Alkylation reactor and alkylation reaction method

An alkylation reactor and reactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical nozzle reactors, chemical/physical/physical-chemical processes, etc., can solve the problem of increasing side reactions, unsuitable discharge Heat and other problems, to achieve the effect of reducing side reactions, good reaction effect, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

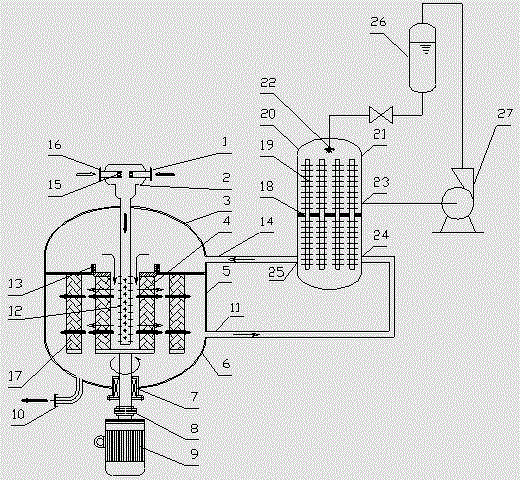

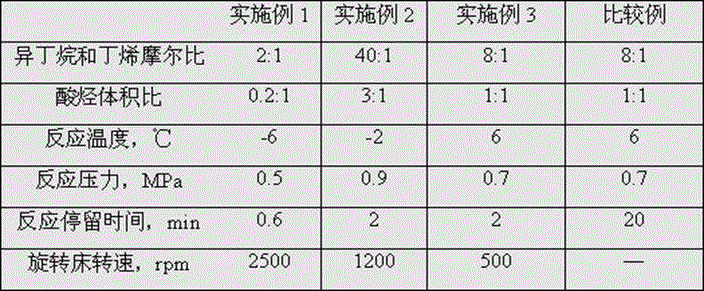

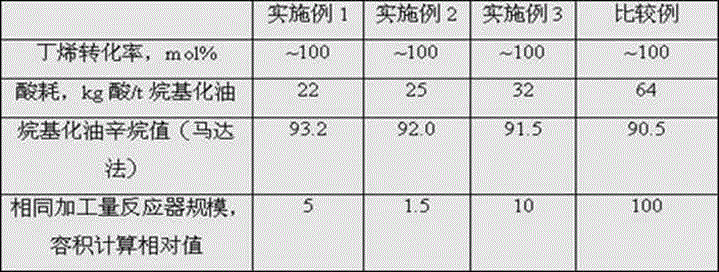

[0038] use as figure 1 In the reactor with the structure shown, the bed of the rotating bed is made of stainless steel mesh packing, the bed porosity of the stainless steel mesh packing is 0.95, and the specific surface area is 4000m 2 / m 3 , the wire diameter is 1mm, and the volume of the rotating bed accounts for 45% of the total volume of the rotating bed reactor. The static bed uses the same wire mesh filler as the rotating bed, and the thickness of the static bed is 50% of the thickness of the rotating bed. The alkylation reaction is carried out using concentrated sulfuric acid with a mass concentration of 95% as a catalyst and isobutane and butene as raw materials.

[0039] The molar ratio of isobutane to butene is 1:1-300:1, preferably 3:1-50:1. The volume ratio of acid to hydrocarbon is 0.1:1~5:1, preferably 0.5:1~1.5:1. The reaction temperature is -20-15°C, preferably -10-10°C, most preferably -5-5°C. The reaction pressure is 0.2~1.5MPa, preferably 0.3~0.8MPa. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com