Low-pressure diffusion technology for crystalline silicon cell

A crystalline silicon cell and diffusion process technology, applied in the field of diffusion process, can solve the problems of difficulty in improving the uniformity of the longitudinal concentration distribution of diffusion doping between wafers, restricting the doping uniformity of silicon wafers, and reducing the service life of a vacuum pump, etc. The effect of cost-effective industrial production, improving the consistency of vertical concentration distribution, and improving the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

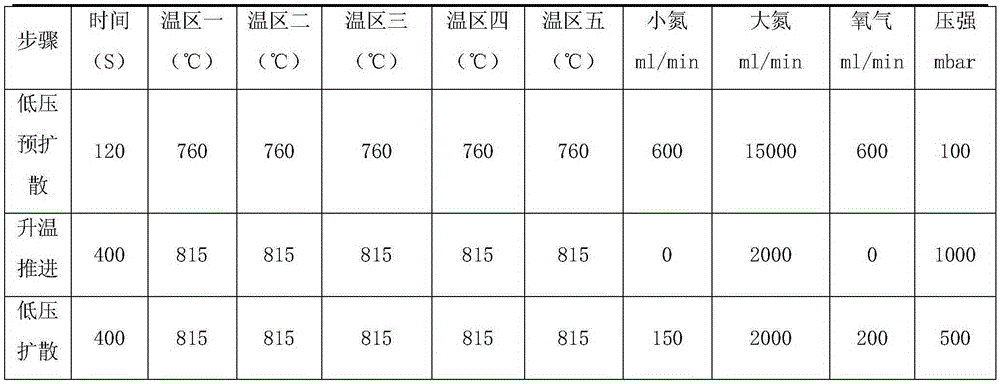

Embodiment 1

[0037] A low-pressure diffusion process of the present invention comprises the following steps:

[0038] (1) High-temperature oxidation before diffusion: After the furnace mouth is closed, pump air to the set low pressure and oxidize at high temperature, and pre-grow nano-scale thickness SiO on the surface of the silicon wafer 2 ;

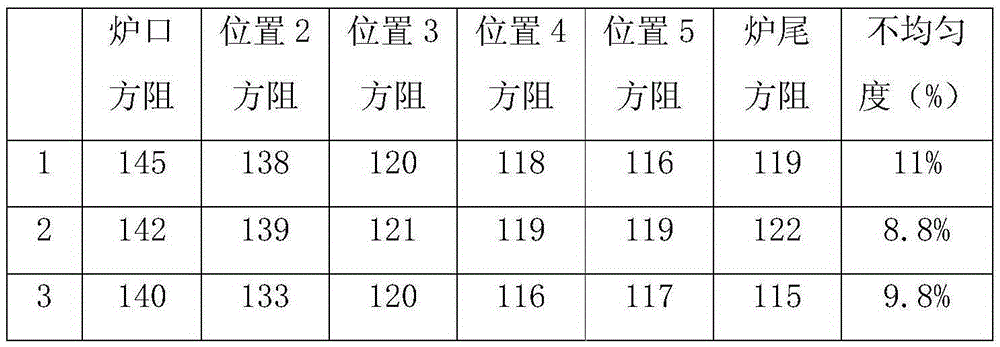

[0039] The specific four-step process steps are shown in Table 3:

[0040] Table 3: Process parameters of the first four steps of diffusion

[0041]

[0042] (2) Low-pressure diffusion: the step-by-step diffusion method is adopted to reduce the temperature difference in each temperature zone, improve the uniformity of diffusion resistance value between sheets and the consistency of vertical doping concentration distribution, reduce the production cost of the diffusion process and reduce the performance requirements of vacuum pumps. Purpose.

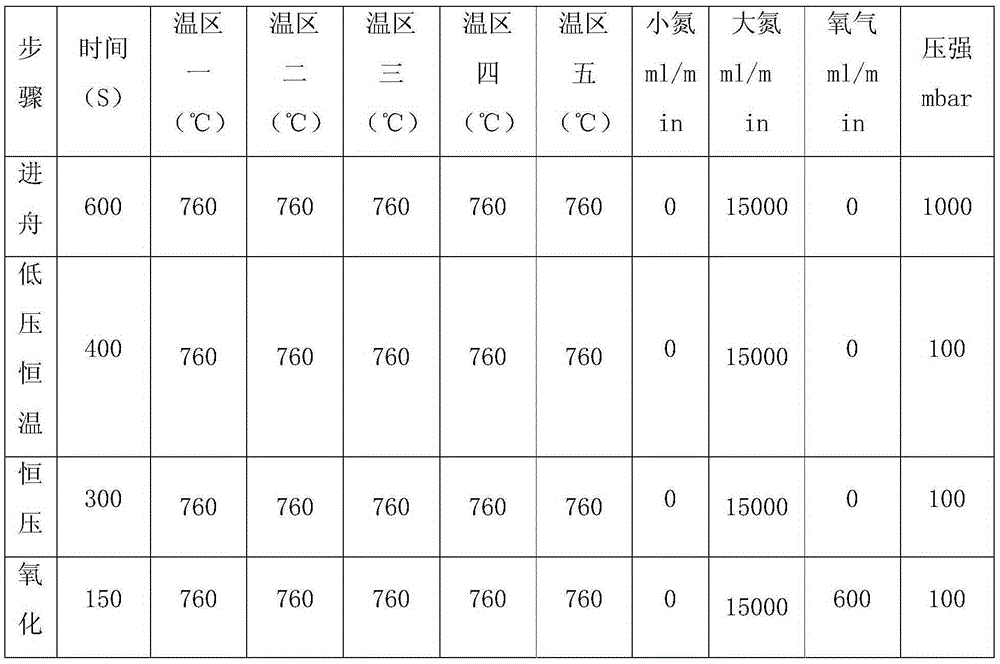

[0043] The specific diffusion steps are as follows:

[0044] The first step is low-pressure pre-diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com