Technology for reclaiming hydrogen chloride tail gas in chemical production

A process technology, chemical production technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as unfavorable industrialized continuous production, waste of time, waste of energy and environmental pollution, and achieve complete recovery and high-efficiency. The effect of added value utilization, improving economic efficiency and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

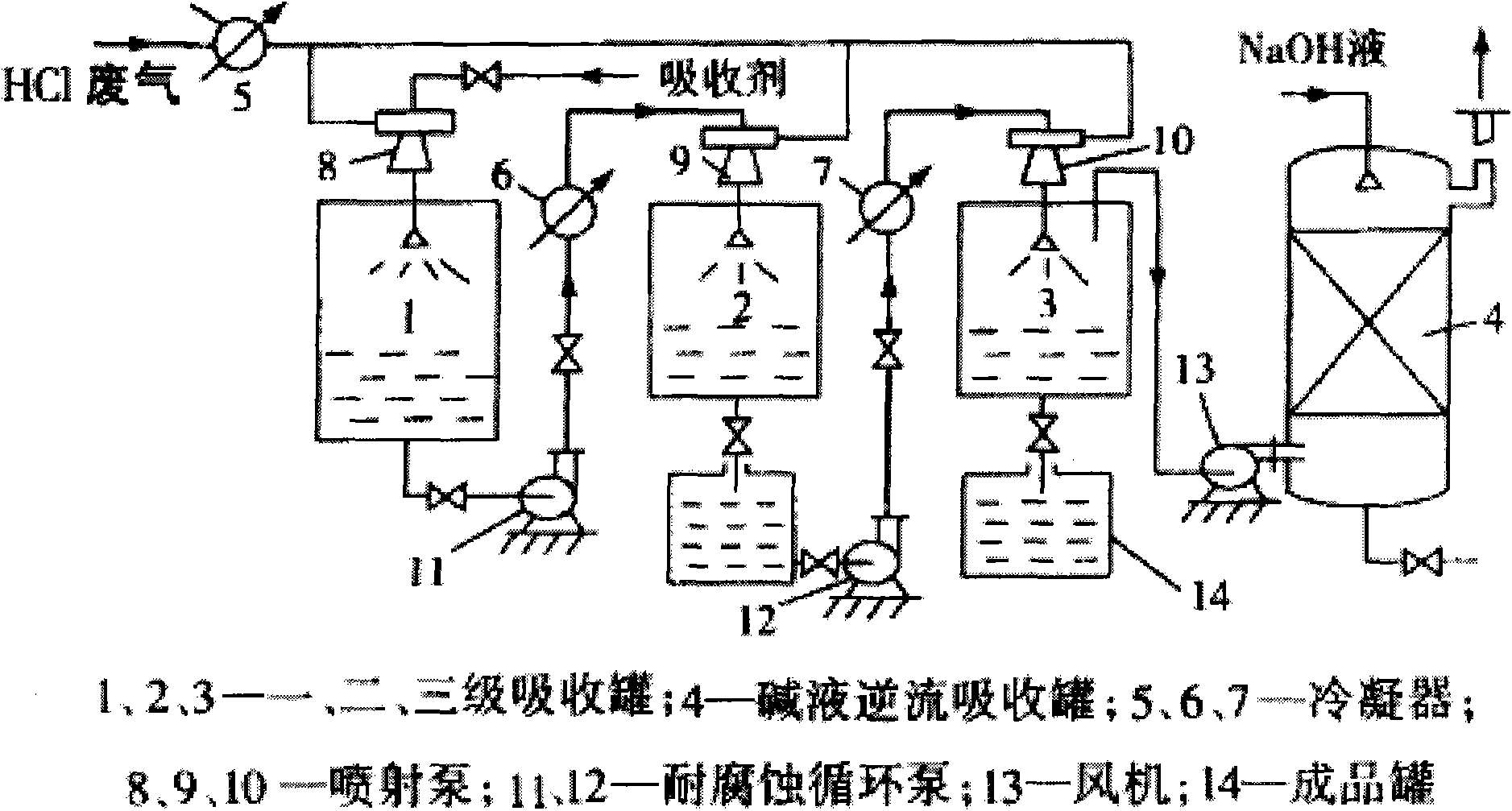

[0009] The absorber 1, 2 and 3 (see image 3 ) into 1 / 2 tower high deionized water absorbent, the lower part of the neutralization tower is filled with industrial ammonia water, the check valves 1 and 2 are closed, and the four-way valve is adjusted so that fan 1 communicates with absorption tower 1. The outer layer (or inner cooling pipe) passes through the coolant along the direction of absorption tower 1-absorption tower 2-absorption tower 3-neutralization tower, and controls the temperature of the absorbent in the absorption tower to be less than 20°C, and the hydrogen chloride produced in the industry After the exhaust gas passes through the cooler and dryer (currently the dryer does not need to be equipped with desiccant), it enters the absorption tower 1 from the fan 1 through the four-way valve. After the hydrogen chloride gas passes through the sand core plate, it forms many gradually rising Hydrogen chloride has tiny bubbles, and the tiny bubbles are absorbed by wate...

Embodiment 2

[0011] When the concentration of hydrogen chloride from tower 1 reaches 38%, adjust the four-way valve, connect absorption tower 2 with blower fan 1, open blower blower 2 and check valve 1, close blower blower 3 and check valve 3, and absorb tower After the hydrochloric acid in 1 is placed in the concentrated hydrochloric acid storage tank, add deionized water absorbent, so that the way for hydrogen chloride gas to be absorbed: absorption tower 2-absorption tower 3-absorption tower 1-neutralization tower is opened. The process of absorbing hydrogen chloride continues until the concentration of hydrogen chloride in the absorbent water reaches 38% by sampling from the tower 2 .

Embodiment 3

[0013] When the concentration of hydrogenchloride reaches 38% from tower 2, adjust four-way valve, absorber 3 is connected with fan 1, fan 3 and check valve 2 are opened, fan 4 is closed, and the hydrochloric acid in absorption tower 2 is released After entering the concentrated hydrochloric acid storage tank, add deionized water absorbent, so that the way hydrogen chloride gas is absorbed: absorption tower 3-absorption tower 1-absorption tower 2-neutralization tower is opened. The process of absorbing hydrogen chloride continues until the concentration of hydrogen chloride in the absorbent water reaches 38% by sampling from the tower 3 .

[0014] The way that hydrogen chloride gas is absorbed in embodiment 1 is: absorption tower 1-absorption tower 2-absorption tower 3-neutralization tower, the way that hydrogen chloride gas is absorbed in embodiment 2 is: absorption tower 2-absorption tower 3- Absorption tower 1-neutralization tower, the way that hydrogen chloride gas is abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com