Systems and methods for monitoring and controlling water consumption

a technology of consumption system and water consumption flow, applied in the direction of lighting and heating apparatus, instruments, packaged goods types, etc., can solve the problems of frequent buildup and corrosion of mineral deposits, impair operation, and the possibility of catastrophic failure, and achieve the effect of monitoring and controlling the daily water consumption flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

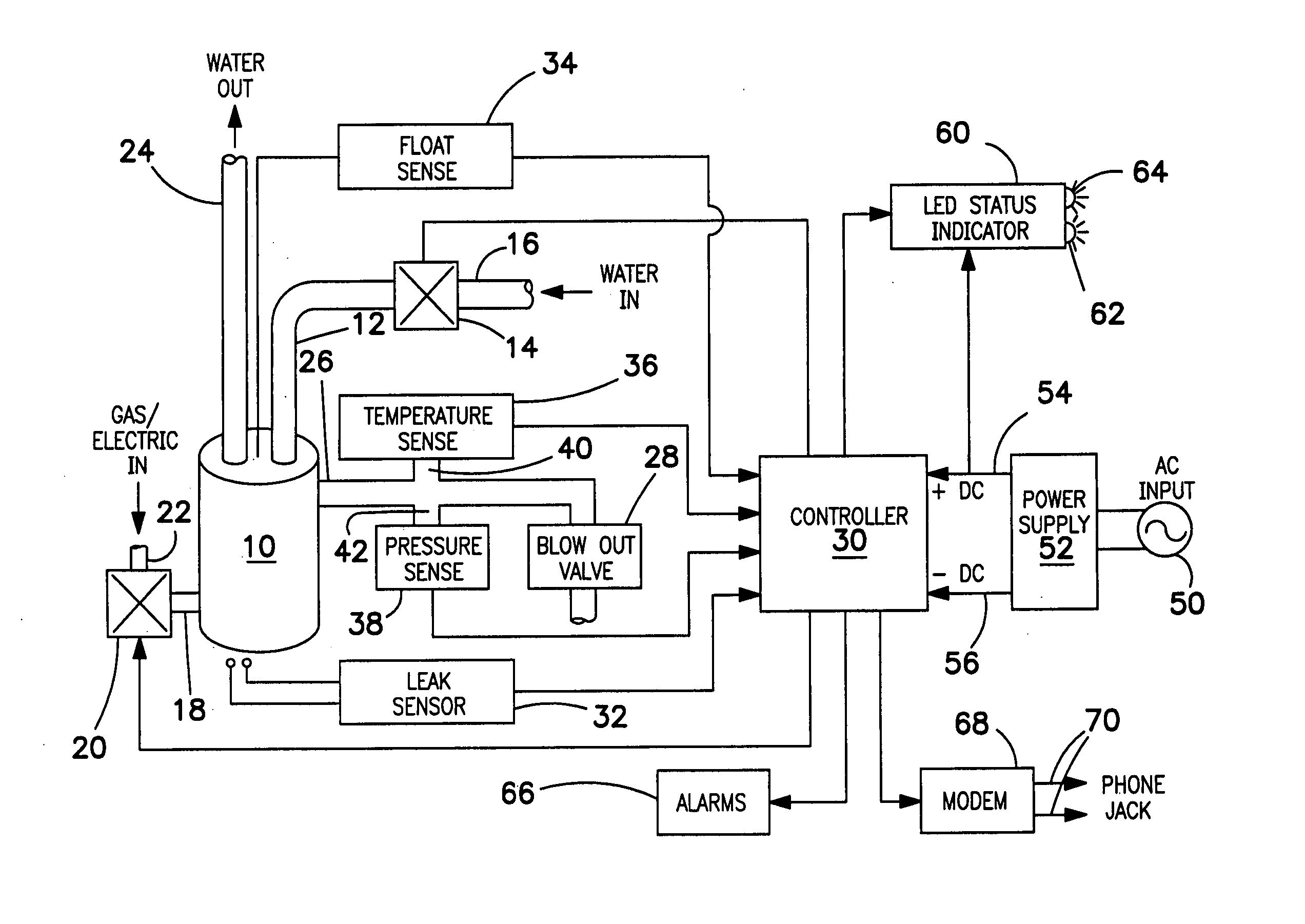

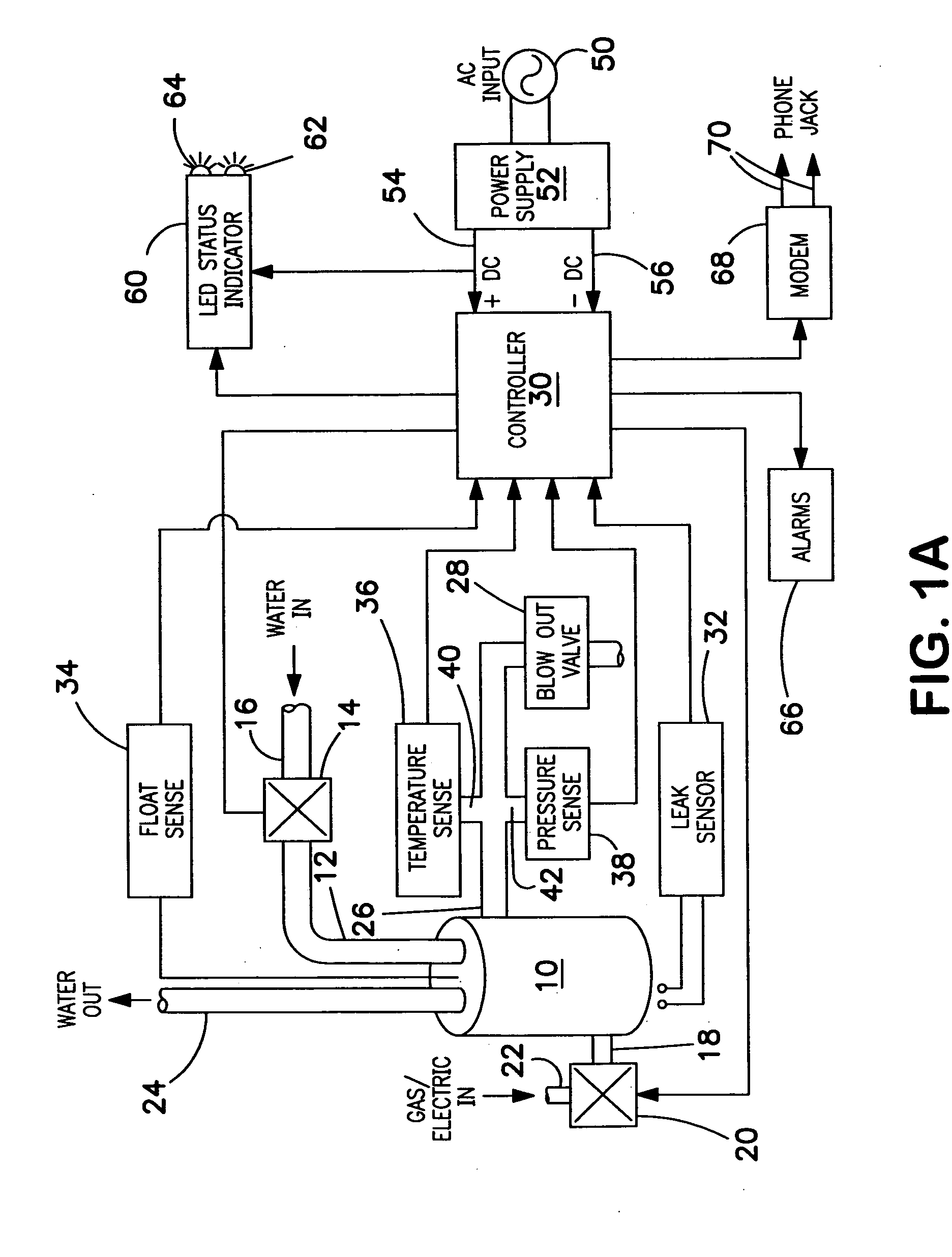

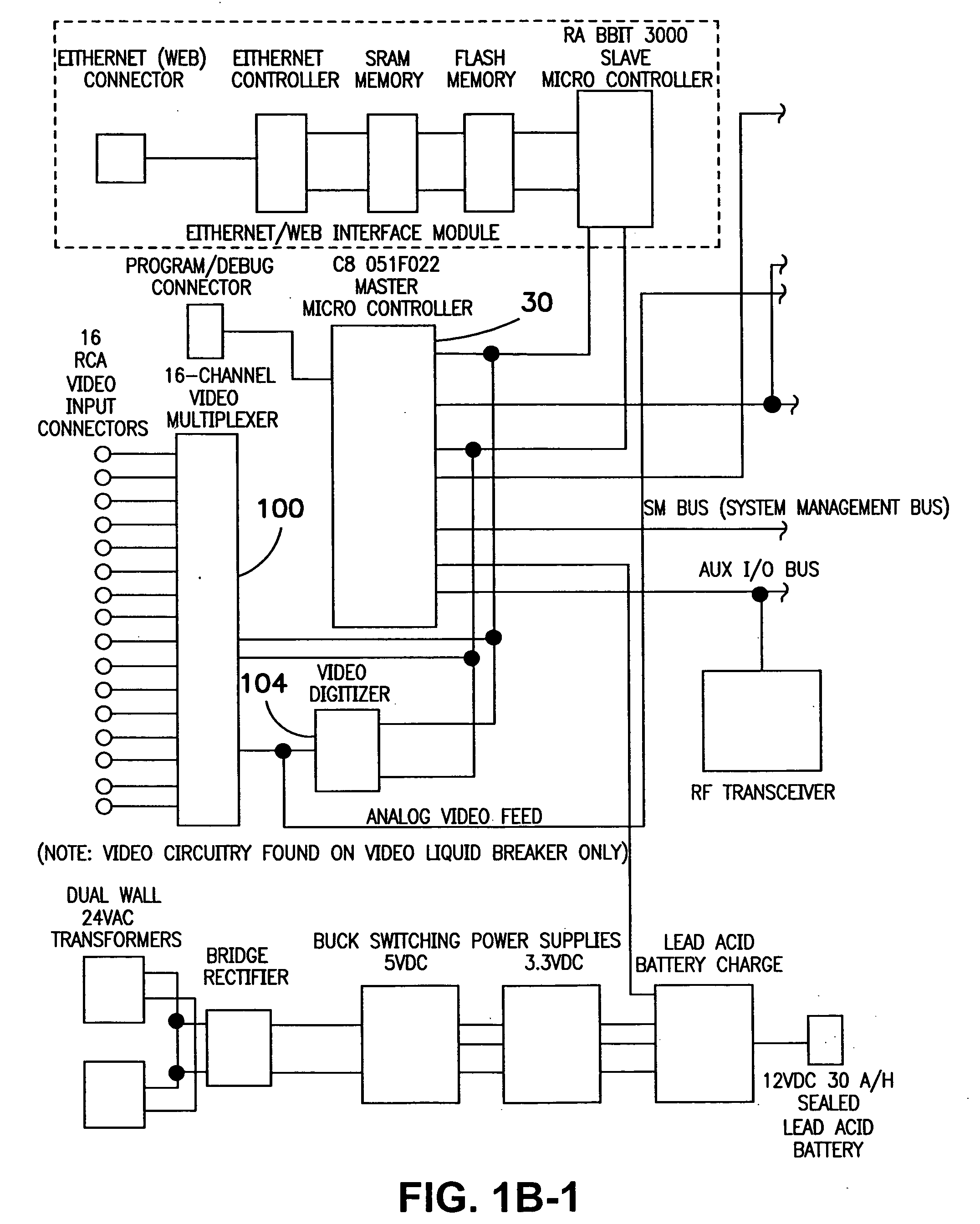

[0033] Reference now should be made to the drawings, in which the same reference numbers are used throughout the different figures to designate the same or similar components. FIGS. 1A and B are block diagrams of water monitoring systems providing comprehensive monitoring of various alarm conditions representative of malfunctioning parameters in water-based systems and the like. In addition, the system of FIG. 1A operates in response to a water appliance or system malfunction to turn off the input water supply and to disconnect the energy source supplying heat to the water appliance or system when such a malfunction occurs.

[0034] In the monitoring system shown in FIG. 1A, a hot water tank 10, which may be of any conventional type, is illustrated. The hot water tank 10 may be heated either by a gas supply or an electric supply. The system operates in the same manner, irrespective of which type of heat source is employed for the hot water tank 10. Inlet or make-up water for the hot w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com