Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Good acid solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for separating iron, vanadium and titanium from schreyerite

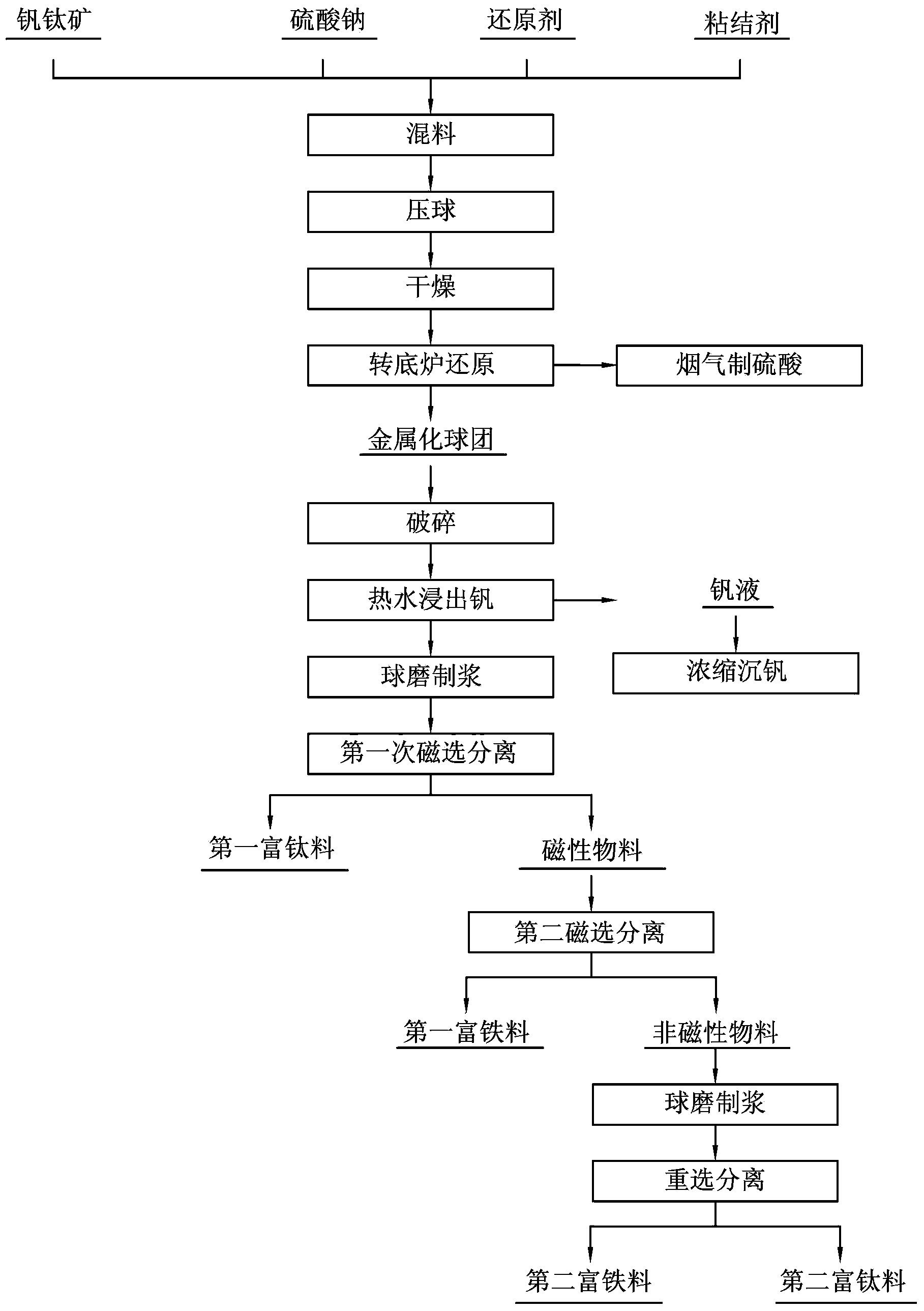

ActiveCN103526051AEfficient separationAvoid high temperature reduction and meltingMagnetic separationAdhesiveMetal

The invention discloses a method for separating iron, vanadium and titanium from schreyerite, which comprises the following steps: mixing schreyerite, sodium sulfate, a reducer and an adhesive, pressing into mineral coal pellets, drying the mineral coal pellets, filling into a rotary hearth furnace, and roasting at 1000-1300 DEG C for 20-60 minutes to obtain metalized pellets, wherein a neutral or micro-oxygenation atmosphere is in the rotary hearth furnace; crushing the metalized pellets, leaching at 70-90 DEG C while controlling the pH value at 3-5, and filtering the leach solution to obtain a vanadium solution; slurrying the leaching leftovers by ball milling while controlling the particle size at 0.045mm, and carrying out primary magnetic separation under the magnetic field intensity of 0.3-0.5T to obtain a nonmagnetic material which is a first titanium-rich material; carrying out secondary magnetic separation on the magnetic material under the magnetic field intensity of 0.02-0.04T to obtain a magnetic material which is a first iron-rich material; and slurrying the nonmagnetic material from the secondary magnetic separation by ball milling, and reseparating to obtain a second iron-rich material and a second titanium-rich material.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Fine pore formation agent for porous resin film and composition containing the same for porous resin film

ActiveUS20090030100A1Uniform diameterDiameter is limitedCalcium/strontium/barium carbonatesSynthetic resin layered productsElectrical batteryInorganic particles

A fine pore formation agent for a porous resin film is provided which comprises inorganic particles satisfying (a) 0.1≦D50≦1.5 (μm) (D50: average particle diameter of particles in 50% cumulative total by weight from the larger particle side by micro-track FRA), (b) Da≦20 (μm) (Da: maximum particle diameter by micro-track FRA), (c) 3≦Sw≦60 (m2 / g) (Sw: BET specific surface area measured by nitrogen adsorption method), (d) Ir≦1.0×105 (Ω·cm) (Ir: volume resistivity (Ω·cm).The fine pore formation agent for a porous resin film is capable of providing a resin composition giving a porous resin film useful in uses for electric parts such as capacitors and battery separators.

Owner:MARUO CALCIUM COMPANY +1

Water-absorbent resin temporary plugging agent and preparation method thereof

InactiveCN104449613AImprove adaptabilityWith elastic deformation functionDrilling compositionSolubilityAbsorption capacity

The invention relates to a water-absorbent resin temporary plugging agent and a preparation method thereof, belongs to the technical field of oilfield chemistry, and in particular relates to a petroleum drilling plugging agent. The water-absorbent resin temporary plugging agent is prepared by performing aqueous solution polymerization reaction on an acrylic acid monomer A, an acrylamide monomer B, a powdery acid-soluble inorganic filling material C and a crosslinking agent in the presence of an oxidization-reduction initiating system; the obtained gel-like product is pelletized and dried to obtain the water-absorbent resin temporary plugging agent for drilling solutions. The water-absorbent resin temporary plugging agent has acid solubility of more than 85 percent in 15 percent hydrochloric acid, temperature resistance of 150 DEG C, saturated water absorption capacity of 5-8 times and high self-adaption ability for leaking channels with different shapes and different sizes, and is high in toughness; moreover, the tensile elongation rate is up to 800-1,200 percent, and the tensile breaking strength is up to more than 2MPa. The water-absorbent resin temporary plugging agent is applied to plugging in a drilling and completion process, in particular to a reservoir drilling and completion process, and plugging of leaking reservoirs with different well depths under a hypersalinity condition.

Owner:CHINA PETROCHEMICAL CORP +1

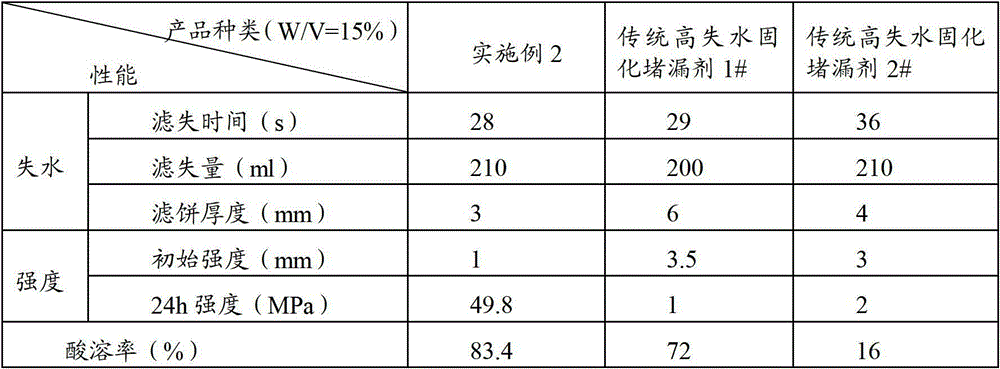

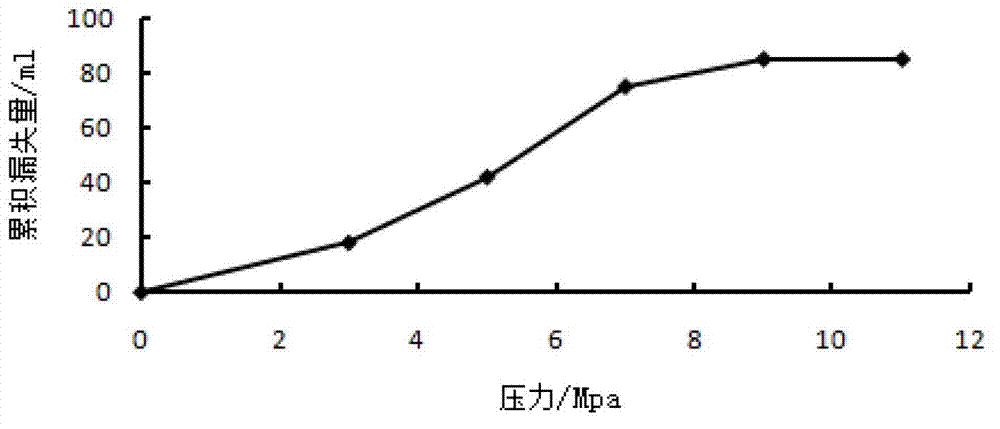

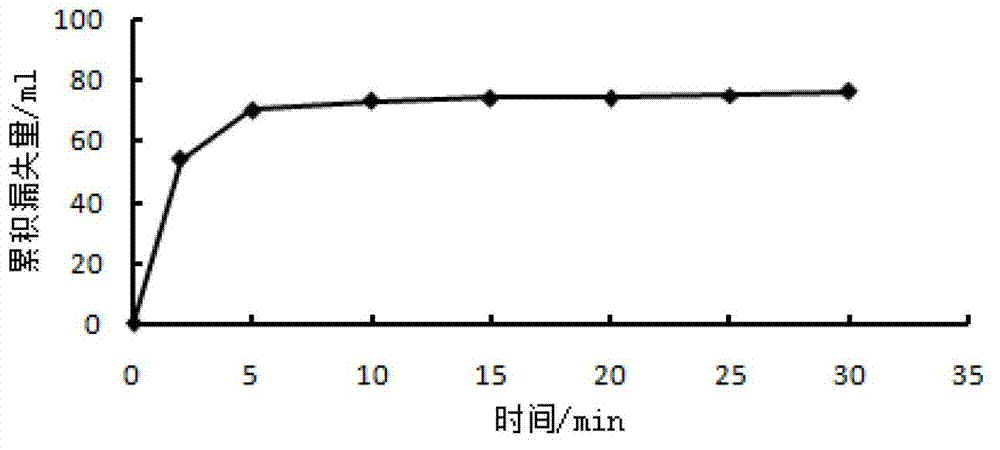

High-water-loss curing plugging agent for plugging fissures

The invention relates to a high-water-loss curing plugging agent for plugging fissures. The high-water-loss curing plugging agent comprises the following components in parts by weight: 50-70 parts of main materials, 7-15 parts of filter aid, 10-25 parts of curing agent, 5-10 parts of fiber materials and 5-10 parts of bridging materials. The curing plugging agent has the advantages of fast plugging, good effect, high acid solubility, easiness in unplugging, low cost and less environmental pollution.

Owner:CHINA NAT OFFSHORE OIL CORP +1

High titanium type petroleum oil pressing crack propping agent and production method thereof

InactiveCN1730422AReduce manufacturing costImprove low efficiencySolid waste managementClaywaresSurface finishingAluminium

The invention provides a high-titanium type petroleum fracturing propping agent, whose chemical constituents comprise (by weight ratio) 5-45% of high-titanium blast furnace slag, 10-30% of high-alumina brick, 17-77% of bauxite, and 4-8% of composite agglutinant, its preparation process comprises the following steps, (1) grinding the raw material, making mother balls with an atomizing granulation system, charging the mother balls into a sugar-coating machine, squeezing and dressing so as to obtain blank pellets, (2) drying the blank pellets through a drying system, loading into high temperature kiln for agglutination, (3) cooling down and carrying out surface polishing through high speed rotation in a friction tube, (4) elevating the temperature to 80-100 deg. C, carrying out surface treatment with acid-resisting organics, finally cold-setting.

Owner:攀枝花环业冶金渣开发有限责任公司

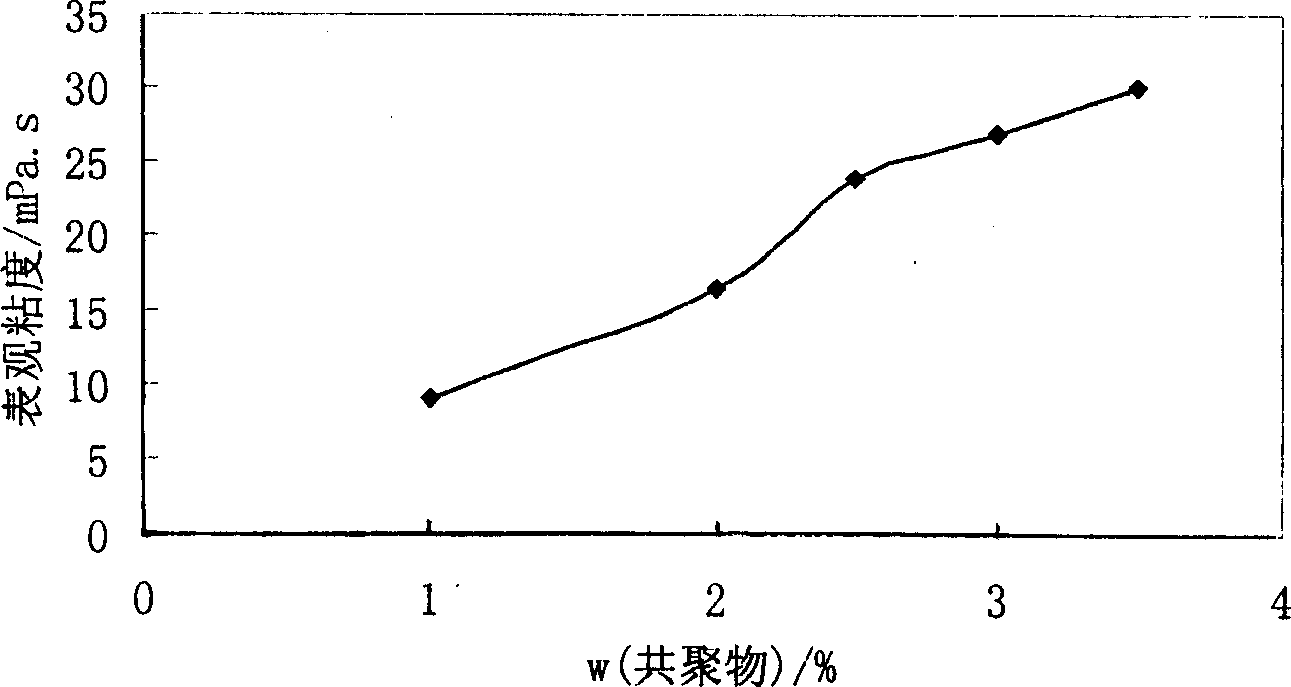

Water soluble amphoteric ion copolymer and preparation process thereof

A water-soluble zwitterionic copolymer contains two structure units: 2-methyl-2- acrylamido propanesulfonic acid and methyl acrylyloxyethyl trimethyl ammonium chloride. Its preparing process includes such steps as proportionally adding the anhydrate sorbitol monooleate and the anhydrated sorbitol monostearate to kerosene, proportionally dissolving two monomers in water and regulating its pH=7, proportionally mixing oil phase with water phase, filling N2, adding redox trigger, and redox reaction in constant-temp water bath.

Owner:SOUTHWEST PETROLEUM UNIV

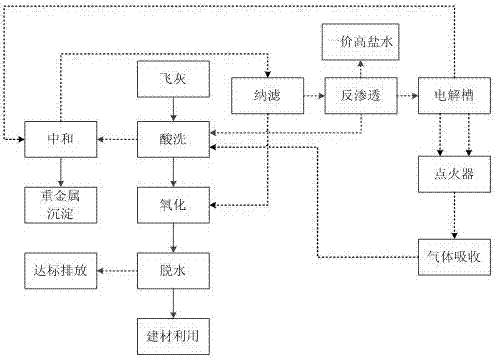

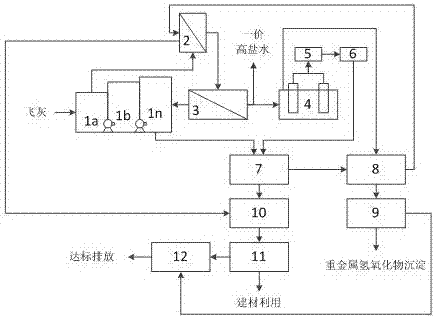

Low-energy incineration fly ash innocent treatment method and device

ActiveCN107138505AGuaranteed qualityLow costTransportation and packagingSolid waste disposalResource utilizationSaline solutions

The invention provides a low-energy incineration fly ash innocent treatment method. The low-energy incineration fly ash innocent treatment method and device are provided for solving the problems that an existing incineration fly ash treatment technology is high in cost, true removal of heavy metal cannot be achieved through stabilizing treatment, Dioxin heat treatment energy consumption is high, and treatment is not complete. Fly ash is subject to desalting, heavy metal removal and Dioxin removal in sequence, a one-valent saline solution with very high purity is obtained, and heavy metal sediment and building materials without contaminant can be subject to resource utilization.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

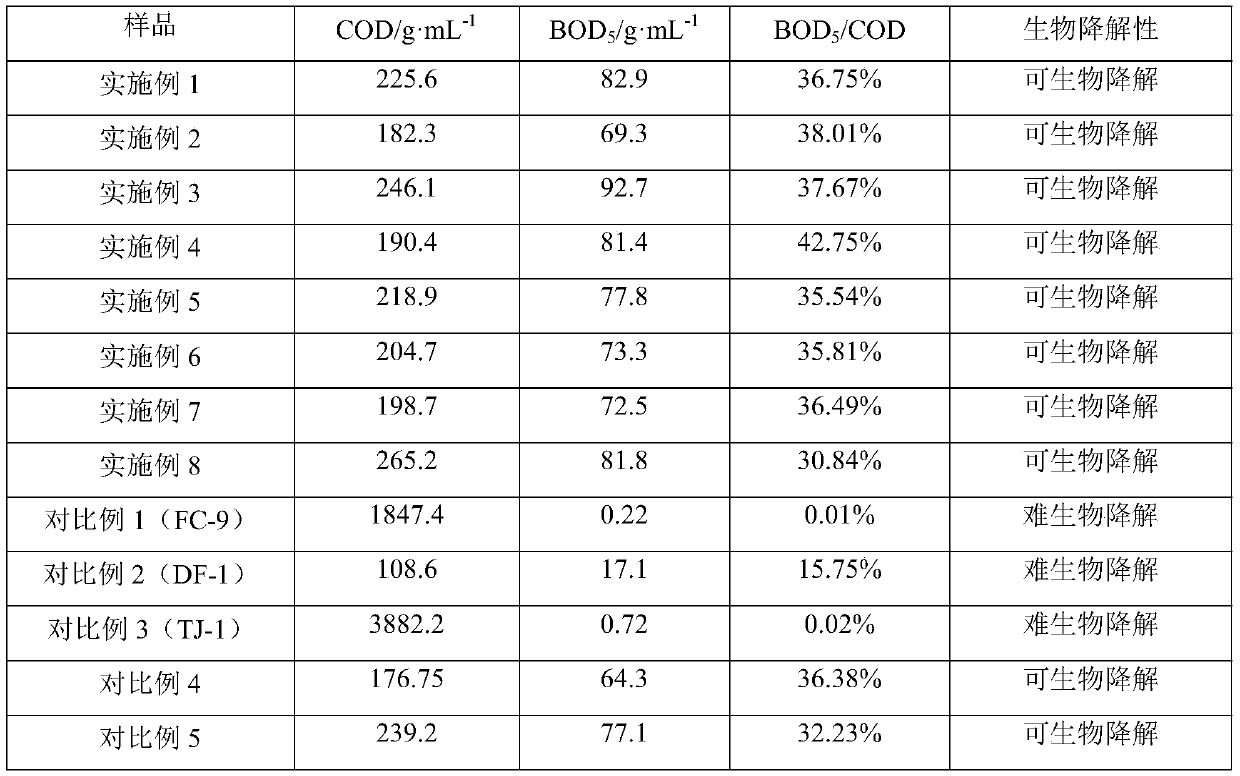

Temporary plugging agent for drilling fluid and water-based drilling fluid and application

ActiveCN109776728AGood acid solubilityGood rheological fluid lossDrilling compositionMeth-Filtration

The invention relates to the technical field of environment-friendly drilling fluid temporary plugging in a petroleum drilling process and discloses a temporary plugging agent for a drilling fluid anda water-based drilling fluid and an application. The temporary plugging agent is prepared by carrying out a polymerization reaction between gelatinized starch and a vinyl grafted monomer in an activator solution in the presence of a crosslinking agent and an initiator. The vinyl grafted monomer comprises acrylic acid, acrylamide and 2-acrylamide-2-methyl propanesulfonic acid and the gelatinized starch is prepared by carrying out a gelatinization reaction of starch added into deionized water. The temporary plugging agent provided by the invention can be biodegraded, the degradation rate of thetemporary plugging agent in soil for 90 days can reach 50% or higher, and the temporary plugging agent is environmentally friendly. The water-based drilling fluid with the temporary plugging agent has a good rheologic filtration property and can temporarily plug strata of different permeability self-adaptively, and the permeable temporary plugging reaches 100%. The temporary plugging agent is high in acid solubility, the permeability recover value can reach 85% or higher after the temporary plugging agent is acidized to unplug, and the reservoir protection ability is obvious.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

High dehydration solidification pressuring bearing plugging agent

ActiveCN104152125AIncrease flow resistanceReduce mud lossDrilling compositionAcid dissolutionFilter cake

The invention discloses a high dehydration solidification pressuring bearing plugging agent. The high dehydration solidification pressuring bearing plugging agent comprises, by mass, 45-65 of an inorganic mineral material, 10-20% of a fiber, 15-25% of a solidifying agent, 5-10% of an inorganic reinforcing agent and 0-8% of a filter aid. The adoption of the inorganic acid-soluble mineral and the fiber guarantees that all components are acid-soluble substances, and has no influences on the acid dissolution rate of the pressure bearing plugging agent and the strength of a filter cake; and the inorganic mineral fiber has strong tensile strength and toughness, so a leak layer can be effectively plugged by the high dehydration solidification pressuring bearing plugging agent without adding a bridging material, and the pressure bearing capability of stratums is improved.

Owner:ASTAR PETROTECH

Method for extracting titanium from vanadium-titanium magnetite

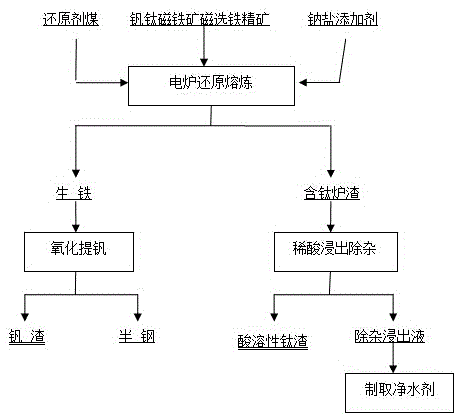

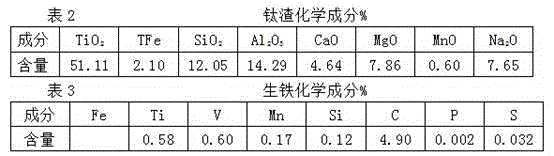

InactiveCN105112689AEfficient and reasonable useSolve the technical problems of efficient separation and extractionProcess efficiency improvementElectric furnaceAluminateSmelting process

The invention discloses a method for extracting titanium from vanadium-titanium magnetite. The method comprises the following steps: adding sodium or potassium salt additive in the reduction smelting of an iron ore concentrate electric stove to obtain liquid iron and titanium-containing slag, wherein vanadium and iron are reduced to enter liquid iron, under a smelting high temperature condition, silicon and aluminum impurities form sodium aluminosilicate capable of being dissolved in dilute acid with the sodium or potassium salt additive, and enabling the sodium aluminosilicate and titanium and aluminum magnesium impurities to remain in the titanium-containing slag; purifying the titanium-containing slag by virtue of a wet-method metallurgical impurity removal method, to acquire a titanium slag product with TiO2 content more than 75 percent. For the application problem of titanium in the iron ore concentrate, the slag modification additive is added in the reduction smelting process, so that not only is the mobility of the slag improved, but also a condition is created for removing the later silicon-aluminum impurities of the slag, the high-efficiency separation and extraction problem of the titanium in the iron ore concentrate can be well solved, the resource utilization rate of the iron, titanium and vanadium is greatly increased, and the utilization rate of the titanium is increased about 3 times compared with the flow of a blast furnace.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

A diatom ooze decoration material and a preparing method thereof

InactiveCN107201065AImprove adhesionImprove insulation performanceFireproof paintsAntifouling/underwater paintsWear resistantAdhesive

A diatom ooze decoration material is disclosed. Raw materials of the decoration material include, by weight, 30-50 parts of diatomite, 7-13 parts of bentonite, 10-20 parts of calcined kaolin, 3-8 parts of modified nanometer bamboo charcoal powder, 6-14 parts of mica powder, 5-10 parts of titanium dioxide, 1-2 parts of hydroxypropyl methyl cellulose, 3-5 parts of anti-cracking fibers, 4-9 parts of graphene oxide, 2-3 parts of a tourmaline powder anion additive, 7-11 parts of a modifier, 1.5-2.5 parts of a dispersant, 6-13 parts of an inorganic adhesive, and 0.5-1.5 parts of a catalyst-grade nanometer zinc oxide. The decoration material has characteristics of zero VOC, and capability of being temperature-resistant, fireproof and wear-resistant, has a plurality of functions, such as a breathing function and a function of adsorbing formaldehyde, toluene and other organic matters, has stable performance and long effective service lifetime.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Multifunctional cleaning agent for oil fields, preparation method therefor and applications thereof

ActiveCN104152127AGood acid solubilityReduce corrosionDrilling compositionActive agentCleansing Agents

The invention relates to a multifunctional cleaning agent for oil fields, a preparation method therefor and applications thereof. The cleaning agent is composed of 0.2%-1.0% of composite nonylphenol polyoxyethylene ether active agents, 0.2%-1.0% of composite quaternary ammonium salt positive ion active agent chlorides, 0%-1.0% of composite acid pickling corrosion inhibitors, 0%-1.0% of composite Fe ion chelating agents, 0%-10.0% of organic carboxylic ester, and the balance being water. The cleaning agent has good acidolysis solution removing effects on inorganic chemistry scales of CaCO3, Fe2O3 and FeS at the temperature of 60-80 DEG C, has dispersion and melting effects on oil stains, wax scales and heavy oil stains, has a killing effects on oil field fungi, has a peeling effect on sticky dirt, and is suitable for cleaning of devices of oil field production well shafts, gathering pipelines, oil and water separation settling tanks, flocculation settling tanks, oil storage tanks, sewage storage tanks and the like.

Owner:PETROCHINA CO LTD

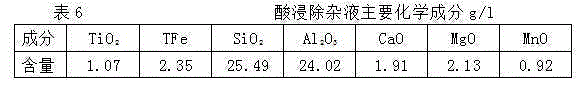

Method and system for preparing cerium hydroxide

ActiveCN103910373AHigh purityLow non-rare earth impuritiesRare earth metal compoundsCerium nitrateRare earth

The invention discloses a method for preparing cerium hydroxide. The method is characterized by comprising the following steps: dissolving cerous carbonate of which the purity is greater than 99.99% as a raw material by using nitric acid to obtain cerium nitrate feed liquid; carrying out hydrolysis to remove impurities in the dissolving process, and filtering for at least two times; filtering the obtained filtrate by using a precision filter, and transferring into a storage container to stand for a plurality of days, wherein the content of general non-rare earth impurities of the obtained cerium nitrate feed liquid is smaller than 5ppm; transforming the purified feed liquid into cerium hydroxide by taking ammonium hydroxide as a transforming agent and hydrogen peroxide as an oxidant; soaking and washing by strong alkalinity liquid to remove nitrate; filtering prepared cerium hydroxide; washing a filter cake by overheated secondary water, and pumping; putting the filtered material into an oven, and baking at 90-95 DEG C for a plurality of times, so as to obtain a cerium hydroxide product with over-high purity and ultra-high gross. According to the cerium hydroxide product prepared by the method, the nitrate content is smaller than 500ppm; the rate-earth purity is greater than 99.99%; the content of general non-rare earth impurities is smaller than 10ppm; the Cl<-> content is smaller than 10ppm; the SO4<2-> content is smaller than 10ppm; the oxidation rate is 98-99.9%; the oxide gross is greater than 90%.

Owner:江西金世纪新材料股份有限公司

Environmentally-friendly strong sealing oil-based drilling fluid

The invention provides an environmentally-friendly strong sealing oil-based drilling fluid. The environmentally-friendly strong sealing oil-based drilling fluid is based on a base liquid, and comprises 10-20wt% of an aqueous solution of calcium chloride, 1-2wt% of a main emulsifier, 1-2wt% of an auxiliary emulsifier, 2-3wt% of a wetting agent, 3-5wt% of organic soil, 2-3wt% of calcium oxide, 2-4wt% of a sealing agent, 2-4wt% of a filtrate reducer, and 0-150wt% of a weighting material. The drilling fluid can effectively seal shale formation, improves the stability of a borehole wall, and reduces the pollution to environment; and the novel weighting material used in the invention has small influences on the rheological performance of the oil-based drilling fluid and reduces damages to reservoirs.

Owner:CHINA PETROCHEMICAL CORP +1

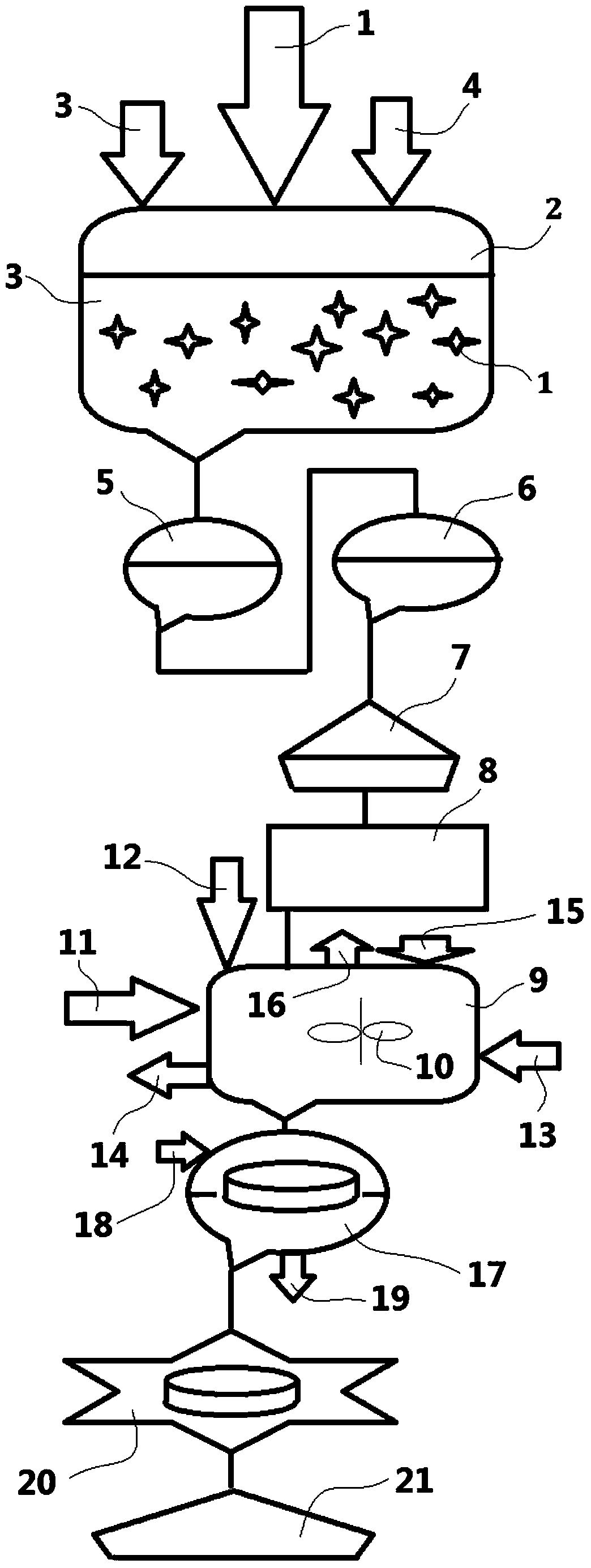

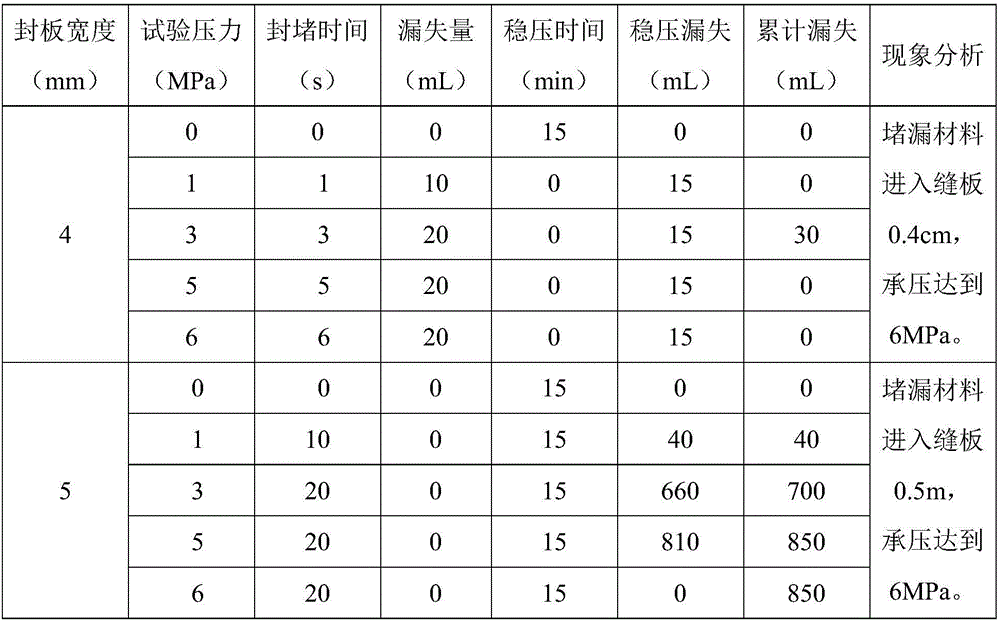

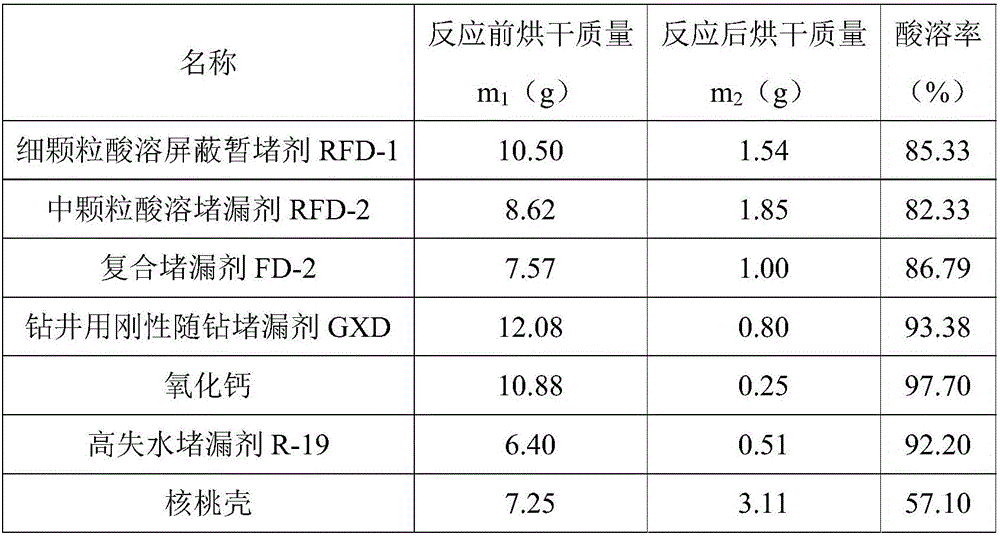

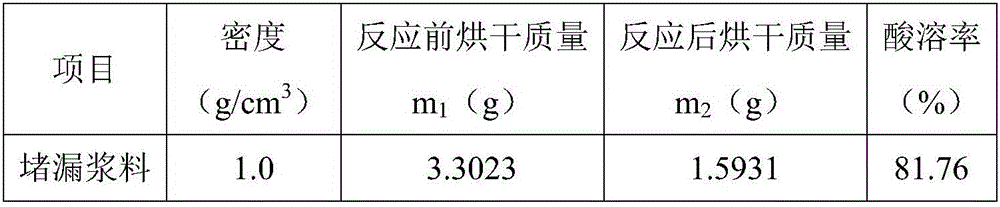

Plugging material and plugging slurry for protecting reservoir stratum with low fracturing fracture ability

The invention discloses a plugging material and plugging slurry for protecting a reservoir stratum with the low fracturing fracture ability. The plugging material is prepared from, by weight, 5-6 parts of walnut shell powder, 2-3 parts of a composite plugging agent, 1.5-2 parts of an agent for plugging while drilling, 4-5 parts of an acid soluble plugging agent, 4-5 parts of a high-dehydration-rate plugging agent and 0.2-0.3 part of calcium oxide. The natural plant inertia material, the fiber plugging agent and the acid soluble plugging agent are mixed according to the certain matching ratio to form the acid soluble plugging material in granule and fiber shapes. The material has the advantages that the bridging effect of a bridging material is good and the plugging success rate is high, and also has the advantages that the density is low, stratum pressure is effectively balanced, the stratum damage is small, the plugging property is strong and acid solubility is achieved. The plugging slurry prepared from the plugging material and water has the advantages of being low in density, high in pressure bearing capability, good in malignant leakage plugging effect, high in acid solubility and the like; the on-site preparation process is simple, construction is safe and reliable, and the purposes of reducing well leakage loss and protecting the reservoir stratum can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

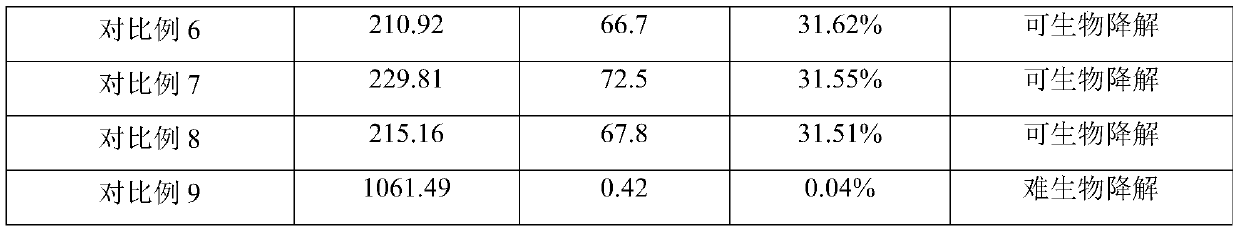

High-temperature-resistant polymer for acidizing fracturing and preparation method of polymer

ActiveCN107793529AGood water solubilityGood acid solubilityDrilling compositionSolubilityPolymer science

The invention discloses a high-temperature-resistant polymer for acidizing fracturing and a preparation method of the polymer. The polymer is prepared by polymerizing raw materials comprising the following components: acrylamide, methacrylamide, a cationic monomer, a temperature-resistant salt-resistant monomer, a molecular weight regulator, an initiator and water; wherein the total mass of all components except water is taken as 100%, the mass percent of the components are as follows: 20%-65% of the acrylamide, 5%-15% of the methacrylamide, 5-18% of the cationic monomer, 15%-55% of the temperature-resistant and salt-resistant monomer, 0.01%-0.5% of the molecular weight regulator, and 0.1-0.5% of the initiator, and the total mass concentration of all components except water is 20-35%. Thepolymer disclosed by the invention has good water solubility, acid solubility, instant dissolution, temperature resistance, shearing resistance and excellent thickening effect, and can be applied to the fields of acidizing fracturing construction, reinforced oil production operation and the like in oil exploitation at a temperature of 160 DEG C or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pressure-bearing lost circulation additive for drilling fluid and for stably bearing pressure on smooth fracture leakage wall surface

InactiveCN102876303AIncrease bearing pressureIncrease internal frictionDrilling compositionBridge materialFilling materials

The invention relates to a pressure-bearing lost circulation additive for a drilling fluid and for stably bearing pressure on a smooth fracture leakage wall surface. The lost circulation additive is composed of 10%-20% of damping material, 45%-50% of bridging material and 35%-40% of filling material by weight, wherein the damping material is an industrial metal screen, having the size of the damping material is 1.0*1.0mm to 3.0*3.0 mm and the thickness of the damping material is about 0.5 mm; the bridging material is calcium carbonate particles, and the standard mesh number of the screening mesh product of the bridging material is lower than 20 meshes; the filling material is a mixture composed of calcium carbonate powder and flexible graphite powder; the calcium carbonate powder is further divided into three grades to realize multi-grade filling and to form a compact shielding layer; and the mesh number of the flexible graphite is greater than 150, and the anti-pressure ability of a bridge plug section is improved. With the pressure-bearing lost circulation additive for the drilling fluid and for stably bearing pressure on the smooth fracture leakage wall surface disclosed by the invention, leak stoppage success rate and bearing pressure for smooth fracture leakage can be improved, leakage stoppage failure due to complexity is reduced, the benefits of exploring and developing a bored well are improved; and the preparation process of the lost circulation additive is simple and convenient, the source of the materials of the lost circulation additive is broad, and the lost circulation additive is easy to spread and apply.

Owner:SOUTHWEST PETROLEUM UNIV

Acid soluble mineral fiber fine bridging agent, bridging fluid and preparation method thereof

The invention relates to the technical field of auxiliaries for oil-gas exploration drilling in oil fields, in particular to an acid soluble mineral fiber fine bridging agent, a bridging fluid and a preparation method thereof.In raw materials of the acid soluble mineral fiber fine bridging agent, the particle size of limestone is 0.045mm-2.5mm, the particle size of mica is 1.4mm-2.5mm, and the particle size of vermiculite is 0.3mm-2.0mm. After the acid soluble mineral fiber fine bridging agent is added into plugging slurry under conditions of deep wells, ultradeep wells, high temperature, high density and high pressure, normal fluidity of drilling fluid can be kept; due to high acid solubility, when strong acid is injected for oil-gas exploitation after leakage stoppage, the acid soluble mineral fiber fine bridging agent is dissolved, so that pollution-free smooth oil-gas exploitation is guaranteed; the bridging fluid obtained by adoption of the acid soluble mineral fiber fine bridging agent is applicable to various leakage layers and excellent in leakage stopping effect.

Owner:XINJIANG LUMING TECH CO LTD

Method for preparing primary titanium-rich material from high calcium-magnesium-titanium headings

The invention relates to a technique refining junior titanium-rich material with high calcium magnesium titanium fine ore. Crash titanium ore of purity 45.00 to 50.00 percent till particles of which the size is smaller than 0.074mm taking 60 to 80 percent weight, then add in with water 8 to 20 percent weight of the ore, adherent sodium silicate 3 to 5 percent, chark 10 to 20 percent, 1 to 5 percent addition sodium sulfate, 1 to 3 percent addition iron powder, 3 to 5 percent addition potassium chloride, making complex balls sized 10 to 15 mm, and acquire junior titanium-rich material after microwave drying, microwave heating and restoring, ore selecting and separating. As the titanium ore is highly wave absorptive, the heating speed is high, and the restore temperature is lowered by 80-120 deg.C, extraneous material calcium and magnesium are of good acid dissolvability which ensures the high purity of the junior titanium-rich material.

Owner:KUNMING UNIV OF SCI & TECH

High-temperature acidizing corrosion inhibitor for oil-gas fields and preparation method thereof

ActiveCN103865506AGood acid solubilityGood corrosion inhibitionOrganic chemistryScale removal and water softeningReaction temperatureFORMALDEHYDE SOLUTION

The invention relates to a method for preparing a high-temperature acidizing corrosion inhibitor for oil-gas fields. The method comprises the following steps: firstly a certain amount of alkynol, a formaldehyde solution and imidazoline are added into a reaction kettle with a mixer and a condensing device, and simultaneously the pH value is adjusted using hydrochloric acid; the condensing device is turned on, heating and mixing are started, a mannich base is obtained based on reflux reaction, and excessive formaldehyde and hydrogen chloride are removed by vacuum distillation; then a quaternization reagent is dripped into the mannich base, and the mixture is heated and maintained the temperature for continuous reaction to obtain mannich quaternary ammonium salt, wherein the mole ratio of alkynol, formaldyhyde and imidazoline is 1:1.0-1.5:1, the pH value of the reaction system is smaller than or equal to 2, the reaction temperature is 80-120 DEG C, and the reaction time is 3-10 hours; the quaternization reagent is chlorohydrocarbon, the dripping speed is 300-1000 kg / h per ton of production capacity, the reaction temperature of quatermization is 90-120 DEG C, and the reaction time is 3-7 hours.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

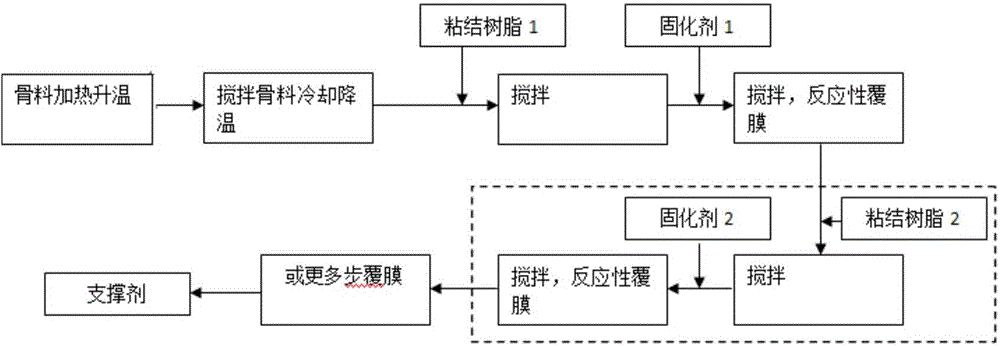

Proppant and preparation method thereof

The invention discloses a proppant and a preparation method thereof, and belongs to the technical field of oil and gas exploitation. The proppant comprises an aggregate and at least two layers of resin coated films coated on the aggregate, wherein the weight ratio of the aggregate to the resin coated film is 100:3-100:13; and the aggregate is quartz sand, ceramsite, glass microspheres, sintered bauxite, sintered aluminum oxide, sintered zirconium oxide or a mixture thereof, and the size of the aggregate is 10-200 meshes, preferably 20-70 meshes. By virtue of a multilayer film coating technology, the sphericity of the proppant can be improved, the density of the proppant can be reduced, and the chemical inertness and strength can be improved. The proppant disclosed by the invention can be widely applied to oil and gas field exploitation, is beneficial to improvement of the sand ratio, reduces the usage of fracturing fluid, eases the embedding of the proppant, improves the water resistance of the proppant, improves the fracture conductivity, and prolongs the effective fracturing period.

Owner:BEIJING RECHSAND SCI & TECH GRP

Method for preparing oil-free rare earth carbonate

ActiveCN101880053AEasy to achieve large-scale productionGood acid solubilityRare earth metal compoundsProcess efficiency improvementNitrateSulfate

The invention discloses a scale preparation method for producing oil-free rare earth carbonate. The method is characterized by comprising the following steps of: (1) performing oil removal treatment on single or mixed rare earth chloride liquid, rare earth nitrate liquid, rare earth sulfate liquid and precipitating agent; (2) preparing single rare earth carbonate or mixed rare earth carbonate solid from sediment; and (3) bleaching, centrifuging and dehydrating the solid. The prepared oil-free single rare earth carbonate or oil-free mixed rare earth carbonate has powdery solid appearance and good acid dissolubility, the solution is clear, and the insoluble substances are less than or equal to 0.2 percent. The method has the advantages of strong adaptability, low equipment investment, convenient operation, low cost, more than 97 percent of yield and stable product quality, is easy to realize scale production of the oil-free rare earth carbonate, and solves the problem of poor acid dissolubility (the oil is much and the insoluble substances are more than 0.5 percent) of the common rare earth carbonate at the same time.

Owner:YIYANG HONGYUAN RARE EARTH

Acidification corrosion inhibitor based on interpolymer indolizine derivative as well as preparation method and application thereof

InactiveCN108440527AEfficient corrosion inhibitionGood corrosion inhibitionOrganic chemistryDrilling compositionAcetic acidQuaternary ammonium cation

The invention discloses an acidification corrosion inhibitor based on an interpolymer indolizine derivative as well as a preparation method and application thereof. The acidification corrosion inhibitor contains the interpolymer indolizine derivative; the interpolymer indolizine derivative is prepared by carrying out decarboxylation on heterocyclic alkali including (substituted) quinoline, (substituted) pyridine and the like, and carboxymethyl heterocyclic alkali quaternary ammonium salt obtained by alpha-haloacetic acid, and then carrying out intermolecular addition polymerization reaction onquaternary ammonium salt of the heterocyclic alkali including the (substituted) quinoline, the (substituted) pyridine and the like. The acidification corrosion inhibitor disclosed by the invention has relatively good corrosion inhibition performance under the condition that common corrosion inhibition synergists including alkynol and the like do not need to be compounded; the use amount of the acidification corrosion inhibitor is less and the acidification corrosion inhibitor can reach, even be better than the requirements of an acidification corrosion inhibitor performance testing method andfirst-grade to third-grade standards in evaluation indexes SY / T 5405-1996 when being independently used.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Curable leak-stopping agent

ActiveCN102191024BCuring time controllableImprove performanceDrilling compositionPhysical chemistryCotton fibre

The invention relates to a curable leak-stopping agent. The curable leak-stopping agent comprises the following components which are mixed by weight percentage: 30 to 50 percent of curable material blast furnace, 5 to 15 percent of high filtration material diatomite or fly ash, 15 to 25 percent of fibrous material asbestos fiber, cotton fiber or cob, 2 to 5 percent of soft elasticity expansion material elastic tyre rubber and 20 to 30 percent of acid-soluble material calcium carbonate. The leak-stopping agent provided in the invention can be used independently. The curing time is controllable; the leak-stopping efficiency is high and the leak-stopping agent does not discriminate leakage layer apertures or crack dimensions. The leak-stopping agent is an efficient and curable leak-stopping agent which can be used to stop crack leakage and cave nonreservoir and reservoir leakage.

Owner:DAQING PETROLEUM ADMINISTRATION +1

High-temperature microemulsion cleanup additive used for fracturing, and preparation method thereof

ActiveCN106244131AImprove surface activityHigh discharge rateDrilling compositionMass ratioFracturing fluid

The invention provides a high-temperature microemulsion cleanup additive used for fracturing, and a preparation method thereof. The preparation method comprises the following steps: 1, adding 10-20 parts by mass of water into a reactor, adding 40-60 parts by mass of a cosurfactant to water, and stirring the cosurfactant and water at room temperature until the cosurfactant is completely dissolved; and 2, sequentially adding 20-40 parts by mass of a gemini surfactant and 3-4 parts by mass of a nonionic surfactant into the reactor, supplementing water to the reactor until the mass part number of a mixture obtained in the reactor is 100, and uniformly stirring the mixture at room temperature to obtain the high-temperature microemulsion cleanup additive. The high-temperature microemulsion cleanup additive is directly added to a fracturing fluid or an acidifying liquid according to a mass ratio of 0.1-0.3:100 when used.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of oil-free rare earth carbonate

InactiveCN107879370ASolve the problem of non-recyclable and non-recyclable extractantLow costRare earth metal carbonatesRare earthCarbonate

The invention discloses a preparation method of oil-free rare earth carbonate, which includes steps of: deoiling a rare earth material liquid, obtained via extraction and separation, and a precipitator; mixing the oil-free rare earth material liquid and the precipitator solution and performing precipitation; and washing and filtering solid rare earth carbonate to obtain the oil-free rare earth carbonate. The method solves the problem that the deoiling material cannot be used repeatedly and the extraction agent cannot be recycled.

Owner:BAOTOU RES INST OF RARE EARTHS +1

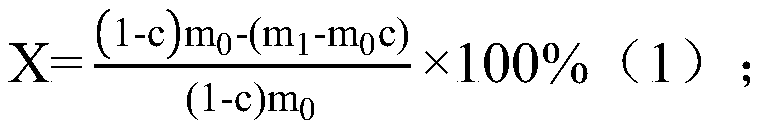

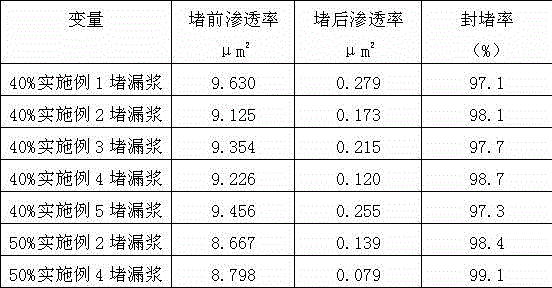

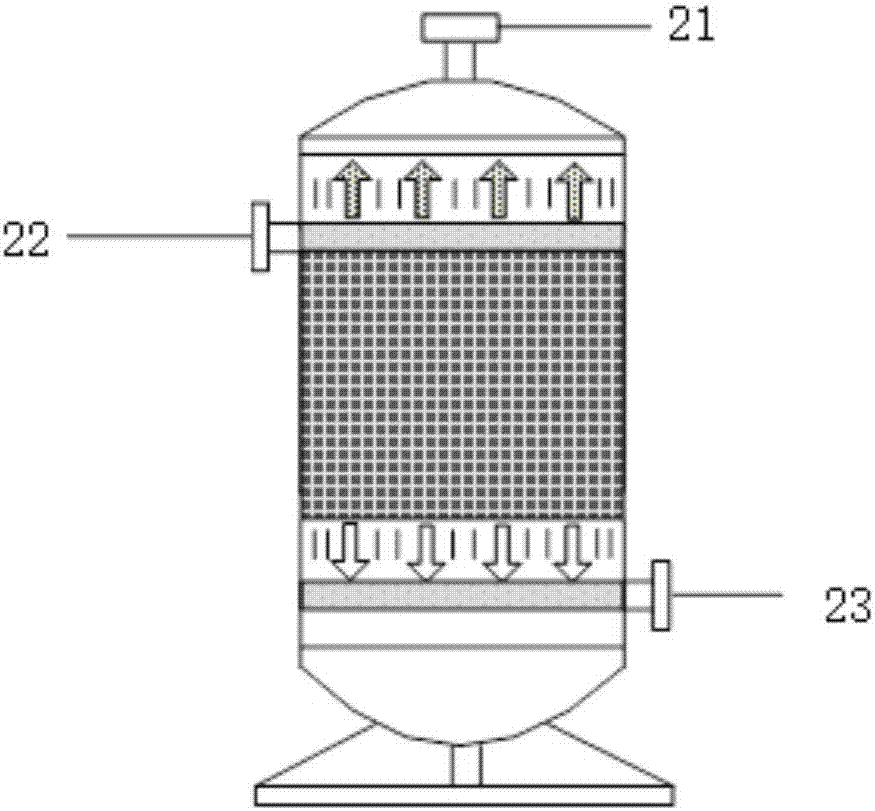

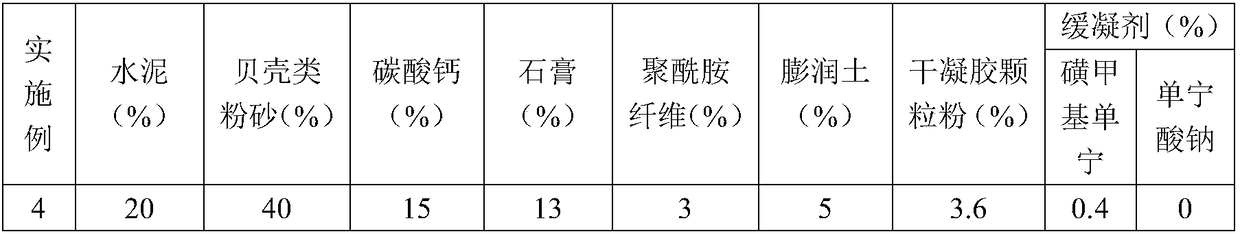

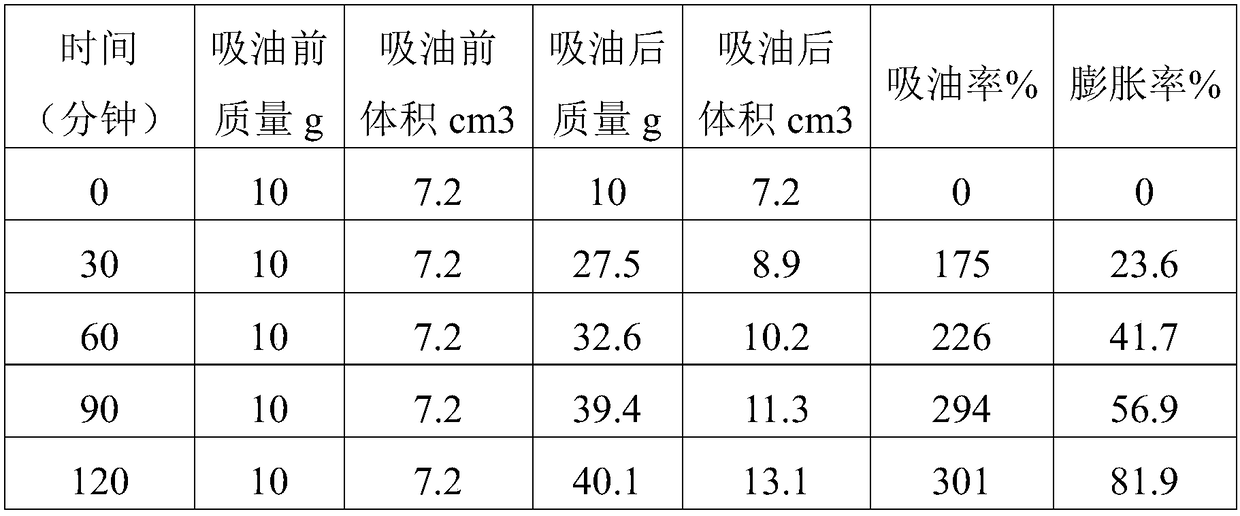

Acid-soluble plugging agent, acid-soluble plugging fluid and preparation method therefor

PendingCN109423262AHigh compressive strengthGood acid solubilityDrilling compositionSealing/packingSodium BentoniteAdditive ingredient

The invention relates to an acid-soluble plugging agent, acid-soluble plugging fluid and a preparation method therefor and belongs to the technical field of oilfield chemistry. The acid-soluble plugging agent disclosed by the invention is prepared from the following ingredients in parts by weight: 20-30 parts of cement, 20-40 parts of shell silt, 14-25 parts of calcium carbonate, 10-15 parts of gypsum, 3-6 parts of polyamide fibers, 5-10 parts of bentonite, 0.3-0.6 part of setting retarder and 3-10 parts of xerogel particles. According to the acid-soluble plugging agent and the acid-soluble plugging fluid, disclosed by the invention, a variety of ingredients are compounded, the defects in the prior art that the pressure resisting level is relatively low, the plugging radius is small, the effective period of plugging is short, and the like are overcome, the pressure resistance reaches 25MPa or more, the plugging radius reaches 2.0 meters or more, and the acid-soluble rate reaches 70% ormore during unplugging.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of acid soluble soy protein

InactiveCN103202384AGood acid solubilityImprove solubilityProtein foodstuffs working-upSolubilityPhytase

The invention discloses a preparation method of acid soluble soy protein. The acid soluble soy protein is prepared by the steps of carrying out alkali dissolution to low temperature defatted soybean meal to obtain a soy protein solution, adding phytase, stirring, ultra-filtering, sterilizing and drying to obtain the acid soluble soy protein. The method is simple in steps and high in yield; and the acid soluble soy protein prepared by the method is remarkably high in acid solubility, transparency and mouthfeel.

Owner:EAST CHINA NORMAL UNIV +1

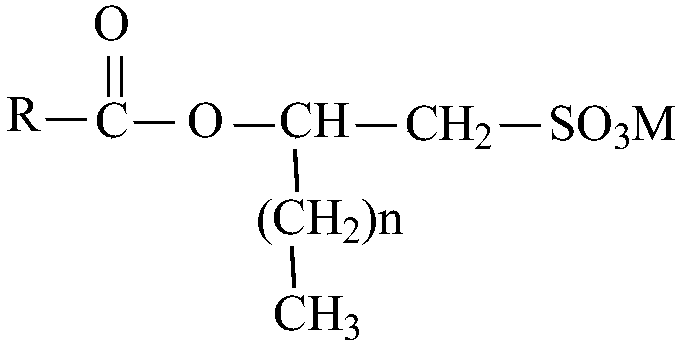

Acidizing corrosion inhibitor and preparation method thereof

InactiveCN103992782AGood corrosion inhibitionWide variety of sourcesOrganic chemistryDrilling compositionSolubilityQuinoline

The invention discloses an acidizing corrosion inhibitor and a preparation method thereof. The structural general formula of the acidizing corrosion inhibitor is as shown in formula (I), and the preparation method comprises the steps of (1) uniformly mixing an initiator, a catalyst and halogenated epoxypropane, and carrying out ring opening polymerization reaction at 20-40 DEG C; and (2) adding quinoline into the reaction product of step (1) and mixing uniformly, condensing and back flowing for 8-10 hours at 120-180 DEG C, and carrying out quaterisation reaction so as to prepare the acidizing corrosion inhibitor, wherein the mass ratio of the initiator to the catalyst to the halogenated epoxypropane to the quinoline is (2-4):(1-2):(50-100):(10-30). The corrosion inhibitor has the characteristics of good water solubility, less use level, good corrosion inhibition and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

High-density oil-based drilling fluid plugging liquid and preparation method and application thereof

The invention discloses a high-density oil-based drilling fluid plugging liquid which comprises, by weight percentage, 3-6% of aluminum alloy particles GYD, 5-6% of non-permeating treatment agent BYD,3-9% of high acid soluble calcium particles KGD, and the balance drilling fluid. The high-density oil-based drilling fluid plugging liquid has good dispersion in high-density oil-based mud, does notsettle, does not float and has high temperature resistance, high compressive strength and high overall acid solubility, the overall concentration of the plugging liquid is not high, and the plugging liquid is favorable for acidification transformation of a later oil layer after entering the formation.

Owner:KMS OIL FIELD CHEM & TECHNICAL SERVICES LTD BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com