A kind of anti-crack anti-penetration high durability concrete and its preparation method

A durable concrete and anti-penetration technology, which is applied in the field of building materials, can solve the problems of impermeability, crack resistance and durability, brittleness and cracks affecting the safety of concrete structures, and poor durability, so as to achieve good workability and durability. Volume stability, improvement of volume stability, and effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

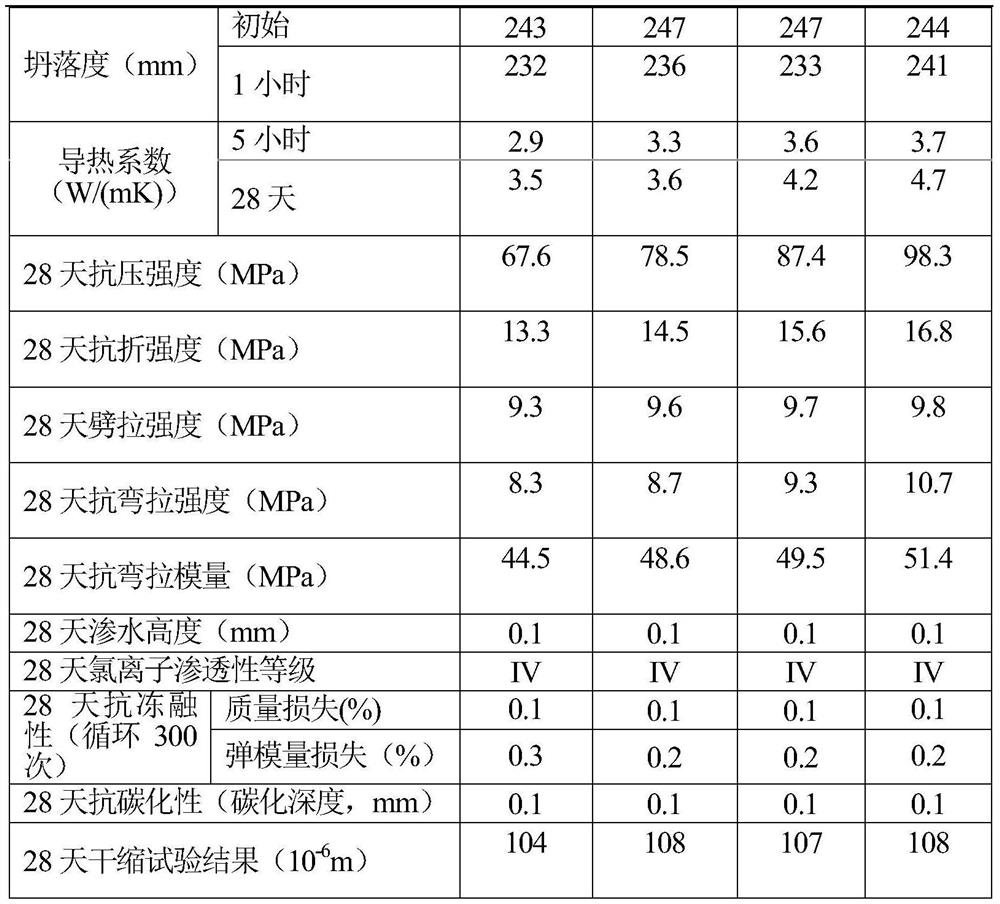

Embodiment 1

[0040] Example 1: Preparation method of C60 anti-crack, anti-permeation and high durability concrete

[0041] Step 1, put 1120 parts of gravel, 686 parts of sand, 32 parts of silicon powder, 19 parts of boron nitride powder, and 1.2 parts of polyvinyl alcohol fiber into the mixer according to the number of parts by mass, and stir to make them fully mixed evenly;

[0042] Step 2: 336 parts of cement, 37 parts of fly ash, 28 parts of coal gangue powder and 14 parts of phosphorous slag powder are sequentially added to the mixture of step 1 and stirred to make it evenly mixed according to the number of parts by mass;

[0043] Step 3: Mix 4.7 parts of dispersing activator, 9.3 parts of water reducing agent, 65.2 parts of modified graphene oxide dispersion and 108.7 parts of water in parts by mass and stir to obtain a mixture;

[0044] Step 4, under stirring, gradually add the mixture prepared in Step 3 to the mixture prepared in Step 2 and stir to obtain crack-resistant, permeable ...

Embodiment 2

[0064] Example 2: Preparation method of C70 anti-crack, anti-permeation and high durability concrete

[0065] Step 1, put 1110 parts of gravel, 651 parts of sand, 33 parts of silicon powder, 19 parts of boron nitride powder, and 1.3 parts of polyvinyl alcohol fiber into the mixer according to the number of parts by mass, and stir to make them fully mixed evenly;

[0066] In step 2, 343 parts of cement, 38 parts of fly ash, 29 parts of coal gangue powder and 14 parts of phosphorus slag powder are sequentially added to the mixture of step 1 and stirred to make it evenly mixed in parts by mass;

[0067] Step 3: Mix 4.8 parts of dispersing activator, 9.5 parts of water reducer, 76.2 parts of modified graphene oxide dispersion and 89.2 parts of water in parts by mass and stir to obtain a mixture;

[0068] Step 4, under stirring, gradually add the mixture prepared in Step 3 to the mixture prepared in Step 2 and stir to obtain crack-resistant, permeable and high-durability concrete. ...

Embodiment 3

[0070] Example 3: Preparation method of C80 anti-crack, anti-permeation and high durability concrete

[0071] Step 1, put 1105 parts of gravel, 648 parts of sand, 34 parts of silicon powder, 19.4 parts of boron nitride powder, and 1.3 parts of polyvinyl alcohol fiber into the mixer according to the number of parts by mass and stir to make them fully mixed;

[0072] Step 2: 350 parts of cement, 39 parts of fly ash, 29.2 parts of coal gangue powder and 15 parts of phosphorus slag powder are sequentially added to the mixture of step 1 and stirred to make it evenly mixed according to the number of parts by mass;

[0073] Step 3: Mix 4.9 parts of dispersing activator, 9.7 parts of water reducer, 87.5 parts of modified graphene oxide dispersion and 77.3 parts of water in parts by mass and stir to obtain a mixture;

[0074] Step 4, under stirring, gradually add the mixture prepared in Step 3 to the mixture prepared in Step 2 and stir to obtain crack-resistant, permeable and high-dura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com