 8 percent of sodium bicarbonate, 1 to 10 percent of sodium carbonate, 1 to 5 percent of sodium nitrate, 1 to 10 percent of potassium nitrate, 1 to 15 percent of calcium carbonate, 1 to 10 percent of sodium hydroxide, 2 to 10 percent of calcium hydroxide, 1 to 10 percent of potassium permanganate, 3 to 15 percent of potassium chloride, 10 to 35 percent of sodium chloride, 1 to 10 percent of ammonium chloride, 1 to 15 percent of calcium chloride, 1 to 10 percent of borax, 1 to 10 percent of macaroni, 1 to 5 percent of potassium carbonate, 1 to 5 percent of calcium nitrate, 1 to 5 percent of iron oxide, and the balance being micro turpentine, sulfur and paraffin wax. The bunker coal environment-friendly synergist makes flame of combustion be more rampant and denser, the furnace temperature rise to a higher level, the hearth be brighter and cleaner and tail gas be cleaner.

Owner:李政 +1

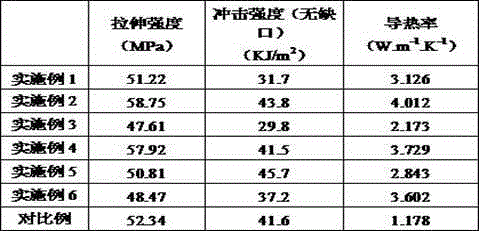

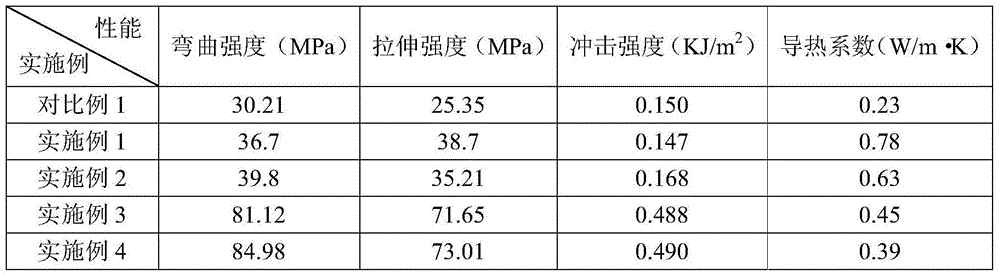

Heat-conduction epoxy resin composite material and preparation method thereof

The invention relates to the field of high-molecular composite materials, and concretely relates to a heat-conduction epoxy resin composite material and a preparation method thereof. The heat-conduction epoxy resin composite material comprises the following compositions in parts by mass: 0.5-3.0 parts of carbon nanotubes, 0.5-10.0 parts of nanometer aluminium nitride, 0.1-1.0 part of a silane coupling agent, 0.1-0.5 part of stearic acid, 60-80 parts of epoxy resin and 8-30 parts of a curing agent. According to the preparation method, amino-functionalized carbon nanotubes and nanometer aluminium nitride subjected to surface modification by employing a coupling agent are dispersed in epoxy resin, so that the epoxy resin material with heat-conduction function is prepared, the operation technology is simple, on the one hand, the heat conduction performance of the material is guaranteed, and on the other hand, the cost is reduced. The addition amount of functional materials employed by the composite material is less, the stability of the product is good, and the composite material is applicable to electric appliances, electron heat radiation and other aspects.

Owner:东莞市福佑电子科技有限公司

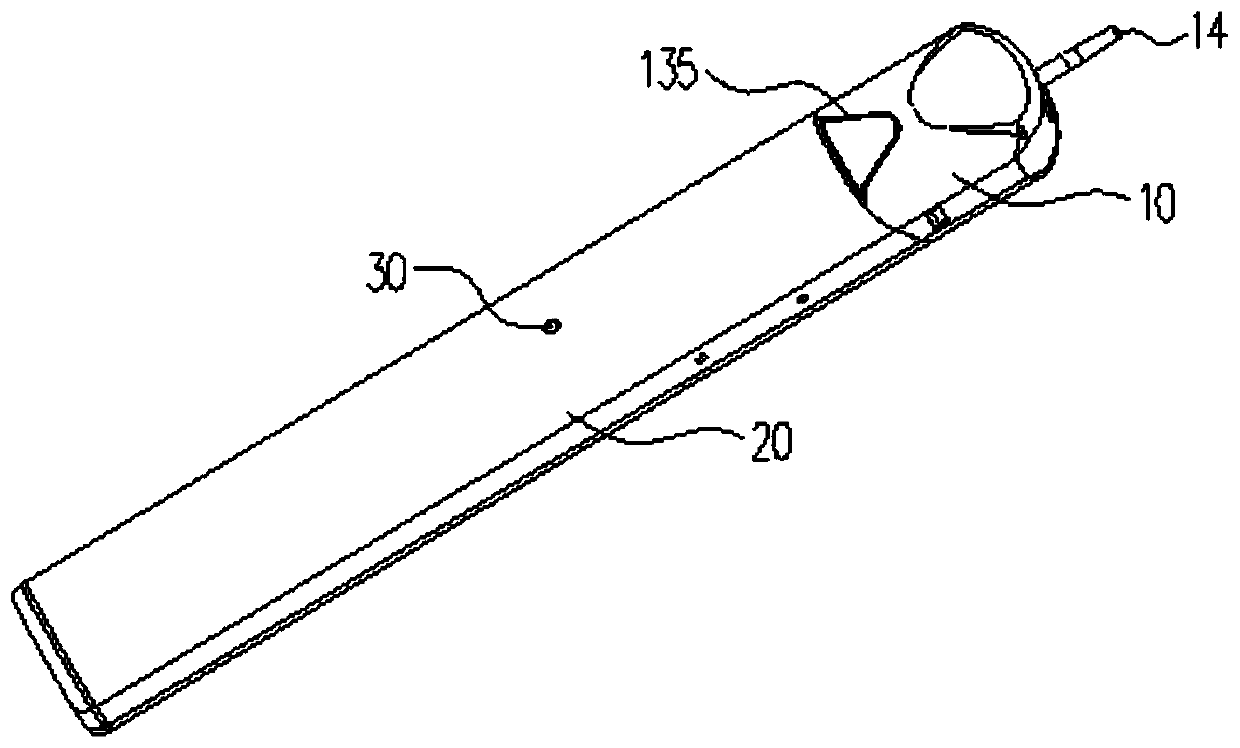

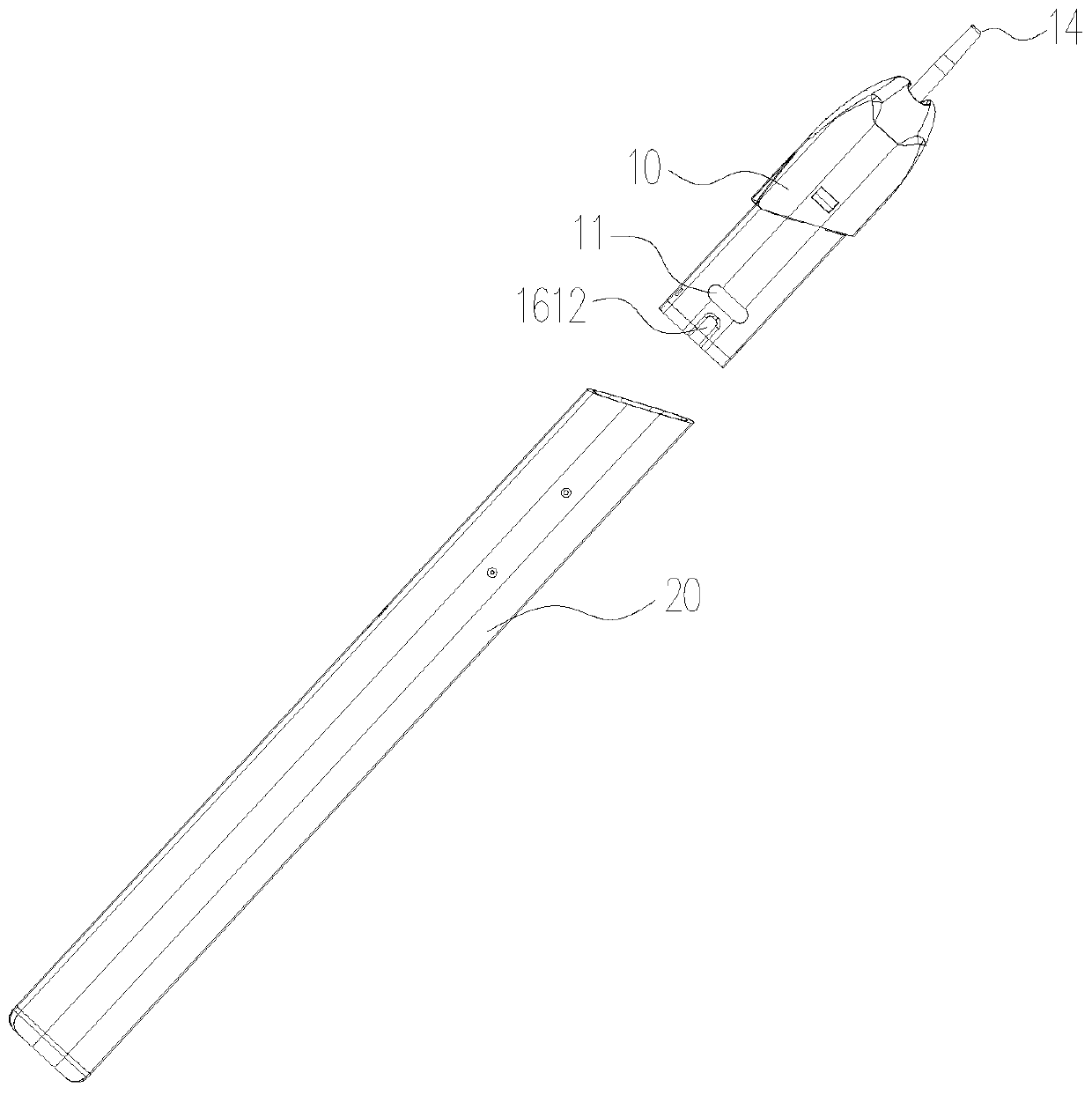

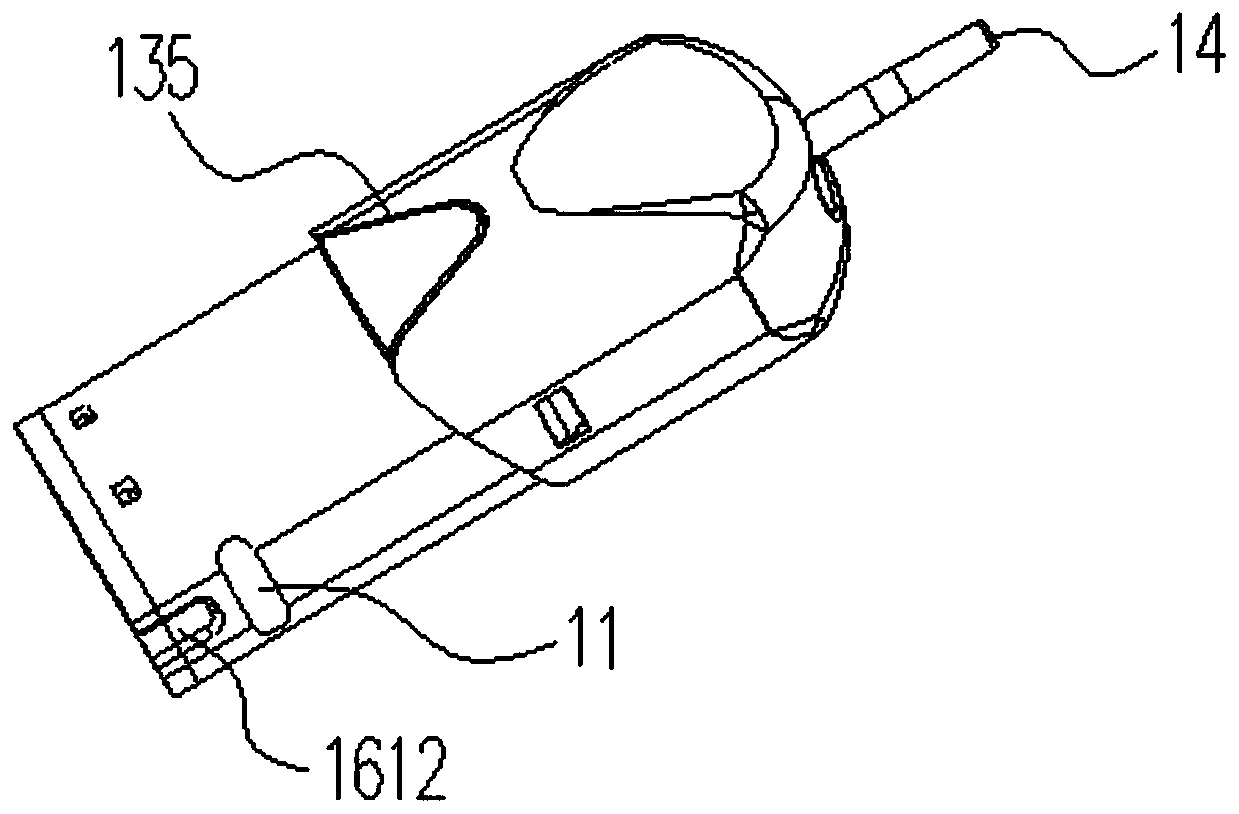

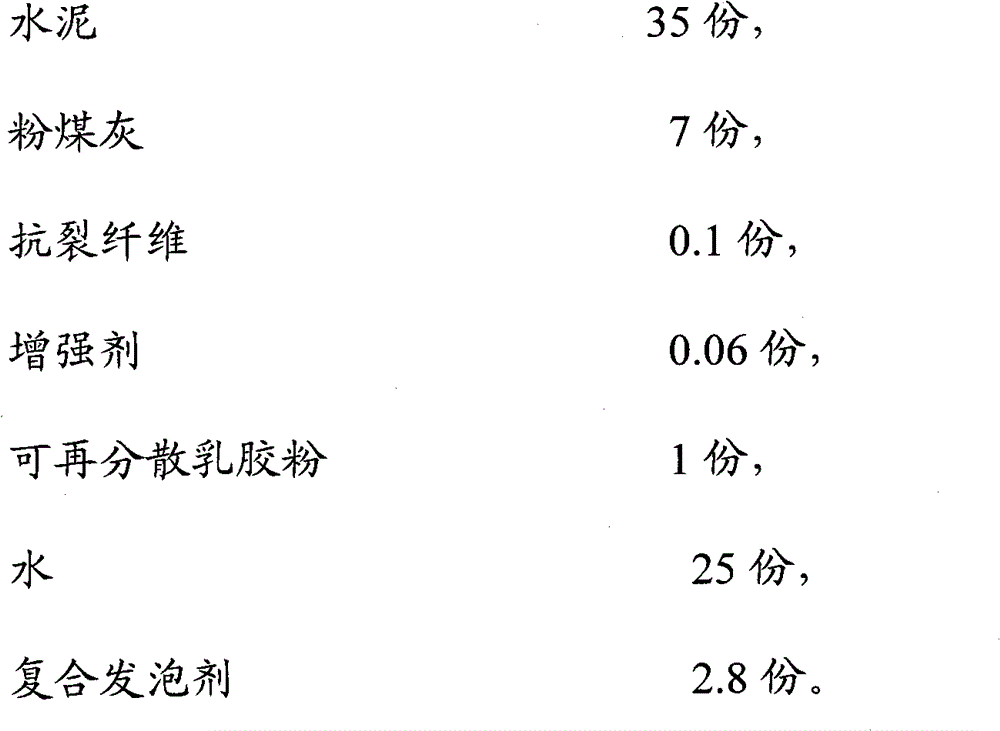

Electronic cigarette

ActiveCN109717519APrevent leakagePrevent spoilageTobacco devicesElectrical batteryElectronic cigarette

The invention discloses an electronic cigarette. The electronic cigarette comprises a cartridge and a battery device which are detachably connected, the battery device comprises a battery, a heating piece, a detection assembly, a sensor and a first control panel, and the detection assembly is used for generating a connecting signal when the cartridge is connected with the battery device; the sensor is used for generating a smoking signal under the smoking effect, and if and only if the detection assembly generates the connecting signal, and the sensor generates the smoking signal, the first control panel controls the battery to supply power to the heating piece, so that the heating piece conducts atomizing operation. According to the electronic cigarette, if and only if the detection assembly generates the connecting signal, and the sensor generates the smoking signal, the first control panel can control the battery to supply power to the heating piece, and the function of protecting safety of children is achieved.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

Grapheme modified polypropylene master batch and preparation method thereof

InactiveCN103819815AKeep the cladding structureThere will be no local unevennessHeat conductingAntioxidant

The invention provides a grapheme modified polypropylene master batch and a preparation method thereof. The grapheme modified polypropylene master batch comprises the following raw materials in parts by weight: 100 parts of polypropylene particles, 0.01 to 5 parts of grapheme dry powder, 0.01 to 1 part of an antioxidant, 0.1 to 10 parts of a plasticizer, 1 to 10 parts of a light stabilizer, 1 to 10 parts of a lubricant, and 0 to 40 parts of a filler. The preparation method comprises the following steps: performing spraying modification on the polypropylene particles through the grapheme dry powder with static electricity, uniformly mixing the modified polypropylene particles with the rest of constituents, then feeding the mixture into a double-screw extruder for fusing and mixing, and finally extruding for granulation. The method enhances the mechanical property of the polypropylene material under the condition that the heat-conducting property of the polypropylene material is greatly improved.

Owner:北京纳新天地科技发展有限公司

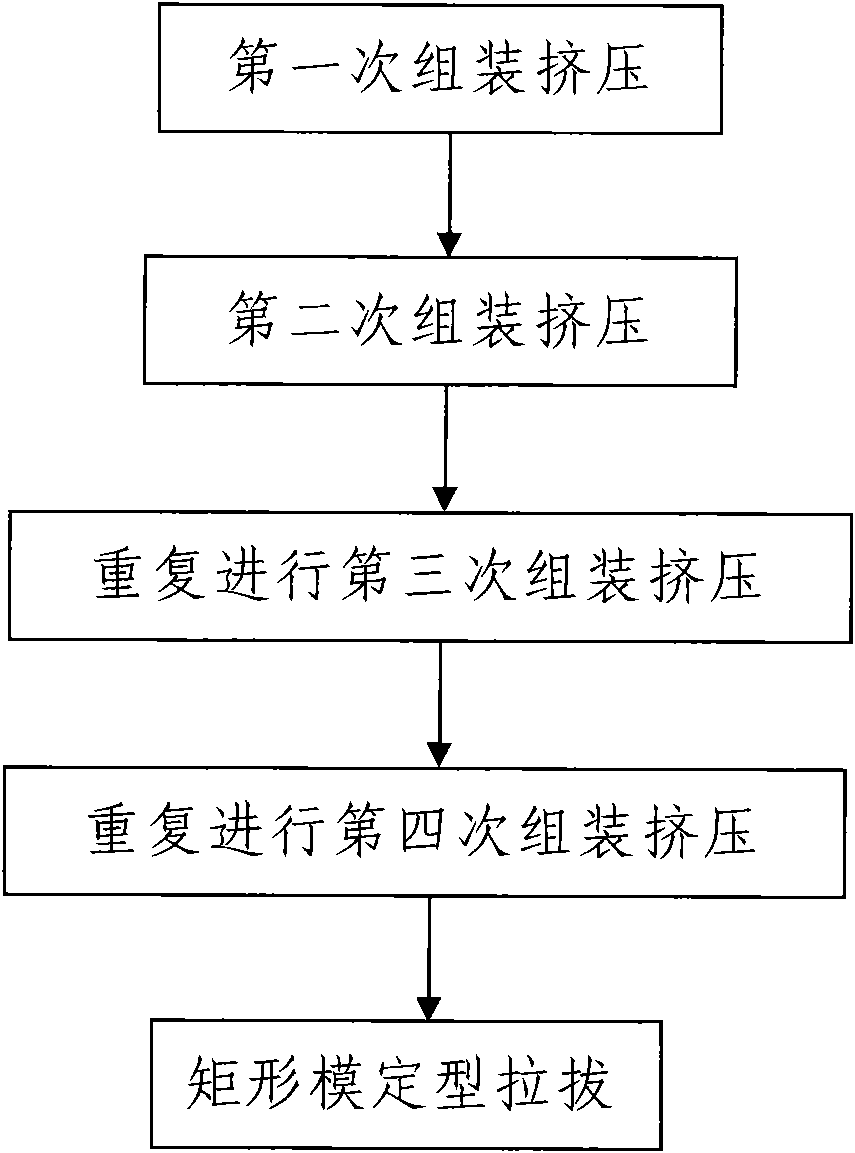

Preparation method of Cu-Nb multi-core composite wire with rectangular cross-section

InactiveCN101872660AThe process steps are simpleShort processSuperconductors/hyperconductorsManufacturing extensible conductors/cablesL&D processExtrusion

The invention discloses a preparation method of a Cu-Nb multi-core composite wire with the rectangular cross-section, which comprises the following steps: firstly, carrying out first extrusion assembly and drawing for a single pure Nb rod and a first outer oxygen-free copper sheathing; secondly, carrying out second extrusion assembly and obtaining a first Cu-Nb multi-core composite filament; secondly, according to the extrusion assembly method and related process parameters in the step 2, repeatedly carrying out third extrusion assembly; thirdly, according to the extrusion assembly method and related process parameters in the step 2, repeatedly carrying out fourth extrusion assembly; and finally, setting and drawing by a rectangular mold. The invention has simple process step, short process, high production efficiency, low preparation cost and good use effect, and the produced Cu-Nb multi-core composite wire has superior performance; and the invention is suitable for mass production, can better control the dimensional accuracy of the rectangular cross-section, and can machine any size and length of hundred-million-magnitude-order Cu-Nb multi-core composite wires with the rectangular cross-section.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

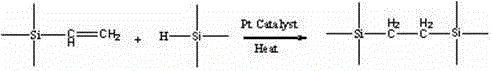

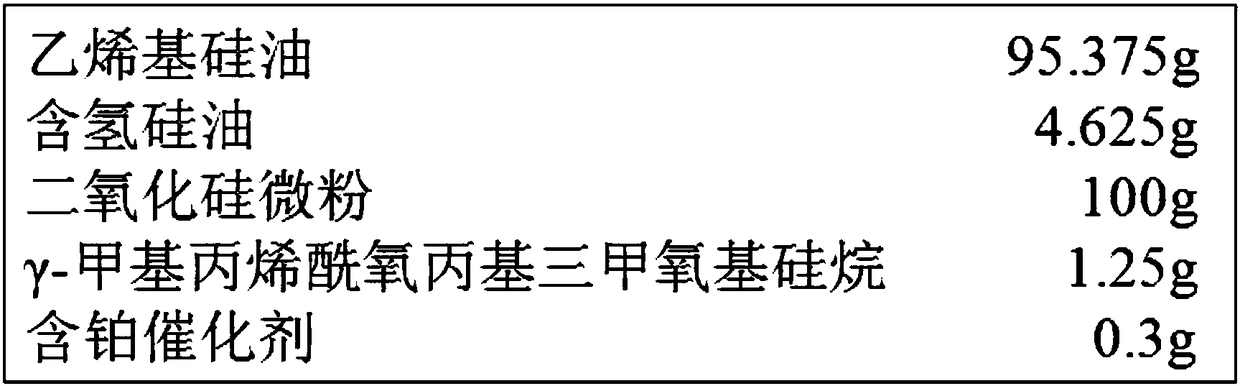

Low release quantity additive halogen-free flame-retardant heat-conduction organic silicon pouring sealant and preparation method thereof

InactiveCN104804705AImprove liquidityImprove thermal conductivityNon-macromolecular adhesive additivesRubber materialHydrogen

The invention belongs to the technical field of organic silicon pouring sealants, and particularly relates to a low release quantity additive halogen-free flame-retardant heat-conduction organic silicon pouring sealant and a preparation method thereof. The pouring sealant comprises an A component and a B component, wherein the A component and the B components are mixed in weight ratio of 1:1; the A component comprises basic rubber materials, polymethyl hydrogen siloxane and crosslink breaker; the weight ratio of the basic rubber materials, the polymethyl hydrogen siloxane and the crosslink breaker is 100:2.5-4:0.01-0.5; the B component comprises basic rubber materials and catalyzer; the weight ratio of the rubber materials and the catalyzer is 100:0.15-0.2; the A component and the B component are uniformly mixed according to the equal weight ratio and are defoaming to obtain the pouring sealant. The pouring sealant is good in flowability, can be heat and cured at room temperature, has favorable heat conductivity and flame retardancy, has the release quantity being lower than 0.5 percent under the condition of 120 DEG C*24h, and is particularly applicable to pouring with the heat-conduction and flame-retardant requirements under a seal system in the LED (Light-emitting Diode) industry.

Owner:CHENGDU TALY TECH CO LTD

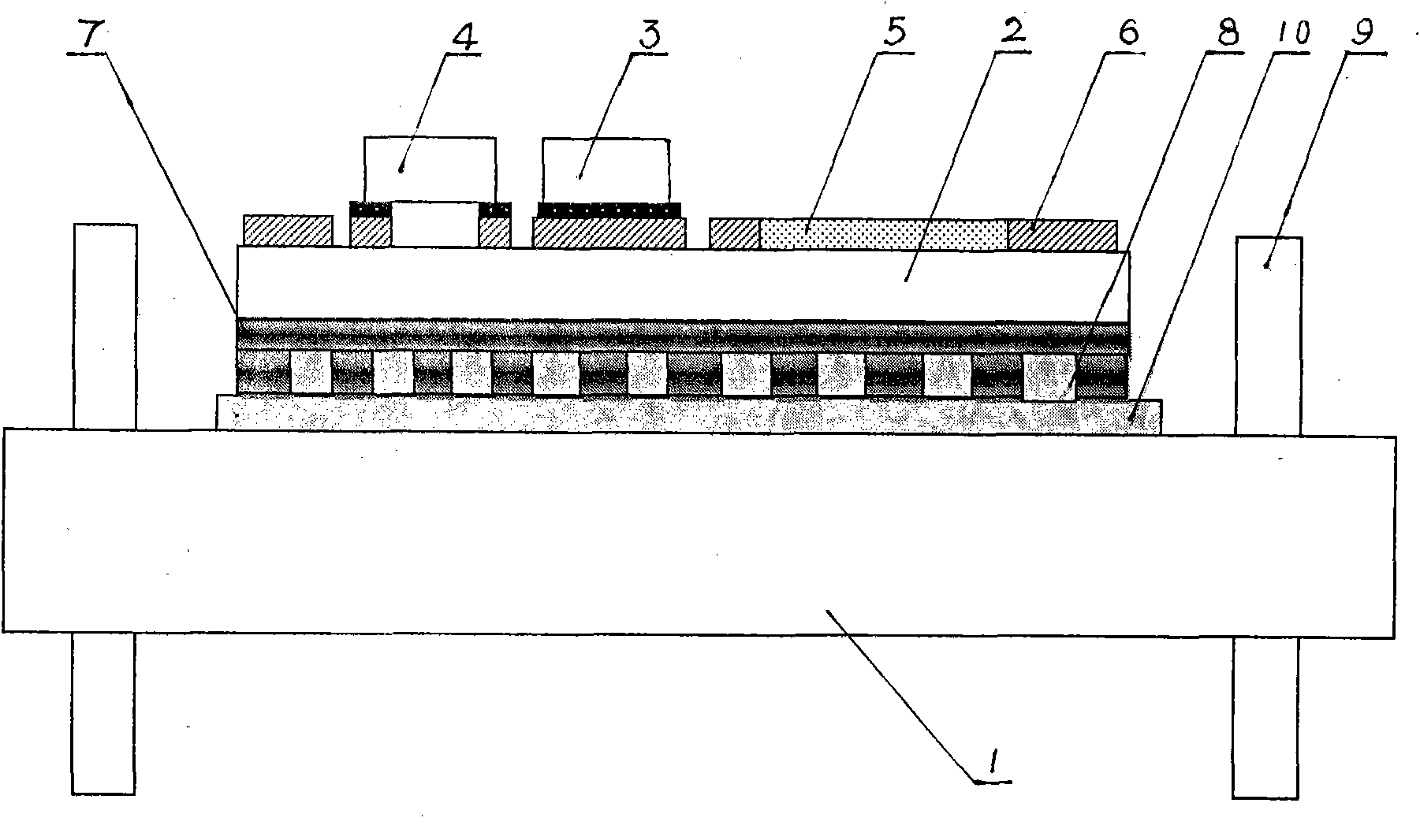

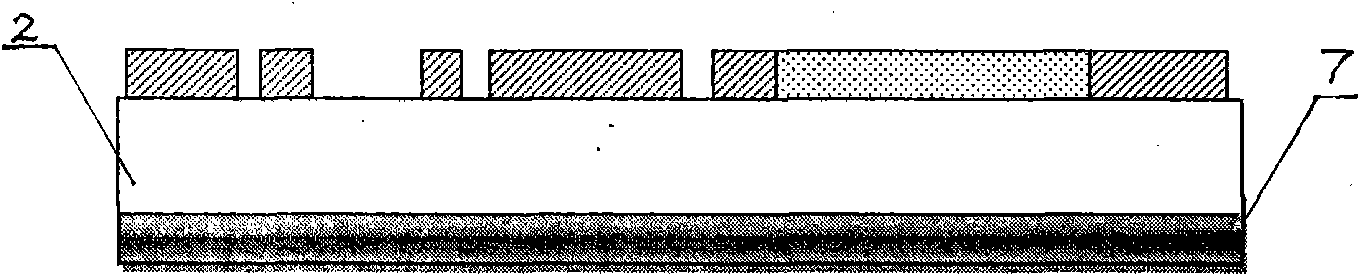

Integration method of high-reliability power hybrid integrated circuit

InactiveCN101866861AExcellent performanceGuaranteed compactnessSolid-state devicesSemiconductor/solid-state device manufacturingHybrid integrated circuitIntegrated circuit

The invention discloses an integration method of a high-reliability power hybrid integrated circuit. The method comprises the following steps of: (1) firstly, washing an original thick film substrate with ultra sound and drying; (2) forming a multilayer Cu-Ni-Cr-Au composite film at the back of a ceramic substrate in a high-vacuum magnetically-controlled sputtering platform in one step by using a high-vacuum sputtering method; (3) selectively sputtering another Cu-Ni-Cr-Au composite film again on the basis so that a multilayer metal film grooved mesh is formed in a selected region; (4) then, annealing at a high temperature to obtain a thick film substrate; and (5) assembling the thick film substrate on a shell base, assembling a semiconductor chip and other separate devices, bonding with silicon-aluminum wires to connect the circuit and seal a lid to obtain a made high-reliability power hybrid integrated circuit. The integrated circuit made by the method has favorable welding system compactness, adhesion, heat conductivity, rapid radiation and circuit reliability and is widely applied to the fields of aerospace, aviation, ships, precise instruments, geological exploration, oil exploration, communication, and the like.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

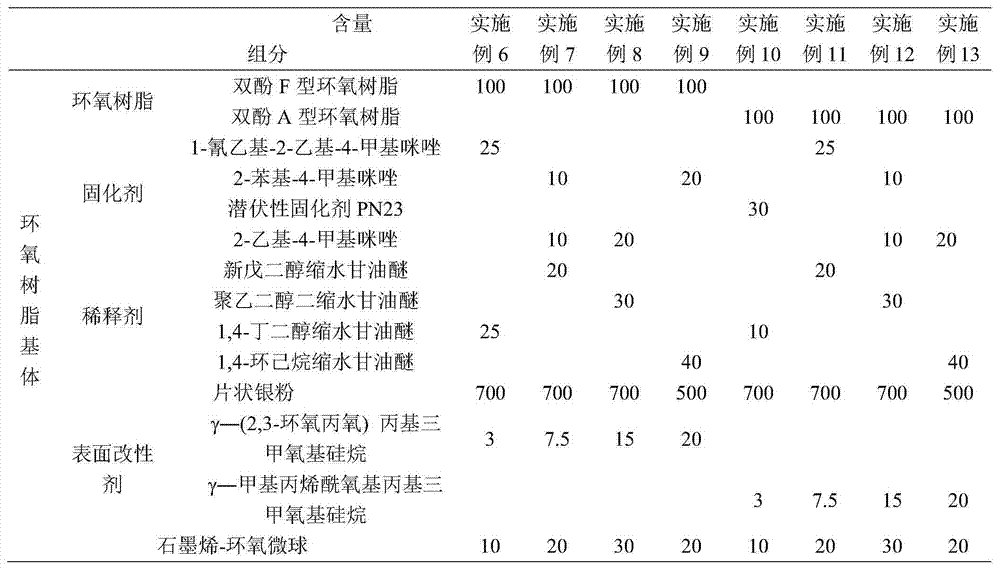

High-performance conductive silver adhesive containing graphene and preparation method thereof

ActiveCN104774573AReduce the content of organic mediaImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyResin microsphere

The invention discloses a high-performance conductive silver adhesive containing graphene. The high-performance conductive silver adhesive containing graphene comprises the following raw materials by weight: 100 parts of epoxy resin, 10 to 50 parts of a curing agent, 10 to 40 parts of an epoxy diluent, 5 to 50 parts of a graphene-epoxy microsphere, 0.5 to 5 parts of a surface modifier and 240 to 990 parts of a silver strip, wherein the graphene-epoxy microsphere is prepared from graphene oxide and an epoxy resin microsphere in a mass ratio of 1: 4-19. The invention further discloses a preparation method for the high-performance conductive silver adhesive containing graphene. The high-performance conductive silver adhesive containing graphene has the advantages of low cost and good conductive performance.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Thin continuous uniform air flowing characteristic numerical simulation method

ActiveCN107729691AGuaranteed viscous stressGuaranteed thermal conductivityDesign optimisation/simulationComplex mathematical operationsFluid fieldConstitutive equation

The invention relates to a thin continuous uniform air flowing characteristic numerical simulation method. The method comprises the following steps: introducing a spatial derivative directly associated with a conservation variable when solving a conservation equation of a nonlinear coupled constitutive model, and secondly expressing the conservation variable U and an additional variable S into linear expression of one set of primary functions so as to discretize the conservation variable U and the additional variable S; converting conservation quantity under an original unstructured grid to astandard grid, integrating on a control volume, carrying out each step of iteration to obtain initial values of viscous stress and heat conduction items of a constitutive relation equation, introducing the initial values of viscous stress and heat conduction items of the constitutive relation equation into a nonlinear algebraic constitutive equation set converted to a differential equation initialvalue problem, then carrying out iteration to obtain the viscous stress and the heat conduction items, then returning back and substituting into the conservation equation, determining that the calculation is ended after the specific problems meet the error conditions, and outputting the flowing characteristic of the flow field.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

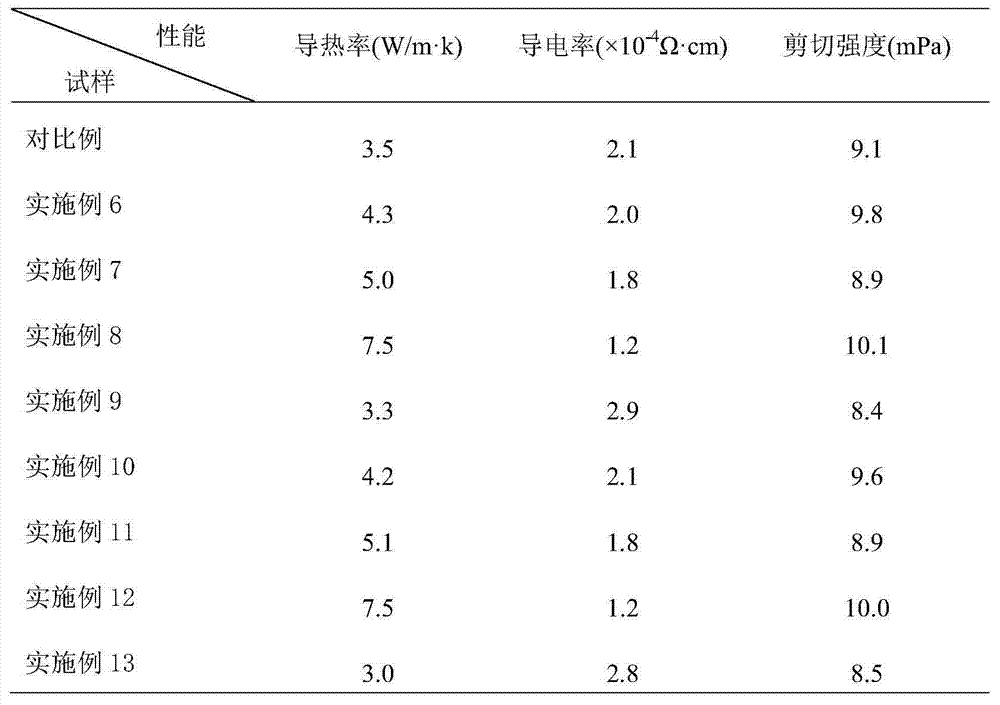

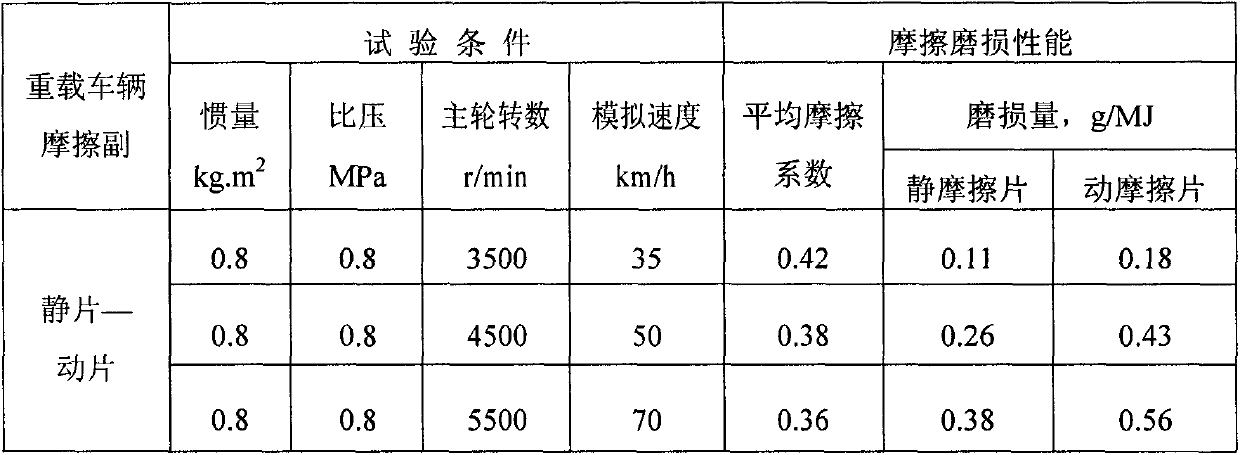

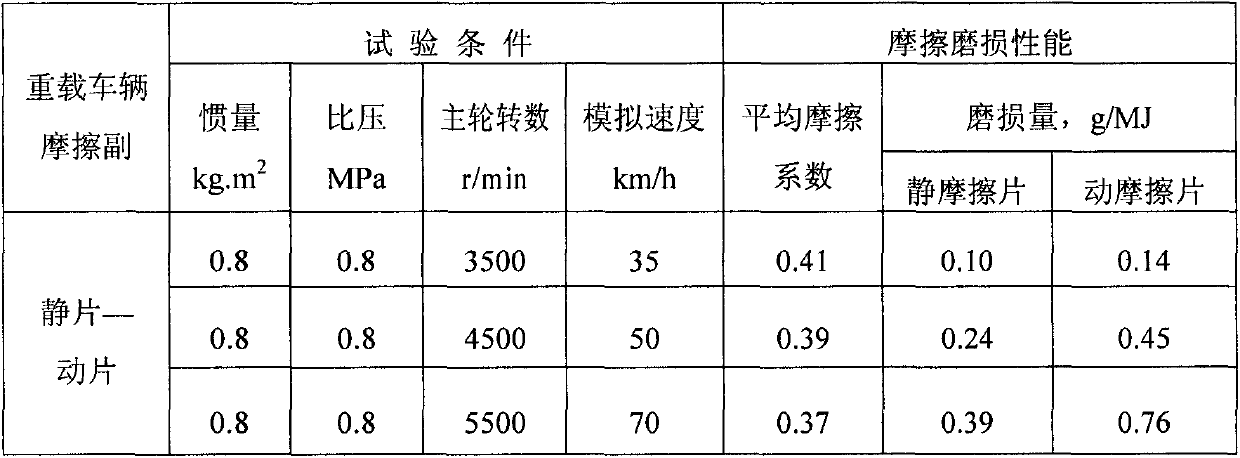

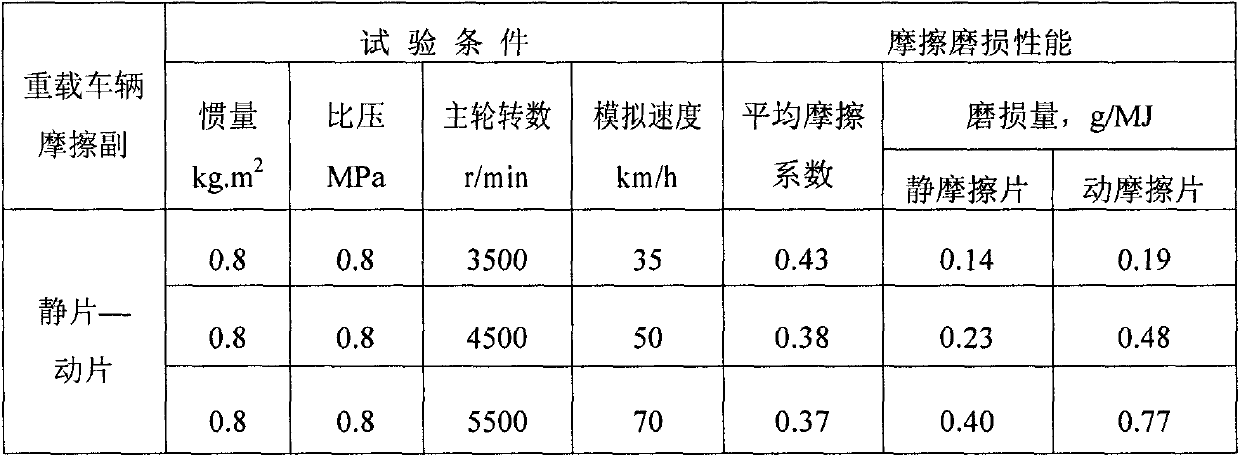

Powder metallurgy friction pair for braking of heavy-load vehicle and preparation technology thereof

ActiveCN103785824AGuaranteed uniformityGuaranteed friction and wear performanceAdditive ingredientHeat conducting

The invention relates to a powder metallurgy friction pair for braking of a heavy-load vehicle and a preparation technology thereof. A static friction piece comprises, by weight, 60-70 parts of reduced iron powder, 12-18 parts of electrolytic copper powder, 2-4 parts of molybdenum disulfide powder, 1-3 parts of ferro-manganese alloy powder, 1-3 parts of electrolytic nickel powder, 3-5 parts of silicon dioxide powder and 6-10 parts of crystalline flake graphite powder. A kinetic friction piece comprises, by weight, 14-18 parts of the reduced iron powder, 40-60 parts of the electrolytic copper powder, 2-4 parts of the molybdenum disulfide powder, 4-6 parts of tin powder, 1-3 parts of ferro-chrome alloy powder, 2-4 parts of the ferro-manganese alloy powder, 1-3 parts of the electrolytic nickel powder, 1-3 parts of chromium powder, 1-3 parts of aluminum oxide powder, 4-7 parts of the silicon dioxide powder and 10-14 parts of the crystalline flake graphite powder. The preparation technology of the powder metallurgy friction pair for braking of the heavy-load vehicle includes the steps of production, sand blasting, reshaping and electroplating of a steel backing and the steps of compounding, mixing, chemical analysis on ingredient uniformity, prepressing shaping, pressure sintering, mechanical processing, product finishing and checking of the power materials. Known from an MM1000 test that the prepared powder metallurgy friction pair for the heavy-load vehicle has the advantages of excellent frictional wear resistance, stable braking performance, low energy consumption and wear rate, good material uniformity and heat-conducting performance and long service life, and the problems of a large breaking wear rate, short service life and the like resulted from severe decline of a high-temperature friction coefficient of an existing friction pair for the heavy-load vehicle are solved.

Owner:北京优材百慕航空器材有限公司

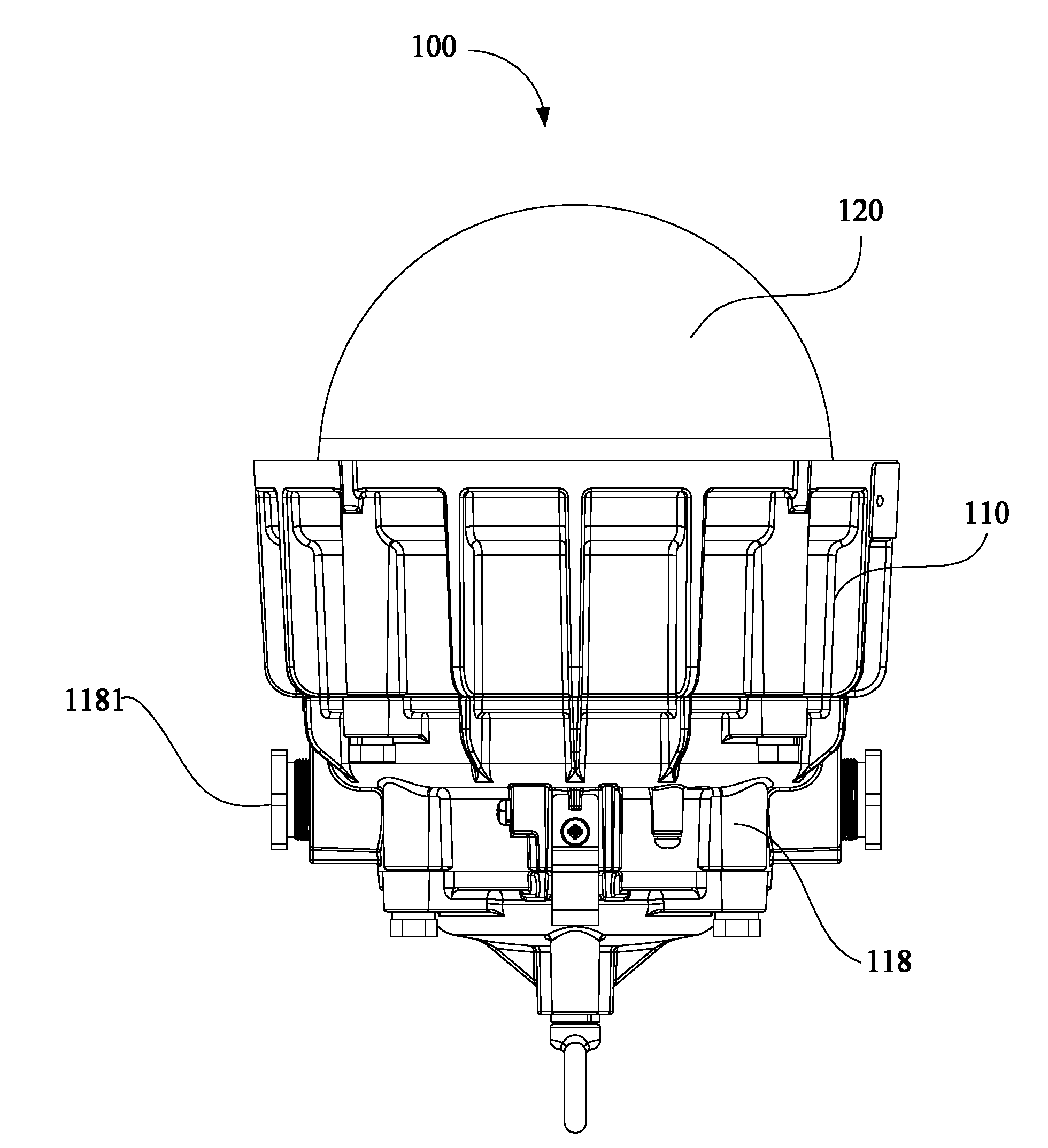

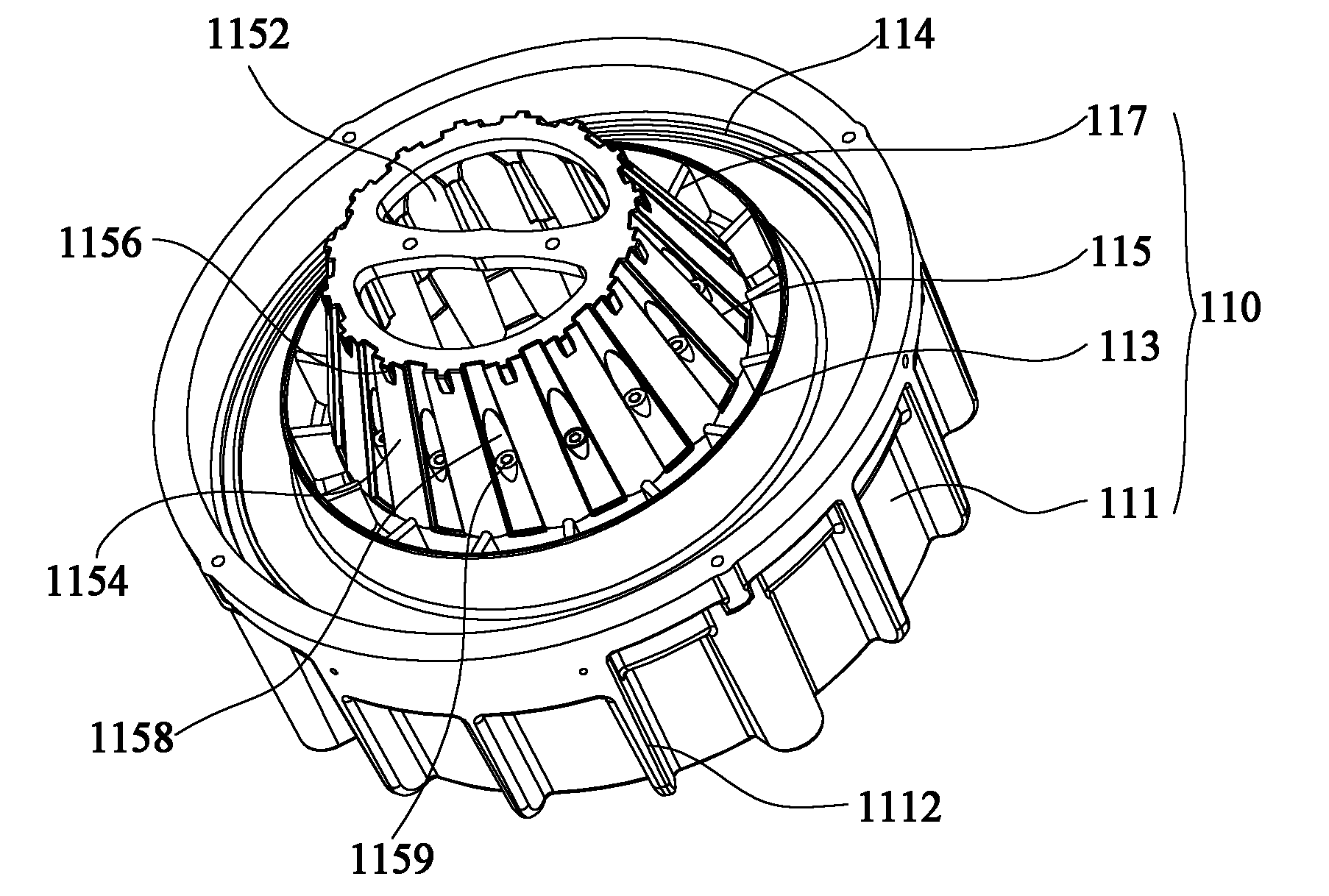

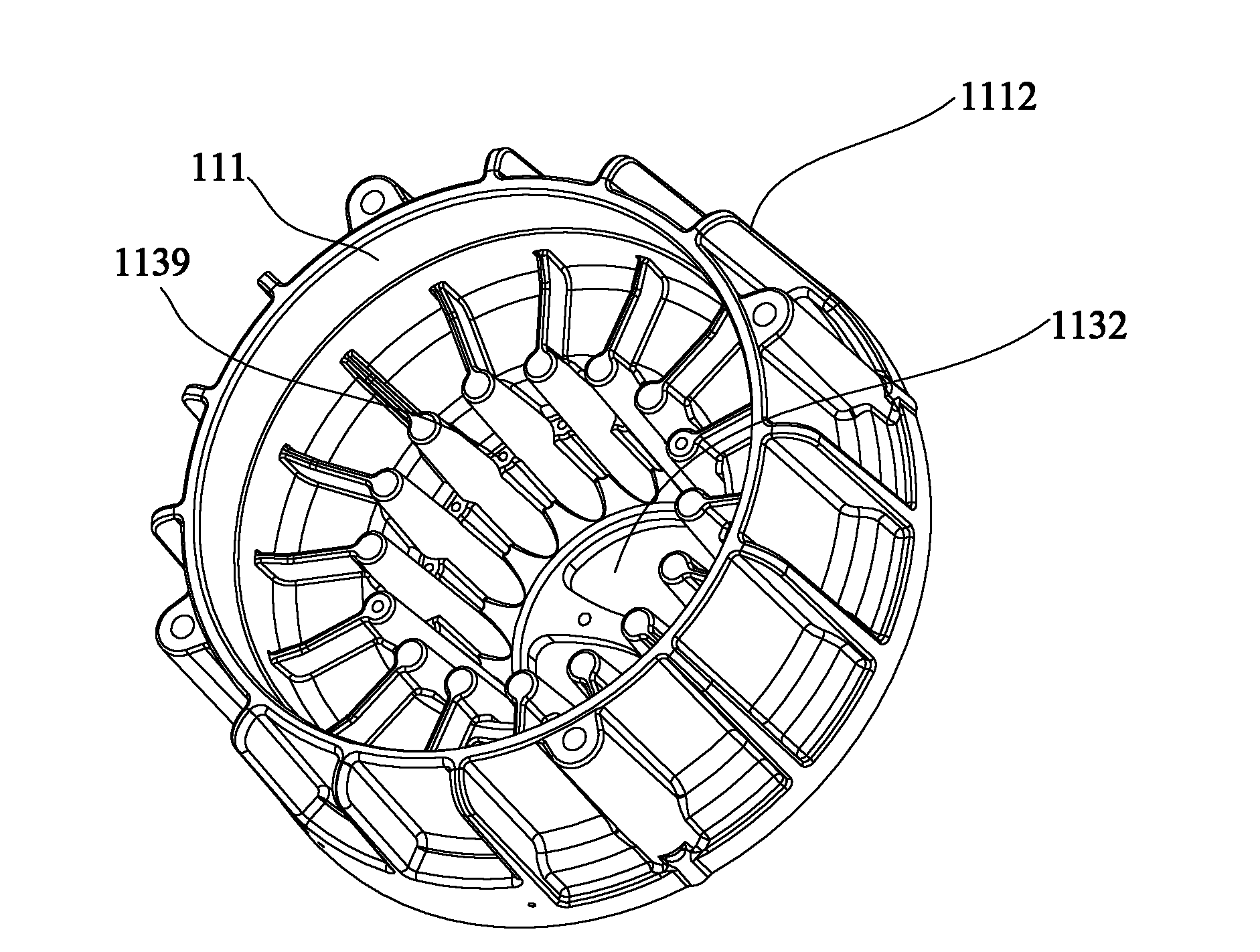

LED (Light Emitting Diode) lamp

InactiveCN102759030AImprove cooling efficiencySpeed up the flowPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses an LED (Light Emitting Diode) lamp, which comprises a lamp holder, an LED substrate and a plurality of LED light sources, wherein the LED substrate is fixedly arranged on the lamp holder; the LED light sources are fixedly arranged on the LED substrate; the lamp holder comprises an outer shell, an inner shell in the outer shell and a frustum-shaped light source mounting table of a hollow structure; the light source mounting table is provided with a large end and a small end opposite to the large end; the large end is fixedly arranged in the inner shell; the small end protrudes out of the inner shell; the outer surface of the light source mounting table is provided with a plurality of radiating columns; the LED substrate is fixedly arranged on the radiating columns; the light source mounting table of the LED lamp has the hollow structure; and the LED substrate is fixedly arranged on the radiating columns on the outer surface of the light source mounting table to increase the radiating efficiency of the LED light source.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

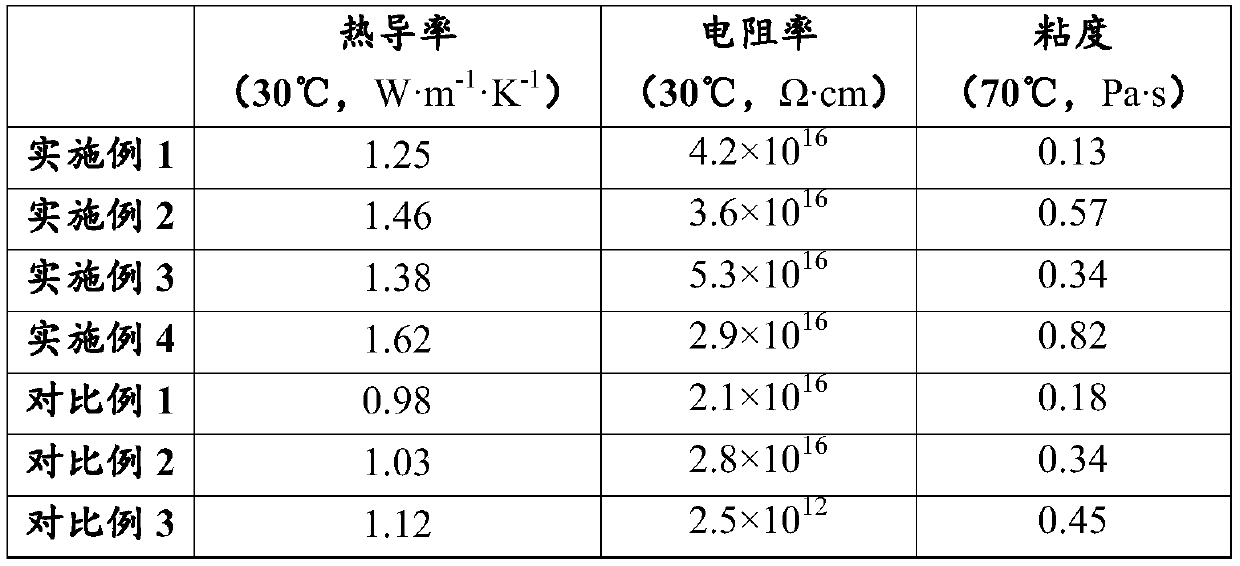

Epoxy resin thermally conductive insulating material and preparation method thereof

ActiveCN110016205AImprove thermal conductivityFunction increasePlastic/resin/waxes insulatorsHeat-exchange elementsEpoxyOmega

The invention belongs to the technical field of thermally conductive and insulating materials, and particularly relates to an epoxy resin thermally conductive insulating material and a preparation method thereof. The material includes an epoxy resin basic material, inorganic filler and a curing agent, wherein the inorganic filler is composed of fillers of three different particle sizes. The epoxyresin thermally conductive insulating material has excellent thermal conductivity and insulation performance only through selection of the ratio of three different particle size grading of the inorganic filler, the ratio of the use amount of the filler of different particle sizes and the particle sizes, and no surface-modified inorganic filler is needed, so that the material cost is reduced, and the preparation method of the material is simpler. The thermal conductivity of the material can reach 1.25 W.m<-1>.K<-1> at 30 DEG C, the highest thermal conductivity can reach 1.62 W.m<-1>.K<-1>, theresistivity of the material is 2.9x10<16> omega.cm or above below 30 DEG C, and application requirements of power electronic transformers, saturation resistors and other high insulation scenes can bemet fully.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Method for preparing polymer-based composite material with high dielectric constant

The invention discloses a method for preparing a polymer-based composite material with a high dielectric constant. The method comprises the following steps: A, co-blending solutions to prepare master batch: dissolving 100 parts by weight of polyvinylidene fluoride into N,N-dimethyl formamide to obtain a solution I; ultrasonically dispersing 10 parts by weight of boron nitride into the N,N-dimethyl formamide to obtain a solution II; dispersing 1.6-2 parts by weight of carbon nanotube into the N,N-dimethyl formamide to obtain a solution III; mixing the solution I, the solution II and the solution III, and performing ultrasonic treatment to obtain a mixed solution; heating the mixed solution to 70-100 DEG C, preserving heat for 2-4 hours, and putting the mixed solution into a vacuum oven for drying to obtain the master batch; B, melt blending: extruding and granulating the master batch in a micro-extruder at the temperature of 190 DEG C for 6-10 minutes to obtain the polymer-based composite material. The composite material prepared with the method has the advantages of extremely high dielectric constant, low dielectric loss, high heat conductivity, simple process and contribution to large-scale production.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of diamond/copper composite high in heat conduction performance

ActiveCN107916356AImprove protectionSimple separation processTransportation and packagingMetal-working apparatusPowder mixtureRoom temperature

The invention discloses a preparation method of a diamond / copper composite high in heat conduction performance. The preparation method comprises the following steps of 1, uniformly mixing diamond obtained after surface of the diamond is subjected to degreasing and roughening treatment with tungsten powder according to the mass ratio of 1: 4.5, heating a powder mixture under the vacuum condition, conducting heat preservation for 2-8 hours at the temperature of 1030 DEG C, and finally, separating out modified tungsten-plated diamond, wherein the vacuum degree is 10<-2>-10<-4> Pa, and the temperature rising rate is 5 DEG C / min; and 2, uniformly mixing the tungsten-plated diamond, with the mean particle size being 125 microns, obtained after surface modification with copper powder with the mean particle size being 45 microns with the total volume content of the tungsten-plated diamond accounting for 55%, sintering an obtained powder mixture, and then cooling the obtained power mixture to the room temperature, so that the diamond / copper composite is obtained, wherein the sintering parameters are that the pressing pressure is 40 MPa, the temperature is 1000 DEG C, the temperature risingrate is 100 DEG C / min, the sintering time is 10 minutes, and the atmosphere is vacuum.

Owner:ZHENGZHOU UNIV

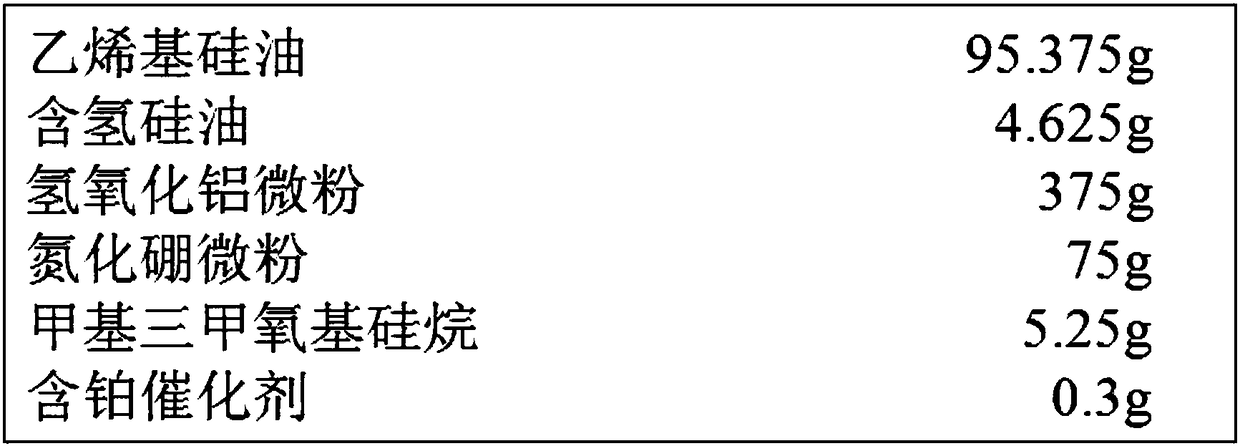

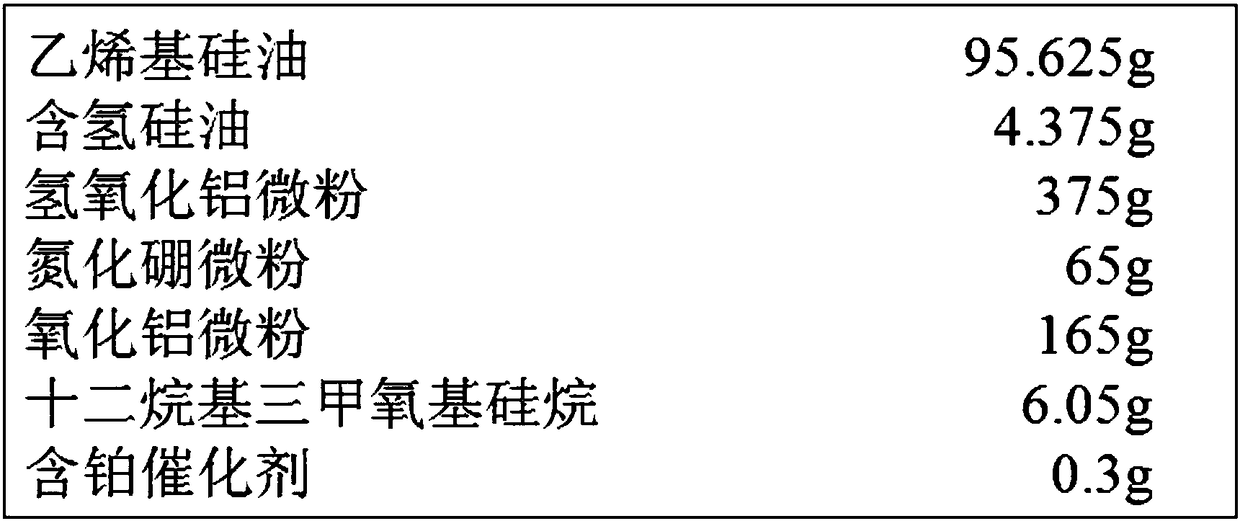

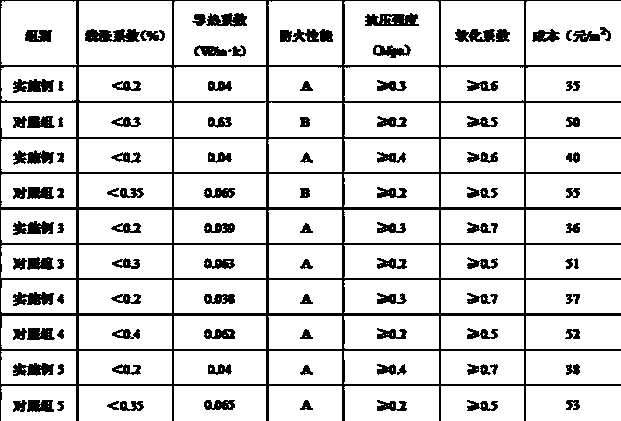

Low-specific-weight heat-conducting silica-gel gasket for new-energy vehicle and preparation method thereof

InactiveCN108440971ARegular Performance GuaranteedGuaranteed thermal conductivityHeat-exchange elementsAluminium hydroxideHeat conducting

The invention discloses a low-specific-weight heat-conducting silica-gel gasket for a new-energy vehicle. The low-specific-weight heat-conducting silica-gel gasket is prepared from the following components in parts by weight: 100 parts of organopolysiloxane, 200-2000 parts of high-heat-conductivity inorganic filler, 0-50 parts of lightweight filler, 0.05-0.5 part of catalyst and pigment, wherein the organopolysiloxane is a composition of vinyl polysiloxane and hydrogen-containing polysiloxane; the high-heat-conductivity inorganic filler is prepared from one or more of silicon dioxide, aluminium oxide, zinc oxide, magnesium oxide, aluminium hydroxide, aluminium nitride, silicon nitride, boron nitride and silicon carbonate; the particle size of the high-heat-conductivity inorganic filler is0.1-100mu m. The low-specific-weight heat-conducting silica-gel gasket disclosed by the invention has the beneficial effects that the conventional performances of the heat-conducting silica-gel gasketcan be ensured, meanwhile the low specific weight of the heat-conducting silica-gel gasket is realized, the weight of the low-specific-weight heat-conducting silica-gel gasket under the equal heat-conductivity coefficient is 40%-70% of that of the conventional heat-conducting gasket in the prior art, and the lightweight requirement for the new-energy vehicle is met.

Owner:苏州佰旻电子材料科技有限公司

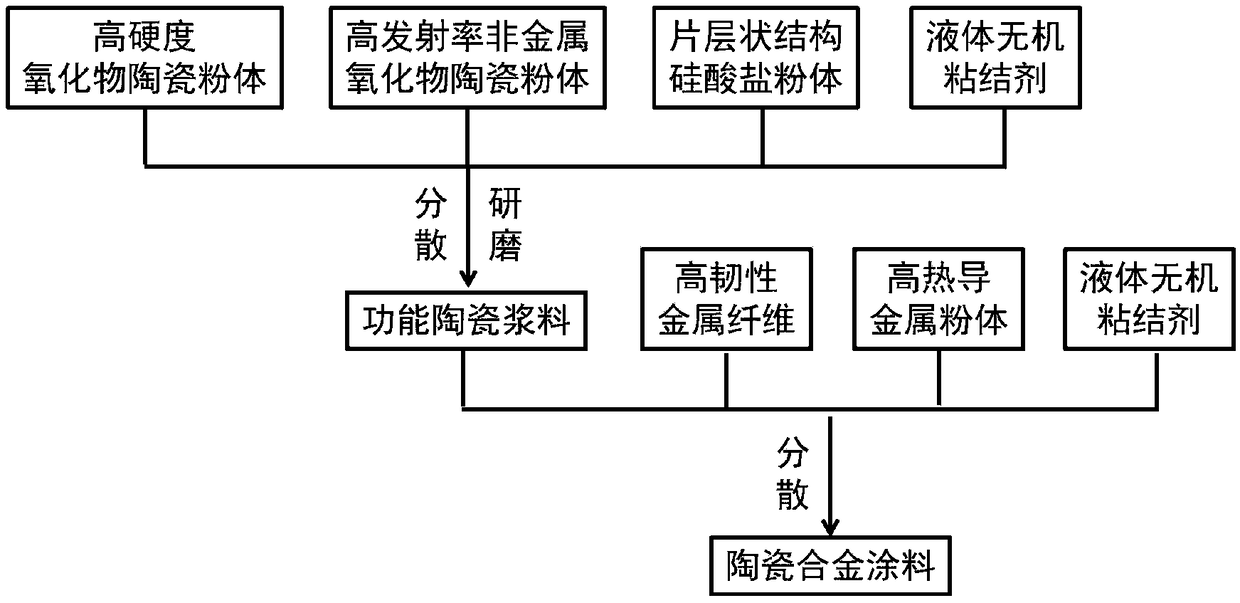

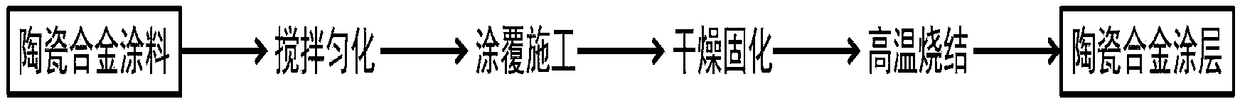

Ceramic alloy coating and coating layer

The invention discloses a ceramic alloy coating and a coating layer, wherein the coating includes a ceramic solid phase component, a metal solid phase component and a liquid phase component; the ceramic alloy coating is characterized in that the ceramic solid phase component includes high-hardness oxide ceramic powder, high-emissivity non-metallic oxide ceramic powder and lamellar structural silicate powder; the metal solid phase component includes high-toughness metal fibers and high-thermal-conductivity metal powder; the liquid phase component is one of a liquid silicate inorganic binder, aliquid phosphate inorganic binder and a liquid sol inorganic binder, the strength and toughness of the ceramic coating layer can be effectively improved. Moreover, the preparation method is simple andis prone to promotion and application.

Owner:深圳陶金材料科技有限公司

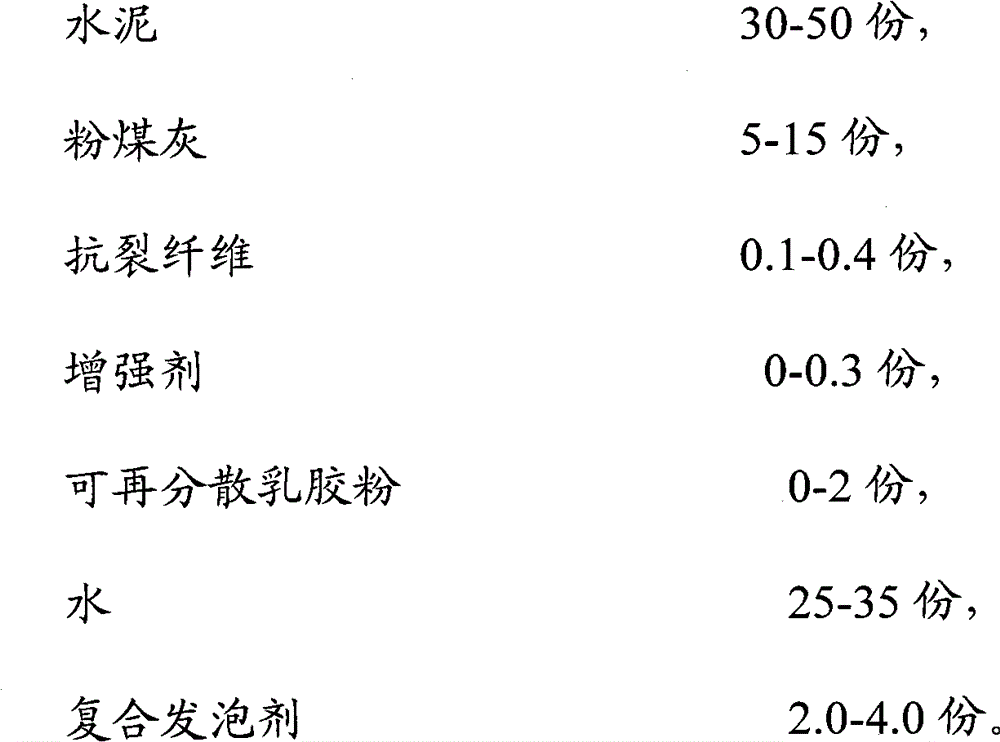

High performance polymer foaming cement thermal insulation material and preparation method thereof

The present invention discloses a high performance polymer foaming cement thermal insulation material, which comprises, by weight, 30-50 parts of cement, 5-15 parts of fly ash, 0.1-0.4 part of anti-cracking fiber, 0-0.3 part of a reinforcing agent, 0-2 parts of redispersible latex powder or an emulsion, 25-35 parts of water, and 2.0-4.0 parts of a composite foaming agent. The preparation method comprises: weighing various components; adding the water, the anti-cracking fiber and the reinforcing agent; stirring for 1-2 minutes; then adding the fly ash and the cement, and stirring for 2-3 minutes; then adding the composite foaming agent, and stirring for 10-20 seconds; placing the resulting slurry in a mold, standing for 2-3 hours, and then carrying out demolding; and cutting after 24 hours, then packaging, and carrying out concrete curing until the curing time is 28 days. The foaming cement thermal insulation material of the present invention is a lightweight material with a fire-protection rating of class A, has characteristics of thermal insulation, durability, heat insulation, sound insulation and environment protection, and is used for building interior and exterior insulation materials, fire barriers, roofing thermal insulation materials, and the like.

Owner:JIANGSU NIGAO SCI & TECH +1

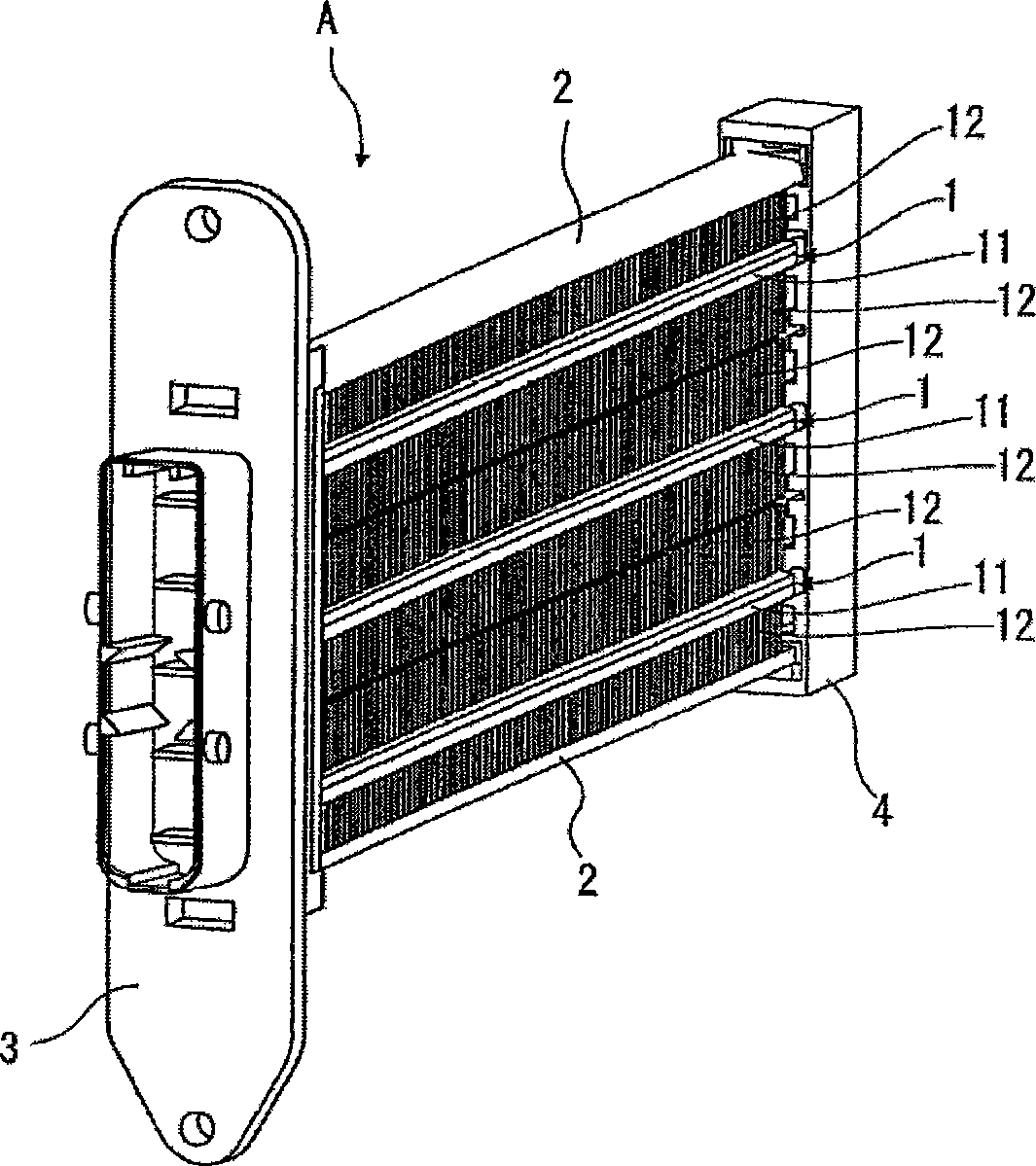

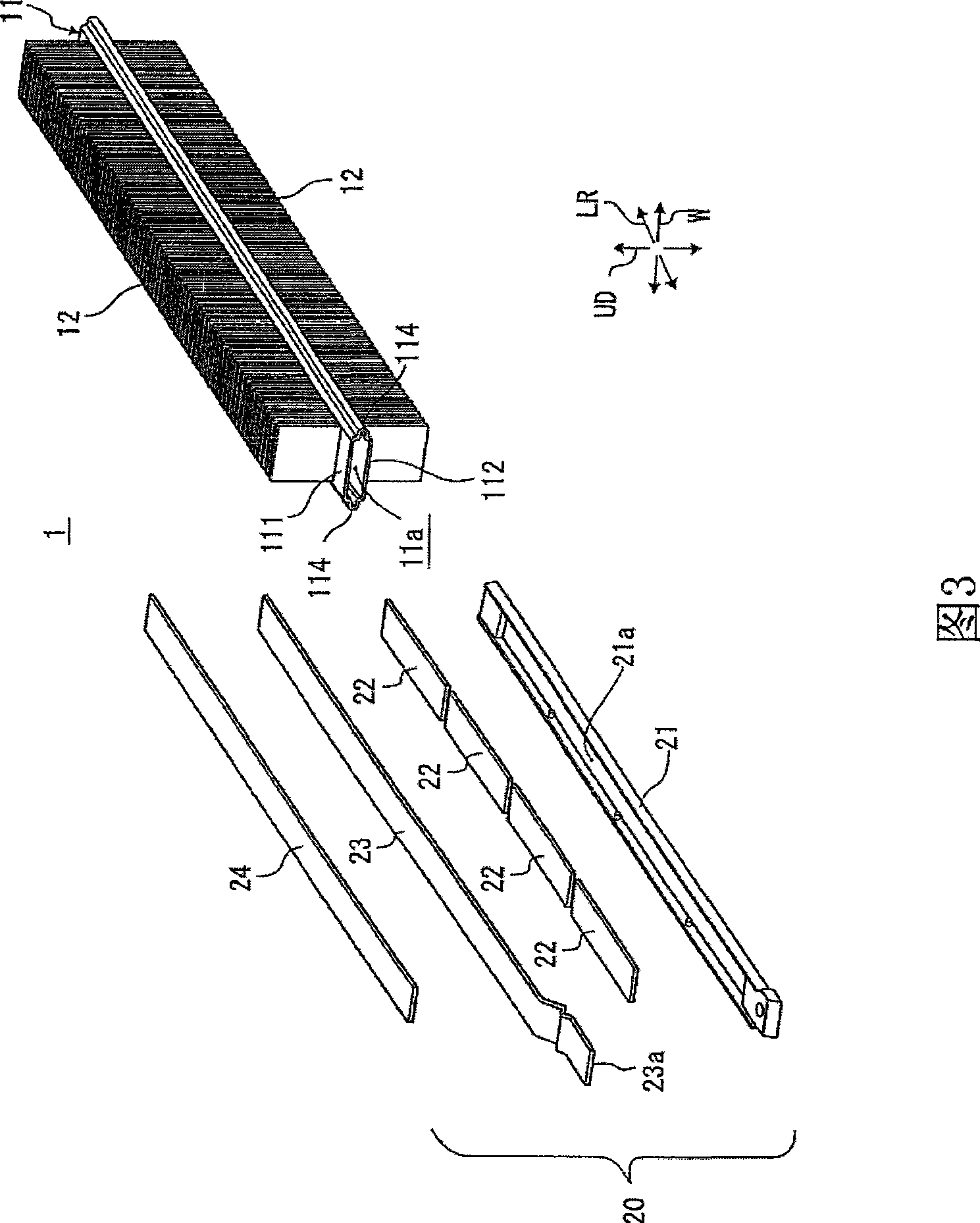

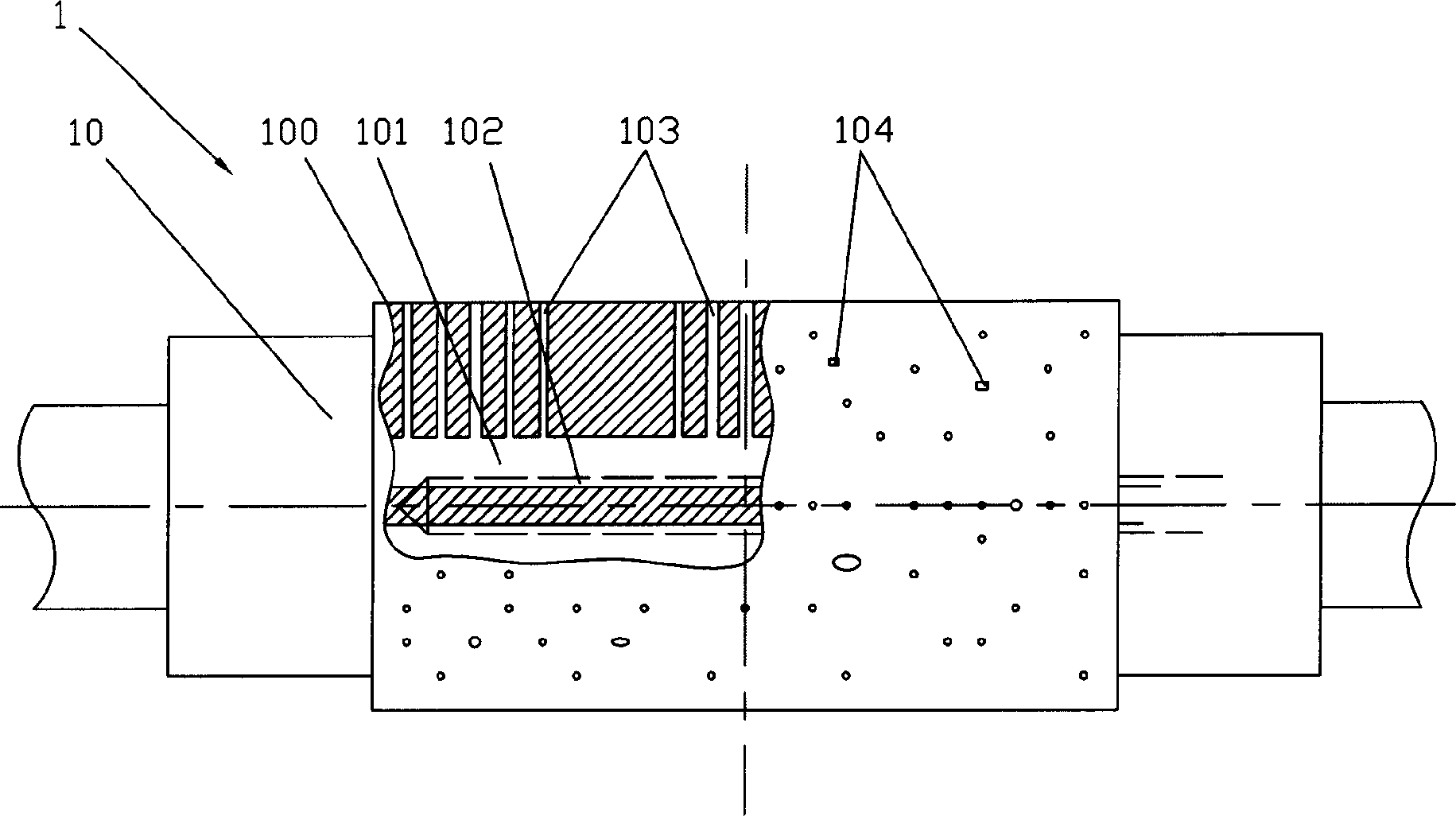

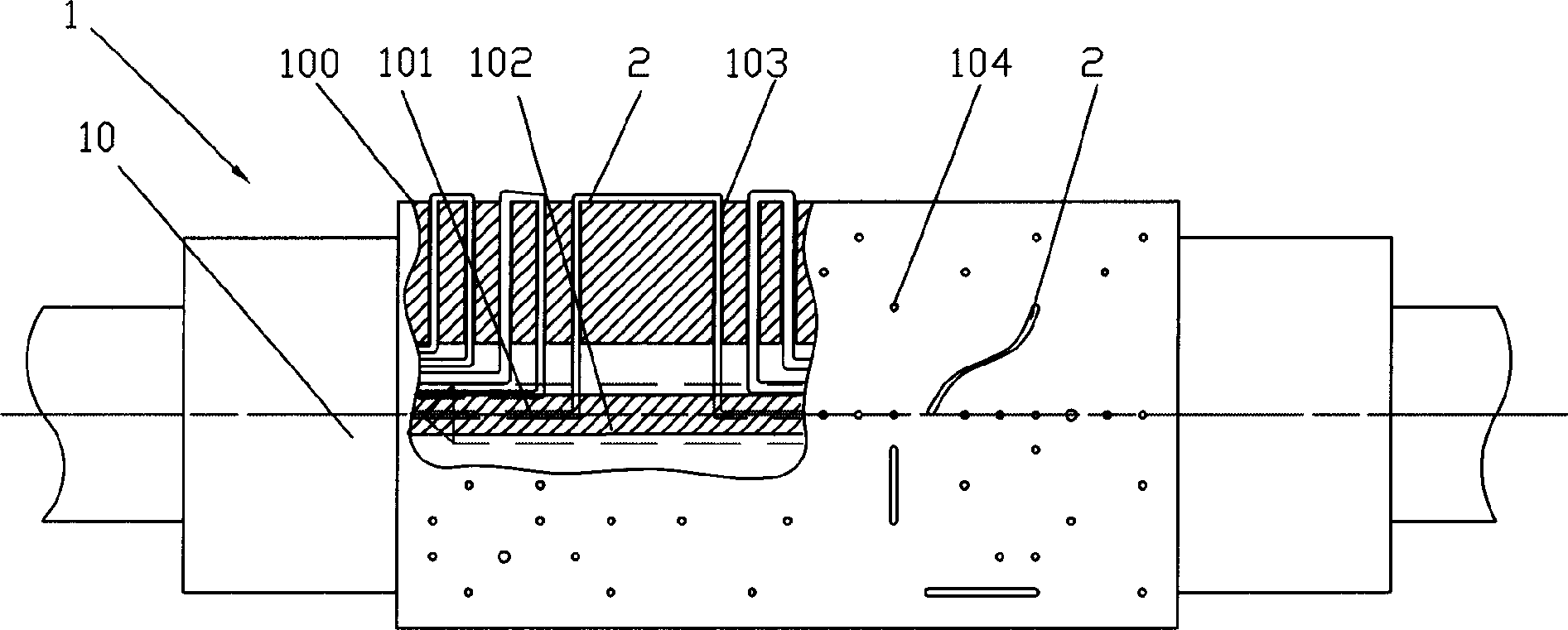

Electrical heating apparatus, method of manufacturing heat generator unit and pressing jig

InactiveCN101420798AImprove heating effectGuaranteed contact pressureAir-treating devicesAir heatersHeat sinkElectric heating

An electrical heating apparatus has: a fin brazed on at least one of a main body upper wall and a main body lower wall of a tube; an insertion unit having an electro-heat-generating element pressure-welded to a wall of one of the main body upper wall and the main body lower wall; and an edge part projected in the width direction from each of main body vertical walls to form an edge space. The edge space is formed so as to be continuous with the insertion space and is smaller in thickness dimension than the thickness dimension of the insertion unit.

Owner:CALSONIC KANSEI CORP

Copper-based bonding lead and production process thereof

InactiveCN106252319AGood mechanical propertiesSmall diameterSemiconductor/solid-state device detailsSolid-state devicesYttriumOxidation resistant

The invention relates to a copper-based bonding lead and a production process thereof. In the copper-based bonding lead, high-purity copper-based alloy is used as a substrate, a surface of the substrate is plated with a high-purity palladium protection layer, and the substrate material comprises microelements such as silver, indium, phosphorus and yttrium. The preparation comprises the following steps of high-purity copper smelting, single-crystal copper-based alloy casting, rough pulling, medium pulling, palladium plating, fine pulling, slight pulling, cleaning and passivation, compound winding and packaging. The prepared copper-based bonding lead has excellent performance such as mechanical property, welding performance, electrical conductivity, heat conductivity and oxidation resistance, and meanwhile, the copper-based bonding lead is small in wire diameter and is suitably used for package of a high-density and multi-pin integrated circuit.

Owner:佛山市南海松岗新亚太铜业有限公司

Mortar-coated heat-preserving plate

ActiveCN104060710ABreakage rateReduce breakage rateClimate change adaptationInsulation improvementBruciteChemical stability

The invention discloses a mortar-coated heat-preserving plate which comprises a base plate. Glass fiber cloth layers are attached to the upper end face and / or the lower end face of the base plate. Mortar layers are arranged on the glass fiber layers on the upper end face and / or the lower end face in a coated mode, mortar comprises 33-37 parts of silicate cement, 6-7 parts of brucite fibers, 23-27 parts of expanded perlite, 0.3 part of hydroxypropyl methylcellulose, 0.1 part of polypropylene fibers, 0.5 part of calcium stearate, 17-26 parts of modified aerogel particles and 0.3-0.6 part of a promoter. The modified aerogel particles are prepared due to the fact that a surface modifier is sprayed on the surfaces of aerogel particles for surface modification. The heat-preserving mortar is made of inorganic materials, is resistant to acid, alkali and corrosion, does not crack or disengage, is high in stability, is identical to a building wall in service life, and has excellent temperature stability and chemical stability. Surface modification is carried out on the aerogel particles, so that the physical property that the aerogel particles are easy to break and can be easily combined with water is overcome, the heat conductivity of the surface-modified aerogel heat-preserving mortar reaches below 0.04W / m.K, and the heat-preserving effect of the heat-preserving mortar is improved.

Owner:江苏圣奎节能科技有限公司

Solar heat collecting and storing aluminum foil and manufacturing method thereof

ActiveCN104357722AGuaranteed mechanical propertiesGuaranteed corrosion resistanceSolar heating energyAbsorbing elementsEtchingCopper oxide

The invention relates to a solar heat collecting and storing aluminum foil and a manufacturing method thereof. The solar heat collecting and storing aluminum foil comprises the following chemical components in percentage by mass: 0.01-0.07% of Si, 0.01-0.12% of Fe, 0.08-0.12% of Cu, smaller than or equal to 0.005% of Mn, smaller than or equal to 0.005% of Zn, smaller than or equal to 0.005% of Mg, 0.01-0.03% of Ti and the balance of Al and inevitable impurities. The aluminum foil has a thickness ranging from 0.043 to 0.045mm, the tensile strength of 250-280MPa, the yield strength of 235-265MPa, the elongation greater than or equal to 1%, and the thermal conductivity greater than or equal to 225W / (m.K) at 25 DEG C. Through reasonable setting of contents of copper and other alloy elements in the aluminum foil, a black copper oxide film layer with a strong surface colorizing capability is formed during surface chemical etching of the aluminum foil, so that the aluminum foil increases the solar energy absorbing rate and decreases the reflection coefficient.

Owner:江阴新仁铝箔科技有限公司

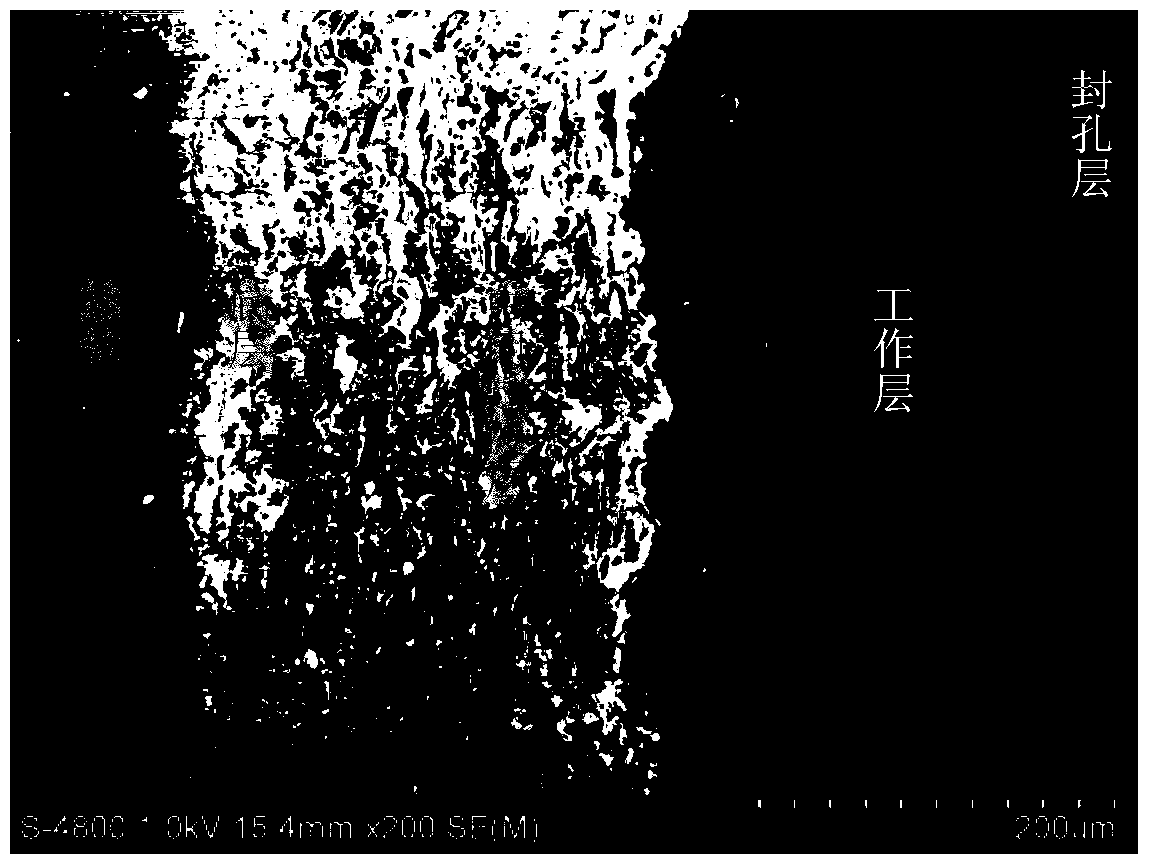

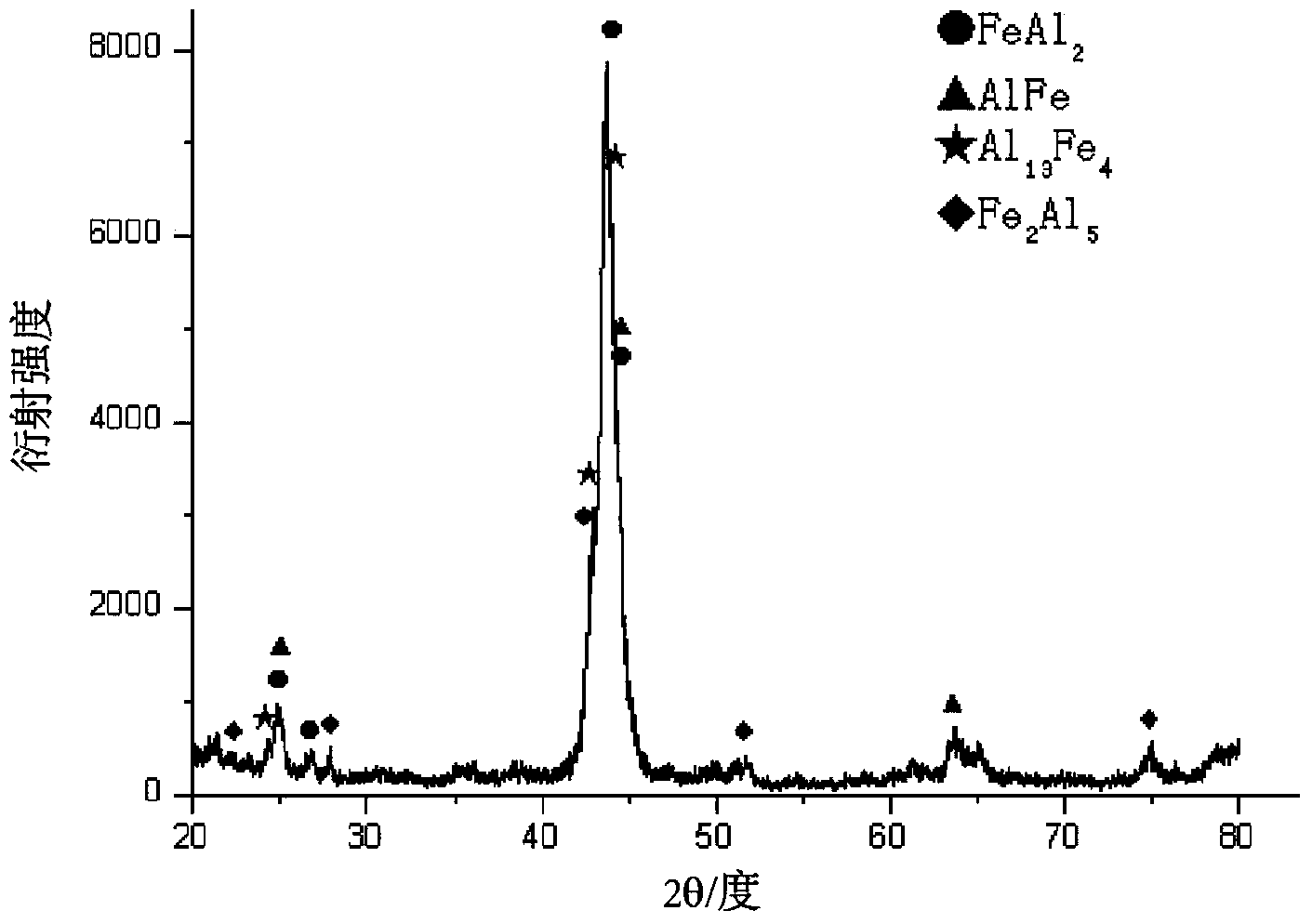

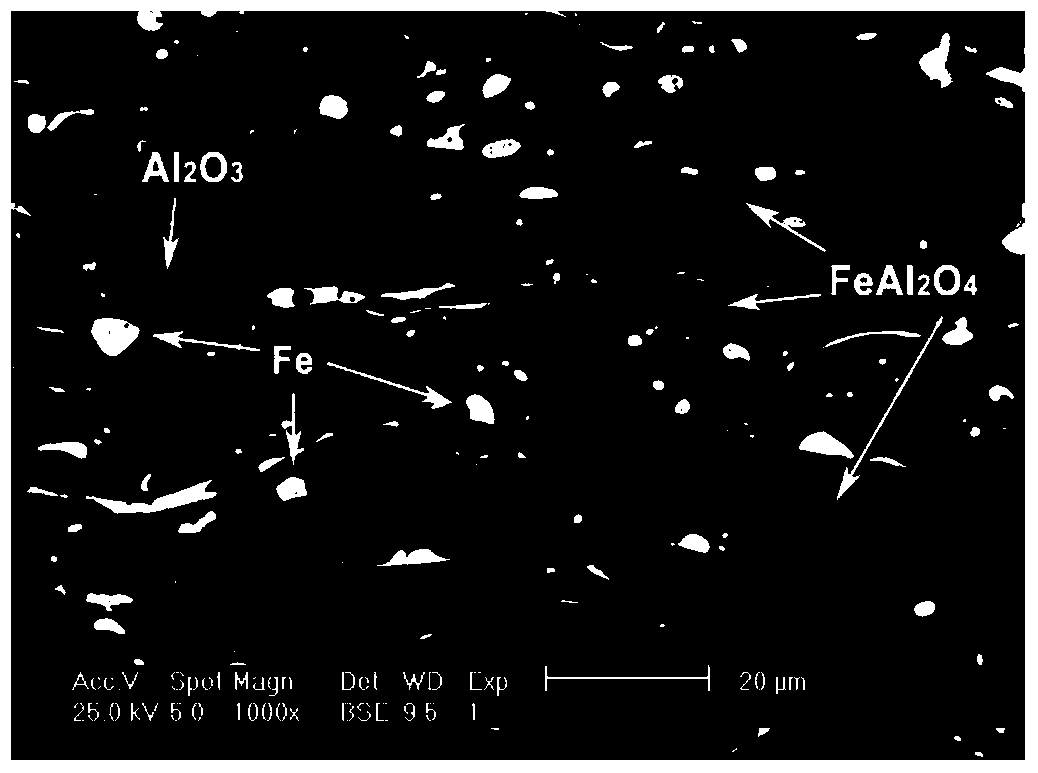

Multilayer composite ceramic coating used for hot-dip zinc galvanization, and preparation method of the multilayer composite ceramic coating

InactiveCN103522653AGood resistance to liquid zinc corrosionResistant to liquid zinc corrosionMolten spray coatingMetal layered productsOxide ceramicComposite ceramic

The invention discloses a multilayer composite ceramic coating used for hot-dip zinc galvanization, and a preparation method of the multilayer composite ceramic coating, and relates to plating of metal materials. A base material of the multilayer composite ceramic coating is plain carbon steel containing 0.05-0.22 wt% of carbon. A nano crystal self-fluxing alloy layer of Fe-Al, Ni-Al, CoCrArAlY or NiCrAlY is used as a bottom player. A ceramic-based nano ceramic-metal complex phase layer synthesized by an aluminothermy self-reaction of Al-Fe2O3 or Al-Cr2O3 is used as a middle transition player. An oxide ceramic layer, holes of which are sealed by ceramic-glass, of ZrO2, Al2O3, Cr2O3 or Al2O3-ZrO2 is used as a working player. Accordingly, the multilayer composite ceramic coating used for the hot-dip zinc galvanization, which has a microcrystalline-nanocrystalline-amorphous crystalline multilevel structure, is prepared. The preparation method includes painting the prepared raw materials in order by using a plasma spraying method. The multilayer composite ceramic coating and the preparation method overcome disadvantages of poor corrosion resistance to liquid zinc, poor mechanical performances, poor thermal conductivity or short service lifetime of materials at present.

Owner:天津市卧龙冶金设备有限公司

Alloy gray cast iron glass mould and method for producing same

ActiveCN102828103BGuaranteed thermal conductivityGuaranteed insulation effectThermal dilatationPhosphate

An alloy gray cast iron glass mould and a method for producing the same belong to the technical field of glass mould materials. The alloy gray cast iron glass mould consists of the following chemical elements by mass percent: 3.35-3.55% of carbon, 1.8-2.1% of silicon, 0.5-0.7% of manganese, 0.4-0.8% of molybdenum, 0.1-0.16% of vanadium, 0.15-0.25% of titanium, 0.3-0.6% of chromium, 0.01-0.02% of sulfur, 0.03-0.04% of phosphate and the balance of iron. The alloy gray cast iron glass mould has the advantages that the mould can have good anti-oxidation performance, thermal fatigue resistance, growing resistance, thermal conductivity and low thermal expansion performance; and the reaction time of carbide forming elements and pearlite stable elements with molten iron can be obviously shortened, generation of primary carbide and pearlite can be effectively inhibited, the temperature of molten iron to be poured into a casting ladle is controlled, not only can the molten iron be thermally insulated at the discharging temperature, but also the impurities in the molten iron can be purified, and the purity of the molten iron is improved.

Owner:ORI MOLD TECH SUZHOU

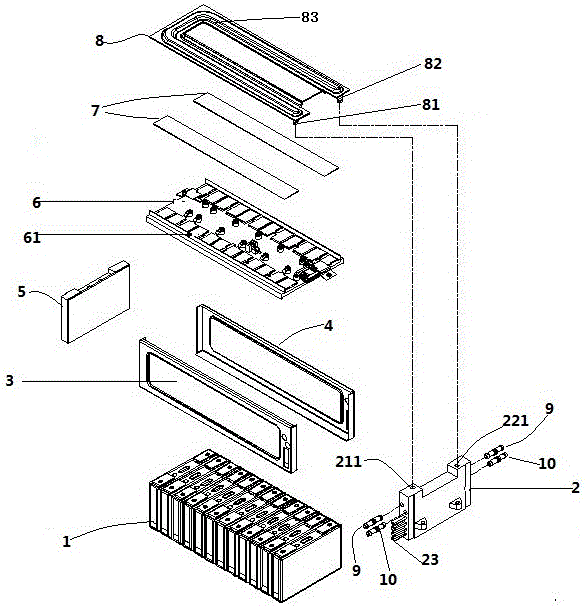

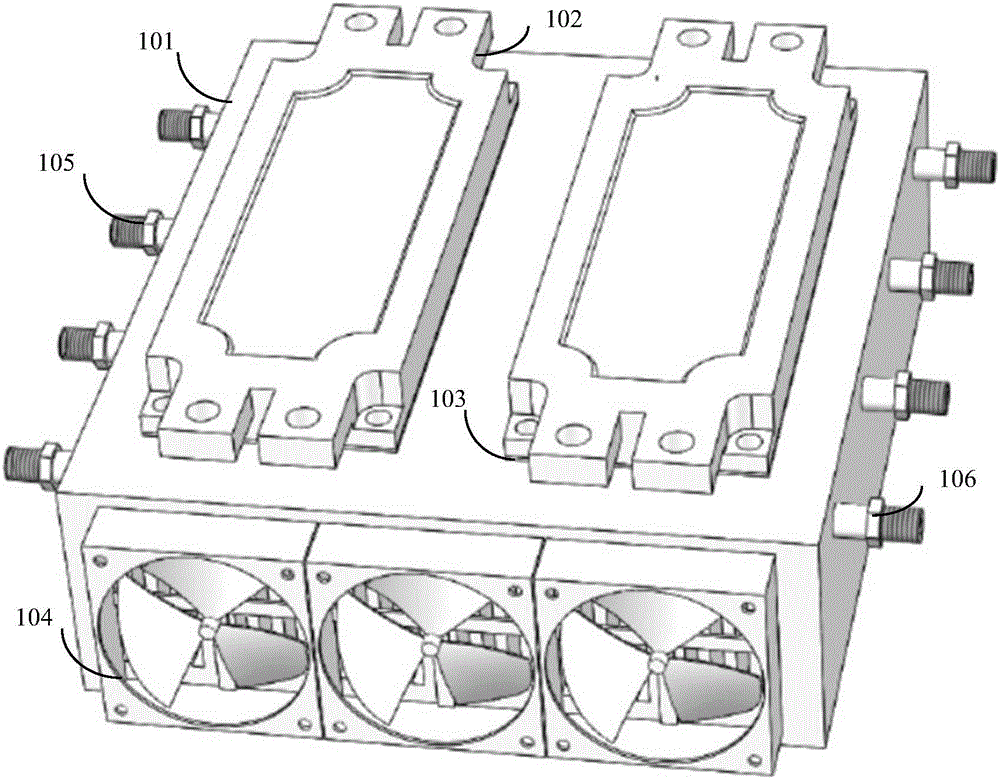

Battery module with water-cooling heat dissipation for tabs

The invention provides a battery module with water-cooling heat dissipation for tabs. The battery module comprises a plurality of battery module units, wherein each battery module unit comprises a battery core group consisting of a plurality of battery cores, a front end plate arranged at the front side of the battery core group, a left side plate and a right side plate respectively arranged at the left side and right side of the battery core group, a rear end plate arranged at the rear side of the battery core group, a bracket arranged above the battery core group, and heat-dissipating fins and a water-cooling plate close to the bracket, wherein the bracket is provided with tabs which are arranged at the left side and right side of the bracket; the water-cooling plate is provided with a water feeding pipe, a water discharging pipe and a water-cooling pipeline, and the water-cooling pipeline is wholly U-shaped; the front end plate is provided with a water feeding pipeline, a water discharging pipeline, a positioning pin and a positioning groove, and a vertical water inlet connected with the water feeding pipe is formed in the water feeding pipe and above the front end plate; and a vertical water outlet connected with the water discharging pipe is formed in the water discharging pipe and above the front end plate. Different battery module units are connected and fixed by the positioning pin and the positioning groove. The battery module provided by the invention has the advantages that the heat-dissipating fins and the water-cooling plate are arranged above the tabs generating maximum heat, and the front end plate is provided with the water feeding pipeline and the water discharging pipeline communicated with the water-cooling plate, so that the heat-dissipation efficiency is high, the assembly is simple and the appearance is clean and tidy.

Owner:HUIZHOU EPOWER ELECTRONICS

Aluminum base carbon fiber graphite composite material and preparation method

The invention relates to an aluminum base composite material, in particular to an aluminum base carbon fiber graphite composite material and a preparation method. The method comprises the following steps of: firstly, adopting finely sorted, processed and checked graphite fluoride powder as raw materials for preparing spherical graphite particles through granulation and spheroidization; then, using a stainless steel plate as a cathode and pure aluminum as an anode, filling insert gas between the two electrodes, exerting voltage, soaking the spherical graphite particles by glucose amide containing 0.23 to 0.6 percent of boron, cleaning and baking the spherical graphite particles, placing the spherical graphite particles on a disc between the cathode and the anode, shaking the disc while exerting the voltage, and arranging latticed high-performance carbon fiber in a casting mold at the arrangement density determined according to the intensity requirement of the materials; filling the spherical graphite particles with the diameter between 1 and 5mm in the casting mold, finally, injecting aluminum liquid, applying pressure at the upper part of the mold so that the aluminum liquid can be filled between the spherical graphite particles, and obtaining products after cooling. The composite material is simple to prepare, and has the advantages of high product intensity, light weight, wear resistance, low raw material consumption and high production efficiency.

Owner:蔡乐勤

Aluminium foil produced by utilization of cast-rolled slabs and used for dynamic functional materials and preparing method thereof

ActiveCN104611616AReduce precipitationUniform grainElectrode carriers/collectorsSurface cleaningSurface roughness

The invention discloses aluminium foil produced by utilization of cast-rolled slabs and used for dynamic functional materials. The aluminium foil comprises following chemical components: more than 99.30% of Al, 0.30-0.5% of Fe, 0.05-0.2% of Si, 0.045-0.1% of Cu, 0.015-0.025% of Ti and 0.006-0.015% of Sr, with the balance being impurities, and the sum of mass percentages of the Al, the Fe, the Si, the Cu, the Ti, the Sr and the impurities being 100%. A preparing method of the aluminium foil is also disclosed. The aluminium foil prepared by the method has advantages of strength, high elongation percentages, good compactness, uniform surface roughness and high surface cleanliness.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

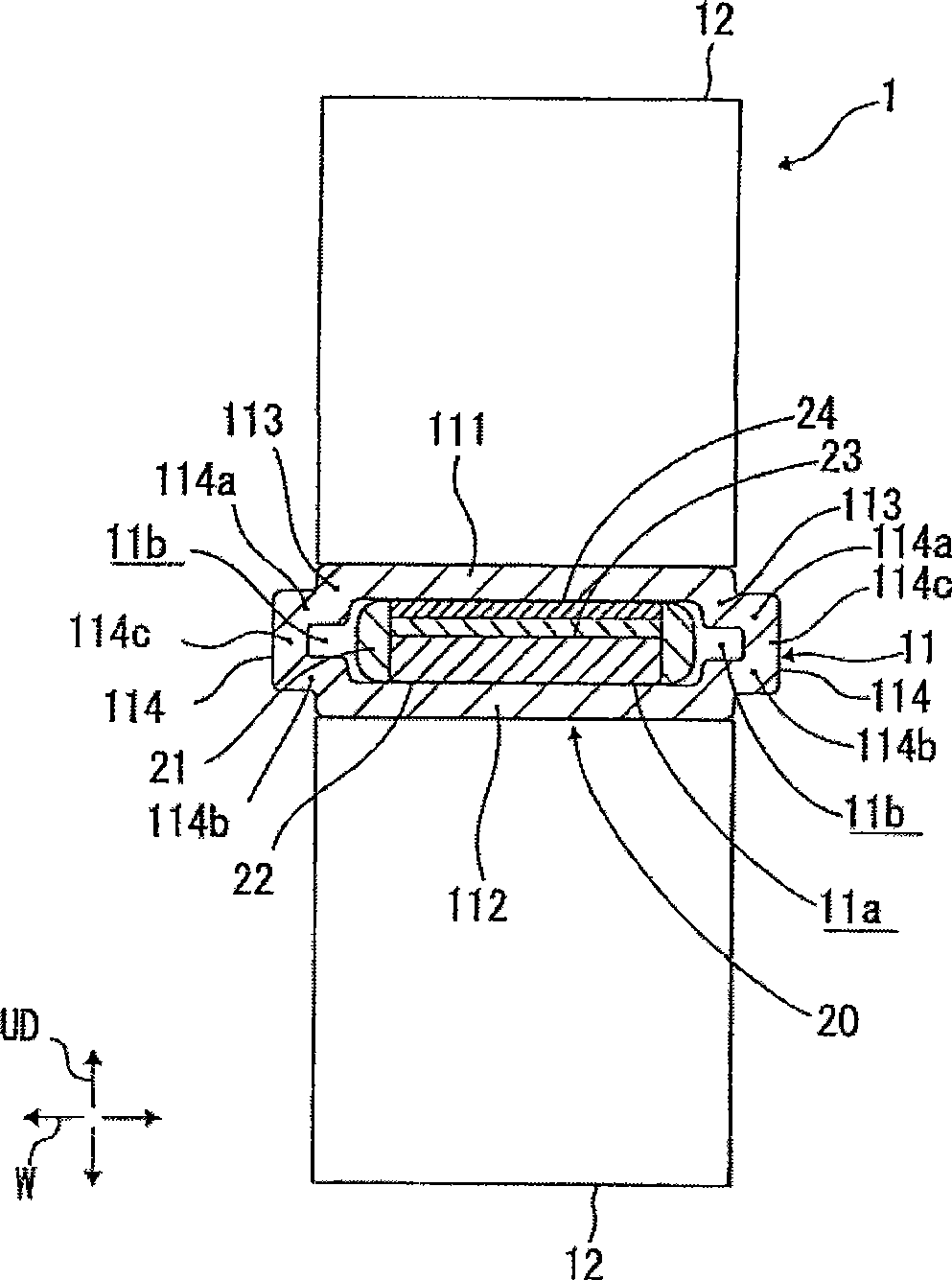

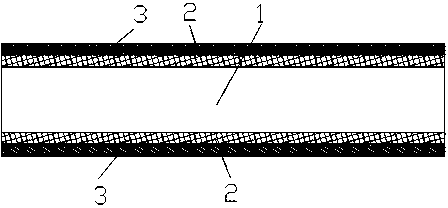

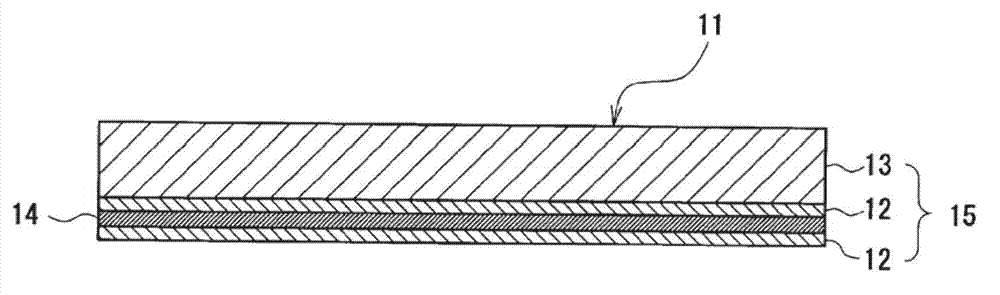

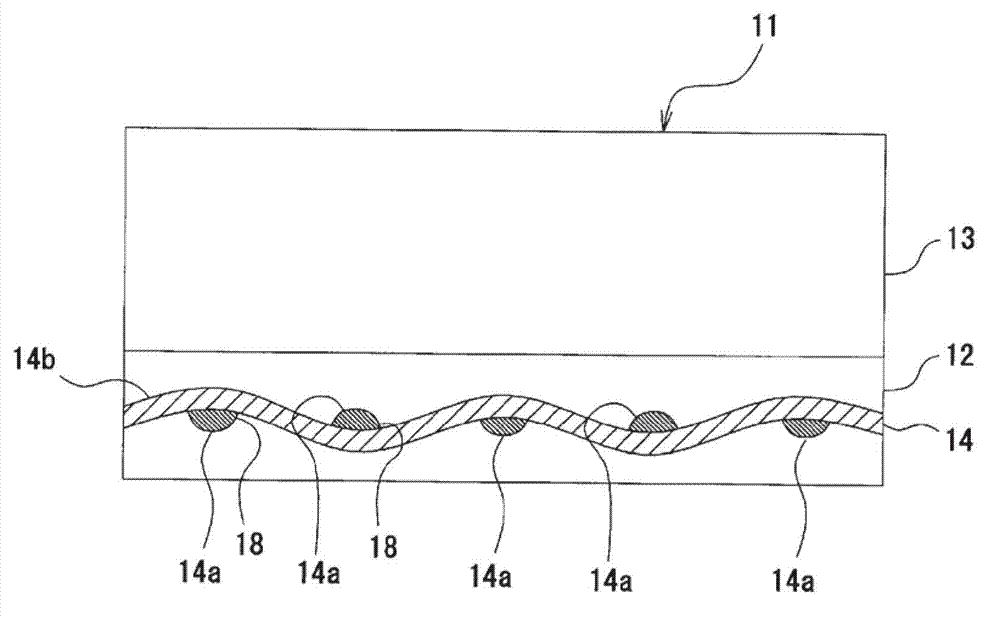

Thermally conductive sheet

ActiveCN103079819AGuaranteed thermal conductivityEasy to operateFilm/foil adhesivesSemiconductor/solid-state device detailsThermal conductivityAir bubble

Disclosed is a thermally conductive sheet which comprises a thermally conductive composition comprising a resin composition and a thermally conductive filler and a mesh sheet, both surfaces of the mesh sheet being coated with the thermally conductive composition so as to form a thermally conductive layer, and in which air bubble inclusion was eliminated to make the thermally conductive sheet have satisfactory thermal conductivity and high strength and be less apt to be torn. The mesh sheet (14) comprises filamentous materials (14a) and (14b) which cross each other to form a network, and bubble inclusion inhibition parts (18) which inhibit air bubbles from coming into the interface between the thermally conductive composition (12) and the mesh sheet (14) have been formed at the intersections where the filamentous materials (14a) and (14b) cross. The bubble inclusion inhibition parts (18) may be fusion-bonded parts (18a), press-bonded parts (18b), etc.

Owner:SEKISUI POLYMATECH CO LTD

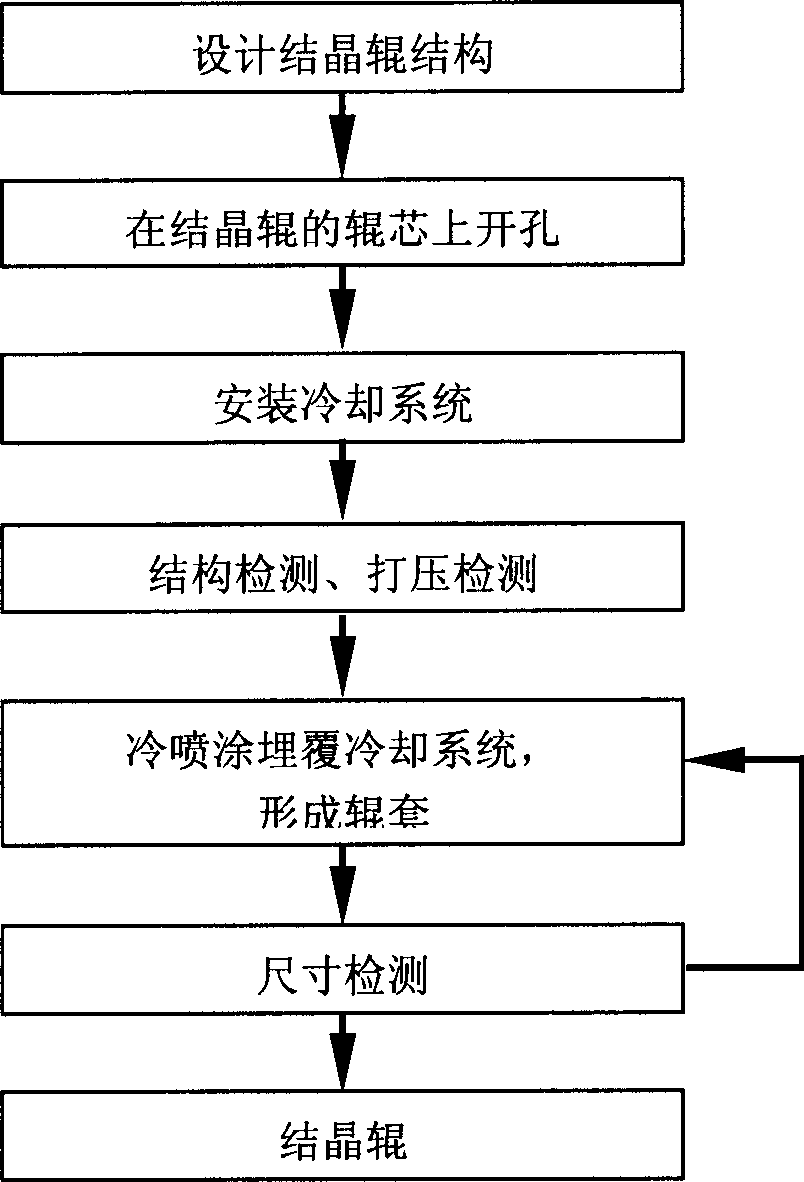

Method for producing continuous casting crystalli-zing roll

ActiveCN1781623AThe manufacturing method is simple and reliableEliminate the adsorbed oxygen layerNon-electric welding apparatusEngineeringMetal

The process of producing continuous casting crystallization roller includes the following steps: cutting axial water inlet hole and water outlet hole on roller core, and forming water guide hole on the core wall to communicate the water inlet hole and the water outlet hole with outside surface of the core; installing metal pipe outside the core to form crystallization roller cooling system with several cooling loops; and cold pneumatic spraying through driving metal grains with pressure over 1.0 MPa to bump the outer surface of the core at high speed so as to make metal grains deform sufficiently for adhering onto the surface of the core and the outer surface of the cooling loops, filling the gaps, forming coating in enough thickness to cover the cooling loops and forming roller sleeve in enough thickness.

Owner:BAOSHAN IRON & STEEL CO LTD

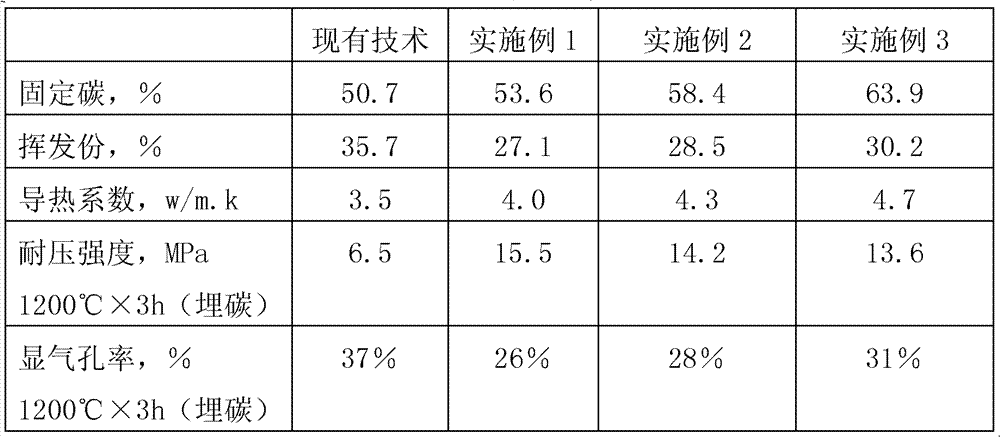

Environment-friendly type carbonaceous press material for maintaining blast furnace hearth

The invention provides an environment-friendly type carbonaceous press material for a maintaining blast furnace hearth. The environment-friendly type carbonaceous press material comprises the following components by weight: 15-35% of electrode graphite, 20-32% of crystalline flake graphite, 4-11% of silicon carbide, 5-15% of quartz sand, 1.0-3.0% of boron carbide, and 24-35% of environmental protection modified tar, wherein the sum of the components is 100%. The various said dry raw materials, in the proportions, can be used in a production field after weighted, burdened, uniformly mixed, uniformly stirred with a liquid binder and sealedly packaged. The carbonaceous press material of the invention has advantages of good fluidity and fallibility, high density and intensity, high thermal conductivity, good anti-aggressivity to melt molten iron and slag, high temperature air-flow flushing resistance, and good anti oxidizability, and is especially in favor of raising a blast furnace life and in favor of safety production. The carbonaceous press material contains less poisonous and harmful substances like benzopyrene, and is in favor of environmental protection.

Owner:BAOSHAN IRON & STEEL CO LTD

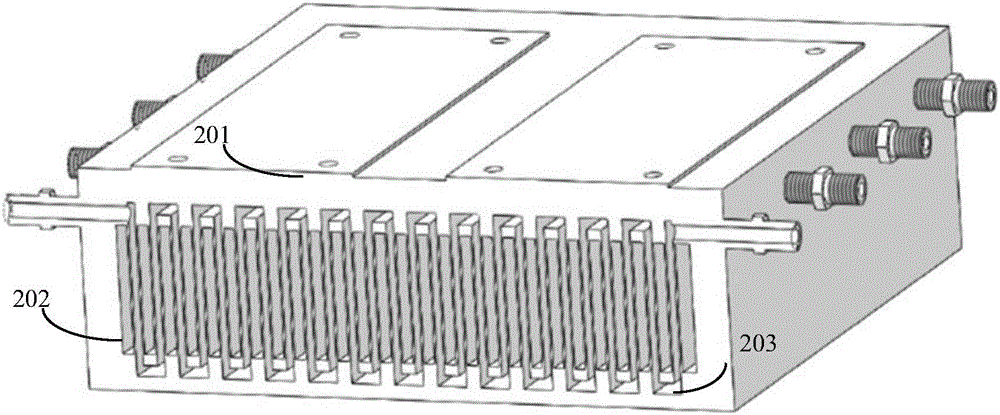

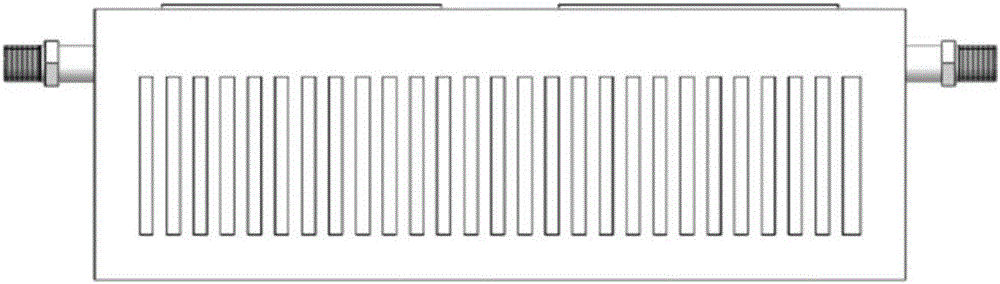

Air-cooling and water-cooling hybrid radiating module for large-power series connected IGBT (Insulated Gate Bipolar Translator)

InactiveCN106711110AGuaranteed thermal conductivitySuper cooling performanceSemiconductor/solid-state device detailsSolid-state devicesInsulated-gate bipolar transistorCooling channel

The invention discloses an air-cooling and water-cooling hybrid radiating module for a large-power series connected IGBT (Insulated Gate Bipolar Translator). The radiating module comprises a radiator body, a heat-conducting material, and a fan, wherein the radiator body comprises an air-cooling channel and a water-cooling channel; an IGBT module is installed on the frontage of a radiator through the heat-conducting material; a sealed water-cooling water inlet and a sealed water-cooling water outlet are formed in a side face the radiator; and the fan is installed on the side face vertical to the water inlet-outlet; the side face of the radiator is matched with an air outlet side of the fan in size, the seal connection is formed between the air outlet of the fan and a heat sink, thereby forming the forced air-cooling heat exchange. The air-cooling and water-cooling hybrid radiating module disclosed by the invention can select the radiating way and flexibly control the heat release, and the volume of the radiating equipment is reduced to a large extent. The radiating demand in the large-power IGBT parallel application occasion can be satisfied.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com