Iron-based nanocrystalline composite coating for protecting boiler tail heating surface and laser-cladding forming process of iron-based nanocrystalline composite coating

A technology of laser cladding molding and iron-based nanocrystals, which is applied in the coating process and coating of metal materials, can solve the problems of low bonding strength, failure to meet the comprehensive protection requirements of boiler tube erosion resistance, and easy peeling off of the coating , achieve shallow heat-affected zone, promote recycling, avoid cracks and voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

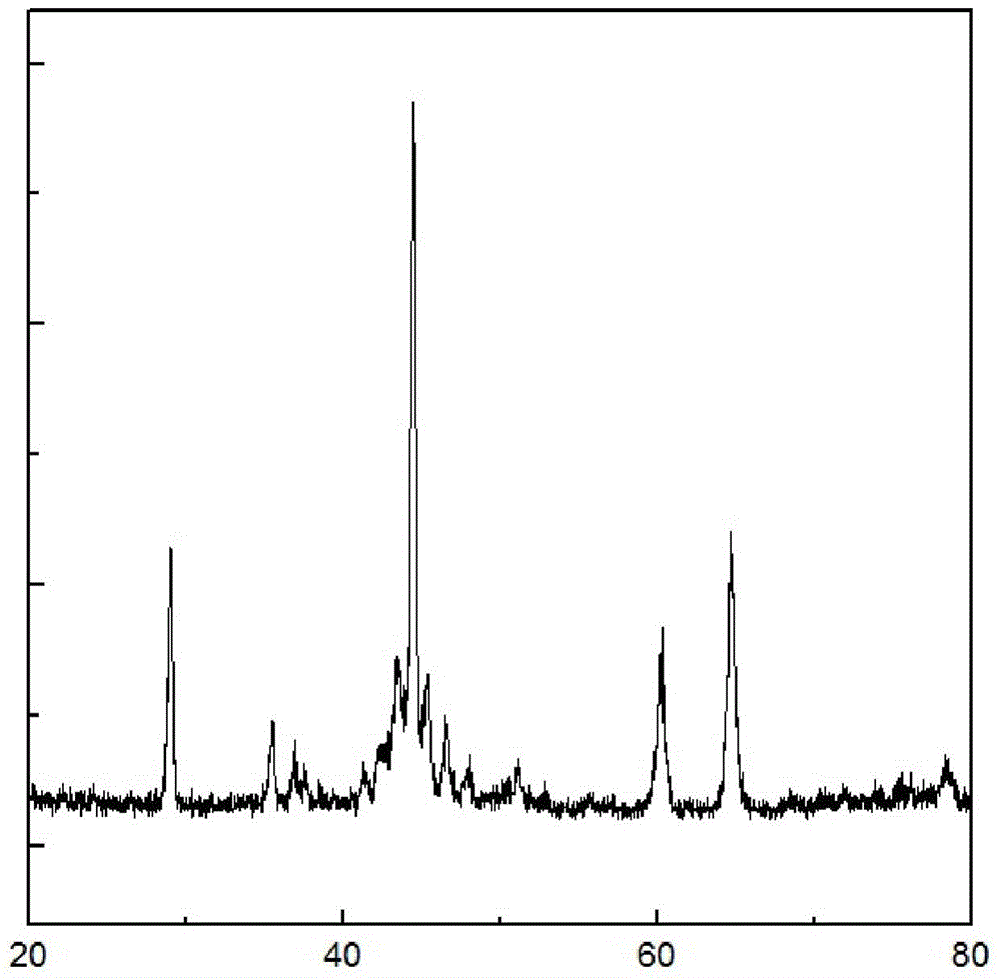

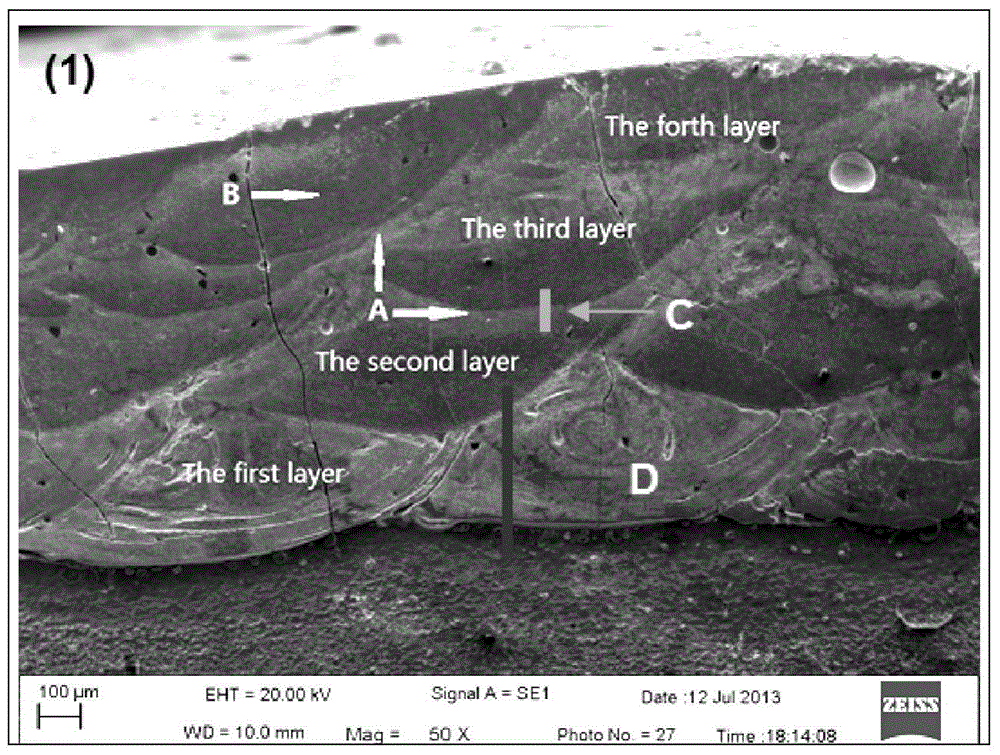

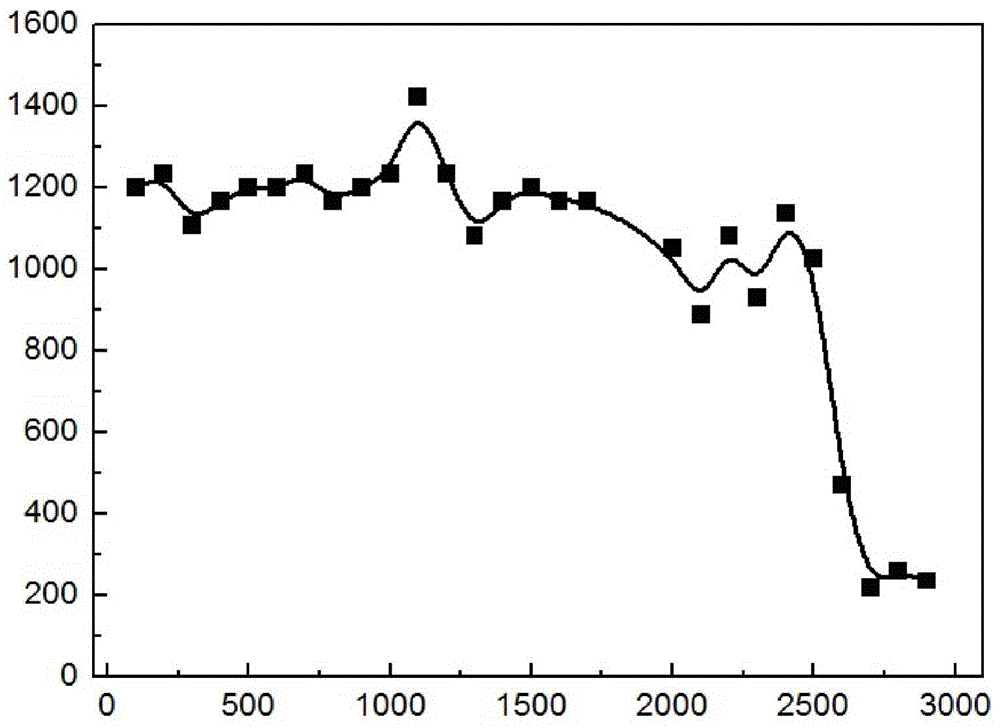

[0037] An iron-based nanocrystalline composite coating for protecting the heating surface at the tail of a boiler. The components in the iron-based nanocrystalline composite coating and their mass percentage wt.% are: Fe: 55.4, Cr: 17.5, Mo: 12.4, B: 3.4, C: 1.0, Mn: 1.6, W: 5.5, Si: 1.4, RE: 1.8, where RE represents Nd.

[0038] The laser cladding forming process of the iron-based nanocrystalline composite coating for the protection of the heating surface of the boiler tail includes the following steps:

[0039] (1) Alloy powder is prepared through the existing gas atomization powder making technology, and the particle size of the alloy powder is 50-400 mesh; each component and its mass percentage wt.% in the alloy powder are: Fe: 55.4 , Cr: 17.5, Mo: 12.4, B: 3.4, C: 1.0, Mn: 1.6, W: 5.5, Si: 1.4, RE: 1.8, where RE stands for Nd, and the powder needs to be baked at 110°C for 24 hours before use dry treatment;

[0040] (2) Before laser cladding, sand blast and derust the su...

Embodiment 2

[0048] An iron-based nanocrystalline composite coating for protecting the heating surface at the tail of a boiler. The components in the iron-based nanocrystalline composite coating and their mass percentage wt.% are: Fe: 53.8, Cr: 18.8, Mo: 12.5, B: 3.5, C: 1.0, Mn: 1.7, W: 5.5, Si: 1.4, RE: 1.8, where RE represents Nd.

[0049] The laser cladding forming process of the iron-based nanocrystalline composite coating for the protection of the heating surface of the boiler tail includes the following steps:

[0050] (1) Alloy powder is prepared by the existing gas atomization powder making technology, and the particle size of the alloy powder is 50-400 mesh; each component and its mass percentage wt.% in the alloy powder are: Fe: 53.8 , Cr: 18.8, Mo: 12.5, B: 3.5, C: 1.0, Mn: 1.7, W: 5.5, Si: 1.4, RE: 1.8, where RE stands for Nd, the powder needs to be baked at 110°C for 24 hours before use dry treatment;

[0051] (2) Before laser cladding, sand blast and derust the surface of ...

Embodiment 3

[0058] An iron-based nanocrystalline composite coating for protecting the heating surface at the tail of a boiler. The components in the iron-based nanocrystalline composite coating and their mass percentage wt.% are: Fe: 58.0, Cr: 15.3, Mo: 12.2, B: 3.4, C: 0.9, Mn: 1.6, W: 5.4, Si: 1.4, RE: 1.8, where RE represents Nd.

[0059] The laser cladding forming process of the iron-based nanocrystalline composite coating for the protection of the heating surface of the boiler tail includes the following steps:

[0060] (1) Alloy powder is prepared through the existing gas atomization powder making technology, and the particle size of the alloy powder is 50-400 mesh; each component and its mass percentage wt.% in the alloy powder are: Fe: 58.0 , Cr: 15.3, Mo: 12.2, B: 3.4, C: 0.9, Mn: 1.6, W: 5.4, Si: 1.4, RE: 1.8, where RE stands for Nd, and the powder needs to be baked at 110°C for 24 hours before use dry treatment;

[0061] (2) Before laser cladding, sand blast and derust the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com