Preparation method of m-fluorotoluene

A technology of m-fluorotoluene and fluorotoluene, which is applied in the field of preparation of fluorine-containing compounds, can solve the problems of many side reactions, product purity and yield reduction, and achieve the effects of avoiding separation and transfer, increasing yield, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

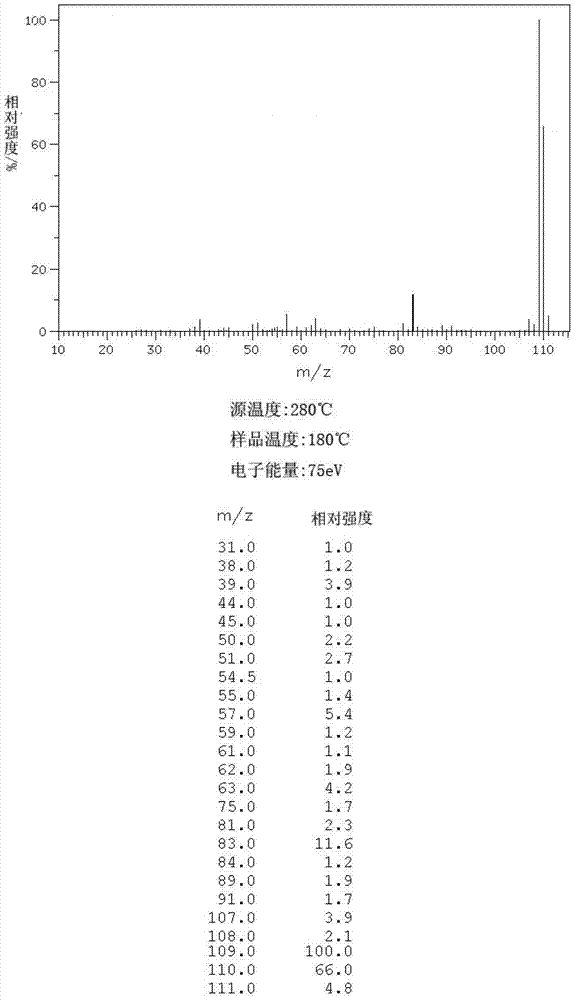

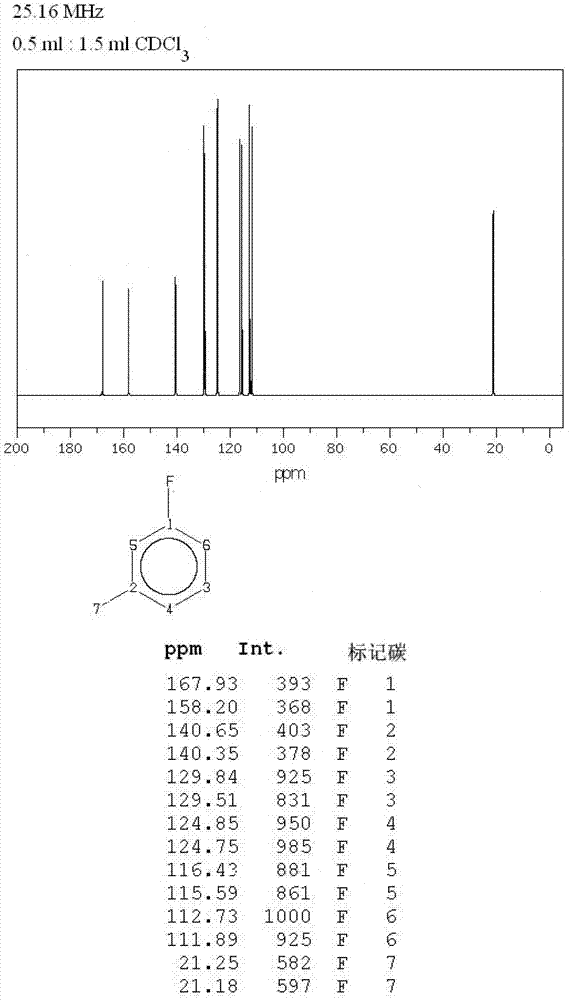

Image

Examples

Embodiment 1

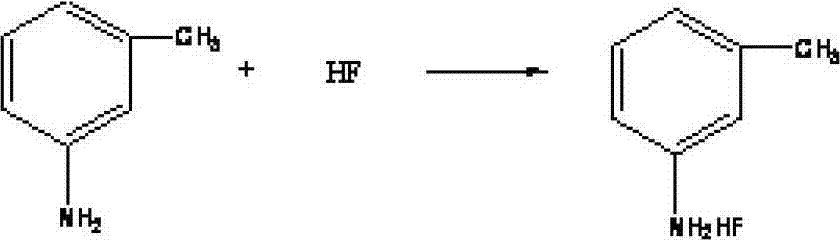

[0027] The preparation method of m-fluorotoluene of the present invention comprises the following steps:

[0028] 1. Salt forming step: Add 1 mol of m-toluidine dropwise to 2 mol of anhydrous hydrofluoric acid at a constant speed at 5-7°C. The dropping process is completed within 7 hours. Under the condition of insulation reaction for 1 hour, the mixture 1 was obtained;

[0029] 2. Diazotization step: Add 1 mol of sodium nitrite dropwise to mixture 1 at a constant speed under the condition of -3-0°C. The dropping process is completed within 8 hours. React for 1 hour to obtain mixture 2;

[0030] 3. Thermal decomposition step: thermally decompose the 2 mixture, and the thermal decomposition is divided into the following four stages:

[0031] The first stage is 6 hours in total, control the temperature at 0-20°C: control the temperature at 0-4°C in the first hour, control the temperature at 4-8°C in the second hour; control the temperature at 8-12°C in the third hour, and cont...

Embodiment 2

[0040] Prepare according to the preparation method of embodiment 1 mesofluorotoluene, only change the following parameters of the following steps of embodiment 1:

[0041] Salt-forming step: Add 1 mol of m-toluidine dropwise to 5 mol of anhydrous hydrofluoric acid at a constant speed at 5-7°C, the dropping process is completed within 10 hours, and keep warm at 5-7°C after the addition Reacted for 3 hours to obtain mixture 1;

[0042] Diazotization step: Add 1.5 mol of sodium nitrite dropwise to the mixture 1 at a constant speed under the condition of -3-0°C, the dropping process is completed within 10 hours, and then react under the condition of 0-3°C after the addition is completed 3 hours, to obtain mixture 2;

[0043]Recovery of waste hydrofluoric acid: Mix the waste acid with 3mol of 98% by mass sulfuric acid, distill, and the temperature in the still is from low to high, ensuring that the top temperature of the tower is at 40-45°C in the early stage, and the temperature ...

Embodiment 3

[0046] Prepare according to the preparation method of embodiment 1 mesofluorotoluene, only change the following parameters of the following steps of embodiment 1:

[0047] Salt-forming step: Add 1 mol of m-toluidine dropwise to 3.5 mol of anhydrous hydrofluoric acid at a constant speed at 5-7°C. The dropping process is completed within 9 hours. Under the insulation reaction for 2 hours, the mixture 1 was obtained;

[0048] Diazotization step: Add 1.5 mol of sodium nitrite dropwise to mixture 1 at a constant speed under the condition of -3-0°C, the dropping process is completed within 9 hours, and then react under the condition of 0-3°C after the addition is completed 2 hours, to obtain mixture 2;

[0049] Recovery of waste hydrofluoric acid: Mix the waste acid with 3mol of 98 mass% sulfuric acid, distill, and the temperature in the distillation pot is from low to high, ensuring that the top temperature of the tower is 40-45°C in the early stage, and the temperature of the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com