Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2530results about How to "Improve assembly quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

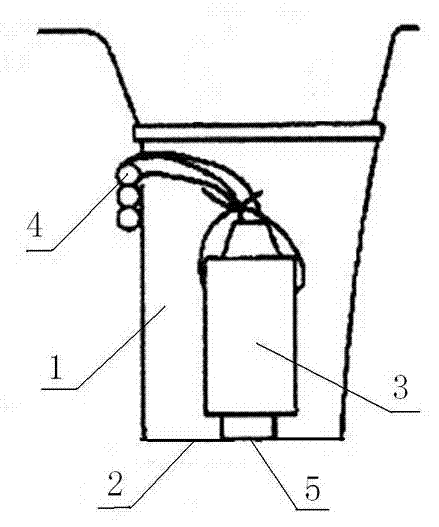

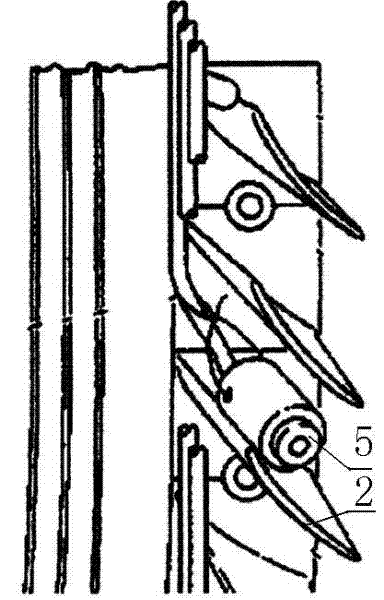

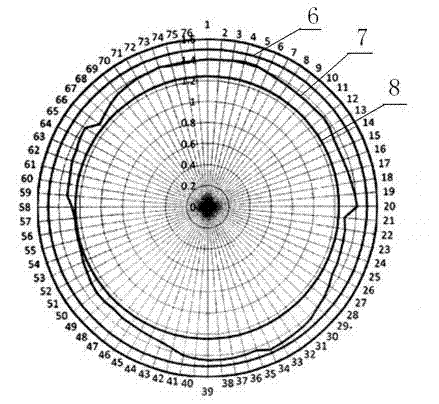

Non-contact measuring method for leaf apex radial clearance of engine rotor

InactiveCN102175135AImprove assembly qualityReduce disassemblyEngine testingUsing electrical meansCapacitanceFailure rate

The invention relates to a non-contact measuring method for a leaf apex radial clearance of an engine rotor, and the method comprises the following steps: 1) assembling a measuring system, calibrating a sensor and determining the relation between the radial clearance and voltage of a leaf apex; 2) preparing before measuring; and 3) measuring the leaf apex radial clearance of the engine rotor. In the measuring method provided by the invention, a measurement technique based on a capacitance method is adopted; the measuring course and the assembling are synchronously carried out; the once cartridge disassembly and assembly is reduced; the measuring time is shortened; the production efficiency is improved; and the measuring accuracy is improved, thereby improving the assembly quality of an engine and reducing the failure rate of the engine. The non-contact measuring method provided by the invention is mainly used for measuring the leaf apex radial clearance of the rotors of parts such as an engine, a high-pressure compressor, a low-pressure compressor, a high-pressure turbine, a low-pressure turbine and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

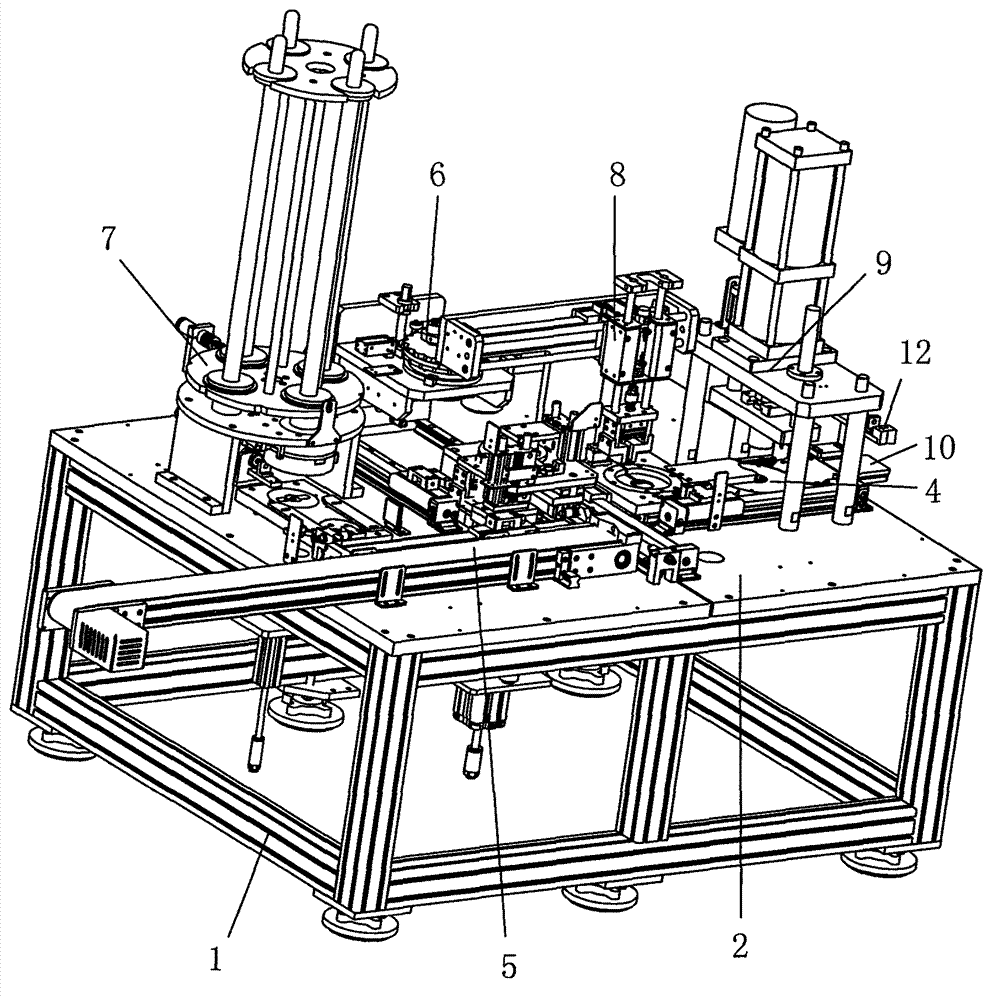

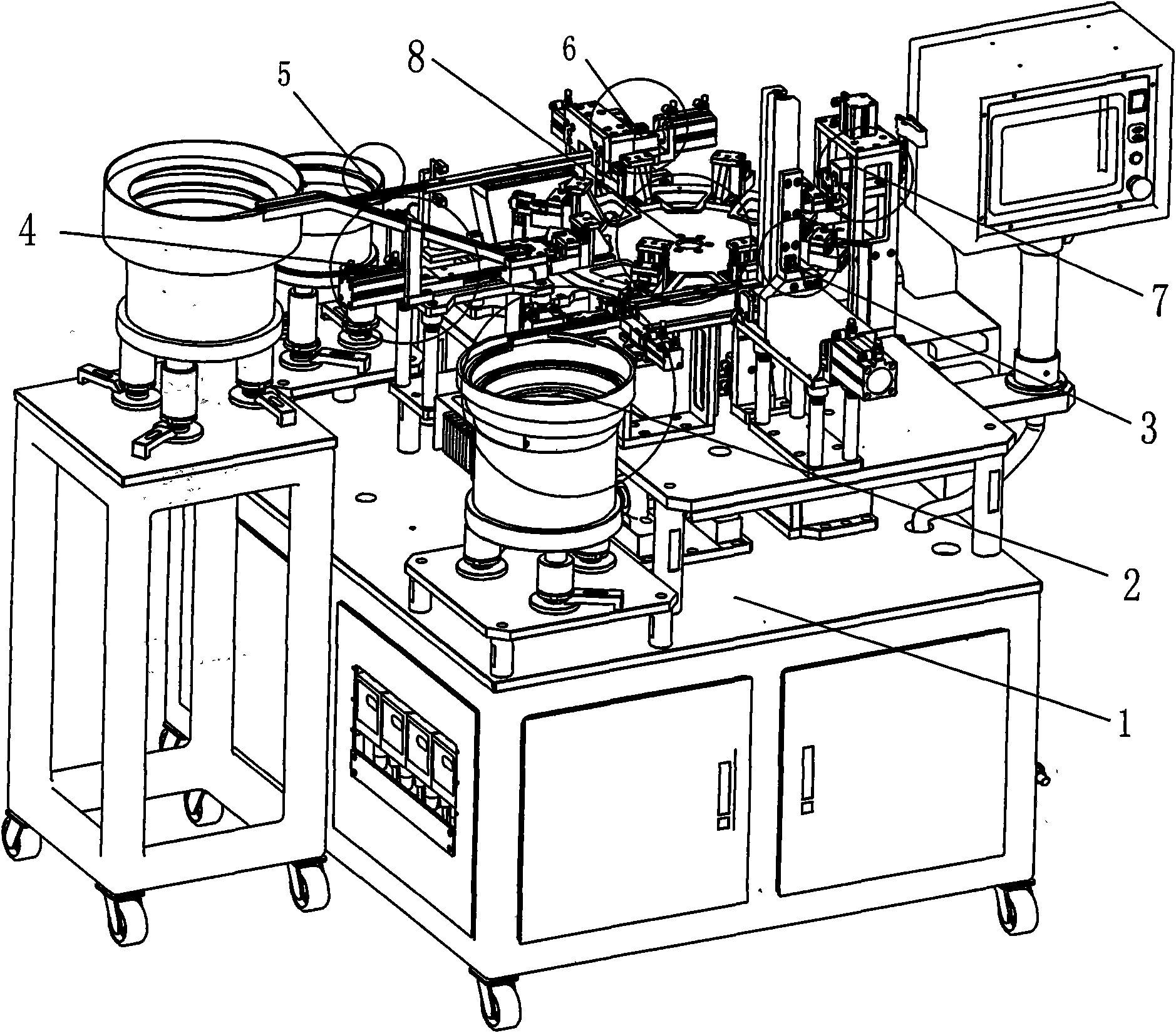

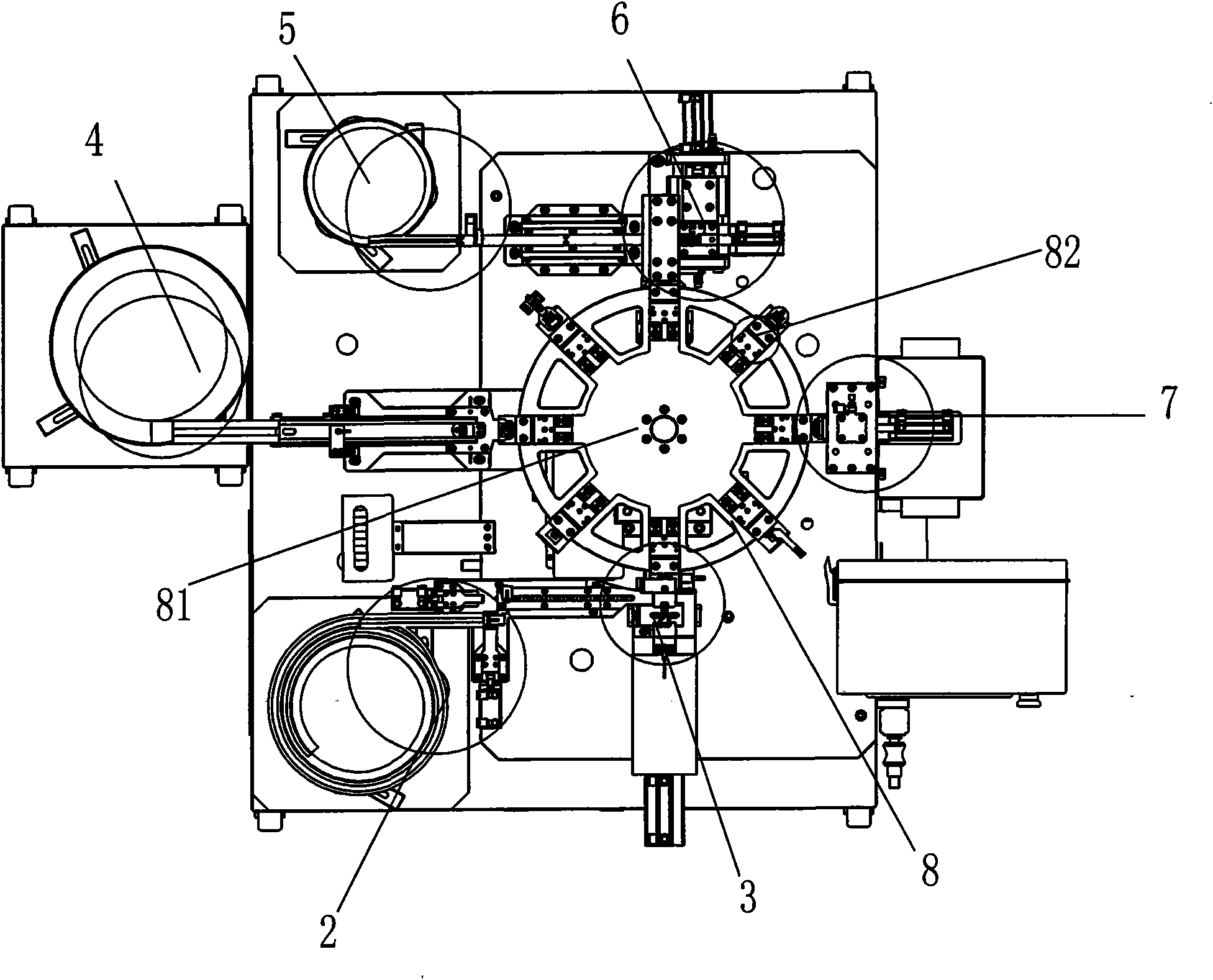

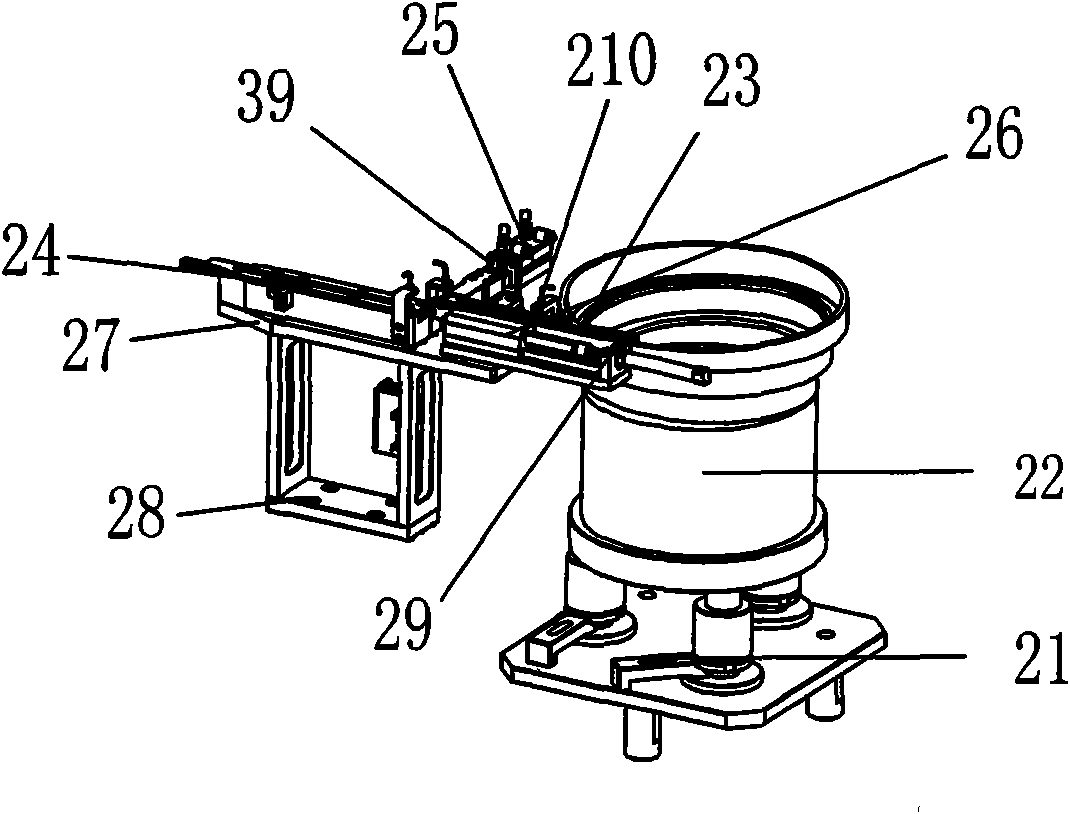

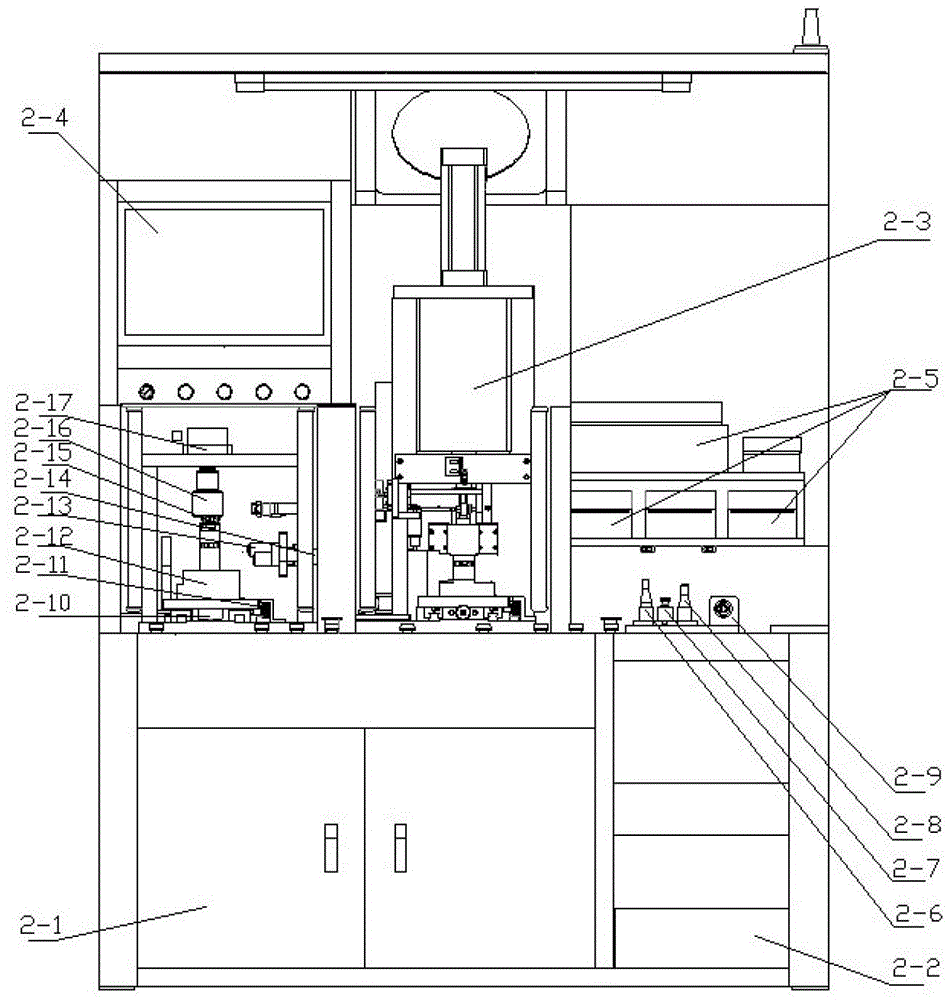

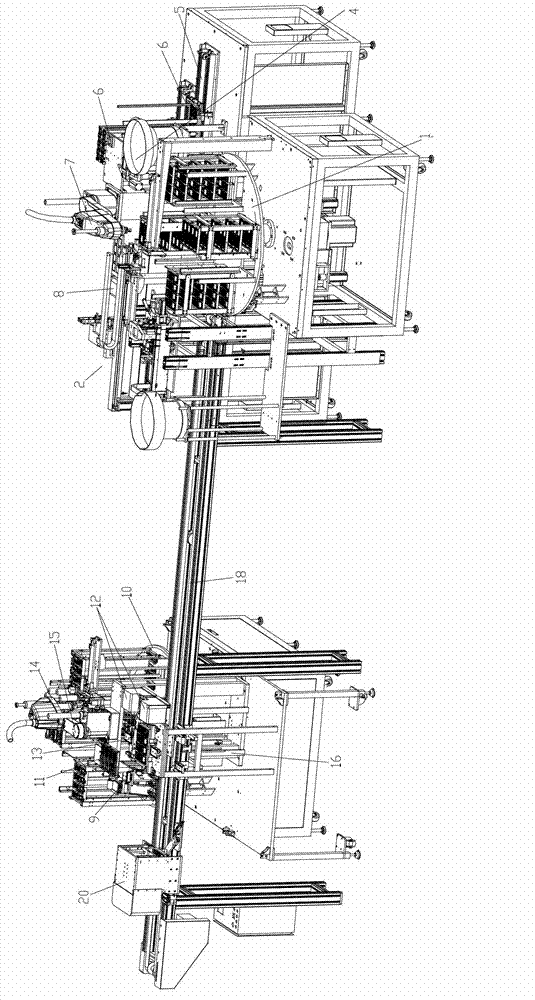

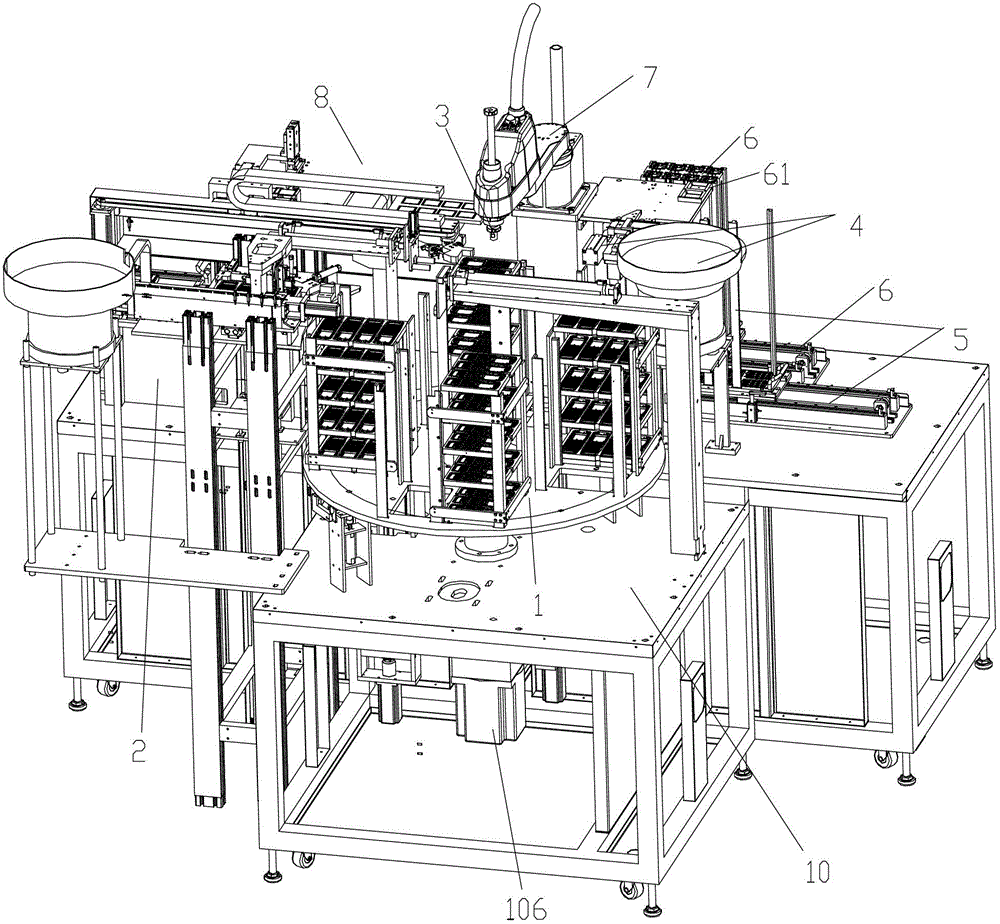

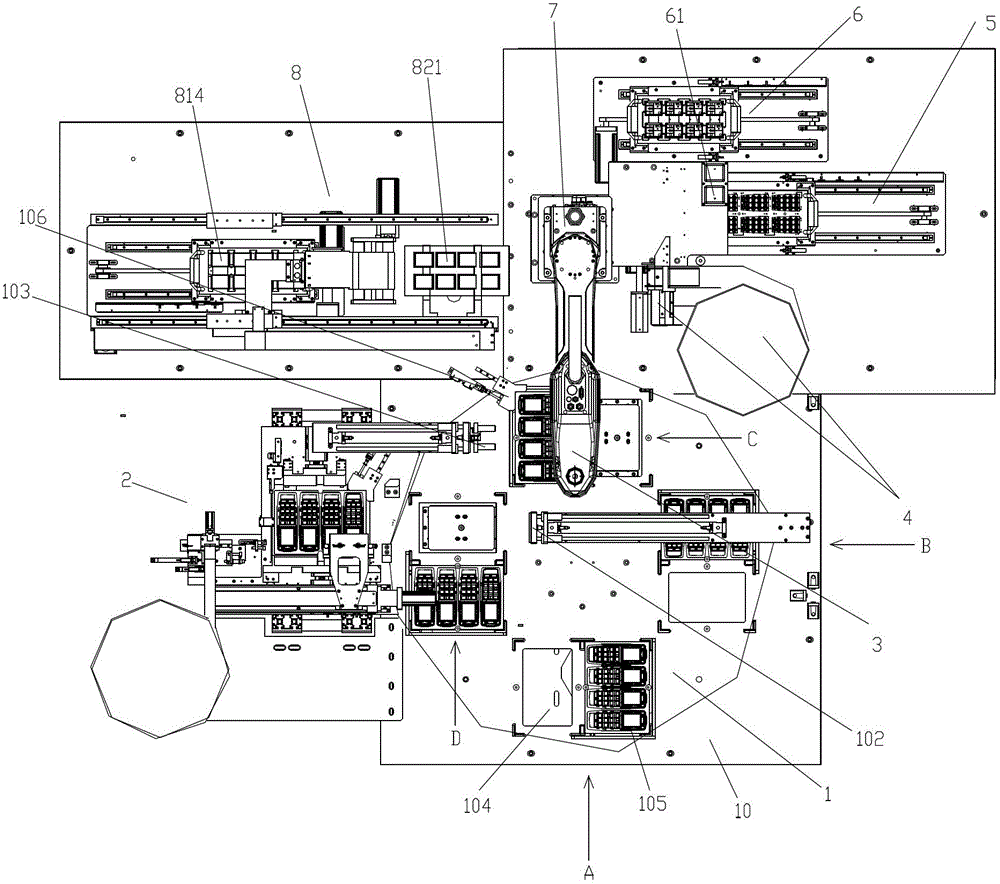

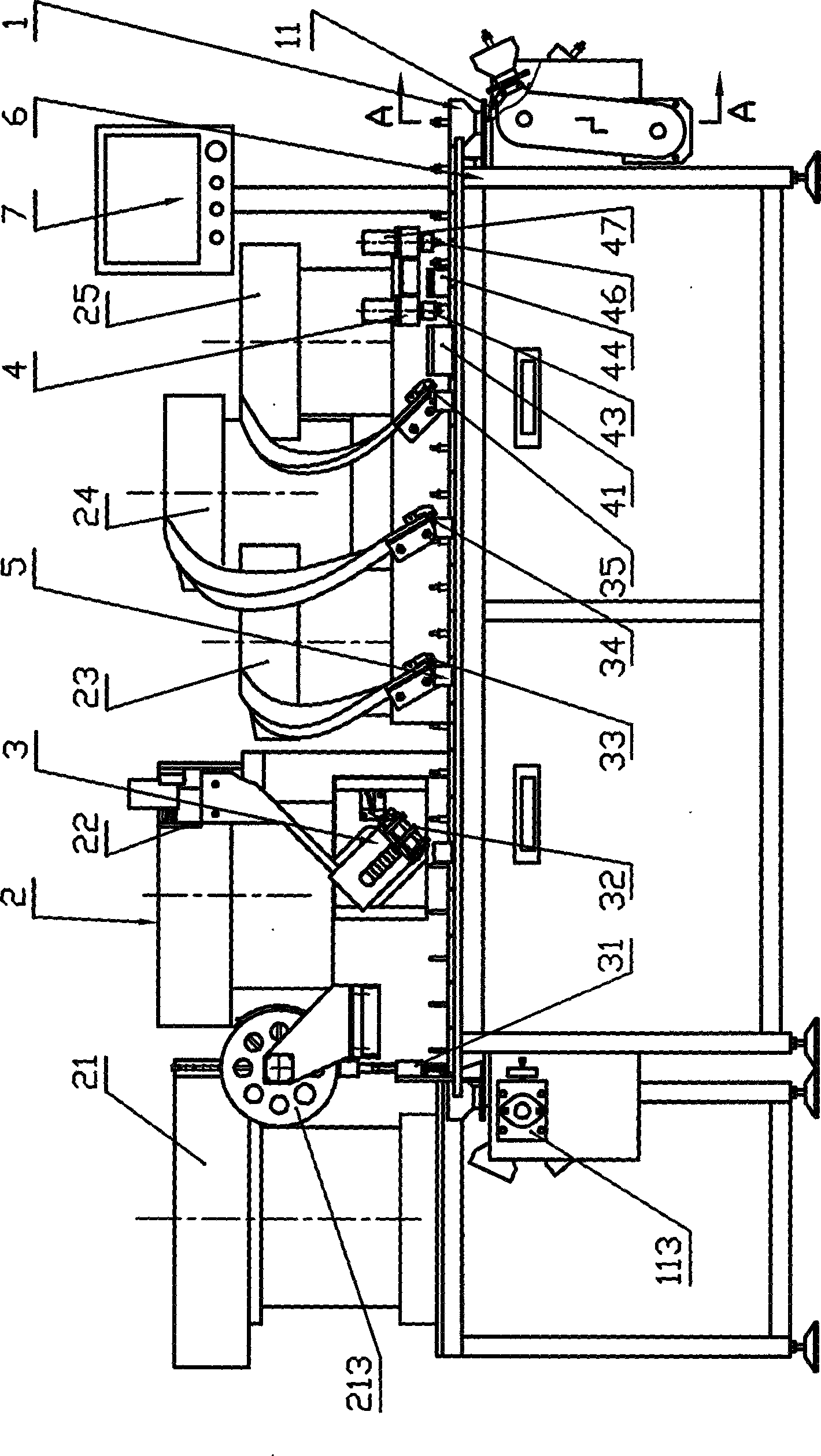

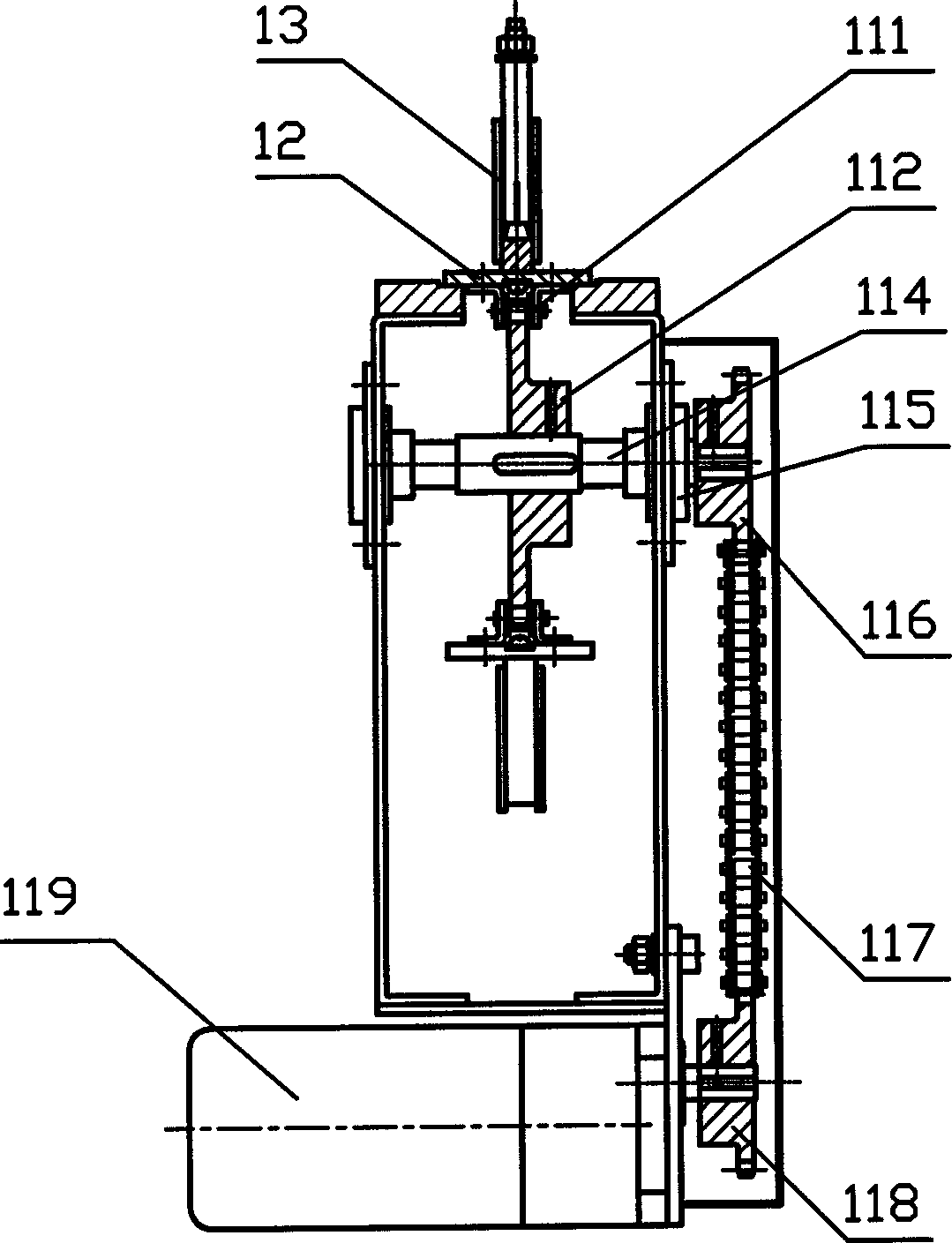

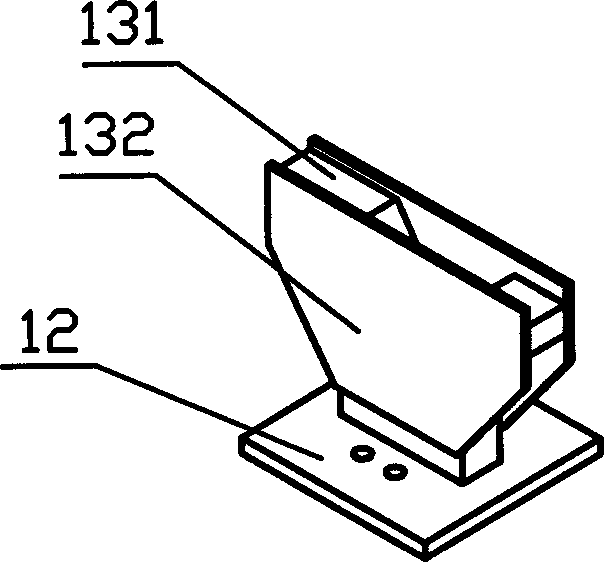

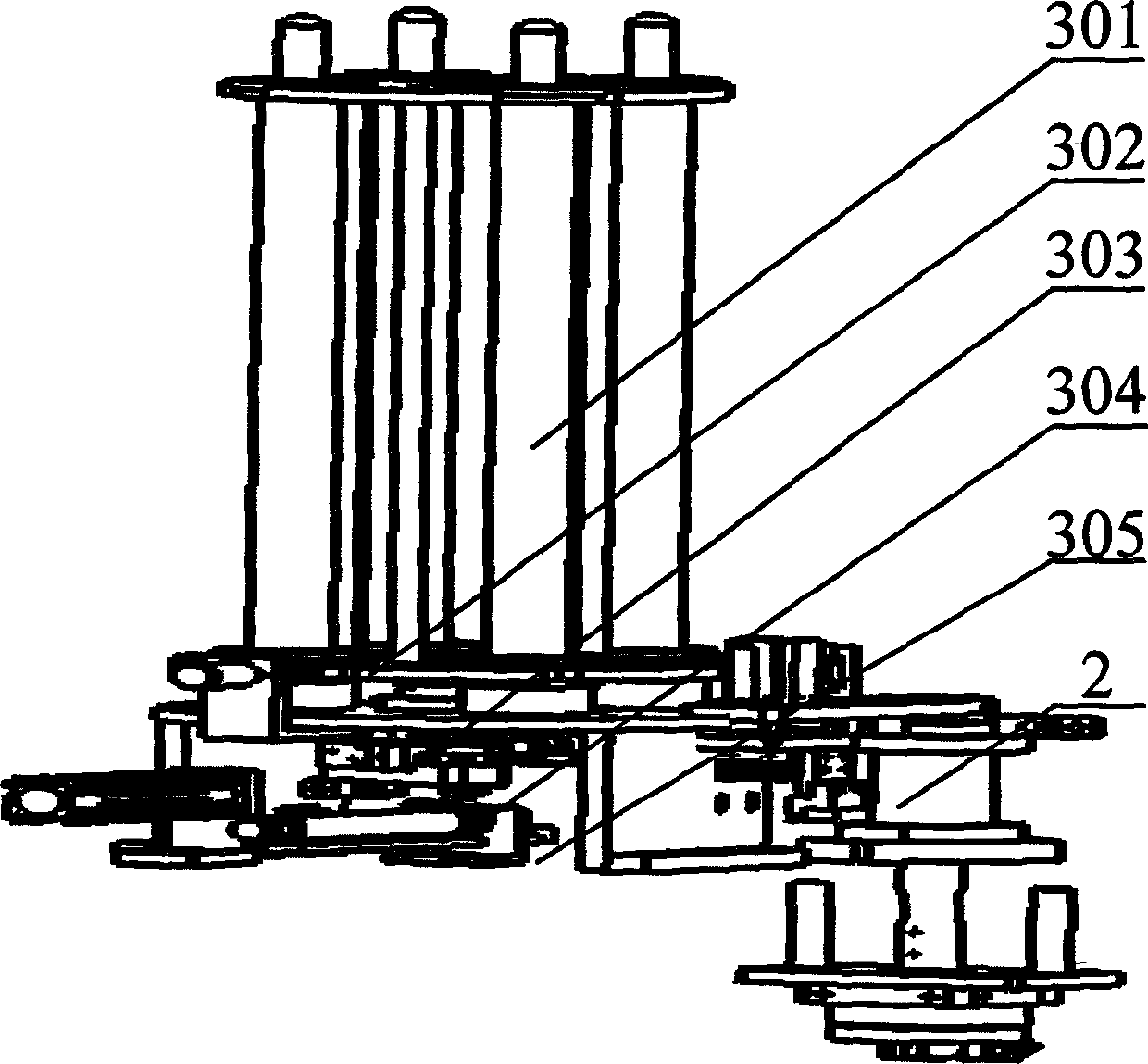

Full-automatic bearing assembly machine

ActiveCN103047300AImprove assembly efficiencyImprove assembly qualityBearing componentsEngineeringTransfer mechanism

The invention discloses a full-automatic bearing assembly machine. The assembly machine comprises a base, a working platform, a assembling station and a press fit station, wherein the assembling station and the press fit station are arranged on the working platform; an inner-ring feeding mechanism is arranged in the front of the assembling station, and a roller assembling mechanism is arranged behind the assembling station; a roller feeding mechanism is arranged behind the roller assembling mechanism; a holder feeding mechanism is arranged on one side of the assembling station; the inner ring of the bearing, the holder and a tapered roller are assembled together to form an inner assembly of the bearing; an assembly transferring mechanism which can convey the inner assembly of the bearing from the assembling station to the press fit station is arranged between the other side of the assembling station and the inner side of the press fit station; a press fit mechanism is arranged on the press fit station; a material discharging passage is arranged outside the press fit station; and a material pushing mechanism is arranged on the material discharging passage. With the adoption of the structure, assemblies of the holder, the tapered roller and the inner ring of the bearing can be performed automatically, and the inner assembly of the bearing is transferred to the press fit station for pressing through the assembly transferring mechanism, so that the assembly efficiency and the assembly quality are improved greatly, and potential safety hazards are eliminated.

Owner:宁波江宸智能装备股份有限公司

Folding key assembling machine

InactiveCN101972932ARealize automatic feedingRealize the assemblyAssembly machinesSemi automaticControl circuit

The invention relates to a folding key assembling machine, which comprises a worktable, and a plastic head feeding mechanism, a hardware press-in mechanism, a key handle feeding mechanism, a pin feeding mechanism, a pin pressing mechanism, a loading mechanism and an assembling and conveying mechanism which are arranged on the worktable, wherein the assembling and conveying mechanism is provided with a key holder; the hardware press-in mechanism, the key handle feeding mechanism and the pin pressing mechanism are connected with the assembling and conveying mechanism in turn; the output end of the plastic head feeding mechanism is connected with the hardware press-in mechanism; the output end of the pin feeding mechanism is connected with the pin pressing mechanism; and the mechanisms are connected with the main control circuit electrically. In the invention, the automatic feeding mechanism and the automatic assembling mechanism are combined scientifically; the operation mechanicals form a continuous operation streamline for automatically feeding and assembling folding keys in place of the manual and semi-automatic ways of assembling the folding keys; thus, the production efficiency of the folding keys is improved obviously, assembly quality is improved, production cost is saved and labor intensity is lowered.

Owner:周俊雄

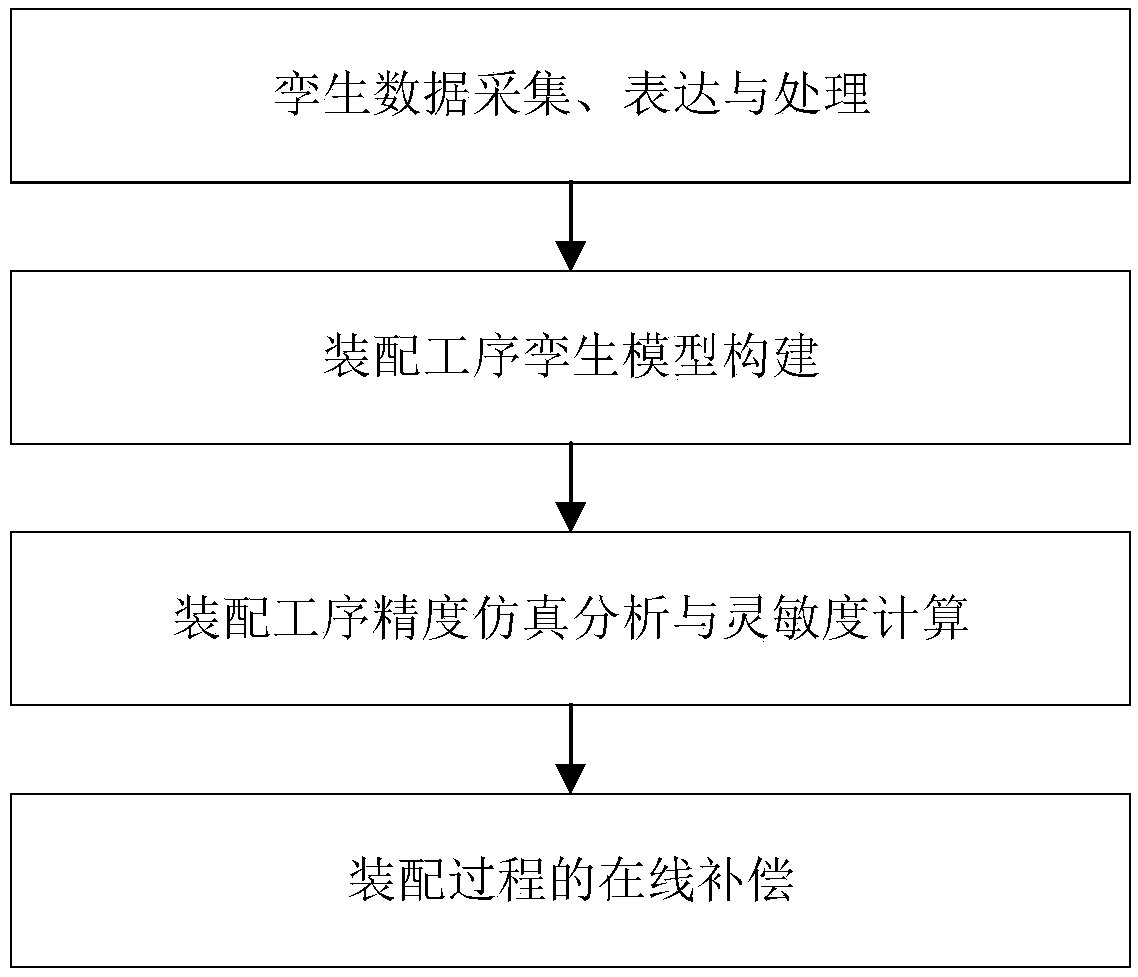

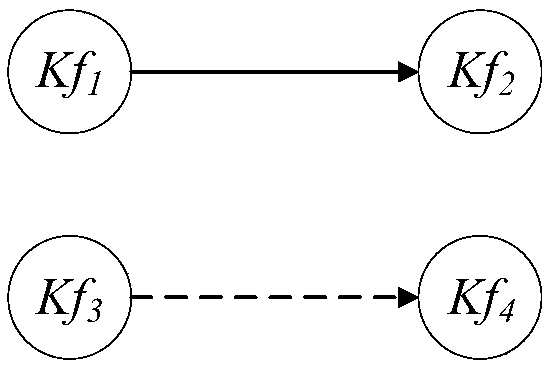

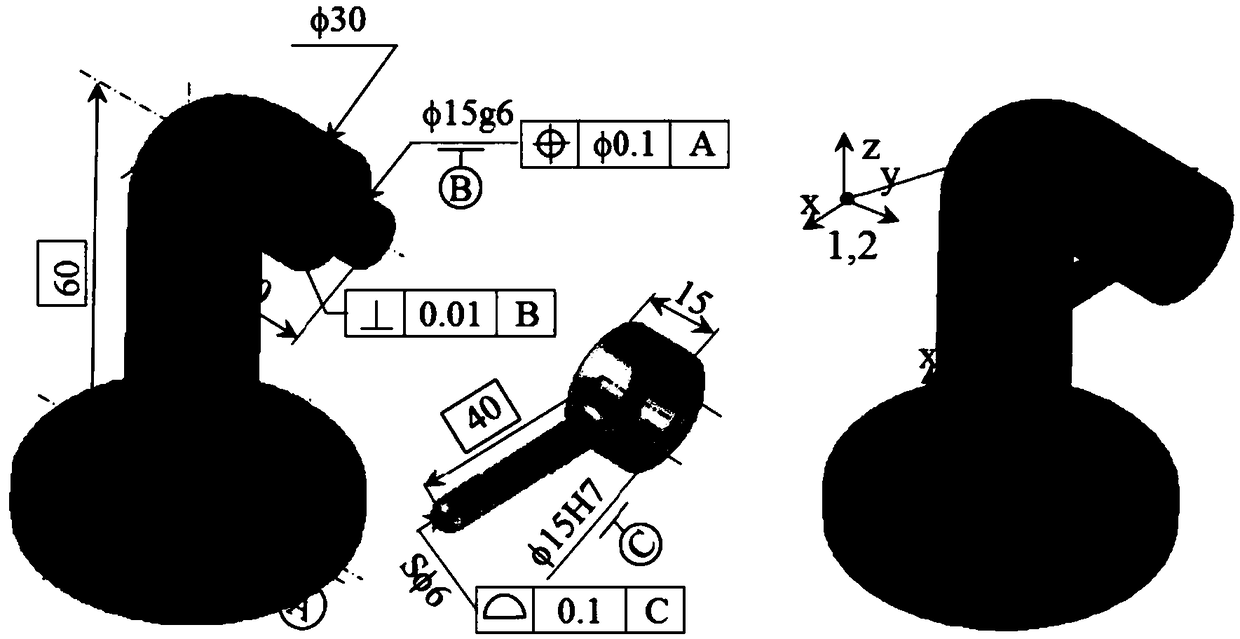

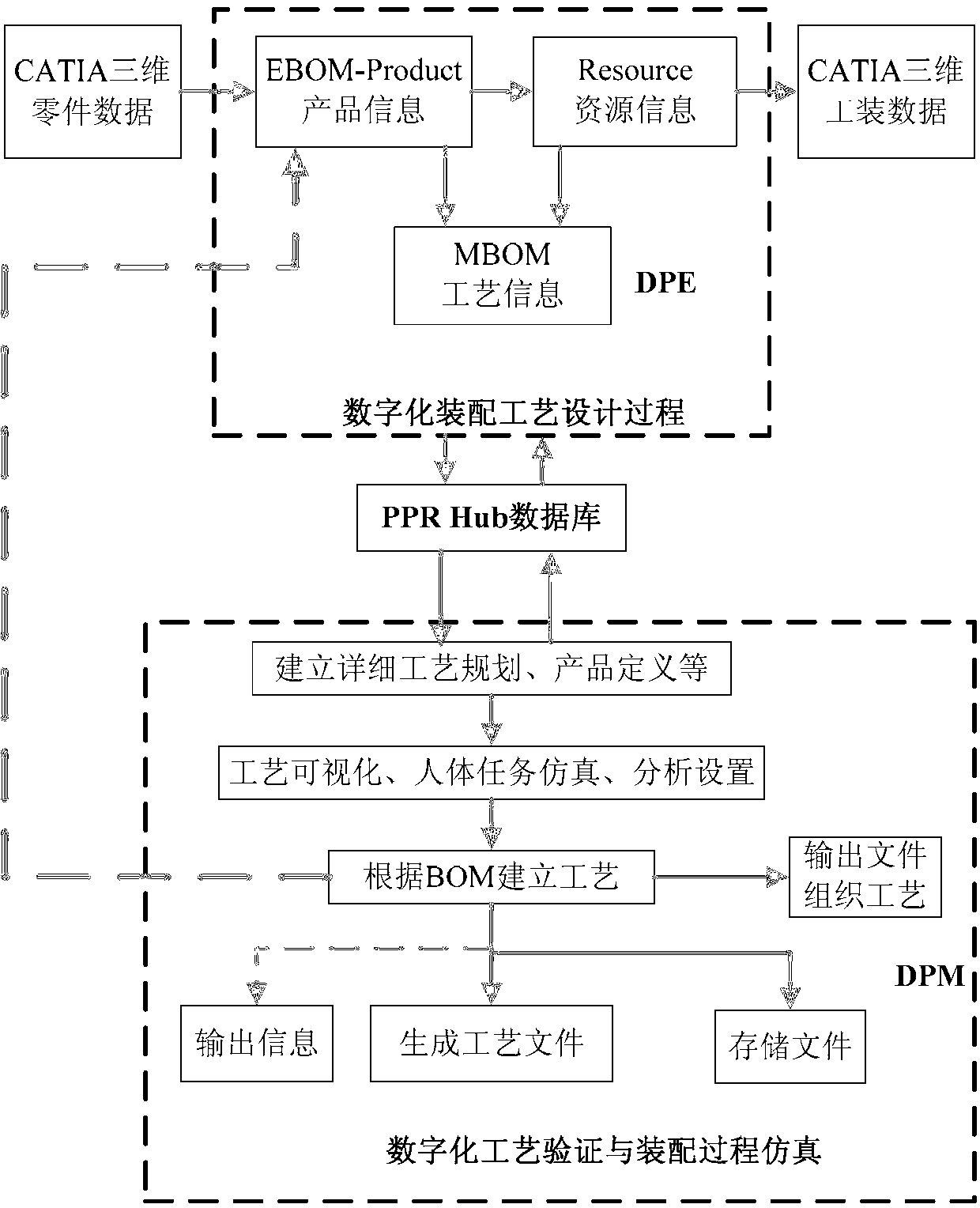

Digital twinning-based assembly precision simulation analysis method and system

InactiveCN109445305ARealize scientific assemblyQuality improvementSimulator controlInformation spacePhysical space

The invention discloses a digital twinning-based assembly precision simulation analysis method and system. According to the digital twinning-based assembly precision simulation analysis method and system, as for key processes in complex product assembly, the twin data of a physical assembly site are collected and processed, and twin data information is expressed and stored; an assembly process model is obtained in a 3D assembly process design system, and the assembly process model is reconstructed based on the twin data, so that an assembly process twin model is generated; the assembly processtwin model is introduced into commercial assembly tolerance analysis software, so that assembly precision simulation and sensitivity calculation can be performed; and the online compensation and precise control of the assembly process are performed according to assembly process precision simulation analysis results. With the digital twinning-based assembly precision simulation analysis method andsystem of the invention adopted, the deep fusion of the physical space and information space of the assembly site can be realized. The method and system are of great significance for realizing the intelligent closed-loop control of a complex product assembly process and improving assembly quality and efficiency.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

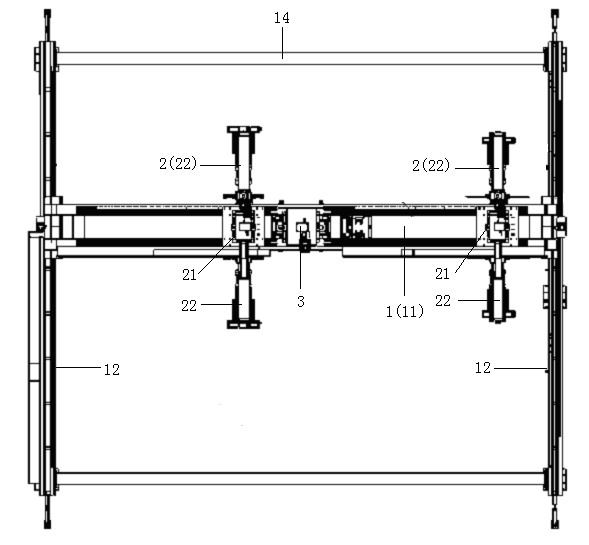

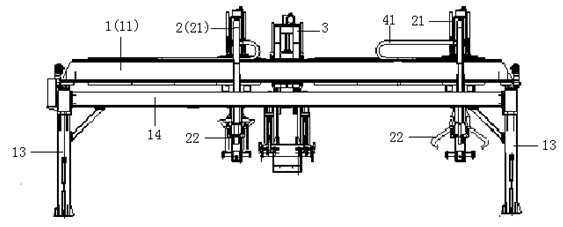

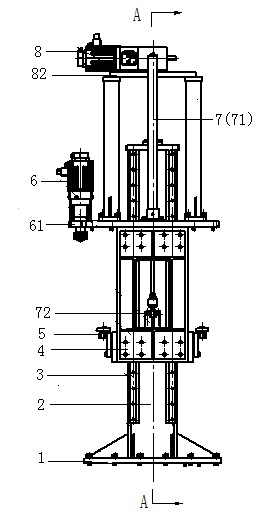

Special portal-type bolster frame assembly manipulator for truck bogie production line

ActiveCN102430906AEliminate potential safety hazardsImprove assembly qualityProgramme-controlled manipulatorMetal working apparatusBogieProduction line

The invention provides a special portal-type bolster frame assembly manipulator for a truck bogie production line, which is mainly composed of a frame, two side frame manipulators, a swing bolster manipulator and an electric control unit, wherein the side frame manipulators, swing bolster manipulator and electric control unit are installed on the frame; the frame is mainly composed of a cross beam, a support beam, a vertical support and a traveling beam which are connected with each other; the two side frame manipulators are installed on the cross beam, and each side frame manipulator is composed of a side frame transverse operating / vertical lifting unit and a side frame grabbing / clamping / turning unit; and the swing bolster manipulator is installed on the cross beam and positioned betweenthe two side frame manipulator. The invention provides an indispensable important apparatus of the key position bolster frame assembly for a truck bogie production line; the side frame manipulators can operate leftward and rightward or forward and backward to grab and lift the side frames transported by the transport vehicle, and smoothly align and assemble the side frame with the swing bolster grabbed by the swing bolster manipulator, and thus, the degree of mechanization and automation is high; and the invention has the advantages of labor saving, time saving and high assembly quality, and eliminates the potential safety hazard in the craning process.

Owner:江苏中创机械装备制造有限公司

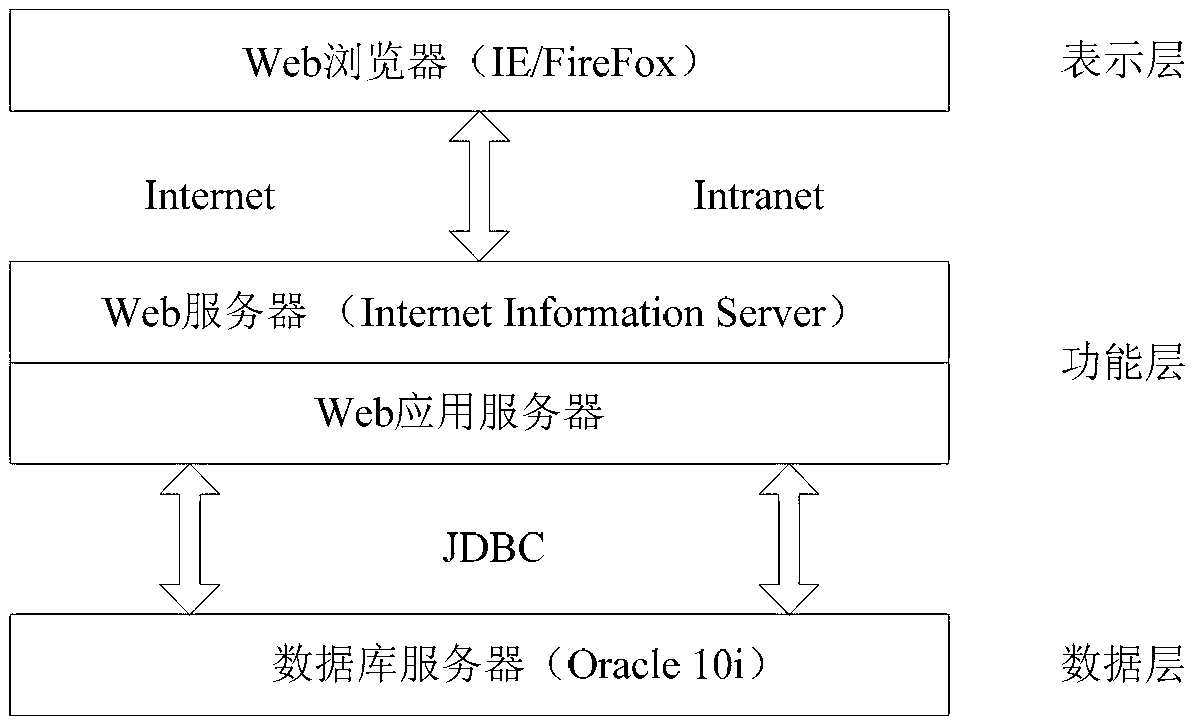

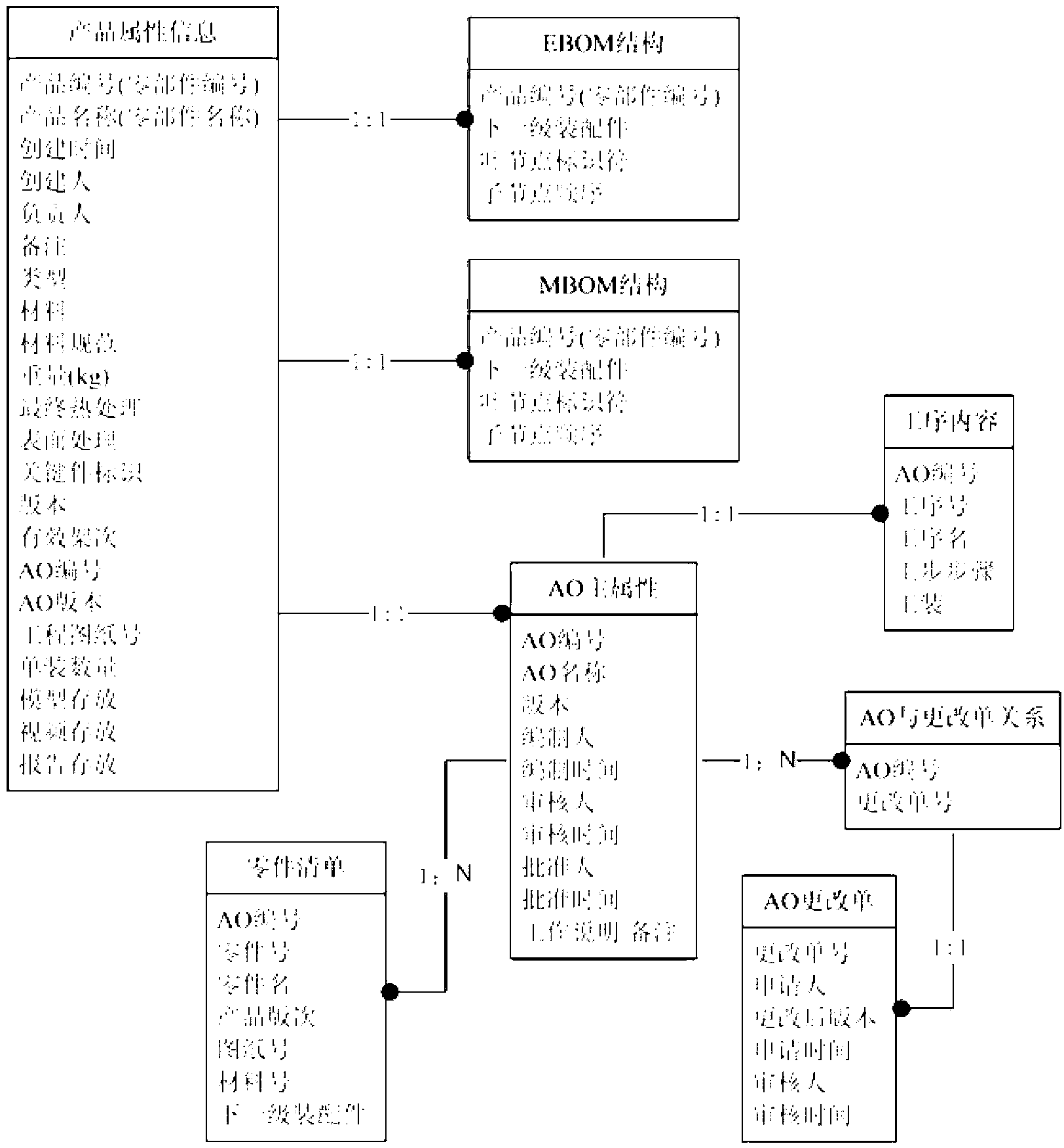

Aircraft assembly data visualization method based on Web

ActiveCN103020393ARealize online browsingReduce redundancySpecial data processing applicationsBill of materialsSimulation

The invention relates to an aircraft assembly data visualization method based on Web. The method comprises four steps as follows: step 1, setting up system architecture and development environment; step 2, visualization AO (Assembly Order) designing; step 3, assembling process simulation; and step 4, using in an assembly site. The method is used for realizing visual online browse of data such as BOM (Bill of Material), AO, product information and the like, and the assembly quality and the working efficiency of aircrafts are increased. The method has a better practical value and a wide application prospect in the aircraft industry.

Owner:BEIHANG UNIV

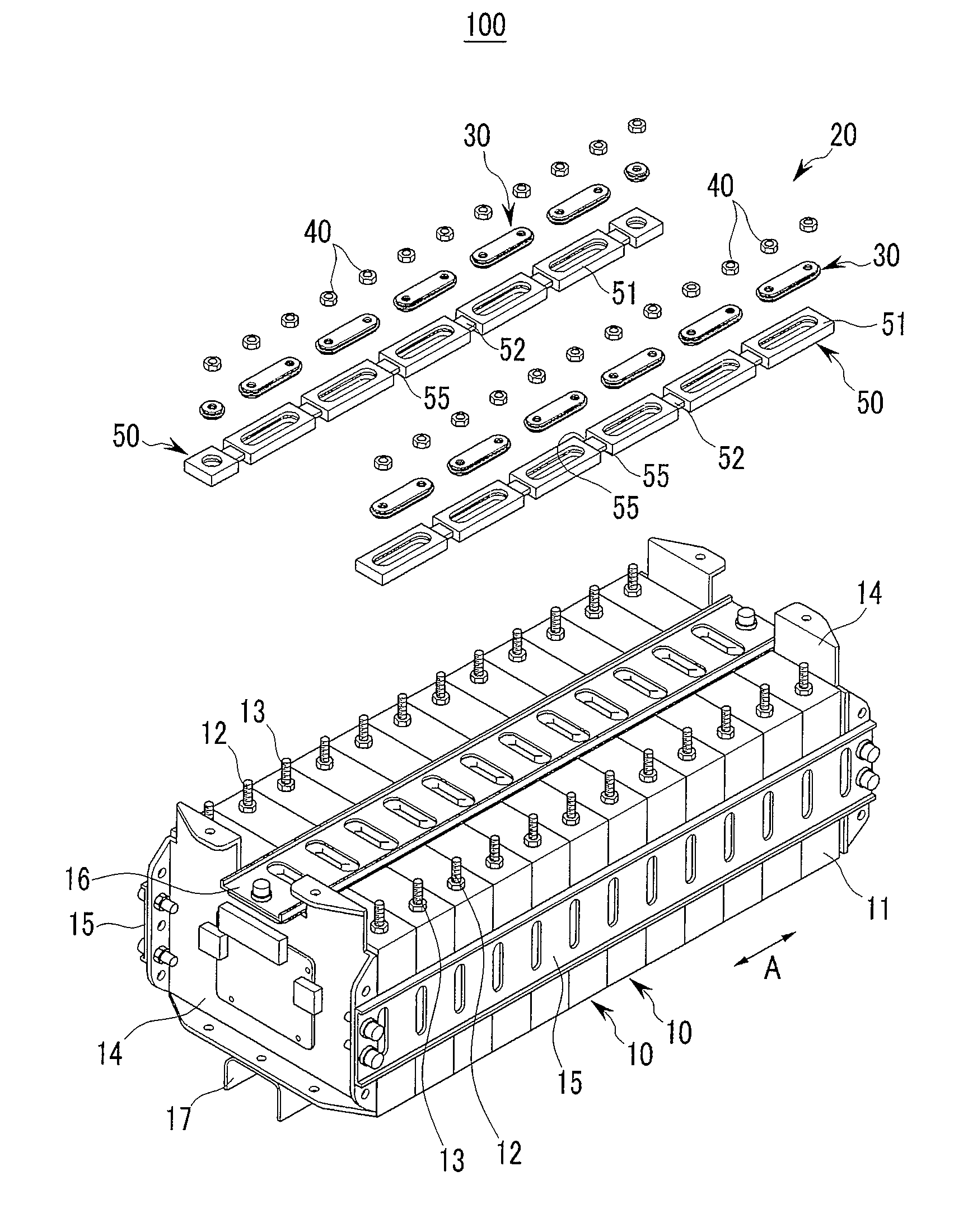

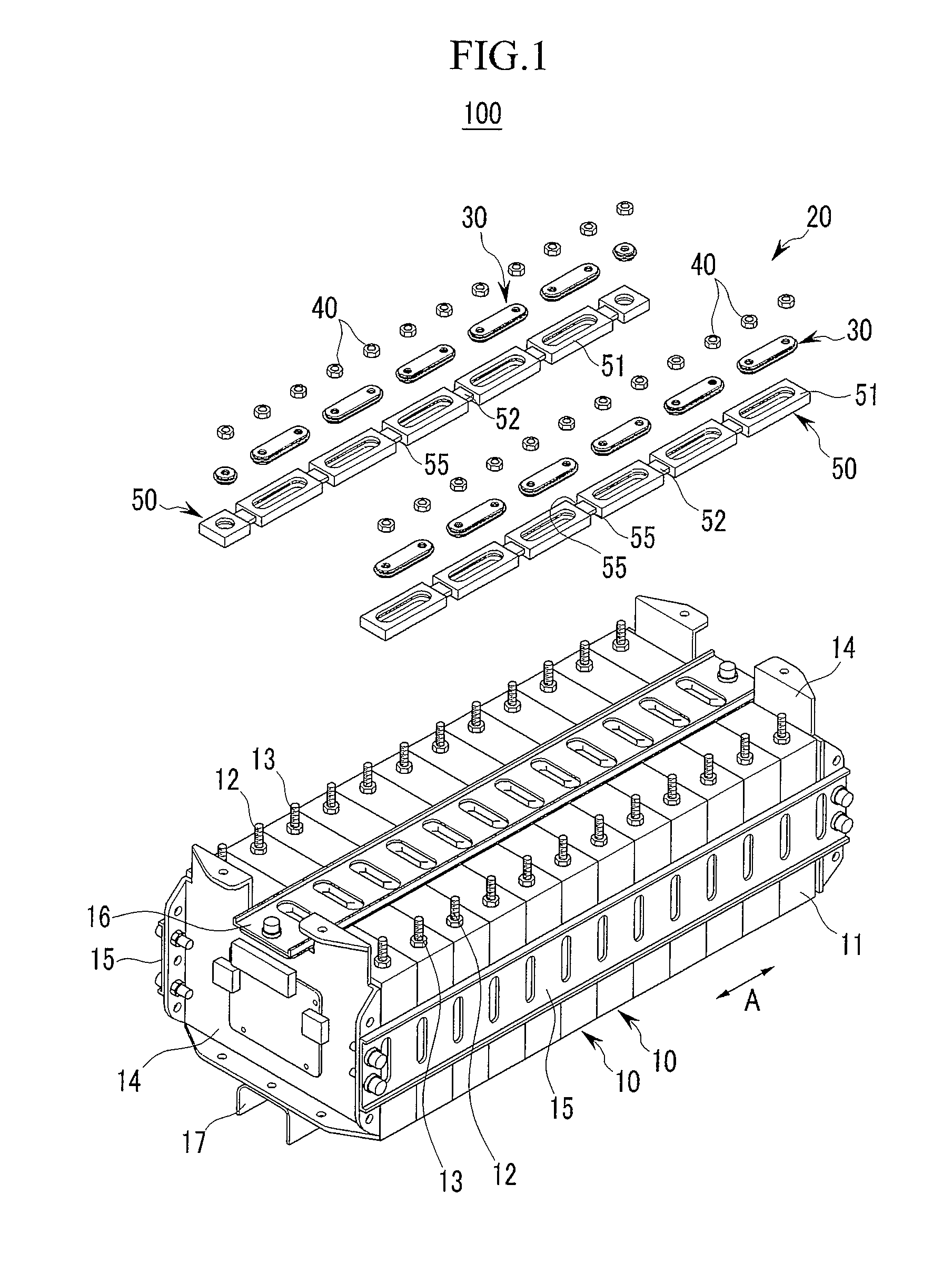

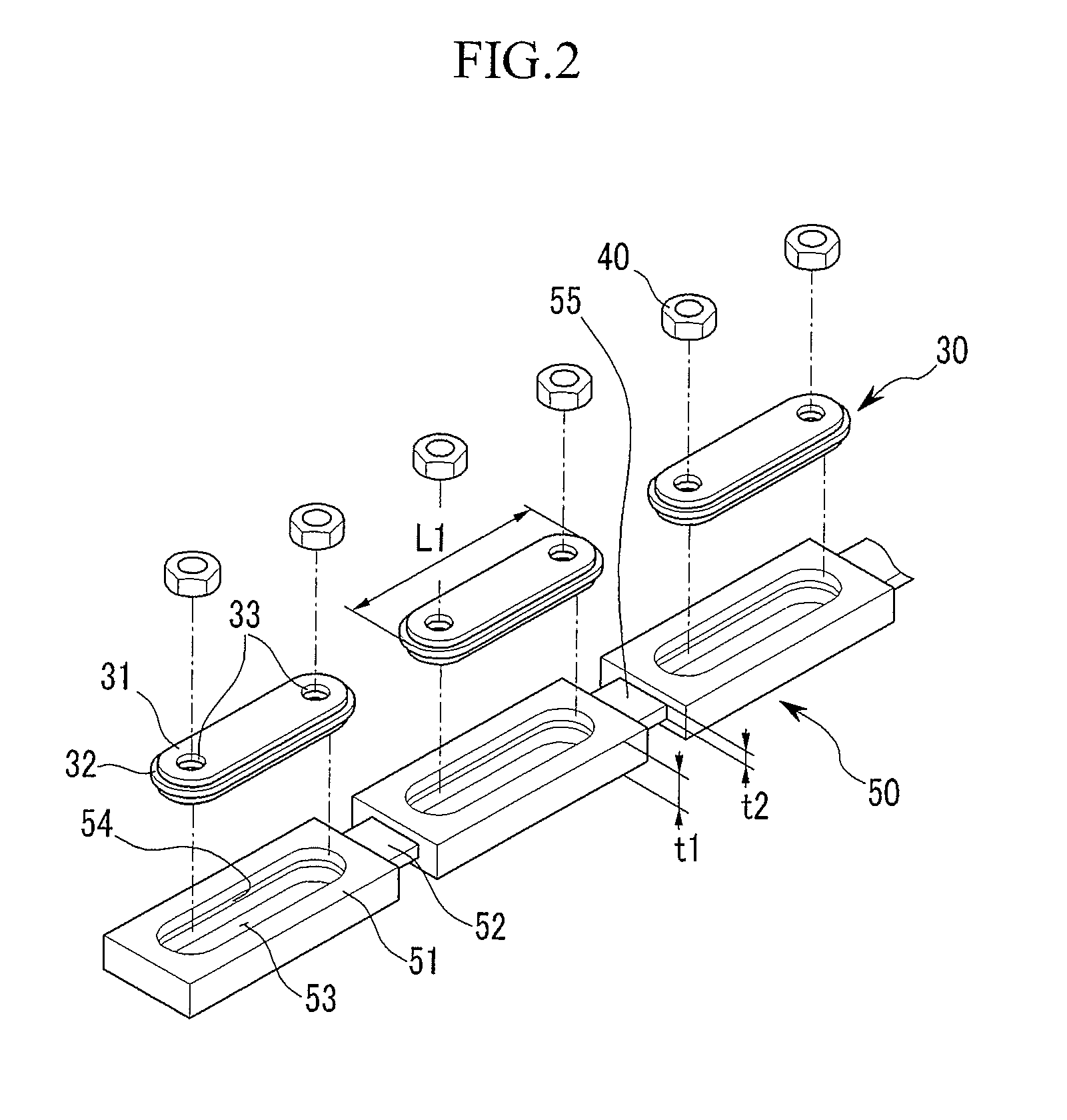

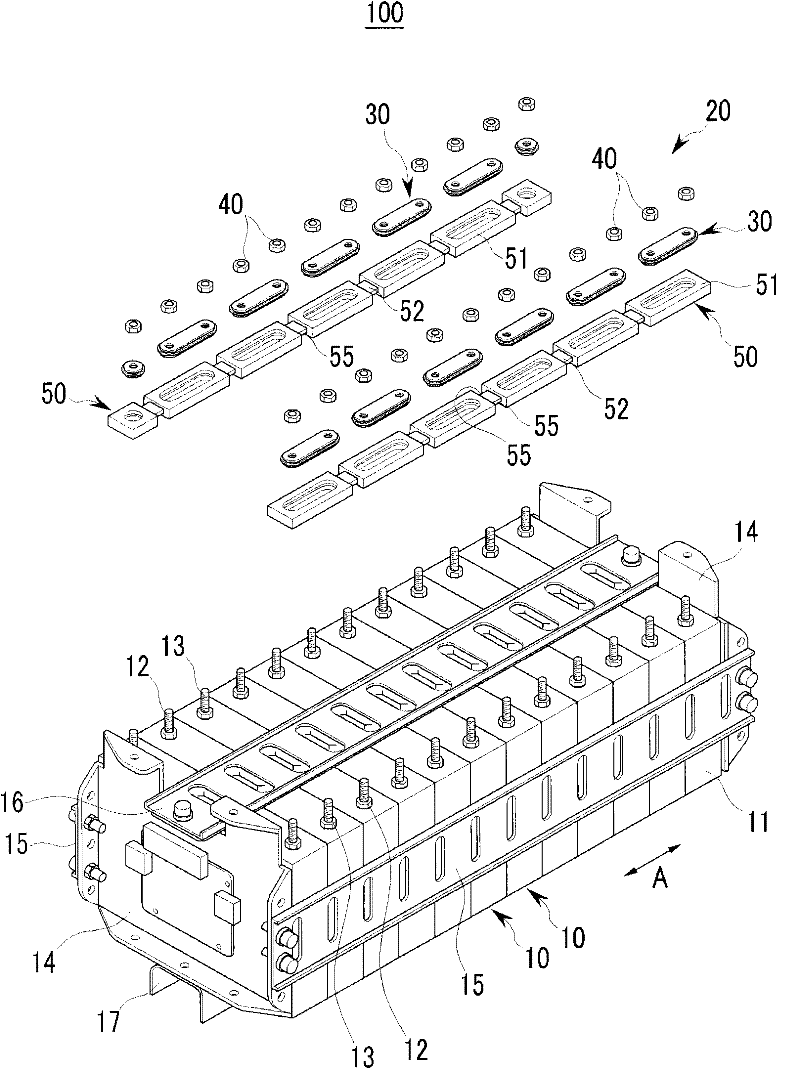

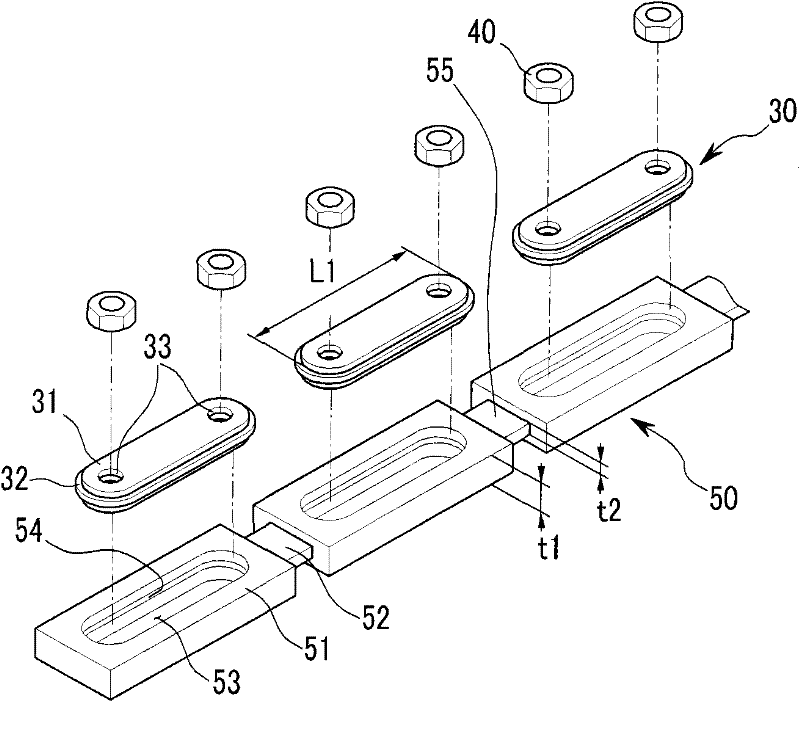

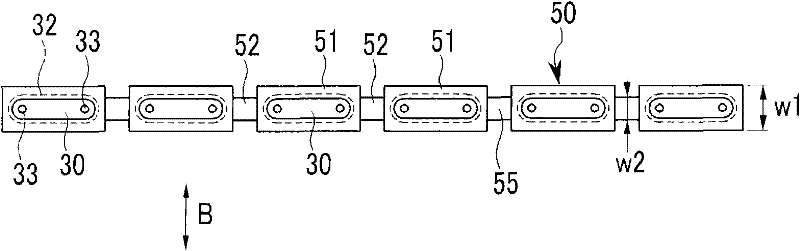

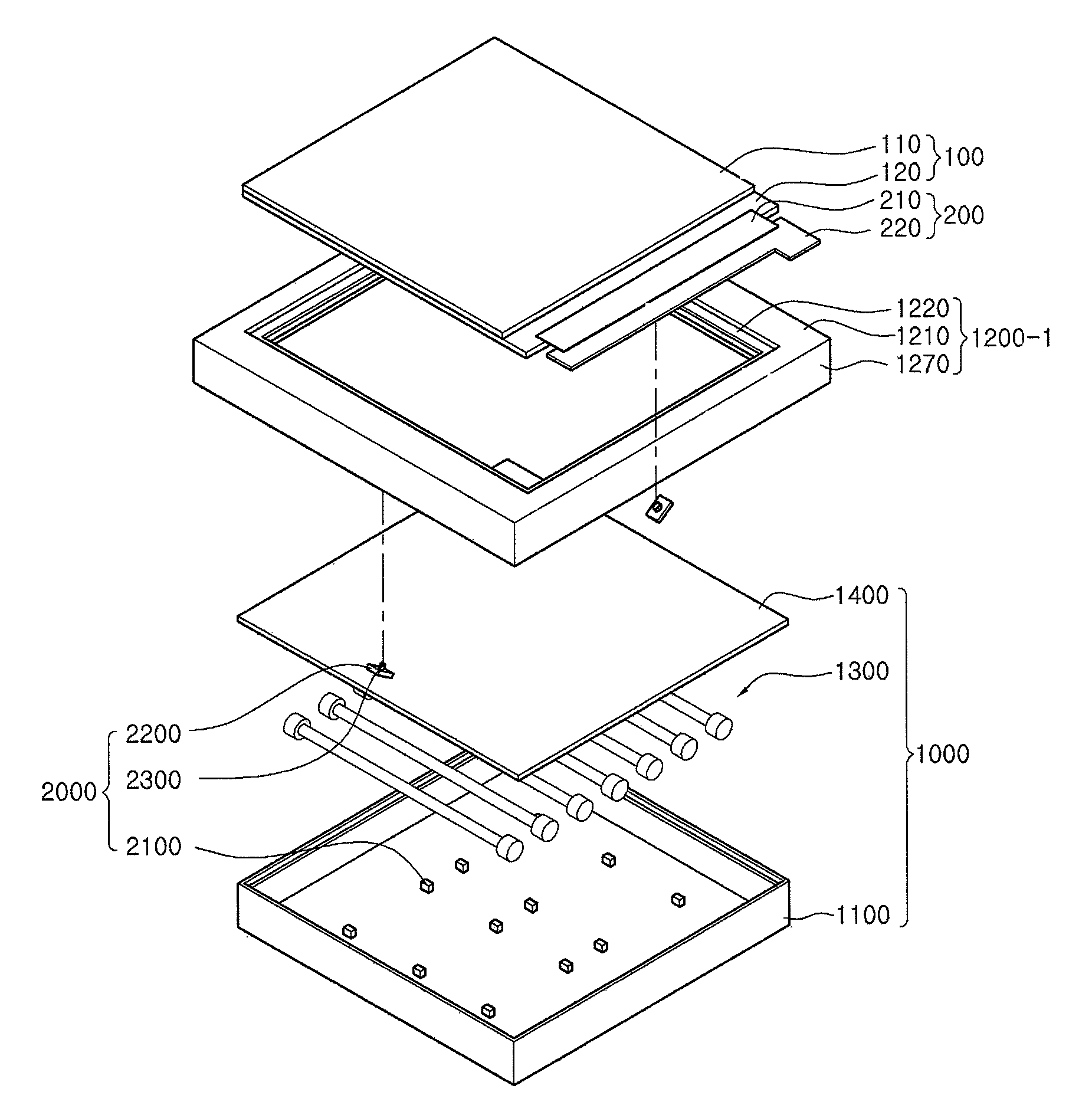

Battery module

InactiveUS20110287299A1Convenient to accommodateShorten the timePrimary cell to battery groupingFinal product manufactureEngineeringElectrical and Electronics engineering

A battery module of the present invention includes a plurality of unit batteries and a connection member electrically connecting the plurality of unit batteries. The connection member includes: a plurality of bus bars, each of the plurality of bus bar having two through-holes respectively corresponding to two electrode terminals protruding from two adjacent unit batteries of the plurality of unit batteries; and an insulating guide having a plurality of holder units configured to support the plurality of bus bars, and a plurality of narrow width portions positioned between the plurality of holder units and connecting the plurality of holder units along a first direction.

Owner:ROBERT BOSCH GMBH +1

Electric circuit module

ActiveUS7206204B2Stable heat resistanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical devices

An electric circuit module comprising: an electric device comprising an electric circuit to serve for passage and interruption of electric current, a packing material packing the electric circuit and a plurality of wiring members to electrically connect the electric circuit with an external circuit; and a heat sink to radiate heat from the electric device. The electric circuit module includes a fixture to fix the heat sink and the electric device together so that a heat radiating surface of the electric device comes into contact with the heat sink. The fixture is formed with a recess to accommodate therein a part of the electric device so that the heat radiating surface of the electric device is exposed from the fixture. When the electric device is fixed to the heat sink by the fixture, the heat radiating surface comes into contact with the heat sink.

Owner:HITACHI IND EQUIP SYST CO LTD

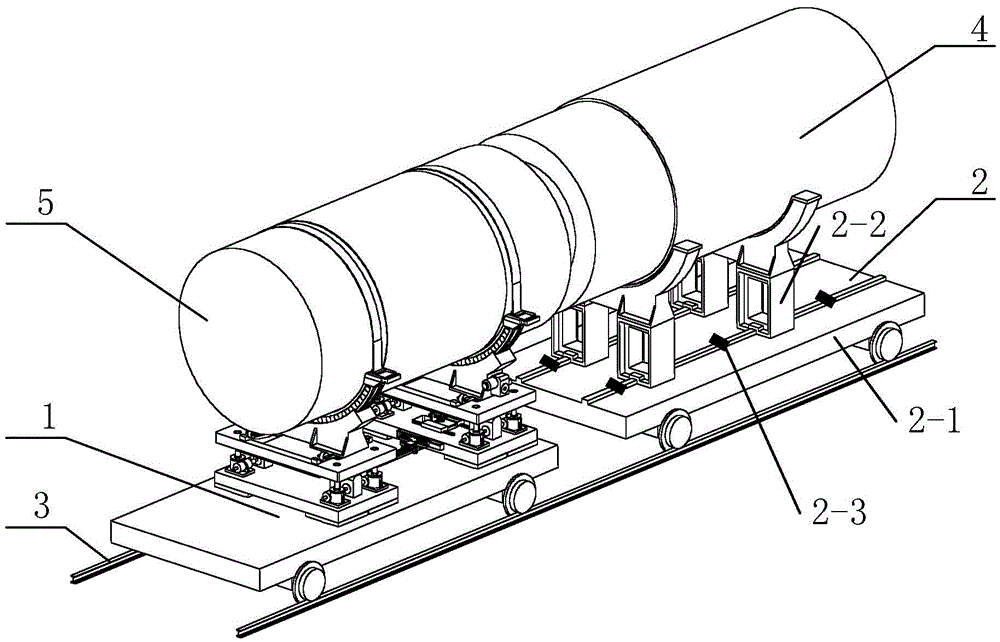

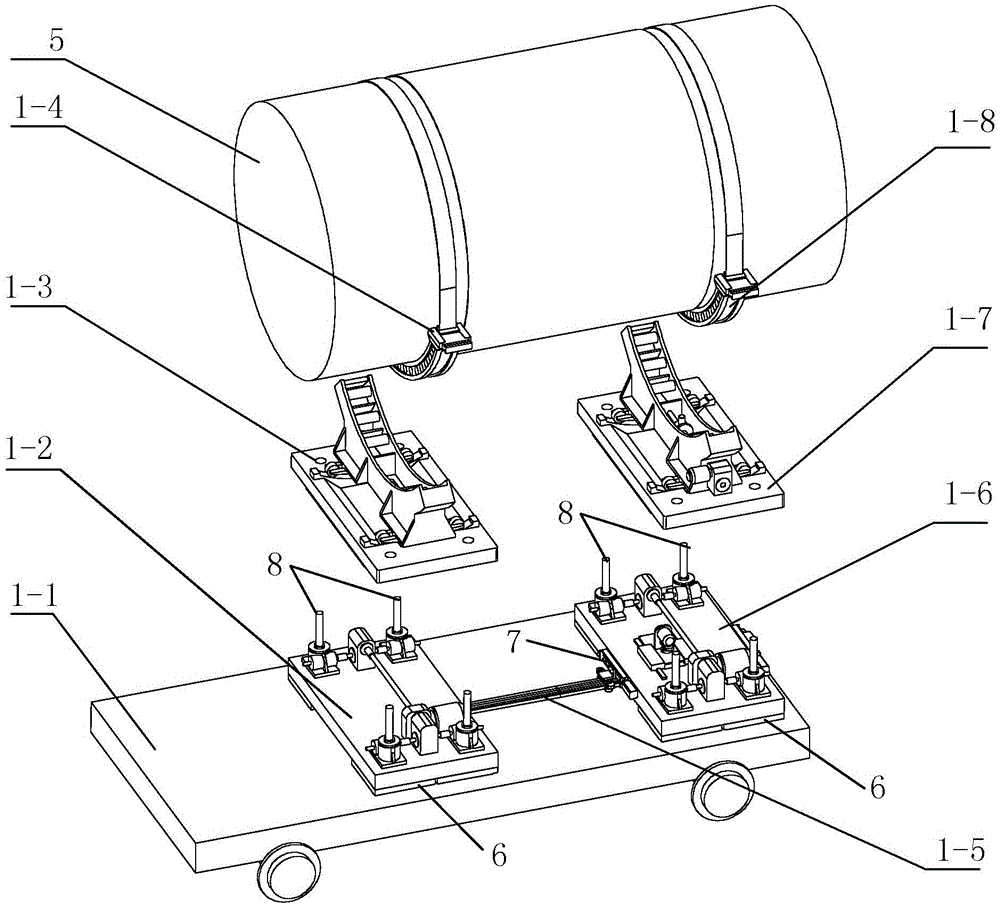

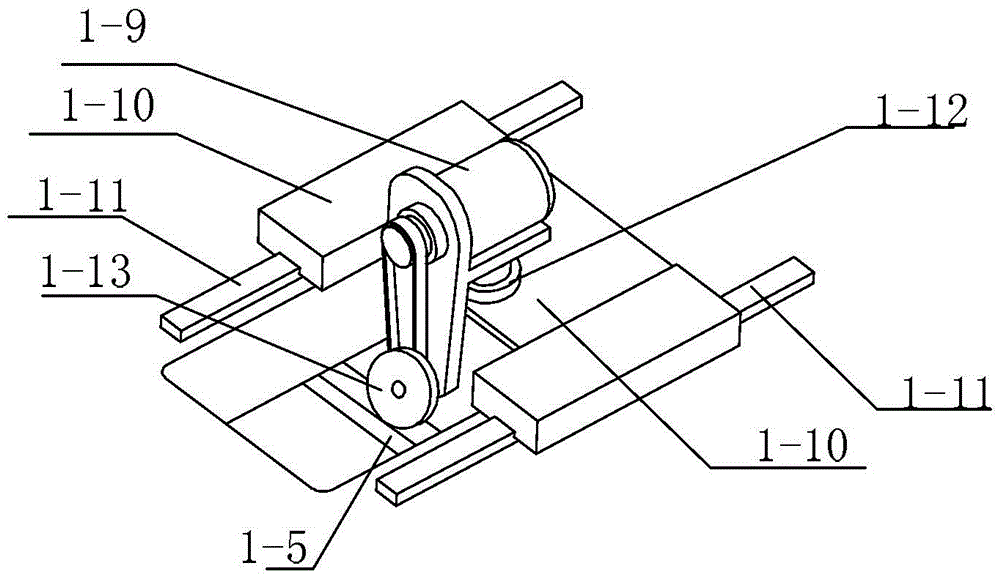

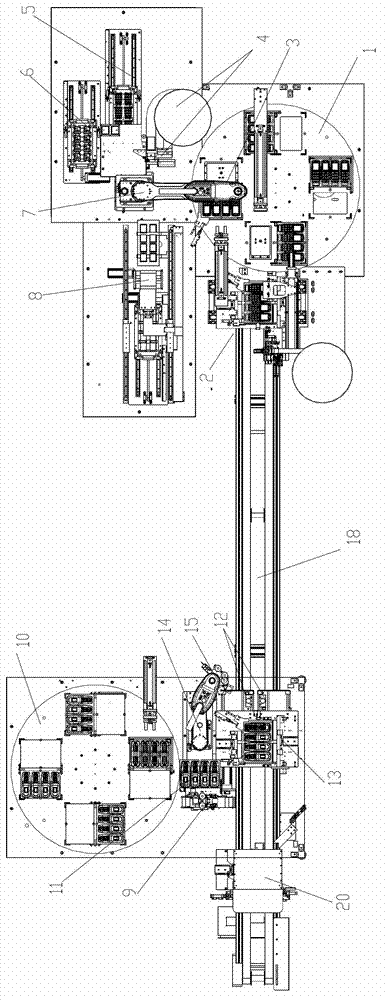

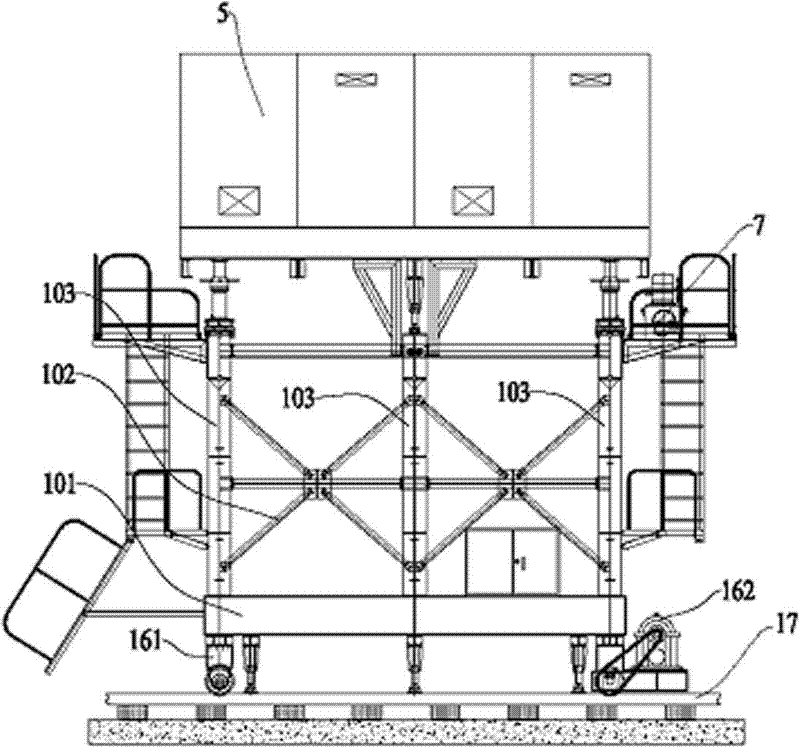

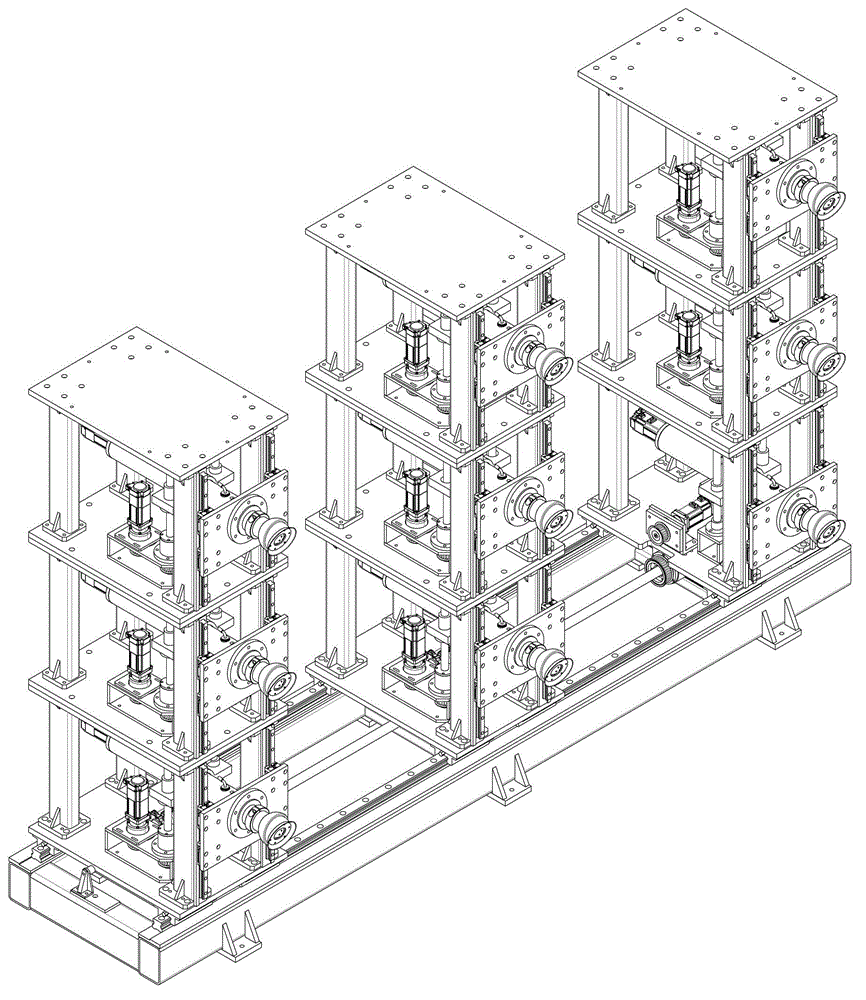

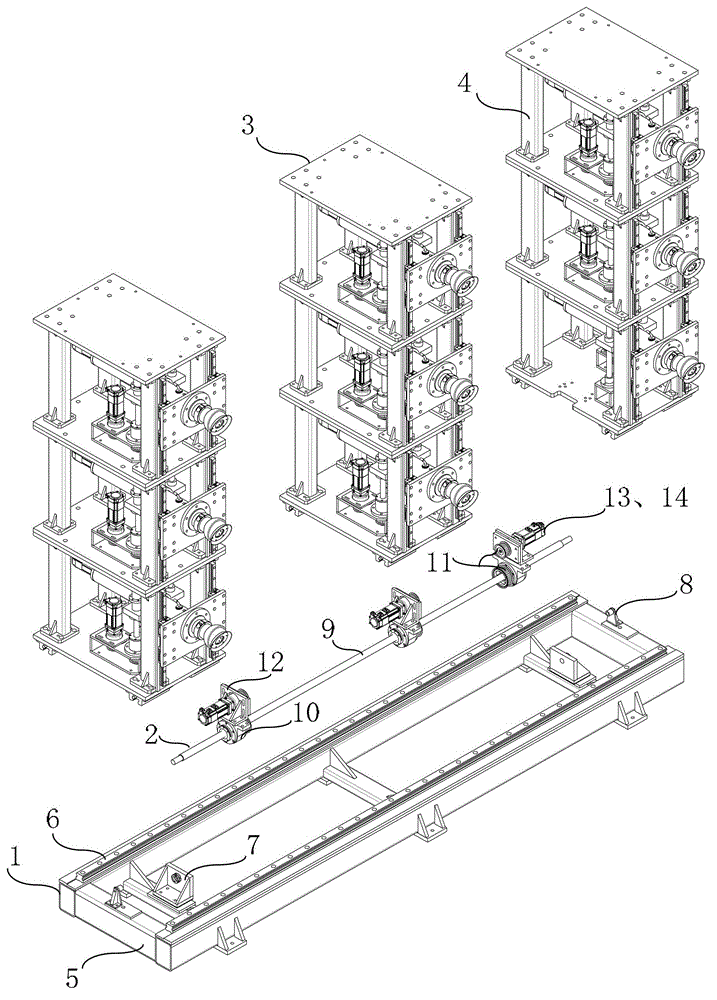

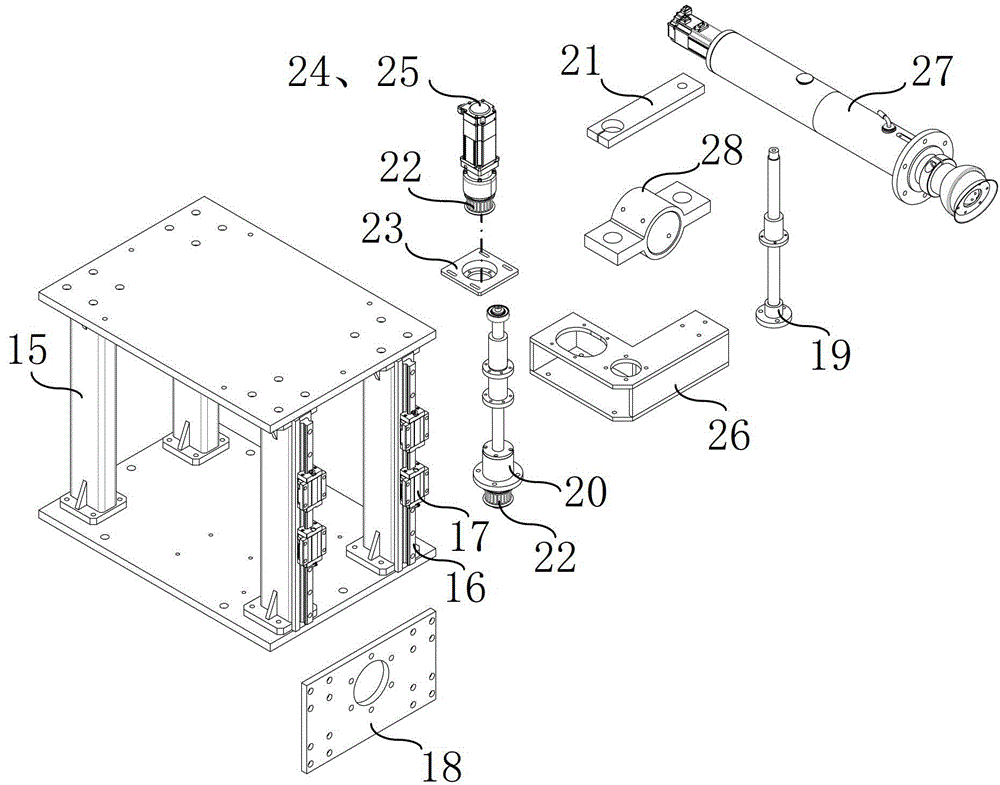

Air-floating type flexible assembly butt-joint system

ActiveCN105619049AImprove assembly efficiencyImprove assembly qualityMetal working apparatusButt jointEngineering

The invention relates to an air-floating type flexible assembly butt-joint system, which relates to the technical field of flexible assembly, and aims at solving problems of low assembling precision, inferior efficiency and inferior flexibility of traditional large-scale cabin section type products. The air-floating type flexible assembly butt-joint system comprises a driving assembly butt-joint vehicle, a driven assembly butt-joint vehicle and a rail, wherein the driving assembly butt-joint vehicle and the driven assembly butt-joint vehicle slide along the same rail; the driven assembly butt-joint vehicle is used for lifting a driven butt-joint cabin section; the driving assembly butt-joint vehicle is used for lifting a driving butt-joint cabin section and controlling the driving butt-joint cabin section to move for butt joint along the extending direction of the rail, move along the direction vertical to the extending direction of the rail, vertically move along the longitudinal direction, rotate in a yawing form, rotate in a pitching form and rotate in a rolling form, so that the butt joint between the driving butt-joint cabin section and the driven butt-joint cabin section lifted on the driven assembly butt-joint vehicle is realized; the driving assembly butt-joint vehicle is used for lifting the driving butt-joint cabin section in an air-floating form. The air-floating type flexible assembly butt joint system is mainly used for fine butt-jointing of large-scale cabin section type products.

Owner:HARBIN INST OF TECH

Rapid manufacturing method for sprayed and cured molding sand

InactiveCN104999031AReduce distortionImprove assembly qualityFoundry mouldsMould handling/dressing devicesCasting moldUltimate tensile strength

The invention discloses a rapid manufacturing method for sprayed and cured molding sand. The rapid manufacturing method is characterized by comprising the following steps: molding sand is mixed with a curing agent in advance, and diluted resin is sprayed onto the molding sand mixed with the curing agent through a spray; through powder layering and resin spraying, the molding sand with sprayed resin is cured, and then adhesive forming is realized; the formed layers are heated for drying; the entity of a casting mold is formed through layer-by-layer printing, stacking and curing, and then the strength of the casting mold is improved through further drying. Through adoption of the rapid manufacturing method, the problem that the amount of gas evolution of the casting mold is overlarge can be solved through reduction of the resin consumption, the spray is protected from blockage, the curing speed is increased, the assembly quality of the casting mold and a mold core is improved, and finally the casting mold with relatively high strength is obtained.

Owner:宁波高新区多维时空科技有限公司

Water pump automatic circulation assembly line

ActiveCN102284860AAccurate detectionOptimizationPump testingAssembly machinesDifferential lineEngineering

The invention discloses an automatic flow assembly line for a water pump. The automatic flow assembly line comprises a circulated flow line mainly consisting of a differential chain line and an arc flat chain line and is characterized in that the circulated flow line is provided with an automatic water pump comprehensive testing platform, an air tightness testing unit, a main sealing automatic pressing table and more than two manual placement stations. The circulated flow line is also provided with circularly delivered tool plates. The automatic water pump comprehensive testing platform, the air tightness testing unit, the main sealing automatic pressing table and the manual placement stations are respectively provided with a tool plate jacking unit and a positioning stopper. In the automatic flow assembly line for the water pump, a part to be assembled can be conveniently placed on the tool plate for corresponding installation during assembly, and different automatic tests can be performed on different stations, so the labor intensity is reduced, and the production efficiency is improved.

Owner:JUNHE PUMPS HLDG

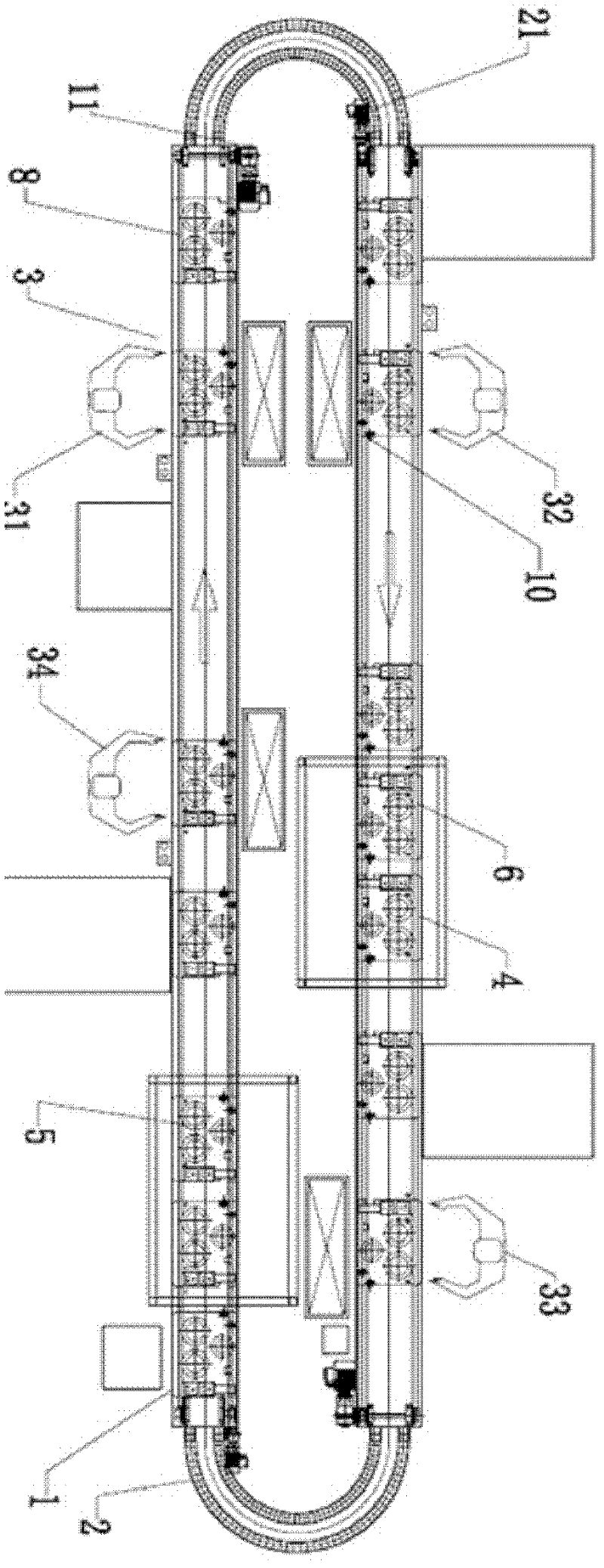

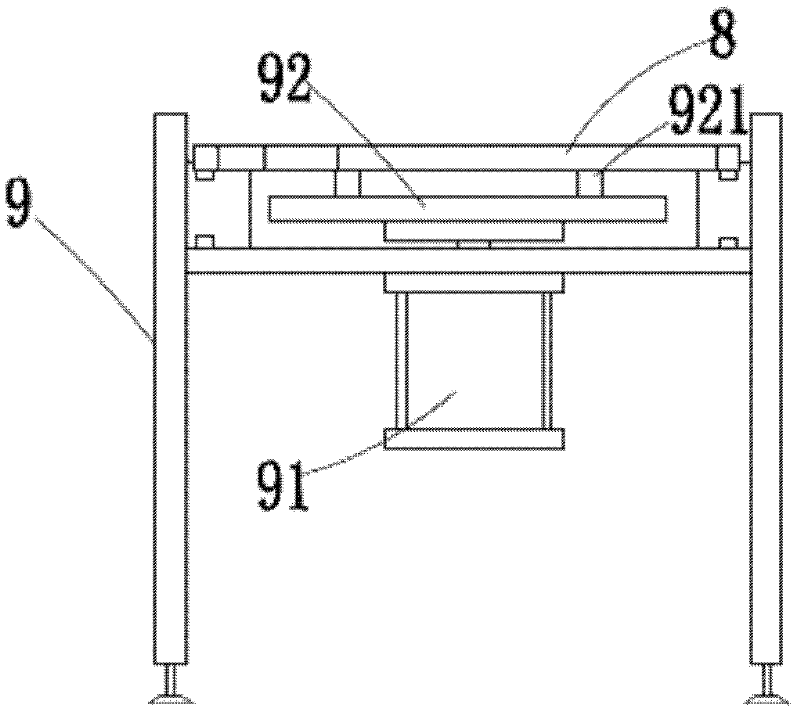

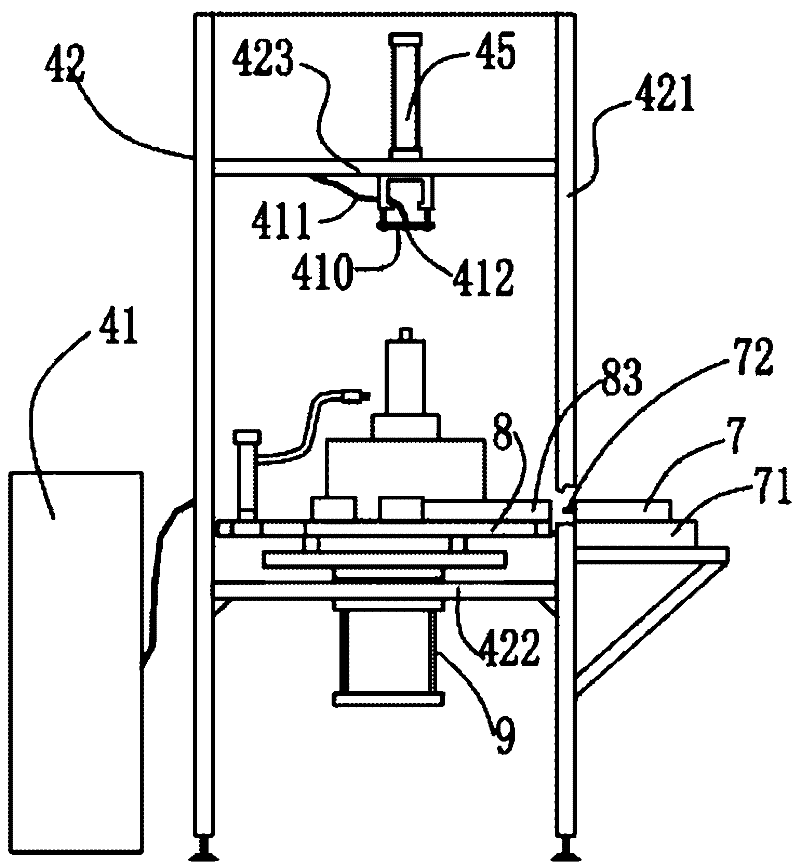

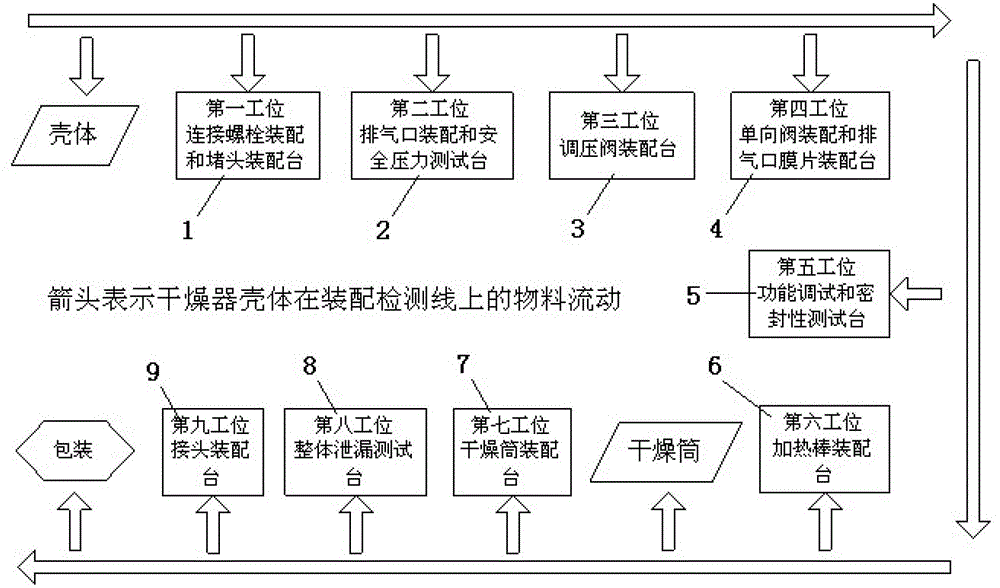

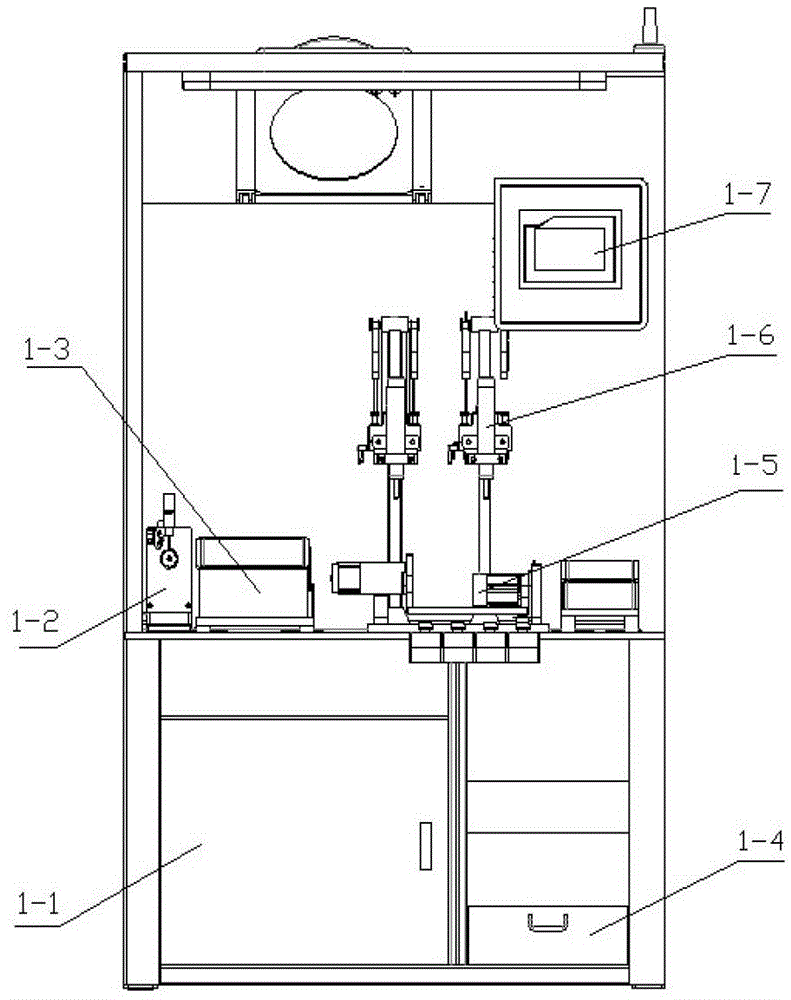

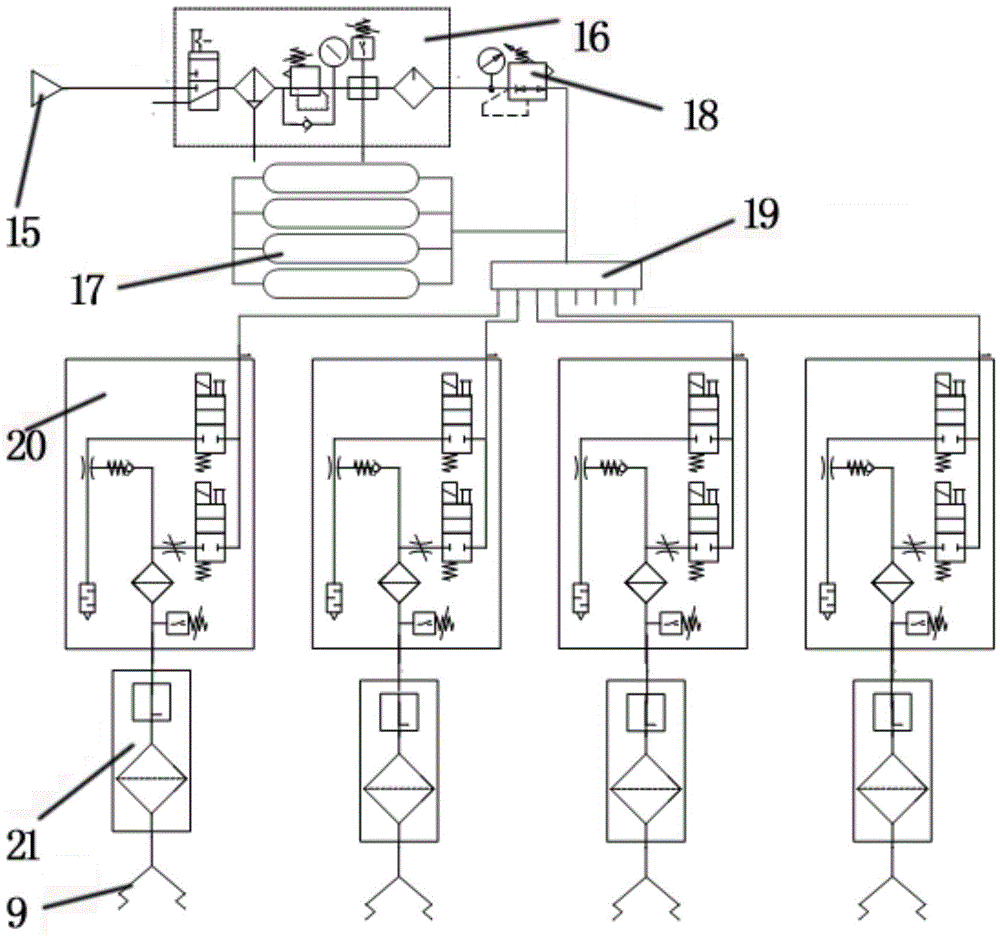

Automobile air dryer assembling and testing production line

ActiveCN103182645AReasonable structural designFlexible layout adjustmentVehicle testingMeasurement of fluid loss/gain rateTest efficiencyProduction line

The invention discloses an automobile air dryer assembling and testing production line. At present, assembly of most of automobile air dryers at home is in a scattered operation state and a testing method is a manual intermittent partial testing method; however, selection and matching of the conventional assembling and testing equipment are not reasonable enough and poor in coordination; and therefore, the assembling process of the automobile air dryer is poor in smoothness and low in assembling and testing efficiency. The automobile air dryer assembling and testing production line comprises a U-shaped workbench line body, wherein the U-shaped workbench line body comprises six assembling workstations, two testing workstations and an assembling and testing workstation, namely a first workstation, a second workstation, a third workstation, a fourth workstation, a fifth workstation, a sixth workstation, a seventh workstation, an eighth workstation and a ninth workstation sequentially; the adjacent workstations are related to each other through a material conveying belt. A shell of the assembled and tested air dryer is transferred among the workstations through the material conveying belts between the workstations, working procedures are continuous, and the workstations are related through the material conveying belts, so that the assembling pace is ensured and the manufacturing cost is reduced.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

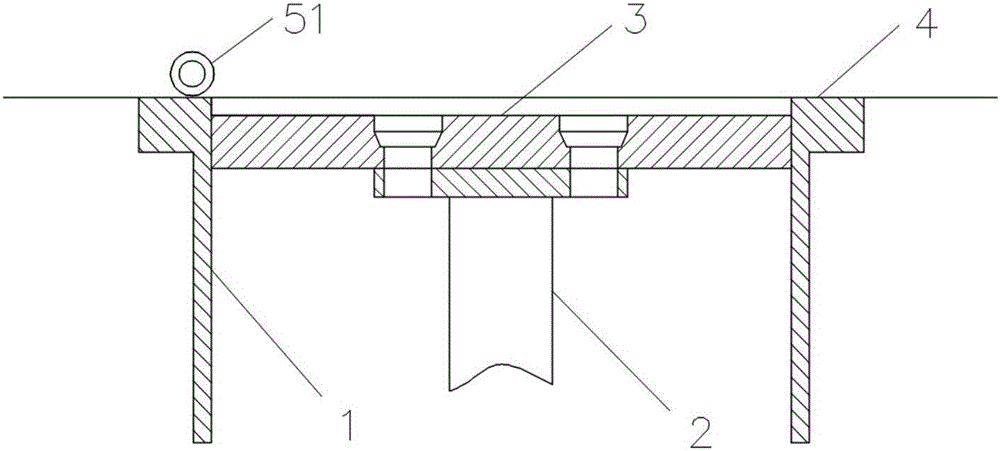

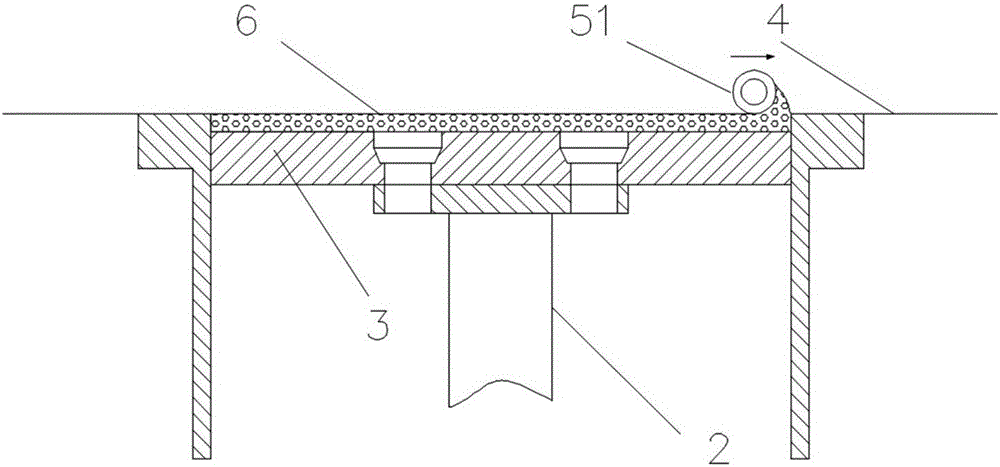

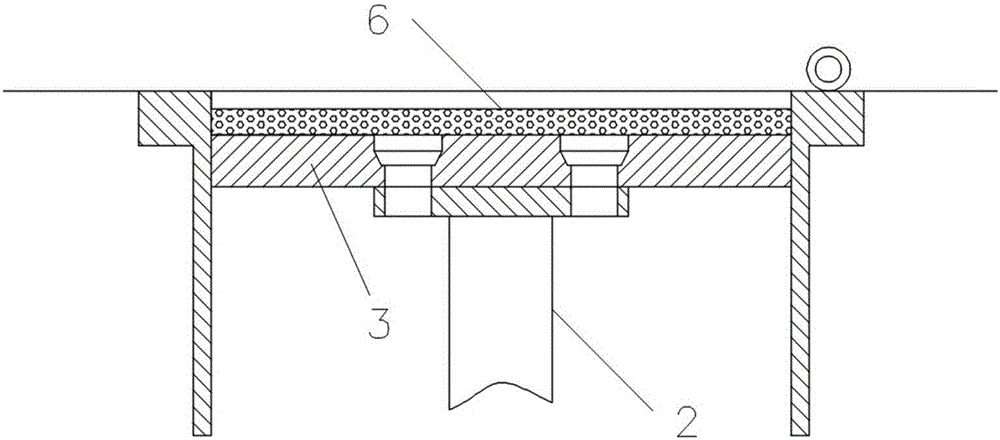

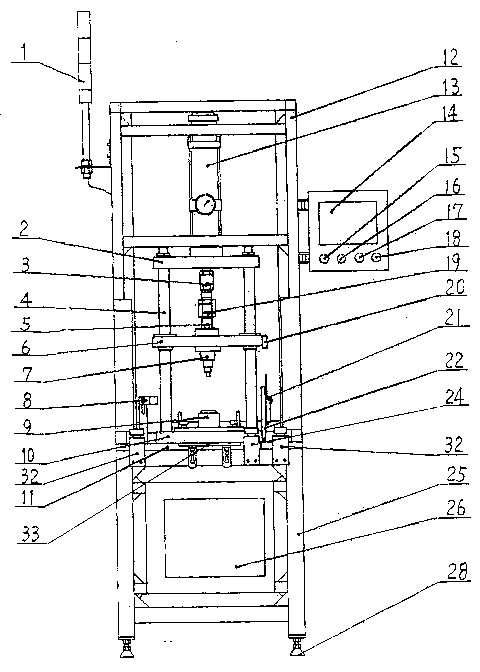

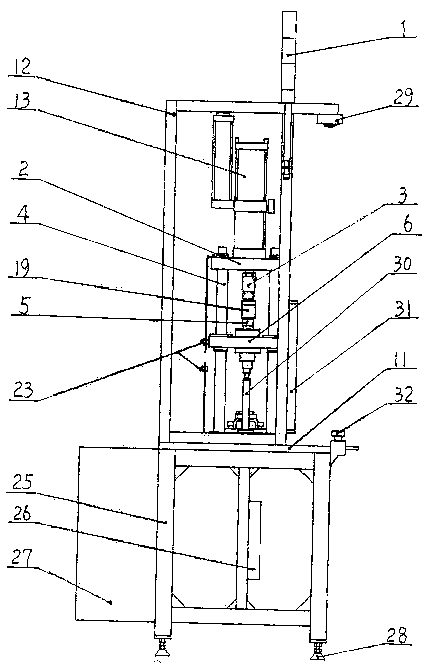

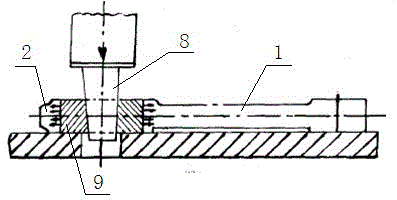

Semi-automatic press for mechanical assembly

InactiveCN103121162AReasonable structureSimple and safe operationMetal working apparatusControl systemOptical axis

The invention belongs to machinery production technological devices and particularly relates to a semi-automatic press for mechanical assembly. A pneumatic control system (26) and an electrical control system (27) are fixedly mounted on a lower framework (25), a work panel (11) is fixedly mounted at the upper end of the lower framework (25), an optoelectronic switch (8) a safety limited post (30), an upper framework (12) and four guide optical axes (4) are respectively and fixedly mounted on the work panel (11), a gas-liquid pressurized cylinder (13) is fixed on an upper fixed plate (2), a pressure head (7) used for mounting a workpiece in a pressing mode is fixed below a movable guide plate (6), a press block (20) used for triggering a sensor is fixed on one side face of the movable guide plate (6), and a fixture (9) is fixedly mounted at a place, corresponding to the pressure head (7), in the middle of the upper face of a lower fixed plate (10). The semi-automatic press for the mechanical assembly is reasonable in structure and safe, convenient and fast to operate, can accurately judge the press-in position of a part and whether pressure is right and appropriate or not, and can realize accurate measurement of displacement and the pressure and achieve an automatic alarming function when an out-of-tolerance situation happens.

Owner:FUXIN DARE AUTOMOTIVE PARTS

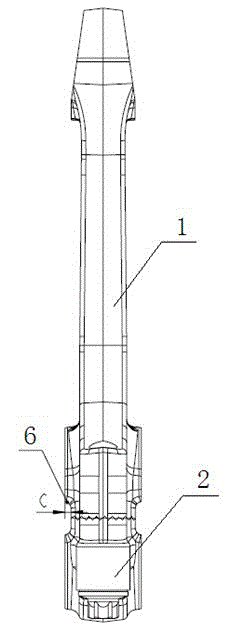

Device for assembling O-shaped ring on valve stem

ActiveCN103909495AThe machine is easy to operateSmall sizeMetal working apparatusMetal-working hand toolsValve stemEngineering

The invention relates to the technical field of valve stem assembling equipment, in particular to a device for assembling O-shaped rings on valve stems. The device comprises a frame, an O-shaped ring feeding mechanism, an O-shaped ring positioning mechanism, a valve stem feeding mechanism, a valve stem positioning mechanism, an O-shaped ring conveying and assembling mechanism and a finished product discharging and distributing mechanism are fixed on the frame, the O-shaped ring positioning mechanism is arranged on one side of the O-shaped ring feeding mechanism, the O-shaped ring conveying and assembling mechanism is arranged on the other side of the O-shaped ring feeding mechanism and capable of conveying an O-shaped ring in the O-shaped ring positioning mechanism to the position of the valve stem positioning mechanism and assembling the O-shaped ring in a valve stem of the valve stem positioning mechanism, the valve stem positioning mechanism is disposed on one side of the valve stem feeding mechanism, and the finished product discharging and distributing mechanism is arranged on the lower side of the valve stem positioning mechanism. The device for assembling the O-shaped rings on the valve stems has the advantages that assembling efficiency is high, demanded manpower is saved greatly, assembling time is saved, and product quality is guaranteed greatly.

Owner:ZHEJIANG VALOGIN TECH

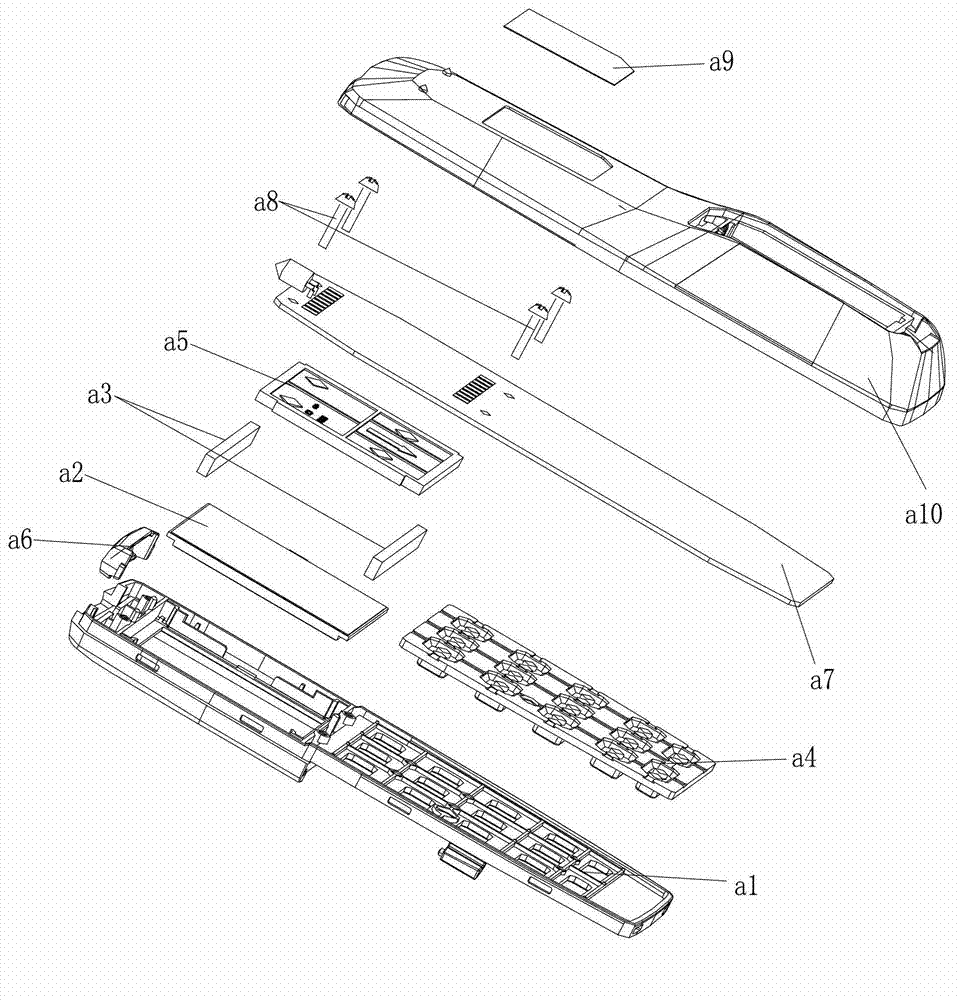

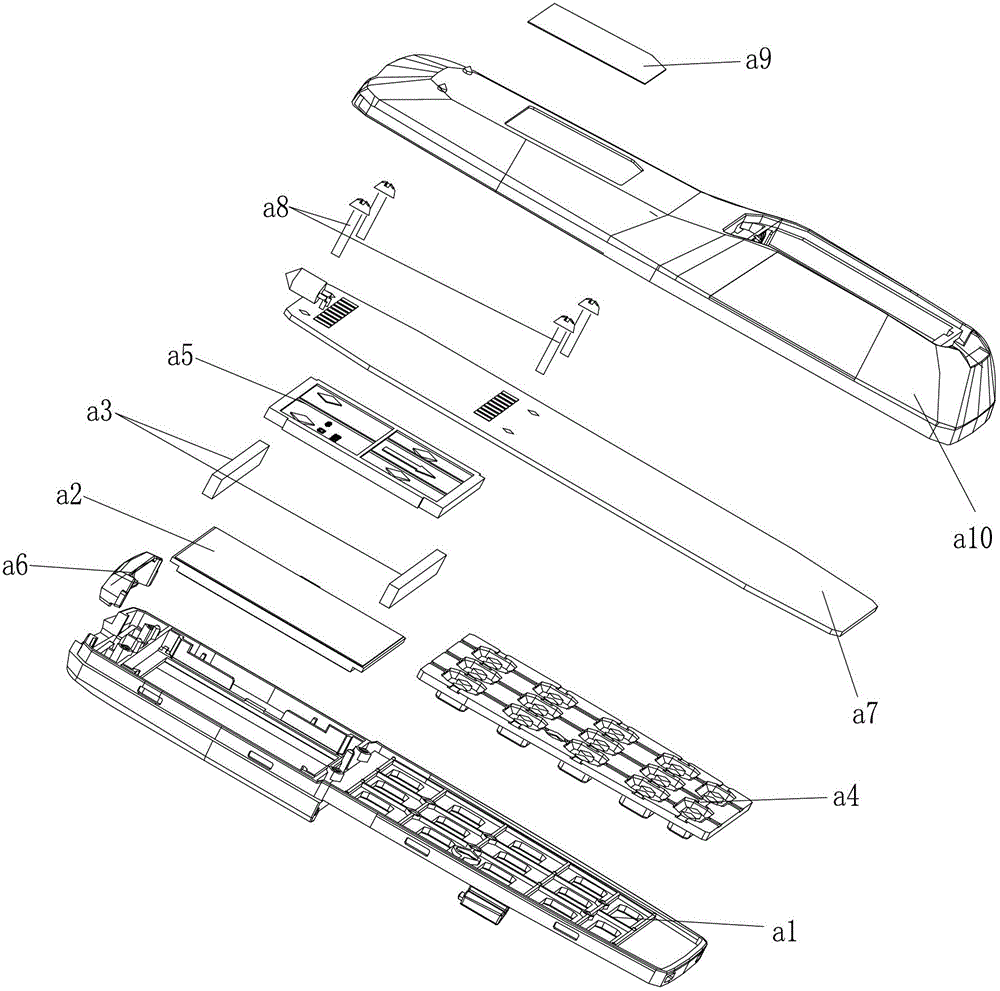

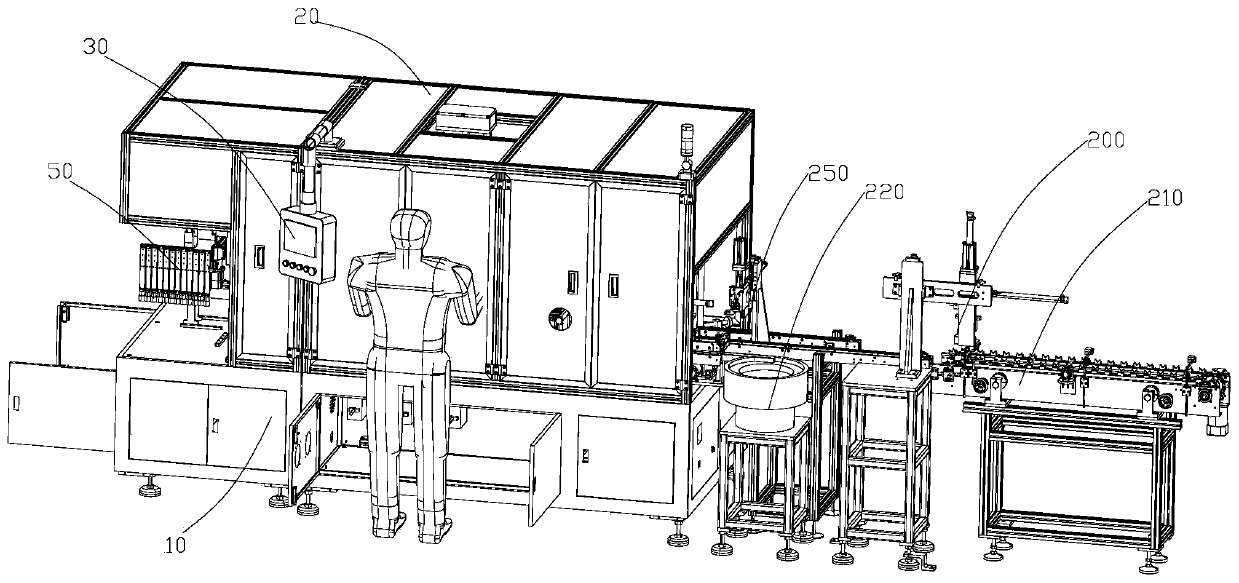

Automatic assembling machine and method of air conditioner remote controller

InactiveCN103192260AImprove assembly efficiencyImprove assembly qualityAssembly machinesKey pressingLiquid-crystal display

The invention discloses an automatic assembling machine and method of an air conditioner remote controller. The automatic assembling machine comprises an automatic assembling machine of a panel and an automatic assembling machine of a machine core cover plate. The automatic assembling machine of the panel comprises a launch window feed assembling device, a panel assembling combined grip device and a panel assembling mechanical arm, wherein the launch window feed assembling device is used for launch window feeding and assembling between a launch window and the panel; the panel assembling combined grip device is used for comprehensive assembling of the panel and a liquid crystal display, a press plate, a key and an adhesive tape; and the panel assembling mechanical arm is used for installing the panel assembling combined grip device. The automatic assembling machine of the machine core cover plate comprises a cover plate assembling combined grip device and a cover plate assembling mechanical arm, wherein the cover plate assembling combined grip device is used for cover plate labeling, machine core plate fastening and upper cover plate assembling; and the cover plate assembling mechanical arm is used for installing the cover plate assembling mechanical arm. The panel and an output shaft of the cover plate assembling mechanical arm have three moving freedom degrees for moving in the space and one rotating freedom degree for rotating around the output shaft. The automatic assembling machine and method improve assembling efficiency and assembling quality and reduce labor cost.

Owner:江门格兰达硕数控有限公司

battery module

ActiveCN102263301AAvoid deformationImprove assembly qualityFinal product manufactureSmall-sized cells cases/jacketsEngineeringElectrical and Electronics engineering

A battery module of the present invention includes a plurality of unit batteries and a connection member electrically connecting the plurality of unit batteries. The connection member includes: a plurality of bus bars, each of the plurality of bus bar having two through-holes respectively corresponding to two electrode terminals protruding from two adjacent unit batteries of the plurality of unit batteries; and an insulating guide having a plurality of holder units configured to support the plurality of bus bars, and a plurality of narrow width portions positioned between the plurality of holder units and connecting the plurality of holder units along a first direction.

Owner:SAMSUNG SDI CO LTD +1

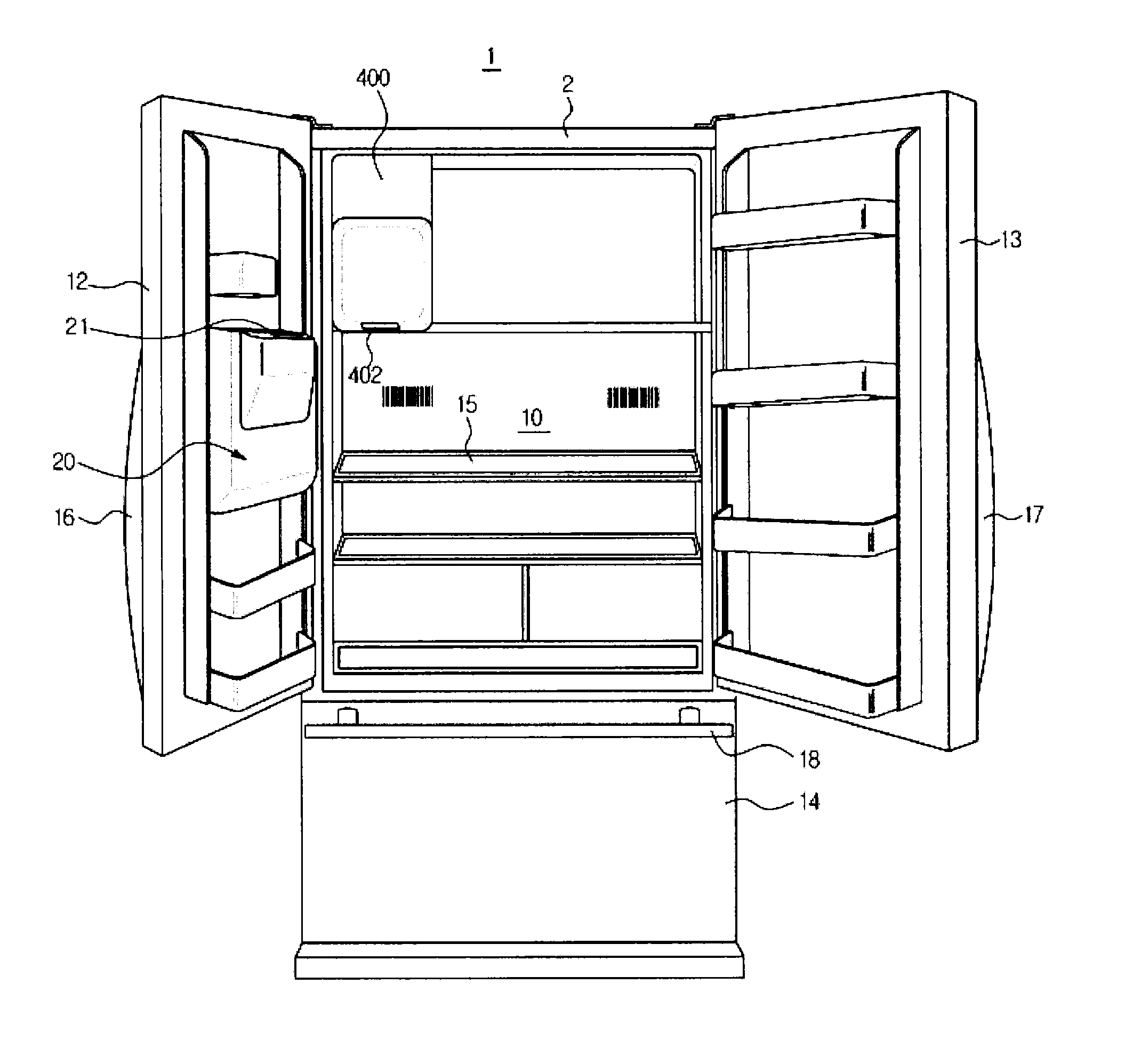

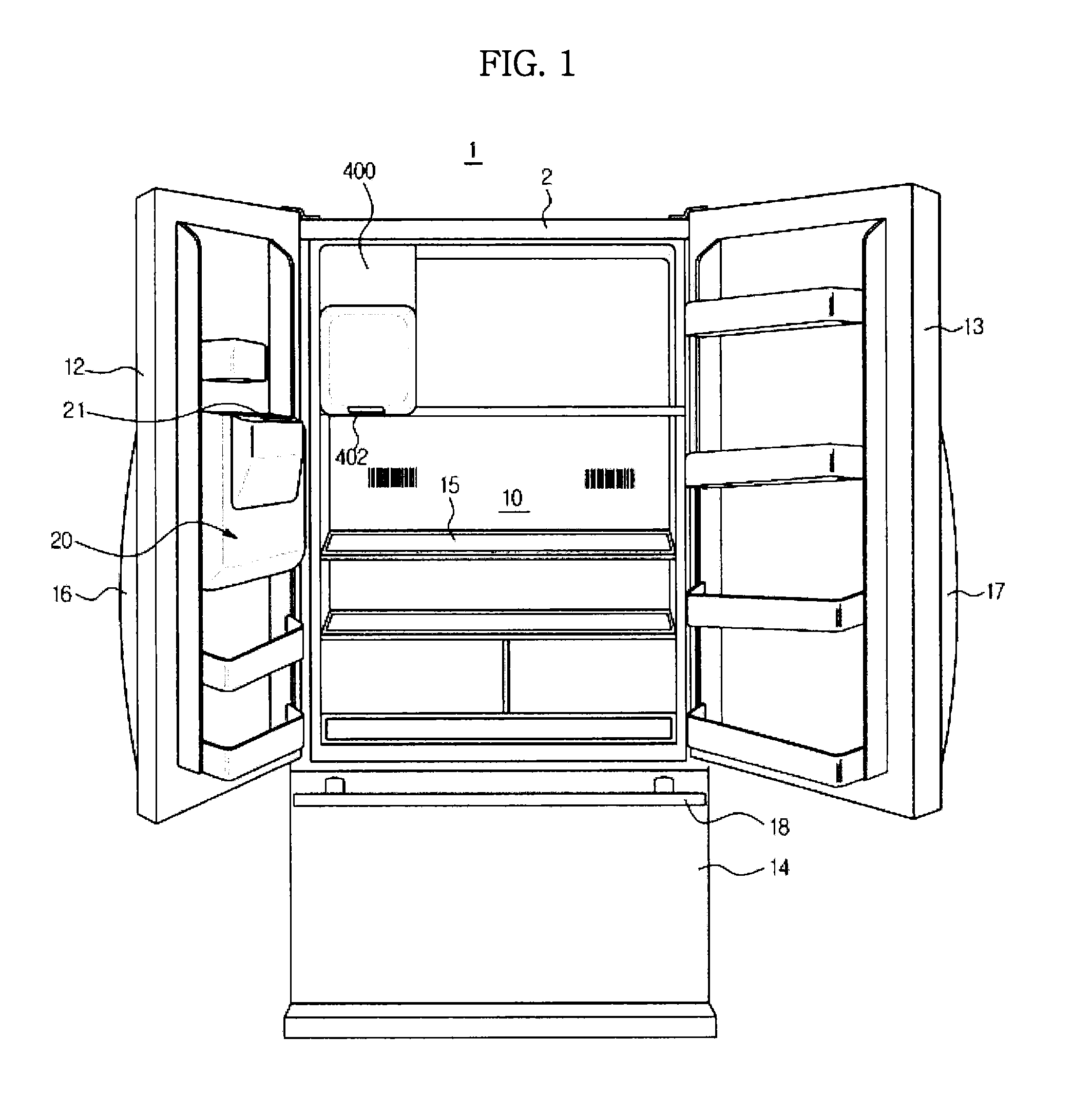

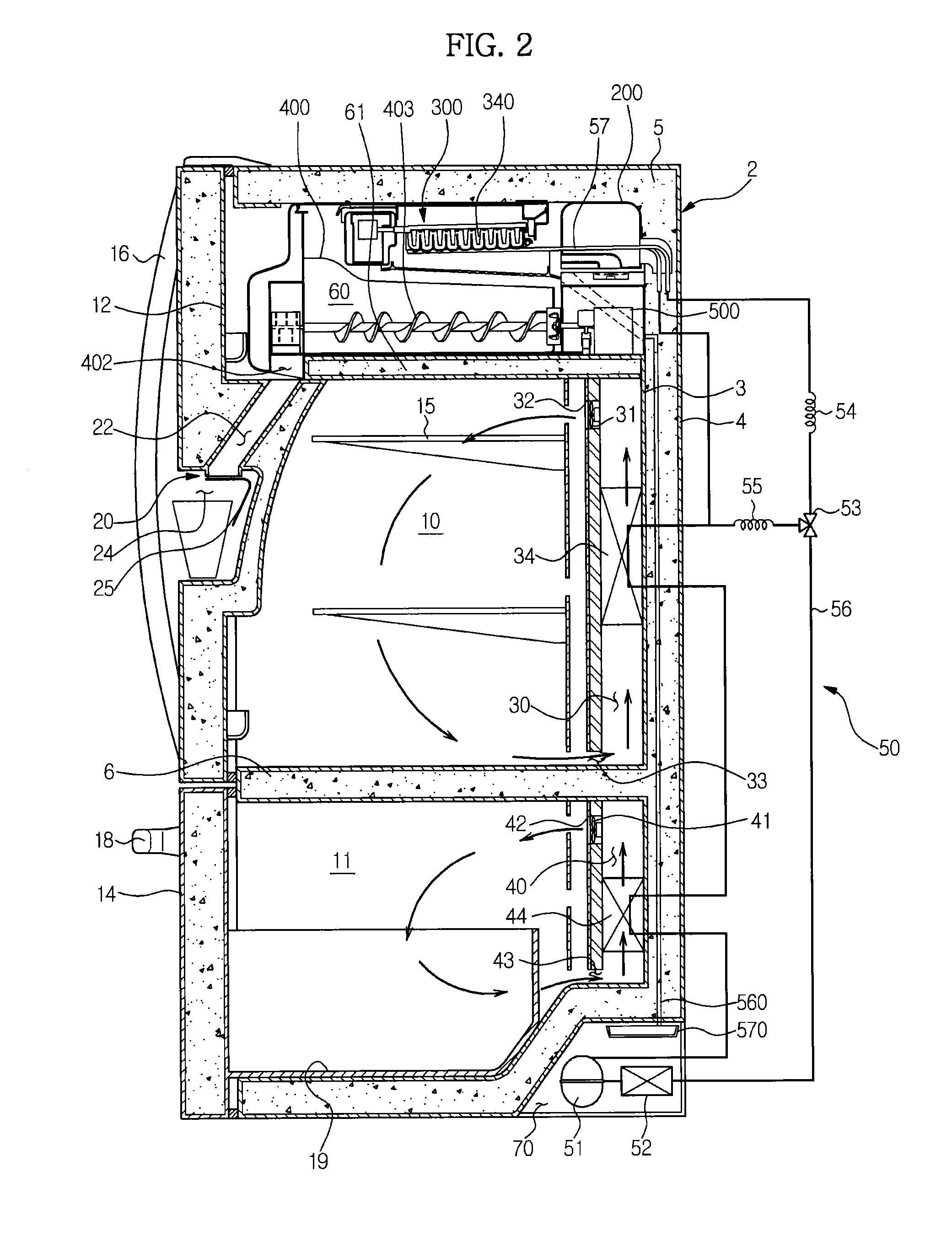

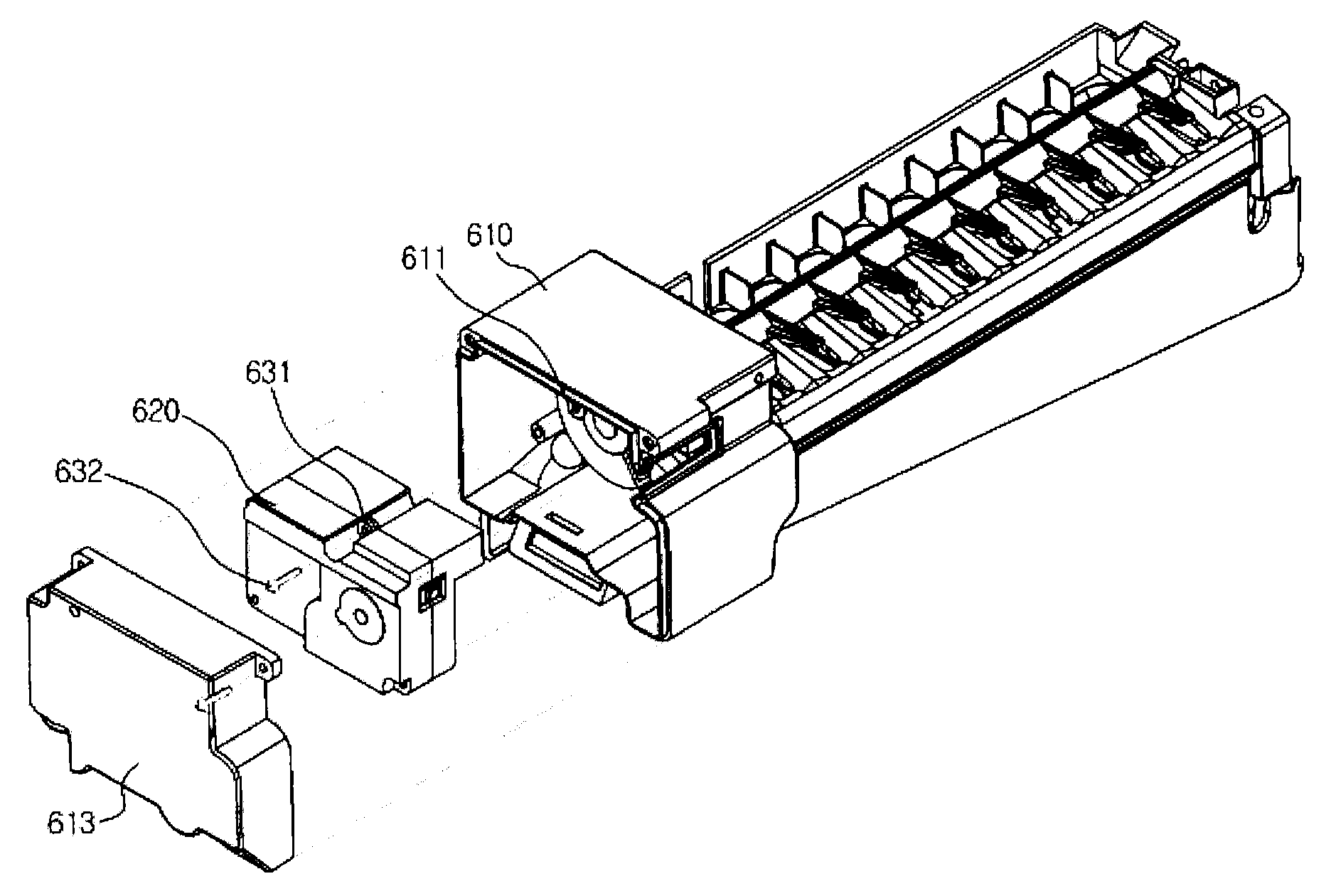

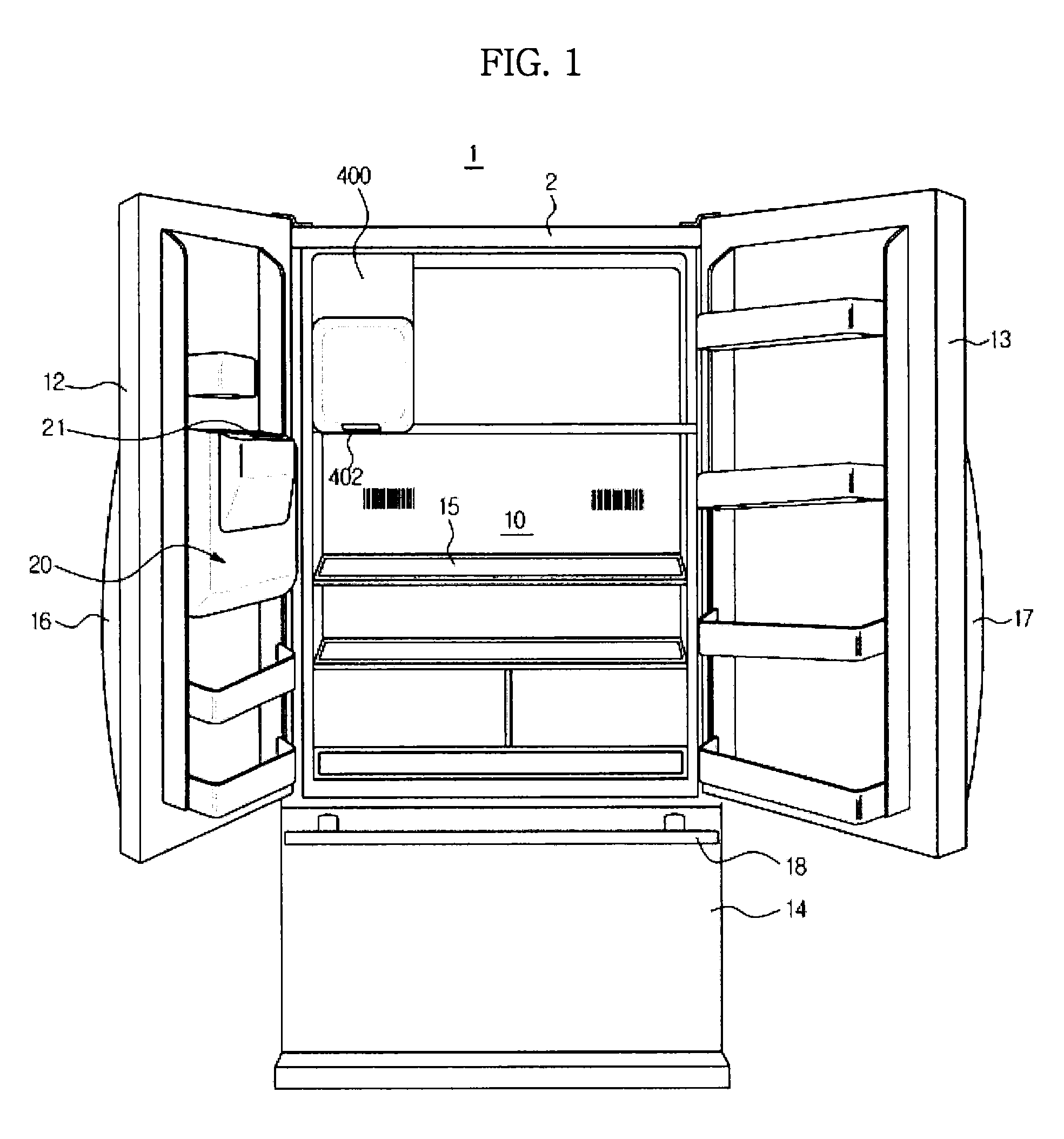

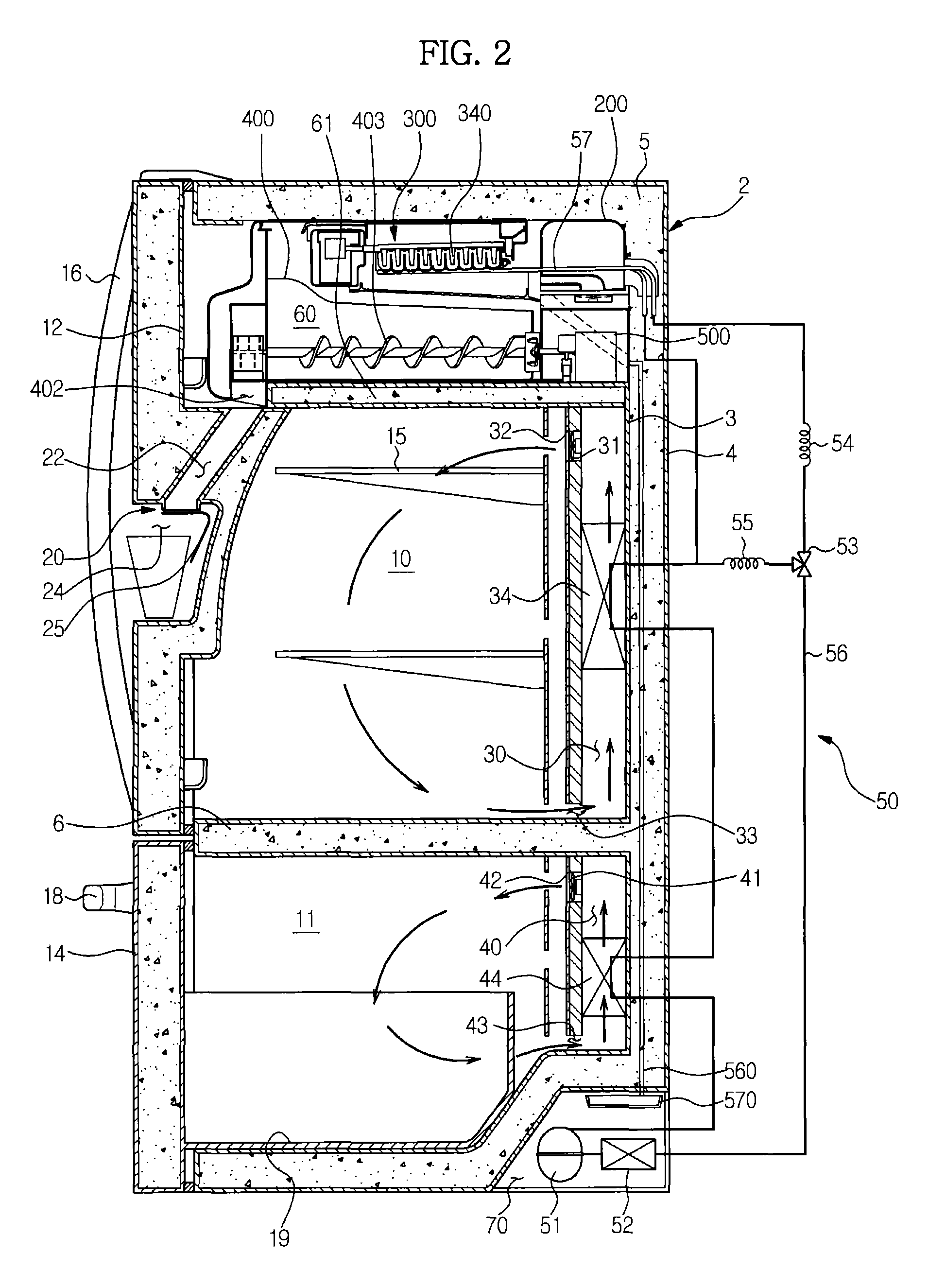

Refrigerator

ActiveUS20130167575A1Improve assembly qualityAvoid failureLighting and heating apparatusIce productionFrostEngineering

A structure of a driving apparatus capable of easily organizing a driving apparatus that is configured to drive an ejector of an ice maker, and preventing frost from being formed on inner compartments, the driving apparatus including a case and a driving module detachable to the inner side of the case, wherein the driving module includes an ice separating motor to drive the ejector, a circuit board to control an ice making process, an electro-motion member to deliver a rotational force of the ice separating motor to the ejector, and a module case to accommodate the components of the driving module.

Owner:SAMSUNG ELECTRONICS CO LTD

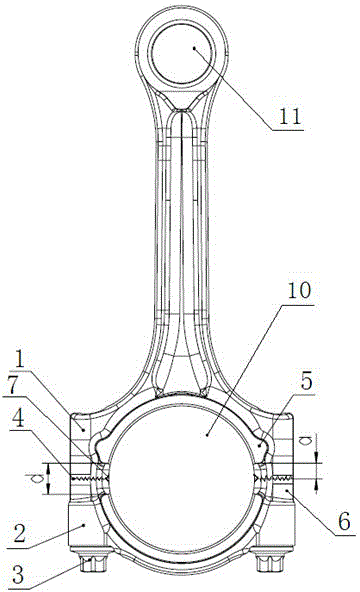

Engine cracking connecting rod and machining method thereof

The invention discloses an engine cracking connecting rod and a machining method of the engine cracking connecting rod. The engine cracking connecting rod comprises a connecting rod body and a connecting rod cover, wherein the connecting rod body is connected with the connecting rod cover in a cracking position of a connecting rod big head through a connecting bolt, U-shaped grooves which are symmetrical relative to a cracking surface are formed in the cracking position of the connecting rod big head, V-shaped splitting grooves are formed in the inner edge, corresponding to the cracking position, of a big head hole of the connecting rod big head, and the V-shaped splitting grooves are symmetrical relative to the cracking surface. The machining method comprises the steps that a forged connecting rod blank with the two symmetrical U-shaped grooves is machined in a rough mode; the connecting rod is cracked into the connecting rod body and the connecting cover; the cracked connecting rod is machined in a fine mode, and a cracking connecting rod finished product is formed. The engine cracking connecting rod and the machining method of the engine cracking connecting rod can lower the cracking difficulty, guarantee the cracking effect, reduce production work procedures, improve reset accuracy after cracking, and guarantee the overall performance of the connecting rod.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

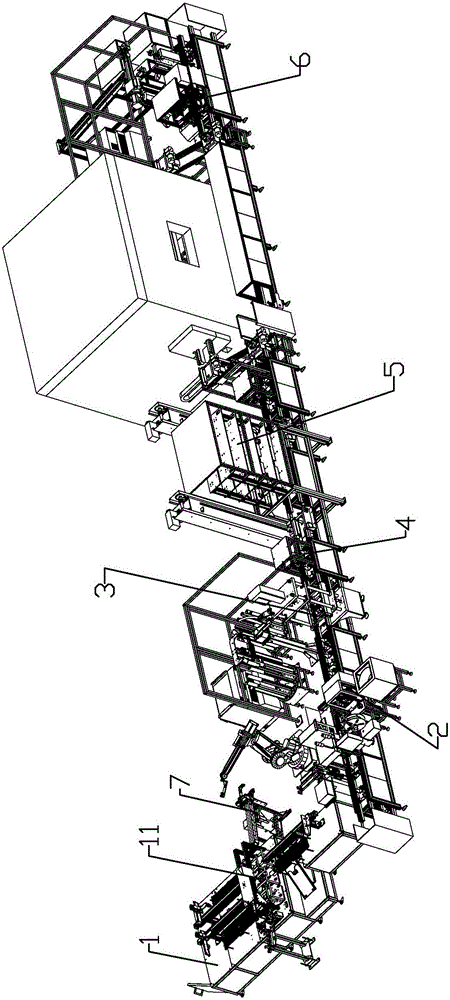

Automatic assembling line for motors

ActiveCN105871129AHigh degree of automationImprove assembly qualityManufacturing dynamo-electric machinesElectricityEngineering

The invention discloses an automatic assembling line for motors. The automatic assembling line for the motors comprises a frame, an automatic conveying belt, a motor rotor bearing bit synchronization oiling device, an automatic motor rotor bearing press-fitting device, an automatic spring washer distributing and detecting device, a motor end cap press-fitting device, an automatic motor bearing gap detecting device, an automatic motor ageing testing device and an automatic gluing air dryer for the motors, wherein the automatic conveying belt which is electrically connected with a circuit controller is arranged on the frame; and the motor rotor bearing bit synchronization oiling device, the automatic motor rotor bearing press-fitting device, the automatic spring washer distributing and detecting device, the motor end cap press-fitting device, the automatic motor bearing gap detecting device, the automatic motor ageing testing device and the automatic gluing air dryer for the motors are successively connected together by the automatic conveying belt and are electrically connected with the circuit controller. The automatic assembling line for the motors is high in assembling stability and good in assembling quality, and testing automation of components of the motors can be realized.

Owner:GUANGDONG LXD ROBOTICS CO LTD

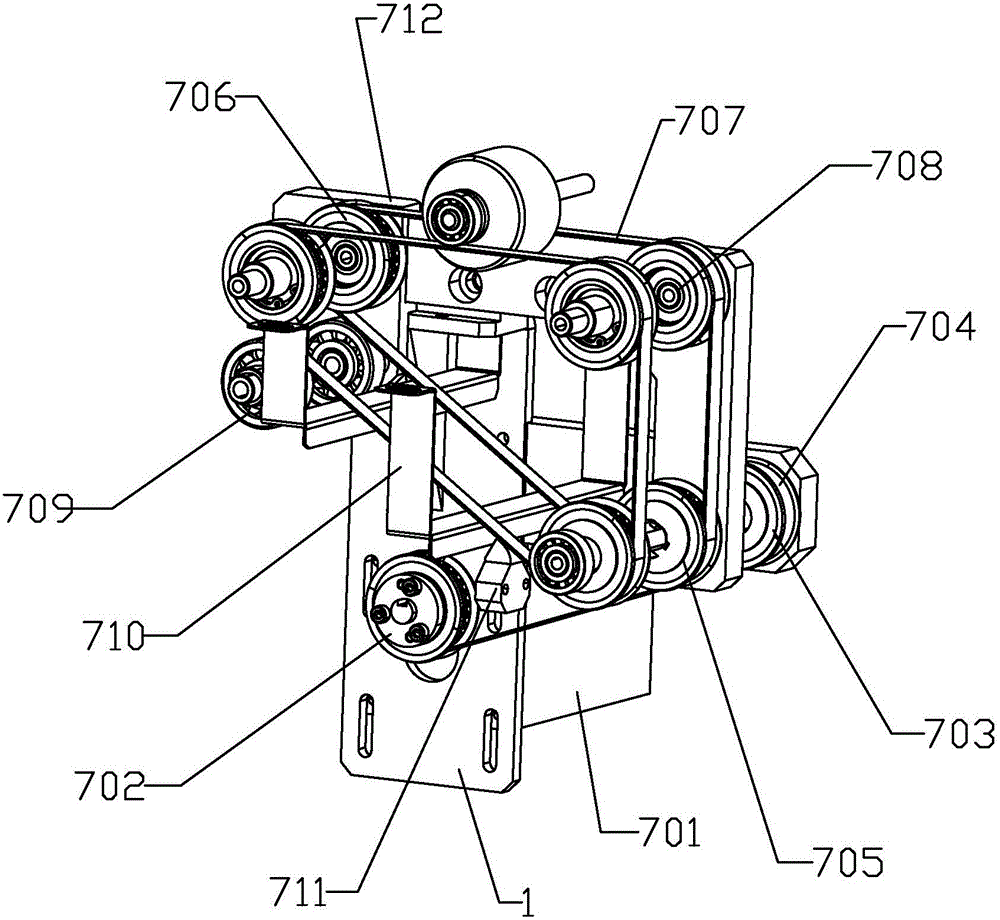

Walking mechanism and walking method of crawling robot

The invention discloses a walking mechanism of a crawling robot. The walking mechanism is characterized by comprising a moving frame, a plurality of outer legs and a plurality of inner legs, wherein the moving frame is rectangular; the outer legs are symmetrically mounted on two symmetrical lateral sides of the moving frame, and the inner legs are symmetrically mounted on the other two symmetrical lateral sides of the moving frame; each outer leg comprises an outer-leg frame and a telescopic leg arranged in the outer-leg frame; each inner leg comprises an inner-leg frame and a telescopic leg arranged in the inner-leg frame; suction cups are mounted at the bottoms of the outer legs and the inner legs; the telescopic legs of the outer legs are connected with the moving frame, and the moving frame ascends and descends with the telescopic legs of the outer legs; the inner-leg frames are rigidly connected with the moving frame, and the inner-leg frames ascend and descend with the moving frame; the outer-leg frames are mounted on the moving frame through guide rails; transverse feed motors are mounted on the moving frame, and the transverse feed motors drive transverse feed screws; the inner legs and the outer legs are both provided with longitudinal feed motors, and the longitudinal feed motors drive longitudinal feed screws.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

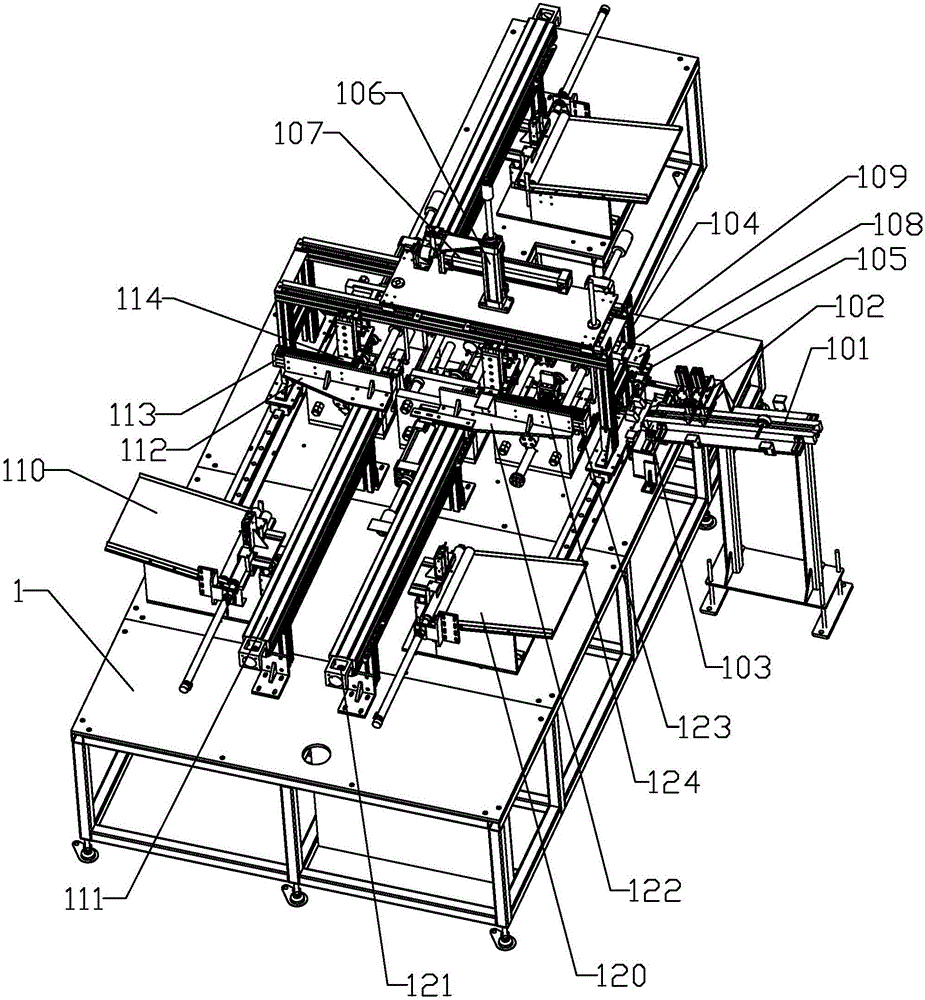

Automatic assembling machine and automatic assembling method for air conditioner remote controller panel

InactiveCN103143935AImprove assembly efficiencyImprove assembly qualityAssembly machinesKey pressingEngineering

The invention discloses an automatic assembling machine and an automatic assembling method for an air conditioner remote controller panel. The automatic assembling machine comprises a panel material tray feeding and transferring device for realizing workstation switching, a transmitting window feeding and assembling device for loading a transmitting window and assembling between the transmitting window and the panel, a panel assembling combined gripper device and a panel assembling manipulator, wherein the panel assembling combined gripper device for comprehensively assembling the panel together with a liquid crystal screen, a pressure plate, keys and an adhesive tape is fixedly arranged on an output shaft of the panel assembling manipulator; the transmitting window feeding and assembling device comprises a transmitting window feeding unit and a transmitting window assembling unit; the transmitting window feeding unit comprises a transmitting window vibrating disk and a transmitting window transferring module which is used for transferring the transmitting window provided by using the transmitting window vibrating disk to a transmitting window feeding position; and the transmitting window assembling unit comprises a transmitting window transferring and assembling module which is used for grabbing the transmitting window positioned at the transmitting window feeding position to the transmitting window placing position of the panel positioned at the transmitting window assembling position. Due to the adoption of the assembling machine and the assembling method disclosed by the invention, the assembling efficiency is increased, the assembling quality is improved, and the labor cost is lowered.

Owner:GRAND TECH SHENZHEN

Automatic assembling machine of expansion screw bolts

The invention relates to an automatic assembling machine of expansion screw bolts and belongs to the field of hardware machinery. The assembling machine consists of a chain plate type conveying device, a part feeding device, a part escapement device, a screw nut screwing device, a screw rod small head lateral positioning device, a machine frame and a control system, wherein the part feeding device and the part escapement device are used for the ranging, the storage for package and the one-by-one release of parts, the chain plate type conveying device is arranged on the machine frame, semi-finished products and finished products with different stations are transferred through expansion screw bolt seat combination elements arranged on a chain plate, the screw rod small head lateral positioning device is arranged at the front end of the part escapement device for realizing the lateral positioning of each station screw rod, the screw nut screwing device comprises a screw nut pre-screwing friction plate, a first screw nut screwing wheel, a clamping stagnation release friction plate, a second screw nut screwing wheel, a small motor and the like. The assembling machine can realize the automatic assembly of each part of the expansion screw bolts and has the characteristics that the assembly efficiency is high, and the cost is low; and screw nuts are subjected to two links of pre-screwing and screwing, and the assembly quality is ensured.

Owner:ZHENGZHOU UNIV

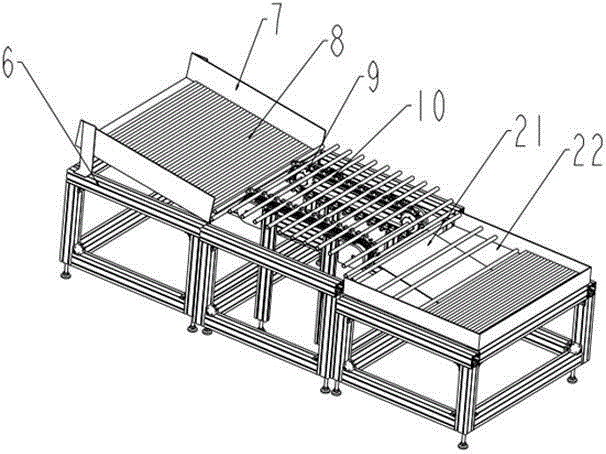

Automatic assembling device and method for lamp strips of LED lamp tubes

ActiveCN105344562AImprove efficiencyImprove work efficiencyLiquid surface applicatorsCoatingsEngineeringLED lamp

The invention relates to an automatic assembling device for lamp strips of LED lamp tubes. The automatic assembling device comprises a feeding platform which is used for stacking glass tubes which are not assembled, an automatic lamp tube feeding mechanism, a lamp strip dispensing mechanism, a pressure holding mechanism and a discharging platform. The input end of the automatic lamp tube feeding mechanism is connected with the feeding platform, receives glass tubes on the feeding platform in sequence and transfers the glass tubes to corresponding positions. The lamp strip dispensing mechanism is adjacent to one side edge of the automatic lamp tube feeding mechanism, conducts dispensing on the LED lamp strips evenly and is inserted into the LED lamp strips into the corresponding glass tubes. The pressure holding mechanism is arranged above the automatic lamp tube feeding mechanism and presses the glass tubes so that the LED lamp strips can be stuck to the inner walls of the glass tubes so as to form LED lamp tubes. The discharging platform is connected with the output end of the automatic lamp tube feeding mechanism and receives the assembled LED lamp tubes. The invention further relates to an automatic assembling method for the lamp strips of the LED lamp tubes, and the method is achieved through the assembling device. According to the automatic assembling device and method for the lamp strips of the LED lamp tubes, automatic feeding and discharging of the LED lamp tubes can be achieved, automatic dispensing and assembling of the lamp strips can be achieved, and the lamp strip assembling quality and efficiency of the LED lamp tubes can be effectively improved.

Owner:SHANGHAI RADIO EQUIP RES INST

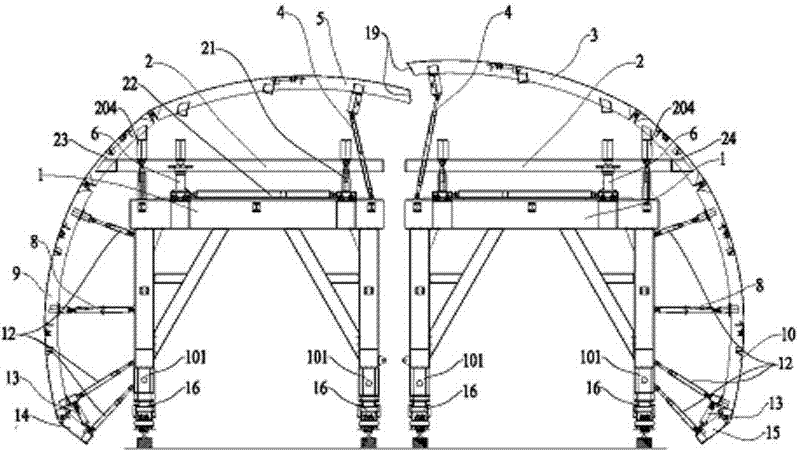

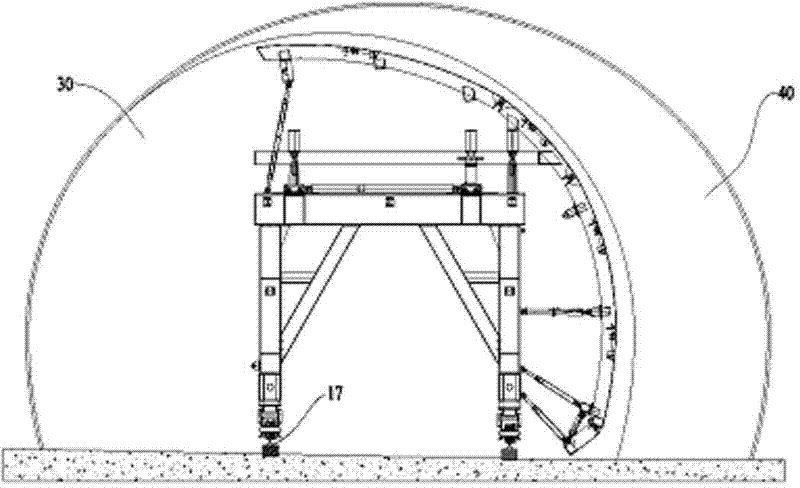

A lining method for a tunnel emergency avoidance zone and a tunnel lining trolley

ActiveCN102296971AImprove lining efficiencyImprove assembly qualityUnderground chambersTunnel liningEngineering

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

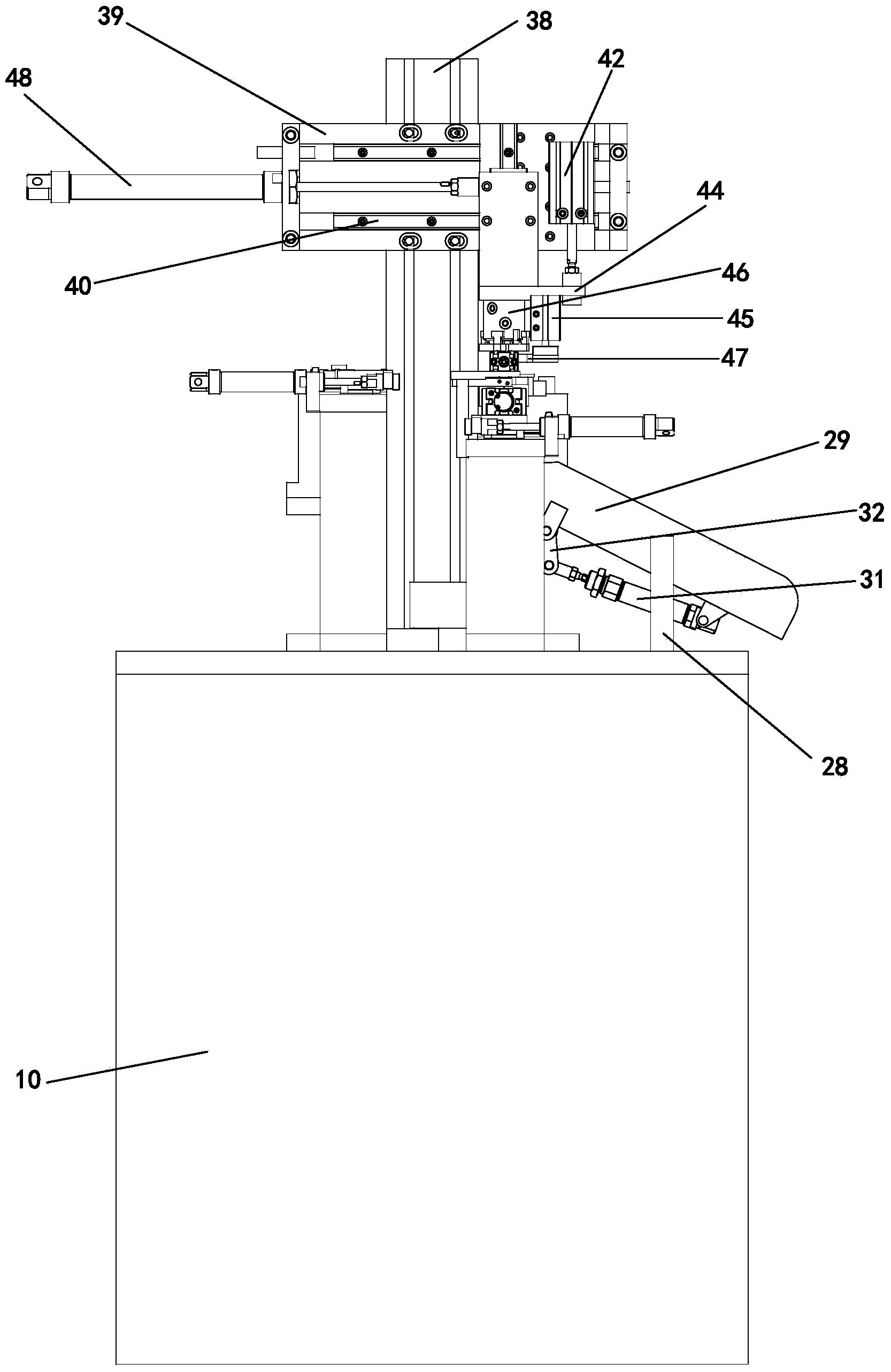

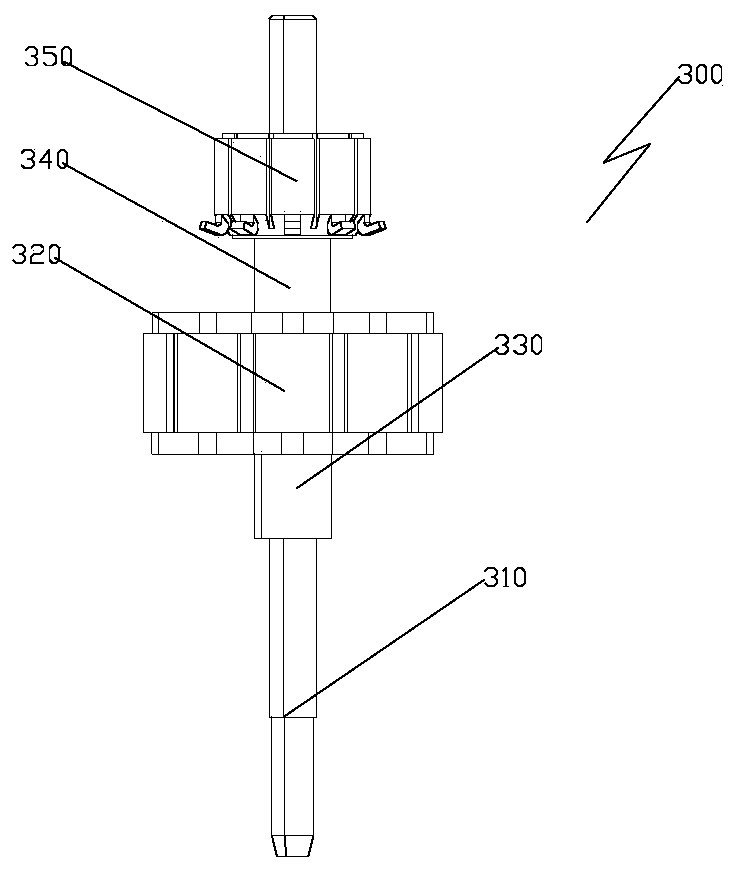

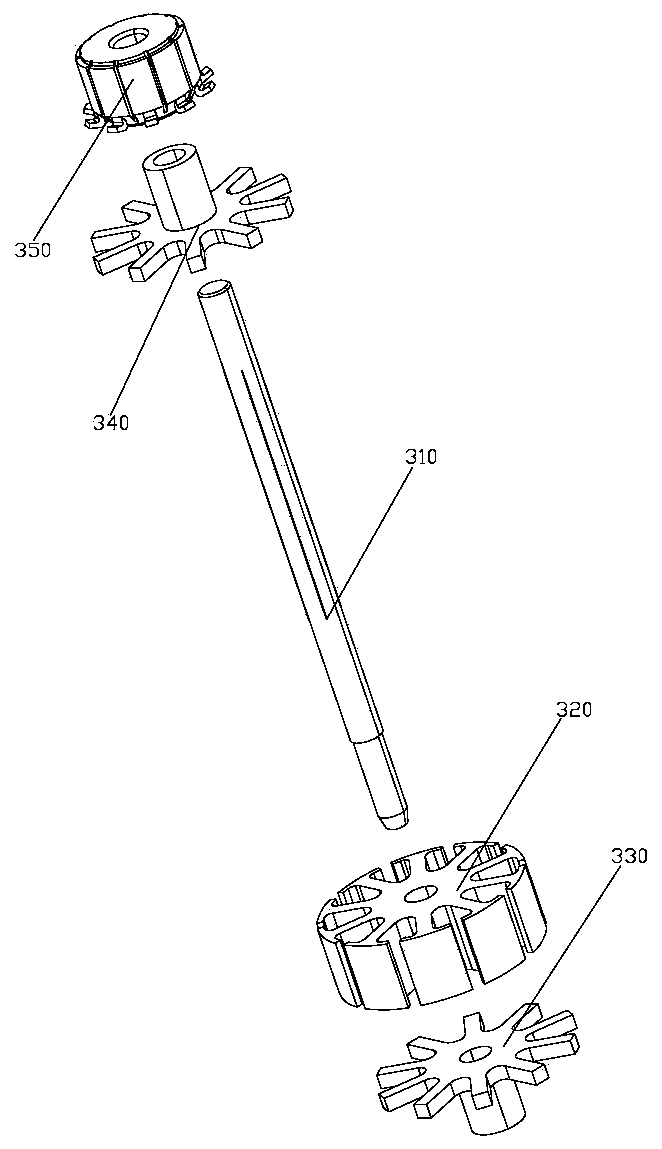

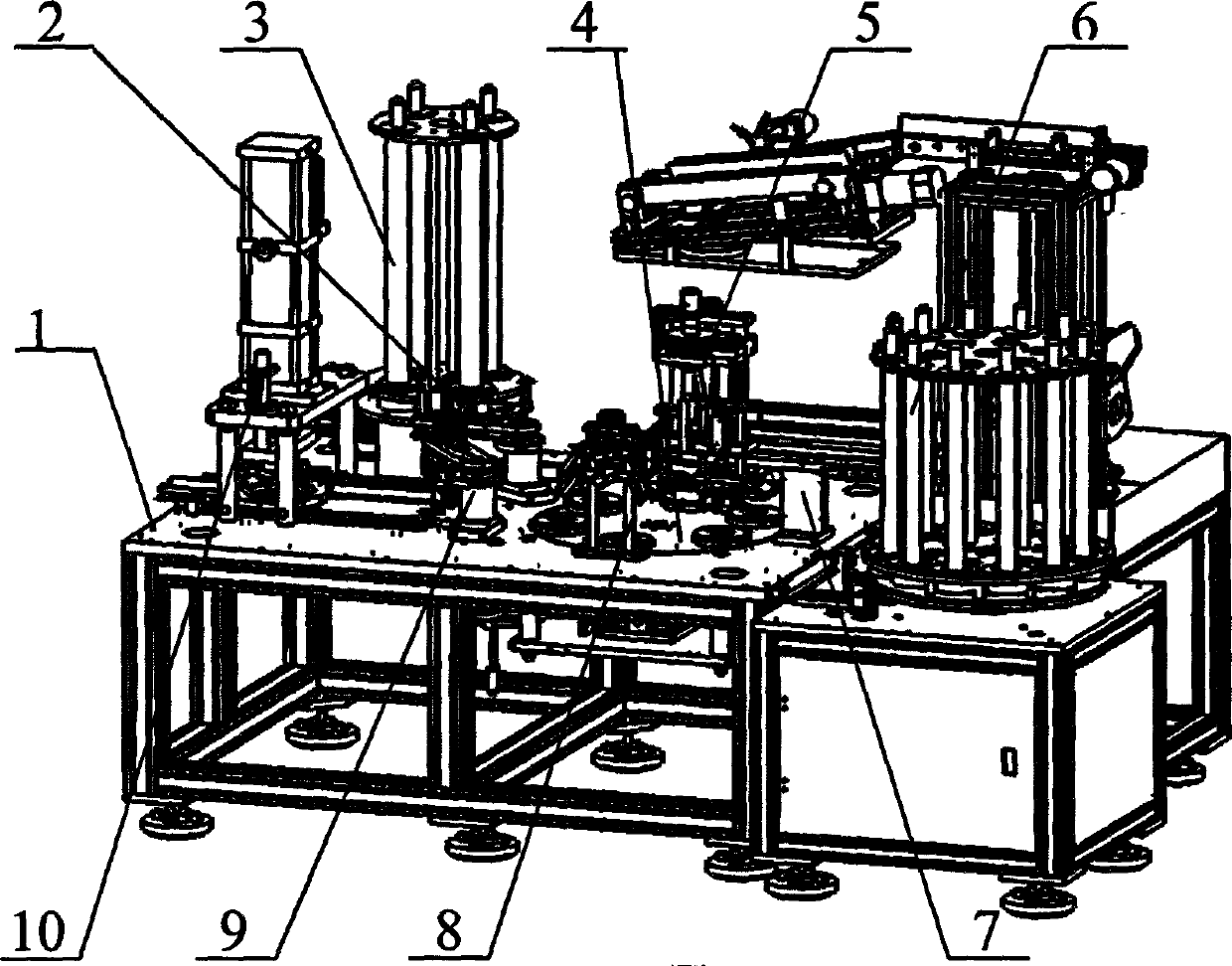

Electric machinery rotor automatic press-fitting machine

ActiveCN110142590ARealize automated assemblyIncrease productivityManufacturing stator/rotor bodiesMetal working apparatusElectric machineryCharging station

The invention discloses an electric machinery rotor automatic press-fitting machine. The electric machinery rotor automatic press-fitting machine comprises a machine frame, an iron core conveying device, a limiting transfer platform, a rotary workbench and a discharging conveying device; an iron core charging device is arranged on one side of the front end of the iron core conveying device; a mandrel charging device and a mandrel press-in device are arranged at the corresponding positions of the two sides of a mandrel insertion station at the front end of the limiting transfer platform; an automatic discharging device corresponding to a limiting transfer channel of the limiting transfer platform is arranged; the mandrel press-in device is arranged on one side of a mandrel press-in stationlimiting transfer channel at the rear end of the limiting transfer platform; a transition conveying device is arranged between the tail end of the limiting transfer platform and the rotary workbench;and a lower end plate charging station, a lower end plate insertion station, an upper end plate insertion station, a commutator insertion station, a commutator correction adjustment station, a commutator press-in station and a rotor discharging station are uniformly arranged on the rotary workbench. Automatic assembly of electronic rotors can be achieved, the production efficiency is high, and theassembly quality is stable.

Owner:深圳市兴特创自动化设备有限公司

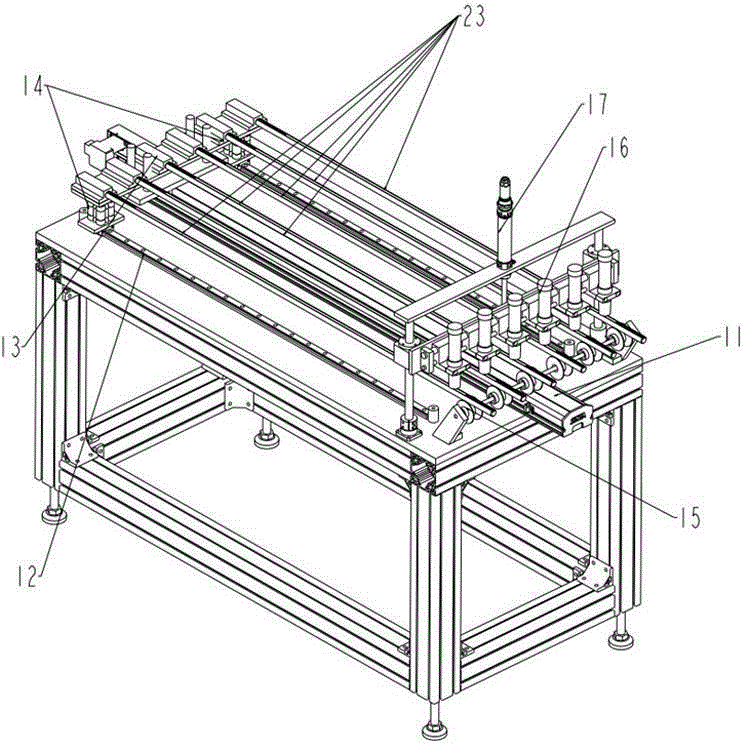

Flexible tool for assembling row-line chuck type wall board

A flexible tool for assembling a row-line chuck type wall board comprises a guide rail base, an X-direction driving unit and an upright post shape-adjusting assembly unit, wherein the guide rail base is fixedly connected to the ground; the upright post shape-adjusting assembly unit is arranged on two X-direction linear guide rails of the guide rail base and can move along the X-direction linear guide rails; and the X-direction driving unit is positioned between the bottom of the upright post shape-adjusting assembly unit and the guide rail base, is fixedly connected with the guide rail base and is connected with the bottom of the upright post shape-adjusting assembly unit. According to the flexible tool disclosed by the invention, aircraft panel assemblies are adsorbed, clamped and digitally positioned by a dot matrix vacuum chuck and stability and reliability in clamping and positioning and high positioning precision are obtained; and the digitalized positioning and drilling and riveting assembly of different wall board assemblies can be realized by reconfiguration through the dot matrix chuck of the tool. The flexible tool has higher practical value and broad application prospect in the fields of mechanical engineering / aircraft assembly.

Owner:BEIHANG UNIV

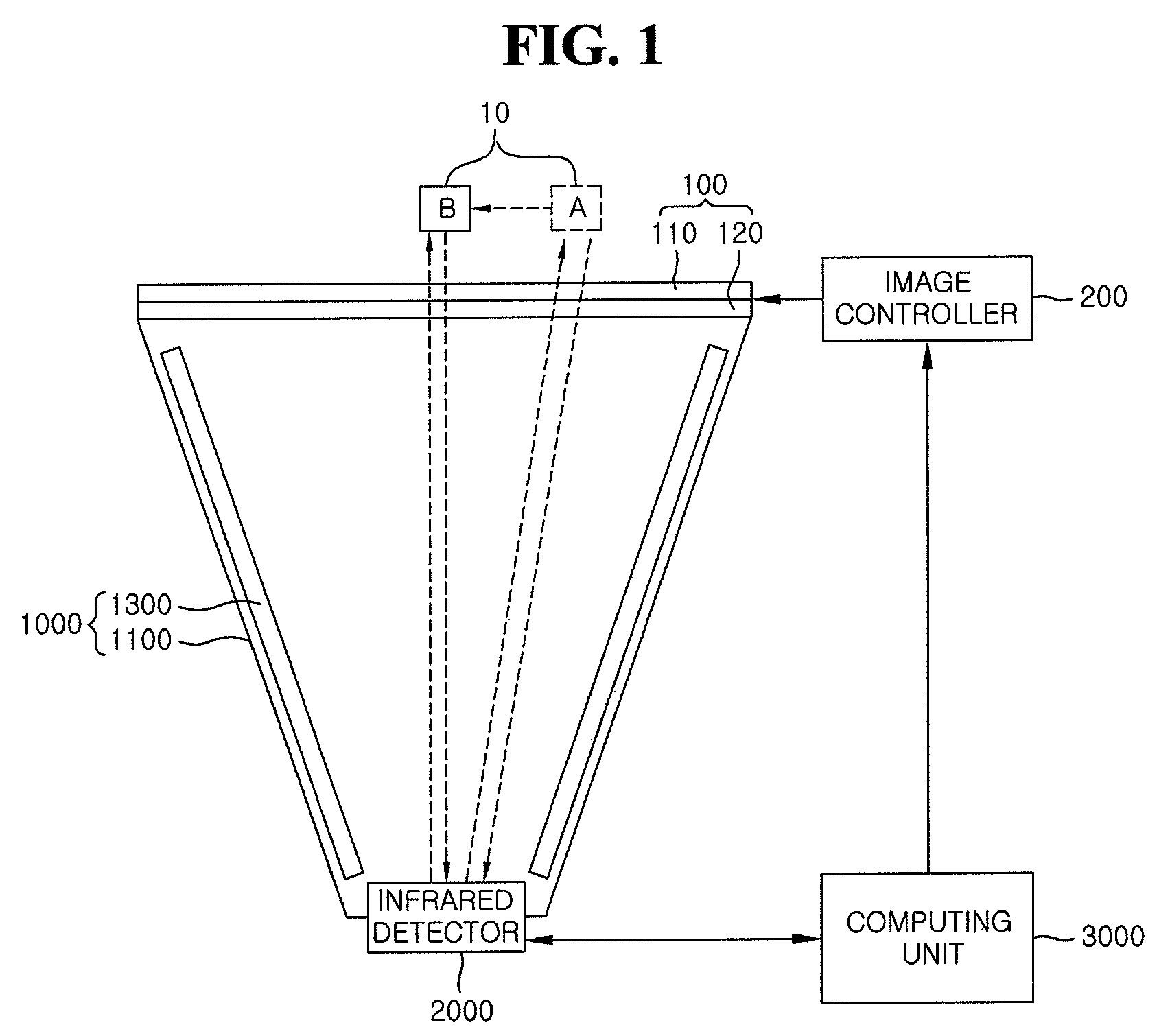

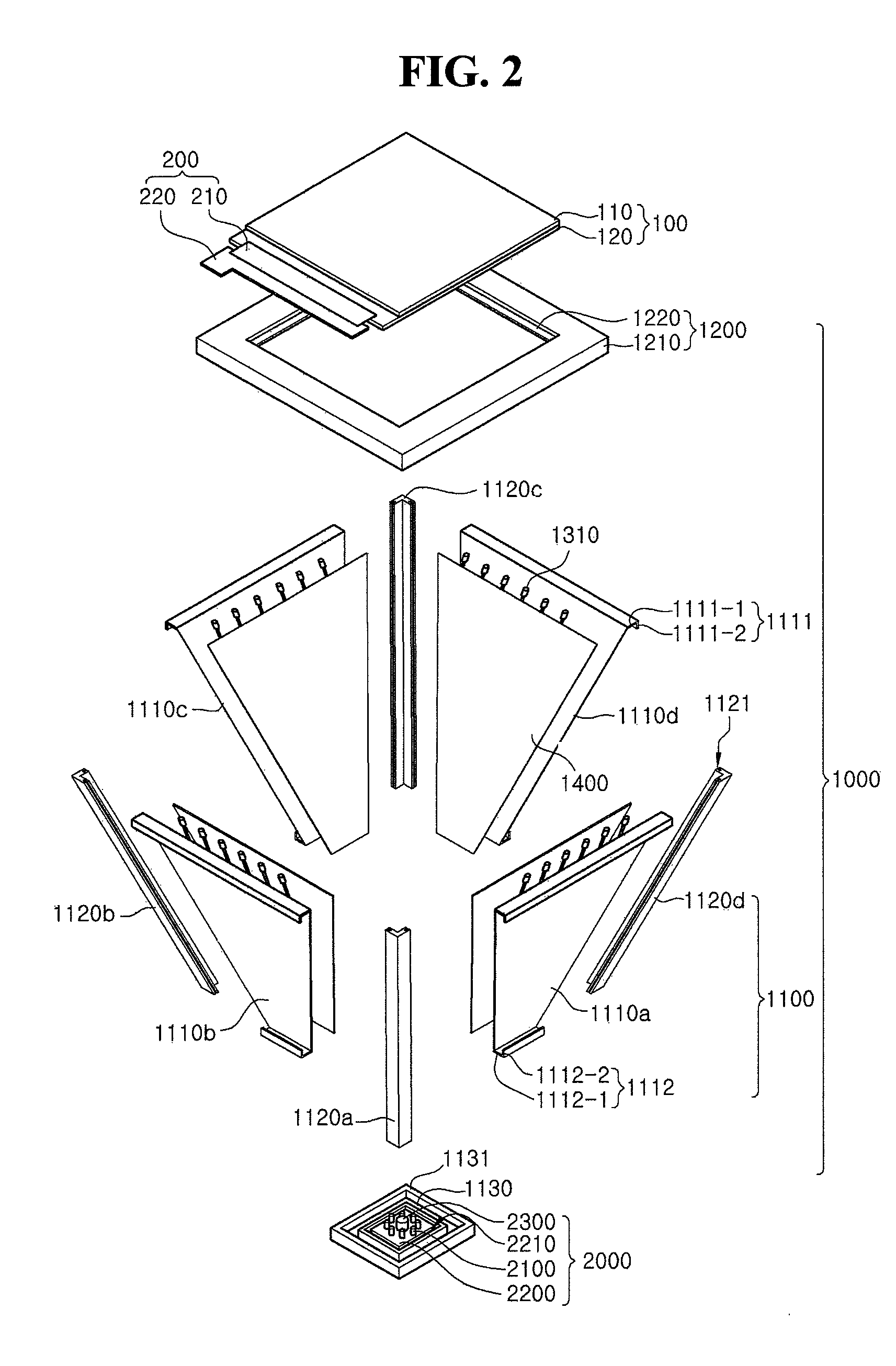

Display system

InactiveUS8023061B2Improve brightness uniformityEasy to detectStatic indicating devicesDigital data processing detailsLiquid-crystal displayEngineering

Owner:SAMSUNG DISPLAY CO LTD

Refrigerator

ActiveUS9080799B2Improve assembly qualityAvoid failureLighting and heating apparatusIce productionFrostEngineering

A structure of a driving apparatus capable of easily organizing a driving apparatus that is configured to drive an ejector of an ice maker, and preventing frost from being formed on inner compartments, the driving apparatus including a case and a driving module detachable to the inner side of the case, wherein the driving module includes an ice separating motor to drive the ejector, a circuit board to control an ice making process, an electro-motion member to deliver a rotational force of the ice separating motor to the ejector, and a module case to accommodate the components of the driving module.

Owner:SAMSUNG ELECTRONICS CO LTD

Slip casting control shield attitude and deviation correcting construction method

The invention discloses a construction method for controlling the posture of a shield by grouting, and for deviation rectification. The method comprises the following steps: first, grouting holes are additionally arranged on a shield shell body; second, grouting material is prepared; third, grout used for grouting is stored and transported; fourth, grouting is performed to the shield shell body. The method adopts shearing resistant high gravity single slurry mainly including sand as the grouting material, grouting is performed through the grouting holes of the shield shell body, and the purposes of shield posture adjustment and deviation rectification can be achieved. The method has the advantages that the method is simple and feasible, the effect is obvious, and meanwhile, the influence of the shield construction to the periphery environment can be reduced. Therefore, the method is especially suitable for the tunnel construction of the large-scale shield, and can particularly be used for shield posture adjustment and deviation rectification during the construction of the shield with ultra large diameter larger than 11 m.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

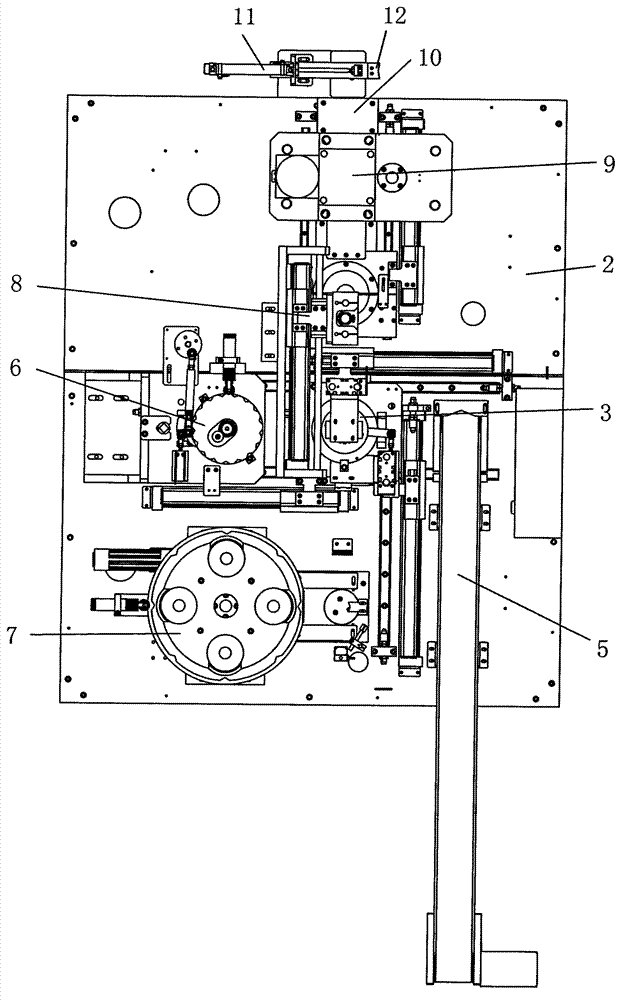

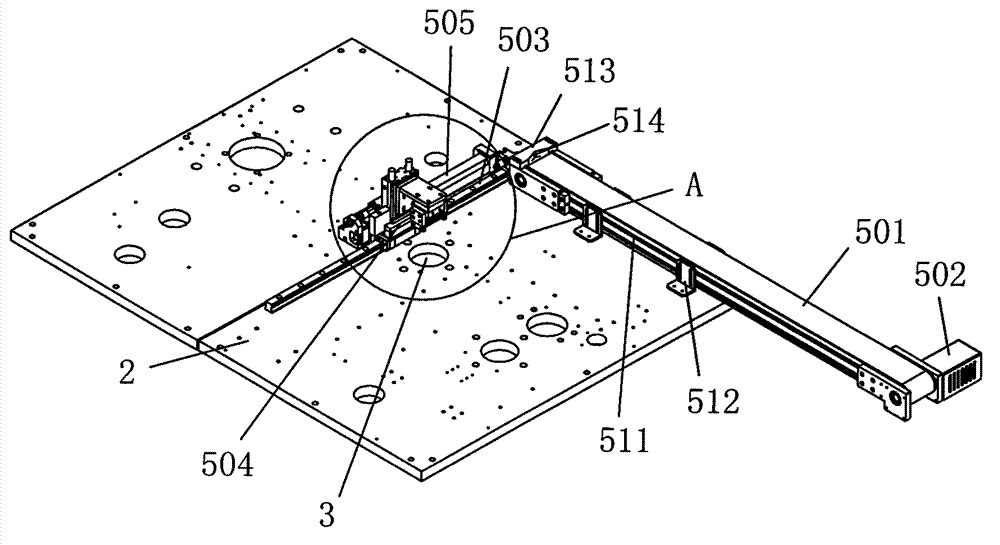

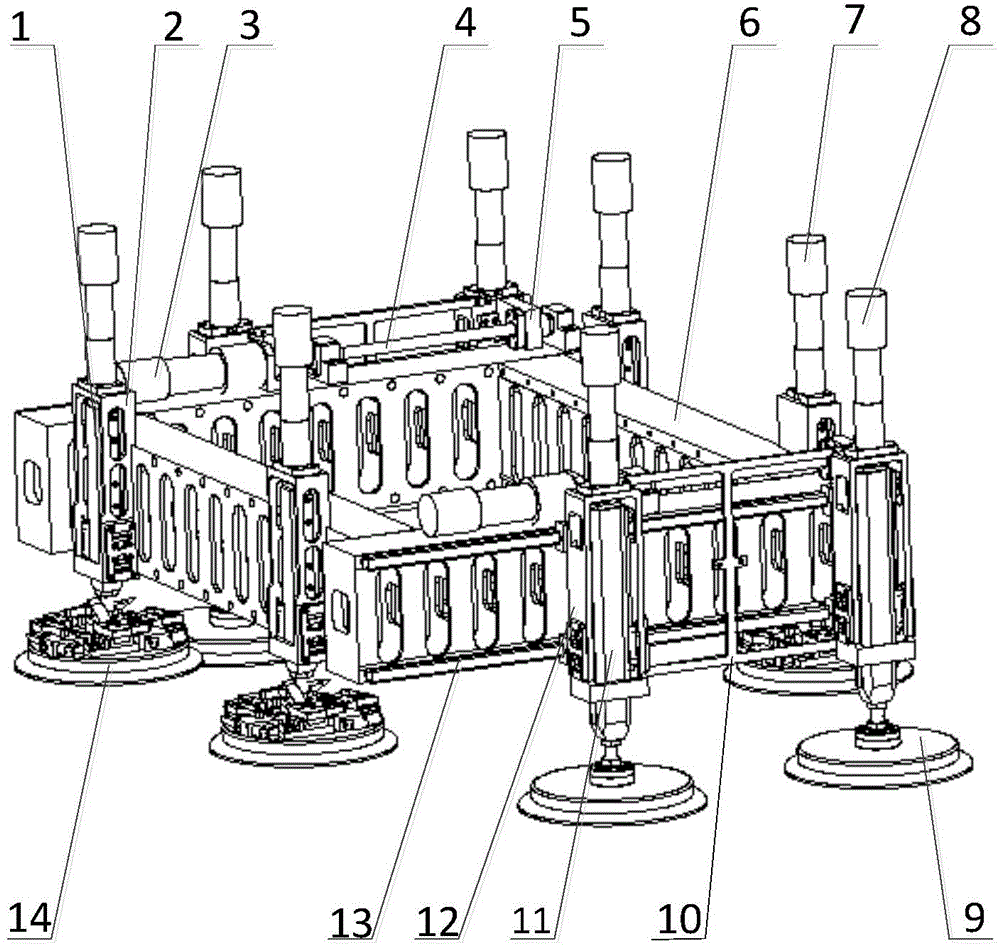

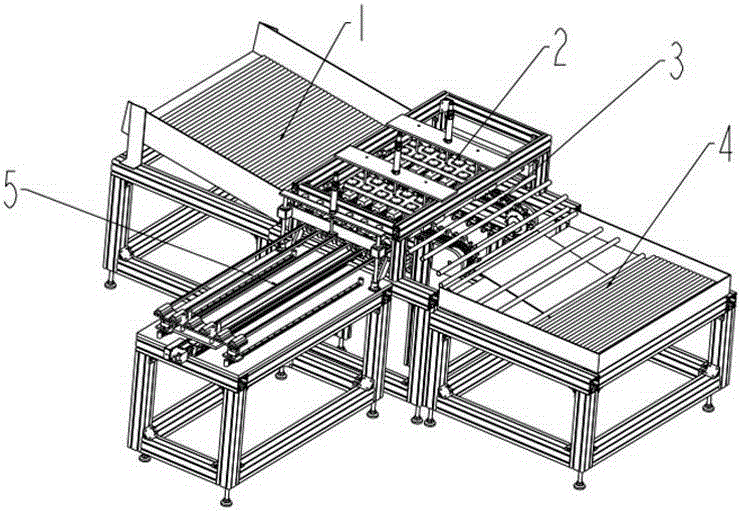

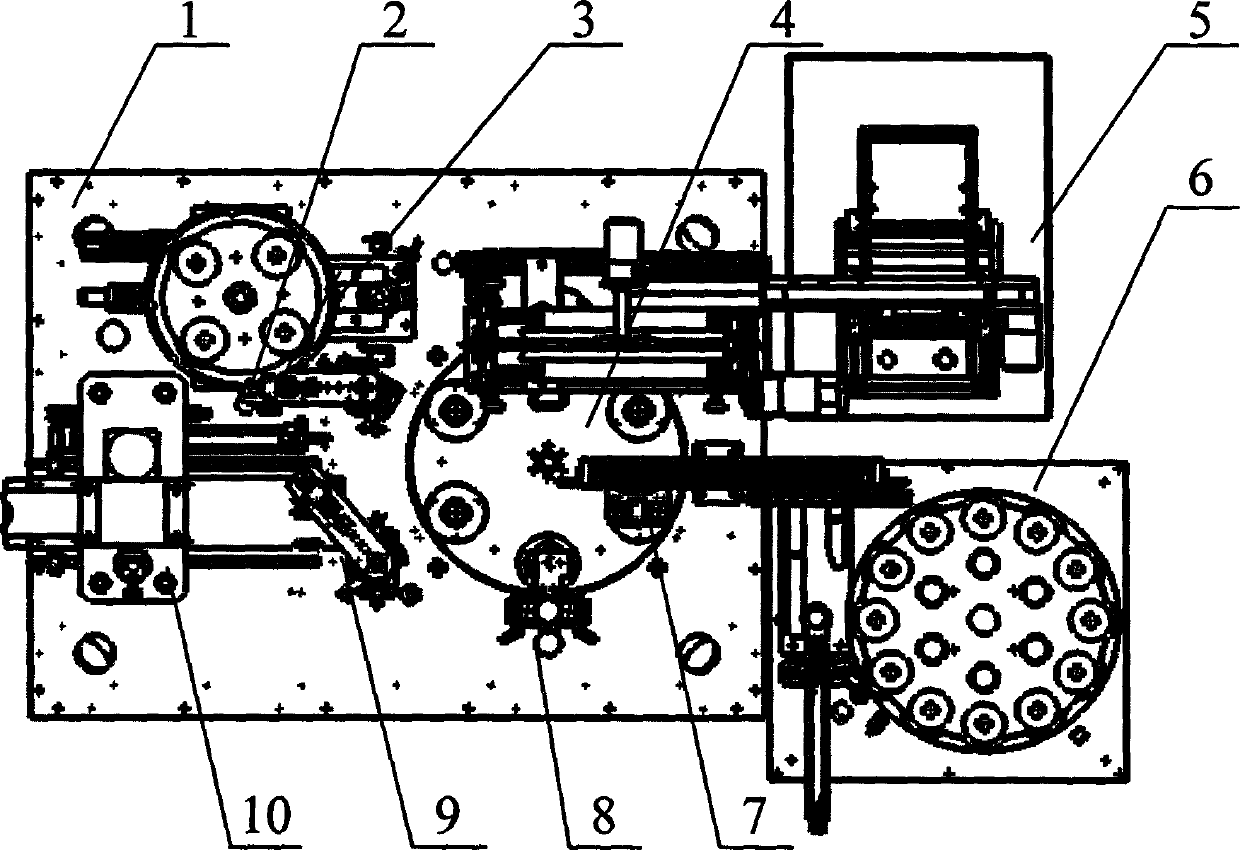

Rotary disk type full-automatic bearing assembly machine

ActiveCN105508445AImprove assembly efficiencyImprove assembly qualityBearing componentsEngineeringAssembly machine

The present invention relates to a rotary disk type full-automatic bearing assembly machine, which comprises a rotary disk assembly arranged on a work table, wherein a holding frame material feeding assembly, a roller assembling assembly, an inner ring material feeding assembly, an image leakage detection assembly and a pressing-installing assembly are sequentially and uniformly arranged on the periphery of the rotary disk assembly, the alignment sequence of various assemblies is consistent with the rotating direction of the rotary disk, and the operation sequence of various assemblies is consistent with the product production process sequence. According to the present invention, the rotary disk type structure is used, various assemblies are rationally integrated, and the processes such as holding frame material feeding, roller material feeding and assembly, inner ring material feeding, roller leakage detection, inner assembly riveting pressing and the like can be automatically completed, such that the bearing assembly efficiency and the assembly quality are substantially improved, and the security risk is eliminated.

Owner:NINGBO ZEE AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com