Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154 results about "2-methylbutane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isopentane, C5H12, also called methylbutane or 2-methylbutane, is a branched-chain alkane with five carbon atoms. Isopentane is an extremely volatile and extremely flammable liquid at room temperature and pressure.

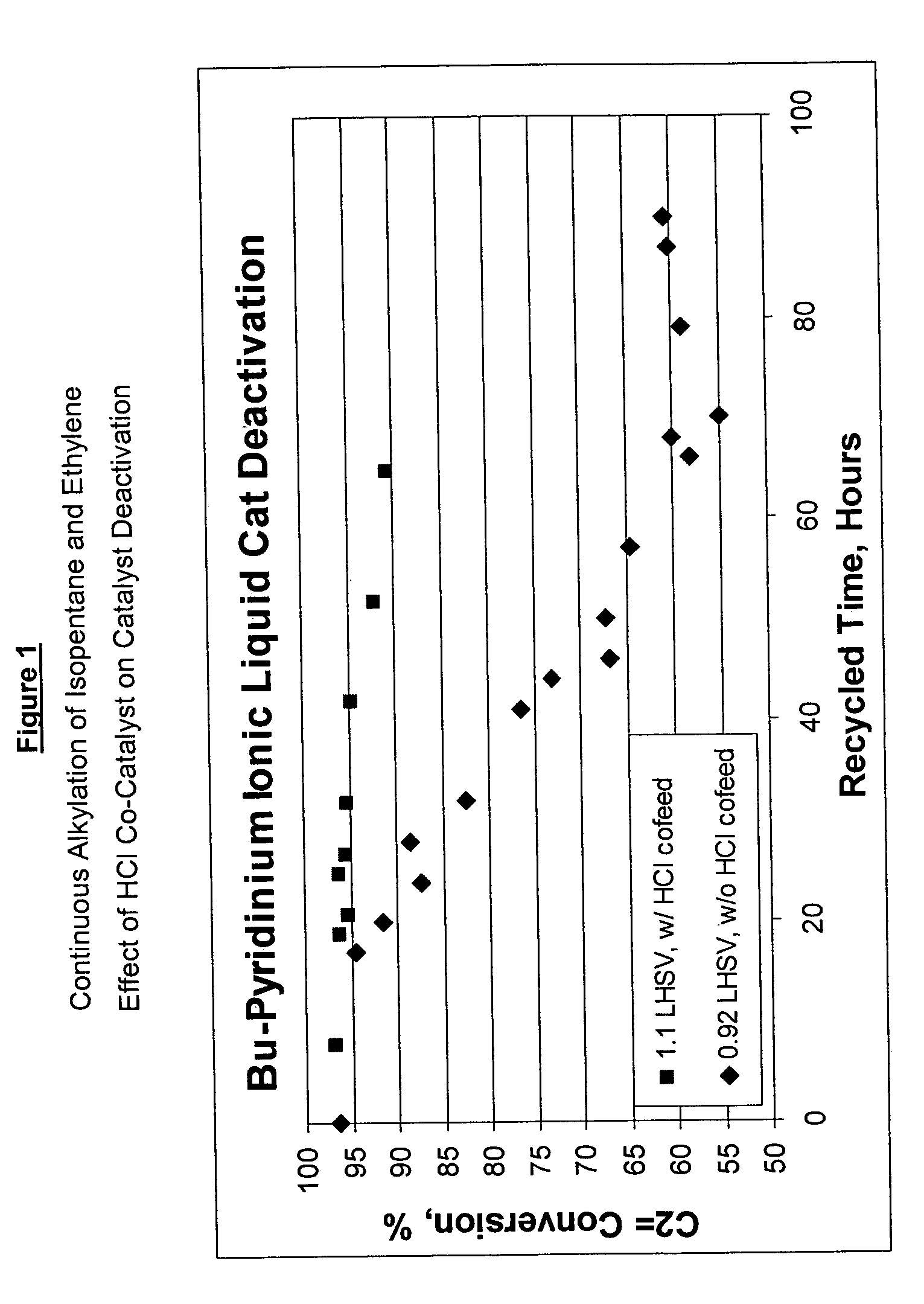

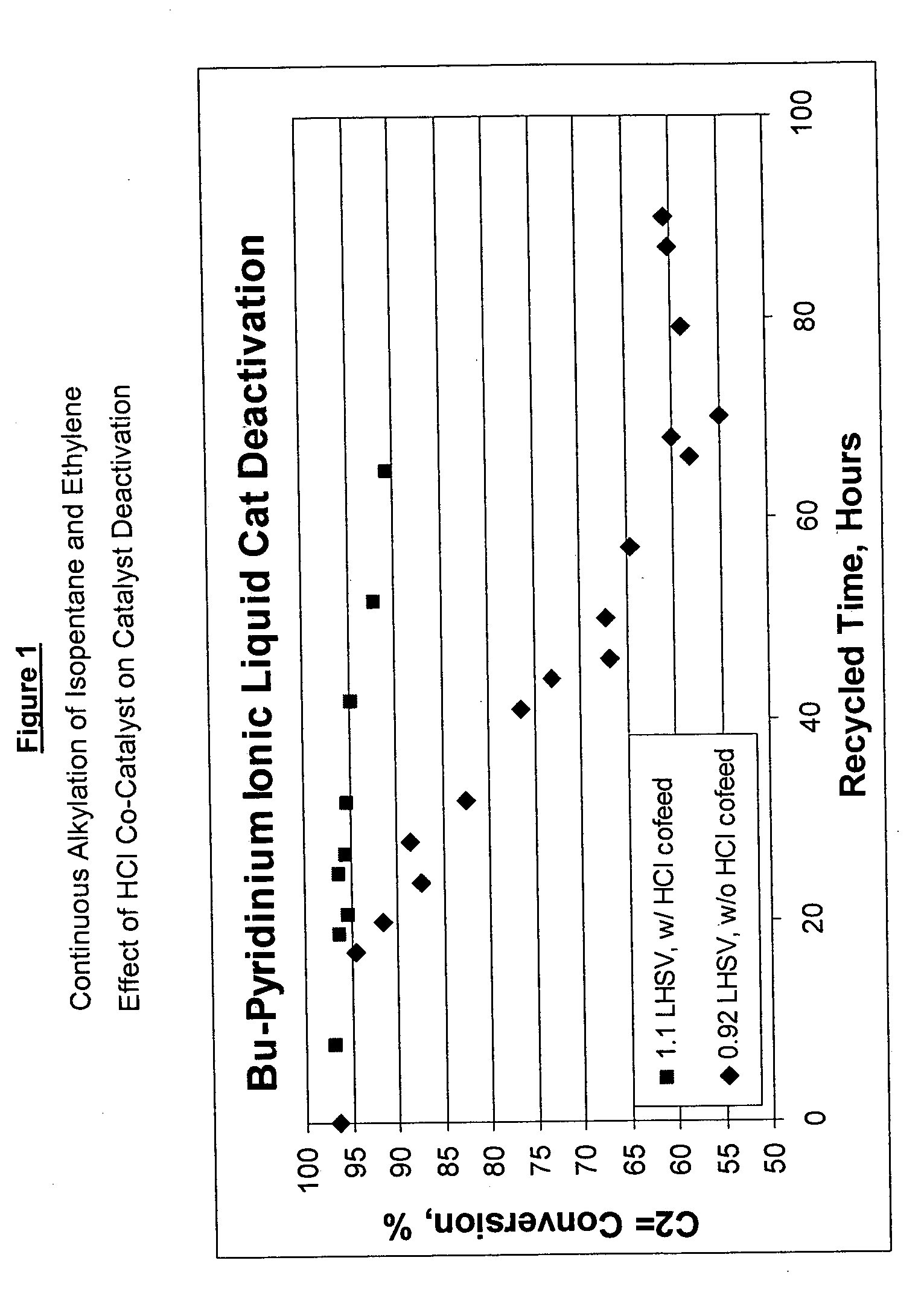

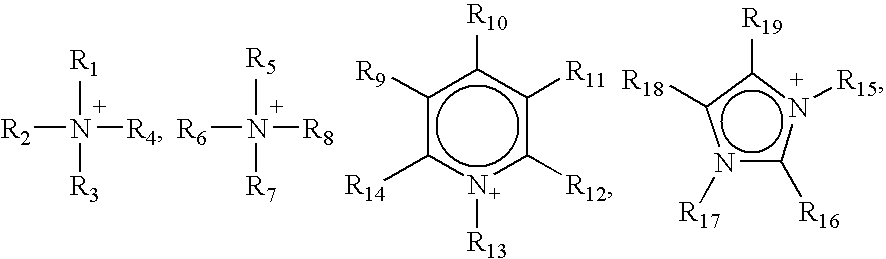

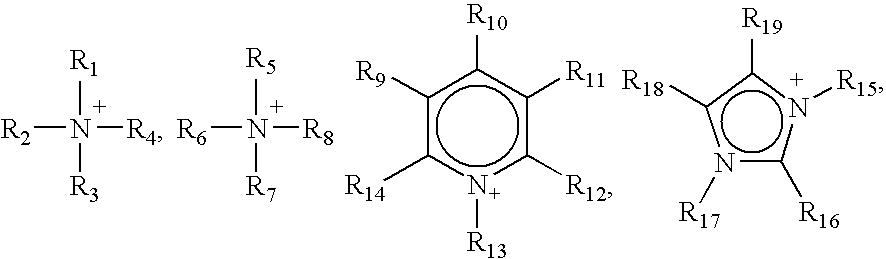

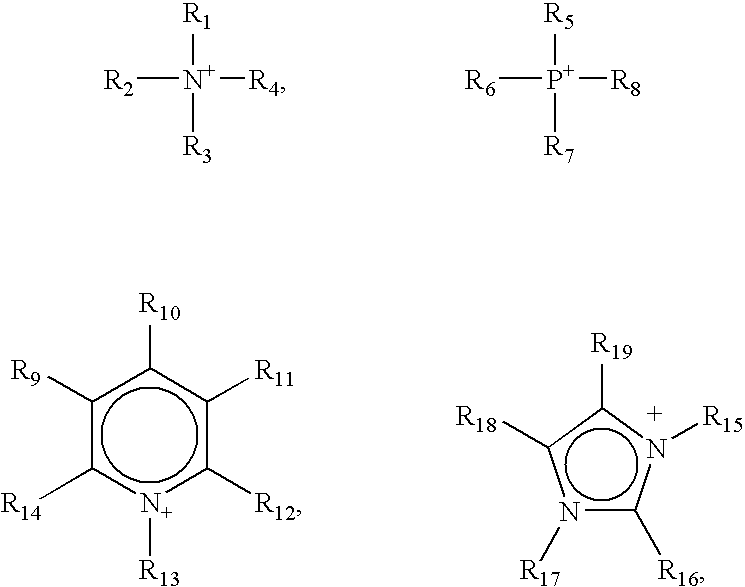

Alkylation process using chloroaluminate ionic liquid catalysts

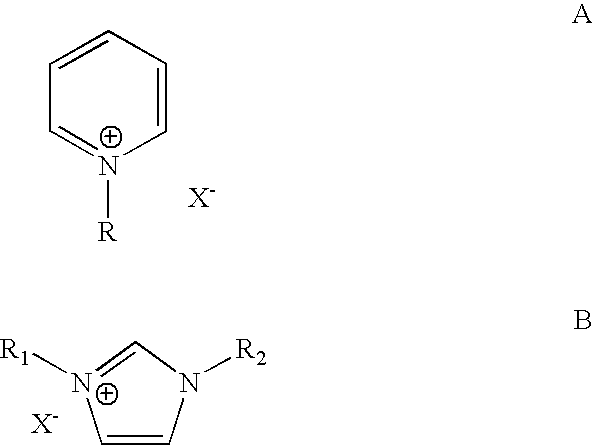

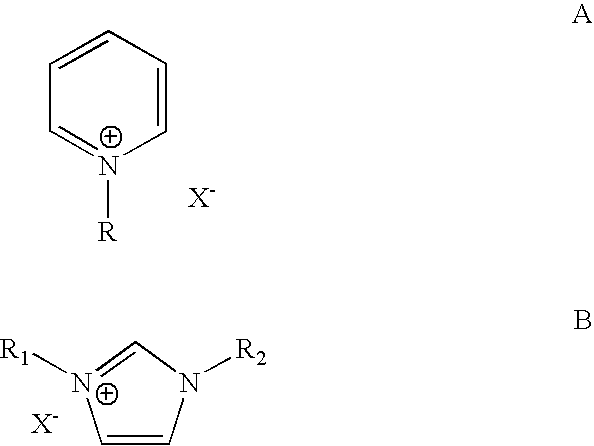

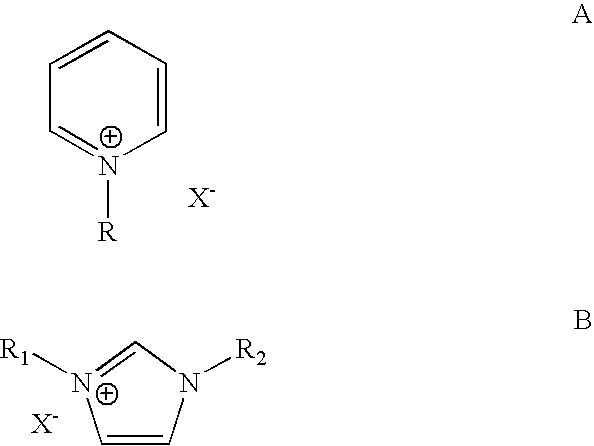

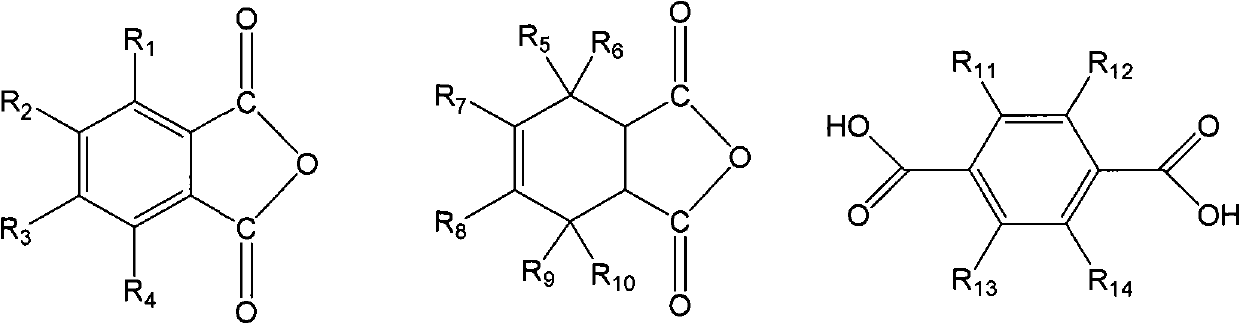

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium chloroaluminate or a hydrocarbyl substituted imidazolium chloroaluminate of the general formulas A and B, respectively.Where R═H, methlyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a chloroaluminate, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

Alkylation process using chloroaluminate ionic liquid catalysts

ActiveUS20060135839A1Quality improvementLiquid hydrocarbon mixtures productionHydrocarbons2-methylbutanePyridinium

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium halide or a hydrocarbyl substituted imidazolium halide of the general formulas A and B, respectively. Where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

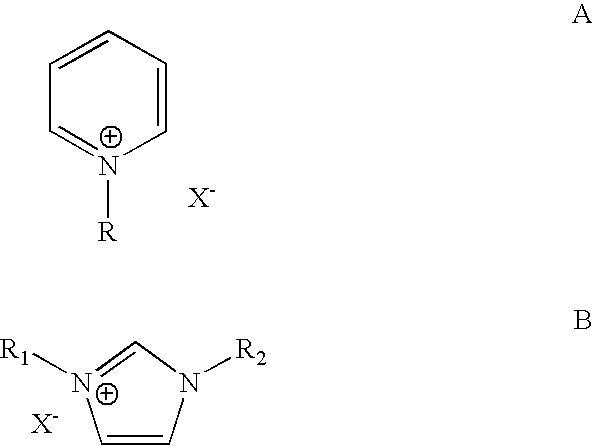

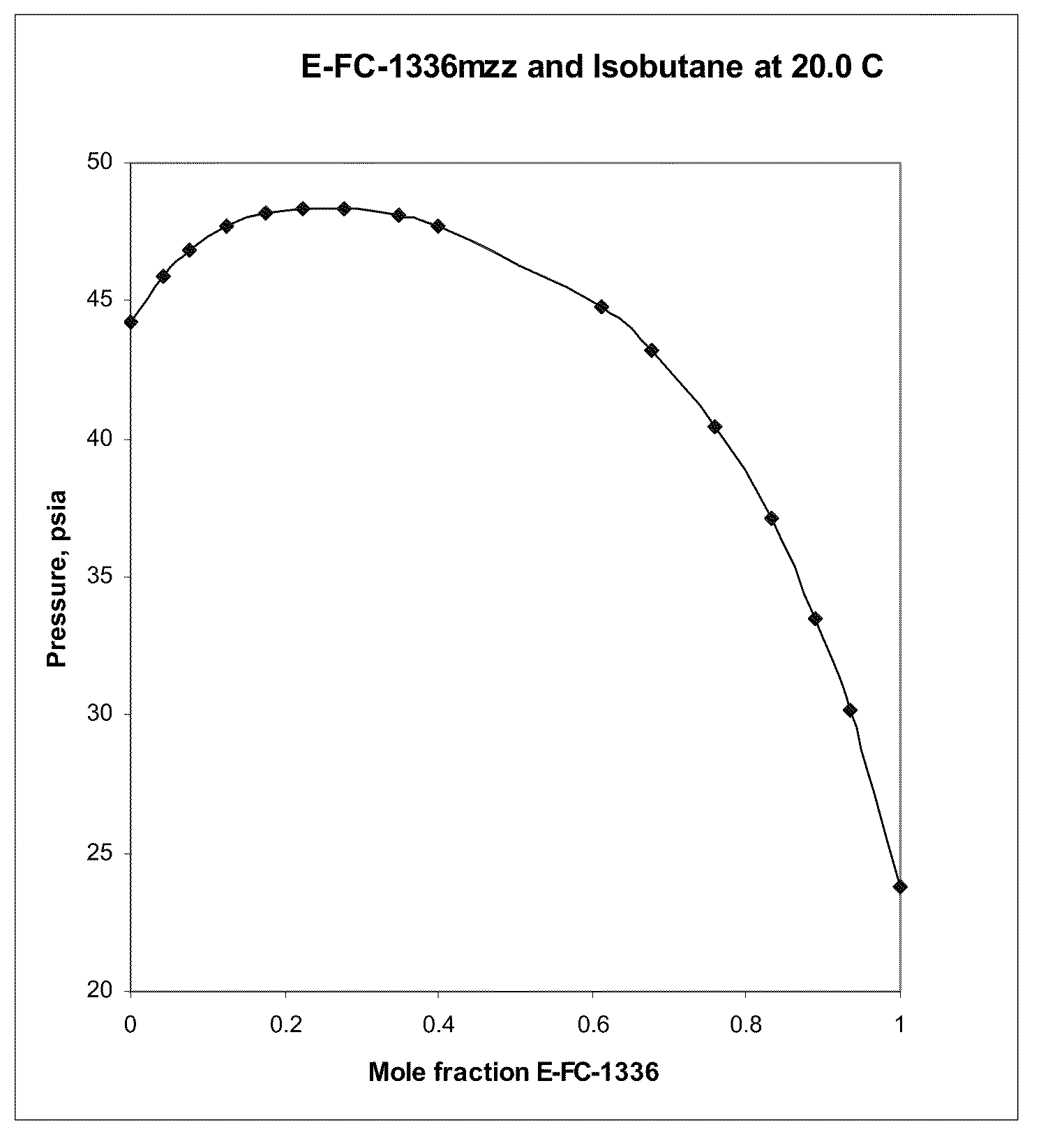

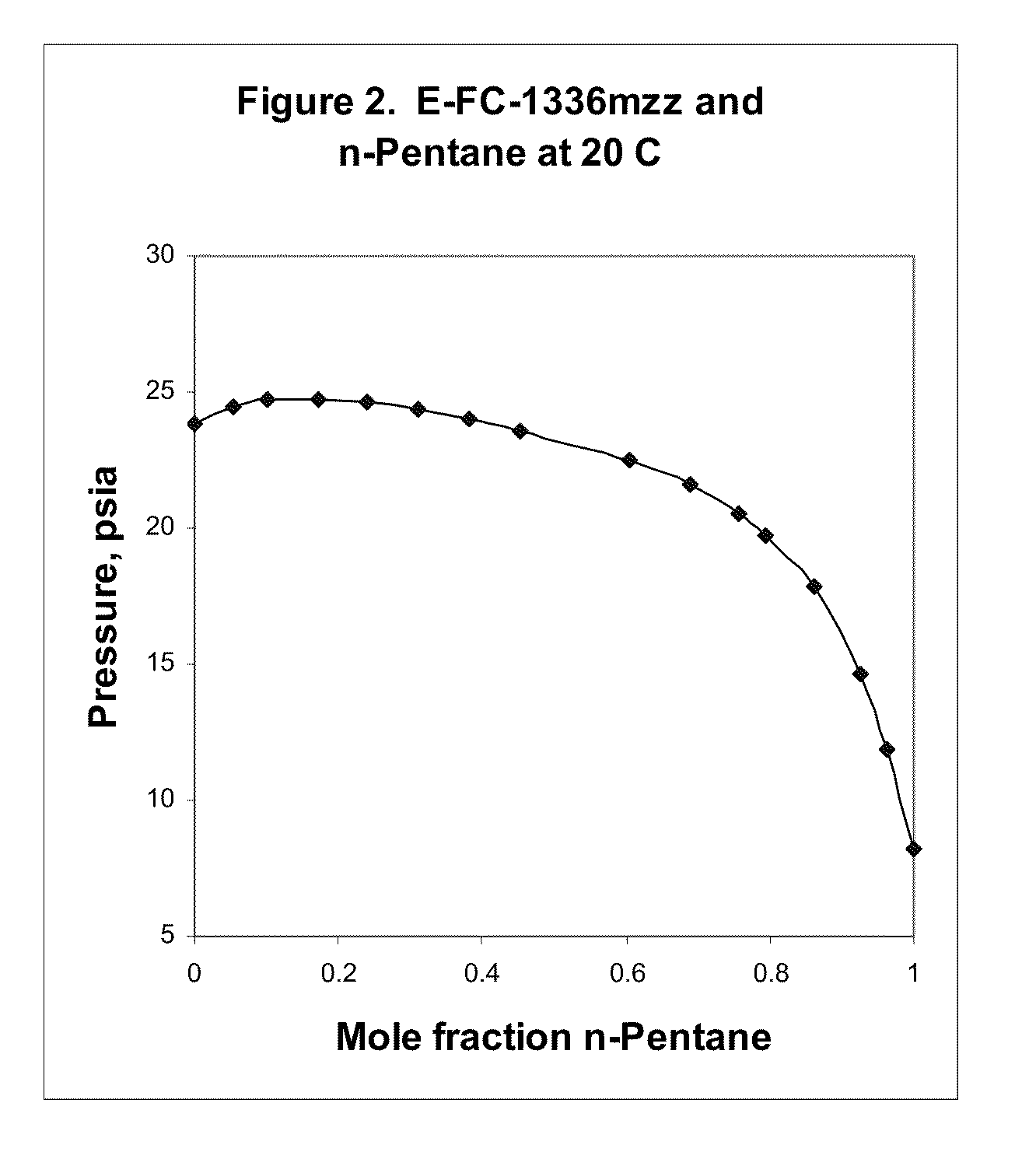

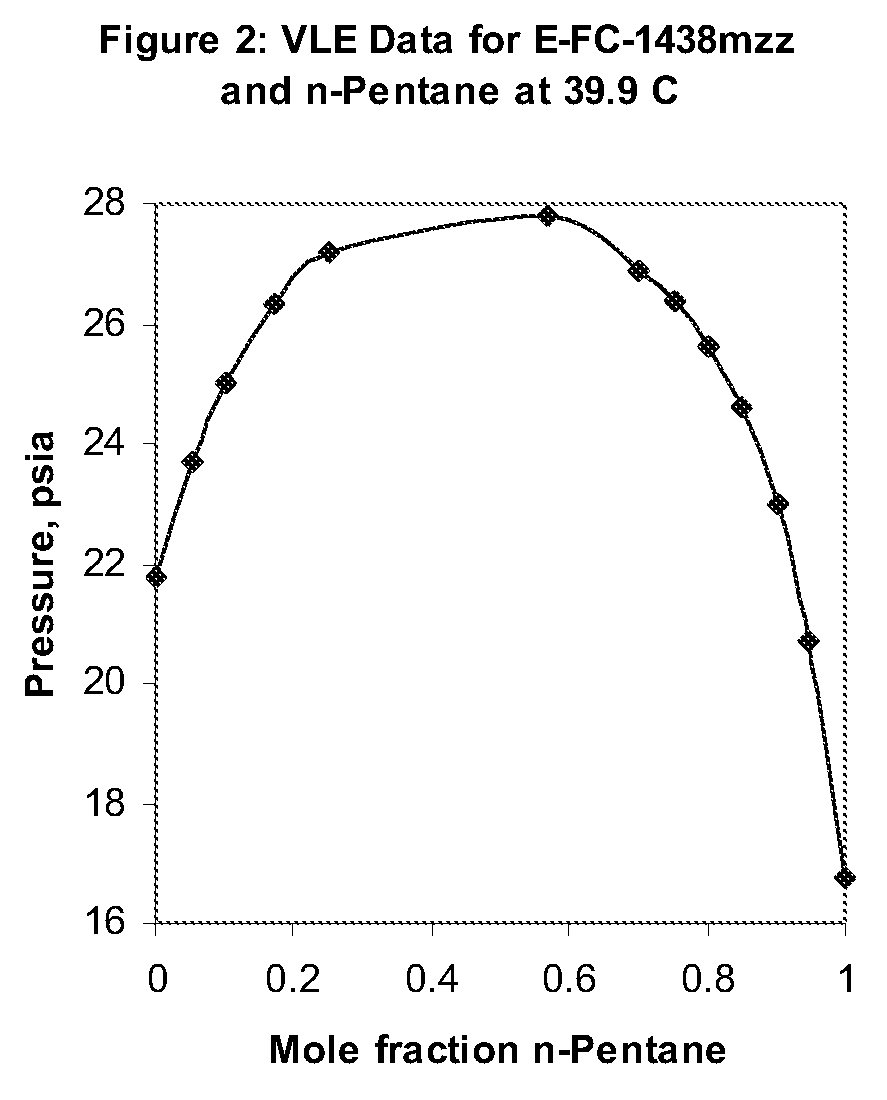

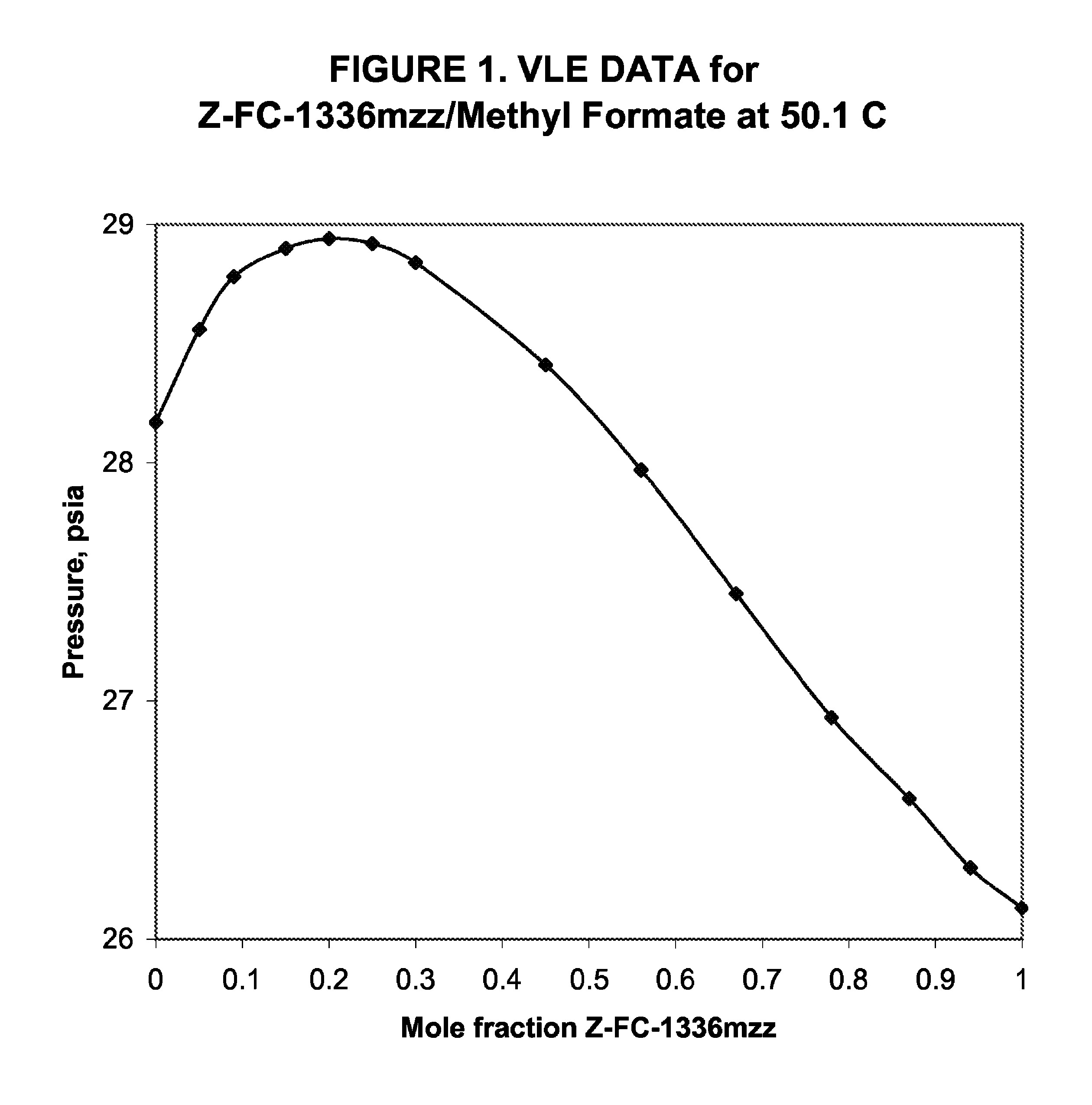

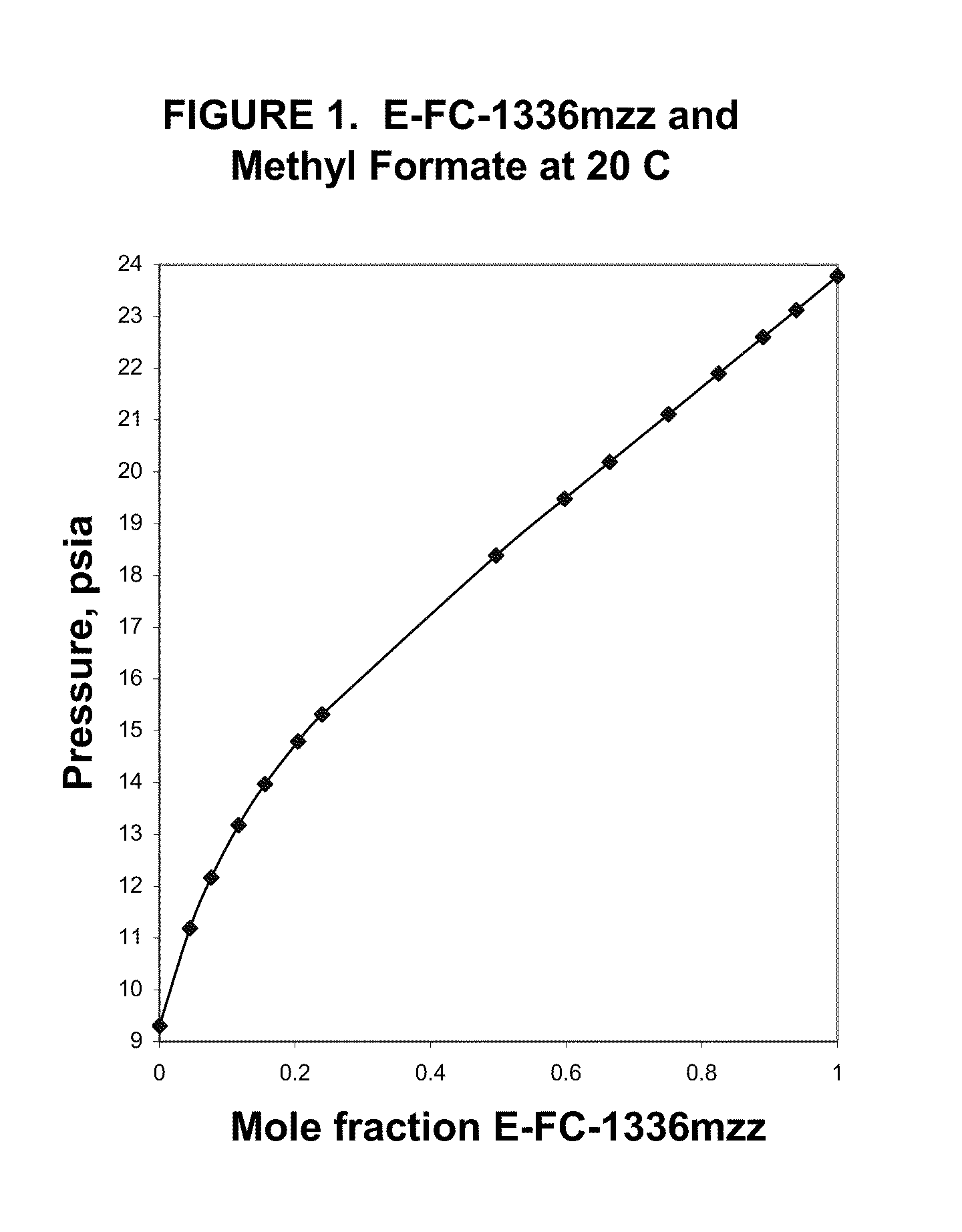

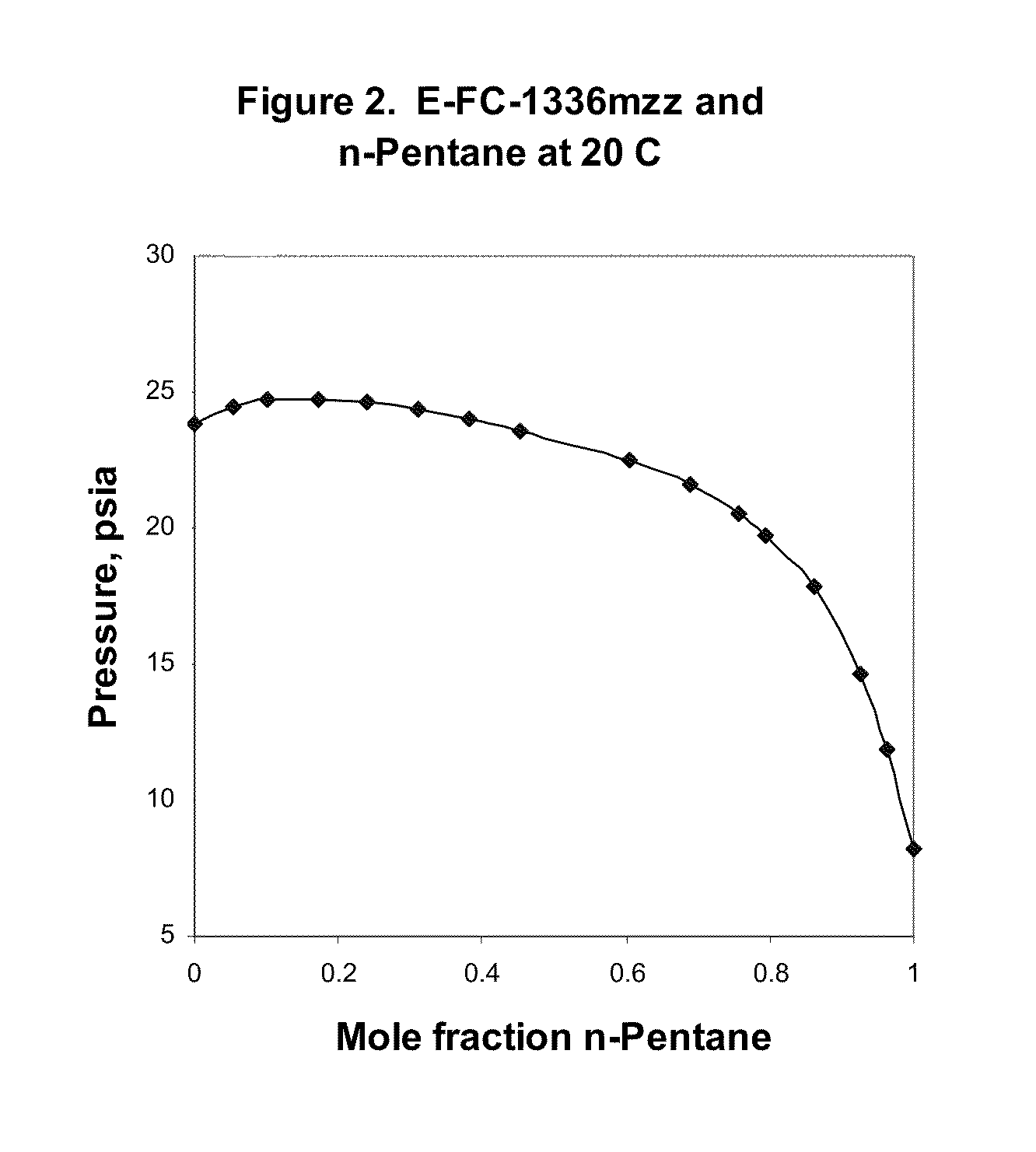

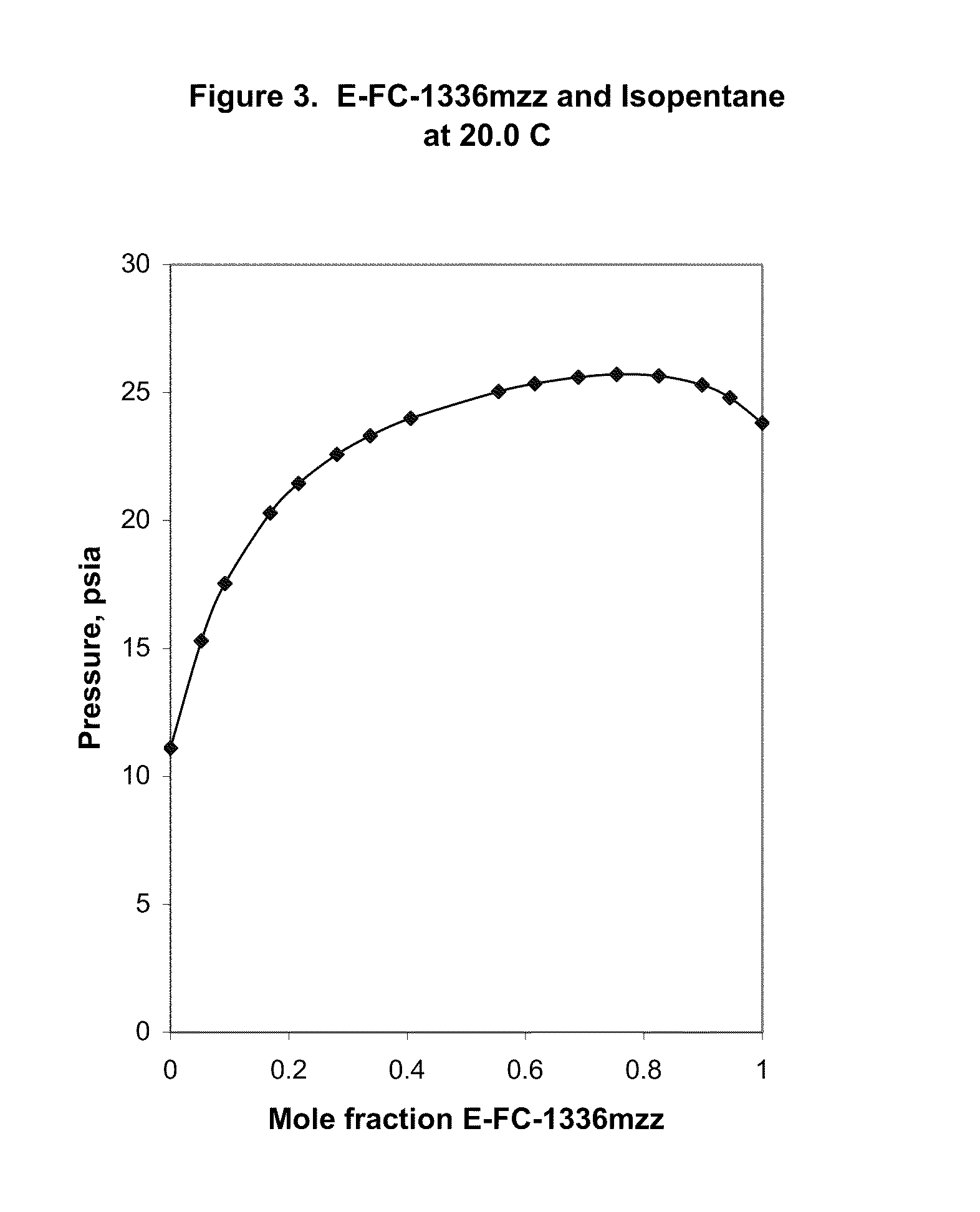

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, n-pentane, 2-methylbutane trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, n-butane or isobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Supported ionic liquid and the use thereof in the disproportionation of isopentane

InactiveUS20050033102A1Increased product formationIncreased formationOrganic-compounds/hydrides/coordination-complexes catalystsCatalysts2-methylbutaneAlkane

A catalyst system containing an ionic liquid dispersed on a support having an average pore diameter greater than about 225 Å is disclosed. The catalyst system is employed in a process to disproportionate a C5 paraffin.

Owner:CONOCOPHILLIPS CO

Processes for making higher octane motor fuels having a low reid vapor pressure from naphtha boiling range feedstocks

ActiveUS7485768B1Low vapor pressureLower energy requirementsHydrocarbon by hydrogenationCatalytic naphtha reforming2-methylbutaneNaphtha

Owner:UOP LLC

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,5,5,5-octafluoro-2-pentene

InactiveUS20100243943A1Organic compounds purification/separation/stabilisationOther chemical processesDielectricThermoplastic

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,5,5,5-Octafluoro-2-pentene with methyl formate, n-pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, cyclopentane or Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions as propellants. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics. Also disclosed is a process for the separation of a chemical compound from a mixture of two or more chemical compounds using such azeotropic or azeotrope-like compositions.

Owner:THE CHEMOURS CO FC LLC

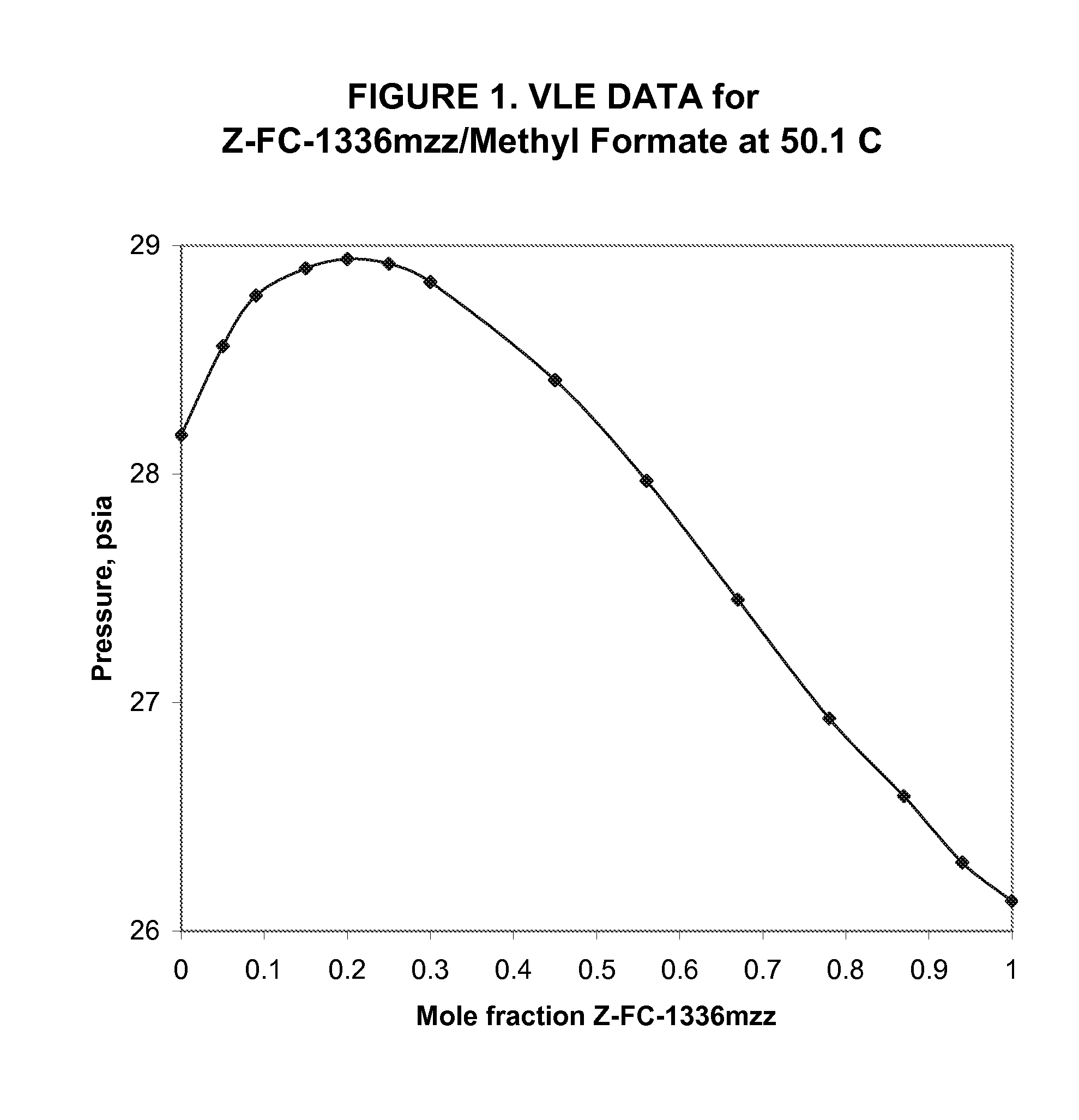

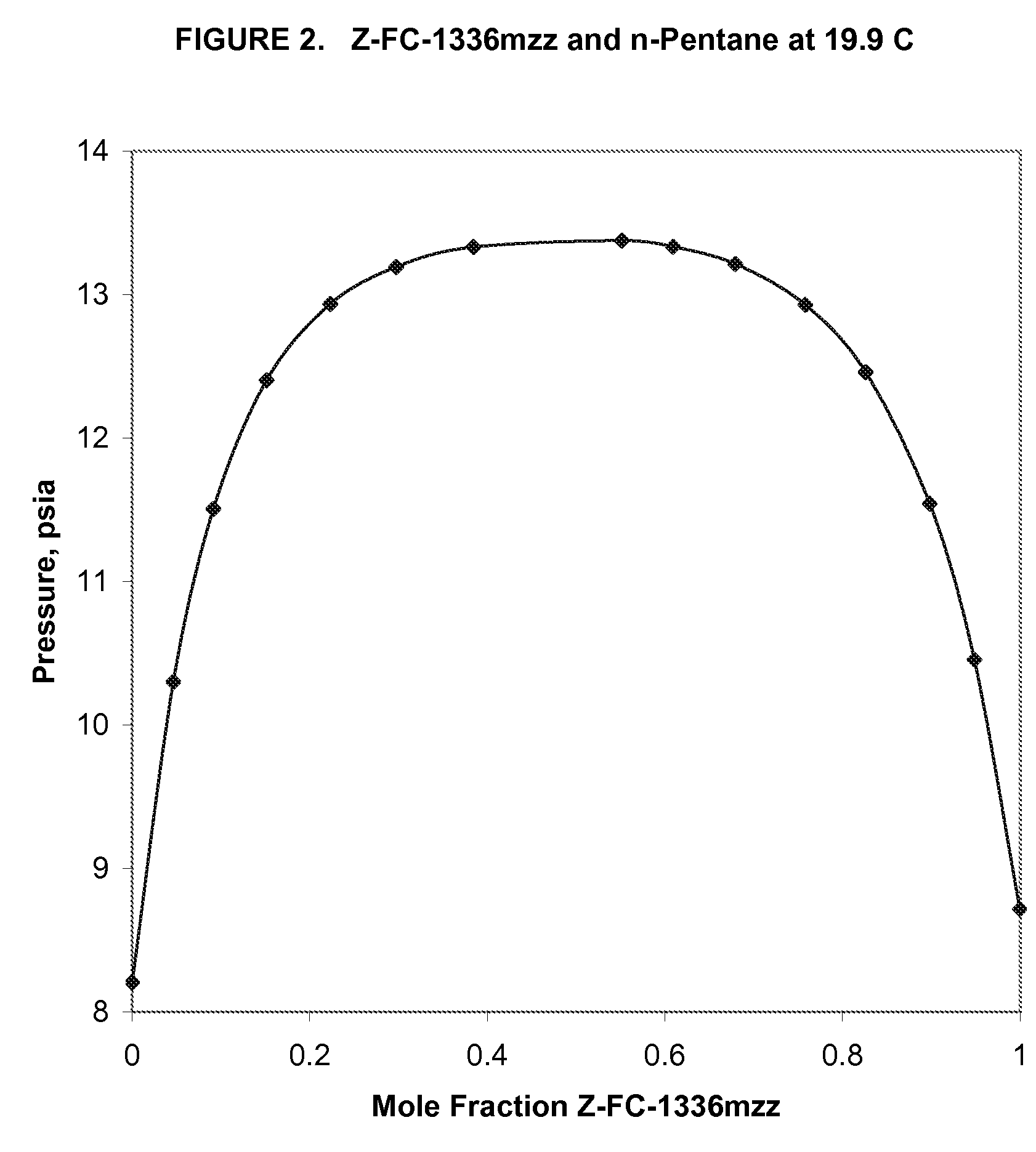

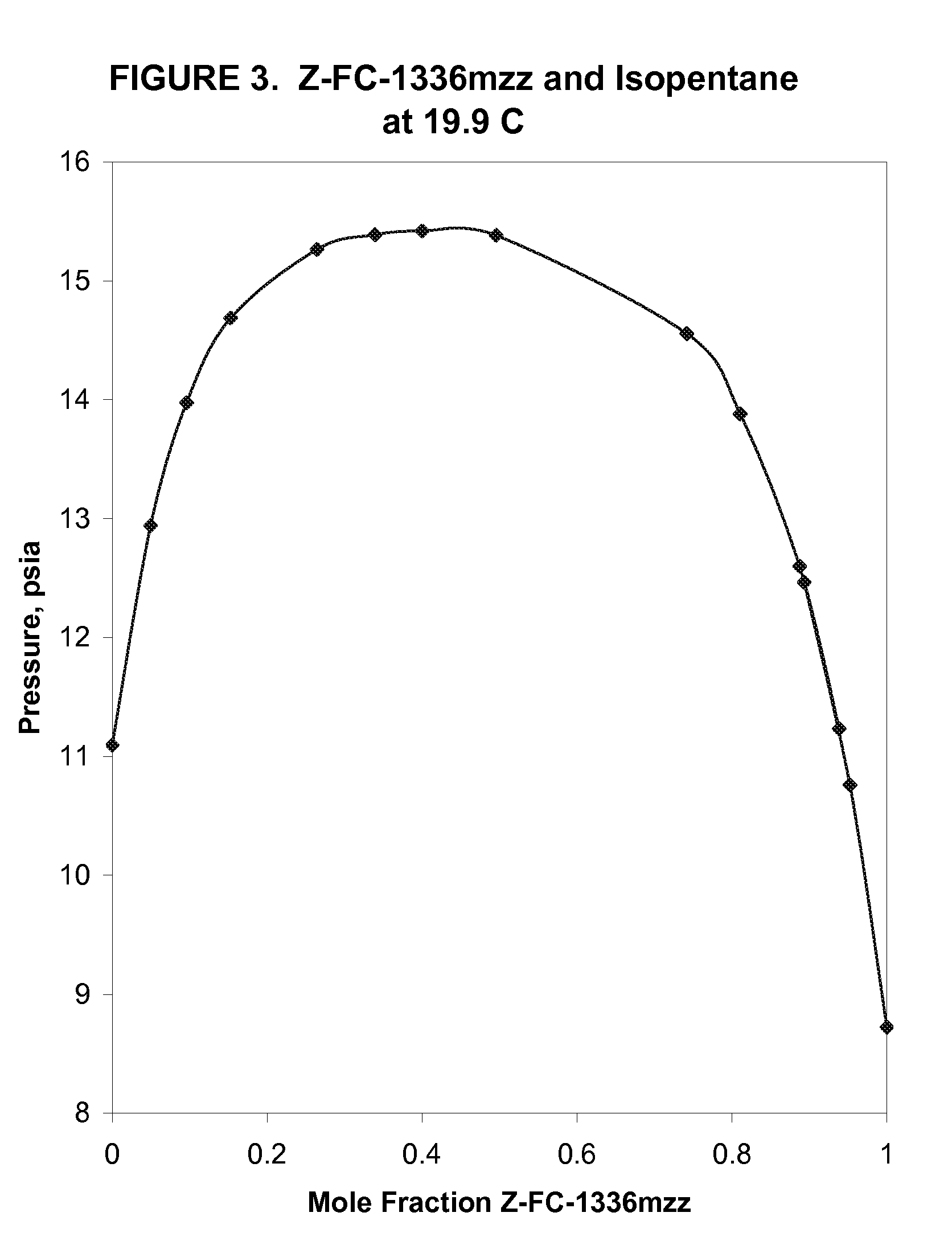

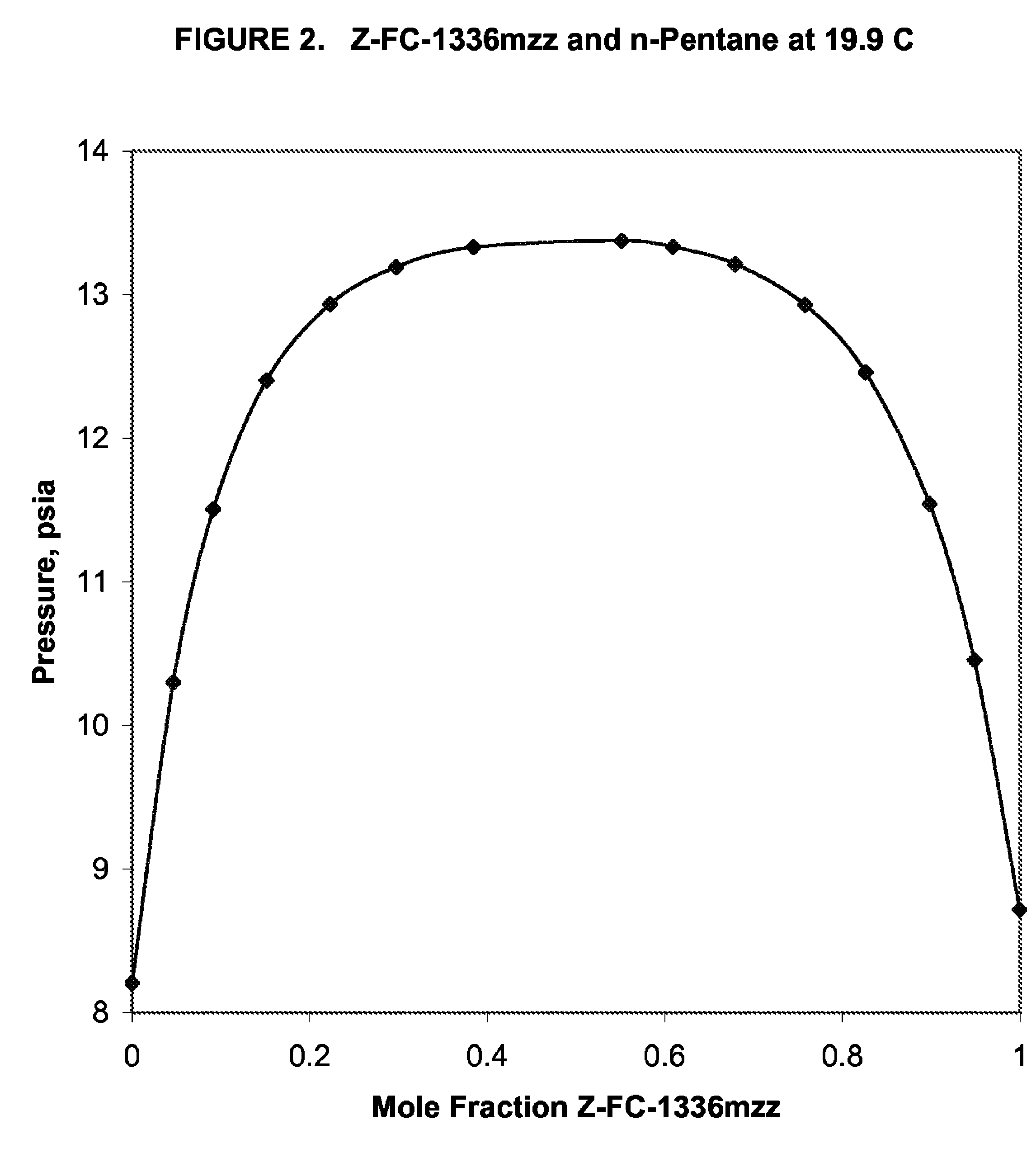

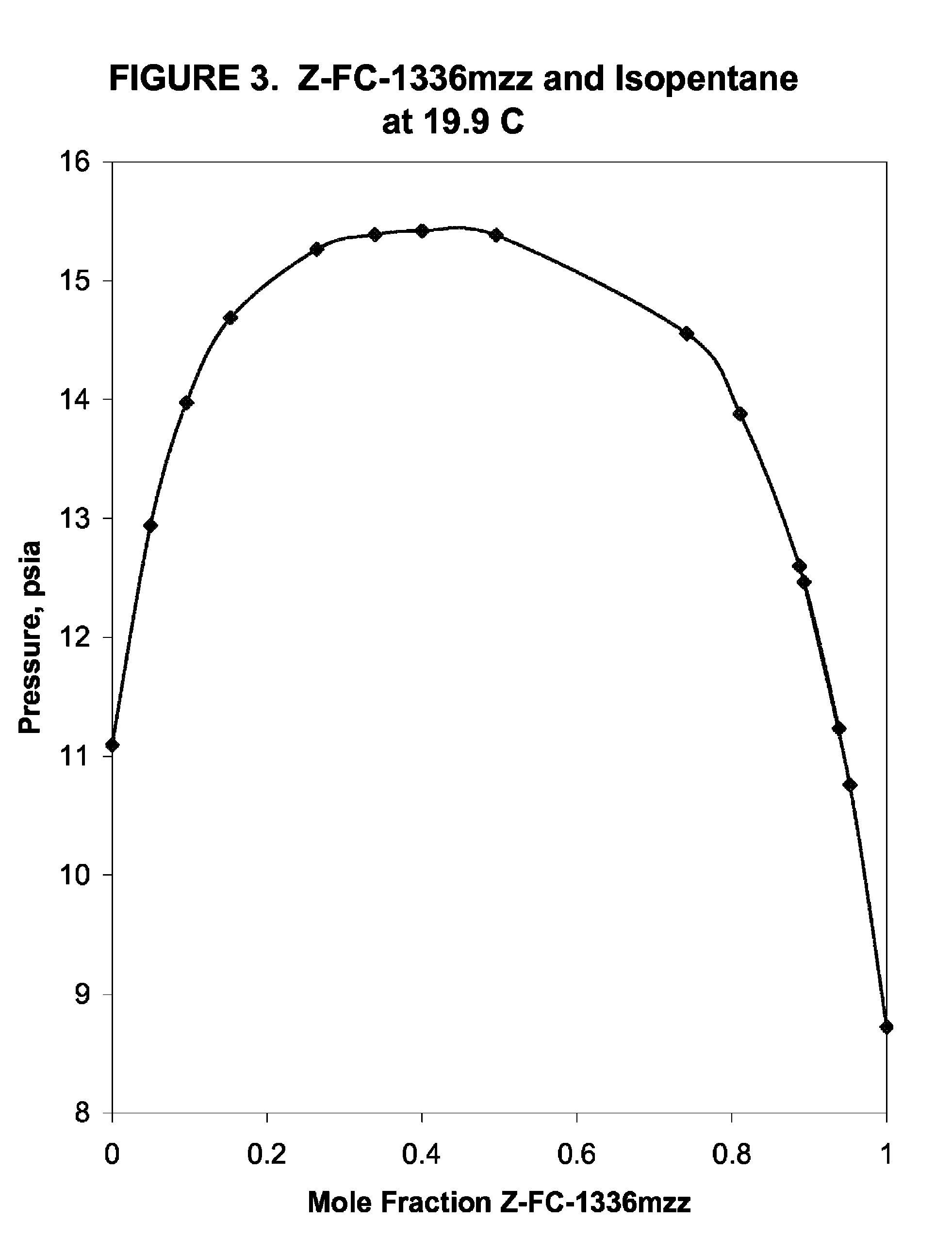

Azeotropic and azeotrope-like compositions of z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

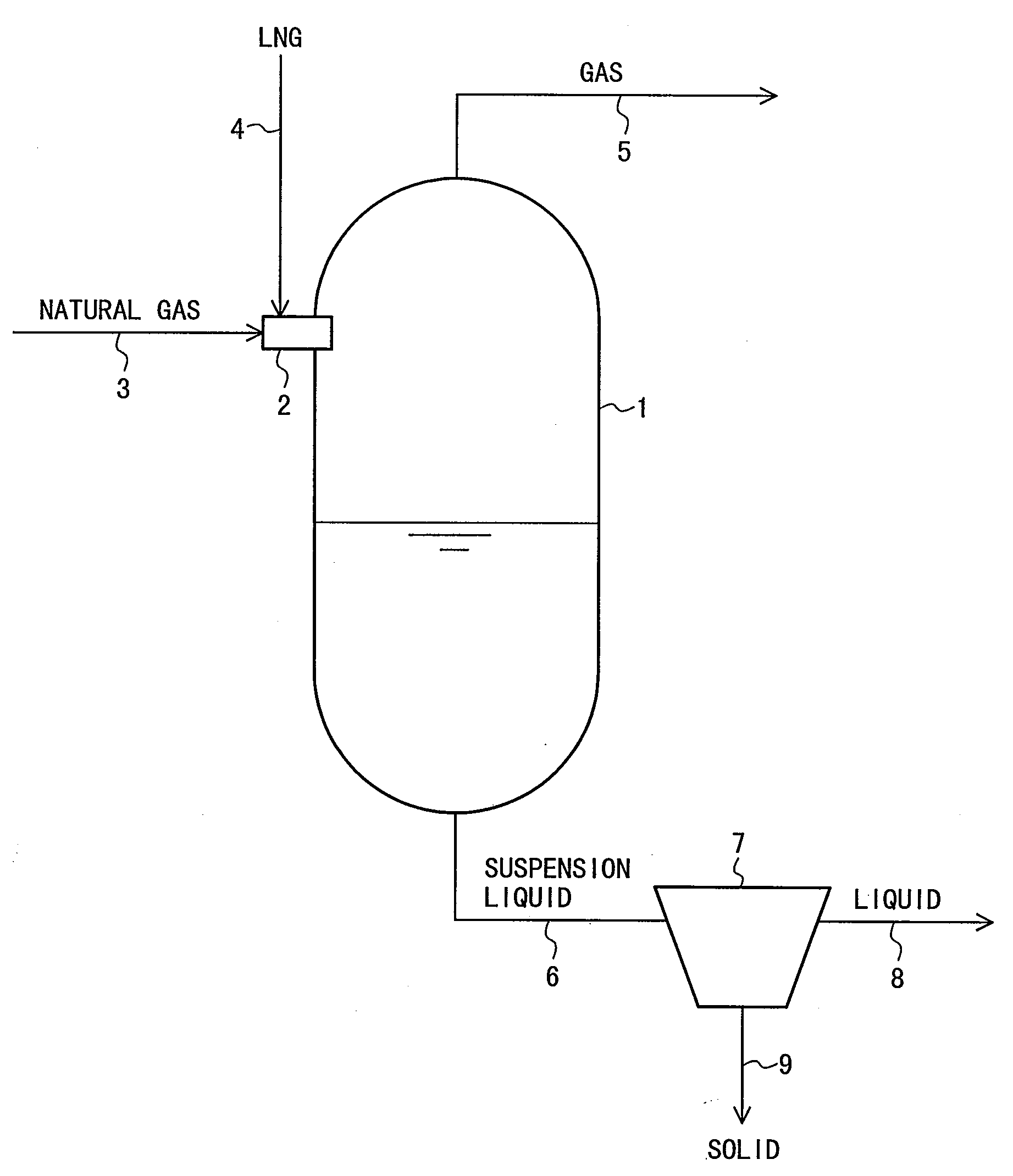

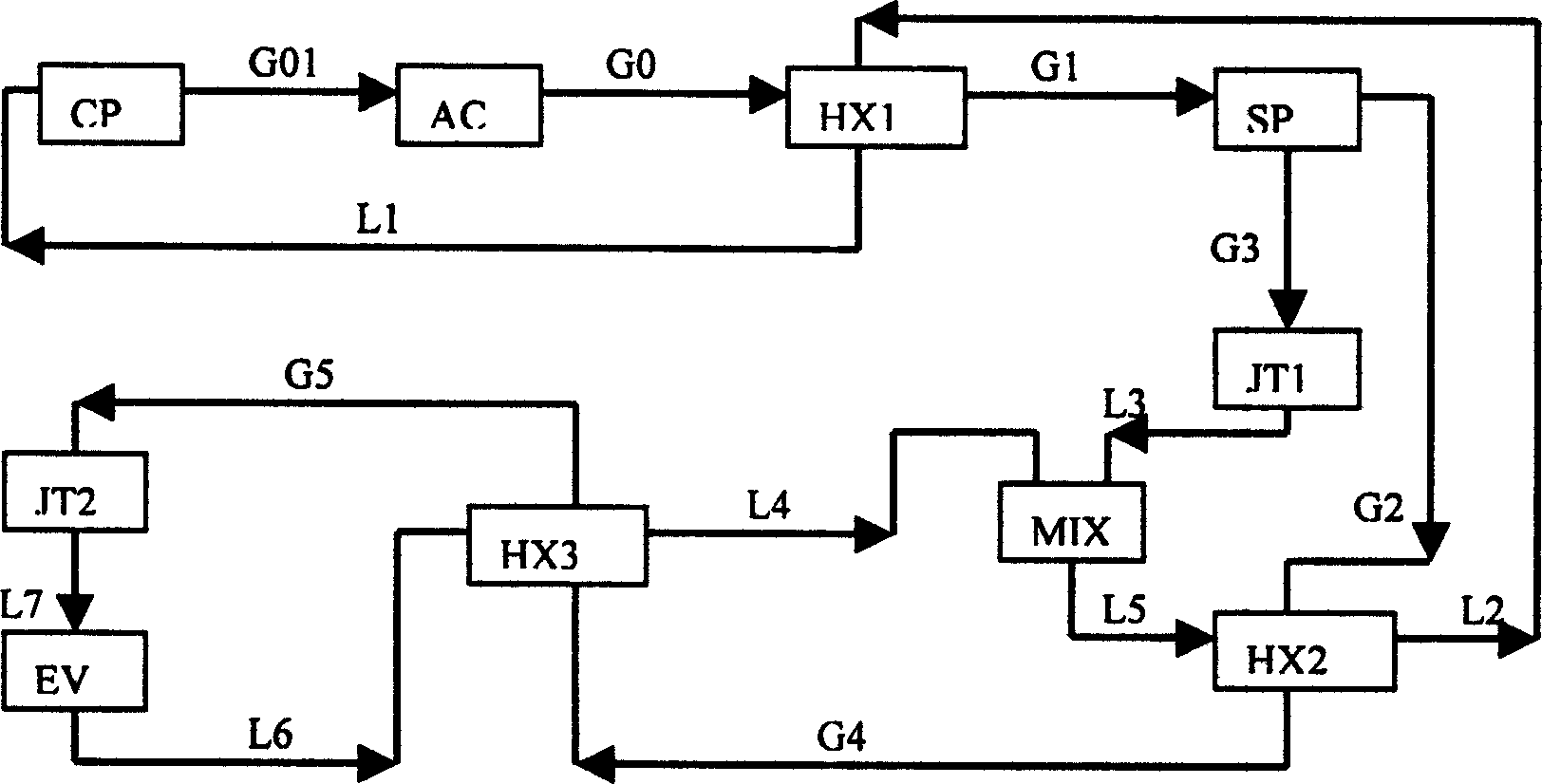

Method of refining natural gas and natural gas refining system

InactiveUS20080307827A1Improve product qualityQuality improvementSolidificationLiquefaction2-methylbutaneGas phase

A method and system of refining natural gas that improves the quality of liquefied natural gas and enables separation and recovery of hydrocarbons other than methane. The method of refining natural gas containing methane; any other hydrocarbon selected from the group consisting of ethane, ethylene, propane, propylene, n-butane, isobutane, 1-butene, n-pentane, and isopentane; carbon dioxide; and hydrogen sulfide, includes adjusting a pressure and temperature of the natural gas so that the methane is in the gas phase, the other hydrocarbon in the liquid phase, and the carbon dioxide and the hydrogen sulfide in the solid phase, respectively; separating the natural gas, of which the pressure and temperature has been adjusted, into a gas containing the methane and a suspension liquid; and separating the separated suspension liquid into a liquid containing the other hydrocarbon and a solid containing the carbon dioxide and the hydrogen sulfide.

Owner:HITACHI LTD

Azeotropic and azeotrope-like compositions of Z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

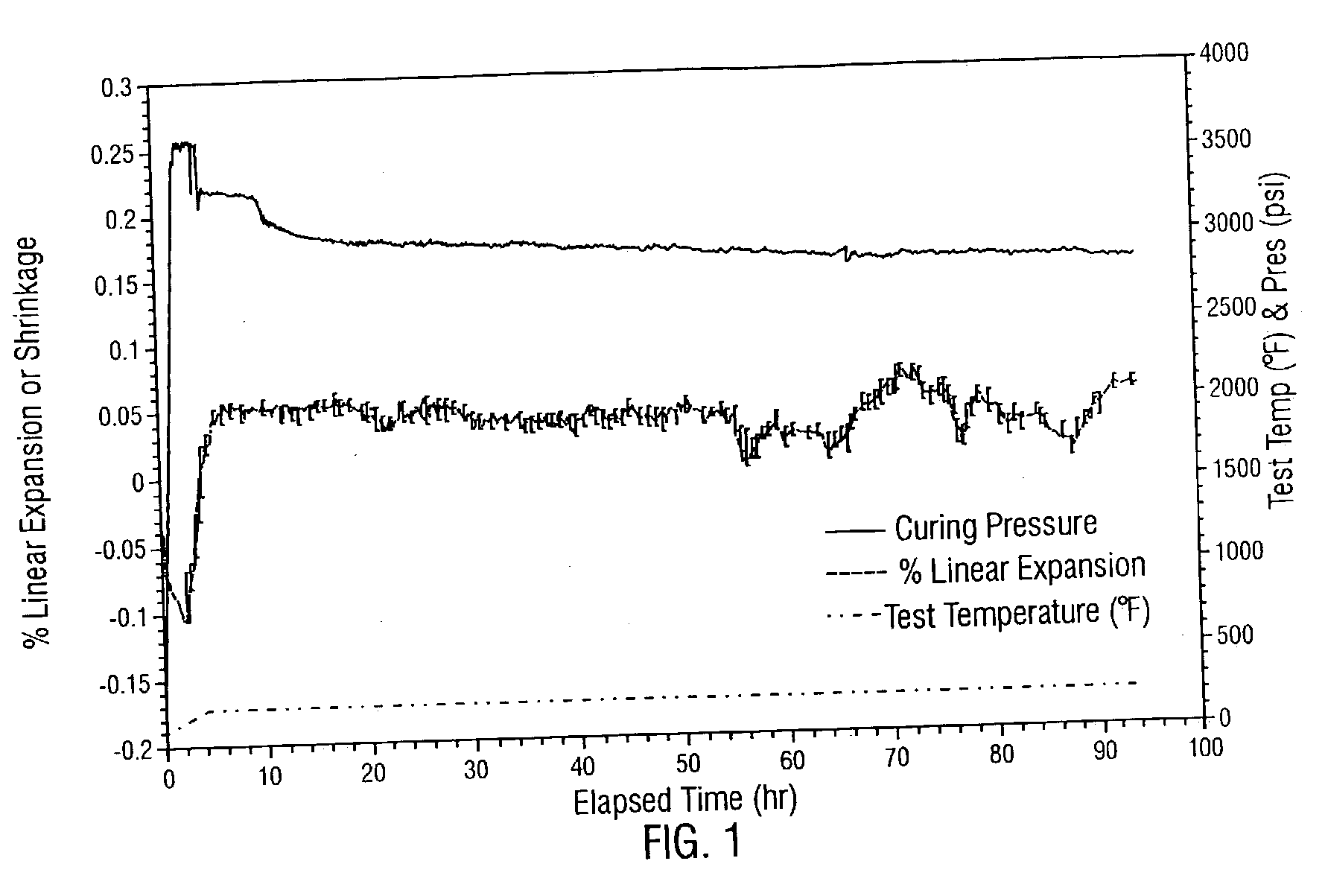

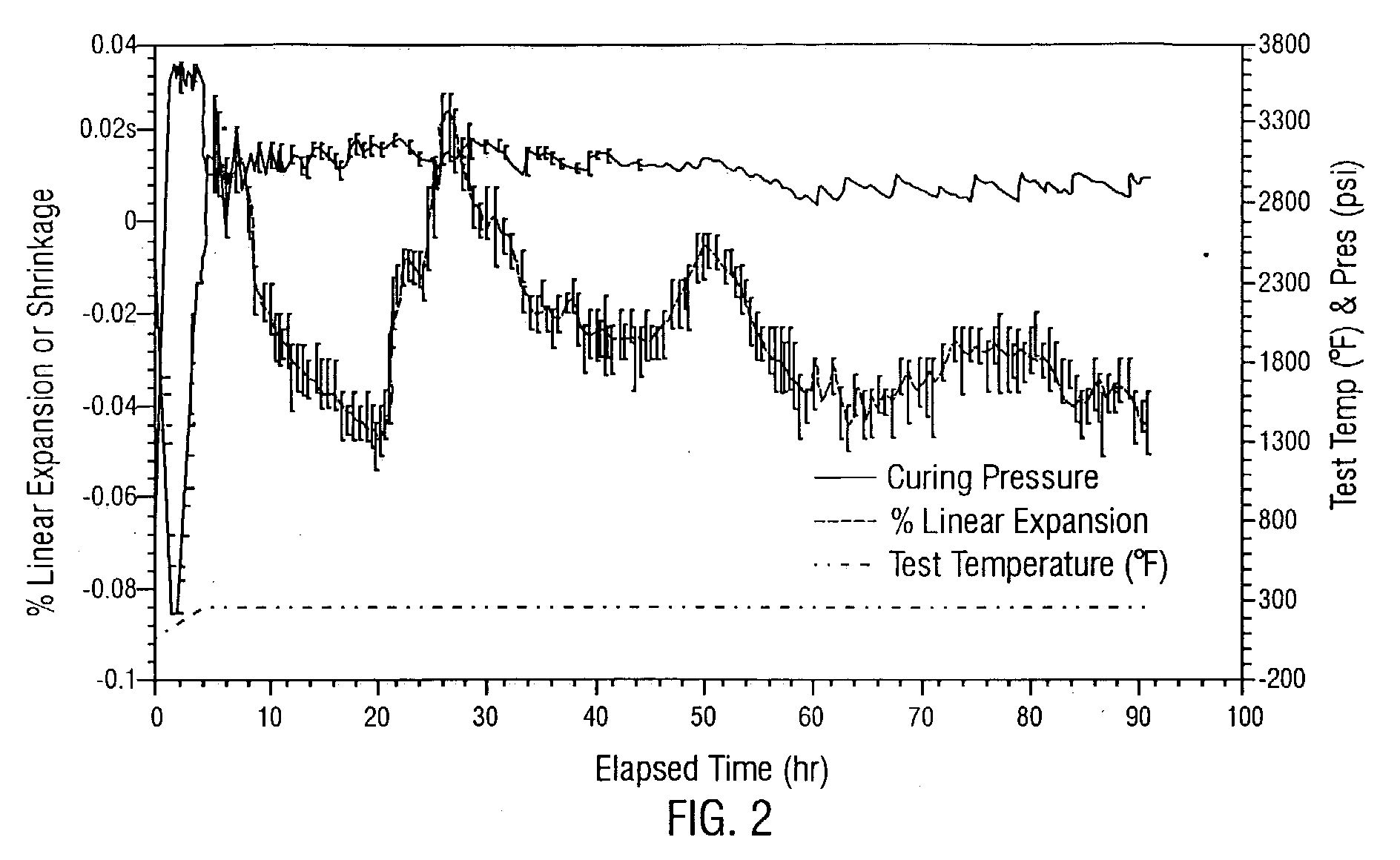

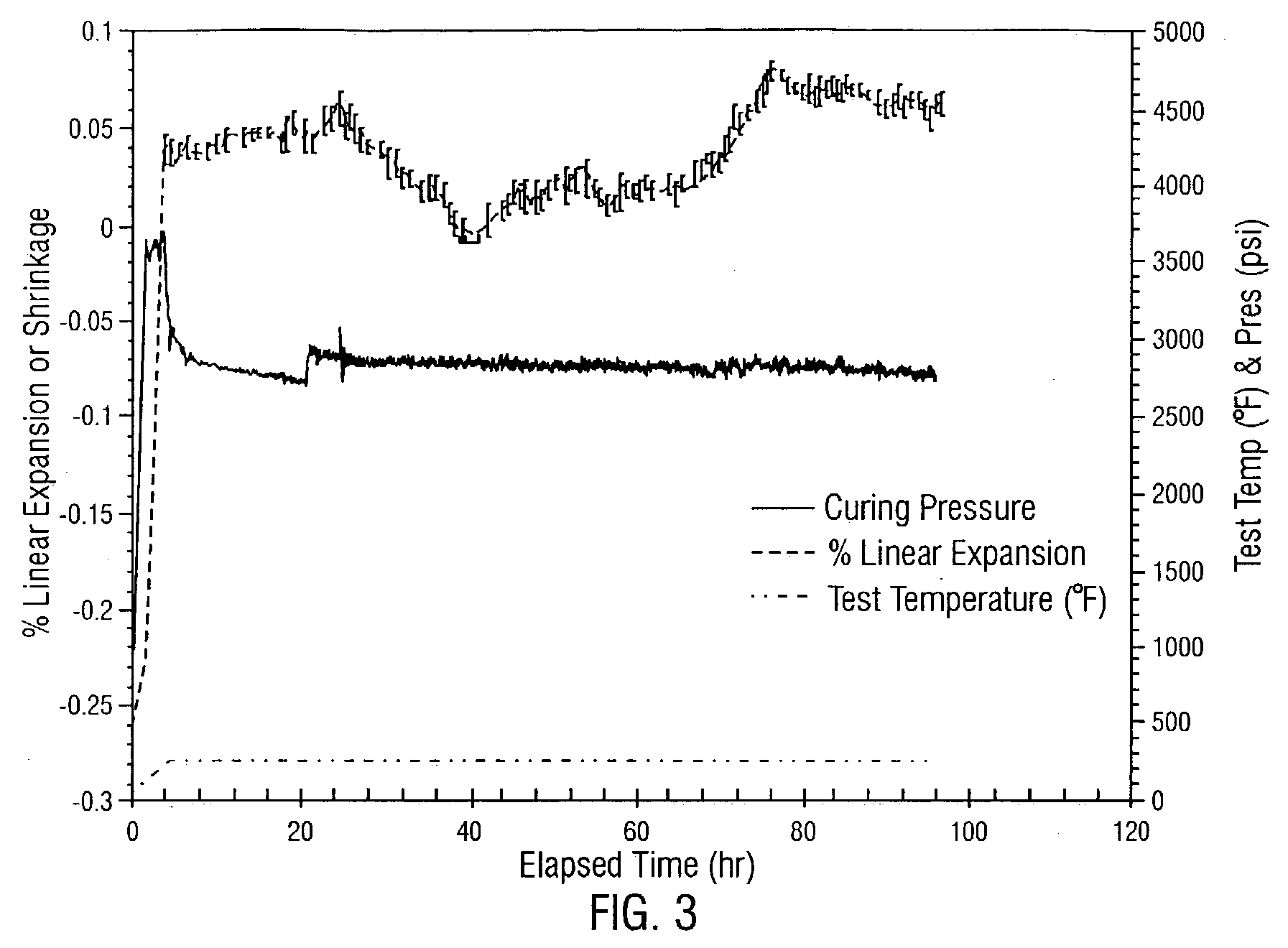

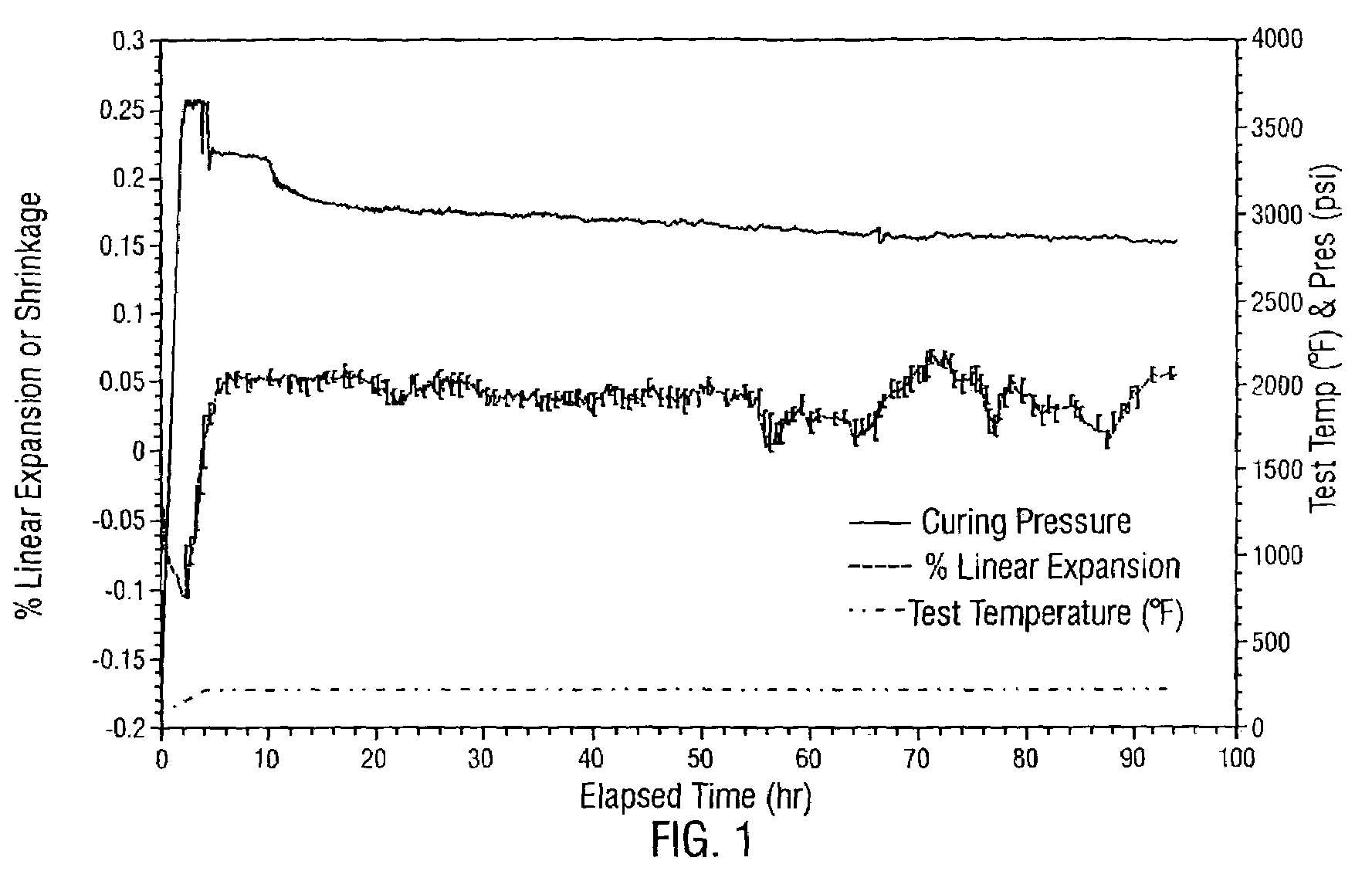

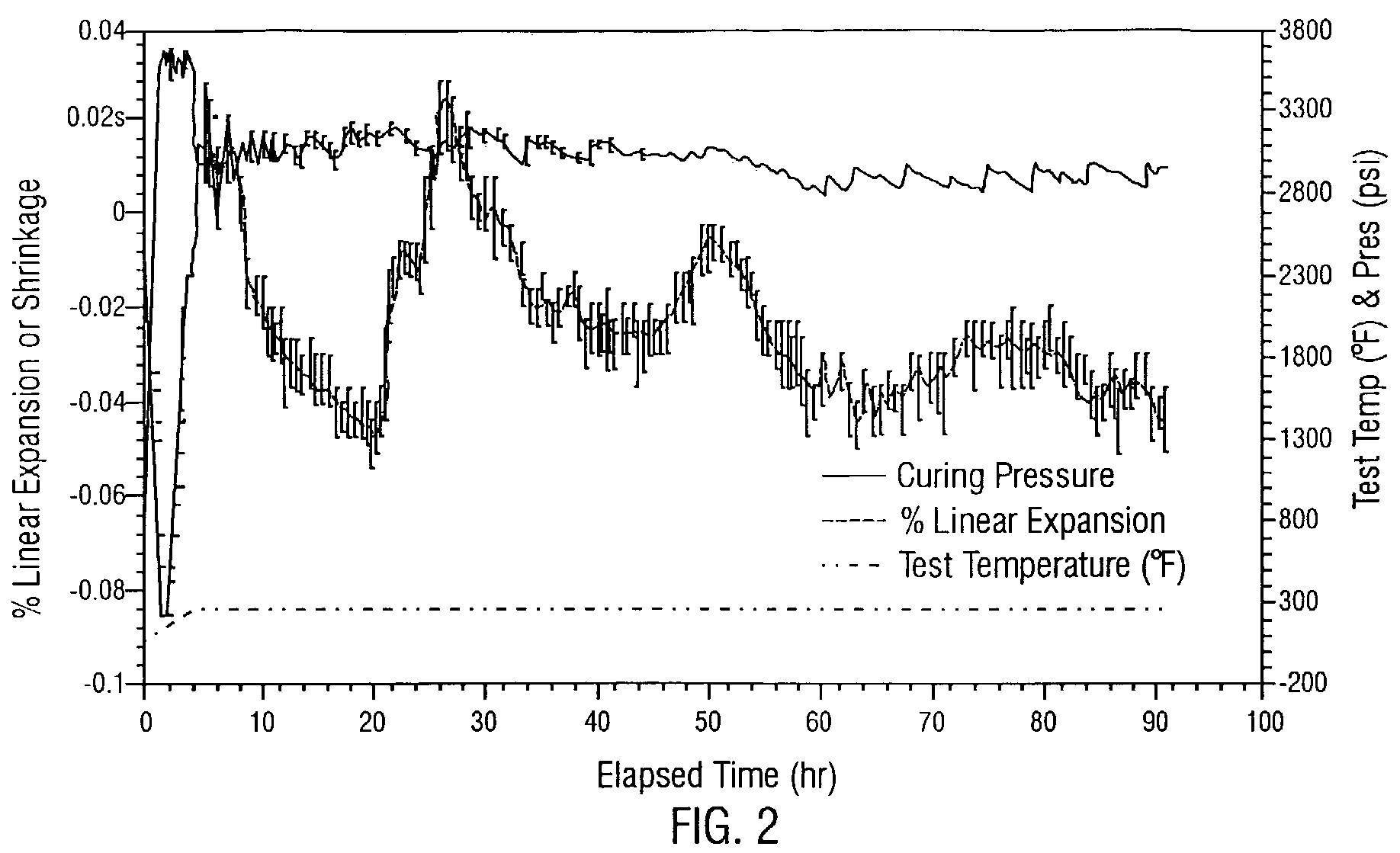

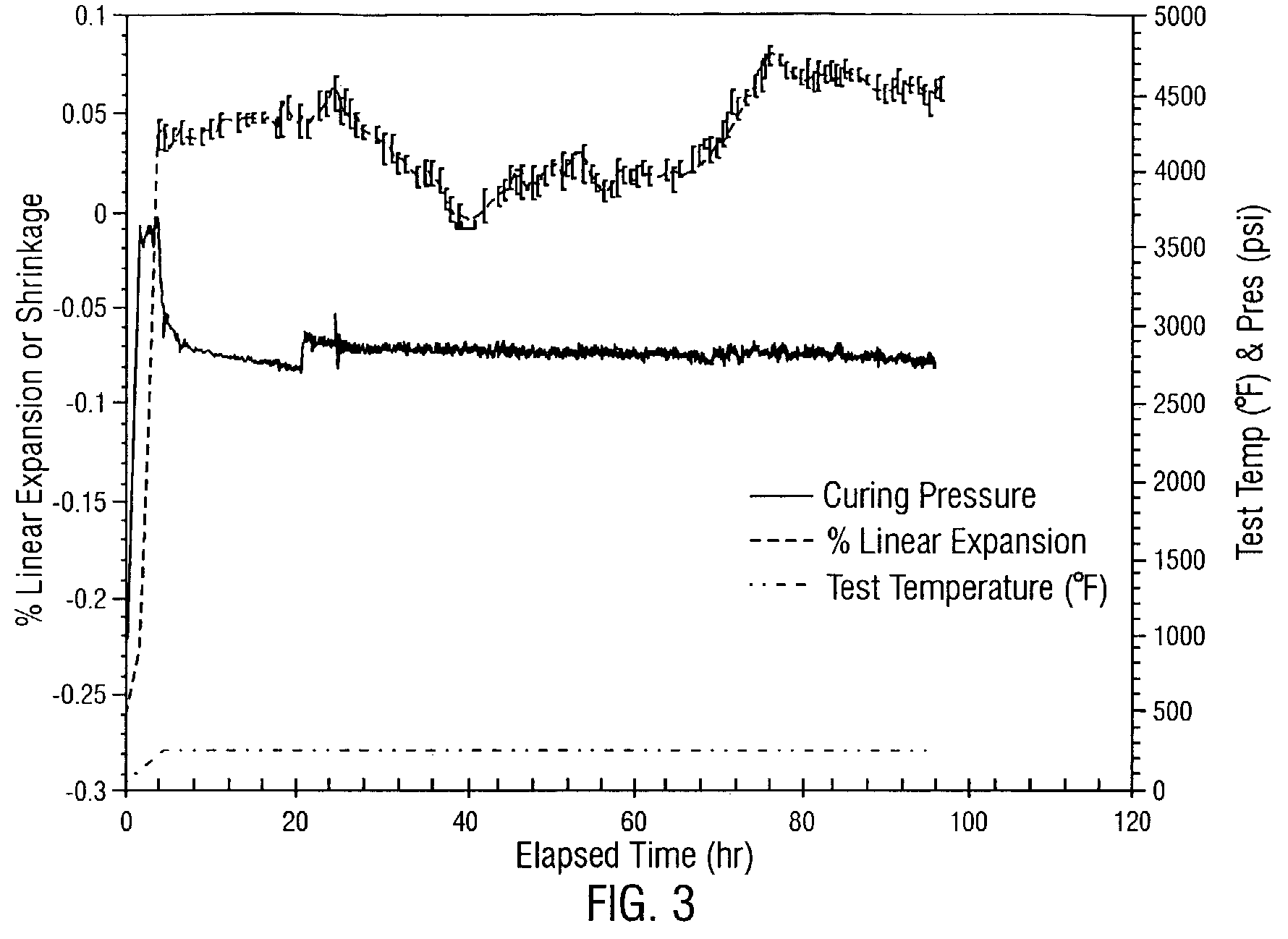

Polymer shell encapsulated gas as a cement expansion additive

ActiveUS20040147406A1Minimizes and prevents escapeDecrease and minimize occurrenceFluid removalFlushing2-methylbutaneOil and natural gas

Cement compositions containing an expandable material are disclosed. The compositions are suitable for use in oil and gas wells. An example of such an expandable material is a polymer encapsulated chemical that expands upon heating. Examples of cement compositions containing polymer encapsulated isobutane or isopentane are disclosed. The use of cement compositions containing an expandable material can reduce the formation of micro-annulus or other deleterious physical properties in the set cement.

Owner:BAKER HUGHES INC

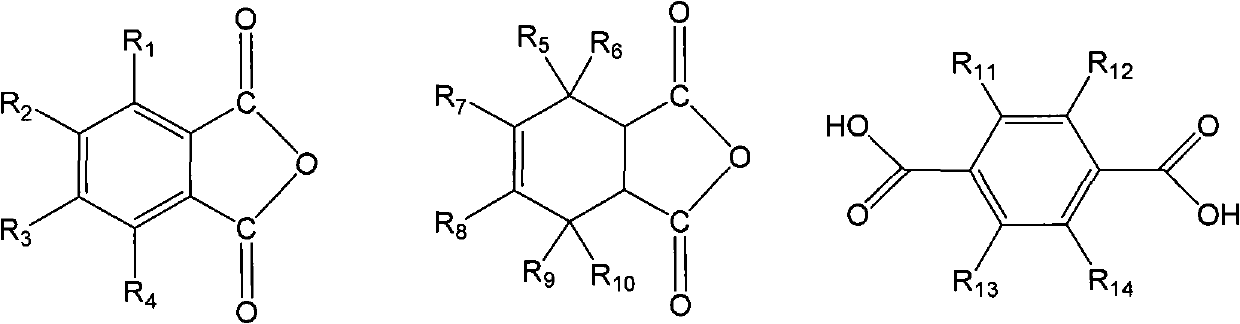

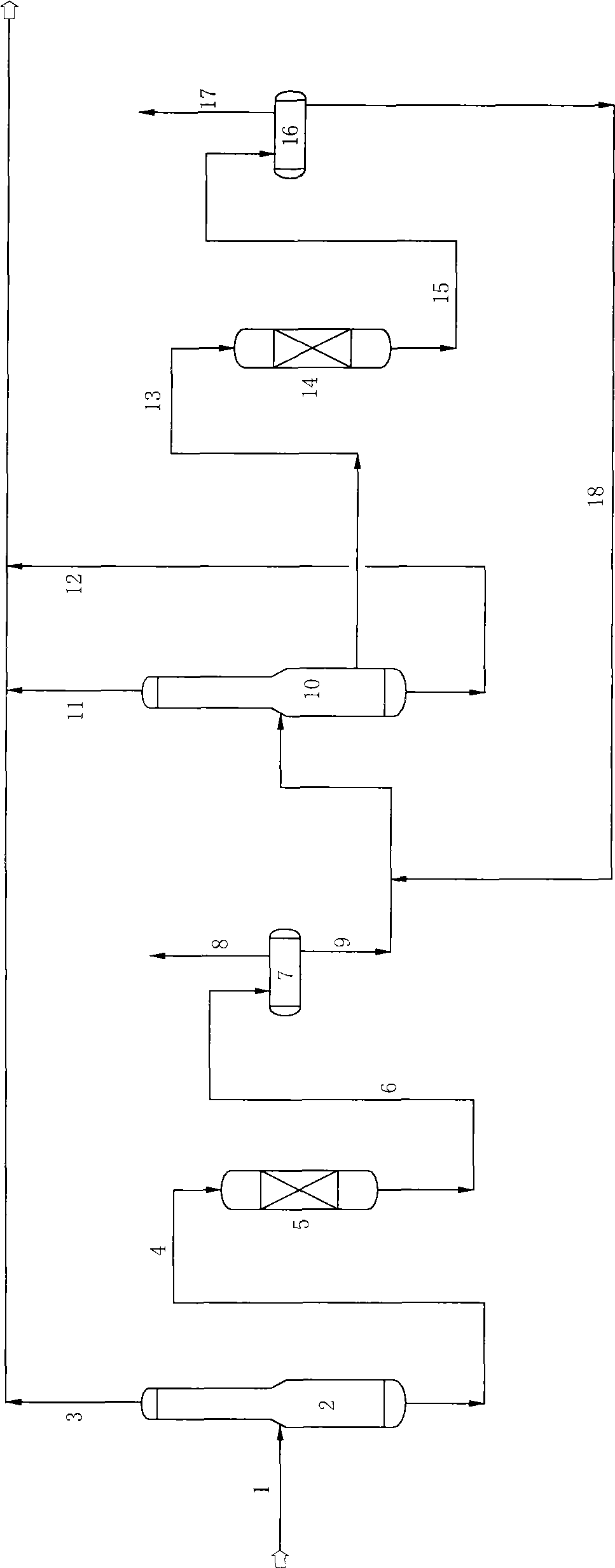

Process for extracting C4-C6 normal paraffins and coproducing isopentane and heterogeneous hexane cooperatively produced from light naphtha

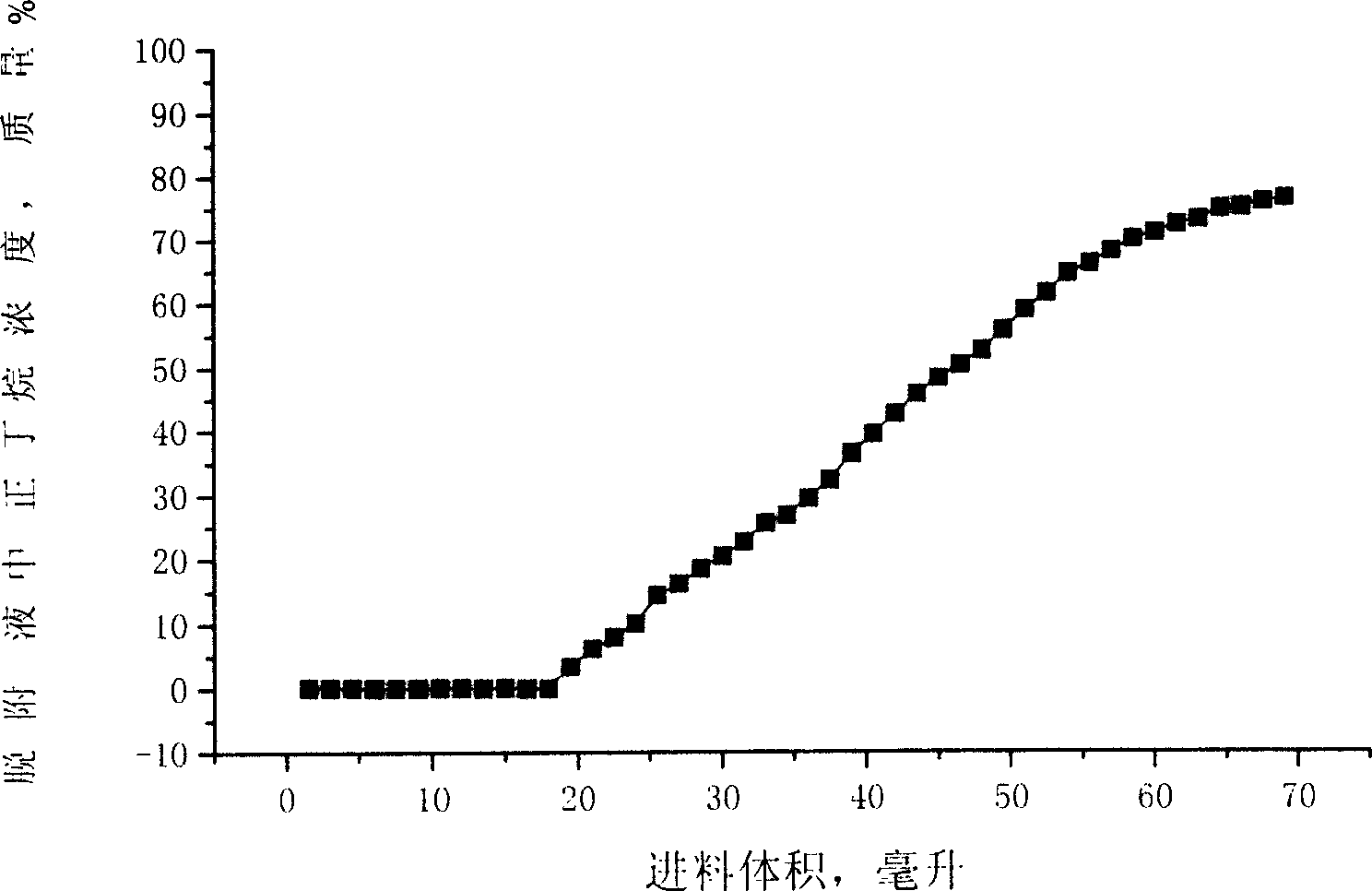

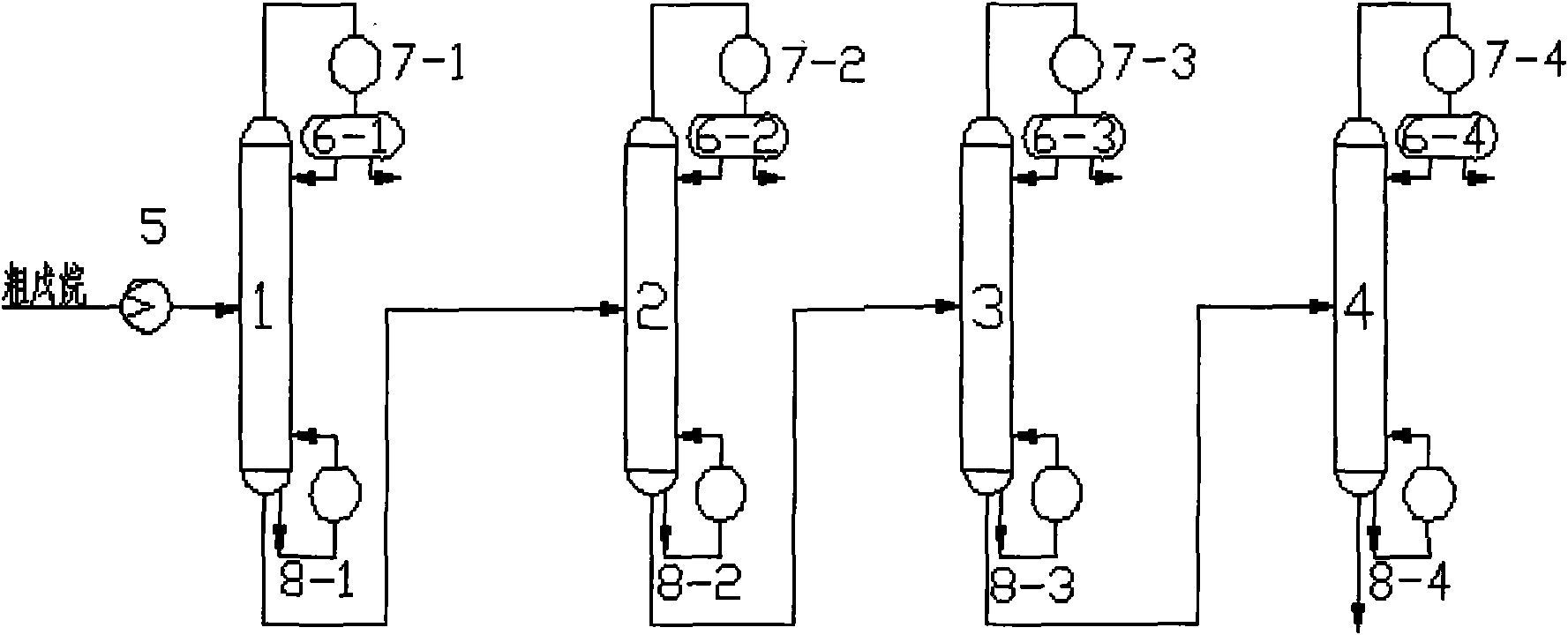

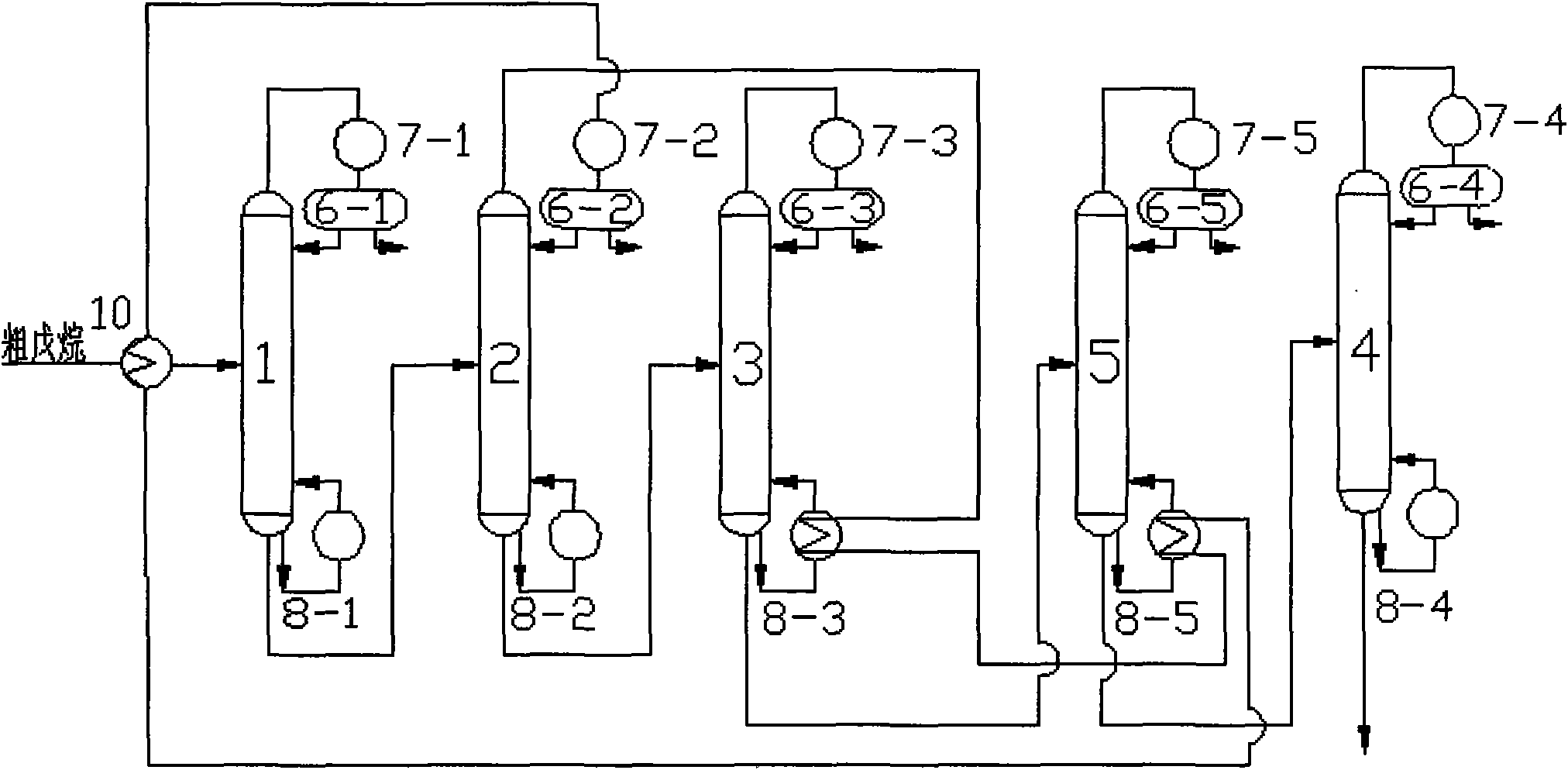

InactiveCN103254932AEasy to separateAdsorption and separation energy consumption is reducedDistillation purification/separationAdsorption purification/separation2-methylbutaneDesorption

The invention relates to a chemical separation process and in particular relates to a process for extracting C4-C6 normal paraffins and coproducing isopentane and heterogeneous hexane from light naphtha. A multi-tower variable pressure adsorption and distillation separation coupling process is adopted by the invention. The process comprises the following steps of: introducing mixed gaseous C4-C6 normal paraffins and isohydrocarbons serving as raw materials into an adsorption tower for adsorption and separation; desorbing a bed by taking gaseous C7-C9 normal paraffins as a desorption reagent after the adsorption ends; introducing the desorbed material into a rectifying tower to separate out the product C4-C6 normal paraffins and the desorption reagent C7-C9 normal paraffins; recycling the desorption reagent; then regenerating the adsorption tower which absorbs the C7-C9 normal paraffins by using the un-adsorbed C4-C6 isohydrocarbons; and rectifying and separating the regenerated material twice to obtain high-purity desorption reagent C7-C9 normal paraffins, high-purity isopentane and high-purity heterogeneous hexane. By adopting the process disclosed by the invention, normal paraffins and isohydrocarbons can be effectively separated; the adsorbent is easy to regenerate; the process flow is simple and economic benefit is high; and the energy consumption in the process disclosed by the invention is greatly reduced in comparison with the energy consumption in other desorption processes.

Owner:NANJING UNIV OF TECH

Method of utilizing cracked, C5 fraction

ActiveCN1810743AHigh purityOptimize the marketHydrocarbon by hydrogenationHydrocarbon by hydrocarbon cracking2-methylbutaneHydrogenation process

The method of utilizing cracked C5 fraction includes the first dimerizing cyclopentadiene in the cracked C5 fraction into dicyclopentadiene, separating dicyclopentadiene, selectively hydrogenating diene in the residual material into monoene and directly converting olefine to produce ethylene and propylene. The method may have etherification reaction before or after olefine conversion to produce methyl tert-amyl ether product and high purity isoamylene product further. The method may include a full hydrogenation process to produce pentane, which may be used as cracked material in a main cracking furnace or separated into n-pentane produce and isopentane product. The method is flexible and practical.

Owner:CHINA PETROLEUM & CHEM CORP

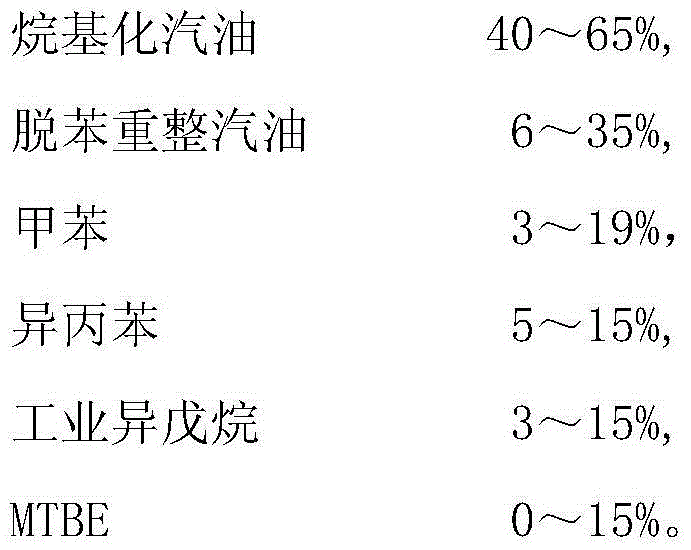

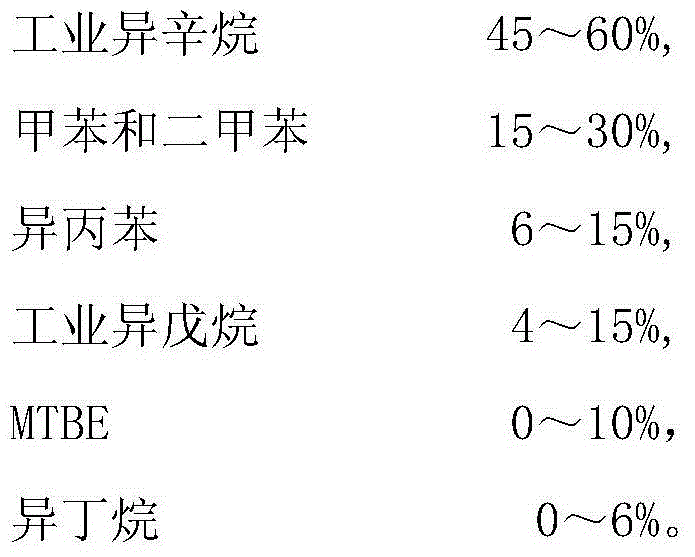

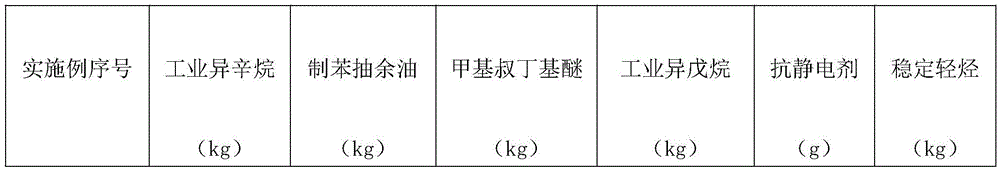

Lead-free high-quality clean aviation gasoline

The invention discloses lead-free high-quality clean aviation gasoline which comprises the following components by volume percent: 40%-65% of alkylation gasoline, 6%-35% of debenzolized and reformulated gasoline, 3%-19% of methylbenzene, 5%-15% of isopropyl benzene, 3%-15% of industrial isopentane and 0-15% of MTBE; when industrial isooctane is selected as the alkylation gasoline and a mixture of methylbenzene and xylene is used as the debenzolized and reformulated gasoline, the aviation gasoline comprises the following components by volume percent: 45%-60% of industrial isooctane, 15%-30% of methylbenzene and xylene, 6%-15% of isopentane, 4-15% of industrial isopentane, 0-10% of MTBE and 0-6% of iso-butane. The blend aviation gasoline which is prepared by refining the raw materials and optimizing the components of the raw materials can meet the requirements of No.95 gasoline specified in GB1787-2008 under the condition of not adding lead.

Owner:EAST CHINA UNIV OF SCI & TECH

Azeotropic and azeotrope-like compositions of E-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, n-pentane, 2-methylbutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, n-butane or isobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

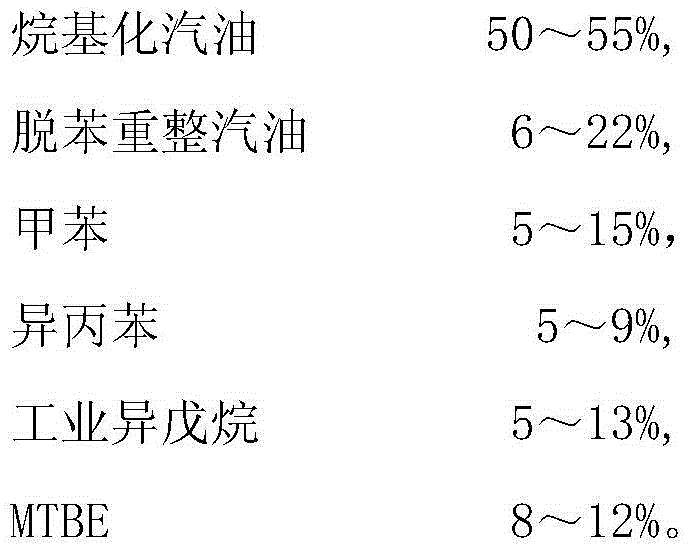

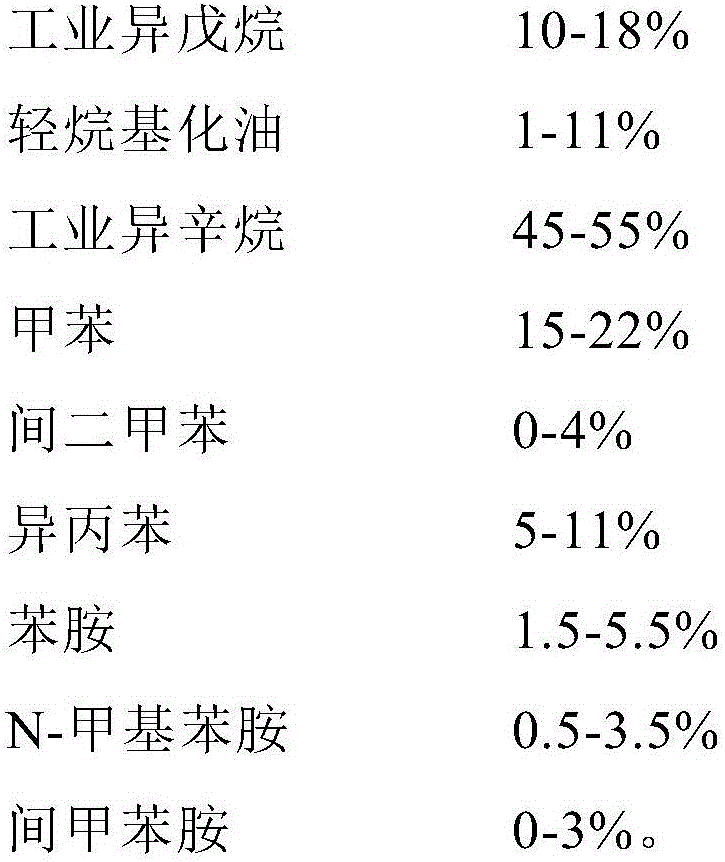

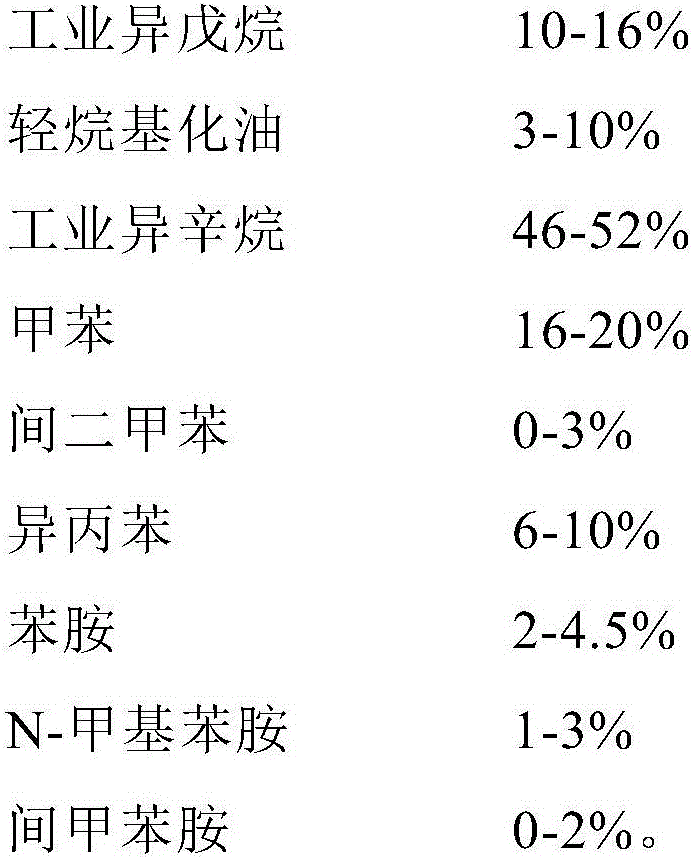

100# lead-free aviation gasoline and preparation method thereof

ActiveCN106398783AMeet the quality standard requirementsTackling lead pollutionLiquid carbonaceous fuels2-methylbutaneAviation

The invention relates to 100# lead-free aviation gasoline and a preparation method thereof. The 100# lead-free aviation gasoline comprises, by volume, 10-18% of industrial isopentane, 1-11% of light alkylated oil, 45-55% of industrial isooctane, 15-22% of toluene, 0-4% of m-xylene, 5-11% of cumene, 1.5-5.5% of aniline, 0.5-3.5% of N-methyl aniline and 0-3% of m-toluidine. The components are blended to form the finished product. Compared with the prior art, the 100# lead-free aviation gasoline does not contain lead and solves the problem of lead pollution of aviation gasoline. Through the optimized combination of the components, the 100# lead-free aviation gasoline quality is high and the 100# lead-free aviation gasoline satisfies the quality index requirements. The 100# lead-free aviation gasoline has a high economic value. The 100# lead-free aviation gasoline blending process is simple and is conducive to industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Method of producing polystyrene-based resin foam street

InactiveUS20060022366A1Suitable for productionSolution to short lifeFlat articles2-methylbutaneFoaming agent

A method of producing a polystyrene-based resin foam sheet, including kneading a polystyrene-based resin and a physical blowing agent with heating in an extruder to obtain a foamable resin composition, and extruding the foamable composition through a die, wherein the physical blowing agent comprises 60 to 95 mole % of a first blowing agent selected from isobutane, n-pentane, isopentane and mixtures thereof and 5 to 40 mole % of a second blowing agent selected from water, carbon dioxide, ethers having a boiling point of 140° C. or lower, dialkylcarbonates having a boiling point of 140° C. or lower and mixtures thereof, and wherein the total mole % of the physical blowing agent is equal to 100 mole %.

Owner:JSP CORP

Production method of C5 enol

InactiveCN102381940AInhibit side effectsSimple processPreparation by hydrolysis2-methylbutaneOil phase

The invention relates to a production method of a C5 enol. The production method uses isoprene and hydrogen chloride as raw materials and comprises the following steps: 1) performing addition reaction on isoprene and hydrogen chloride to generate a mixture of 1-chloro-isopentene and 3-chloro-isopentene; and 2) performing a hydrolysis reaction on the product of the addition reaction, adding one or more of toluene, ethylbenzene, n-hexane, cyclohexane, 2-methylpentane, 3-methylpentane, 2,2-dimethylbutane, 2,3-dimethylbutane and heptane as the solvent in the hydrolysis process, separating out the oil phase product after the hydrolysis, and rectifying to obtain products, namely methylbutenol and 3-methyl-2-buten-1-ol. Compared with the C5 enol production process of the prior art, the side reaction, in which dichloro-isopentane is generated, in the addition reaction process is effectively inhibited; after the solvent is added in the hydrolysis reaction, the yield of the hydrolysis reaction can be increased and the purification of the product can be facilitated; the yields of the addition reaction and the hydrolysis reaction are both more than 98% and are obviously increased as compared with the prior art; and the production cost is greatly reduced.

Owner:赵明江

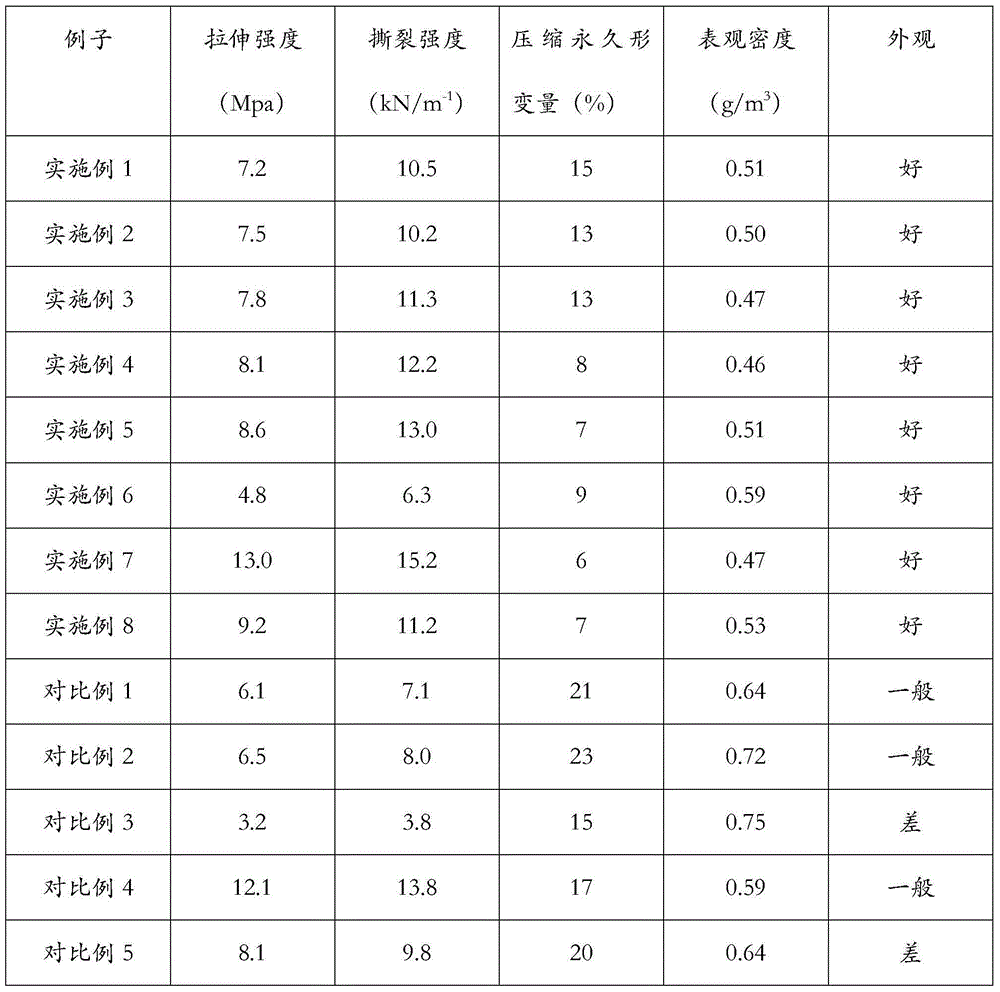

Aromatic polyester modified polyether polyol and preparation method thereof

The invention provides modified polyether polyol and a preparation method thereof. The preparation method comprises the following step of: under the condition of no oxygen and the protection of nitrogen, performing ring-opening polymerization on an epoxy compound with 2 to 4 carbon atoms by taking aromatic polyether polyol and polyol with the functionality of 3 to 9 as a co-initiator in the presence of amine catalysts to obtain the modified polyether polyol. The method overcomes the defects of low intersolubility of the conventional polyether polyol and a physical foaming agent, or low compression strength and dimensional stability of polyurethane prepared from tolylenediamine or vegetable oil modified polyether polyol. The modified polyether polyol can be widely applied to production of rigid polyurethane foam, and has quite good intersolubility with fluorine-free pentane, such as cyclopentane, isopentane, n-pentane and other mixed foaming agents; and the prepared rigid polyurethane foam has high compression strength, dimensional stability and toughness, and is more fine and smooth.

Owner:SHANGHAI DONGDA POLYURETHANE

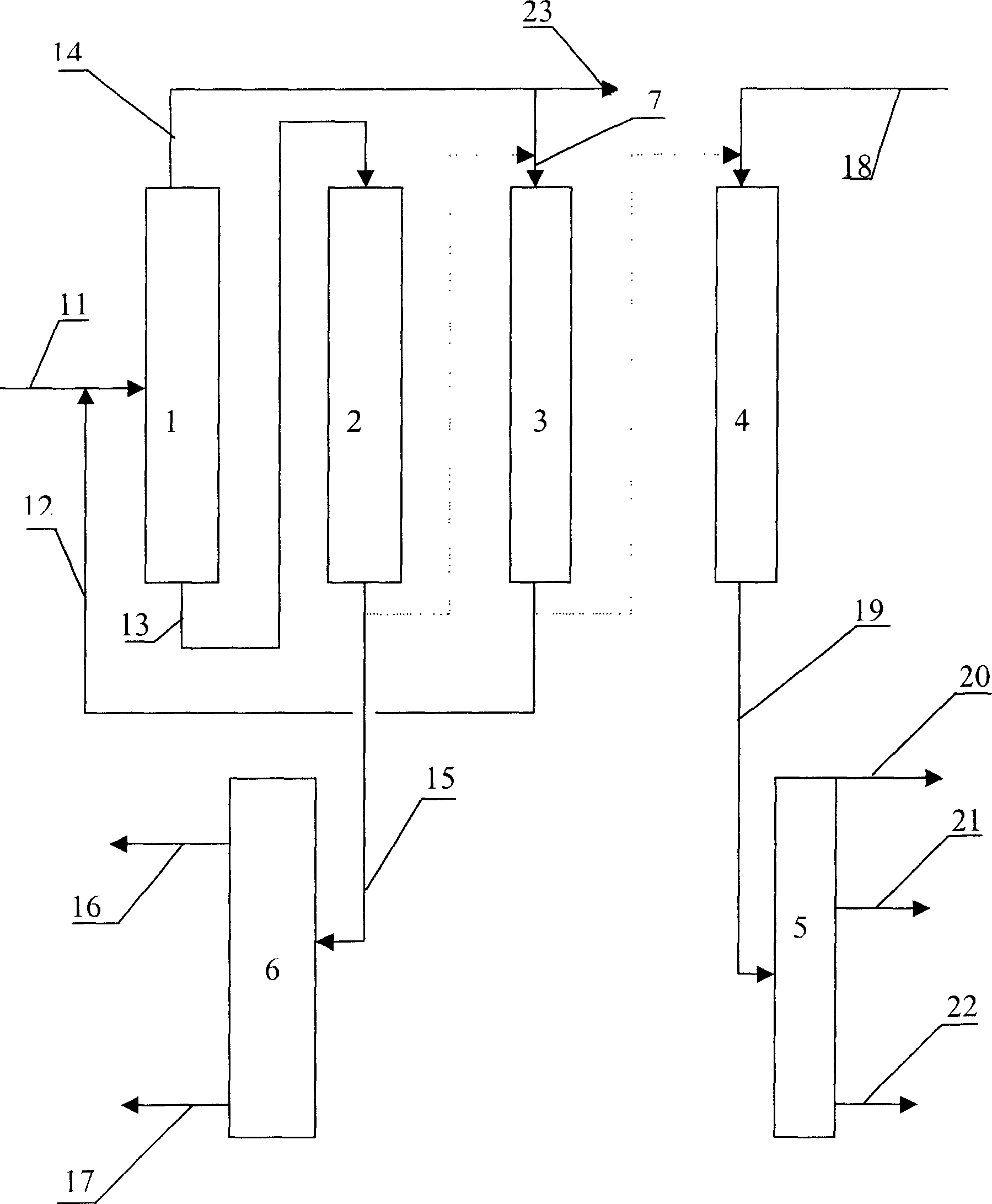

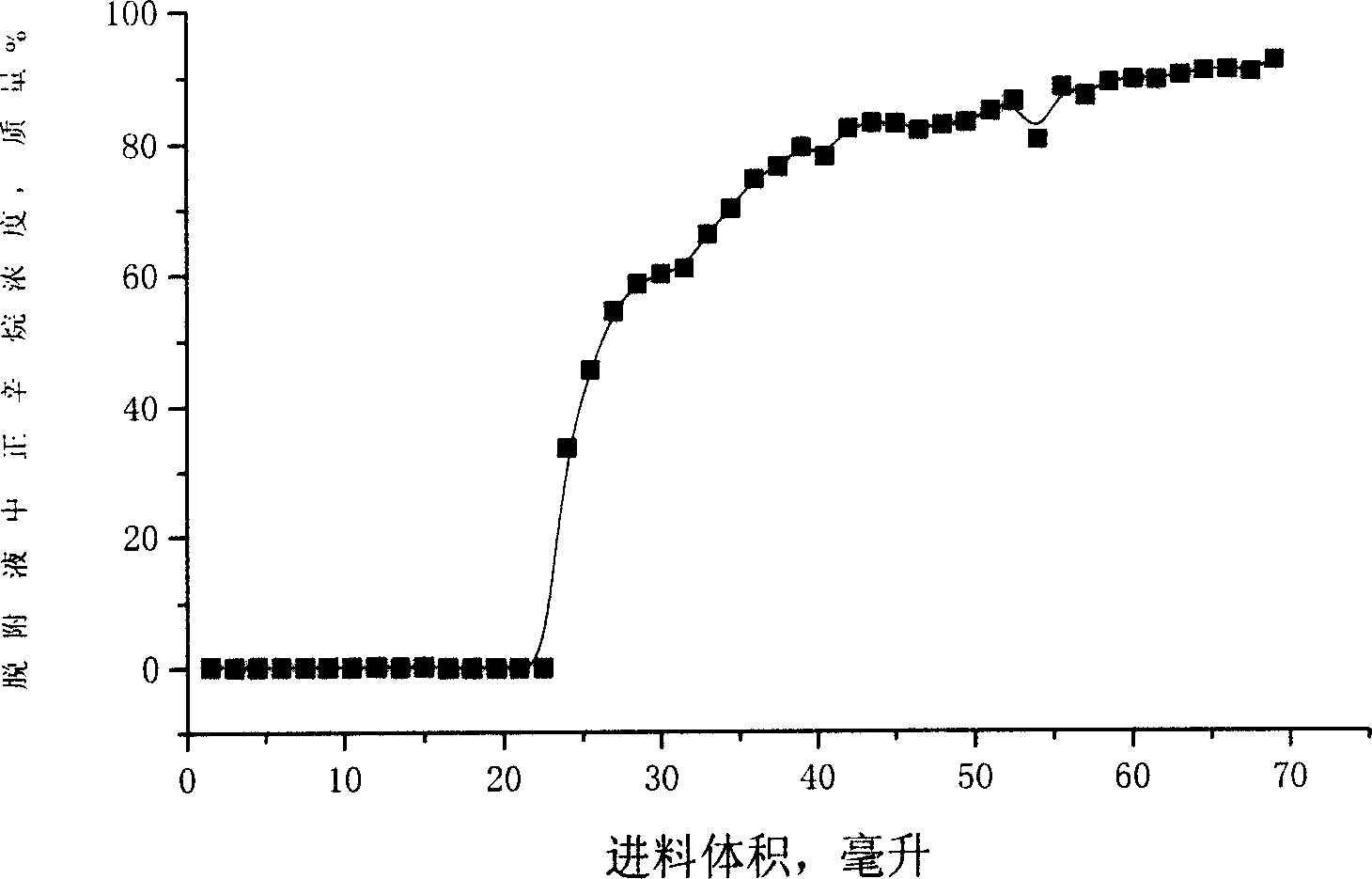

Method for separating n-alkane from C5 to C6 alkane isomerized products

Disclosed is a method for separating normal alkane from C5 to C6 alkane isomerized products. Isopentane is removed from raw materials, and the obtained materials are added into an adsorption separation post to adsorb normal alkane under 2.0-4.0 MPa, 100-150íµ and liquid phase condition, after saturation by adsorption, the adsorption separation post is flushed with flushing agent of isopentene, then desorbed by desorbing agent of C7 to C9 normal alkane. The method can separate normal alkane in light hydrocarbon isomerized products, and the used desorbing agent is less, the desorbing time is short.

Owner:CHINA PETROLEUM & CHEM CORP +1

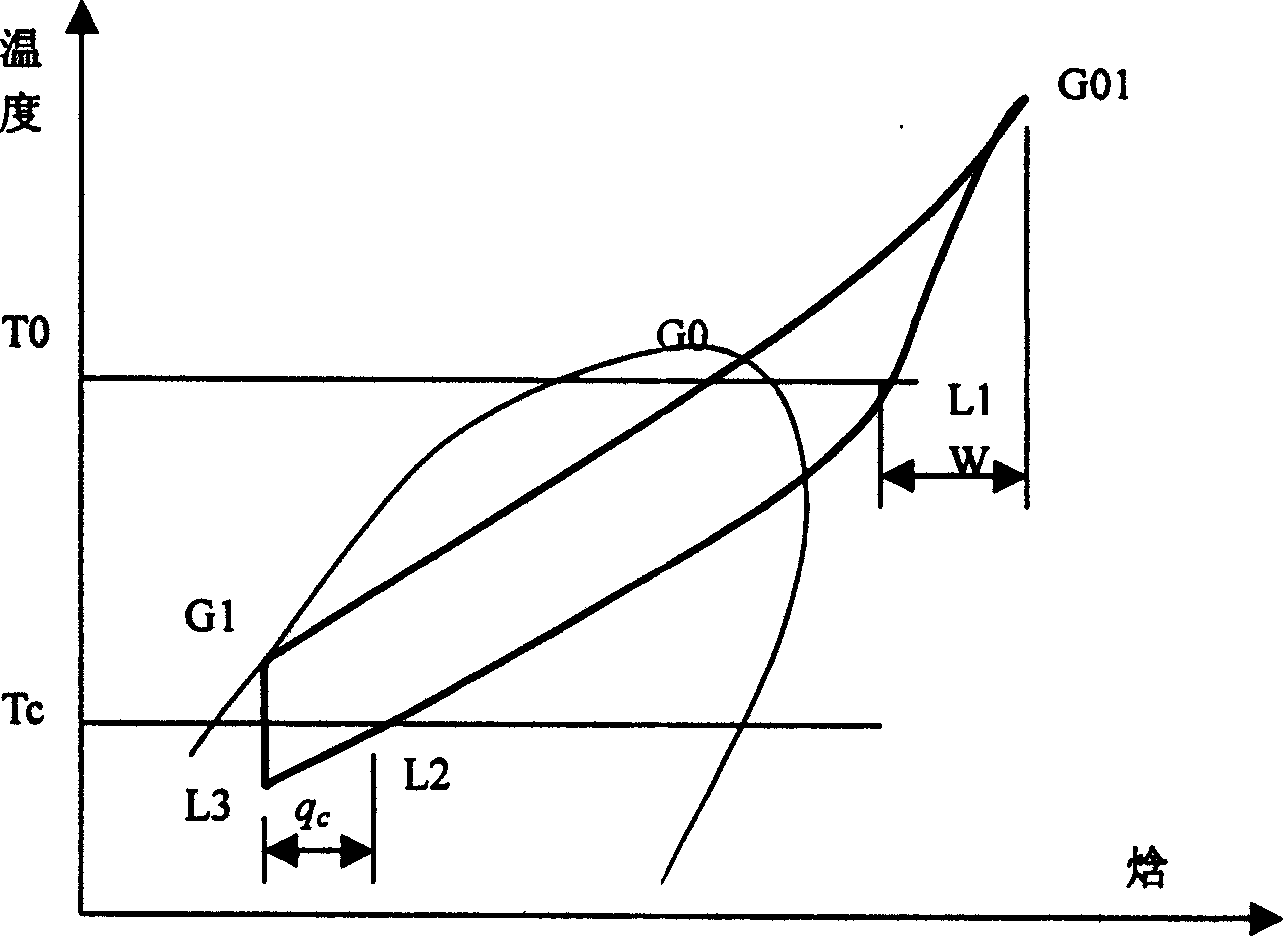

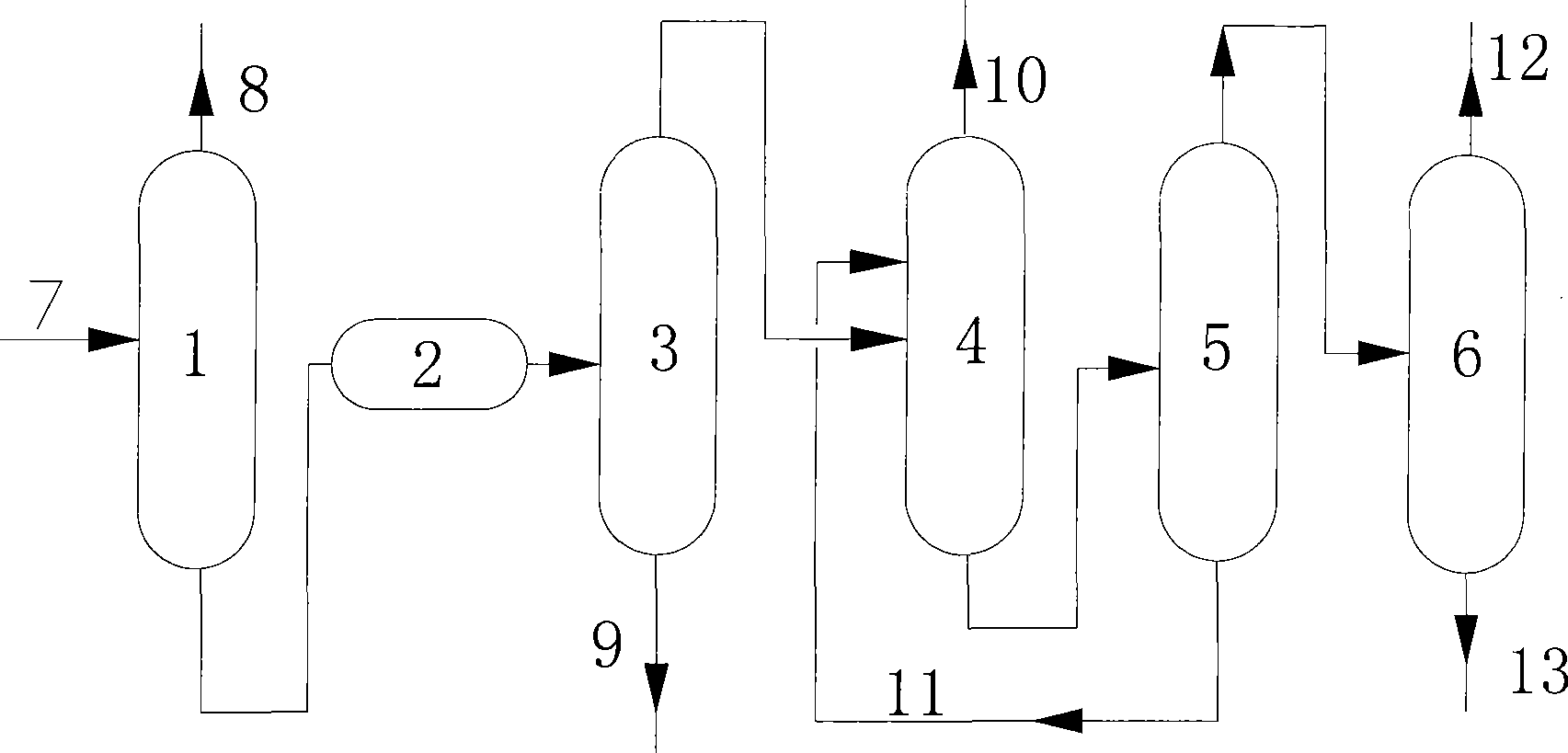

Double-effect rectification method and system thereof for finely separating hybrid pentane isomer

ActiveCN101602641AImprove product qualityReduce consumptionDistillation purification/separation2-methylbutaneReboiler

The invention discloses a double-effect rectification method for finely separating hybrid pentane isomer, which comprises the following steps: introducing a crude pentane raw material into a condensation preheater, a dehydrogenation tower of which the top is connected with a condenser and a reflux tank and the bottom is connected with a reboiler, an isopentane tower, an n-pentane tower, an azeotrope tower and a cyclopentane tower in turn to be rectified and separated, feeding total vapor at the tower top of the isopentane tower into the n-pentane tower and the reboiler as heat sources thereof, condensing the vapor into a two-phase mixture of vapor and liquid after heat exchange, then feeding the mixture to the azeotrope tower and the reboiler to exchange heat, re-preheating the crude pentane raw material by the waste heat after heat exchange, and finally beating the liquid to the isopentane tower as reflux liquid by a reflux pump of the isopentane tower. The method has the advantages of high product purity and low energy consumption and water consumption; and the product can be flexibly controlled according to the requirement.

Owner:TIANJIN UNIV

Foamable resin particle and method for preparing foaming material from same

The invention provides a foamable resin particle. The foamable resin particle comprises EVA (ethylene vinyl-acetate copolymer) and a micro-sphere foaming agent, wherein the micro-sphere foaming agent comprises a polymer shell and a foaming agent covered with the polymer shell, and the polymer shell of the micro-sphere foaming agent adopts a single-layer or double-layer structure comprising acrylic polymer; the covered foaming agent in the micro-sphere foaming agent is one or a mixture of ethane, propane, propylene, iso-butane, butane, isobutene, n-pentane, isopentane and petroleum ether. The invention further provides foamable composition comprising a thermoplastic elastomer and the foamable resin particle as well as a foaming material prepared from the foamable composition, a method for preparing the foaming material and a product comprising the foaming material.

Owner:浙江杰上杰新材料股份有限公司

Polymer shell encapsulated gas as a cement expansion additive

InactiveUS7494544B2Minimizes and prevents escapeDecrease and minimize occurrenceFluid removalFlushing2-methylbutaneProduct gas

Cement compositions containing an expandable material are disclosed. The compositions are suitable for use in oil and gas wells. An example of such an expandable material is a polymer encapsulated chemical that expands upon heating. Examples of cement compositions containing polymer encapsulated isobutane or isopentane are disclosed. The use of cement compositions containing an expandable material can reduce the formation of micro-annulus or other deleterious physical properties in the set cement.

Owner:BAKER HUGHES INC

Fuel oil for use both in internal combustion in engine and fuel cell

InactiveUS20030145514A1Easy to useEfficient productionHydrogenLiquid carbonaceous fuels2-methylbutaneFuel oil

A fuel oil for use both in an internal combustion engine and in a fuel cell containing 50% by volume or more of an alkylate gasoline, and, optionally, 1 to 50% by volume of isopentane, 1 to 12% by volume of a hydrocarbon having 4 carbon atoms, 7% by volume or less of an oxygen-containing compound, and 1 to 30% by volume of a desulfurized light naphtha; and a fuel oil for use both in an internal combustion engine and in a fuel cell containing 10 to 60% by volume of a desulfurized light naphtha, 40 to 90% by volume of a benzene-free reformed gasoline and 0 to 10% by volume of a hydrocarbon having 4 carbon atoms. Each of the above fuel oils is a fuel oil for a fuel cell which can produce hydrogen with good efficiency, has no adverse effect on reforming catalysts and electrodes for a fuel cell, and is reduced in deactivation of reforming catalysts and the like, and a fuel oil for an internal combustion engine which has a high octane number and can be used without causing knocking or the like.

Owner:IDEMITSU KOSAN CO LTD

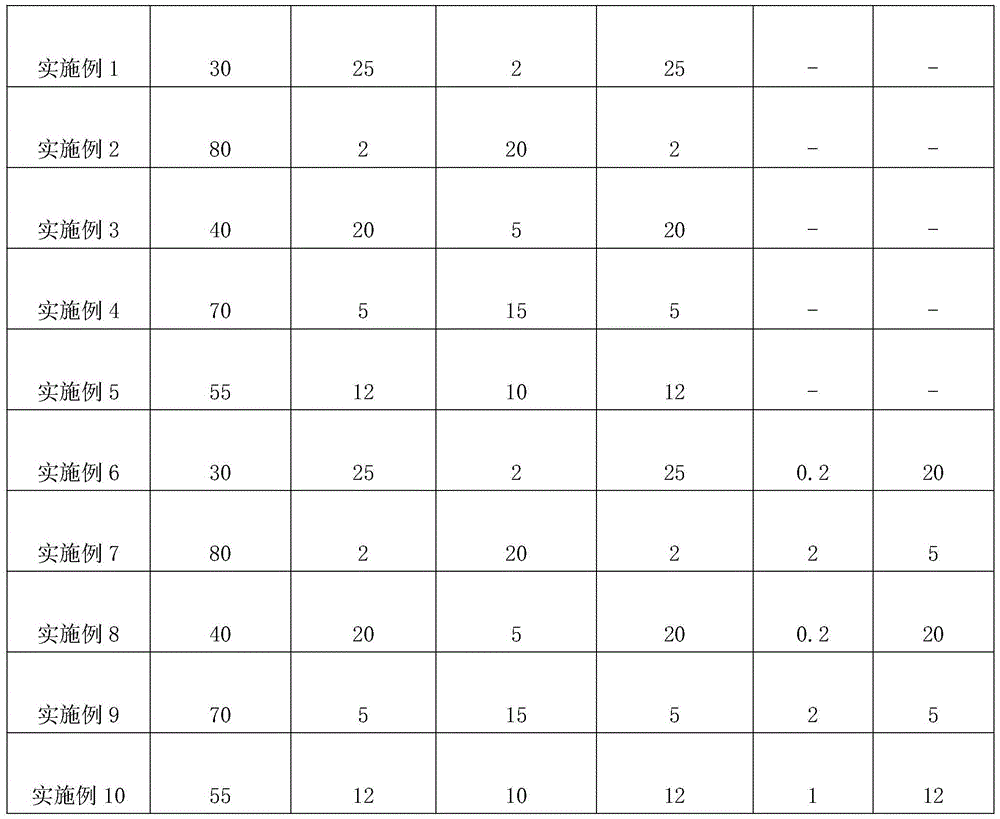

Foaming raw material of bio-based polyurethane foaming plastic foamed by pentane serving as foaming agent and product thereof

The invention relates to a foaming raw material of bio-based polyurethane foaming plastic foamed by pentane serving as a foaming agent and a product thereof. The conventional pentane-foamed bio-based polyurethane foaming plastic has poor dimensional stability. Therefore, the foaming raw material comprises a material A and a material B separately packaged, wherein the material A consists of 100 weight parts of polyether polyols, 2 to 3 weight parts of foam stabilizer, 1.0 to 1.5 weight parts of deionized water, 2 to 4 weight parts of composite catalyst and 12 to 14 weight parts of cyclopentane or isopentane; and the material B comprises 135 to 155 weight parts of PAPI, wherein the 100 weight parts of polyether polyols in the material A consists of 57 to 62 weight percent of bio-based polyether polyols, 15 to 20 weight percent of petroleum-based polyether polyols with the functionality of 3 or 4, 8 to 12 weight percent of high-activity polyether polyols and 15 to 20 weight percent of petroleum-based polyether polyols with the functionality of 5 or 6. The foaming raw material is suitable to be used as a thermal insulation material of electric equipment.

Owner:ZIBO LIANCHUANG POLYURETHANE

First filled oil and preparation method thereof

ActiveCN105419887AImprove stabilityImprove rust resistanceLiquid carbonaceous fuelsFuel additives2-methylbutaneBenzene

The invention relates to first filled oil and a preparation method thereof. The first filled oil is mainly prepared from, by weight, 30-80 parts of isooctane, 2-25 parts of benzene producing raffinate oil, 2-20 parts of methyl tert-butyl ether and 2-25 parts of isopentane. The first filled oil has excellent stability, anti-rust property, cleaning property and low-temperature startability and can meet the long-term storage need and the using requirements under harsh environmental conditions. The preparation method has the advantages of being simple and convenient to operate and stable in finished product.

Owner:北京中燕恒成能源有限公司

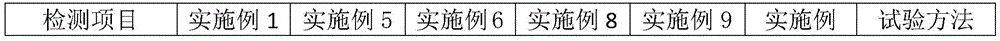

Process for preparing liquefied natural gas (LNG) by low concentration coal bed methane oxygen bearing copious cooling liquefaction

ActiveCN103175381ASolve the blockageAchieve the goal of energy saving and emission reductionSolidificationLiquefaction2-methylbutaneEvaporation

The invention discloses a process for preparing liquefied natural gas (LNG) by low concentration coal bed methane oxygen bearing copious cooling liquefaction. The process for preparing LNG by low concentration coal bed methane oxygen bearing copious cooling liquefaction comprises the following steps: (1), compression and purification process; (2), liquefaction and separation process which comprises a, main procedure process; b, refrigeratory process, wherein the refrigeratory process comprises b1, mixing cryogen process; and b2, nitrogen cryogen process. Nitrogen cryogen sequentially passes through a first level heat exchanger, a second level heat exchanger, a third level heat exchanger and a subcooler for cooling after being compressed and cooled, the nitrogen cryogen after throttling enters an overhead condenser to output cold quantity, and then the gaseous nitrogen cryogen sequentially passes through the subcooler, the third level heat exchanger, the second level heat exchanger, and the first level heat exchanger, the gaseous nitrogen cryogen is warmed gradually to normal temperature, and then flows back to a nitrogen compressor for being circularly used. The mixing cryogen process is used for controlling evaporation capacity at the bottom of a tower, the nitrogen cryogen process is used for controlling condensation capacity at the top of the tower, and independently adjusting purity coefficient and yield coefficient of natural gas products is achieved. The cryogen in a low temperature region only possesses a nitrogen component, and heavy components of isobutane, isopentane and the like do not exist in the low temperature region, and therefore the problems of being free of refrigeration in the process of throttling, or congestion of a cryogen channel are solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

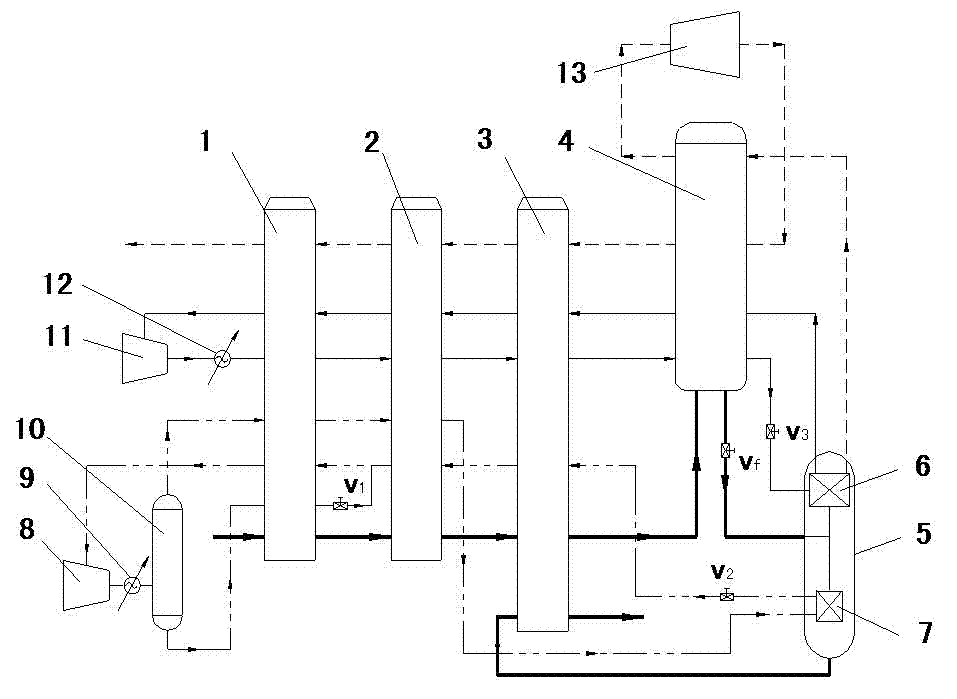

Multicomponent mixed work medium throttling refrigerant applicable to medium-low temperature zone

The multicomponent mixed work medium throttling refrigerating agent applicable to medium-low temp. zone includes five groups of substances, the sum of their mole concentration is 100%, in which first group includes methane, krypton or mixture, total mole concentration is 5%-45%, second group includes tetrafluoromethane, nitrogen trifluoride or mixture, total mole concentration is 15%-55%; fourth group includes propylene, propane, perfluoropane, 1,1,1-trifluoroethane, 1,1-bifluoroethane, fluoroethane, propadiene, cyclopropane, or mixture, total mole concentration is 5%-25%; fifth group includes 1-butylene, isobutane, 2-methylbutane, 1-pentene, 3-methyl-1-butylene, 2-methylpentane, 2-butylene, isobutylene, n-butane, perfluorobutane, n-pentane or mixture, total mole concentration is 5%-25%.

Owner:中科赛凌(北京)科技有限公司

Light hydrocarbon isomerization method

ActiveCN101544905AIncrease the rate of isomerizationGuaranteed isomerization rateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeleton2-methylbutaneIsomerization

The invention relates to a light hydrocarbon isomerization method comprising the following steps: light hydrocarbon materials are firstly separated by a de-isopentane tower, tower top streams are extracted as isomerization products, and tower bottom streams enter a front isomerization reactor to generate isomerization reaction; liquid phase streams obtained by the gas-liquid separation of outlet streams of the front reactor are separated in a de-isohexane tower, and tower top streams and tower bottom streams of the de-isohexane tower are extracted and then mixed with the tower top streams of the de-isopentane tower and are together taken as a gasoline-stripping stabilization system of the isomerization products; siding streams of the de-isohexane tower are extracted into a rear isomerization reactor; and liquid phase streams obtained by the gas-liquid separation of reaction streams of the rear isomerization reactor completely return and are mixed with the liquid phase streams of a gas-liquid separator of the front isomerization reaction system and together taken as feeding materials of the de-isohexane tower. The method has higher normal paraffin isomerization ratio, wherein the C6 normal paraffin realizes the complete isomerization basically, thereby greatly improving the octane number of the light hydrocarbon materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating carbon 5 fraction by NMP method and one-stage extraction and rectification

ActiveCN101423450AAvoid corrosionAvoid problems such as cloggingHydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon addition2-methylbutaneDehydrogenation

The invention discloses a method for separating C5 fraction through first-stage extraction rectification by a NMP method. The method comprises the steps of dehydrogenation, dimerization reaction, deheavy, extraction rectification, steam stripping and refining, wherein isopentane is utilized to take most of acetylene hydrocarbon away from the tower top in the dehydrogenation step; and a mixed solvent of NMP and a saline solution is adopted as an extracting agent in the step of extraction rectification. The method improves the extracting agent, increases the selectivity of the extracting agent, cancels a two-stage extraction rectification unit, and reduces the using amount and the regeneration amount of the solvent, thereby reducing operating cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

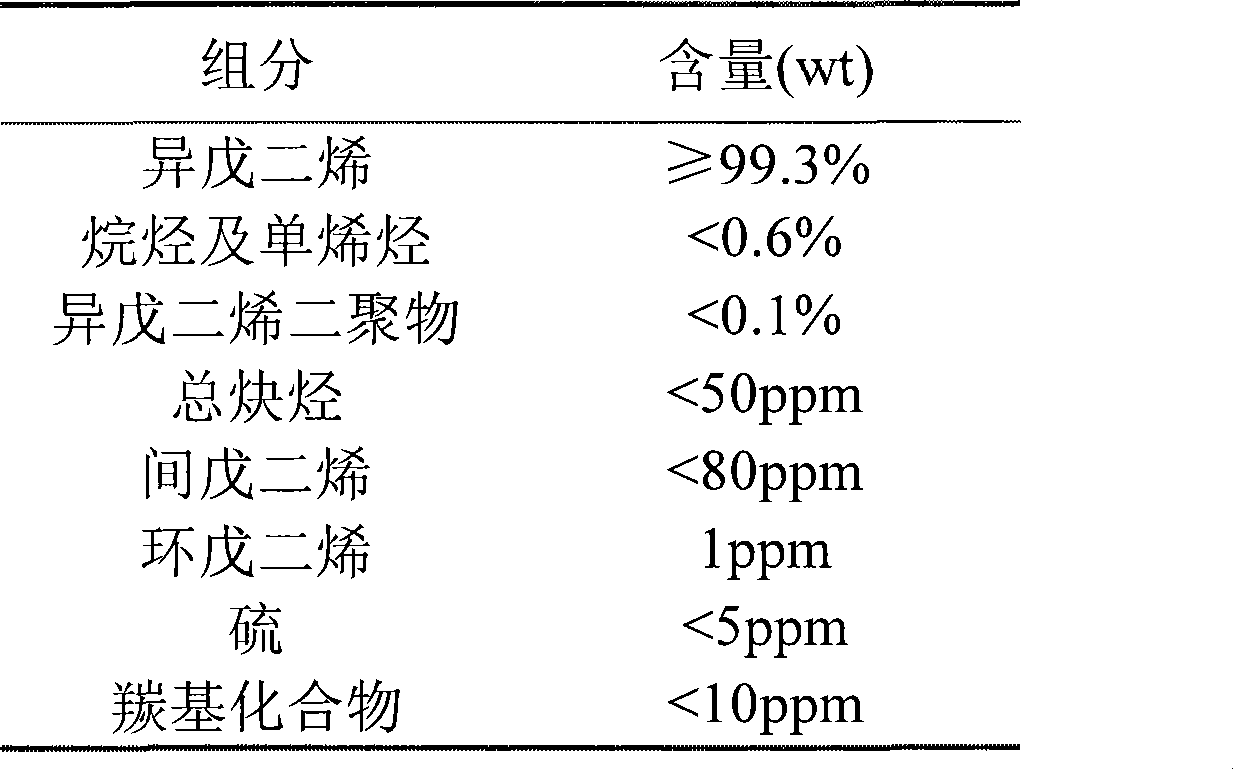

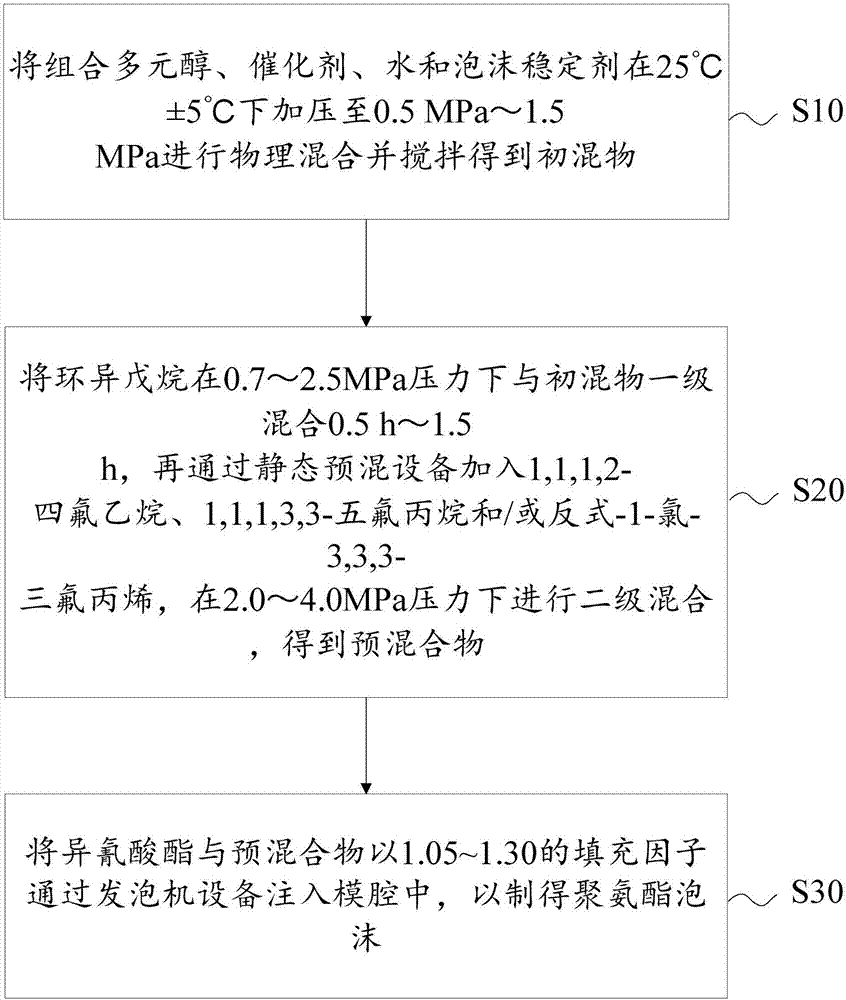

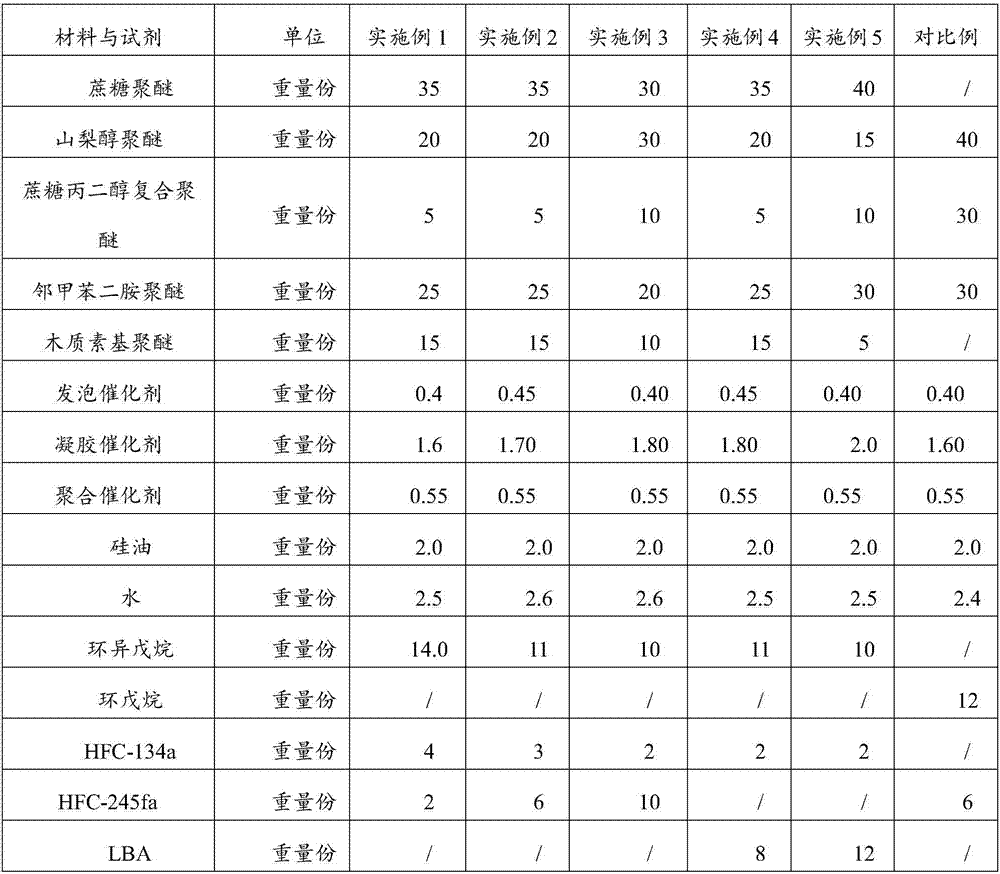

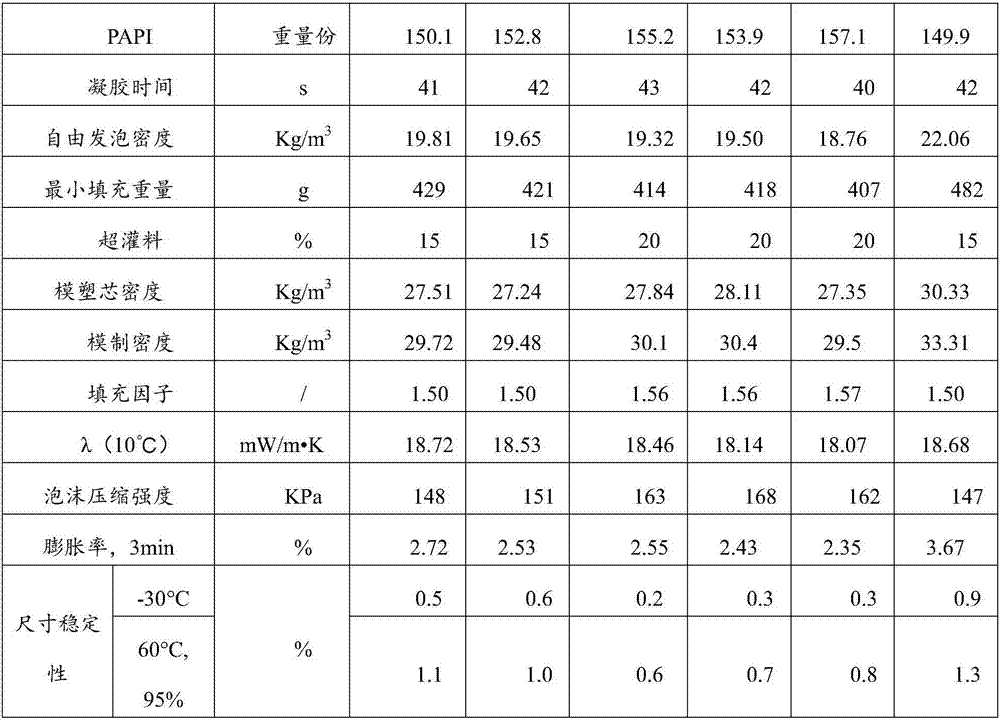

Polyurethane foam as well as preparation method and application thereof

The invention provides polyurethane foam as well as a preparation method and application thereof. The polyurethane foam is prepared from the following components in parts by weight: 100 parts of combined polyether, 12 to 25 parts of mixed foaming agent, and 130 to 160 parts of isocyanate, wherein combined polyol in the combined polyether comprises lignin-based polyol, and the combined foaming agent comprises cyclo-isopentane and 1,1,1,2-tetrafluoroethane. According to the polyurethane foam provided by the invention, on one hand, lignin contains a great amount of benzene rings, phenolic hydroxyl groups and alcoholic hydroxyl groups, and the polyurethane foam prepared from the lignin-based polyol can improve the strength of the polyurethane; on the other hand, the polyurethane foam prepared by adopting the foaming system with a low boiling point containing cyclo-isopentane (the cyclo-isopentane consists of cyclopentane and isopentane) and 1,1,1,2-tetrafluoroethane (HFC-134a) is super-low in free foam density (18 to 20 kg / m3), and the core density of the polyurethane product is 27 to 29 kg / m<3>.

Owner:HEFEI HUALING CO LTD +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com