Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

252 results about "Toluidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

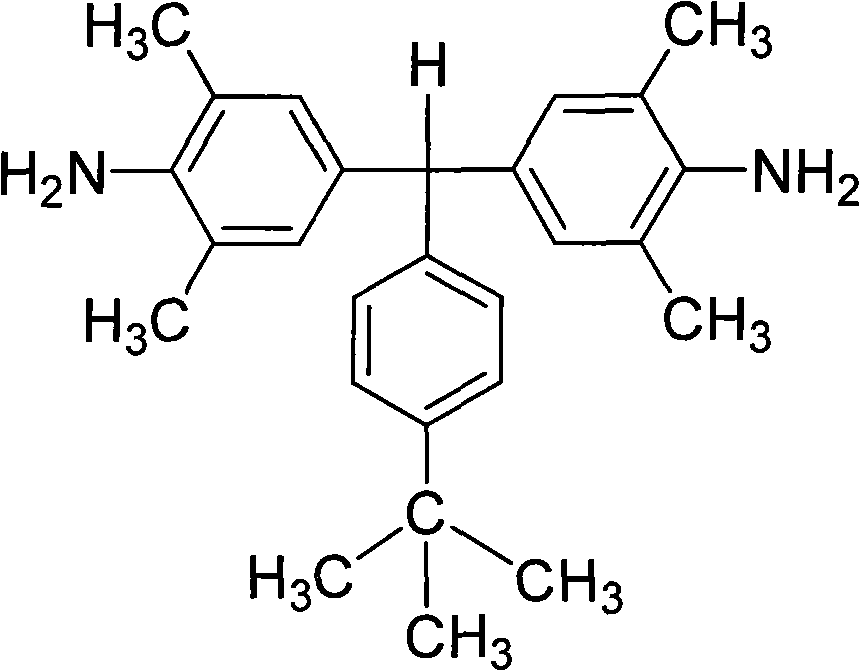

There are three isomers of toluidine, which are organic compounds. These isomers are o-toluidine, m-toluidine, and p-toluidine, with the prefixed letter abbreviating, respectively, ortho; meta; and para. All three are aryl amines whose chemical structures are similar to aniline except that a methyl group is substituted onto the benzene ring. The difference between these three isomers is the position where the methyl group (–CH₃) is bonded to the ring relative to the amino functional group (–NH₂); see illustration of the chemical structures below.

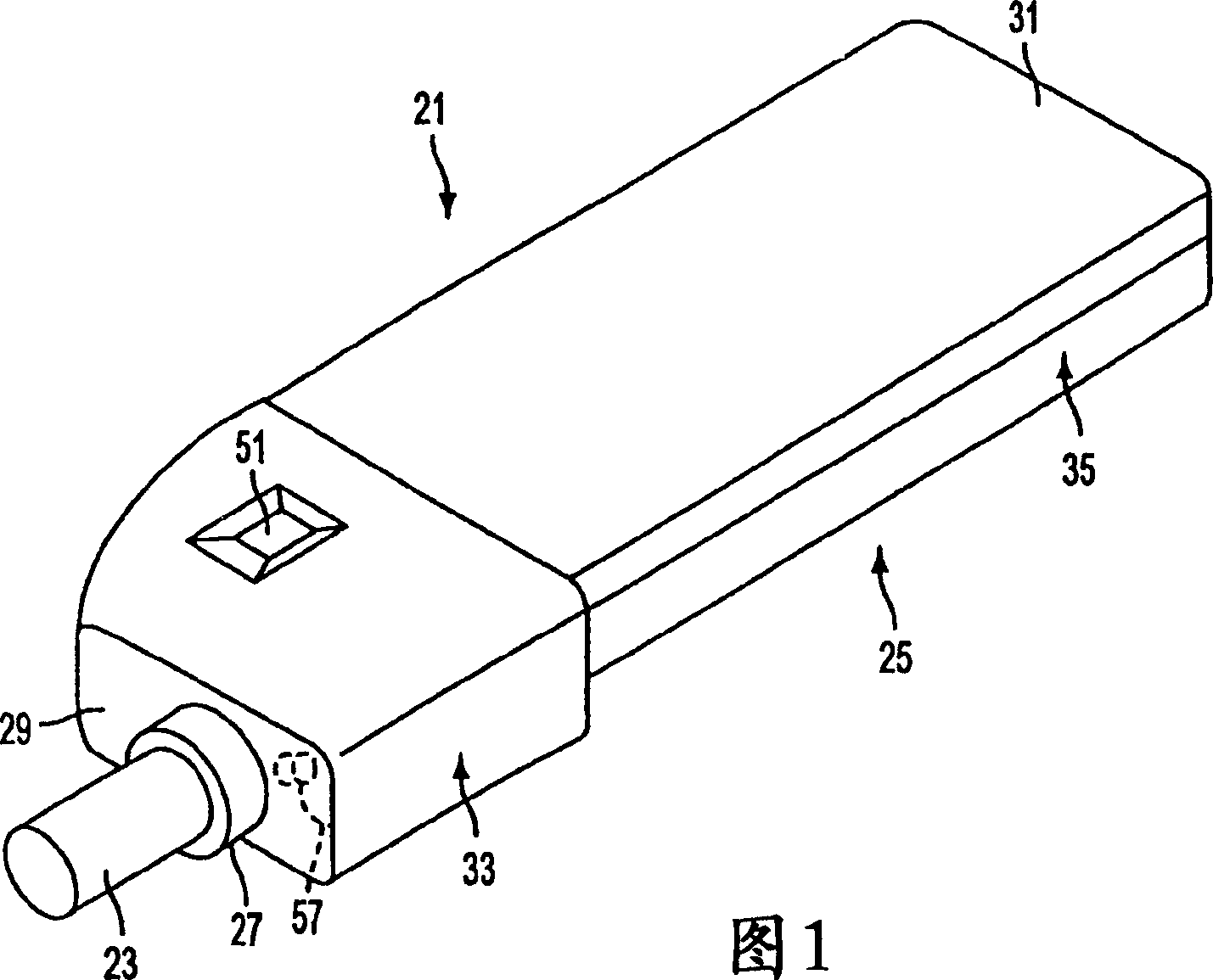

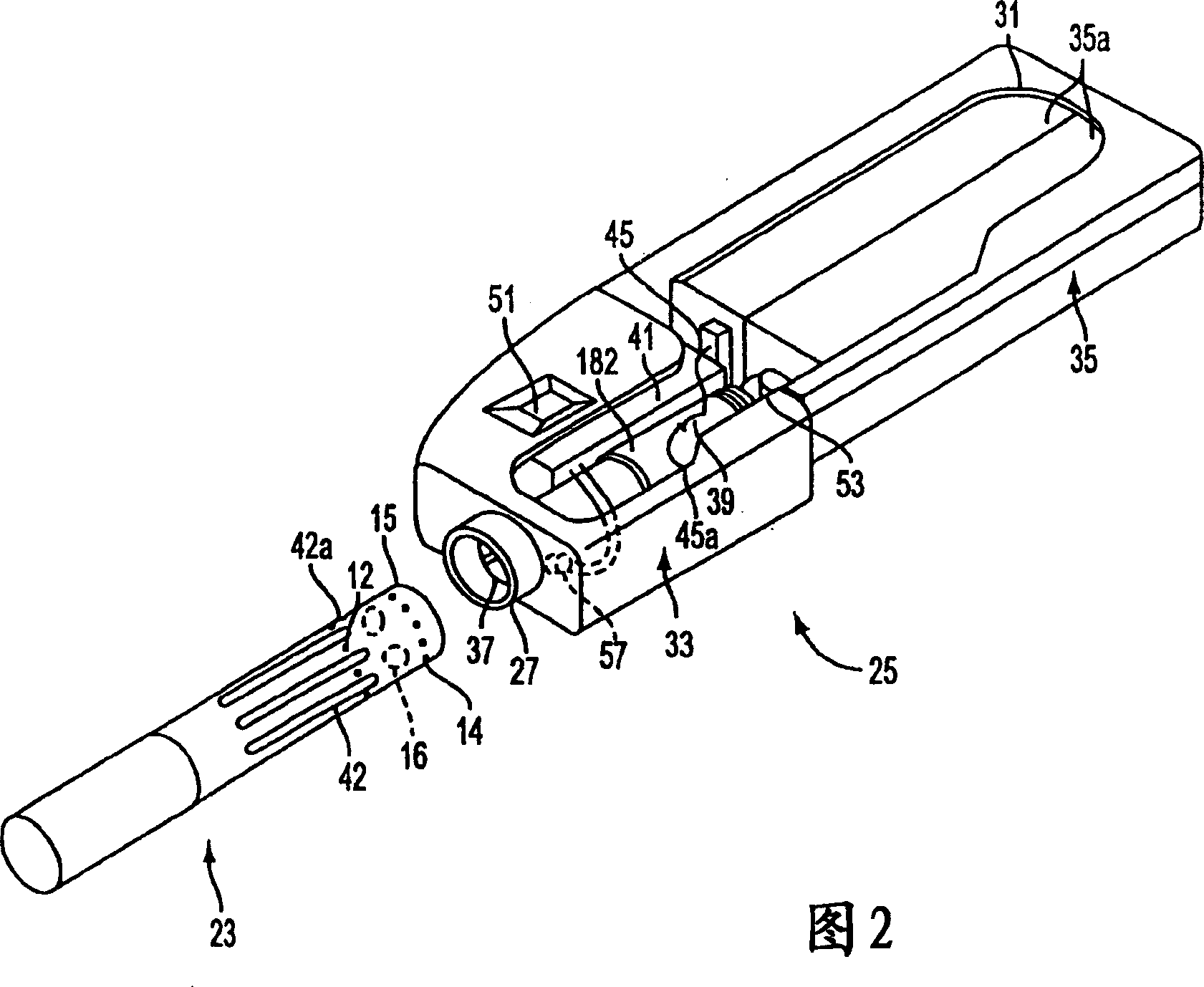

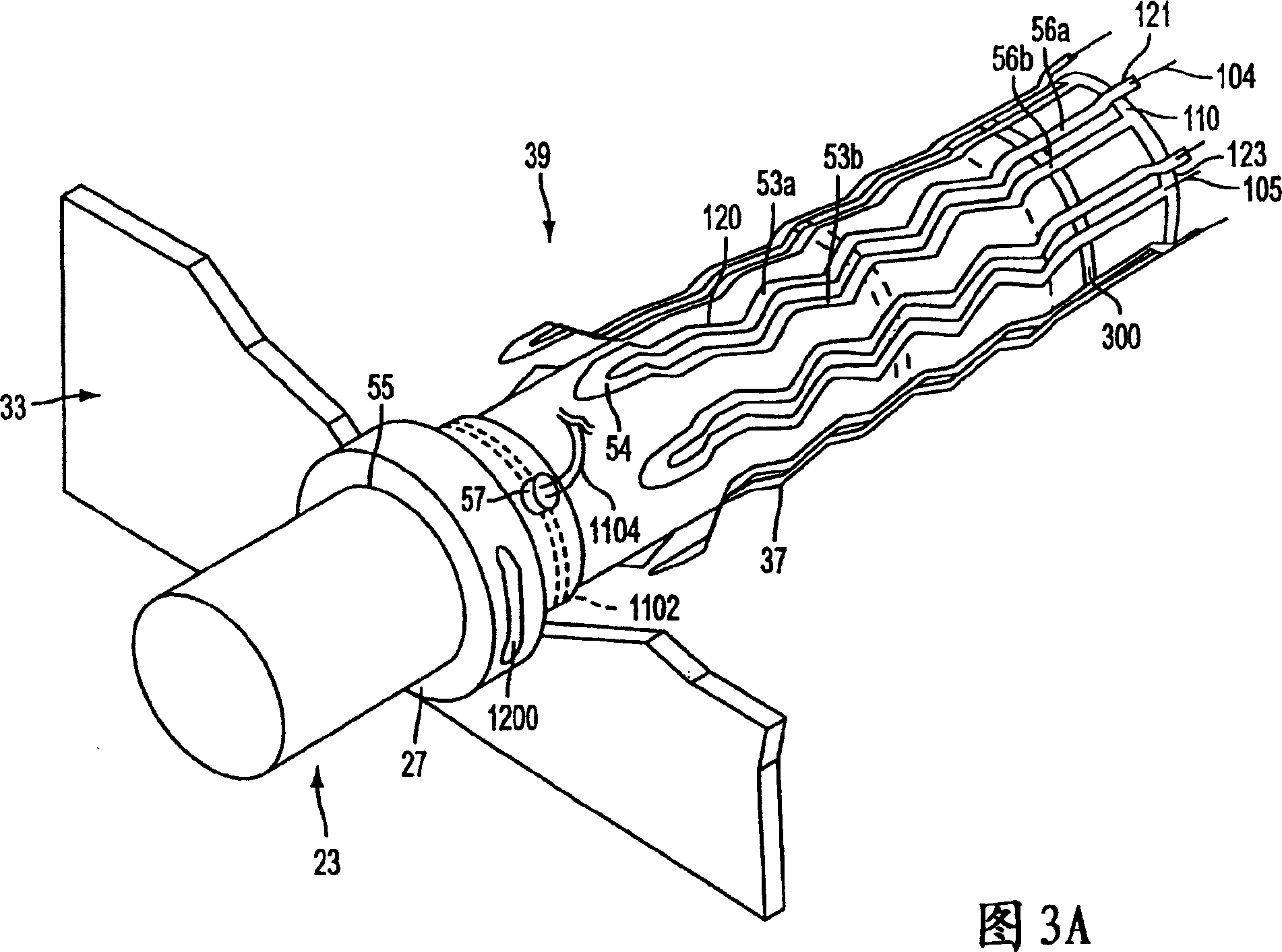

Electrical smoking system and method

InactiveCN1633247AReduce gaseous componentsIncandescent ignitionCigar manufactureIntegratorAcrylonitrile

An electric smoking system includes a cigarette including a cylindrical tobacco web partially filled with tobacco material to define a filled tobacco rod portion and an unfilled tobacco rod portion, and an electric lighter. The wrapper includes a filler of ammonium-containing compounds effective to reduce the gaseous constituents of the smoke produced during smoking. The system includes a pilot burner including at least one heating vane and a controller adapted to control heating of the heating vane. The lighter is configured to at least partially contain the cigarette such that the heater blade heats the heating region of the cigarette. Manipulating the controller to limit the heating of the heater blades to a predetermined temperature range which allows the delivery of the smoke generated when the portion of the tobacco rod is heated while at least reducing the amount of smoke present in the smoke as compared to smoking a cigarette having only calcium carbonate as filler. A gaseous component. The gaseous components that can be reduced include carbon monoxide, 1,3 butadiene, isoprene, acrolein, acrylonitrile, hydrogen cyanide, 0-toluidine, 2-naphthylamine, nitrogen oxide, benzene, NNN, Phenol, catechol, benzanthracene and benzopyrene.

Owner:PHILIP MORRIS PROD SA

Preparation method and application of anti-soil polymer

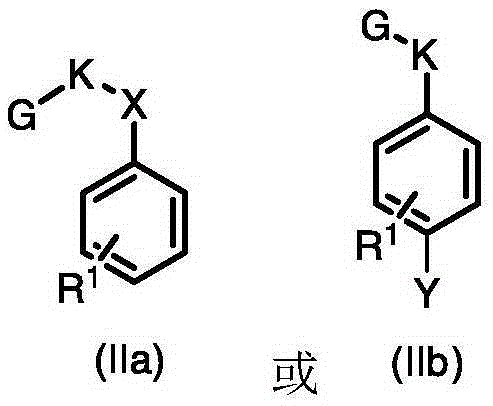

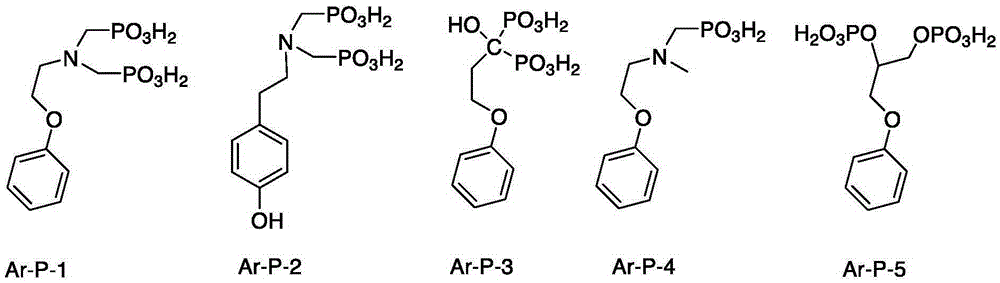

The invention provides a preparation method and application of an anti-soil polymer. The prepared polymer is used as a dispersant for a hydraulic cementing agent and / or an aqueous dispersion for potential hydraulic cementing agent and has good anti-soil performance. The preparation method the anti-soil polymer comprises a step of subjecting polyether macromonomer A with a special structure, monomer B containing a phosphoric acid or phosphorous acid group, optional monomer D and aldehyde C to condensation polymerization so as to prepare the anti-soil polymer, wherein the monomer D is selected from the group consisting of phenol, aniline, p- / o-aminobezene solfonic acid, p- / o-hydroxybenzoic acid, p- / o-aminobenzoic acid, p- / o-hydroxyezene solfonic acid, p- / o-toluidine and p- / o-methylphenol, a mol ratio of the polyether macromonomer A to the monomer B to the monomer D is 1: (0.5-12): (0-8.0), and a mol ratio of the polyether macromonomer A to the monomer B and the monomer D is 1: (0.5-12.0).

Owner:JIANGSU SOBUTE NEW MATERIALS +1

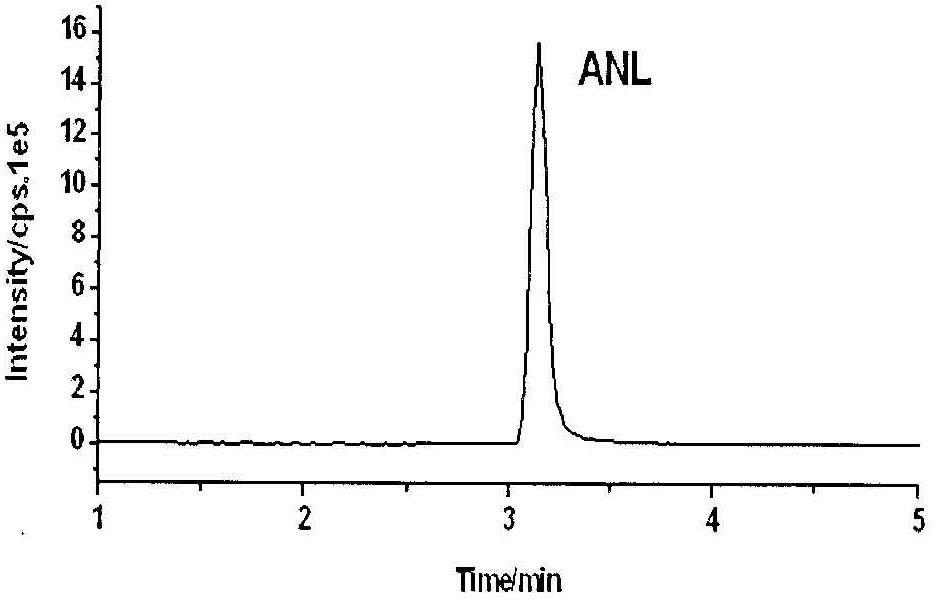

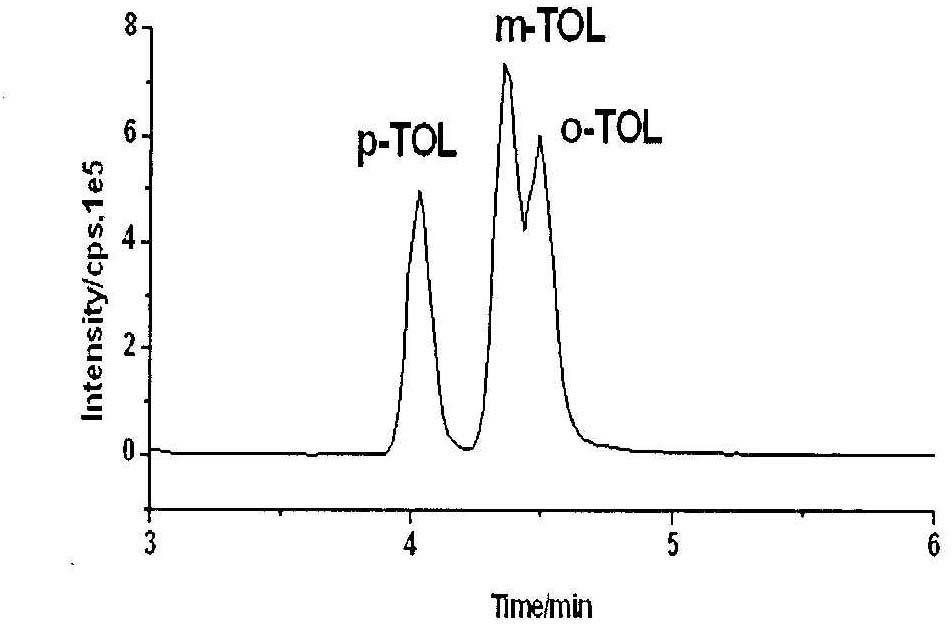

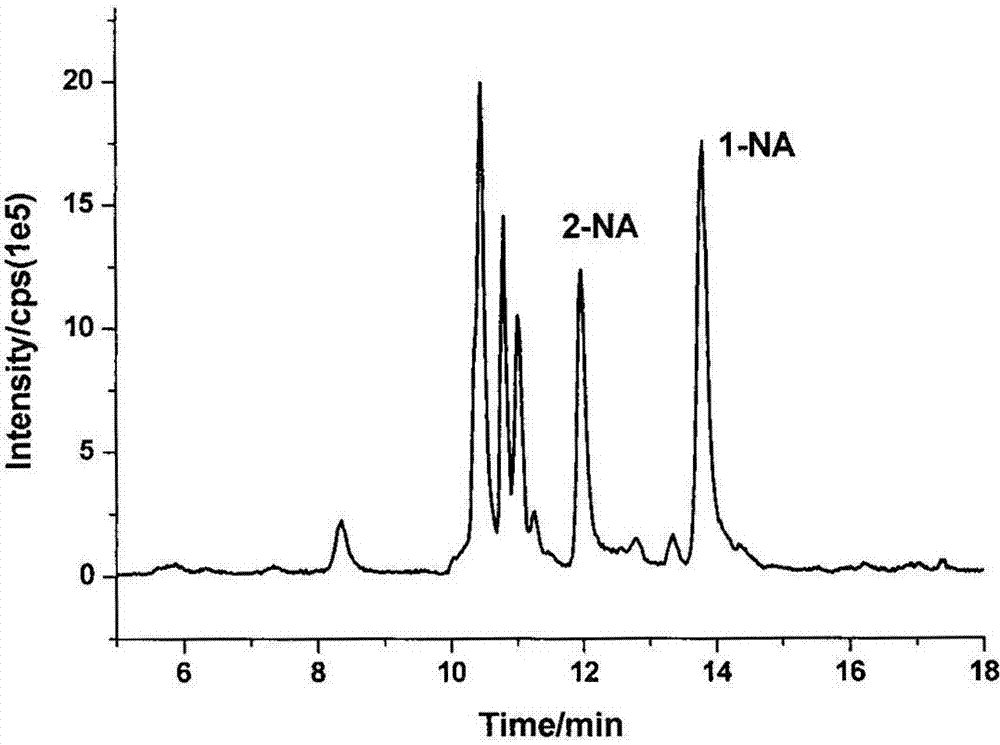

Method for detecting 10 types of aromatic amines compounds in cigarette mainstream smoke by liquid chromatography-tandem mass spectrometry

ActiveCN102608232ASimplified processing stepsSaving volume and smoking experiment timeComponent separationToluidineAniline

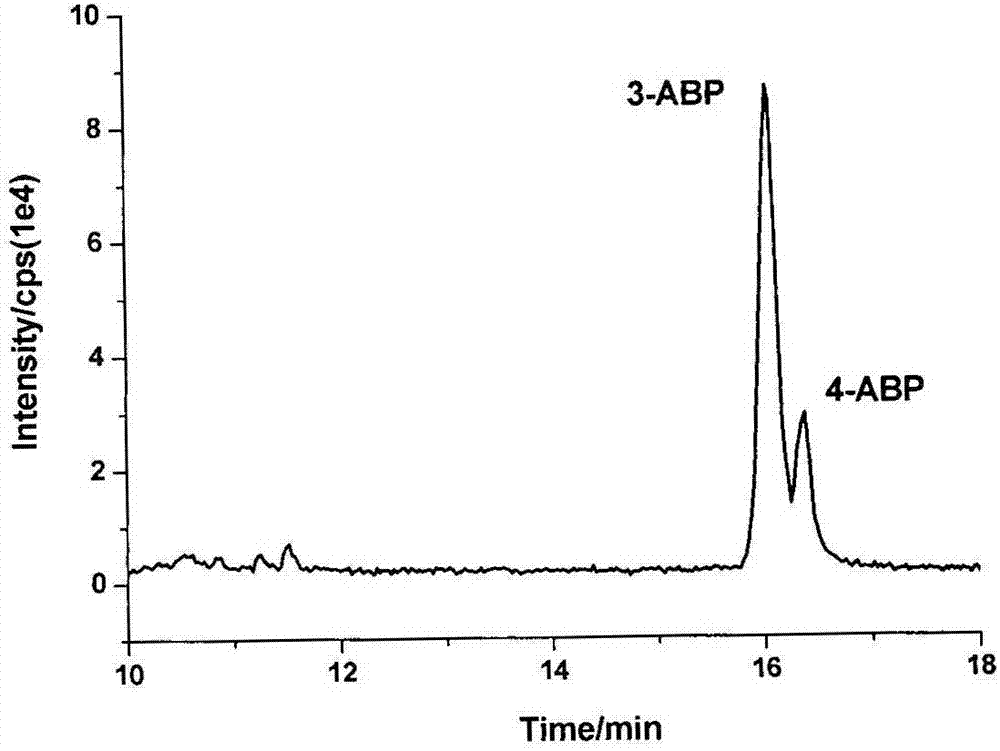

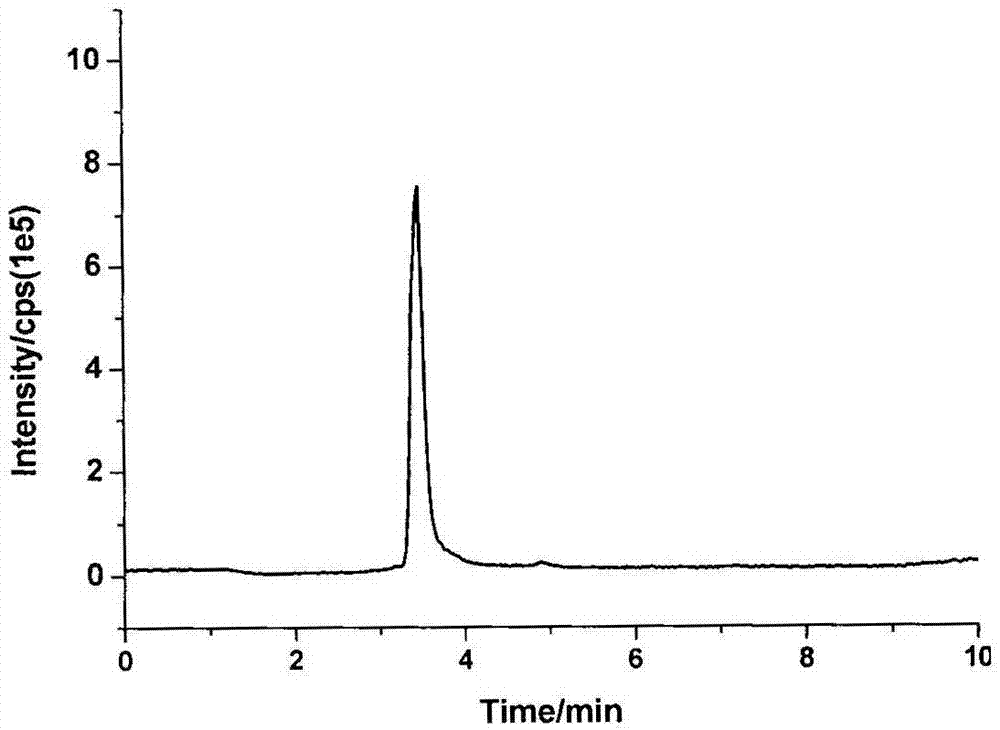

A method for detecting 10 types of aromatic amines compounds (including aniline, ortho toluidine, m-toluidine, p-aminotoluene, m-phenylenediamine, m-methoxyaniline, 1- naphthylamine, 2- naphthylamine, 3- aminobphenyl and 4- aminobphenyl) in cigarette mainstream smoke by liquid chromatography-tandem mass spectrometry is characterized in that a Cambridge filter and an absorbing bottle containing 5%of HC1 solution respectively gather the aromatic amines compounds in a particle phase matter and a gas phase matter of mainstream smoke, after the 5%HCI solution is used for extracting the aromatic amines compounds on the filter, the aromatic amines compounds are purified by an HLB (hydrophile-lipophile balance) solid-phase extraction column, and a liquid chromatography-tandem mass spectrometry instrument is used for determining the 10 types of aromatic amines in the mainstream smoke in cigarettes. Compared with an existing GC-MS (gas chromatography-mass spectrometer) analysis method for detecting aromatic amines in mainstream smoke of cigarettes, the method does not need derivatization reaction or liquid-liquid extraction operation, greatly simplifies pretreatment steps of samples, improves analysis efficiency, and can more comprehensively detect harmful aromatic amines compounds in mainstream smoke of cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

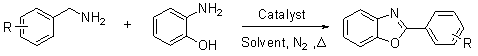

Method for preparing 2-substituted benzoxazole compound

The invention discloses a method for preparing a 2-substituted benzoxazole compound. According to the method, a benzylamine compound or a benzaldehyde compound or a benzyl alcohol compound, and o-toluidine-N-methyl-o-phenylenediamine, ortho-aminophenol and o-aminobenzenethiol serve as raw materials, metals palladium, platinum or ruthenium serves as a catalyst, and N,N-dimethylformamide, N,N-dimethylacetamide or N-methylpyrrolidone serves as a solvent. The method comprises the following preparation steps: (1) mixing the raw materials; (2) reacting; (3) separating and extracting; and (4) drying and concentrating. An oxidant and a hydrogen acceptor are not required in the whole preparation process, and the used partial catalysts can be recycled. The method is high in atom economy, simple in aftertreatment and mild in reaction conditions and has a certain industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

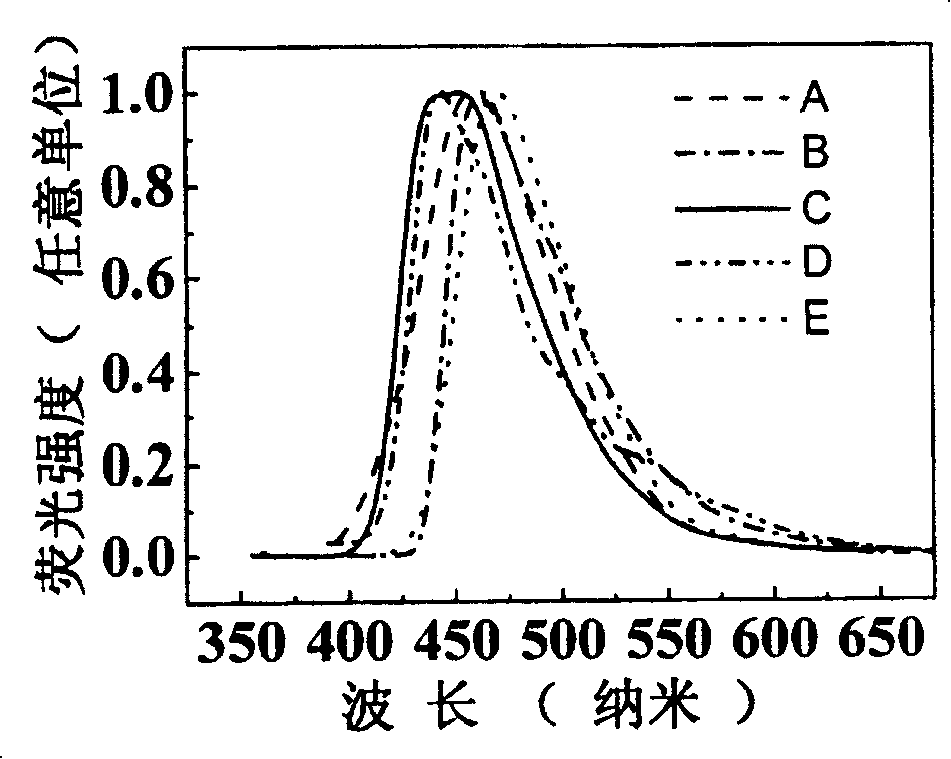

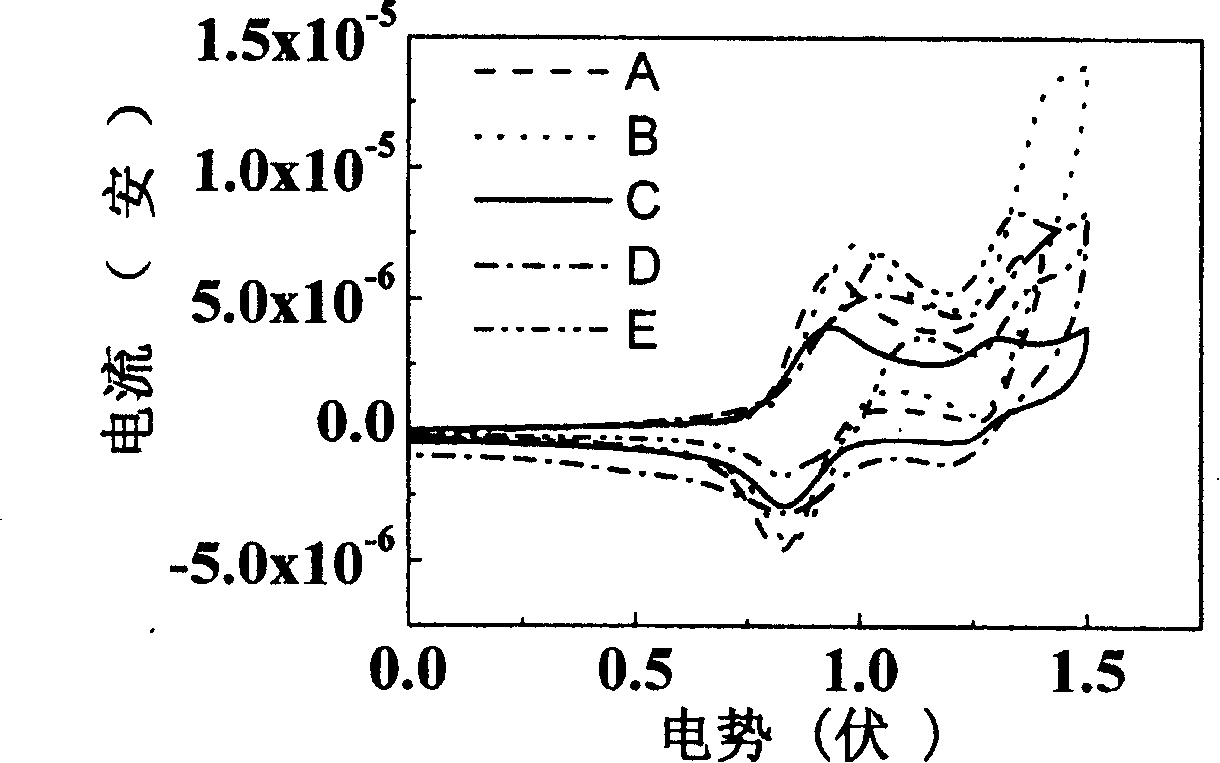

Hole-transporting type blue luminescent material as well as preparation and uses thereof

InactiveCN101225298AHigh fluorescence quantum yieldImprove thermal stabilitySolid-state devicesSemiconductor/solid-state device manufacturingSolventNitrogen gas

The invention relates to a hole-transporting blue color compound, which is a fluorine derivative based on 9, 9-bi-(4-(bi-p-methypheny) aminophenyl). The preparation method is to first mix 9, 9-bi-[4-(N, N-bi-p-toluidine) phenyl]-2-dibromofluorine and boric acid pinacol ester of conjugate radicle, or to mix 9, 9-bi-[4-(N, N-bi-p-tolyl-amino) phenyl] fluorine -2, 7-bi-boric acid pinacol ester and bromide of conjugate radicle; and then add in toluene, potash solution, aliquat336 and catalyst tetrakis (triphenylphosphine) palladium, and heat and reflow for 10 to 30 hours in nitrogen environment; when the reaction is done, decompress, remove the solution and get the target product, the derivative based on 9, 9-bi-(4-(bi-p-methypheny) aminophenyl) fluorine substituted by unilateral conjugate radical. The compound can be used as the hole-transporting layer and the luminescent layer as well in electroluminescent devices.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Method for detecting seven aromatic amine compounds in human urine through liquid chromatography-series mass spectrometry

The invention provides a method for detecting seven aromatic amine compounds in human urine through a liquid chromatography-series mass spectrometry. The method is to detect aniline, o-toluidine, m-toluidine, 1-naphthylamine, 2-naphthylamine, 3-aminobphenyl and 4-aminobphenyl, and is characterized by comprising the steps of hydrolyzing urine via concentrated HCl, purifying the sample through PAH (Polycyclic Aromatic Hydrocarbon) molecular imprinting columns, and analyzing through the liquid chromatography-series mass spectrometry (LC-MS / MS). Compared with the prior art, the method has the advantages that the LC-MS / MS method is adopted, so that higher sensitivity is achieved, and the pre-processing of the sample can be greatly simplified (about 2 hours are consumed); the pre-processing through a GC-MS (Gas Chromatography-Mass Spectrometer) method as shown in a literature is complicated and wastes time (by more than 6 hours). The method provided by the invention can effectively improve the analyzing efficiency, and is relatively suitable for analyzing seven aromatic amine compounds in human urine.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

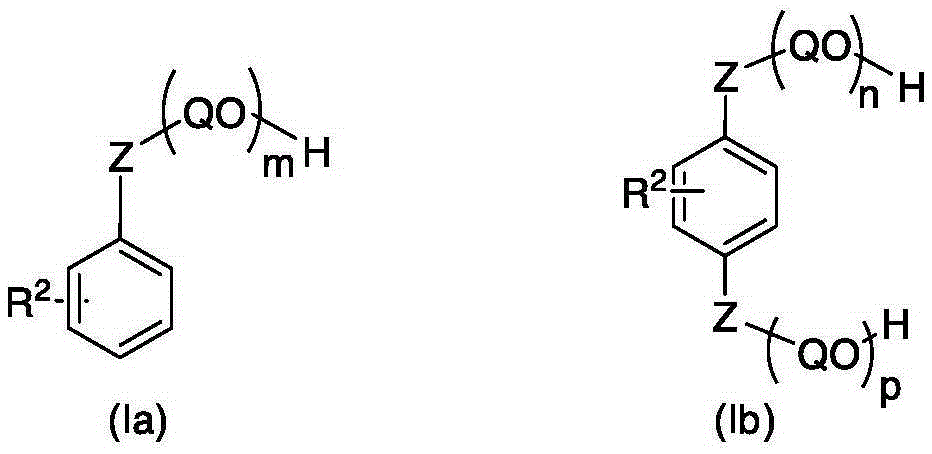

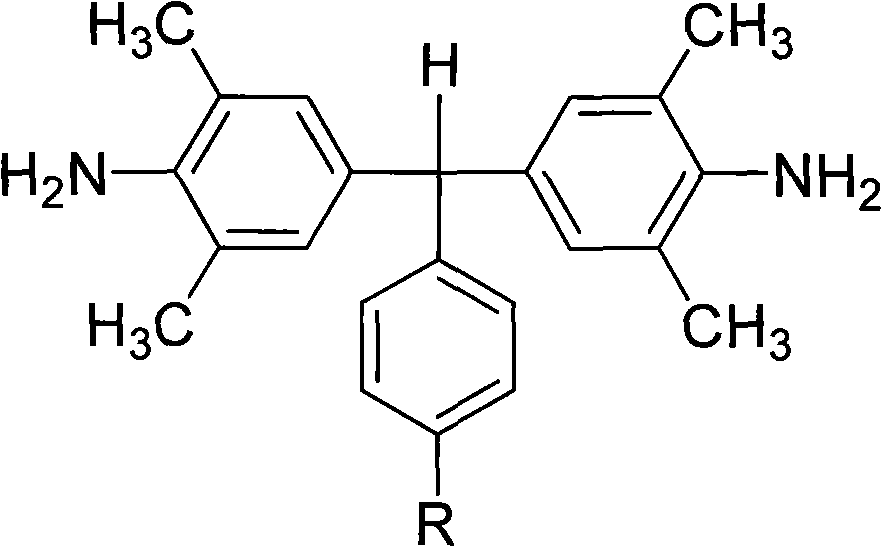

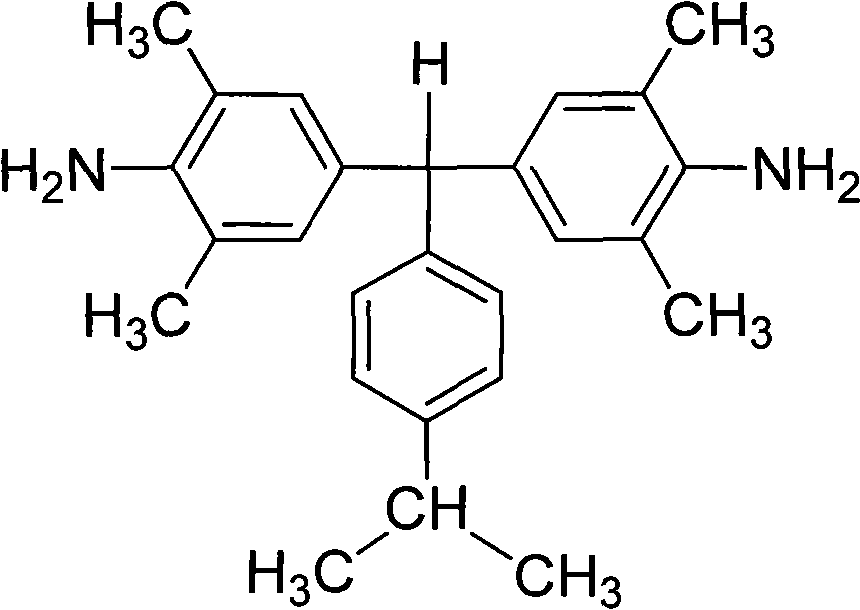

Polyalkyl-substituted aromatic diamine monomer and preparation and application thereof

InactiveCN101514164AHigh purityStable at room temperatureOrganic compound preparationAmino compound preparationChromatographic separationDimethylaniline N-oxide

The invention relates to a polyalkyl-substituted aromatic diamine monomer, and the general formula of the structural formula is shown in the figure, wherein R is -CH(CH3)2 or -C(CH3)3; and the preparation is as follows: under nitrogen protection, 2,6-methyl toluidine is heated to the temperature of 100 to 120 DEG C, and the mixed liquid of aromatic formaldehyde and hydrochloric acid is slowly dropped in the 2,6-methyl toluidine and then the mixture is heated for carrying out reflux; after being cooled, 10% aqueous sodium hydroxide solution is dropped into the mixture till the pH value thereof is neutral, and then alcohol is added, the obtain sediment is washed with methanol; after drying of the mixture, chromatographic separation and purification is carried out on the mixture by silicagel column, thus obtaining the polyalkyl-substituted aromatic diamine monomer; the application can be used to prepare soluble, high-temperature resistant polyimide film material with high transparency and low dielectric constant. The substituted aromatic diamine monomer containing polyalkyl prepared in the invention has high purity and is table at room temperature; the preparation method has simple operation and low cost without any special requirement for equipment, thereby being applied to industrial production.

Owner:DONGHUA UNIV

Synthetic method of 2,5-diaminotoluene and sulphate thereof

ActiveCN101450904AThe pre-processing process is simpleReduce unit consumptionPreparation by N-O/N-N bondsWater dischargeToluidine

Owner:宁夏瑞鼎科技有限公司

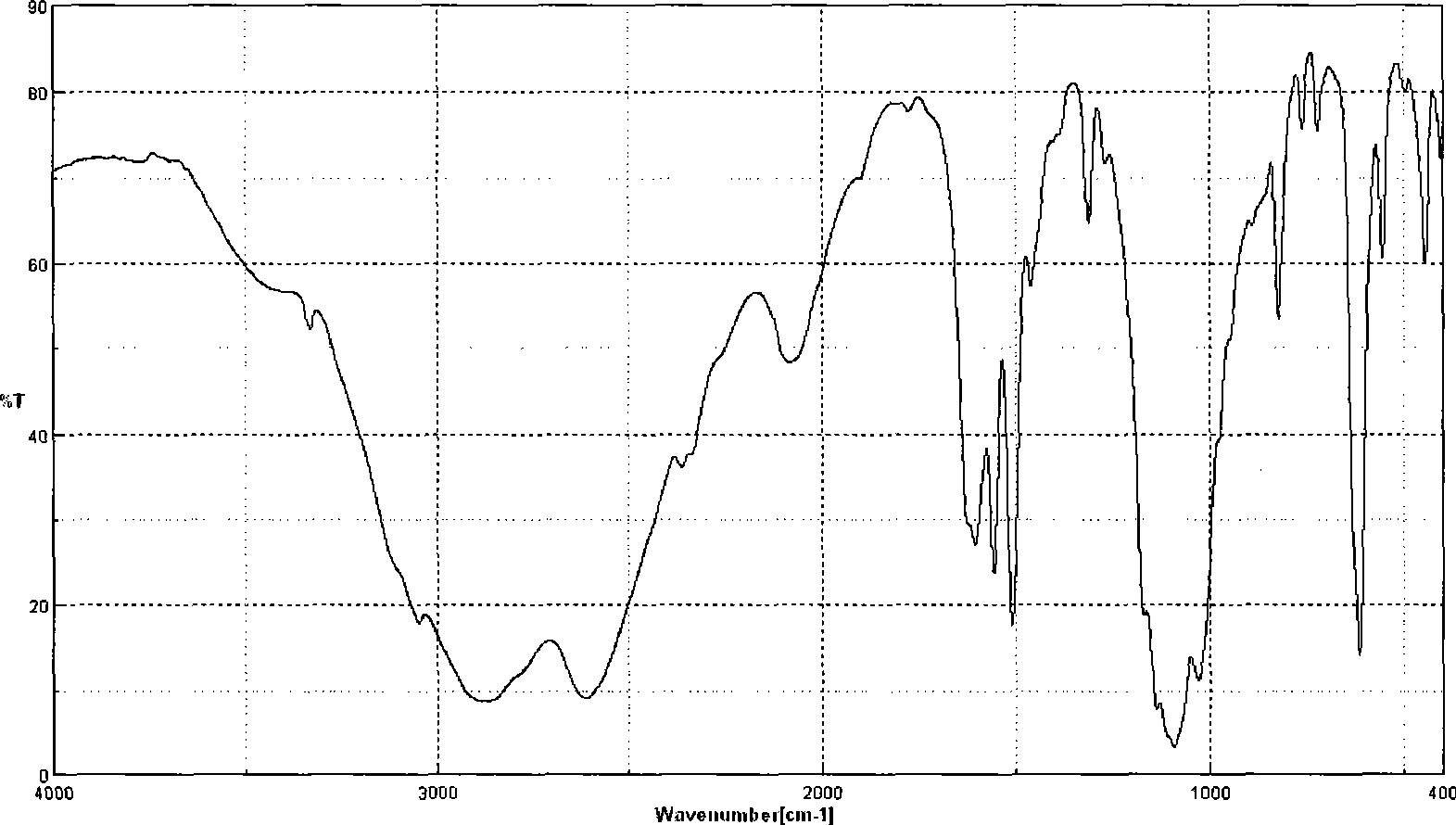

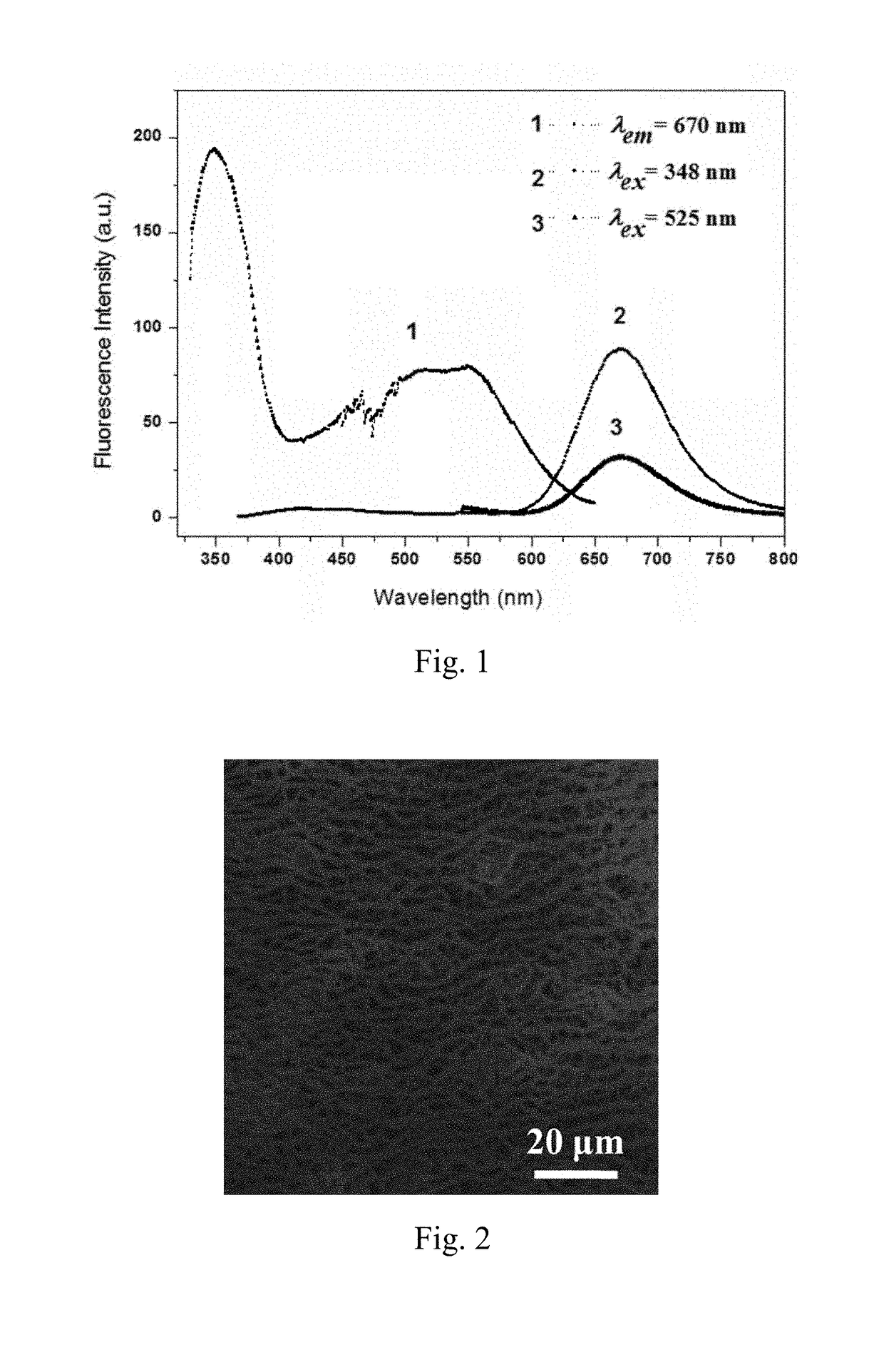

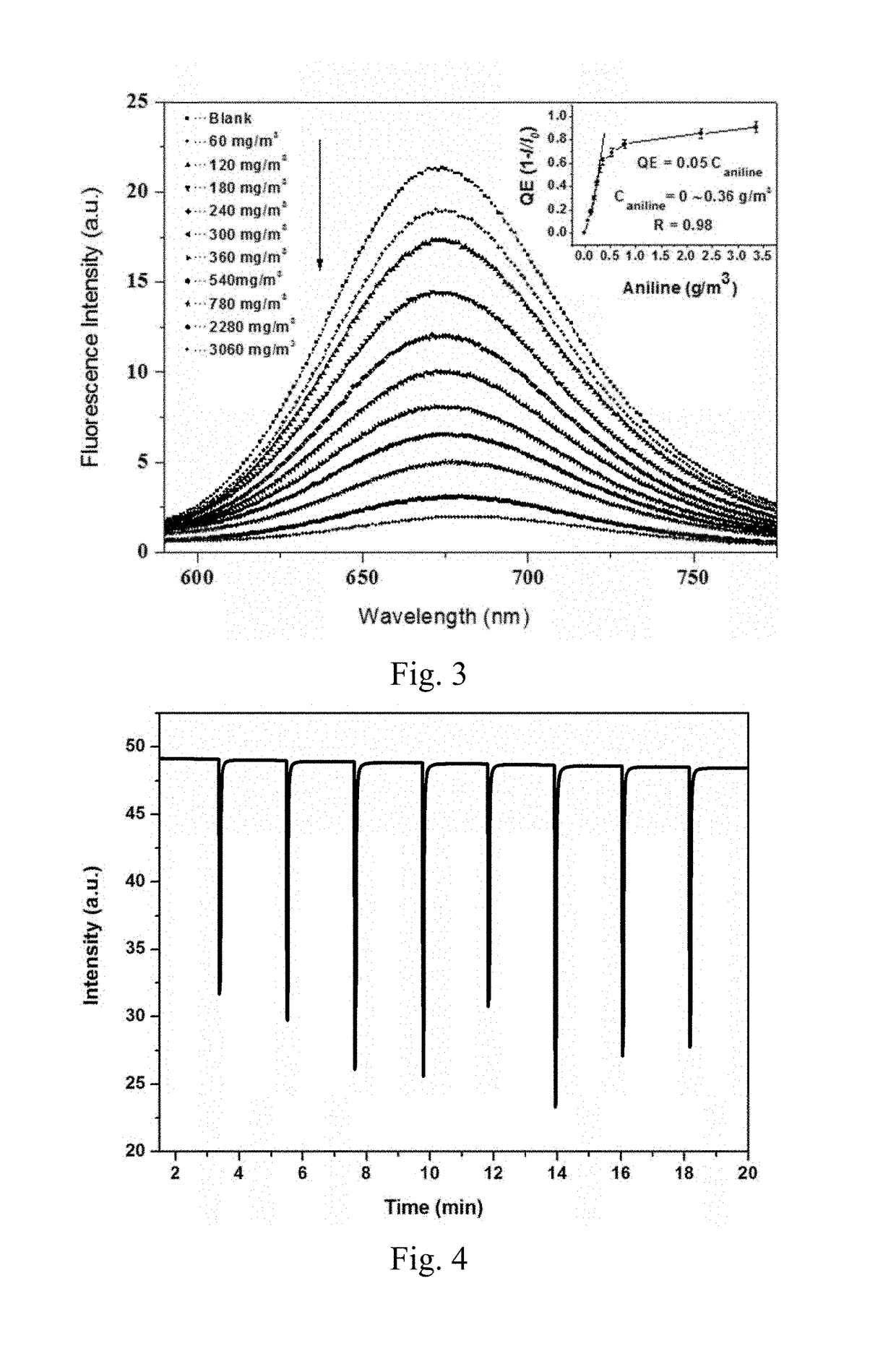

Preparation method and application of fluorescent compound having sensing ability to aniline and o-toluidine gas, and fluorescent film with the same

ActiveUS20190062629A1Easy to operateImprove stabilityOrganic chemistryFluorescence/phosphorescenceSolubilityTerra firma

The present invention discloses a fluorescent compound having a sensing ability to aniline and o-toluidine, a preparation method thereof, a preparation method and application of a fluorescent sensing film. The compound contains a naphthalenediimide (NDI) unit, two alkynyl aniline conjugate fragments and two long alkyl chain fragments; compared with perylene anhydride (PDI), naphthalenediimide (NDI) has better solubility, rich photophysical property, good photochemical stability and strong π-π stacking effect; these building units make the prepared fluorescent compound have supramolecular characteristics and more abundant gelling behavior and assembly behavior. Therefore, the sensing film prepared with the fluorescent compound is controllable in the microstructure, good in stability, high in sensitivity, long in service life and able to be repeatedly used. The present invention achieves the sensitive detection of aniline, and more importantly, the detection is completely reversible, so as to lay the solid foundation for the realization of aniline fluorescence sensor.

Owner:SHAANXI NORMAL UNIV

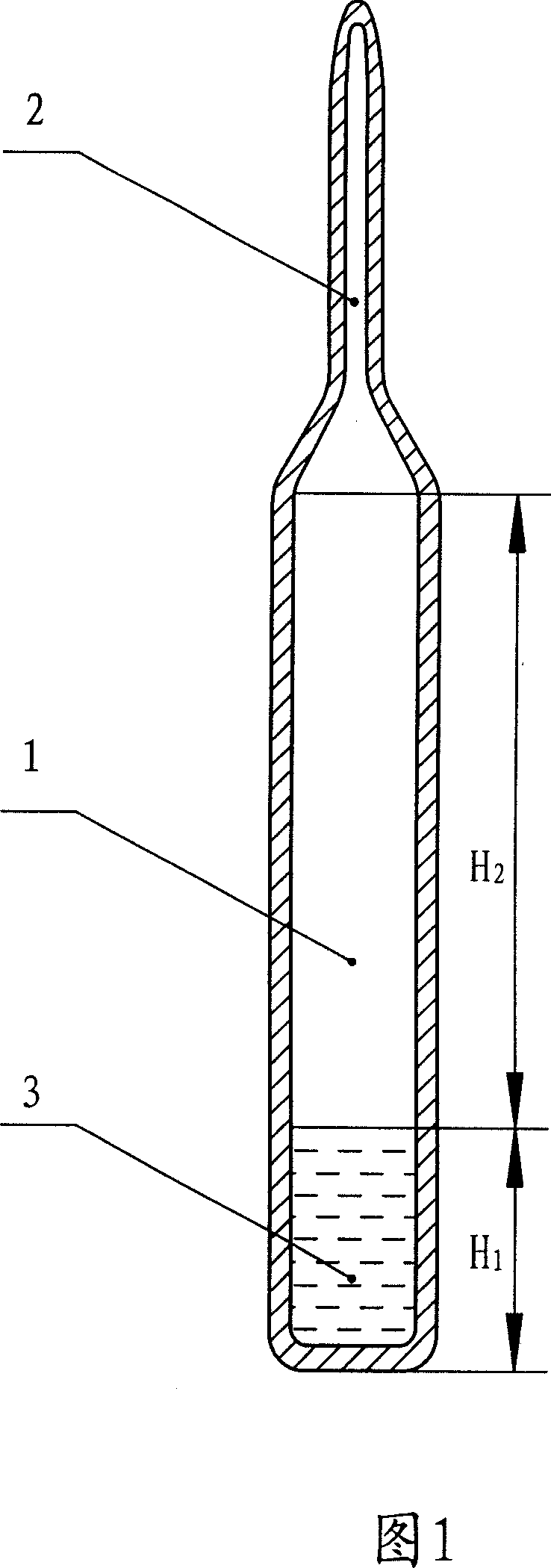

Liquid for testing hydrogen sulfide and its colorimetric testing tube

InactiveCN101029872AHigh detection sensitivityLess distracting factorsMaterial analysis by observing effect on chemical indicatorToluidineTesting tubes

An experiment test solution used fro quickly determining hepatic gas is prepared from 1-2 volume of 2% para-azyl methyl toluidine salt, 10-25 volume of 6% sulfuric acid solution and 4-6 volume of 10% molysite solution. The experiment test tube of hepatic gas is also disclosed.

Owner:白莉

Aqueous metal antirust agent and preparation method thereof

InactiveCN103409743AEvenly dispersedGood dispersionMetallic material coating processesToluidineHuman health

The invention discloses an aqueous metal antirust agent and a preparation method thereof. The aqueous metal antirust agent is prepared from following raw materials by weight: 10-20 parts of dodecylbenzenesulfonic acid, 20-30 parts of pentaerythritol tetraoleate, 40-45 parts of butyl oleate, 10-15 parts of o-toluidine, 7-15 parts of sodium sulfate, 10-20 parts of sodium hydroxide, 10-15 parts of sodium silicate and 40-50 parts of water. The aqueous metal antirust agent can be uniformly dispersed in water without impurities such as suspended solids, etc. and has good dispersity. The content of volatile organic compounds is 0.3-0.5 ppm. The content of harmful volatile compounds is low, thus having no harm to human health, and therefore the aqueous metal antirust agent is environment friendly and healthy.

Owner:JIANGXI GRESS TECH CORP

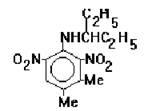

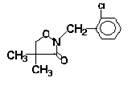

Microcapsule suspension containing pendimethalin and clomazone and preparation method thereof

InactiveCN102669115AMeet the basic requirements of prevention and controlLow toxicityBiocideAnimal repellantsSoil treatmentToluidine

The invention provides a microcapsule suspension containing pendimethalin and clomazone. The microcapsule suspension containing pendimethalin and clomazone comprises pendimethalin, clomazone, a capsule core solvent, a capsule wall material, a dispersing agent, a protective agent, a waterborne monomer and water, wherein the microcapsule suspension containing pendimethalin and clomazone is obtained by complexing binitro toluidine and oxazolone herbicides according to a certain ratio through a chemical process; the microcapsule suspension containing pendimethalin and clomazone is a novel disposable paddy field soil treatment pesticide, which can be absorbed by roots and seedlings of plants, can stop the generation of chlorophyll of a sensitive plant and the accumulation of plastid pigment, generates albinism on the plants, inhibits hill reaction in weed photosynthesis, causes chlorosis at pointed ends and edges of weed leaves; and finally, the whole weed plants are withered and die; and a pesticide composite provided by the invention has a very good control effect on grassy weeds, Cyperaceae weeds and broad leaf weeds of crops.

Owner:上海沪联生物药业(夏邑)股份有限公司

Hydrocarbon fuel compositions

InactiveUS20100115829A1Readily availableImprove economyGaseous fuelsLiquid carbonaceous fuelsTorchProduct gas

The present invention relates to a hydrocarbon fuel composition comprising (i) at least 99% by weight of a base gas; and (ii) additives comprising (a) 2 to 50 ppm organometallic compound; and (b) 100 to 5000 ppm aniline or substituted aniline and 100 to 5000 ppm toluidine. The present invention discloses addition of an additive or additive mixture to base fuel preferably, liquefied petroleum gas. The addition of additive mixture not only improves the properties of the base fuel for use as torch gas for cutting and welding application, but also reduces the consumption of both fuel and oxygen for cutting applications.

Owner:BHARAT PETROLEUM CORP LTD

Immunohistochemical hematoxylin-toluidine blue double-redyeing method for melanocyte

InactiveCN104990781ADoes not affect color renderingWithout compromising intuitive advantagesPreparing sample for investigationAntigenToluidine

The invention provides an immunohistochemical hematoxylin-toluidine blue double-redyeing method for melanocyte. The method comprises the following steps: (1), carrying out conventional xylene dewaxing on a slice and carrying out gradient alcohol dehydration; (2), blocking and inactivating endogenous peroxide enzyme; (3), repairing an antigen; (4), carrying out serum sealing; (5), dropwise adding primary antibodies; (6) dropwise adding secondary antibodies; (7), carrying out DAB developing; (8), carrying out hematoxylin redyeing and hydrochloric acid alcohol differentiation; (9), redyeing by a toluidine blue working solution and carrying out glacial acetic acid differentiation; (10), dehydrating to be transparent and sealing the slice. According to the invention, positive granules are still brownish yellow after redyeing, and original melanin granules in the tissue become deep green, so that distinction is obvious, the melanin granules are easily distinguished from brown granules, the developing of hematoxylin is not influenced, cell nucleuses of background cells are clearly visible, the color difference of immunohistochemical positive brownish yellow granules, deep green melanin granules and blue cell nucleus is obvious and intuitive, and distinguishing is convenient. Toluidine blue dyeing liquid is prepared simply and conveniently.

Owner:CHUGOKU IGAKU KAGAKUIN HIFUBIYOU KENKYUSHO

Method for preparing CI pigment red 57:1

The invention discloses a method for preparing CI pigment red 57:1. The method comprises the steps as follows: 2-isonaphthol and a sodium hydroxide solution have a carboxylation reaction with carbon dioxide after directly salified and dehydrated; a product is neutralized and subjected to filter pressing to obtain a monosodium salt solution of 2-hydroxyl-3-naphthoic acid; the solution directly has a coupling reaction with diazonium salt of 4-toluidine-3-sulfoacid after purified by a resin absorption column; and a product is subjected to color lake by an inorganic calcium compound to obtain the CI pigment red 57:1 finally. According to the method, the step of purification by the resin absorption column is added, and the steps that in the prior art, 2, 3-acid powder is obtained by droppwise adding sulfuric acid to a monosodium salt solution of 2, 3-acid, drying and packaging are performed, then the sodium hydroxide solution is added to obtain the monosodium salt solution of 2, 3-acid again and the like are omitted; therefore, the problems that the use amount of sulfuric acid and the sodium hydroxide solution is large, 2, 3-acid powder requires to be dried and packaged and the like in a conventional preparation process are solved, the emission of inorganic salt to the environment is reduced, energy consumption and manpower cost are reduced, and wastewater emission load is obviously reduced.

Owner:苏州思睿屹新材料股份有限公司

Energy-saving texture thermal insulation coating used for building external wall

InactiveCN104762007ALight weightFunction increaseFilling pastesPolyurea/polyurethane coatingsDimethylaniline N-oxideToluidine

The invention belongs to the field of buildings, and relates to an energy-saving texture thermal insulation coating used for a building external wall. The energy-saving texture thermal insulation coating is composed of, by weight, 10 parts to 15 parts of water, 40 parts to 50 parts of hand feeling filler, 15 parts to 20 parts of quartz sand, 8 parts to 13 parts of silica-based adhesives, 6 parts to 9 parts of putty, 12 parts to 18 parts of diphenyl guanidine, 2 parts to 4 parts of zinc stearate, 1 part to 3 parts of organic zirconium complex, 3 parts to 5 parts of methyl toluidine, 4 parts to 7 parts of pentaerythritol, 3 parts to 6 parts of modified floating beads and 1 part to 3 parts of texture particles. The texture particles are prepared by adding, by weight, 6 parts to 10 parts of chlorinated paraffin, 3 parts to 7 parts of ethylene-propylene-diene monomer (EPDM), 1 part to 4 parts of silane coupling agents, aluminic acid ester coupling agents or aluminum-titanium composite coupling agents and 0.6 part to 1.2 parts of a mixture formed by mixing phenols main antioxygen 1010 and auxiliary antioxygen 168, and by conducting blending modification plastification and extrusion granulation. The hand feeling filler is a mixture of polyurethanes fluff powder and elastic powder or a mixture of crylic acid fluff powder and elastic powder. The texture thermal insulation coating has the excellent water-retaining property, and is high in caking property and alkali resistance, safe and environmentally friendly.

Owner:肖先波

Environment-friendly type lubricating oil additive

InactiveCN104974825AImprove wear resistanceImprove extreme pressure performanceAdditivesToluidineActive agent

An environment-friendly type lubricating oil additive is composed of the following raw materials in parts by weight: 7 to 12 parts of castor oil polyoxyethylene ether, 3 to 6 parts of molybdenum disulfide colloid, 2 to 7 parts of n-octadecanoic acid, 4 to 8 parts of critic acid, 6 to 13 parts of molybdenum dialkyldithiophosphate, 4 to 8 parts of butyl oleate, 3 to 6 parts of tackifier, 5 to 8 parts of o-toluidine / m-toluidine, 6 to 8 parts of methyl citrate, 4 to 7 parts of triphenyl phosphorothionate, 6 to 12 parts of sulfurized isobutylene, 5 to 8 parts of benzotriazole amine, 2 to 6 parts of n-butyl acetate, 1 to 4 parts of p-methoxyl styrene, 8 to 16 parts of linoleic acid, 4 to 6 parts of methanol, 7 to 13 parts of polyethylene glycol monomethyl ether, 4 to 7 parts of magnesium silicate, and 4 to 6 parts of fluorine surfactant. The provided environment-friendly type lubricating oil additive can improve the wear-resistant performance, extreme pressure resistant performance, and oxidation resistant performance of lubricating oil, has the advantages of convenient operation and environment-friendliness, and is according with the green and environment-protection requirements.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

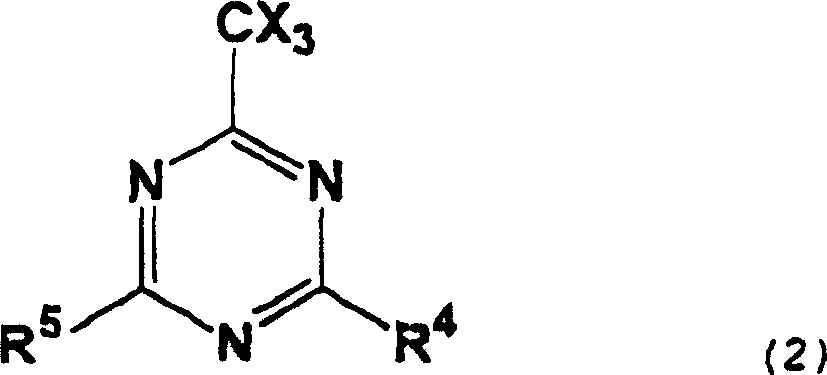

Photoepolymerization initiater

ActiveCN1537870AHigh polymerization activityHigh mechanical strengthImpression capsDentistry preparationsP-dimethylaminobenzoic acidBenzoic acid

A photopolymerization initiator comprising (A) an alpha -diketone compound such as camphorquinone, (B1) an aliphatic amine compound such as triethanolamine or N-methyldiethanolamine, (B2) an aromatic amine compound such as ethyl p-dimethylaminobenzoate or N,N-dimethyl p-toluidine, and (C) a triazine compound substituted with a trihalomethyl group, such as 2,4,6-tris(trichloromethyl)-s-triazine or 2-phenyl-4,6-bis(trichloromethyl)-s-triazine. The photopolymerization initiator remains stable against the environmental light such as the indoor illumination light from a fluorescent lamp or the dental light illuminating the interior of the oral cavity, is excellently handled, is quickly cured by the irradiation with an intense light emitted from a light irradiator for polymerization, provides a cured body having excellent properties, can be stably preserved even at high temperatures, and is very useful as a dental composite resin.

Owner:TOKUYAMA CORP +1

Photosensitizer formula for photodynamically treating periodontitis, as well as preparation method and application thereof

InactiveCN106822894ANo side effectsNo immune responseAntibacterial agentsPhotodynamic therapyOral diseaseGel preparation

The invention discloses a photosensitizer formula for photodynamically treating periodontitis and an application thereof. A hydrogel preparation for treating periodontitis takes toluidine blue as a photoactive substance and carbopol as a gel. A formula for optimizing the gel preparation comprises the following components by mass concentration: 0.05%-3% of carbopol, 0.001%-1% of toluidine blue, 0.01%-0.4% of sodium hydroxide or 0.07%-2% of triethanolamine and the balance of water. A method for photodynamically treating periodontitis, provided by the invention, can be used for replacing an antibiotic therapy, so that the problem of antibiotics abuse can be prevented; when the preparation is used for treating the oral diseases caused by infections, such as, periodontitis, the antibacterial rate of once irradiation treatment can reach up to 99.99%; serious patients can be repeatedly treated at intervals; and the photosensitizer formula is free from toxic or side effect to normal organ tissues and has wide market prospects and high application values.

Owner:ZHEJIANG UNIV OF TECH

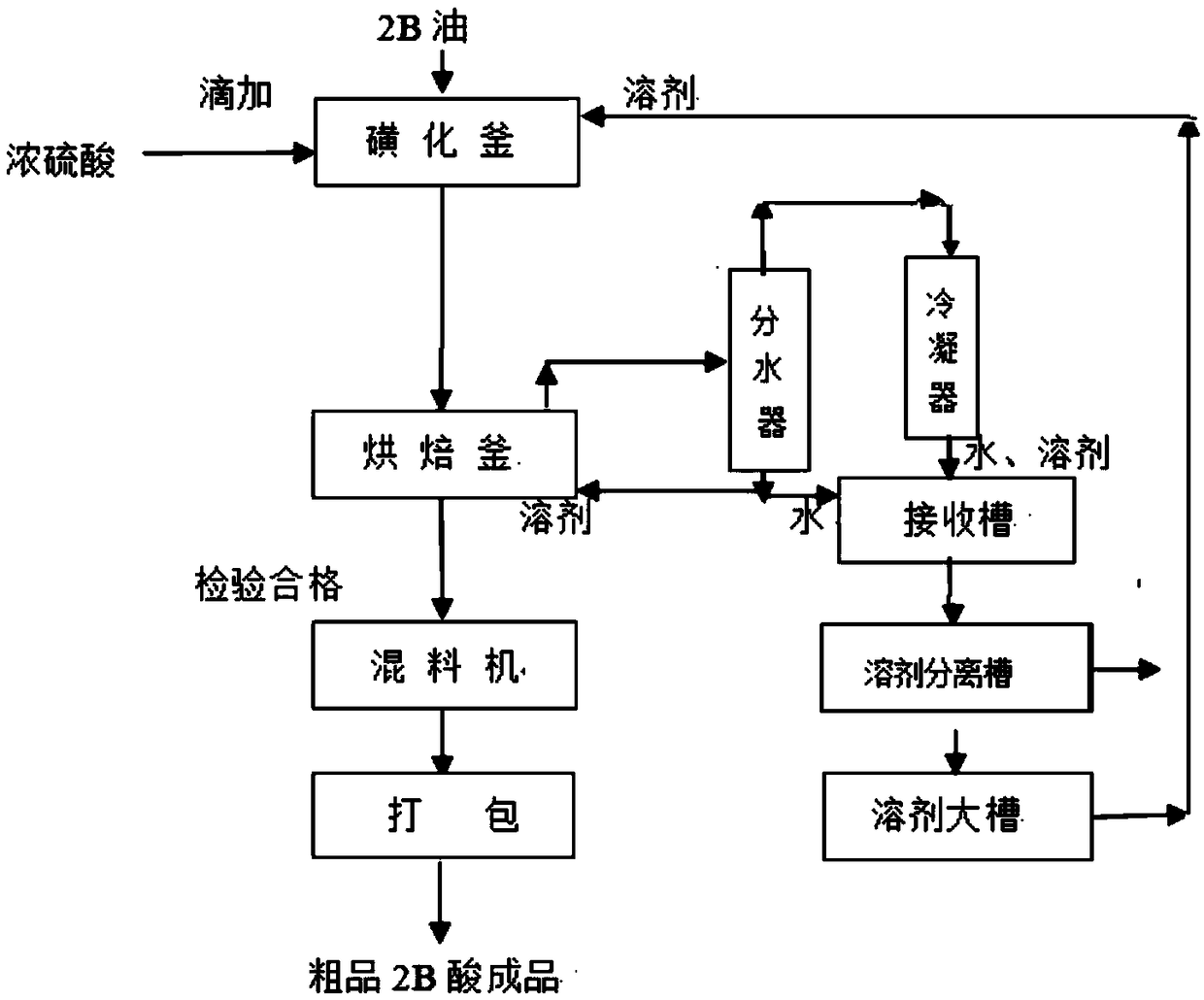

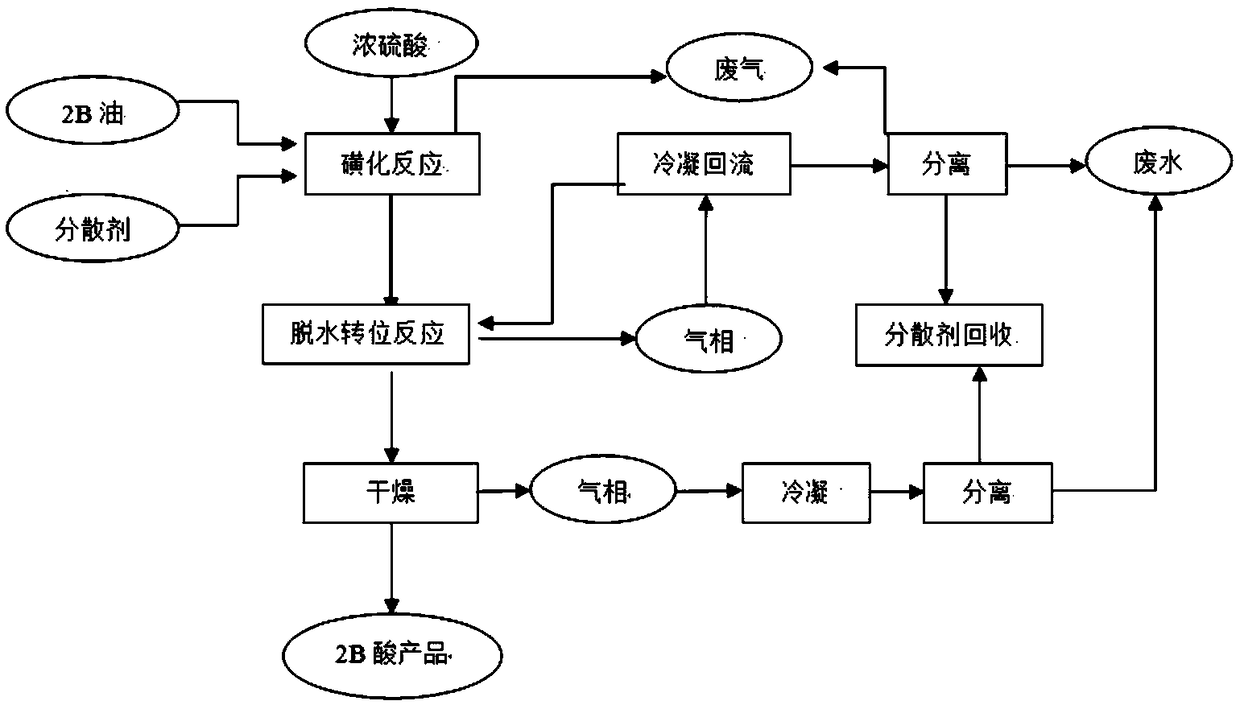

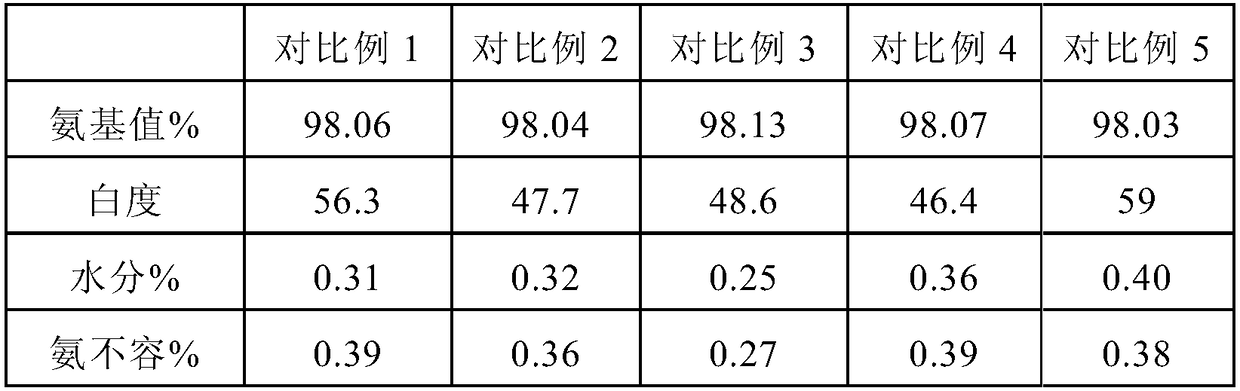

Method for preparing 3-chloro-p-toluidine-6-sulfonic acid by liquid-phase baking method

ActiveCN109180537AThorough responseUniform heat and mass transferSulfonic acid preparationOrganic solventToluidine

The invention provides a method for preparing 3-chloro-p-toluidine-6-sulfonic acid by a liquid-phase baking method. The method comprises the following steps: mixing high-purity 2B oil as a raw material with an organic solvent serving as a liquid dispersant, performing a sulfonation reaction on the 2B oil and concentrated sulfuric acid in the liquid phase dispersant, and dehydrating and drying thesulfonated product to obtain 2B acid. By adopting the method, the high quality 2B acid is directly prepared by dehydrating and translocating in a liquid phase, and refining processes such as alkali dissolving, decolorizing, filtering, acid separating, dehydrating, drying and the like, so that the 'Three Wastes' can be greatly reduced, no solid waste is generated, waste gas and waste water have extremely small amount and can be easily treated, energy consumption can be reduced, and the existing sulfonating process is broken through. The method has the advantages of high conversion rate, low carbonization, few processes and low energy consumption.

Owner:浙江友联化学工业有限公司

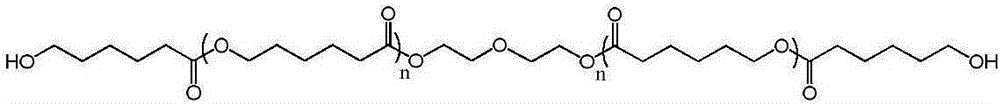

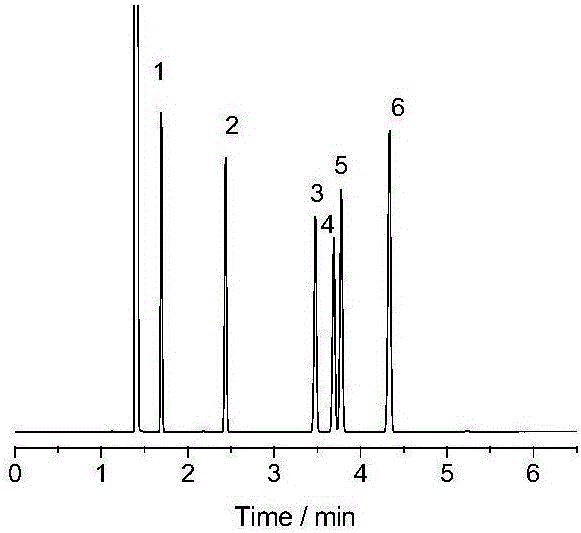

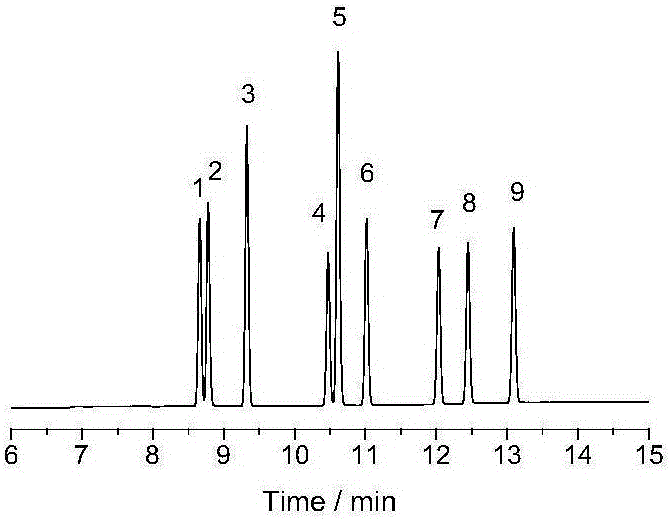

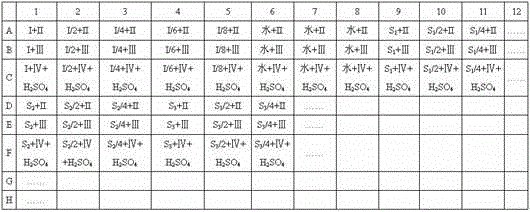

Preparation method and application of polycaprolactone glycol capillary gas chromatographic column

ActiveCN105921136AIon-exchange process apparatusOther chemical processesCapillary gas chromatographyToluidine

The invention relates to a preparation method and application of a polycaprolactone glycol capillary gas chromatographic column. A polycaprolactone glycol polymer is used as a capillary gas chromatographic stationary phase, and the polymer is smeared onto the inner wall of an elastic molten quartz capillary which is pre-roughened by utilizing sodium chloride and methanol suspension by virtue of a static method. The obtained capillary column is high in column efficiency, good in inertness and good in heat stability, can be used for separating components different in polarity such as aliphatic and aromatic hydrocarbons, alcohols, ketones, aldehydes, amines and phenols, and positional isomers of the components, is particularly suitable for effectively separating the isomers which are difficult to separate such as dimethylbenzene, toluidine and methylphenol and has good application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

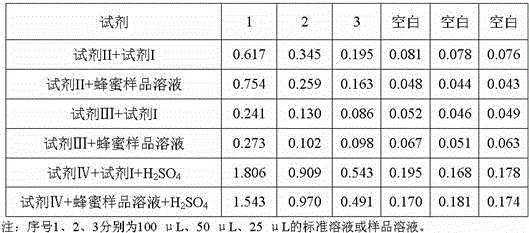

Kit for simultaneously and rapidly measuring content of glucose, fructose and total sugar and application of kit

InactiveCN104360012ALarge amount of processingSimple methodAnalysis using chemical indicatorsColor/spectral properties measurementsBiotechnologyFructose

The invention discloses a kit for simultaneously and rapidly measuring content of glucose, fructose and total sugar and an application method of the kit. The kit is developed based on a principle that carbohydrates are dehydrated to generate hydroxymethyl furfural under the acid action and the hydroxymethyl furfural and a developing agent are condensed to form a colored compound. The kit comprises four reagents, wherein the reagent I refers to a mixed standard substance of glucose, fructose and cane sugar; the reagent II refers to an ortho-toluidine reagent and is used for measuring the content of glucose; the reagent III refers to a resorcinol reagent and is used for measuring the content of fructose; and the reagent IV refers to a phenol reagent and is used for measuring the content of total sugar. The kit is used for simultaneously measuring the content of glucose, fructose and total sugar, has the characteristics of high specificity and high sensitivity, can realize high-flux and rapid detection of the glucose, fructose and total sugar, is large in sample treatment amount and relatively low in cost, is suitable for measuring the content of glucose, fructose and total sugar in honey, fruits and vegetables and other samples and is particularly suitable for large-scale field sample analysis.

Owner:FUJIAN AGRI & FORESTRY UNIV

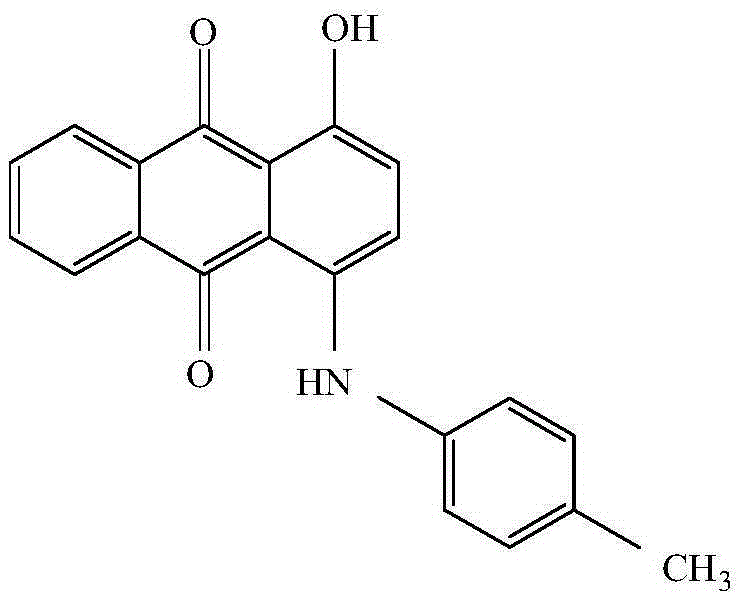

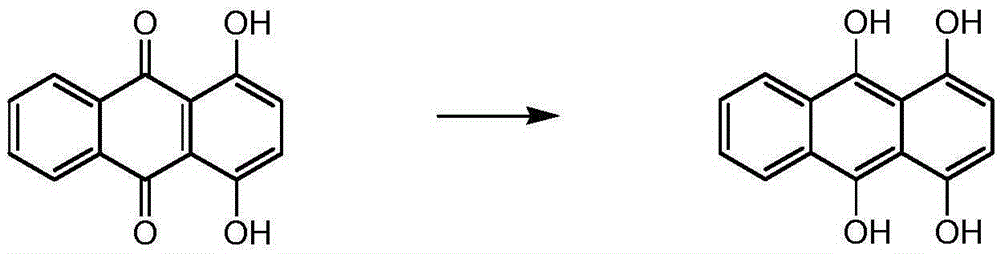

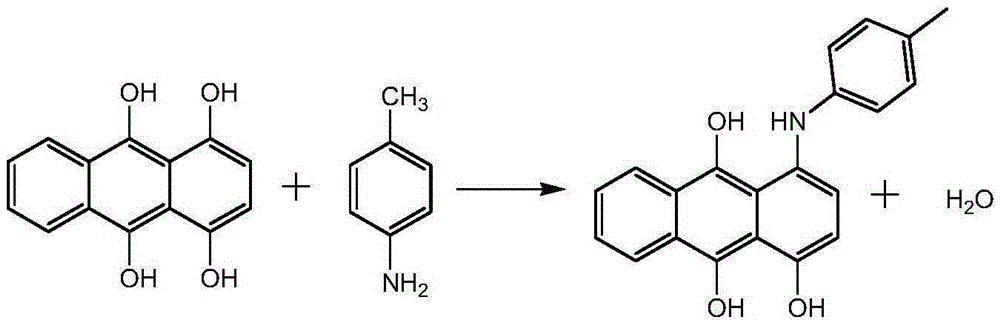

Synthetic method for solvent violet 13

ActiveCN105237417AReduced post-processingSave manpower and material resourcesOrganic chemistryOrganic compound preparationToluidineMaterial resources

The invention discloses a synthetic method for solvent violet 13, and develops a new route for synthesizing violet 13 by employing a one-pot process. The method comprises successively adding methanol, 1,4-dihydroxyanthraquinone, 4-nitrotoluene, iron powder and boric acid into a pressure container, sealing the container and performing nitrogen displacement, then heating with stirring, introducing hydrogen for hydrogenation reduction, after the reaction system stops absorbing hydrogen, performing warm-keeping reaction, heating after the reaction is finished, performing condensation reaction, cooling after the reaction is finished, releasing the pressure, introducing air and performing oxidation reaction, and finally adding hydrochloric acid for beating, filtering, washing and drying, so as to obtain violet 13. According to the method, the initial raw material p-toluidine is replaced by 4-nitrotoluene, direct usage of the highly-toxic raw material p-toluidine is avoided, and the synthetic technology is low in toxicity and friendly to environment. By pouring all of the raw materials into the container, the postprocessing process of the intermediate step is saved, and a large amount of manpower and material resource is saved.

Owner:JIANGSU DAOBO CHEM

Hydrocarbon fuel compositions

InactiveUS8163042B2High flame temperatureKindle the base metal rapidlyGaseous fuelsLiquid carbonaceous fuelsTorchProduct gas

The present invention relates to a hydrocarbon fuel composition comprising (i) at least 99% by weight of a base gas; and (ii) additives comprising (a) 2 to 50 ppm organometallic compound; and (b) 100 to 5000 ppm aniline or substituted aniline and 100 to 5000 ppm toluidine. The present invention discloses addition of an additive or additive mixture to base fuel preferably, liquefied petroleum gas. The addition of additive mixture not only improves the properties of the base fuel for use as torch gas for cutting and welding application, but also reduces the consumption of both fuel and oxygen for cutting applications.

Owner:BHARAT PETROLEUM CORP LTD

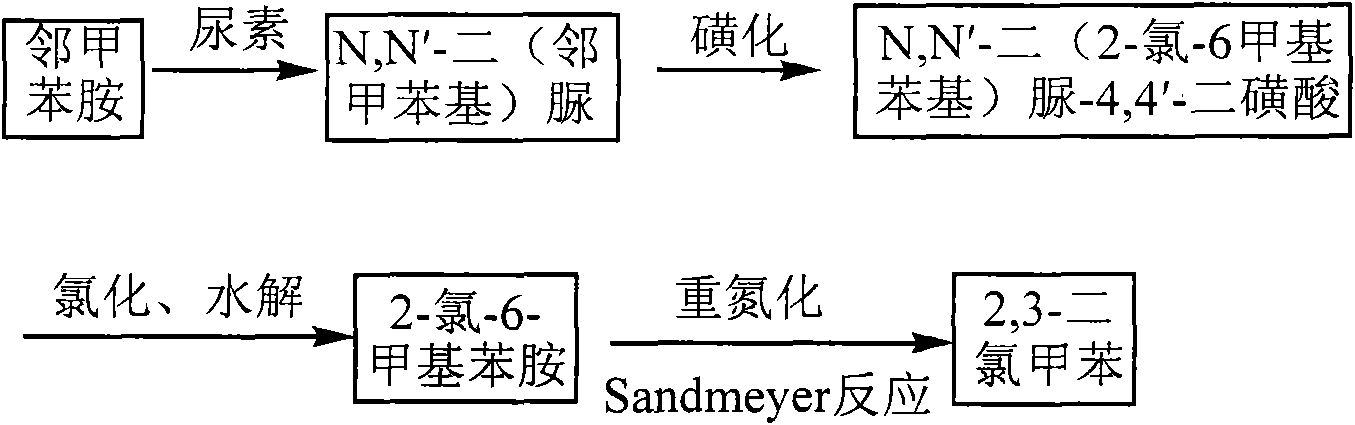

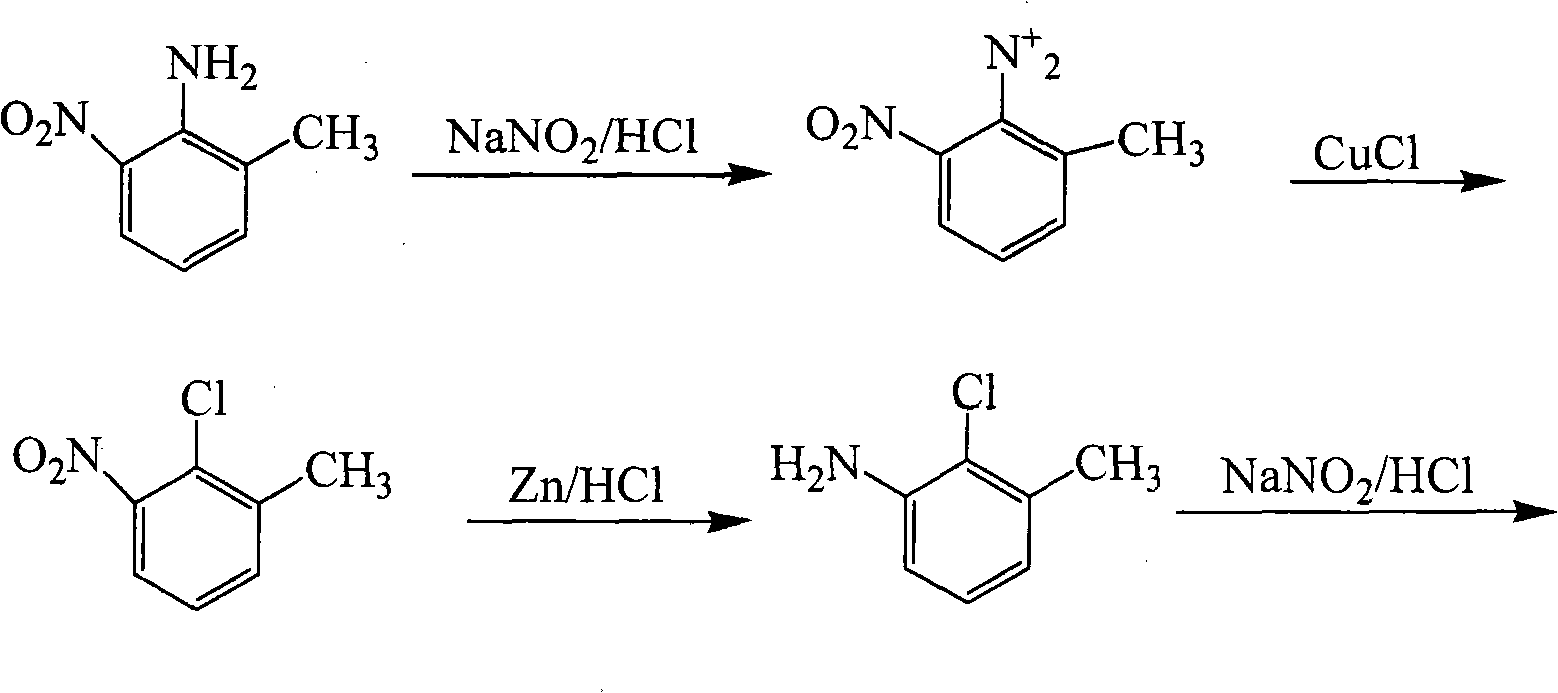

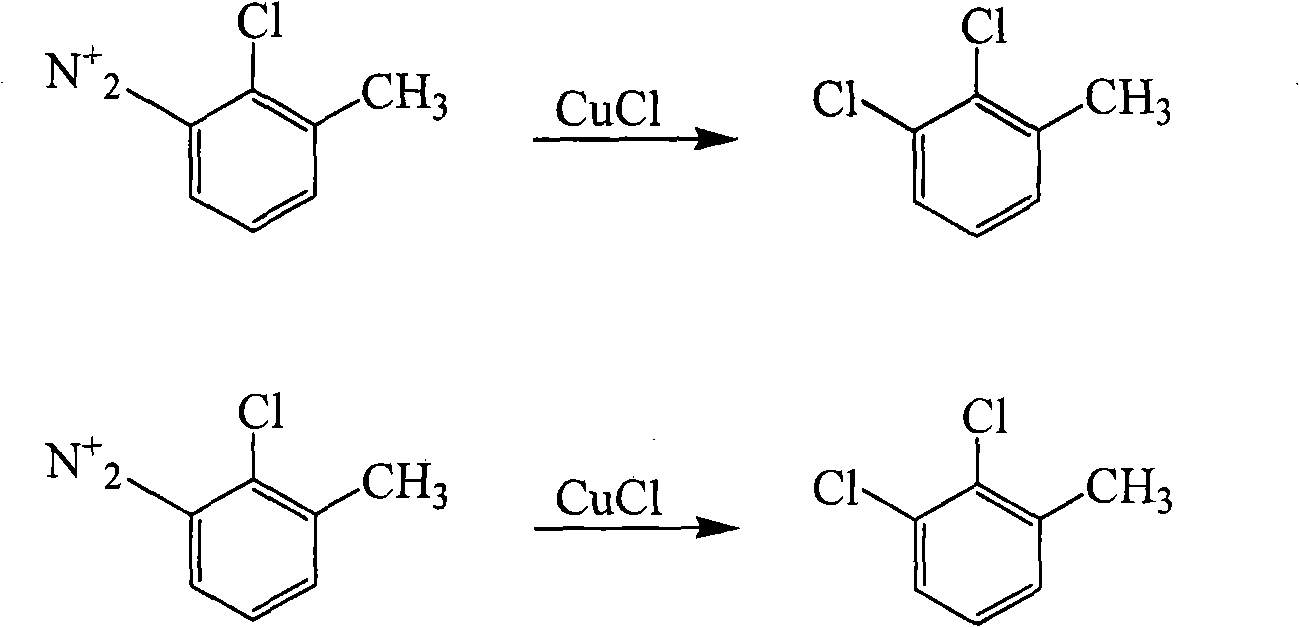

Method for preparing 2,3-dichlorotoluene

InactiveCN102079688ALow priceThe reaction operation is not cumbersomeChemical recyclingHalogenated hydrocarbon preparationSandmeyer reactionMethylaniline

The invention discloses a method for preparing 2,3-dichlorotoluene. The method comprises the following steps of: performing condensation on o-toluidine serving as an initiative raw material and urea to obtain N,N'-di(tolyl) urea; forming a sulfonic blocking group at an amino para-position through sulfonation; performing chlorination, removing carbonyl through hydrolysis and removing the blocking group through hydrolysis to obtain 2-chlorine-6-methylaniline; and performing diazotization and a Sandmeyer reaction to synthesize 2,3-dichlorotoluene to obtain the product. The method has the advantages of environmental friendliness, simple process, low cost and the like.

Owner:INNER MONGOLIA UNIV OF TECH

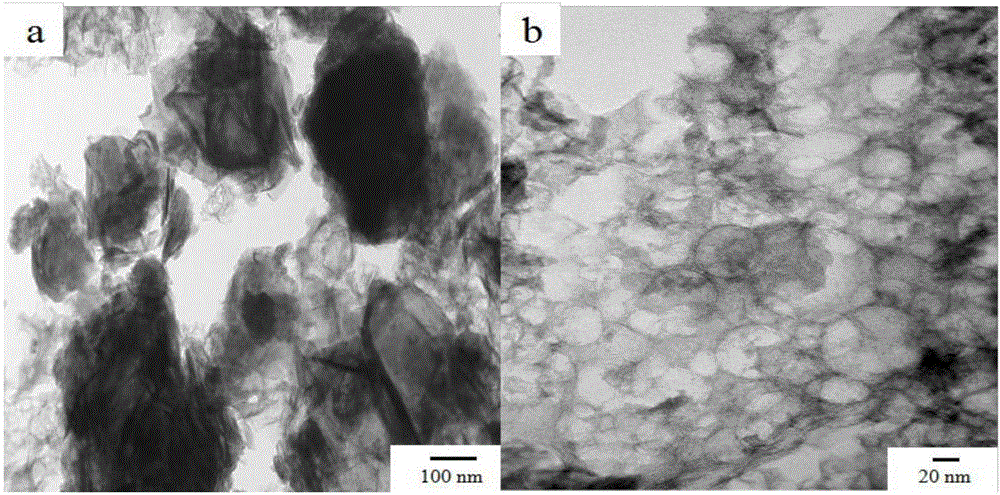

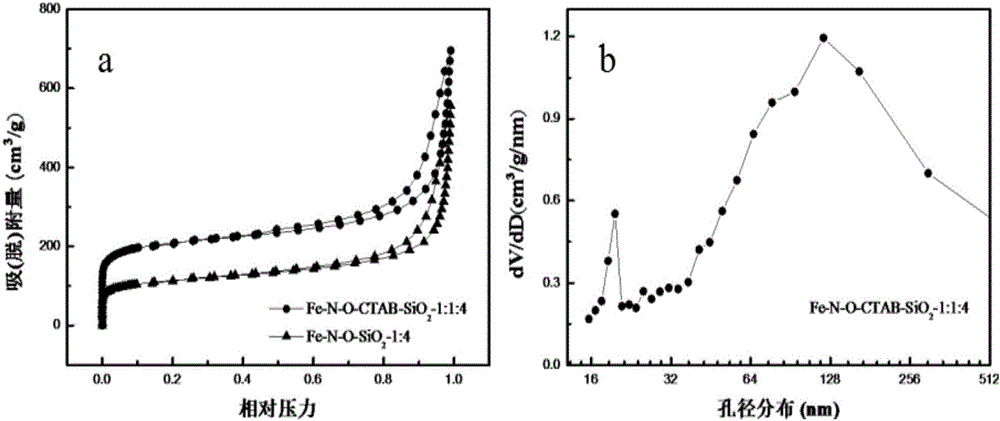

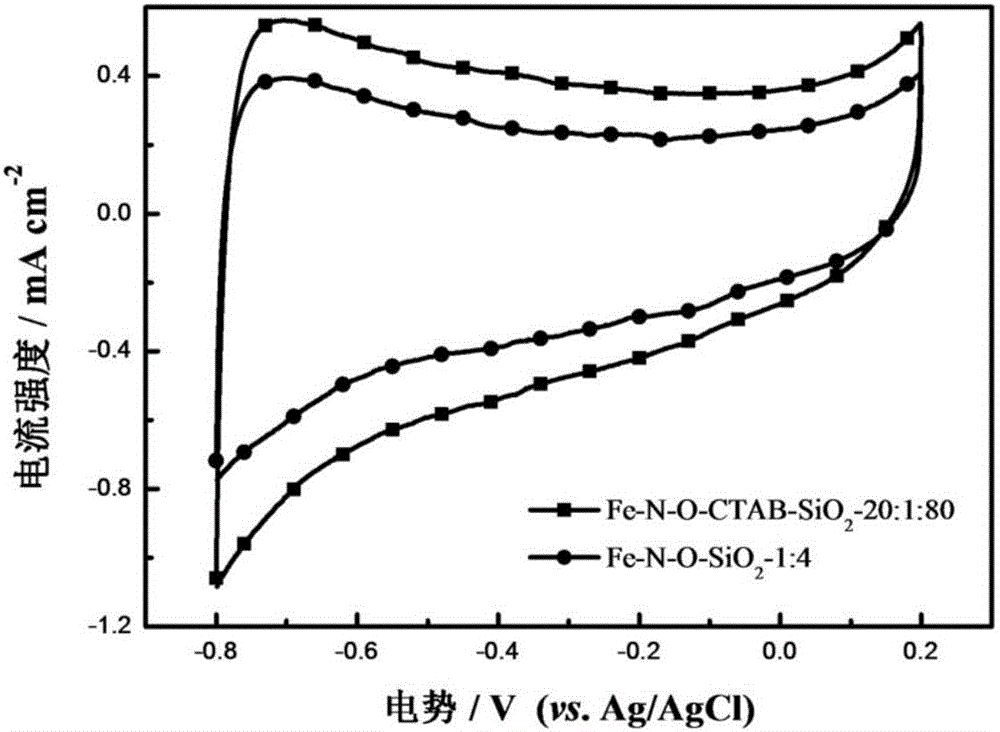

Three-dimensional porous Fe-N-C catalyst based on cetyl trimethyl ammonium bromide as carbon material pore-forming agent and preparation method

InactiveCN106602080AImprove catalytic performanceEasy to passCell electrodesDecompositionCalcination

The invention belongs to the field of fuel-cell catalysts, and relates to a three-dimensional porous Fe-N-C catalyst based on cetyl trimethyl ammonium bromide as a carbon material pore-forming agent and a preparation method. The three-dimensional porous Fe-N-C electrocatalyst is obtained through high-temperature calcination of o-toluidine as a C source and an N source, FeCl3.6H2O as a metal source, CTAB as a soft template and SiO2 as a hard template under an N2 atmosphere. In the preparation process, the size and the shape of a micelle can be accurately controlled through changing the concentration of the CTAB, a three-dimensional interconnected porous structure with a lot of active sites exposed on the surface can be finally formed after the templates are removed due to CTAB micelle decomposition after high-temperature calcination, the quantity of the active sites for catalytic oxygen reduction reaction is ensured, the mass transfer requirements can be met and improvement of the ORR activity of the catalyst is facilitated. Compared with a traditional Fe-N-C electrocatalyst, the three-dimensional porous Fe-N-C catalyst has the advantages that the three-dimensional porous structure of the catalyst is more beneficial to oxygen transfer and adsorption, the preparation process is flexible and controllable, the raw materials are cheap and available, massive production is facilitated and the three-dimensional porous Fe-N-C catalyst has relatively high practical value.

Owner:DALIAN UNIV OF TECH

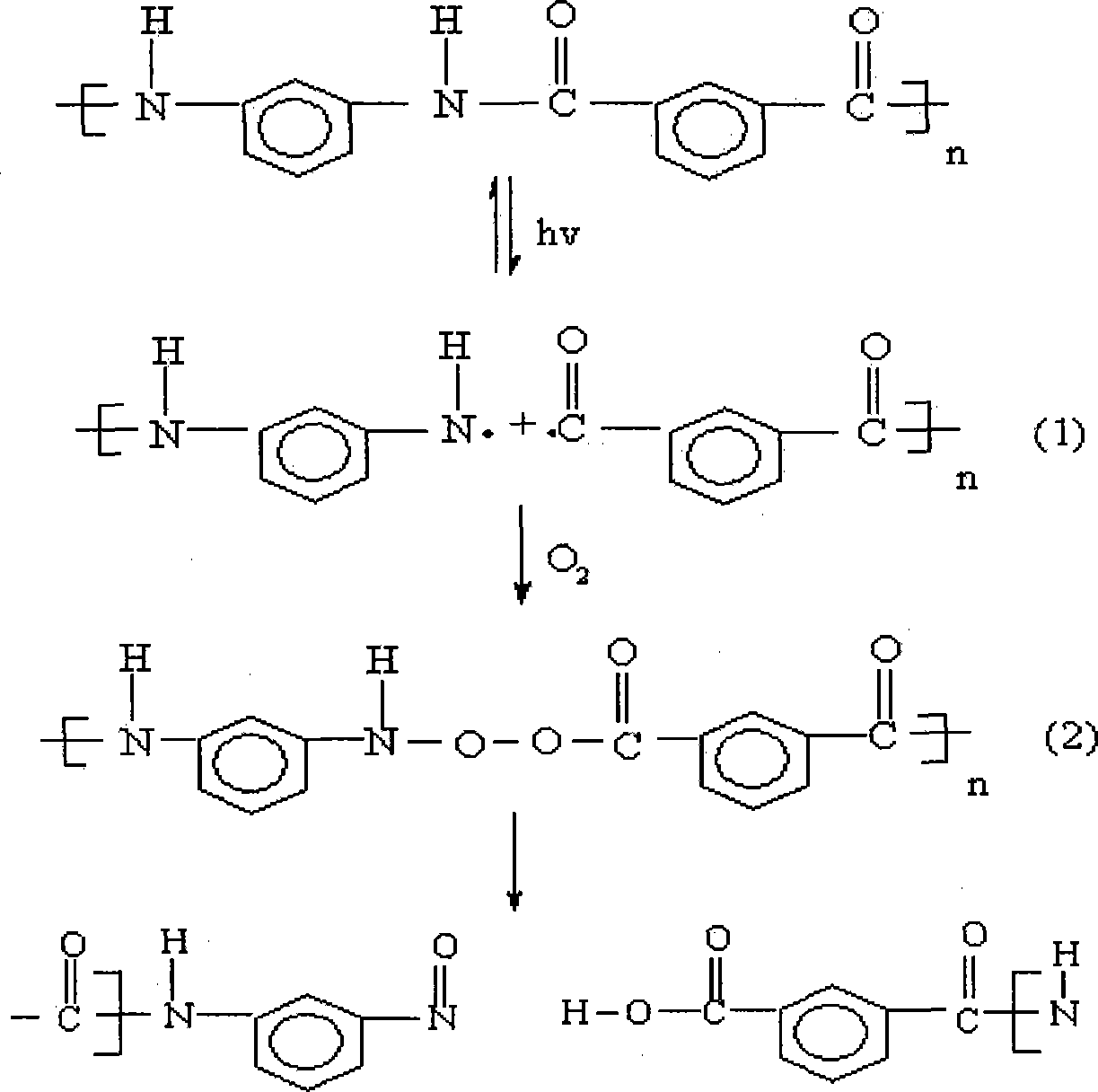

Light ageing resisting finishing method for aromatic polyamide fabric

The invention relates to an anti-light ageing finishing method of aromatic polyamidoester fibre cloth, and the method comprises processing aromatic polyamidoester fibre cloth in anti-light ageing finishing agent for 90+-5 minutes under the temperature of 120+-2 DEG C, washing cloth with surface active agent and drying after finishing, wherein the mass ratio of aromatic polyamidoester fibre cloth and anti-light ageing finishing agent is 100:20+-1, the anti-light ageing finishing agent is emulsion whose solid content is 20+-1% and is formed by N,N-diethylm-toluidine, alkyl phenol polyoxyethylene ether and alkylbenzene polyoxyethylene ether which are dissolved in water according to the mass ration which is 80+-0.5:15+-0.5:5+-0.5. The method can lead the intensity after aramid fiber cloth is aged through ultraviolet to reach 87%, and the method has no influence to the physical and chemical property of aramid fiber cloth, and the mechanical property after finishing has no loss. The method of the invention has the advantages of simple technique, strong operability, convenient operation and low production cost.

Owner:海安县福兴织造有限公司

Unsaturated polyester putty for automobile sheetmetal

The invention discloses unsaturated polyester putty for automobile sheetmetal. Main agent of the unsaturated polyester putty comprises, by weight, 100 parts of unsaturated polyester resin, 5-7 parts of methyl hydroxyethyl toluidine, 1-2 parts of styrene, 0.8-1.2 part of polytetrafluoroethylene wax, 0.5-1 part of hydroquinone, 1-2 parts of gaseous SiO2, 4-6 parts of titanium dioxide, 1-2 parts of hollow glass beads, 5-8 parts of pulvistalci and 5-6 parts of expansion ultrafine powder. Initiator of the unsaturated polyester putty comprises, by weight, 60-70 parts of benzoyl peroxide, 25-35 parts of dibutyl phthalate, and 2-8 parts of silicon dioxide.

Owner:TIANCHANG CITY TONGTIAN CHEM

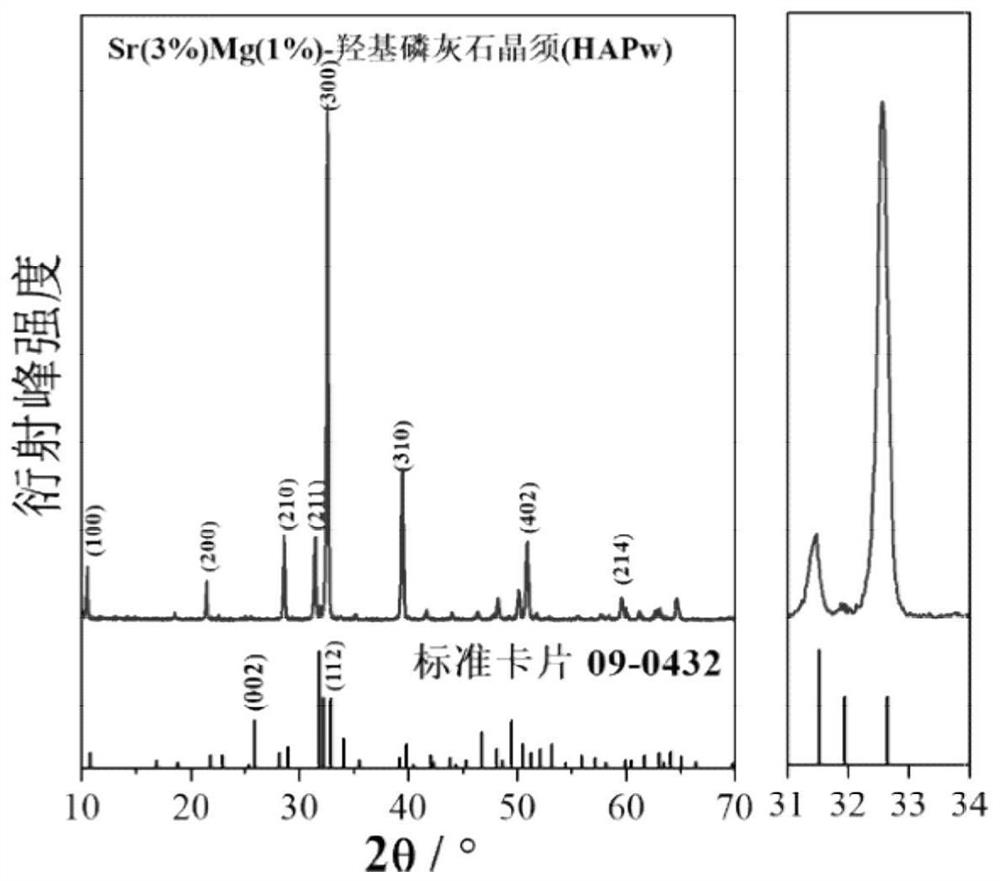

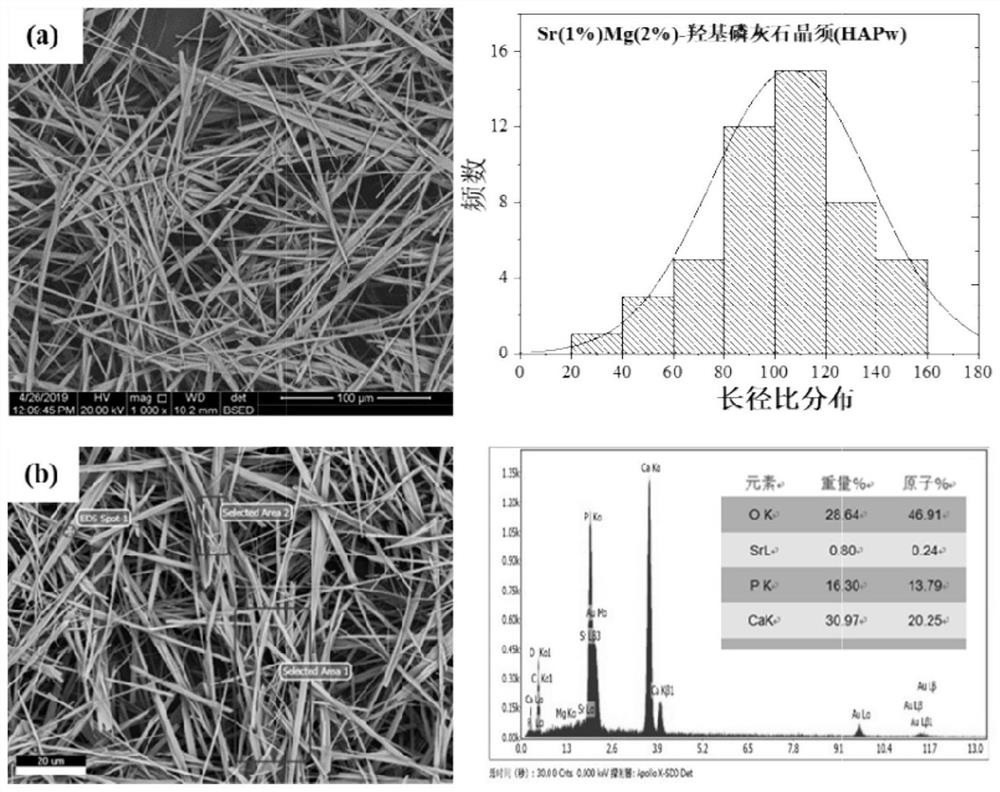

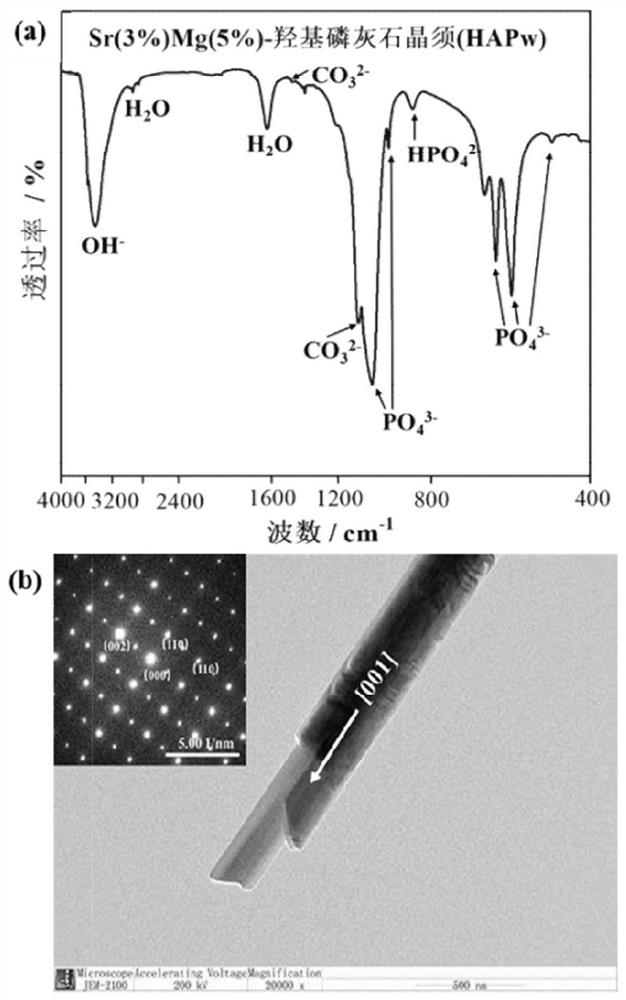

Novel composite bone cement with biological activity

InactiveCN113289058APreferred growth orientationImprove biological activityTissue regenerationPhosphorus compoundsBenzoyl peroxideToluidine

The invention discloses novel composite bone cement with biological activity, raw materials comprise powder and liquid, the powder comprises the following parts in percentage by mass: 39%-84.3% of polymethyl methacrylate microspheres, 5%-15% of zirconium dioxide, 0.5%-3% of benzoyl peroxide, 0.2%-2% of gentamicin sulfate and 10%-41% of strontium-magnesium co-doped hydroxyapatite whiskers, The liquid comprises the following parts in percentage by mass: 98-99.6% of methyl methacrylate and 0.4-2% of N, N-dimethyl p-toluidine, mixing the powder and the liquid, stirring, standing, shaping and curing to obtain the novel composite bone cement. Bone-like apatite can be induced to be deposited on the surface of the bone cement in in-vitro simulated human body fluid, new bones can be promoted to grow on the interface of the bone cement and bone tissues in animal model rabbit bodies, good biological activity and osteogenesis promoting capacity are shown, and the compressive strength, bending strength and bending elastic modulus of the bone cement are all higher than those of conventional bone cement.

Owner:KUNMING UNIV OF SCI & TECH

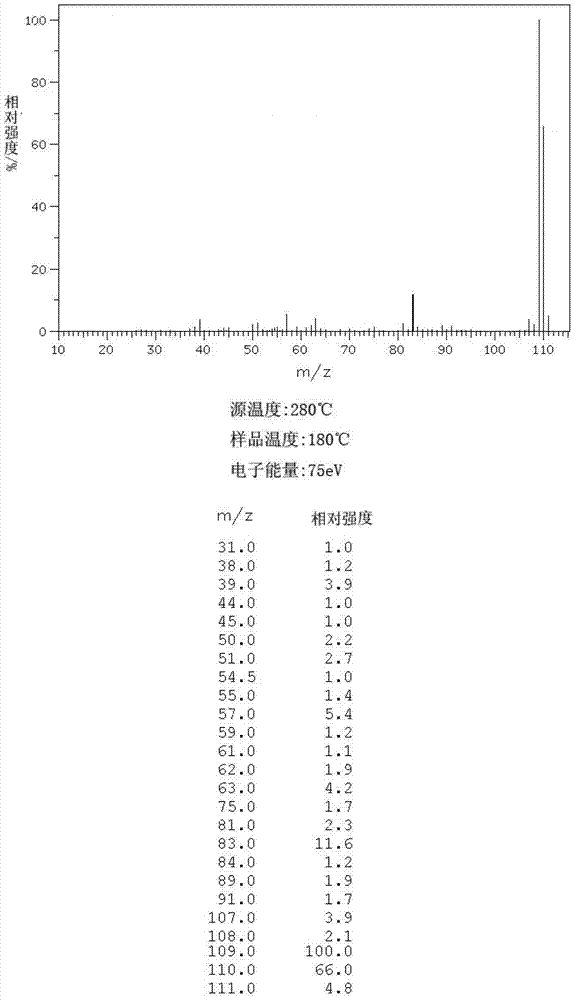

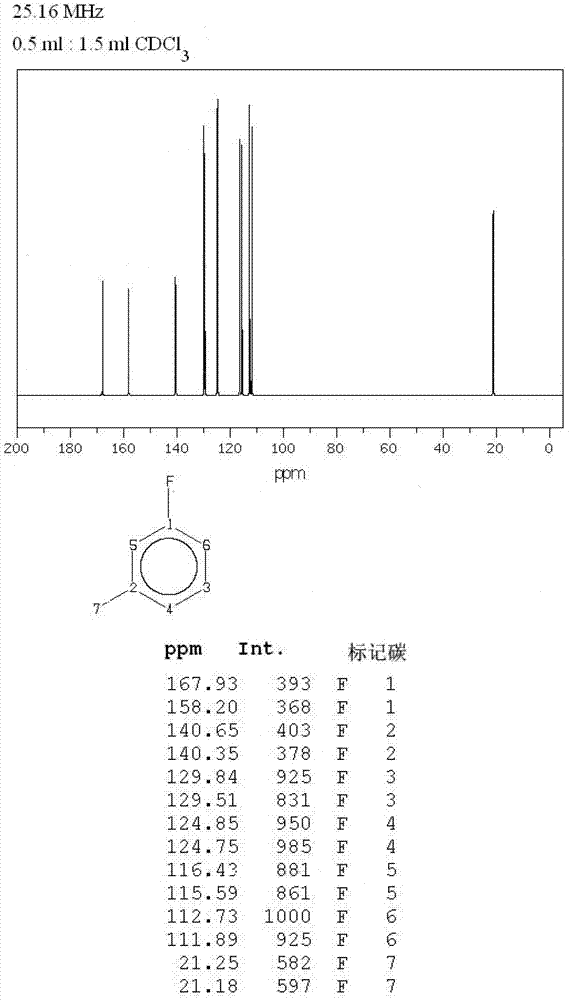

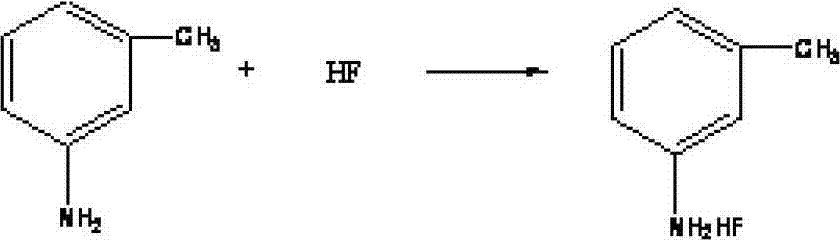

Preparation method of m-fluorotoluene

ActiveCN102786385AAvoid diversionLess side effectsFluorine/hydrogen-fluorideHalogenated hydrocarbon preparationHydrofluoric acidToluidine

The invention relates to a preparation method of m-fluorotoluene, and the preparation method has the advantages of fewer steps, high yield and high purity of the obtained product. The preparation method of m-fluorotoluene provided by the invention comprises the following steps: (1) salt formation step: anhydrous hydrofluoric acid and m-toluidine are mixed at a mole ratio of (2-5):1 to obtain a mixture 1 through dripping the whole m-toluidine into anhydrous hydrofluoric acid within 7-10 hours at a constant rate and then reacting for 1-3 hours at 5-7 DEG C; (2) diazotization step: sodium nitrate is dripped into the mixture 1 at a mole ratio of sodium nitrate to m-toluidine in the salt formation step of (1-1.5):1 to obtain a mixture 2 through dripping the whole sodium nitrate into the mixture 1 within 8-10 hours at a constant rate and then reacting for 1-3 hours at 0-3 DEG C; and (3) thermal decomposition step: the mixture 2 is heated to decompose at 0-50 DEG C.

Owner:山东福尔有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com