Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

365results about How to "Achieve impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

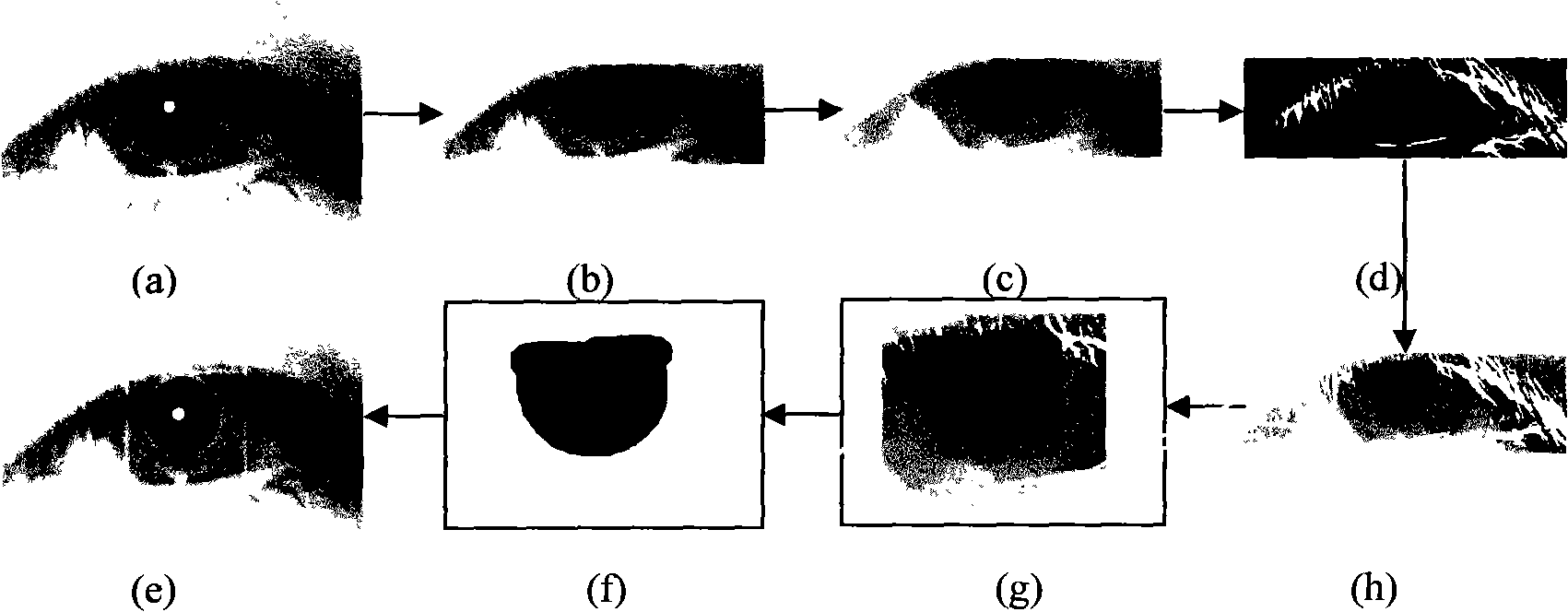

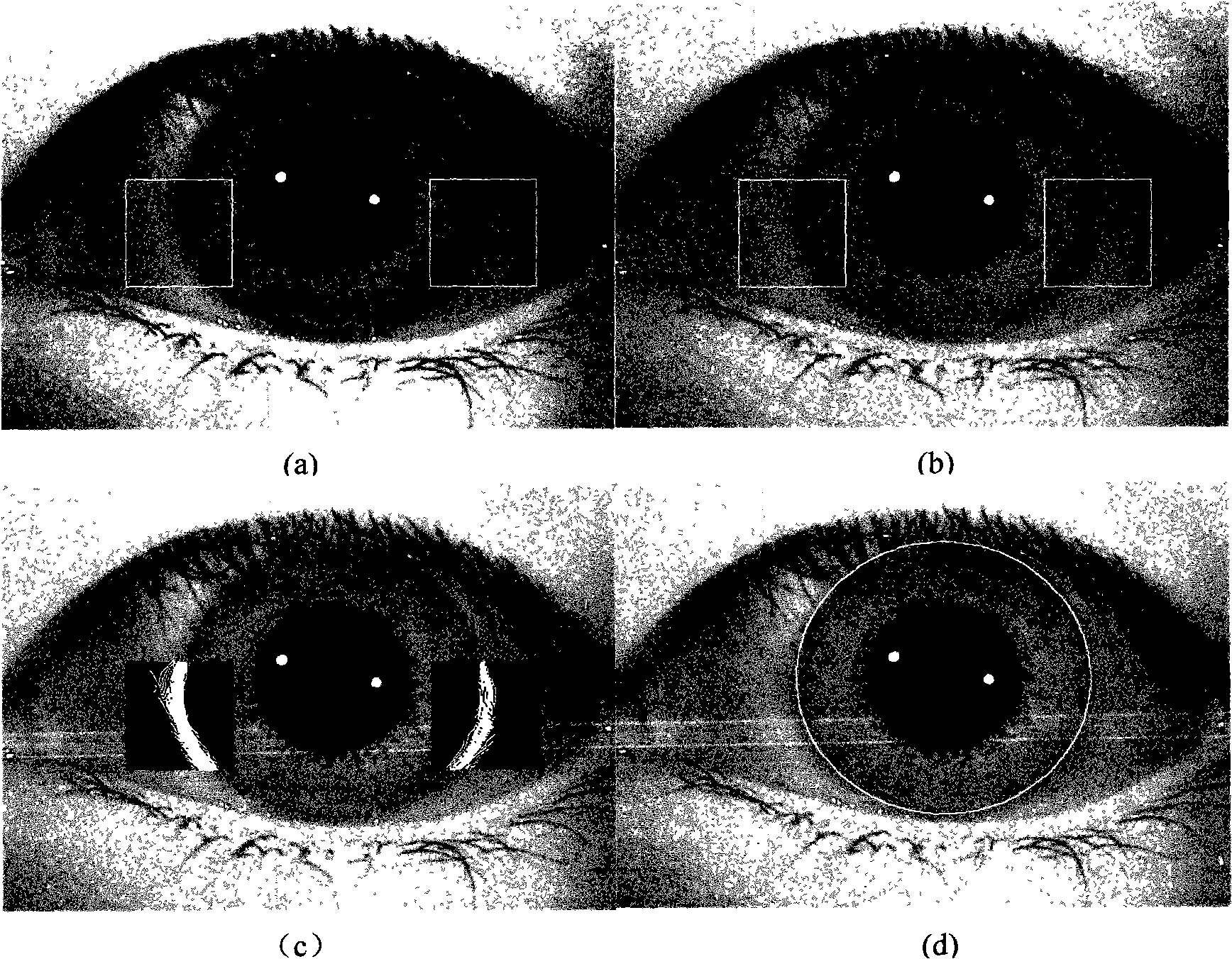

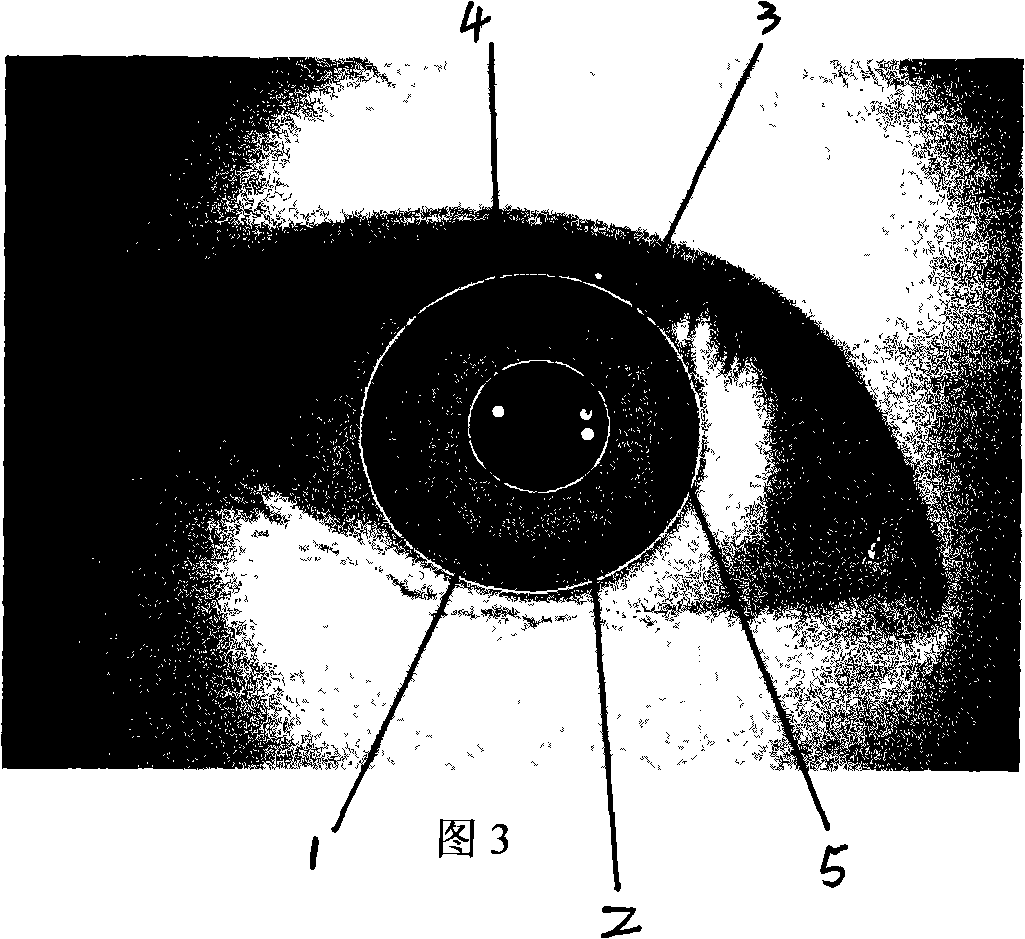

Iris positioning method based on Maximum between-Cluster Variance and gray scale information

InactiveCN101359365AFast positioning timeMeet the requirements of real-time processingCharacter and pattern recognitionCurve fittingKnowledge extraction

The invention adopts the between-class square error and the gray scale information to realize the rapid positioning of the inside and outside boundaries of the iris. Firstly, the interested pupil region is extracted through blocking; the between-class square error is adopted to obtain the pupil binary threshold for the extracted pupil region; then the inside boundary of the iris is positioned accurately through the searching of the boundary points and the curve fitting; the interested region of the iris outside boundary is extracted according to the prior knowledge and the pupil position parameter; the selected region is processed with median filtering and first-order gradient conversion; the iris outside boundary is determined through the local gradient integration method; finally, the iris outside boundary parameter is determined through the circle fitting. The method avoids the image binary from depending on the histogram; the image positioning time is greatly improved because only the interested region is processed; the whole image is not processed; the experiment indicates that the robustness and the positioning efficiency of the algorithm can satisfy the real-time processing requirement of the image.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

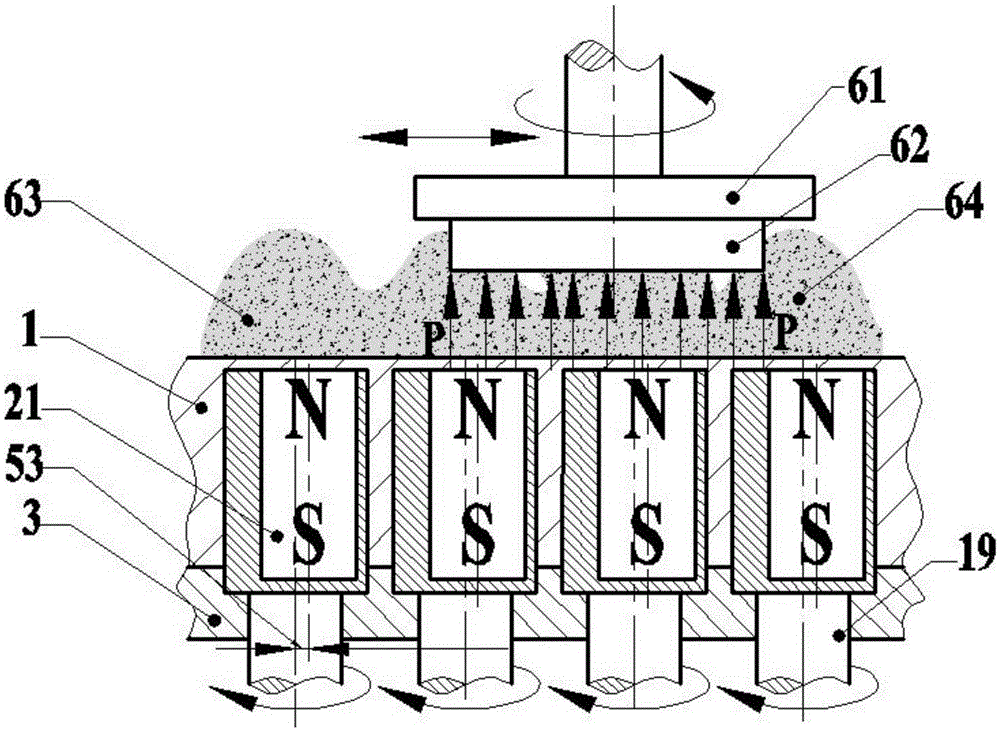

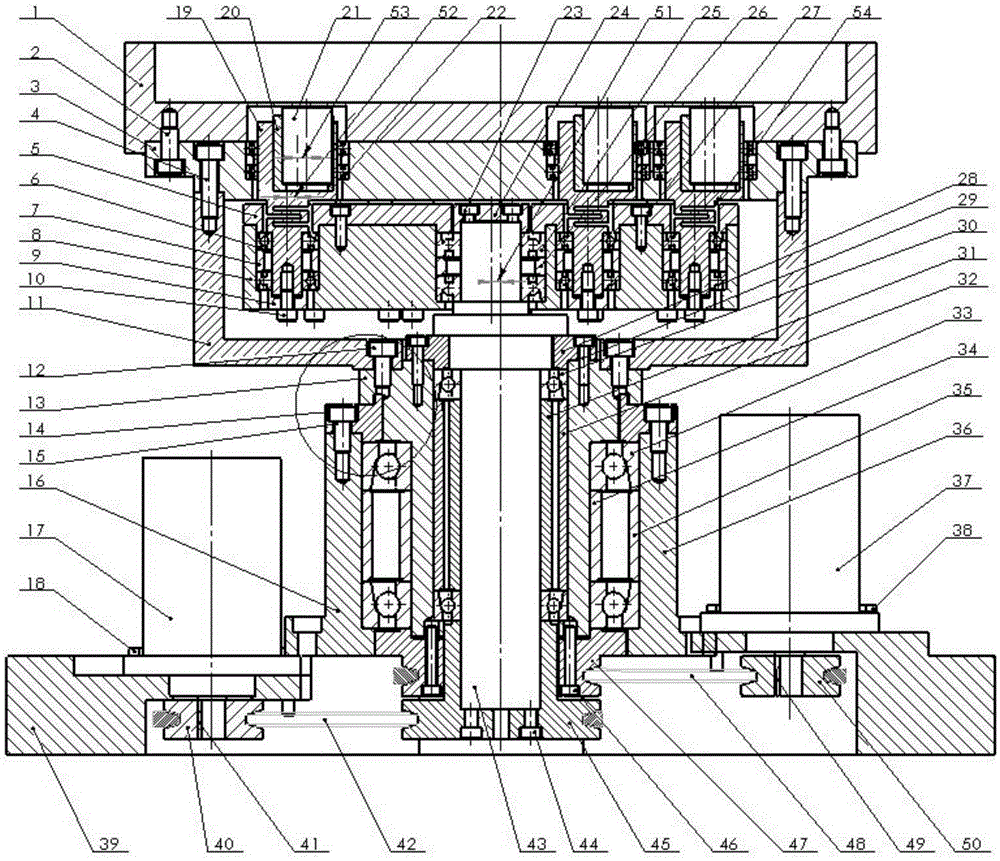

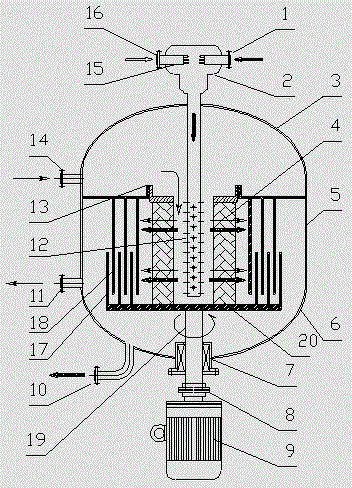

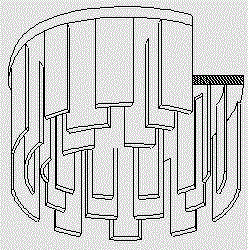

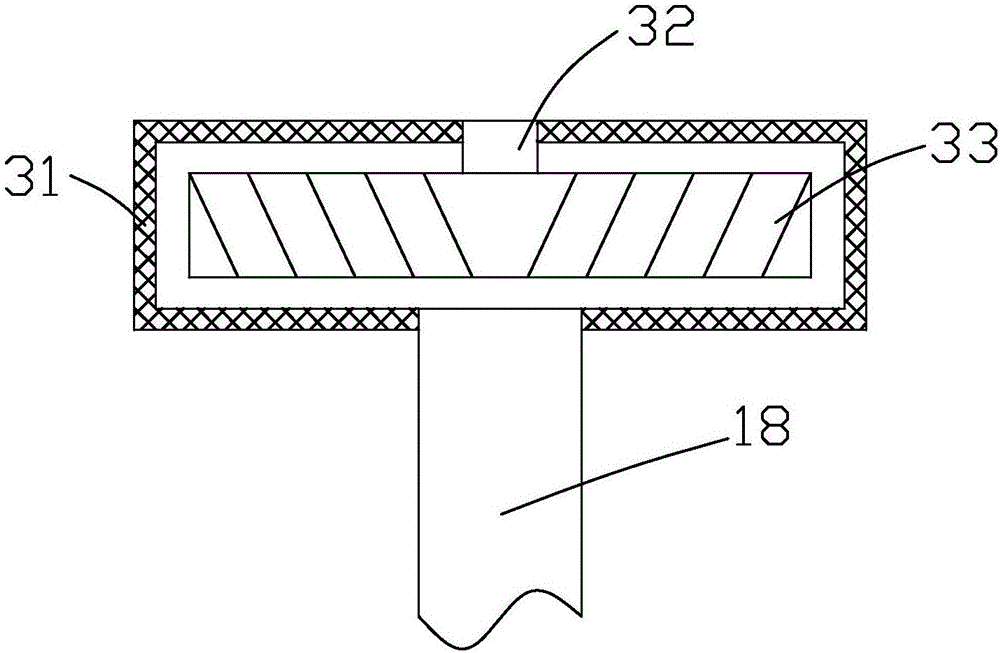

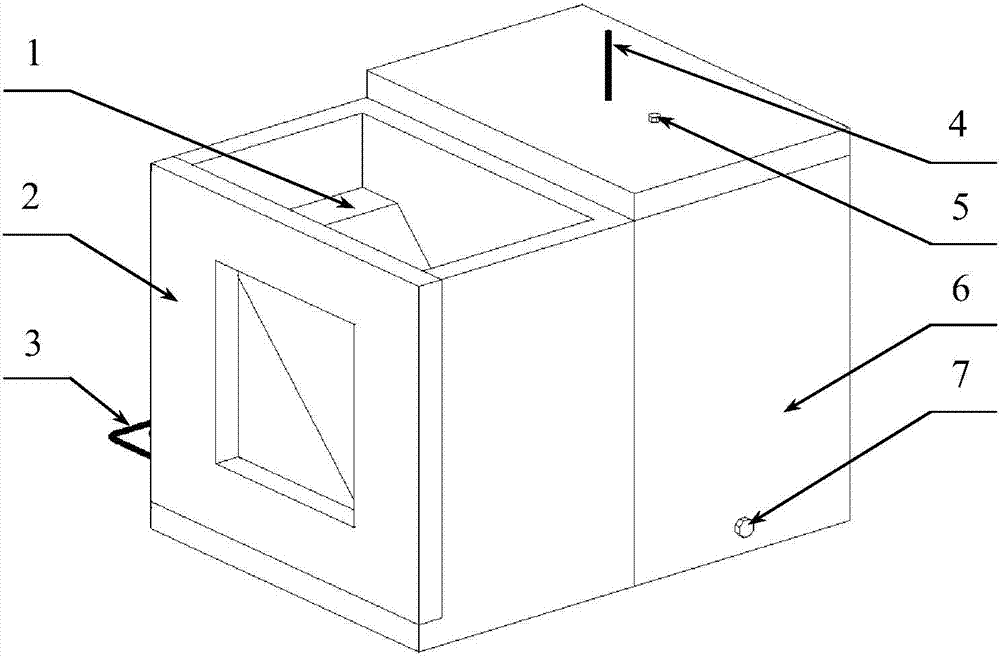

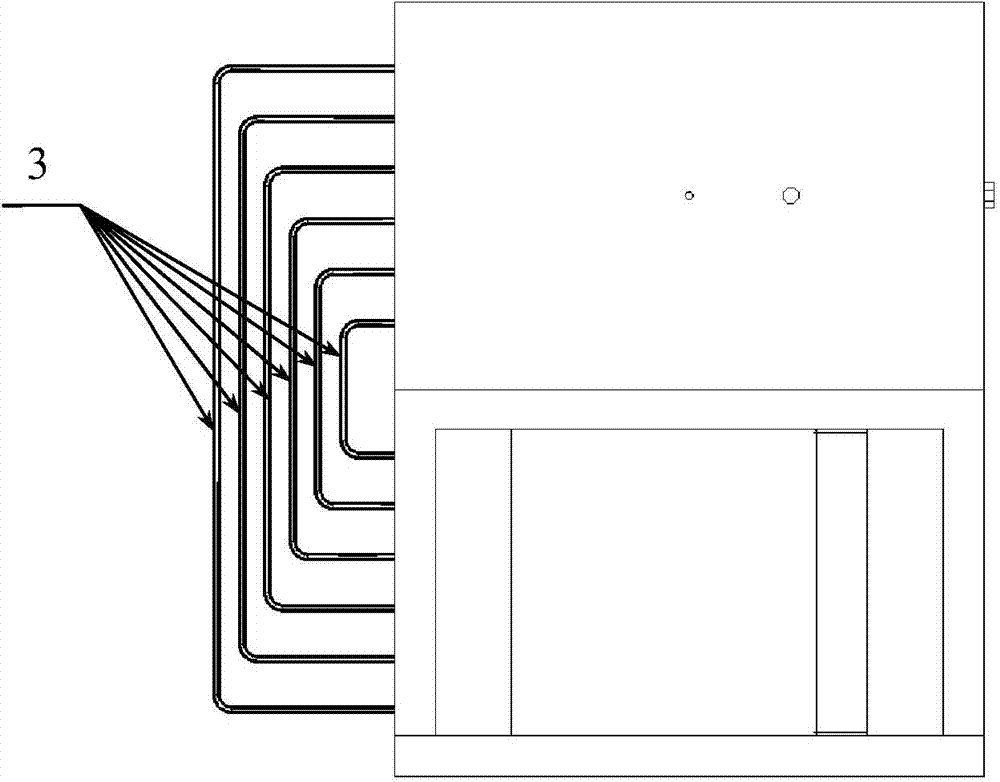

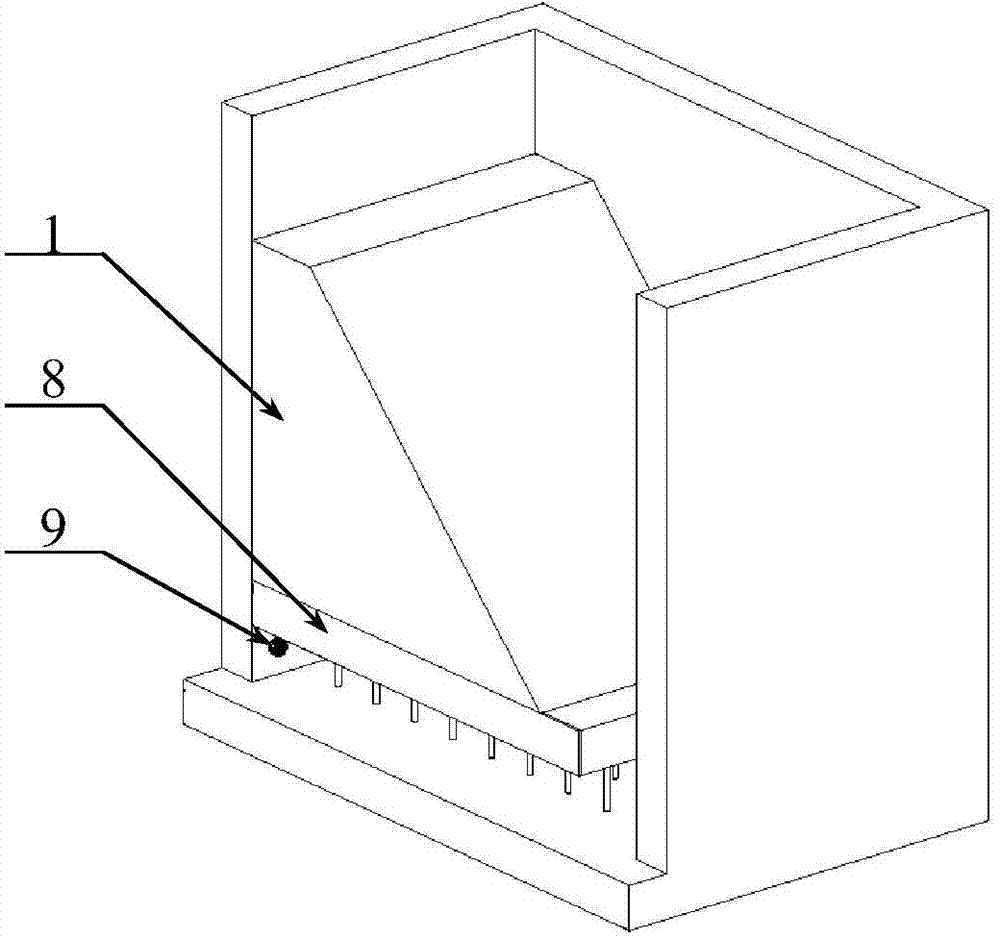

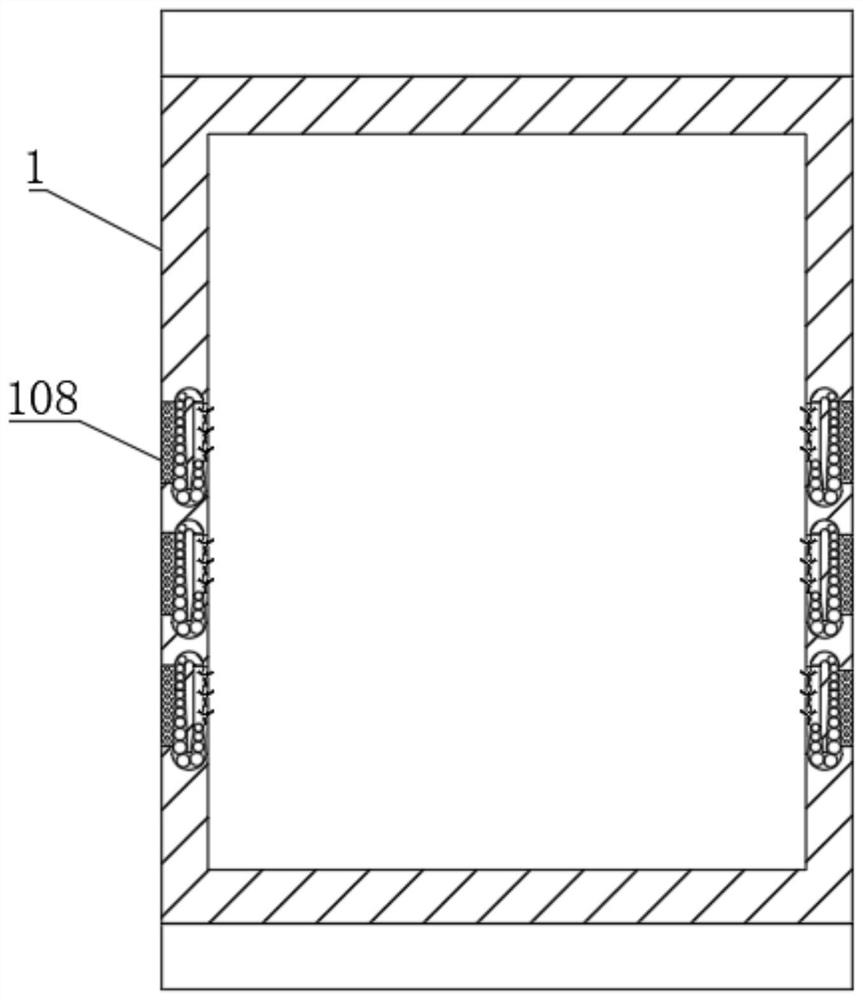

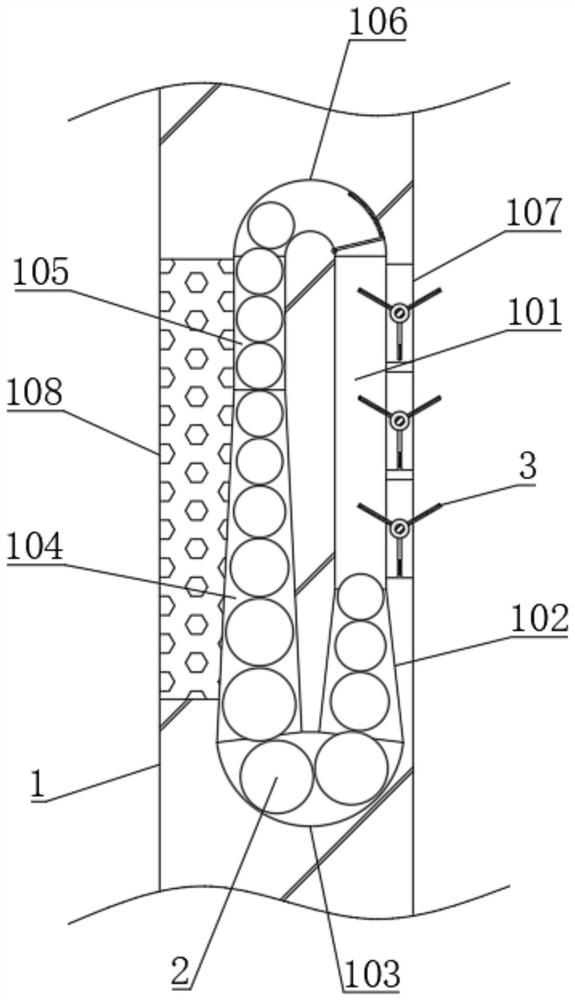

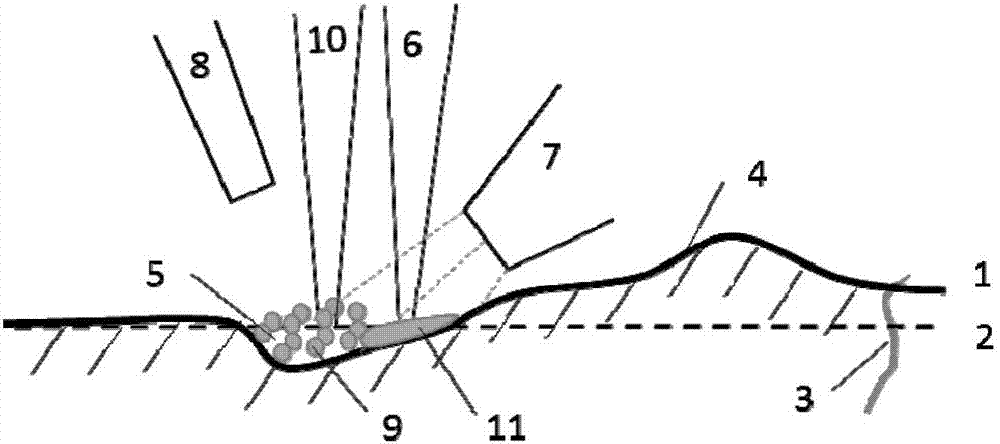

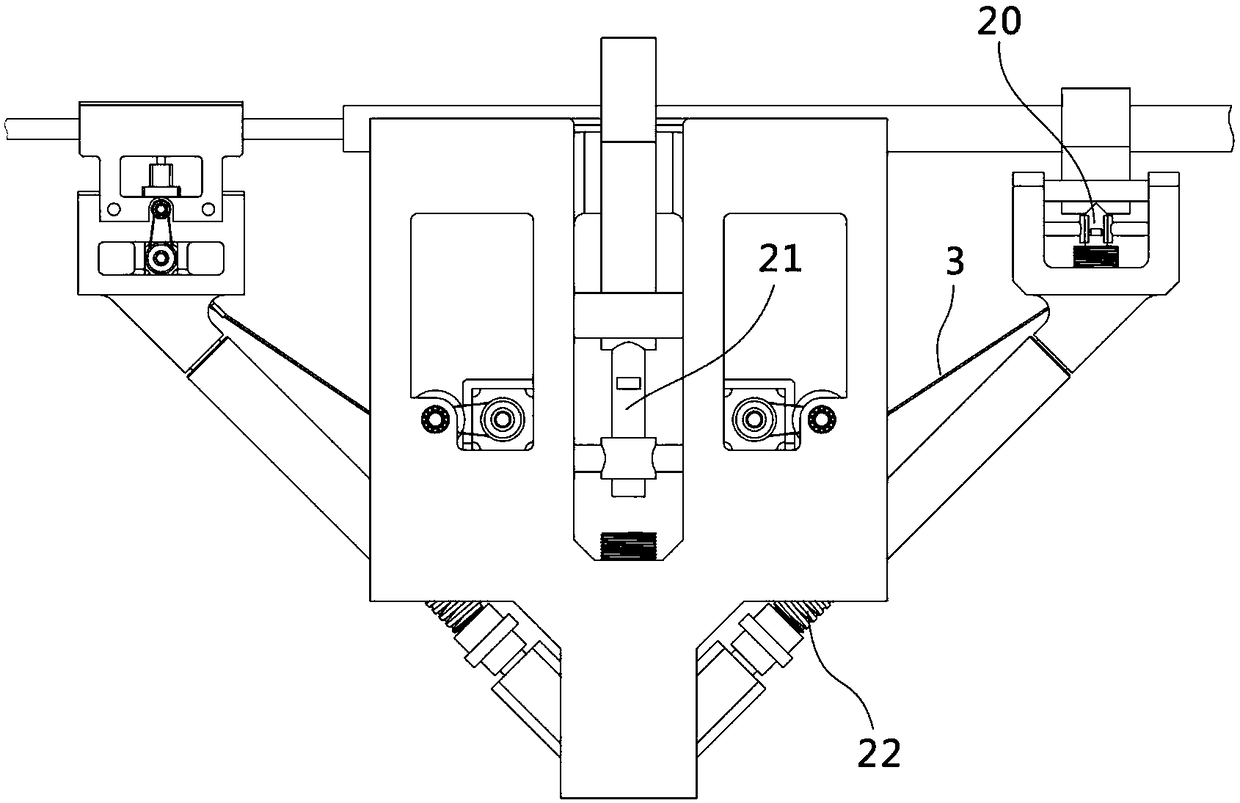

Dynamic magnetic field self-sharpening finishing device for flexible magnetorheological finishing pad and finishing method for dynamic magnetic field self-sharpening finishing device

ActiveCN105328516ASave spaceAchieve impactGrinding drivesAbrasive surface conditioning devicesExperimental researchMagnetic current

The invention relates to a dynamic magnetic field self-sharpening finishing device for a flexible magnetorheological finishing pad and a finishing method for the dynamic magnetic field self-sharpening finishing device. The dynamic magnetic field self-sharpening finishing device comprises a finishing disk revolution mechanism and a multi-magnetic-pole synchronous rotation driving mechanism, wherein the finishing disk revolution mechanism comprises a driving shaft motor, a drive shaft, an adapting disk, an eccentric shaft fixing disk, a cup-like finishing disk and a driving shaft transmission mechanism; the multi-magnetic-pole synchronous rotation driving mechanism comprises an eccentric spindle, synchronous rotation driving plates, flexible eccentric rotating shafts, eccentric sleeves, magnetic poles, the eccentric shaft fixing disk, a spindle motor and the like. According to the finishing device and the finishing method disclosed by the invention, the conditions that a circulating device is adopted for updating magnetorheological fluid and the magnetorheological fluid is changed in the processing process are avoided, so that the space is saved, and the whole process from rough finishing to fine finishing can be realized by one-time processing; obtained workpieces are good in surface consistency, high in processing efficiency, free from of surface and subsurface damage and low in cost, so the finishing device and the finishing method are suitable for high-efficiency ultra-smooth uniform finishing processing of planes of large-diameter optical elements; meanwhile, the finishing device and the finishing method disclosed by the invention are also suitable for experimental researches such as a material removing mechanism and subsurface damage detection of optical planar materials.

Owner:GUANGDONG UNIV OF TECH

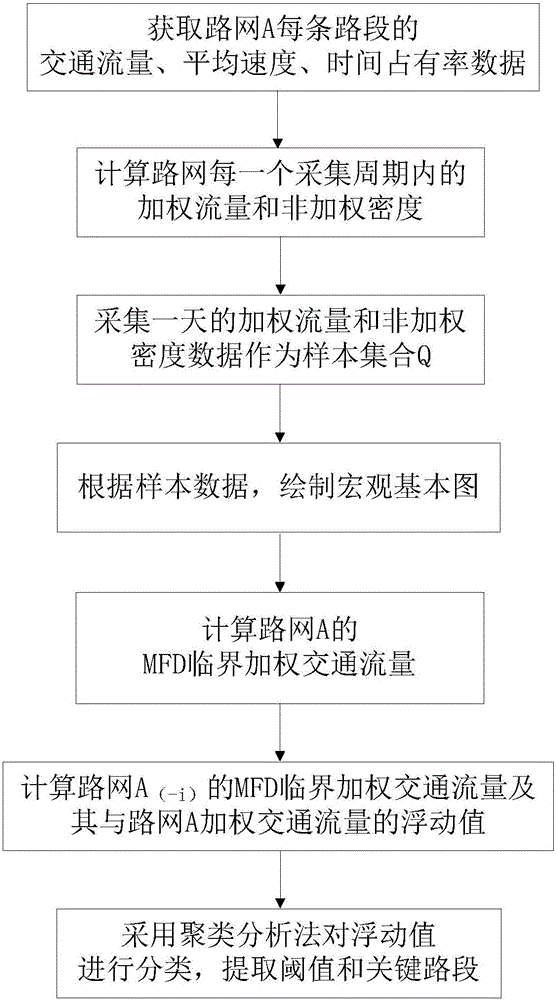

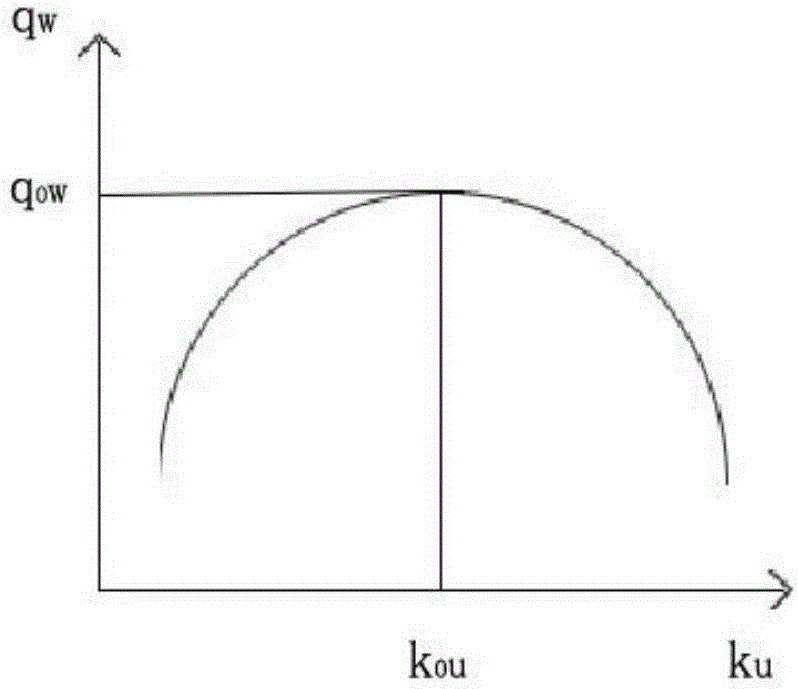

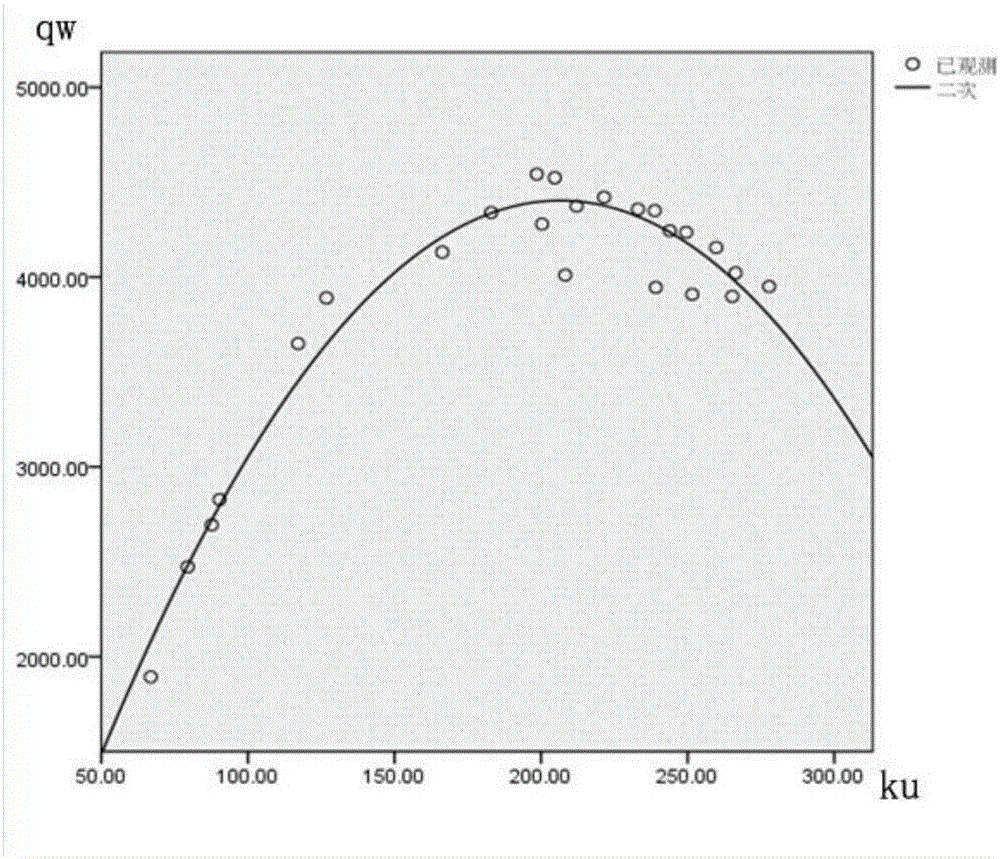

Macroscopic fundamental diagram-based road network key section identification method

ActiveCN105702031AImprove dynamic traffic characteristics requirementsImprove defects such as dynamic traffic characteristics requirementsDetection of traffic movementFloat ValueStructure recognition

The invention discloses a macroscopic fundamental diagram-based road network key section identification method. The method comprises the steps of 1, acquiring the traffic flow, the average speed and the time occupancy data of each road section of an urban road network A; 2, calculating a weighted flow and a non-weighted density of the road network within each acquisition period; 3, getting a set of samples; 4, drawing a macroscopic fundamental scatter diagram; 5, calculating the critical weighted traffic flow of the road network MFD; 6, arbitrarily deleting one road section, and calculating the critical weighted traffic flow of the road network (-i)MFD without the above deleted road section and the floating value of the MFD critical weighted traffic flow of the road network A; 7, adopting the clustering analysis method for classification, and extracting a threshold r and a key road section. According to the technical scheme of the invention, the defect that the key section identification result based on the static topology structure of the road network is not consistent with the dynamic characteristics of the road network traffic flow can be overcome. Therefore, the method is more applicable to the change characteristics of the road network traffic flow. Therefore, the reliability of calculated data is ensured to be high.

Owner:BEIHANG UNIV

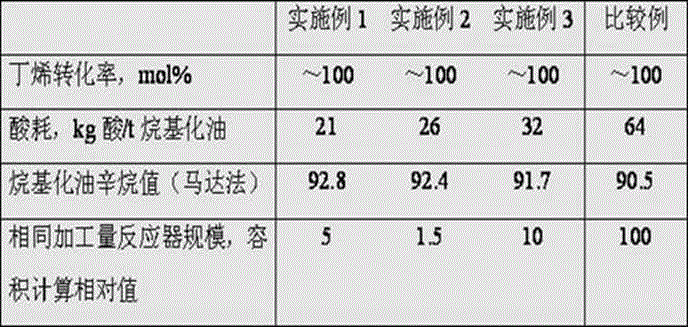

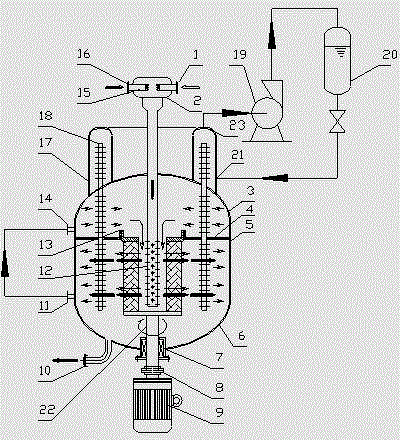

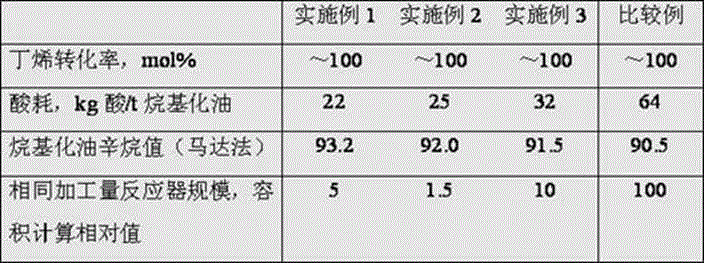

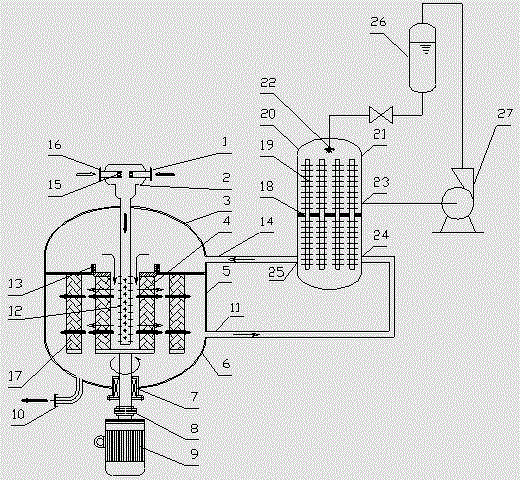

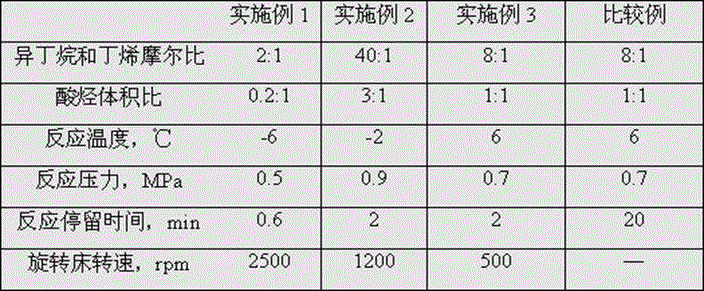

Alkylation reactor and alkylation process method

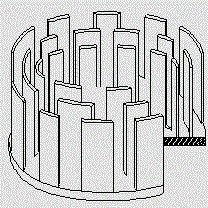

The invention discloses an alkylation reactor and an alkylation process method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas refrigeration system and a circulating cooling gas outlet, wherein a closed reactor shell body is formed by the reactor tube body and the closure heads, and the revolving bed is vertically located at the internal middle part of the shell body; a sealing member is arranged between the upper part of the revolving bed and the reactor shell body, the upper part of the revolving bed and the sealing member are of rotatable connection, the circulating cooling gas inlet and the circulating cooling gas outlet are respectively formed in the shell body at the upper and lower sides of the sealing member, and the circulating cooling gas refrigeration system is located between the circulating cooling gas inlet and the circulating cooling gas outlet. According to the alkylation method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation process method, the alkylation reaction can be carried out at low temperature, the acid consumption is low, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

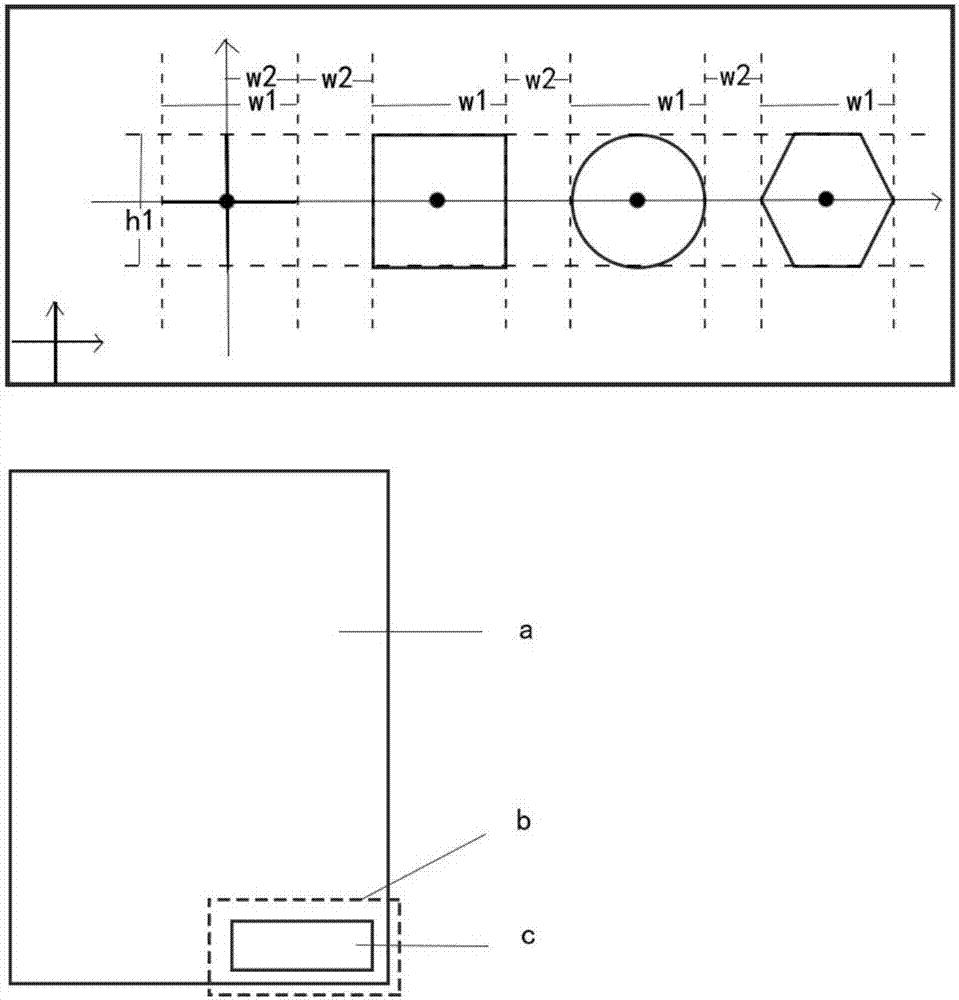

Machine vision-based overprint error detection method

The present invention provides a machine vision-based overprint error detection method. According to the method, a target image is acquired through a camera, wherein the target image contains a plurality of positioning marks; the area of the positioning marks is calculated, if the difference value of the area of the positioning marks and a standard area is not larger than a specified threshold value, and template matching is used to extract the centers of the positioning marks; overprint error is detected according to the deviation quantity of the positions of the centers and standard positions; if the difference value of the area of the positioning marks and the standard area is larger than the specified threshold value, edge segmentation is adopted to extract the edges of the positioning marks, and overprint error is detected according to the deviation quantity of the positions of the edges and standard positions; and after the error detection is completed, and a printer is automatically adjusted. According to the method of the invention, the image segmentation and the template matching are utilized, so that the technical problems of large computation quantity, large error, low robustness and incapability of performing automatic adjustment according to error in the prior art can be solved. The method is suitable for being popularized in the printing industry.

Owner:TONGJI UNIV

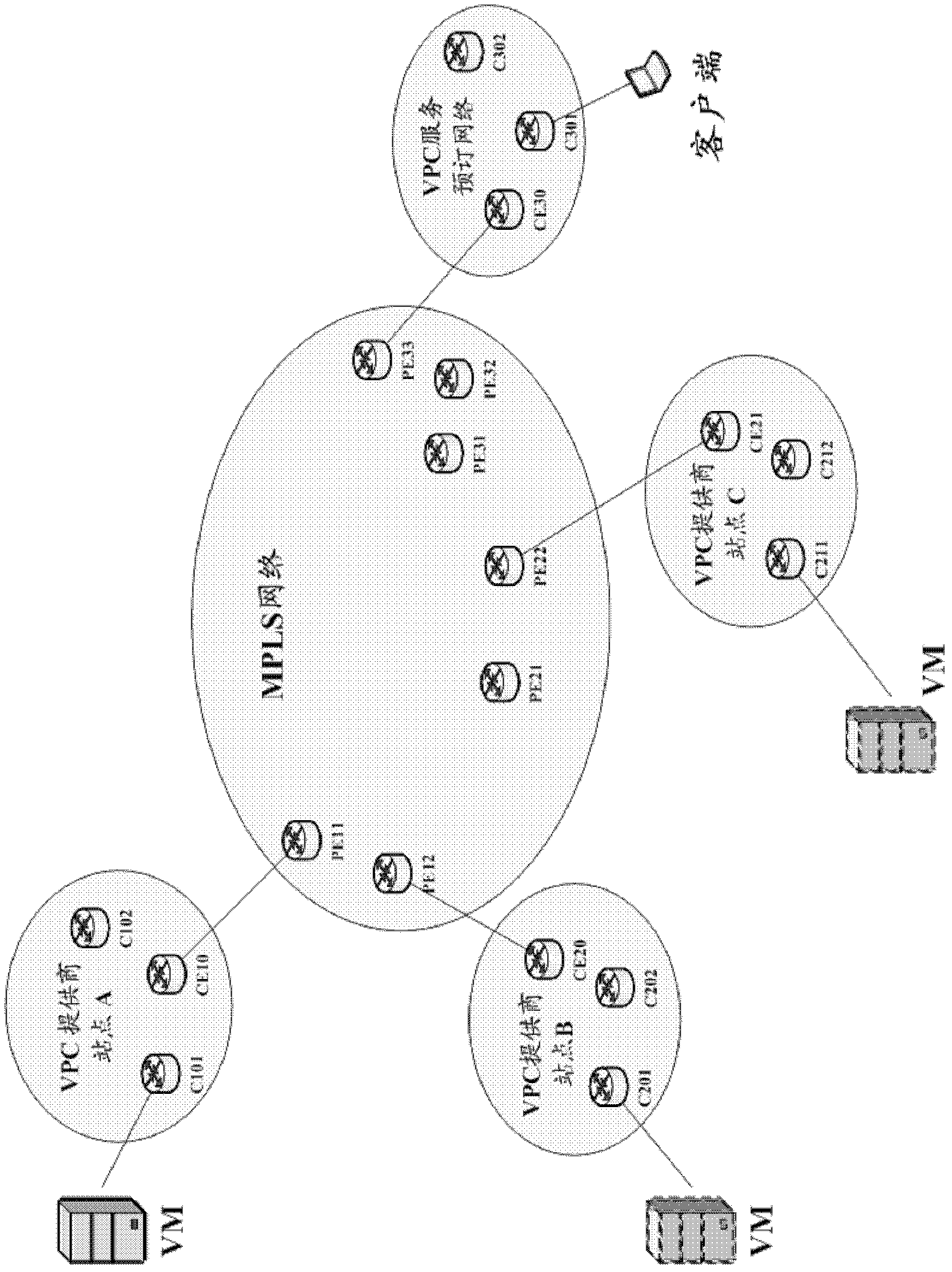

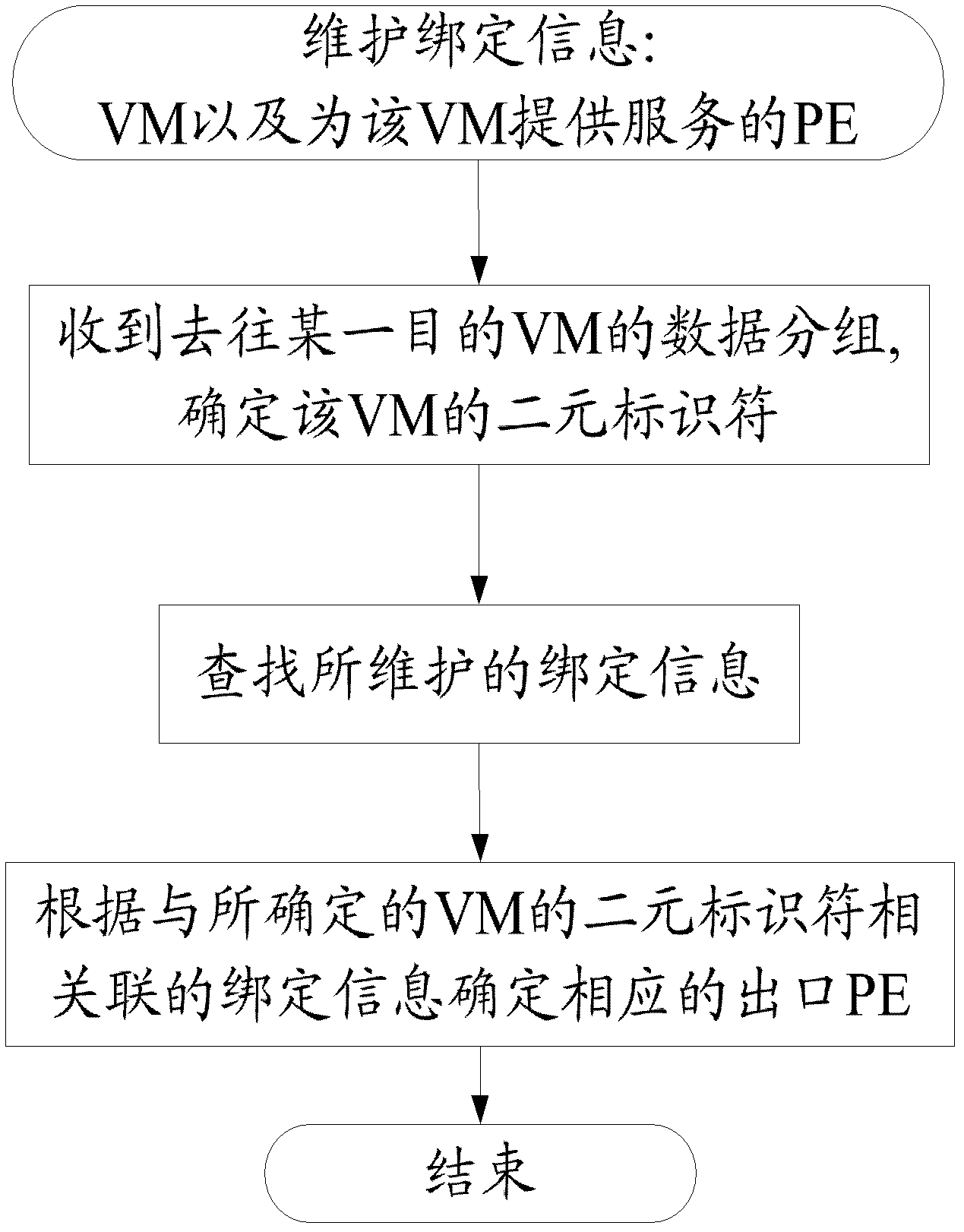

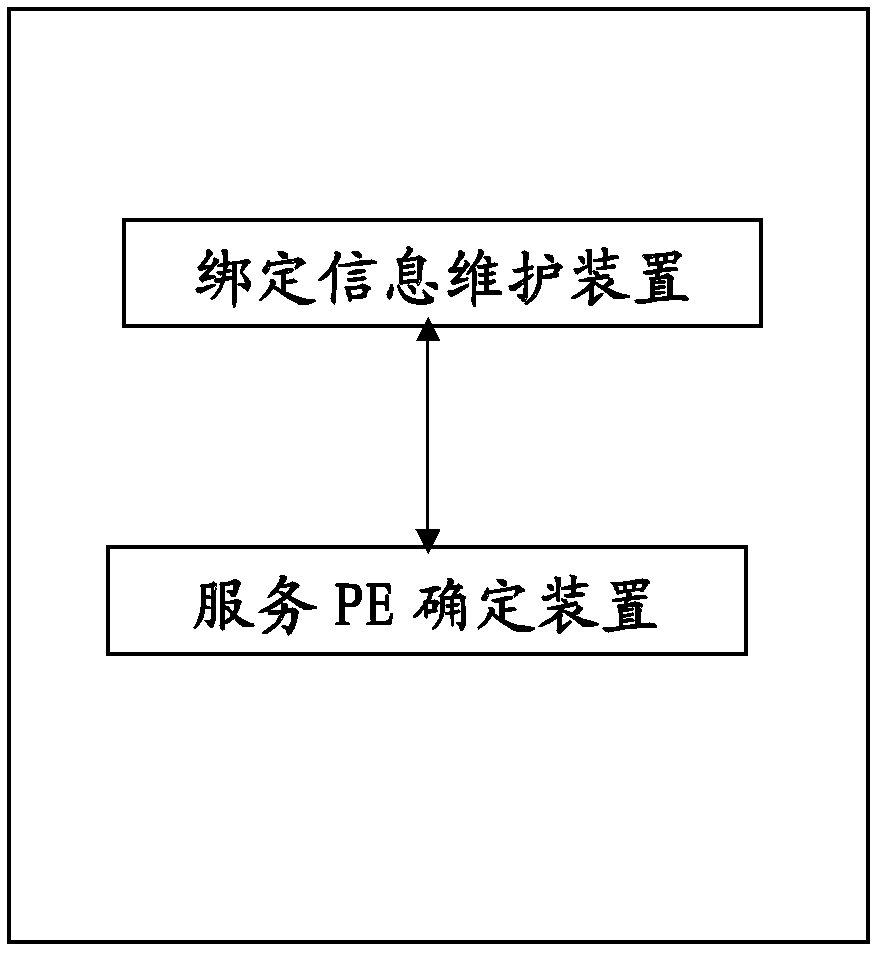

Method and device for achieving migration of virtual machine in virtual private cloud (VPC)

ActiveCN103036919AAchieve migrationEasy to integrateNetworks interconnectionPrivate IPPrivate network

The invention provides a method and a device for achieving migration of a virtual machine in VPC. The method includes maintaining binding information between a virtual machine binary identifier for identifying the virtual machine and a provider edge router for providing service for the virtual machine; and under the condition that grouped data to the virtual machine are received, determining a binary identifier of a target virtual machine based on a received data packet, and determining the provider edge router associated with the binary identifier according to the maintained binding information, wherein the grouped data are to be routed to the determined provider edge router, and the binary identifier of the virtual machine comprises a private IP address of the virtual machine and a specificator capable of identifying a virtual private network (VPN) where the virtual machine is located.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

Alkylation reactor and alkylation reaction method

ActiveCN104549110ALow powerFully dispersedLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystProcess engineering

The invention discloses an alkylation reactor and an alkylation reaction method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas outlet and a circulating cooling gas refrigeration system, wherein a shell body is formed by the reactor tube body and the closure heads, the revolving bed is arranged at the internal middle part of the shell body and is connected with a driving device through a revolving shaft, the charge distribution pipe is arranged in a hollow tube structure of the center of the revolving bed and is communicated with the charging pipe, the discharging opening is formed in the lower part of the shell body of the reactor, a sealing member is arranged between the upper part of the revolving bed and the shell body, static components and revolving components are sequentially arranged at the radial outer side of the revolving bed, and the circulating cooling gas refrigeration system is located between the circulating cooling gas inlet and the circulating cooling gas outlet. According to the alkylation reaction method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation reaction method, the alkylation reaction can be carried out at relatively low temperature, the acid consumption is low, the quality of products is high, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

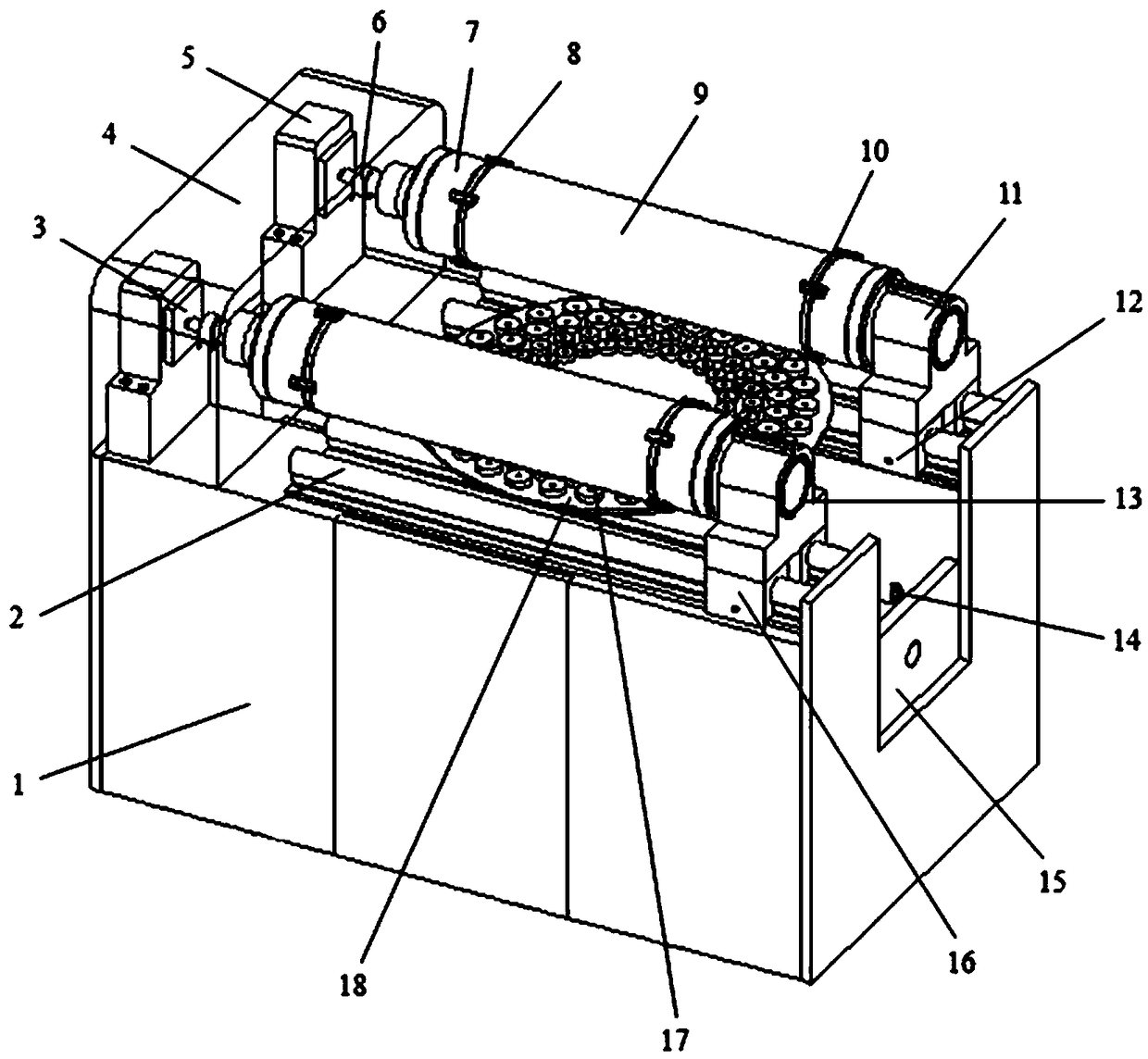

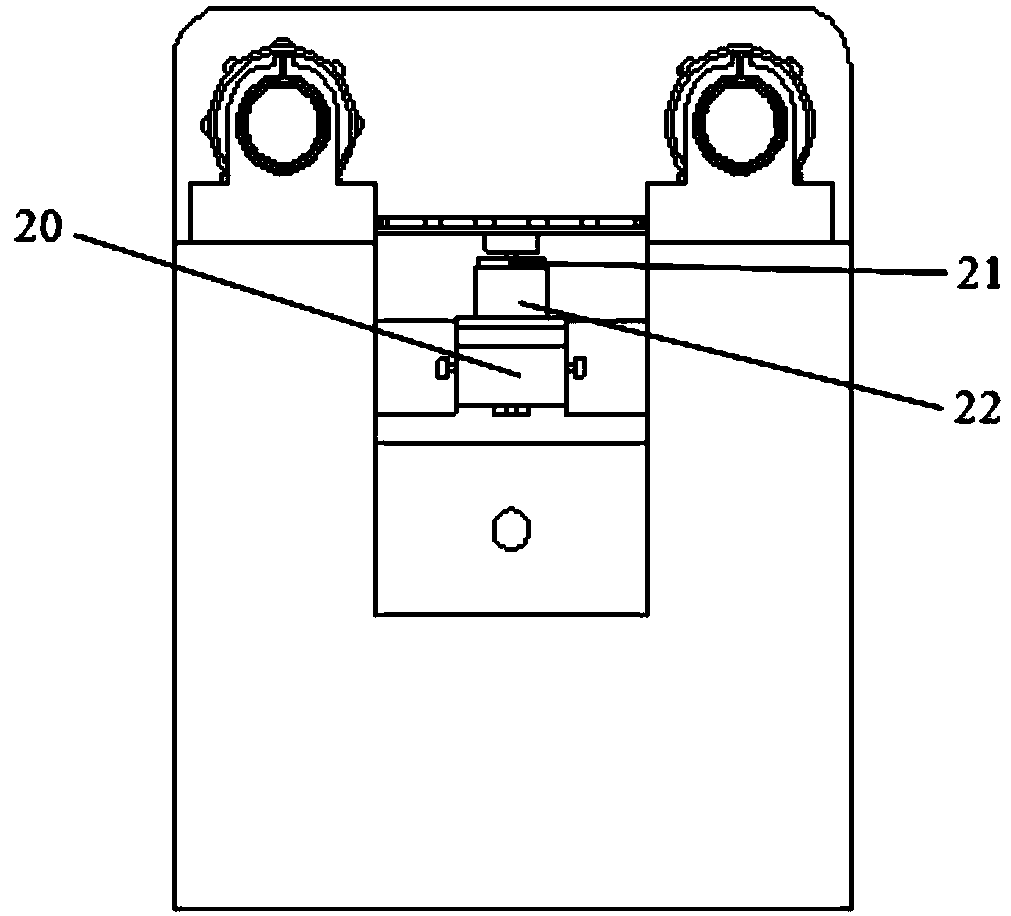

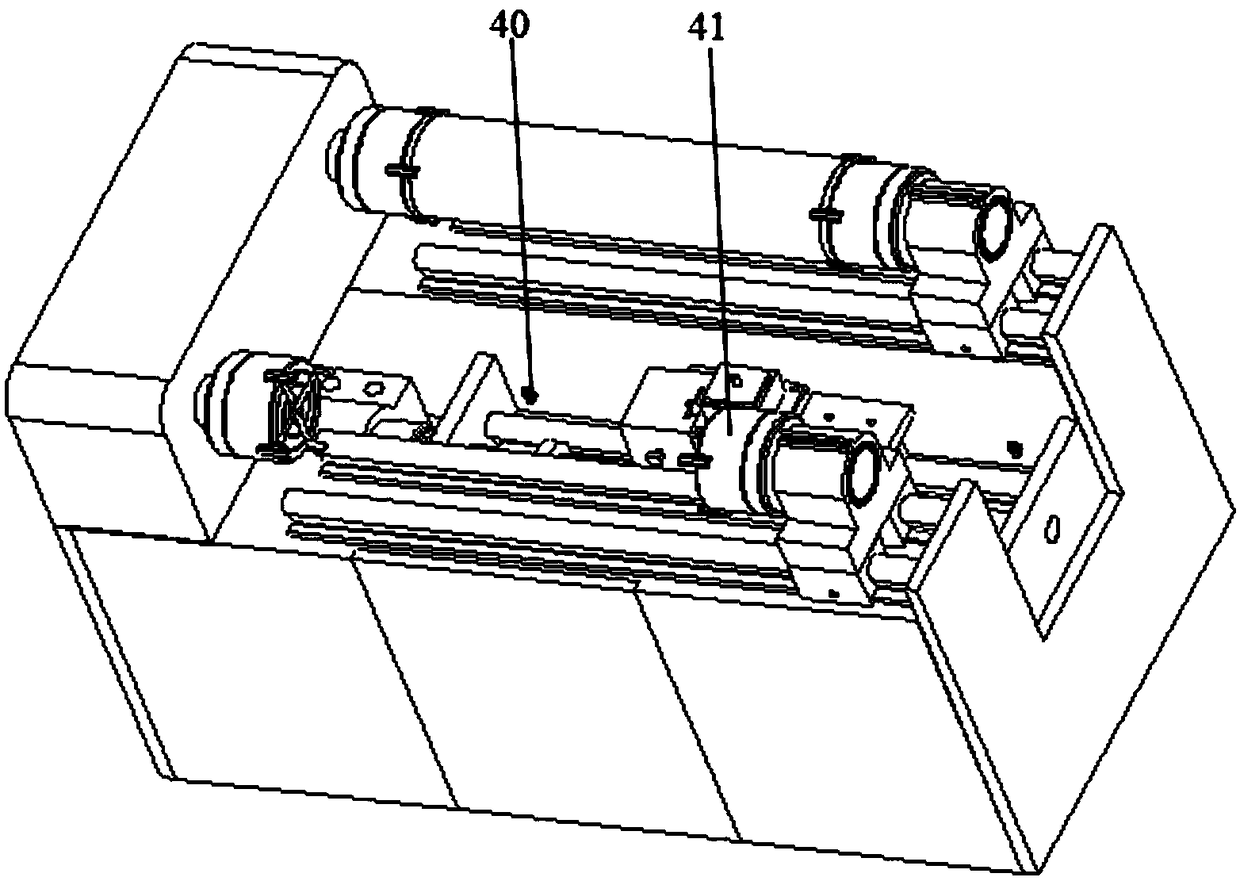

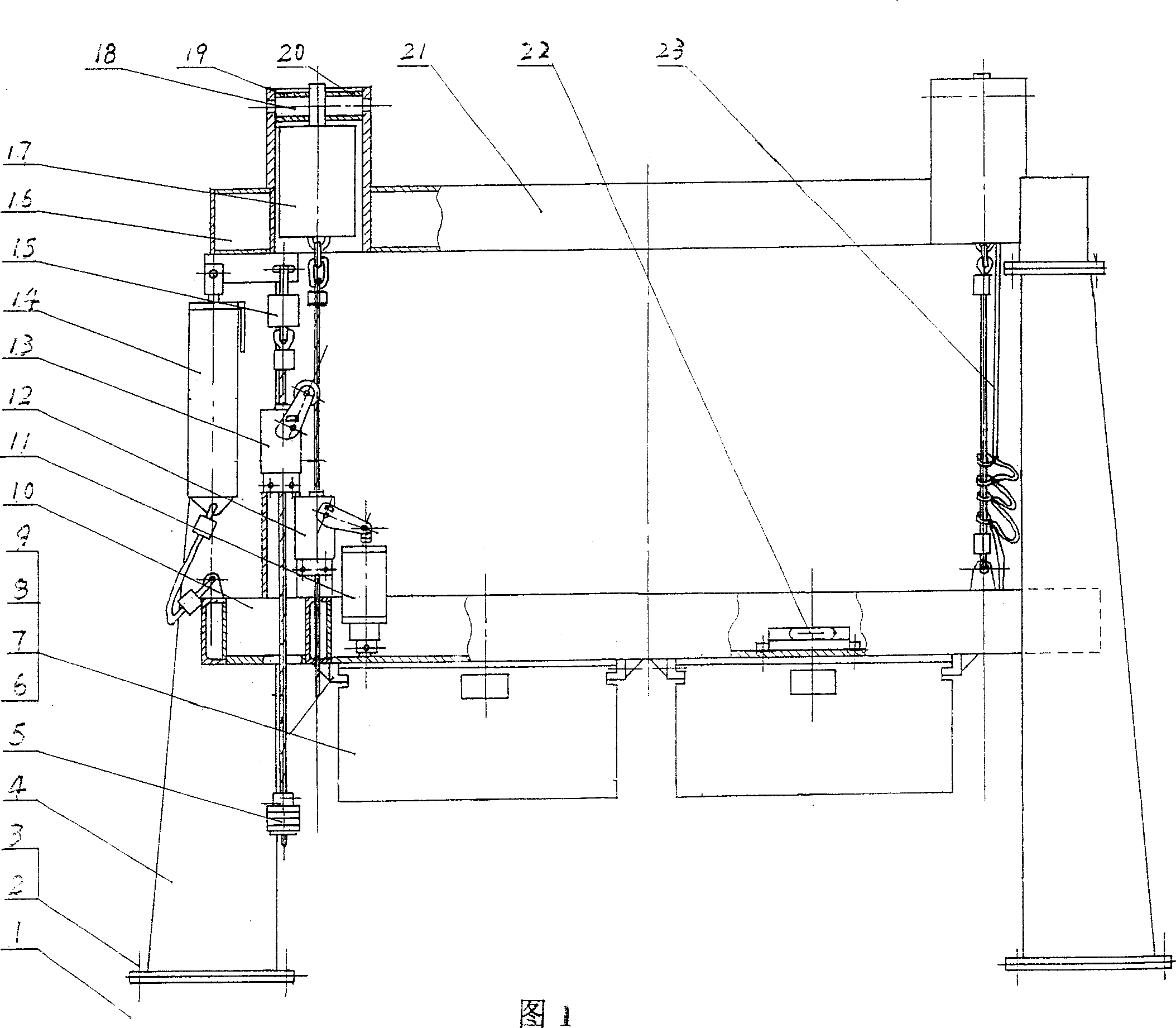

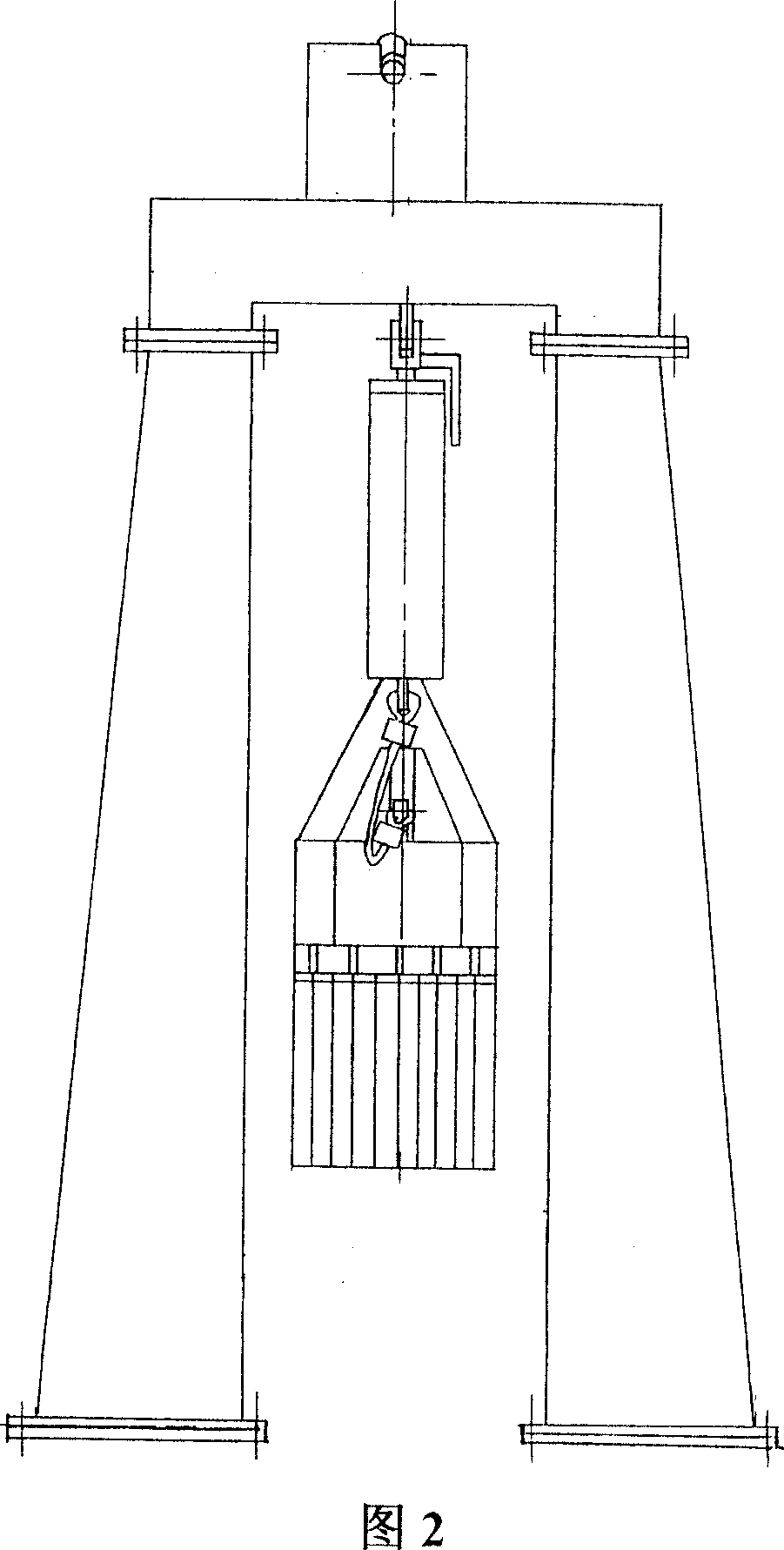

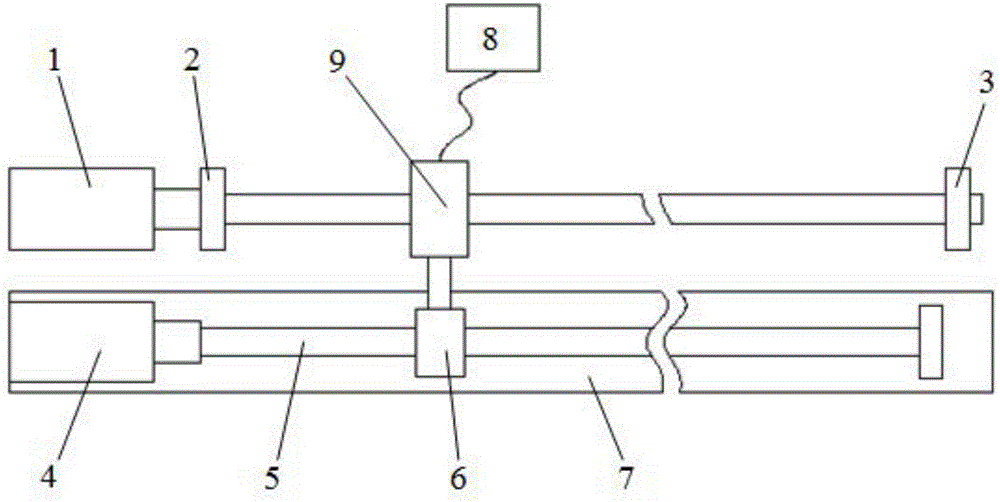

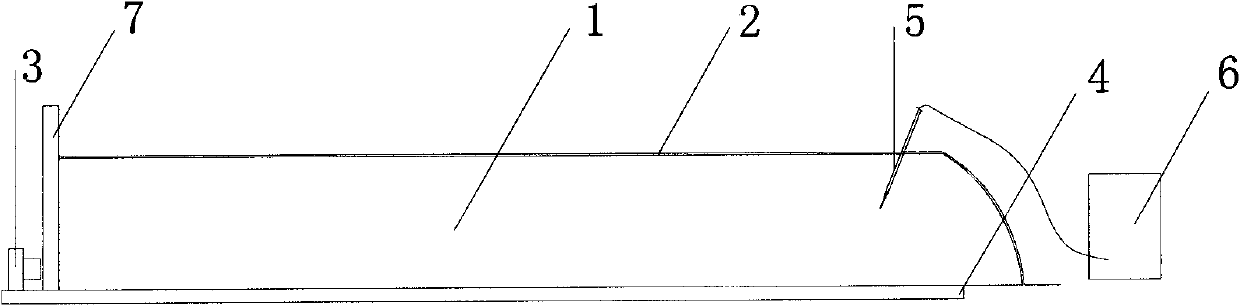

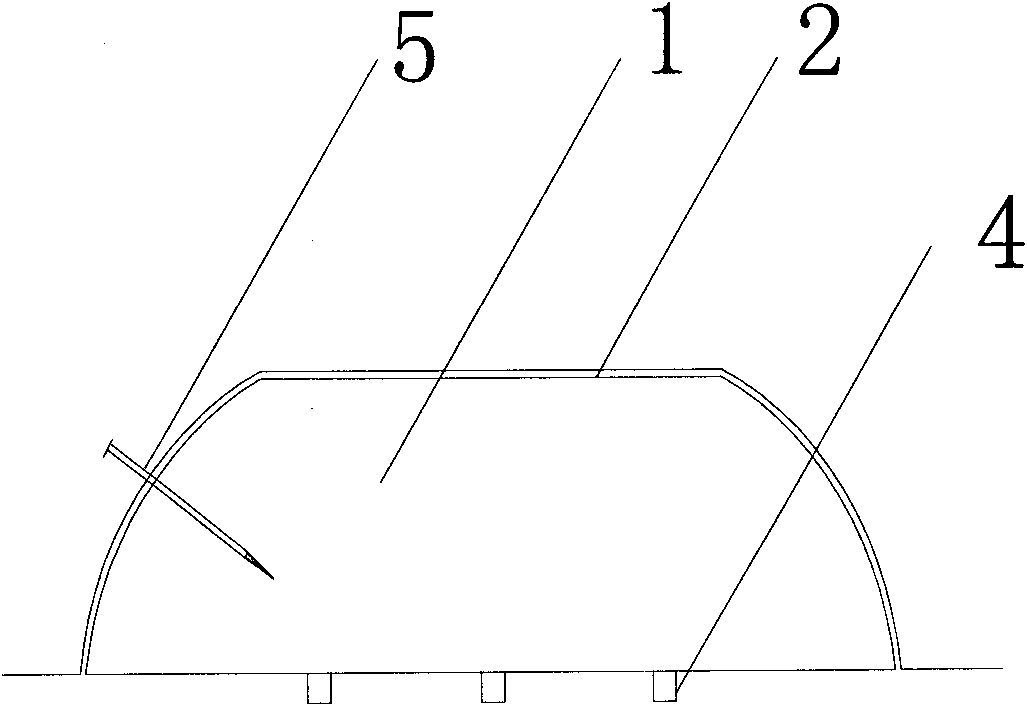

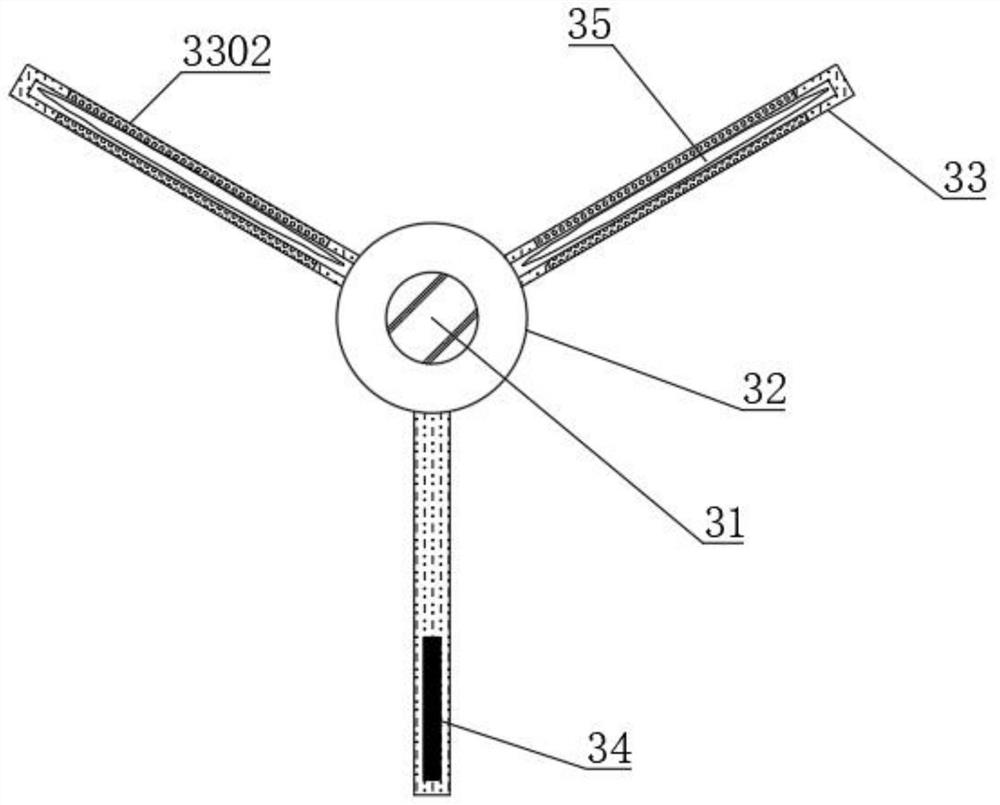

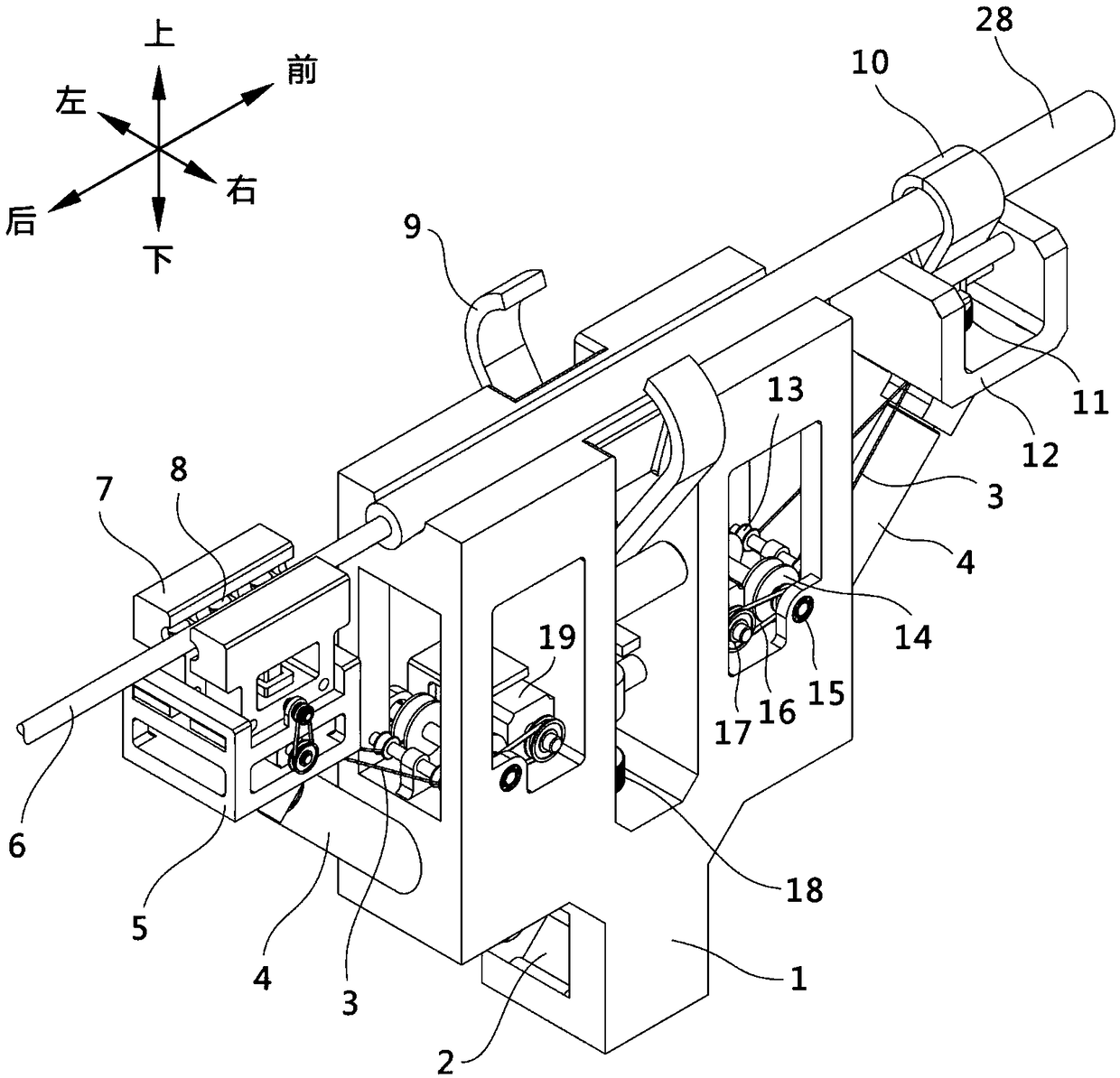

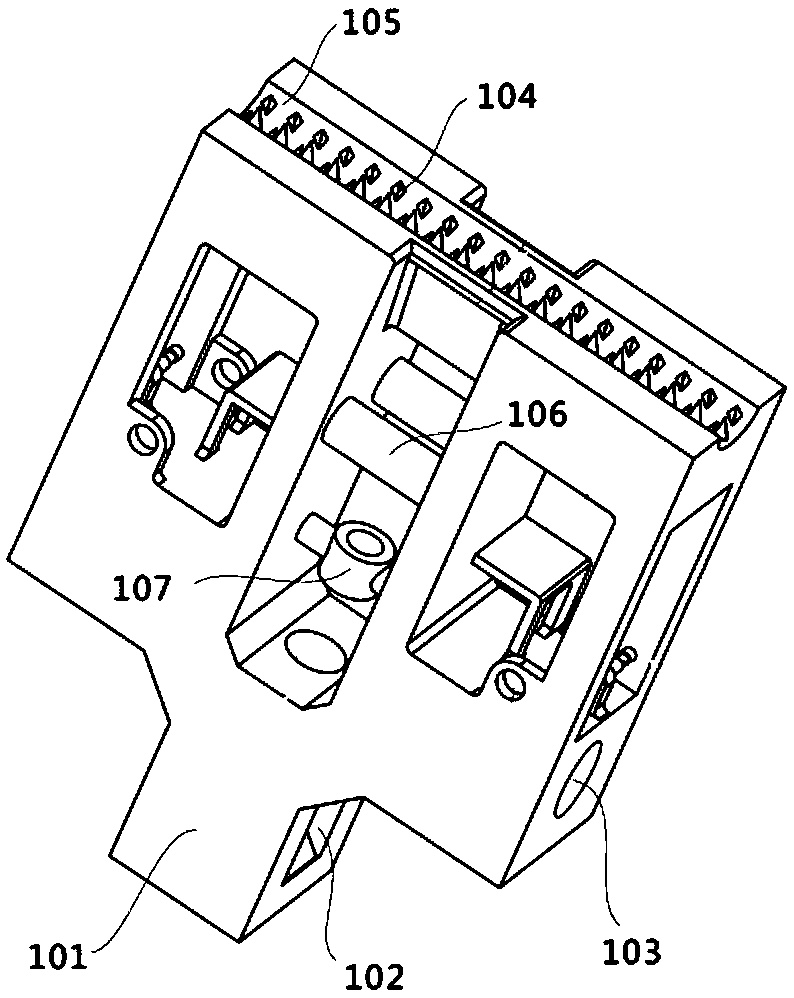

Device and method for magnetically grinding inner surfaces of large-diameter long and straight pipes

PendingCN108857605AHigh degree of automationImprove processing efficiencyEdge grinding machinesPolishing machinesMotor driveMachining

The invention relates to a device and a method for magnetically grinding the inner surfaces of large-diameter long and straight pipes. The device comprises a bed, spindle motors, couplings, a magneticpole disc, a motor driving slide rail device and a hoisting device. Two ends of each pipe fitting can be sealed by pipe fitting plugs and are fixed by the aid of four-jaw chucks, the four-jaw chuck at one end of each pipe fitting is connected with the corresponding spindle motor by the corresponding coupling, the four-jaw chuck at the other end of each pipe fitting is connected with a support seat by bearings, support seat slide rails are fixed onto the bed, and the support seats are slidably connected with the support seat slide rails by support seat sliders; the motor driving slide rail device is arranged at the bottom of the bed, and the magnetic pole disc is connected with the motor driving slide rail device by the hoisting device, can be lifted under the control of the hoisting device and can axially move along the pipe fittings under the control of the motor driving slide rail device. The device and the method have the advantages that finish machining can be carried out on the inner surfaces of the pipe fittings by the aid of magnetic grinding processes, and carbon deposits, oil stain and rust stain which are accumulated at grooves inside the pipe fittings can be effectivelyremoved by the aid of the device and the method.

Owner:UNIV OF SCI & TECH LIAONING

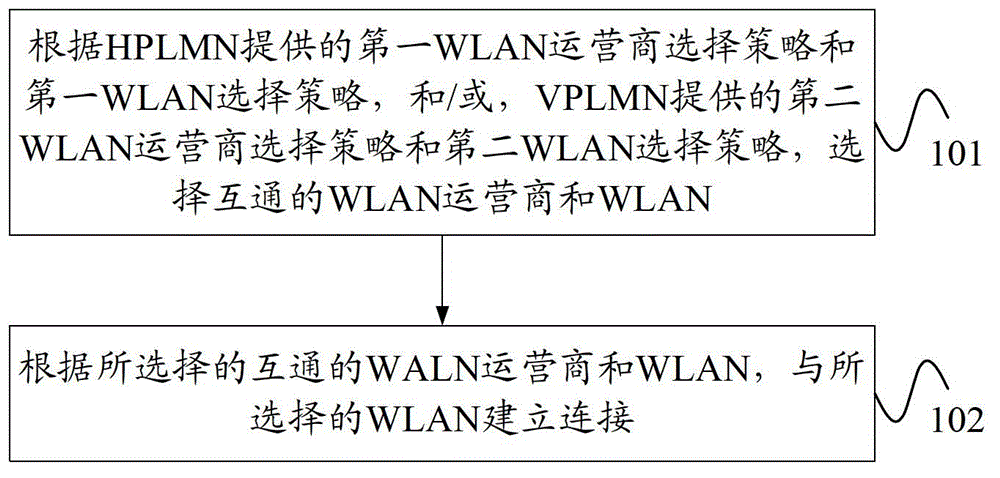

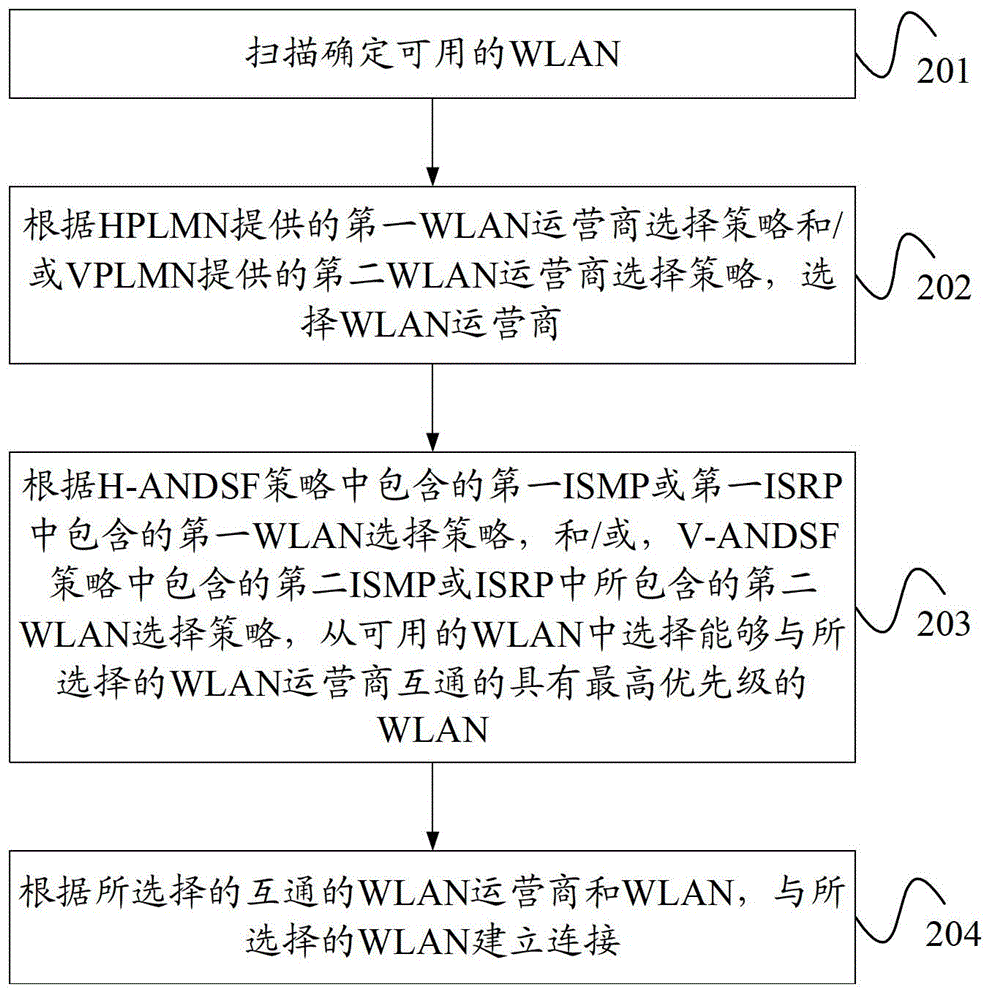

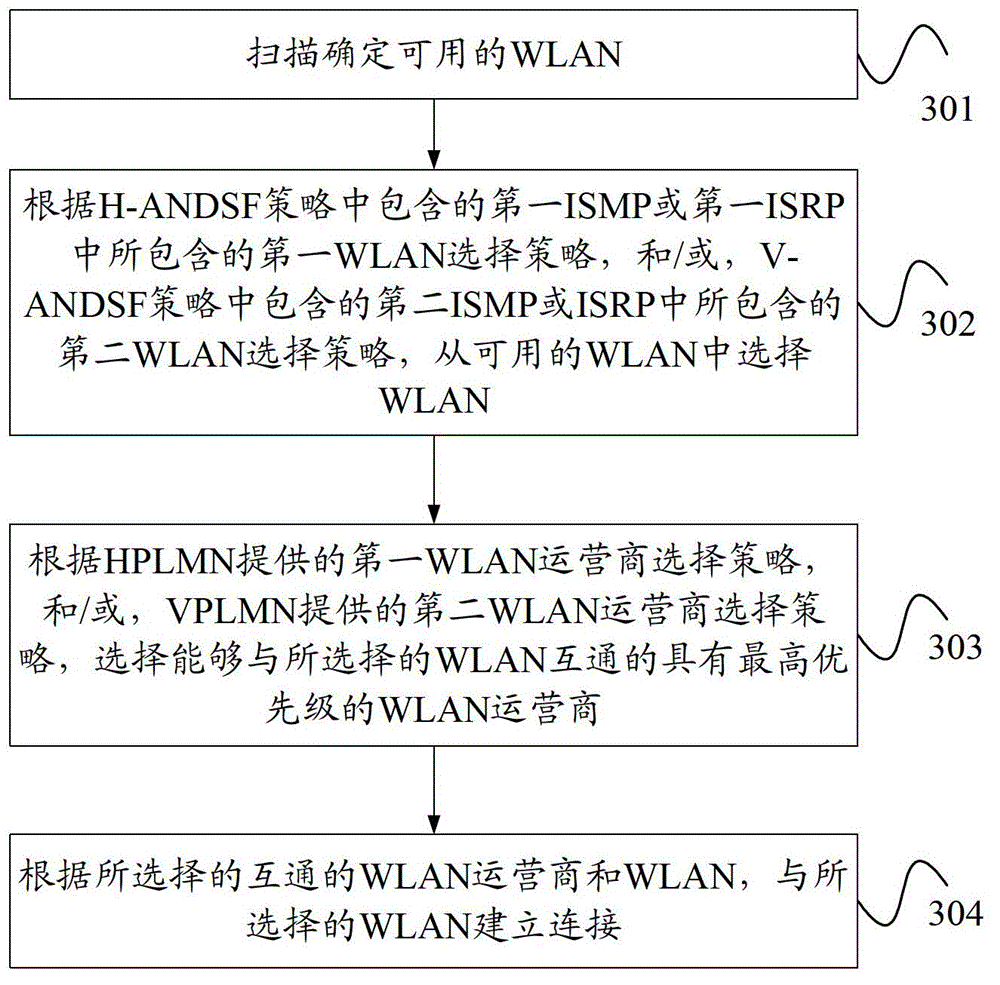

Method for selecting wireless local area network (WLAN) service provider and WLAN, and user equipment (UE)

ActiveCN104066154AAchieve impactEasy to controlNetwork traffic/resource managementAssess restrictionNetwork onUser equipment

Provided are a method for selecting a wireless local area network (WLAN) operator and a WLAN and a user equipment. The method comprises: selecting a WLAN operator and a WLAN which are in communication in accordance with a first WLAN operator selection policy and a first WLAN selection policy provided by a HPLMN and a second WLAN operator selection policy and / or a second WLAN selection policy provided by a VPLMN; and establishing a connection with the selected WLAN in accordance with the selected WLAN operator and WLAN which are in communication. Because the priority of the first WLAN operator selection policy is higher than the priority of the second WLAN operator selection policy, a UE gives priority to the selection of an available WLAN provided by the WLAN operator that has a WLAN roaming partnership with a HPLMN network when selecting a WLAN, thereby realizing the influence and the control of a 3GPP network on the selection of the WLAN operator for the UE, increasing the access success rate of a user, bringing better experience for the user during switching and roaming, and also reducing the expense of the user when roaming.

Owner:HUAWEI DEVICE CO LTD

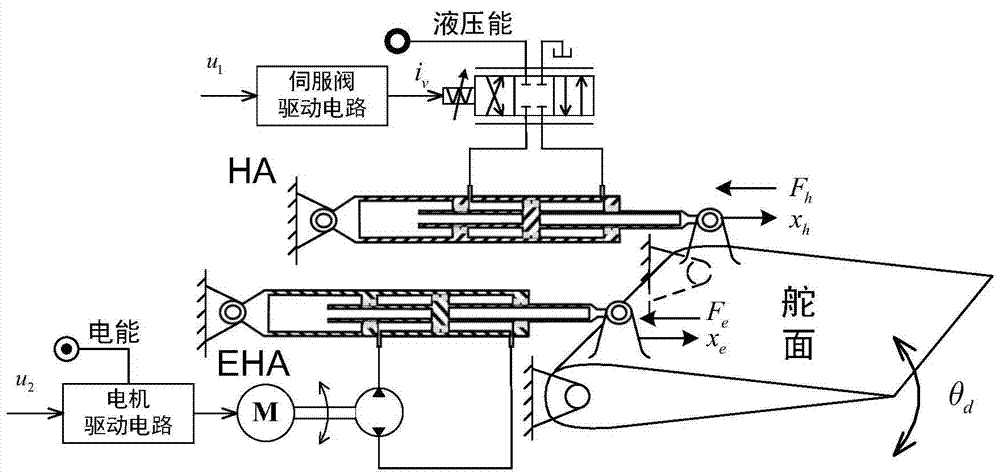

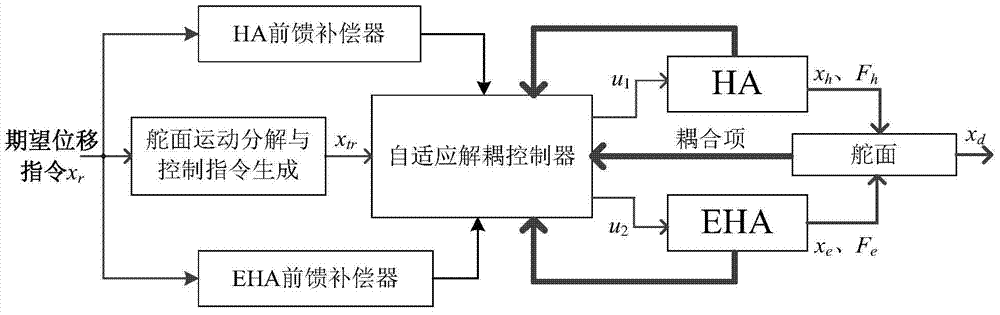

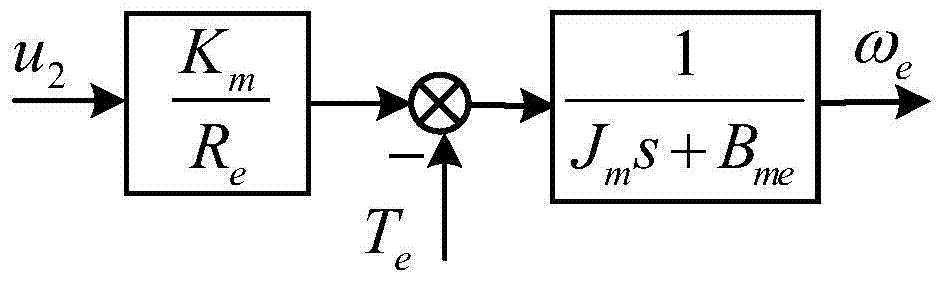

Self-adaption decoupling control method based on motion state synchronization

InactiveCN104265708AEliminate the effects ofGuaranteed synchronicityAircraft controlServomotorsActuatorControl theory

The invention provides a self-adaption decoupling control method based on motion state synchronization. The self-adaption decoupling control method based on motion state synchronization is applied to a dissimilarity redundancy hybrid actuation system composed of a hydraulic actuator (HA) and an electro-hydrostatic actuator (EHA). According to the self-adaption decoupling control method based on motion state synchronization, the coupling model of the dissimilarity redundancy hybrid actuation system is established, and the different items between the HA and the EHA are compensated for; the state equation of a control surface model is decomposed, and a follow-up control instruction of the sum of the displacement of the HA and the EHA is generated; a synchronous self-adaptation decoupling control method is designed, the influence of a coupling item on the system is eliminated, accurate follow-up control over the control surface displacement instruction is achieved, and the force-fighting problem between different actuators is solved. By the adoption of the self-adaption decoupling control method based on motion state synchronization, accurate follow-up control over the control surface displacement instruction can be achieved, and the magnitude of force-fighting between different actuators is effectively reduced; in addition, the designed self-adaption control rule can accurately approach the true values of estimated parameters, and therefore the influence of uncertainty of the parameters on the control performance of the system is eliminated.

Owner:BEIHANG UNIV

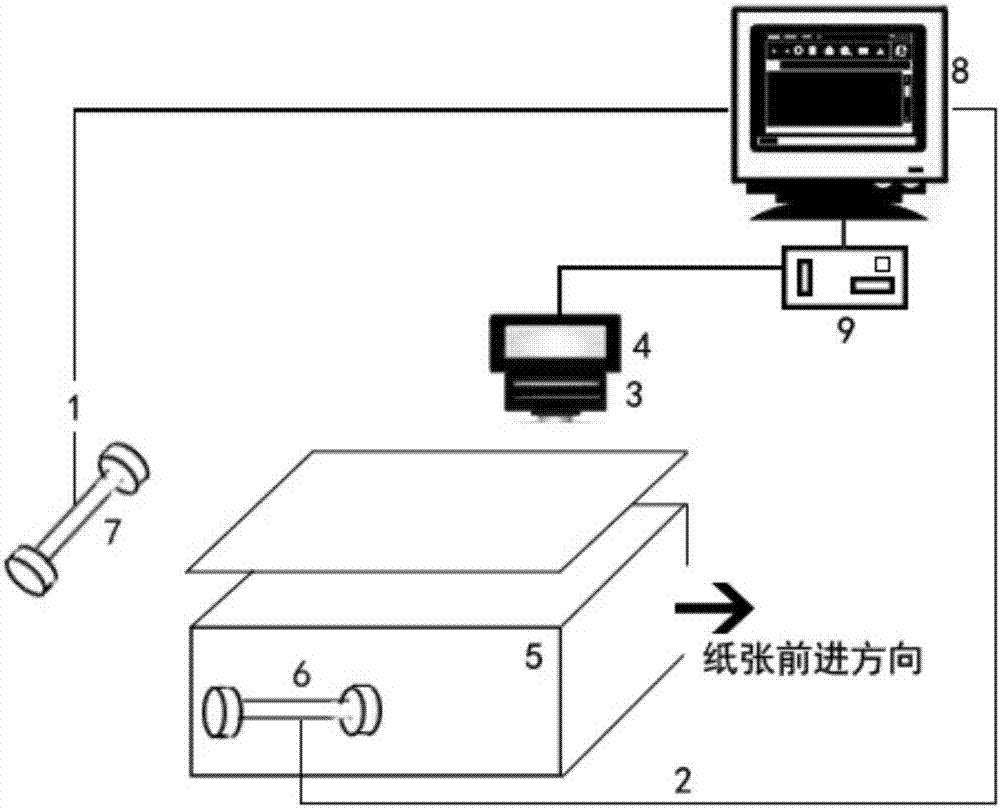

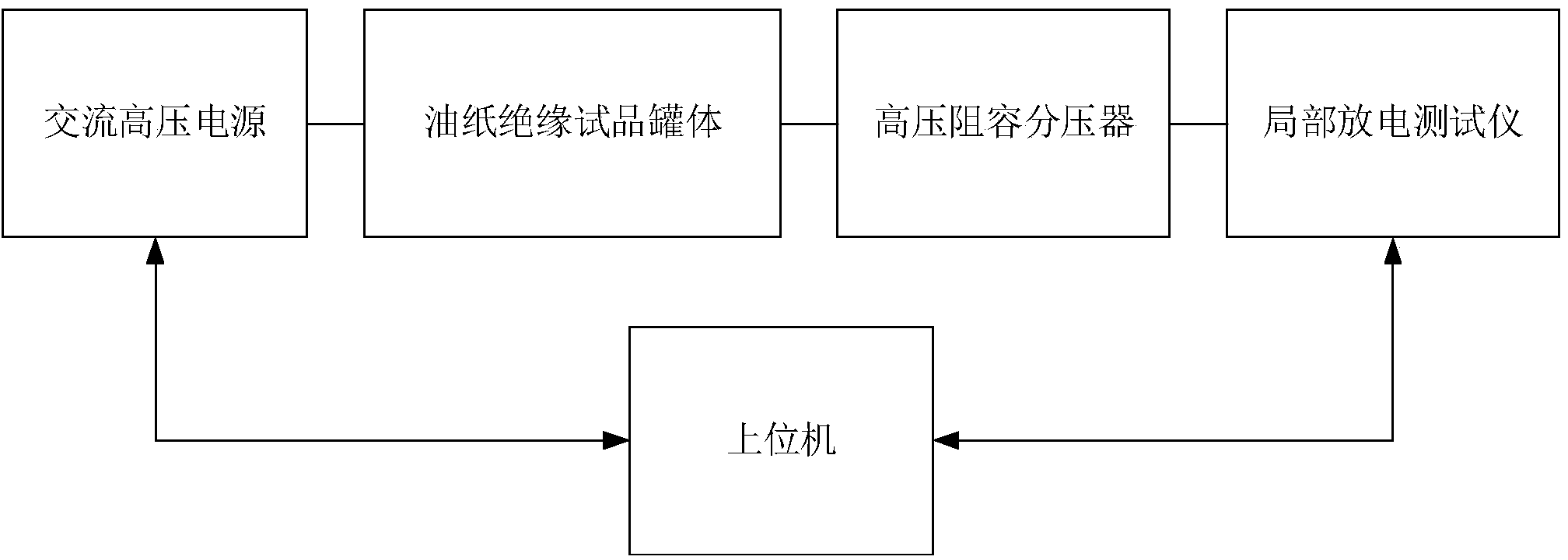

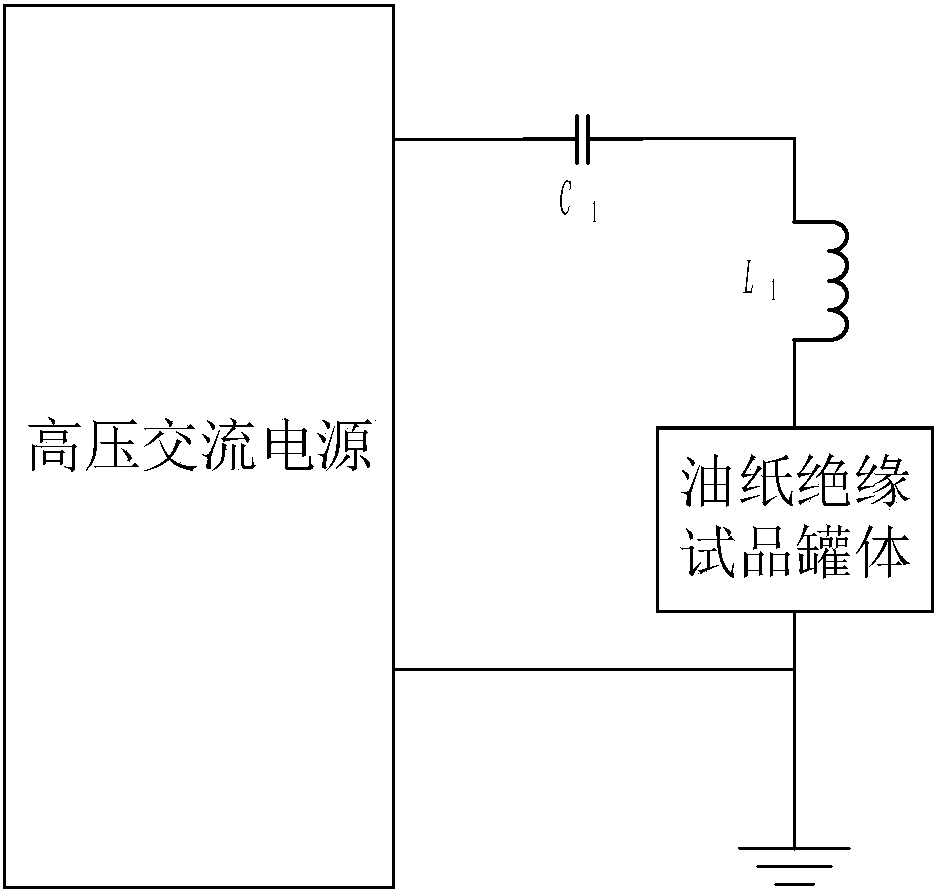

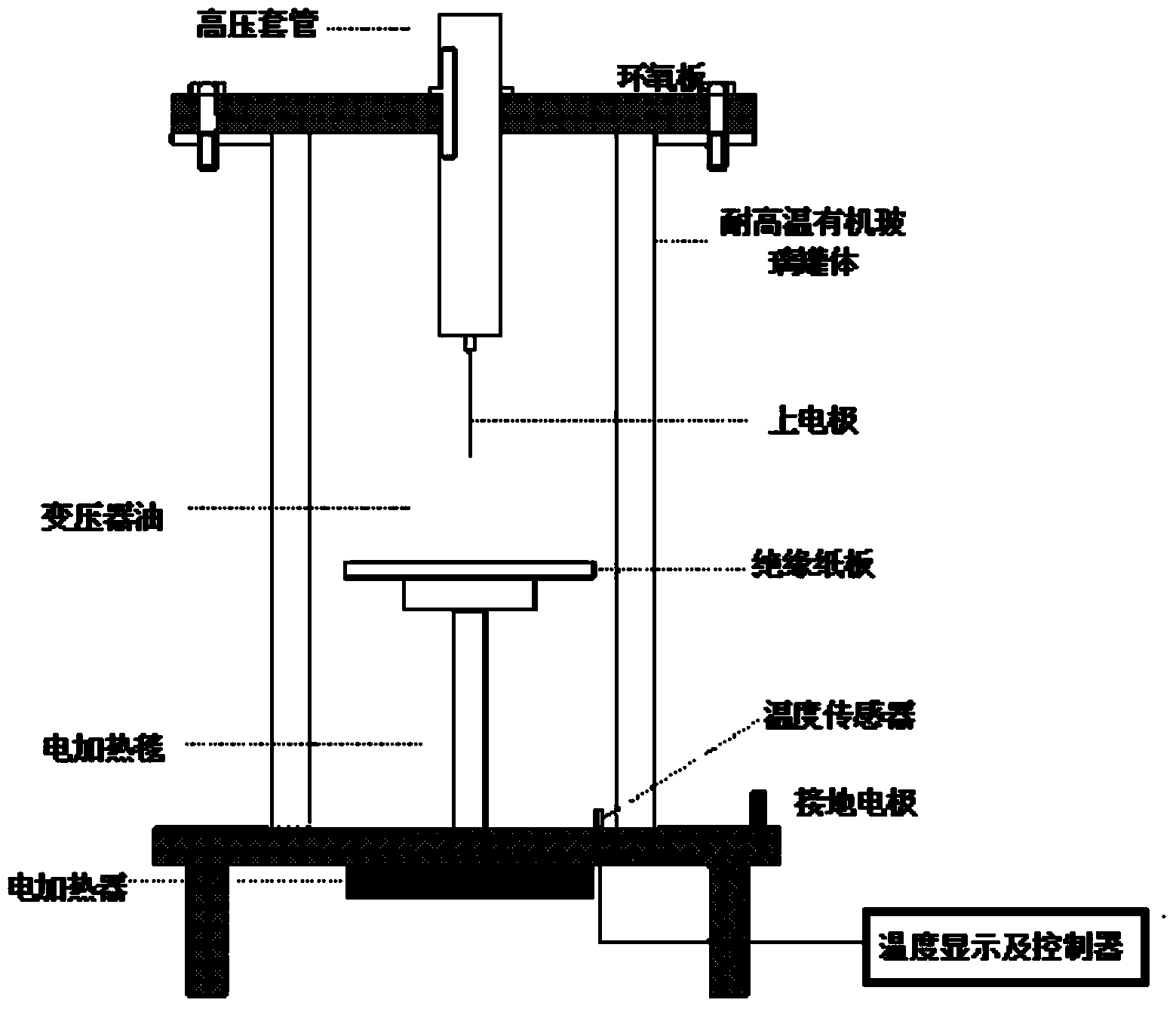

Oiled paper insulation partial discharge inception voltage test system

InactiveCN103954896AAccurate measurementAchieve impactTesting dielectric strengthCapacitanceMeasuring instrument

The invention discloses an oiled paper insulation partial discharge inception voltage test system which comprises an alternating current high voltage power supply, a high voltage capacitance-resistance divider, an oiled paper insulation sample tank, a partial discharge measuring instrument and an upper computer. The alternating current high voltage power supply is connected with the oiled paper insulation sample tank. The high voltage capacitance-resistance divider is connected with the oiled paper insulation sample tank. The partial discharge measuring instrument is connected with the oiled paper insulation sample tank, and collects partial discharge signals inside an oiled paper insulation sample. The upper computer is in two-way communication connection with the alternating current high voltage power supply and the partial discharge measuring instrument. According to the oiled paper insulation partial discharge inception voltage test system, the partial discharge measuring instrument is adopted for testing the partial discharge inception voltage of oiled paper compound insulation with different temperatures and different electrode structures, and the partial discharge inception voltage of the oiled paper insulation system is accurately measured.

Owner:STATE GRID CORP OF CHINA +3

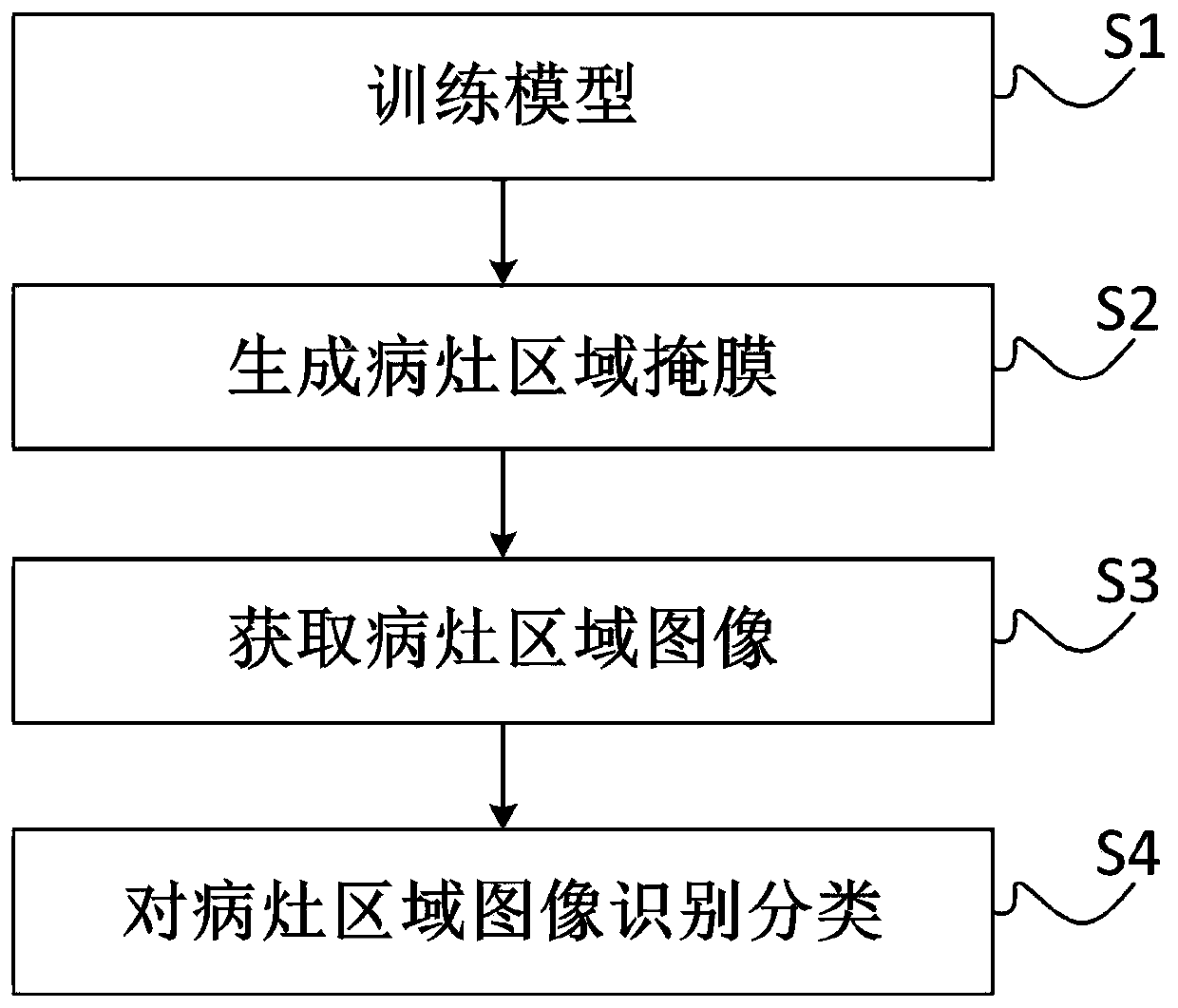

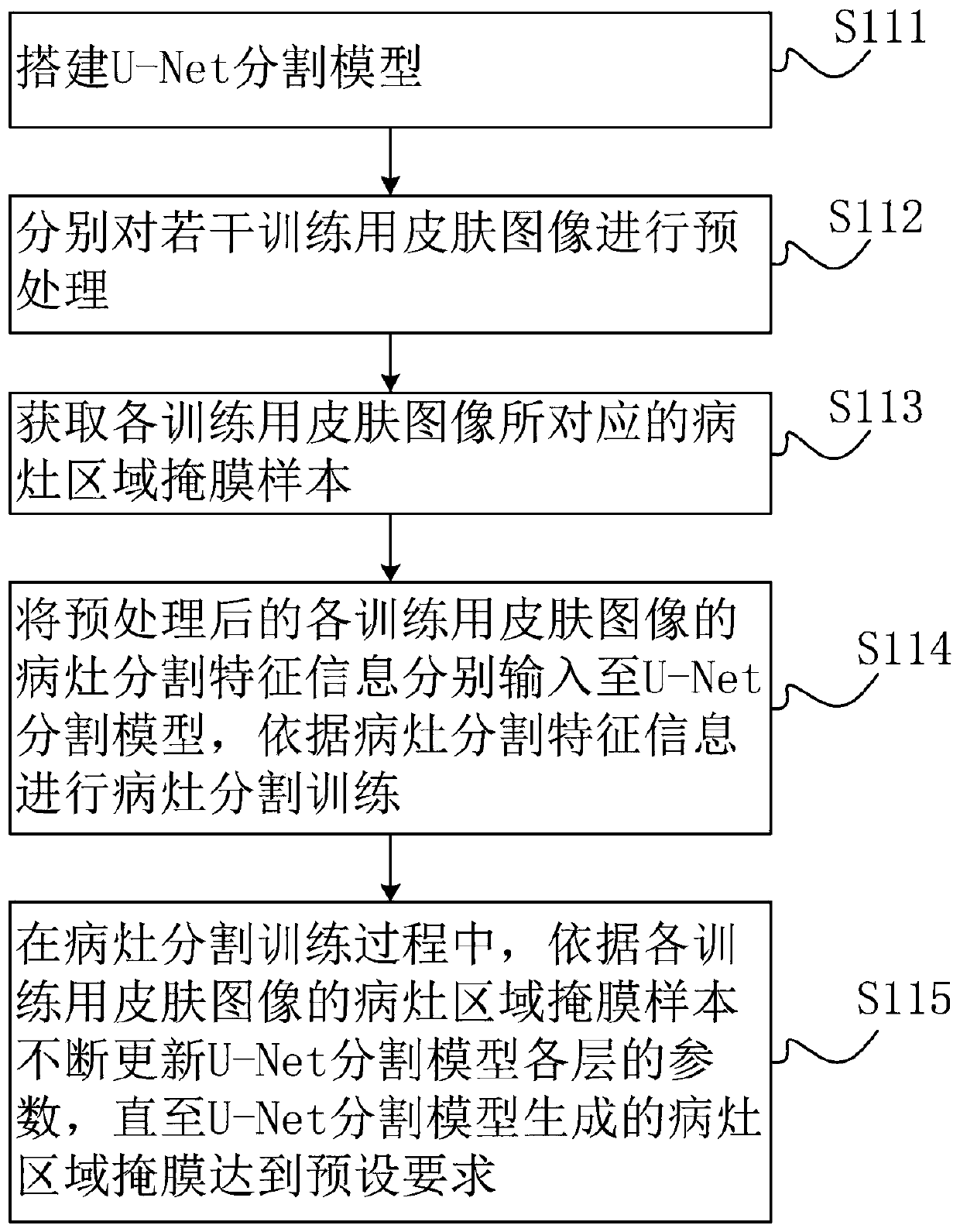

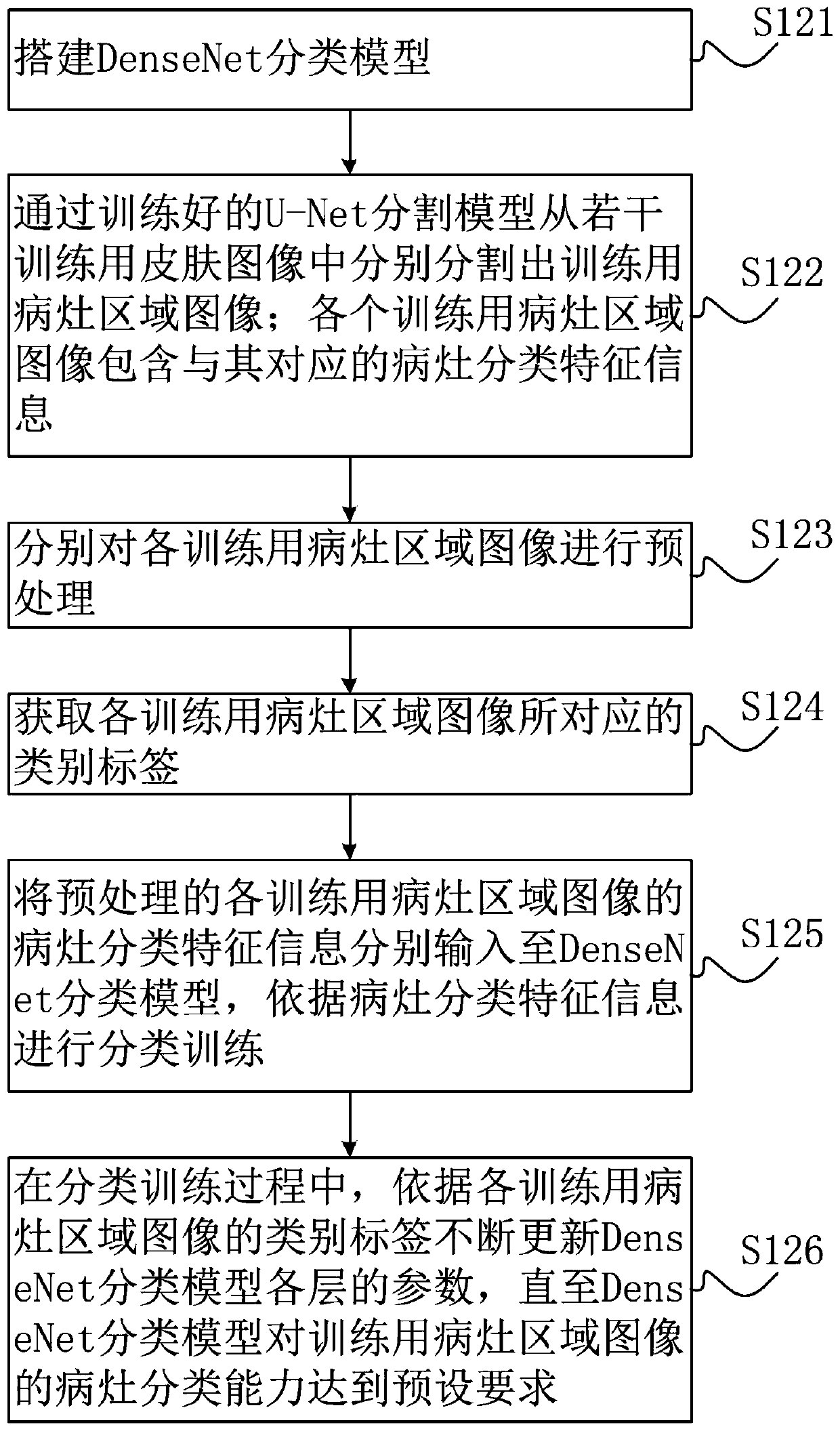

Skin cancer type identification method and system, computer equipment and storage medium

PendingCN109712111AAccurate automatic classificationImprove accuracyImage analysisCharacter and pattern recognitionPattern recognitionInterference factor

The invention relates to a skin cancer type recognition method and system, computer equipment and a storage medium. The method comprises training a U-Net segmentation model and a DenseNet classification model; wherein the U-Net segmentation model forms a focus area mask; obtaining a focus area image;and identifying and classifying the lesion area images according to the extracted lesion classification feature information through a DenseNet classification model. The skin cancer symptom types are distinguished according to image recognition, the influence of other interference factors in the skin image is reduced, the extracted classification feature information is finer and more concentrated on a lesion part, and the skin cancer classification accuracy is greatly improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

Temperature-adjustable alkylation reactor and alkylation reaction method

ActiveCN104549109AImprove the mixing effectLow reaction temperatureLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPhysicsEngineering

The invention discloses an alkylation reactor and an alkylation reaction method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas outlet and heat pipe elements, wherein a closed shell body is formed by the reactor tube body and the closure heads, the revolving bed is arranged at the internal middle part of the shell body and is connected with a driving device through a revolving shaft, the charge distribution pipe is arranged at the center of the revolving bed and is communicated with the charging pipe, and the discharging opening is formed in the lower part of the shell body; a sealing member is arranged between the revolving bed and the shell body, the heat pipe elements are arranged at the outer side of the revolving bed and sequentially penetrate through the sealing member and the shell body, the heat pipe elements outside the shell body are sealed with a jacket, a refrigerant inlet and a refrigerant outlet are formed in the jacket, and the circulating cooling gas inlet and the circulating cooling gas outlet are formed in the shell body. According to the alkylation reaction method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation reaction method, the alkylation reaction can be carried out at low temperature, the acid consumption is low, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

Test device for safety lock of high-rise working cradle

InactiveCN1971236AReflect the design conceptRealize electric controlStructural/machines measurementBuilding support scaffoldsDistribution controlSheet steel

An experimental unit of suspended basket security keylock in high-lift operation relates to an experimental unit that comprises: supporting leg, dropped iron, parallel, pusher clusters, elastic machine, sensor, upper beam, elevator, bridging beam, power distribution wire, power distribution control pedestal, safe tension monitoring device, platform horizontal monitoring mechanism. The upper beam and the bridging beam are mounted on the upper part of supporting leg via flanged connection, the elevator is mounted on the beam, the elastic machine and parallel are hung on the elevator, the elastic machine is connected with the pusher clusters via brace, the dropped iron is mounted under the parallel equipped with additional weight iron, the suspended buffer and sensor are located on the beam, the safe tension monitoring device consists of tension sensor and secondary instrument, the upper beam is case welded by steel sheet; The unit reinforces quality inspection for security keylock, eliminates the accident potential caused by quality problems of security keylock. The equipment and personal safety can be safeguarded effectively.

Owner:辽宁省安全科学研究院

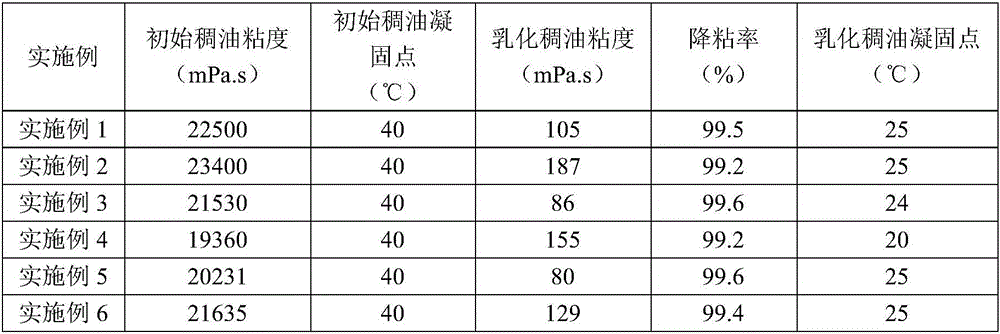

Pour point depressing and viscosity reducing composition for heavy oil, pour point depressing and viscosity reducing agent for heavy oil and preparation method of pour point depressing and viscosity reducing agent

ActiveCN105950127AHigh acid-base stabilityImprove solubilityDrilling compositionAlkyl aminePetroleum

The invention relates to pour point depressing and viscosity reducing composition for heavy oil, a pour point depressing and viscosity reducing agent for the heavy oil and a preparation method of the pour point depressing and viscosity reducing agent, and belongs to the technical field of oil exploitation. The pour point depressing and viscosity reducing composition for the heavy oil comprises components in parts by weight as follows: 25-55 parts of a surfactant, 5-20 parts of a dispersing agent, 15-20 parts of an inhibitor and 20-50 parts of a co-emulsifier, wherein the dispersing agent contains polyoxyethylene alkyl amine, and polyoxyethylene alkyl amine accounts for not lower than 9% of the dispersing agent in percentage by mass. The pour point depressing and viscosity reducing composition for the heavy oil has good emulsifying viscosity reduction functions on the heavy oil with the gum asphalt content of 40% and the freezing point of 40 DEG C, the viscosity reducing rate can be up to 99% or higher and the pour point depressing range can be up to 15 DEG C or higher only through addition of 0.5% by mass of the pour point depressing and viscosity reducing agent product, and the problems of high entering-pump resistance of crude oil and difficulty in shaft lifting can be solved very well.

Owner:CHINA PETROLEUM & CHEM CORP +1

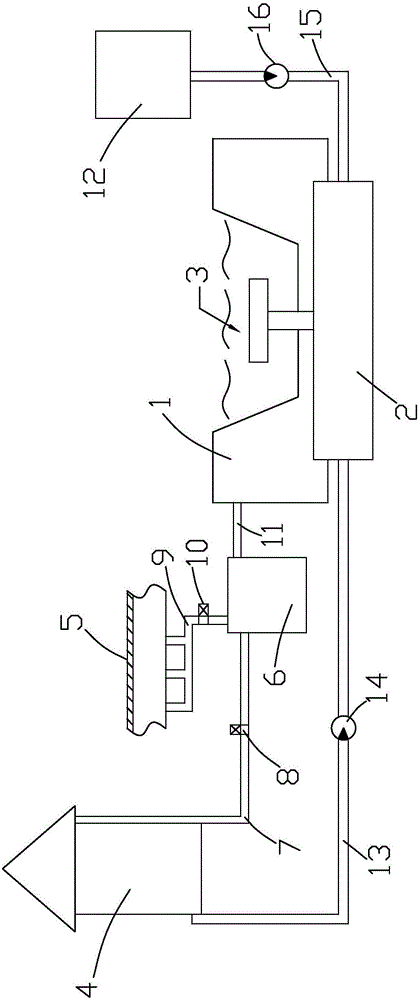

Intelligent urban rainwater storage regulation system and construction method thereof

ActiveCN106759781APrevent leakagePrevent waterloggingFatty/oily/floating substances removal devicesSewerage structuresResidenceEngineering

The invention discloses an intelligent urban rainwater storage regulation system and a construction method thereof. The system comprises a rainwater storage regulation tank, a water through device, a filter device and a water distribution tank. A first water level sensor and a second water level sensor are arranged on the inner side of a park pool, and the water through device is positioned between the first water level sensor and the second water level sensor and close to the second water level sensor. A silt clearing tank is arranged at the top of the park pool, the filter device is connected with a residence region and a road surface through a first water inlet pipe and a second water inlet pipe respectively, and the rainwater storage regulation tank is connected with the residence region and the water distribution tank through a first water drain pipe and a second water drain pipe respectively. The method includes steps of survey setting-out, rainwater storage regulation tank construction, filter device construction, water distribution tank construction, road surface construction, pipeline connection arrangement and rainwater storage regulation system commissioning. The construction method is simple in step, rainwater quick drainage and storage are facilitated, flood or waterlogging is prevented, and stored rainwater can be used for irrigation and domestic water.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

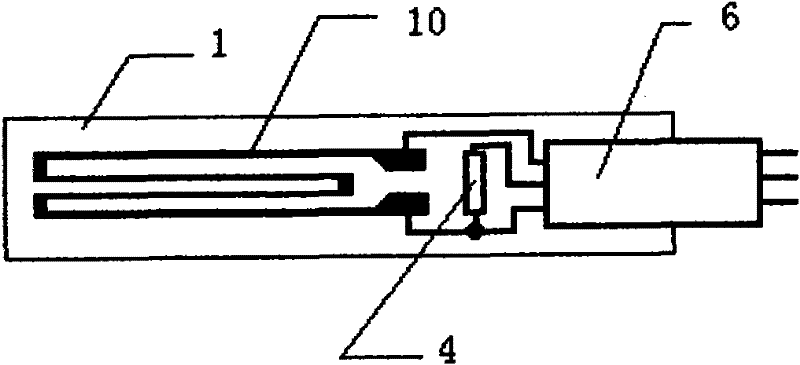

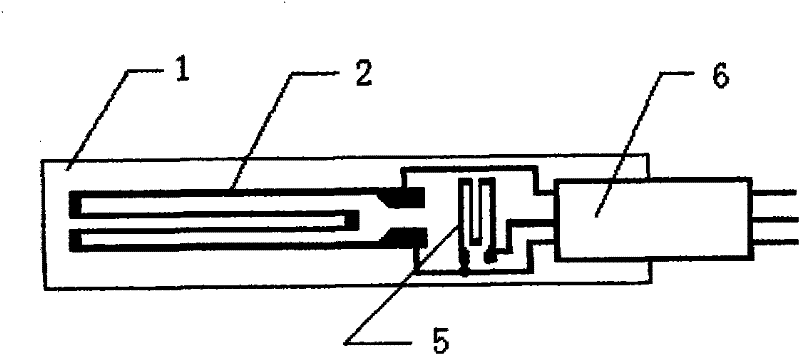

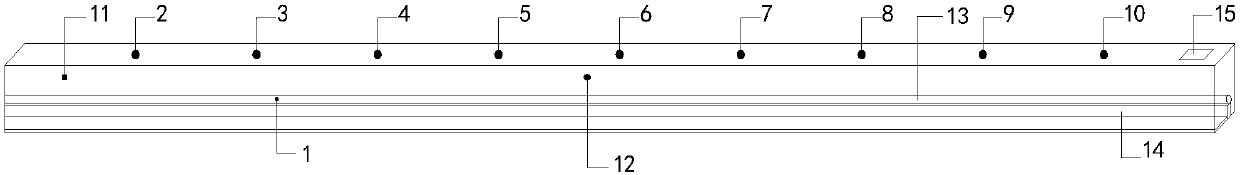

Fiber preform rod flexibility measurement method

The invention discloses a fiber preform rod flexibility measurement method. The method comprises steps that 1), initial setting is carried out; 2), a to-be-measured rod is clamped and positioned; 3), the to-be-measured rod is kept to rotate continuously, a laser diameter measurement instrument is utilized to carry out 360-DEG all-round scanning for a first selected cross section, the laser diameter measurement instrument is moved to a next cross section, and the step is repeated till all the cross sections are scanned; 4), a set of dynamic distances between a dynamic cross section surface and a reference surface is acquired each time when scanning is carried out by the laser diameter measurement instrument, difference of the largest value and the smallest value of the set of distances is calculated, and one half of the difference is flexibility of the cross section; 5), two-dimensional curve fitting is carried out for flexibility of all the cross sections, namely a flexibility curve is acquired; and 6), the largest flexibility of all the cross sections is taken as flexibility of the to-be-measured rod. The method is advantaged in that one-time automatic measurement on rod flexibility is realized through employing a scanning and rotation mode, high measurement precision is realized, analysis data can be automatically generated, and measurement efficiency is high.

Owner:JIANGSU AOWEIXIN HENGTONG OPTICAL TECH

Alkylation reactor and alkylation reaction method

ActiveCN104549111AFully dispersedBoost octaneLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferEngineering

The invention discloses an alkylation reactor and an alkylation reaction method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas refrigeration system and a circulating cooling gas outlet, wherein a closed reactor shell body is formed by the reactor tube body and the closure heads, and the revolving bed is vertically located at the internal middle part of the shell body; a static bed layer is arranged at the radial outer side of the revolving bed, and a suitable gap exists between the static bed layer and the revolving bed; a sealing member is arranged between the upper part of the revolving bed and the reactor shell body, the upper part of the revolving bed and the sealing member are of rotatable connection, the circulating cooling gas inlet and the circulating cooling gas outlet are respectively formed in the shell body at the upper and lower sides of the sealing member, and the circulating cooling gas refrigeration system is located between the circulating cooling gas inlet and the circulating cooling gas outlet. According to the alkylation reaction method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation reaction method, the alkylation reaction can be carried out at low temperature, the acid consumption is low, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

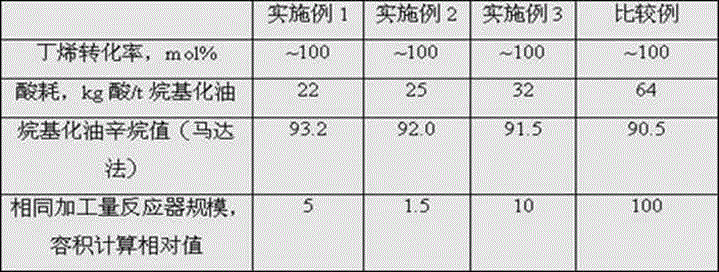

Organic solid waste film covering high-temperature aerobic fermentation method

InactiveCN101792339AThermal insulationReduce the impactBio-organic fraction processingClimate change adaptationControl systemAgricultural engineering

The invention relates to the technical field of organic solid waste processing, in particular to an organic solid waste film covering high-temperature aerobic fermentation method. The fermentation method is characterized in that the organic solid waste is pretreated; the pretreated material is piled in strip pile; the material strip pile is provided with a sensor and covered with a waterproof breathable film; a blower and an air-pipe under the material are used for supplying oxygen to the material; an intelligent ventilating control system is used for optimizing the fermentation process; after the material is fully decomposed, the waterproof breathable film on the material strip pile is removed, and then the material strip pile is transported into a clinker storing or processing area. Compared with the prior art, the fermentation method has short building period, few disposable investment, flexible construction, low operating cost, small odor influence, rain-proof, wind prevention and heat preservation effect and can protect the material from being affected by outside weathers.

Owner:SHANGHAI YUANJUN ENVIRONMENTAL PROTECTION TECH CO LTD

A self-compensating concrete-integrated strain gauge

InactiveCN102269567AReduce volumeEliminate the effect of detection sensitivityElectrical/magnetic solid deformation measurementFiberElectrical resistance and conductance

The invention discloses a self-compensating concrete integrated strain gauge, which is mainly characterized in that a compensation resistor is provided on the strain gauge, the compensation resistor and the working piece form a half-bridge or full-bridge working mode, and the compensation resistor adopts a high-precision resistor with no stress output Or small grid strain gauges, which can automatically compensate the influence of temperature on the bridge and wires, overcome the difficulty that it is impossible to equip each measuring point with a compensation block and ensure that its temperature and change are consistent; it can also eliminate the influence of wire length on detection sensitivity At the same time, the reinforced fiber insulation base and flexible waterproof sealing material are used to carry out the overall waterproof sealing treatment, which not only ensures the technical requirements of the insulation resistance of the strain gauge, but also has the effect of convenient, fast, accurate and safe on-site installation. .

Owner:陈彦平

Water level rising and falling device of geotechnical centrifuge

ActiveCN104846771AOvercoming turbulent flow problemsRealize sudden rise and fallHydraulic modelsPressure transmissionWater level rise

The invention discloses a water level rising and falling device of a geotechnical centrifuge. The water level rising and falling device comprises a model box installed in a hanging basket of the centrifuge. A model base plate is arranged at the bottom of the model box and supported by stand columns located below the model base plate. A gap is reserved between one lateral face of the model base plate and the corresponding side wall of the model box. The bottom of a test water tank is connected with the bottom of the model box through connecting pipes. An air inlet pipe is connected to the top of the test water tank. A method for simulating rising and falling of the water level through the water level rising and falling device when the geotechnical centrifuge runs includes the steps that high-pressure air is led into the test water tank, water is pressed into the model box, and the pressure of the high-pressure air is controlled to achieve stable and repeated rising and stable and repeated falling of the water level in the model box. According to the water level rising and falling device, rising and falling of the water level are achieved through the characteristics that air pressure transmission is rapid and almost free of gravity influences, and can be carried out under the condition that the centrifuge does not stop; influences, caused by a high centrifuge field generated by the geotechnical centrifuge, on rising and falling of the water level can be avoided, the structure is simple, and operation is convenient.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T +1

Internal heat circulation type dehumidification and heat dissipation type power distribution cabinet

InactiveCN112165012AAchieving low tide treatmentReduce the impactGas treatmentSubstation/switching arrangement cooling/ventilationHeat flowWater vapor

The invention discloses an internal heat circulation type dehumidification and heat dissipation type power distribution cabinet, belongs to the field of power distribution cabinets. The cabinet realizes the circulation flow of a heat dissipation settlement ball in a closed airflow channel through the heat absorption and heat release processes of the heat dissipation settlement ball, performs continuous heat dissipation on the interior of a cabinet body, and in the circulation flow process of the heat dissipation settlement ball, a rotary moisture reducing device is pushed to rotate through thevertical falling process of the heat dissipation settlement ball, so that the flowing of air flow in the cabinet body is accelerated, the heat dissipation efficiency can be improved, the heat in thecabinet body can be uniformly distributed, local moisture in the cabinet body is heated, the vaporization of the moisture is promoted, Water vapor can be discharged to the outside along with heat flow. In addition, the rotary moisture reduction device also has an absorption effect on vaporized moisture, the influence of the moisture on electrical equipment is reduced, and the absorbed water vaporcan be quickly diffused to the outside along with the air flow along with the rotary movement of the rotary moisture reduction device, so that the moisture reduction treatment on the interior of the cabinet body is realized.

Owner:劳业鸿

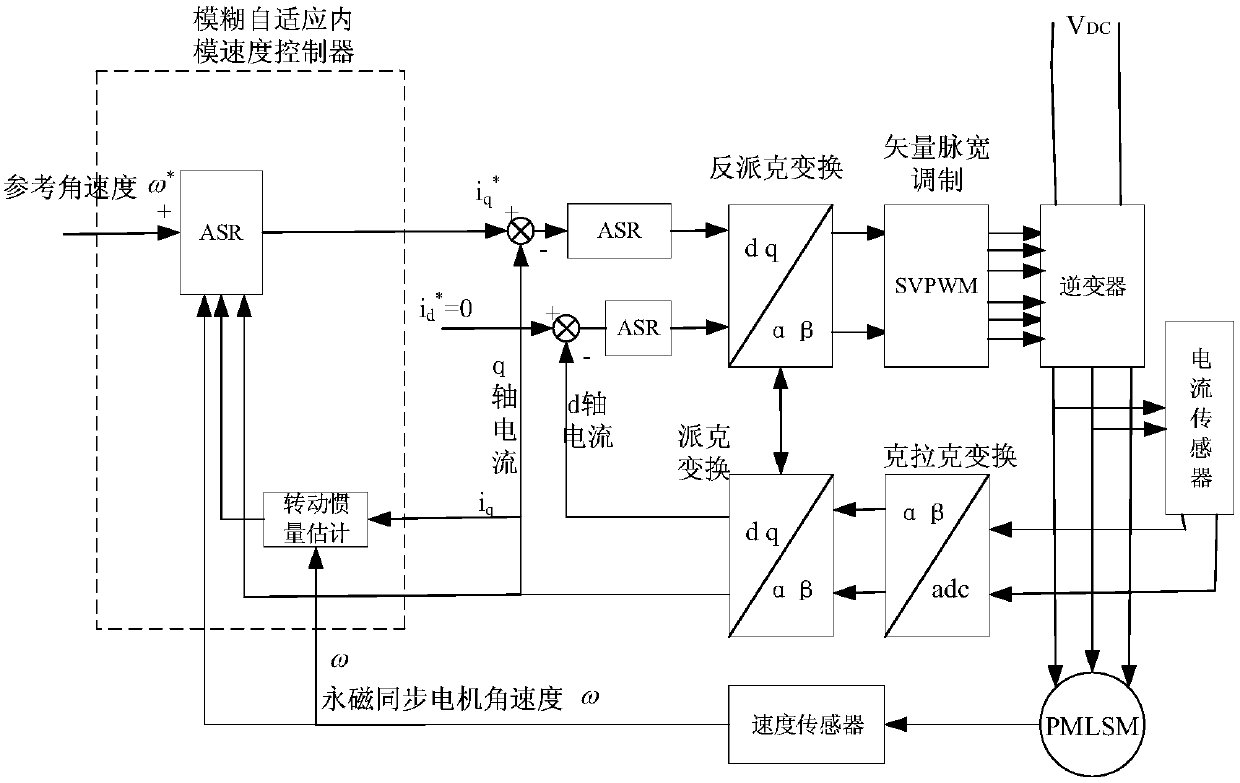

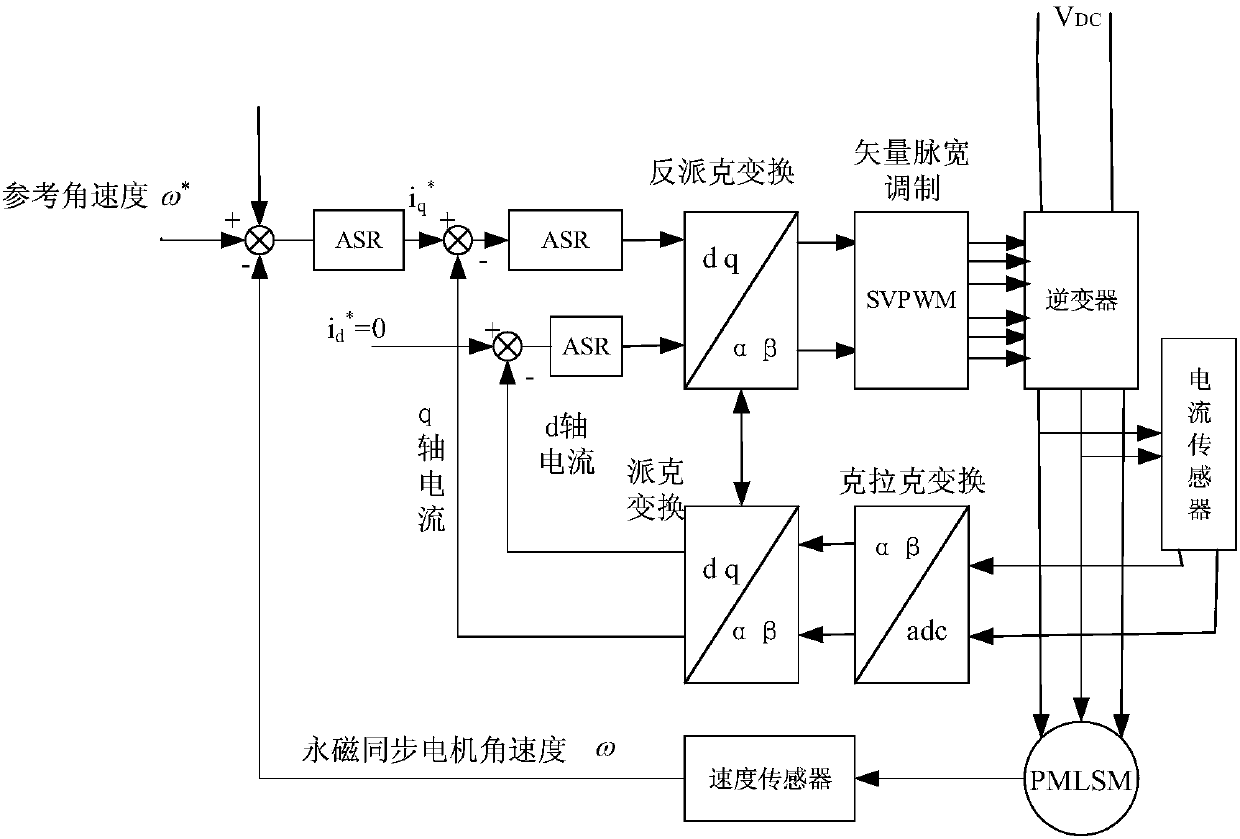

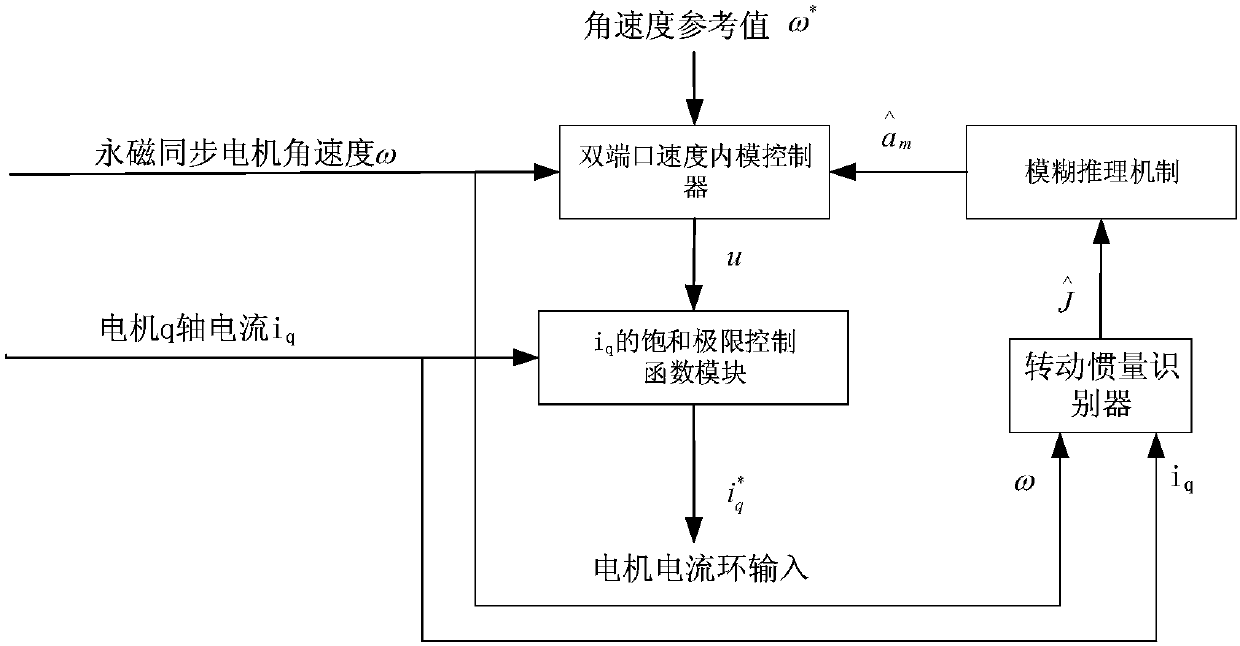

Permanent magnet synchronous motor speed adjusting system based on internal model control and design method thereof

InactiveCN108365787AAchieve impactHigh speedElectronic commutation motor controlVector control systemsRobustificationPermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motor speed adjusting system based on internal model control and a design method thereof. The method includes the steps of designing a standard speed internal model controller, designing a dual-port speed internal model controller, designing a fuzzy self-adaptive speed internal model controller, and determining a final q-axis current referencevalue according to the designed fuzzy self-adaptive speed internal model controller to realize the dual-closed-loop vector control of a motor. The influences caused by motor model mismatch and external interference on motor operation are solved, the motor control effects of enhancing the control system speed tracking performance and anti-interference performance are realized, and speed tracking and load disturbing can be well realized. The influences caused by model mismatch and external interference on motor operation can be overcome, and therefore the robustness and stability of the systemare improved.

Owner:SOUTHEAST UNIV

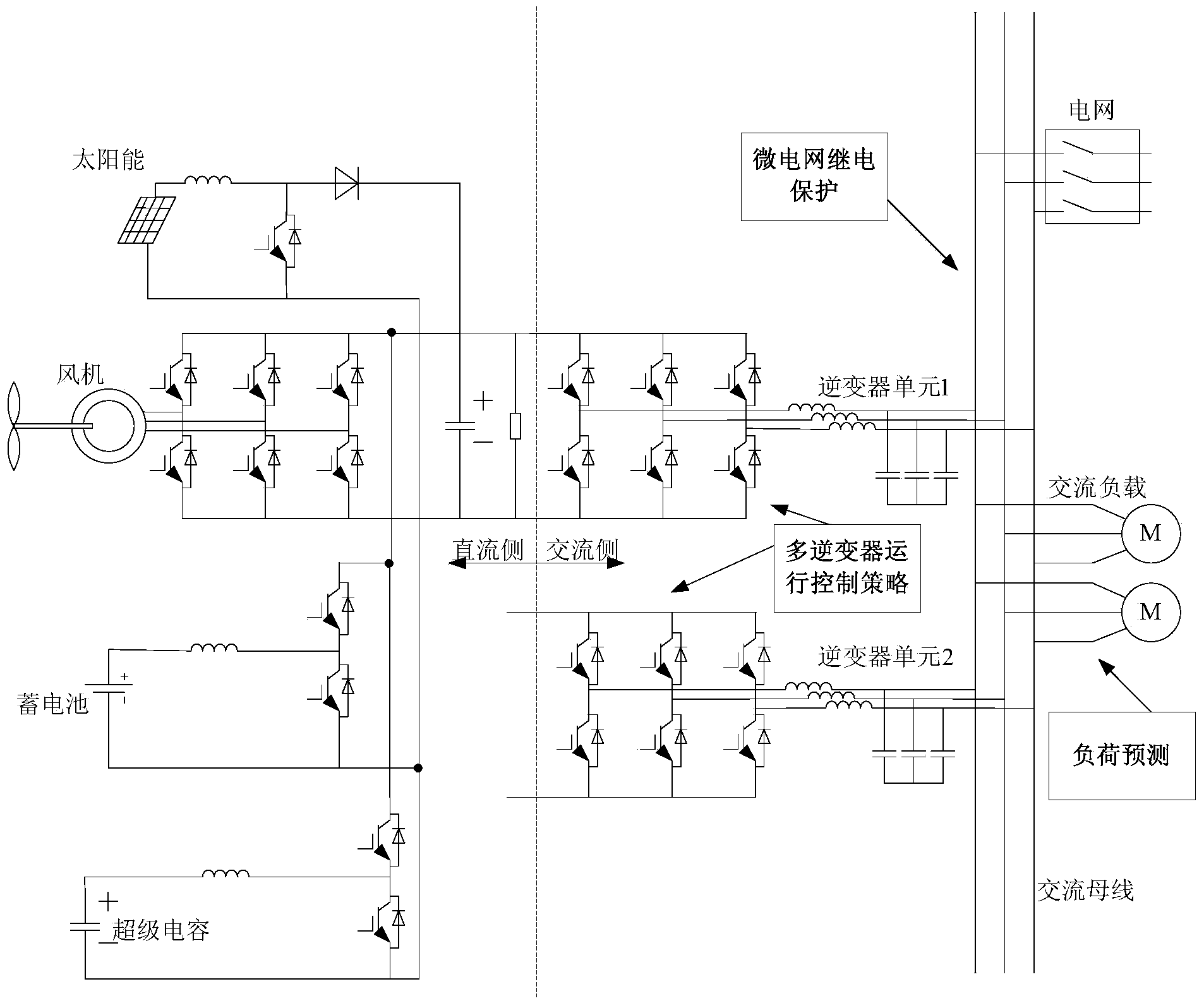

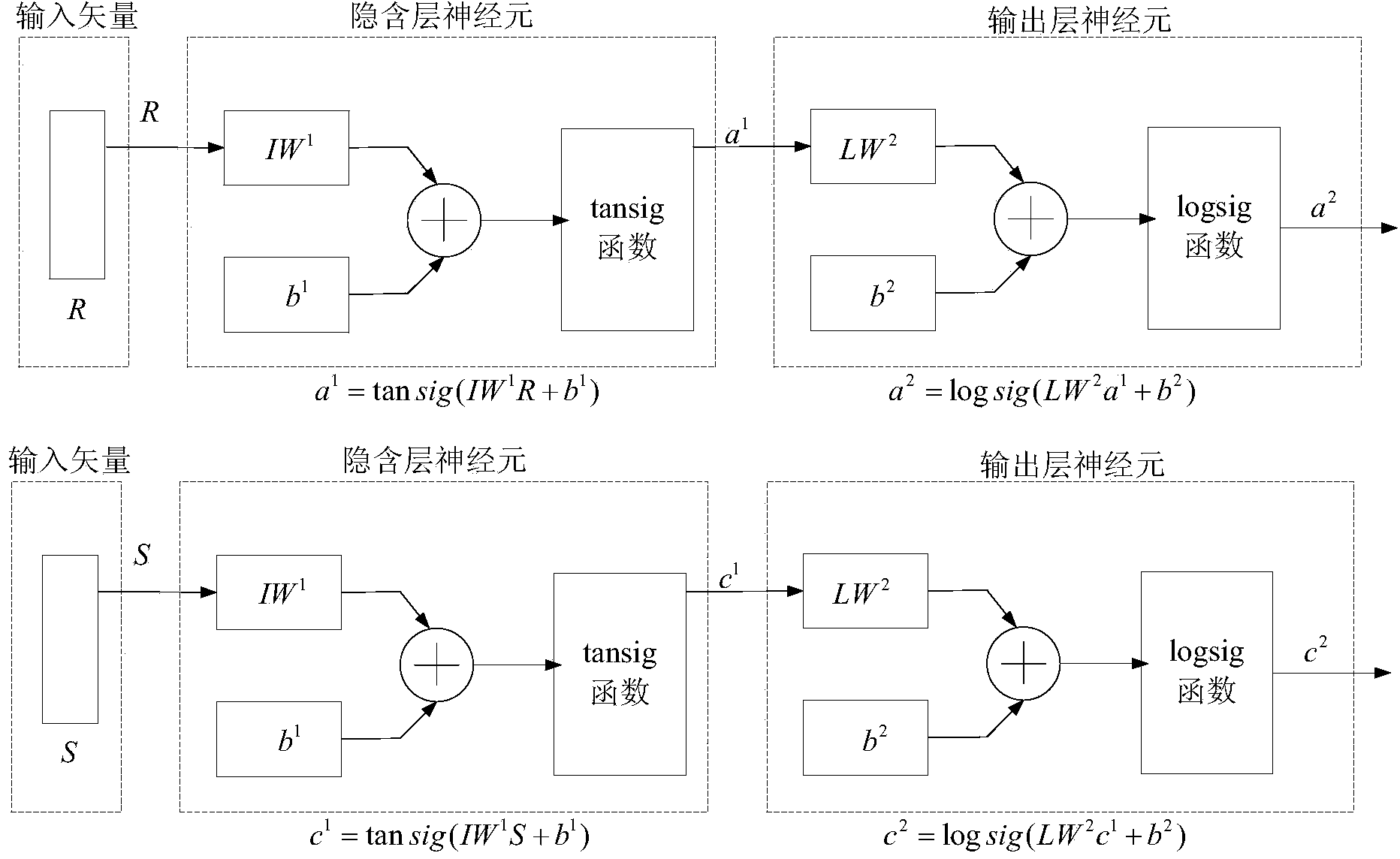

Micro-grid system with functions of improving operation, control and protection performance

InactiveCN104184166AImprove parallel performanceAchieving Conservation ImpactPower network operation systems integrationEmergency protective circuit arrangementsPower gridNetwork model

The invention discloses a micro-grid system with functions of improving operation control and protection performance. The micro-grid system mainly comprises a multi-inverter-parallel-operation control strategy, a micro-grid relay protection scheme and micro-grid load prediction, wherein an improved droop control algorithm is adopted for the multi-inverter-parallel-operation control strategy, region differential-motion main protection, overcurrent backup protection and fault component comprehensive impedance bus protection of normalization brake coefficients are adopted for the micro-grid relay protection scheme, and a neural network model is adopted for the micro-grid load prediction. According to the micro-grid system, the improved droop control algorithm of the multi-inverter-parallel-operation control strategy and the region differential-motion main protection, the overcurrent backup protection and the fault component comprehensive impedance bus protection of the normalization brake coefficients of the control strategy of the micro-grid relay protection and the neural network model of the micro-grid load prediction are combined together, the operation, control and protection performance and intelligent level in switching among different modes of a micro-grid are improved.

Owner:SOUTHEAST UNIV

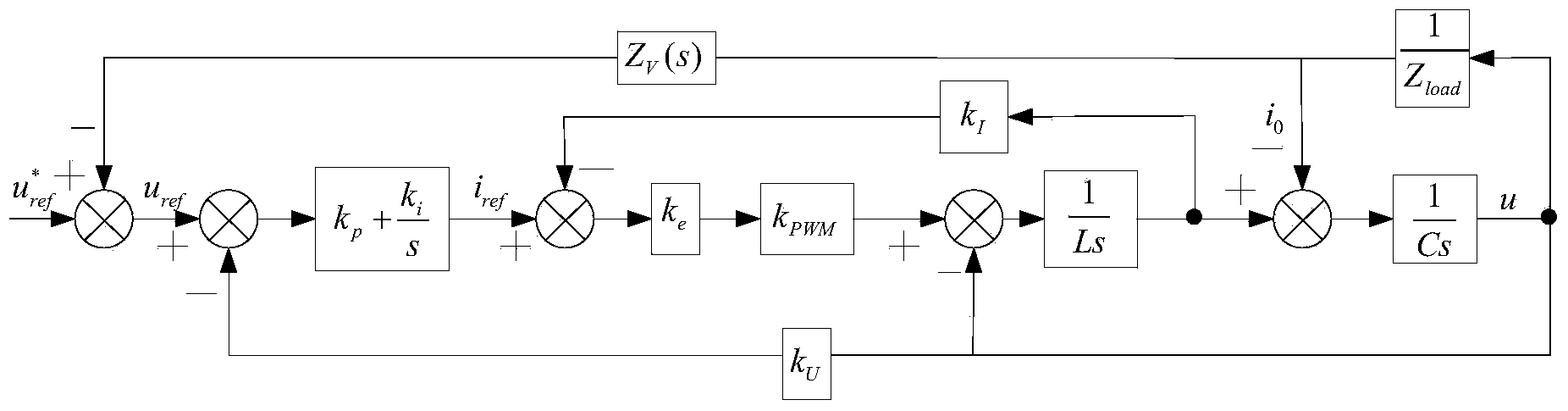

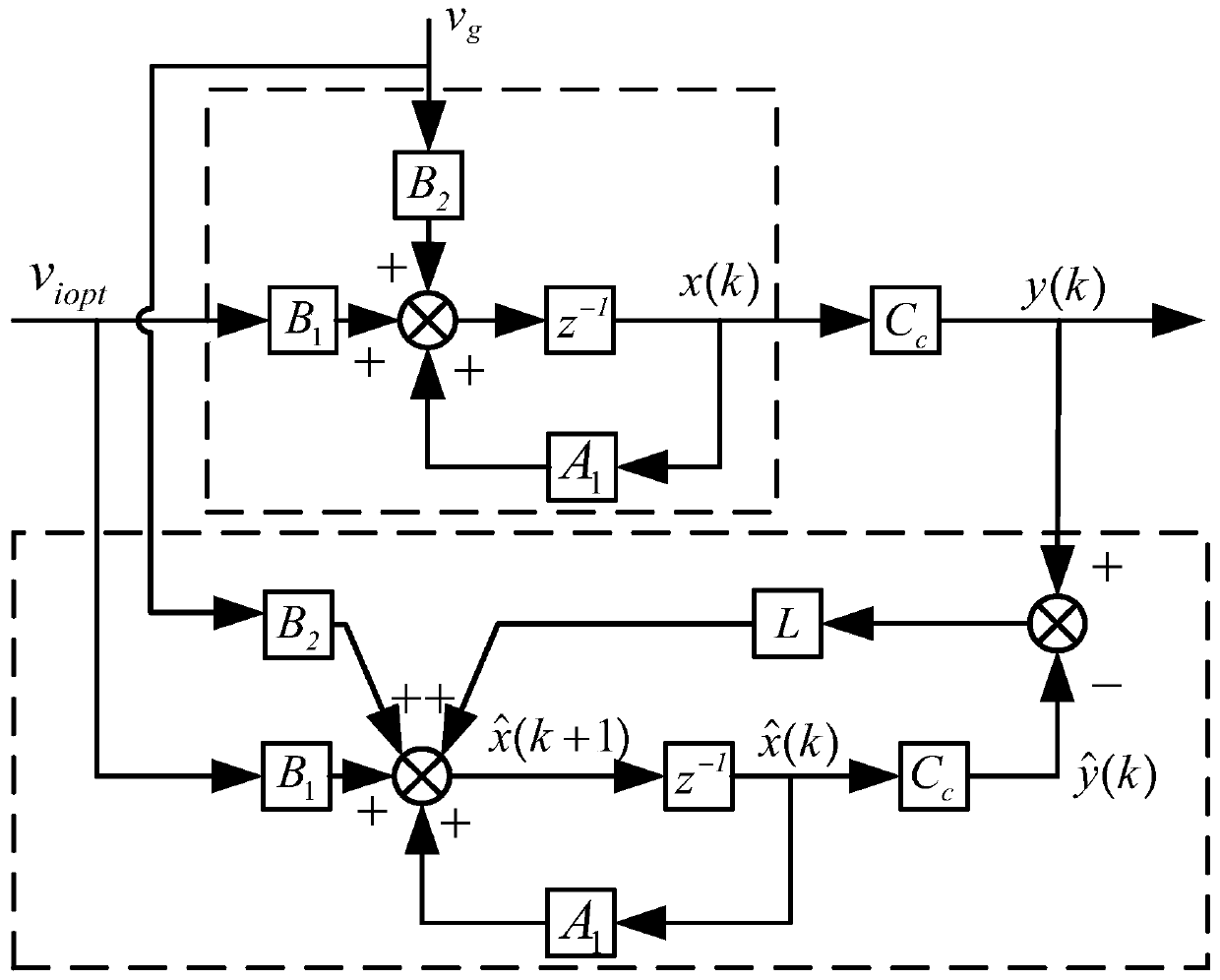

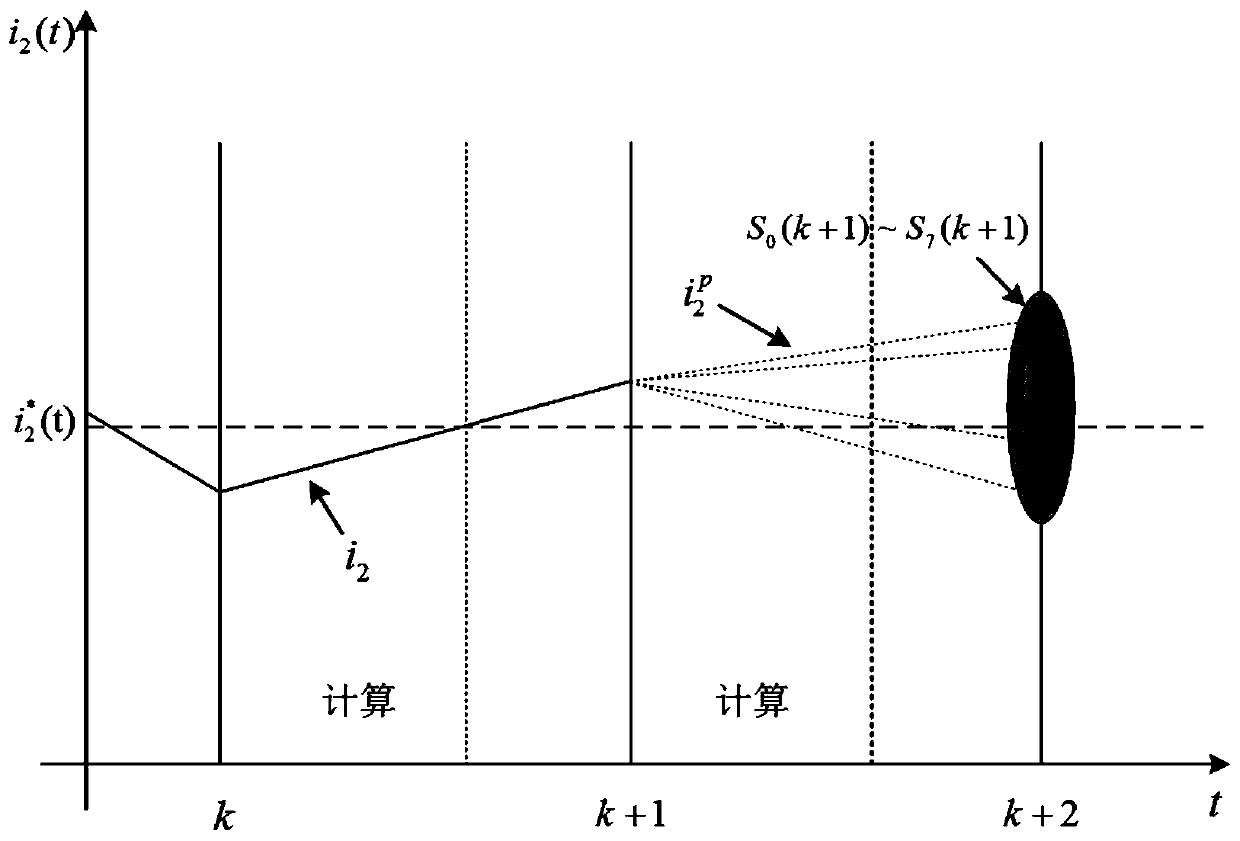

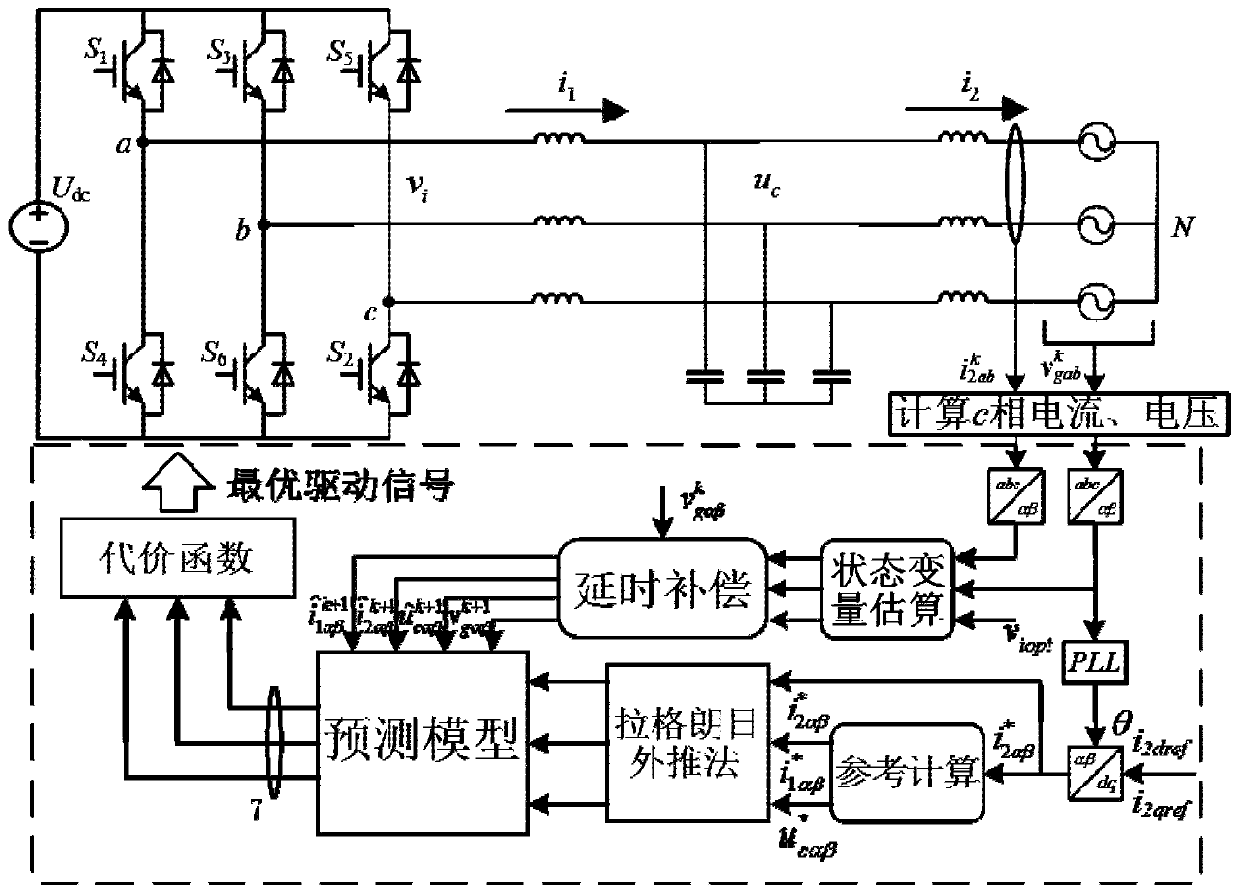

Finite control set model predictive control method of LCL energy storage converter

ActiveCN110535161AReduce in quantityReduce controlAc-dc conversionAc network load balancingControl setCapacitor voltage

The invention discloses a finite control set model predictive control method of an LCL type energy storage converter. The state variable estimation is combined with delay compensation. The converter side current, the capacitor voltage and the grid current are estimated by sampling grid current, and the error between the sampled grid current and the estimated grid current is subjected to a correction matrix to reduce the influence caused by model mismatch and parameter drift, and then the estimated state variables are subjected to the finite control set model predictive control algorithm with the delay compensation link so as to improve the system performance and finally realize the control of the LCL energy storage converter. The number of sensors can be reduced, the cost can be reduced and the reliability of the system can be enhanced; and the influence of calculation delay on the system performance is eliminated through combination of the delay compensation algorithm and thus the quality of incoming current is improved.

Owner:安徽船途数字科技有限公司

Method for repairing and polishing ceramic part through laser

ActiveCN107378276ARealize modelingAchieve fixWelding/soldering/cutting articlesLaser beam welding apparatusMetallurgySurface roughness

The invention discloses a method for repairing and polishing ceramic parts through laser. The method comprises the steps of S1, cleaning the ceramic part, and assembling the ceramic part to a three-dimensional moving platform; S2, scanning the surface contour of the ceramic part, comparing the scanned contour model with a standard model, and dividing the surface of the ceramic part into an etching region, a polishing region and a sintering region; S3, processing the etching region by using excimer laser equipment; S4, carrying out preset powder feeding on the sintering region, and carrying out sintering repair by using long-wavelength laser; S5, carrying out rough polishing on the sintering region; S6, carrying out overall polishing on the processing area; and S7, scanning the surface roughness of the ceramic part, executing the step S6 if the roughness does not meet the requirement, and completing the excimer laser polishing process if the roughness meets the requirement. The method has the advantages that the controllability is good, the automatic production can be realized conveniently, the precise processing of the micro-area can be realized, any curved surface and any part can be treated, the influence on a ceramic matrix is remarkably reduced, and the precision, the quality and the efficiency of part repairing and polishing are guaranteed.

Owner:RAINBOW SOURCE LASER RSLASER

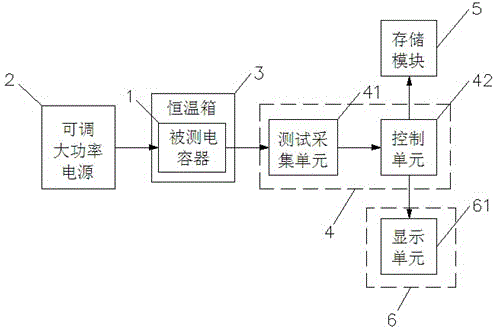

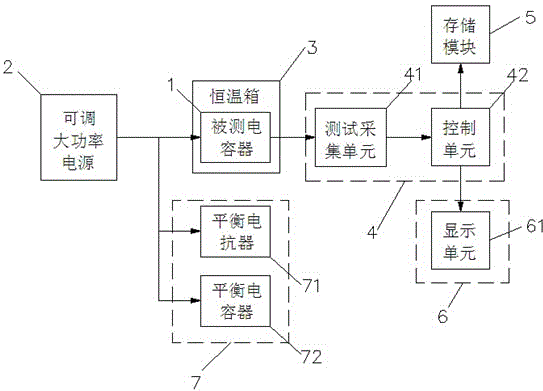

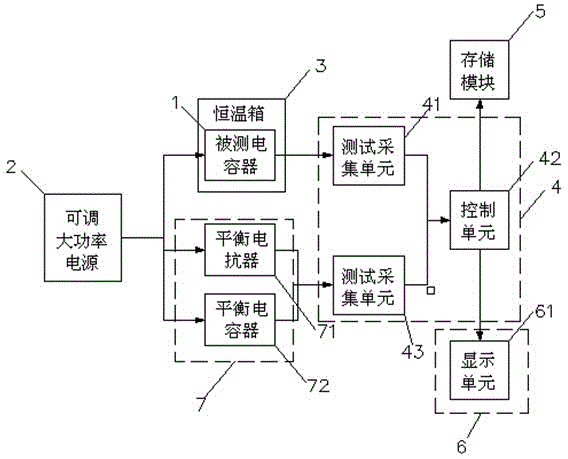

Capacitor testing device and capacitor testing method

InactiveCN104597363AImprove pass rateBalance system currentTesting dielectric strengthElectrical and Electronics engineeringTest set

The invention discloses a capacitor testing device used for testing the performance of a to-be-tested capacitor. The capacitor testing device comprises a power supply module including an adjustable high-power power supply, a testing module including a testing collection unit and a control unit, a storage module connected with the control unit, and a man-machine interaction module including a display unit. By arranging the testing collection unit, the control unit, the storage unit and the display unit, complete record and effective comparison of related performance indexes of the to-be-tested capacitor and more user-friendly man-machine interaction can be realized. Finally, the performance of the to-be-tested capacitor can be analyzed based on a temperature characteristic curve, a voltage withstanding characteristic curve and an attenuation characteristic curve graph drawn by the control unit, and the first-pass yield of capacitors can be improved in an automatic way. The invention further discloses a capacitor testing method.

Owner:南通富士特电力自动化有限公司

Obstacle surmounting deicing device and method of high-voltage wire

ActiveCN108649515ASolve slipperyWide applicabilityOverhead installationApparatus for overhead lines/cablesEngineeringHigh pressure

The invention provides an obstacle surmounting deicing device and method of a high-voltage wire. The obstacle surmounting deicing device comprises a suspended workbench,a workbench suspending unit,a front arm lifting unit and a rear arm lifting unit are arranged on the suspended workbench,and the front arm lifting unit and the rear arm lifting unit are symmetrically arranged by taking the verticalaxis of the suspended workbench as the center; a front arm is connected with the front arm lifting unit and is controlled by the front arm lifting unit; a rear arm is connected with the rear arm lifting unit and is controlled by the rear arm lifting unit; the front arm,the rear arm and the workbench suspending unit are all suspended on the high-voltage wire. The obstacle surmounting deicing device can achieve reliable suspending and meanwhile provide power for walking along the wire on the wire with frozen ice columns,and does not easily slip,and the workbench suspending unit and the walkingunit work independently and do not interfere with each other.

Owner:YULIN UNIV

Utility tunnel gas leakage concentration field prediction and correction and leakage rate estimation method

ActiveCN108280849AInhibition effectAchieve impactImage analysisData processing applicationsEngineeringUtility tunnel

The invention discloses a utility tunnel gas leakage concentration field prediction and correction and leakage rate estimation method. The utility tunnel gas leakage concentration field prediction andcorrection and leakage rate estimation method integrates real-time monitoring data of a gas sensor, a wind speed and direction sensor and a temperature and humidity sensor inside a utility tunnel, structures a numerical calculation model of gas leakage and diffusion inside the utility tunnel and applies a data assimilation method to predict and estimate of a gas leakage and diffusion process andthe gas pipe leakage rate, wherein the data assimilation method is an improved ensemble Kalman filter algorithm, and the state vectors of the improved ensemble Kalman filter algorithm are composed ofgas concentration and the leakage rate. The utility tunnel gas leakage concentration field prediction and correction and leakage rate estimation method combines monitoring data of the wind speed and direction sensor and the temperature and humidity sensor, can inhibit the influence of uncertainty of wind flow speed and diffusion coefficient on results after adding noise meeting practical situations into the wind flow speed and the diffusion coefficient, and can acquire the internal gas concentration distribution inside the utility tunnel and meanwhile accurately perform inverse estimation on the gas pipe leakage rate, thereby well meeting the practical situations.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

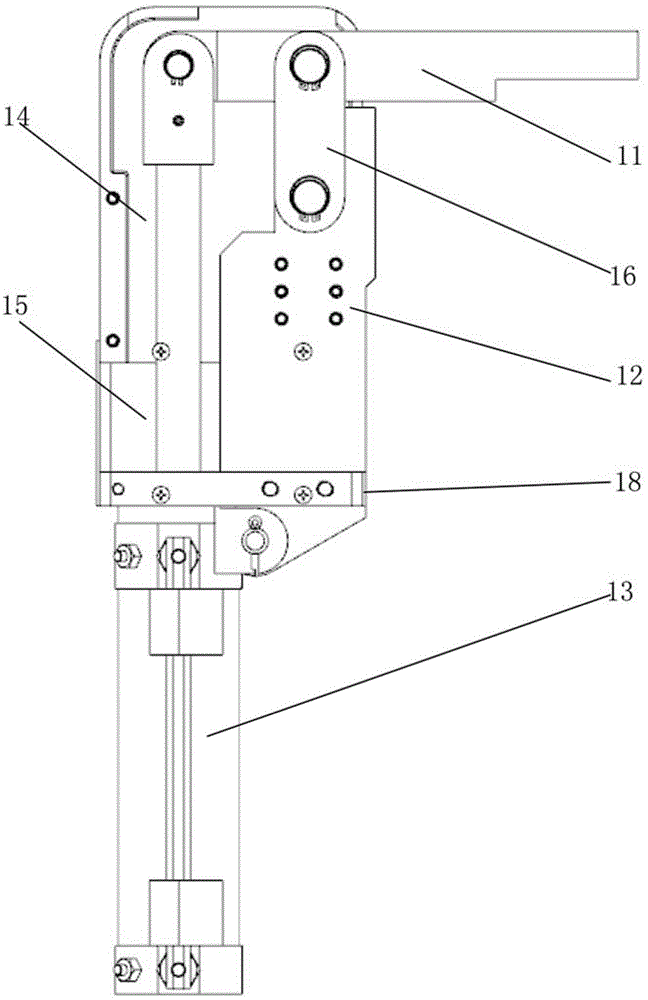

Modularization positioning fixture and positioning fixture assembly

ActiveCN105773024AExtended service lifeEasy to installWelding/cutting auxillary devicesAuxillary welding devicesModular fixtureModularity

The invention discloses a modularization positioning fixture and a positioning fixture assembly. The modularization positioning fixture comprises a pressure head, a first connecting plate, a first clamping air cylinder and a dustproof cover; one end of the pressure head is hinged to the front end of an extending rod of the first clamping air cylinder, and the middle portion of the pressure head is hinged to the first connecting plate; and the periphery of the extending rod of the first clamping air cylinder is surrounded by the dustproof cover. The modularization positioning fixture is simple in structure and small in size; moving parts are effectively protected, and the service life of the fixture is prolonged; the modularization positioning fixture is convenient to install, safe in use and high in efficiency; and standard modules are directly called, the machining period is short, the cost is low, and the opening angle of the fixture is large.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com