Partial transient liquid phase bonding method for carbon/carbon composite material and nickel-base superalloy

A nickel-based superalloy, instantaneous liquid phase connection technology, applied in the field of connection of dissimilar materials, can solve the problem of difficult connection with nickel-based superalloy, and achieve the effect of high shear strength and effective connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

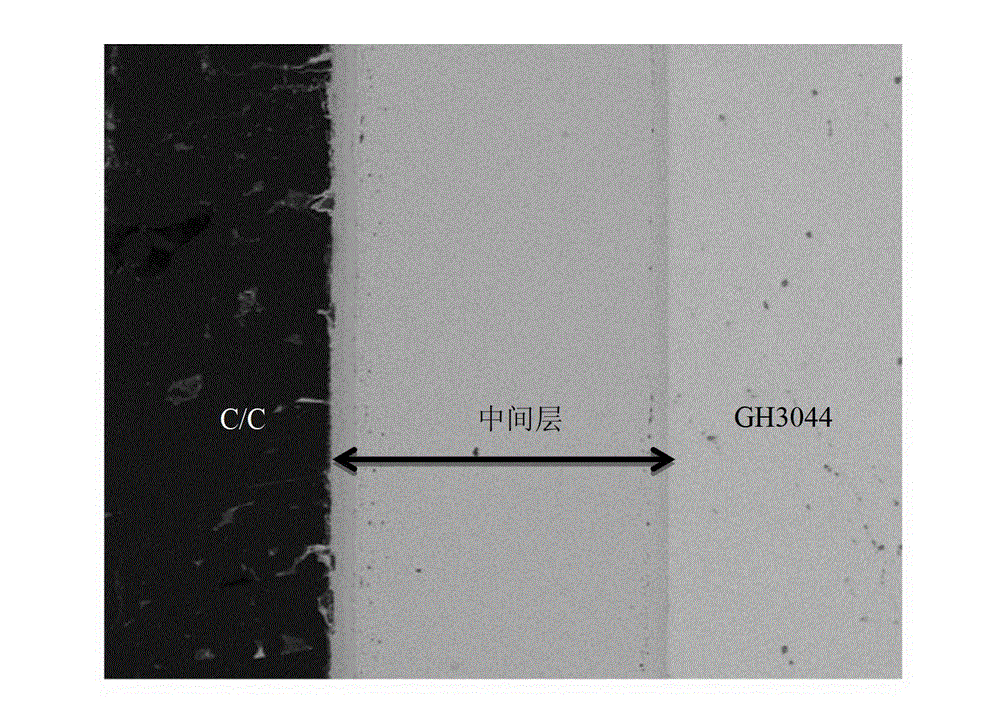

Image

Examples

Embodiment 1

[0025] A 15mm×10mm×4mm carbon / carbon composite material and a nickel-based superalloy of equal size were joined at 890°C.

[0026] (1) Use 400# sandpaper to polish the surface to be connected between the carbon / carbon composite material and the nickel-based superalloy, and then use 600#, 800#, and 1000# sandpaper to polish the nickel-based superalloy. Clean the polished sample with alcohol for 30 minutes with an ultrasonic cleaner, and then dry it in an oven at 100°C for 1 hour.

[0027] (2) Cut all the foils into small pieces of 15mm×10mm, gently polish and clean the oxide film on the surface of Ti foil and Ni foil with 2000# sandpaper, and pickle the Cu foil to remove the oxide film. Dry the cleaned foil in an oven at 80 °C for 20 min.

[0028] (3) Place the foil on the surface to be connected of the carbon / carbon composite material in the order of Ti foil / Ni foil / Cu foil / Ni foil, and then place the nickel-based superalloy to be connected on the Ni foil to form carbon / Car...

Embodiment 2

[0038] A 15mm×10mm×4mm carbon / carbon composite material and a nickel-based superalloy of equal size were joined at 1010°C.

[0039] (1) Use 400# sandpaper to polish the surface to be connected between the carbon / carbon composite material and the nickel-based superalloy, and then use 600#, 800#, and 1000# sandpaper to polish the nickel-based superalloy. Clean the polished sample with alcohol for 30 minutes with an ultrasonic cleaner, and then dry it in an oven at 100°C for 1 hour.

[0040] (2) Cut all the foils into small pieces of 15mm×10mm, gently polish and clean the oxide film on the surface of Ti foil and Ni foil with 2000# sandpaper, and pickle the Cu foil to remove the oxide film. Dry the cleaned foil in an oven at 80 °C for 20 min.

[0041] (3) Place the foil on the surface to be connected of the carbon / carbon composite material in the order of Ti foil / Ni foil / Cu foil / Ni foil, and then place the nickel-based superalloy to be connected on the Ni foil to form a carbon / ...

Embodiment 3

[0051] A 15mm×10mm×4mm carbon / carbon composite material and a nickel-based superalloy of equal size were joined at 1030°C.

[0052] (1) Use 400# sandpaper to polish the surface to be connected between the carbon / carbon composite material and the nickel-based superalloy, and then use 600#, 800#, and 1000# sandpaper to polish the nickel-based superalloy. Clean the polished sample with alcohol for 30 minutes with an ultrasonic cleaner, and then dry it in an oven at 100°C for 1 hour.

[0053] (2) Cut all the foils into small pieces of 15mm×10mm, gently polish and clean the oxide film on the surface of Ti foil and Ni foil with 2000# sandpaper, and pickle the Cu foil to remove the oxide film. Dry the cleaned foil in an oven at 80 °C for 20 min.

[0054] (3) Place the foil on the surface to be connected of the carbon / carbon composite material in the order of Ti foil / Ni foil / Cu foil / Ni foil, and then place the nickel-based superalloy to be connected on the Ni foil to form a carbon / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com