Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Fast foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Magnesium cement foam material

InactiveCN102101787AUniform foamingFast foamingSolid waste managementCeramicwareThermal insulationMagnesium

The invention relates to a magnesium cement foam material which is prepared by the following steps: mixing 10-90 wt% of light-burnt magnesium oxide powder, 5-89 wt% of filler and 0.8-10% of compound foaming agent, and mixing with a magnesium chloride solution which accounts for 100-150 wt% of the mixture; and evenly stirring, casting and forming to obtain the magnesium cement foam material. The invention can effectively lower the load of the buildings, has favorable thermal insulation property, and can be widely used for building blocks, heat engineering equipment, and various ventilating ducts and industrial ducts in industrial and civil buildings.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

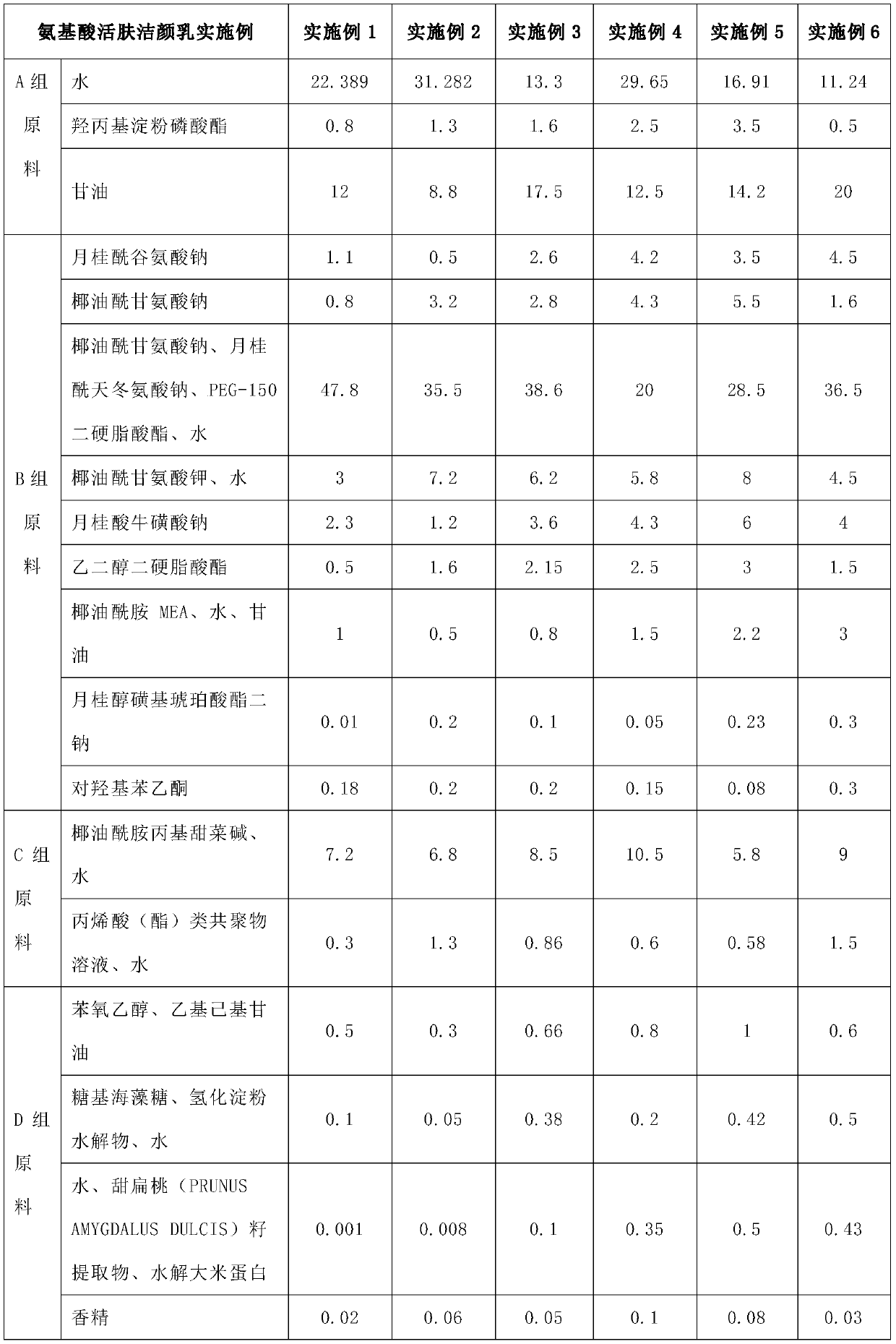

Mild cleansing and moisture preservation amino acid skin activating and face cleansing milk and preparation method thereof

InactiveCN110151578AEasy to cleanFast foamingCosmetic preparationsToilet preparationsSolubilityAdditive ingredient

The invention provides mild cleansing and moisture preservation amino acid skin activating and face cleansing milk and a preparation method thereof, and relates to the field of face cleansing milk. The face cleansing milk is prepared from 26.59 to 78.4 parts of group B raw materials; the group B raw materials is prepared from the following ingredients in parts by weight: 0.5 to 4.5 parts of sodiumlauroyl glutamate, 0.8 to 5.5 parts of oleoyl sodium glycinate, 20 to 47.8 parts of surfactants, 3 to 8 parts of potassium cocoyl glycinate solution, 1.2 to 6 parts of sodium taurine laurate, 0.5 to3 parts of glycol distearate, 0.5 to 3 parts of moisturizing foaming agents, 0.01 to 0.3 part of lauryl sulfosuccinate disodium and 0.08 to 0.3 part of p-hydroxyacetophenone. The face cleansing milk provided by the invention belongs to amino acid type face cleansing milk with the advantages of mild effect, strong cleaning power, high water solubility, excellent foaming performance and elastic andstable foam. The invention also provides a preparation method of the mild cleansing and moisture preservation amino acid face cleansing milk. The preparation method has the advantages that the processis simple; the operation is easy; the amino acid type face cleansing milk with high stability can be produced.

Owner:广东天源生物科技有限公司

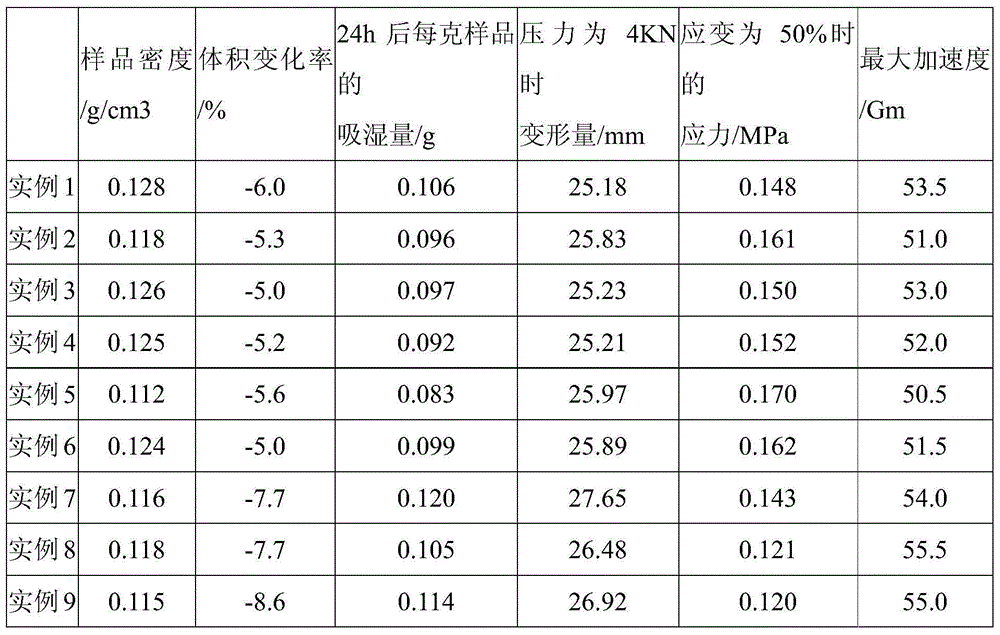

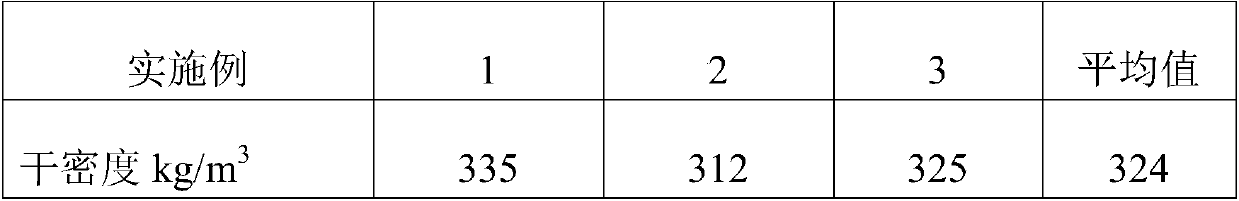

Micronized plant fiber buffer material and preparation method thereof

The invention discloses a micronized plant fiber buffer material and a preparation method thereof. According to the micronized plant fiber buffer material, bleached plant fibers are used as main raw materials, high-beating-degree micronized plant fibers are obtained through beating by a PFI beater, then cationic starch and polyvinyl alcohol paste, a plasticizer and a foaming agent are added, the mixture is mixed evenly to be injected into a mold and fully foamed with a microwave foaming technology, and after the mixture is molded, the plant fiber foamed buffer material is obtained through demolding and drying. According to the micronized plant fiber buffer material and the preparation method thereof, raw material sources are rich, the method technology is simple, and the production energy consumption and the cost are low; the prepared foamed buffer material is lower in apparent density, lower in volume change rate and hygroscopic capacity, capable of being prepared into products with different shapes and sizes according to actual requirements, excellent in applicability and buffer performance, easy to degrade, free from environmental pollution and widely applicable to the packaging field.

Owner:GUANGXI UNIV

Thermal insulation material

The invention discloses a thermal insulation material which comprises the following raw materials in parts by mass: 100 parts of a solid mixture and 100-150 parts of a magnesium chloride solution, wherein the solid mixture comprises the following components in percentage by mass: 10-90% of magnesium oxide powder, 5-89% of packing and 0.8-10% of a foaming agent; and the packing can be any one of fly ash, dolomite powder, calcium carbonate powder, gypsum powder, perlite, red mud, lake sludge, river sand and coal gangue. In the thermal insulation material, the foaming agent is prepared by mixing peroxides, a sizing agent and a foam stabilizer; when used in the preparation of the thermal insulation material, the foaming agent is high in foaming speed and uniform in foaming; and the thermal insulation material disclosed by the invention not only can effectively reduce the bearing of a building, but also has good thermal insulation properties; therefore, the thermal insulation material can be widely applied to building blocks, thermal equipment and various ventilating pipes and industrial pipes in industrial and civil buildings.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

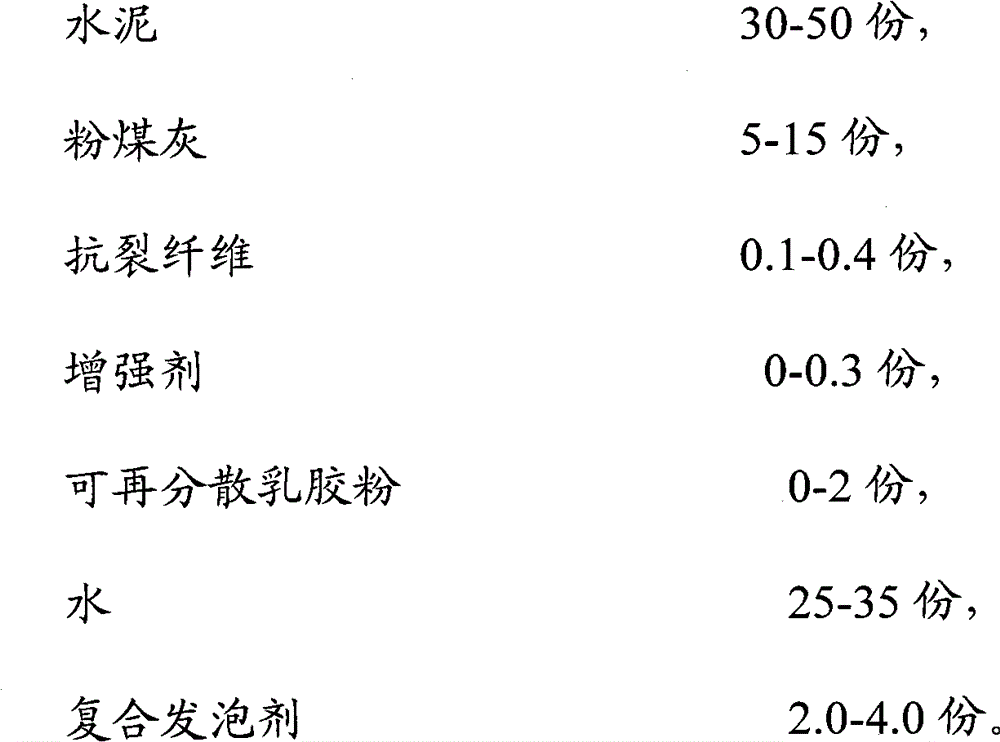

High performance polymer foaming cement thermal insulation material and preparation method thereof

The present invention discloses a high performance polymer foaming cement thermal insulation material, which comprises, by weight, 30-50 parts of cement, 5-15 parts of fly ash, 0.1-0.4 part of anti-cracking fiber, 0-0.3 part of a reinforcing agent, 0-2 parts of redispersible latex powder or an emulsion, 25-35 parts of water, and 2.0-4.0 parts of a composite foaming agent. The preparation method comprises: weighing various components; adding the water, the anti-cracking fiber and the reinforcing agent; stirring for 1-2 minutes; then adding the fly ash and the cement, and stirring for 2-3 minutes; then adding the composite foaming agent, and stirring for 10-20 seconds; placing the resulting slurry in a mold, standing for 2-3 hours, and then carrying out demolding; and cutting after 24 hours, then packaging, and carrying out concrete curing until the curing time is 28 days. The foaming cement thermal insulation material of the present invention is a lightweight material with a fire-protection rating of class A, has characteristics of thermal insulation, durability, heat insulation, sound insulation and environment protection, and is used for building interior and exterior insulation materials, fire barriers, roofing thermal insulation materials, and the like.

Owner:JIANGSU NIGAO SCI & TECH +1

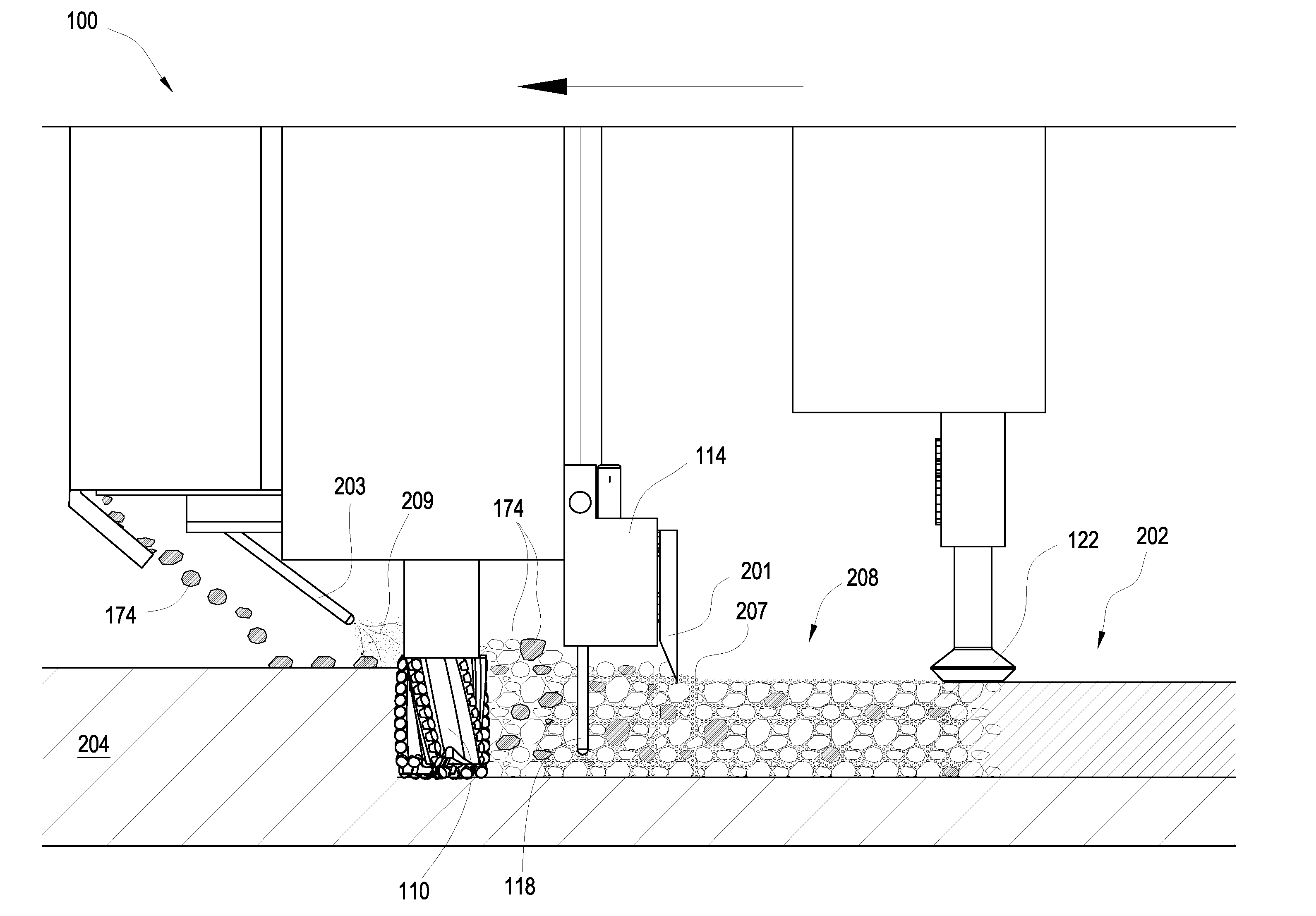

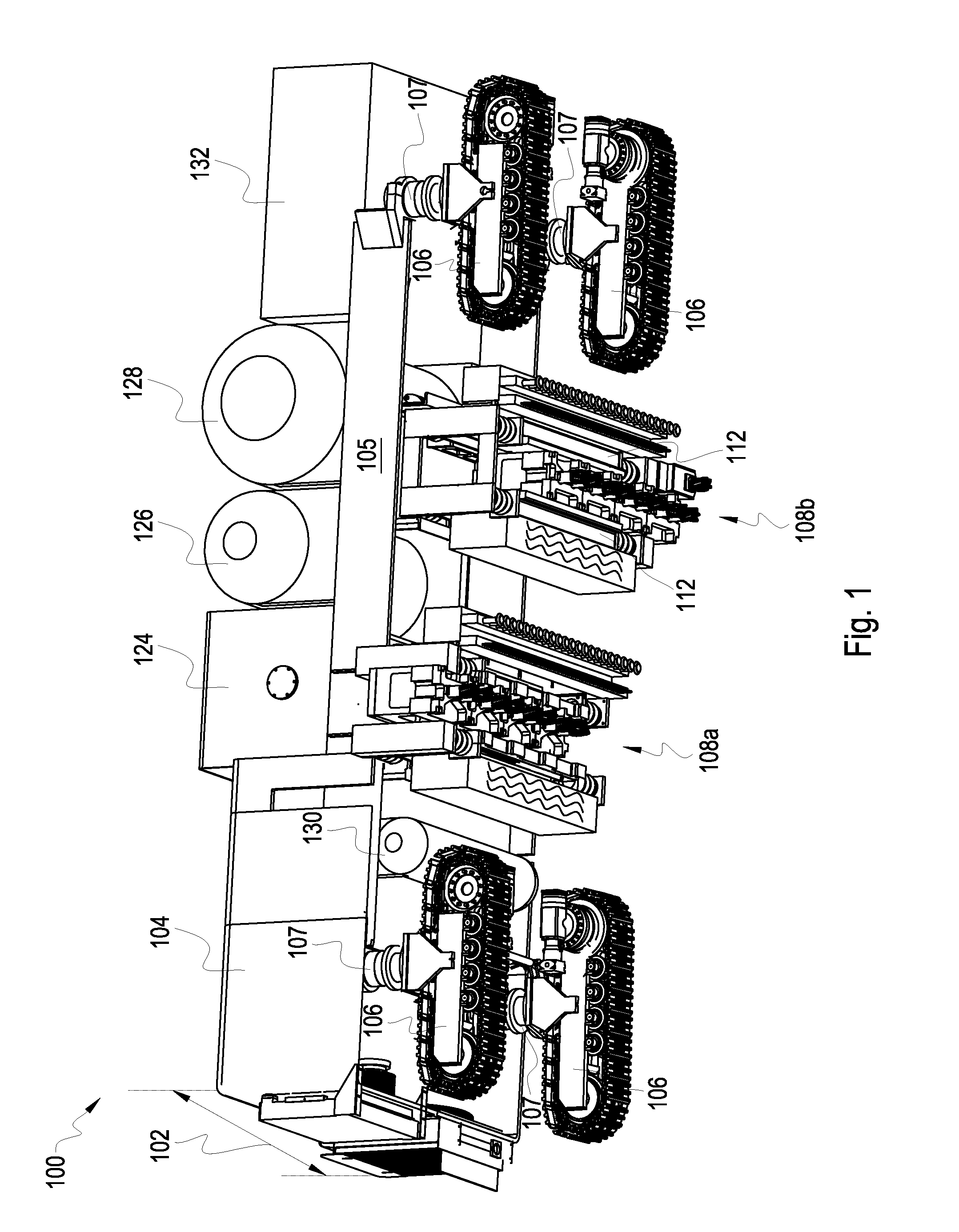

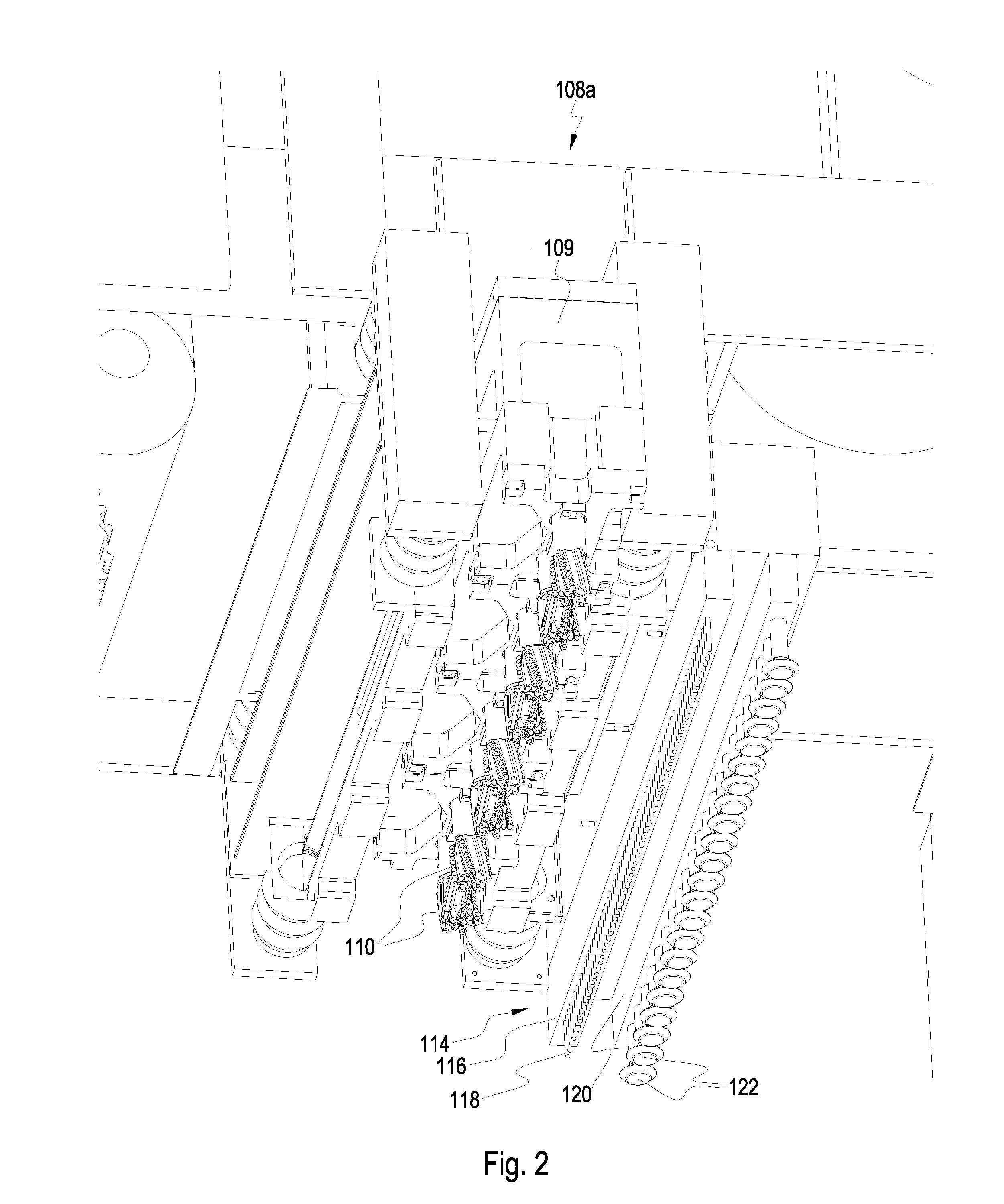

Method for Depositing Pavement Rejuvenation Material into a Layer of Aggregate

InactiveUS20060198698A1High surface energyFast foamingIn situ pavingsPaving detailsEngineeringRoad surface

Owner:NOVATEK IP

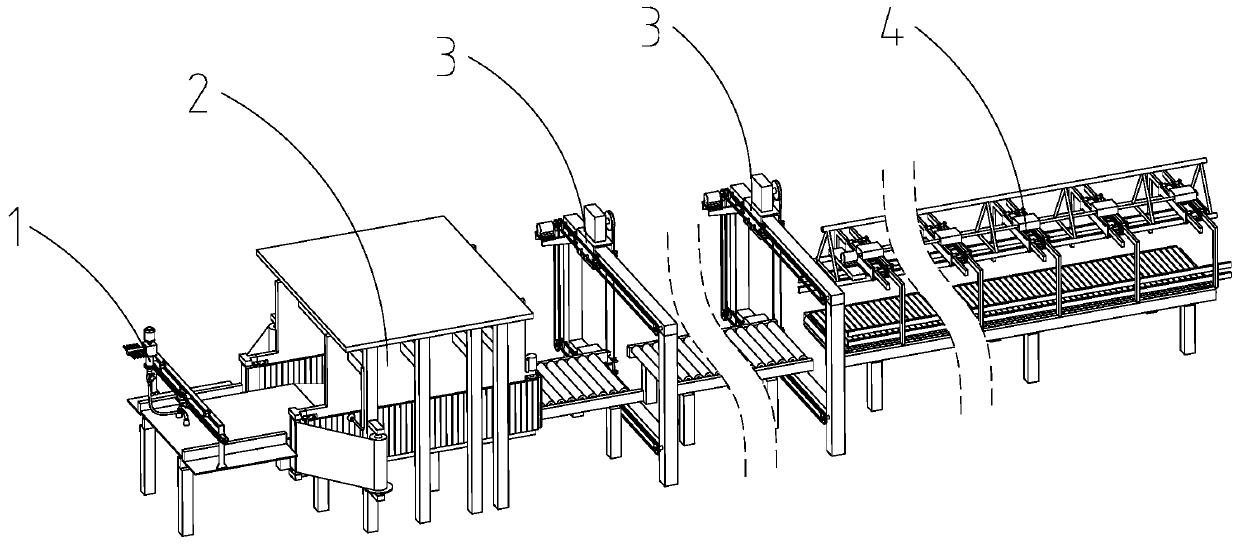

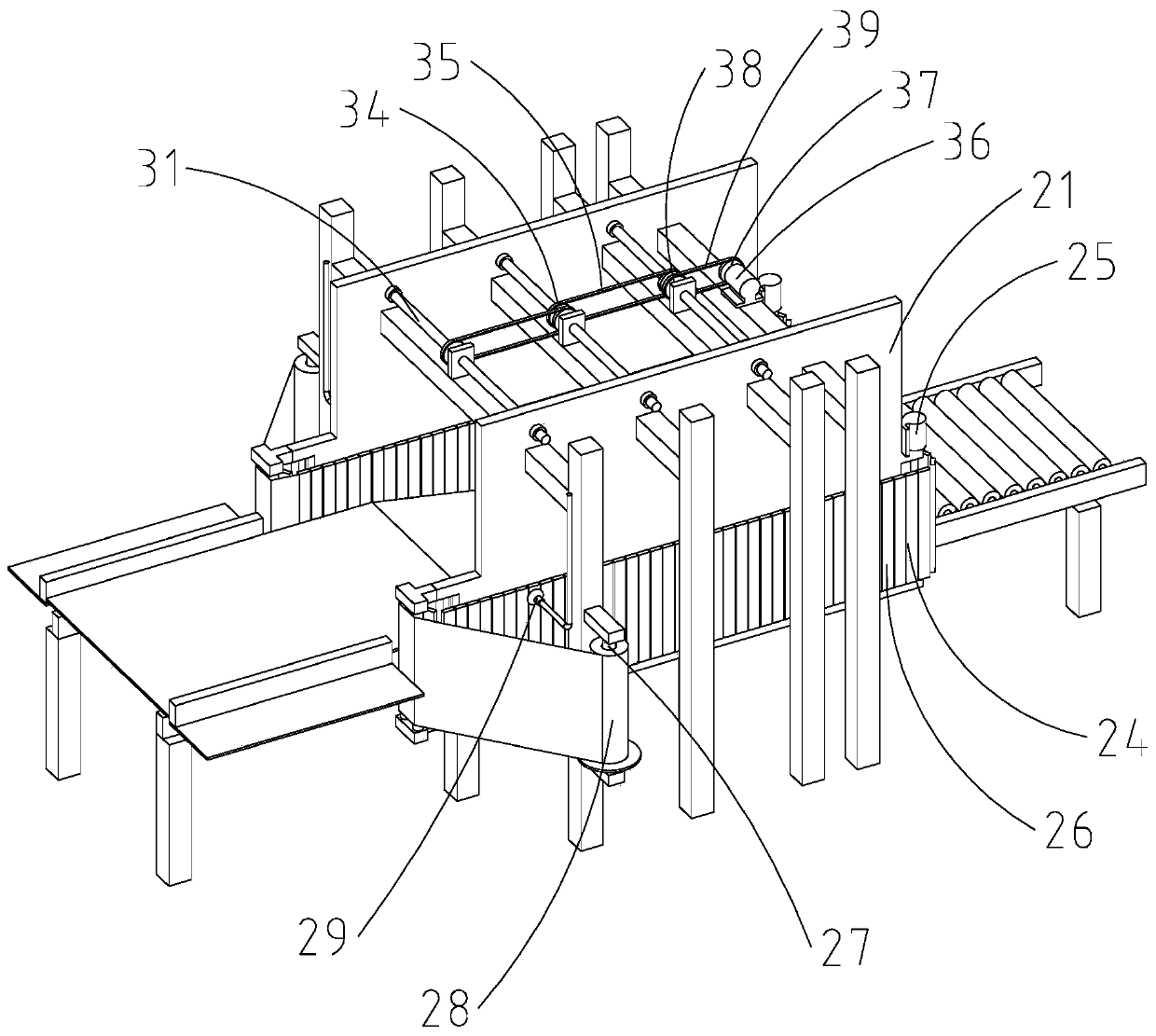

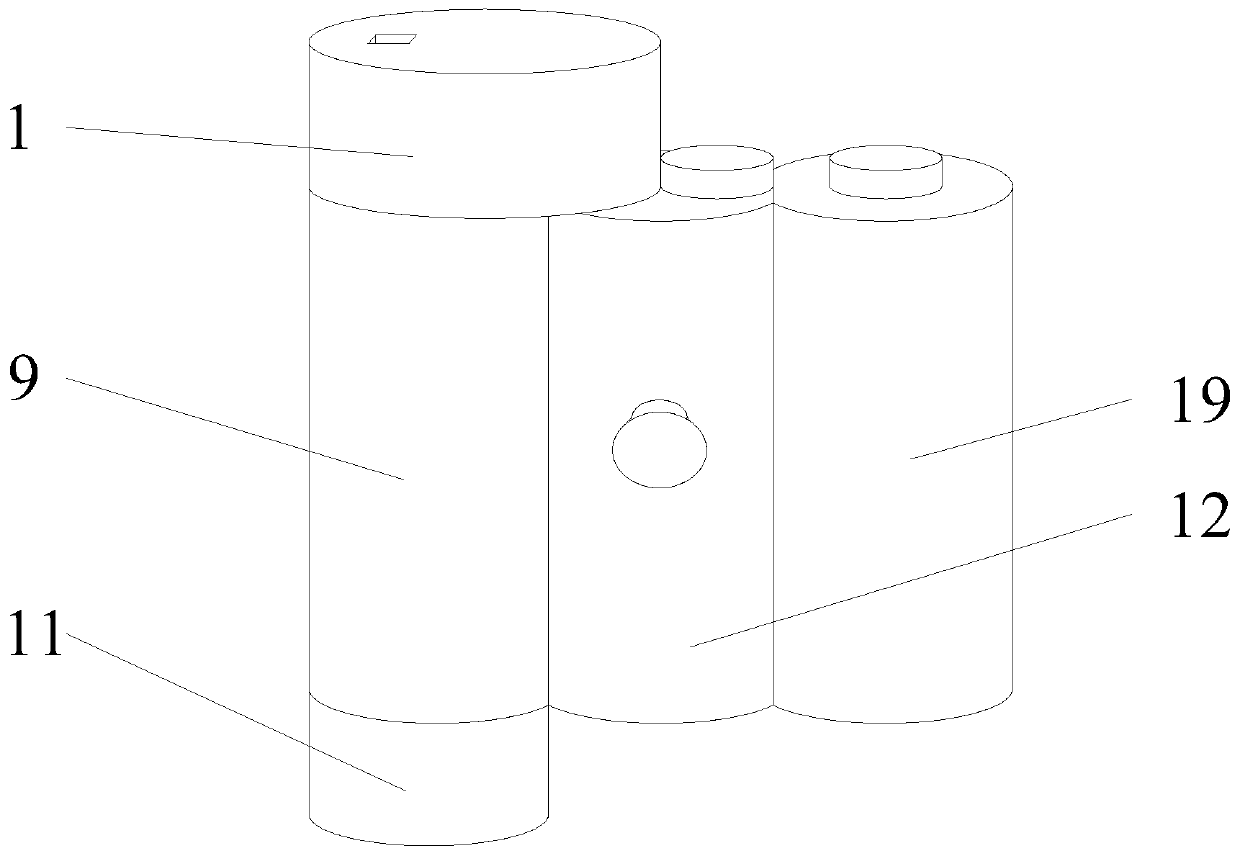

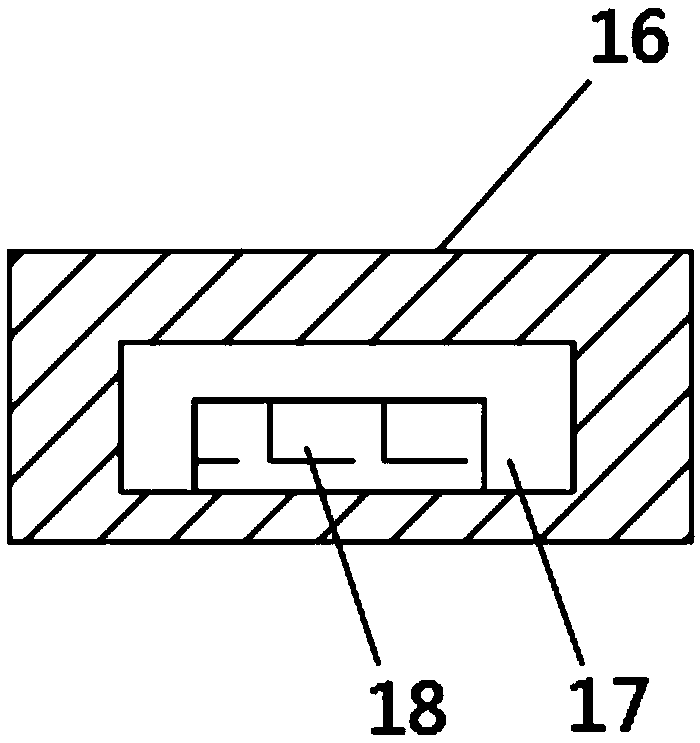

Sponge foaming equipment and working method thereof

PendingCN109986738AFast foamingHigh degree of automationMetal working apparatusEngineeringAutomation

The invention discloses sponge foaming equipment. The sponge foaming equipment comprises a frame, a feeding device, a foaming conveying device, a heating device, a cutting device and an unloading device, wherein a foaming sponge conveying channel is arranged on the frame; the feeding device, the foaming conveying device, the cutting device and the unloading device are sequentially arranged along the advancing direction of the foaming sponges in the foaming sponge conveying channel; the feeding device is arranged on the frame and is used for accessing raw materials, uniformly stirring the raw materials and unloading the raw materials into the foaming sponge conveying channel; and the foaming conveying device is arranged on the frame and is used for clamping and conveying the foaming spongesbeing foamed in the foaming sponge conveying channel forwards. According to the sponge foaming equipment, the production and processing of the foaming sponges can be automatically completed, the automation degree is high, the production efficiency is high, the product quality is good, the structure is simple, and the operation cost is low.

Owner:江苏华艺泡棉科技有限公司

Flame-retardant high-strength foam concrete and preparation method thereof

InactiveCN108623243AReduce heat of hydrationReduce early shrinkage crackingCeramicwareFire retardantWater resistance

The invention provides flame-retardant high-strength foam concrete and a preparation method thereof. The foam concrete comprises the following components by mass: 40-60 parts of cement, 20-30 parts ofgrade-II fly ash, 15-30 parts of fine sand, 2-6 parts of an inorganic flame retardant, 5-15 parts of silicate, 4-11 parts of an expansion agent, 0.4-0.7 part of a foaming agent, 0.4-1.2 parts of a foam stabilizer, 0.6-1.1 parts of a water reducing agent, 0.3-1.5 parts of an early-strength agent, 0.6-1.2 parts of a water repellent, 0.1-0.2 part of fibers and 25-45 parts of water. The invention provides the flame-retardant high-strength foam concrete and the preparation method thereof; and the prepared foam concrete has high strength, flame retardation performance, water resistance and anti-cracking performance.

Owner:上海天行新型材料有限公司

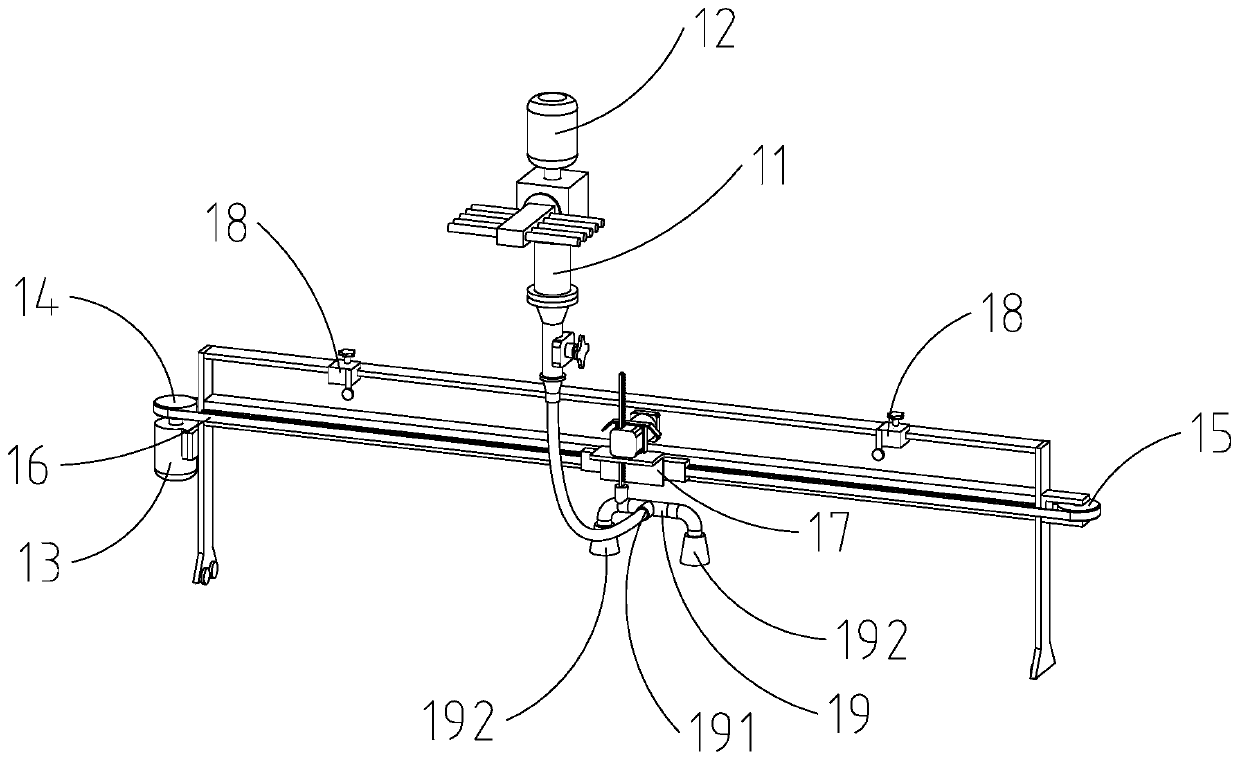

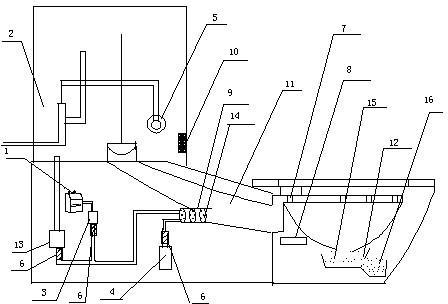

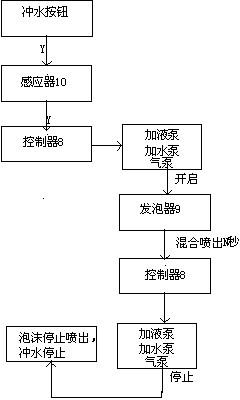

Foaming-type flushing closestool

The invention provides a foaming-type flushing closestool which is characterized in that a stock solution tank is connected with a makeshift-up pump through a pipeline; the makeshift-up pump, an air pump and a water tank are respectively connected with a foam generator through pipelines; the pipeline for communicating the water tank and the foam generator is provided with a make-up water pump; the interior of the foam generator is provided with a multilayer porous mesh; and a stock solution, air and water are fully mixed in the foam generator and then pass by the porous mesh so as to form small foams. The foam generator provided by the invention can be used for overcoming the preconception of a traditional technology; according to the traditional technology, the foaming effect is better only when the foaming tank is larger; the foam generator provided by the invention is space-saving, has the volume much smaller than that of the traditional foaming tank, is rapid in foaming speed, can be used for saving more water and the stock solution, high in foam yield, achieves fine and smooth foams, and is simple in structure, less in fault and easy to maintain; and a water counterweight tank is used as a clump weight, has a good time-delay action and ensures that foams can cover a urinal conveniently.

Owner:郭东箭

Production method of solvent-free foaming type polyurethane synthetic leather

InactiveCN107419542AMeet needsAvoid defectsTextiles and paperEnvironmental resistanceCarboxylic salt

The invention discloses a production method of solvent-free foaming type polyurethane synthetic leather. The method comprises steps as follows: solvent-free polyurethane foaming slurry is applied to base cloth after being uniformly mixed, and then is heated and cured, and foaming polyurethane base cloth is obtained; surface layer slurry is applied to release paper after being mixed uniformly, dried to serve as a surface layer and then attached to the obtained foaming polyurethane base cloth, embossing is performed, the release paper is stripped after cooling, and the solvent-free foaming type polyurethane synthetic leather is obtained; the solvent-free polyurethane foaming slurry is prepared from a component A and a component B in the weight ratio being (2-4):1 through mixing, wherein the component A is prepared from polyhydric alcohols, white carbon black, hydroxyl silicone oil, fatty acid, fatty acid metal salt, unsaturated carboxylate, organic peroxides and a functional aid I, and the component B is prepared from isocyanate; the surface layer slurry is prepared from waterborne polyurethane resin, higher aliphatic alcohol and a functional aid I. Compared with the prior art, the production method has the advantages of being clean, environment-friendly, simple and convenient to operate and the like.

Owner:三明建华纺织有限公司

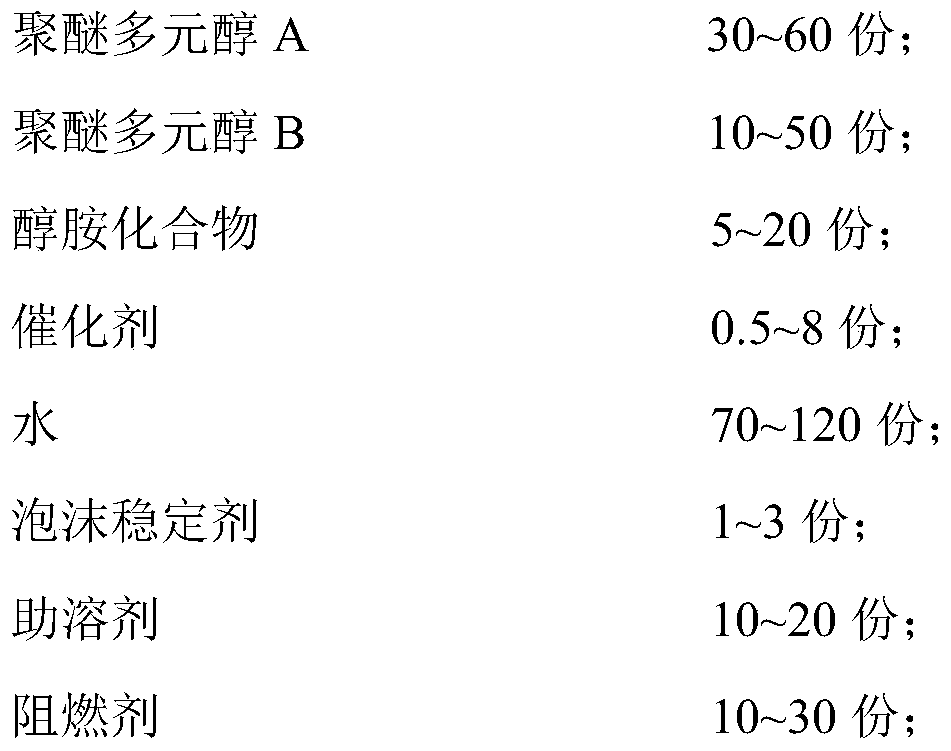

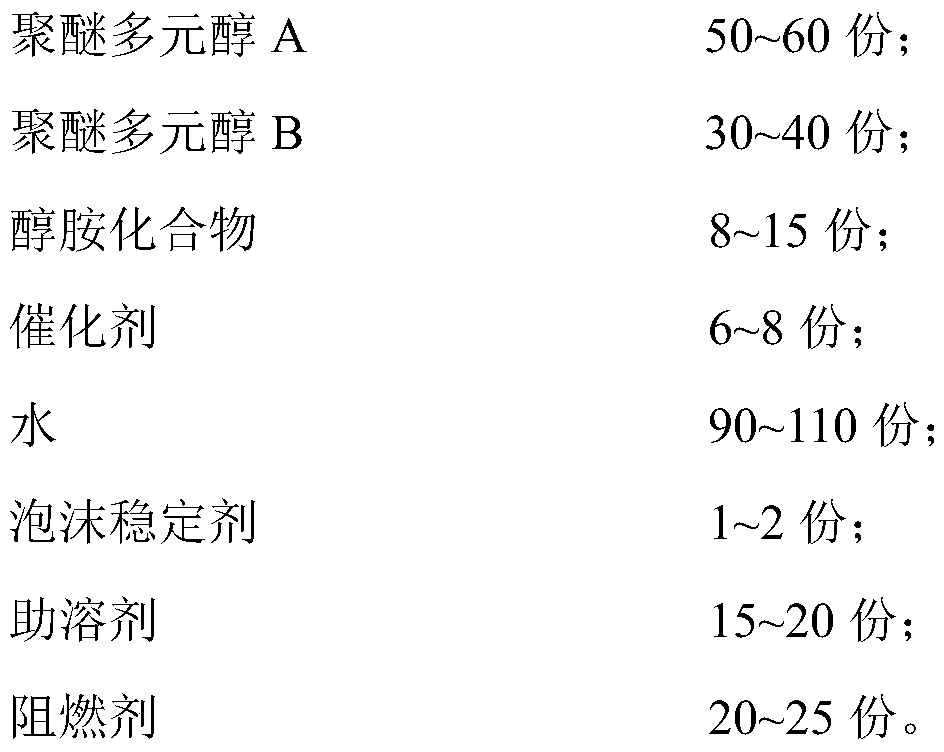

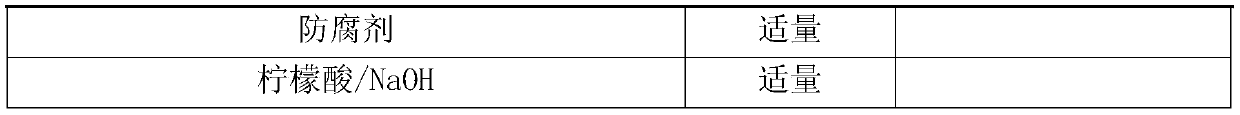

Low-temperature rapid sealing material for high gas coal mine and preparation method thereof

InactiveCN110003787AEliminate potential safety hazardsReduce internal temperatureFireproof paintsPolyurea/polyurethane coatingsPolyolAlcohol

The invention relates to the technical field of polyurethane spraying materials, specifically to a low-temperature rapid sealing material for high gas coal mine and a preparation method thereof. The sealing material comprises an ingredient A and an ingredient B. The ingredient A comprises the following raw materials (by weight): 30-60 parts of polyether polyol A, 10-50 parts of polyether polyol B,5-20 parts of an alcohol amine compound, 0.5-8 parts of a catalyst, 70-120 parts of water, 1-3 parts of a foam stabilizer, 10-20 parts of a cosolvent and 10-30 parts of a fire retardant. The ingredient B is isocyanate. The mixed volume ratio of the ingredient A to the ingredient B is 1:1-5. The low-temperature rapid sealing material for high gas coal mine can be used in large quantity in a high-gas environment of the mine without heat accumulation and has low reaction temperature. Excellent performance of the polyurethane foam material is guaranteed, and potential safety hazard of the polyurethane foam material is also eliminated during its using process. The invention also provides a preparation method of the low-temperature rapid sealing material.

Owner:山东润义金新材料科技股份有限公司

Surface active agent composition for improving foaming property of detergent and preparation method and application thereof

InactiveCN110283668AImprove performanceIncrease expansionInorganic/elemental detergent compounding agentsCosmetic preparationsNatural sourceSURFACTANT BLEND

The invention discloses a surface active agent composition for improving the foaming property of a detergent. The surface active agent composite is composed of, by weight, 1-4 parts of a cationic surfactant, 10-20 parts of a nonionic surfactant, 1-4 parts of a high molecular surfactant and 10-20 parts of plant saponin extract. The composition for improving the foaming property is compounded from the natural source surfactants and therefore has the advantages that foaming speed is high, the total quantity of foams is high, and foam stability is high.

Owner:苏州绿叶日用品有限公司

Magnesium oxysulfate cement-based building block and production method thereof

The invention discloses a magnesium oxysulfate cement-based building block. The magnesium oxysulfate cement-based building block comprises 100 parts of active magnesium oxide powder, 140-270 parts of a filler, 1-2 parts of a foaming agent and 200-600 parts of an aqueous solution of magnesium sulfate. The magnesium oxysulfate cement-based building block has small unit weight, and can effectively reduce the bearing of a building. The invention also discloses a production method of the magnesium oxysulfate cement-based building block. The production method comprises the following steps: 1, uniformly mixing 100 parts of the active magnesium oxide powder with 140-270 parts of the filler to obtain a first mixture; 2, adding 200-600 parts of the aqueous solution of magnesium sulfate to the first mixture, and uniformly mixing to obtain a second mixture; 3, adding 1-2 parts of the foaming agent to the second mixture, and uniformly mixing to obtain a third mixture; and 4, placing the third mixture in a die, and curing the third mixture to obtain the magnesium oxysulfate cement-based building block. The production method has the advantages of no high-temperature or high-pressure curing technology and low production cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Foam concrete

The invention discloses foam concrete which is prepared from the following raw materials in parts by mass: 200-300 parts of cement, 250-370 parts of ceramsite, 380-460 parts of sand, 3-6 parts of tensile fibers, 150-350 parts of water, 3.5-5.4 parts of a foaming agent and 4-7 parts of a water reducer. The foam concrete disclosed by the invention can be lighter in mass, higher in strength and highin hole forming quality, so that physical properties, for example, compressive strength, seepage resistance, sound isolation, heat isolation and the like, of the foam concrete are improved.

Owner:兴业县银基混凝土有限公司

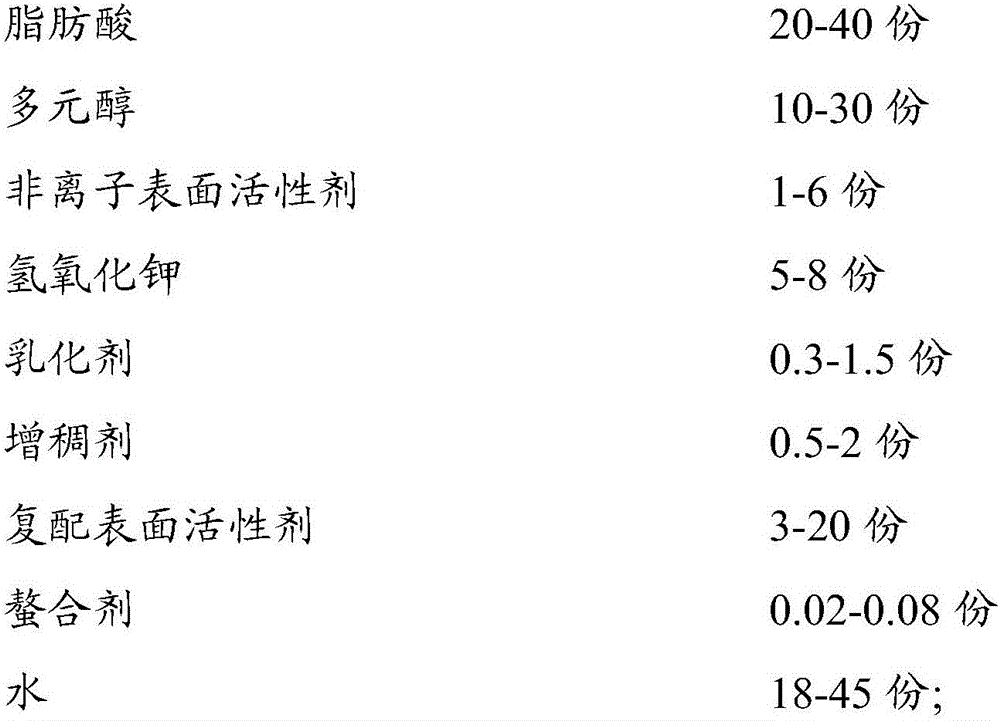

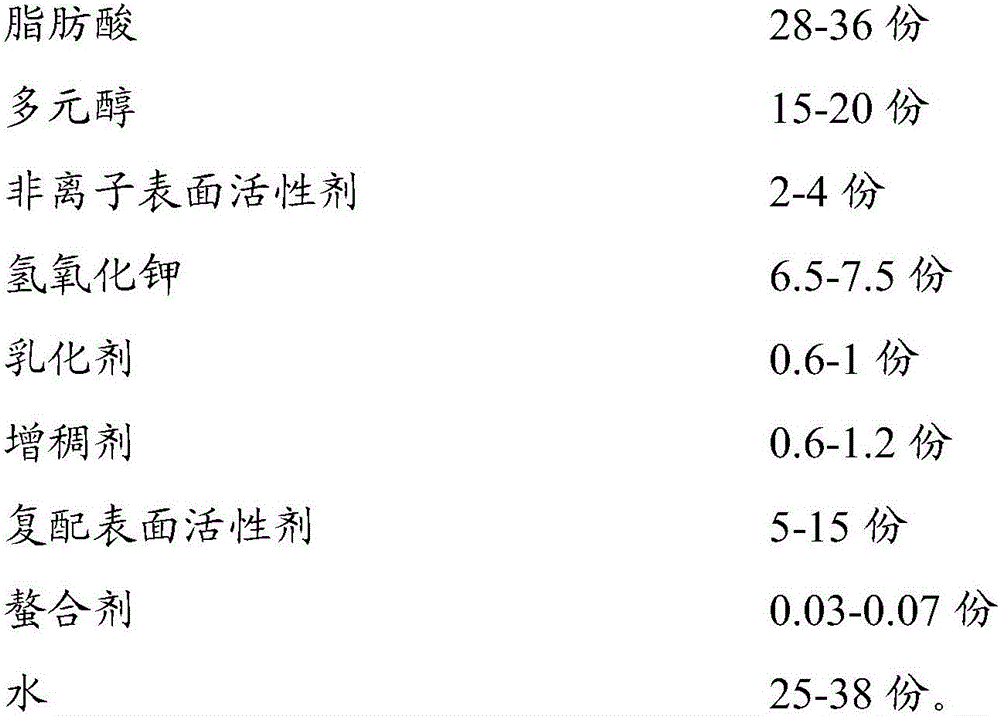

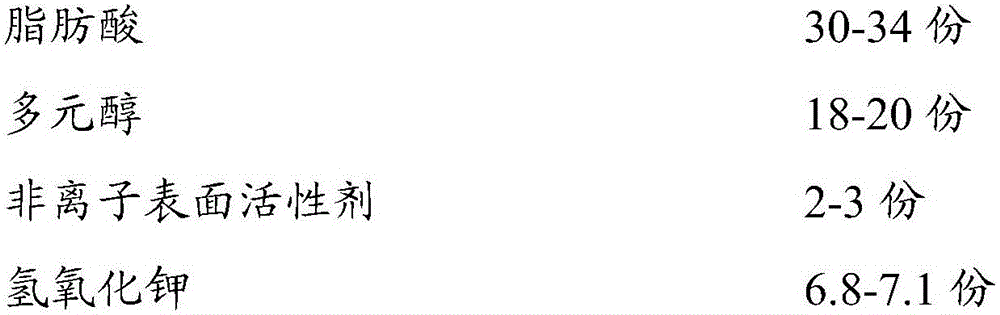

Facial cleanser containing mixed surfactant and preparation method of facial cleanser

ActiveCN105963154AGood moisturizing effectLess irritatingCosmetic preparationsToilet preparationsCleansers skinAlcohol

The invention relates to a facial cleanser containing a mixed surfactant and a preparation method of the facial cleanser. The facial cleanser is prepared from the following components in parts by weight: 20-40 parts of fatty acid, 10-30 parts of polyhydric alcohols, 1-6 parts of a nonionic surfactant, 5-8 parts of alkali, 0.3-1.5 parts of emulsifier, 0.5-2 parts of a thickener, 2-20 parts of the mixed surfactant, 0.02-0.08 part of a chelating agent, and 18-45 parts of water, wherein the nonionic surfactant is a composition formed by PEG / PPG-25 / 30 copolymer and PEG-6, and the mixed surfactant is a composition formed by PEG-6, polyquaternium-43 and PEG / PPG-300 / 55 copolymer. The facial cleanser is rapid in foaming, has rich, smooth and elastic foam, has good moistening property and good moisture retention, has no stimulation, can be easily cleaned after washing, has very good stability, has heat resistance, and is uniform and stable at 48 DEG C, and after temperature returning, the cream is fine and uniform.

Owner:GUANGZHOU HONDU FINE CHEM CO LTD

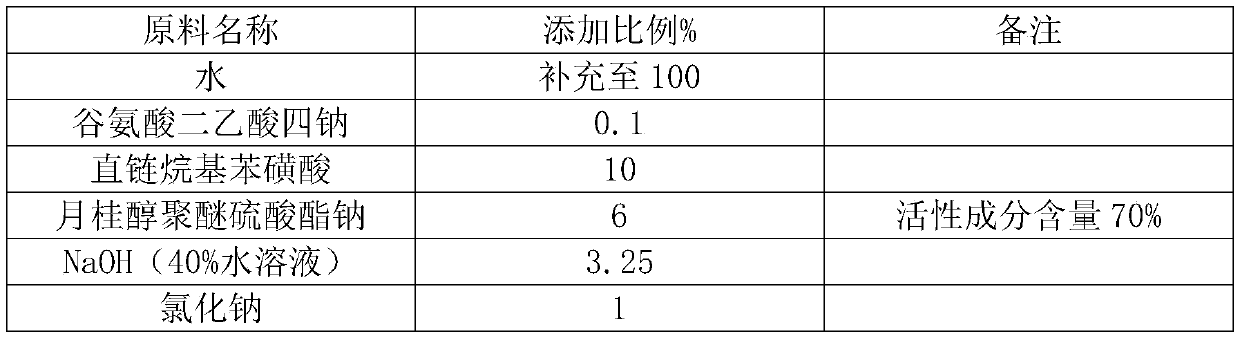

Water-based industrial cleaning agent and preparation method thereof

InactiveCN108795592AEasy to useNo destructive effectNon-ionic surface-active compoundsFoam regulating compositionsWater basedCleansing Agents

The invention relates to a water-based industrial cleaning agent. The water-based industrial cleaning agent comprises the following components in percentage by weight: 0.1-40% of an N-acyl amino acidanionic surfactant, 0.1-20% of fatty acid methyl ester ethoxylate, 0.1-8% of alkyl glycoside, 0.1-8% of hydroxypropyl methyl cellulose, 0.1-10% of an auxiliary agent, and 30-89% of water. The cleaningagent has the characteristics of simple formula, safe use, environment-friendliness and the like, has little irritation to skin, low toxicity, good biodegradability, good use stability and storage stability, and can further improve the traditional cleaning process and improve the cleaning quality while reducing sewage discharge and environmental protection pressure.

Owner:CHANGSHA PUJI BIOTECH

Environment-friendly solvent-free polyurethane for synthetic leather and manufacturing method of polyurethane

PendingCN111041843AImprove protectionPromote sustainable developmentTextiles and paperSaturated fatty acid esterPolymer science

The invention discloses environment-friendly solvent-free polyurethane for synthetic leather. The polyurethane comprises base cloth, a water-based surface layer, a water-based adhesive layer, a foaming layer and a functional auxiliary agent, wherein the water-based surface layer comprises water-based polyurethane emulsion, a thickening agent, a water-based defoaming agent, water-based color pasteand a leveling agent; the water-based adhesive layer comprises water-based polyurethane emulsion, a water-based polyurethane crosslinking agent and water-based color paste; the foaming layer comprisesa polyol compound, white carbon black, an organometallic catalyst, hydroxyl silicone oil, fatty acid, an organic amine catalyst, a filler and toluene diisocyanate; and the functional auxiliary agentcomprises sorbitol, maltitol, oligosaccharide, glycerin saturated fatty acid ester, a coloring agent and a surfactant. The environment-friendly solvent-free polyurethane for the synthetic leather is clean and environment-friendly; the foaming layer is free of an organic solvent, so that the polyurethane is more environment-friendly and environmental protection and sustainable development are facilitated; and meanwhile, the polyurethane has the relatively good toughness.

Owner:福建成杰高分子材料有限公司 +1

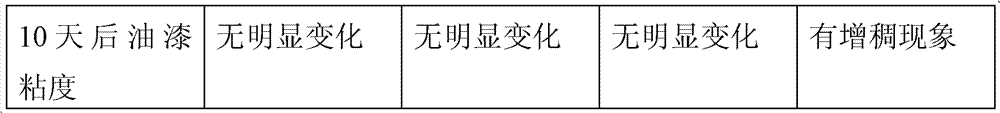

Defoaming method of unsaturated polyester transparent undercoat

InactiveCN103087616AElimination of defoaming effectFast foamingPolyester coatingsFoam dispersion/preventionPolyesterFiltration

The present invention provides a defoaming method of unsaturated polyester transparent undercoat, which is characterized by comprising the steps of: (1) preparing the unsaturated polyester transparent undercoat including: producing unsaturated polyester transparent undercoat; (2 ) leaching by a suction filtration machine including: leaching the unsaturated polyester transparent undercoat by using a suction filtration machine; wherein the leaching temperature is 0-50 DEG C, the leaching pressure is 0.1-0.25 Mpa, and the leaching speed is 1.2-1.8 t / h; and (3) packaging including: directly packaging the unsaturated polyester transparent undercoat after leaching. The defoaming time of the present invention is shortened from the original 48 hours to 1-4 hours. All air bubbles and small bubbles are removed. The product prepared by the present invention has no pinholes in the coating process.

Owner:上海展辰涂料有限公司 +2

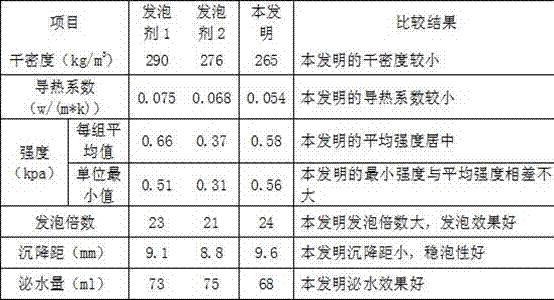

Foaming agent and preparation method thereof

InactiveCN107986677AControl the speed of decompositionStable and easy to storeFoaming agentMaterials science

The invention provides a foaming agent, relates to a building admixture, particularly relates to a foaming agent added into concrete and also relates to a preparation method of the foaming agent. A compound type foaming agent is prepared on the basis of the original foaming agent; several types of materials with excellent foaming performance are added into the foaming agent; then other admixturesare added into the foaming agent, so that the effects of increasing foam, stabilizing foam and adjusting are achieved; the compound type foaming agent prepared by the invention has been verified in the actual production; the compound type foaming agent has the prominent properties of high foaming capacity, low foam loss, low influence on strength and the like.

Owner:云南森博混凝土外加剂有限公司

Organic polyurethane fireproof and heat insulating material for solar water tank

The invention relates to an organic polyurethane fireproof and heat insulating material for a solar water tank. The material is mainly prepared from a component A and a component B through mixing, wherein the component A comprises isocyanate, polyvinyl alcohol and a foaming agent; the component B comprises polyether glycol, gelatin powder, activated aluminum oxide, calcium carbide, tributyl phosphate and deionized water. According to the organic polyurethane fireproof and heat insulating material for the solar water tank, uniformly distributed and fine pores are formed, and the material is stable in heat insulating property, high in foaming speed and convenient to use; sepiolite is added to a white material, calcium powder enables the prepared heat insulating material to have a good flameretardant effect and a fireproof function; a proper amount of gelatin powder is added to the white material, the problem of poor flexibility of the heat insulating material can be effectively solved,and the prepared heat insulating material is convenient to use; a proper amount of tributyl phosphate is added to the white material, the problem of higher water absorbency of the heat insulating material can be effectively solved, and the prepared heat insulating material is low in water absorption.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

Easy-to-rework foam dual-layer adhesive tape for assembling television

InactiveCN107502216AProne to stratificationSimple structureFilm/foil adhesivesThermoplastic polyurethaneUltimate tensile strength

The invention discloses an easy-to-rework foam dual-layer adhesive tape for assembling a television. The dual-layer adhesive tape comprises a thermoplastic polyurethane layer, a PU elastic layer and a PET layer, wherein the upper surface of the thermoplastic polyurethane layer is coated with a first acrylic pressure-sensitive adhesive layer, the lower surface of the thermoplastic polyurethane layer is bonded with the PU elastic layer by virtue of a second acrylic pressure-sensitive adhesive layer, the lower surface of the PU elastic layer is provided with the PET layer, and the outer surface of the PET layer is coated with a third acrylic pressure-sensitive layer. The easy-to-work foam dual-layer adhesive tape is simple in structure, high in strength, good in elasticity and toughness, high in heat conductivity, good in bonding performance, excellent in aging resistance, suitable for assembling the television and capable of improving the bonding performance after the assembly.

Owner:NANTONG KANGERLE MEDICAL MATERIALS CO LTD

Preparation method of body or door of refrigerator

ActiveCN104290235AImprove thermal insulation performanceTimely and fast dischargePolyesterMicrobubbles

The invention discloses a preparation method of a body or a door of a refrigerator. The method finishes the preparation of the body or the door of the refrigerator through such process steps as preheating, vacuumizing, pressure maintaining injection, pressure maintaining foaming and air cooling; and because of the effect of negative pressure, when polyether glycol, polyester glycol, cyclopentane and isocyanate are mixed to be injected in a body shell or a door shell, microbubbles generated in the foaming can be timely and quickly discharged, so that the resistance effect generated by the growing expansion of the microbubbles is prevented, the polyurethane foaming speed is quickened, and the insulating performance of the refrigerator is improved.

Owner:ZHEJIANG RIPU ELECTRONICS SCI & TECH

Facial cleanser foaming device

The invention discloses a facial cleanser foaming device. The device comprises a linkage chamber, a foaming chamber, a first storage chamber and a second storage chamber, and a second rotating motor is mounted on one side of the top in the linkage chamber; a driving shaft is arranged at the bottom end of an output shaft of the second rotating motor; a second gear is arranged in the middle of the driving shaft; a first gear is arranged on the side surface of the second gear; a driven shaft penetrates through the center of the first gear, stirring blades are arranged at the bottom end of the driving shaft and the bottom end of the driven shaft, a foaming chamber is arranged at the bottom of the linkage chamber, a first storage chamber is arranged on the side face of the linkage chamber, an equipment chamber is arranged at the top of the linkage chamber, and a first rotating motor is installed on one side of the interior of the equipment chamber. By means of powerful stirring, the foamingspeed of the facial cleanser is higher, foam is finer, smoother and denser, the cleaning effect is good, manual rubbing and foaming are not needed, and time and labor are saved; and the amount of thefacial cleanser and the amount of water can be accurately controlled, and the problems of excessive use amount, waste or insufficient use amount and poor cleaning effect are avoided.

Owner:上海梵木苒贸易有限公司

Preparation method for high-temperature lightweight tough mullite aggregate

ActiveCN110040995AIncrease productivityReduce manufacturing costCeramicwareFoaming agentPolymer science

The invention relates to a preparation method for a high-temperature lightweight tough mullite aggregate. According to the technical scheme, the preparation method comprises the following steps: mixing 40-65 parts of mullite powder, 5-25 parts of 94.5% silica powder, 20-55 parts of soft clay and 0.3-0.5 part of water reducer in parts by weight with water while stirring at a stirring rate of 500 rad / min, thereby fully mixing main materials and forming into a uniform slurry; adding 10-40 parts of foaming agent and 0.1-0.6 part of foam stabilizer into the uniform slurry. According to the invention, a manner of one-step foaming is combined with a unique stirring process, for fully and uniformly distributing the foaming agent into the slurry and lastly forming a foam slurry; the production process is simple and practicable; volume density of aggregate body is 0.5kg / m3-0.6kg / m3; volume density of sintered aggregate is 0.3kg / m3-0.4kg / m3.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Technology for fabricating foaming slag in arc furnace molten pool

ActiveCN104131134AGood effectAvoid wear and tearProcess efficiency improvementElectric furnaceAlkalinityElectric arc furnace

The invention discloses a technology for fabricating foaming slag in an arc furnace molten pool. The technology comprises the following steps: using a powder spraying tank and a powder spraying tank conveying pipeline to spray carbon powder containing powder material for producing foaming slag, into an arc furnace, controlling the slag alkalinity, FeO content, and molten pool temperature, wherein the carbon powder containing powder material for producing foaming slag is a graphite-like material, the fixed carbon content is not less than 80%, the water content is not more than 0.5%, the particle size is less than 3 mm; and continuously and evenly spraying the graphite-like material to the slag surface in the arc furnace to produce foaming slag when the temperature of the arc furnace molten pool reaches 1550 to 1600; wherein the spraying pressure is 0.3 to 0.5 MPa, the spraying strength is 15 to 25 kg / min, and the spraying amount is 6 to 7 kg / t. The graphite-like powder material is adopted to avoid the wear on the powder spraying tank conveying pipeline. Under an iron / water ratio of 30 to 75%, foaming slag operation during the whole process can be achieved, and the using amount of graphite-like material is reduced by 20% or more, compared to that of carbon powder. The graphite-like material is safer than the coke, and the service life of the conveying pipeline is prolonged.

Owner:LAIWU IRON & STEEL GRP

Prefoaming machine for foam pad plate preparation

The invention relates to a prefoaming machine for foam pad plate preparation, and solves the problems that the existing prefoaming machine generally belongs to a low-speed stirring type; gas is introduced through low-speed rotation blades; the bubble yield is small; the foaming efficiency is low, or the prefoaming machine belongs to a high-speed impeller type; air is introduced through a high-speed rotation impeller; the bubble diameter size cannot be controlled; the foam is not uniform; meanwhile, the whole moving is inconvenient; the pressure regulation is inconvenient; the pressure deviation can easily occur; the safety is poor. The prefoaming machine comprises a prefoaming machine body, wherein a bottom fixing plate is arranged at the bottom end of the prefoaming machine body; supportfeet are arranged at the bottom end of the bottom fixing plate; grooves are formed in positions, near the support feet, of the bottom end of the bottom fixing plate; a hydraulic cylinder is arranged at the top end, positioned at the groove, inside the bottom fixing plate. The prefoaming machine has the advantages that the structure is novel; the whole can conveniently move; meanwhile, high pressure is used, so that the bubble generating speed is high; the efficiency is high; the bubbles are uniform and fine; the pressure can be guaranteed; meanwhile, the warning on the pressure can be realized; the efficiency is high; safety and reliability are realized.

Owner:浏阳市华诚泡沫塑料制品有限公司

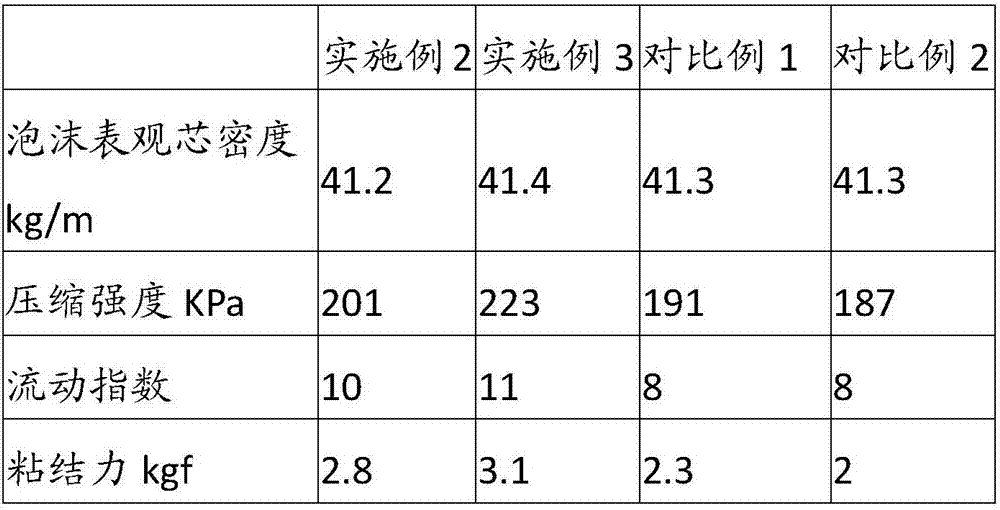

Foam composition, polyurethane plastic, and preparation method and application of polyurethane plastic

The invention provides a foam composition, a polyurethane plastic, and a preparation method and application of the polyurethane plastic. The foam composition is prepared from the following components in parts by weight: 70 to 90 parts of polyalcohol composition, 1 to 12 parts of composite catalyzing additive, 1 to 3 parts of water, and 1 to 1 parts of foaming agent HFC-245fa. The polyurethane plastic comprises isocyanate and the foam composition according to a mass ratio of (1.2 to 1.35):1, and is used for manufacturing sheets, heat-insulation containers, heat-insulation building outer walls and filling rolling gates. The prepared polyurethane plastic has the advantages that the fluidity is good, the foam strength is high, the binding force with substrate is high, the environment-friendly effect is realized, the appearance core density of foam reaches 41.2kg / m<3> or above, the compression strength reaches 201KPa or above, the fluidity index reaches 10 or above, the adhering force reaches 2.8kgf or above, and the foam property is excellent. The prepared polyurethane plastic is used for manufacturing the sheets, the heat-insulation containers, the heat-insulation building outer walls and the filling rolling gates.

Owner:广东宝丽多新材料科技有限公司

Foaming solution applied to environment-friendly mobile toilets

The invention discloses foaming solution applied to environment-friendly mobile toilets. The foaming solution is characterized by being prepared from the following components in percentage by weight: 60% of deionized water, 20% of sodium lauryl alcohol ether sulfate, 5% of fatty alcohol-polyoxyethylene ether, 5% of lauroyl glutamic acid, 5% of sodium chloride and 5% of sodium alginate. The foaming solution has the characteristics of being high in foaming speed, intensive in foam and low in cost, and has the function of effectively shielding the toilet mouths to ensure safety and health after being applied to mobile toilets.

Owner:上海华杰生态环境工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com