Saline-alkali tolerant high polymer modified asphalt polyester reinforcement waterproof coiled material

A polymer modified, waterproof membrane technology, applied in asphalt layered products, roofs using flexible materials, water conservancy projects, etc., can solve the problems of aggravated water leakage, water seepage, waterproof performance decline, high salinity corrosion, etc. , to achieve excellent salt-alkali corrosion resistance, prolong service life, and good root puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

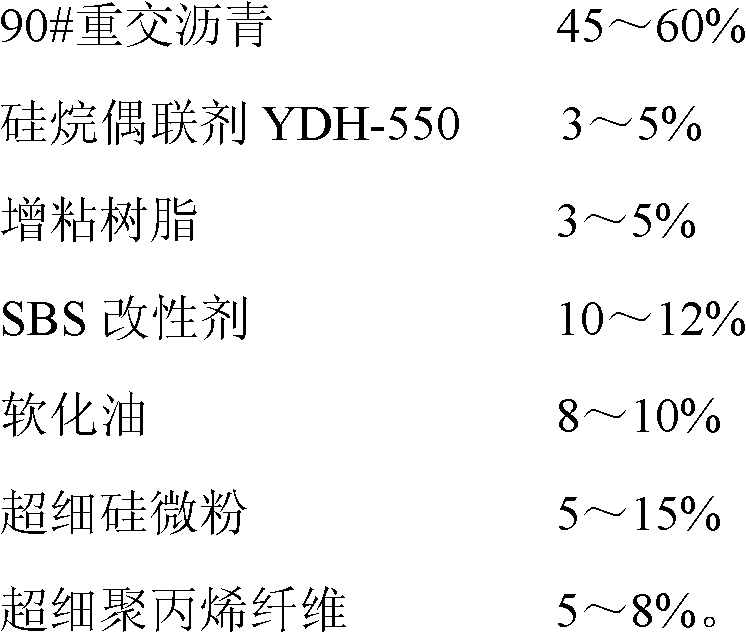

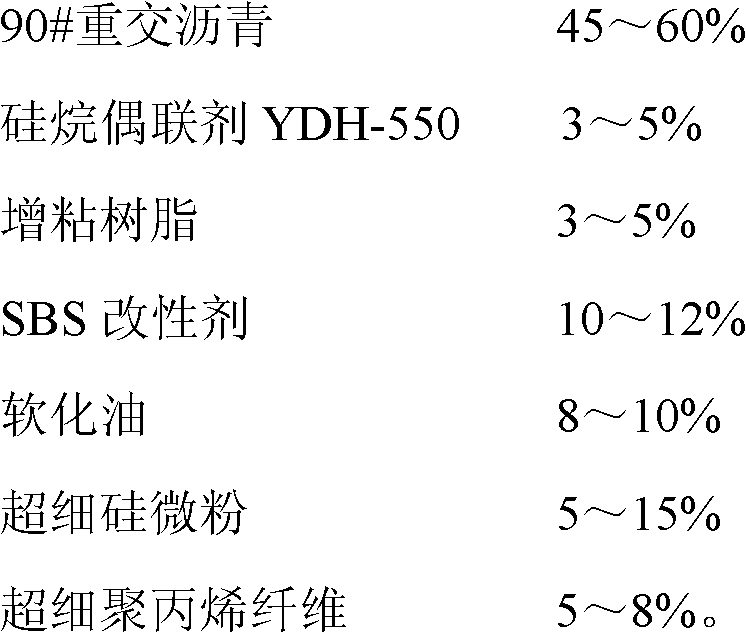

[0038] Preparation of tire-covering rubber for salt-alkaline-resistant polymer modified asphalt polyester tire waterproofing membrane

[0039] Add 90# heavy-duty asphalt into the 500L reactor according to the formula, turn on the heating device and raise the temperature to 150-160°C, add tackifying resin, SBS modifier, and softening oil according to the formula, start stirring, and heat up to 180°C while stirring Keep warm at about ±5°C, stir at a constant speed for 1.5-2 hours, until the modified material is fully mixed in the hot melt colloid, cool down to about 170±5°C, add ultrafine silica powder, ultrafine polypropylene fiber, and silane coupling agent YDH-550, heat preservation and stirring for 1.0~1.5h, turn off the heating device, naturally cool down to 140~150°C, use an asphalt pump to pump the prepared rubber material from the batching kettle into the forming storage kettle.

Embodiment 2

[0041] Scratch-coating process of tire-coated rubber sheet for salt-alkali-resistant polymer modified asphalt polyester tire waterproofing membrane

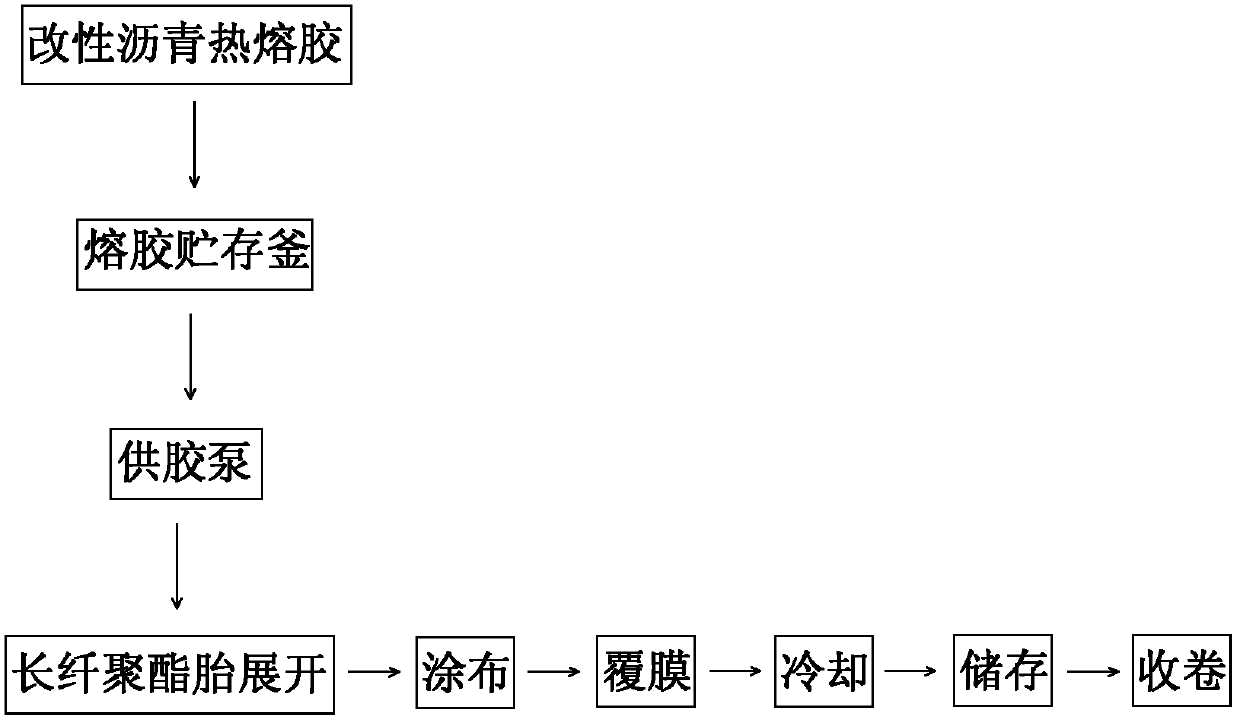

[0042] Such as figure 1 Shown, the sheet scraping process of the present invention is as follows:

[0043] 1. Melt glue discharge: Turn on the electric control switch of the melt glue storage kettle, set the temperature to 130-140°C, and open the discharge valve when the glue material has fluidity;

[0044] 2. Tire loading, tire stretching, and alignment;

[0045] 3. Coating, laminating, and heating to control the temperature at 130°C to 140°C;

[0046] 4. According to the thickness and weight, adjust the clamping distance between the coating die roller and the polyester tire, and turn on the cooling water of the coating roller.

[0047] 5. After the preparation steps are completed, the PLC coating button can be turned on; the glue supply pump pumps the glue into the coating roller machine, and the system automatically check...

Embodiment 3

[0050] Equipment operating procedure of the present invention

[0051] 1. Melt glue discharge: Turn on the electric control switch of the melt glue storage kettle, set the temperature to 140-150°C, and open the discharge valve when the glue material has fluidity;

[0052]2. Tire loading preparation: put the long-fiber polyester tire and PE anti-adhesive film on the unwinding rack, pass through the coating pair of rollers and the middle of the film-coating pair of rollers, and pass through the cooling roller, storage and adjustment rack, etc. until winding;

[0053] 3. Clean up and pay attention to whether there is any foreign matter on the coating roller; set the heating temperature to 130-140°C and heat to adjust the clamp distance between the roller and the coil, and determine it with plug R;

[0054] 4. Coating: When the glue in the glue storage kettle melts and reaches the set temperature, turn on the PLC main switch to set the running speed, and the cooling water in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com