Method for repairing and reinforcing pile foundations in ocean splash zones

A technology of splash zone and pile foundation, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of weakening the durability of concrete, reducing the normal service life, and cracking of piles, and achieves significant economic benefits and low operating costs Considerable, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

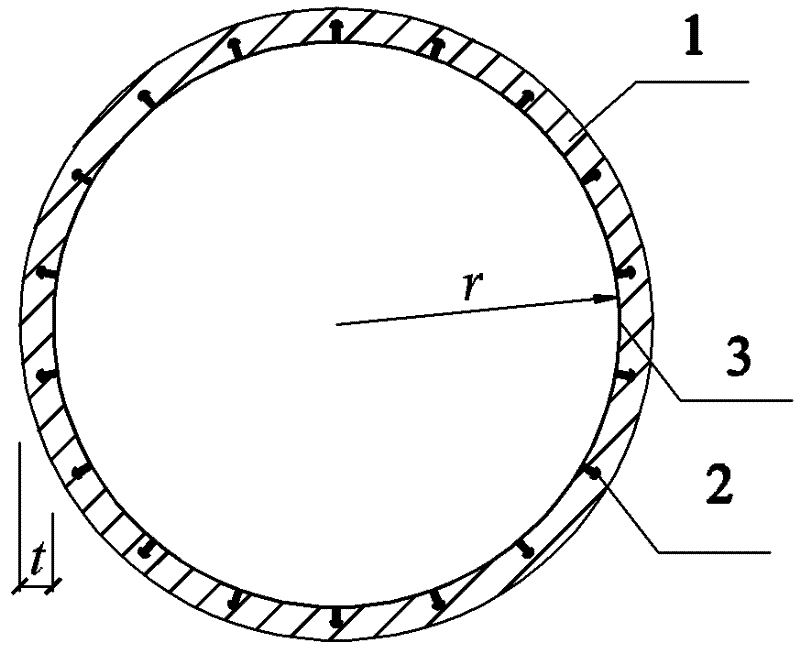

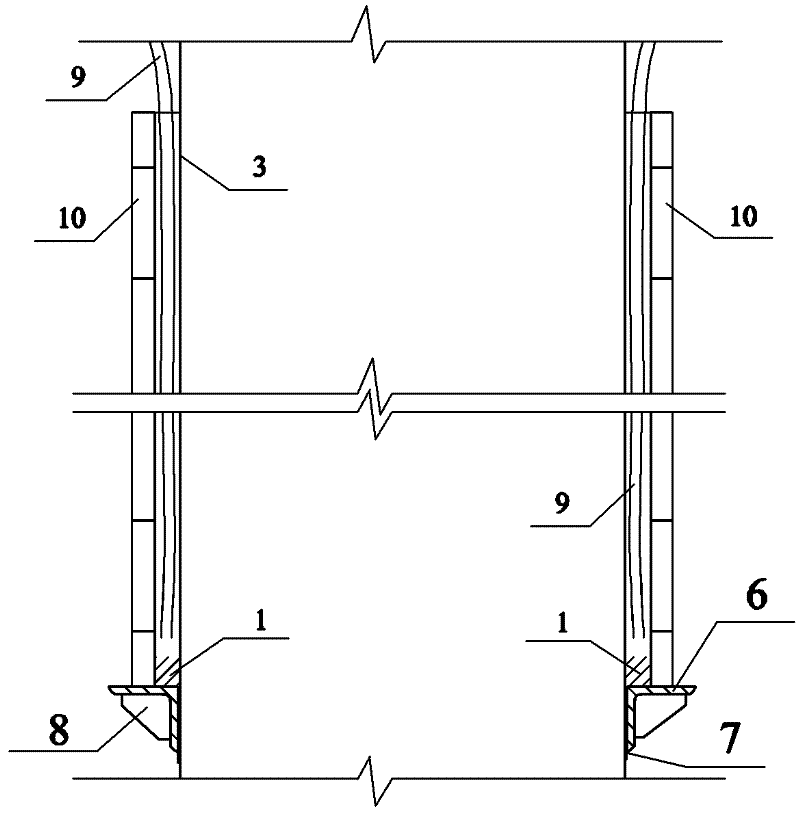

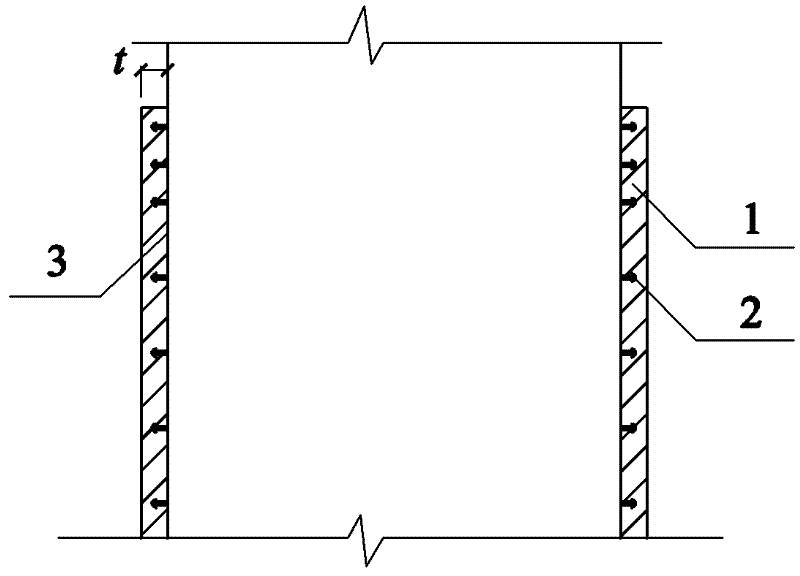

[0029] Example 1, reinforcement and repair of the splash area of steel pipe piles at the wharf, refer to figure 1 , 2 , 3.

[0030] According to the actual corrosion situation, the splash area and the area below 1 m are designated as the repair area. The total repair height is 3 m, the repair thickness t is 70 mm, and r is the outer diameter of the pipe pile. The specific parameters of steel pipe piles are 1200 mm in diameter, 20 mm in wall thickness, and Q345 steel. The specific implementation steps are as follows:

[0031] (1) First, sandblast large areas of anti-corrosion parts with quartz sand to remove surface rust spots, and further use manual derusting for other severely corroded parts, or knock off floating rust with a hammer. Use a steel shovel to remove floating rust bumps and attached sea organisms (sea oysters, etc.), and use a steel brush and coarse sandpaper to remove attached seaweed, etc.

[0032] (2) The shear connectors are arranged at a certain distanc...

Embodiment 2

[0038] Example 2, reinforcement and repair of splash area of wharf concrete pile, refer to Figure 4 .

[0039] According to the actual corrosion situation, the splash area and the area below 1 m are designated as the repair area, the total repair height is 3 m, and the repair thickness t is 70 mm. The specific implementation steps are as follows:

[0040] (1) Firstly, remove the loose concrete in the local severely corroded part, and then perform a hair removal treatment on the entire repaired area to remove the surface laitance, expose a fresh interface, and make the surface uneven, with a hair removal depth of 3 to 5 about mm.

[0041] (2) If the thickness of the repair exceeds 50 mm, an additional shear connector 5 is required to ensure reliable bonding between the newly poured UHTCC and the original concrete. In this embodiment, the shear connector 5 is provided.

[0042] Arrange the L-shaped anchor bar shear connectors 5 with a diameter of 8 mm, and set the connecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com