Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

939 results about "Propylsulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-acrylamide-2-methylpropanesulfonic acid and process for producing the same

ActiveUS20100274048A1Large molecular weightHigh purityOrganic compound preparationSulfonic acid preparationSulfur trioxideMethyl group

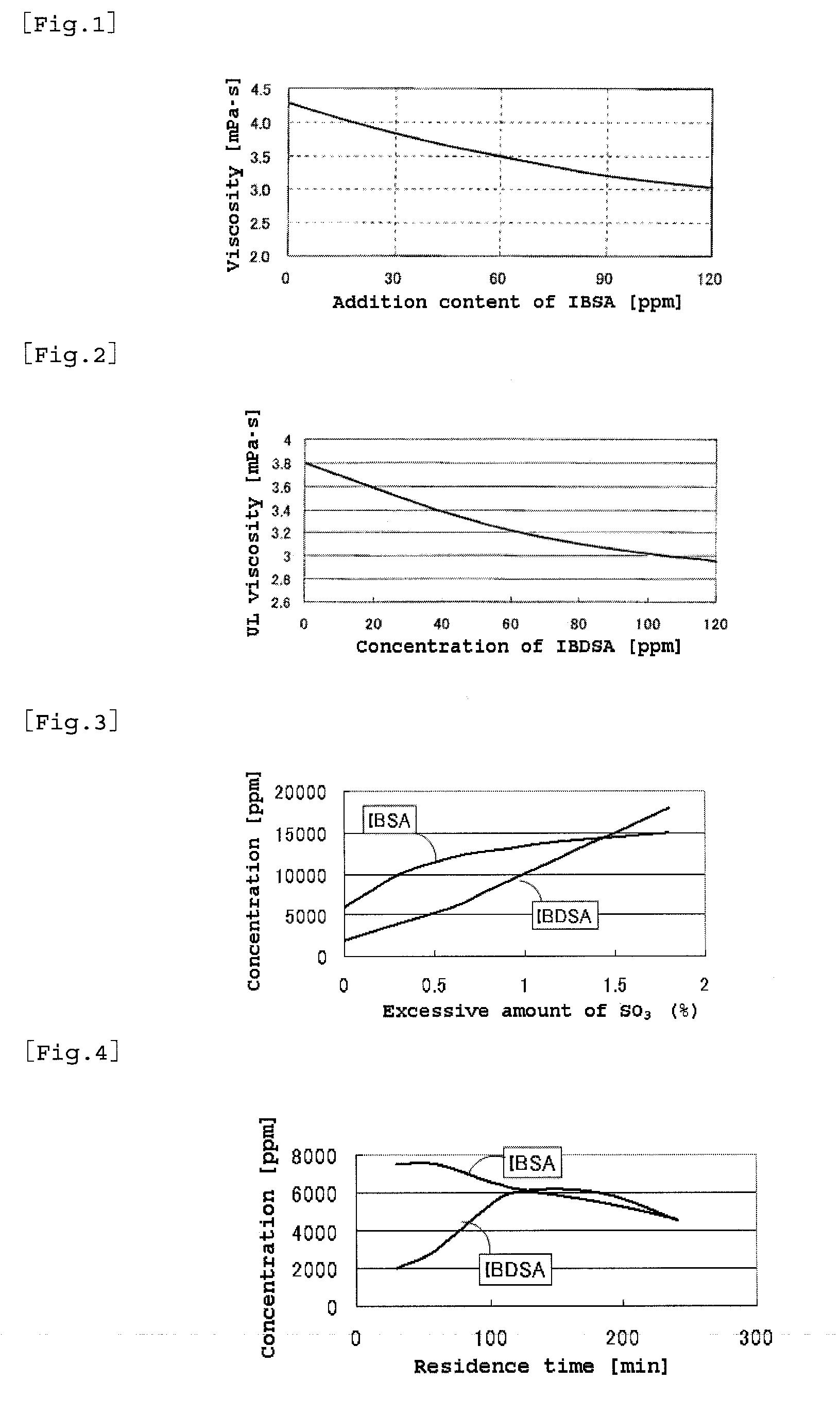

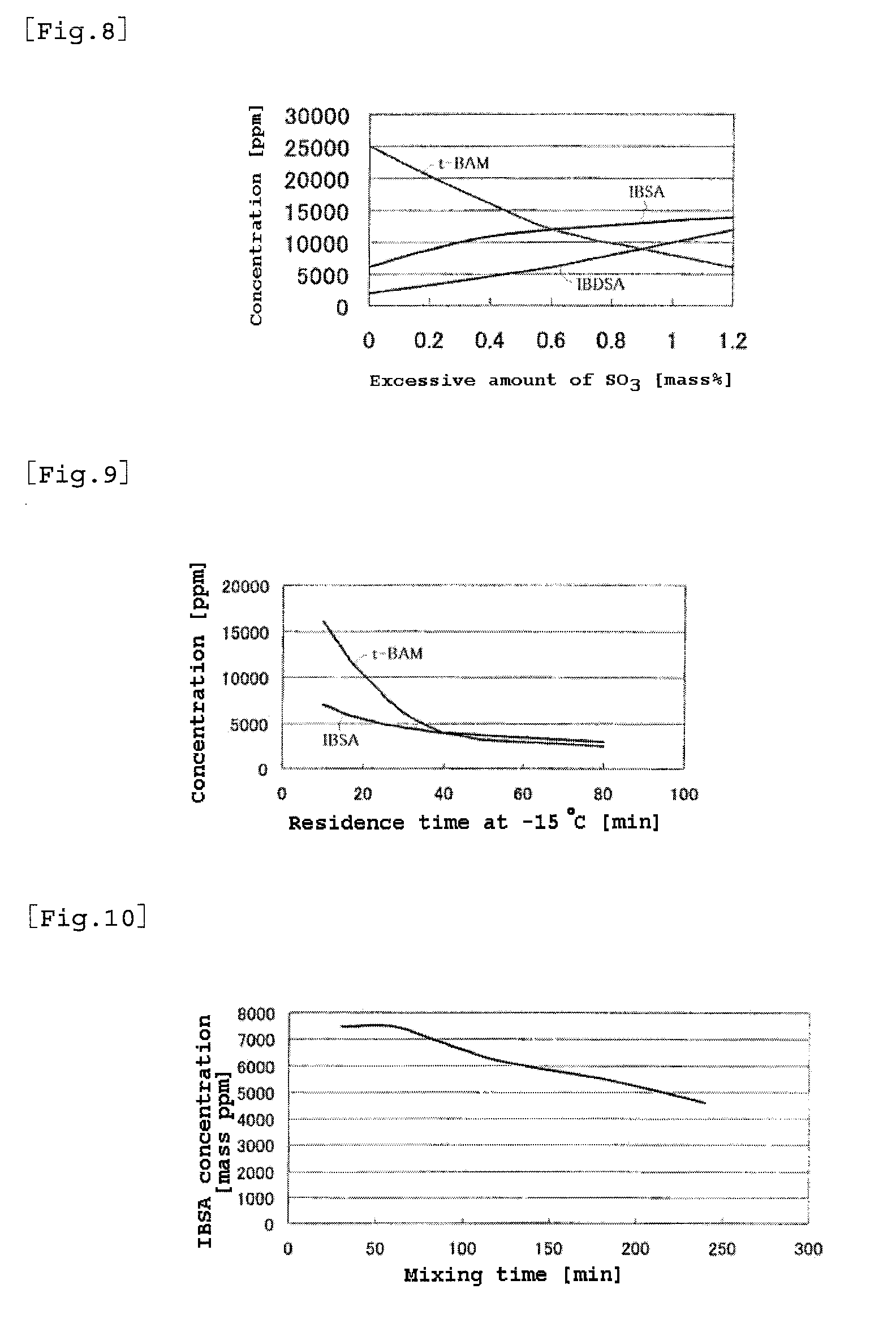

A process for producing 2-acrylamide-2-methyl propane sulfonic acid (ATBS) which comprises reacting acrylonitrile, fuming sulfuric acid, and isobutylene. During the reaction, the concentration of 2-methyl-2-propenyl-1-sulfonic acid (IBSA) and / or that of 2-methylidene-1,3-propylenedisulfonic acid (IBDSA) in the reaction system are determined. When the IBSA concentration exceeds 12,000 mass ppm and / or the IBDSA concentration exceeds 6,000 mass ppm, then the concentration of sulfur trioxide in the reaction system is reduced. Thus, ATBS having an IBSA content of 100 mass ppm or lower and an IBDSA content of 100 mass ppm or lower is produced.

Owner:TOAGOSEI CO LTD

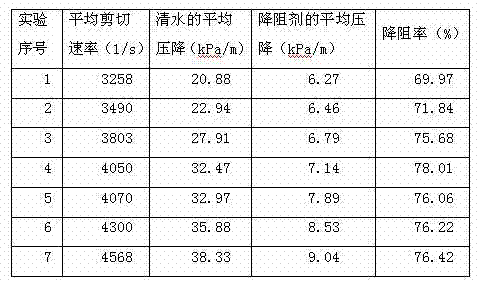

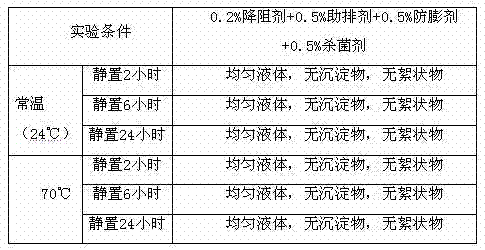

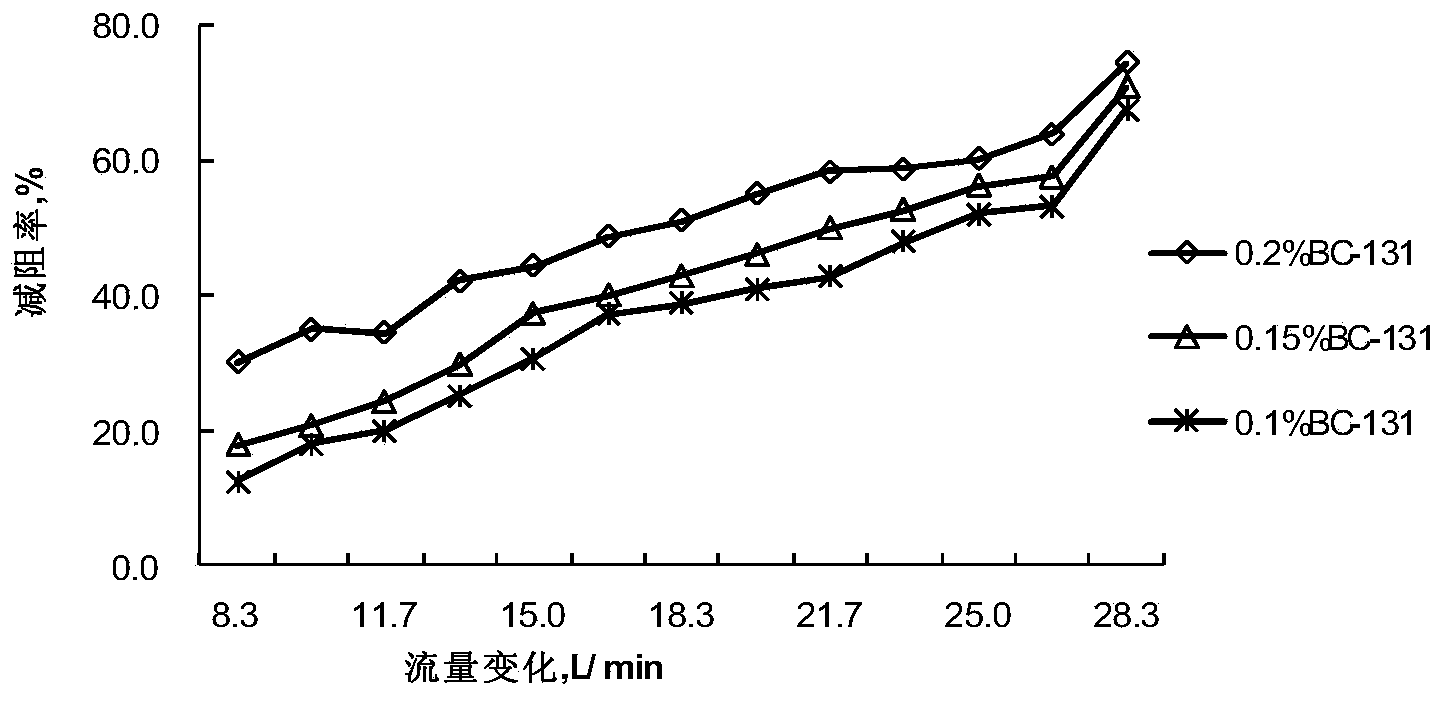

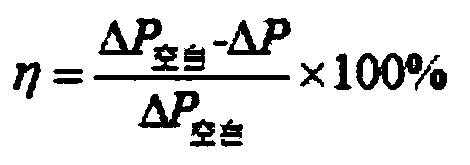

Shale gas acid fracturing drag reducer and reparation method thereof

InactiveCN103694984AImprove acid resistanceImprove stabilityDrilling compositionEthylenediamineOil phase

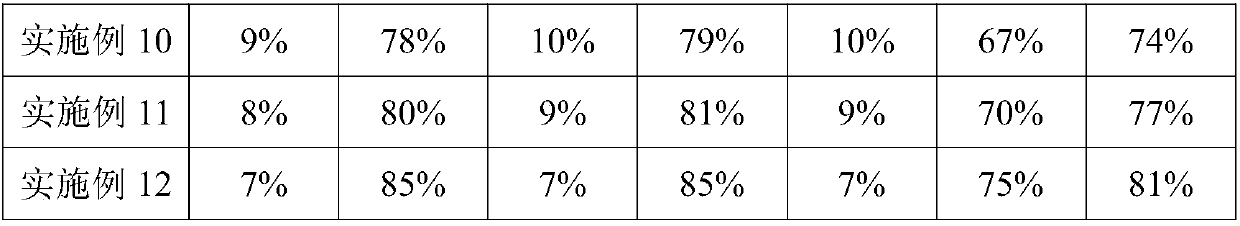

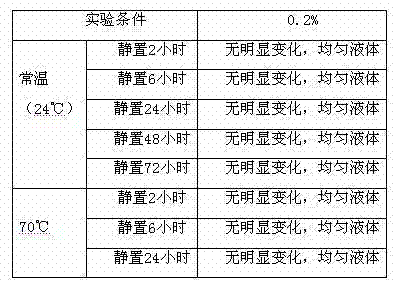

The invention discloses a shale gas acid fracturing drag reducer and a reparation method of the shale gas acid fracturing drag reducer. The preparation method comprises the following steps: mixing monomer acrylic acid and 2-acrylamide-2 methyl propane sulfonic acid, dissolving in water, subsequently adding acrylamide, and finally adding ethylenediamine tetraacetic acid disodium to prepare into a water phase; mixing and dissolving a compounded surfactant with base oil to form an oil phase; performing inverse emulsion polymerization on the oil phase and the water phase to prepare the shale gas acid fracturing drag reducer. As a great amount of acid resistance monomers are introduced into the drag reducer, the acid resistance of the dreg reducer is greatly improved; the dreg reducer is milk white emulsion in appearance, is high in stability, non-ignitable, non-explosive, safe to transport and store, rapid to dissolve in water and free of fisheye; the requirements of continuous blending in shale gas acid fracturing can be met; the resistance reduction rate of a dreg reducer solution with the mass percentage of 0.2% can be greater than 70%.

Owner:SOUTHWEST PETROLEUM UNIV

Method of dewatering thin stillage processing streams

ActiveUS7497955B2Improve agglomerationAbility to withstandWater treatment parameter controlWater treatment compoundsSodium methacrylateSodium salt

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and flocculated solids; and separating the water from the flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

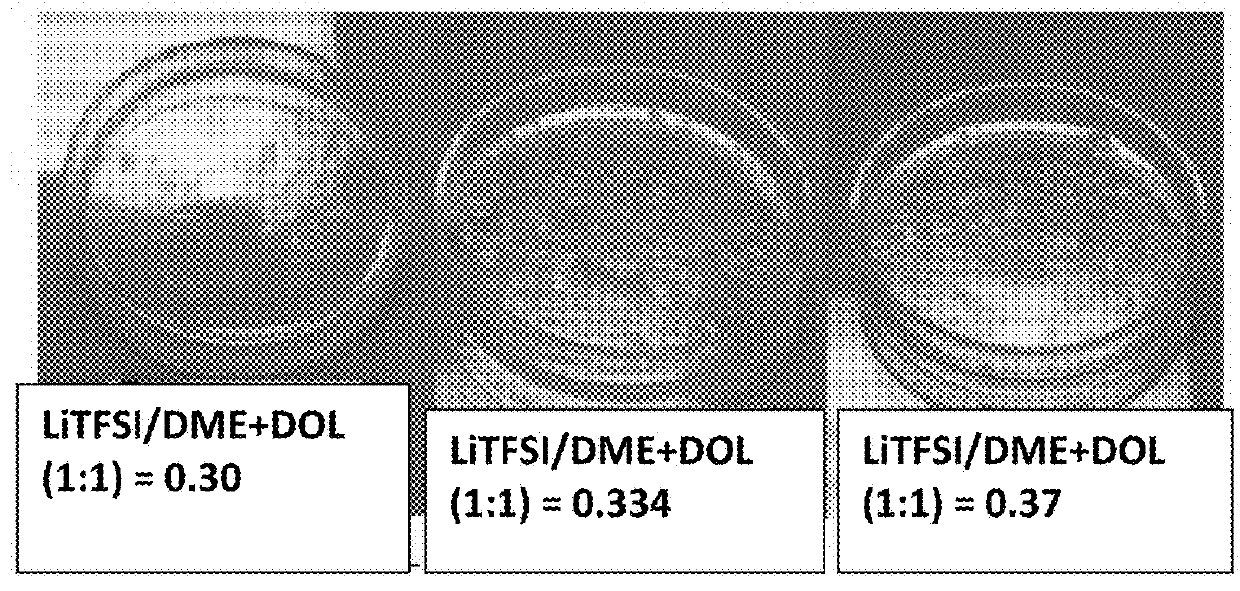

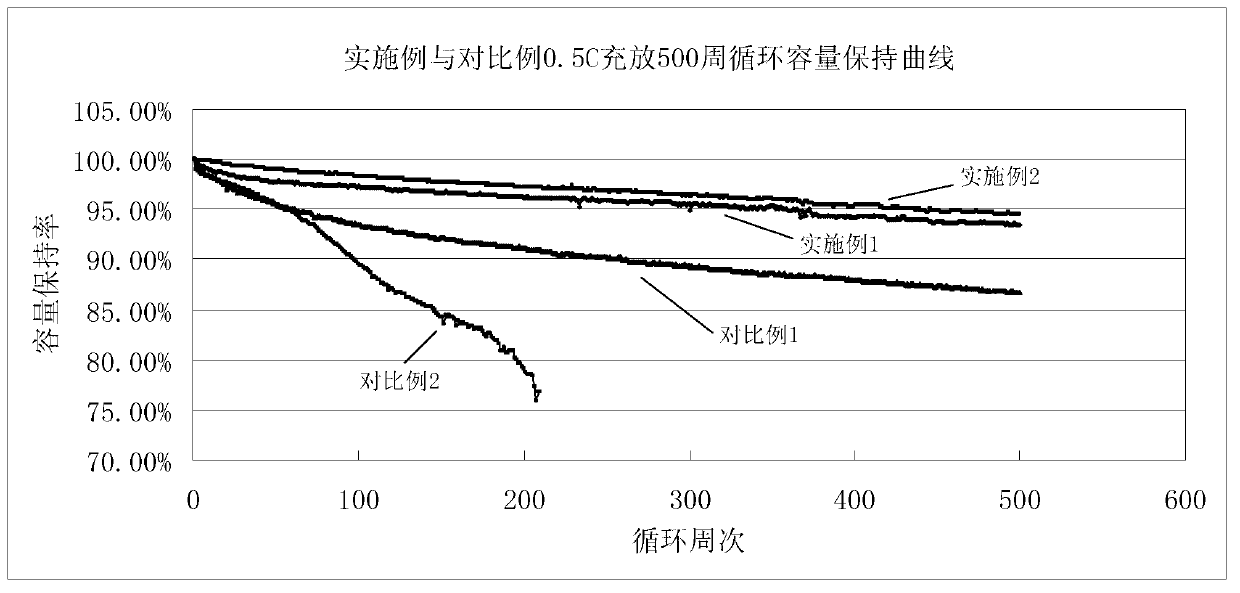

Lithium ion electrolyte and lithium ion battery using same

InactiveCN109546219AImproved high temperature storage and high temperature cycling performanceIncrease solubilitySecondary cells servicing/maintenanceOrganic electrolytesSolventVinylene carbonate

A lithium ion electrolyte and a lithium ion battery using the same are provided. The lithium ion electrolyte includes a solvent, a lithium salt, and an additive. The lithium salt includes lithium hexafluorophosphate (LiPF6), high-content bistrifluoromethylsulfonimide (LiTFSI) and / or lithium bis(fluorosulfonyl)imide (LiFSI). The additive includes vinylene carbonate ester (VC), fluoroethylene carbonate (FEC), 1,3 propane sultone (PS), and ethylene carbonate (VEC). The electrolyte of the present invention can improve the cycling and high-temperature storage performance of a lithium battery by using the high-content bistrifluoromethylsulfonimide (LiTFSI) and / or lithium bis(fluorosulfonyl)imide (LiFSI) in combination with a negative electrode film-forming additive and / or a positive electrode protective additive. The lithium ion electrolyte is applicable to lithium ion batteries in a range of 4.2V and above.

Owner:ZHUHAI COSMX BATTERY CO LTD

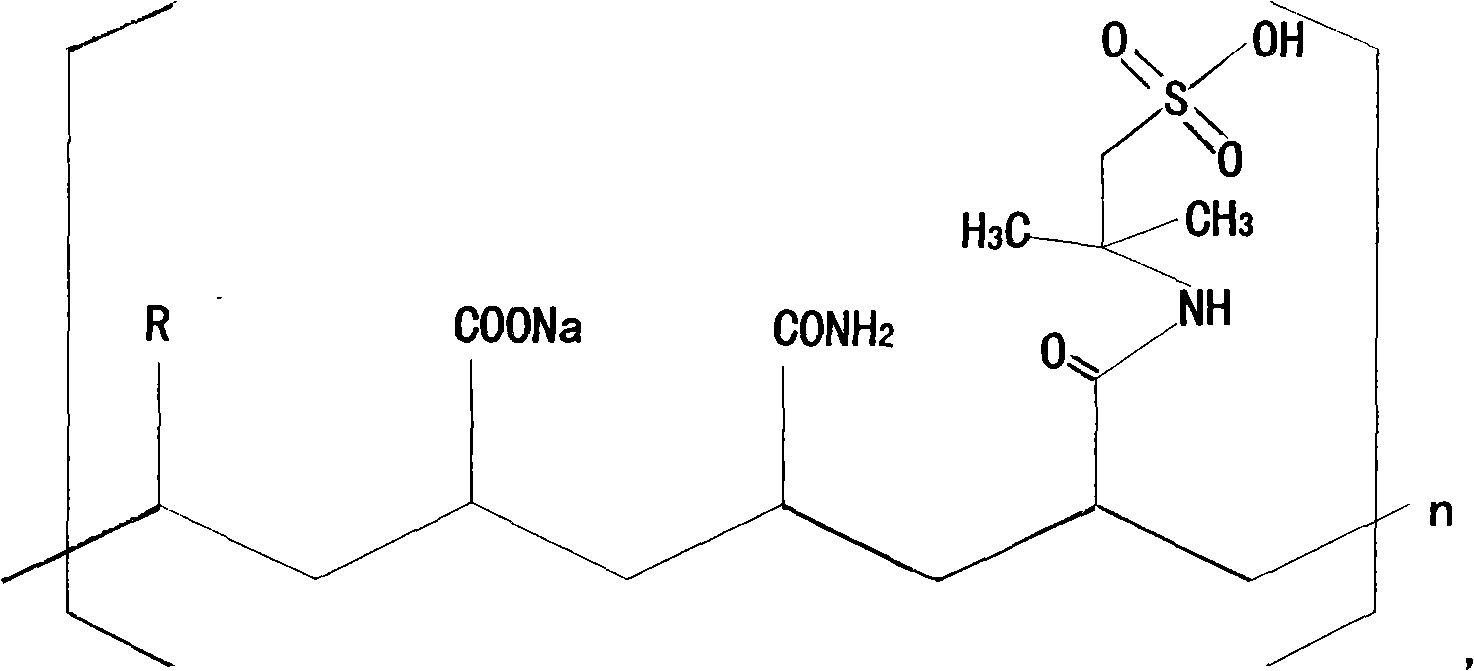

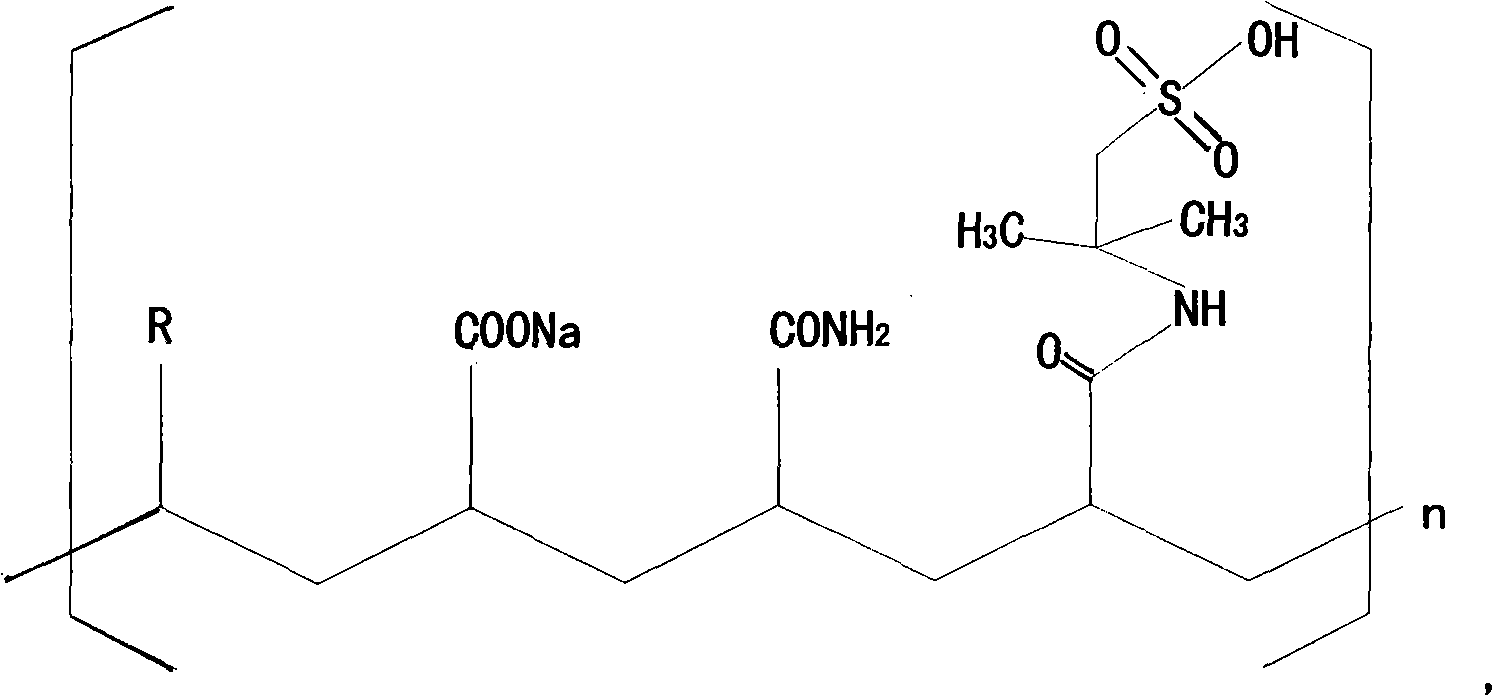

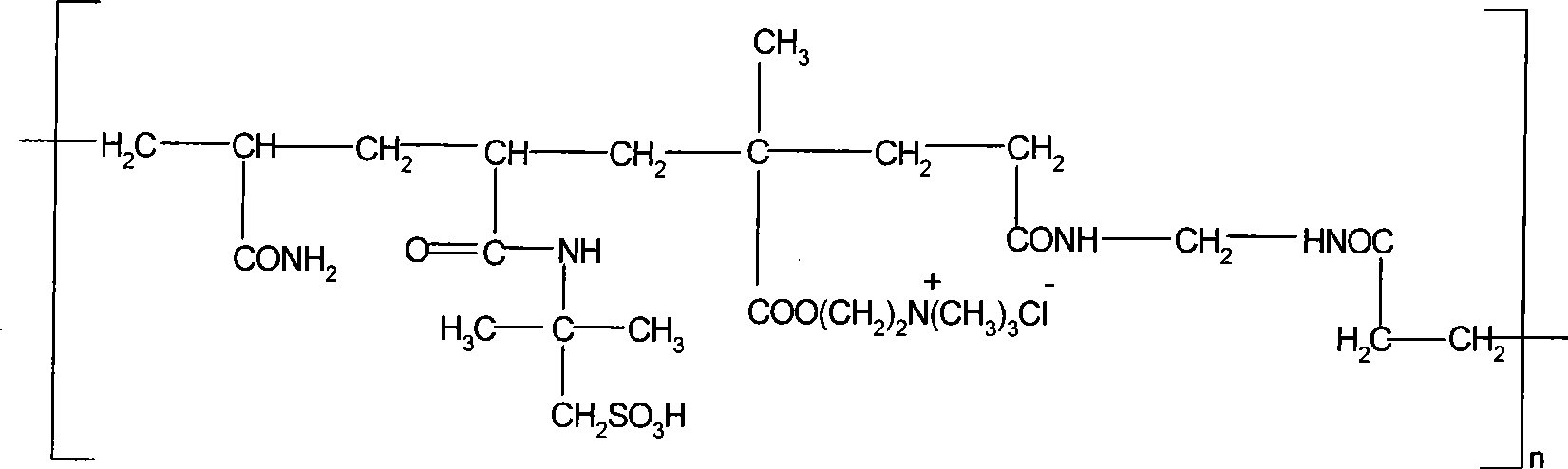

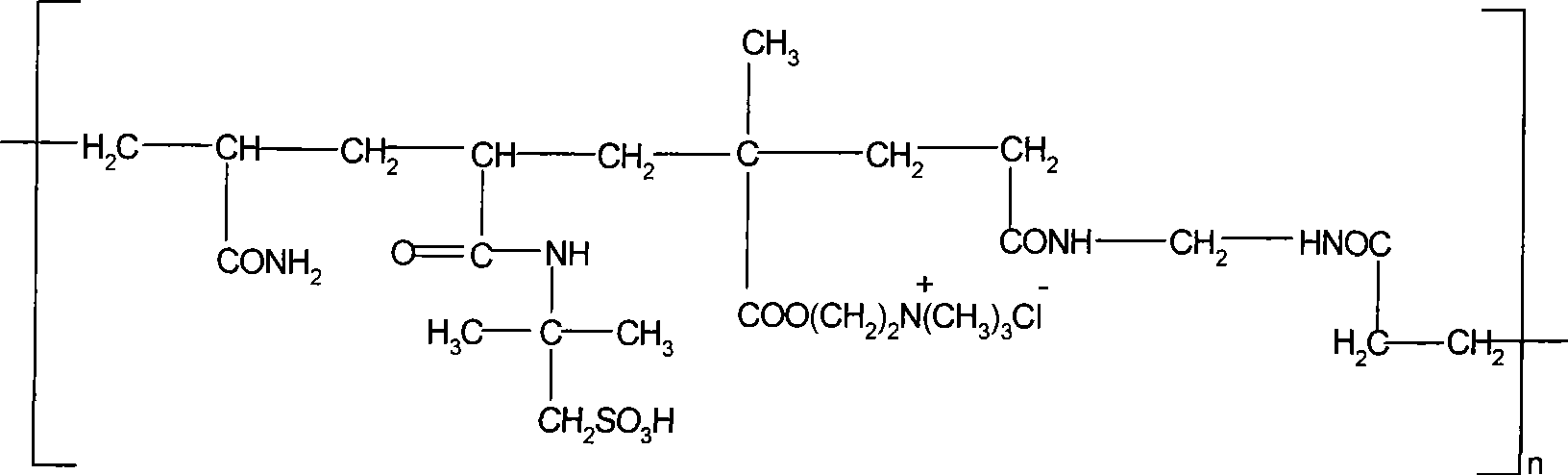

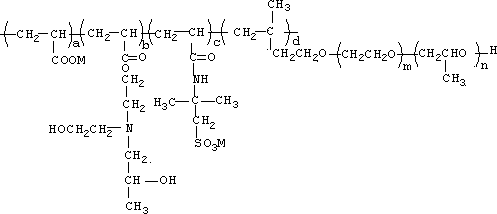

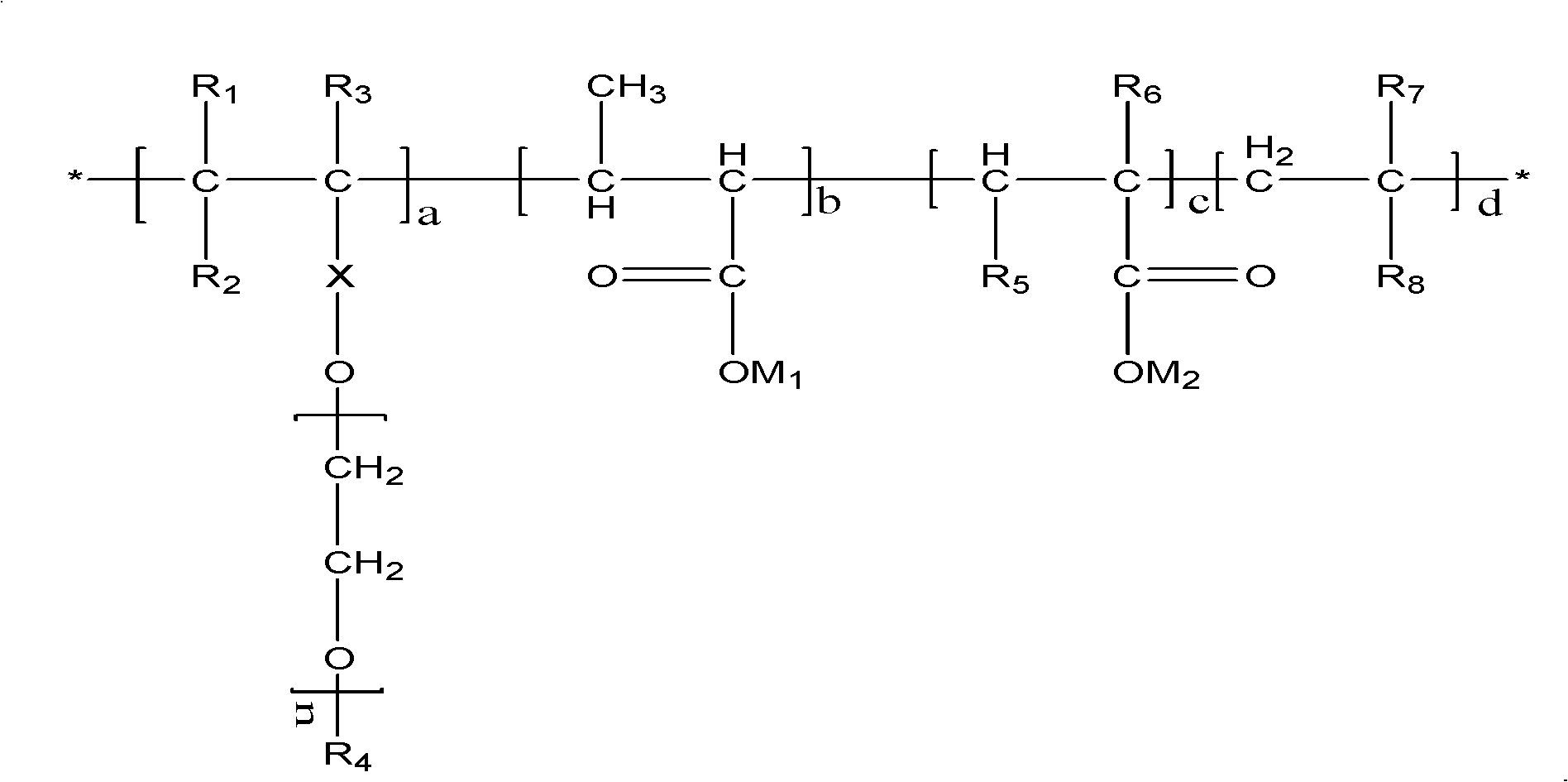

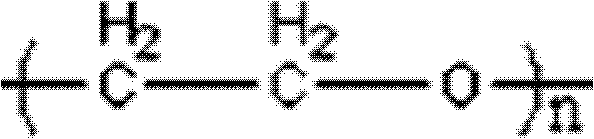

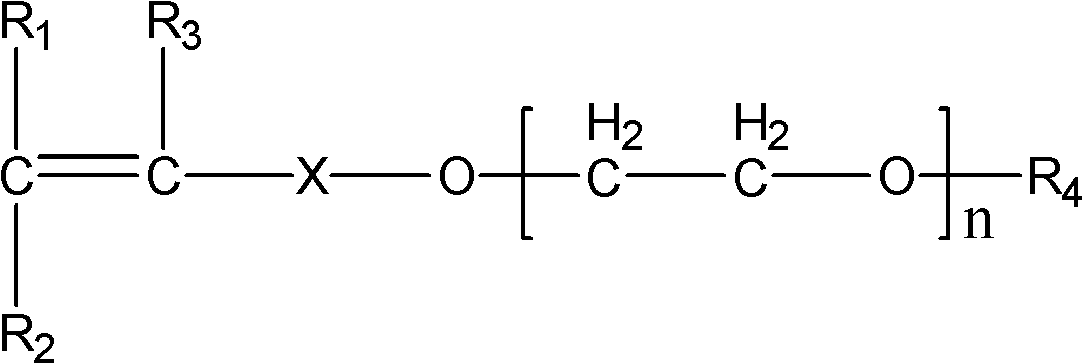

Comb-type structure activity polymer and its preparation technique and application

InactiveCN101260171AGood water solubilityHigh molecular weightDrilling compositionFunctional monomerHigh surface

The invention discloses a comb-type structural reactive polymer with the molecular weight ranging between 1x10<5> and 5x10<6>, wherein the main chain of the reactive polymer is obtained through the copolymerization of acrylamide monomer and functional monomers such as 2-acrylamido-2-methylpropanesulfonic acid and acrylic acid sodium salt, etc., which endues polymer aqueous solution with higher apparent viscosity and better temperature resistance and salt resistance; and the branched chain of the reactive polymer consists of unsaturated macromonomer molecule, which endues the polymer aqueous solution with higher surface activity. The invention also discloses a preparation method for the polymer, comprising the following steps: firstly, through process operation including esterification, prepolymerization and sulfonation, polyurethanes active macromonomer with a novel structure is prepared; then, under the action of oxidation reduction initiator, the copolymerization reaction of the active macromonomer and other functional micromolecule monomers is initiated quickly at low temperature. The comb-type structural reactive polymer can be used as oil displacement agent and has the advantages of high molecular weight and low surface tension, etc.

Owner:SHANDONG UNIV

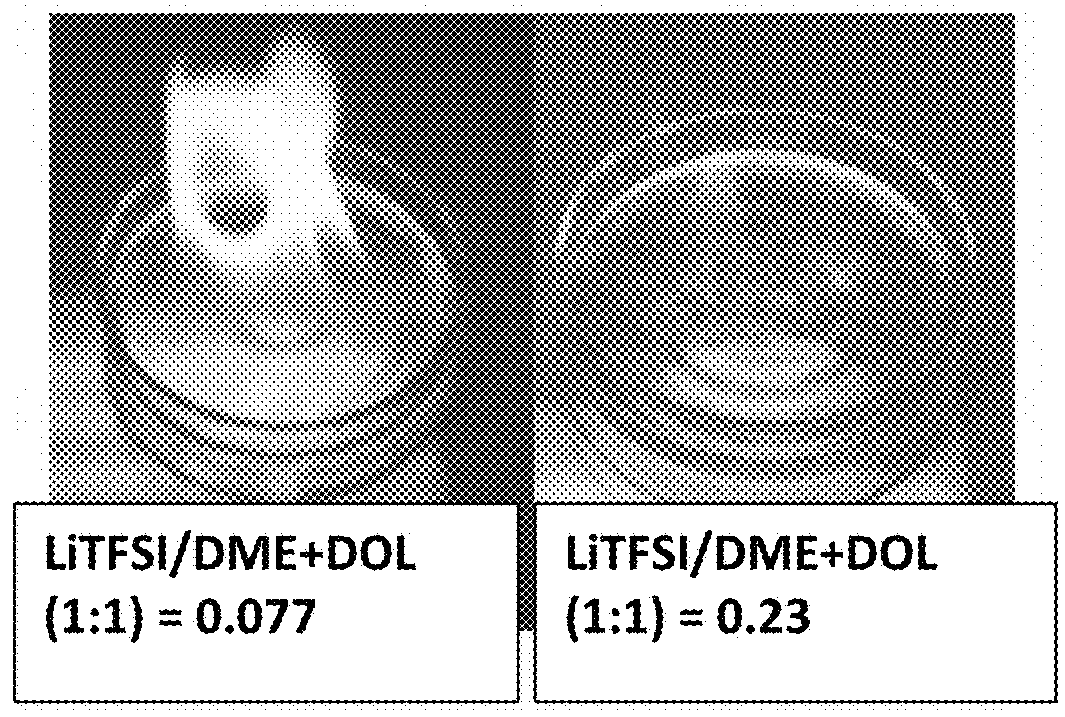

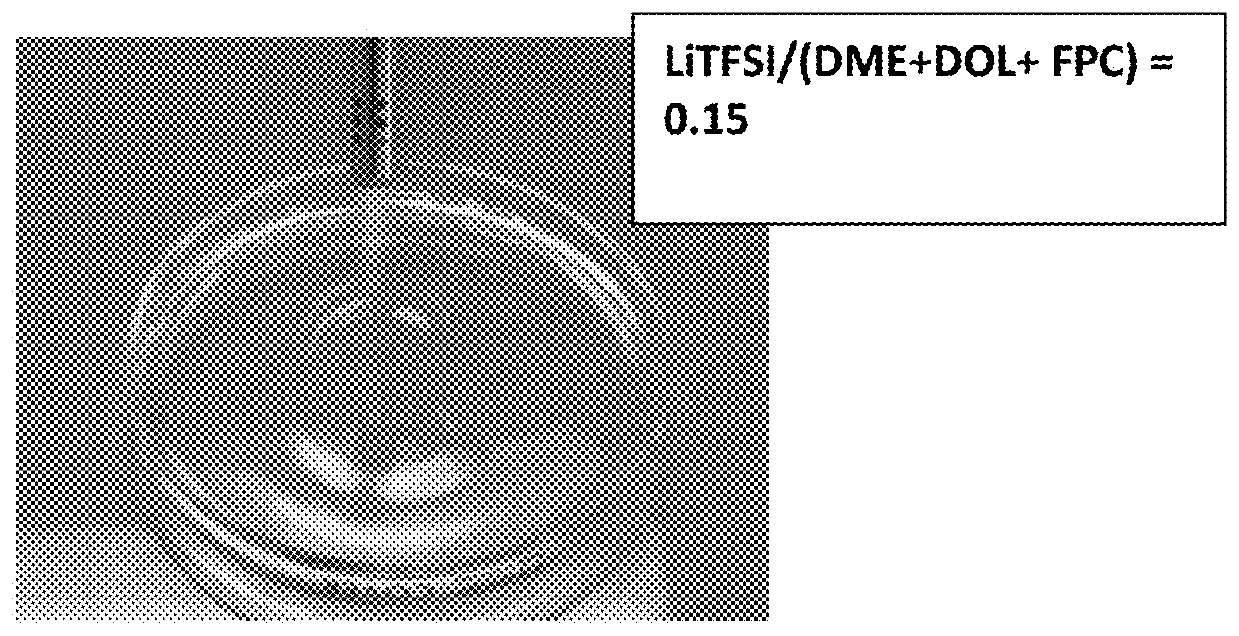

Non-flammable Quasi-Solid Electrolyte and Lithium Secondary Batteries Containing Same

PendingUS20180277913A1Reduce electrical conductivityLow ionic conductivityFuel and secondary cellsCell electrodesSolid state electrolyteCelsius Degree

A rechargeable lithium cell comprising a cathode, an anode, a non-flammable quasi-solid electrolyte containing a lithium salt dissolved in a mixture of a liquid solvent and a liquid additive having a salt concentration from 1.5 M to 5.0 M so that said electrolyte exhibits a vapor pressure less than 0.01 kPa, a vapor pressure less than 60% of the vapor pressure of the liquid solvent alone, a flash point at least 20 degrees Celsius higher than the flash point of the liquid solvent alone, a flash point higher than 150° C., or no flash point, wherein the liquid additive is selected from Hydrofluoro ether (HFE), Trifluoro propylene carbonate (FPC), Methyl nonafluorobutyl ether (MFE), Fluoroethylene carbonate (FEC), Tris(trimethylsilyl)phosphite (TTSPi), Triallyl phosphate (TAP), Ethylene sulfate (DTD), 1,3-propane sultone (PS), Propene sultone (PES), Diethyl carbonate (DEC), Alkylsiloxane (Si—O), Alkylsilane (Si—C), liquid oligomeric silaxane (—Si—O—Si—), Tetraethylene glycol dimethylether (TEGDME), or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

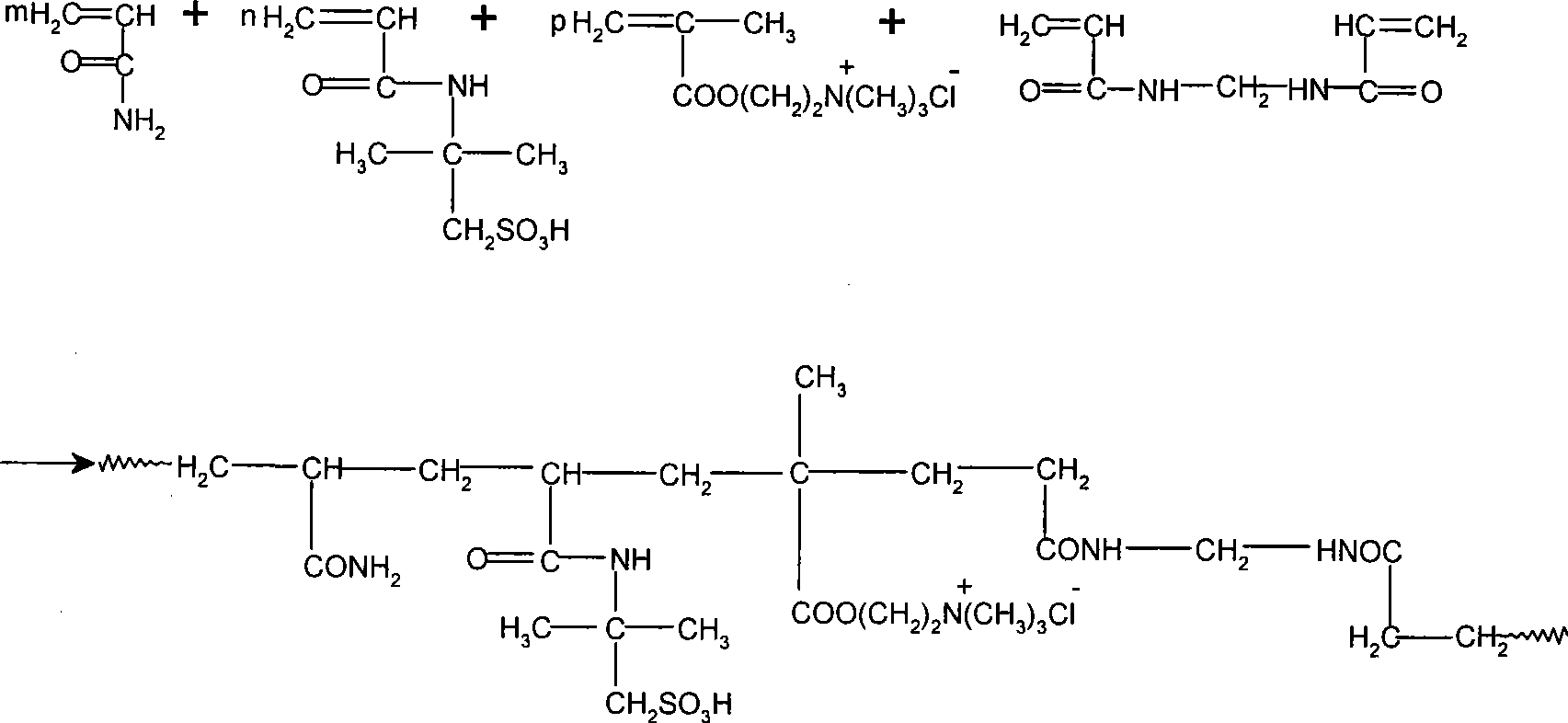

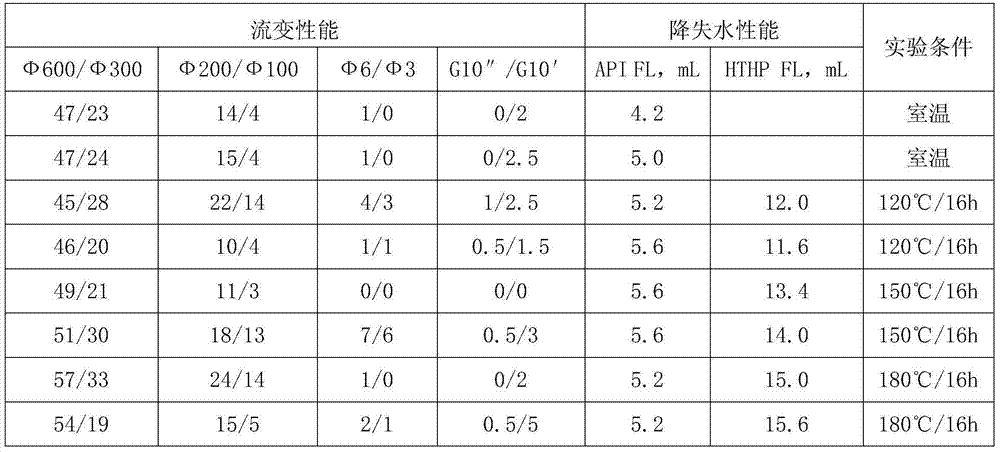

Acid fracturing thickening agent and preparation thereof

InactiveCN101412906AHigh viscosityImprove high temperature resistanceDrilling compositionTemperature resistancePetroleum

The invention discloses a novel acidified fractured thickening agent and a preparation method thereof, and belongs to the field of macromolecular synthesis. The thickening agent is prepared by the method comprising the following steps: adopting a water solution polymerizing method, oxidizing and reducing an evocating agent, adding proper amount of chain extender into a sealed system, and copolymerizing the mixture by the reaction of methacryloyloxy trimethyl-ammonium chloride (DMC), acrylamide (AM) and 2-acrylamido-2-methyl propane sulfonic acid (AMPS). The thickening agent has the advantages of acid resistance and high temperature resistance, has favorable thickening effect, and is applied to the fields of acidified fracturing construction, strengthening oil extraction work and the like in petroleum extraction.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Ethers early strength type polycarboxylate water reducer and preparation method thereof

The invention discloses an ethers early strength type polycarboxylate water reducer and a preparation method thereof. The water reducer regards unsaturated esters, N,N-bis(2-hydroxyethyl)isopropanolamine (DIEPA), 2-acrylamide-2-methylpropanesulfonic acid (AMPS), methyl allyl polyoxyethylene polyoxypropylene ether (TPEG) and the like as main chemical synthesis raw materials, and the main chemical synthesis raw materials are subjected to amidation and copolymerization in certain conditions under the action of a catalyst, an initiator, a chain transfer agent and the like, so that a high-molecular polymer with an amphoteric structure is obtained. The molecular structure of the water reducer comprises hydrophilic hydroxyl, hydrophilic carboxyl, hydrophilic acylamino, hydrophilic sulfonyl, hydrophobic carbon chains and a polyoxyethylene polyoxypropylene ether long-chain structure with certain stereo-hindrance effects, wherein an N containing group can improve early strength of concrete obviously. Therefore, the ethers early strength type polycarboxylate water reducer is applicable to pre-cast concrete components which need improvement of early strength.

Owner:KZJ NEW MATERIALS GROUP CO LTD

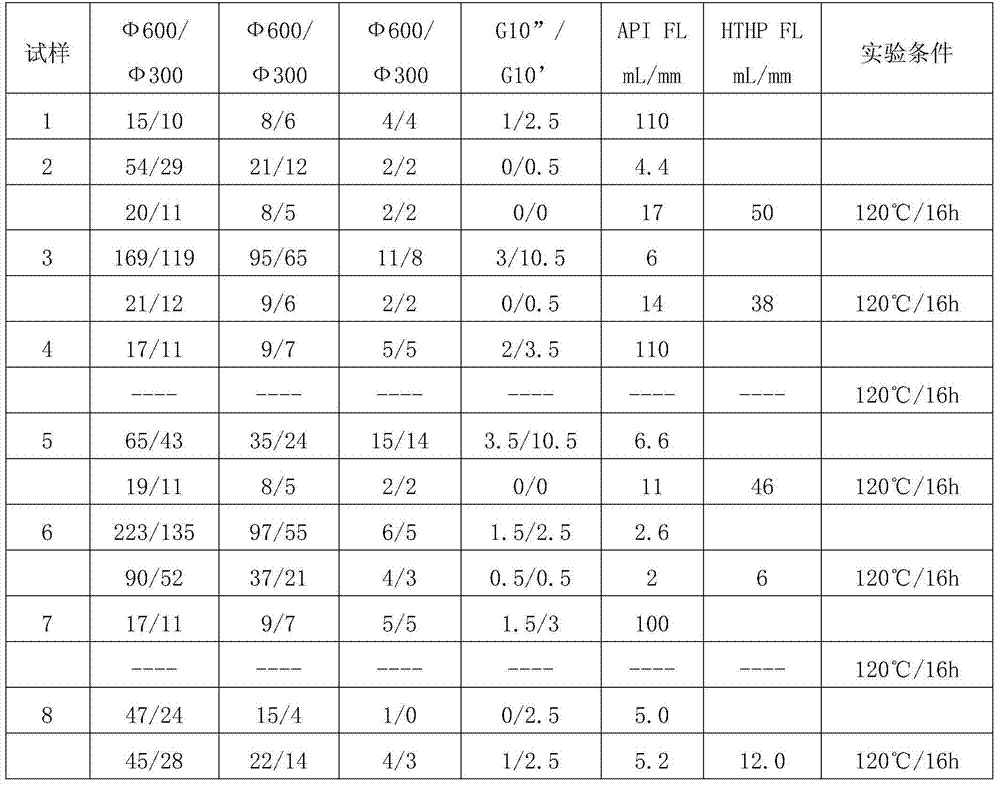

Multi-element co-polymerization oil well cement fluid loss additive and preparation method thereof

ActiveCN101397491ASimple preparation processDrilling compositionPotassium persulfateSodium hydroxide

The invention relates to a multicomponent copolymerization oil well cement fluid loss additive and a preparation method thereof. The method comprises: 10-120 portions of 2-acrylamide-2-methyl-1-AMPSA, 1-5 portions of acrylic acid and 15-50 portions of deionized water are added, stirred and then added with sodium hydroxide aqueous solution with the mass fraction of 5-10 percent for neutralizing to pH equal to 3-11; then 10 portions of acrylamide, 0.1-1 portion of complexing agent EDTA and 0.01-1 portion of chain transfer agent are added, the chain transfer agent is isopropyl alcohol or sodium benzoate, the temperature is controlled between 30 DEG C and 60 DEG C and N2 is introduced for 30 minutes; 2-10 portions of N-vinyl pyrrolidone and 0.01-0.5 portion of initiator are added, the initiator is potassium persulfate or ammonium persulfate, and the reaction is carried out for 4-12 hours. The solution keeps still for 5 hours at the temperature of 180 DEG C, and is cooled through flowing water after being taken out, without sedimentation or water separating; and the water loss is zero at the temperature of 180 DEG C according to the standards of drilling fluid, and the water loss is 48ml according to the standards of cement.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Amphoteric cellulose material and application thereof

InactiveCN103497278ARenewableDegradableOther chemical processesWater/sewage treatment by sorptionCellulosePolymer science

The invention discloses amphoteric cellulose material and application thereof. Cellulose is subjected to alkali pretreatment to obtain alkali cellulose and achieve hydroxyl activation; 3-chloro-2 hydroxypropyl trimethyl ammonium chloride is used as etherifying agent to perform quaternization modification on the alkali cellulose so as to obtain quaternized cellulose; ceric ammonium nitrate is used as initiator and monomer 2-acrylamide-2-methyl propane sulfonic acid to perform sulphonation on the quaternized cellulose. The prepared quaternized and sulfated cellulose has good hydrophilicity, high reaction activity, bulky macrostructure and porous microstructure, is capable of adsorbing negatively charged anion, negatively charged anionic compound, positively charged cation and positively charged compound in the same time, is high in adsorption capacity, is applicable to the fields such as treatment of heavy metal ion waste water and treatment of organic waste water, and can also serve as functional carriers of other materials.

Owner:SUZHOU UNIV

Production method for 2-acryloylamino-2-methylpropane sulfonic acid

InactiveCN101284805ALarge crystal sizeEasy to centrifugeSulfonic acid preparationSulfonateRoom temperature

The invention relates to a method for synthesizing a chemical substance, in particular to a production method for 2-acrylamide-2-methyl propyl sulfonic acid. The method comprises the following steps that: A) firstly, 150 to 180 weight portions of acrylonitrile is added into a reactor, then 30 to 50 weight portions of sulfuric acid with the concentration of between 95 and 100 percent is stirred and synchronously added into the reactor, isobutene is aerated when the adding amount of the sulfuric acid is up to between 15 and 25 percent of the total amount, the reaction temperature is controlled between 10 and 40 DEG C, the produced pasty product is cooled to the room temperature and is separated and dried by a centrifuger to obtain a crude product of 2-acrylamide-2-methyl propyl sulfonic acid. The method adds an organic sulfonate during the reaction, which not only suppresses secondary reactions but also makes the product have larger crystal size with easy centrifugal separate, is convenient to realize the industrial production, and has high purity and yield.

Owner:魏光波 +1

Resistance reducing agent for fracturing quick water of shale gas and preparation method thereof

ActiveCN103755868AHigh temperature resistantReduce frictionDrilling compositionEmulsion polymerizationOil phase

The invention relates to a resistance reducing agent for fracturing quick water of a shale gas and a preparation method thereof. The resistance reducing agent for fracturing quick water of the shale gas is formed by reverse emulsion polymerization by means of combination of a water phase and an oil phase, wherein the weight part ratios of monomers to water in the water phase are sequentially as follows: the ratio of acrylamide: 2-acrylamide-2-methyl propanesulfonic acid: water is (0.7-1.3):(0.7-1.5):1; the weight ratio of monomers to oil in the oil phase is sequentially as follows: the ratio of tween 80:OP-10: white oil is (0.1-0.35):(0.1-0.35):1; and the weight ratio of the water phase to the oil phase is 1:(0.35-0.85). The preparation method comprises the following steps: (1) selecting acrylamide and 2-acrylamide-2-methyl propanesulfonic acid, and dissolving acrylamide and 2-acrylamide-2-methyl propanesulfonic acid in proportion in deionized water to prepare the water phase; (2) selecting tween 80 and white oil and mixing the tween 80 and white oil in a certain proportion to form the oil phase; (3) proportioning the water phase and the oil phase in a certain proportion, and fully mixing to form a stable water-in-oil inverse emulsion base fluid; and (4) catalyzing and initiating by an initiator to synthesize the resistance reducing agent.

Owner:郑州三山石油技术有限公司

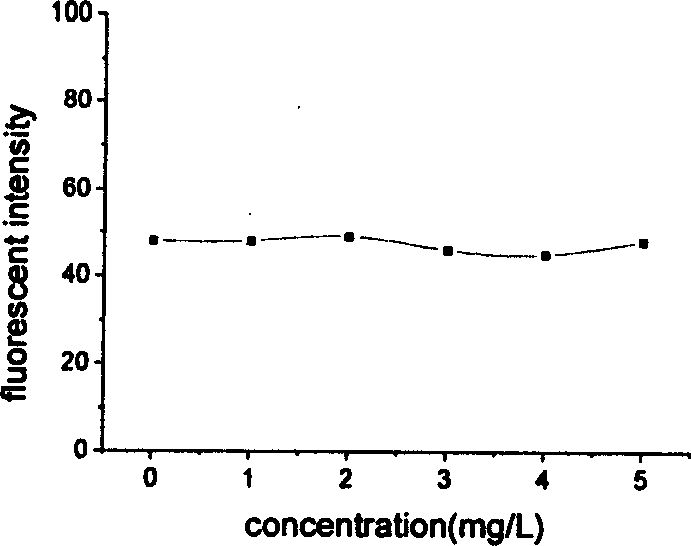

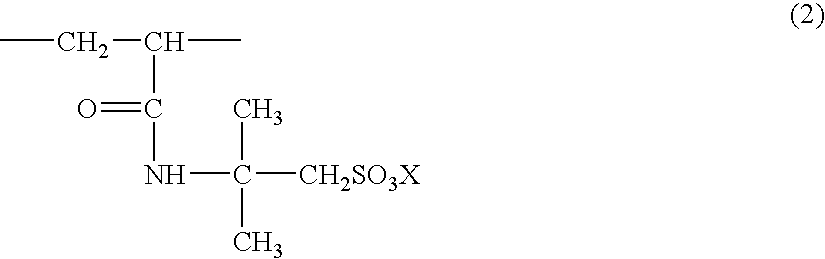

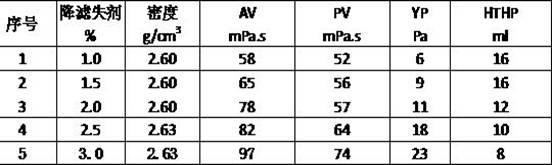

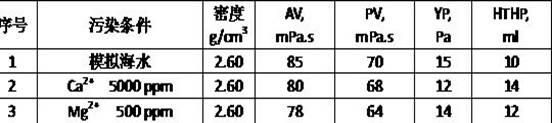

Salt-resistant and calcium-resistant filtrate reducer applied to drilling fluid and preparation method of filtrate reducer

ActiveCN104497995AAnti-calciumMagnesium and other divalent ions are strongDrilling compositionMeth-Propylsulfonic acid

The invention discloses a salt-resistant and calcium-resistant filtrate reducer applied to a drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer is prepared from raw materials and water, wherein the raw materials comprise 2-acrylamide-2-methyl propane sulfonic acid, acrylic acid, acrylamide and dimethyl diallyl ammonium chloride; the ratio of m(2-acrylamide-2-methyl propane sulfonic acid) to m(acrylic acid) to m(acrylamide) to m(dimethyl diallyl ammonium chloride) to m(initiator) to m(molecular weight control agent) is (40-60) to (6-10) to (30-40) to (5-9) to (1-2) to (0.1-0.5). The molecular weight of the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid and prepared by the preparation method is greatly improved; the coating property, the inhibition property, the heat stability and the salt-resistant and calcium-resistant pollution capacity of the filtrate reducer are greatly improved; by virtue of the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid, the rheological property of the drilling fluid can be greatly improved; the salt-resistant and calcium-resistant filtrate reducer applied to the drilling fluid also has a high temperature-resistant effect at 150-180 DEG C.

Owner:北京奥凯立科技发展股份有限公司

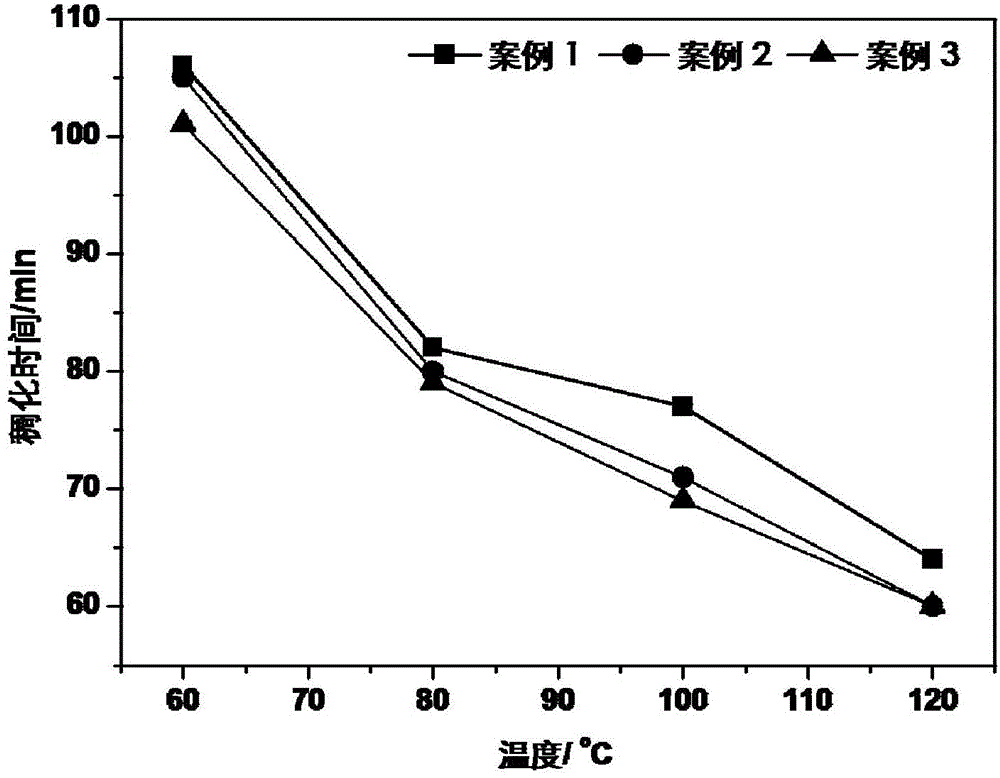

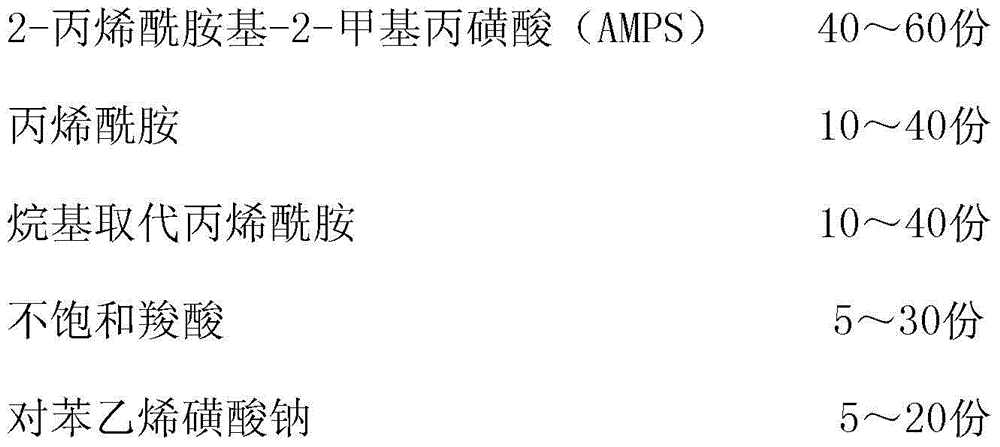

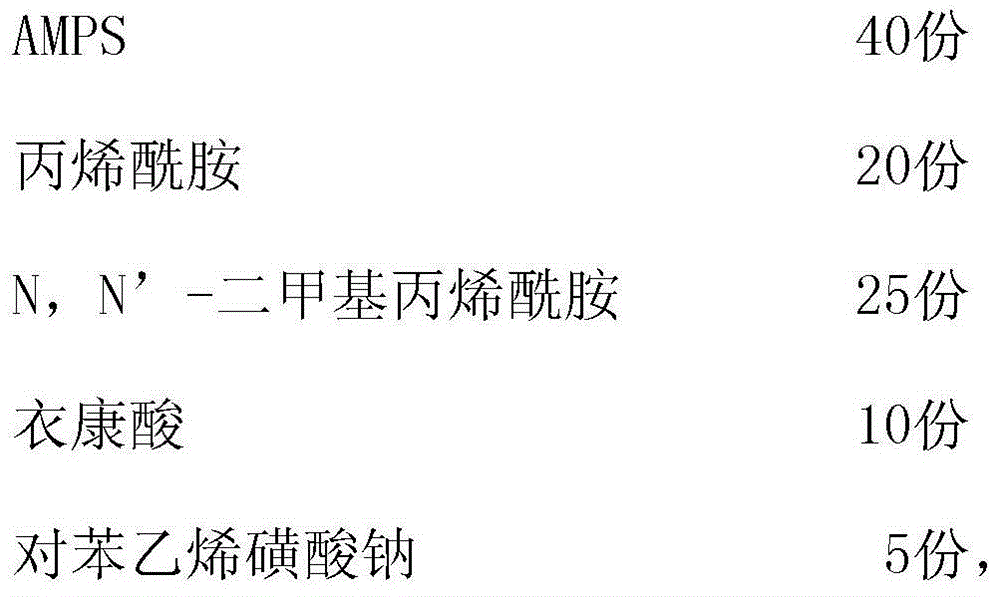

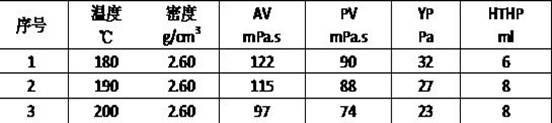

High-temperature-resistant salt-resistant fluid loss agent and preparation method thereof

The invention discloses a high-temperature-resistant salt-resistant fluid loss agent which is prepared by polymerizing the following components in parts by weight: 40-60 parts of 2-acrylamido-2-methylpropanesulfonic acid, 10-40 parts of acrylamide, 10-40 parts of alkyl substituted acrylamide or N-vinyl-2-pyrrolidone, 5-30 parts of unsaturated carboxylic acid and 5-20 parts of sodium p-styrenesulfonate, and an initiator which accounts for 0.1-1.0 wt% of the five components above. The invention also provides a preparation method of the fluid loss agent. The fluid loss agent has better high temperature resistance, and the maximum normal use temperature can reach 200 DEG C. The fluid loss agent has higher salt resistance, and can resist a saturated NaCl solution. The cement mortar with the fluid loss agent has the advantages of high system stability and high compression strength, and does not have the phenomenon of longer thickening time along with the temperature increase.

Owner:CNPC BOHAI DRILLING ENG

Stimuli-responsive textile fabric and method for preparing same

The invention relates to an environment-response intelligent weave fabric and relative preparation. Wherein, adding the fabric which is induced by argon microwave low-temperature plasma to generate free group on surface, into the dual monomer solution of 2-acrylamide-2-methanesulfonic acid and N-isopropyl acrylamide that contains N and N'-methylene dual acrylamide cross linker to process graft polymerization reaction, while the bath ratio is 1:40, to graft the dual intelligent gel on the fiber macromolecule of fabric, to attain said inventive product. When the invention is dry, it has no difference from general fabric, but when it is wet, the gel will adsorb water to expand and block the slits between fibers, to reduce the water and gas permeability of fabric, and avoid outer penetrating into the inner layer of fabric to stop heat emission. The invention can be used to produce army waterproof clothes, heat-accumulation temperature adjustable special clothes, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Crotonic acid system polycarboxylic acid high-performance water reducer

The invention relates to the field of chemical industry, in particular to a crotonic acid system polycarboxylic acid high-performance water reducer. The water reducer is prepared by copolymerizing 60 to 80 mass percent of first monomers, 20 to 40 mass percent of second monomers and 0 to 20 mass percent of third monomers, wherein the first monomers comprise methoxy polyethylene glycol crotonate, methoxy polyethylene glycol mono-crotonate, allylpolyethyleneglycol (APEG) and the like; the second monomers comprise crotonic acid, ethyl crotonate or ethyl crotonate and the like; and the third monomers comprise acrylic acid, methacrylic acid, maleic anhydride, methylmaleic acid, itaconic acid, methyl acrylate, hydroxyethyl acrylate, hydroxy-propyl acrylate, sodium allylsulfonate or acrylamide and the like. a preparation process for the water reducer is simple and low in cost, and the polycarboxylic acid high-performance water reducer with excellent performance can be prepared under the condition of not using high-cost monomers such as methacrylic acid, acrylic acid or 2-acrylamide-2-methylpropanesulfonic acid, sodium methallylsulphonate, sodium allylsulfonate and the like.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

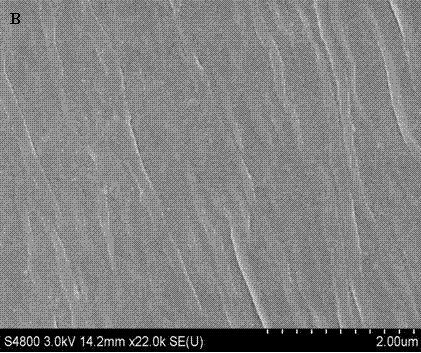

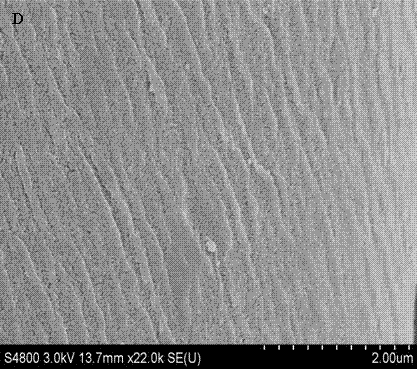

Additive for producing low-profile electrolytic copper foil and production process

The invention relates to low-profile electrolytic copper foil, particularly relates to an additive for producing the low-profile electrolytic copper foil, and also relates to a production process. The additive for producing the low-profile electrolytic copper foil is mixed by the following components: 0.2-0.4 part of sodium 3-mercapto-1-propanesulfonate; 0.8-1.2 part of polyvinyl alkylimine or polyethyleneimine alkyl compounds; 1.0-2.0 parts of polyethylene glycol 8000; 0.08-0.12 part of N,N-diethyl thiourea; and 20 parts of pure water. Electrolytic copper foil produced by the additive and the production process of the invention can not only maintain a low profile tolerance and low impedance, but also maintain high peel strength, and also is suitable for the manufacture of interior and exterior lines.

Owner:惠州联合铜箔电子材料有限公司

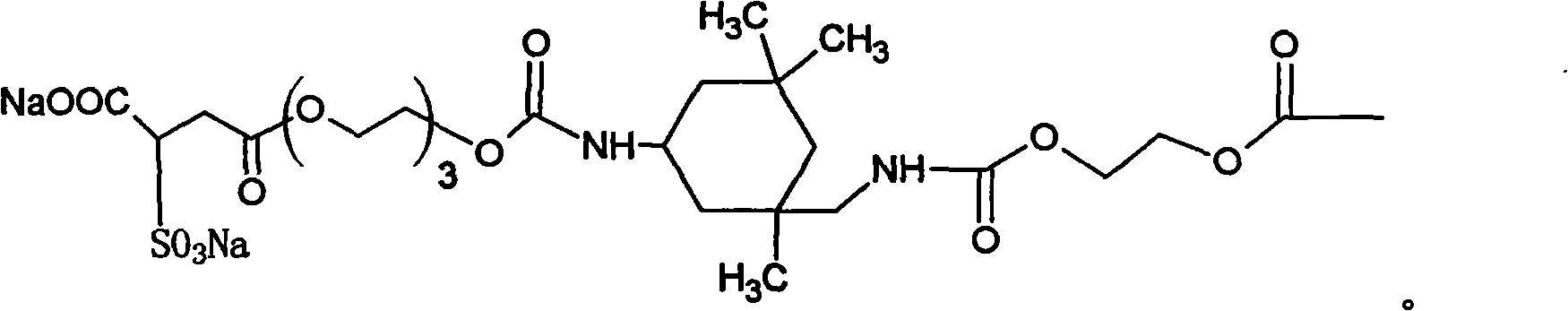

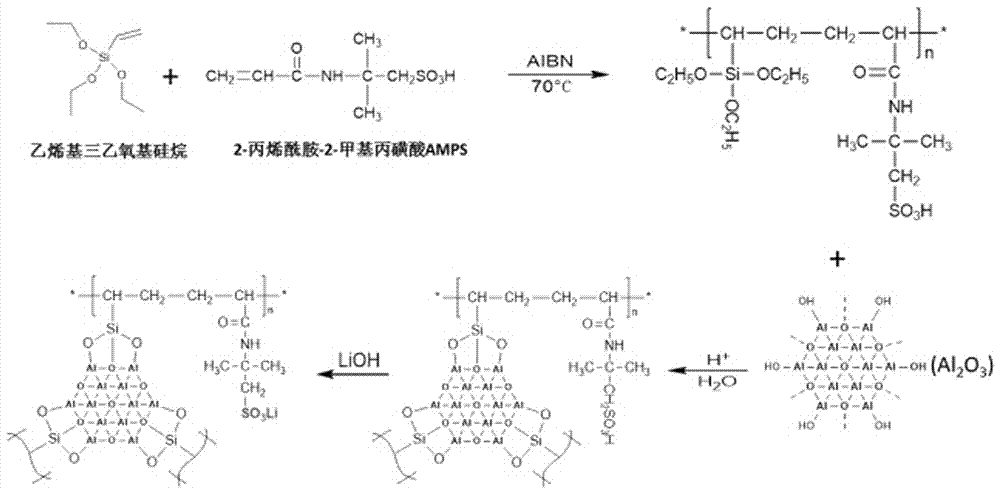

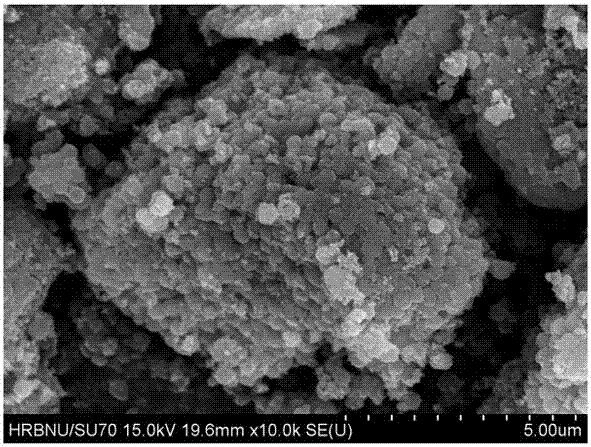

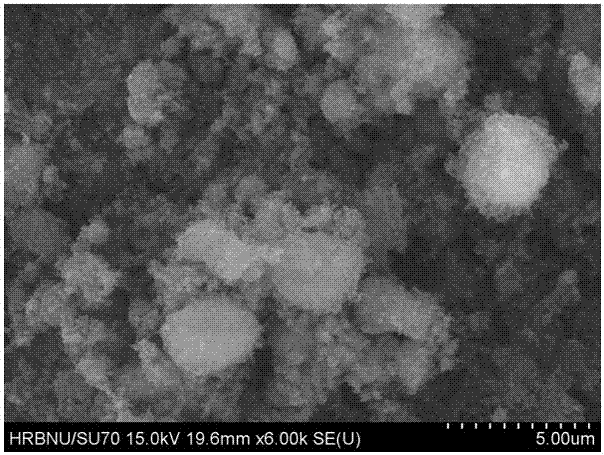

Surface-modified inorganic nanoparticles as well as preparation method and application thereof

ActiveCN107134590AGood dispersionEvenly dispersedMaterial nanotechnologySolid electrolytesDispersityMetal oxide nanoparticles

The invention discloses surface-modified inorganic nanoparticles as well as a preparation method and application thereof. The surface-modified inorganic nanoparticles are composed of a core of inorganic metal oxide nanoparticles and amphipathic organic segments grafted on the surface of the particles, wherein the amphipathic organic segments grafted on the surface of the particles account for 0.1-50% of total mass of the surface-modified inorganic nanoparticles; the inorganic metal oxide nanoparticles refer to one or several in aluminum oxide, silicon dioxide, titanium dioxide, zirconium dioxide and zinc oxide inorganic nanoparticles; and the amphipathic organic segments are produced from a vinyl silicane coupling agent and 2-acrylamido--methylpropane sulfonic acid through solution polymerization. The surface-modified inorganic nanoparticles can be used for preparing polymer electrolyte. Therefore, the inorganic nanoparticles are high in dispersity in a polymer matrix, and the prepared polymer electrolyte is high in lyotropic property, high in ionic conductivity and stable in electrochemical performance.

Owner:浙江久功新能源科技有限公司

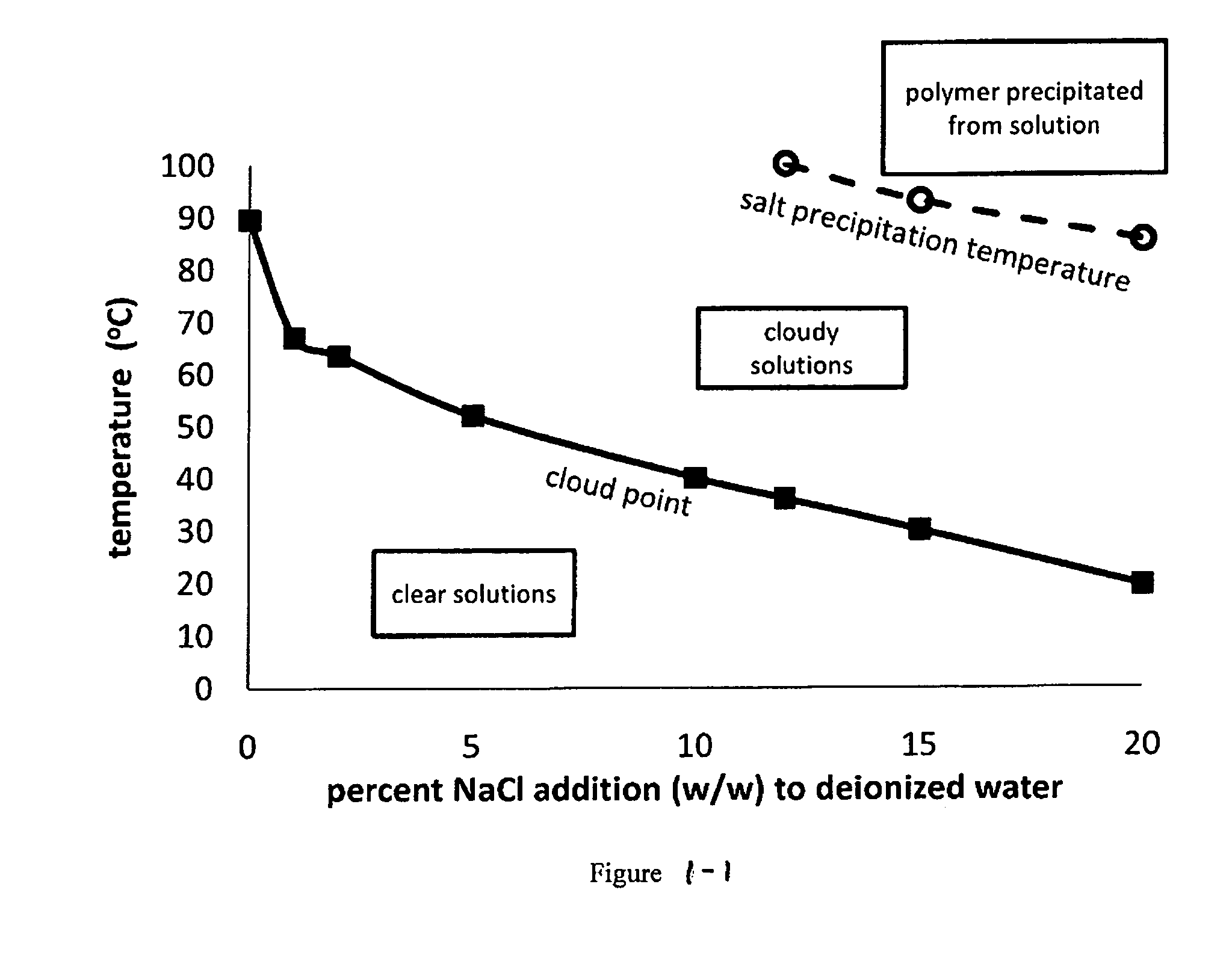

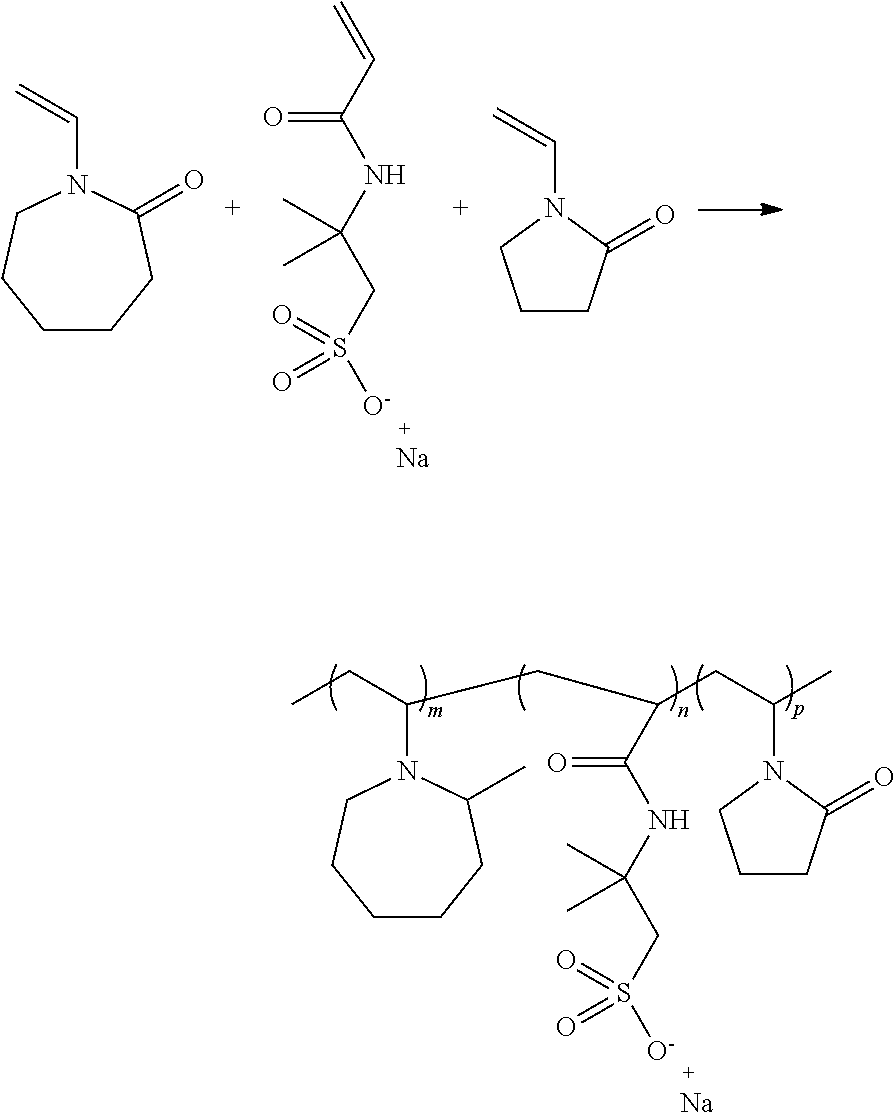

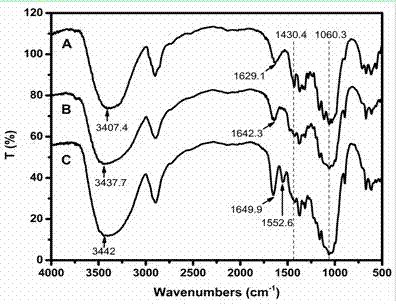

Non-homopolymers exhibiting gas hydrate inhibition, salt tolerance and high cloud point

Polymers are provided that offer gas hydrate inhibition, salt tolerance, and high cloud point. The polymers are polymerized from at least (A) 50 mole percent or more of a monomer selected from the group consisting of: N-vinyl-2-caprolactam, one of its analogues, and combinations thereof, (B) an alkenyl sulfonic acid monomer, salt thereof, or combinations thereof, and (C) an TV-vinyl amide, a (meth)acrylamide or one of its analogues, or combinations thereof. In one embodiment, the (A) monomer is N-vinyl-2-caprolactam, the (B) monomer is 2-acrylamido-2-methylpropane sulfonic acid or salt thereof, and the (C) monomer is N-vinyl-2-pyrrolidone, acrylamide, methacrylamide, or combinations thereof.

Owner:ISP INVESTMENTS INC

Preparation method of amphoteric cellulose material

InactiveCN103497279ARenewableDegradableOther chemical processesWater/sewage treatment by sorptionCelluloseMeth-

The invention discloses a preparation method of amphoteric cellulose material. The method includes: performing alkali pretreatment on cellulose to obtain alkali cellulose and achieve hydroxyl activation, using 3-chloro-2 hydroxypropyl trimethyl ammonium chloride as etherifying agent to perform quaternization modification on the alkali cellulose to obtain quaternized cellulose, using ceric ammonium nitrate as initiator and monomer 2-acrylamide-2-methyl propane sulfonic acid to perform sulphonation on the quaternized cellulose so as to achieve amphoterism of the cellulose. Preparation conditions are mild, the process is simple, operation is convenient, scaling is easy, the method has promising industrial popularization prospect, and products have high adsorption capacity, can be applied to the fields such as treatment of heavy metal ion waste water and treatment of organic waste water and can also be used as functional carriers of other materials.

Owner:SUZHOU UNIV

Acid liquor friction reducer and preparation method thereof

InactiveCN103820099AHigh resistance reduction rateImprove temperature resistanceDrilling compositionMeth-Pump pressure

The invention discloses an acid liquor friction reducer and a preparation method thereof. According to the invention, the preparation method comprises the following steps: weighing monomer 2-acrylamide-2-methylpro panesulfonic acid; placing into a beaker; adding deionized water for dissolution; adding caustic soda flakes to adjust to the pH value of the system to be 8-10; adding monomer acrylamide and long-chain cation monomer; mixing under the condition of supplying an inert gas; adjusting the water bath temperature to be the initiation reaction temperature and adding an initiator; reacting to obtain transparent gelatin blocks; manually cutting the transparent gelatin blocks; drying, smashing, and screening with 100 mesh to obtain powdered acid liquor friction reducer. According to the invention, the synthesis method is simple, the raw materials are easy to obtain, and the cost is lowered; the acid liquor friction reducer prepared by the invention has a friction reducing rate as high as 65%, the pump pressure is reduced, the pipe line loss is reduced, and the service life of equipment is prolonged; the acid liquor friction reducer is good in temperature tolerance and compatibility, and has a certain speed reducing effect.

Owner:CHENGDU BAICHUN PETROLEUM TECH

Electrolyte and application thereof

InactiveCN103000945AImprove cycle performanceHigh densitySecondary cellsElectrolytic agentOrganosolv

The invention relates to an electrolyte. The electrolyte comprises an organic solvent, lithium hexafluorophosphate and additives, wherein the additives comprise lithium tetrafluoroborate, 1,3-propane sultone, lithium bis(oxalate) borate, adiponitrile, vinylene carbonate and fluoroethylene carbonate, and in the electrolyte, the mass concentration of the lithium tetrafluoroborate is 0.5%-2%, the mass concentration of the 1,3-propane sultone is 1%-4%, the mass concentration of the lithium bis(oxalate) borate is 1%-5%, the mass concentration of the adiponitrile is 1%-3%, the mass concentration of the vinylene carbonate is 0.5%-2%, and the mass concentration of the fluoroethylene carbonate is 2%-5%. The electrolyte can be used for improving the cycle performance, the high-temperature storage performance and the initial energy density of a lithium-ion battery. The invention further provides an application of the electrolyte in the lithium-ion battery.

Owner:EVE HYPERPOWER BATTERIES INC +1

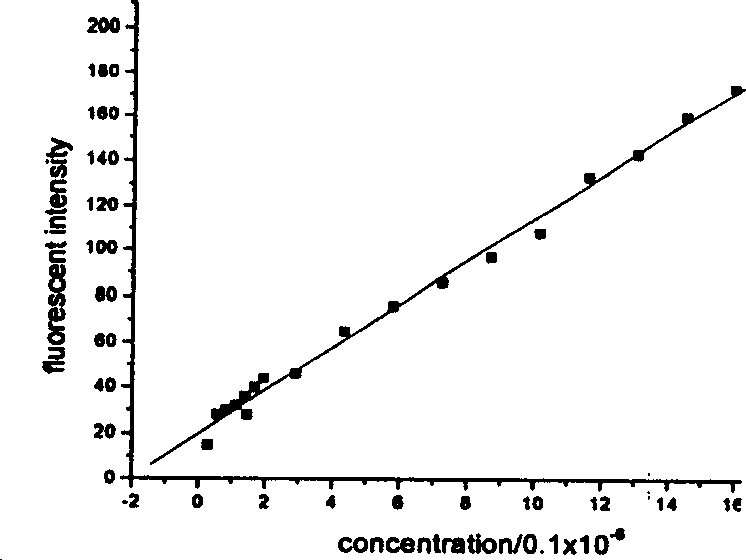

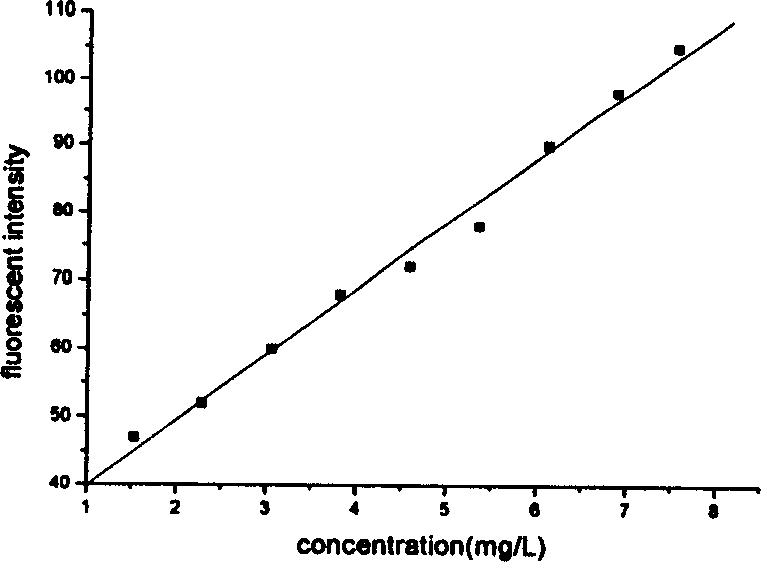

Methoxy group naphthyl fluorescence marked water treating agent and its preparing method

InactiveCN1781857ARaw materials are easy to getMild reaction conditionsScale removal and water softeningSodium methoxideFluorescence

The present invention discloses water treating agent containing methoxy naphthalene as fluorescent marker. The water treating agent is prepared through the first reaction of 4-chloro-1, 8-naphthalic anhydride, glacial acetic acid and 3-dimethylamino propylamine to obtain 4-chloro-N-3-dimethylamino propyl-naphthyl imide; the subsequent reaction with sodium methoxide to introduce methoxy group and obtain 4, 4-methoxyl-N-3-dimethylamino propyl-naphthyl imide, which is reacted with allyl chloride to obtain quaternary ammonium salt of 4-methoxyl-N-3-dimethylamino propyl-naphthyl imide allyl chloride as fluorescent monomer with fluorescent characteristic and double bond; and the final polymerization with phosphorus containing compound, acrylic acid and other monomer to obtain the multifunctional water treating agent with corrosion retarding, scale inhibiting, dispersing and fluorescent tracing functions.

Owner:NANJING UNIV OF SCI & TECH

Aqueous antisun/sunscreen compositions comprising amphiphilic 2-acrylamidomethylpropanesulfonic acid polymers and water-soluble silicones

Photoprotective compositions well suited for the photoprotection of the skin, lips and / or hair against the damaging effect of UV-radiation comprise at least one aqueous phase and at least one system for screening out UV-radiation, and which also contain:(a) at least one partially or totally neutralized, crosslinked or non-crosslinked amphiphilic polymer of 2-acrylamidomethylpropanesulfonic acid (AMPS), and(b) at least one water-soluble silicone comprising at least one terminal or pendent monovalent polyoxyalkylene group.

Owner:LOREAL SA

Filtrate reducer for water-based drilling fluid and preparation method of filtrate reducer

ActiveCN102585784ALow biological toxicityGood filter loss reduction effectDrilling compositionMeth-Magnesium ion

The invention discloses a filtrate reducer for a water-based drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer for the water-based drilling fluid comprises the following components in percentage by mass: 30-40 percent of acrylamide, 10-20 percent of 2-acryloylmino-2-methylpropyl sulfonate, 20-30 percent of maleic anhydride, 20-40 percent of sodium allylsulfonate, 0.1-0.2 percent of initiator and the balance of water. The filtrate reducer disclosed by the invention has the advantages of low biotoxicity, strong resistance to pollution of calcium ions and magnesium ions and good temperature resistance; and the requirements of the drilling of a gypsum-salt layer on a drilling fluid treating agent can be satisfied, and meanwhile, the filtrate reduction effect is still good in the high-density condition.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

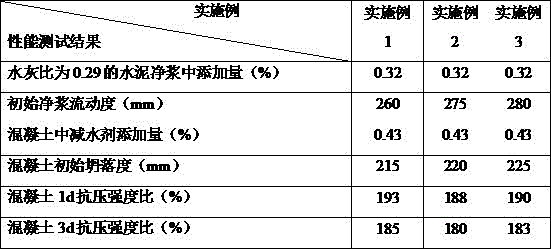

Early-strength polycarboxylate type high-performance water reducing agent and preparation method

The invention relates to an early-strength polycarboxylate type high-performance water reducing agent and a preparation method. The early-strength polycarboxylate type high-performance water reducing agent is prepared from methyl allyl polyethenoxy ether, acrylic acid, maleic anhydride, 2-acrylamide-2-methyl propane sulfonic acid, sodium methallyl sulfonate, hydrogen peroxide, ammonium persulfate, L-ascorbic acid, dihydrate sodium formaldehyde sulfoxylate, mercaptoacetic acid, mercaptopropionic acid, sodium hydroxide and water. The newly-stirred concrete added with the water reducing agent has good workability; the water reducing rate can reach 30 percent or more; the 1d pressure-resistant intensity of the concrete can reach 185 percent to 198 percent; the 3d pressure-resistant intensity ratio can reach 176 percent to 187 percent; the concrete setting time is obviously shortened; the early strength of the concrete can be obviously improved; the rustiness effect on steel bars does not exist; no alkali-aggregate reaction occurs; a series of advantages such as concrete structure durability are practically guaranteed; the market prospects are wide. The product is widely applicable to various stages of commodity concrete and high-quality concrete for high-speed railways, high-speed highways, large-scale bridges, prefabricated components, airports, port buildings and the like, and is particularly suitable for being used for various concrete engineering constructions with the early strength requirements and concrete construction in low-temperature environment.

Owner:河南新汉材料科技有限公司

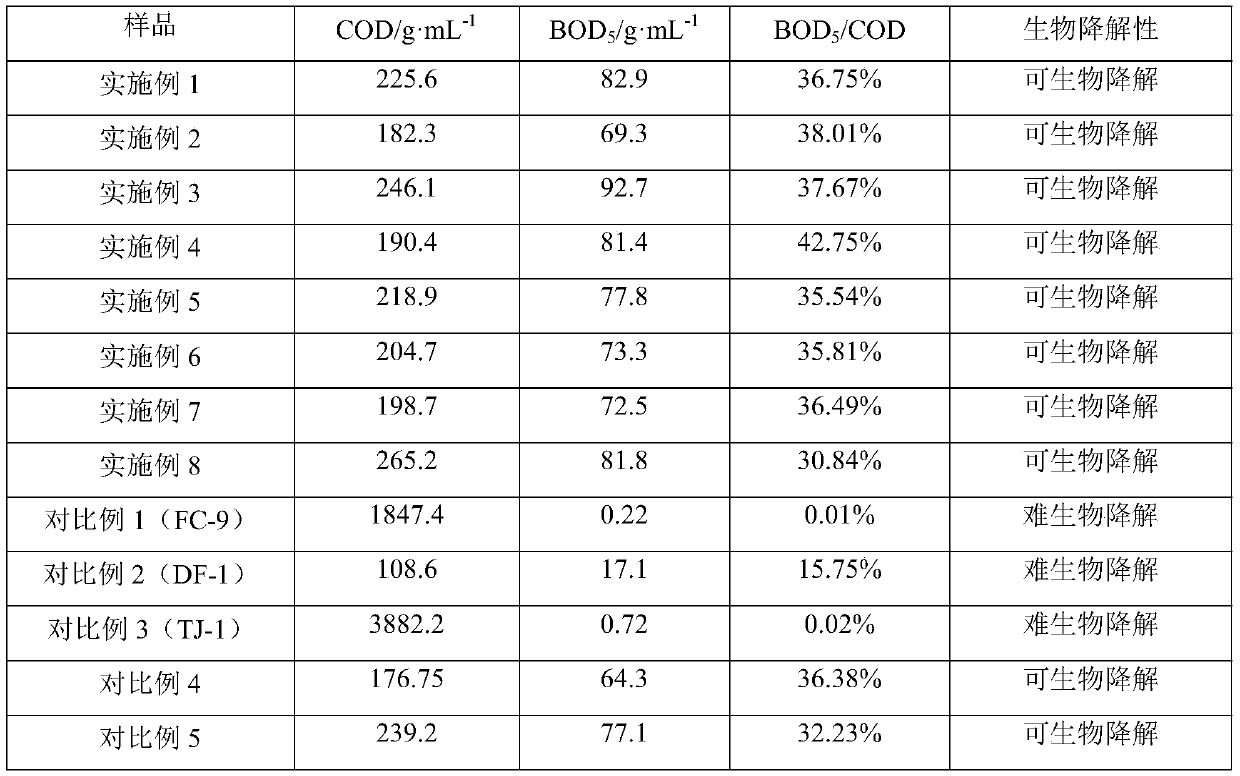

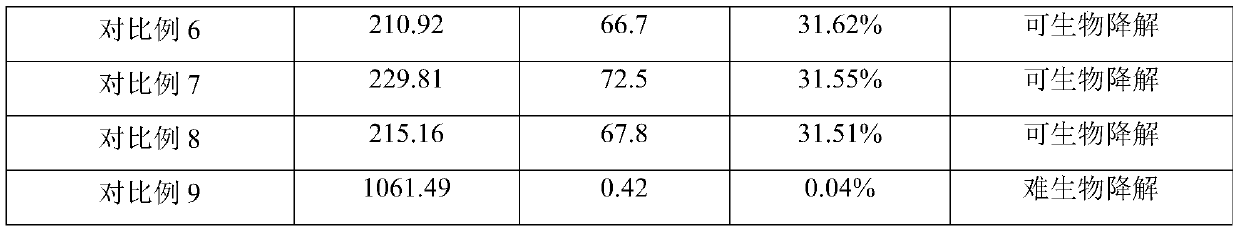

Temporary plugging agent for drilling fluid and water-based drilling fluid and application

ActiveCN109776728AGood acid solubilityGood rheological fluid lossDrilling compositionMeth-Filtration

The invention relates to the technical field of environment-friendly drilling fluid temporary plugging in a petroleum drilling process and discloses a temporary plugging agent for a drilling fluid anda water-based drilling fluid and an application. The temporary plugging agent is prepared by carrying out a polymerization reaction between gelatinized starch and a vinyl grafted monomer in an activator solution in the presence of a crosslinking agent and an initiator. The vinyl grafted monomer comprises acrylic acid, acrylamide and 2-acrylamide-2-methyl propanesulfonic acid and the gelatinized starch is prepared by carrying out a gelatinization reaction of starch added into deionized water. The temporary plugging agent provided by the invention can be biodegraded, the degradation rate of thetemporary plugging agent in soil for 90 days can reach 50% or higher, and the temporary plugging agent is environmentally friendly. The water-based drilling fluid with the temporary plugging agent has a good rheologic filtration property and can temporarily plug strata of different permeability self-adaptively, and the permeable temporary plugging reaches 100%. The temporary plugging agent is high in acid solubility, the permeability recover value can reach 85% or higher after the temporary plugging agent is acidized to unplug, and the reservoir protection ability is obvious.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

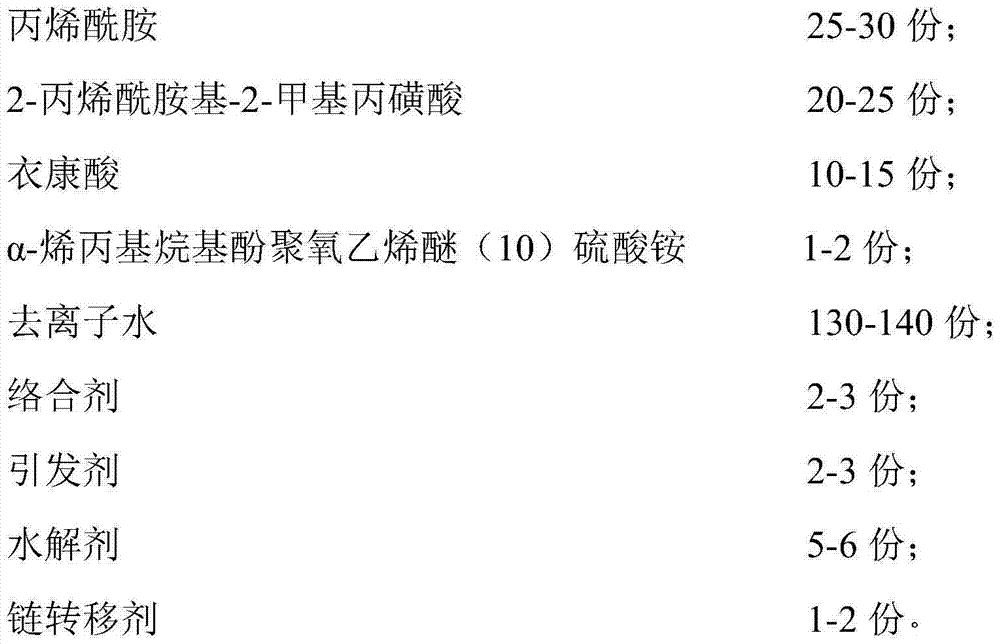

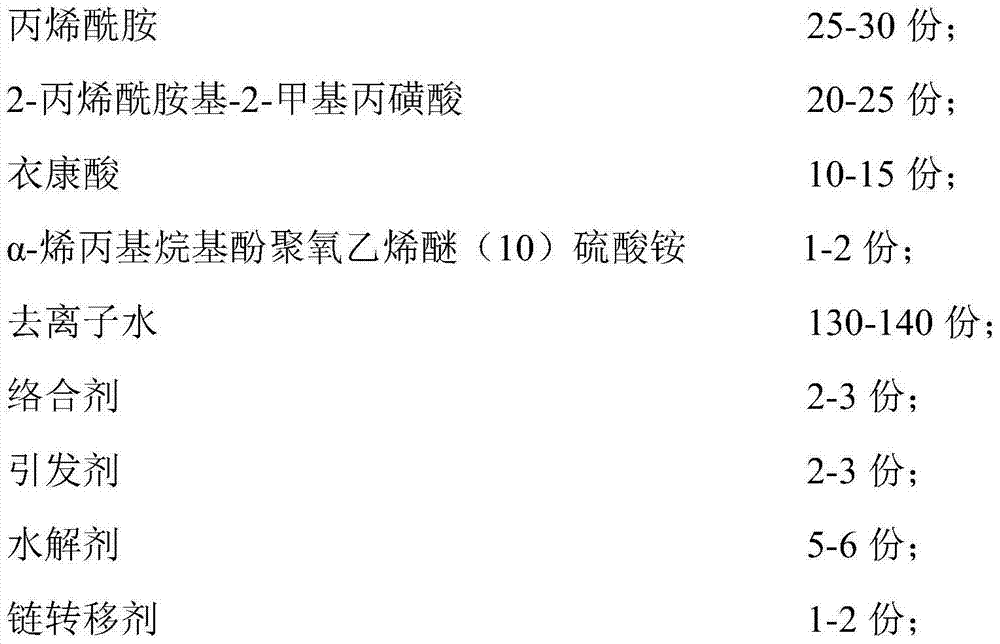

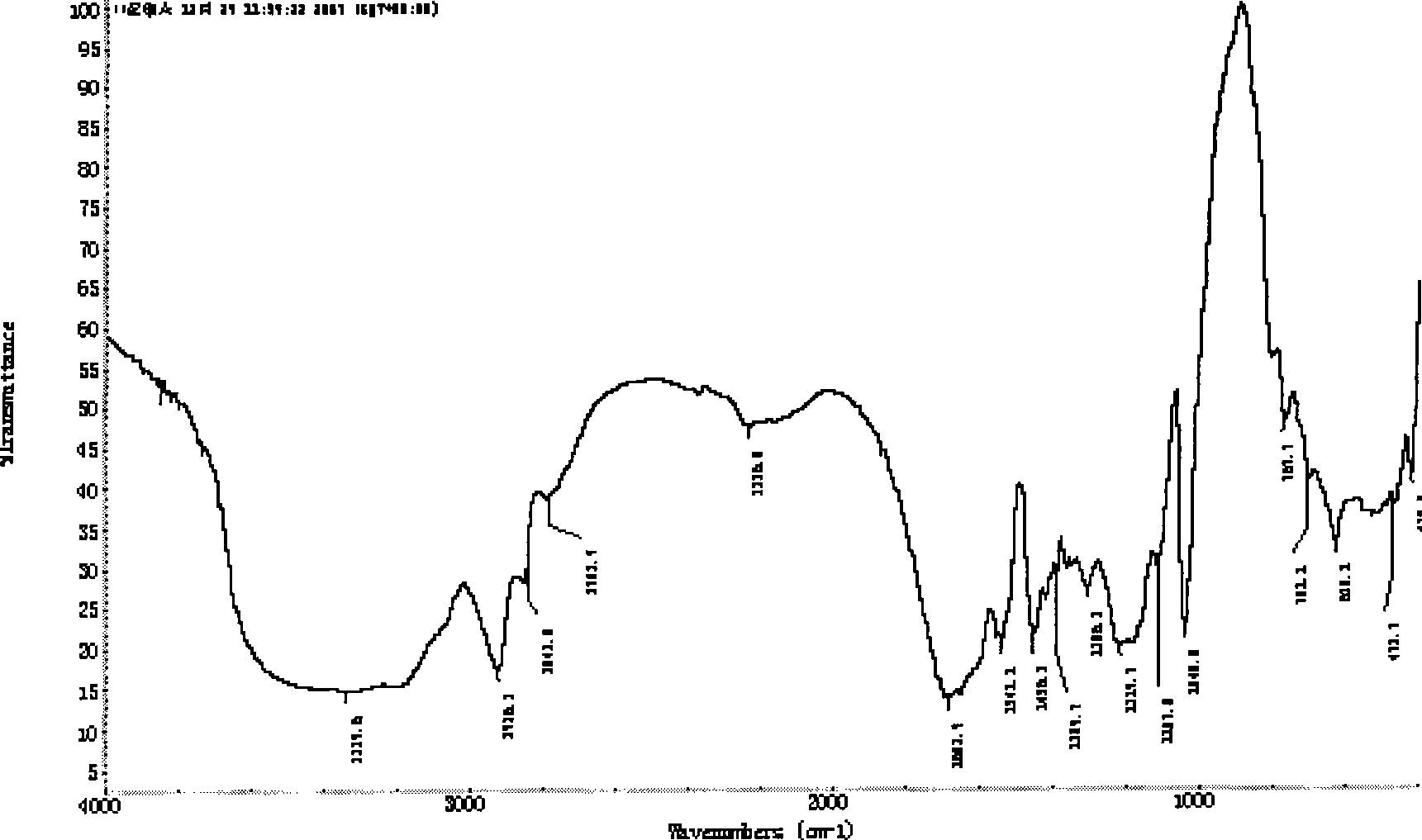

High-temperature resistant and salt-tolerance filtrate reducer for drilling fluid and preparation method thereof

ActiveCN104263329AIncrease the polymerization rateHigh degree of polymerizationDrilling compositionFiltrationEmulsion polymerization

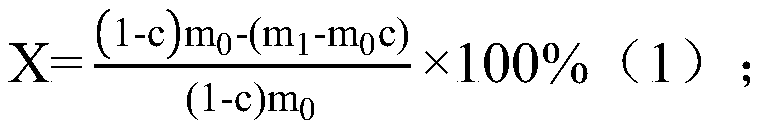

The invention discloses a high-temperature resistant and salt-tolerance filtrate reducer for drilling fluid. The method comprises the following steps: copolymerizing three monomers, namely acrylamide, 2-acrylamido-2-methyl-propanesulfonic acid and itaconic acid by using an emulsion polymerization method to obtain a copolymer, and then hydrolyzing under an alkaline condition; and participating and drying to obtain the filtrate reducer. The filtrate reducer has relatively good thermal stability and strong temperature resistance; after 0.5%-1% of high-temperature resistant filtrate reducer is added, the filtrate reducer disclosed by the invention has a good filtration reduction effect in fresh water, saline water, composite saline water and saturated brine drilling liquid. The invention also provides an emulsion polymerization method of the high-temperature resistant and salt-tolerance filtrate reducer for the drilling fluid. In comparison with a conventional polymerization method, the polymerization method disclosed by the invention has the advantages that the polymerization rate and the polymerization degree are obviously improved, the reaction time is obviously reduced, and the production cost is reduced under the premise of good product properties.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hydrophobic associating polymer containing capsaicine and sulfonic group and preparation method thereof

InactiveCN101392041AIncrease viscosityImprove salt toleranceDrilling compositionPolymer scienceFatty alcohol

The invention discloses a hydrophobic association polymer containing capsaicine and sulfonyl, and a preparation method thereof. During the preparation, compounds containing capsaicine functional groups, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid and (methyl) acrylic acid long-chain fatty alcohol ester are polymerized under the initiation of a a redox initiator; the mole percentage ratio of the compounds containing the capsaicine functional groups, the acrylamide, the 2-acrylamide-2-methylpropanesulfonic acid and the (methyl) acrylic acid long-chain fatty alcohol ester is 0.5-5 to 65-92.5 to 6.5-20 to 0.5-10; the reaction temperature is 30 DEG C to 120 DEG C; and the reaction time is 1h to 20h. The preparation method simultaneously introduces sulfonyl that is insensitive to salt and capsaicine functional group units with rigidity into the large molecules of the hydrophobic association polymer, thereby obtaining the water soluble hydrophobic association polymer which has high tackification and the properties of anti-salt and high temperature resistance, and can be applied to the tertiary oil recovery in oil fields as a novel oil-displacing agent.

Owner:OCEAN UNIV OF CHINA

Acrylamide crosslinking copolymer emulsion and preparation method thereof

the invention discloses a acrylamide crosslinking copolymer emulsion with 35-44% acrylamide crosslinking copolymer and water and preparing method in the reversed phase emulsion-typed macromolecular thickener of cosmetic, drug and ink industry, which comprises the following steps: blending acrylamide and 2-acrylamide-2-methanesulfonic acid; adding adjuvant to mix with oil phase; adding emulsifier of water-in-oil type and adjuvant emulsion; adding emulsifier of the oil-in-water type to obtain the product.

Owner:GUANGZHOU TINCI MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com