Manufacturing method of silver ion graphene

A manufacturing method and graphene technology, applied in the field of graphene, can solve the problem of few functional applications of graphene with ions, and achieve the effects of achieving economic and safety benefits, easy processing, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

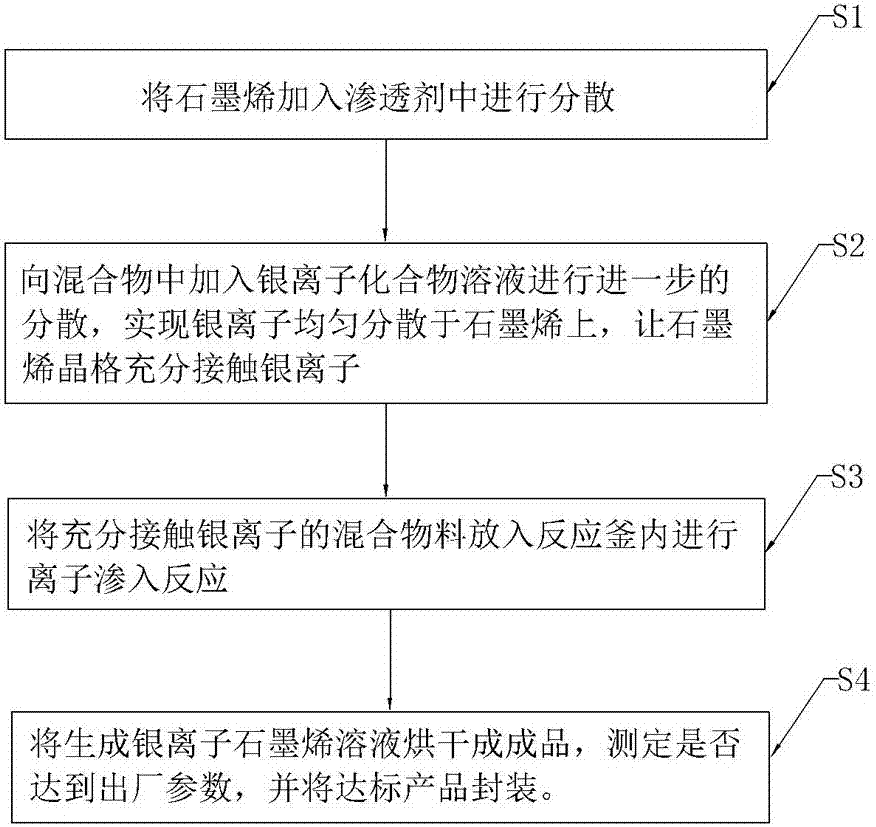

[0024] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0025] refer to figure 1 , the manufacture method of a kind of silver ion graphene of the present invention comprises following manufacture process:

[0026] S1. Penetrant dispersion: 2D graphene materials with less than four layers are added to the penetrant for dispersion. The penetrant is a non-ionic chelating agent (NH4)4‧EDTA or (NH4)4‧PTDA, and the penetrant is mixed with graphene The molar ratio is 2:1;

[0027] S2. Silver ion dispersion: add silver ion compound solution to the mixture for further dispersion, realize the uniform dispersion of the silver ion compound solution on the graphene, let the graphene lattice fully contact the silver ion, the pH value of the silver ion compound solution is 6.8 Between -8.4, the mixing molar ratio of silver ion compound solution and graphene is 1:3;

[0028] S3. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com