Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

789 results about "Remanence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remanence or remanent magnetization or residual magnetism is the magnetization left behind in a ferromagnetic material (such as iron) after an external magnetic field is removed. Colloquially, when a magnet is "magnetized" it has remanence. The remanence of magnetic materials provides the magnetic memory in magnetic storage devices, and is used as a source of information on the past Earth's magnetic field in paleomagnetism.

Preparation of Rare Earth Permanent Magnet Material

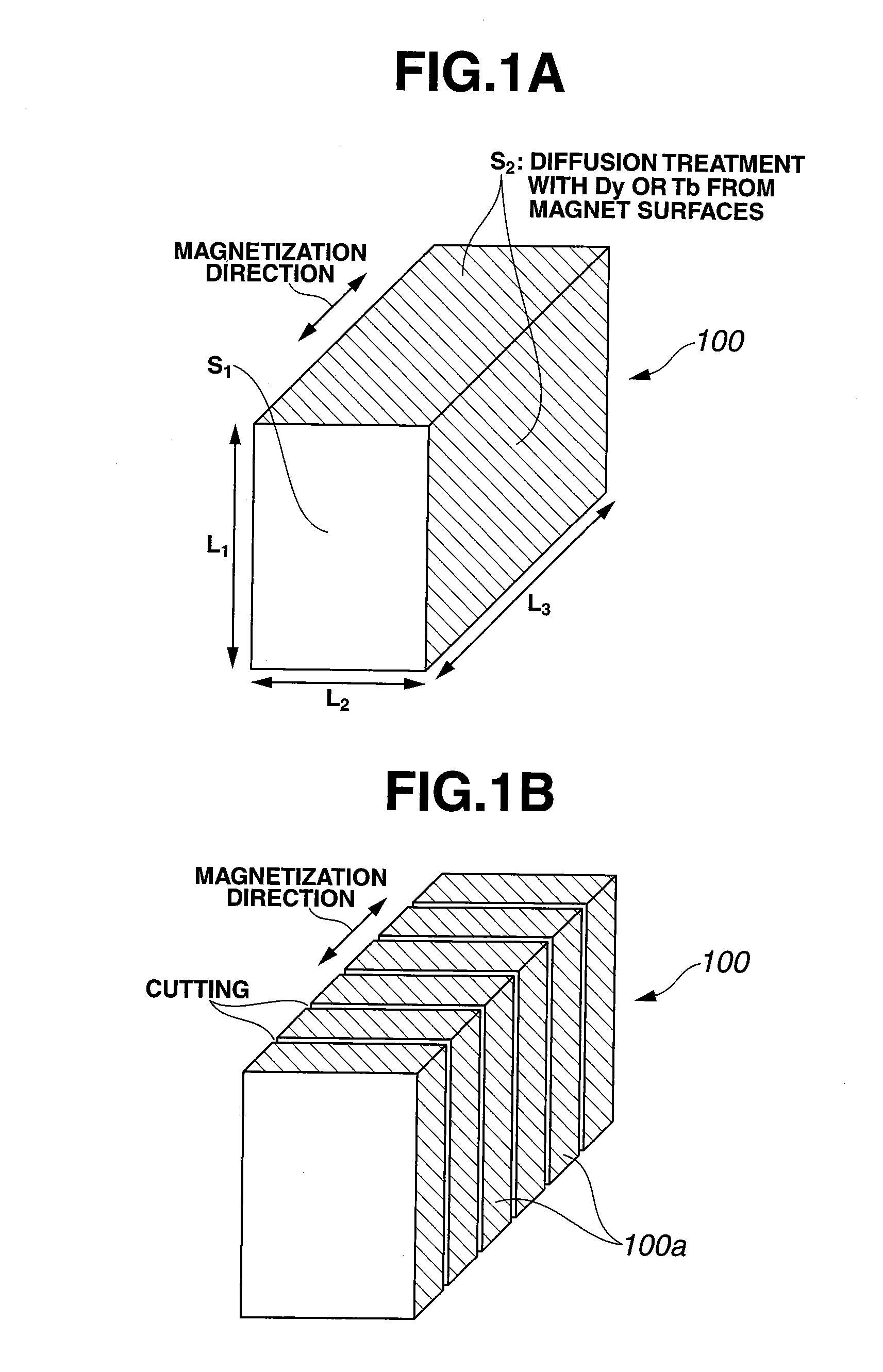

ActiveUS20080245442A1Improve remanenceImprove coercive forceElectric discharge tubesPermanent magnetsRare-earth elementRemanence

A method for preparing a rare earth permanent magnet material comprising the steps of:disposing a powder comprising one or more members selected from an oxide of R2, a fluoride of R3, and an oxyfluoride of R4 wherein R2, R3 and R4 each are one or more elements selected from among rare earth elements inclusive of Y and Sc on a sintered magnet form of a R1—Fe—B composition wherein R1 is one or more elements selected from among rare earth elements inclusive of Y and Sc, andheat treating the magnet form and the powder at a temperature equal to or below the sintering temperature of the magnet in vacuum or in an inert gas.The invention offers a high performance, compact or thin permanent magnet having a high remanence and coercivity at a high productivity.

Owner:SHIN ETSU CHEM IND CO LTD

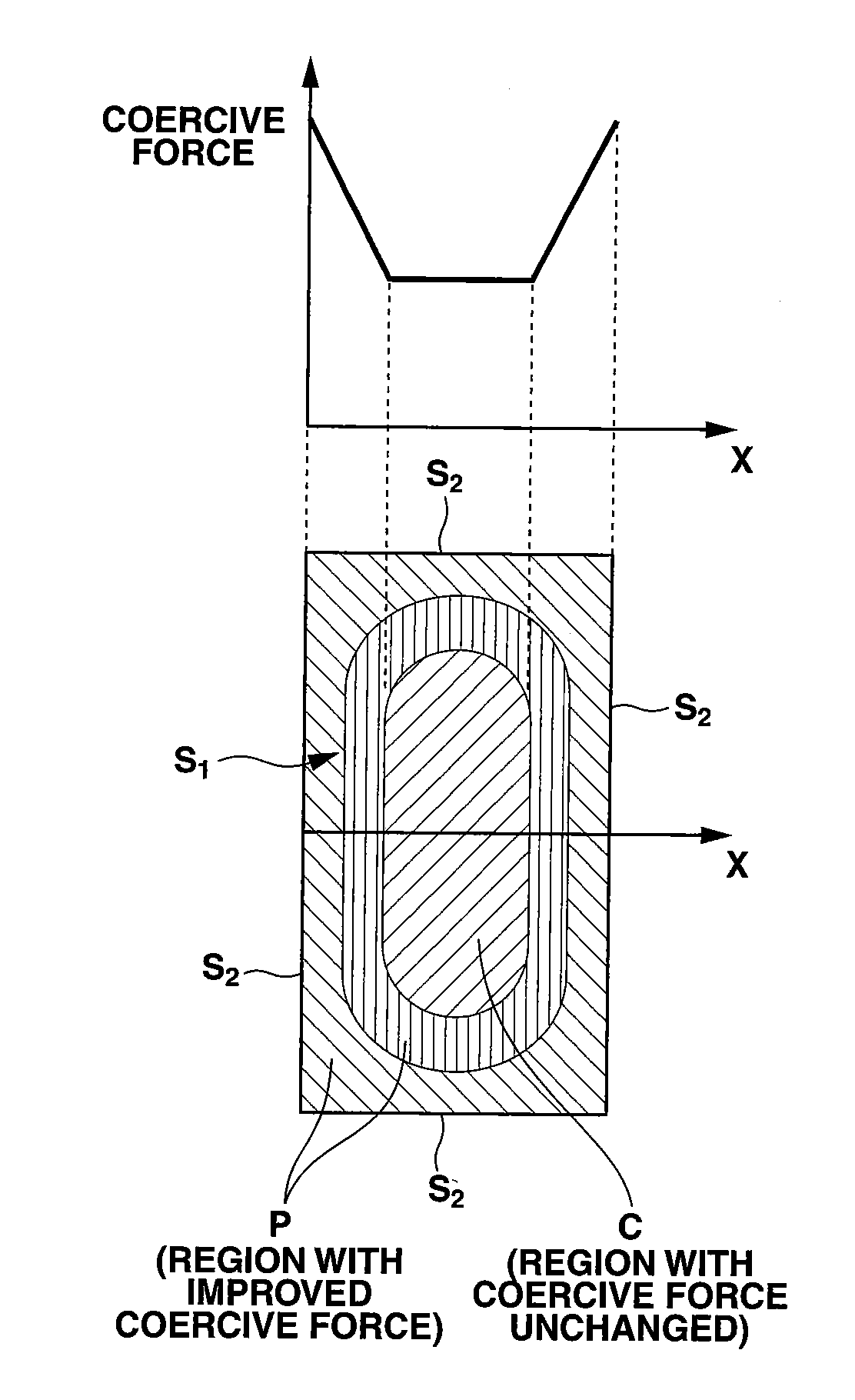

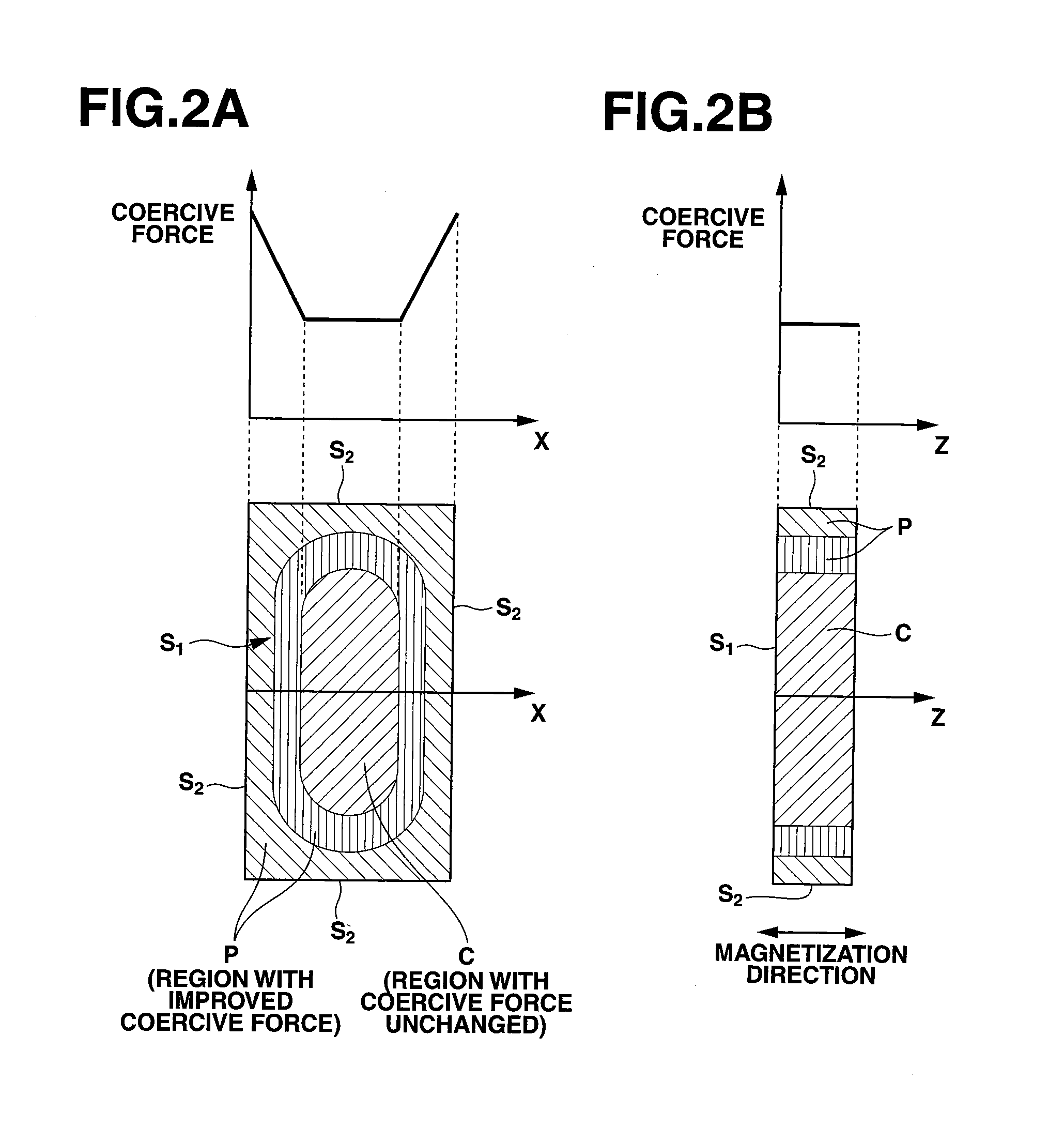

Rare earth permanent magnet and its preparation

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol % of an intermetallic compound phase on a sintered body of R—Fe—B system, and heating the sintered body having the powder disposed on its surface below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM IND CO LTD

Magnetoplumbite permanent magnetic ferrite and method of producing the same

InactiveCN101552069AIncrease the degree of substitutionGuaranteed stabilityInorganic material magnetismInductances/transformers/magnets manufactureRemanenceMetallurgy

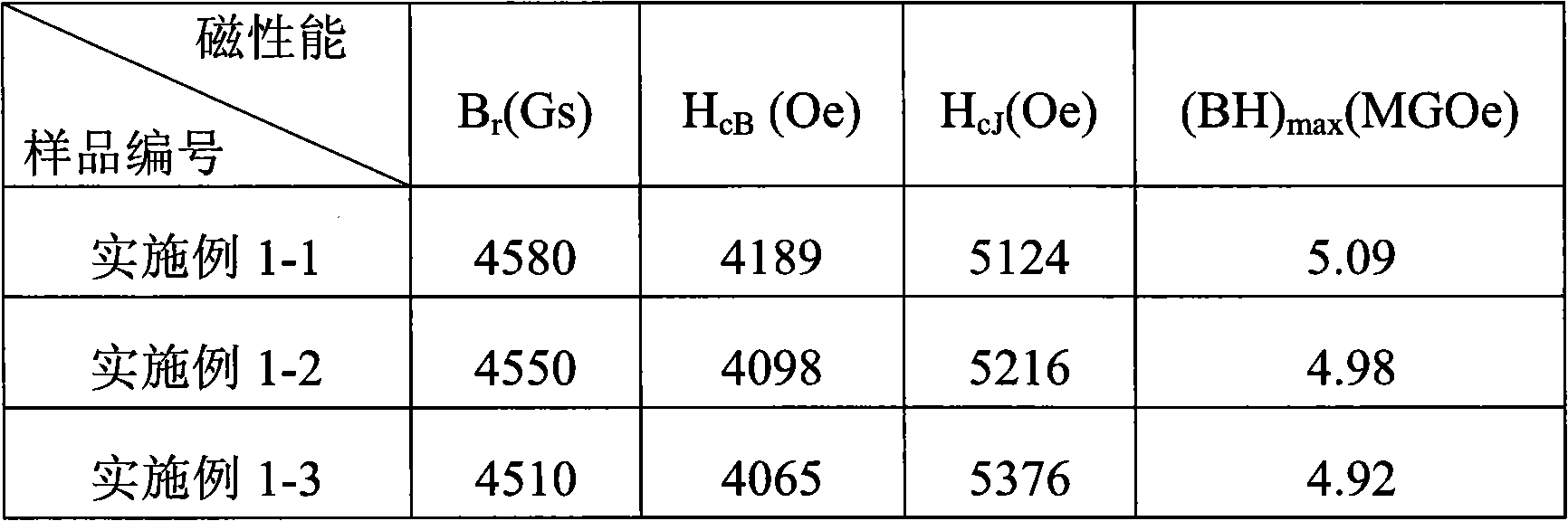

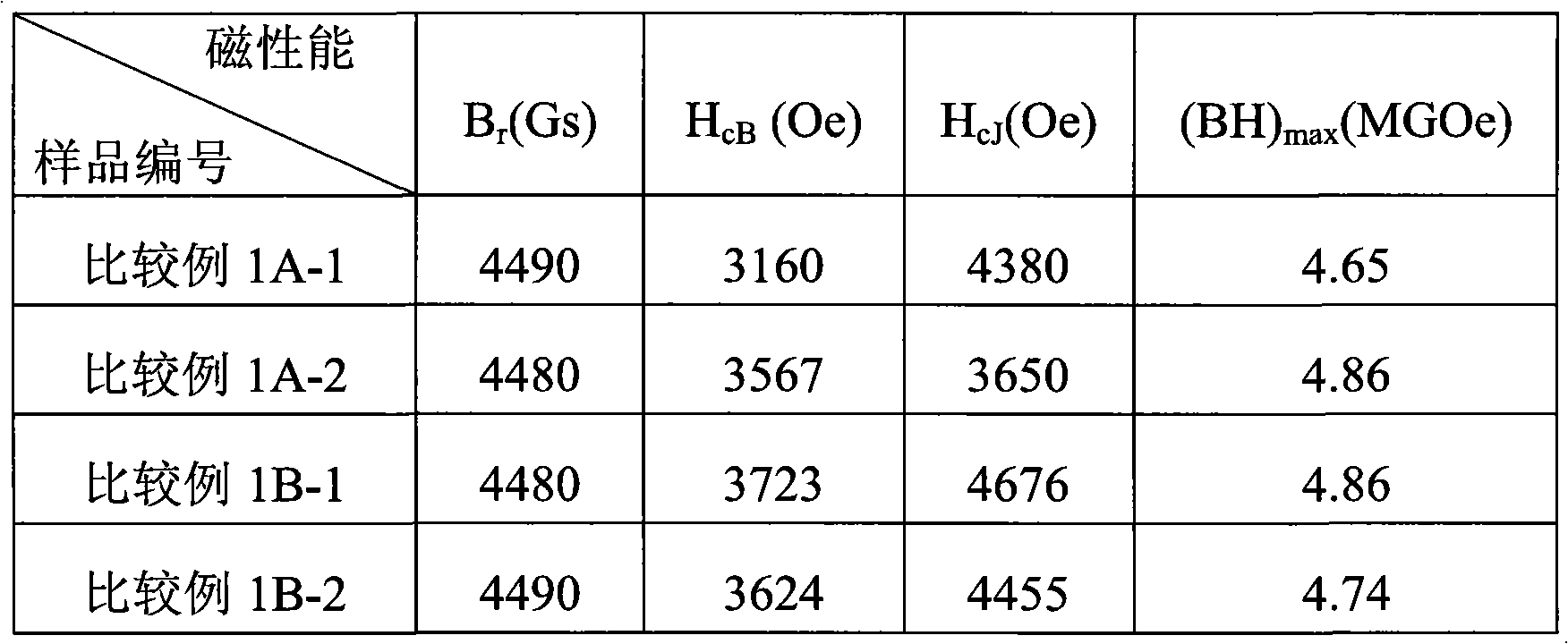

The present invention relates to a magnet powder formula of hexagonal type magnetoplumbite permanent magnetic ferrite, sintered magnet and method of producing the same. The invention provides a sintered permanent magnetic ferrite and magnet powder capable of acquiring remanence of more than 4500 Gs and Intrinsic coercivity of more than 5000 Oe at the same time, pointing to problems of unable to acquire high magnetic property and high Intrinsic coercivity at the same time in prior technology, and method of producing the same. major formula of the invention is a permanent magnetic ferrite powder containing hexagonal type magnetoplumbite permanent magnetic ferrite of the following formula as main phase: A[1-x-y]Ca[x]R[y]Fe[2n-z]M[z]O[19], A represents Sr or Sr and Ba, R represents at least one of La, Pr, Nd or Bi, and La is needed; M represents at least one of Co, Ni and Zn, and Co is needed; x, y, z represents addition percentage of each main metal elements.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Preparation method of neodymium iron boron magnet

ActiveCN102103916AReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Preparation of rare earth permanent magnet material

ActiveUS20110150691A1Improve remanenceImprove coercive forceElectric discharge tubesPermanent magnetsRare-earth elementRemanence

A method for preparing a rare earth permanent magnet material comprises the steps of: disposing a powder comprising one or more members selected from an oxide of R2, a fluoride of R3, and an oxyfluoride of R4 wherein R2, R3 and R4 each are one or more elements selected from among rare earth elements inclusive of Y and Sc on a sintered magnet form of a R1—Fe—B composition wherein R1 is one or more elements selected from among rare earth elements inclusive of Y and Sc, and then heat treating the magnet form and the powder at a temperature equal to or below the sintering temperature of the magnet in vacuum or in an inert gas. The result high performance, compact or thin permanent magnet has a high remanence and coercivity at a high productivity.

Owner:SHIN ETSU CHEM CO LTD

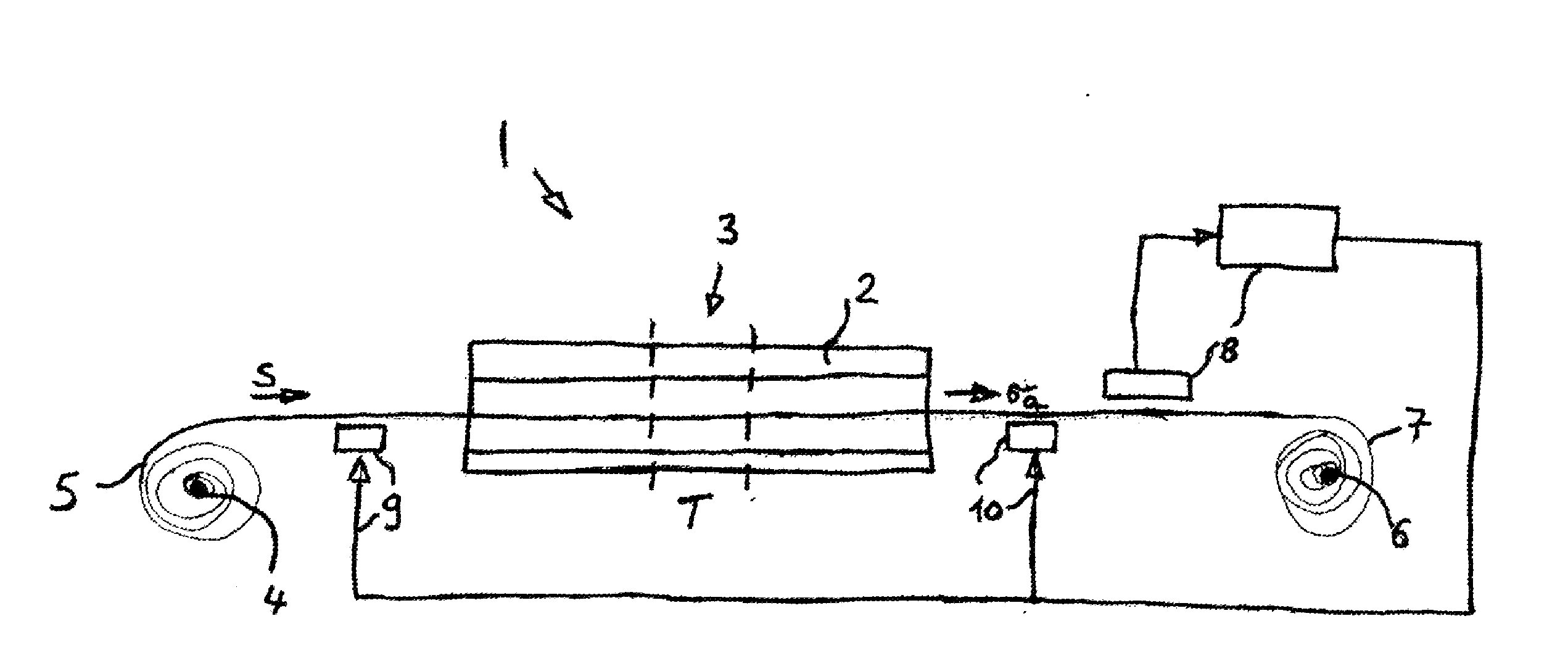

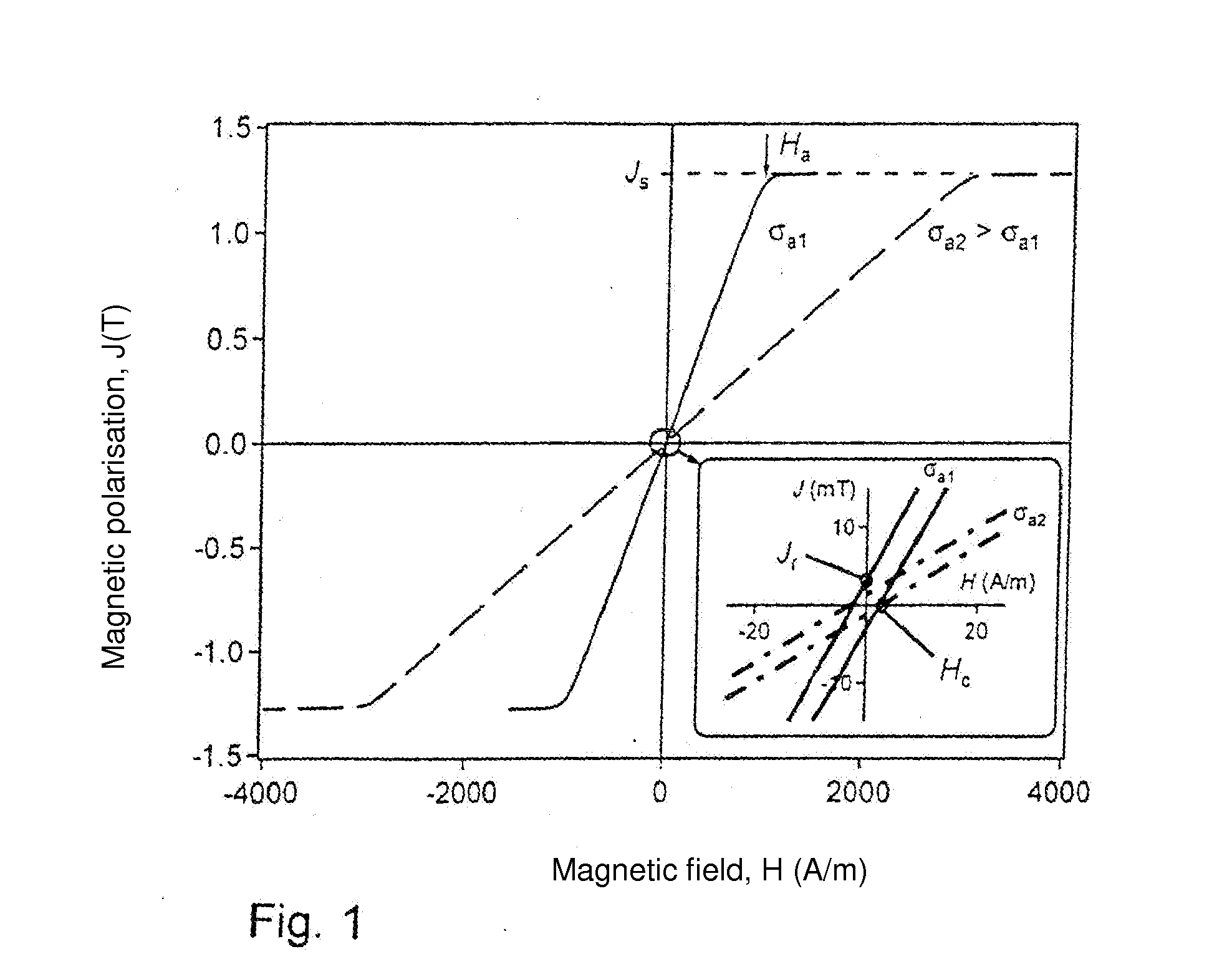

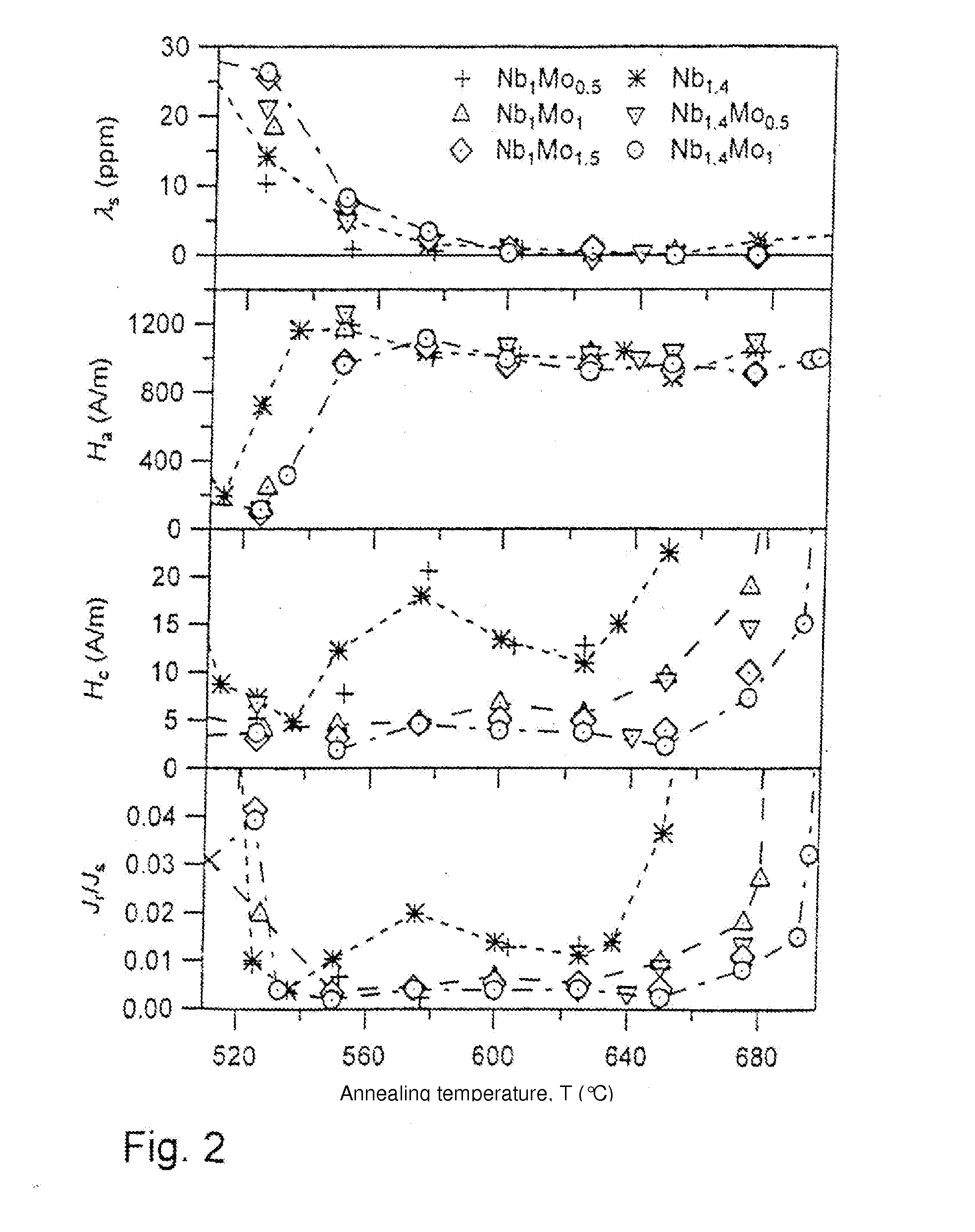

Alloy, magnet core and method for producing a strip from an alloy

ActiveUS20140104024A1Degradation of magnetic propertyUniformity of soft magnetic propertyInductances/transformers/magnets manufactureMagnetic materialsAlloyImpurity

An alloy of Fe100-a-b-c-d-x-y-zCuaNbbMcTdSixByZz and up to 1 atomic % impurities; M is one or more of Mo or Ta, T is one or more of V, Cr, Co or Ni and Z is one or more of C, P or Ge, wherein 0.0 atomic % a <1.5 atomic %, 0.0 atomic % b <3.0 atomic %, 0.2 atomic % c 4.0 atomic %, 0.0 atomic % d <5.0 atomic %, 12.0 atomic %<x<18.0 atomic %, 5.0 atomic %<y<12.0 atomic % and 0.0 atomic % z<2.0 atomic %, and wherein 2.0 atomic % (b+c) 4.0 atomic %, produced in the form of a strip and having a nanocrystalline structure in which at least 50% by volume of the grains have an average size of less than 100 nm, a remanence ratio Jr / Js<0.02, Jr being the remanent polarisation and Js being the saturation polarisation, and a coercitive field strength Hc which is less than 1% of the anisotropic field strength Ha and / or less than 10 A / m.

Owner:VACUUMSCHMELZE GMBH & CO KG

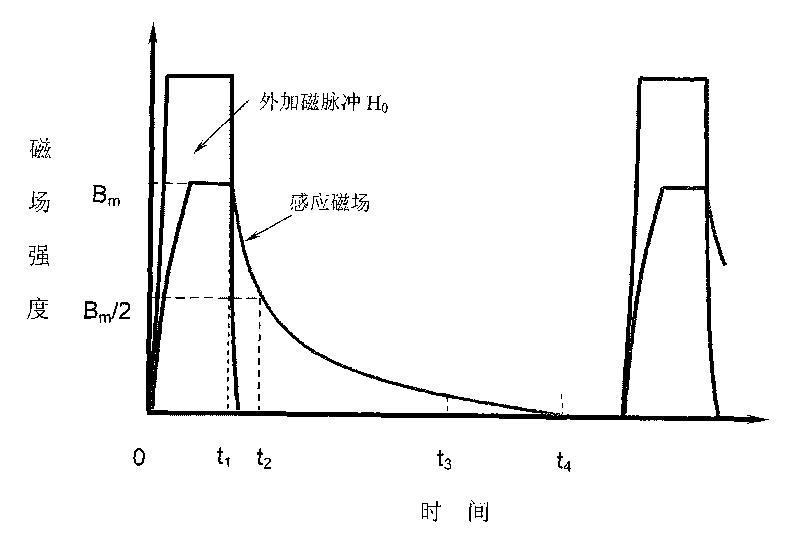

Time-resolved remanence relaxation detector and application thereof in detection of superparamagnetic nanomaterial

ActiveCN101726535AReduce distractionsHigh detection sensitivityBiological testingMaterial magnetic variablesMagnetic beadSuperparamagnetism

The invention relates to a weak magnetism detecting instrument based on time-resolved remanence relaxation detection and application thereof. The detecting instrument consists of a detecting unit provided with a sensitive element with high sensitivity therein, a sample bracket, a pulse magnetic field generator, a signal data acquiring and converting system and a computer. The working principle of the detecting instrument is that the superparamagnetic nanomaterial is magnetized via pulse by means of a pulse magnetic field with a steep edge, then a magnetism sensitive element with a high sensitivity is utilized to carry out track analysis on the remanence relaxation generated by the superparamagnetic nanomaterial under the action of the pulse magnetic field, and then a quantitative detection of superparamagnetic nanomaterial is realized. By means of the instrument, biological analysis with high sensitivity can be realized by combining with nano-particles or magnetic beads. The instrument and method of the invention have fast detection speed, low cost, high sensitivity and good stability, and are suitable for fields of biological analysis, disease diagnosis, food security, environment monitoring and the like.

Owner:BEIJING SHUOWANG TECH

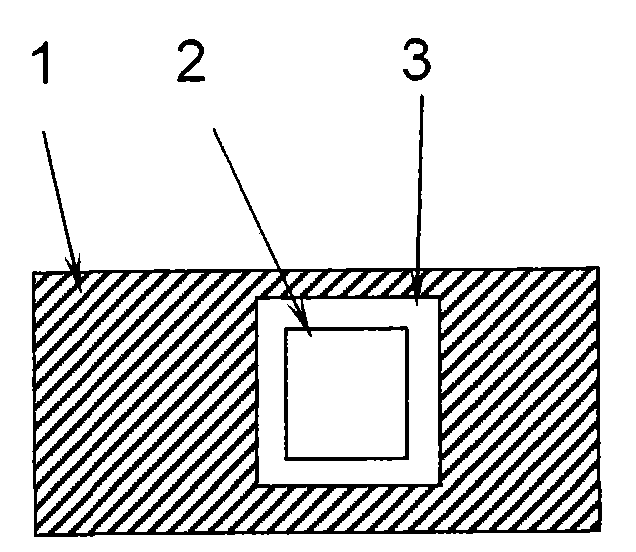

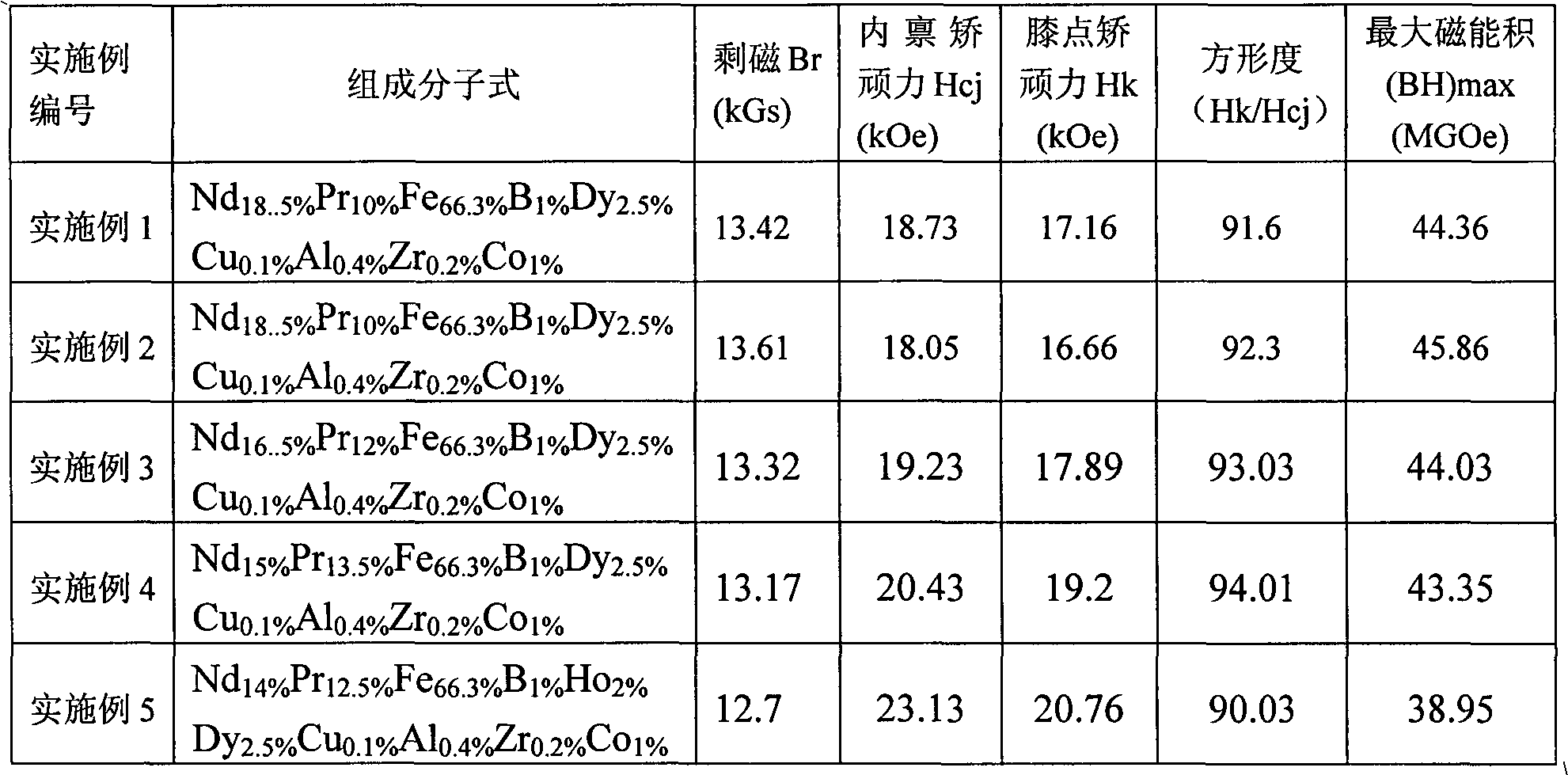

Sintered Nd-Fe-B permanent-magnet material and preparation method thereof

InactiveCN101982855AIncrease contentImprove coercive forceInorganic material magnetismRemanenceRare earth

The invention discloses a sintered Nd-Fe-B permanent-magnet material and a preparation method thereof. The molecular formula of the sintered Nd-Fe-B permanent-magnet material is (NdPr)aFe[100%-a-b-c]BbMc, wherein M is one or a plurality of Dy, Ho, Nb, Zr, Co, Ga, Al and Cu; a, b and c represent the mass percentages of the corresponding elements; a is greater than or equal to 20% and smaller than or equal to 32%, b is greater than or equal to 0.9% and smaller than or equal to 1.2%, and c is greater than or equal to 0% and smaller than or equal to 6%; and the mass of the element Pr accounts for 20-49% of the mass of PrNd alloy. Compared with the prior art, the sintered Nd-Fe-B permanent-magnet material has the following advantage: the content of the element Pr in the Nd-Fe-B permanent-magnet material is increased by adjusting the composition and content of the Nd-Fe-B permanent-magnet material, so that the mass percentage of the element Pr in the light rare earth Nd is increased to 20-49%. Compared with the prior Nd-Fe-B permanent-magnet material, the Nd-Fe-B permanent-magnet material obtained by the invention has the advantages that the high coercive force can be maintained and simultaneously the cost is greatly lowered without reducing the remanence.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

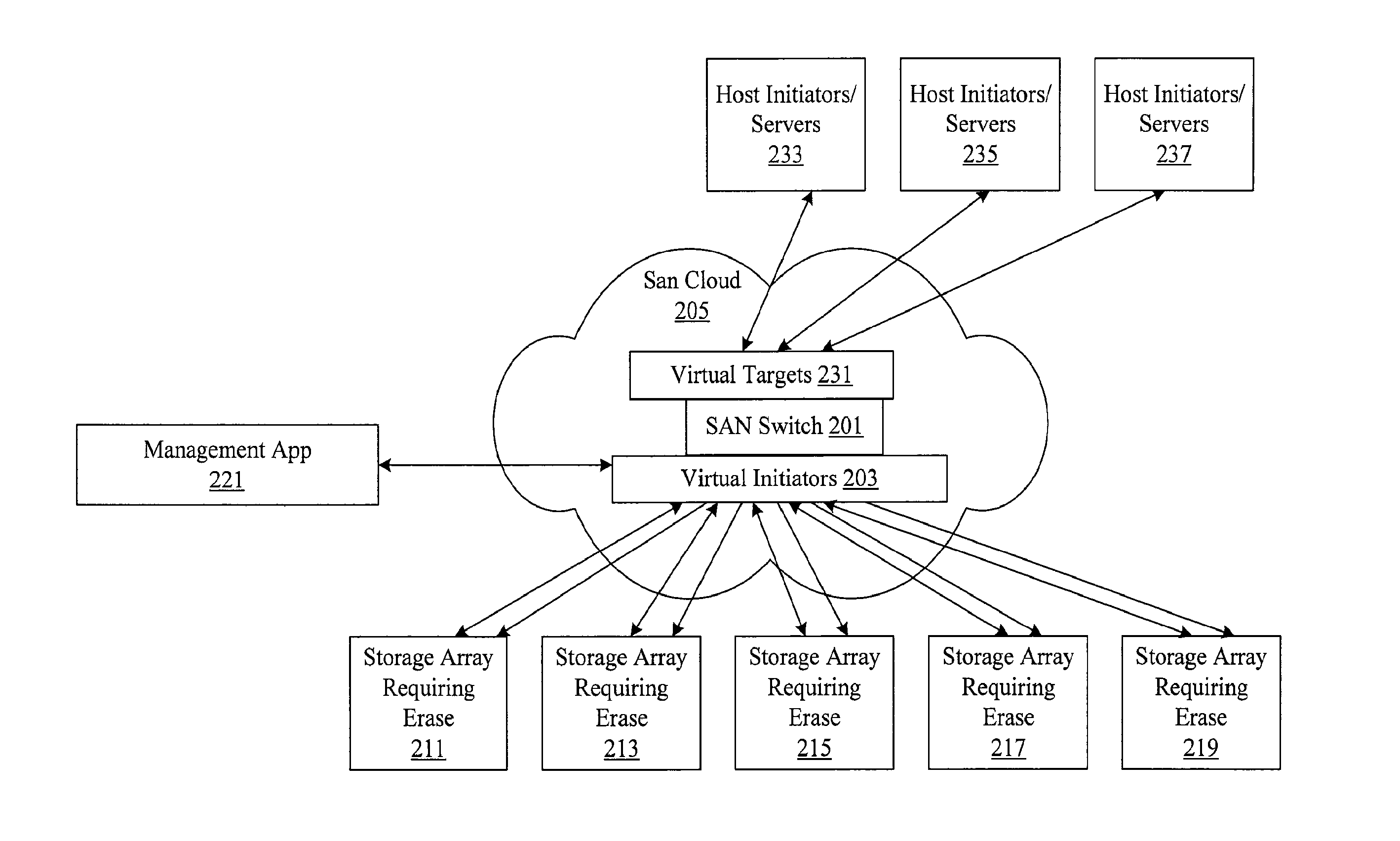

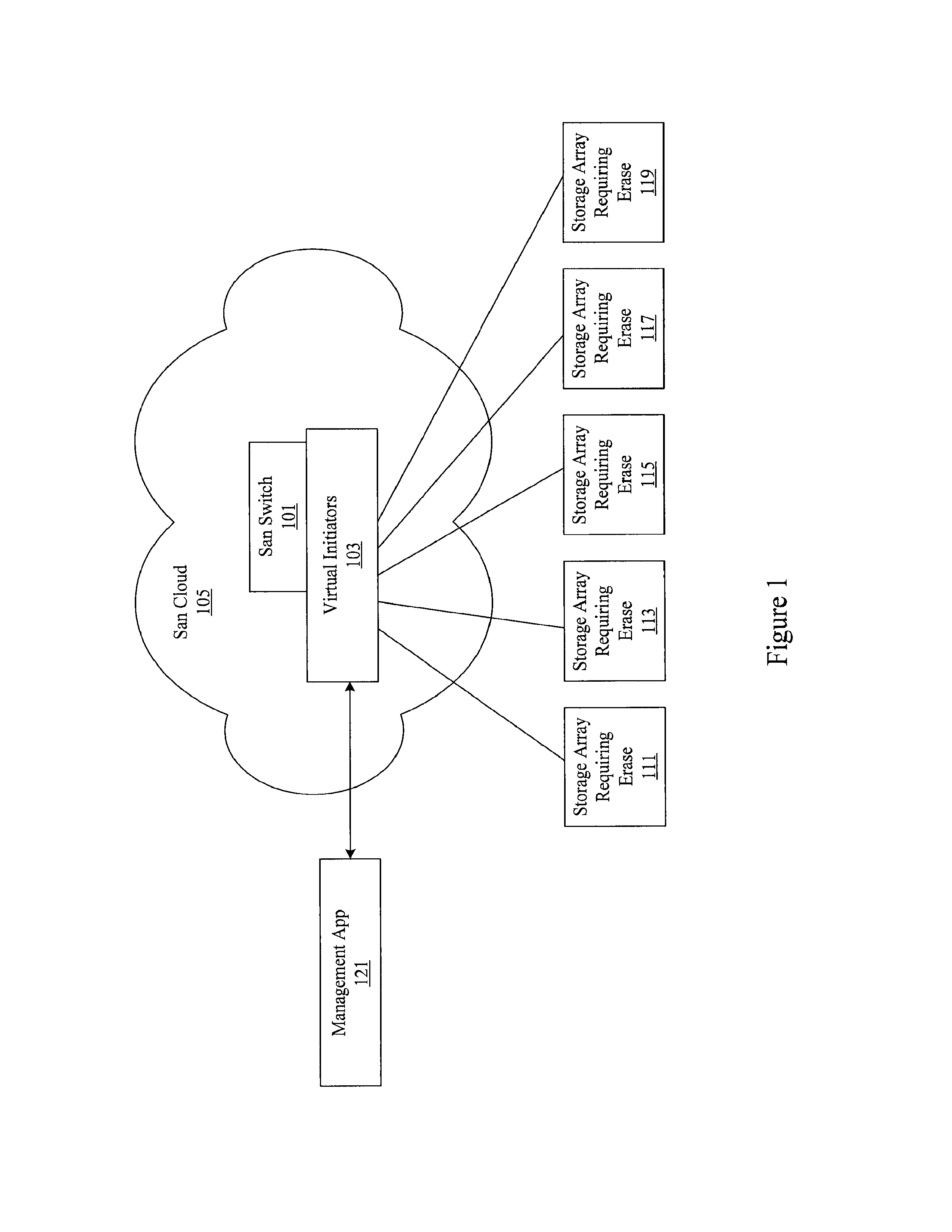

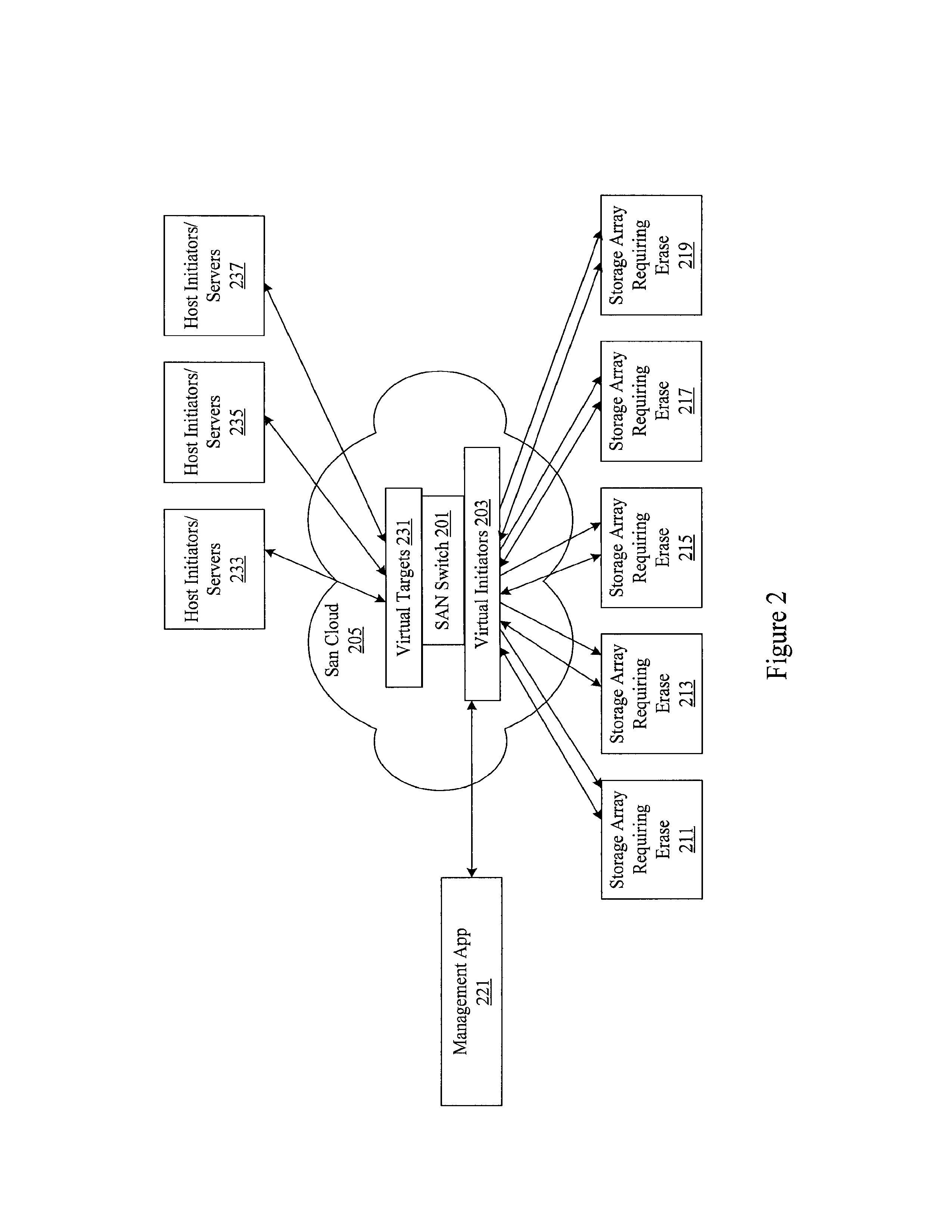

Storage area network (SAN) switch multi-pass erase of data on target devices

Techniques are provided for performing multi-pass erase. An erase command is received at a storage area network (SAN) switch in a storage area network. The erase command is associated with a block of data on a target device. A virtual initiator is determined for performing the erase command on the block of data. Multiple bit patterns are generated using a multi-pass erase algorithm. The multiple bit patterns are generated for writing over the block of data on the target device. Repeated writes are performed over the block of data using the bit patterns. The block of data is repeatedly overwritten to remove remanence of the block of data on the target device.

Owner:CISCO TECH INC

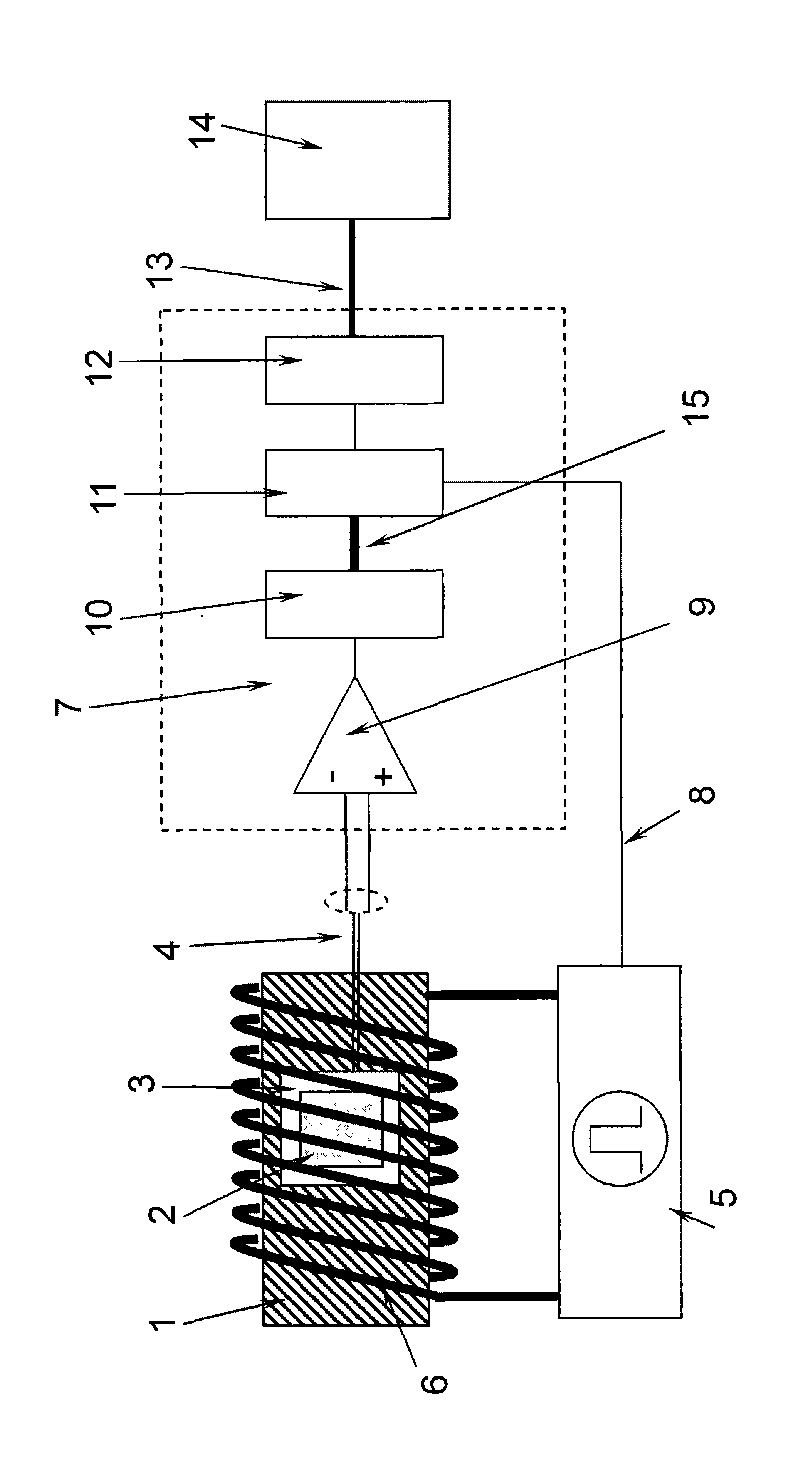

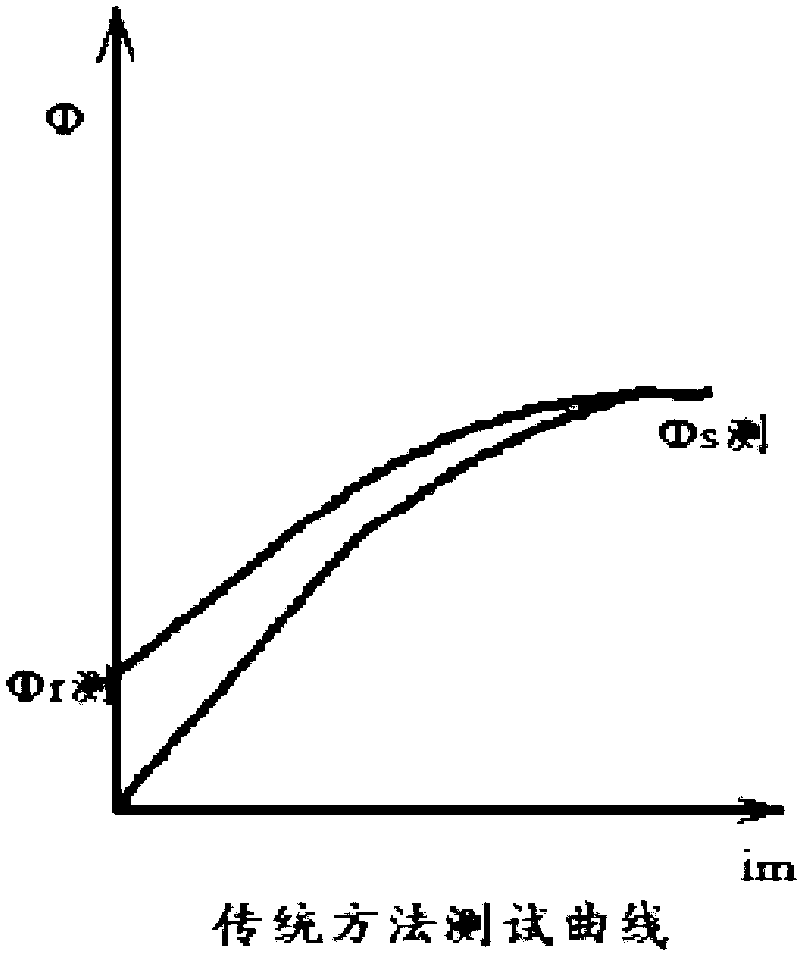

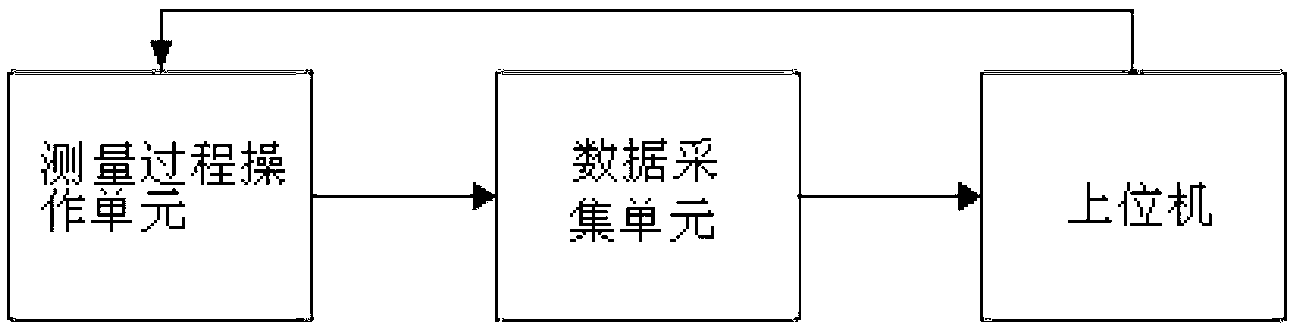

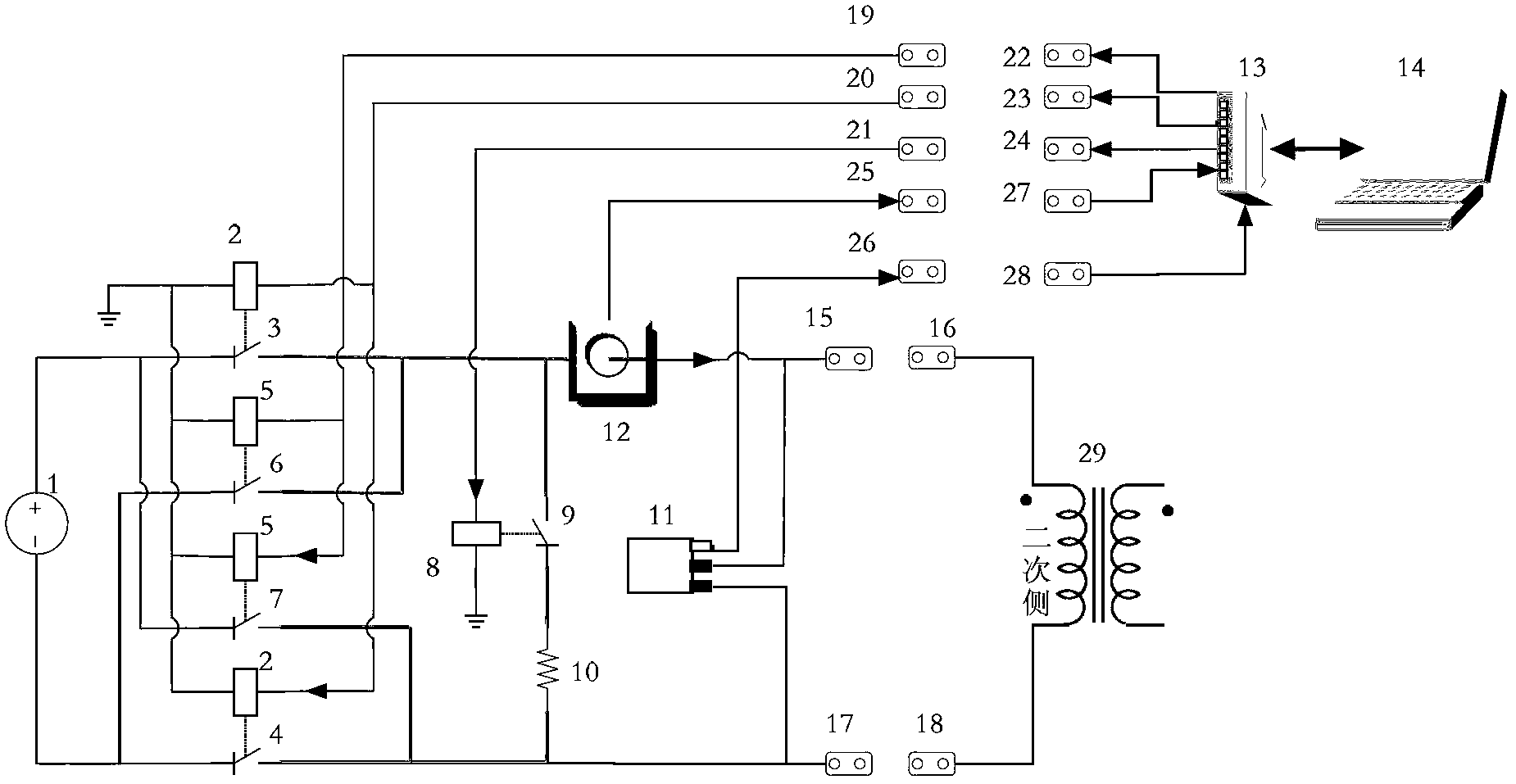

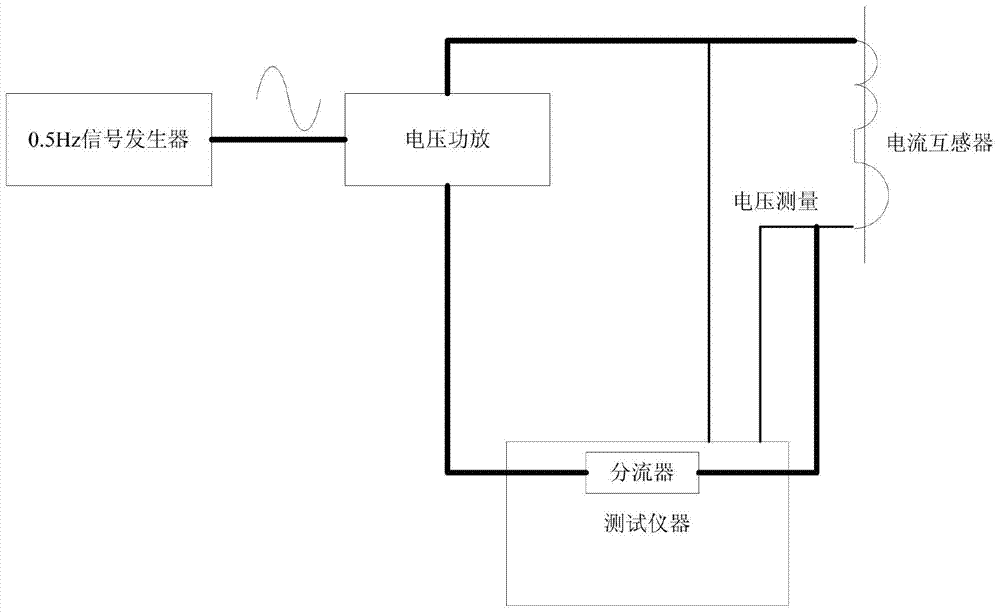

Current transformer remanence measurement system and method

ActiveCN103176147AImprove accuracyEnsure fairnessMagnetic property measurementsObservational errorRemanence

The invention discloses current transformer remanence measurement system and method. An upper computer receives current transformer data signals transmitted by a data unit. Related data processing is performed to calculate remanence coefficient. Operation states of an operating unit are automatically judged during measurement, and on and off of a relay are controlled. When the primary side of a current transformer is open, the secondary side is sequentially subjected to positive charging, discharging and revere charging until the current transformer is saturated. Flux variations in positive charging process, discharging process and revere charging process are obtained by calculation. The three flux variations are then calculated to obtain accurate remanence coefficient. Therefore, errors in remanence coefficient measurement caused when initial core flux of the current transformer is not zero are eliminated, accuracy in remanence coefficient measurement for the current transformer is increased, and fairness in electric energy measurement and trade settlement for the current transformer is guaranteed. The current transformer remanence measurement system and method have promising application prospect.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +3

Rare earth permanent magnet and preparation method thereof

ActiveCN102610355AImprove uniformityResidue reductionPermanent magnetsInductances/transformers/magnets manufactureRemanencePhosphate

Disclosed are a rare earth permanent magnet and a preparation method. The preparation method of the rare earth permanent magnet is capable of improving coercivity of the magnet while keeping binding strength of a base body and a plated layer or coated layer after plating or coating on the basis without reducing remanence and magnetic energy product of the magnet and includes: firstly dissolving powder of fluoride containing R2, nitrate containing R3 and phosphate containing R4 into water or alcohol to prepare solution; uniformly applying the solution on the surface of a magnet to be treated; then dewatering or performing alcohol treatment on the magnet to be treated; finally, enabling the magnet to be treated to be subjected to diffusion heat treatment to obtain the treated magnet. By the aid of the preparation method, uniformity of the powder on the surface of the magnet can be improved, powder residues on the surface of the magnet after heat diffusion are reduced, the coercivity of the magnet is improved, and the binding strength of the magnet of the base body and the plated layer or coated layer after plating or coating is kept constant.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Transformer remanence detection and demagnetization method and device

ActiveCN105093140ADegaussing completelyMeet the equipment volumeMagnetic bodiesMagnetic property measurementsRemanenceResidual flux

The invention discloses a transformer remanence detection and demagnetization method which comprises the following steps: collecting residual flux content of a test transformer, and inputting the residual flux content into an intelligent analysis system; reading the residual flux content of the test transformer through a human-computer interaction interface, and inputting corresponding control instructions; controlling the output of a frequency conversion voltage-regulating unit through the control instructions; and outputting by the frequency conversion voltage-regulating unit a low-frequency AC voltage required for demagnetization, and carrying out demagnetization on the test transformer. The invention also discloses a transformer remanence detection and demagnetization device which comprises an AC power supply module, a power supply conversion module, a DC power supply module, a control acquisition module, the frequency conversion voltage-regulating unit, a man-machine interaction unit, a data acquisition module, the intelligent analysis system and the test transformer. The low-frequency AC voltage is utilized for demagnetization, thereby reducing power capacity and size of the demagnetization device; and through the man-machine interaction unit, operation personnel can obtain the demagnetization processing progress accurately and visually, and input the corresponding control instructions, thereby realizing thorough demagnetization of the test transformer.

Owner:国网四川省电力公司阿坝供电公司 +2

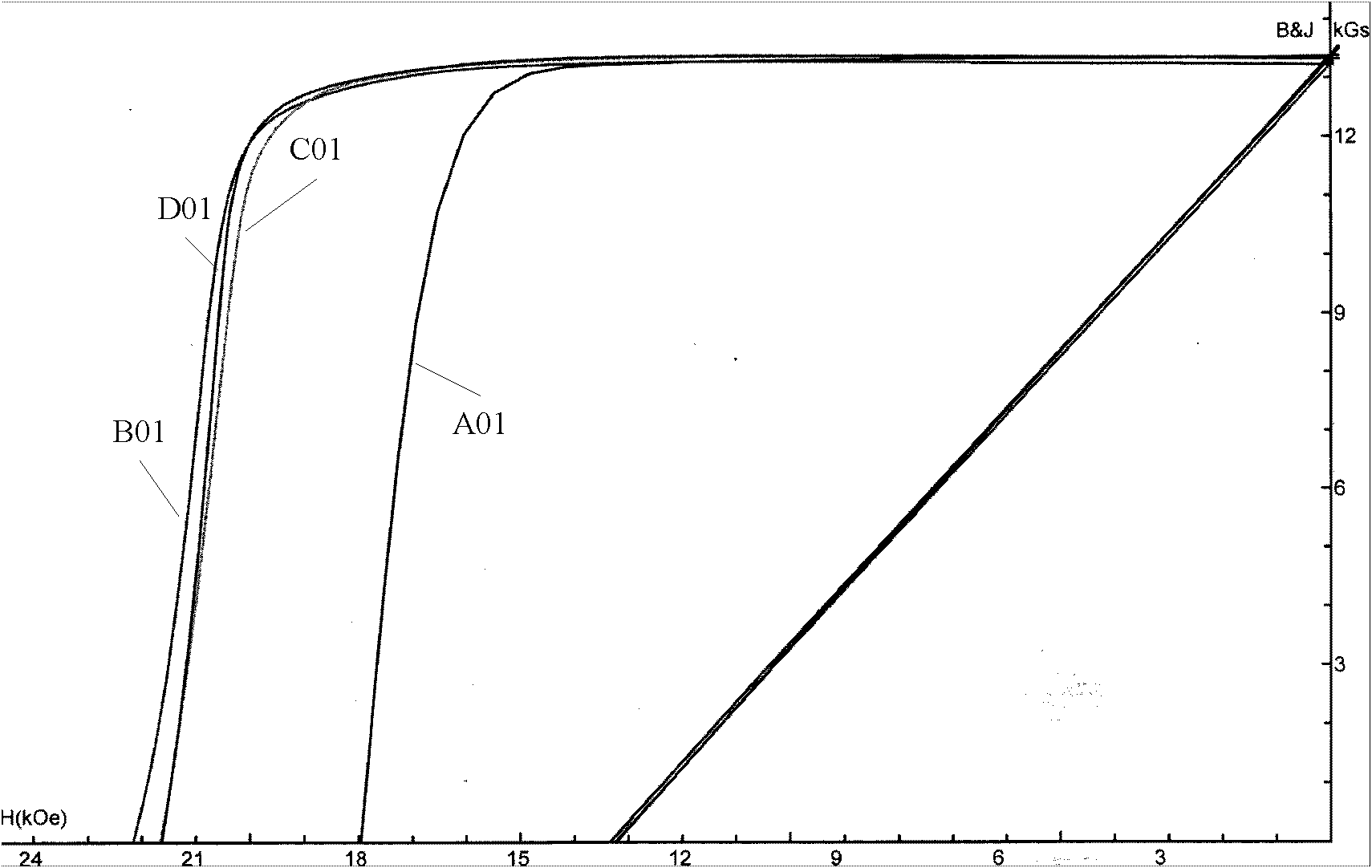

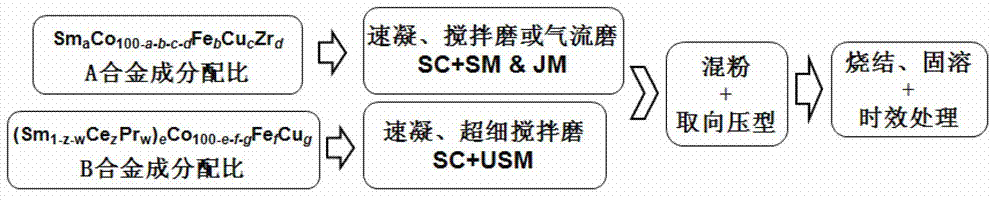

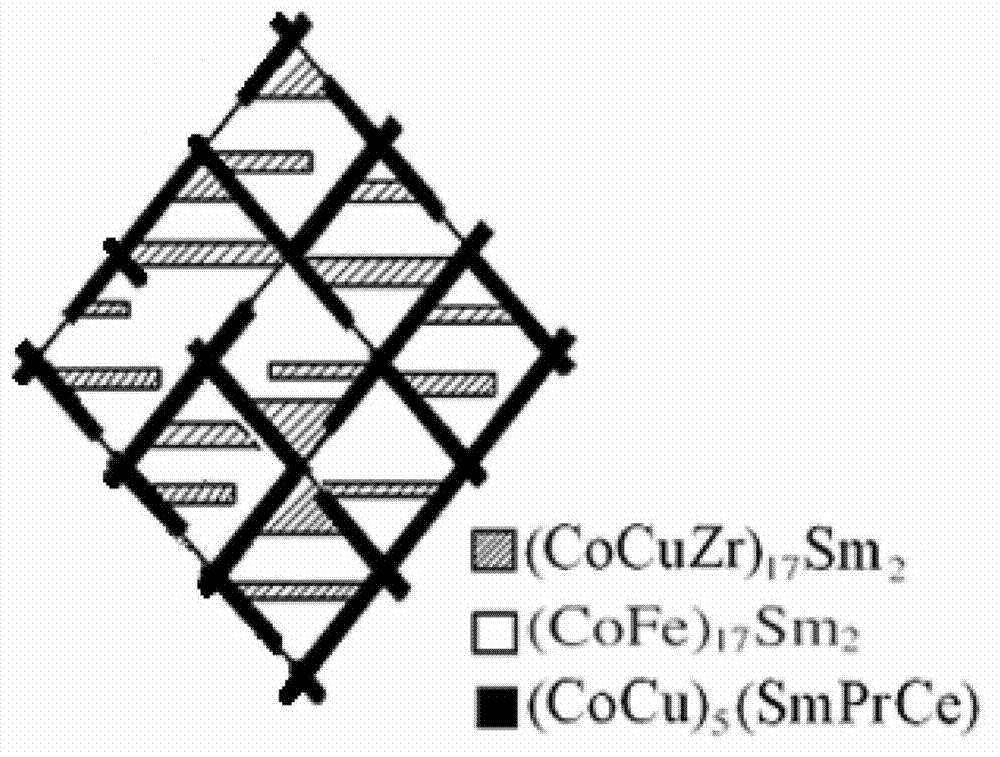

High-remanence low-coercivity samarium cobalt permanent magnetic material and preparation method

ActiveCN102760545AHigh surface magnetic fieldReduce sinteringMagnetic materialsRemanenceChemical composition

The invention belongs to the field of rare earth permanent magnetic material manufacturing, and relates to a high-remanence low-coercivity samarium cobalt permanent magnetic material and a preparation method. The chemical components of the permanent magnetic material by mass percent are shown as follows: 23-26.5% of [Sm1-x-y(Prx, Cey)], 17-20% of Fe, 3-6% of Cu, 1-3% of Zr, and the balance of Co, wherein x is not less than 0 and not more than 0.1, and y is not less than 0 and not more than 0.1. In the preparation method, a double main phase alloying method and a rapid hardening technology are used, a rapid hardening belt with two components is needed only, and a high-remanence low-coercivity magnet can be prepared; an anti-oxidation lubricant is added in a jet milling process so as to prevent agglomeration and oxidation of magnetic powder, and the oxygen content of the magnet is less than 1500ppm. By addition of Ce and Pr, the thermal treatment temperature of the samarium cobalt permanent magnetic material is reduced. The magnet performance is shown as follows: Br=11.0-11.5kGs, Hcj=10-20kOe, and (BH)max=28-33MGOe.

Owner:CENT IRON & STEEL RES INST

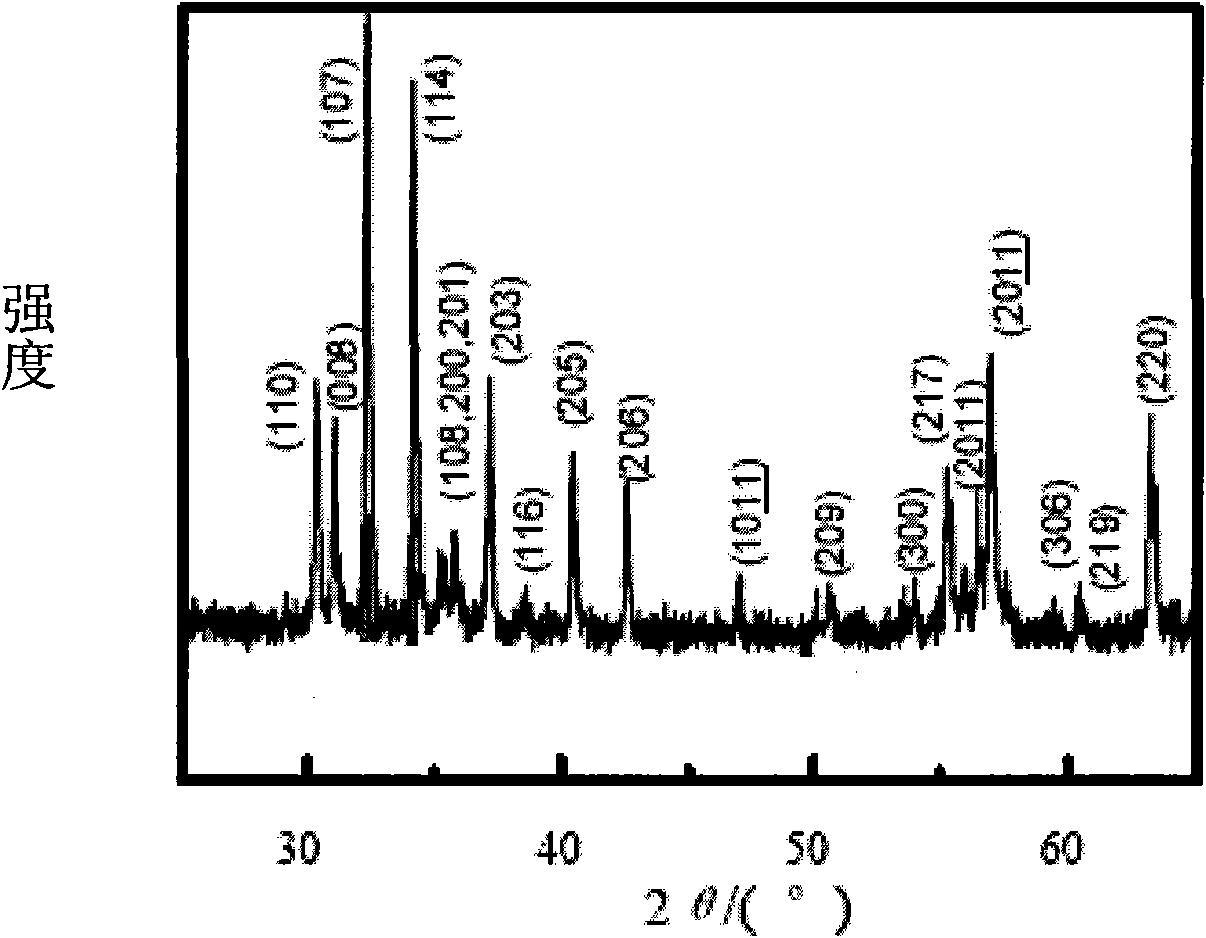

Method for preparing sintered samarium-cobalt magnet

ActiveCN103065788AGet over the actual ingredientsTo overcome the large deviation of design componentsInorganic material magnetismInductances/transformers/magnets manufactureRemanenceSamarium–cobalt magnet

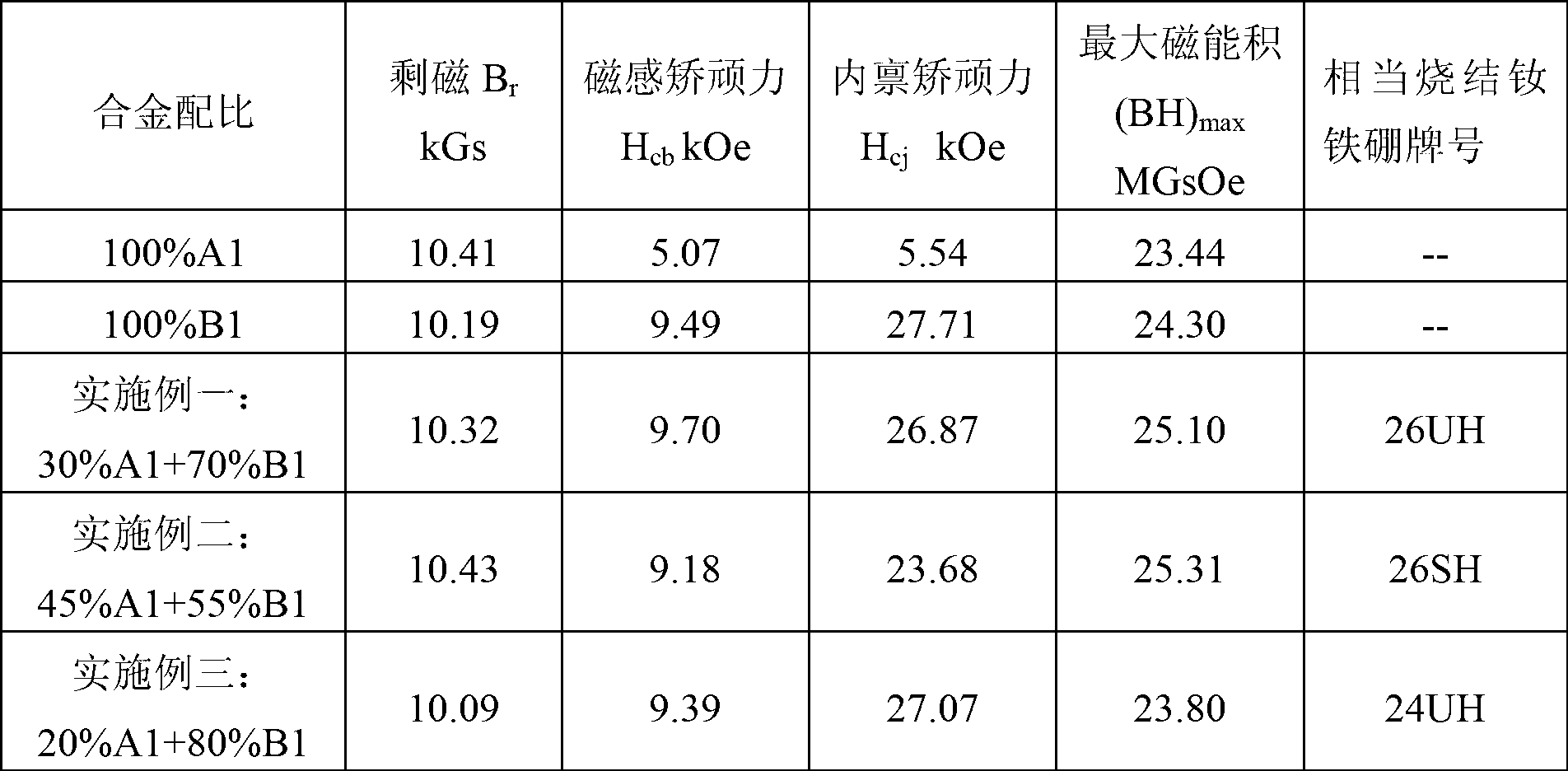

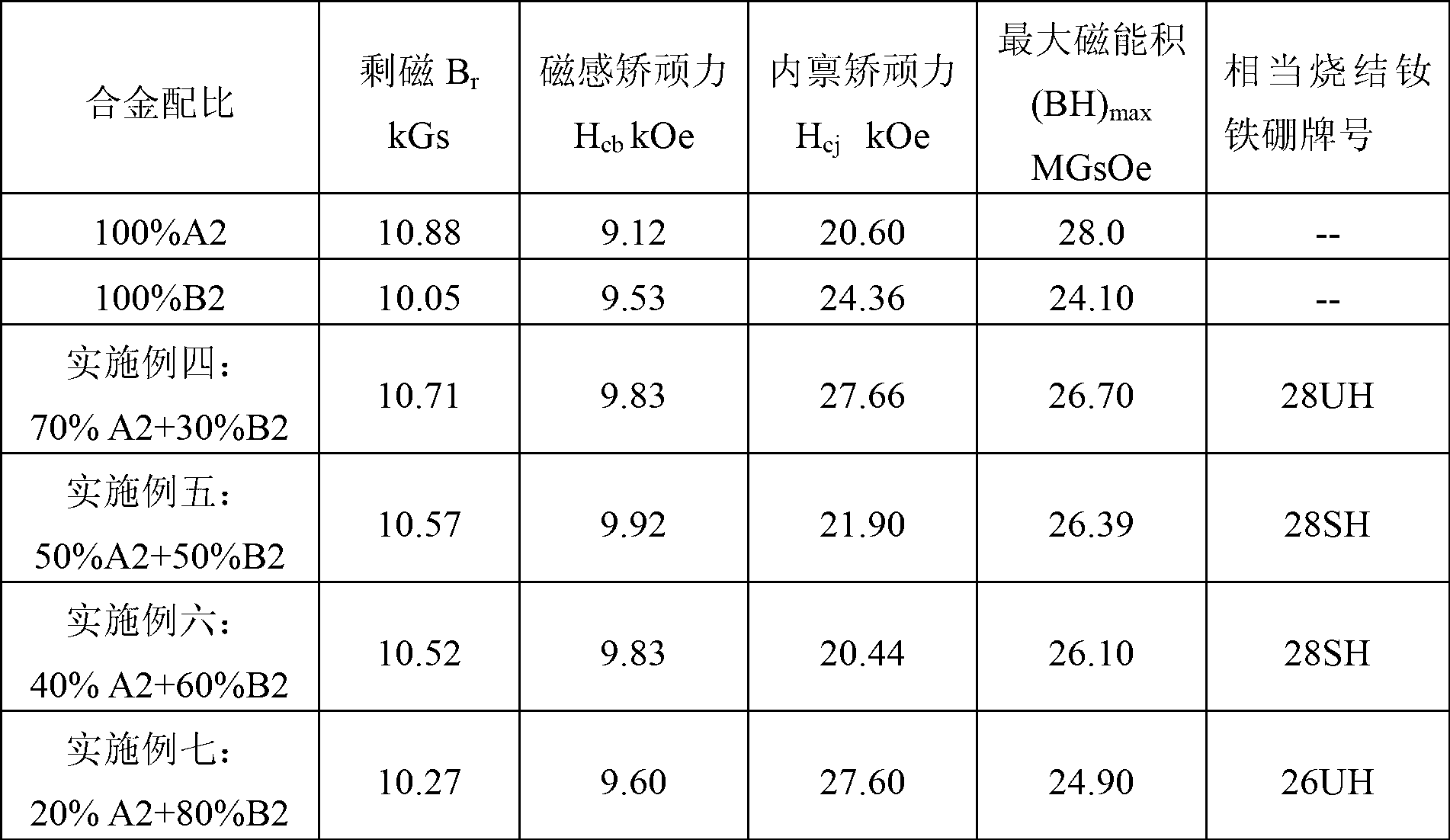

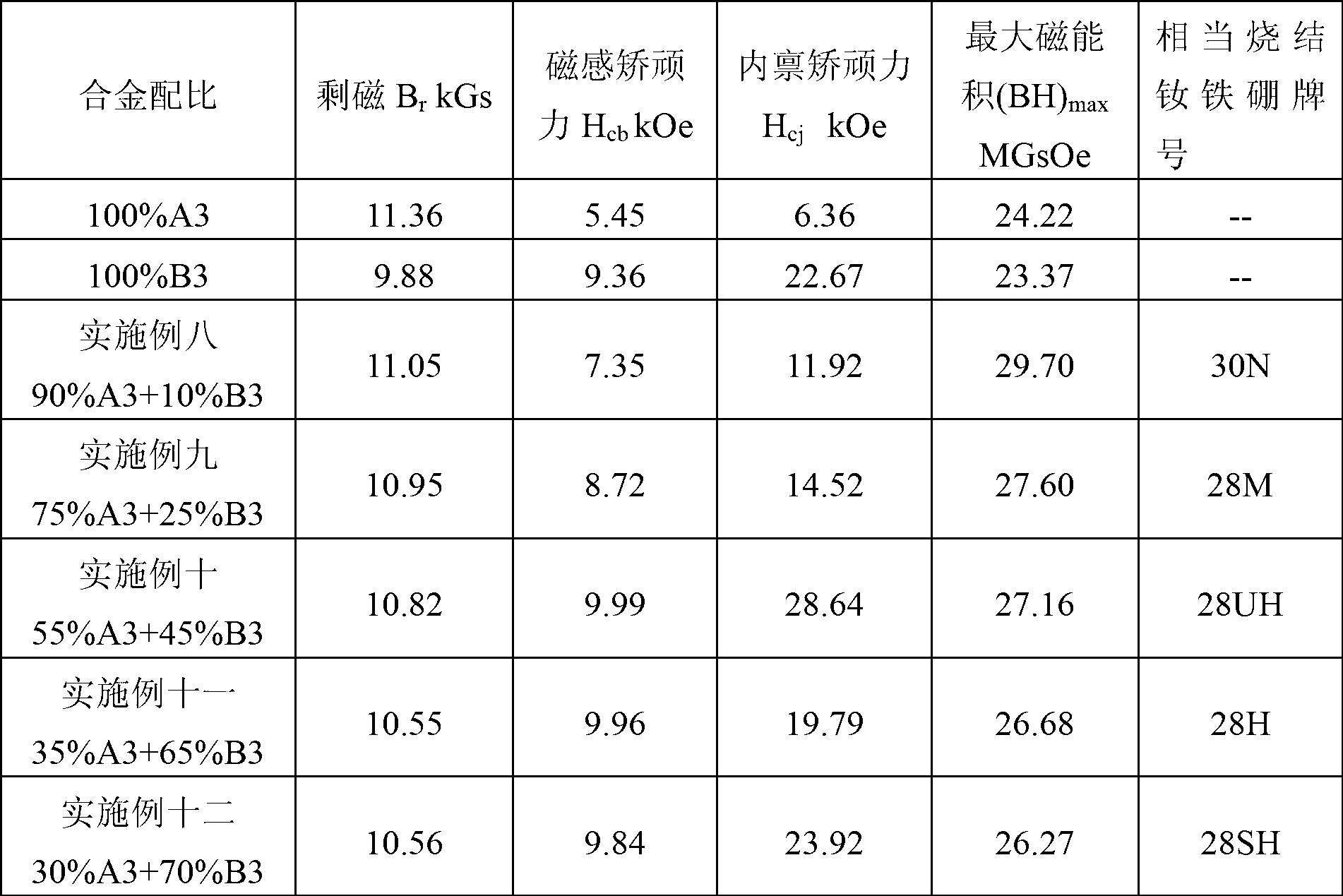

The invention discloses a method for preparing a sintered samarium-cobalt magnet. The method comprises the following steps of: preparing a first samarium-cobalt alloy and a second samarium-cobalt alloy; performing primary crushing on the first samarium-cobalt alloy and the second samarium-cobalt alloy; mixing first samarium-cobalt alloy primarily crushed magnetic powder and second samarium-cobalt alloy primarily crushed magnetic powder, and performing fine crushing, so that primarily crushed mixed magnetic powder is refined, and components are homogenized; and performing magnetic field orientation forming, cold isostatic pressing, sintering, solid solution treatment and ageing treatment on samarium-cobalt magnetic powder obtained by fine crushing in sequence. The method has the advantages that the first samarium-cobalt alloy has high remanence component characteristic, the second samarium-cobalt alloy has high coercivity component characteristic, the sintered samarium-cobalt magnets with various magnetic properties can be obtained by adjusting the mixing ratio of the first samarium-cobalt alloy primarily crushed magnetic powder to the second samarium-cobalt alloy primarily crushed magnetic powder, and the process is stable and low in cost.

Owner:NINGBO YUNSHENG +3

Permanent magnet field small DC motor

InactiveUS6995488B1Stronger static magnet fieldEnsure correct executionMagnetic circuit stationary partsManufacturing stator/rotor bodiesCompression moldingRemanence

A permanent magnet field small DC motor includes an arc-shaped rare earth magnet of maximum thickness 1 mm or less fabricated by compression molding from rare earth iron based melt-spun flakes and a binder. The magnet is provided with a certain specific portion at both ends in the circumferential direction, which has no back yoke when the magnet is press-fit in a soft-magnetic frame. The arc-shaped rare earth magnet fabricated by compression molding from a material containing more rare earth iron based melt-spun flakes exhibits simultaneous increase of both a remanence as a function of magnetizing field and a coercivity; and hence, exhibits a well-balanced demagnetization curve even in an unsaturated magnetized state.

Owner:PANASONIC CORP

Method for preparing permanent magnet oxysome material

The invention belongs to the permanent-magnet material field and provides a method for preparing permanent magnet oxysome material, which mainly comprises a novel technique adopted in wet ball-milling stage, that is, being receiving wet ball-milling to reach a certain granularity, a pre-sintering material firstly receives low-temperature resintering, and then receives wet remilling for a short time, so as to prepare needed slurry for facilitating sintering after forming. Through adopting the method provided by the invention, the sample coercitive force is effectively upgraded to obtain excellent comprehensive magnetic property on the basis that magnetic remanence is not reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

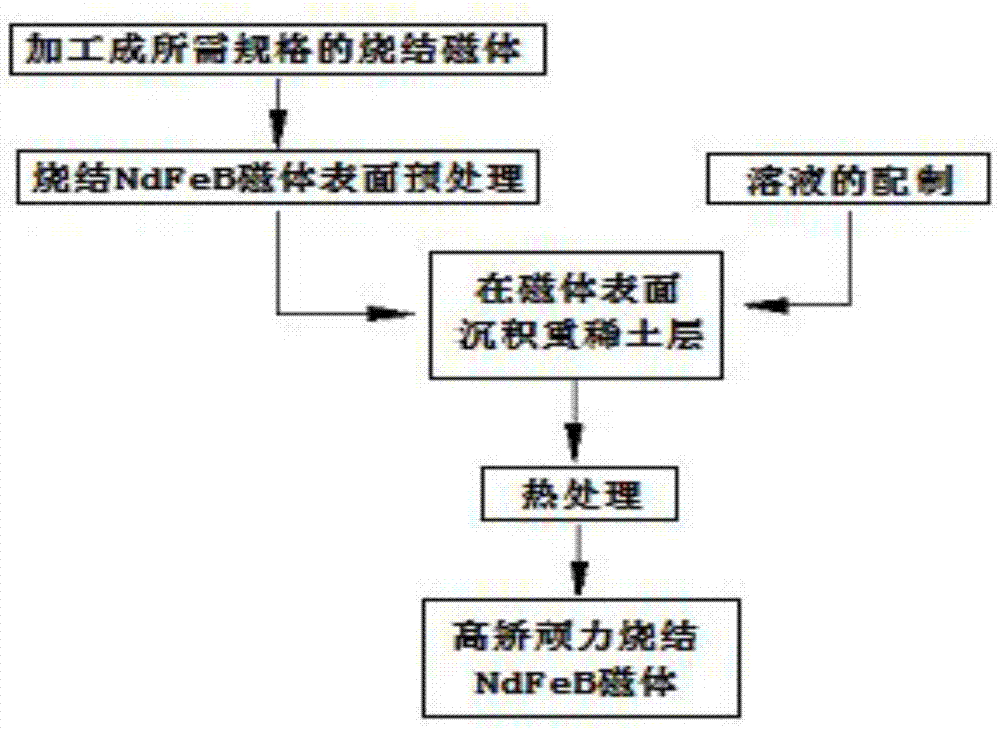

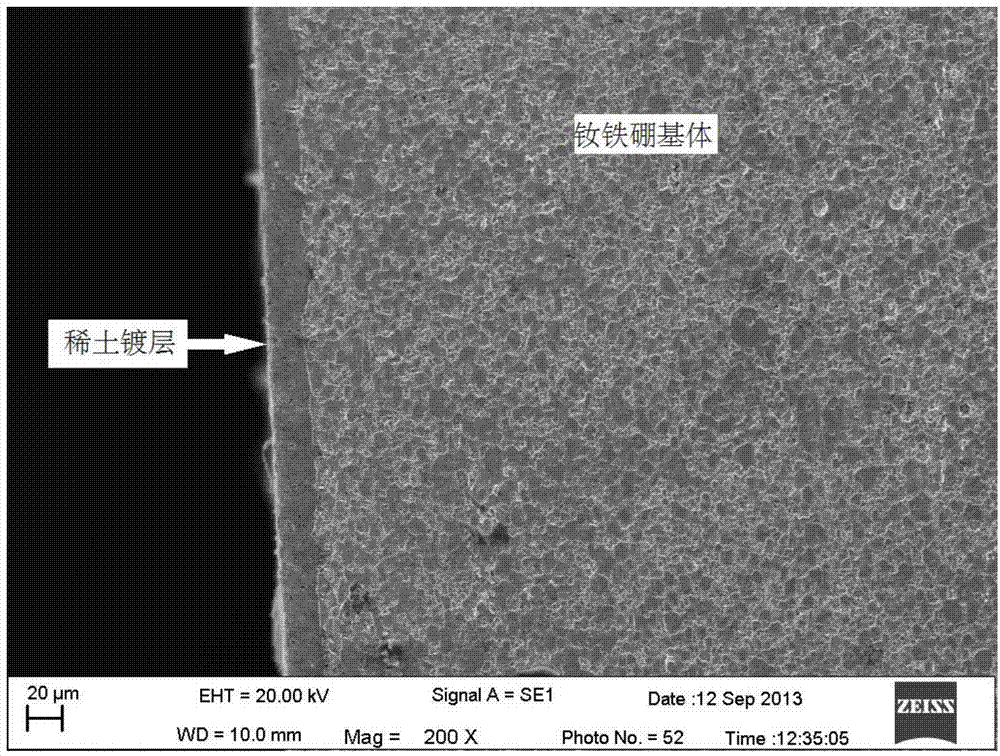

Heavy rear earth adhering method of sintered NdFeB magnet

InactiveCN103617884AImprove coercive forceIncrease the diffusion coefficientInorganic material magnetismInductances/transformers/magnets manufactureMischmetalRemanence

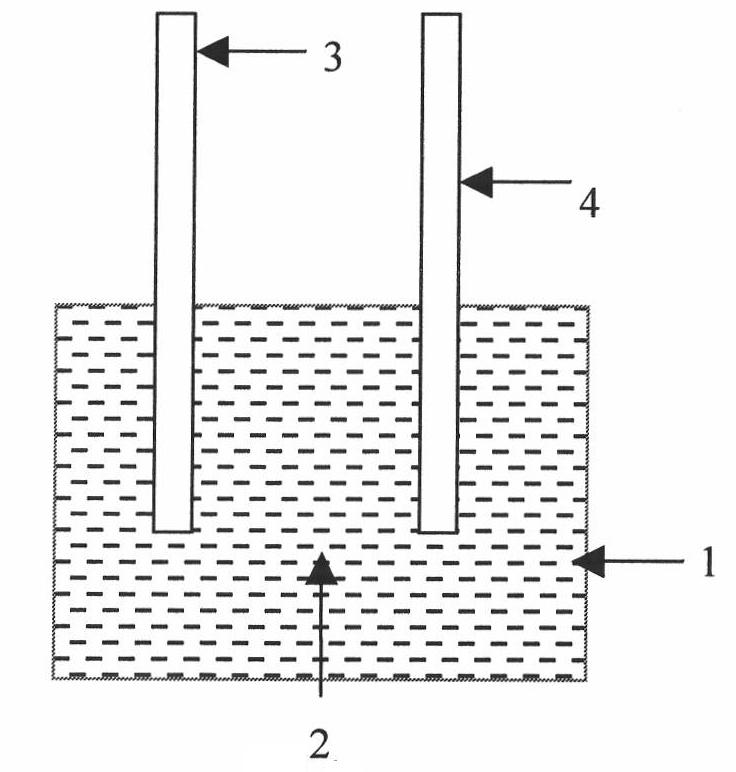

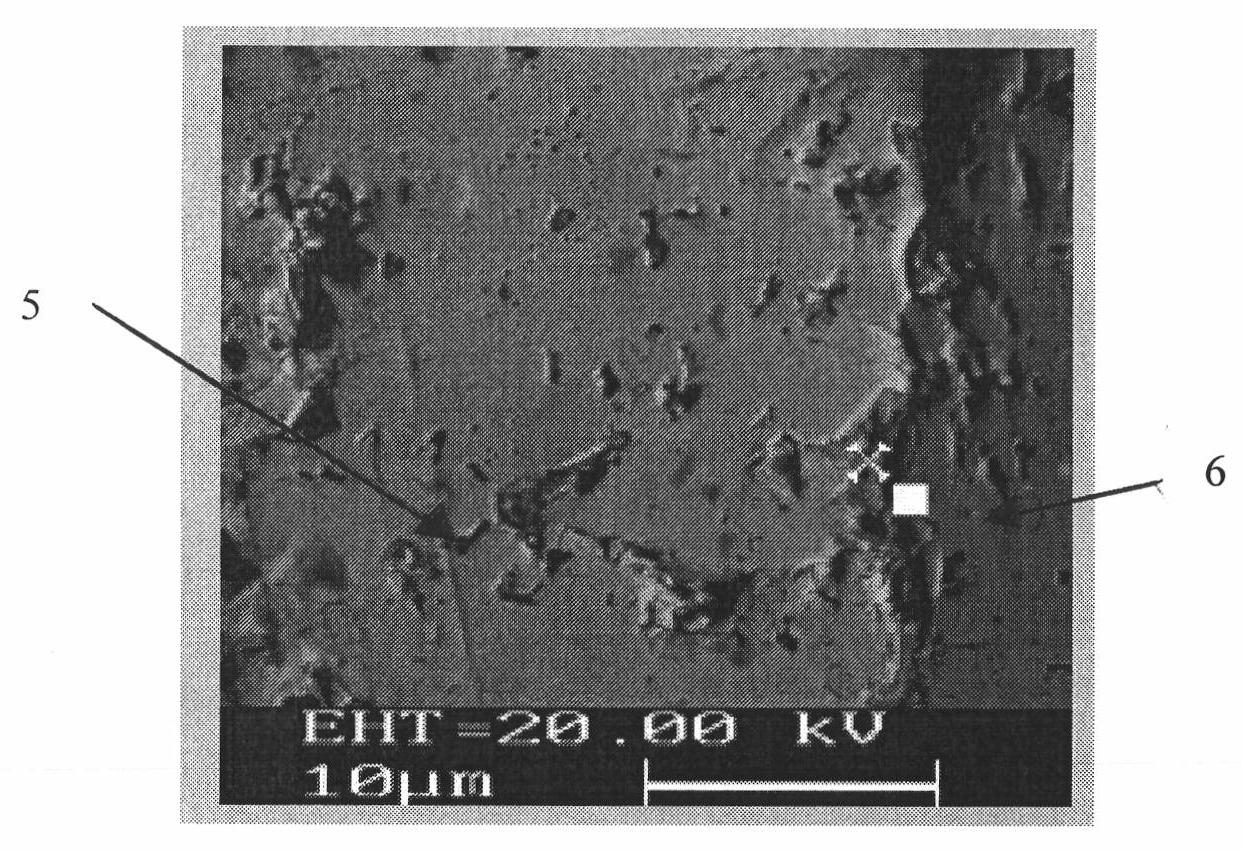

The invention provides a heavy rear earth adhering method of a sintered NdFeB magnet, and belongs to the technical field of rear earth magnetic functional materials and preparation. The preparation technology particularly includes the steps that the sintered NdFeB magnet after surface pretreatment is placed in a heavy rear earth salt organic solution, under the action of currents, heavy rear earth elements are deposited on the surface of the sintered NdFeB magnet and form a dense heavy rear earth metal thin layer, and then the heavy rear earth elements in a heavy rear earth metal film diffuse into the magnet through grain boundaries in the process of high temperature diffusion treatment or high temperature diffusion and low temperature tempering two-stage thermal treatment. Coercivity of a sintered NdFeB rear earth permanent magnetic material prepared through the method is remarkably improved, remanence is not obviously reduced, heavy rear earth consumption is small, the process is simple and controllable, efficiency is high, and the method is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

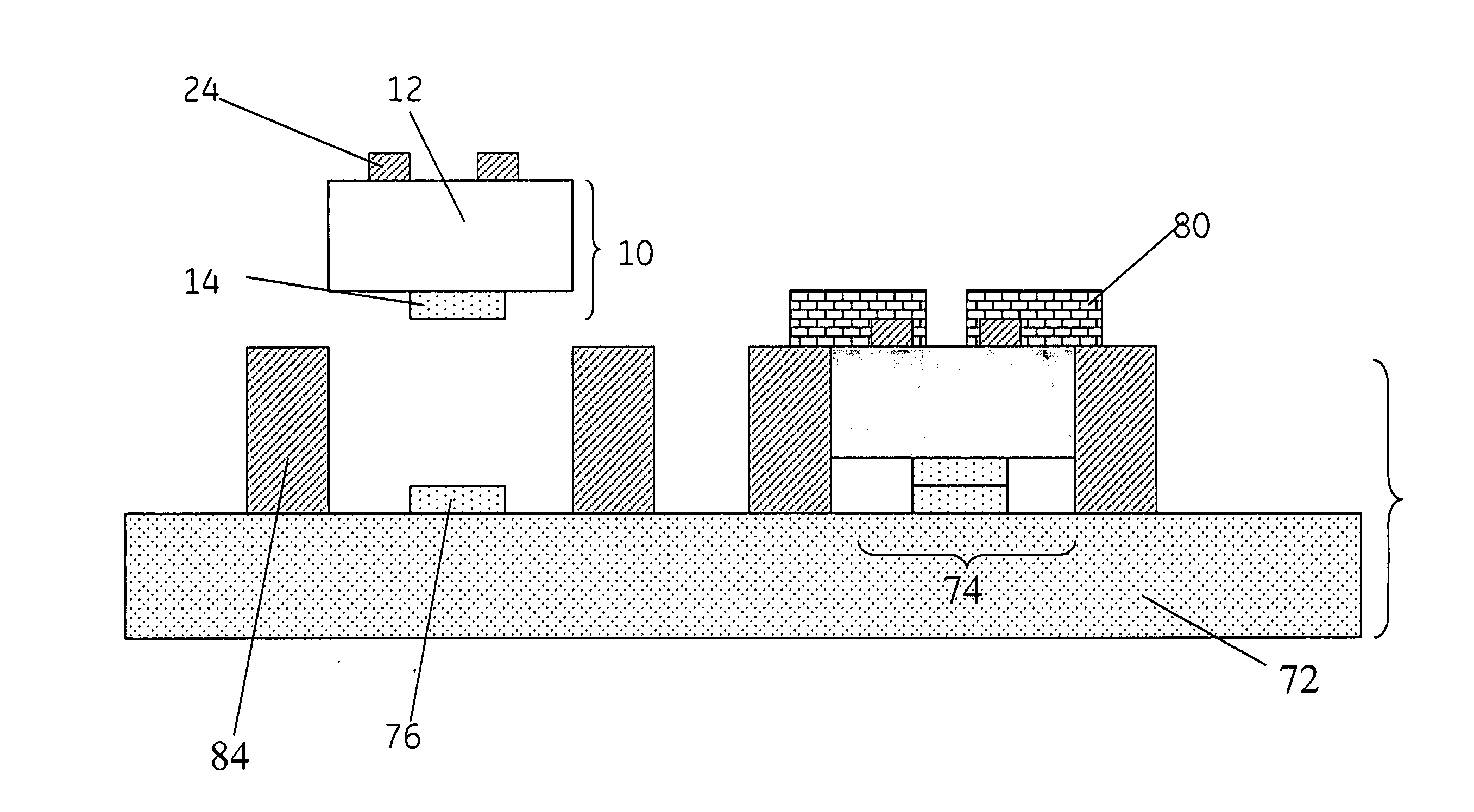

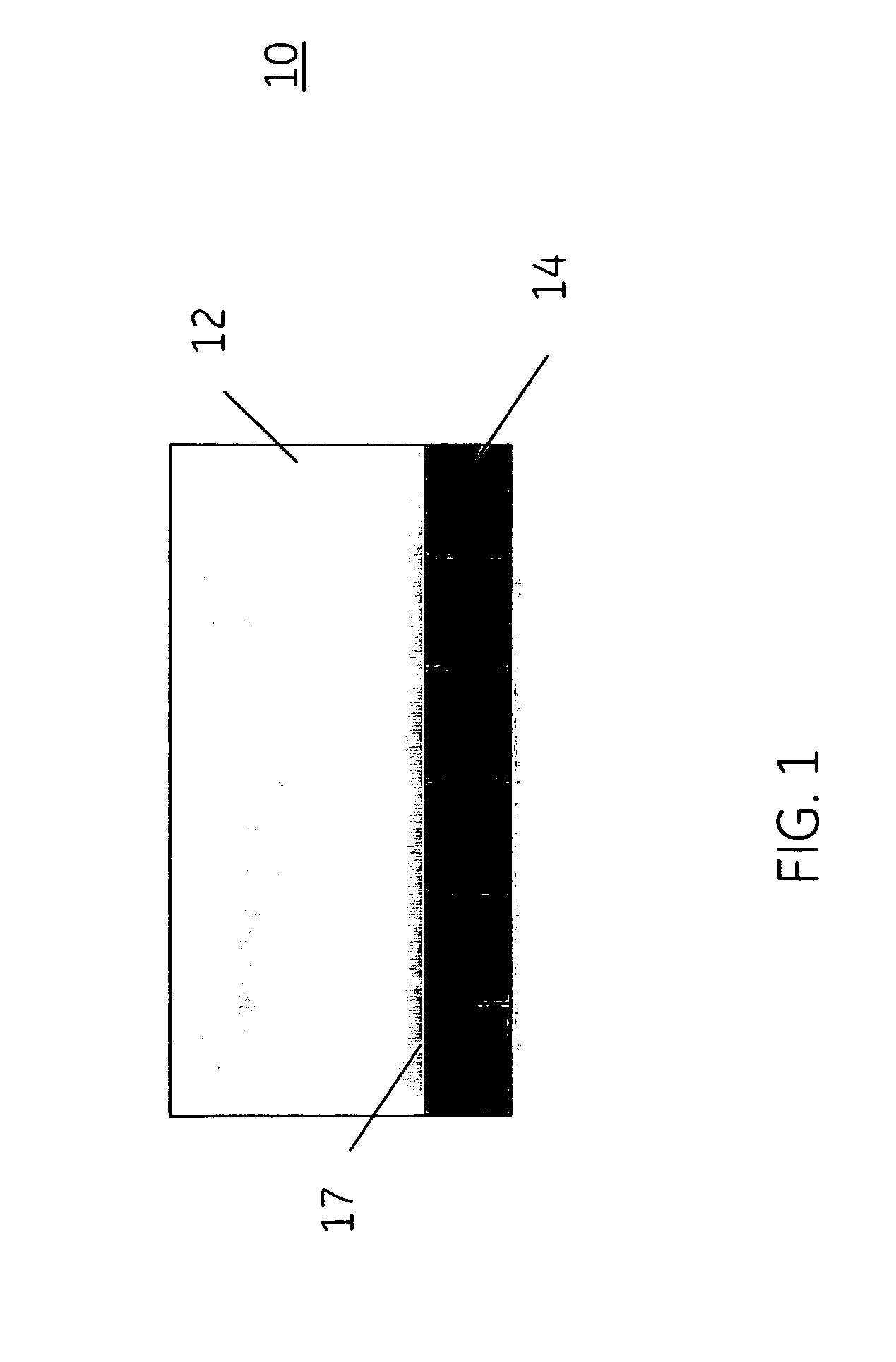

Articles and assembly for magnetically directed self assembly and methods of manufacture

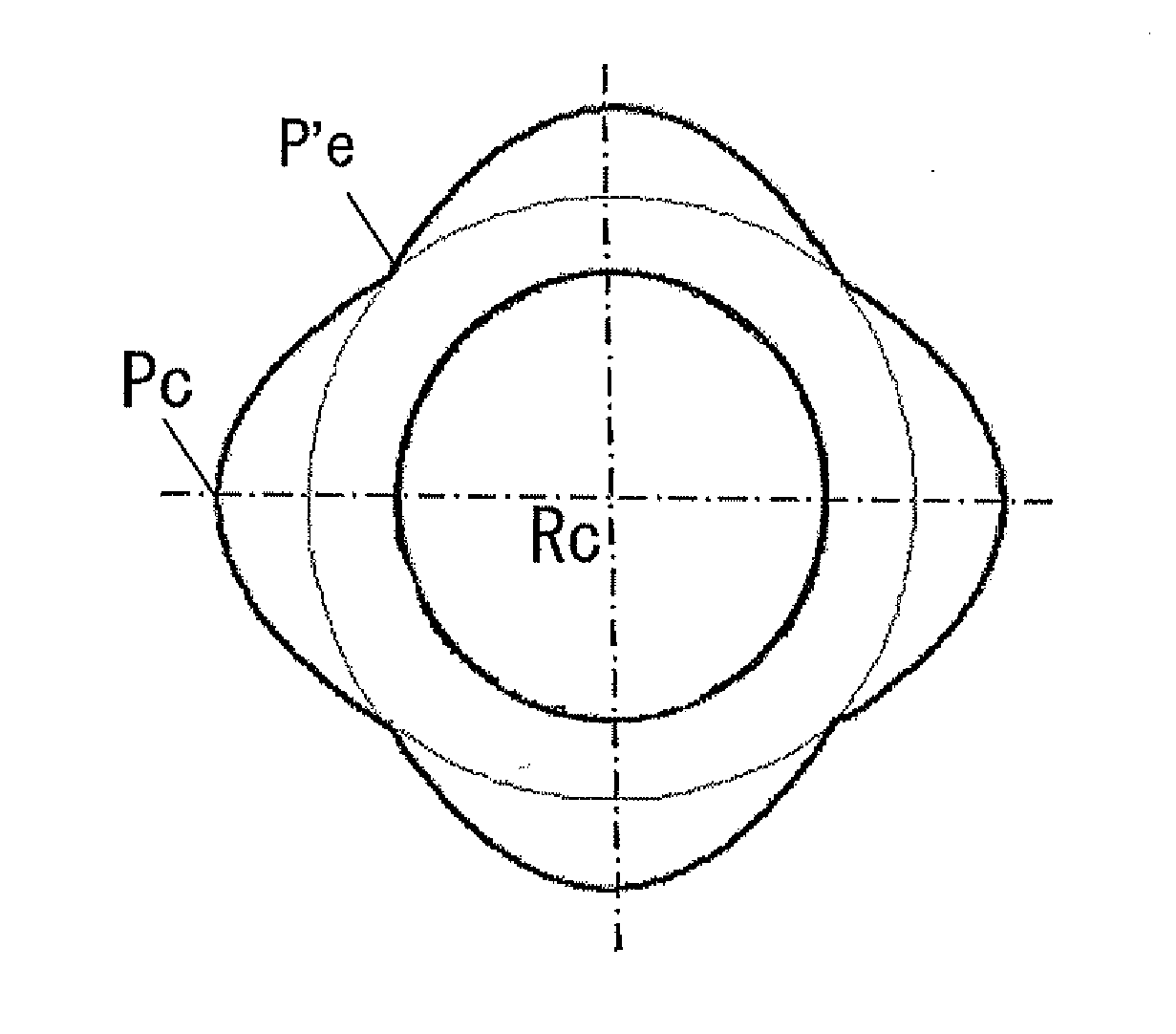

A functional block for assembly includes at least one element and a magnetic film attached to the element and having a magnetic remanence (MR / MS) of less than about 0.2, having a coercive field (Hc) of less than about 100 Oersteds (100 Oe) and having a permeability (μ) of greater than about two (2). At least one element is selected from the group consisting of a semiconductor device, a passive element, a photonic bandgap element, a luminescent material, a sensor, a micro-electrical mechanical system (MEMS), an energy harvesting device and combinations thereof. An article for assembly includes a substrate and a patterned magnetic film disposed on the substrate and defining at least one receptor site. The patterned magnetic film is magnetized primarily in a longitudinal direction and is characterized by a BH product of greater than about 1 megaGauss Oe.

Owner:GENERAL ELECTRIC CO

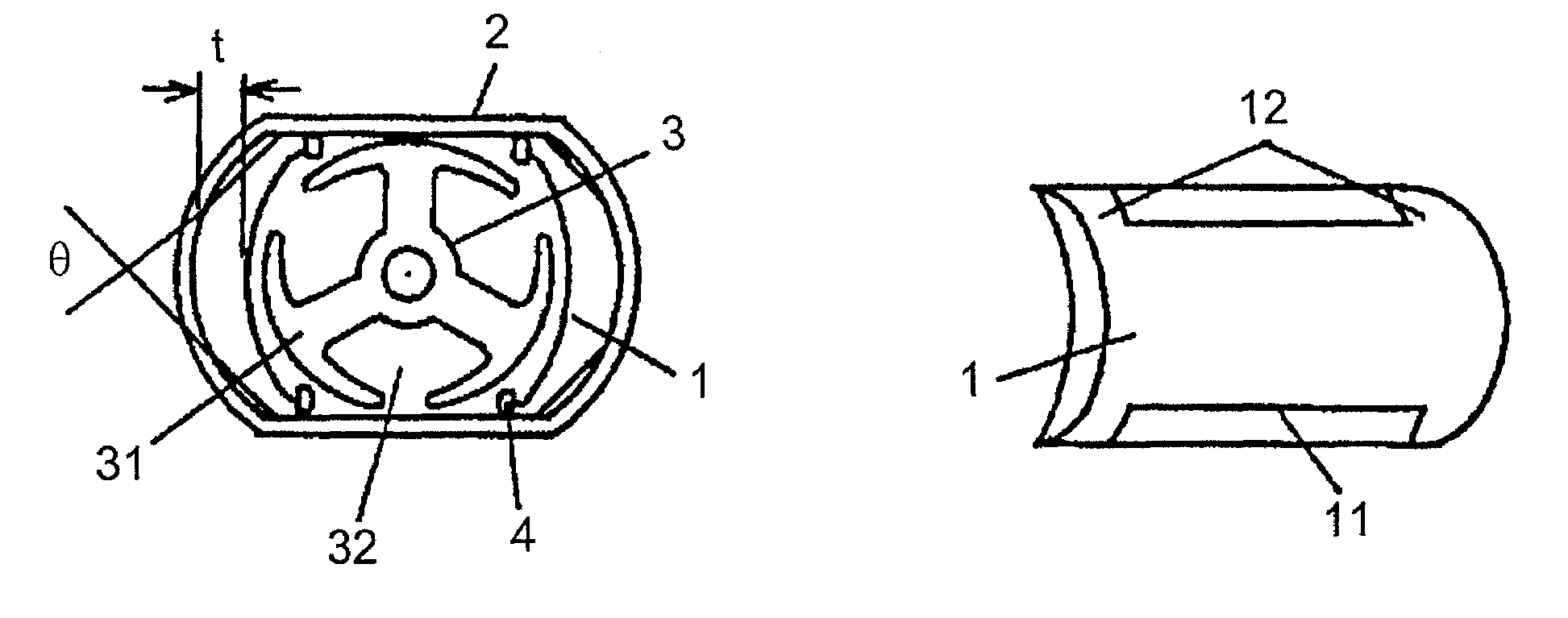

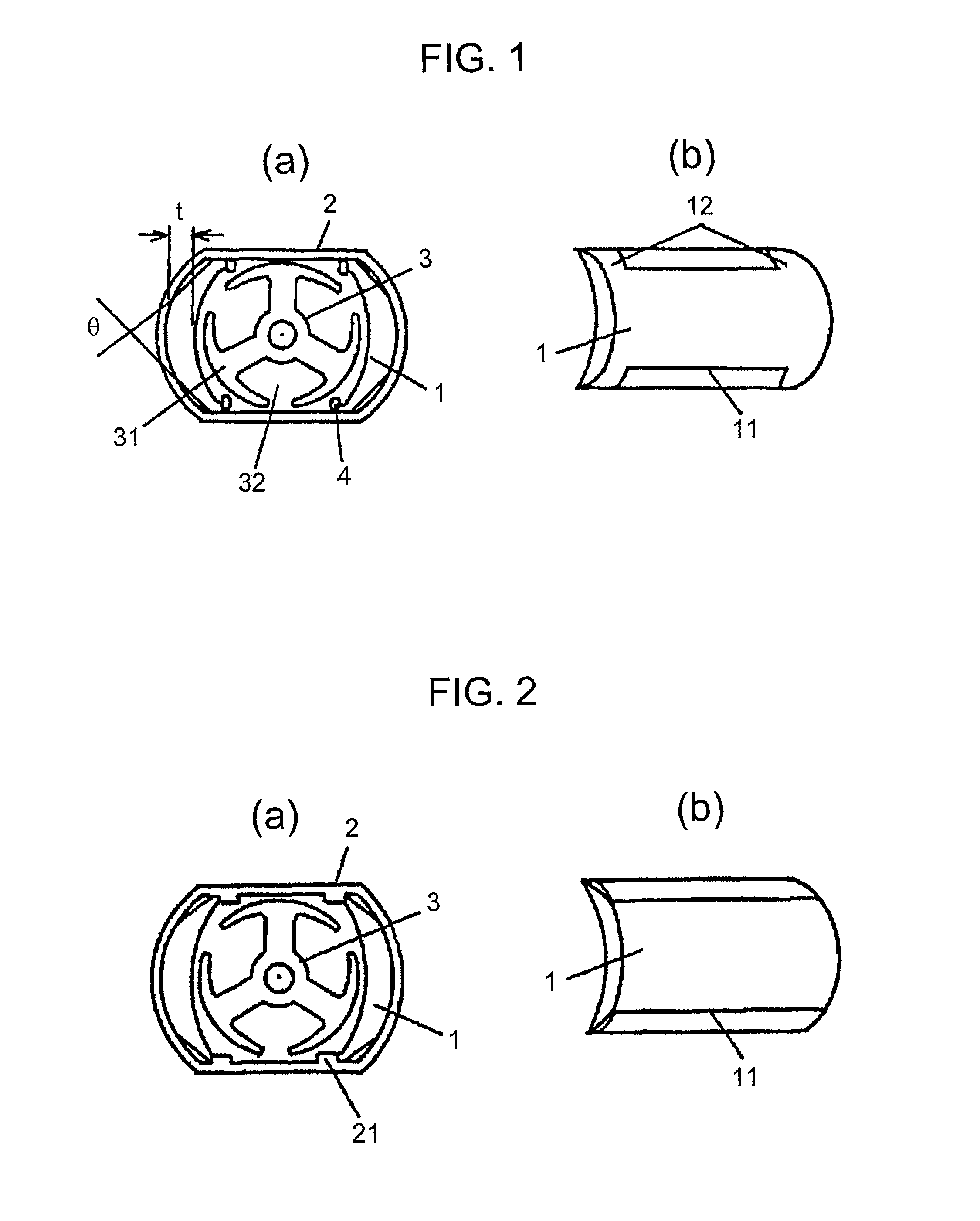

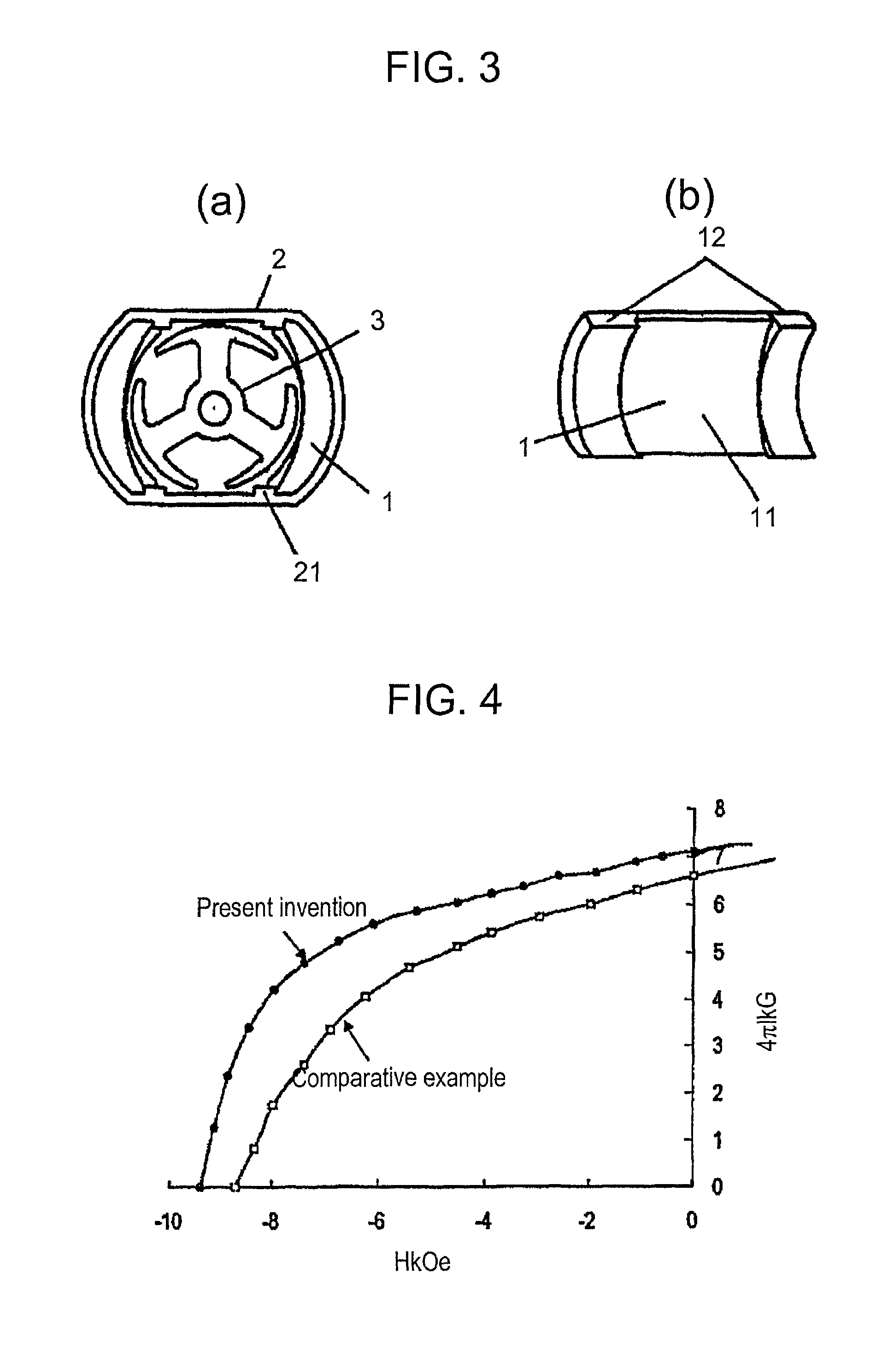

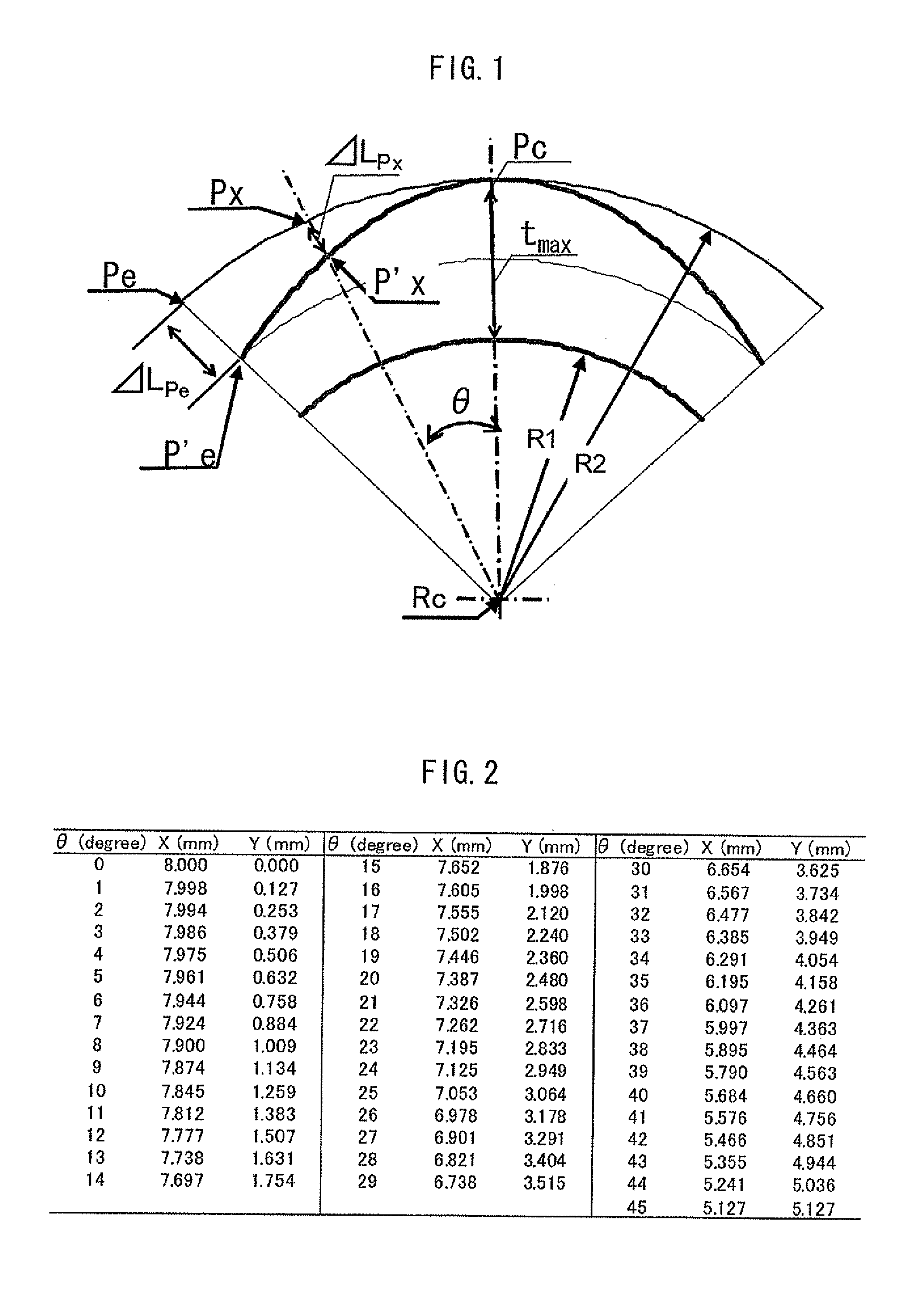

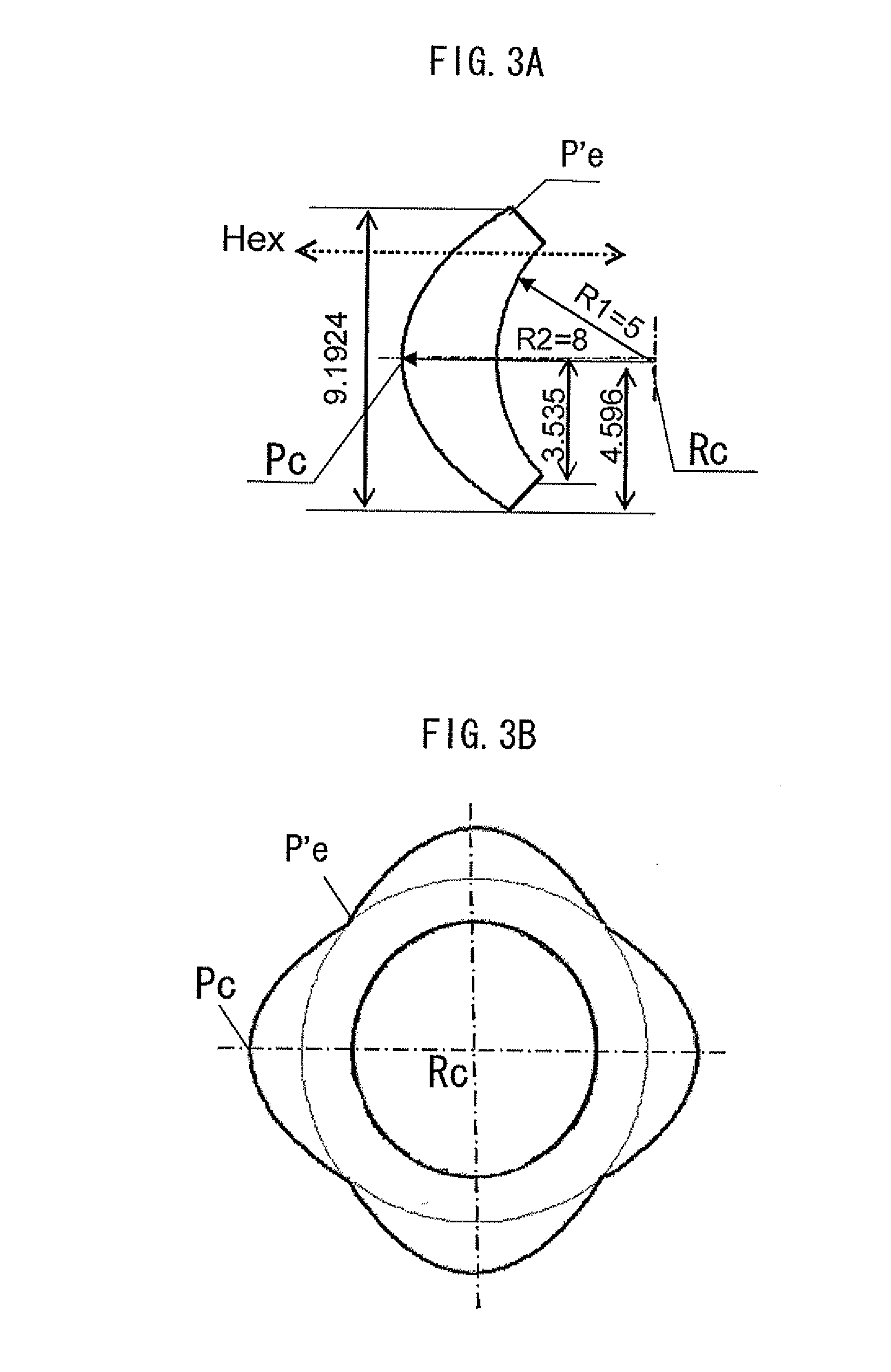

Inner rotor-type permanent magnet motor

InactiveUS20130088114A1Improve the rotation effectReduce noiseManufacturing dynamo-electric machinesMagnetic circuit characterised by magnetic materialsRemanenceRotational axis

Owner:MINEBEA CO LTD

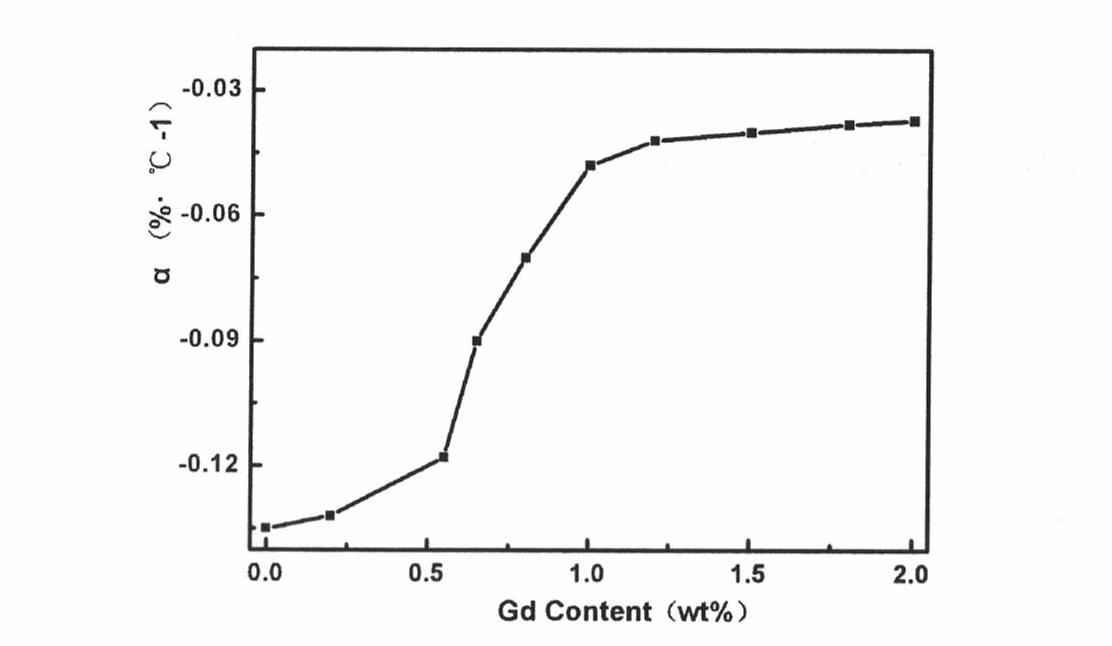

Neodymium iron boron magnet, preparation method and device applying same

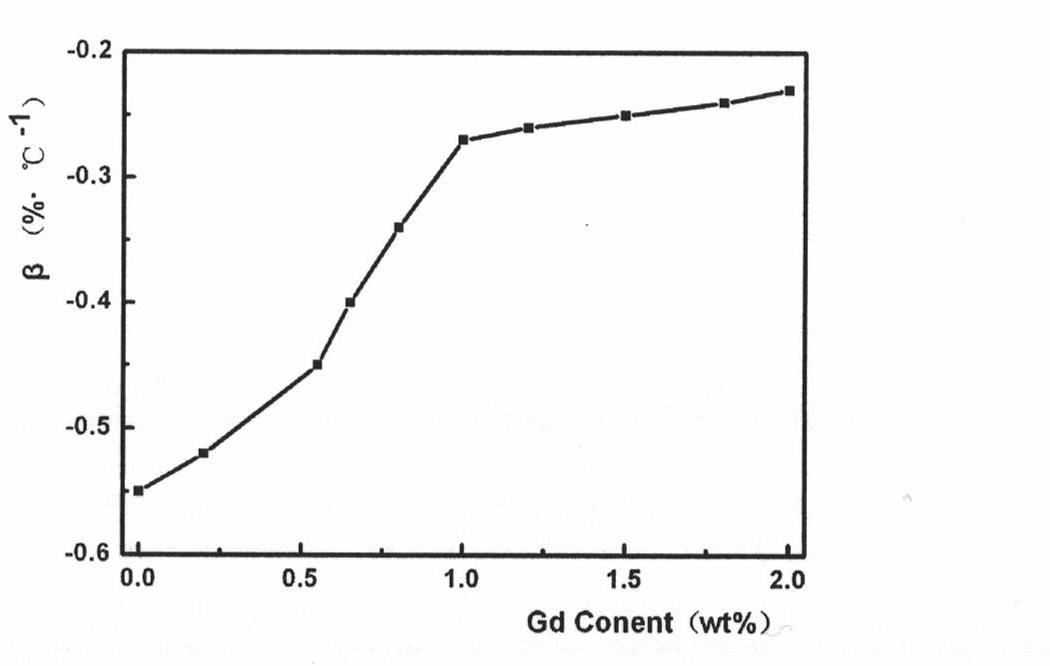

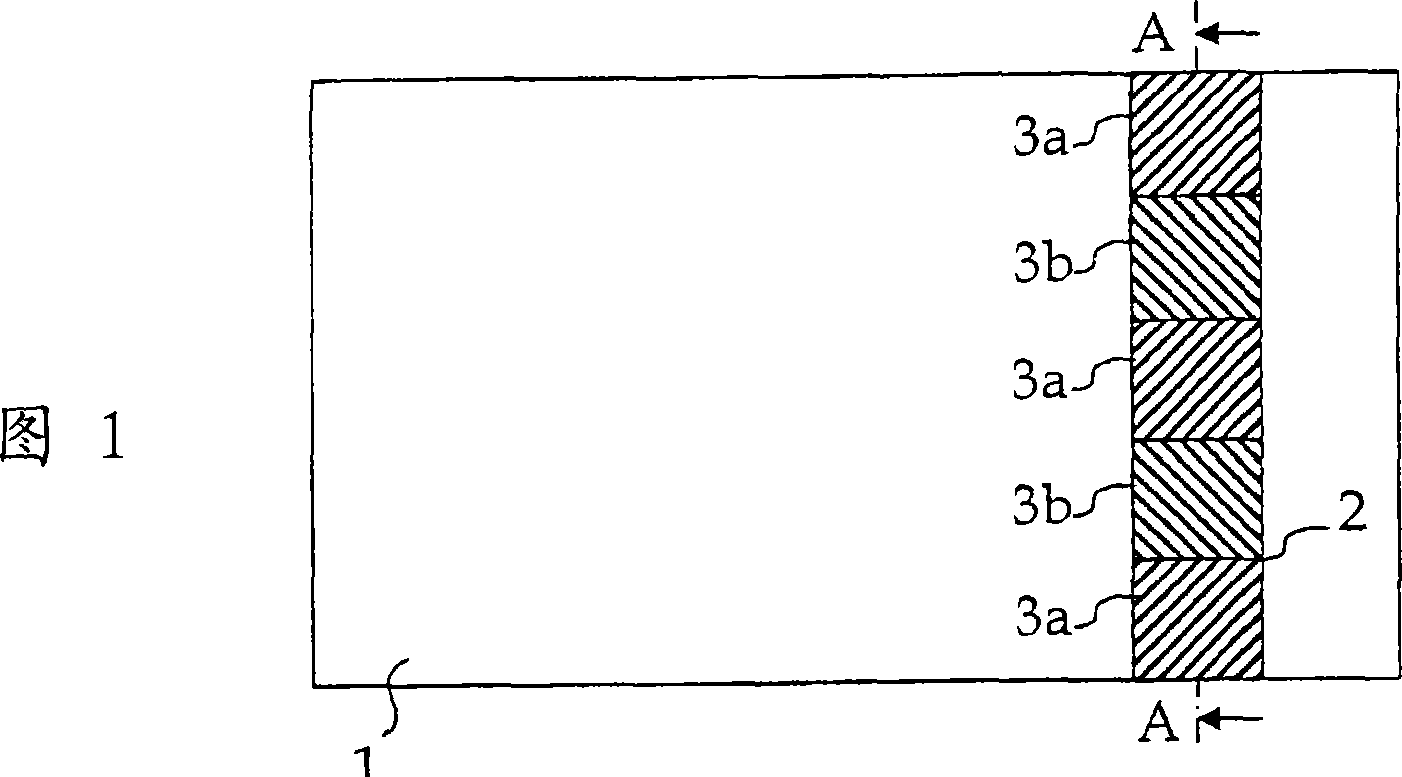

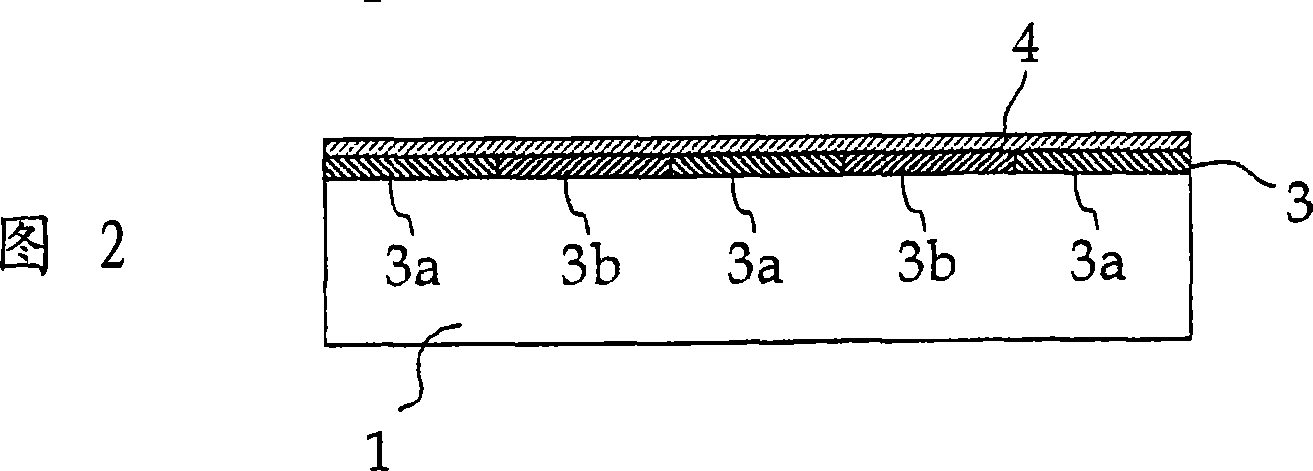

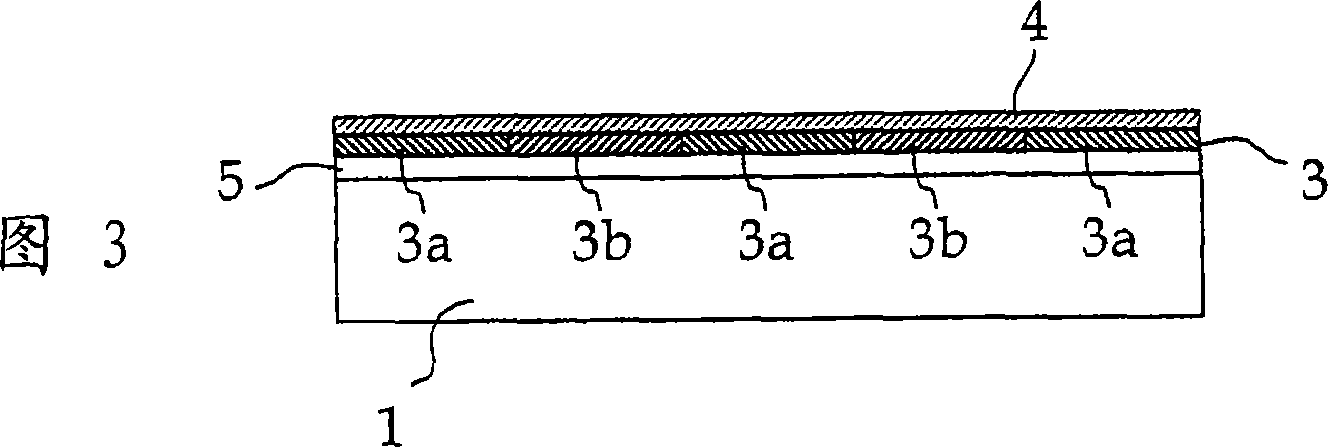

ActiveCN102103917ASmall temperature coefficientImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetallurgy

The invention discloses a neodymium iron boron magnet, a preparation method and a device applying the same, belonging to the field of magnetic materials. The magnet comprises the following components in percentage by weight according to the general formula: 27 to 35 percent of R representing one or two rare-earth elements except Gd, 0.55 to 2 percent of Gd, 0.5 to 3.5 percent of Co, 0.05 to 0.5 percent of M1 representing one transition metal element such as Cu, Al or Ge, 0 to 0.5 percent of M2 being one or two transition metal elements except Co and M1, 0.9 to 1.2 percent of B (namely boron) and the balance of Fe and unavoidable impurities. The neodymium iron boron magnet disclosed by the invention is compounded with Gd, Co, M1 and M2, thus the reversible magnetic induction temperature coefficient alpha and the coercive force temperature coefficient beta are better improved, the coercive force of the magnet is greatly improved while the magnetic energy product and residual magnetism are guaranteed not to reduce, the heavy rare earth element Gd is effectively utilized, and the performance is improved while the manufacturing cost is well saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Mn-Zn ferrite with wide temperature range and high magnetic conductivity and its prepn process

InactiveCN1810710AHigh activityHigh initial permeabilityInorganic material magnetismRemanenceMaterials science

The present invention is Mn-Zn ferrite with high magnetic permeability in wide temperature range and its preparation process. The Mn-Zn ferrite consists of main components including Fe2O3 51-56 mol%, MnO 34-40 mol% and ZnO 6-12 mol%, and supplementary components. The Mn-Zn ferrite has relatively high initial magnetic permeability, power consumption difference lower than 70 kW / cu m in the temperature range of 25-120 deg.c at 100 KHz and 200 mT, minimum power consumption below 350 kW / cu m in the said temperature range, remanence below 85 mT at Hú¢1194 A / m and 25 deg.c, and excellent DC superposition characteristic.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

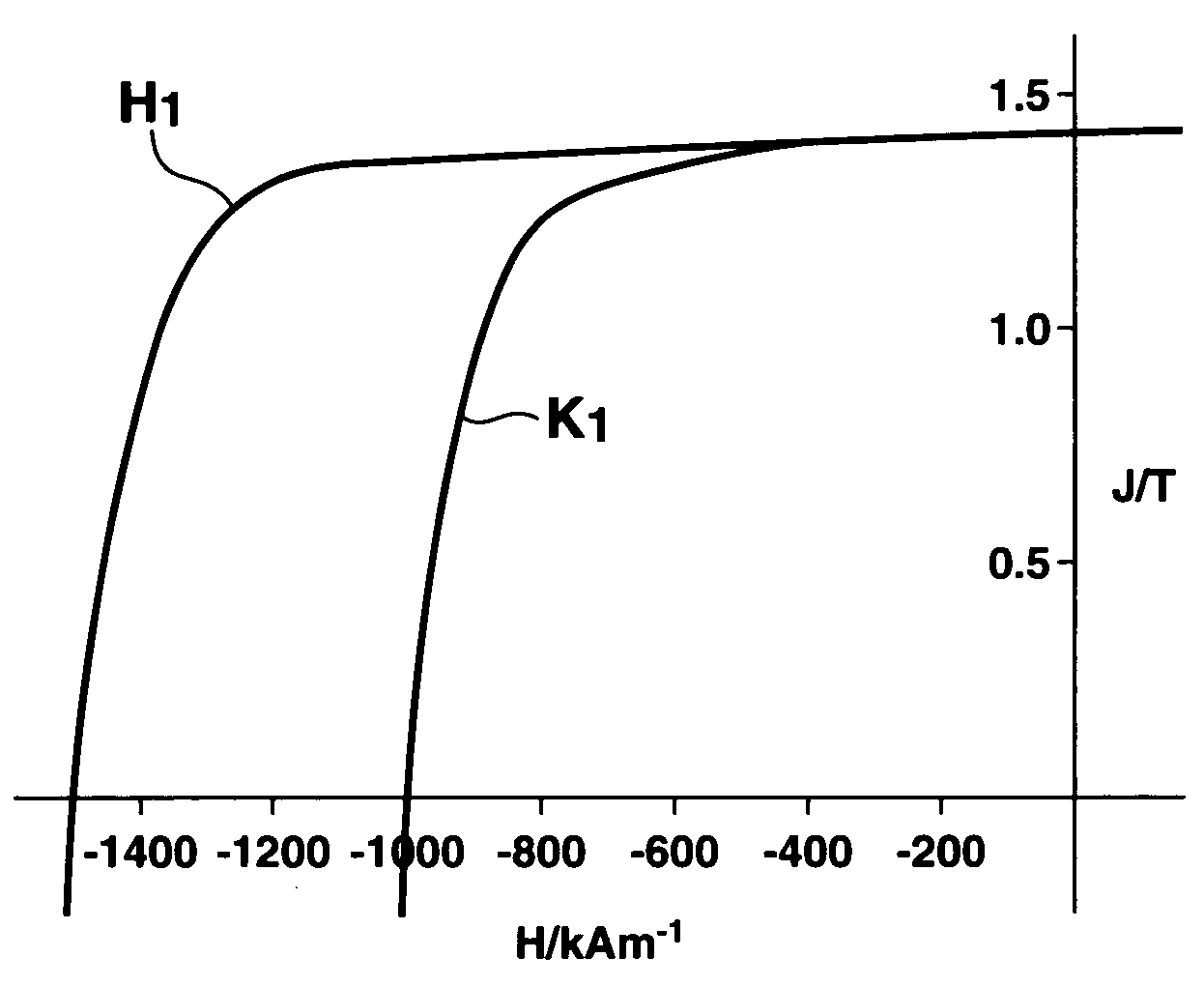

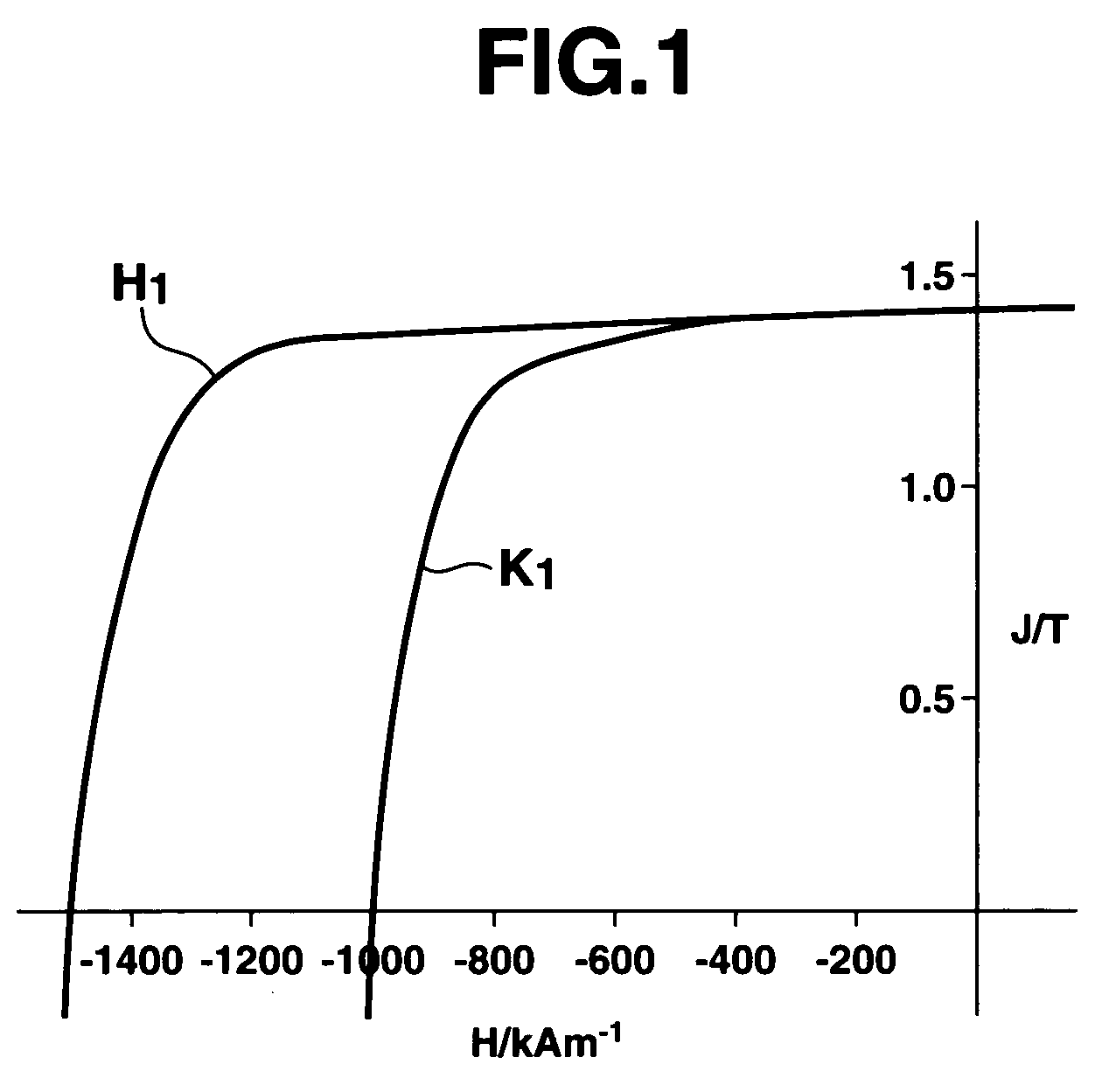

Security element comprising magnetic materials having the same remanence and a different coercive field intensity

ActiveCN101076454AImprove clarityOther printing matterPaper-money testing devicesRemanenceEngineering

The invention relates to a security element for protecting documents of value, which has magnetic material. Furthermore, the invention relates to a document of value, a transfer material and method for producing such security elements and documents of value as well as a method and an apparatus for checking such a security element or document of value. According to the invention the security element has at least two magnetic materials, wherein the magnetic materials have different coercive field strengths and are applied onto and / or incorporated in the security element in such a manner that their remanence is equally high.

Owner:GIESECKE & DEVRIENT CURRENCY TECHNOLOGY GMBH

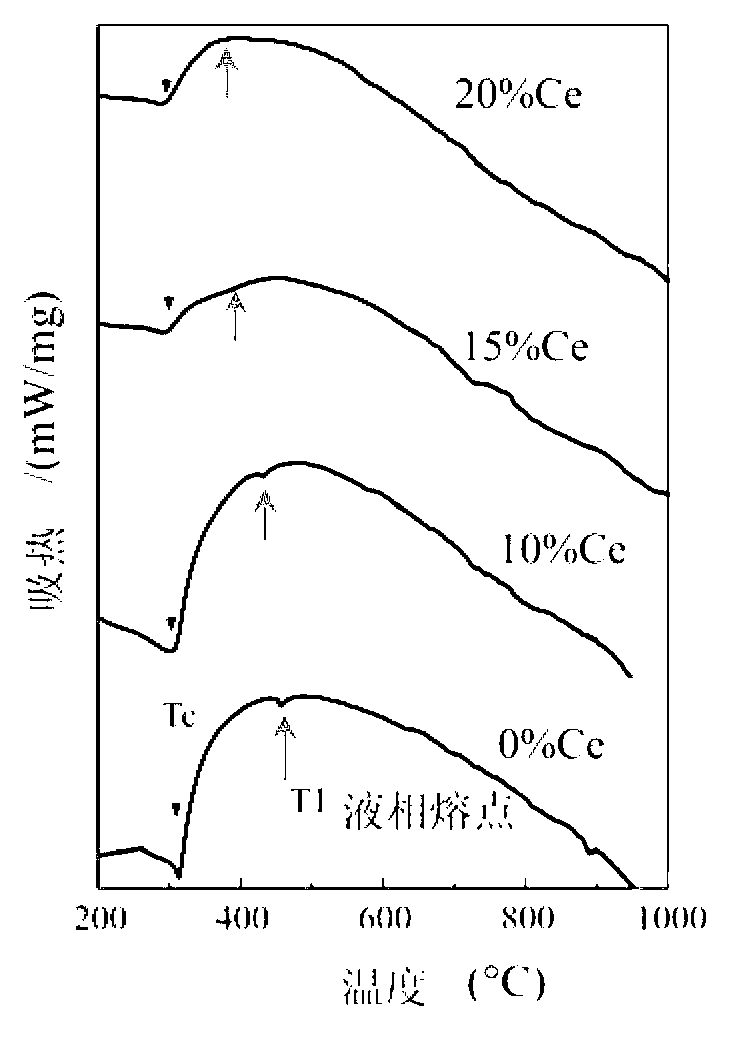

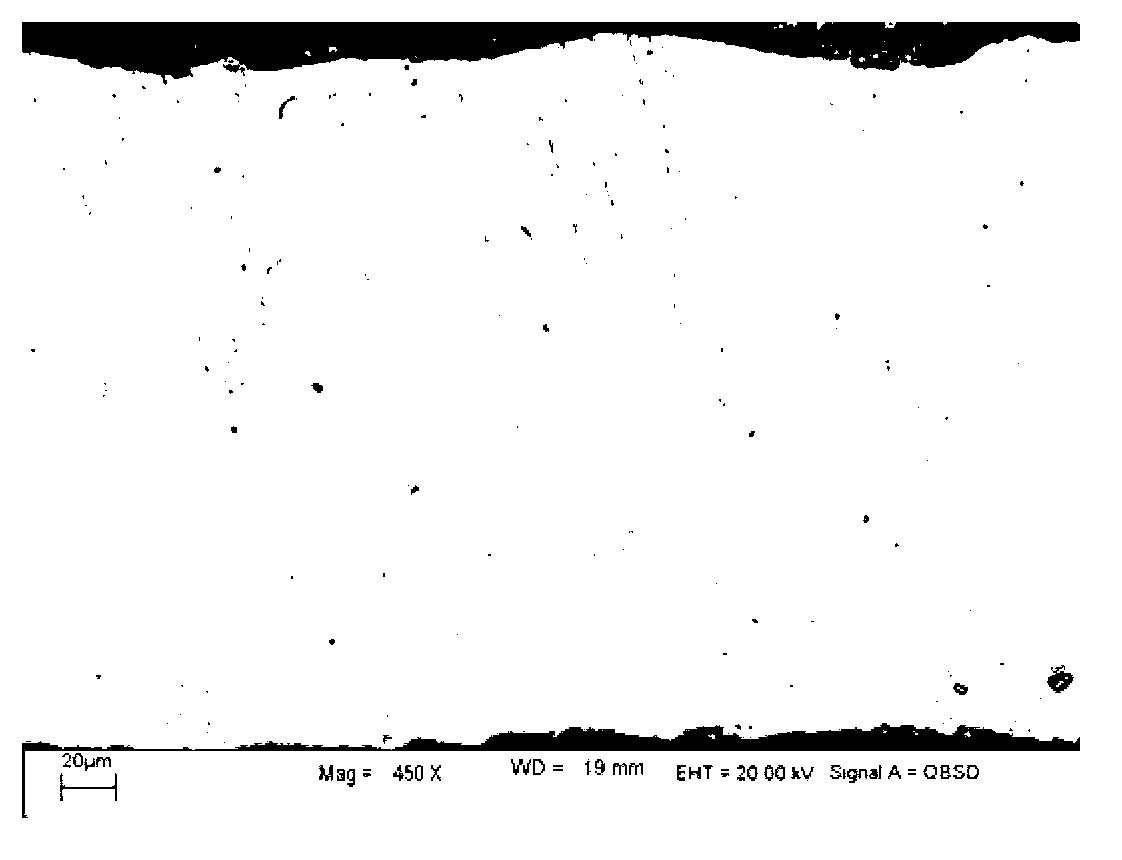

Cerium-containing low-melting-point rare-earth permanent magnet liquid phase alloy and production method of permanent magnet comprising same

ActiveCN103280290AReduce entryImprove remanenceMagnetic liquidsInductances/transformers/magnets manufactureCeriumRare earth

The invention relates to the technical field of rare-earth permanent magnet materials, in particular to cerium-containing low-melting-point rare-earth permanent magnet liquid phase alloy, a permanent magnet comprising the liquid phase alloy and a production method of the permanent magnet. According to mass percent, the chemical formula of the liquid phase alloy is that (Cex,Nd1-x)y-Mz-Fe100-y-z, wherein 0.1<=x<=1.0, 0.04<=y<=0.9, 0<=z<=5, M is one or several of Co, Al, Cu, Ga, Nb, Mo, Ti, Zr and V. The liquid phase alloy is added in an alloy or rapid hardening mode, cerium elements entering the principal phase can be reduced and the residual magnetism can be improved by aid of scientific and reasonable composition design, the sintering temperature of the neodymium iron boron magnet can be reduced through the low-melting-point liquid phase, and therefore low-temperature sintering is achieved, and reducing of the crystal grain dimension of the magnet is benefited. The microstructure of the liquid phase is controlled through the oxygen content so that the liquid phase is ensured to be of a cerium-containing face-centered cubic structure with high coercivity, further the coercivity of the magnet is improved, and good combination property can be obtained.

Owner:CENT IRON & STEEL RES INST

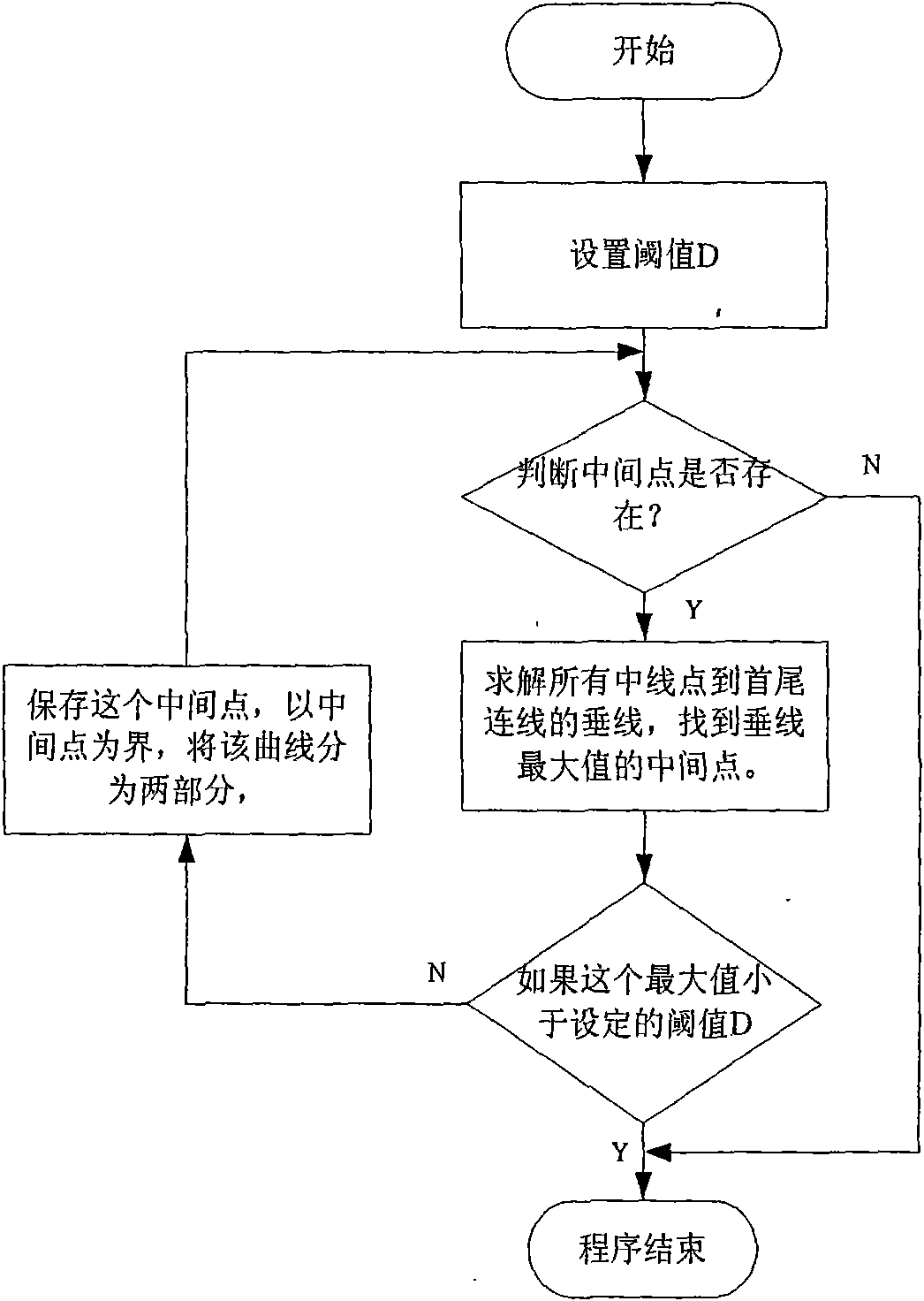

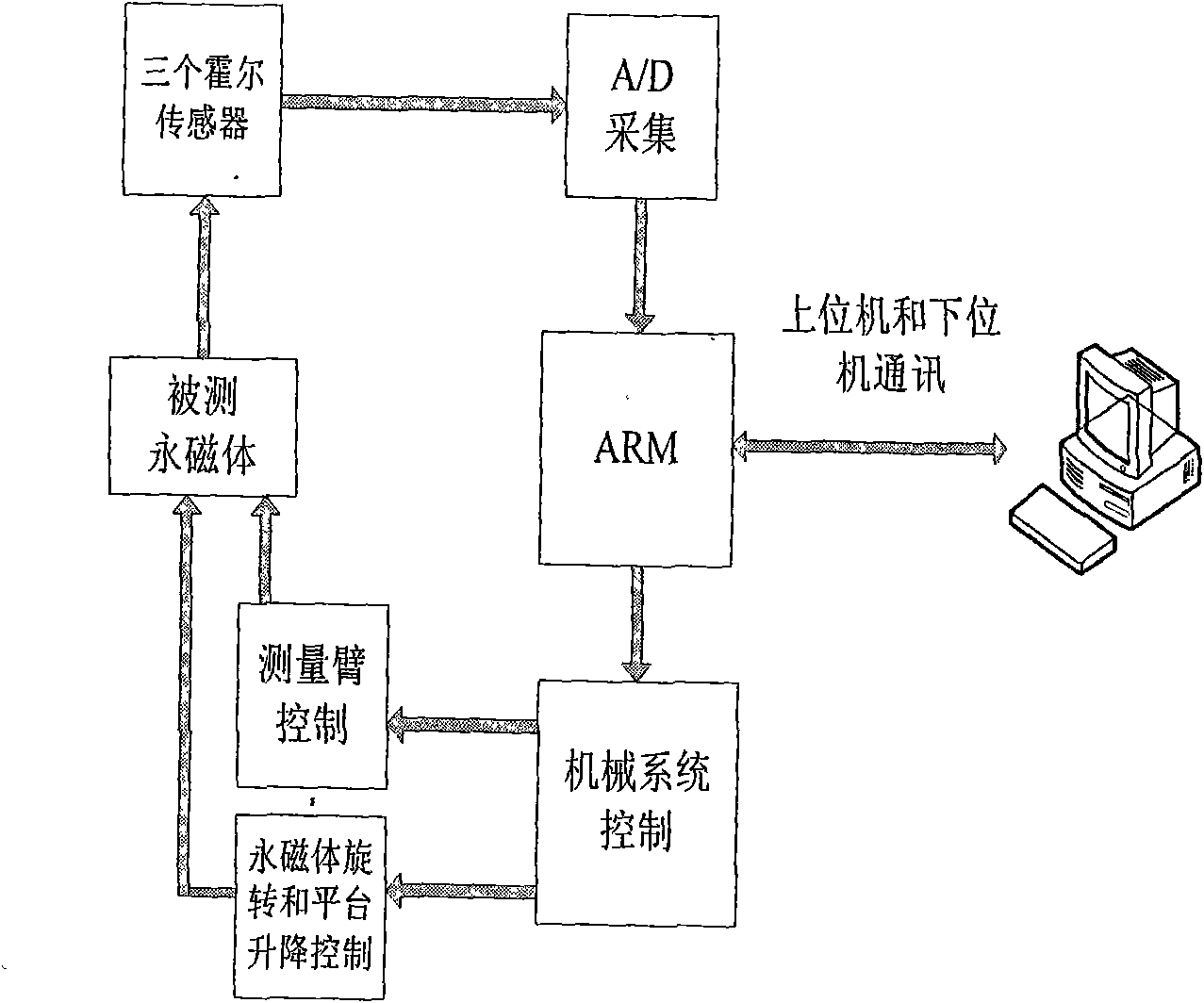

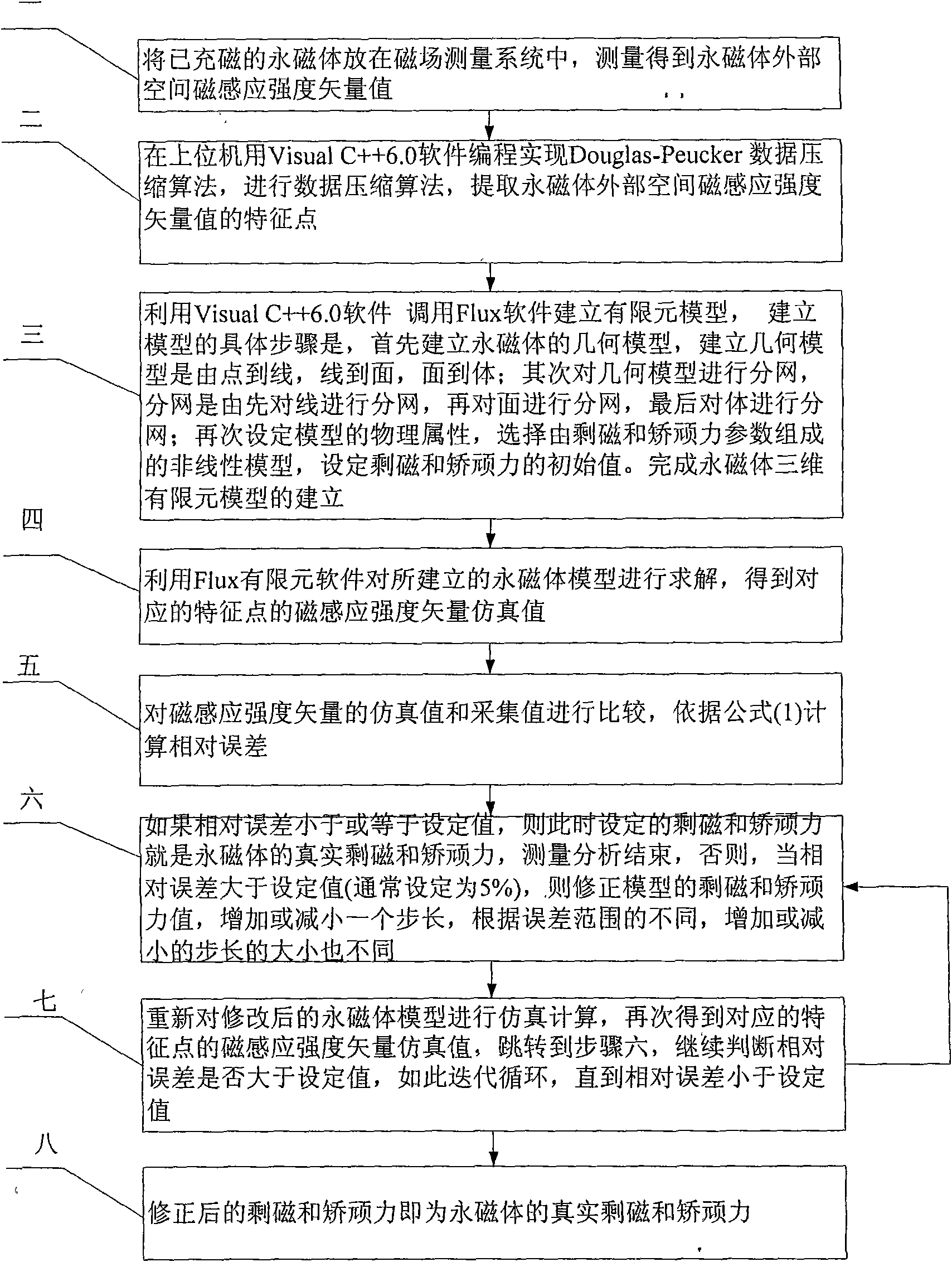

Method for measuring parameter of magnetic characteristic of permanent magnet

InactiveCN101561480AReduce storageHas practical valueMagnetic property measurementsData compressionRemanence

The invention aims to provide a method for measuring a parameter of magnetic characteristic of a permanent magnet, which adopts a data compression algorithm to carry out characteristic point extraction, redundant data deletion and data storage reduction on a magnetic strength value acquired from the outside of the permanent magnet. The spatial magnetic strength value outside the permanent magnet can be acquired through a magnetic field measurement system; the characteristic point is extracted by the data compression algorithm; a three-dimensional finite element model of the permanent magnet is established; remanence and coercive force are initially set; an emulation value of the magnetic strength of the characteristic point is obtained through emulation calculation; the remanence and the coercive force are constantly corrected by comparing the emulation value with a measured value until the difference of the emulation value and the measured value is smaller than a certain error range, thereby obtaining the remanence and the coercive force of the permanent magnet. The whole flow is realized through a software system. The invention provides a method for measuring the parameter of the aged magnetic characteristic, and has the characteristics of high automation degree and strong flexibility.

Owner:HARBIN INST OF TECH

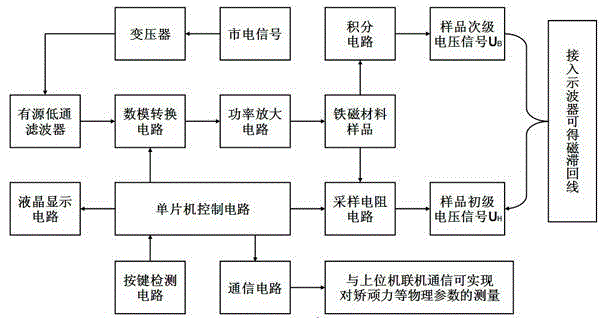

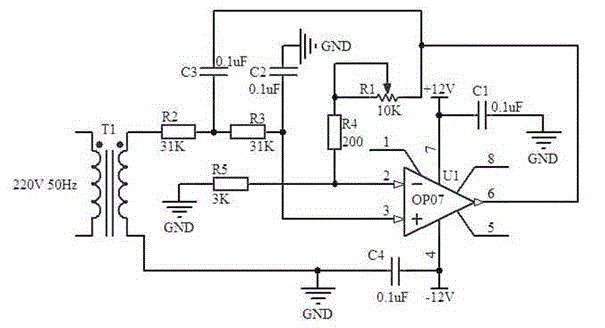

Measuring device for hysteresis loop made of ferromagnetic material and application method of measuring device

InactiveCN102721939ASolve the problem of easy contactSolve the shortcomings such as easy loose gearsHysteresis curve measurementsHysteresisMicrocontroller

The invention discloses a measuring device for a hysteresis loop made of a ferromagnetic material and an application method of the measuring device. The measuring device for the hysteresis loop made of the ferromagnetic material comprises an excitation circuit, a control circuit, an integrating circuit, a sampling resistor circuit, a liquid crystal display circuit, a key detecting circuit and an oscilloscope. According to the method, step values of excitation voltage and excitation resistance are set through programming a singlechip; the oscilloscope displays the hysteresis loop to be measured; and an upper computer measures and analyzes the coercivity, the remanence induction strength, the maximum field, the maximum magnetic induction strength and the magnetic hysteresis loss of the ferromagnetic material according to the hysteresis loop. The original mechanical switch and manual knob type switch control mode is replaced by a program control mode, and shortcomings that contacts of a knob switch are in a poor contact state easily, gears are easy to loosen, and the like are overcome. By an experimental instrument developed in the invention, the reliability of experimental equipment can be increased, and the service life of the experimental equipment can be prolonged. Owing to the program control mode, the step values of the excitation voltage are low, gears of the excitation voltage are sufficient, measurement precision is high, and practicality and accuracy are good.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nd based sintered magnet and its preparation

ActiveUS20110210810A1Improve coercive forceUnsusceptible to demagnetizationMagnetic circuitPermanent magnetsRemanenceMetallurgy

Owner:SHIN ETSU CHEM IND CO LTD

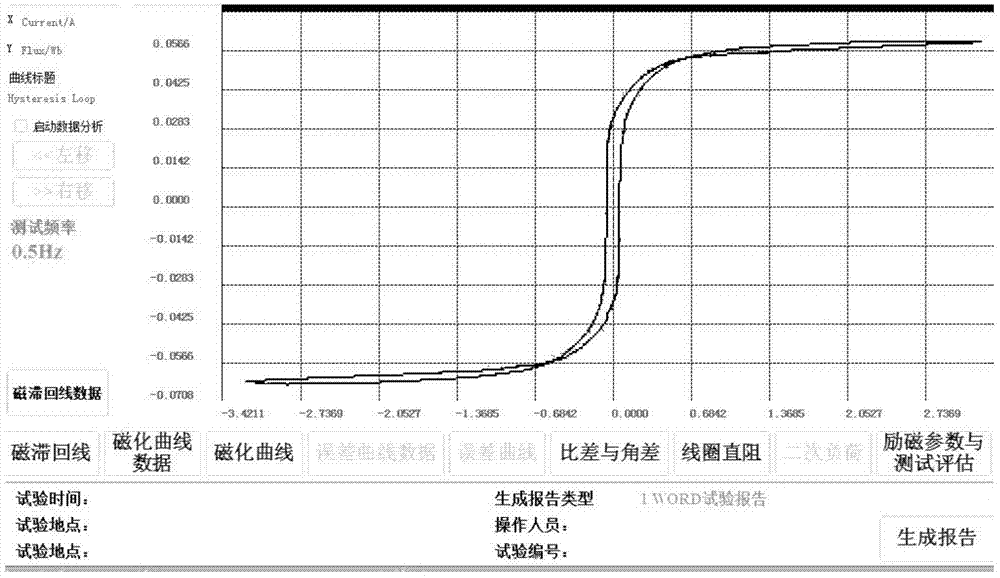

Hysteresis loop measuring method of current transformer

InactiveCN104749537AHysteresis loop measurement is easy to implementReduce voltageHysteresis curve measurementsHysteresisRemanence

The invention relates to a hysteresis loop measuring method of a current transformer. The hysteresis loop measuring method includes steps of (1) boosting and reducing voltage of a secondary coil of the current transformer slowly by working-frequency voltage before measuring hysteresis loop, so as to demagnetize the iron core of the current transformer to ensure it in the zero-flux state; (2) testing excitation characteristics of the current transformer by 0.5 Hz low-frequency voltage source, and integrating voltage and time in real time so as to obtain a magnetic flux curve of the iron core of the current transformer; (3) measuring the magnetic flux curve of the current transformer under the 0.5 Hz voltage and drawing the hysteresis loop, and reading remanence coefficient of the current transformer on the hysteresis loop, so as to obtain accurate and reliable measuring results of the remanence coefficient. The hysteresis loop measuring method is an effective method for measuring hysteresis loop of the current transformer and is accurate, reliable and convenient to operate, accurate and reliable data can be quickly acquired, and the required instruments are small and portable and very applicable to the field.

Owner:STATE GRID CORP OF CHINA +1

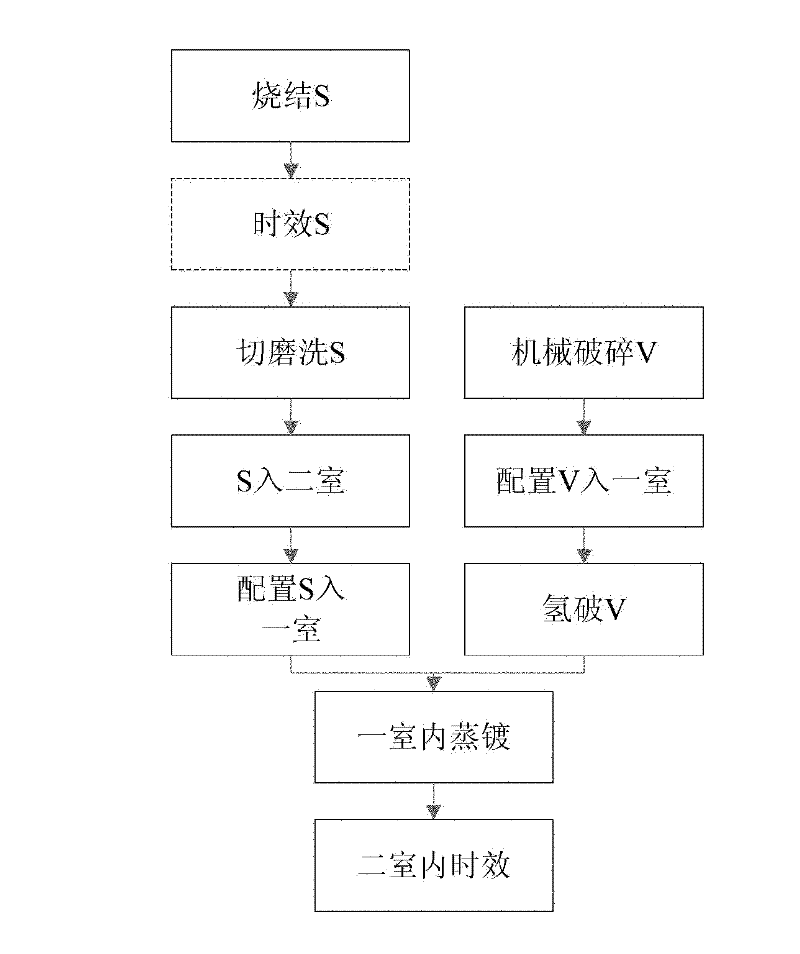

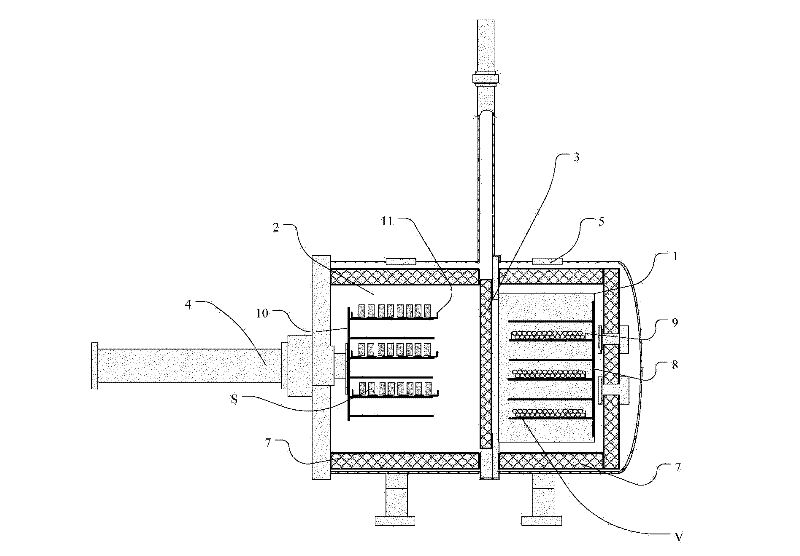

Preparation method of rare-earth permanent magnet, preparation device and rare-earth permanent magnet prepared thereby

ActiveCN102682987AImprove coercive forceStrong corrosion resistanceVacuum evaporation coatingSputtering coatingPressure decreaseRemanence

The invention discloses a preparation method of a rare-earth permanent magnet, a preparation device and a rare-earth permanent magnet prepared thereby, and relates to the preparation technology of sintered rare-earth permanent magnet with high coercivity. The invention is characterized in that the preparation method is carried out in two-chamber vacuum equipment which can be communicated with each other and also can carry out pressure increasing and decreasing treatment and heating treatment, and comprises the following steps of: firstly putting an evaporation material in a first chamber for crushing; putting a treated piece in a second chamber, vacuumizing the second chamber and enabling the vacuum degree of the second chamber to be equivalent to that of the first chamber; transferring the treated piece into the first chamber and carrying out heat diffusion treatment in the first chamber; carrying out pressure decreasing on the first chamber, and enabling the vacuum degree of the first chamber to be equivalent to that the second chamber; and transferring the treated piece back into the second chamber, and carrying out aging treatment in the second chamber. The preparation method disclosed by the invention has the advantages that no powder is remained on the surface of the magnet; the metal powder is adopted for evaporation, so that the evaporation efficiency is greatly increased, and the purpose of providing high-coercivity and high-remanence magnet by using fewer heavy rare-earth materials can be realized; and simultaneously, the magnet has stronger corrosion resistance.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

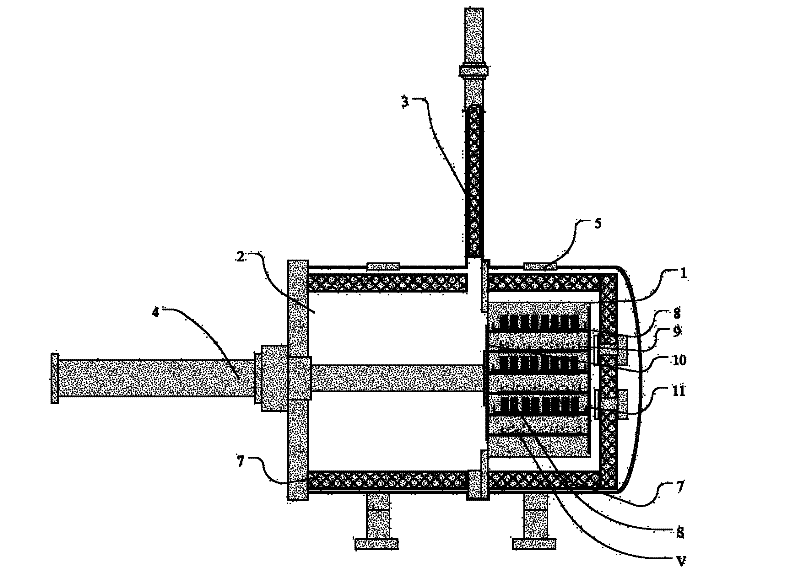

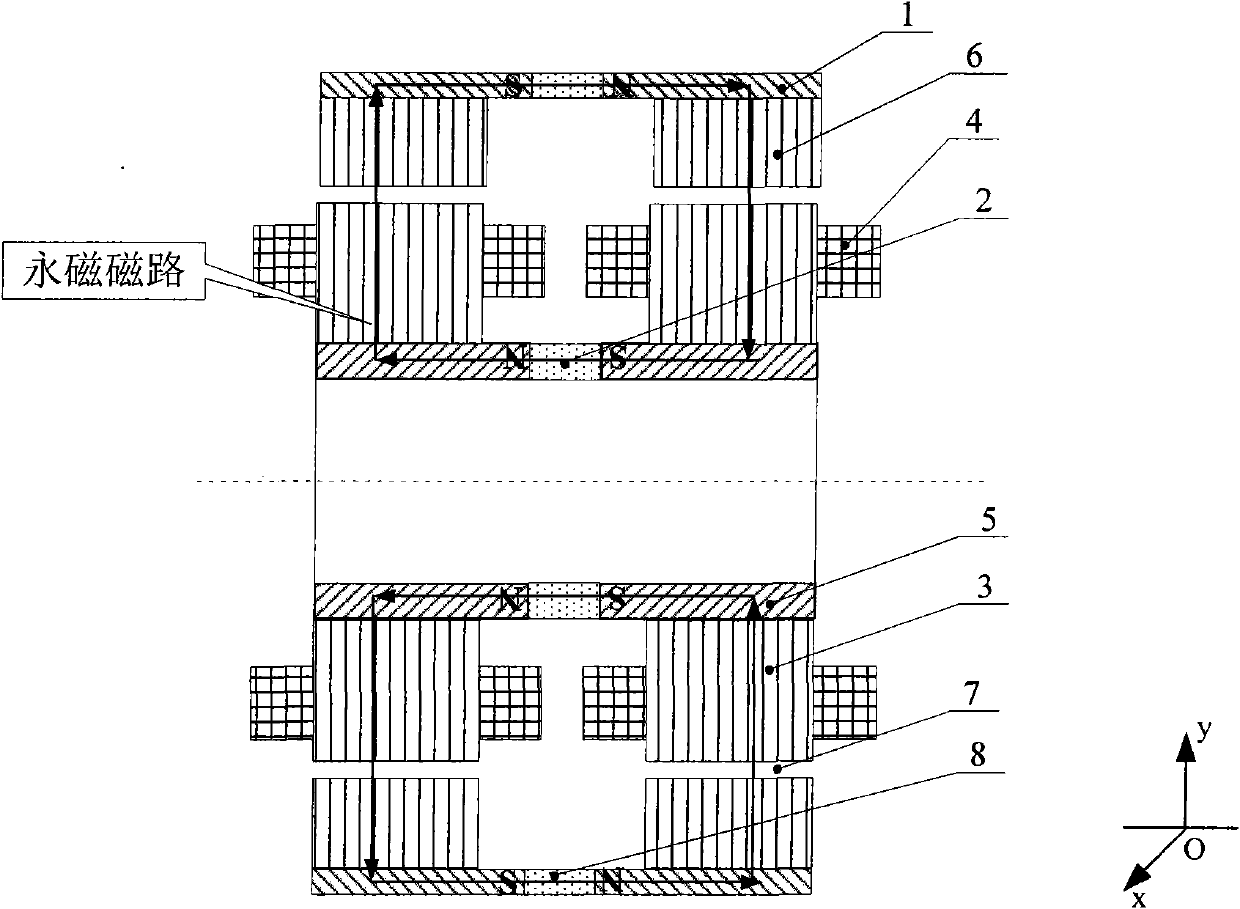

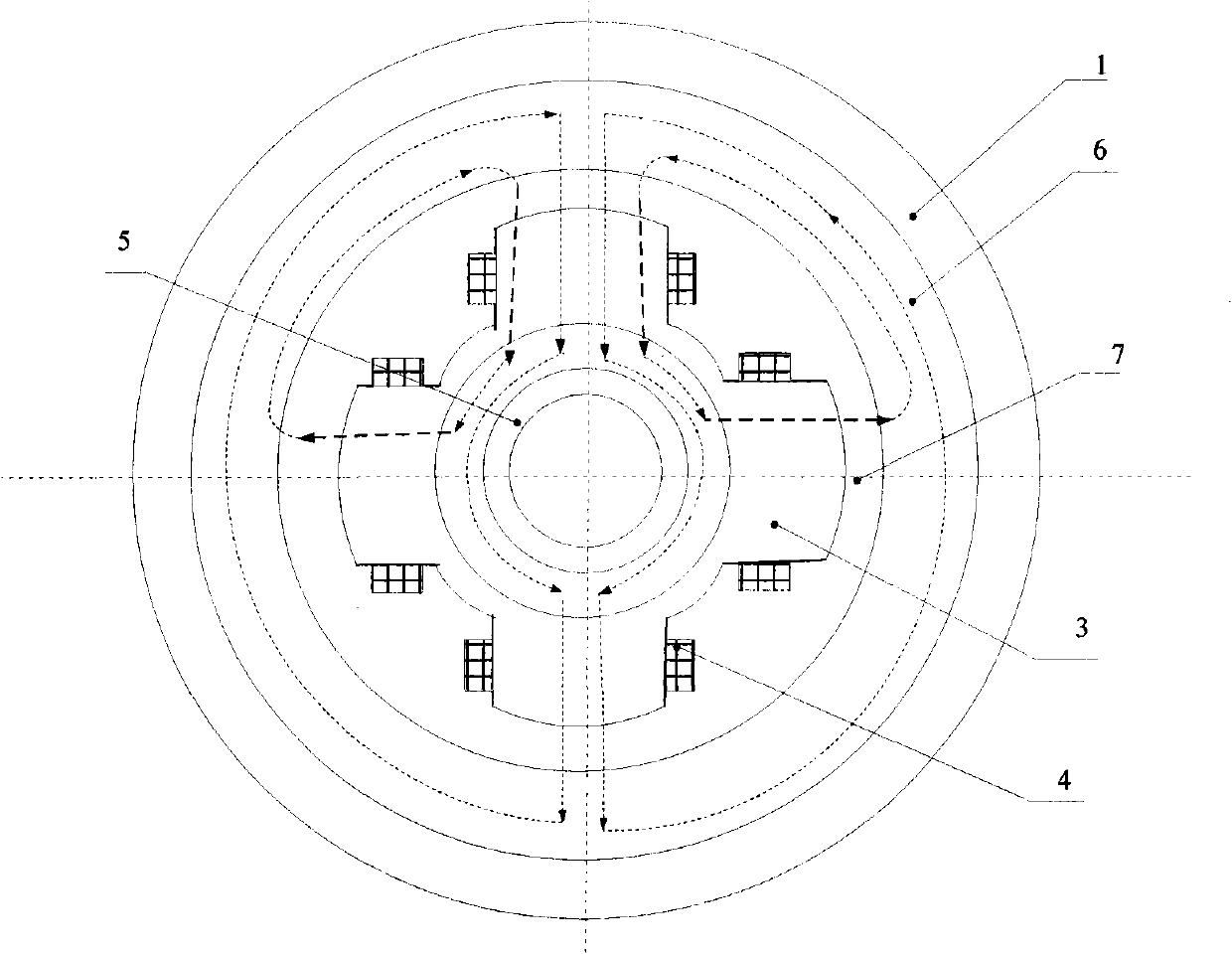

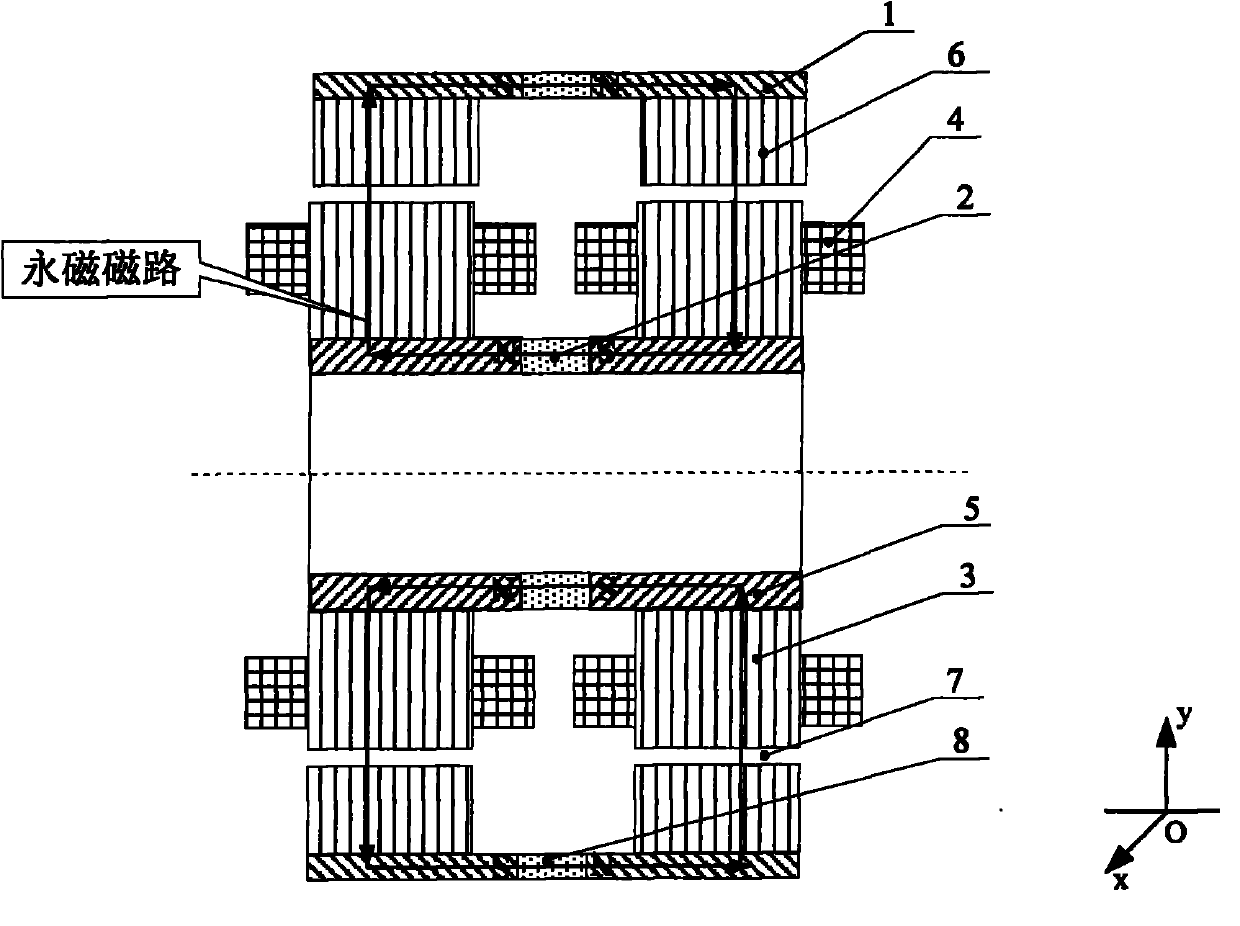

Double-permanent magnet outer-rotor permanent magnet biased radial magnetic bearing

InactiveCN101994761AReduce the remanent magnetic momentOvercome the complex defect of the magnetic compensation methodShaftsRotary machine partsRemanenceMagnetic bearing

Owner:BEIHANG UNIV

Commercial rare earth permanent magnet produced from high-abundance rare earth and preparing method thereof

ActiveCN103794323AImprove remanenceHigh energy productPermanent magnetsInductances/transformers/magnets manufactureElectrode potentialRemanence

The invention discloses a commercial rare earth permanent magnet produced from high-abundance rare earth and a preparing method of the commercial rare earth permanent magnet. The commercial rare earth permanent magnet comprises a main phase and a grain boundary modification phase, wherein the main phase comprises low H (RE100-aMMa)-Fe-B alloy and high H Nd-Fe-B alloy. According to the commercial rare earth permanent magnet, two kinds of main alloy is adopted, the ingredients of the magnet are controlled, a stable 2:14:1 phase is formed by the high-abundance rare earth, and decomposing will not happen in the sintering process; the Cu element high in electrode potential is added into the grain boundary modification phase, the corrosion resistance of the magnet is improved, and meanwhile the microstructure of the magnet can be optimized by the grain boundary modification phase. According to the method, the two main alloy method is combined with the grain boundary modification technology, the advantages of both the two main alloy method and the grain boundary modification technology are achieved simultaneously, the problems that because of addition of the high-abundance rare earth, the corrosion resistance, the residual magnetism and the magnetic energy product of the magnet are reduced are solved, and the prepared rare earth permanent magnet meets the application requirements of commercial magnets.

Owner:ZHEJIANG UNIV +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com