Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9262results about "Measurement of fluid loss/gain rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for leak detection in heat transfer systems

InactiveUS20080314073A1Low vapor pressureMeasurement of fluid loss/gain rateCompression machines with non-reversible cycleTransfer systemSystem pressure

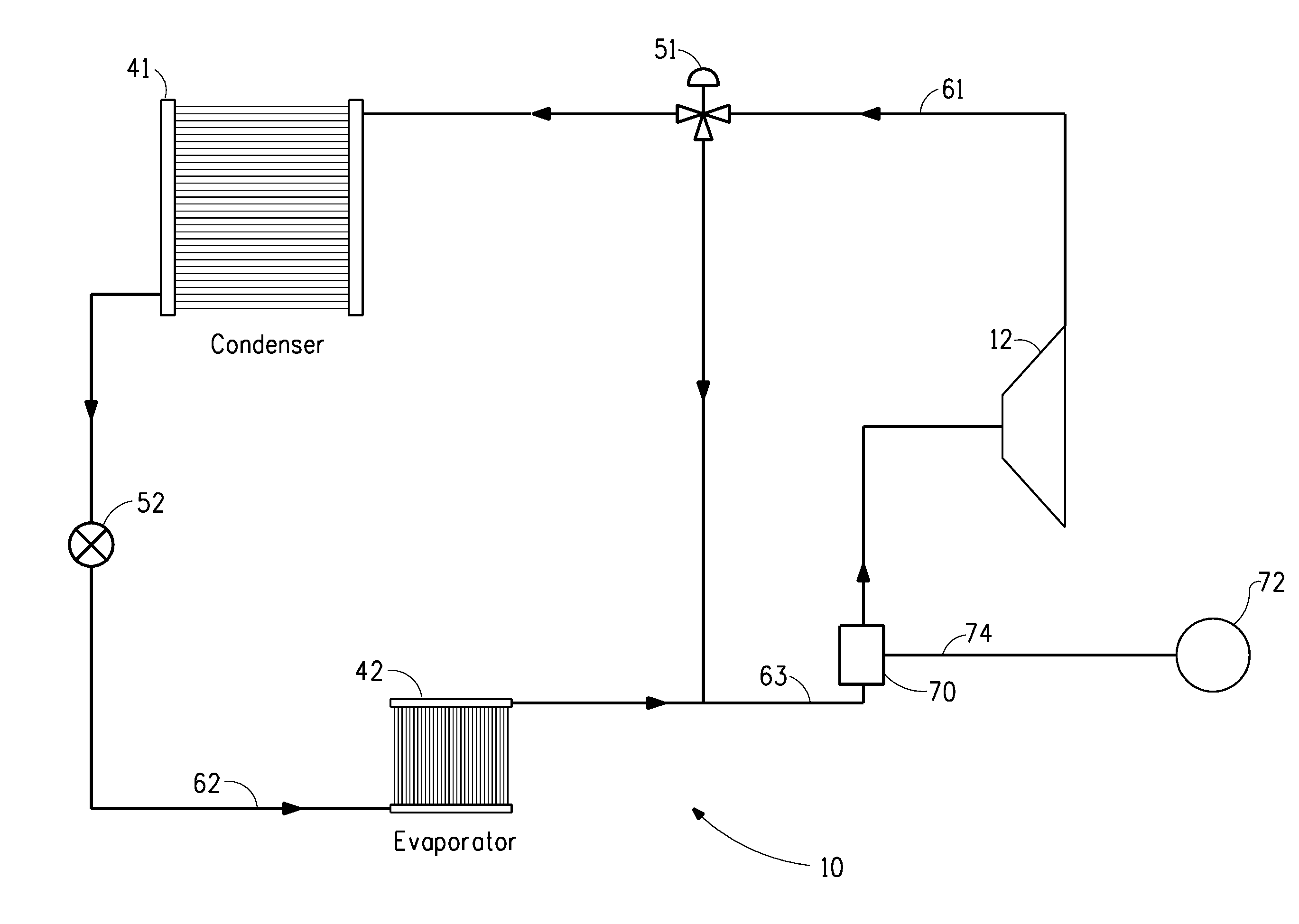

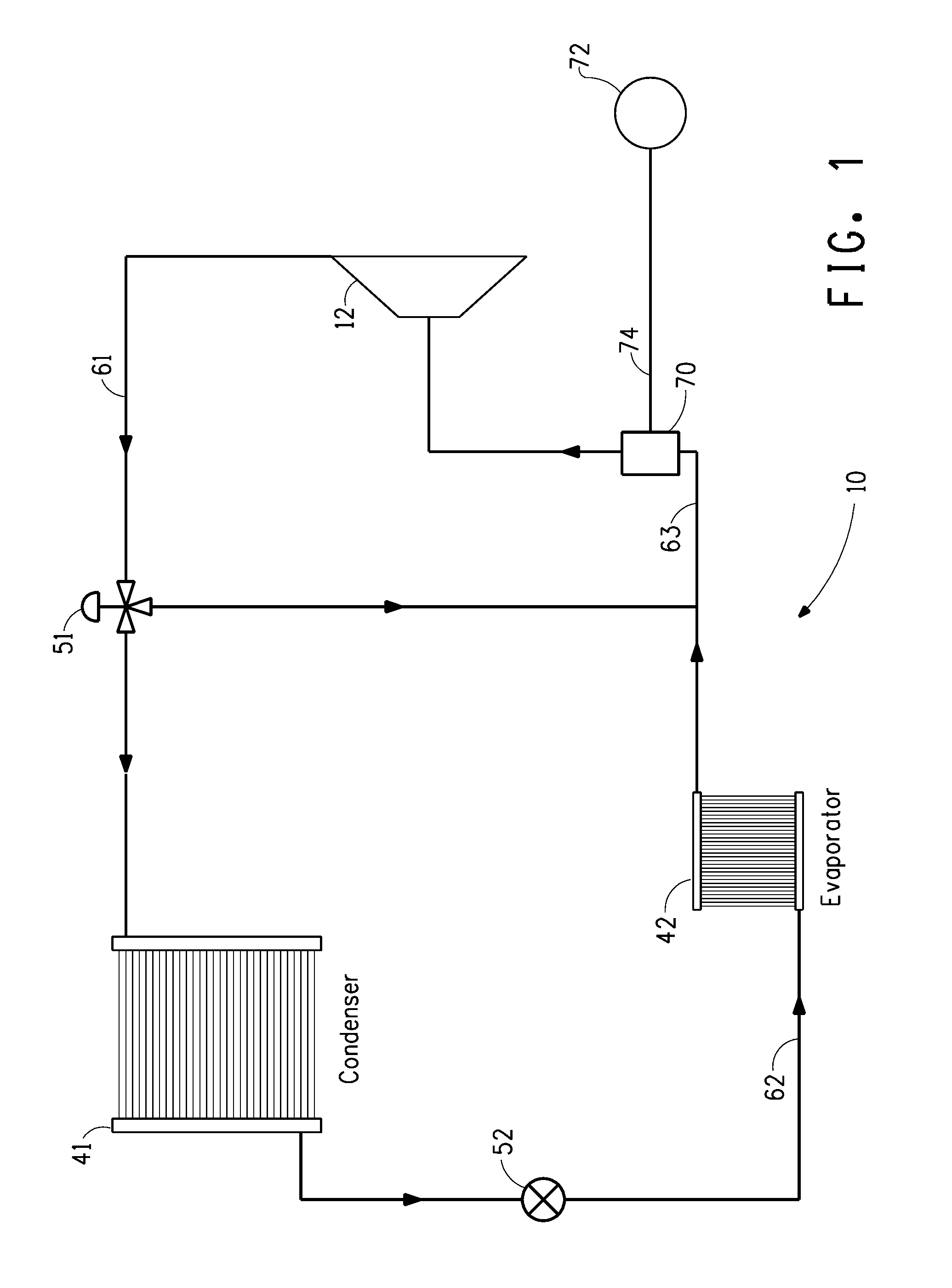

Disclosed is a method for detecting a leak in a closed loop heat transfer system comprising monitoring the pressure of the heat transfer composition inside said heat transfer system, wherein a drop in pressure indicates a leak. Also disclosed is a heat transfer system comprising an evaporator, a compressor, a condenser, an expander and a device for measuring internal system pressure. The system pressure measuring device is disposed inside the closed loop heat system. The internal system pressure measuring means may be located either between the evaporator and the condenser, between the expander and the evaporator, between the compressor and the condenser, or between the condenser and the expander.

Owner:EI DU PONT DE NEMOURS & CO

Tube occluder and method for occluding collapsible tubes

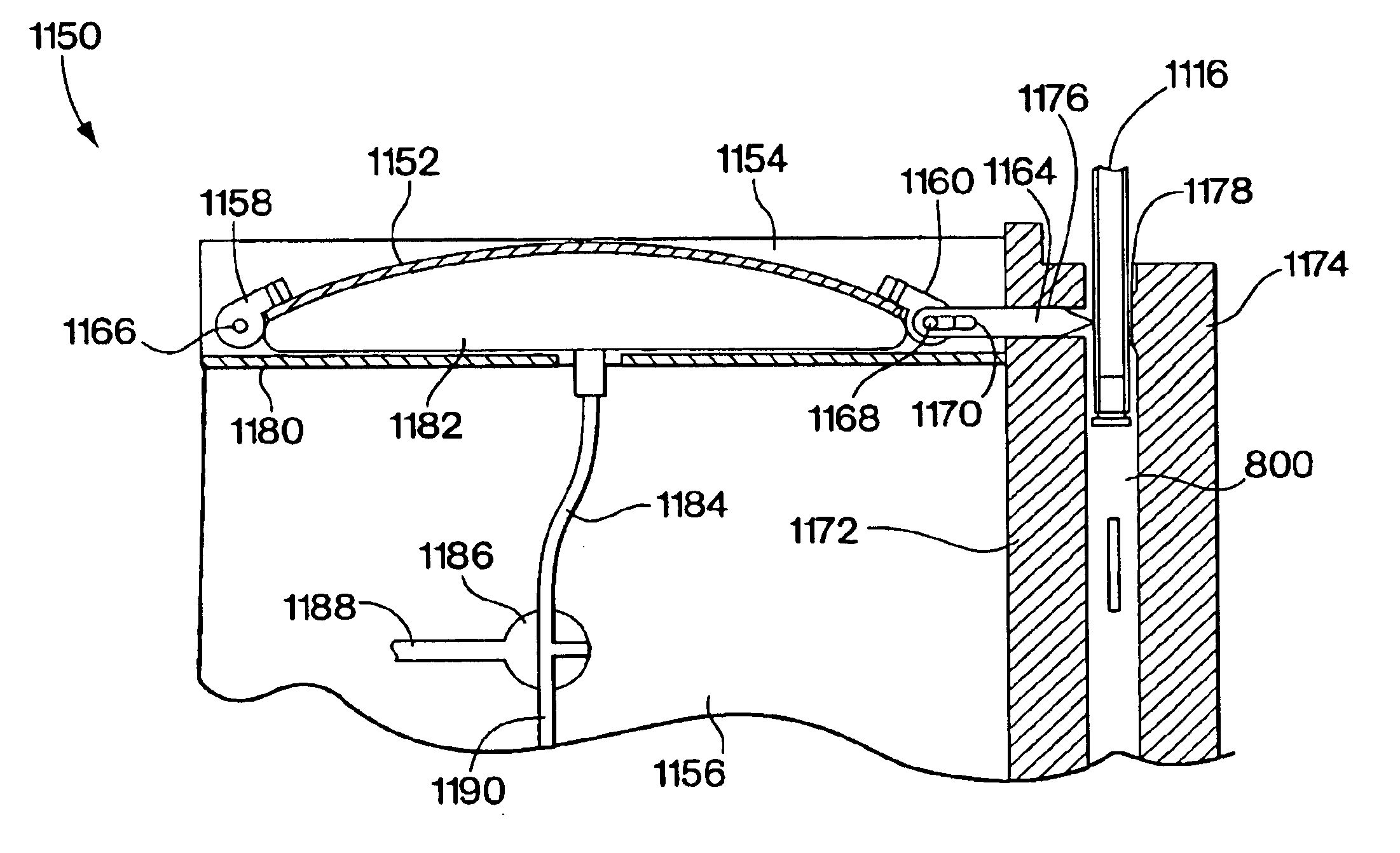

The present invention involves, in some embodiments, mechanisms and methods of occluding collapsible tubing with an occluder to prevent fluid flow therethrough. In some embodiments, a tube occluding mechanism is disclosed that includes a bendable occluding member for creating a force that can be applied to a collapsible tube to occlude the tube. In some embodiments, the collapsible tube can be an inlet / outlet tube on a removable pumping cartridge that is coupled to a reusable pump drive component when the system is in operation. In such embodiments, the occluding mechanism can be attached to the reusable component and can be used to block fluid flow to and from the pumping cartridge. In some embodiments, the occluding member can comprises a spring plate which can create a force to occlude tubing when in a relaxed, unbent configuration, and which can be bent to unocclude the tubing. In some preferred embodiments, in a default configuration of the tube occluder mechanism (when no external force is applied to the occluding member) the tubes are occluded, so that the tube occluder mechanism provides a fail-safe configuration preventing fluid flow to and from a pumping cartridge to which the tubes can be connected.

Owner:DEKA PROD LLP

Tube occluder for occluding collapsible tubes

Owner:DEKA PROD LLP

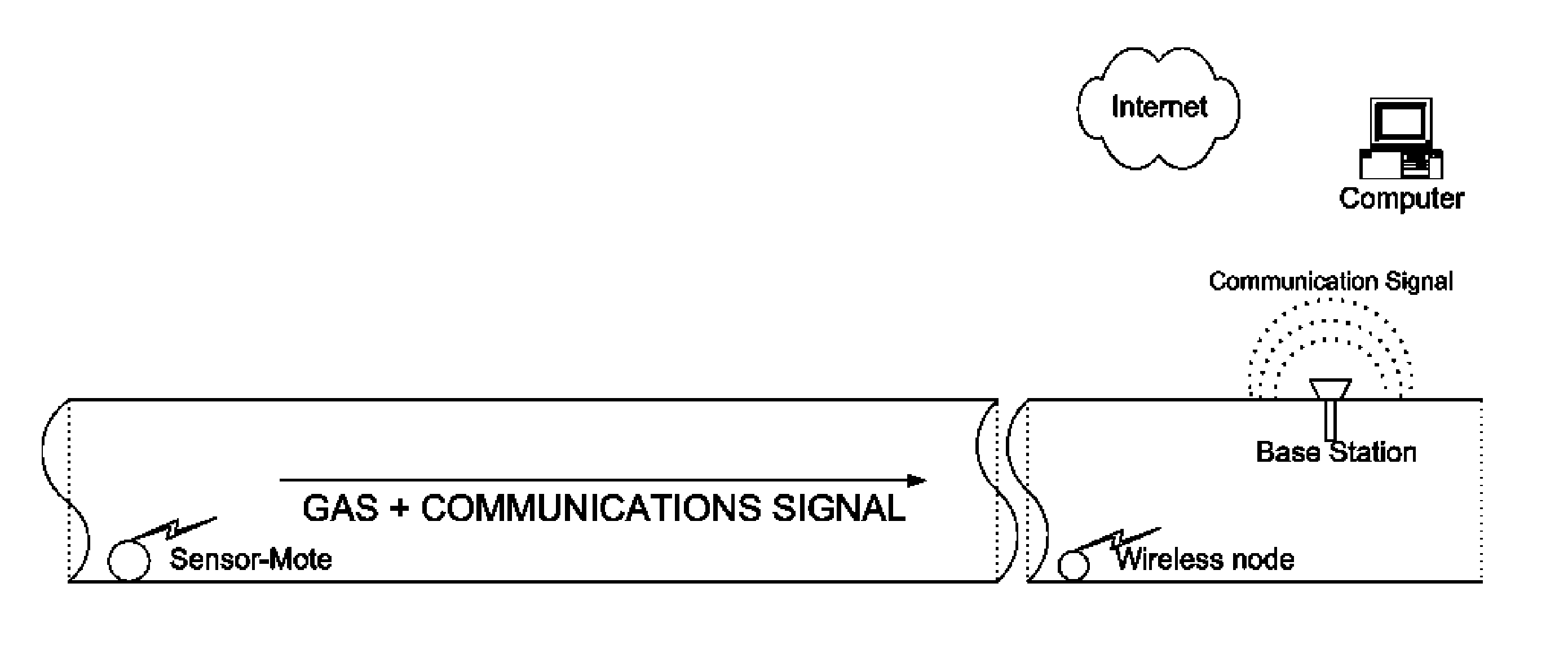

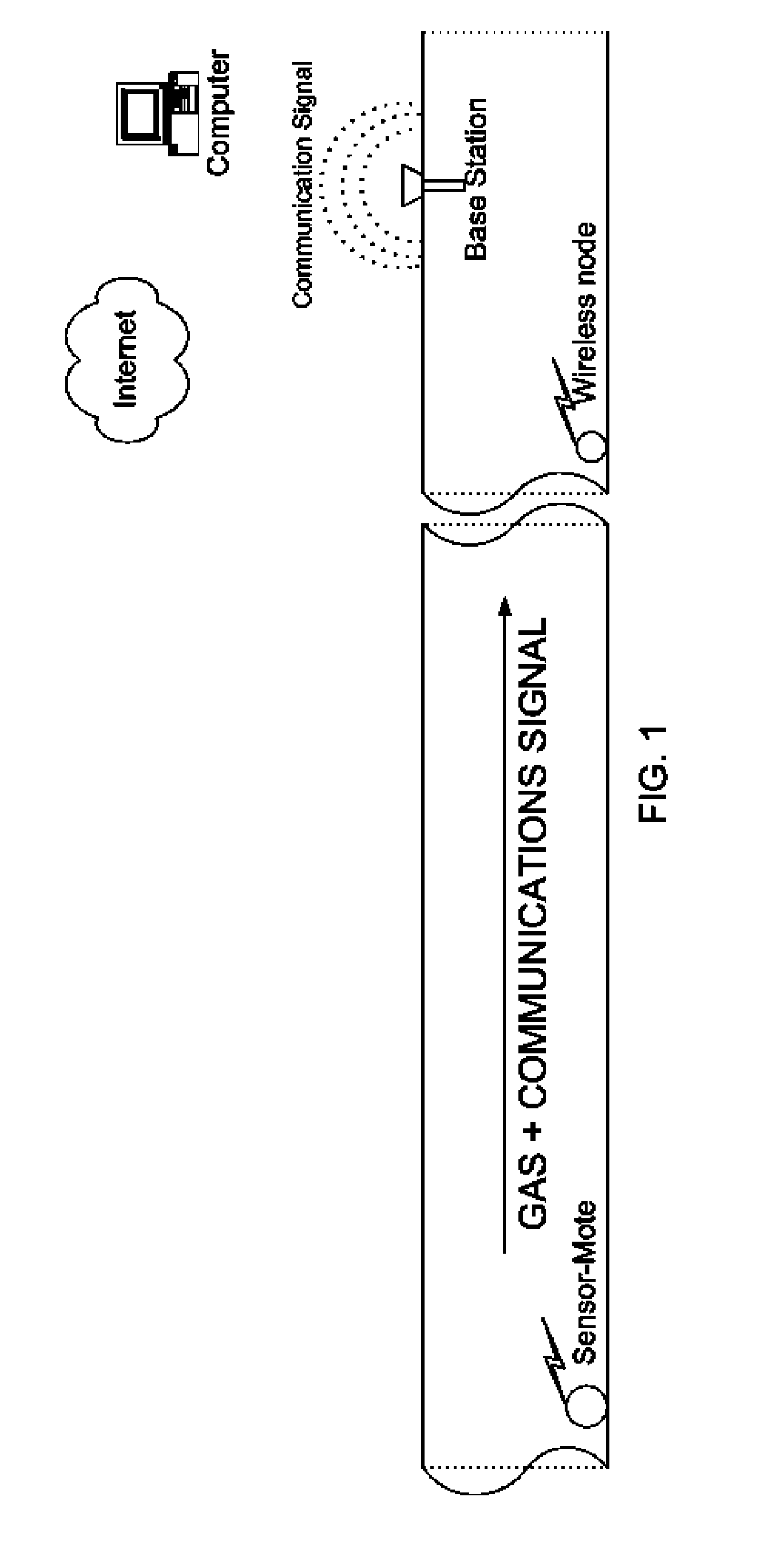

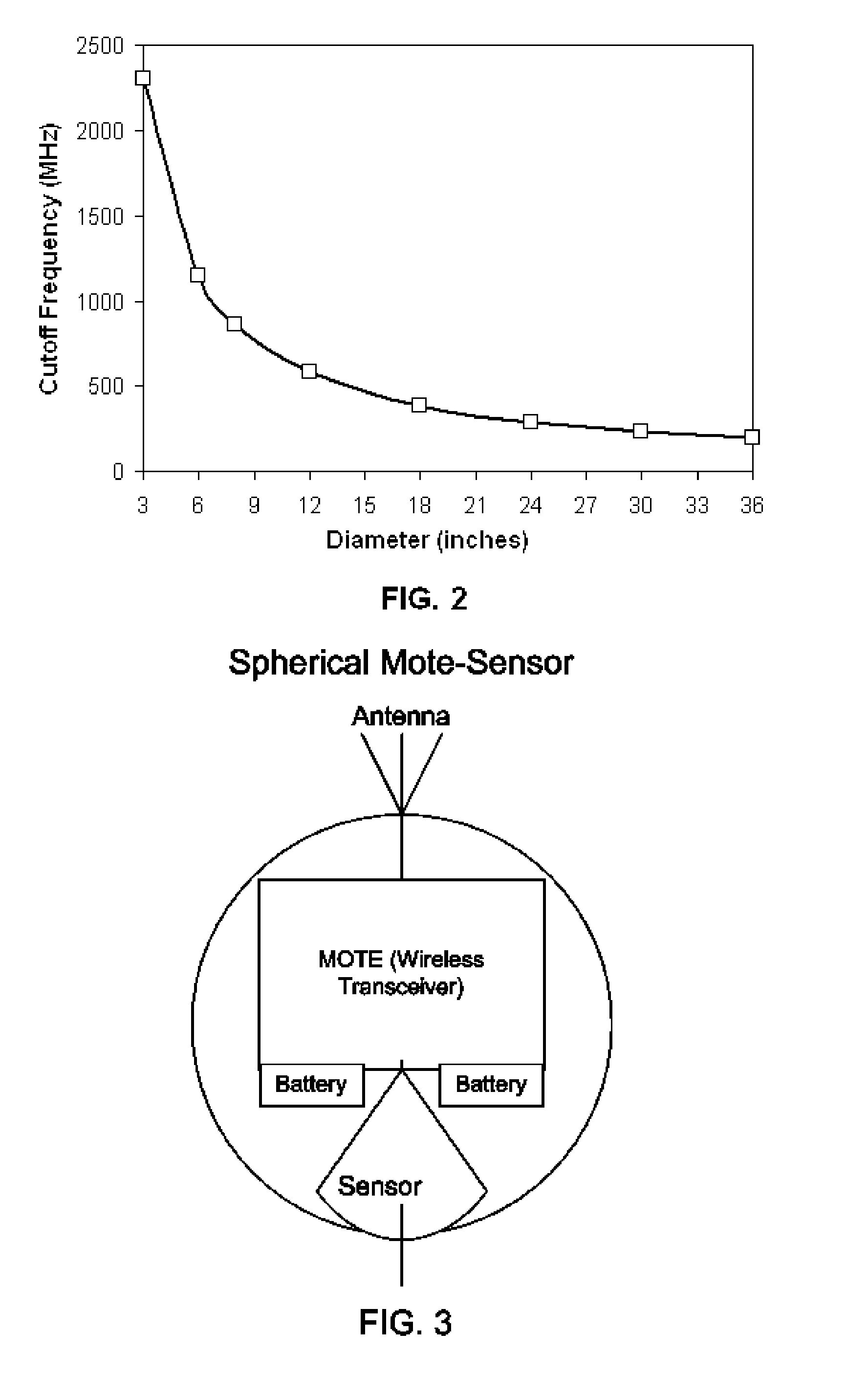

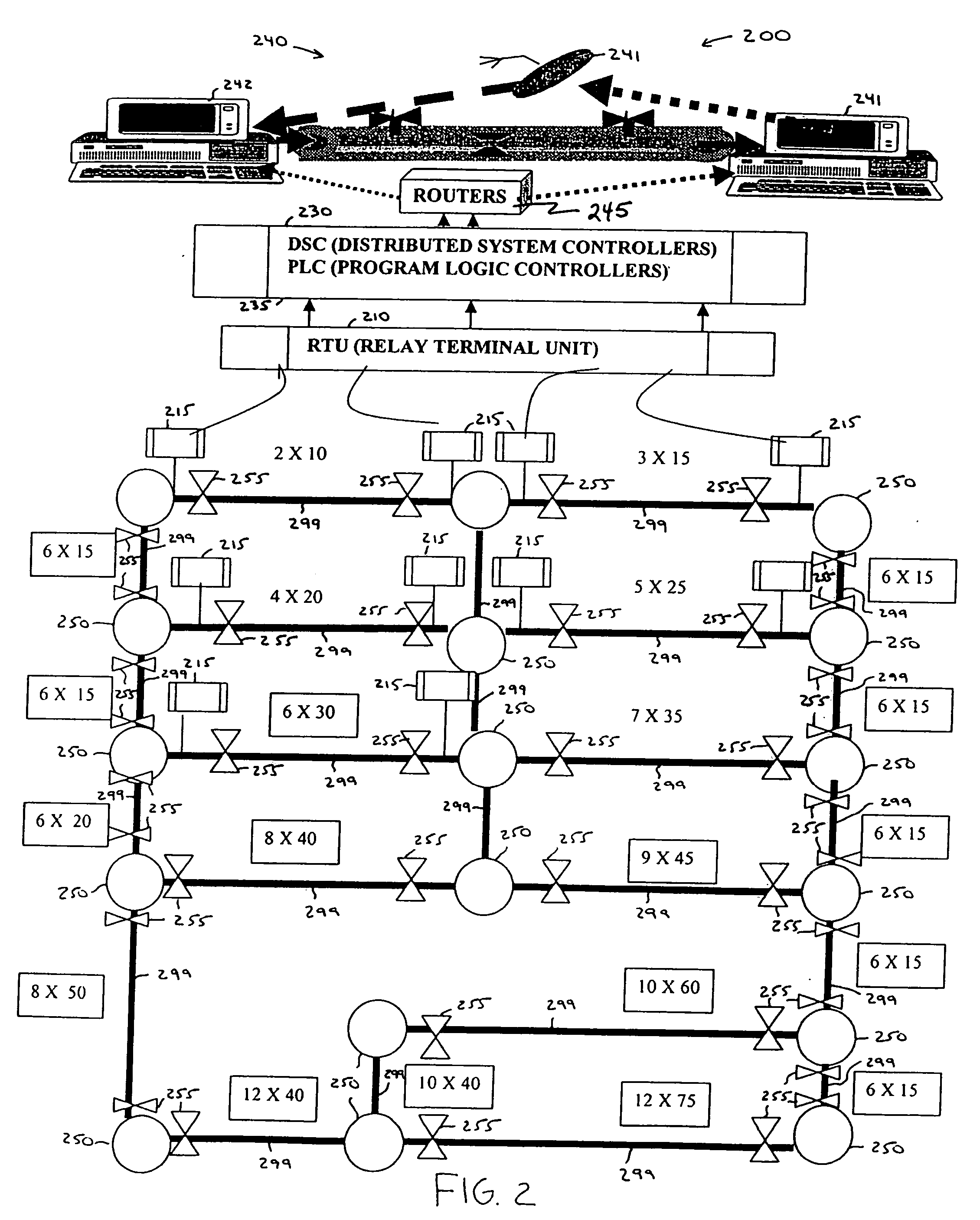

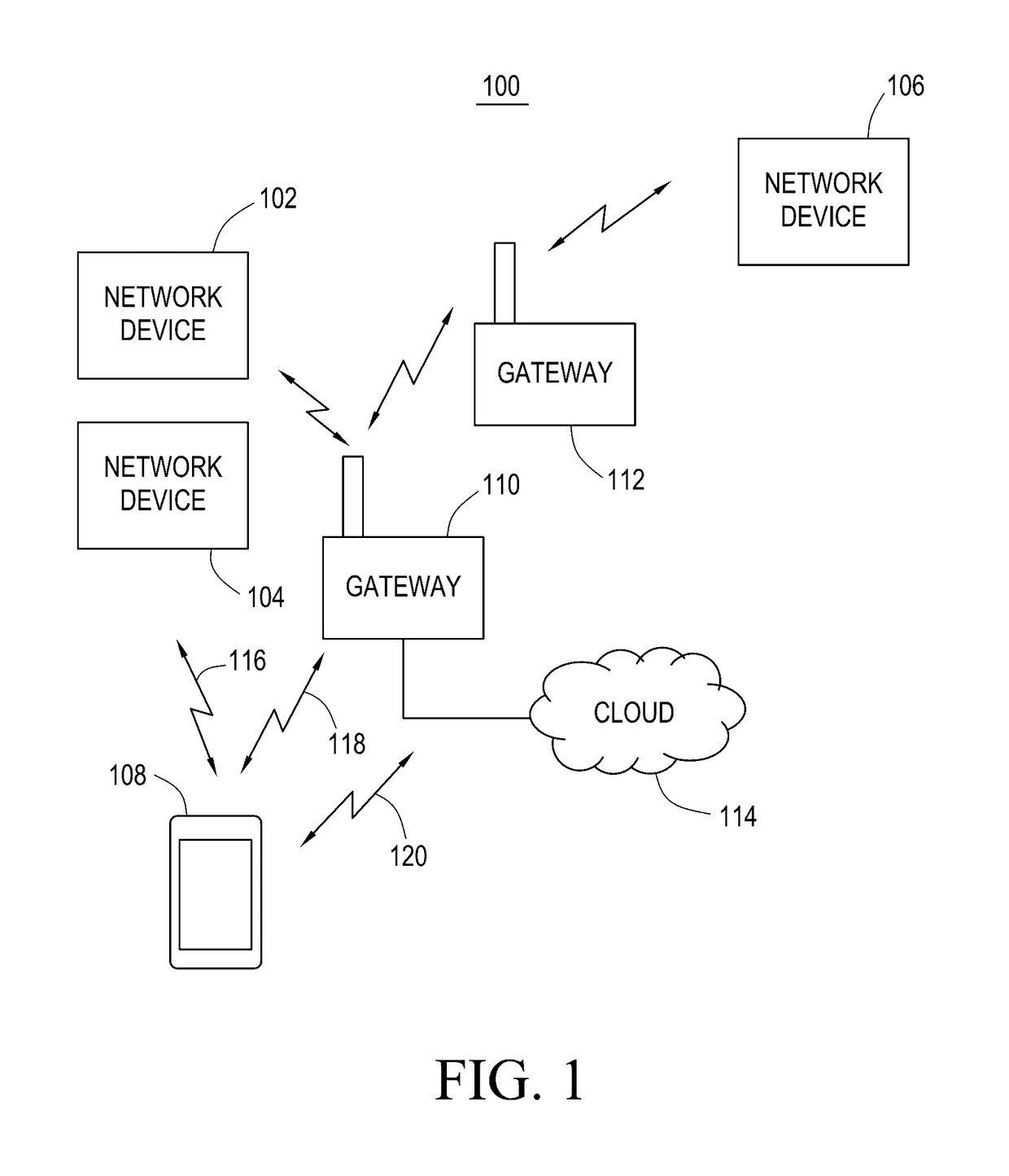

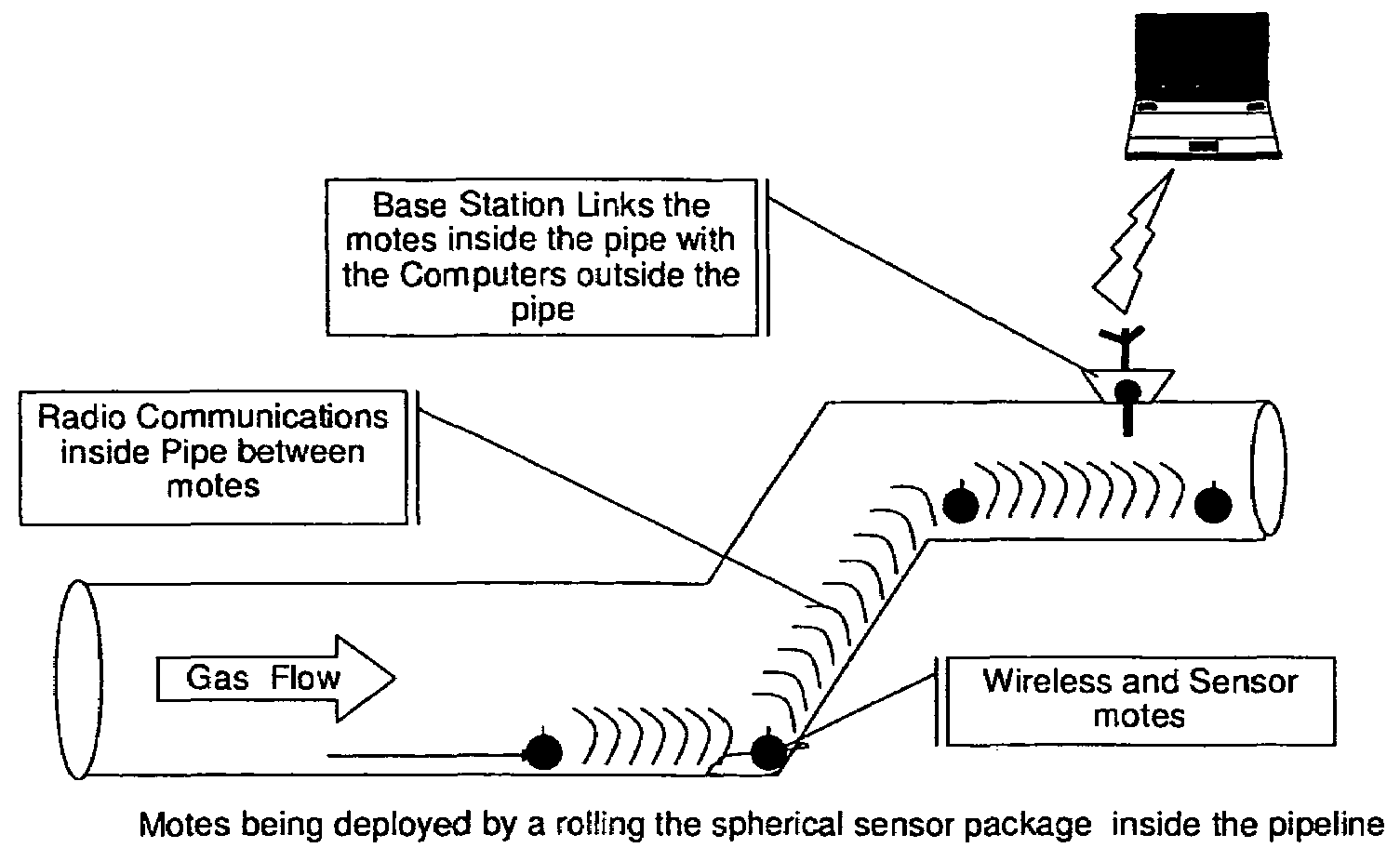

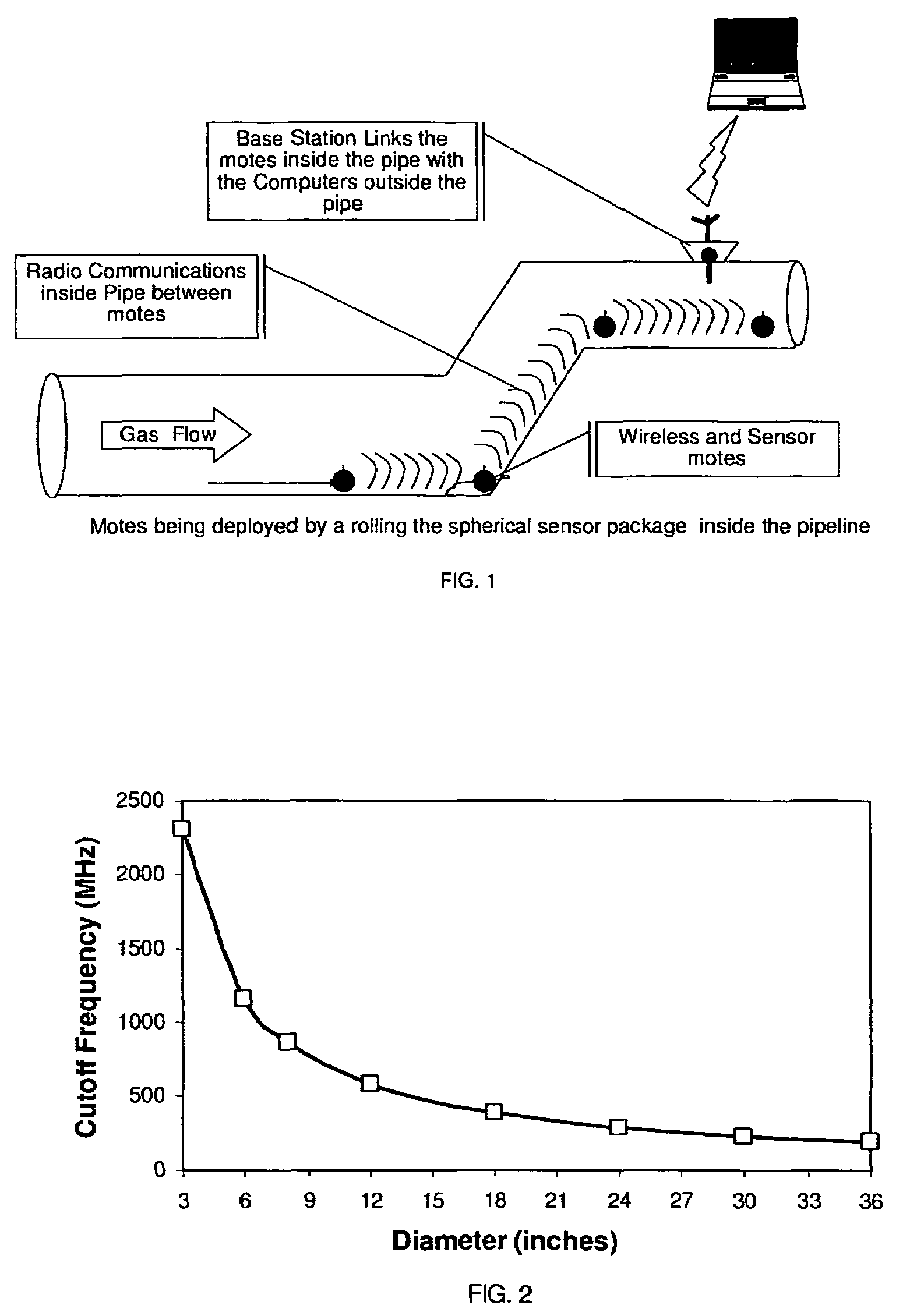

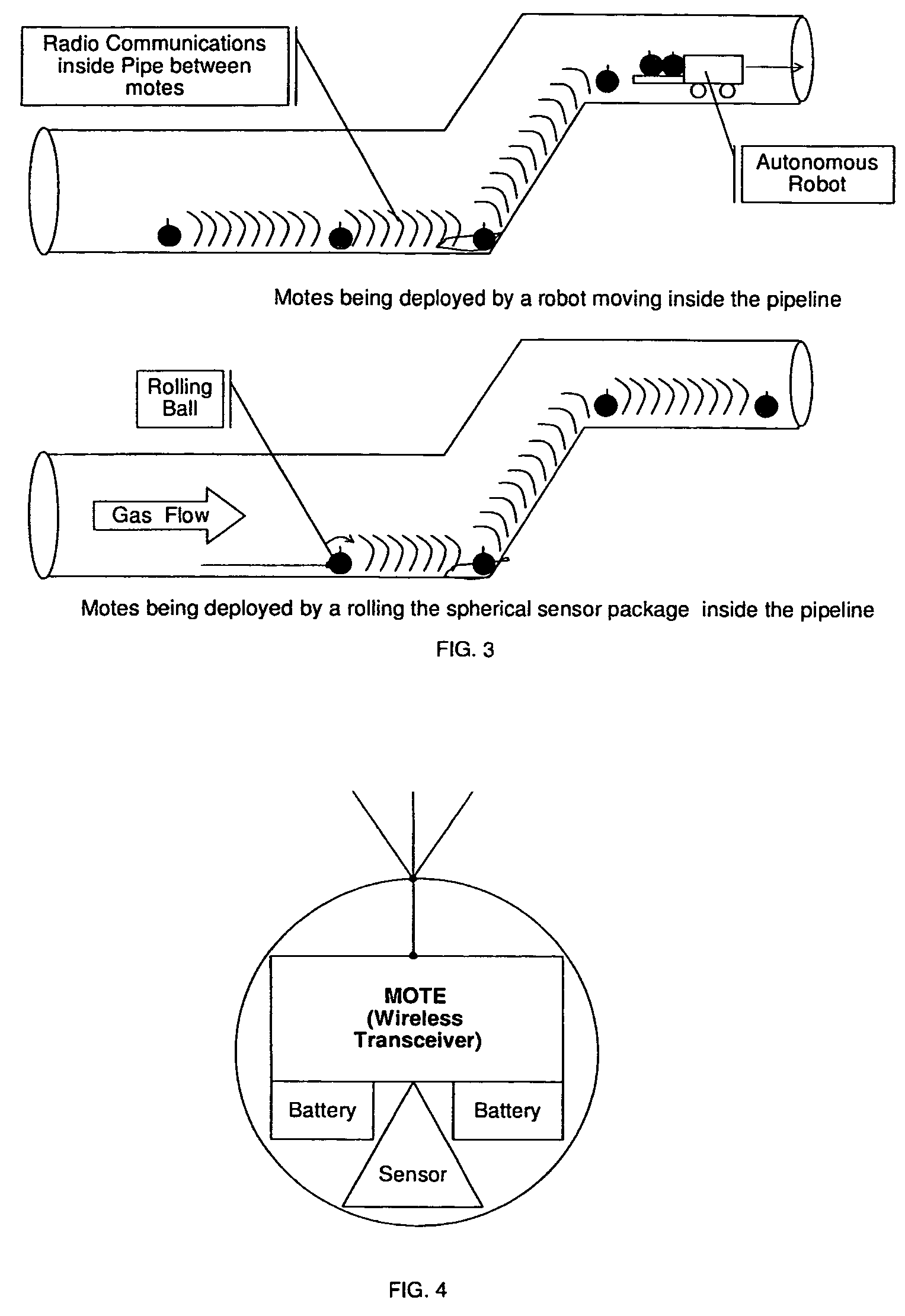

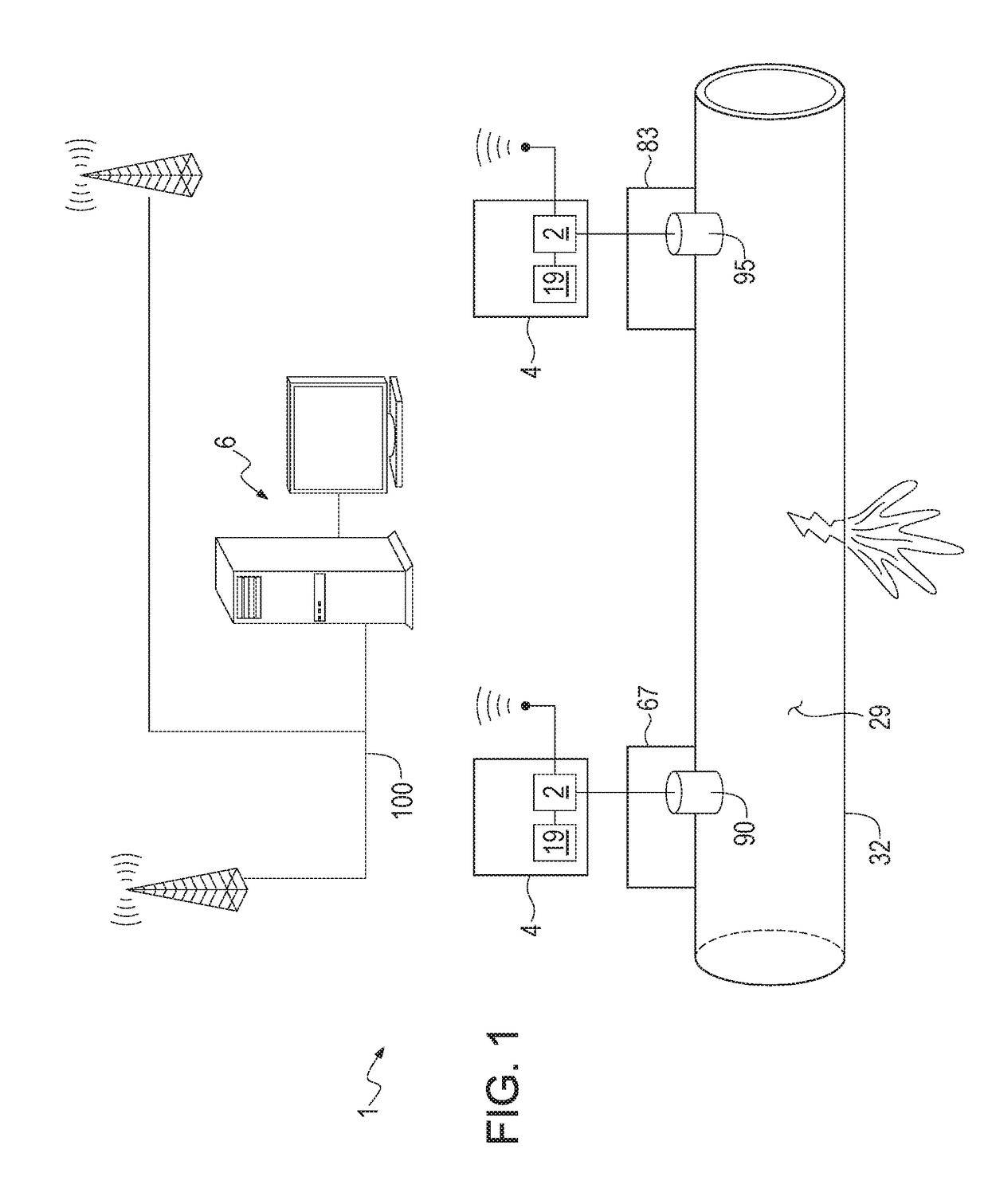

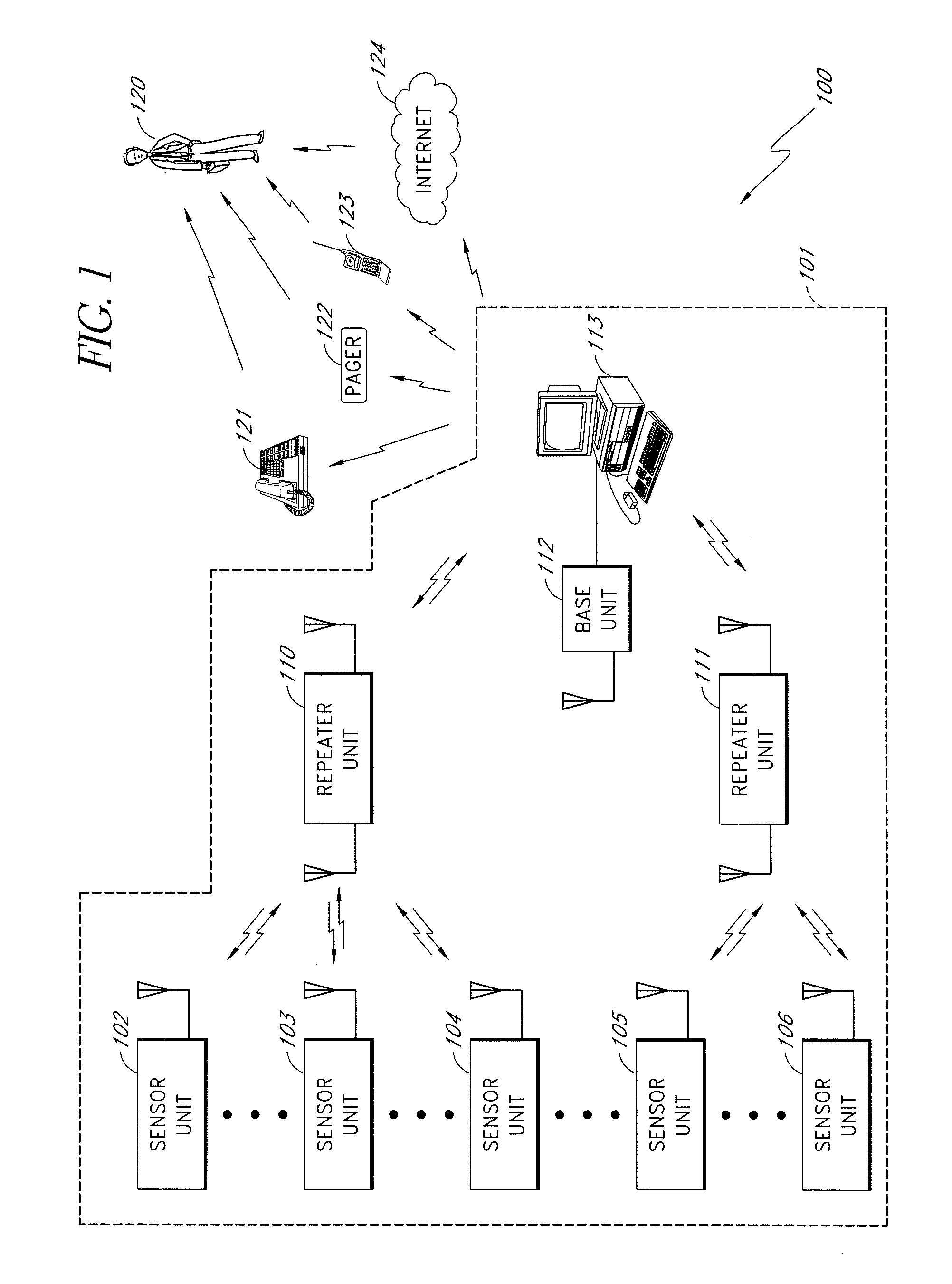

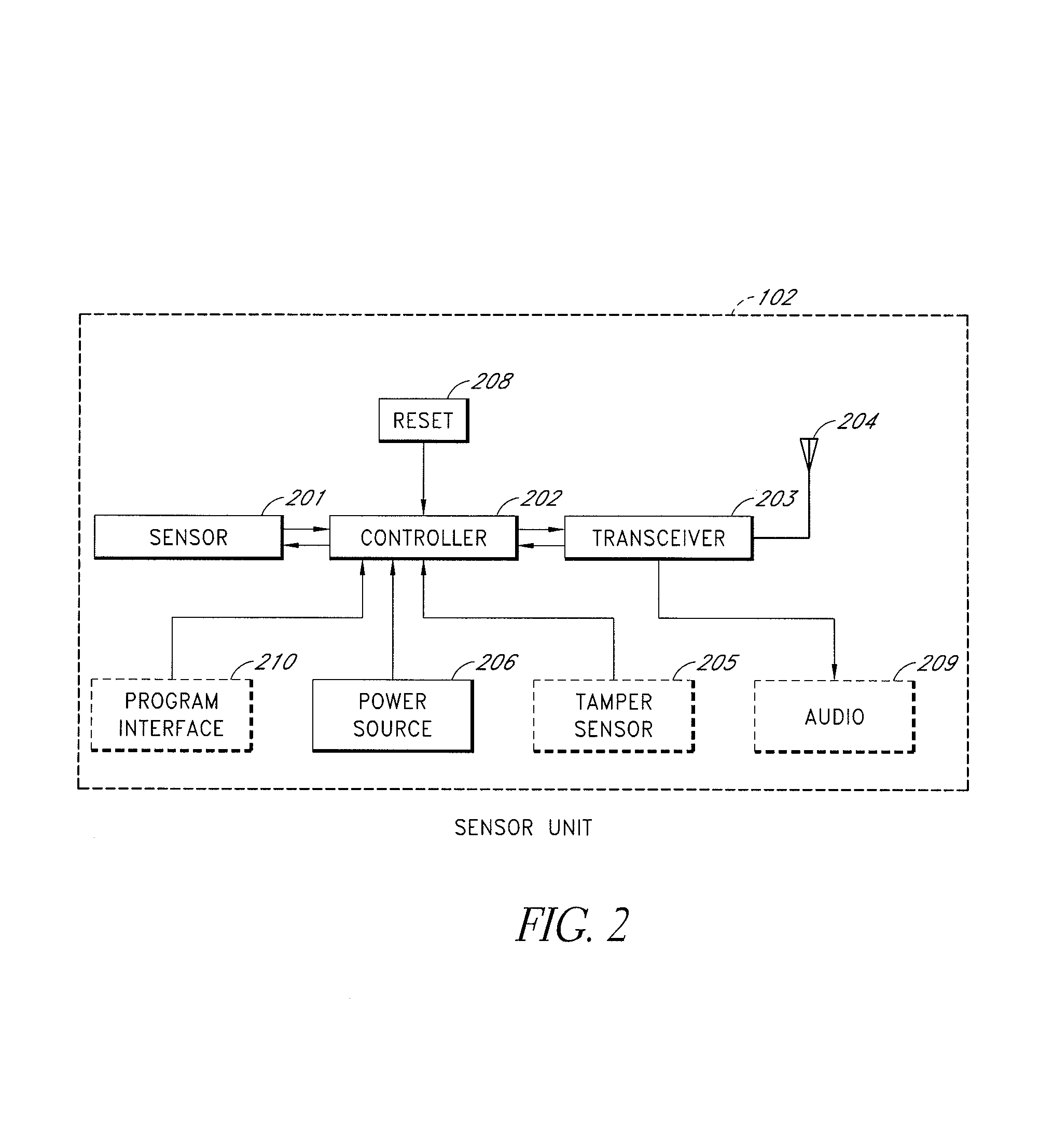

Remote Monitoring of Pipelines using Wireless Sensor Network

InactiveUS20050145018A1Low costLittle powerVehicle testingDetection of fluid at leakage pointLine sensorWireless transceiver

A wireless sensor system is installed inside pipelines using sensors and wireless transceivers that are small, low-cost, and rugged. The objective is monitoring the pipeline and recommending maintenance and repair at specific locations in the pipeline. Maintenance includes detection of leaks and prevention of catastrophic failures as a result of internal corrosion or other damage, such as third party mechanical damage, using multitude of sensors. After establishing the wireless sensor network the network is activated so the sensor can make measurements periodically or continuously using instructions transmitted via the base station. The sensor data from the various sensors are transmitted inside the pipe and extracted to access points in the pipeline to a remote computer that stores the data within the computer memory. The sensed information can be used for monitoring as well as analysis using a recommendation engine to provide maintenance and repair alerts.

Owner:SOUTHWEST RES INST

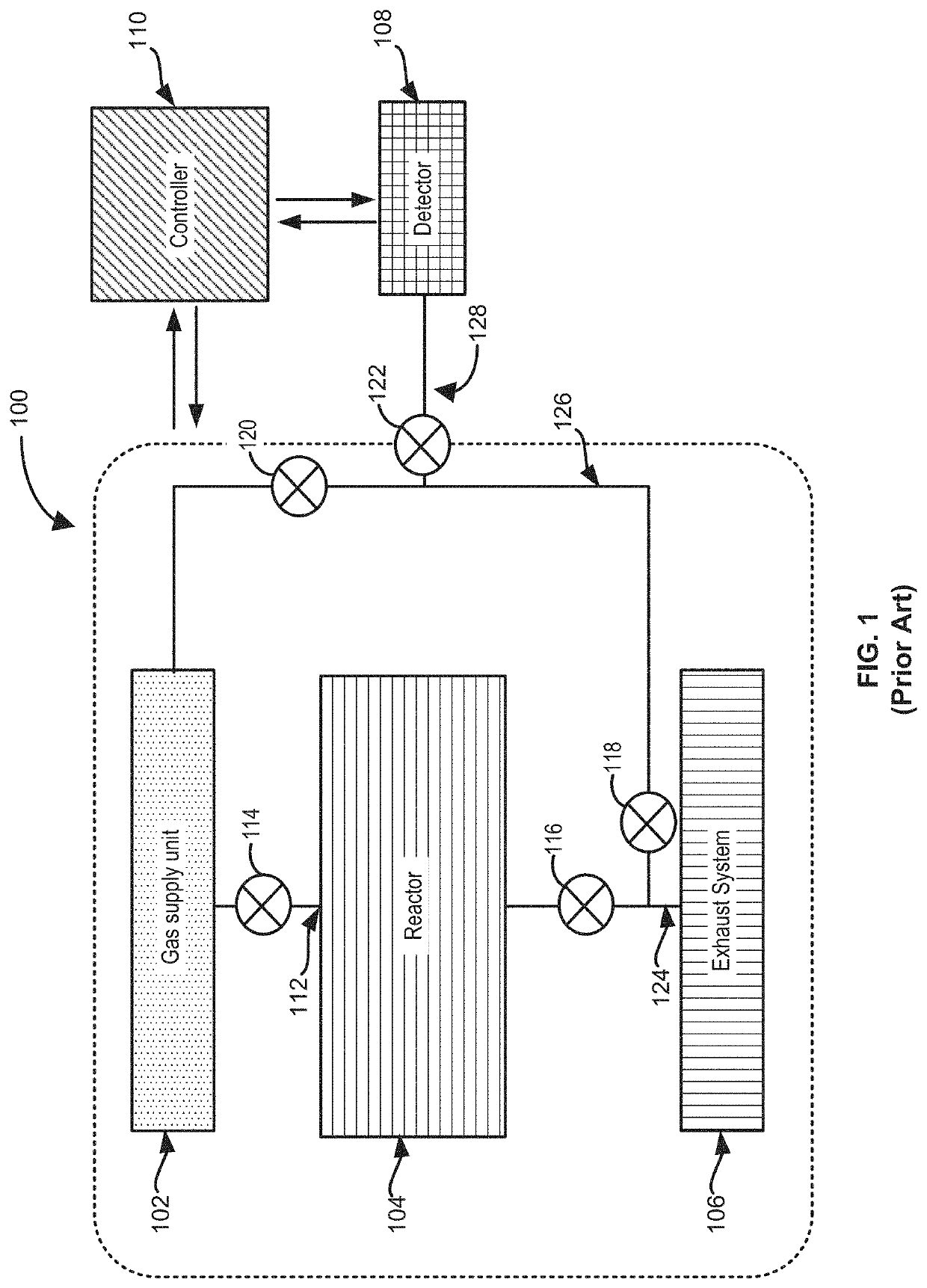

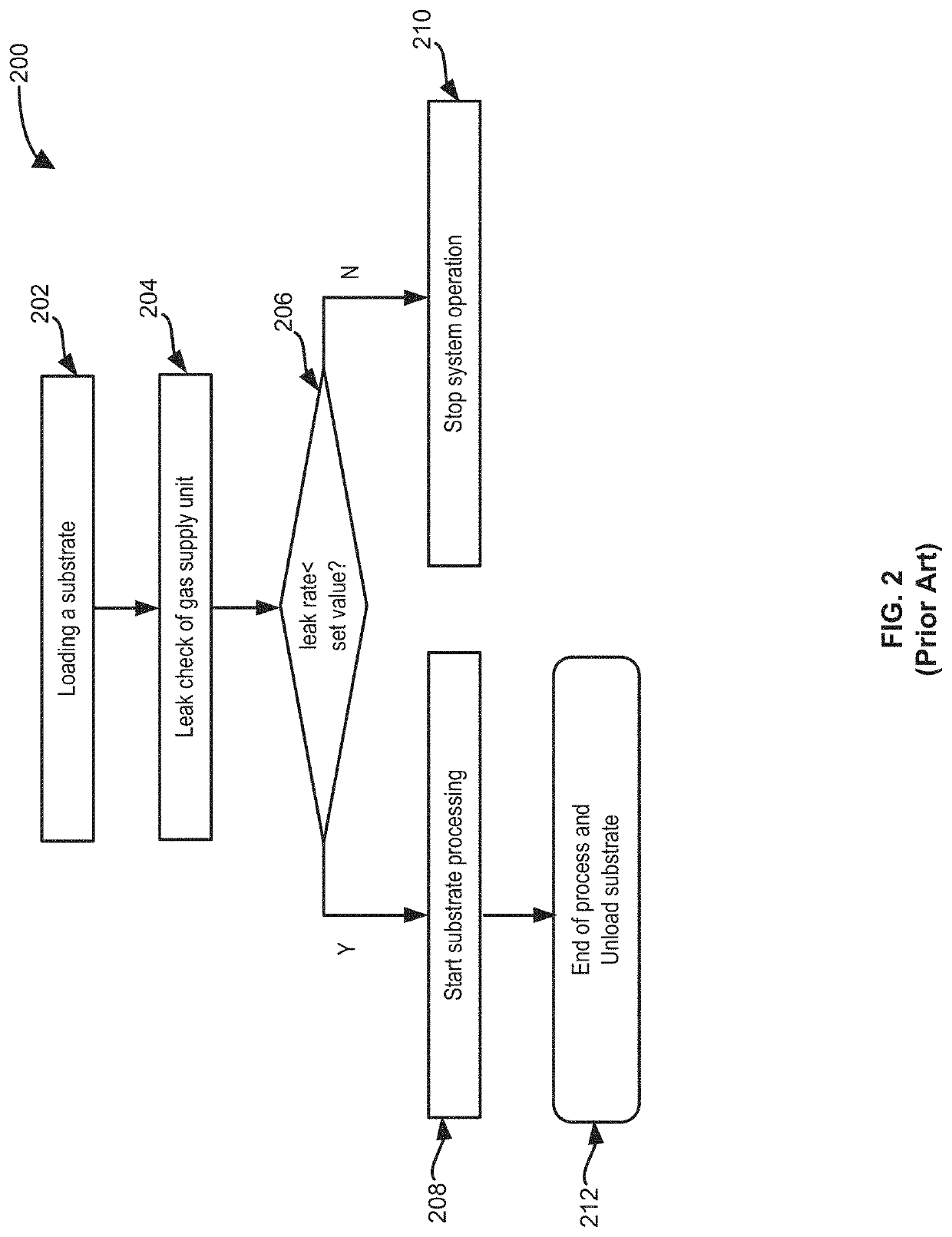

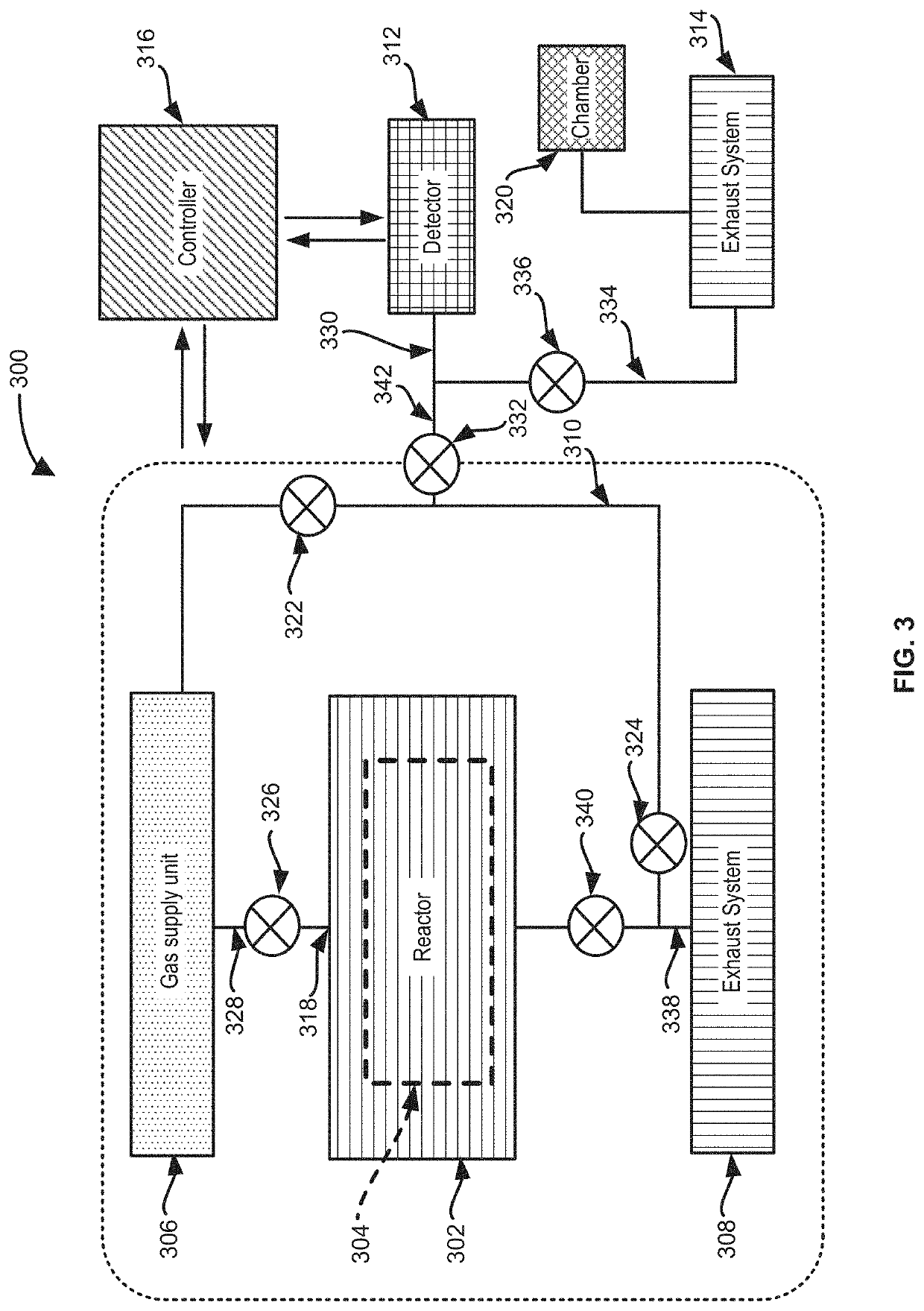

Method of using a gas-phase reactor system including analyzing exhausted gas

ActiveUS20200385868A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateThermodynamicsReactor system

Methods of and systems for performing leak checks of gas-phase reactor systems are disclosed. Exemplary systems include a first exhaust system coupled to a reaction chamber via a first exhaust line, a bypass line coupled to a gas supply unit and to the first exhaust system, a gas detector coupled to the bypass line via a connecting line, a connecting line valve coupled to the connecting line, and a second exhaust system coupled to the connecting line. Methods include using the second exhaust system to exhaust the connecting line to thereby remove residual gas in the connecting line that may otherwise affect the accuracy of the gas detector.

Owner:ASM IP HLDG BV

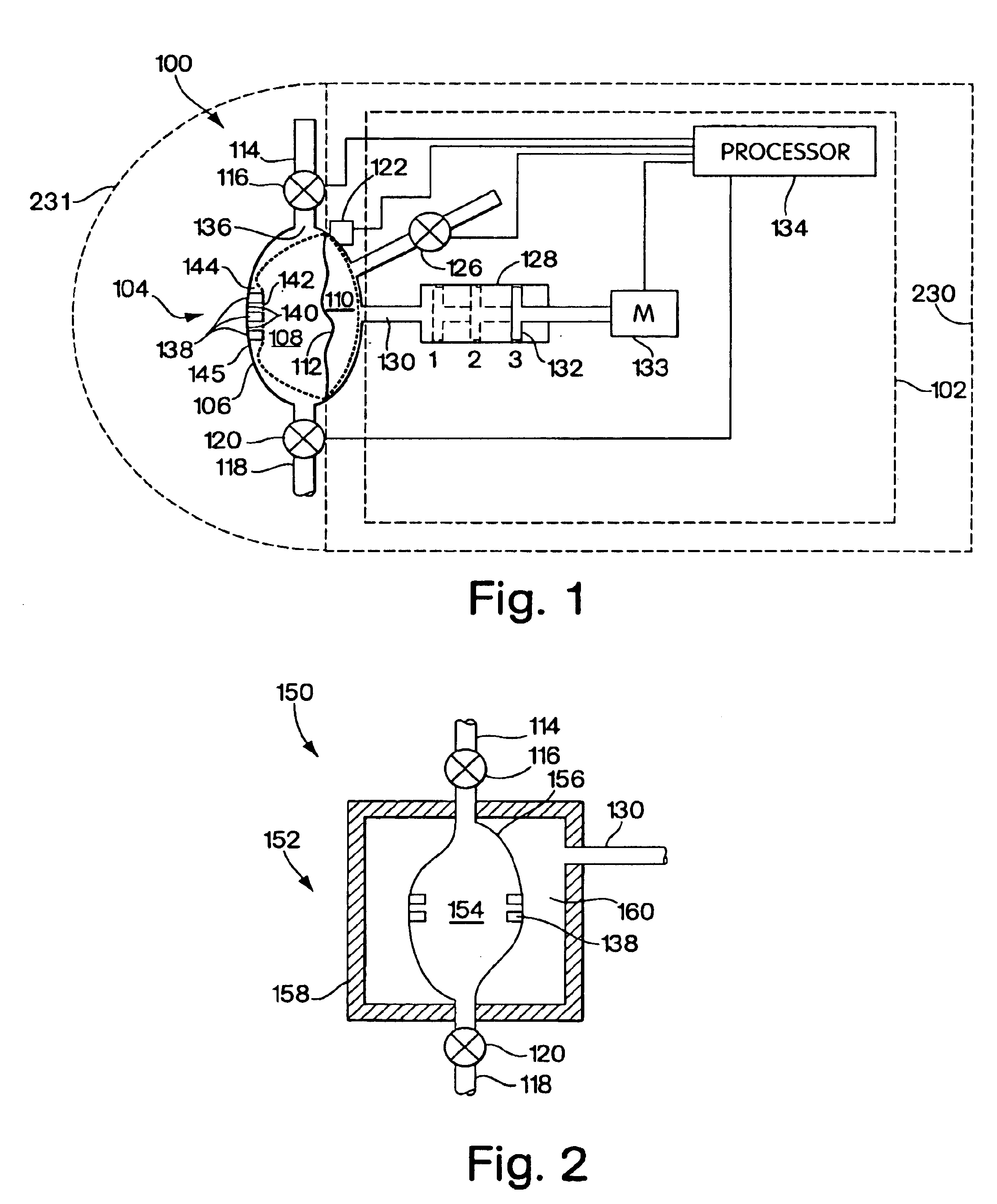

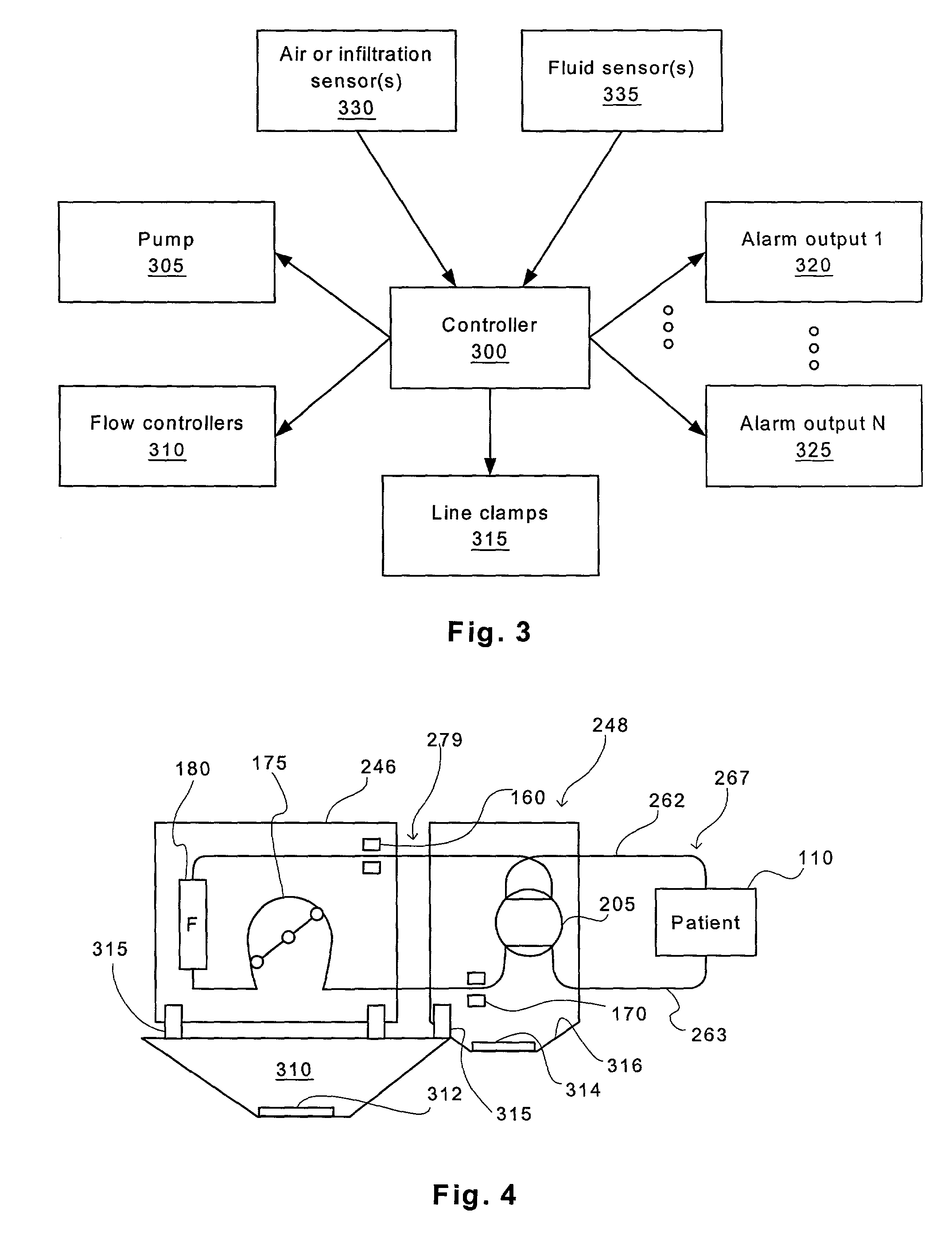

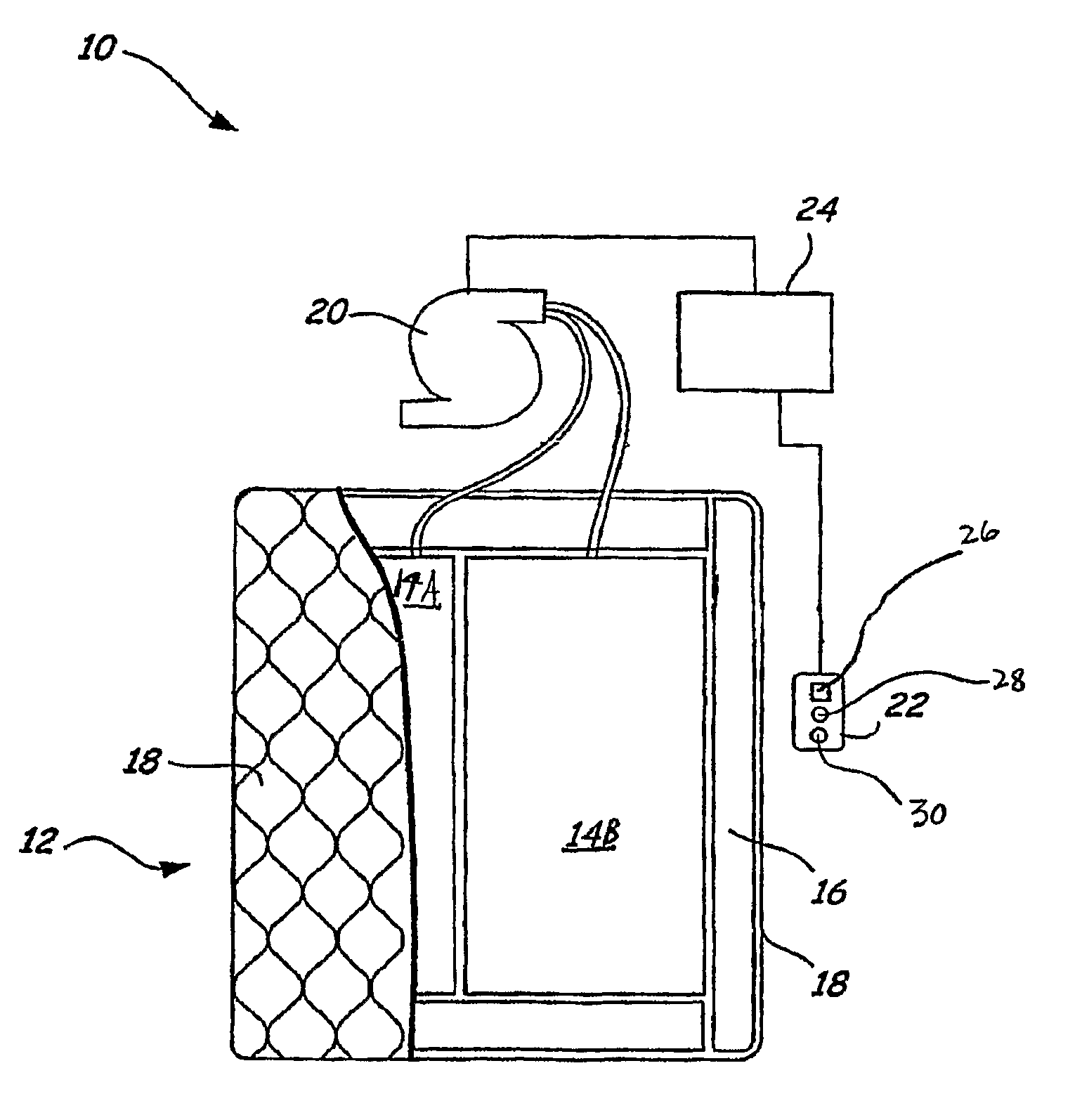

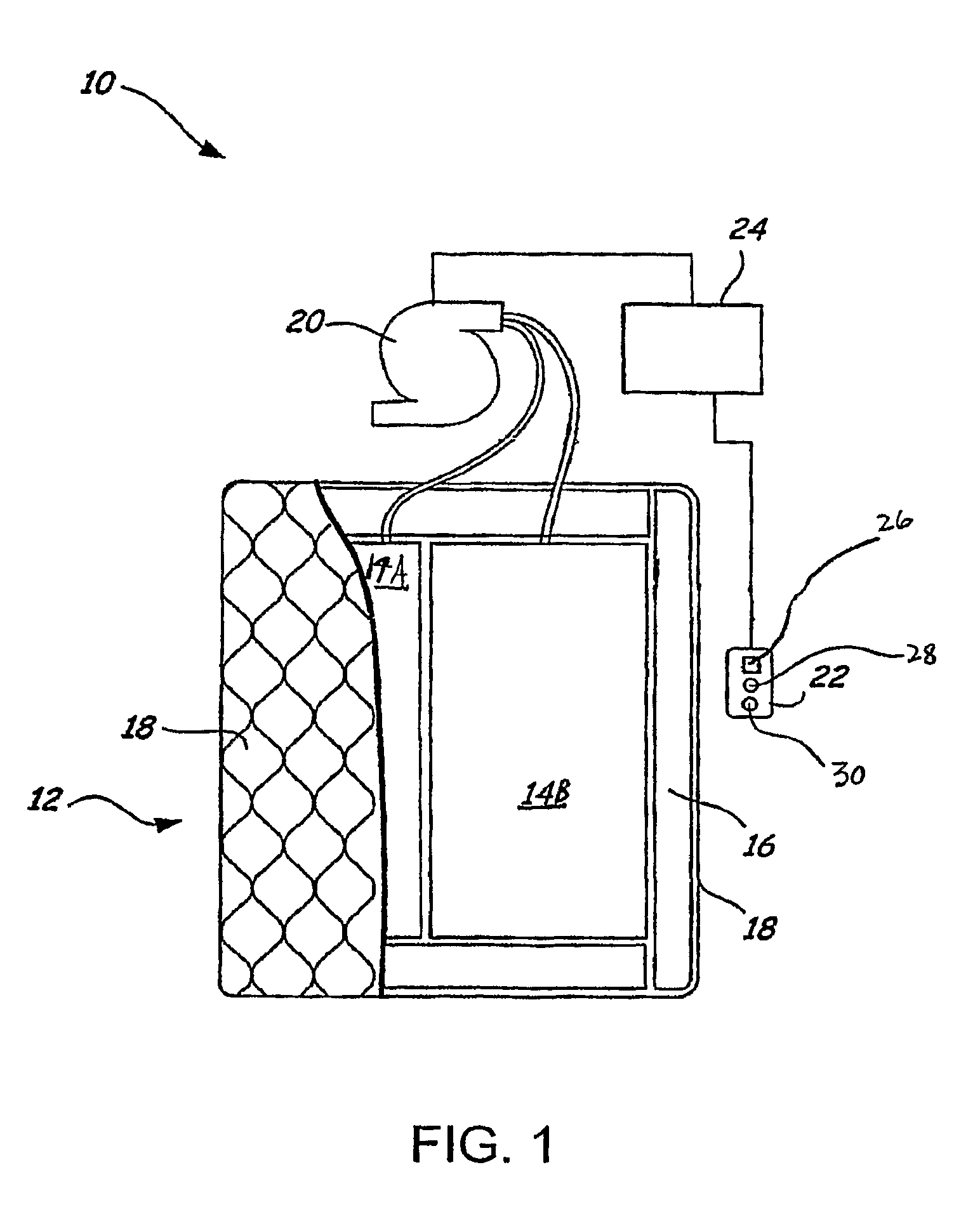

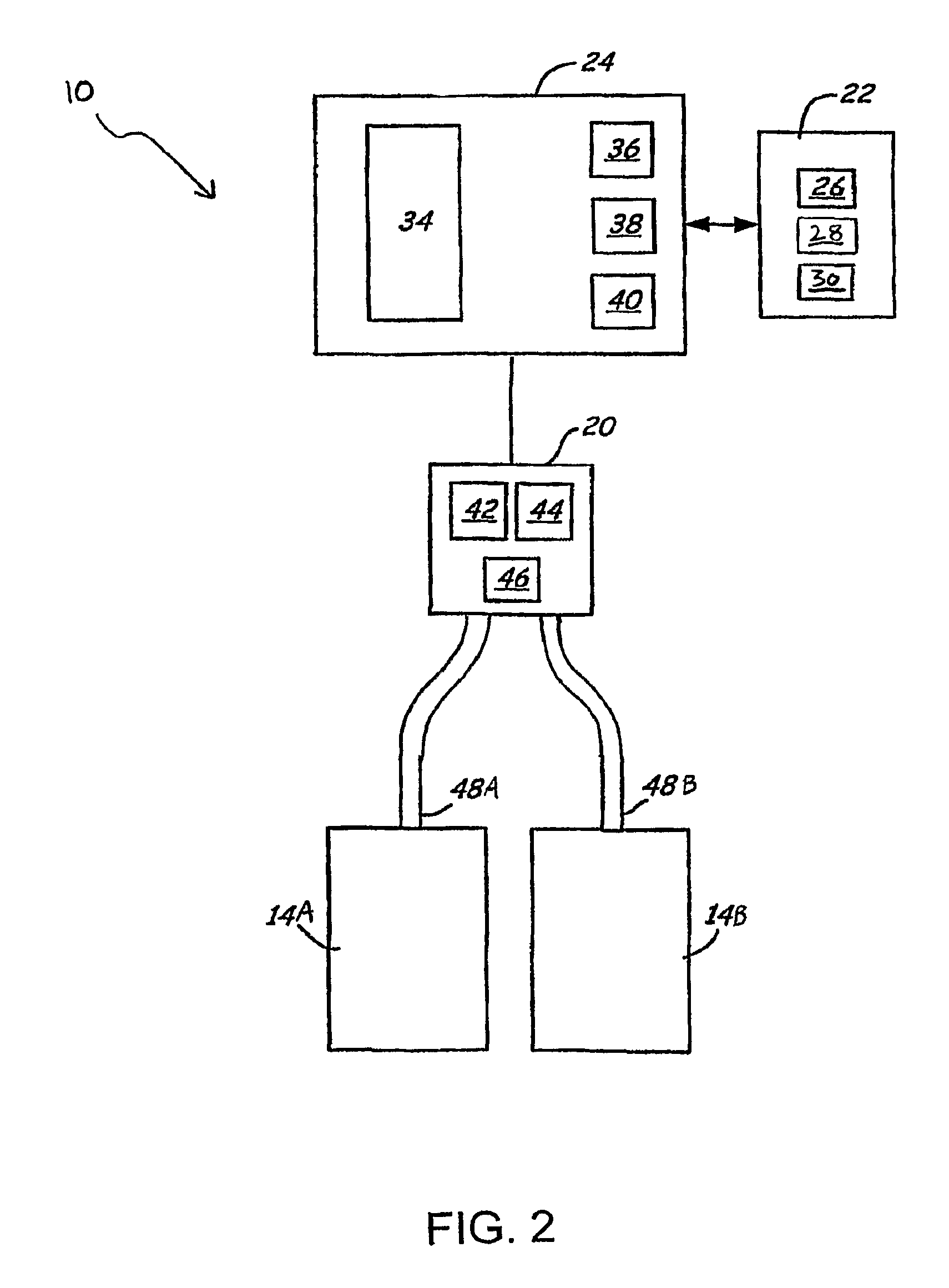

Method and apparatus for leak detection in blood circuits combining external fluid detection and air infiltration detection

InactiveUS7040142B2Improve reliabilityHigh sensitivityDetection of fluid at leakage pointMeasurement of fluid loss/gain rateBlood treatmentsHigh rate

One of the most significant safety concerns in the automation of extracorporeal blood treatments such as dialysis is the risk of blood leakage. Extracorporeal blood treatment systems draw blood at such a high rate that a loss of integrity in the blood circuit can be catastrophic. There are a number of mechanisms for detecting and preventing leaks and / or air infiltration, but none is perfect. According to the present invention, multiple inputs are combined to provide greater security against leakage and / or air infiltration by providing sensors for external presence of liquid (plasma, replacement fluid, blood, etc.) outside a fluid circuit and infiltration of air or bubbles into the fluid circuit.

Owner:NXSTAGE MEDICAL

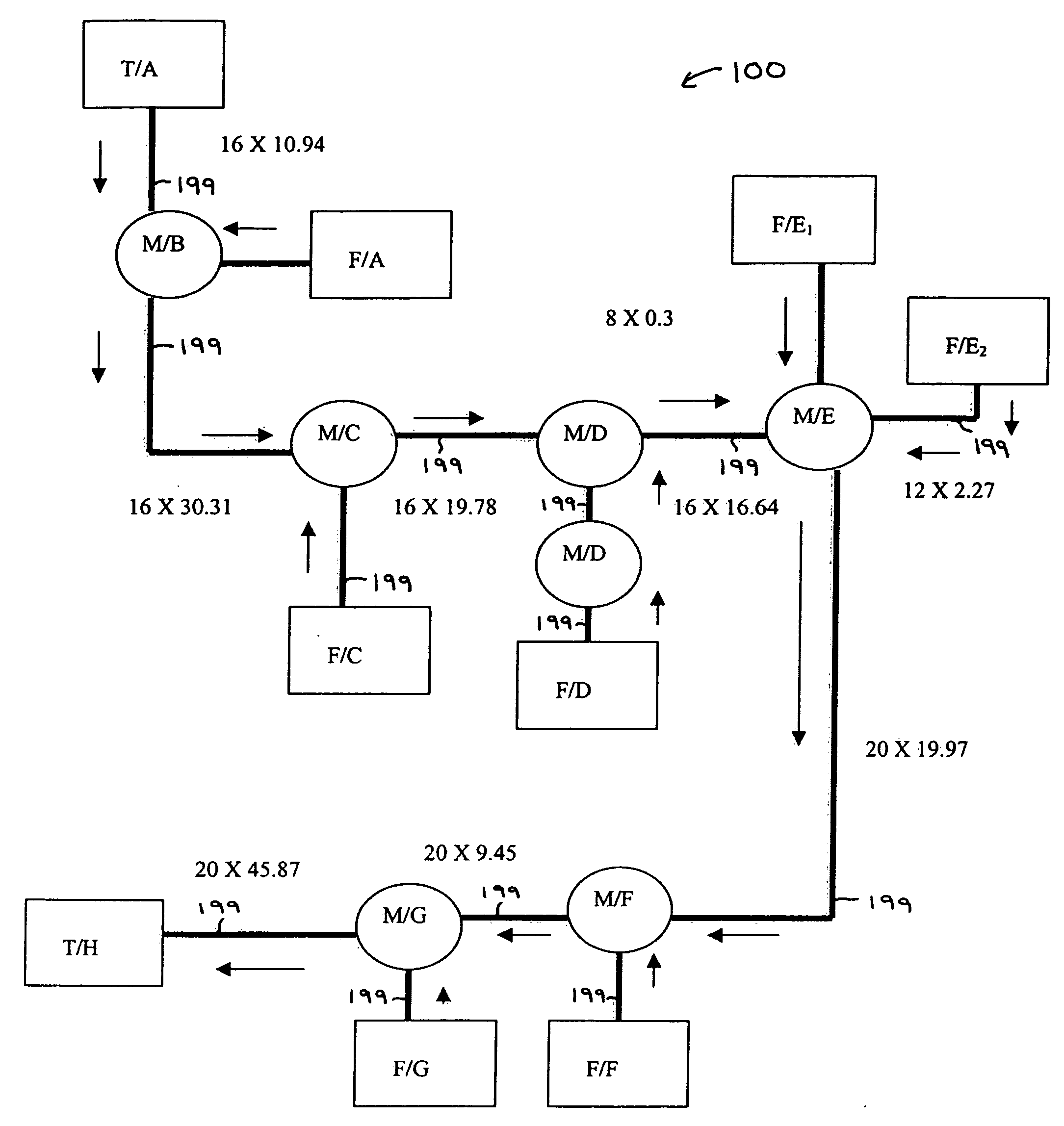

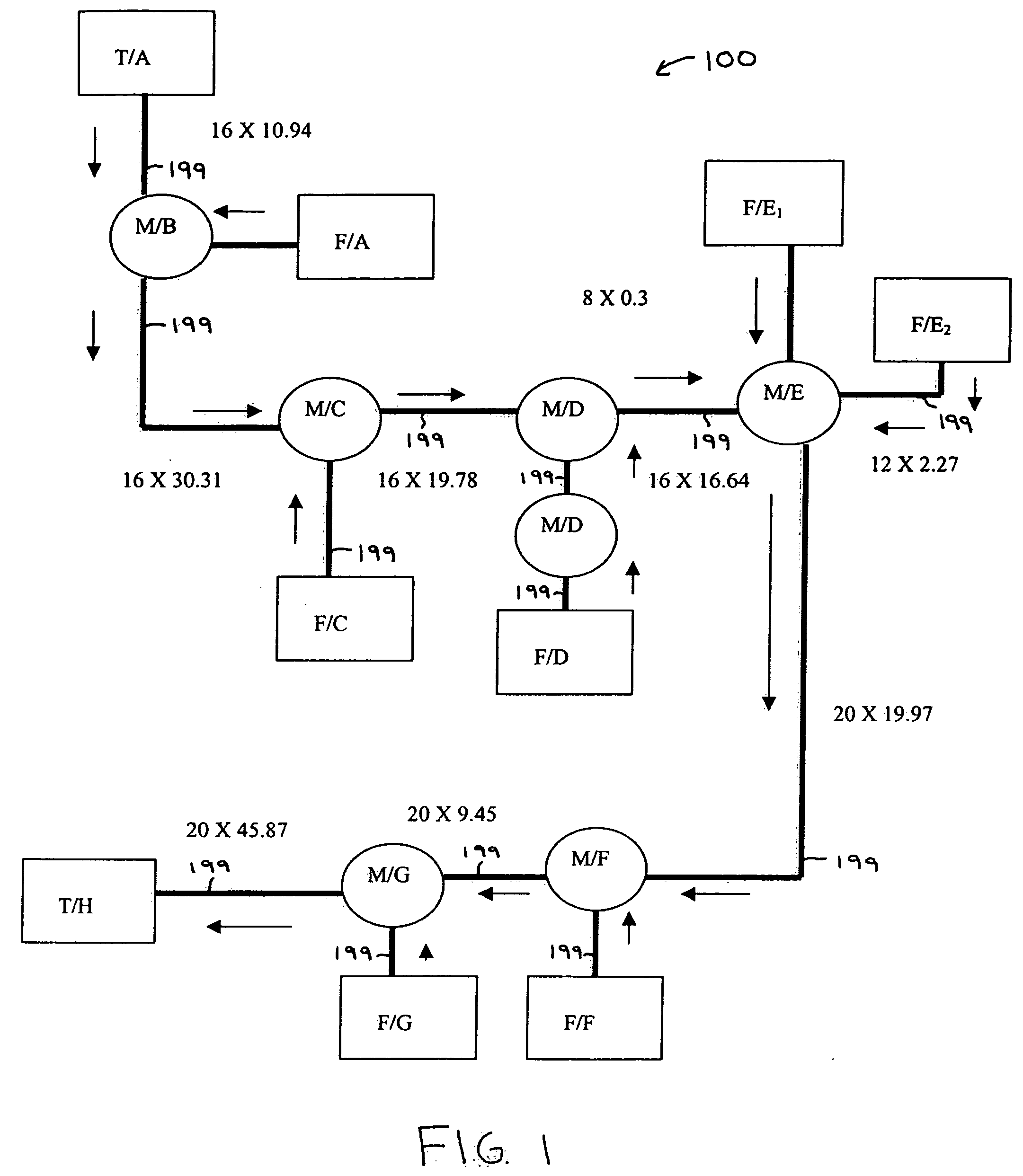

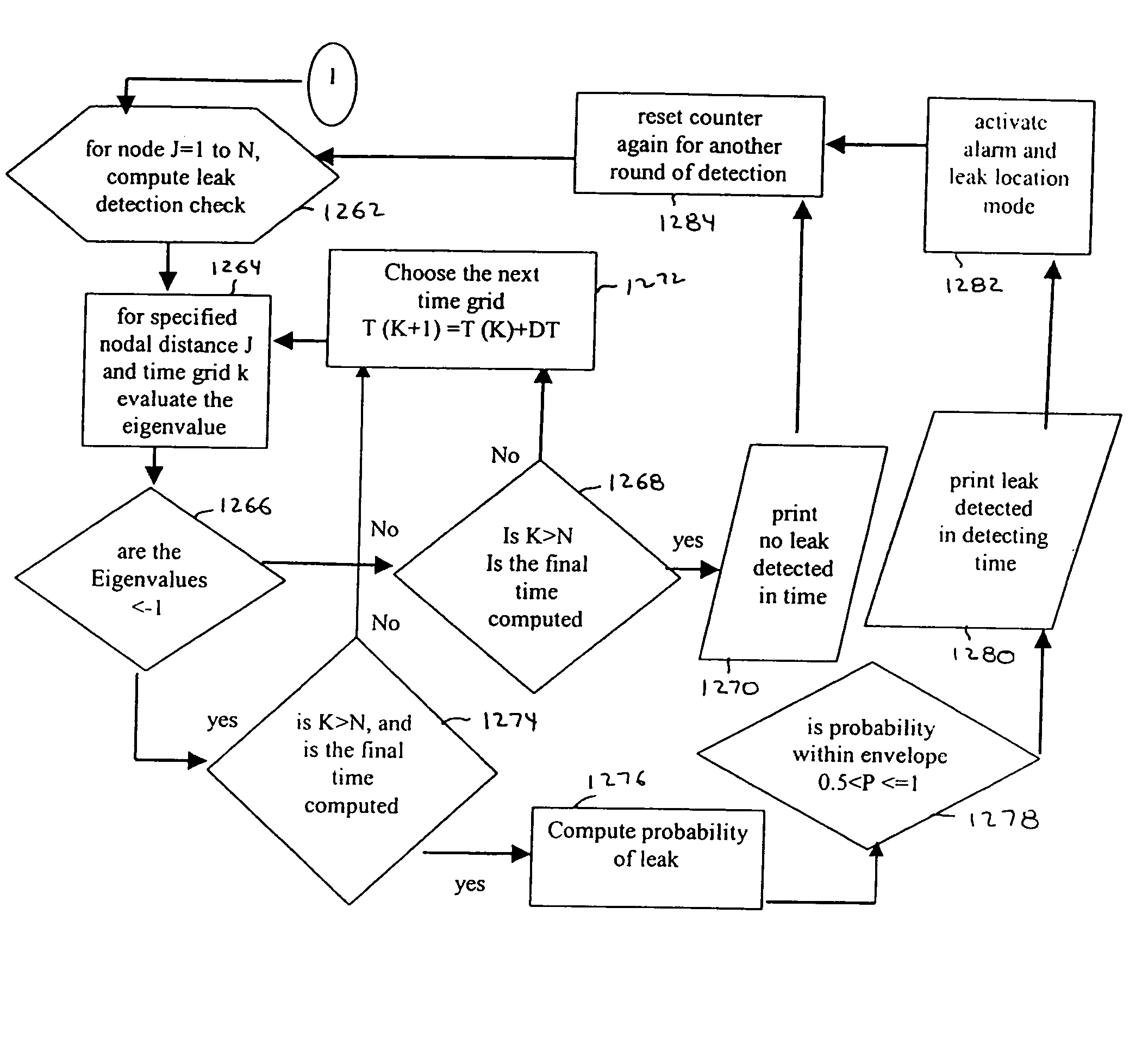

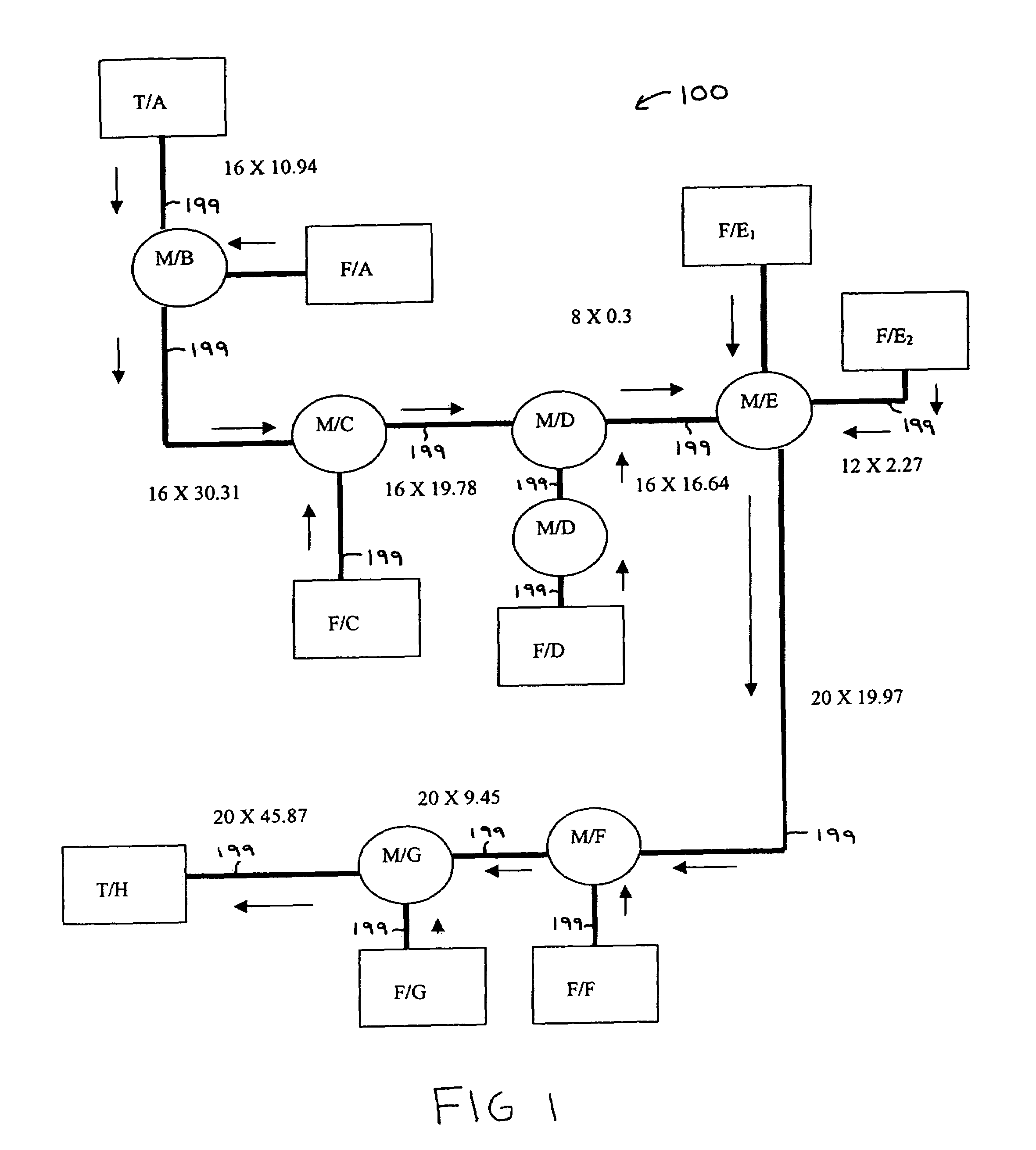

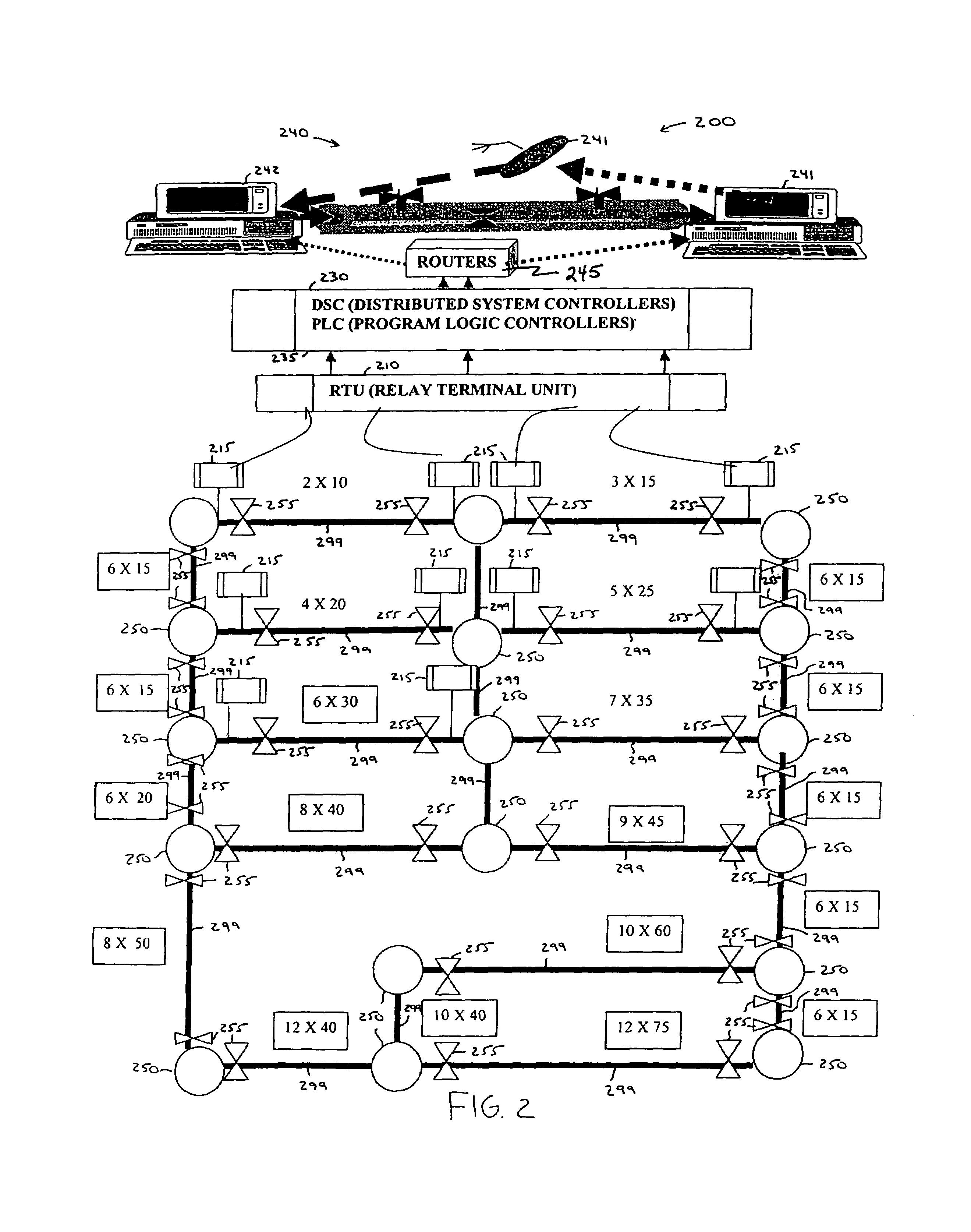

Realtime computer assisted leak detection/location reporting and inventory loss monitoring system of pipeline network systems

ActiveUS20050246112A1Fast response timeImprove abilitiesDetection of fluid at leakage pointMeasurement of fluid loss/gain rateStability theoryMonitoring system

There is provided a method for detecting and locating leaks in a pipeline network in real-time. A flow model is provided that characterizes flow behavior for at least one of steady and unsteady states respectively corresponding to an absence and a presence of model leaks in the pipeline network, the flow model including a leaking factor kL. A deterministic model is provided to evaluate at least one of a leak status and a no leak status relating to the pipeline network using deterministic criteria. The deterministic criteria is based on a Liapunov Stability Theory. A deviation matrix is constructed based on the flow model and the deterministic model to generate eigenvalues. A leak alarm is generated when at least one of the eigenvalues is less than a predetermined value.

Owner:KINGSLEY E ABHULIMEN +1

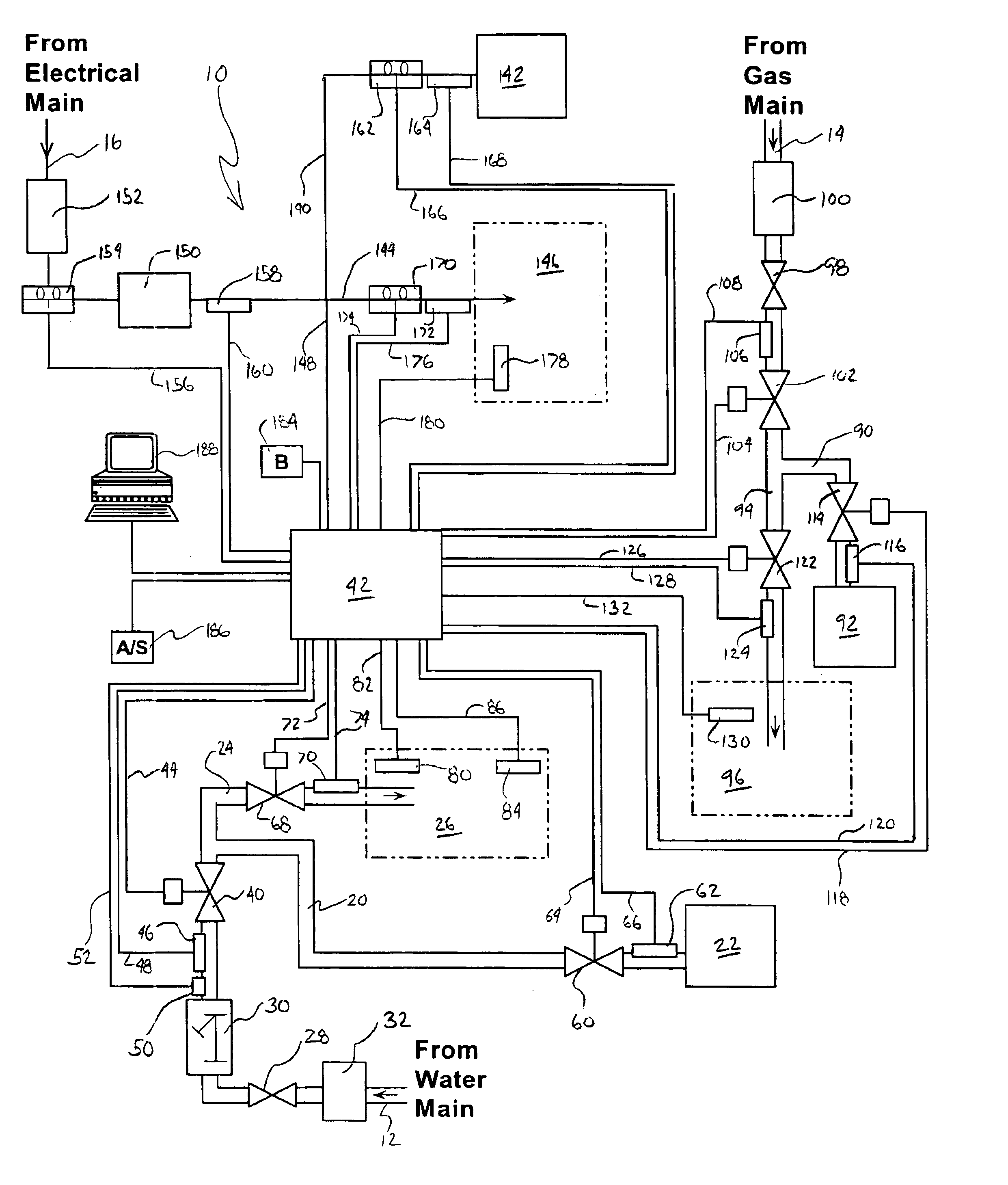

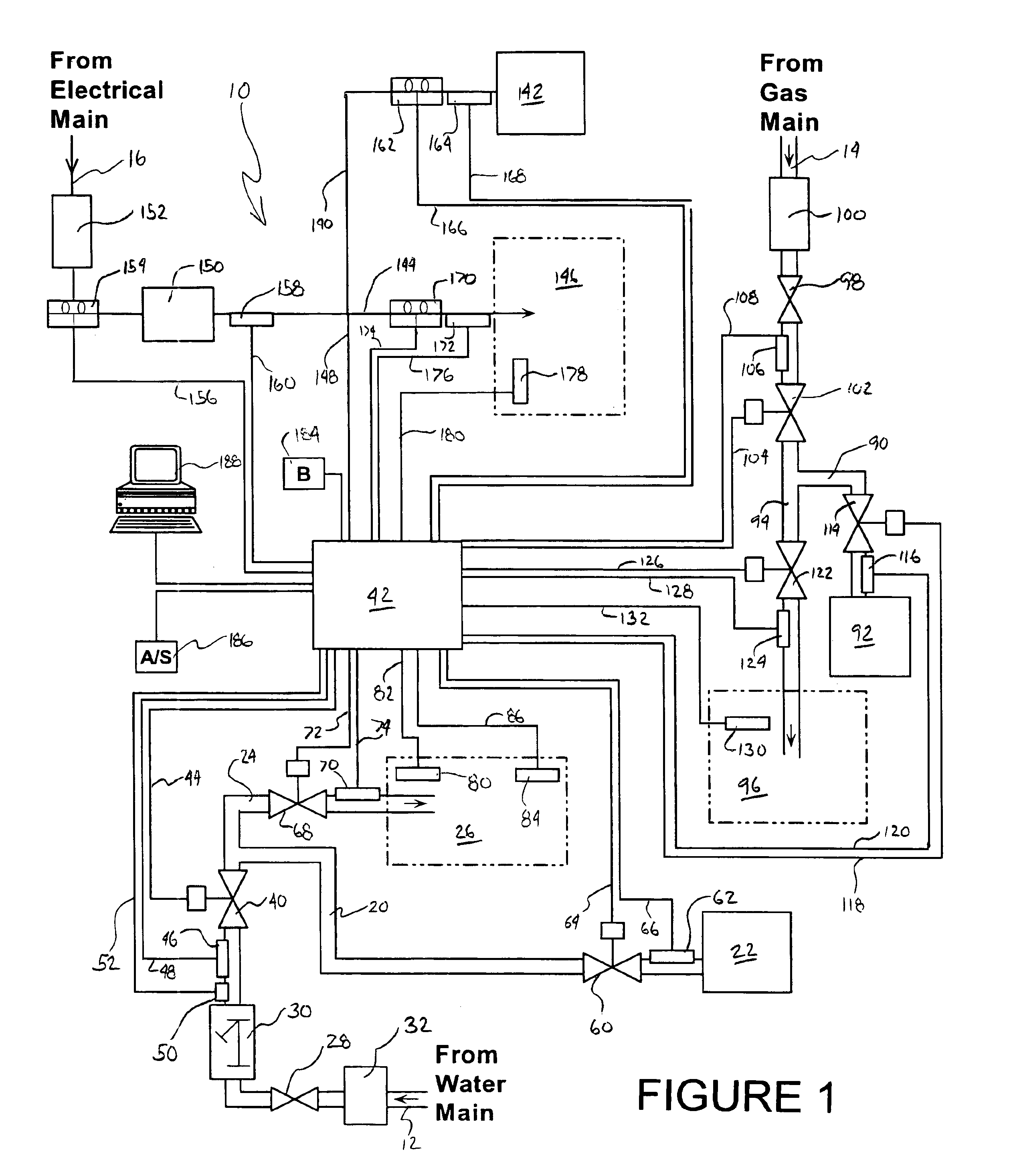

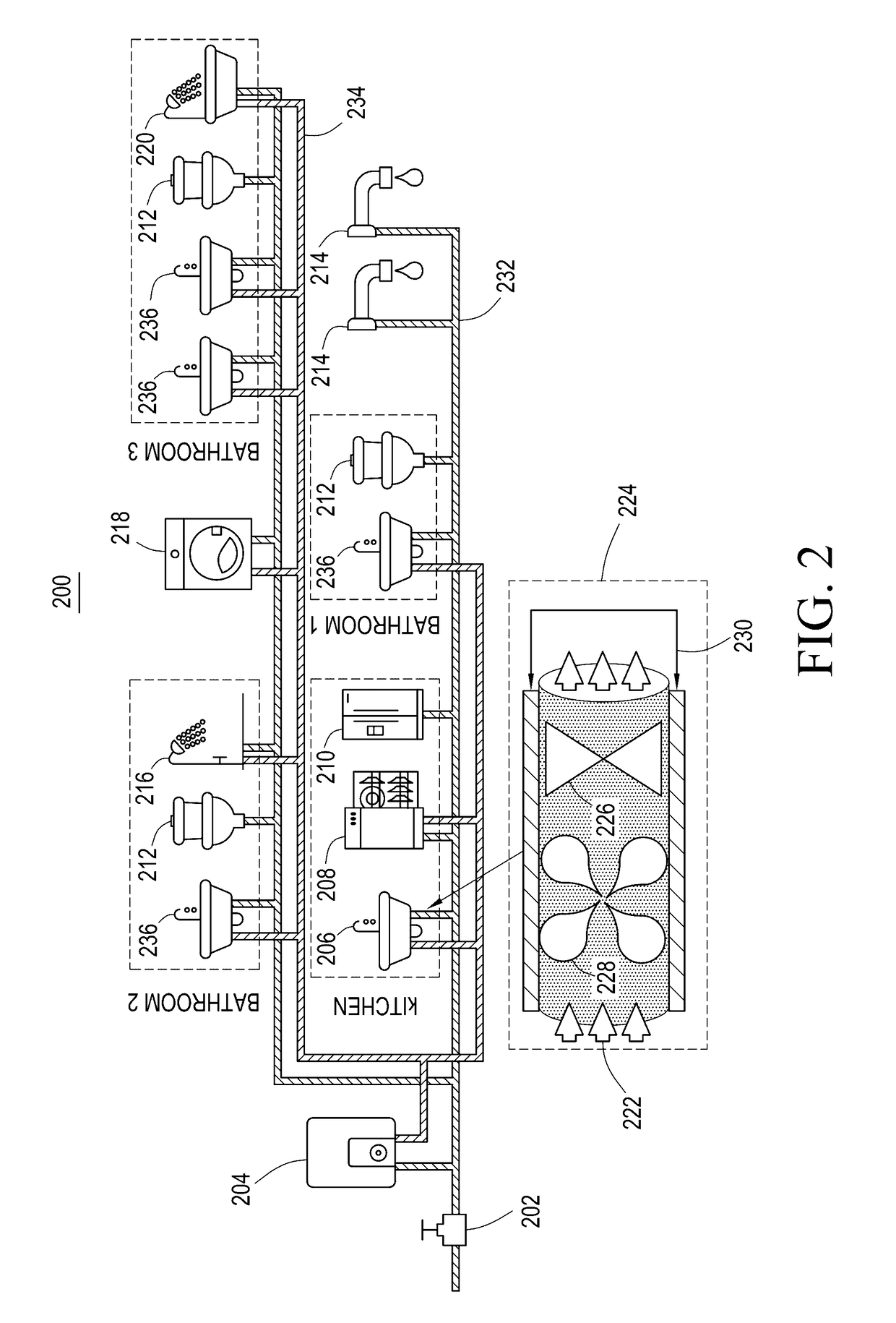

System and method for monitoring and controlling utility systems

A system for monitoring and controlling one or more utility systems includes a utility system main supply line for supplying a utility to at least one of a structure, an area and a building and a controlled shut-off device on the utility system main supply line. The controlled shut-off device is bias toward an open position and is movable toward a closed position upon receipt of an actuation signal wherein the utility is prevented from passing by the controlled shut-off device. A main utility sensor is on the utility system main supply line and a motion sensor that detects occupancy is in the building. A processor communicates with the controlled shut-off device, the main utility sensor and the motion sensor. The processor sends the actuation signal to the controlled shut-off device to move the controlled shut-off device toward the closed position when input from the main utility sensor and the motion sensor indicates occurrence of an abnormal event.

Owner:UHLER KENNETH J

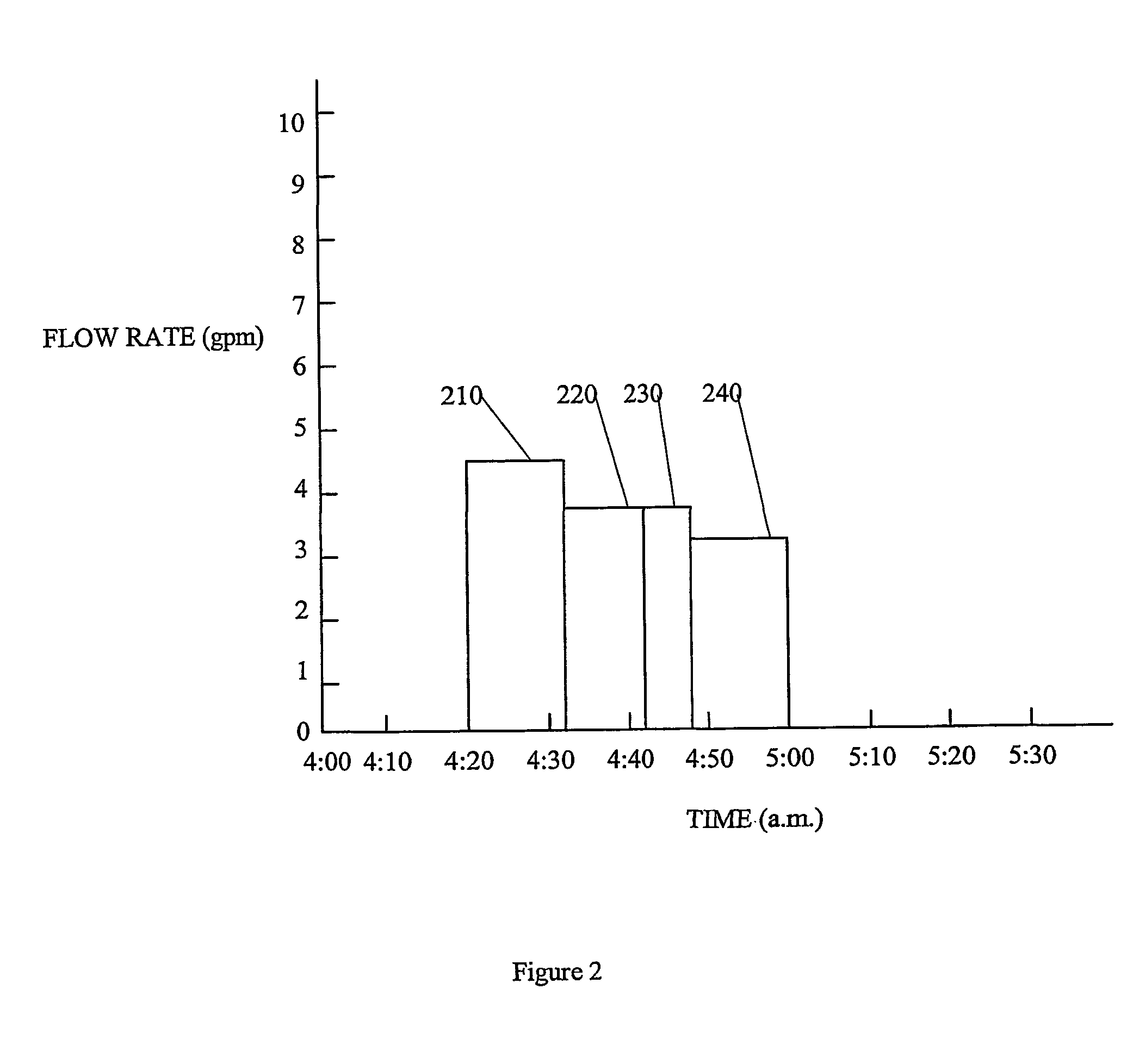

Water leak detection using pressure sensing

ActiveUS20170131174A1Inexpensive to fixWater consumptionMeasurement of fluid loss/gain rateGeneral water supply conservationEngineeringWater leak

A system including a sensing device including a pressure sensor configured to measure pressure of water in a water system of a structure. The sensing device can be configured to generate pressure measurement data representing the pressure of the water as measured by the pressure sensor. The system also can include one or more processing units including one or more processors and one or more non-transitory storage media storing machine executable instructions configured when run on the one or more processors to perform detecting a non-cyclical pressure event corresponding to a water leak in the water system of the structure during a first time period based on an analysis of information including the pressure measurement data. The information analyzed in the analysis does not include any flow measurement data that represents a total amount of flow of the water in the water system of the structure during the first time period. The pressure sensor can be coupled to the water system of the structure at a single location of the water system of the structure when measuring the pressure of the water in the water system of the structure. Other embodiments are provided.

Owner:PHYN LLC

System and method for detecting a leak in an air bed

ActiveUS8336369B2Detection of fluid at leakage pointMeasurement of fluid loss/gain rateAtmospheric airEngineering

Owner:SLEEP NUMBER CORP

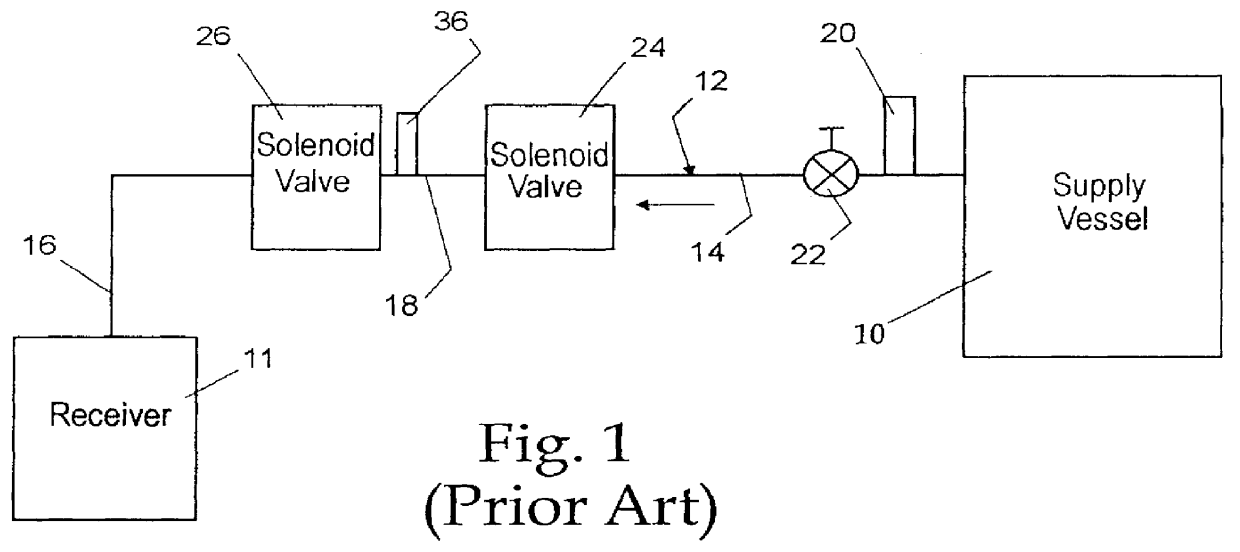

Fluid delivery apparatus

A line, especially for delivery of liquefied gas at ambient temperature, has two solenoid valves connected in series with an intermediate section of the line between them. In normal operation when both valves are closed, the isolated intermediate section contains liquid which absorbs heat from the atmosphere and / or from a heater, and the resulting increase in pressure is detected by a pressure sensor. If either valve fails to close fully to shut off flow, the intermediate section is not then isolated, so the absence of a signal from the sensor (the valves being set to close fully) indicates that at least one of them has not properly closed, and an alarm is given.

Owner:PLANER PROD LTD

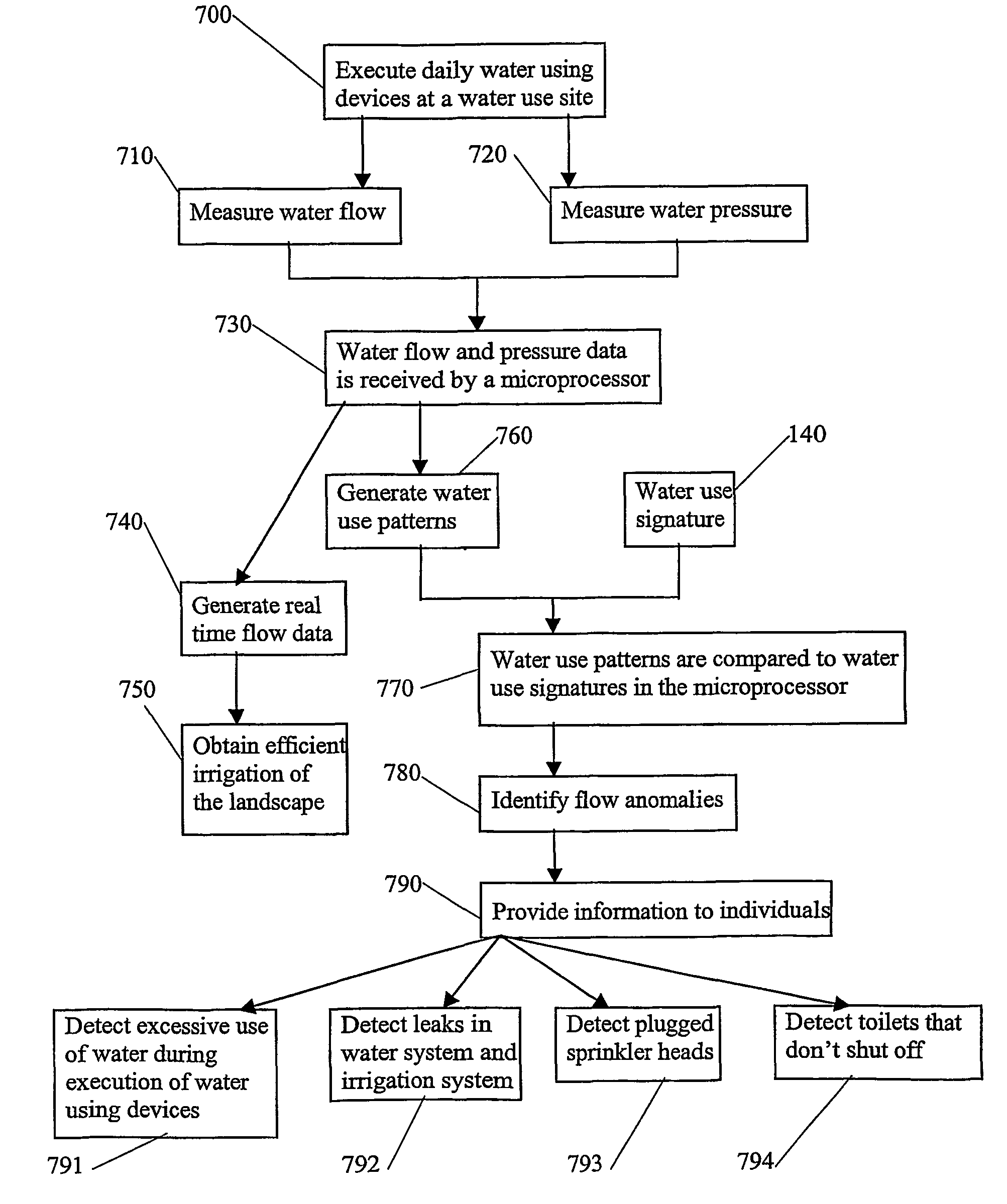

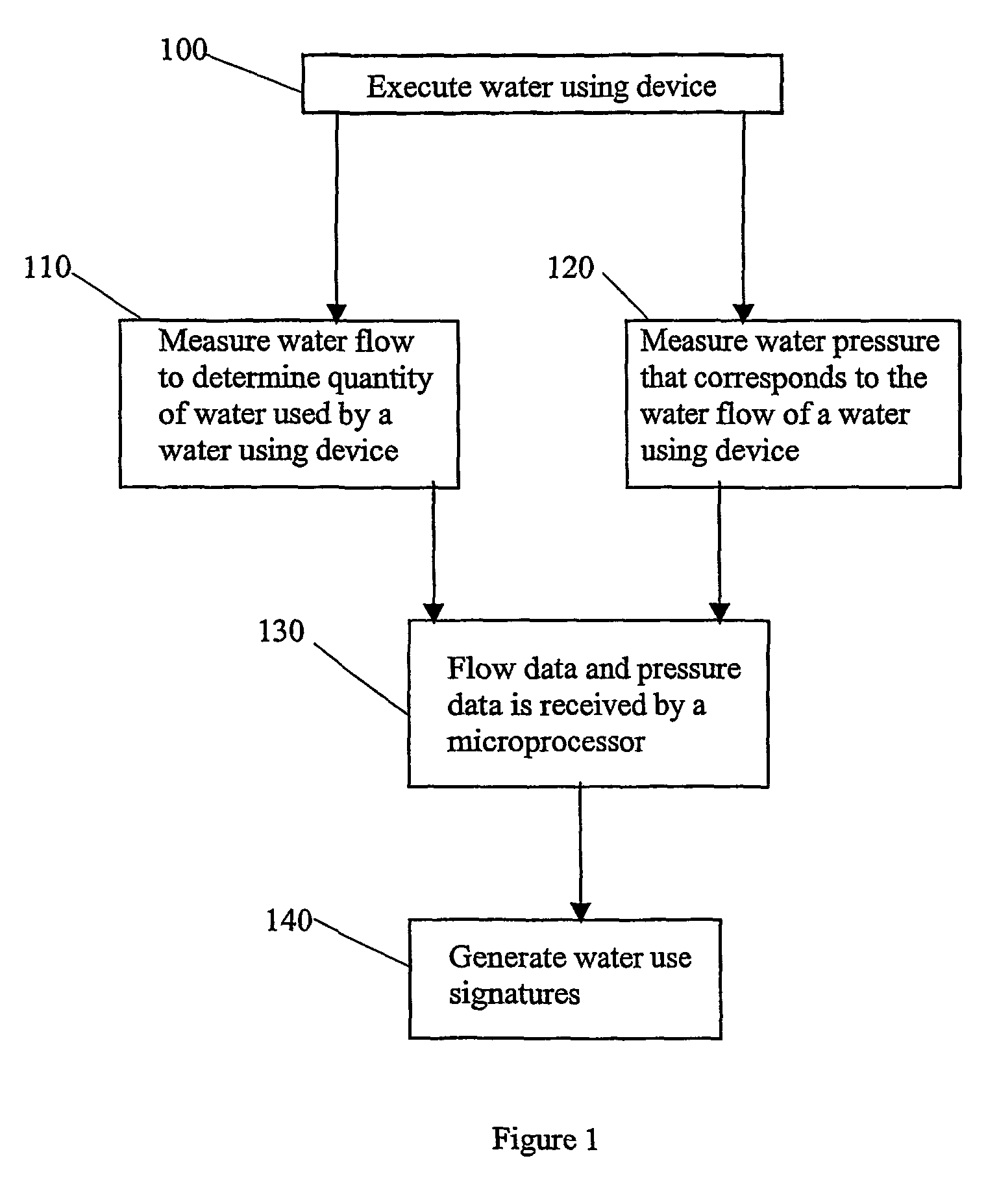

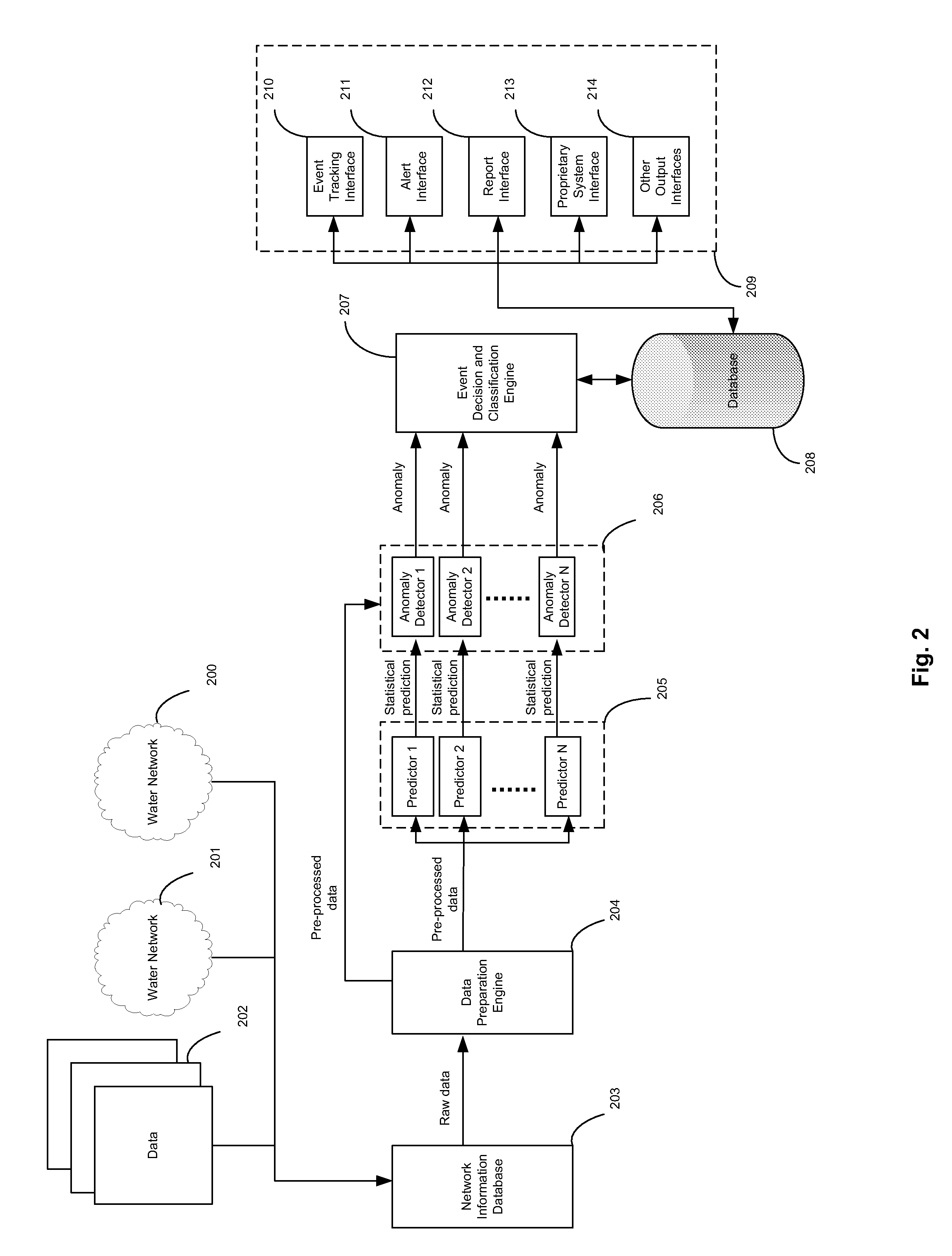

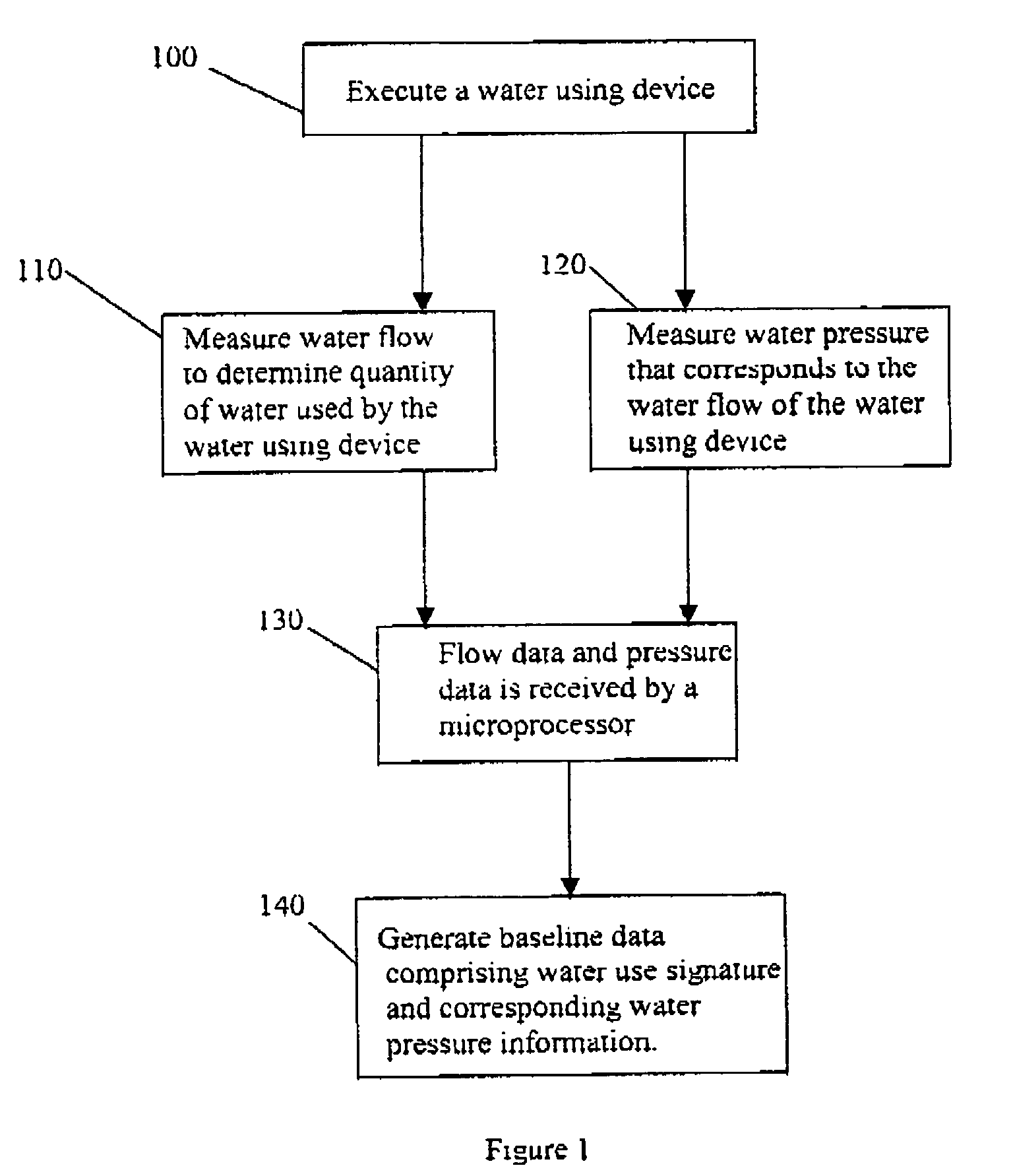

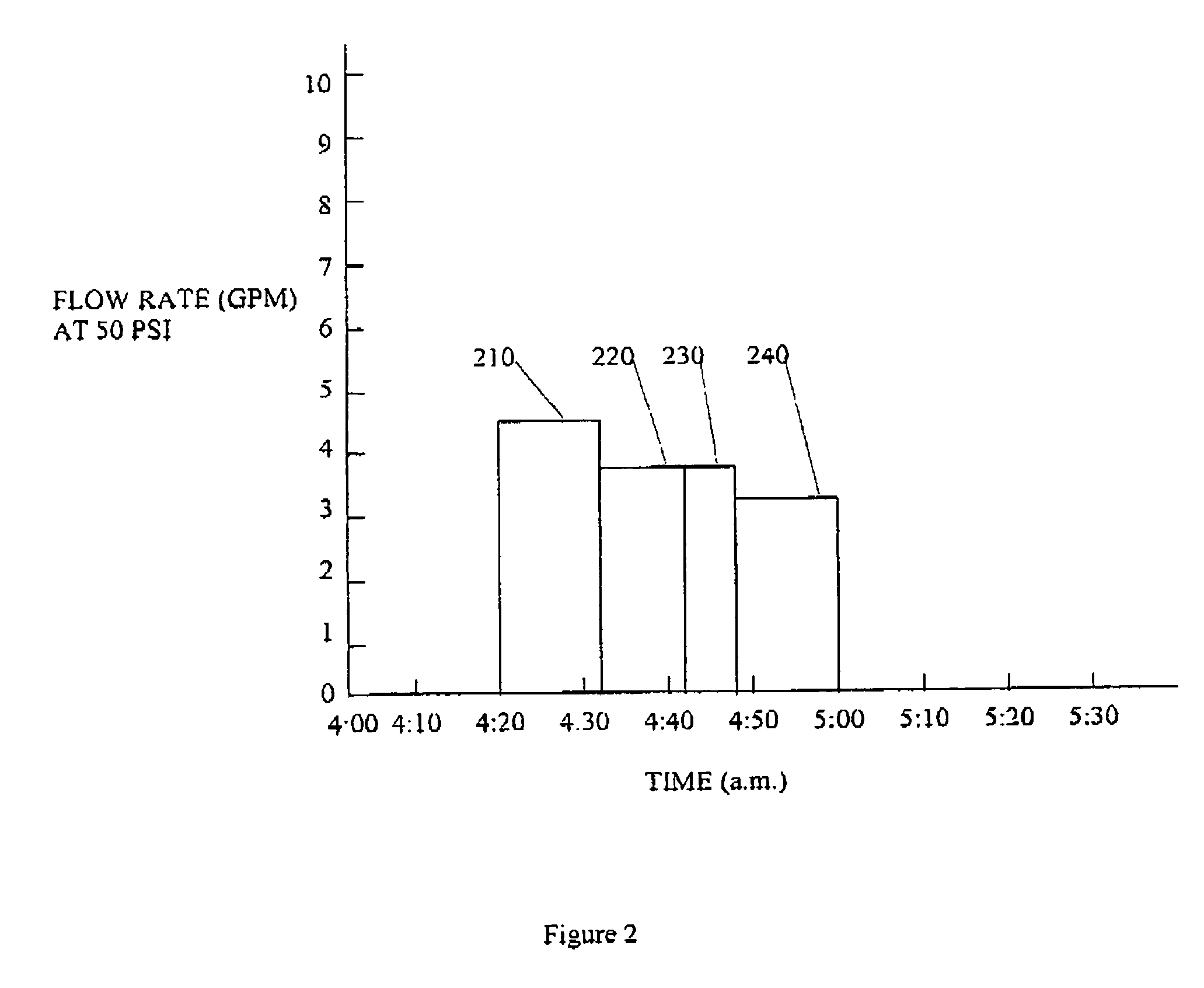

Methods and apparatus for using water use signatures in improving water use efficiency

InactiveUS6963808B1Reduce wasteImprove efficiencyMeasurement of fluid loss/gain rateGeneral water supply conservationWater useWater-use efficiency

The present invention provides systems and methods that identify a flow anomaly to an operator or other person by: executing a first device of a plurality of water using devices; receiving flow data on a quantity of water used by the first device during a time period required to generate a first water use signature from the first device; comparing a future water use pattern against the first water use signature to identify a flow anomaly with the first device; and providing information regarding the flow anomaly to the person. Identifying anomalies can be useful in numerous ways, including discovering problems that need fixing, reducing waste, and even calculating appropriate irrigation application rates.

Owner:AQUA CONSERVATION SYST

Remote monitoring of pipelines using wireless sensor network

InactiveUS7526944B2Low powerLow costVehicle testingDetection of fluid at leakage pointWireless transceiverWireless mesh network

A wireless sensor network is installed inside pipelines using sensors and wireless transceivers that are small, low-cost, and rugged. The objective is monitoring the pipeline and recommending maintenance and repair at specific locations in the pipeline. Maintenance includes detection of internal corrosion using sensors that can result in leaks. Furthermore detection of leaks for prevention of catastrophic failures as a result of damage, such as third party mechanical damage. After establishing the wireless sensor network, the network is activated so the sensors can make measurements periodically or continuously using instructions transmitted via a base station. The sensor data from the various sensors are transmitted inside the pipe and extracted to access points in the pipeline to a remote computer that stores the data within the computer. The sensed information can be used for monitoring as well as analysis using a recommendation engine to provide maintenance and repair alerts.

Owner:SOUTHWEST RES INST

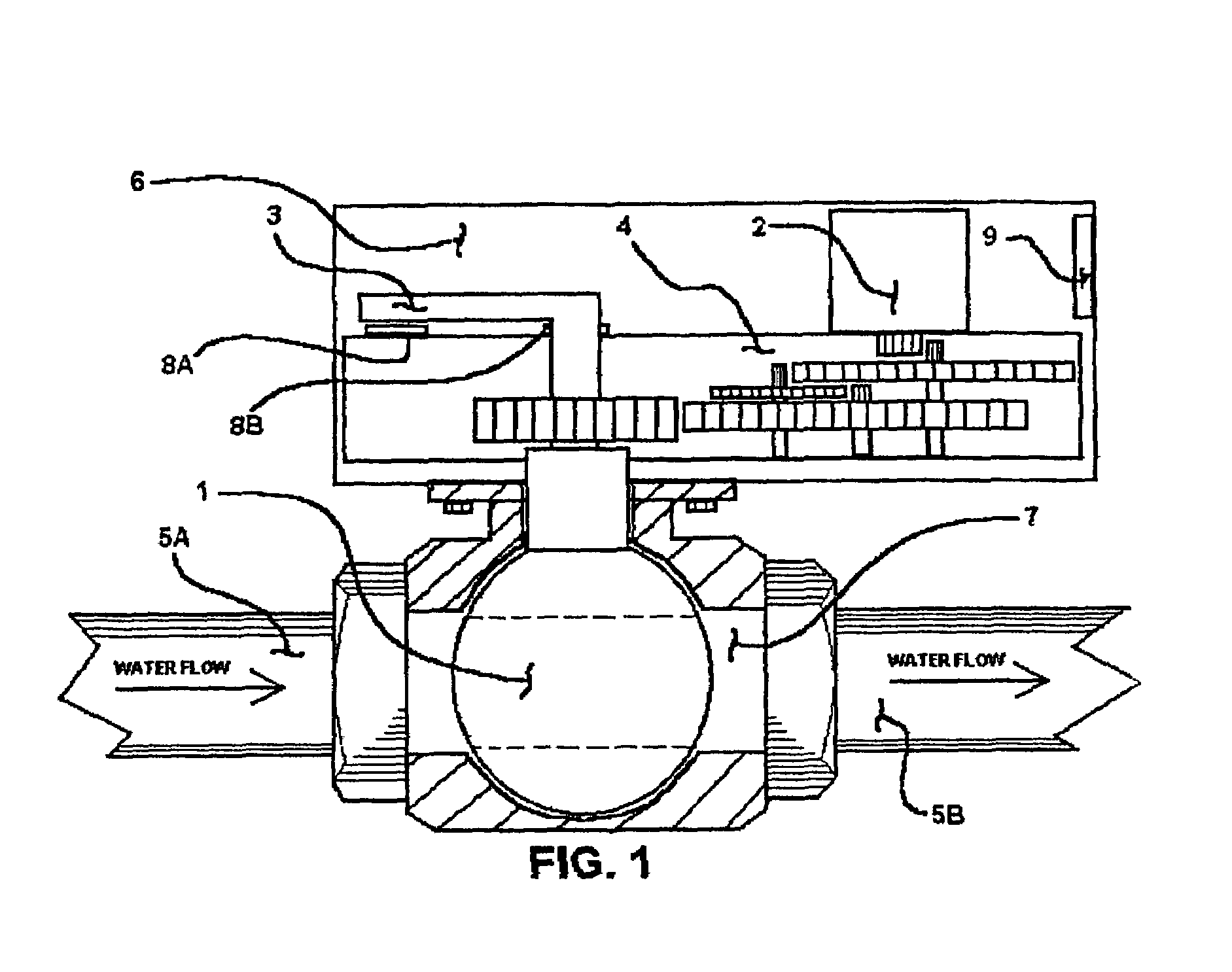

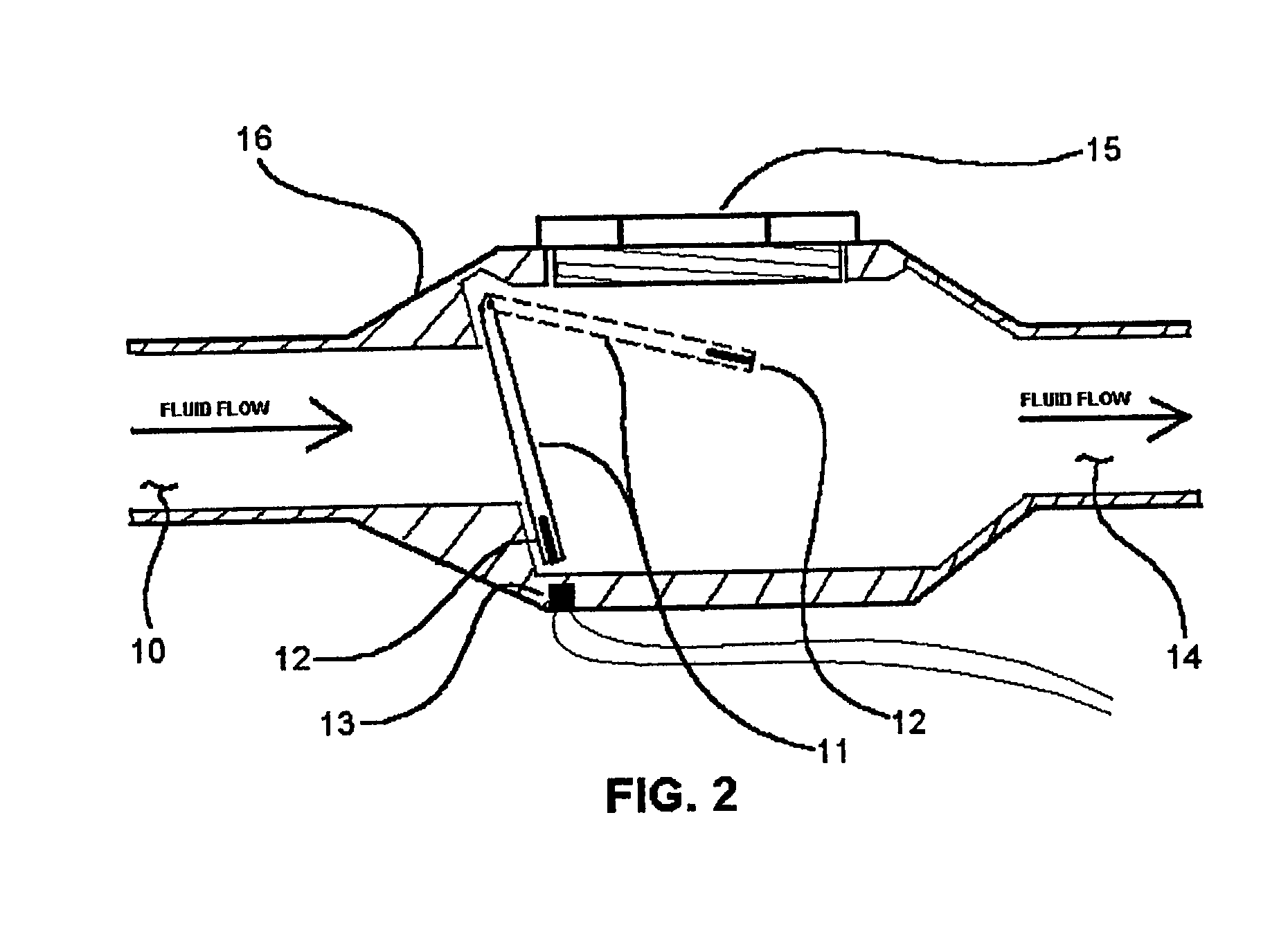

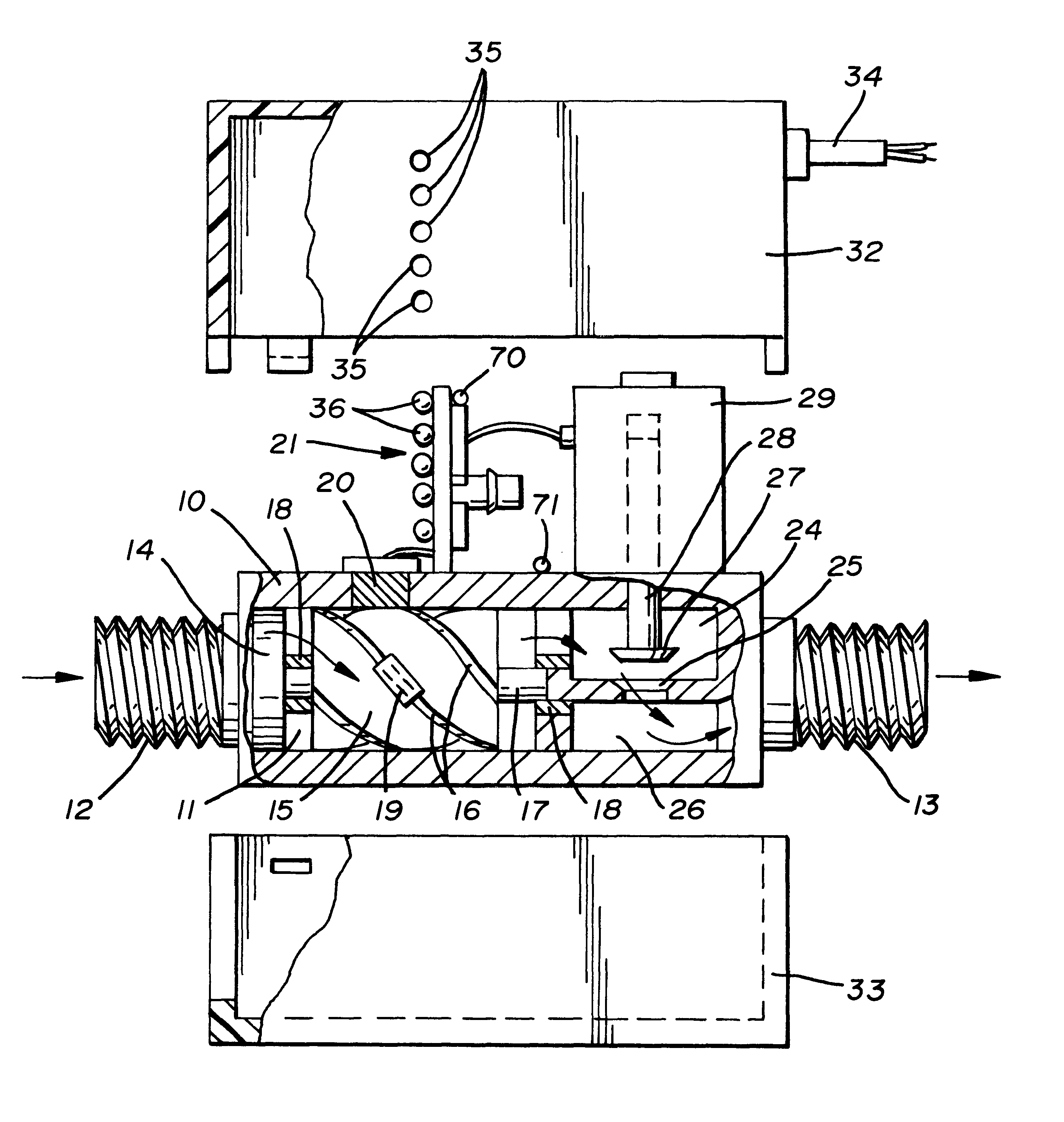

Ultrasonic Flow Meter Leak Detection System and Method

ActiveUS20170307466A1Well formedMeasurement of fluid loss/gain rateVolume/mass flow measurementUltrasonic sensorTransducer

The use of ultrasonic transducers installed in utility meters is provided for the detection of fluid leaks in a conduit. Such transducers are normally used to transmit acoustic waves in order to measure the velocity of fluid flow, but it is disclosed that such transducers are also capable of detecting leak noises in addition to such transmitted acoustic waves.

Owner:NEPTUNE TECH GROUP

Liquid leak detector and automatic shutoff system

InactiveUS7032435B2Reduce leakageDetection of fluid at leakage pointMeasurement of fluid loss/gain rateCatheterGuide tube

Owner:HASSENFLUG BRIAN EDWARD

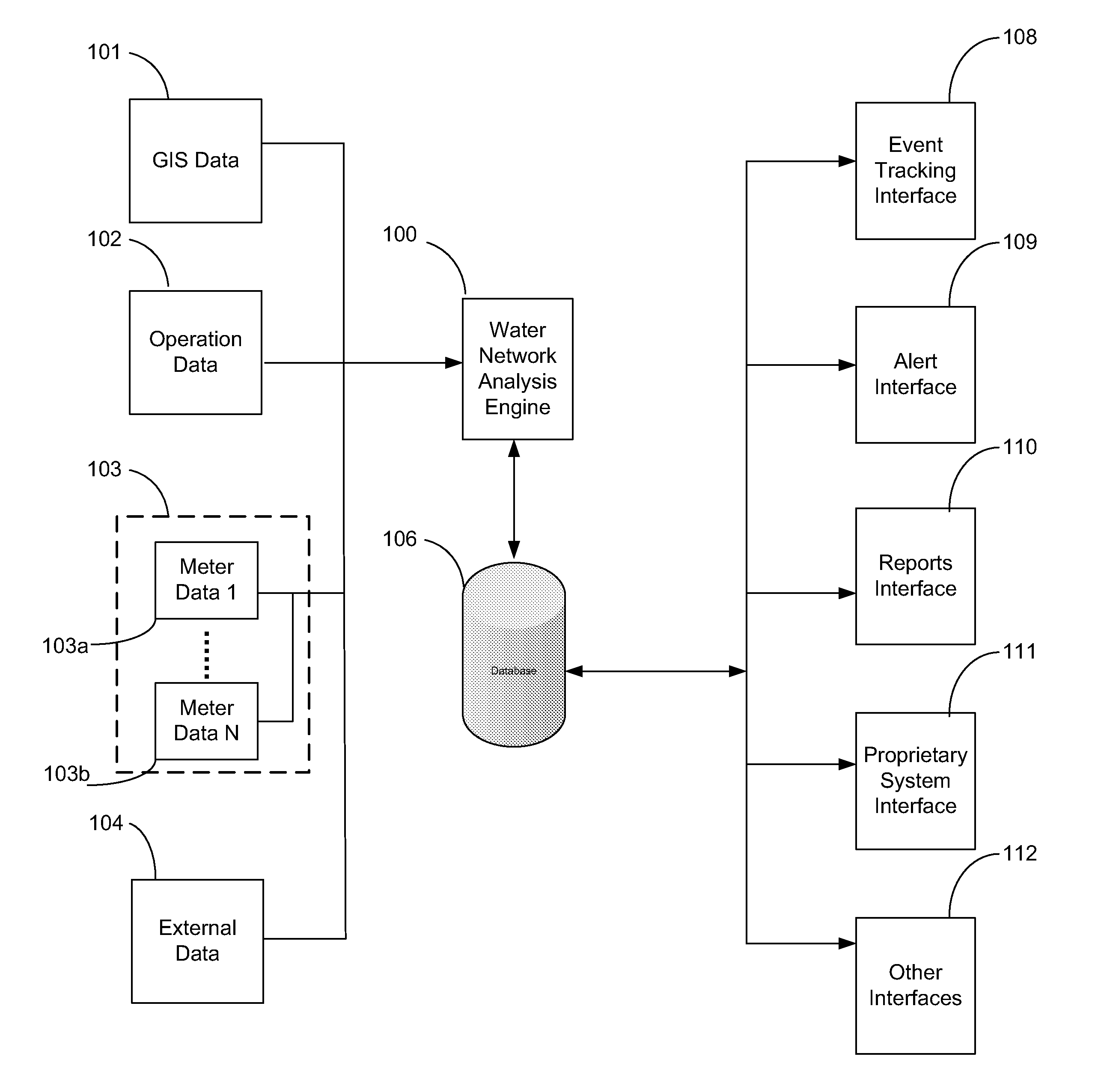

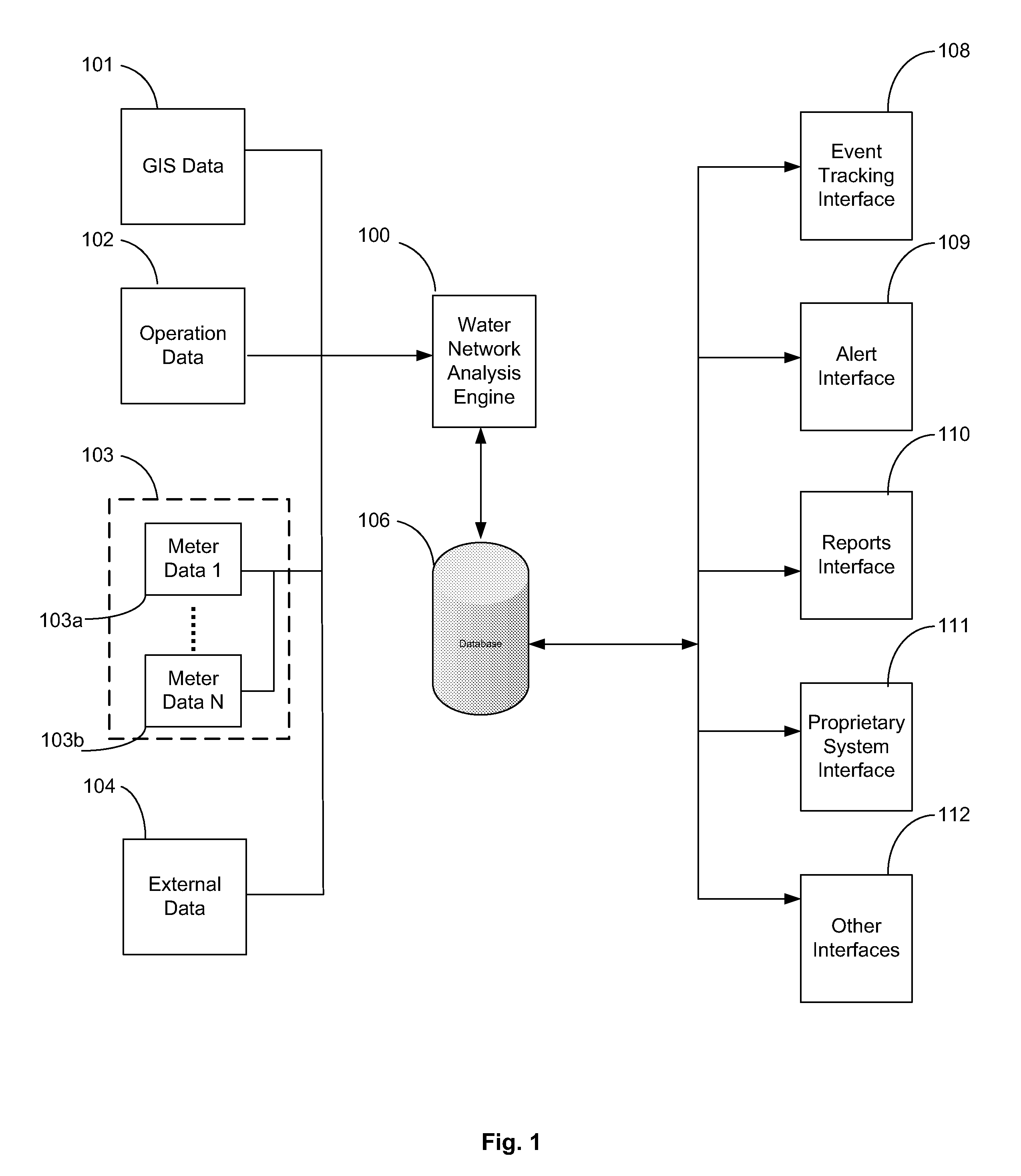

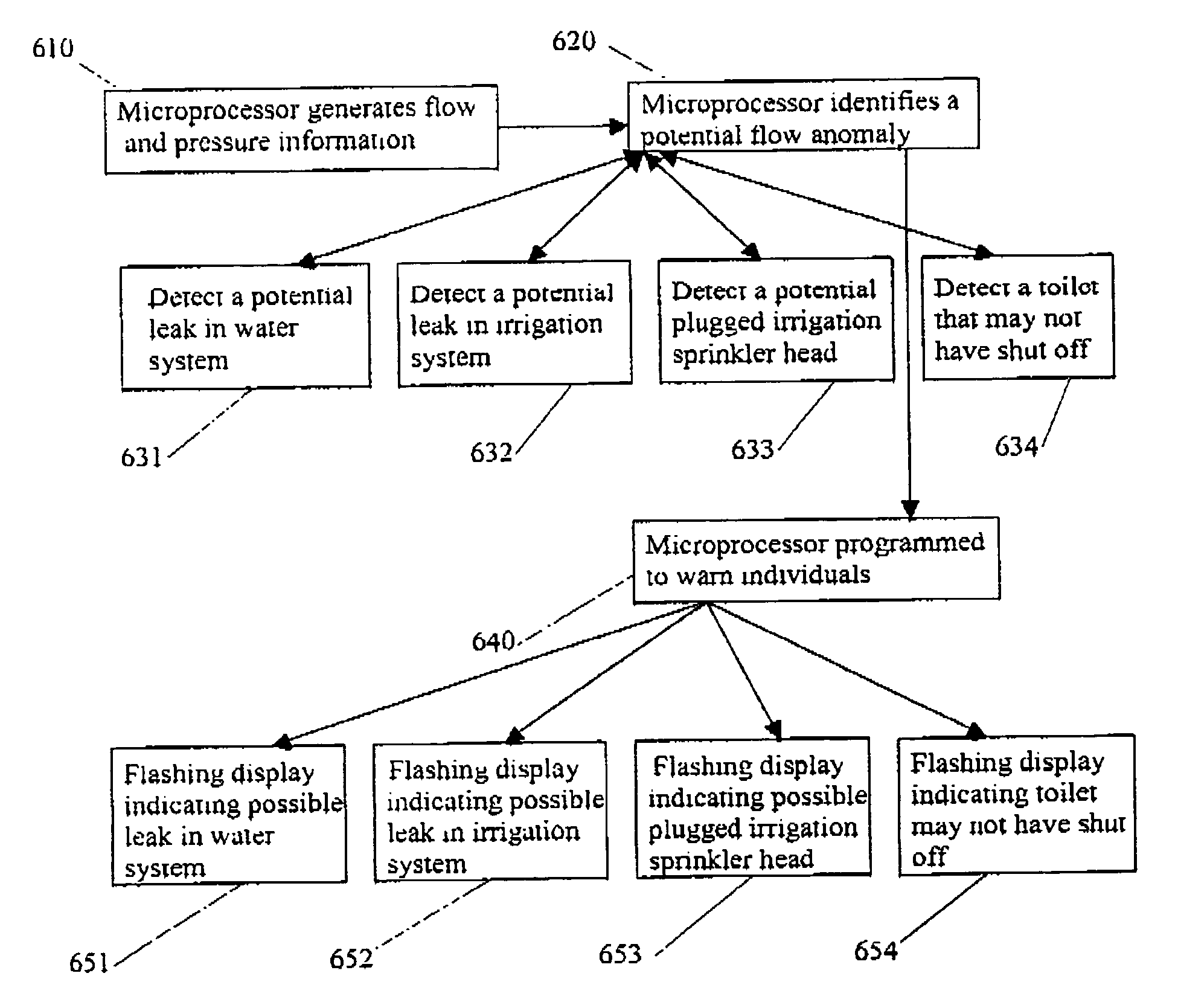

System and method for monitoring resources in a water utility network

ActiveUS20110215945A1The result is accurateReduce or eliminate false alarmsElectric signal transmission systemsMeasurement of fluid loss/gain rateWater utilityTurbidity

A computerized method for monitoring a water utility network, the water utility network comprising a network of pipes for delivering water to consumers and a plurality of meters positioned within the pipes across the water distribution network. The method includes receiving meter data representing parameters measured by the meters, such as flow, pressure, chlorine level, pH and turbidity of the water being distributed through the pipes. The method also includes receiving secondary data from sources external to the meters and representing conditions affecting consumption of water in a region serviced by the water utility network such as weather and holidays. The meter and secondary data is analyzed using statistical techniques to identify water network events including leakage events and other events regarding quantity and quality of water flowing through the pipes and operation of the water network. The events are reported to users via a user interface.

Owner:TAKADU

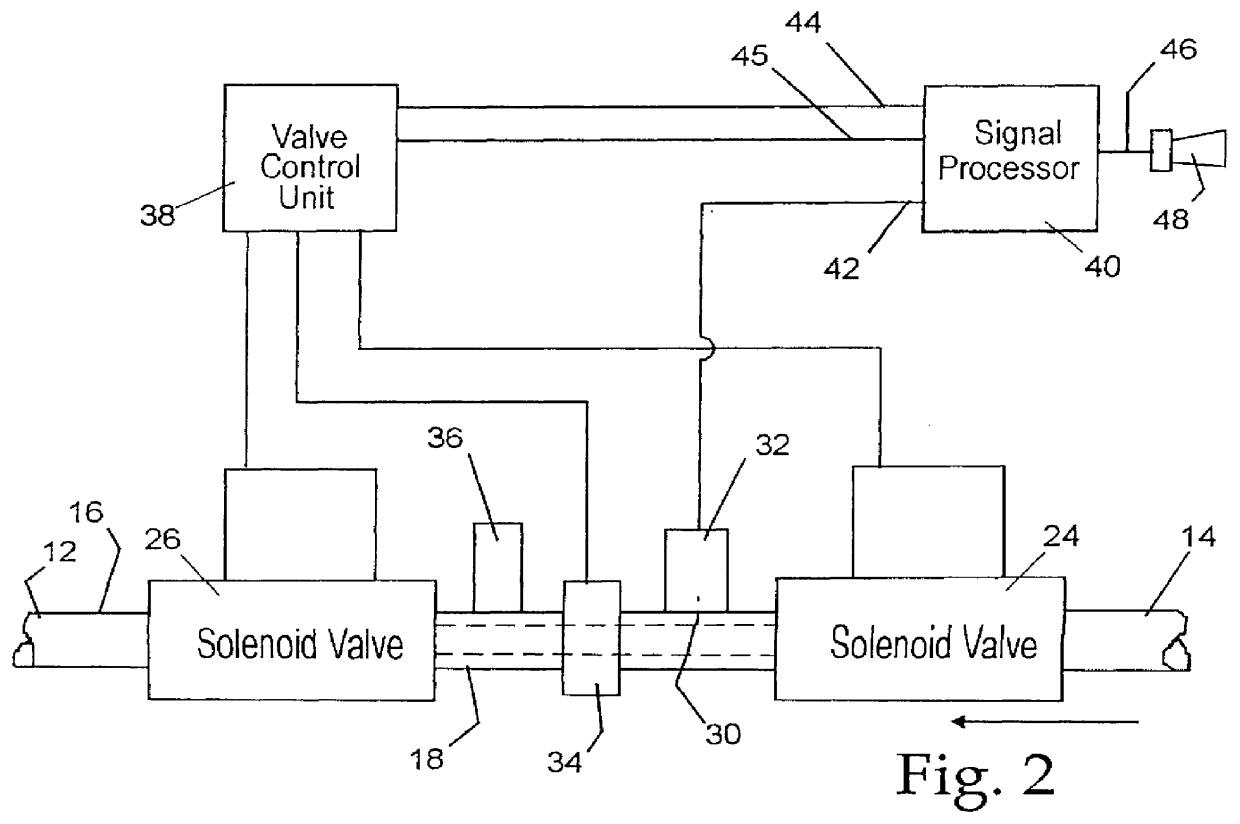

Methods and apparatus for using water use signatures and water pressure in improving water use efficiency

InactiveUS7330796B2Measurement of fluid loss/gain rateGeneral water supply conservationBaseline dataWater use

A method to identify a water flow anomaly in a system having first and second water using devices to generate baseline data that preferably has water use signatures and corresponding water pressure information regarding the water using devices; comparing the baseline data with actual water usage signatures and corresponding actual water pressure information to identify a flow anomaly with the water using devices; and providing information on the flow anomaly to an individual. It is especially contemplated that baseline data are generated for multiple devices coupled to a common water supply system, with baseline data from two or more water using devices compared against future water use patterns of the same devices. Apparatus to accomplish these tasks is preferably housed in an irrigation controller, which may be advantageously coupled to a flow meter.

Owner:AQUA CONSERVATION SYST

Realtime computer assisted leak detection/location reporting and inventory loss monitoring system of pipeline network systems

ActiveUS6970808B2Fast response timeImprove abilitiesDetection of fluid at leakage pointMeasurement of fluid loss/gain rateStability theoryMonitoring system

There is provided a method for detecting and locating leaks in a pipeline network in real-time. A flow model is provided that characterizes flow behavior for at least one of steady and unsteady states respectively corresponding to an absence and a presence of model leaks in the pipeline network, the flow model including a leaking factor kL. A deterministic model is provided to evaluate at least one of a leak status and a no leak status relating to the pipeline network using deterministic criteria. The deterministic criteria is based on a Liapunov Stability Theory. A deviation matrix is constructed based on the flow model and the deterministic model to generate eigenvalues. A leak alarm is generated when at least one of the eigenvalues is less than a predetermined value.

Owner:KINGSLEY E ABHULIMEN +1

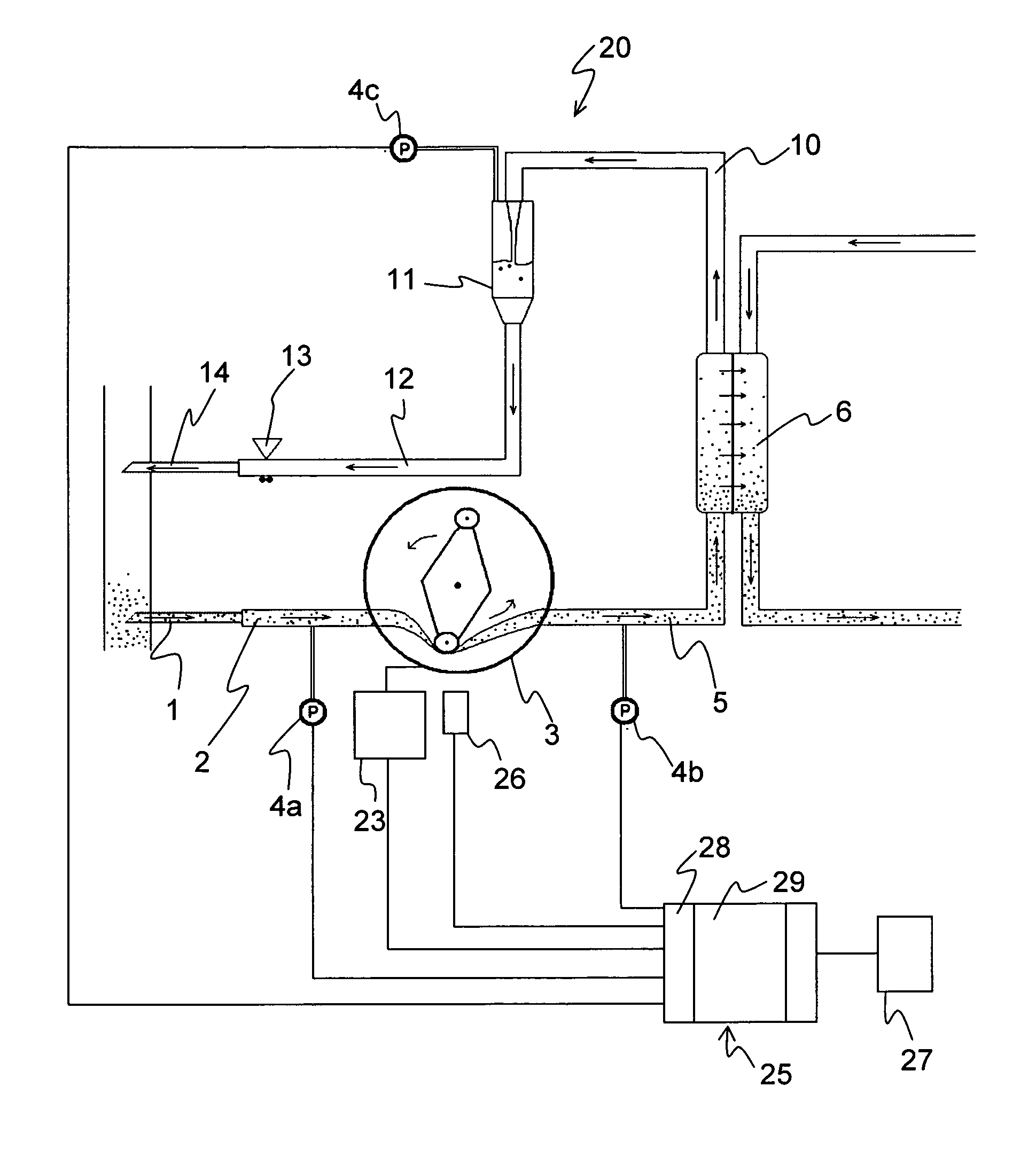

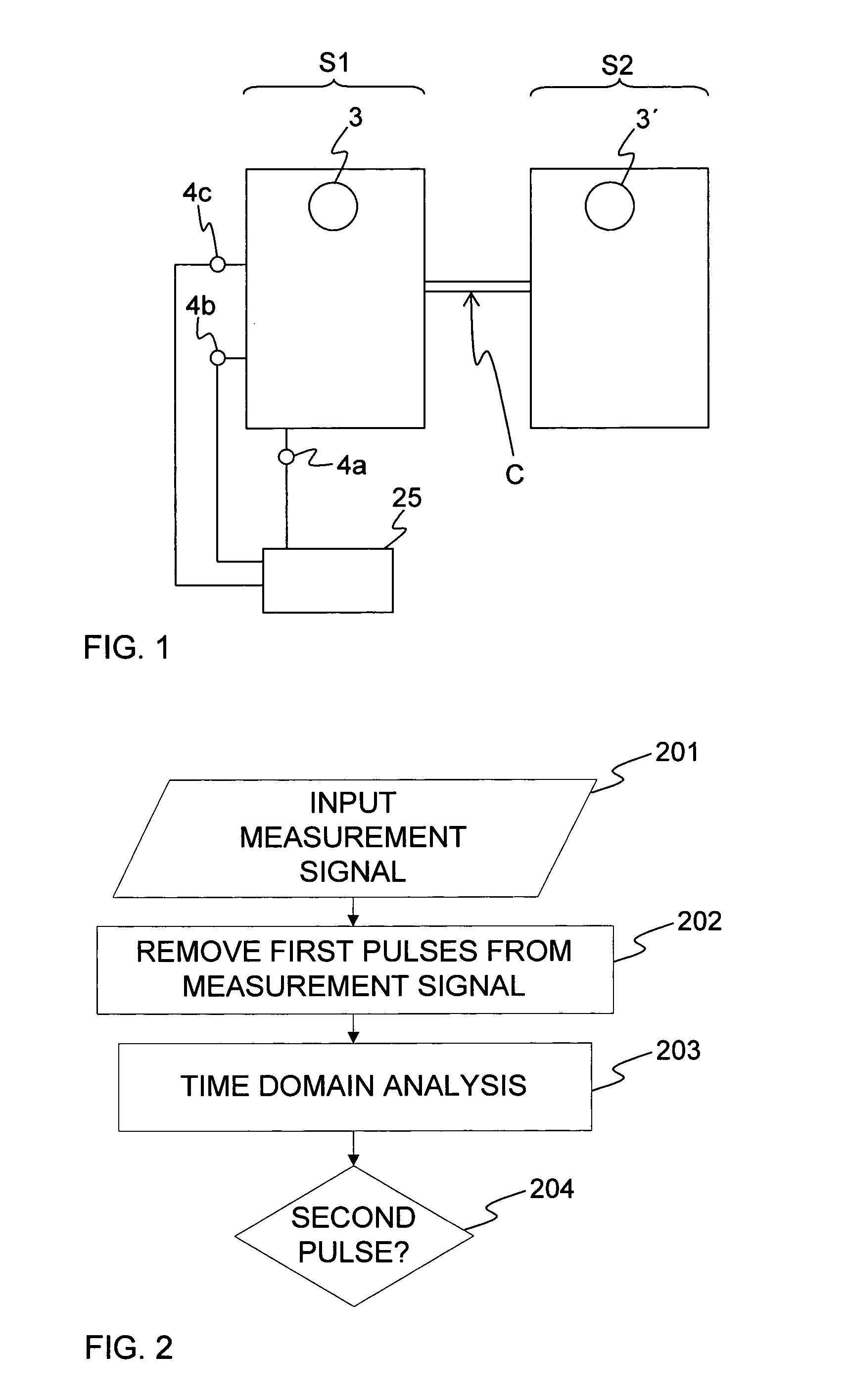

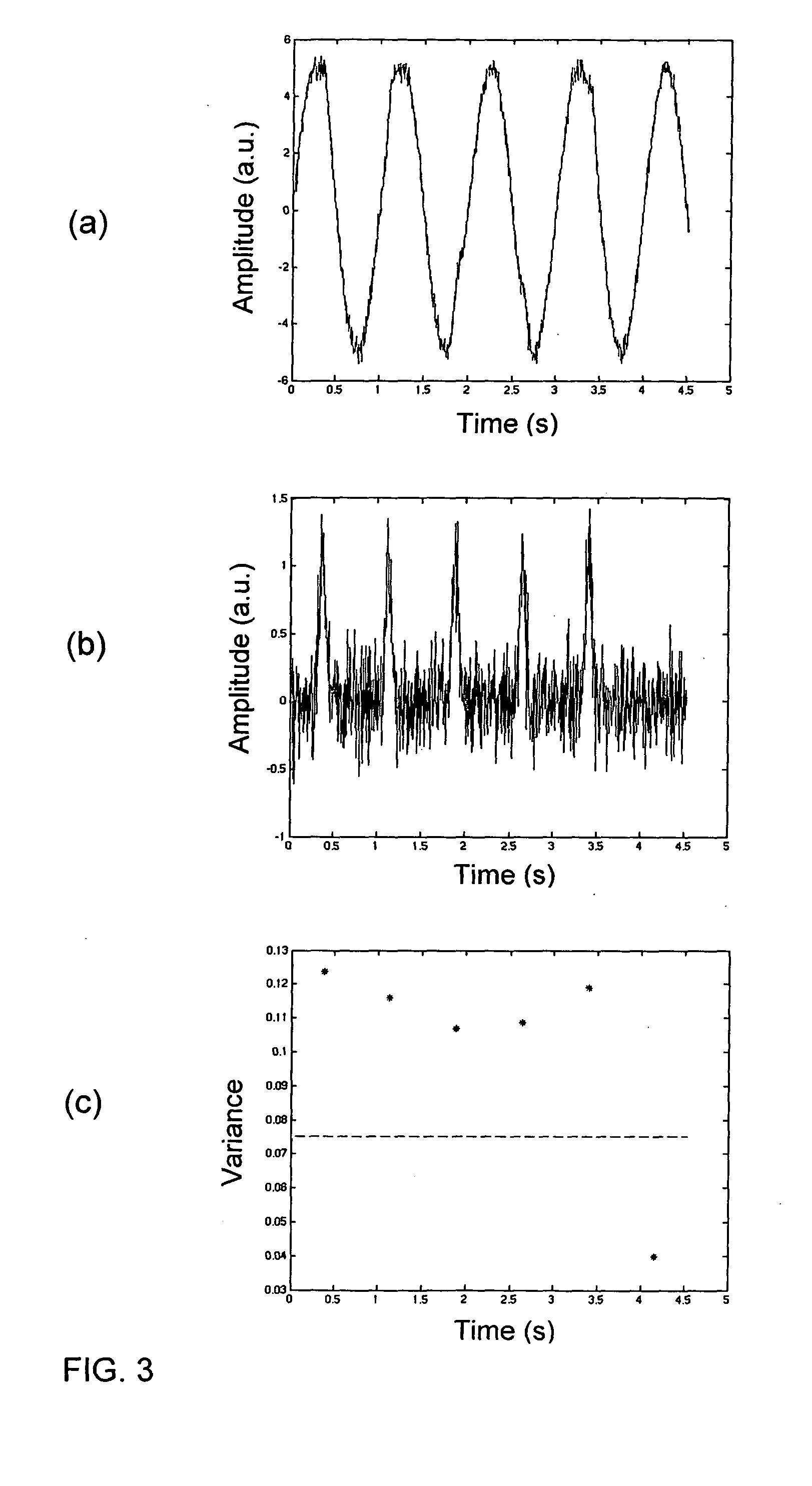

Methods and devices for monitoring the integrity of a fluid connection

ActiveUS20110106466A1Improve robustnessImprove certaintyMeasurement of fluid loss/gain rateOther blood circulation devicesTime domainBlood flow

A surveillance device monitors the integrity of a fluid connection between first and second fluid containing systems based on at least one time-dependent measurement signal from a pressure sensor in the first fluid containing system. The first fluid containing system comprises a first pulse generator, and the second fluid containing system comprises a second pulse generator. The pressure sensor is arranged to detect first pulses originating from the first pulse generator and second pulses originating from the second pulse generator. The integrity of the fluid connection is determined based on the presence of second pulses in the measurement signal. The second pulses may be detected by analysing the measurement signal in the time domain and / or by using timing information indicative of the timing of the second pulses in said at least one measurement signal. The analysis may be based on a parameter value that represents a distribution of signal values within a time window of the measurement signal. The parameter value may be calculated as a statistical dispersion measure of the signal values, or may result from a matching of the signal values within the time window to a predicted temporal signal profile of a second pulse. The fluid connection may be established between a human blood system and an extracorporeal blood flow circuit.

Owner:GAMBRO LUNDIA AB

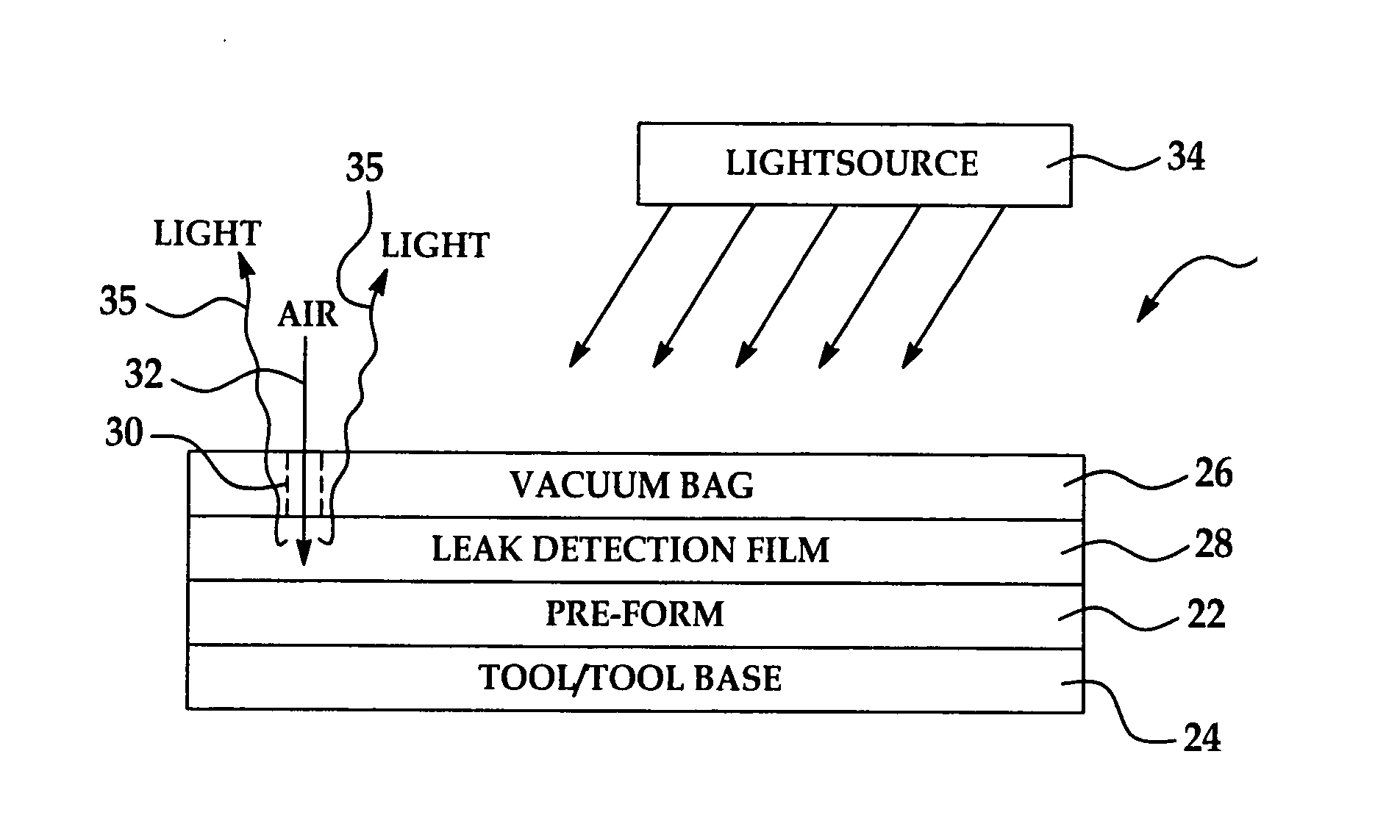

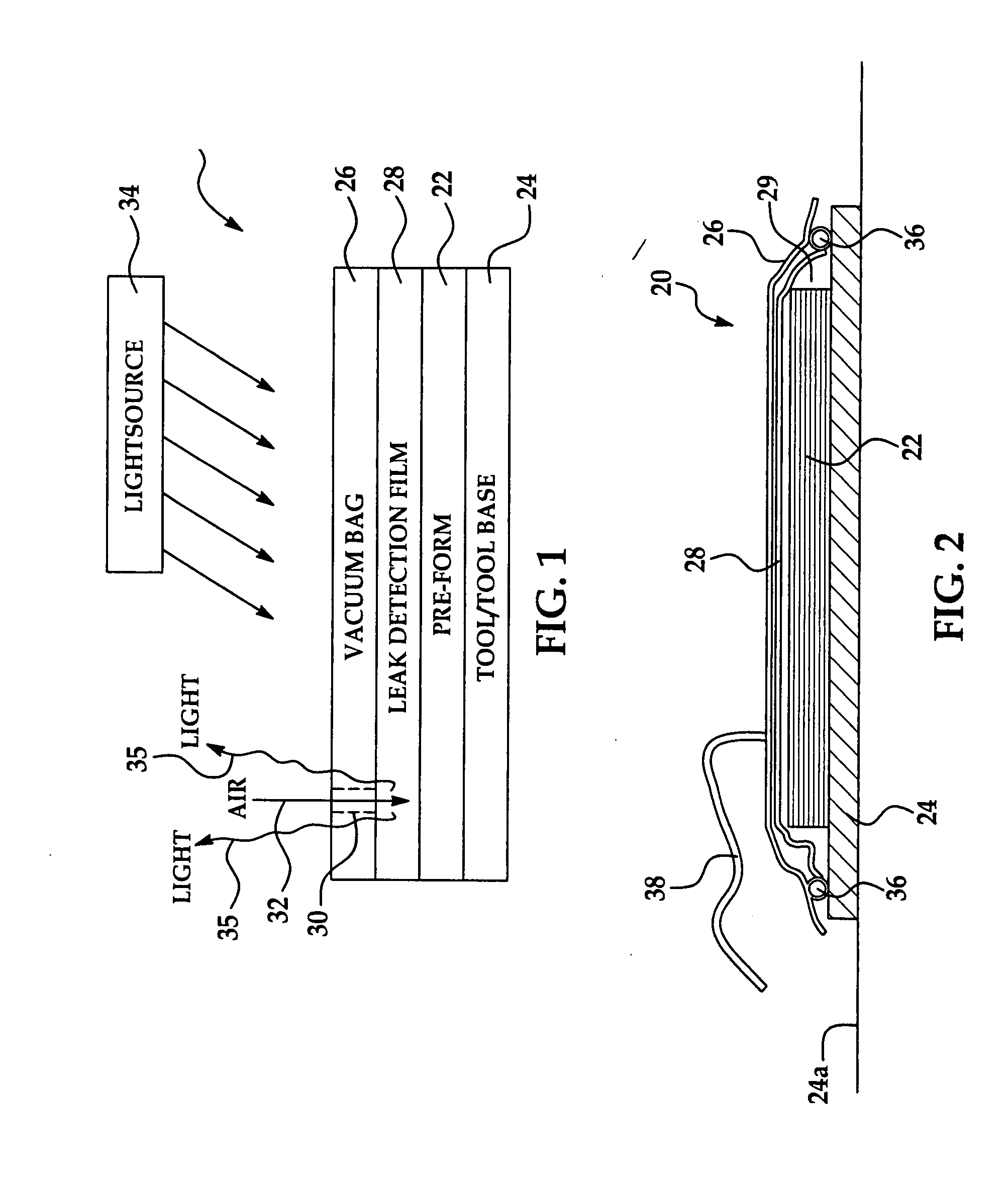

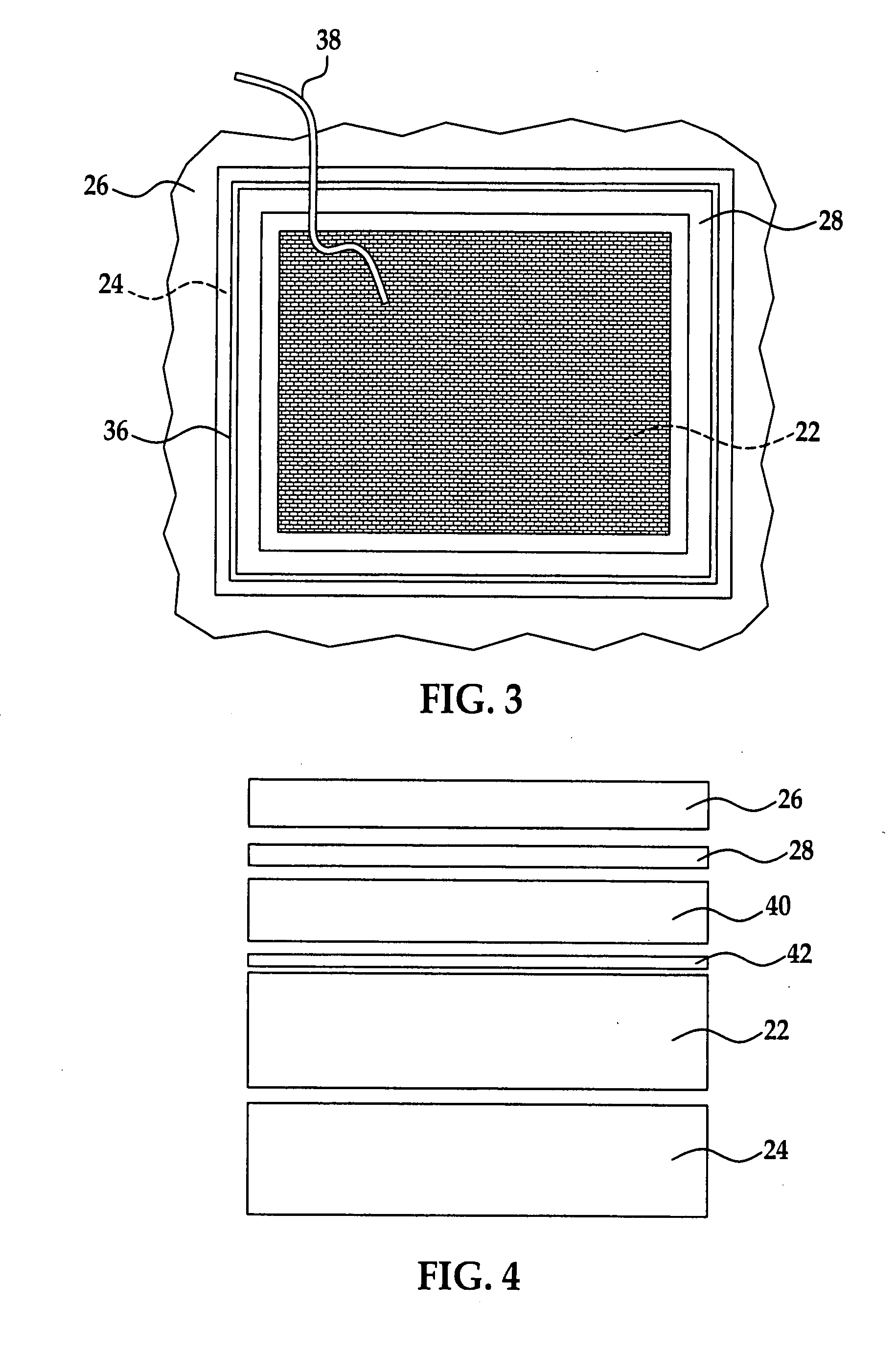

Leak Detection in Vacuum Bags

ActiveUS20080148817A1Keep the pressureDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringLength wave

Air leaks in a vacuum bag are detected using a leak detection film covering the inside face of the bag. The film includes a gas permeable binder carrying oxygen sensitive material that changes in physical appearance at the location of an air leak. The film may be adhered to the inside face of the bag or may form a separate membrane that is placed over a layup being molded in the bag. The film may be illuminated with light having a wavelength selected to cause the film to luminesce.

Owner:THE BOEING CO

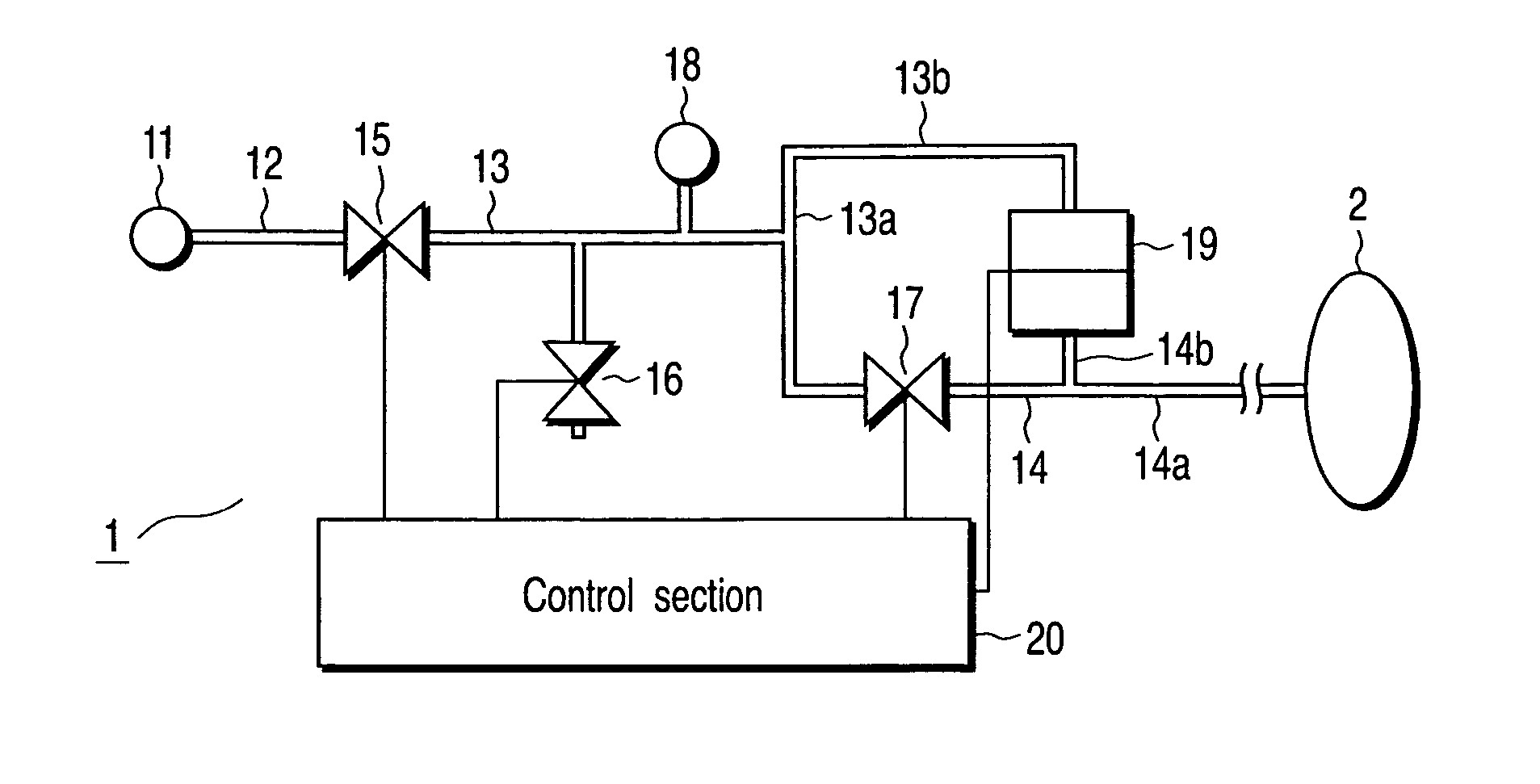

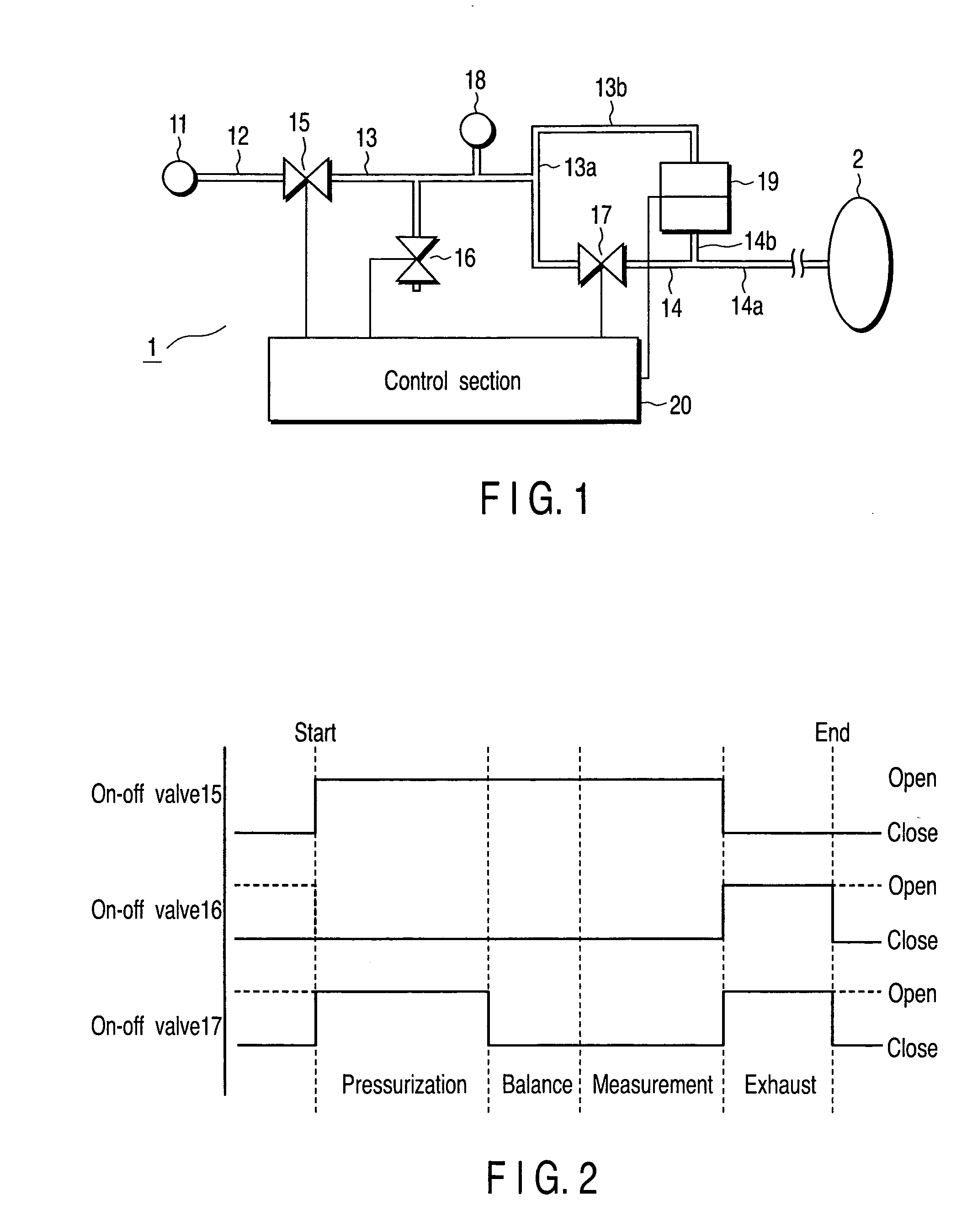

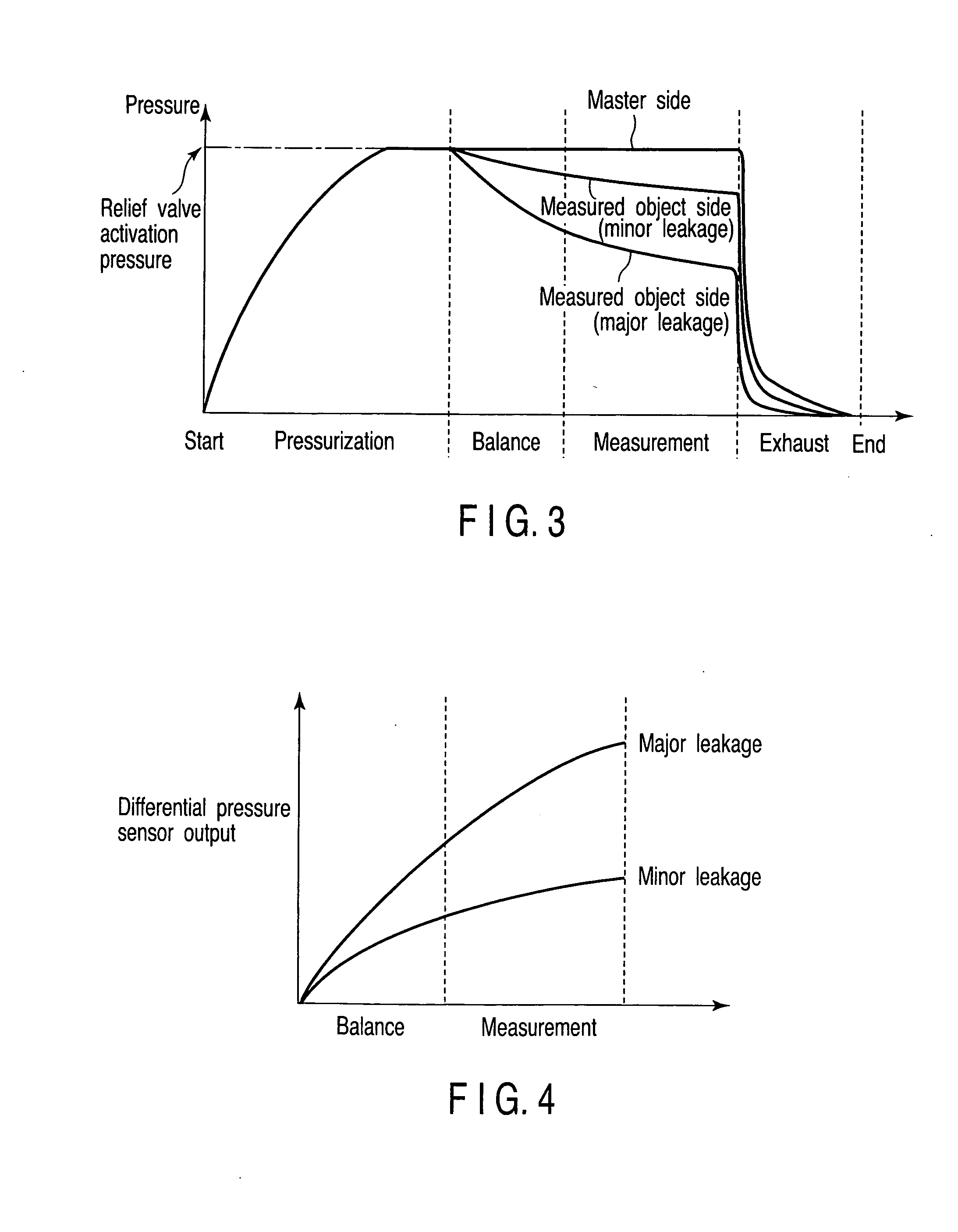

Leak tester

InactiveUS20050056081A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateDifferential pressureGas leak

A leak tester which detects leakage of a gas from a measured object, the leak tester including a source of a pressurized gas which supplies the pressurized gas, a differential pressure detecting section which detects a pressure difference between the pressure of a gas in the measured object and the pressure of a pressurized gas supplied by the source of the pressurized gas, and a pressure adjusting section which makes the pressure of the pressurized gas supplied by the source of the pressurized gas constant.

Owner:OLYMPUS CORP

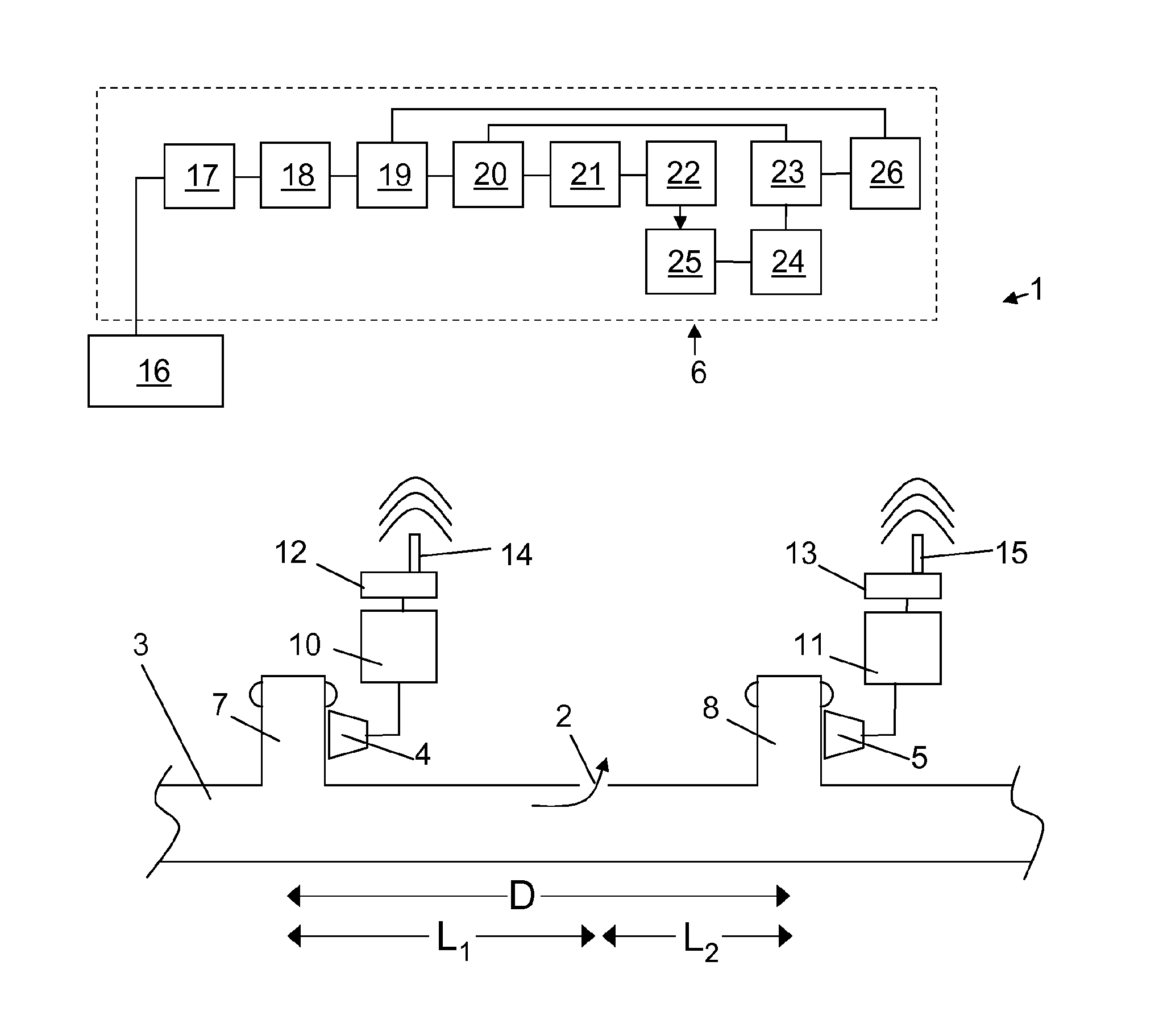

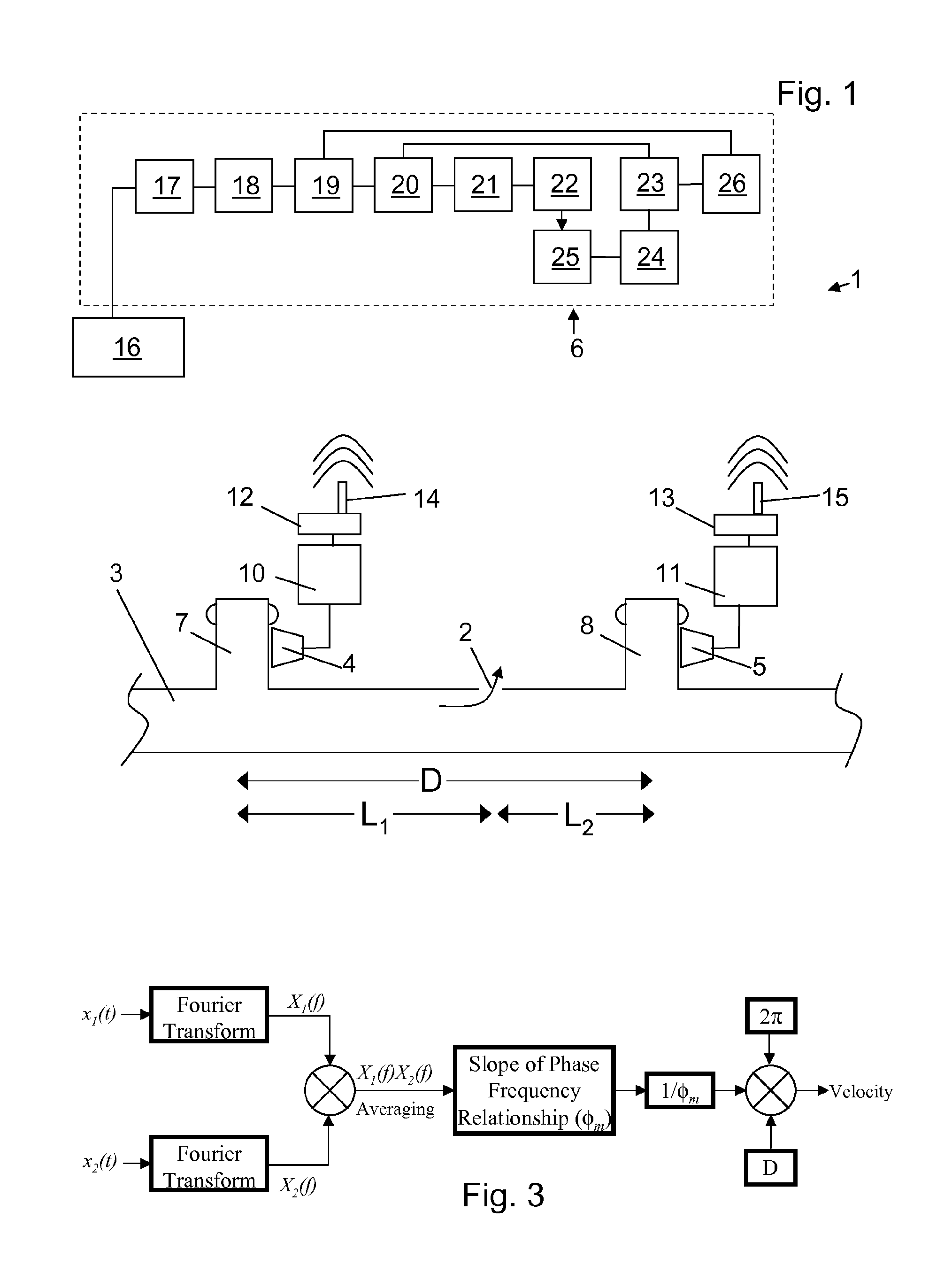

Leak detector

ActiveUS20120007744A1Accurate identificationAccurately and repeatably locate leakMeasurement of fluid loss/gain rateFlow propertiesEngineeringLeak detector

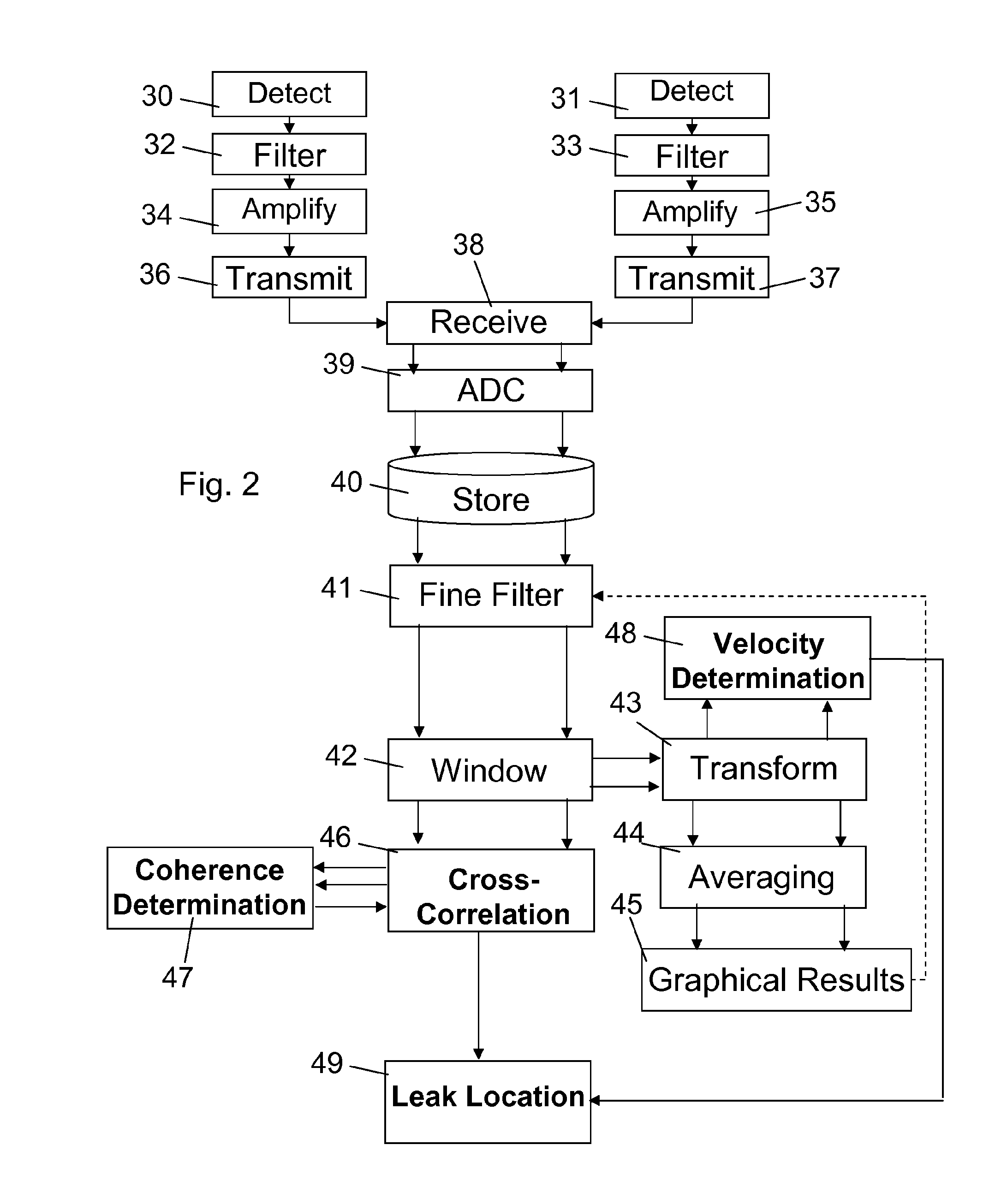

A leak detector for detecting and locating leaks in a water supply pipe of plastics, the leak detector comprising a first sensor at a first position arranged to detect a leak signal travelling along a pipe, a second sensor arranged to detect a leak signal travelling along the pipe at a second position spaced from the first position, and a processing device adapted to receive the signals from the first sensor and the second sensor. The processing device may be adapted to determine the velocity of the signals from characteristics of the leak signals. The processing device is adapted to use the velocity and distance between the first sensor and the second sensor to determine the location of a leak. The characteristics may be the relationship between the phase and frequency of the leak signals.

Owner:SEVERN TRENT WATER LTD

Method and apparatus for detecting severity of water leaks

InactiveUS7561057B2Low costIncrease rangeMeasurement of fluid loss/gain rateElectric testing/monitoringWater leakEngineering

A system for detecting water leaks is described. In one embodiment, the system includes a plurality of sensors, selected from a moisture sensor, a water level sensor, and / or a water temperature sensor. A processor collects moisture readings from the sensors. In one embodiment, the processor reports a possible water leak when a moisture sensor detects moisture above a moisture threshold value. In one embodiment, the processor reports a water leak when the water level reading exceeds a water threshold value and / or when the temperature reading exceeds a temperature threshold value.

Owner:GOOGLE LLC

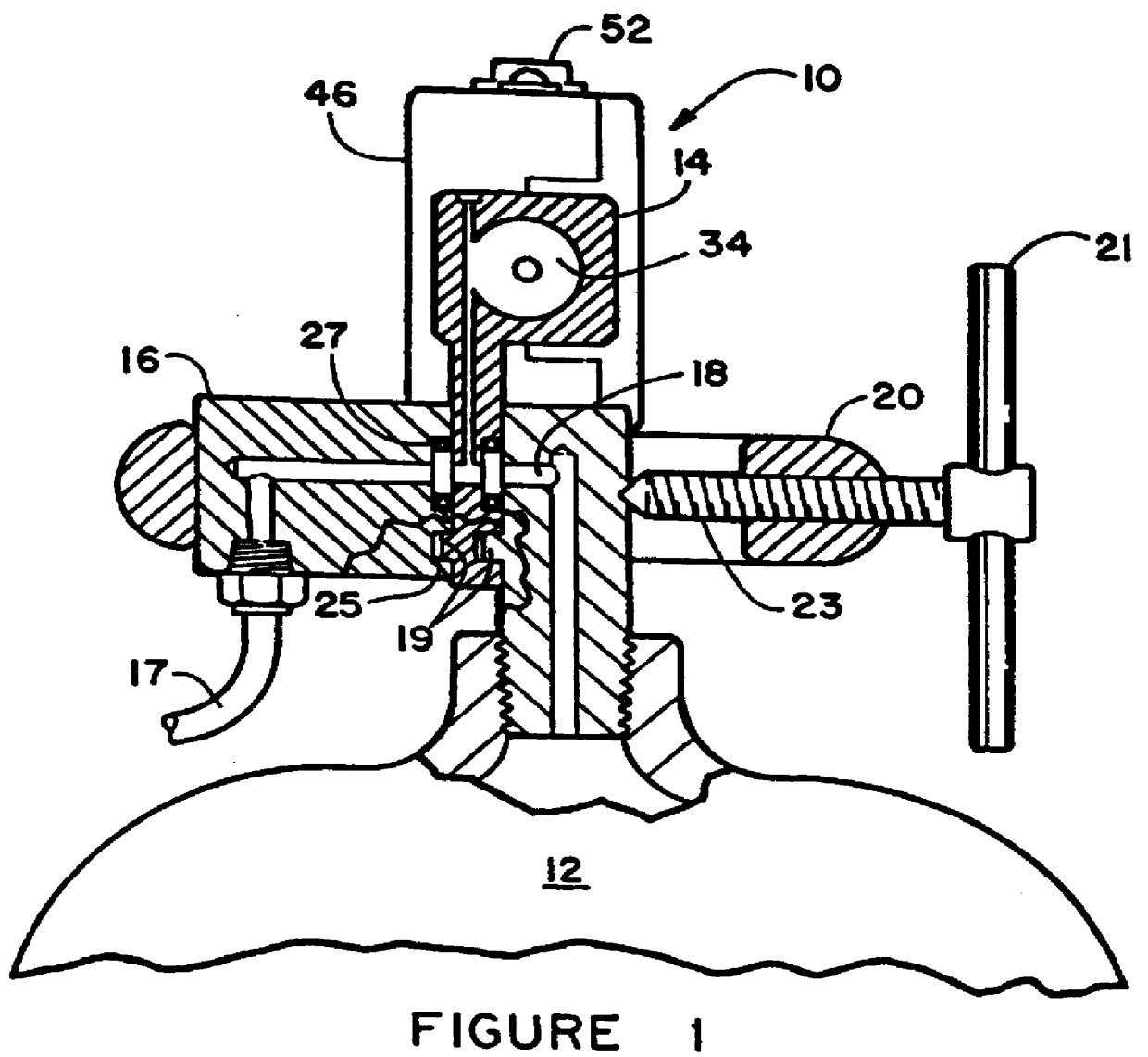

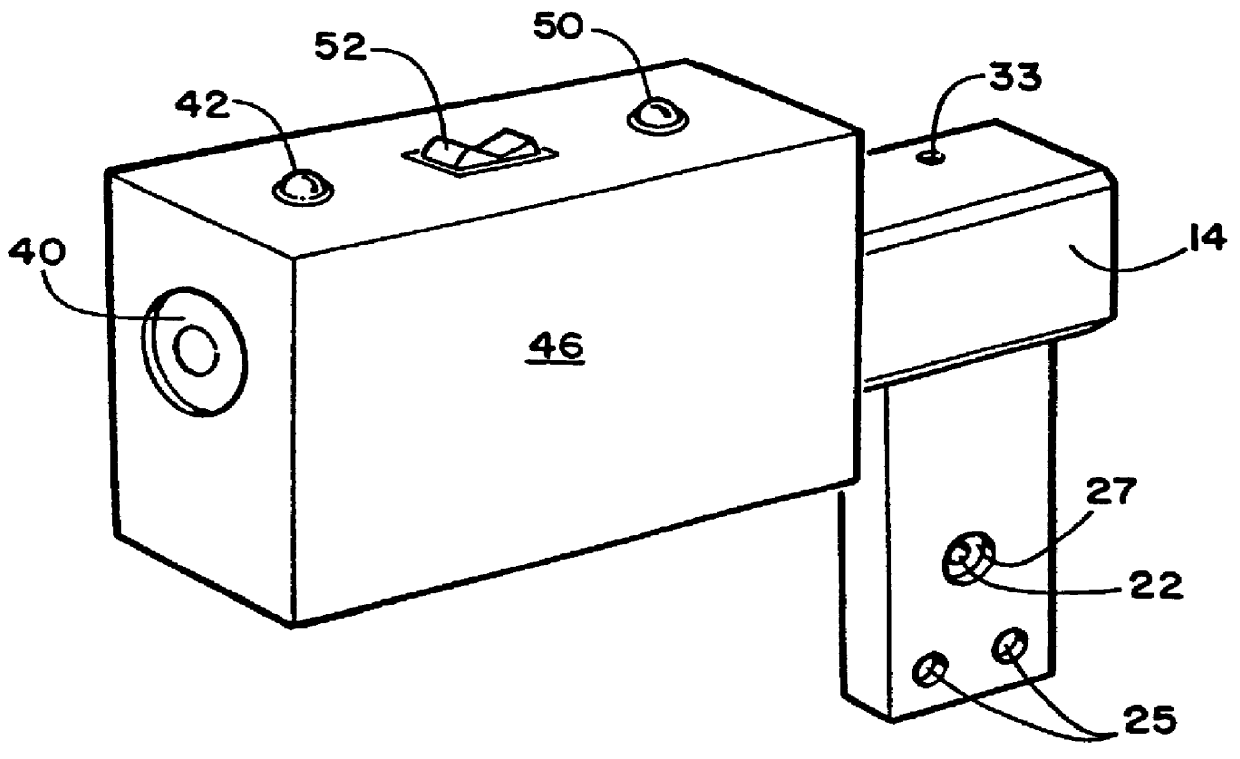

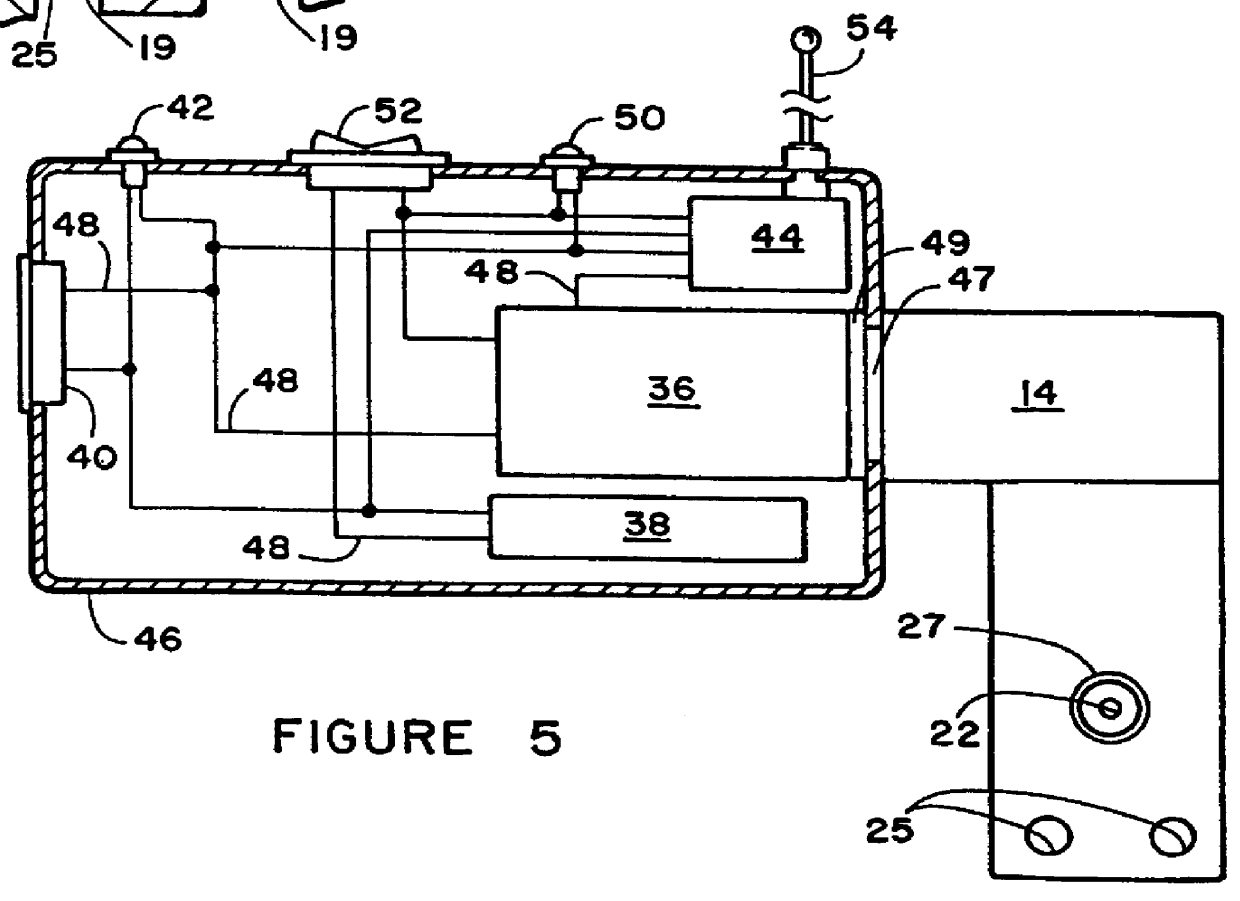

Pressure monitor and alarm for compression mounting with compressed gas storage tank

InactiveUS6137417AImprove securityReduce tank pressureValve arrangementsMeasurement of fluid loss/gain rateGas cylinderEngineering

A warning device configured for removable mounting in combination with a high pressure gas cylinder and a regulator used to regulate the high pressure gas supplied by the cylinder. The device compression mounts between the regulator and tank outlet on conventional portable oxygen and gas supply systems using a specially configured manifold. The device features one or a combination of alarms, from a group including audio, visual, electronic, and remotely transmitted alarms. These alarms are activated by a pressure switch monitoring the remaining supply in the gas cylinder through a conduit the manifold. The alarm signal from the device alerts the user, or a third party monitoring the user, of current tank pressure or will sound an alarm when remaining high pressure gas inside the gas cylinder drops below a predetermined level.

Owner:INGEN TECH

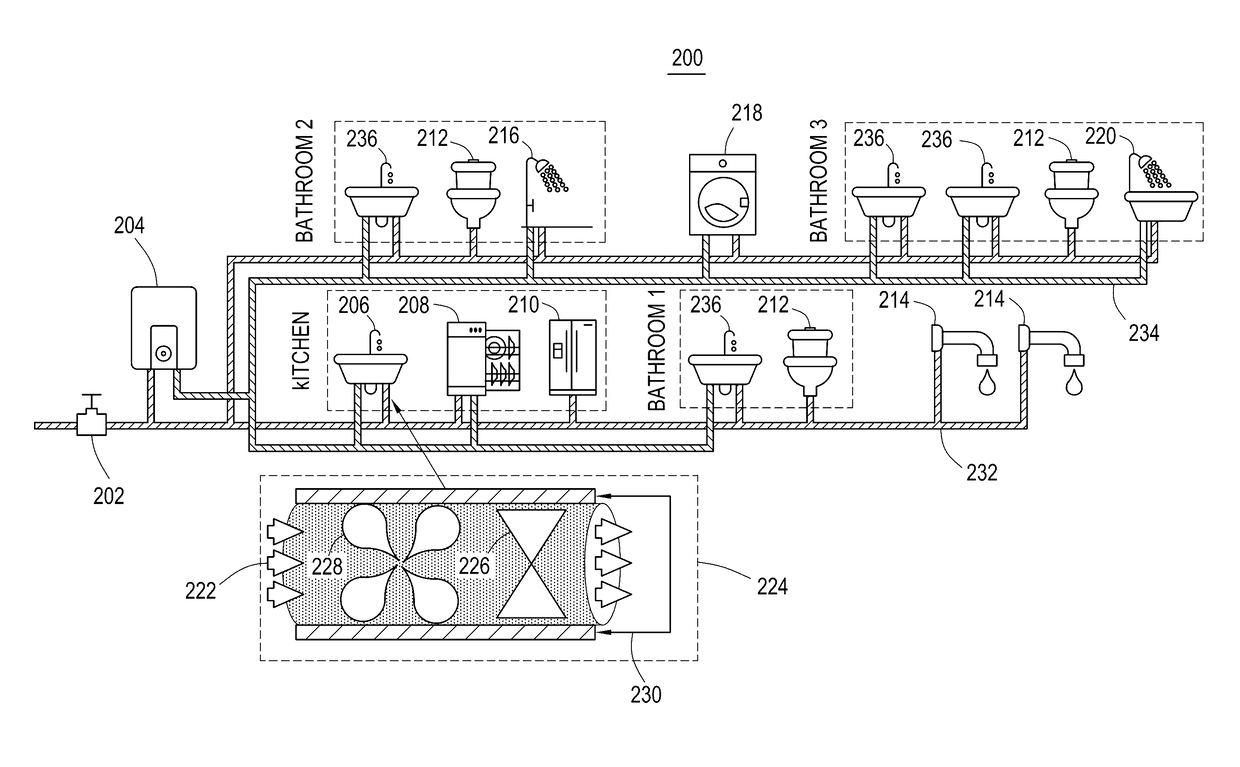

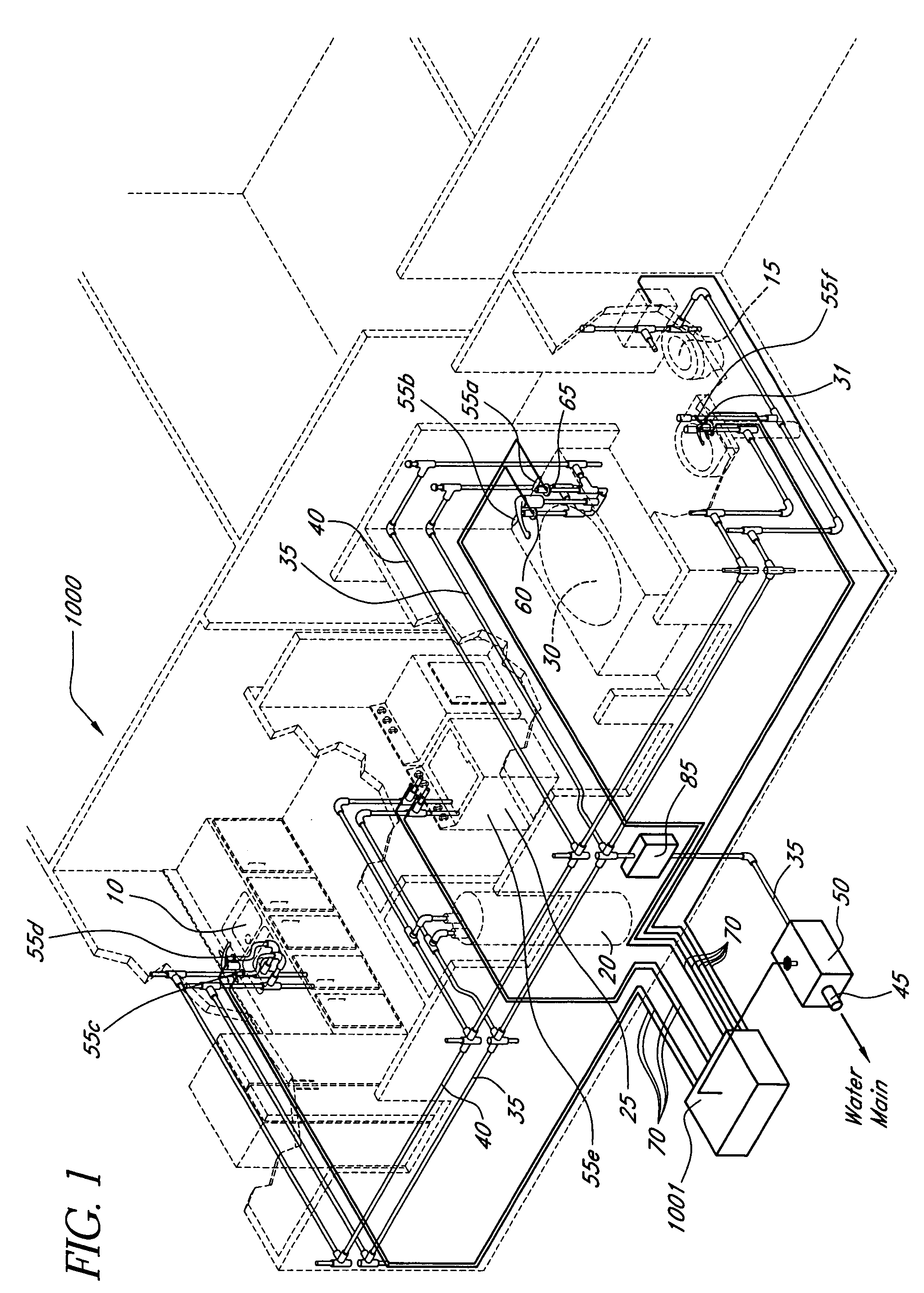

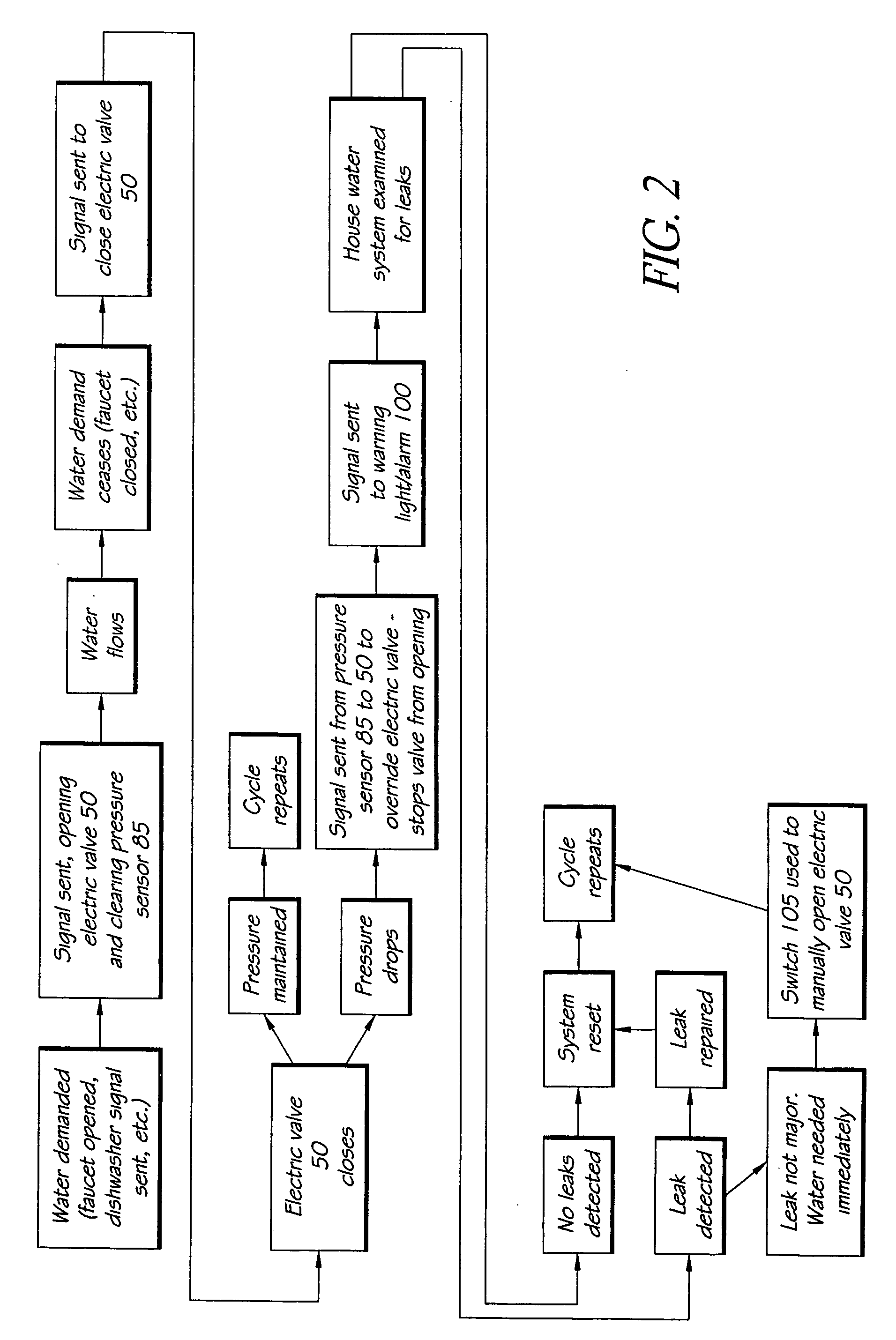

Water leak detection and prevention systems and methods

ActiveUS20050224118A1Avoid damagePrevent any substantial leakMeasurement of fluid loss/gain rateOperating means/releasing devices for valvesWater pipeOperating energy

Water leak detection and prevention systems and methods in which water is only delivered to the water pipes in the building when a faucet or appliance demands water and water is delivered through a normally closed shut off water valve. During the period that the main water is shut off, the water pressure in the water pipes is continuously monitored to detect a water leak in the building. Detection of a leak causes an alarm to be sounded and a continued closure of the shut off valve.

Owner:TORNAY PAUL G

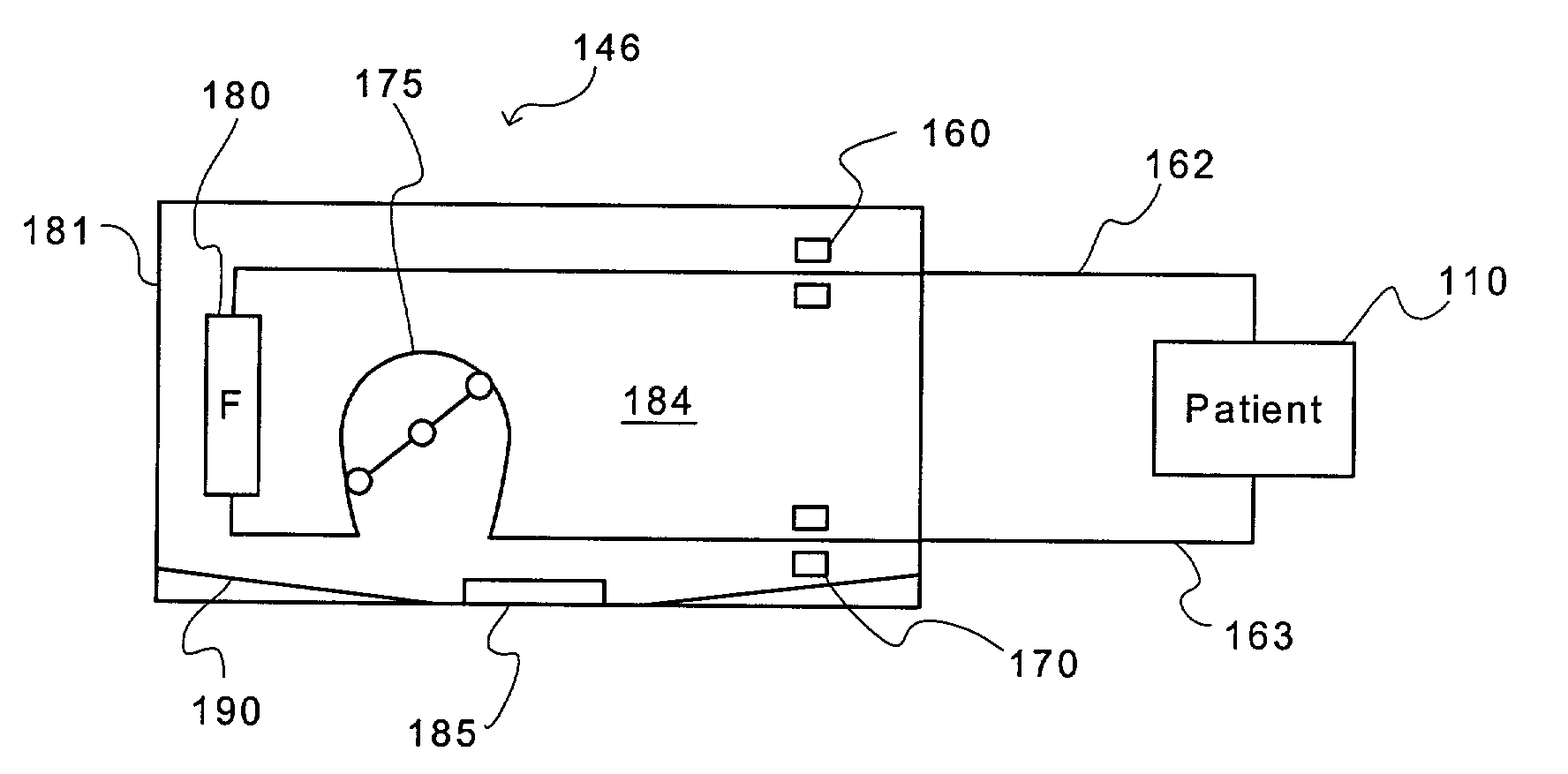

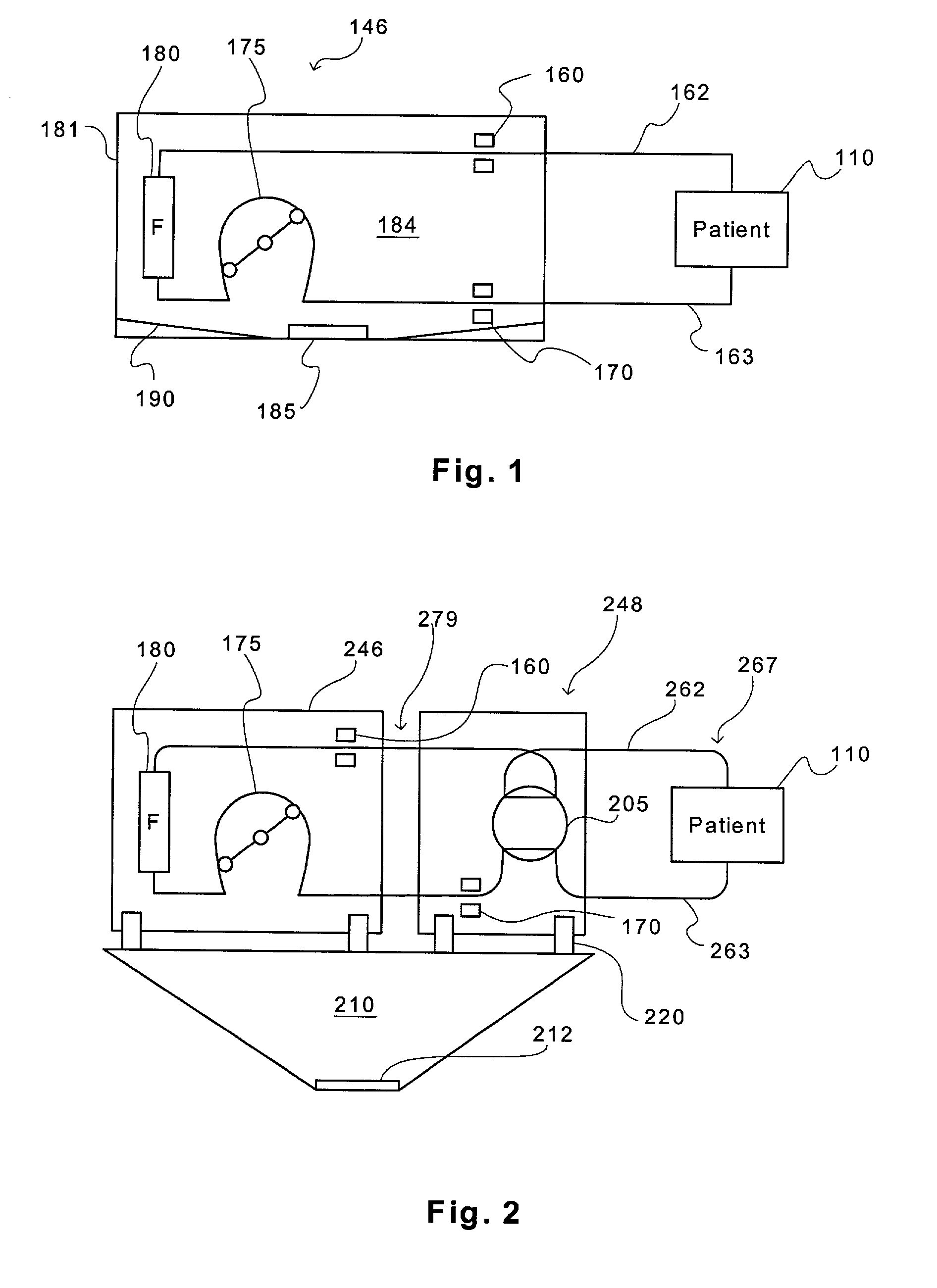

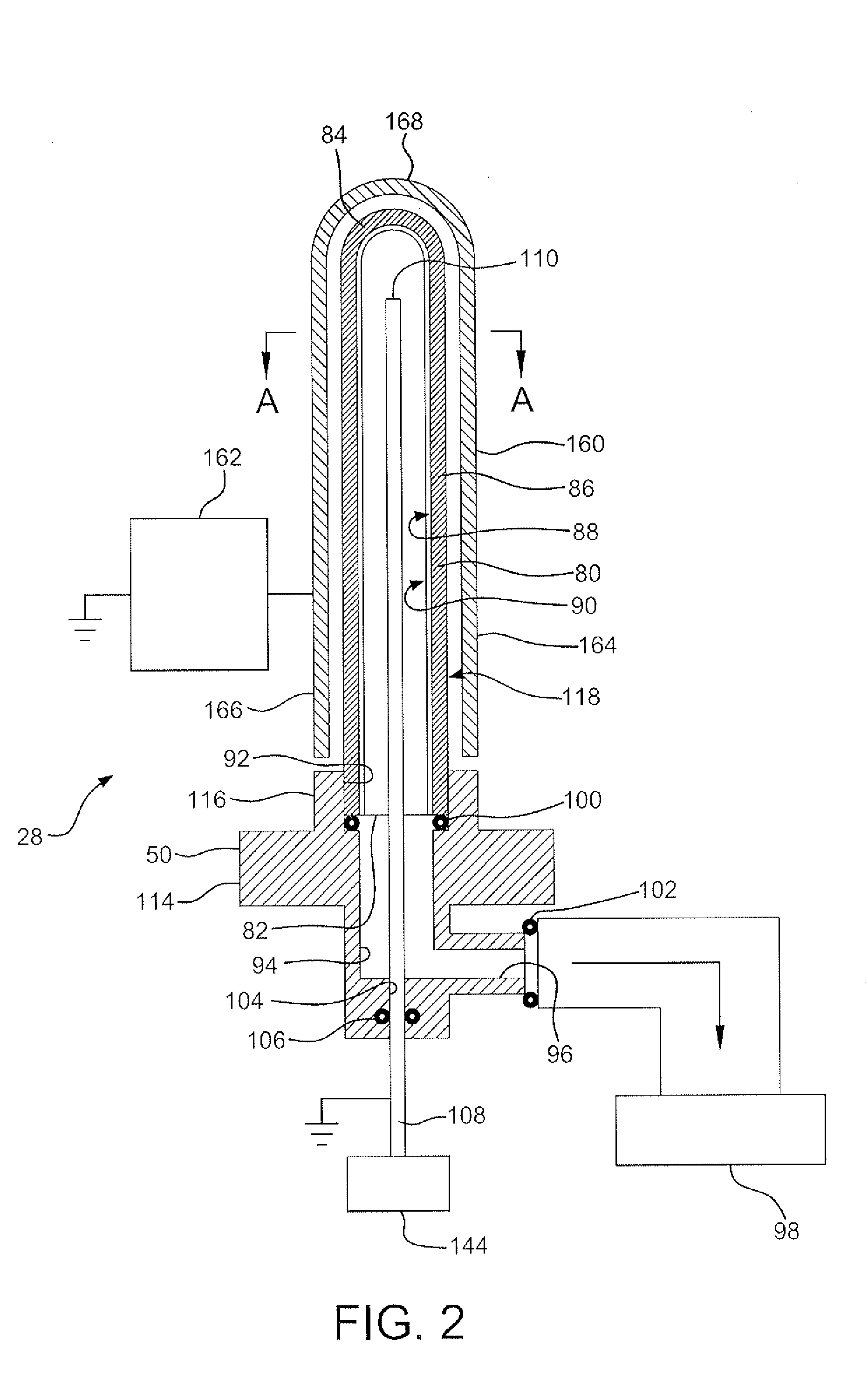

Vessel inspection apparatus and methods

ActiveUS20110252899A1Simplified determinationGlovesPharmaceutical delivery mechanismMarine engineeringBlood vessel

Methods for processing a vessel, for example to provide a gas barrier or lubricity, are disclosed. First and second PECVD or other vessel processing stations or devices and a vessel holder comprising a vessel port are provided. An opening of the vessel can be seated on the vessel port. The interior surface of the seated vessel can be processed via the vessel port by the first and second processing stations or devices. Vessel barrier, lubricity and hydrophobic coatings and coated vessels, for example syringes and medical sample collection tubes are disclosed. A vessel processing system and vessel inspection apparatus and methods are also disclosed, for example using material outgassed from a surface to inspect the properties of a surface coating.

Owner:SI02 MEDICAL PRODS

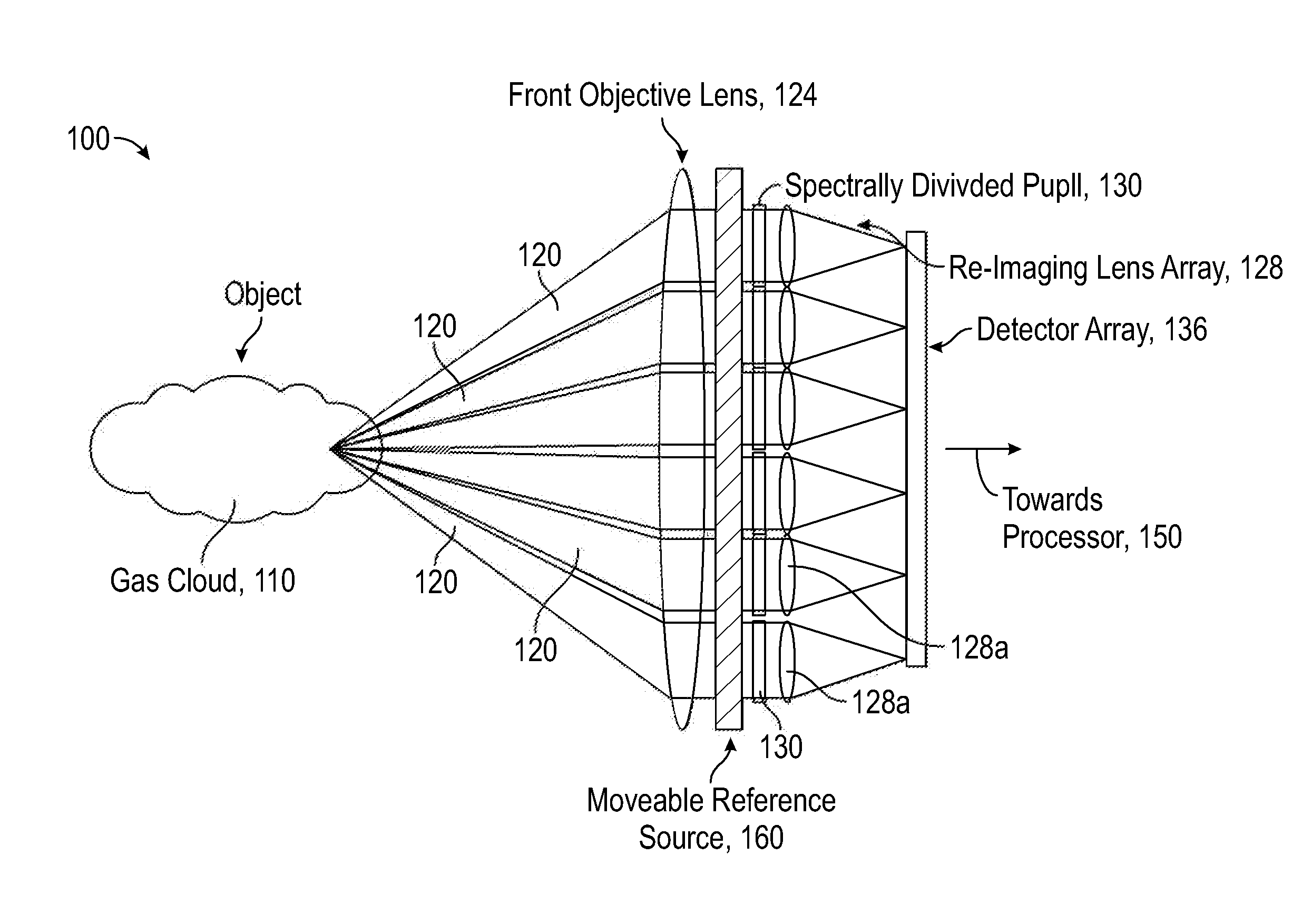

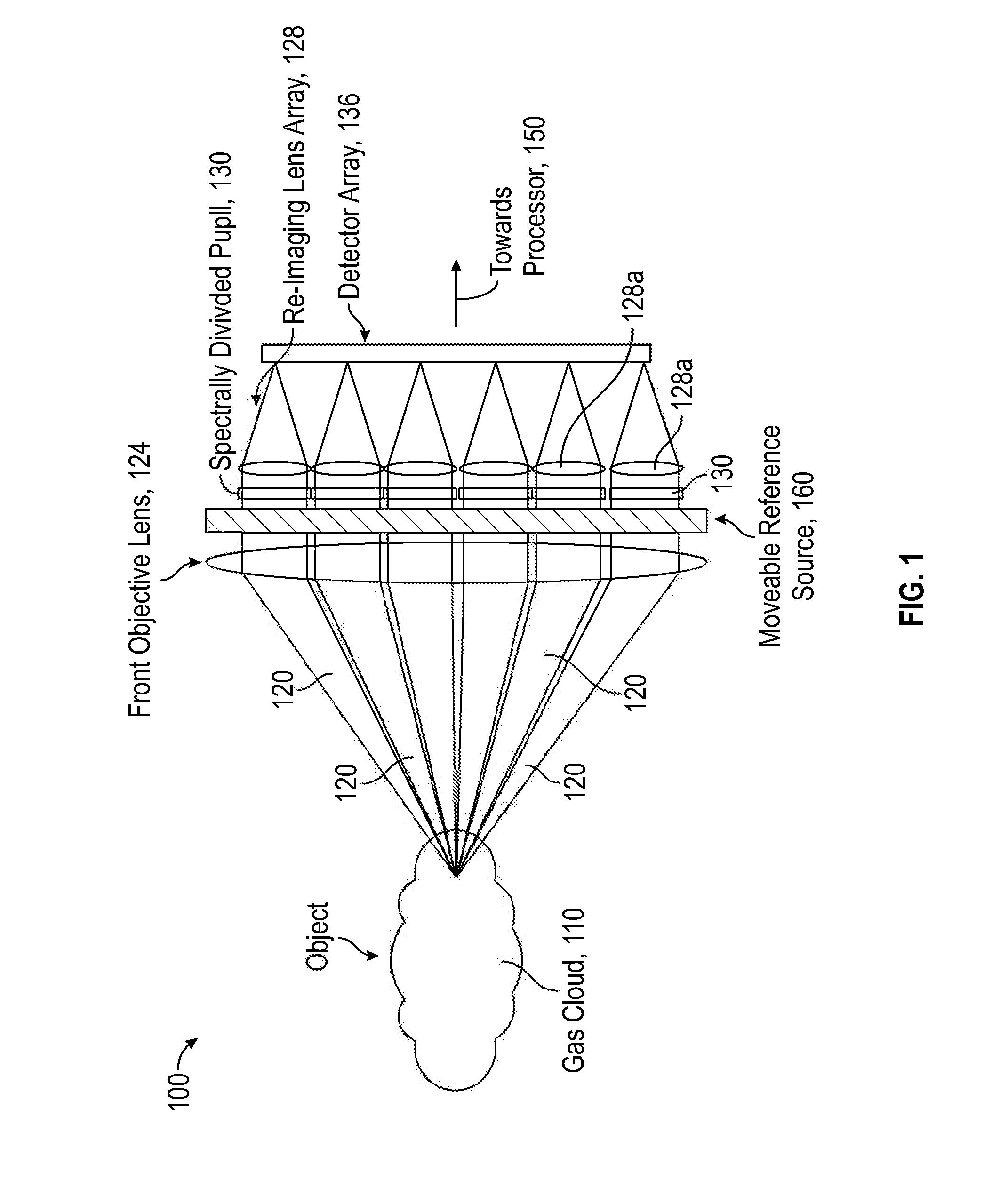

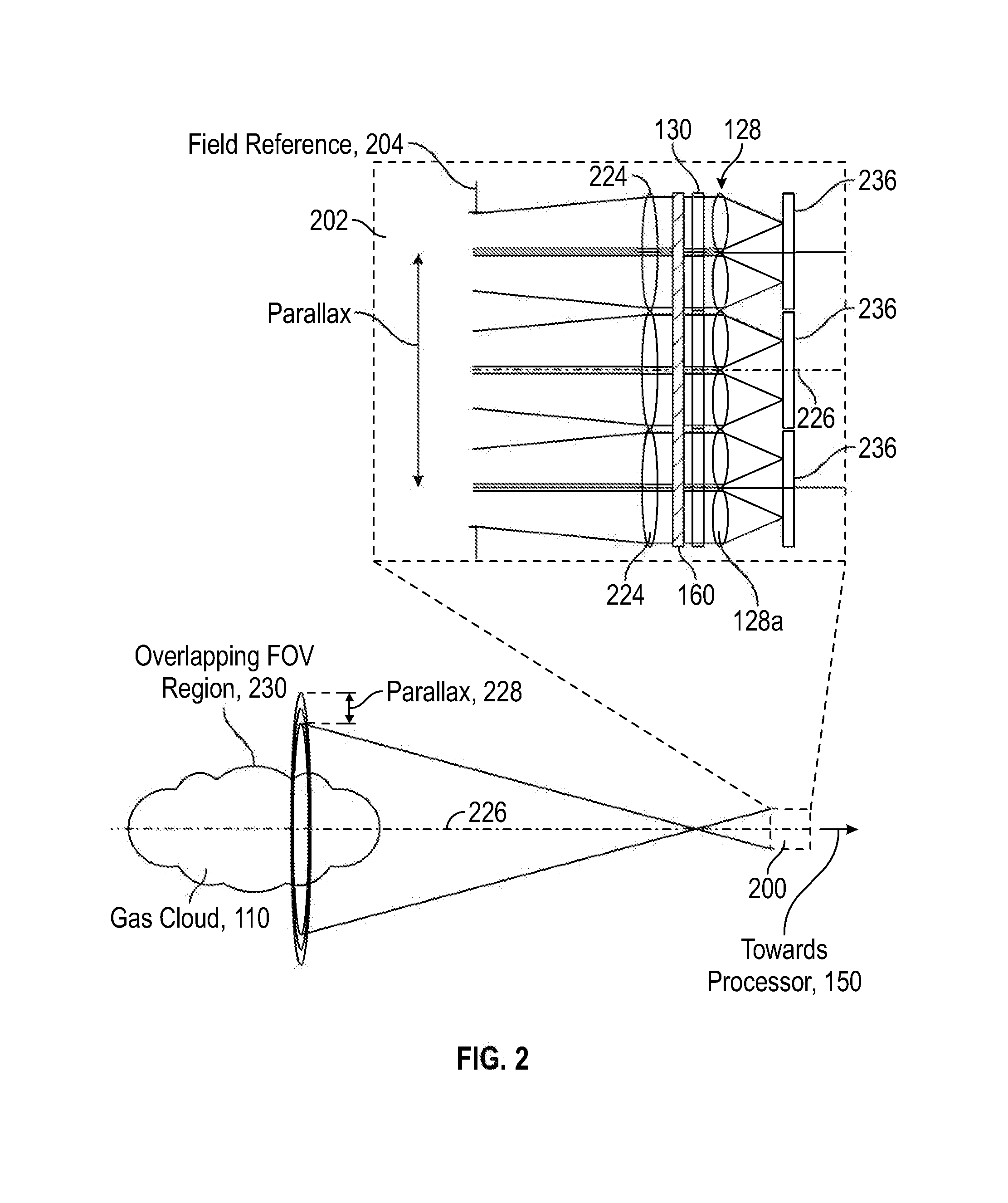

Gas leak emission quantification with a gas cloud imager

An instrument and method for analyzing a gas leak. The instrument can obtain a time series of spectra from a scene. The instrument can compare spectra from different times to determine a property of a gas cloud within the scene. The instrument can estimate the column density of the gas cloud at one or more locations within the scene. The instrument can estimate the total quantity of gas in the cloud. The instrument can estimate the amount of gas which has left the field of view of the instrument. The instrument can also estimate the amount of gas in the cloud which has dropped below the sensitivity limit of the instrument.

Owner:REBELLION PHOTONICS

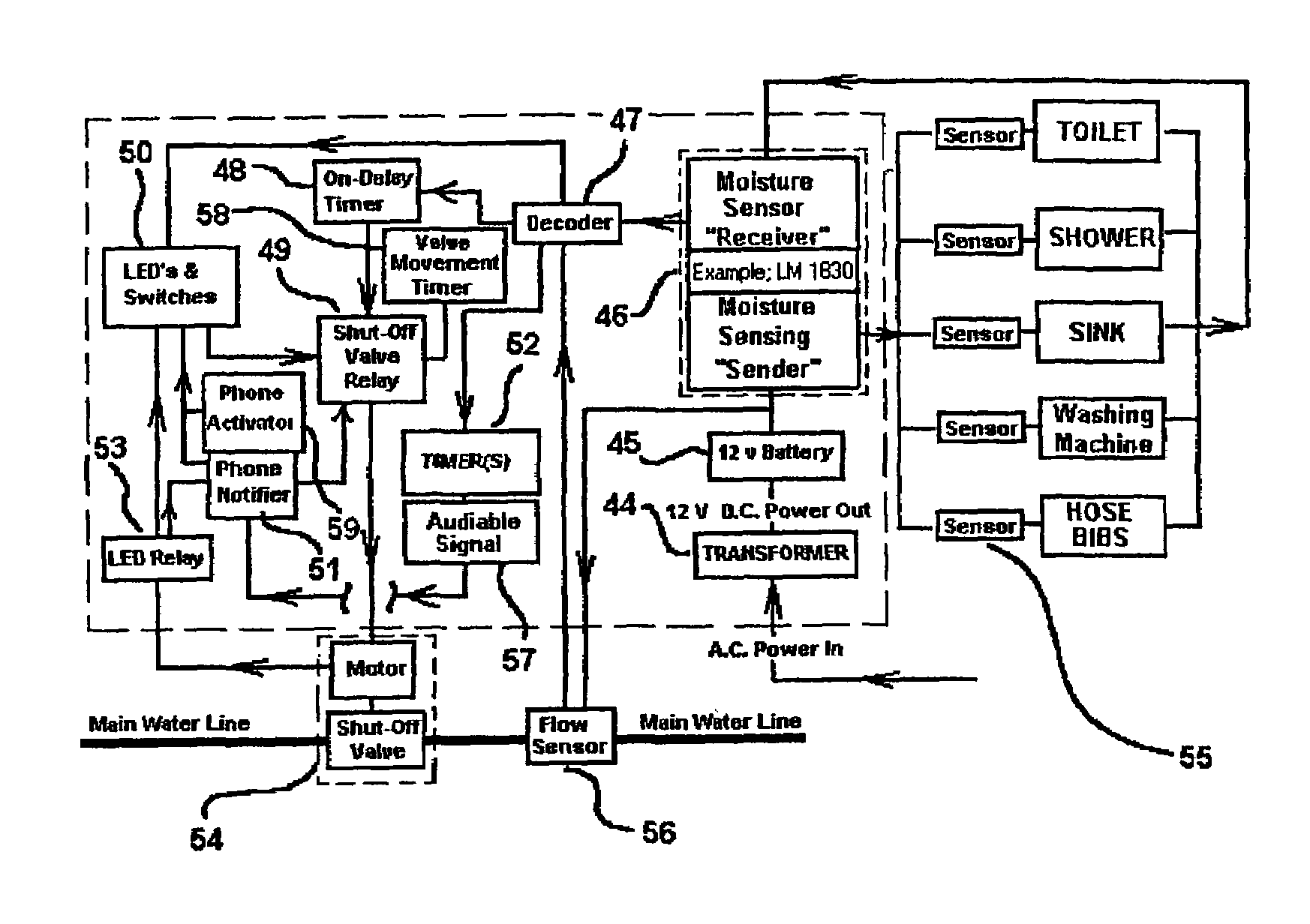

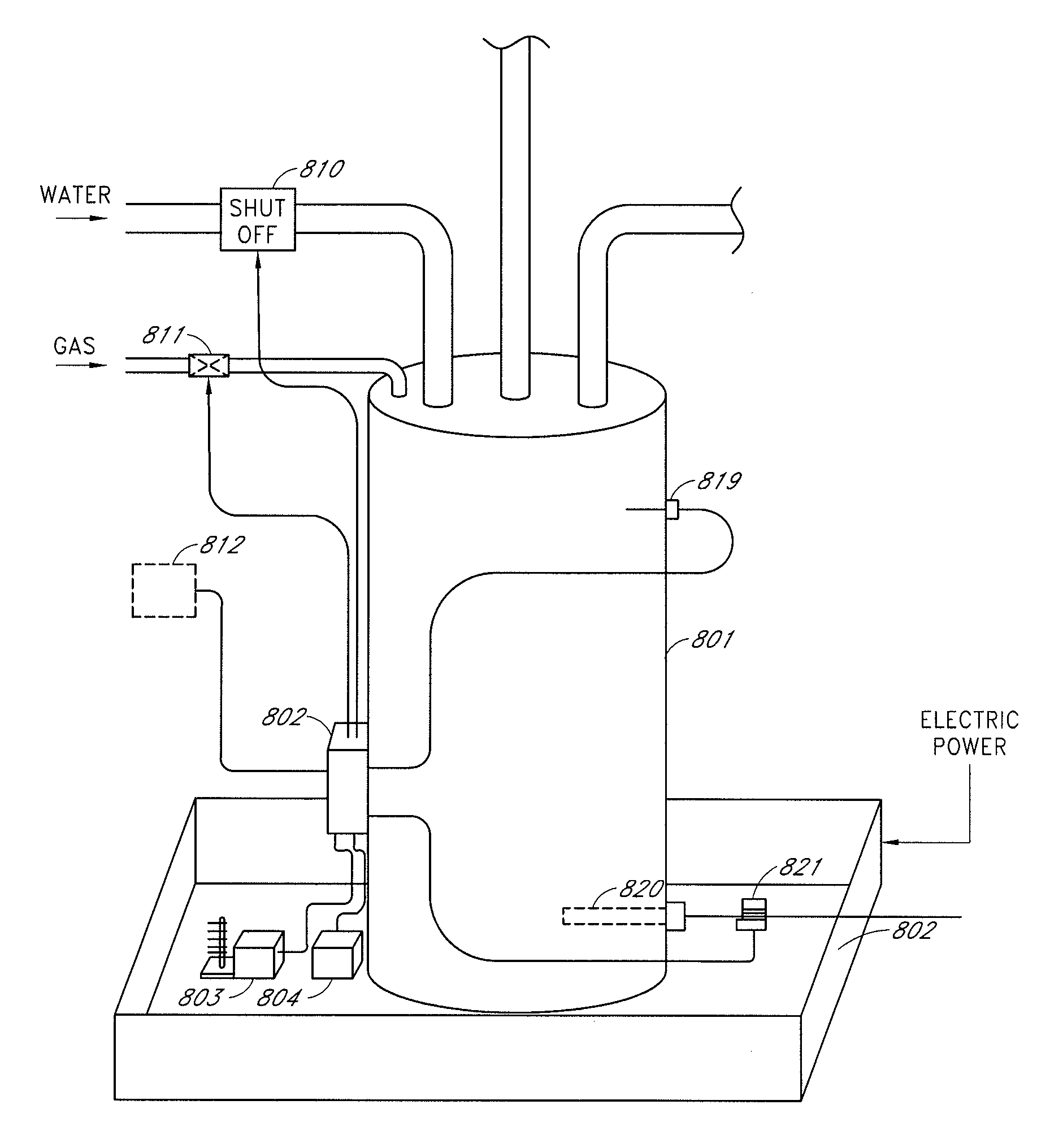

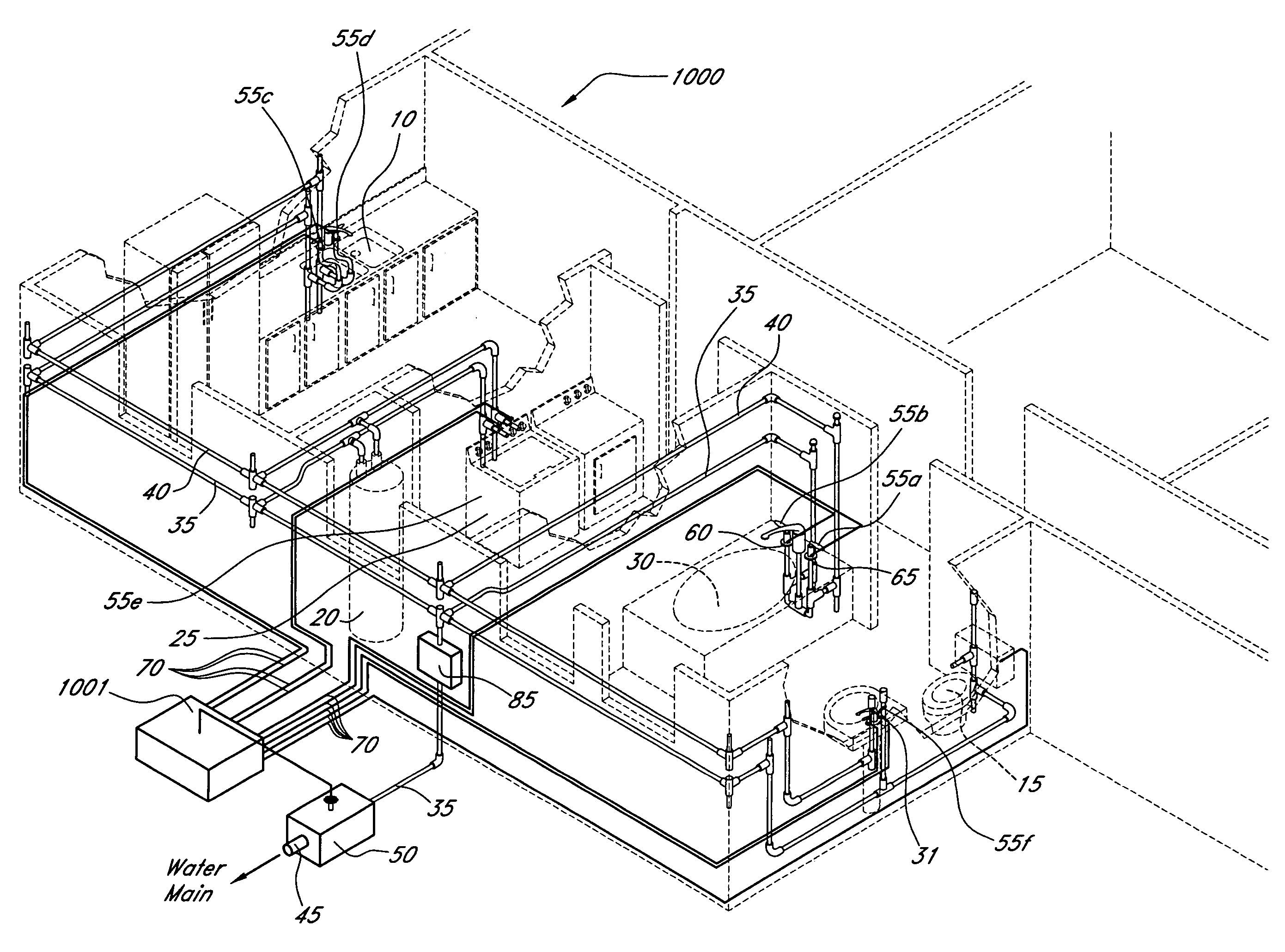

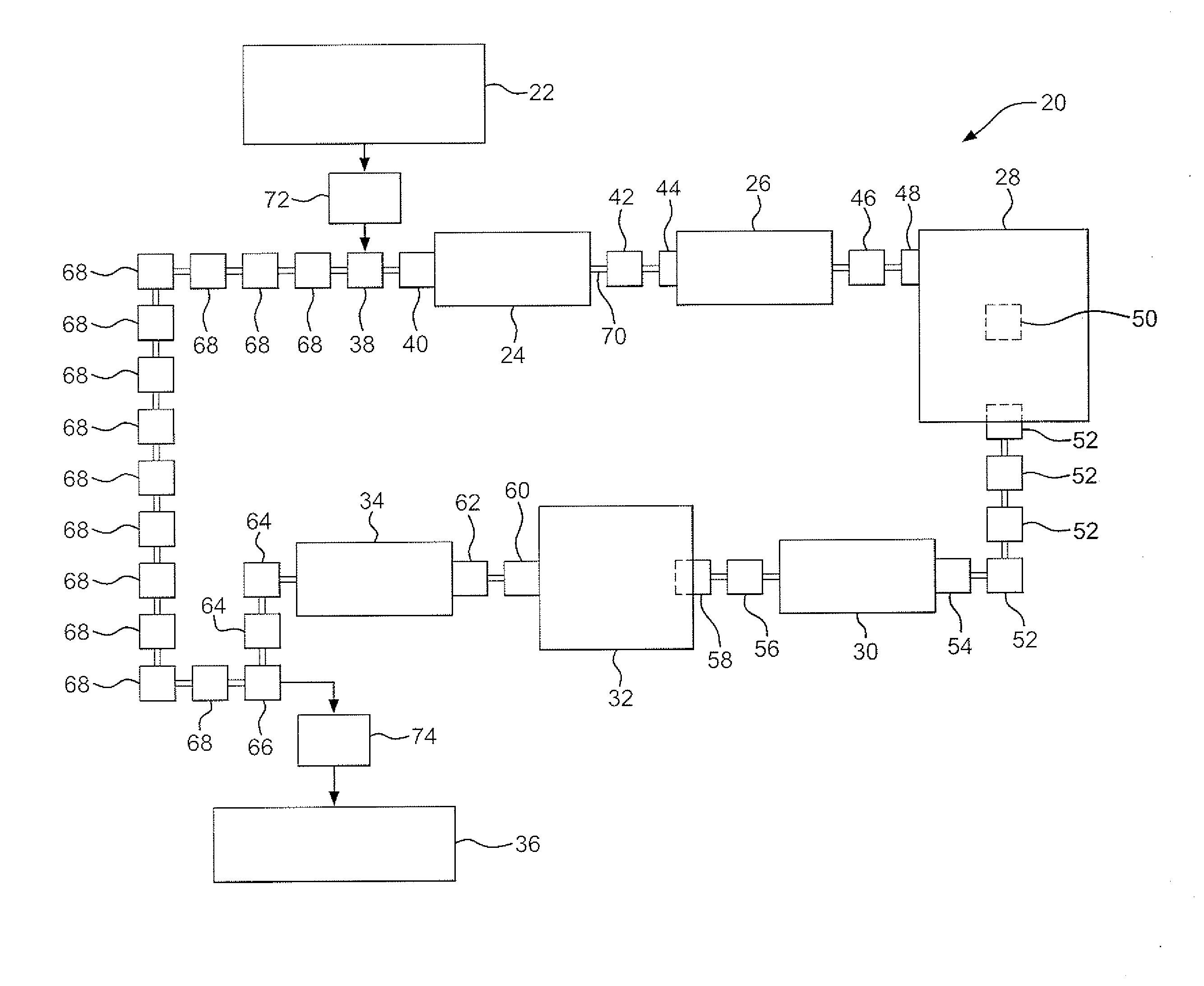

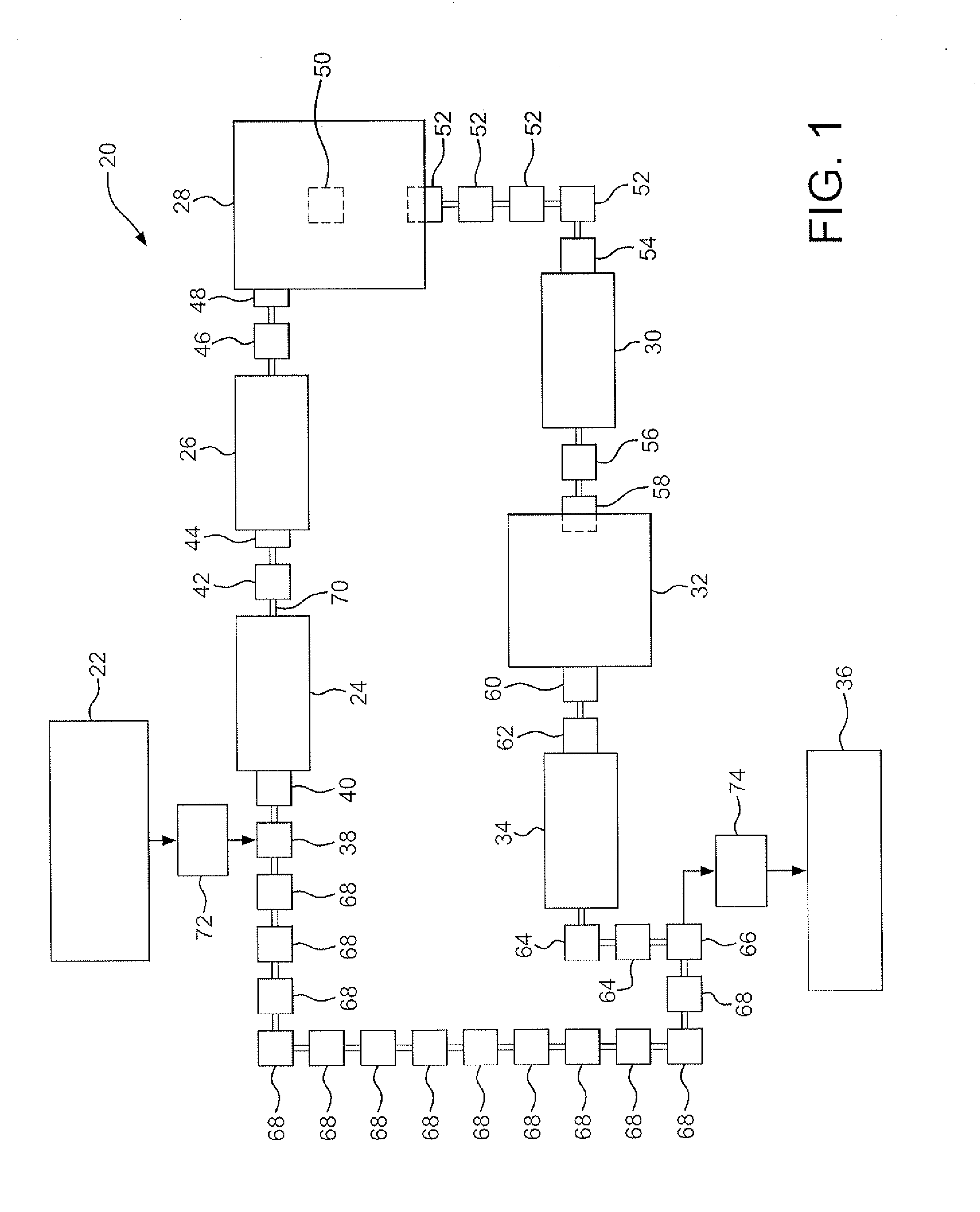

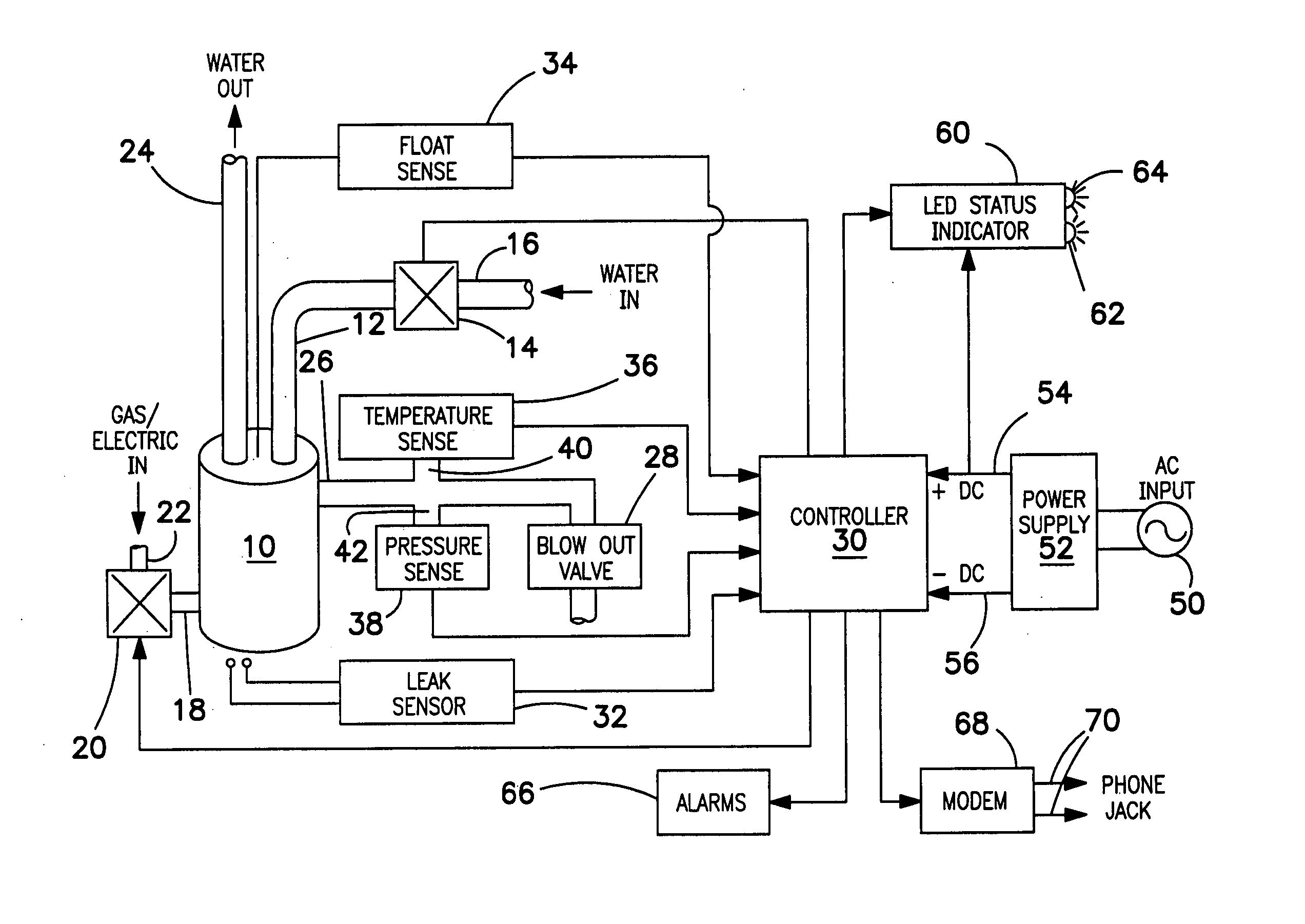

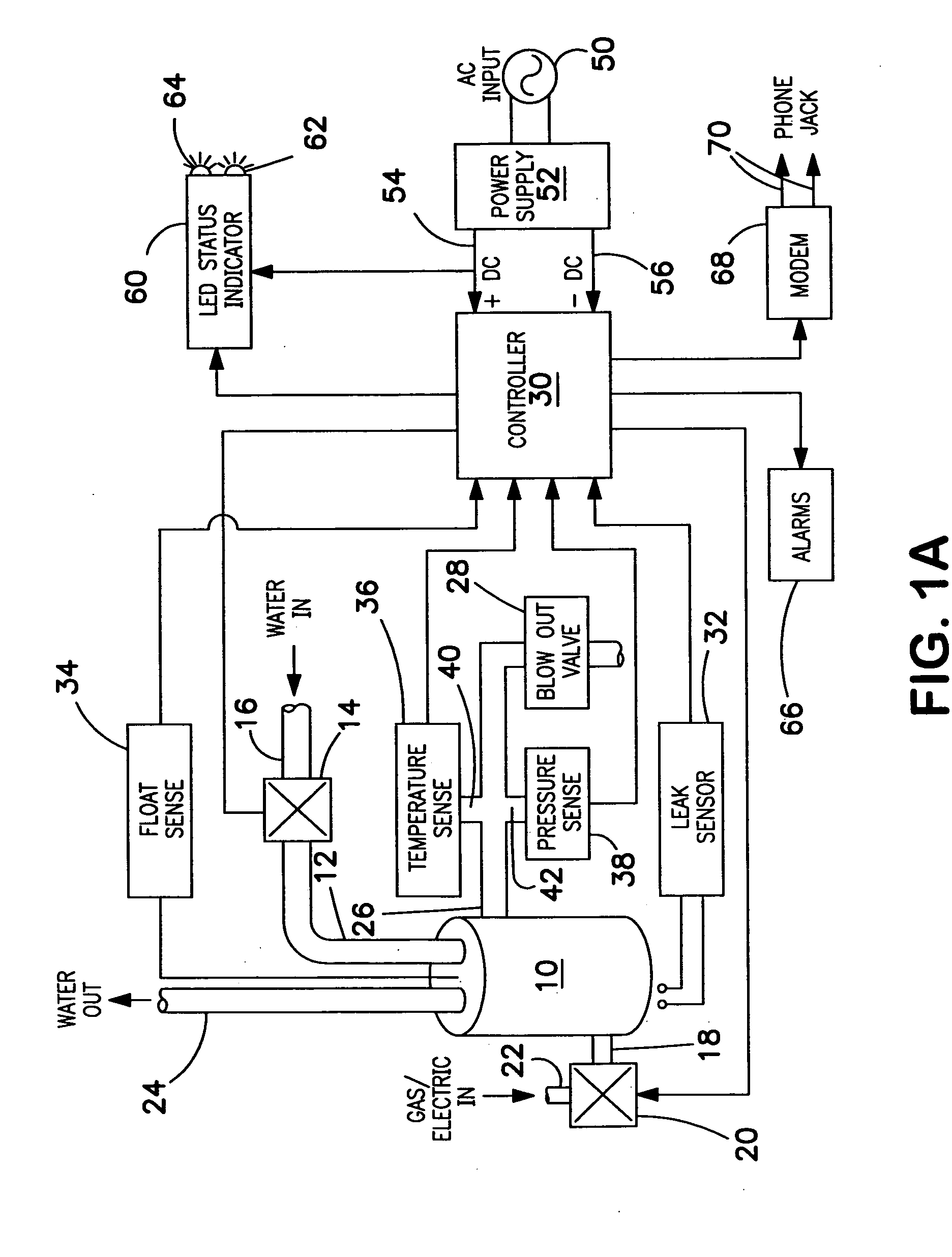

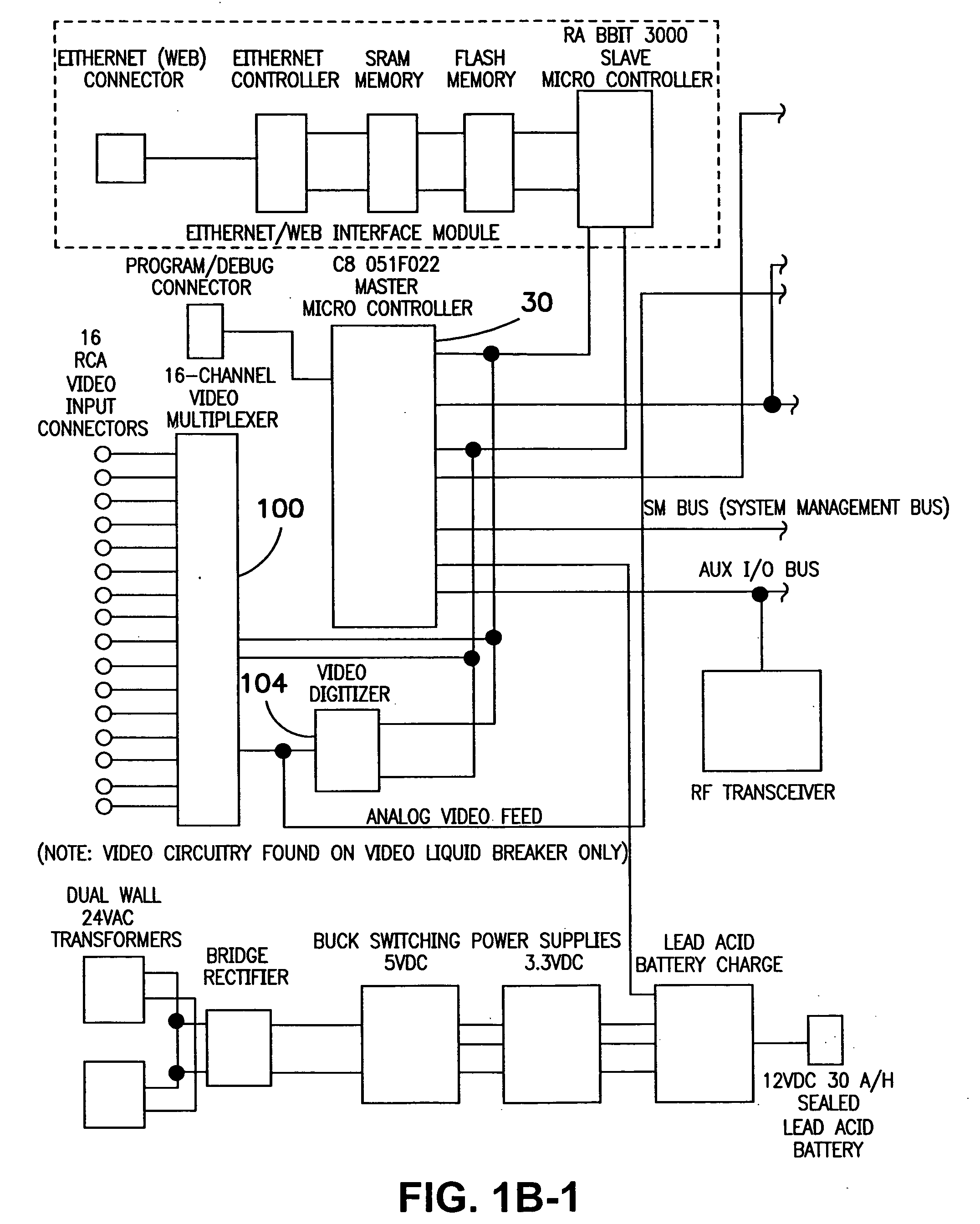

Systems and methods for monitoring and controlling water consumption

InactiveUS20050067049A1Monitor and control daily water consumption flowProtection malfunctionDetection of fluid at leakage pointMeasurement of fluid loss/gain rateInformation processingWater based

Systems and methods for monitoring and controlling water consumption in a water-based system are disclosed using one or more sensors for generating signals indicative of the operation thereof. One or more interface modules are provided as breaker circuits for receiving the generated signals, and a fluid control device is operable for limiting the water consumption. A motherboard receives the interface modules and provides communication therebetween for information processing. Signals from the various sensors are supplied to a controller, which provides signals to status indicators, and also operates to provide alarm signals via network interfaces to remote locations and to operate an alarm. In an alternate embodiment, a water monitoring system is designed to shut off the water supply to the water device and to shut off either the electrical supply or the gas supply to the heating unit of the water device in response to sensing a malfunction through one or more of a number of different sensed parameters. These parameters include a water leak detector located beneath the water device, a water level float sensor, a temperature sensor to sense excess temperature, and a pressure sensor located in line.

Owner:FIMA RAOUL G

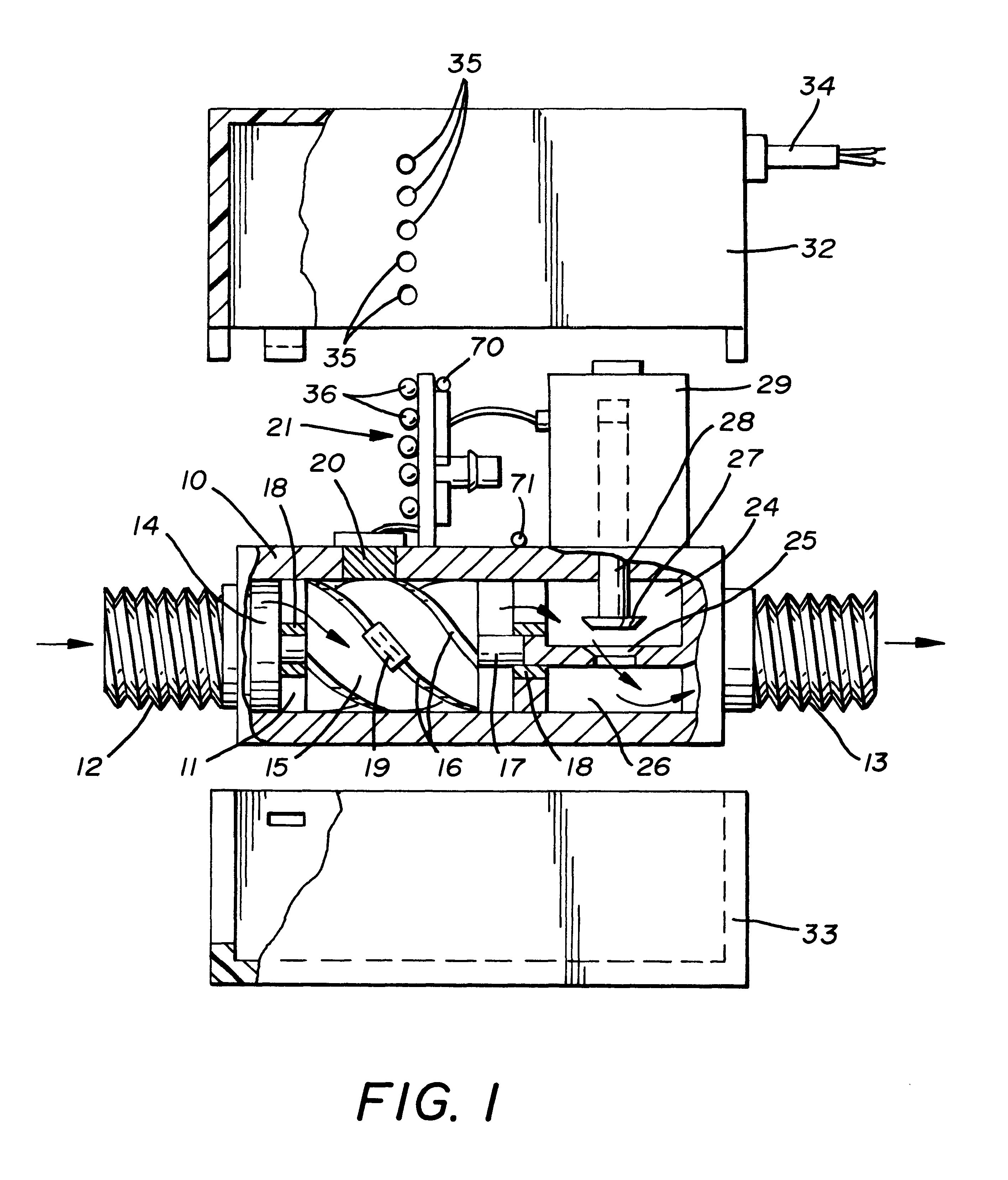

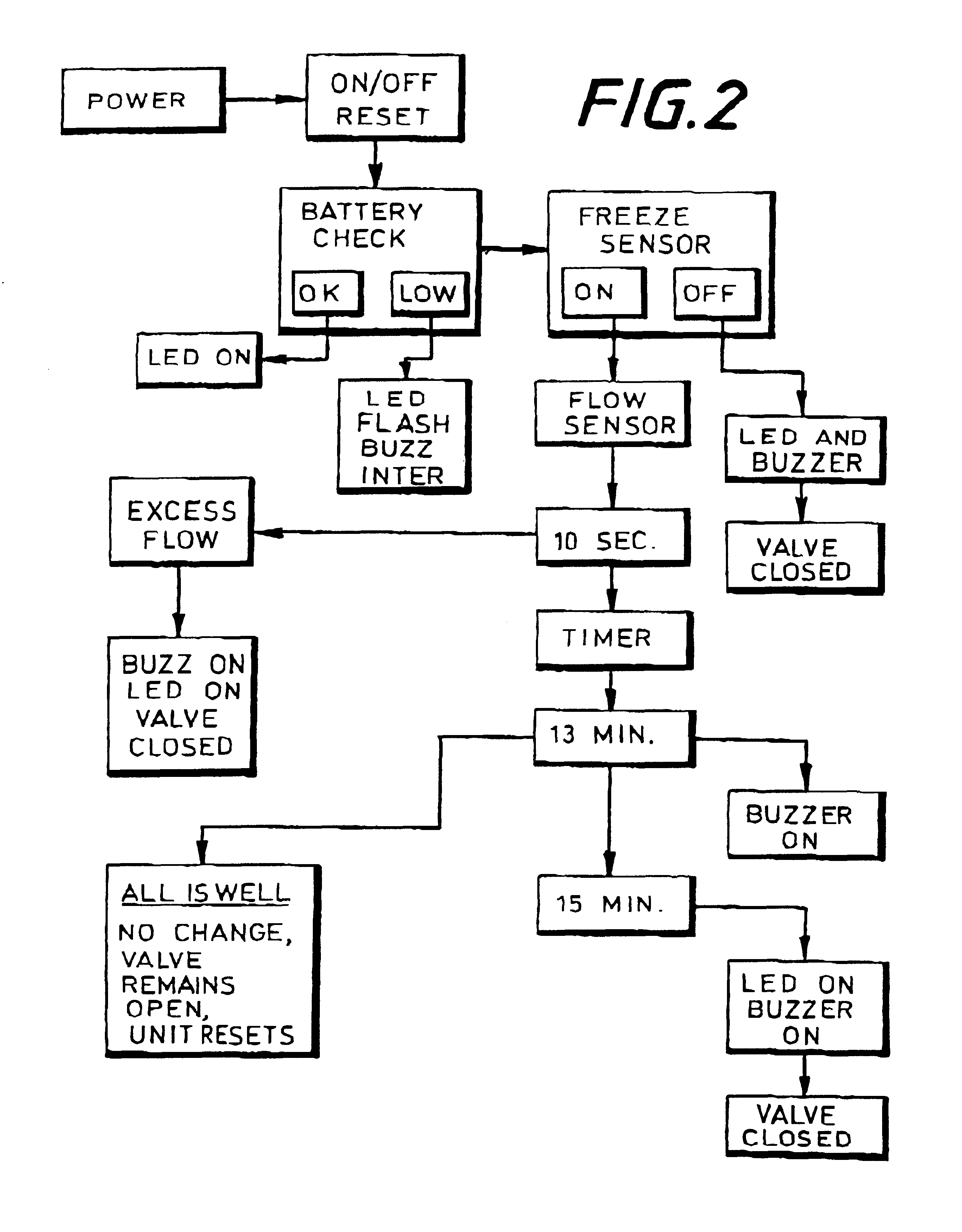

Liquid flow control valve

InactiveUS6837271B1Minimise water wastageReduce wasteMeasurement of fluid loss/gain rateOperating means/releasing devices for valvesEngineeringControl valves

A liquid flow control valve has a valve body 10 in which is mounted a valve member 41 moveable between valve open and closed positions. A turbine 15 senses liquid flow through the valve body 10 and generates electrical pulses which are counted by a control circuit, over a pre-set period. An electro-magnet 54,55 controls operation of the valve member 41 and is driven by the control circuit so as to close the valve in the event that flow continues for longer than the pre-set period or the flow is greater than at a pre-set rate. The valve may also be closed should the temperature fall to about 0° C.

Owner:SAINT WILLIAM HENRY

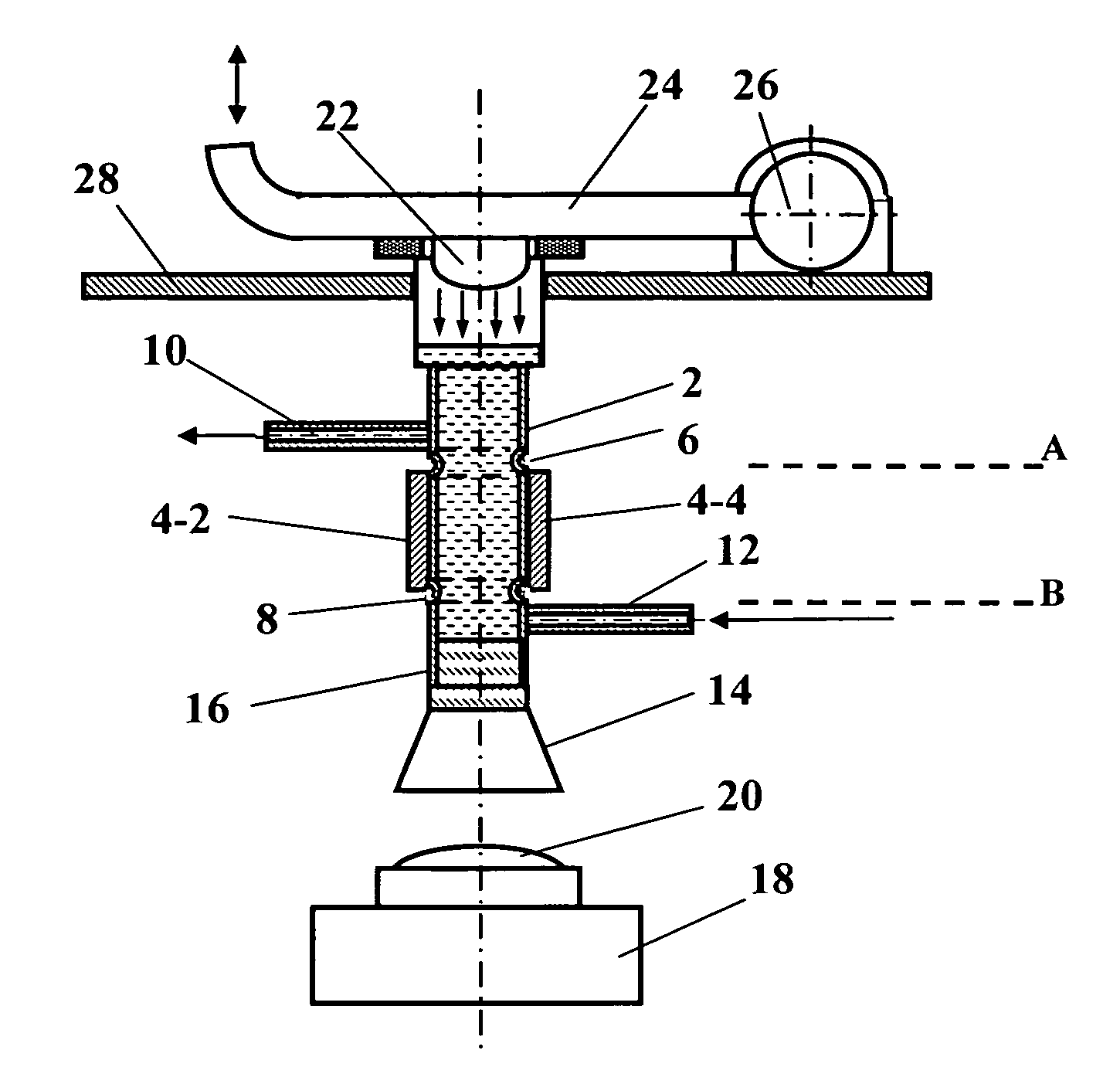

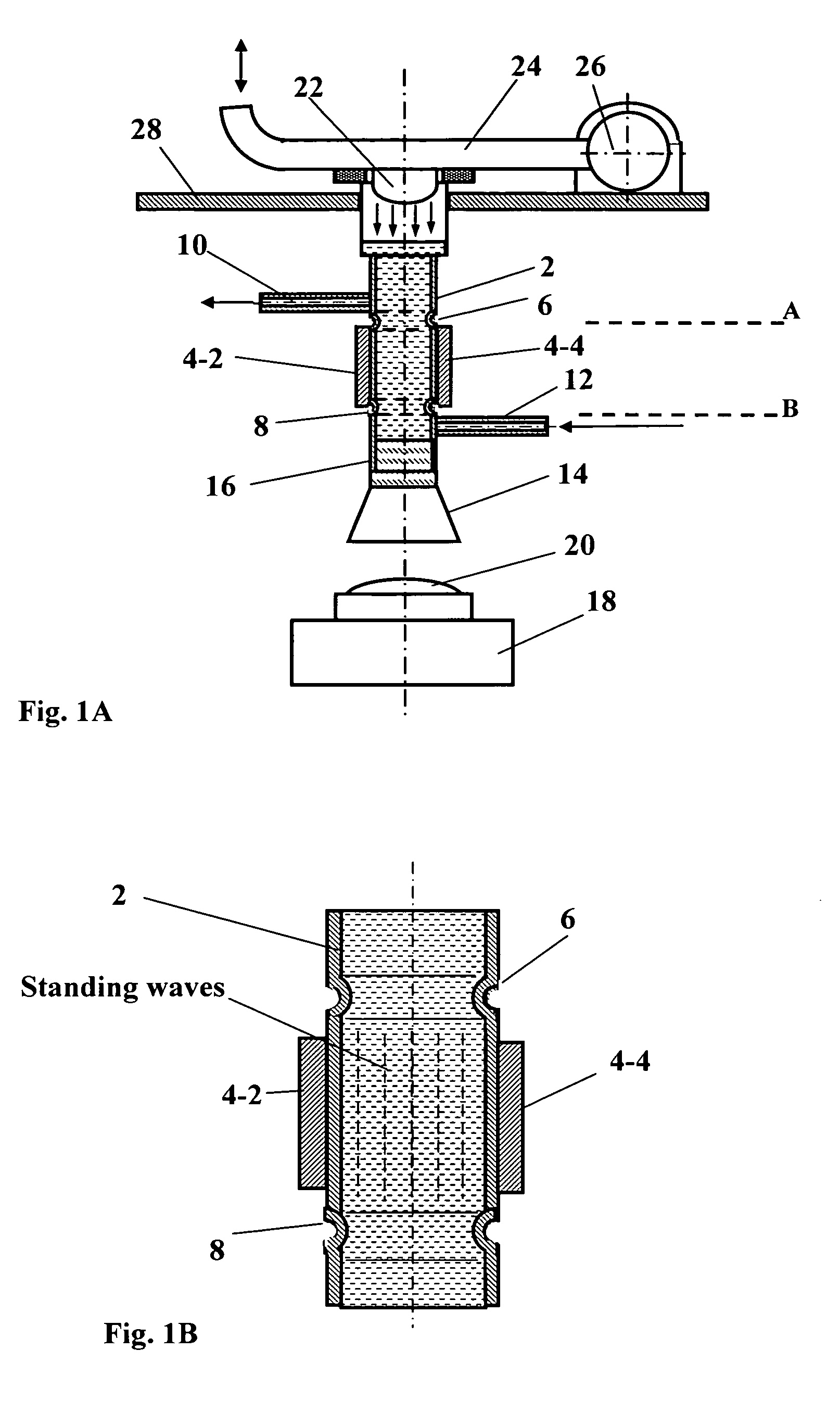

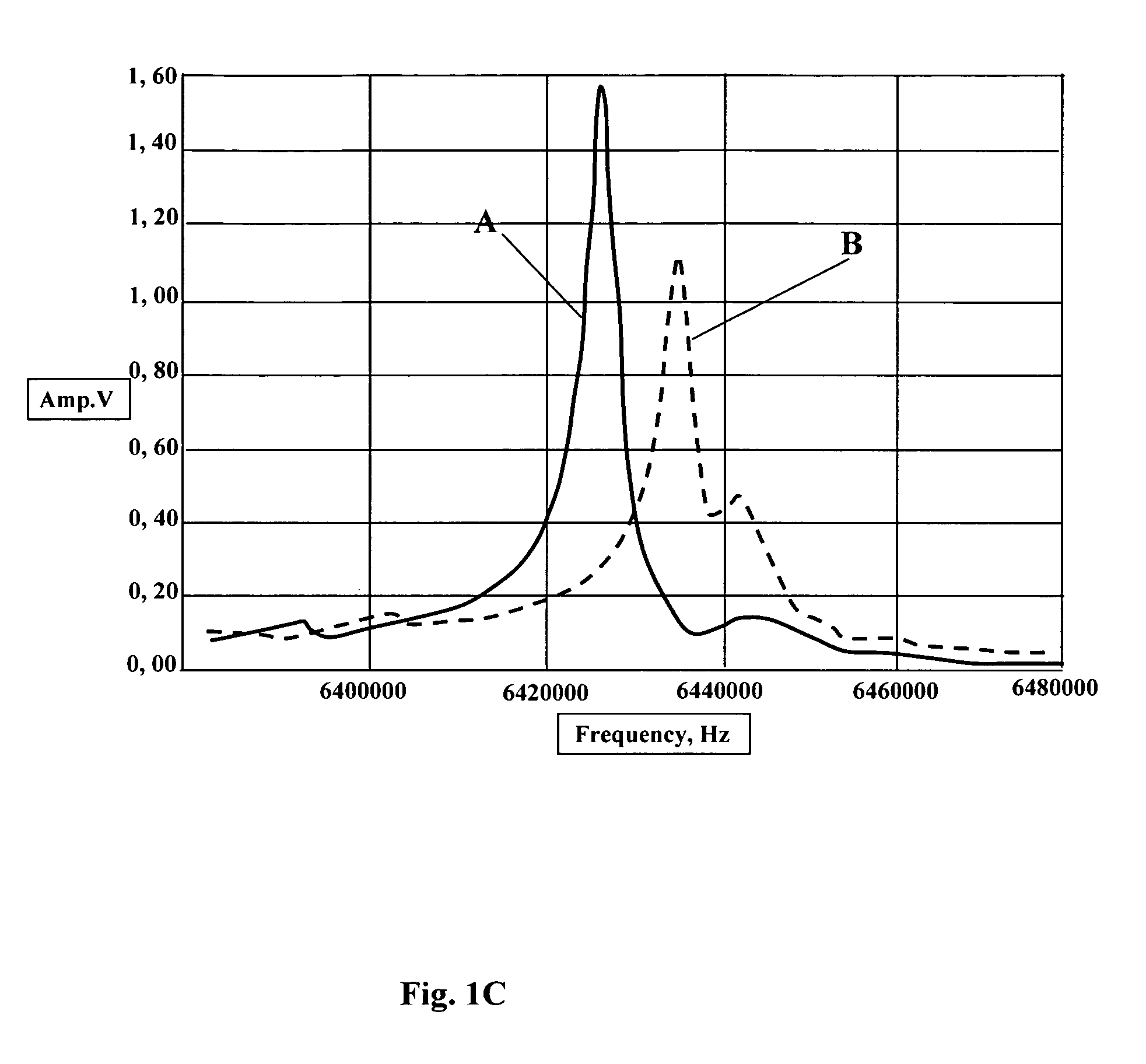

Method and apparatus for determination of the concentration of particles in multi-component fluid systems

InactiveUS20070119239A1Low temperature controlVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid systemLarge particle

A method for determining the concentration of a large particle component in a multi-component system. The method requires first separating and concentrating the large particle component of the system by acoustic means and then measuring an acoustical parameter of the separated large particle component. The invention also provides for an apparatus for determining the concentration of large particles in a multi-component fluid system. The apparatus is comprised of an acoustic standing wave resonator, at least one acoustic standing wave generating source, electronic circuitry for actuating, controlling and processing the acoustic standing wave generating source and means for measuring at least one parameter of the multi-component system after the large particles have been concentrated and aggregated by the generated standing wave(s).

Owner:NANOALERT ISRAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com