Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4236results about "Spindle sealings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

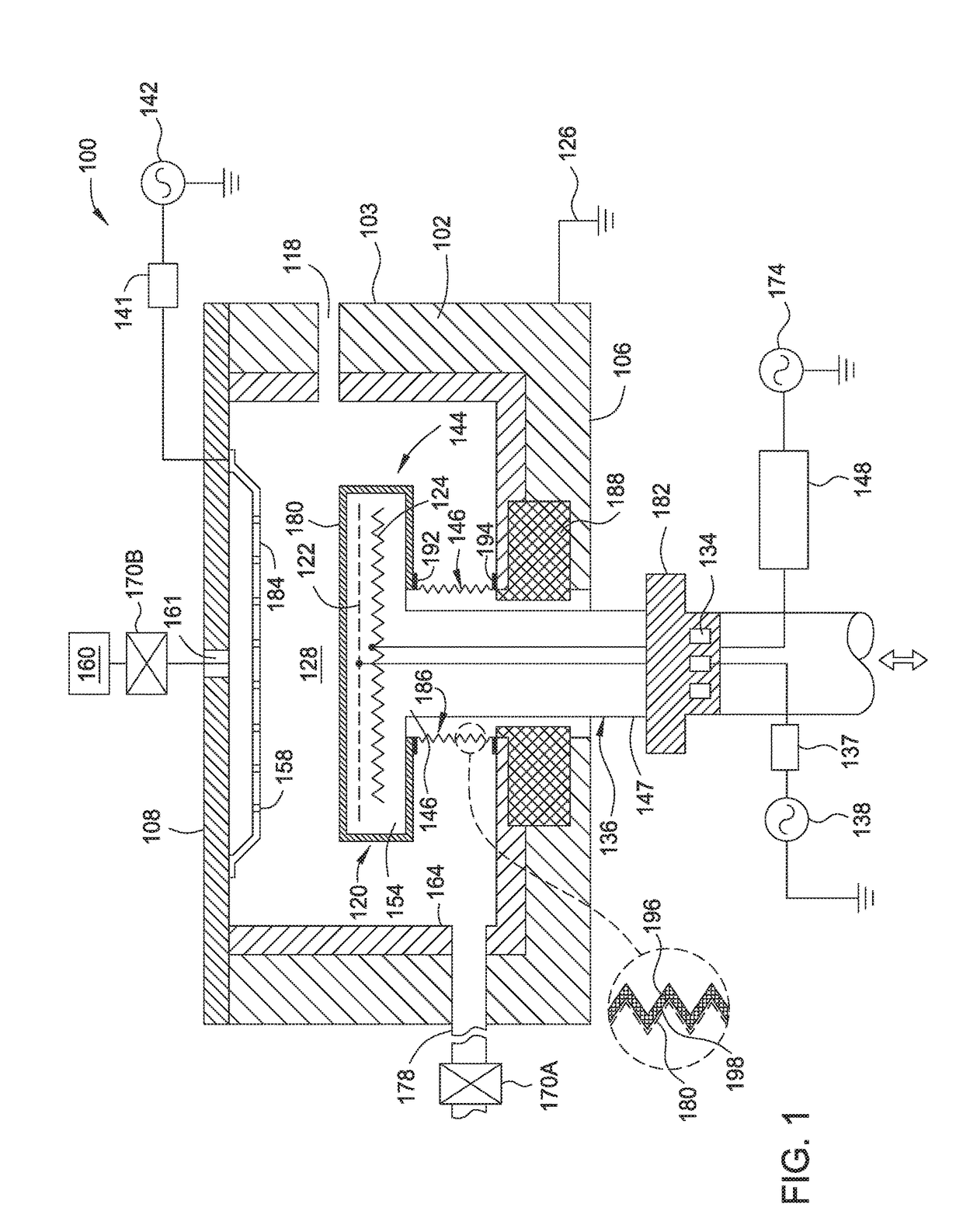

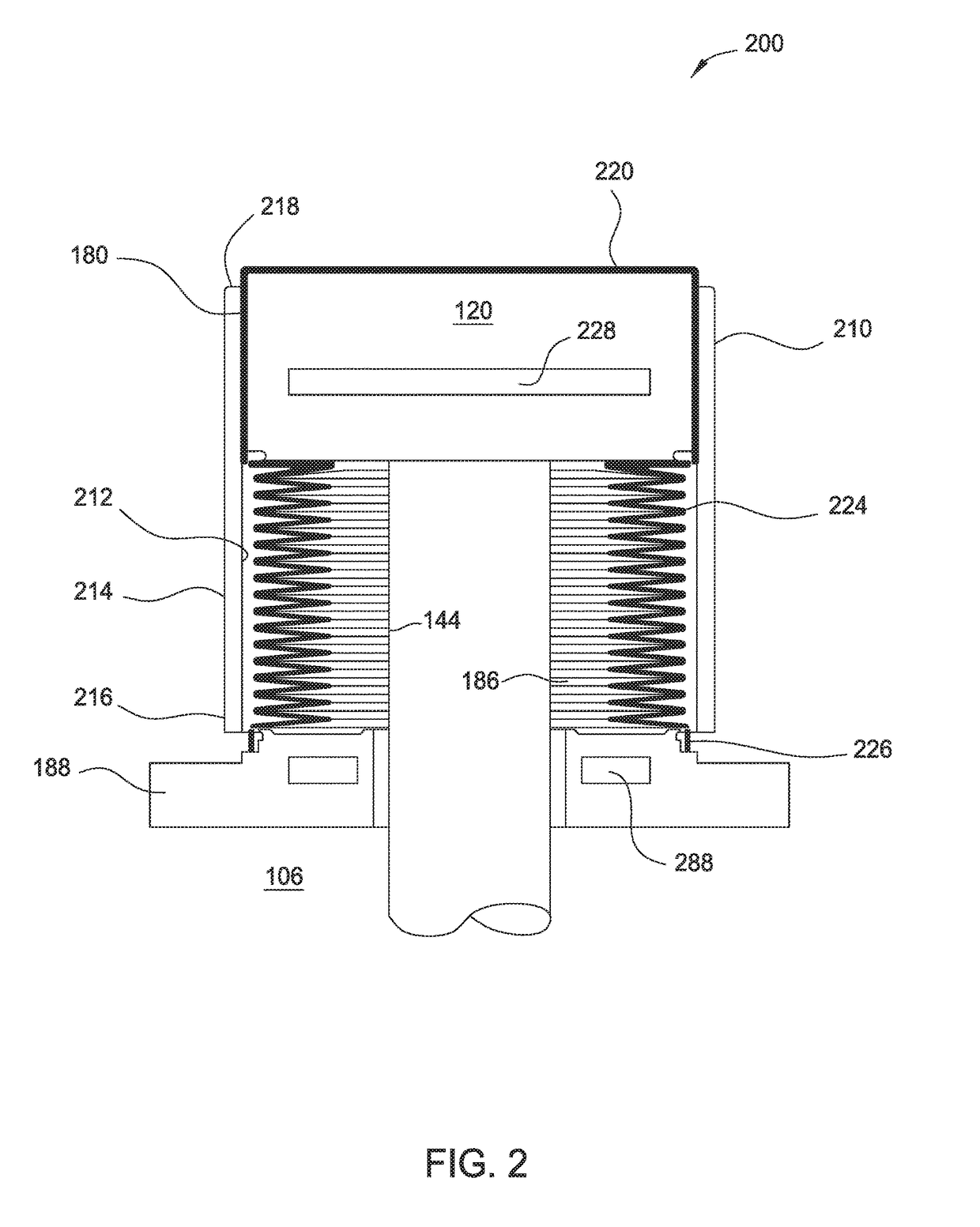

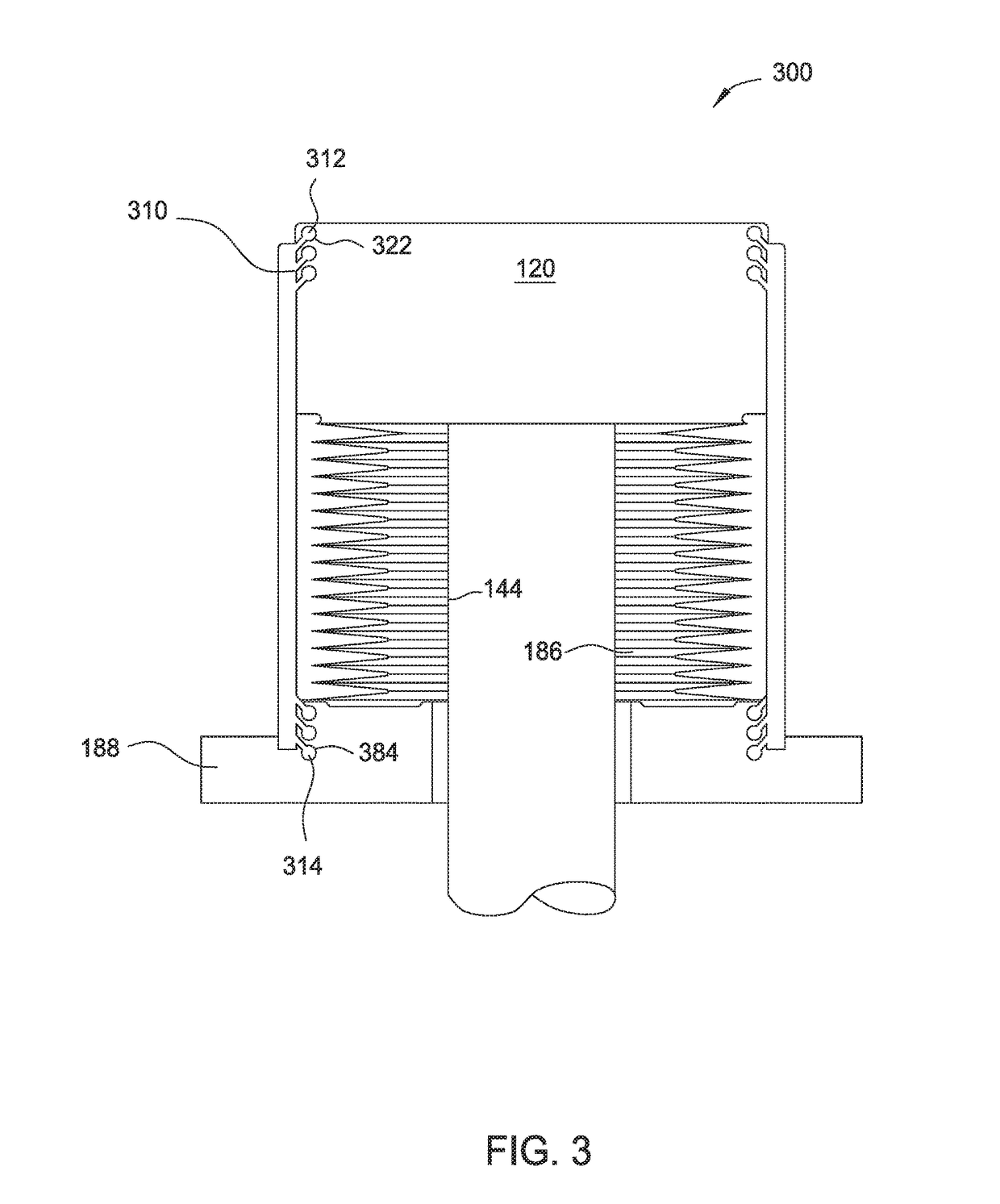

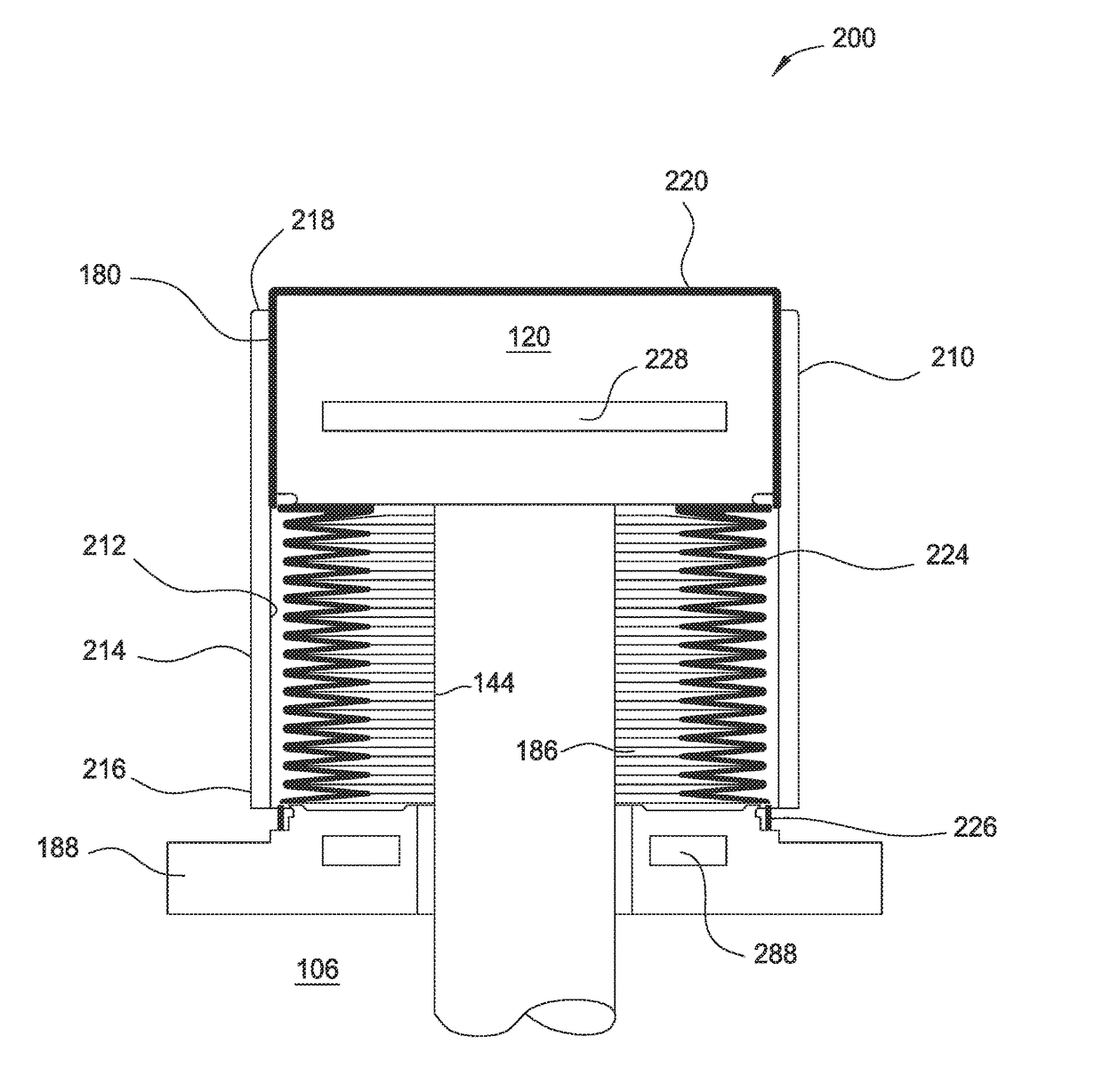

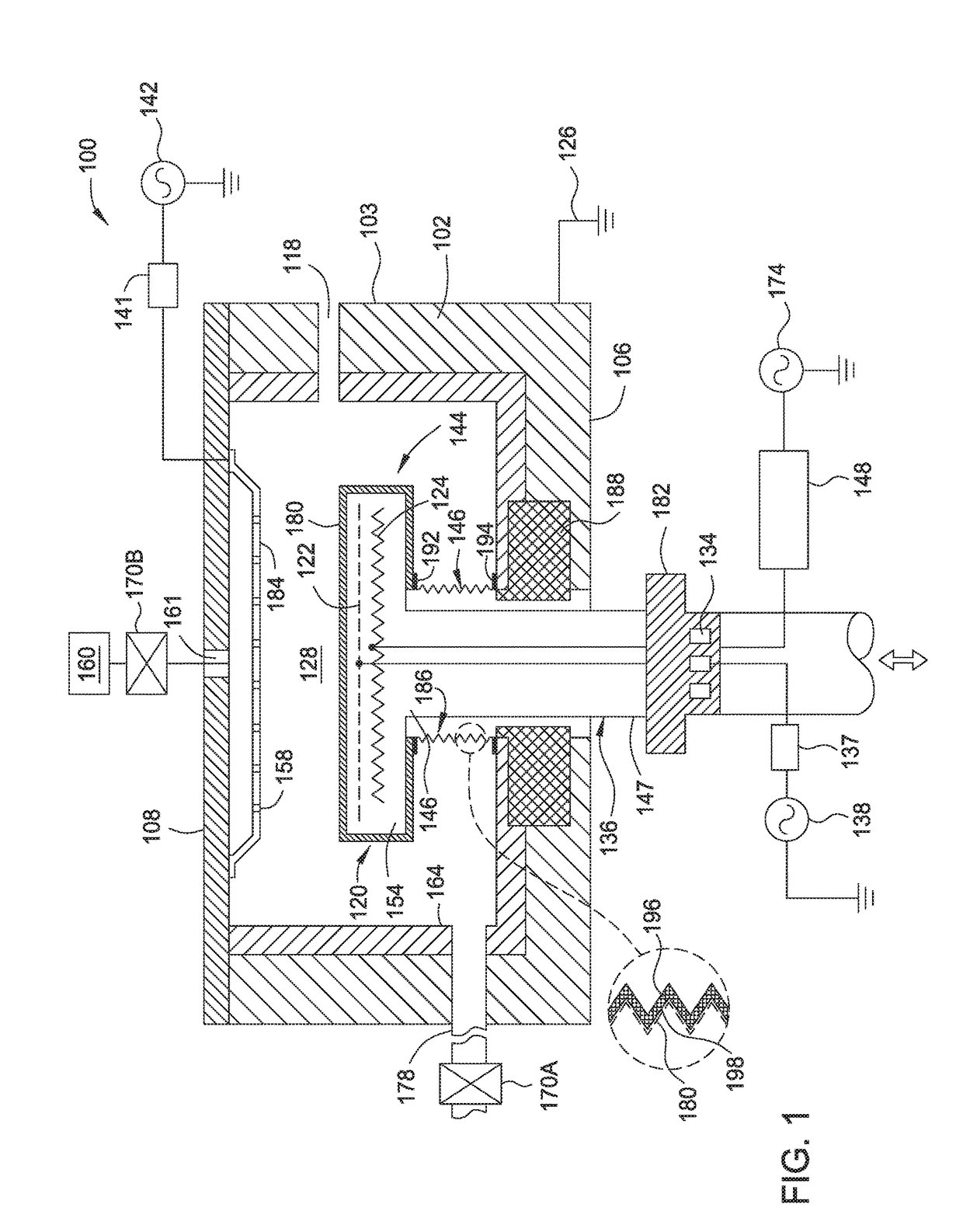

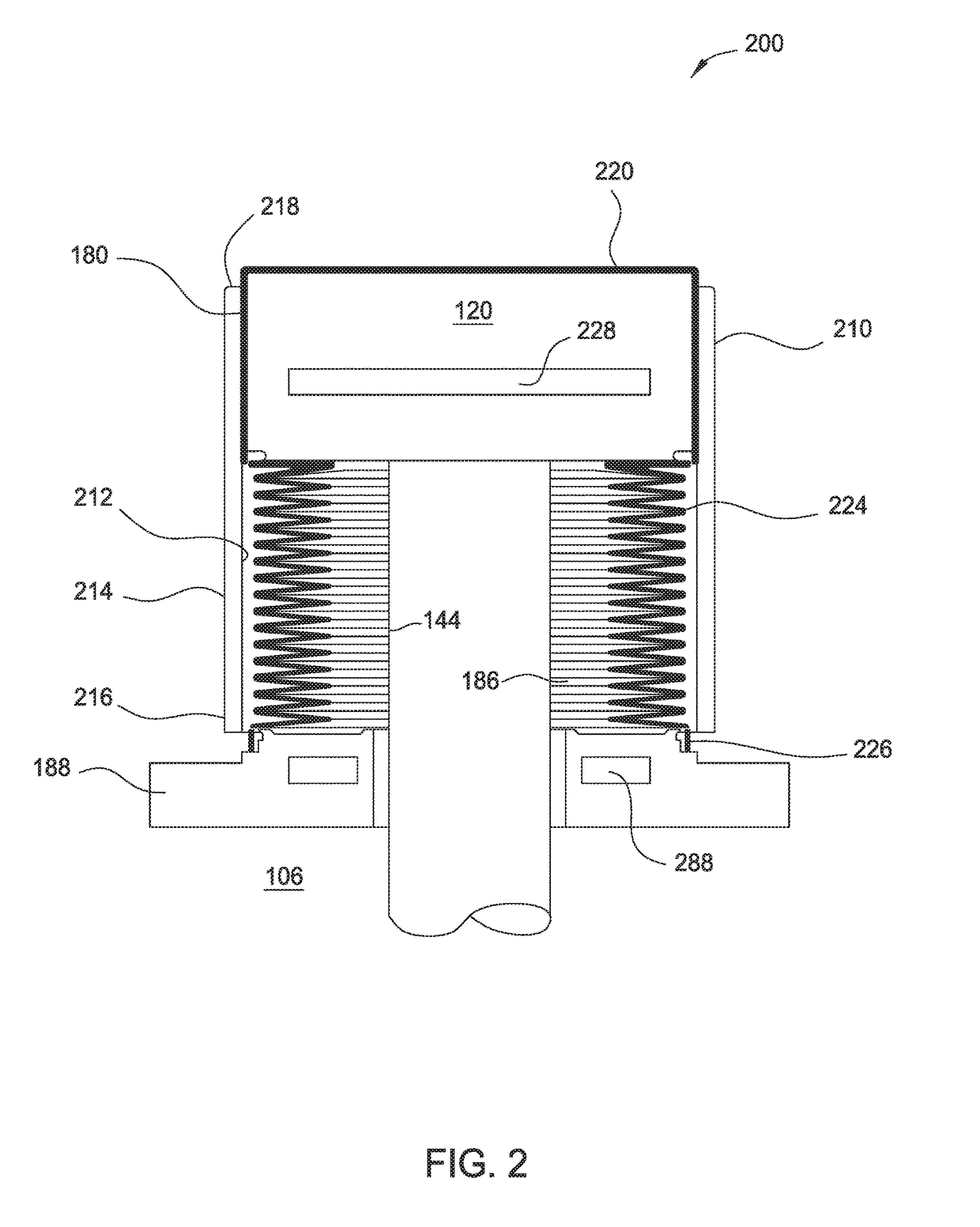

Corrosion control for chamber components

Owner:APPLIED MATERIALS INC

Corrosion control for chamber components

ActiveUS20170152968A1Protection cleanSpindle sealingsElectric discharge tubesParyleneDiamond-like carbon

Implementations described herein protect a chamber components from corrosive cleaning gases used at high temperatures. In one embodiment, a chamber component includes at least a bellows that includes a top mounting flange coupled to a bottom mounting flange by a tubular accordion structure. A coating is disposed on an exterior surface of at least the tubular accordion structure. The coating includes of at least one of polytetrafluoroethylene, parylene C, parylene D, diamond-like carbon (DLC), yttria stabilized zirconia, nickel, alumina, or aluminum silicon magnesium yttrium oxygen compound. In one embodiment, the chamber component is a valve having an internal bellows.

Owner:APPLIED MATERIALS INC

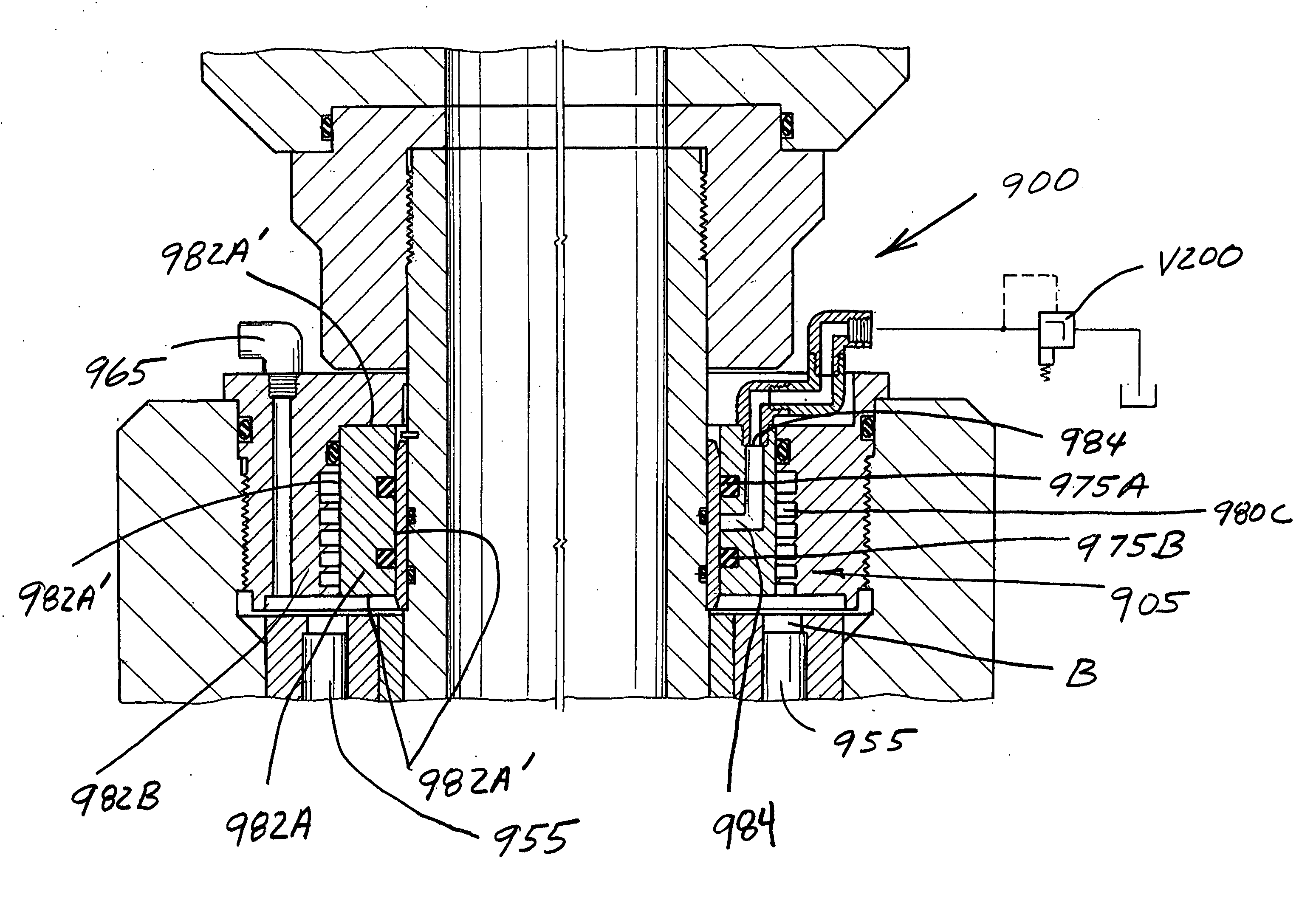

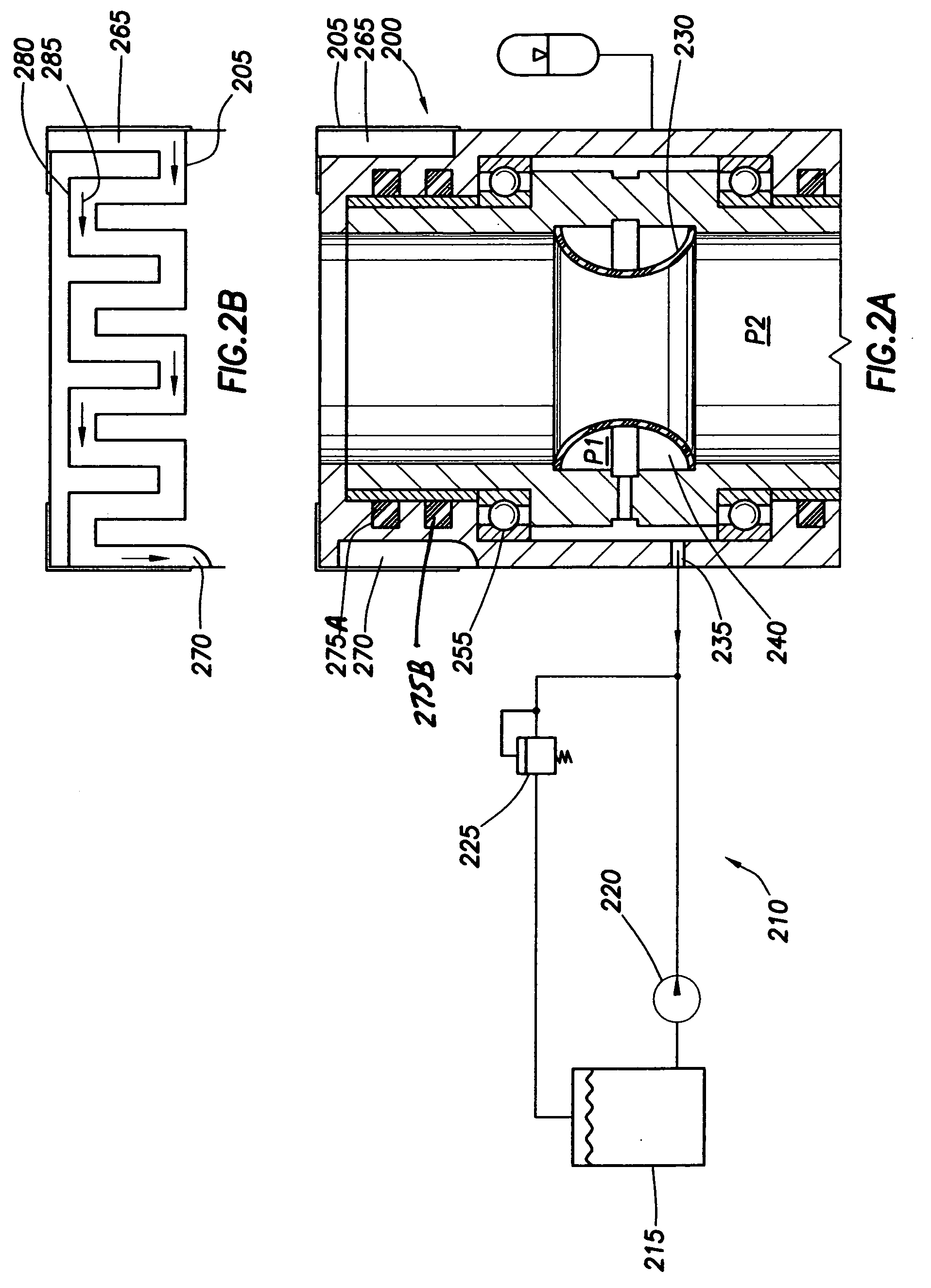

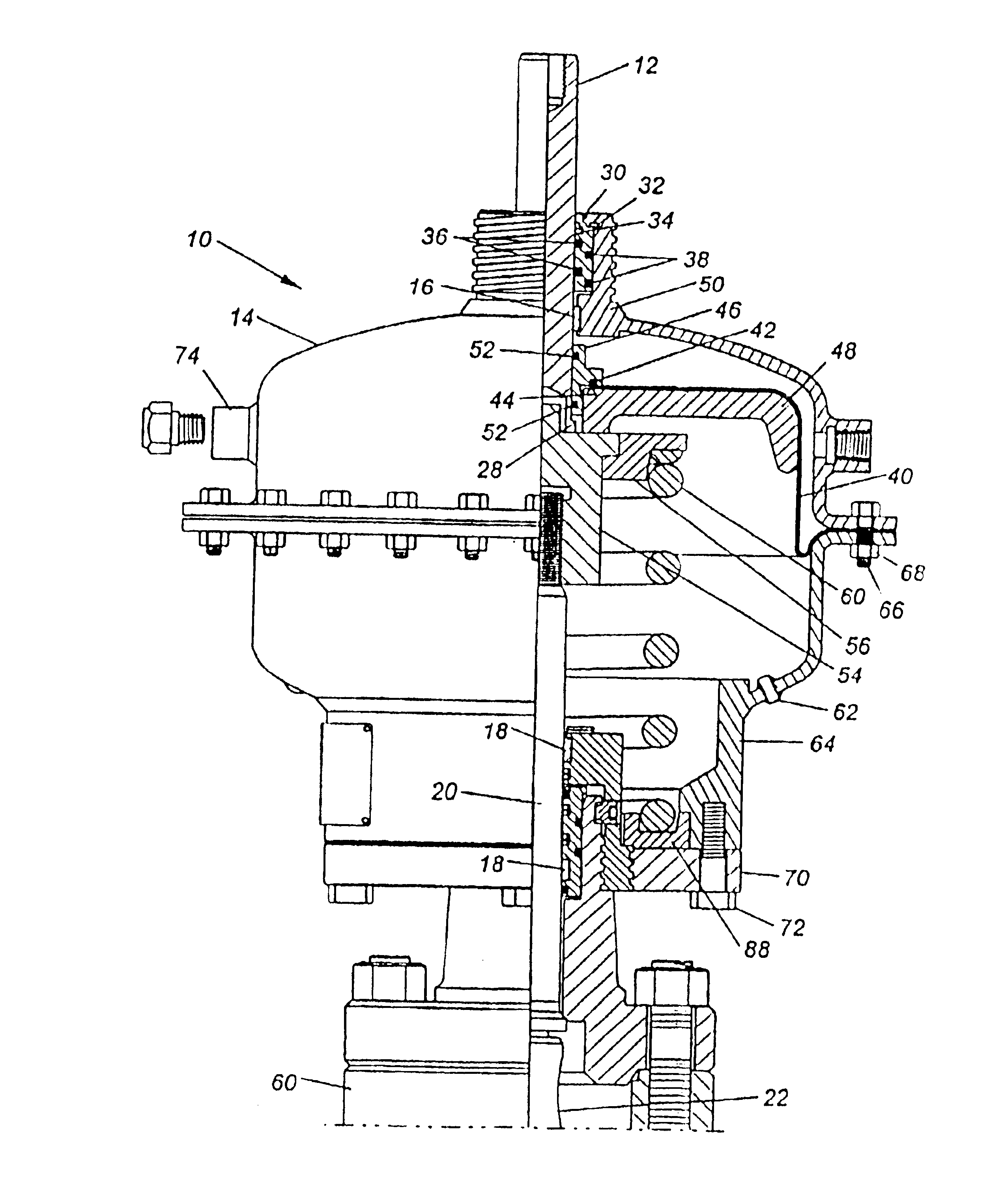

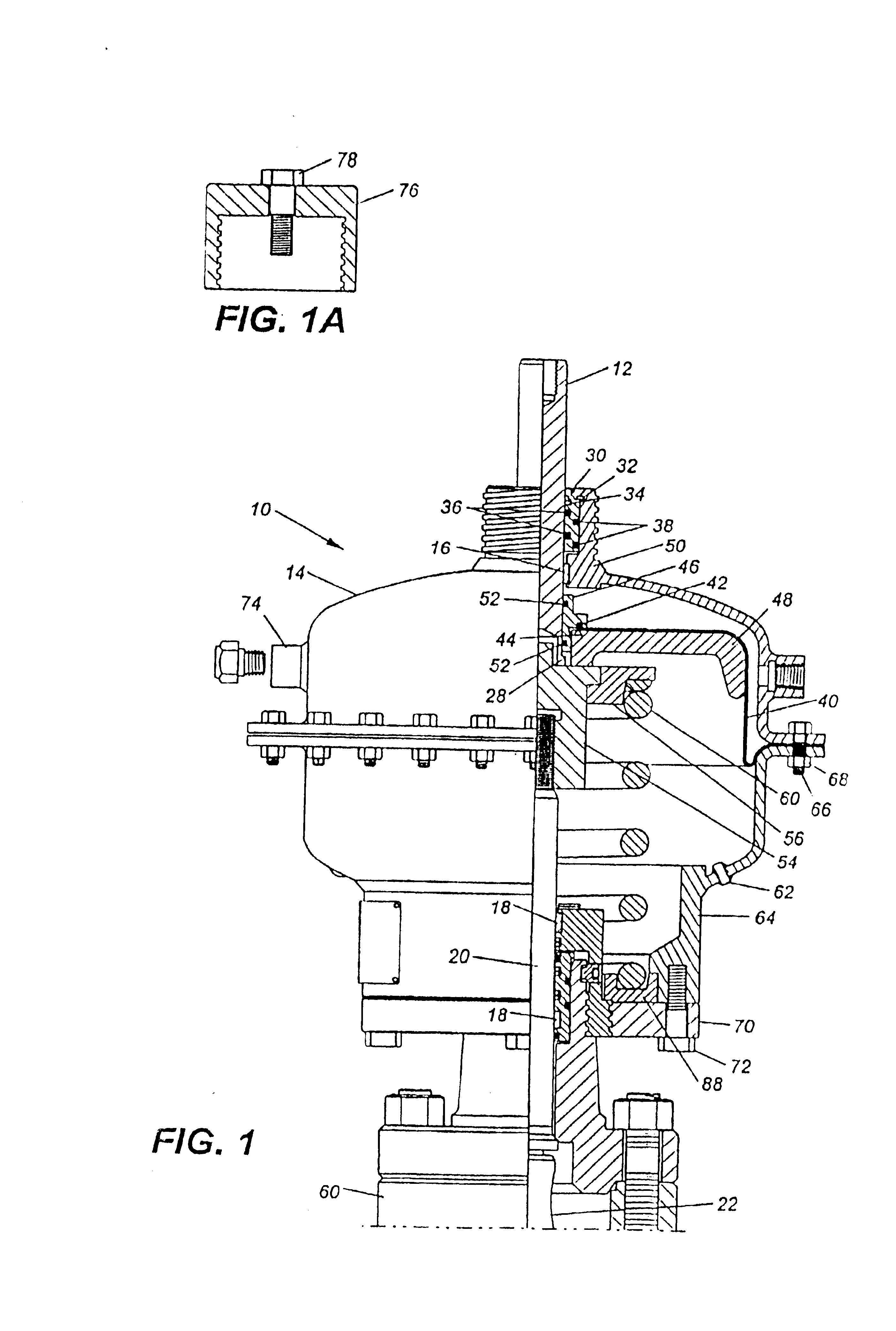

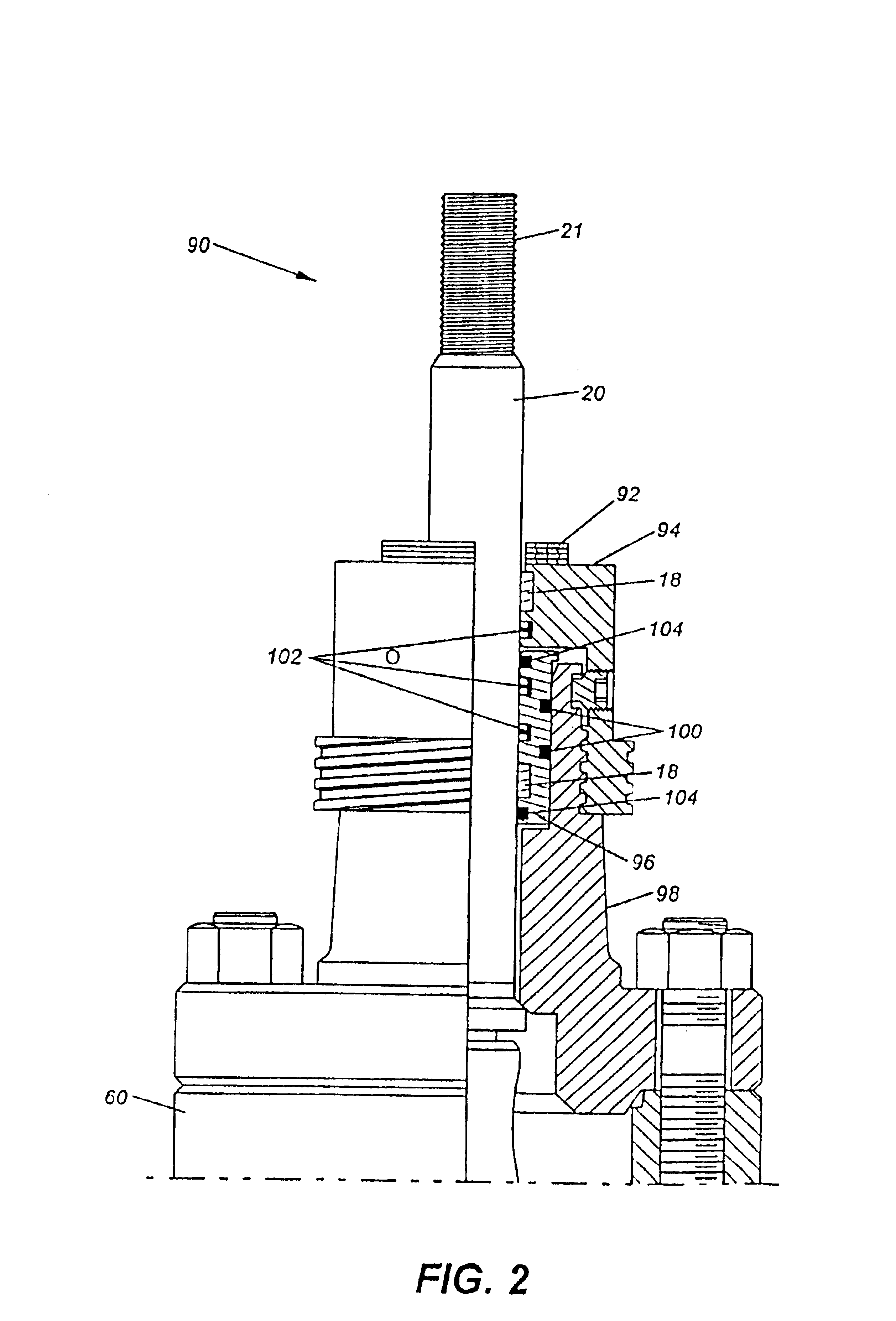

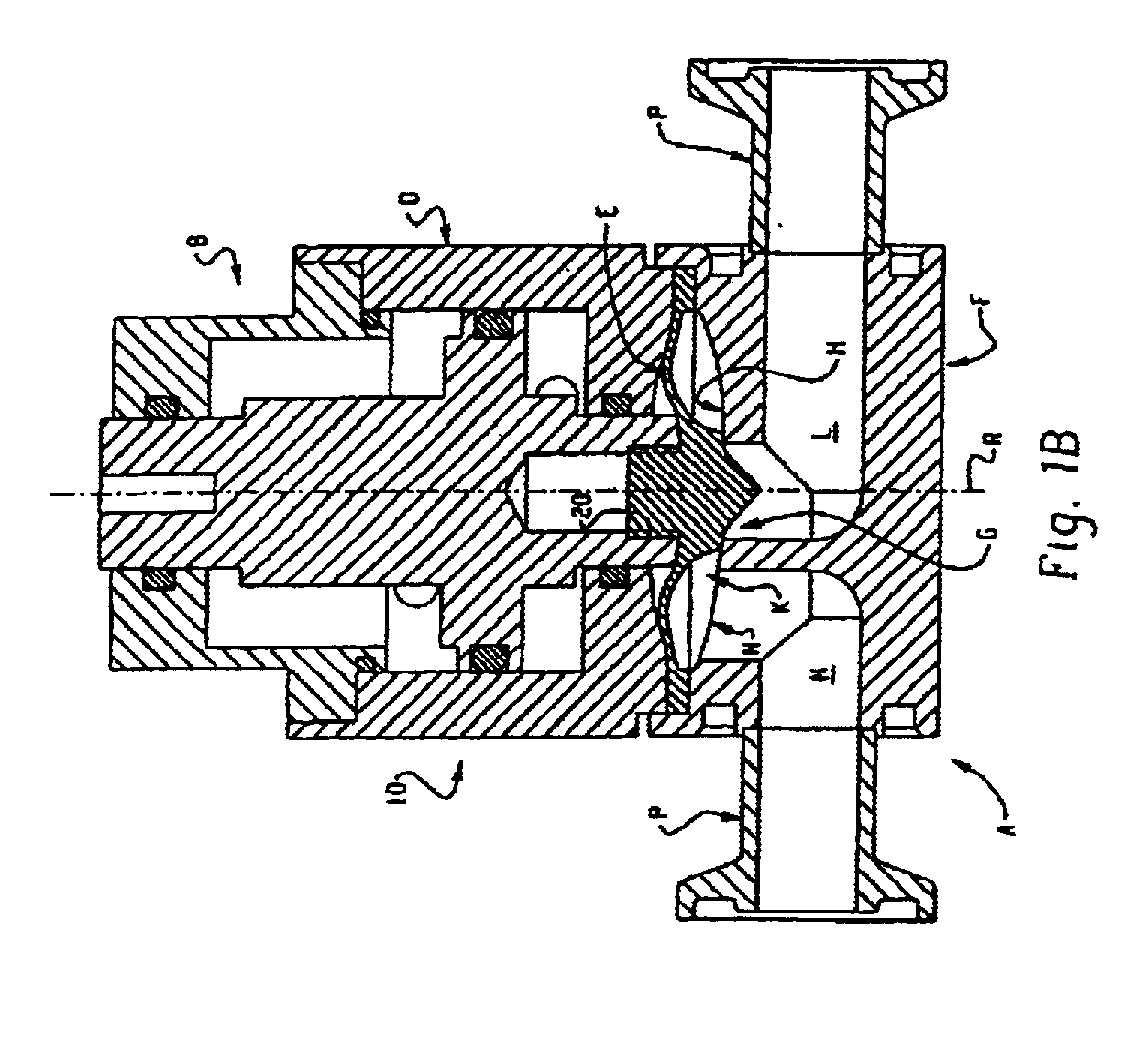

Rotating control head radial seal protection and leak detection systems

Owner:WEATHERFORD TECH HLDG LLC

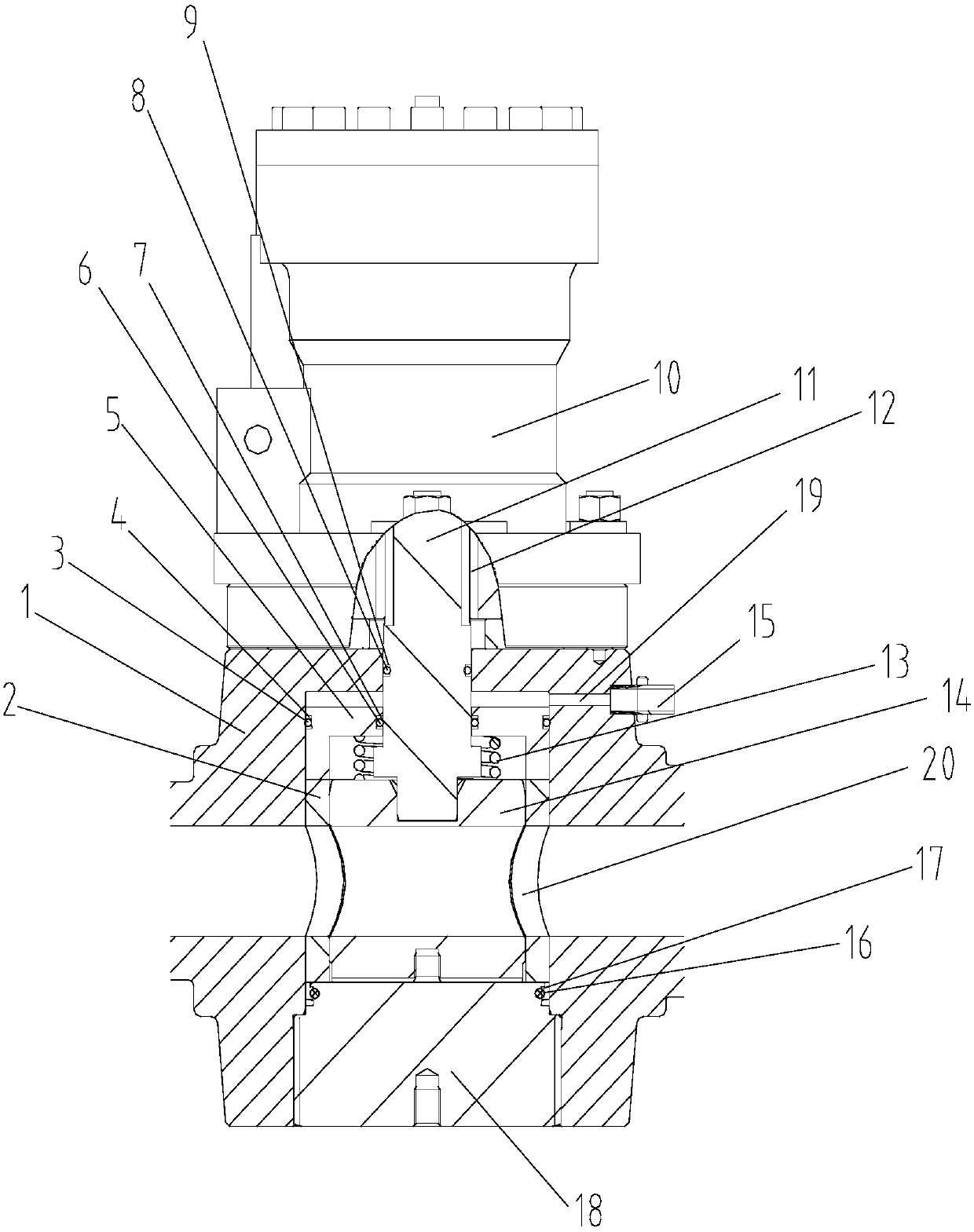

Anti-sand-accumulation plug valve

ActiveCN108036071AClearance adjustableGap noSpindle sealingsPlug valvesEngineeringMechanical engineering

The invention relates to the technical field of oil-gas field construction operation equipment, in particular to an anti-sand-accumulation plug valve which comprises a valve body, a valve cover and aplug rod arranged in the valve body. The valve body is connected with the valve cover; the lower end part of the plug rod is connected with a plug; a driver is arranged on the upper end part of the valve body and is connected with the valve body; the driver transmits a torque to the plug rod through a flat key; a sealing rubber core is arranged on the outer part of the plug; a piston is arranged on the upper part of the sealing rubber core; an annular seal cavity is formed among the plug, the plug rod and the piston; a spring is arranged in the seal cavity; the piston, the plug rod, the sealing rubber core and the plug are located in an inner core of the valve body; the inner core of the valve body communicates with an oil passage; and the oil passage is filled with hydraulic oil for driving the piston to move up and down. According to the anti-sand-accumulation plug valve provided by the invention, a gap between the sealing rubber core and the plug can be adjusted, and no gap exists among the plug, the sealing rubber core and the valve body during a pressure-bearing and fluid conveying process, so that sand is prevented from being accumulated.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

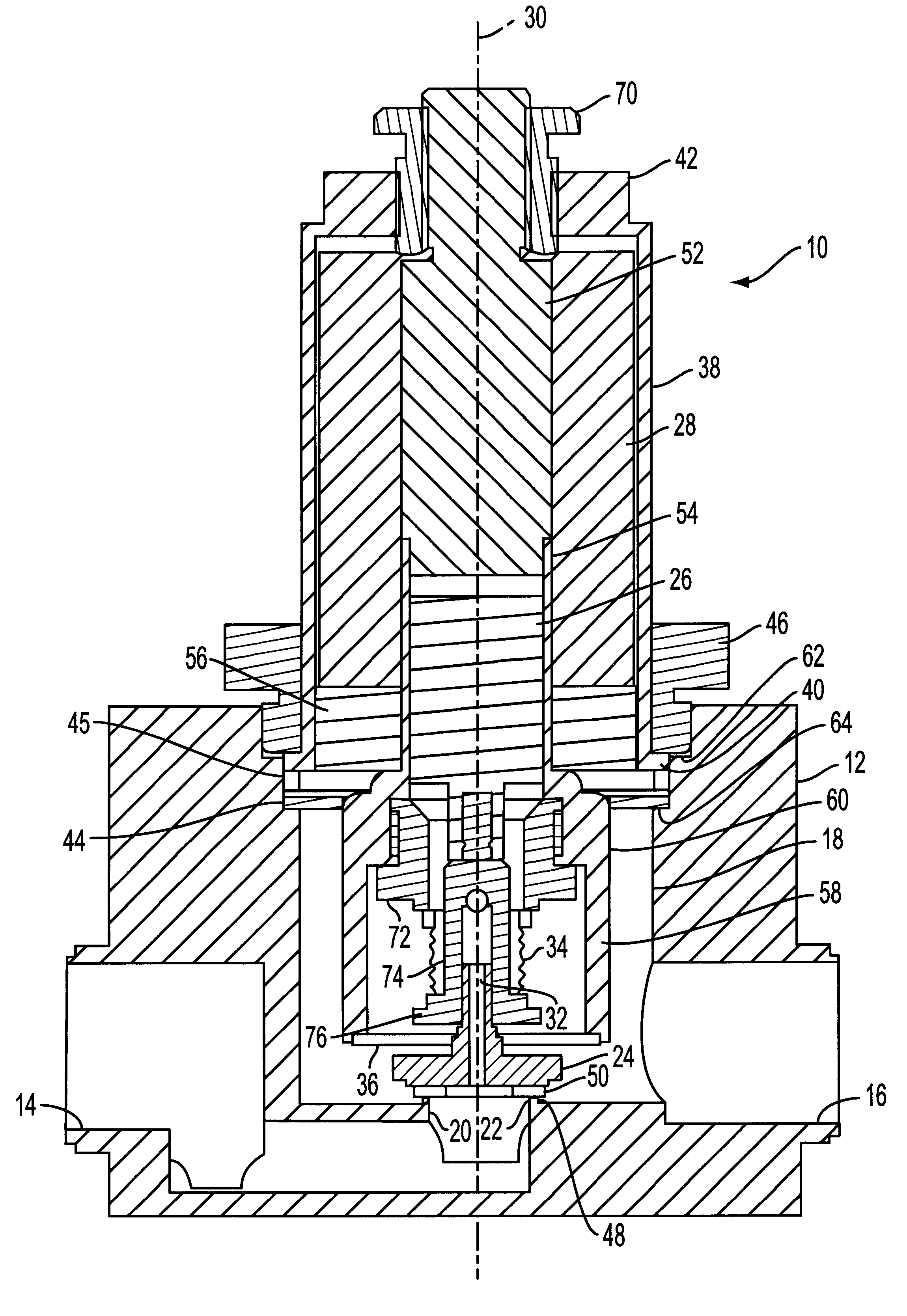

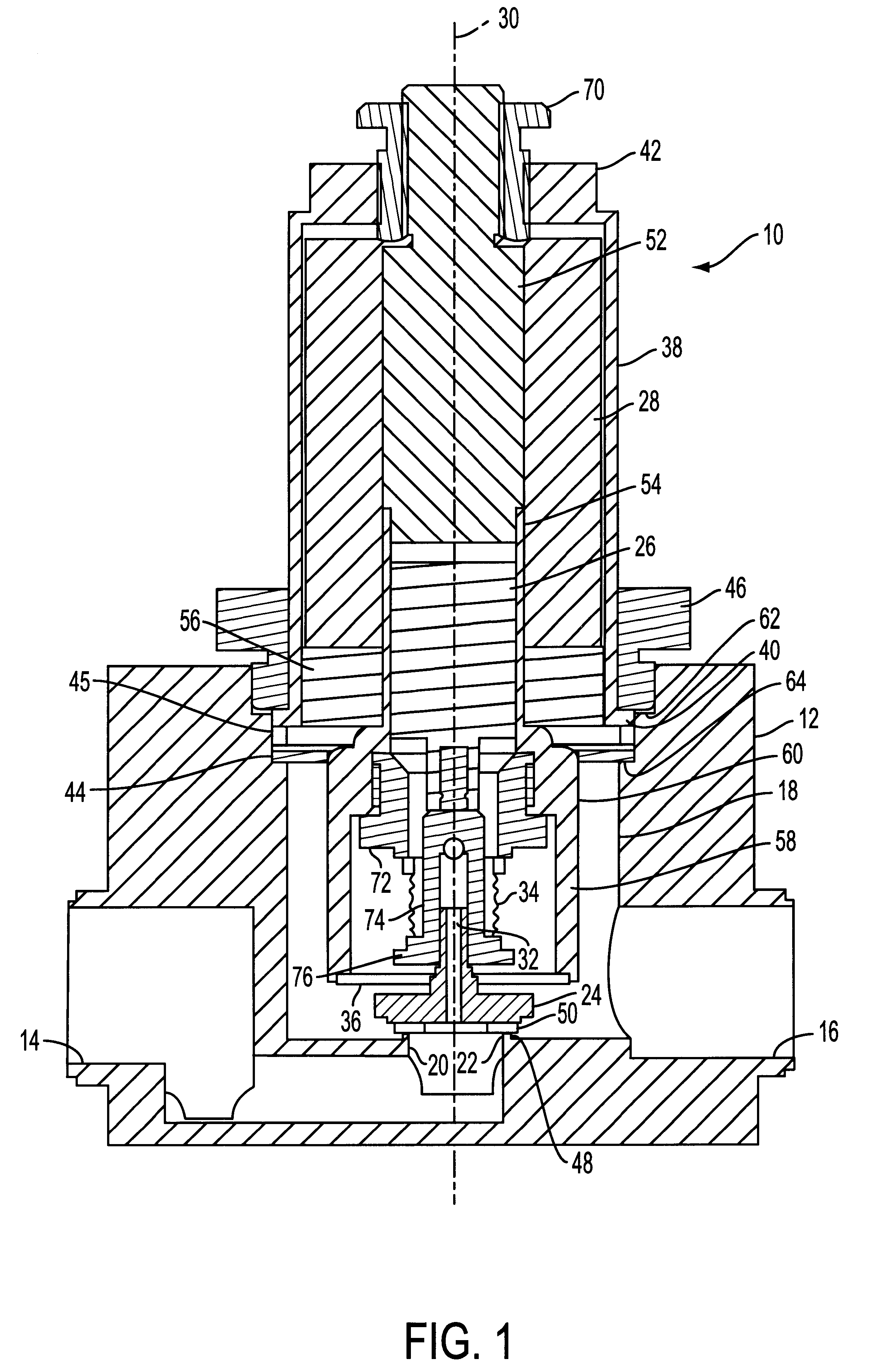

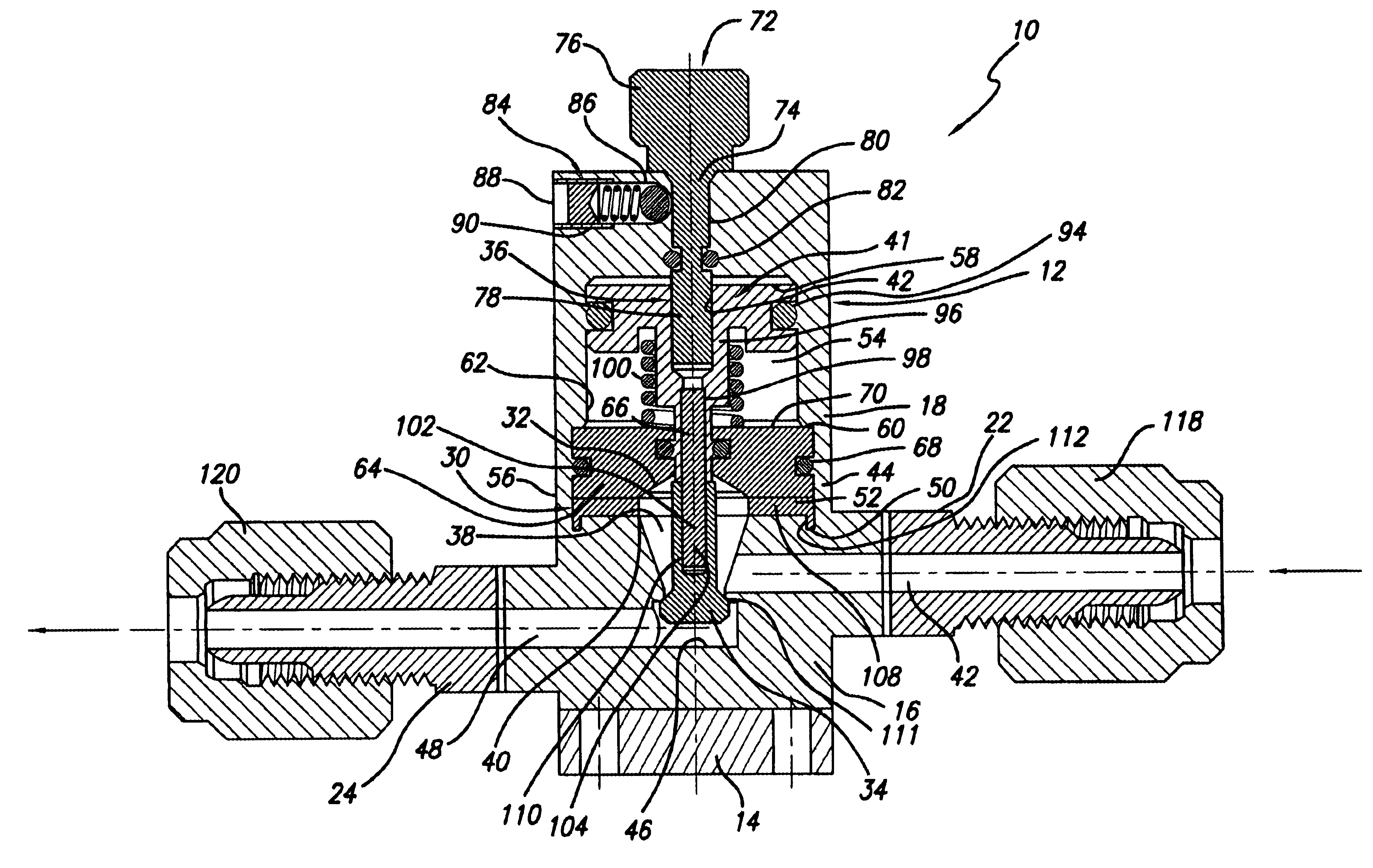

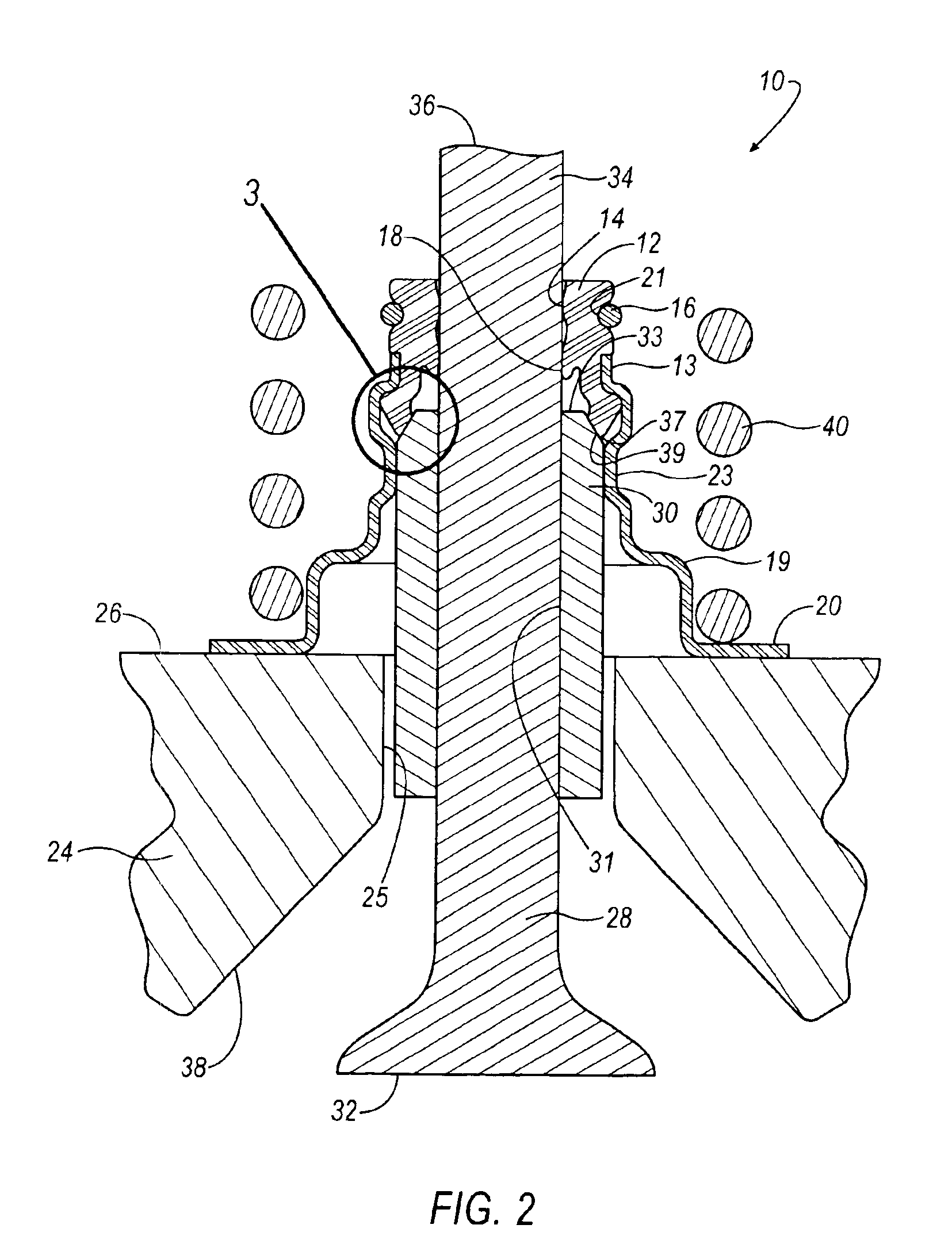

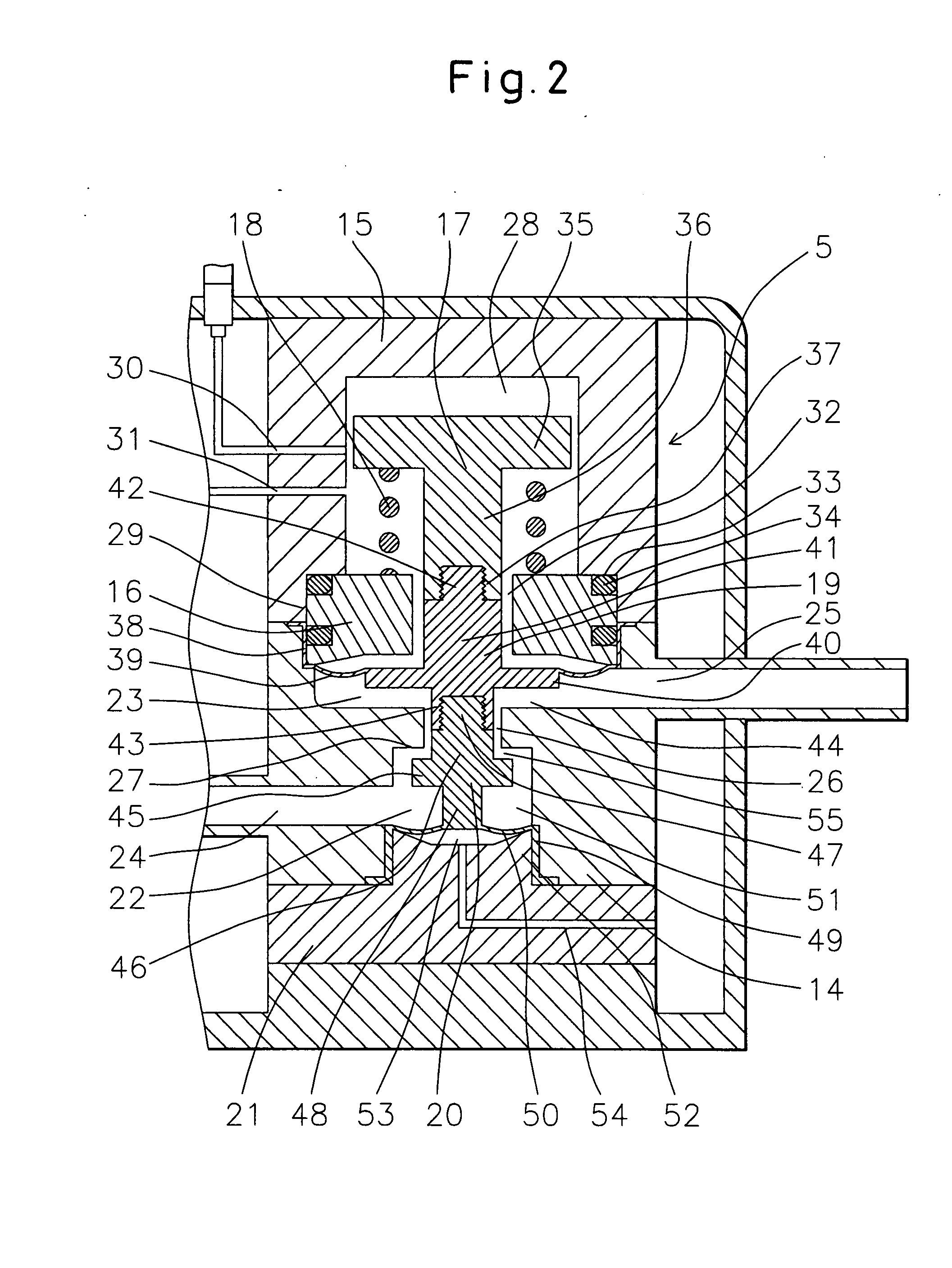

Solenoid valve

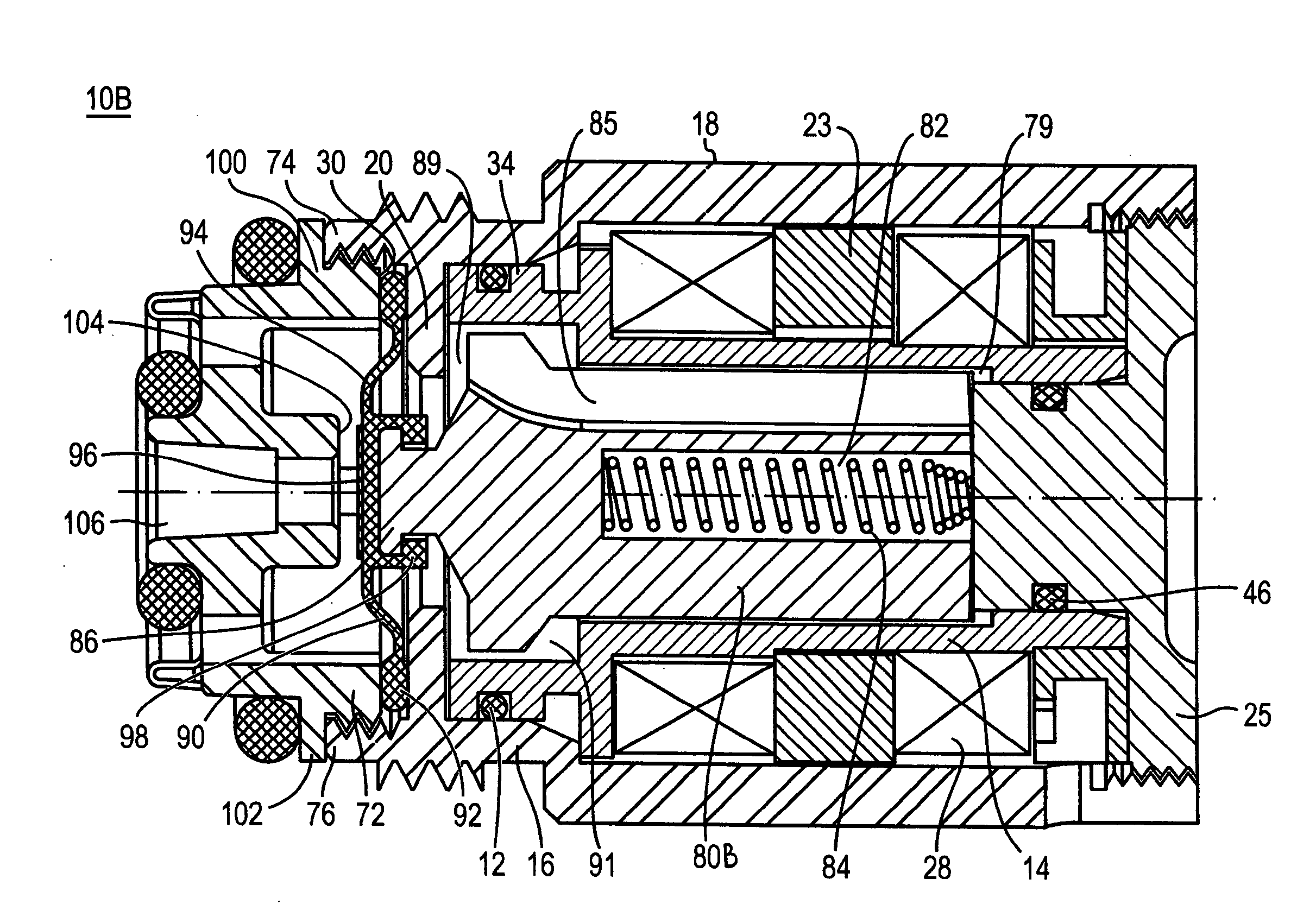

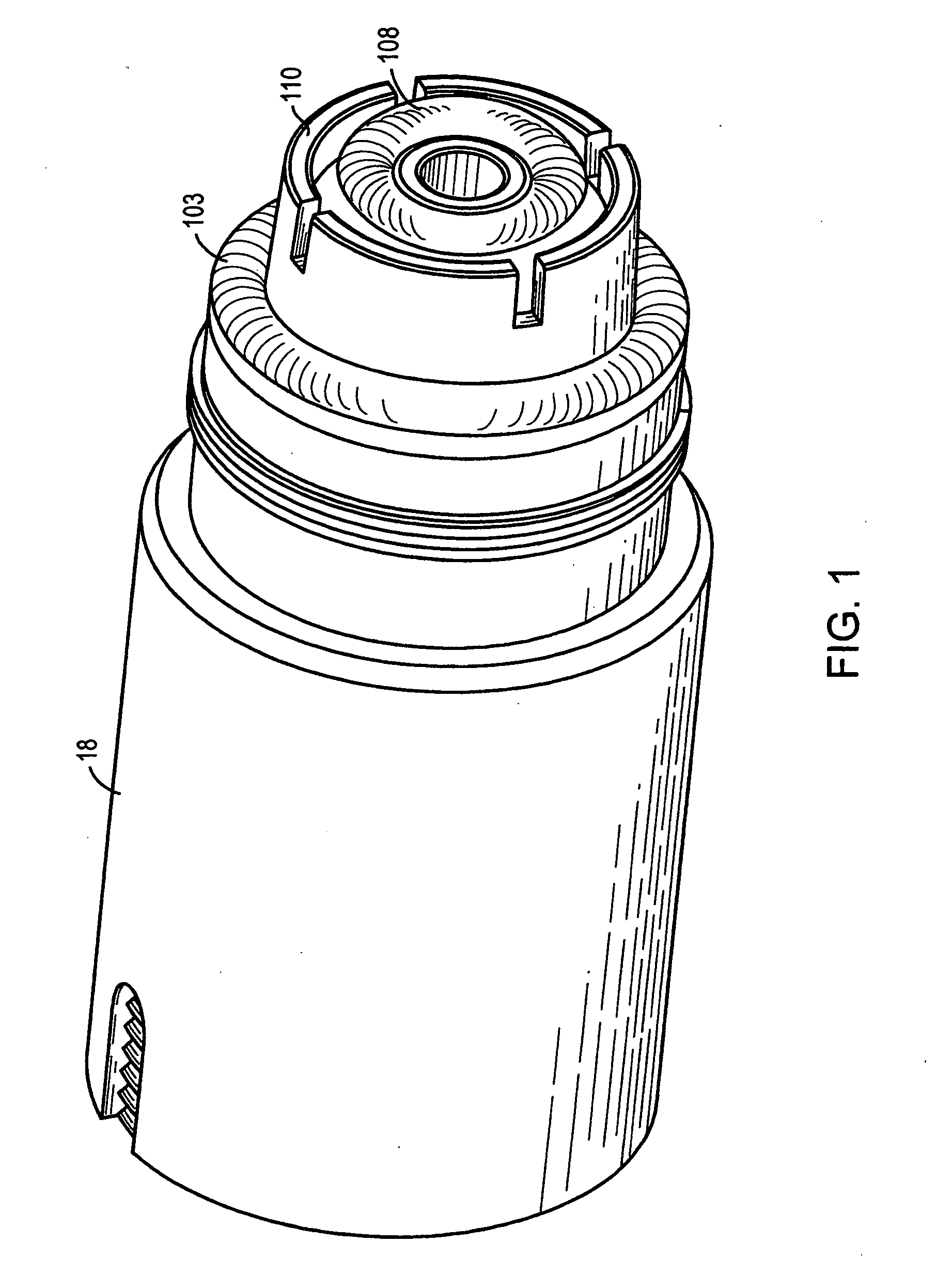

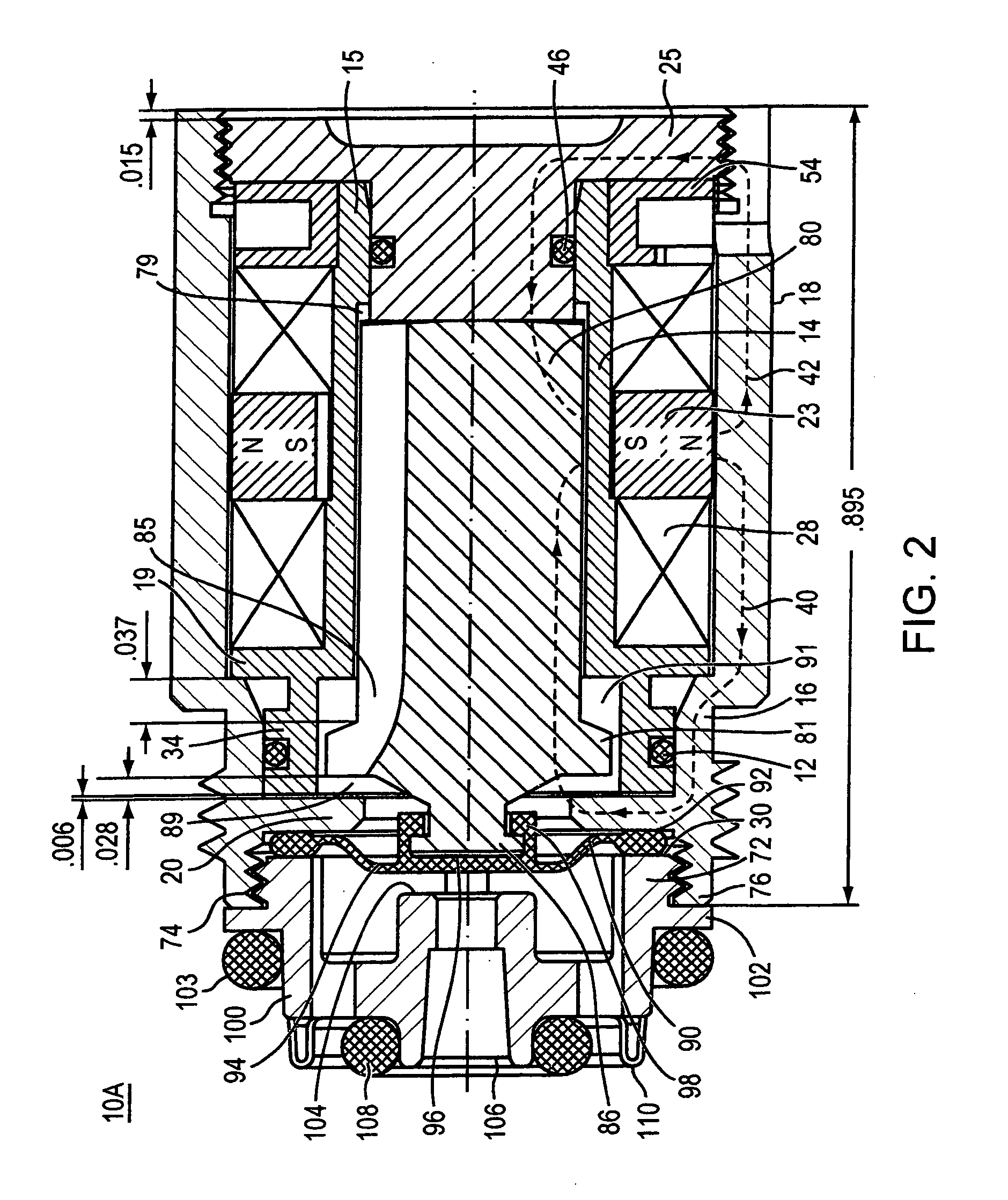

InactiveUS6505812B1Simple designEasily assembled togetherSpindle sealingsOperating means/releasing devices for valvesSolenoid valveEngineering

A valve assembly including a body having an inlet port, an outlet port, and a valve seat having a passageway. An electrical solenoid assembly moves a valve member upon being energized to control fluid flow between the inlet and the outlet ports. The valve assembly also includes a fluid-tight bellows positioned to apply a force to the valve member, and a pressure balancing passageway connects the inlet port to the bellows. The valve assembly further includes a housing received over the solenoid assembly and having a flange received against the valve body. A seal is positioned between the flange of the housing and the valve body, and a collar is secured in a continuous manner to the valve body over the housing flange, thereby securing the housing to the valve body and applying a sealing force to the seal in a substantially even manner.

Owner:MKS INSTR INC

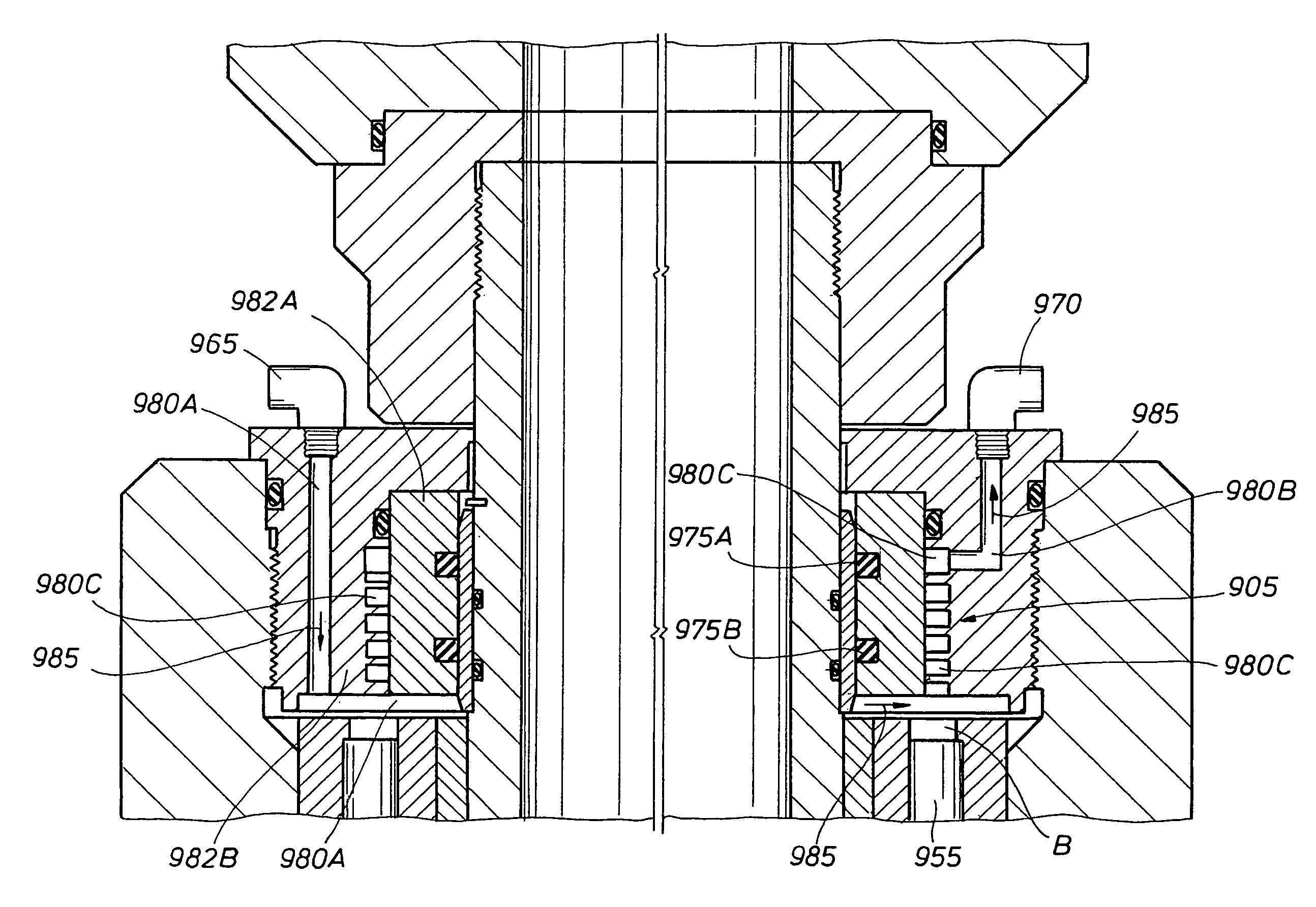

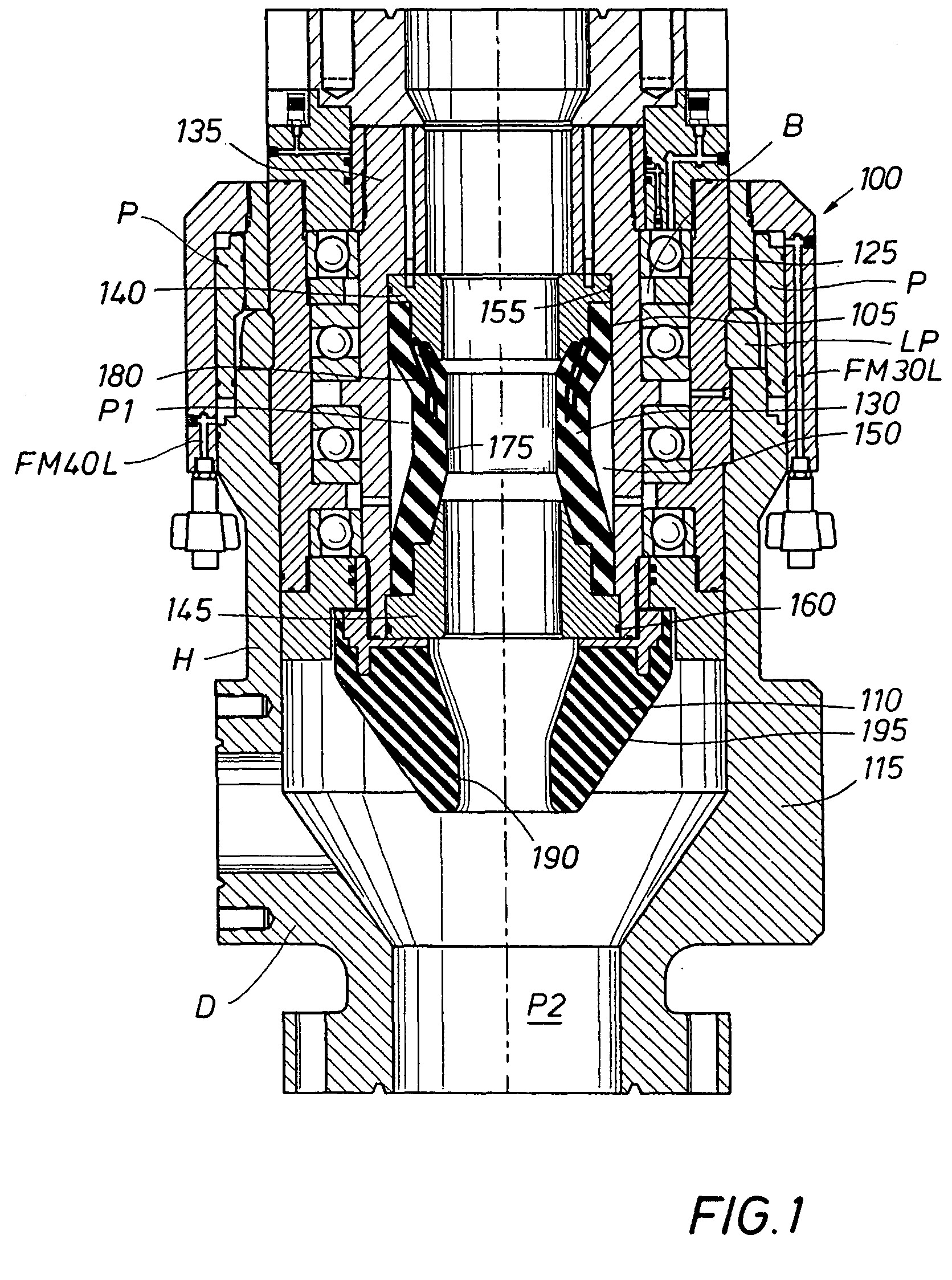

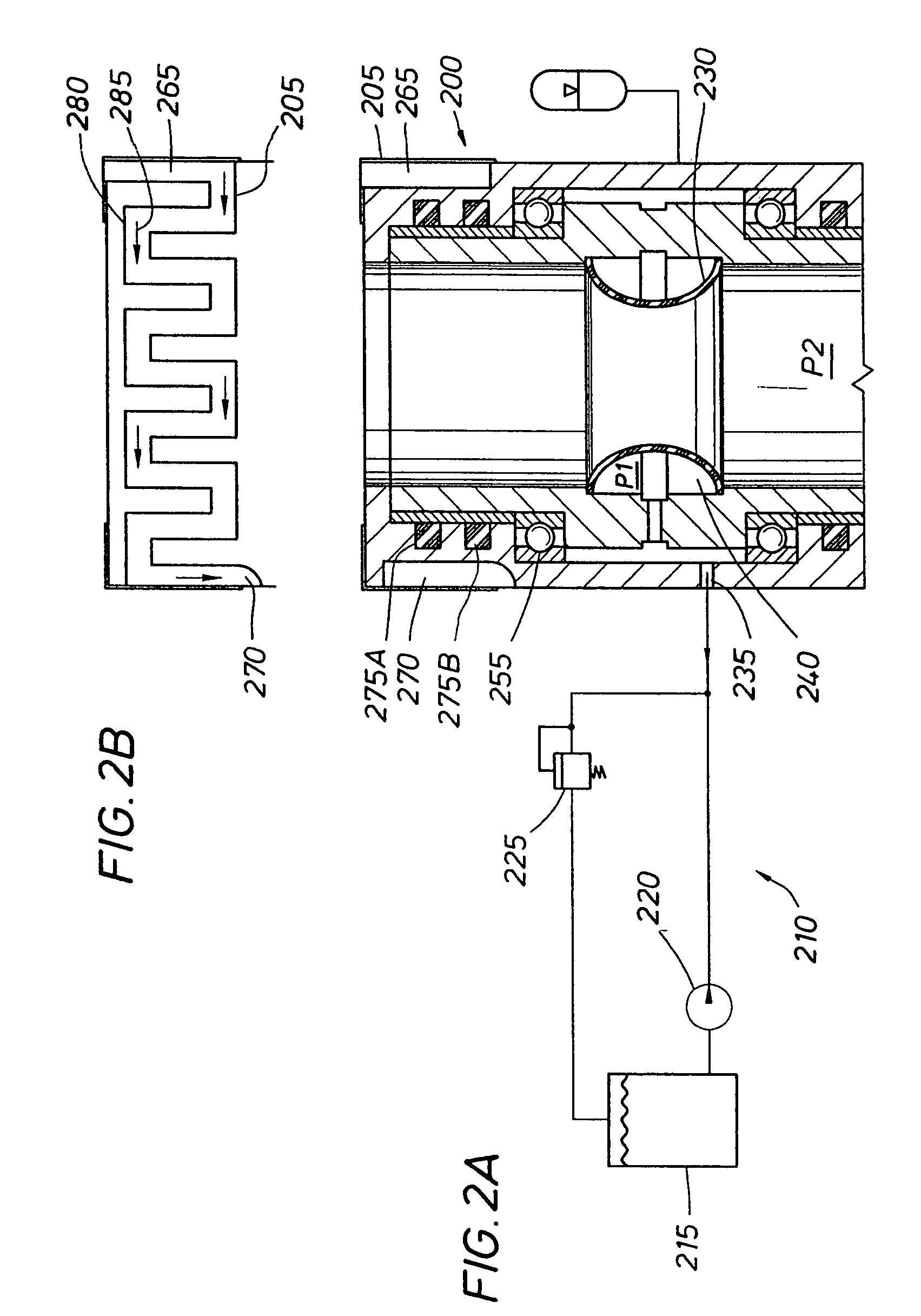

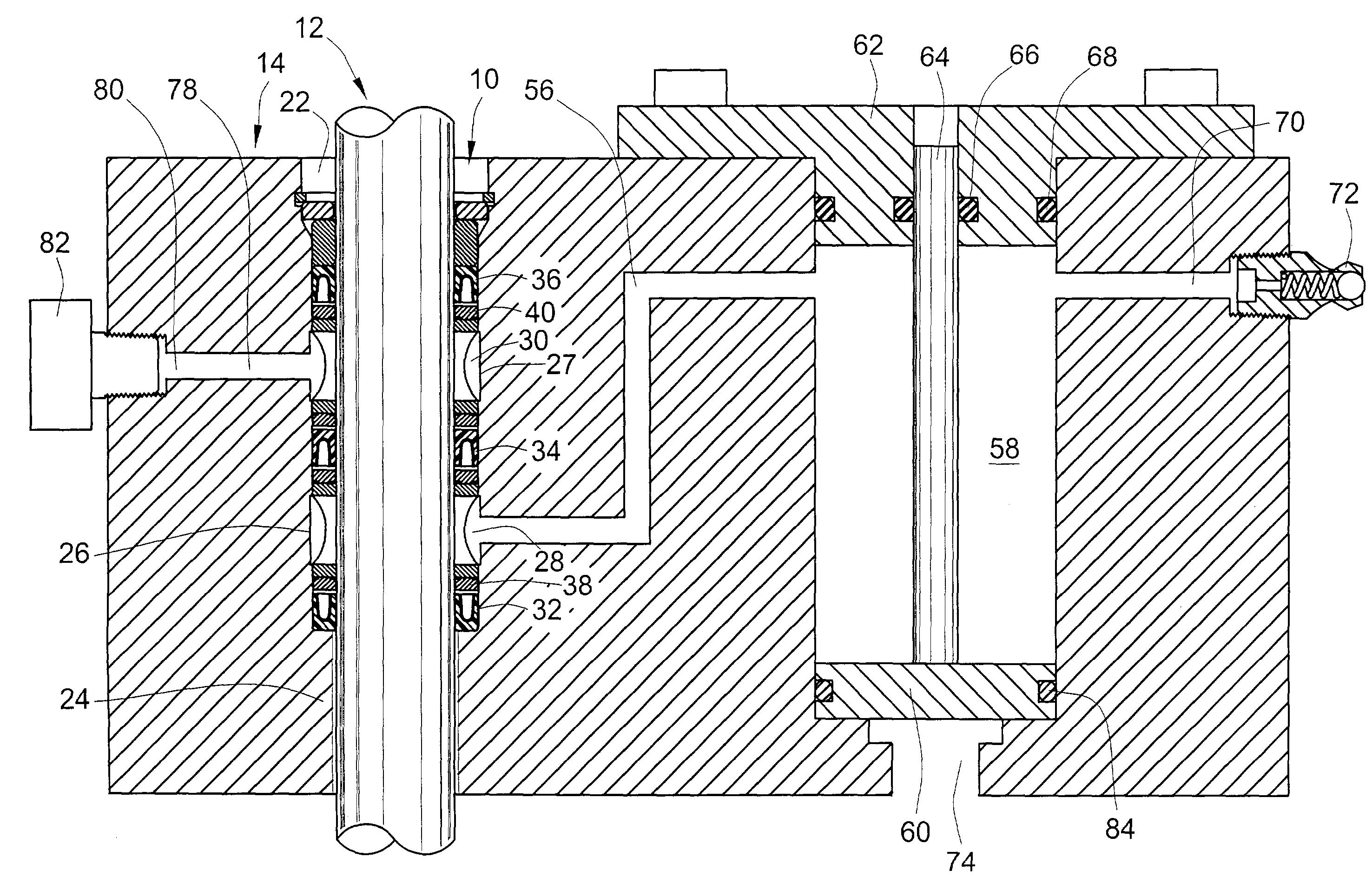

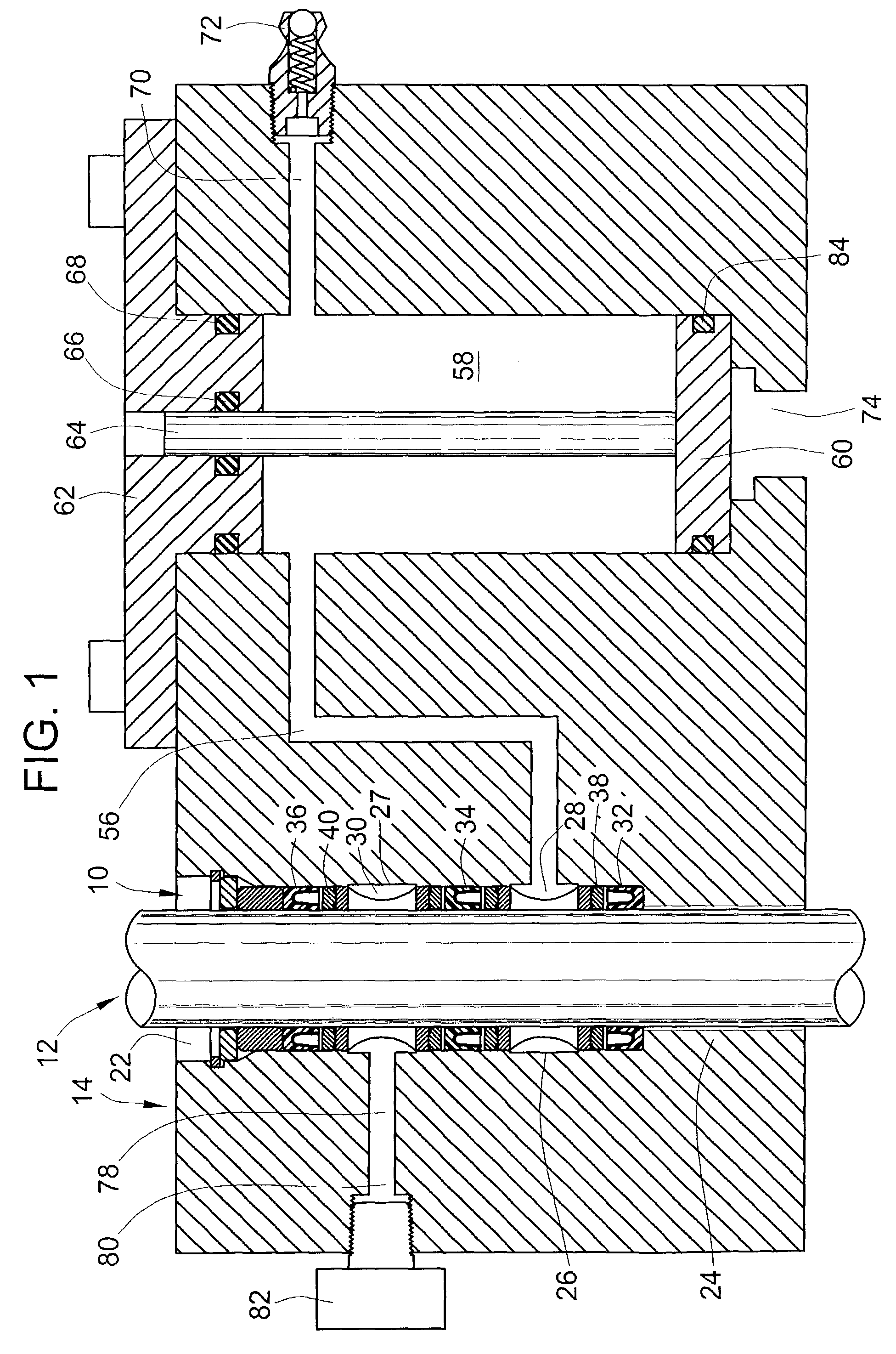

Rotating control head radial seal protection and leak detection systems

A system and method for reducing wear to radial seals in a rotating control device. The seals may be cooled by a thermal transfer fluid circulating through a passageway making more than one pass. Also, the differential pressure between multiple seals may be regulated and lowered, thereby increasing seal life.

Owner:WEATHERFORD TECH HLDG LLC

Electromagnetic apparatus and method for controlling fluid flow

InactiveUS20070241298A1Reduce energy wasteReduce energy consumptionSpindle sealingsDiaphragm valvesDriving currentBobbin

An actuator including actuator base, bobbin, and pole piece forming a pocket for a ferromagnetid armature located therein. The actuator including a radial magnet and a solenoid coil constructed and arranged to cause a linear displacement of the armature upon application of a coil drive current from a control circuit. The actuator may include a flexible membrane that partially encloses the armature to form an armature chamber filled with an incompressible fluid. In a valve design, a fluid flow is stopped by driving the membrane against a valve seat. Pressure from the controlled fluid in the conduit is transmitted through the membrane to the fluid within the armature chamber so that the armature does not need to counteract force applied to the membrane by the conduit fluid's pressure. A fluid flow is opened by driving the membrane away from the valve seat.

Owner:SLOAN VALVE COMPANY

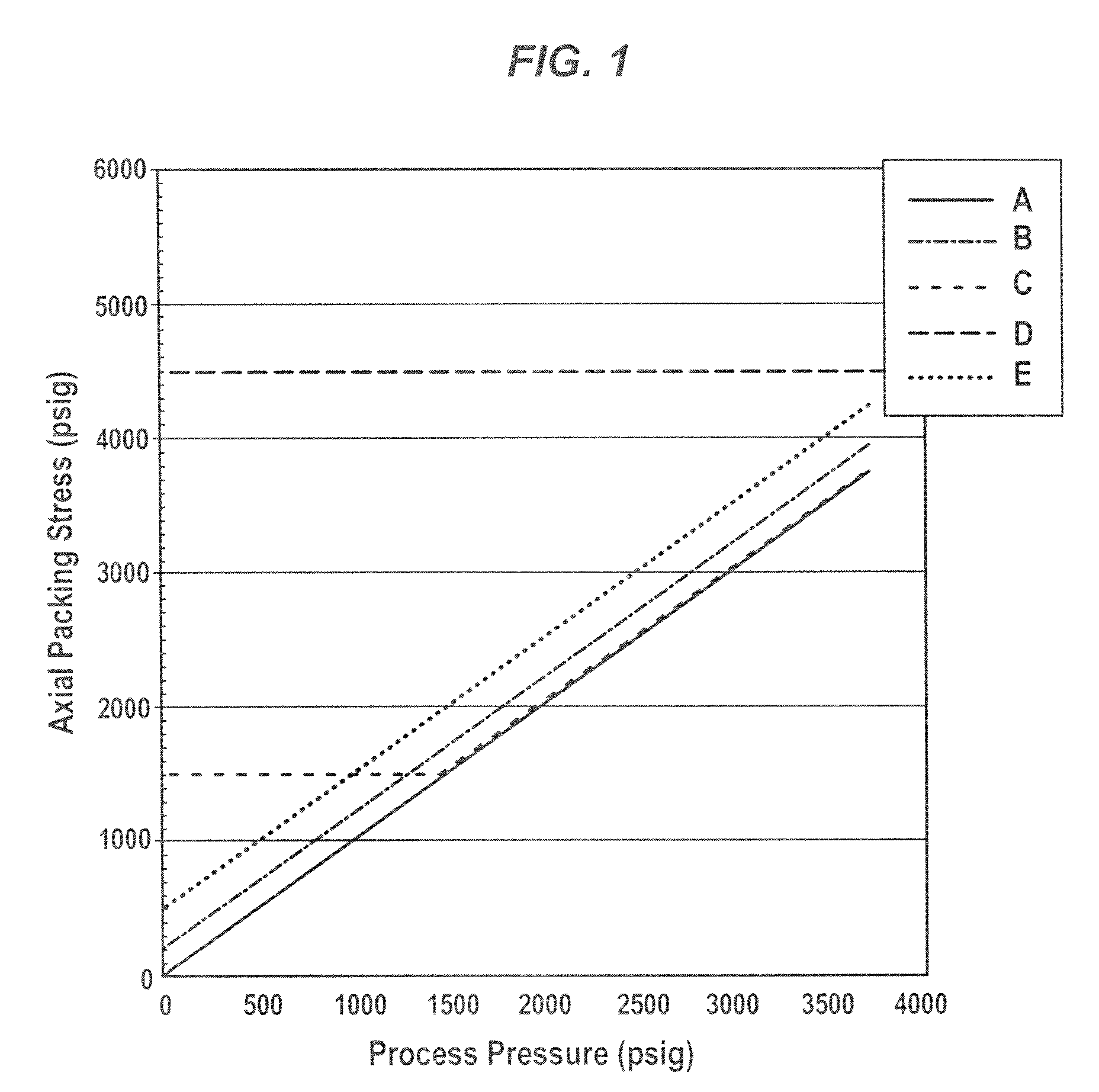

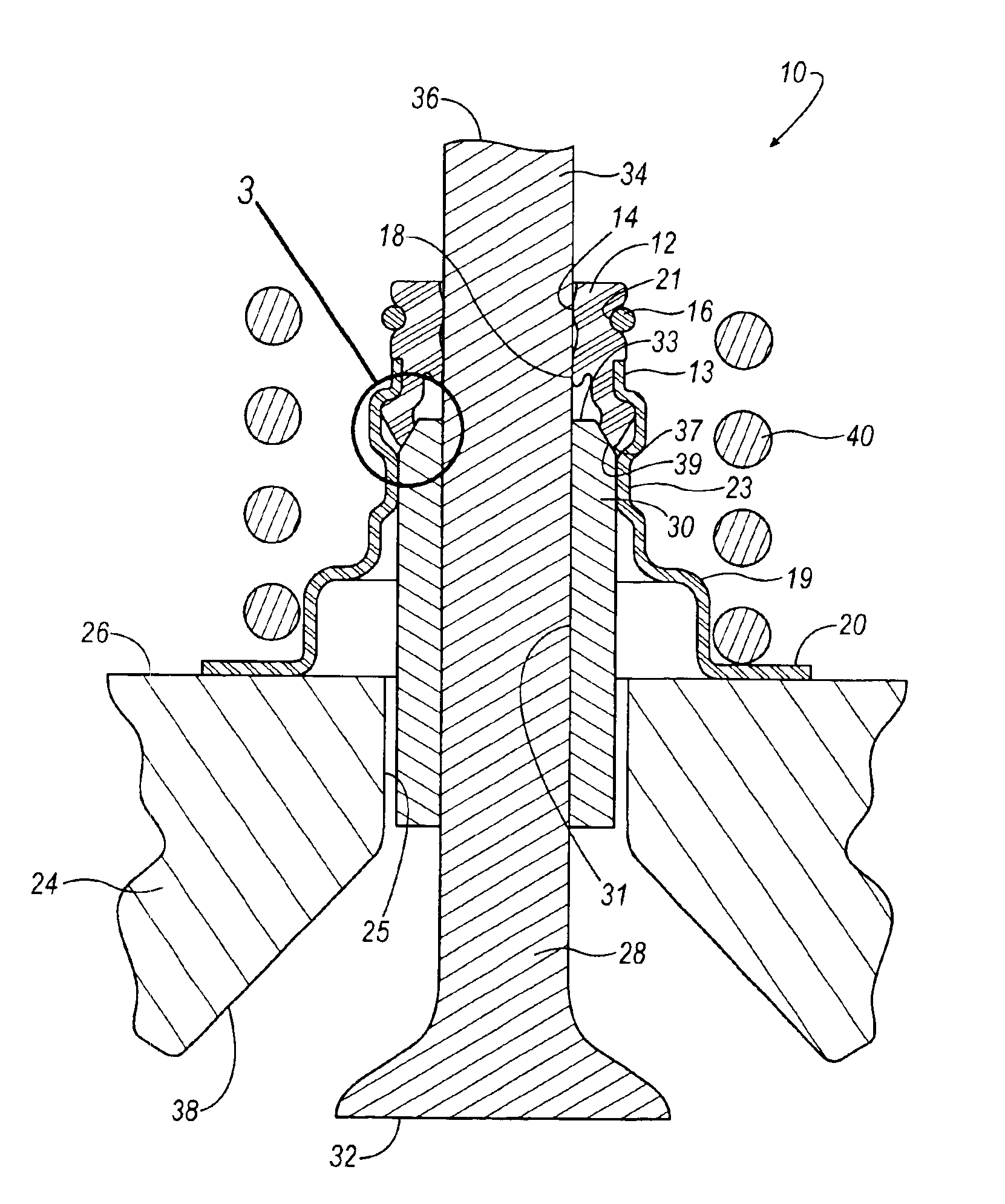

Low friction live-loaded packing

ActiveUS7963502B2Reduce packing friction and packing wearAvoid squeezingSpindle sealingsOperating means/releasing devices for valvesEngineeringControl valves

Owner:FISHER CONTROLS INT LLC

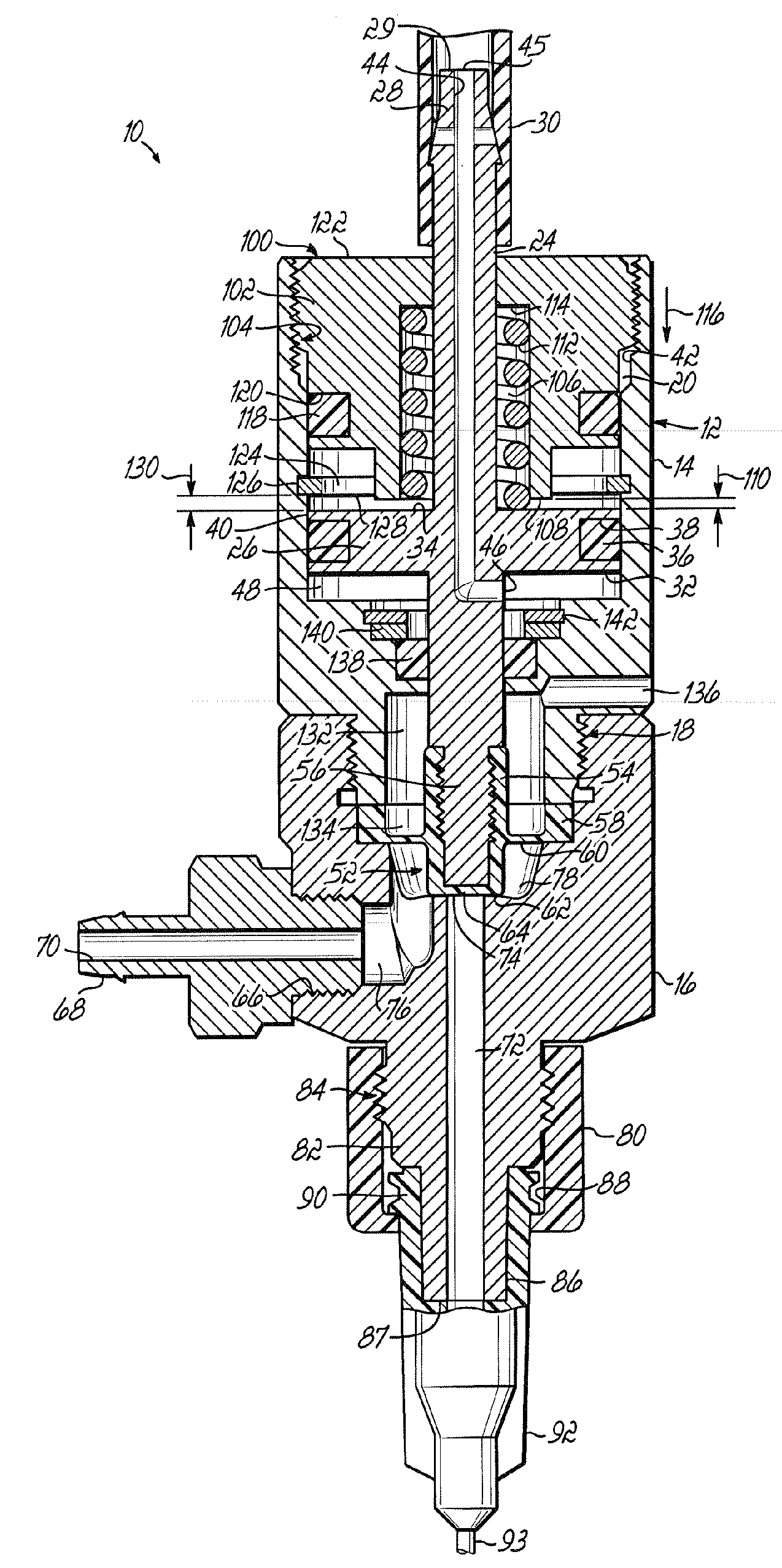

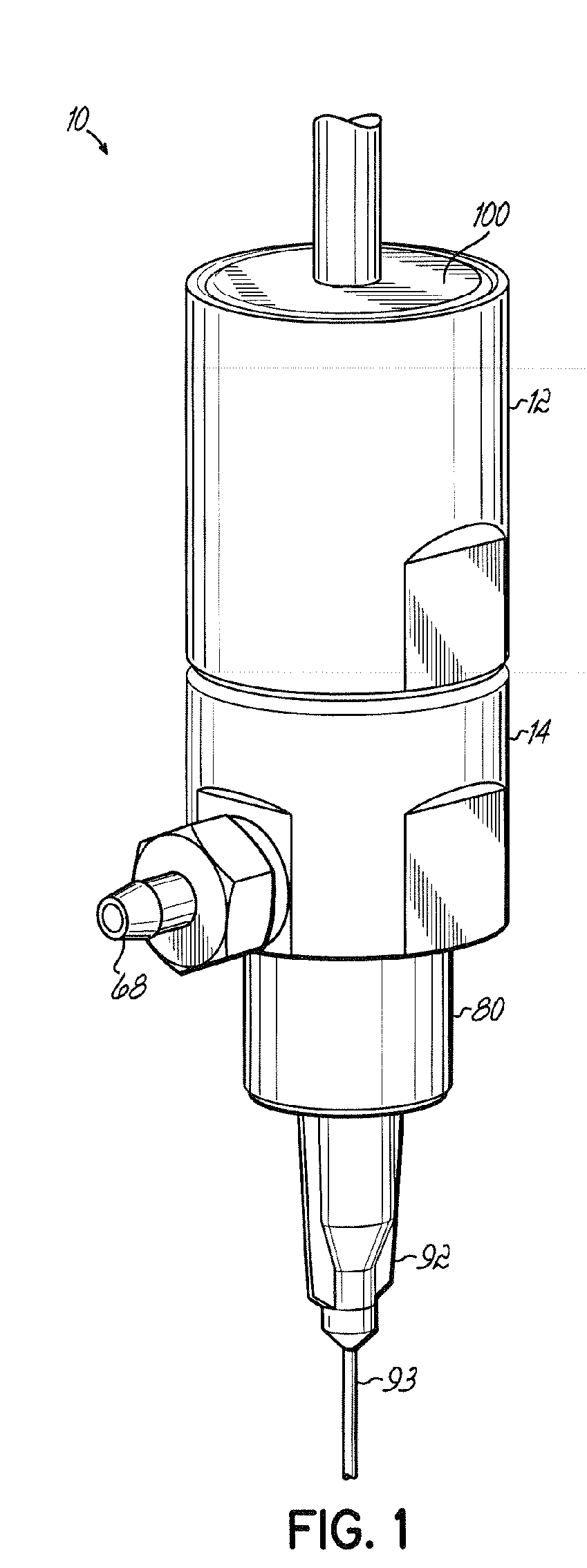

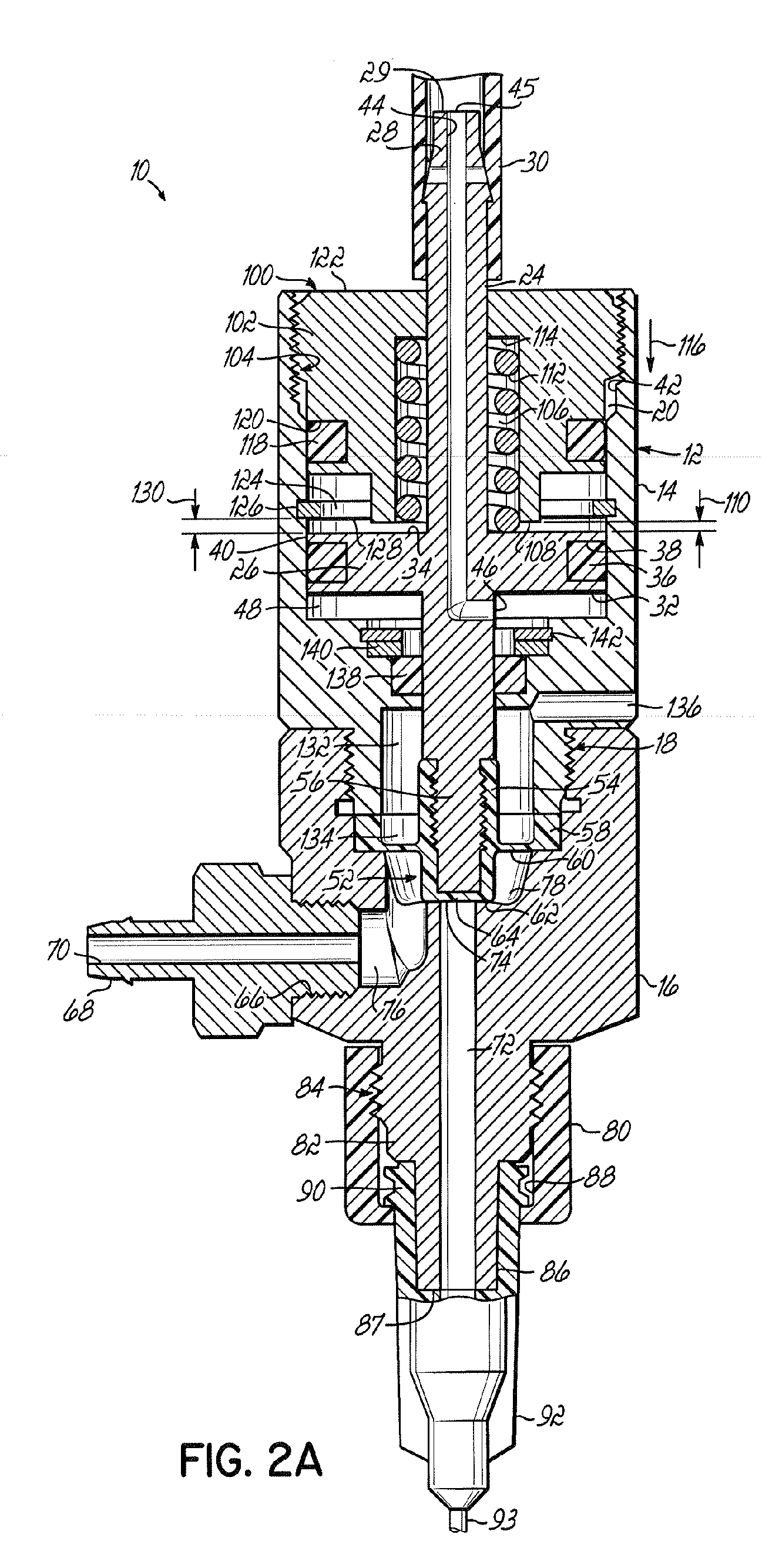

Anti-pumping dispense valve

Anti-pumping dispense valves, constructed according to principles of this invention, comprise a fluid transport housing having a fluid inlet passage extending into the housing, a fluid outlet passage extending out of the housing, and a fluid transport chamber disposed within the housing. The fluid transport chamber includes an valve seat. An actuator housing is attached to the fluid transport housing and includes an actuator chamber that is in contact with the fluid transport chambers. A diaphragm / poppet assembly is disposed within the fluid transport chamber and comprises a poppet positioned downstream of the seat for placement against the seat to stop fluid flow through the first fluid transport chamber. An actuator is disposed within the actuator chamber for moving the diaphragm / poppet assembly. Dispense valves of this invention operate to provide a slight vacuum within the fluid flow passageway in the valve to retain or pull back into the valve any nondispensed liquid, thereby eliminating and / or greatly reducing the possibility product contamination via unwanted excess liquid dispensement or dried residual liquid dispensement.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

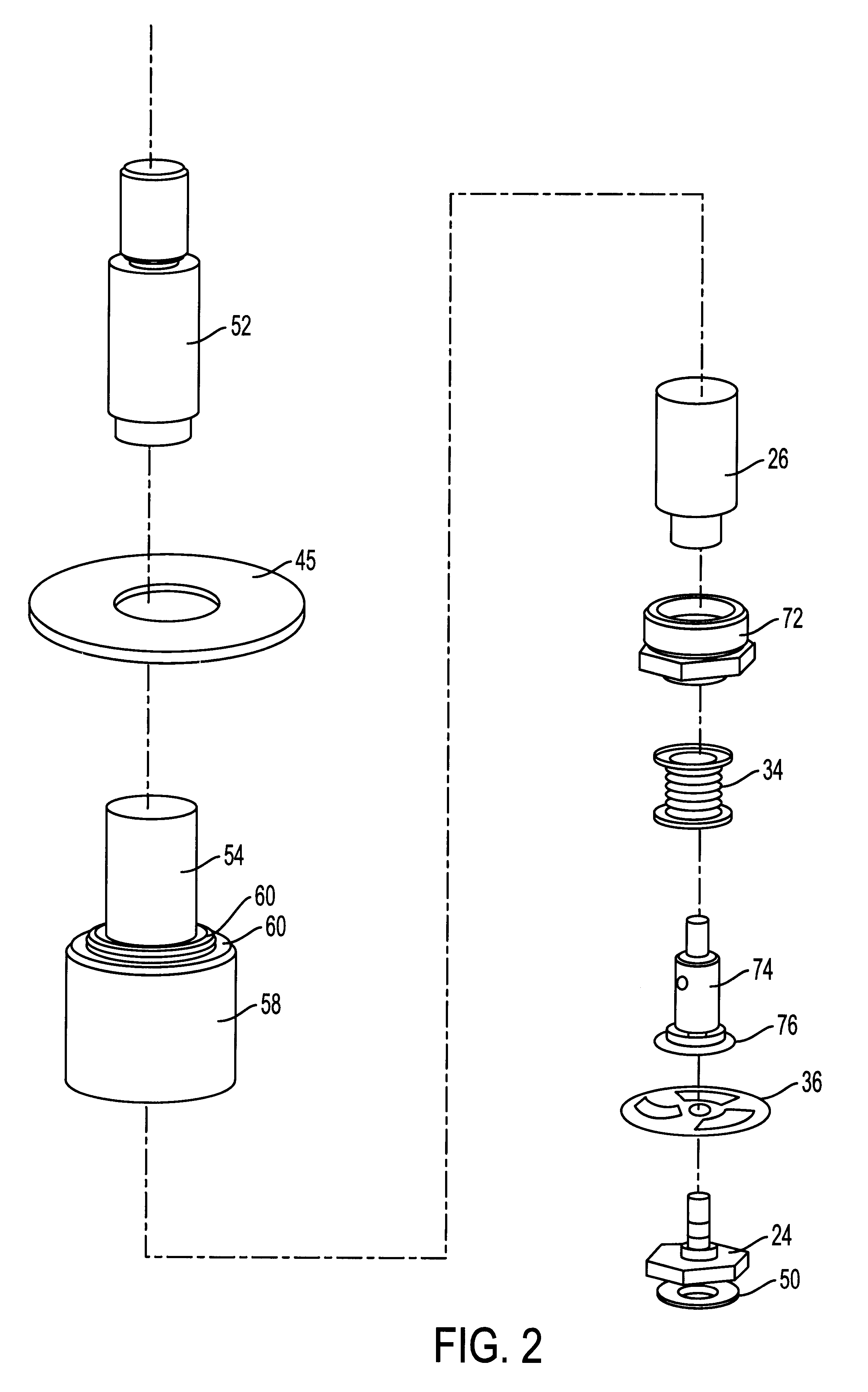

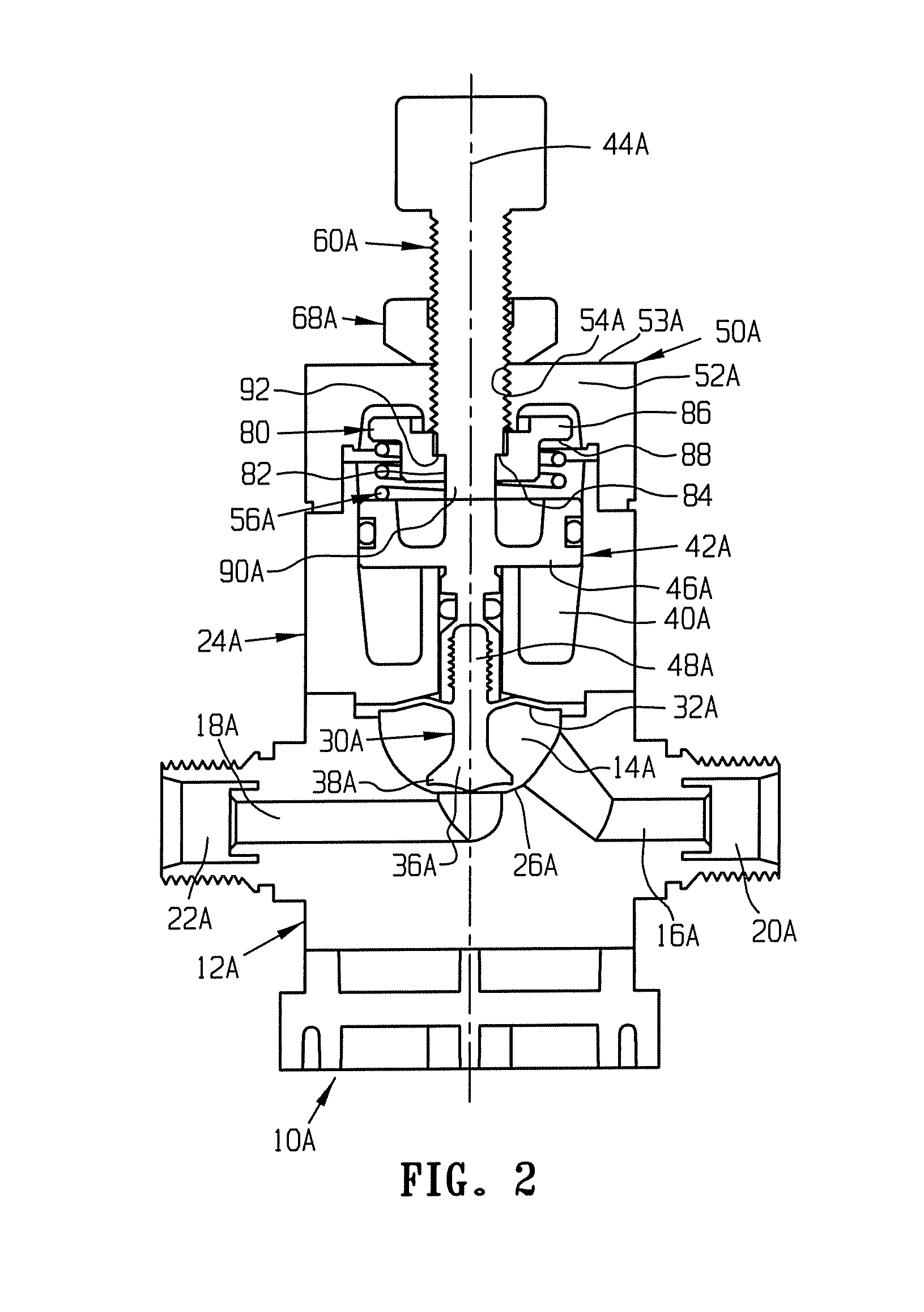

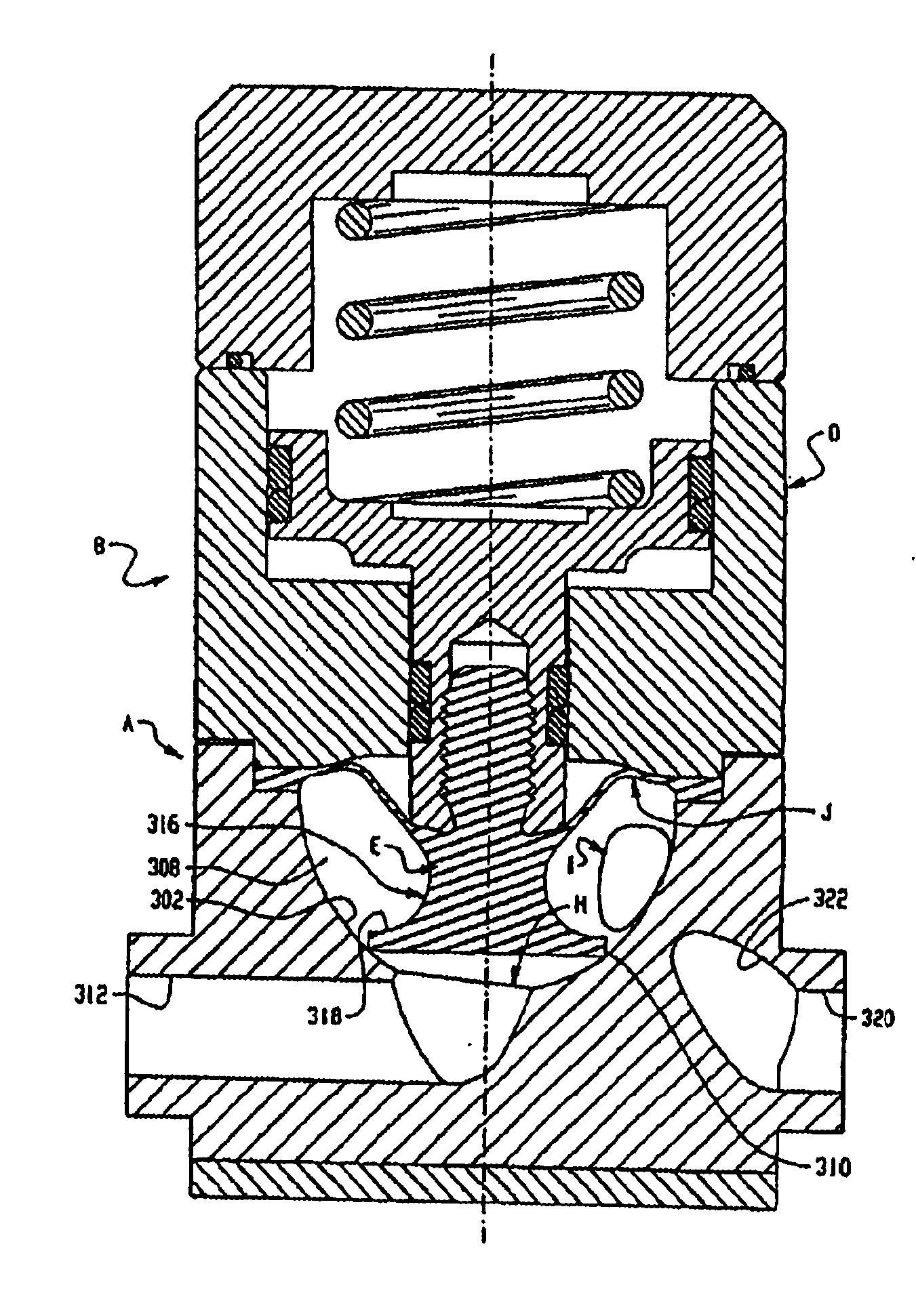

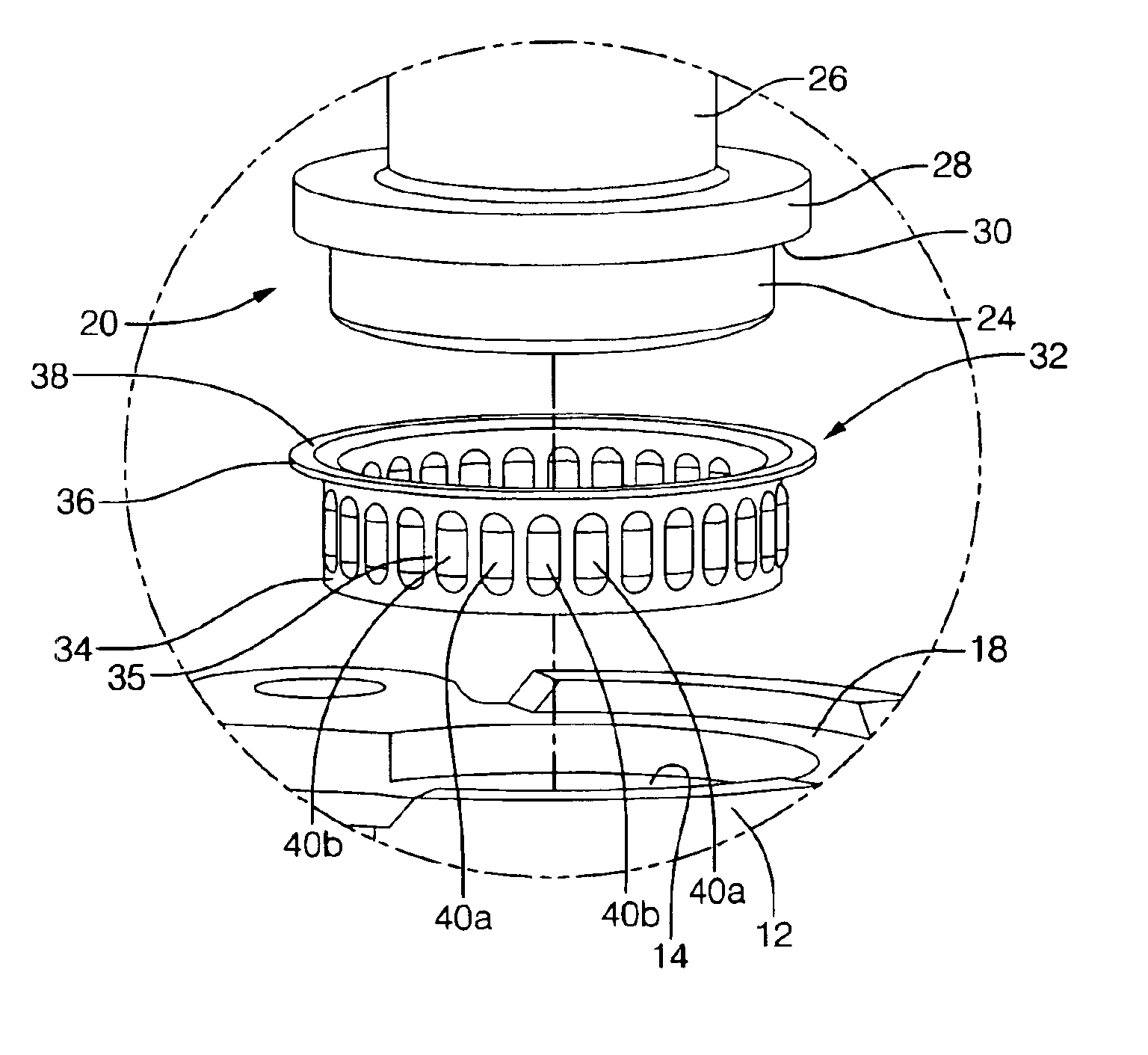

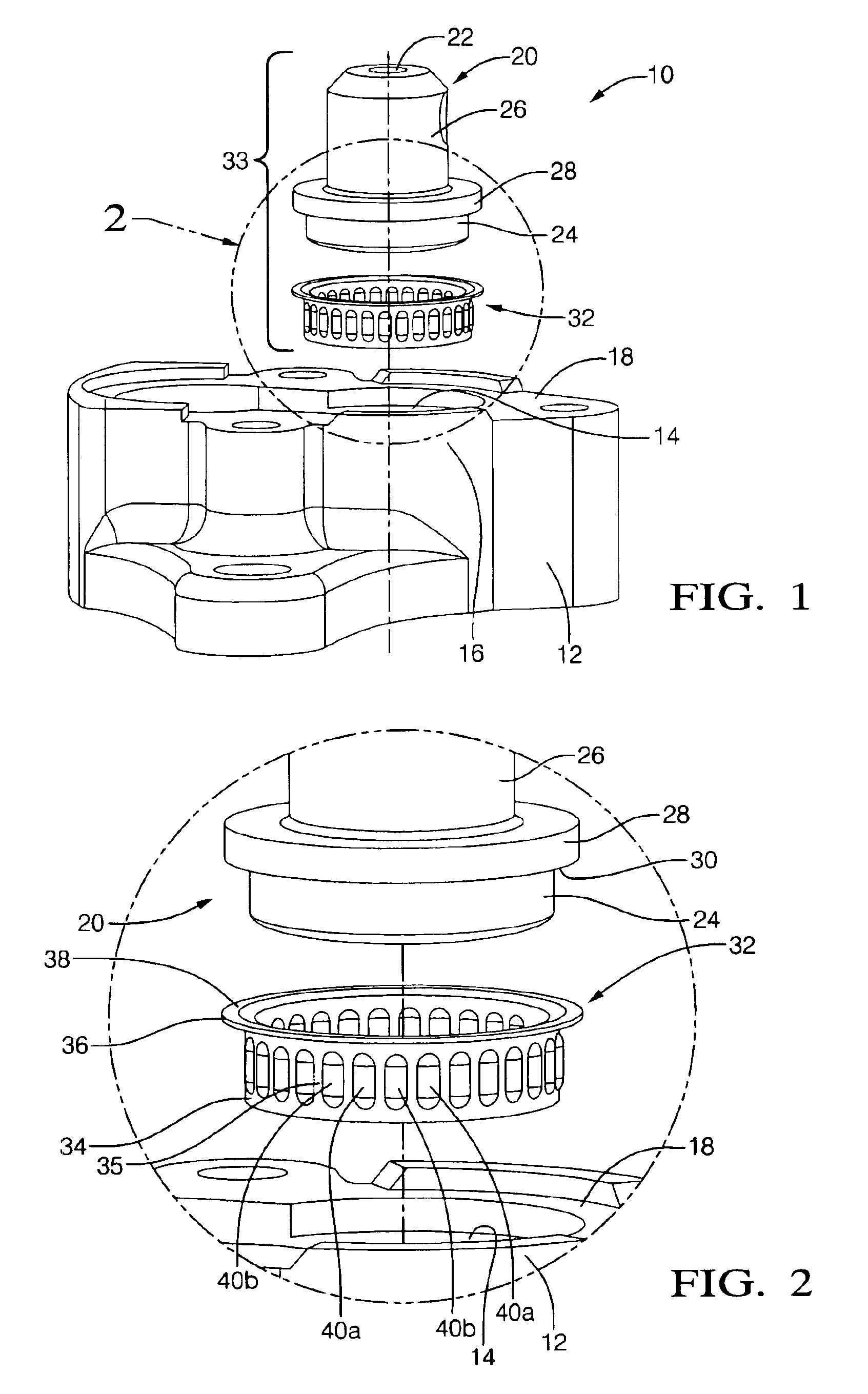

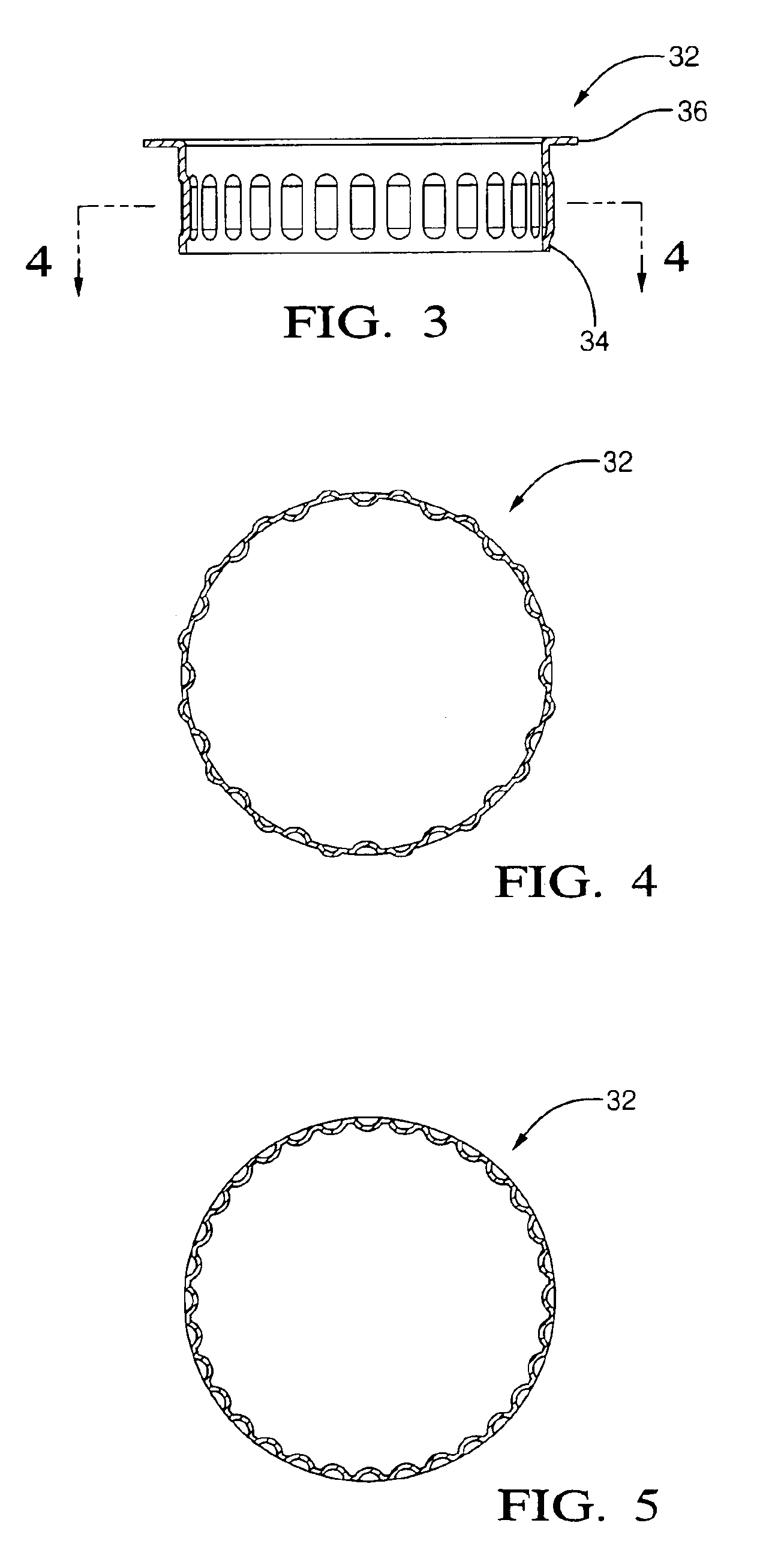

Valve actuator apparatus

InactiveUS6854704B1Inexpensive to constructSimple yet reliable in constructionSpindle sealingsOperating means/releasing devices for valvesValve actuatorTorque transmission

A valve actuator apparatus and method comprises an operator housing secured to a bonnet assembly. The bonnet assembly is secured to the valve body, and includes a bonnet stem movably within a bonnet housing for moving a gate within the valve body to open and close the valve. A downstop member is fixably secured to the bonnet stem and engages removable stem spacers which are added or removed to obtain a selected bonnet stem drift setting. The operator housing connects to a base ring that surrounds the bonnet housing and rotates to allow positioning of a fluid port in the operator housing. The operator housing may removed and replaced without altering the bonnet stem drift adjustment. A top shaft extends from the operator housing and rotates with respect to the bonnet stem to prevent torque transmission from the top shaft to the bonnet stem. A replaceable sealing cartridge sealingly supports the top shaft for axial movement within the operator housing.

Owner:SAFOCO

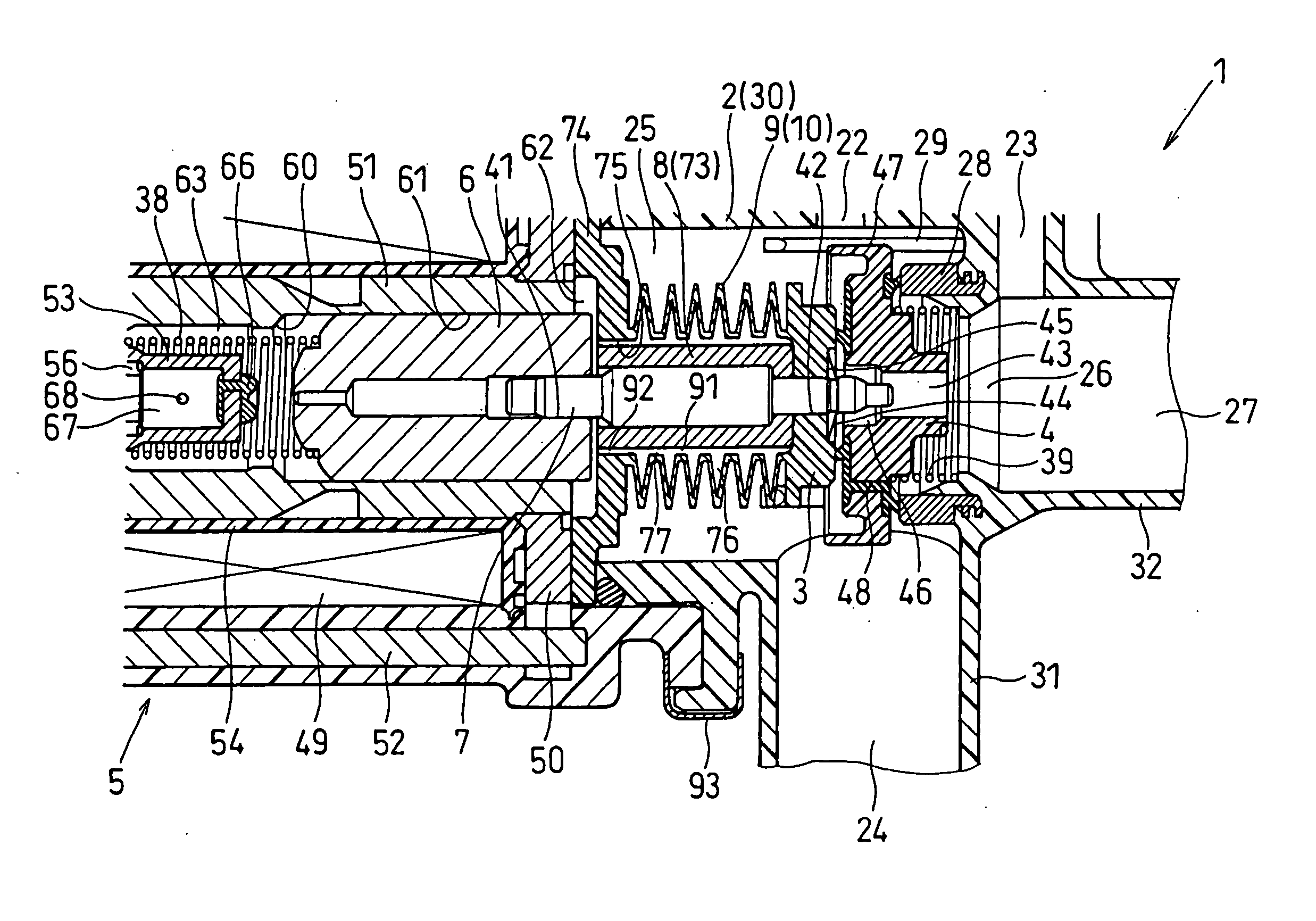

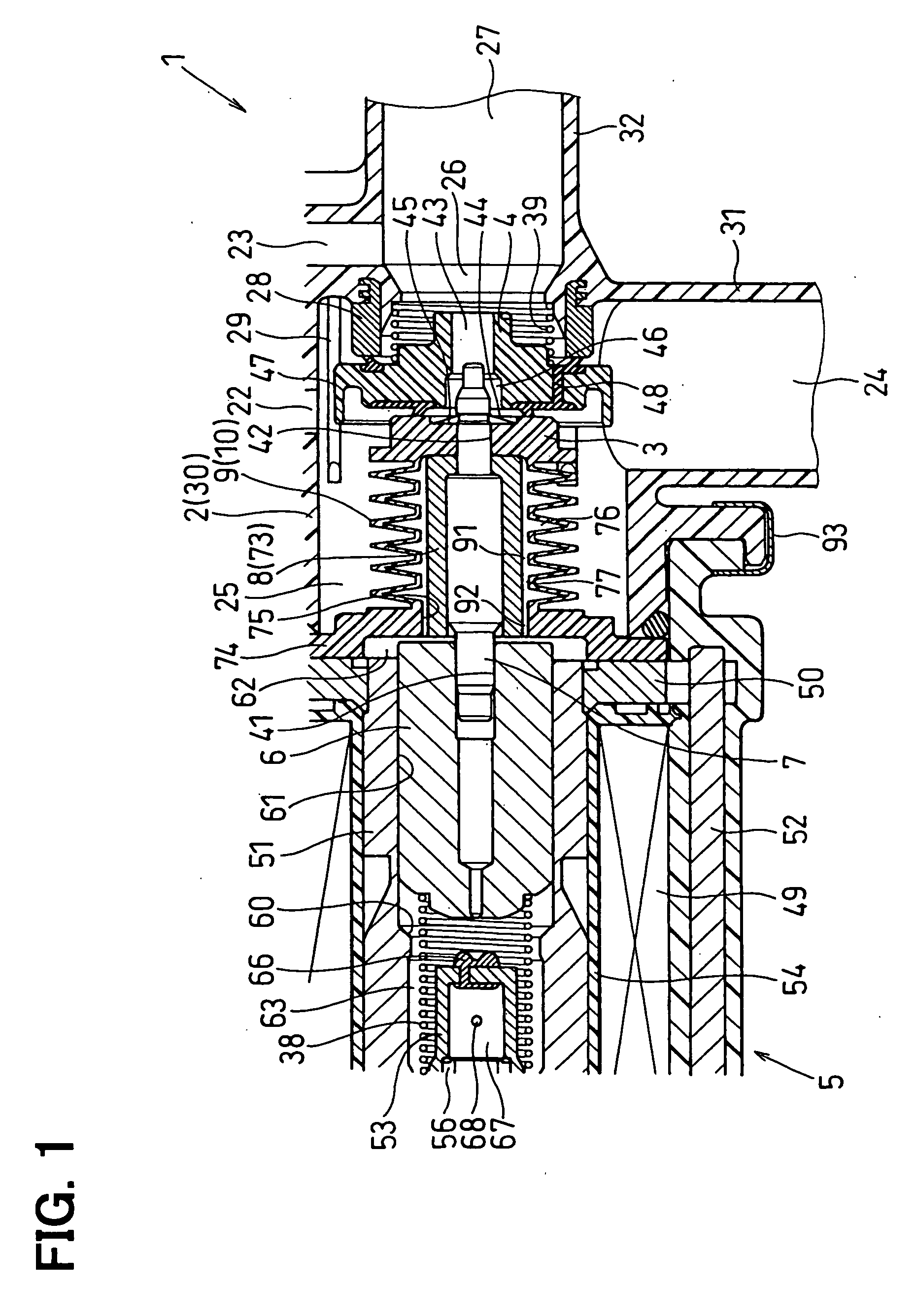

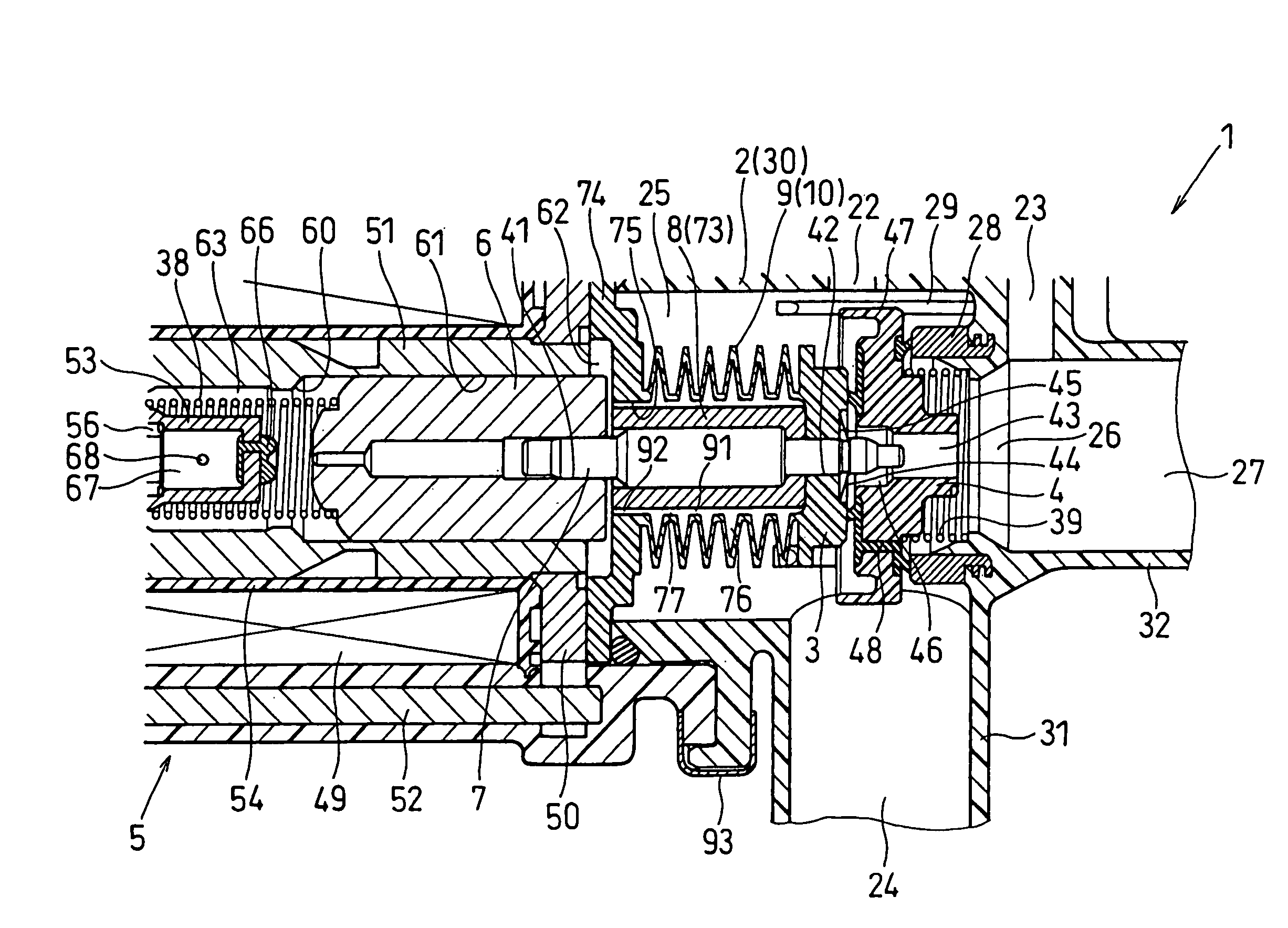

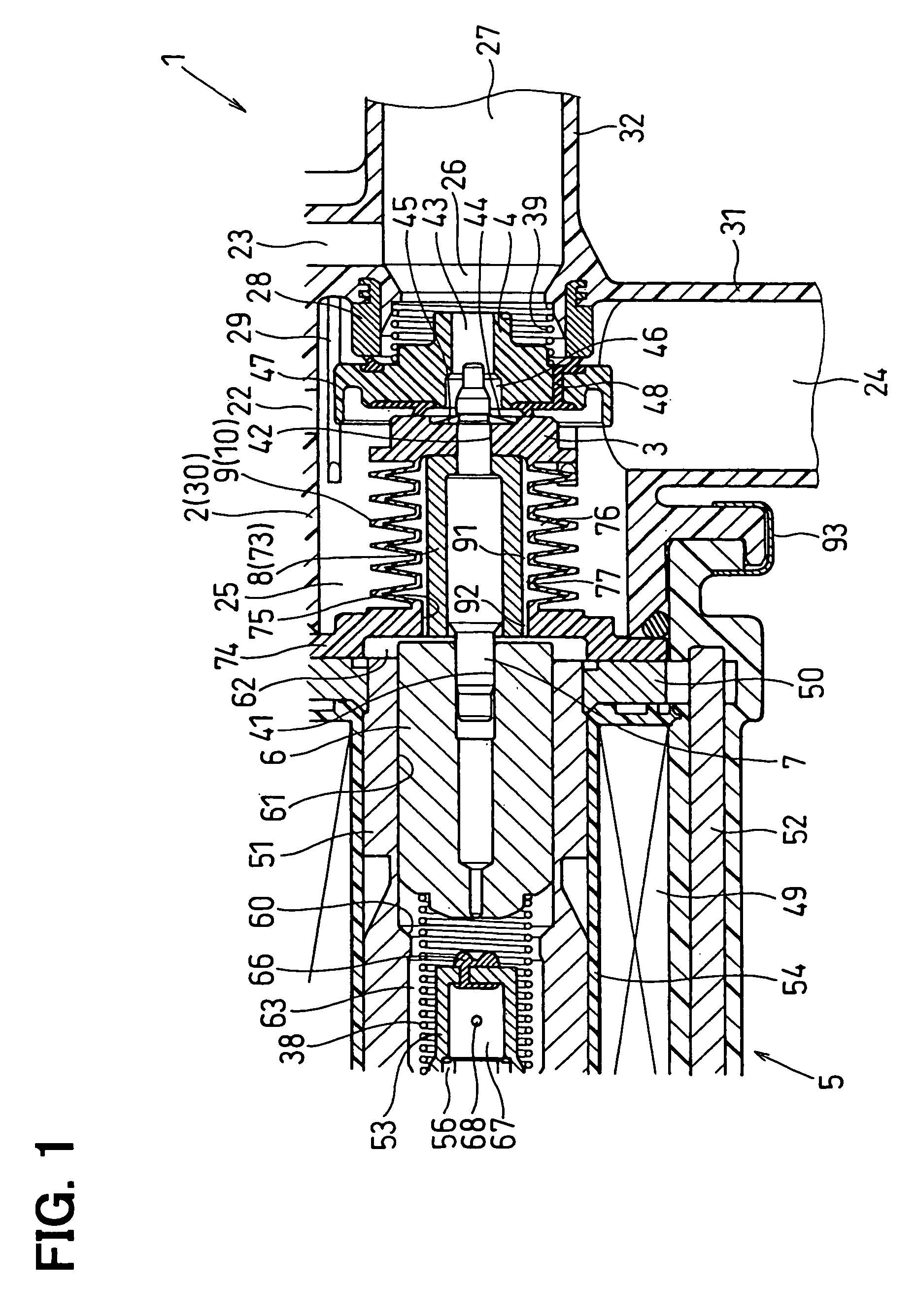

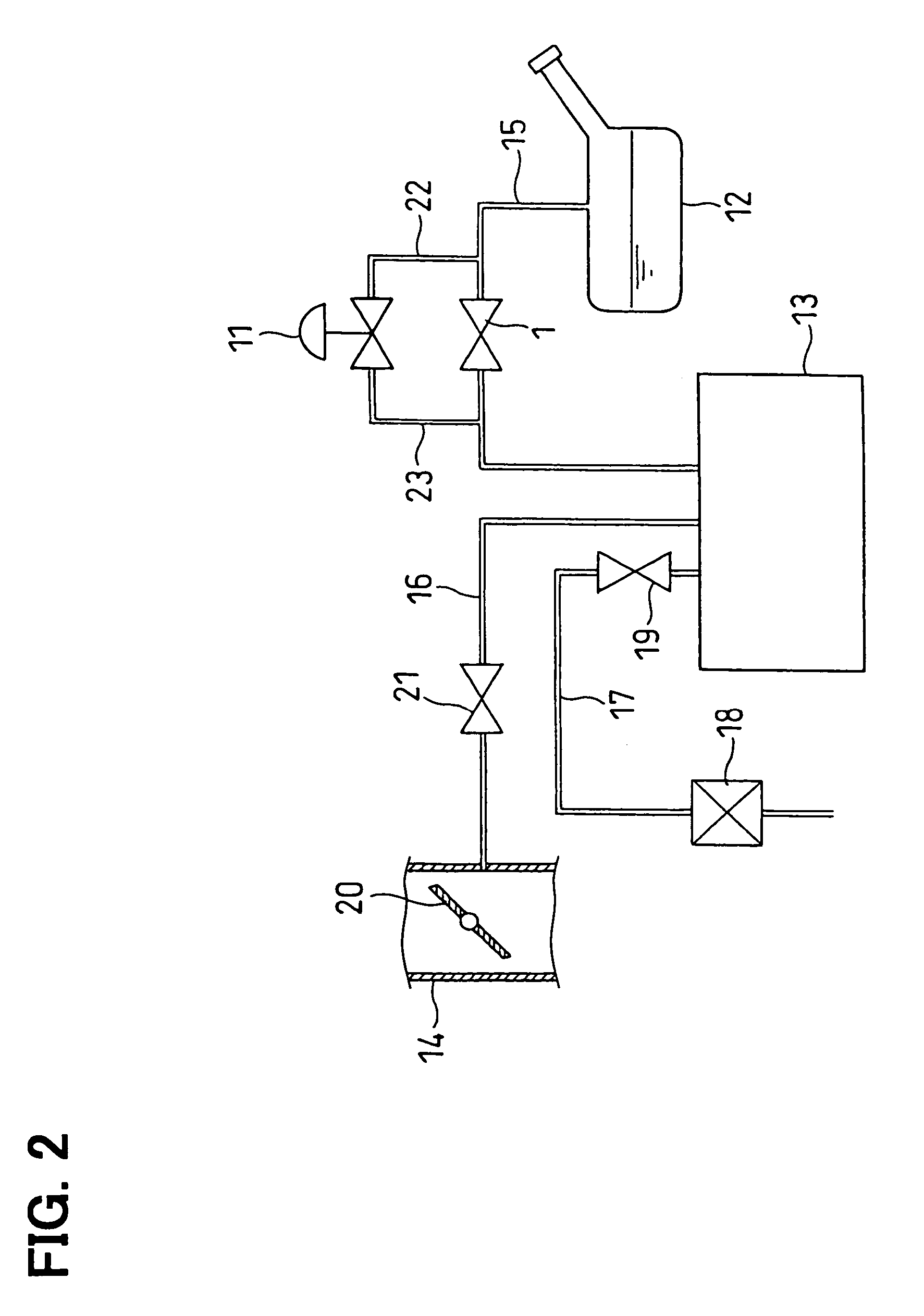

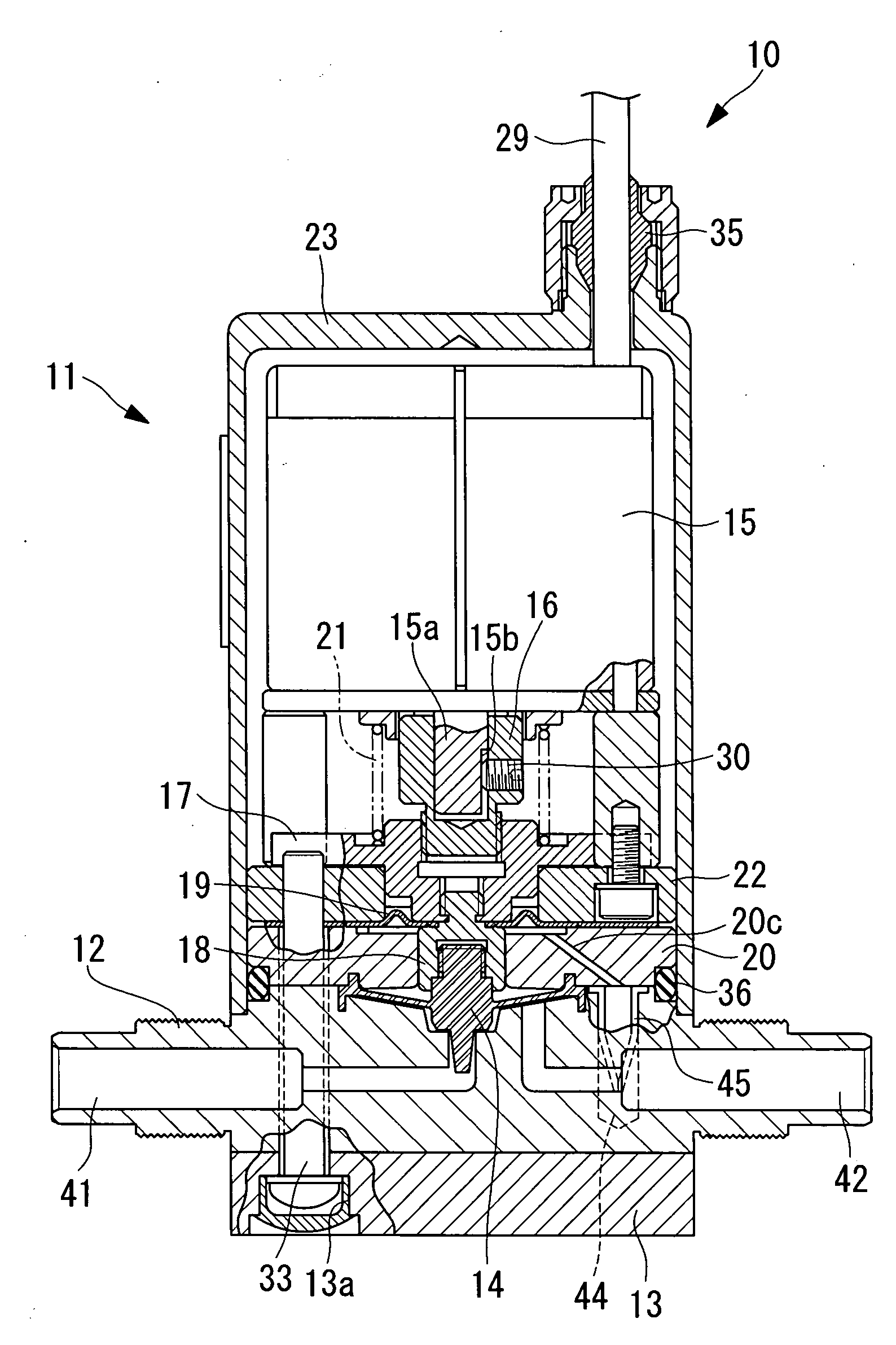

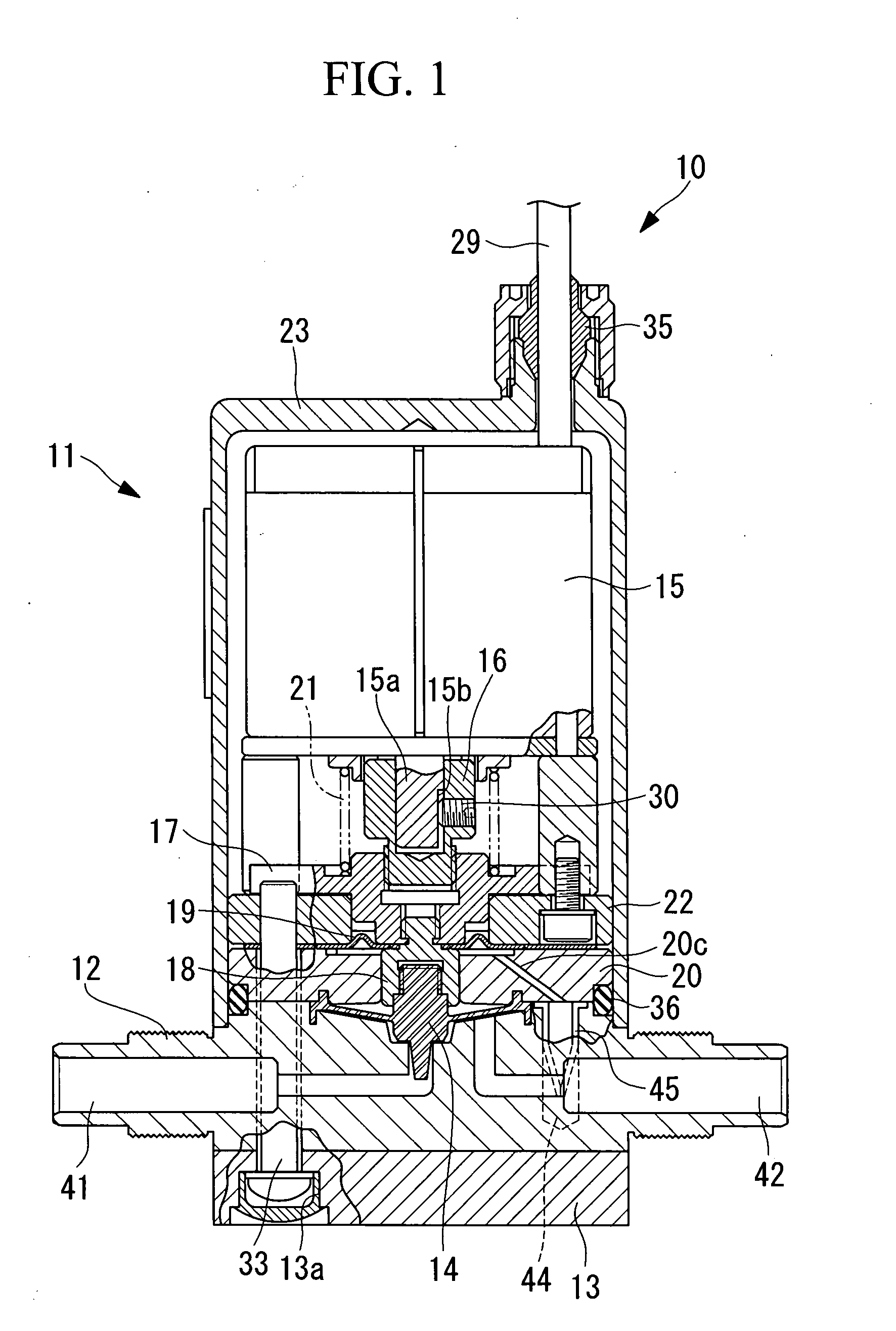

Electromagnetic valve

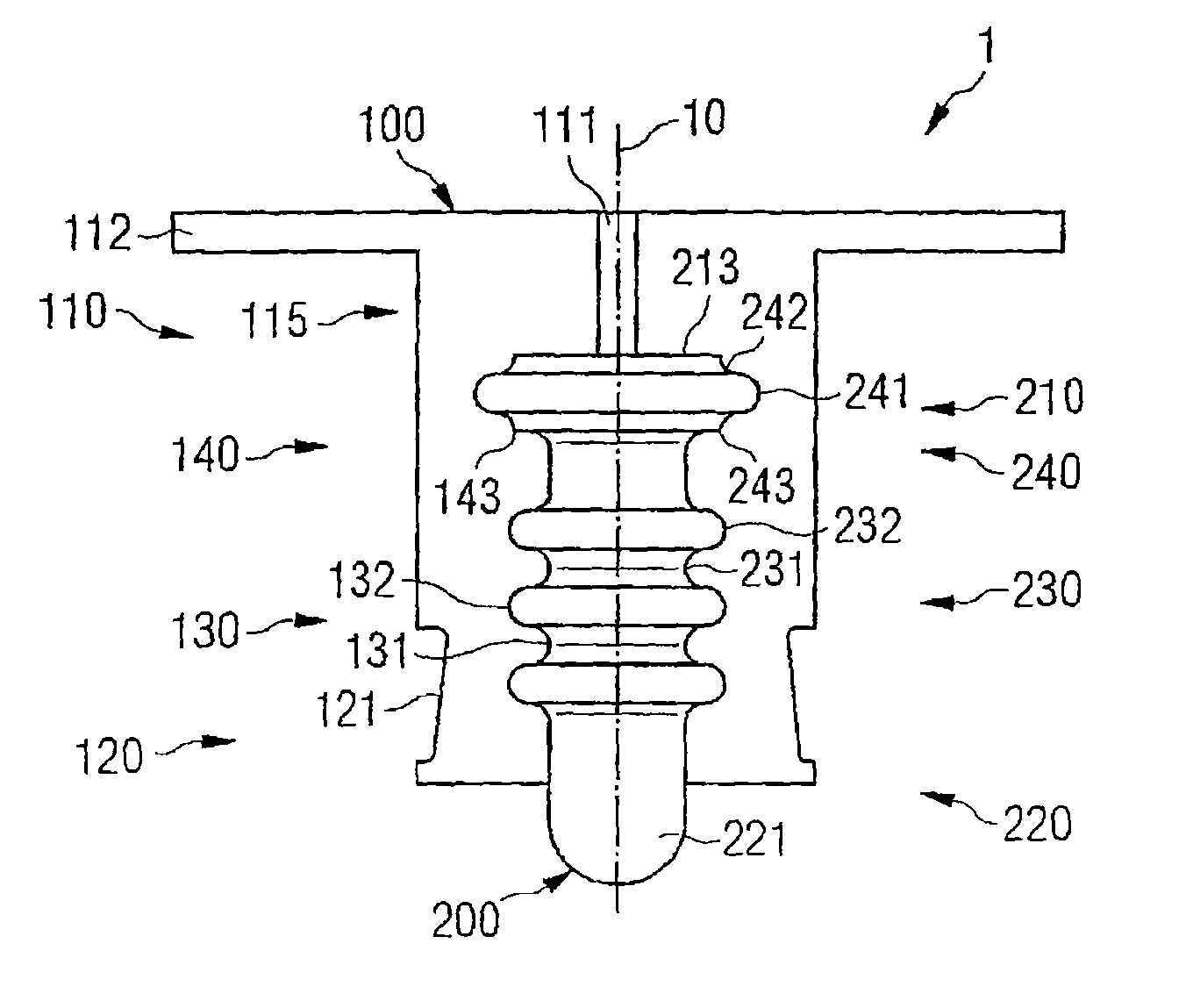

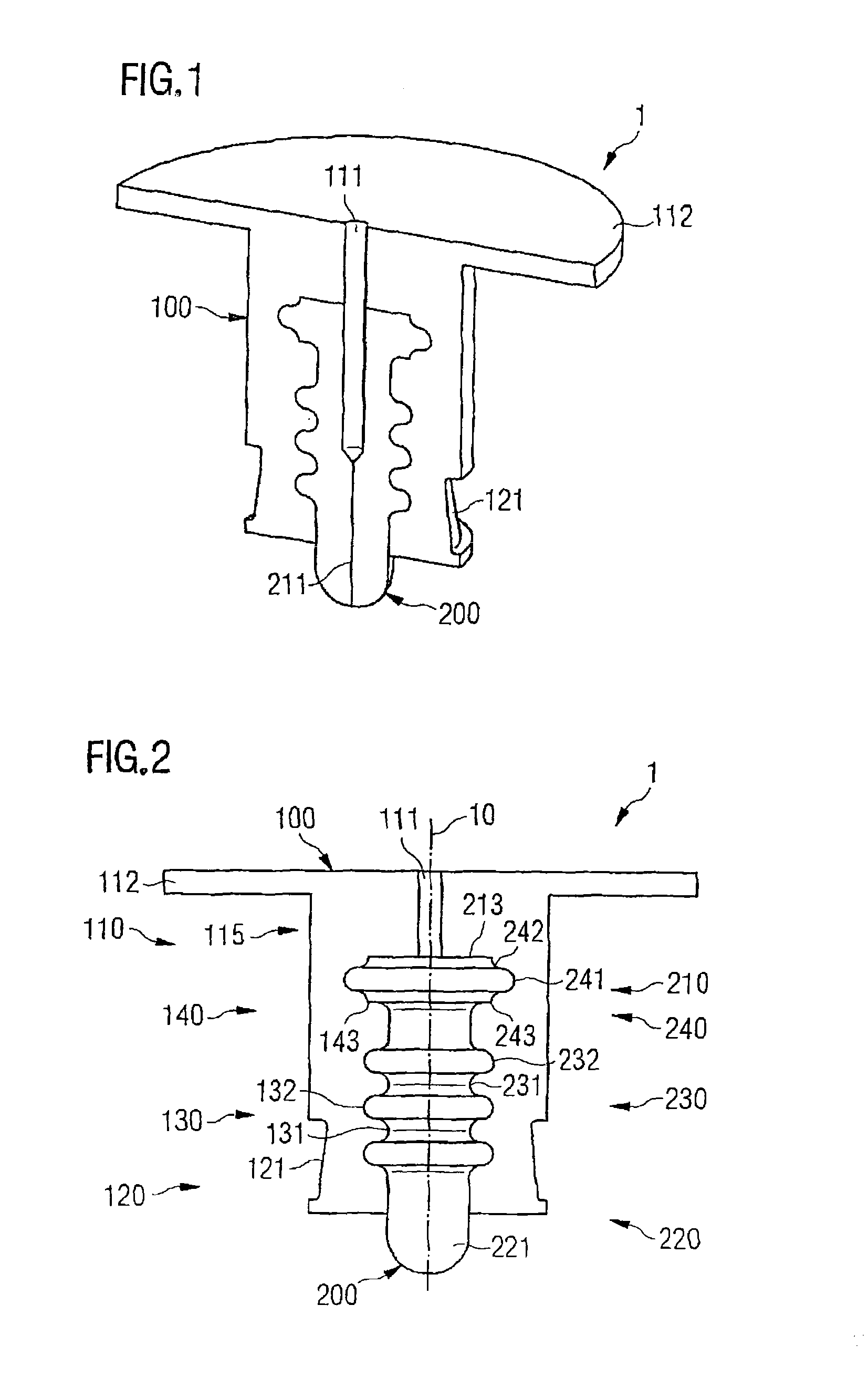

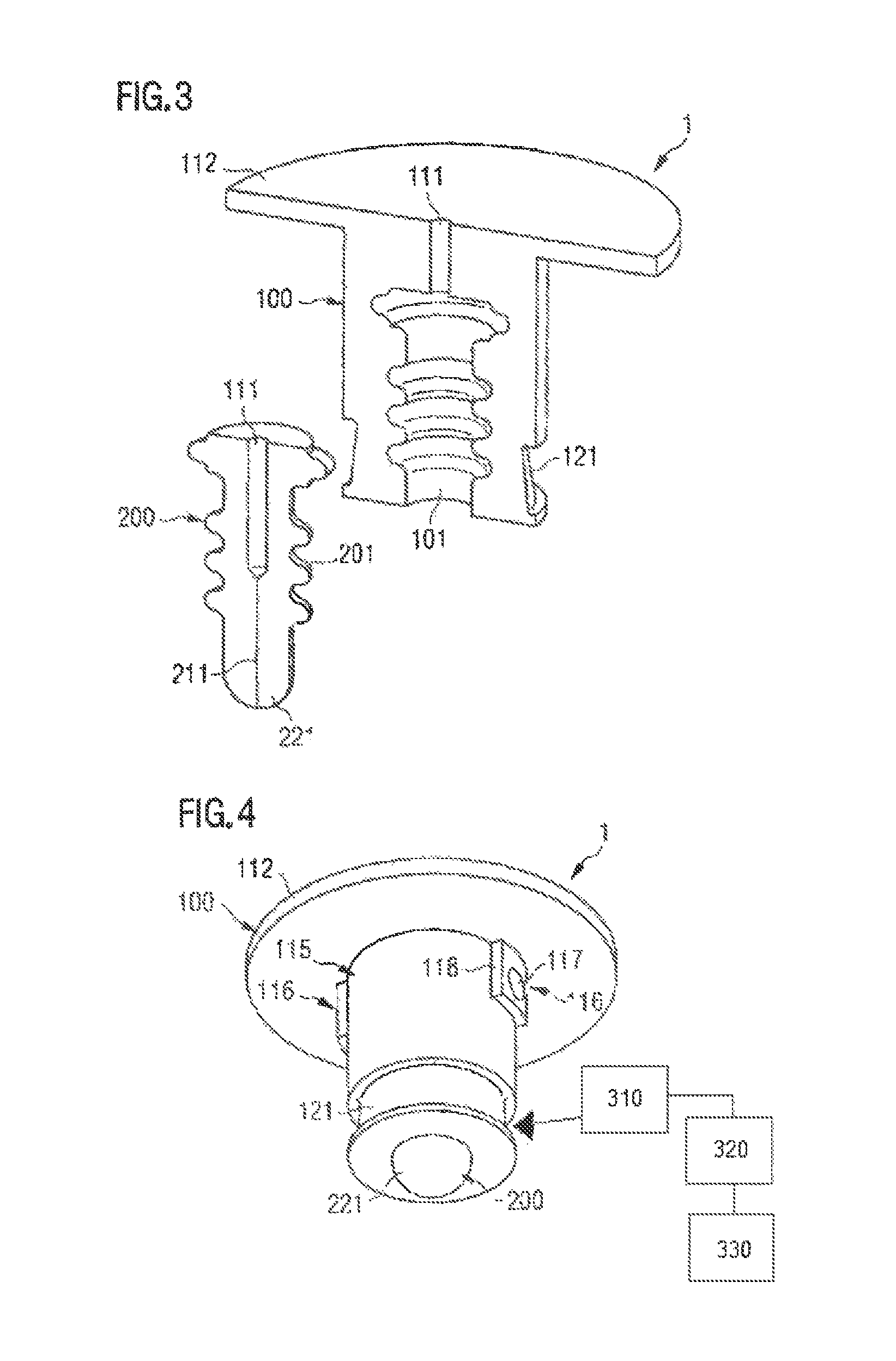

InactiveUS20060207663A1Reduce running noiseLow reliabilitySpindle sealingsOperating means/releasing devices for valvesInterior spaceMagnetomotive force

In an electromagnetic valve, a valve member is slidably installed in a housing to open and close a valve hole. A moving core is slidably installed in the housing, and a coil generates a magnetomotive force to attract the moving core to one side when it is energized. The valve shaft links a motion of the moving core with a motion of the valve member. A bellows surrounds the valve shaft to form a cylindrical inner space between the valve shaft and itself. The bellows is subjected to both positive and negative pressures to extend and shrink in accordance with the motions of the valve member and the moving core. An inner volume of the inner space increasing and decreasing in accordance with extending and shrinking operations of the cylindrical bellows portion. The opening of the bellows and the valve shaft form a narrow opening passage.

Owner:DENSO CORP

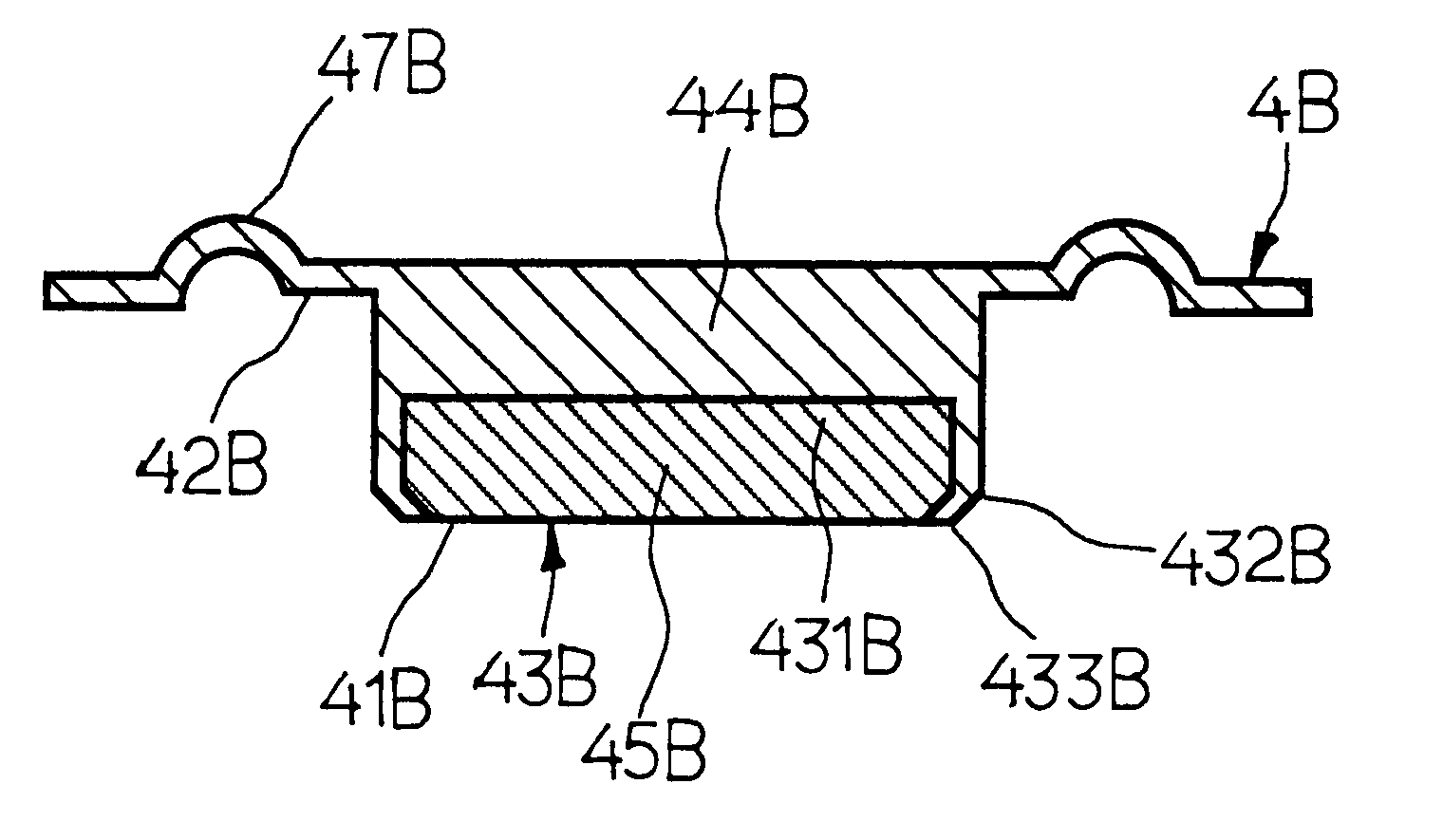

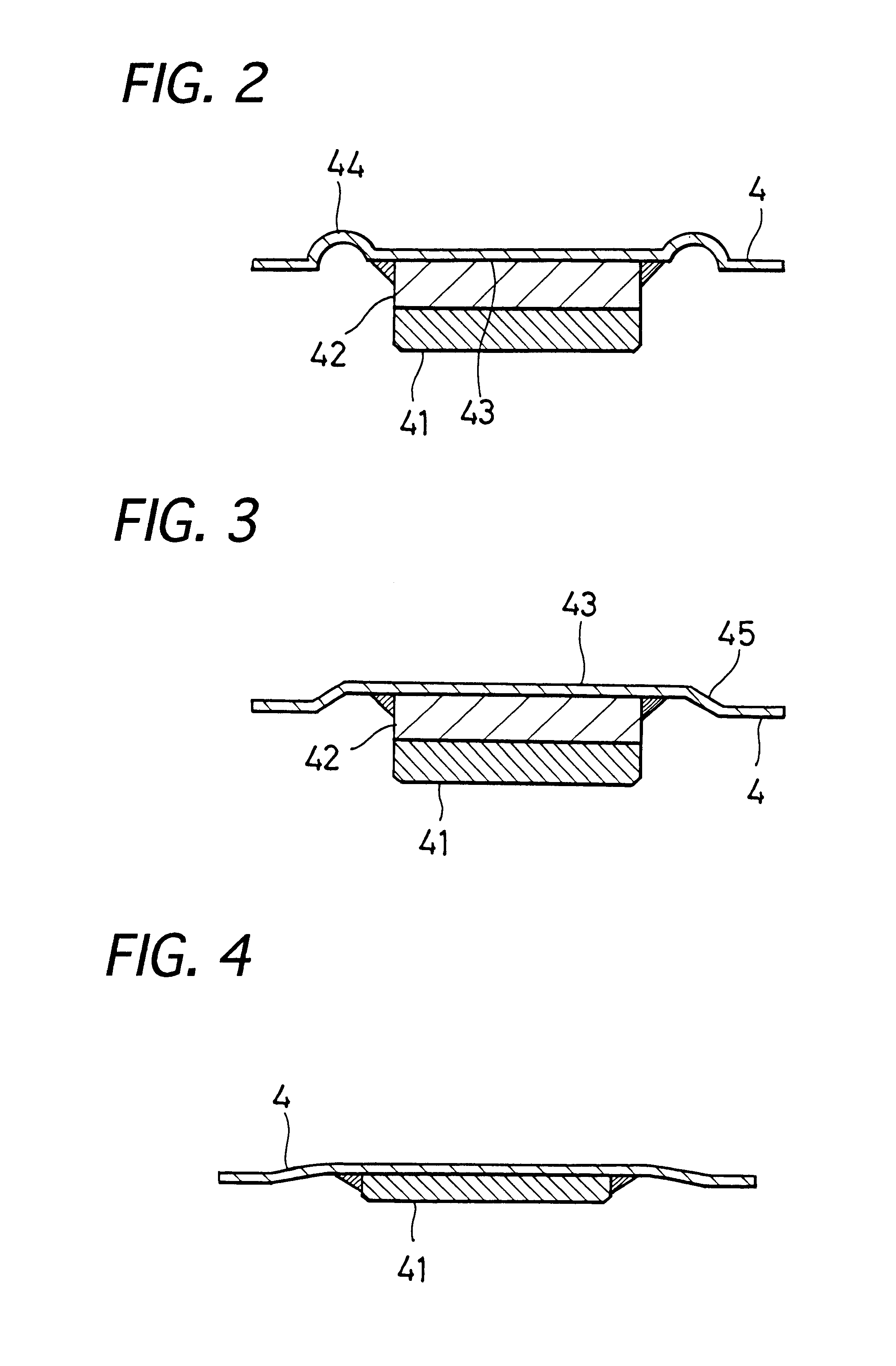

Control valve and diaphragm for use in the control valve

The control valve according to the present invention has a high durability, so that the valve is not easily damaged even in case that the valve is provided in a corrosion gas current path. The valve has a construction such that a diaphragm (4) is contained in the valve body (2), which has a valve chamber (23) between the gas current in path (25) and the gas current out path (26). The diaphragm 4 is urged against an opening (252) formed in the center of the valve seat 231 in the valve chamber (23) to open and close the opening. The valve has a valve control member (5), which has a clamping member (3) to clamp the diaphragm and is made to contact to the diaphragm from outside to open and close the opening. The diaphragm has an urging member (41) made of ceramic, which is fixed to the opening (252) side of the diaphragm so that the resistance to corrosion of the diaphragm is improved.

Owner:HAMAI INDS

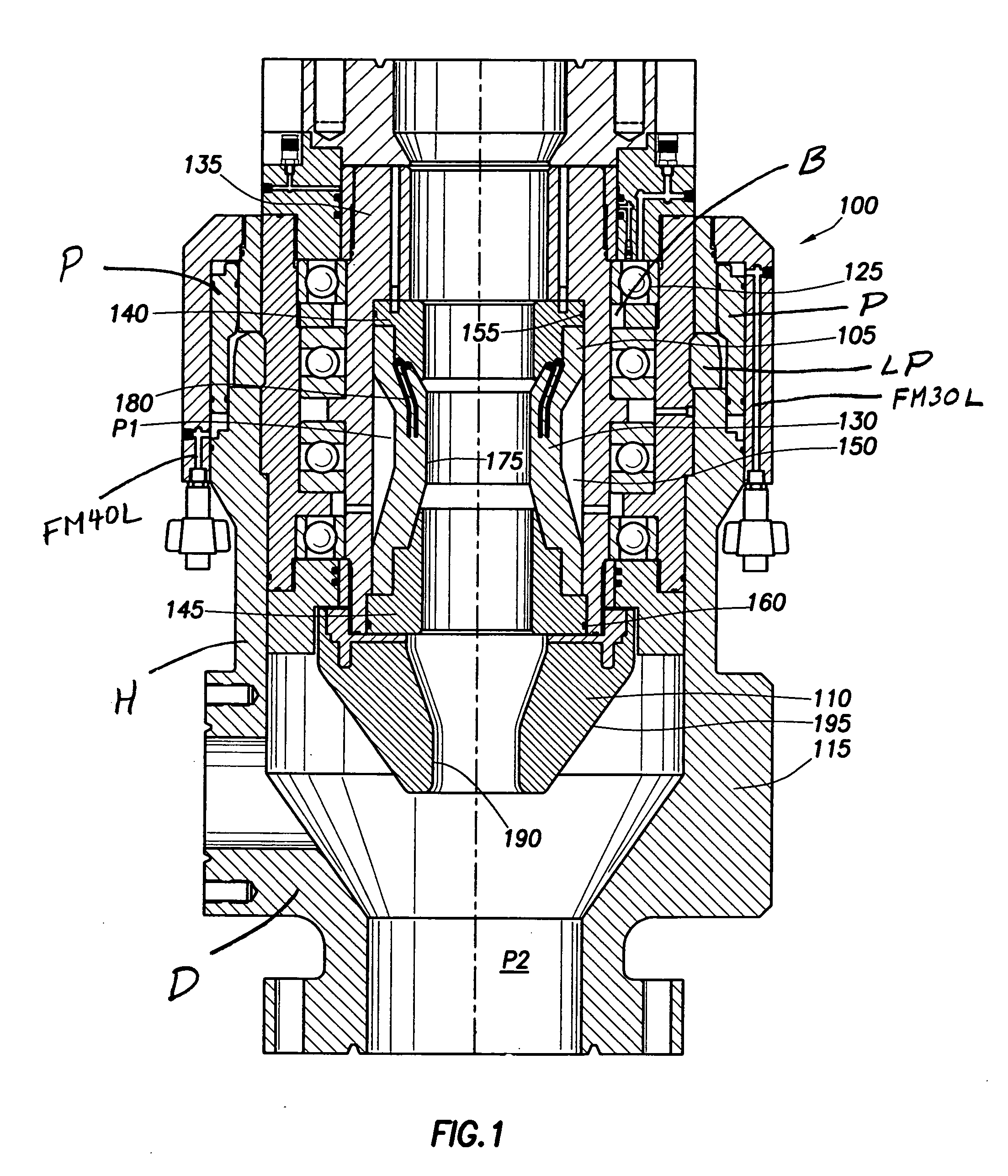

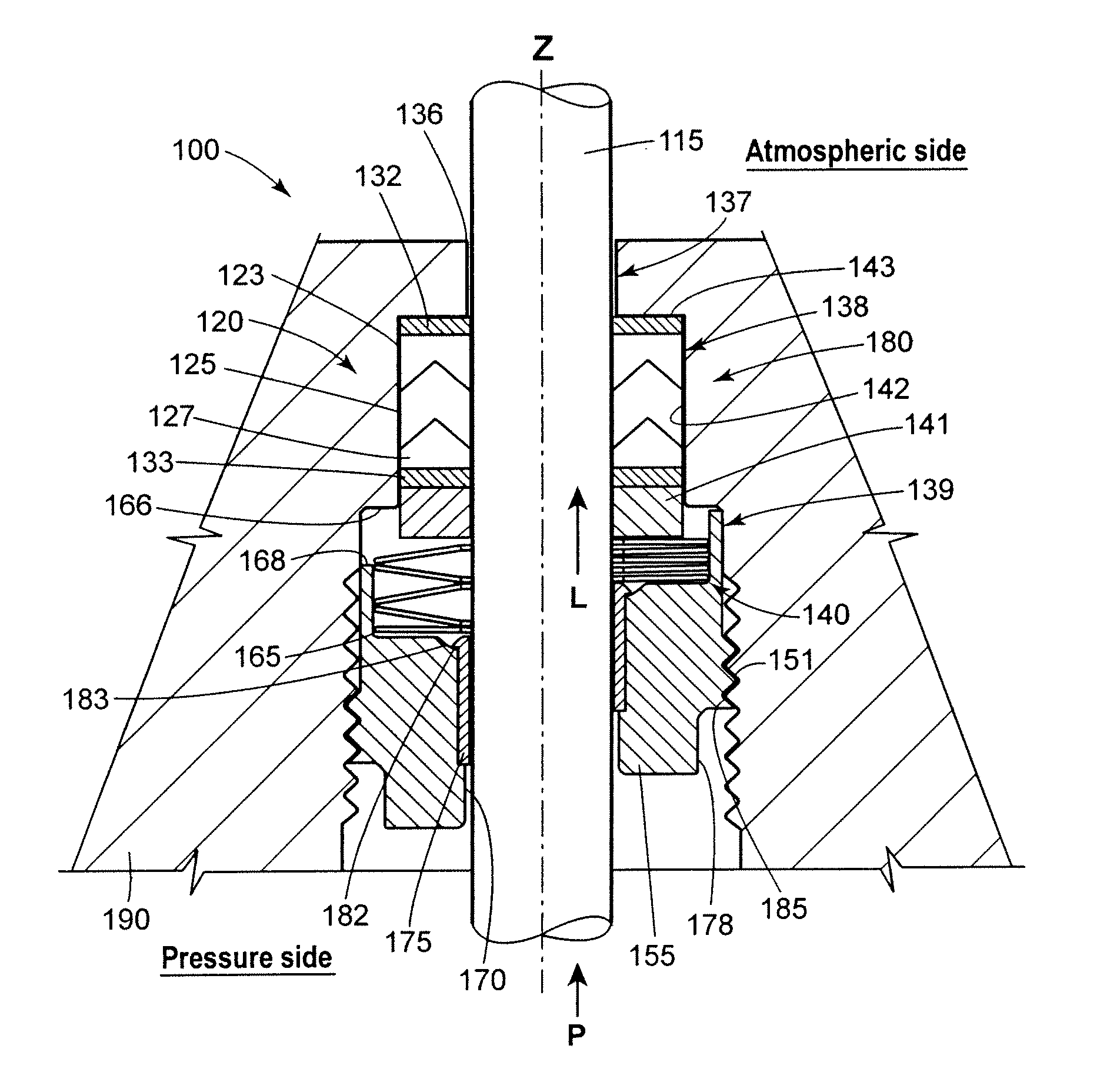

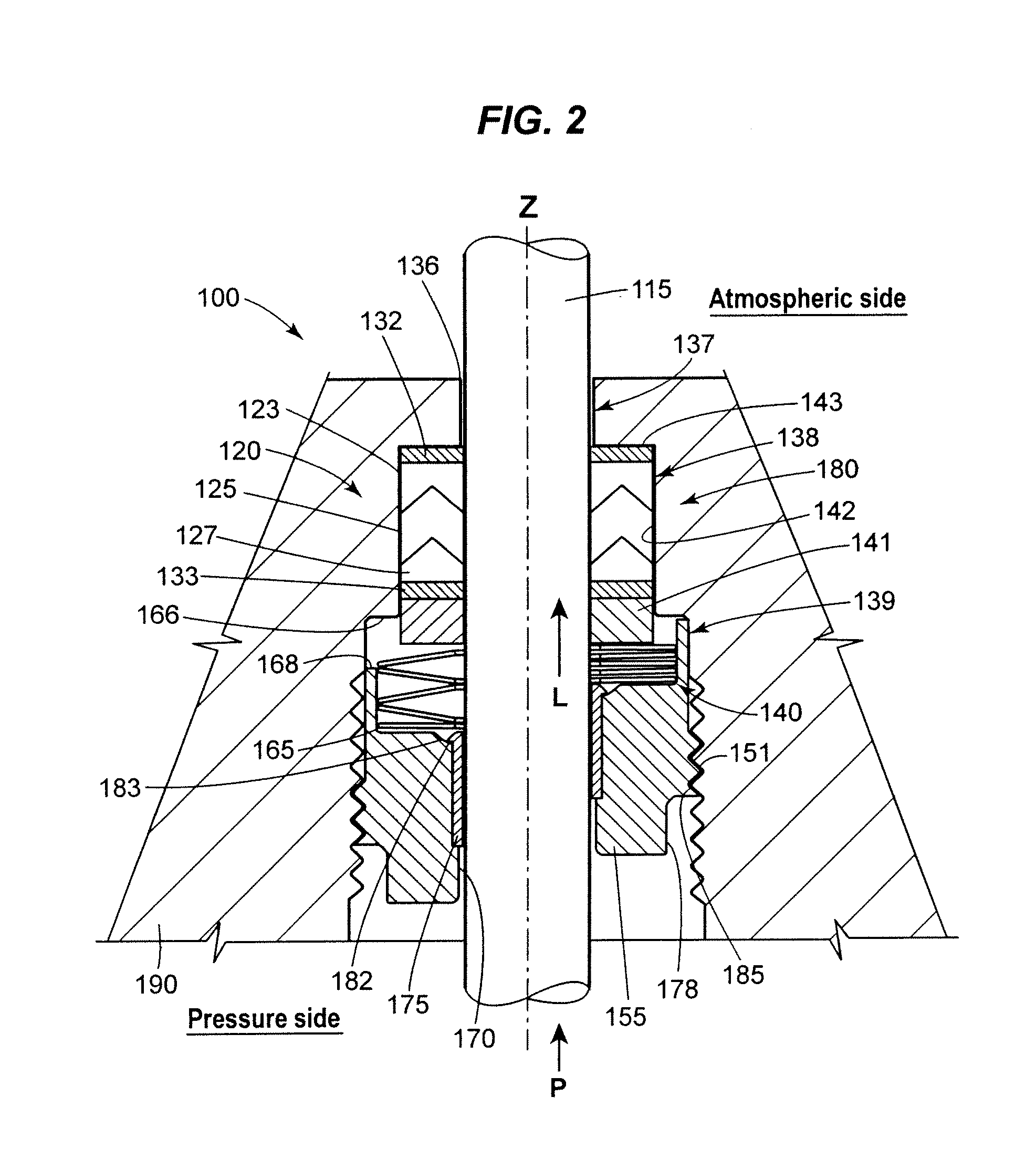

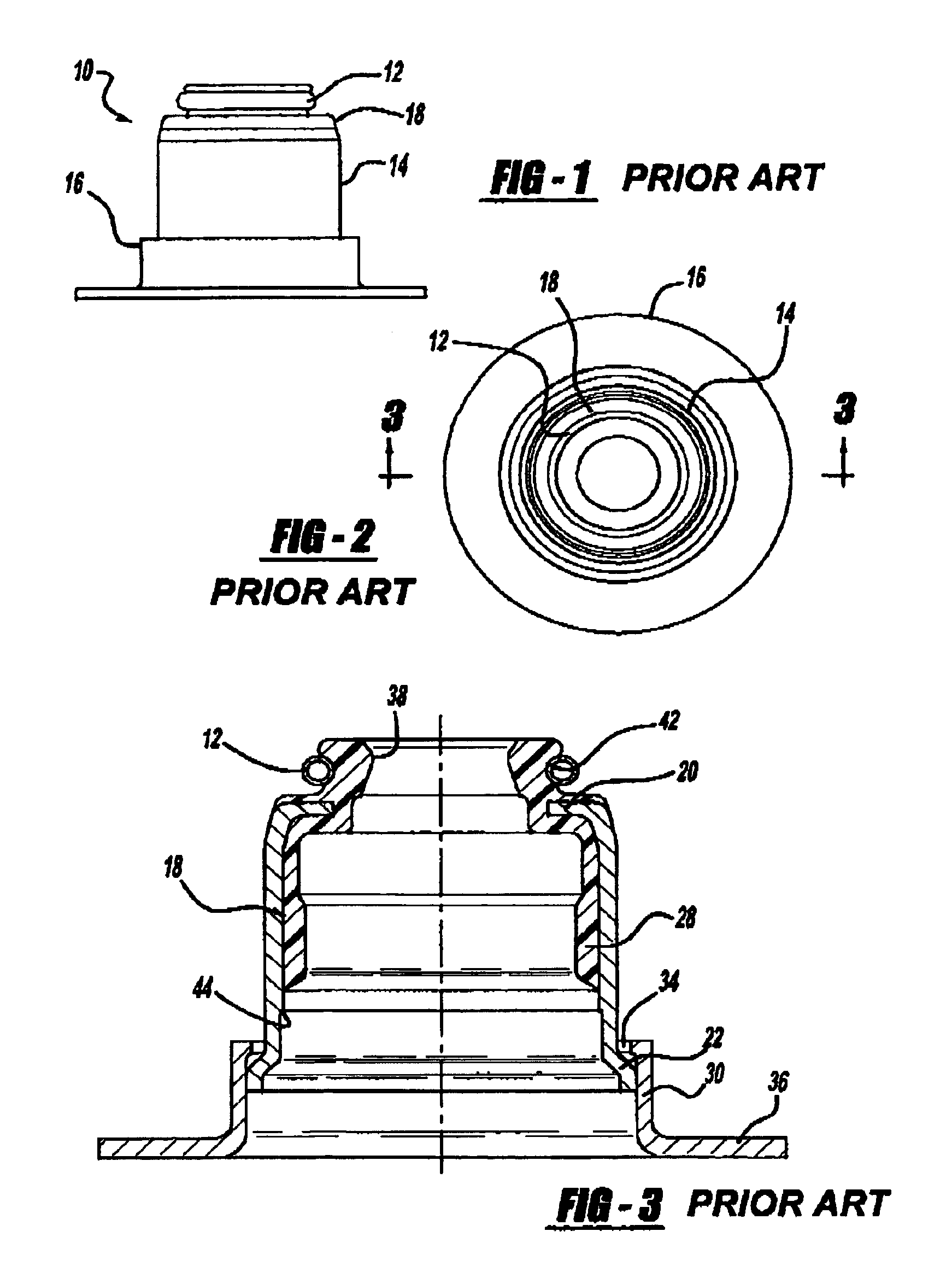

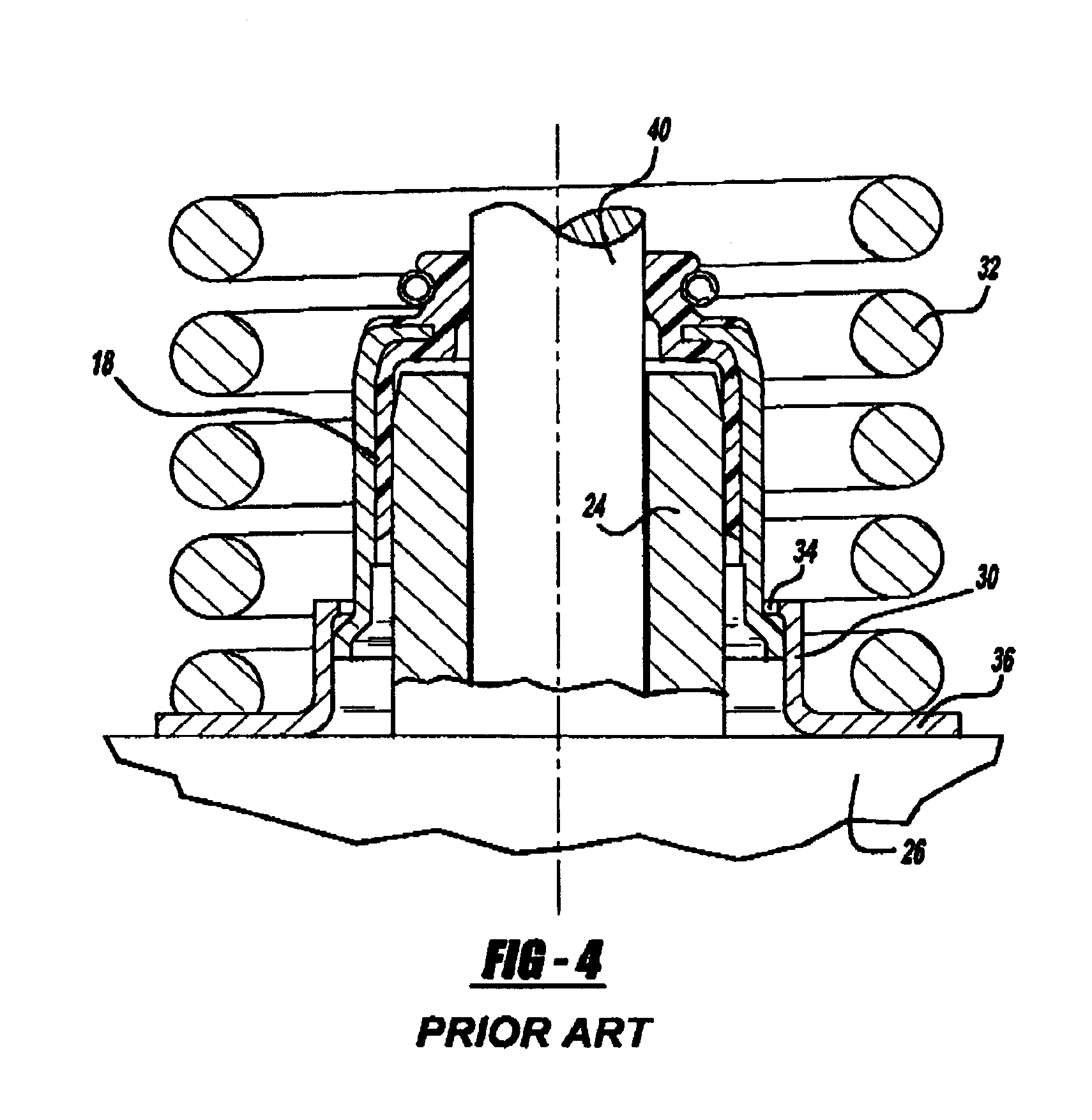

Dynamic sealing arrangement for movable shaft

InactiveUS7118114B2Avoid problemsMinimization requirementsSpindle sealingsEngine sealsEngineeringSealant

A dynamic sealing arrangement for preventing leakage of a fluid along a shaft includes multiple seals and pressurized barrier sealant. According to one aspect, at least three seals are arranged along the shaft with pressurized barrier sealant between the first and second seals and a collection area is provided between the second and third seals to collect any leakage that might occur. Collected leakage, if any, is ported to an output port. According to another aspect, a unitary seal block member is provided that supports the dynamic sealing arrangement for the shaft and defines a piston chamber and a drilled passageway connecting the piston chamber and barrier sealant pressurization chamber between two seals. A substantial amount of plumbing is self contained in a single body minimizing the need for additional components or complexity.

Owner:WOODWARD GOVERNOR CO

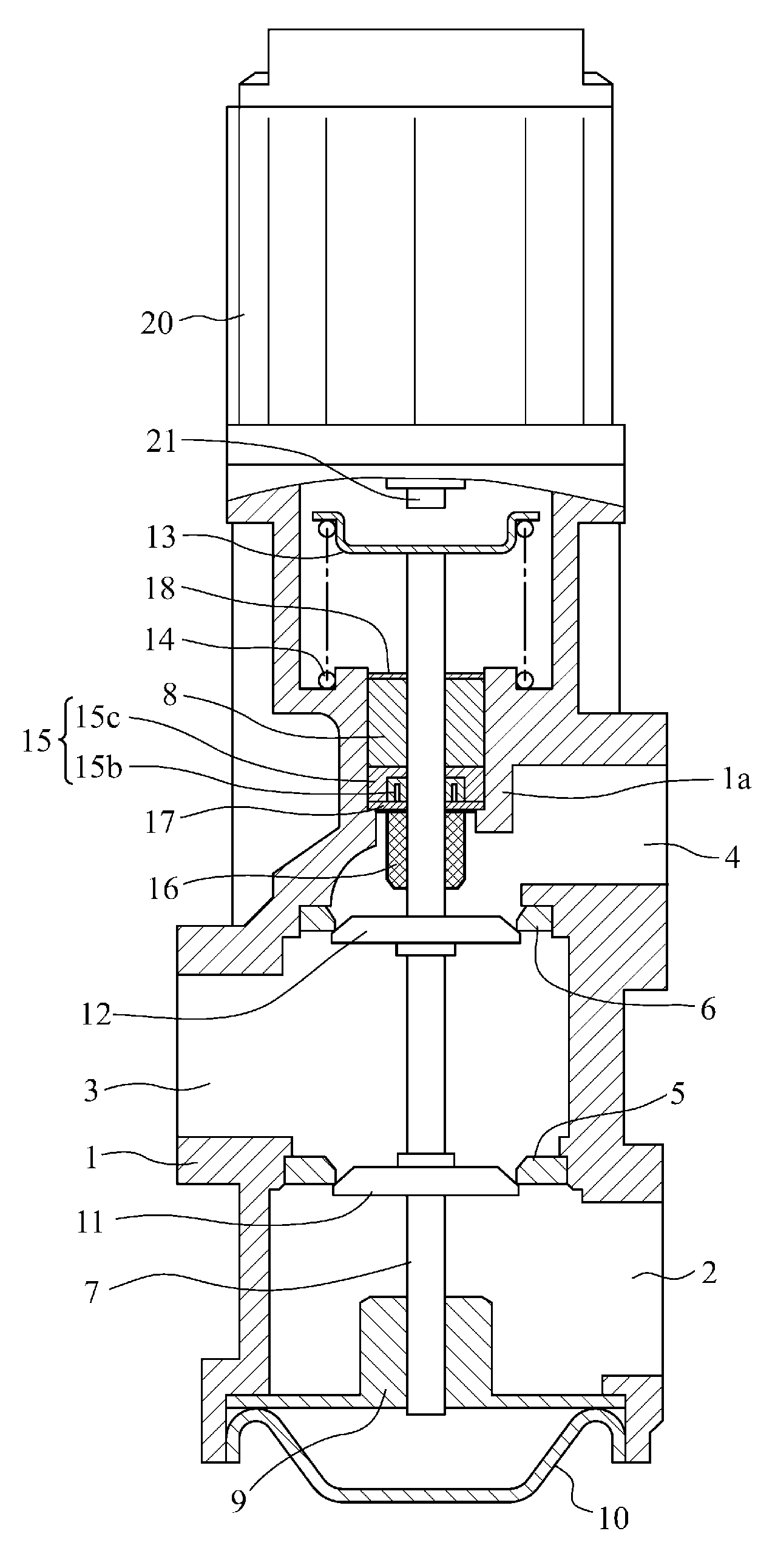

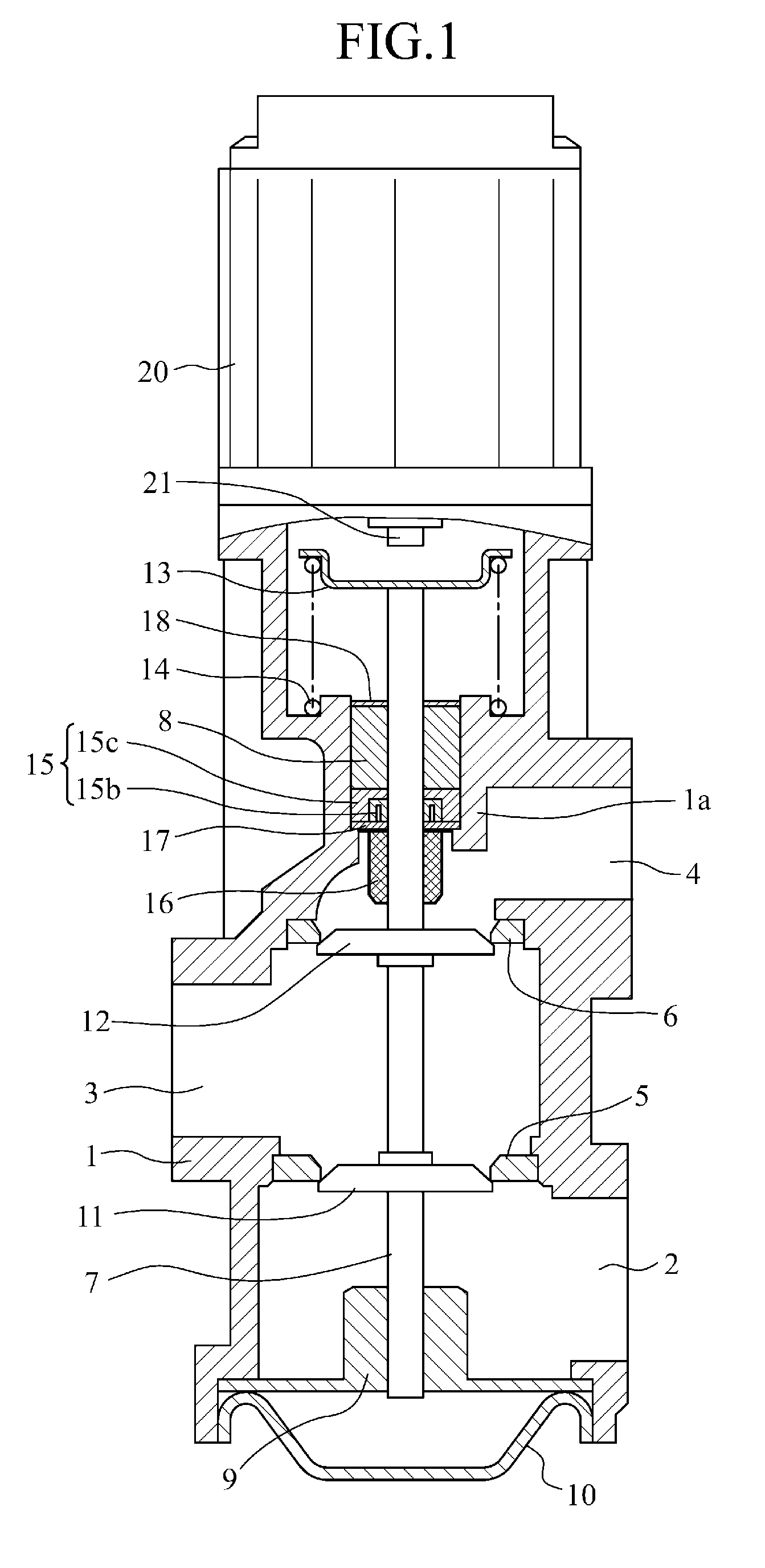

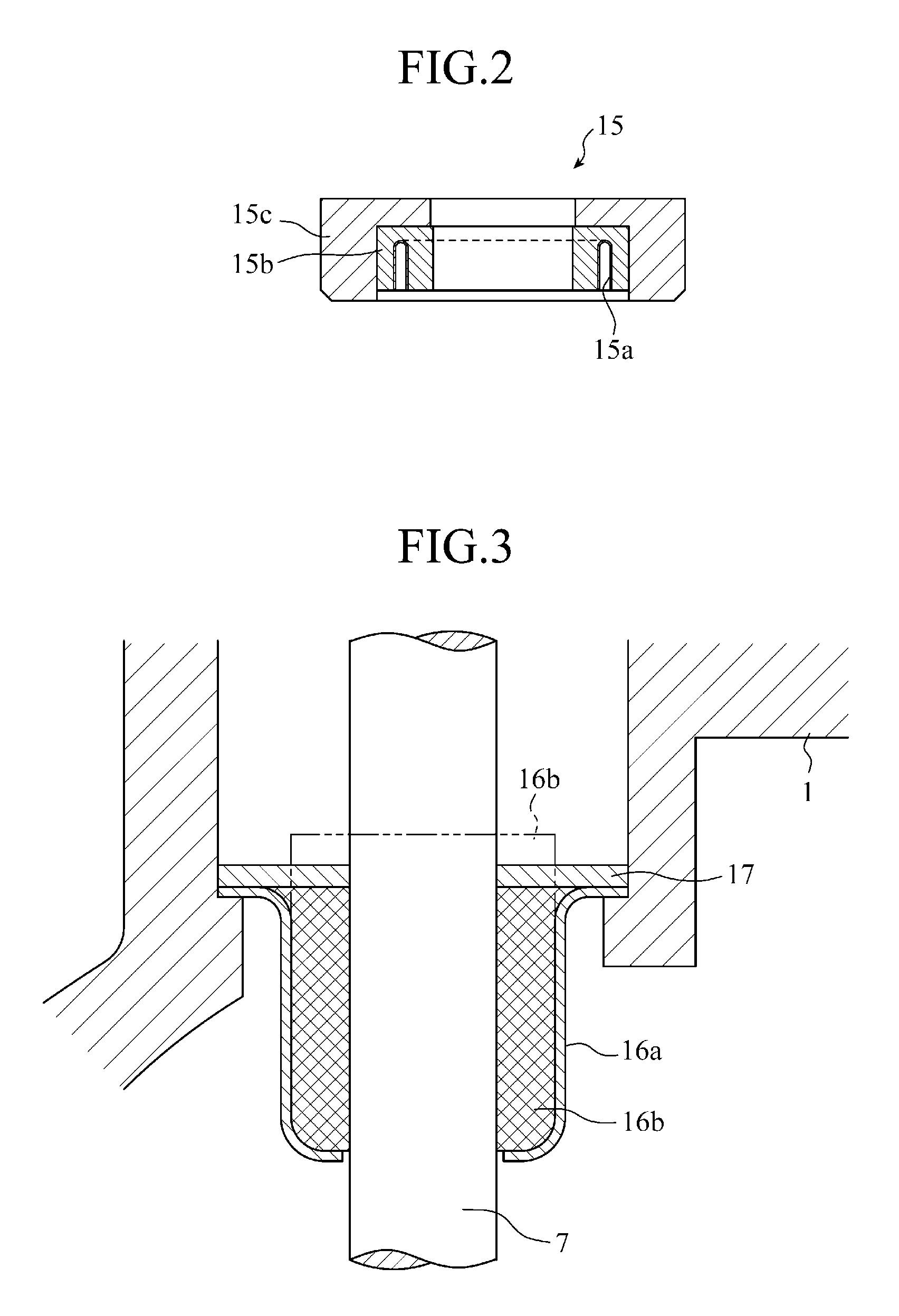

Exhaust gas recirculation valve device

InactiveUS20110094481A1Easy to attachGood adhesionSpindle sealingsInternal combustion piston enginesEngineeringExhaust gas recirculation

In an exhaust gas recirculation valve device, a sealing member 15 supported by a plug 15c is disposed between a portion of a housing 1 on an exhaust gas passage side of a bearing 8, and a valve shaft 7.

Owner:MITSUBISHI ELECTRIC CORP

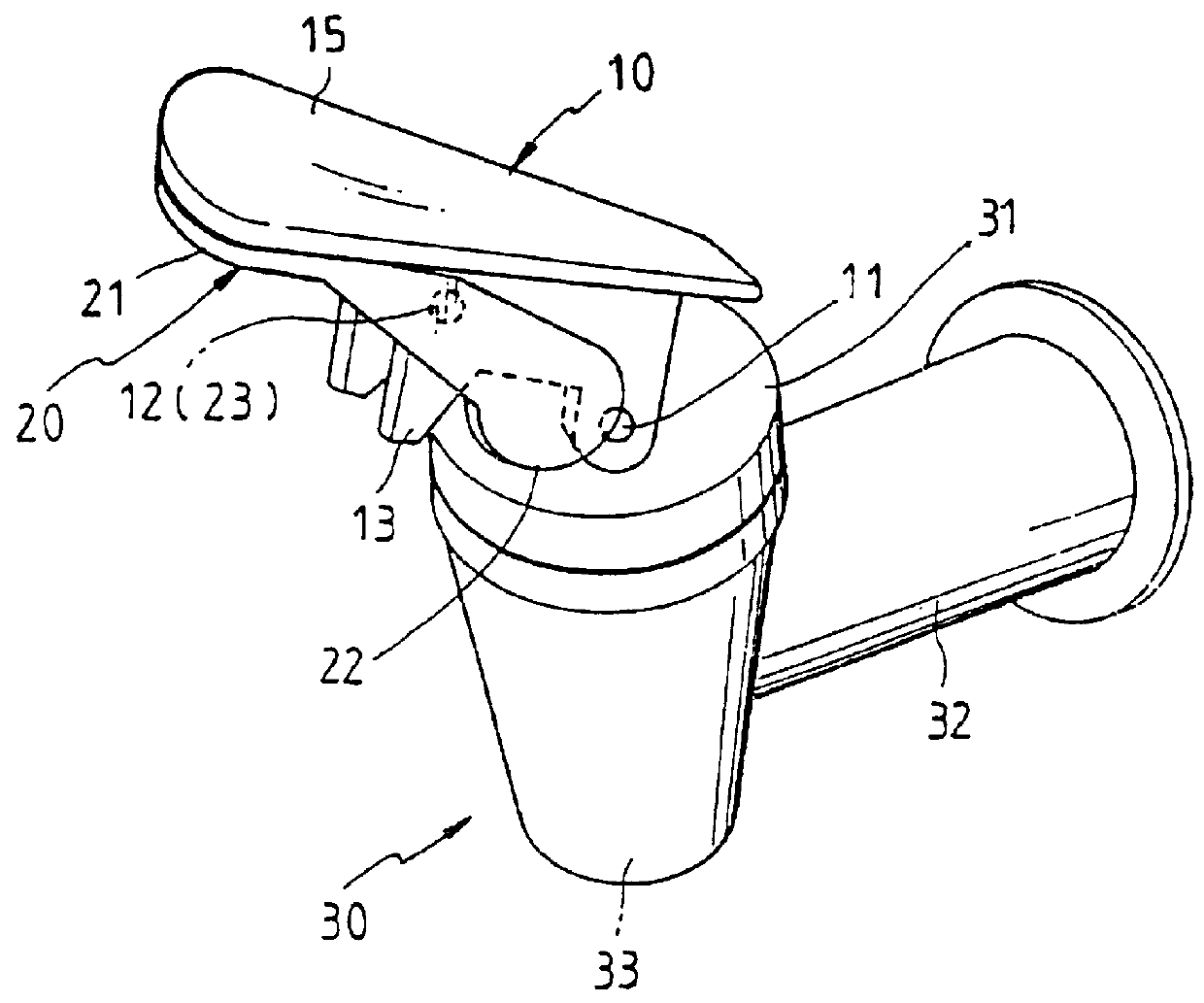

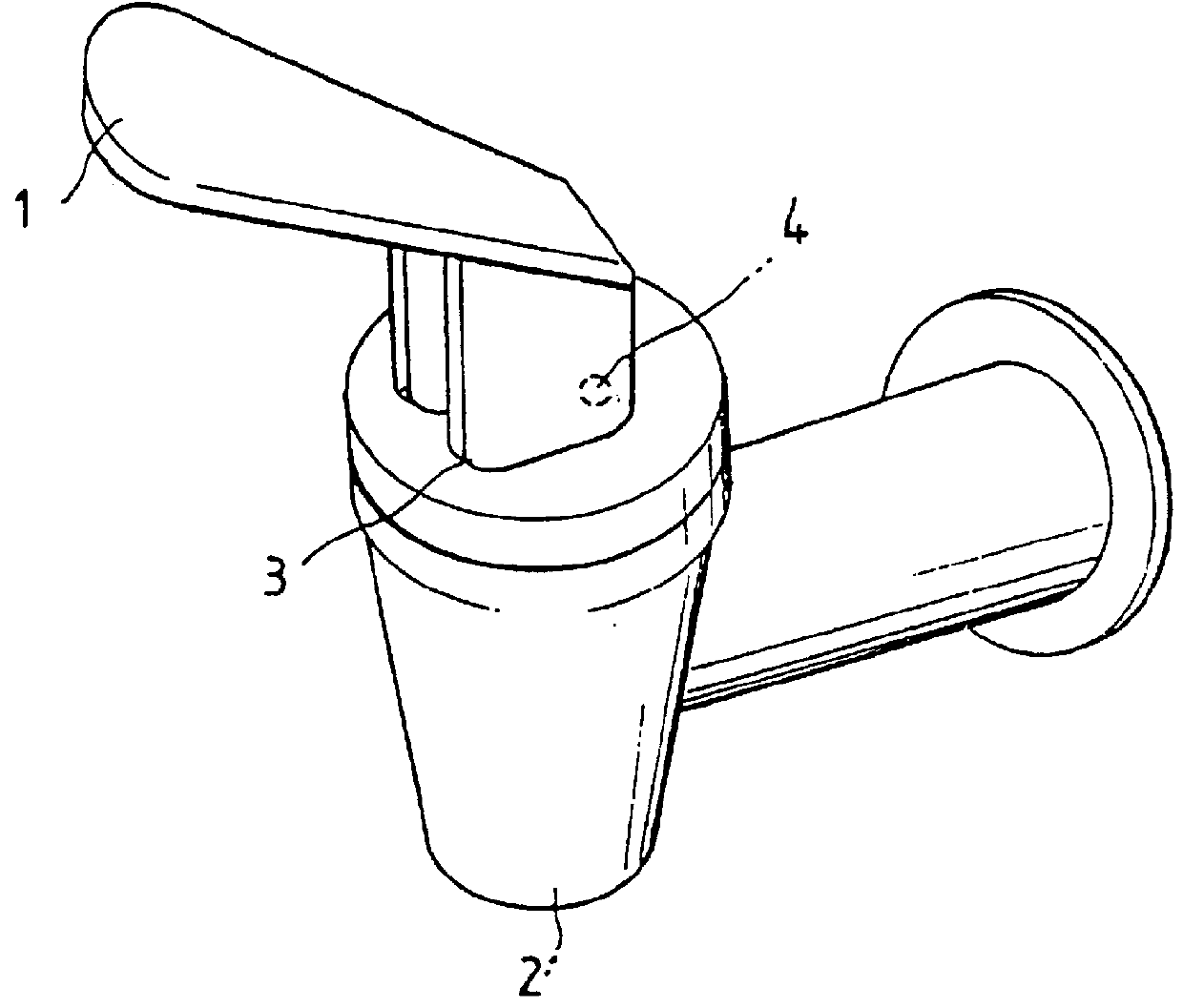

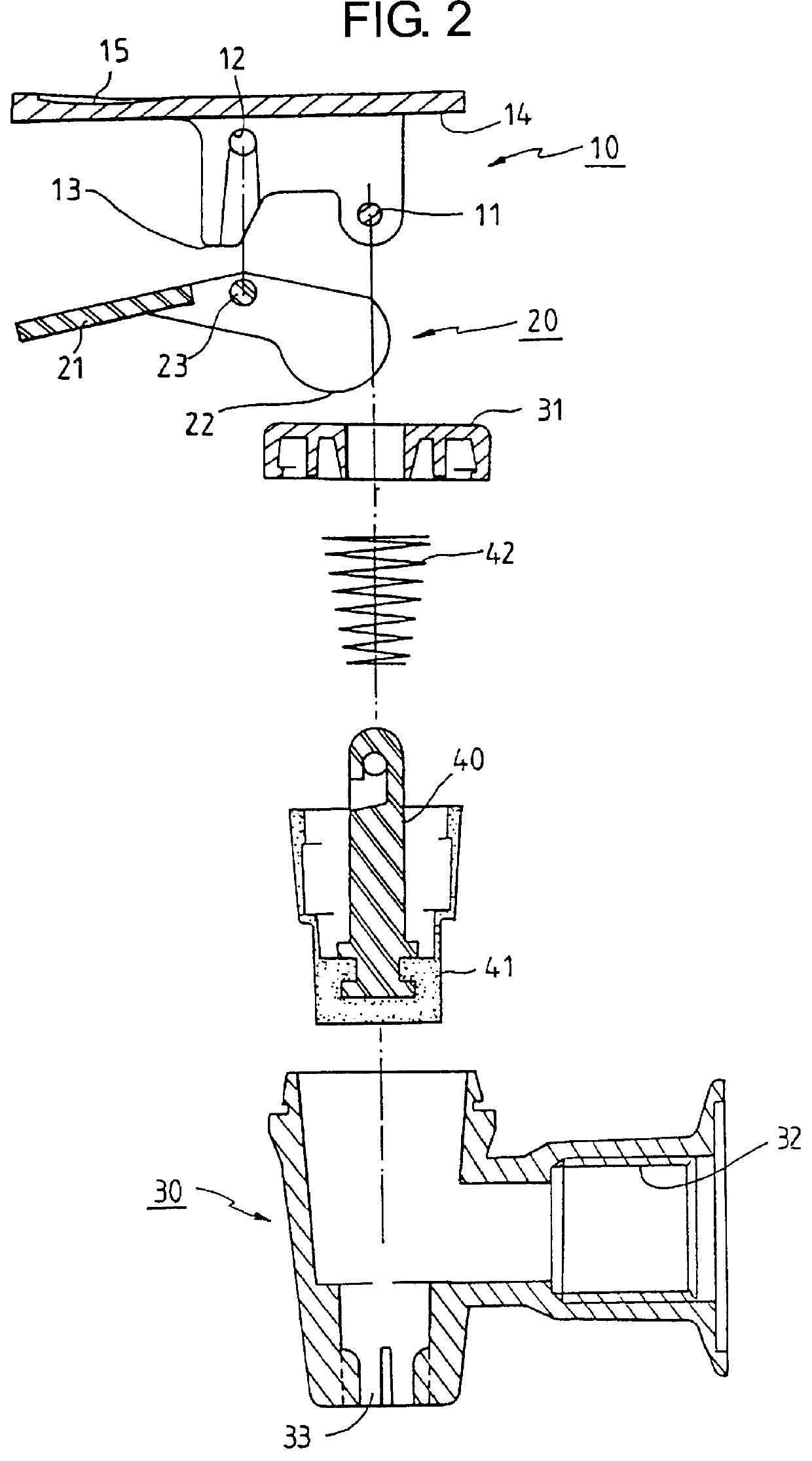

Tap with safety mechanism

InactiveUS6086045ASpindle sealingsOperating means/releasing devices for valvesEngineeringSupport point

A tap attached to one end of a water pipe or a connecting pipe of a water dispenser, and controlling the flow of water or liquid by opening and closing an outlet by the operation of a handle actuated by the leverage, the tap including a body having a shaft with a compression spring, connected to a packing used for opening and closing the outlet, and a lid serving to support a support point when turning or, or off the tap; a push handle mounted on the upper portion of the body and having a shaft connecting boss coupled to the front end of the shaft, a downward rotation stopper, an upward rotation stopper, a push portion, and a race formed on its middle; and an auxiliary handle inserted into the race of the push handle and varying the support point of the push handle according to its two-stage operation, thus controlling the opening / closing of the packing with safety.

Owner:CLOVER CO LTD

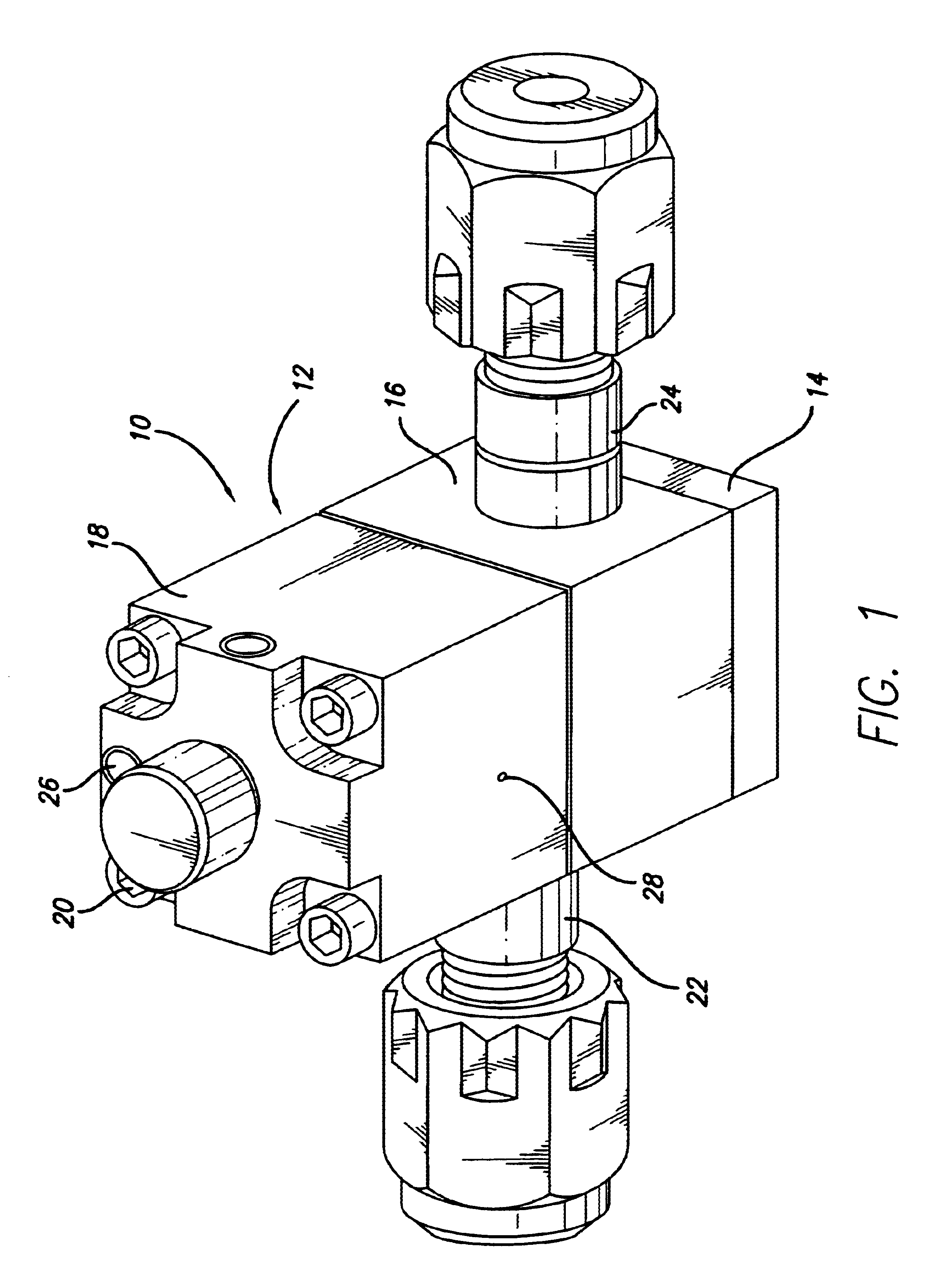

Valve with adjustable stop

InactiveUS7337805B2Prevent overtravelImprove cycle lifeSpindle sealingsDiaphragm valvesAxial displacementEngineering

An adjustable mechanism for a valve or actuator is provided. The adjustable mechanism cooperates with one or more pistons, which in turn cooperates with a valve element to limit the axial displacement of the valve element relative to the valve seat. The adjustable mechanism can be adjusted axially, thereby providing a greater or lesser distance for the piston and diaphragm to travel. Embodiments incorporating the adjustable mechanism include a trickle valve, an on / off valve and a mixing valve. The adjustable mechanism also provides to the adjustment of the piston stroke to match or closely mirror the stroke of the vale element.

Owner:SWAGELOK CO

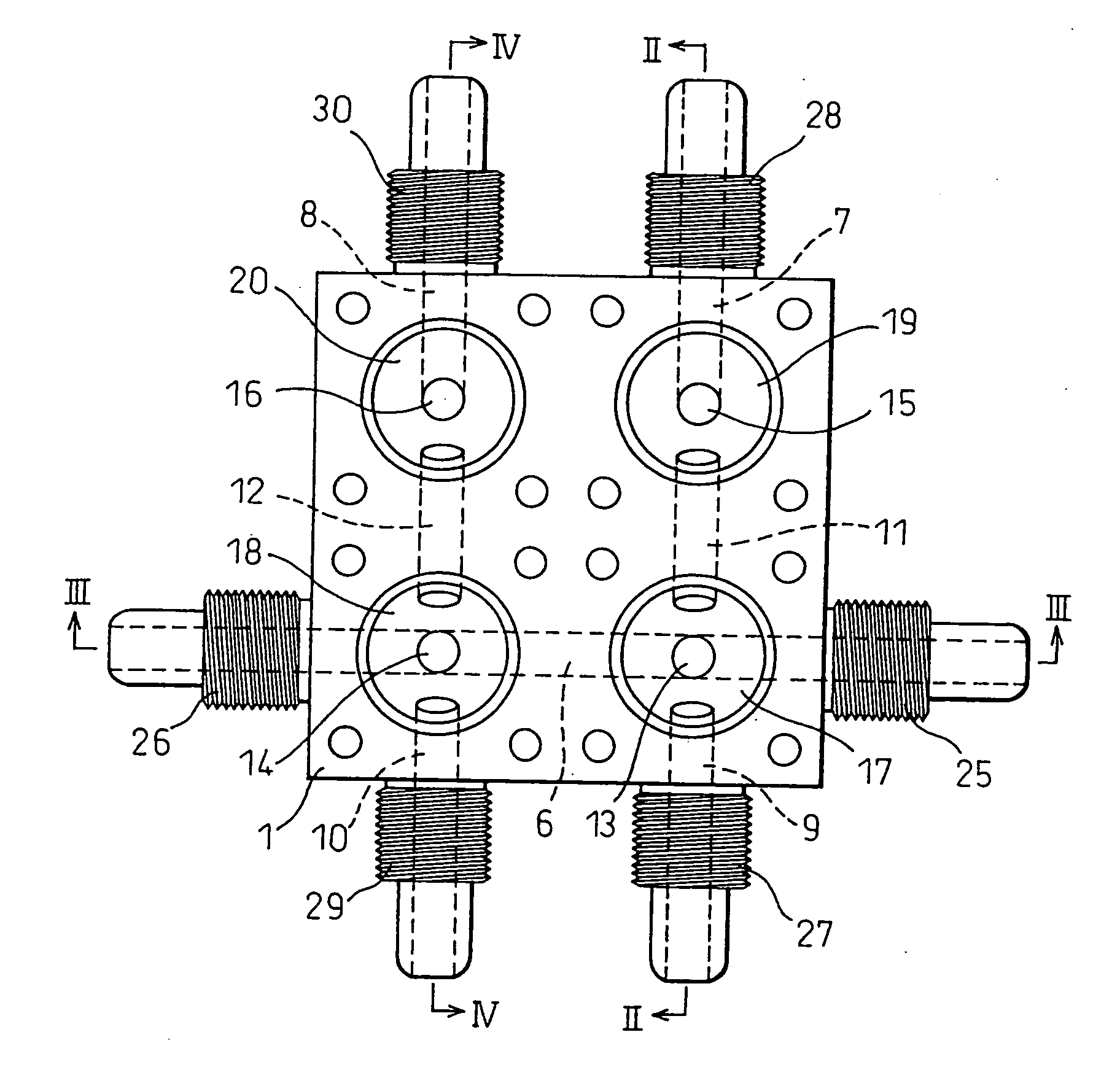

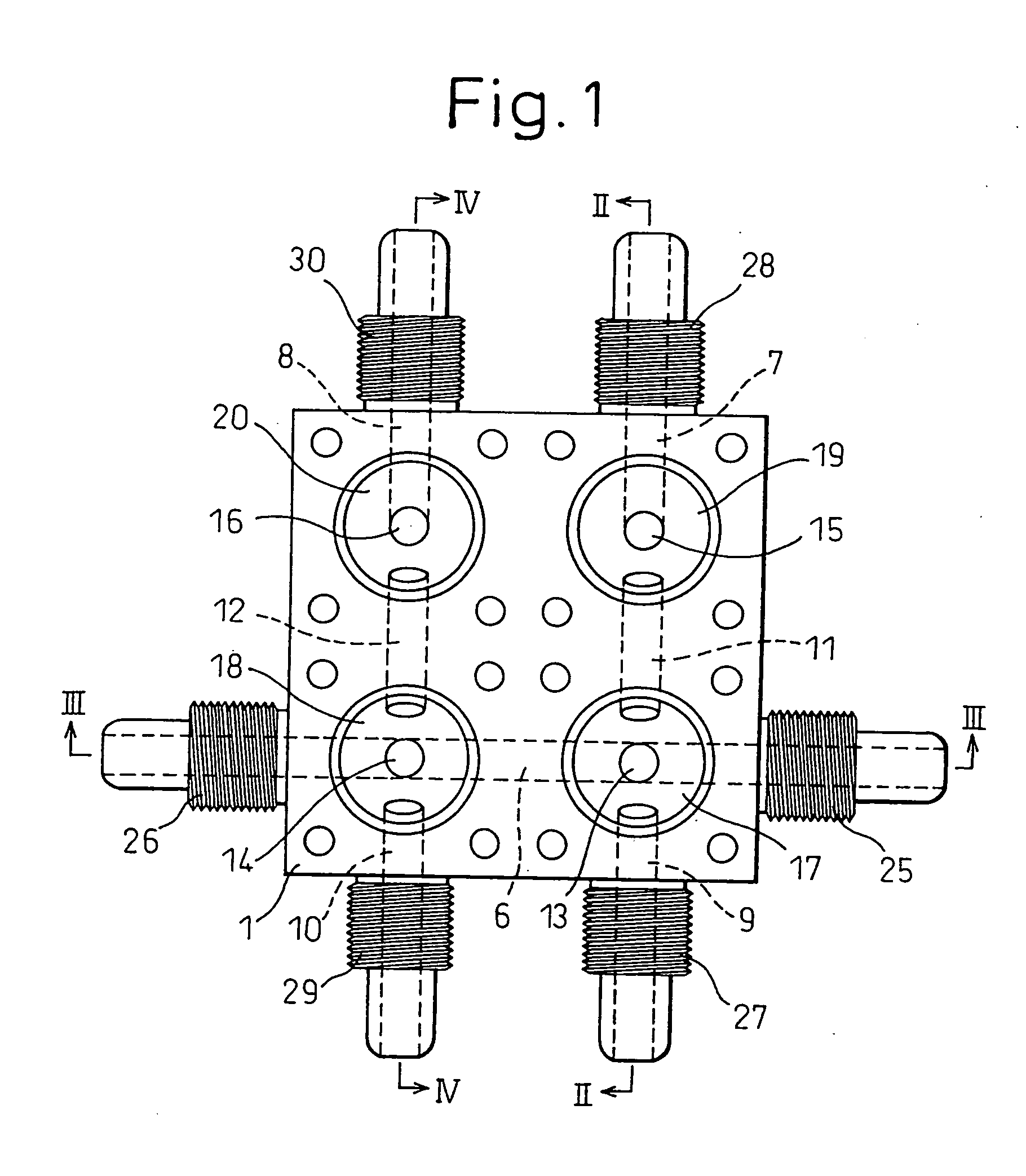

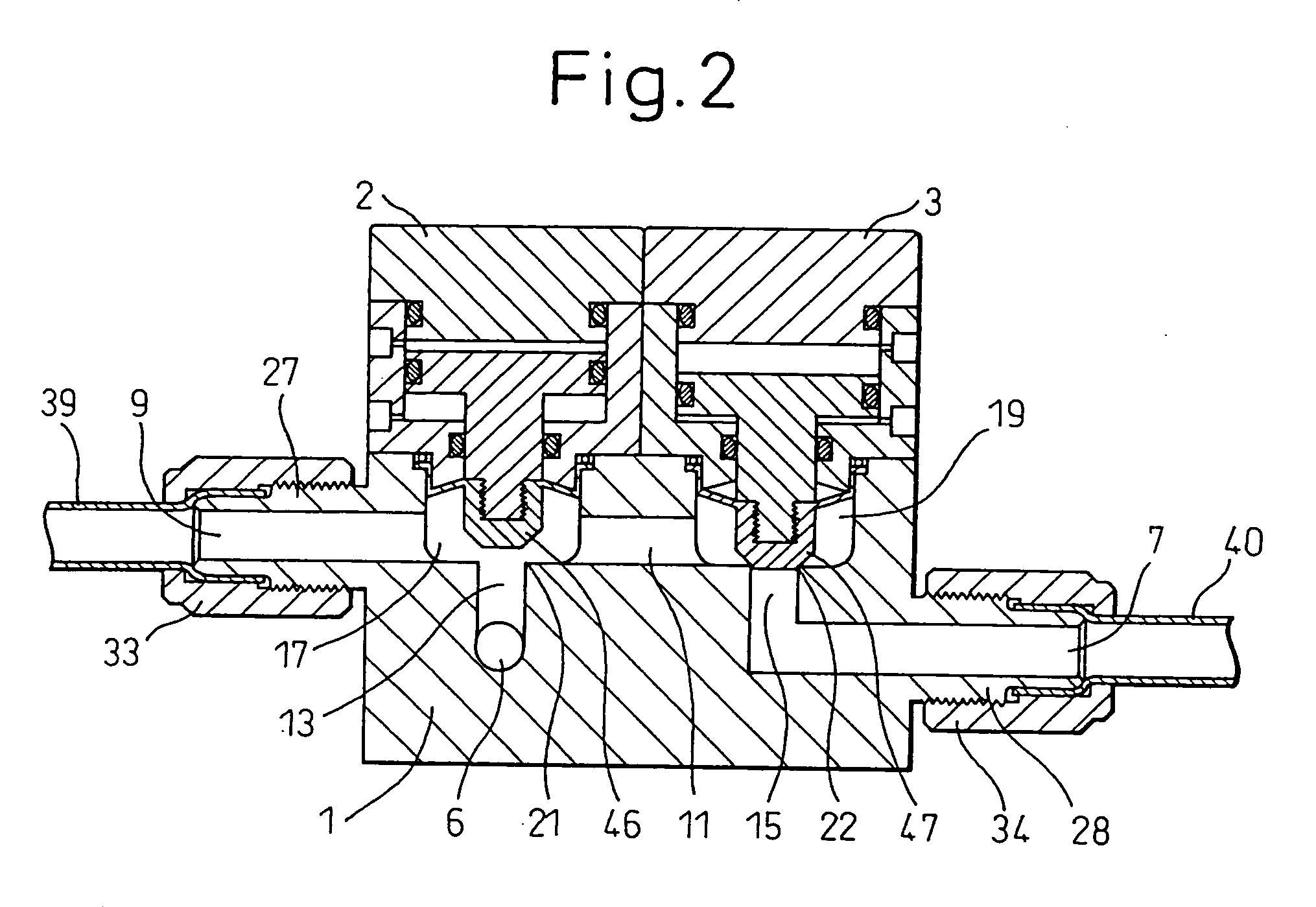

Manifold valve

InactiveUS20050072481A1Small sizeEasy to cleanSpindle sealingsOperating means/releasing devices for valvesActuatorVALVE PORT

Owner:ASAHI YUKIZAI KOGYO CO LTD

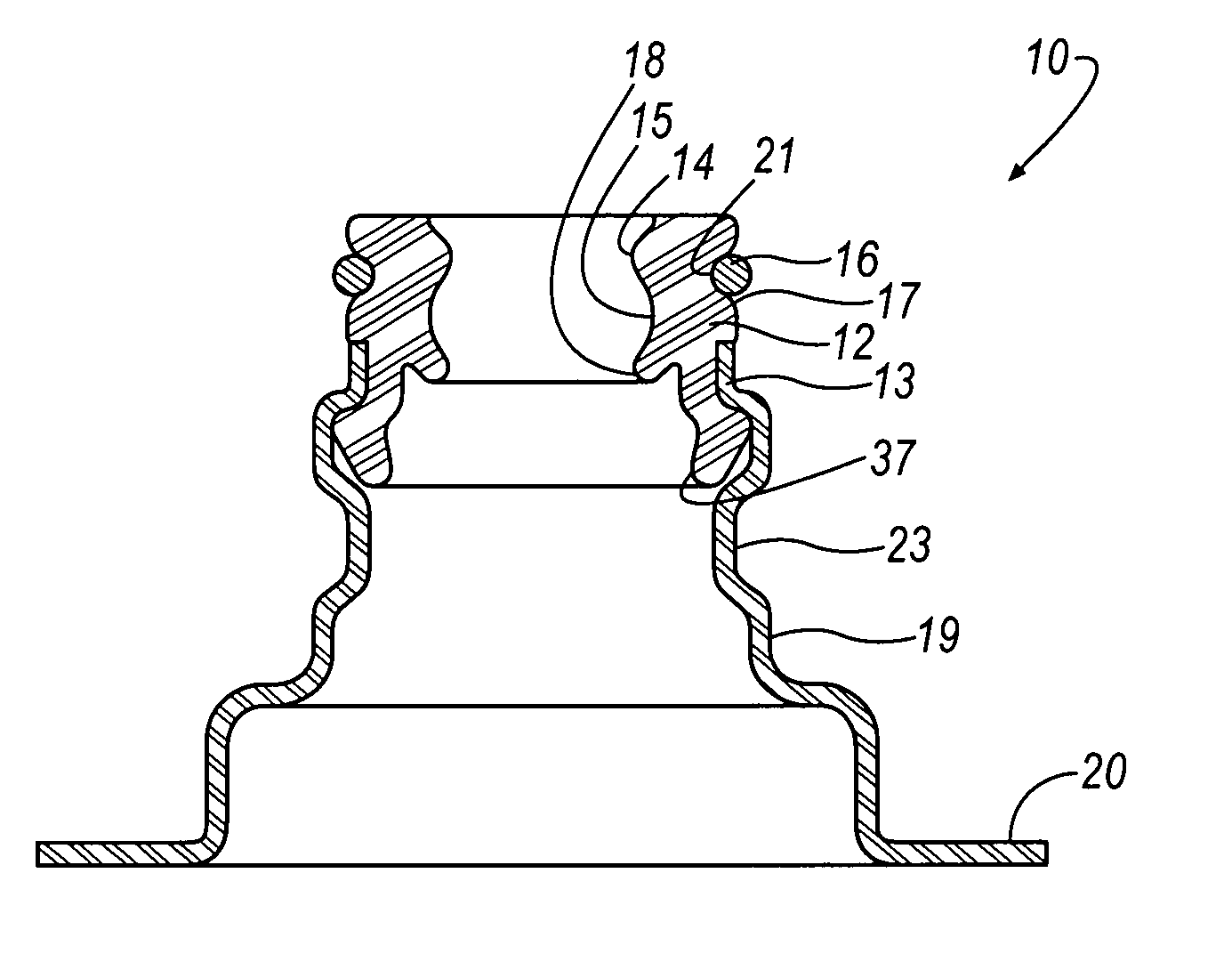

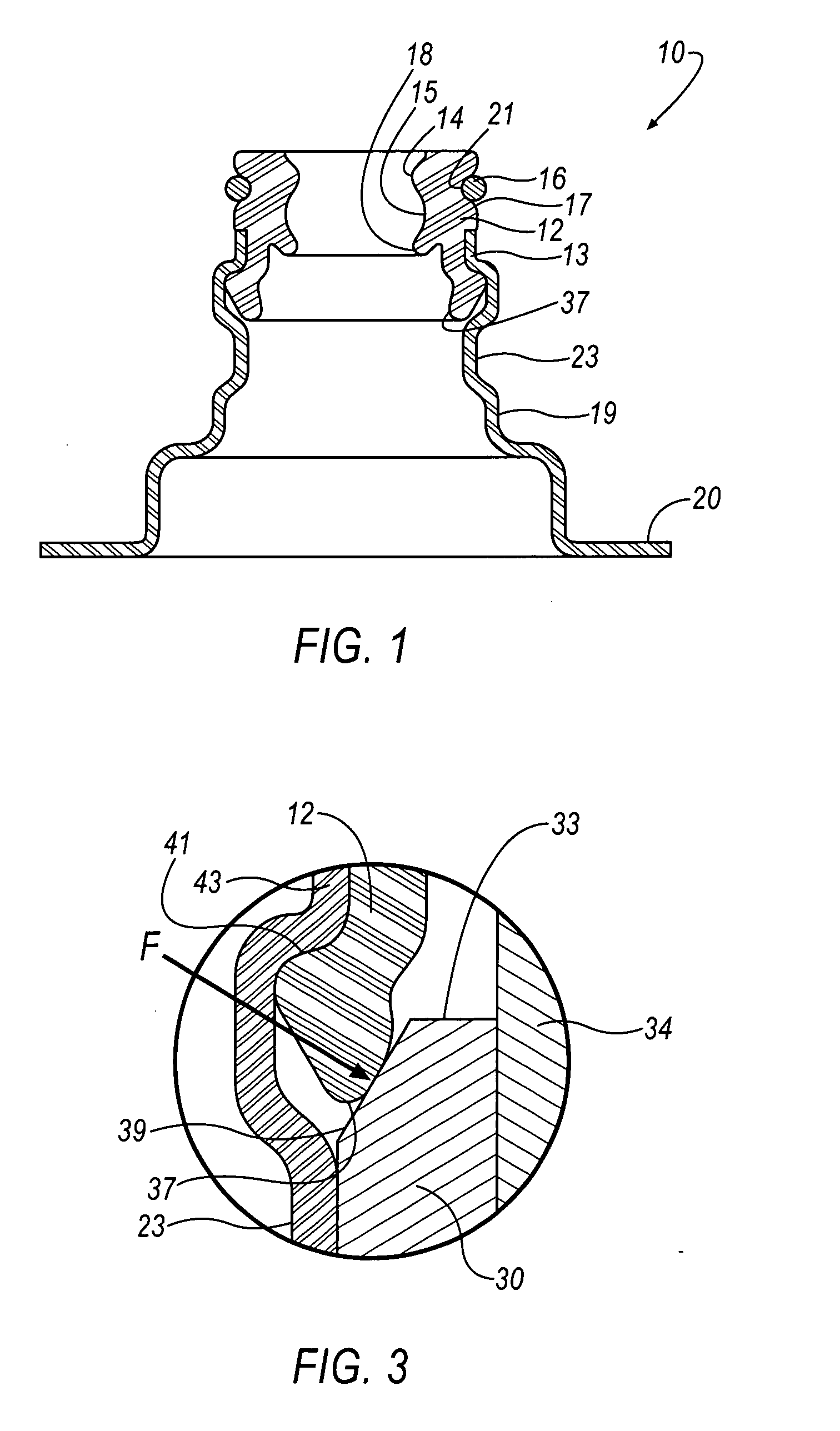

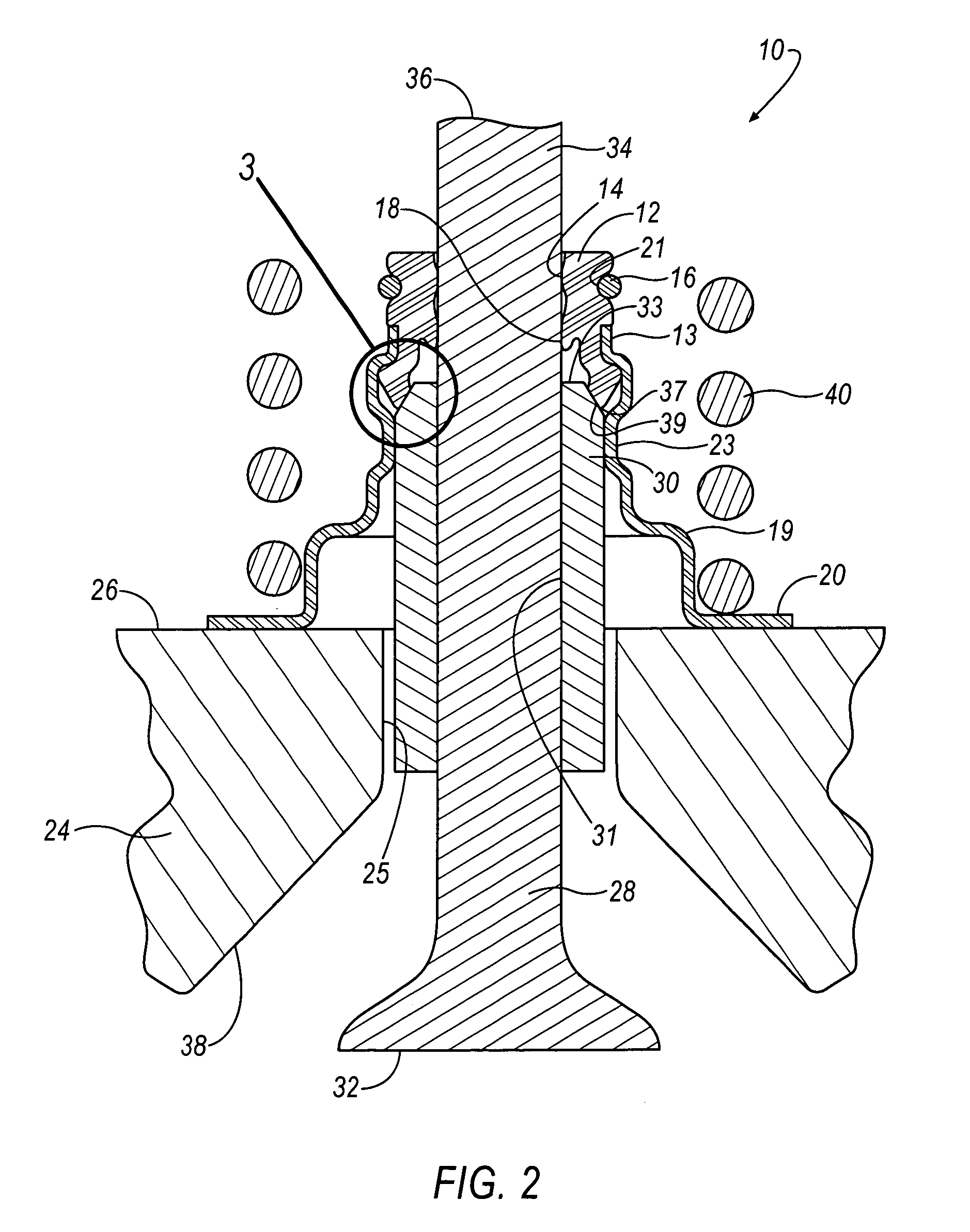

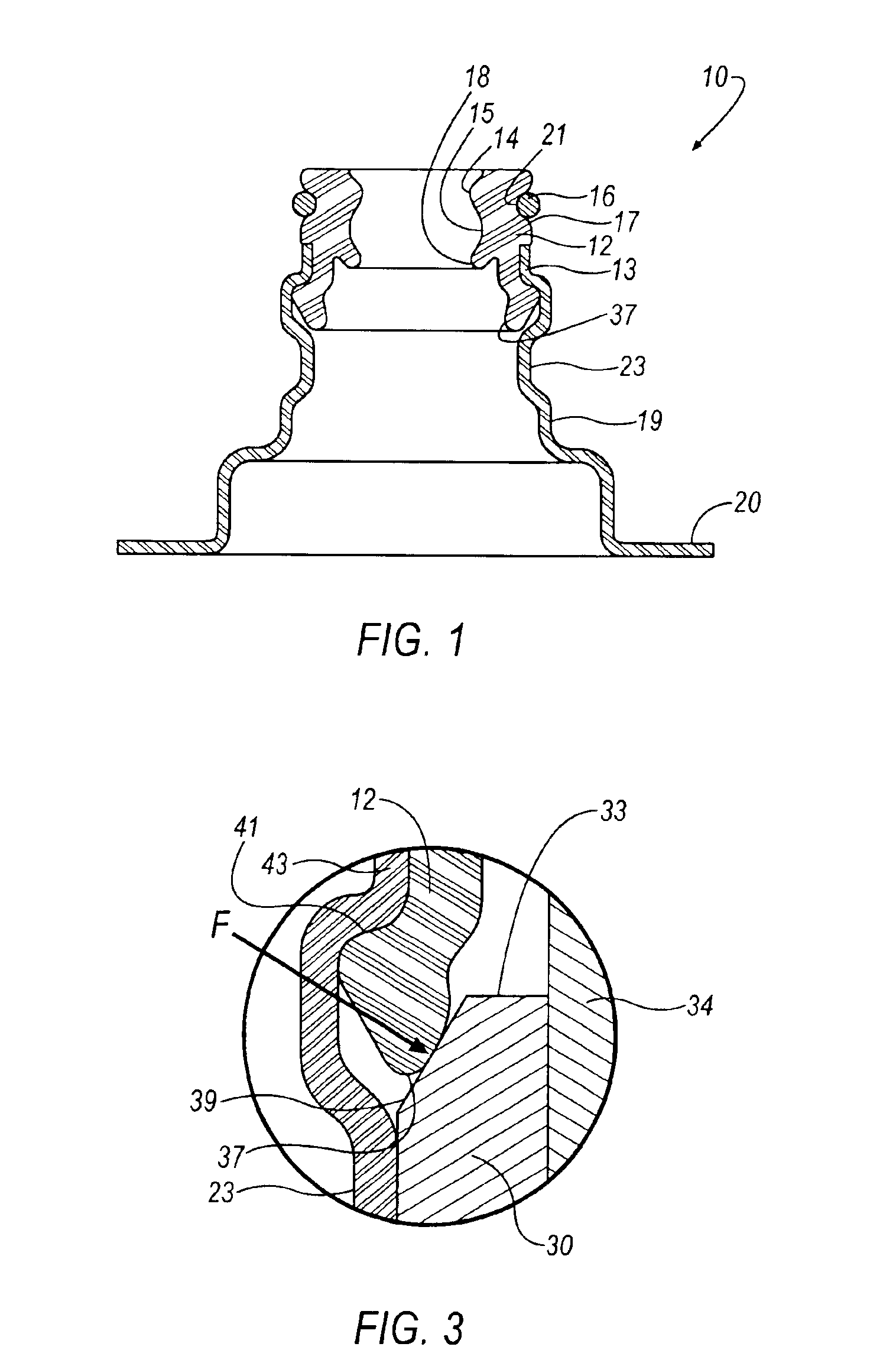

Valve stem seal assembly

InactiveUS20050001196A1Spindle sealingsOperating means/releasing devices for valvesSubject matterEngineering

A valve stem seal assembly includes a retainer and a sealing element disposed within the retainer. The retainer includes a step and one or more installation pads. The sealing element includes a first sealing lip for sealing a valve stem, and a second sealing lip for sealing a chamfer of a valve guide. The step of the retainer exerts a compression force, F, against the second sealing lip to seal the second sealing lip against the chamber of the valve guide. The one or more installation pads exerts a frictional force against the valve guide to prevent movement of said valve stem seal assembly. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:DANA AUTOMOTIVE SYST GRP LLC

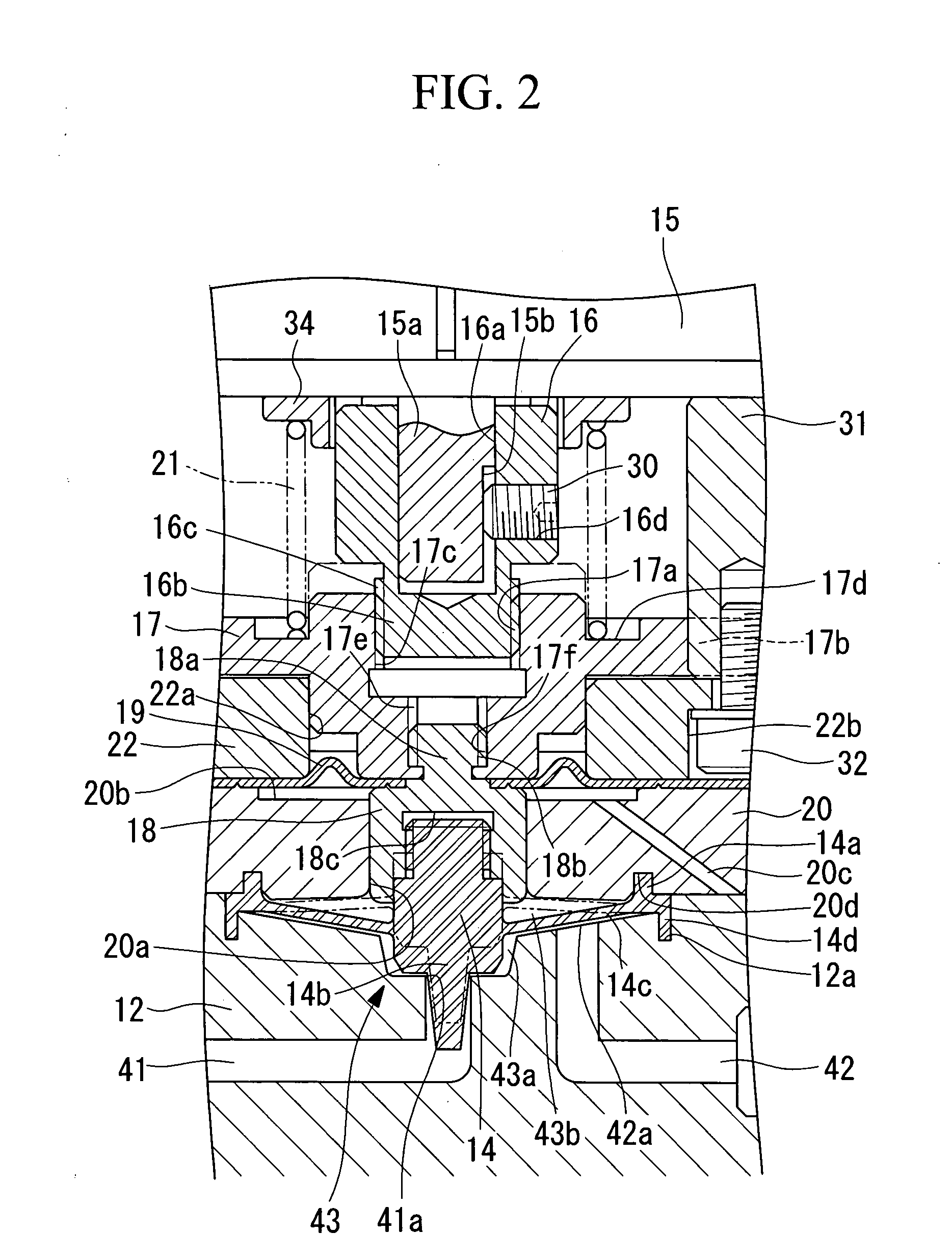

Electromagnetic valve

InactiveUS7591281B2Low reliabilityReduce running noiseSpindle sealingsOperating means/releasing devices for valvesInterior spaceMagnetomotive force

In an electromagnetic valve, a valve member is slidably installed in a housing to open and close a valve hole. A moving core is slidably installed in the housing, and a coil generates a magnetomotive force to attract the moving core to one side when it is energized. The valve shaft links a motion of the moving core with a motion of the valve member. A bellows surrounds the valve shaft to form a cylindrical inner space between the valve shaft and itself. The bellows is subjected to both positive and negative pressures to extend and shrink in accordance with the motions of the valve member and the moving core. An inner volume of the inner space increasing and decreasing in accordance with extending and shrinking operations of the cylindrical bellows portion. The opening of the bellows and the valve shaft form a narrow opening passage.

Owner:DENSO CORP

Adjustment Valve

InactiveUS20080099081A1Easy flow regulationImprove anti-corrosion performanceSpindle sealingsDiaphragm valvesThick wallEngineering

An adjustment valve includes a first diaphragm integrally formed from an attachment section engaged with and fixed to the bottom of a rod, a joining section to which a valve body is fixed, a thin film section radially extending from a shoulder section, a thick wall section continuous with the thin film section, and a seal section provided at the peripheral edge of the thick wall section. The second diaphragm has a central hole, and includes an integrally formed thin film section radially extending from a thick wall section at the center hole, and a seal section is provided at the peripheral edge thereof. A diaphragm hold-down member penetrates the central hole at the shoulder section of the rod, causing the second diaphragm to be sandwiched and fixed. The rod is disposed with play in the through-hole in the bottom of the cylinder, and is supported by a spring engaged between a step section of the cylinder and the bottom surface of the shoulder in a state such that radial movement is prevented.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Valve for a ball and method for manufacturing same

ActiveUS8292764B2Avoid deformationSpindle sealingsHollow inflatable ballsMechanical engineeringEngineering

Owner:ADIDAS

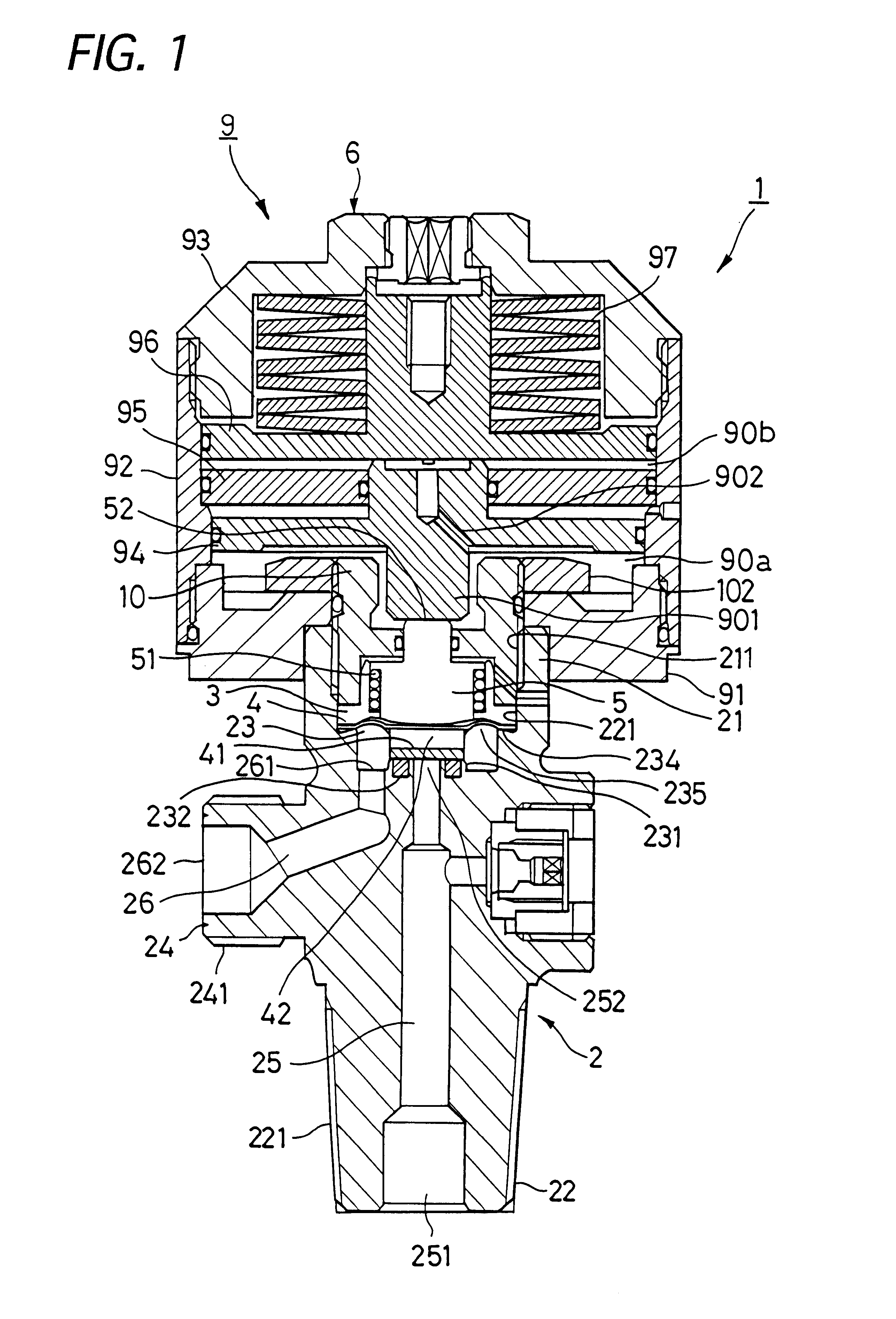

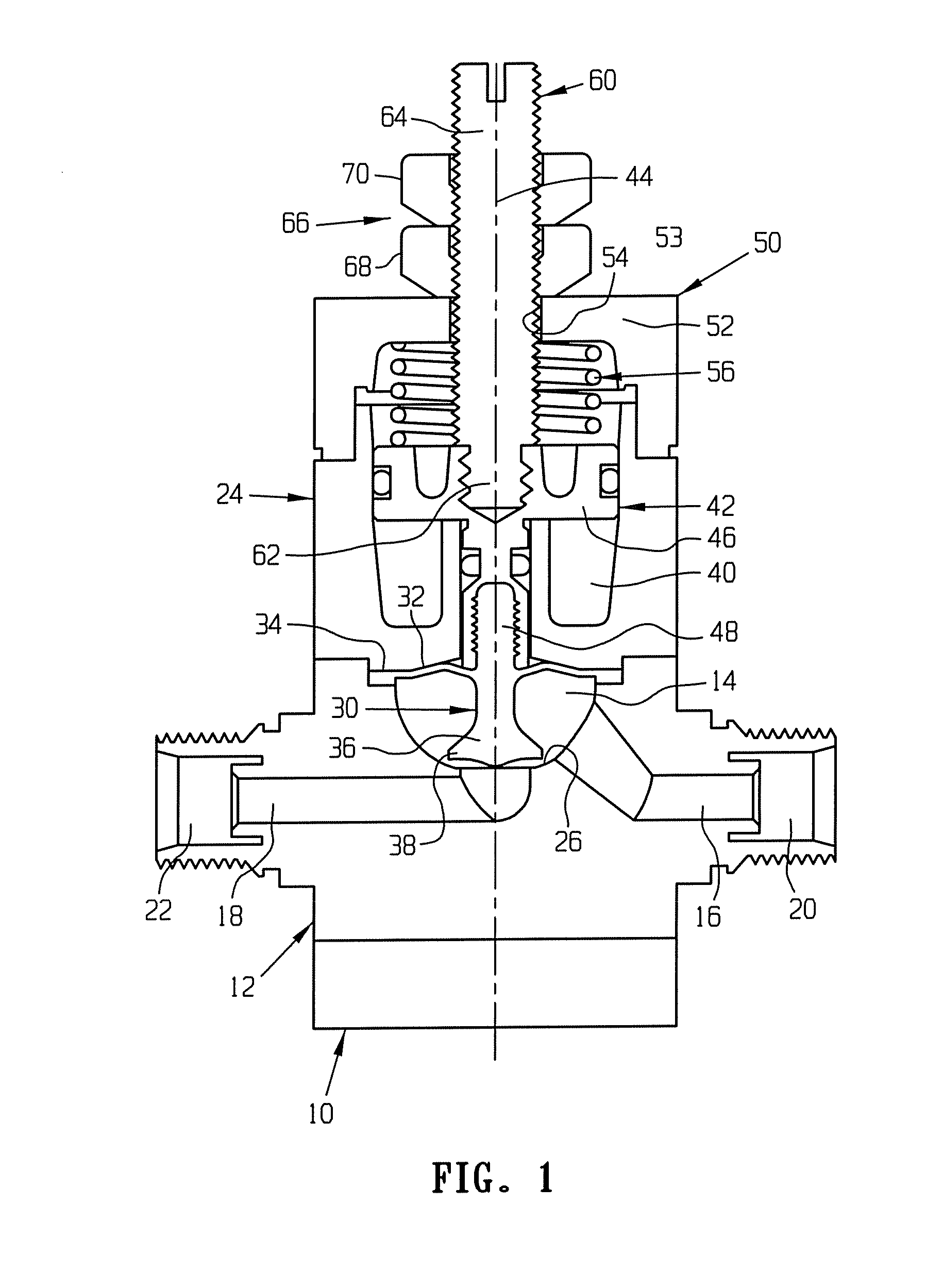

Flow control valve

ActiveUS20090072173A1Reduce loadKeep movingSpindle sealingsDiaphragm valvesRotational axisControl valves

An object is to provide a flow control valve that is capable of reducing or eliminating backlash generated between a male threaded portion and a female threaded portion engaged with the male threaded portion and preventing or eliminating hysteresis in the flow level. The flow control valve includes a body having a fluid inlet and a fluid outlet, a cover attachable to the body, a motor disposed in a space defined by the body and the cover, a valving element connected to a rotary shaft of the motor with a screw member, and an urging member that urges the valving element toward the motor side or toward the side opposite to the motor.

Owner:SURPASS IND

Two-piece valve stem seal

A two piece valve stem seal assembly including first and second generally cylindrical shells, one of which is partially axially nested or inserted within the other. The valve stem seal assembly also includes an engagement portion on the one of the shells for grippingly engaging the outer shell in order to substantially prevent or at least minimize the possibility of axial separation of the shells during subsequent assembly into an engine or other valve-containing device. The assembly may also optionally include a discontinuity on the one of the shells for axially retaining or axially interlocking the shells in order to substantially prevent or at least minimize such possibility of axial separation.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

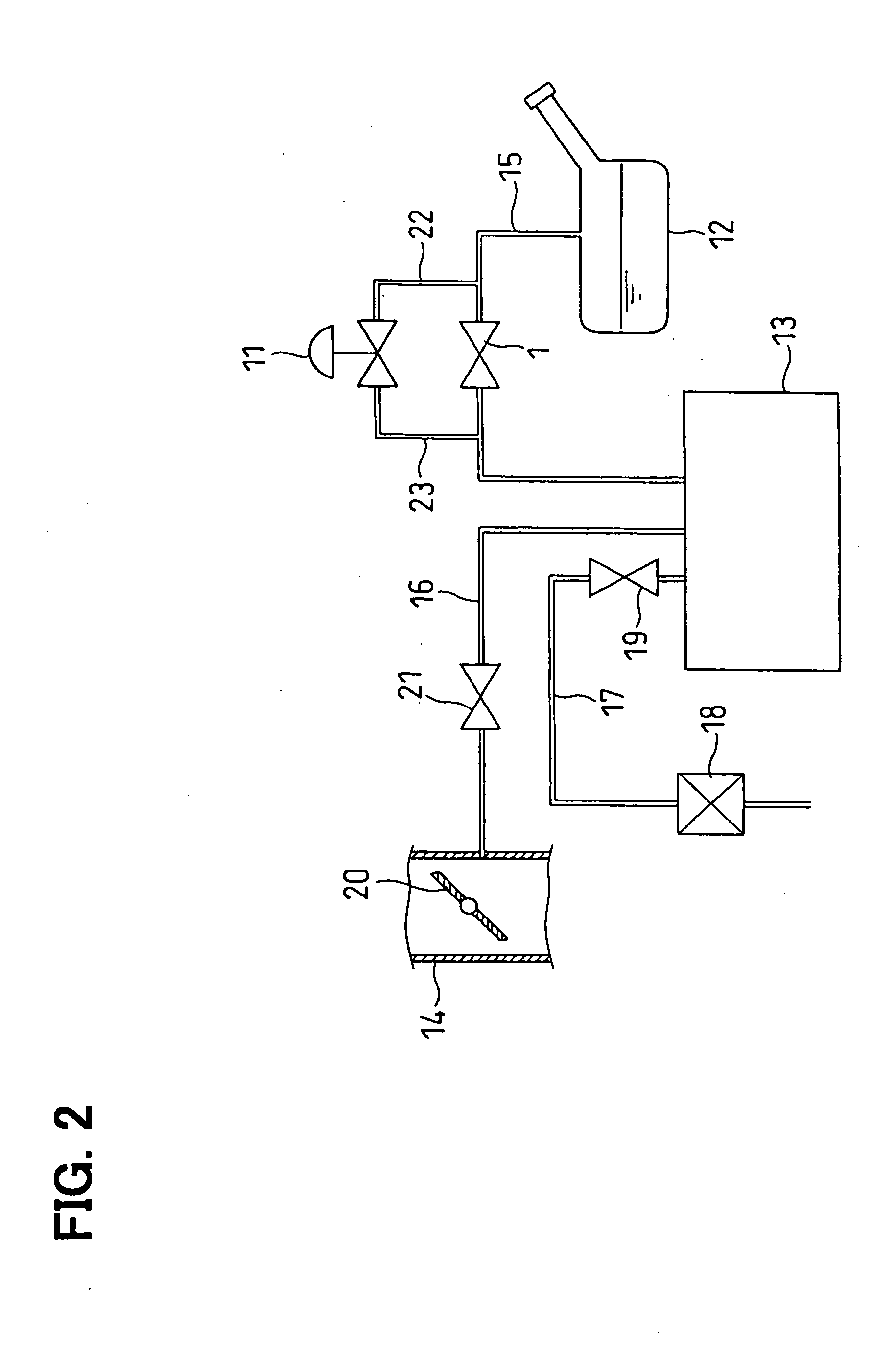

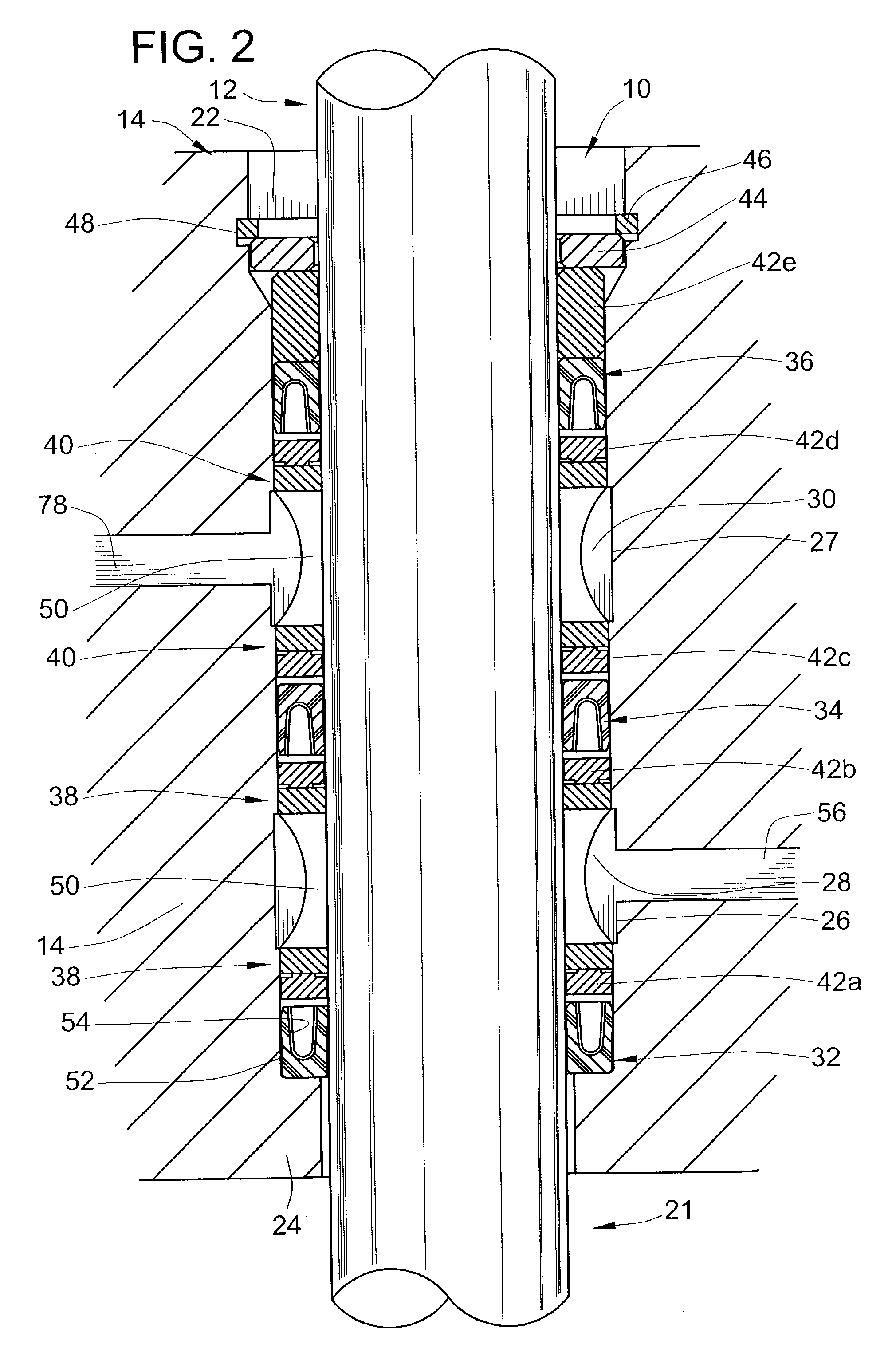

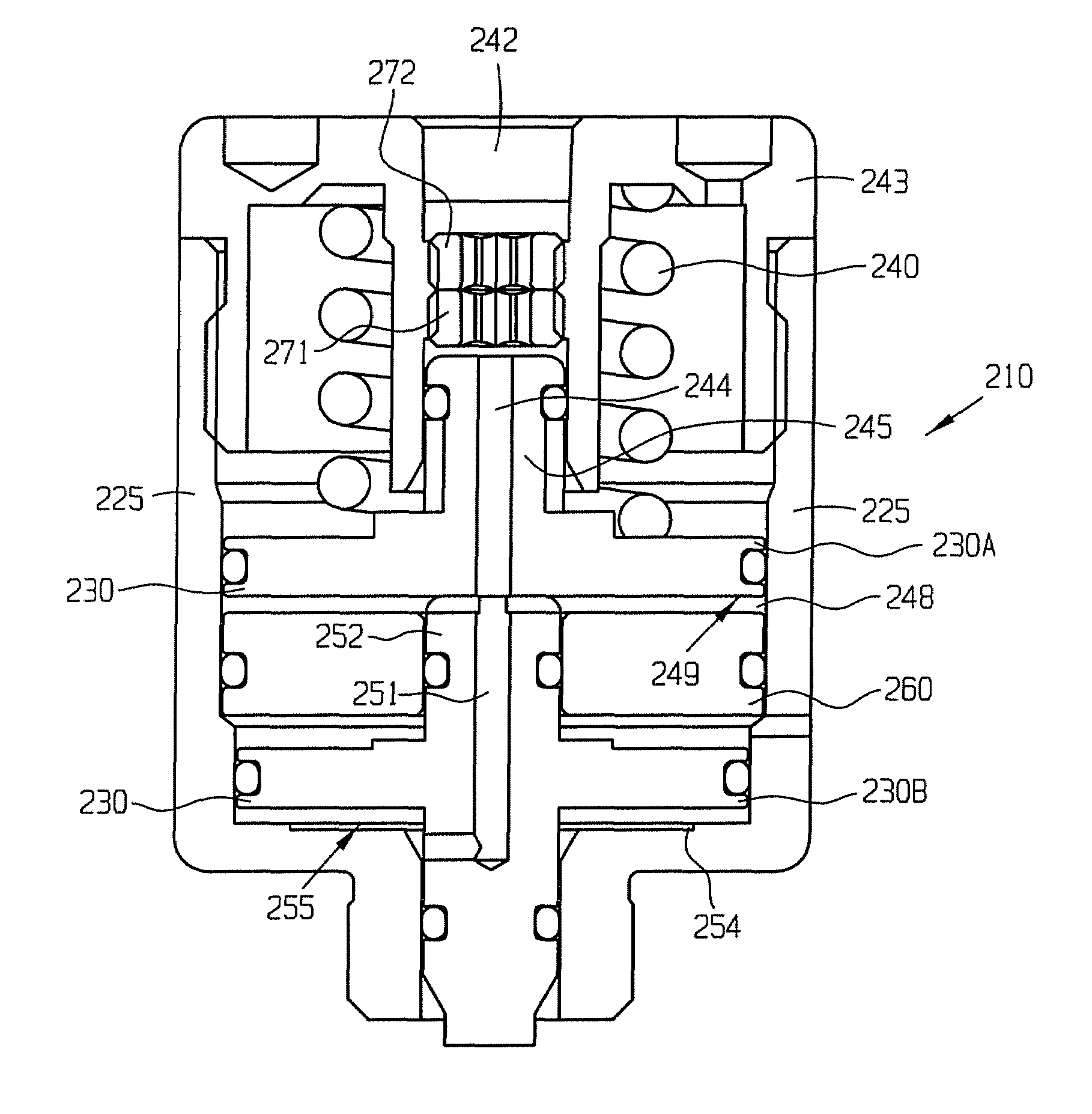

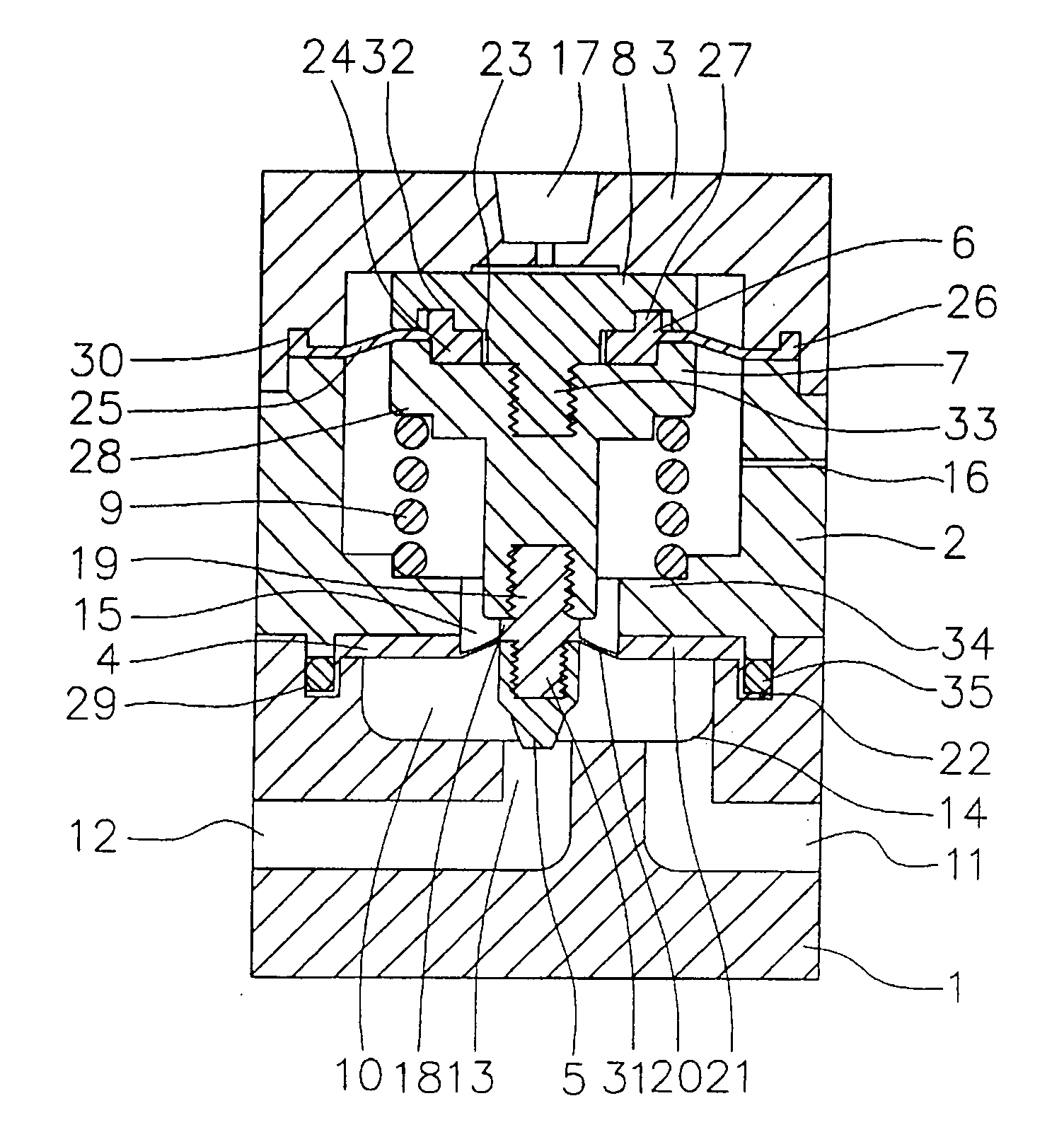

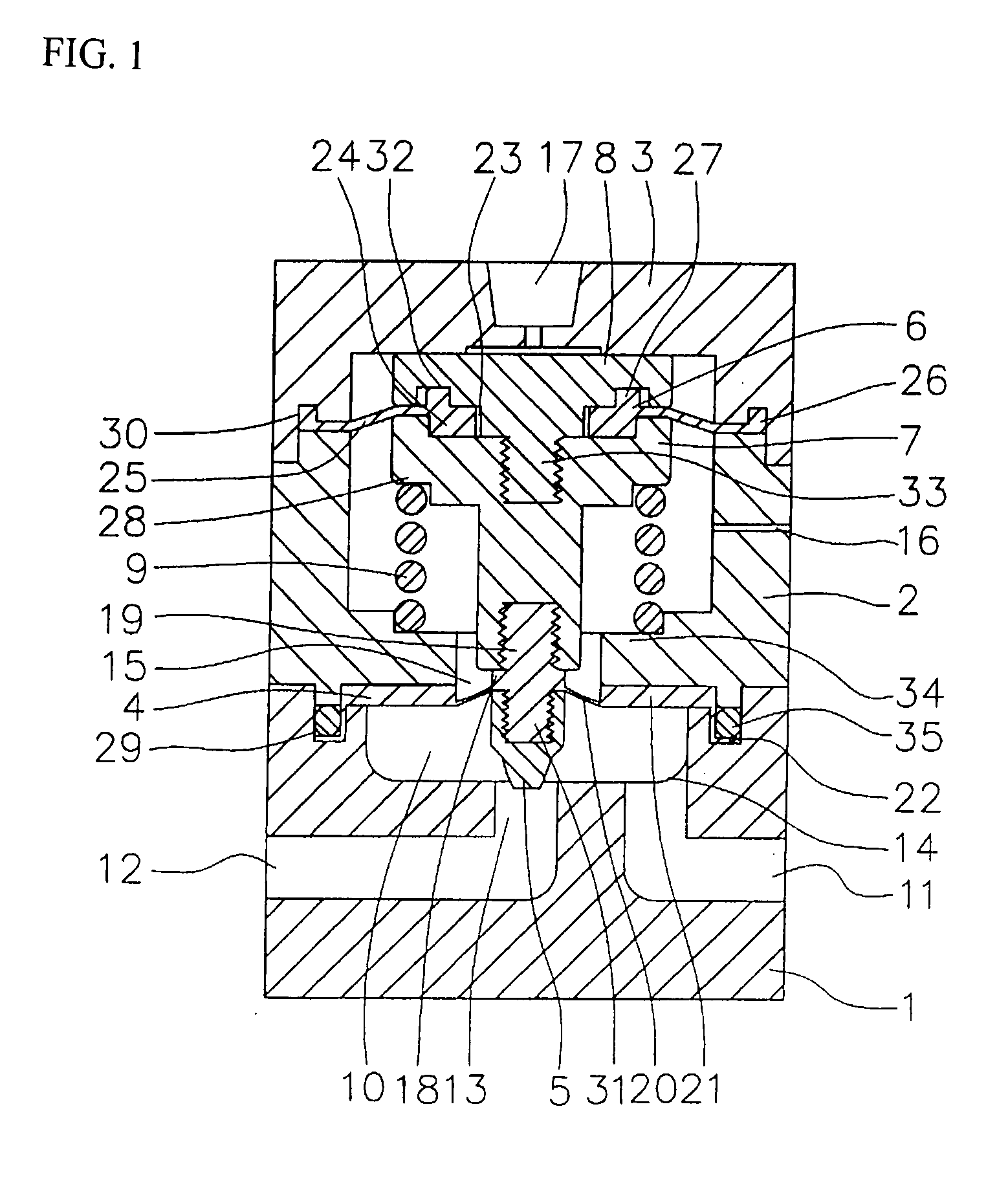

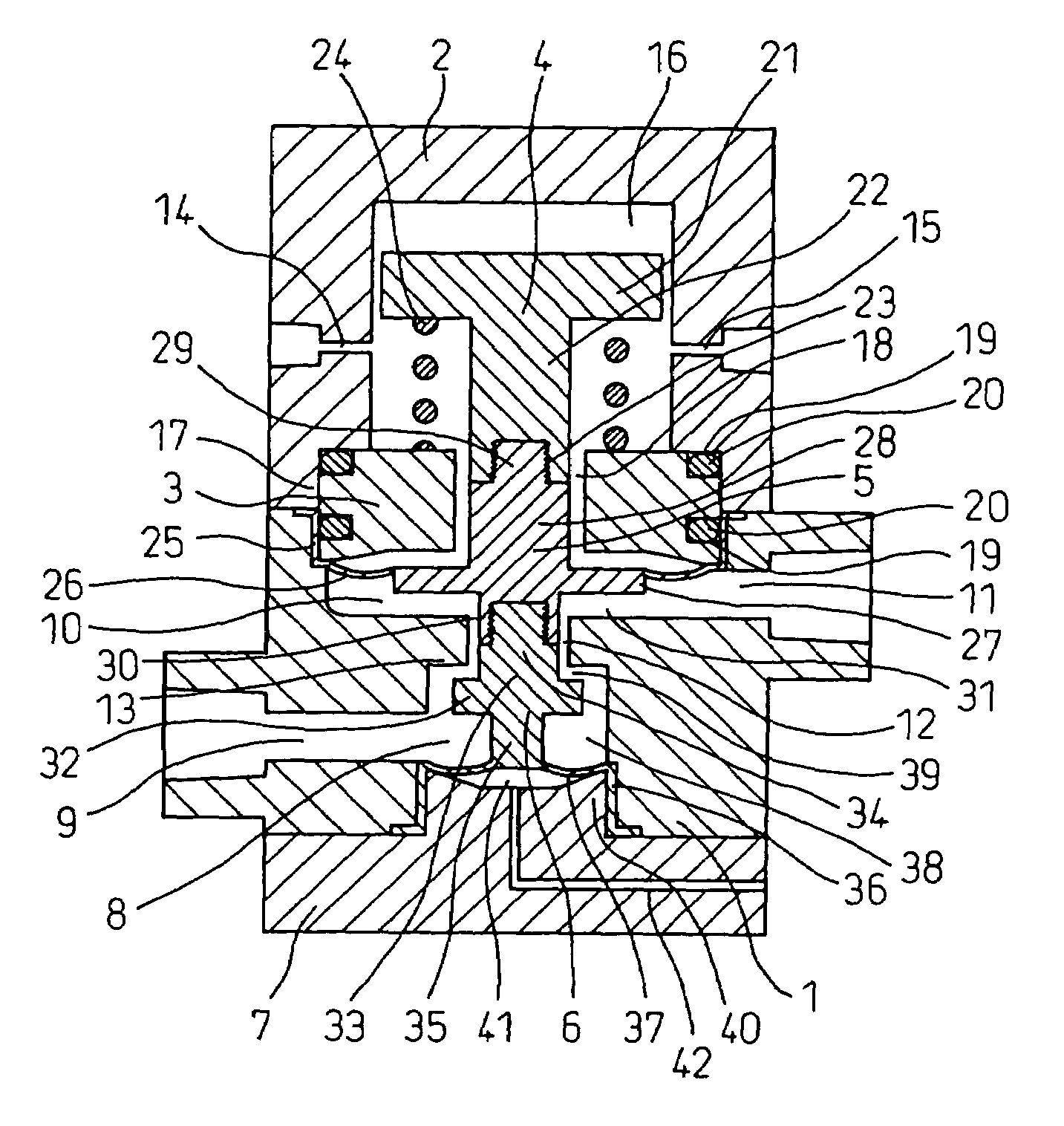

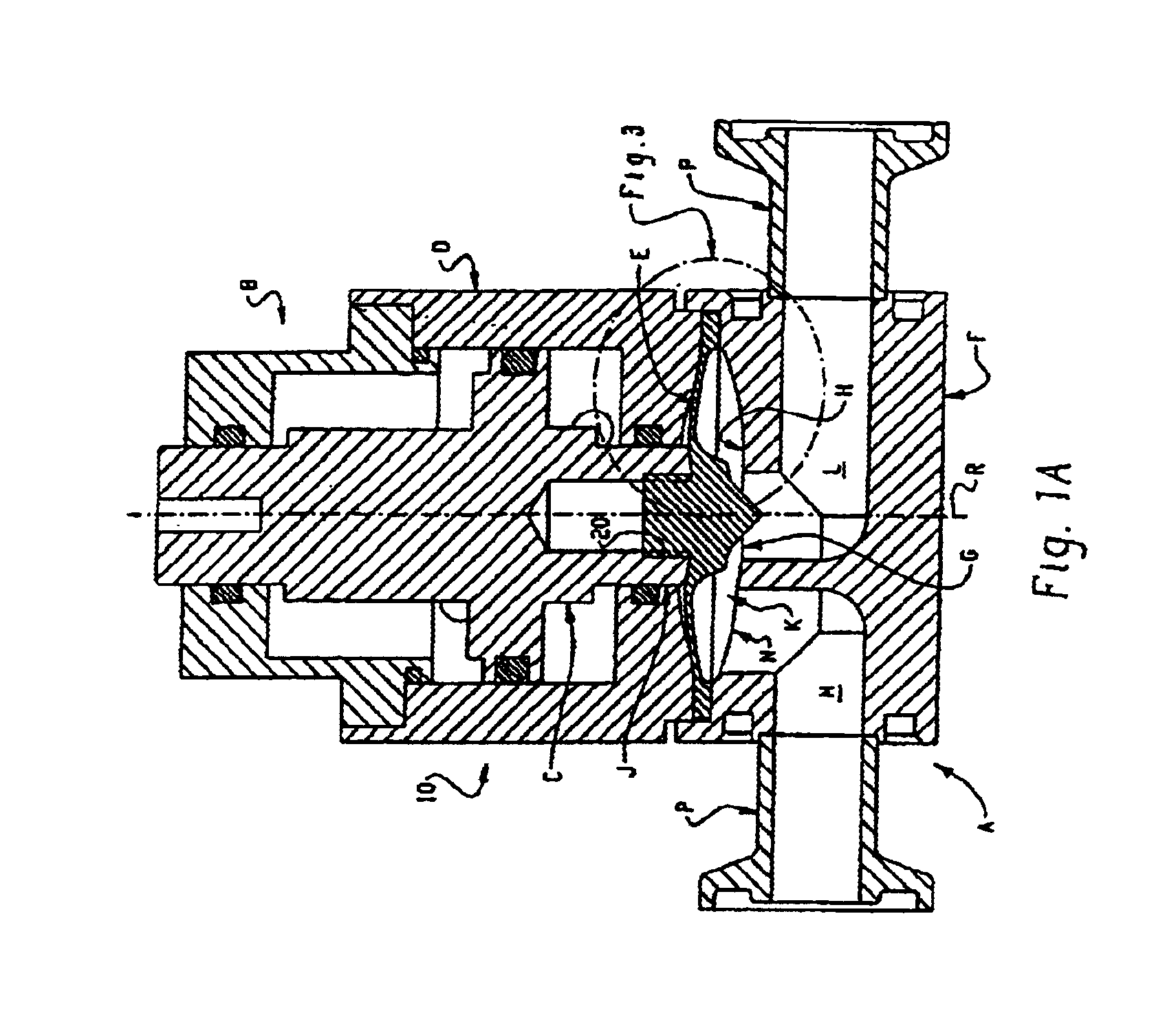

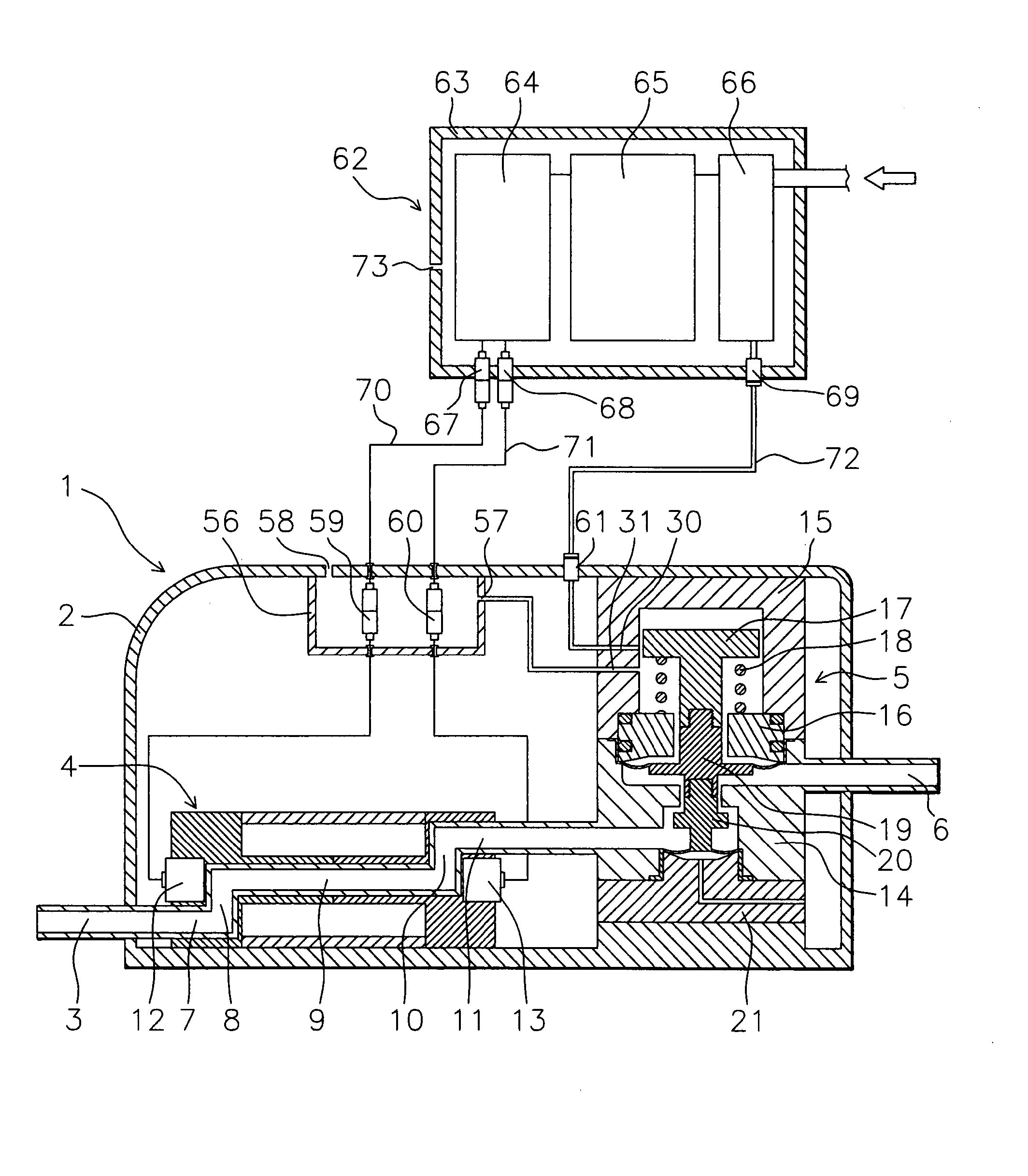

Flow control valve

InactiveUS7108241B2High yieldReduce manufacturing costSpindle sealingsOperating means/releasing devices for valvesControl valvesVALVE PORT

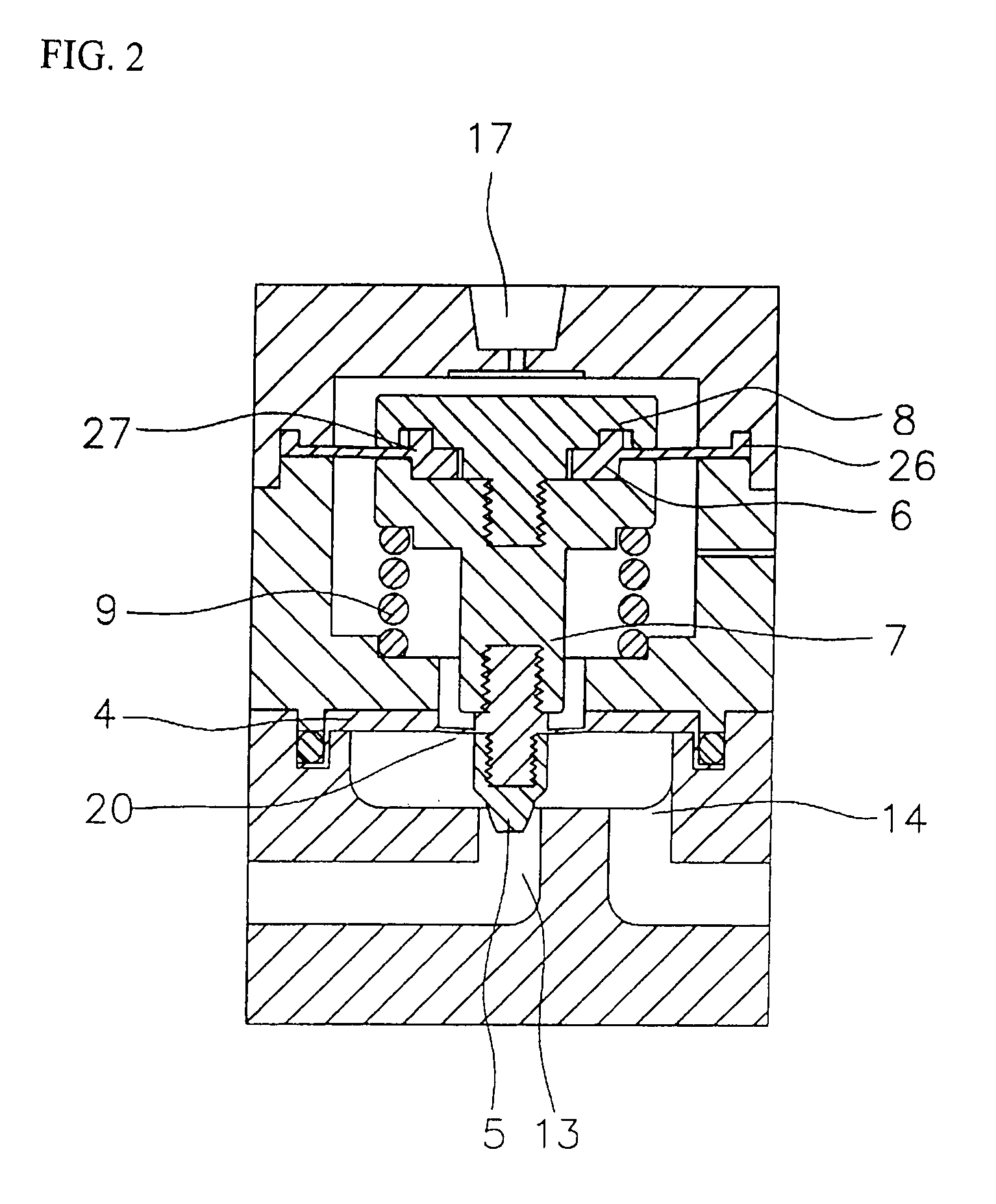

A flow control valve includes a main body 1, bonnet 2, spring receiving portion 3, piston 4, spring 24, first diaphragm 27, first valve member 5, second valve member 6 and base plate 7, wherein an opening area of a hydraulic control portion composed of a valve element of the second valve member and a valve seat of the main body is changed according to a motion of the piston.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Valve stem seal assembly

InactiveUS6938877B2Spindle sealingsOperating means/releasing devices for valvesSubject matterEngineering

A valve stem seal assembly includes a retainer and a sealing element disposed within the retainer. The retainer includes a step and one or more installation pads. The sealing element includes a first sealing lip for sealing a valve stem, and a second sealing lip for sealing a chamfer of a valve guide. The step of the retainer exerts a compression force, F, against the second sealing lip to seal the second sealing lip against the chamber of the valve guide. The one or more installation pads exerts a frictional force against the valve guide to prevent movement of said valve stem seal assembly. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:DANA AUTOMOTIVE SYST GRP LLC

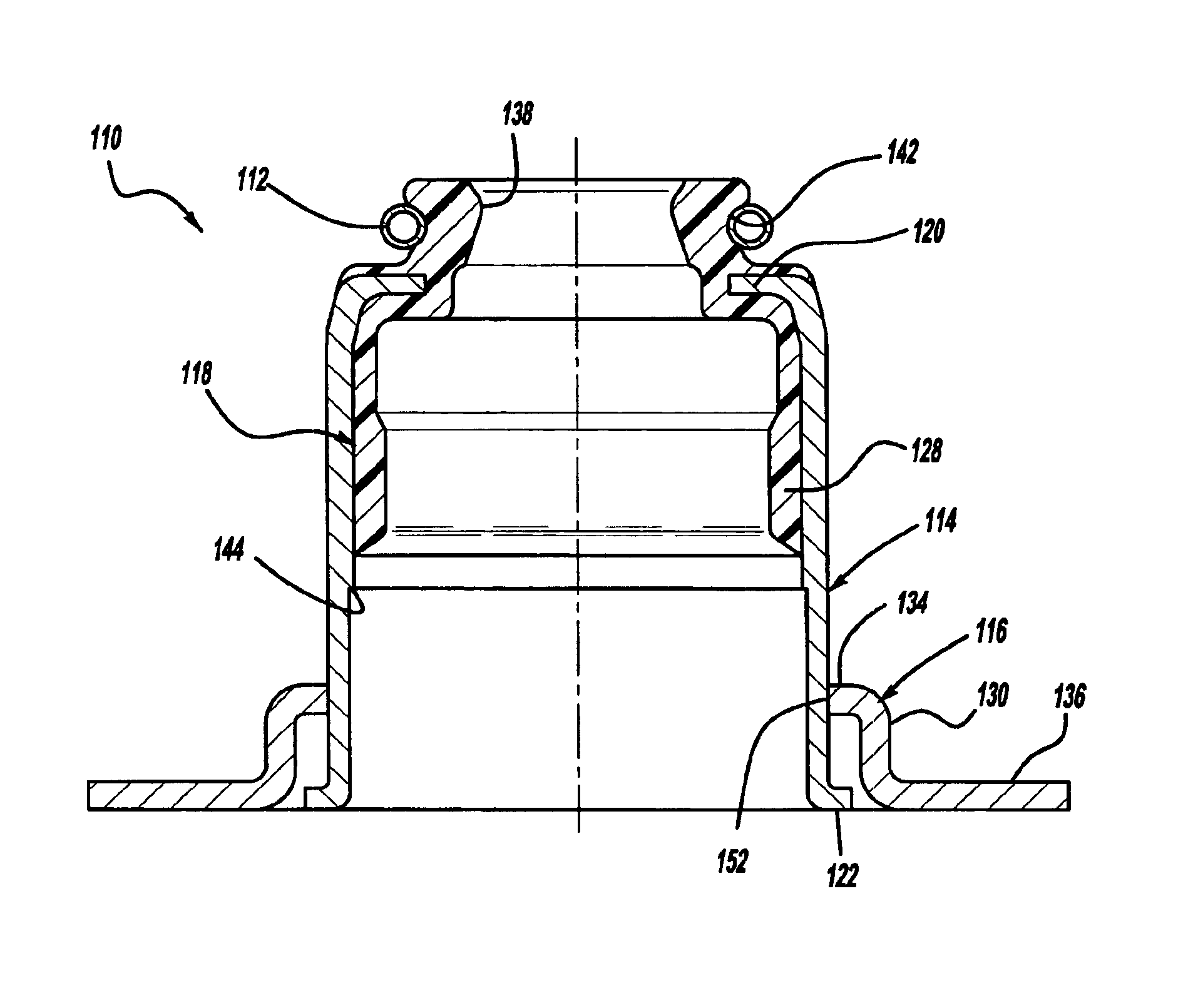

Sanitary diaphragm valve

InactiveUS6883780B2Relieve pressureIncrease flow rateSpindle sealingsDiaphragm valvesValve actuatorDiaphragm valve

A sanitary diaphragm valve is provided that includes a generally dome shaped diaphragm having a central boss that can be connected to or driven by a valve actuator. The diaphragm includes an outer peripheral edge and a relatively thin web portion that connects the boss to the outer edge. In one embodiment, the web portion is arcuate or dome shaped. The thinner web portion permits the diaphragm to have an extended cycle life and to permit the valve to operate at higher fluid pressures. The diaphragm may be made from a chemically resistant material and optimized to maintain high flexure.

Owner:SWAGELOK CO

Poppet valve bushing with tolerance ring

A pintle bushing assembly for a poppet valve assembly including a tolerance ring which is disposable between the pintle bushing and a bore in the body of the valve to both seal and center the bushing in the bore. The tolerance ring includes a plurality of radially-extending dimples which are deformable during assembly such that the valve pintle can be aligned coaxially with the valve seat under all conditions. An axial flange on the tolerance ring is sealed against axial surfaces of the valve body adjacent the bore and a flange on the bushing to prevent leakage past the bushing.

Owner:DELPHI TECH INC

Diaphragm valve

InactiveUS20060065868A1Increase wall thicknessSmall and lightSpindle sealingsDiaphragm valvesDiaphragm valveValve stem

A valve is provided for use in a fluid dispensing system. The valve includes a valve body having an interior cavity and a valve stem mounted for axial movement between open and closed positions within the valve body. The valve stem includes an actuation air passageway having an air inlet and an air outlet, with the air inlet being adapted to be coupled to a source of pressurized actuation air. The air outlet communicates with said interior cavity. The valve also includes a piston element carried by the valve stem and positioned within the interior cavity. The valve further includes a liquid inlet, a liquid outlet, and a valve seat positioned between the liquid inlet and the liquid outlet, whereby the valve stem is movable from the closed position to the open position relative to the valve seat when pressurized actuation air is introduced into the interior cavity through the actuation air passageway and acts against the piston element.

Owner:NORDSON CORP

Fluid Control Device

InactiveUS20080029174A1Firmly connectedPerform work in shortSpindle sealingsCircuit elementsCorrosionEngineering

A fluid control system with easy installation in a semiconductor production system etc. and pipe and wiring connections, with reduced pressure loss due to pipe connections, with easy change of arrangement of modules, free from corrosion even using a corrosive fluid for the fluid, and enabling control of the flow rate even with pulsation of the inflowing fluid is provided. The fluid control system of the present invention is characterized by having a flowmeter sensor part having an ultrasonic oscillator generating an ultrasonic wave in a fluid and an ultrasonic oscillator receiving the ultrasonic wave generated from the ultrasonic oscillator and outputting a signal to a flowmeter amplifier and a control valve controlling the state of flow of fluid to a predetermined state by a working pressure, wherein the flowmeter sensor part and the control valve are arranged inside a casing having a fluid inlet and a fluid outlet.

Owner:ASAHI YUKIZAI KOGYO CO LTD

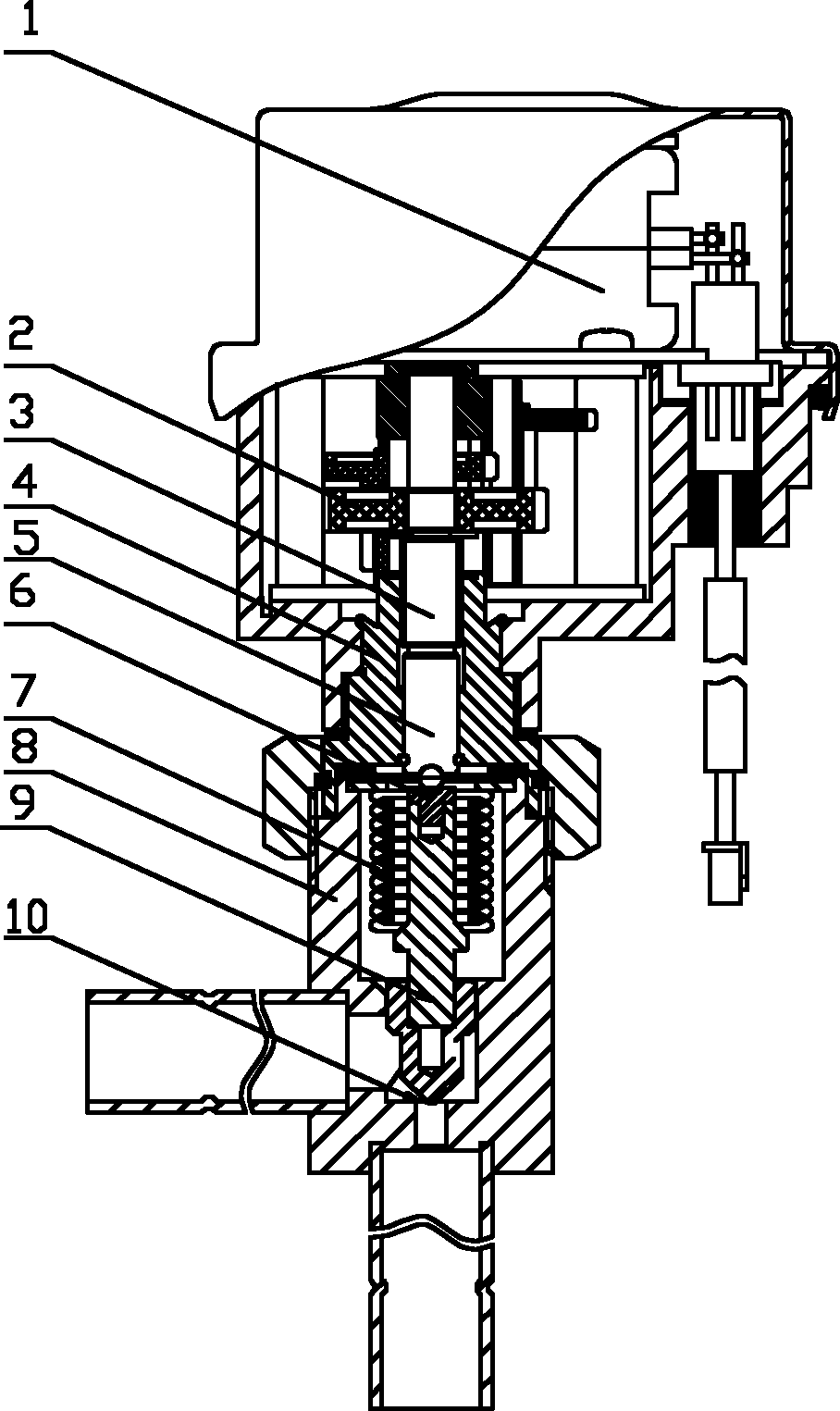

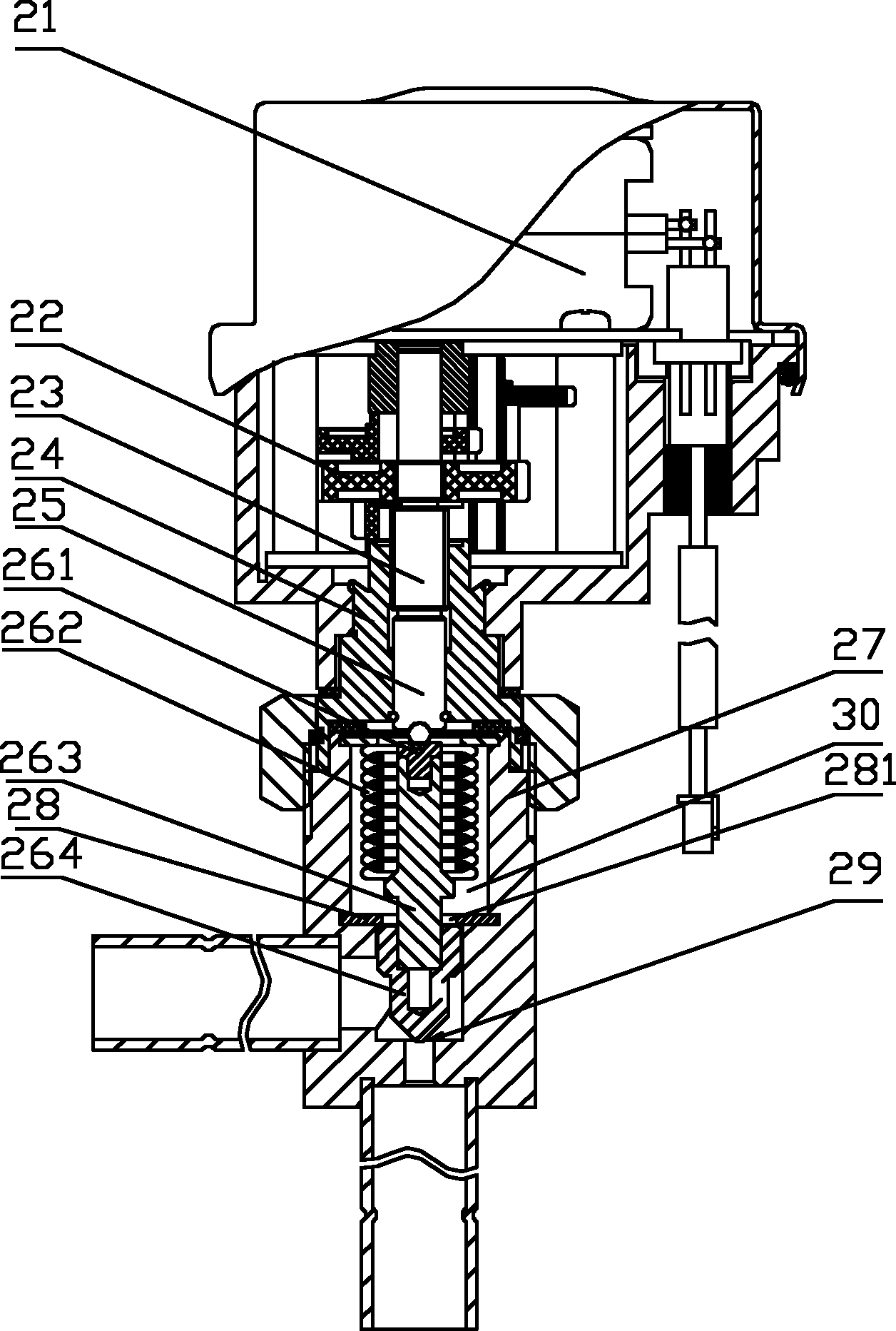

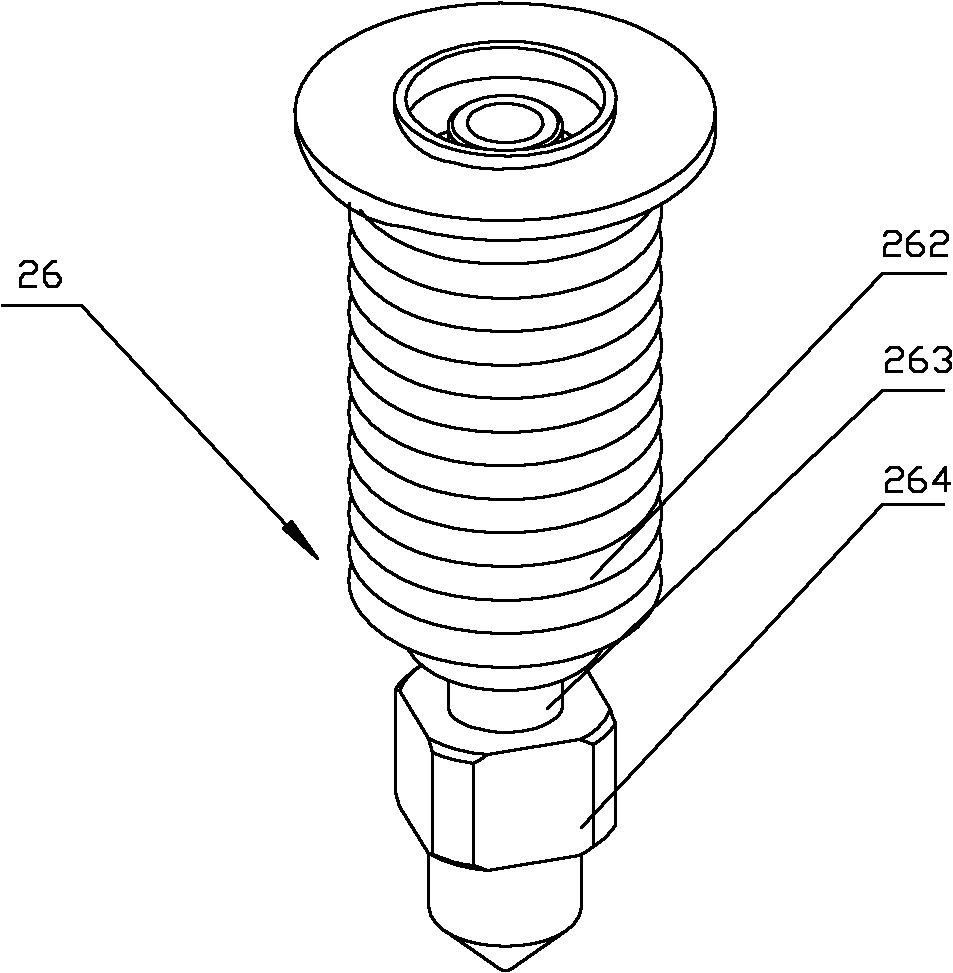

Electronic expansion valve

ActiveCN102644785APrevent overcompressionExtended service lifeSpindle sealingsFluid circulation arrangementElastic componentEngineering

The invention discloses an electronic expansion valve, comprising a drive mechanism, a transmission mechanism, a valve seat and a valve needle component, wherein the valve needle component is provided with a valve needle axially moving along the valve cavity of the electronic expansion valve to control the openness of a valve opening, a valve rod, and an elastic component for reset. The electronic expansion valve is characterized by further comprising a limit structure arranged in the valve cavity and provided with an axial channel, and the valve needle component is provided with a transversal flange; and the limit structure is located above the flange in the case that the valve needle component moves upwards until the valve opening has the maximum openness, and the minimum radial dimension of the axial channel is less than the maximum radial dimension of the flange. The valve needle component of the electronic expansion valve cannot continue to move upwards due to the resisting of the limit structure in case of moving upwards to the position where the valve opening is the largest or slightly higher, and the valve needle component cannot greatly move upwards to compress the elastic component for reset in excess in case of coil detachment and replacement and in the other cases of needing to separate the valve needle component from other components above, thus prolonging the service life of the elastic component.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com