Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Promote secondary hydration reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

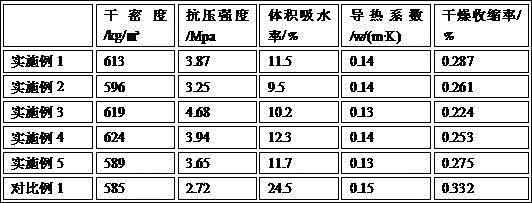

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

High folding resistance road concrete material and preparing method thereof

InactiveCN101265066AImprove compactnessImprove flexural strengthSolid waste managementSlagSodium fluoride

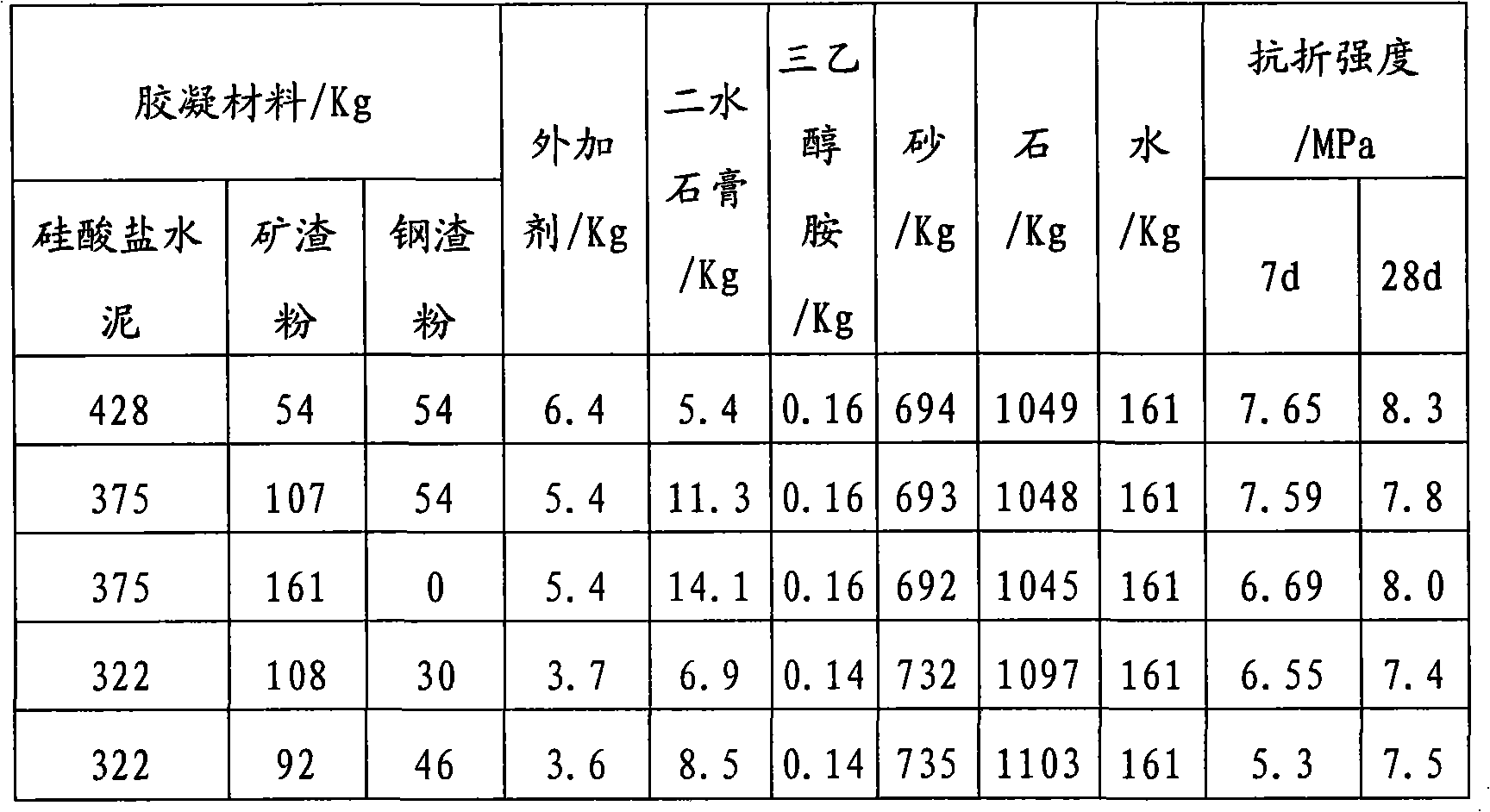

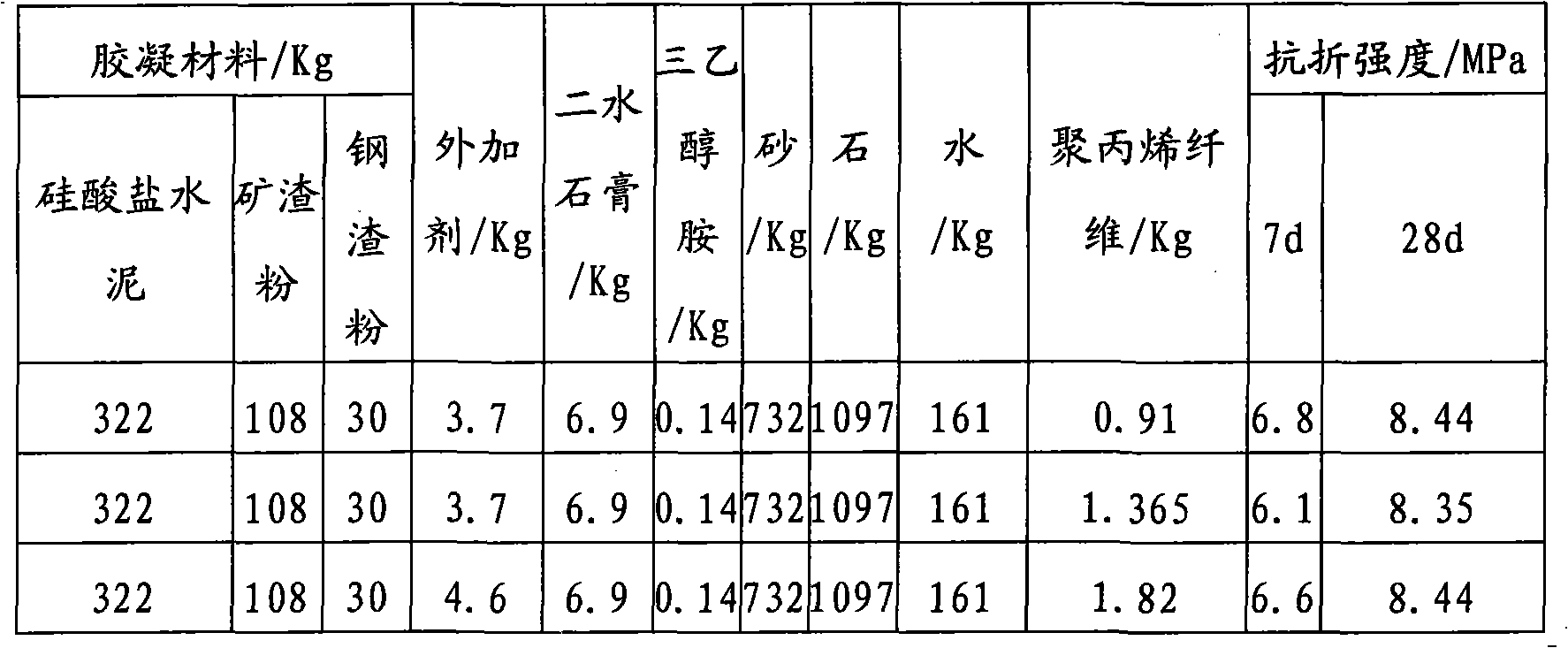

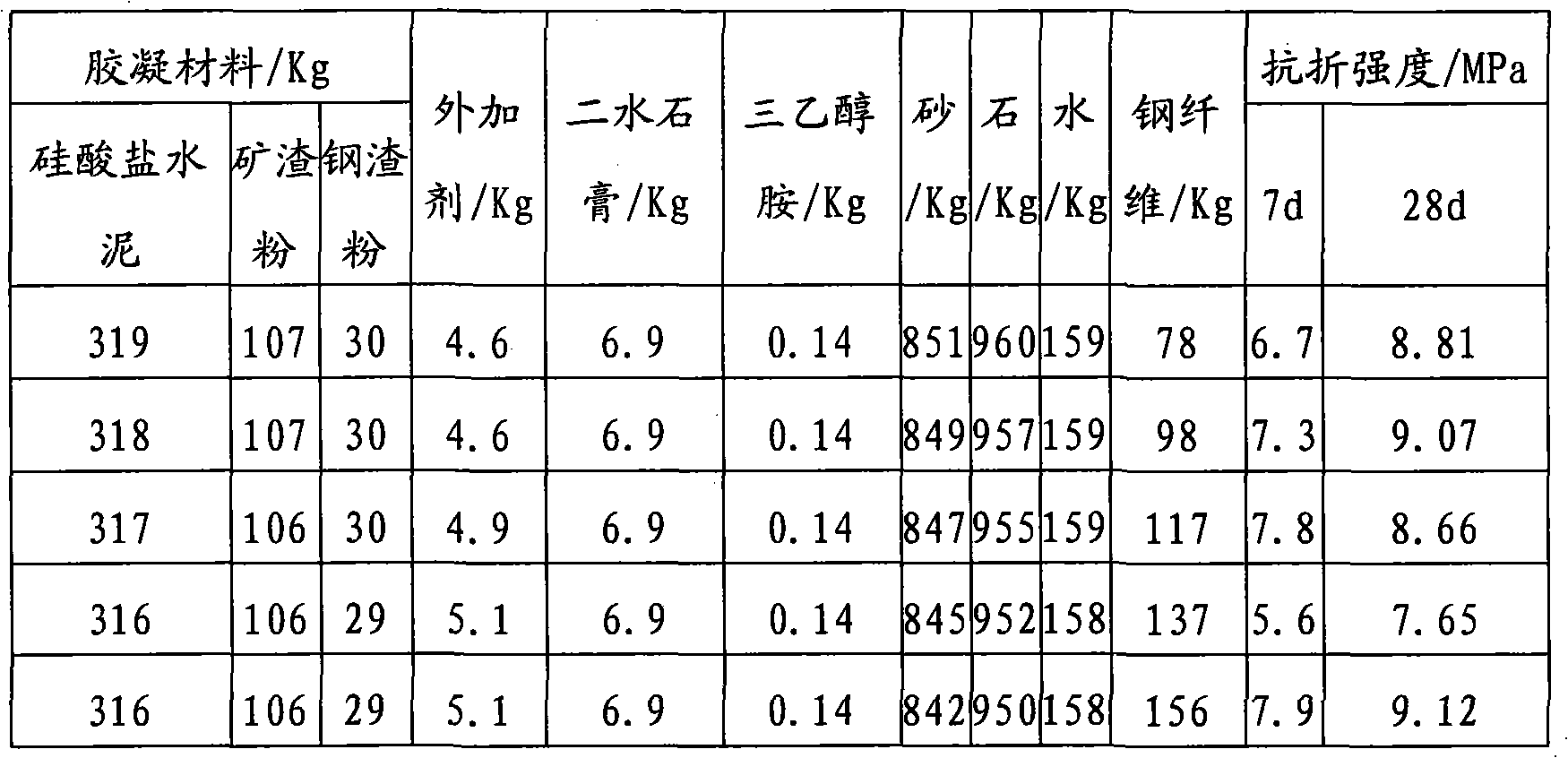

The invention discloses a road concrete material with high folding strength and a production method thereof. The road concrete material with high folding strength mainly contains binding agent, sand stone aggregate, mixing water, concrete admixture and excitant. The binding agent is composed of common silicate cement, ore slag powder and steel slag powder. The mass percentages of the components are as follows: 60-70% of common silicate cement, 20-30 % of ore slag powder and 0-10% of steel slag powder. The additional amount of the excitant is 5.0-10.0% of the total mass of the ore slag powder and the steel slag powder. The excitant is selected from gypsum, sodium sulfate, sodium fluoride, triethanolamine or a mixture thereof. By adding the excitant, the latent activity of the ore slag and the steel slag is excited, so that the compactness of concrete is improved and the folding strength of the road concrete is greatly improved.

Owner:SHENZHEN UNIV

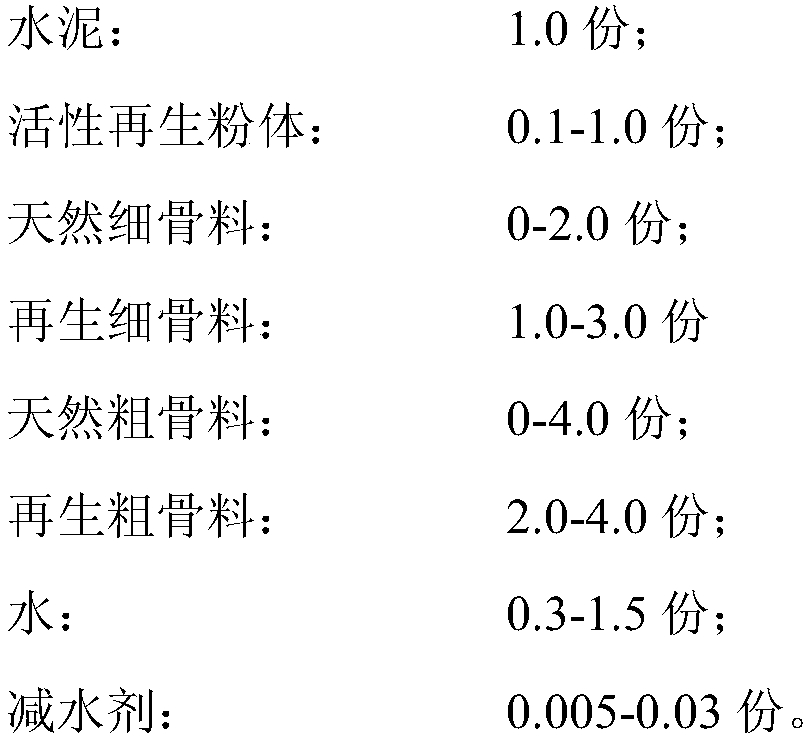

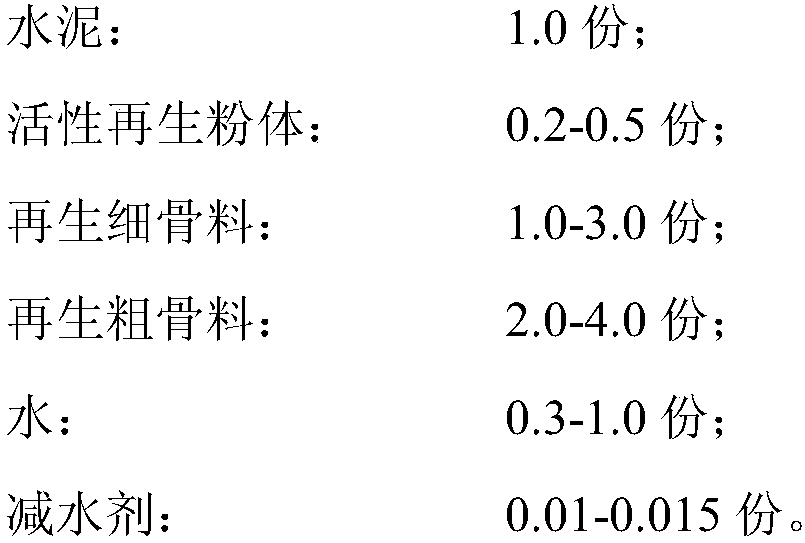

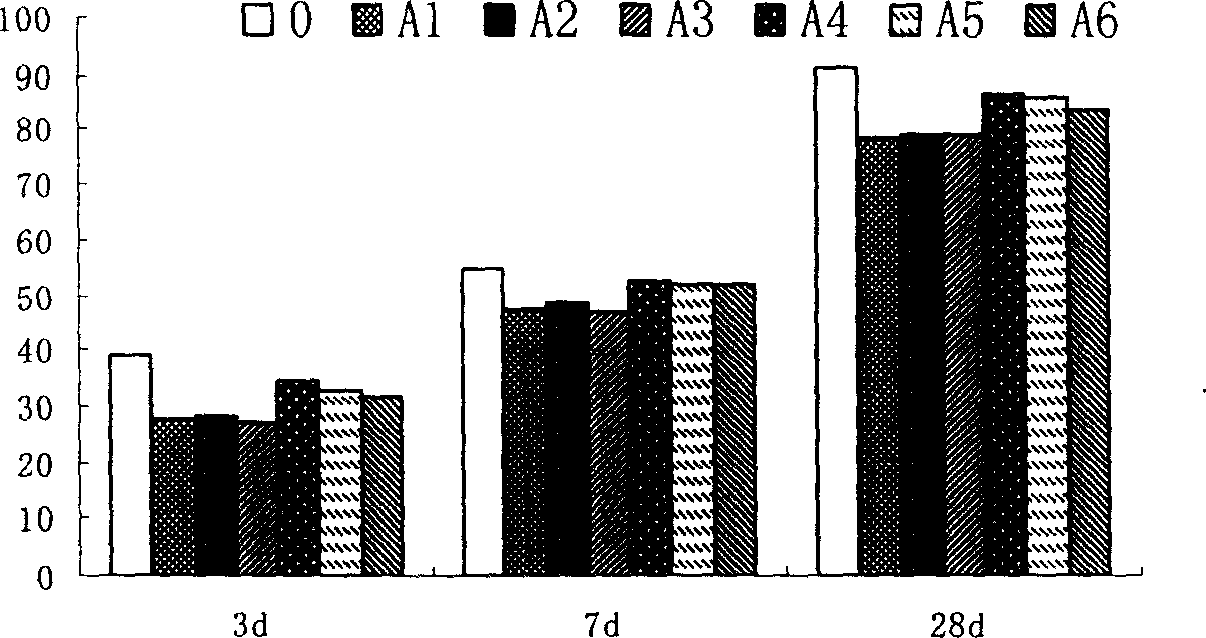

Regenerated concrete block material and production method thereof

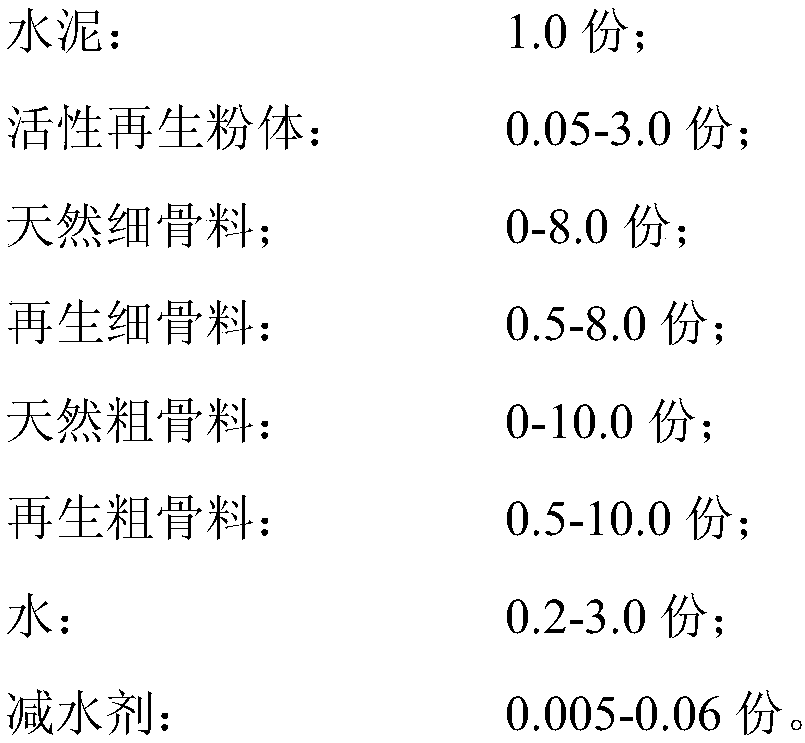

InactiveCN108558303AImprove resource utilizationReduce manufacturing costSolid waste managementCement productionSocial benefitsHydration reaction

The invention provides a formula for preparing a regenerated concrete block material by using high activity regenerated powder and a regenerated aggregate. The invention further provides a productionmethod of the regenerated concrete block material based on a system of 'regenerated powder-regenerated coarse aggregate-regenerated fine aggregate'. The regenerated concrete block material prepared byusing the system of 'regenerated powder-regenerated coarse aggregate-regenerated fine aggregate' has excellent mechanical strength, the strength level range is 5-50 MPa, and the requirements of the concrete block material strength under different working conditions are met. The invention provides a novel developing route for the resource recycling of construction wastes. The performance of the regenerated powder is similar to the performance of mineral admixture such as fly ash and the like, the activity is higher, secondary hydration reaction of a cement-based material can be promoted to relieve the current situation of insufficient supplying of mineral admixture such as fly ash and the like, and the regenerated concrete block material has higher economic benefit and social benefit.

Owner:TONGJI UNIV

High-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete and preparation method thereof

The invention discloses high-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete and a preparation method thereof. The high-strength, high-toughness, high-heat conductivity and high-impermeability large-volume concrete comprises cement, fly ash, silicon powder, steel slag powder, boron nitride, graphene oxide flake powder, sand, gravel, high-strength polyvinyl alcohol fiber, a polycarboxylic acid water reducing agent, a dispersion activator, a modified graphene oxide dispersion and water. The obtained concrete has the initial and 28-day-old heat conductivity of 6.26-7.53W / (m.K) and 9.58-12.73W / (m.K) respectively and has the capability of dispersing and conducting cement hydration heat and resisting temperature cracks caused by environment temperature change; 28-day-old concrete has the compressive strength of 87.6-116.7MPa, the rupture strength of 17.6-19.5MPa, the splitting tensile strength of 11.7-12.6MPa, the bending tensile strength of 12.4-13.8MPa and the bending tensile modulus of 45.7-52.5GPa; the water permeability resistance, the chloride ion permeability resistance, the freeze-thaw resistance and the carbonation resistance reachthe highest levels; and the prepared concrete has good social and economic benefits.

Owner:SHAANXI UNIV OF SCI & TECH

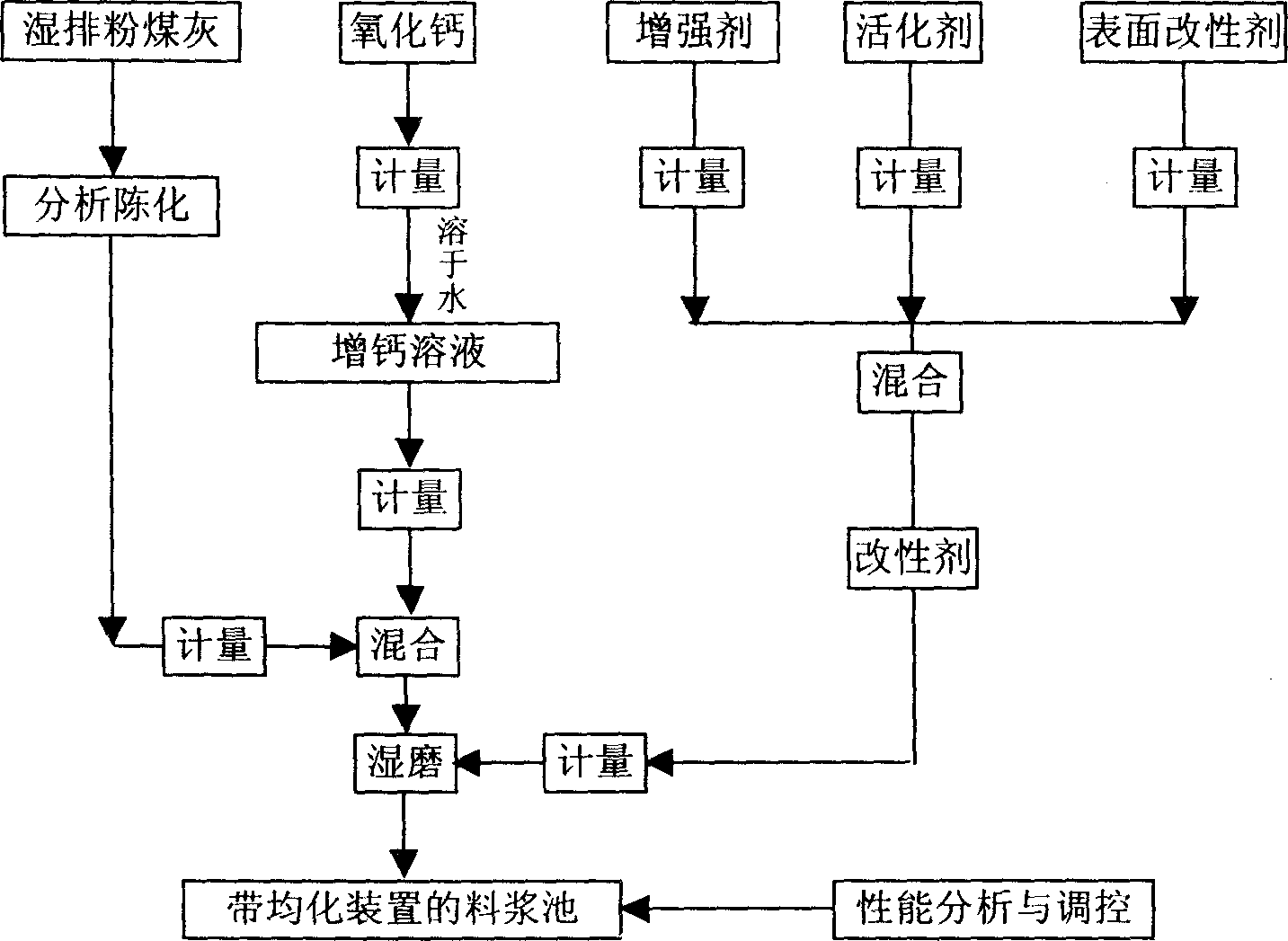

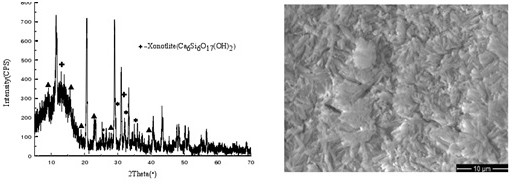

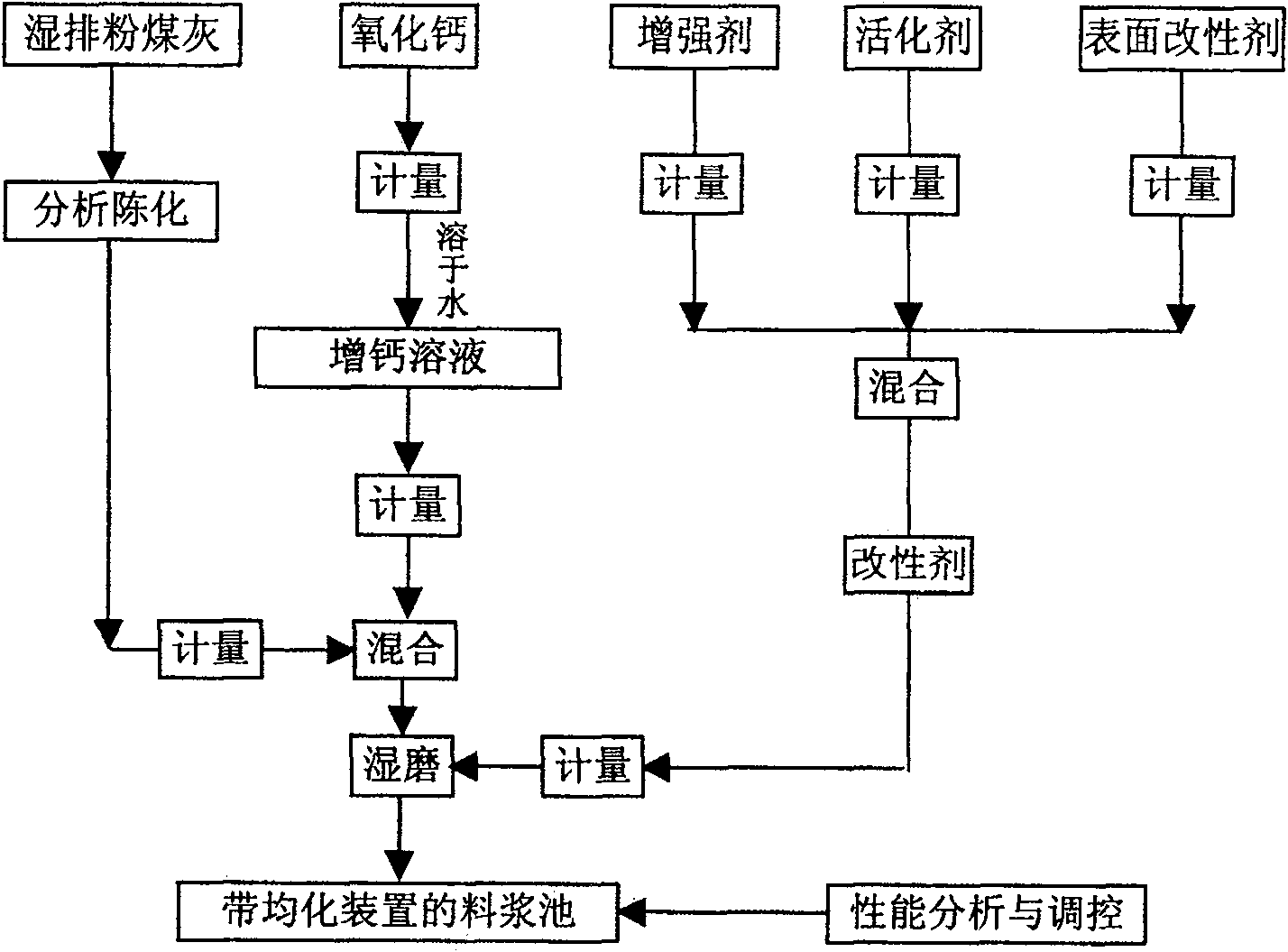

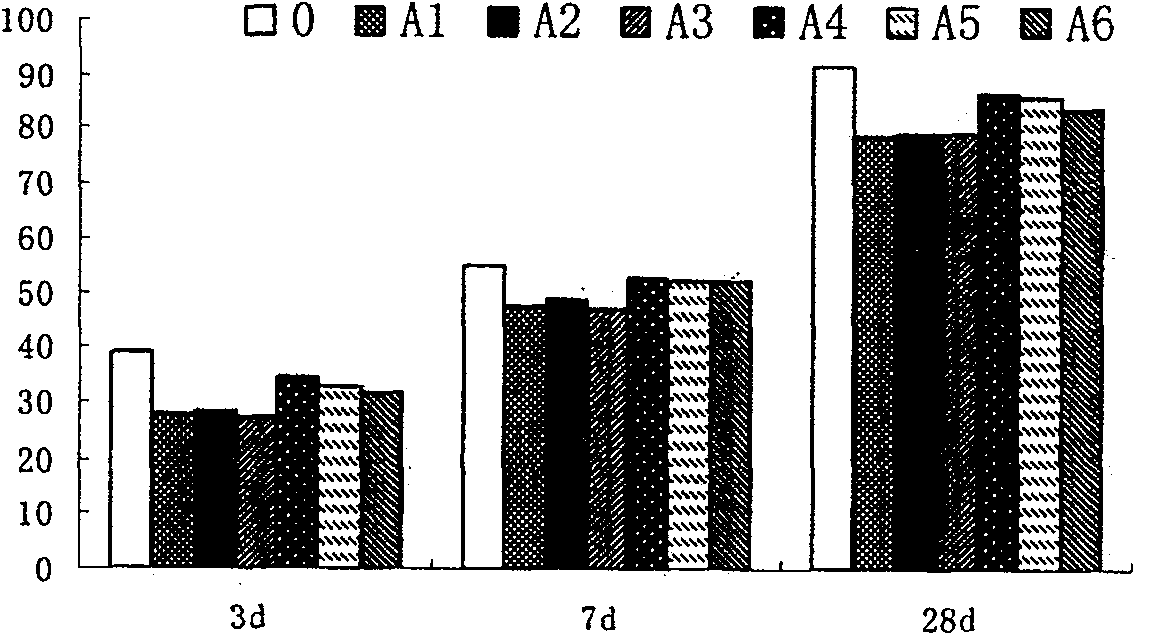

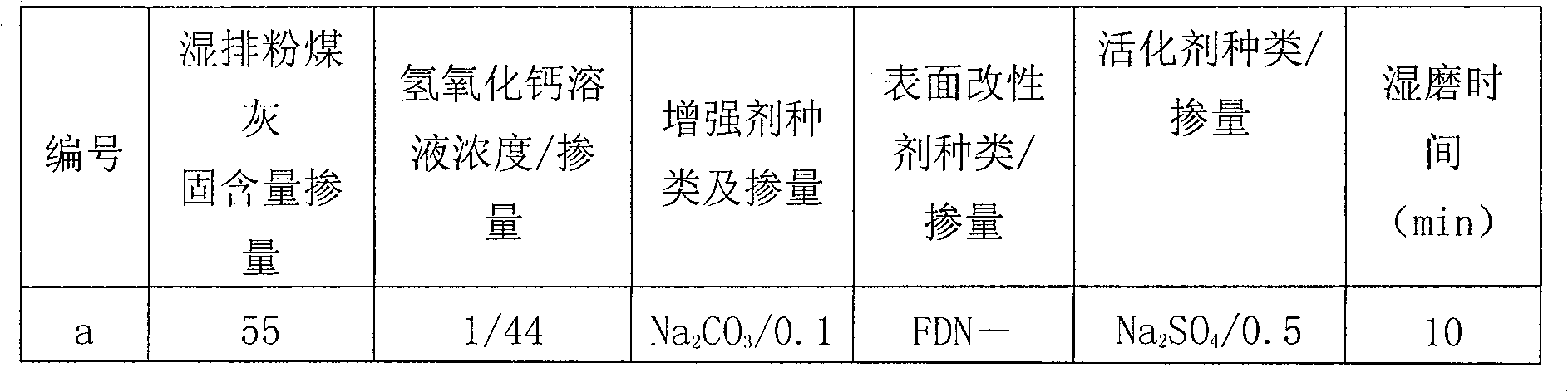

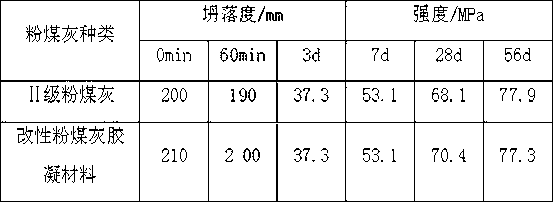

High-activity admixture slurry made of wet fly-ash and method for preparing same

The invention discloses high-active doping slurry and preparing method, which comprises the following parts: 55-65 percent wet-discharge coal ash, 30-44 percent calcium-increasing solution and 1-5 percent modifier, wherein the calcium-increasing solution is calcium hydroxide solution; the modifier is composed of 10-30 percent reinforcer, 20-40 percent surface modifier and 30-50 percent activist.

Owner:WUHAN UNIV OF TECH

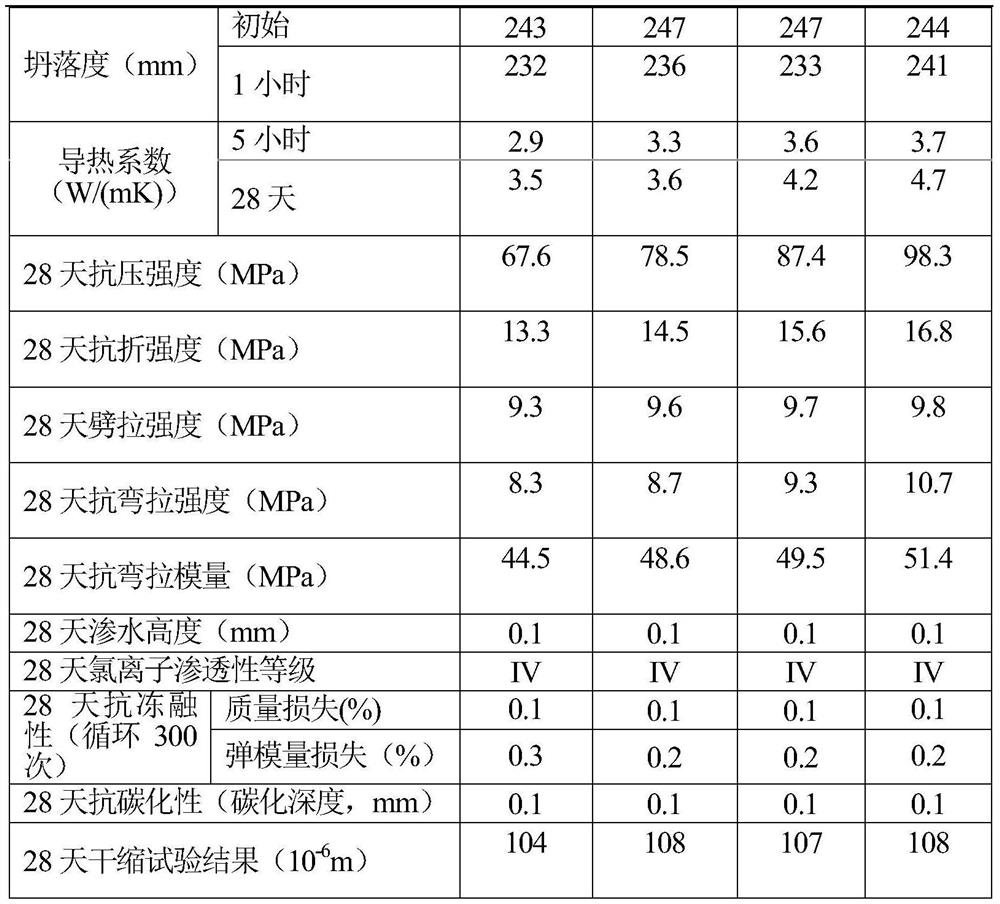

Concrete with anti-cracking, anti-seepage and high-durability effects and preparation method thereof

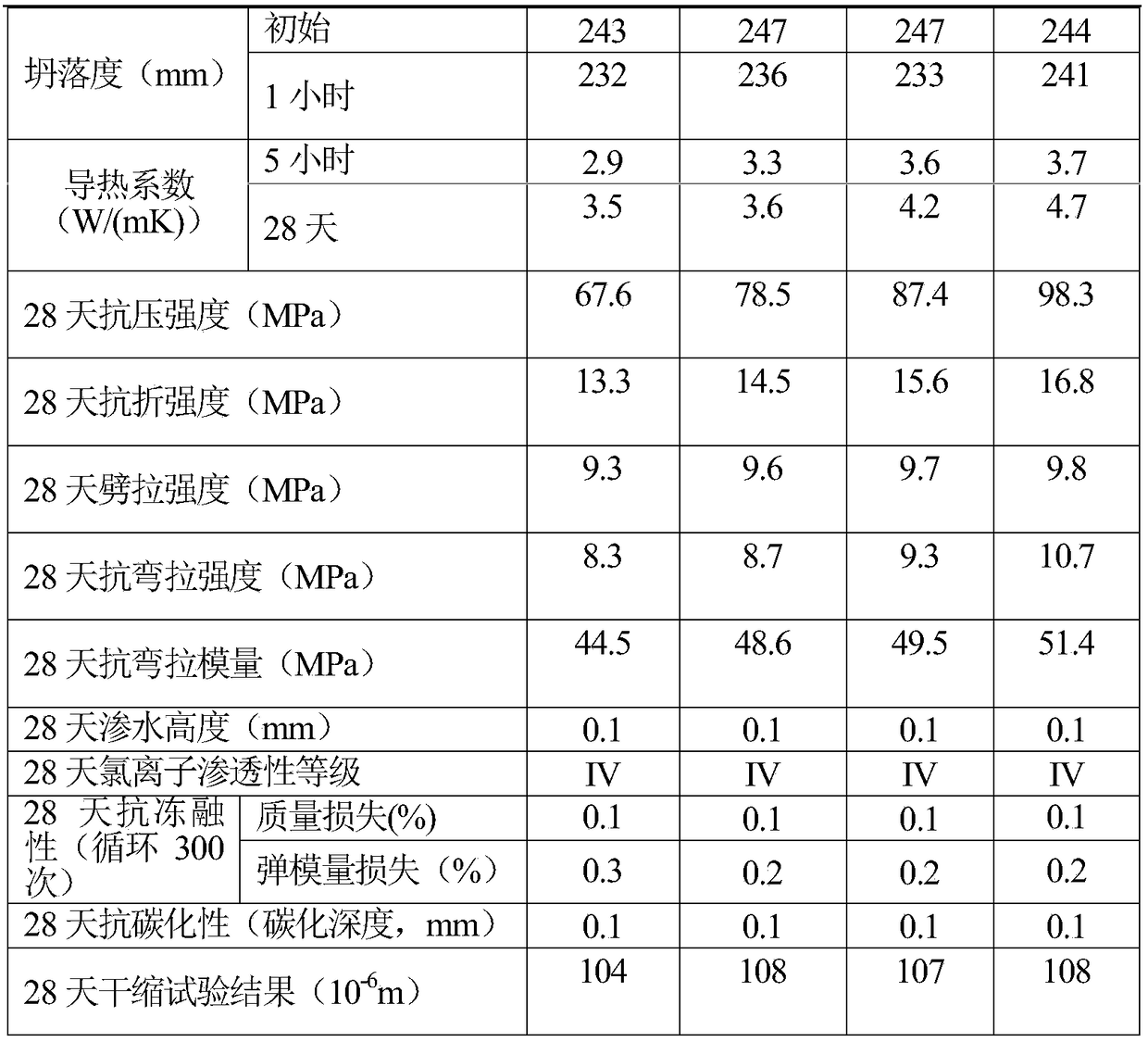

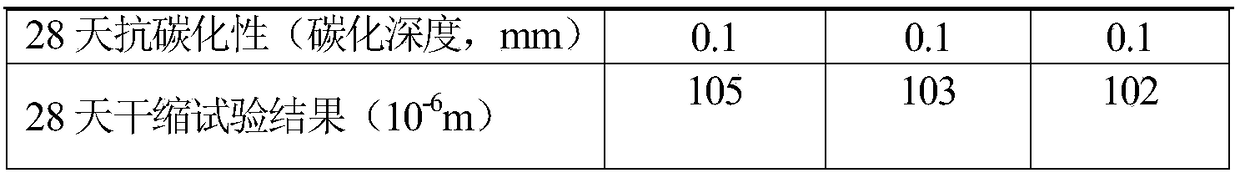

The invention relates to a concrete with anti-cracking, anti-seepage and high-durability effects and a preparation method thereof. The concrete is prepared from the following components of cement, flyash, silicon powder, coal gangue powder, boron nitride, phosphor residue powder, sand, crushed stone, high-strength polyvinyl alcohol fiber, a water reduction agent, a dispersing activator, a modified graphene oxide dispersion liquid and water. The concrete has the advantages that the heat conduction coefficient in the 1h age period is 2.9 to 3.7W / (m.K), the heat conduction coefficient in the 28-day age period is 3.5 to 4.7W / (m.K), the compressive strength is 67.6 to 98.3MPa, the break strength is 13.3 to 16.8MPa, the split strength is 9.3 to 9.8MPa, the tensile strength is 8.3 to 10.7MPa, and the tensile elastic modulus is 44.5 to 51.4GPa; the anti-water permeation property, anti-chlorine ion permeation property, anti-freezing and thawing property, and anti-carbonizing property can reachthe highest level; the working property is high, the volume stability is high, the durability is high, the toughness is high, the anti-cracking ability is high, and the anti-seepage ability is high.

Owner:CHONGQING YABO BUILDING MATERIALS CO LTD

Steel-slag inflaming-retarding heat-preservation foam concrete and preparing method thereof

InactiveCN106220067AReduce water consumptionReduce volumeSolid waste managementCeramicwareIndustrial wasteScrap

The invention discloses a steel-slag inflaming-retarding heat-preservation foam concrete. The steel-slag inflaming-retarding heat-preservation foam concrete is prepared from, by mass, 30-60 parts of cement, 30-70 parts of steel-slag water washing dust sludge, 10-40 parts of steel slag composite powder, 0.05-1.0 part of water reducing agent, 0.02-0.2 part of thickening agent, 0.05-1.0 part of water repellent, 1-10 parts of sintered desulfurized ash, 0.06-0.2 part of anti-cracking agent, 0.1-0.4 part of foaming agent and 0.30-0.60 part of water. The steel-slag inflaming-retarding heat-preservation foam concrete has the advantages that the preparing technology is simple, the foam concrete is high in strength, low in shrinkage, good in hydrophobicity, excellent in heat insulation performance and capable of meeting different heat preserving requirements of buildings, industrial waste such as the steel-slag water washing dust sludge, the steel slag composite powder and the sintered desulfurized ash is sufficiently used, and the excellent waste-utilizing and energy-saving environment-protection effect and good economic benefits are achieved.

Owner:广西玉林市绿盛科贸有限责任公司

High-flow-state anti-cracking concrete and preparation method thereof

InactiveCN111484282AImprove crack resistanceImprove impermeabilitySolid waste managementEpoxyWater reducer

The invention relates to high-flow-state anti-cracking concrete comprising the following components in parts by weight: 220-430 parts of cement, 130-200 parts of water, 30-90 parts of fly ash, 70-130parts of mineral powder, 550-880 parts of a fine aggregate, 1100-1350 parts of a coarse aggregate, 6-15 parts of a super absorbent resin particles, 20-60 parts of sponge rubber particles, 3-15 parts of steel fibers, 2-8 parts of epoxy resin and 4-10 parts of a water reducing agent, wherein the sponge rubber particles are formed by crushing sponge rubber. The preparation method comprises the steps:S1, uniformly mixing the super absorbent resin particles with the sponge rubber particles; S2, adding the mixture obtained in the step S1 into water to enable the super absorbent resin particles andthe sponge rubber particles to pre-absorb water, so as to obtain a pre-water-absorbing mixture; and S3, mixing the cement, the fly ash, the mineral powder, the fine aggregate, the coarse aggregate, the steel fibers, the epoxy resin, the water reducing agent, water and the pre-water-absorbing mixture, and uniformly stirring to obtain the high-flow-state anti-crack concrete. The high-flow-state anti-cracking concrete is good in anti-cracking performance and has the effect of improving the durability of the concrete.

Owner:上海练定新材料科技有限公司

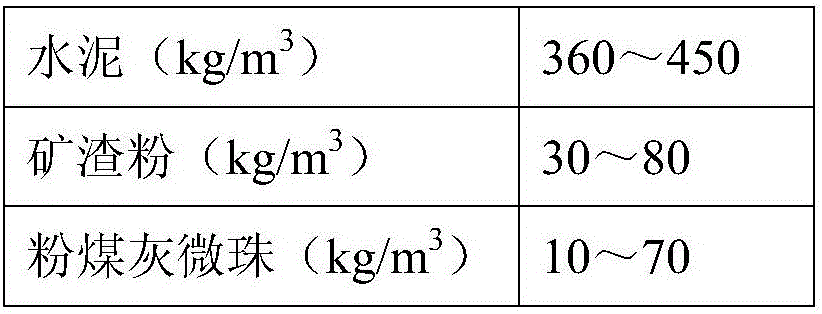

Concrete for large tubular pile of autoclaving-free process

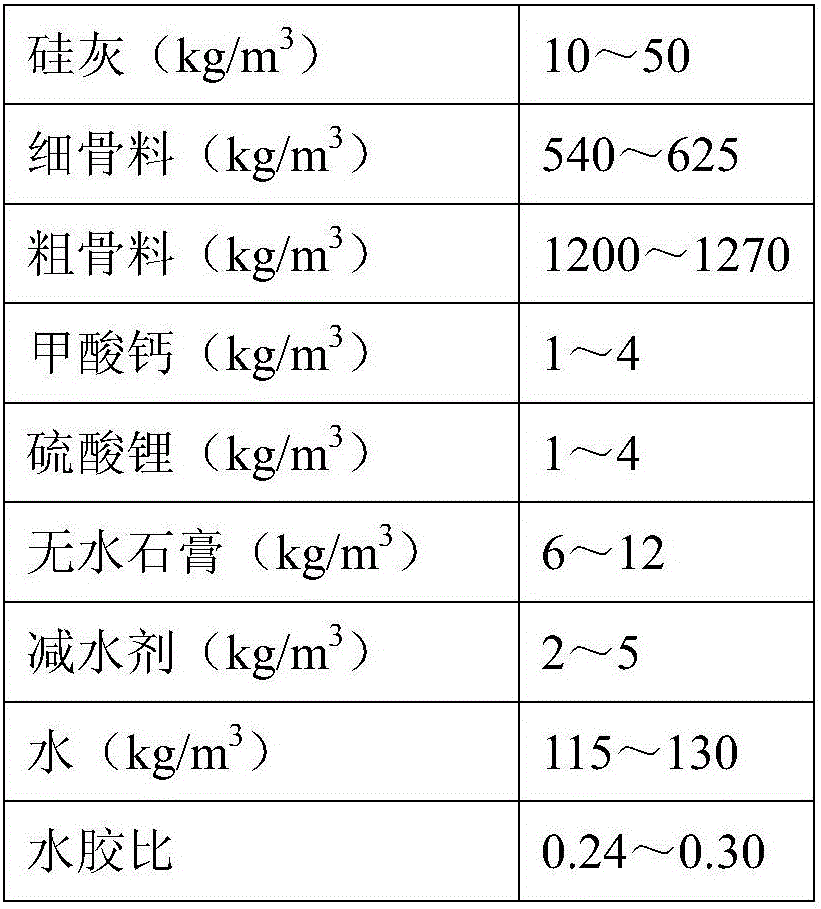

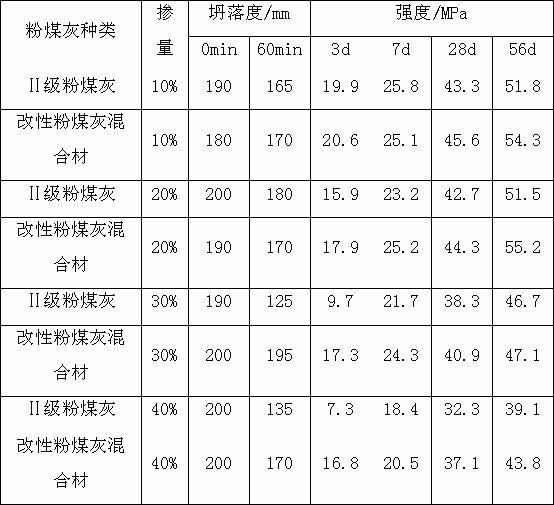

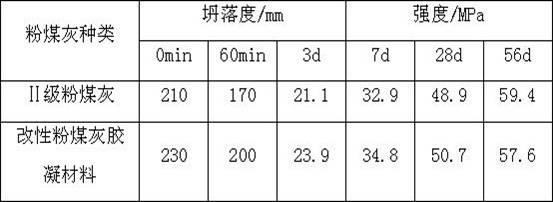

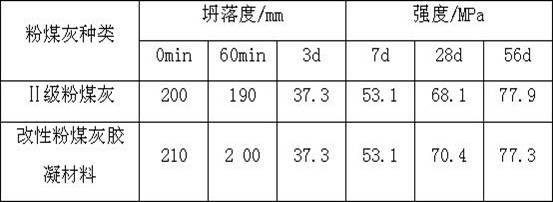

The invention belongs to the technical field of concrete materials, and in particular relates to concrete for a large tubular pile of an autoclaving-free process. Each cubic meter of preparation materials of the concrete comprise the following components: 360-450kg of cement, 30-80kg of slag powder, 10-70kg of coal ash microbeads, 10-50kg of silicon ash, 540-625kg of fine aggregate, 1200-1270kg of coarse aggregate, 1-4kg of calcium formate, 1-4kg of lithium sulfate, 6-12kg of anhydrite, 2-5kg of a water reducing agent and 115-130kg of water. A series of tests and studies on the proportioning ratio of the concrete provided by the invention are implemented, and an optimal concrete proportioning ratio which can meet the requirement of large tubular pile demolding strength and strength of C60 concrete within a relatively short time at a normal temperature can be obtained.

Owner:CCCC THIRD HARBOR ENG +2

Anti-crack, anti-permeability and high-durability concrete and preparation method thereof

ActiveCN109293303AImprove toughnessImprove penetration resistanceSolid waste managementFiberCrack resistance

Provided are anti-crack, anti-permeability and high-durability concrete and a preparation method thereof; the concrete is prepared from cement, silica powder, boron nitride powder, sand, polyvinyl alcohol fibers, crushed stone, fly ash, coal gangue powder, phosphorus slag powder, a water reducing agent, a dispersing activator, a modified graphene oxide dispersion liquid and water. The thermal conductivity coefficients of the obtained concrete at 1 h and 28 days of age is 2.62-3.23 W / (m*K) and 3.53-4.35 W / (m*K) respectively, the compressive strength at 28 days of age is 38.7-57.6 MPa, the breaking strength is 13.3-14.6 MPa, the splitting tensile strength is 8.4-9.7 MPa, the bending-tensile strength is 7.3-9.0 MPa and the bending-tensile elasticity modulus is 28.7-33.4 GPa. Meanwhile, all the water permeability resistance, chloride ion permeability resistance, freeze-thaw resistance and carbonization resistance reach the best level. The concrete has high workability, high volume stability and abilities of high durability, high toughness, high crack resistance and high permeability resistance, and is suitable for the requirements of ordinary high performance concrete under various complex environmental conditions.

Owner:衢州鑫业建材有限公司

Low grade fly ash mixed slurry used for concrete and preparation method thereof

InactiveCN102633474AImprove the environmentPromote hydrationSolid waste disposalLower gradeLow graded

The invention discloses a low grade fly ash mixed slurry used for concrete. The mixed slurry is prepared by wet grinding the following components by mass percent: 35-55% of low grade fly ash, 9-16% of industrial residue, 1-4% of modifying agent and 35-45% of mixing plant recycled water; and the mixing plant recycled water contains the quality of the water in the low grade fly ash. The invention also discloses a preparation method of the low grade fly ash mixed slurry used for the concrete. The invention provides a low grade fly ash mixed slurry used for the concrete and a preparation method, wherein the mixed slurry is high in activity, low in cost and high in waste utilization rate.

Owner:XIAMEN TIANRUN JINLONG BUILDING MATERIAL

High-tenacity high-anti-permeability high-durability concrete and preparation method thereof

ActiveCN109231918AImprove crack resistanceHigh compressive strengthSolid waste managementFiberCrack resistance

The invention discloses high-tenacity high-anti-permeability high-durability concrete and a preparation method thereof. The high-tenacity high-anti-permeability high-durability concrete comprises cement, coal ash, silica powder, steel slag powder, boron nitride, low-concentration oxidized graphene slice layer powder, phosphorus slag powder, sand, gravels, high-strength polyvinyl alcohol fibers, awater reducing agent, a dispersing excitant, modified oxidized graphene dispersion liquid and water. The prepared concrete has high-strength, high-tenacity, high-crack-resistance, high-anti-permeability and high-durability. A heat conductivity coefficient of the concrete is 3.63-3.75 W / (mK), a heat conductivity coefficient of 28 days of aged concrete is 4.62-4.67 W / (mK), compressive strength is 135.4-156.2 MPa, breaking strength is 21.5-23.9 MPa, splitting strength is 12.6-14.4 MPa, flexural strength is 15.4-19.6 MPa, and an anti-bending elastic modulus is 47.7-61.2 GPa. The prepared concreteis in comply with requirements of the C130-C150 high-performance long-durability concrete.

Owner:广州天达混凝土有限公司

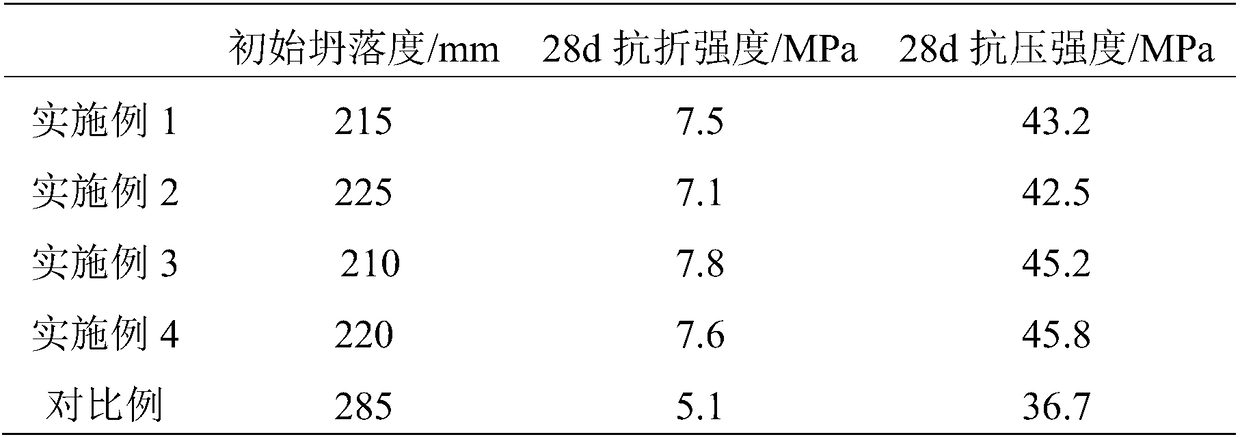

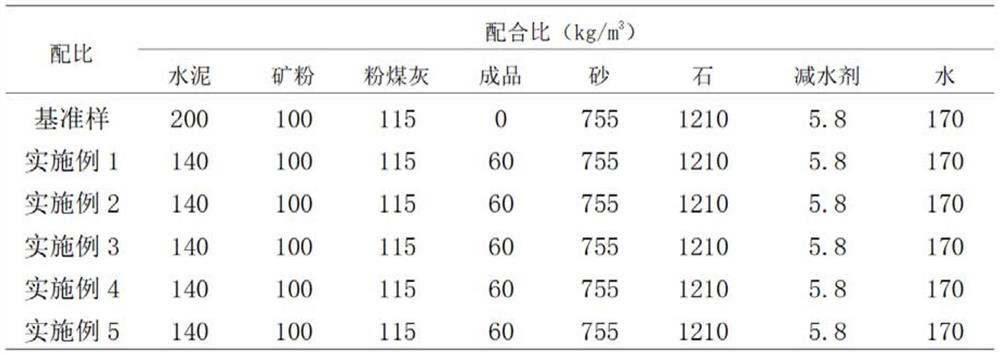

Road concrete and preparation method thereof

ActiveCN106431144AIncrease profitOvercoming performance deficienciesSolid waste managementBreaking strengthSlag

The invention discloses road concrete. The concrete is prepared from components in parts by mass as follows: 50-80 parts of Portland cement, 20-40 parts of ferro-nickel slag micropowder, 10-24 parts of slag powder, 5-10 parts of fly ash, 5-10 parts of steel slag micropowder, 40-300 parts of fine aggregate, 300-400 parts of coarse aggregate, 1.2-1.5 parts of an additive, 0.8-2 parts of an activator and 50-80 parts of water. All the components are mixed in a mixer, the road concrete is prepared, the preparation method is simple, and the technical requirement is not high. The ferro-nickel slag micropowder and the slag powder are added to the road concrete to serve as main admixtures, the superimposed effect of all the mixed components is played, the components complement one another, and the performance deficiency caused by simple mixing of certain components is avoided; the activator is added, the utilization rate of the ferro-nickel slag micropowder can be remarkably increased, the production cost can be reduced, the activity of the ferro-nickel slag micropowder, the slag powder, the fly ash and the steel slag micropowder is fully played, and the breaking strength and compressive strength of the road concrete are greatly improved.

Owner:YOUNGWOO CHEMTECH

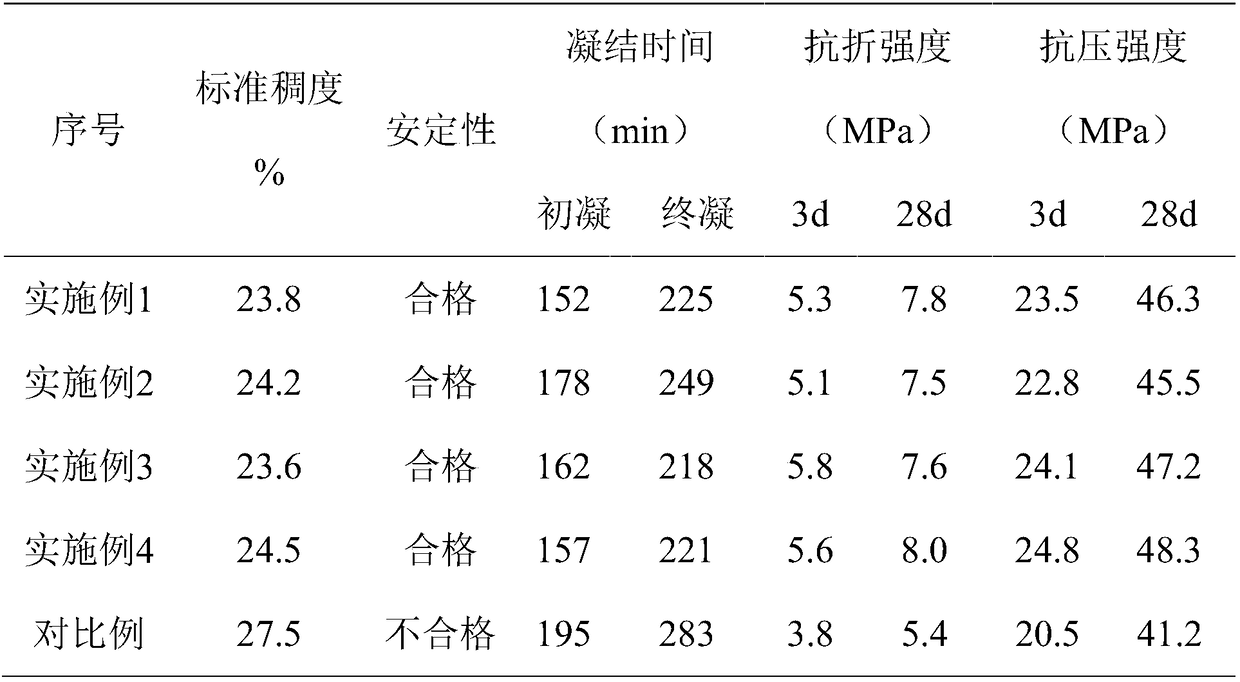

Early-strength sulphoaluminate cement paste capable of being easily pumped, and preparation method thereof

InactiveCN108409267AShorten the timeDoes not affect mobility too muchHydration reactionToxic industrial waste

The invention provides an early-strength sulphoaluminate cement paste capable of being easily pumped, and a preparation method thereof. The accumulation of industrial waste materials can be reduced, the practical input of cement can be reduced, and economic cost is lowered. The preparation method for the early-strength sulphoaluminate cement paste capable of being easily pumped is characterized inthat the sulphoaluminate cement paste is taken as a base stock, high-calcium fly ash is taken as modifier, and lithium carbonate is taken as modified modifier to be blended to obtain the early-strength sulphoaluminate cement paste, wherein the mass ratio of the sulphoaluminate cement, the high-calcium fly ash to lithium carbonate is (75-85):(15-25):(0.01-0.025). According to the early-strength sulphoaluminate cement paste, the initial setting time and the final setting time of the sulphoaluminate cement can be obviously shortened, in addition, the fluidity of the cement can not be excessivelyaffected, the secondary hydration reaction of the high-calcium fly ash can be fully accelerated, and the compressive strength of the sulphoaluminate cement paste base material can be effectively enhanced.

Owner:WUHAN UNIV OF SCI & TECH

High-toughness, high-permeability-resistance and high-durability concrete for seawater environment and preparation method thereof

PendingCN109293302AImprove the strengthening and toughening effectImprove penetration resistanceFreeze thawingFiber

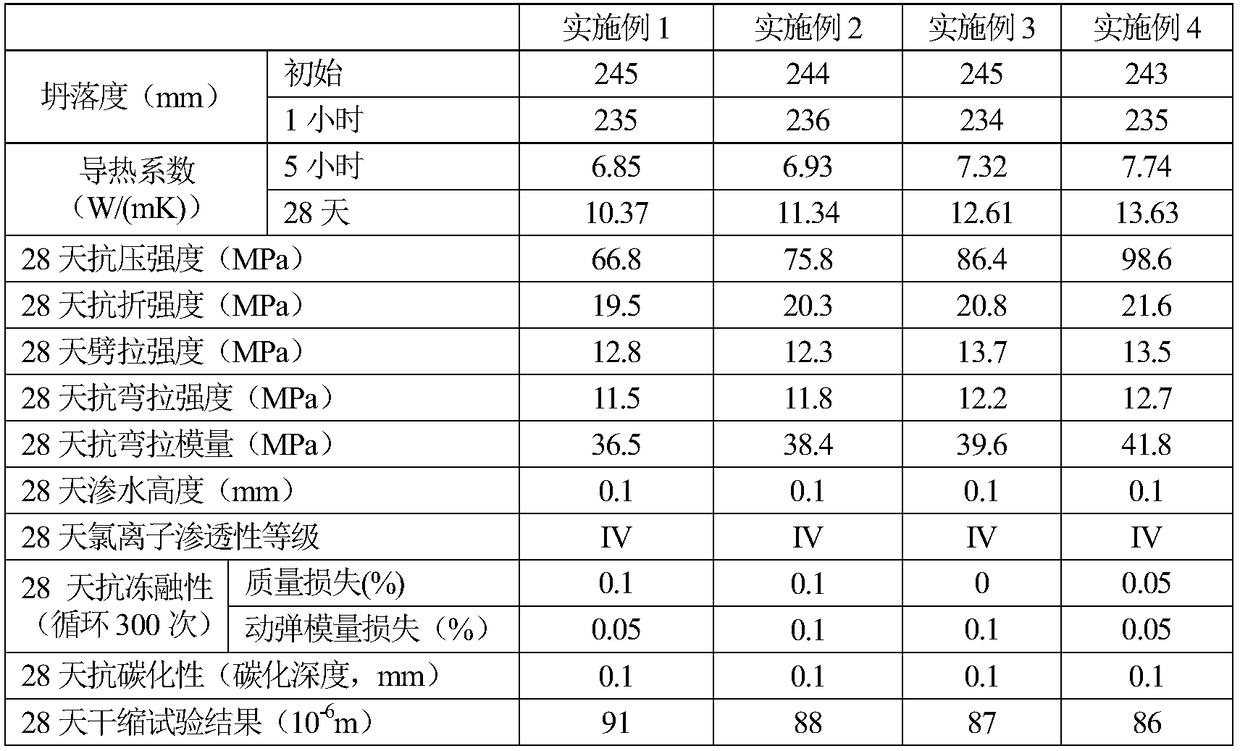

Provided are high-toughness, high-permeability-resistance and high-durability concrete for a seawater environment and a preparation method thereof. The concrete is prepared from cement, fly ash, silica powder, phosphorus slag powder, boron nitride, low-grade graphene oxide lamellar powder, sand, gravel, high-strength polyvinyl alcohol fibers, a polycarboxylic acid water reducer, a dispersing activator, a modified graphene oxide dispersion solution and water. The initial and 28-day age thermal conductivity coefficients of the obtained concrete are 6.85-7.74 W / (m*K) and 10.37-13.63 W / (m.K) respectively; the concrete has the ability to eliminate cracks caused by hydration heat and environmental temperature. The compressive strength of the concrete at 28-day age is 66.8-98.6 MPa, the breakingstrength is 19.5-21.6 MPa, the splitting tensile strength is 12.8-13.5 MPa, the bending tensile strength is 11.5-12.7 MPa, and the bending tensile elasticity modulus is 36.5-41.8 GPa; and the chlorideion penetration, freeze-thawing, carbonization and the like almost have no effect on the properties.

Owner:SHAANXI UNIV OF SCI & TECH

High-toughness, high-impermeability and high-durability concrete and preparation method thereof

The invention discloses high-toughness, high-impermeability and high-durability concrete and a preparation method thereof. The concrete is prepared from cement, coal ash, silicon powder, steel slag powder, boron nitride, low-alcohol graphene oxide sheet powder, phosphorus slag powder, sand, gravels, high-intensity polyvinyl alcohol fibers, a water reducing agent, a dispersive activator, modified graphene oxide dispersion liquid and water. The prepared concrete has a heat conduction coefficient of 3.46 to 4.32 W / (m.K) in the age of 1 hour, and has a heat conduction coefficient of 4.83 to 5.54 W / (m.K), the compressive strength of 106.8 to 127.5 MPa, the breaking strength of 17.3 to 19.8 MPa, the splitting tensile strength of 10.7 to 11.8 MPa, the bending strength of 11.2 to 12.7 MPa and an anti-bending elastic modulus of 52.6 to 57.6 GPa in the age of 28 days; meanwhile, the water impermeability, the chloride ion impermeability, the freeze-thawing property and the carbonization resistance of the concrete are at the best level.

Owner:SHAANXI UNIV OF SCI & TECH

Carbon fiber reinforced nano metakaolin recycled concrete and preparation method thereof

The invention belongs to the technical field of recycled concrete, and particularly relates to carbon fiber nano metakaolin recycled concrete and a preparation method thereof.The recycled concrete is prepared from, by weight, 0-3.5 parts of carbon fibers, 0-45 parts of nano metakaolin, 175-1166 parts of recycled coarse aggregate, 0-991 parts of natural coarse aggregate, 656 parts of natural fine aggregate and 3.7 parts of sodium dodecyl benzene sulfonate; 328 to 373 parts of cement and 215 to 249 parts of water; the recycled concrete has the advantages of good compressive strength, good splitting tensile strength, good ductility and the like, the used raw materials are low in cost, and a foundation is laid for wide application of the recycled concrete while the problem of environmental pollution caused by construction waste is solved and the problem of over mining of natural coarse aggregate is relieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

A kind of road concrete and preparation method thereof

ActiveCN106431144BOvercoming performance deficienciesImprove flexural strengthSolid waste managementBreaking strengthPortland cement

The invention discloses a road concrete, which comprises the following components in parts by mass: 50-80 parts of Portland cement, 20-40 parts of ferronickel slag micropowder, 10-24 parts of slag powder, and 5-10 parts of fly ash 5-10 parts of fine steel slag powder, 40-300 parts of fine aggregate, 300-400 parts of coarse aggregate, 1.2-1.5 parts of admixture, 0.8-2 parts of activator, and 50-80 parts of water. The road concrete of the invention is prepared by stirring and mixing components in a mixer, the preparation method is simple, and the technical requirements are not high. Add ferronickel slag micropowder and slag powder to the road concrete of the present invention as the main admixture, exert the "superposition effect" between the various admixture components, complement each other's advantages, and avoid the performance defects caused by single admixture of a certain component; By adding the activator, the utilization rate of ferronickel slag powder can be significantly improved, and the production cost can be reduced. At the same time, the activity of ferronickel slag powder, slag powder, fly ash and steel slag powder can be fully exerted, which greatly improves the resistance of road concrete. flexural strength and compressive strength.

Owner:YOUNGWOO CHEMTECH

Two-dimensional reinforced hydraulic cementing material based on granite stone powder

PendingCN113716886AOptimizing the Group Distribution RatioImprove adhesionCement productionCalcium hydroxideMineral Sources

The invention provides a two-dimensional reinforced hydraulic cementing material based on granite stone powder, which is prepared by weighing the following raw materials, by mass: 45-60 parts of granite stone powder, 25-35 parts of furnace bottom slag, 7-12 parts of cement clinker, 2-3 parts of desulfurized gypsum, 1-3 parts of calcium hydroxide, 1-3 parts of water glass, 1-3 parts of sodium hydroxide and 0.03-0.04 part of few-layer graphene. The hydraulic cementing material is prepared by mixing the raw materials, so that the deep processing technology of the granite stone powder is expanded, the granite stone powder is fully utilized, the problem of waste of land resources and mineral resources caused by stacking of the granite stone powder is solved, and the hydraulic cementing material can replace cement, mineral powder and fly ash to be used in concrete preparation; the problem of shortage of cement, mineral powder and fly ash resources is solved, and the preparation method has the advantages of being easy to operate, safe, reliable and low in cost.

Owner:湖北荔众新材料科技有限公司

A kind of lightweight high-performance foam concrete and its preparation method

ActiveCN104108912BHigh CaO contentImprove early strengthSolid waste managementCeramicwareFiberFoam concrete

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Road water stabilizing layer material and preparation method thereof

ActiveCN114133197AHigh reactivityHydrate fastSolid waste managementPortland cementEnvironmental engineering

The invention relates to a road water-stable layer material. The road water-stable layer material is prepared by the following steps: (1) mixing 79-90% of phosphogypsum and 2-6% of lime according to a weight ratio, and aging for 24 hours; then adding 6-10% of Portland cement, and uniformly mixing to obtain a mixture; and (2) adding 2-5% of ardealite hydraulicity exciting agent into the mixture, and uniformly mixing to obtain the road water-stable layer material. The phosphogypsum-based road water-stable layer material disclosed by the invention is used for replacing a traditional road water-stable layer material and is constructed according to a standard road construction method, and a formed road water-stable layer reaches technical parameters of a high-grade road.

Owner:武汉圣清之源科技有限公司

High-activity admixture slurry made of wet fly-ash and method for preparing same

InactiveCN1884175BImprove work performanceControl loss over timeSolid waste managementCALCIUM HYDROXIDE SOLUTIONSlurry

The invention discloses high-active doping slurry and preparing method, which comprises the following parts: 55-65 percent wet-discharge coal ash, 30-44 percent calcium-increasing solution and 1-5 percent modifier, wherein the calcium-increasing solution is calcium hydroxide solution; the modifier is composed of 10-30 percent reinforcer, 20-40 percent surface modifier and 30-50 percent activist.

Owner:WUHAN UNIV OF TECH

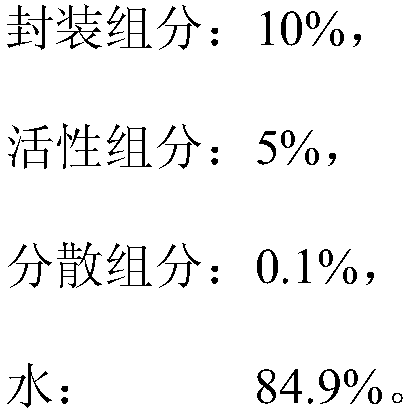

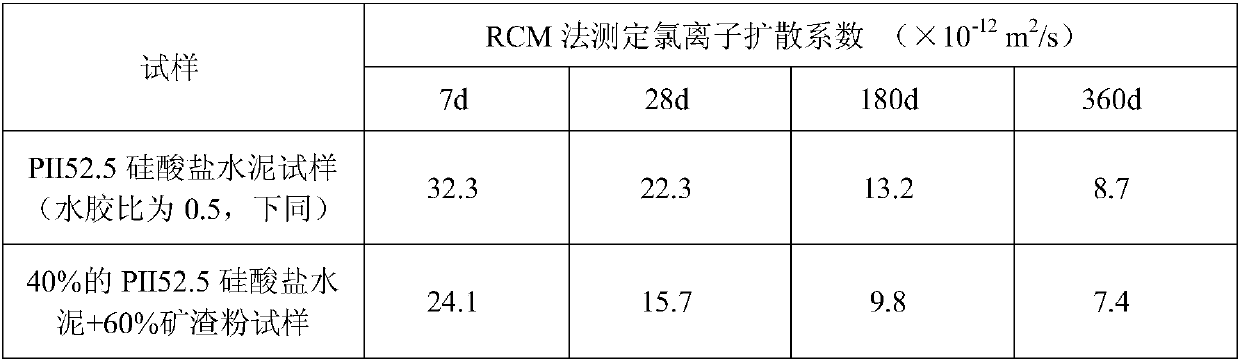

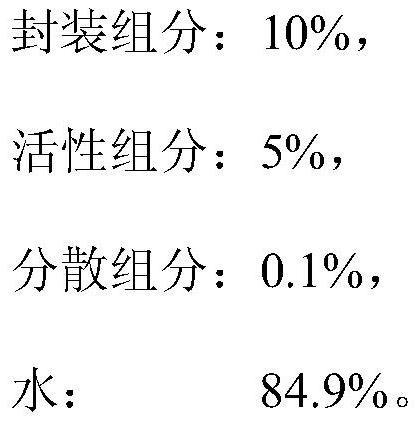

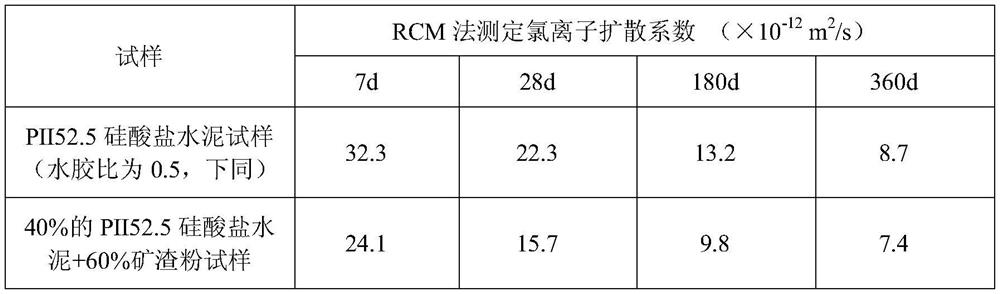

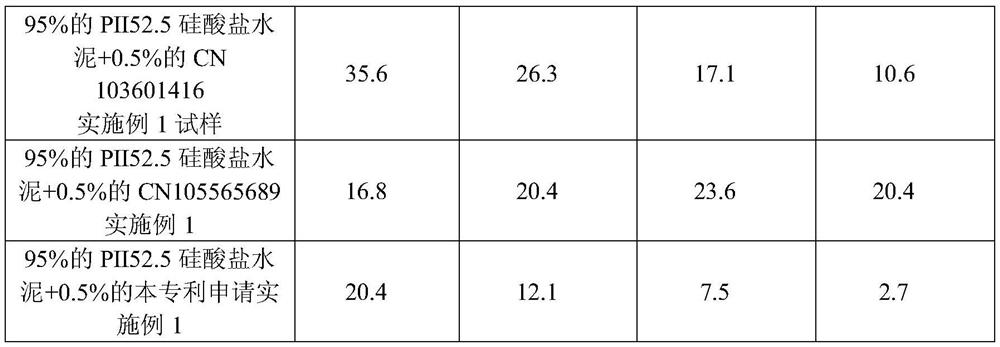

Concrete medium erosion resistant additive based on in-situ reaction encapsulation technology and preparation method

ActiveCN109665738AReduce the diffusion coefficient of chloride ionsDiffusion coefficient is smallCore componentSilicon dioxide

The invention discloses a concrete medium erosion resistant additive based on an in-situ reaction encapsulation technology and a preparation method. Core components of the concrete medium erosion resistant additive based on the in-situ reaction encapsulation technology are encapsulated active components, the encapsulation is to absorb and encapsulate active components in an interlayer structure byvirtue of an encapsulation component, and the ratio of the encapsulation component to the active component is 0.5 to 8. According to the invention, inorganic nano-silica particles with high hydrationreaction activity are encapsulated on the basis of a coating technology, and then the ionization, release and reaction of the inorganic nano-silica particles in a concrete hydration microenvironmentare packaged at a later stage, so that the long-term chloride ion diffusion coefficient of the concrete is obviously reduced by virtue of optimization of the concrete microstructure in the service process, and the concrete medium erosion resistant additive based on the in-situ reaction encapsulation technology and the preparation method are provided for a concrete durability improvement technology.

Owner:JIANGSU SOBUTE NEW MATERIALS

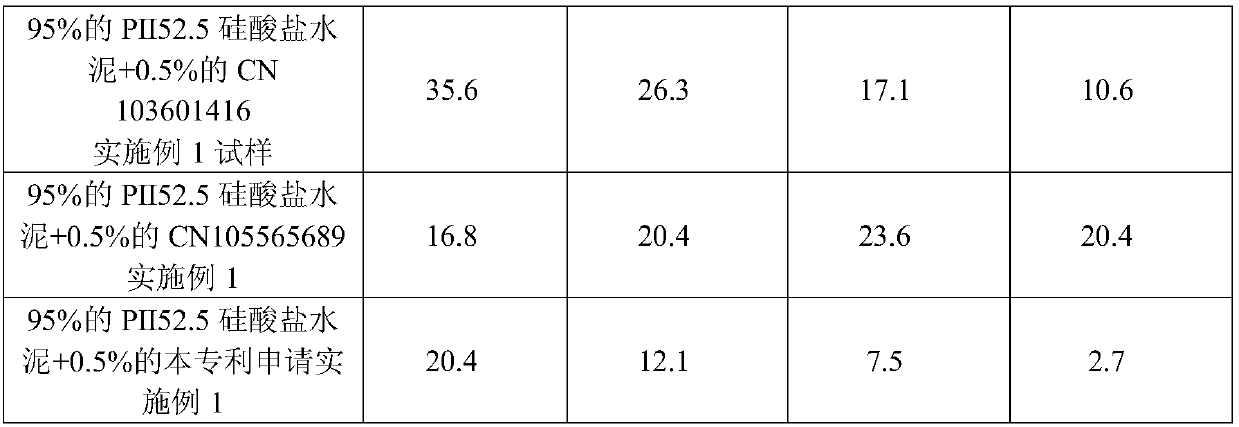

A kind of graphite lightning protection grounding module and preparation method thereof

ActiveCN104529451BReduce ground resistanceImprove water retentionConnection contact member materialGraphiteUltimate tensile strength

The invention relates to the field of a lightning-protection grounding geographic pole and particularly relates to a graphite lightning-protection grounding module and a preparation method thereof. The graphite lightning-protection grounding module is made from graphite powder, granular graphite and asphalt. The preparation method comprises the steps of material preparing, kneading, blank preparing, roasting, post processing, and the like. The graphite lightning-protection grounding module disclosed by the invention is low in electrical resistivity, relatively high in mechanical strength, resistant to corrosion and long in service life.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

A concrete anti-medium erosion admixture based on in-situ reaction encapsulation technology and its preparation method

ActiveCN109665738BReduce the diffusion coefficient of chloride ionsDiffusion coefficient is smallSilica particleHydration reaction

The invention discloses a concrete anti-medium erosion admixture based on in-situ reaction encapsulation technology and a preparation method. The core component of the concrete anti-medium erosion admixture based on in-situ reaction encapsulation technology is an encapsulated active component, and the encapsulation is to absorb and encapsulate the active component in the interlayer structure by the encapsulation component, The ratio between the encapsulating component and the active component is 0.5-8. The present invention encapsulates the inorganic nano-silica particles with high hydration reaction activity based on the coating technology, and then encapsulates the dissociation, release, and reaction of the inorganic nano-silica particles in the concrete hydration microenvironment in the later stage, and passes through the service process of the concrete The optimization of the microstructure realizes the obvious reduction of the long-term chloride ion diffusion coefficient of concrete, and provides a concrete anti-medium erosion admixture and preparation method based on in-situ reaction packaging technology for the improvement of concrete durability.

Owner:JIANGSU SOBUTE NEW MATERIALS

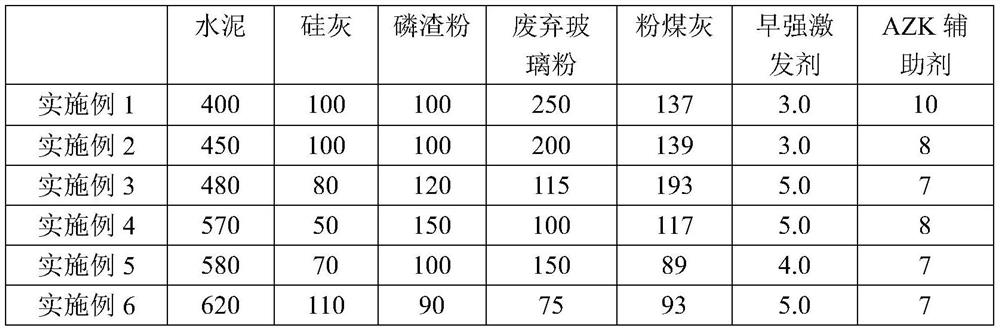

Cementing material for inhibiting metamorphic rock alkali aggregate reaction and preparation method thereof

The invention relates to a cementing material for inhibiting metamorphic rock alkali aggregate reaction and a preparation method thereof. The cementing material comprises the following components: cement, silica fume, phosphorus slag powder, waste glass powder, fly ash, an early strength activator and an AZK auxiliary agent according to a mass ratio of (400-620): (50-100): (90-105): (75-250): (89-193): (3.0-5.0): (7.0-10.0). The cementing material for inhibiting metamorphic rock alkali aggregate reaction is developed through a creative synergistic effect of a cementing material compounding technology, a cementing material secondary hydration process control technology and a cementing material excitation technology, the performance of inhibiting metamorphic rock alkali aggregate reaction is excellent, the comprehensive utilization of industrial wastes such as silica fume, fly ash, phosphorus slag powder and waste glass powder is further enhanced, and the cementing material is green and environment-friendly.

Owner:贵阳中建西部建设有限公司 +1

A kind of less clinker cement and preparation method thereof

The invention discloses a clinker-less cement, which comprises the following components in parts by mass: 60-80 parts of ferronickel slag fine powder, 5-15 parts of fly ash, 3-12 parts of slag, and 3-8 parts of desulfurized gypsum , 5-25 parts of cement clinker, 2-11 parts of activator, and 1-8 parts of slaked lime. The clinker-less cement is prepared through the steps of grinding and mixing, the preparation method is simple, and the technical requirements are not high. The less-clinker cement of the present invention contains a large amount of ferronickel slag micropowder, fly ash, slag, and desulfurized gypsum industrial waste, and the amount of cement clinker contained is small, and a large amount of industrial waste such as ferronickel slag micropowder and fly ash is consumed It solves the problem of solid waste discharge and environmental pollution in the metallurgical industry, and also finds a source of raw materials for the preparation of cement materials, reducing production costs.

Owner:YOUNGWOO CHEMTECH

Low grade fly ash mixed slurry used for concrete and preparation method thereof

InactiveCN102633474BImprove the environmentPromote hydrationSolid waste disposalLower gradeLow graded

The invention discloses a low grade fly ash mixed slurry used for concrete. The mixed slurry is prepared by wet grinding the following components by mass percent: 35-55% of low grade fly ash, 9-16% of industrial residue, 1-4% of modifying agent and 35-45% of mixing plant recycled water; and the mixing plant recycled water contains the quality of the water in the low grade fly ash. The invention also discloses a preparation method of the low grade fly ash mixed slurry used for the concrete. The invention provides a low grade fly ash mixed slurry used for the concrete and a preparation method, wherein the mixed slurry is high in activity, low in cost and high in waste utilization rate.

Owner:XIAMEN TIANRUN JINLONG BUILDING MATERIAL

A kind of anti-crack anti-penetration high durability concrete and its preparation method

The invention relates to a concrete with anti-cracking, anti-seepage and high-durability effects and a preparation method thereof. The concrete is prepared from the following components of cement, flyash, silicon powder, coal gangue powder, boron nitride, phosphor residue powder, sand, crushed stone, high-strength polyvinyl alcohol fiber, a water reduction agent, a dispersing activator, a modified graphene oxide dispersion liquid and water. The concrete has the advantages that the heat conduction coefficient in the 1h age period is 2.9 to 3.7W / (m.K), the heat conduction coefficient in the 28-day age period is 3.5 to 4.7W / (m.K), the compressive strength is 67.6 to 98.3MPa, the break strength is 13.3 to 16.8MPa, the split strength is 9.3 to 9.8MPa, the tensile strength is 8.3 to 10.7MPa, and the tensile elastic modulus is 44.5 to 51.4GPa; the anti-water permeation property, anti-chlorine ion permeation property, anti-freezing and thawing property, and anti-carbonizing property can reachthe highest level; the working property is high, the volume stability is high, the durability is high, the toughness is high, the anti-cracking ability is high, and the anti-seepage ability is high.

Owner:CHONGQING YABO BUILDING MATERIALS CO LTD

Preparation method of nano attapulgite recycled concrete

PendingCN113773016AObvious filling effectApparent activitySolid waste managementMaterials scienceChemistry

The invention discloses a preparation method of nano attapulgite recycled concrete, and belongs to the field of building materials. The nano attapulgite recycled concrete is prepared from the following components in parts by weight: 520-570 parts of cement, 0-50 parts of nano attapulgite, 660 parts of natural fine aggregate, 0-1100 parts of natural coarse aggregate, 0-1100 parts of recycled coarse aggregate, 260 parts of water, and 0-20 parts of additional water. The preparation method further comprises the following steps: S1, uniformly stirring the cement, the sand and the coarse aggregate to form a mixture; S2, adding nano attapulgite into water, and dispersing the nano attapulgite in the water for 10 minutes by adopting a mechanical stirring method to form turbid liquid; and S3, uniformly mixing and stirring the step S1 and the step S2 to obtain the nano attapulgite recycled concrete. According to the invention, waste concrete blocks are crushed to partially or completely replace coarse aggregate, so that the environmental pollution caused by construction waste is solved, and the problem of over-exploitation of natural aggregate is relieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com