Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173 results about "Ion permeation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

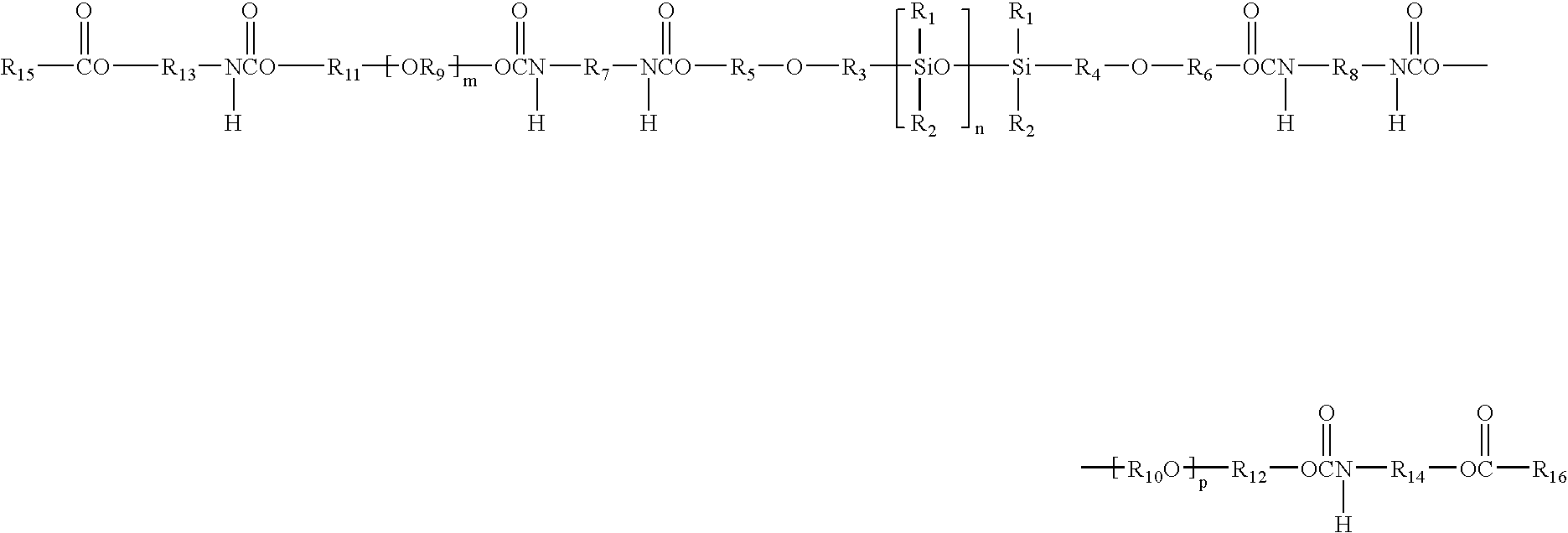

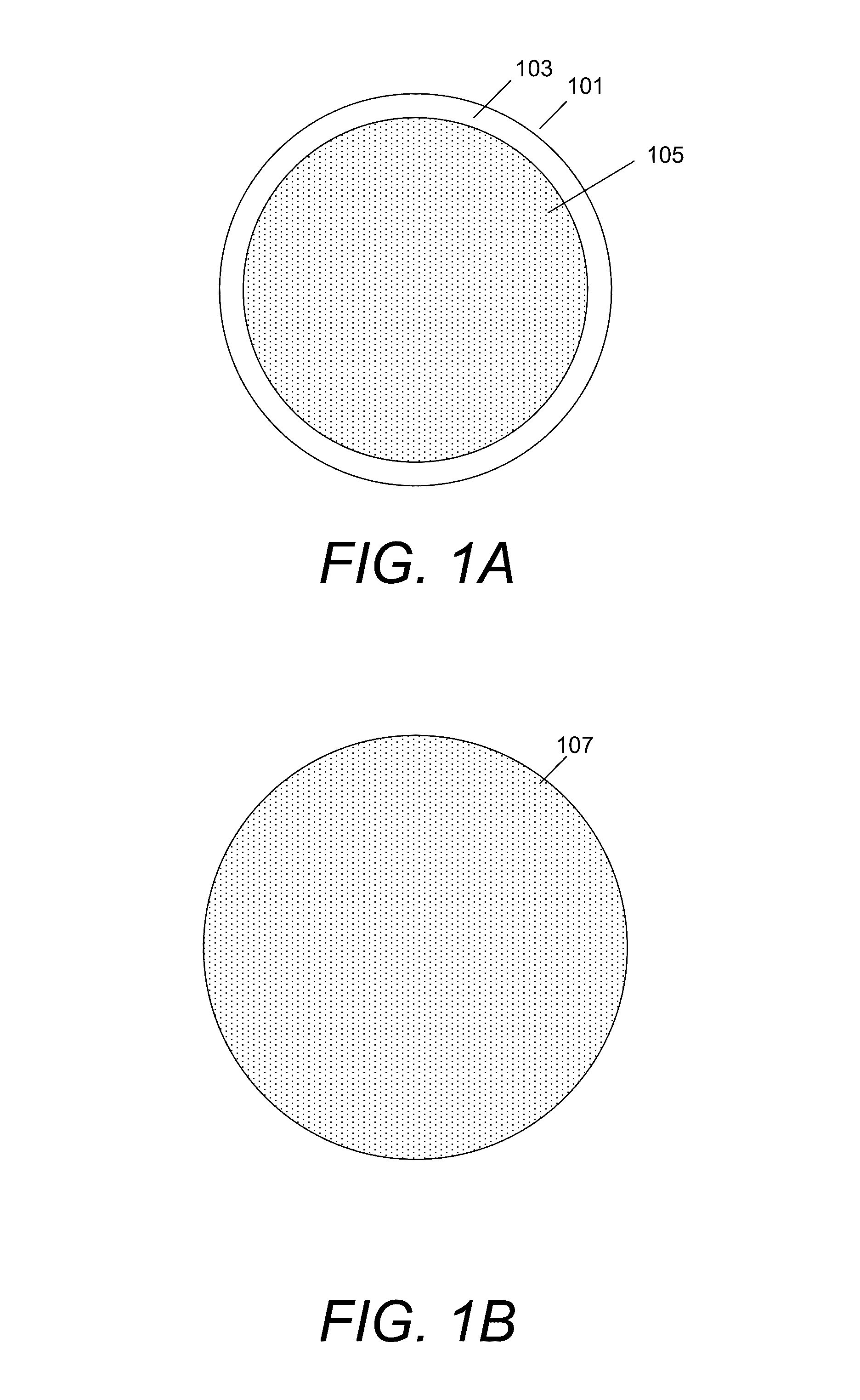

Extended wear ophthalmic lens

InactiveUS5760100AExcellent ion permeabilityGood water permeabilityLiquid surface applicatorsEye implantsExtended wear contact lensesIon permeation

Owner:NOVARTIS AG

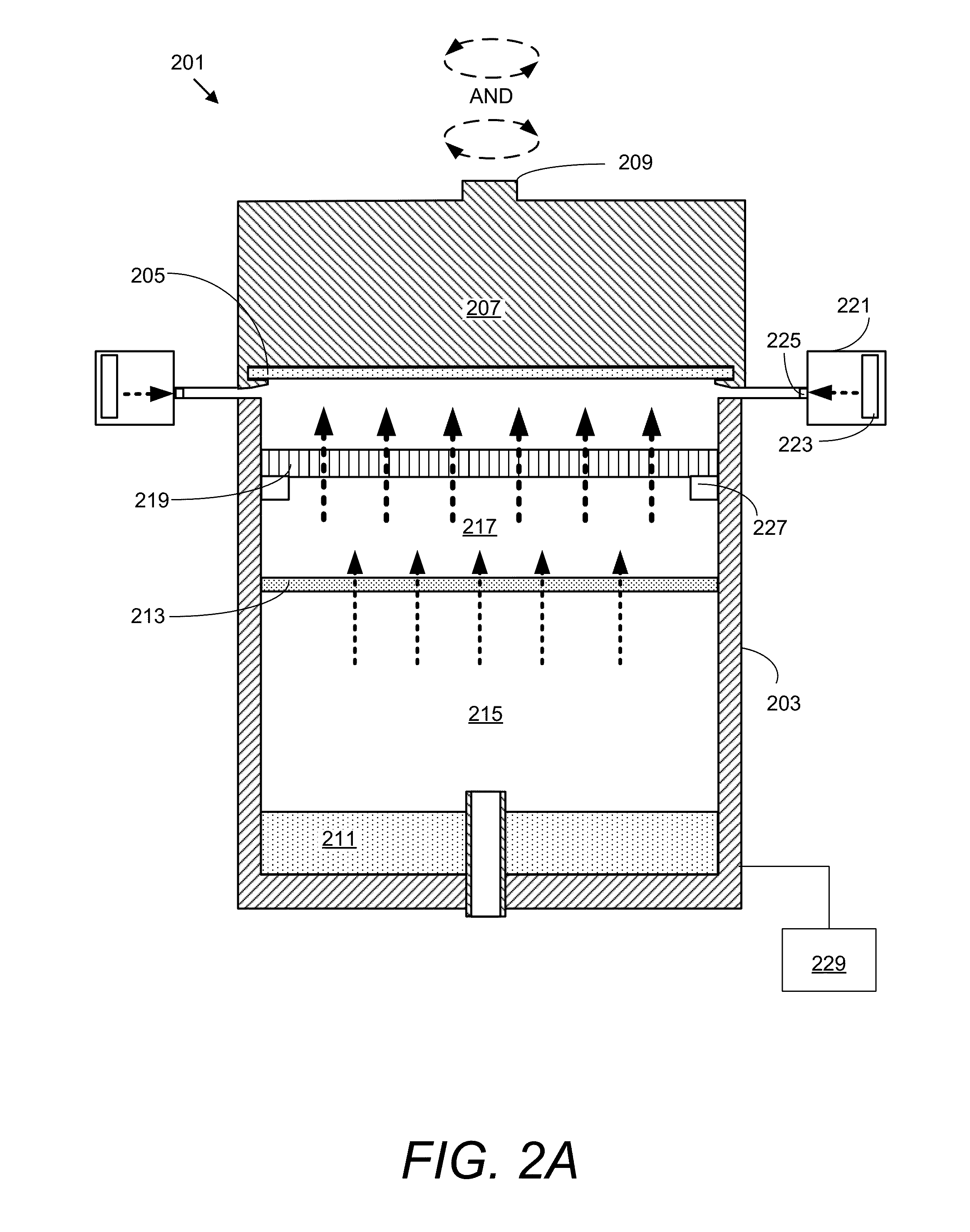

Method and apparatus for electroplating

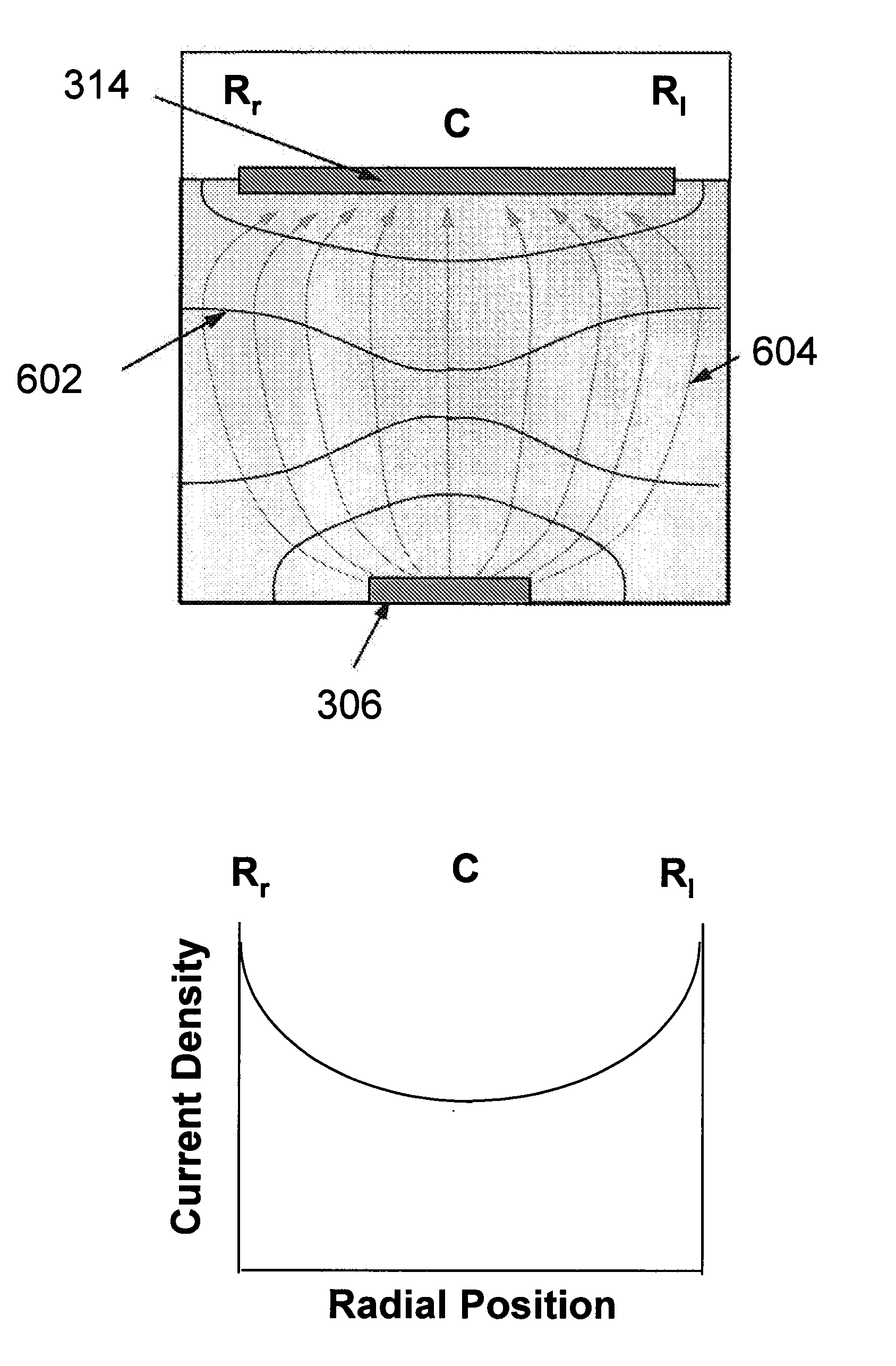

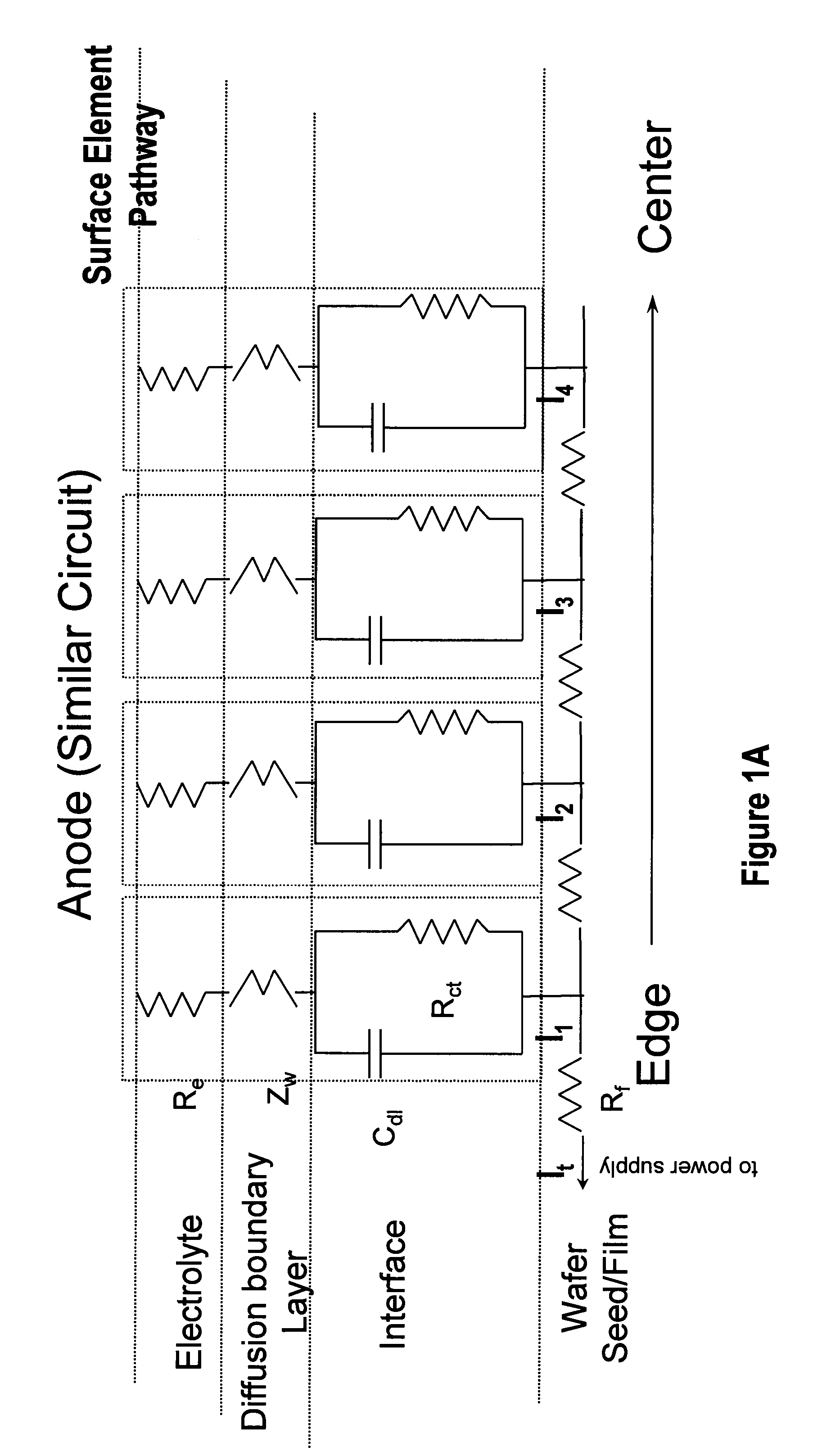

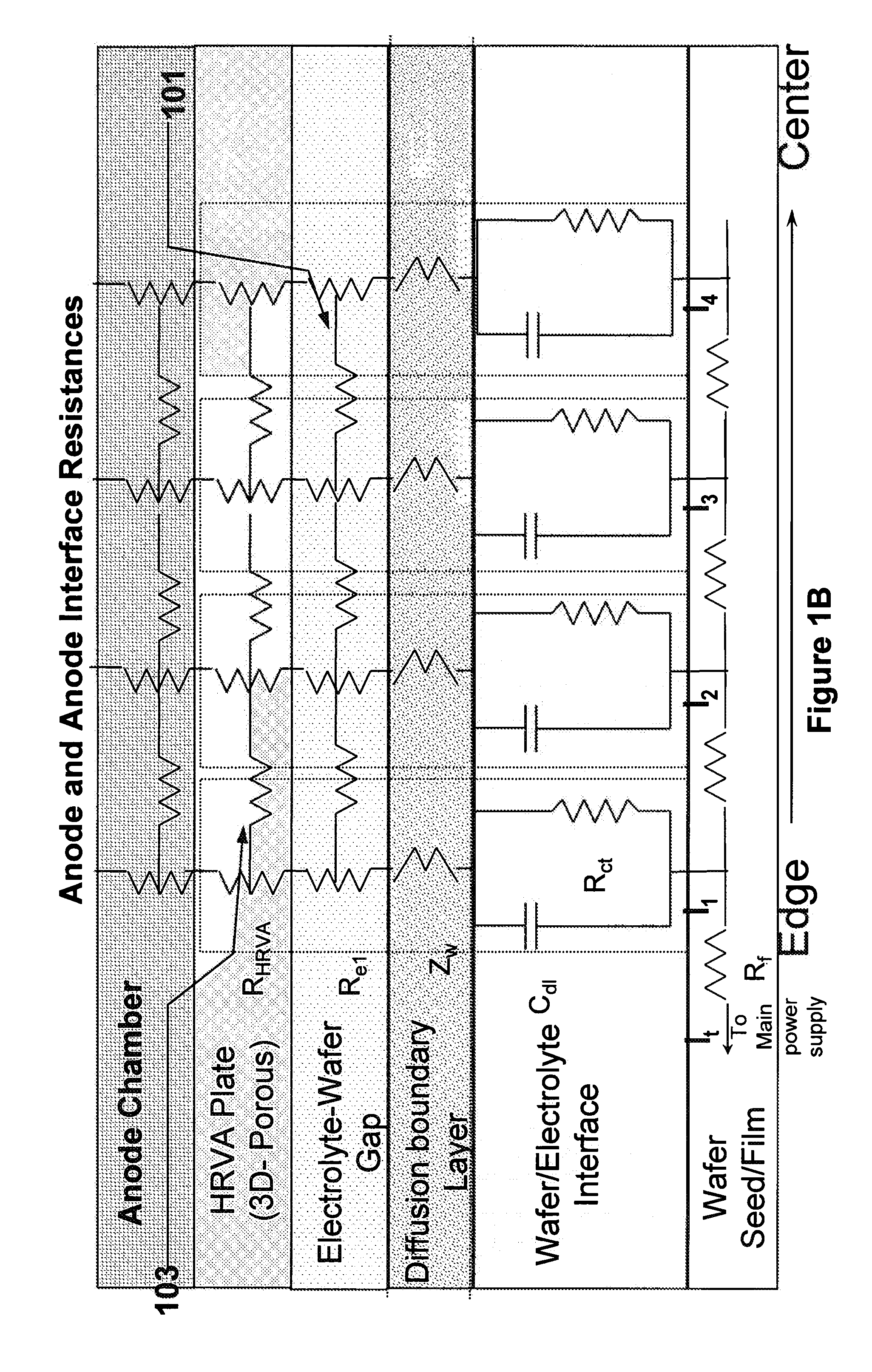

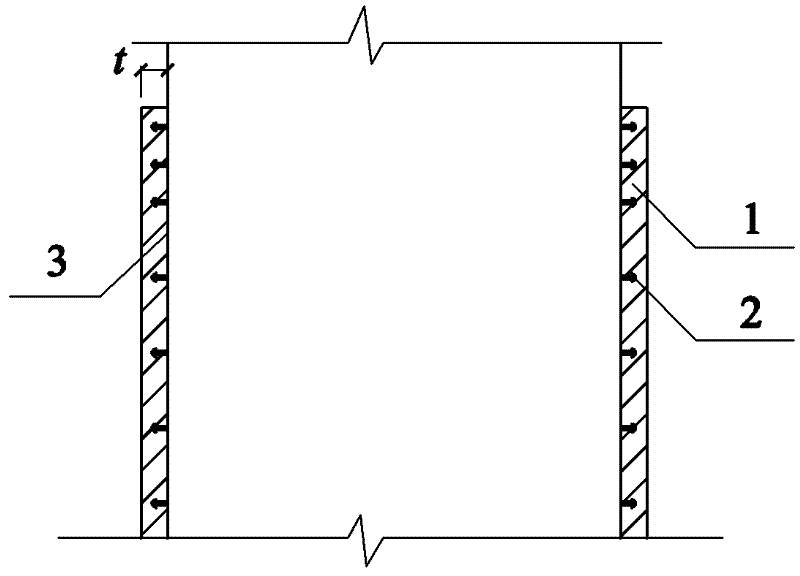

An apparatus for electroplating a layer of metal onto the surface of a wafer includes an ionically resistive ionically permeable element located in close proximity of the wafer and an auxiliary cathode located between the anode and the ionically resistive ionically permeable element. The ionically resistive ionically permeable element serves to modulate ionic current at the wafer surface. The auxiliary cathode is configured to shape the current distribution from the anode. The provided configuration effectively redistributes ionic current in the plating system allowing plating of uniform metal layers and mitigating the terminal effect.

Owner:NOVELLUS SYSTEMS

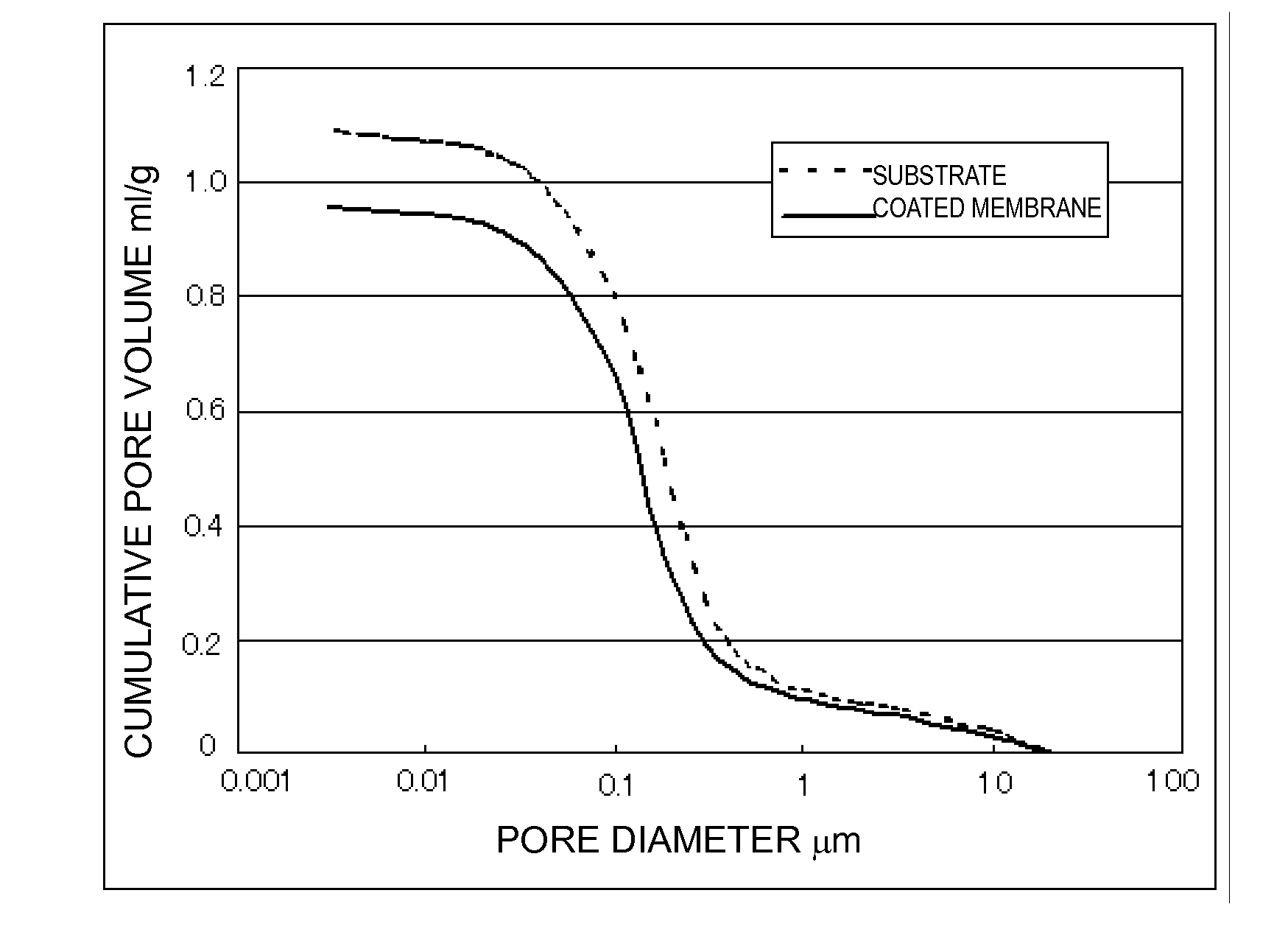

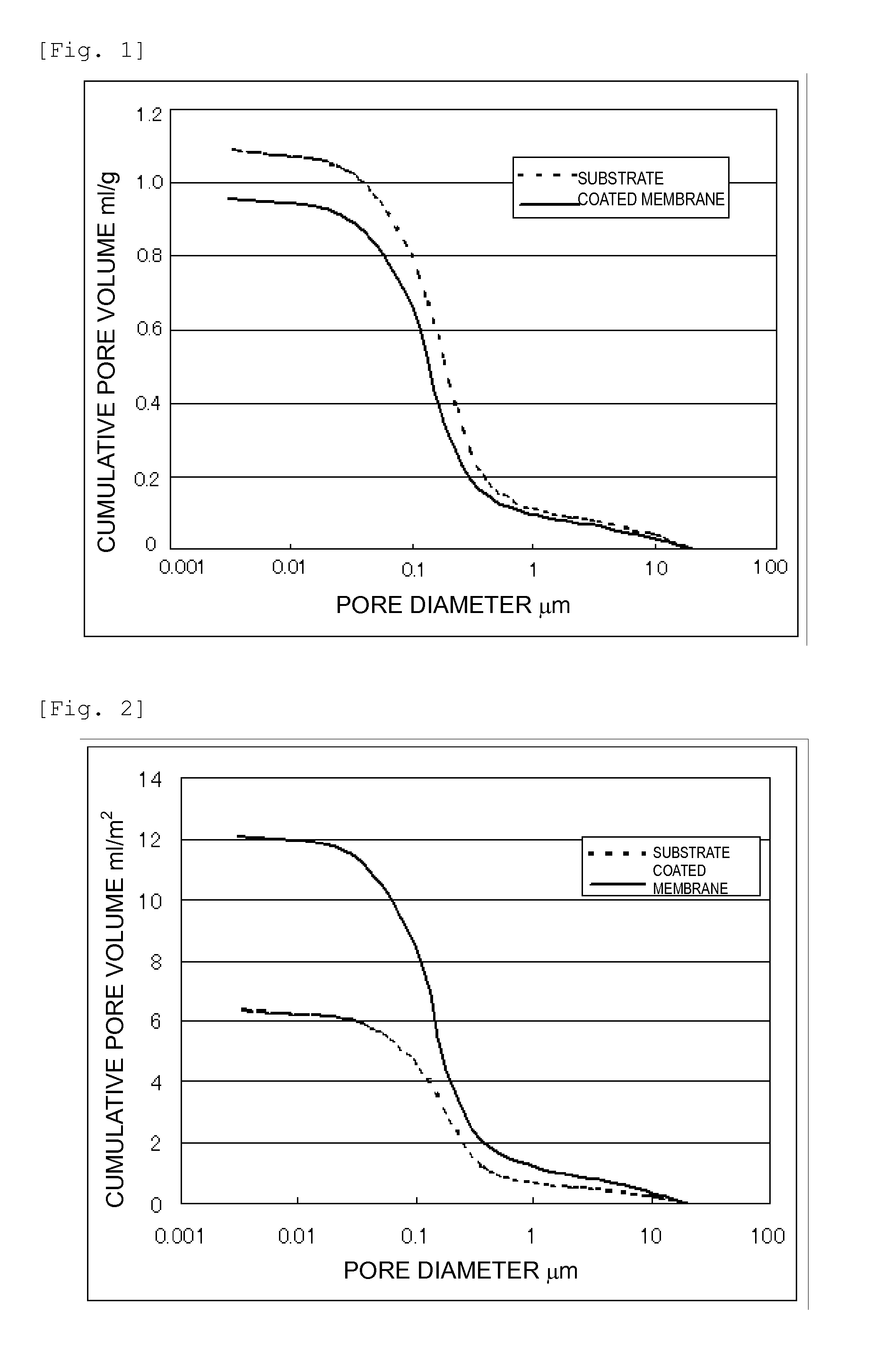

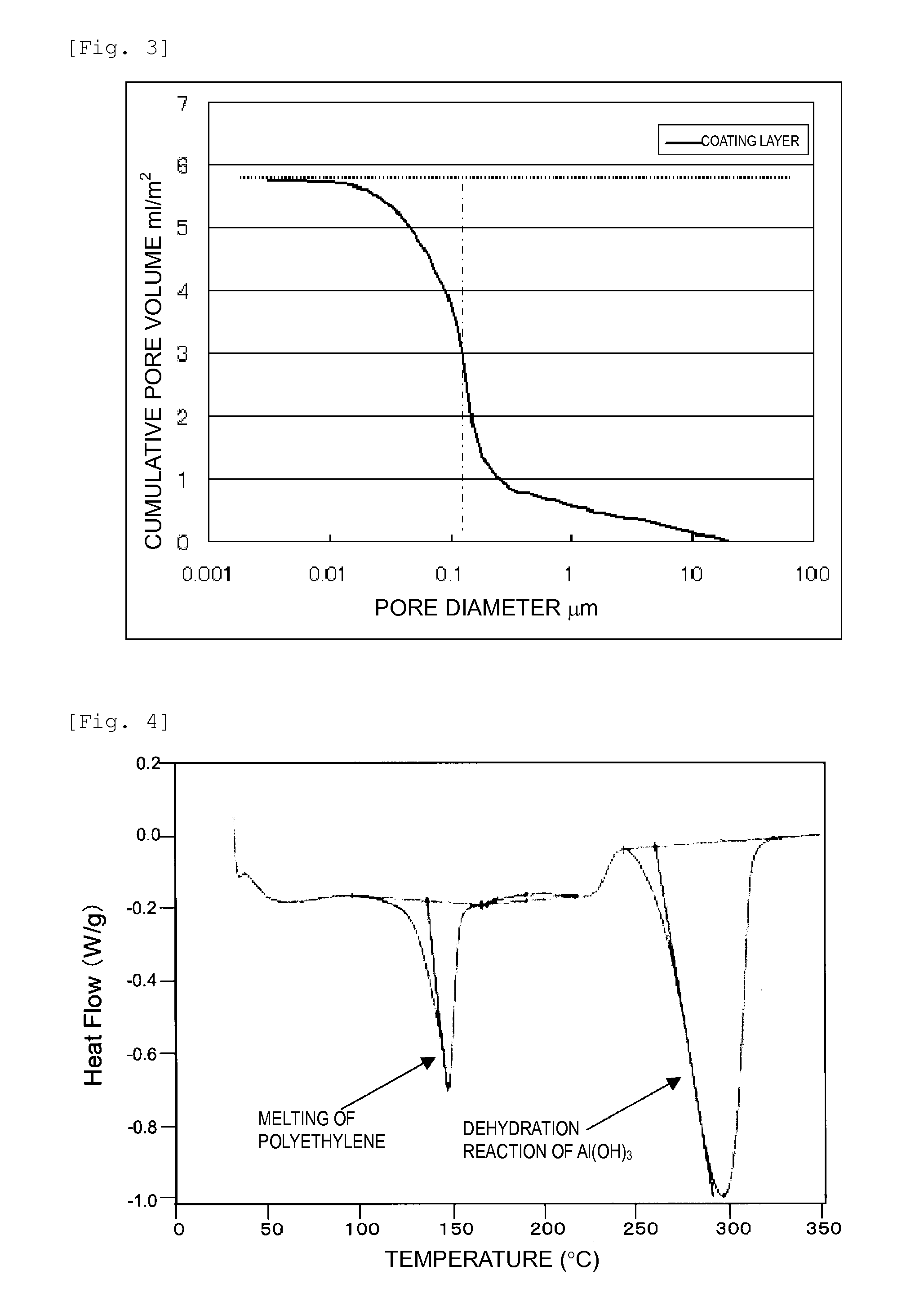

Separator for nonaqueous secondary battery

ActiveUS20110143185A1Improve heat resistanceImprove securitySecondary cellsCell component detailsFiberPolyolefin

An object of the present invention is to provide a separator for a nonaqueous secondary battery having excellent heat resistance and excellent ion permeation as well as shut-down properties. The first invention is a separator for a nonaqueous secondary battery, comprising a porous composite membrane which includes a substrate comprising a polyolefin microporous membrane and a heat-resistant porous layer comprising a heat-resistant resin, the heat-resistant porous layer being formed on at least one surface of the substrate, wherein the separator is characterized in that the sheet resistance (A) of the substrate, the Gurley value (B) of the substrate, the sheet resistance (C) of the porous composite membrane, and the Gurley value (D) of the porous composite membrane satisfy a specific relationship. The second invention is characterized in that the heat-resistant porous layer has an average pore size of 0.1 to 0.2 μm as measured by mercury intrusion porosimetry. The third invention is characterized in that the heat-resistant resin fibrils have an average fibril diameter of 10 to 80 nm, and the pores in the heat-resistant porous layer have an average pore size of 50 to 250 nm.

Owner:TEIJIN LTD

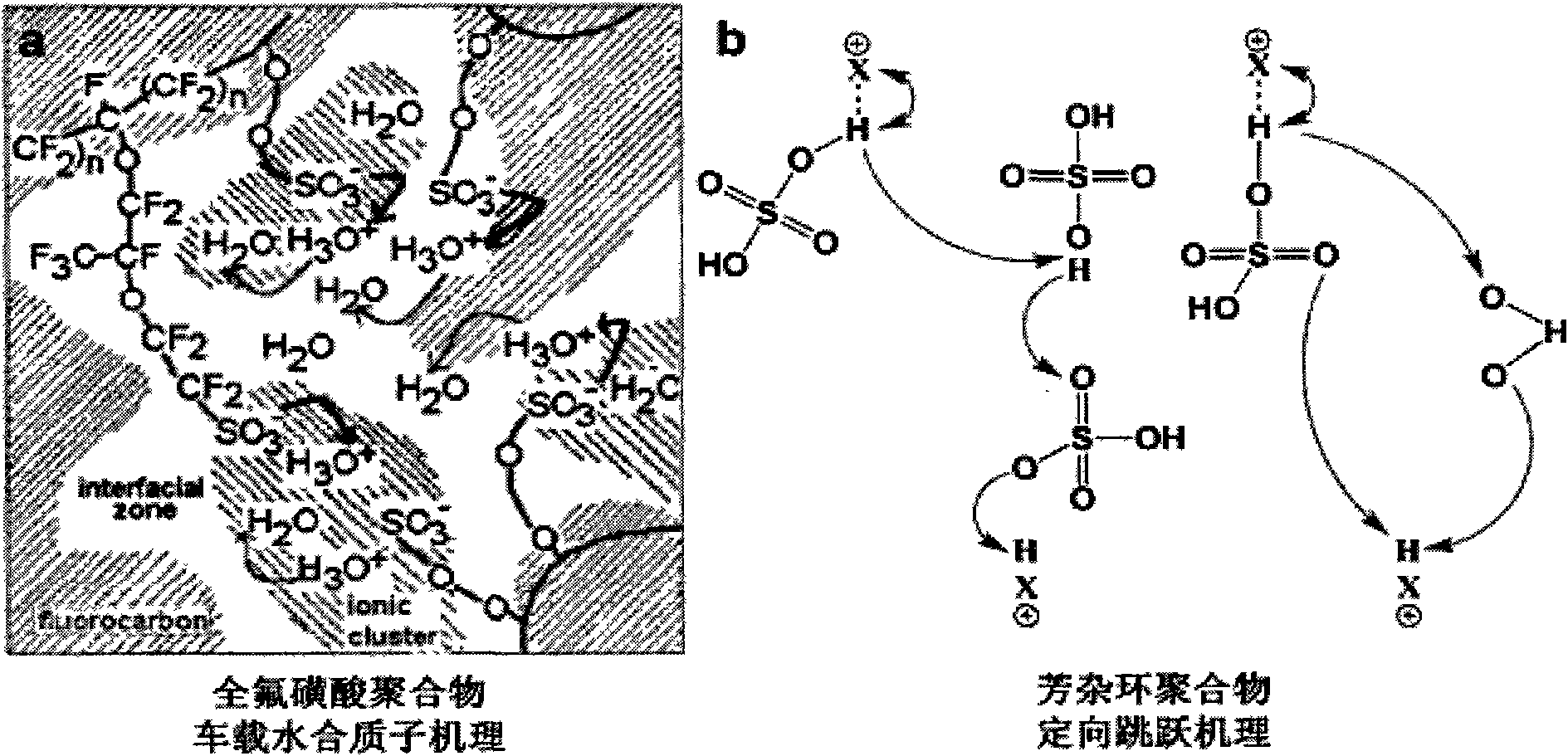

Preparation method of metal-organic framework material/polymer composite proton exchange membrane

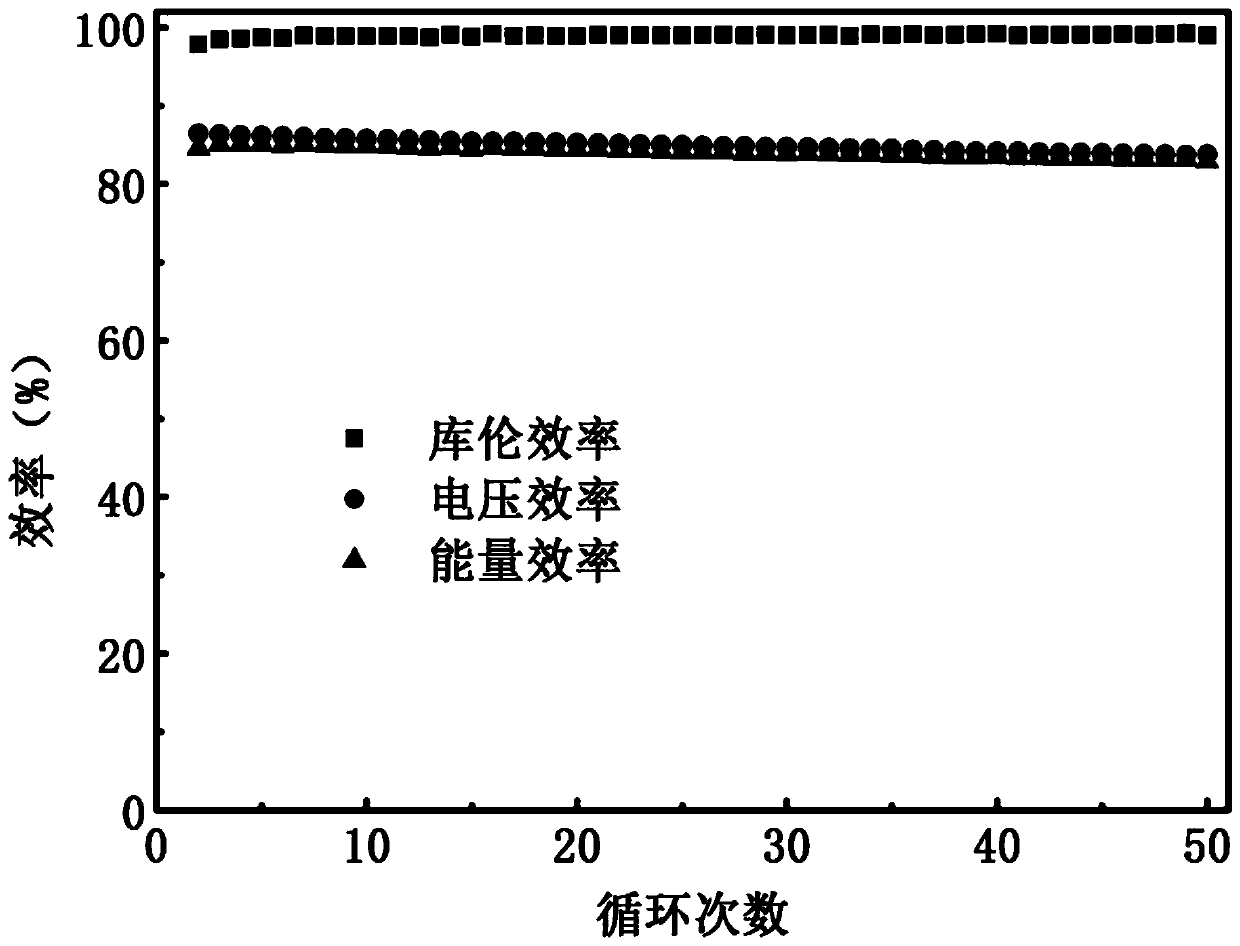

ActiveCN105789668AStrong penetrating powerImprove performanceRegenerative fuel cellsVanadium redox batteryMetal-organic framework

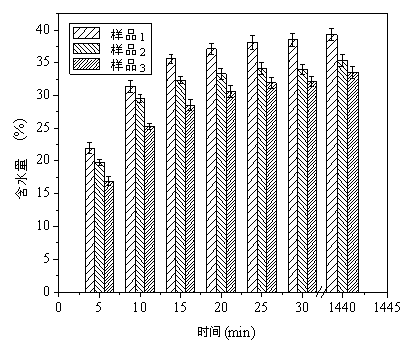

The invention relates to a preparation method of a metal-organic framework material / polymer composite proton exchange membrane. The method is characterized by comprising the following steps: dissolving a polymer matrix and a certain amount of metal-organic framework material with an organic solvent and carrying out ultrasonic dispersion to form a uniform membrane liquid; coating the flat and smooth surface of a glass plate with the obtained membrane liquid, and then removing the organic solvent to obtain a composite membrane; and carrying out vacuum drying on the composite membrane for 24 hours to prepare the composite proton exchange membrane for an all-vanadium redox flow battery. The composite proton exchange membrane is smooth in surface; the internal structure of the membrane is regular; the membrane is uniform in thickness and free of a defect; and the thickness is 10-300 microns. The composite proton exchange membrane provided by the invention has excellent vanadium ion permeation blocking ability, keeps excellent proton transfer performance, overcomes the defect of relatively high vanadium ion permeability of an existing all-vanadium redox flow battery membrane, and has the advantages of being simple in preparation process, high in proton transmittance, excellent in vanadium blocking property, excellent in oxidative resistance, easy to industrially amplify and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

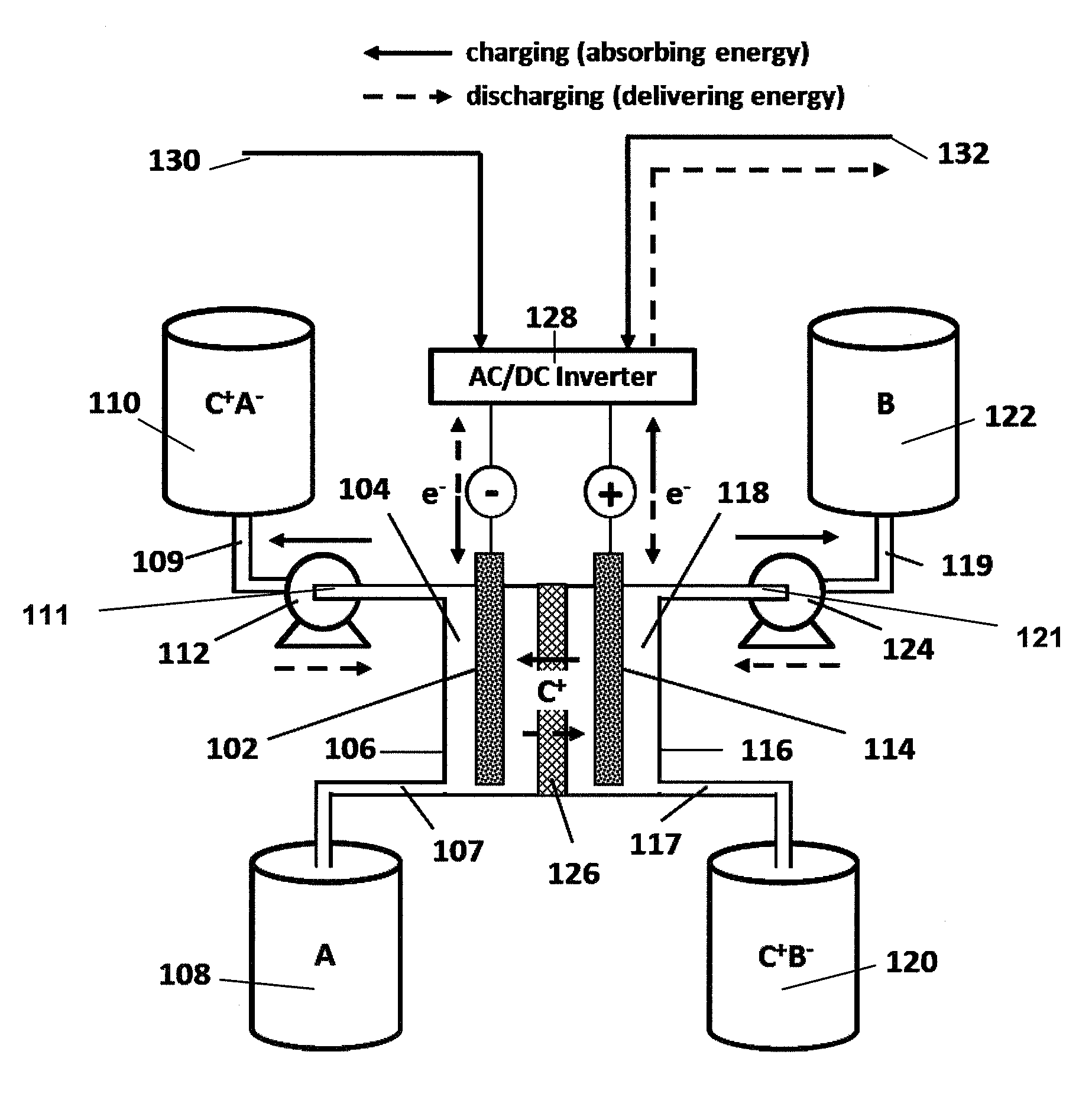

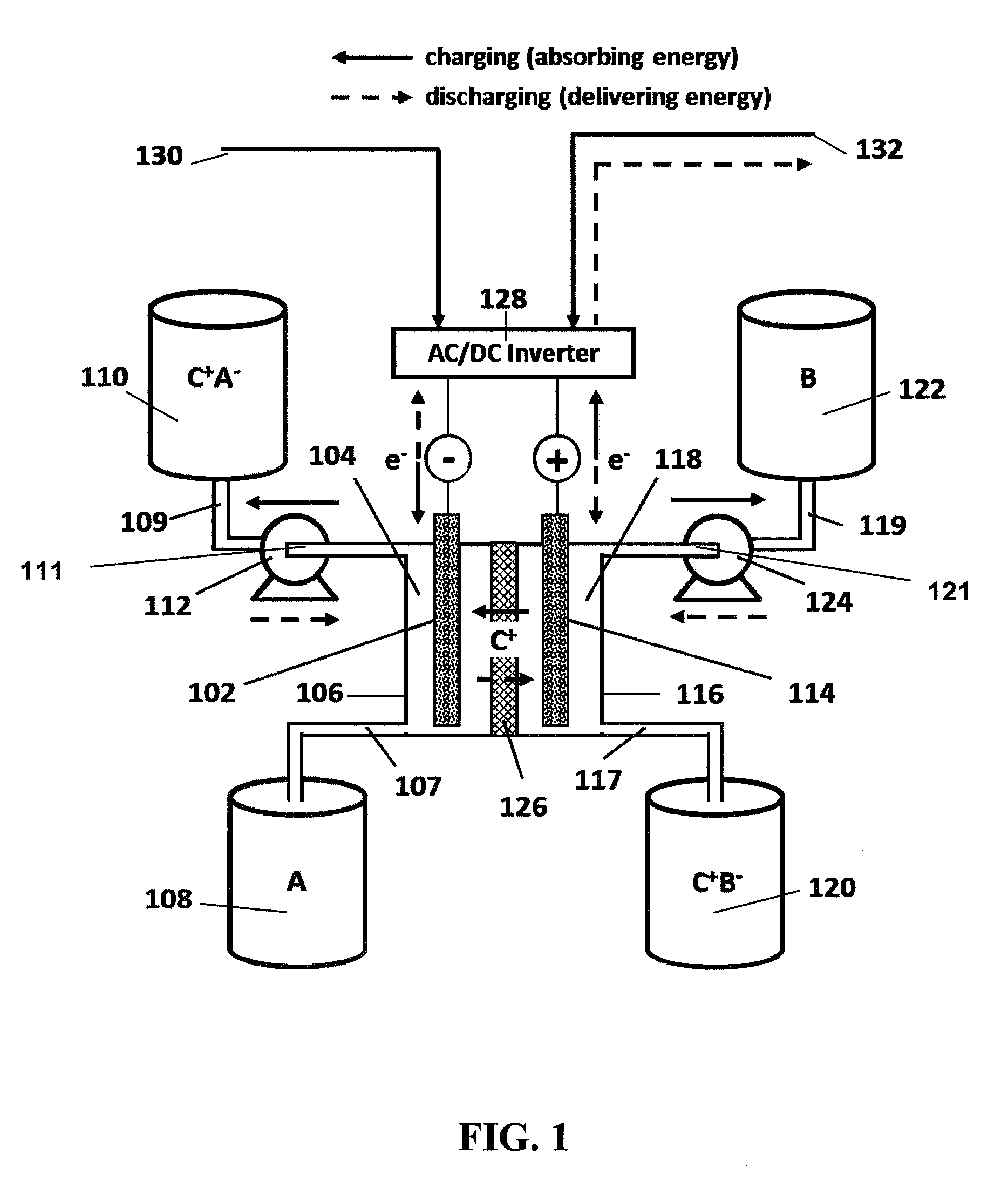

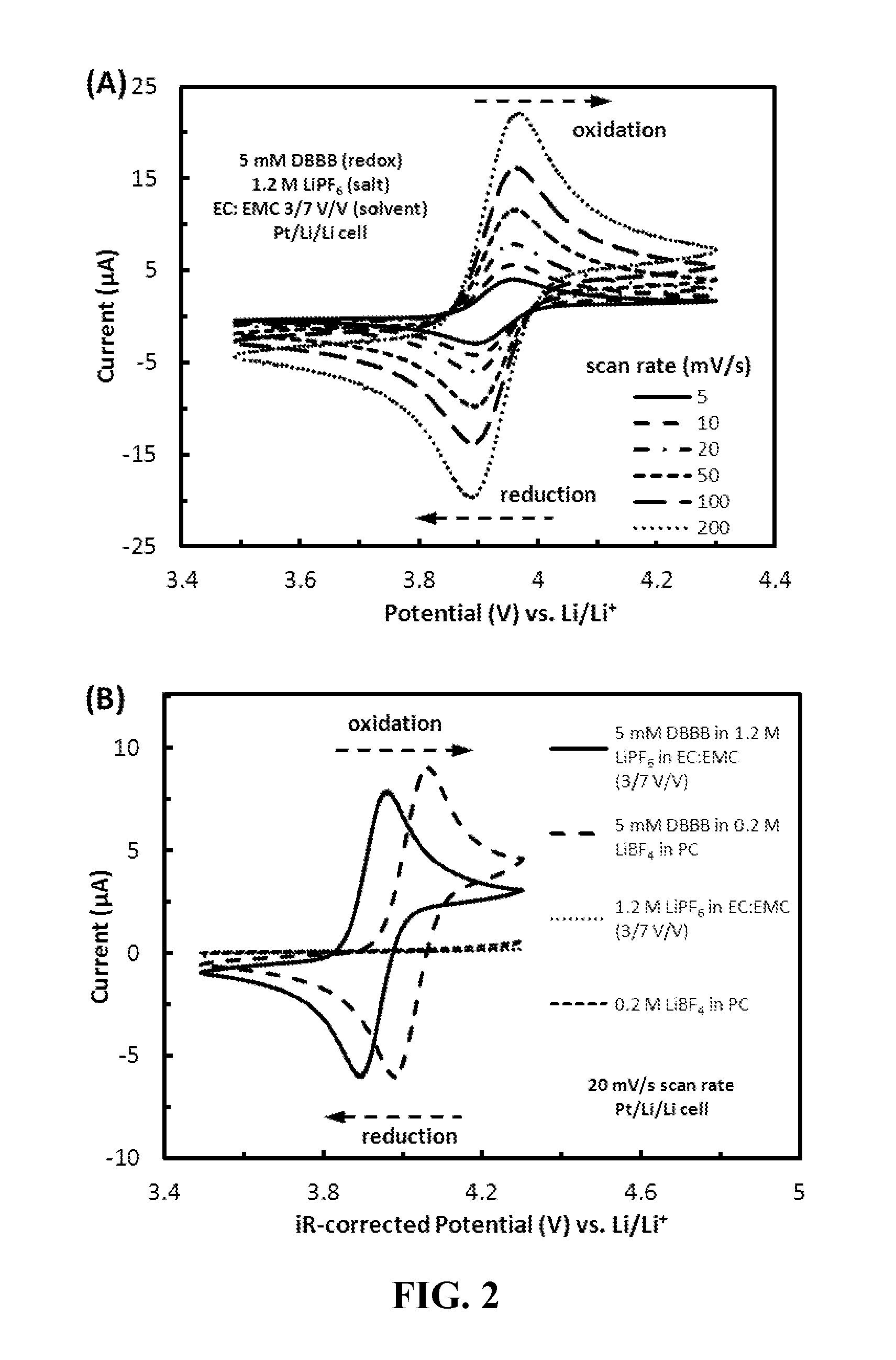

Organic non-aqueous cation-based redox flow batteries

Owner:UCHICAGO ARGONNE LLC

Electrolyte membrane and application of composite membrane thereof in liquid-flow energy storage battery with acidic electrolyte

ActiveCN101807678AExtended service lifeReduce uneven distributionFinal product manufactureRegenerative fuel cellsPermeationElectrical resistivity and conductivity

The invention relates to an electrolyte membrane and application of a composite membrane thereof in a liquid-flow energy storage battery with acidic electrolyte. The electrolyte membrane uses polybenzimidazole or other aromatic heterocyclic polymers as a base membrane or is doped with a strong-acidity solution through composite techniques comprising an organic / inorganic technique, an organic / organic technique, a blending technique, a crosslinking technique, a strengthening technique and the like so that the acid content, the proton conductivity and the mechanical strength of the composite membrane are improved. Different from the traditional electrolyte membrane containing functional groups, the novel electrolyte membrane does not contain iron conduction groups, but utilizes acid in the electrolyte as the electrolyte to conduct protons. Due to the adoption of a Hopping conduction mechanism, the membrane reduces the iron permeation and the water migration of the liquid-flow energy storage battery, greatly reduces the crossing of anode and cathode electrolyte and prolongs the service life of the electrolyte. The preparation process is simple, and the prepared electrolyte membrane can effectively satisfy the requirements on the performance and the stability of the liquid-flow energy storage battery.

Owner:DALIAN RONGKE POWER

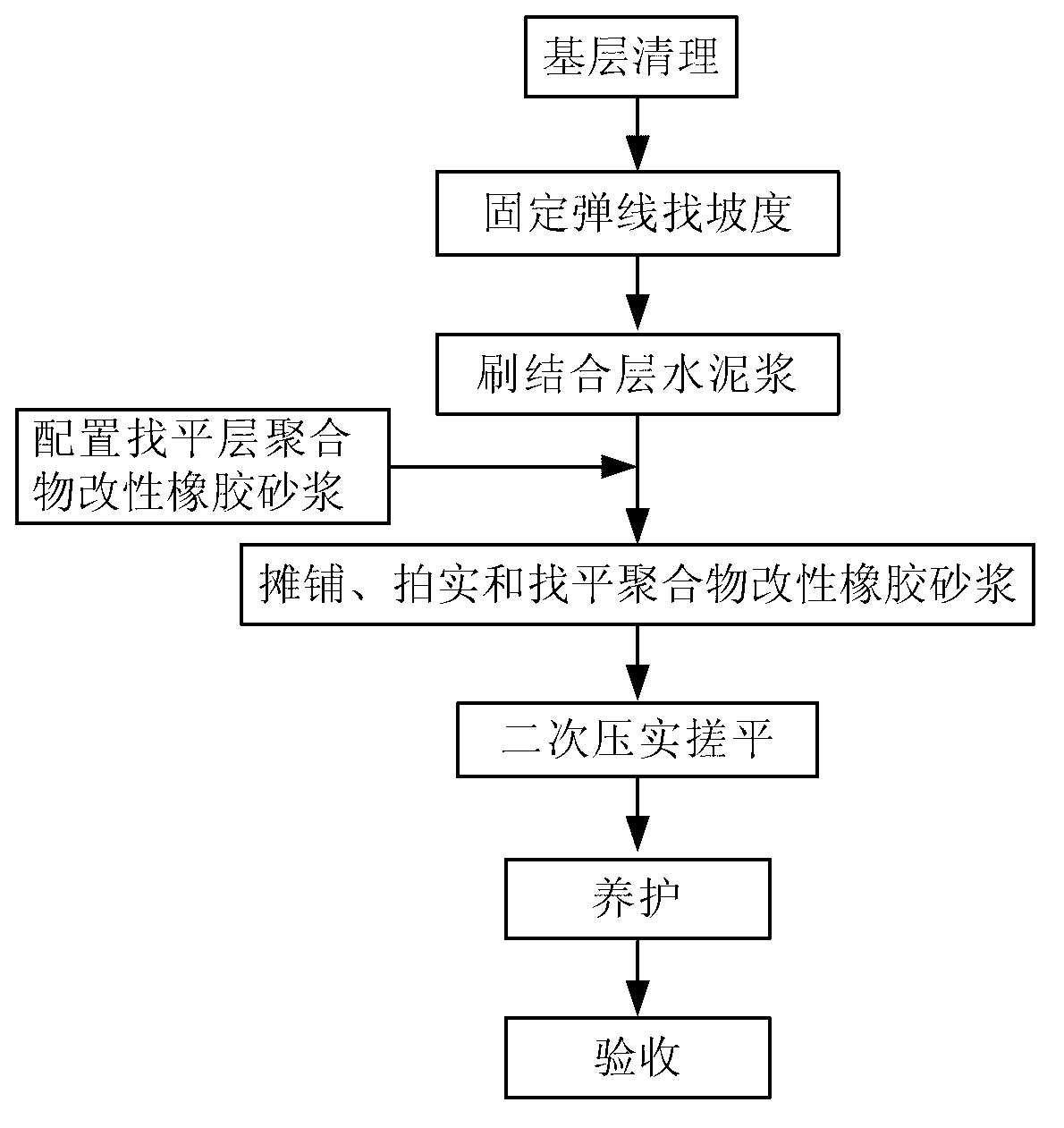

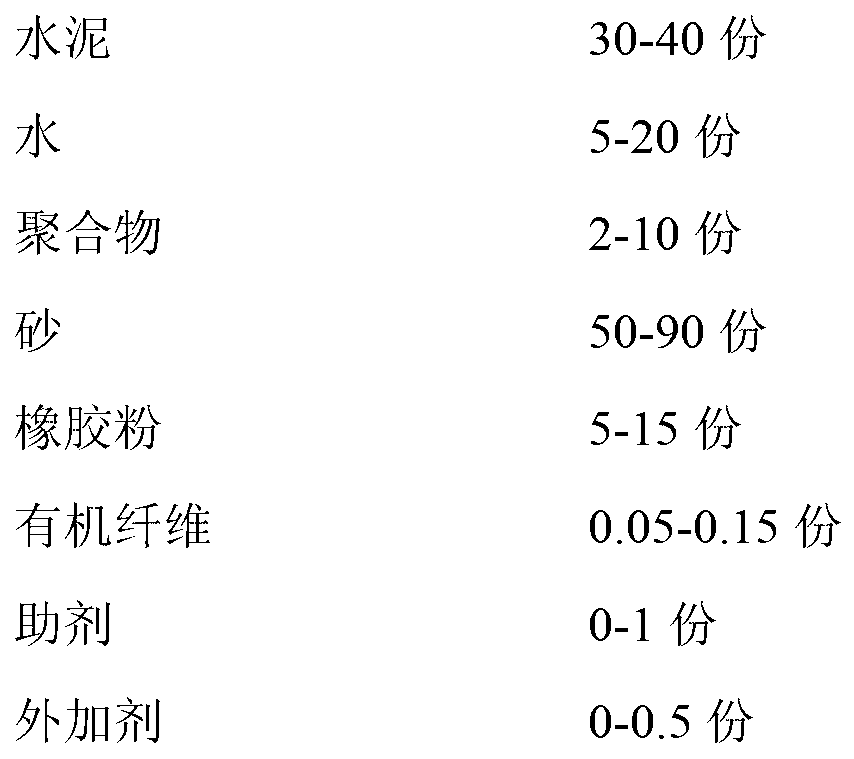

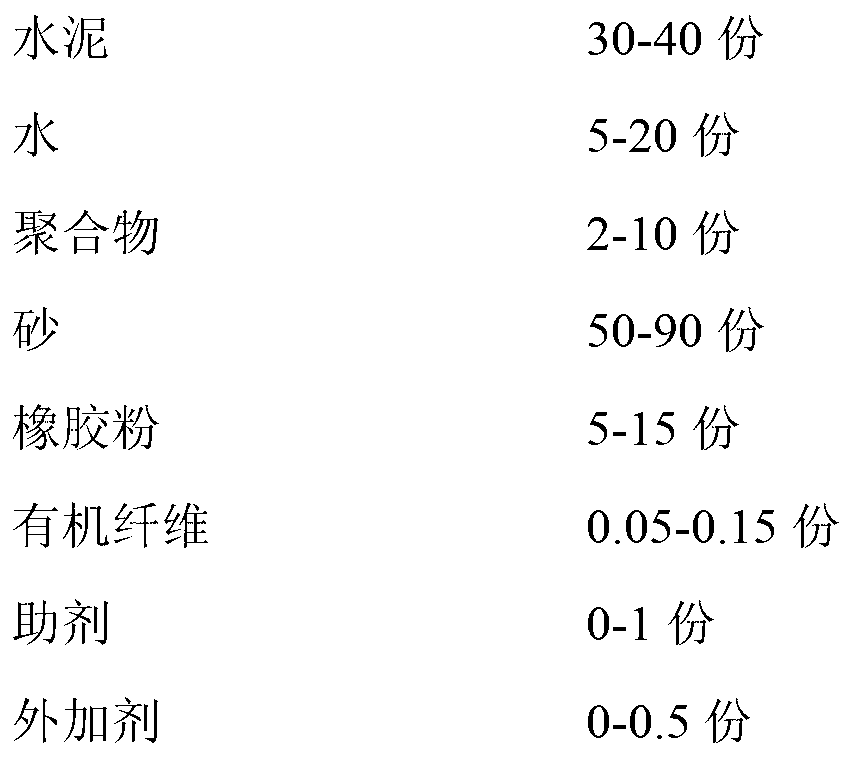

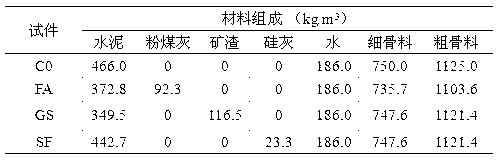

Polymer modified rubber mortar used for building leveling layer and construction method of polymer modified rubber mortar

ActiveCN103342520AGood flexibilitySignificant flexibility advantageCovering/liningsSolid waste managementFiberPolymer modified

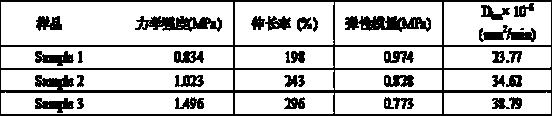

The invention discloses polymer modified rubber mortar for a building leveling layer. The polymer modified rubber mortar is formed by doping three modified materials including rubber powder, a polymer and an organic fibre into modified cement mortar. The polymer modified rubber mortar is formed by mixing the following components in parts by weight: 30-40 parts of cement, 5-20 parts of water, 2-10 parts of the polymer, 50-90 parts of sand, 5-15 parts of the rubber powder, 0.05-0.15 part of the organic fibre, 0-5 parts of mineral admixtures, 0-1 part of an auxiliary, and 0-0.5 part of an additive. According to the freshly-mixed polymer modified rubber mortar, the thickness is controlled to be 7cm, during the curing period of 7 days, the compressive strength of the mortar is not less than 10 MPa, the rupture strength is not less than 3.5 MPa, during the curing period of 28 days, the compressive strength of the mortar is not less than 15 MPa, the rupture strength is not less than 5 MPa, the chloride ion permeation coefficient is not larger than 50*10<-14>m<2> / s, and the heat conductivity coefficient is not larger than 0.5W / m.k. The polymer modified rubber mortar disclosed by the invention can be used for effectively solving the problems of sugaring, peeling, crispiness, bulging, cracking and the like existing in the traditional cement mortar leveling layer, has the performance advantages of permeability resistance, crack prevention, thermal insulation, high tenacity and the like, can fully utilize waste rubber, can turn waste into wealth, and is suitable for various building leveling layers.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

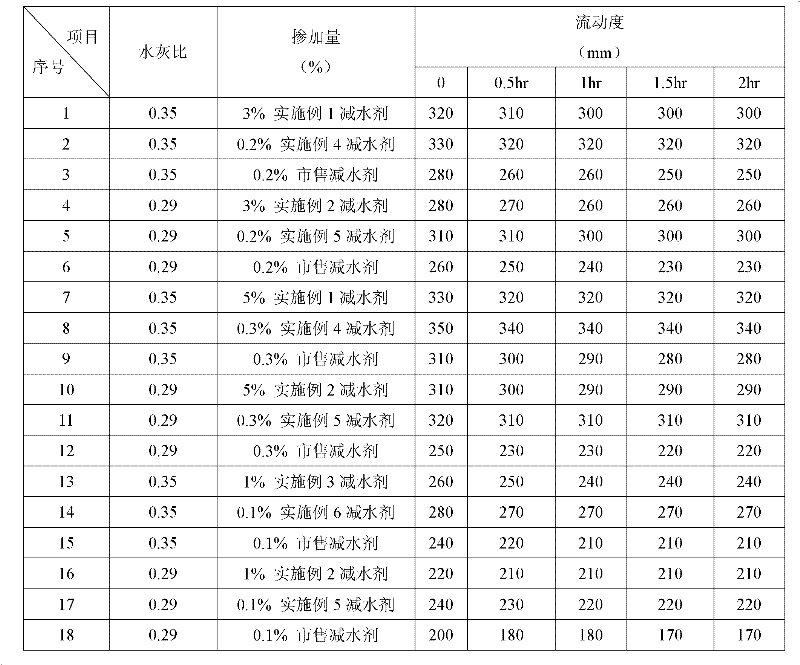

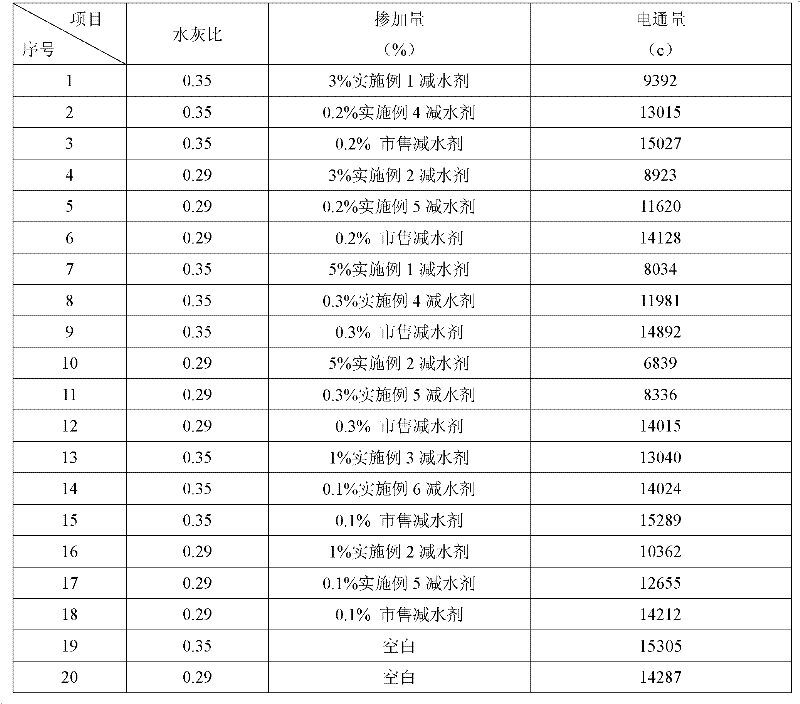

Method for preparing nanoparticle water reducing agent

The invention discloses a method for preparing a nanoparticle water reducing agent, which belongs to the technical field of the preparation of building material admixtures. The water reducing agent at a certain doping amount can achieve the dispersing and water reduction effects at the early stage of cement paste; meanwhile, the water reducing agent has the functions of room-temperature film formation and emulsion modification, so the comprehensive performance of cement concrete such as late-stage waterproofness, compactness, chloride ion permeation resistance, mechanical properties, durability and the like can be greatly improved. The nanoparticle water reducing agent can be widely applied to the fields of railways, bridges, tunnels, dams, offshore engineering, remedial works and the like.

Owner:TSINGHUA UNIV

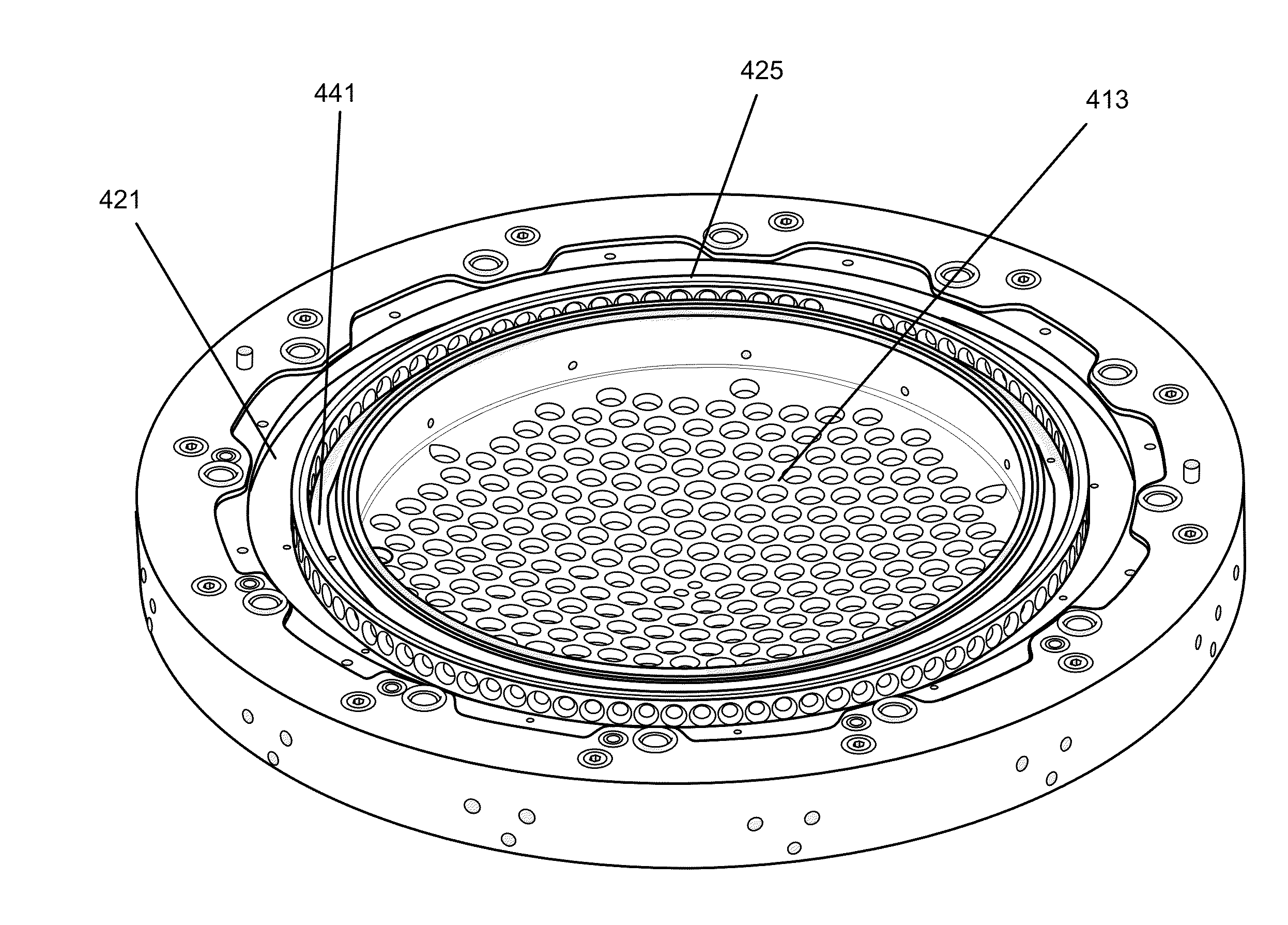

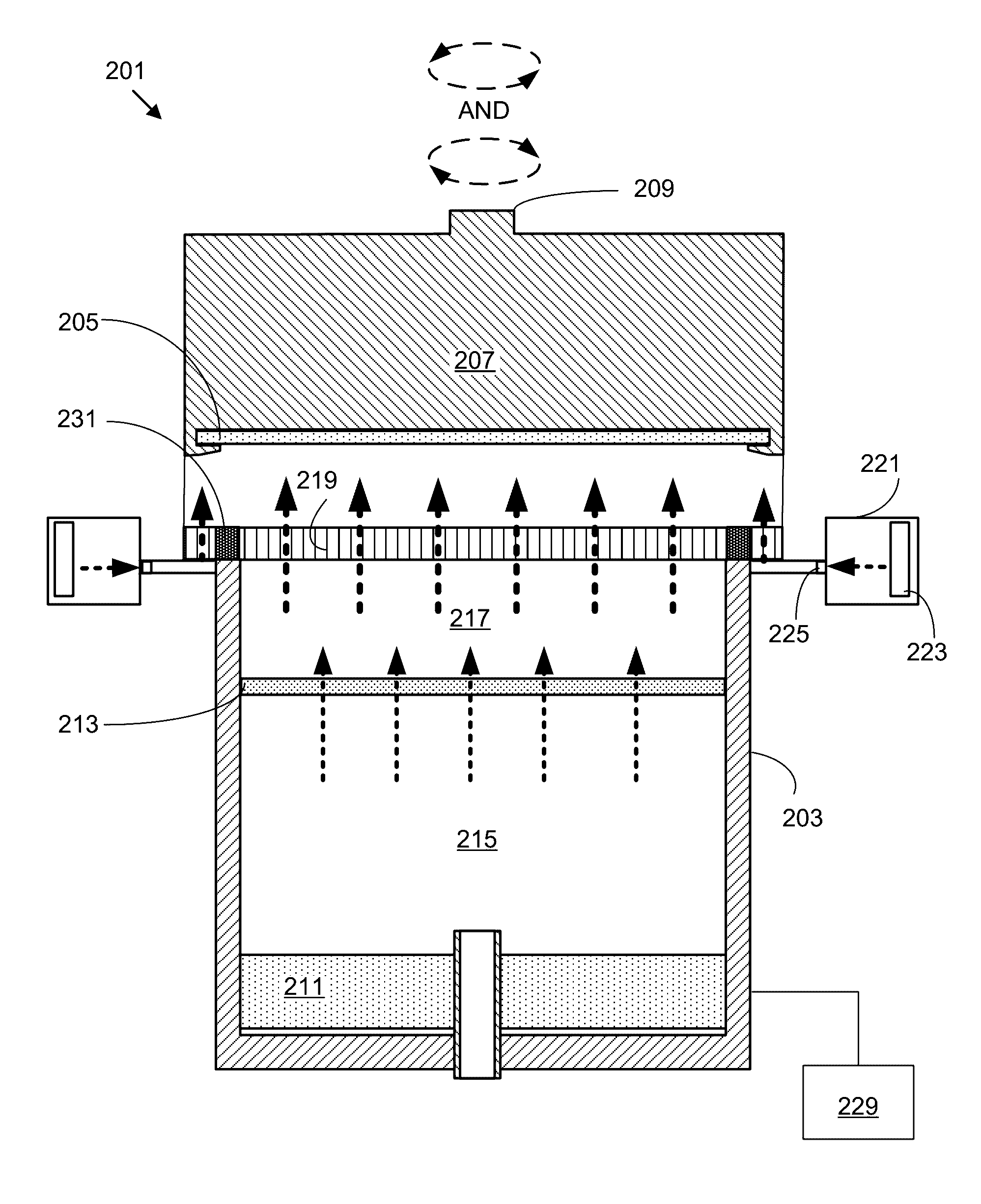

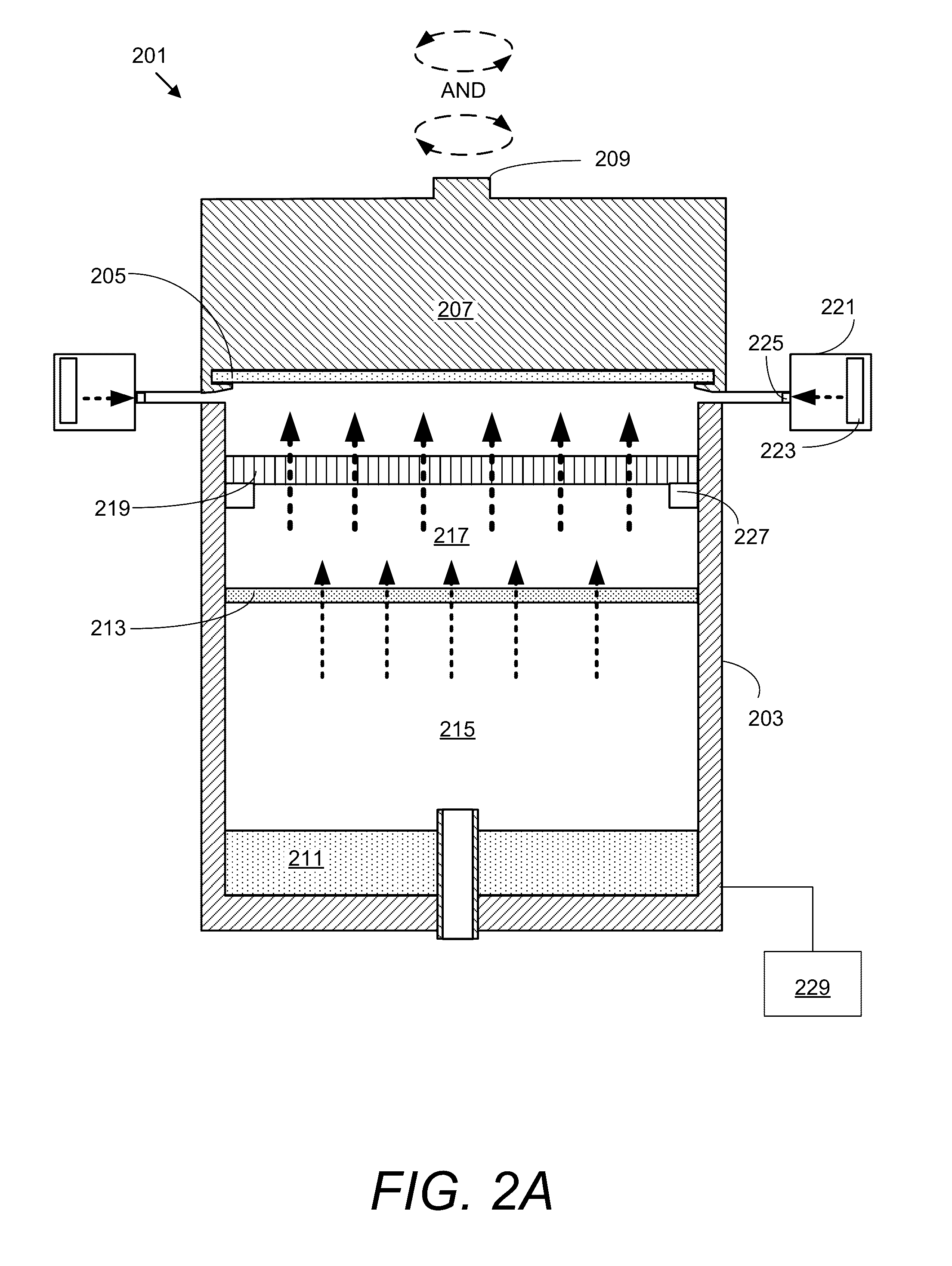

Apparatus and method for dynamic control of plated uniformity with the use of remote electric current

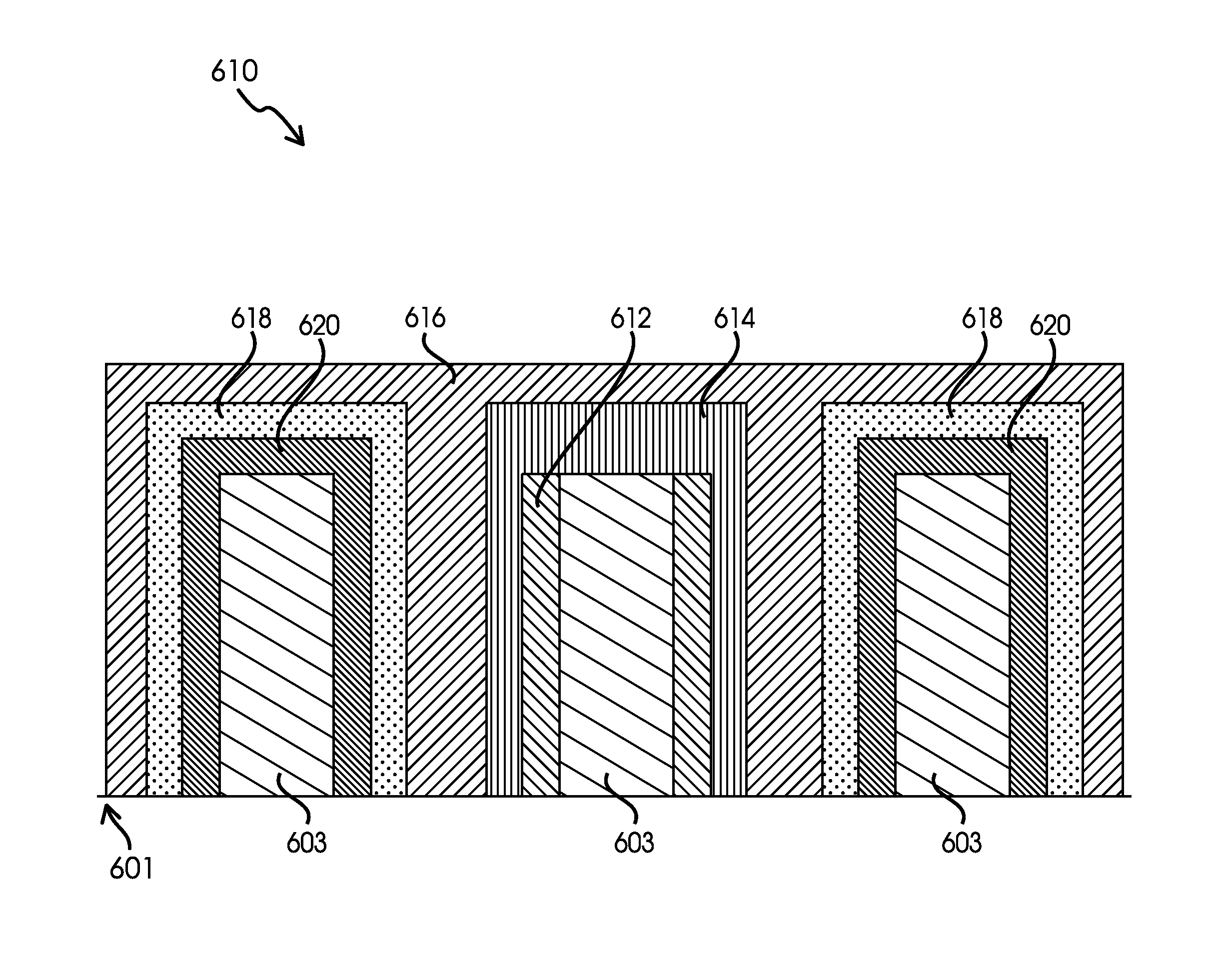

ActiveUS20160215408A1Reduce processReduce downtimeCellsCurrent conducting devicesEngineeringAuxiliary electrode

An apparatus for electroplating metal on a substrate while controlling plating uniformity includes in one aspect: a plating chamber having anolyte and catholyte compartments separated by a membrane; a primary anode positioned in the anolyte compartment; an ionically resistive ionically permeable element positioned between the membrane and a substrate in the catholyte compartment; and a secondary electrode configured to donate and / or divert plating current to and / or from the substrate, wherein the secondary electrode is positioned such that the donated and / or diverted plating current does not cross the membrane separating the anolyte and catholyte compartments, but passes through the ionically resistive ionically permeable element. In some embodiments the secondary electrode is an azimuthally symmetrical anode (e.g., a ring positioned in a separate compartment around the periphery of the plating chamber) that can be dynamically controlled during electroplating.

Owner:LAM RES CORP

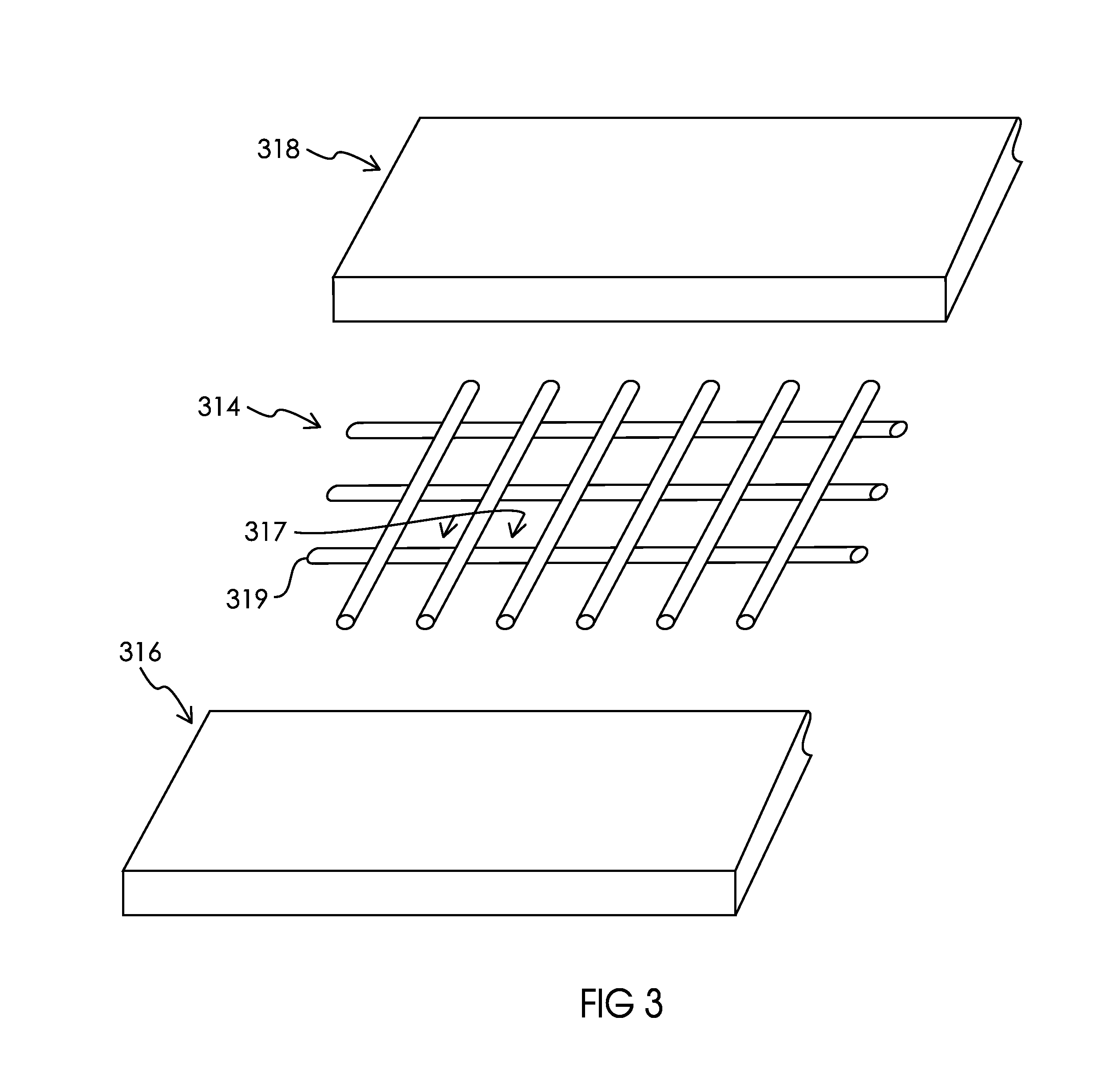

Ionically permeable structures for energy storage devices

ActiveUS9356271B2Reduce inactive component weight and volumePack the devices more efficientlyElectrode thermal treatmentCell seperators/membranes/diaphragms/spacersElectrical conductorEnergy storage

An electrochemical stack comprising carrier ions, an anode comprising an anode active material layer, a cathode comprising a cathode active material layer, a separator between the anode and the cathode comprising a porous dielectric material and a non-aqueous electrolyte, and an ionically permeable conductor layer located between the separator and an electrode active material layer.

Owner:ENOVIX CORP

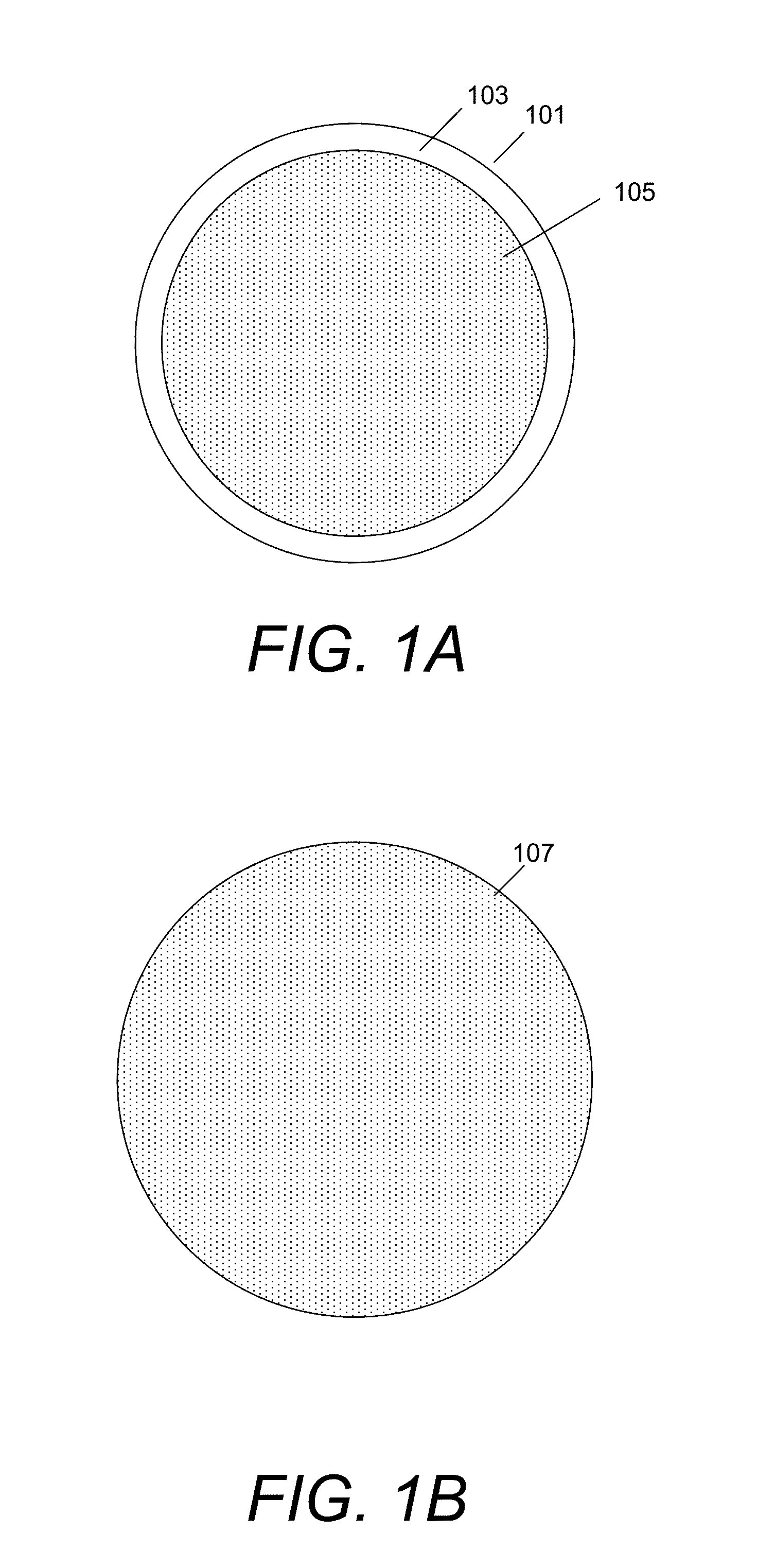

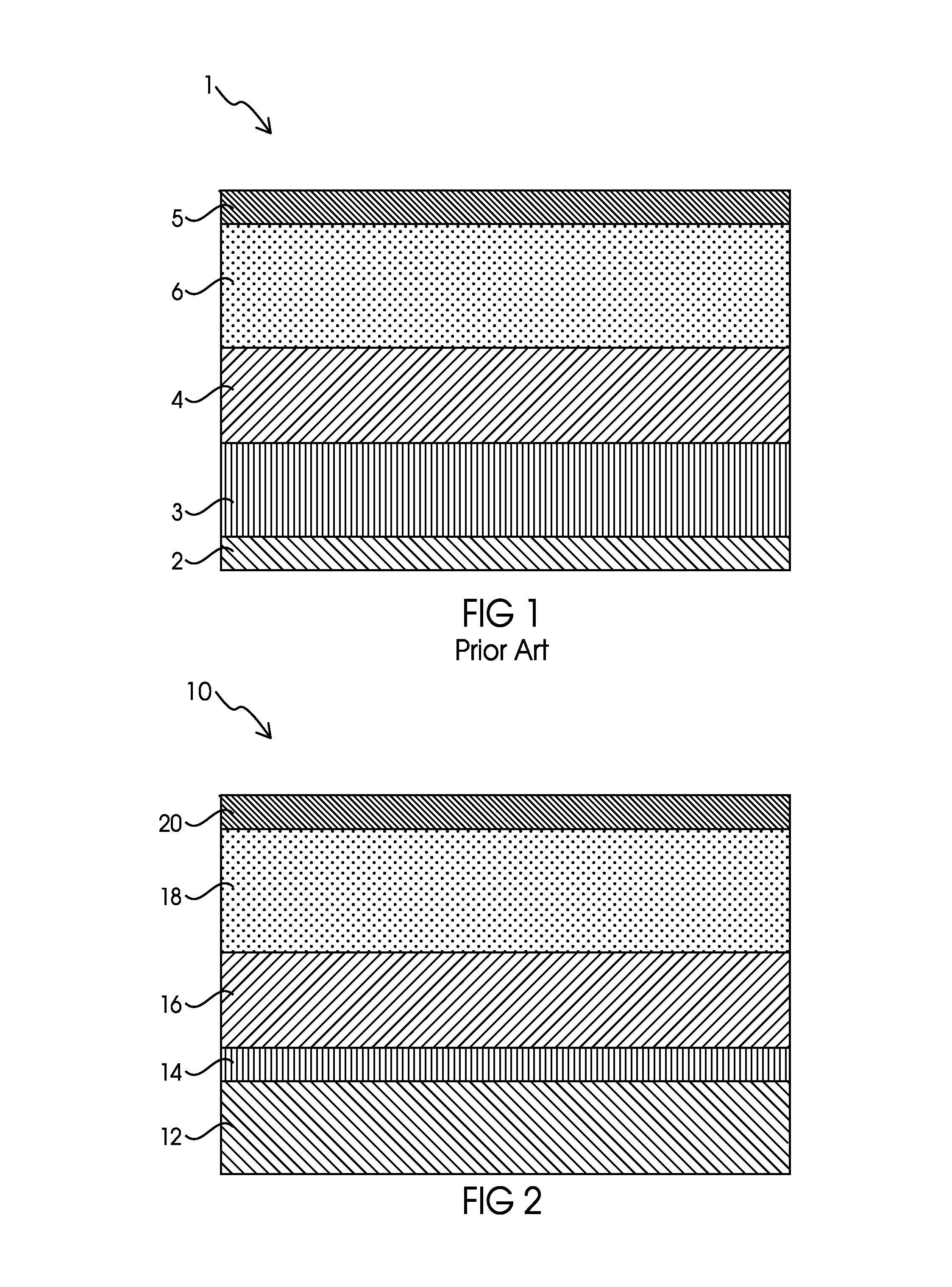

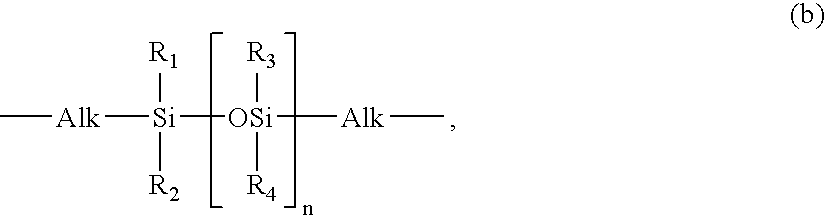

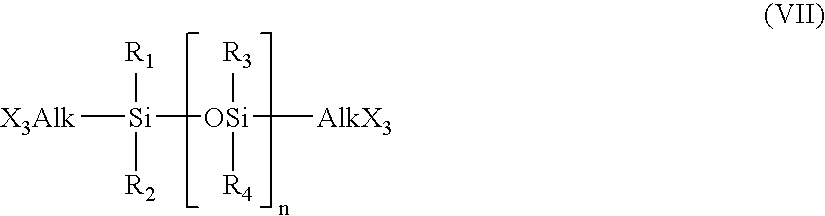

Extended Wear Ophthalmic Lens

InactiveUS20070105973A1Sufficient for corneal healthSubstantial adverse impact on ocular health or consumerOptical articlesProsthesisExtended wear contact lensesEye movement

An ophthalmic lens suited for extended-wear periods of at least one day on the eye without a clinically significant amount of corneal swelling and without substantial wearer discomfort. The lens has a balance of oxygen permeability and ion or water permeability, with the ion or water permeability being sufficient to provide good on-eye movement, such that a good tear exchange occurs between the lens and the eye. A preferred lens is a copolymerization product of a oxyperm macromer and an ionoperm monomer. The invention encompasses extended wear contact lenses, which include a core having oxygen transmission and ion transmission pathways extending from the inner surface to the outer surface.

Owner:NOVARTIS AG

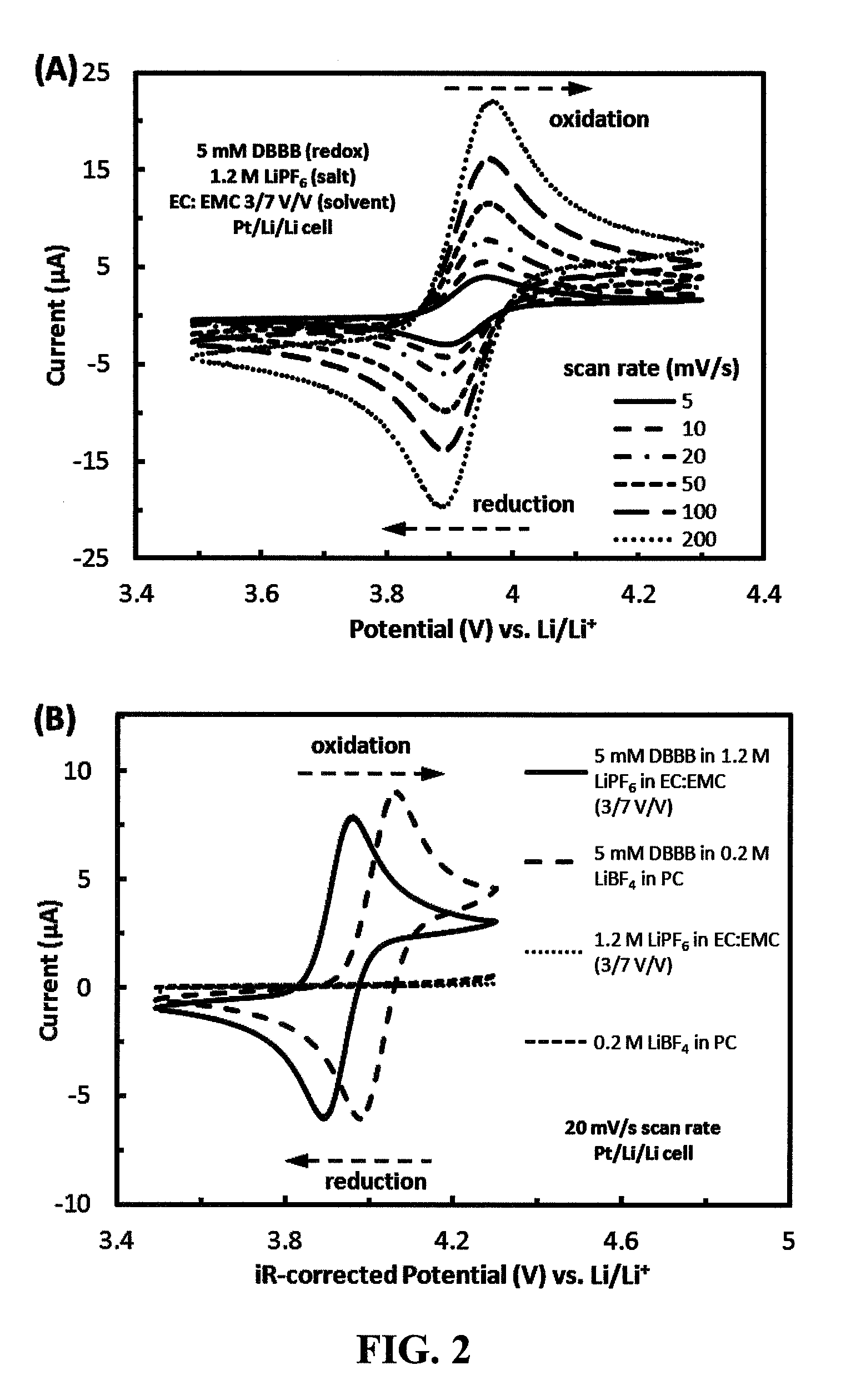

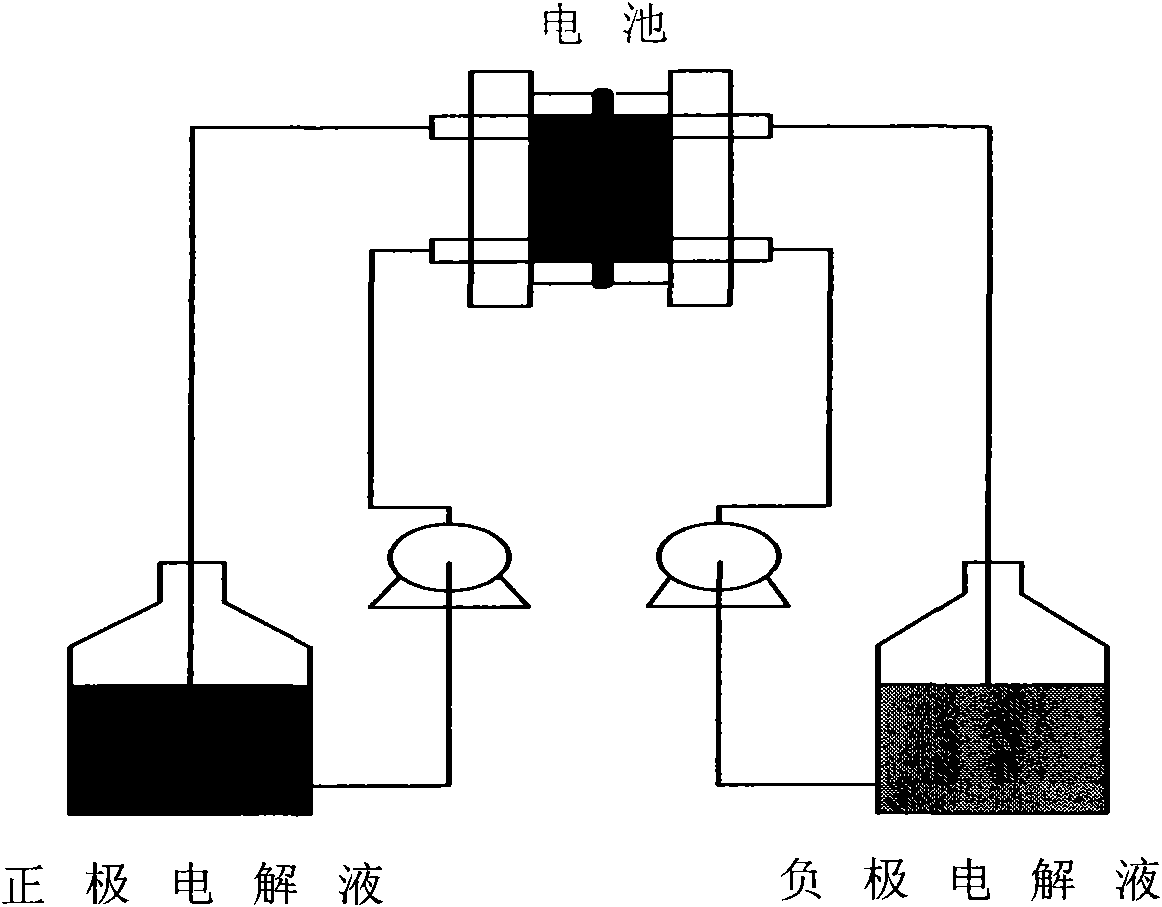

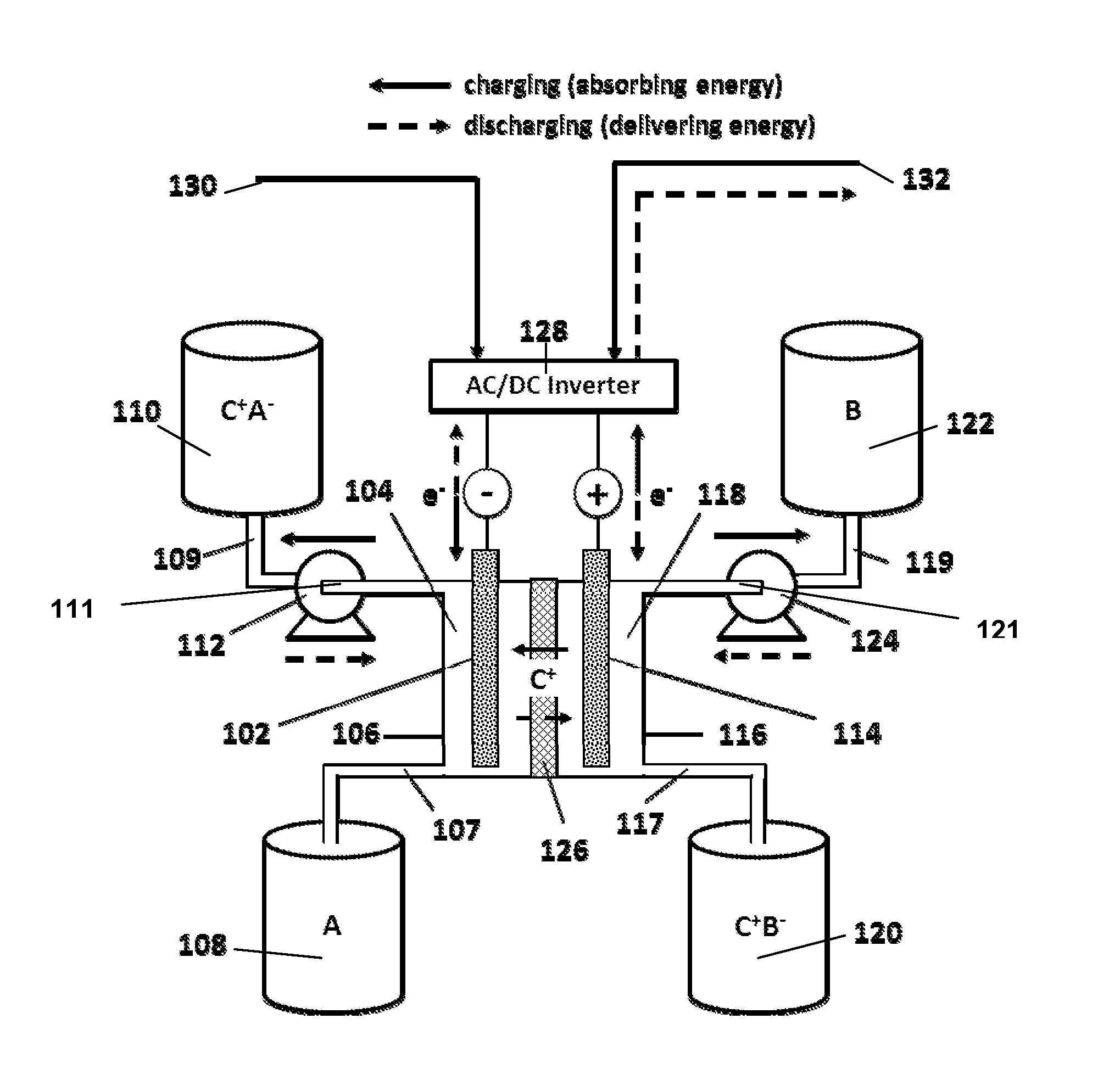

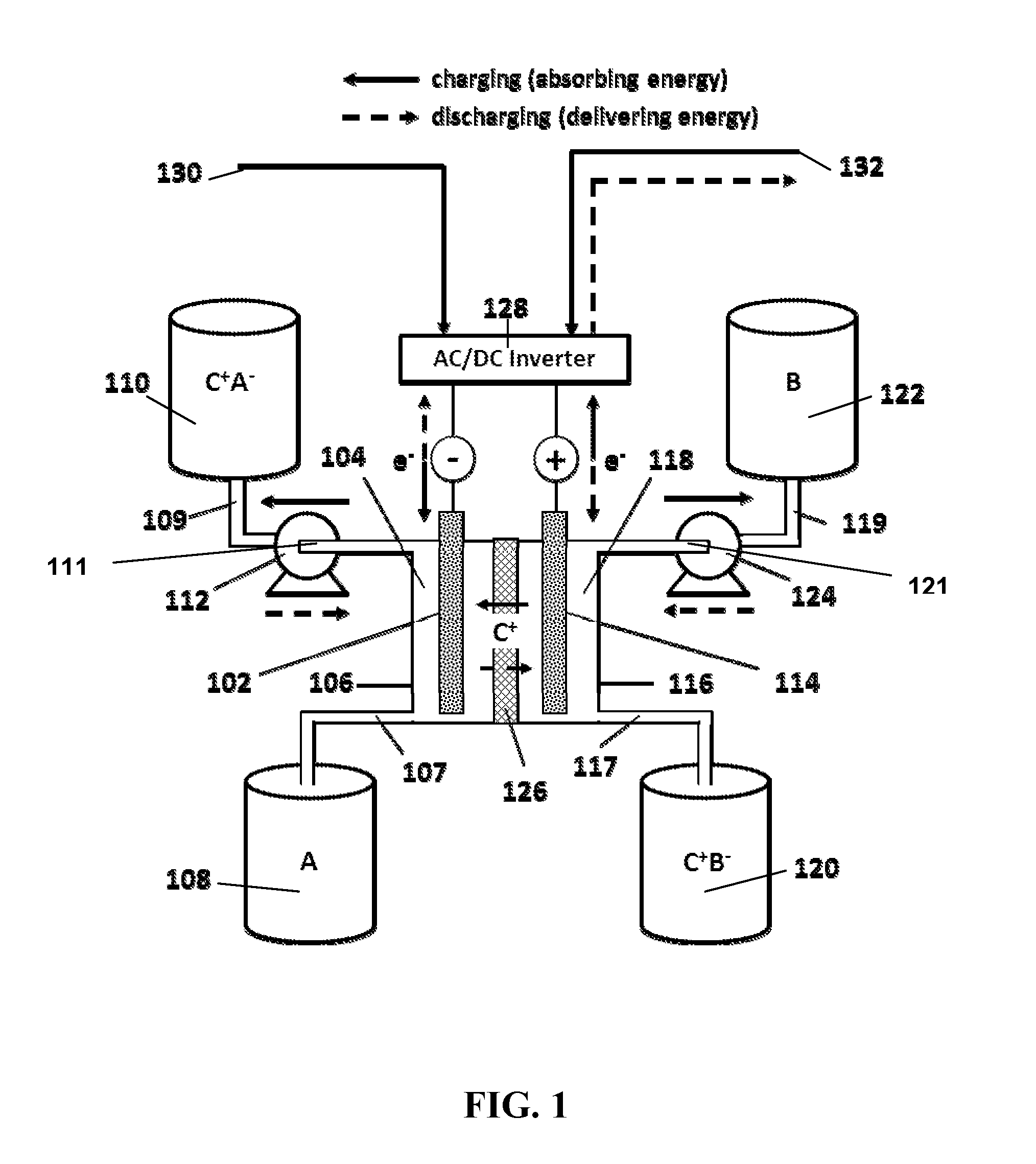

Organic non-aqueous cation-based redox flow batteries

ActiveUS20140370405A1Improves redox potentialImprove solubilityCell electrodesRegenerative fuel cellsElectrochemistryOrganic compound

The present invention provides a non-aqueous redox flow battery comprising a negative electrode immersed in a non-aqueous liquid negative electrolyte, a positive electrode immersed in a non-aqueous liquid positive electrolyte, and a cation-permeable separator (e.g., a porous membrane, film, sheet, or panel) between the negative electrolyte from the positive electrolyte. During charging and discharging, the electrolytes are circulated over their respective electrodes. The electrolytes each comprise an electrolyte salt (e.g., a lithium or sodium salt), a transition-metal free redox reactant, and optionally an electrochemically stable organic solvent. Each redox reactant is selected from an organic compound comprising a conjugated unsaturated moiety, a boron cluster compound, and a combination thereof. The organic redox reactant of the positive electrolyte comprises a tetrafluorohydroquinone ether compound or a tetrafluorocatechol ether compound.

Owner:UCHICAGO ARGONNE LLC

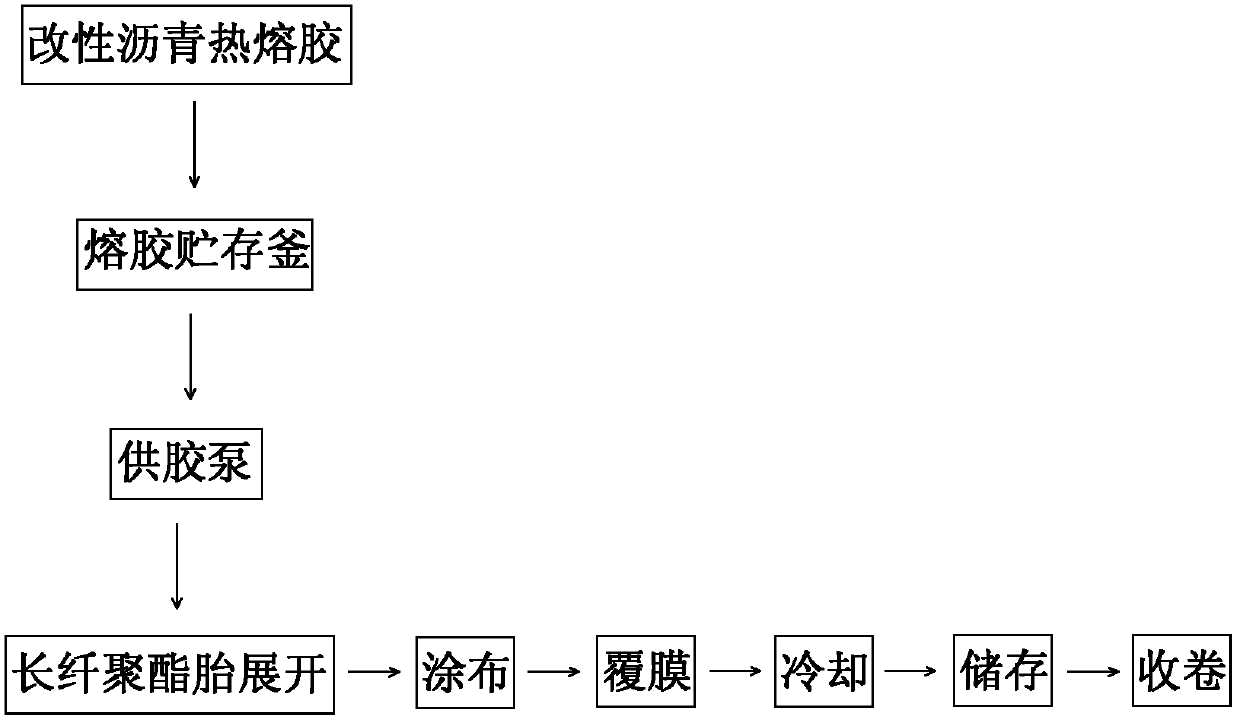

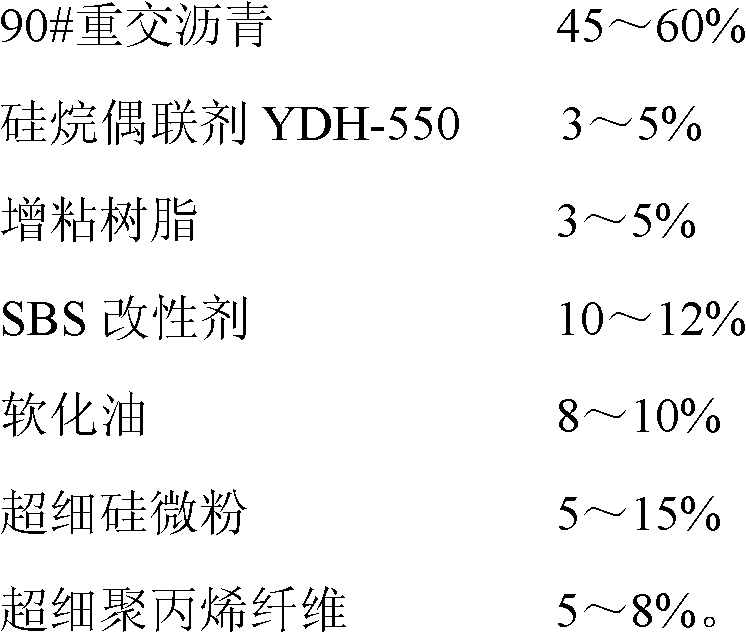

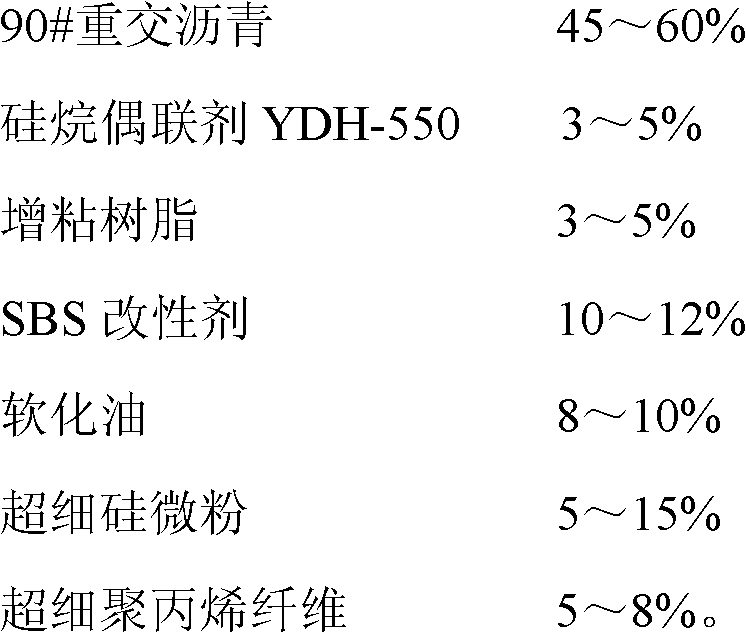

Saline-alkali tolerant high polymer modified asphalt polyester reinforcement waterproof coiled material

InactiveCN102605866AHigh tensile strengthGood root puncture resistanceUnderground chambersRoof covering using flexible materialsPolyesterIon permeation

The invention discloses a saline-alkali tolerant high polymer modified asphalt polyester reinforcement waterproof coiled material, which comprises a layer of high-strength long fiber polyester reinforcement (PY) with the thickness ranging from 1.2mm to 1.4mm. Special super-viscous SBS (styrene-butadiene-styrene block copolymer) and chemical saline-alkali tolerant accessories are covered on two surfaces of the polyester reinforcement to modify rubber asphalt, and the polyester reinforcement, the modified rubber asphalt and a PE (polyethylene) black film or fine sand materials are jointly used for preparing the saline-alkali tolerant high polymer modified asphalt polyester reinforcement waterproof coiled material by the aid of special process. The saline-alkali tolerant high polymer modified asphalt polyester reinforcement waterproof coiled material realizes excellent chlorine ion permeation performance and saline-alkali tolerance when used in building waterproofing engineering in coastal areas and high-saline and high-alkali areas, and can effectively prevent a building structural main body from being eroded by corrosive media.

Owner:KESHUN WATERPROOF TECH CO LTD

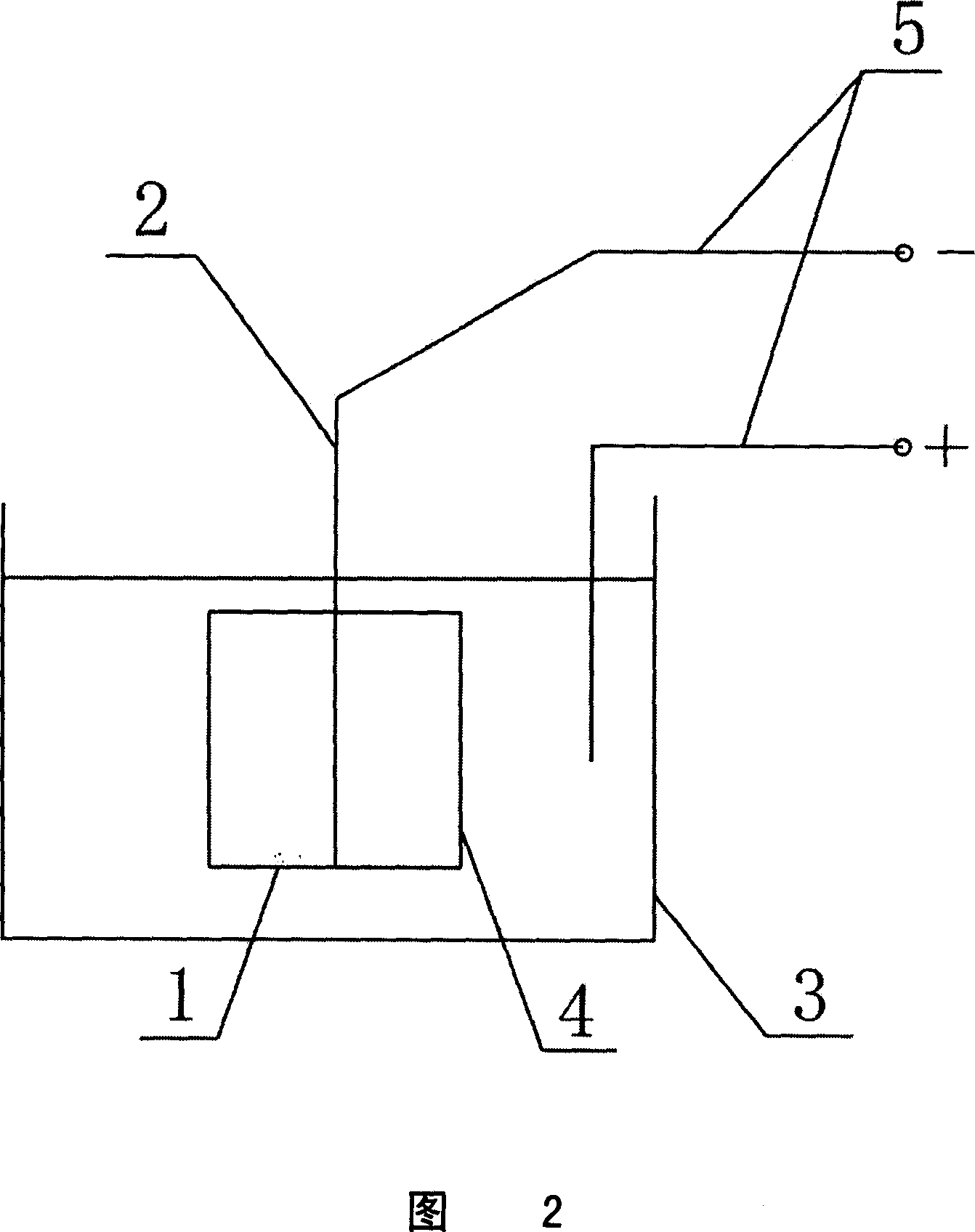

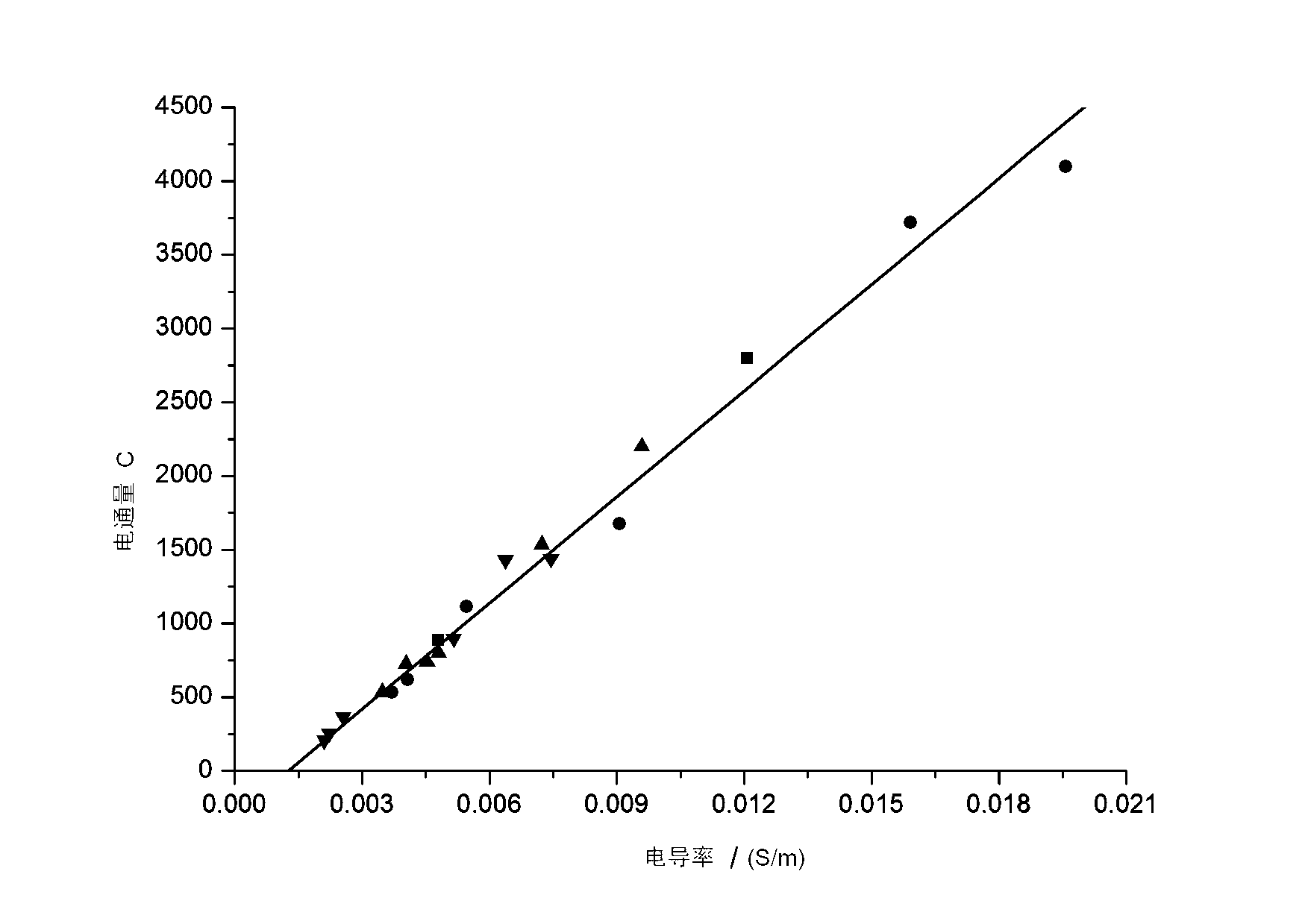

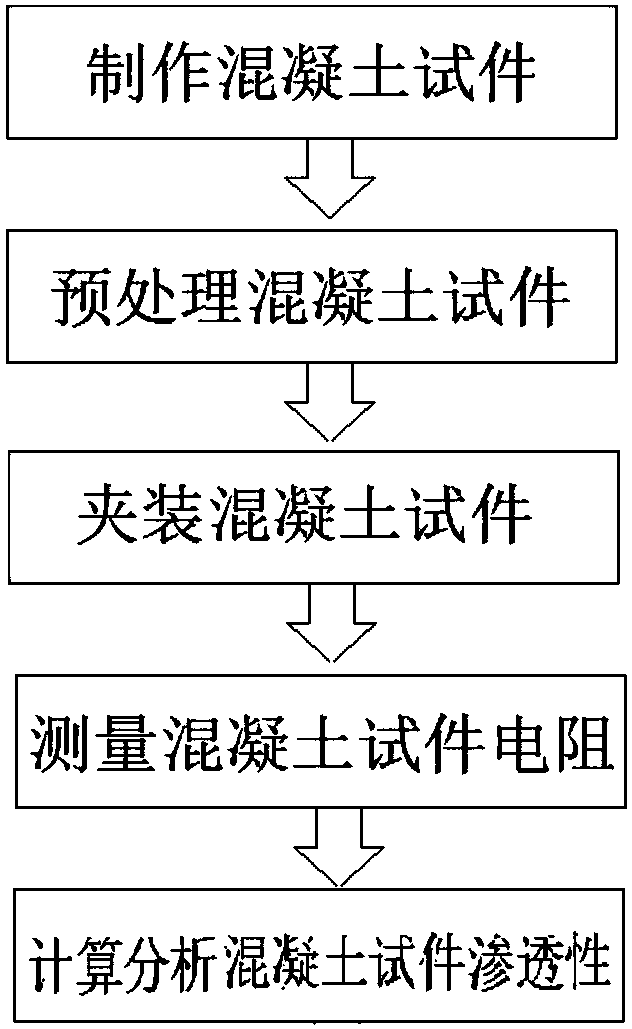

Concrete chloride ion permeation property quick rust testing method

InactiveCN101071132AFast testStrong theoreticalWithdrawing sample devicesMaterial testing goodsDistilled waterIon permeation

This invention introduces a concrete chloride ion permeability fast - corrosion testing method is: put the concrete specimen has a network-reinforced in the middle in the NaCl and 0.3 M NaOH, distilled water preparation and 3.0% in the chemical percentage of pure quality NaCl, and 0.3 M NaOH aqueous solution mixed, in the environmental temperature was 23 or so, with NaCl solution should be soaked every one week replacement once, in the testing process after inspection and test soaking solution of NaCl concentration of 60 +- 0.1 volts the plus DC, in the test cycle, not more than 24 hours in regular record current value, and growth of over 10% / 24 hours, the application of NT BUILD 208, AAHSTO T260 accurate determination of concrete powder samples of the acid chloride Cl-content, chlorine ion concentration measurement accuracy should reach 0.001%.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

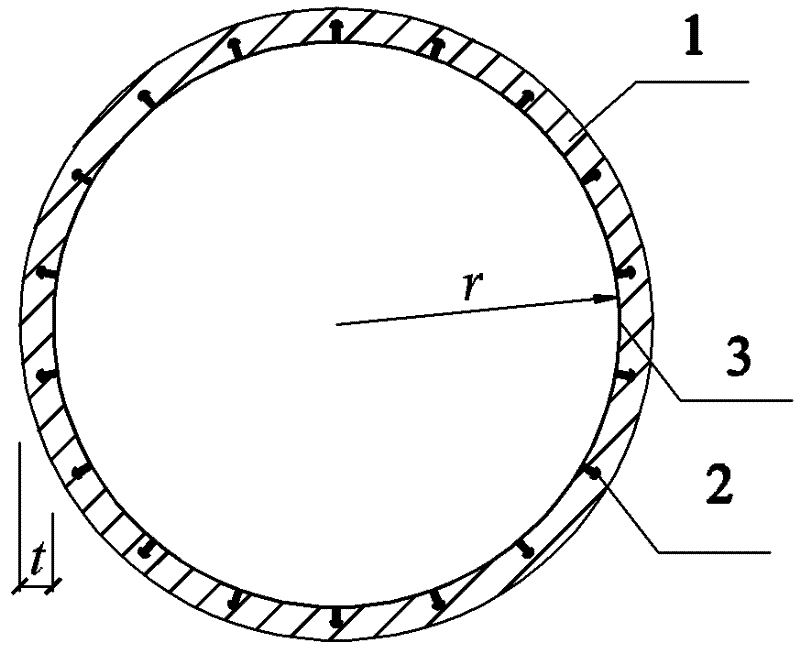

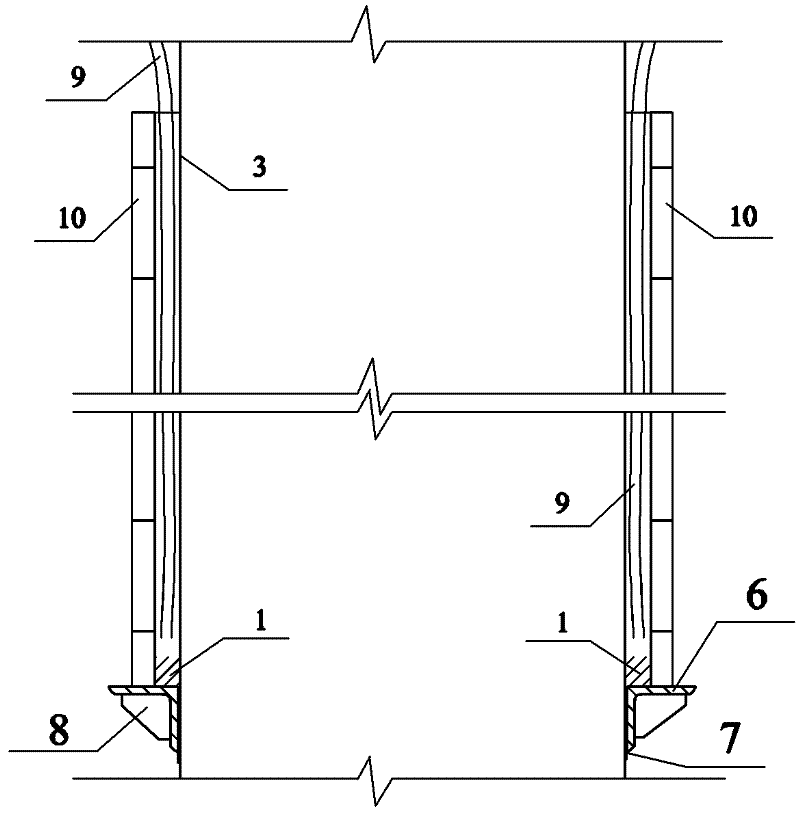

Method for repairing and reinforcing pile foundations in ocean splash zones

The invention provides a method for repairing and reinforcing pile foundations in ocean splash zones. The method is characterized by comprising the following steps: firstly carrying out interface treatment on the splash zones and the zones needing repair near the splash zones aiming at different pile body types, fixing end hoops for bearing upper construction loads on the lower edges of the repaired zone, installing external molds and then continuously pouring a self-compaction ultra high toughness cementitious composite (UHTCC). The method has the following beneficial effect: erosion of dry-wet alternation and chloride ion permeation in the splash zones, temperature difference and sea wave impact effect can be effectively resisted, thus ensuring the durability of pile bodies under the environmental condition of severe corrosion.

Owner:浙江固邦新材料有限公司

Extended Wear Ophthalmic Lens

InactiveUS20070105974A1Sufficient for corneal healthSubstantial adverse impact on ocular health or consumerOptical articlesProsthesisExtended wear contact lensesEye movement

An ophthalmic lens suited for extended-wear periods of at least one day on the eye without a clinically significant amount of corneal swelling and without substantial wearer discomfort. The lens has a balance of oxygen permeability and ion or water permeability, with the ion or water permeability being sufficient to provide good on-eye movement, such that a good tear exchange occurs between the lens and the eye. A preferred lens is a copolymerization product of a oxyperm macromer and an ionoperm monomer. The invention encompasses extended wear contact lenses, which include a core having oxygen transmission and ion transmission pathways extending from the inner surface to the outer surface.

Owner:NOVARTIS AG

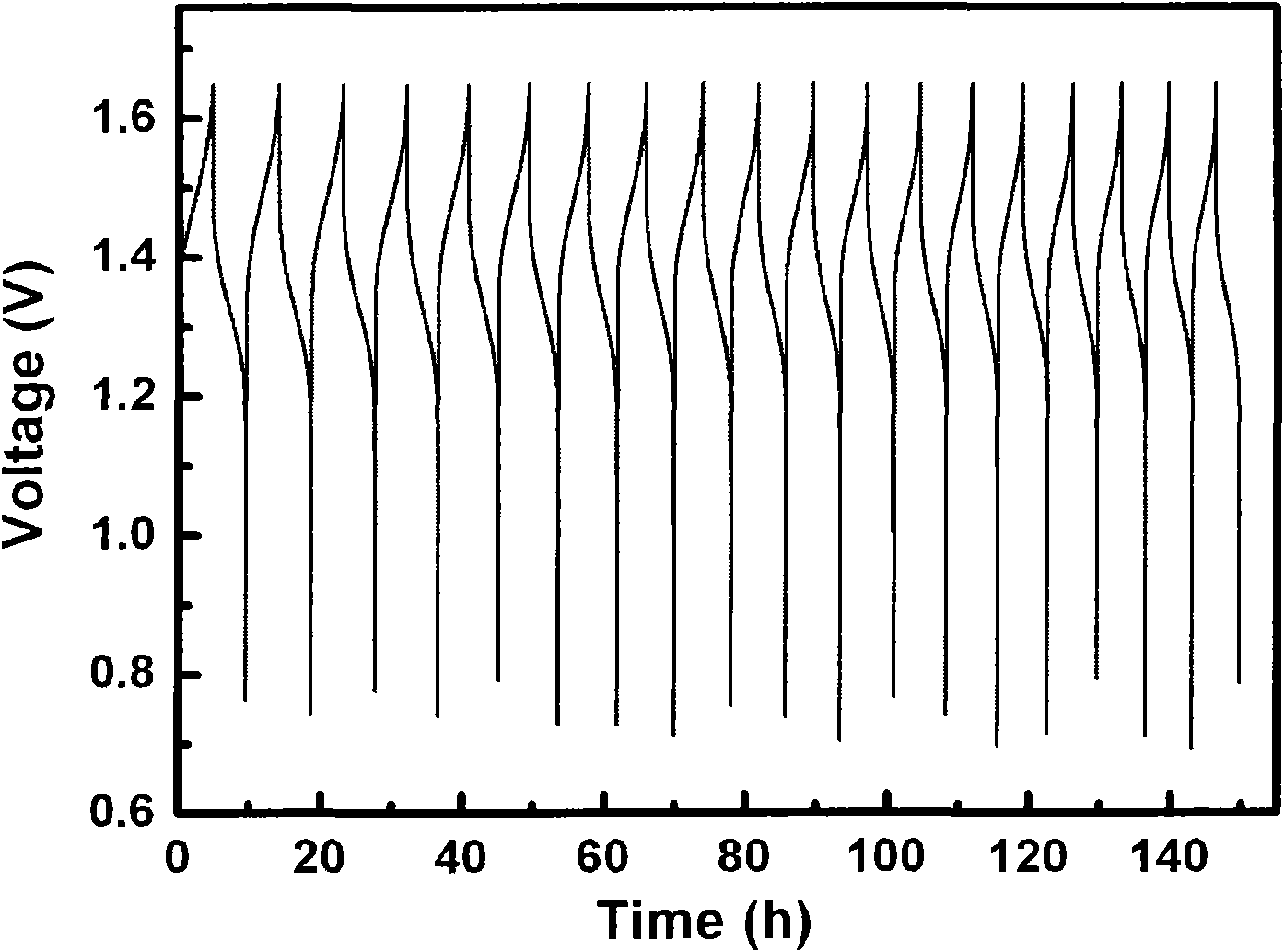

Method for sealing liquid reservoir for liquid flow battery

ActiveCN102244281ASolve permeabilitySolve problems such as diaphragm agingElectrolyte stream managementEngineeringAtmospheric pressure

The invention relates to a method for sealing a liquid reservoir for a liquid flow battery, which comprises the following steps of: installing a seal cover on the liquid reservoir, filling the liquid reservoir with electrolyte, and sealing the liquid reservoir; indirectly sealing the sealed liquid reservoir with liquid or gas. The pressure in the liquid reservoir indirectly sealed by the liquid or gas always stays at one standard atmospheric pressure. The liquid or gas used for indirect sealing is sealing liquid or sealing gas. The sealing liquid or sealing gas and the liquid reservoir are connected through a conduit. One end of the conduit is outside the liquid reservoir. The invention has the advantages that the sealing method is simple, convenient and efficient; the problem of inconsistent charging states of battery anode and cathode caused by oxidation of low-valence ions and the problems of ion permeation, water permeation, membrane aging and the like caused by the problem of pressure unbalance are solved; the service life of the membrane can be effectively prolonged; and the coulomb efficiency of the liquid flow battery is improved and the service life of the liquid flow battery can be effectively prolonged.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

Method for rapidly determining chloride ion permeation resistance of concrete

InactiveCN103175764AShort test timeReduce electric flux test errorPermeability/surface area analysisDielectricElectricity

The invention relates to a method for rapidly determining the chloride ion permeation resistance of concrete. The method comprises the following steps: slicing concrete, putting the obtained sliced concrete into a vacuum water-saturated device, pumping to a certain vacuum degree, injecting deionized water to the obtained vacuum chamber, and maintaining the vacuum degree for a certain period of time to make apertures in the concrete full of water; and carrying out alternating current impedance test of a test piece to obtain a characteristic conductivity, and calculating via a conversion formula to obtain an equivalent dielectric flux in order to evaluate the chloride ion permeation resistance of concrete. The method has the advantages of determination of the dielectric flux of concrete within a very short period of time, simplicity, reliable data, no less, and realization of multi-time test of the same test piece.

Owner:SHIJIAZHUANG TIEDAO UNIV

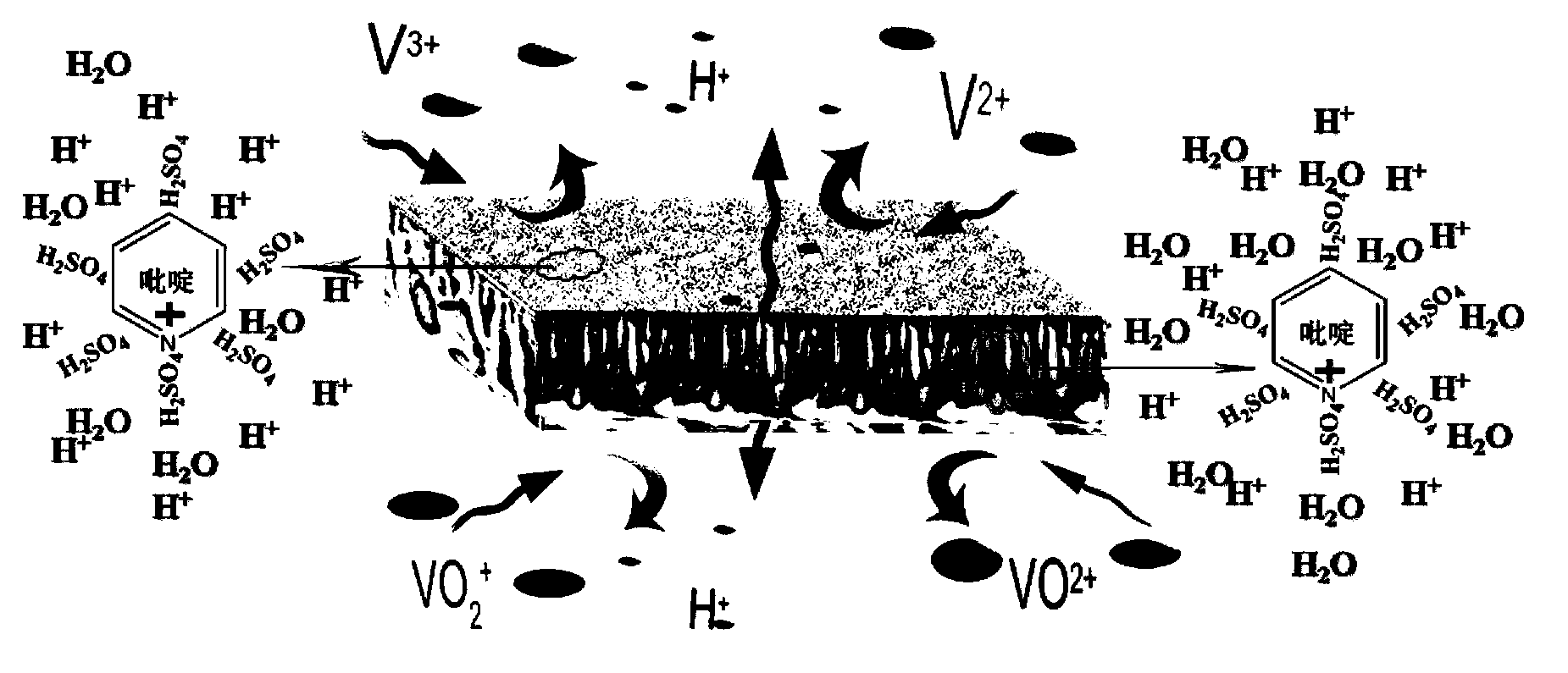

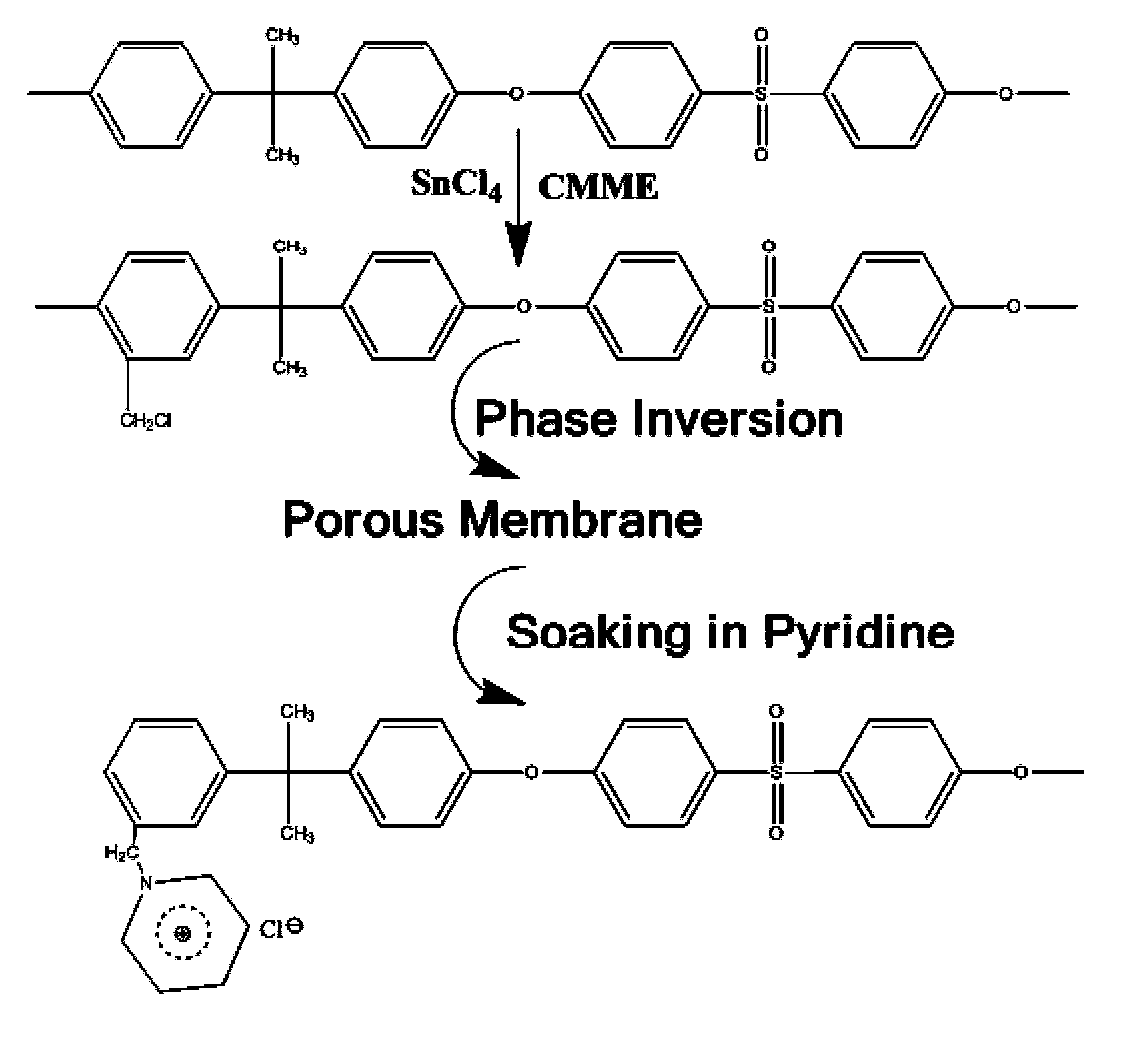

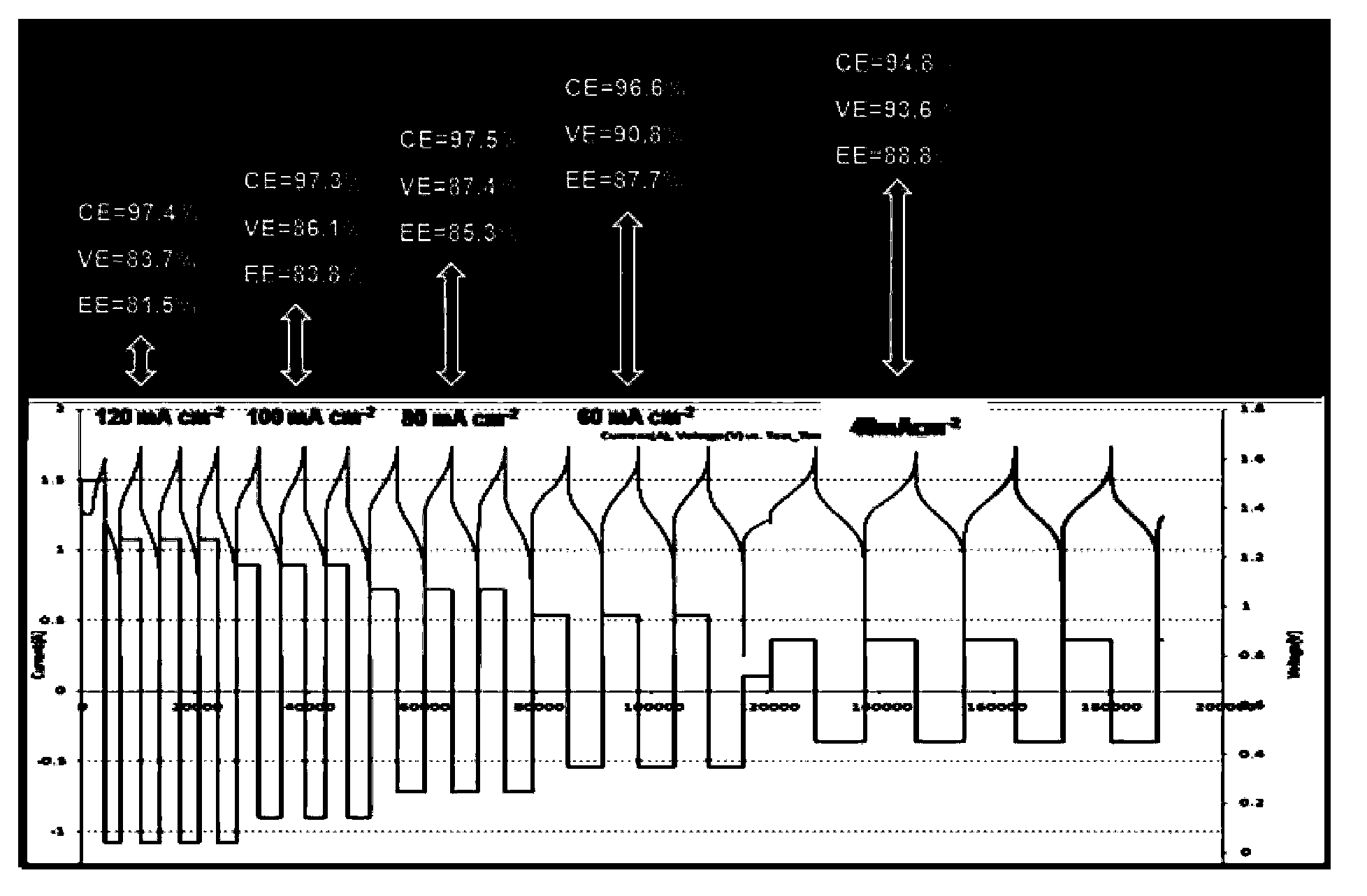

Application of basic porous membrane in liquid flow energy storage battery

ActiveCN103682212AImprove mechanical propertiesImprove proton conductivityElectrolyte holding meansCell component detailsPorous membranePore diameter

The invention relates to application of a basic porous membrane in a liquid flow energy storage battery. According to the basic porous membrane, polyaromatic resin containing chloromethyl or bromomethyl group is used as a matrix and can be blended with other resins, and a basic group is grafted on the chloromethyl or bromomethyl group of the matrix, wherein the content of matrix in the blended resin is 5-100 percent by weight. The basic porous membrane is simple in preparation method, controllable in pore diameter and adjustable in content of basic groups, and large-scale production can be easily realized. According to the basic porous membrane, the ionic conductivity of a diaphragm can be effectively improved, vanadium ion permeation can be effectively prevented due to the action of electrostatic repulsion, and the energy conversion efficiency of a full-vanadium liquid flow battery can be greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Self-electroosmosis hydrogel adhesive film

InactiveCN101862505APromote osmotic absorptionSelf-produced electroosmotic effectElectrotherapyOrganic filmAdhesive

The invention relates to a self-electroosmosis hydrogel adhesive film, which combines an electrochemical primary batter consisting of two polar materials with different electrochemical potential difference with functional active substance-containing hydrogel. A method for manufacturing the self-electroosmosis hydrogel adhesive film comprises the following steps of: printing conductive paste on an organic film to form a collector layer; producing a positive electrode layer and a negative electrode layer and printing the positive electrode layer and the negative electrode layer on the collector layer respectively; adhering all the layers on a non-woven fabric substrate; coating a conductive adhesive layer on the two electrodes respectively; and coating a functional active substance-containing hydrogel layer on the conductive adhesive layer. During use, the hydrogel adhesive film is contacted with the skin of a human body, and the two electrodes and the skin of the human body form a current loop through the hydrogel comprising a certain amount of moisture, so that permeation rate of the active substance can be increased and the adsorption rate of the skin on the active substance can be increased. The hydrogel adhesive film has the advantages of overcoming the defects that a power supply needs to be added, the film cannot be used at any time and the cost is high in the conventional ion permeation technique, and effectively increasing the permeation rate of the functional active substance, along with simple structure, low cost, convenient storage and carrying and convenient use.

Owner:SICHUAN UNIV +1

Method for preparing natural high-molecular material by utilization of rare earth metal ion coordination

InactiveCN106243240AOvercome toxicityOvercome compatibilityProsthesisDiffusion methodsStructural regularity

The invention discloses a method for preparing a natural high-molecular material by the utilization of rare earth metal ion coordination. Through strong coordination between rare earth metal ion and oxygen atom in carboxyl function group, the rare earth metal ion coordinated natural high-molecular material is prepared by an ion permeation and diffusion method. According to the method, carboxyl-modified graphene oxide is introduced into the natural high-molecular material such that mechanical strength of the material is enhanced and structural regularity of the material also can be boosted. By selecting one ingredient from sodium alginate and xanthan gum as the base material, the material can be endowed with good biocompatibility and biodegradability. The method of the invention is simple and feasible. Reaction condition is mild. The prepared natural high-molecular material has good biocompatibility and strong mechanical properties.

Owner:SOUTHEAST UNIV

Concrete with anti-cracking, anti-seepage and high-durability effects and preparation method thereof

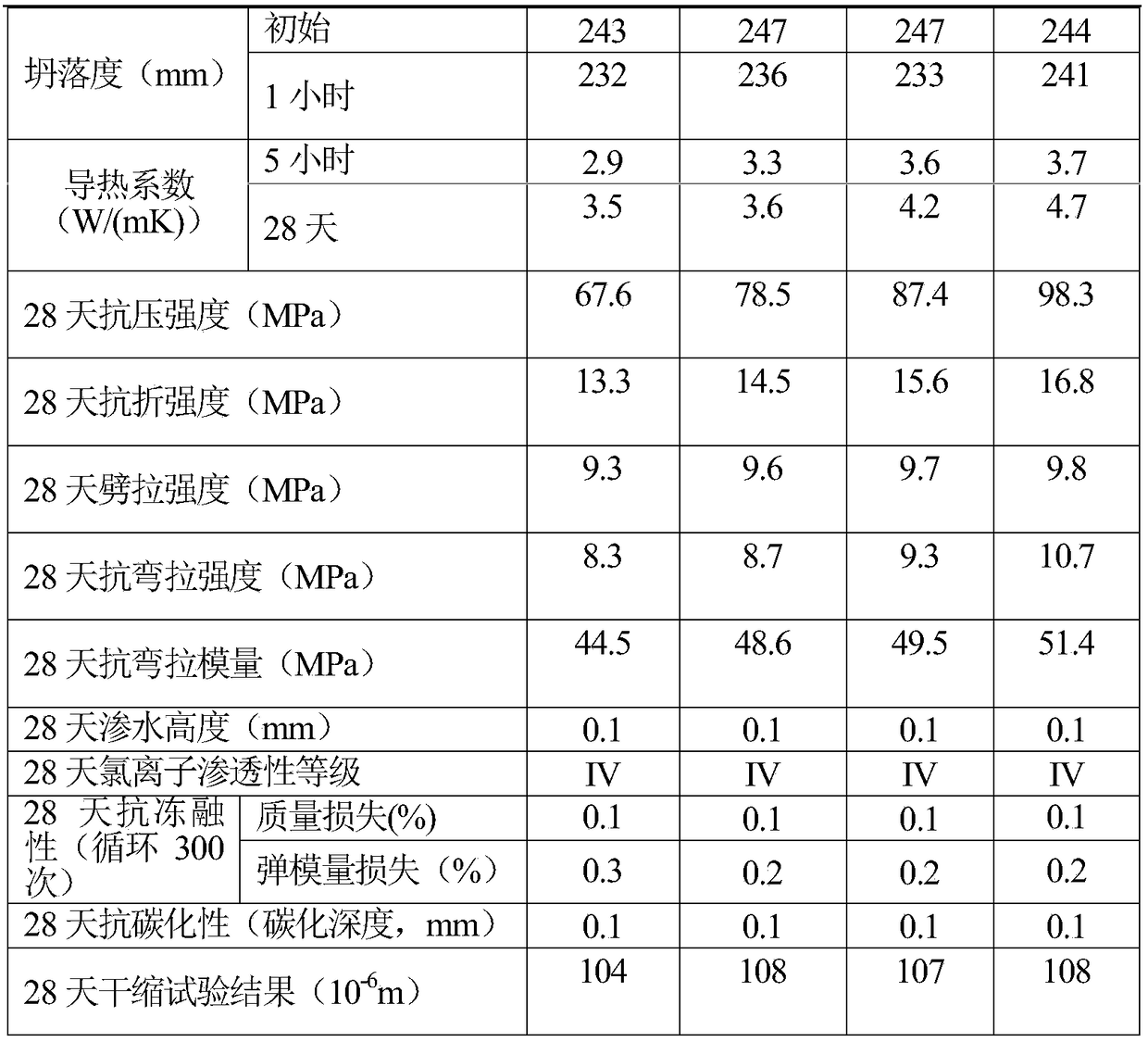

The invention relates to a concrete with anti-cracking, anti-seepage and high-durability effects and a preparation method thereof. The concrete is prepared from the following components of cement, flyash, silicon powder, coal gangue powder, boron nitride, phosphor residue powder, sand, crushed stone, high-strength polyvinyl alcohol fiber, a water reduction agent, a dispersing activator, a modified graphene oxide dispersion liquid and water. The concrete has the advantages that the heat conduction coefficient in the 1h age period is 2.9 to 3.7W / (m.K), the heat conduction coefficient in the 28-day age period is 3.5 to 4.7W / (m.K), the compressive strength is 67.6 to 98.3MPa, the break strength is 13.3 to 16.8MPa, the split strength is 9.3 to 9.8MPa, the tensile strength is 8.3 to 10.7MPa, and the tensile elastic modulus is 44.5 to 51.4GPa; the anti-water permeation property, anti-chlorine ion permeation property, anti-freezing and thawing property, and anti-carbonizing property can reachthe highest level; the working property is high, the volume stability is high, the durability is high, the toughness is high, the anti-cracking ability is high, and the anti-seepage ability is high.

Owner:CHONGQING YABO BUILDING MATERIALS CO LTD

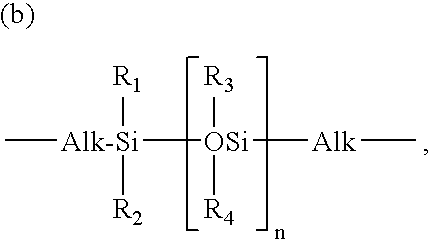

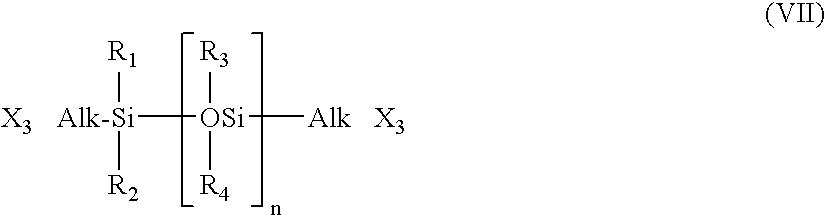

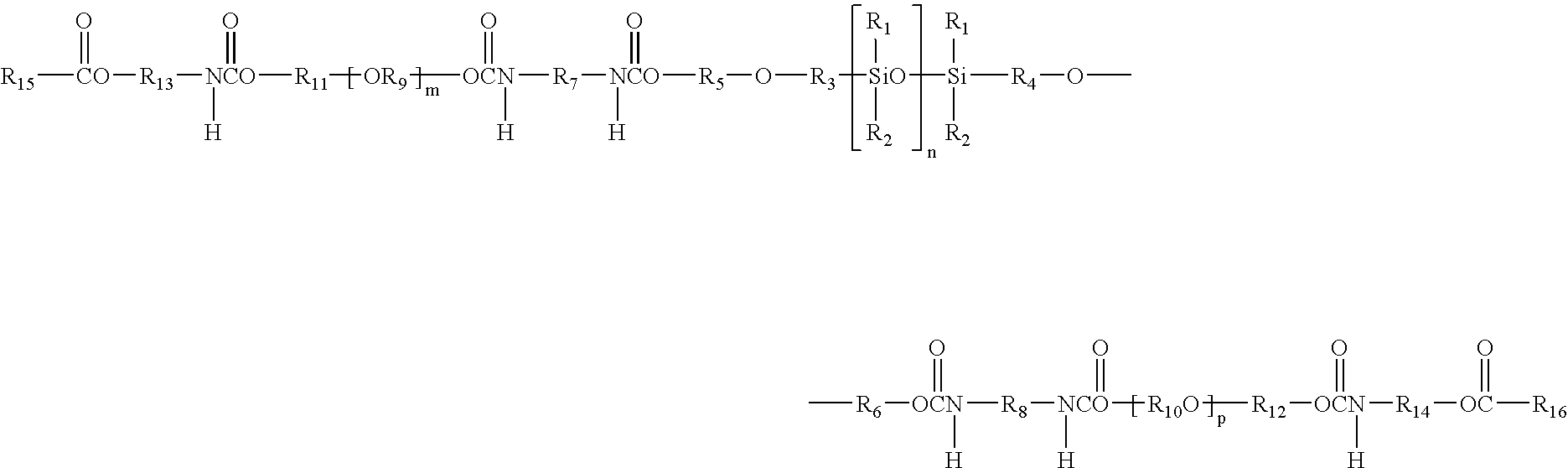

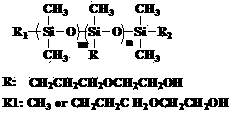

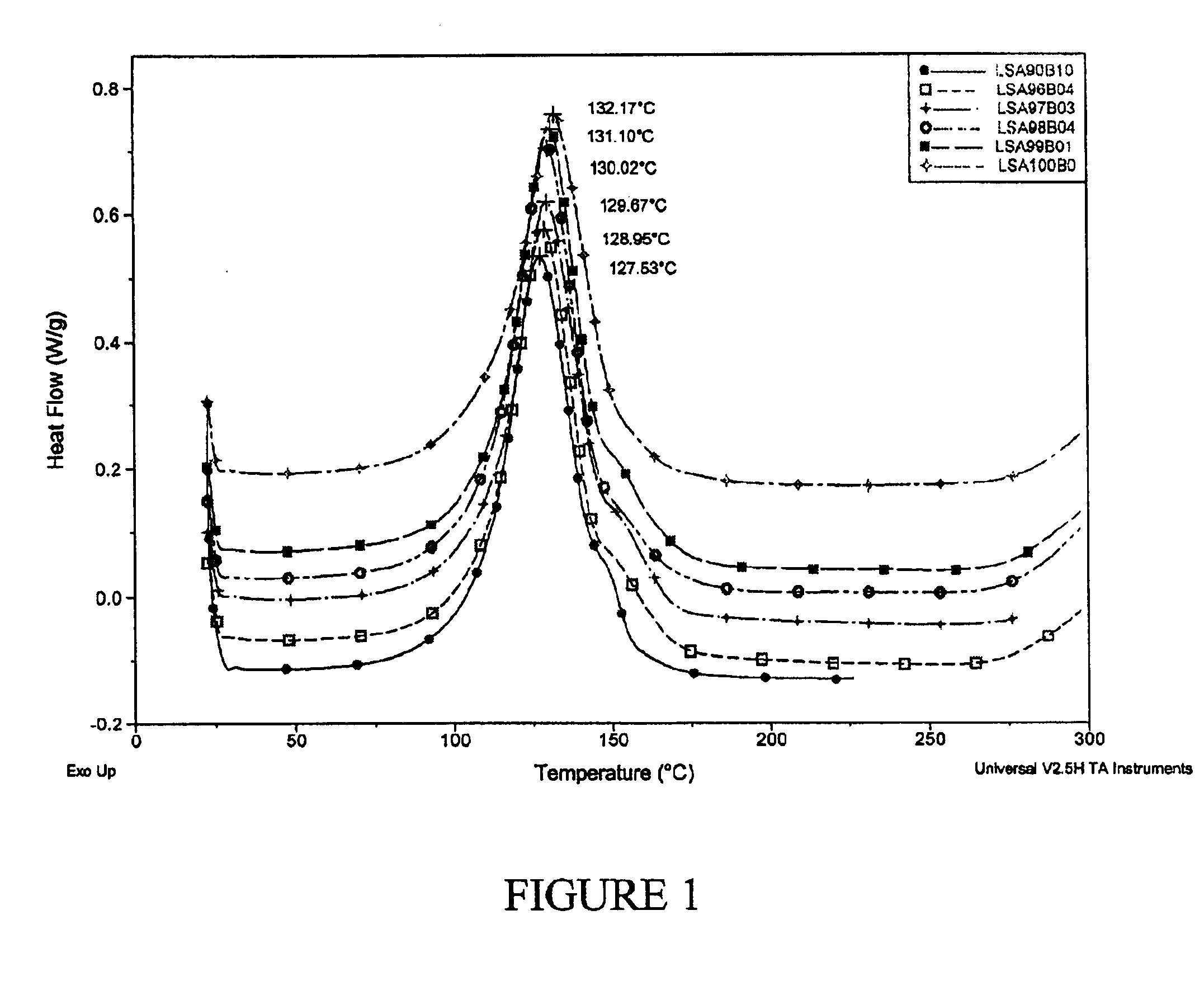

Simultaneous interpenetrating silicon hydrogel and preparation method thereof

The invention relates to a simultaneous interpenetrating silicon hydrogel and a preparation method thereof, and the synchronous forming of two networks can be triggered by simple light or heat. One network is a hydrophilic network, and obtained by free radical polymerization; the other network is obtained by a chemical reaction between polyisocyanate as a crosslinking agent and hydroxyl containing polysiloxane, and specifically, is prepared by mixing the hydroxyl containing polysiloxane, a polymerization monomer and the crosslinking agent, and adding an initiator, a catalyst and the like for one-step curing. The hydrophilic network gives the material water absorbing and ion permeation properties; and the organosilicone network gives the material high oxygen permeability. The simultaneous interpenetrating silicon hydrogel has good biocompatibility, and can be used for biomedical materials, such as a corneal contact lens, medical implant materials, artificial skin, a drug delivery carrier and the like.

Owner:QILU UNIV OF TECH

Apparatus and method for dynamic control of plated uniformity with the use of remote electric current

An apparatus for electroplating metal on a substrate while controlling plating uniformity includes in one aspect: a plating chamber having anolyte and catholyte compartments separated by a membrane; a primary anode positioned in the anolyte compartment; an ionically resistive ionically permeable element positioned between the membrane and a substrate in the catholyte compartment; and a secondary electrode configured to donate and / or divert plating current to and / or from the substrate, wherein the secondary electrode is positioned such that the donated and / or diverted plating current does not cross the membrane separating the anolyte and catholyte compartments, but passes through the ionically resistive ionically permeable element. In some embodiments the secondary electrode is an azimuthally symmetrical anode (e.g., a ring positioned in a separate compartment around the periphery of the plating chamber) that can be dynamically controlled during electroplating.

Owner:LAM RES CORP

PDVF coating method for battery separator

InactiveCN107611315AShorten the timeImprove conductivityCell component detailsEngineeringCharge discharge

The invention discloses a PDVF coating method for a battery separator and aims at providing a PDVF coating method for a battery separator with the advantages of reducing a barrier of a coating layer to ion permeation and improving the energy density of a battery on the premise of not affecting surface modification of the separator. According to the main points of the technical scheme, atomized droplets with PVDF particles are sprayed on the surface of a base layer of the battery separator or coat the surface in a spinning manner, the atomized droplets are dried to form a plurality of point sediments and a modified layer is formed. According to the PDVF coating method, the interaction between a coating and the separator can be reduced and the resistance when ions migrate on the interface isreduced. Improvement of the conductivity of the battery is facilitated, the influence of the modified layer on the charge-discharge performance of the battery is reduced, meanwhile, the influence ofa gel layer on the ionic conductivity is reduced, the time of balancing liquid absorption of the modified layer and of the separator is shortened and the whole conductivity of the battery is improvedto improve the performance of the separator and the battery.

Owner:无锡沄沨科技有限公司

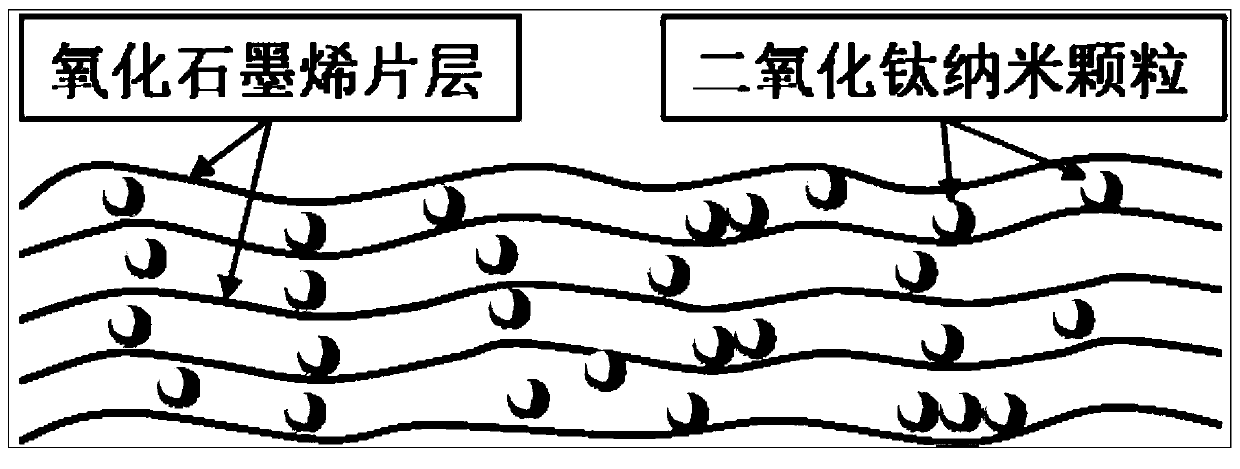

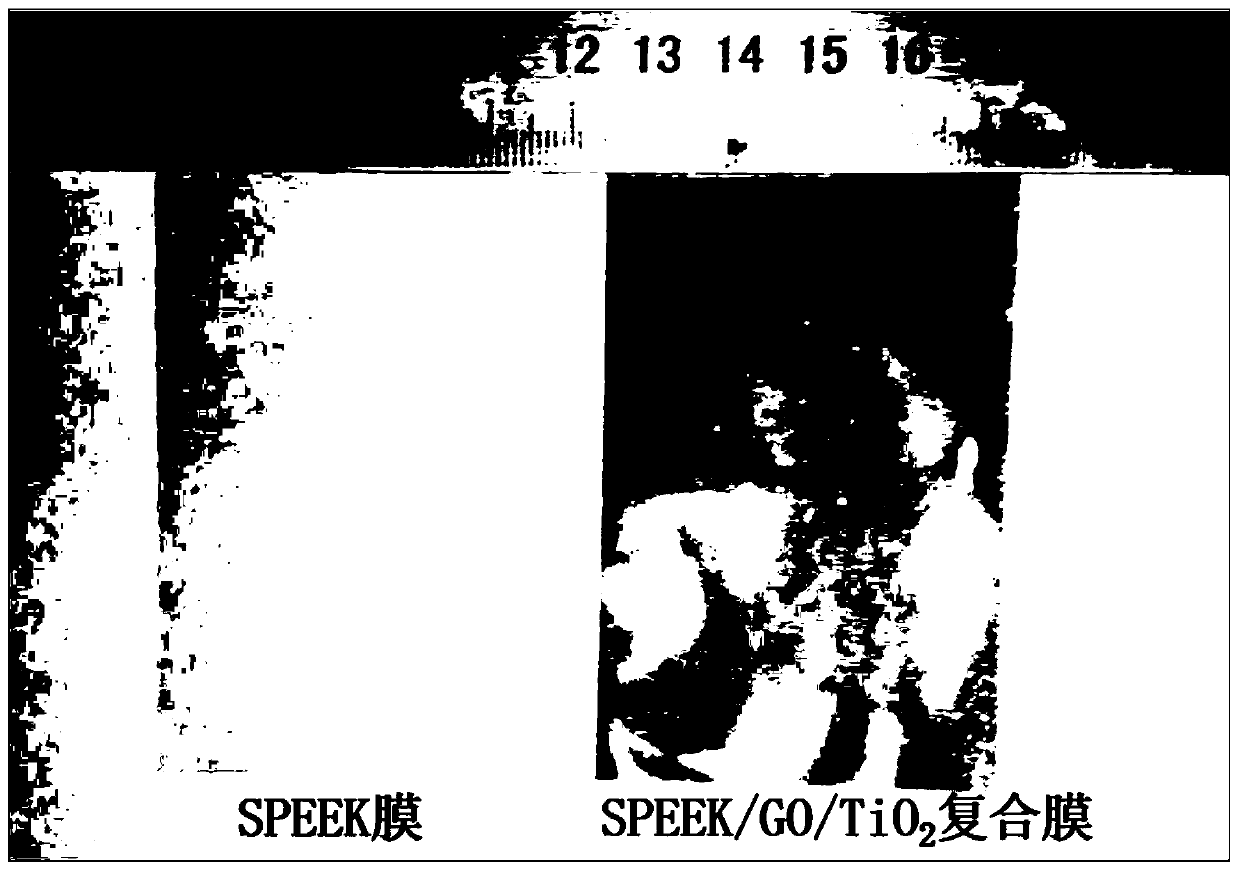

Preparation method for selecting SPEEK/GO/TiO2 composite ion selection membrane in nanometer insertion layer

ActiveCN110350223AImprove conductivityImprove conduction abilityRegenerative fuel cellsVanadium redox batteryIon permeation

The invention relates to the field of a diaphragm for an all-vanadium oxygen-reduction redox flow battery, in particular to a preparation method for selecting a sulfonated polyetheretherketone / graphene oxide / titanium dioxide nanometer particle composite ion selection membrane in a nanometer insertion layer. By the preparation method, the problems of vanadium ion permeation seriousness, poor ion selectivity and high cost of a proton exchange membrane in an existing commercial diaphragm are solved. The low-cost sulfonated polyetheretherketone (SPEEK) is used as a base film, a graphene oxide / titanium dioxide nanometer particle (GO / TiO2) insertion layer composite material is used for controlling an ion selection conduction passage, and the SPEEK / GO / TiO2 composite ion selection membrane is prepared by a film formation method such as dispersion step by step and solution pouring. The composite ion selection membrane prepared by the invention has the advantages of favorable ion selection conductivity, excellent vanadium ion blocking performance, favorable mechanical property, chemical stability and excellent single VRB battery performance and the like and is widely applied to the field ofthe all-vanadium oxygen-reduction redox flow battery.

Owner:山东奥德储能科技有限公司

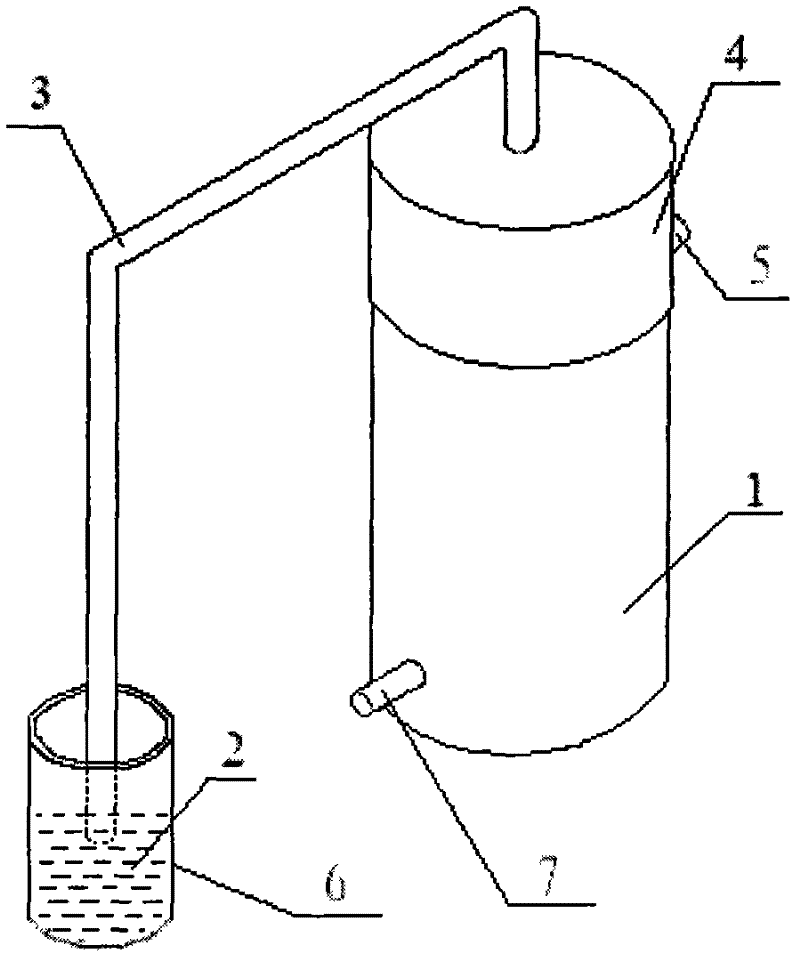

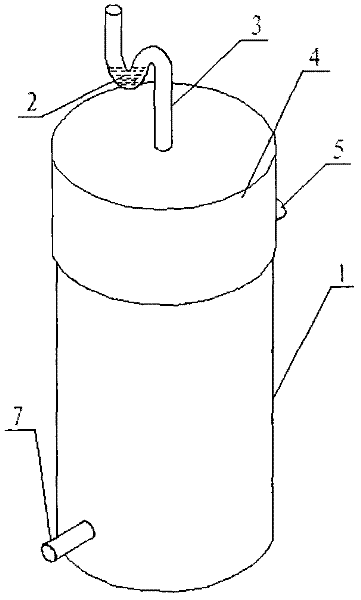

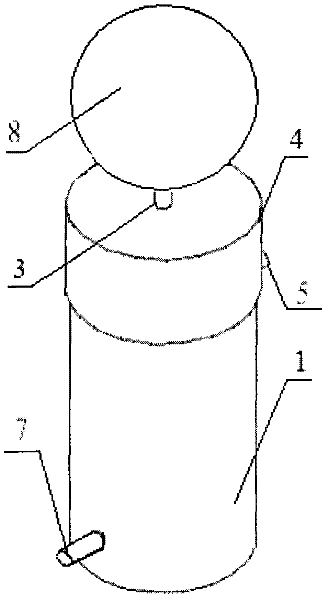

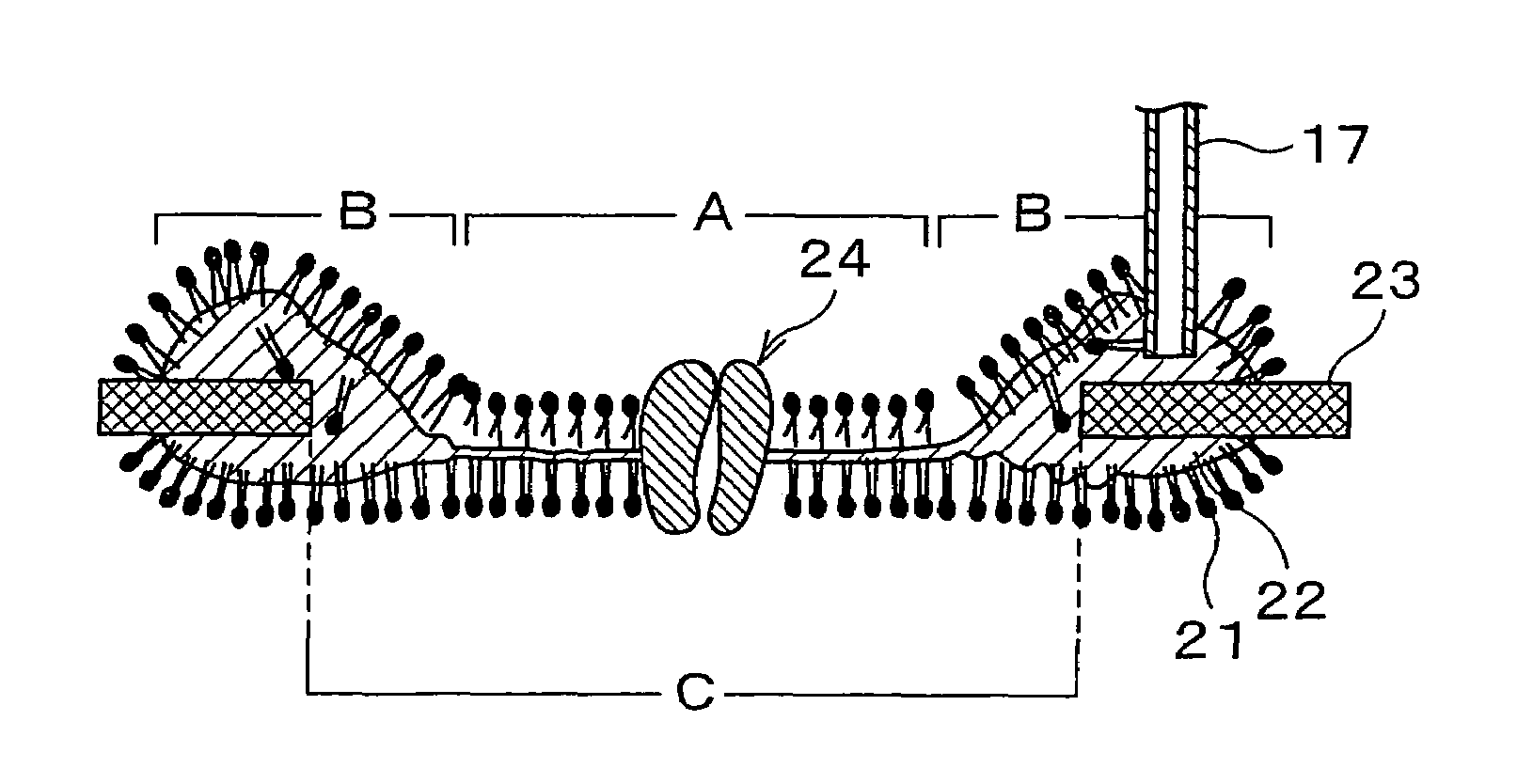

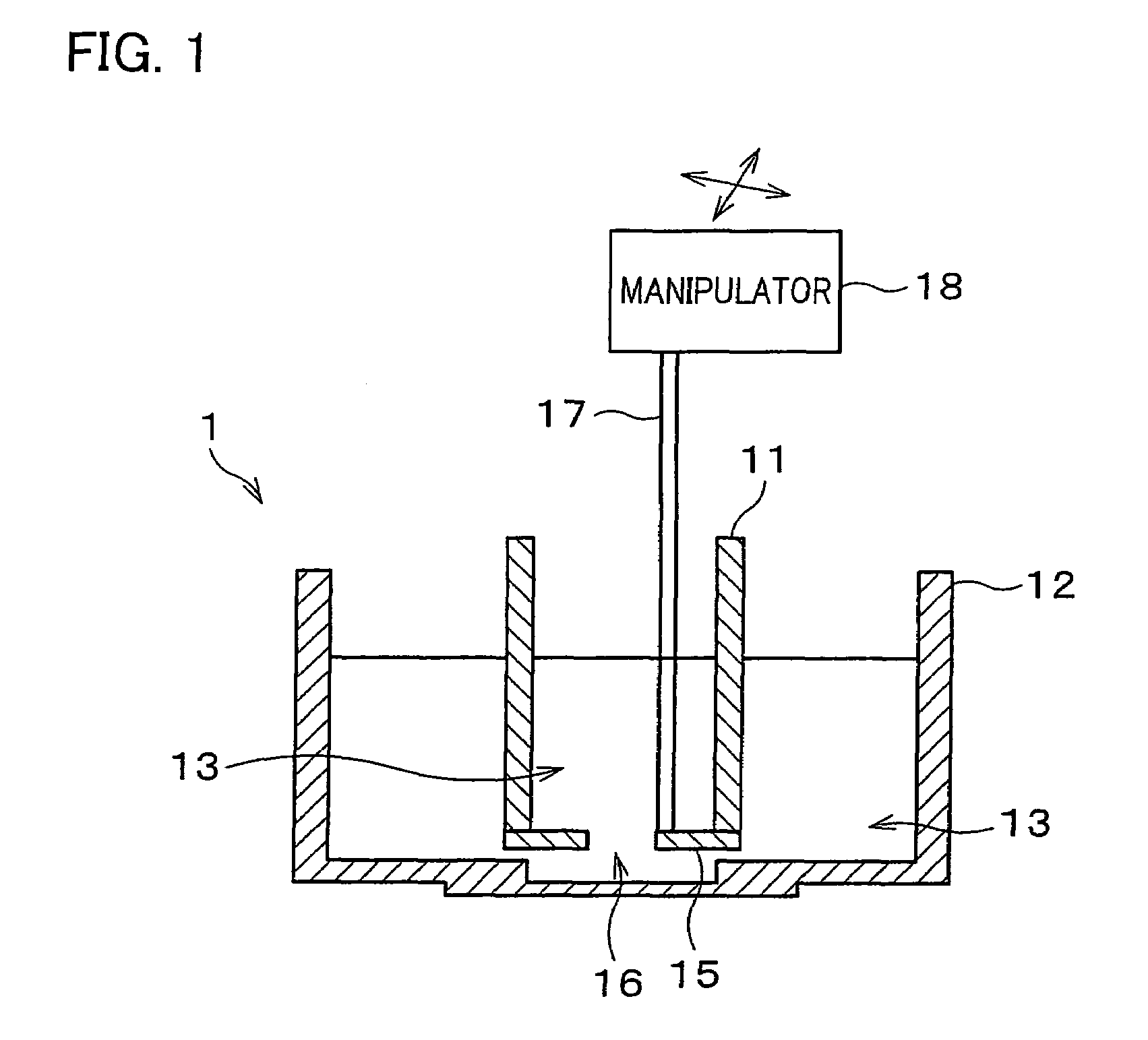

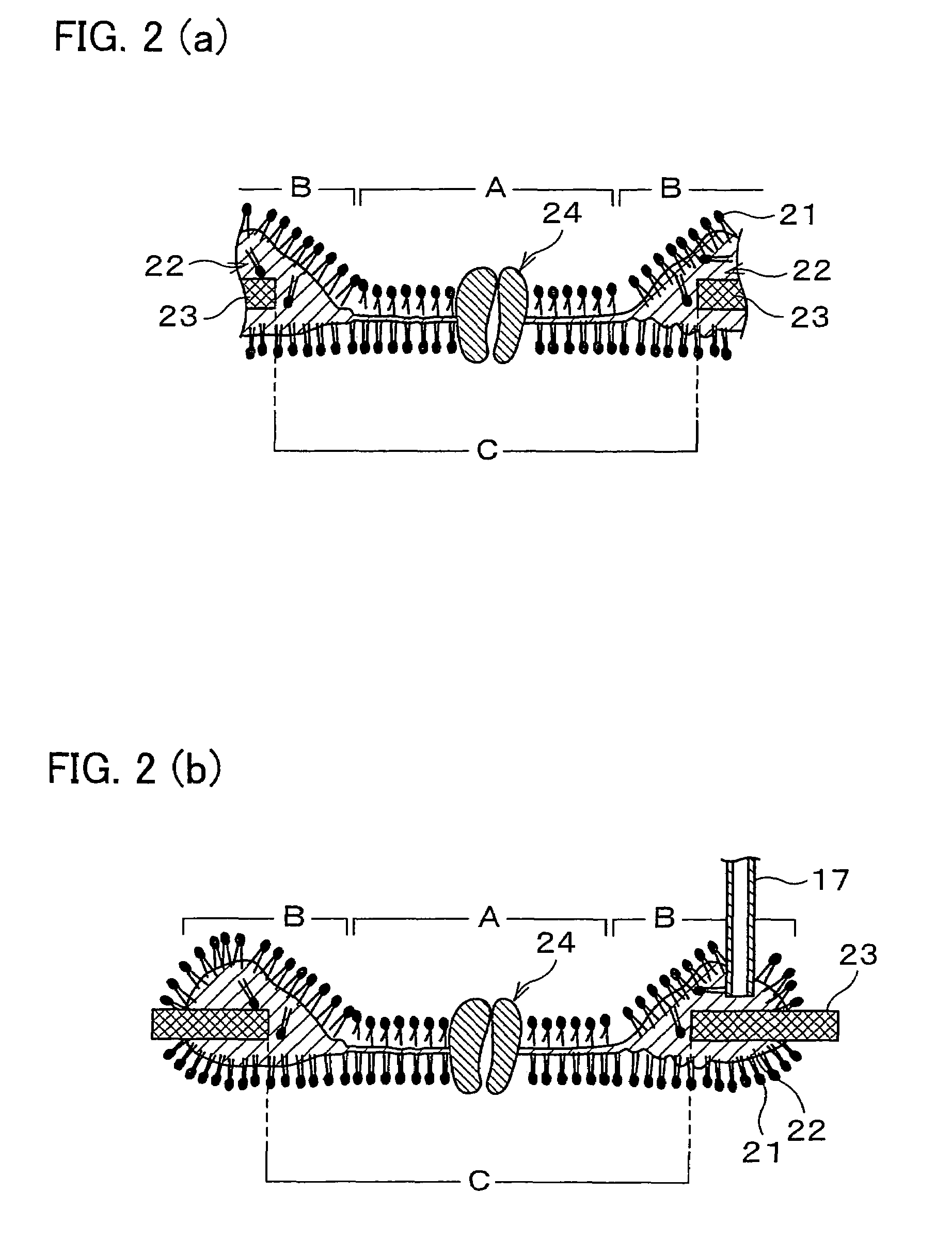

Artificial lipid bilayer membrane lipid substitution method, artificial lipid bilayer membrane obtained by using lipid substitution method, artificial lipid bilayer membrane formation device and ion permeation measuring device

InactiveUS7638092B2Easy to changeEfficient use ofLaboratory glasswaresAnalysis by subjecting material to chemical reactionLipid formationMembrane lipids

An artificial lipid bilayer membrane formation device is disclosed, which includes: an upper solution chamber (first solution chamber) and a lower solution chamber (second solution chamber), both of which are filled with aqueous solution. It further includes a partition wall disposed between the upper solution chamber and the lower solution chamber so as to part the upper and lower solution chambers from each other. The partition wall has an opening, and a first lipid solution is applied to a portion around the opening, thereby forming an artificial lipid bilayer membrane on the opening. Further, in the formation device, a tubule for lipid substitution is attached to the partition wall so as to be positioned on a bulk phase of the artificial lipid bilayer membrane. A second lipid solution is added via the tubule, thereby forming an artificial lipid bilayer membrane whose lipid composition is changed.

Owner:JAPAN SCI & TECH CORP

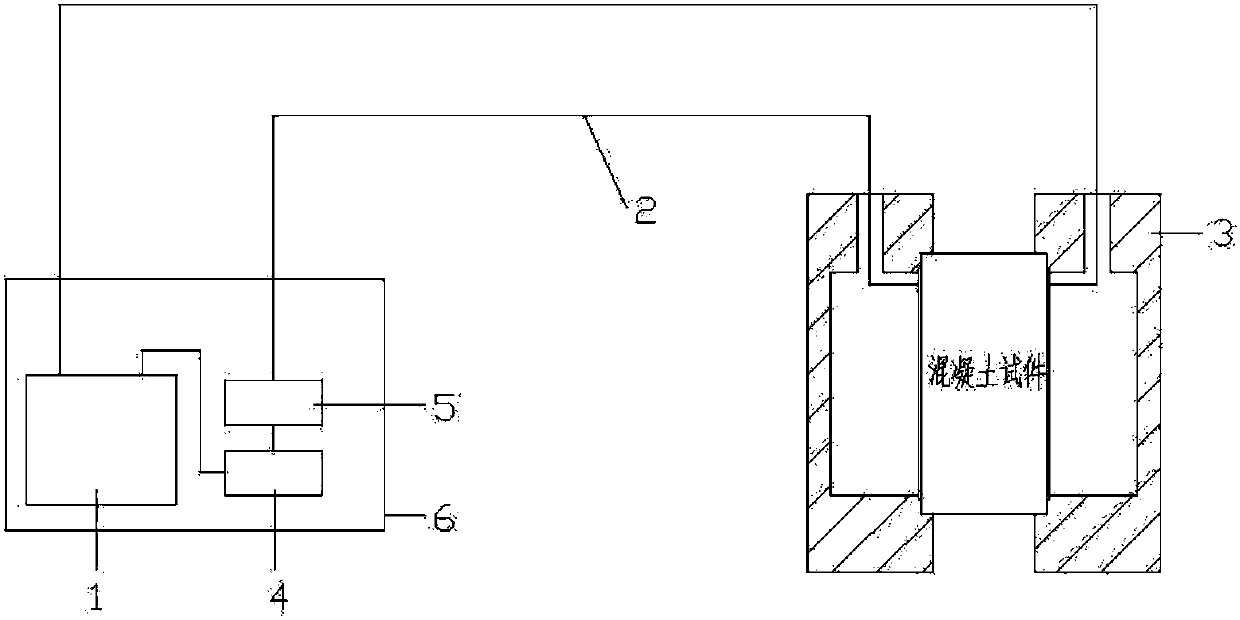

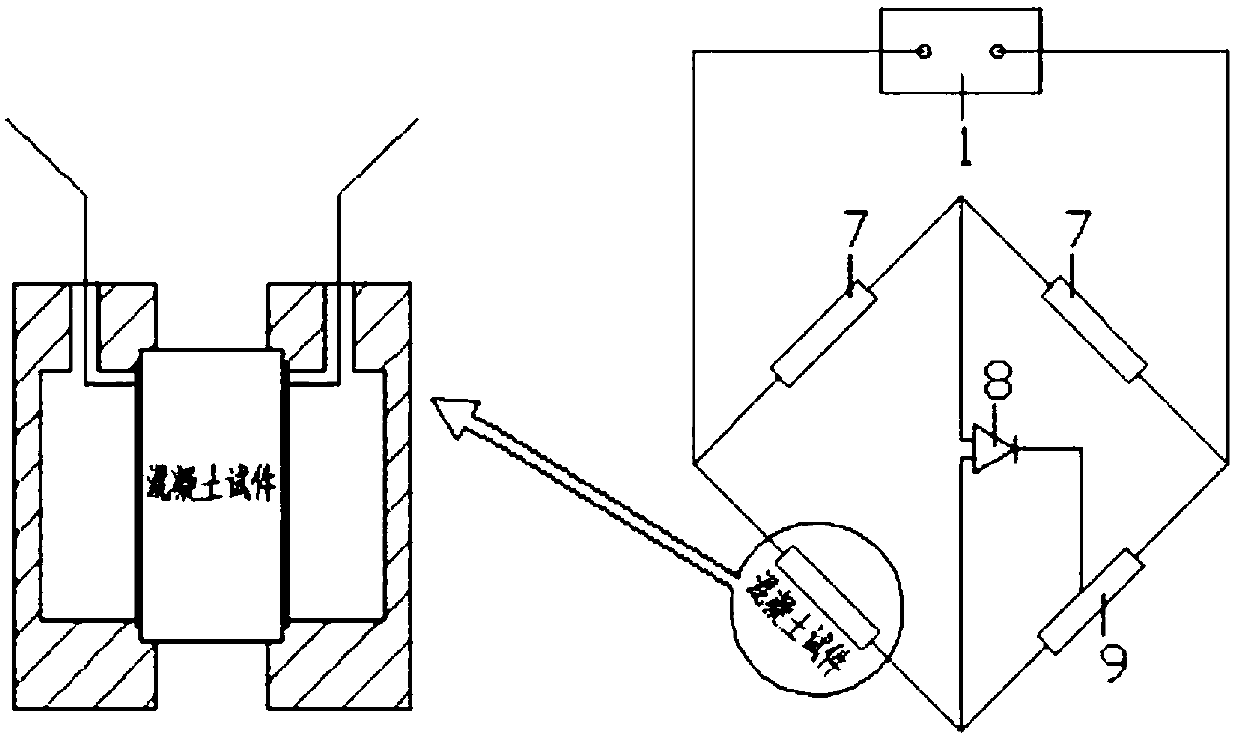

Method for measuring chloride ion penetration resistance of concrete

PendingCN107843539AOvercoming polarizationThe principle is scientific and reliablePreparing sample for investigationPermeability/surface area analysisElectrical resistance and conductanceLow voltage

The invention belongs to the technical field of performance testing method of civil engineering materials, and relates to a method for measuring chloride ion penetration resistance of concrete. An apparatus for measuring chloride ion penetration resistance of concrete is used for realization, and a concrete technological process comprises the following five steps: a concrete test piece is prepared, the concrete test piece is pretreated, the concrete test piece is clamped and mounted, the concrete test piece resistor is measured, and permeability of the concrete test piece is calculated and analyzed. Low voltage high-frequency AC electricity whose voltage is 1 volt and frequency is 1000 Hertz is used for measuring resistor of the concrete test piece which is pretreated by saturated water, resistance value reflects capability of chloride ion penetration resistance of the concrete test piece, so that the phenomenons that a polarization reaction is easy to happen in a DC test method and heat is generated in a solution under the effects of voltage for a long time are overcome, the disadvantage of generation of interference on resistance value is overcome, and ASTM C1202 which is recommended by American Society for Testing and Materials is improved; the method has the advantages of scientific and reliable principles, simple measuring flow, fast measuring speed, accurate measuring results, and easy promotion and usage.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

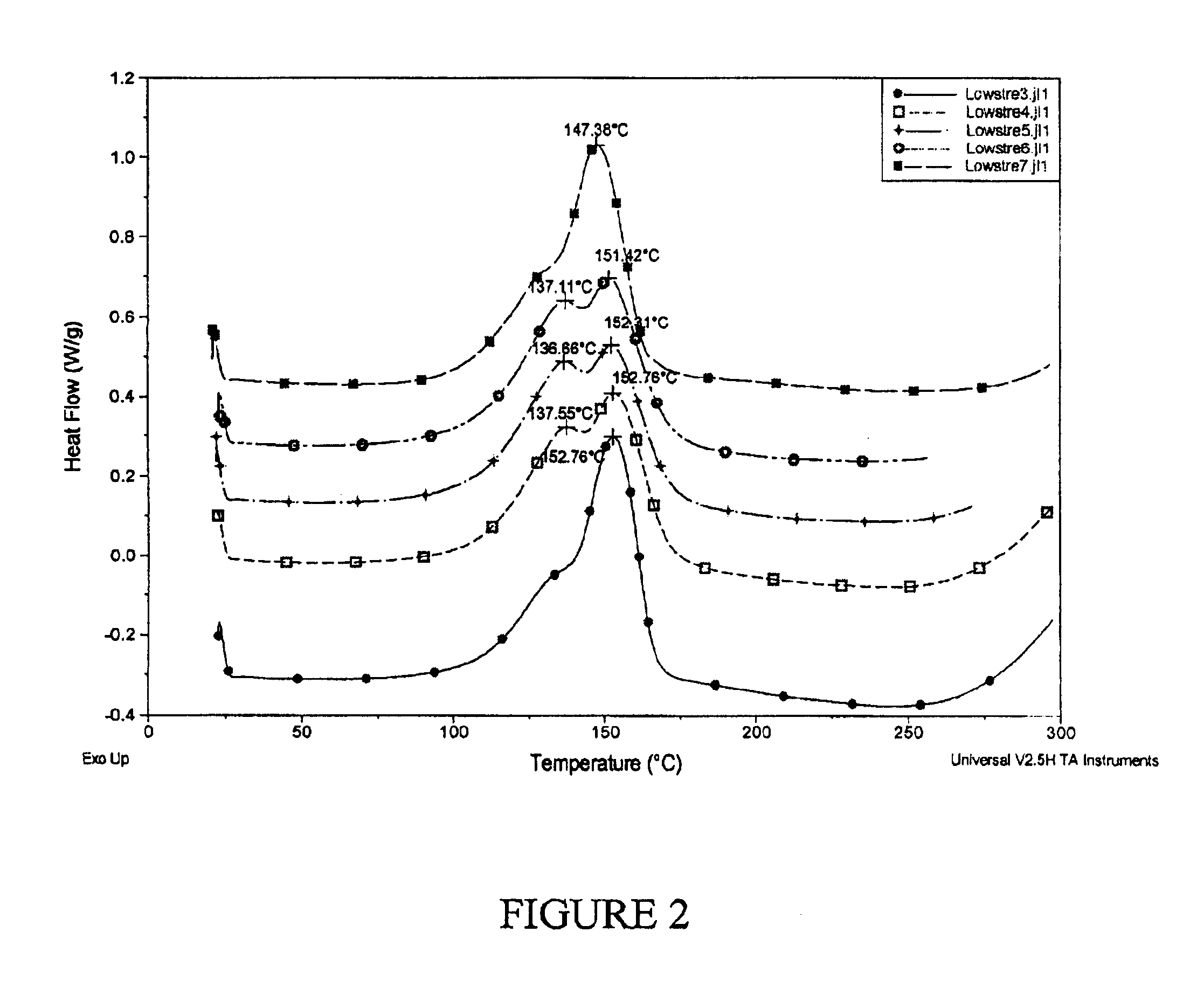

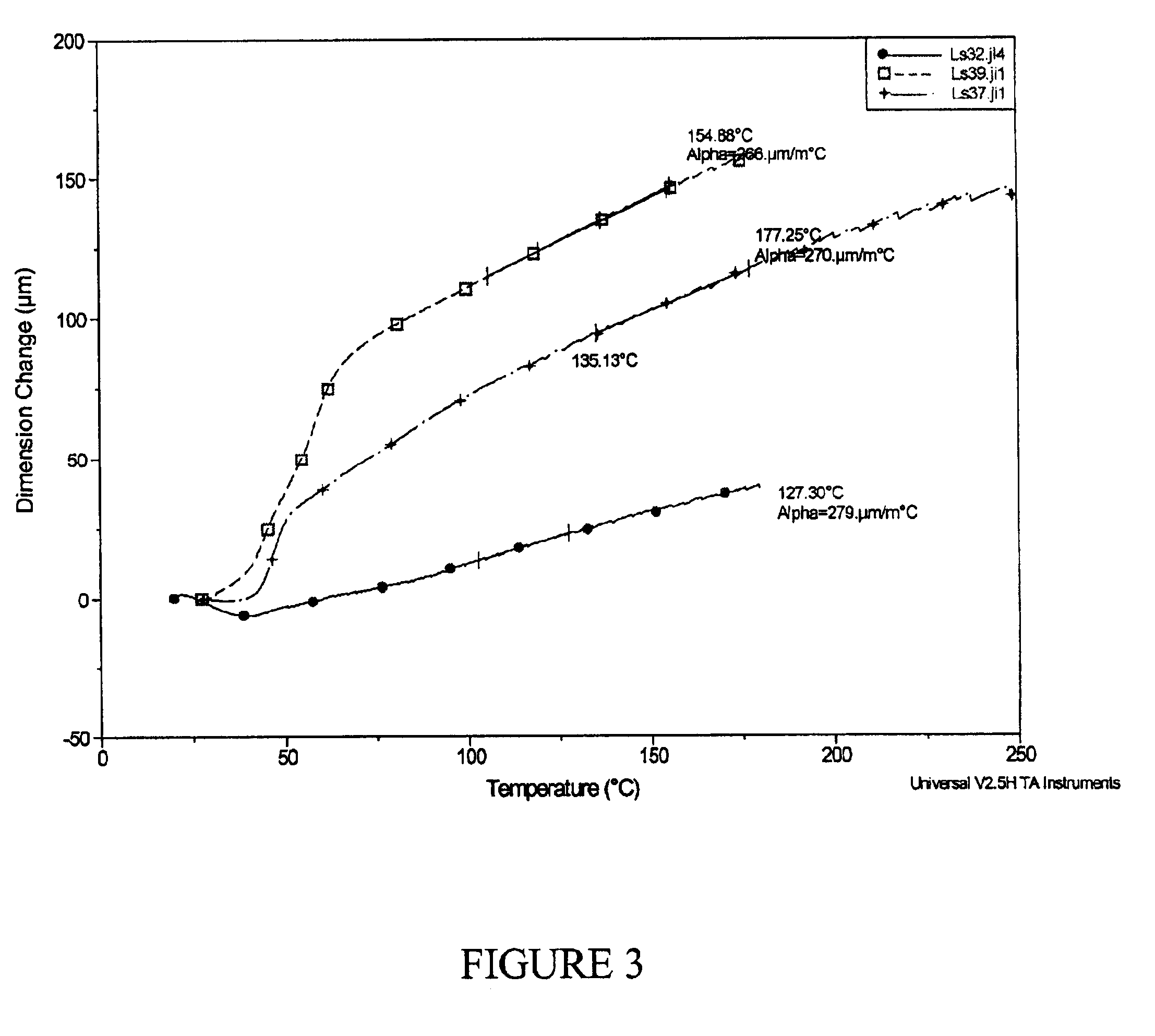

Low stress conformal coatings of reliability without hermeticity for microelectromechanical system based multichip module encapsulation

InactiveUS6989433B2Reduce stressLow viscositySynthetic resin layered productsPretreated surfacesEpoxyMetal chelate

The present invention provides low stress non-hermetic conformal coatings for the protection of microelectronic devices, such as a Microelectromechanical system (MEMS) based multichip module from adverse environments. The induced stress from these two coatings due to the thermal cycling and manufacture processing will not cause any influence on sensing accuracy of the piezopressure sensor or similar functional MEMS devices. Furthermore, the conformal coatings have the merits of low glass transition temperature, good elongation, low moisture uptake and mobile ion permeation, room temperature curability and good contamination resistance to the jet fume, which promise a high reliability for the aerospace and avionics application. One conformal coating comprises a composition / formulation containing a rubber, siloxane or urethane oligomer modified epoxy and an organic hardener, and optionally an organic diluent and a curing catalyst. Another conformal coating comprises a composition / formulation containing a silicone elastomer or gel and a metal chelate catalyst, and optionally a silica filler, a diluent and an adhesion promoter or coupling agent.

Owner:GEORGIA TECH RES CORP

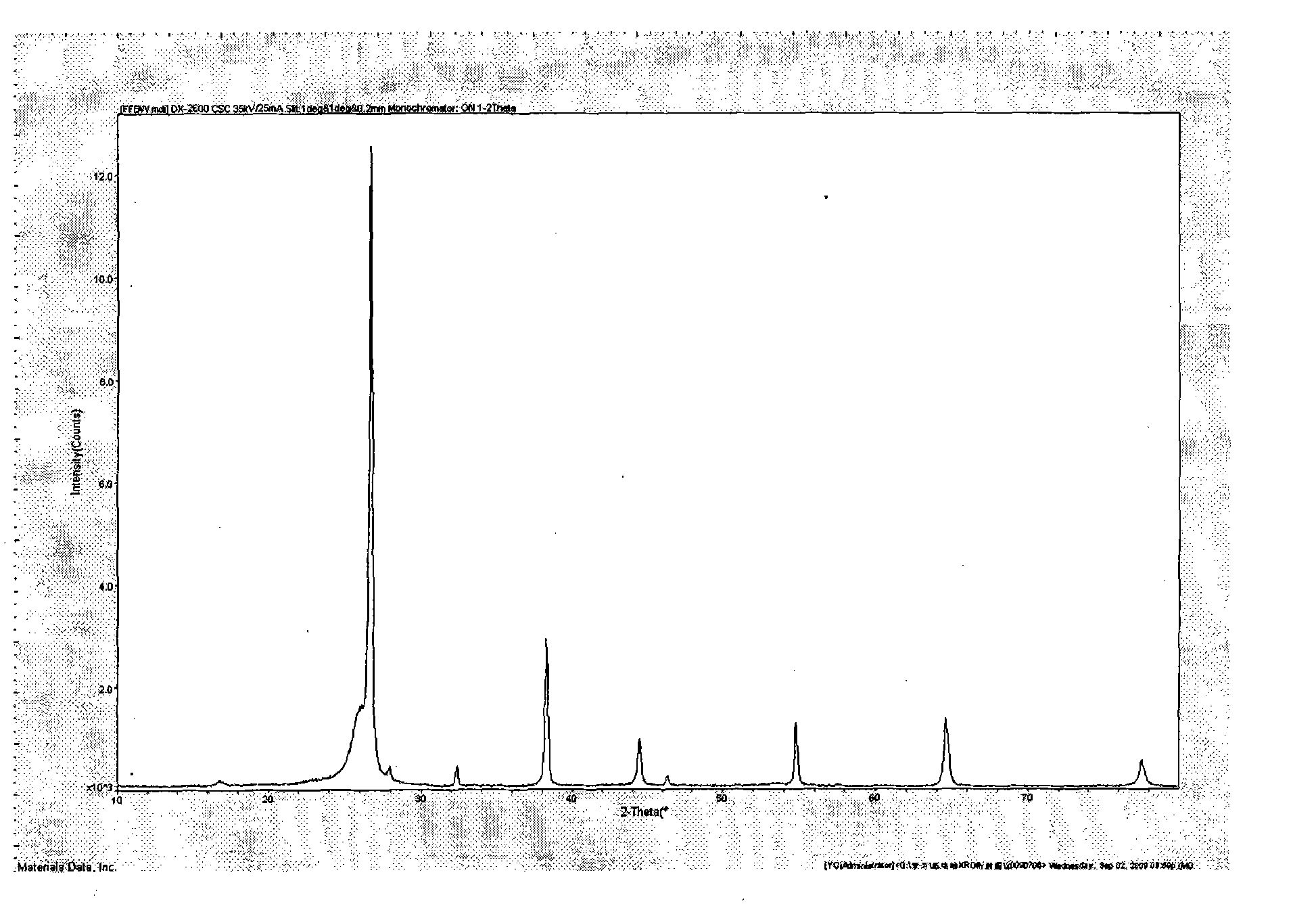

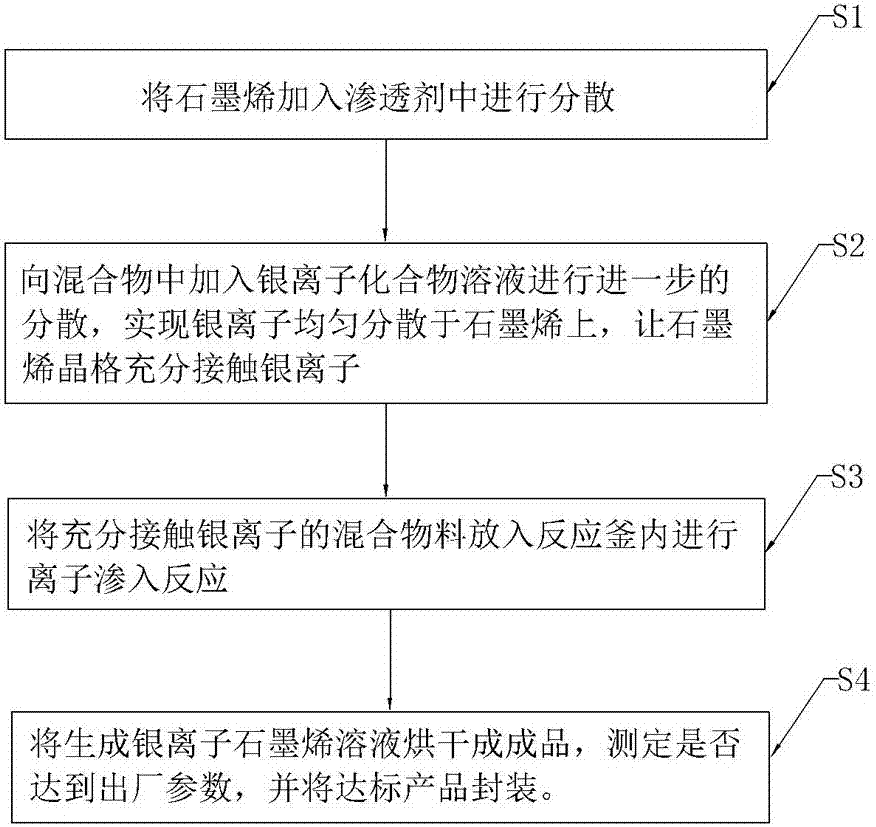

Manufacturing method of silver ion graphene

InactiveCN107393619AImprove featuresGood effectMetal/alloy conductorsCarbon-silicon compound conductorsSilver ionIon permeation

The invention discloses a manufacturing method and an application of silver ion graphene. The manufacturing method comprises the steps of adding graphene into a penetrating agent to be dispersed, wherein the penetrating agent is a non-ionic chelate; adding a silver ion compound solution to the mixture to be further dispersed to enable the silver ion compound solution to be uniformly dispersed on graphene and to enable graphene crystal lattices to be in full contact with silver ions; putting the mixture material in full contact with silver ions to a reaction kettle to be subjected to an ion permeation reaction; and drying the generated silver ion graphene solution into a finished product, measuring whether delivery parameters are reached or not, and packaging the qualified products.

Owner:柯良节 +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com