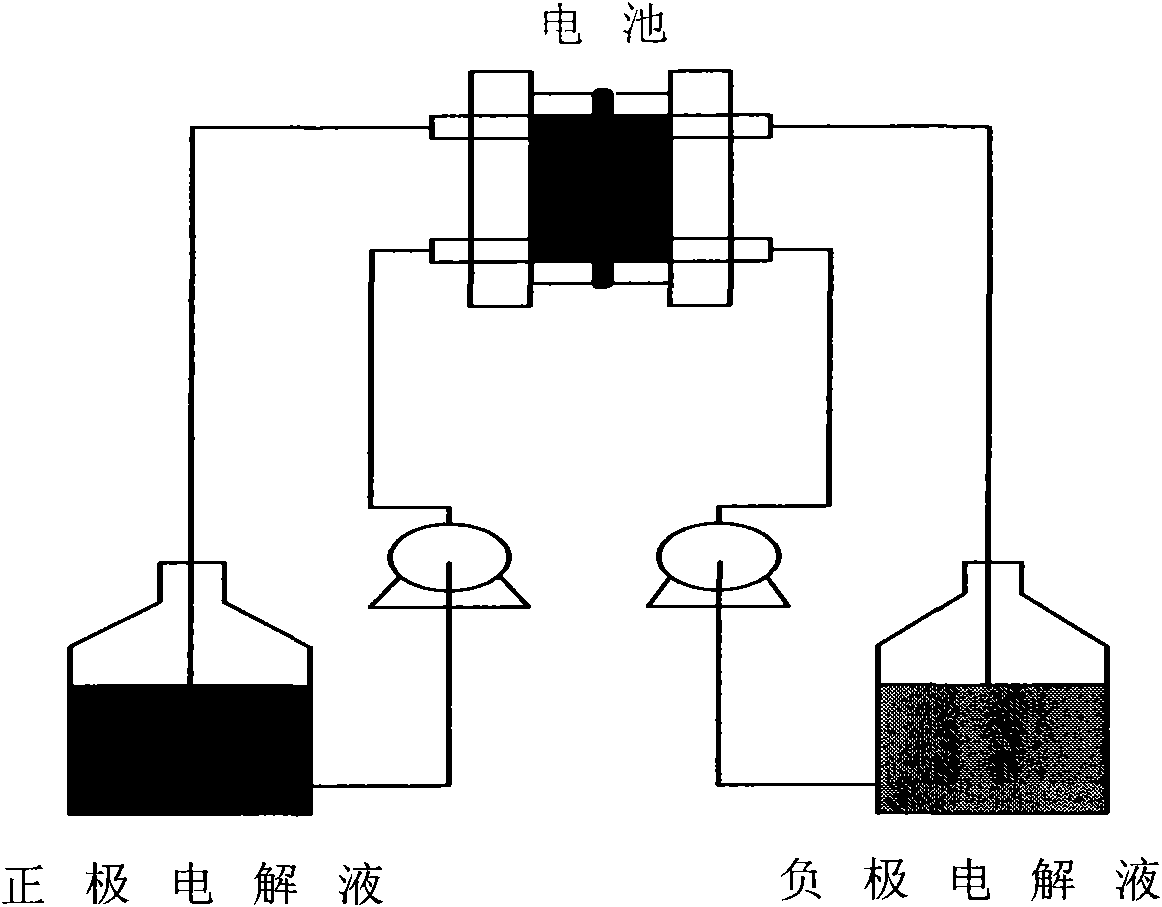

Electrolyte membrane and application of composite membrane thereof in liquid-flow energy storage battery with acidic electrolyte

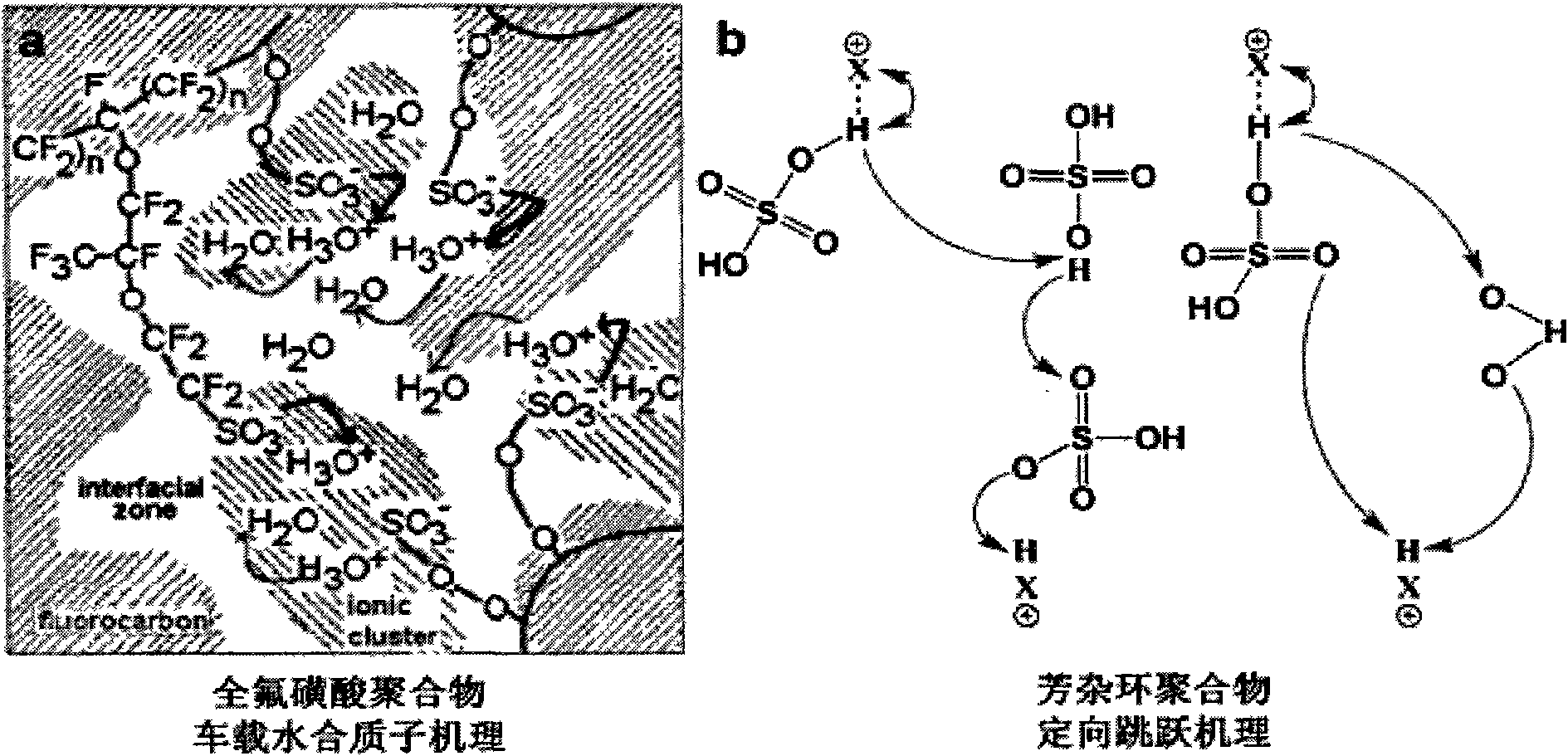

A liquid flow energy storage battery and electrolyte diaphragm technology, which is applied in the direction of secondary batteries, regenerative fuel cells, battery components, etc., can solve problems such as low selectivity and current efficiency, reduced service life of electrolyte, and battery capacity attenuation , to achieve low water mobility, reduce uneven distribution and self-discharge phenomenon, and improve proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1 g of polybenzimidazole was dissolved in N,N-dimethylacetamide to prepare a polymer solution with a mass fraction of 10%.

[0047] The obtained polymer solution was evaporated at 60° C. to obtain a polymer film.

[0048] The polymer film was placed in a vacuum oven at 160°C and heat-treated for 3h.

[0049] Remove the membrane, place the heat-treated membrane in deionized water for 100 hours to wash away residual impurities, and dry it.

[0050] The membrane treated by the above process was immersed in 5M / L sulfuric acid for acid treatment at room temperature for 48h.

[0051] After wiping off the residual acid on the surface of the membrane with filter paper, store it in a dry place for later use.

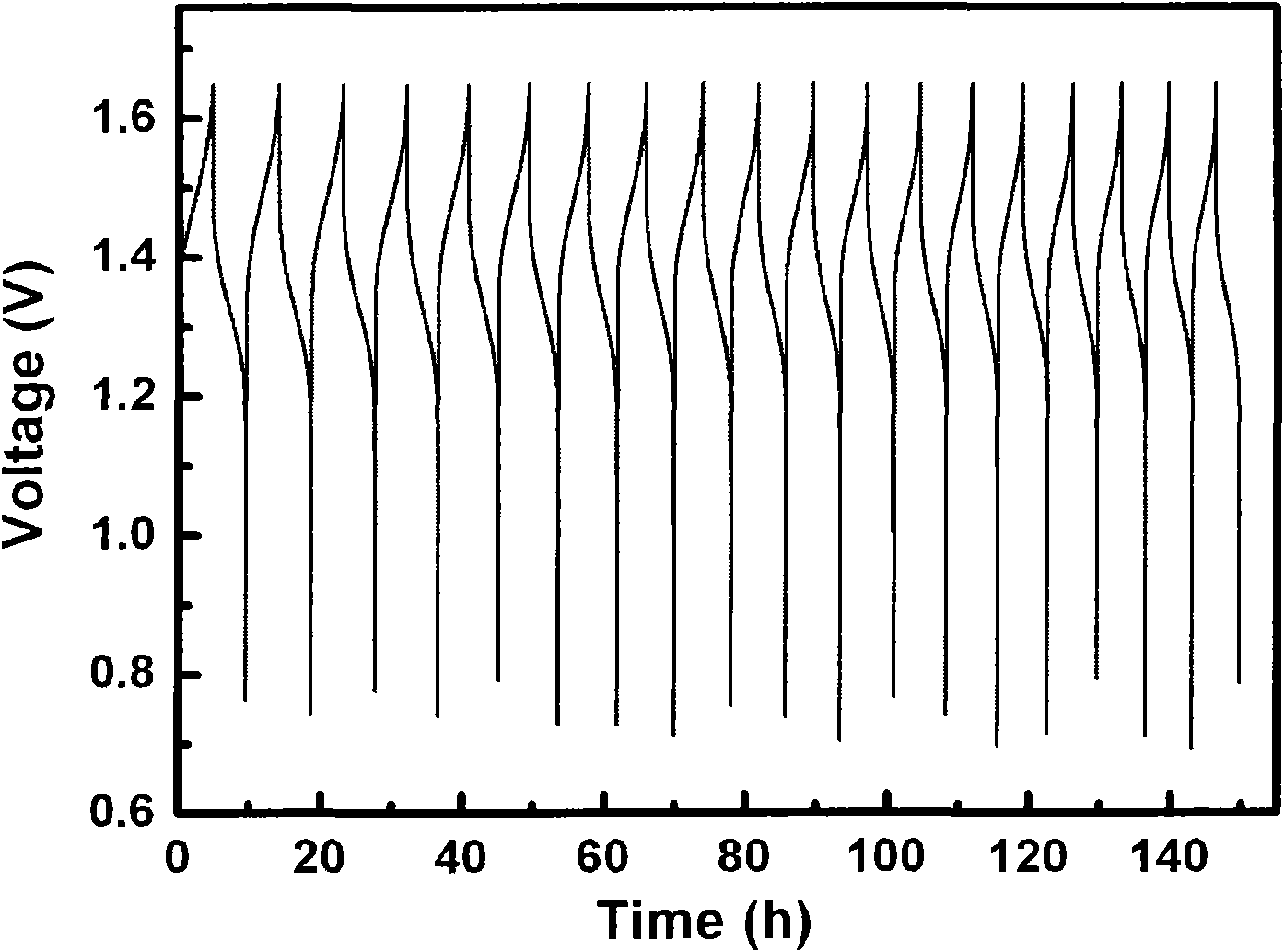

[0052] The acid-treated polybenzimidazole film and the non-acid-treated polybenzimidazole film were simultaneously assembled into VRB single cells, and their single cell performance was tested. The thickness of the electrolyte separator used is 30 microns, and the elect...

Embodiment 2

[0056] 1 g of polybenzimidazole was dissolved in N,N-dimethylacetamide to prepare a polymer solution with a mass fraction of 10%.

[0057] The obtained polymer solution was evaporated at 60° C. to obtain a polymer film.

[0058] The polymer film was placed in a vacuum oven at 160°C and heat-treated for 3h.

[0059] Remove the membrane, place the heat-treated membrane in deionized water for 100 hours to wash away residual impurities, and dry it.

[0060] The membrane treated by the above process was immersed in 3M / L sulfuric acid for acid treatment at room temperature for 72h.

[0061] After wiping off the residual acid on the surface of the membrane with filter paper, store it in a dry place for later use.

Embodiment 3

[0063] 1 g of polybenzimidazole was dissolved in N,N-dimethylacetamide to prepare a polymer solution with a mass fraction of 10%.

[0064] The obtained polymer solution was evaporated at 60° C. to obtain a polymer film.

[0065] The polymer film was placed in a vacuum oven at 160°C and heat-treated for 3h.

[0066] Remove the membrane, place the heat-treated membrane in deionized water for 100 hours to wash away residual impurities, and dry it.

[0067] The membrane treated by the above process was immersed in concentrated phosphoric acid for 20min at 60°C.

[0068] After wiping off the residual acid on the surface of the membrane with filter paper, store it in a dry place for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com