Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

233 results about "Oleum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oleum (Latin oleum, meaning oil), or fuming sulfuric acid, is a term referring to solutions of various compositions of sulfur trioxide in sulfuric acid, or sometimes more specifically to disulfuric acid (also known as pyrosulfuric acid). Oleum is identified by the CAS number 8014-95-7 (EC/List number: 616-954-1 ; ECHA InfoCard: 100.116.872).

2-acrylamide-2-methylpropanesulfonic acid and process for producing the same

ActiveUS20100274048A1Large molecular weightHigh purityOrganic compound preparationSulfonic acid preparationSulfur trioxideMethyl group

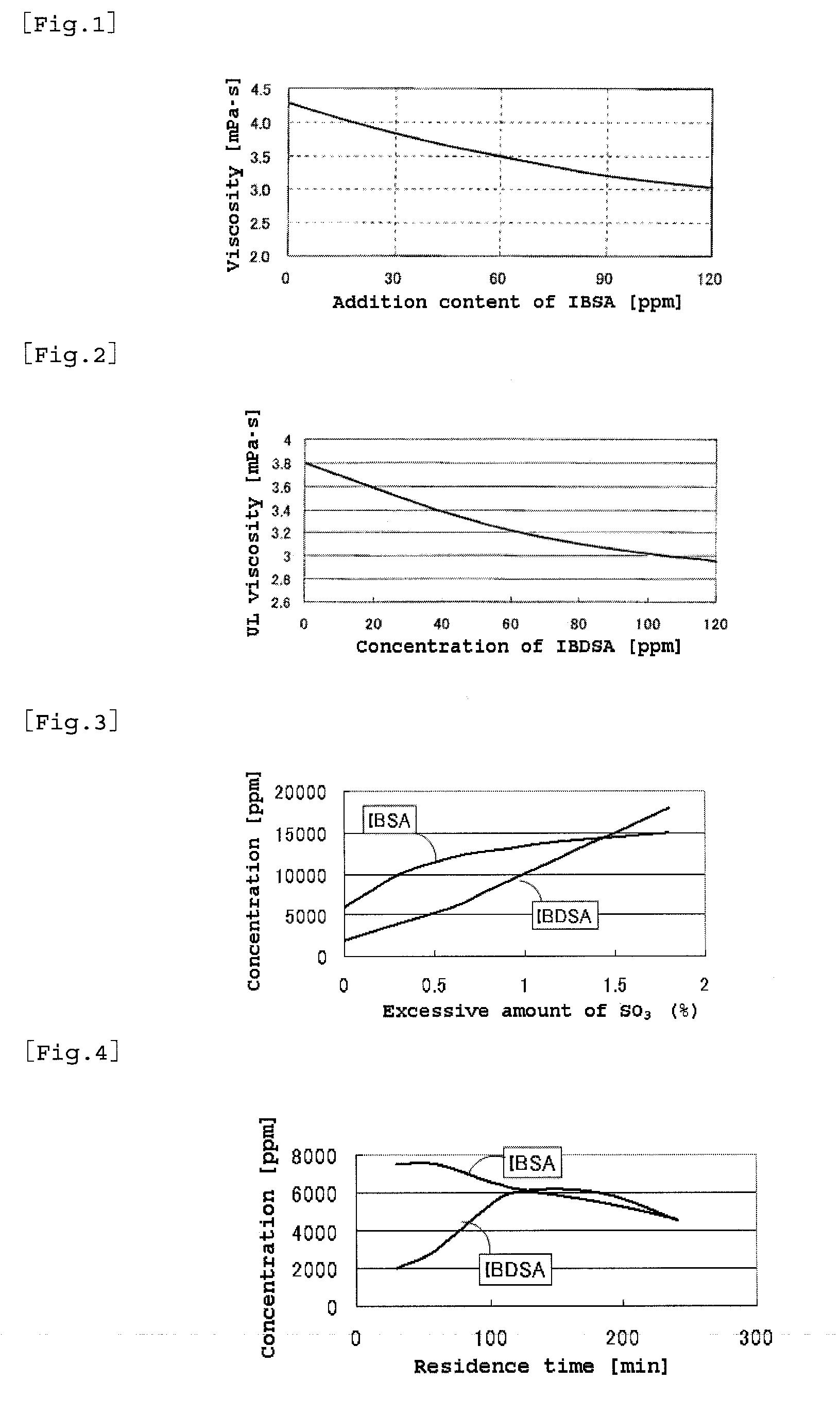

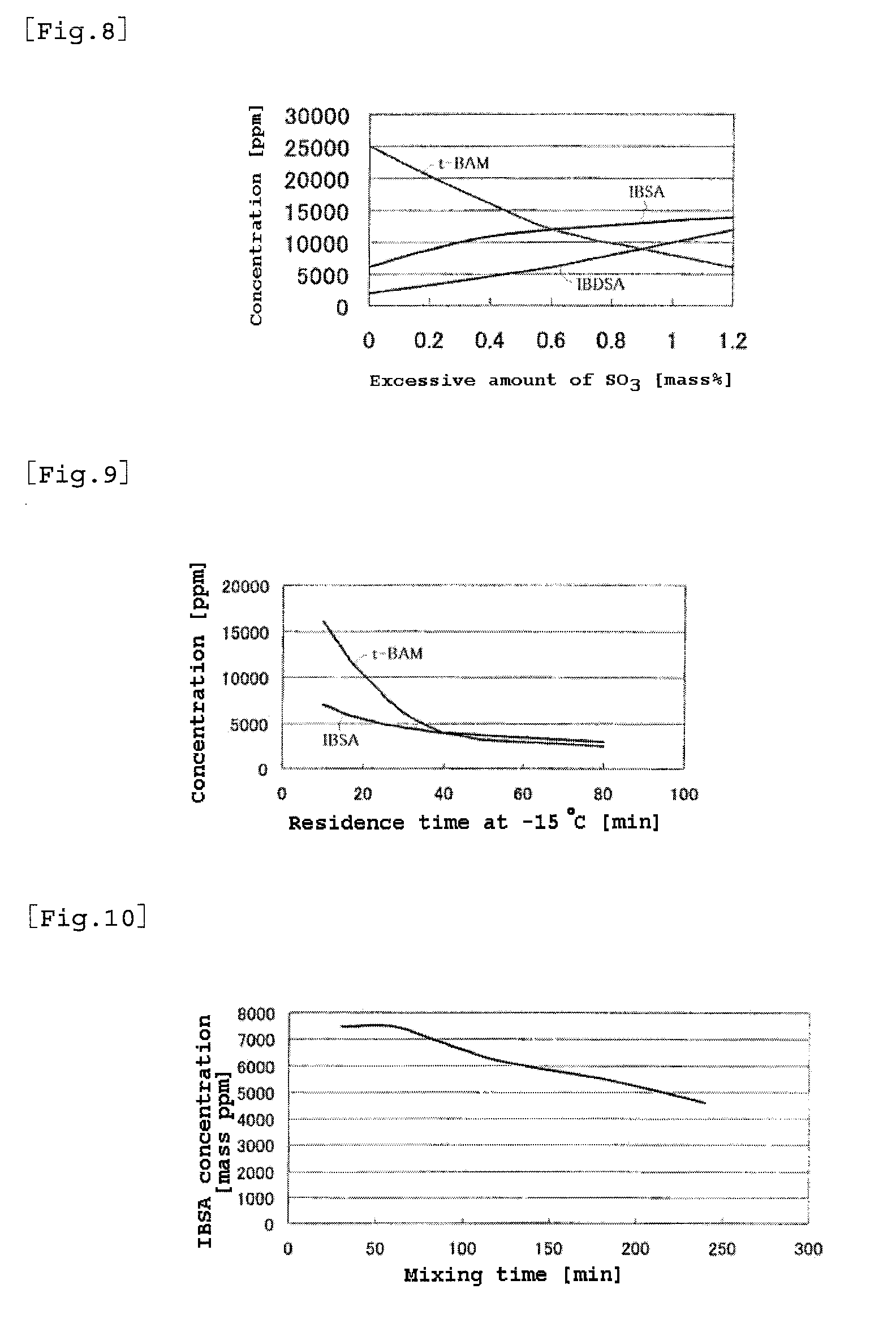

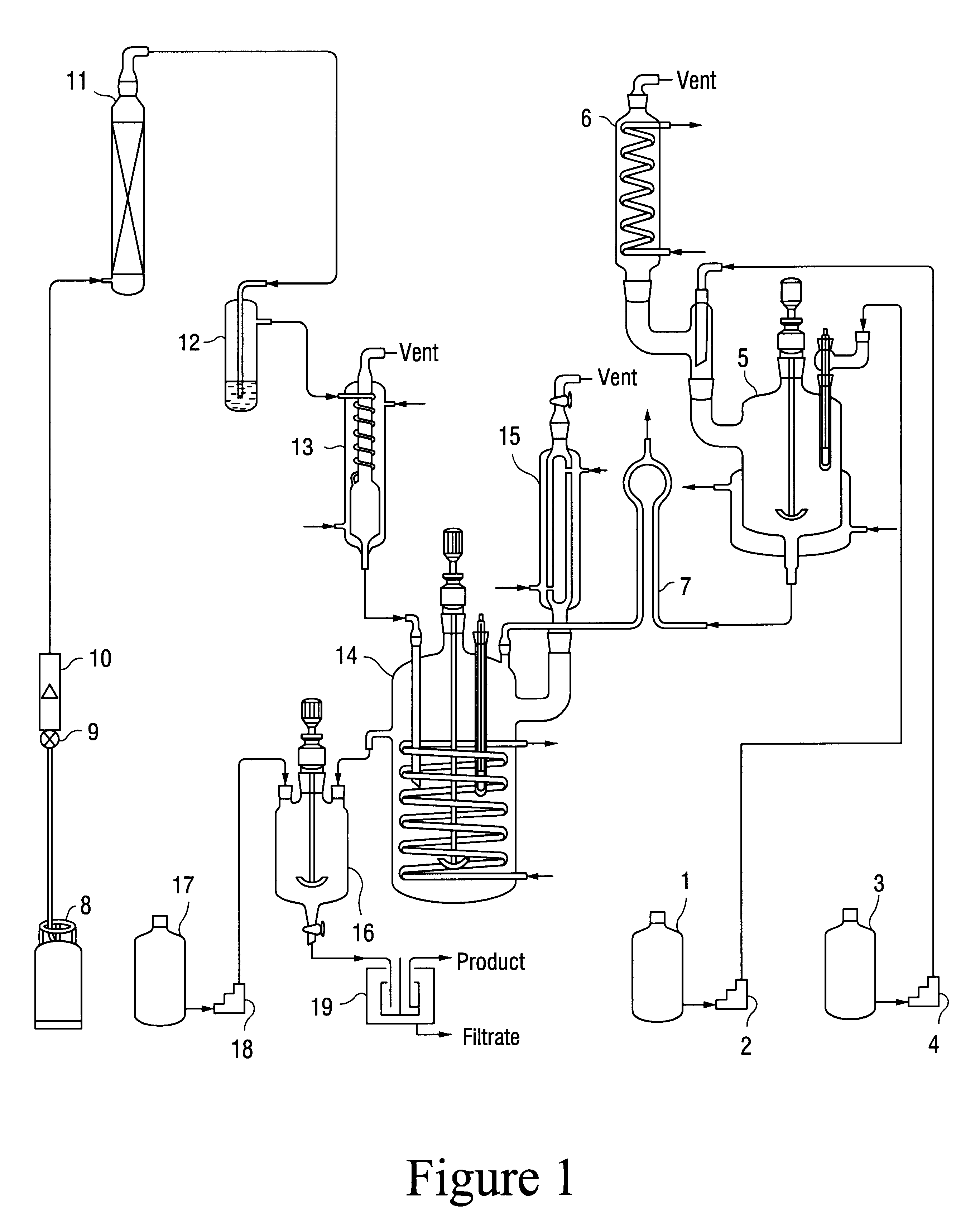

A process for producing 2-acrylamide-2-methyl propane sulfonic acid (ATBS) which comprises reacting acrylonitrile, fuming sulfuric acid, and isobutylene. During the reaction, the concentration of 2-methyl-2-propenyl-1-sulfonic acid (IBSA) and / or that of 2-methylidene-1,3-propylenedisulfonic acid (IBDSA) in the reaction system are determined. When the IBSA concentration exceeds 12,000 mass ppm and / or the IBDSA concentration exceeds 6,000 mass ppm, then the concentration of sulfur trioxide in the reaction system is reduced. Thus, ATBS having an IBSA content of 100 mass ppm or lower and an IBDSA content of 100 mass ppm or lower is produced.

Owner:TOAGOSEI CO LTD

Composition for etching

ActiveCN105273718ASemiconductor/solid-state device manufacturingSurface treatment compositionsSilane compoundsO-Phosphoric Acid

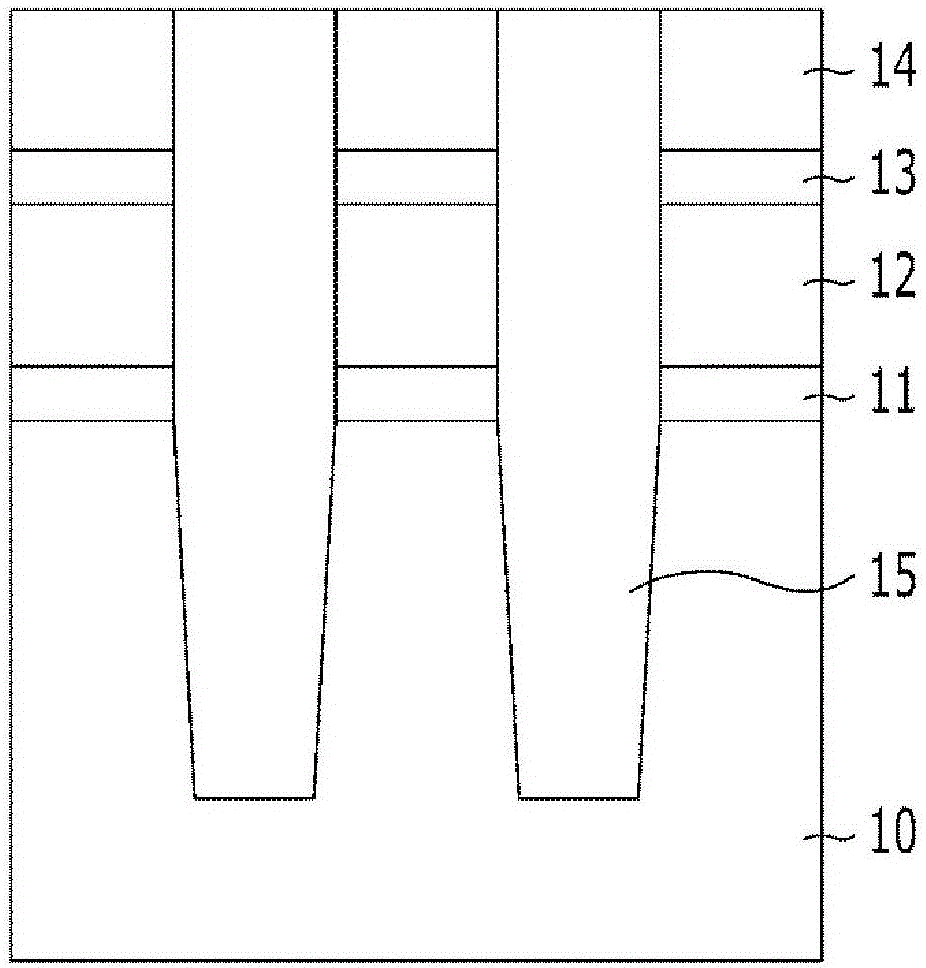

The disclosure is related to a composition for etching, a method for manufacturing the composition, and a method for fabricating a semiconductor using the same. The composition may include a first inorganic acid, at least one of silane inorganic acid salts produced by reaction between a second inorganic acid and a silane compound, and a solvent. The second inorganic acid may be at least one selected from the group consisting of a sulfuric acid, a fuming sulfuric acid, a nitric acid, a phosphoric acid, and a combination thereof.

Owner:SOULBRAIN CO LTD

Preparation of o-nitro p-methylsulfonylbenzoic acid

ActiveCN101503383AIncrease concentrationSlow down decompositionOrganic chemistryOrganic compound preparationBenzoic acidOleum

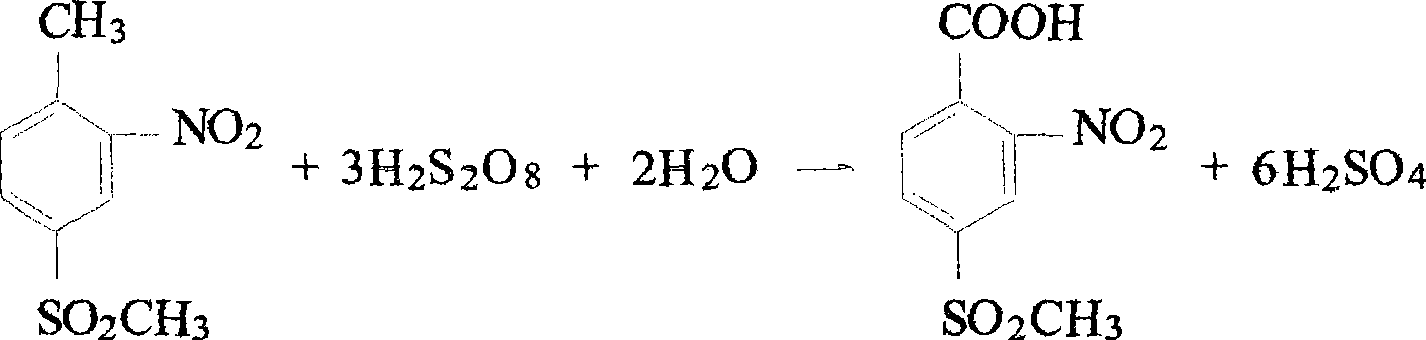

The invention relates to a preparation method of o-nitro-p-methysulfonyl benzoic acid. O-nitro-p-methylsulfonyl toluene is oxidized by persulphuric acid to obtain the o-nitro-p-methysulfonyl benzoic acid. The preparation method comprises the following processes: (a) oxyful and oleum are mixed at a low temperature to prepare persulphuric acid; (b) o-nitro-p-methylsulfonyl toluene is dissolved in sulphuric acid; and (c) the persulphuric acid obtained from the step (a) is dripped into the liquid obtained from the step (b) for purpose of reaction to obtain the o-nitro-p-methysulfonyl benzoic acid. In the method, the reaction of the oleum and the oxyful relatively improves the concentration and the oxidization capability of the oxyful and reduces the decomposition speed of the oxyful; as vanadic oxide is not used, waste acid treatment, recovery and the like are omitted; and the persulphuric acid in use is automatically transformed into sulphuric acid after the oxidization is finished and can finally be used indiscriminately with a mother liquid. Compared with the prior art, the amount of the oxyful in use is greatly reduced, and the production cost remarkably decreases. Compared with the nitric acid oxidization process, the preparation method is safer, environment-friendly and clean.

Owner:浙江嘉福新材料科技有限公司

Method for preparing permonosulfuric hydrogen-pottassium compound salt

InactiveCN1528660AHigh active oxygen contentImprove stabilityPeroxyhydrates/peroxyacidsOleumPotassium hydroxide

The invention is a potassium peroxy-monohydrosulfate compound salt preparing method, using oleum, perhydrol and potassium hydroxide as raw material. Firstly, adding stabilizing agent-containing perhydrol in the reactor, then dropping in the oleum to react, then dropping in potassium hydroxide solution and at the same time adding in crystal shape modifier, vacuum-condensing, cooling and crystallizing, and then drying to obtain its dried product; the perhydrol solution concentration is 45-80% and the oleum concentration 35-65%. It uses oleum to replace the vitriol oil and thick perhydrol solution to replace dilute perhydrol solution, and adds in potassium hydroxide to adjust the components. It has better stability.

Owner:陶华西

Preparation method for high heat conduction and radiation material by intercalating metal particles between layers of thin-layer graphene

InactiveCN102807845AMature technologyImprove thermal conductivityHeat-exchange elementsMetal chlorideOleum

The invention discloses a preparation method for a high heat conduction and radiation material by intercalating metal particles between layers of thin-layer graphene. The preparation method comprises the steps as follows: A, mixing graphite with hydrogen peroxide with the concentration of 30-60%, adding fuming sulfuric acid with 20% of sulfur trioxide or 96% of concentrated sulfuric acid and phosphorus pentoxide to prepare sulfuric acid intercalated graphite, washing by water and drying; B, carrying out microwave treatment to obtain expanded thin-layer graphene, ultrasonically cleaving and drying; C, repeating the steps A and B for one or more times, and enabling the prepared graphene to have 2-50 layers, the sheet layer size of 2-300 microns and the carbon-to-oxygen ratio of 20-100; D, intercalating metal chloride or metallic simple substance; and E, recovering the thin-layer graphene with the metal chloride intercalation by hydrogen. The metal particles are stored between the layers of the thin-layer graphene in an in-situ way, so that the heat conductivity in the Z direction is improved; and the preparation method is low in environment pollution and cost and suitable for industrial batch production.

Owner:叶全惠

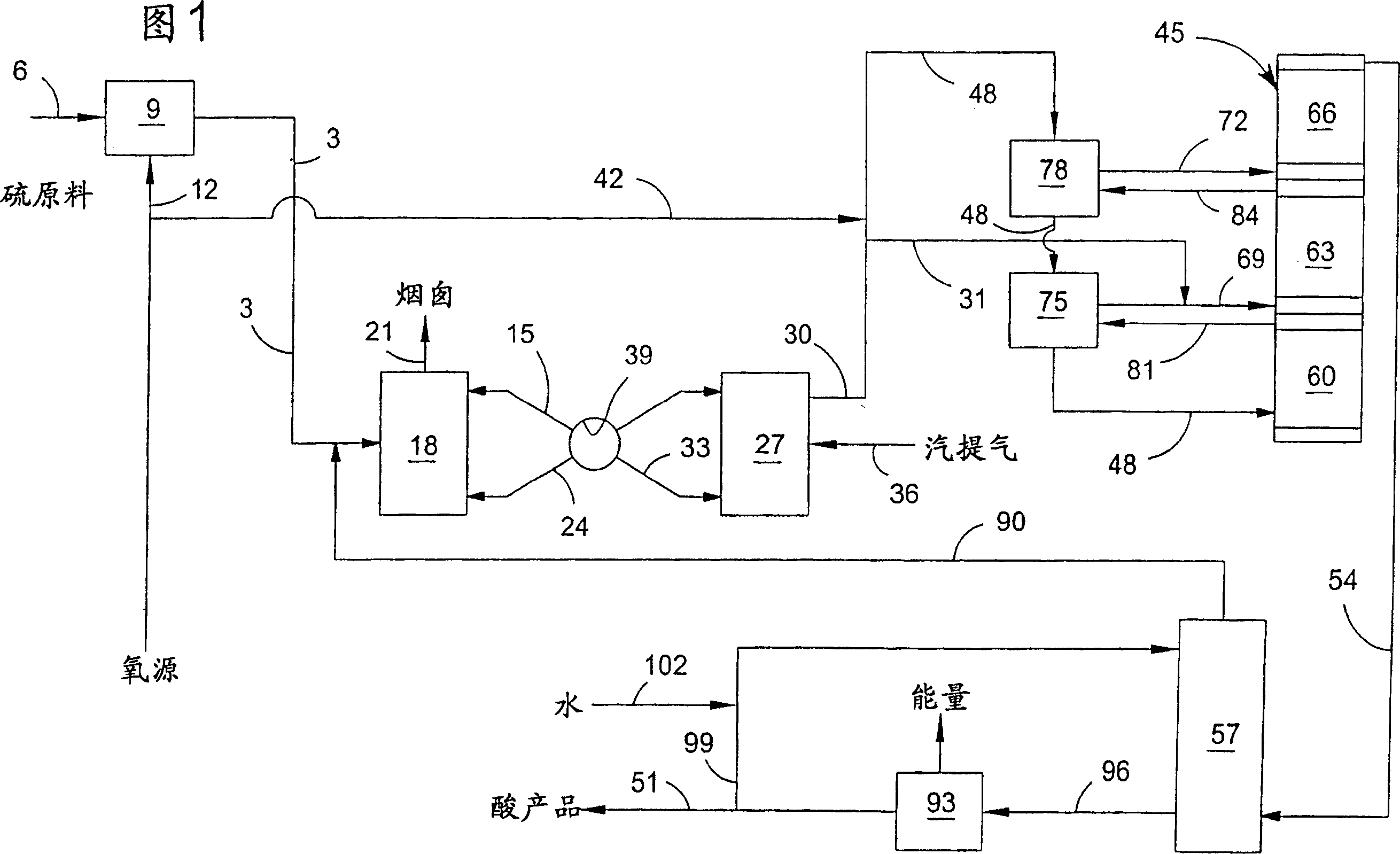

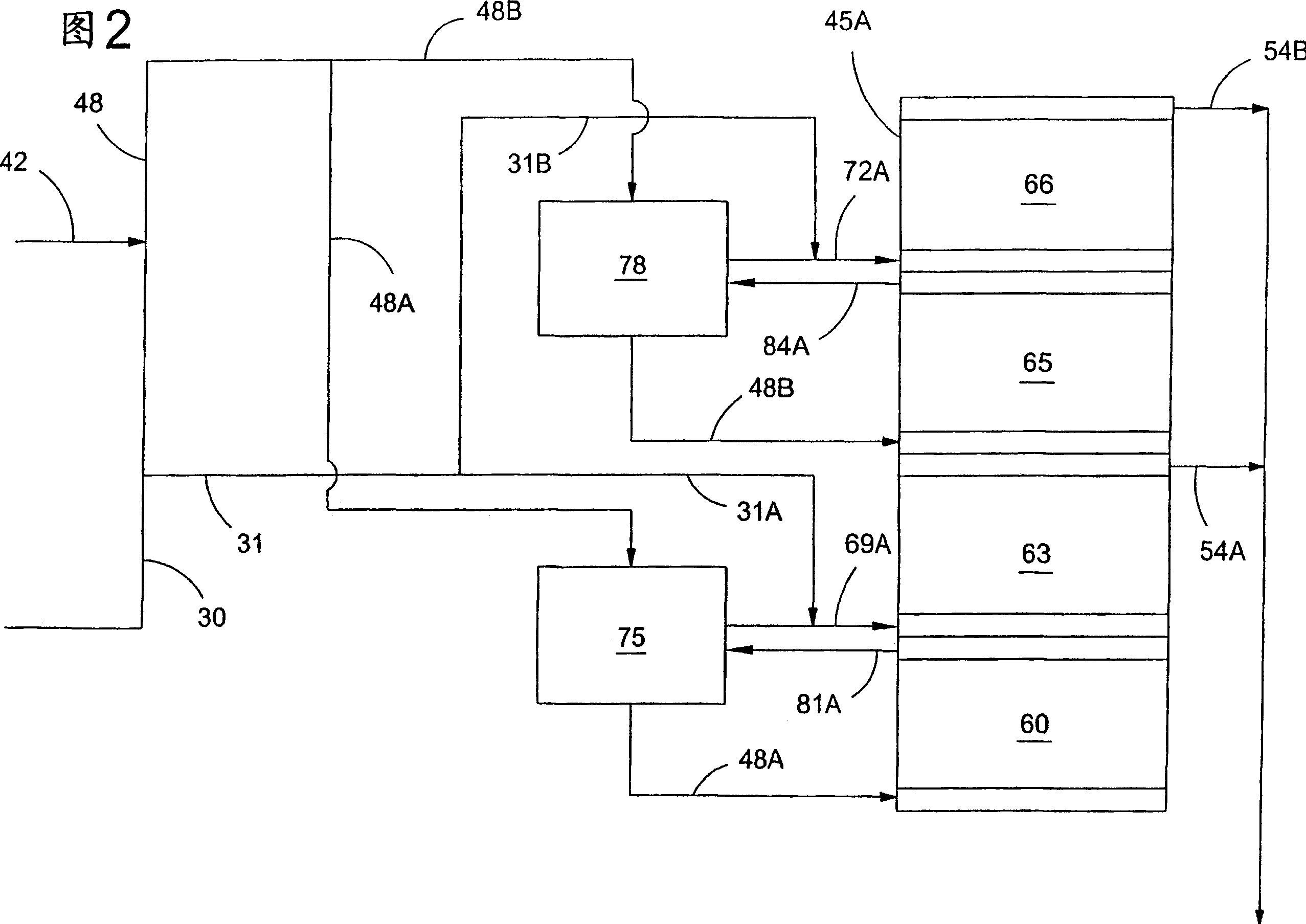

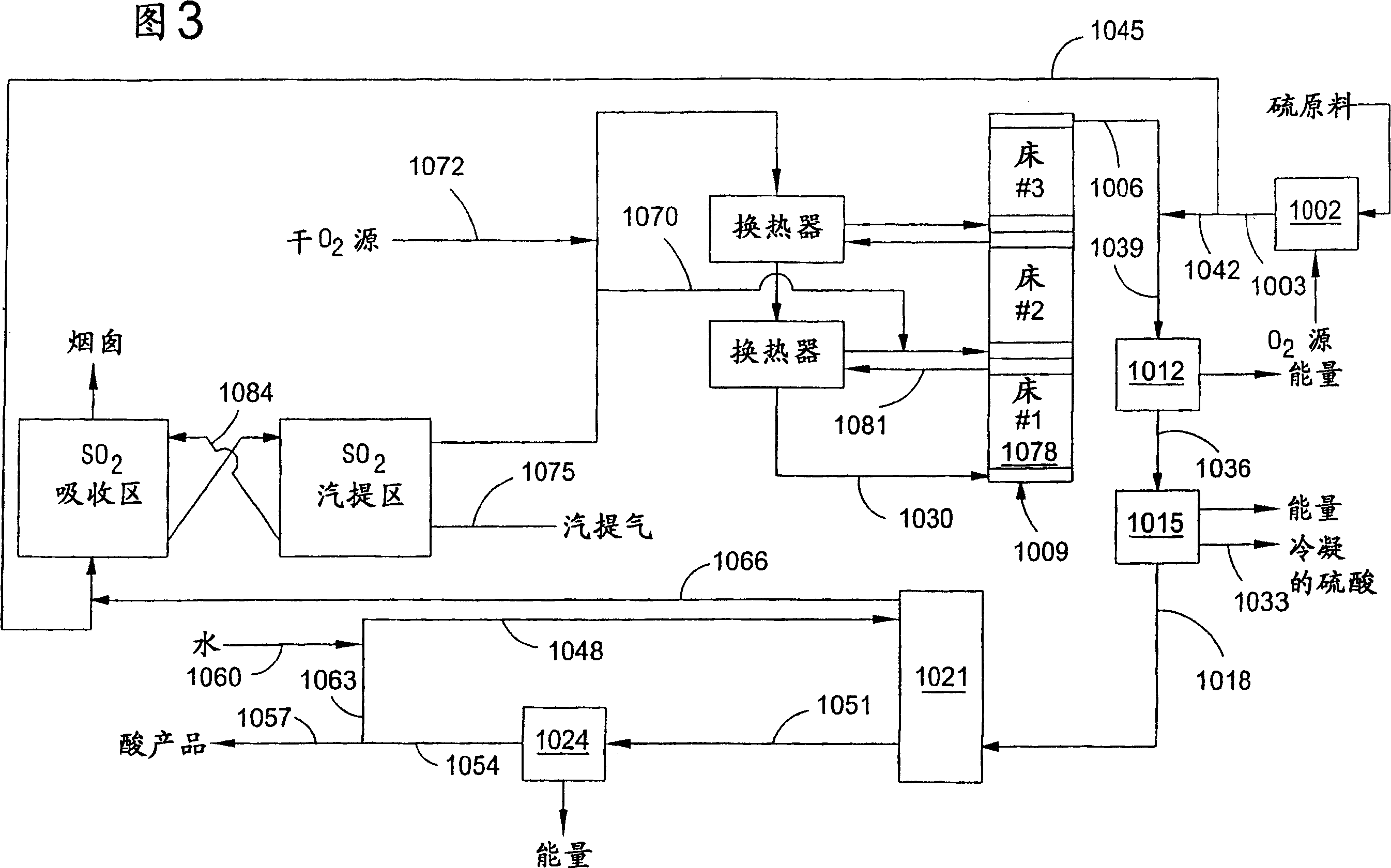

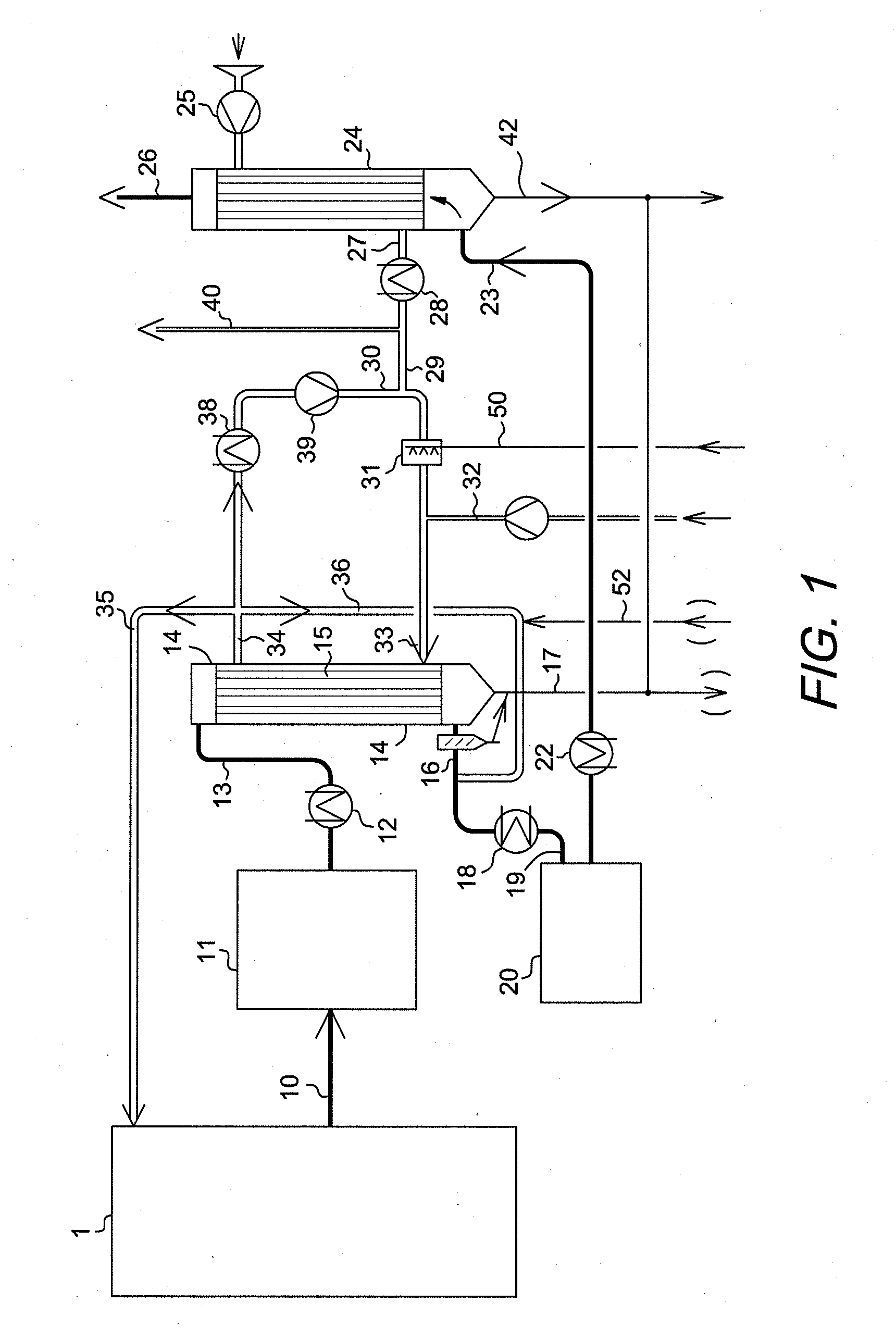

Method for making sulfur trioxide, sulfuric acid, and oleum from sulfur dioxide

A first portion of the converter feed gas comprising a SO 2 -enriched stripping gas is formed. Passing the converter feed through a plurality of catalyst beds in series to form a reformed gas comprising SO3 and residual SO2, the plurality comprising at least 2 and no more than 4 catalyst beds. The second portion of the SO2-enriched gas is introduced into at least one catalyst bed downstream of the most upstream catalyst bed of the plurality of catalyst beds to increase the SO2 concentration in the gas fed to the downstream bed. The invention also relates to a process for the production of sulfuric acid and / or oleum from a feed gas comprising SO2. The SO2-enriched stripping gas is passed through multiple series-connected catalyst beds to form a reformed gas comprising SO3 and residual SO2. mixing the reformed gas with water vapor to form a product acid gas comprising: (a) sulfuric acid from the gas phase reaction between SO3 from the oxidation product gas and water vapor, thereby generating gas phase heat of sulfuric acid formation; (b) SO3 ; and (c) SO2. Thermal energy is recovered from gas phase sulfuric acid generation heat by heat transfer from the product acid gas to steam or feed water in an indirect heat exchanger. The cooled product acid gas is then contacted with sulfuric acid liquid in the SO3 absorption zone to form additional sulfuric acid and / or oleum and SO3-depleted gas containing SO2.

Owner:MONSANTO CO (MONSANTO CY)

Method for preparing lithium hexafluorophosphate

ActiveCN101570328AImprove product qualityRich sourcesLead-acid accumulatorsPhosphorus compoundsOleumReaction rate

The invention relates to a method for preparing lithium hexafluorophosphate. The method comprises the following steps: (1), enabling anhydrous hydrogen fluoride and phosphorus pentoxide to react underthe protection of inert gas to prepare hexafluorophosphoric acid; (2), adding oleum to the hexafluorophosphoric acid under cooling stirring to prepare phosphorus pentafluoride gas; (3), dissolving high-pure lithium fluoride in an anhydrous hydrogen fluoride solution to form an anhydrous hydrogen fluoride solution containing the lithium fluoride; (4), cooling the phosphorus pentafluoride gas at 40DEG C below zero, guiding the phosphorus pentafluoride gas to the anhydrous hydrogen fluoride solution containing the lithium fluoride, and reacting, crystallizing, separating and drying the phosphorus pentafluoride gas to obtain a pure lithium hexafluorophosphate product; and (5), continuously pumping the unreacted cooled phosphorus pentafluoride gas after a reaction to the other anhydrous hydrogen fluoride solution containing the lithium fluoride and continuously reacting to obtain a lithium hexafluorophosphate finished product. The invention has rich material resources and easily obtainable raw materials, low production cost, high reaction rate, high product quality and thorough reaction and can realize semi-continuous production by the series connection of double kettles.

Owner:DO FLUORIDE CHEM CO LTD

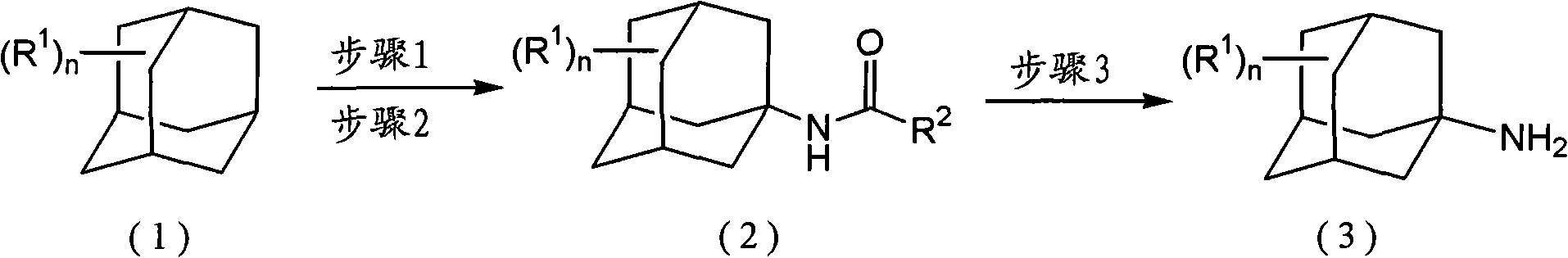

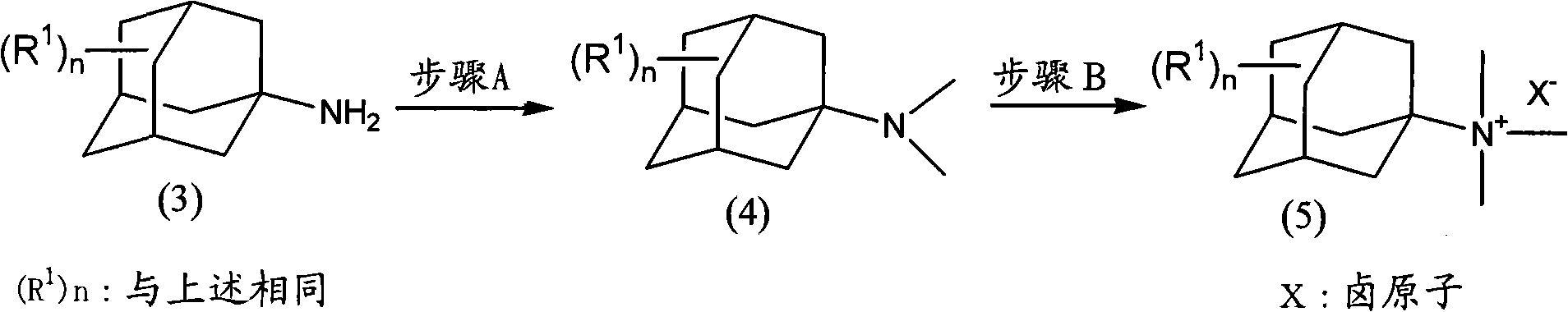

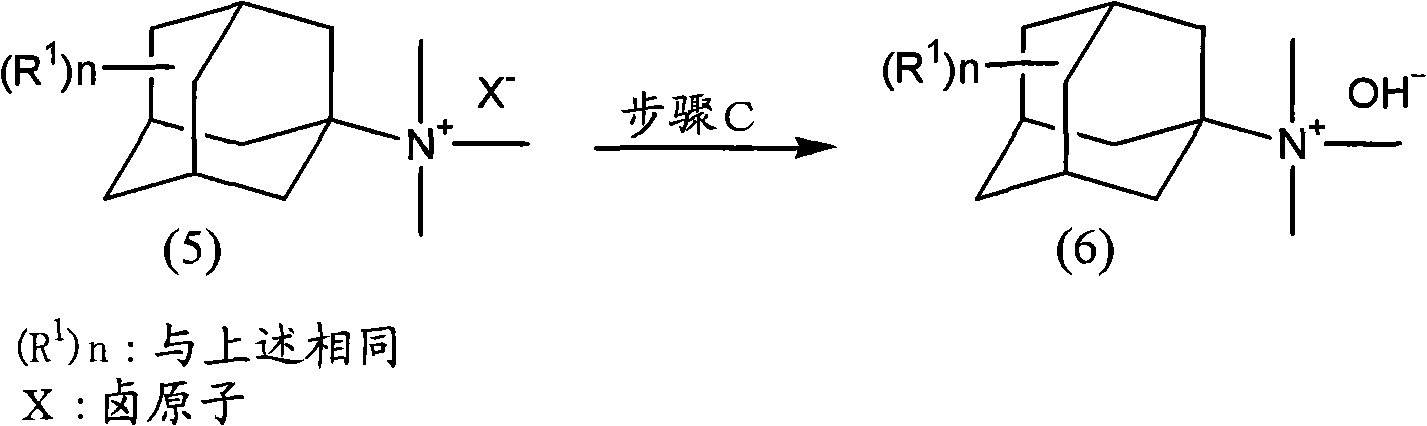

Method for producing amine series and quaternary ammonium salts with adamantane framework

InactiveCN101993377AEfficient manufacturingHigh purityAmino preparation from aminesOrganic compound preparationHalomethaneOleum

The present invention provides a method for producing amine series with an adamantane framework, including the following steps: step 1: reacting adamantane series in a mixed liquid containing oleum and organic nitrile compounds; step 2: performing hydrolyzing treatment to a reaction liquid obtained in the step 1 to form acidamide series with the adamantane framework; step 3: performing alkali treatment to the acidamide series obtained in the step 2 to form the amine series with the adamantane framework. A method for producing quaternary ammonium salts with the adamantane framework in sequence includes the following steps: step A: reacting the amine series with the adamantane framework dissolved in a dissolvant a with aminic acid and methylene oxide or paraformaldehyde, to form dimethylamine series with the adamantane framework; step B: dissolving the dimethylamine series with the adamantane framework obtained in the step A in a dissolvant b to react with halomethane so as to form quaternary ammonium salt halogenide with the adamantane framework; step C: performing ion exchange to the quaternary ammonium salt halogenide with the adamantane framework to form quaternary ammonium salt hydroxides with the adamantane framework.

Owner:IDEMITSU KOSAN CO LTD

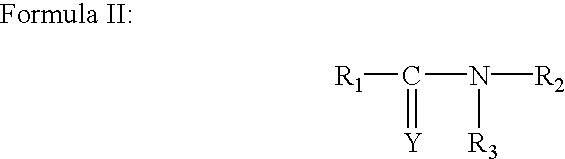

Method for preparing amide using nonhomogeneous phase oximation rearrangement

ActiveCN1762985ALow costGood economic valueOrganic compound preparationCarboxylic acid amides preparationBeckmann rearrangementReaction temperature

The present invention discloses oximation and rearrangement process of preparing amide with aliphatic and / or cyclic aliphatic ketone as material. The preparation process includes catalytic reaction of ketone, hydrogen peroxide solution and ammonia inside inert solvent to produce ketoxime solution, Beckmann rearrangement of the oil phase product under the action of fuming sulfuric acid, and hydrolysis to neutralize and produce amide. The present invention has shortened technological process, lowered cyclohexyl ketoxime rearranging reaction temperature, lowered sulfuric acid consumption and reduced side product.

Owner:HUBEI JINXIANGNING CHEM ENG TECHENOLOGY CO LTD

Process for the production of sulphuric acid

Owner:HALDOR TOPSOE AS

Process for the preparation of 2-acrylamido-2-methyl-1-propanesulfonic acid

InactiveUS6504050B1Reduce the ratioLow costOrganic compound preparationSulfonic acid preparationOrganic sulfonic acidOleum

The present invention provides a process for the preparation of highly pure 2-acrylamido-2-methyl-1-propanesulfonic acid in high yield, with improved appearance, by the reaction of acrylonitrile with more than 98% sulfuric acid or oleum and liquefied isobutylene in presence of weak inorganic acids or organic sulfonic acids.

Owner:COUNCIL OF SCI & IND RES

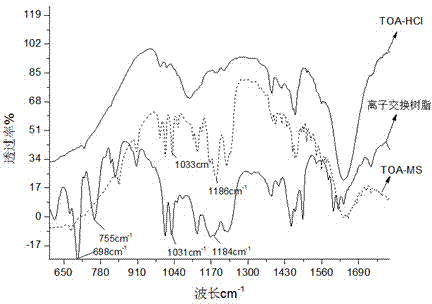

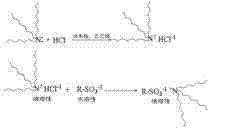

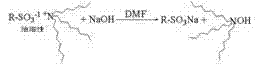

Strong-acid cation exchange resin and preparing method thereof

The invention discloses strong-acid cation exchange resin and a preparing method thereof. The strong-acid cation exchange resin relates to white spherical particles having a particle size of 0.42-1.4 mm prepared by suspension polymerization initiated by free radicals, wherein oil soluble unsaturated alkyl (aryl) sulfonate and styrene are adopted as monomers and raw materials, and a divinyl monomer is adopted as a crosslinking agent, the sulfonic acid group content of the cation exchange resin is 23.5-29.2%, and the ion-exchange capacity is 2.91-3.51 meq / g. The preparing method omits a sulfonation step in preparation processes of traditional cation exchange resin, and is free of use of concentrated sulfuric acid, fuming sulfuric acid and chlorosulfonic acid which have strong oxidizing properties as a sulfonation agent, thus solving an environment pollution problem caused by large-amount discharge of waste acid, and a production safety problem in traditional processes. The strong-acid cation exchange resin is used for removal of calcium ion and magnesium ion in water, and used for catalyzing heterogeneous organic synthesis reactions, such as condensation reactions of organic acids and alcohols, and alkylation reactions of phenols.

Owner:SHANGHAI RESIN FACTORY

Sulfamic acid production process

ActiveCN101391759ASimple and fast operationSimplify labor intensityOrganic chemistryAmidosulfonic acidOleumAfter treatment

The invention discloses a novel sulfamic acid after-treatment process, which comprises: carbamide is adopted to be sulfonated with oleum for preparing sulfamic acid; after the reaction the dilute sulphuric acid with the concentration of 5 to 30 percent is added to regulate the concentration of the sulphuric acid in an reaction kettle to be about 70 percent, and the sulphuric acid is isolated after holding; then the dilute sulphuric acid with the concentration of 1 to 10 percent or water is added into the reaction kettle for a second time acidity regulation to regulate the concentration of the sulphuric acid in the reaction kettle to be 5 to 20 percent; then the high pure product with the purity greater than 99.9 percent can be obtained after recrystallization, filtering and drying. The after-treatment process is easy for operation and the labor hardship is lower; and the purity of the product is high and the quality is better.

Owner:中国中化股份有限公司 +1

Preparation method of lithium hexafluorophosphate

ActiveCN101570326AImprove product qualityRich sourcesLead-acid accumulatorsPhosphorus compoundsOleumPhosphoric acid

The invention relates to a preparation method of lithium hexafluorophosphate. The method comprises the following steps: (1), enabling anhydrous hydrogen fluoride and strong phosphoric acid to react under the protection of inert gas to prepare hexafluorophosphoric acid; (2), adding oleum to the hexafluorophosphoric acid prepared in the step (1) under cooling stirring to prepare phosphorus pentafluoride gas; (3), dissolving high-purity lithium fluoride in an anhydrous hydrogen fluoride solution to form an anhydrous hydrogen fluoride solution containing the lithium fluoride; (4), cooling and guiding the phosphorus pentafluoride gas into the anhydrous hydrogen fluoride solution containing the lithium fluoride, reacting, crystallizing, separating and drying to obtain a pure lithium hexafluorophosphate product; and (5), continuously guiding the unreacted and cooled phosphorus pentafluoride gas to the anhydrous hydrogen fluoride solution containing the lithium fluoride and continuously reacting to obtain a lithium hexafluorophosphate finished product. The phosphorus pentafluoride in the process is cooled to fully react so as to prevent incomplete reacted phosphorus pentafluoride powder from causing environmental-protection pressure.

Owner:DO FLUORIDE CHEM CO LTD

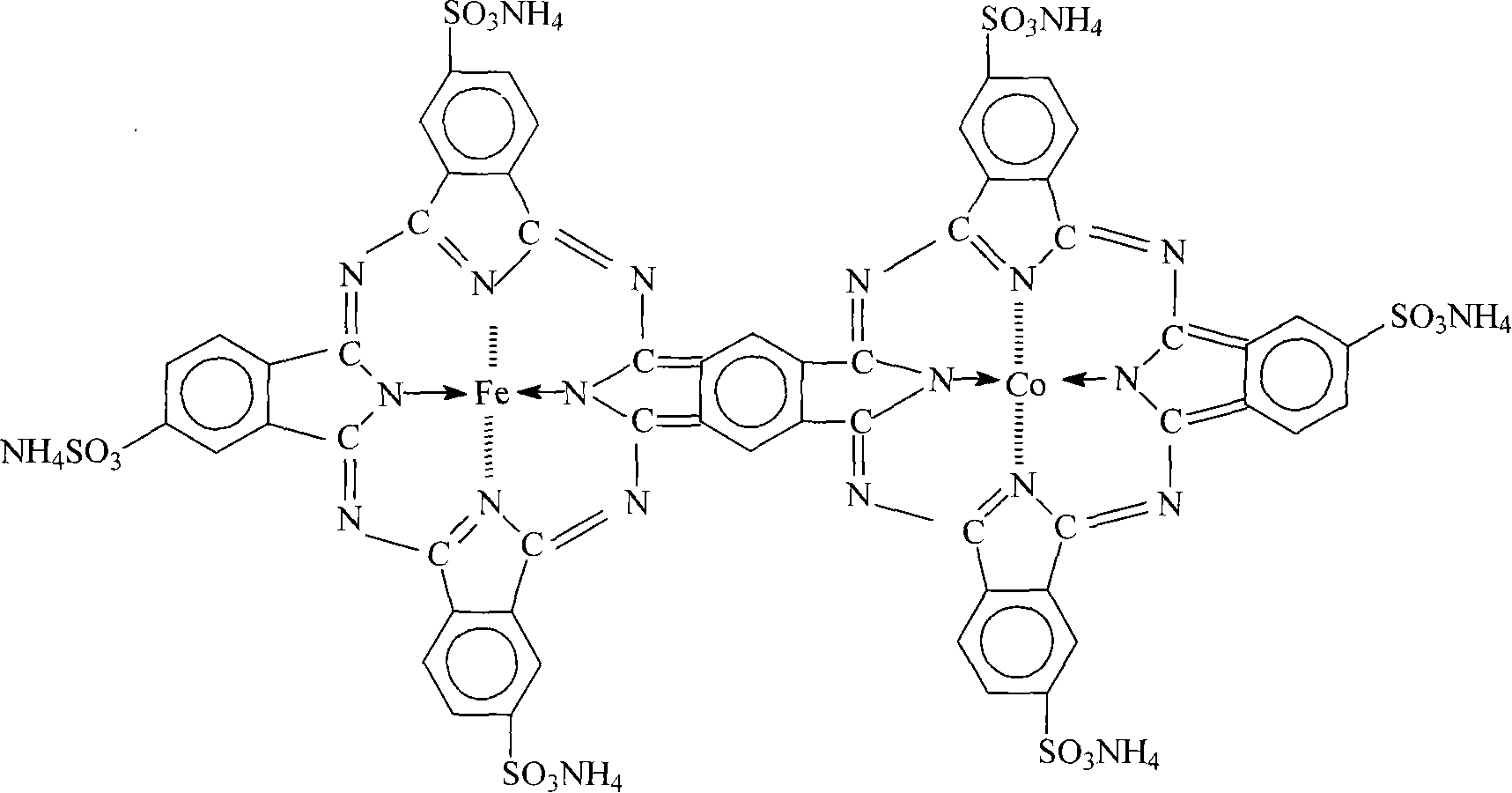

Desulphurization catalyst of sulfosalt of phthalocyanine iron cobalt, and preparation method

InactiveCN101049576AHigh catalytic activityImprove desulfurization efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationIron saltsPhthalocyanine

A phthalocyanin-iron-cobalt-ammonium sulfonate as the dsulfurizing catalyst with high catalytic activity and desulfurizing efficiency (more than 99%) is prepared through preparing the sulfonated chemical from phthalic anhydride as raw material and smoking sulfuric acid as sulfonating agent, preparing phthalocyanin-iron-cobalt- ammonium sulfonate from said sulfonated chemical, ammonium molybdate as catalyst, urea, cobalt chloride and iron salt, drying, and pulverizing.

Owner:汪晓梅

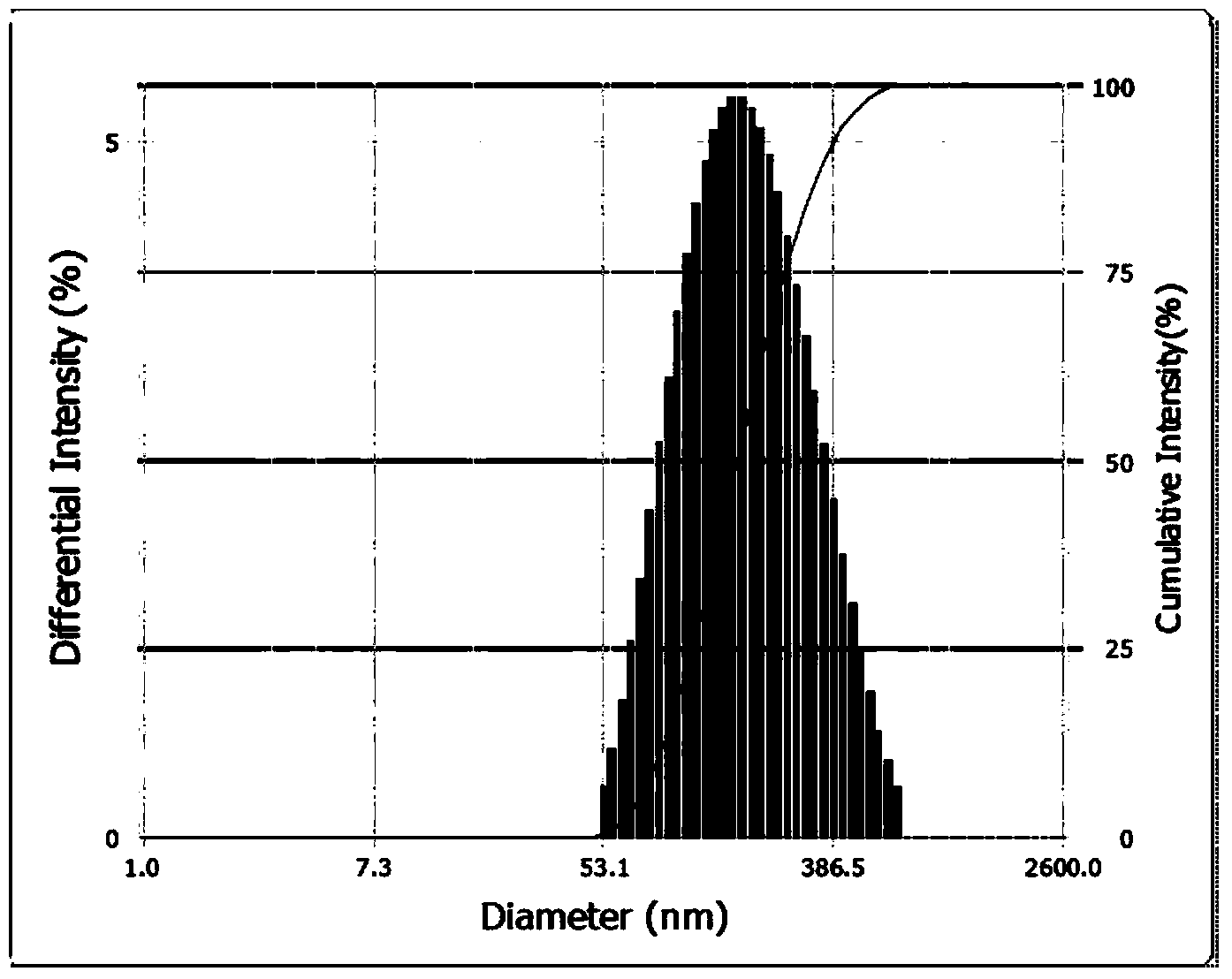

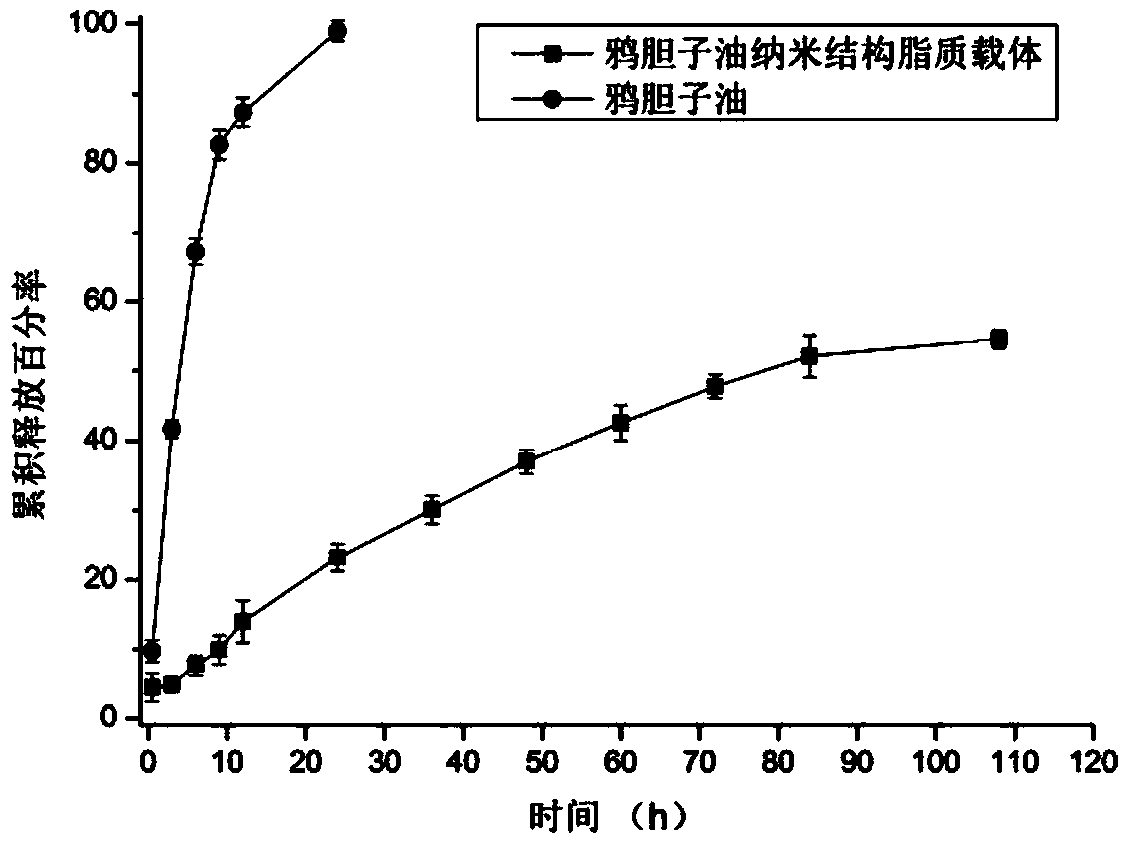

Preparation method of oleum fructus bruceae nano structure lipid carrier and freeze-dried powder thereof

ActiveCN104337851AGood curative effectUniform particle size distributionPowder deliveryLyophilised deliveryLipid formationSide effect

The invention discloses a preparation method of an oleum fructus bruceae nano structure lipid carrier and freeze-dried powder thereof. The method comprises the following steps: (1) respectively dissolving an oil phase and oleum fructus bruceae at 70 DEG C, wherein the oil phase is solid grease or a mixture of solid grease and liquid grease; and the mass ratio of the oil phase to the oleum fructus bruceae is (1: 1) to (2: 1); (2) dissolving an emulsifier into ultra-pure water, and preheating at 70 DEG C, wherein the mass ratio of the emulsifier to the ultra-pure water is (1: 200) to (1: 800); the mass ratio of the emulsifier to the oleum fructus bruceae is (1: 1.5) to (1: 12); (3) mixing a water solution obtained in the step (2) with the grease obtained in the step (1), and preparing colostrum by adopting a high-speed shearing machine in a shearing manner; and (4) pouring the colostrum obtained in the step (3) into a high-pressure homogenizer, and circulating for 5-7 times under the pressure of 50-70MPa to obtain the oleum fructus bruceae nano structure lipid carrier. The drug-loading capacity is improved by oleum fructus bruceae nano lipid disclosed by the invention; the oleum fructus bruceae nano structure lipid carrier has relatively good stability; the curative effect of the oleum fructus bruceae is improved; and the toxic and side effects are reduced.

Owner:EAST CHINA UNIV OF SCI & TECH +1

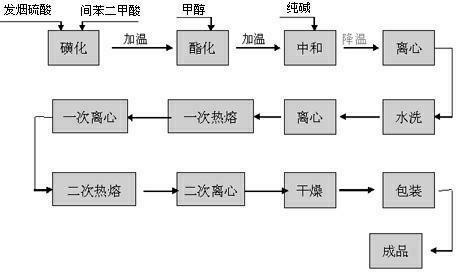

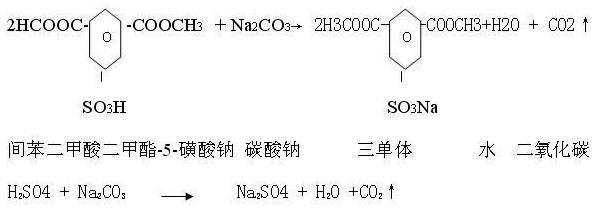

Method for preparing sodium dimethyl isophthalate-5-sulfonate from high-concentration fuming sulfuric acid

ActiveCN102617413AReduce productionReduce the difficulty of refiningSulfonic acids salts preparationHigh concentrationOleum

The invention relates to a chemical product preparation method, particularly a method for preparing sodium dimethyl isophthalate-5-sulfonate from high-concentration fuming sulfuric acid, which comprises the following steps: (1) mixing m-phthalic acid and 60-70% fuming sulfuric acid to carry out sulfonation reaction, thereby obtaining a sulfonated product; (2) adding methanol into the sulfonated product to carry out esterifying reaction, thereby obtaining the esterified product; (3) adding water into the esterified product, adding sodium carbonate at 20-55 DEG C to regulate the pH value to 5-7.5, thereby obtaining a neutralized material; and (4) separating and purifying the neutralized material, and drying to obtain the sodium dimethyl isophthalate-5-sulfonate finished product. The ternary-monomer generated in the invention has the advantage of high product quality, and the mother liquor process water can be utilized cyclically, thereby thoroughly implementing closed circulation of the process water and completely achieving zero discharge in the whole production process.

Owner:潍坊德润化学有限公司

Manufacturing method of anthypnotic wet tissue

The invention provides a manufacturing method of anthypnotic wet tissue. During pulping, 2-5wt% wet strength agent and 1-2wt% softener are added, a large roll of toilet paper can be produced by the conventional paper-making process and, is subjected to back-rolled and is cut into small rolls. The paper is soaked in an anthypnotic liquid medicine so thatto enable that the water content is in a range of 40-100% and packaged tightly to form the product. The anthypnotic liquid medicine consists of components A and B. The component A is prepared by dissolving 6-12 parts of oleum menthae, 2-4 parts of wintergreen oil, 4-12 parts of menthol, 4-8 parts of camphor, 2-6 parts of borneol, 5-10 parts of ginger extract, 1-2 parts of clove oil and 1-3 parts of eucalypus oil in 100-400 parts of ethanol, and adding 5-20 parts of emulsifier. The component B is prepared by dissolving 20-100 parts of glycerol, 20-200 parts of propylene glycol, and 0.5-5 parts of acetic chlorhexidine in 500 parts of water. The product is flexible in texture and good in toughness, and can be used as anthypnotic and refreshing healthcare facial tissue.

Owner:严积芳

Preparation method of calcium sulfonate salt with low alkali value

ActiveCN101602696AHigh speedLow reaction temperatureOrganic compound preparationSulfonic acids salts preparationOleumNitrogen gas

The invention relates to a preparation method of calcium sulfonate salt with low alkali value. The preparation method comprises the following steps that: synthesis alkylbenzene with the molecular weight between 300 and 450 is sulfonated by oleum, a certain amount of water is added after sulfonation for 2-5 hours, then nitrogen gas is used for purging, an inert solvent and base oil are used for dilution, then standing and stratification are carried out to obtain coarse sulfonic acid of an upper layer, an alkali filter aid is used for filtration to obtain synthesis alkyl benzene sulphonate diluted by a purifying solvent, the total acid value of the synthesis alkyl benzene sulphonate is 60 to 120mgKOH / g, and the concentration of free acid is controlled below 0.2%; and then, a sodium hydroxide water solution is used for carrying out a neutralization reaction, then solid calcium chloride is added to carry out a double-decomposition reaction, and finally, stratification, water washing and distillation are carried out to obtain low-alkali-value synthesis alkyl benzene calcium sulfonate salt which does not contain or contains trace sulfate radicals and chlorine radicals and has good antirust performance and superior cleaning performance.

Owner:LIAONING BODA CHEM

Method for preparing emulsified medicinal composition containing oleum fructus bruceae

InactiveCN101683367AGood diameter uniformityImprove physical stabilityMetabolism disorderDigestive systemYolkHemolysis

The invention discloses a method for preparing an emulsified medicinal composition containing oleum fructus bruceae, which comprises the following steps: (1) mixing a proper amount of water and 1 to 10ml of glycerin; (2) adding at least one of yolk lecithin and poloxamer into liquid prepared in step (1), and performing shear mixing uniformly, wherein the yolk lecithin is between 0.5 and 10g, and the poloxamer is between 0.1 and 5g; and (3) slowly adding 5 to 30ml of oleum fructus bruceae into liquid prepared in step (2), adding water to make the total content be 100ml, adjusting the pressure of a high pressure homogenizer, adopting two-step emulsification method, and continuously circulating 3 to 6 times to prepare the emulsified medicinal composition containing the oleum fructus bruceae.The oleum fructus bruceae emulsion injection prepared by the method has good stability, no hemolysis in a period of validity, and safety, and is favorable for clinical promotion and application.

Owner:ZHEJIANG JIUXU PHARMA

Industrial production method of high-purity beta-elemi alkene bulk medicament

InactiveCN101402544AHydrocarbon active ingredientsDistillation purification/separationOleumVolatiles

The invention provides a method for preparing high-purity beta elemene from natural plants containing the beta elemene such as curcuma zedoary (earthnuts or tubers of the curcuma zedoary), cedronella (fresh leaves of the cedronella), yellowtop (roots, stems, leaves, flowers and seeds of the yellowtop) and so on, which can improve the production efficiency from starting materials to the high-purity beta elemene and reduce the production cost. Compared with the prior art, the method is mainly different in that the roots, stems, leaves, flowers and seeds of the natural plants are taken as raw materials; oleum volatile of specific parts of the natural plants is obtained by methods for extracting different oleum volatiles, and is rectified by the rectification method to obtain the beta elemene with high content; impurity compositions are removed by the macroporous adsorption resin separation method or macroporous adsorption resin combined with the ethanol extraction method, and the silver nitrate complex extraction method in turn; and finally the beta elemene with the content between 95.0 and 99.9 percent is obtained through reduced pressure distillation or rectification. The bulk pharmaceutical chemicals not only can be prepared into oral dosing preparation such as emulsion oral liquid, self-emulsifying / self-microemulsifying capsules, soft capsules and so on, but also can be prepared into non-alimentary dosing preparation such as emulsion injection, liquid drugs injection, transdermal absorbent, lung sprays, suppository and so on. The method has the advantages of novel design, simple apparatus, concise operating steps, obvious shortened operating time, improvement of the production efficiency and high yield coefficient, and is suitable for industrialized production.

Owner:沈阳万爱普利德医药科技有限公司

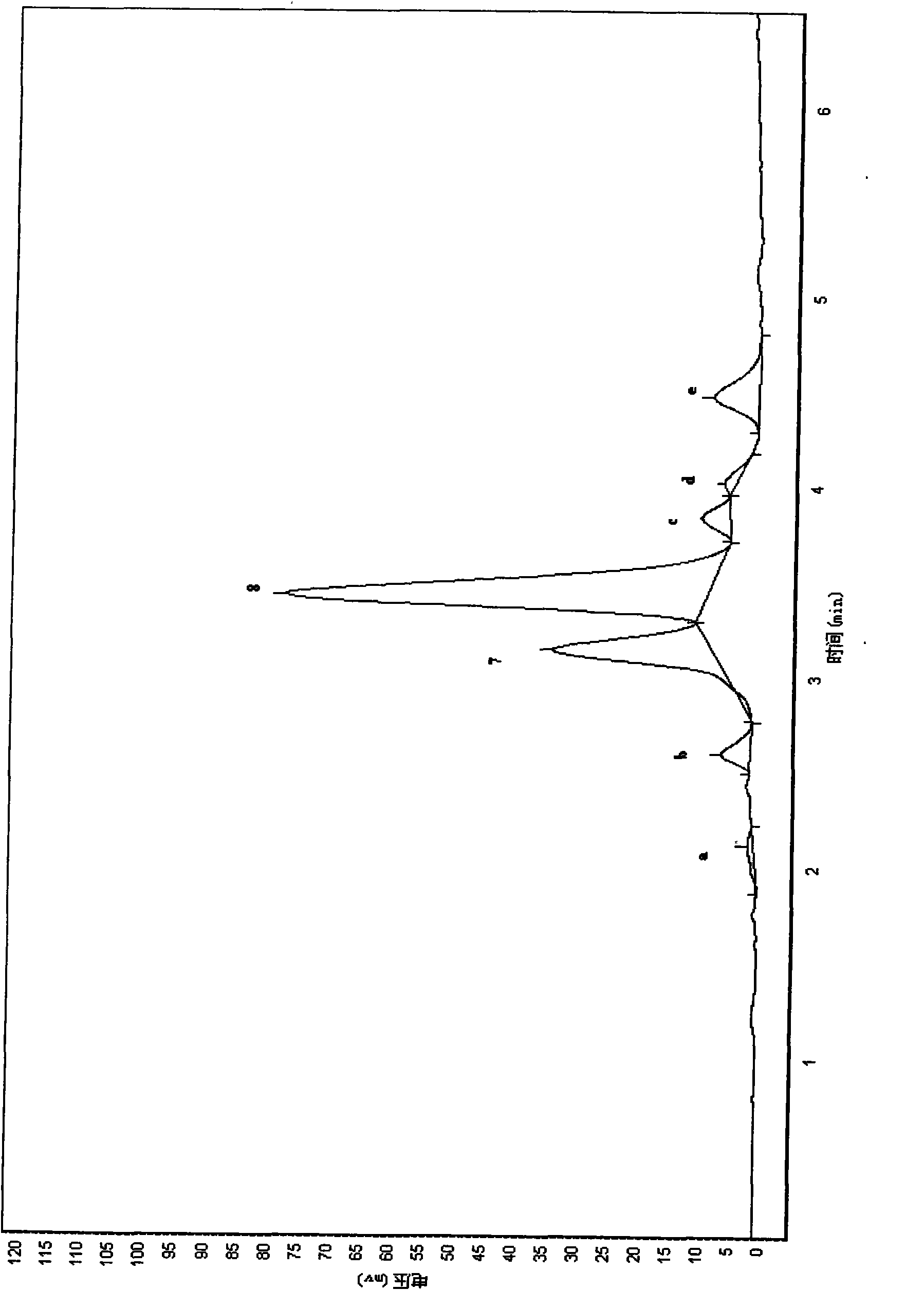

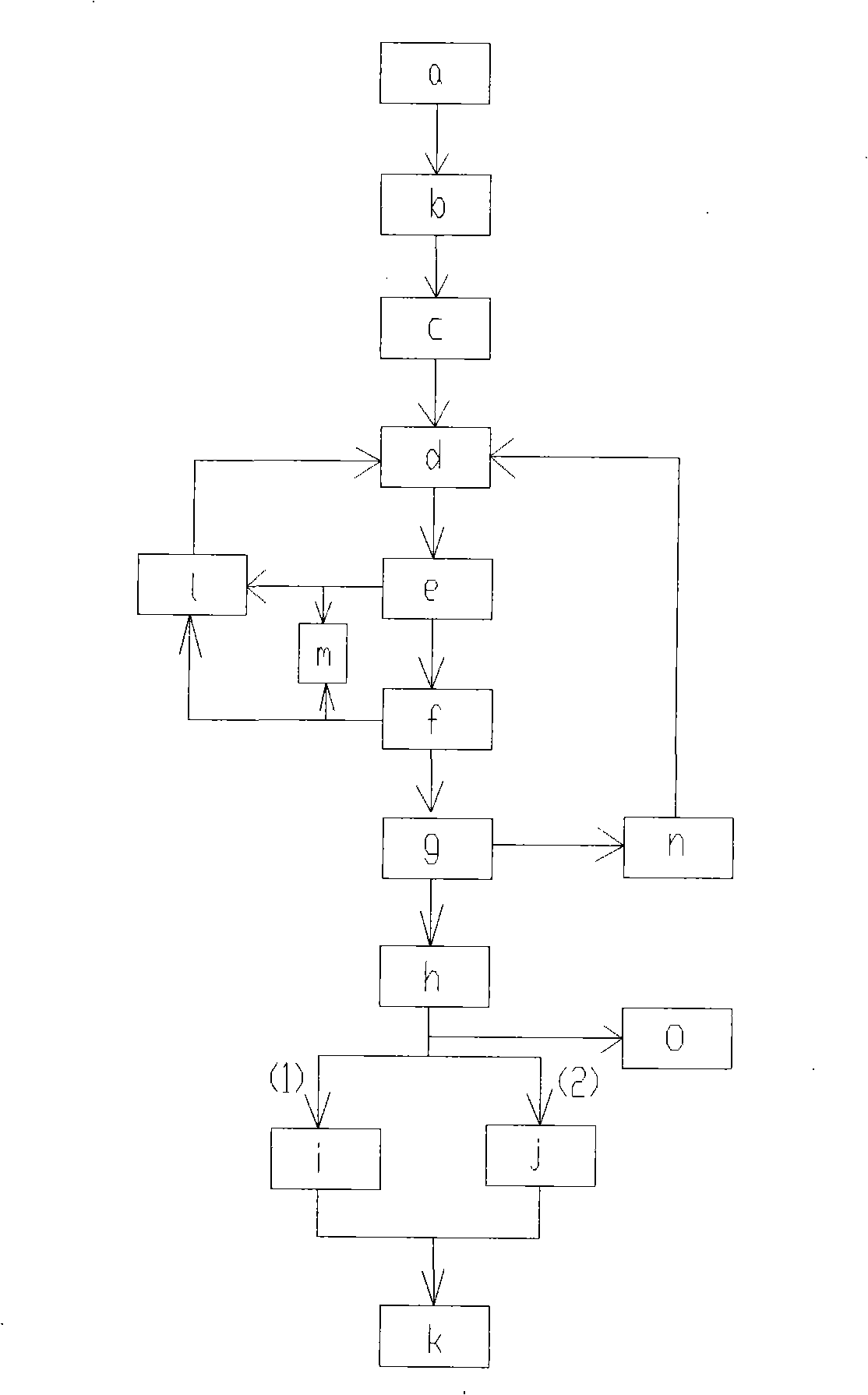

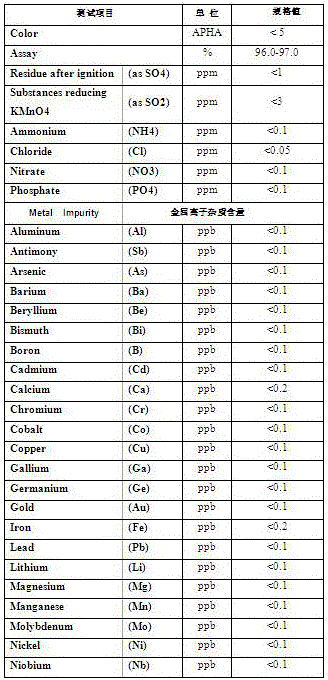

Preparation method of ultra-pure sulfuric acid

The invention discloses a preparation method of ultra-pure sulfuric acid. Fuming sulfuric acid is used as a raw material. The preparation method includes following steps: (1), distilling; (2), purifying and filtering; (3), separating sulfur trioxide liquid; (4), second evaporation; (5), multistage absorption; (6), impurity removal through a stripping tower; (7), obtaining a finished product. In the ultra-pure sulfuric acid, concentration of particles greater than or equal to 0.5 um is less than 5 p / ml, concentration of particles greater than or equal to 0.2 um is less than 100 p / ml, content of single metal ions is less than 0.1 ppb, and content of sulfuric dioxide is less than 3 ppm. The preparation method is simple in process and low in energy consumption; the ultra-pure sulfuric acid of ppt grade is obtained through a reasonable purification impurity removal process to obtain sulfur trioxide gaspure and then through multistage absorption and steam stripping, so that content of trace sulfur dioxide impurities in the ultra-pure sulfuric acid is controlled effectively and a foundation is laid for producing new-generation ultra-pure sulfuric acid.

Owner:JIANGSU DENOIR TECH CO LTD

Preparation for single wall carbon nano-tube monomer-containing compound for PBO polymerization

ActiveCN101274983AEvenly dispersedReduced tangle structureLiquid crystal compositionsOleumCarbon nanotube

The invention provides a preparation method of single walled carbon nanotube monomer complex substances used for the polymerization of PBO, which relates to a preparation method of complex substances. The preparation method of the invention solves the problem of easy union owing to large superficial area of SWNT and high surface energy. The method of the invention is as follows: single walled carbon nanotube aqueous solution, carboxylated single walled carbon nanotube aqueous solution and single walled carbon nanotube aqueous solution which is processed by oleum, cut short and carboxylated are added into para-phthalic sodium aqueous solution to form mixed solution which is heated and added with 4, 6-diamino resorcinol hydrochloride aqueous solution; under the protection of N2 and at temperature of 70 to 95 DEG C, the reaction is continued for 5 to 20min, then the reaction product can be gained by being filtered and dried after cooling the temperature to room temperature. The complex substances prepared by adopting the method of the invention show cuboid rod-shaped structure and are even in size and without tangle.

Owner:HARBIN INST OF TECH

Preparation method for hyperpure sulphuric acid

InactiveCN105565281AReduce energy consumptionControl contentSulfur-trioxide/sulfuric-acidOleumSulfur trioxide

The invention discloses a preparation method for hyperpure sulphuric acid, and fuming sulphuric acid is taken as raw materials. The preparation method comprises the following steps of 1 distilling; 2 purifying and filtering; 3 sulfur trioxide liquid separating; 4 evaporating; 5 multi-stage absorbing; 6 gas stripping tower impurity removing; 7 finished product obtaining. In the hyperpure sulphuric acid, the concentration of particles with the particle size larger than or equal to 0.5 micrometer is smaller than 5 p / ml, the concentration of particles with the particle size larger than or equal to 0.2 micrometer is smaller than 100 p / ml, the content of single metal ions is smaller than 0.1 ppb, and the content of sulfur dioxide is smaller than 3 ppm. According to the preparation method for hyperpure sulphuric acid, the technology is simple, the energy consumption is low, purified sulfur trioxide gas is firstly obtained through a reasonable purifying and impurity removing technology, then ppt-grade hyperpure sulphuric acid is obtained through multi-stage absorbing and gas stripping, the content of trace sulfur dioxide impurities in hyperpure sulphuric acid is effectively controlled, and a foundation is laid for production of a new generation of hyperpure sulphuric acid.

Owner:韩功篑

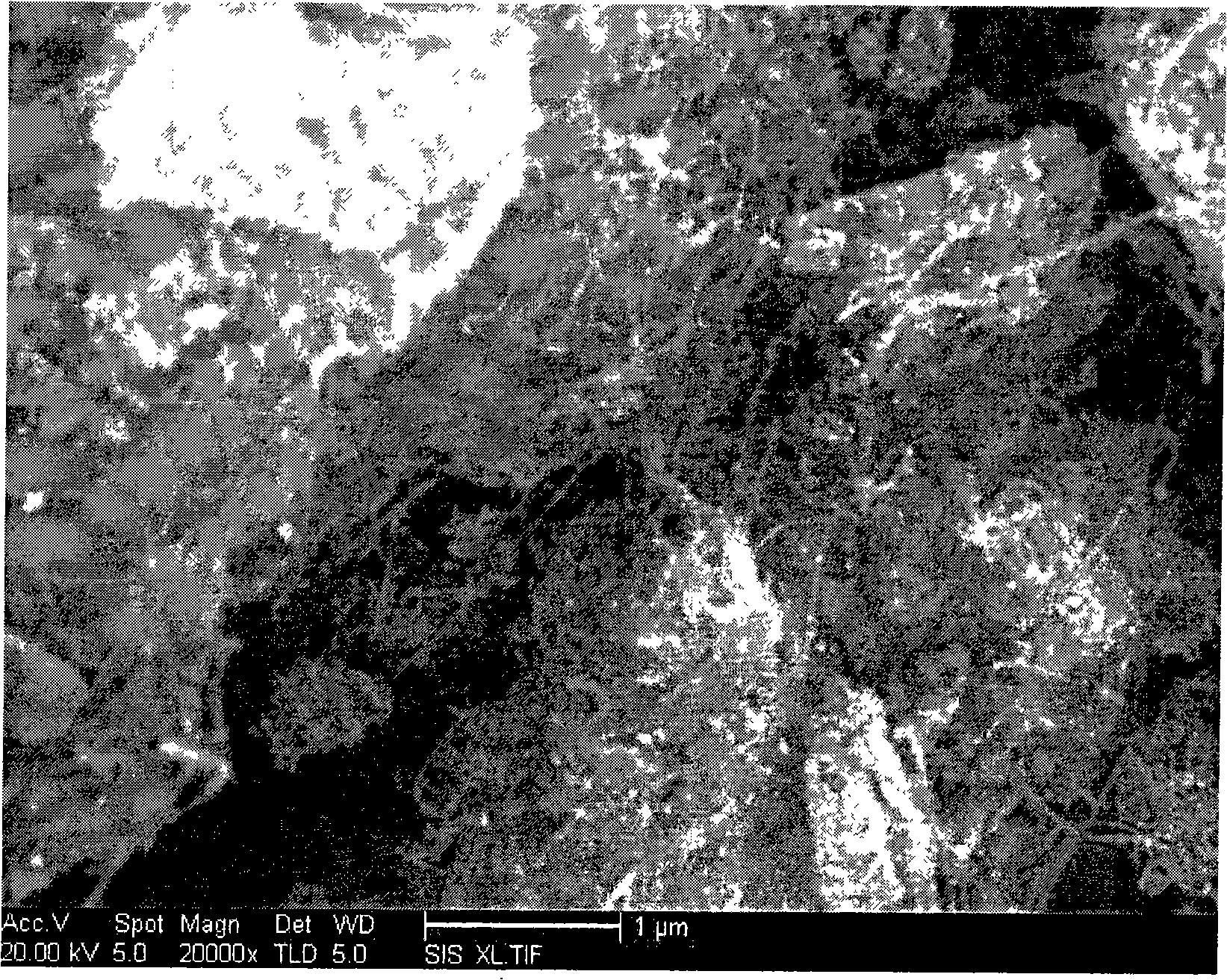

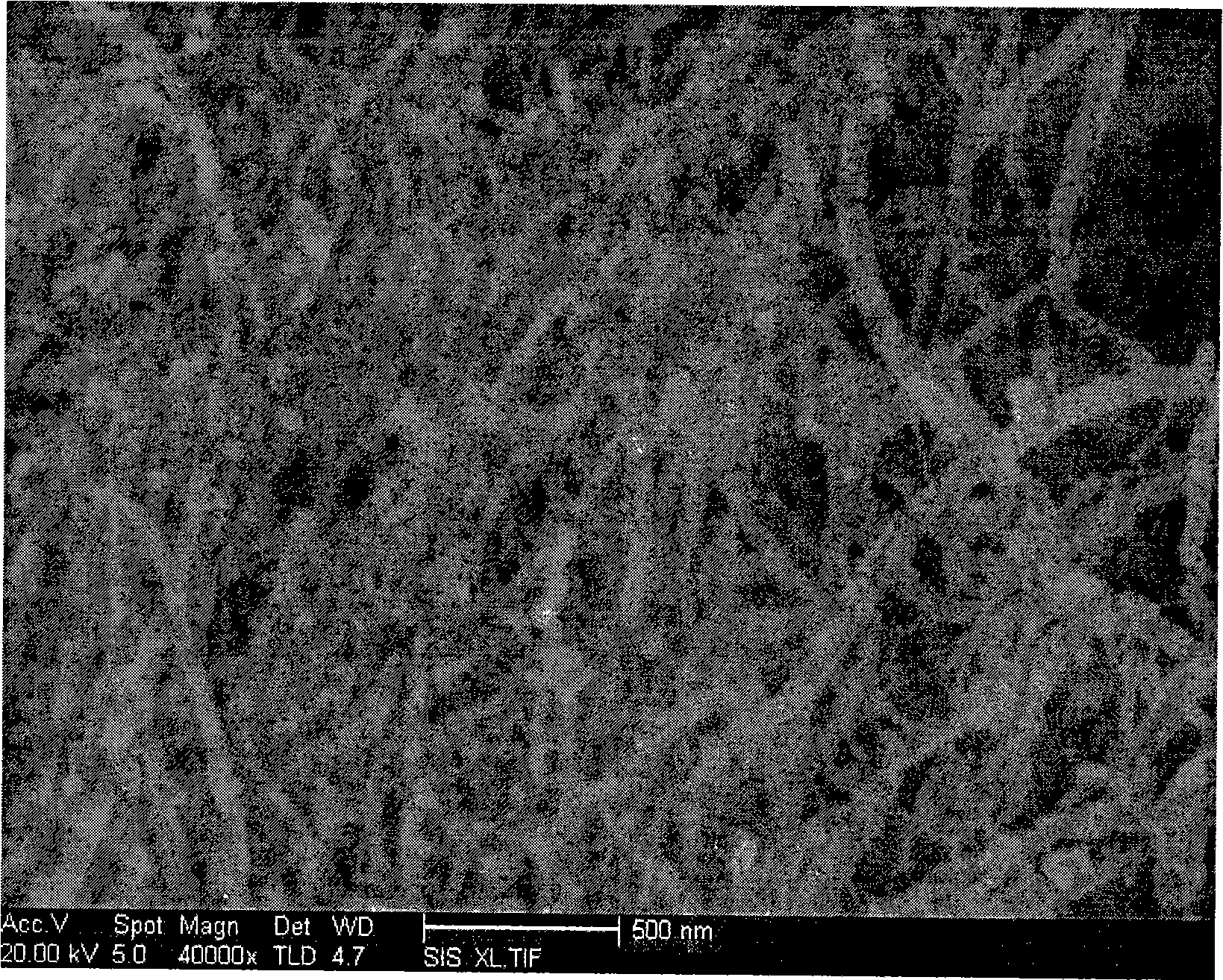

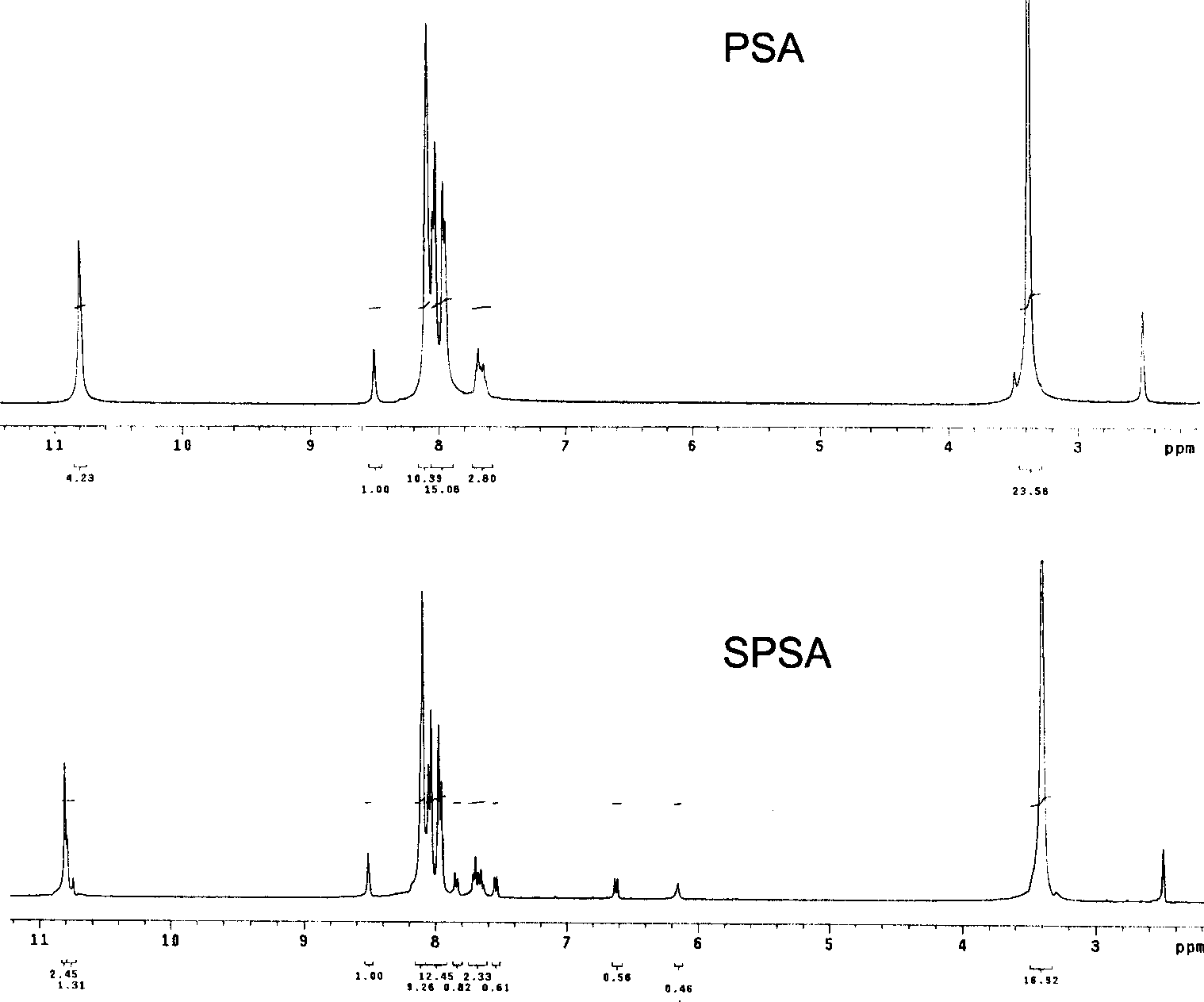

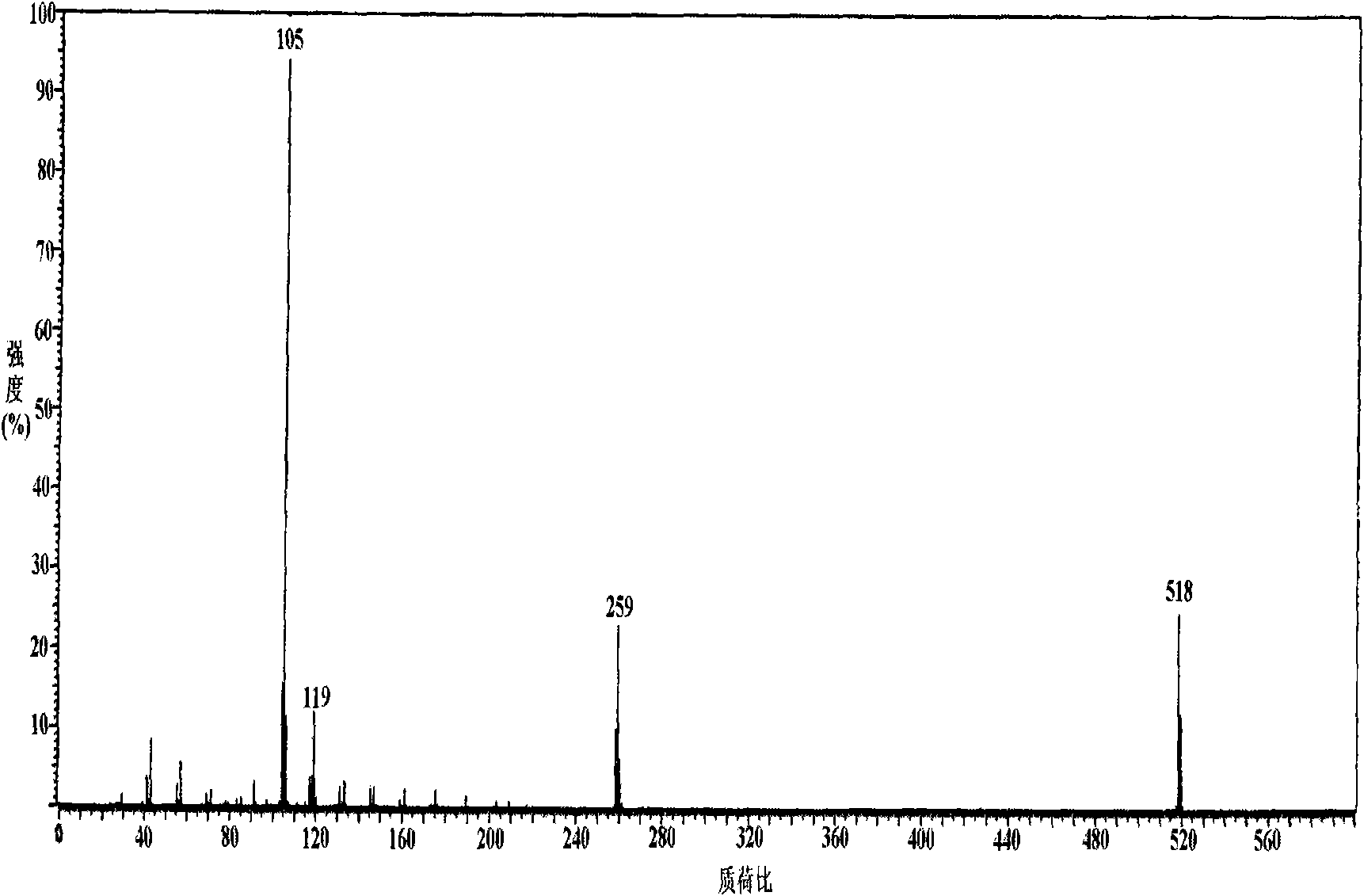

Sulfonated polysulfonamide proton exchange membrane and preparation thereof

The invention discloses a sulfonated polysulfoneamide proton exchange membrane and a preparation method thereof. By selecting the new materials of the polysulfoneamide as raw materials, the invention prepares the sulfonated membrane materials. The amide and the sulfonyl group in the PSA molecule are connected with each other on the para phenyl and form a linear macromolecule with the para phenyl; as the strong electro-withdrawing phenyl group exists on the macromolecular chain, the molecular structure is driven to have more excellent heat resistance, thermal stability and thermal oxidation resistance than the traditional acromatic polyamide through the double-bond conjugation of the benzene ring. The mixed acids comprising the concentrated sulfuric acids and oleums are selected as the sulfonating agents, thus lowering material viscosity and helping heat transfer and being beneficial to uniform and complete implementation of the sulfonation and reducing occurrence of the side reaction. The high activity of the oleums is helpful for enhancing the sulfonation degree of the sulfonated bodies. The introduction of the sulfonic group (-SO3H) in the main-chain structure of the polymer can remarkably enhance the proton conductivity and water content of the polymers. The invention has the advantages that the invention provides a proton exchange membrane which endures high temperature, has stable chemical performance, high proton conductivity, excellenet antioxidation property and thermal stability, etc., and has low cost and is suitale for fuel cells, and also can be used as various ultrafiltration membranes, nanofiltration membranes or reverse osmosis membranes and has wide application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Petroleum sulfonate compounded system for oil displacement and preparation method thereof

InactiveCN102604620AHigh content of active ingredientsGood solubility and dispersibilityDrilling compositionSal ammoniacChemistry

The invention relates to a compound adjustment method of petroleum sulfonate, which provides a petroleum sulfonate compounded system for oil displacement, which ensures that lamination does not occur when a product is laid within 30 days at normal temperature and a preparation method of the petroleum sulfonate compounded system. The system takes petroleum distillate oil as raw material, takes gaseous sulfur trioxide, liquid sulfur trioxide or fuming sulfuric acid as sulfonating agent, takes petroleum sulfonate, the active matter content of which is larger than 28 percent, formed by neutralizing ammonia or sodium hydroxide as a base, and is formed by adding dodecyl benzene sulfonic acid, heavy alkyl benzene sulfonic acid, alpha-olefin sulfonic acid, alkali or water. The system comprises the following components by mass: 40 to 90 percent of petroleum sulfonate, 0 to 20 percent of dodecyl benzene sulfonic acid, 0 to 20 percent of heavy alkyl benzene sulfonic acid, 0 to 10 percent of alpha-olefin sulfoacid, 0 to 30 percent of alkali and 0 to 40 percent of water. By adopting the technical scheme, the adaptability of petroleum sulfonate products in an oil field is improved, the product stabilizing capacity is enhanced, and the production process of the petroleum sulfonate is simplified.

Owner:胜利油田中胜环保有限公司

Method for preparing high purity phosphorus pentafluoride gas

InactiveCN101391760AReduce moisture contentLow impurity contentPhosphorus halides/oxyhalidesOleumProcess equipment

The invention discloses a preparation method of high-pure phosphorus pentafluoride gas, which comprises: phosphorus pentoxide is put into a reaction container lined with PTFE and is introduced with anhydrous hydrogen fluoride, and the temperature is preserved to be minus 20 to 0 DEG C; according to the chemical reaction counting, the anhydrous hydrogen fluoride is overdosed by 50 to 60 percent; the reaction is carried out for 3 to 5 hours. After the reaction is completed, 60 percent of oleum is added in an intermittent way with stirring and the dosage of the oleum is 35 to 40 percent more than a theoretic value. The intermediate outcome of the reaction is heated for decomposing under the temperature of 120 to 150 DEG C so as to generate the phosphorus pentafluoride; the product is guided into a condenser for cooling the impurity and then the high-pure phosphorus pentafluoride is obtained. The content of PF<5> obtained by the method is greater than 99.9 percent, the content of impurity is low, the water content is less than 10ppm, HF content is less than 50ppm; moreover, the process equipment is comparatively simple, thus being beneficial to the industrial manufacturing.

Owner:CENT SOUTH UNIV

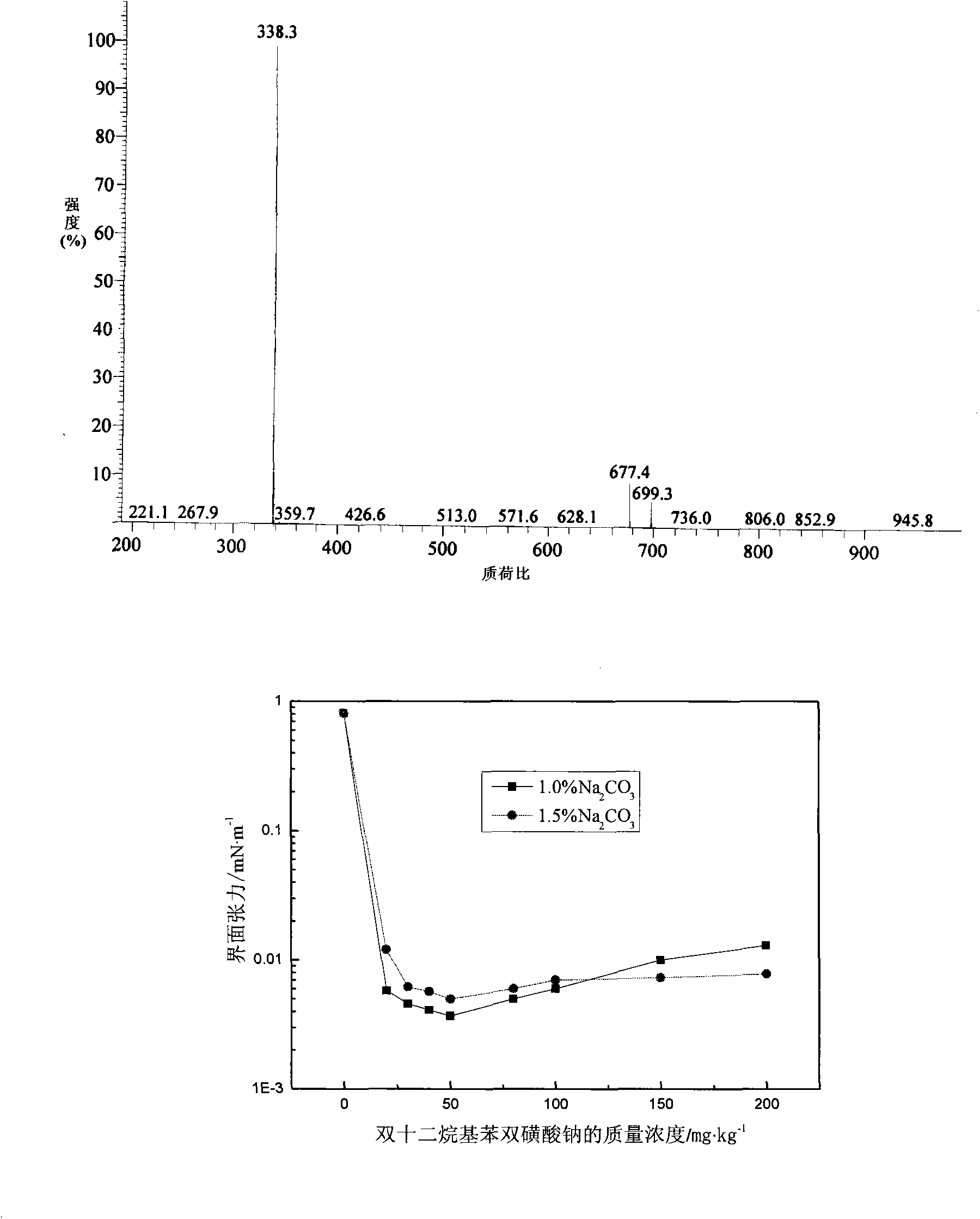

Method for preparing gemini long-chain alkyl benzene sulfonate oil displacement agents

ActiveCN101684405ASingle structureFew reaction stepsDrilling compositionSulfonic acid preparationOleumN dimethylformamide

The invention relates to a method for preparing gemini long-chain alkyl benzene disulfonate oil displacement agents. The method comprises: adding 100 mL of distilled water and N,N-dimethylformamide mixed solvent in a volume ratio of 1:1, 0.05 mol of iron powder and 0.005 mol of copper powder and aging the materials for 10 minutes at 30 DEG C; adding 0.004 mol of cuprous chloride; raising the temperature to 70 DEG C and adding 0.1 mol of long-chain alkyl benzyl chloride dropwise; performing reaction for 20 hours at 90 DEG C; diluting filtrate with petroleum ether and rotationally steaming organic layers to remove the petroleum ether; diluting 0.04 mol of the obtained product with 40 mL of carbon tetrachloride, controlling the temperature below 5 DEG C and adding 10 mL of 50 percent oleum dropwise; and diluting reactant with 200 mL of water and 50 mL of carbon tetrachloride, removing aqueous solution in an upper layer and performing neutralization by use of sodium hydroxide solution or ammonia. The oil displacement agents with the concentration of 20 mg / kg can reduce interfacial tension to 5.8*10<-3>mN / m.

Owner:PETROCHINA CO LTD

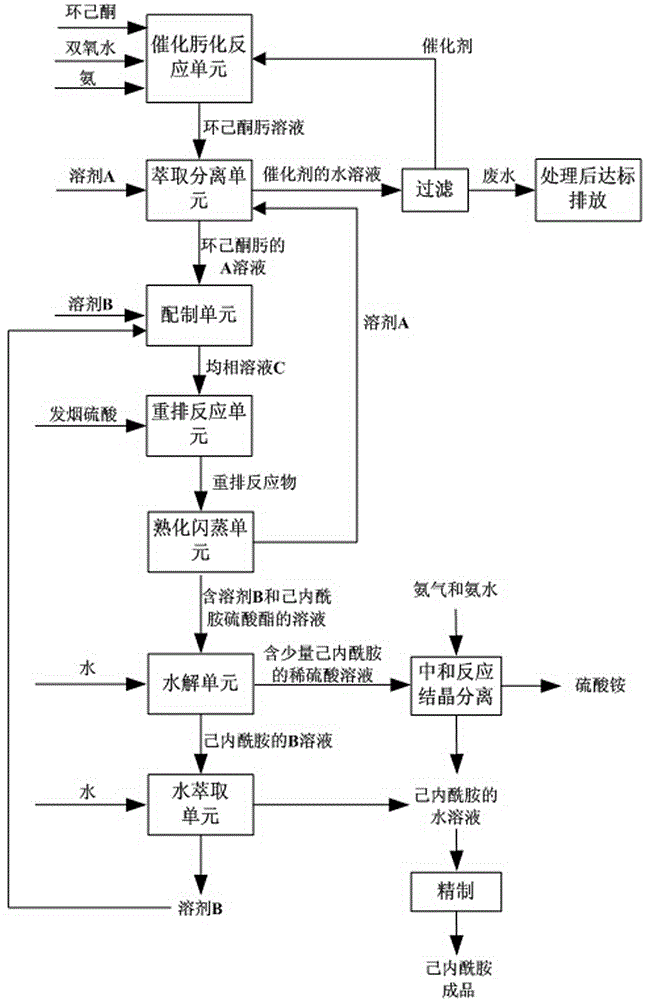

Caprolactam preparation method

InactiveCN104910071AShort production processReduce consumptionLactams preparationBeckmann rearrangementOleum

The invention discloses a caprolactam preparation method. The method is characterized in that caprolactam is prepared from cyclohexanone through oximation and rearrangement, and the method comprises the following steps: carrying out a catalytic reaction on cyclohexanone, hydrogen peroxide and ammonia to generate cyclohexanone oxime, extracting and separating by using a solvent A, adding a solvent B to the above obtained oil phase, carrying out a Beckmann rearrangement reaction under the action of oleum, carrying out slaking flash evaporation separation on the obtained product, hydrolyzing, extracting by using water, and carrying out original process refining to prepare finished caprolactam. The method shortens the caprolactam production process flow, reduces the consumption of raw materials and energy, generates less ammonium sulfate than original technologies, and improves the quality of the caprolactam product.

Owner:河北美邦工程科技股份有限公司

Proton exchange membrane materials based on sulfonated poly (phthalazinones)

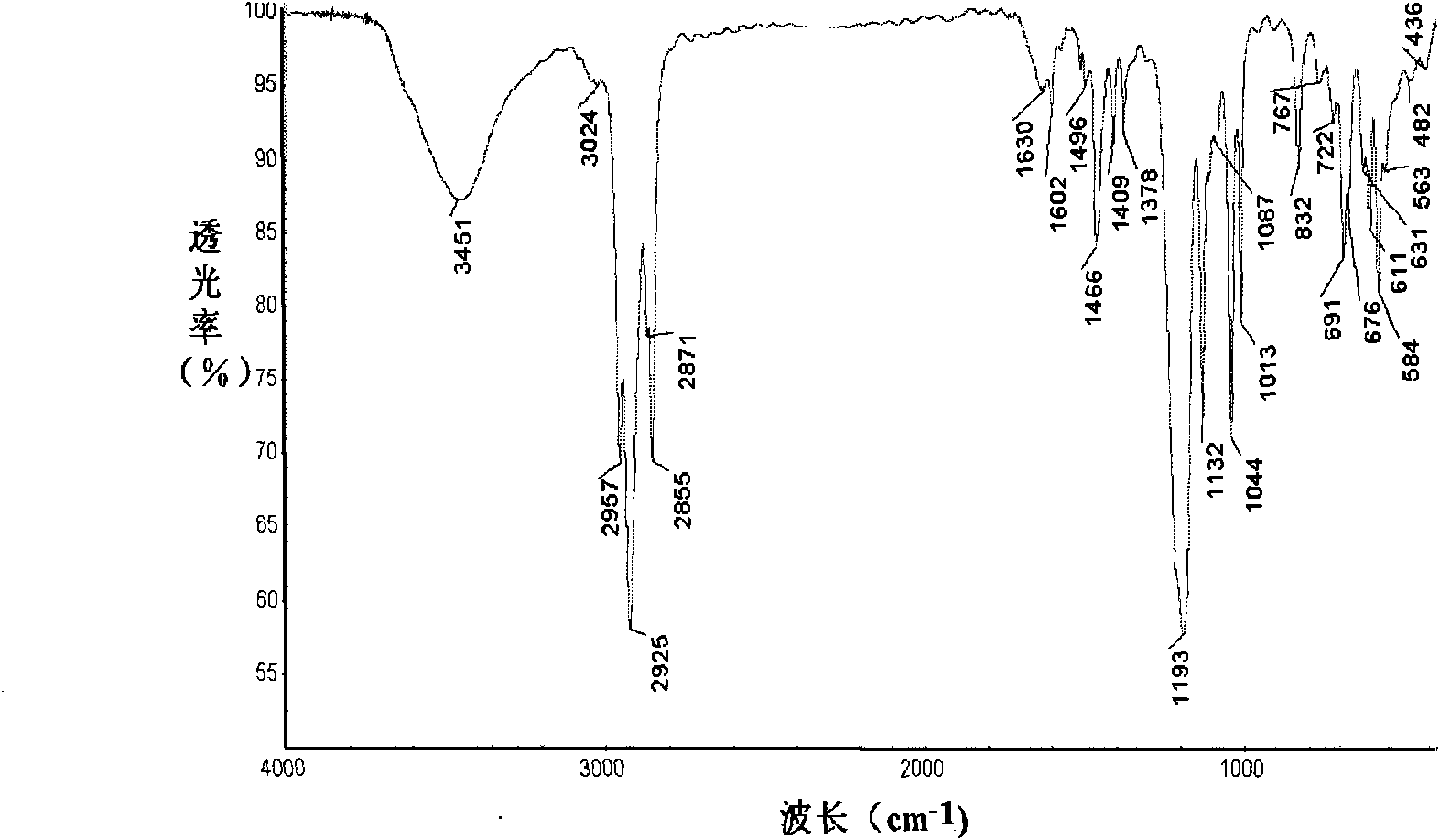

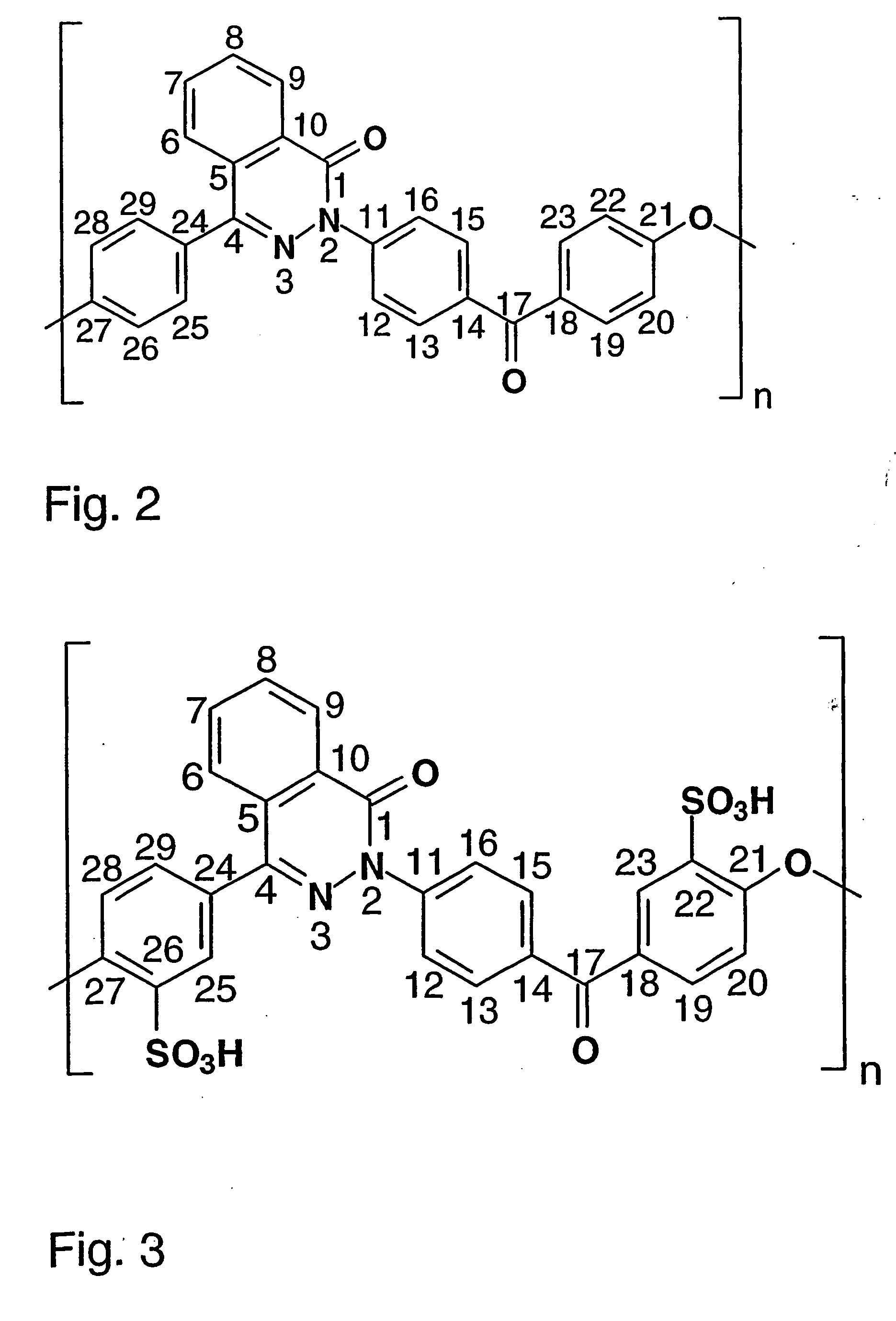

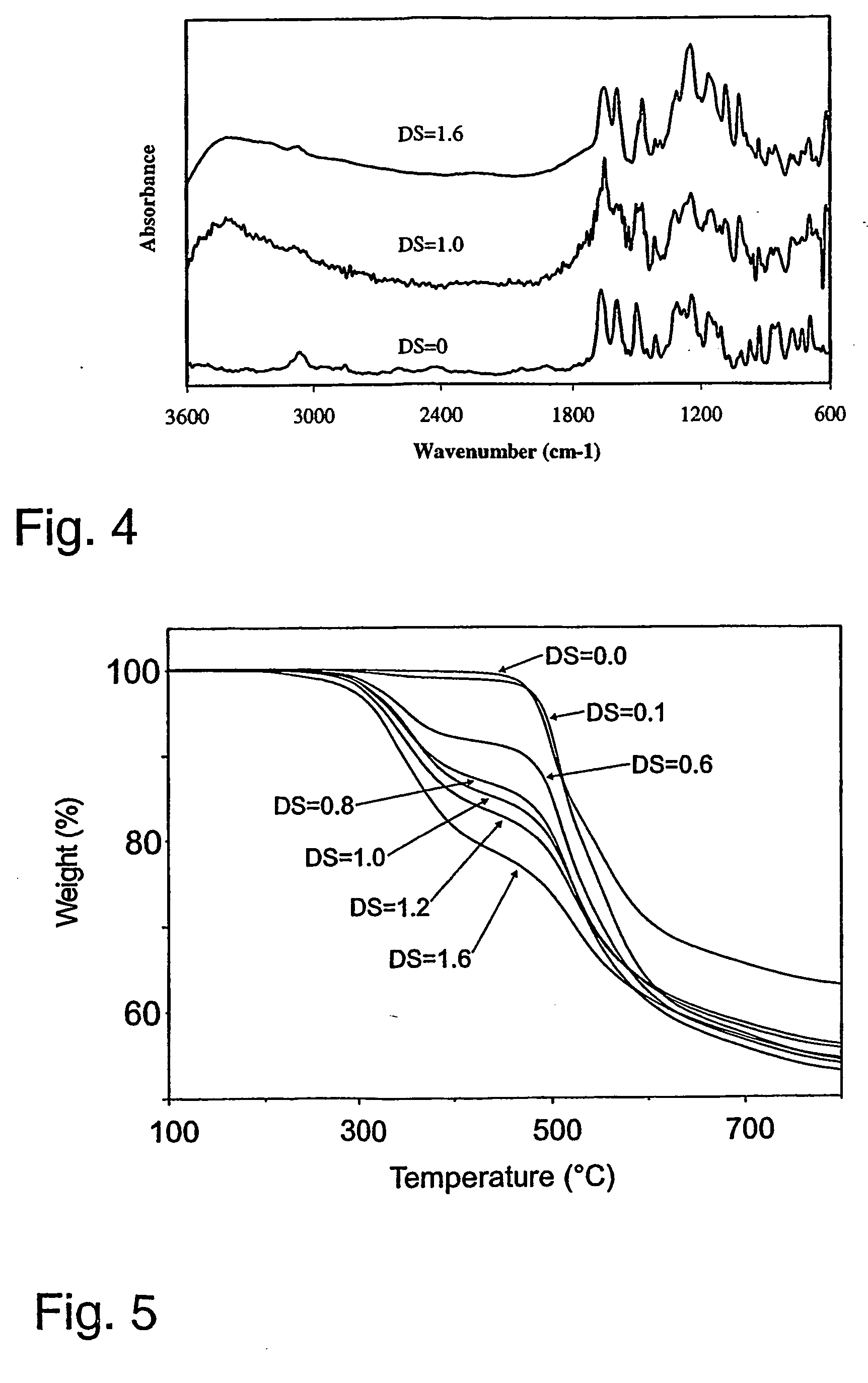

A novel class of proton exchange membrane materials, sulfonated poly(phthalazinones), were prepared by modification of poly(phthalazinone). Sulfonation reactions were conducted at room temperature using mixtures of 95-98% concentrated sulfuric acid and 27-33% fuming sulfuric acid with different acid ratios in order to get SPPEK with degree of sulfonation (DS) in the range of 0.6 to 1.0. The presence of sulfonic acid groups was confirmed by FT-IR analysis, and the DS and structures were characterized by NMR. The introduction of sulfonic groups into the polymer chains led to an increase in the glass transition temperature and a decrease in the decomposition temperature. Membrane films were cast from solution in N,N-dimethylformamide or N,N-dimethylacetamide. Water uptakes and swelling ratios of the membrane films increased with DS and sulfonated polymers with DS>1.2 were water soluble at 80° C. Proton conductivity increased with DS and temperature up to 95° C., reaching 10−2S / Cm.

Owner:NAT RES COUNCIL OF CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com