Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

245results about "Fluorine/hydrogen-fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

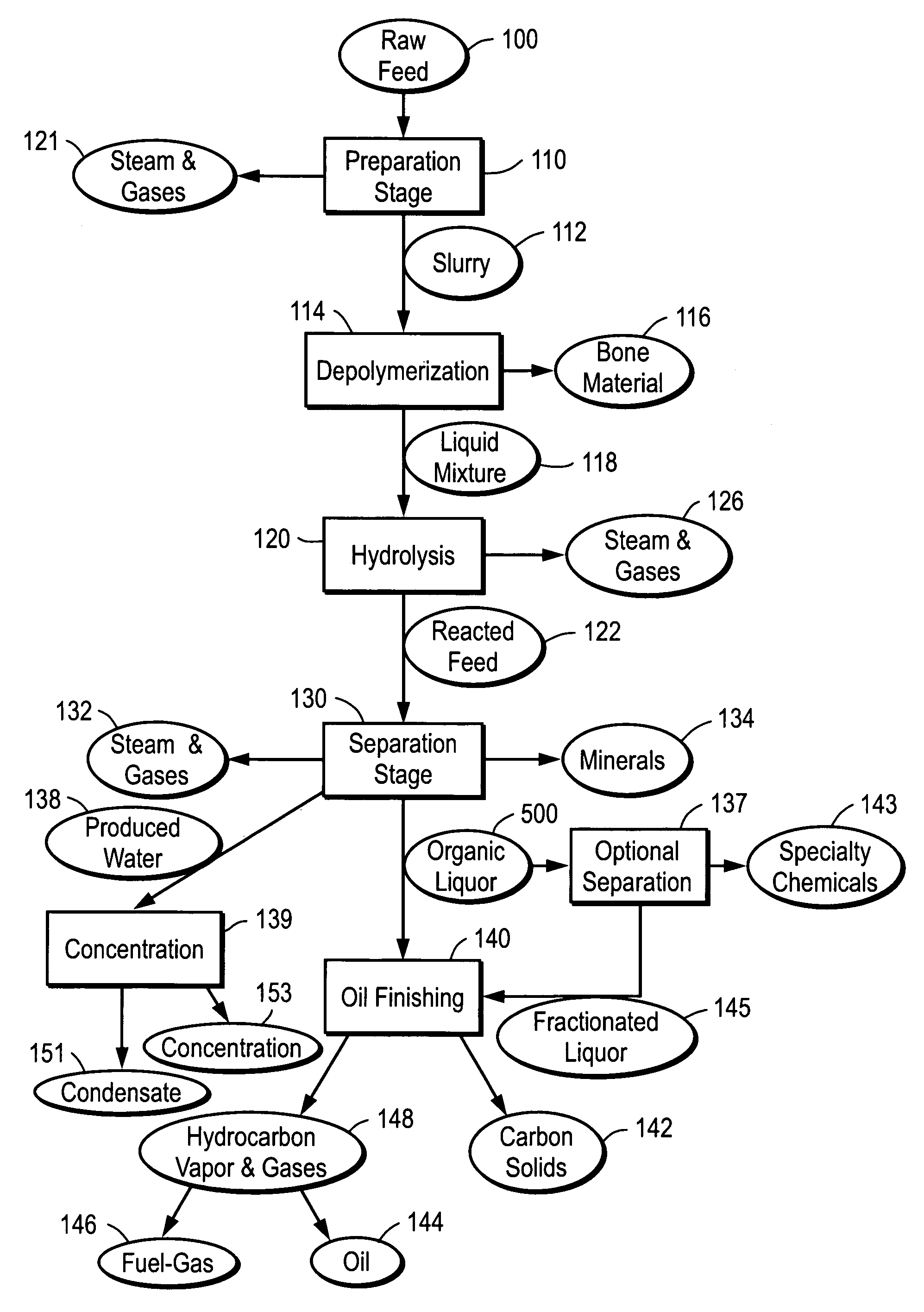

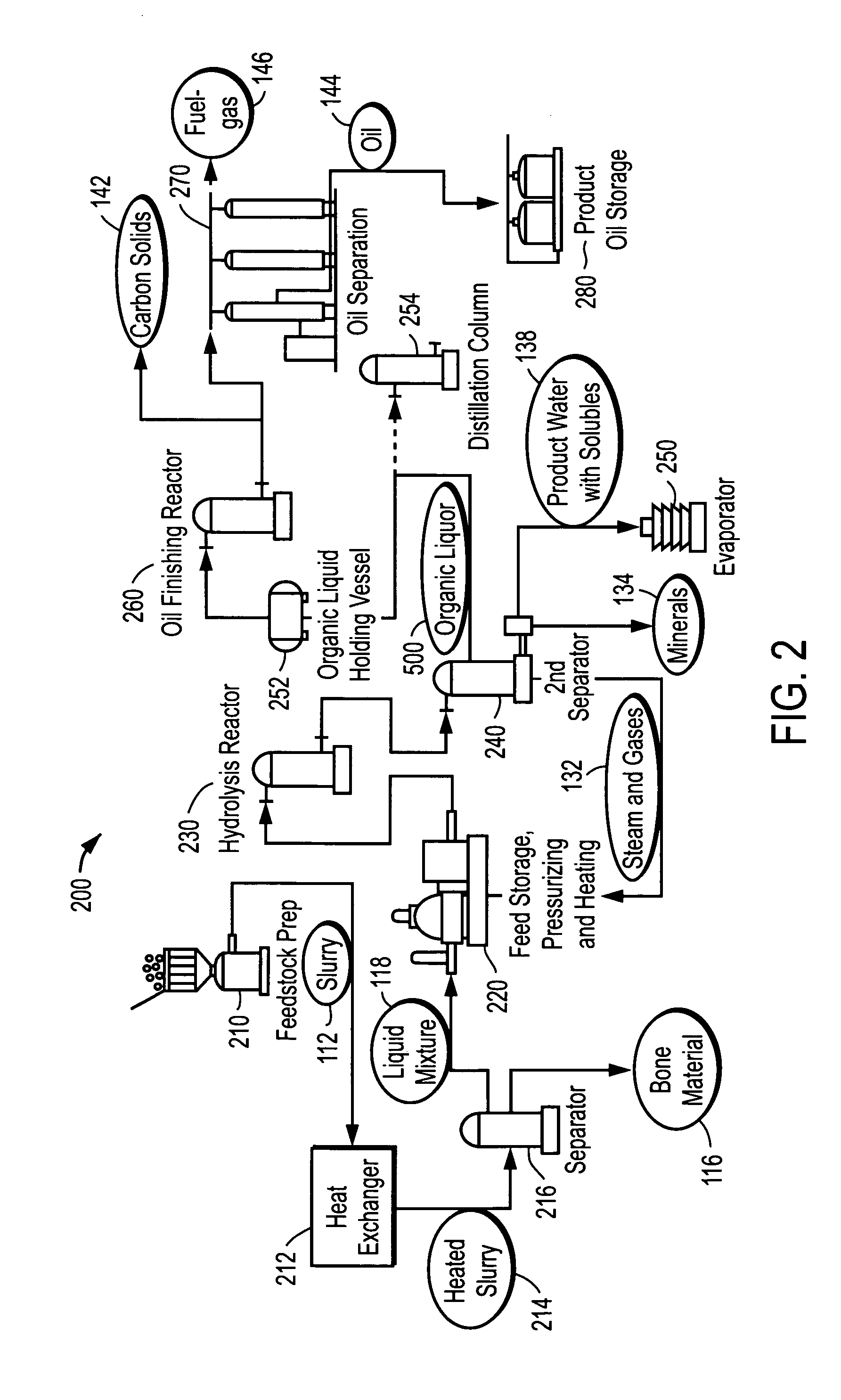

Depolymerization process of conversion of organic and non-organic waste materials into useful products

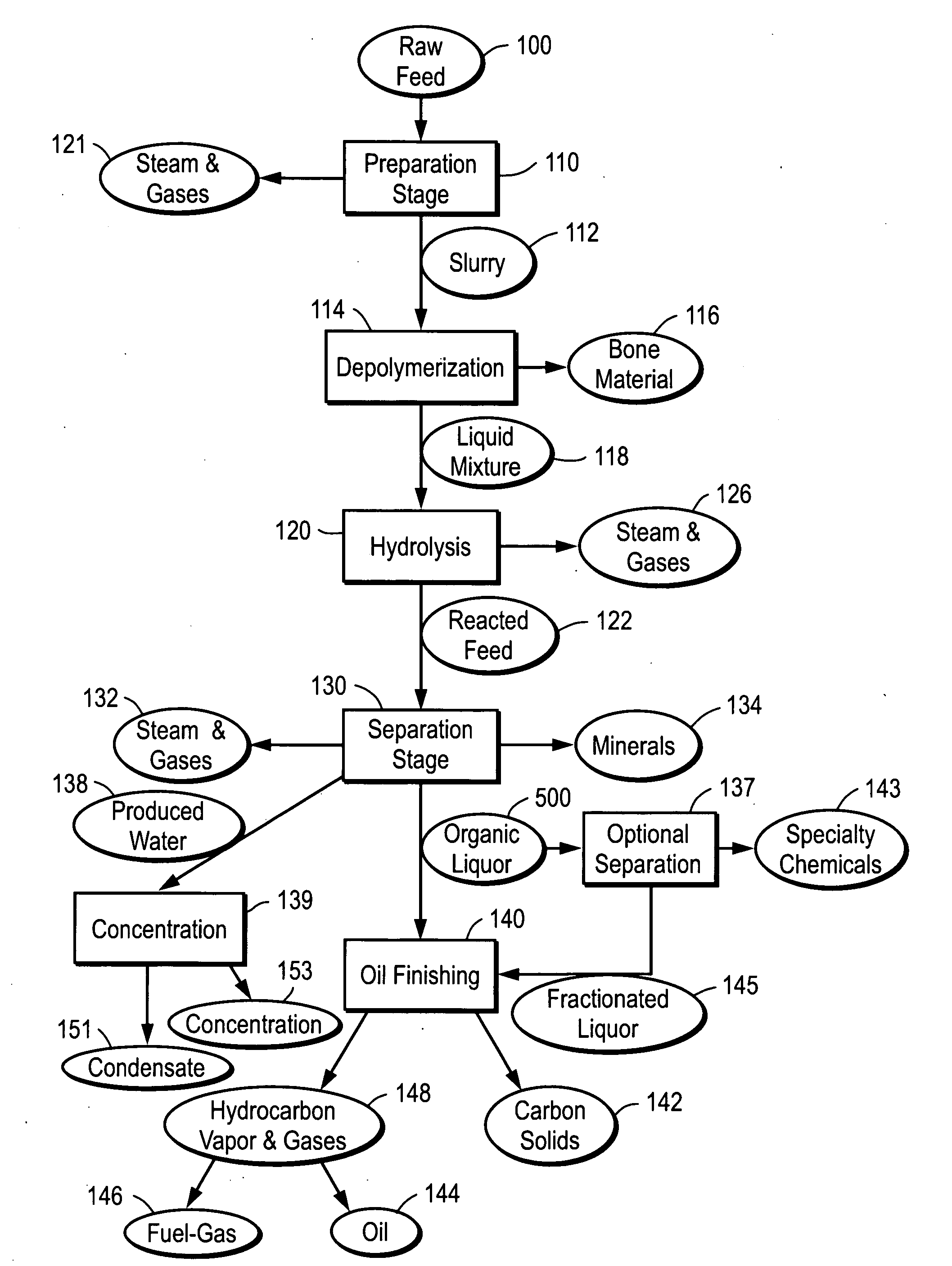

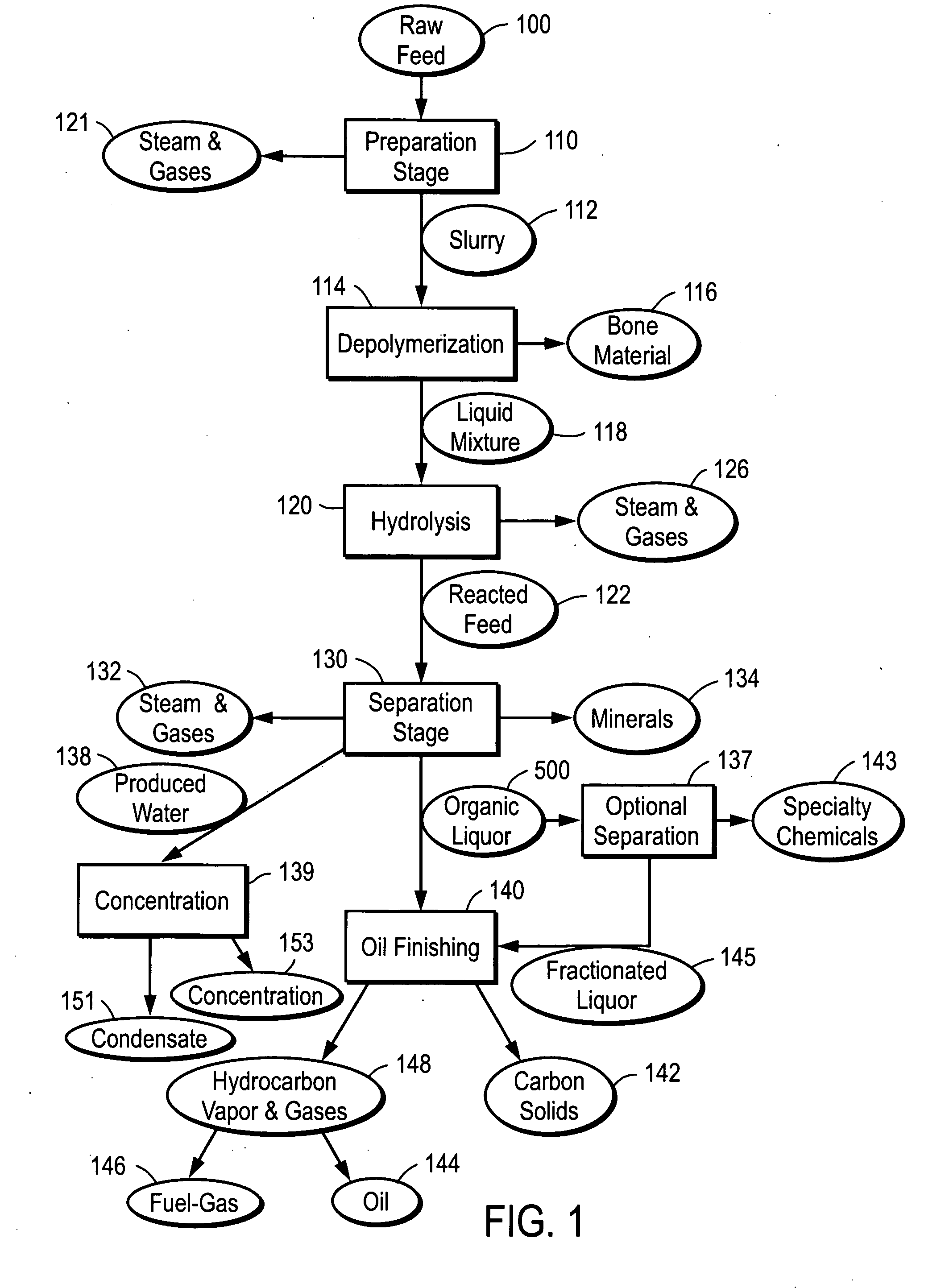

ActiveUS20070098625A1Improve energy efficiencyAcceptable costWaste based fuelLiquid hydrocarbon mixture productionDepolymerizationCost effectiveness

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

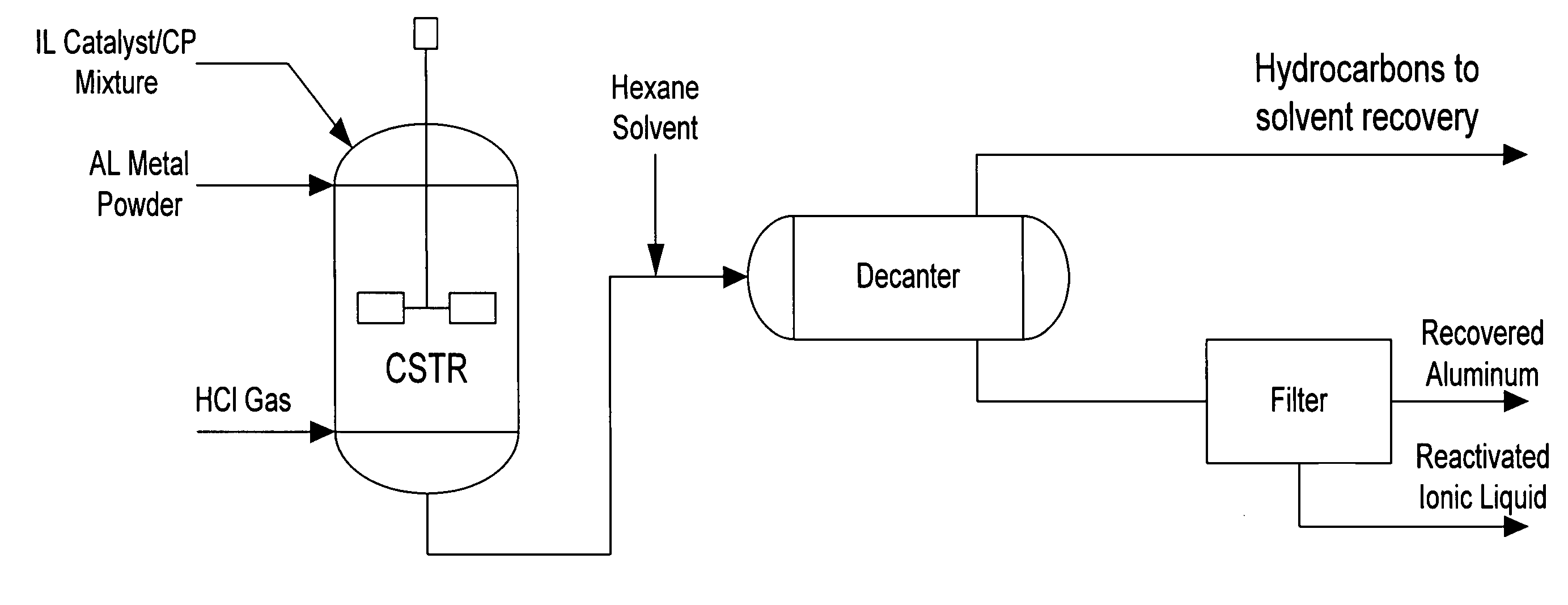

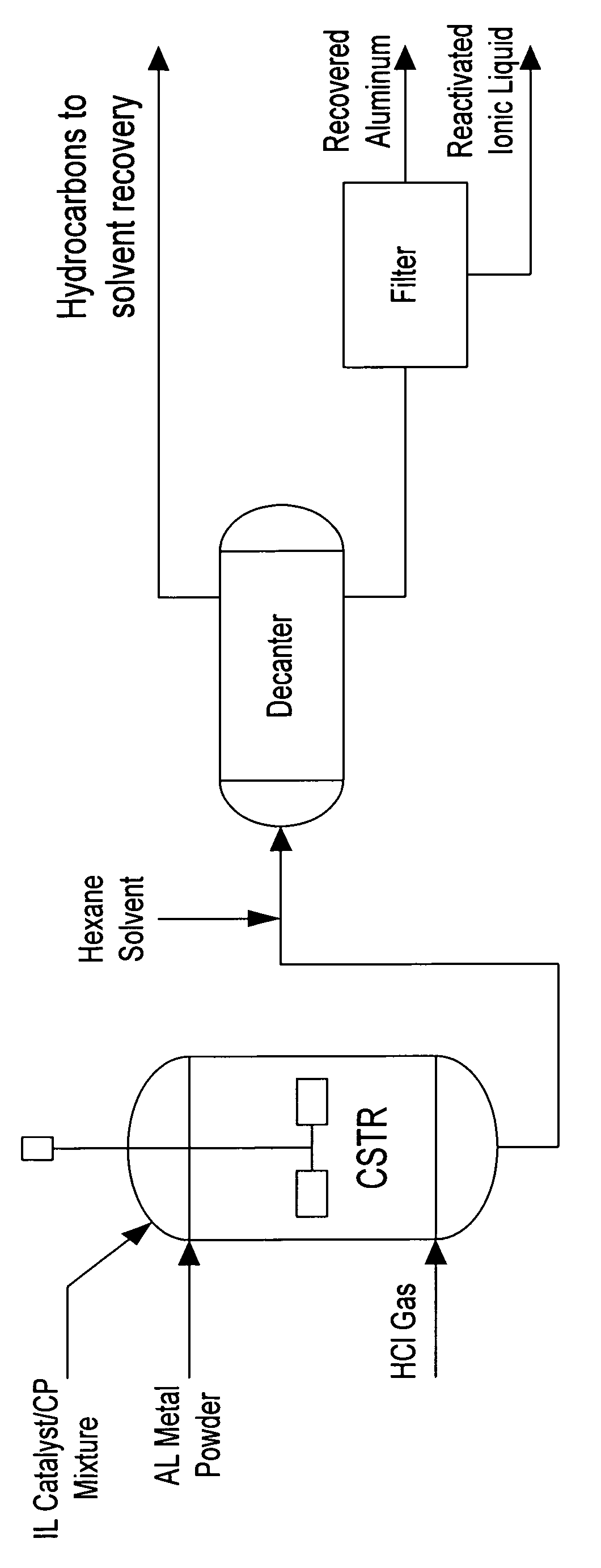

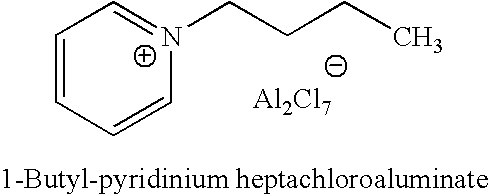

Regeneration of acidic catalysts

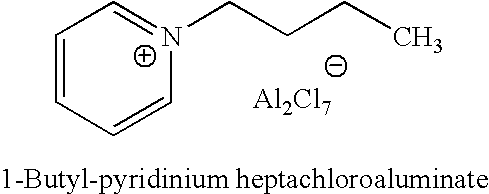

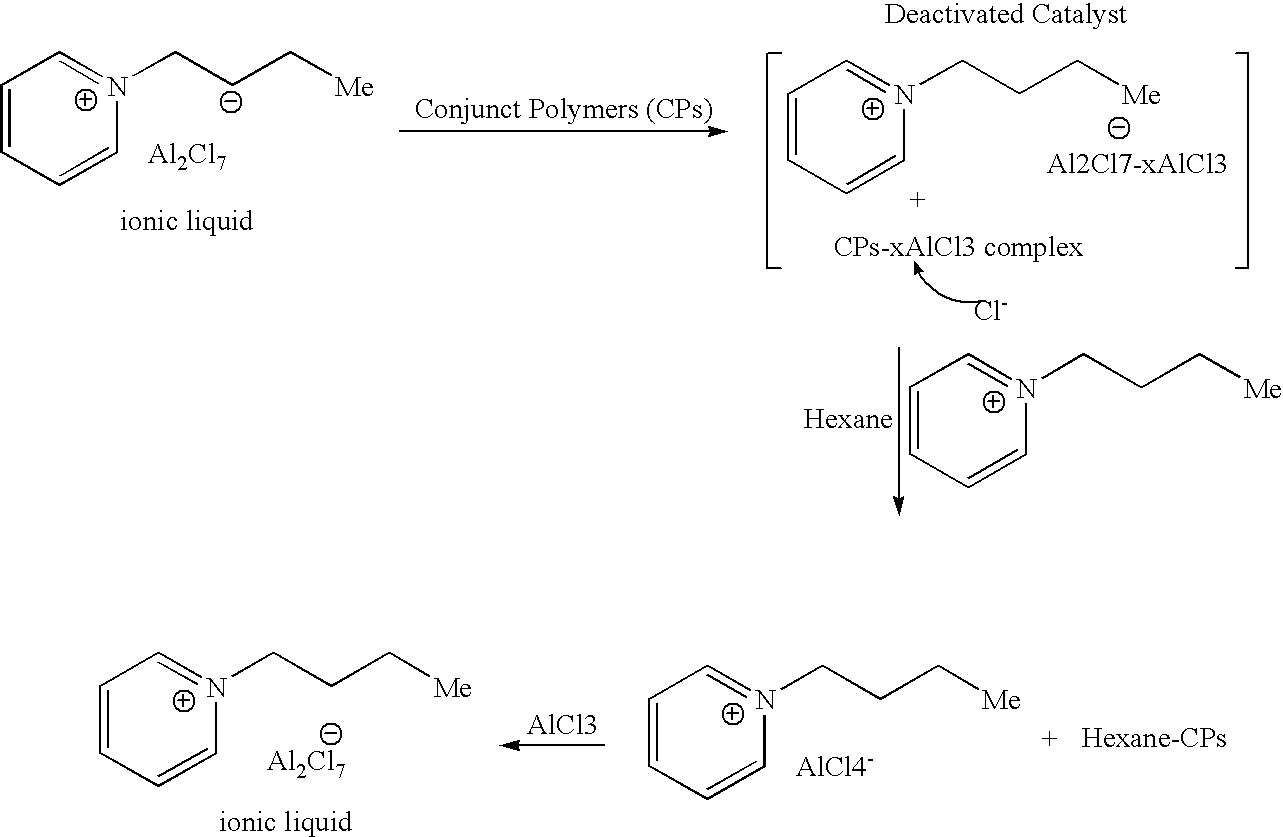

ActiveUS20070142213A1High activityChlorine/hydrogen-chloride purificationSulfur compoundsAlkyl transferIonic liquid

A process for regenerating a used acidic catalyst which has been deactivated by conjunct polymers by removing the conjunct polymers so as to increase the activity of the catalyst is disclosed. Methods for removing the conjunct polymers include hydrogenation, addition of a basic reagent and alkylation. The methods are applicable to all acidic catalysts and are described with reference to certain ionic liquid catalysts.

Owner:CHEVROU USA INC

Depolymerization process of conversion of organic and non-organic waste materials into useful products

ActiveUS7771699B2Efficient processingSmooth connectionWaste based fuelLiquid hydrocarbon mixture productionSpeciality chemicalsDepolymerization

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

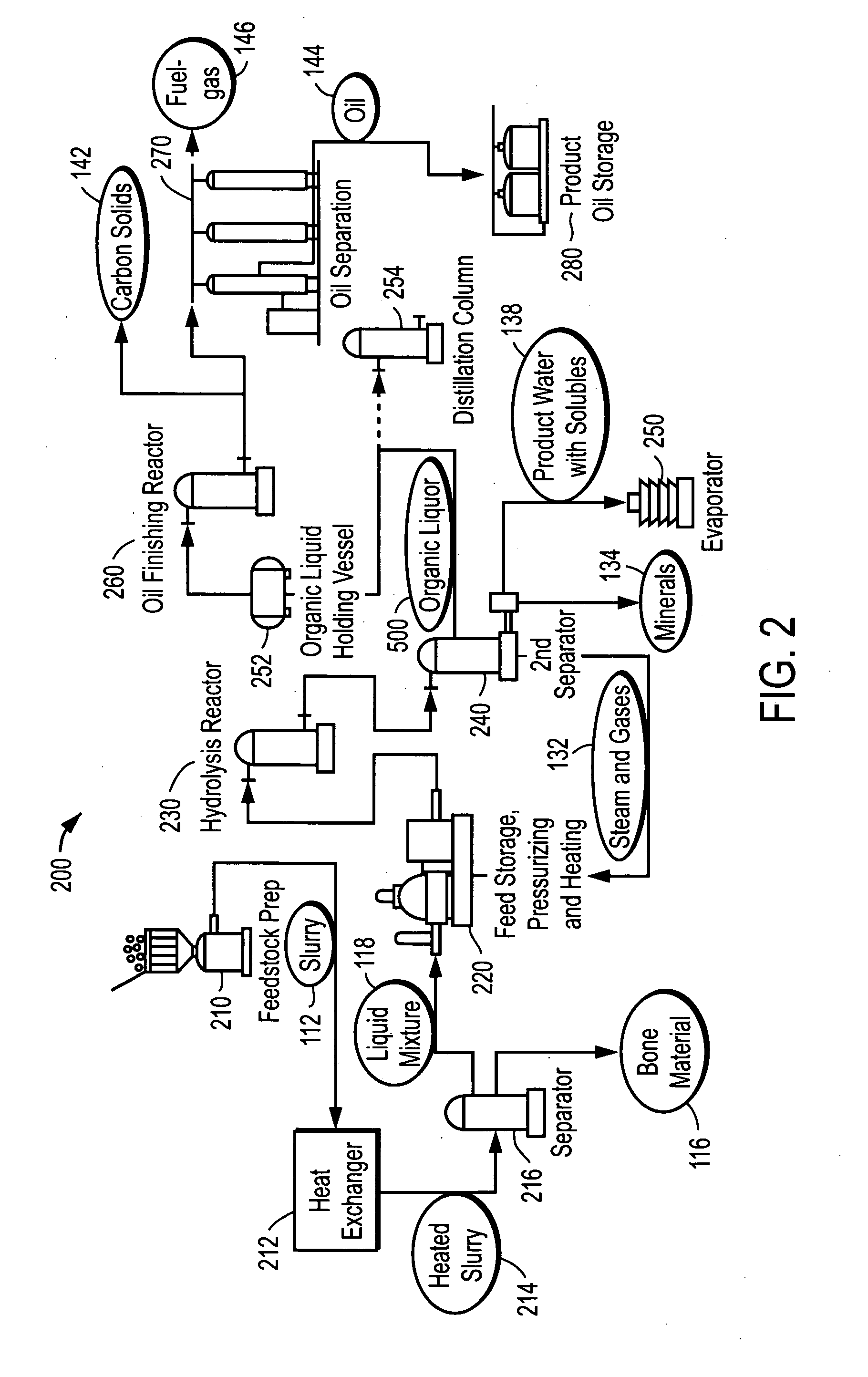

Regeneration of acidic catalysts

ActiveUS7732363B2High activityChlorine/hydrogen-chloride purificationHydrocarbon purification/separationAlkyl transferIonic liquid

A process for regenerating a used acidic catalyst which has been deactivated by conjunct polymers by removing the conjunct polymers so as to increase the activity of the catalyst is disclosed. Methods for removing the conjunct polymers include hydrogenation, addition of a basic reagent and alkylation. The methods are applicable to all acidic catalysts and are described with reference to certain ionic liquid catalysts.

Owner:CHEVROU USA INC

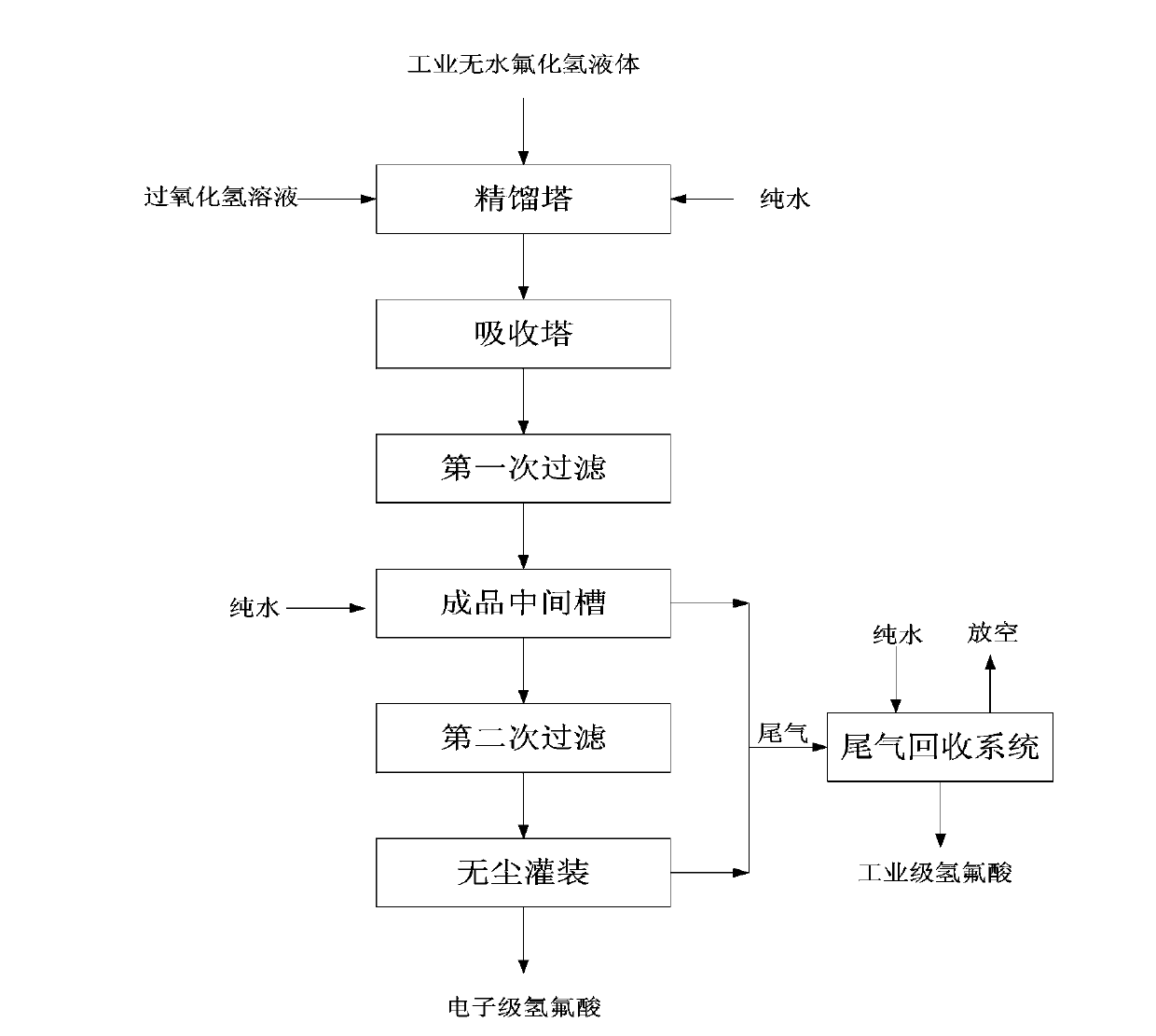

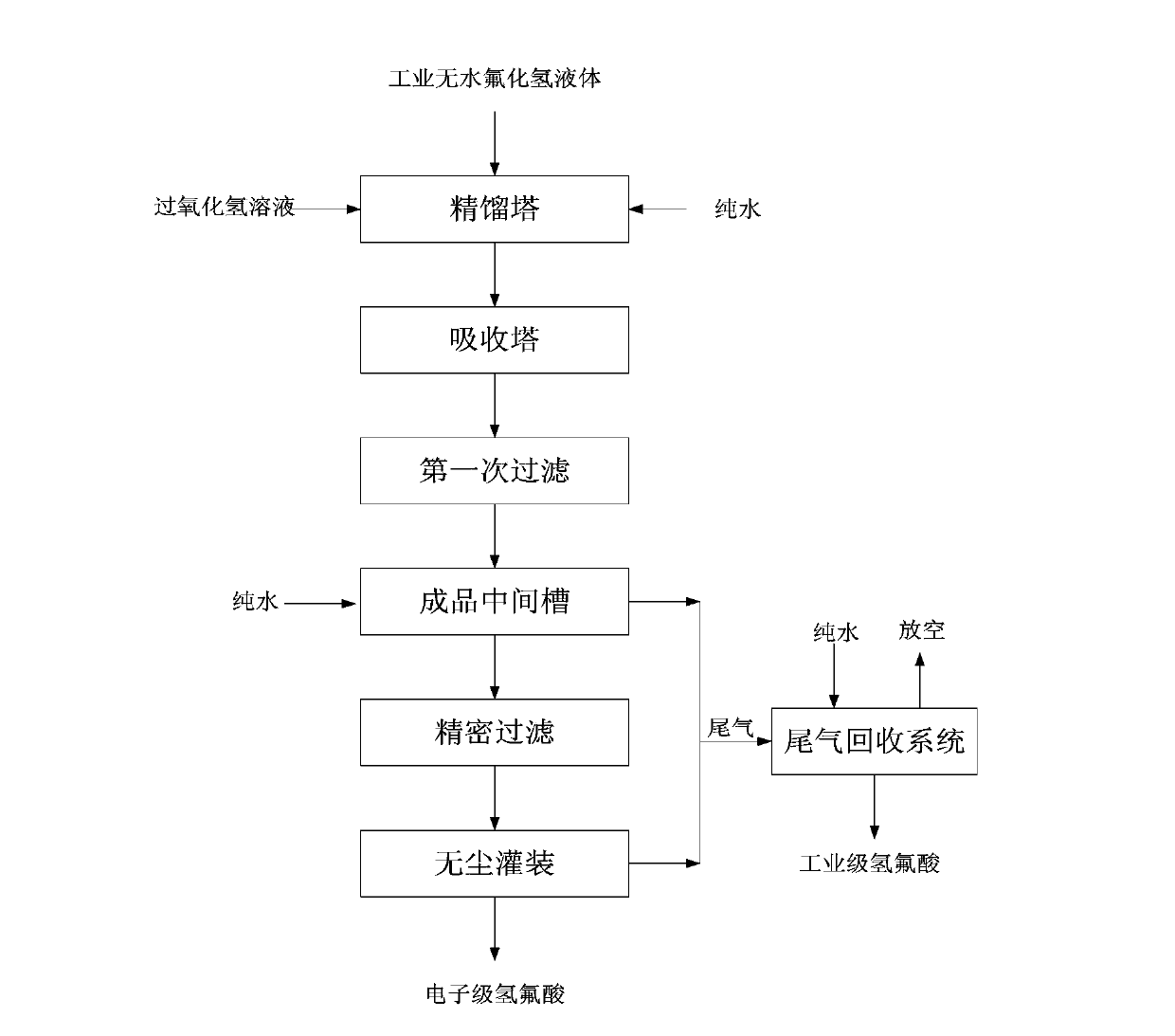

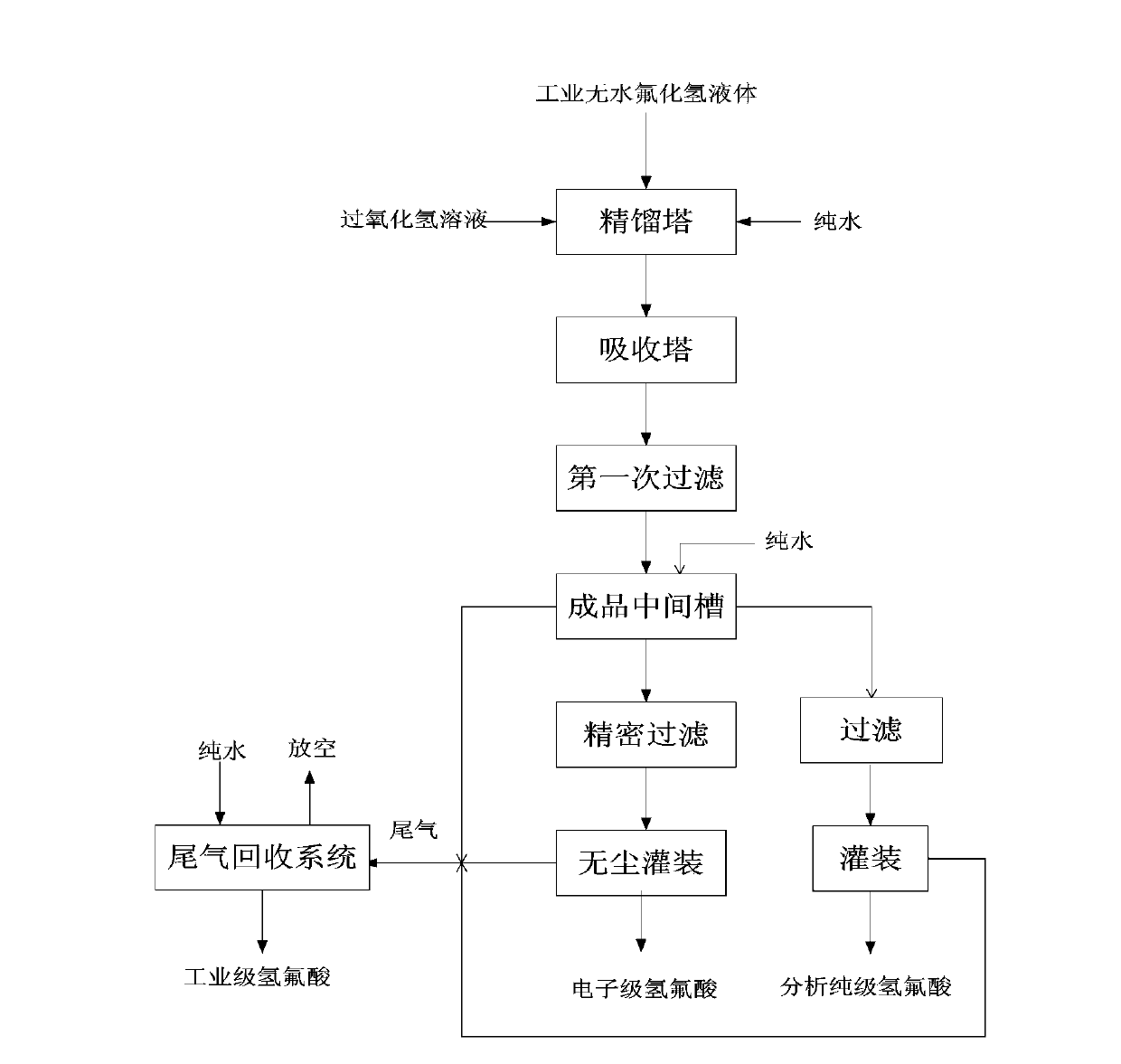

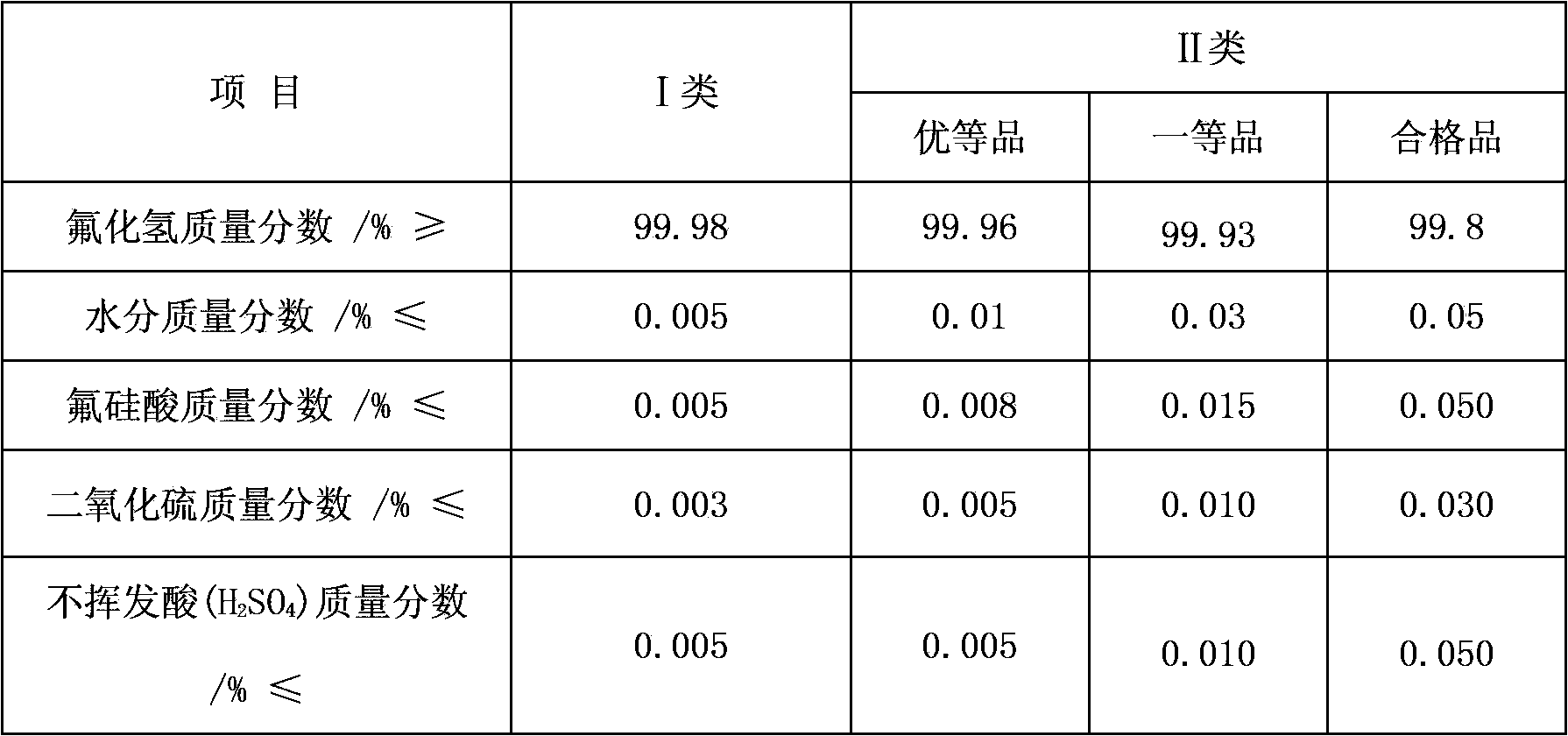

Preparation method for electron-grade hydrofluoric acid

ActiveCN103991847AReduced purification processFluorine/hydrogen-fluorideHydrogen fluorideHydrofluoric acid

A preparation method for electron-grade hydrofluoric acid comprises the following steps: introducing an industrial waterless hydrogen fluoride liquid and pure water into a rectifying tower, so as to form hydrofluoric acid with a first concentration; then adding a hydrogen peroxide solution for obtaining arsenic and silicon impurities in hydrofluoric acid, and then performing rectification; condensing the hydrogen fluoride gas obtained through rectification to form a hydrofluoric acid liquid, performing first filtration, and performing absorbing by utilizing pure water to form hydrofluoric acid with a second concentration, and performing second filtration, so as to obtain the electron-grade hydrofluoric acid product; and absorbing tail gas with pure water, so as to prepare industrial-grade hydrofluoric acid. The preparation technology is simple, and no extra impurities are introduced; the prepared electron-grade hydrofluoric acid reaches international standard SEMI-C7 standard of semiconductor equipment and materials; the yield is high and the cost is low; and by employing one production process, the electron-grade hydrofluoric acid and analytically-pure-grade hydrofluoric acid can be both prepared.

Owner:FUJIAN YONGJING TECH CO LTD

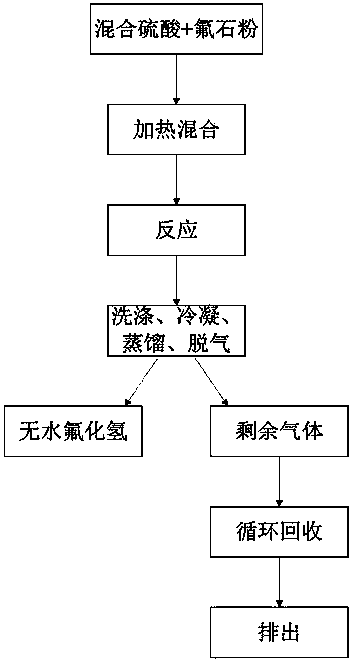

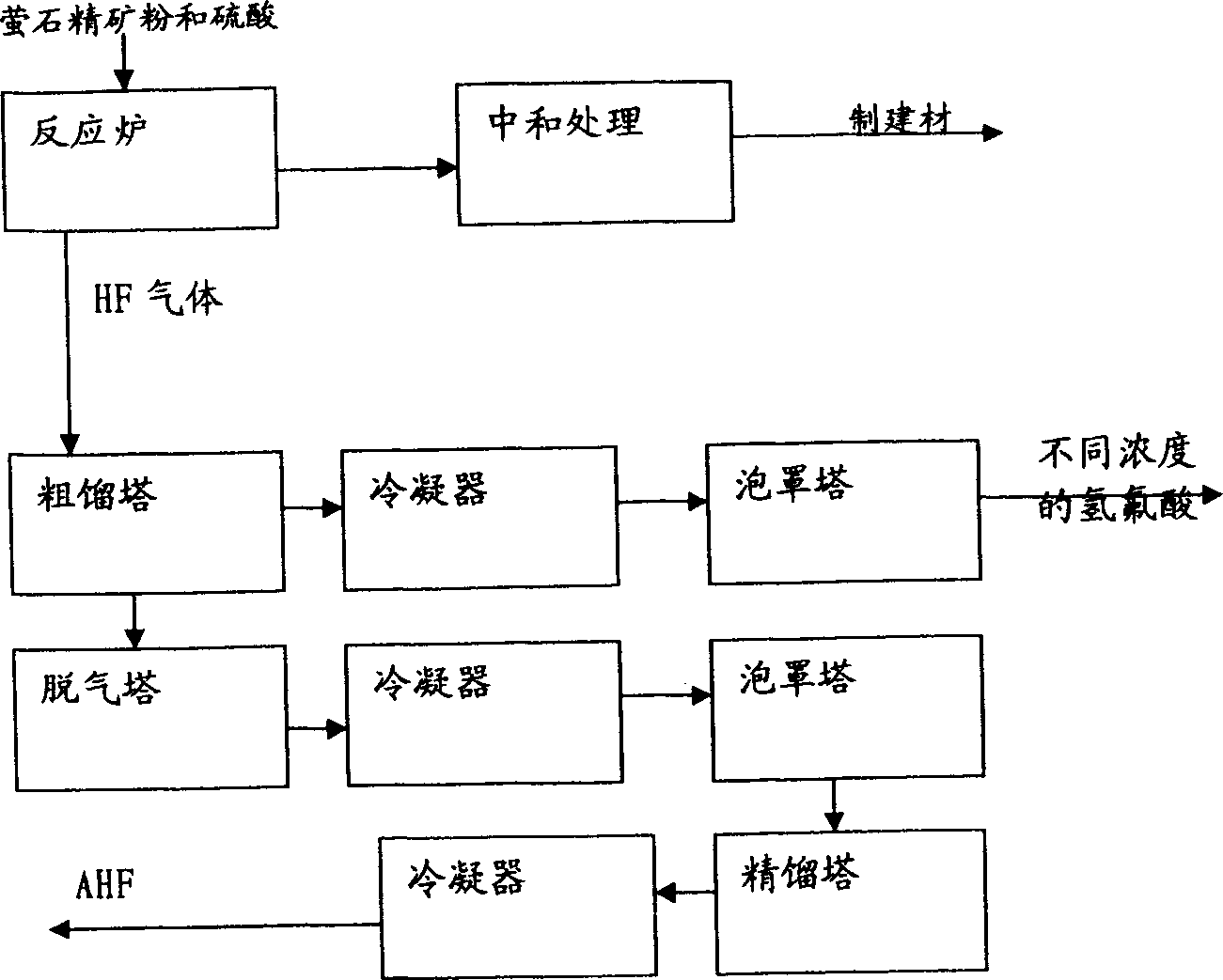

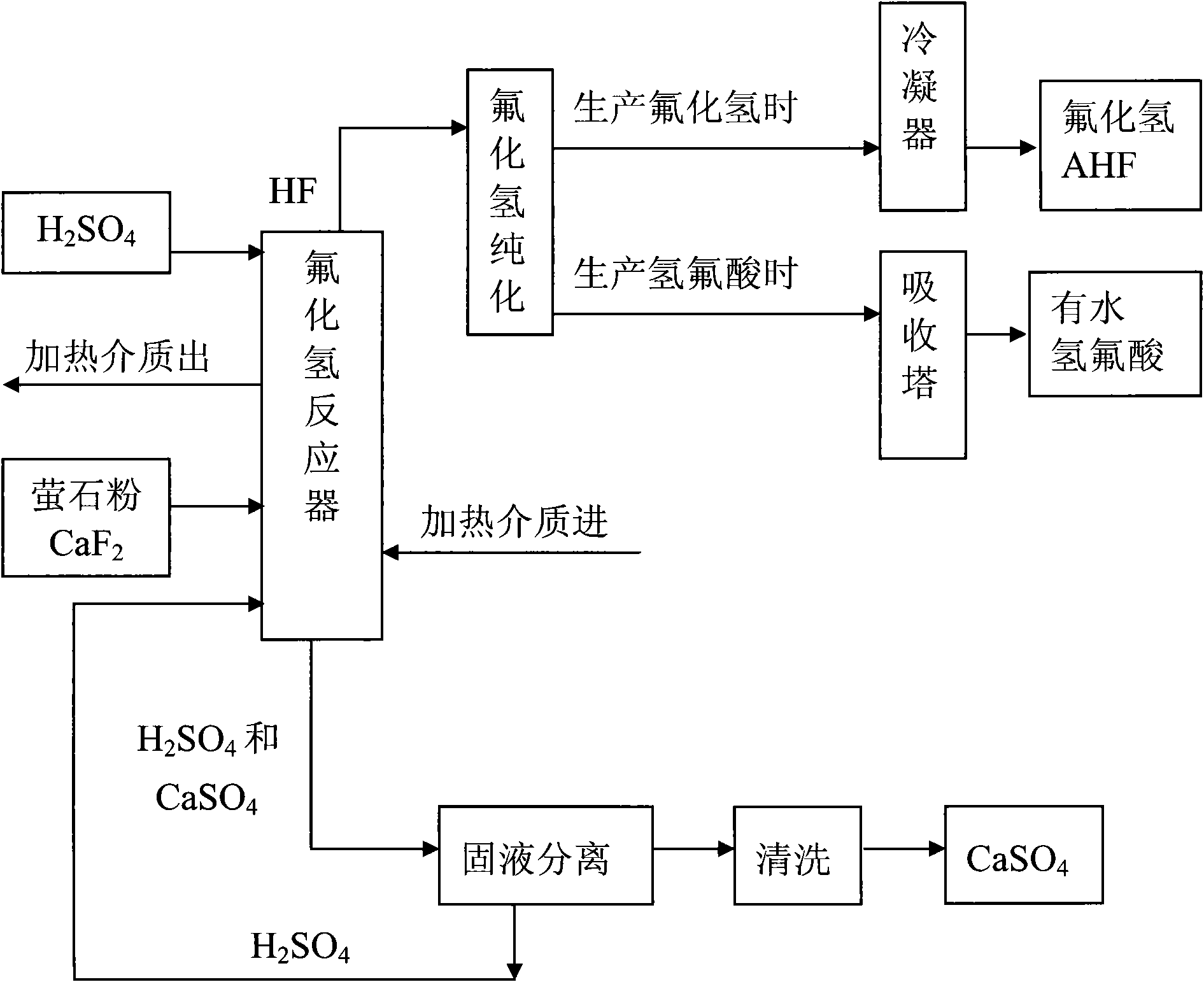

Preparation method for anhydrous hydrogen fluoride

ActiveCN103848400AIncrease temperatureIncrease contact areaFluorine/hydrogen-fluorideHydrogen fluorideChemistry

A disclosed preparation method for anhydrous hydrogen fluoride comprises the following steps: respectively adding a mixed sulfuric acid ( concentrated sulfuric acid and oleum) and fluorspar powder according to a certain material pouring ratio into a pre-reactor for a pre-reaction; sending to a converter reactor, reacting under the heating condition to obtain a large amount of crude hydrogen fluoride gas; and processing by a washing tower, a condenser, a rectifying tower and a degassing tower, so as to prepare pure hydrogen fluoride gas. An incompletely reacted material in the converter reactor is processed through recycle, and a gas uncollected after the crude hydrogen fluoride gas generated in the reaction is refined is secondarily utilizable through two-time circulation absorption, so that the yield of the preparation method is substantially improved.

Owner:FUJIAN YONGJING TECH CO LTD

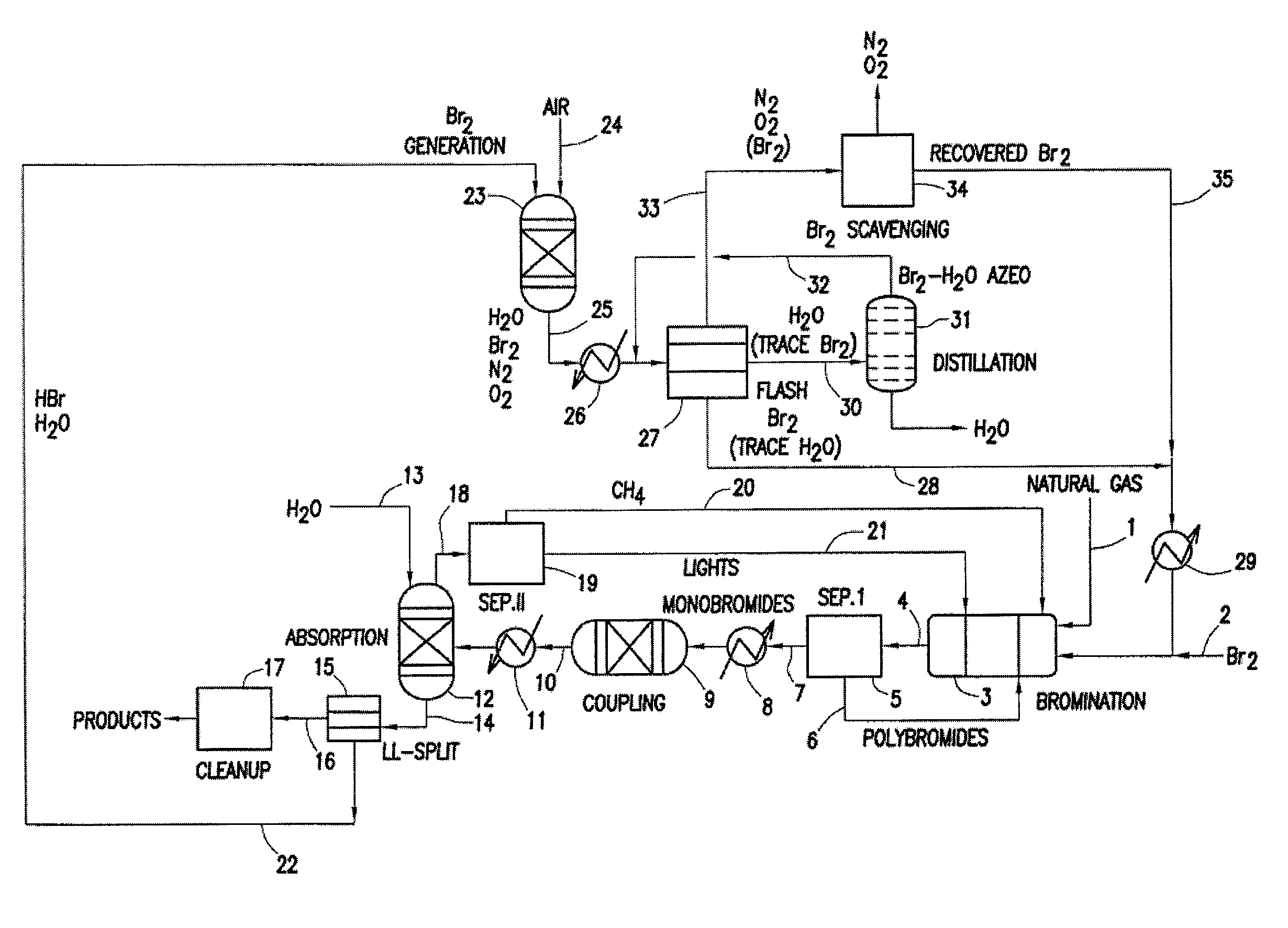

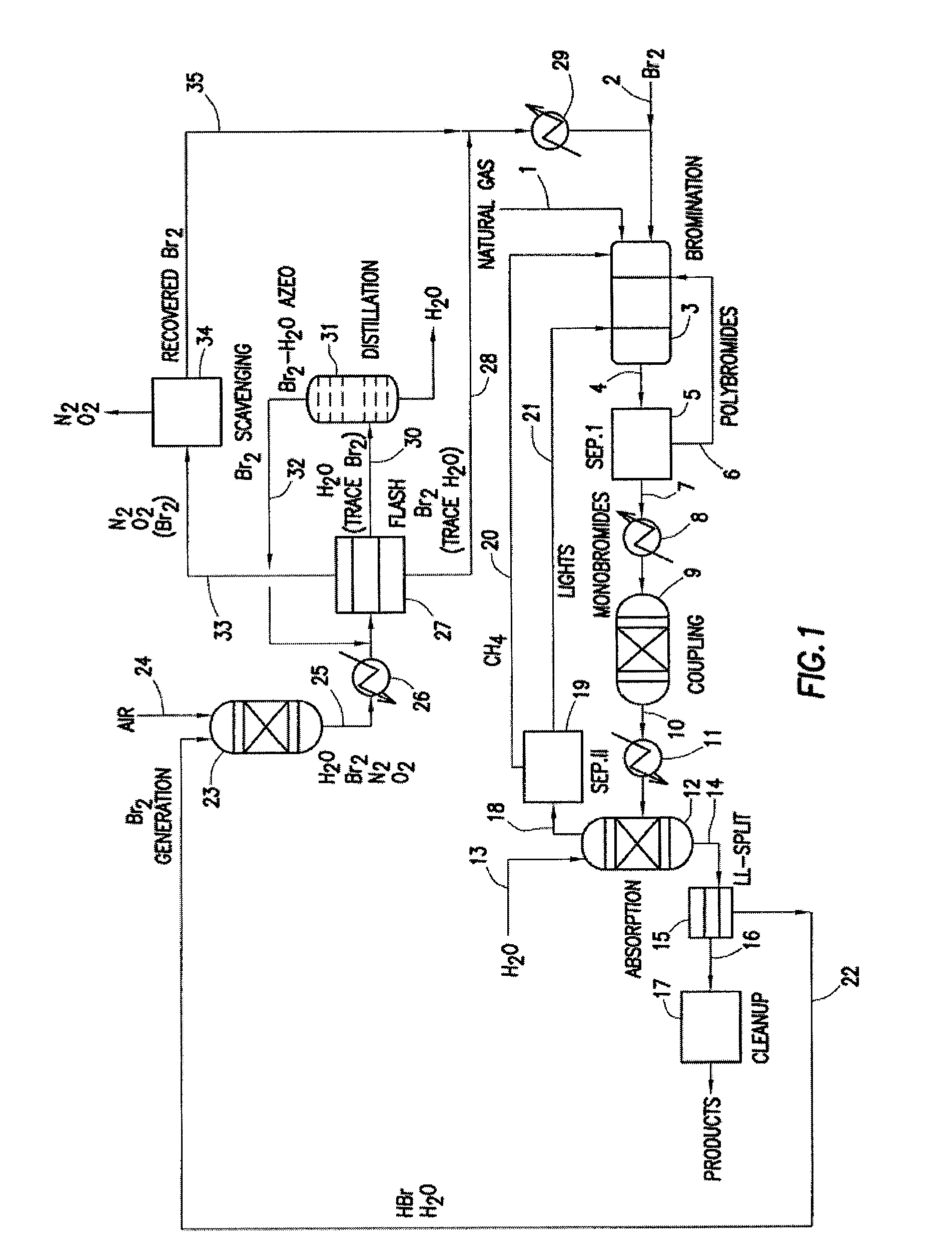

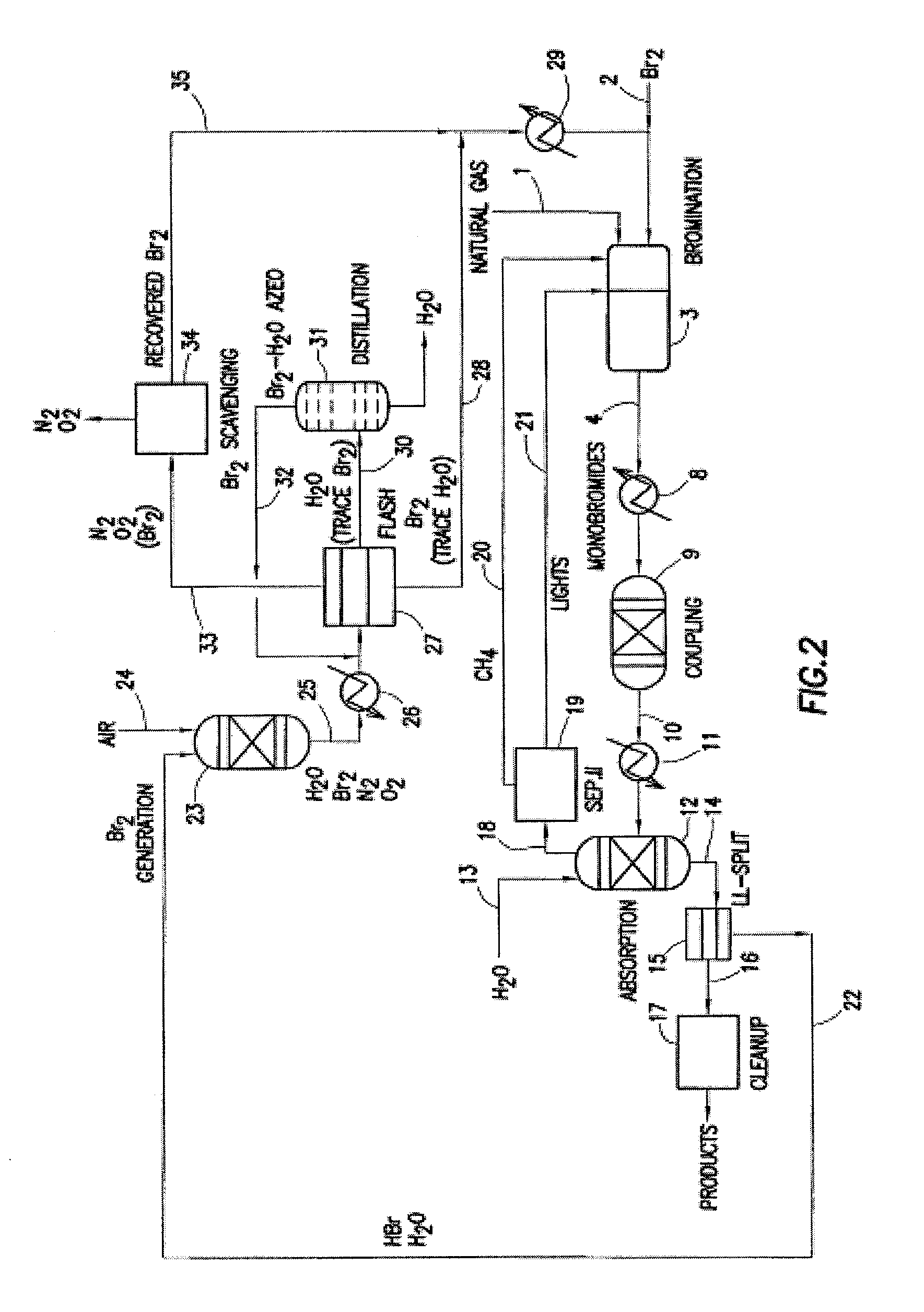

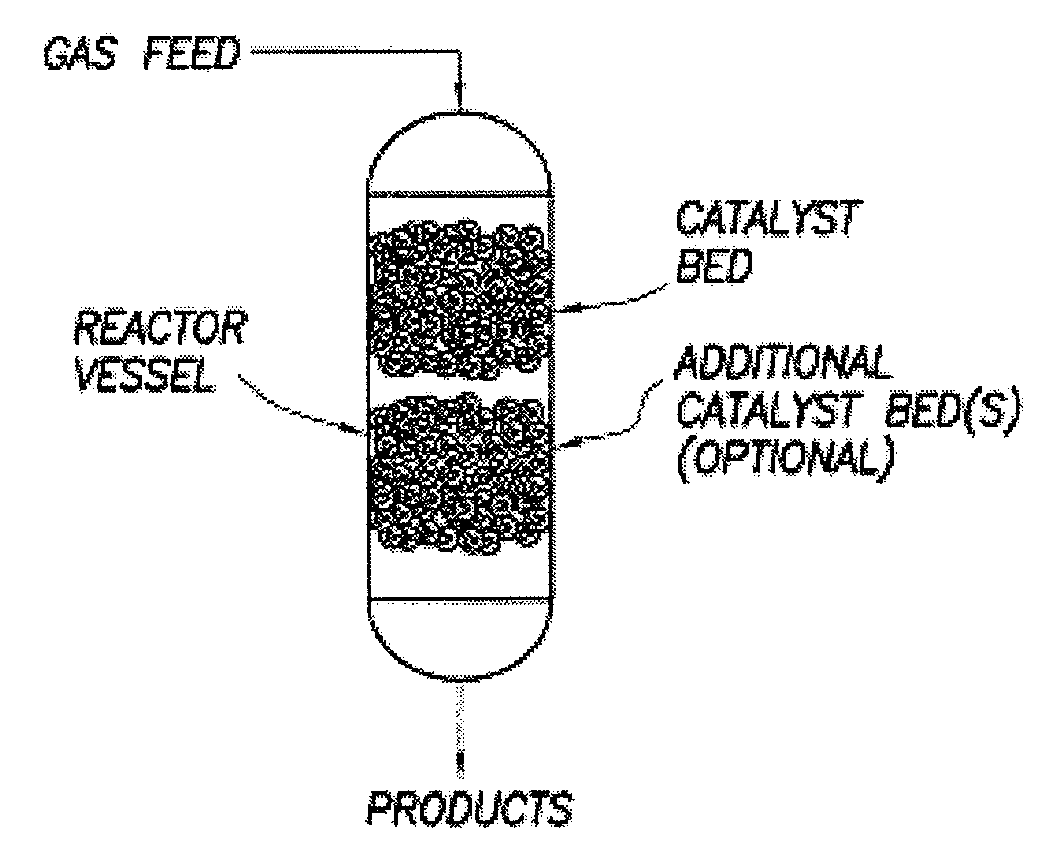

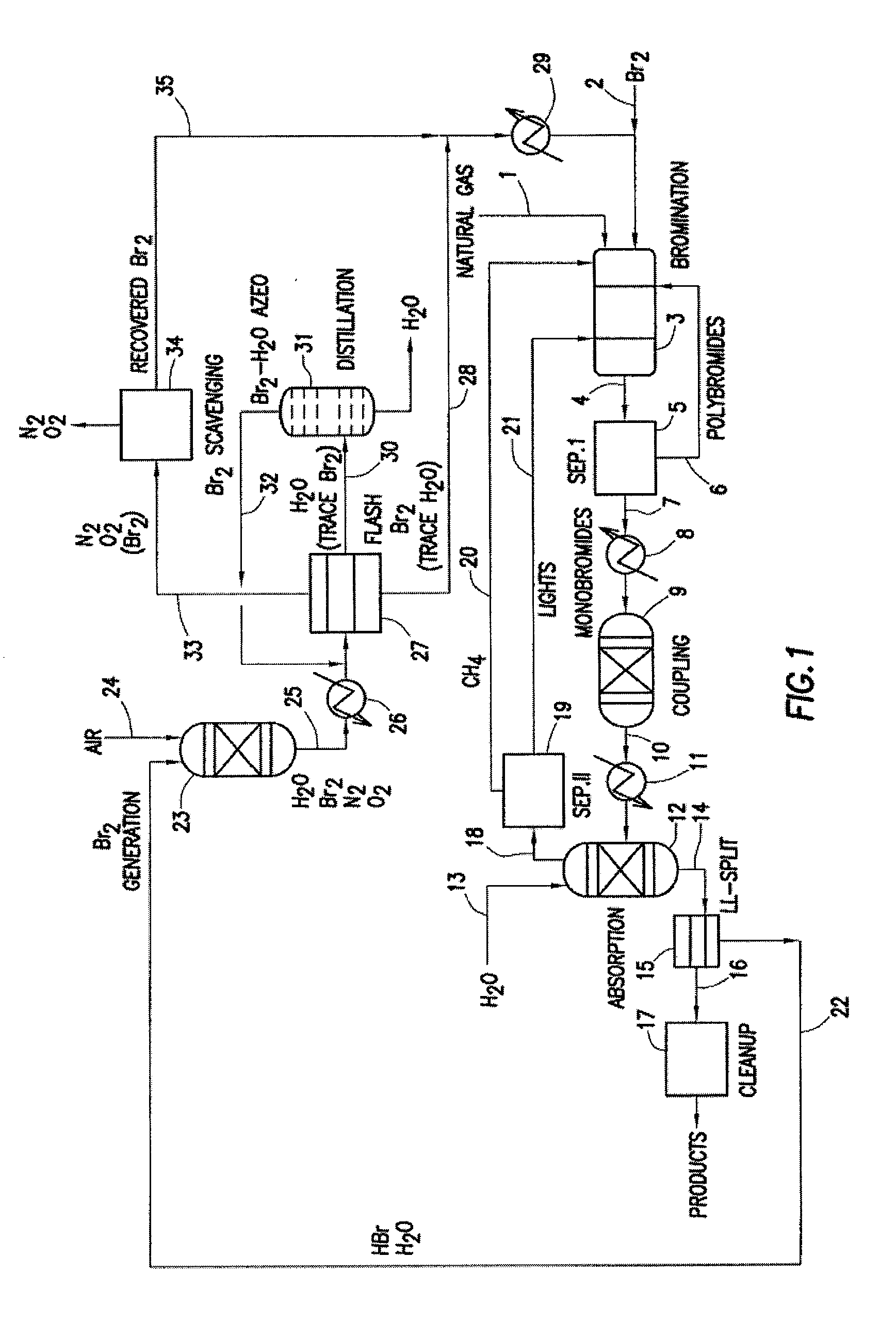

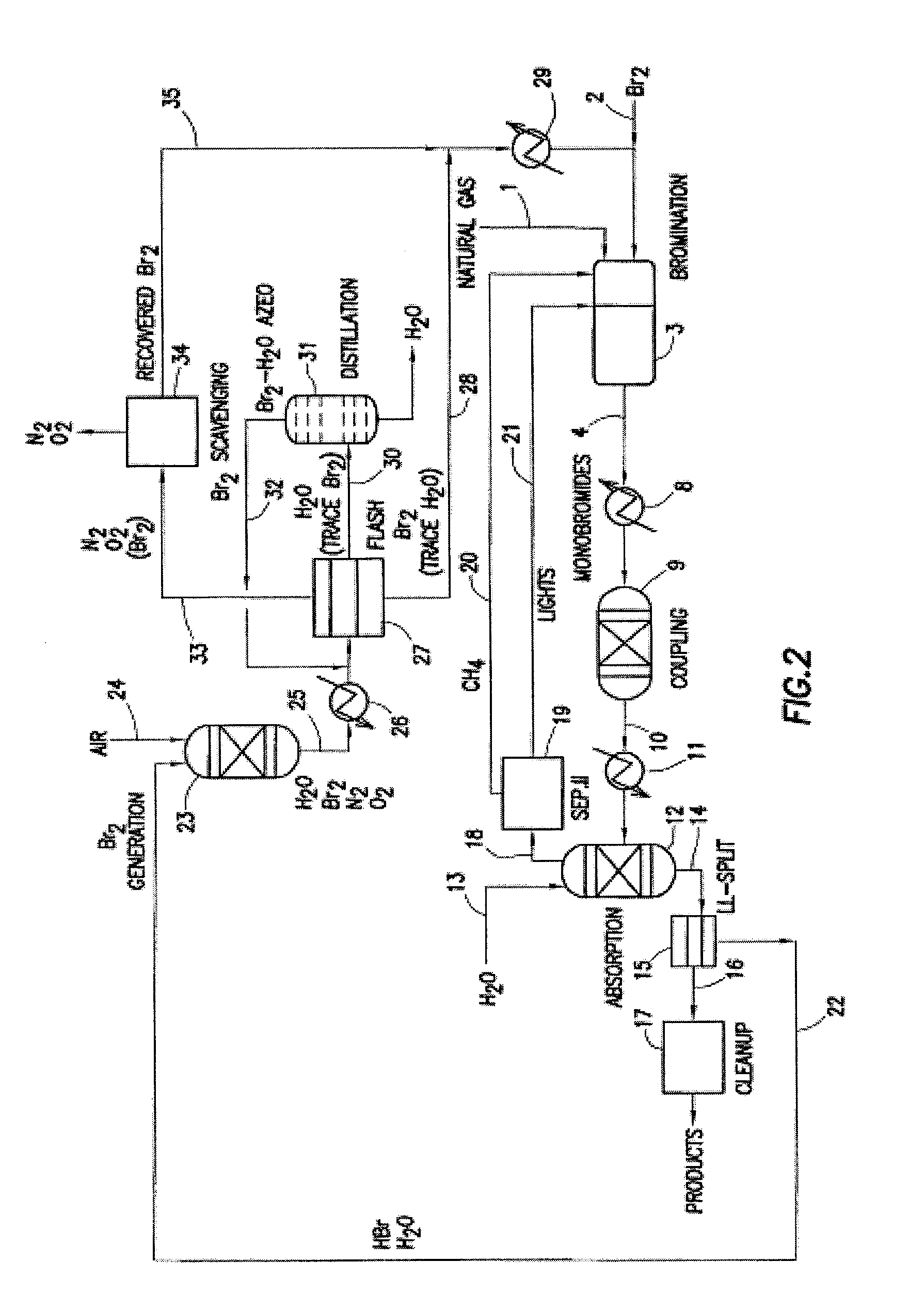

Continuous Process for Converting Natural Gas to Liquid Hydrocarbons

A method comprising: providing an alkyl halide stream; contacting at least some of the alkyl halides with a coupling catalyst to form a product stream comprising higher hydrocarbons and hydrogen halide; contacting the product stream with a solid reactant to remove at least a portion of the hydrogen halide from the product stream; and reacting the solid reactant with a source of oxygen to generate a corresponding halogen.

Owner:REACTION 35 LLC

Method for comprehensively recovering tungsten and fluorine from minerals

InactiveCN102586632AHigh recovery rateImprove solubilitySilicaProcess efficiency improvementDecompositionApatite

The invention provides a method for comprehensively recovering tungsten and fluorine from minerals, namely a mixed acid of phosphoric acid and sulfuric acid is adopted for decomposing complex calcium-containing minerals containing fluorite, scheelite, apatite, and calcite, wherein the fluorite is decomposed to fluorine hydride or silicon tetrafluoride to escape, and absorption treatment is performed for preparing hydrofluoric acid or a fluoride salt; and the scheelite is transformed to phosphotungstic acid to enter into a solution, and filtrate after filtration is supplemented into the consumed sulfuric acid and the phosphoric acid after extraction of the tungsten and returned to the new-round mineral leaching. The method disclosed by the invention has the advantages of comprehensively recovering the fluorine and the tungsten from the minerals, reducing the requirements on the fluorite or the tungsten ore raw material, reducing the pressure on a mineral dressing link, improving the comprehensive recovery rate and simultaneously ensuring the decomposition rate of the fluorite and the scheelite, wherein the decomposition rate of the fluorite is above 98%, and WO3 contained in decomposition slag is reduced to below 0.5%; furthermore, a leaching agent can be recycled, so that leaching cost and wastewater emission are greatly reduced; and the method also has the advantages of simple leaching equipment, convenience in operation and easiness in realization of industrialization.

Owner:CENT SOUTH UNIV

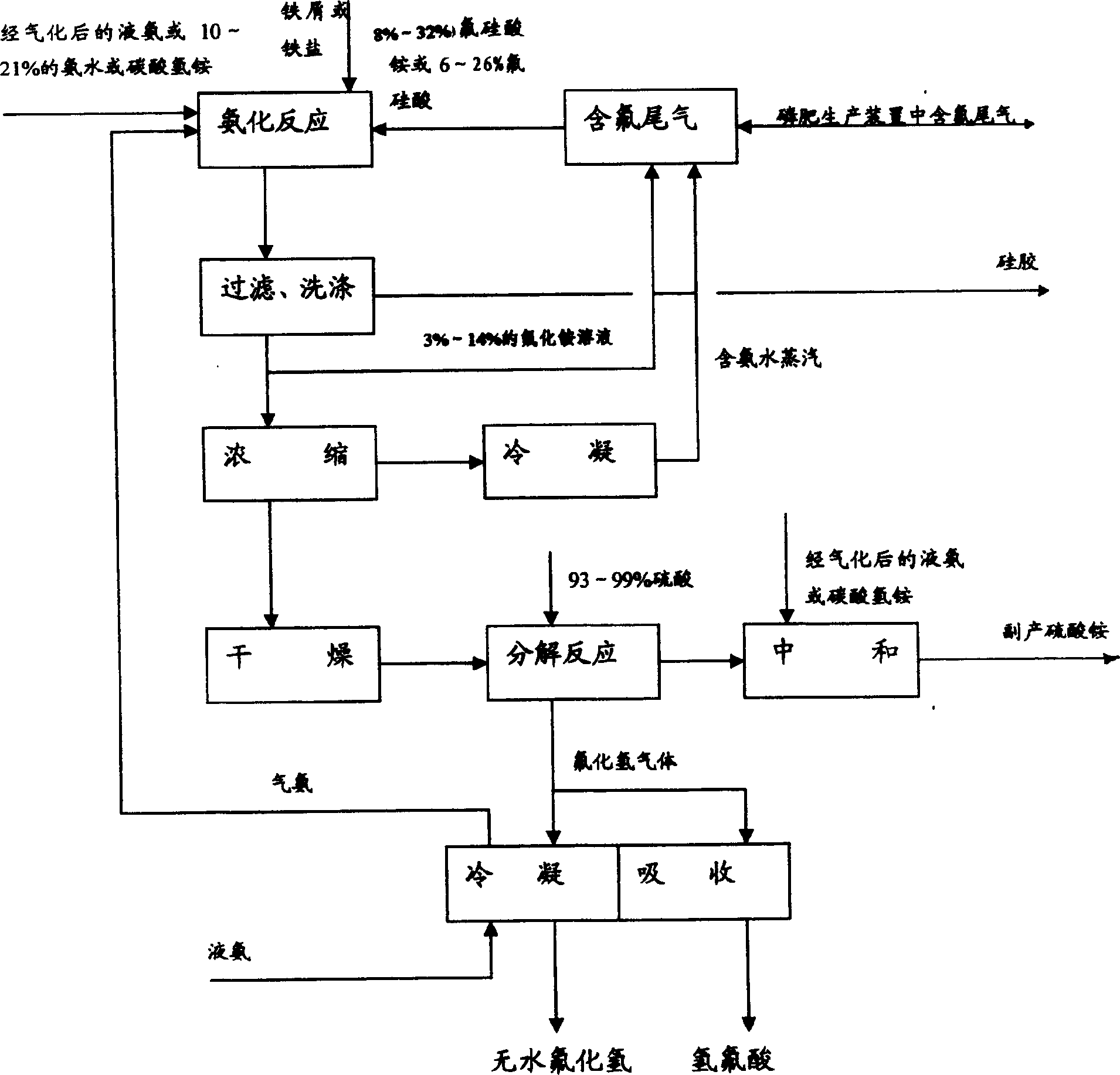

Method for comprehensively utilizing phosphate fertilizer by-product

InactiveCN1554570AReasonable designReduce material requirementsSolid waste disposalFluorine/hydrogen-fluorideIron saltsAmmonium fluorosilicate

The method of comprehensively utilizing phosphate fertilizer by-product includes utilizing ammonium fluoride solution of 3-14% concentration to absorb side product fluorine containing tail gas ammonium fluorosilicate solution; adding iron scrap or iron salt to fluorosilicic acid as one other by-product to eliminate phosphorus; adding liquid ammonia, ammonia water or ammonium bicarbonate; filtering, washing, and eliminating silica precipitate; returning ammonium fluoride solution to phosphate fertilizer absorbing system, concentration and drying to obtain ammonium hydrogen fluoride; reacting solid ammonium hydrogen fluoride and sulfuric acid at high temperature to obtain HF gas, absorbing HF gas to obtain hydrofluoric acid, purification and condensation to obtain anhydrous HF; and mixing the mixture of ammonium sulfate and ammonium bisulfate with ammonium bicarbonate or ammonia in a mixer, curing and crushing to ammonium sulfate fertilizer.

Owner:云南三环化工有限公司 +1

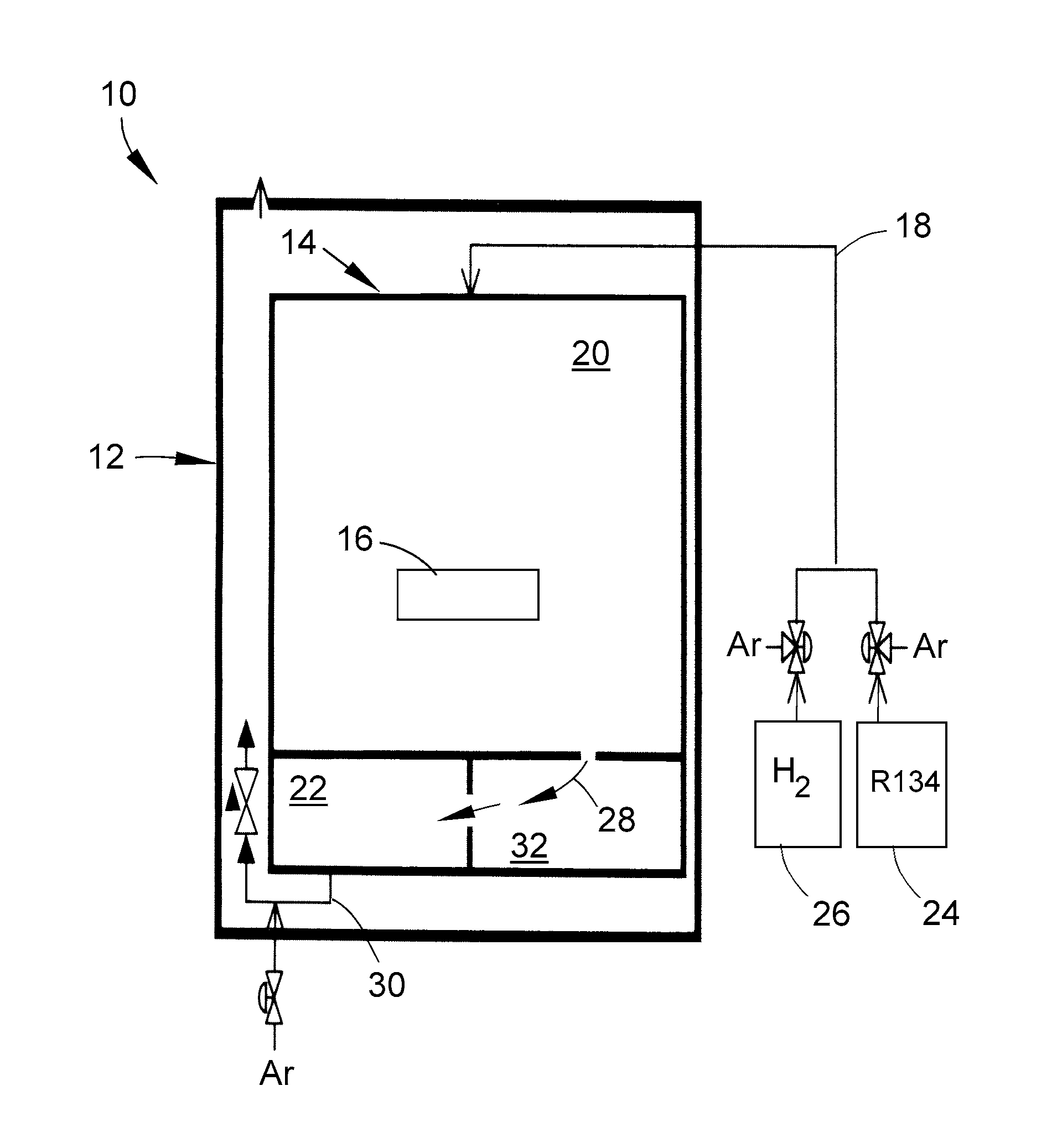

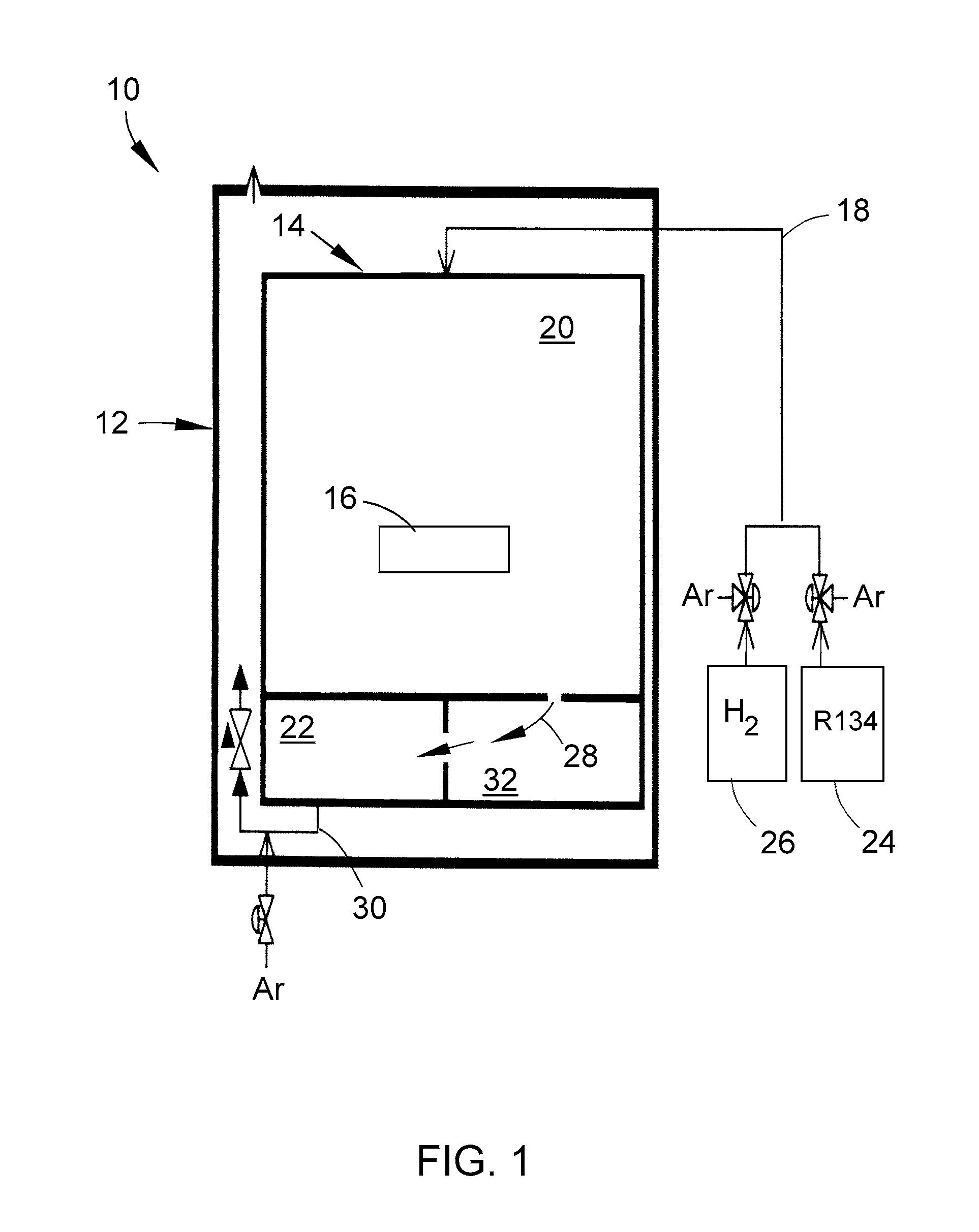

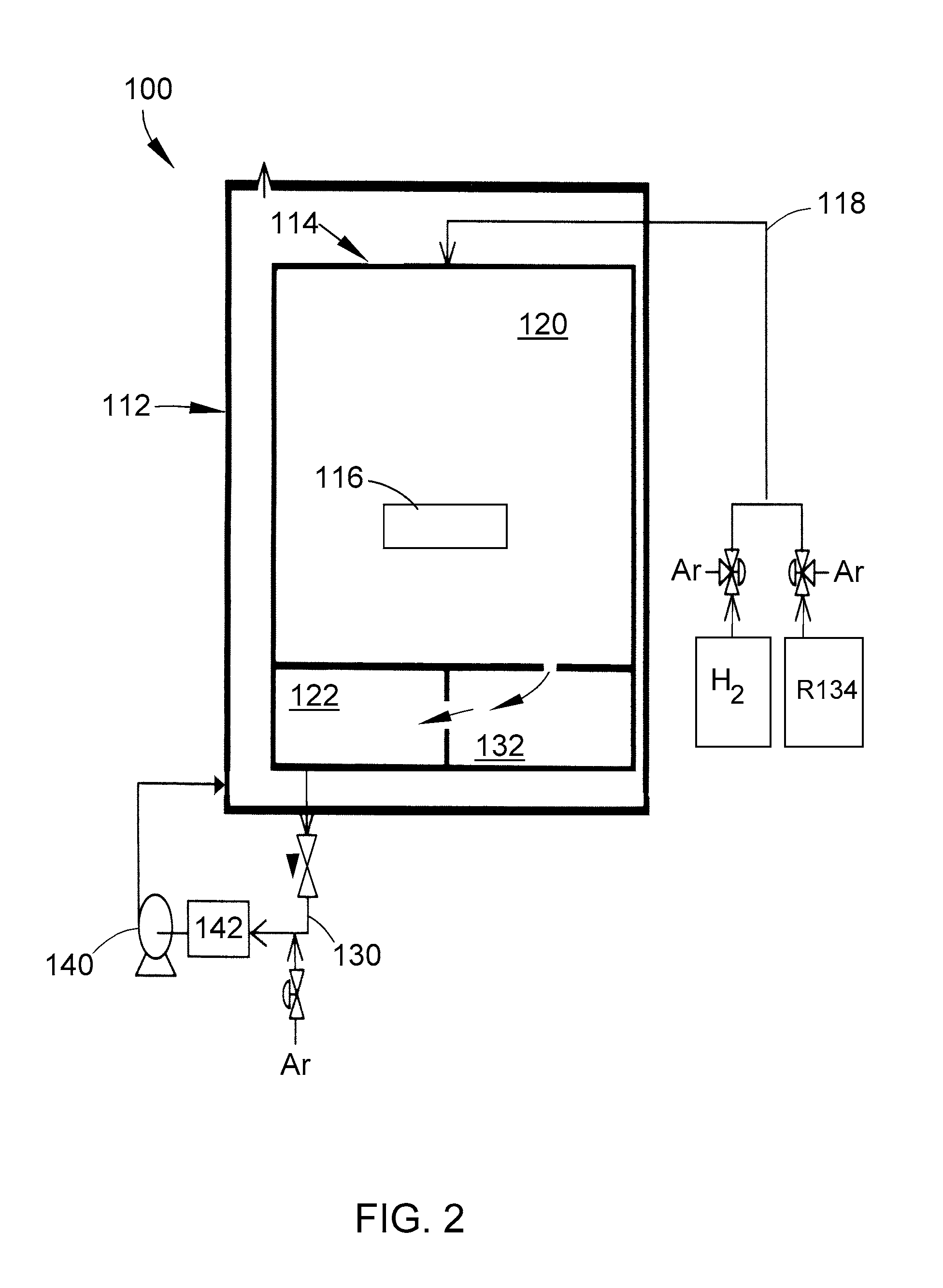

Azeotrope And Azeotrope-Like Compositions Useful For The Production Of Haloolefins

ActiveUS20120215039A1Reduce pointsReadily apparentOther chemical processesPreparation by halogen replacementHFO-1234yfPentafluoropropane

The present invention pertains to ternary azeotrope and azeotrope-like composition including 2-chloro-3,3,3-trifluoropropene (HCFO-1233xf), HF, and either 1,1,2,3-tetrachloropropene (TCP) or 1,1,1,2,2-pentafluoropropane (HFC-245cb). The present invention also relates to binary azeotropes of 2,3,3,3-tetrachloropropene and HF. Such azeotropic and azeotrope-like compositions are useful as intermediates in the production of 2,3,3,3-tetrafluoropropene (HFO-1234yf).

Owner:HONEYWELL INT INC

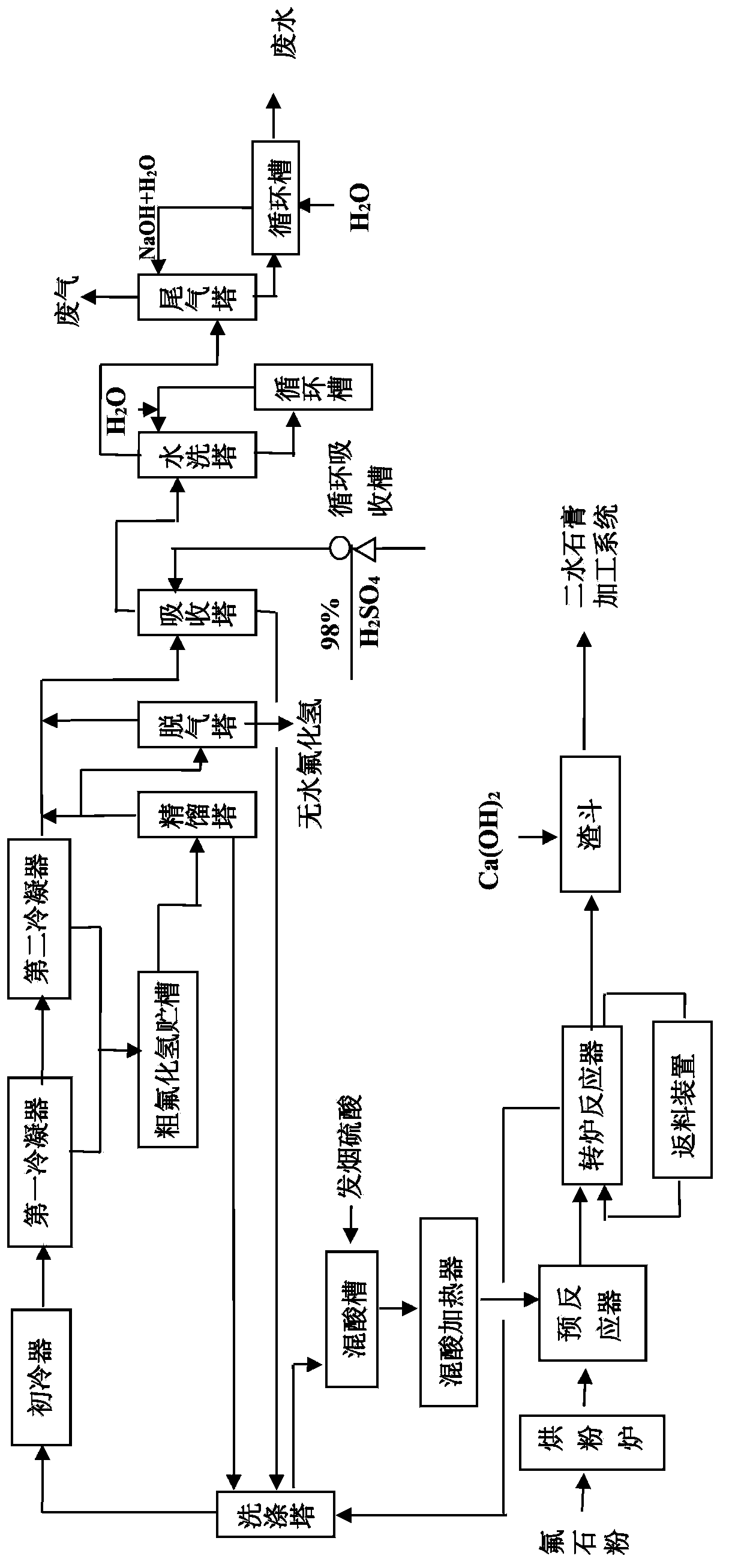

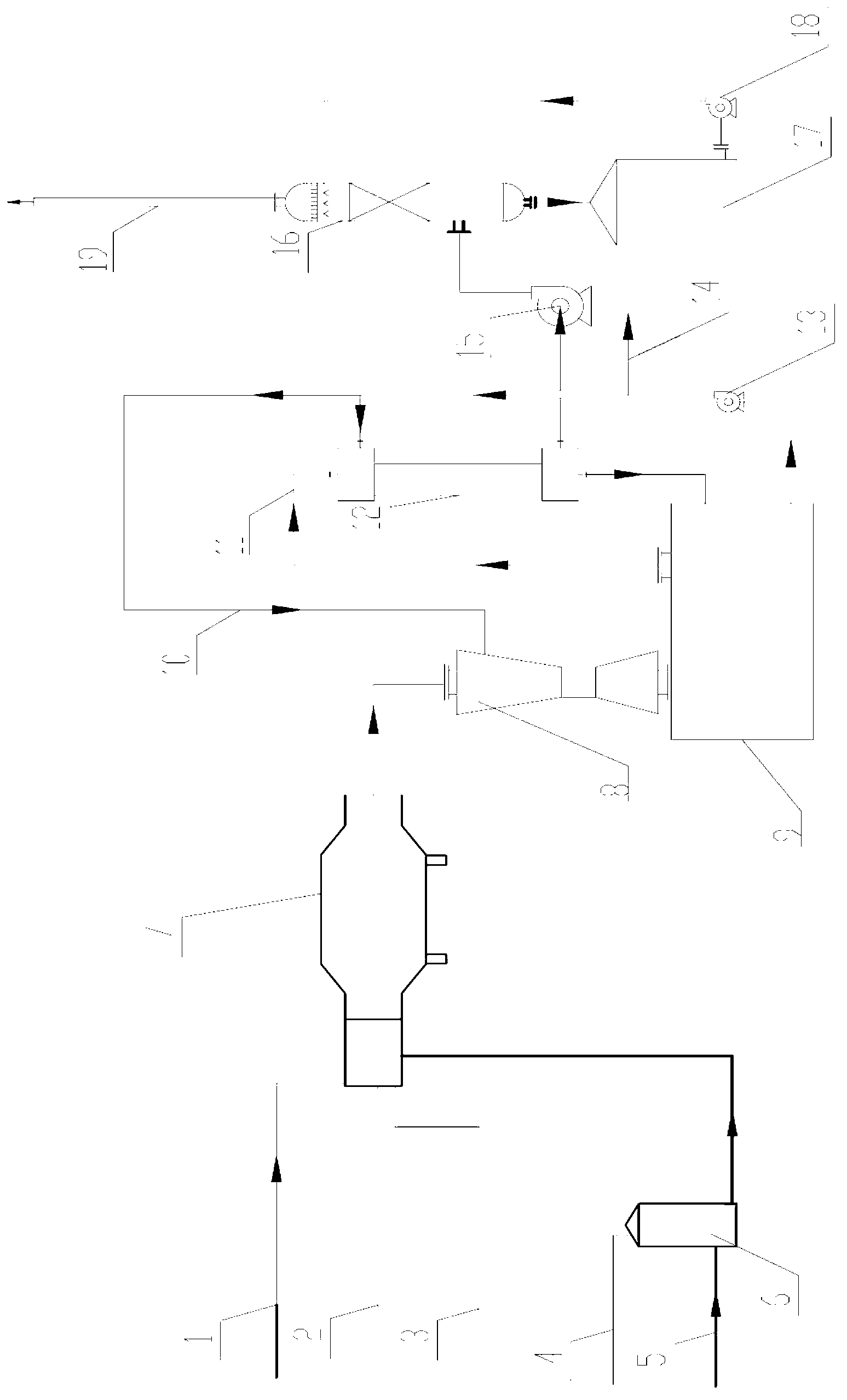

Anhydrous hydrogen fluoride production method

ActiveCN103350985AImprove conversion rateLow costFluorine/hydrogen-fluorideHydrogen fluoridePhysical chemistry

The invention discloses an anhydrous hydrogen fluoride production method which comprises the following steps: conveying fluorite powder and sulfuric acid to a pre-reactor, fully mixing the fluorite powder and the sulfuric acid and enabling the fluorite powder and sulfuric acid to react to generate coarse hydrogen fluoride gas; removing impurities from the coarse hydrogen fluoride gas through a pre-purifying tower and a washing tower, cooling the coarse hydrogen fluoride gas, and conveying the coarse hydrogen fluoride gas to a rectifying tower for refining; enabling the anhydrous hydrofluoric acid to get out of the rectifying tower with the help of the pressure of the tower, and leading the anhydrous hydrofluoric acid to an anhydrous hydrofluoric acid finished product storage tank through a finished product cooler. According to the invention, the hydrogen fluoride discharged from the gas can be recycled, the conversion rate of the product is increased, the cost is lowered, and useful by-products such as gypsum and fluosilicic acid are produced.

Owner:ANHUI JINYANG FLUORINE CHEM

Method for treating waste gas containing fluorochemical

InactiveUS6602480B1Physical/chemical process catalystsDispersed particle separationDecompositionCompounds of fluorine

A method for decomposing a fluorine-containing compound by contacting an exhaust gas 1 containing a fluorine-containing compound, such as C2F6, with aluminum oxide 3, such as gamma-alumina, which has been heated to a high temperature of, for example, 800° C. to 900° C. There may be such a necessary or larger number of moles of H2 that the fluorine atoms in the fluorine-containing compound become HF. The method has a high decomposition rate of a fluorine-containing compound, a long life, and involves minimal occurrence of CO.

Owner:EBARA CORP

Method for purifying ultra-pure hydrofluoric acid

ActiveCN101125639AIt is not easy to solve this difficult problemHigh purityFluorine/hydrogen-fluorideHydrofluoric acidHydrogen fluoride

The invention relates to a purifying method of ultrahigh pure hydrofluoric acid, comprising the technological steps as follows: filling industrial anhydrous hydrogen fluoride liquid into a rectifying still, and adding potassium permanganate with 0.16 to 1 percent weight, stirring, then stopping; after that, adding hydrogen peroxide with 0.16 to 1 percent weight, stirring, then stopping; heating up to 60 to 80 DEG C, the hydrogen fluoride liquid is gasified and generated into purified hydrogen fluoride gas; subsequently, filling the purified hydrogen fluoride gas which goes out of the rectifying still into a cooler for cooling and filtering; injecting deionized water into an absorption tower whose bottom is provided with a gas distribution plate tube, after that, filling the hydrogen fluoride gas which goes out of the cooler into the gas distribution plate tube at the bottom of the tower; after sprayed out of the gas distribution holes on the tube wall of the gas distribution plate tube, the hydrogen fluoride gas is absorbed by the deionized water and produced into semi finished product of hydrofluoric acid; finally, filling the semi finished product of hydrofluoric acid which goes out of the absorption tower into a filter in 0.05Mum, after that, obtaining the finished product of ultrahigh pure hydrofluoric acid. The product prepared by the method of the invention has high fineness and output, according to the requirements of the environmental protection.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Method for producing electronic-stage hydrofluoric acid

ActiveCN101570318ASolve hard-to-remove problemsHigh purityFluorine/hydrogen-fluorideHydrofluoric acidBoiling point

The invention relates to a method for producing electronic-stage hydrofluoric acid. The method comprises the following steps: (1), preheating and roughly distilling a measured anhydrous hydrofluoric acid raw material to remove low boiling point matter; (2), using ultra-pure water to absorb hydrofluoric acid roughly distillated and exhausted from a condenser outlet to be 48 to 49 percent of hydrous hydrofluoric acid solution; (3), distilling an absorbed hydrofluoric acid semi-finished product by a fluoroplastic resin sub-boiling distiller, gasifying fluorine hydride liquid to generate ultra-pure electronic-stage hydrofluoric acid gas, condensing to be 48 to 49 percent of anhydrous hydrofluoric acid solution and remaining high boiling point matter and heavy metals at the bottom of the sub-boiling distiller; and (4), secondarily filtering the hydrofluoric acid semi-finished product output from the fluoroplastic resin sub-boiling distiller, and finally, automatically filling to prepare 48 percent of ultra-pure hydrofluoric acid finished product. The method fully utilizes the different of boiling points between the anhydrous hydrofluoric acid and various impurities in the anhydrous hydrofluoric acid to remove the impurities at different temperatures, particularly remove silicon so that the impurity content of the obtained ultra-pure hydrofluoric acid is decreased to the minimum.

Owner:DO FLUORIDE CHEM CO LTD

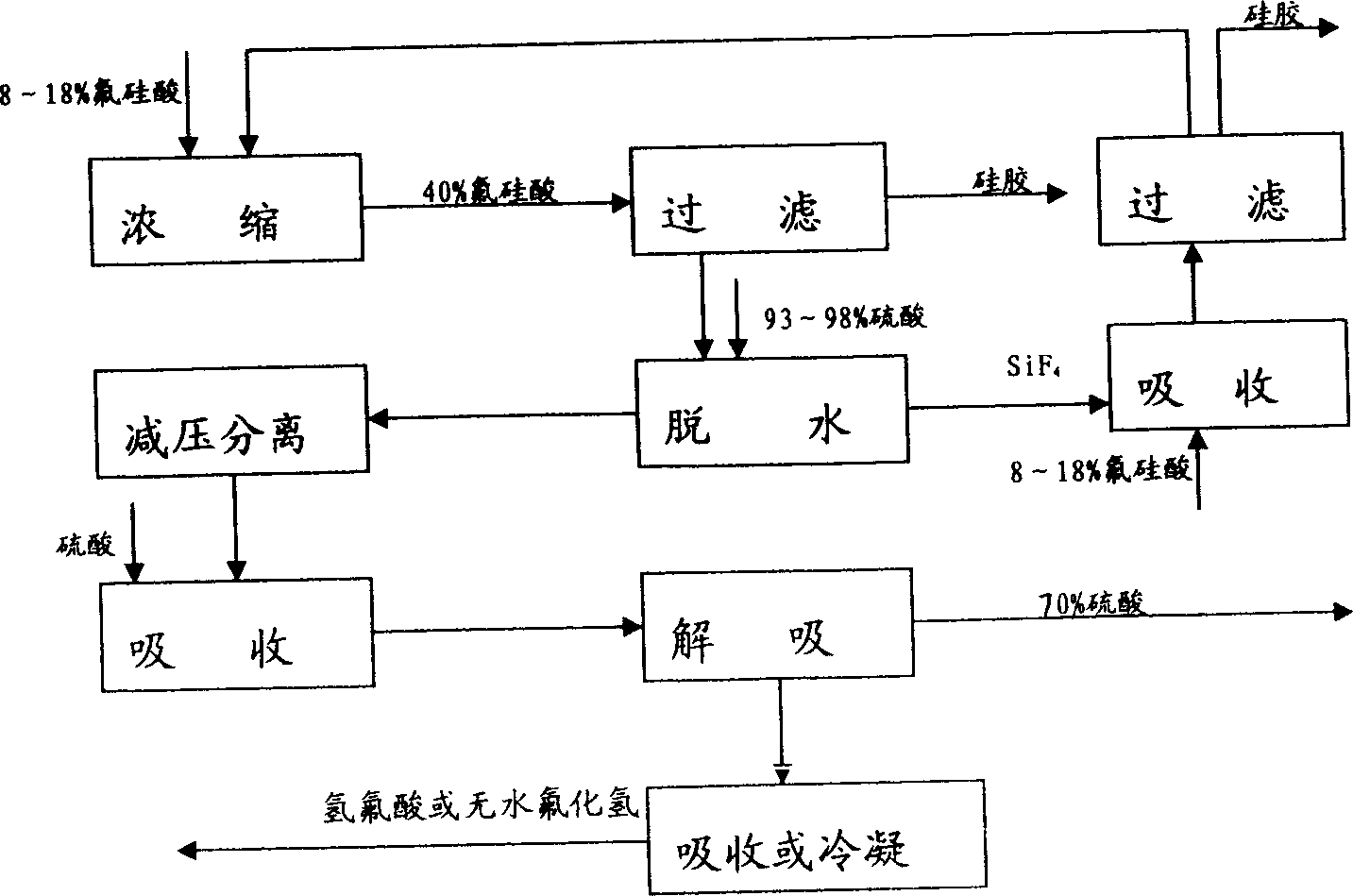

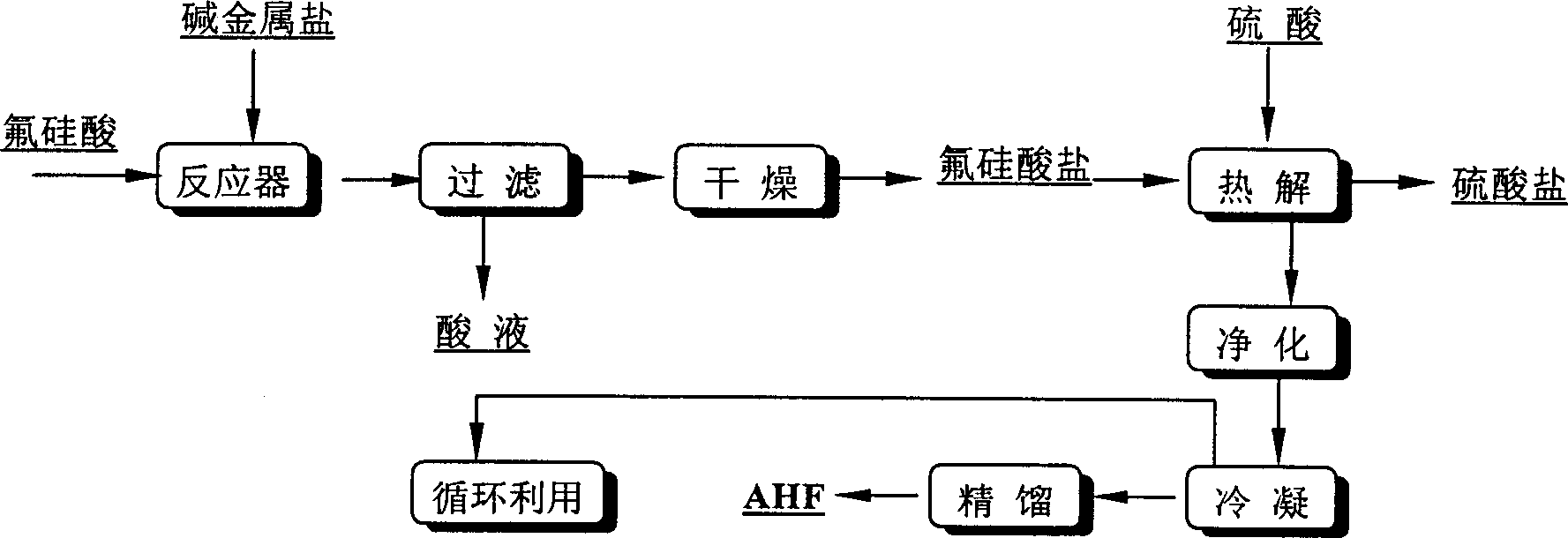

Technique for preparing waterless hydrogen fluoride on high purity

A process for preparing high-purity anhydrous hydrogen fluoride from the fluorosilicic acid as industrial by-product and concentrated sulfuric acid features that the fluorosilicid acid is deposited out in salt mode and the traditional fluorespar approach is then used. The generated sulfate as by-product can be used as precipitant of fluorosilicic acid system.

Owner:SICHUAN UNIV

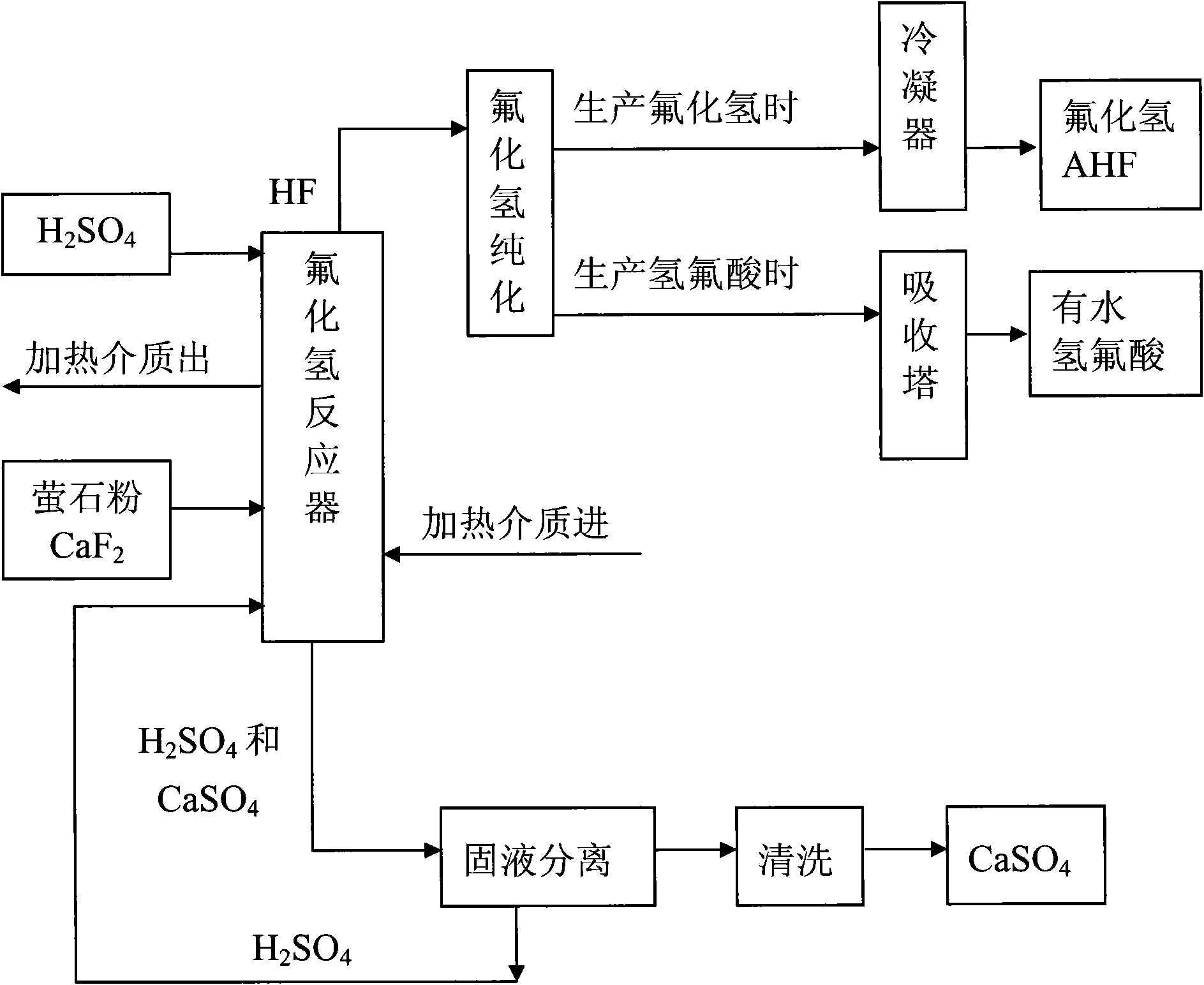

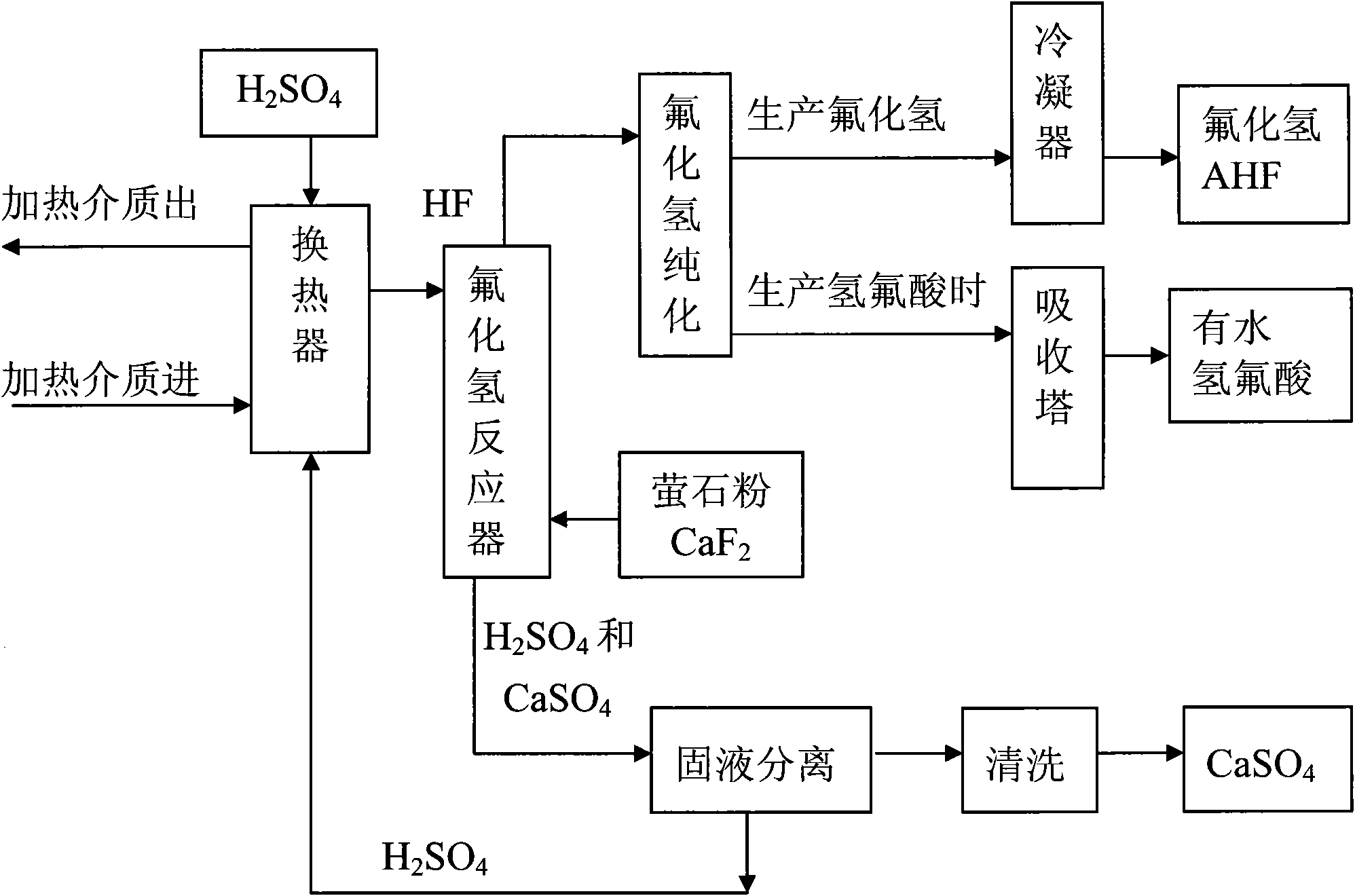

Method for preparing hydrogen fluoride from flousper powder and sulfuric acid

ActiveCN101913565ANovel process routeEasy to operateCalcium/strontium/barium sulfatesFluorine/hydrogen-fluorideHydrofluoric acidHydrogen fluoride

The invention discloses a method for preparing hydrogen fluoride from flousper powder and sulfuric acid. The method comprises the following specific steps of: adding solution of sulfuric acid and the flousper powder into a reactor with a stirrer respectively, wherein the molar ratio of calcium fluoride to the sulfuric acid is 1:3-1:30, the granularity of the flousper powder is 280 to 1,220 meshes, and the reaction temperature is controlled to between 90 and 300 DEG C; generating hydrogen fluoride gas and calcium sulfate solid after the reaction; purifying, condensing and rectifying the hydrogen fluoride gas to obtain anhydrous hydrogen fluoride, or purifying and absorbing the hydrogen fluoride gas to obtain hydrofluoric acid; transferring the calcium sulfate solid and the sulfuric acid toa filtering system from the reactor to perform solid-liquid separation; returning the separated solution of sulfuric acid to the reactor; and washing and drying the calcium sulfate solid separated from the sulfuric acid to form a by-product. The method has the advantages of simple equipment, high reaction efficiency, low cost and easy industrialized production.

Owner:衢州市鼎盛化工科技有限公司

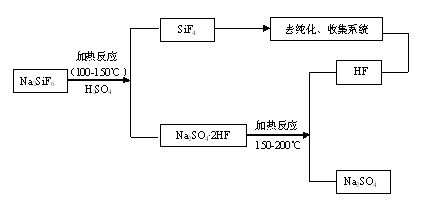

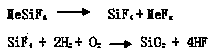

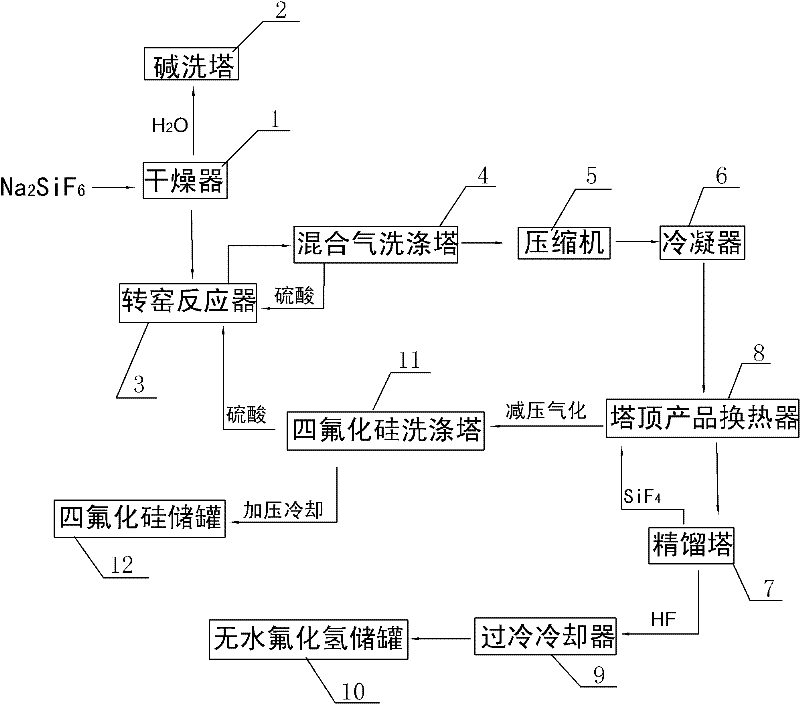

Method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride from sodium fluosilicate acidified by sulfuric acid

InactiveCN101948114ATake advantage ofEfficient use ofFluorine/hydrogen-fluorideHalogenated silanesChemical industryHydrogen fluoride

The invention provides a method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride from sodium fluosilicate acidified by sulfuric acid, which relates to the technical field of fluorine chemical industry, in particular to a method for preparing silicon tetrafluoride gas and anhydrous hydrogen fluoride gas by reaction of sodium fluosilicate and sulfuric acid. The method of the invention comprises the following steps: (a) stirring sodium fluosilicate and excessive sulfuric acid at the temperature lower than 150 DEG C for reacting to obtain silicon tetrafluoride gas, wherein hydrogen fluoride remains in solid residues; (b) dedusting, cooling, drying, refining and compressing the silicon tetrafluoride gas generated in the step (a) to obtain high-purity silicon tetrafluoride gas; (c) continuously heating to 200 DEG C to enable the hydrogen fluoride gas to escape; and (d) dedusting, cooling, drying, refining and compressing the hydrogen fluoride gas escaping in the step (c) to obtain the anhydrous hydrogen fluoride (AHF) gas. The invention enables the specific fluorine and silicon resources of phosphate fertilizer enterprises to be fully and efficiently utilized.

Owner:YUNNAN CHEM RES INST

Electron-grade high purity hydrofluoric acid preparation method

The invention discloses an electron-grade high purity hydrofluoric acid preparation method, comprising the following steps: (1) preprocessing liquid anhydrous hydrogen chloride; (2) rectifying liquid anhydrous hydrogen chloride; (3) preparing a hydrofluoric acid semifinished product; (4) preprocessing the hydrofluoric acid semifinished product; (5) removing metal ions in the hydrofluoric acid semifinished product; and (6) obtaining electron-grade high purity hydrofluoric acid. The production technology of the invention avoids the onerous processes of absorbing hydrofluoric acid with anhydrous hydrogen fluoride and re-rectification and directly uses anhydrous hydrogen fluoride liquid for rectification purification; the production technology can effectively remove inorganic impurities such as arsenic trifluoride, SO2, SO3, H2SiF6 and the like, deeply remove various metallic impurities and solid particles, and purify the industrial hydrofluoric acid to refine the ultraclean high purity hydrofluoric acid agent which reaches the quality of ultraclean electron-grade hydrofluoric acid and meets the SIME-C8 standard, thus being applicable to the production of super precision integrated circuit.

Owner:广东光华化学厂有限公司 +1

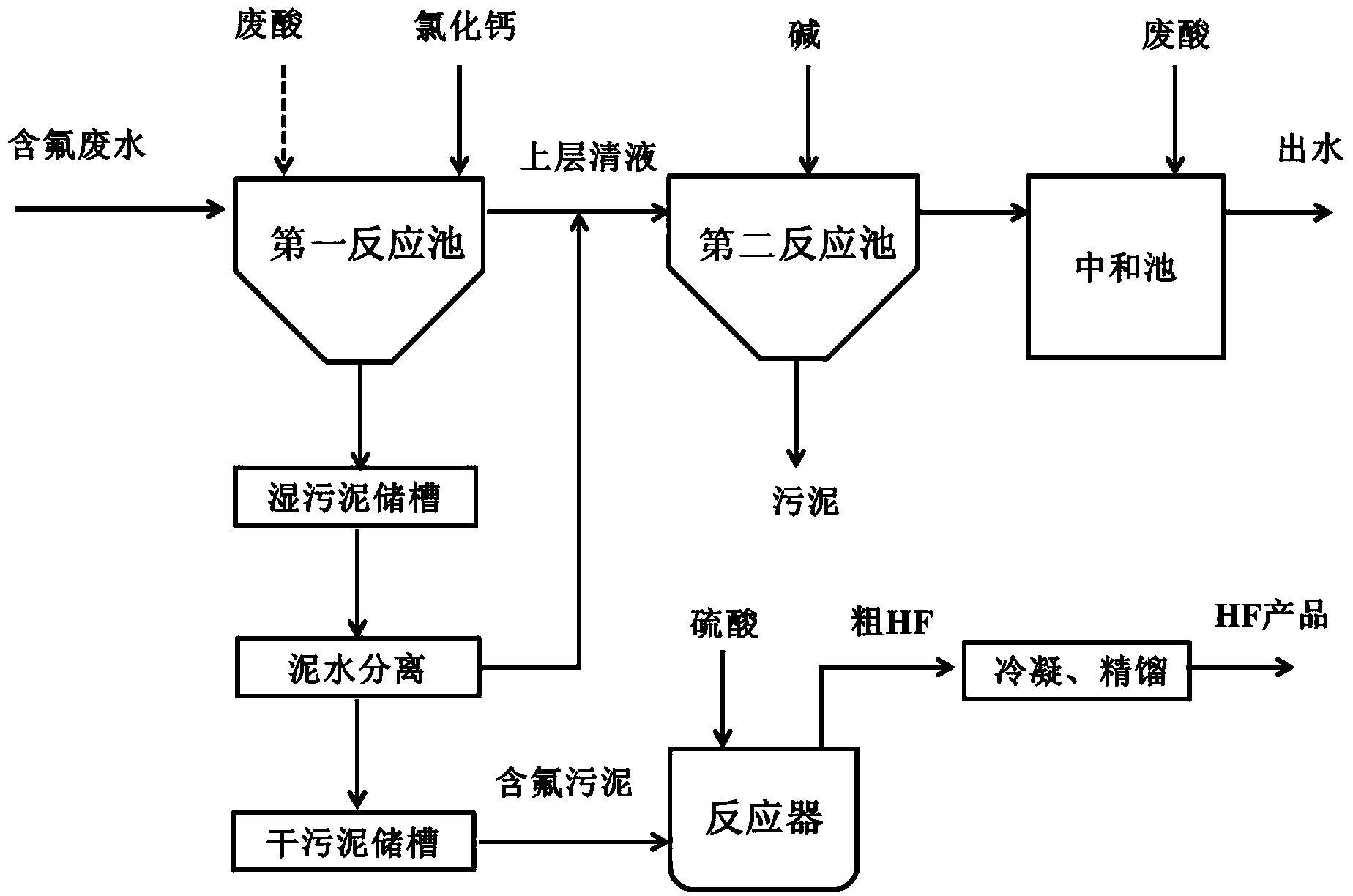

Method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater

ActiveCN103848522ATreatment up to standardReduce dosageSludge treatmentWater contaminantsSludgeImpurity

The invention discloses a method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater. The method comprises the steps of reacting the fluorine-containing wastewater with calcium chloride under the acidic condition formed by adding a waste acid matter, performing crystallization sedimentation to remove most fluorine ions from the wastewater to form high-purity fluorine-containing sludge, removing dissolved calcium fluoride and other impurities from supernate through alkali sedimentation to form a small amount of fluorine-containing sludge with relatively low purity, then neutralizing the supernate, and discharging effluent, wherein the concentration of fluorine ions of the effluent is lower than 10 mg / L and accords with national discharge standards; drying the high-purity fluorine-containing sludge, then adding the dried sludge and excessive sulfuric acid into a reactor with a stirring device, reacting at 150-300 DEG C to prepare hydrogen fluoride, and condensing and rectifying the obtained crude hydrogen fluoride gas to obtain an anhydrous hydrogen fluoride product.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

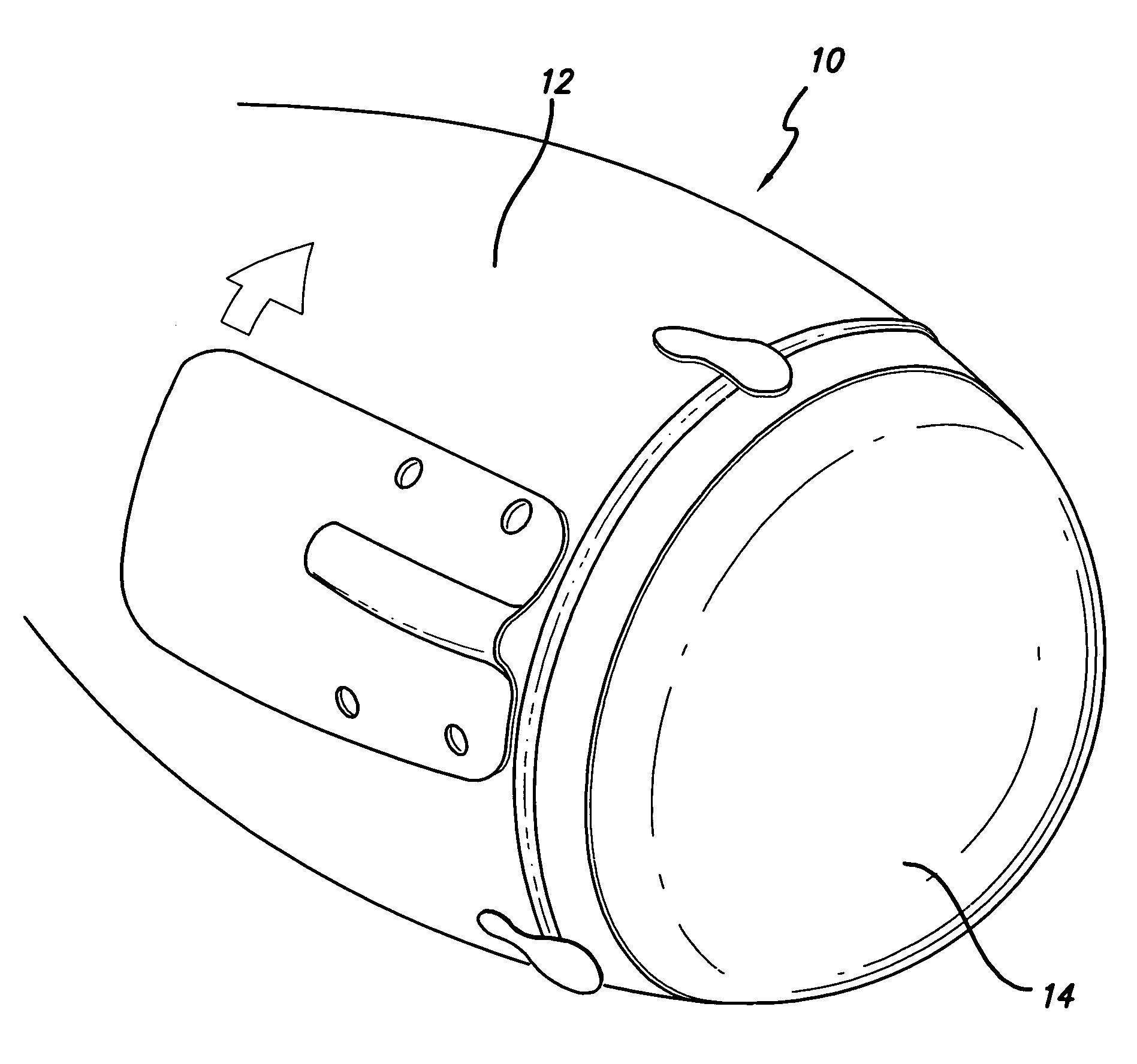

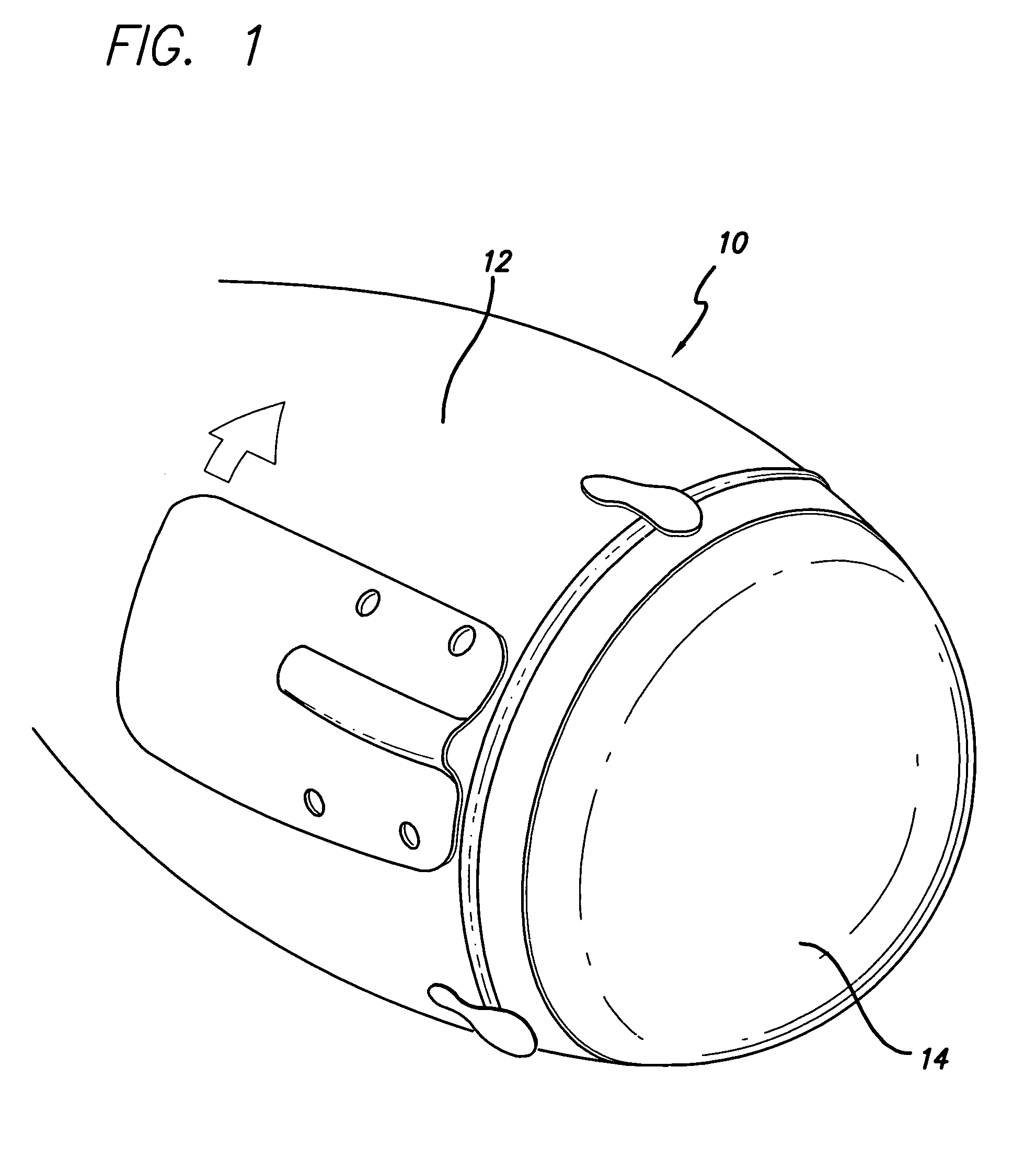

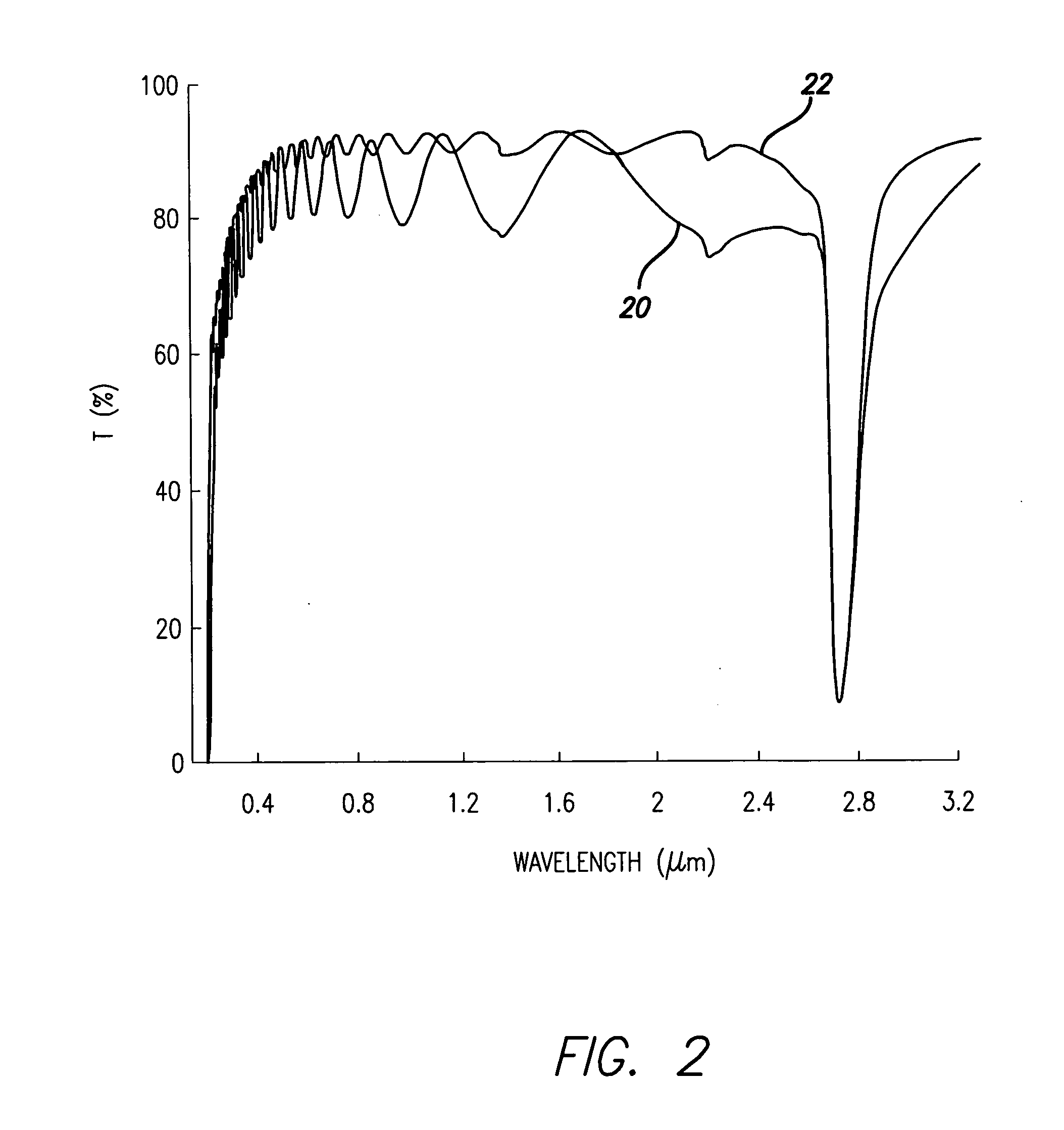

Durable antireflective multispectral infrared coatings

InactiveUS20100035036A1Synthetic resin layered productsVacuum evaporation coatingOptoelectronicsMetal

Owner:RAYTHEON CO

Method for preparing electronic grade ultrahigh purity hydrofluoric acid

The invention provides a method for preparing electronic grade ultrahigh purity hydrofluoric acid. The method comprises the following technical steps: (1) pretreating industrial anhydrous hydrogen fluoride; (2) treating in a reboiler; (3) distilling; (4) cooling; (5) absorbing; (6) performing ion exchange adsorption; and (7) filtering. The invention has the following beneficial effects: hydrogen peroxide is used to oxidize As<3+>, thus the problem that As<3+> is difficult to remove can be completely solved; chelating agent and a weak-base anion-exchange resin system are adopted to deeply remove a small amount of metal ions and impurities; through secondary filtration, all the indexes of hydrofluoric acid can meet the requirements of the electronic grade ultrahigh purity agent; and the method of the invention can be used for large-scale production, and the technology is stable, is easy to control and is suitable for popularization.

Owner:SUZHOU CRYSTAL CLEAR CHEMICAL CO LTD

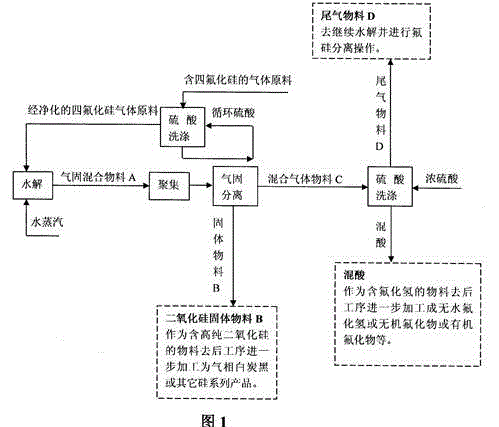

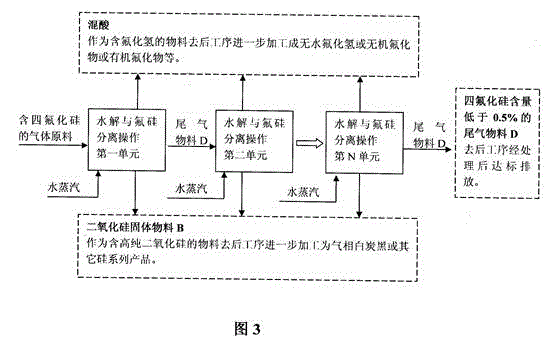

Gas phase hydrolysis and fluoride-silicon separation method of silicon tetrafluoride

InactiveCN103601195ASimple purification methodLow hydrolysis temperatureSilicaFluorine/hydrogen-fluorideChemical industrySilicon tetrafluoride

A two-step method is adopted to carry out low temperature gas phase hydrolysis and fluoride-silicon separation operations of silicon tetrafluoride. In a first step, a silicon tetrafluoride gas is hydrolyzed into a fluosilicic acid gas and silicon dioxide particles at a low temperature; in a second step, a hydrogen fluoride gas is dissolved by a washing operation of high concentrated sulfuric acid so as to promote complete decomposition of the fluosilicic acid into the hydrogen fluoride gas and a silicon tetrafluoride gas; decomposed and separated hydrogen fluoride gas is completely dissolved in high concentrated sulfuric acid; decomposed and separated silicon tetrafluoride can be continuously carried out hydrolysis and fluoride-silicon separation operations; and finally complete separation of the fluoride and silicon elements are realized. The method has the beneficial effects that a gas raw material containing relatively low silicon tetrafluoride content can be used; a method for purifying the raw material is simple; total conversion rate of silicon tetrafluoride introduced into a production apparatus system can reach over 98%; and hydrolysis temperature is relatively low, so that the method can realize industrial production relatively easily. The method is suitable for recovery and utilization of fluoride- and silicon-containing materials from industries such as phosphorus chemical industry, fluorine chemical industry, electron industry, glass processing industry and aluminium alloy processing industry.

Owner:班仁义

Wide mesoporous alumina composites having trimodal pore structure

ActiveUS7790130B2Improve performanceReduced responseMaterial nanotechnologyChlorine/hydrogen-chloride purificationParticulatesSorbent

Wide mesoporous alumina composites are produced by an “in situ reaction” route comprising agglomeration of an alumina powder that is capable of rehydration together with a second reactive powder such as carbonate. In one method of production, the powders are fed to a rotating forming device that is continuously sprayed with liquid under conditions to form particulates. The discharging beads are then subjected to curing and thermal activation to produce the final catalyst or adsorbent. The alumina participates in a pore altering process involving the carbonate component upon formation of hydroxycarbonate intermediates such as Dawsonite. Large fraction of the pore volume of the final product consists of wide mesopores in the 15-50 nanometers range. The alumina composites exhibit a characteristic trimodal pore structure that includes also small micro-meso pores and macropores larger than 200 nanometers.

Owner:UOP LLC

Negative-pressure incineration disposal system and negative-pressure incineration disposal method for fluorine-containing organic waste liquid and exhaust gas

ActiveCN103292332AExtend your lifeImprove conversion rateFluorine/hydrogen-fluorideIncinerator apparatusCombustion chamberDecomposition

The invention provides a negative-pressure incineration disposal system and a negative-pressure incineration disposal method for fluorine-containing organic waste liquid and exhaust gas. The negative-pressure incineration disposal system comprises an incinerator, a fluorine-containing organic waste liquid and exhaust gas supply system, a fuel supply system, a negative-pressure air supply system, a flue gas chilling and HF (hydrogen fluoride) recycling system and an alkali cleaning system. The negative-pressure incineration disposal method includes respectively and simultaneously feeding the fluorine-containing waste liquid and exhaust gas into combustion chambers of the incinerator; enabling the fluorine-containing waste liquid and exhaust gas to carry out high-temperature decomposition reaction at the 1100-1200 DEG C reaction temperature of the inside of the incinerator, under the -50Pa pressure of the inside of the incinerator and in the presence of oxygen; filling H<2> or CH<4> into the incinerator to promote redundant organic fluorine to be converted into inorganic hydrogen fluoride so as to guarantee that all the organic fluorine is converted into inorganic hydrogen fluoride ultimately; treating reaction products discharged from the combustion chambers of the incinerator and then discharging the treated reaction products into the atmosphere via a chimney. The negative-pressure incineration disposal system and the negative-pressure incineration disposal method have the advantages that the parameter adjustment quantity and parameter adjustment links are reduced, operation is facilitated, and long-period stable production running can be maintained.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

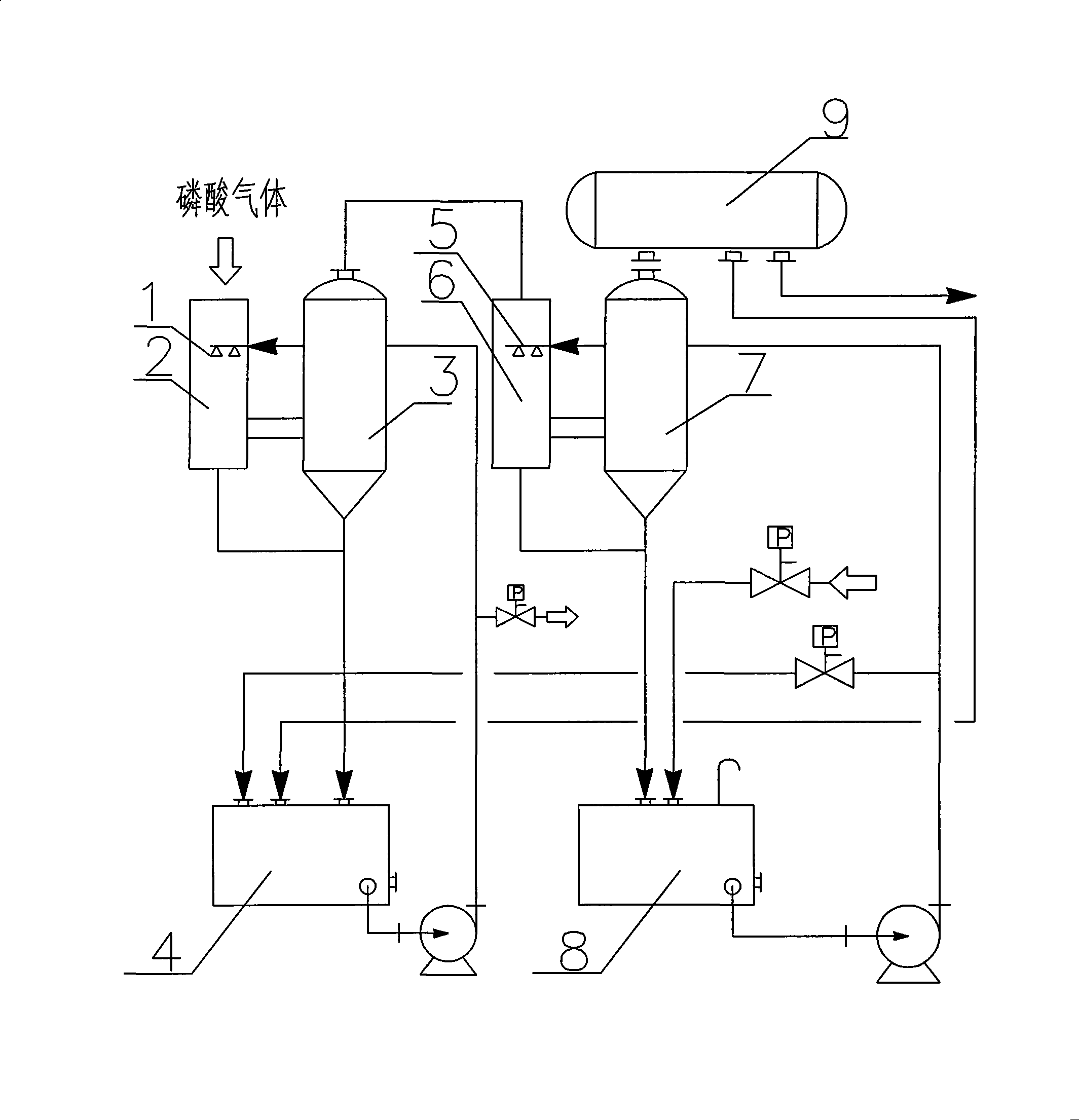

Absorption method of fluorine

ActiveCN101474523AAvoid corrosionImprove separation efficiencyDispersed particle separationSilicon oxidesGas phasePhosphoric acid

The invention discloses a method for absorbing fluorine. Phosphoric acid gas enters into a fluorine washing vacuum tube A(2) with a fluorine washing nozzle A(1) for the first time parallel current and washing in a pipeline, and then enters into a first level separator (3) for gas-liquid separation; the separated liquid phase part enters into a first level scrubber liquid seal trough (4) for circulation cleaning; the separated phosphoric acid gas enters into a fluorine washing vacuum tube B(6) with a fluorine washing nozzle B(5) for the second time washing; the washed gas enters into a secondary level separator (7) for gas-liquid separation; the separated liquid phase enters into a secondary level scrubber liquid seal trough (8) for circulation cleaning; the separated gas phase enters into a fluorine separator (9) for gas-liquid separation; the separated liquid phase part passes through the secondary level scrubber liquid seal trough (8) by a lower liquid pipe; the separated gas enters into a circulating water system. The method has high recovery rate, can effectively lighten corrosion maintenance on devices, thus being convenient for cleaning; in addition, the method has low cost.

Owner:WENGFU (GRP) CO LTD

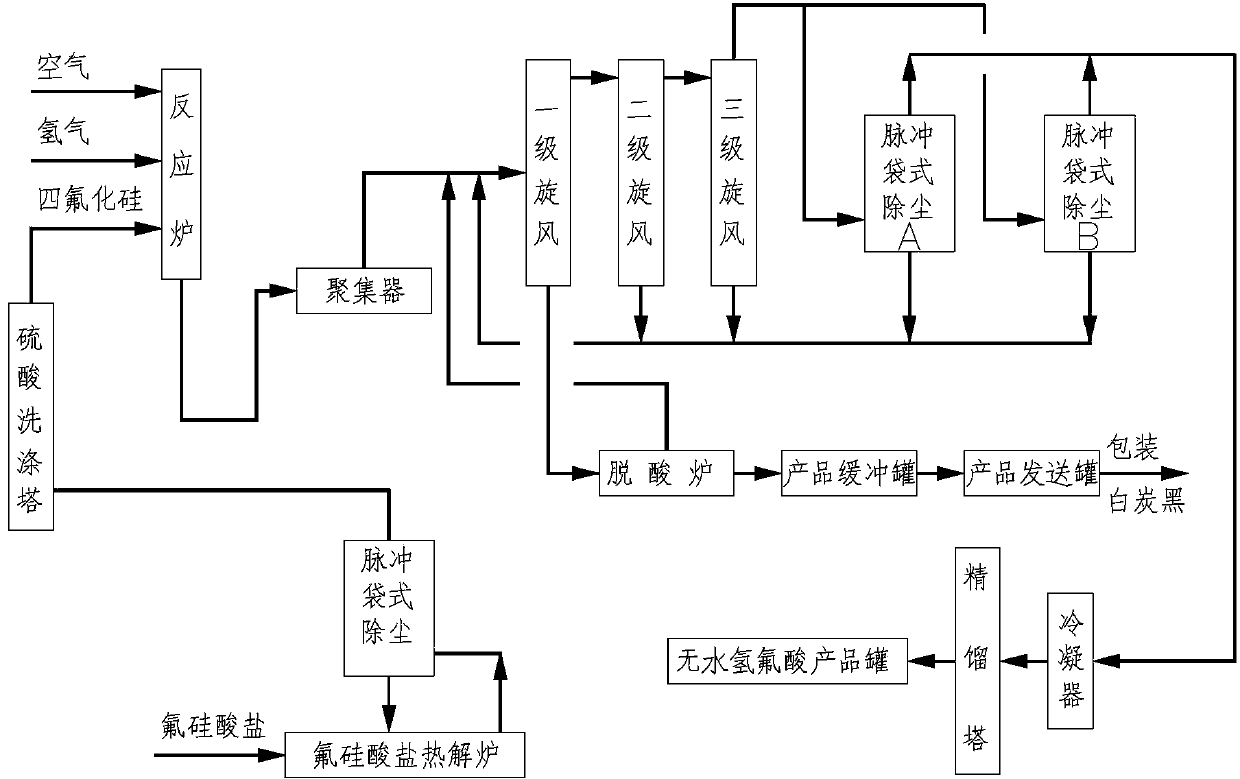

Method for preparing fumed silica and anhydrous hydrofluoric acid by utilizing phosphatic fertilizer by-product fluosilicate as raw material

InactiveCN103420383AIncrease profitHigh purityChemical industrySilicon oxidesDistillationSilicon tetrafluoride

The invention discloses a method for preparing fumed silica and anhydrous hydrofluoric acid by utilizing phosphatic fertilizer by-product fluosilicate as raw material. The method comprises the steps as follows: performing pyrolysis on the phosphatic fertilizer by-product fluosilicate at the temperature of 200-400 DEG C to obtain silicon tetrafluoride, utilizing a filter to remove dust containing in the silicon tetrafluoride, washing the silicon tetrafluoride by 93-98 percent of concentrated sulfuric acid to remove the moisture and impurities, mixing the silicon tetrafluoride, air with hydrogen in a hydrolysis reactor via the volume ratio of 1:2:(0.05-0.3) and performing high-temperature hydrolysis reaction, and then performing aggregation, separation, dust removal, condensation and distillation to obtain the fumed silica and the anhydrous hydrofluoric acid respectively. The method has the advantages that the technical process is simple, the raw material is easy to get, the utilization rate of the raw material is high, energy conservation and environmental protection are realized, the corrosion to the equipment is less, the production cost is reduced, and the produced white carbon black is high in purity.

Owner:SEDIN NINGBO ENG

Fluoride ion cleaning method

Owner:GENERAL ELECTRIC CO

Method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride by taking sodium fluorosilicate as raw material

InactiveCN102557043AWell mixedAdequate responseFluorine/hydrogen-fluorideHalogenated silanesSilicon tetrafluorideSodium sulfate

The invention discloses a method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride by taking sodium fluorosilicate as a raw material. The method is characterized by comprising the following steps of: (1) drying sodium fluorosilicate for removing water; (2) adding the dried sodium fluorosilicate and sulfuric acid into a rotary kiln reactor in the molar ratio of 1:1, and reacting at the temperature of 160-220 DEG C for 30-180 minutes to generate a sodium sulfate solid and a mixed gas of silicon tetrafluoride and hydrogen fluoride; (3) dedusting, pressurizing and precooling to between 20 DEG C below zero and 30 DEG C below zero; (4) feeding the precooled mixed gas into a rectifying tower for separating, controlling the pressure of the rectifying tower at 0.6-0.75 MPaG and the temperature of tower top condenser between 70 DEG C below zero and 80 DEG C below zero, and discharging anhydrous hydrogen fluoride from the tower bottom; and (5) discharging silicon tetrafluoride from the tower top in the form of a liquid phase, decompressing, gasifying, dedusting and feeding into a silicon tetrafluoride washing tower to obtain silicon tetrafluoride gas. The method has the advantages that: corrosion to equipment can be reduced greatly, the obtained silicon tetrafluoride and hydrogen fluoride products have high purity, and the production process has low energy consumption and is environmentally-friendly.

Owner:SEDIN NINGBO ENG

Method for comprehensively recovering fluorine and tungsten from tungsten-containing fluorite mineral

ActiveCN102925670AIncrease profitPromote leachingProcess efficiency improvementFluorine/hydrogen-fluorideDecompositionHeteropoly acid

The invention provides a method for comprehensively recovering fluorine and tungsten from tungsten-containing fluorite mineral. In the method, the tungsten-containing fluorite mineral is roasted by use of sulfuric acid and phosphoric acid (or phosphorite), and the HF gas generated by decomposing the fluorite by sulfuric acid is used for preparing hydrofluoric acid; and meanwhile, the tungsten-containing mineral reacts with the sulfuric acid and phosphoric acid to obtain soluble heteropoly acid which is left in fluorgypsum and can be recovered by a water leaching or acid leaching method. Through the invention, the tungsten in mineral can be efficiently recovered while preparing the hydrofluoric acid; the decomposition rate of fluorite is over 95%, the recovery rate of tungsten exceeds 90%, and the content of WO3 in the fluorgypsum is reduced to below 0.1%; a leaching reagent can be recycled, thus the cost and the waste water discharge are greatly reduced; and the equipment is simple, the operation is convenient, and the industrialization is easy to realize.

Owner:CENT SOUTH UNIV

Popular searches

Hydrocarbons Chemical/physical/physico-chemical processes Liquid-gas reaction processes Hydrocarbon preparation Hydrocarbon from saturated and unsaturated hydrocarbon addition Chemical recycling Filter regeneration Molecular sieve catalysts Organic-compounds/hydrides/coordination-complexes catalysts Catalyst regeneration/reactivation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com