Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1199results about "Liquid hydrocarbon mixtures production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

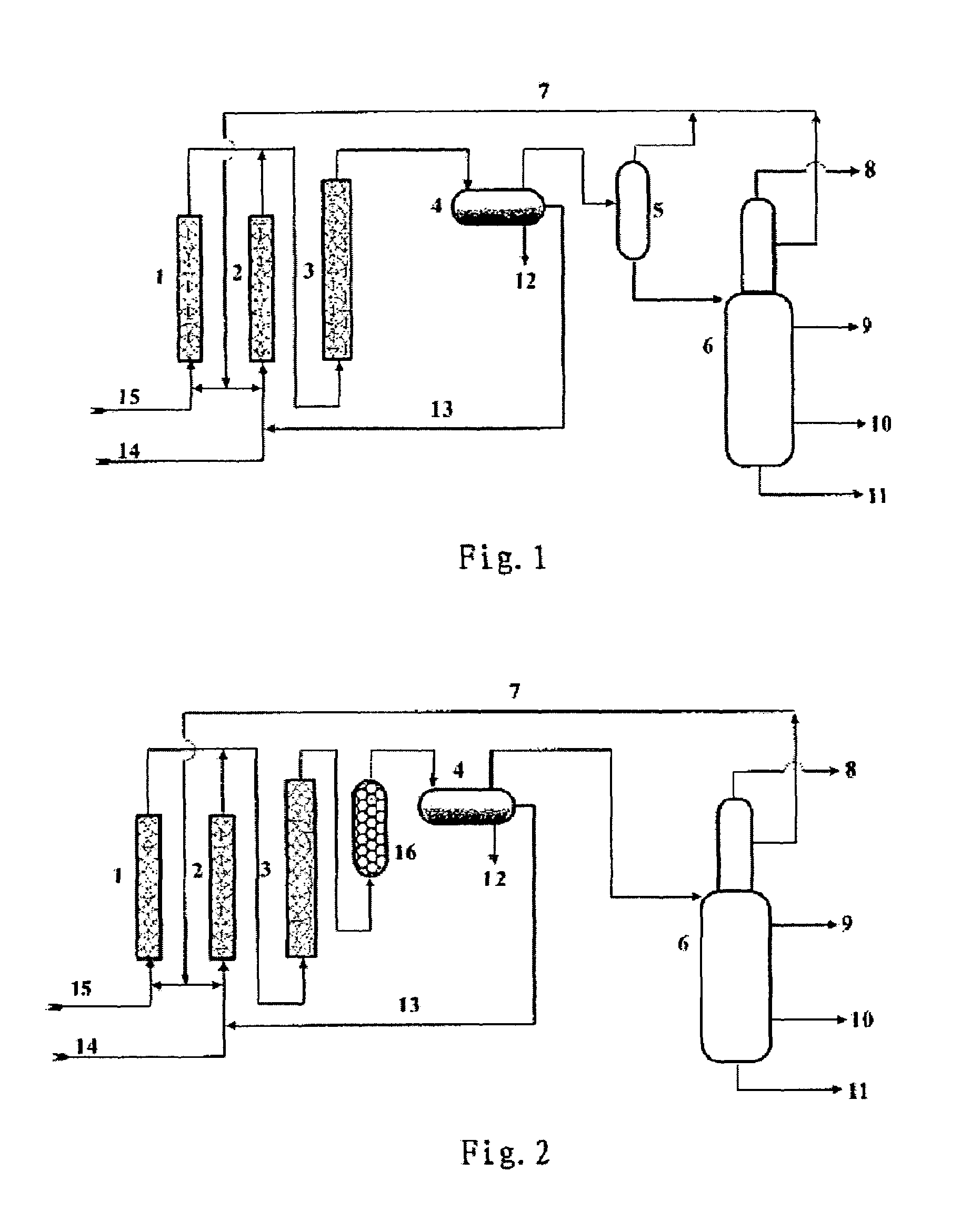

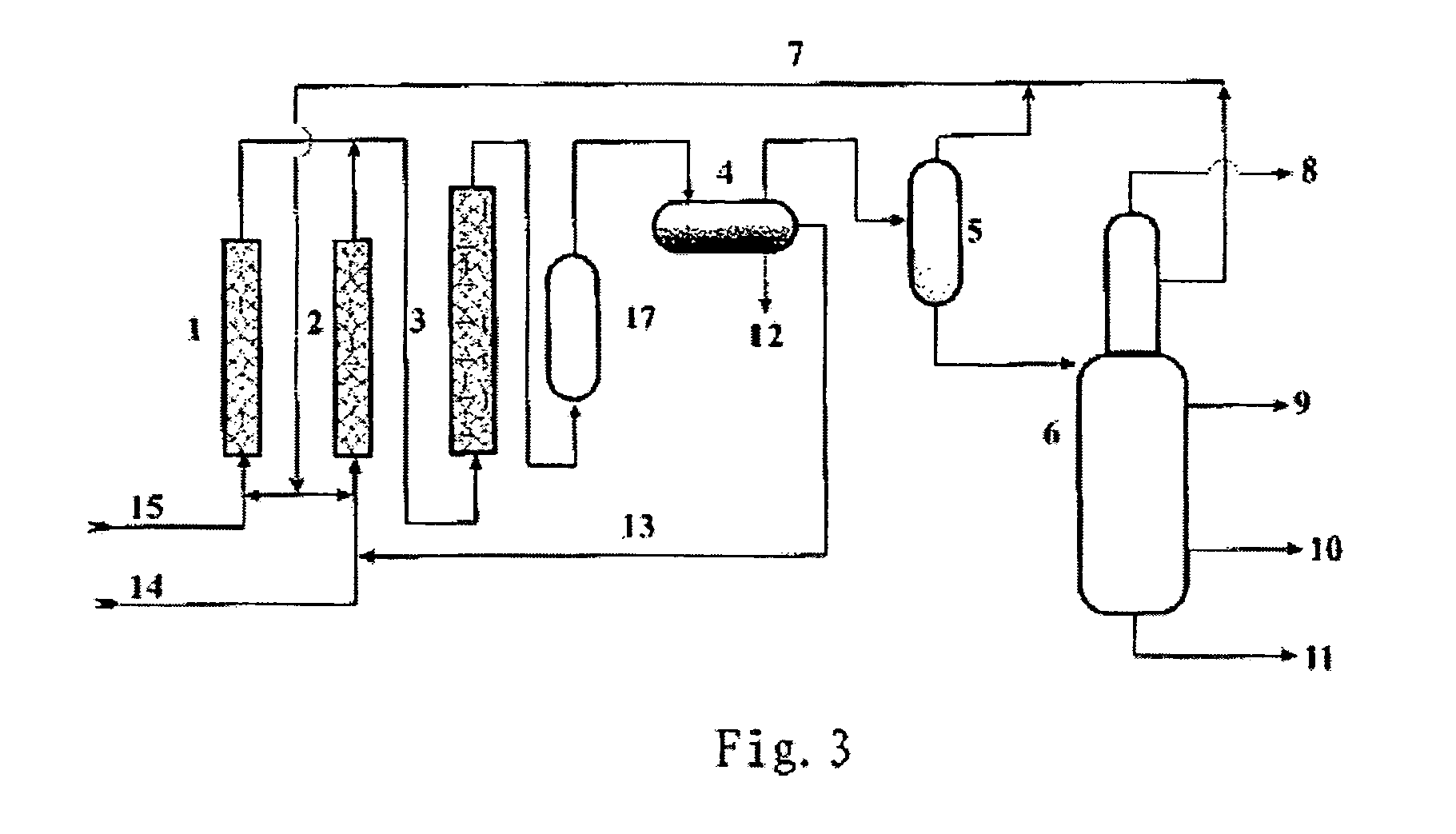

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS20040133056A1Increase contentRaise the ratioOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

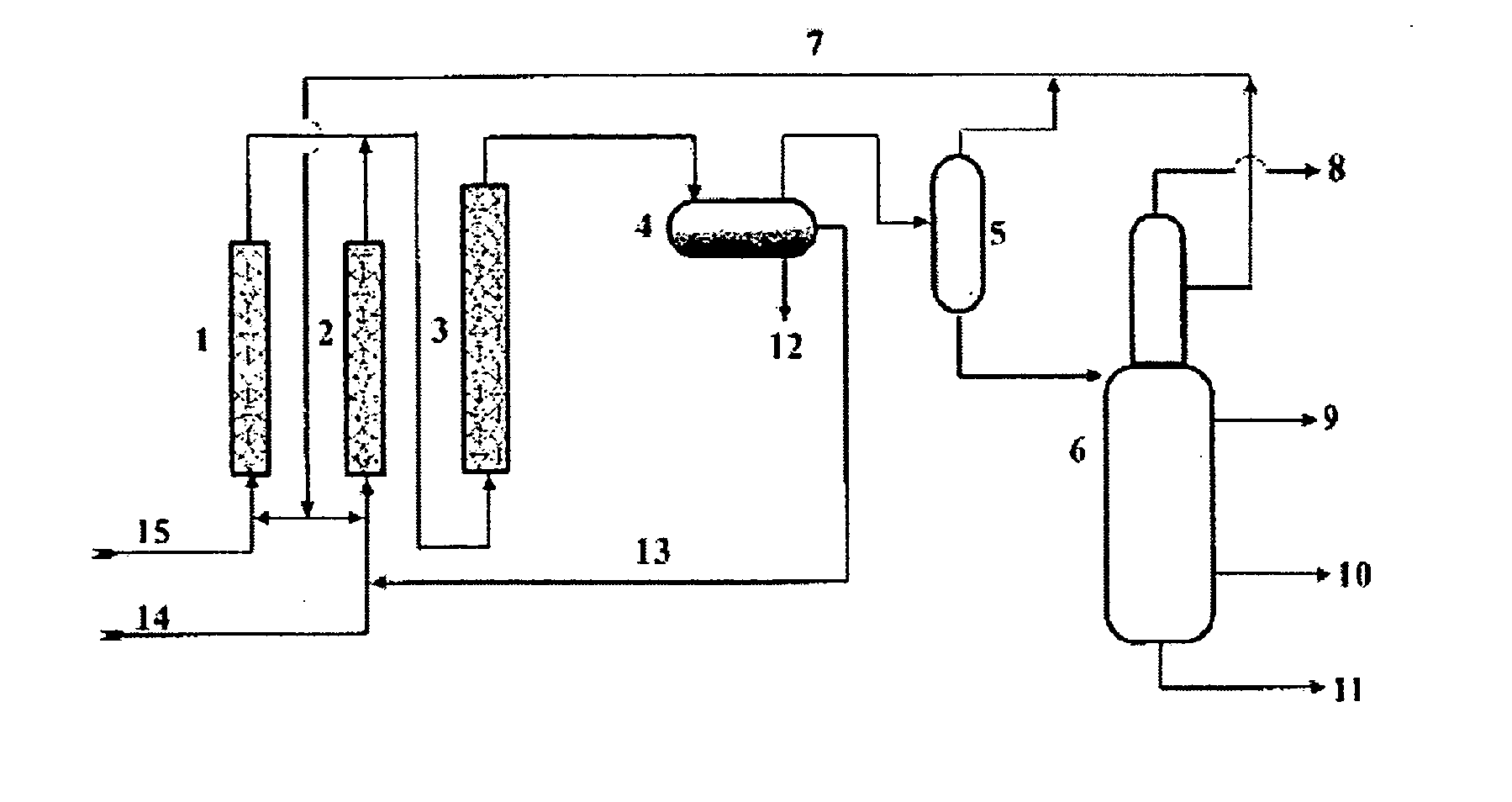

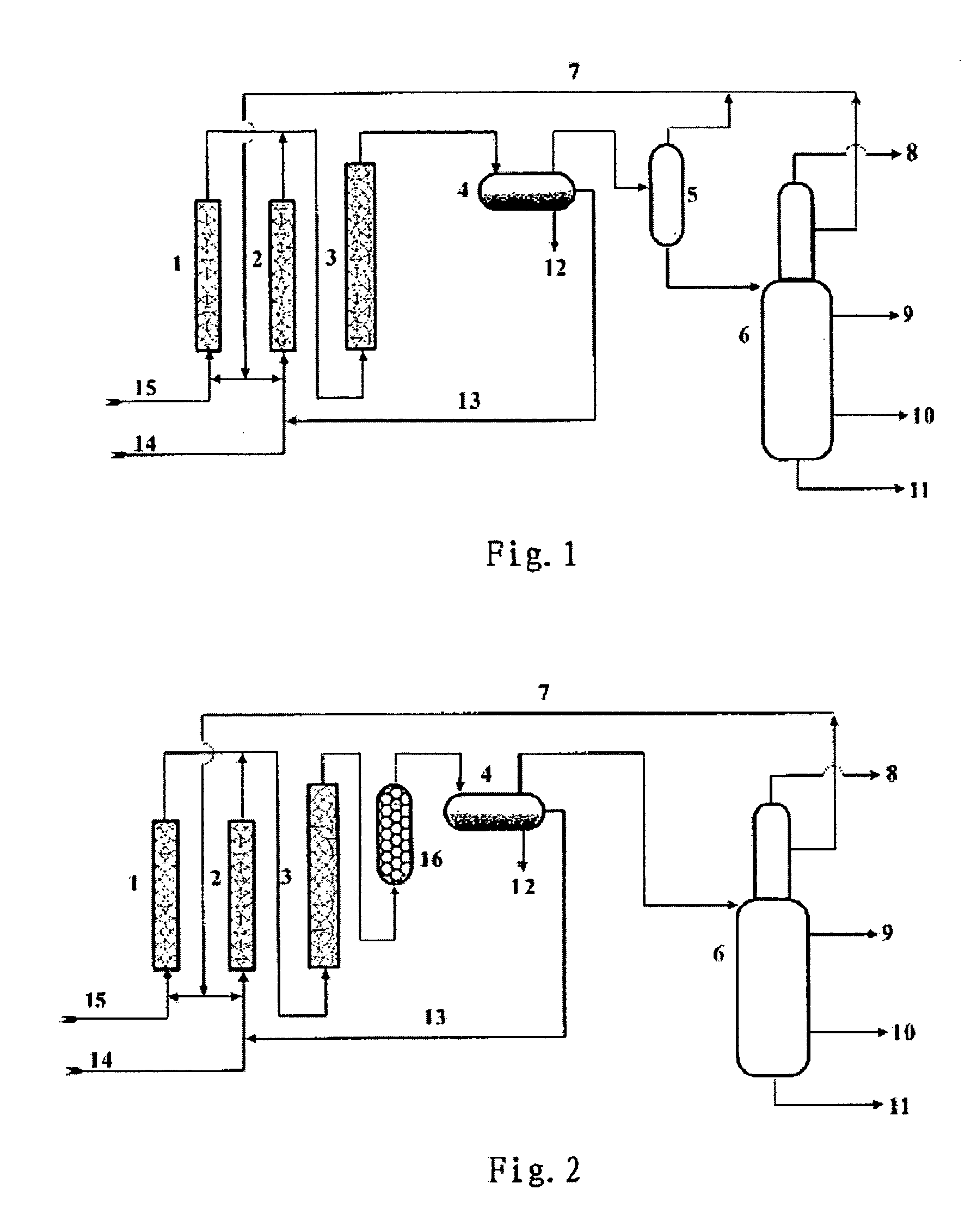

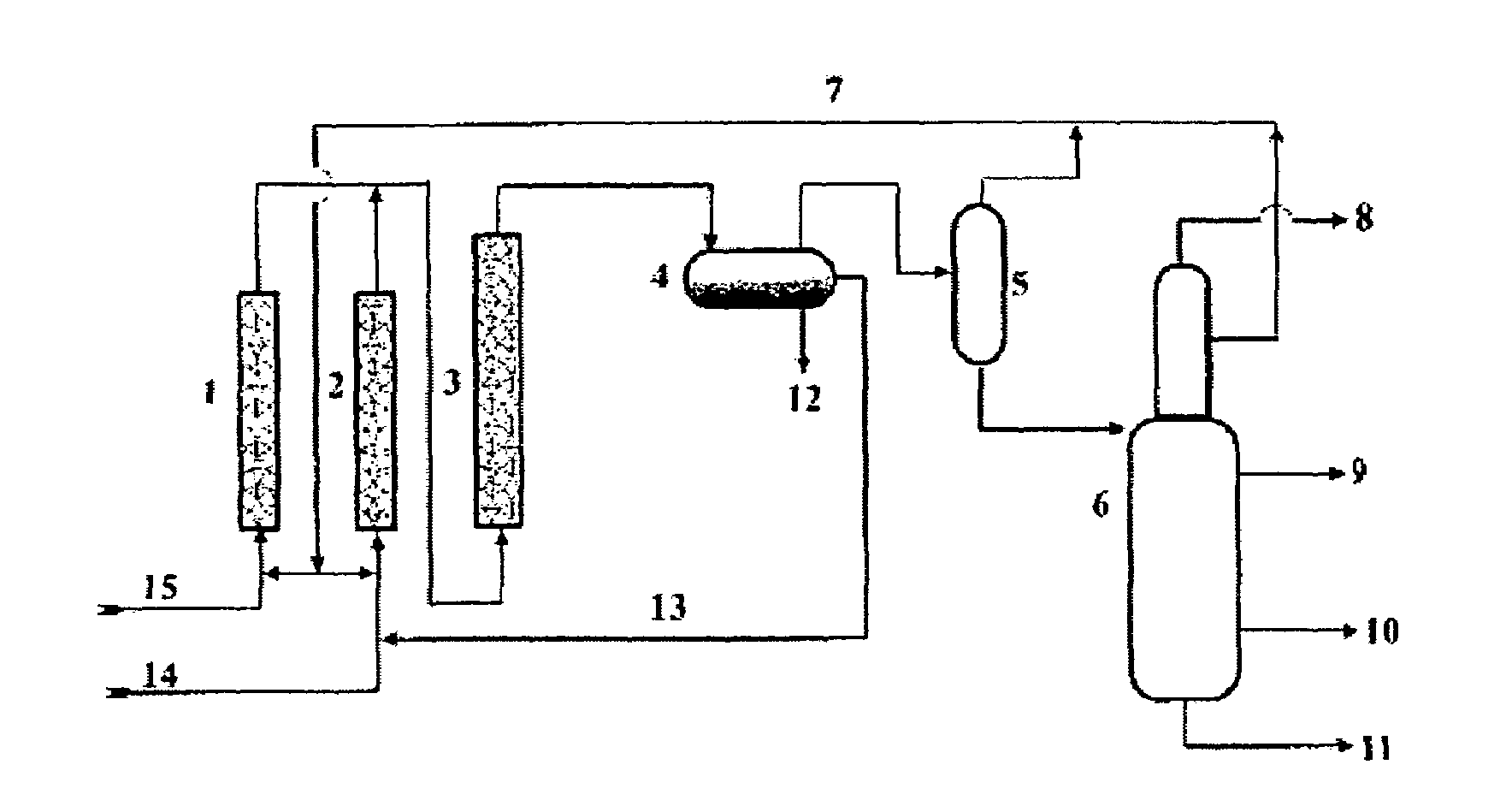

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS7285698B2High selectivityImprove production yieldOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

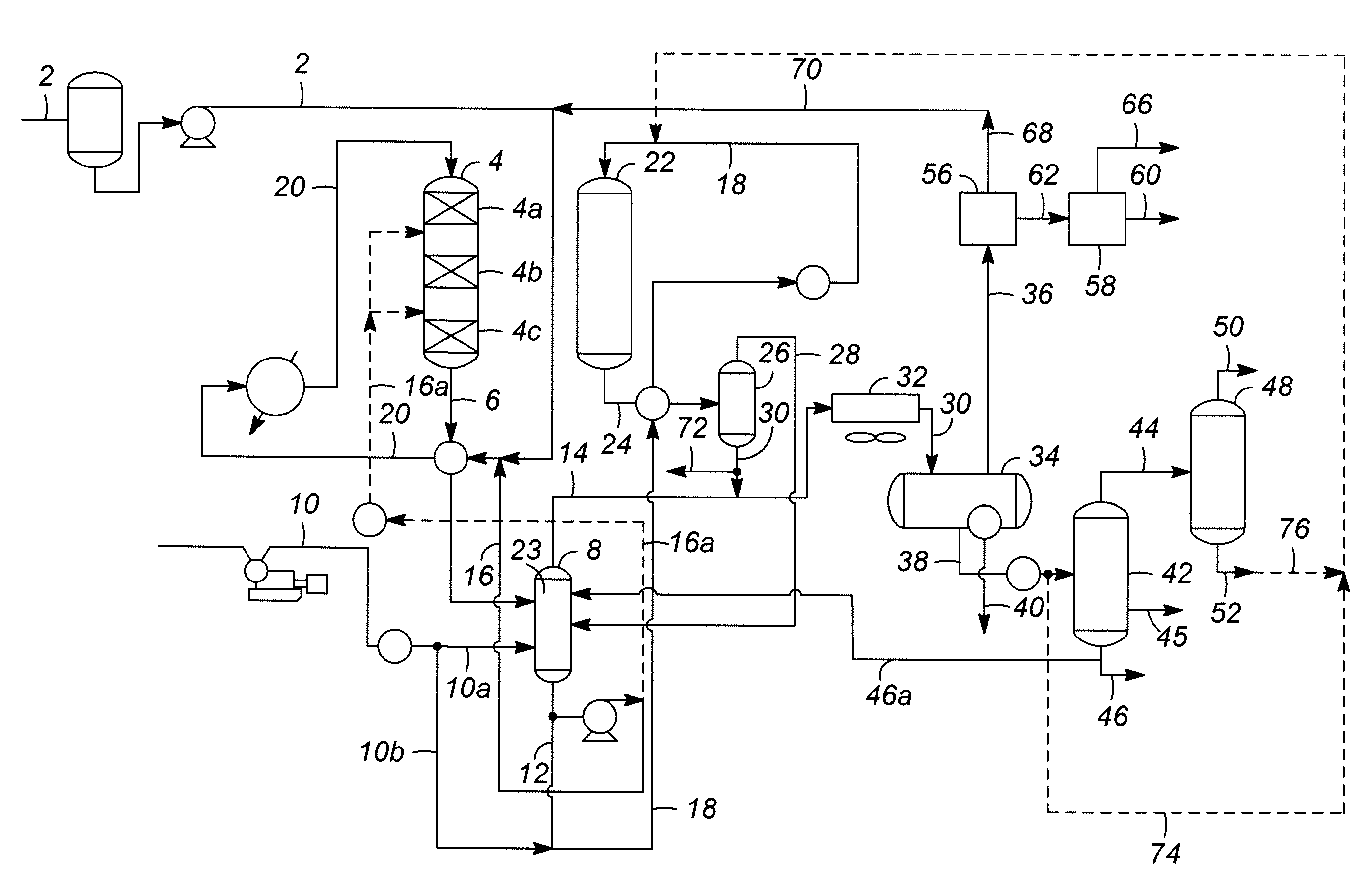

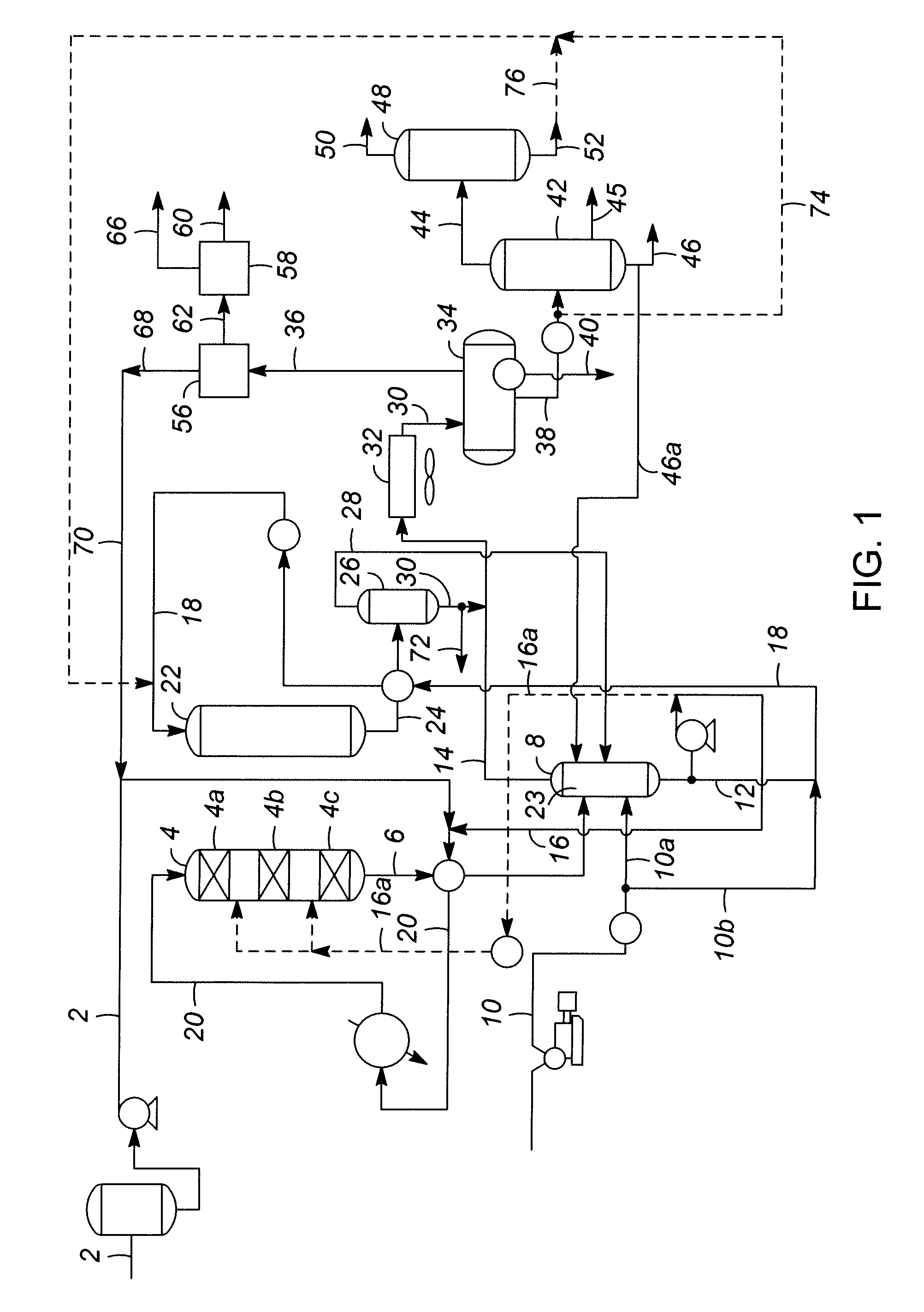

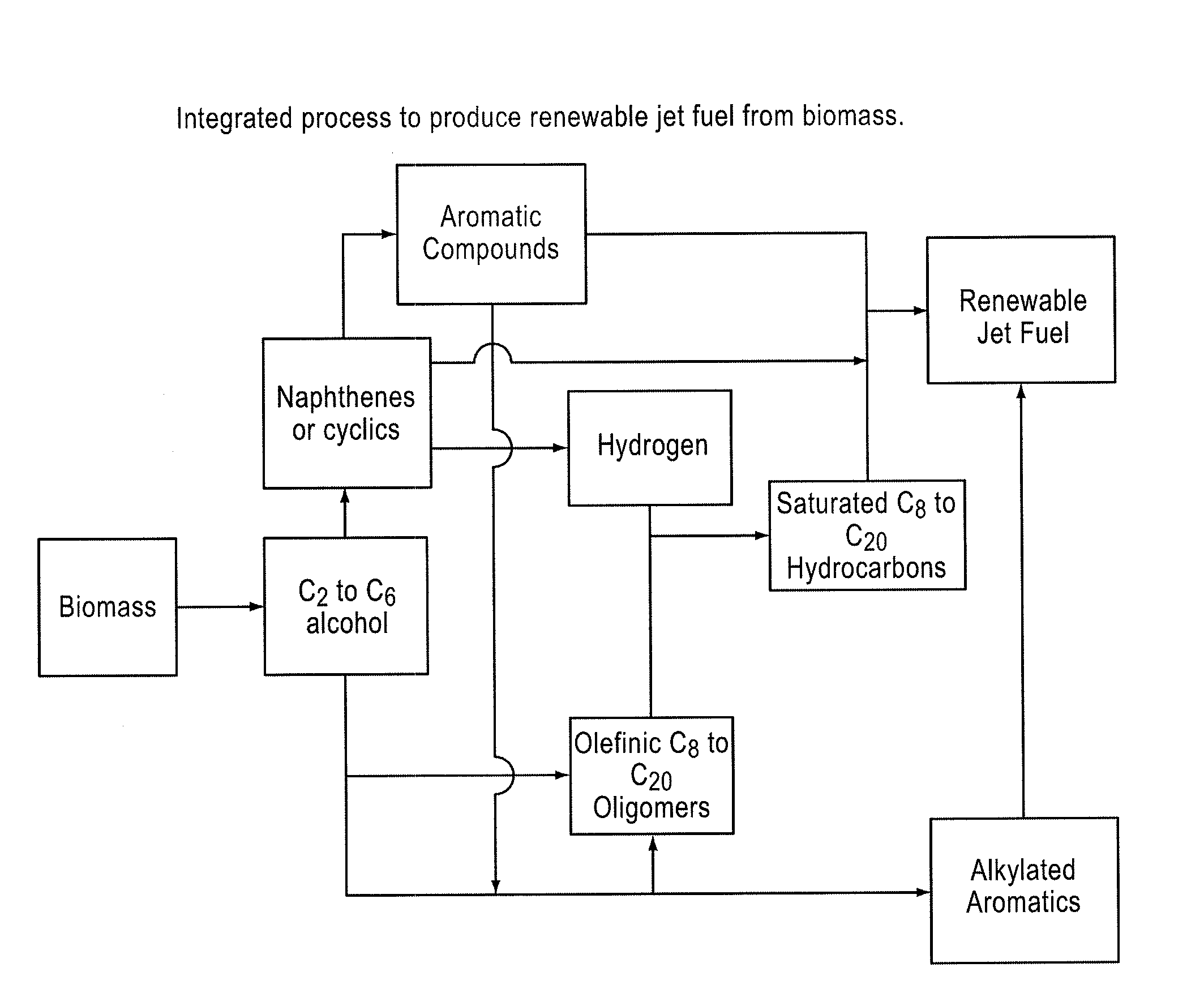

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

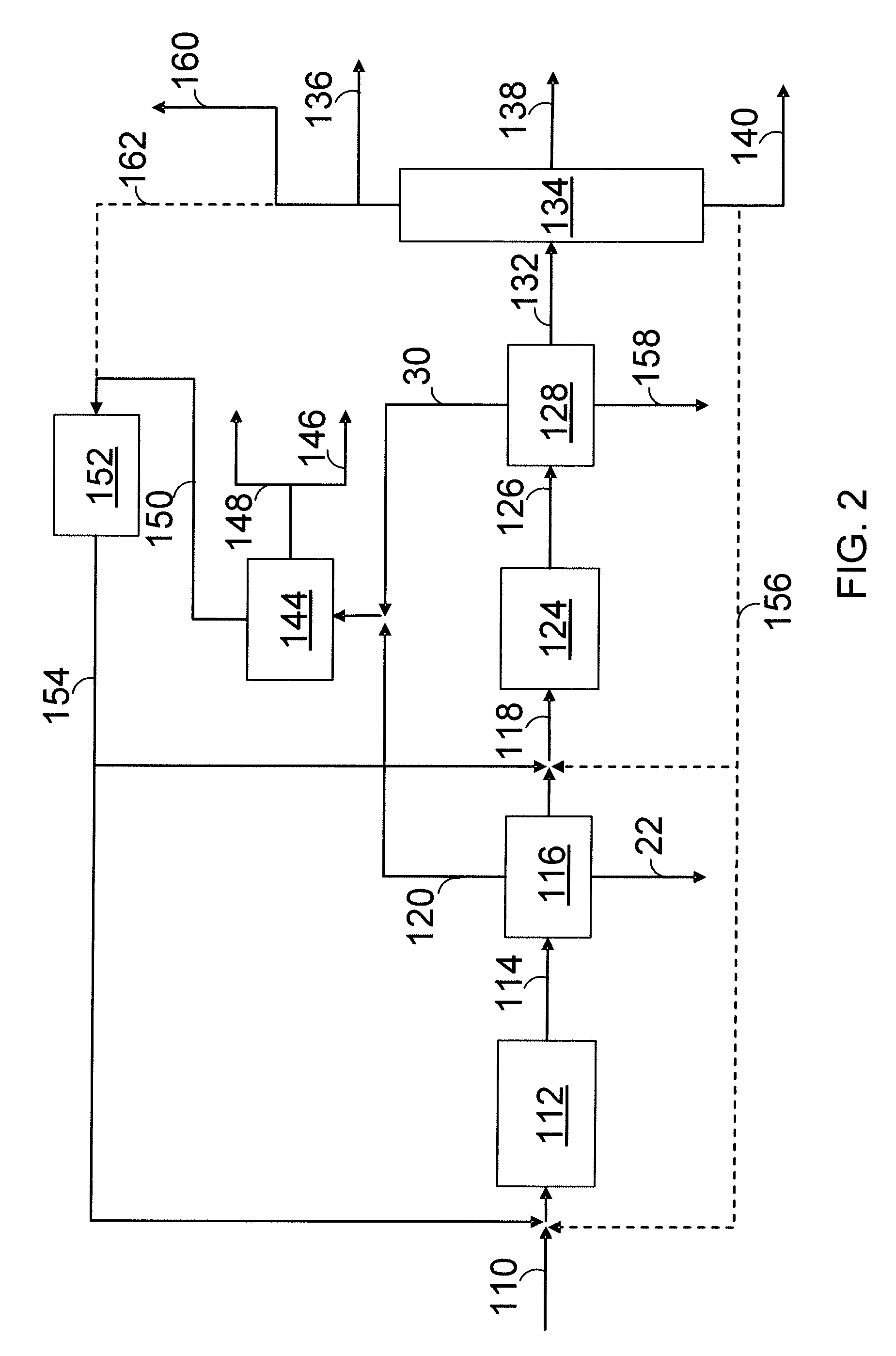

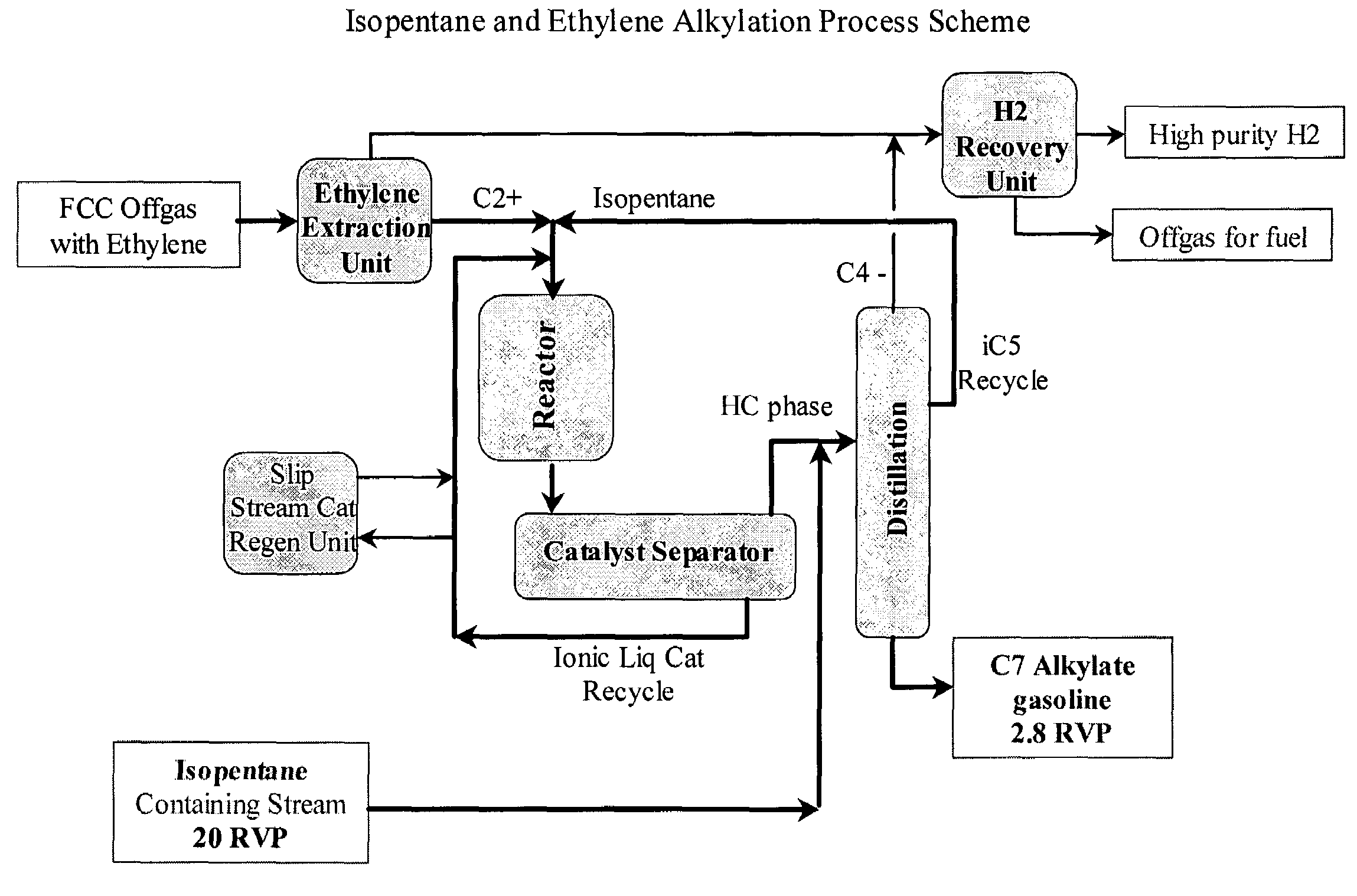

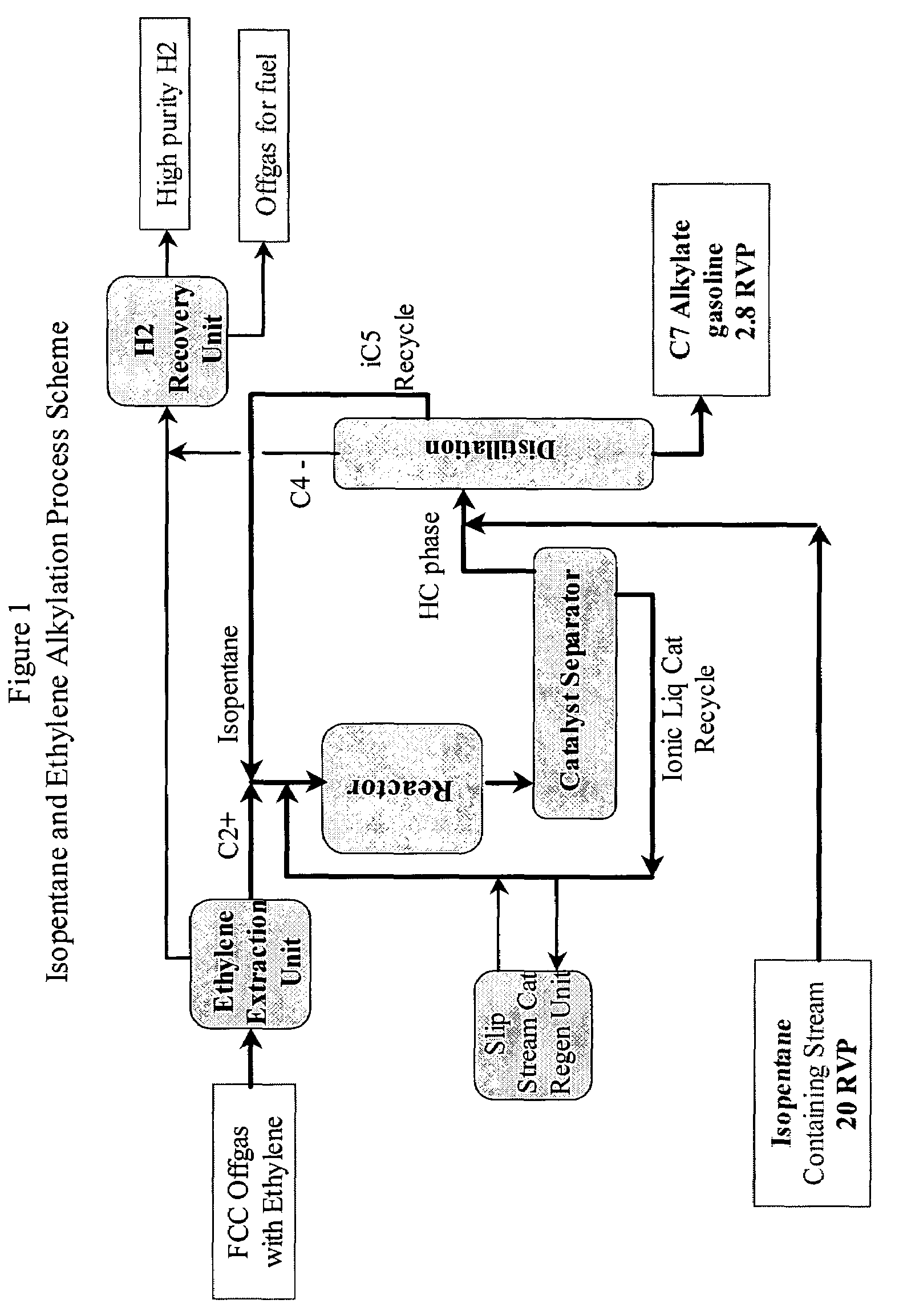

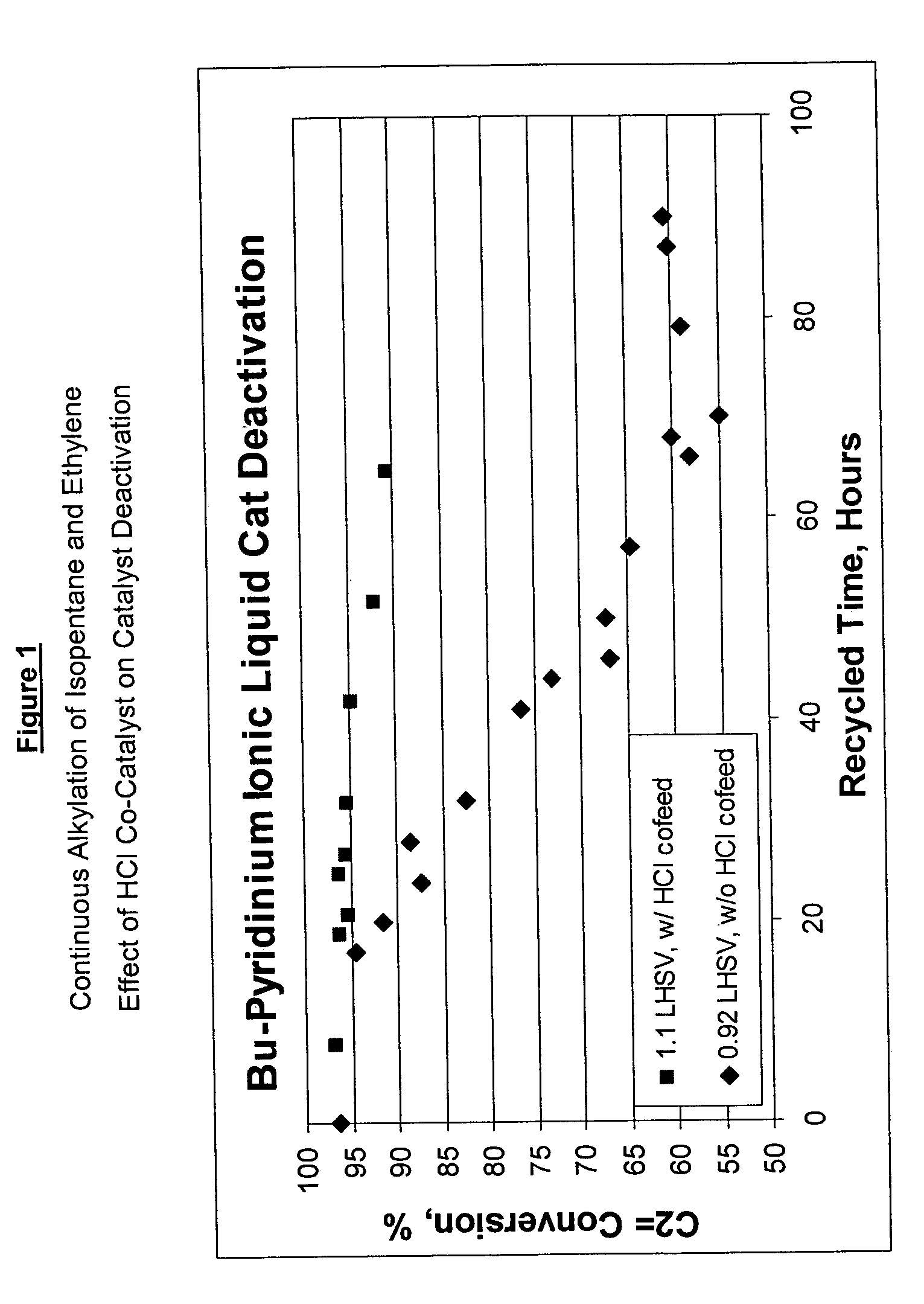

Integrated alkylation process using ionic liquid catalysts

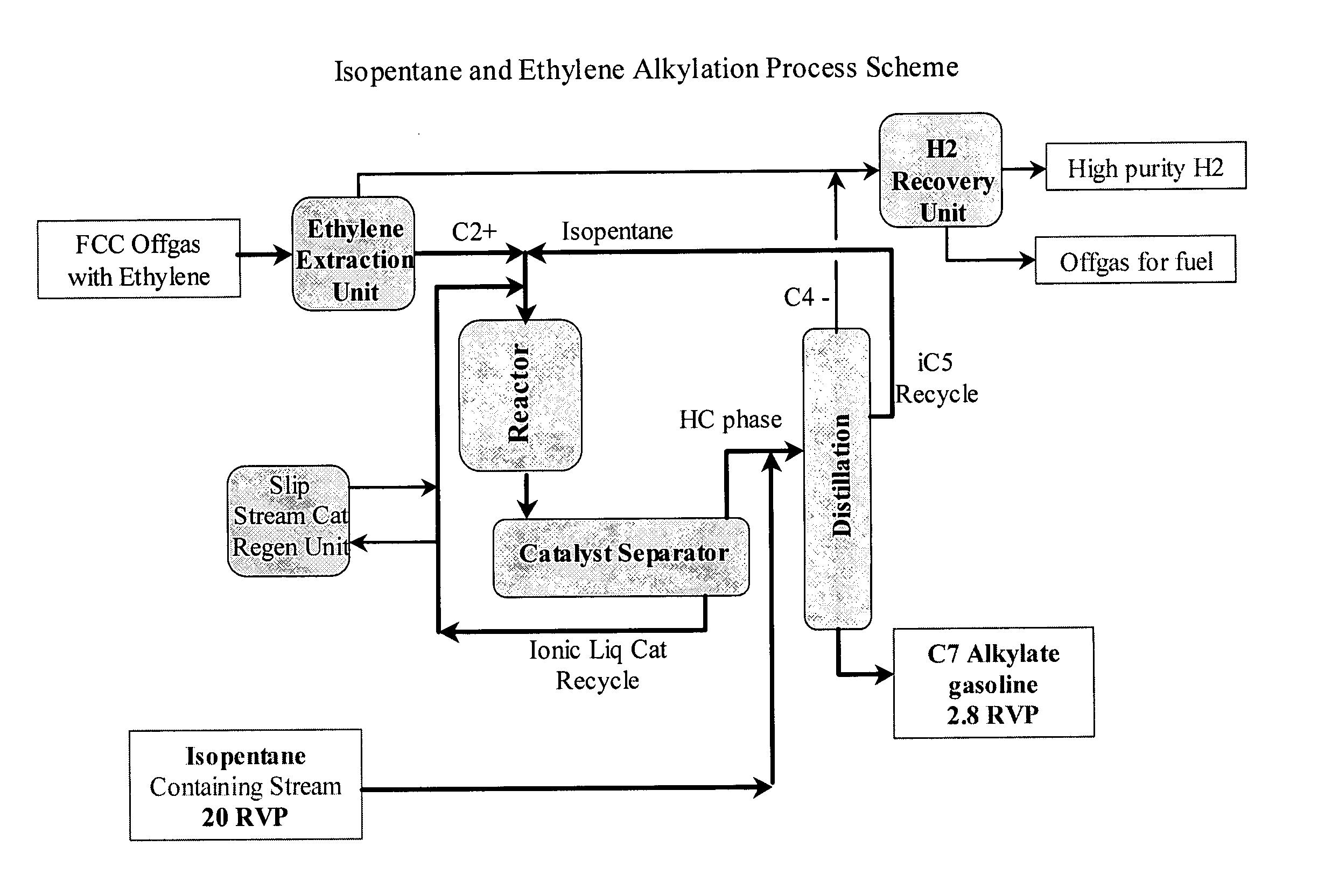

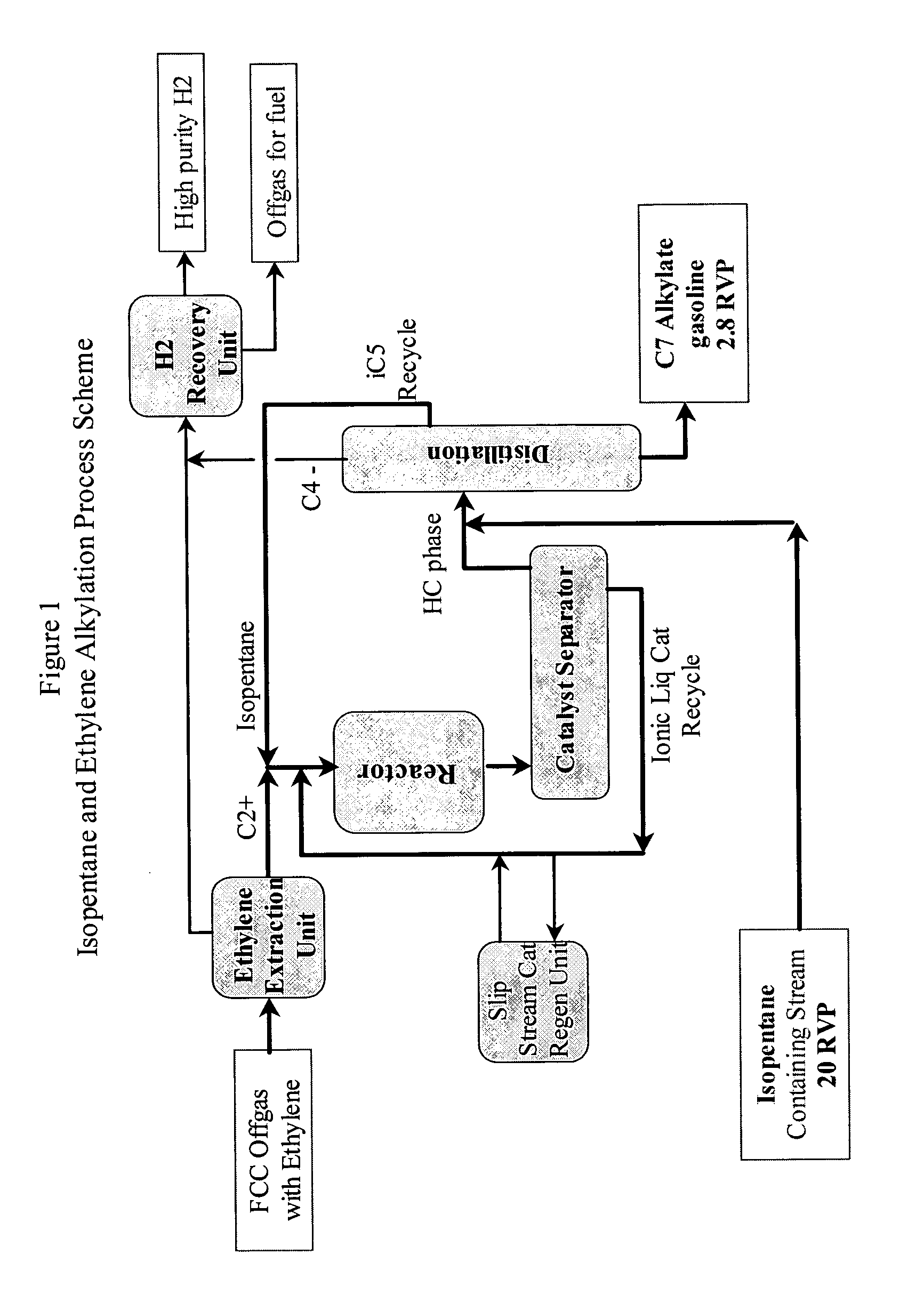

ActiveUS7432408B2Easy to operateReduce gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

Oligomer oils and their manufacture

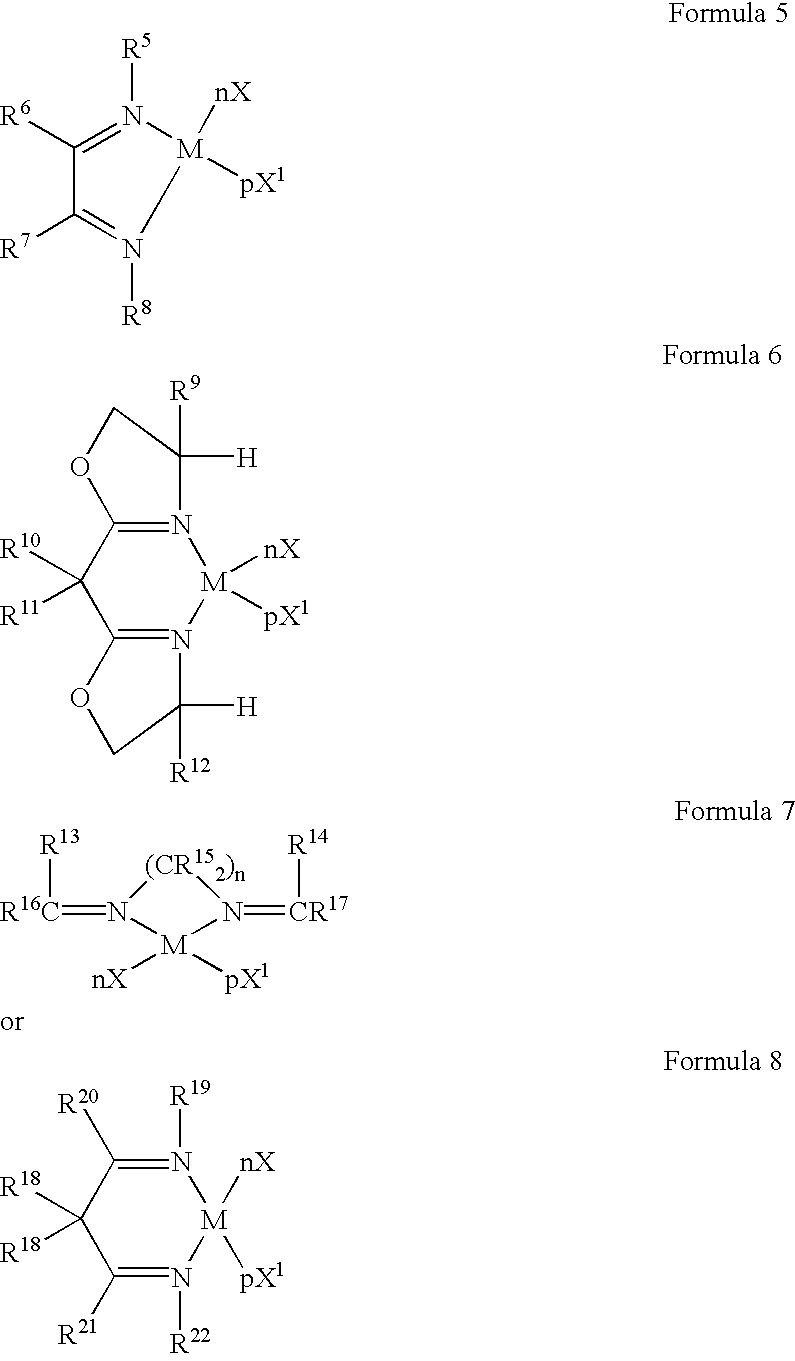

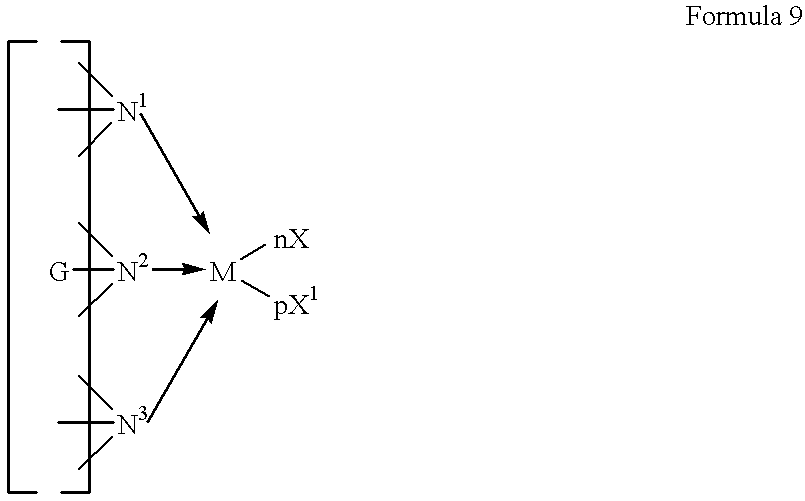

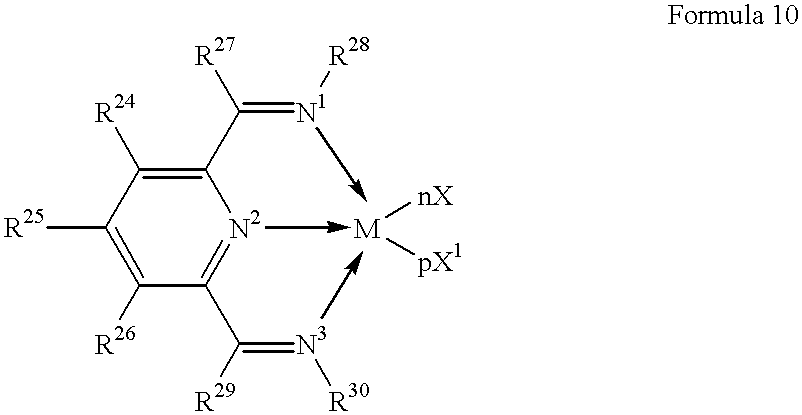

InactiveUS6548724B2Speed up the processImprove distributionOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionOligomerAlkene

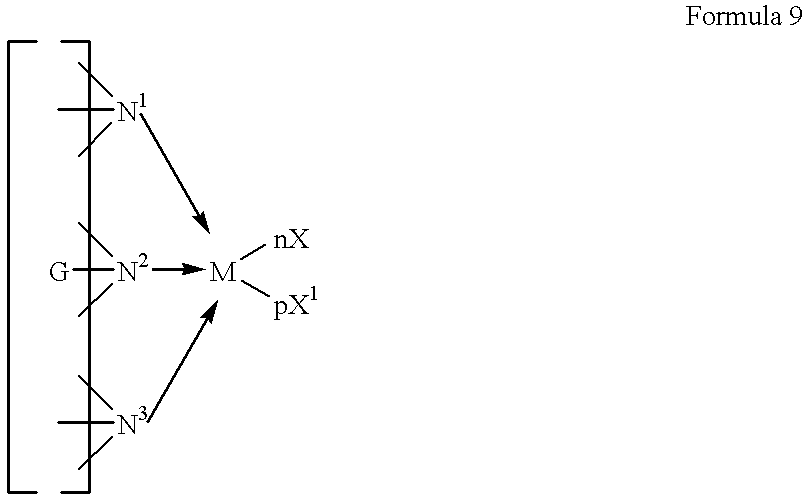

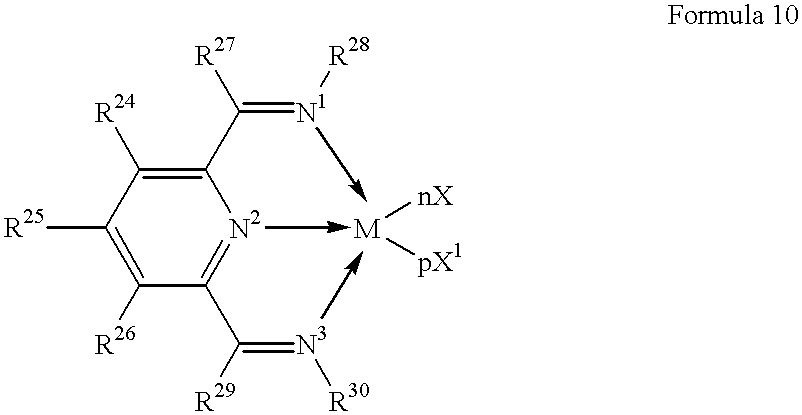

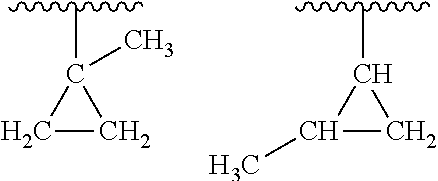

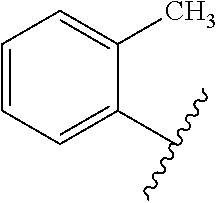

A multistep process for the selective production of an oligomer oil having predetermined properties in which the first step involves the polymerization of a feedstock containing one or more C3 to C20 1-olefins in the presence of a catalyst comprising a bulky ligand transition metal catalyst and in which a subsequent step involves the olgiomerization of at least a preselected fraction of the product of the first step.

Owner:INEOS USA LLC

Oligomer oils and their manufacture

InactiveUS6548723B2Speed up the processImprove distributionOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionPolymer scienceOligomer

Owner:INEOS USA LLC

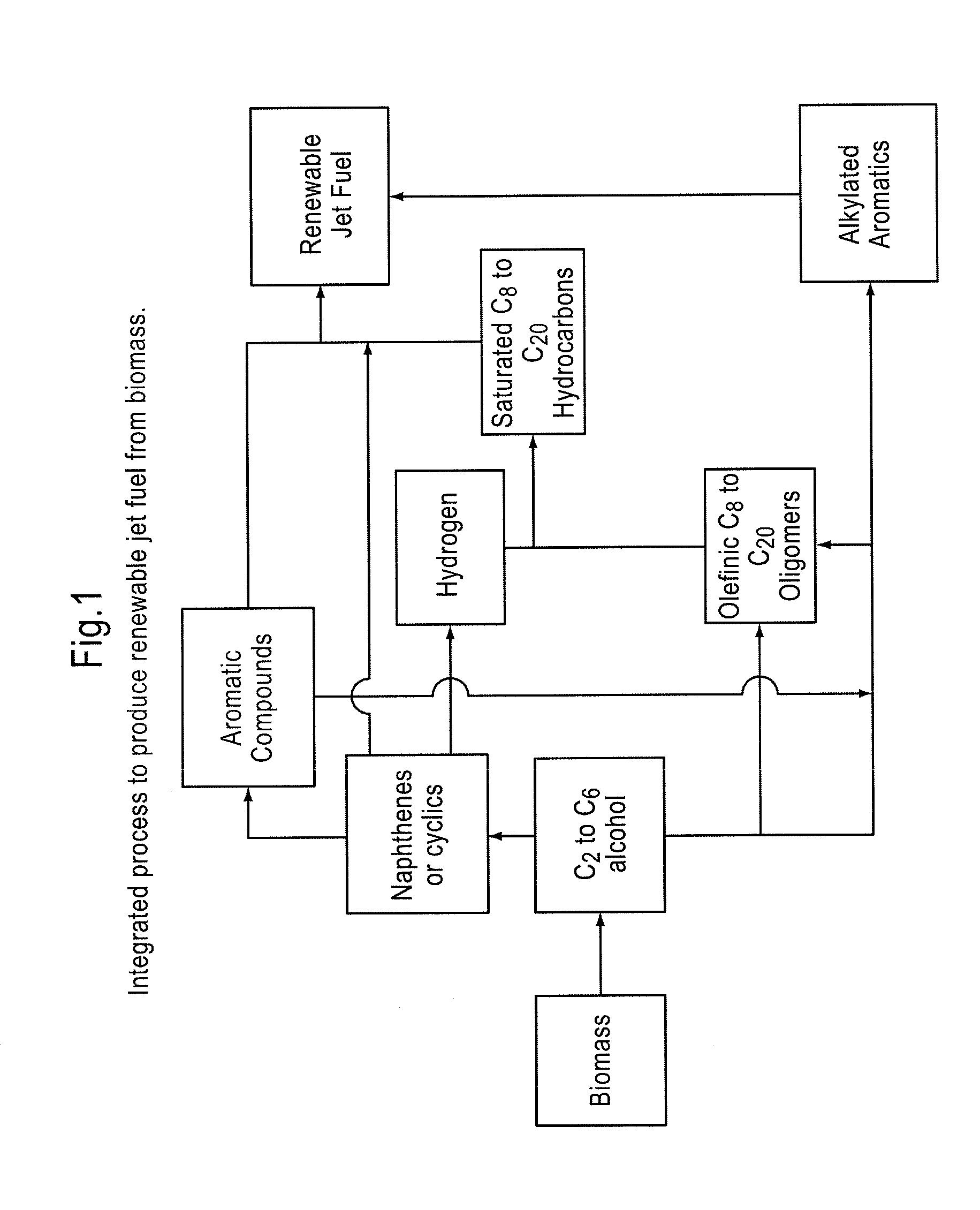

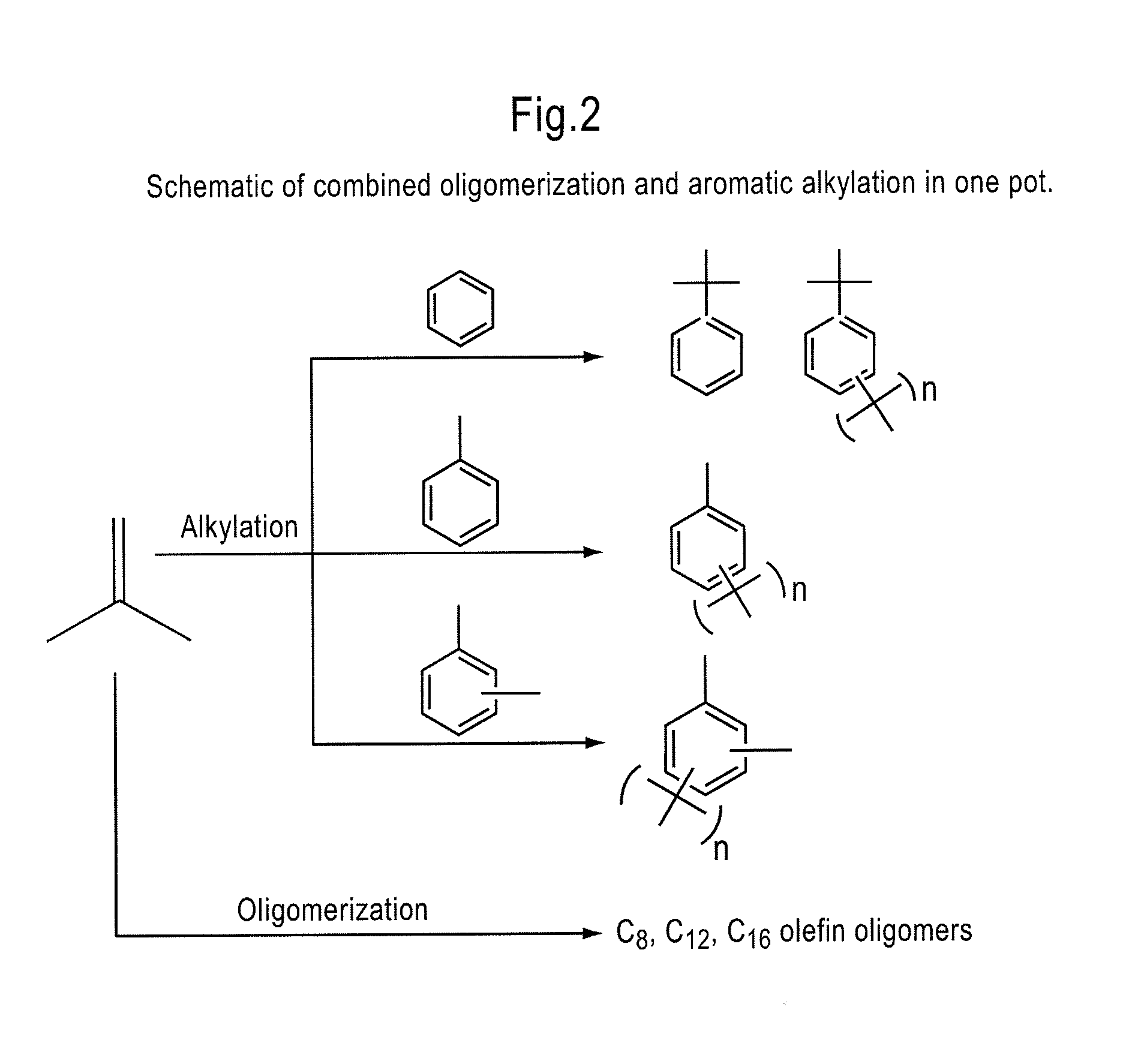

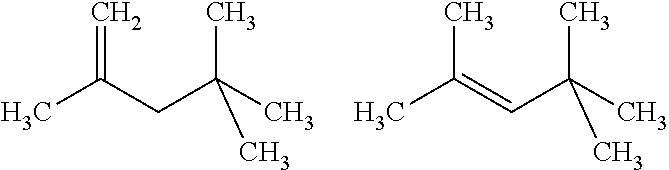

Renewable Compositions

The present invention is directed to renewable compositions derived from fermentation of biomass, and integrated methods of preparing such compositions.

Owner:GEVO INC

Oligomerization of alpha olefins using metallocene-ssa catalyst systems and use of the resultant polyalphaolefins to prepare lubricant blends

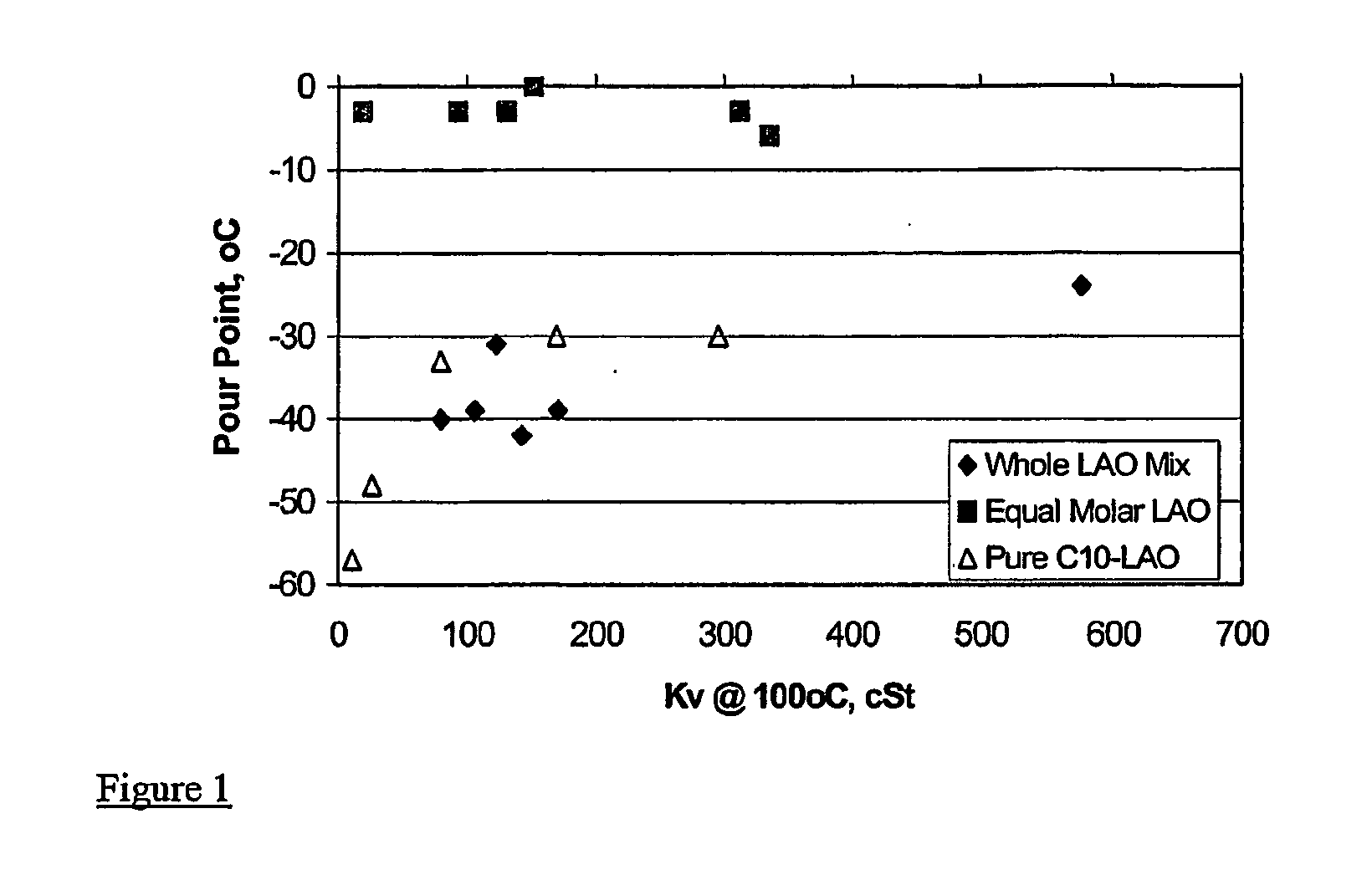

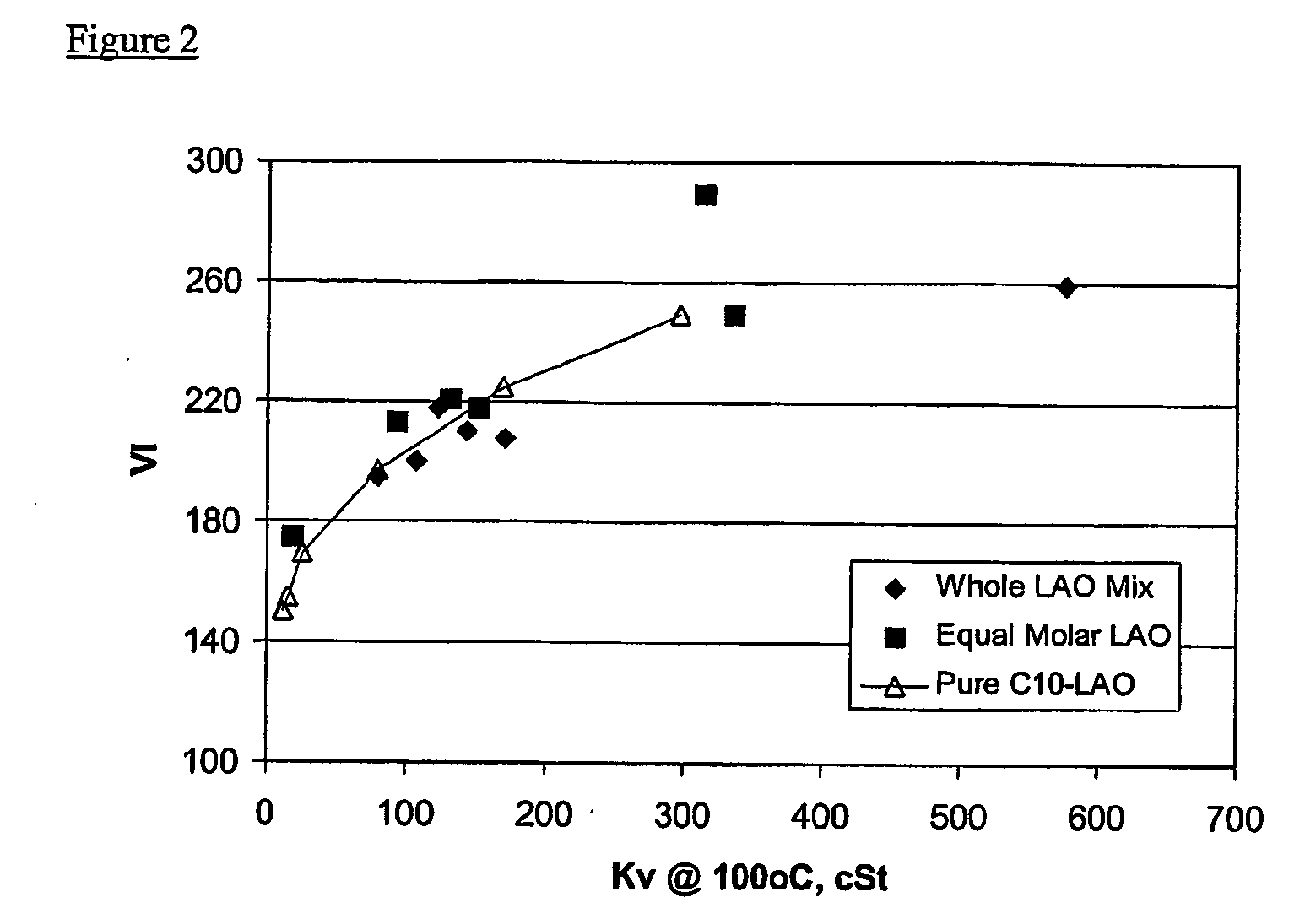

ActiveUS20100317904A1Improve productivityHydrocarbon by hydrogenationAdditivesOligomerViscosity index

This disclosure provides for alpha olefin oligomers and polyalphaolefins (or PAOs) and methods of making the alpha olefin oligomers and PAOs. This disclosure encompasses metallocene-based alpha olefin oligomerization catalyst systems, including those that include at least one metallocene and an activator comprising a solid oxide chemically-treated with an electron withdrawing anion. The alpha olefin oligomers and PAOs prepared with these catalyst systems can have a high viscosity index combined with a low pour point, making them particularly useful in lubricant compositions and as viscosity modifiers.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

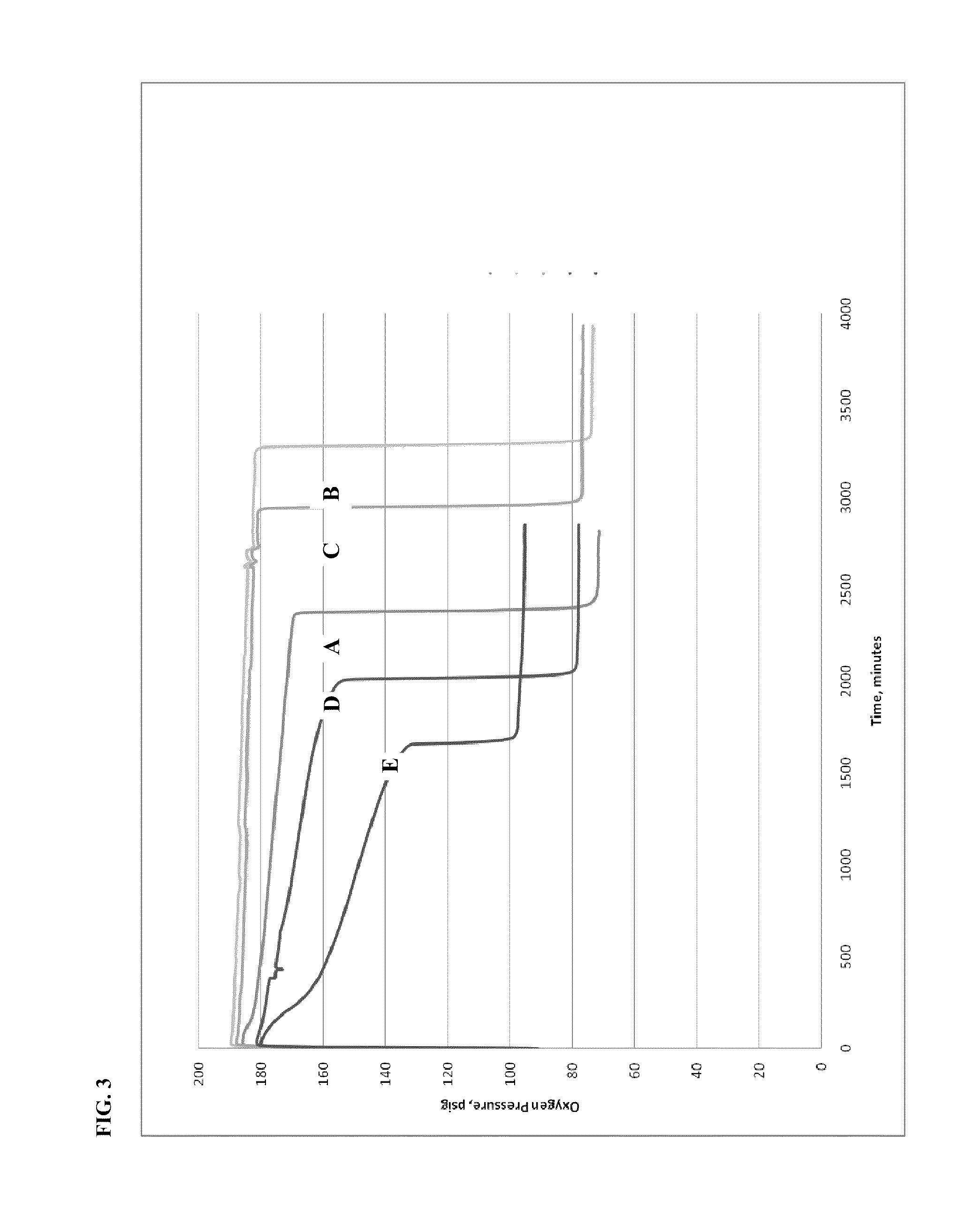

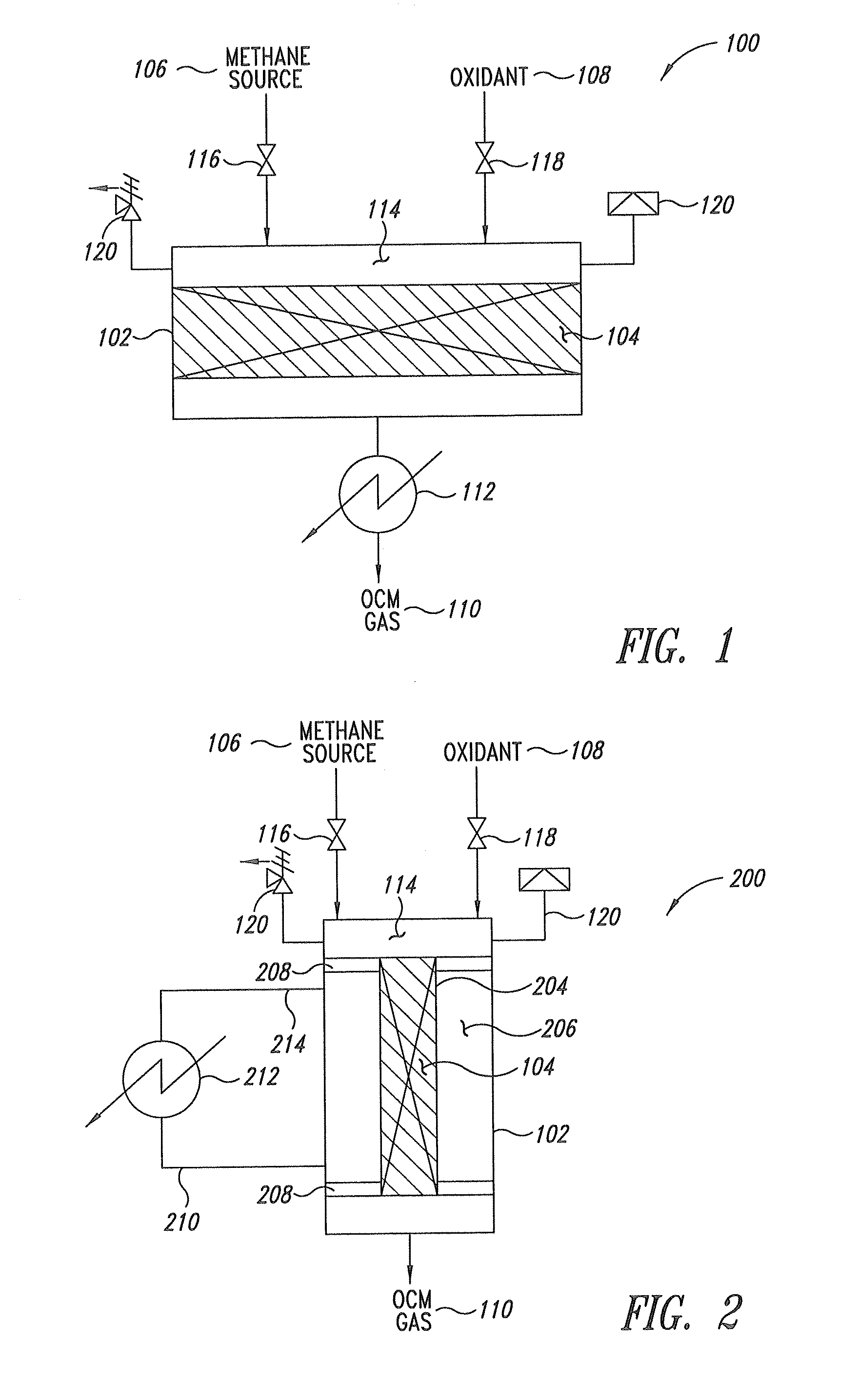

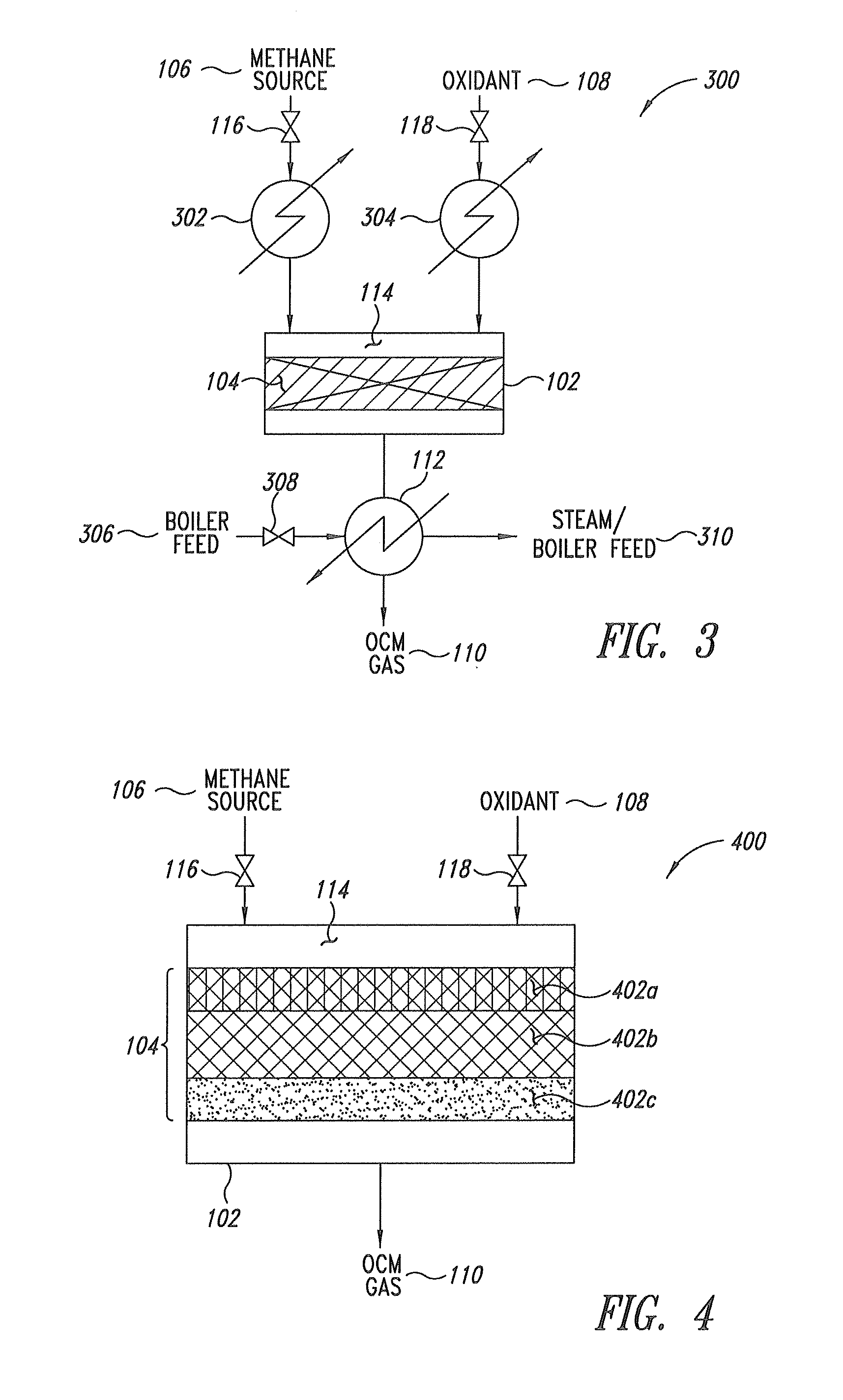

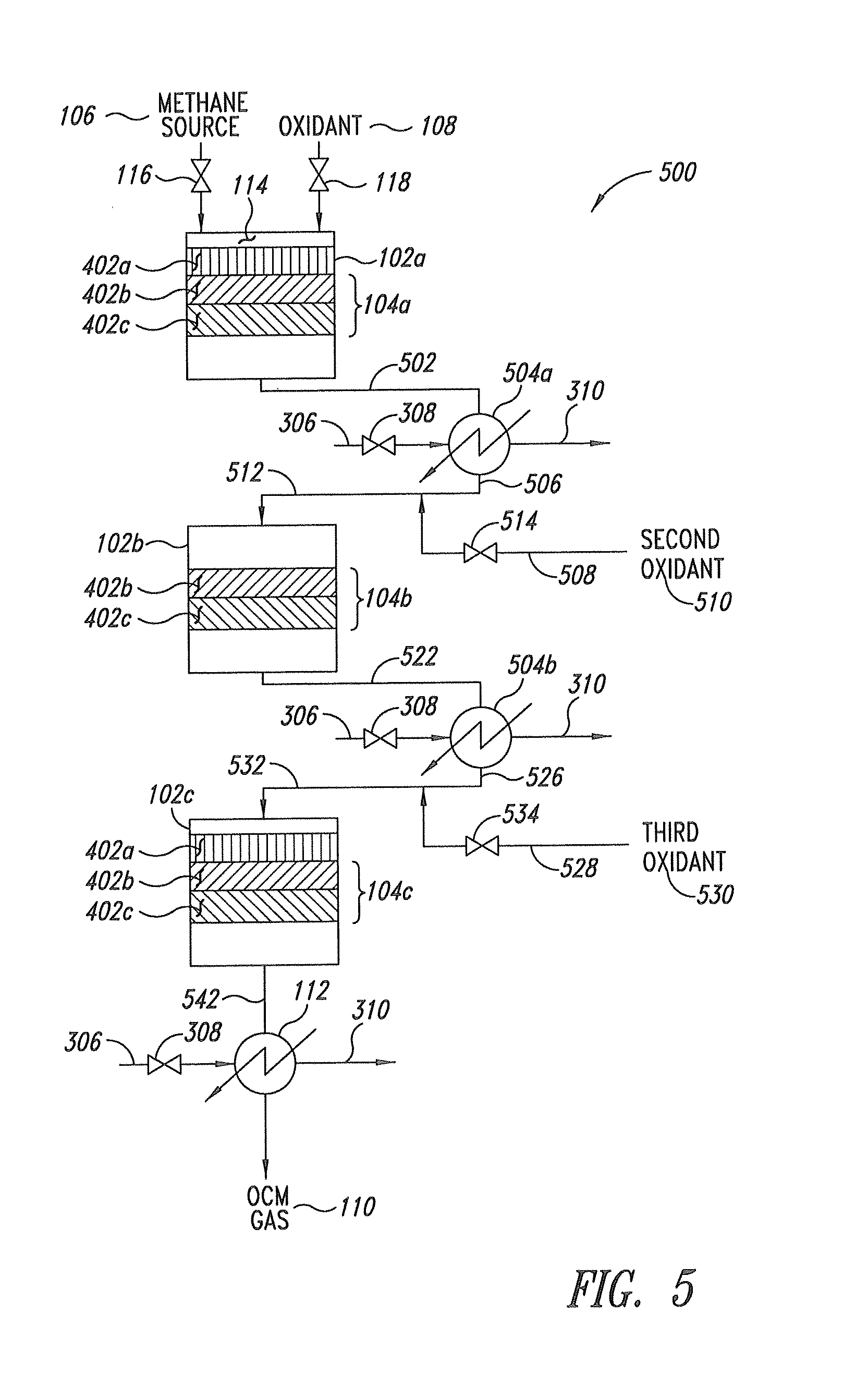

Oxidative coupling of methane systems and methods

ActiveUS20140107385A1Maintain temperatureTemperatue controlLiquid hydrocarbon mixtures productionChemical compositionPhysical form

Systems and methods conducive to the formation of one or more alkene hydrocarbons using a methane source and an oxidant in an oxidative coupling of methane (OCM) reaction are provided. One or more vessels each containing one or more catalyst beds containing one or more catalysts each having similar or differing chemical composition or physical form may be used. The one or more catalyst beds may be operated under a variety of conditions. At least a portion of the catalyst beds may be operated under substantially adiabatic conditions. At least a portion of the catalyst beds may be operated under substantially isothermal conditions.

Owner:LUMMUS TECH LLC

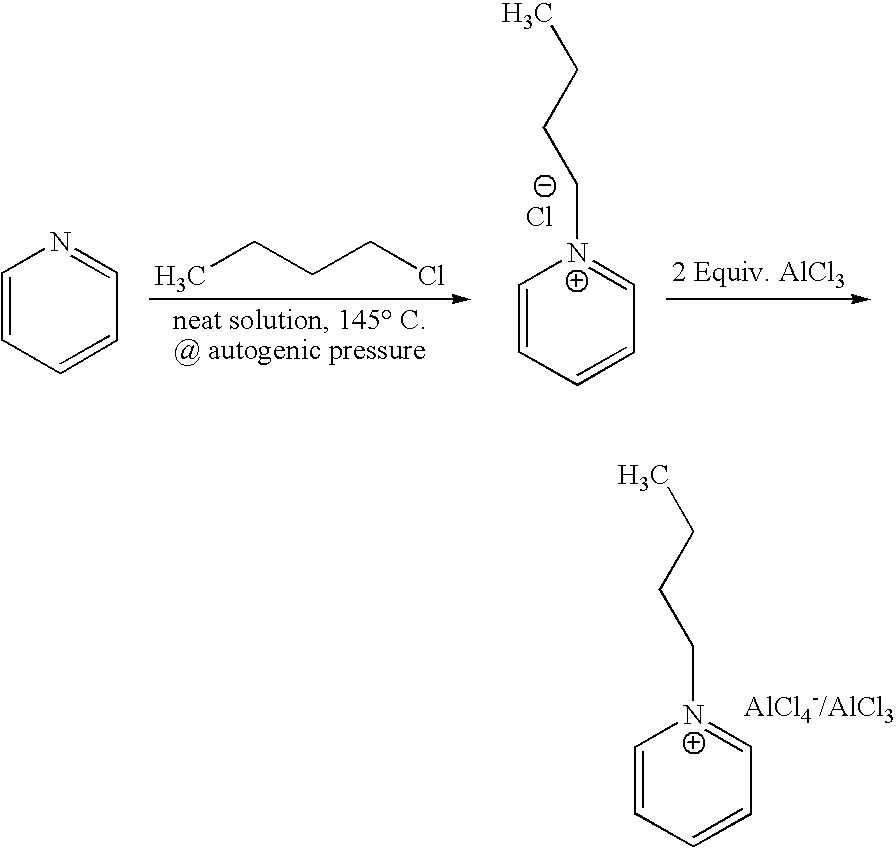

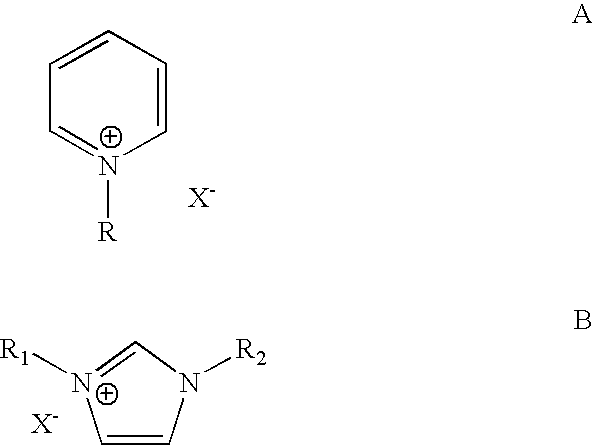

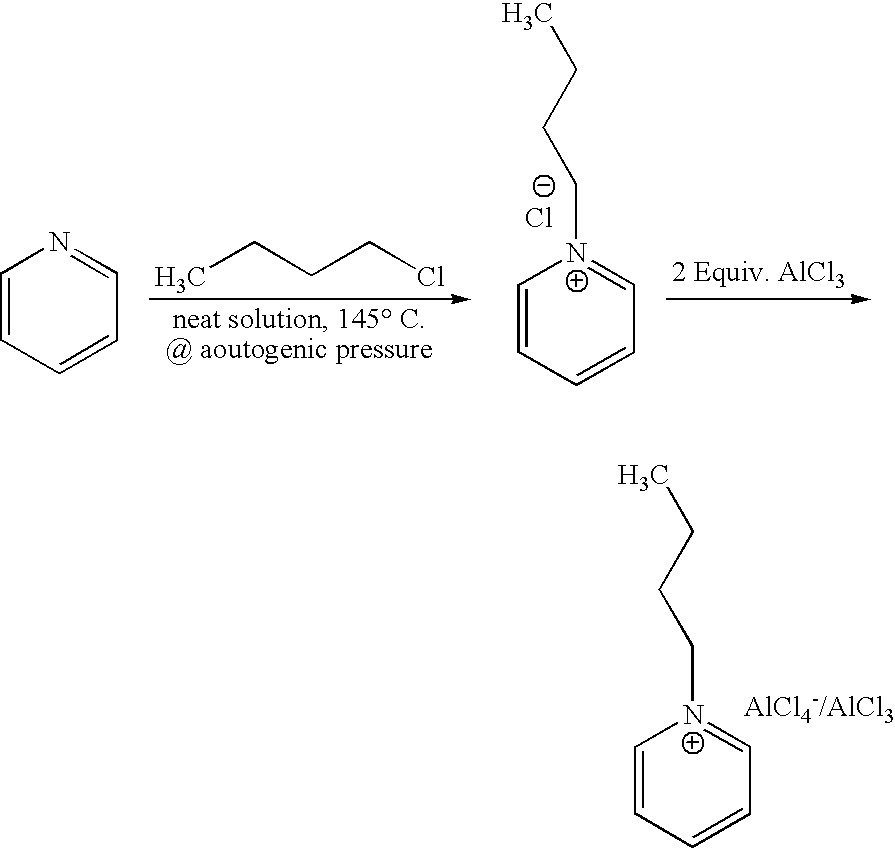

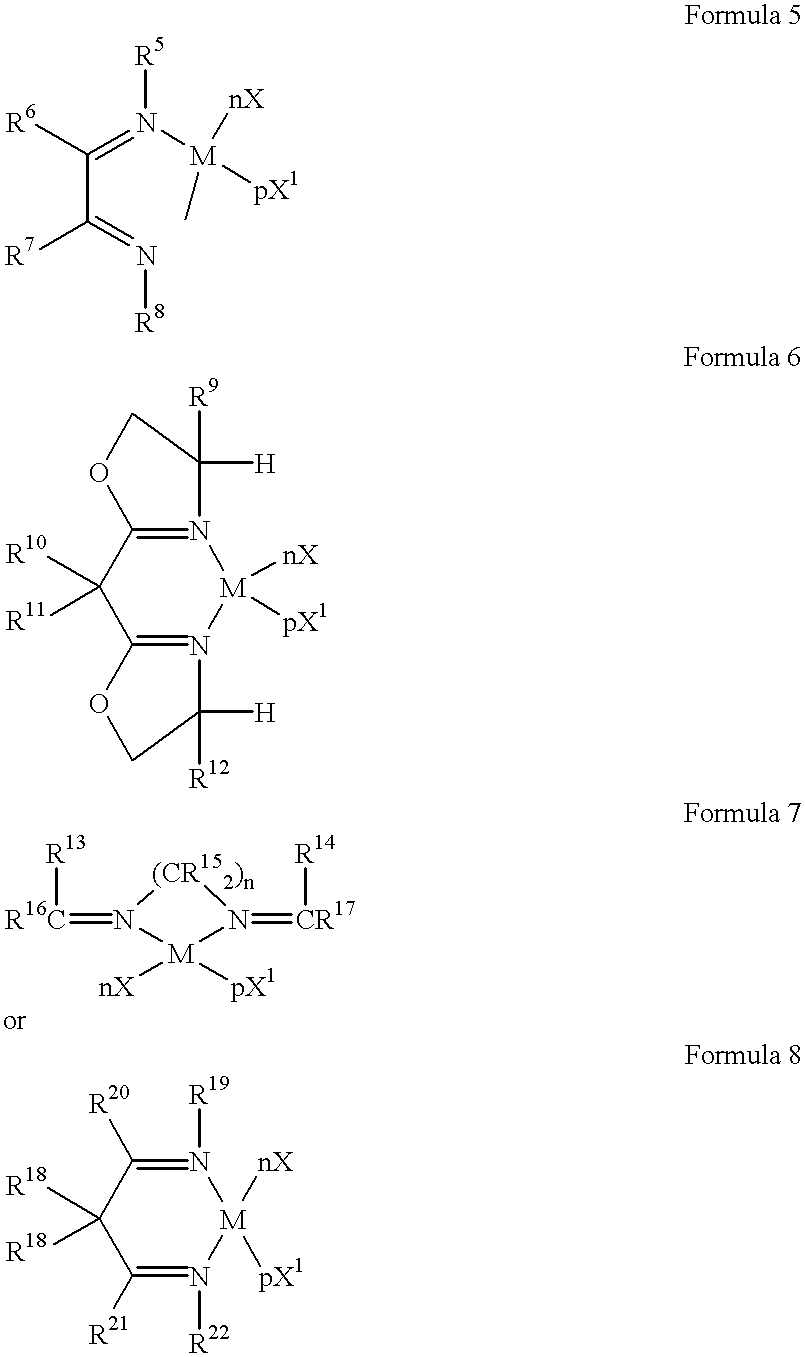

Alkylation process using chloroaluminate ionic liquid catalysts

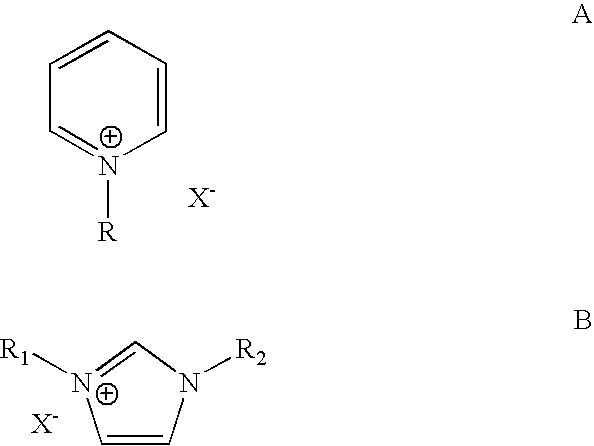

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium chloroaluminate or a hydrocarbyl substituted imidazolium chloroaluminate of the general formulas A and B, respectively.Where R═H, methlyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a chloroaluminate, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

Alkylation process using chloroaluminate ionic liquid catalysts

ActiveUS20060135839A1Quality improvementLiquid hydrocarbon mixtures productionHydrocarbons2-methylbutanePyridinium

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium halide or a hydrocarbyl substituted imidazolium halide of the general formulas A and B, respectively. Where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

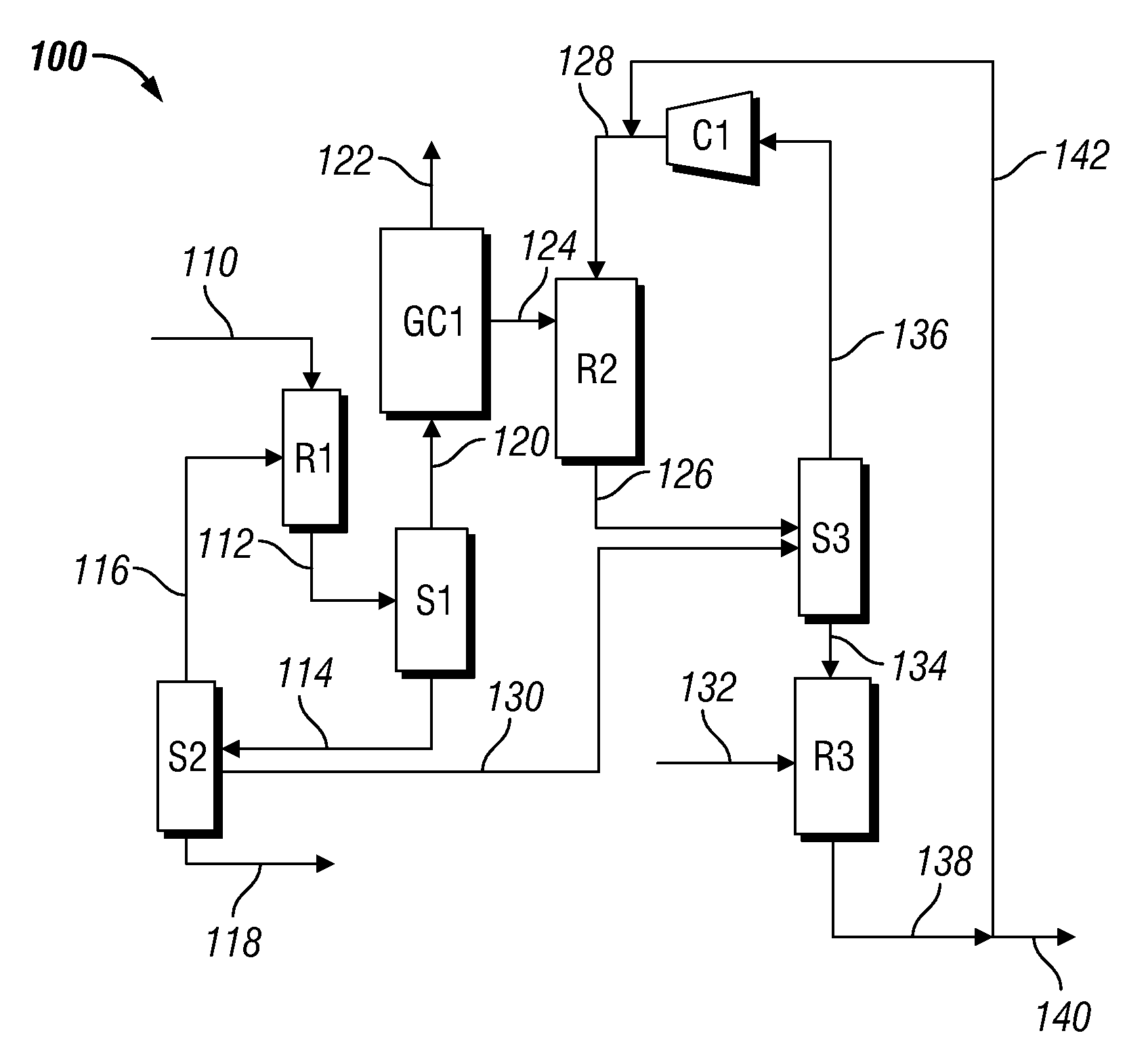

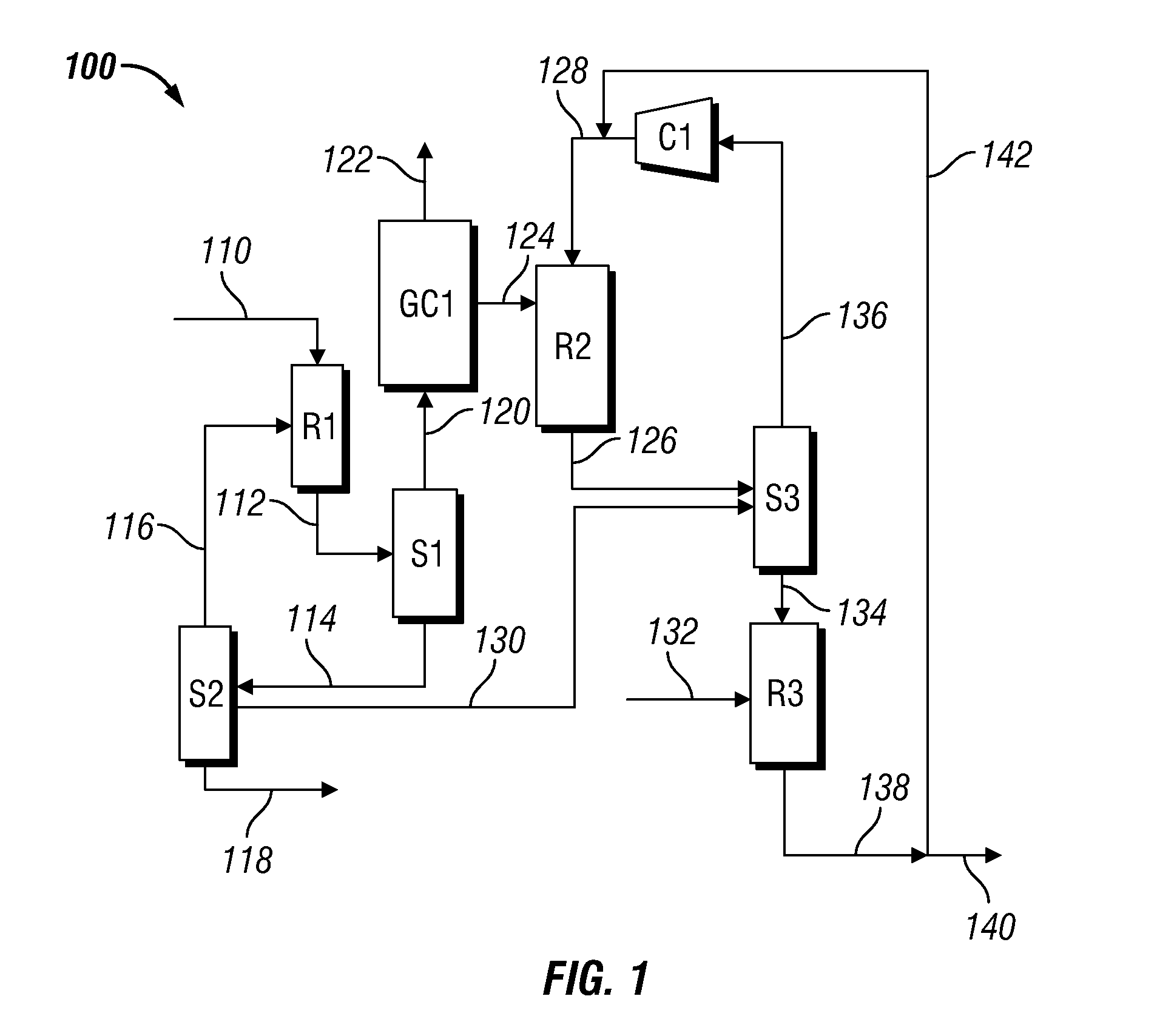

Integrated processes and systems for conversion of methane to multiple higher hydrocarbon products

Integrated systems are provided for the production of higher hydrocarbon compositions, for example liquid hydrocarbon compositions, from methane using an oxidative coupling of methane system to convert methane to ethylene, followed by conversion of ethylene to selectable higher hydrocarbon products. Integrated systems and processes are provided that process methane through to these higher hydrocarbon products.

Owner:LUMMUS TECH LLC

Integrated alkylation process using ionic liquid catalysts

ActiveUS20060131209A1Easy to operateReducing fuel gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

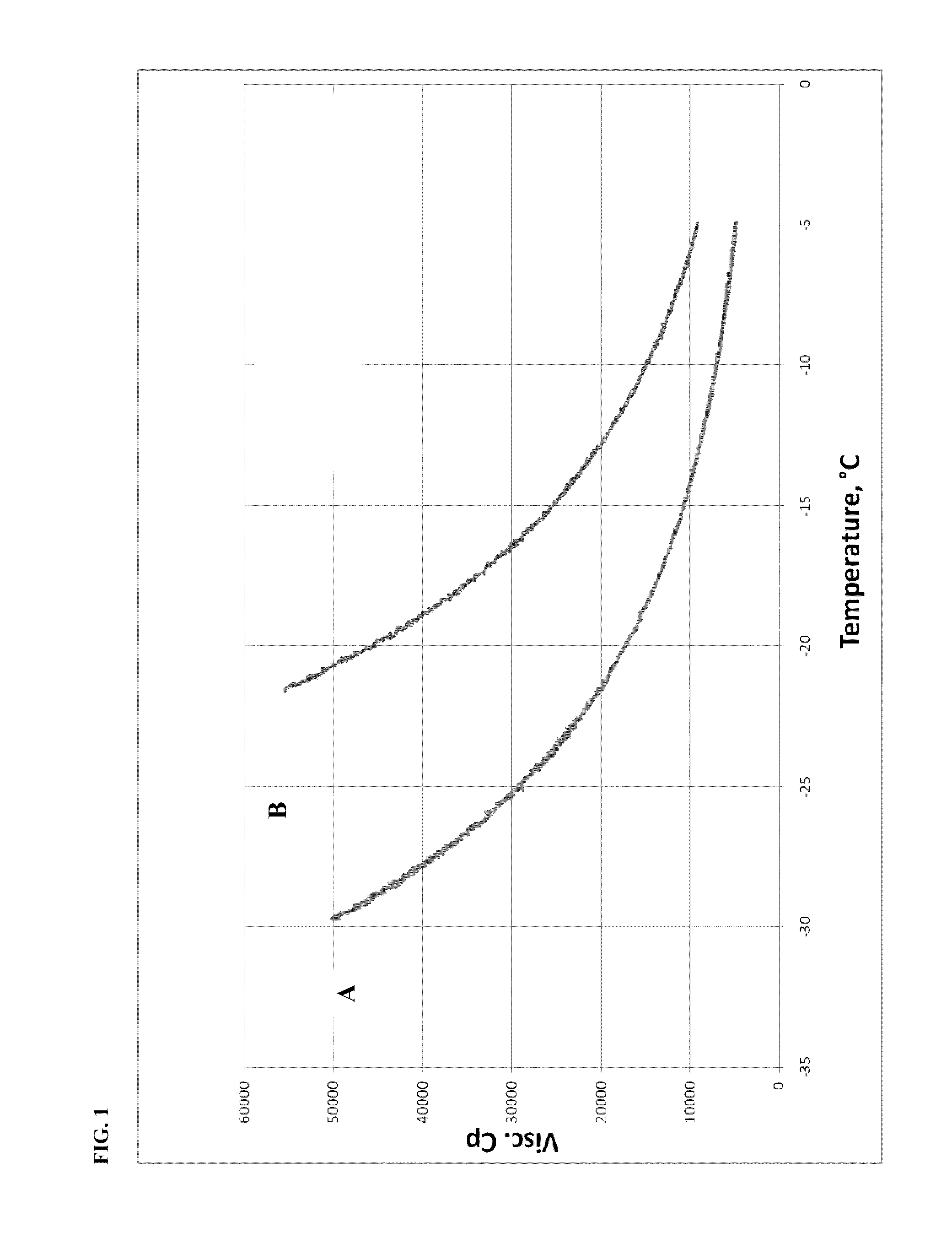

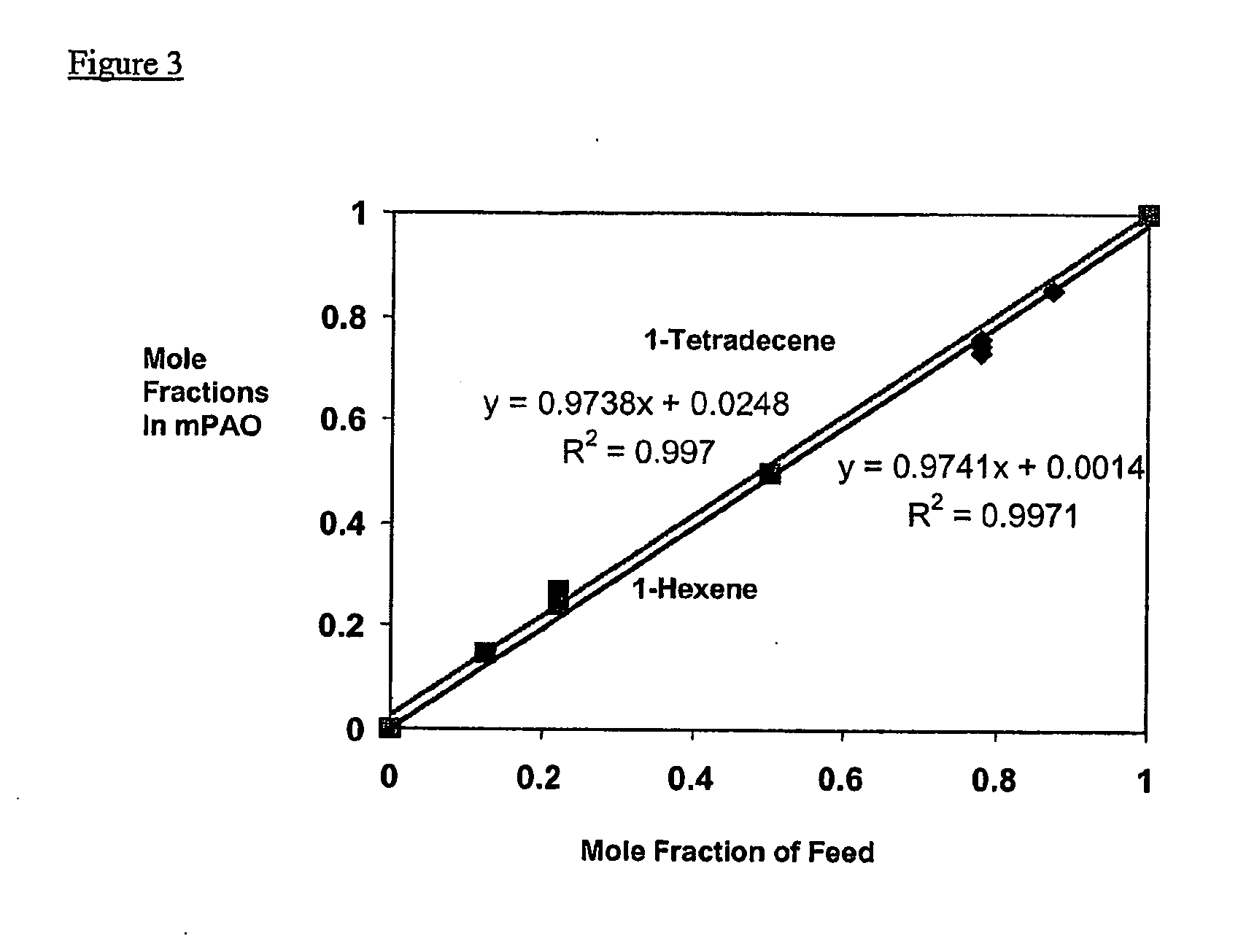

Low viscosity PAO based on 1-tetradecene

ActiveUS7544850B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlcohol1-Hexene

Disclosed herein is a method of making a PAO using tetradecene and particularly mixtures comprising 1-hexene, 1-decene, 1-dodecene, and 1-tetradecene, characterized by a low viscosity and excellent cold temperature properties, using a promoter system comprising an alcohol and an ester. In embodiments, the product has properties similar to those obtainable using a feed of solely 1-decene.

Owner:EXXONMOBIL CHEM PAT INC

Oligomer oils and their manufacture

InactiveUS20010041818A1Speed up the processEasy to controlOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionOligomerAlkene

A multistep process for the selective production of an oligomer oil having predetermined properties in which the first step involves the polymerization of a feedstock containing one or more C3 to C20 1-olefins in the presence of a catalyst comprising a bulky ligand transition metal catalyst and in which a subsequent step involves the olgiomerization of at least a preselected fraction of the product of the first step.

Owner:INEOS USA LLC

Process for oligomerizing olefins using a silica-alumina based catalyst

ActiveUS20060063955A1Hydrocarbon by dehydrogenationLiquid hydrocarbon mixtures productionChemistryAluminium

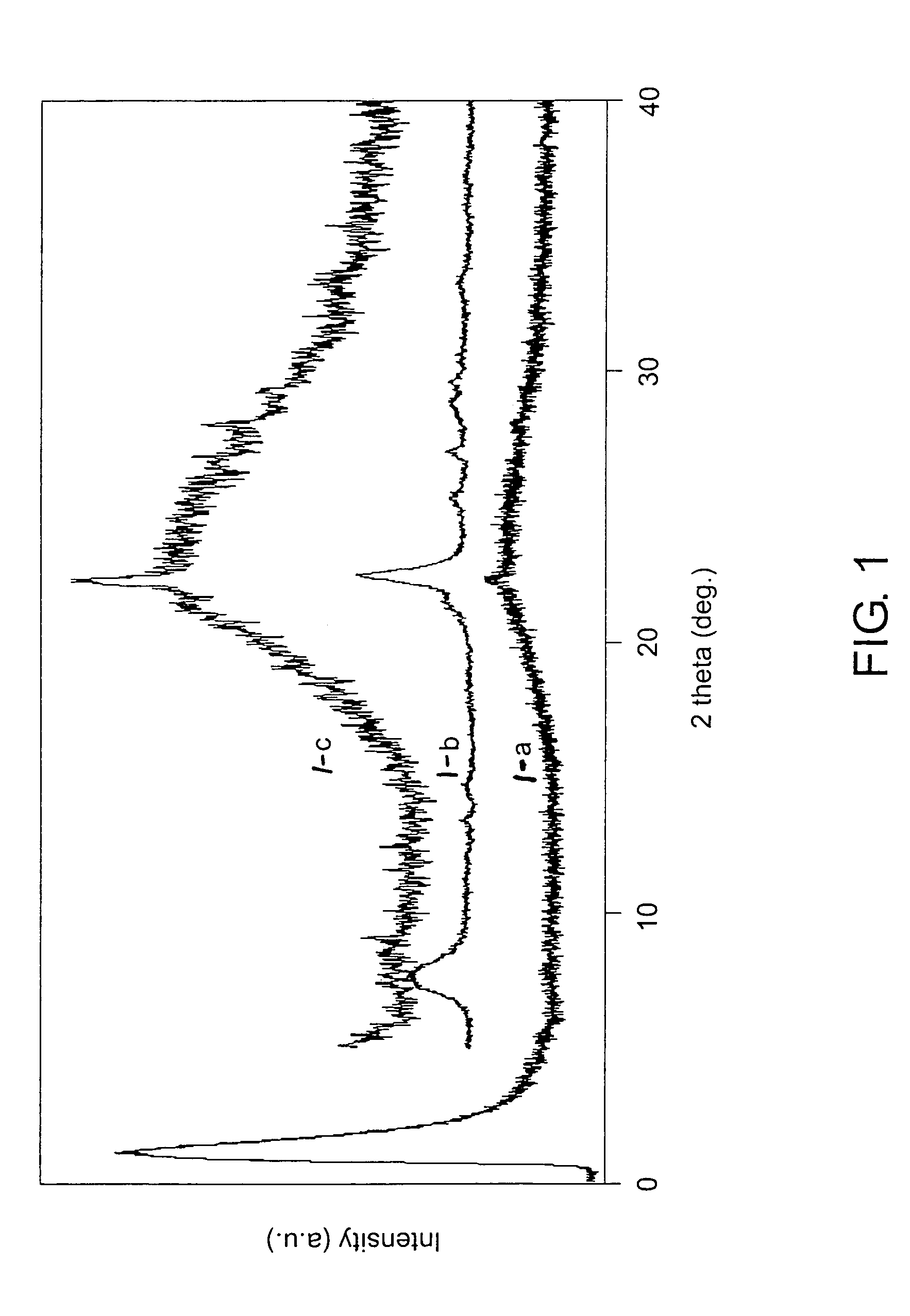

An olefin oligomerization process employs a particular silica-alumina catalyst which comprises a non zeolitic support based on silica-alumina containing a quantity of more than 5% by weight and 95% by weight or less of silica (SiO2) and has the following characteristics: a mean pore diameter, measured by mercury porosimetry, in the range 20 to 140 Å; a total pore volume, measured by mercury porosimetry, in the range 0.1 ml / g to 0.6 ml / g; a total pore volume, measured by nitrogen porosimetry, in the range 0.1 ml / g to 0.6 ml / g; a BET specific surface area in the range 100 to 550 m2 / g; a pore volume, measured by mercury porosimetry, included in pores with a diameter of more than 140 Å, of less than 0.1 ml / g; a pore volume, measured by mercury porosimetry, included in pores with a diameter of more than 160 Å, of less than 0.1 ml / g; a pore volume, measured by mercury porosimetry, included in pores with a diameter of more than 200 Å, of less than 0.1 ml / g; a pore volume, measured by mercury porosimetry, included in pores with a diameter of more than 500 Å, of less than 0.1 ml / g; and an X ray diffraction diagram containing at least the principal characteristic peaks of at least one of the transition aluminas included in the group composed of alpha, rho, khi, eta, gamma, kappa, theta and delta aluminas.

Owner:INST FR DU PETROLE

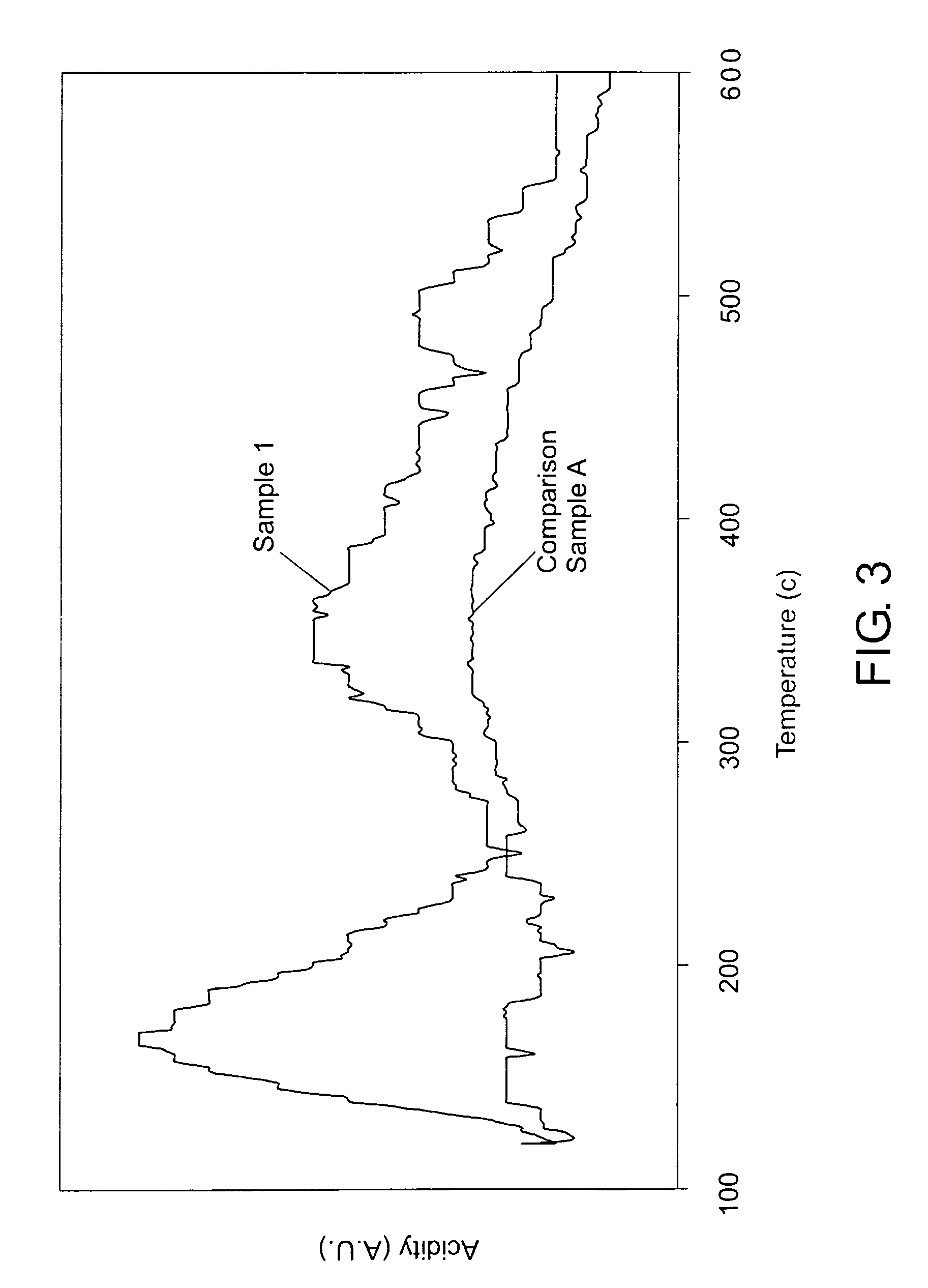

Catalyst for C4 liquefied petroleum gas aromatization and its preparing method

InactiveCN1586721ALess modification stepsLow costMolecular sieve catalystsLiquid hydrocarbon mixtures productionHigh carbonFixed bed

The present invention belongs to the field of catalyst preparation in petrochemical technology, and especially one kind of catalyst for the aromatization of liquefied C4 petroleum gas in fixed bed reactor and its preparation process. Technologically, the catalyst features that its mother substance is high-silicon zeolite with crystal granulation of 10-500 nm and the zeolite is alumina formed and prepared into the hydrogen type catalyst via conventional process, and the hydrogen type catalyst is vapor treated to regulate the acidity and acid treated to expand the pores and restore the pore passage. The catalyst is used in the aromatization of liquefied C4 petroleum gas, and has low reaction temperature, high olefin converting rate and high carbon deposition resistance.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

High viscosity polyalphaolefins based on 1-hexene, 1-dodecene and 1-tetradecene

ActiveUS7547811B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon addition1-OcteneOctene

This invention relates to the use of olefin mixtures containing 1-hexene / 1-decene / 1-dodecene and, additionally, 1-octene or 1-decene to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

Oligomerization of olefin waxes using metallocene-based catalyst systems

InactiveUS20110082323A1Decreased needle penetrationHigh kinematic viscosityOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionNeedle penetrationWax

This disclosure provides for olefin wax oligomer compositions, methods of producing olefin wax oligomer composition, and methods for oligomerizing olefin waxes. This disclosure encompasses metallocene-based olefin wax oligomerization catalyst systems, including those that include a metallocene and an aluminoxane, a metallocene and a solid oxide chemically-treated with an electron withdrawing anion, and a metallocene, a solid oxide chemically-treated with an electron withdrawing anion, and an organoaluminum compound. The olefin wax oligomers prepared with these catalyst systems can decreased needle penetrations, increased viscosity, and an increased drop melt, making them useful as an additive in candles, stone polishes, liquid polishes, and mold release formulations.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Hydrocarbon synthesis

InactiveUS20050171393A1Valid conversionMolecular sieve catalystLiquid hydrocarbon mixtures productionHydrogen halideOxygen

A method of synthesizing hydrocarbons from smaller hydrocarbons includes the steps of hydrocarbon halogenation, simultaneous oligomerization and hydrogen halide neutralization, and product recovery, with a metal-oxygen cataloreactant used to facilitate carbon-carbon coupling. Treatment with air or oxygen liberates halogen and regenerates the cataloreactant.

Owner:REACTION 35 LLC

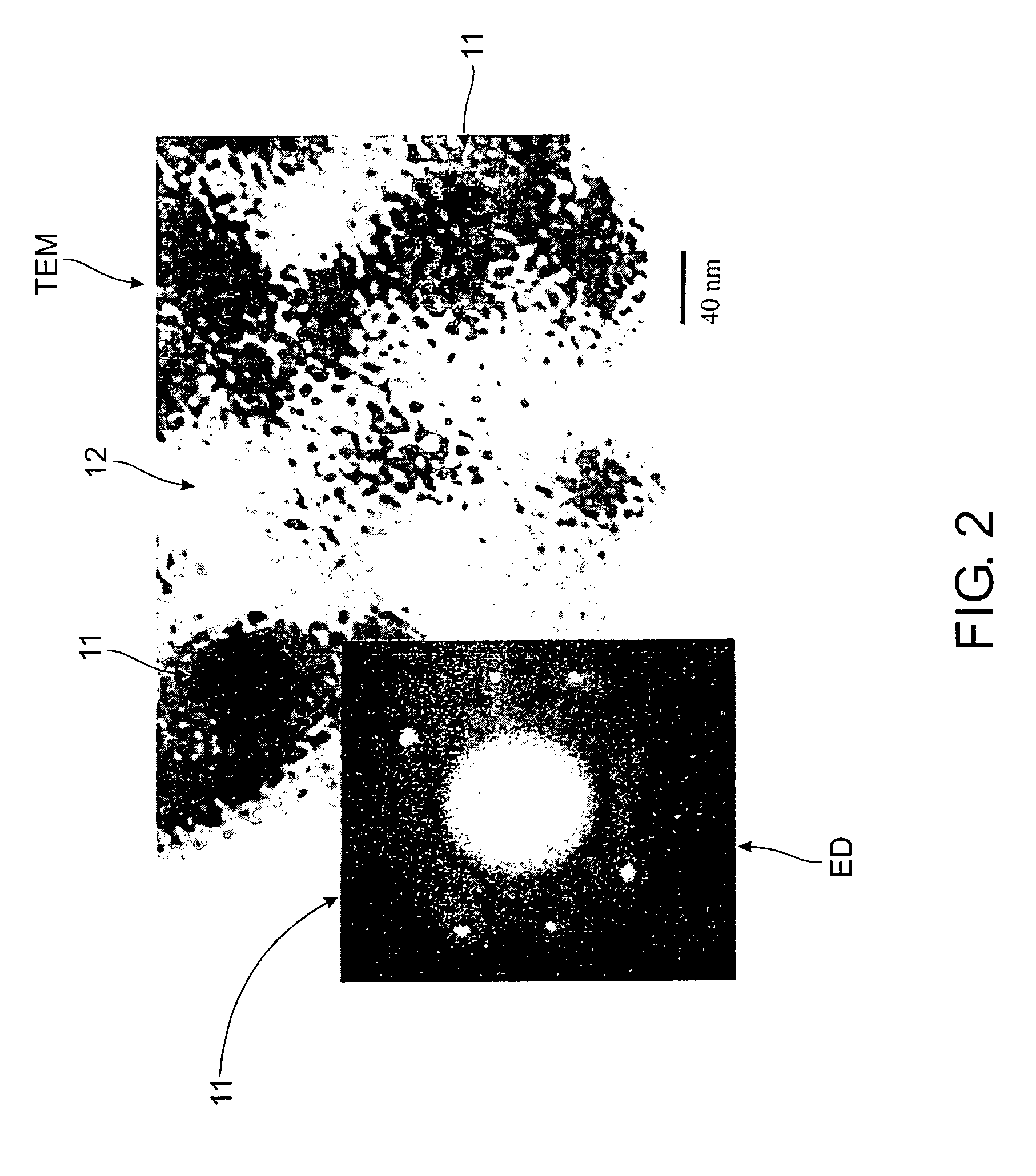

Zeolite composite, method for making and catalytic application thereof

A catalytic material includes microporous zeolites supported on a mesoporous inorganic oxide support. The microporous zeolite can include zeolite Beta, zeolite Y (including “ultra stable Y”—USY), mordenite, Zeolite L, ZSM-5, ZSM-11, ZSM-12, ZSM-20, Theta-1, ZSM-23, ZSM-34, ZSM-35, ZSM-48, SSZ-32, PSH-3, MCM-22, MCM-49, MCM-56, ITQ-1, ITQ-2, ITQ-4, ITQ-21, SAPO-5, SAPO-11, SAPO-37, Breck-6, ALPO4-5, etc. The mesoporous inorganic oxide can be e.g., silica or silicate. The catalytic material can be further modified by introducing some metals e.g. aluminum, titanium, molybdenum, nickel, cobalt, iron, tungsten, palladium and platinum. It can be used as catalysts for acylation, alkylation, dimerization, oligomerization, polymerization, hydrogenation, dehydrogenation, aromatization, isomerization, hydrotreating, catalytic cracking and hydrocracking reactions.

Owner:ABB LUMMUS GLOBAL INC

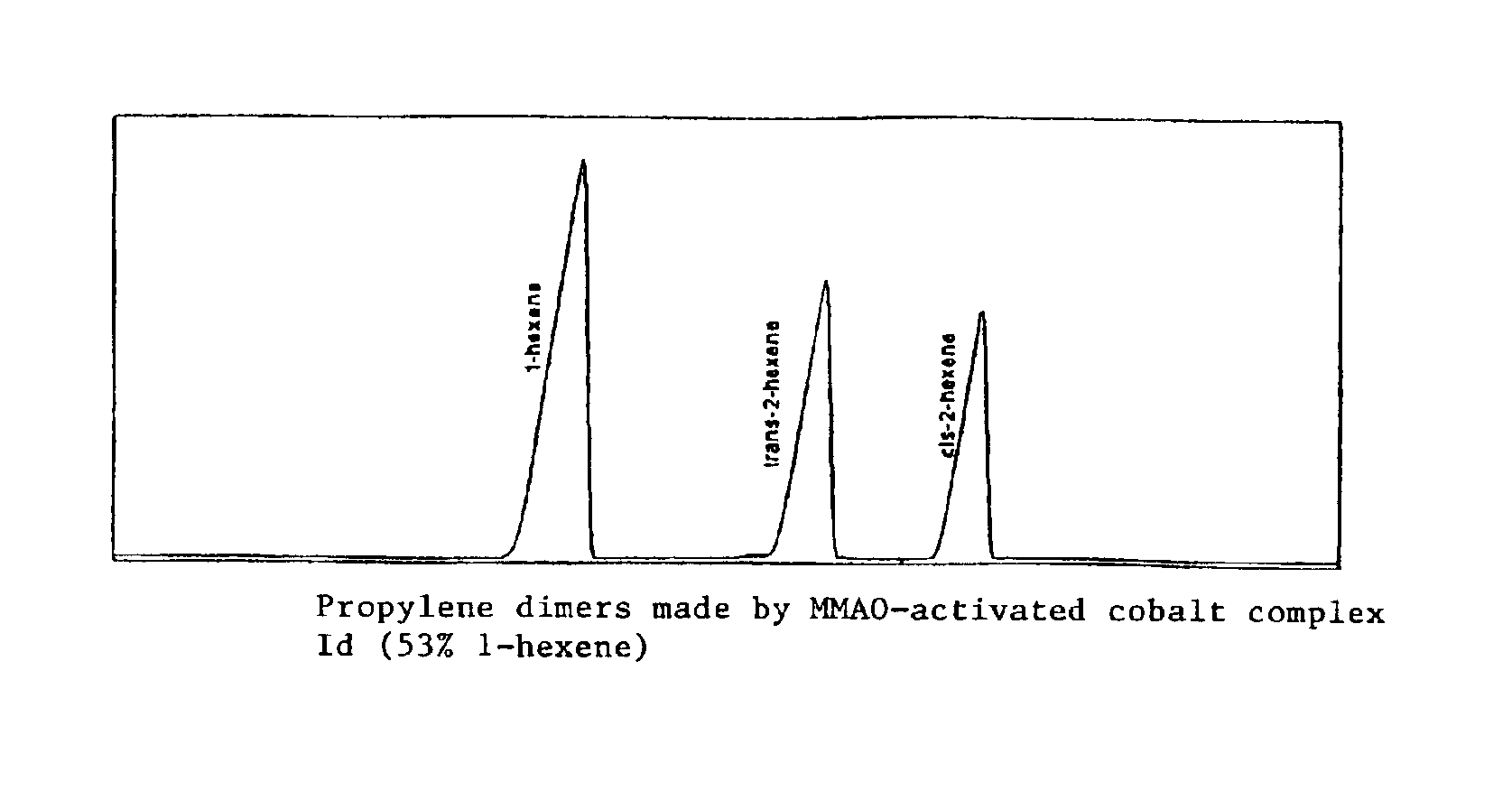

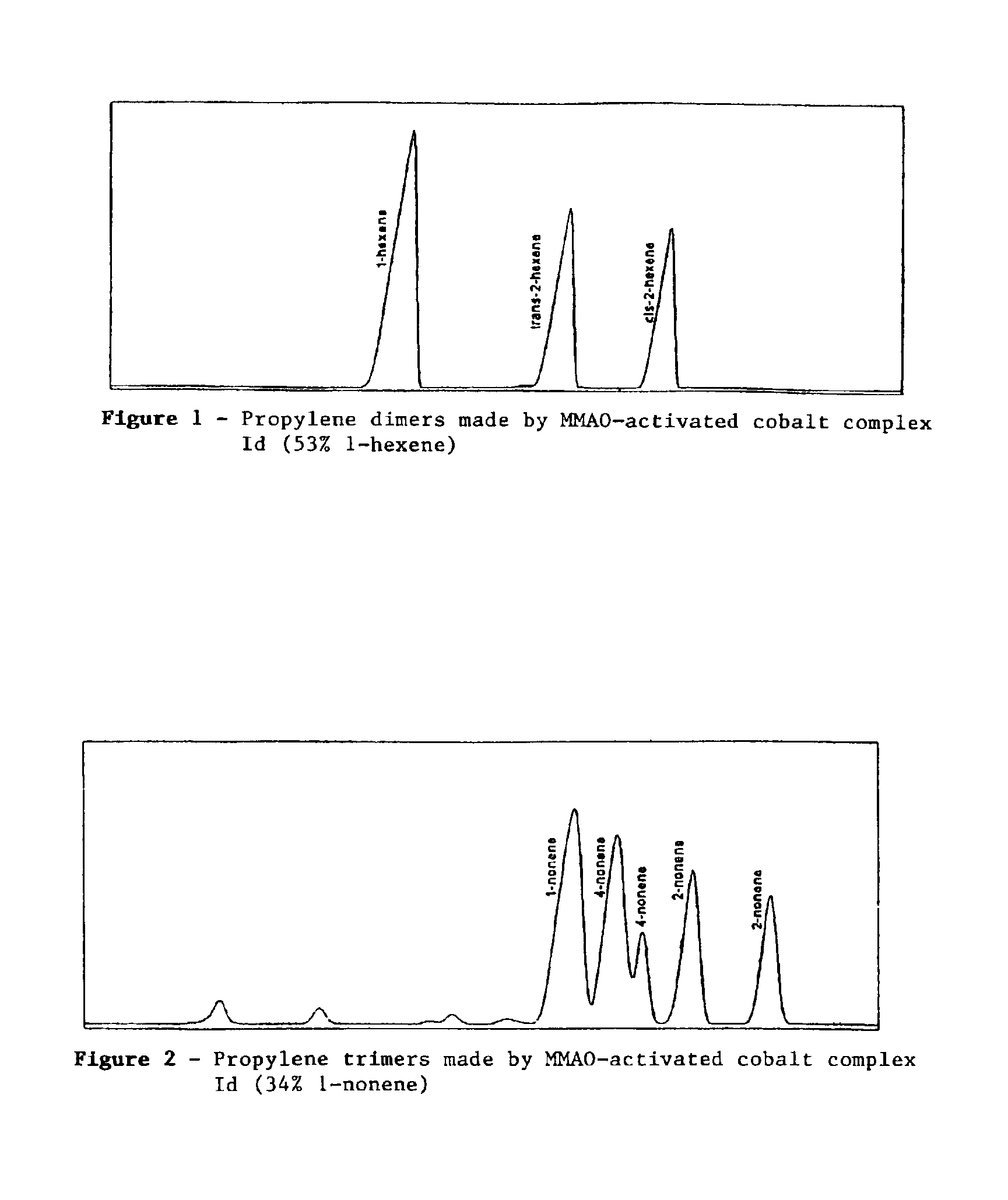

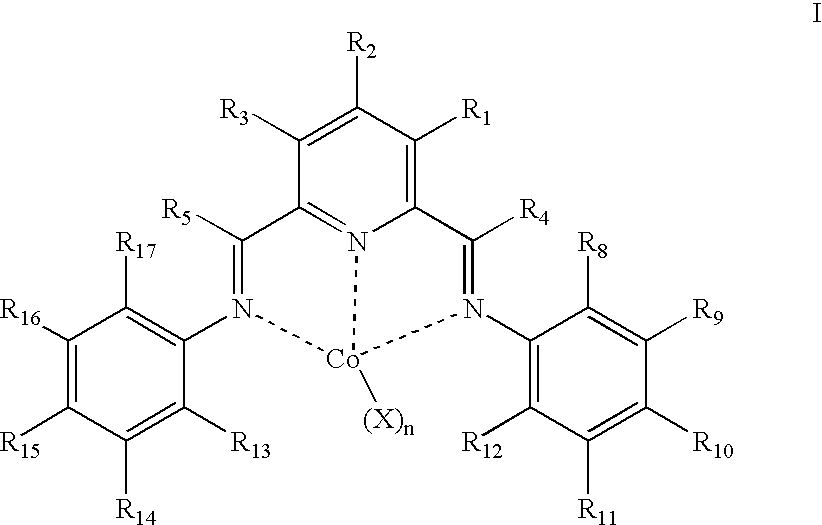

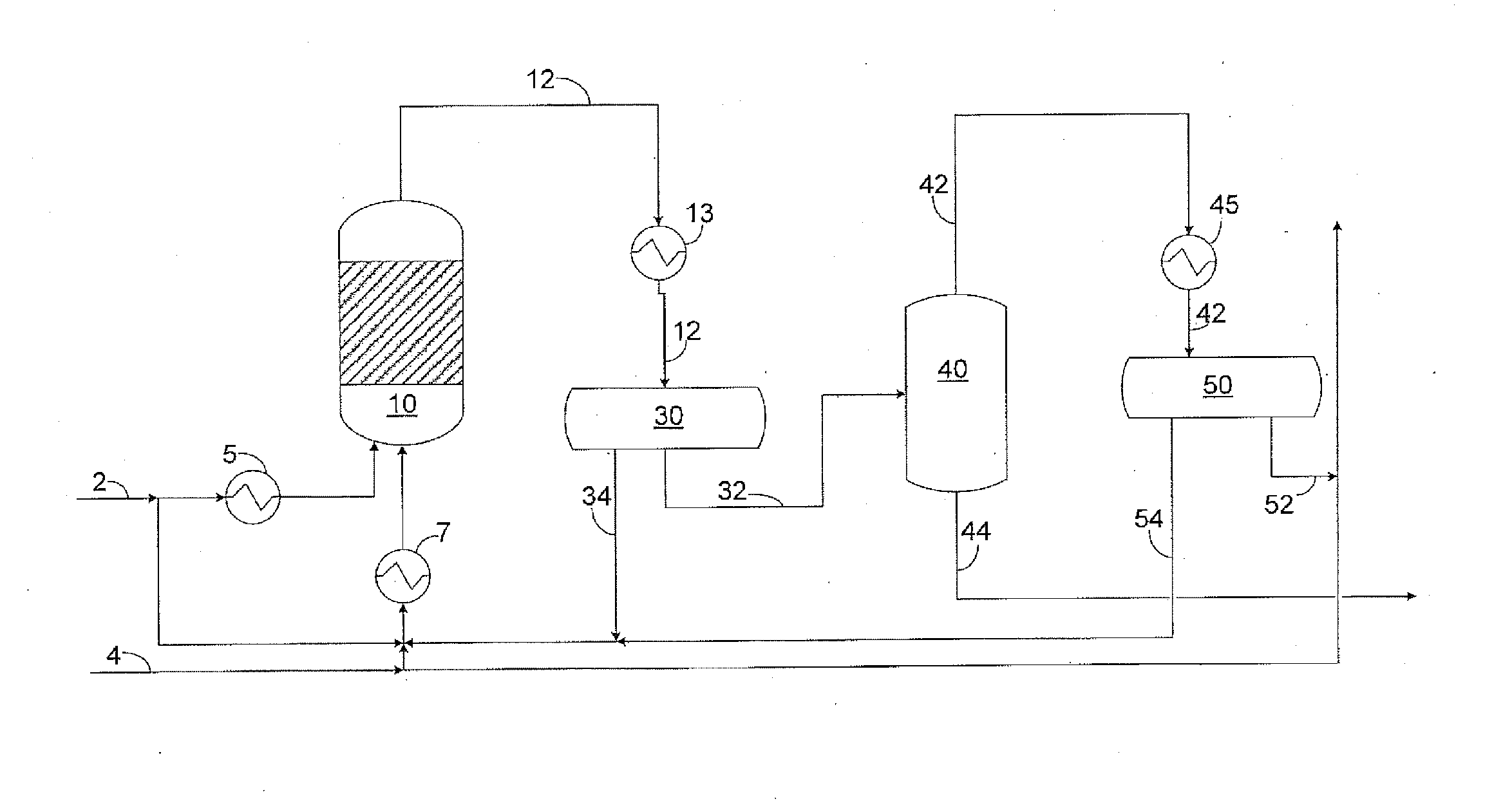

Selective isomerization and linear dimerization of olefins using cobalt catalysts

InactiveUS6911505B2Hydrocarbon by hydrogenationLiquid hydrocarbon mixtures productionIsomerizationAlpha-olefin

Processes for the production of alpha-olefins, including dimerization and isomerization of olefins using a cobalt catalyst complex are provided herein. The olefins so produced are useful as monomers in further polymerization reactions and are useful as chemical intermediates.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Method for contemporaneously dimerizing and hydrating a feed having butene

ActiveUS20130104449A1Increased research octane numberImprove responseLiquid hydrocarbon mixtures productionCatalystsButeneOligomer

Methods for producing alcohols and oligomers contemporaneously from a hydrocarbon feed containing mixed butenes using an acid based catalyst are provided. Additionally, methods for producing fuel compositions having alcohols and oligomers prepared from mixed olefins are also provided as embodiments of the present invention. In certain embodiments, the catalyst can include a dual phase catalyst system that includes a water soluble acid catalyst and a solid acid catalyst.

Owner:SAUDI ARABIAN OIL CO

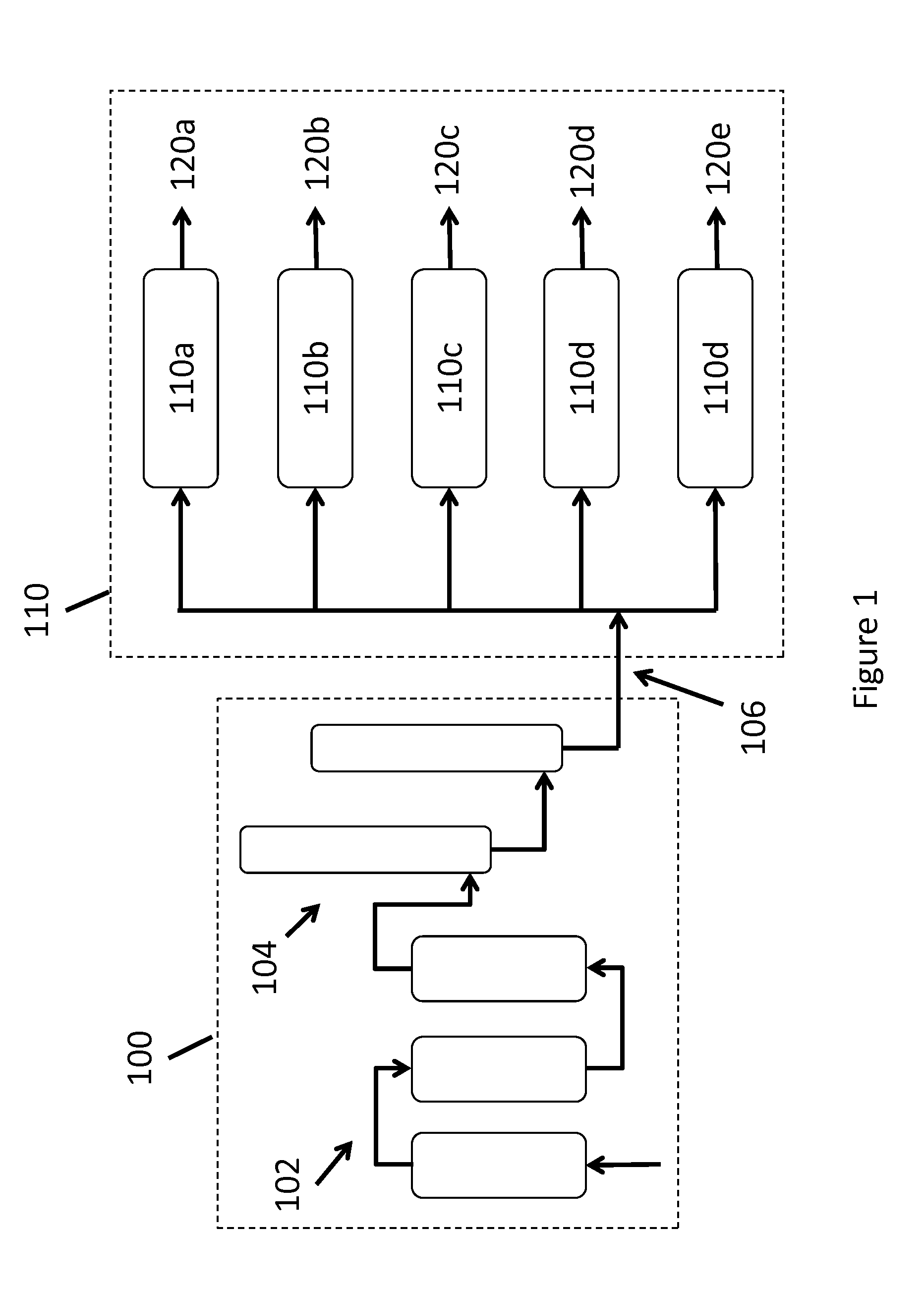

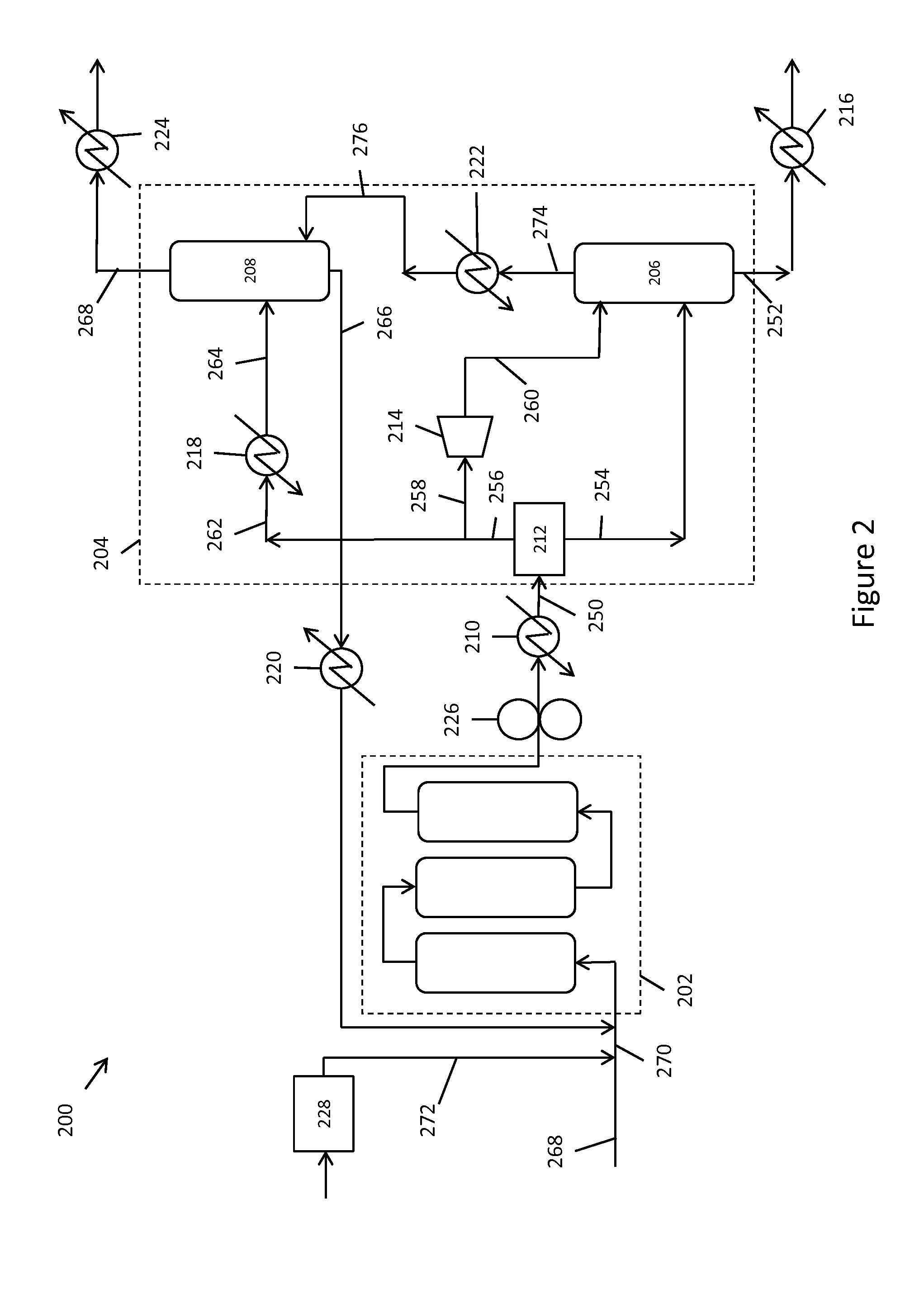

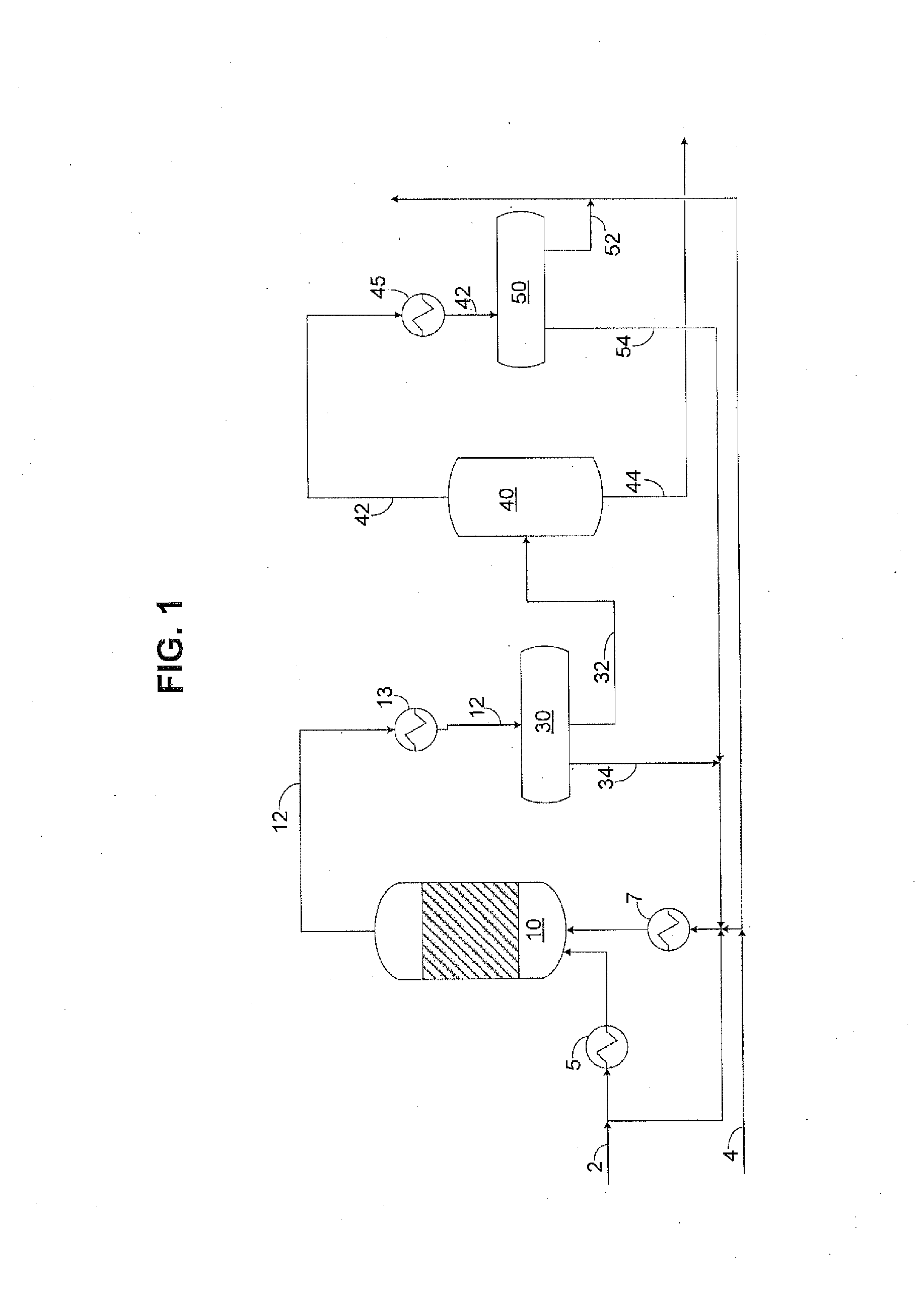

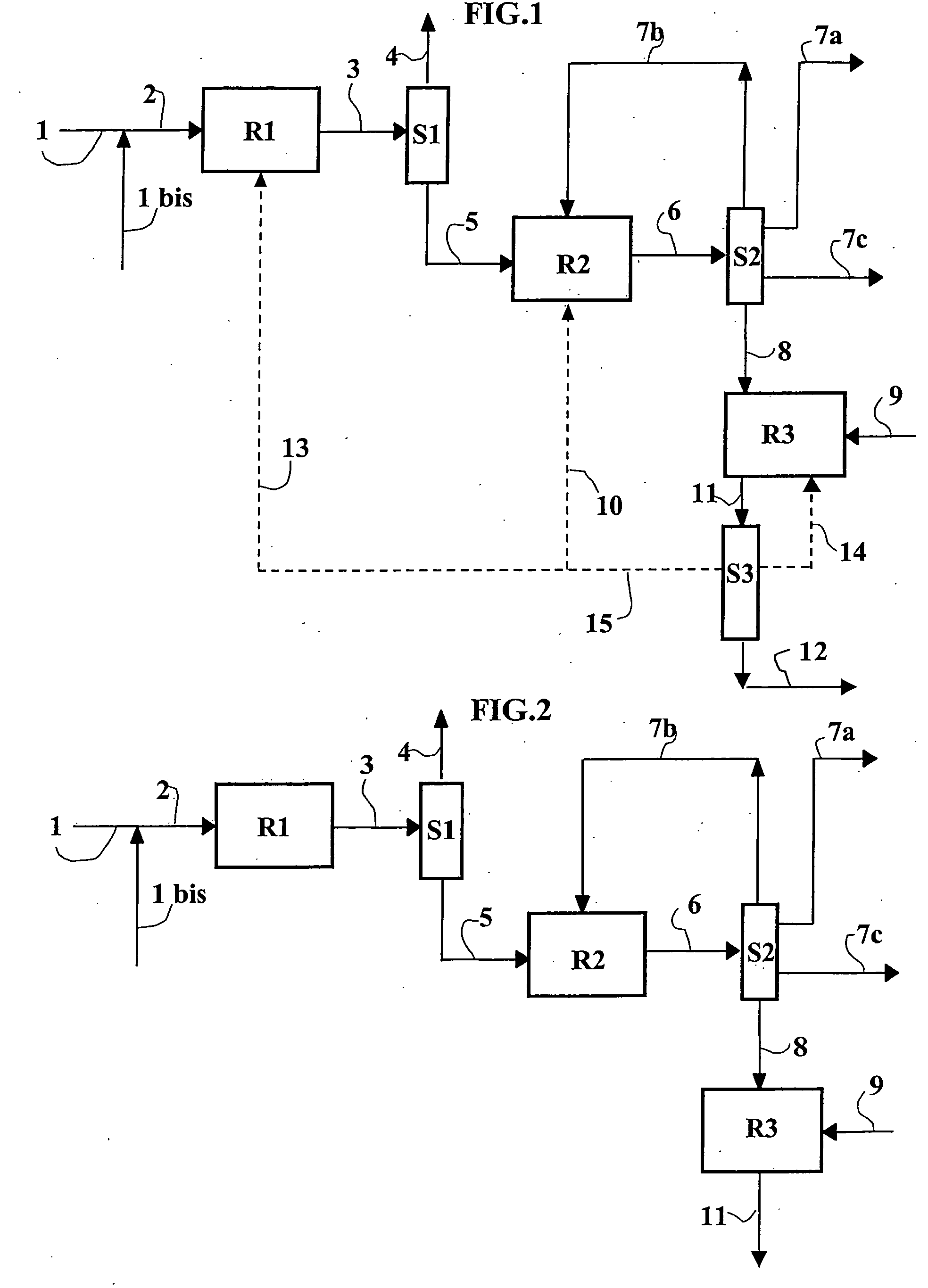

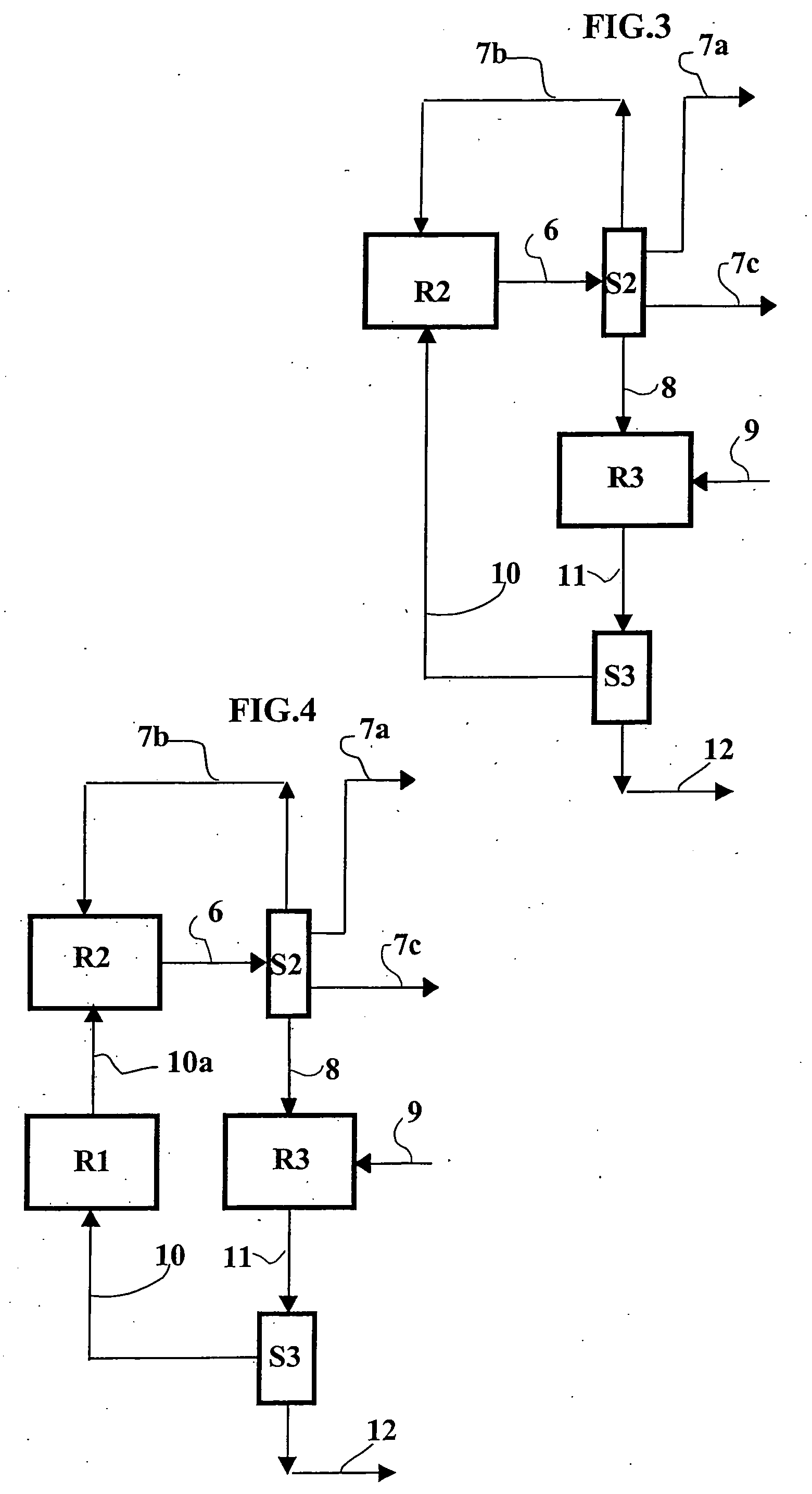

System and method for the production of liquid fuels

InactiveUS20120197053A1Readily apparentHydrocarbon by hydrogenationHydrocarbon purification/separationOligomerLiquid state

A method of producing liquid fuels by providing an olefin feed containing at least one C2-C20 olefin, oligomerizing a part of the feed in the presence of a first catalyst to form a first product comprising oligomers of the at least one olefin, and oligomerizing a portion of the first product in the presence of a second catalyst to produce a second product. A system of producing liquid hydrocarbons, the system including a first reactor configured to provide a first product by oligomerizing, in the presence of a first catalyst, at least a portion of an olefin feed comprising at least one olefin, a separator configured to provide an unreacted olefin-reduced first product by separating unreacted olefin from the first product, and a second reactor configured to provide a second product by oligomerizing, in the presence of a second catalyst, at least a portion of the unreacted olefin-reduced first product.

Owner:SYNFUELS INT

Lubricants from Mixed Alpha-Olefin Feeds

ActiveUS20100292424A1Useful lubricant propertyNarrow molecular weight distributionLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlpha-olefinAlkene

This invention discloses an improved process which employs mixed alpha-olefins as feed over activated metallocene catalyst systems to provide essentially random liquid polymers particularly useful in lubricant components or as functional fluids.

Owner:EXXONMOBIL CHEM PAT INC

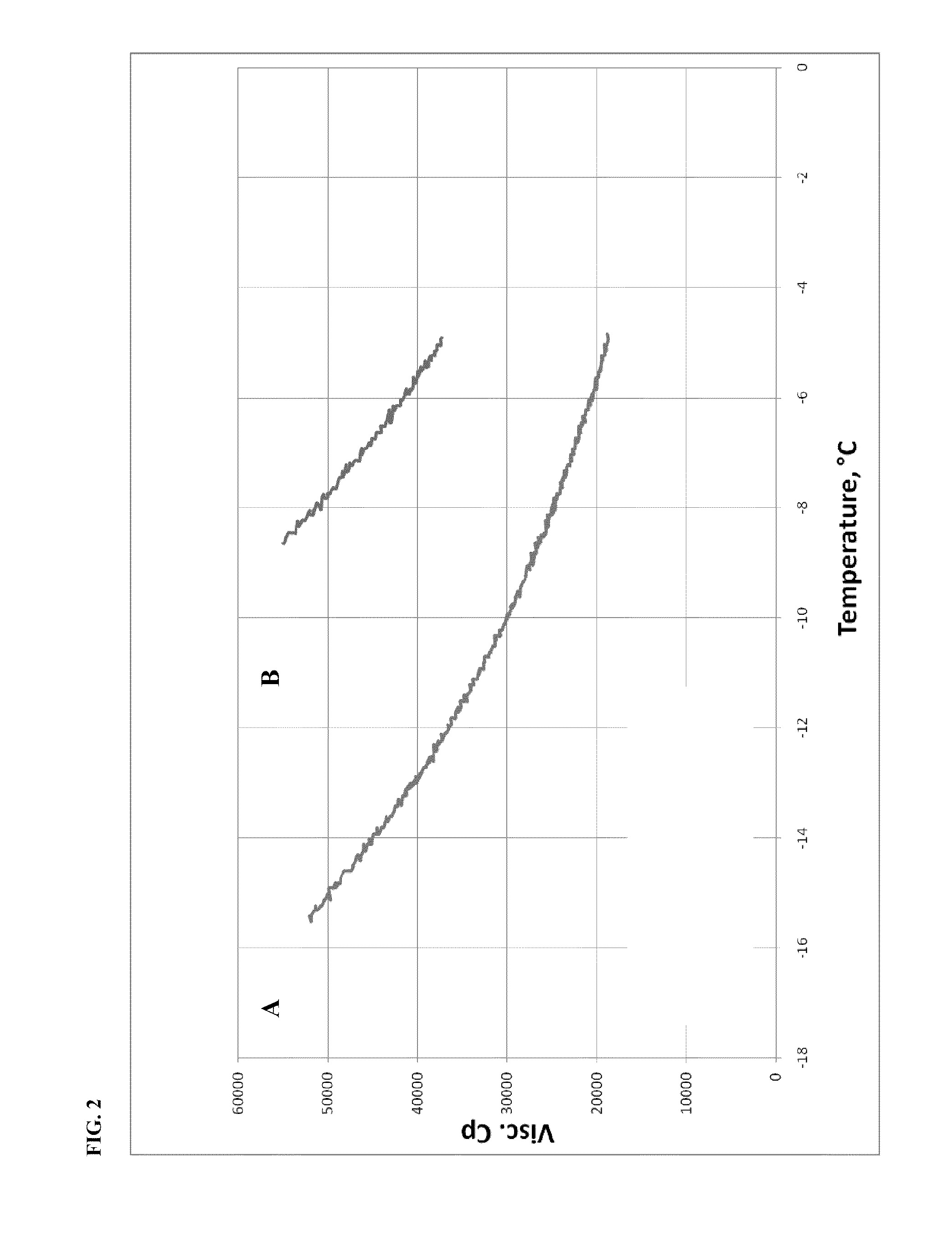

Low viscosity polyalphapolefin based on 1-decene and 1-dodecene

ActiveUS7592497B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlcoholAlpha-olefin

The invention relates to a method of making a PAO from mixtures comprising 1-decene and 1-dodecene, characterized by a low viscosity and excellent cold temperature properties, using a promoter system comprising an alcohol. In embodiments, the product has properties similar to those obtainable using a feed of solely 1-decene.

Owner:EXXONMOBIL CHEM PAT INC

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS20050121361A1Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerBoiling point

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein, the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst, the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

Co-oligomerization of 1-dodecene and 1-decene

InactiveUS6646174B2Quantity minimizationOrganic chemistry methodsLiquid hydrocarbon mixtures productionViscosity indexAlpha-olefin

A process for the co-oligomerization of 1-dodecene and 1-decene to produce a polyalphaolefin having a kinetic viscosity of 4 to 6 cSt at 100° C., a Noack weight loss of 4 to 9%, a viscosity index of 130 to 145, and a pour point of -60° C. to -50° C.

Owner:INEOS USA LLC

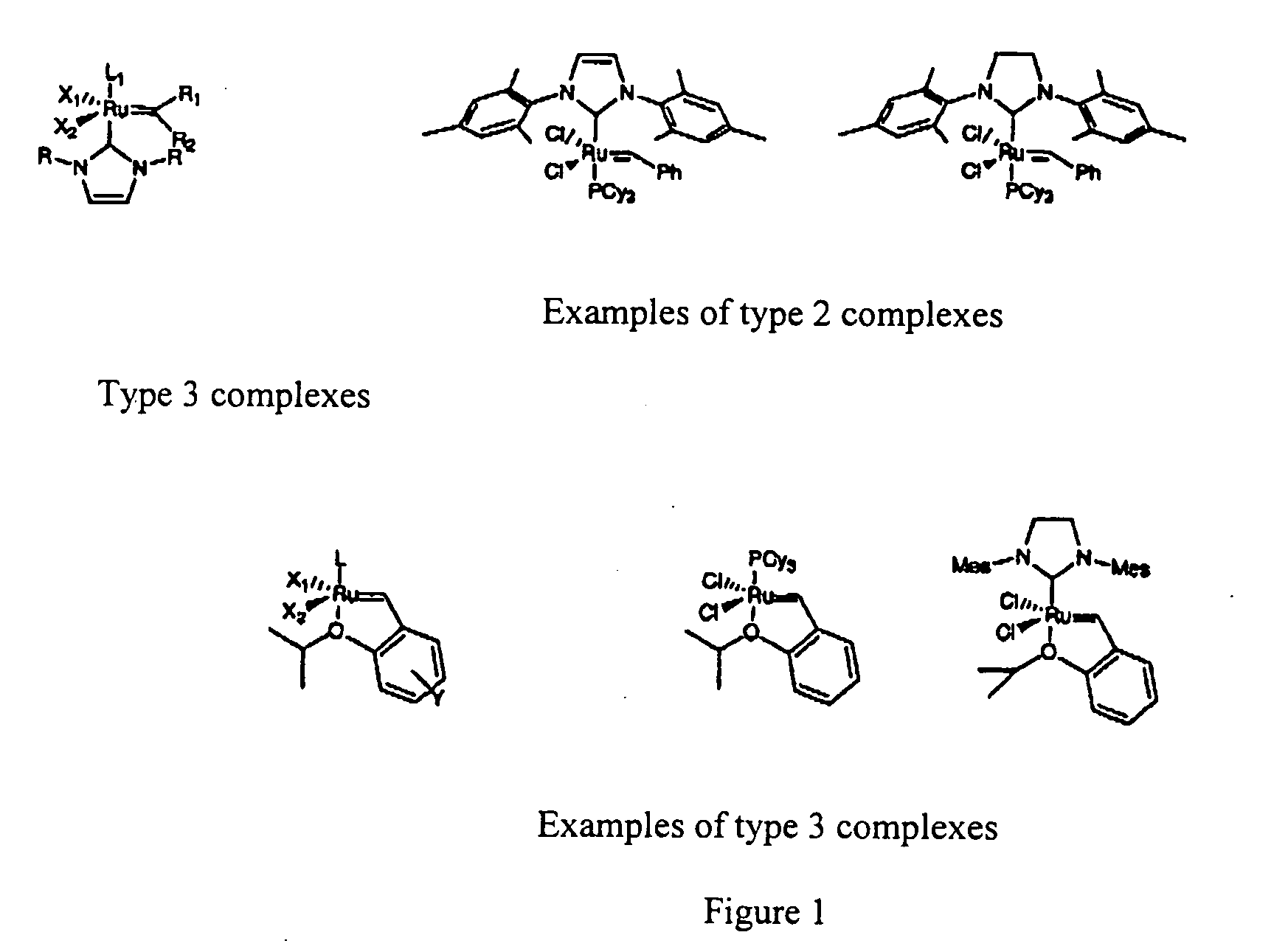

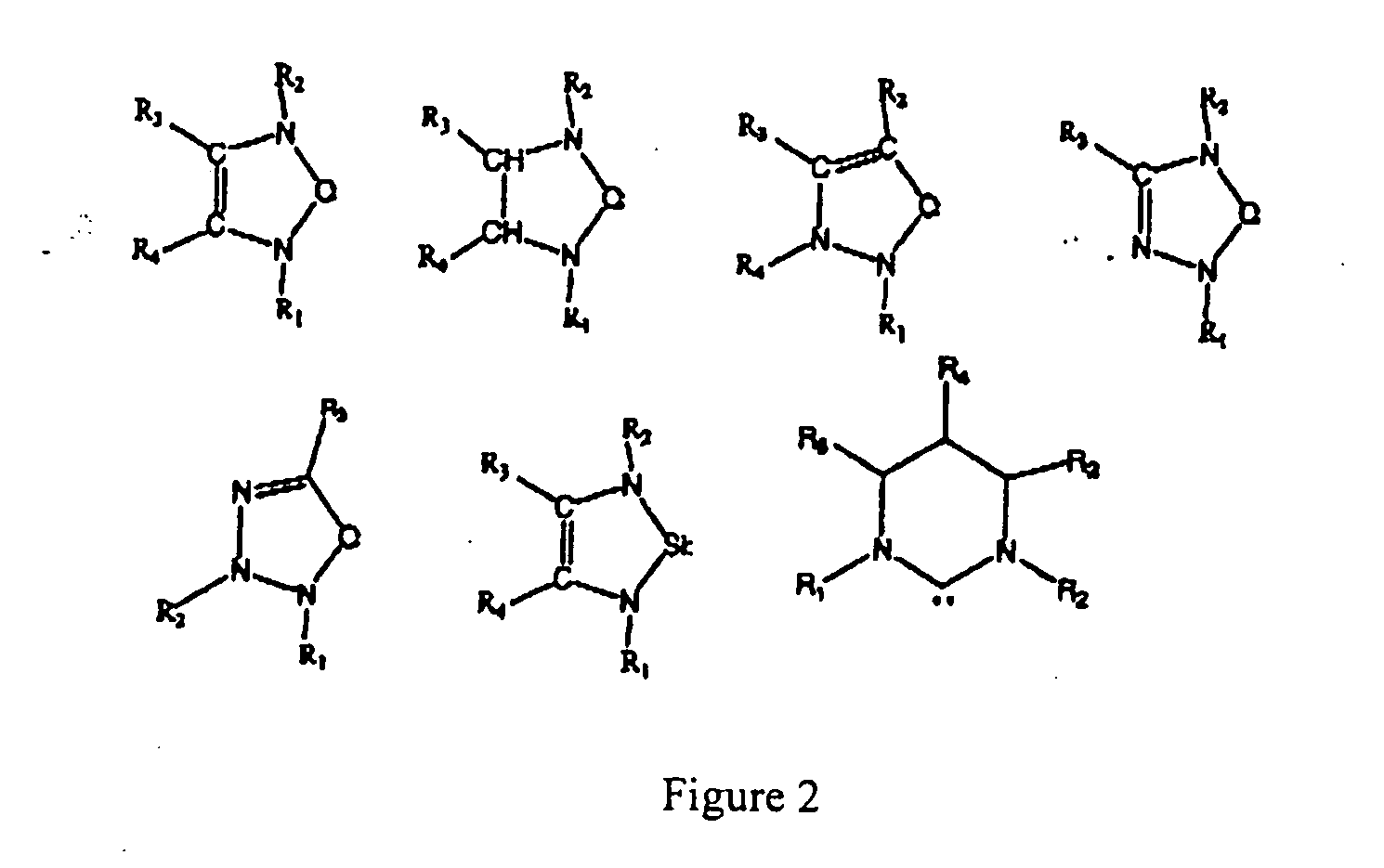

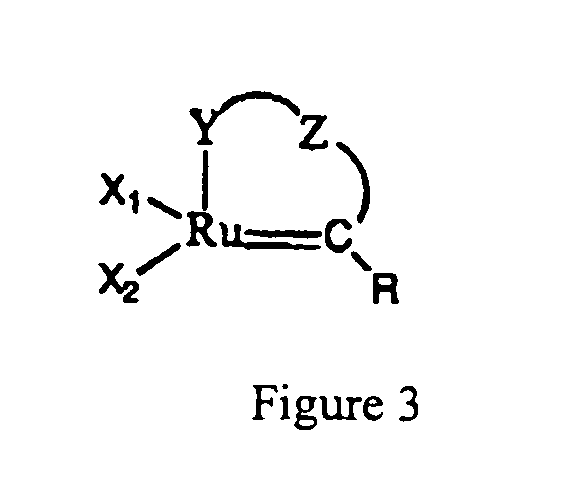

Process for co-producing olefins and esters by ethenolysis of unsaturated fats in non-aqueous ionic liquids

A process is described in which an unsaturated fat is reacted with ethylene in a metathesis reaction in the presence of at least one non-aqueous ionic liquid to produce both an olefinic fraction and a composition of monoalcohol or polyol esters. Particular application to an oleic sunflower seed oil, an oleic rapeseed oil or to a mixture of monoalcohol esters of said oils, the process producing both an olefinic fraction and a monoalcohol or glycerol esters composition generally having more than half of its chains constituted by unsaturated C10 chains.

Owner:INST FR DU PETROLE

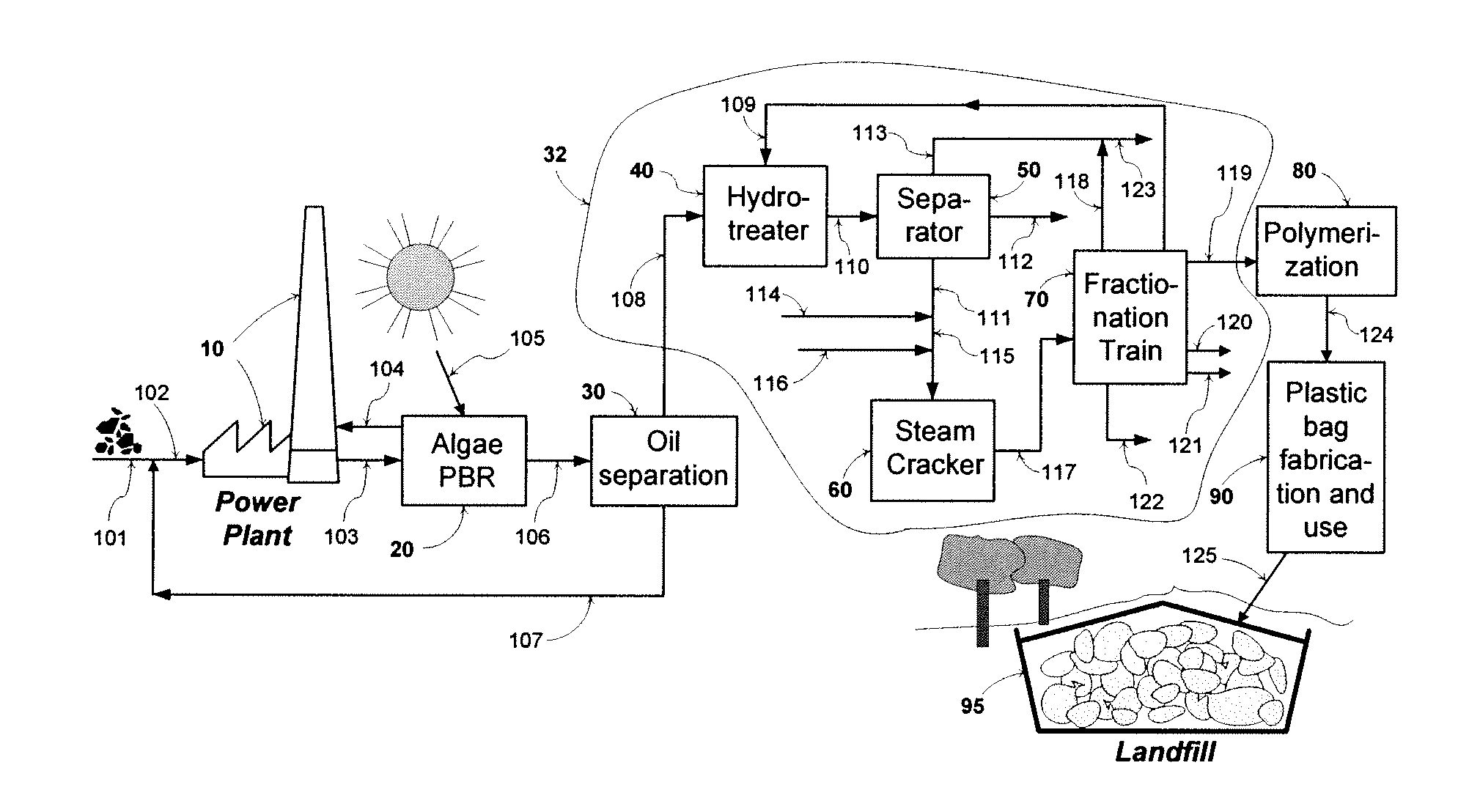

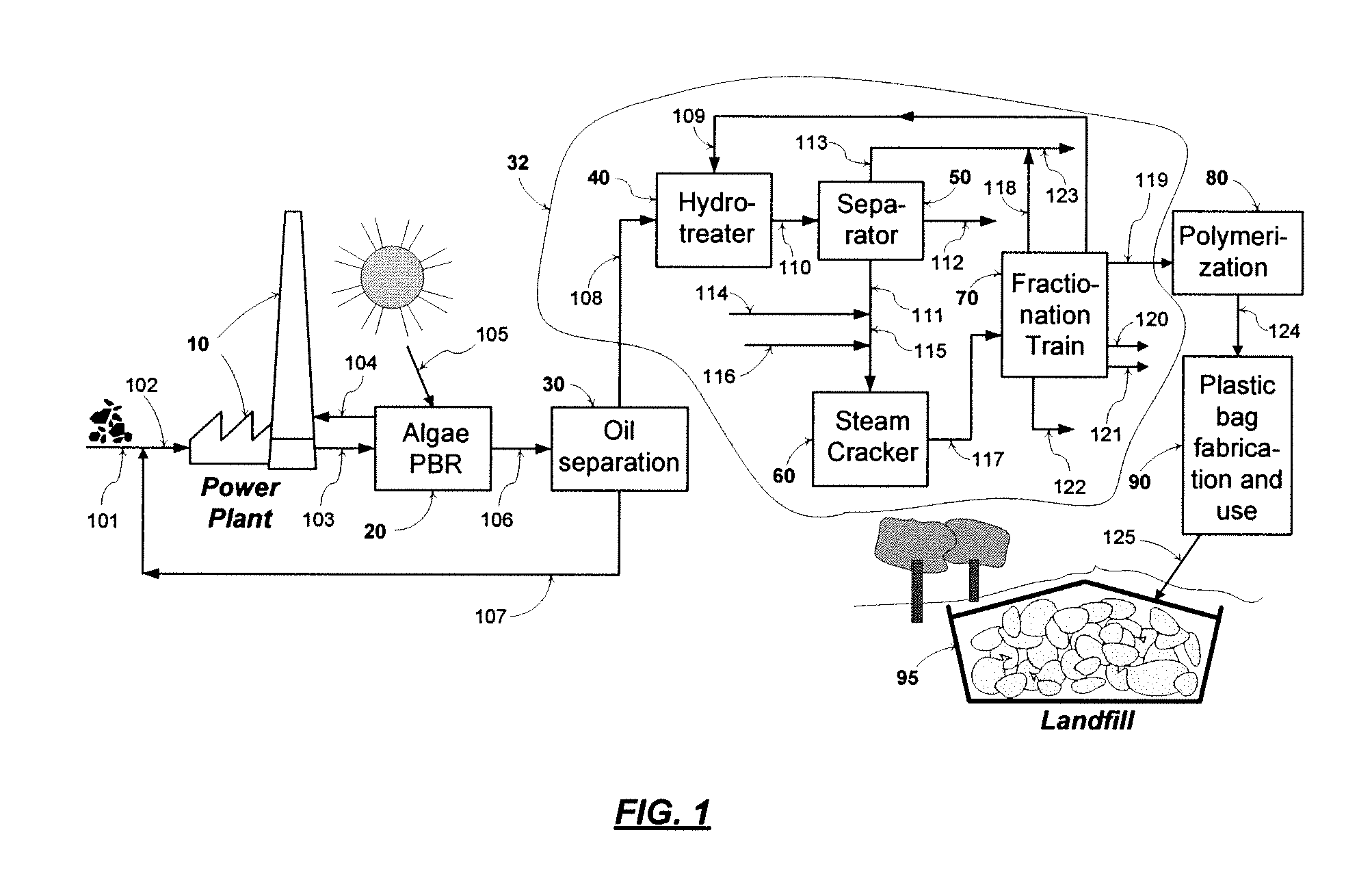

Profitable method for carbon capture and storage

The present invention generally relates to a method for sequestering carbon dioxide. Biomass is converted into paraffinic hydrocarbons. The paraffinic hydrocarbons are steam cracked into olefins. The olefins are polymerized into non-biodegradable polyolefins.

Owner:REG SYNTHETIC FUELS LLC

Popular searches

Hydrocarbon preparation catalysts Chemical/physical/physico-chemical processes Hydrocarbon from saturated and unsaturated hydrocarbon addition Liquid-gas reaction processes Ethylene production Treatment with hydrotreatment processes Bio-feedstock Base-materials Hydrocarbon oils treatment products Solid fuels

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com