Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

506 results about "Diffusion methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

What is Diffusion. Diffusion is the passive movement of molecules along a concentration gradient of a higher concentration to a lower concentration. Three major diffusion methods can be identified: simple diffusion, facilitated diffusion, and osmosis.

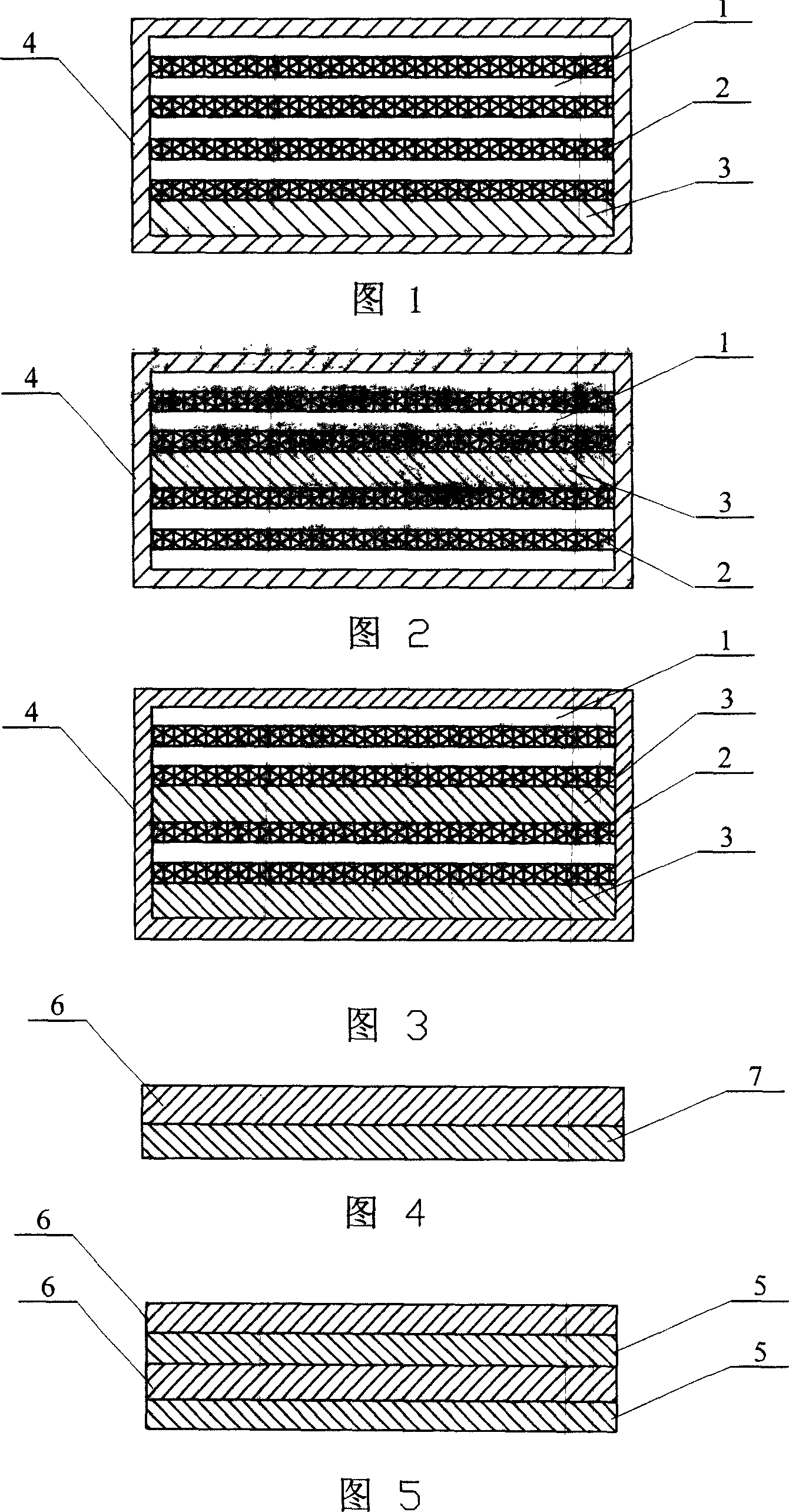

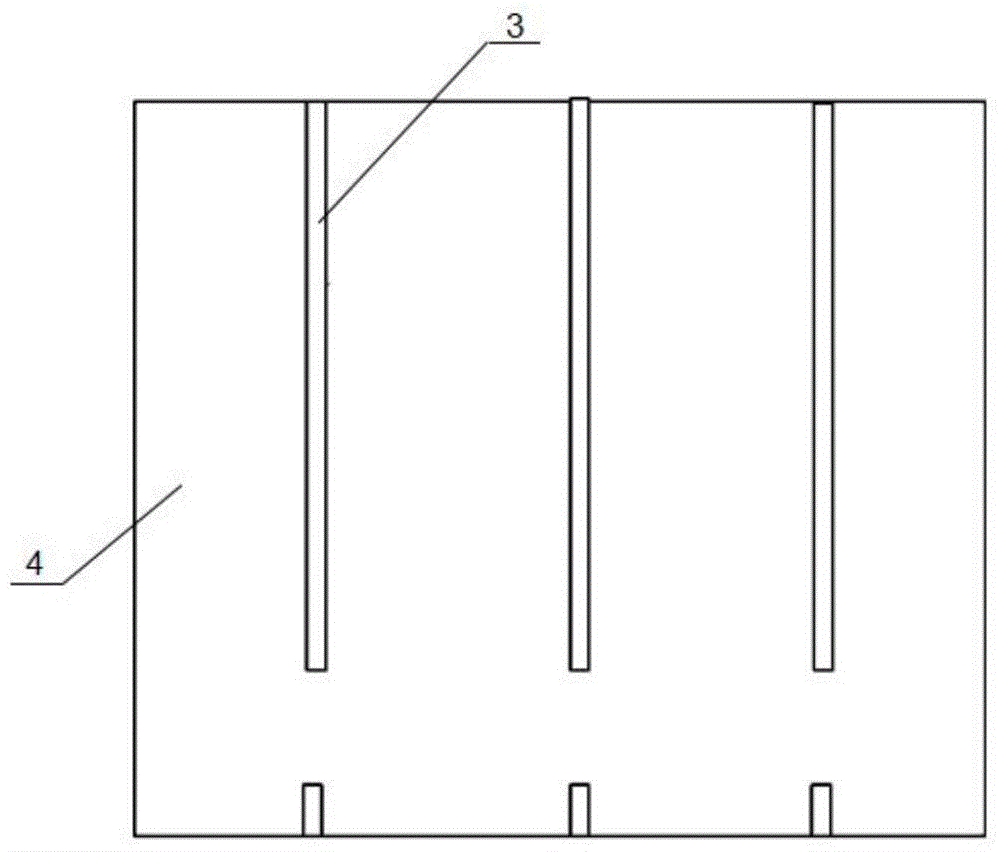

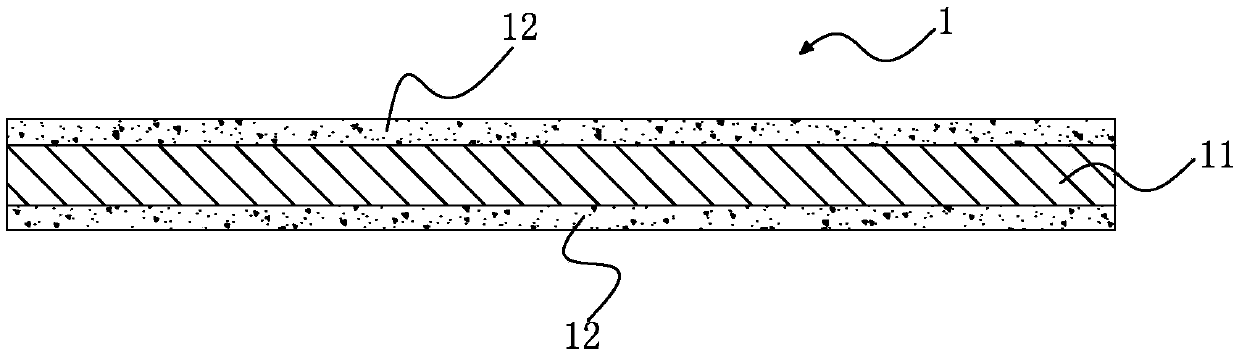

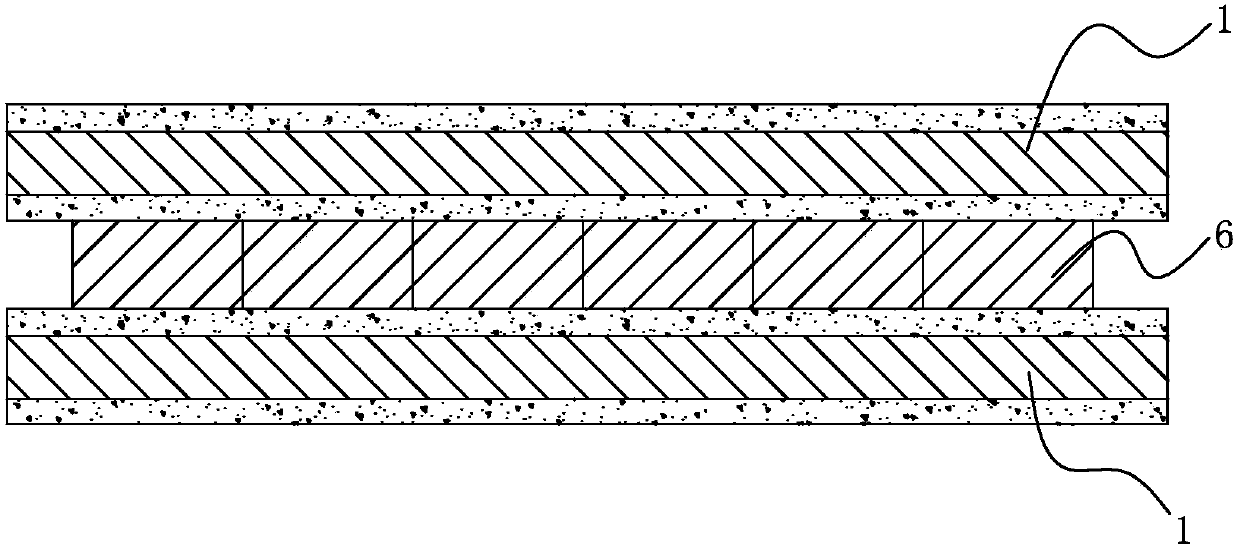

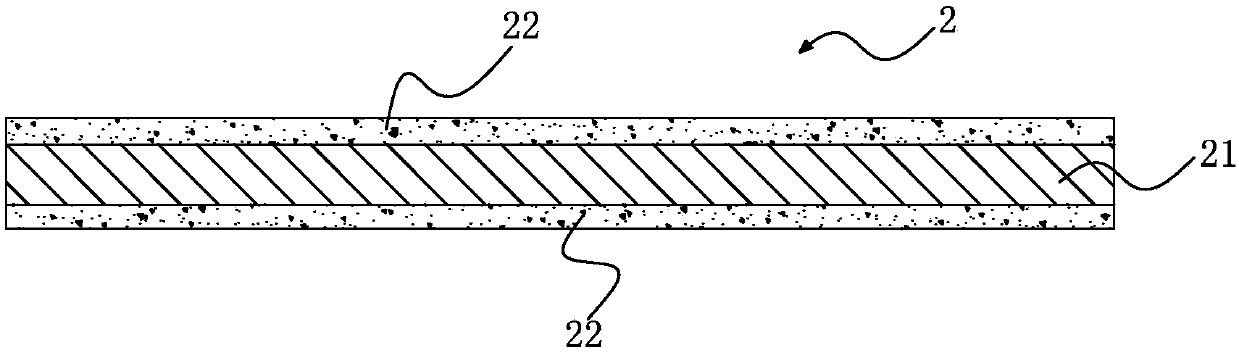

Method for composite preparation of Ti alloy/TiAl alloy composite plate material by using laminated rolling-diffusion method

InactiveCN101011706AReduce manufacturing costThe preparation method is simpleTemperature control deviceFurnace typesDiffusion methodsAlloy composite

The invention discloses a making method of titanium alloy / TiAl composite board, which is characterized by the following: overlapping A (titanium foil) and C (aluminium foil); placing at least one layer B (titanium or titanium alloy foil, titanium or titanium alloy board) on the upper and lower surfaces of overlapped layer or among overlapping layer; setting adjacent layer C to B; adopting three layers or more of A or B as the most outer layer; jacketing; rolling under 20-750 deg.c and 750-1300 deg.c.

Owner:HARBIN INST OF TECH

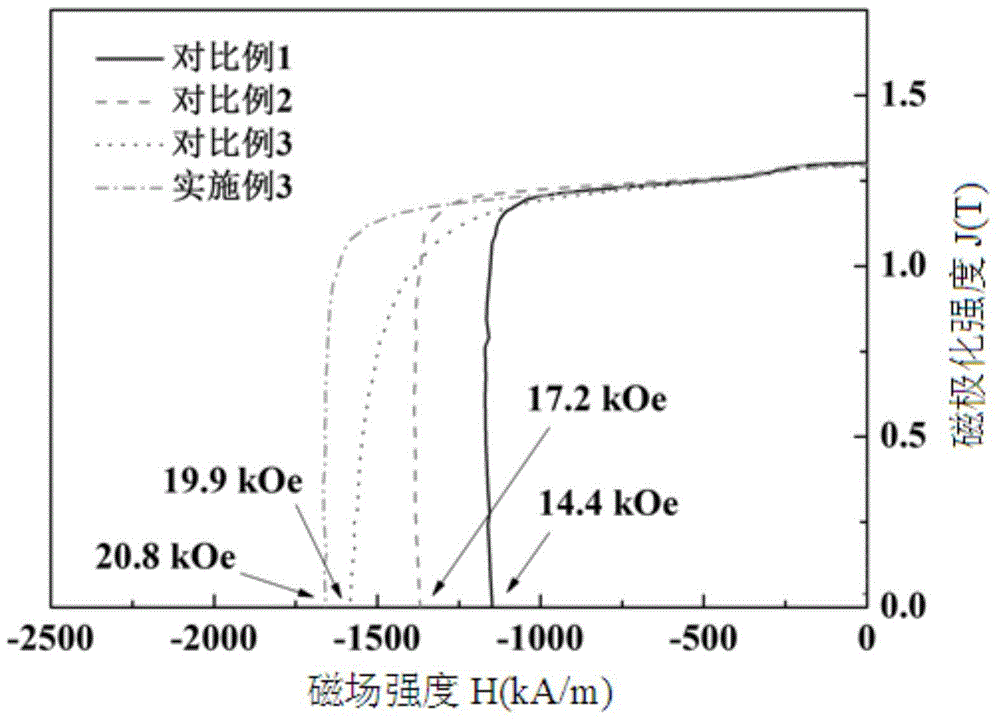

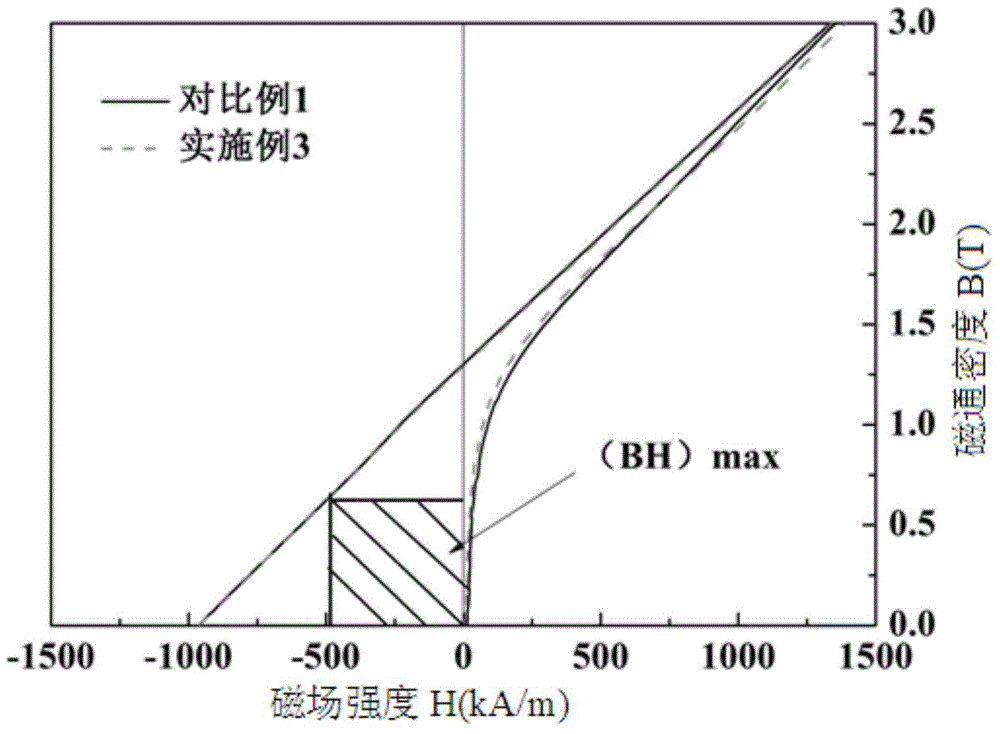

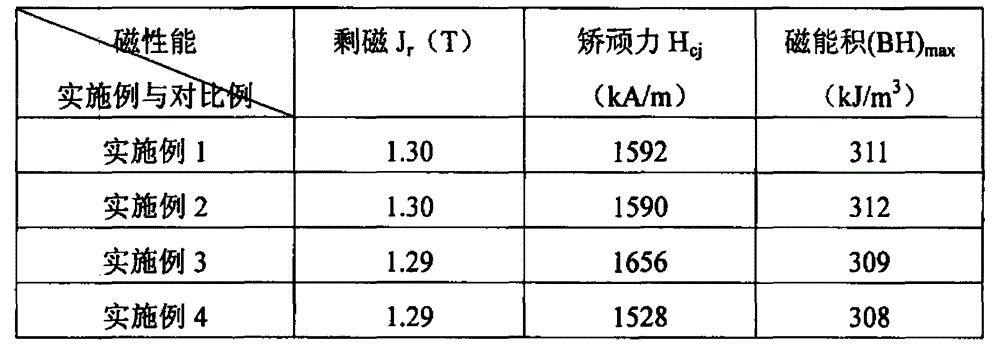

Grain boundary diffusion method for improving properties of sintered NdFeB magnets

ActiveCN104388951AIncreased diffusion kinetic energyLow melting pointInorganic material magnetismRare-earth elementDiffusion methods

The invention relates to a grain boundary diffusion method for improving properties of sintered NdFeB magnets. The grain boundary diffusion method comprises the following steps of stacking sintered NdFeB magnets and diffusion alloy sheets together and placing in a hot-pressing furnace; vacuumizing the hot-pressing furnace until the vacuum degree reaches a set value, heating the hot-pressing furnace, and when the temperature of the hot-pressing furnace reaches a set value, beginning to exert a pressure and maintaining the pressure and putting the diffused sample into a high-vacuum furnace for annealing, wherein the diffusion alloy sheets are low-melting-point eutectic diffusion alloys and are represented by R-TM, R is one or more of Sc, Y, La, Ce, Pr or Nd and TM is one or more of Ti, V, Cr, Mn, Fe, Co, Ni, Cu and Zn. Compared with the prior art, the sintered NdFeB magnets modified by the pressure diffusion method, which is provided by the invention, have the advantages of large diffusion depth of a diffusion agent, uniform distribution of grain boundary phases, high coercivity and the like, especially, low-melting-point diffusion alloys designed by the invention are free of expensive heavy rare earth element dysprosium and thus the cost of the raw materials is relatively low, the diffusion temperature is low and the energy consumption in the diffusion process is small.

Owner:SHANGHAI JIAO TONG UNIV

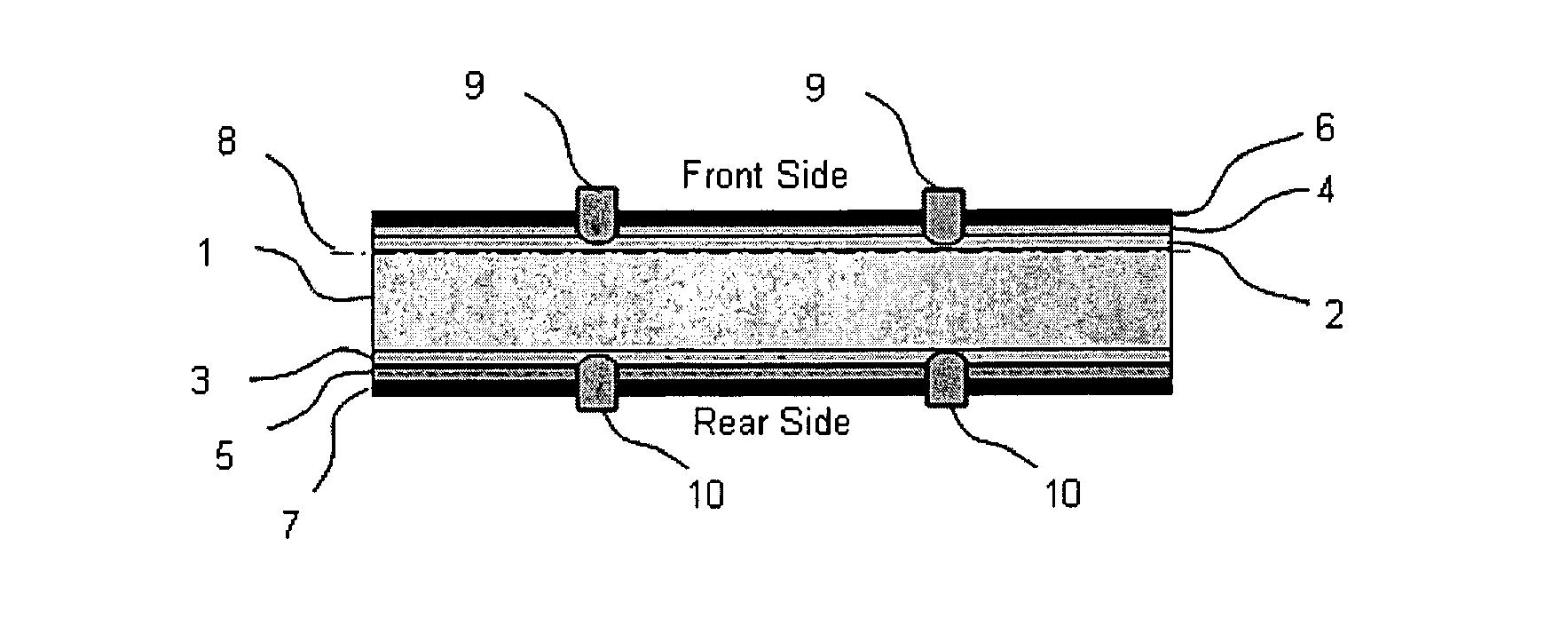

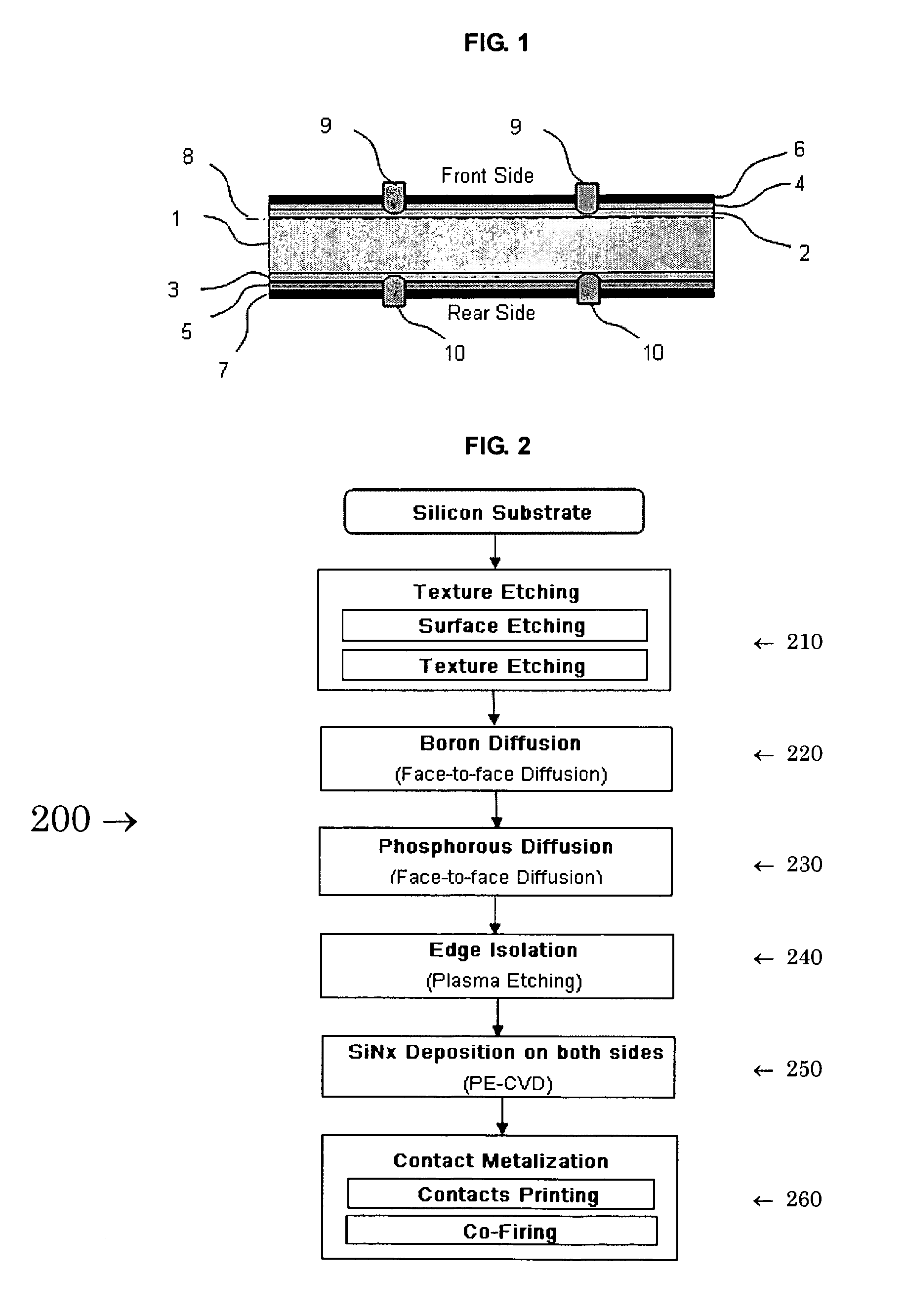

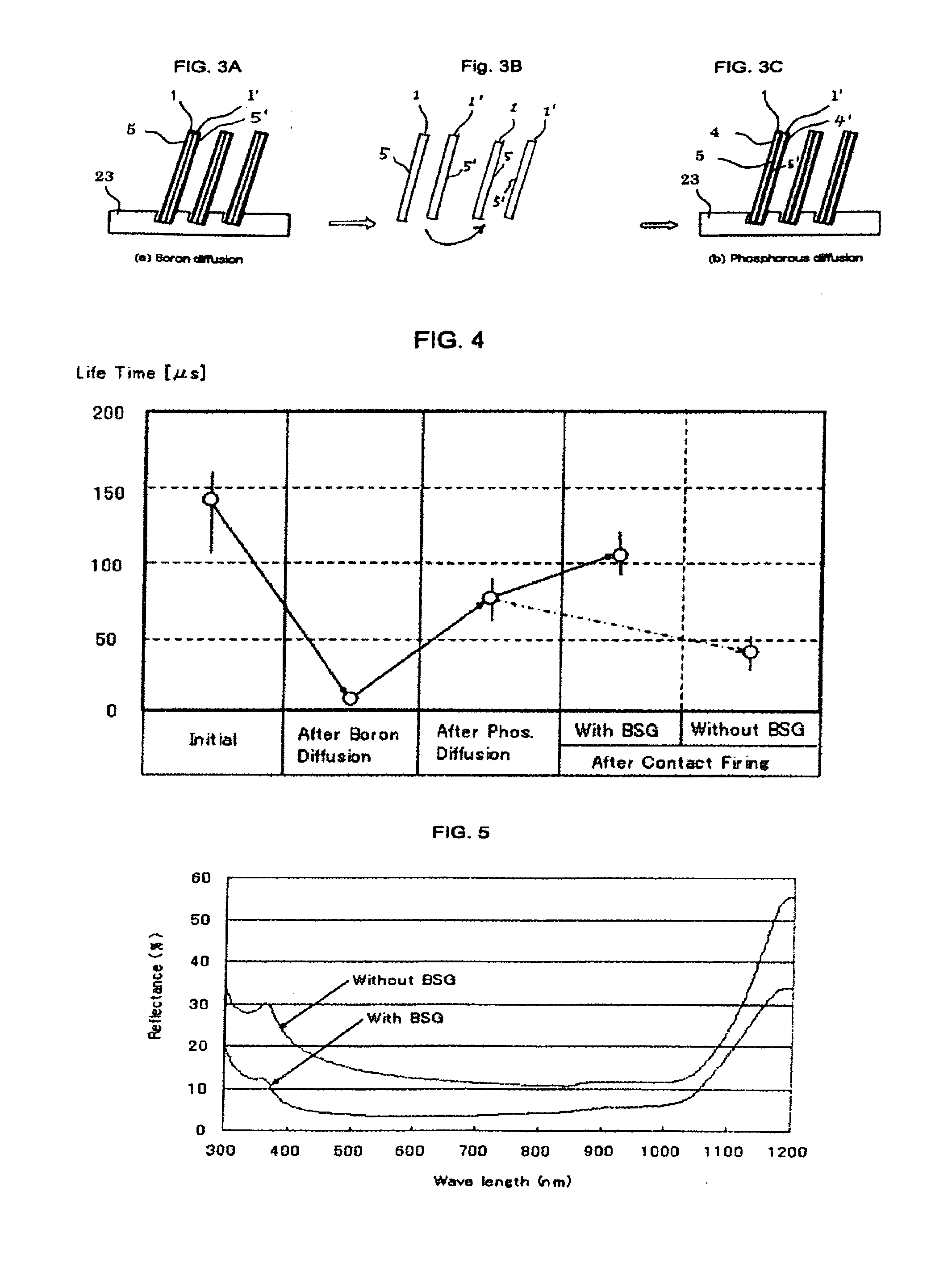

Photovoltaic solar module comprising bifacial solar cells

InactiveUS20110132423A1Without compromising structural integrityLess costly bifacial solar cellsPV power plantsSoldering apparatusDiffusion methodsPhotovoltaic solar energy

A photovoltaic solar cell module comprises a plurality of bifacial solar cells and electrical conductors. Each bifacial solar cell comprises a plurality of bus-bar contacts. A phosphorous silicon glass layer is formed on one side of the bifacial cell by phosphorous diffusion, and a boron silicon glass layer is formed on the other side of the bifacial cell by boron diffusion. The phosphorous diffusion and the boron diffusion are conducted by a face-to-face diffusion method. The combination of the two gettering methods substantially increases the minority carrier life time of the bifacial solar cell.

Owner:GAMMA SOLAR

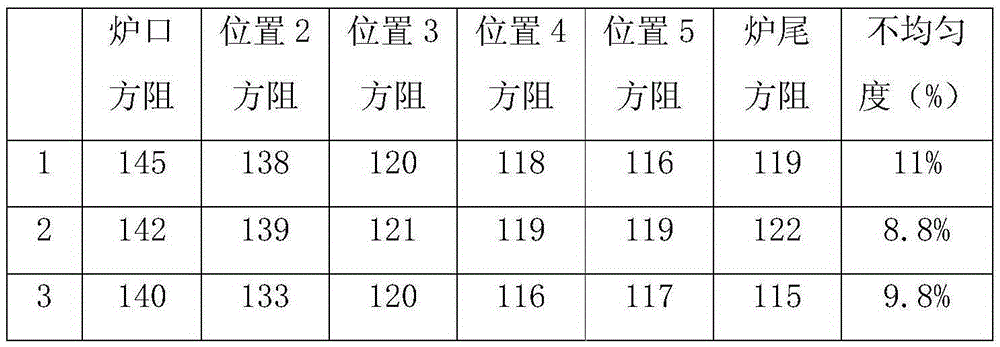

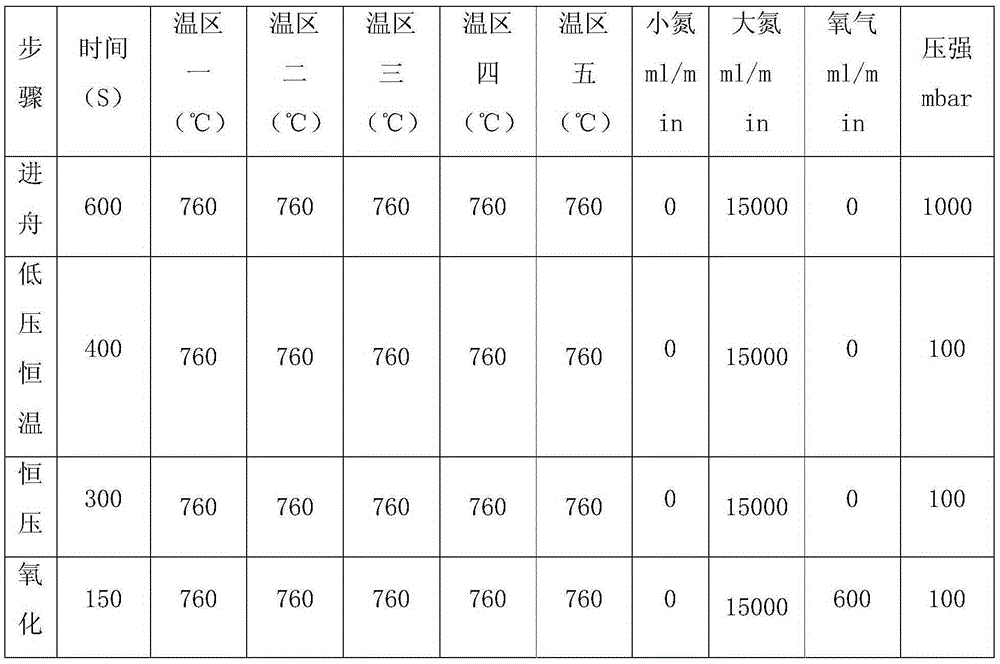

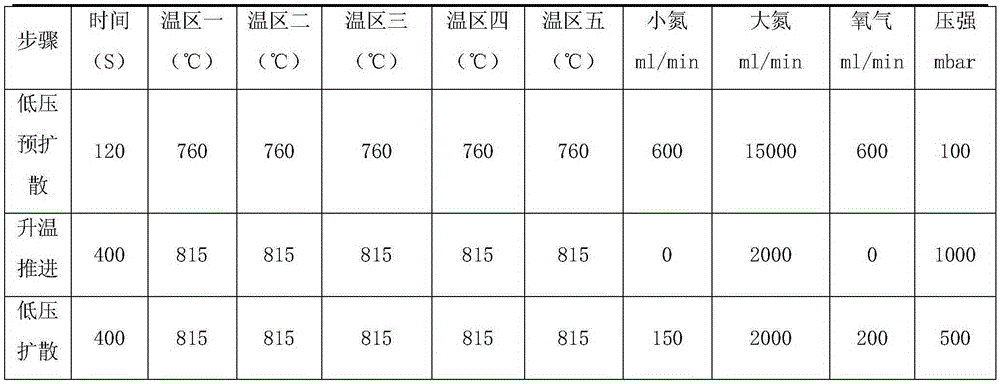

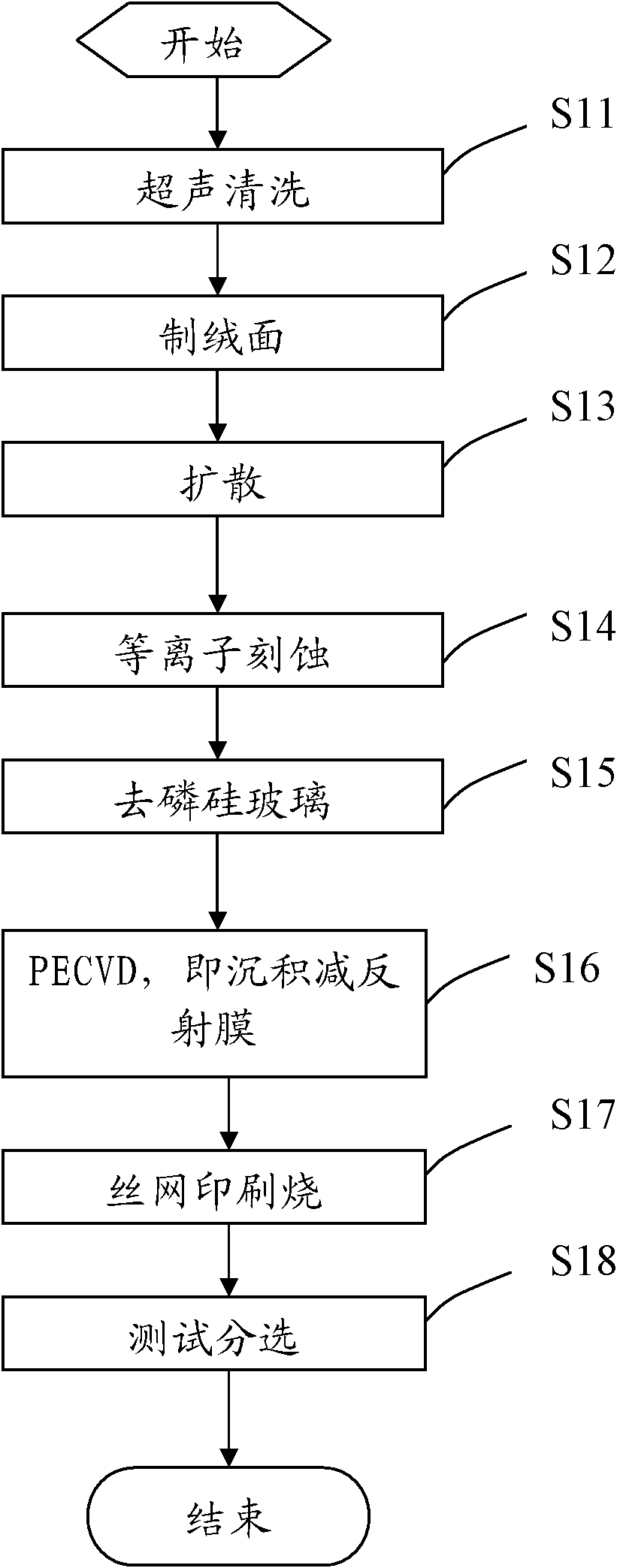

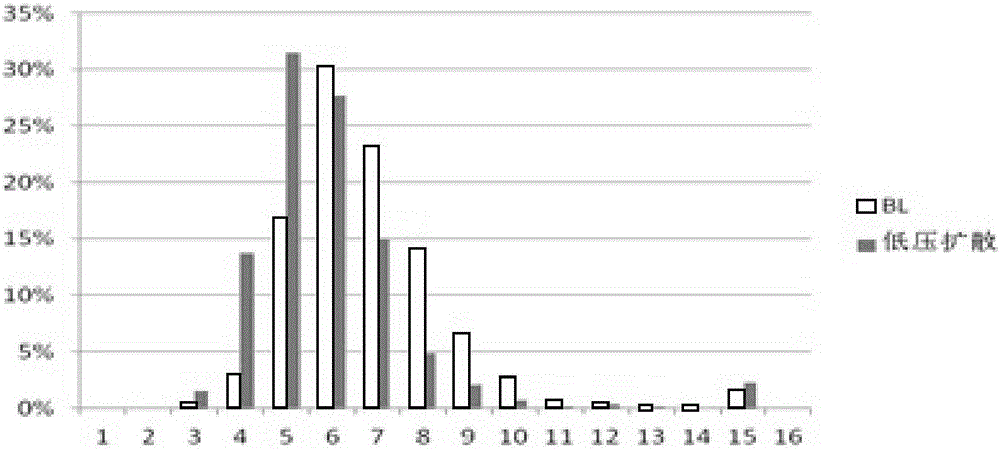

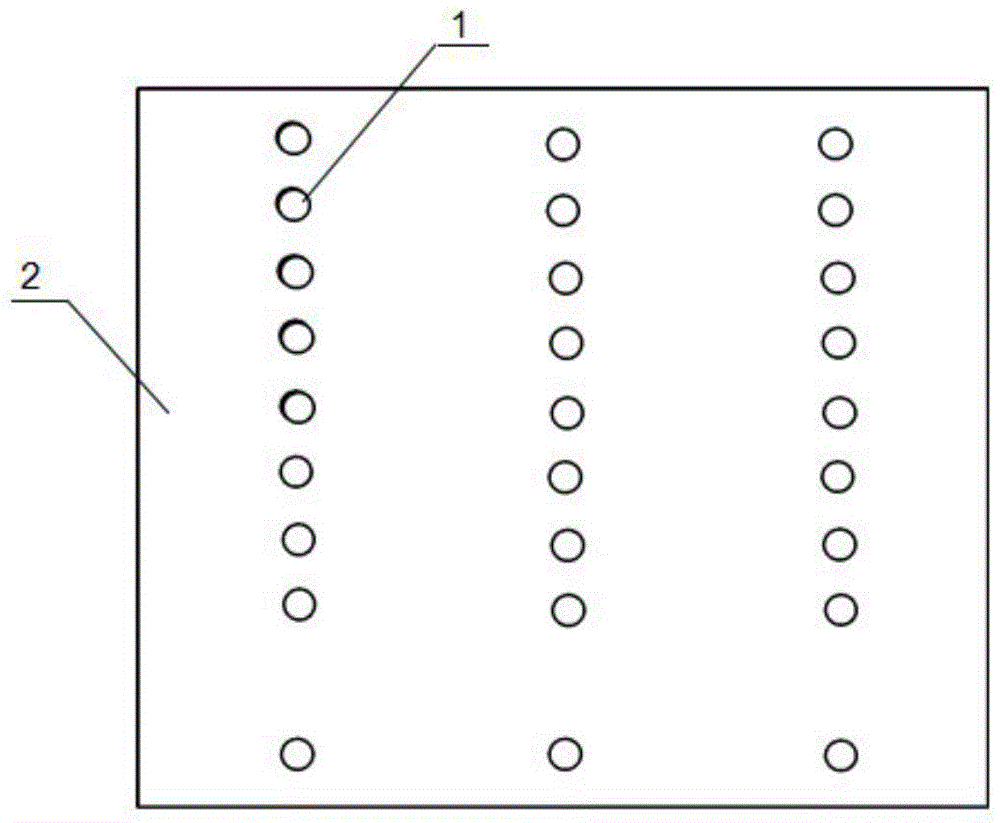

Low-pressure diffusion technology for crystalline silicon cell

ActiveCN105261670AIncrease chance of contactImprove uniformityFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsInternal pressure

The invention discloses a low-pressure diffusion technology for a crystalline silicon cell. The technology comprises the following steps: (1) a high-temperature oxidation before diffusion; (2) a low-pressure diffusion, namely preparing a PN knot by a sub-step diffusion method; and (3) annealing, namely changing internal pressure to remove impurities. According to the low-pressure diffusion technology, the uniformity between diffusion sheets can be improved; the temperature of a temperature zone in a fire hole is lowered, namely the temperature uniformity of various temperature zones of a diffusion tube is improved; the problem of a great fluctuation of sheet resistance of the fire hole of a diffusion furnace is solved; the service lifetime of a vacuum pump is prolonged; and the production cost of a diffusion procedure is reduced.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

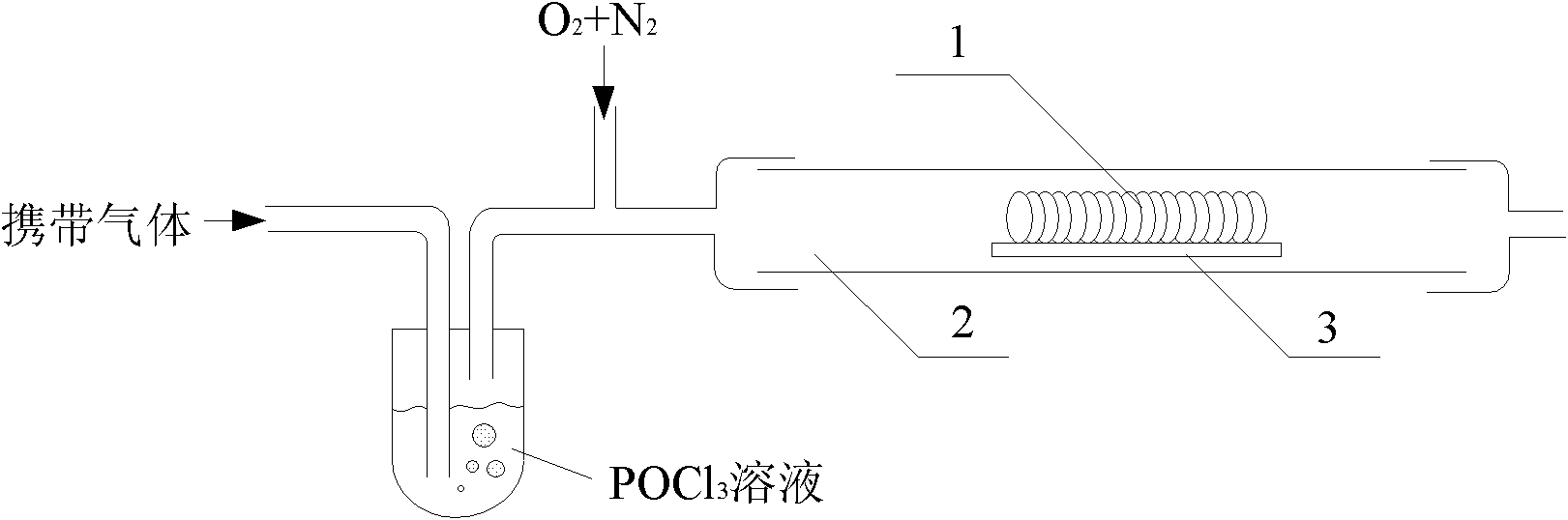

Diffusion method for preparing emitting electrode of polycrystalline silicon solar battery

ActiveCN102148284AExtend your lifeImprove efficiencyFinal product manufactureSemiconductor devicesHigh concentrationDiffusion methods

The invention discloses a diffusion method for preparing an emitting electrode of a polycrystalline silicon solar battery. The diffusion method comprises the following steps: mainly adopting a liquid-state POCl3 phosphorus source and using a high-concentration doped diffusion technology to achieve the purpose of improving the silicon battery performance by improving a phosphorus distribution curve of the emitting electrode. A multiple through-source diffusion method comprises the following steps: after carrying out preoxidation on a silicon wafer, first active diffusion is carried out on the silicon wafer at a lower temperature; and then second active diffusion is carried out at a high temperature; or third active diffusion is carried out at a higher temperature. Compared with the primary active diffusion, the method can improve the efficiency in the condition that the cost is not increased.

Owner:ZHEJIANG JINKO SOLAR CO LTD

Diffusion method for flow engineering link state

InactiveCN1503532AAchieve synchronizationReduce occupancyData switching networksDiffusionDiffusion methods

A method for realizing flow engineering (FE) link state diffusion in optical network characterizes that according to the frequency of TE link attribute variation, different TE link attributes of a same TE link variable frequency are divided into different kinds to contain the said different kinds of TE link attributes in different LSA for flooding to make TELS to diffuse in the network zone, effectively realizing diffusion of TELS in the zone and reducing network bandwidth occupied by flood of flow information to realize TEDB synchronization quickly.

Owner:HUAWEI TECH CO LTD

Crystalline silica solar cell chip diffusion method

ActiveCN103618019ASpread evenlyImprove uniformityFinal product manufactureDiffusion/dopingVacuum pumpingDiffusion methods

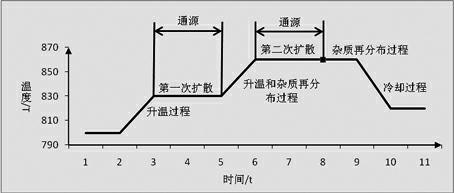

The invention discloses a crystalline silica solar cell chip diffusion method. Hydrofluoric acid or nitric acid is used for cleaning oil stain on the surface of a silicon chip and etching the surface of the silicon chip, the cleaned and etched silicon chip is placed in a vertical diffusion furnace to be diffused, and the diffusion technology includes following steps of (1) putting into the furnace: putting a quartz boat containing crystalline silica chips into the furnace at a uniform speed; (2) carrying out vacuum-pumping, wherein the pressure in a furnace chamber is 300 + / -50 mTorr after the step of vacuum-pumping; (3) carrying out vacuum leak detection on the furnace chamber; (4) carrying out oxidation in low pressure; (5) carrying out first phosphor source diffusion in low pressure; (6) heating; (7) carrying out second phosphor source diffusion in low pressure; (8) carrying out phosphor impurity propulsion in low pressure; (9) cooling; and (10) taking out form the furnace. By adopting the above crystalline silica solar cell chip diffusion method, the molecule free path of impurity is raised and the uniformity of diffusion of the crystalline silica chip is improved during diffusion, and the conversion efficiency of the crystalline silica solar cell chip is high; and the diffusion method is easy to operate, large in output and low in cost.

Owner:SUZHOU AIKANG PHOTOELECTRIC TECH CO LTD

Grain boundary diffusion method for neodymium-iron-boron magnet

ActiveCN106409497AImprove coercive forceImprove uniformityElectrophoretic coatingsInductances/transformers/magnets manufactureRare-earth elementDiffusion methods

The invention discloses a grain boundary diffusion method for a neodymium-iron-boron magnet. The method comprises the following specific steps: preparing main-phase alloy powders through the neodymium-iron-boron powder metallurgy technique; preparing grain boundary powders of a low-melting-point rare earth alloy through the rare earth alloy powder metallurgy technique; evenly mixing the main-phase alloy powders and the grain boundary powders of the low-melting-point rare earth alloy according to a certain proportion; carrying out orienting compression in a magnetic field to prepare a neodymium-iron-boron magnet blank, and carrying out sintering of the neodymium-iron-boron magnet blank for 3 to 5 hours at a temperature of 1,000 to 1,100 DEG C, so as to prepare a sintered neodymium-iron-boron magnet; coating the magnet surface with a low-melting-point rare earth alloy layer through electrophoresis; and placing the magnet in a vacuum sintering furnace for secondary tempering heat treatment. The method provided by the invention has the beneficial effects that the coercivity of the magnet is improved while the residual magnetism is hardly reduced; the diffusion depth of heavy rare earth elements in the magnet can be improved; the uniformity of the magnet after the diffusion is improved; and the method is applicable for batch production.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

Method for producing Sm-Fe-N permanent magnet alloy powder by reduction diffusion

A process for preparing permanent-magnet Sm-Fe-N alloy powder by reduction-diffusion method includes such steps as choosing and pretreating raw materials, proportioning, mixing, thermal reducing and diffusion alloying at 760-860 deg.C by use of Ca and CaH2 as reducer to obtain Sm-Fe alloy and by-products, chemical separating, dewatering Sm-Fe alloy powder, nitrizing, and preparing anisotropic Sm-Fe-N magnet. Its advantages are low reaction temp, less loss of Sm and high performance.

Owner:UNIV OF SCI & TECH BEIJING

Technology for manufacturing selective emitter junction solar cell by printed phosphorous source one-step diffusion method

ActiveCN101937940ARealize the structureGood diffusion uniformity controlFinal product manufactureSemiconductor devicesDiffusion methodsScreen printing

The invention relates to technology for manufacturing a selective emitter junction solar cell by a printed phosphorous source one-step diffusion method. The method comprises the following steps of: cleaning and texturing a silicon wafer, performing screen printing of phosphorous-containing nano Si slurry, drying at the temperature of between 200 and 350 DEG C for about 20 minutes, and removing the solvent to obtain a phosphorous-containing oxidation layer with the thickness of 30 to 100nm; implementing BOE and RCA cleaning to remove 70 percent of surface phosphorous slurry before diffusion; putting the silicon wafer into a diffusion furnace, adding a POCL3 air source, heating to between 800 and 1,000 DEG C, forming re-diffusion at a grid line of the phosphorous-containing nano slurry on the silicon wafer to form a higher surface concentration-heavily doped region, and forming a shallow diffusion region in other areas. By adopting the screen printing of the phosphorous-containing nano slurry, the phosphorous-containing nano slurry is heated at high temperature for diffusion, forms the heavily doped region at a contact position with the grid line and forms a lightly doped region in other areas. The technology has the efficiency of over 18.5 percent on the premise of better controlling the diffusion uniformity.

Owner:TRINA SOLAR CO LTD

Preparation method of cobalt and oxide embedded porous carbon absorbing material

ActiveCN109181640AImprove absorbing performanceAbsorbing performance controlOther chemical processesDiffusion methodsMicrowave

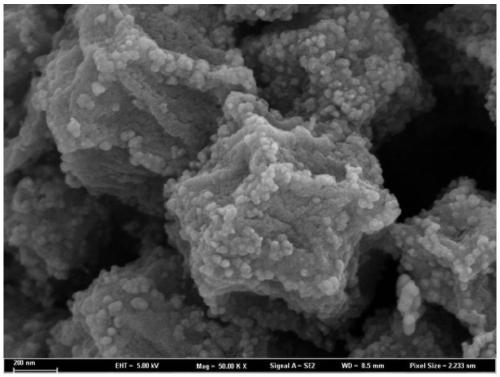

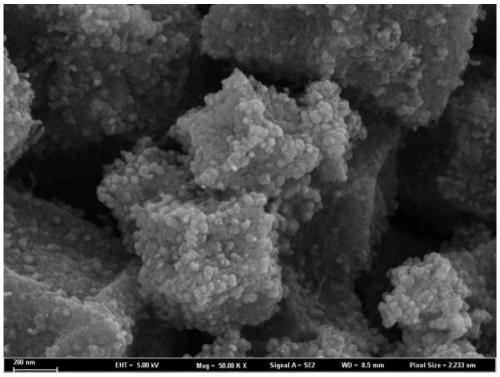

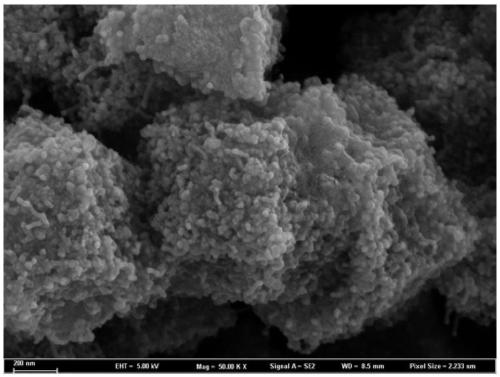

The invention relates to a preparation method of a cobalt and oxide embedded porous carbon absorbing material, which belongs to the technical field of a microwave absorption material. The method adopts a metal organic skeleton ZIF-67 as a precursor, and obtains the preparation method of the nanoporous carbon composite absorbing material embedded with Co / Co3O4 by one-step carbonization. The metal organic skeleton ZIF-67 powder is synthesized by a diffusion method and a coprecipitation method, and the ZIF-67 powder is calcined under inert atmosphere of 500-800 DEG C, after the temperature is lowered to a certain temperature, the powder is taken out and air cooled, Co is oxidized to Co3O4, after being completely cooled, the powder is ground, and the black powder is collected to obtain the Co / Co3O4 embedded nanoporous carbon composite absorbing material with excellent absorbing properties. The process not only has a simple process, but also has low raw material cost, short time-consuming period, no need for any subsequent processing technology and no complicated synthesis equipment, and provides conditions for practical production applications.

Owner:UNIV OF SCI & TECH BEIJING +1

Image restoring method based on isotropic diffusion and sparse representation

InactiveCN101571950AImprove repair effectGuaranteed smoothnessImage enhancementDiffusion methodsPattern recognition

The invention discloses an image restoring method based on isotropic diffusion and sparse representation, which comprises the following steps: dividing a defective region of an image into a homogenous region and a complex region according to information of a surrounding image of the defective region; restoring the homogenous region by an isotropic diffusion method; restoring the complex region by a sparse representation method; and fusing restoration results of the restored homogenous region and the restored complex region to obtain a restoration result of the defective region, and replacing a defective part of a source image with the restoration result of the defective region to obtain a final restoration result image. The restoration result image is superior to results generated by the prior like restoring method; the method has high restoring speed, is suitable to be applied to restoring real pictures and composite images with complicated texture and structure characteristics; moreover, the method is also applicable to digital restoration of artworks and post production of film and TV programs.

Owner:HUNAN UNIV

Method for preparing selective emitter crystalline silicon solar cell

InactiveCN101533874AThe process steps are simpleEase of mass productionFinal product manufactureSemiconductor devicesDiffusion methodsScreen printing

The invention discloses a method for preparing a selective emitter crystalline silicon solar cell, which comprises the following steps: heavily doping a p-type silicon chip by adopting a one-step diffusion method, printing a high molecular polymer material on a silk screen in a front electrode area of the heavily-doped silicon chip as a corrosion-resistant blocking layer, changing the rest non-electrode areas into light doped emitters through chemical corrosion, removing the corrosion-resistant blocking layer to form a selective emitter structure, and finally forming the selective emitter crystalline silicon solar cell by adopting a conventional preparation method of the solar cell. The process steps are relatively simple and easy to achieve large-scale production, and can improve the conversion efficiency of the cells through the emitter structure under the condition of not increasing the manufacturing cost.

Owner:SUN YAT SEN UNIV

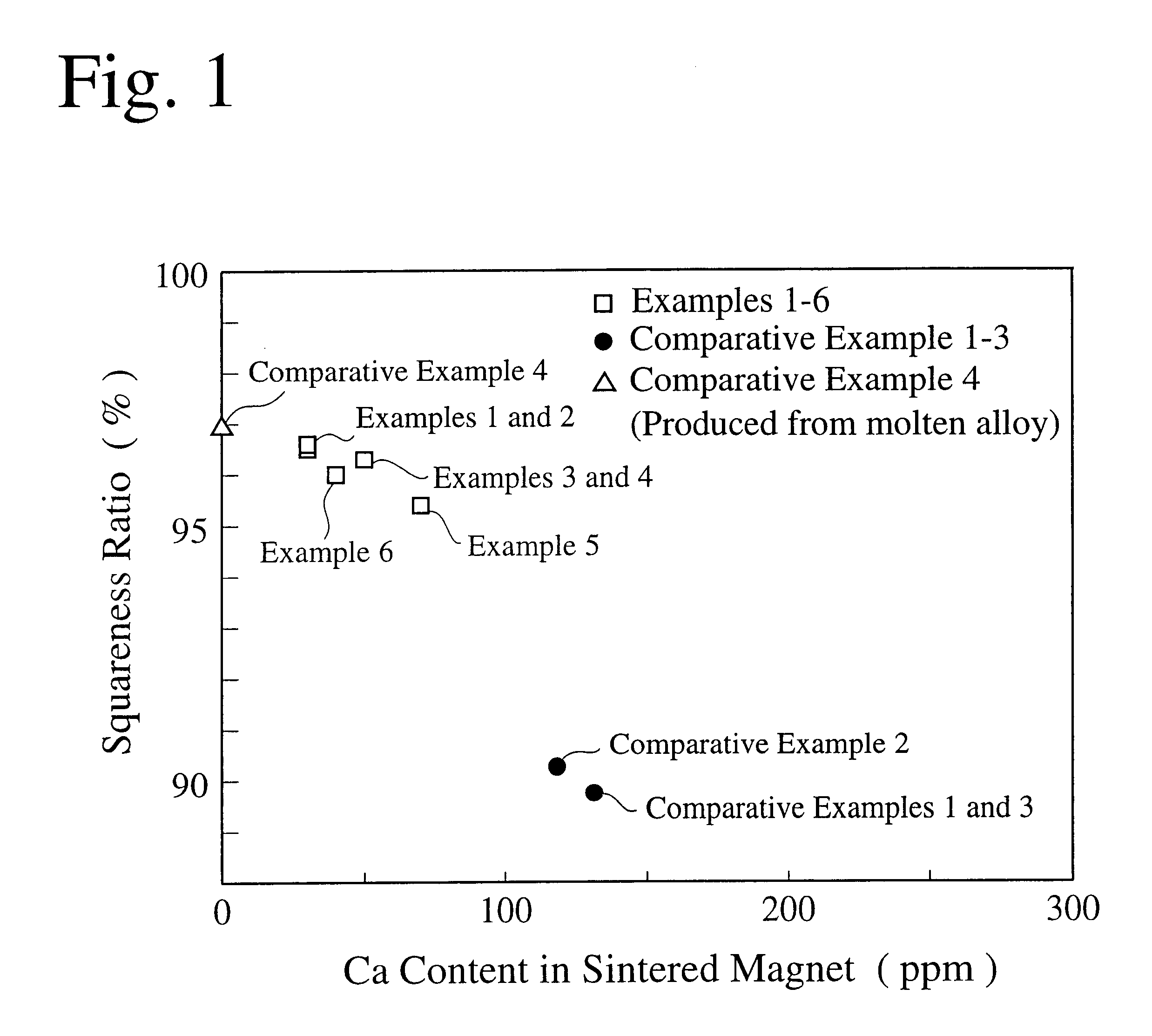

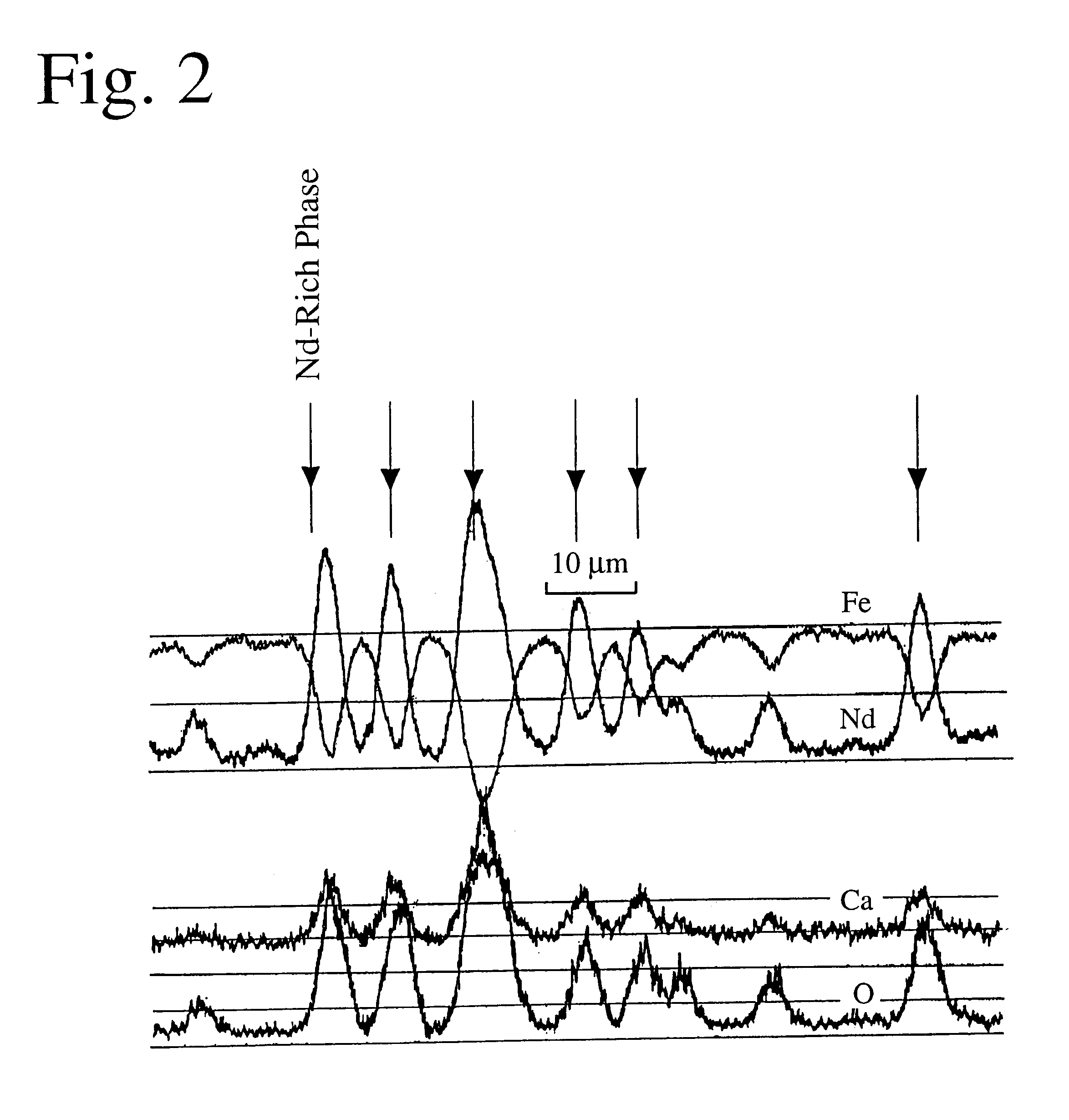

R-T-B rare earth sintered magnet having improved squareness ratio and method for producing same

An R-T-B rare earth sintered magnet containing an R2T14B-type intermetallic compound as a main phase and thus having improved squareness ratio is produced by carrying out a reduction and diffusion method comprising the steps of (a) mixing oxide powder of at least one rare earth element R, T-containing powder, wherein T is Fe or Fe and Co, B-containing powder, and a reducing agent such as Ca, (b) heating the resultant mixture at 900-1350° C. in a non-oxidizing atmosphere, (c) removing reaction by-products from the resultant reaction product by washing, and (d) carrying out a heat treatment for Ca removal by heating the resultant R-T-B rare earth alloy powder at 900-1200° C. in vacuum at 1 Torr or less, followed by pulverization of the resultant alloy powder bulk, molding, sintering in vacuum, heat treatment, and surface treatment. The alloy powder bulk obtained by the heat treatment for Ca removal is preferably pulverized after removal of its surface layer.

Owner:HITACHI METALS LTD

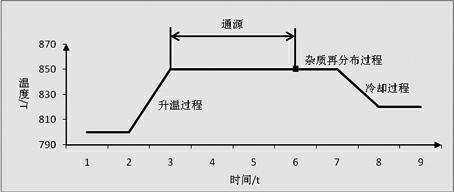

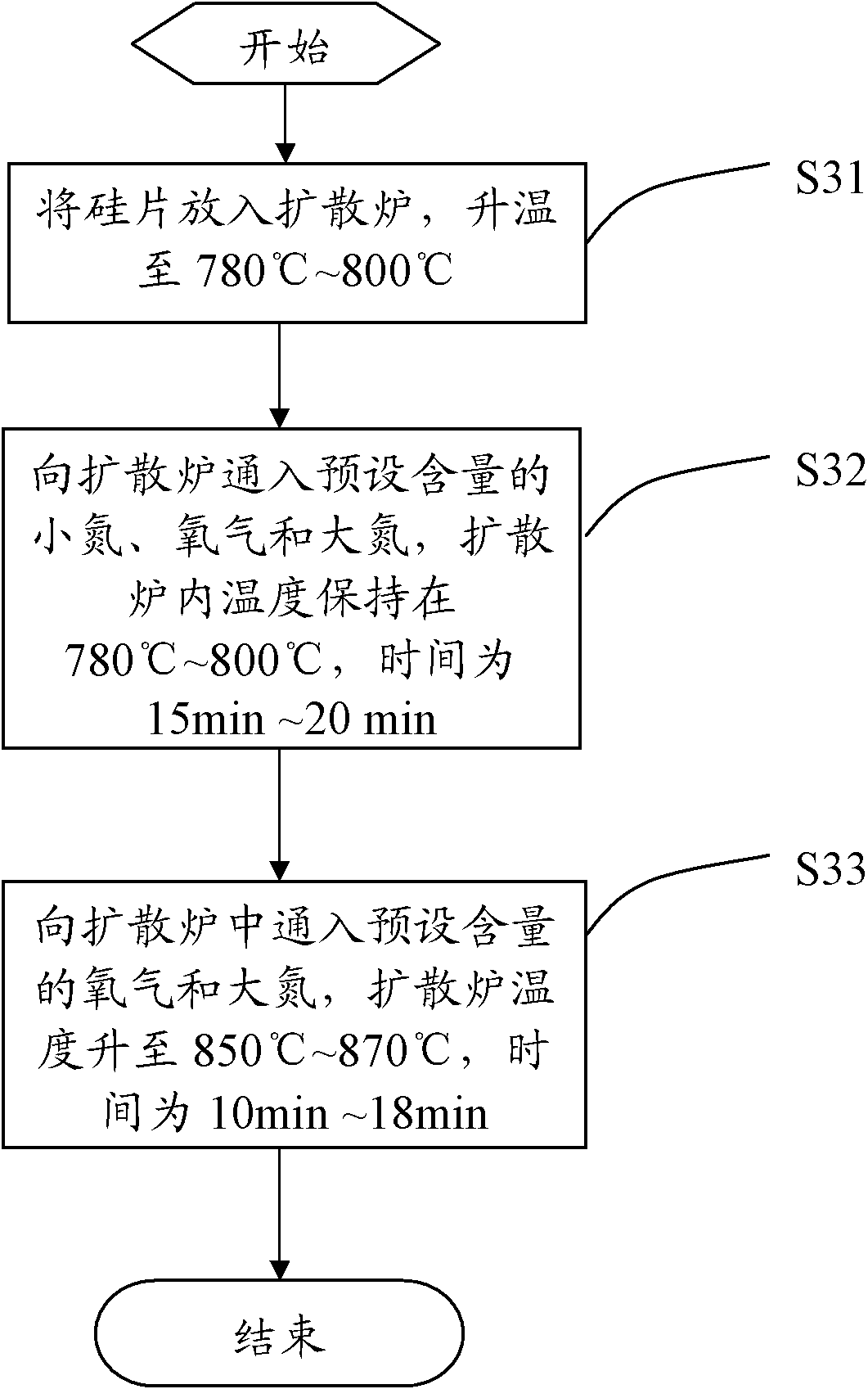

Crystalline silicon solar cell and diffusion method thereof

ActiveCN102254991AReduced activityReduce disturbanceFinal product manufacturePhotovoltaic energy generationDiffusion methodsMetallurgy

The invention discloses a crystalline silicon solar cell and a diffusion method thereof. The method comprises the following steps of: putting a silicon chip into a diffusion furnace and raising the temperature to 780-800 DEG C; introducing a preset amount of small nitrogen, oxygen and large nitrogen into the diffusion furnace through a diffusion furnace tube and keeping the internal temperature of the diffusion furnace at 780-800 DEG C for 15-20 minutes; introducing a preset amount of oxygen and large nitrogen into the diffusion furnace through the diffusion furnace tube and raising the internal temperature of the diffusion furnace to 850-870 DEG C for 10-18 minutes; and cooling the diffusion furnace and taking the silicon chip out, wherein the gas flow in the diffusion furnace tube is constant in the entire diffusion process. The depth of a PN junction of a solar cell produced with the method is small, the square resistance is more uniform, and the conversion efficiency of the solar cell is increased.

Owner:JETION SOLAR HLDG

Rare earth permanent magnet and production method thereof

InactiveUS6159308AResidual magnetic flux density Br is reducedEnhance coercive force iHcInorganic material magnetismRare-earth elementDiffusion methods

A method of producing an R-Fe-B-based, sintered permanent magnet, wherein R is at least one rare earth element including Y, having a small oxygen content. A coarse alloy powder prepared by a reductive diffusion method is milled and recovered into a solvent to form a slurry. The slurry is wet-compacted to form a green body which is then sintered after removing the solvent. The milling, recovering, wet-compacting, solvent-removing and sintering steps are carried out while preventing the powder, slurry and green body from being brought into contact with air to minimize the oxygen content in the final sintered permanent magnet. The sintered permanent magnet produced has a high density and a high magnetic properties due to a low oxygen content.

Owner:HITACHI METALS LTD

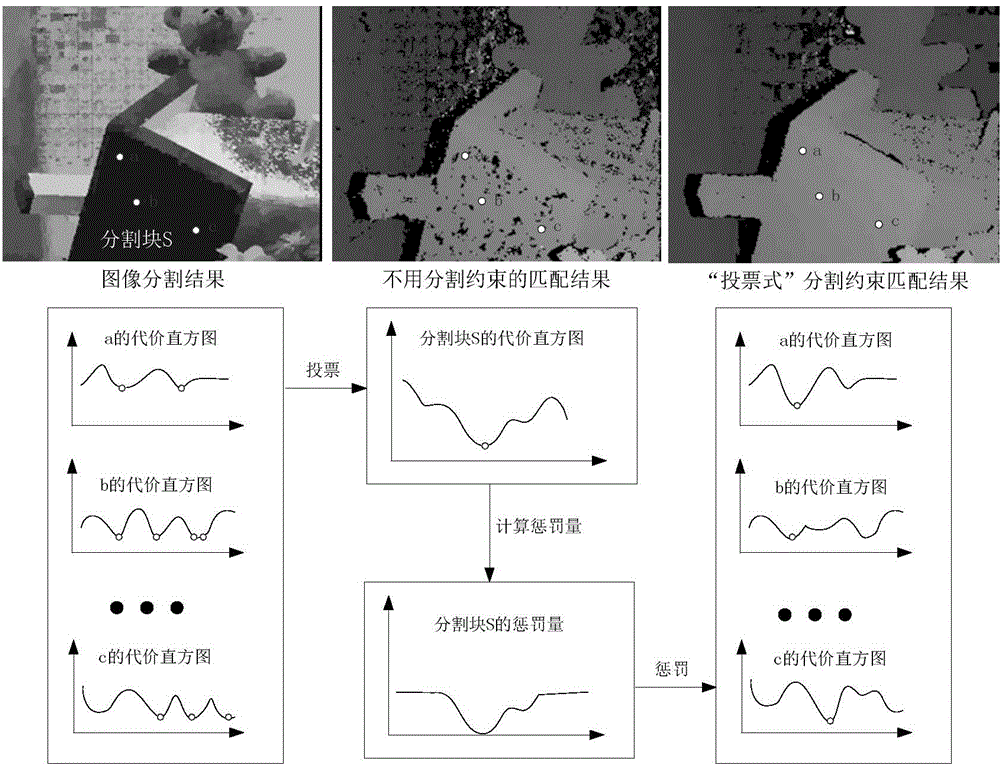

Multi-soft-constraint stereo matching method based on cost matrix

ActiveCN104820991AImprove distinguishabilityGood compatibilityImage enhancementImage analysisParallaxDiffusion methods

The invention discloses a multi-soft-constraint stereo matching method based on a cost matrix. The method comprises the following steps: calculating a three-dimensional matching cost matrix at first, then carrying out multiple-dimension downsampling, and forming a cost matrix pyramid; carrying out the corresponding multiple-dimension downsampling of an image, forming an image pyramid, and carrying out segmentation of all image layers; carrying out cost accumulation of self-adaption weight layer by layer and cost accumulation under the voting-type segmentation constraint secondly, and achieving the cost accumulation under the multiple-dimension constraint through transmitting the cost accumulation results of the upper layer to the lower cost matrix; and achieving stereo matching through combining a reliable point cost diffusion method in a bottom layer cost matrix. The method improves the stability and reliability of matching results, solves the matching problems of weak texture and repeated texture regions and parallax error discontinuous places, and can be used for improving modeling, related to the engineering application of stereo matching, based on images.

Owner:WUHAN UNIV

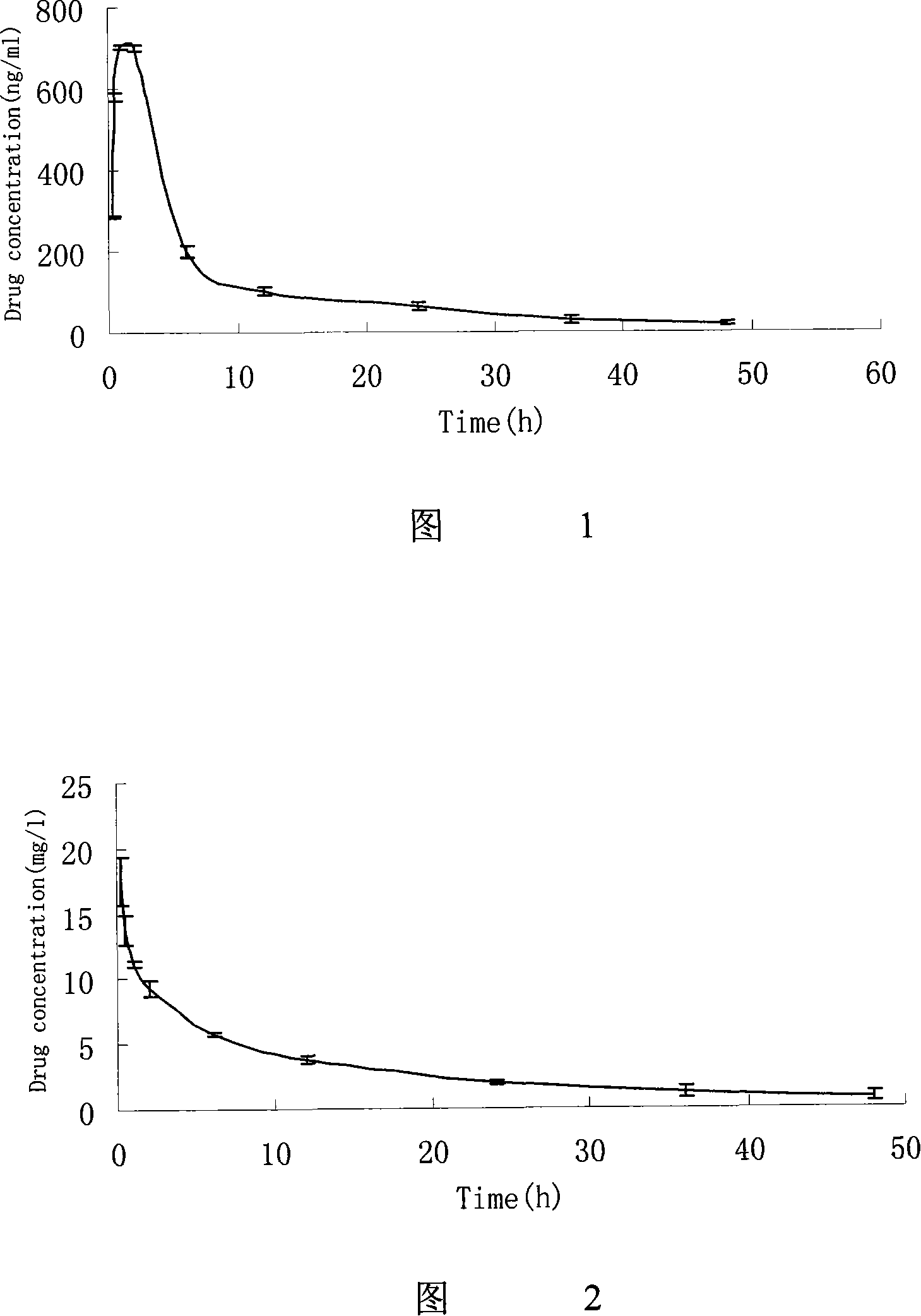

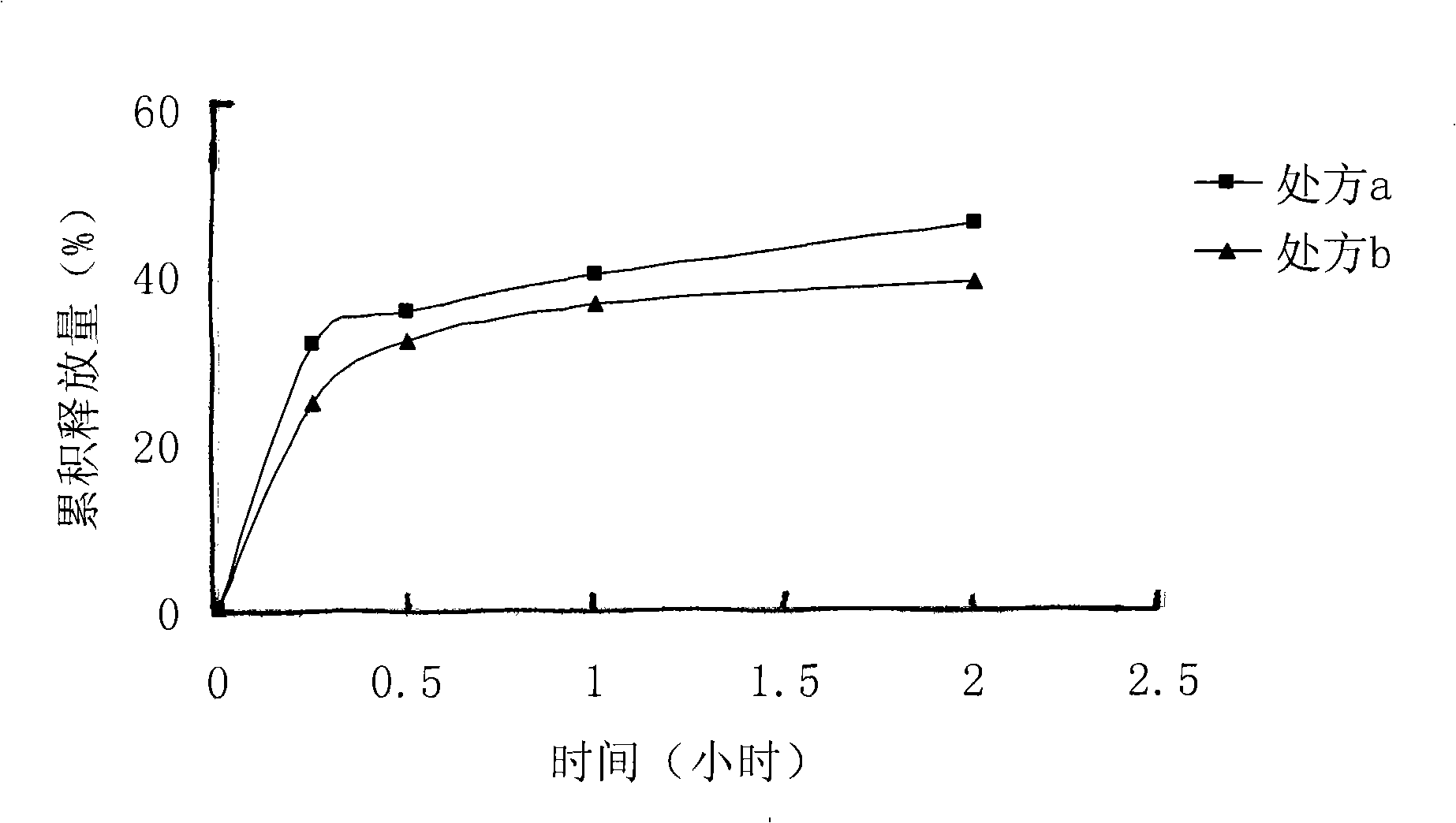

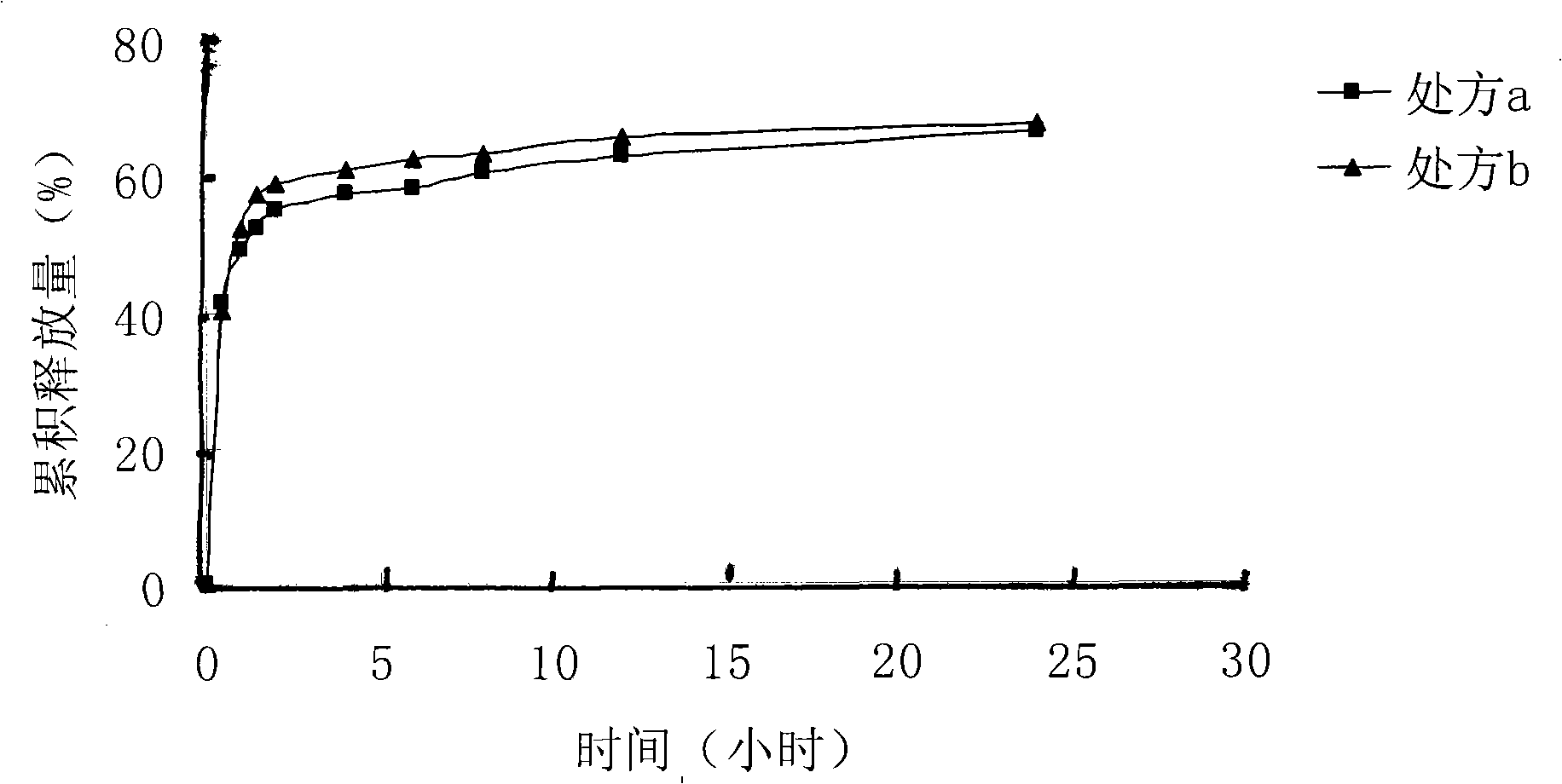

Sirolimus lipidosome freeze-dried acanthopanax powder and technique of preparing the same

InactiveCN101129361AGood curative effectExtension of timeOrganic active ingredientsPowder deliveryDiffusion methodsFreeze-drying

The invention discloses a xiluomosi liposome freeze dried and making technique, which comprises the following steps: selecting liposome component, buffer, organic solvent, antioxidant and freeze-drying protective as raw material; adopting film diffusion method to make the liposome turbid liquor with xiluomosi through high-pressure or hypersonic dispersing method evenly; drying the liposome to improve the storage stability obviously; dispersing the freeze dried at random proportion in the water evenly without any sediment and impurity; making the packing rate of liposome at 96% with the grain size at 50-250nm; improving the drug effect greatly in comparison with oral agent; lengthening the circulating time in the blood; elevating the biological utility of drug.

Owner:山东华诺生物科技有限公司

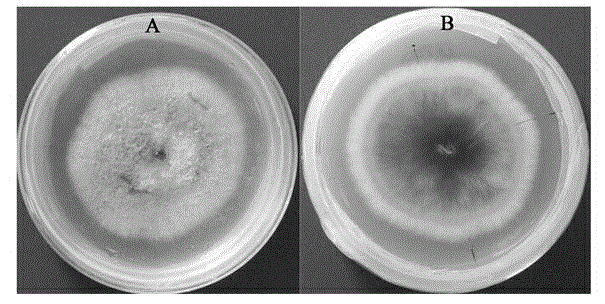

Antagonistic bacterium for controlling radix rehmannia root rot and application of antagonistic bacterium

InactiveCN104877943AStrong antagonistic effectEnhance colonization abilityBacteriaMicroorganism based processesContinuous croppingAspergillus flavus

The invention provides an antagonistic bacterium for controlling radix rehmannia root rot. The antagonistic bacterium is named as pseudomonas aeruginosa LK-12 (the Preservation No.: CGMCC 10966) after authentication. The pseudomonas aeruginosa LK-12 disclosed by the invention is obtained by screening from continuous cropping rhizosphere soil of radix rehmannia root through an agar disk diffusion method. Fusarium oxysporum and aspergillus flavus pathogenic bacteria separated from lesion parts of the radix rehmannia root have a high antagonistic effect; in the meanwhile, fusarium oxysporum, fusarium moniliforme, talaromyces sp. and other pathogenic bacteria separated from lesion parts of radix pseudostellariae also have a remarkable restriction effect and can be used for effectively controlling root rot diseases of medicinal plants comprising the radix rehmannia root to provide a strain for overcoming or relieving replant diseases of the medicinal plants. Therefore, the antagonistic bacterium is a potential biological control strain which is good in biological control effect, free of pollution as well as safe and ecological, and is wide in development and application prospects.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing highly coercive neodymium-iron-boron magnets with heavy rare earth Dy

InactiveCN108899149ASimplified Surface Diffusion Process TechnologyImprove coercive forceMagnetic materialsPermanent magnet manufactureRare-earth elementDiffusion methods

The invention belongs to the field of materials and particularly relates to a method for preparing highly coercive neodymium-iron-boron magnets with heavy rare earth Dy. The method includes: introducing a heavy rare earth diffusion source into pressed green blank in advance, and dipping the pressured green blank into a heavy rare earth complex organic solvent. On the one hand, organic coating of the surface of power particles is achieved to prevent powder from being oxidized, on the other hand, through decomposition of the heavy rare earth organic solvent during the sintering and heat treatment process, elements C and H evaporate into the gas, residual medium and heavy rare earth elements Tb / Dy spread to the surface of main-phase crystal particles to achieve magnetic hardening of the surface of the main-phase crystal particles, and magnetic coercivity is improved; in the method, the heavy rare earth diffusion source is added to the surface of the non-compact green blank in a dipping manner, multiple diffusion channels and deep diffusion depth are achieved, the diffusion methods of coating, steaming and rolling and the like on the sintered compact magnet surface in the conventionaldiffusion process are improved, extra long time high temperature diffusion treatment is not needed, and simple process and high diffusion efficiency are achieved.

Owner:NANJING UNIV OF SCI & TECH

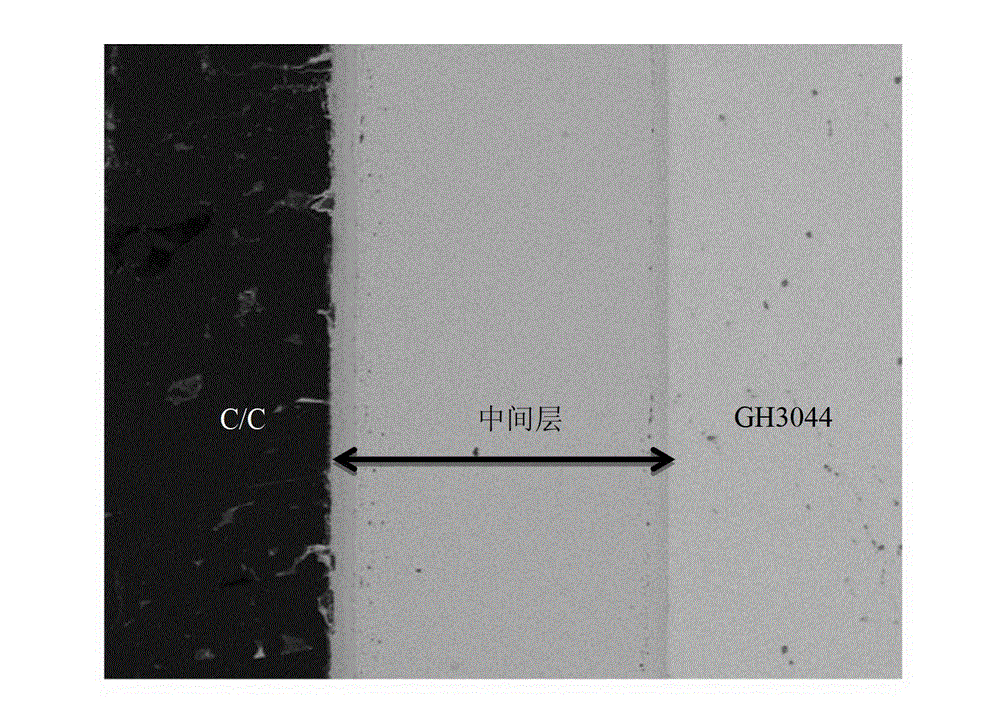

Partial transient liquid phase bonding method for carbon/carbon composite material and nickel-base superalloy

The invention relates to a partial transient liquid phase bonding method for a carbon / carbon composite material and a nickel-base superalloy. The partial transient liquid phase bonding method comprises the following steps: forming an intermediate layer by foils such as a Ti foil, a Ni foil, a Cu foil and the like, placing the intermediate layer between the clean carbon / carbon composite material and the clean nickel-base superalloy to form a sandwich structure according to the sequence of Ti foil, Ni foil, Cu foil and Ni foil, then placing the structure into a vacuum hot-pressing furnace and connecting the carbon / carbon composite material and the nickel-base superalloy by utilizing a partial liquid phase diffusion method; heating to carry out primary partial transient liquid phase bonding so as to implement connection of metal interfaces; and heating to carry out secondary partial liquid phase bonding so as to implement connection of the carbon / carbon composite material and the intermediate layer. The method implements connection of the carbon / carbon composite material and the nickel-base superalloy; and the connection strength is high and the shear strength of a joint reaches 14.99 to 26.1 MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

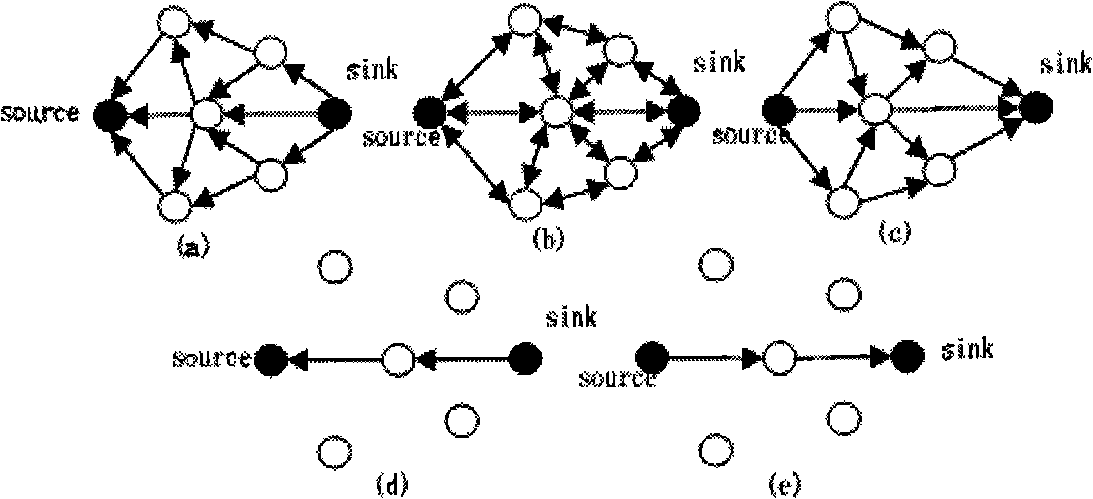

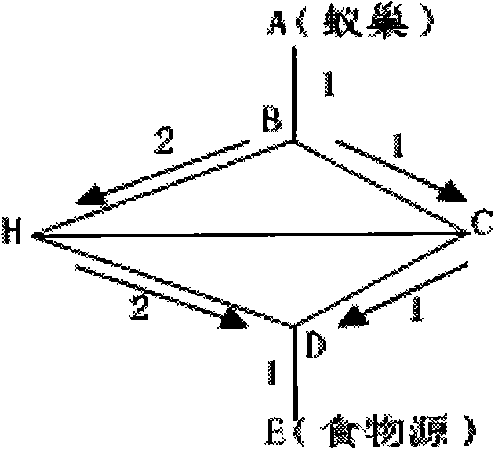

Directional scattering method based on emmet group algorithm in wireless sensor network

InactiveCN101277264AIncreased average energy consumptionExtend the life cycleBiological modelsData switching networksDiffusion methodsWireless mesh network

The invention relates to a directed diffusion method based on ant colony algorithm in wireless sensor network. The method includes steps: 1) ant with interest message starts from sink node and broadcasts whole network in flooding method; 2) in flooding process, ant releases some pheromone in passing route, at the same time, collects residual energy information of each node when reaching each node; 3) bidirectional gradient is established in passing route by employing gradient value formula according with pheromone and residual energy information; 4) detecting grouping source node flooding whole network from possible route for realizing generating and updating of router; 5) detecting grouping reach sink node, and selecting optimal transmission route according with gradient value; 6) selecting transmission route and sending subsequent data. The method provided by the invention considers ant pheromone and node residual energy into grads establishing process, limits route selection into partial nodes, disperses network consumption to whole network, and balances energy consumption of network.

Owner:WUHAN UNIV OF TECH

Method of preparing perm-selective porous membrane and method of separating gases using porous membrane prepared thereby

ActiveUS20180272288A1Improve stabilityImprove thermal stabilitySemi-permeable membranesMembranesSeparation factorDiffusion methods

The present invention relates to a method of preparing a perm-selective porous membrane and a method of separating gases using the prepared porous membrane. According to the present invention, a membrane is synthesized using a hierarchically structured alumina porous support by a counter diffusion method. During this synthesis, the diffusion rate of metal ions loaded on the porous support is controlled by controlling the pore size of the porous support, and the position at which the membrane is synthesized is controlled by synthesizing the membrane inside the support. This can increase the physical stability of the membrane and make the membrane thicker so as to ensure higher H2 / CO2 separation factors.

Owner:KOREA UNIV RES & BUSINESS FOUND

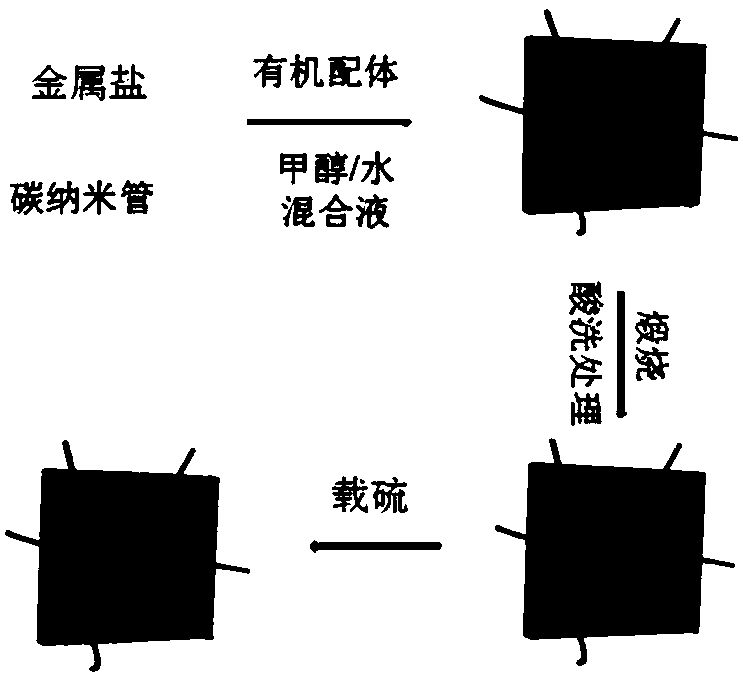

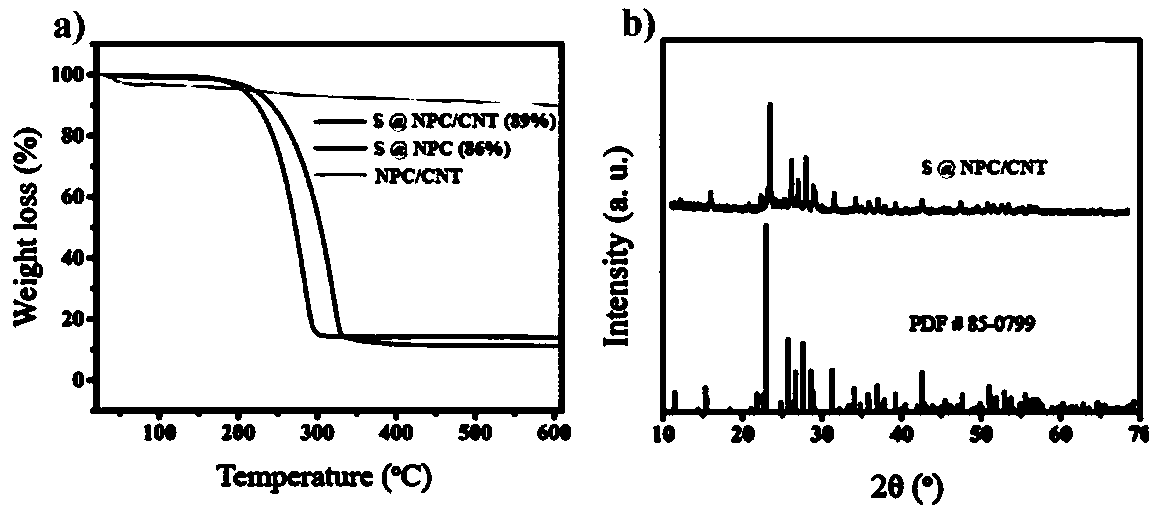

S@NPC/CNT composite material and preparation method and application thereof

InactiveCN109686951AInhibition of dissolutionStop the spreadCell electrodesDiffusion methodsPorous carbon

The invention discloses an S@NPC / CNT composite material and a preparation method and application thereof. The S@NPC / CNT composite material is obtained from an NPC / CNT composite material by sulfur loading. The NPC / CNT composite material is composed of nitrogen doped porous carbon and carbon nanotubes in the interweaving mode. The nitrogen doped porous carbon is a carbon material derived from a Zn / Co-bimetallic organic framework. The nitrogen doped carbon material is obtained by stirring, drying, calcining and acid treatment of a methyl alcohol and water mixed solution containing zinc and / or cobalt transition metal salt, organic ligand and a carbon material, and finally the high sulfur loaded S@NPC / CNT composite material is prepared by a melt diffusion method. The material exhibits extremelyhigh sulfur content. In addition, the invention also discloses the application of the high sulfur loaded nitrogen doped carbon material prepared by the method in a lithium sulfur battery. The composite material is used for an anode material of the lithium sulfur battery. The obtained battery has high area capacity and good electrochemical performance. The efficient method for preparing the nitrogen doped carbon material with high performance and high sulfur content is provided.

Owner:CENT SOUTH UNIV

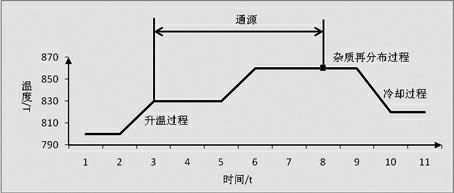

Low-pressure diffusion technology for solar cells

InactiveCN106784153AHigh dopingImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsSilicon solar cell

The invention relates to the technical field of solar cell preparation, in particular to a low-pressure diffusion technology for solar cells. A diffusion technology process is performed in a low-pressure state, so that low impurity source saturated vapor pressure is distributed in a furnace chamber, molecular free paths of impurities are improved, airflow field stability is improved, crystal silicon wafer diffusion evenness is greatly improved, and sheet resistance evenness is improved. The manufactured crystal silicon solar cells have high conversion efficiency, simple operation and large yield; meanwhile loss cost of chemicals and special gas is remarkably reduced, and a multistep diffusion method can reduce surface dead layers and increase the doping amount of electrical active phosphorus; compared with a conventional diffusion technology, open-circuit voltage Voc of the solar cells prepared through the technology is improved by 3mV, the photoelectric conversion efficiency Eff is absolutely improved by 0.1%, and power Pmpp is improved by 0.026W.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Diffusion method for solace cell with polycrystalline silicon selective emitter

ActiveCN102593262AImprove efficiencyShallow dopingFinal product manufactureDiffusion/dopingDiffusionDopant

The invention discloses a diffusion method for a solar cell with a polycrystalline silicon selective emitter. The diffusion method includes the following steps: firstly, placing a silicon chip on which a doping agent grows into a diffusion furnace and raising the temperature to 750-800DEG C, wherein the environment in the furnace is N2 with the flow being 10-30slm; secondly, after the temperature is stabilized, uniformly raising the temperature in each temperature zone in the furnace to 850-900DEG C, introducing 0.2-2slm of N2 carrying trichloroethane, 1-5slm of O2 and 10-30slm of N2 while raising the temperature so as to realize heavy doping and controlling the heavily-doped sheet resistance between 30 and 60 omega / m<2>; thirdly, reducing the temperature of each temperature zone to the diffusion temperature of 820-840DEG C and introducing N2 carrying POCl3 for diffusing; fourthly, reducing the temperature of each temperature zone to 780-800DEG C, stopping introducing the N2 carrying the POCl3 so as to realize shallow doping, wherein the propulsion time is 10-25minutes and controlling the shallow-doped sheet resistance between 70-120 omega / m<2>; and fifthly, cooling the silicon chip, taking out the silicon chip and finishing the diffusion process. According to the diffusion method disclosed by the invention, the diffusion of a doping agent is realized at high temperature and the heavy doping and shallow doping of the selective emitter are realized; and meanwhile, the gettering of a polycrystalline silicon is realized, so that the conversion efficiency is greatly increased.

Owner:CSI CELLS CO LTD +1

Manufacturing method of crystalline silicon solar cell

InactiveCN104966761AIncrease the open circuit voltageImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationDiffusion methodsConductive paste

The invention discloses a manufacturing method of a crystalline silicon solar cell. The manufacturing method includes the following steps that: surface treatment is performed on a cleaned silicon wafer, so that a concavo-convex texturized surface can be obtained; a PN junction is formed on the silicon wafer through adopting a diffusion method; the silicon wafer periphery of the formed PN junction is etched, so that a redundant diffusion layer can be removed, and a film body is deposited on the front surface and the back surface of the silicon wafer respectively, and local film body portions are removed through adopting an etching method, so that dot-shaped or stripe-shaped structures which uniformly expose the silicon wafer can be formed on the film bodies; a front surface conductive paste and a back surface conductive paste are printed on the front surface and the back surface of the silicon wafer respectively; and sintering is performed, so that the solar cell can be obtained. According to the manufacturing method of the invention, the etching method is adopted for the film bodies on the solar cell, so that the local film body portions are removed through etching, and the non-burn-through conductive pastes are printed on the locally-etched film bodies, and therefore, direct electric contact between local metal and silicon can be realized, and the film bodies will not be damaged in high-temperature sintering of the conductive pastes as much as possible, and the open-circuit voltage of the solar cell can be increased, and the contact resistance of the solar cell can be reduced, and therefore, the conversion efficiency of the solar cell can be improved.

Owner:SICHUAN YINHE STARSOURCE TECH CO LTD

Grain boundary diffusion method of R-Fe-B rare-earth sintered magnet, HRE diffusion source and fabrication method thereof

InactiveCN107871602ASmall surface areaAdjustment methodInductances/transformers/magnets manufactureMagnetic materialsDiffusion methodsRare-earth element

The invention discloses a grain boundary diffusion method of an R-Fe-B rare-earth sintered magnet, an HRE diffusion source and a fabrication method thereof. The grain boundary diffusion method comprises the following steps of forming film engineering A on a high-temperature resistant carrier, wherein HRE compound powder is attached onto the film, and the HRE is selected from at least one of Dy, Tb, Gd and Ho; and placing the R-Fe-B rare-earth sintered magnet and the high-temperature resistant carrier processed by the engineering A in a processing room, performing thermal treatment on the R-Fe-B rare-earth sintered magnet and the high-temperature resistant carrier in vacuum or inert atmosphere, and supplying HRE engineering B to a surface of the R-Fe-B rare-earth sintered magnet from the high-temperature resistant carrier. By the method, consumption of a heavy rare-earth element can be reduced, and the loss of residual magnetism Br of the magnet is controlled as well as the coercivity is improved.

Owner:XIAMEN TUNGSTEN

System and method for segmentation of mr flow data using fluid dynamics and tracking

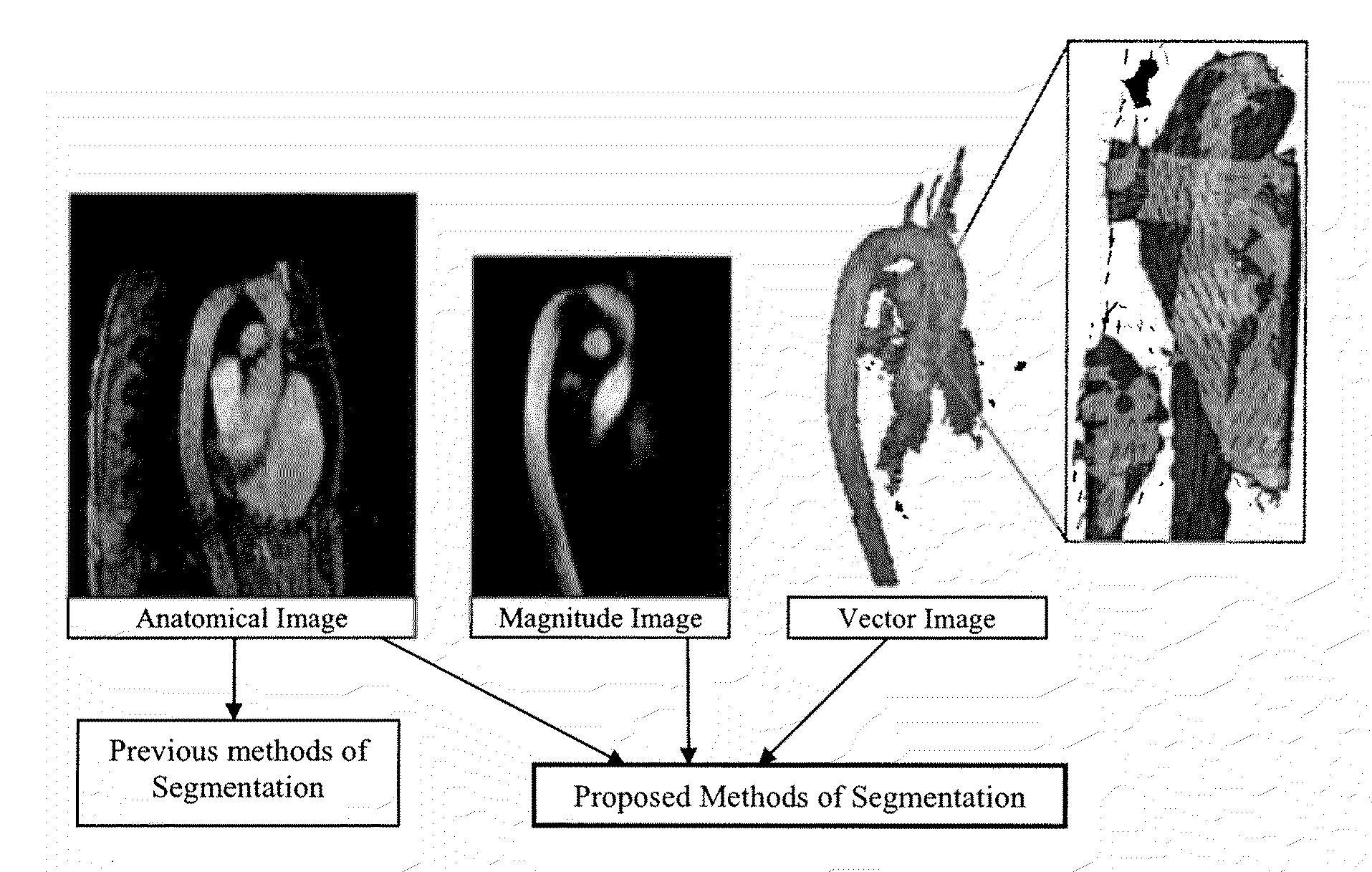

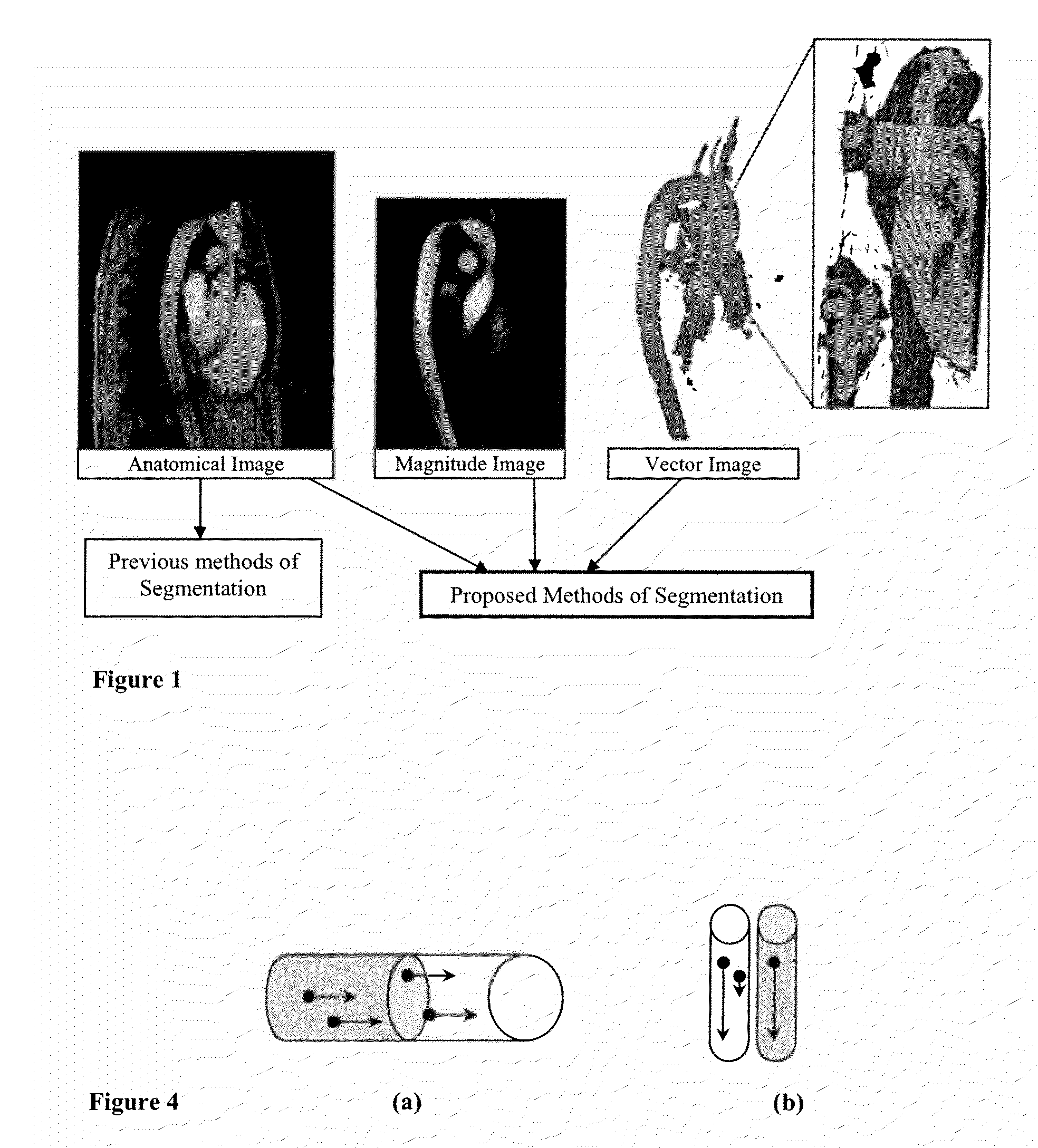

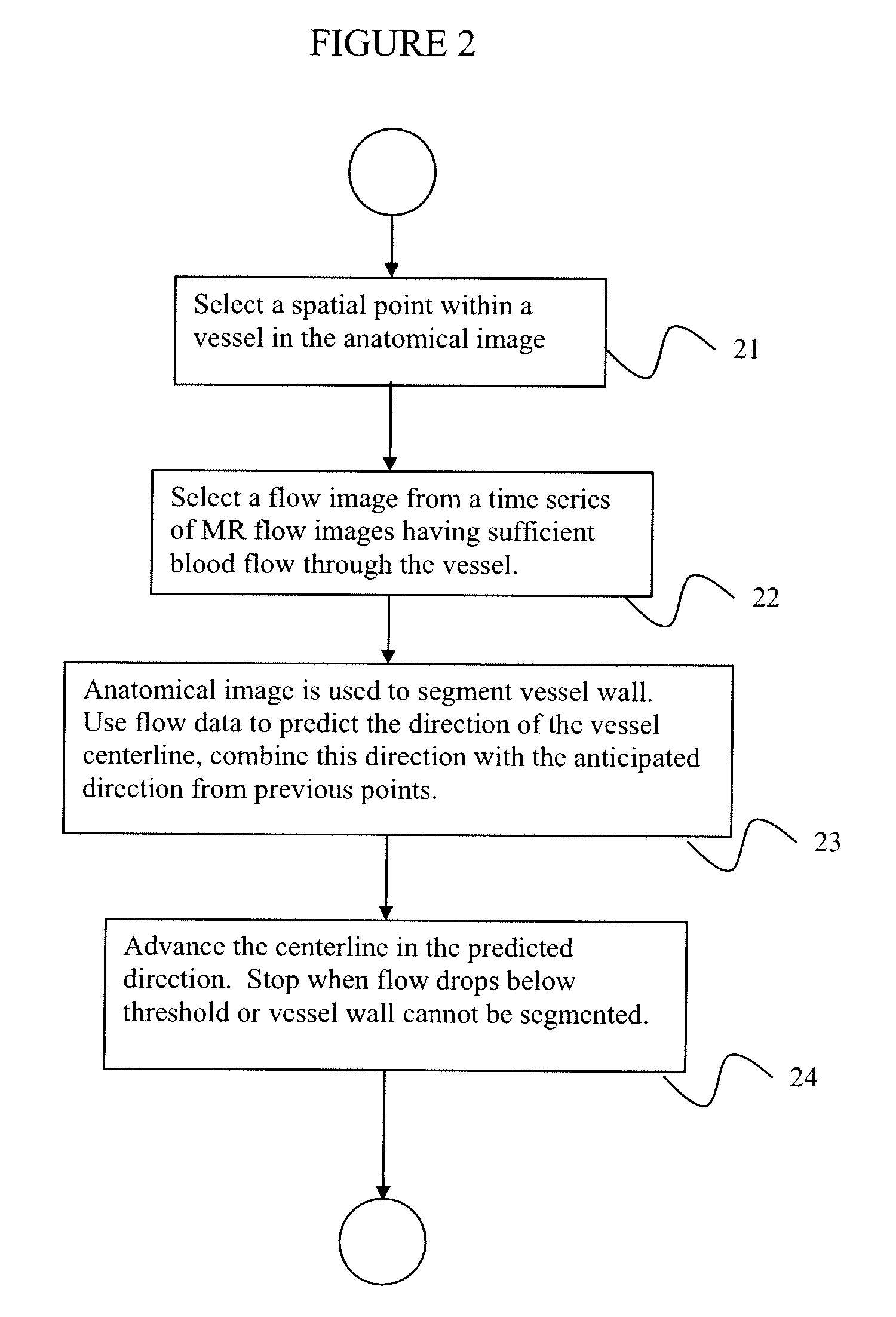

InactiveUS20100014739A1Improve segmentationOptimalImage enhancementImage analysisDiffusion methodsVector field

Methods for vessel segmentation and tracking using 7D MRI flow image data incorporate information from the velocity field and the magnitude. A vessel tracking methods selects a time containing sufficient blood flow through a vessel, uses the magnitude image to determine the vessel boundary and uses the velocity image to define the vessel direction. A method for segmenting tubular and circular objects segments the objects into separate vessels and then uses the velocity data to reunite the objects, where touching components are evaluated by the velocity field where they are connected. If vectors point towards the other component, the two components are reconnected. An advection-diffusion method based on fluid dynamics performs a fluid dynamics simulation with image forces according to the Navier-Stokes equations. With the 7D data, the vector field is available from the flow data, from the time point at which maximal flow occurs in the vessel of interest.

Owner:SIEMENS HEALTHCARE GMBH

Melittin complex nanometer granule for oral dosing and preparation method thereof

InactiveCN101406691AReduce contentReduce allergic reactionsPowder deliveryPeptide/protein ingredientsSolubilityMicroparticle

The invention belongs to the technical field of medicines and discloses melittin complex nanoparticles for oral administration and a preparation method thereof. Water-soluble melittin and an amphiphilic substance are dissolved into a hydrosolvent A to form a hydrophobic protein ion pairing complex; the complex and a suitable polymer material are dissolved into a nonaqueous solvent B; an emulsion solvent diffusion method in a liquid phase is adopted to wrap the complex into the polymer material; and microparticles with the particle diameter between 10 and 1000nm are formed after the solvent is volatilized. The hydrosolvent A is distilled water, double distilled water, deionized water, physiological saline, or a phosphate buffer solution or an acetate buffer solution or a Tris buffer solution with the pH value of between 1 and 11; and the nonaqueous solvent B is a single or mixed solvent of alcohol, acetone, ethyl acetate, methylene dichloride, chloroform and dimethyl sulfoxide. The complex has high fat solubility, and the encapsulation rate of the nanoparticles is more than 90 percent. The preparation process is mild and can assure the biological activity of medicines. The preparation method is suitable to prepare oral administration preparations.

Owner:SHENYANG PHARMA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com