Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Magnetorheological finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetorheological finishing (MRF) is a precision surface finishing technology. Optical surfaces are polished in a computer-controlled magnetorheological (MR) finishing slurry. Unlike conventional rigid lap polishing, the MR fluid's shape and stiffness can be magnetically manipulated and controlled in real time. The optic's final surface form and finishing results are predicted through the use of computer algorithms.

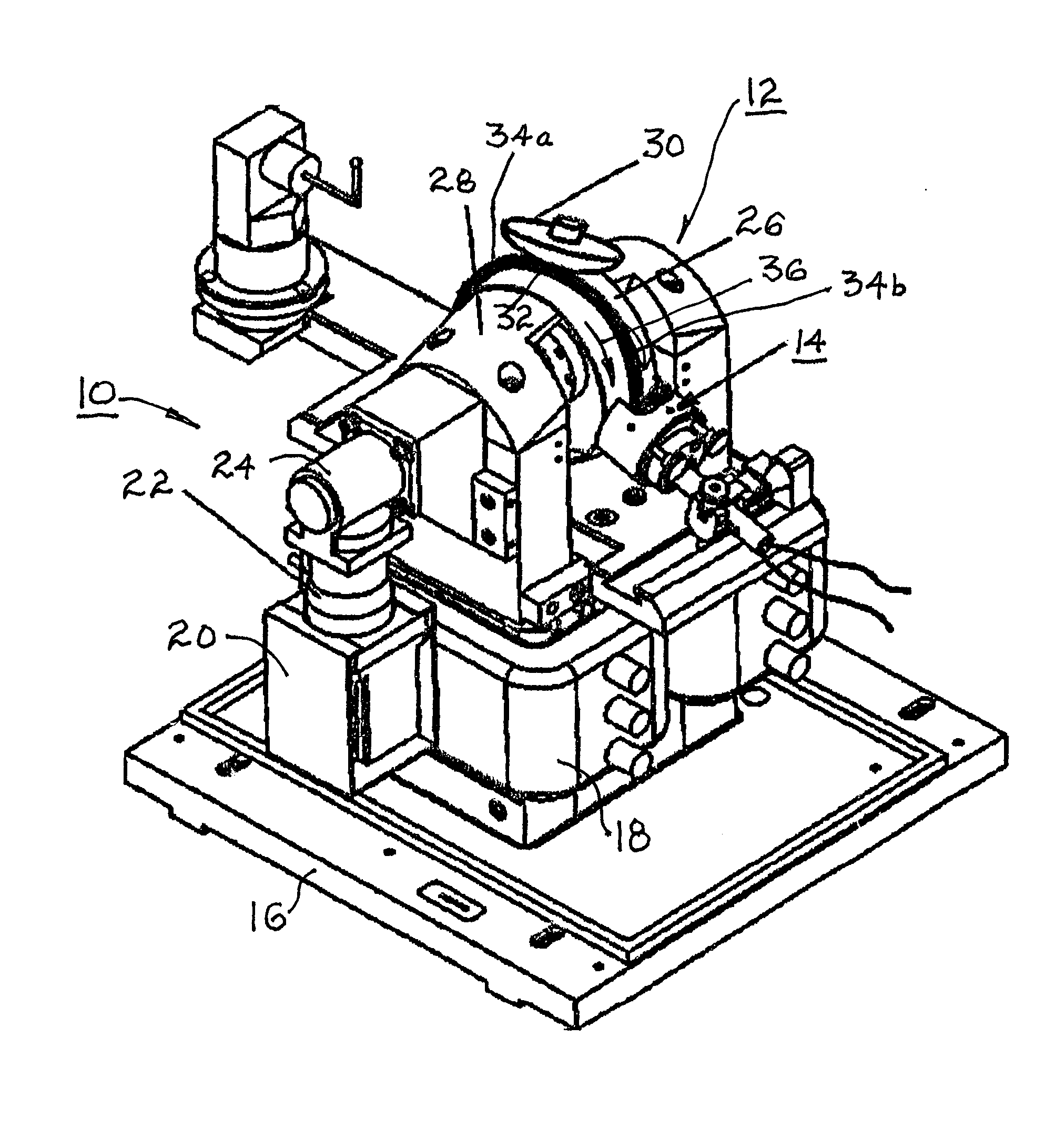

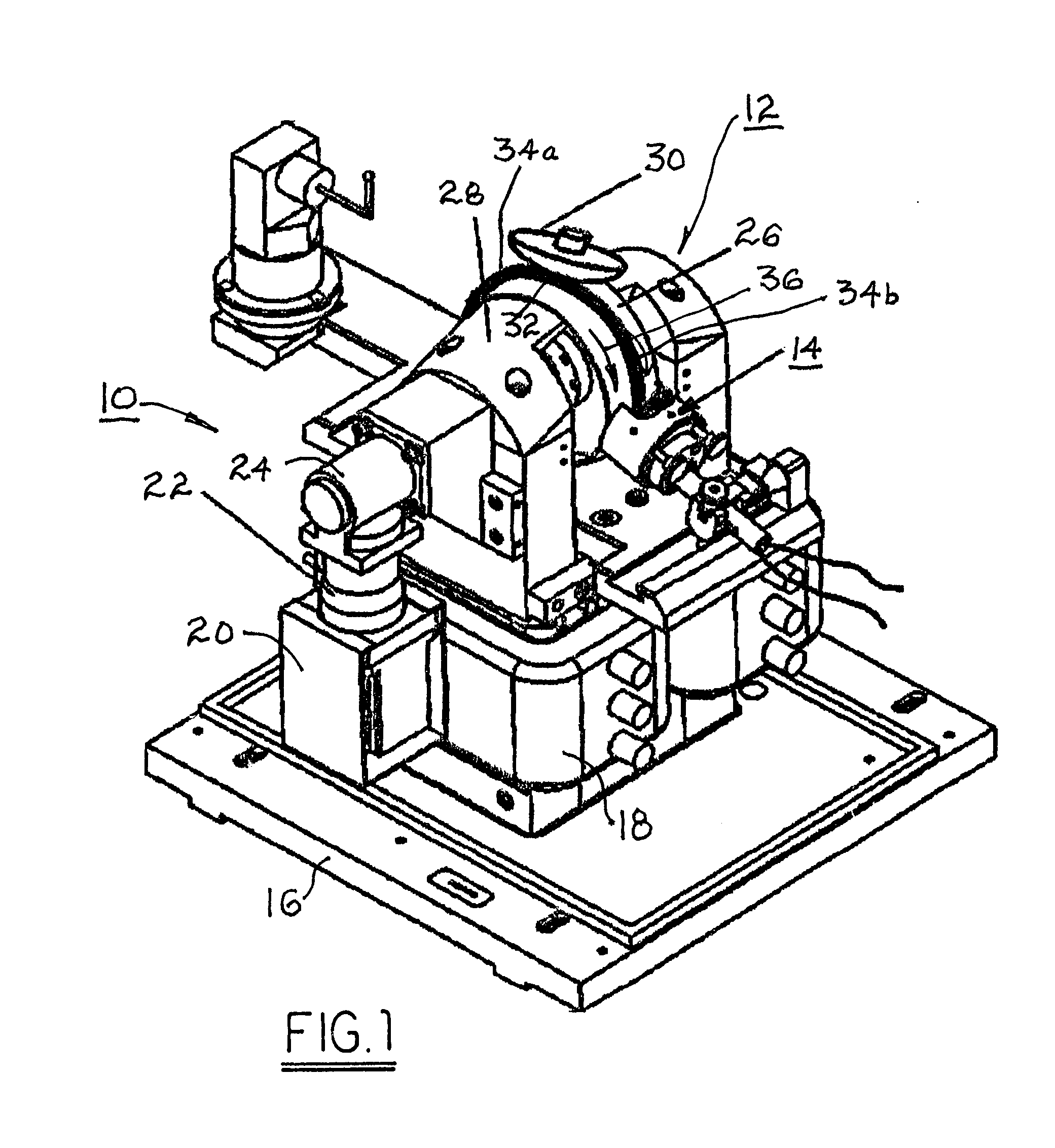

Deterministic magnetorheological finishing

InactiveUS6106380AConstantHigh viscosityEdge grinding machinesNanomagnetismMaterial removalMagnetorheological finishing

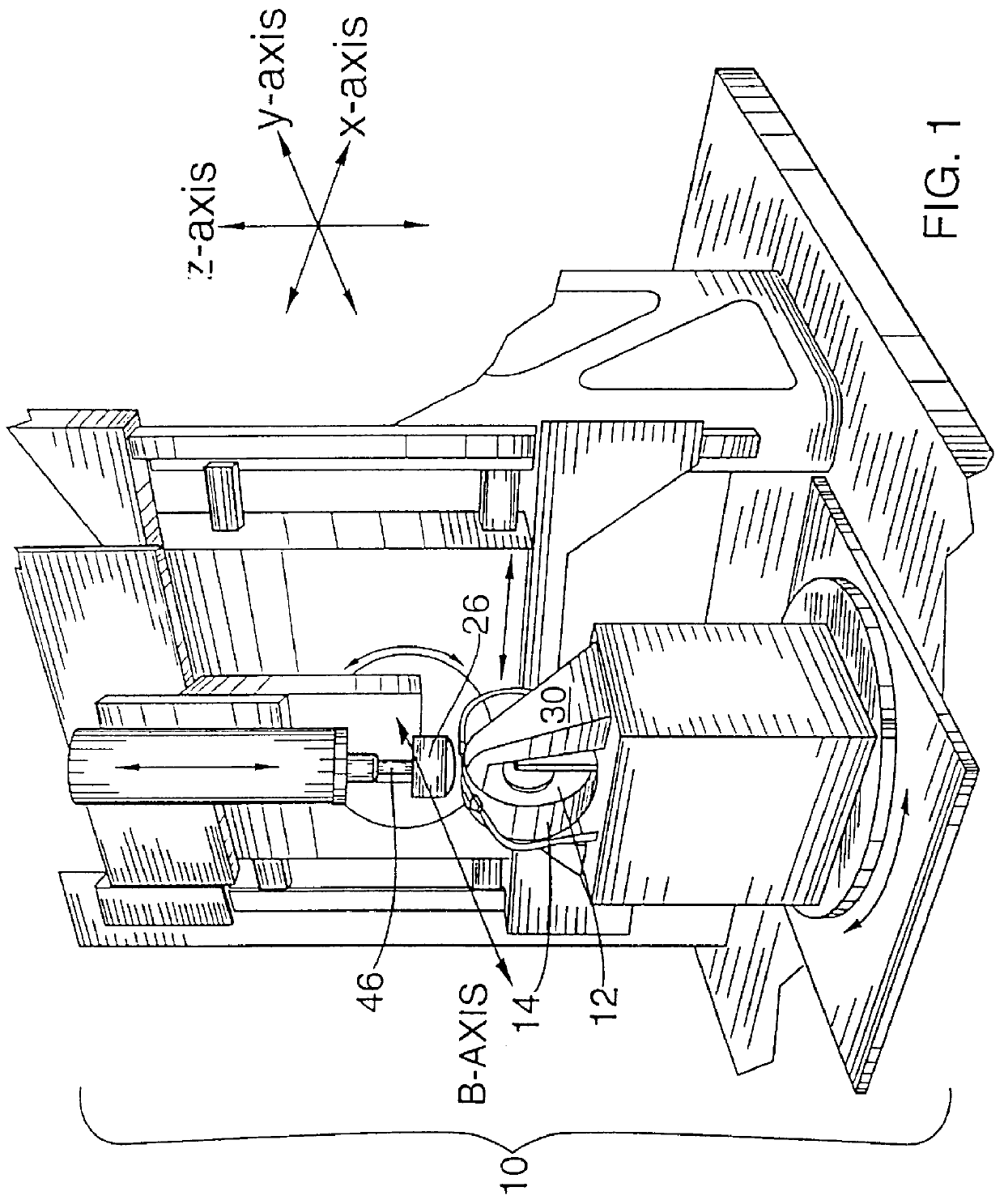

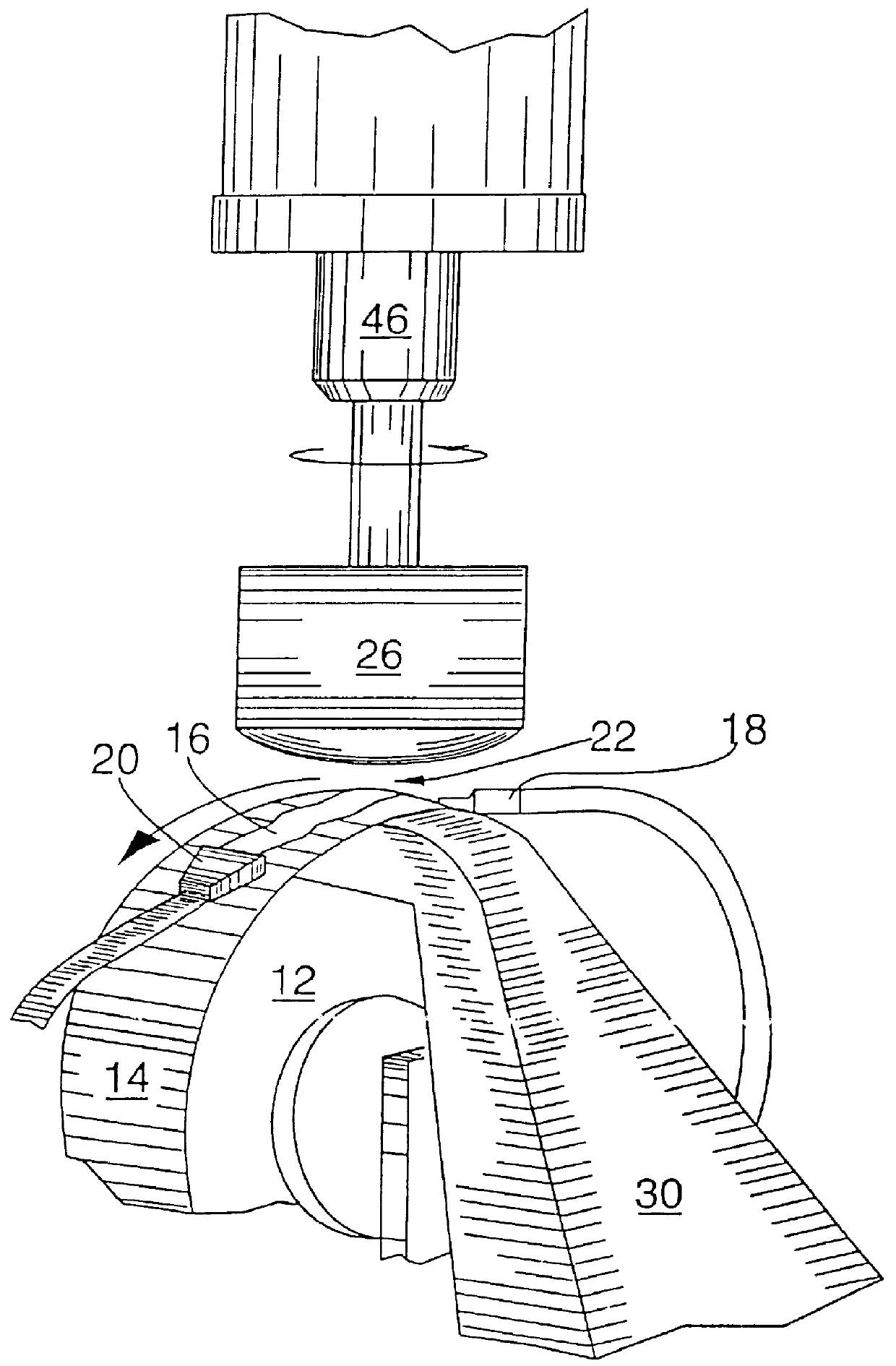

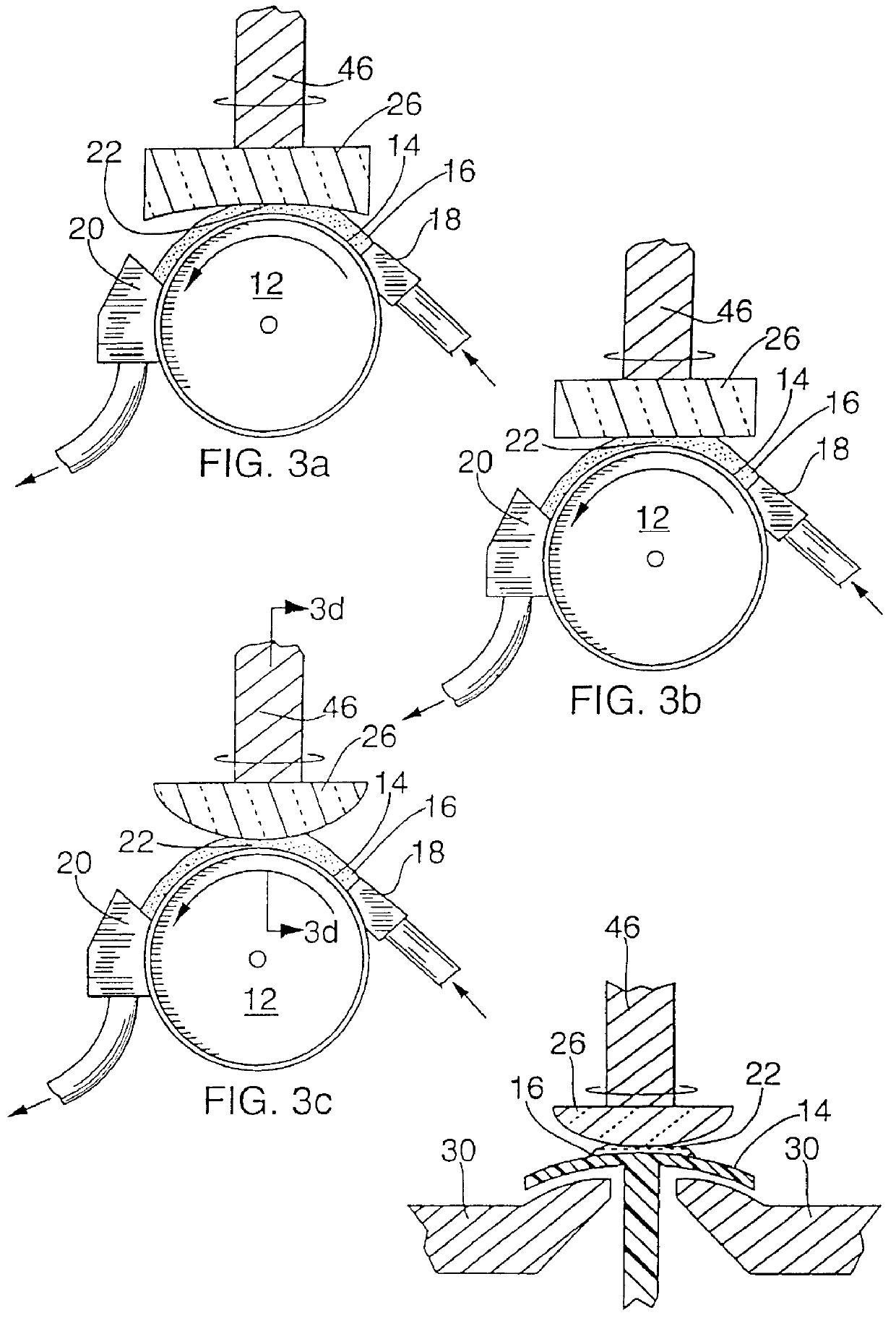

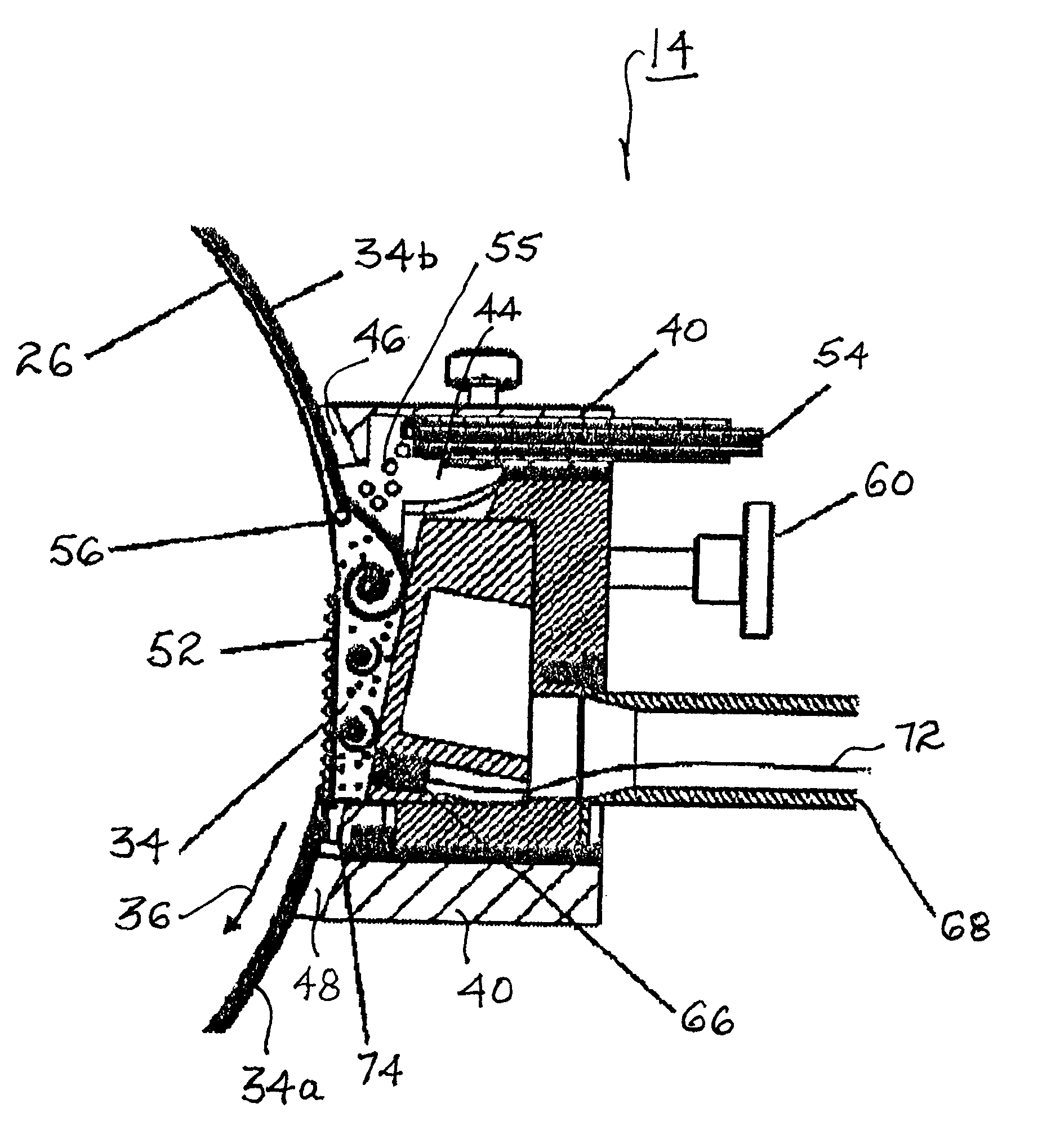

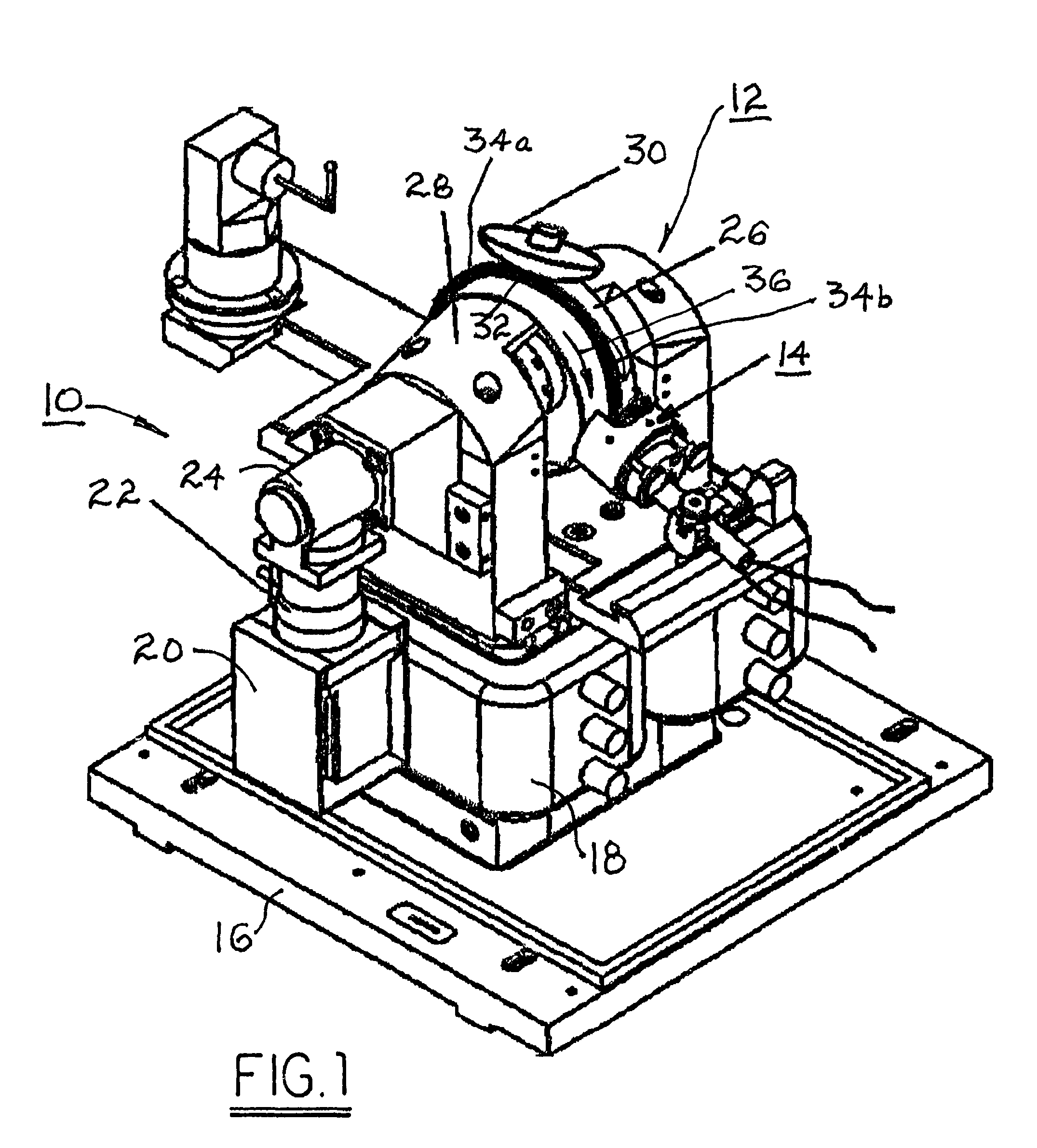

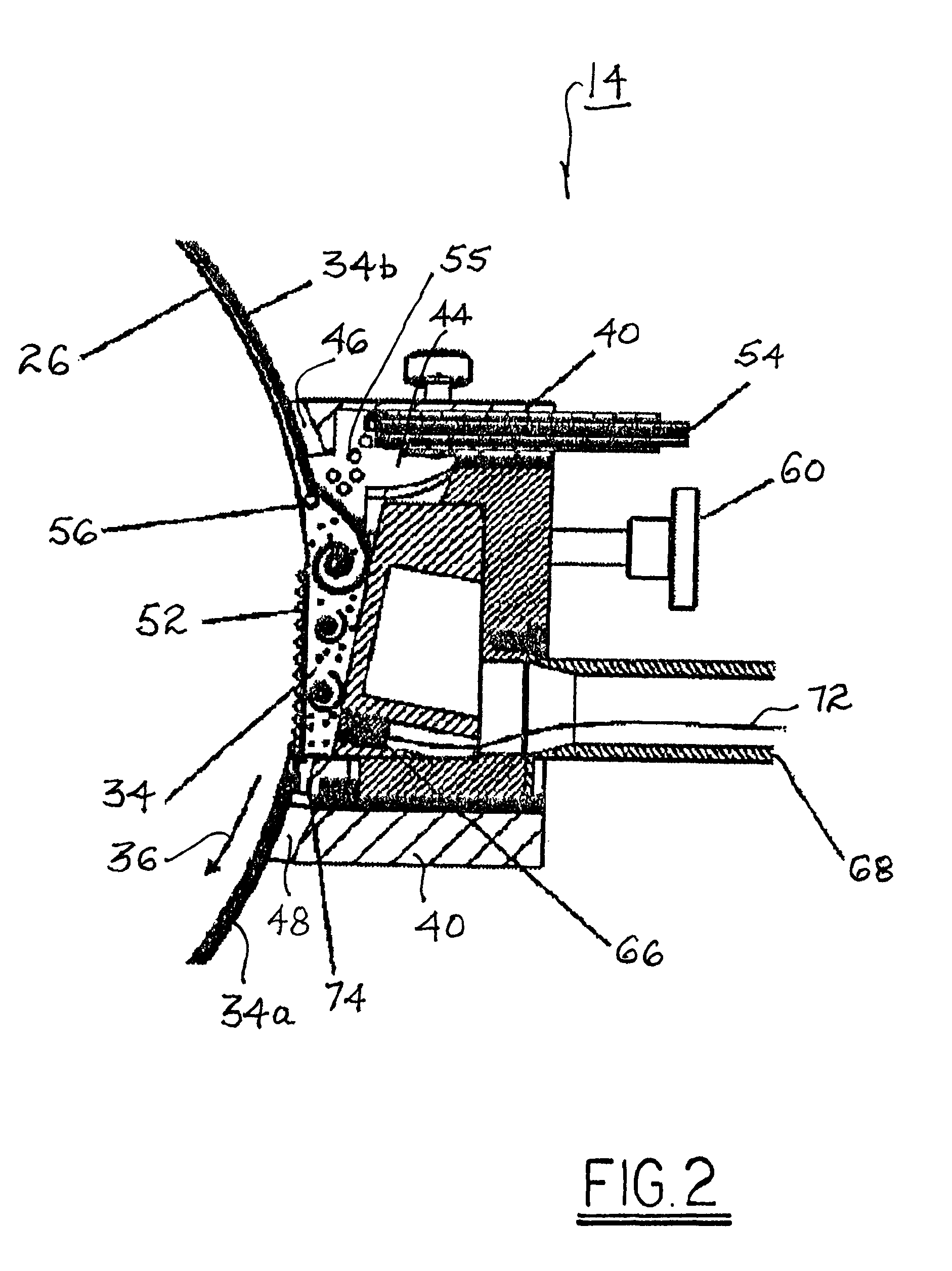

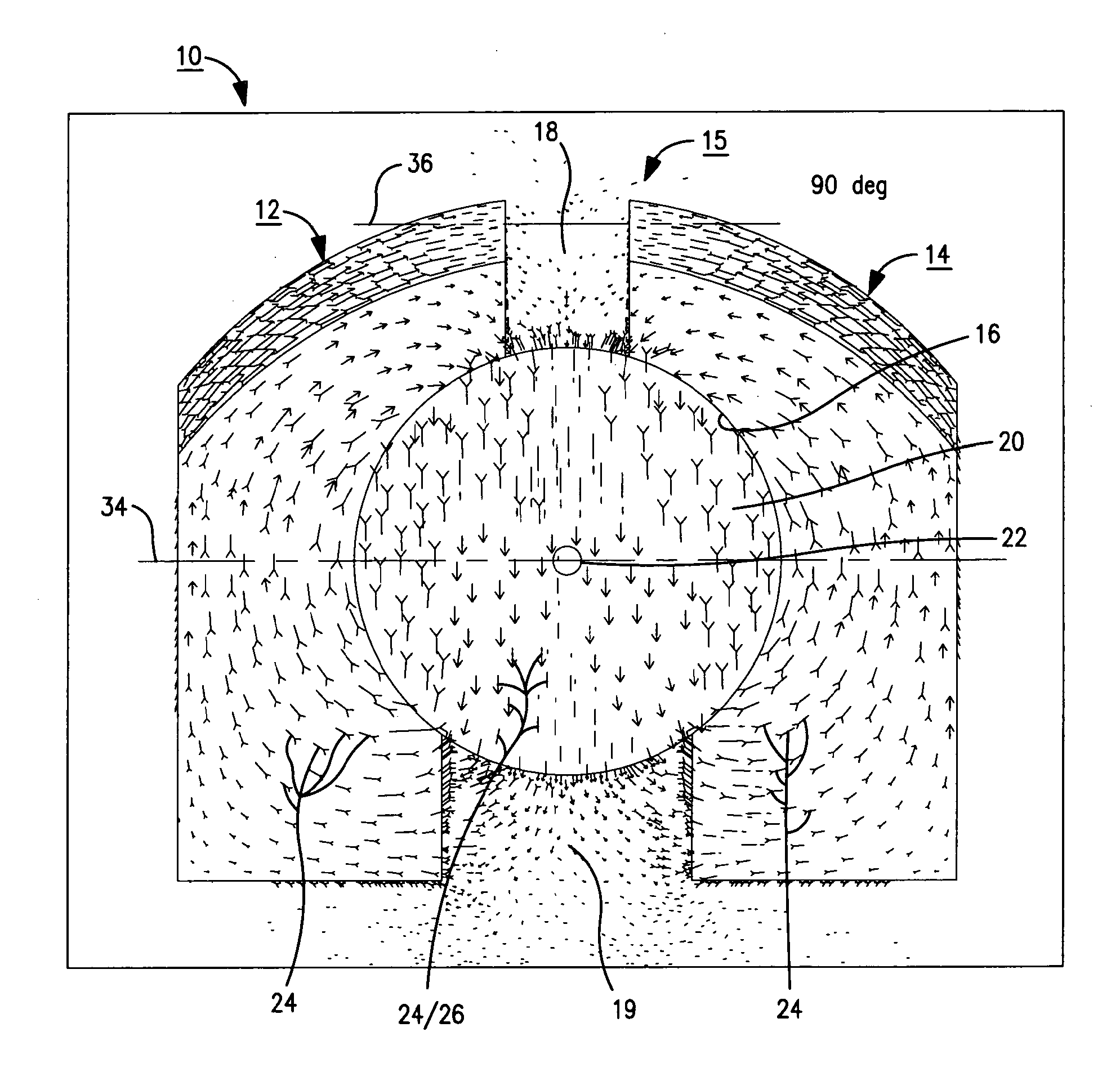

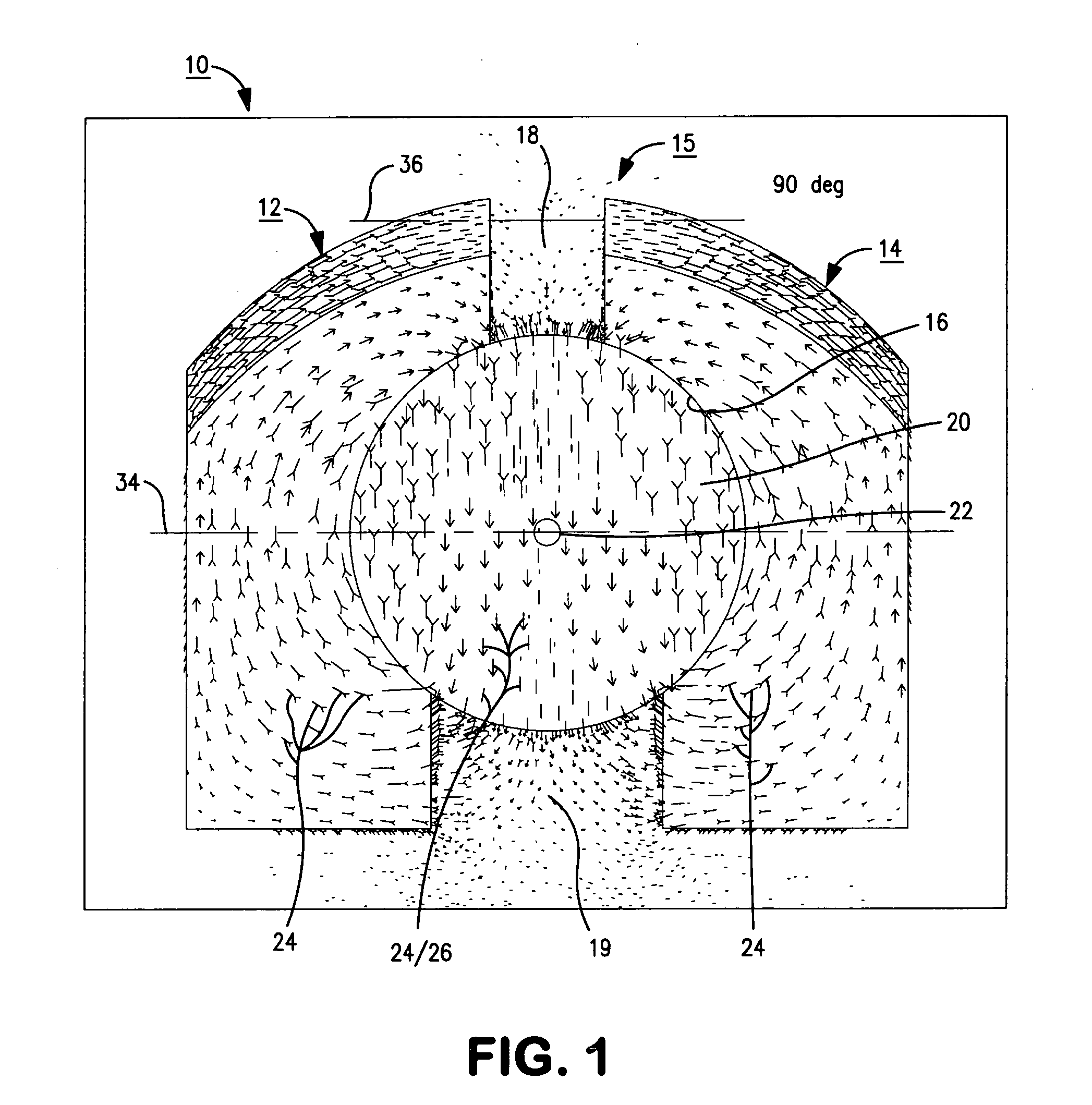

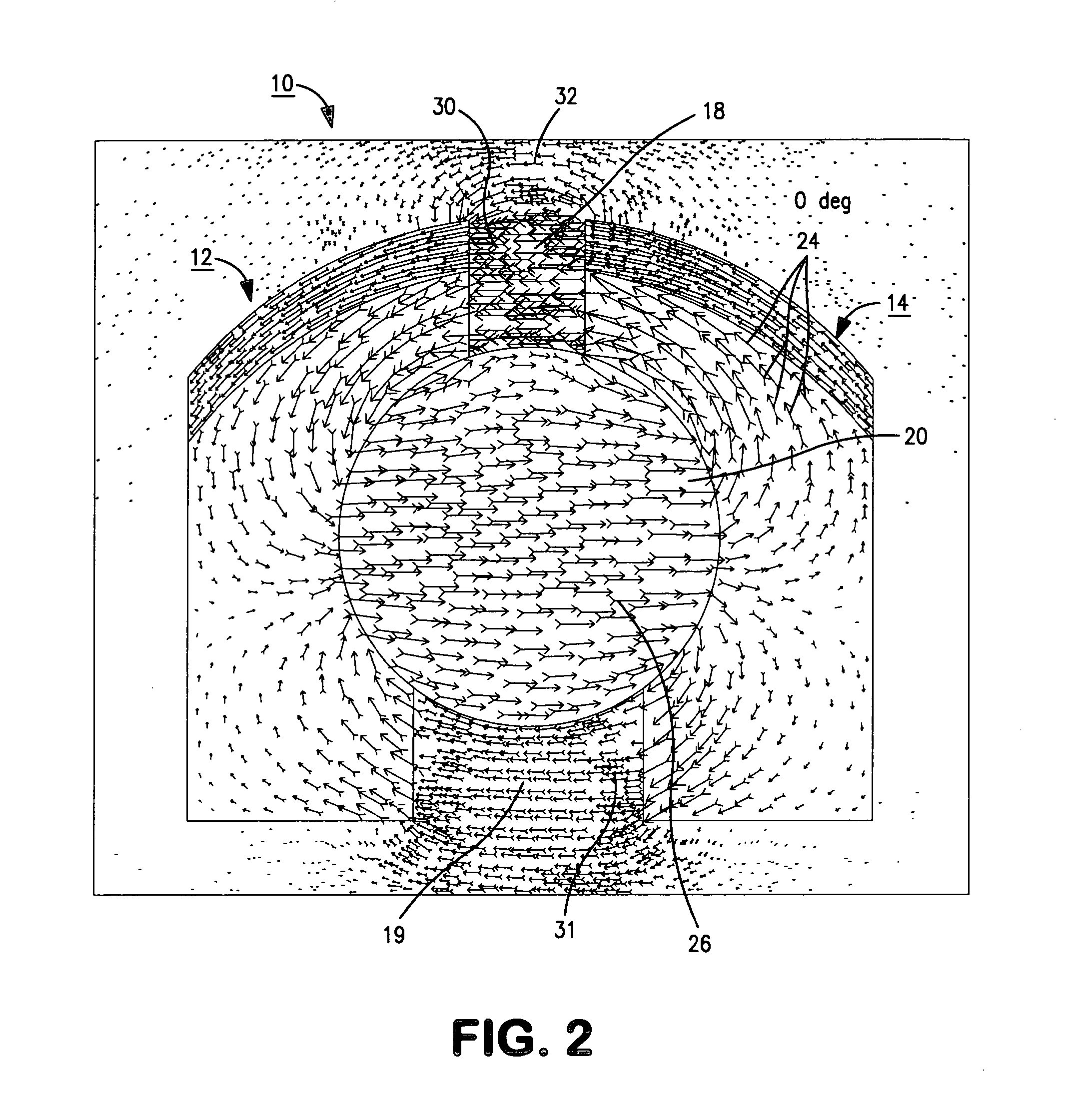

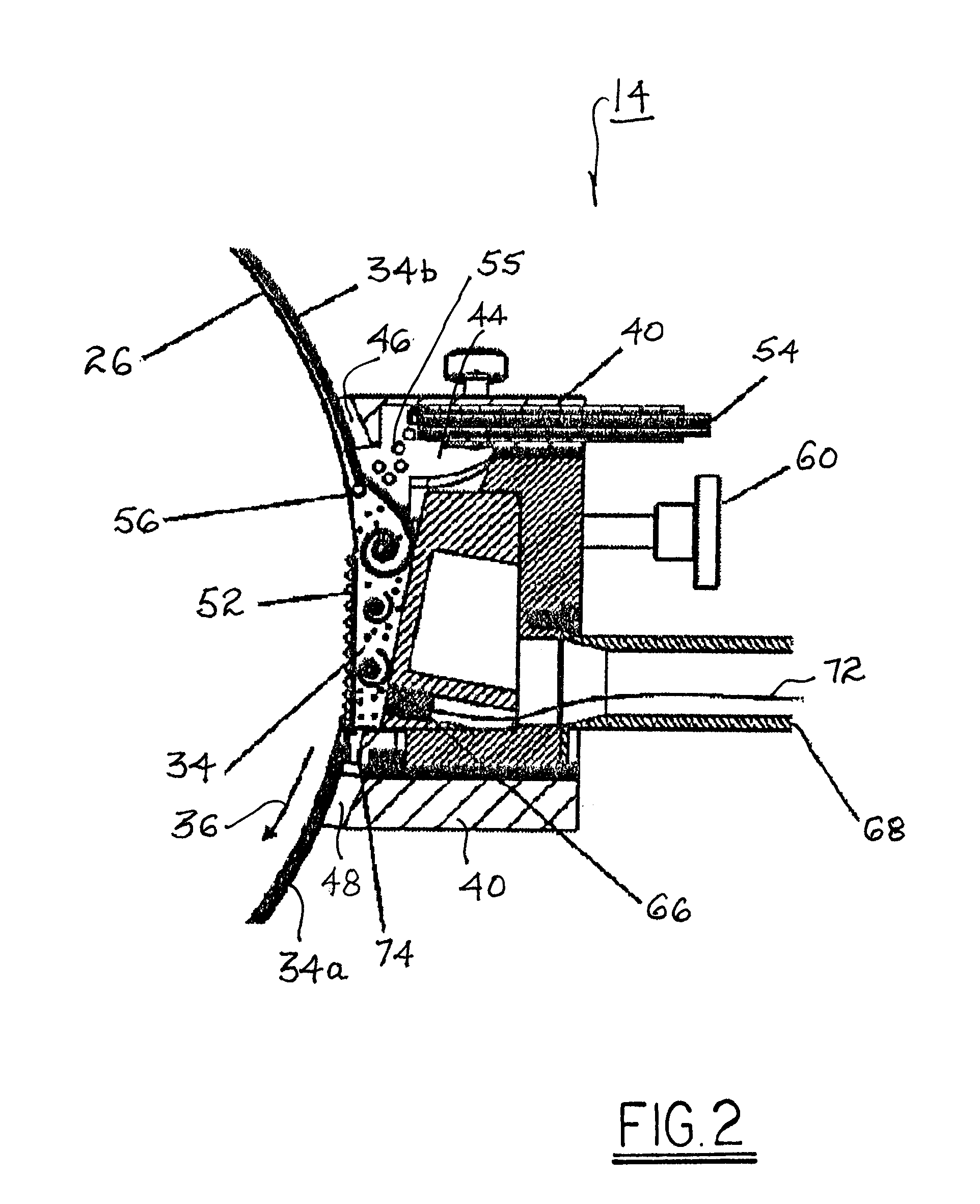

A method and apparatus for finishing a workpiece surface using MR fluid is provided wherein the workpiece is positioned near a carrier surface such that a converging gap is defined between a portion of the workpiece surface and the carrier surface; a magnetic field is applied substantially at said gap; a flow of stiffened MR fluid is introduced into said converging gap such that a work zone is created in the MR fluid to form a sub-aperture transient finishing tool for engaging and causing material removal at the portion of the workpiece surface; and the workpiece or the work zone is moved relative to the other to expose different portions of the workpiece surface to the work zone for predetermined time periods to selectively finish said portions of said workpiece surface to predetermined degrees.

Owner:QED TECH INT

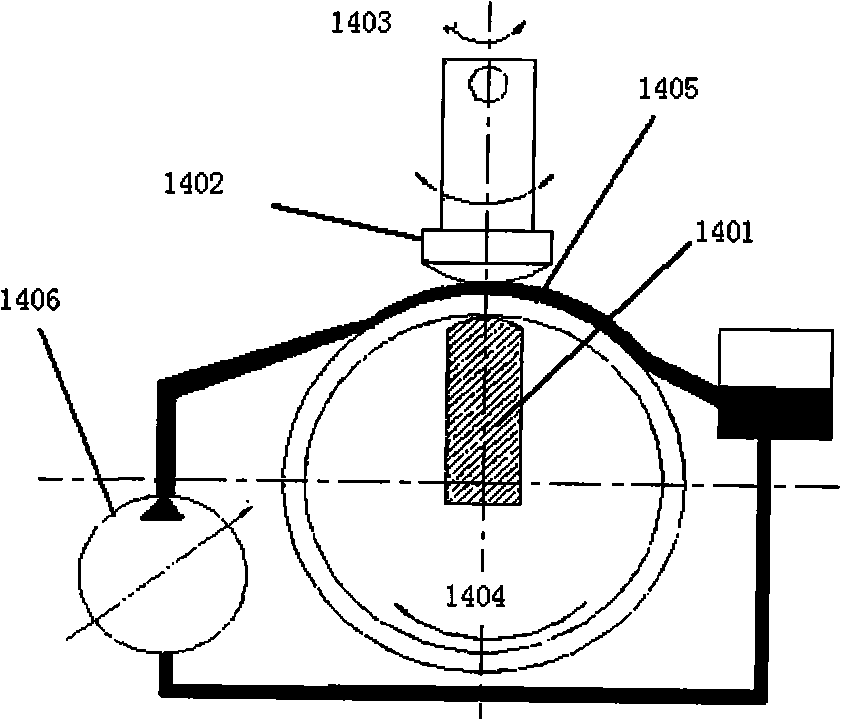

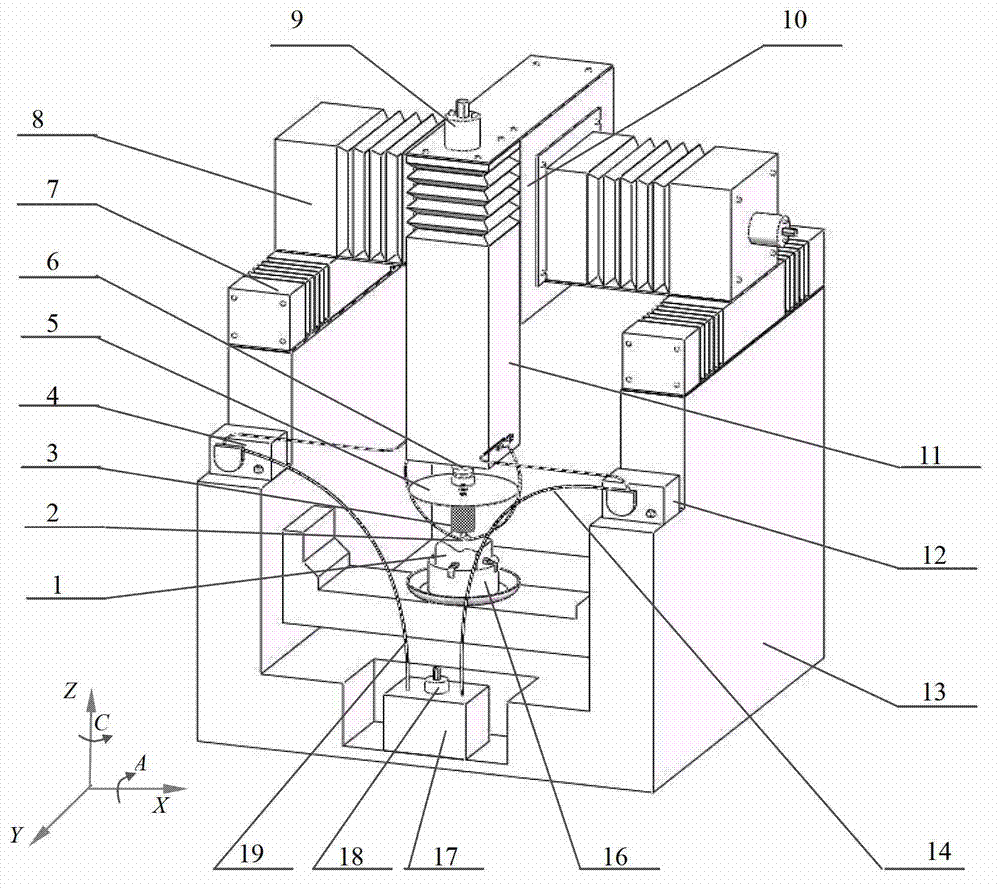

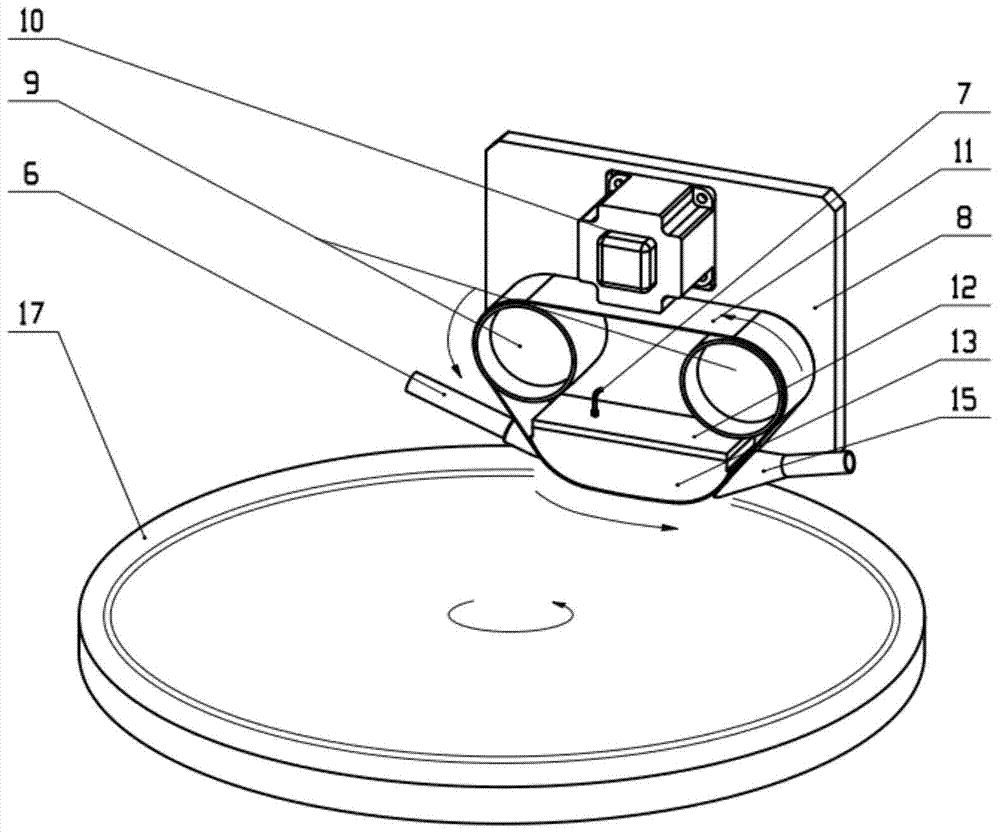

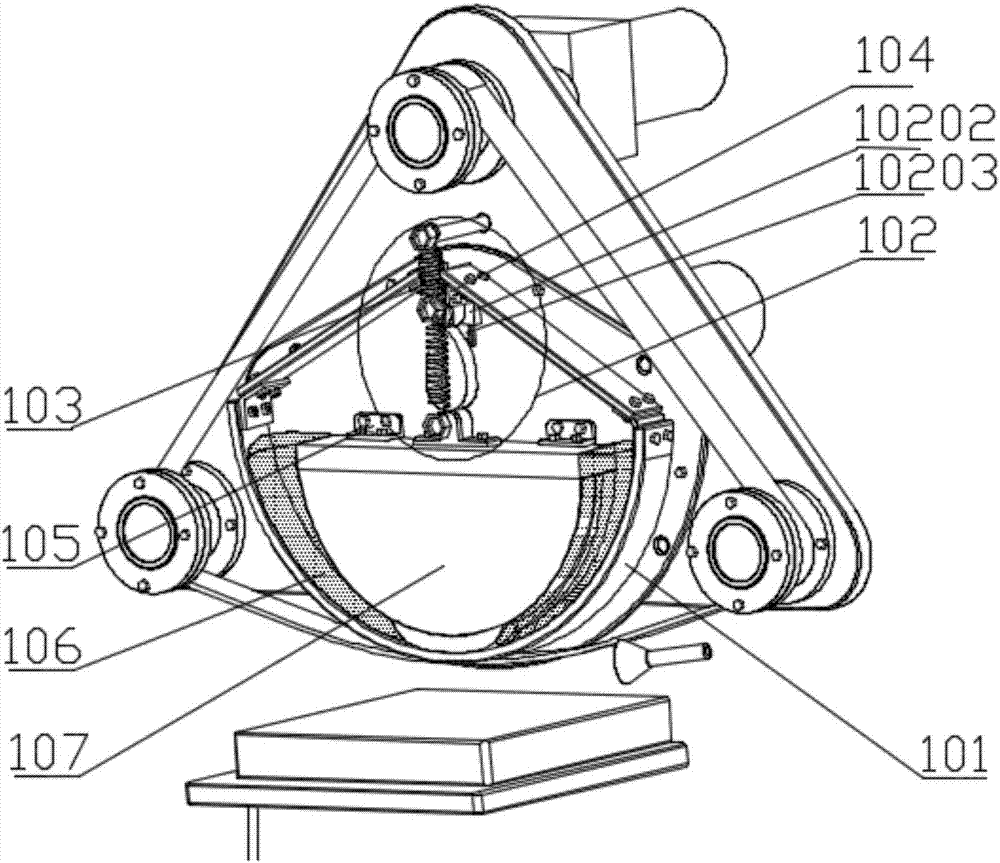

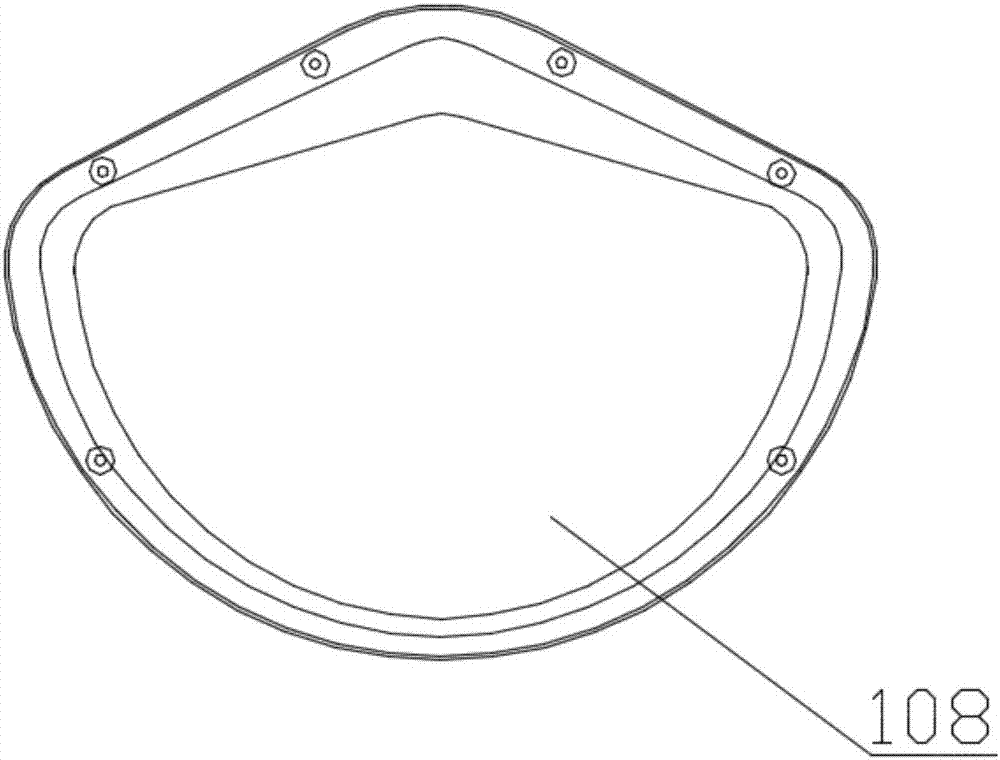

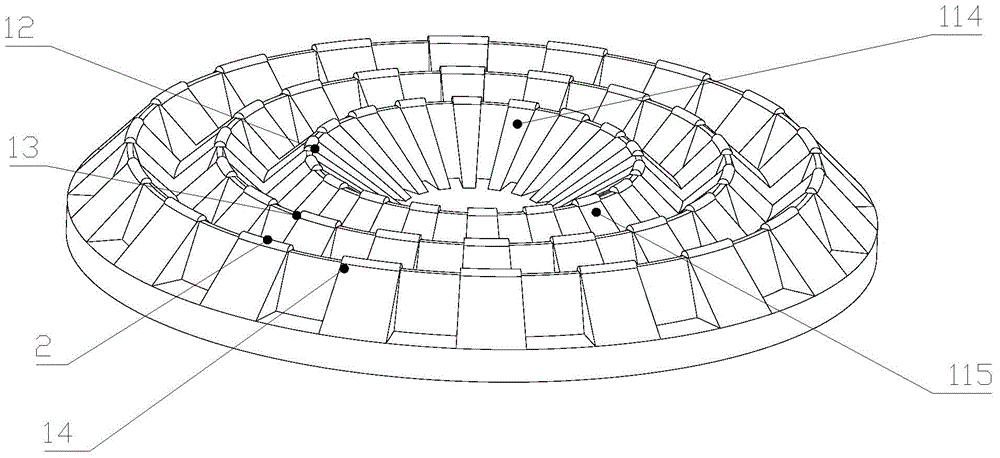

Magnetorheological finishing device for super large caliber aspheric surface optical part

InactiveCN101323097AImprove dynamic characteristicsMeet the needs of magnetorheological polishingOptical surface grinding machinesLinear motionControl system

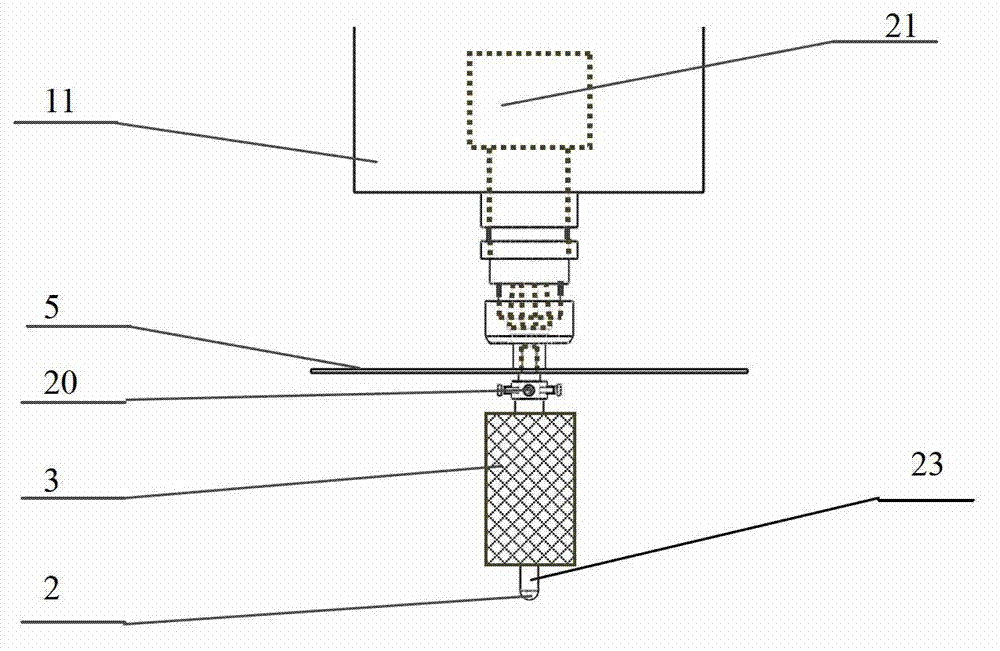

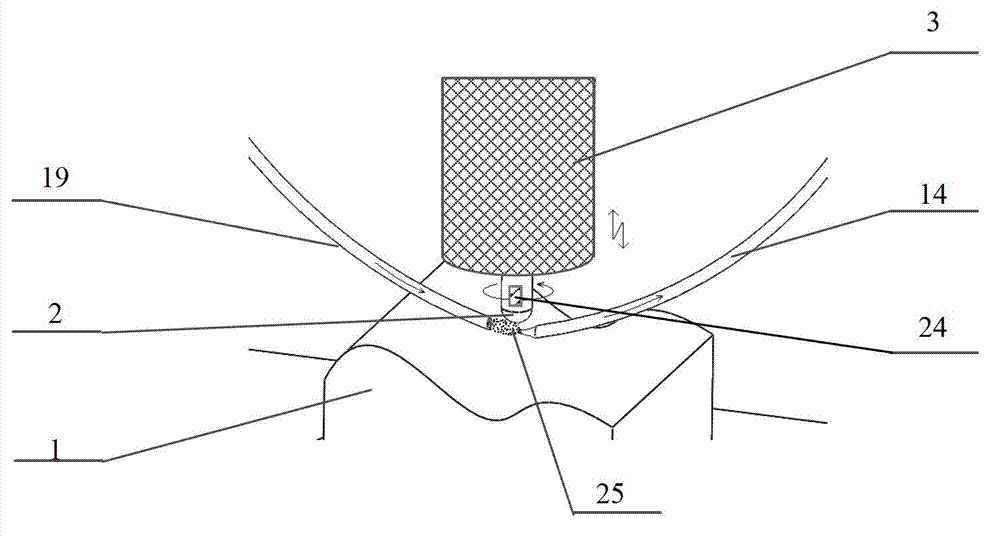

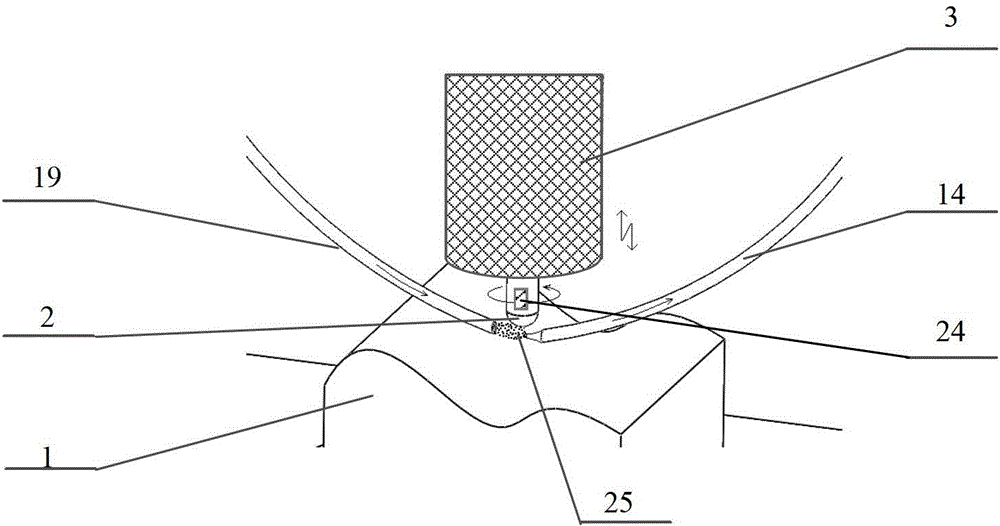

The invention relates to a magnetic rheological polishing device used in an aspheric optical part with a super large caliber, comprising a machine tool, a magnetic rheological polishing device and a control system which is connected with the above components. The machine tool comprises a lathe bed on which the work piece to be processed is placed, an X axial linear motion mechanism is arranged on the two sides of the lathe bed, a movable portal is fixed on a slider of the X axial linear motion mechanism, a Y axial linear motion mechanism is arranged on a cross beam of the movable portal, a Z axial linear motion mechanism is fixed on a slider of the Y axial linear motion mechanism, an A axial rotary table used for arranging the magnetic rheological polishing device is fixed on a slider of the Z axial linear motion mechanism, the magnetic rheological polishing device is fixed on the cross beam by a fourth linear motion mechanism, the two have opposite directions of motion, and the magnetic rheological polishing device is arranged right above the work piece to be processed. The device of the invention has the advantages of simple and compact structure, low cost, easy control and strong processing capacity, and can process the aspheric optical part with the super large caliber.

Owner:NAT UNIV OF DEFENSE TECH

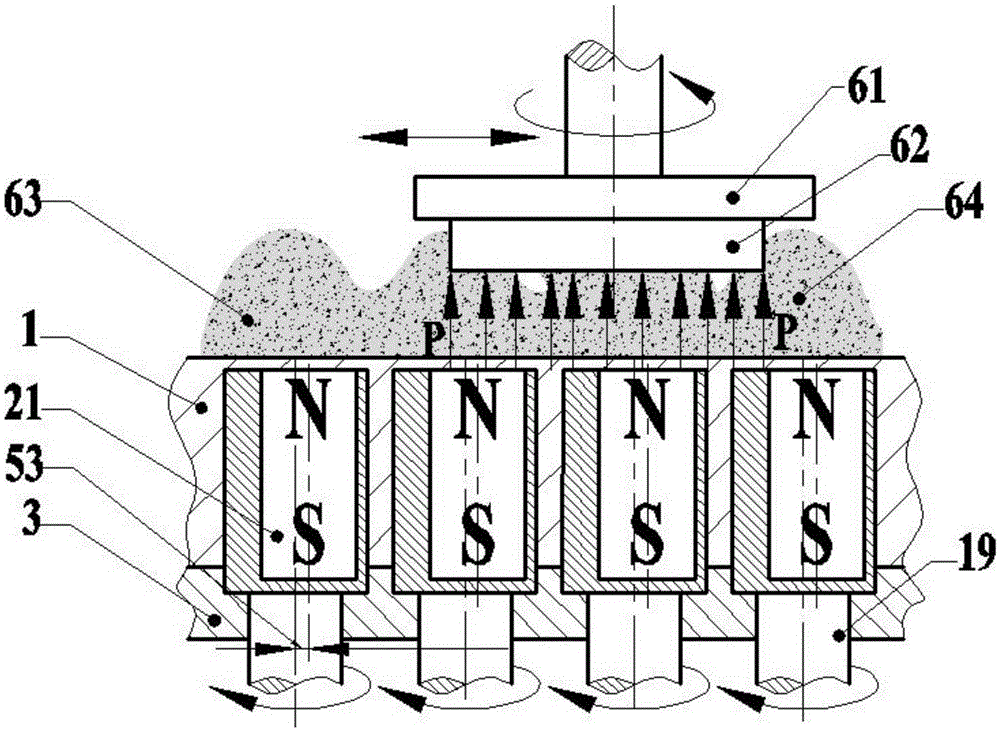

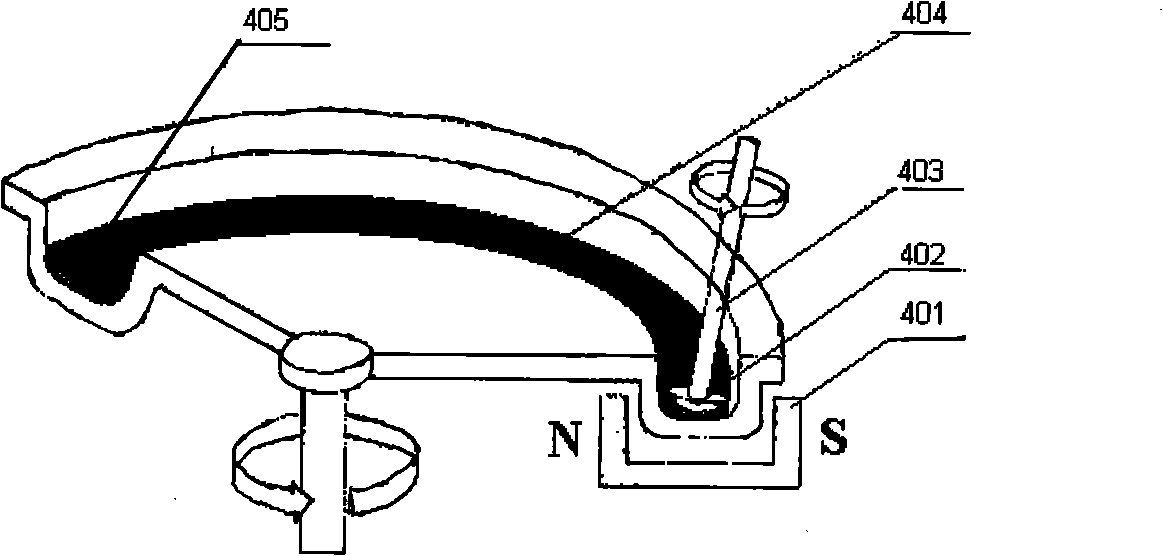

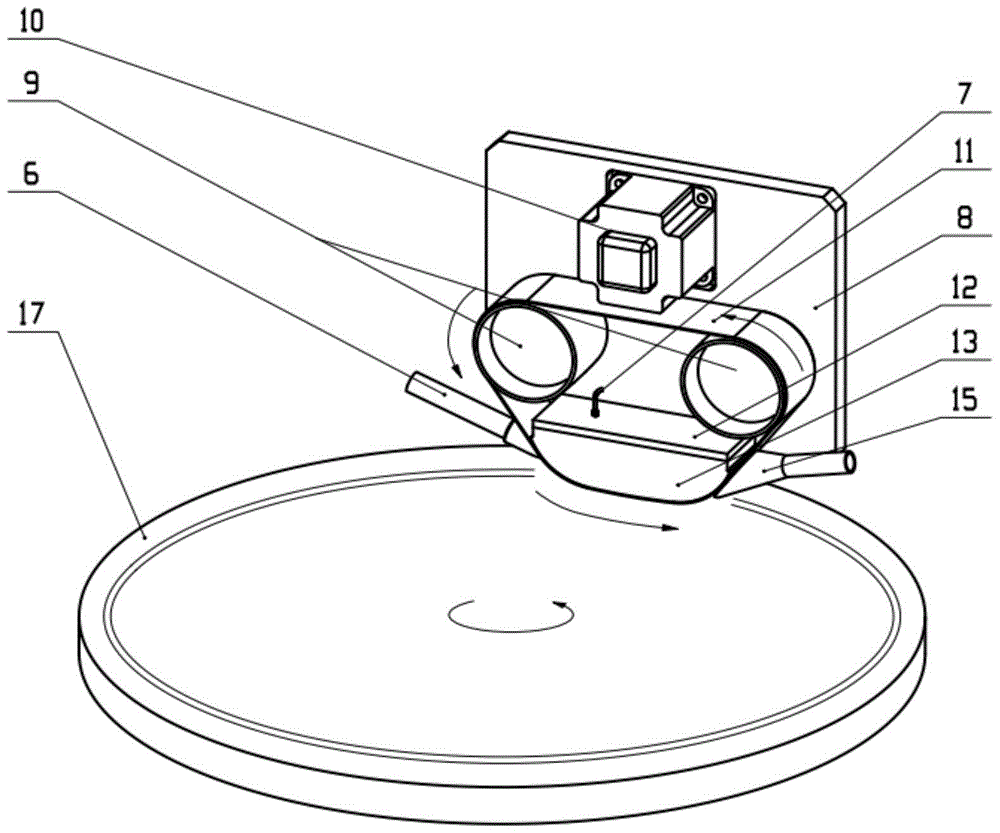

Dynamic magnetic field self-sharpening finishing device for flexible magnetorheological finishing pad and finishing method for dynamic magnetic field self-sharpening finishing device

ActiveCN105328516ASave spaceAchieve impactGrinding drivesAbrasive surface conditioning devicesExperimental researchMagnetic current

The invention relates to a dynamic magnetic field self-sharpening finishing device for a flexible magnetorheological finishing pad and a finishing method for the dynamic magnetic field self-sharpening finishing device. The dynamic magnetic field self-sharpening finishing device comprises a finishing disk revolution mechanism and a multi-magnetic-pole synchronous rotation driving mechanism, wherein the finishing disk revolution mechanism comprises a driving shaft motor, a drive shaft, an adapting disk, an eccentric shaft fixing disk, a cup-like finishing disk and a driving shaft transmission mechanism; the multi-magnetic-pole synchronous rotation driving mechanism comprises an eccentric spindle, synchronous rotation driving plates, flexible eccentric rotating shafts, eccentric sleeves, magnetic poles, the eccentric shaft fixing disk, a spindle motor and the like. According to the finishing device and the finishing method disclosed by the invention, the conditions that a circulating device is adopted for updating magnetorheological fluid and the magnetorheological fluid is changed in the processing process are avoided, so that the space is saved, and the whole process from rough finishing to fine finishing can be realized by one-time processing; obtained workpieces are good in surface consistency, high in processing efficiency, free from of surface and subsurface damage and low in cost, so the finishing device and the finishing method are suitable for high-efficiency ultra-smooth uniform finishing processing of planes of large-diameter optical elements; meanwhile, the finishing device and the finishing method disclosed by the invention are also suitable for experimental researches such as a material removing mechanism and subsurface damage detection of optical planar materials.

Owner:GUANGDONG UNIV OF TECH

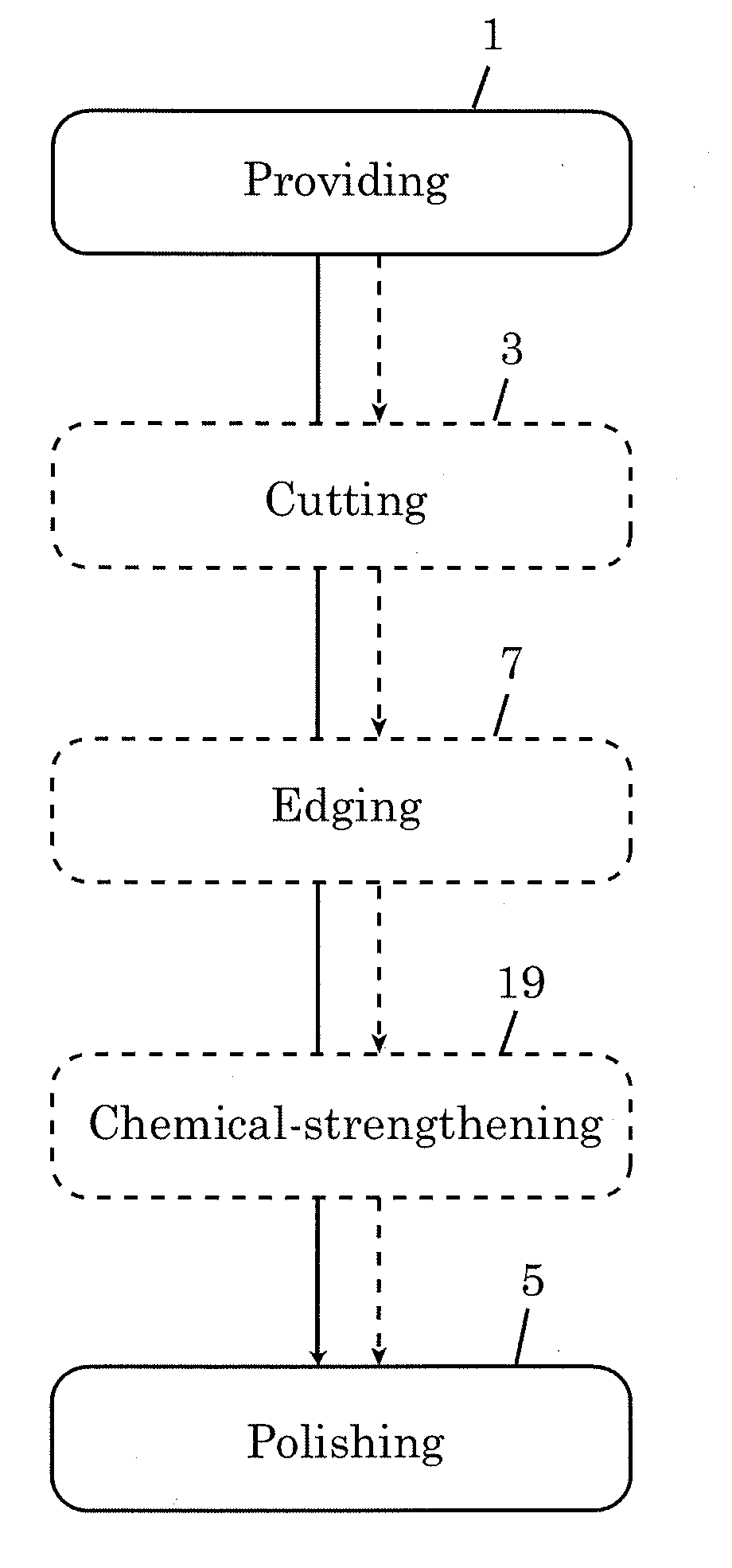

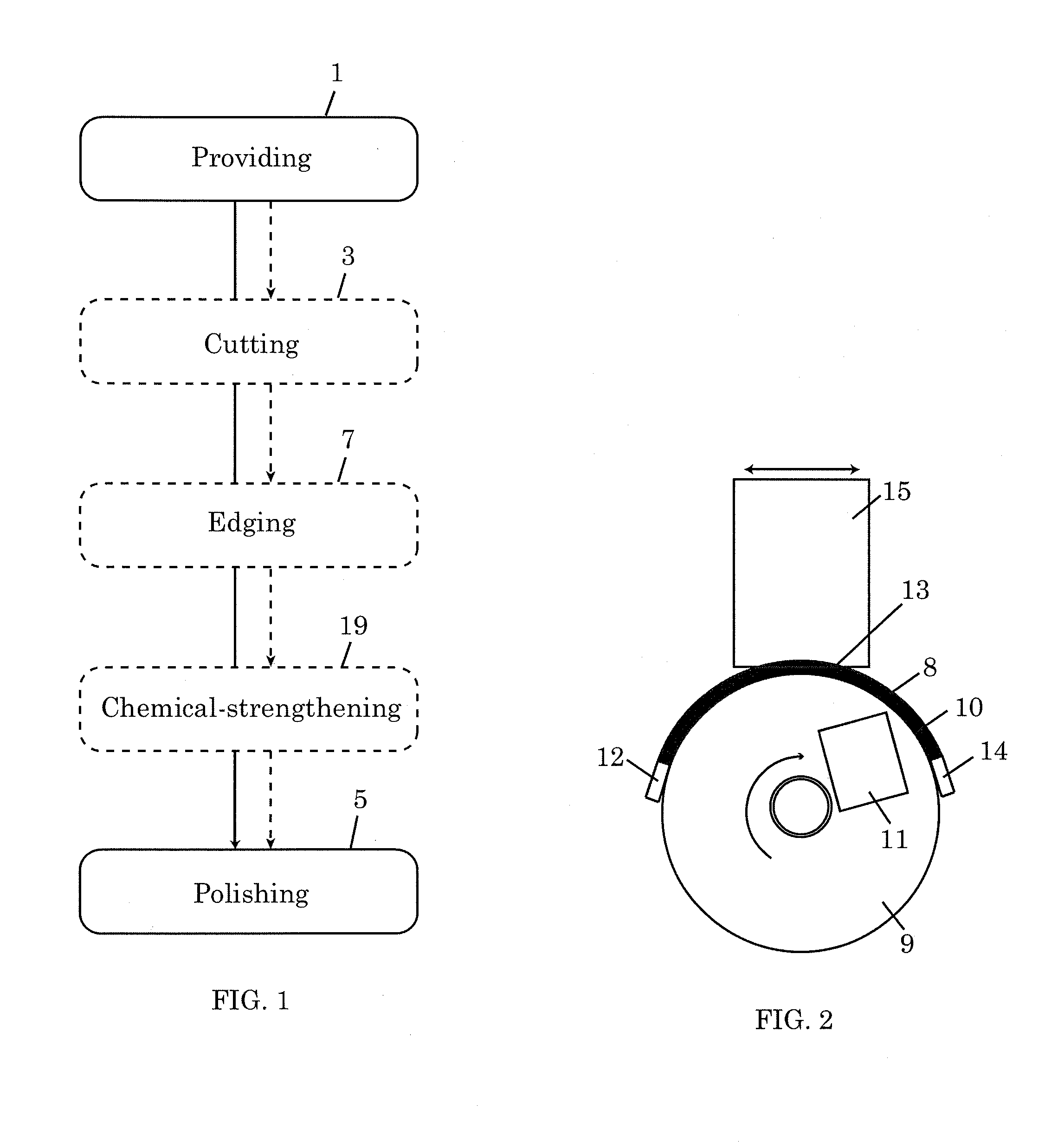

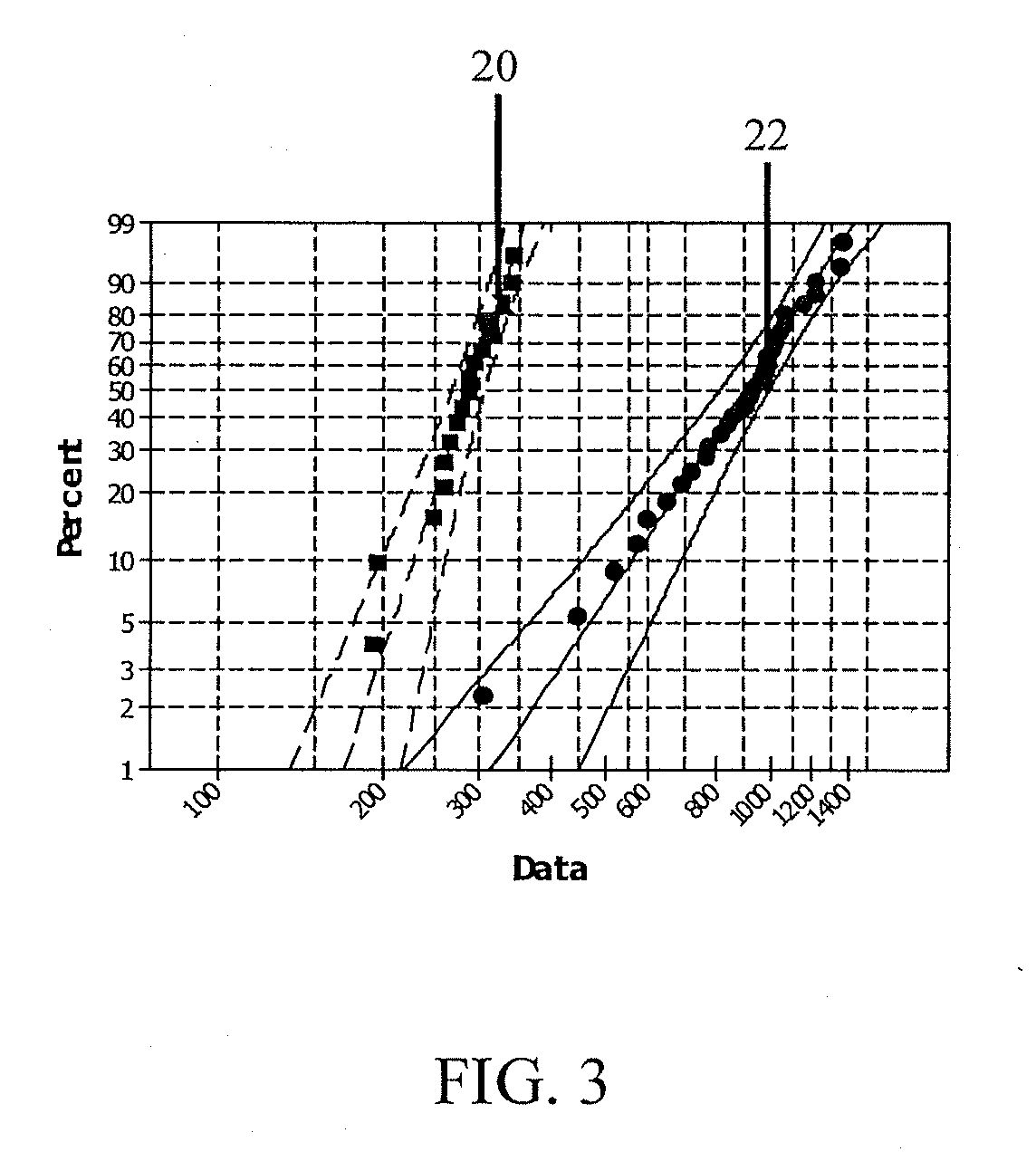

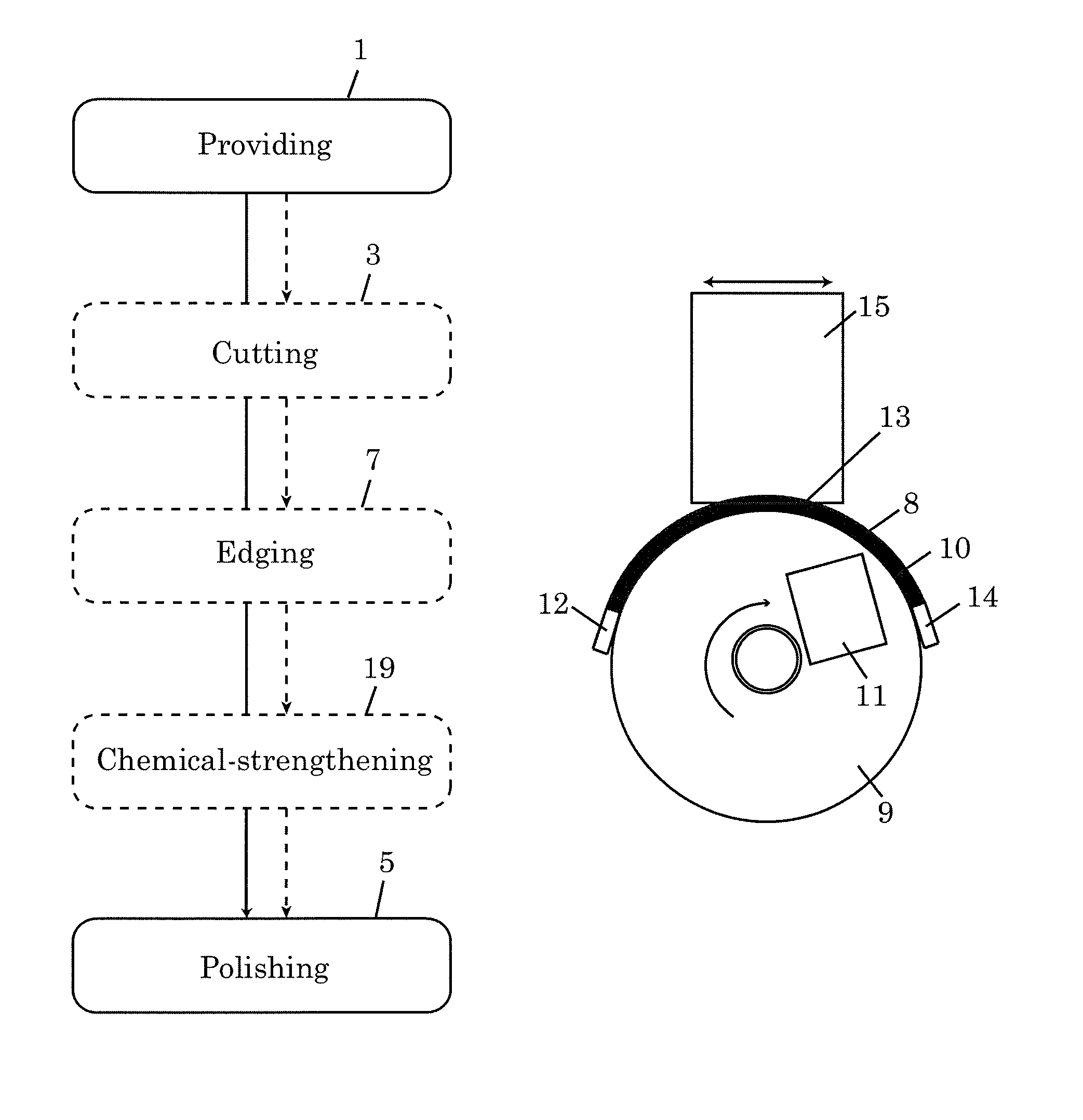

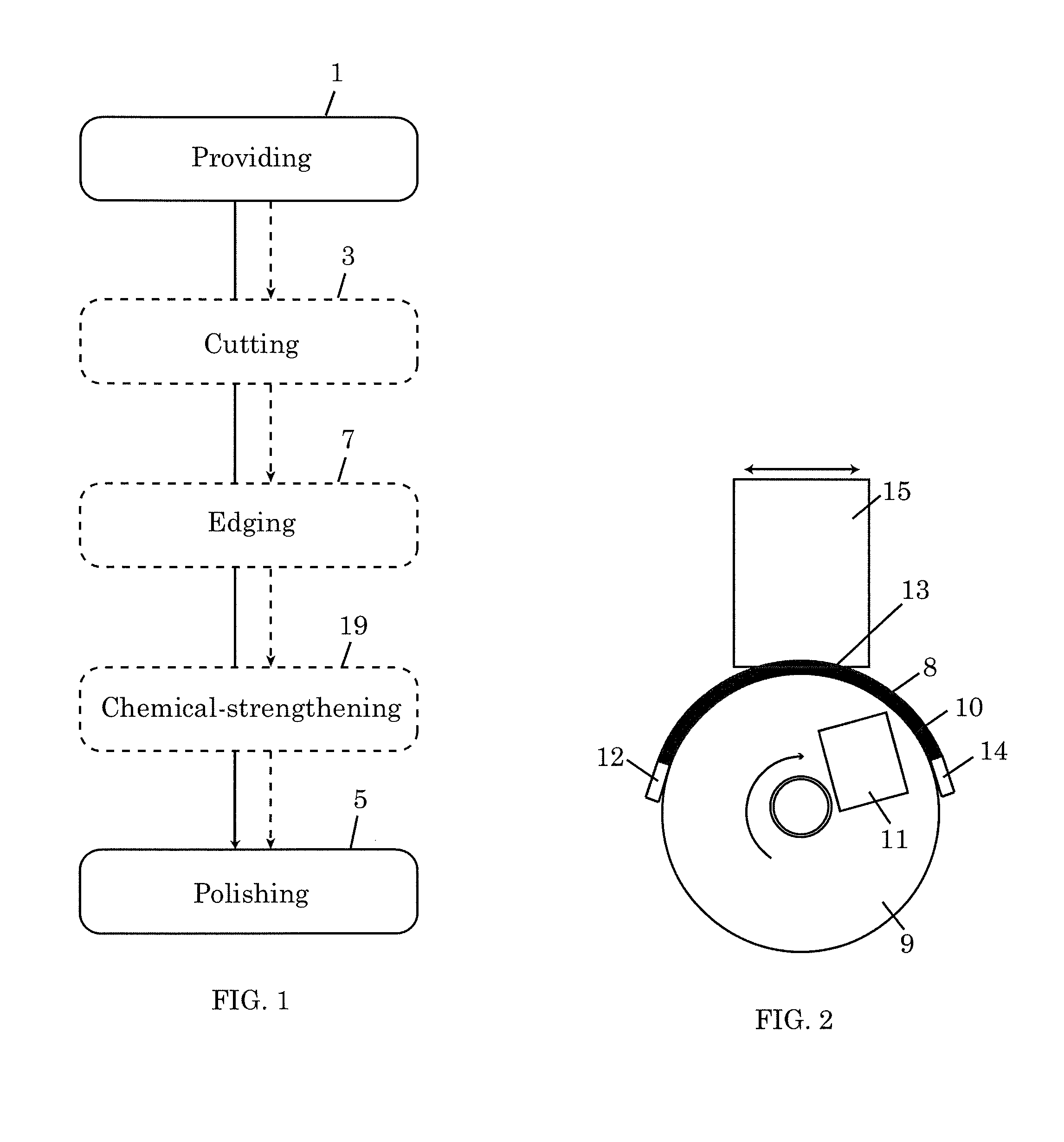

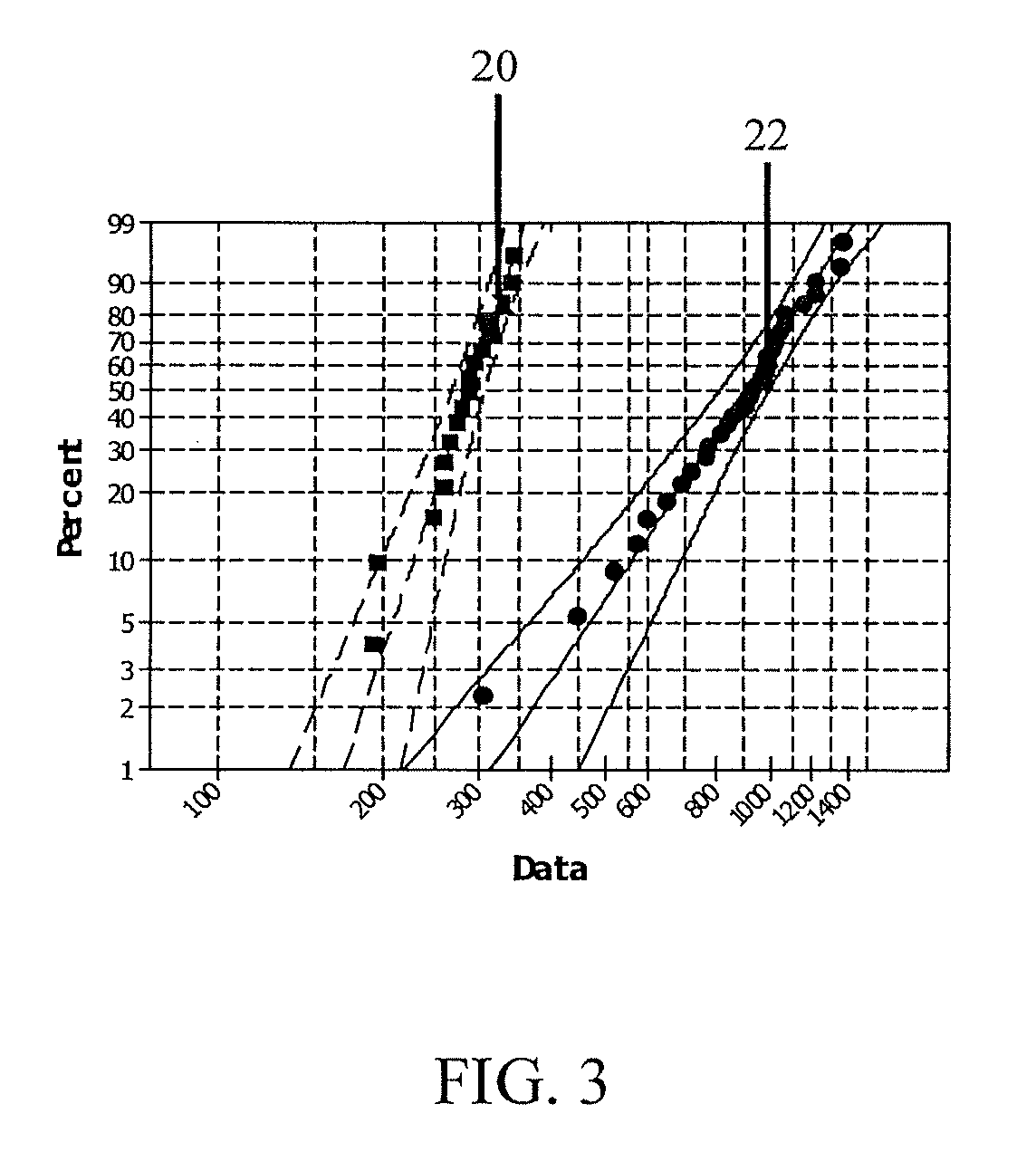

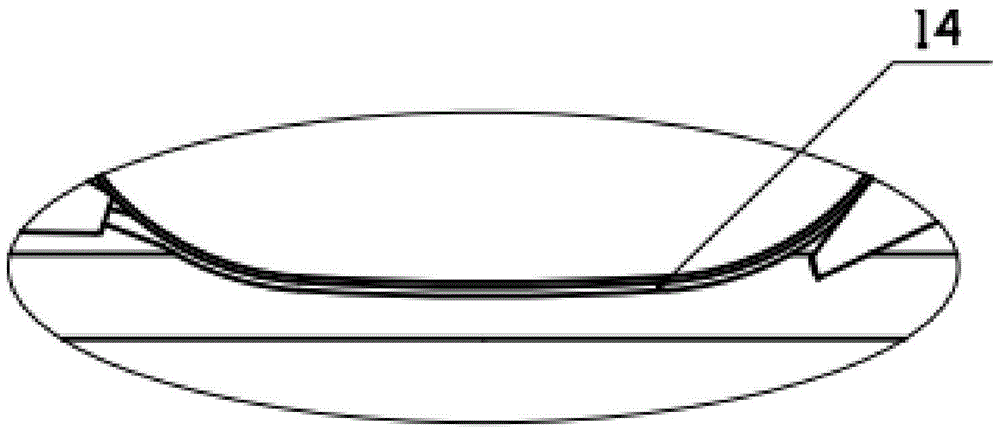

Method of preparing an edge-strengthened article

InactiveUS20110318994A1Edge grinding machinesPolishing machinesEdge strengthMagnetorheological finishing

A method of preparing an edge-strengthened article comprises polishing of an edge of an article having a first edge strength using magnetorheological finishing, wherein after the polishing the article has a second edge strength and the second edge strength is greater than the first edge strength.

Owner:CORNING INC

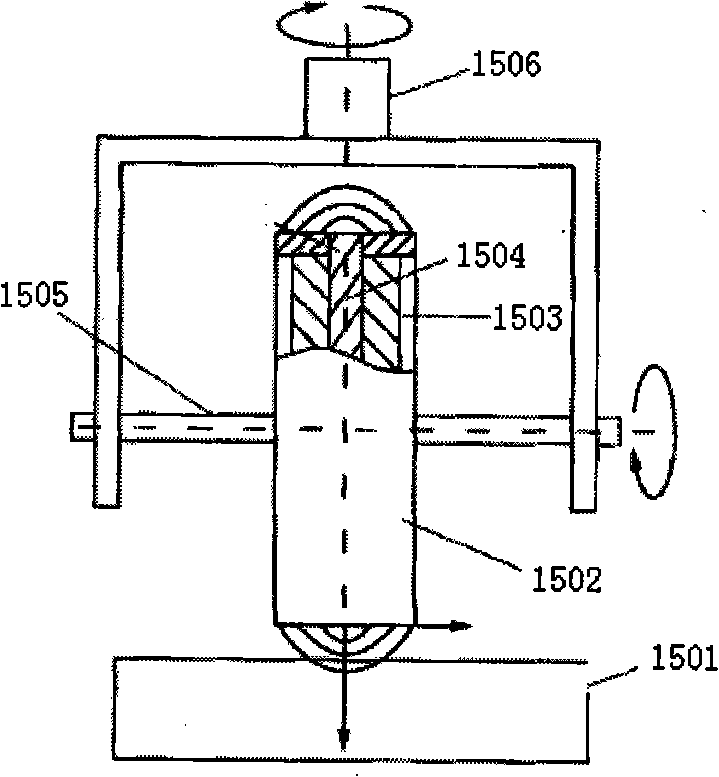

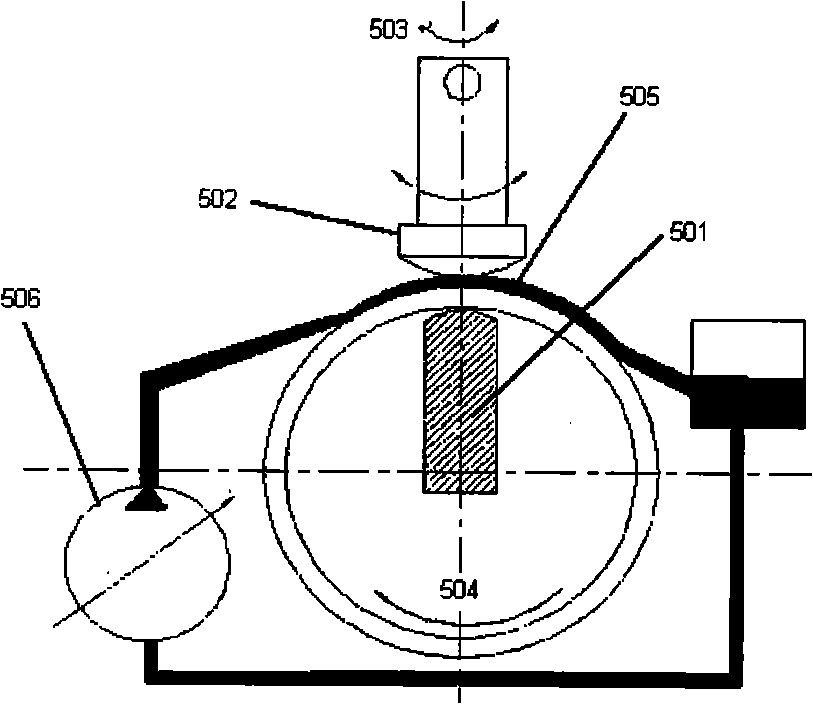

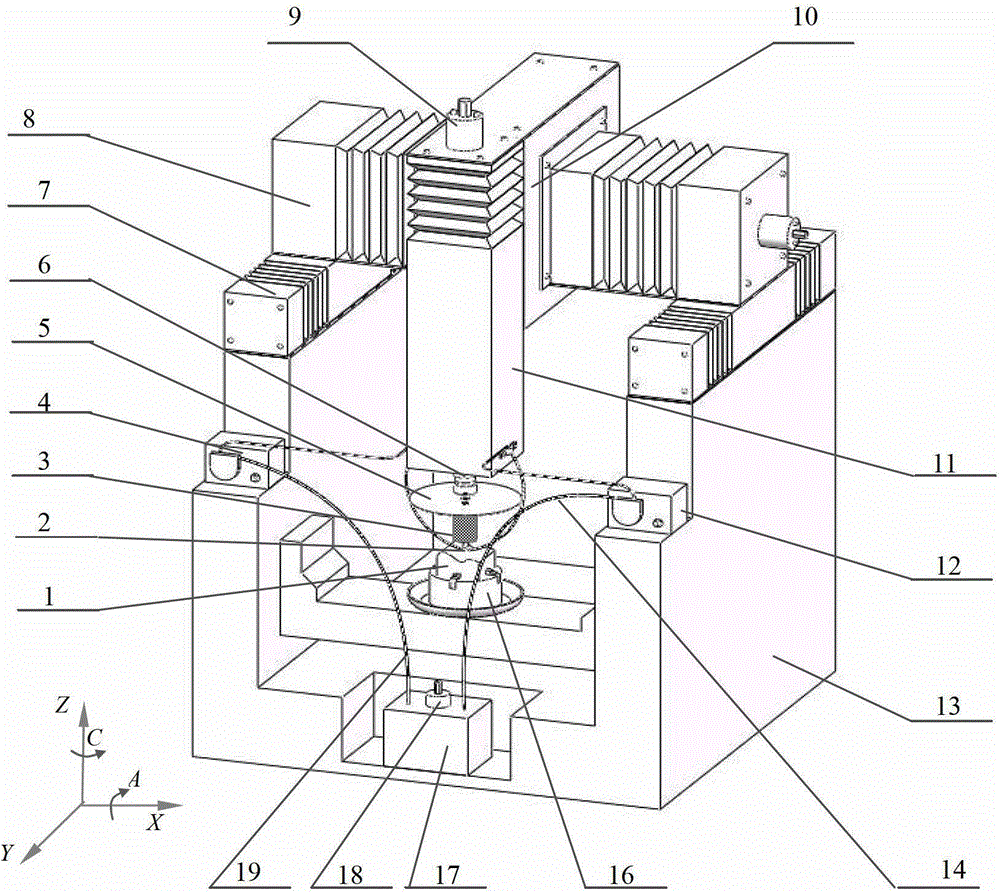

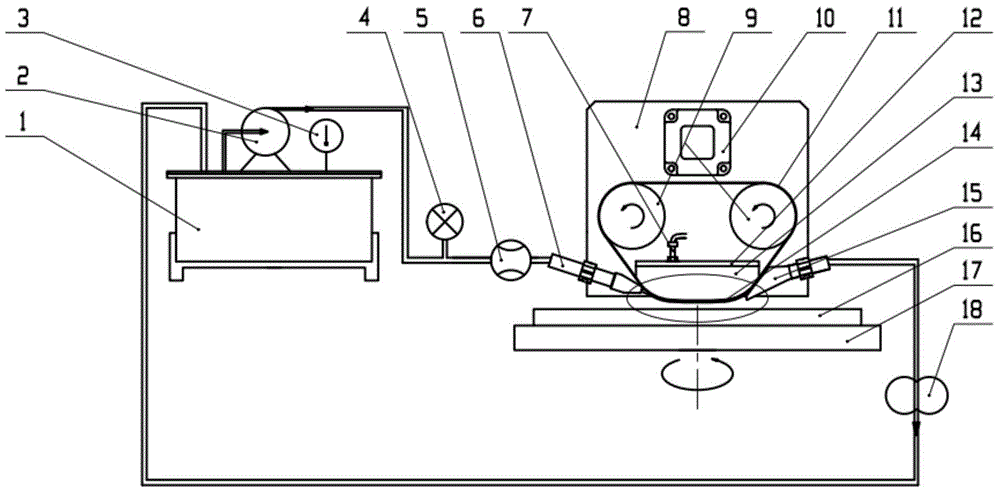

Constant pressure ultrasonic wave aiding magnetorheological finishing method and constant pressure ultrasonic wave aiding magnetorheological finishing device

InactiveCN103042438AUniform compositionUniform abrasive distributionUltrasonic assistedControl system

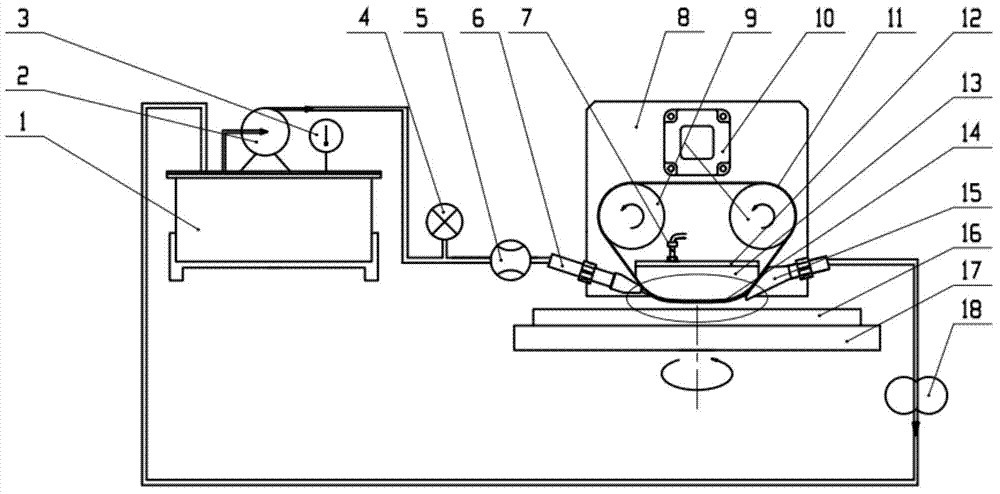

The invention discloses a constant pressure ultrasonic wave aiding magnetorheological finishing method and a constant pressure ultrasonic wave aiding magnetorheological finishing device. The method includes the steps of firstly, mounting a workpiece on a double-rotating workbench; secondly, adjusting distance between a small ball milling head and the workpiece to allow a clearance to be formed between the two, and setting a threshold P1 and a threshold P2 of a force cell at an extending position of an electromagnetic coil iron core mounted above the small ball milling head through a control system; thirdly, starting a spindle to drive the small ball milling head to rotate, simultaneously starting an ultrasonic wave vibrating device to allow ultrasonic vibration of the small ball milling head, and jetting magnetorheological fluid in the clearance formed by the small ball milling head and the workpiece through an output pipeline; and fourthly, repeatedly finishing the workpiece according to the surface shape of the to-be-machined workpiece until the machining of the workpiece is completed. Accurate point removing can be performed on the workpiece surface by the method.

Owner:TIANJIN UNIV

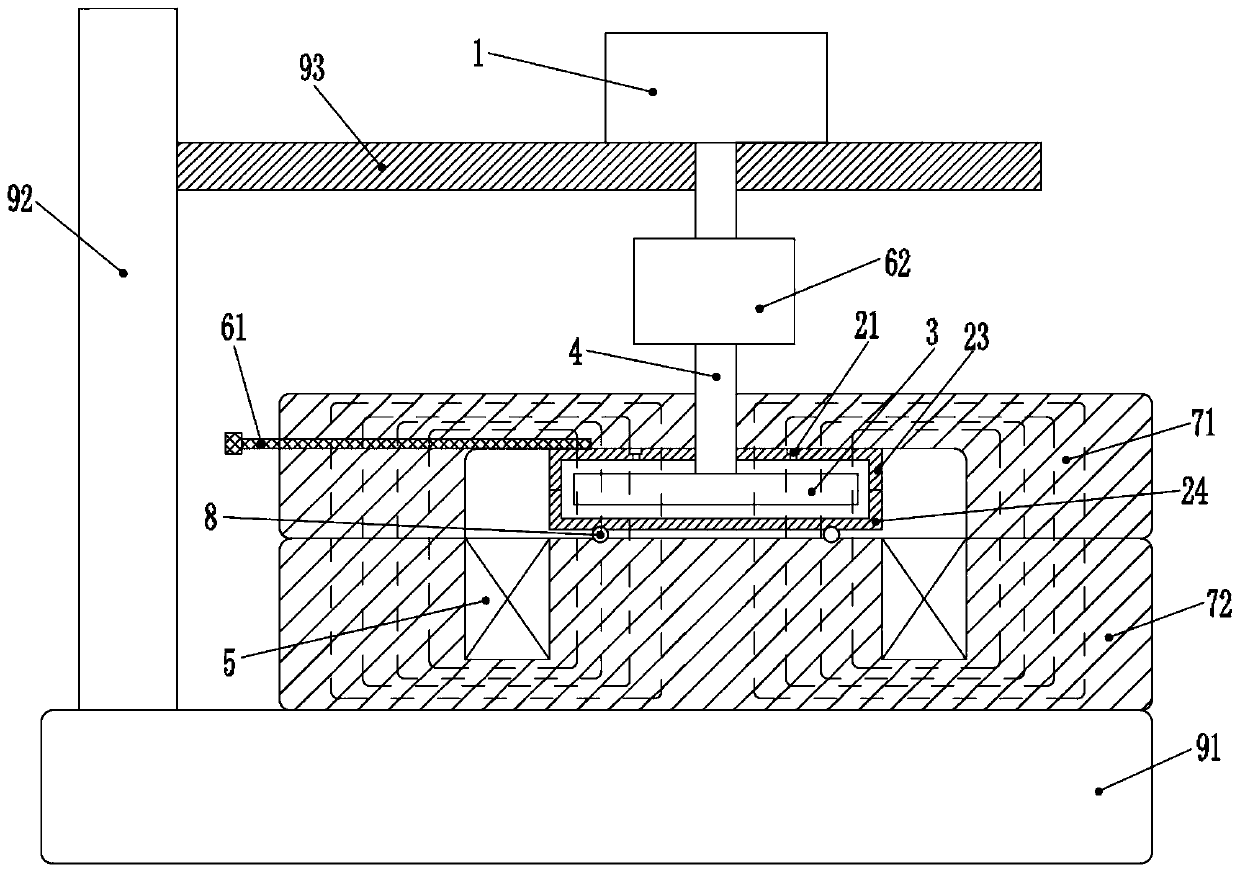

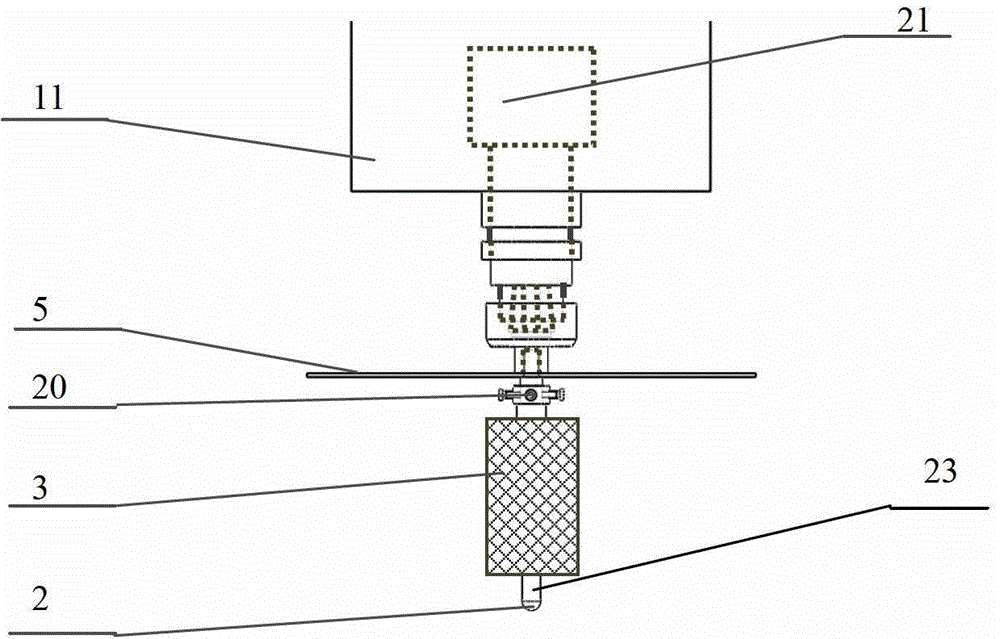

Magnetorheological finishing device applicable to ultra-large-diameter optical processing

The invention relates to a magnetorheological finishing device applicable to ultra-large-diameter optical processing. The magnetorheological finishing device comprises a magnet device and a magnetorheological fluid circulating device. The magnet device is capable of providing a magnetic field, the lower end of the magnet device is provided with a horizontal protruding section, and the magnetorheological fluid circulating device enables magnetorheological fluid flowing through the horizontal protruding section to form a ribbon protrusion under the action of the magnetic field perpendicular to the flowing direction. The magnetorheological finishing device applicable to ultra-large-diameter optical processing can be modified on a finishing machine tool to replace a finishing head, such as a stress plate, a small grinding head and the like of the finishing machine tool without changing an original mechanical structure of the machine tool. The magnetorheological finishing device has the advantages that system size is reduced, mechanical structure is simplified, material removal efficiency is improved, and accordingly the current problems of long processing period and low removal efficiency of large-diameter aspherical processing are solved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

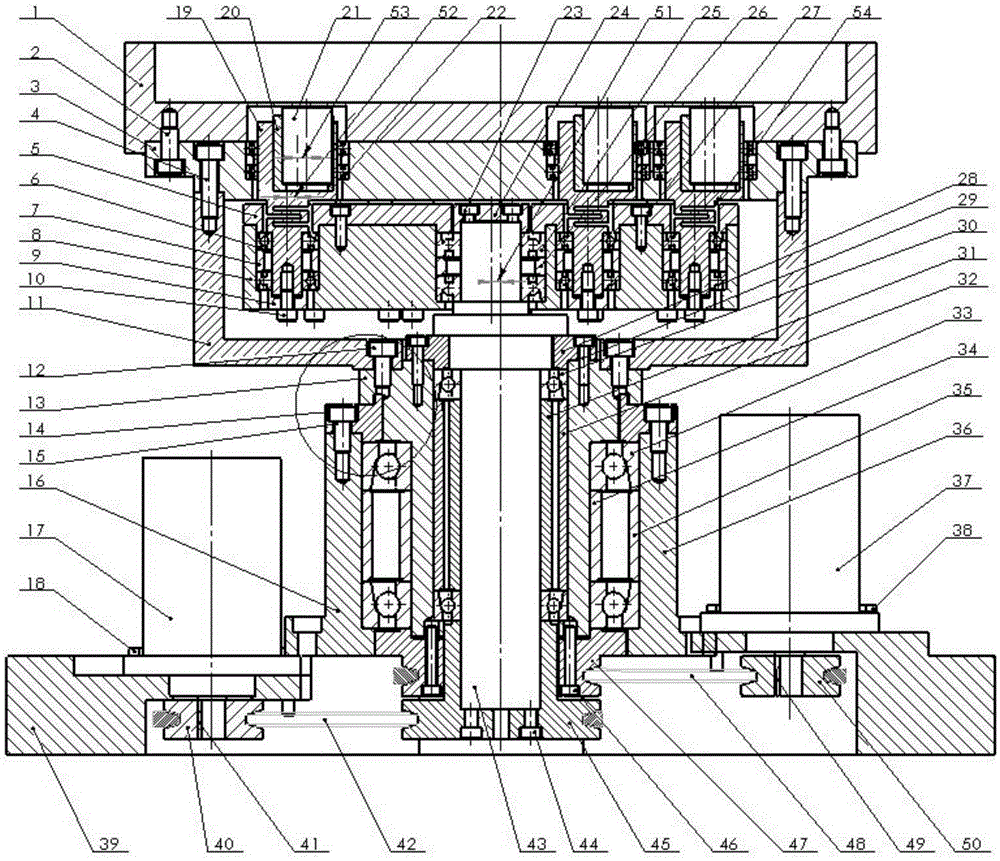

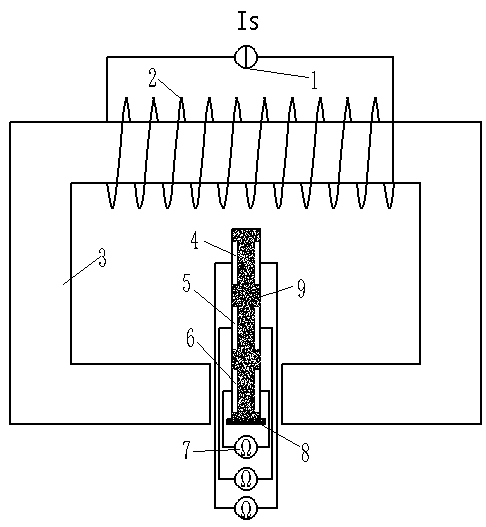

Magnetorheological finishing device for high-steepness optical part

InactiveCN101323098ARealize processingCompact structureOptical surface grinding machinesLinear motionControl system

The invention relates to a magnetic rheological polishing device used in an optical part with high gradient, comprising a machine tool, a magnetic rheological polishing device and a control system which is connected with the above components. The machine tool comprises a horizontal base seat and a vertical base seat, an X axial linear motion mechanism and a Y axial linear motion mechanism are arranged on the horizontal base seat in a cross shape, the X axial linear motion mechanism is fixed on a slider of the Y axial linear motion mechanism, a Z axial linear motion mechanism is arranged on the vertical base seat, a C axial rotary worktable used for arranging the magnetic rheological polishing device is arranged on a slider of the X axial linear motion mechanism, a B axial rotary worktable used for arranging a work piece fixture is arranged on a slider of the Z axial linear motion mechanism, an A axial rotary worktable used for driving the work piece to be processed is arranged at the tail end of the work piece fixture, and the magnetic rheological polishing device is horizontally opposite to the work piece to be processed. The device of the invention has the advantages of simple and compact structure, low cost and easy control, and can realize the processing of the optical part with the high gradient.

Owner:NAT UNIV OF DEFENSE TECH

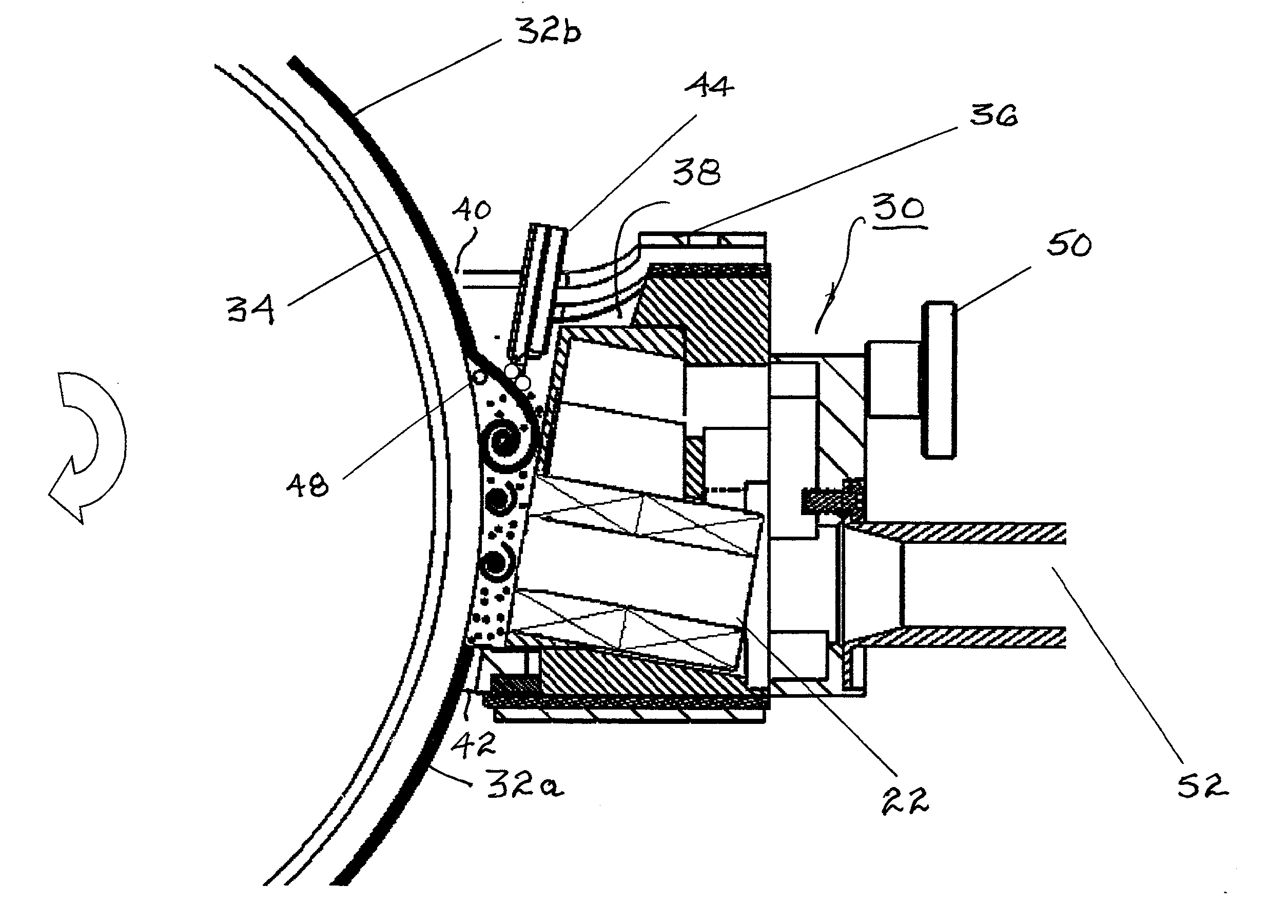

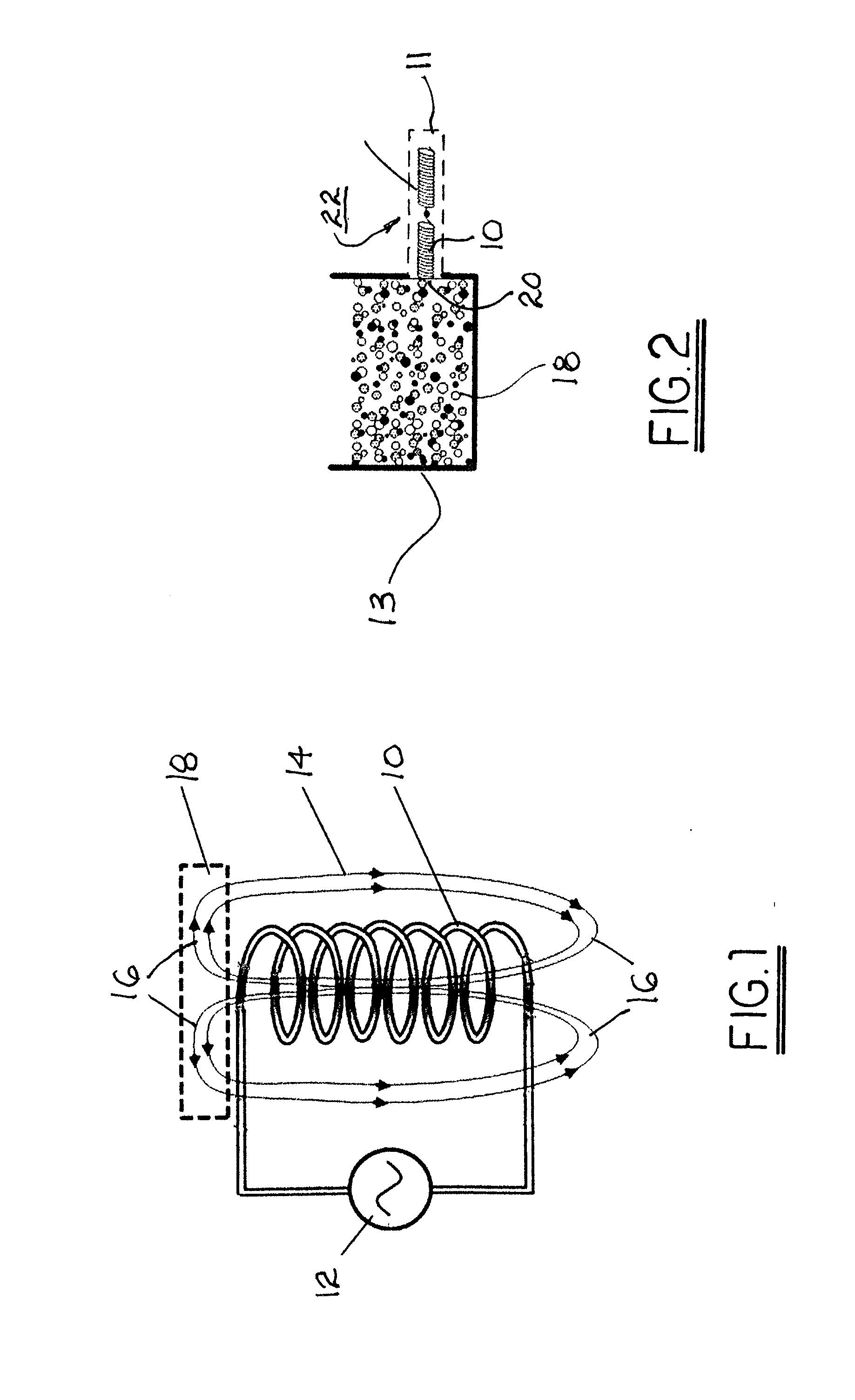

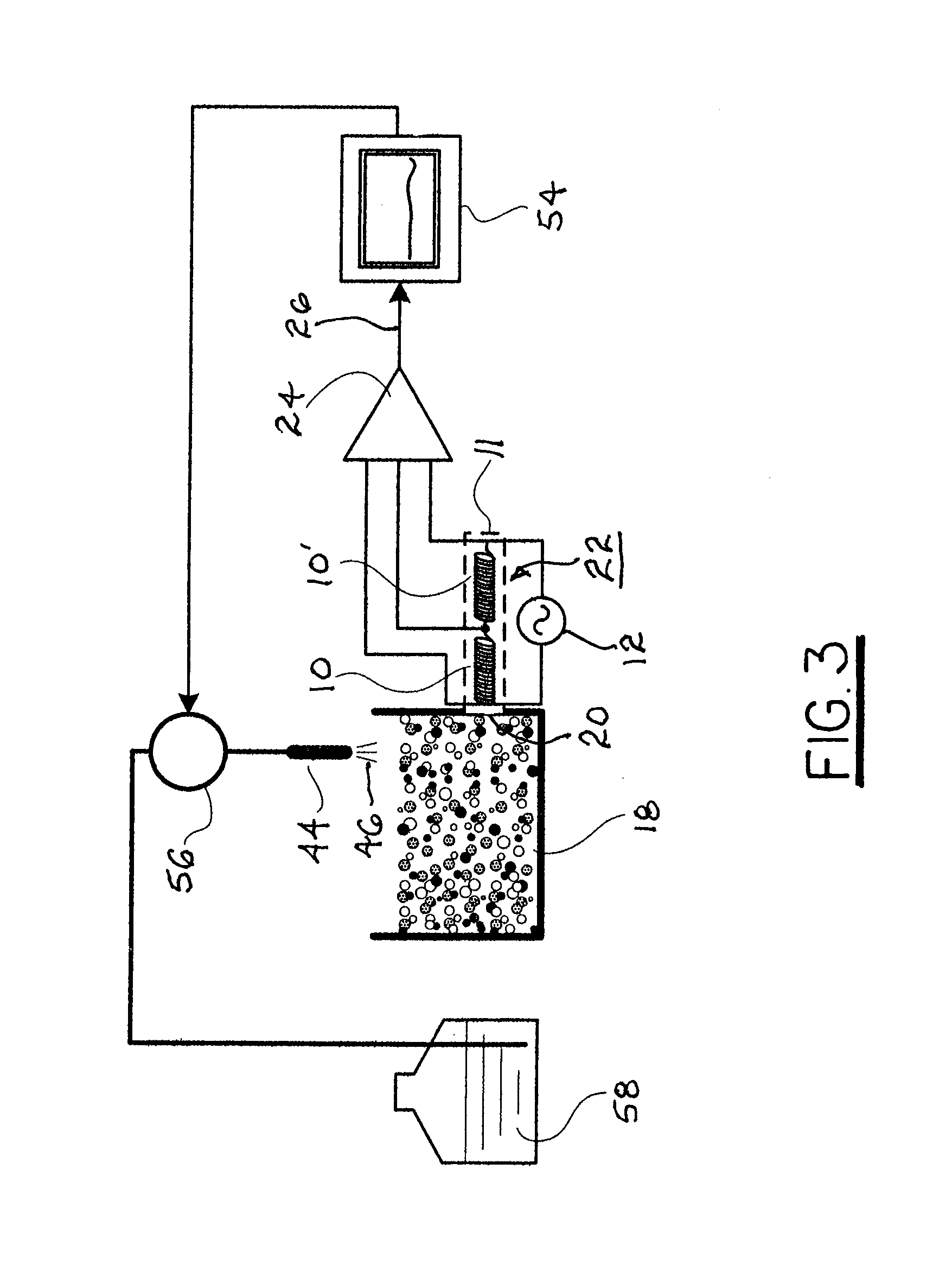

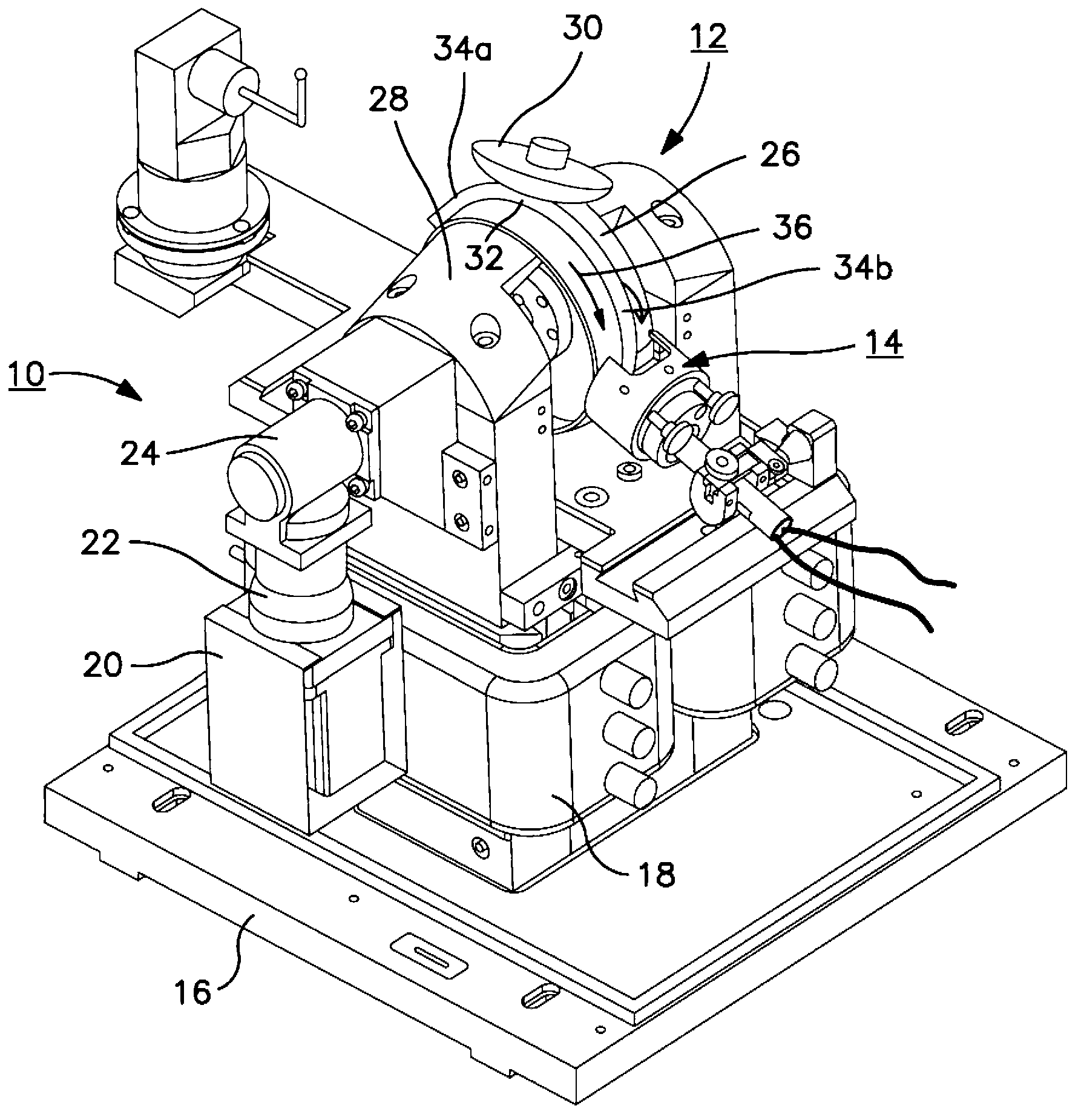

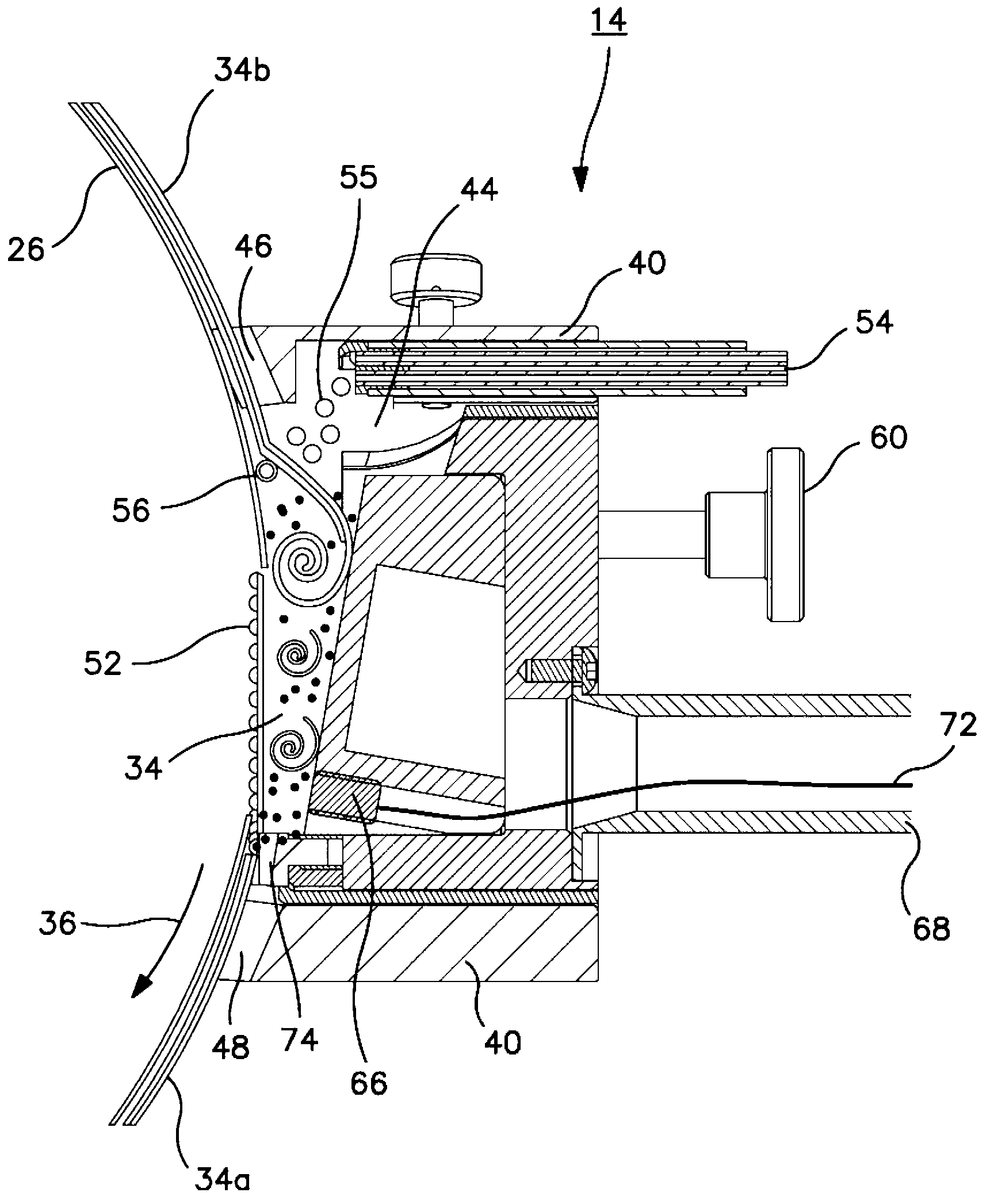

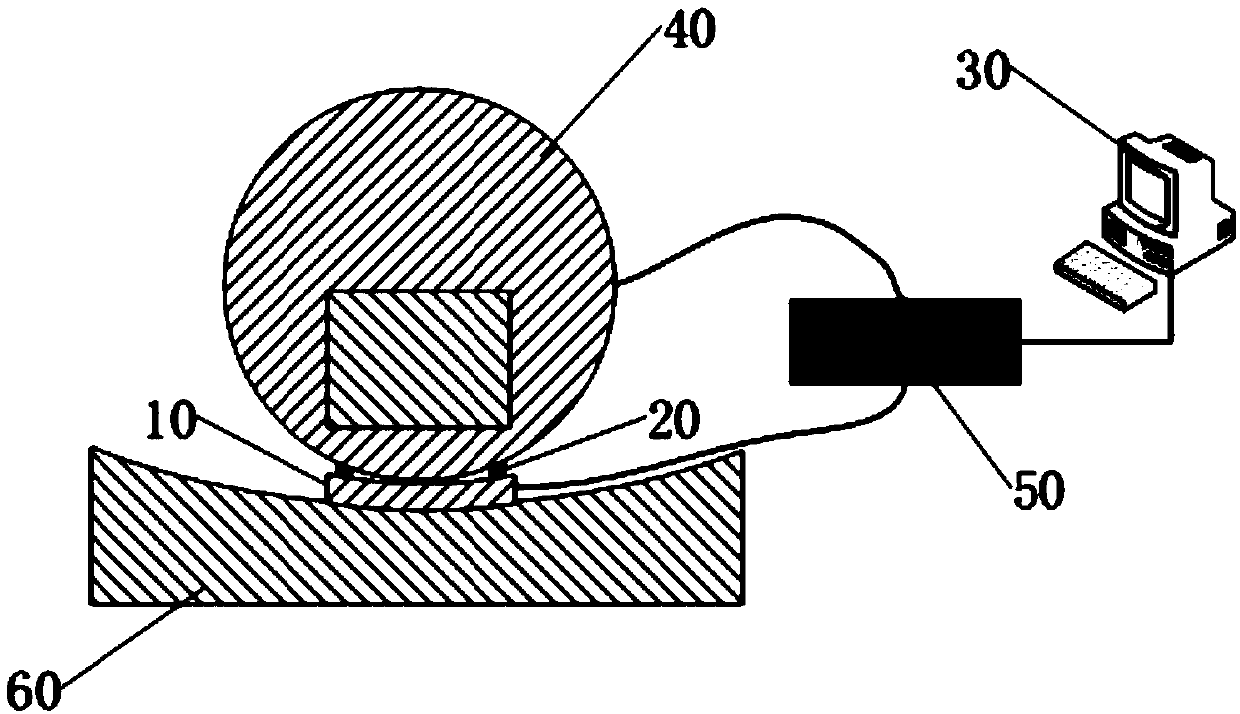

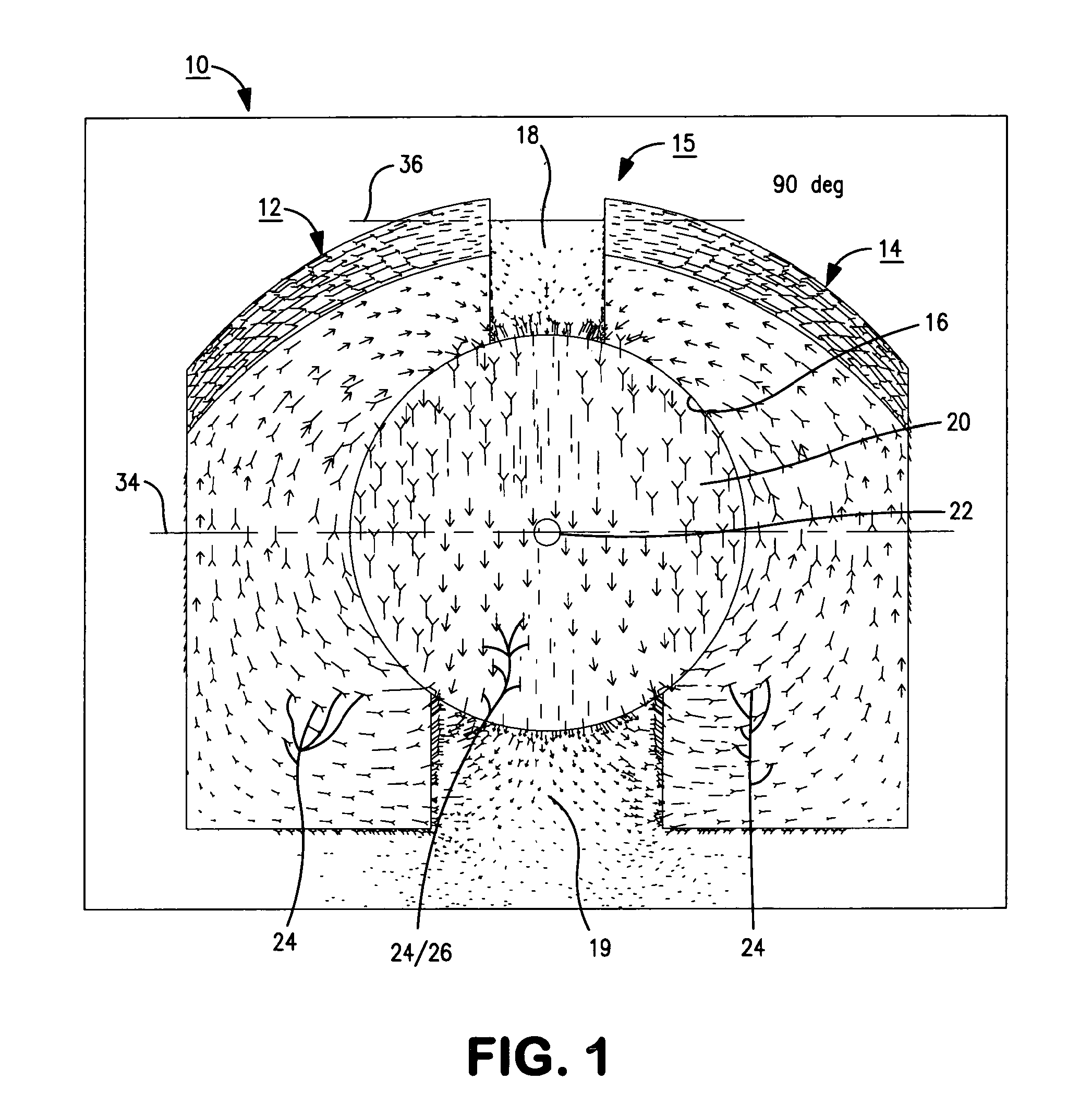

Method and apparatus for measurement and control of magnetic particle concentration in a magnetorheological fluid

A system for sensing and controlling concentration of magnetic particles in magnetorheological fluid comprising a wire coil and an AC voltage generator that, when energized, creates a magnetic flux field including a fringing field. When the fringing field extends through the magnetorheological fluid, the impedance in the circuit is proportional to the concentration of magnetic particles. A reference wire coil identical to the sensing wire coil is connected therewith. A demodulator is connected to each of the coils sends an impedance difference signal to a feedback controller connected to controllable dispensing apparatus for adding a calculated amount of replenishing fluid to the magnetorheological fluid. The system may be incorporated into an integrated fluid management module having apparatus for receiving and replenishing spent magnetorheological fluid and a sensor system in accordance with the present invention for use in a magnetorheological finishing system having a carrier wheel.

Owner:QED TECH INT LLC

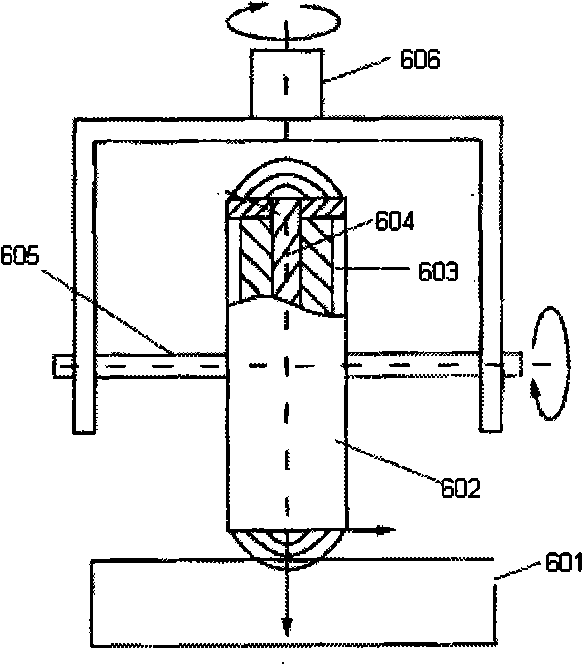

Abrasive band magnetorheological double curvature controllable composite finishing tool

ActiveCN106903586APreserve the advantages of micro-adaptive flexible deformationImprove processing efficiencyGrinding machine componentsBelt grinding machinesDrive wheelOptical processing

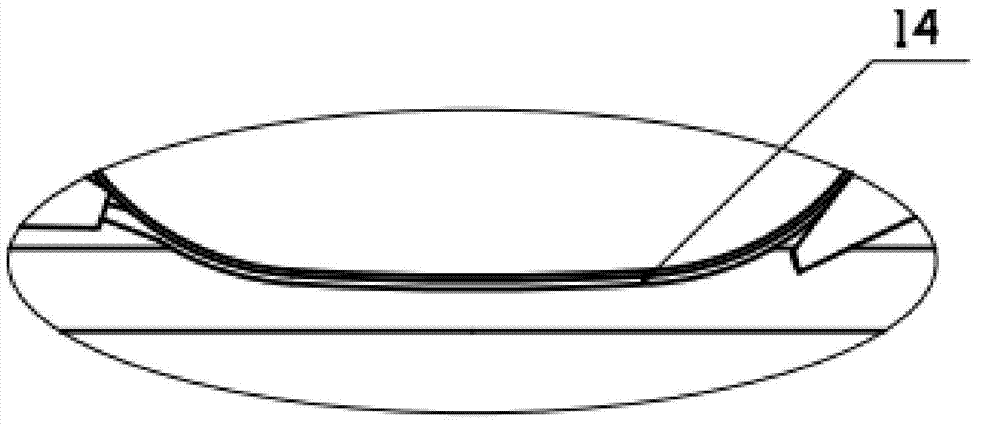

The invention relates to an abrasive band magnetorheological double curvature controllable composite finishing tool, and belongs to the technical field of precision optical machining. A macro curvature adjustment mechanism, a motor, a driving wheel and a tensioning wheel are fixed to a rack, wherein an output shaft of the motor is connected with the driving wheel, the driving wheel, the tensioning wheel and the macro curvature adjustment mechanism are wound by an abrasive band, and a magnetorheological fluid supply and recovery system is arranged below the abrasive band. The abrasive band magnetorheological double curvature controllable composite finishing tool has the following advantages: a microscope self-adapting flexible deformation advantage of magnetorheological finishing can be maintained, a macro active curvature controllable technical advantage of stress disc machining can be exerted, the problem that wide-range complete fitting machining can not be realized in the prior art can be solved, and the machining efficiency and the machining quality of a large workpiece are improved.

Owner:JILIN UNIV

Meter-level large diameter polarizer full-band surface shape processing method

The invention provides a meter-level large diameter polarizer full-band surface shape processing method. According to the method, through combining magnetorheological finishing and conformal fairing finishing, the processing precision of a meter-level large diameter polarizer can be effectively controlled, the meter-level large diameter polarizer with a full-band index which reaches a standard in a high power laser system is manufactured, the concrete indexes of transparent and reflective surfaces are as follows: PV is smaller than or equal to lambda / 3, GRMS is smaller than or equal to 7nm / cm, PSD1RMS is smaller than or equal to 1.8nm, PSD2RMS is smaller than or equal to 1.1nm, and surface roughness is smaller than or equal to 1nm.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

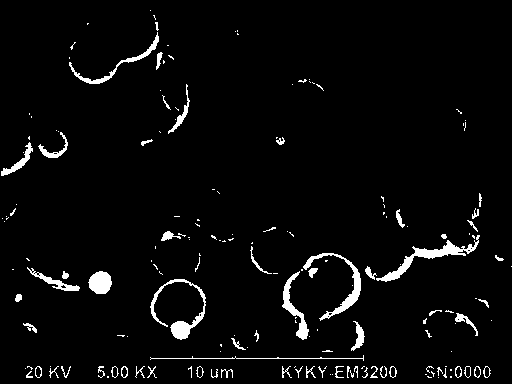

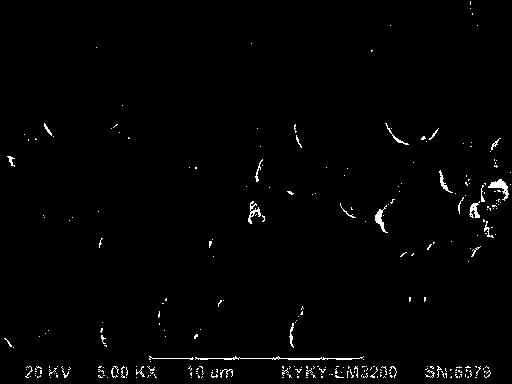

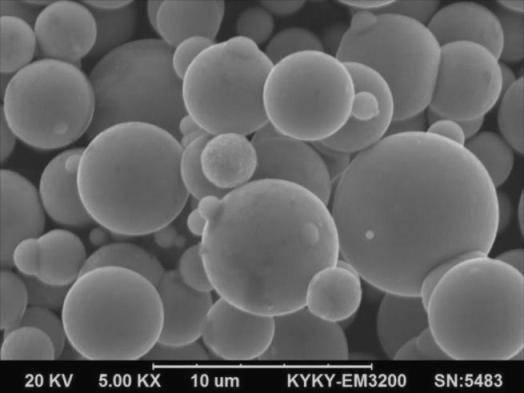

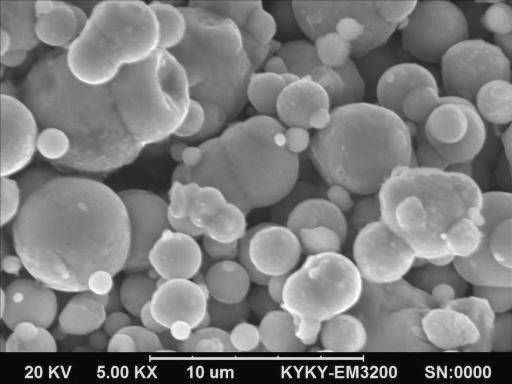

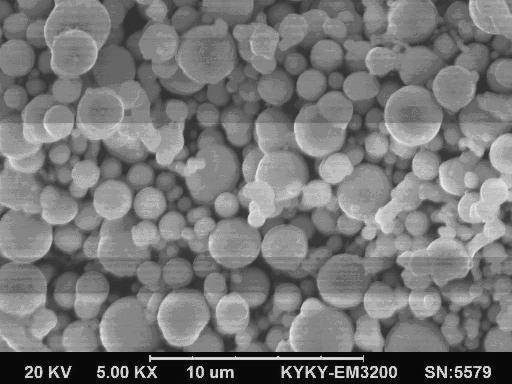

Manufacturing method for composite particle for magnetorheological finishing

ActiveCN108148505AGuaranteed uniformityPlay a polishing roleOther chemical processesPolishing compositions with abrasivesWater basedForce lines

The invention discloses a manufacturing method for preparing a composite particle from a ferromagnetic particle and an abrasive material for magnetorheological finishing. In particular, the surface ofthe ferromagnetic particle is wrapped with the abrasive material, or the abrasive material is embedded into the surface of the ferromagnetic particle; when the composite particle prepared from the ferromagnetic particle and the abrasive material encounters a magnetic field, the composite particle is arrayed by the action of a magnetic force line to form a self-adaptive flexible solid; and when the magnetic field moves, the composite particle moves with the magnetic field. When the movable self-adaptive flexible solid comprising the composite particle acts on the surface of a workpiece, the abrasive material compounded on the surface of the ferromagnetic particle generates an abrading or finishing effect on the surface of the workpiece. The effect of finishing is correspondingly changed with presence and intensity of the magnetic field. That is to say, the finishing is the magnetorheological finishing. The composite particle comprising the ferromagnetic particle and the abrasive material can perform dry abrading and finishing on the workpiece and be put in carrier liquid (including water-based liquid, a solvent or oil-base liquid and assistants of the water-based liquid, the solvent or the oil-base liquid) for the wet magnetorheological finishing of the workpiece.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

System for magnetorheological finishing of substrates

A system for magnetorheological finishing of a substrate. An integrated fluid management module (IFMM) provides dynamic control of the rheological fluid properties of the MR fluid on a conventional MR finishing apparatus, and dispensing of the fluid to the wheel. A magnetically shielded chamber charged with MR fluid is in contact with the carrier wheel. A transverse line removes the spent MR fluid from the wheel as the ribbon leaves the work zone. Replenishment fluid is added to the chamber via a dripper, and preferably an electric mixer agitates MR fluid in the chamber. A grooved magnetically-shielded insert at the exit of the chamber forms a polishing ribbon on the carrier wheel as the wheel is turned. A sensor sensitive to concentration of magnetic particles provides a signal for control of MR fluid properties, particularly, water content in the MR fluid. Means is provided for cooling fluid within the chamber.

Owner:QED TECH INT LLC

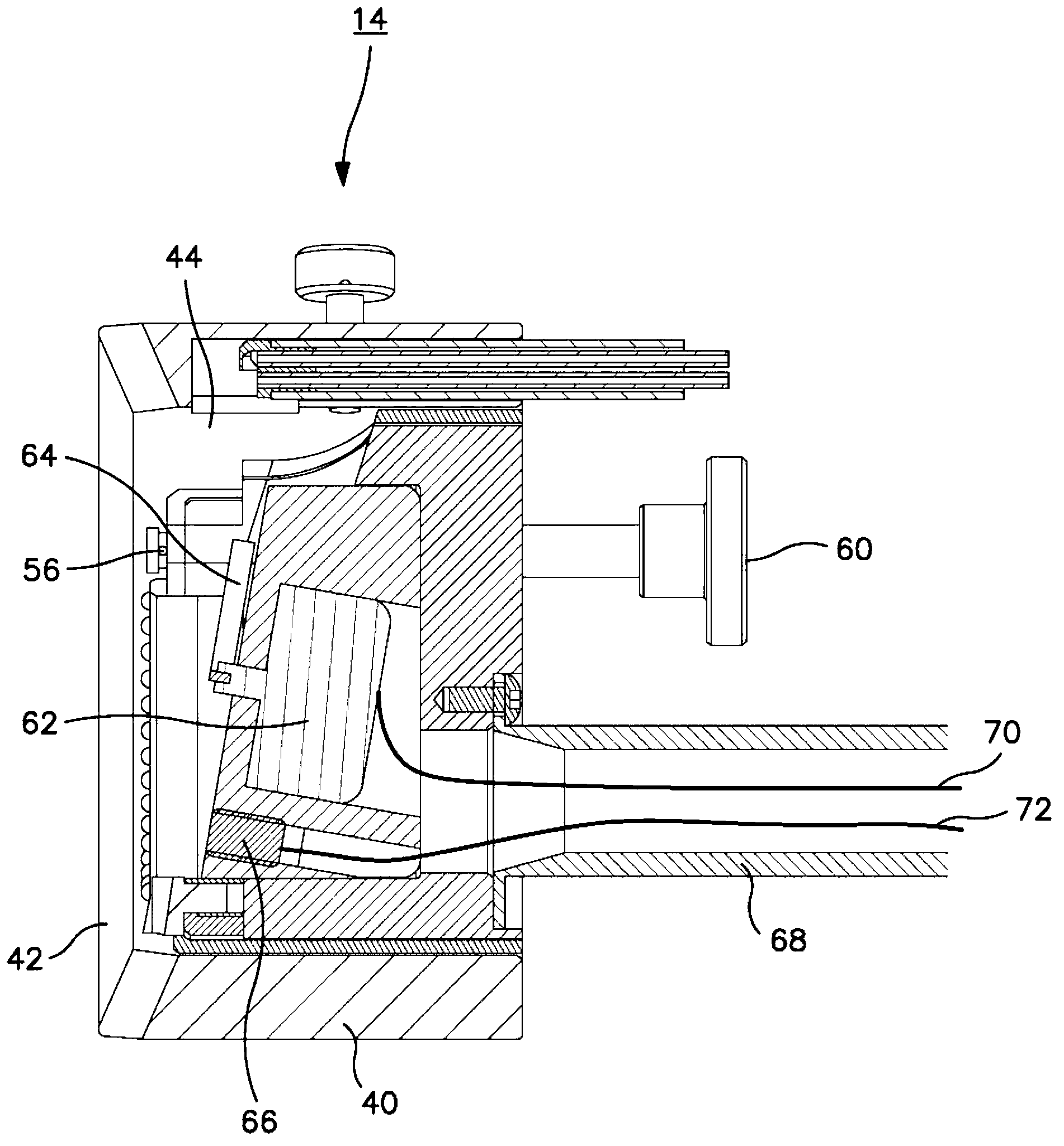

System for magnetorheological finishing of a substrate

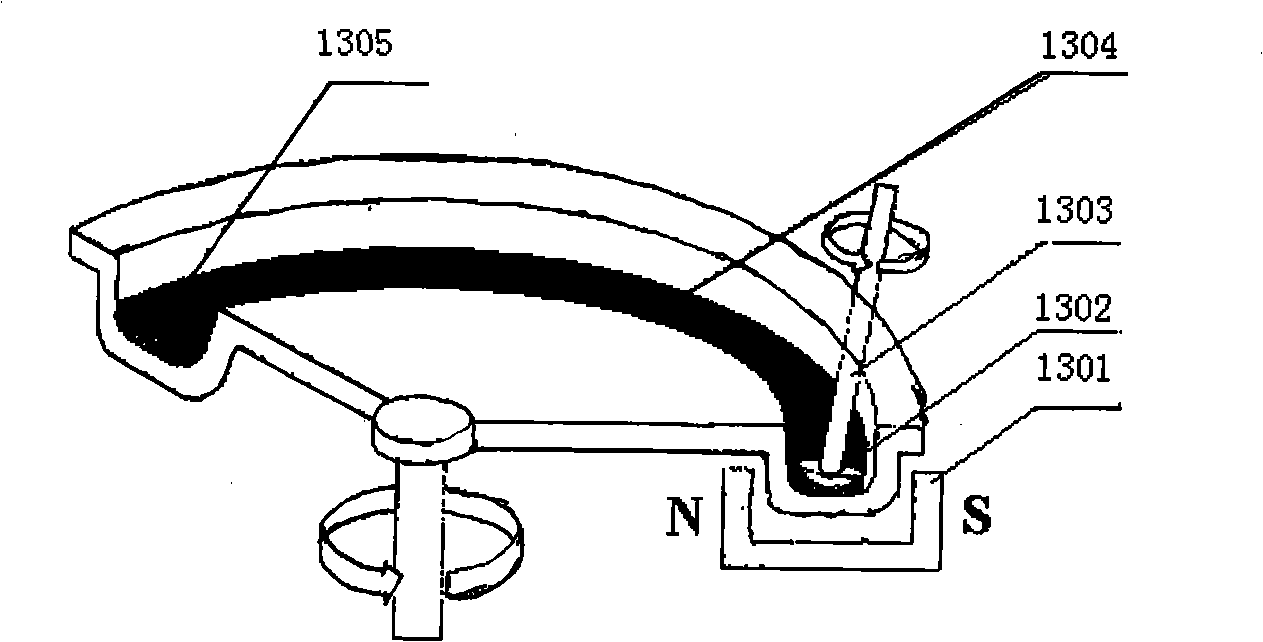

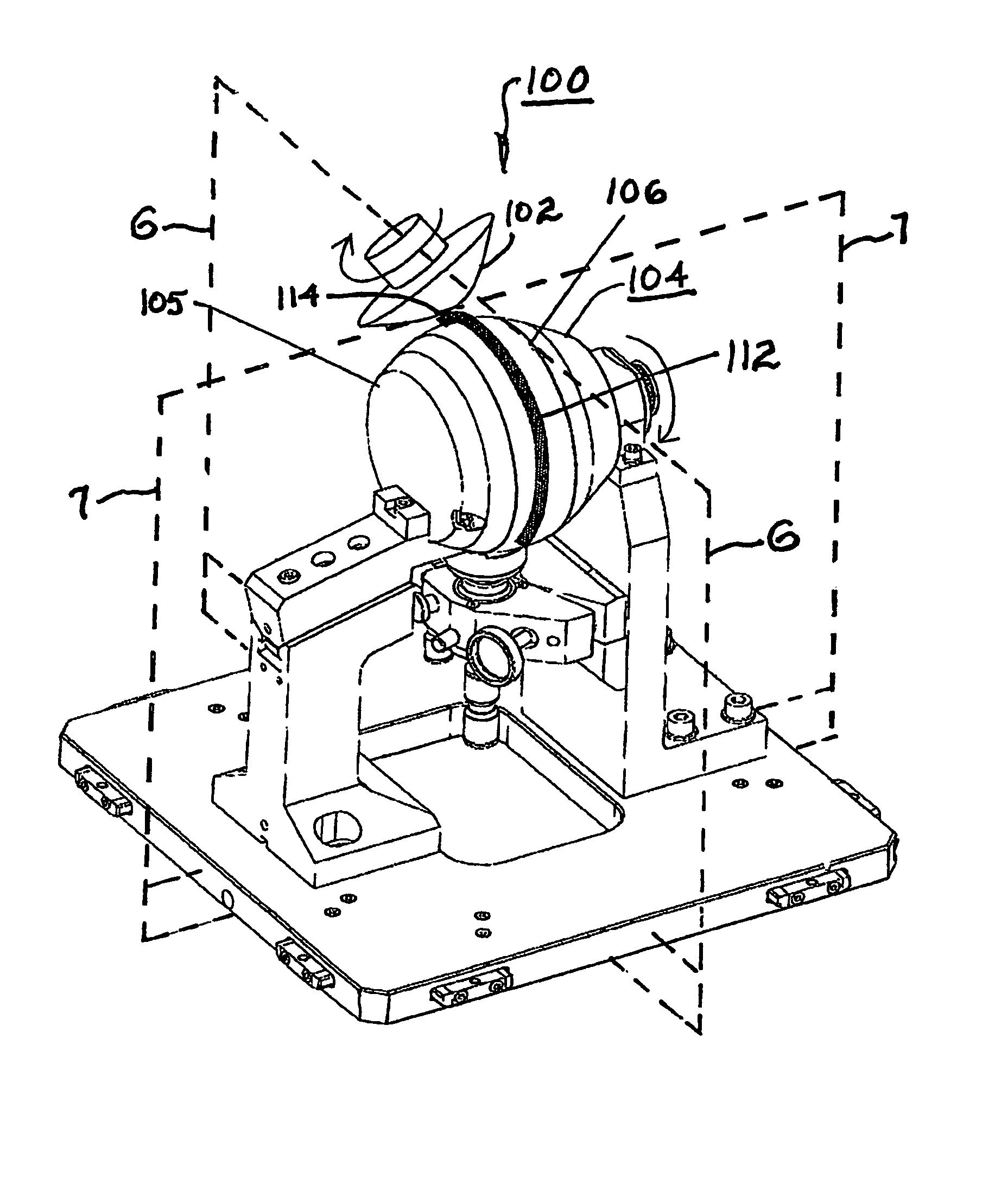

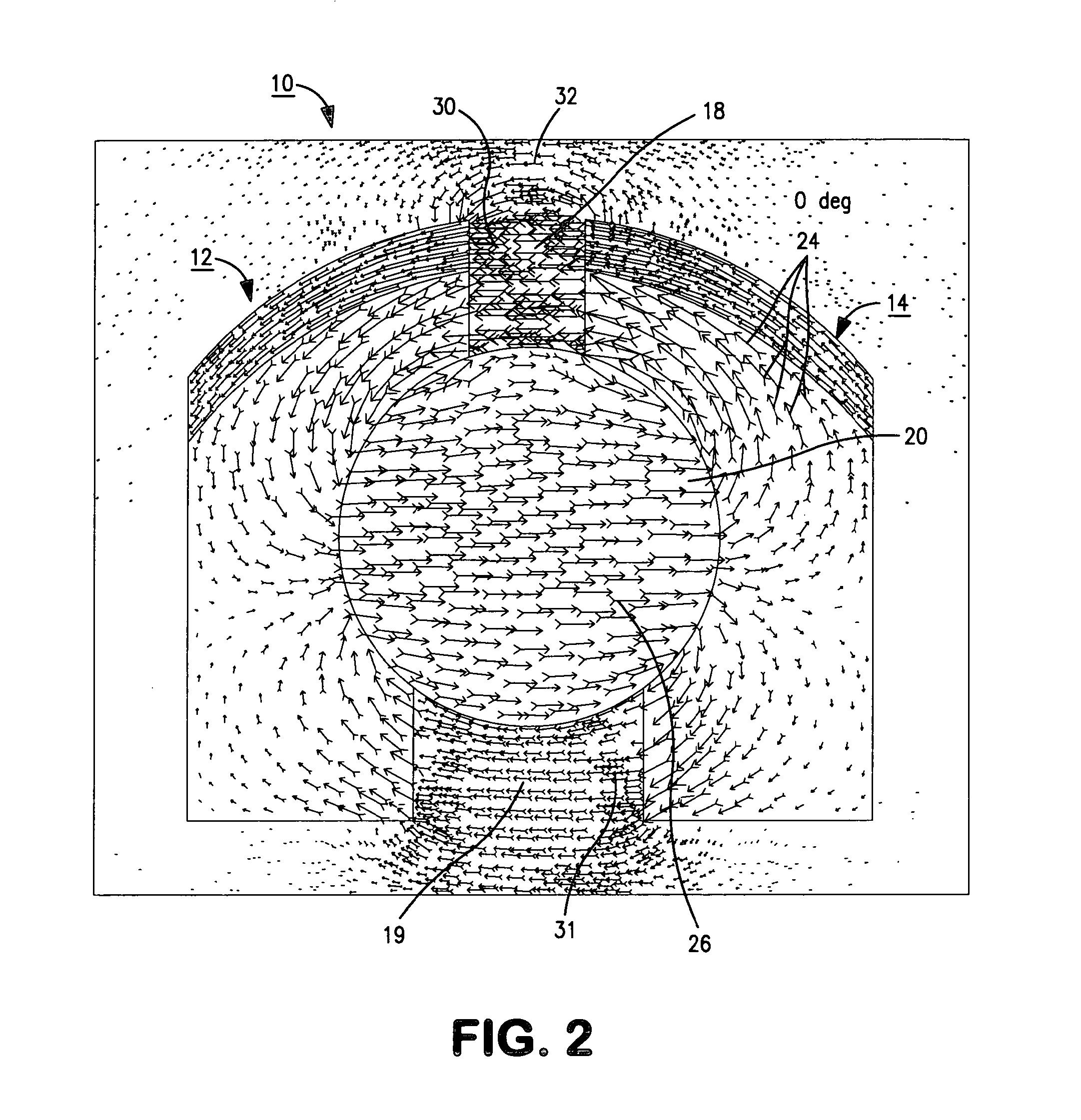

ActiveUS20110312248A1Small sizeVarying stiffnessPolishing machinesPermanent magnetsPole pieceMagnetorheological finishing

A system for magnetorheological finishing of a substrate. A spherical wheel meant for carrying a magnetorheological finishing fluid houses a variable-field permanent magnet system having north and south iron pole pieces separated by primary and secondary gaps with a cylindrical cavity bored through the center. A cylindrical permanent magnet magnetized normal to the cylinder axis is rotatably disposed in the cavity. An actuator allows rotation of the permanent magnet to any angle, which rotation changes the distribution of flux in the magnetic circuit through the pole pieces. Thus, one can control field intensity in the gaps by positioning the permanent magnet at whatever angle provides the required field strength. Because the field also passes above the pole pieces, defining a fringing field outside the wheel surface, the variable field extends through a layer of MR fluid on the wheel, thus varying the stiffness of the MR fluid as may be desired for finishing control.

Owner:QED TECH INT LLC

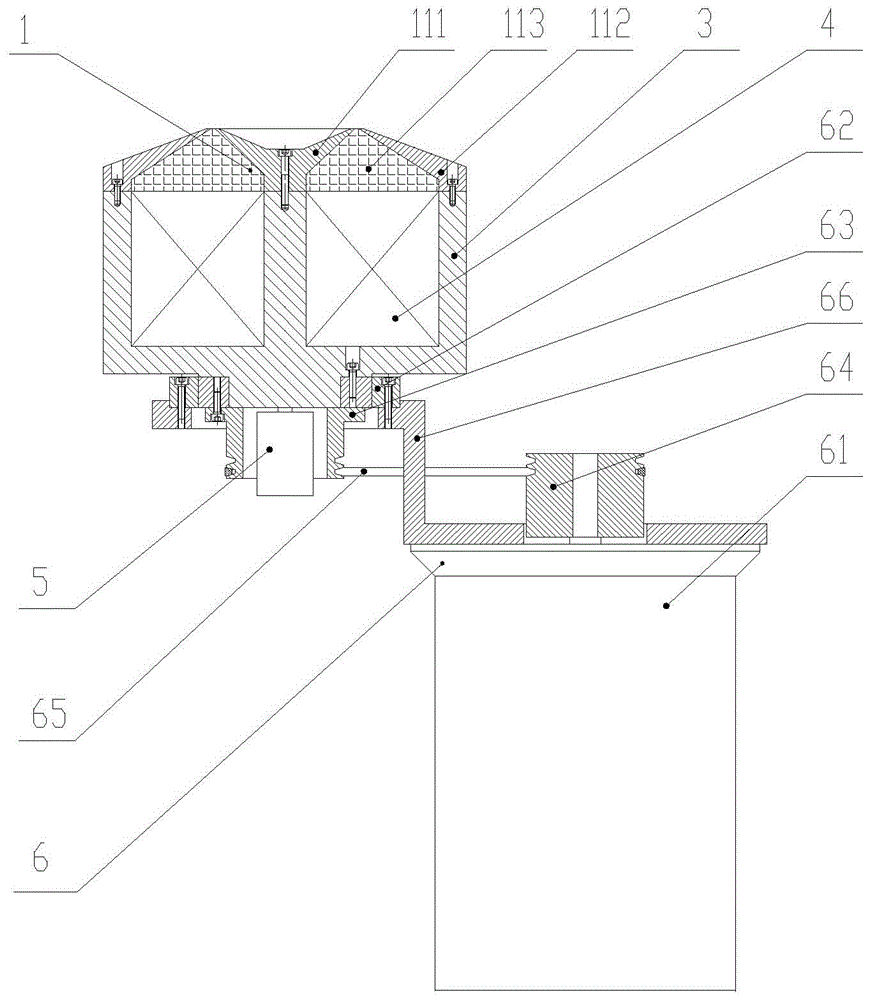

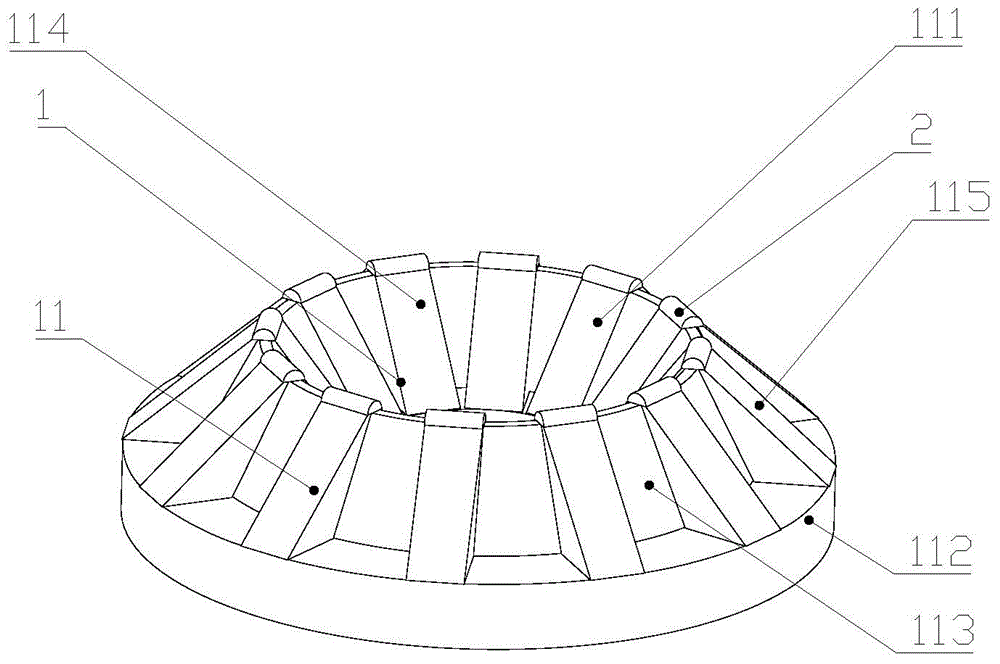

Rotary magnetorheological finishing wheel device

The invention relates to a rotary magnetorheological finishing wheel device mainly comprising a grinding wheel, a magnetic core, a coil, a magnetic brush and a drive mechanism. The grinding wheel comprises at least one magnetic pole structure; each magnetic pole structure comprises an inner magnetic pole which is circular, an outer magnetic pole which is circular, and non-permeable filler arranged between the inner magnetic pole and the outer magnetic pole to separate them. Each inner magnetic pole is peripherally divided into multiple inner magnetic pole blocks arranged at intervals. The outer magnetic pole is peripherally divided into multiple outer magnetic pole blocks arranged at intervals. The inner magnetic pole blocks are in one-to-one correspondence with the outer magnetic pole blocks. In overview, the uppermost of each inner magnetic pole block and that of the corresponding outer magnetic pole block have a shortest distance. When the magnetic pole structures are electrified and generate a magnetic field, magnetorheological fluid is magnetized into interrupted Bingham bodies. By means of the feature that the magnetorheological fluid partially gathers towards the strong magnetic field, machining efficiency is greatly improved; by the use of array arrangement of the multiple magnetic pole structures, large-area finishing can be achieved.

Owner:白素华

System for magnetorheological finishing of substrates

A system for magnetorheological finishing of a substrate. An integrated fluid management module (IFMM) provides dynamic control of the rheological fluid properties of the MR fluid on a conventional MR finishing apparatus, and dispensing of the fluid to the wheel. A magnetically shielded chamber charged with MR fluid is in contact with the carrier wheel. A transverse line removes the spent MR fluid from the wheel as the ribbon leaves the work zone. Replenishment fluid is added to the chamber via a dripper, and preferably an electric mixer agitates MR fluid in the chamber. A grooved magnetically-shielded insert at the exit of the chamber forms a polishing ribbon on the carrier wheel as the wheel is turned. A sensor sensitive to concentration of magnetic particles provides a signal for control of MR fluid properties, particularly, water content in the MR fluid.; Means is provided for cooling fluid within the chamber.

Owner:QED TECH INT

Selective alarm based on magnetorheological fluid

The invention relates to a selective alarm based on magnetorheological fluid, which is used for keeping order in a playground for children and ensuring safety of the children. The device is composed of a flat plate, a sealing circle, a shaft frame, the magnetorheological fluid, electromagnetic coins, an isolator, volume compensators, delay switching contacts, reset springs and a shell. When the electromagnetic coins are energized, magnetic circuits are generated in the shell, the shaft frame and the gap, and thus the magnetorheological fluid is converted to a high-viscosity and low-liquidity Bingham fluid from the original Newton fluid. The shaft frame is fixed inside the shell. When enough pressure (larger than the shearing force of the magnetorheological fluid) is applied to the flat plate, the shaft frame begins to move downwardly until to be contacted with the delay switching contact, and an alarm is given. Through adjusting the magnitude of current passing through the electromagnetic coins, the shearing force of the magnetorheological fluid can enable a child to pass through without giving an alarm and an alarm is given when an adult passes. The device selectively gives an alarm through changing the magnitude of the current, and intelligence of the alarm can be realized.

Owner:ZHEJIANG NORMAL UNIVERSITY

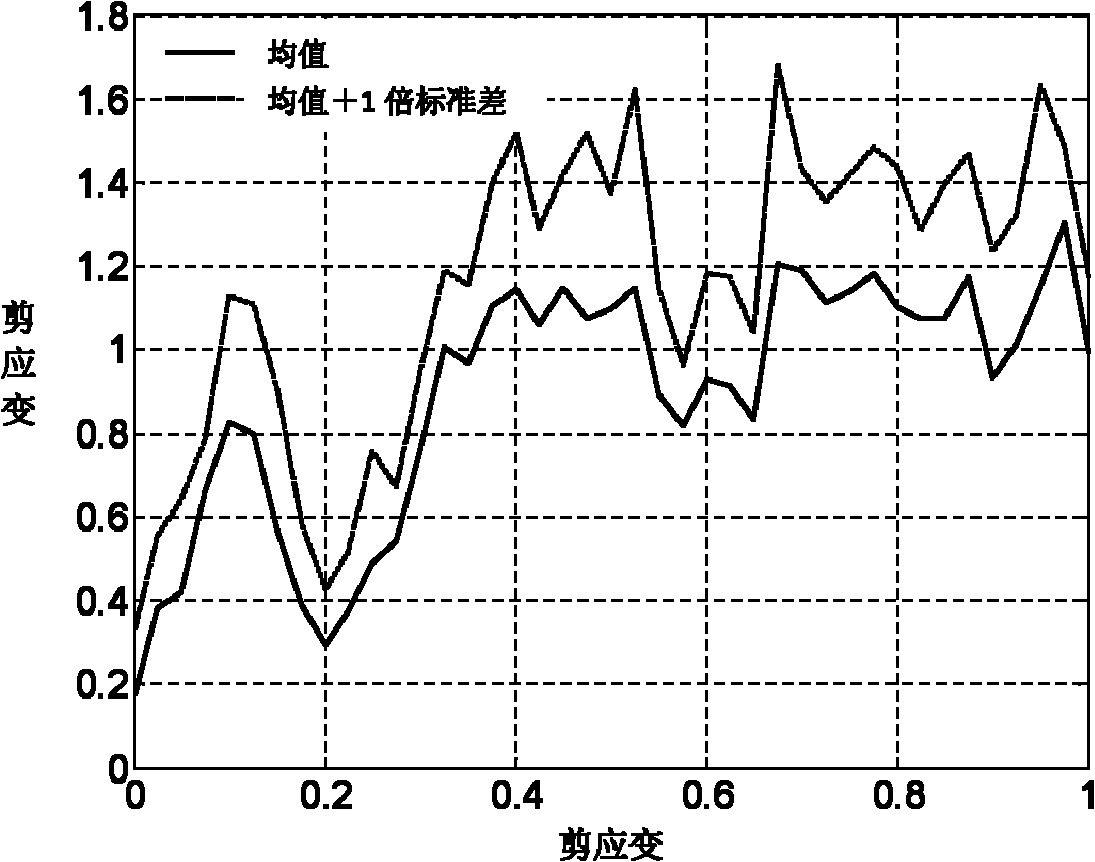

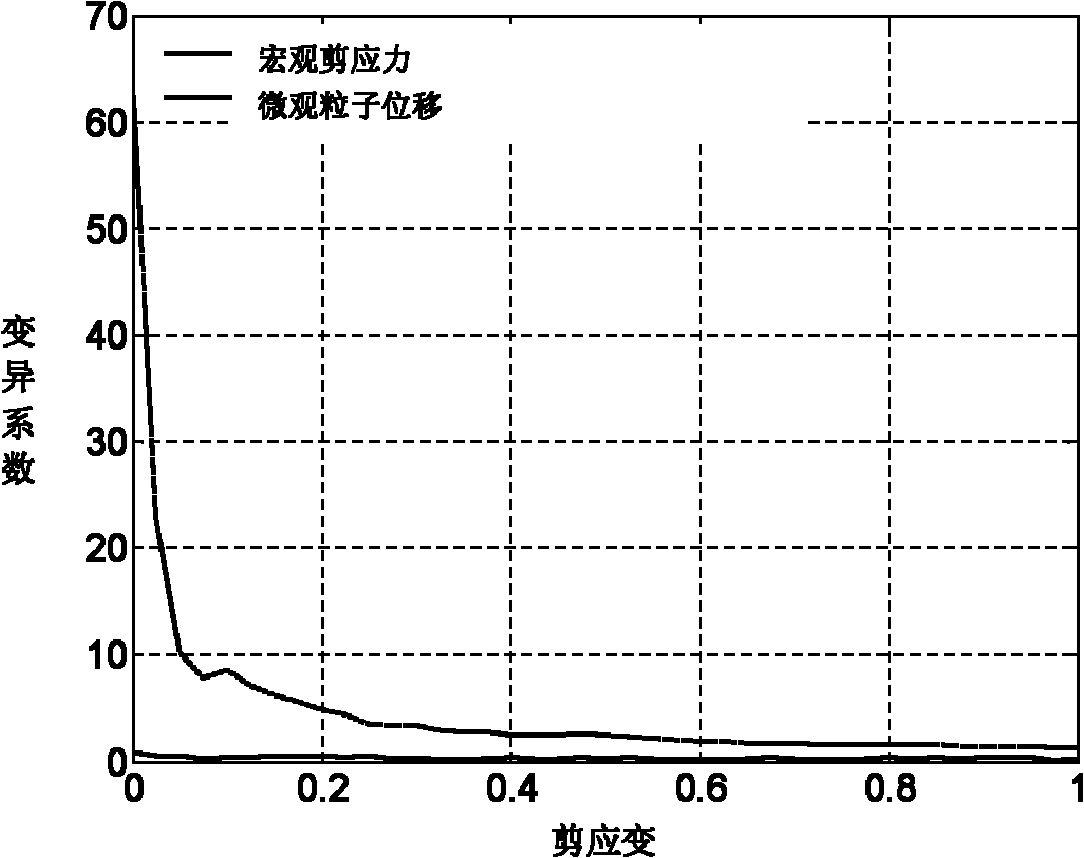

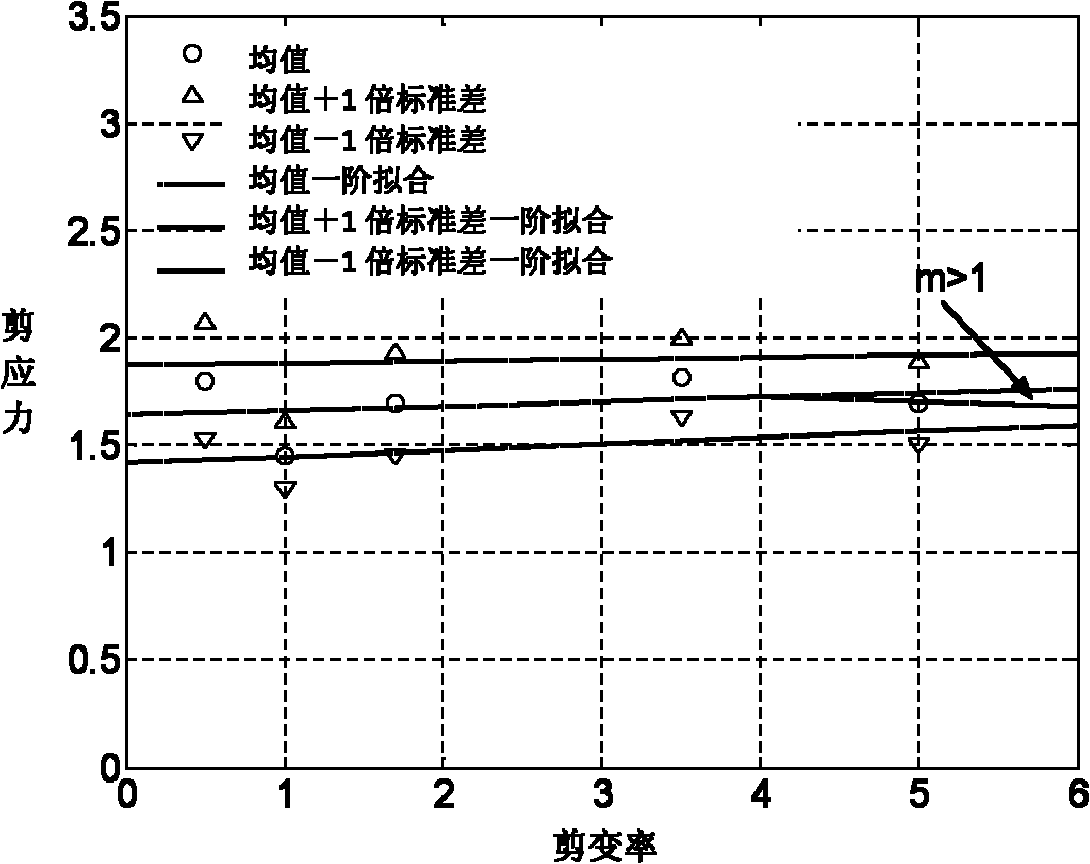

Micro scale method for calibrating dynamic yield variability of magnetorheological fluid

The invention discloses a micro scale method for calibrating dynamic yield variability of a magnetorheological fluid. The method comprises the following steps of: setting magnetorheological fluid material parameters emulated by molecular dynamics according to researched objects; building a langevin equation of suspended particles motion under multiple fields of coupling action, and programming a large scale molecular dynamics emulation program; evolving and simulating the micro structure of the magnetorheological fluid according to the emulation program; building a macro yield stress model with random motion information of micro particles, evolving the emulation result according to the micro structure of the magnetorheological fluid, and performing statistics to acquire a stress-strain constitutive relationship with non-linear fluctuation and random fluctuation; and building a Bingham shear rate constitutive model with random parameters, and identifying the random parameters in the Bingham module by using a least square fitting regulation, and calibrating the variability. By the method of the invention, the traditional phenomenology calibrating method based on testing and analysisis changed so as to provide a deep recognition for designing and optimizing the control elements of the magnetorheological fluid.

Owner:TONGJI UNIV

Method of preparing an edge-strengthened article

InactiveUS8974268B2Edge grinding machinesPolishing machinesEdge strengthMagnetorheological finishing

A method of preparing an edge-strengthened article comprises polishing of an edge of an article having a first edge strength using magnetorheological finishing, wherein after the polishing the article has a second edge strength and the second edge strength is greater than the first edge strength.

Owner:CORNING INC

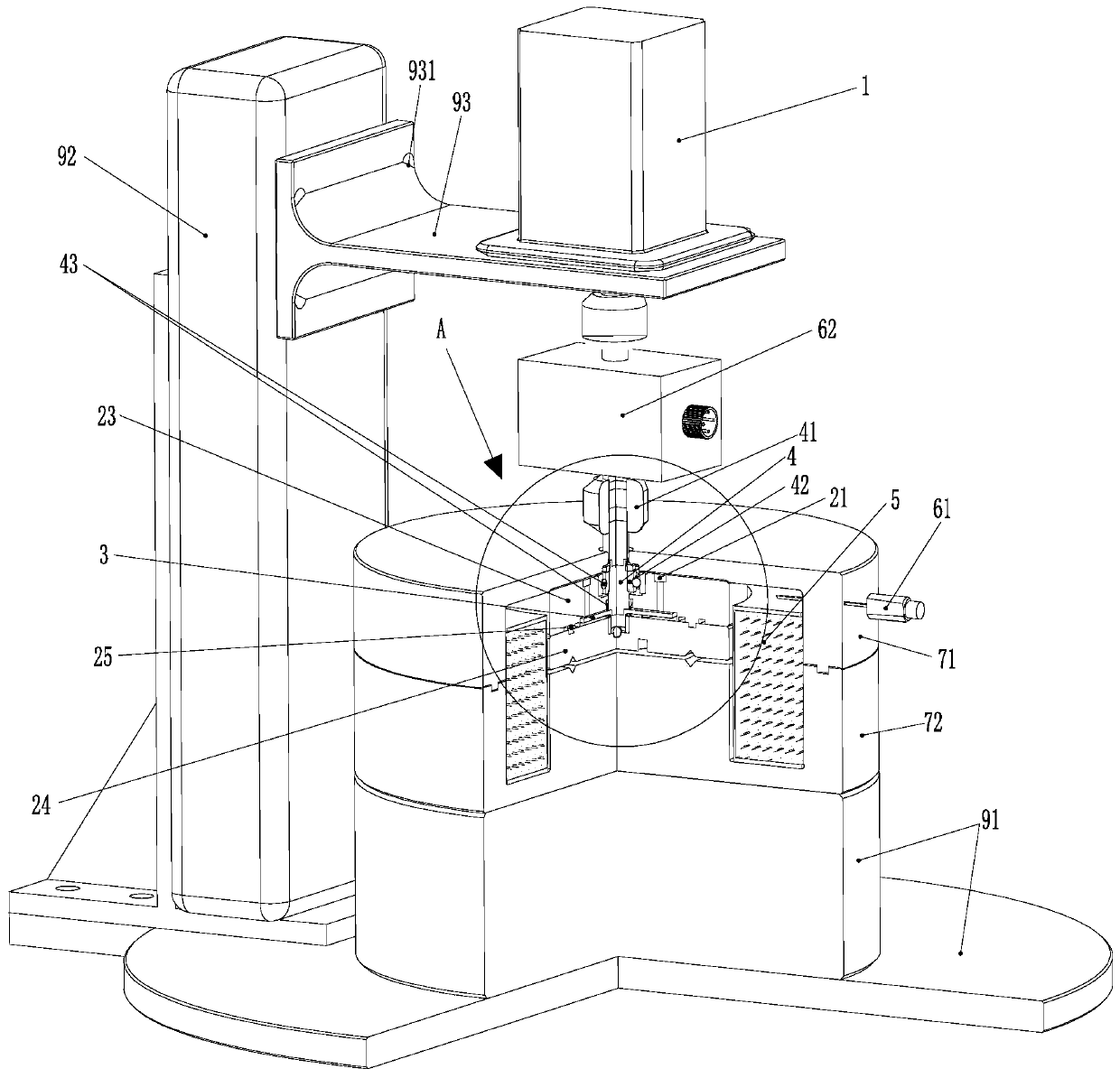

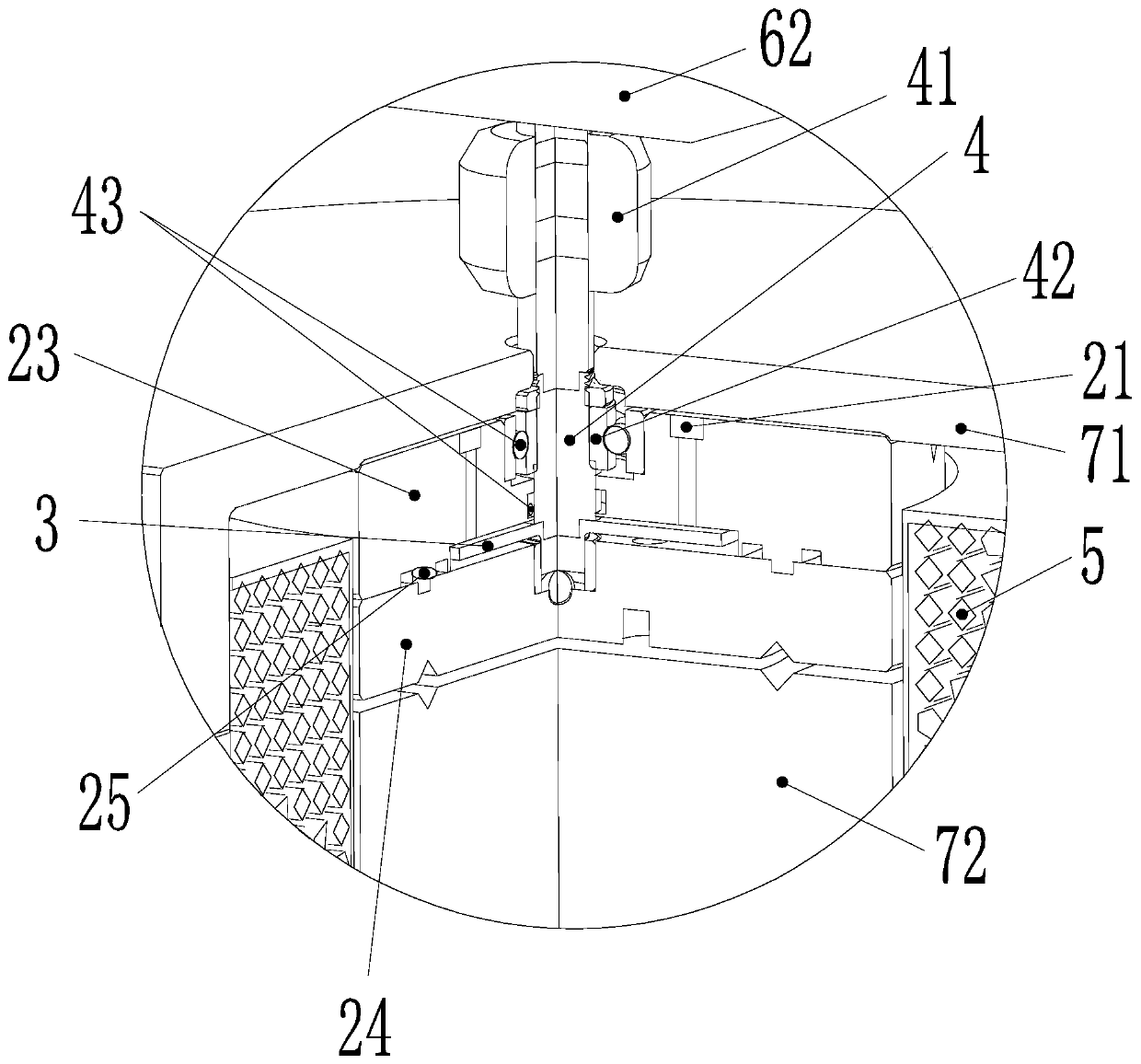

Calibration device of magnetorheological finishing clearance and calibration method

ActiveCN109605134AFully automatedHigh measurement accuracyGrinding/polishing apparatusMagnetic currentEngineering

The invention provides a calibration device of magnetorheological finishing clearance. The device comprises an auxiliary thin sheet, a flexible connecting piece, a signal collecting device, an industrial control upper computer and a magnetorheological polishing wheel, wherein the auxiliary thin sheet is connected with the magnetorheological polishing wheel through the flexible connecting piece, and the auxiliary thin sheet is provided with a first position in contact with the magnetorheological polishing wheel and a second position separated from the magnetorheological polishing wheel; and theindustrial control upper computer is connected with the signal collecting device, one end of the signal collecting device is electrically connected with the magnetorheological polishing wheel, the other end of the flexible connecting piece is electrically connected with the auxiliary thin sheet, and the flexible connecting piece is an insulating piece; and the invention further provides a calibration method of the calibration device based on the magnetorheological polishing clearance. The calibration device of the magnetorheological finishing clearance and the calibration method can realize automatic high-efficiency and high-precision polishing clearance measurement.

Owner:长春长光大器科技有限公司

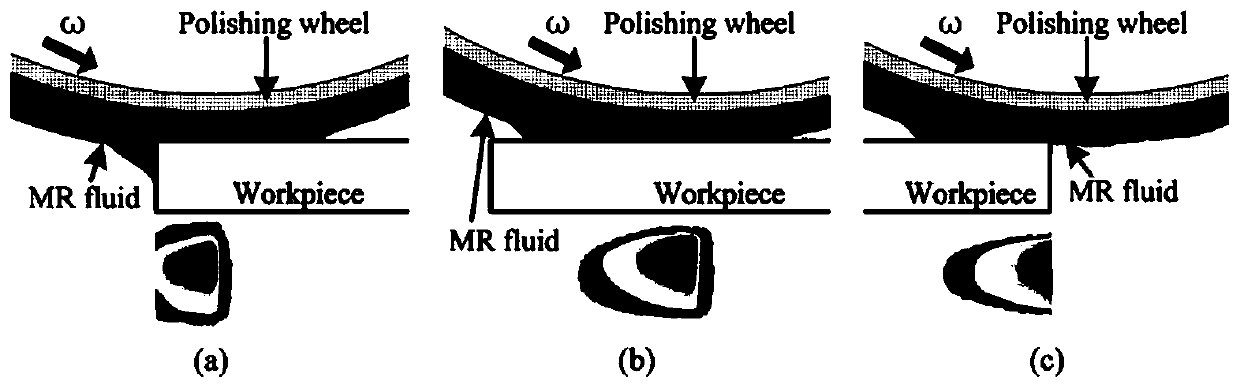

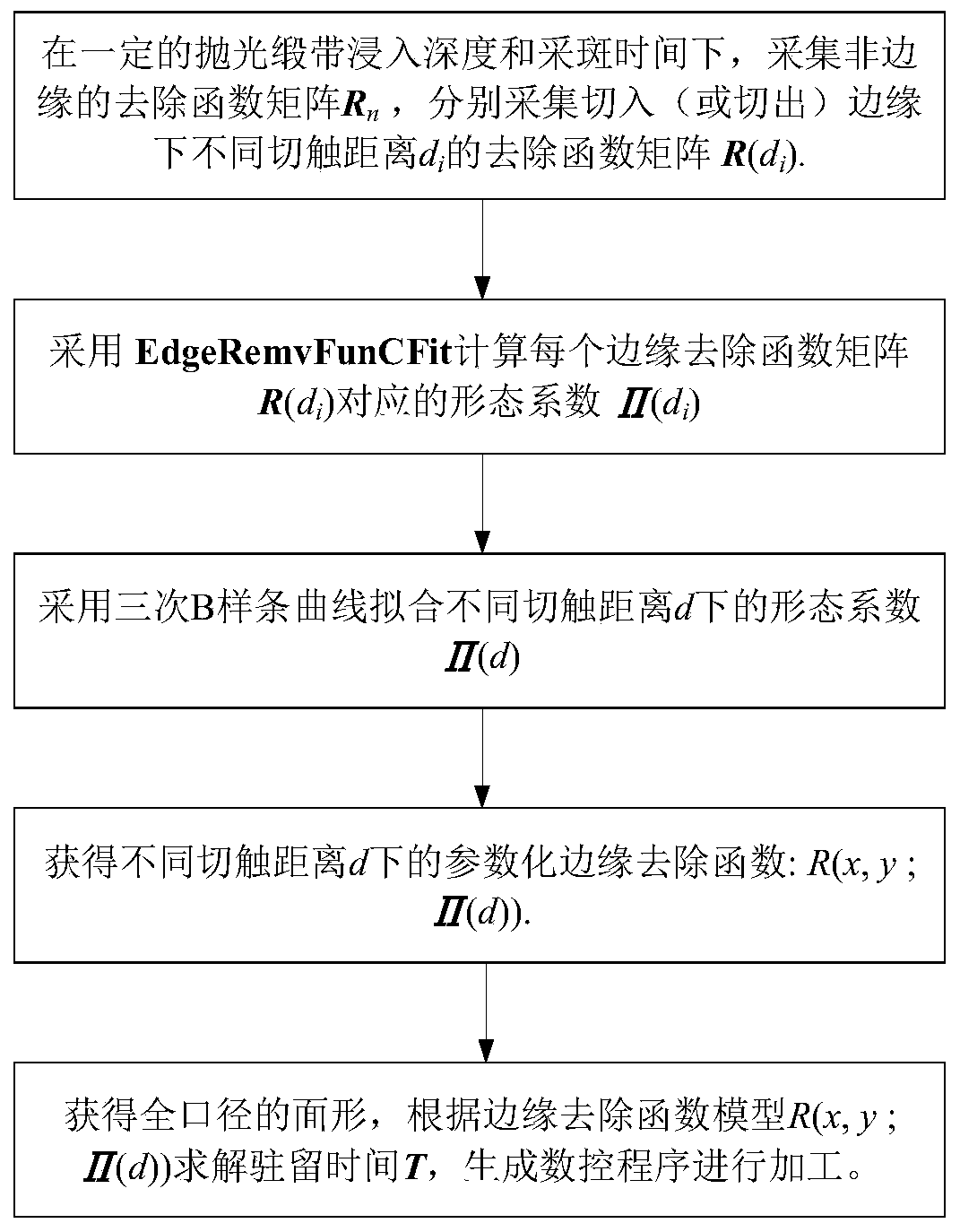

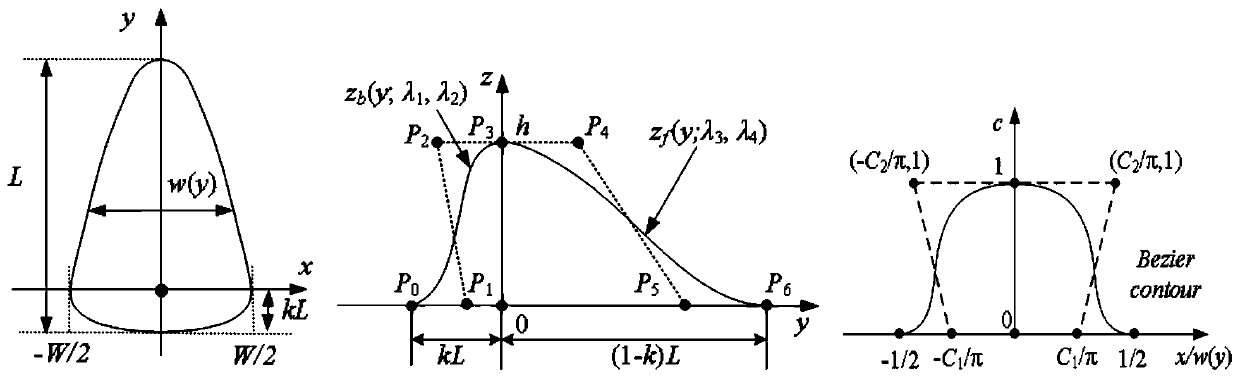

Magnetorheological finishing edge removal function modeling and edge effect suppressing method

ActiveCN110883608AHigh degree of geometric freedomReduce mistakesAutomatic grinding controlEdge surfaceEdge effects

The invention discloses a magnetorheological finishing edge removal function modeling and edge effect suppressing method. The method comprises the following steps of S1, under a certain finishing ribbon immersion depth and spot collection time, collecting non-edge finishing spots and finishing spots at different contact distances in two situations of cut-in edge and cut-out edge respectively, andacquiring the length and width of the non-edge finishing spots; S2, establishing a Bezier spline-based magnetorheological finishing removal function parameterization model; S3, establishing edge removal function reconstruction methods at different contact states; and S4, formulating a residence time solving strategy based on an edge removal function model. According to the method, the designed removal function model has the analytical form and the high geometric degree of freedom, the problems that a current magnetorheological finishing edge removal function compensation method is large in form error and poor in edge surface shape control are solved, and the model precision of the edge removal function and the suppression level of the edge effect are improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

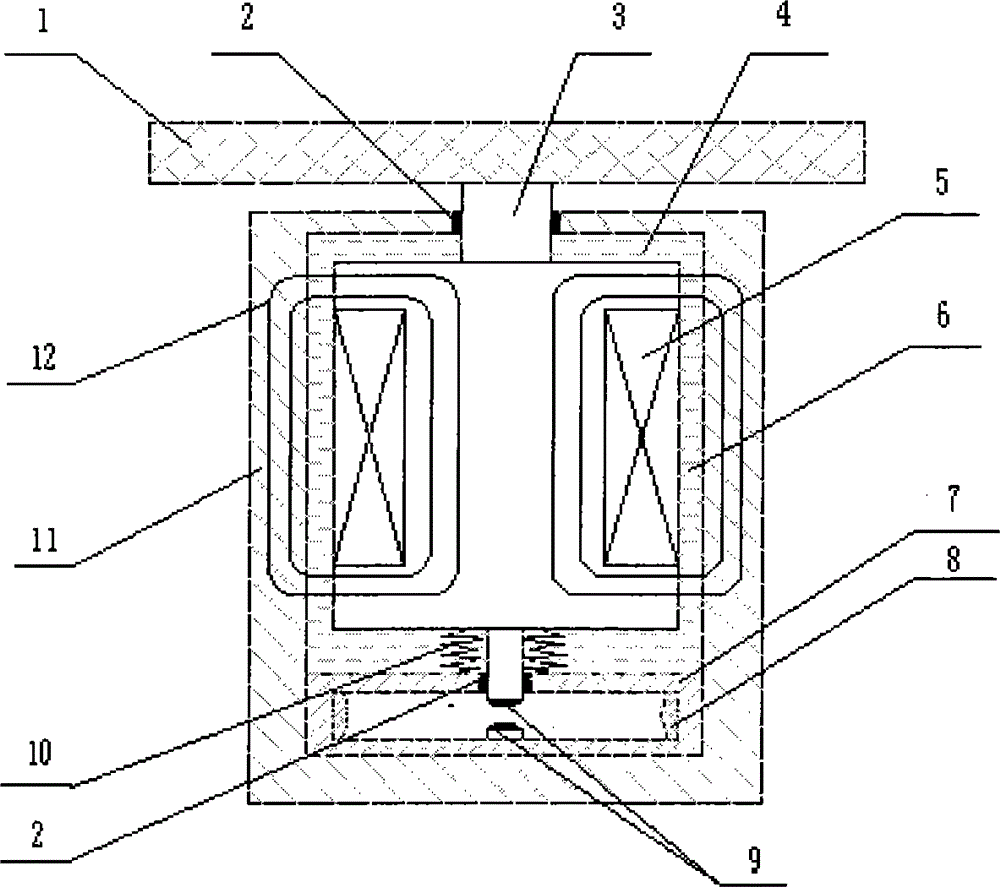

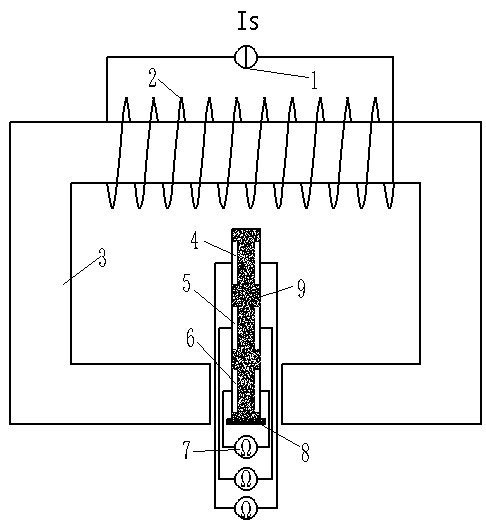

Device and method for measuring response time of magnetorheological fluid

The invention provides a device for measuring the response time of magnetorheological fluid; the device comprises a disc shearing module, a magnetic field generating module, a magnetic guiding module,a motor, a data acquisition module and a processor, wherein the disc shearing module is used for loading and shearing the magnetorheological fluid; the magnetic field generating module is used for generating a magnetic field, wherein the magnetic path of the magnetic field passes through the disc shearing module; and the magnetic guiding module is used for guiding the magnetic field generated bythe magnetic field generating module, so that the magnetic field direction passing through the disc shearing module is perpendicular to the direction of the magnetorheological fluid sheared by the disc shearing module. The device is suitable for measuring the response time of magnetorheological fluid at a high shear rate, and the influence of the magnetorheological fluid splashing and the surfacemeniscus effect on the detection result caused by centrifugal force is avoided, the response time of the magnetorheological fluid can be directly measured and acquired, and the influence of the electrical response time and the mechanical response time of the device on measurement of the response time of the magnetorheological fluid is avoided, and the accuracy and the reliability of the magnetorheological fluid response time obtained by measurement are high.

Owner:CHONGQING UNIV

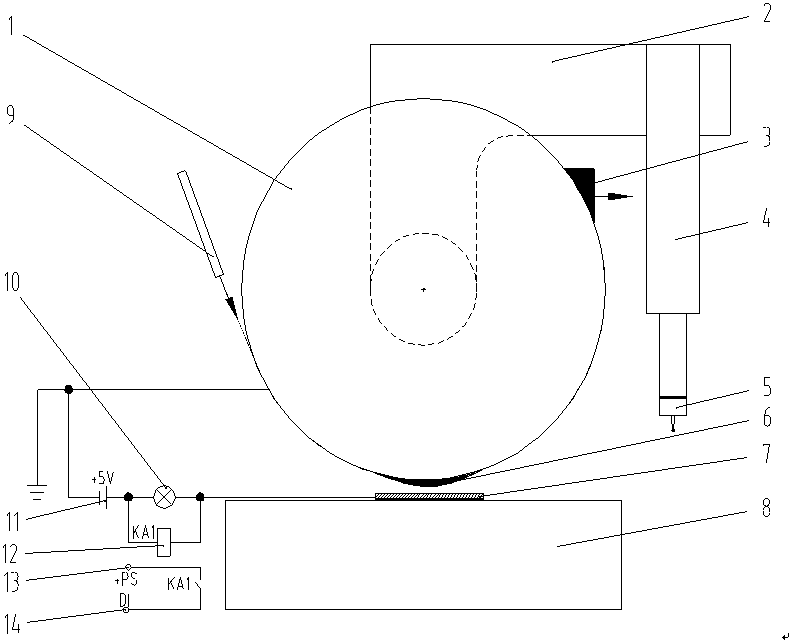

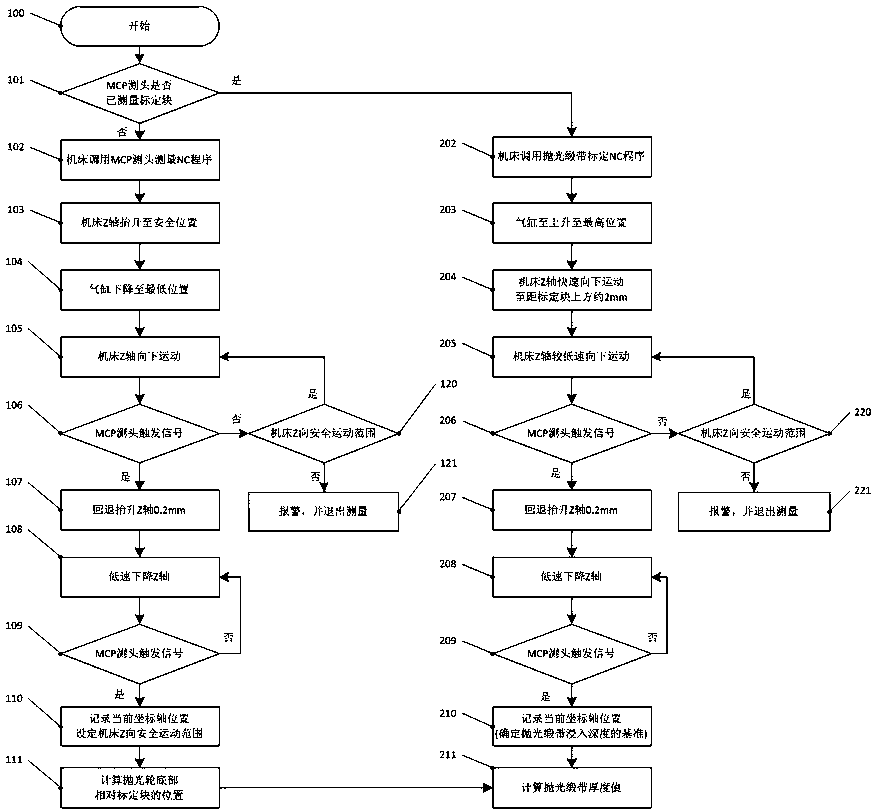

Device for automatic calibration of thickness of magnetorheological finishing ribbon

PendingCN107703881ARealize automatic measurementHigh precisionProgramme controlComputer controlMagnetic currentEngineering

The present invention provides a device for automatic calibration of thickness of magnetorheological finishing ribbon. The device comprises a cylinder and an MCP probe; relative positions of a workpiece and a calibration block relative to a bottom portion of a polishing wheel can be automatically measured; conductivity of a magnetorheological fluid is employed to perform contact measurement; a finishing ribbon is in flexible contact with the conductive calibration block arranged on the workpiece to form a current loop and generate conduction signals; and a computer obtains relative positions of the calibration block and the bottom portion of the finishing ribbon when the finishing ribbon is in flexible contact with the conductive calibration block so that automatic measurement of thicknessof the finishing ribbon is realized. The problems are solved that a manual mode is employed to measure and calibrate thickness of a finishing ribbon in the prior at so that the measurement precisionis not high, the efficiency is low and a potential risk is large, automatic measurement and calibration with high precision, high efficiency and high safety of thickness of the finishing ribbon can berapidly achieved with the low cost, and therefore magnetorheological finishing quality and efficiency can be improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Magnetorheological fluid settleability testing device and testing method

InactiveCN109709156AConductiveEvaluation of SettlingMaterial resistanceElectrical resistance and conductanceOhmmeter

The invention provides a magnetorheological fluid settleability testing device and testing method. The device includes a uniform constant magnetic field generating device, a magnetorheological fluid container arranged in the effective output area of the uniform constant magnetic field generating device, multiple pairs of conducting strips arranged at different heights in the magnetorheological fluid container, and ohmmeters for measuring resistance between each pair of the conducting strips. Under same magnetic field intensity, the rheological effect of a magnetorheological fluid can make magnetic particles arranged according to a magnetic field direction, so that a chain type structure can be formed, and the magnetorheological fluid can have a certain conductivity by utilizing the chain type structure; and through the utilization of the characteristic that resistance reduces with the increasing of particle concentrations, the method of characterizing a magnetorheological fluid settlement process by comparing situations of the change of the resistance of the magnetorheological fluid at different positions with time can be designed, and therefore, ideal technical schemes for evaluating the settlement performance of magnetorheological fluid materials can be obtained.

Owner:FUZHOU UNIV

Constant pressure ultrasonic wave aiding magnetorheological finishing method and constant pressure ultrasonic wave aiding magnetorheological finishing device

InactiveCN103042438BUniform compositionUniform abrasive distributionMagnetic currentUltrasonic assisted

The invention discloses a constant pressure ultrasonic wave aiding magnetorheological finishing method and a constant pressure ultrasonic wave aiding magnetorheological finishing device. The method includes the steps of firstly, mounting a workpiece on a double-rotating workbench; secondly, adjusting distance between a small ball milling head and the workpiece to allow a clearance to be formed between the two, and setting a threshold P1 and a threshold P2 of a force cell at an extending position of an electromagnetic coil iron core mounted above the small ball milling head through a control system; thirdly, starting a spindle to drive the small ball milling head to rotate, simultaneously starting an ultrasonic wave vibrating device to allow ultrasonic vibration of the small ball milling head, and jetting magnetorheological fluid in the clearance formed by the small ball milling head and the workpiece through an output pipeline; and fourthly, repeatedly finishing the workpiece according to the surface shape of the to-be-machined workpiece until the machining of the workpiece is completed. Accurate point removing can be performed on the workpiece surface by the method.

Owner:TIANJIN UNIV

System for magnetorheological finishing of a substrate

ActiveUS8944883B2Small sizeVarying stiffnessEdge grinding machinesPolishing machinesPole pieceMagnetorheological finishing

A system for magnetorheological finishing of a substrate. A spherical wheel meant for carrying a magnetorheological finishing fluid houses a variable-field permanent magnet system having north and south iron pole pieces separated by primary and secondary gaps with a cylindrical cavity bored through the center. A cylindrical permanent magnet magnetized normal to the cylinder axis is rotatably disposed in the cavity. An actuator allows rotation of the permanent magnet to any angle, which rotation changes the distribution of flux in the magnetic circuit through the pole pieces. Thus, one can control field intensity in the gaps by positioning the permanent magnet at whatever angle provides the required field strength. Because the field also passes above the pole pieces, defining a fringing field outside the wheel surface, the variable field extends through a layer of MR fluid on the wheel, thus varying the stiffness of the MR fluid as may be desired for finishing control.

Owner:QED TECH INT LLC

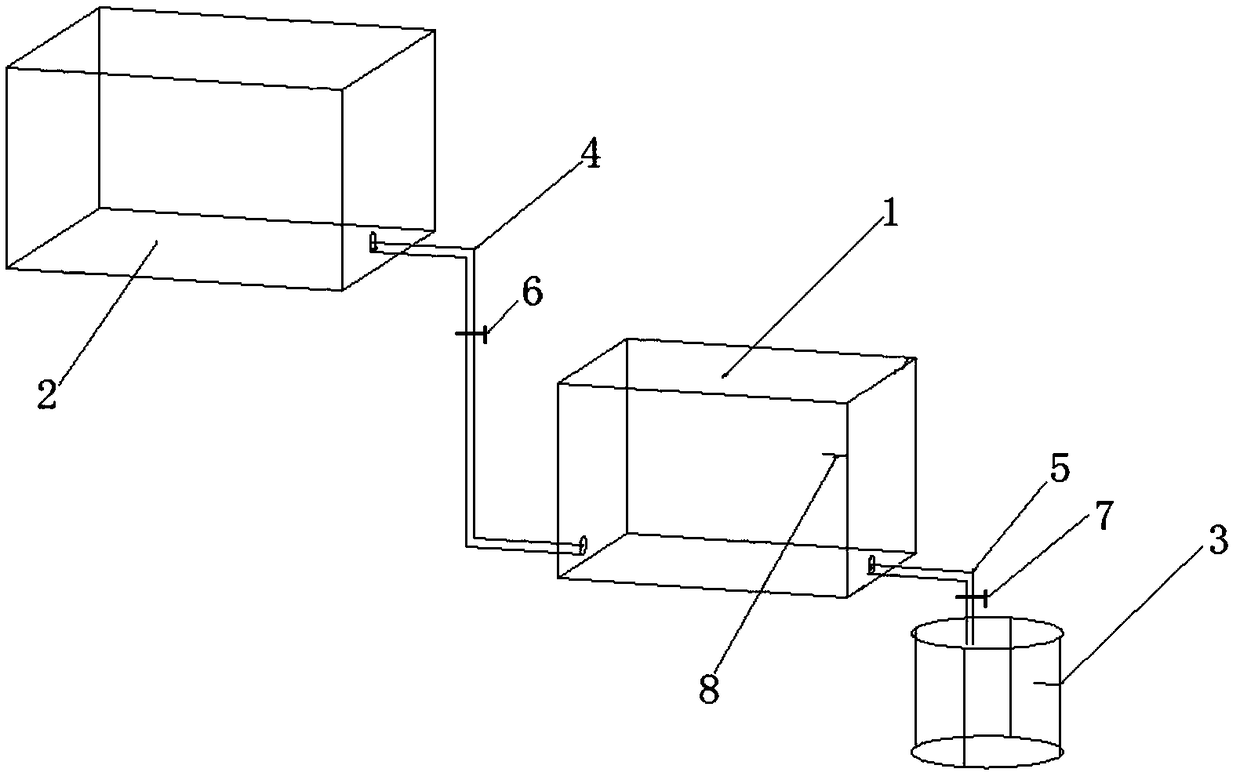

Viscosity testing system for magnetorheological fluid and measuring method

PendingCN109374477ASimple structureThe principle is clearDirect flow property measurementMagnetic currentEngineering

The invention discloses a viscosity testing system for magnetorheological fluid. The viscosity testing system comprises a measuring box, a supply box, a measuring beaker and an external magnetic fielddevice, wherein the measuring box is connected with the supply box by virtue of a liquid inlet pipe; a first valve is arranged on the liquid inlet pipe; the measuring box is connected with the measuring beaker by virtue of a liquid outlet pipe; a second valve is arranged on the liquid outlet pipe; the arrangement position of the supply box is higher than that of the measuring box. The method comprises the following steps: enabling magnetorheological fluid in the supply box to slowly flow into the measuring box by regulating the opening of the first valve and the second valve under different external magnetic field conditions, maintaining the liquid level of the magnetorheological fluid in the measuring box invariable, measuring the volume of the magnetorheological fluid flowing into the measuring beaker in a certain time, and further measuring the viscosity of the magnetorheological fluid. The system and the method disclosed by the invention are capable of accurately measuring the viscosity of the magnetorheological fluid under the effect of different magnetic field intensity, and are simple in structure, clear in principle, convenient to operate and wide in application range.

Owner:SHENYANG JIANZHU UNIVERSITY

Magnetorheological polishing device suitable for ultra-large aperture optical processing

The invention relates to a magneto-rheological polishing device suitable for ultra-large aperture optical processing, comprising: a magneto-rheological fluid polishing device, which includes a magnet device capable of providing a magnetic field; a horizontal protruding section is provided at the lower end of the magnet device; The variable fluid circulation device can make the magneto-rheological fluid circulate through the horizontal protrusion section, and form ribbon protrusions under the action of a magnetic field perpendicular to the flow direction. The invention provides a magneto-rheological polishing device suitable for ultra-large-diameter optical processing, which can be rebuilt on a polishing machine tool, and can replace the polishing head of the polishing machine tool, such as a stress plate, a small grinding head, etc., without changing the original mechanical structure of the machine tool. The magnetorheological polishing device of the present invention not only reduces the volume of the system, simplifies the mechanical structure, but also increases the material removal efficiency, thereby solving the problems of low removal efficiency and long processing cycle of the current large-diameter aspheric surface.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

System for magnetorheological finishing of substrates

ActiveUS20120164925A1Avoid necessityEdge grinding machinesPolishing machinesEngineeringMagnetorheological finishing

A system for magnetorheological finishing of a substrate. An integrated fluid management module (IFMM) provides dynamic control of the rheological fluid properties of the MR fluid on a conventional MR finishing apparatus, and dispensing of the fluid to the wheel. A magnetically shielded chamber charged with MR fluid is in contact with the carrier wheel. A transverse line removes the spent MR fluid from the wheel as the ribbon leaves the work zone. Replenishment fluid is added to the chamber via a dripper, and preferably an electric mixer agitates MR fluid in the chamber. A grooved magnetically-shielded insert at the exit of the chamber forms a polishing ribbon on the carrier wheel as the wheel is turned. A sensor sensitive to concentration of magnetic particles provides a signal for control of MR fluid properties, particularly, water content in the MR fluid. Means is provided for cooling fluid within the chamber.

Owner:QED TECH INT

A method for manufacturing composite particles for magnetorheological polishing

ActiveCN108148505BGuaranteed uniformityPlay a polishing roleOther chemical processesPolishing compositions with abrasivesPolishingCarrier fluid

The invention discloses a manufacturing method for preparing a composite particle from a ferromagnetic particle and an abrasive material for magnetorheological finishing. In particular, the surface ofthe ferromagnetic particle is wrapped with the abrasive material, or the abrasive material is embedded into the surface of the ferromagnetic particle; when the composite particle prepared from the ferromagnetic particle and the abrasive material encounters a magnetic field, the composite particle is arrayed by the action of a magnetic force line to form a self-adaptive flexible solid; and when the magnetic field moves, the composite particle moves with the magnetic field. When the movable self-adaptive flexible solid comprising the composite particle acts on the surface of a workpiece, the abrasive material compounded on the surface of the ferromagnetic particle generates an abrading or finishing effect on the surface of the workpiece. The effect of finishing is correspondingly changed with presence and intensity of the magnetic field. That is to say, the finishing is the magnetorheological finishing. The composite particle comprising the ferromagnetic particle and the abrasive material can perform dry abrading and finishing on the workpiece and be put in carrier liquid (including water-based liquid, a solvent or oil-base liquid and assistants of the water-based liquid, the solvent or the oil-base liquid) for the wet magnetorheological finishing of the workpiece.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

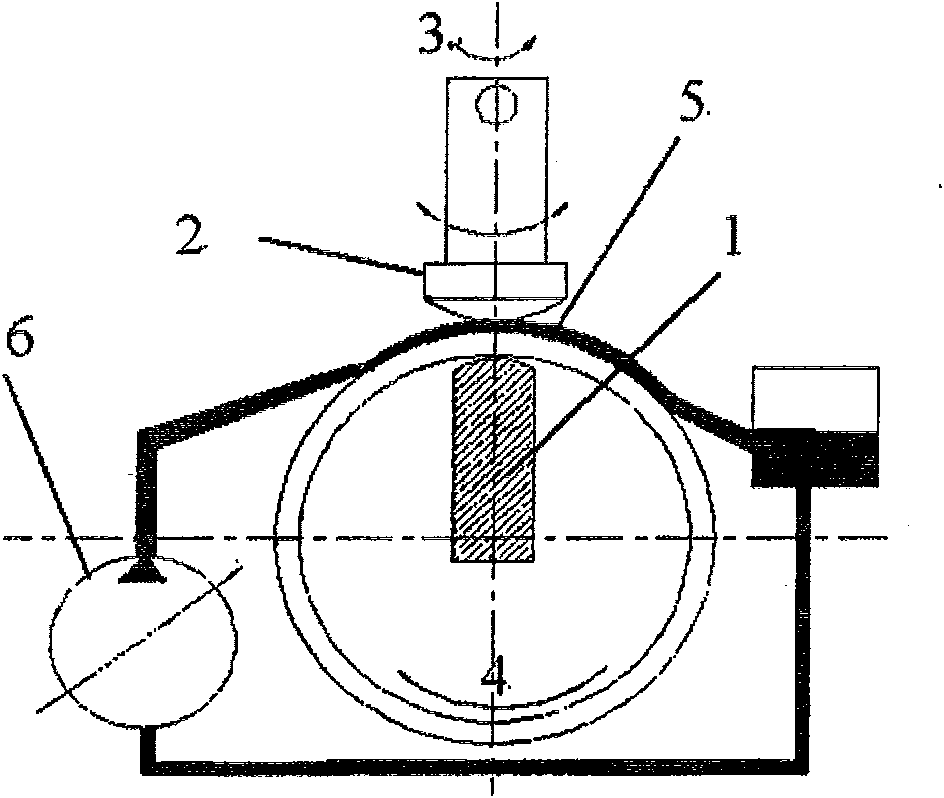

Magnetic current changing polishing device for large caliber aspheric surface optical part

InactiveCN100566935CProcessing size is not limitedEasy to set upGrinding carriagesOptical surface grinding machinesMagnetic currentControl system

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com