High performance polymer foaming cement thermal insulation material and preparation method thereof

A technology of high-performance polymers and foamed cement, which is applied in the field of building materials, can solve problems such as strength and water absorption not meeting the requirements, strength, water absorption, thermal conductivity mismatch, and thermal conductivity decline, etc., to achieve fast foaming speed , Improve strength and crack resistance, reduce water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention also discloses a preparation method of a high-performance polymer foamed cement insulation material, comprising the following steps:

[0028] (1) Weigh each component according to the proportioning;

[0029] (2) First add water, anti-crack fiber, reinforcing agent, redispersible latex powder, stir for 1-2 minutes, then add fly ash and cement, continue to stir well, stir for 2-3 minutes, then add composite foam agent, stir for 10-20 seconds;

[0030] (3) Put the slurry made in step (2) into the mold, stop for 2-3 hours to remove the mold, cut and pack after 24 hours, and maintain it until the age is 28 days.

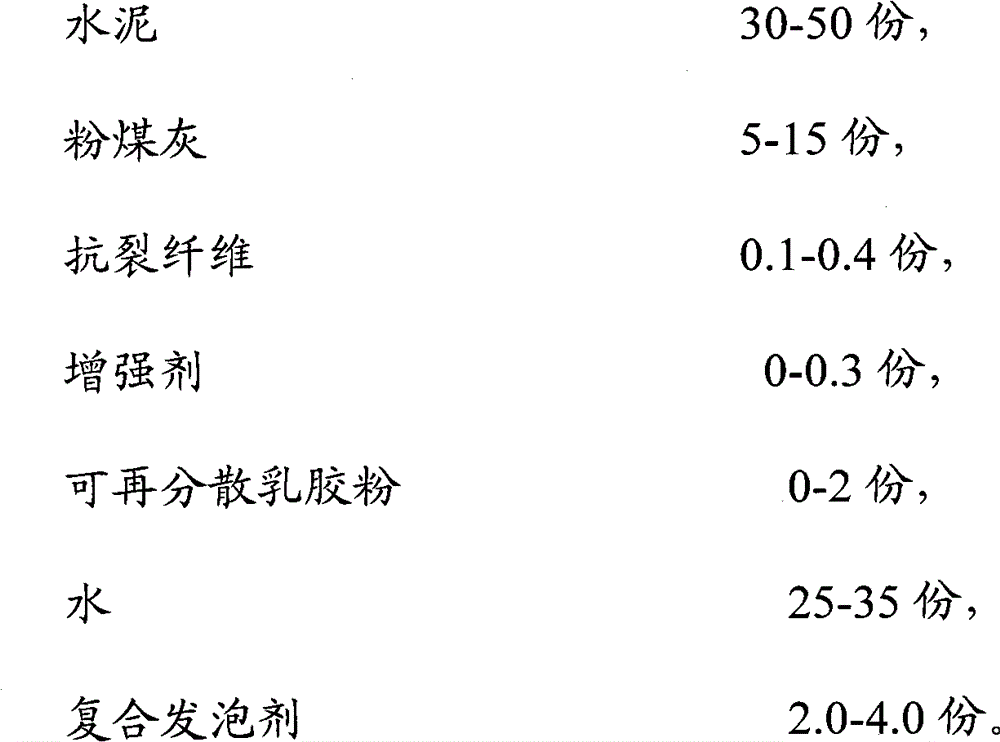

specific Embodiment 1

[0031]

[0032] In this embodiment, the cement is special cement, the fly ash is first-grade fly ash, the crack-resistant fiber is modified polypropylene fiber; the redispersible latex powder is acrylic; the reinforcing agent is polycarboxylate water reducer; The composite foaming agent is composed of a foaming agent and a foam stabilizer, wherein the mass ratio of the foaming agent to the foam stabilizer is 1:0.2, the foaming agent is a hydrogenated foaming agent, and the foam stabilizer is modified sex protein.

[0033] A preparation method of a high-performance polymer foamed cement insulation material: (1) weigh each component according to the proportion; (2) first add water, anti-crack fiber, and reinforcing agent, stir for 1-2 minutes, and then add powder Coal ash and cement, continue to stir well, stir for 2-3 minutes, then add composite foaming agent, stir for 10-20 seconds; (3) Put the slurry into the mold, stop for 2-3 hours to remove the mold, 24 hours Afterward...

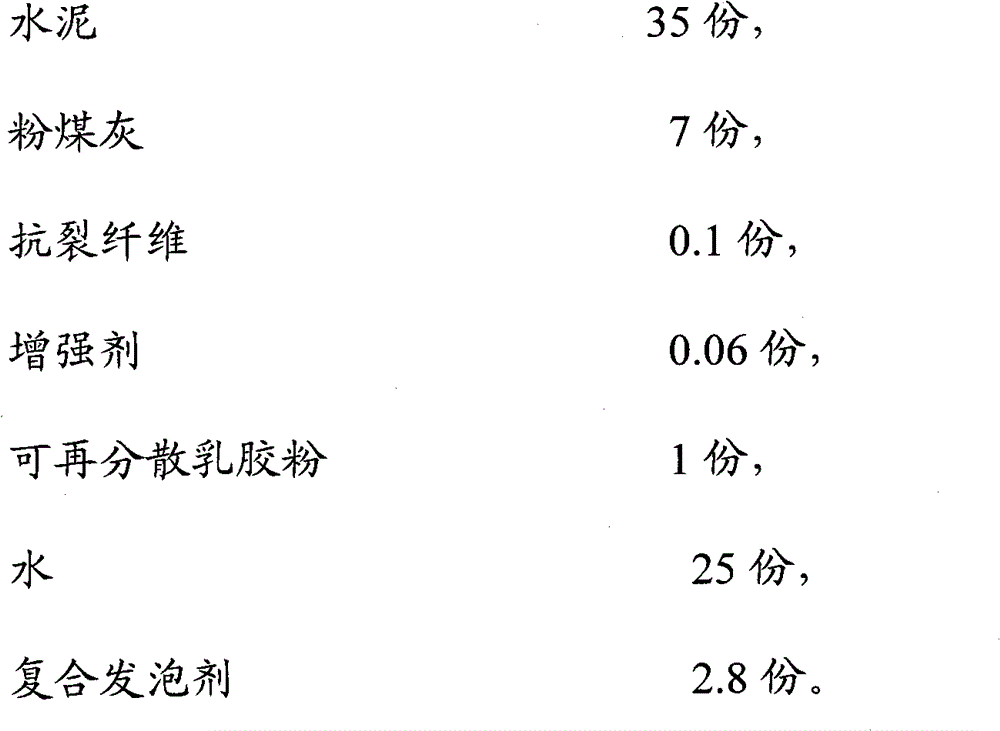

specific Embodiment 2

[0034]

[0035] In this embodiment, the cement is special cement, the fly ash is first-grade fly ash, and the crack-resistant fiber is polyester fiber; the reinforcing agent is polycarboxylate water reducer; the redispersible latex powder is phenylacrylic acid; The foaming agent is composed of a foaming agent and a foam stabilizer, wherein the mass ratio of the foaming agent to the foam stabilizer is 1:0.2, the foaming agent is a hydride foaming agent, and the foam stabilizer is a modified protein.

[0036] A preparation method of a high-performance polymer foamed cement insulation material: (1) weigh each component according to the proportion; (2) first add water, anti-crack fiber, and reinforcing agent, stir for 1-2 minutes, and then add powder Coal ash and cement, continue to stir well, stir for 2-3 minutes, then add composite foaming agent, stir for 10-20 seconds; (3) Put the slurry into the mold, stop for 2-3 hours to remove the mold, 24 hours Afterwards, cut, pack, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com