Water soluble amphoteric ion copolymer and preparation process thereof

A technology of amphoteric ions and copolymers, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of less binary copolymerization, and achieve good water solubility and good viscosity-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0026] Example 1 Synthesis of AMPS / DMC zwitterionic polymer

[0027] Formula-1: (1). Oil phase: Dissolve emulsifiers Span80 and Tween60 in kerosene at a mass ratio of 5:1, emulsifiers account for 6% of kerosene by mass; (2). Water phase: mix 2- Methyl-2-acrylamidopropanesulfonic acid (AMPS) and methacryloxyethyl trimethylammonium chloride (DMC) are weighed at a mass ratio of 6.7:1, dissolved in distilled water to prepare a monomer aqueous solution , Adjust its pH to 7, and the total mass fraction of monomers to 55%; (3) Mix and stir the oil phase and the water phase at 1:2.3 to make a white emulsion, transfer the emulsion to a 250mL three-necked flask, Nitrogen, adjust the temperature of the water bath to 45℃, add 0.6% of the total monomer mass (NH 4 ) 2 S 2 O 8 -Na 2 SO 3 The oxidation-reduction initiator is placed in a constant temperature water bath and stirred for 6 hours to form a slightly pink viscous emulsion, which is a polymerization product; the specific dosage of formul...

Embodiment 2A

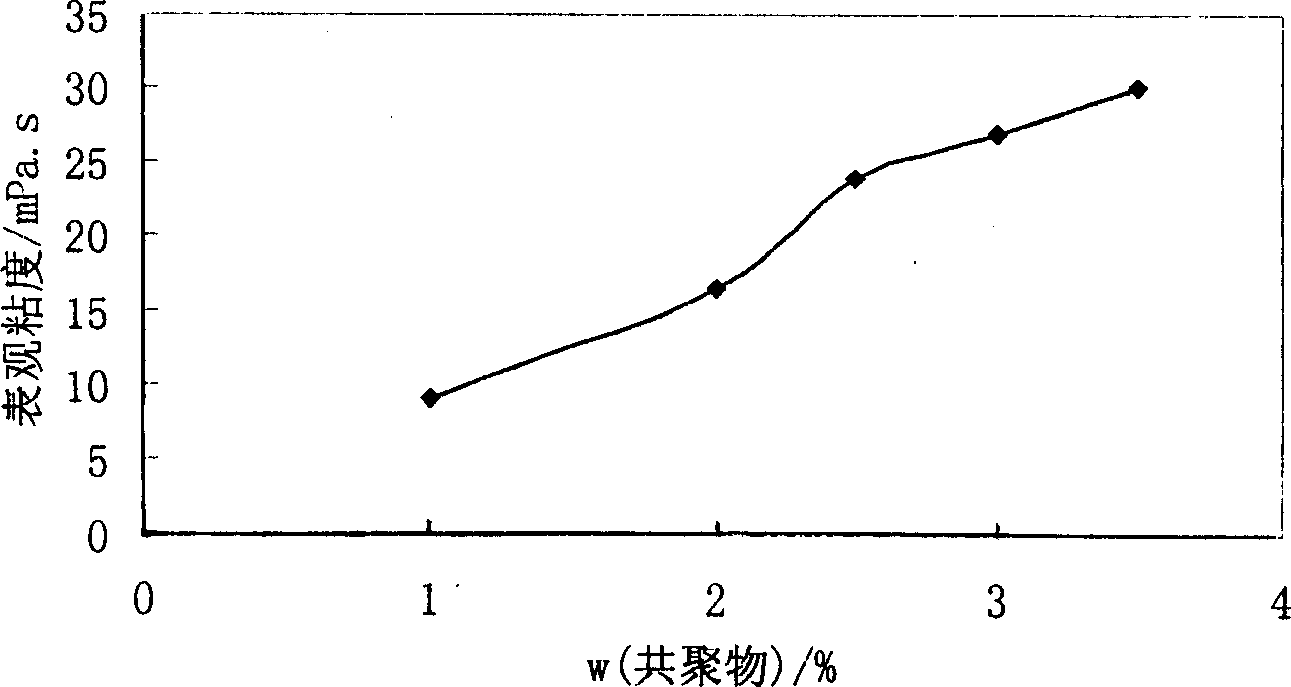

[0031] Example 2 AMPS / DMC zwitterionic polymer acid solution viscosity increase

[0032] see figure 1 The acid solution is 20% HCl. With the increase in the amount of the experimental formula-1 copolymer, the viscosity of the polymer in the acid solution increases, indicating that the copolymer has good viscosity increasing properties as a thickening agent in the acid solution.

Embodiment 3A

[0033] Example 3 Thermal stability of AMPS / DMC zwitterionic polymer in acid solution

[0034] Add 3% mass fraction of experimental formula-1 copolymer to 20% HCl to prepare 3% thickened acid, see figure 2 The apparent viscosity of the thickened acid solution decreases slowly from 30°C to 90°C, indicating that AMPS / DMC zwitterionic copolymer as a thickening agent has good thermal stability in the acid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com