Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

710results about "Magnetic liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic nanoparticle compositions, and methods related thereto

InactiveUS20050271745A1Improve homogeneityHigh metal contentAntibacterial agentsPowder deliveryMagnetite NanoparticlesEngineering

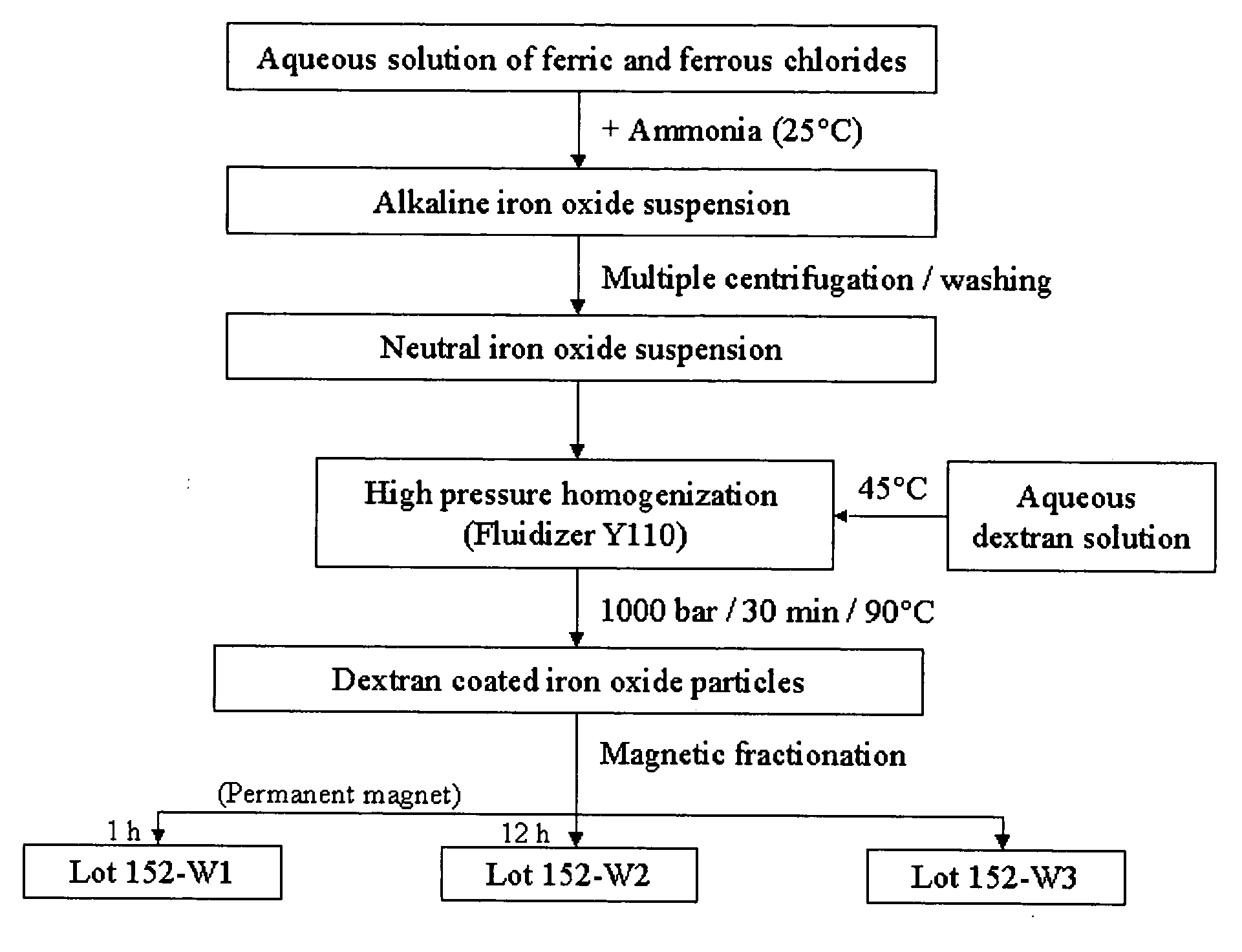

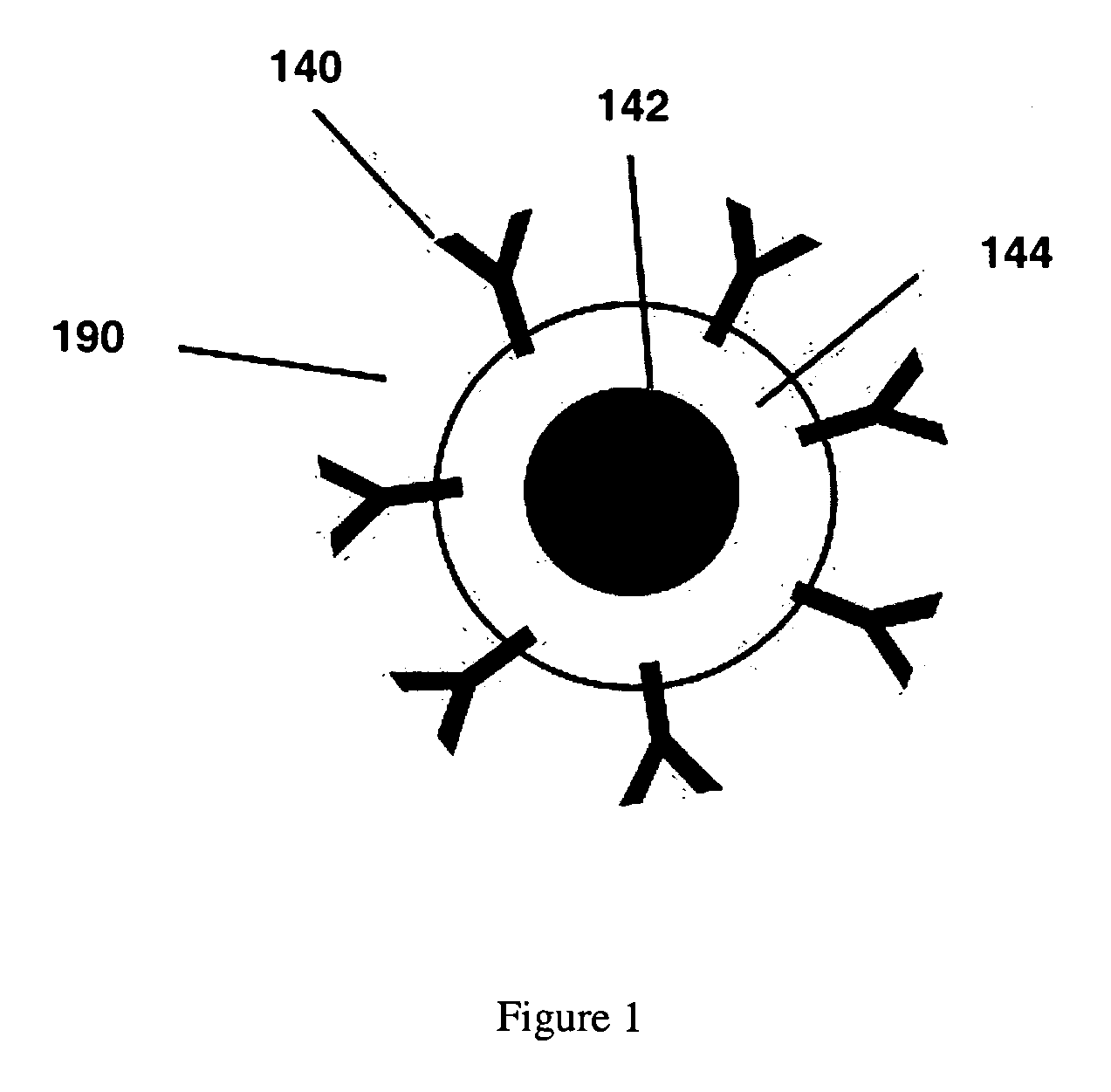

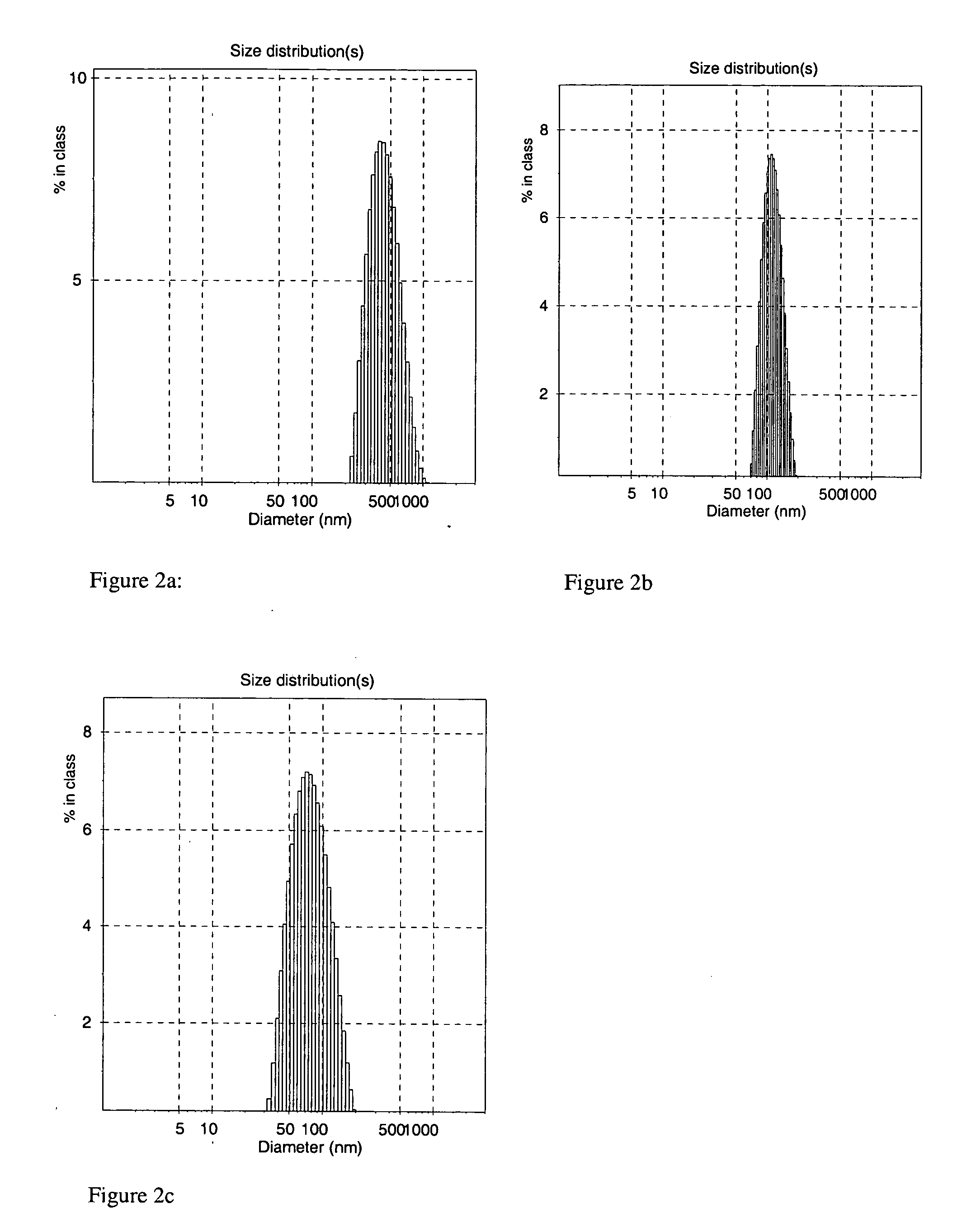

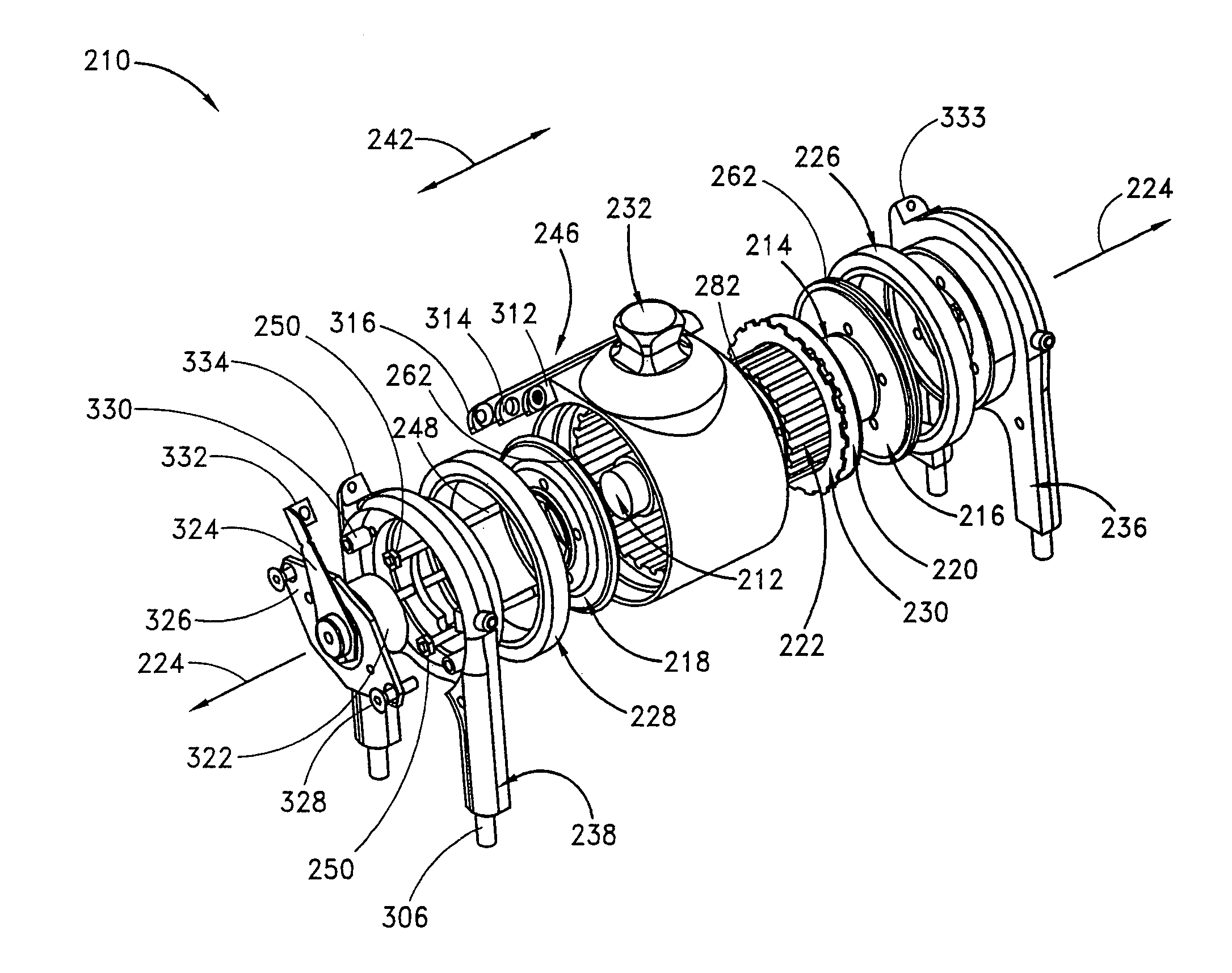

Disclosed are biocompatible magnetic nanoparticle compositions for various therapeutic or biological applications, and methods related thereto. Specifically, the present invention pertains to magnetic nanoparticle compositions prepared via high-pressure homogenization processes that include a turbulent flow zone. The methods of production may involve a two-step or a one-step process. The disclosed magnetic nanoparticle compositions may be useful in the treatment of the body, body part, tissue, cell, or body fluid of a subject for a variety of indications. The disclosed magnetic nanoparticle compositions may also be useful in the fixation, separation, transportation, marking or coding of targets, or energy transformation processes.

Owner:NANOTX INC +1

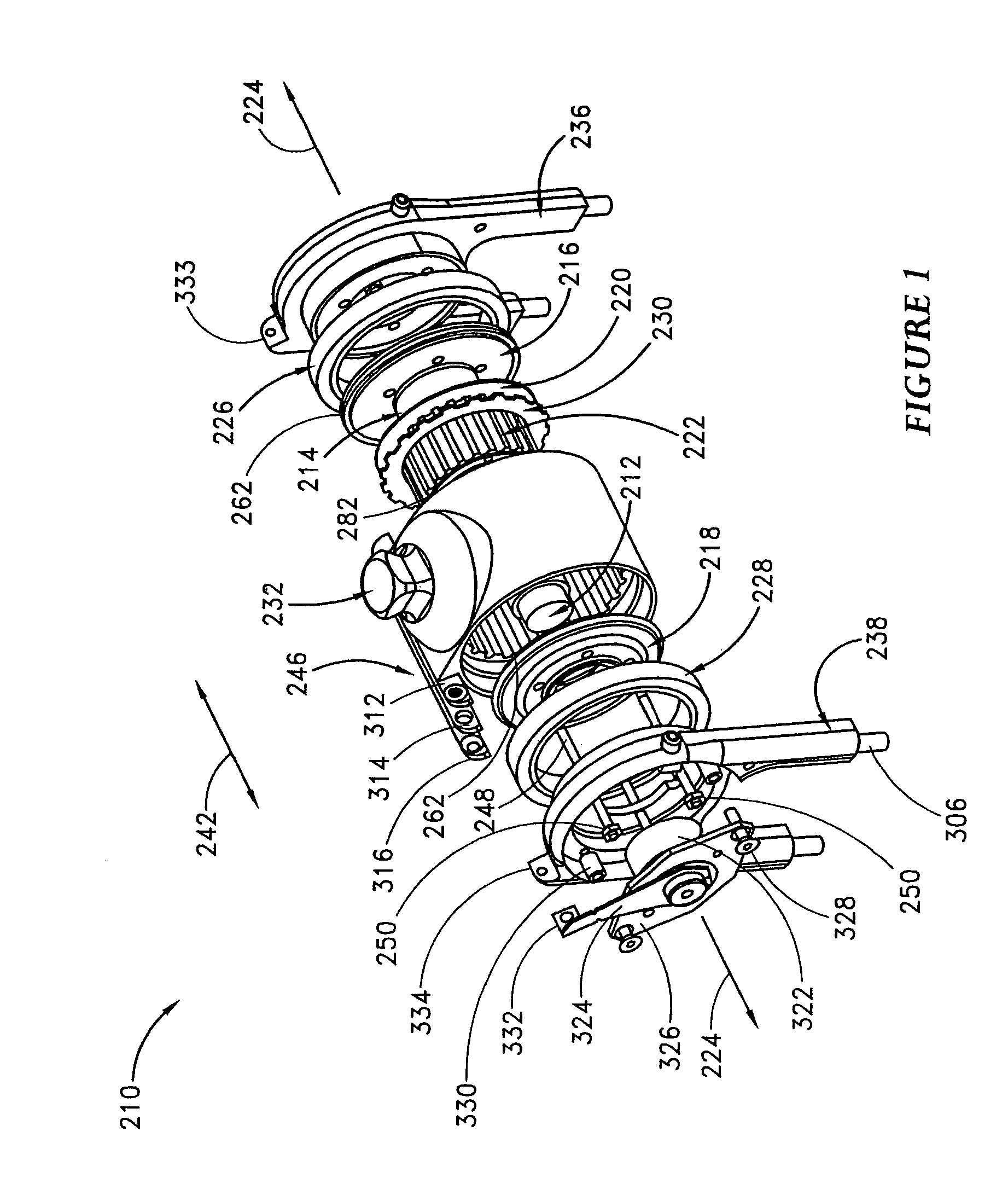

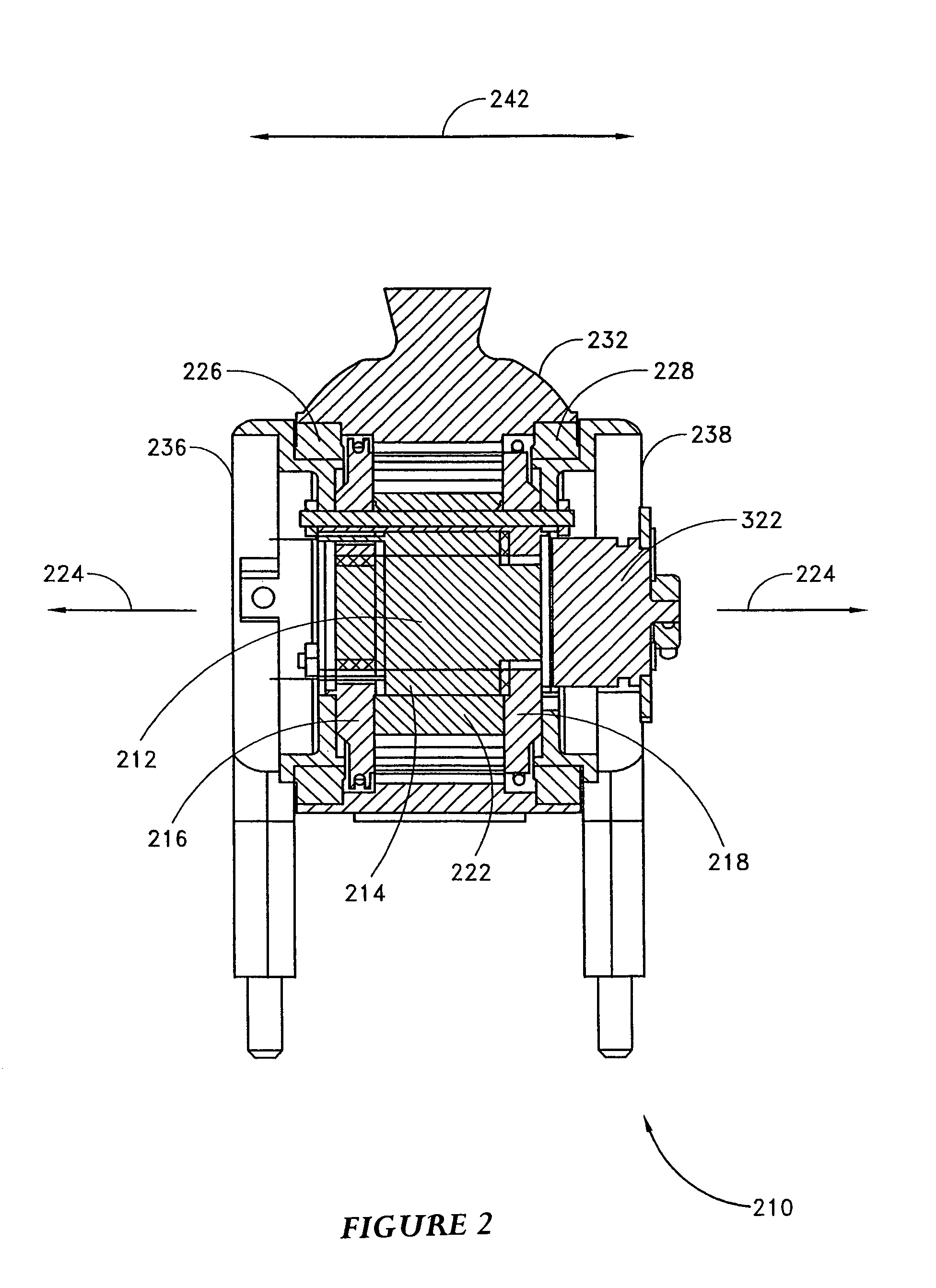

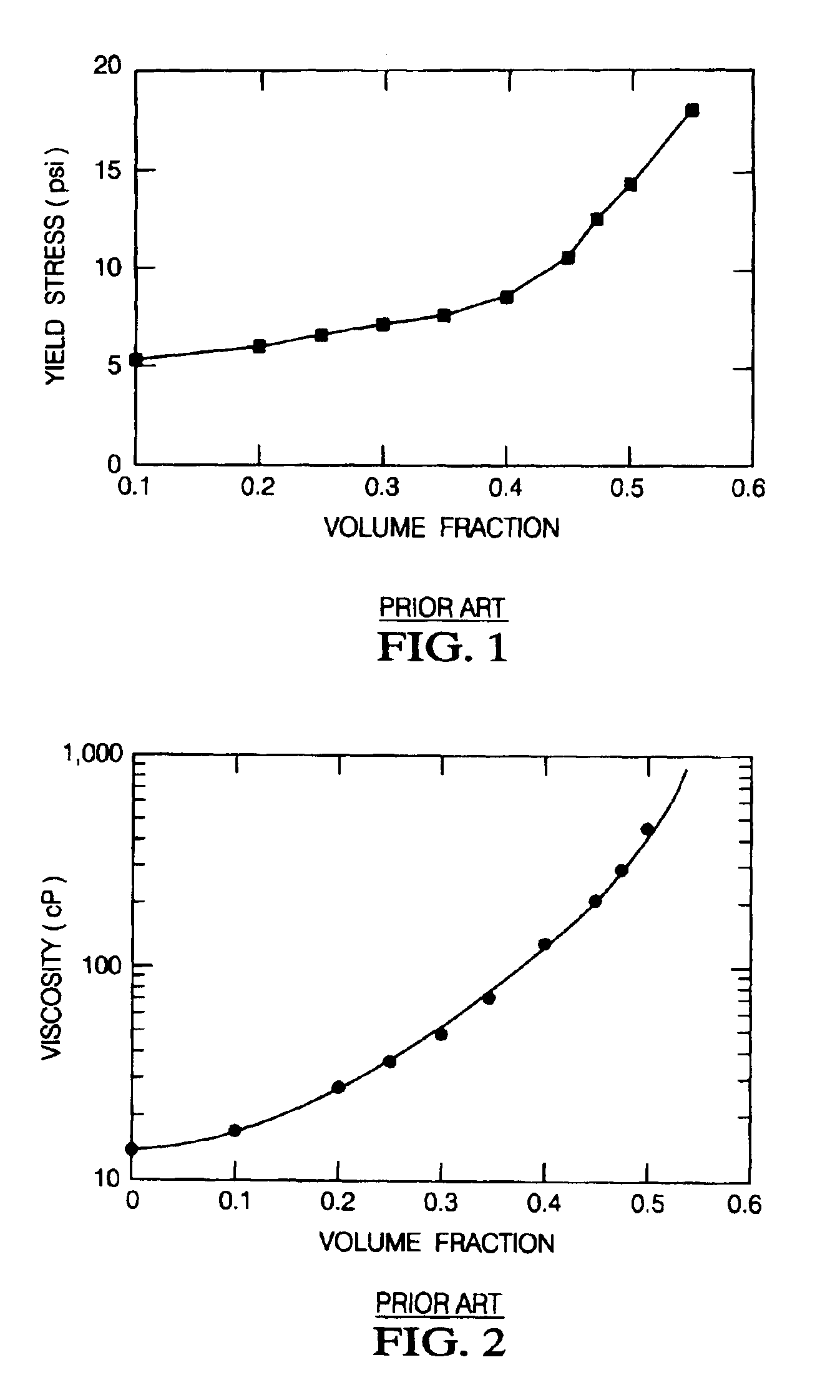

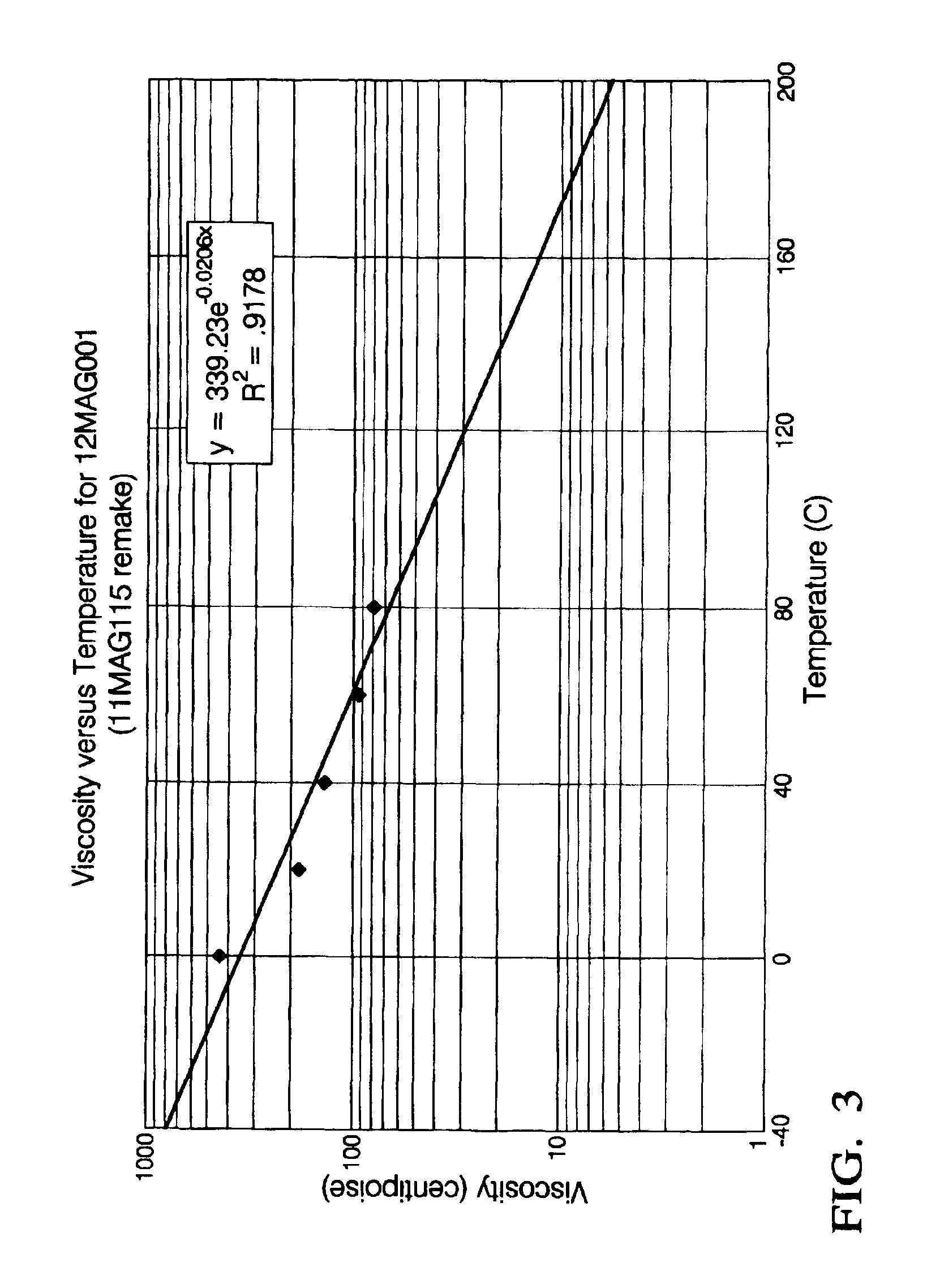

Magnetorheological fluid compositions and prosthetic knees utilizing same

The present invention relates in one embodiment to magnetorheological fluids utilized in prosthetic joints in general and, in particular, to magnetorheological fluids utilized in controllable braking systems for prosthetic knee joints. Preferred magnetorheological fluids of the present invention comprises polarizable iron particles, a carrier fluid, and optionally an additive. Preferred additives include, but are not limited to functionalized carrier fluids as well as derivatized fluoropolymers. Preferred carrier fluids include, but are not limited, to perfluorinated polyethers.

Owner:OSSUR HF

Coated substrate assembly

A coated assembly with an inductance of from about 0.1 to about 5 nanohenries and a capacitance of from about 0.1 to about 10 nanofarads. The coated assembly contains a stent and a coating. When the assembly is exposed to radio frequency electromagnetic radiation with a frequency of from 10 megahertz to about 200 megahertz, at least 90 percent of the electromagnetic radiation penetrates to the interior of the stent.

Owner:BIOPHAN TECH

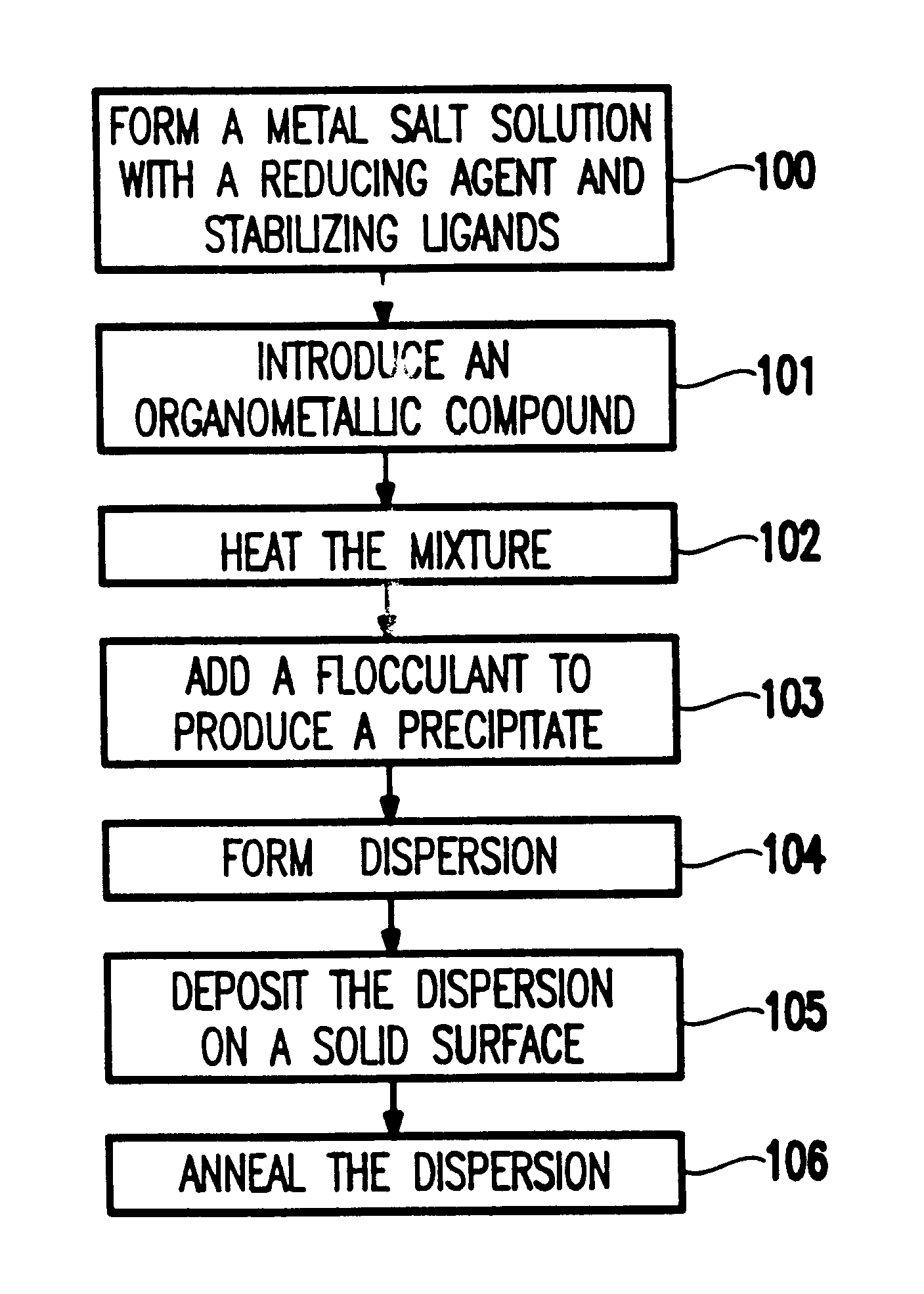

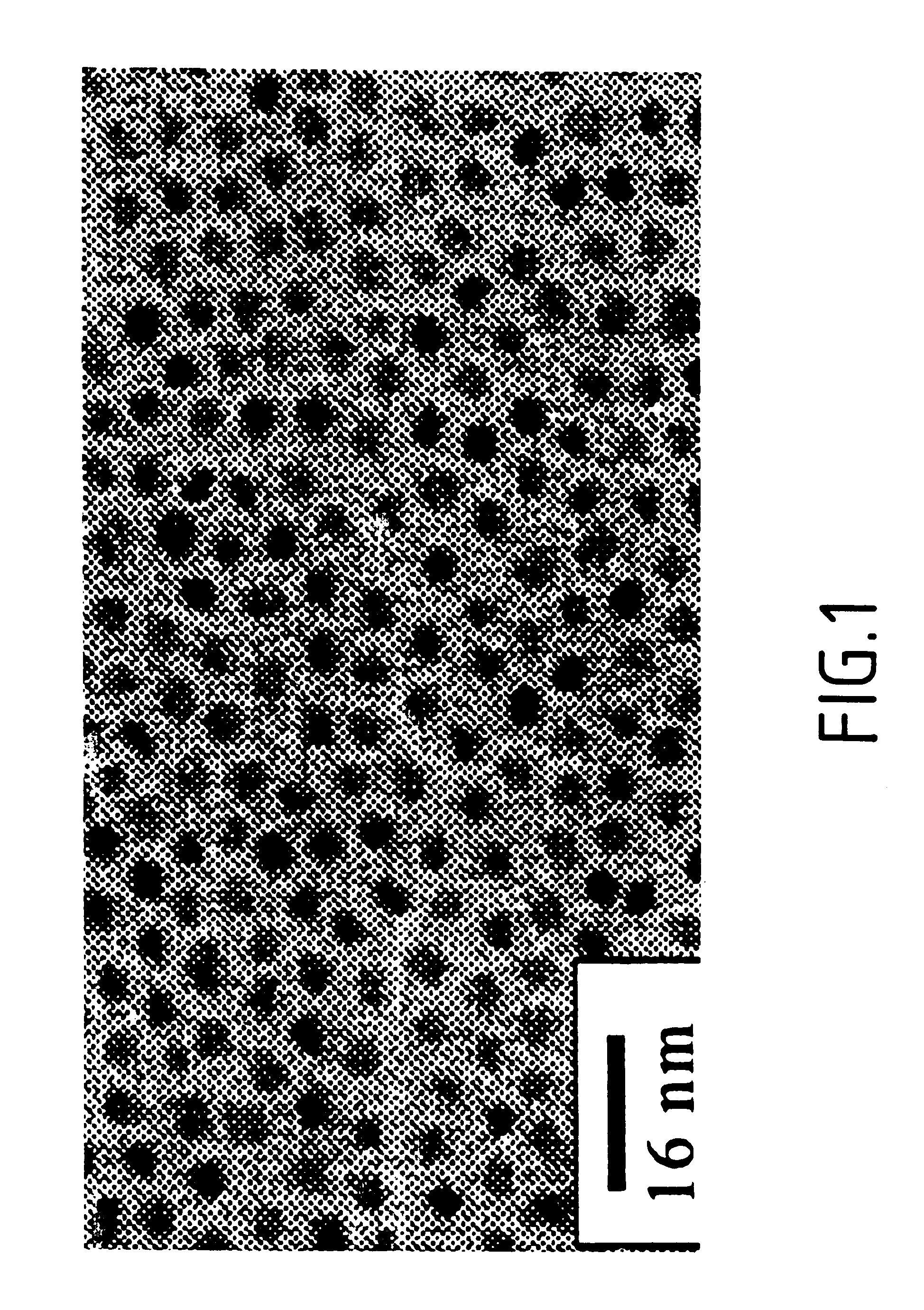

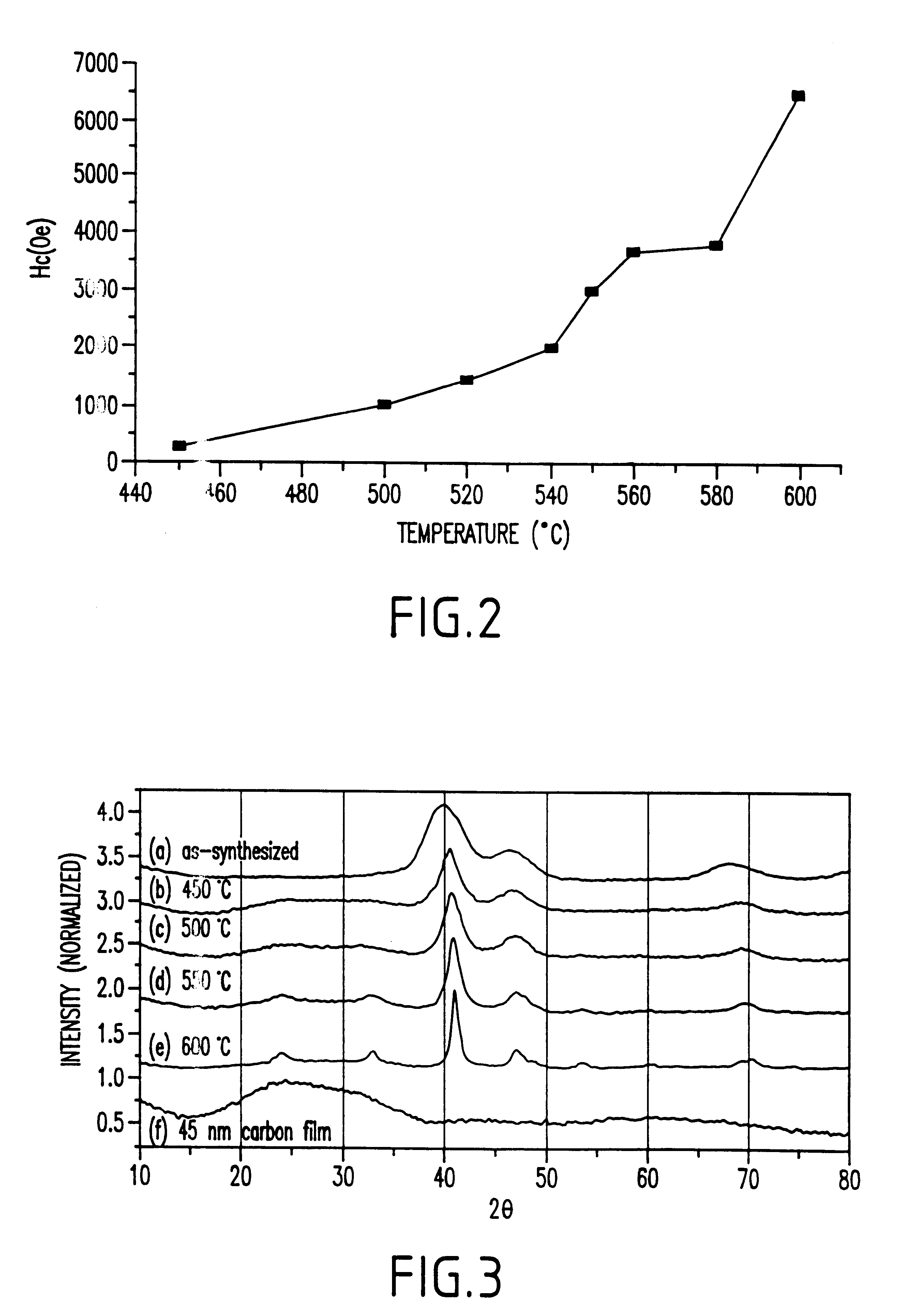

Synthesis of metal nanoparticle compositions from metallic and ethynyl compounds

A process of making metal nanoparticles comprising the steps of: providing a precursor composition comprising at least one metallic compound and at least one organic compound; wherein the organic compound is selected from the group consisting of an ethynyl compound, a metal-ethynyl complex, and combinations thereof, wherein the precursor composition is a liquid or solid at room temperature; and heating the precursor composition under conditions effective to produce metal nanoparticles. A metal nanoparticle composition comprising metal nanoparticles dispersed homogenously in a matrix selected from the group consisting of ethynyl polymer, crosslinked ethynyl polymer, amorphous carbon, carbon nanotubes, carbon nanoparticles, graphite, and combinations thereof.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Chemical synthesis of monodisperse and magnetic alloy nanocrystal containing thin films

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

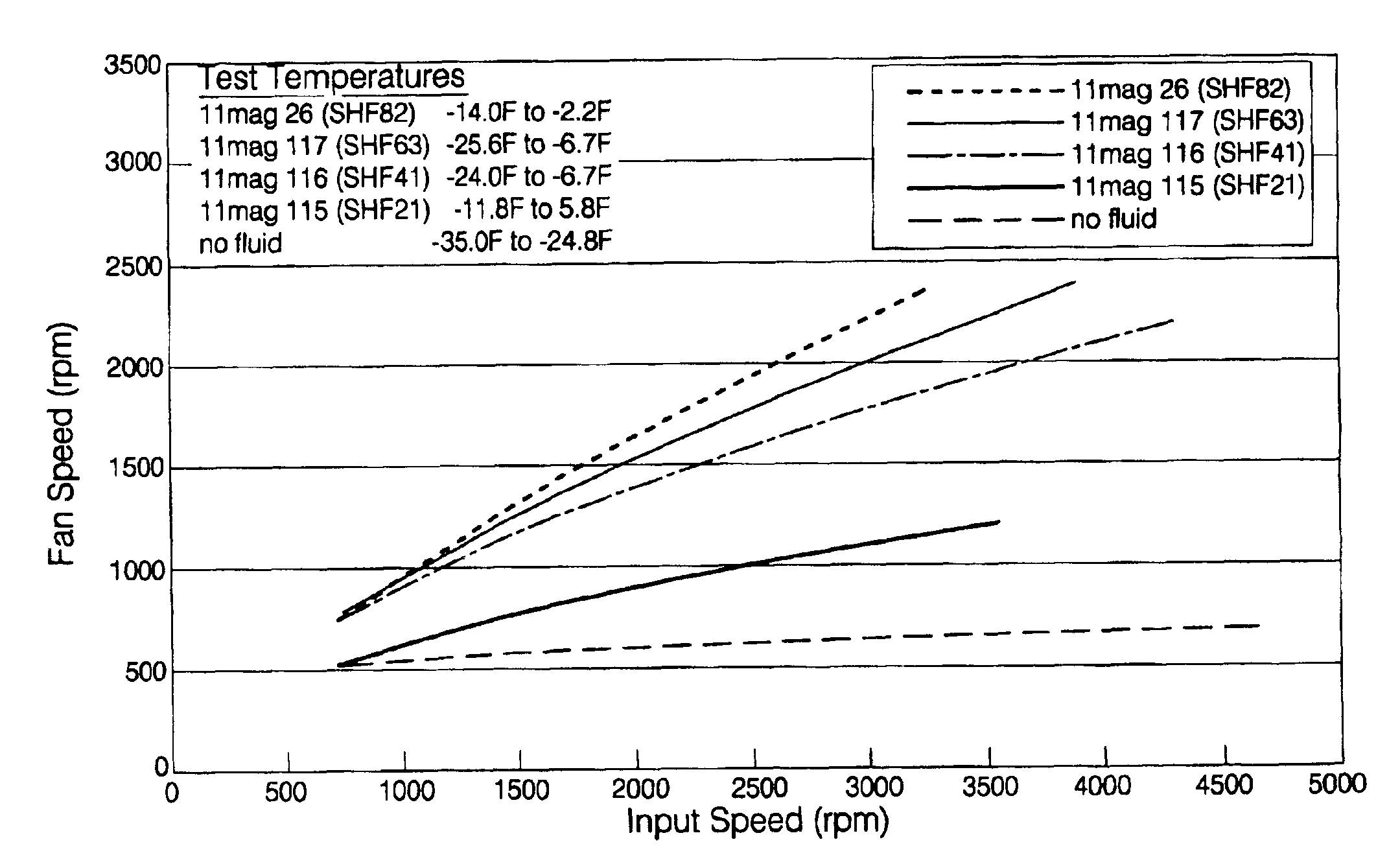

Magnetorheological fluids

InactiveUS6932917B2Increased durabilityLow viscosityOther chemical processesMagnetic liquidsMagnetorheological fluidCentrifugal force

One embodiment of the invention includes an MR fluid of improved durability. The MR fluid is particularly useful in devices that subject the fluid to substantial centrifugal forces, such as large fan clutches. A particular embodiment includes a magnetorheological fluid including 10 to 14 wt % of a hydrocarbon-based liquid, 86 to 90 wt % of bimodal magnetizable particles, and 0.05 to 0.5 wt % fumed silica.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for preparing ethylenediamine modified chitosan composite magnetic microspheres and application thereof

InactiveCN102079823AWide variety of sourcesEasy to makeOther chemical processesMagnetic liquidsMicrosphereWastewater

The invention relates to a method for preparing ethylenediamine modified chitosan composite magnetic microspheres and application thereof. The method specifically comprises the following steps of: mixing acidic aqueous solution of chitosan and a water-based magnetofluid first, then crosslinking by using glutaraldehyde, then adjusting the pH value to form a gelatinous precipitate, then modifying by using ethylenediamine and epichlorohydrin, and washing and drying to obtain a final product. The product has good absorption effect on radionuclide aranium and metal ions such as heavy metal Pb, Cr and the like; the removal rate reaches over 95 percent when the initial concentration of various ions is within the range of 200mg / L; and the product has quick absorption rate and good regeneration performance. The ethylenediamine modified chitosan composite magnetic microspheres can be used for metal recovery and pollution remediation in mines, radioactive waste water, smelteries, electronics factories and waste water of electroplating factories.

Owner:NANHUA UNIV

Method of using triaxial magnetic fields for making particle structures

A method of producing three-dimensional particle structures with enhanced magnetic susceptibility in three dimensions by applying a triaxial energetic field to a magnetic particle suspension and subsequently stabilizing said particle structure. Combinations of direct current and alternating current fields in three dimensions produce particle gel structures, honeycomb structures, and foam-like structures.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

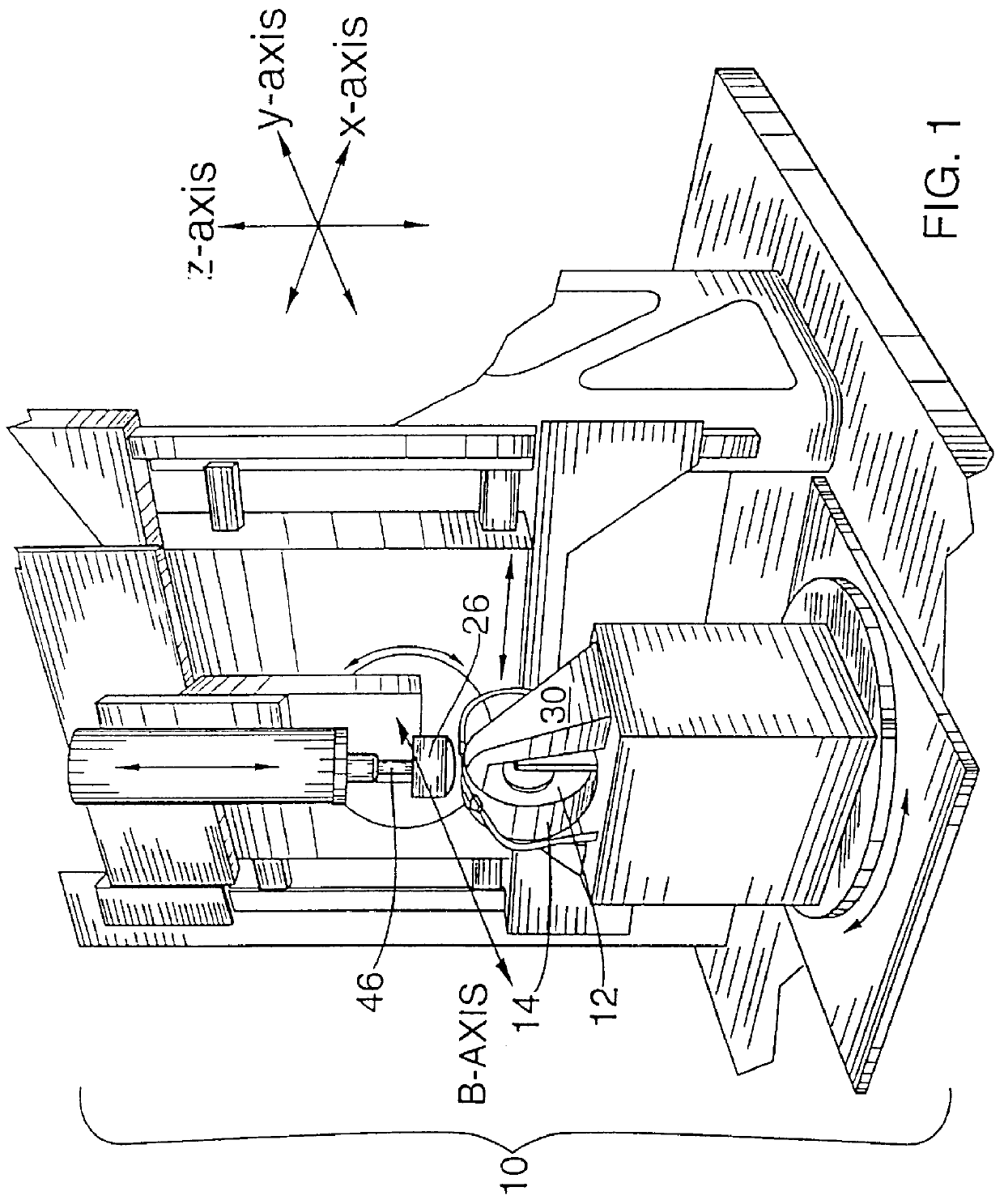

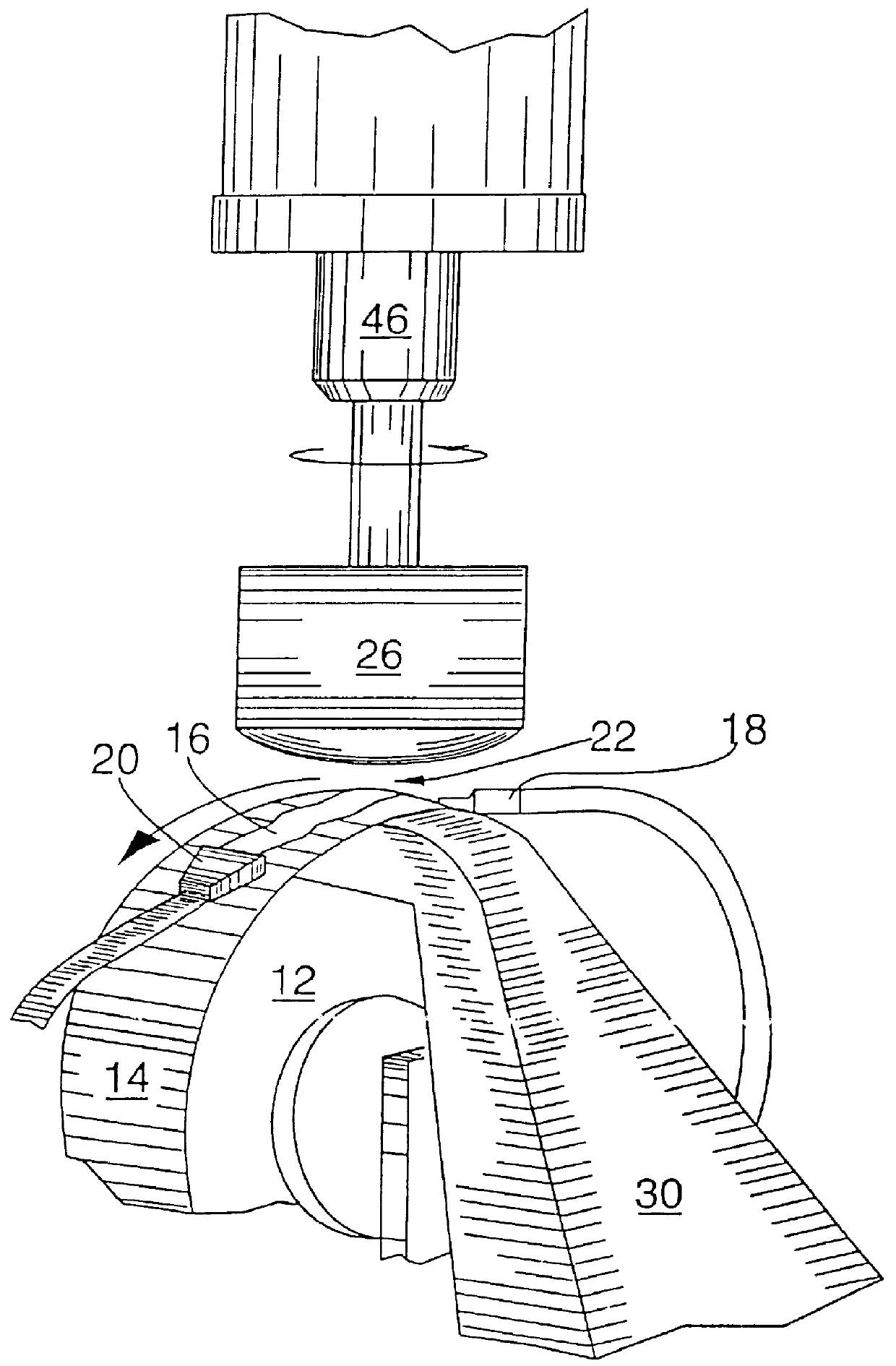

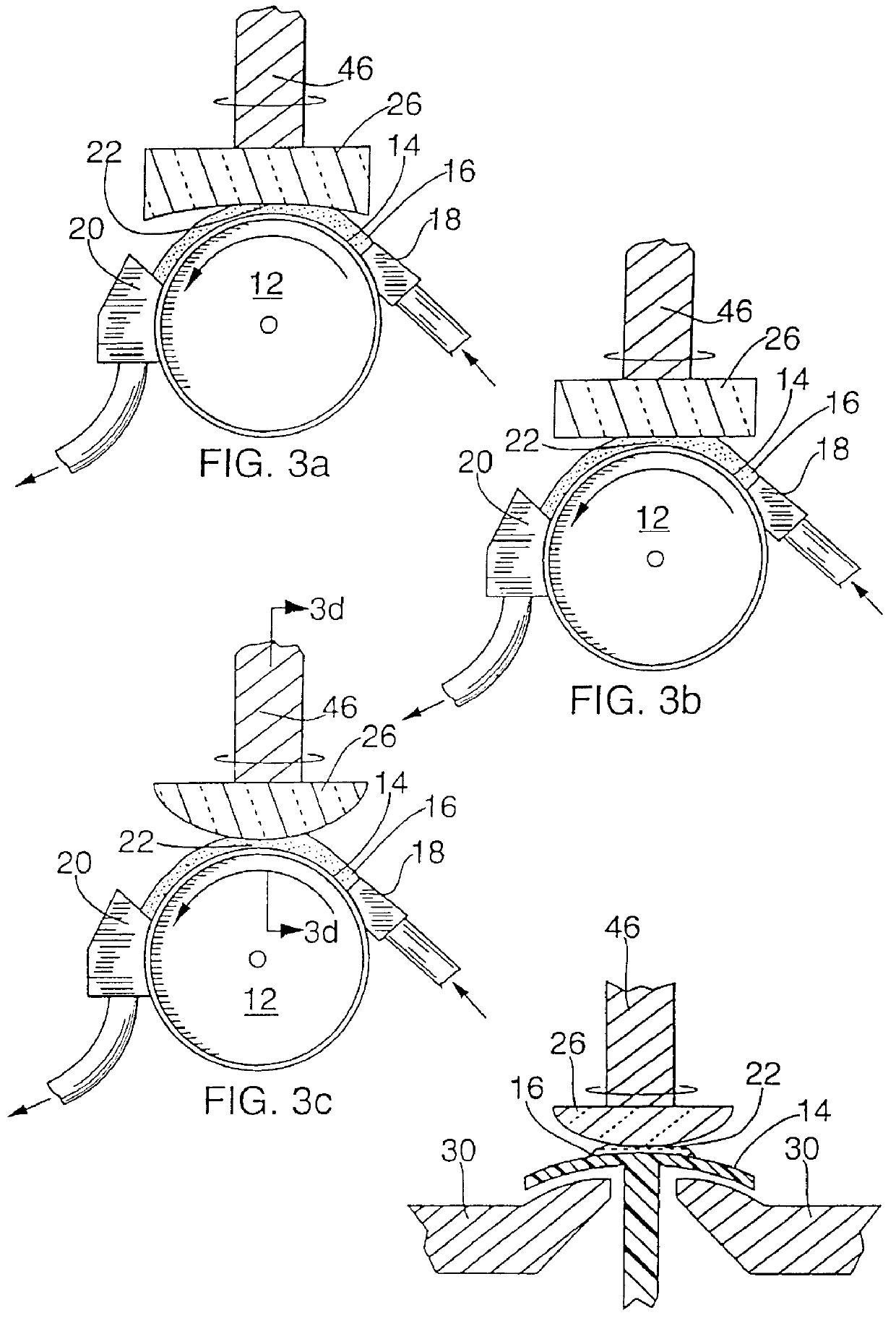

Deterministic magnetorheological finishing

InactiveUS6106380AConstantHigh viscosityEdge grinding machinesNanomagnetismMaterial removalMagnetorheological finishing

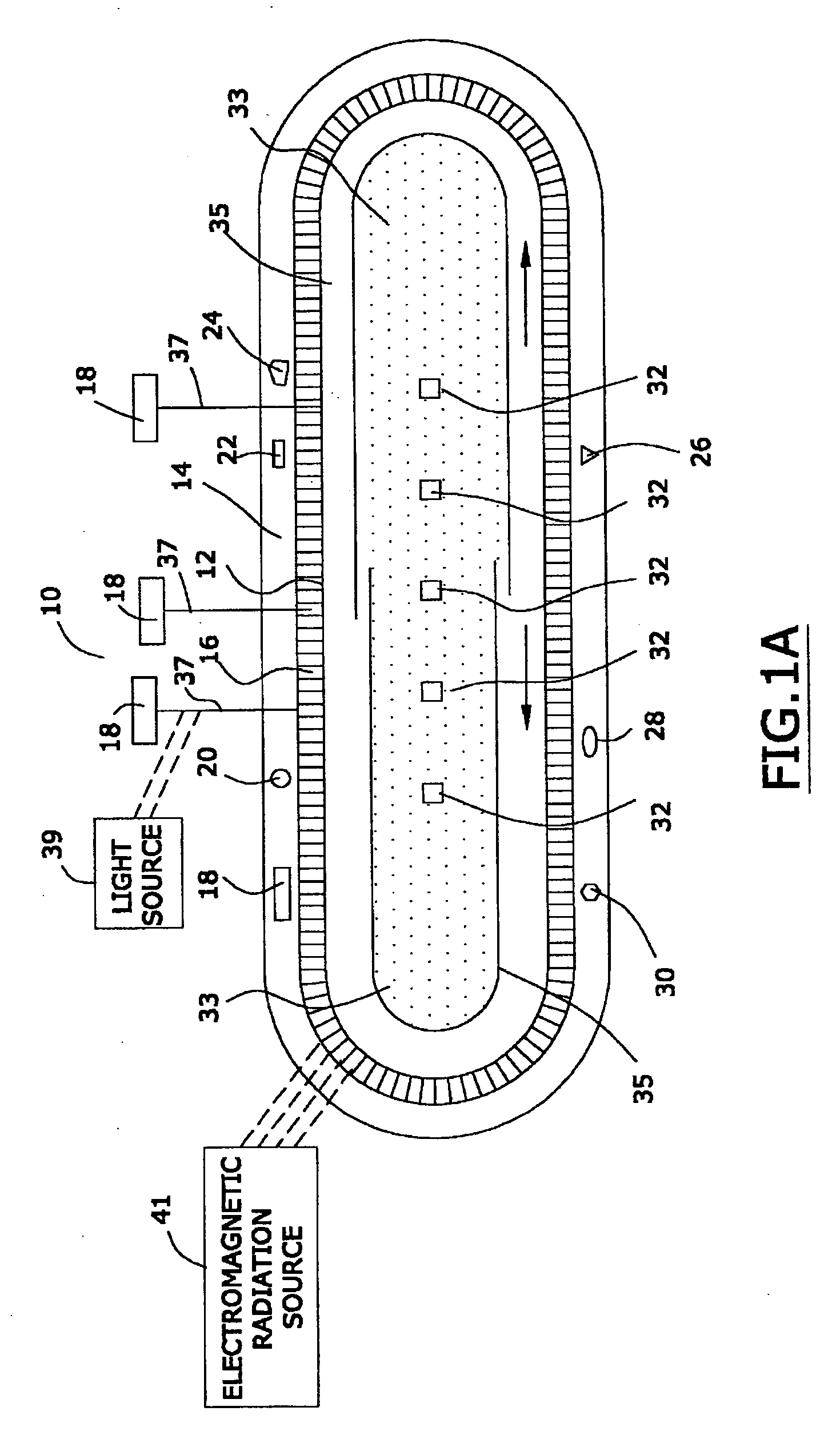

A method and apparatus for finishing a workpiece surface using MR fluid is provided wherein the workpiece is positioned near a carrier surface such that a converging gap is defined between a portion of the workpiece surface and the carrier surface; a magnetic field is applied substantially at said gap; a flow of stiffened MR fluid is introduced into said converging gap such that a work zone is created in the MR fluid to form a sub-aperture transient finishing tool for engaging and causing material removal at the portion of the workpiece surface; and the workpiece or the work zone is moved relative to the other to expose different portions of the workpiece surface to the work zone for predetermined time periods to selectively finish said portions of said workpiece surface to predetermined degrees.

Owner:QED TECH INT

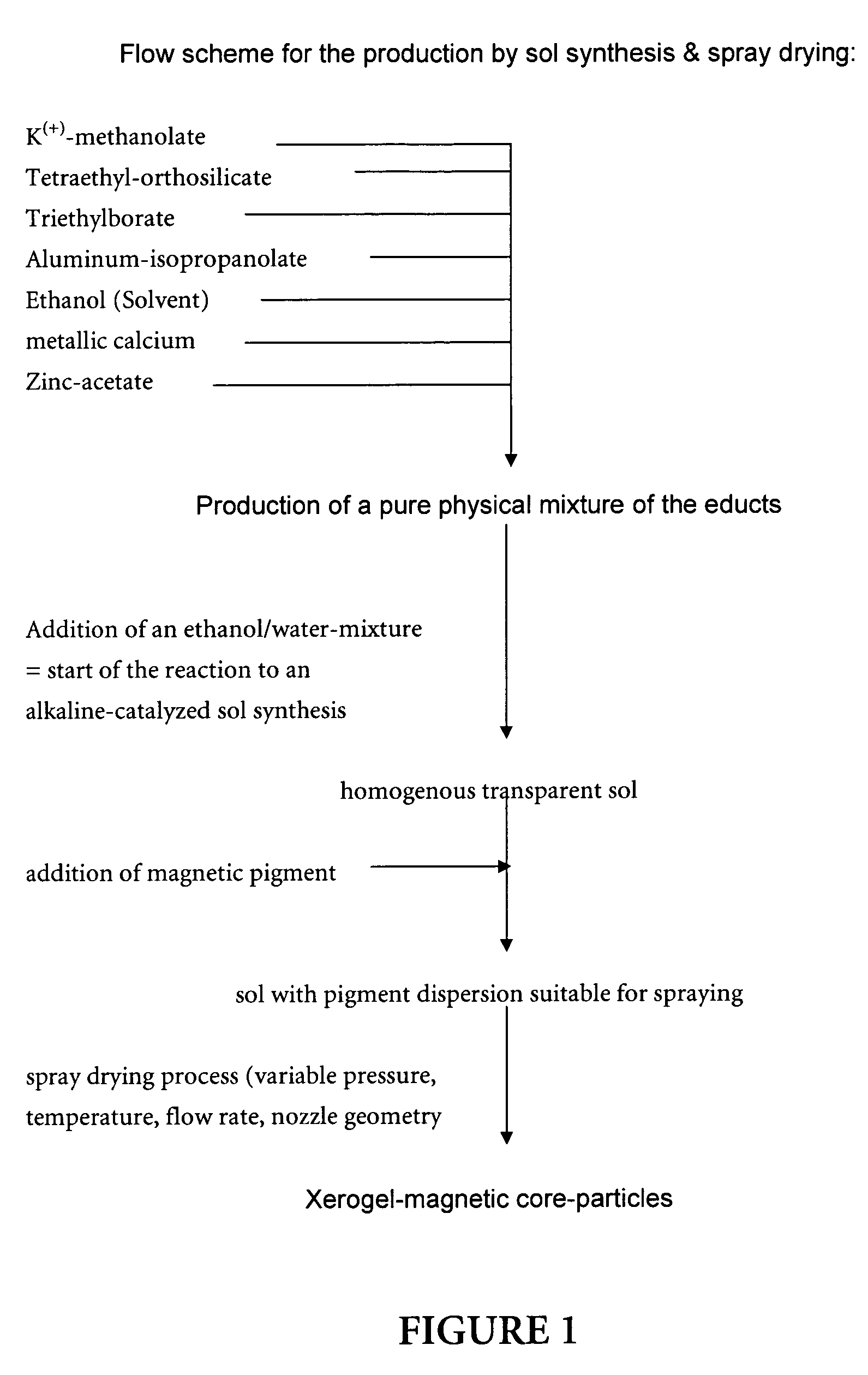

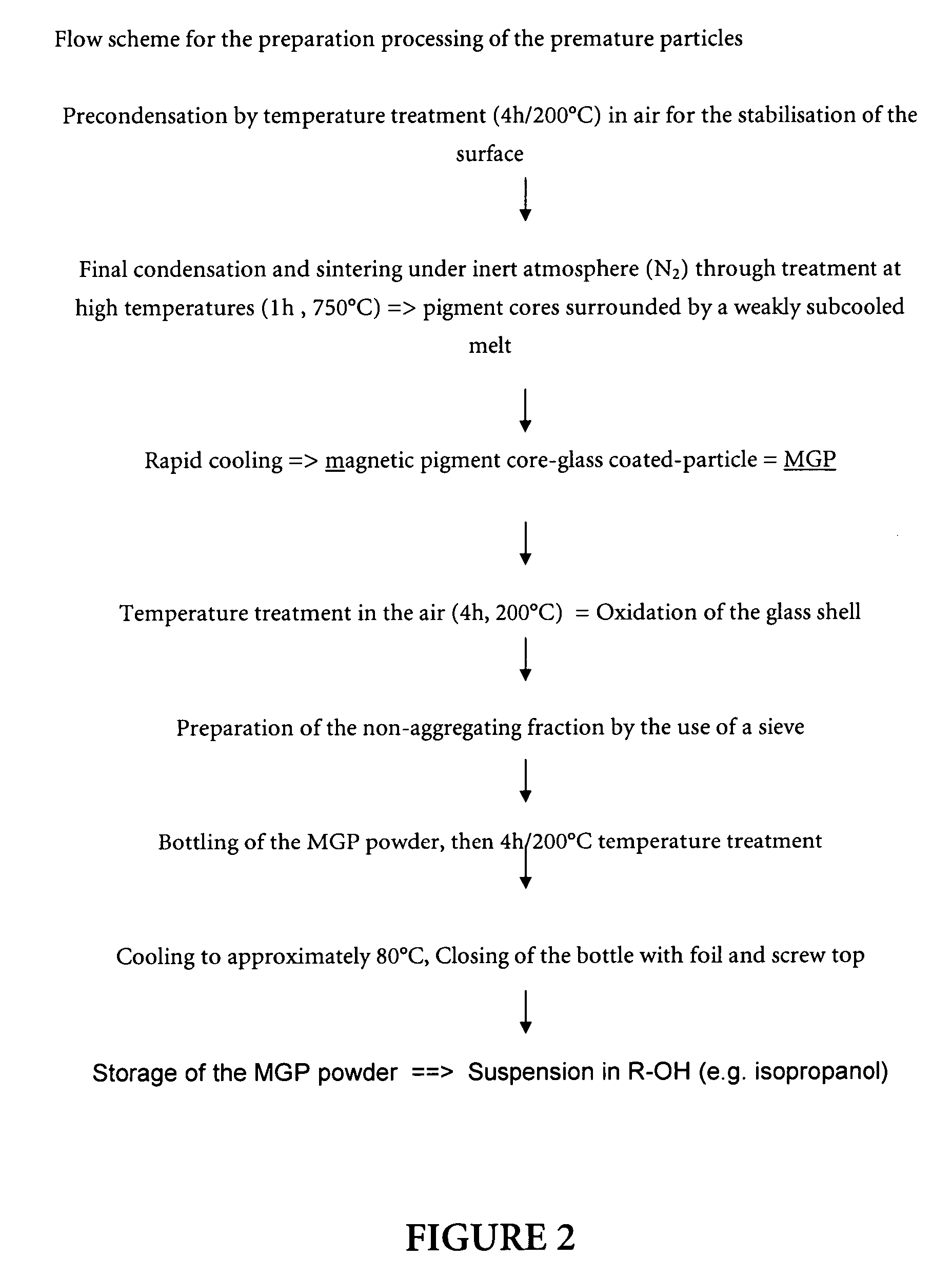

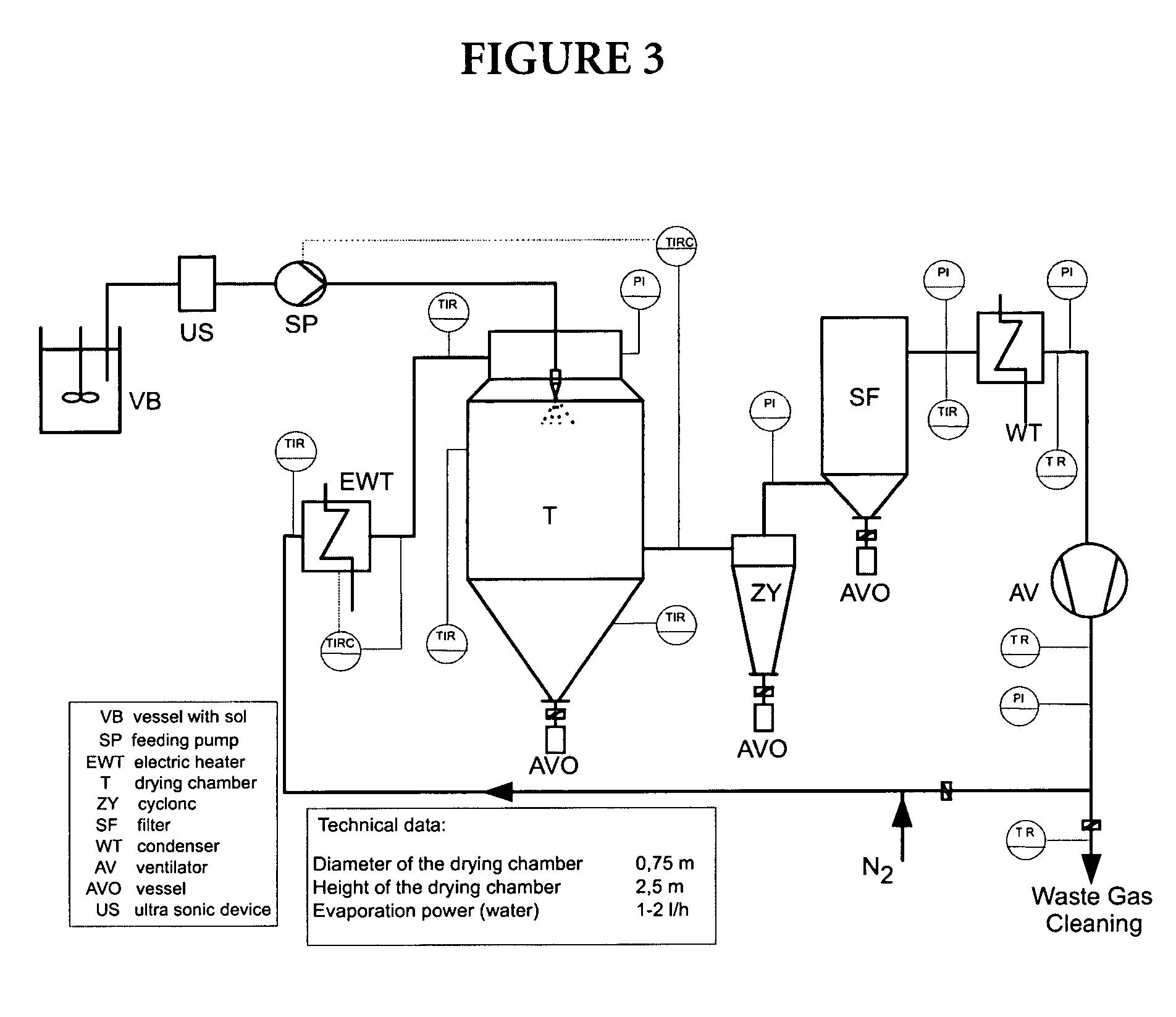

Magnetic glass particles, method for their preparation and uses thereof

InactiveUS8129118B2Promote resultsBioreactor/fermenter combinationsNanomagnetismGlass particleCombinatorial chemistry

Owner:ROCHE DIAGNOSTICS GMBH

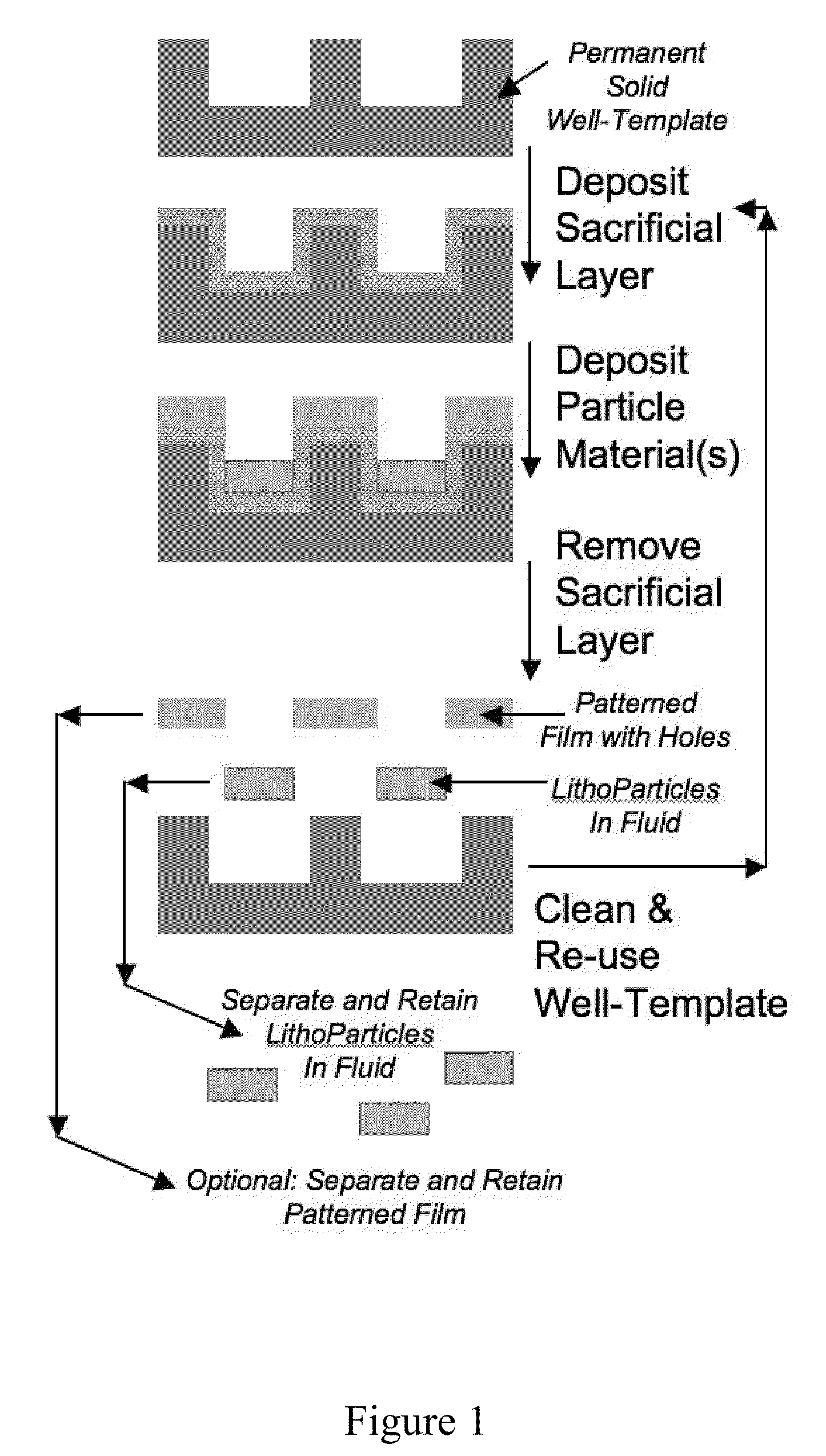

Mechanical process for creating particles in fluid

InactiveUS20100021985A1Impart propertyNanomagnetismLiquid surface applicatorsSurface geometryMaterials science

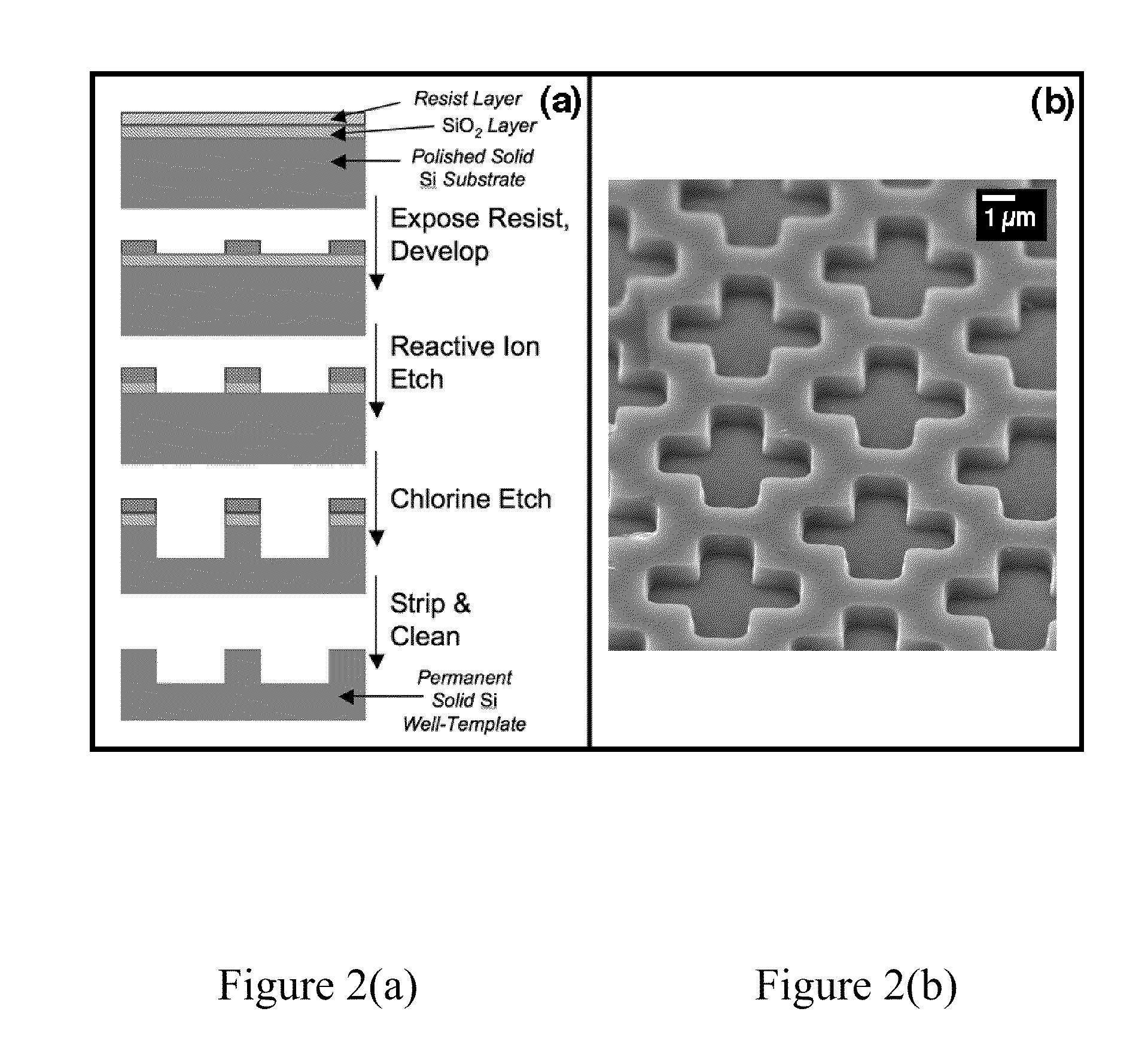

A method of producing at least one of microscopic and submicroscopic particles includes providing a template that has a plurality of discrete surface portions, each discrete surface portion having a surface geometry selected to impart a desired geometrical property to a particle while being produced; depositing a constituent material of the at least one of microscopic and submicroscopic particles being produced onto the plurality of discrete surface portions of the template to form at least portions of the particles; separating the at least one of microscopic and submicroscopic particles comprising the constituent material from the template into a fluid material, the particles being separate from each other at respective discrete surface portions of the template; and processing the template for subsequent use in producing additional at least one of microscopic and submicroscopic particles. A multi-component composition includes a first material component in which particles can be dispersed, and a plurality of particles dispersed in the first material component. The plurality of particles is produced by methods according to embodiments of the current invention.

Owner:RGT UNIV OF CALIFORNIA

Magnetic nanoparticles and method of fabrication

InactiveUS20060177879A1Highly stable compositionIncrease resistanceNanostructure manufactureNanomagnetismFiltrationMagnetite Nanoparticles

A method for making a composition of magnetic nanoparticles. The method includes the step of forming the magnetic nanoparticles, each within a protein template, wherein a liquid composition of said protein templates or subunits thereof is subjected to a microporous membrane filtration step prior to formation of said magnetic nanoparticles.

Owner:NANOMAGNETICS

Magneto sensitive fluid composition and a process for preparation thereof

InactiveUS6743371B2Excellent magnetorheological propertyOther chemical processesLiquid organic insulatorsElectrical conductorFluid composition

Owner:THE ADVISER DEFENCE RES & DEV ORG

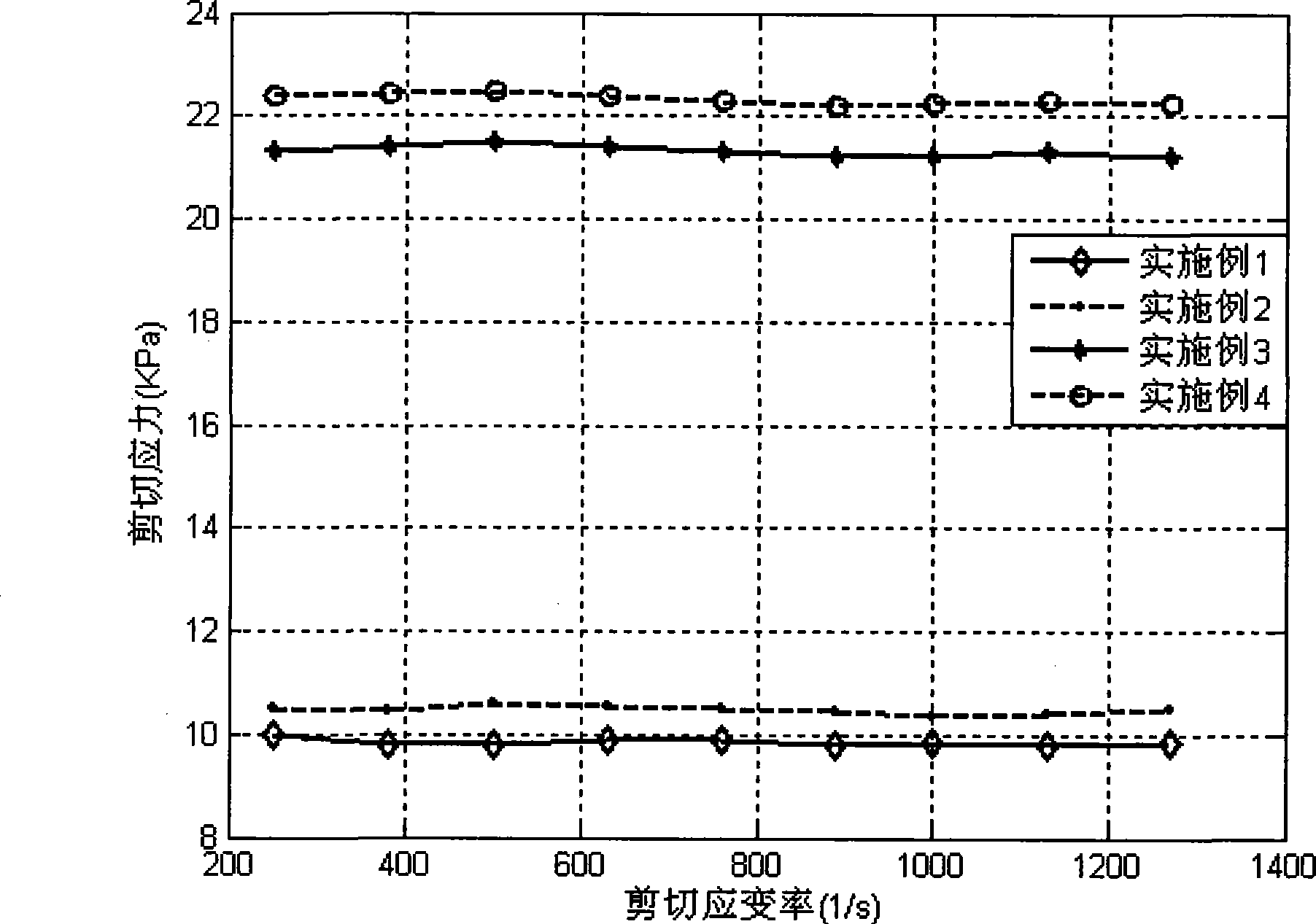

Magnetorheologicai polishing liquid and preparation method thereof

InactiveCN101139504AEasy to polishImprove uniformityMagnetic liquidsPolishing compositionsSurface finishMagnetization

The invention relates to a magnetic rheological polishing fluid and a preparing method for the fluid. The magnetic rheological polishing fluid comprises by volume magnetic particles 30-40%, pure water 45-55%, additive 5-10%, surface active agent 3-5% and polishing powder 5-8%. The preparing method comprises: the magnetic particles are surface cleaned and activated, the surfaces of the magnetic particles are treated by a hi-speed ball pulverizer. The magnetic rheological polishing fluid prepared by the invention is of hydrolyzation function. The preparing method is simple. The fluid is of a good resistance to settlement and conglobation, low zero-field viscosity, high polishing efficiency, good effect, long service life, and is applicable for optic polishing. The invention solves such problems of prior magnetic rheological polishing fluid as high viscosity, weak magnetizing strength, liable to caking, not stable in settling and conglobation, liable to rust, short service life and low efficiency. The magnetic rheological polishing fluid prepared by the invention is of high efficiency, and can facilitate the surface finish of a k9 glass to increase from 400nm to 0.6 nm in 30 minutes. The invention can be widely used in the super surface polishing of optic glass.

Owner:XIAN TECHNOLOGICAL UNIV

Water-based magneto-rheological polishing liquid for optical processing and preparation method thereof

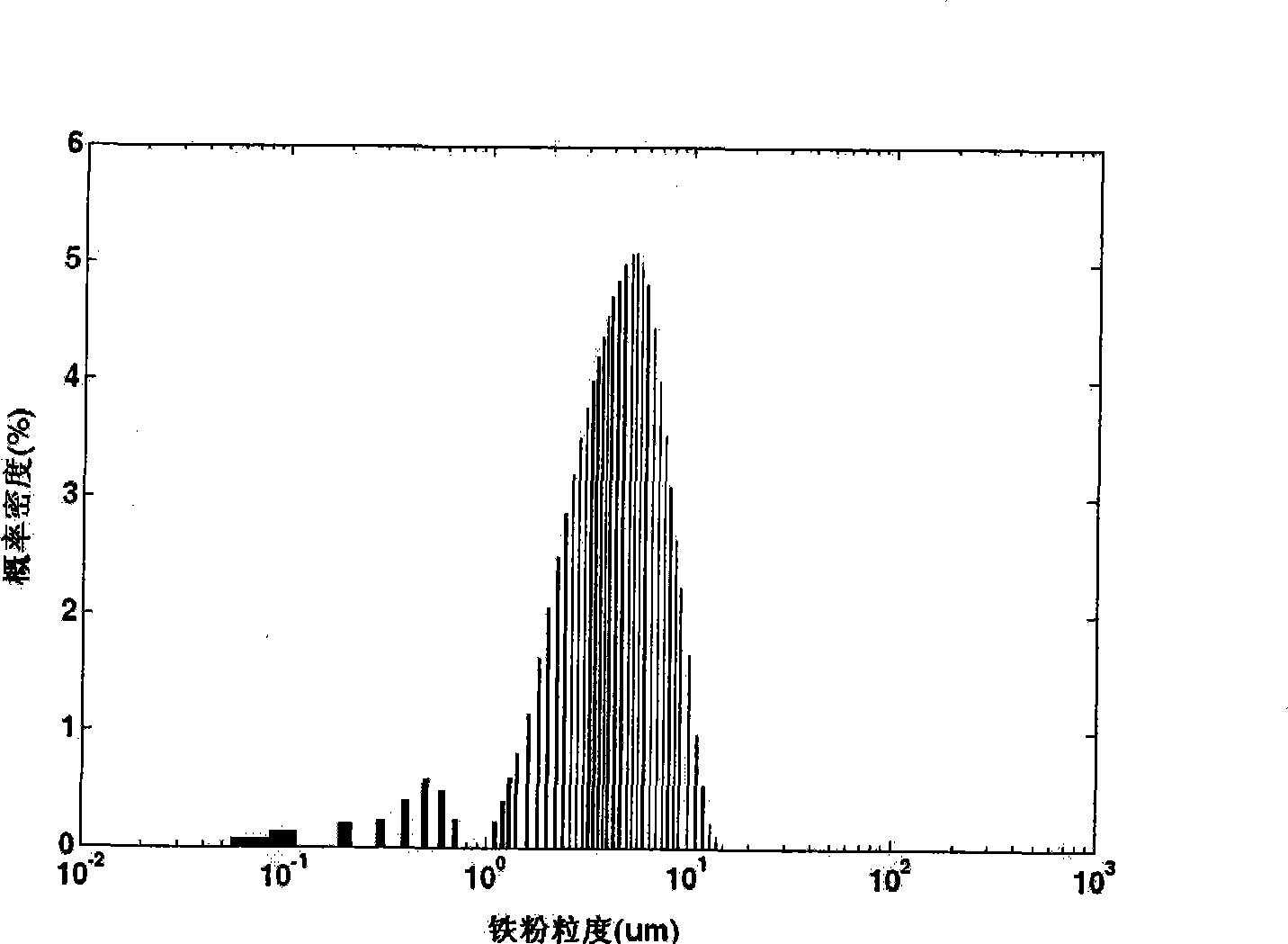

InactiveCN101250380ALow magnetic field viscositySuitable for recyclingMagnetic liquidsPolishing compositions with abrasivesWater basedIron powder

The invention relates to a water-based magnetorheological polishing solution for optical manufacture, which is formed by the following volume components, water-based remixed carrier liquid 25%-75% and additive component 25%-75%, wherein the additive component is dispensed by the following volume percentage, carbonyl iron powder 80%-90%, nanometer iron powder 4%-10% and polishing powder 4%-10%, the water-based remixed carrier liquid which is measured according to volume percentage comprises deionized water 85%-90%, dispersing agent 3%-5%, wetting agent 2%-5% and thixotropic agent 3%-5%, the method for preparing comprises the following steps: mixing deionized water and thixotropic agent, stirring in indoor temperature for 1-2 hours, and adding dispersing agent, stirring in indoor temperature for 0.5-1 hour, and then adding wetting agent, stirring in indoor temperature for 0.5-1 hour, getting water-based remixed carrier liquid, mixing additive component and water-based remixed carrier liquid, adding into a ball-milling tank, adding into a steel ball according to mass ratio which is 1:10, grinding for 3-5 hours in the speed which is 20-30r / m, separating out a steel ball, and getting products. The polishing solution of the invention has the advantages of excellent stability, high rheological property, excellent oxidation resistance property and simple and environmental-friendly preparation technology.

Owner:NAT UNIV OF DEFENSE TECH

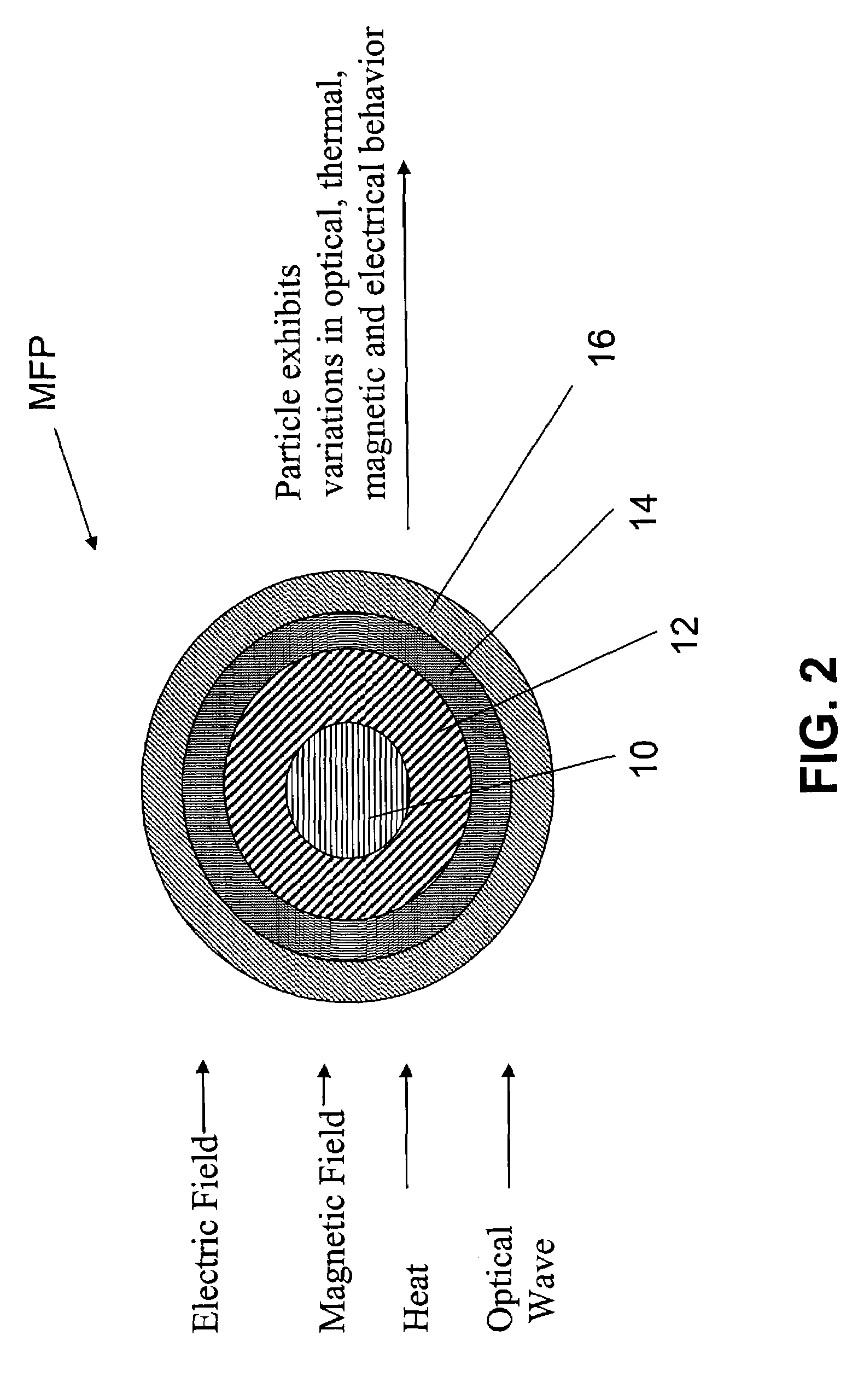

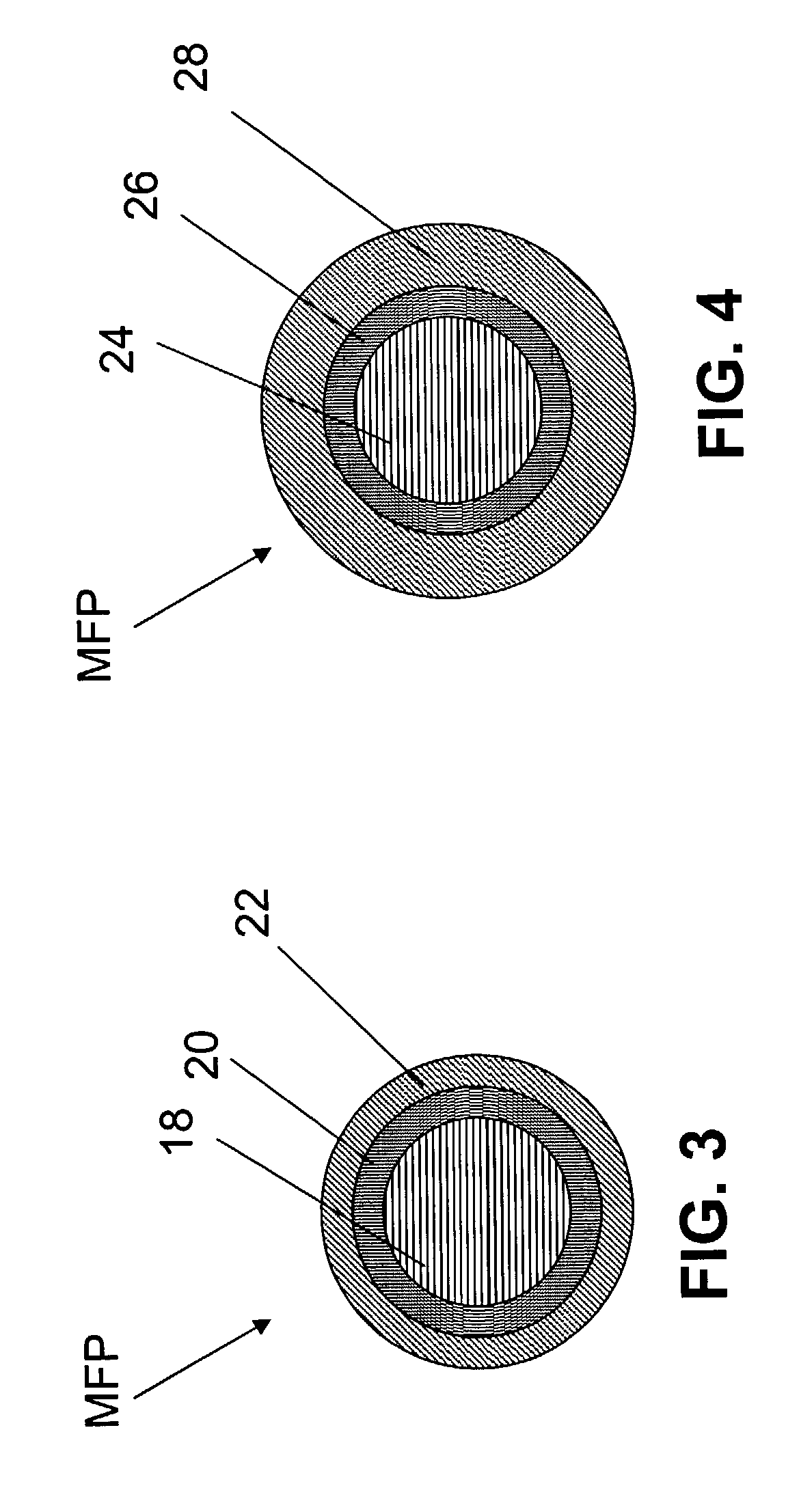

Multifunctional particulate material, fluid, and composition

InactiveUS7560160B2Powder deliveryNon-conductive material with dispersed conductive materialCompound (substance)Lubrication

A multifunctional particulate material, fluid, or composition includes a predetermined amount of core particles with a plurality of coatings. The core particles have an average particle size of about 1 nm to 500 μm. The particulate material, fluid, or composition is capable of exhibiting one or more properties, such as magnetic, thermal, optical, electrical, biological, chemical, lubrication, and rheological.

Owner:MATERIALS MODIFICATION INC

Acid stable aqueous dispersion of metal particles and applications

InactiveUS6811885B1Improve colloidal stabilityProtective coatings for layersMagnetic liquidsMetal particleRecording layer

Aqueous coating compositions containing acid stable metal dispersions, prepared by chemical reduction in aqueous medium, are obtained by using a N-quaternized cellulose derivative as binder. They can be used for the preparation of heat mode recording layers, magnetic layers and conductive layers.

Owner:AGFA GEVAERT AG

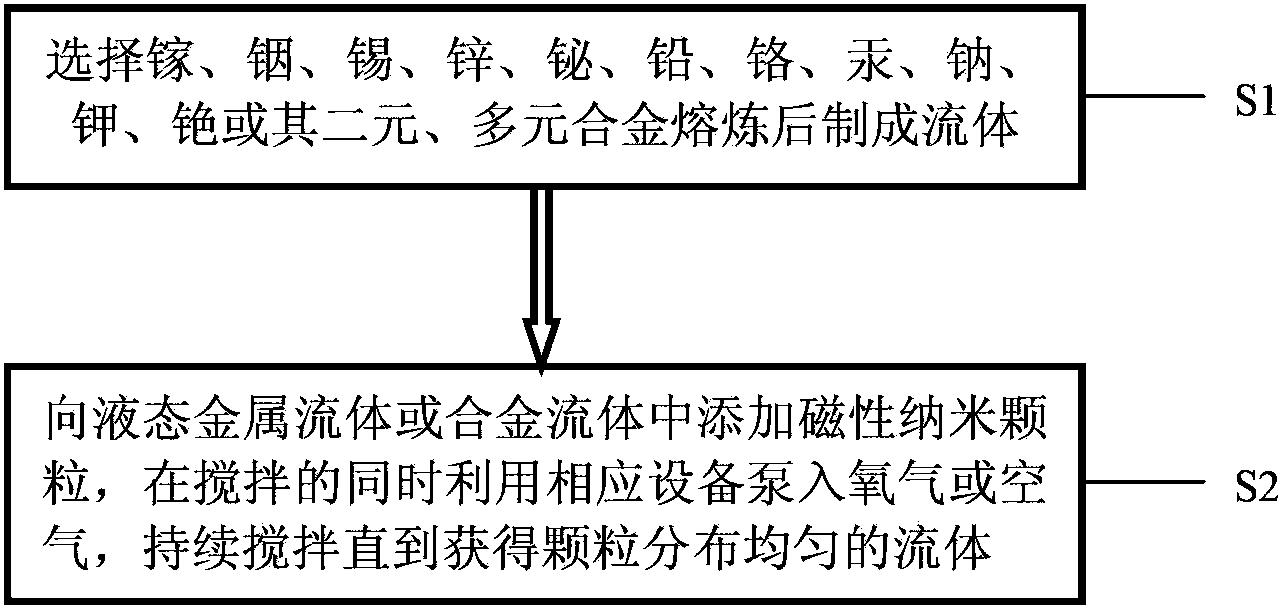

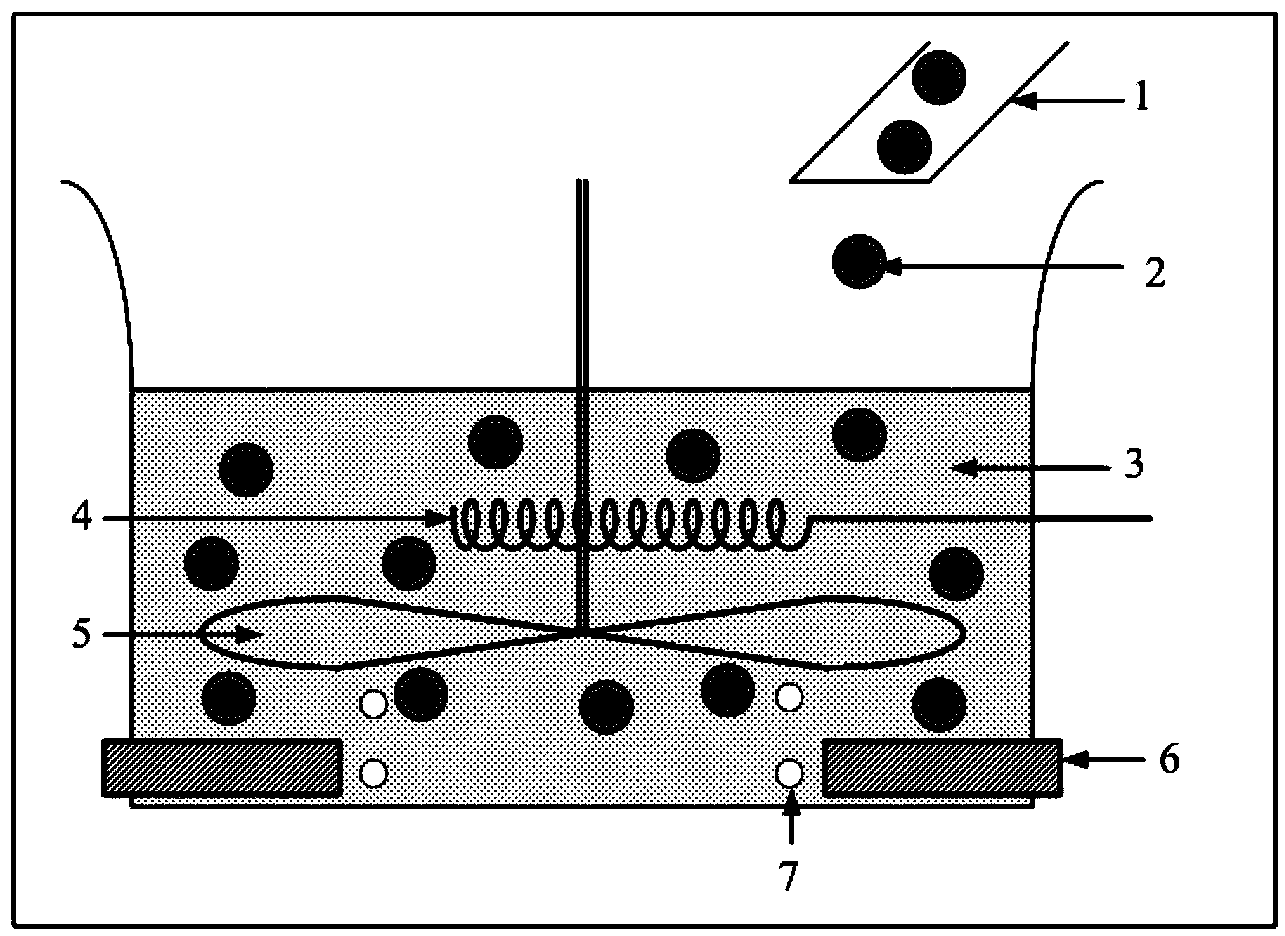

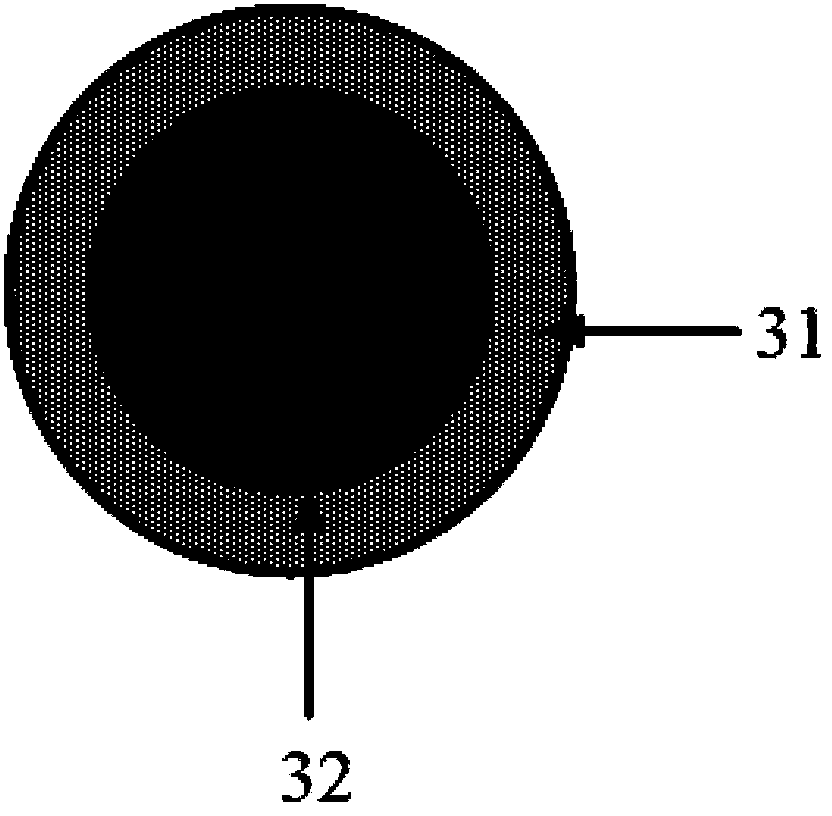

Magnetic nanometer-sized metal fluid and preparation method thereof

ActiveCN104124031AHigh thermal conductivityImprove liquidityMaterial nanotechnologyMagnetic liquidsIndiumPotassium

The invention discloses magnetic nanometer-sized metal fluid. The magnetic nanometer-sized metal fluid comprises liquid gallium, liquid indium, liquid tin, liquid zinc, liquid bismuth, liquid lead, liquid chromium, liquid mercury, liquid sodium, liquid potassium, liquid cesium or a dual-component alloy or a multi-component alloy of the metal materials and magnetic nanometer-sized particles added to the metal materials. The volume ratio of the magnetic nanometer-sized particles to the liquid metal materials / the alloy is smaller than or equal to 0.5:1. Oxygen is actively introduced through a specific oxygen supply mechanism to adjust and control the adhesiveness of the fluid and the particles, and taking the liquid gallium, the liquid indium, the liquid tin, the liquid zinc, the liquid bismuth, the liquid lead, the liquid chromium, the liquid mercury, the liquid sodium, the liquid potassium, the liquid cesium or the dual-component alloy or the multi-component alloy of the metal materials as basic liquid, the magnetic nanometer-sized metal fluid which is high in heat conductivity and electric conductivity, good in fluidity and not prone to volatilization or leakage can be obtained fast and efficiently.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of magnetic antiphase demulsifier

InactiveCN103553181AEasy to separate and recycleReduce organic contentFatty/oily/floating substances removal devicesMagnetic liquidsDemulsifierMicrosphere

The invention discloses a preparation method of a magnetic antiphase demulsifier. The preparation method is characterized by firstly, preparing monodisperse ferroferric oxide magnetic microspheres by a hydrothermal method; secondly, coating a layer of thin silicon dioxide on the surfaces of the monodisperse ferroferric oxide magnetic microspheres, synthesizing magnetic microspheres with nuclear shell structures, performing group functional modification on the nuclear shell magnetic microspheres by using a silane coupling agent KH560; at last, performing grafting reaction by using the activity of functional groups and an antiphase demulsifier to obtain the magnetic antiphase demulsifier; the magnetic antiphase demulsifier prepared by the preparation method can improve the efficiency of original antiphase demulsifiers and has the characteristics of easy separation, high oil removing rate, obvious separation effect to oil-containing sewage, little use amount and high efficiency.

Owner:SOUTHEAST UNIV

High temperature magnetorheological fluid compositions and devices

A magnetorheological fluid composition comprising magnetizable particles in a liquid metal carrier fluid, wherein the liquid metal carrier fluid comprises a metal, a metal alloy, or a solder composition having a melting point from about −40° C. to about 300° C., a boiling point greater than 300° C., and a viscosity greater than about 0.1 centipoise (cp) at the melting point of the liquid based metal carrier fluid. The magnetizable particles can comprise low aspect ratio magnetizable particles, high aspect magnetizable particles, or a combination thereof. Also disclosed herein are high temperature magnetorheological devices operating at temperatures greater than 100° C., and comprising the magnetorheological fluid composition.

Owner:GM GLOBAL TECH OPERATIONS LLC

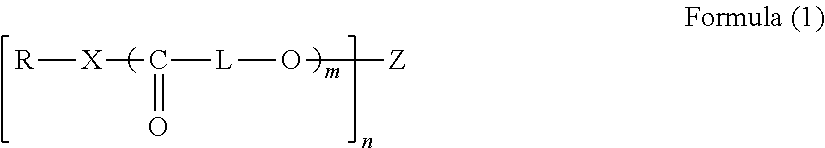

Metal oxide particle dispersion for manufacturing particulate magnetic recording medium, method of manufacturing magnetic layer-forming composition of particulate magnetic recording medium and method of manufacturing particulate magnetic recording medium

ActiveUS20170092316A1Avoid changeNovel featuresMagnetic liquidsRecord information storagePolyesterParticulates

The metal oxide particle dispersion for manufacturing a particulate magnetic recording medium contains metal oxide particles, solvent, and a polyester compound having one or more groups selected from the group consisting of a carboxyl group and a salt thereof, a phosphoric acid group and a salt thereof, a hydroxyl group and a nitrogen-substituted alkylene group, but substantially not containing ferromagnetic powder.

Owner:FUJIFILM CORP

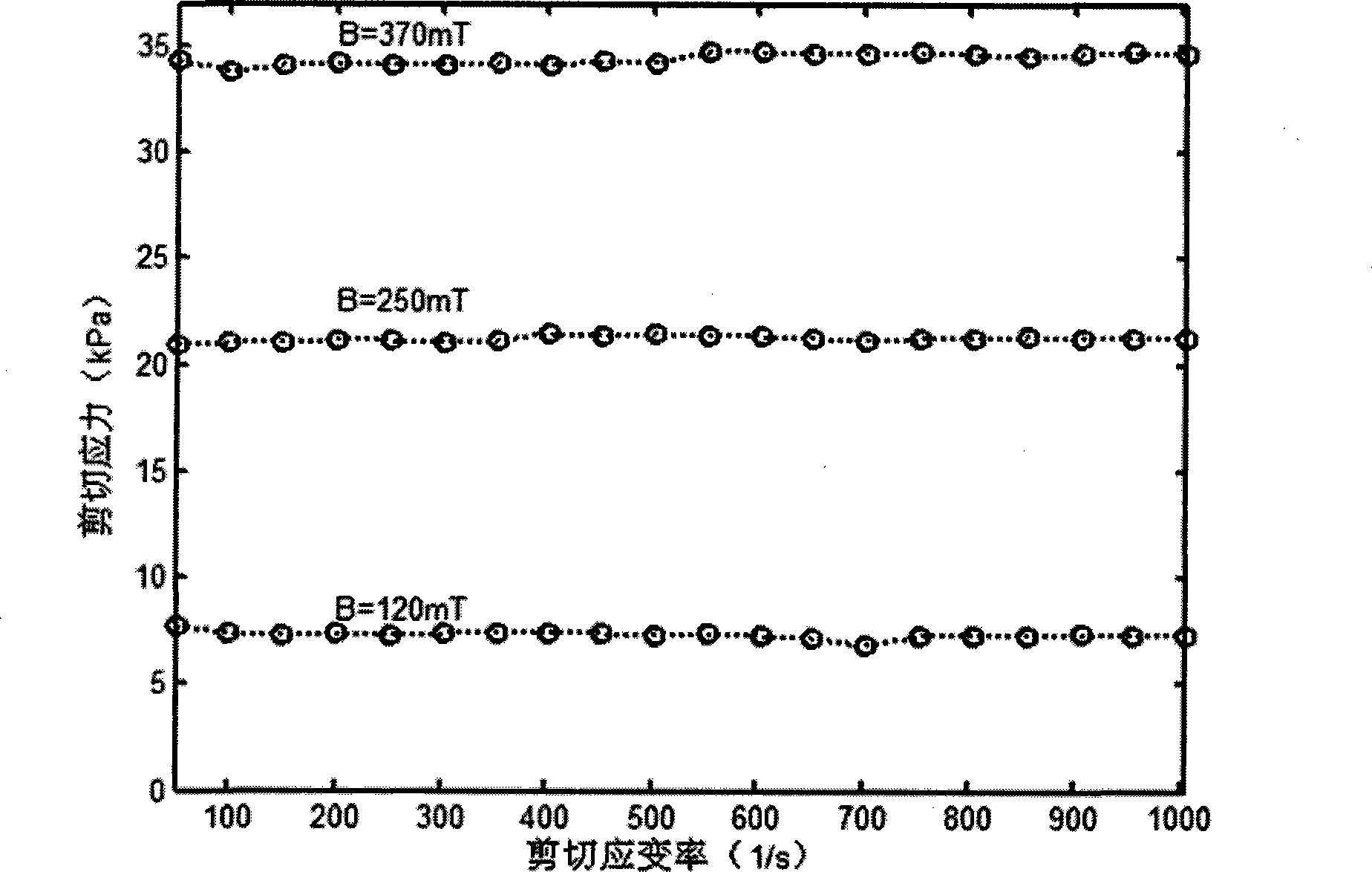

A magnetic rheological fluid and preparing method thereof

InactiveCN1595558ANot easy to fall offImprove suspension stabilityMagnetic liquidsChemical/physical/physico-chemical processesCross-linkSilicon oxide

The invention relates to a magnetic rheologic liquid and its manufacture method. The magnetic rheologic liquid is stable suspension containing micronsized magnetic particle and carrier liquid and magnetic particle and high molecular compound re cross linked on surface, whose composition ratio according to weight percentage is magnetic particle 67-94%, high molecular compound 1-24% and carrier liquid 4-20%. Some supplements whose weight percentage is not larger than 5% can be added into carrier liquid, whose manufacture method is that, firstly produce magnetic particle or magnetic particle covered by silicon oxide and aluminium oxide, then make the magnetic particle to be that which has cross linked on surface with high molecular compound, finally mix and stir the mixture of magnetic particle, carrier liquid and added substance to be magnetic rheologic liquid according to suitable match. The invention has its stability of suspension, mechanical behavior of magnetic rheologic liquid and reversibility of solid-liquid phase transformation all reach the level of magnetic rheologic liquid imported and is suitable in the fields like aerospace, mechanical engineering, automobile industry, precision finishing, building engineering and medical and health.

Owner:SHANGHAI UNIV

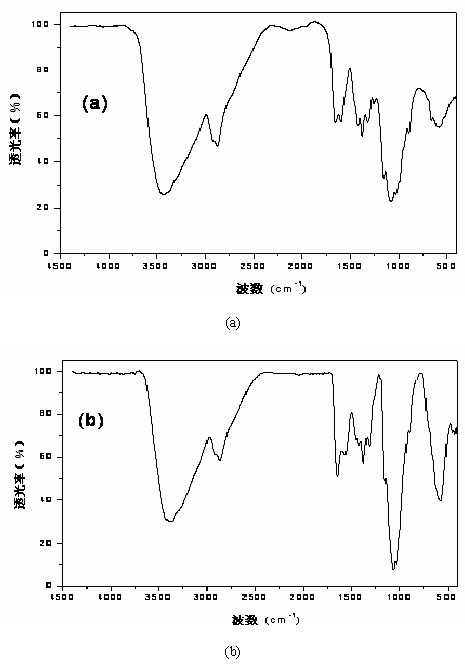

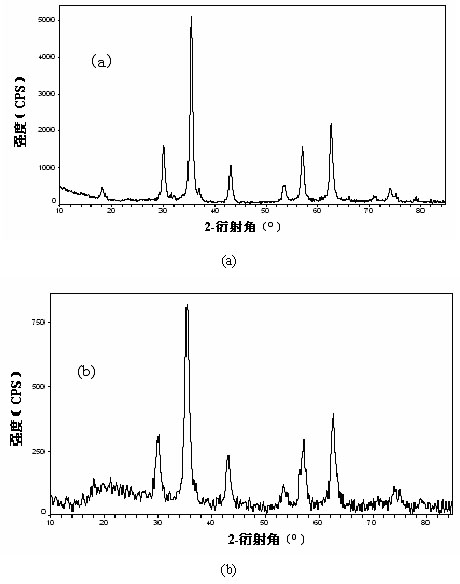

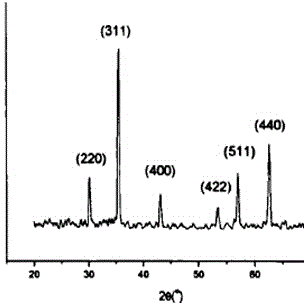

Preparation method of stable nano ferroferric oxide magnetofluid

InactiveCN104528837ASlow growth rateHigh crystallinityMaterial nanotechnologyNanomagnetismSynthesis methodsBiocompatibility Testing

The invention belongs to the technical field of the preparation of iron oxide magnetofluids and particularly relates to an aqueous reduction based synthesis method of superparamagnetic ferroferric oxide nanoparticles. According to the aqueous reduction based synthesis method, an inorganic metal water-soluble compound (ferric salt) serves as an iron source, a reducing compound and a stabilizer which can be coordinated with iron serve as raw materials, and reduction reaction is carried out in an aqueous solution to generate the ferroferric oxide magnetofluid in situ. The aqueous reduction based synthesis method provided by the invention has the advantages of mild reaction condition and good repeatability, is easy to operate and safe, and the ferroferric oxide nanoparticles prepared by adopting the aqueous reduction based synthesis method overcome the defects that the ferroferric oxide particles prepared by adopting the traditional aqueous co-precipitation method are easy to agglomerate, can not be dispersed uniformly and are affected in application. The ferroferric oxide nanoparticles with stable performance are prepared successfully by adopting the aqueous reduction based synthesis method, and the ferroferric oxide nanoparticles have good biocompatibility, can form the magnetofluid in an aqueous solution and can be widely applied to the biomedical fields of magnetic resonance imaging, magnetofluid thermotherapy, cell separation, protein separation, DNA purification, immunodetection, magnetically targeted medicine carriers.

Owner:SHENYANG PHARMA UNIVERSITY

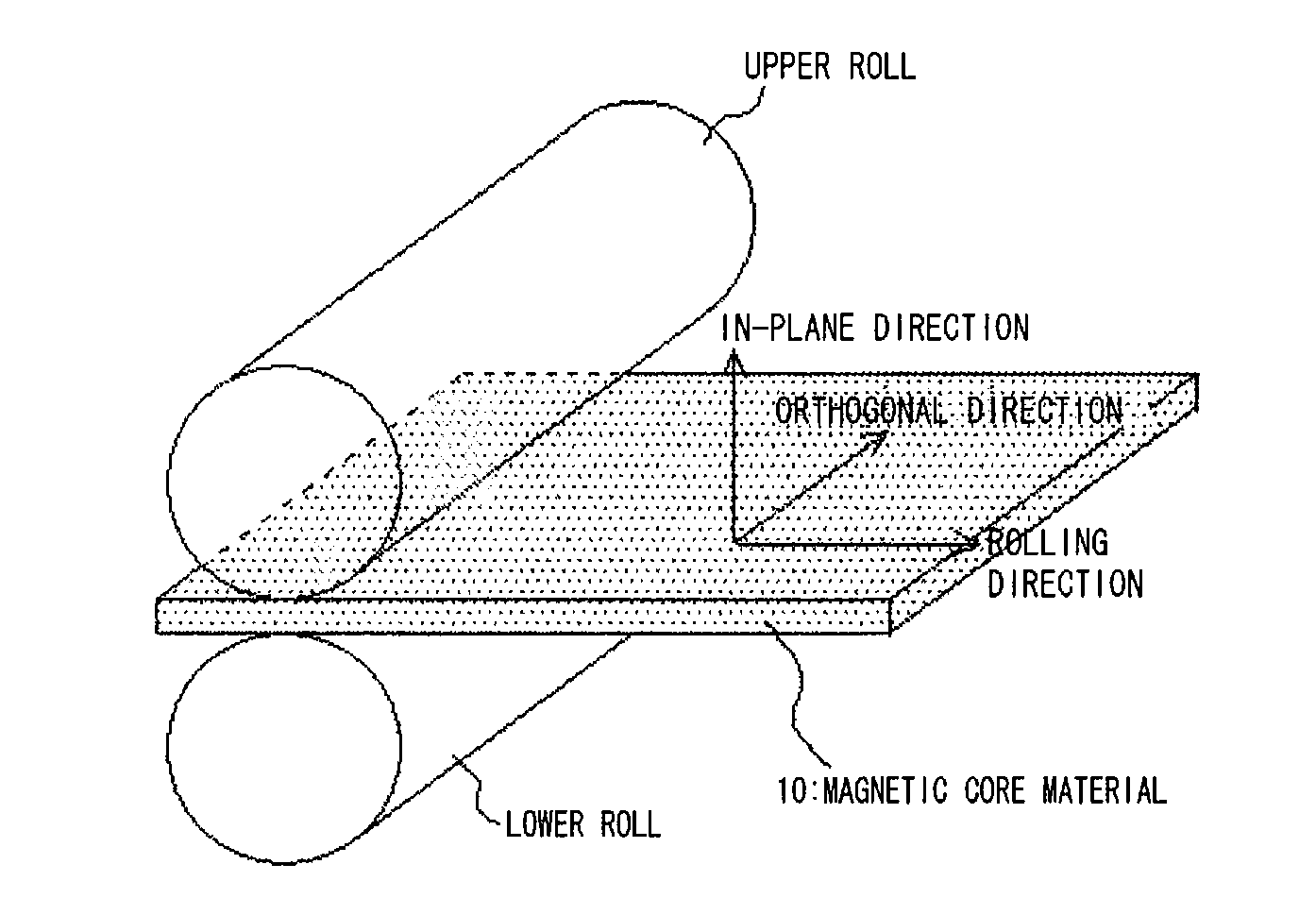

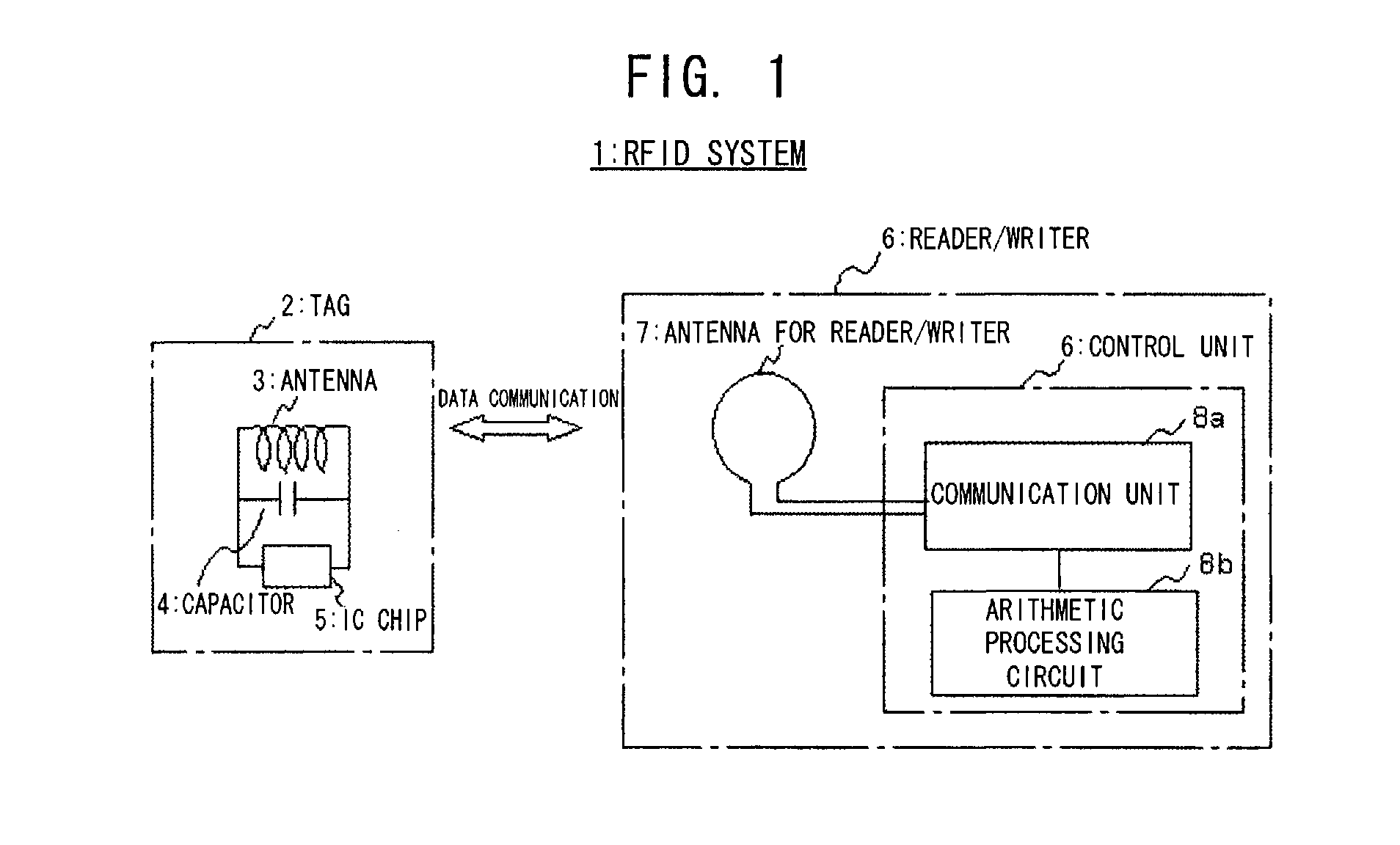

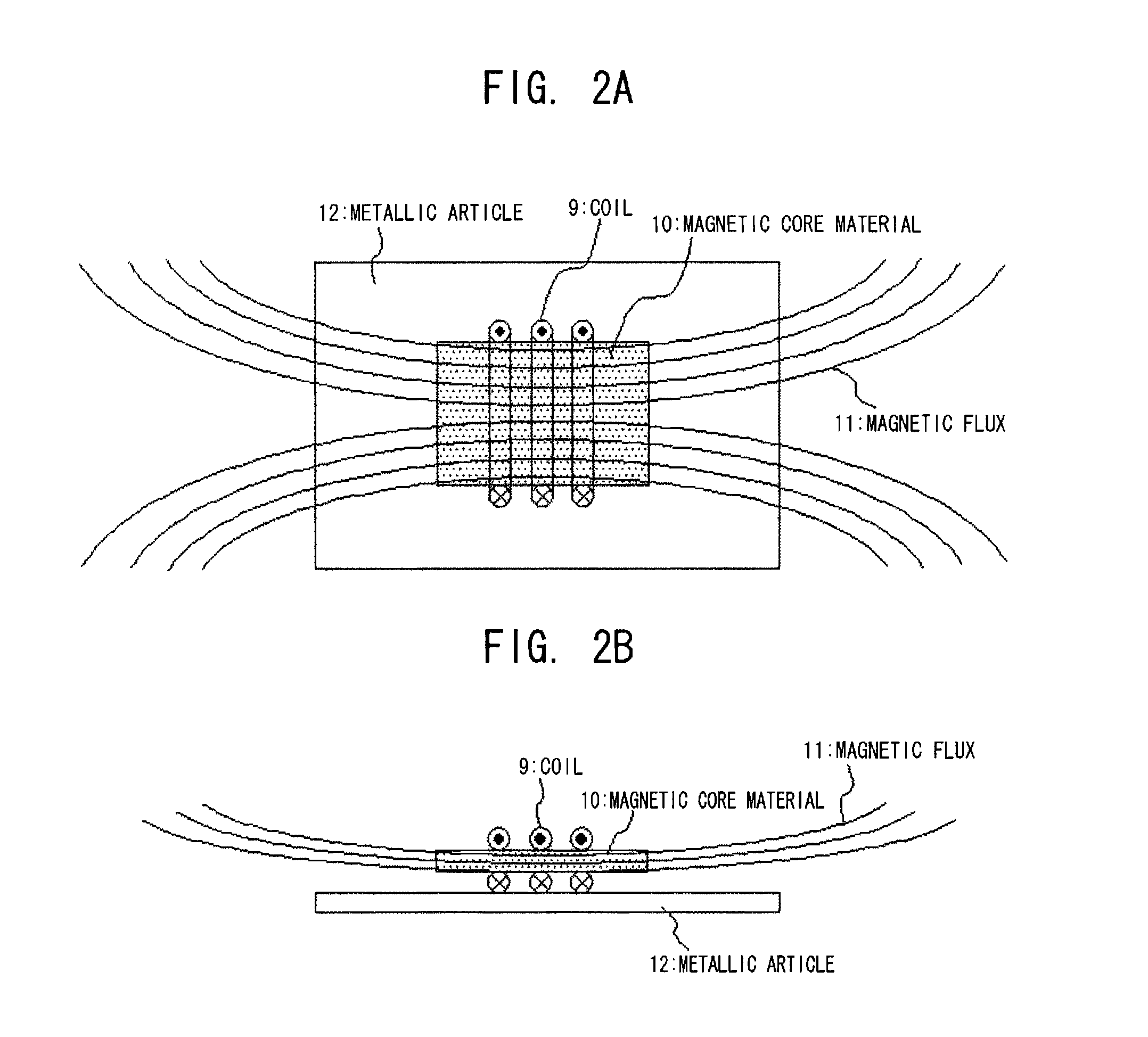

High-frequency magnetic core material, its manufacturing method, and antenna including the magnetic core material

InactiveUS20080003457A1Improve permeabilityHigh dimensional accuracyLoop antennas with ferromagnetic coreOther printing matterMetal powderMagnetic core

A soft magnetic metal powder having a predetermined particle size (about 1 μm) or less is kneaded with plastic or rubber in a volume ratio of about 10% to 50%, and preferably, in a content of 10% to 40%, and the kneaded composite is subjected to working which extends a composite material in one direction, such as extruding, rolling, rolling after extruding, drawing after extruding, or rolling after injection. As a result, the magnetic permeability can be enhanced, the direction dependency can be given to magnetic permeability, the dimensional accuracy can be improved, and the magnetic core material can be made hard to be damaged.

Owner:MITSUBISHI MATERIALS CORP

Binding a target substance

InactiveUS20060188876A1Maximise bindingEfficient separationBioreactor/fermenter combinationsBiological substance pretreatmentsMaterials scienceLiquid phase

Magnetic particles capable of binding a target substance, which comprise a magnetic material and a matrix material, wherein the magnetic material is remanent upon exposure to a magnetic field and the matrix material has a surface comprising functional groups which promote disaggregation of the particles in the presence of a liquid phase.

Owner:SINVENT AS

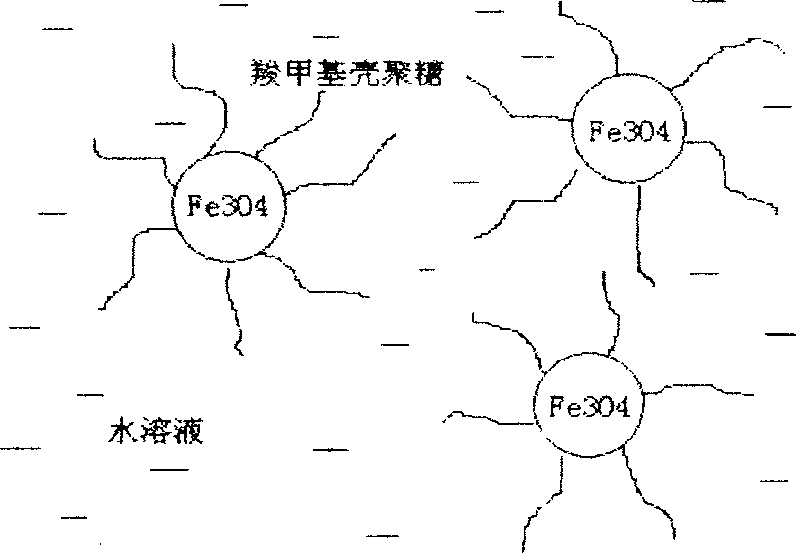

Water-based magnetic liquid and method for making same

InactiveCN1702782AFirmly connectedRich chitin resourcesMagnetic liquidsInductances/transformers/magnets manufactureState of artWater based

This invention relates to water base Fe3O4 magnetic liquid process and provides one water base magnetizing liquid and its process method. This invention adopts shell chitose ramification of CM-sephadex-C25 as surface activity agent to synthesize the Fe3O4 water base magnetizing liquid.

Owner:SUN YAT SEN UNIV

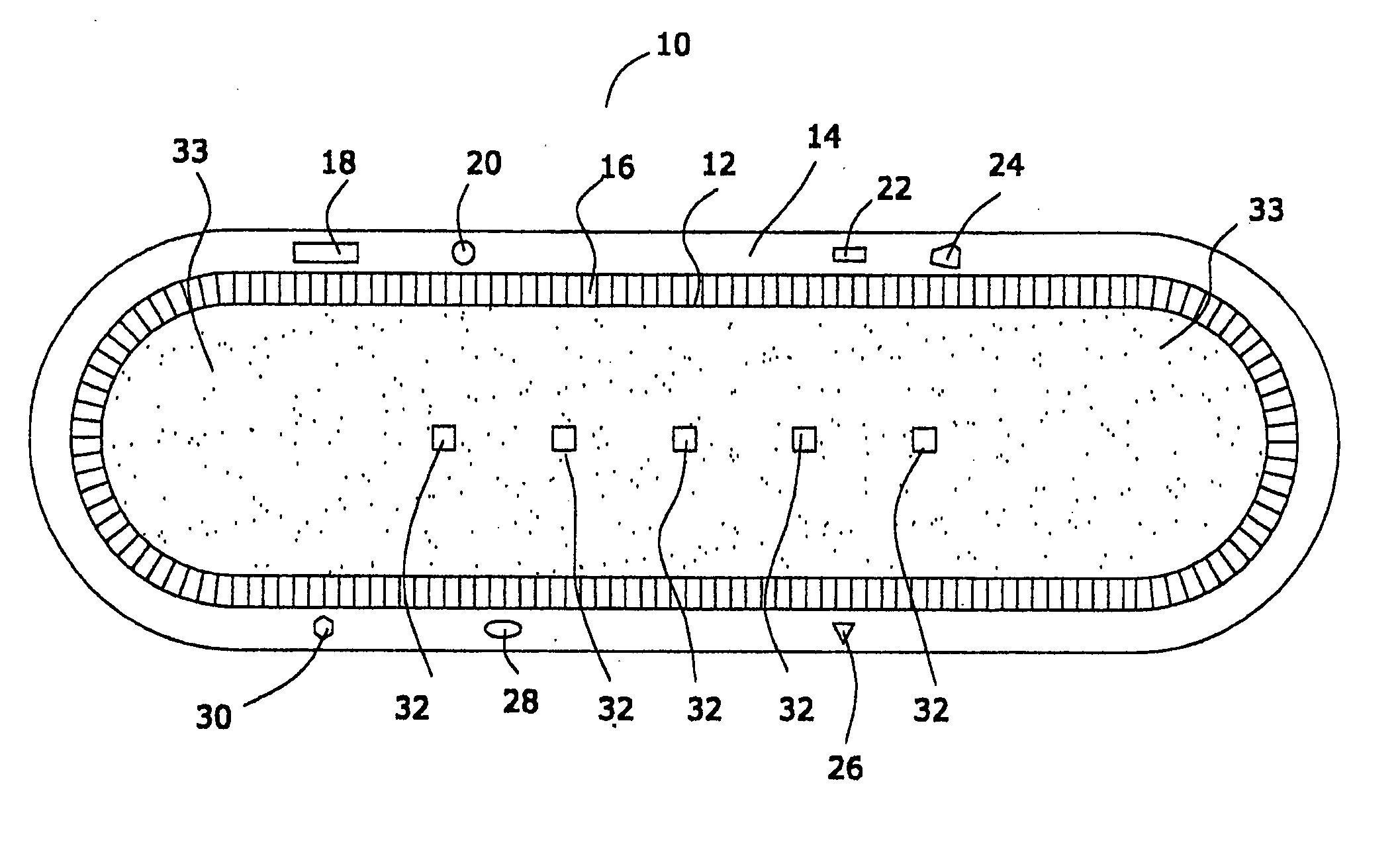

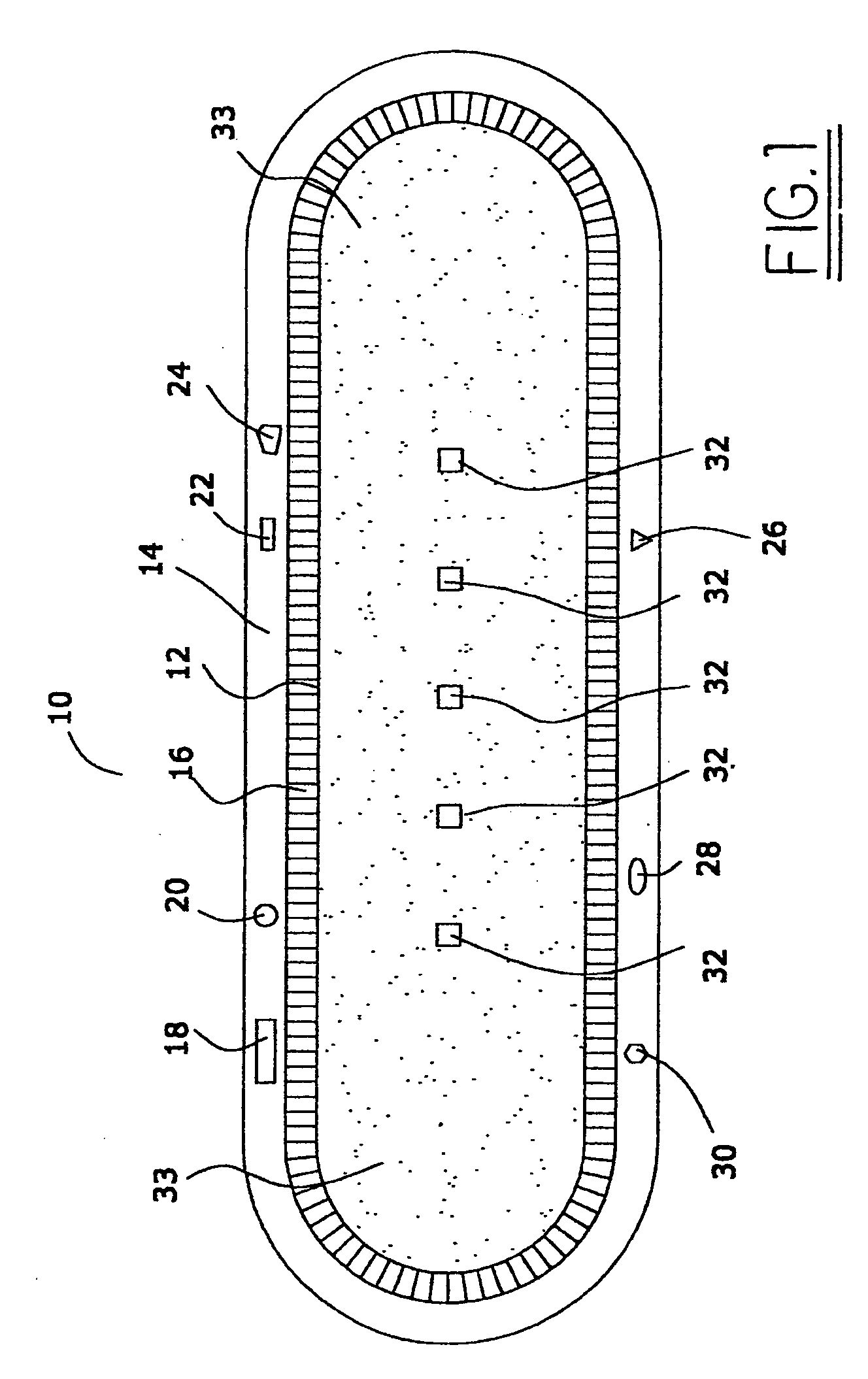

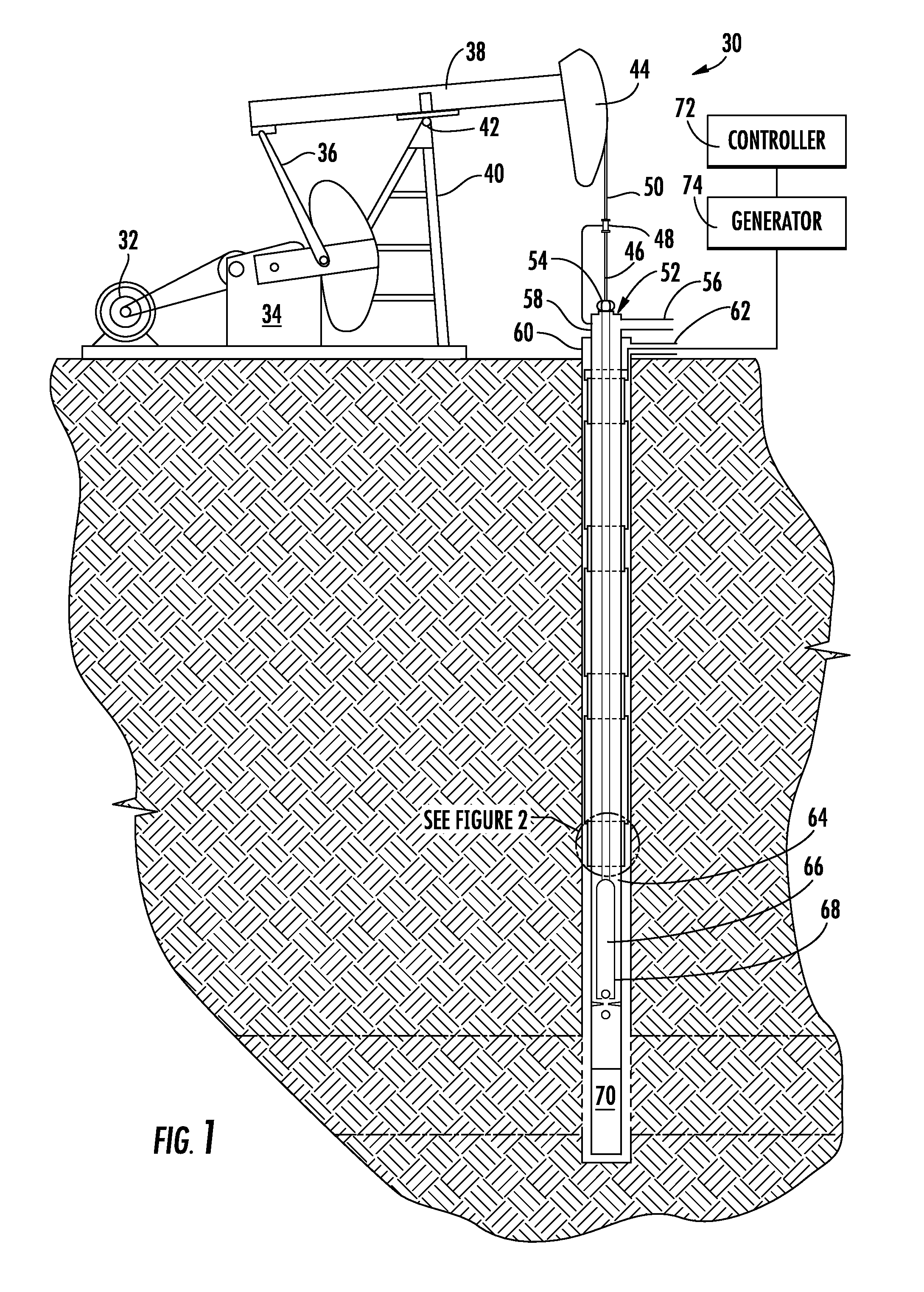

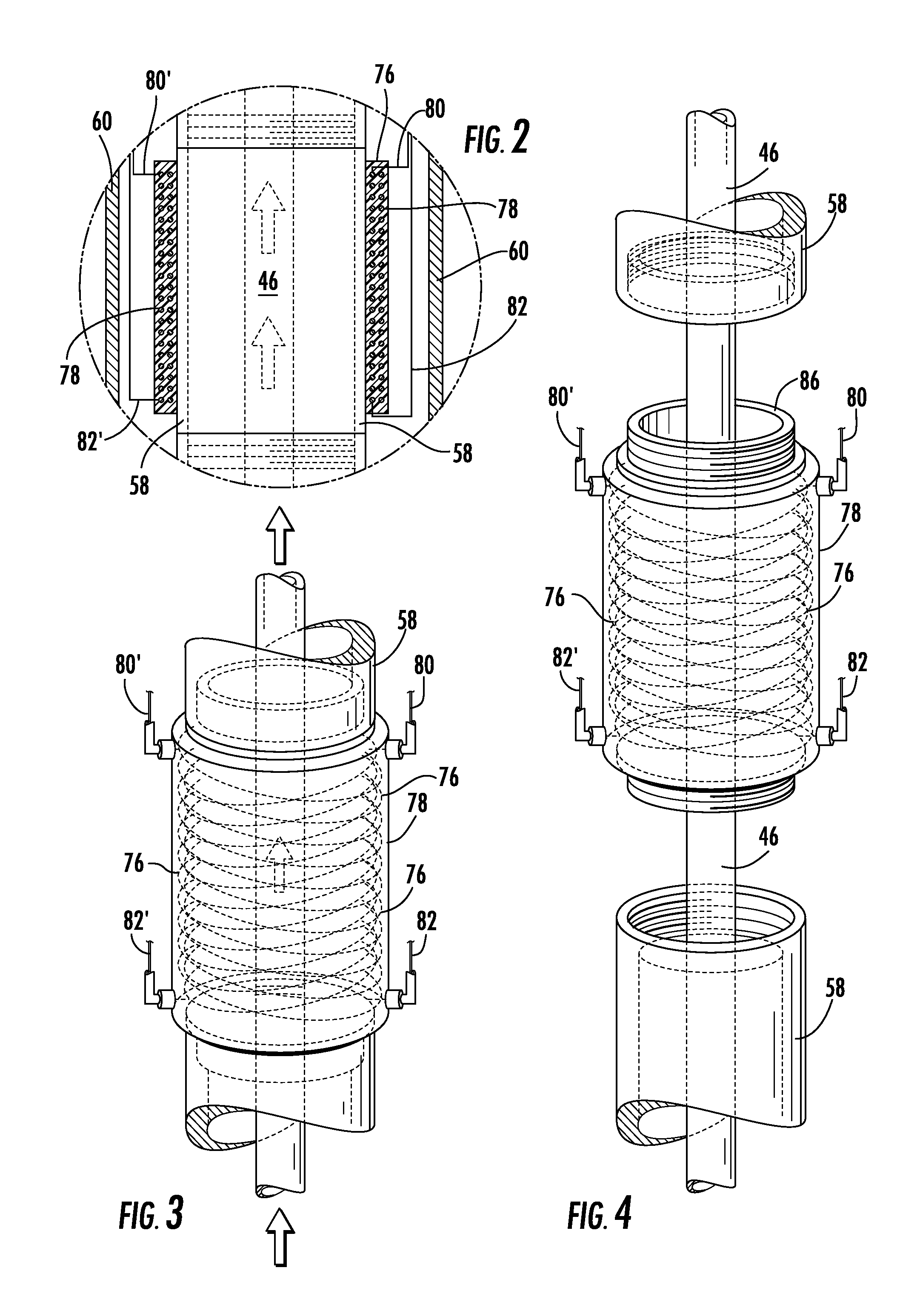

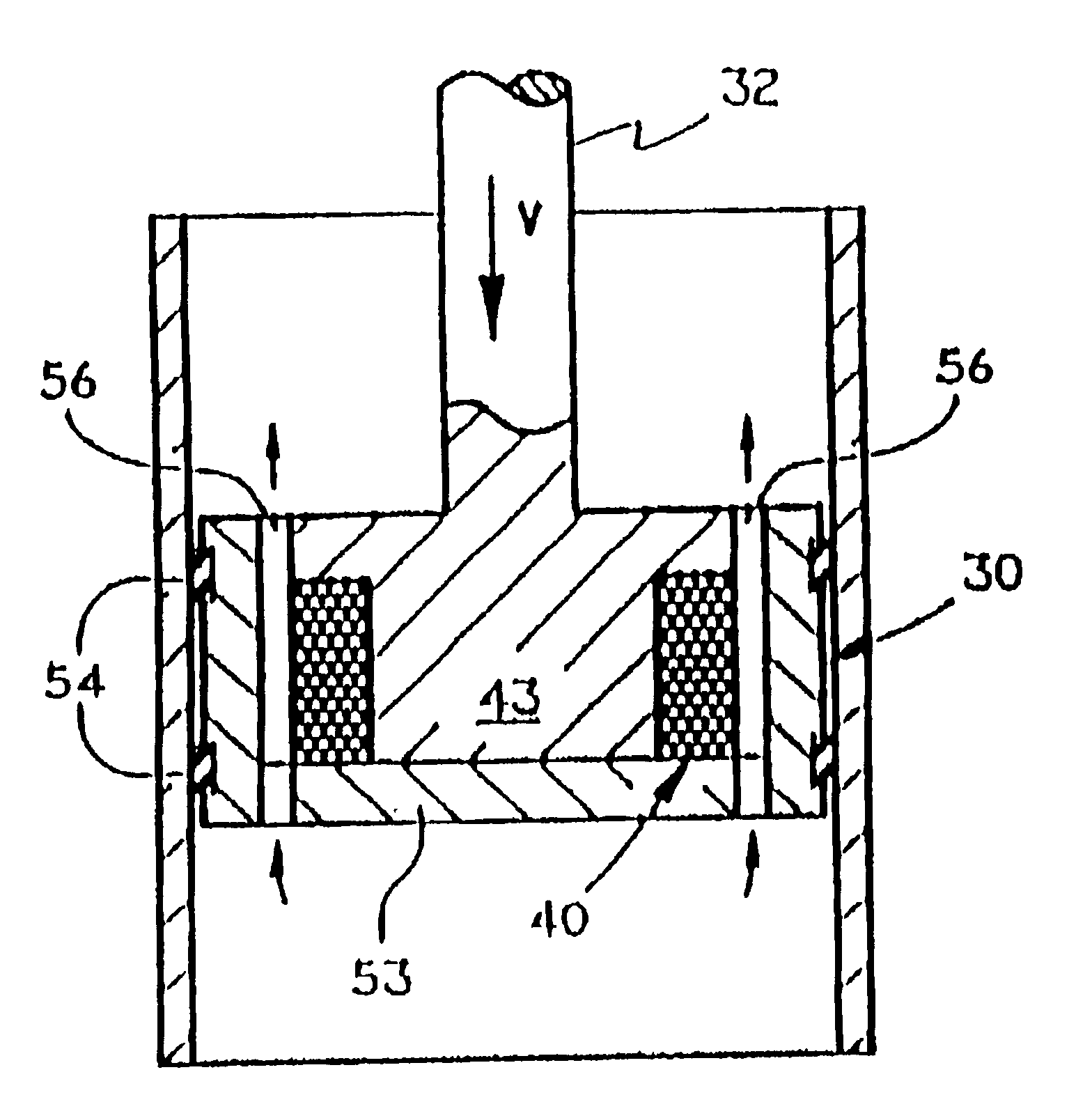

Apparatus and method for magnetically conditioning fluids

InactiveUS20130192682A1Increase oil extractionAvoid corrosionWater treatment parameter controlSpecific water treatment objectivesElectrical conductorEngineering

Methods and apparatus for fluid conditioning to reduce scaling, inactivate microbes, reduce surface tension, maintain fluid composition, and improve pumping are provided for use in treating crude petroleum, industrial water, agricultural water, municipal water supplies, or any fluid flow system and comprise electromagnets of variable control that can be powered or in which a current can be induced by a permanent magnet. Magnetic field direction and intensity can be selected depending on the nature of the fluid and in some embodiments, the field can be varied during operation, including pulsing and variably selecting one or more field directions and intensities, or combinations thereof, during operation. A non-magnetic fluid transfer conduit section has at least one conductor assembly mounted about the section. In one embodiment, the conductor assembly comprises a concentric, tilted double helix coil or multipole coil. If desired, one or more rotating or reciprocating permanent magnets may be located in magnetic field contact with one or more multipole conductor assemblies and rotated or reciprocated to induce a current in the multipole conductor assembly, thereby to induce a magnetic field in the conductor assembly.

Owner:ENVIRONMENTAL TECH INT

Magnetorheological fluid multi-stage treatment device and control method and component manufacturing method thereof

ActiveCN105457392AWell mixedSpeed up the reaction processMagnetic liquidsMembrane filtersMagnetorheological fluidEngineering

The invention discloses a magnetorheological fluid multi-stage treatment device and a control method and component manufacturing method thereof and belongs to the technical field of machine manufacturing. The magnetorheological fluid multi-stage treatment device comprises a preposition piston cylinder, a middle piston cylinder, a postposition piston cylinder, a preposition piston, a middle piston, a postposition piston, a preposition filtering box, a middle filtering box, a postposition filtering box, a preposition filtering mesh, a middle filtering mesh and a postposition filtering mesh. The preposition piston cylinder is connected with the preposition piston through a bolt, the preposition bolt is matched with an inner cavity of the preposition filtering box, the preposition filtering box is vertically arranged, and the axis is in the vertical direction; meanwhile, the invention further provides corresponding control method and a key component manufacturing method of the device. According to the magnetorheological fluid multi-stage treatment device and the control method and component manufacturing method thereof, a two-standing three-filtering mode is adopted to filter mixed liquid, the characteristic of the mixed liquid at each stage is fully utilized, and the purpose of fast and thoroughly separating magnetic substances and solvent is finally achieved.

Owner:浙江永金生物科技有限公司

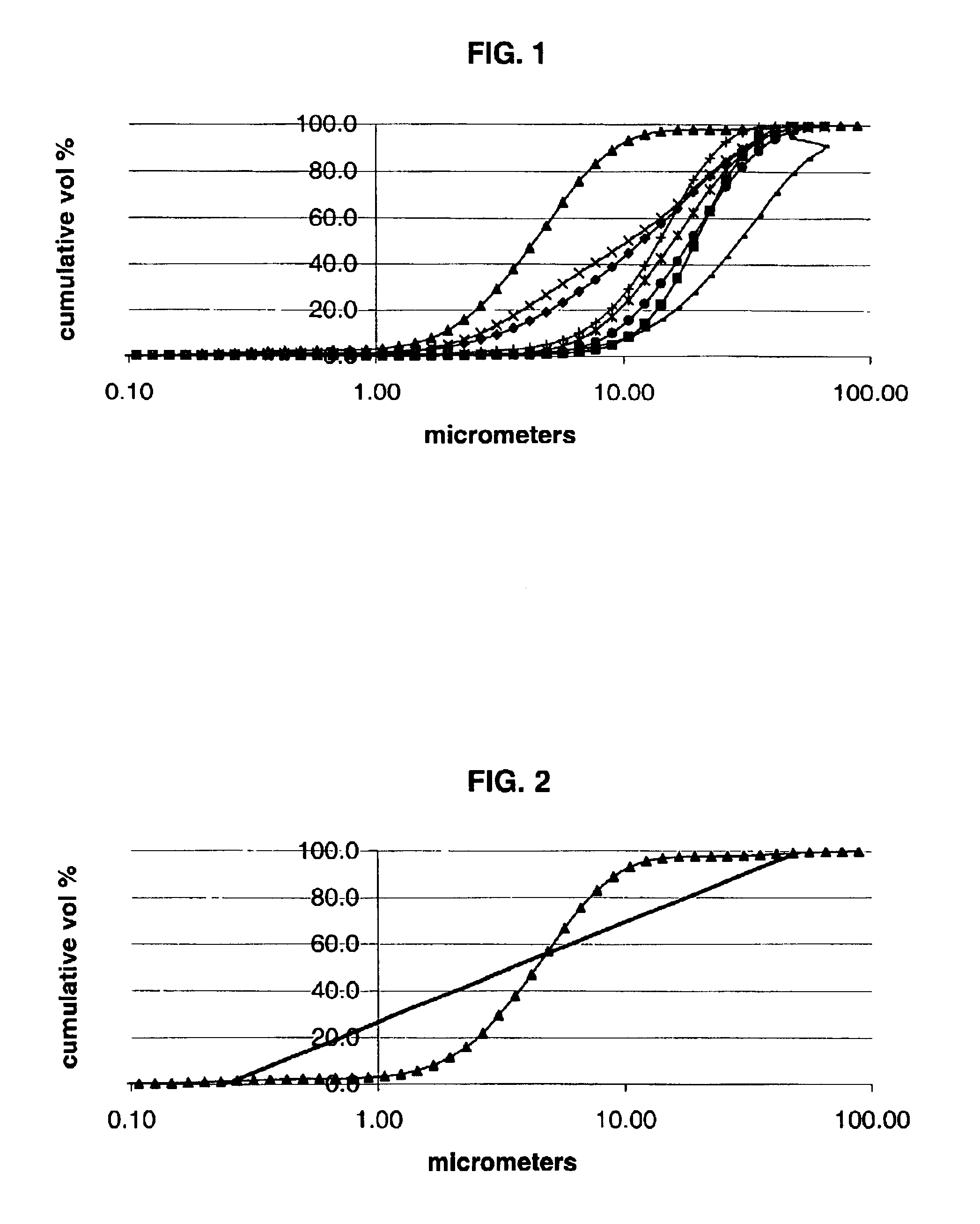

MR fluid for increasing the output of a magnetorheological fluid damper

InactiveUS6886819B2Reduces interparticle frictionMachine framesNon-rotating vibration suppressionSingle processMagnetorheological fluid

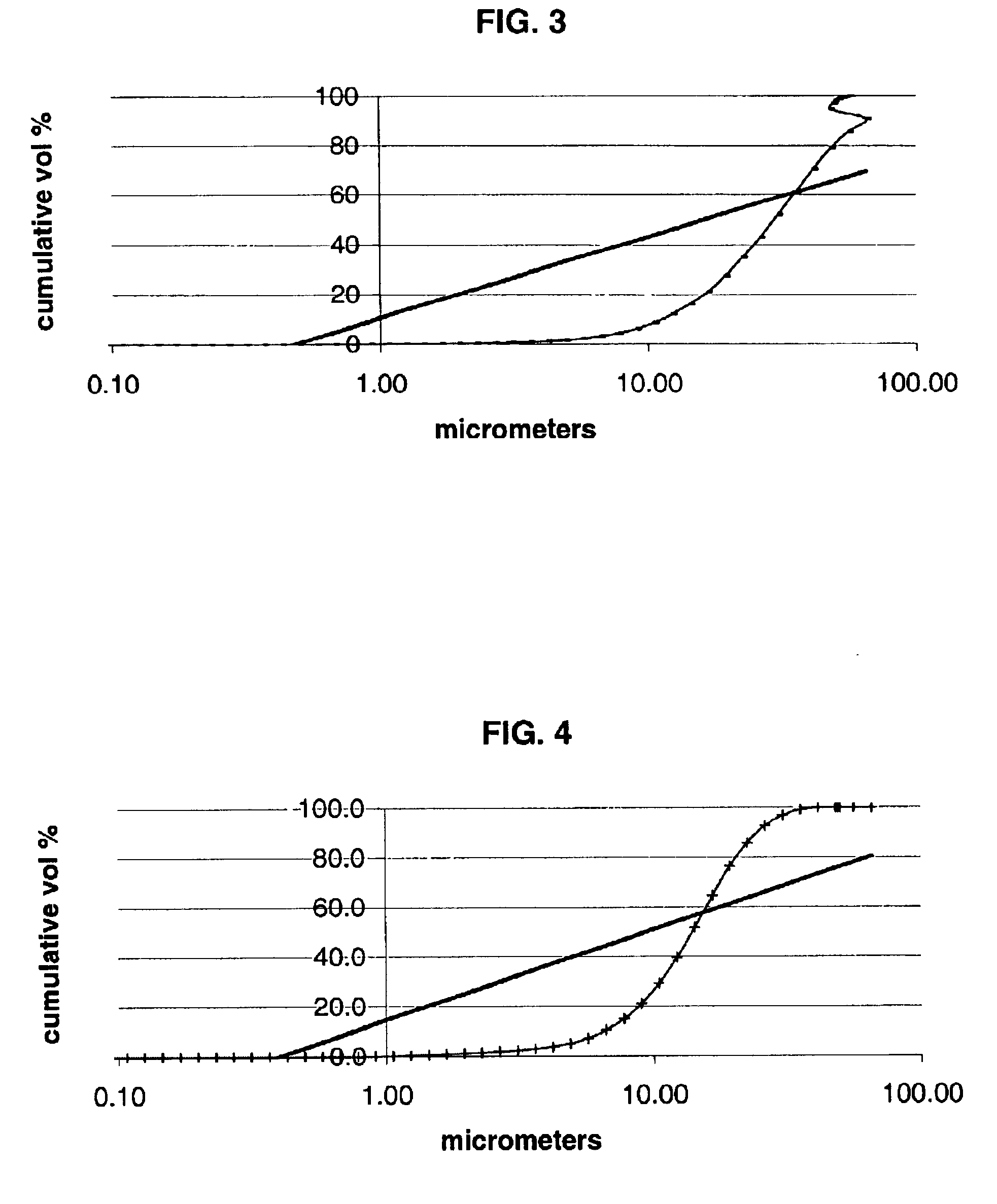

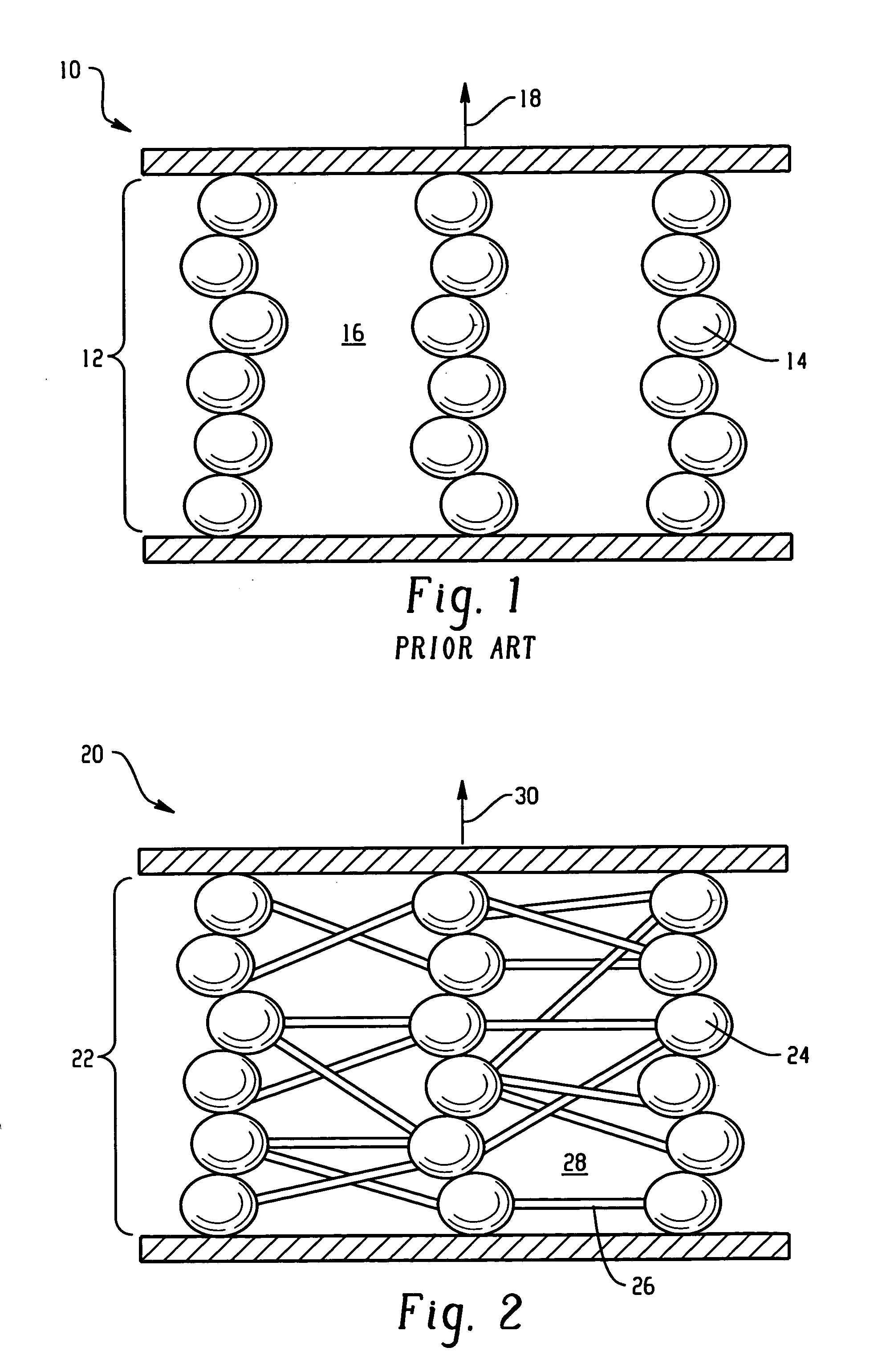

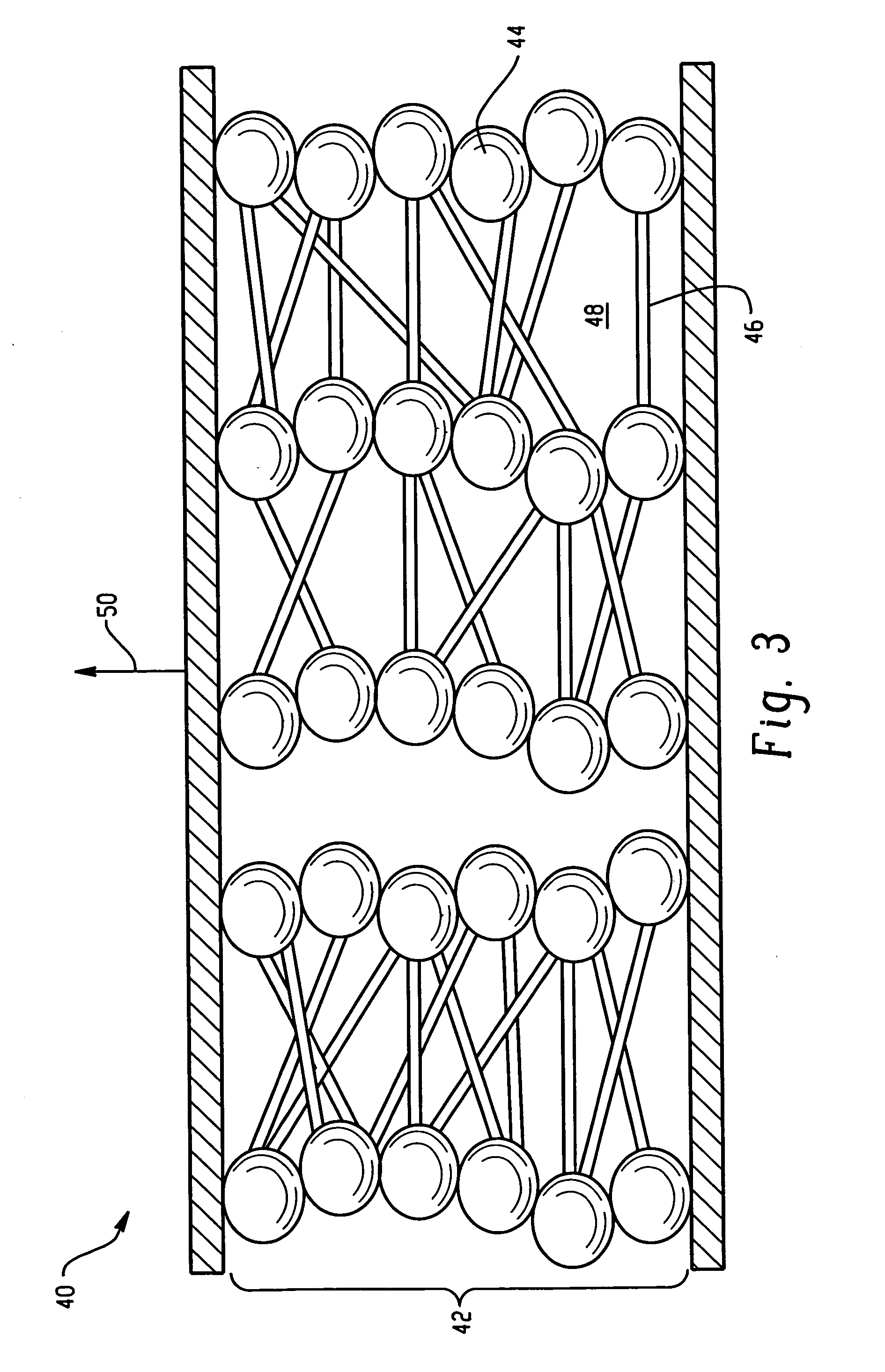

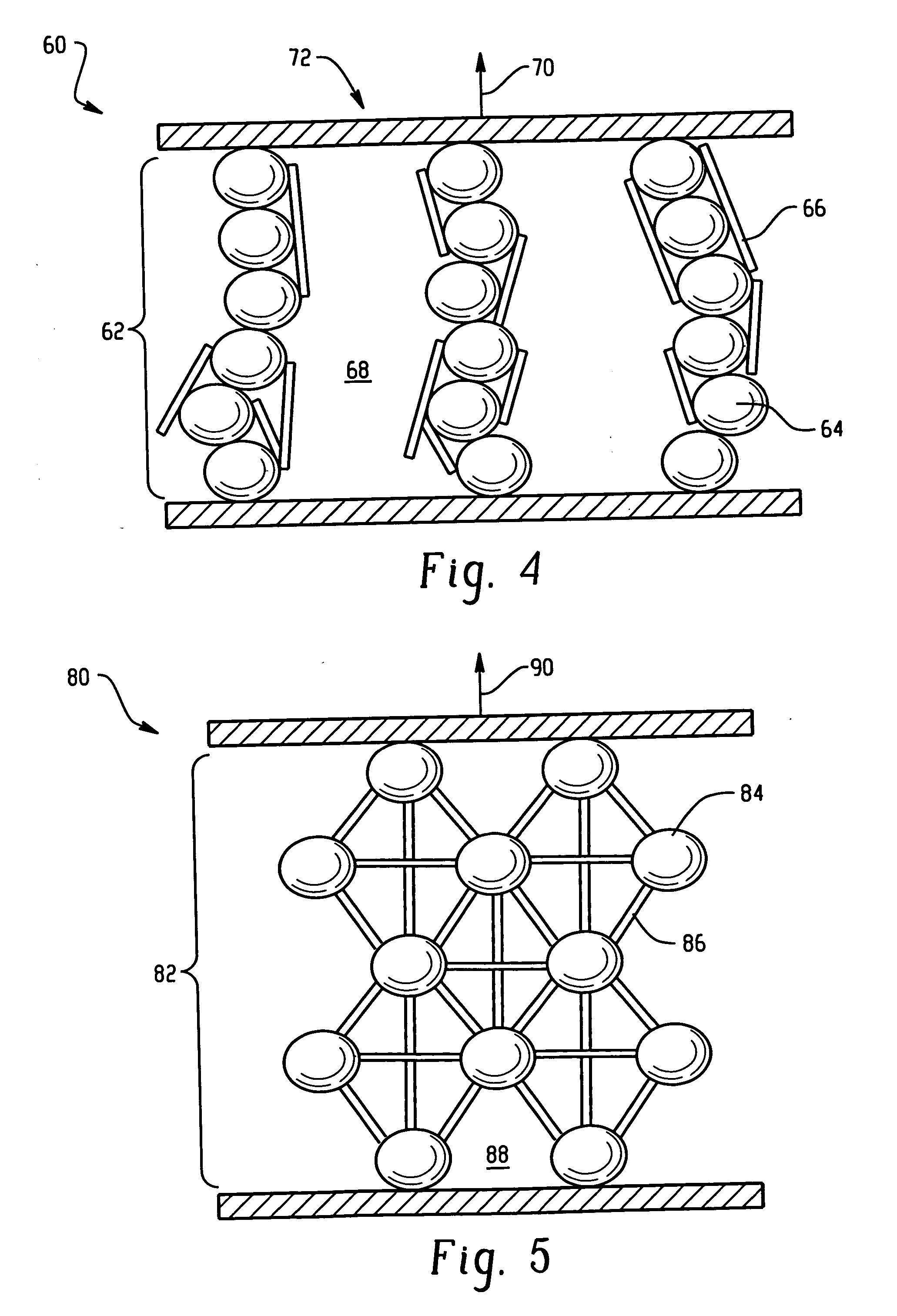

Magnetorheological devices, including damping devices, rotary devices, and haptic systems constructed with said devices are disclosed. The devices contain dry magnetically-responsive particles, or MR fluids containing the magnetically responsive particles. The magnetically soft particles characterized by a single process yield population of atomized particles having a cumulative 10%, 50% and 90% by volume, fraction within specified size, i.e., D10 of from 2 up to and including a D10 of 5 μm, a D50 8 μm up to and including a D50 of 15 μm, a D90 of 25 μm up to and including a D90 of 40 μm, and characterized by a least squares regression of log normal particles size against cumulative volume % fraction of greater than or equal to 0.77.

Owner:LORD CORP

Magnetorheological fluid compositions

InactiveUS20060033068A1Other chemical processesMagnetic liquidsMagnetic currentMagnetorheological fluid

A magnetorheological fluid composition comprising a low aspect ratio magnetizable particle comprising a unimodal particle distribution and an aspect ratio less than 1.5, a high aspect ratio magnetizable particle comprising an aspect ratio greater than 1.5, and a carrier fluid.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com