Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4280 results about "Cooling down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooling down (also known as limbering down or warming down) is an easy exercise, done after a more intense activity, to allow the body to gradually transition to a resting or near-resting state. Depending on the intensity of the exercise, cooling down can involve a slow jog or walk. With lower intensities stretching can be used. Cooling down allows the heart rate to return to its resting rate. Anecdotally cooling down may reduce dizziness for professional or serious athletes and vocal performers after strenuous workouts. Studies are currently inconclusive as to whether the process actually reduces delayed-onset muscle soreness and muscle soreness not caused by lactate production during intense exercise. Some have shown a weak correlation: however, the majority of recent studies discount the relationship. One study has shown that athletes who perform an appropriate cool-down are less likely to become injured.

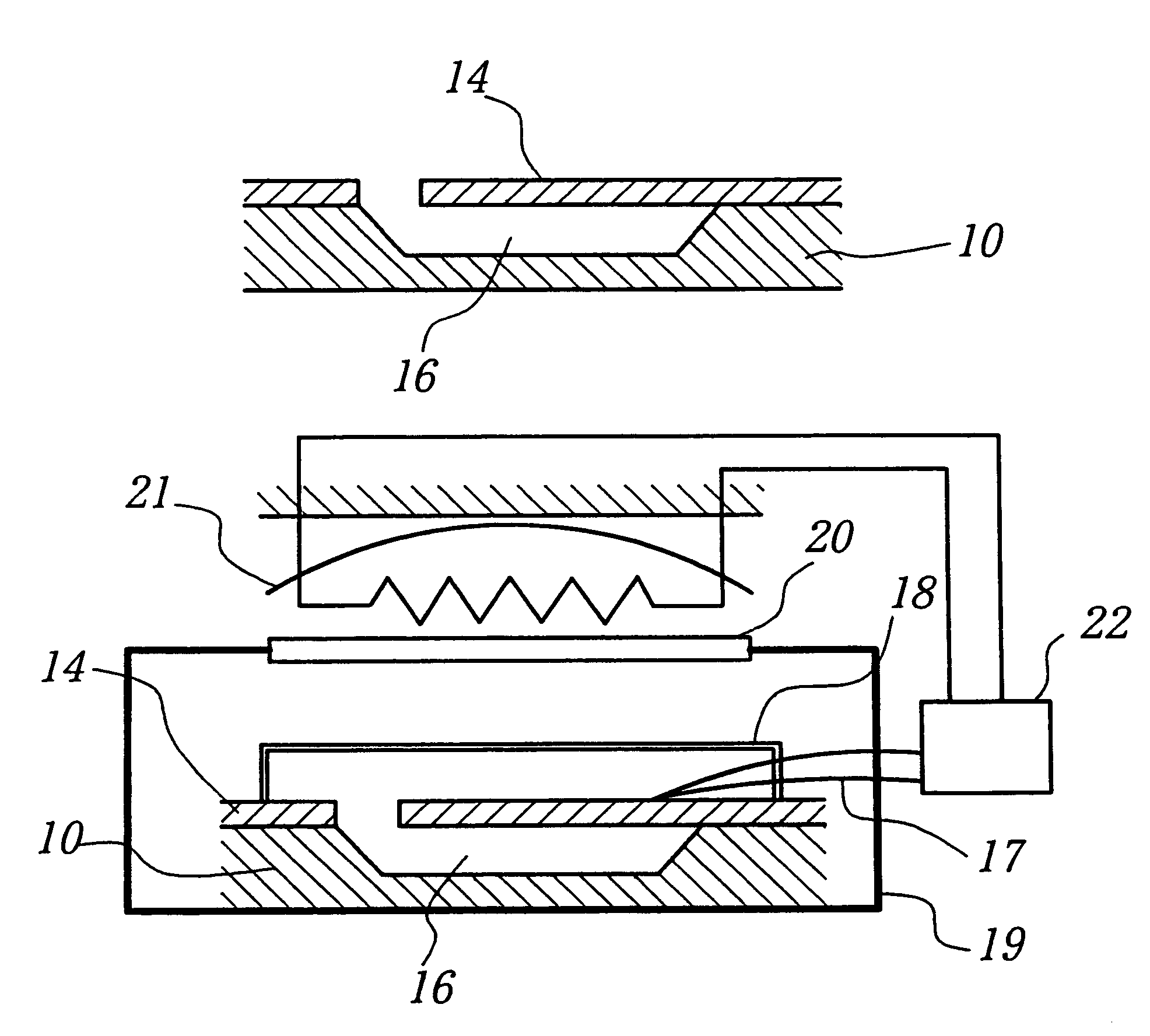

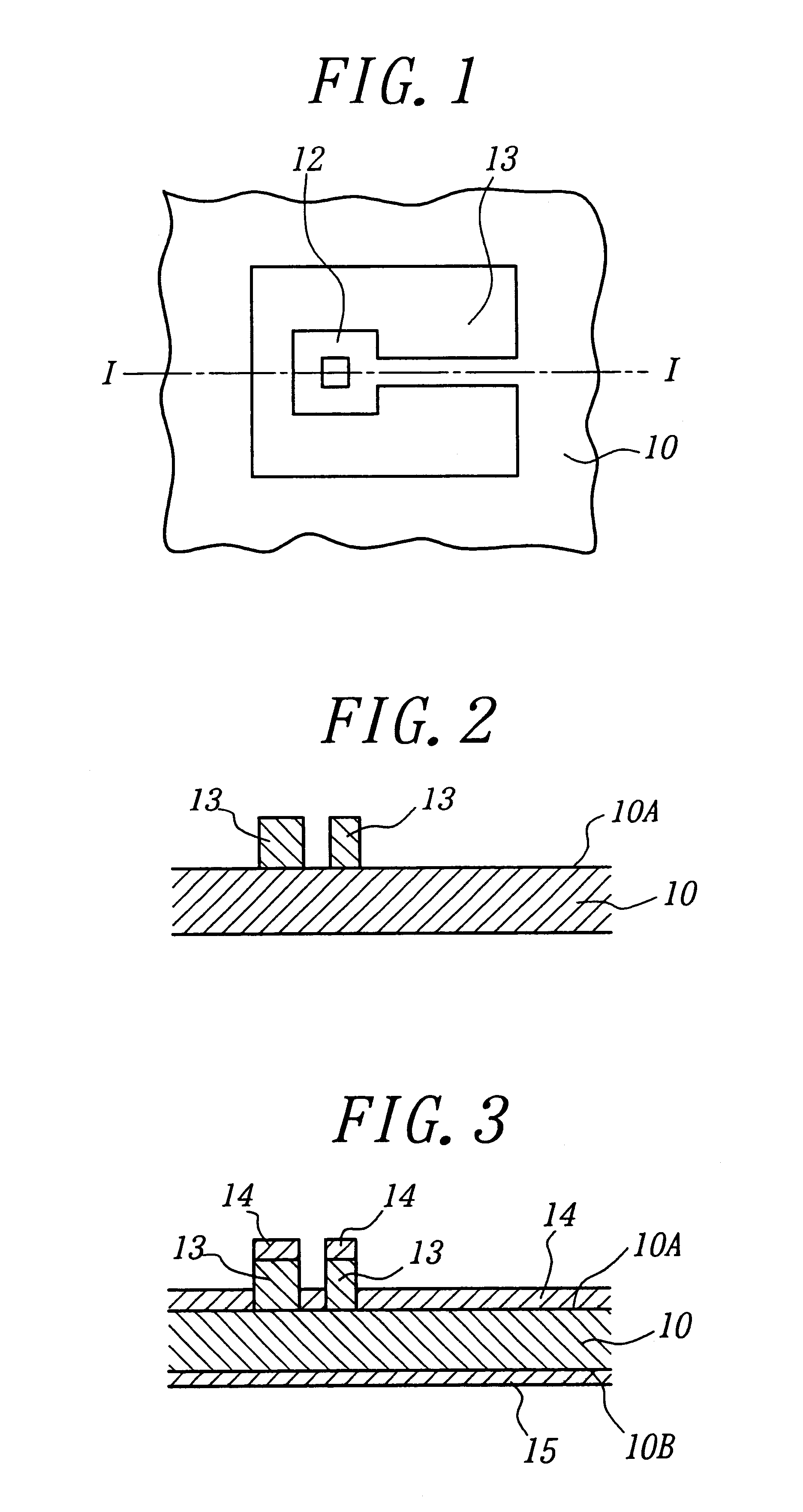

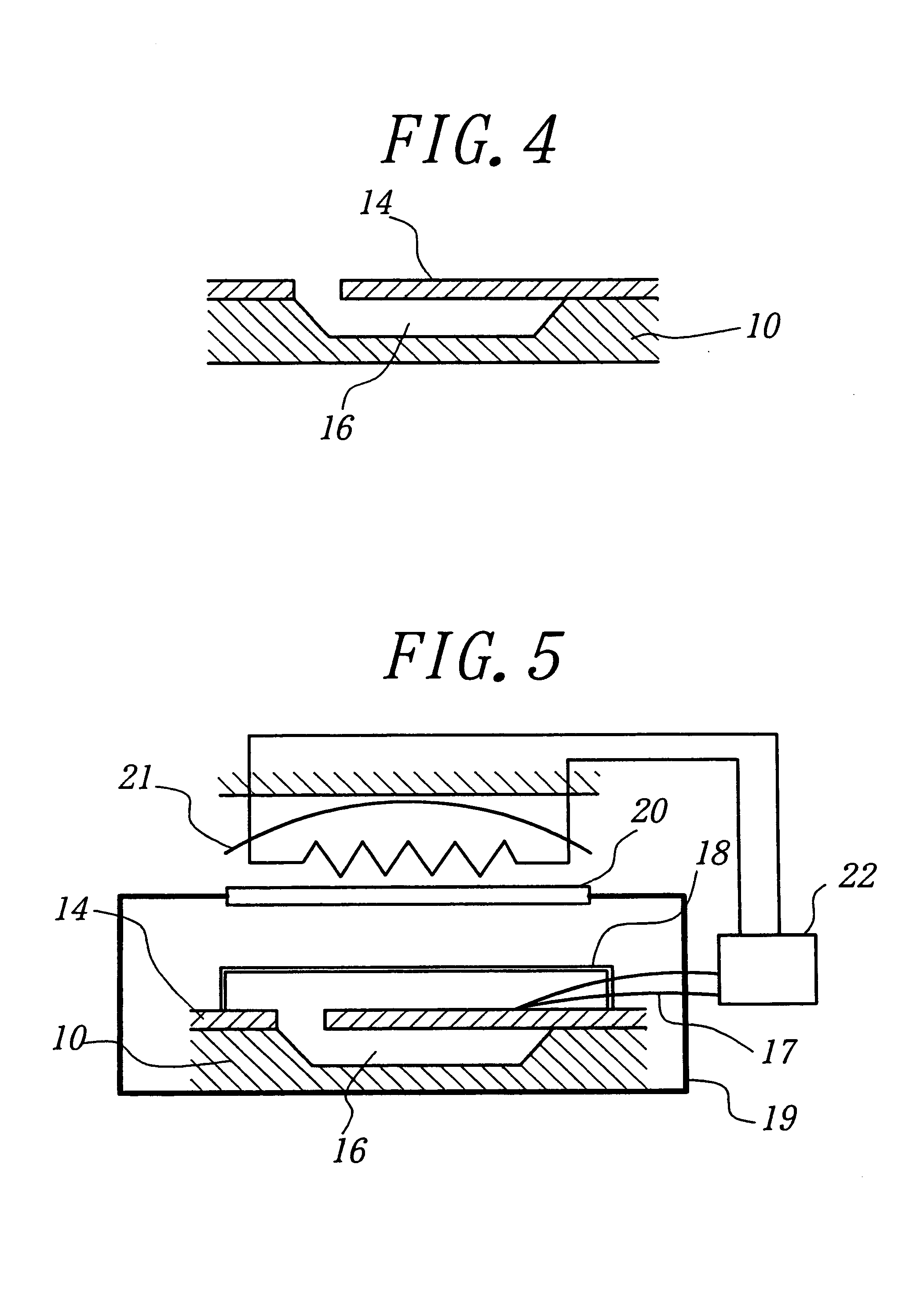

Thin film-structure and a method for producing the same

InactiveUS6759261B2Increase productivityGood reproducibilityLiquid-phase epitaxial-layer growthElectrical measurement instrument detailsRoom temperatureCooling down

A thin film made of an amorphous material having supercooled liquid phase region is formed on a substrate. Then, the thin film is heated to a temperature within the supercooled liquid phase region and is deformed by its weight, mechanical external force, electrostatic external force or the like, thereby to form a thin film-structure. Thereafter, the thin film-structure is cooled down to room temperature, which results in the prevention of the thin film's deformation.

Owner:TOKYO INST OF TECH

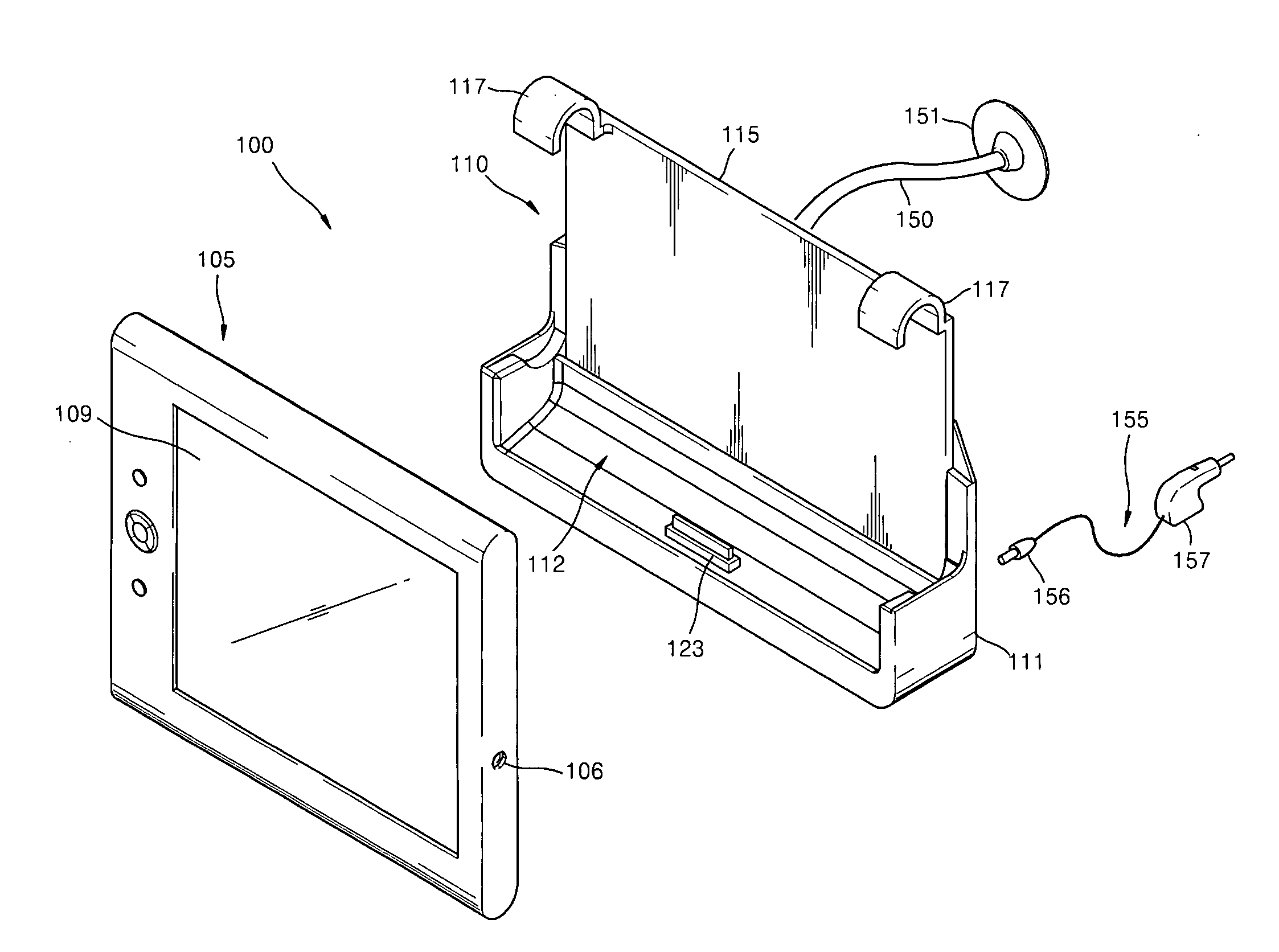

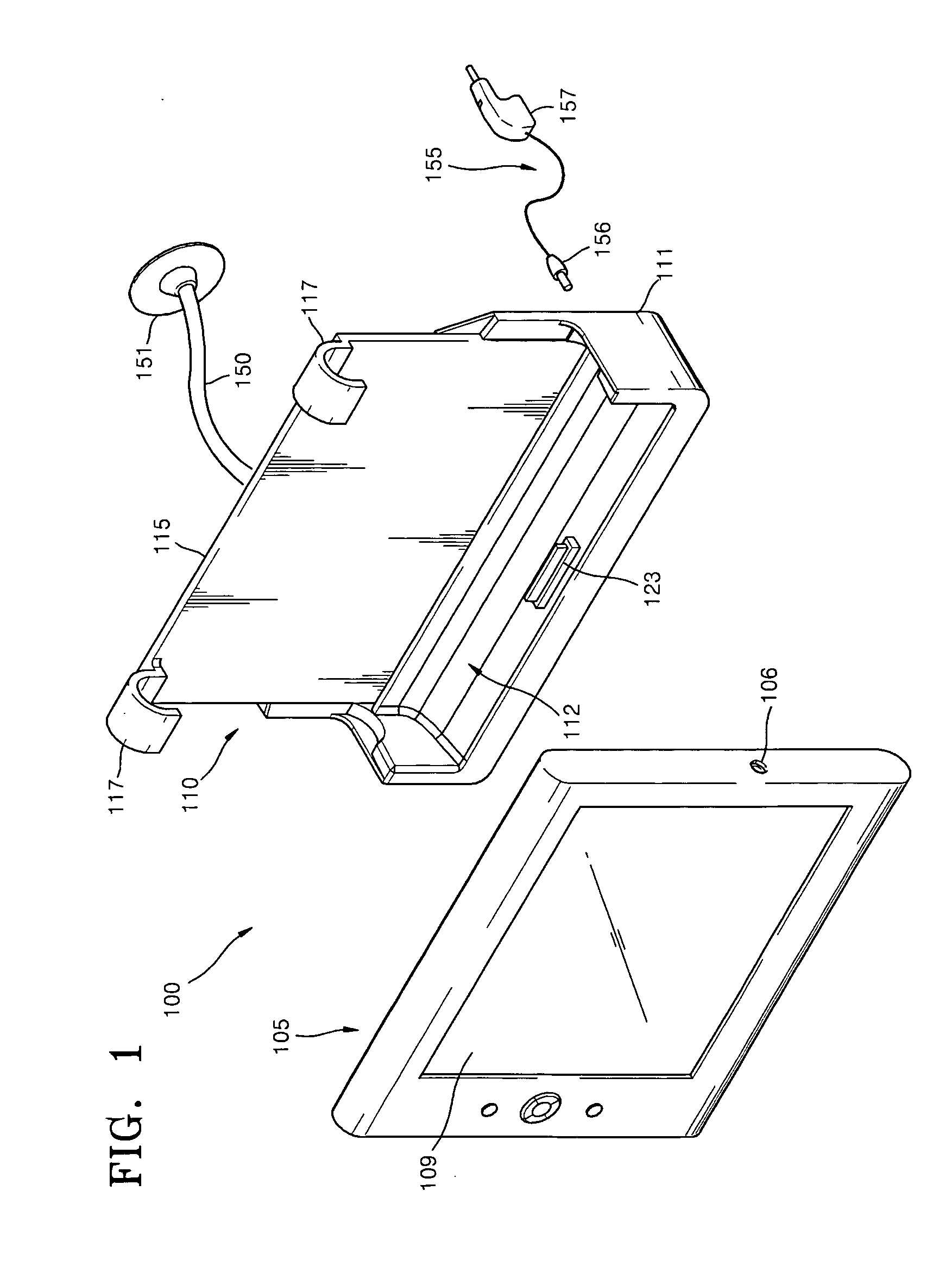

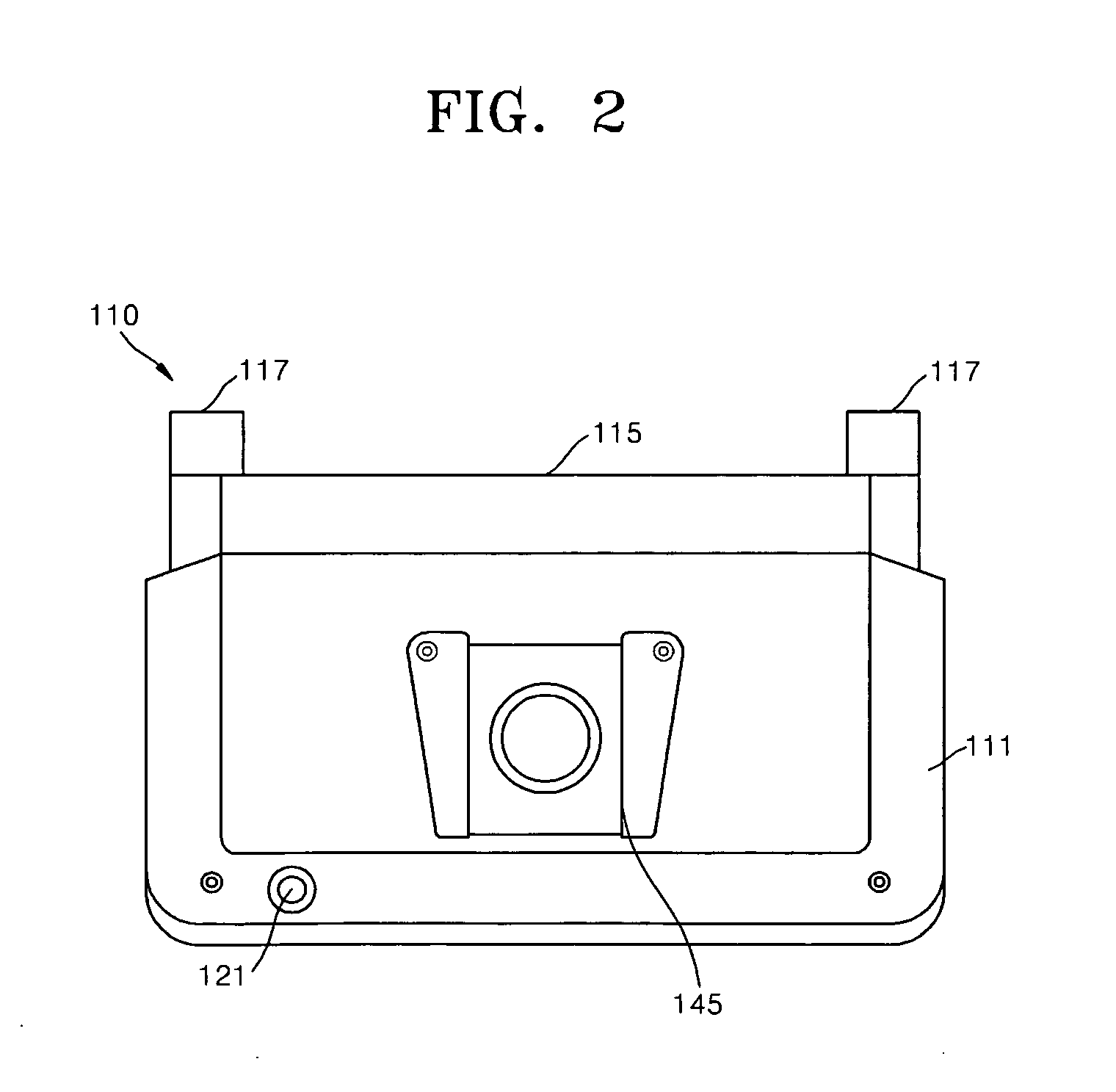

Cradle for use with a portable electronic appliance and a portable electronic appliance set including the cradle

InactiveUS20070152633A1Improve cooling effectBatteries circuit arrangementsDigital data processing detailsCooling downElectric power

A cradle for use with a portable electronic appliance. The cradle includes a frame, including a mounting portion in which the portable electronic appliance is mounted, a temperature sensor to measure a temperature around the portable electronic appliance, a fan to cool down the portable electronic appliance, a power supplying unit to supply electric power to the fan, and a controller. The controller drives the fan when the temperature measured by the temperature sensor is determined to be equal to or higher than a predetermined temperature according to measurements of the temperature sensor.

Owner:SAMSUNG ELECTRONICS CO LTD

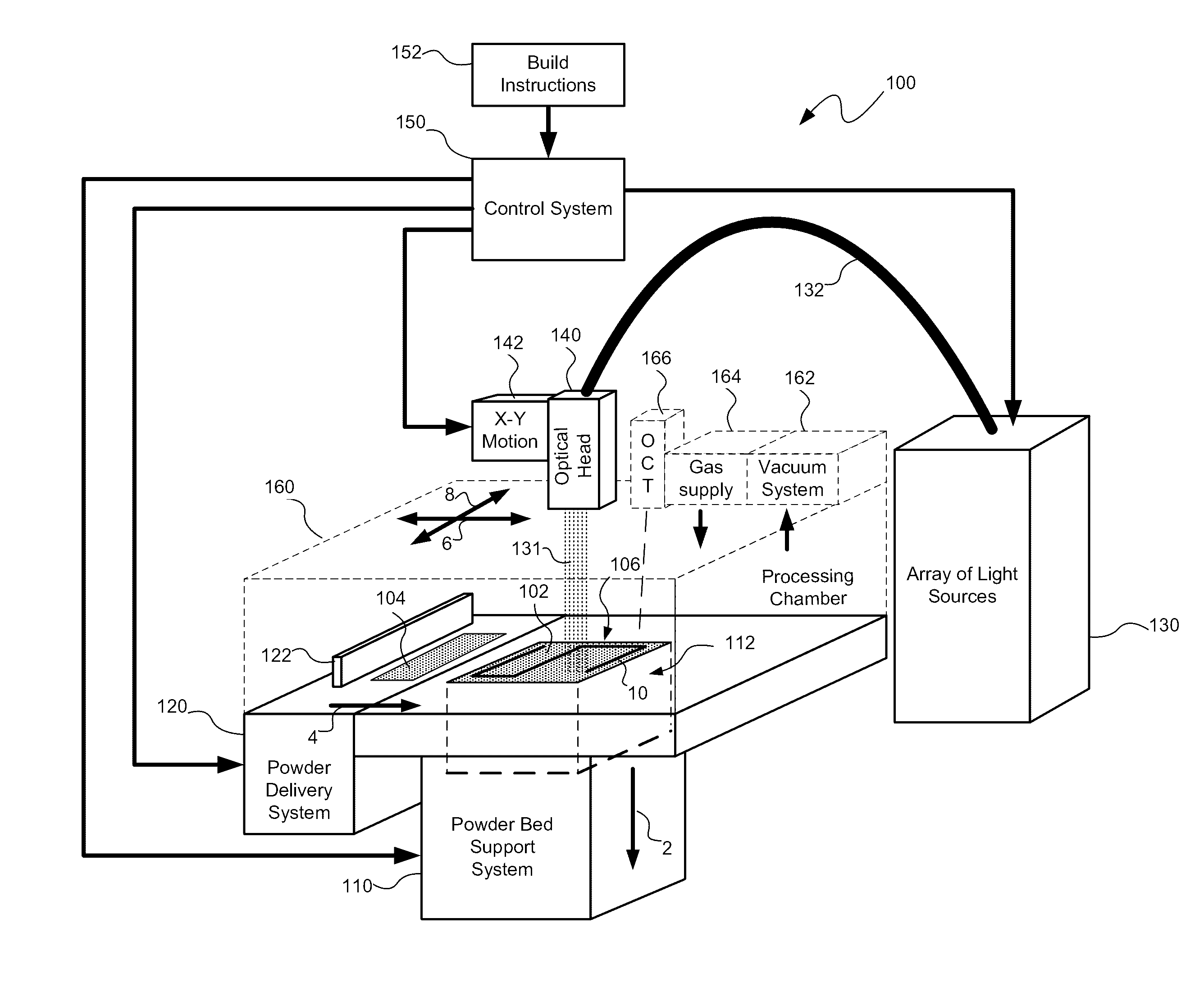

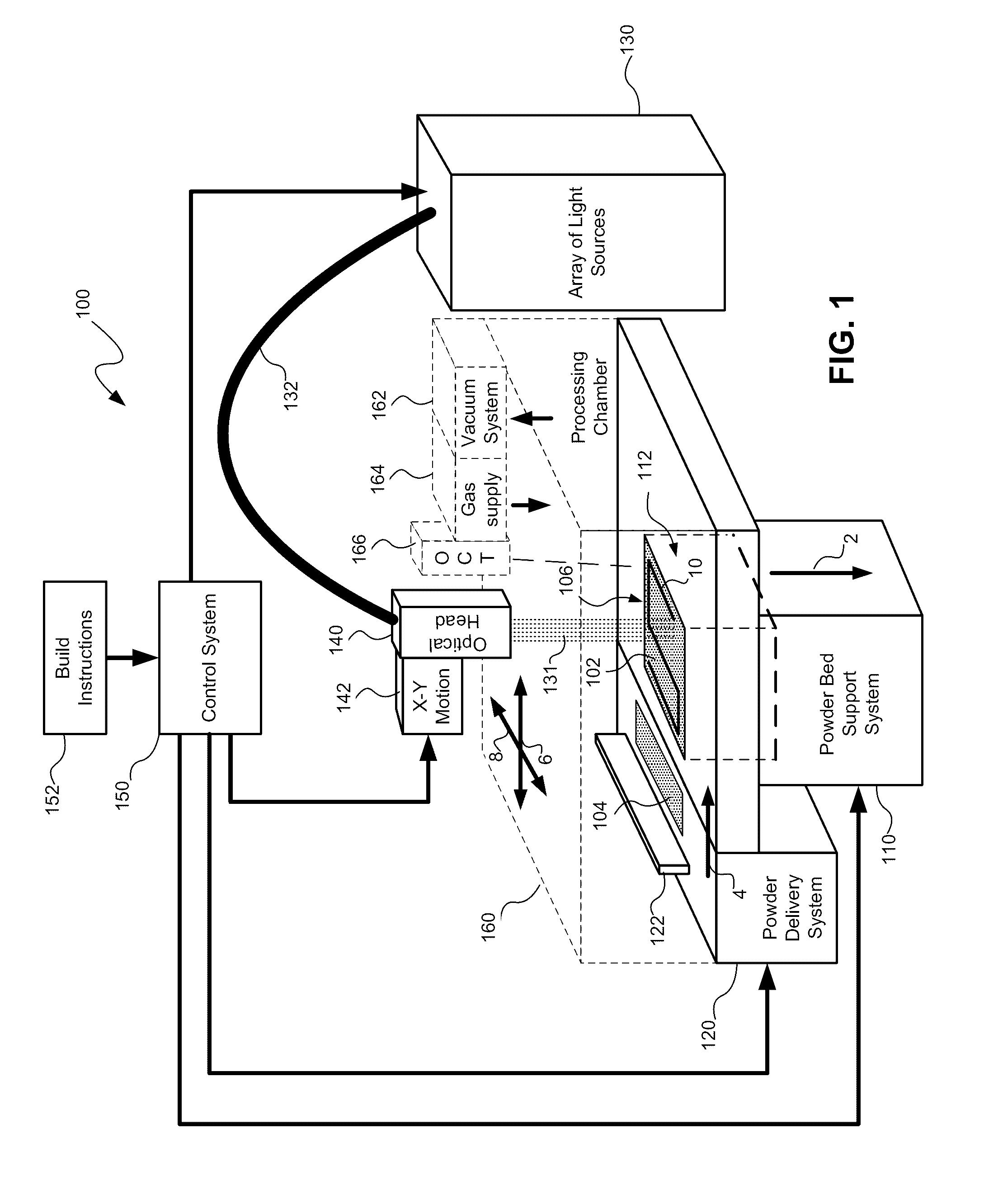

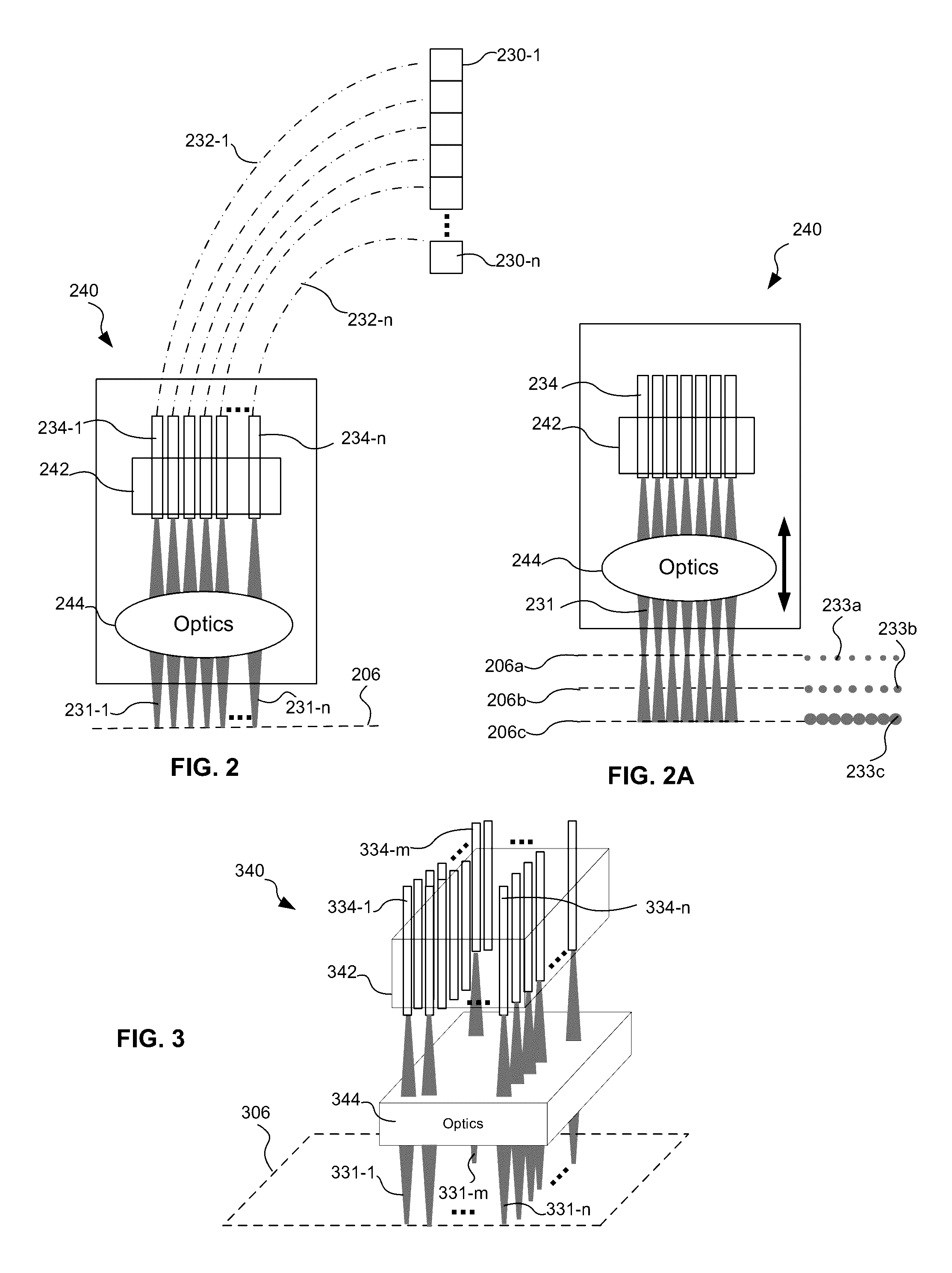

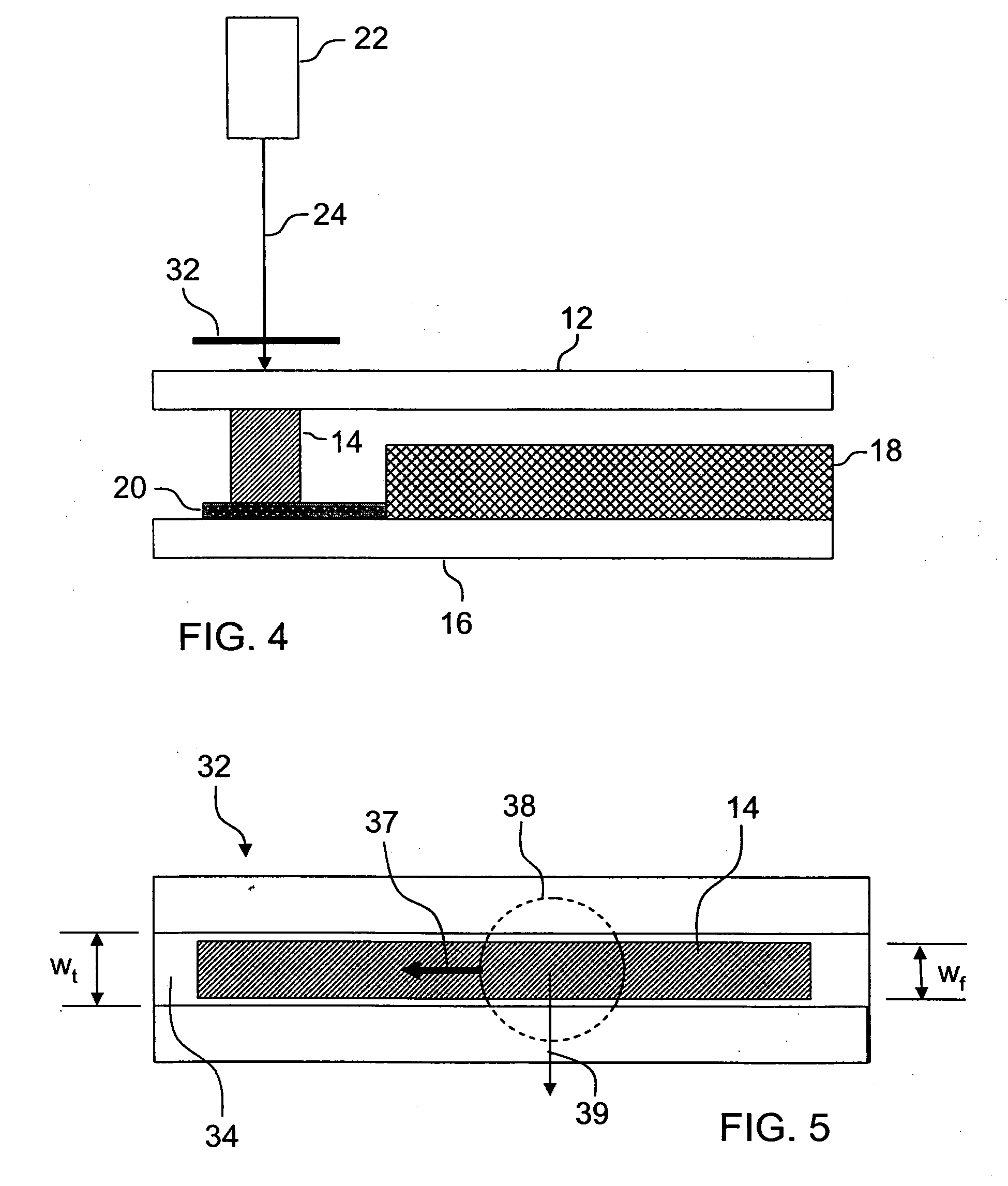

Multiple beam additive manufacturing

Systems and methods for multiple beam additive manufacturing use multiple beams of light (e.g., laser light) to expose layers of powder material in selected regions until the powder material fuses to form voxels, which form build layers of a three-dimensional structure. The light may be generated from selected light sources and coupled into an array of optical fibers having output ends arranged in an optical head in at least one line such that multiple beams are sequentially directed by the optical head to the same powder region providing multiple beam sequential exposures (e.g., with pre-heating, melting and controlled cool down) to fuse the powder region. The multiple sequential beams may be moved using various techniques (e.g., by moving the optical head) and according to various scan patterns such that a plurality of fused regions form each build layer.

Owner:IPG PHOTONICS CORP

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

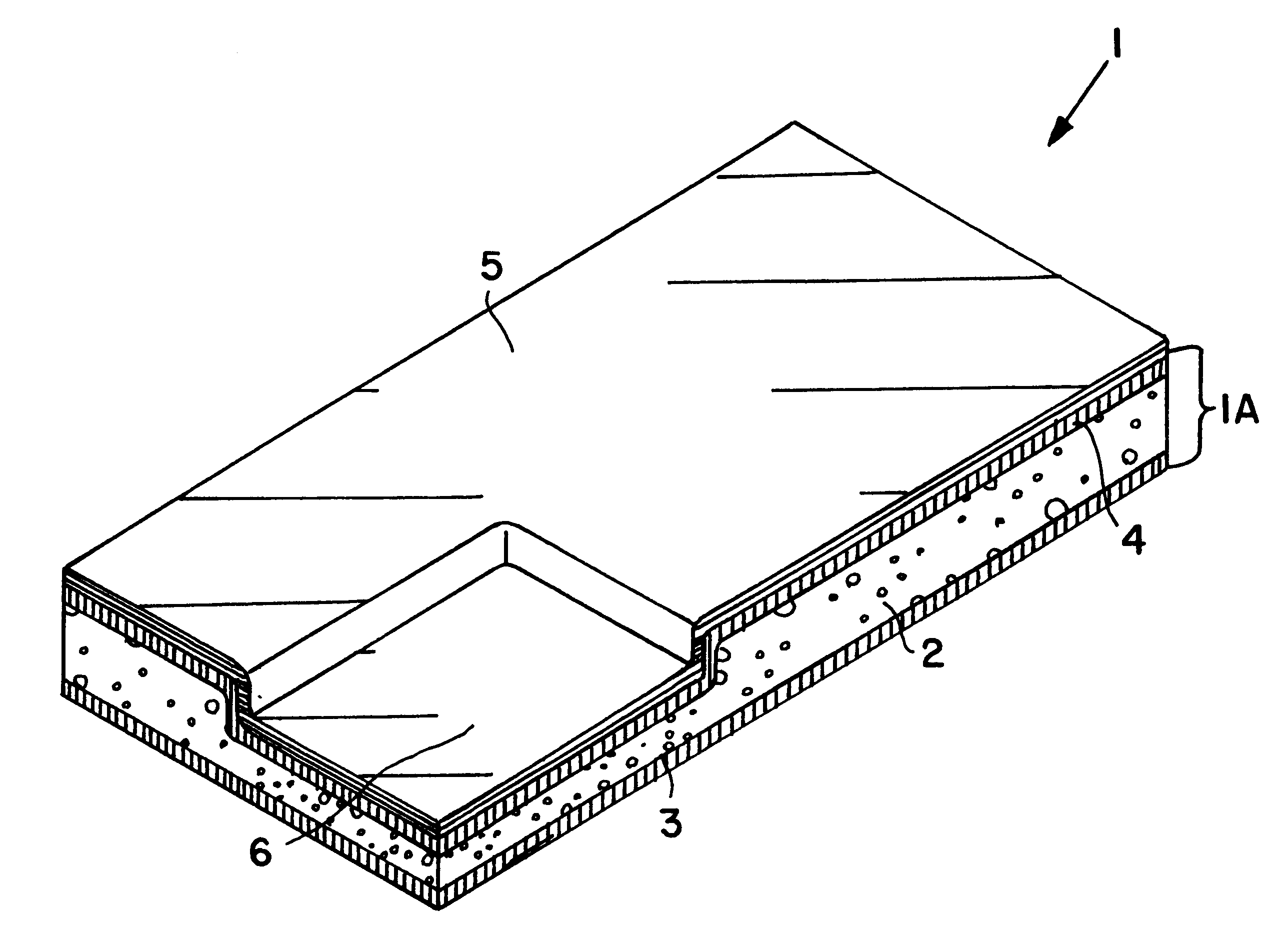

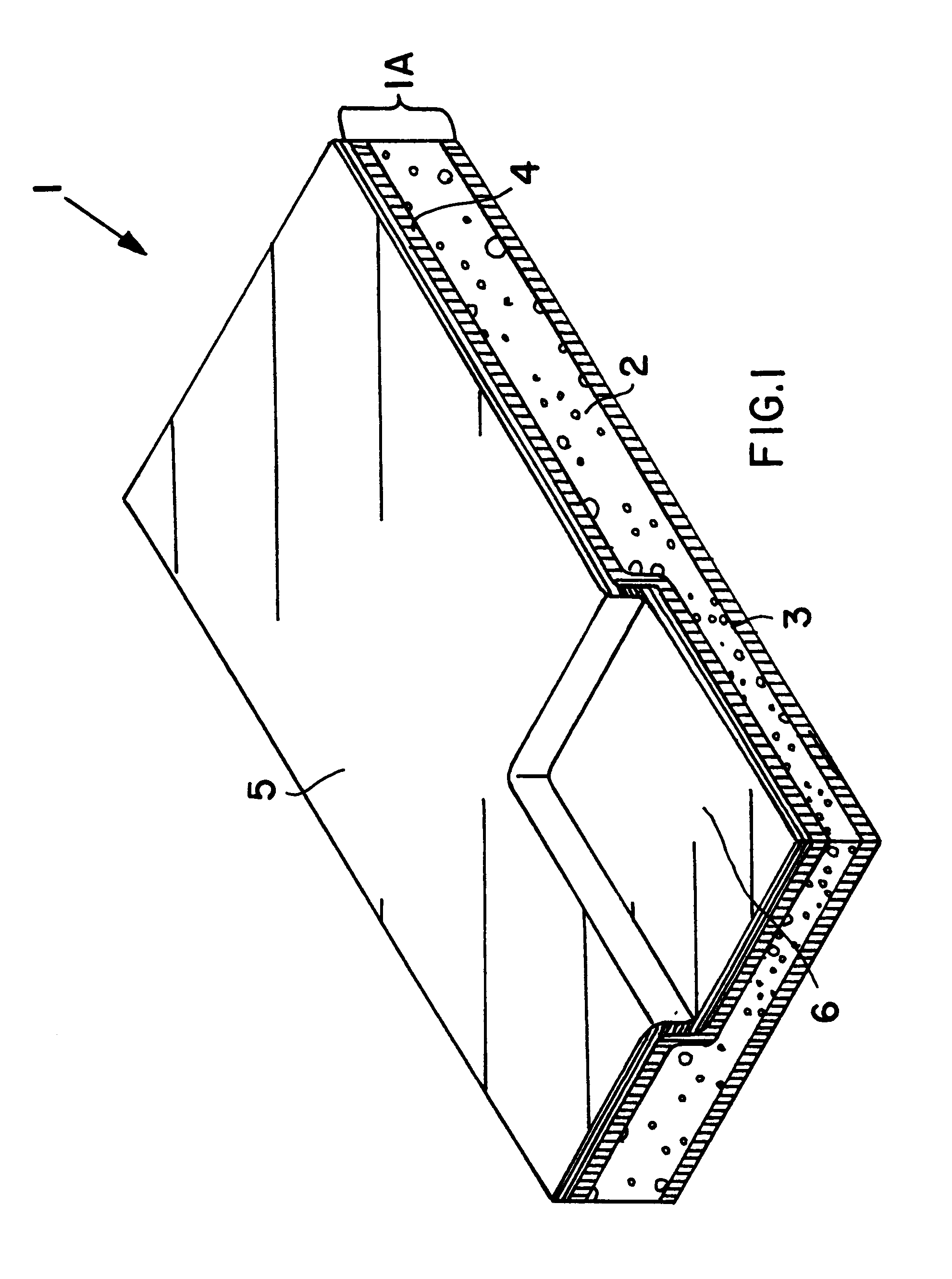

Composite structural panel with thermoplastic foam core and natural fibers, and method and apparatus for producing the same

InactiveUS6287678B1Easy to recycleEasily thermo-processedAdhesive processesLamination ancillary operationsComposite constructionShell molding

A composite structural panel includes a cover sheet laminated onto a three-layered substrate including a thermoplastic foam core sandwiched between two composite outer layers. Each composite outer layer includes natural fibers embedded in a thermoplastic matrix. The thermoplastic material of all layers is preferably polypropylene, and the core consists of an expanded cellular polypropylene rigid foam. In a method for forming the composite structural panel, a first preheated outer layer is laminated and molded onto the foam core in a first molding step, and then the second preheated outer layer and the cover sheet are laminated and molded onto the foam core in a second molding step, with a cooling-down time allowed between the two molding steps. In this manner, each preheated outer layer provides enough heat to thermally fuse the outer layer onto the foam core, without overheating the foam core to the point of softening or melting the foam core. The low density foam core provides a spacing distance between the strong composite outer layers, and therefore the finished composite structural panel has a high strength and rigidity, and a high strength-to-weight ratio. The structural panel can be molded into any desired three-dimensional contoured configuration during the molding process.

Owner:HERBERT OLBRICH

Reverse thermal gels and the use thereof for rapid prototyping

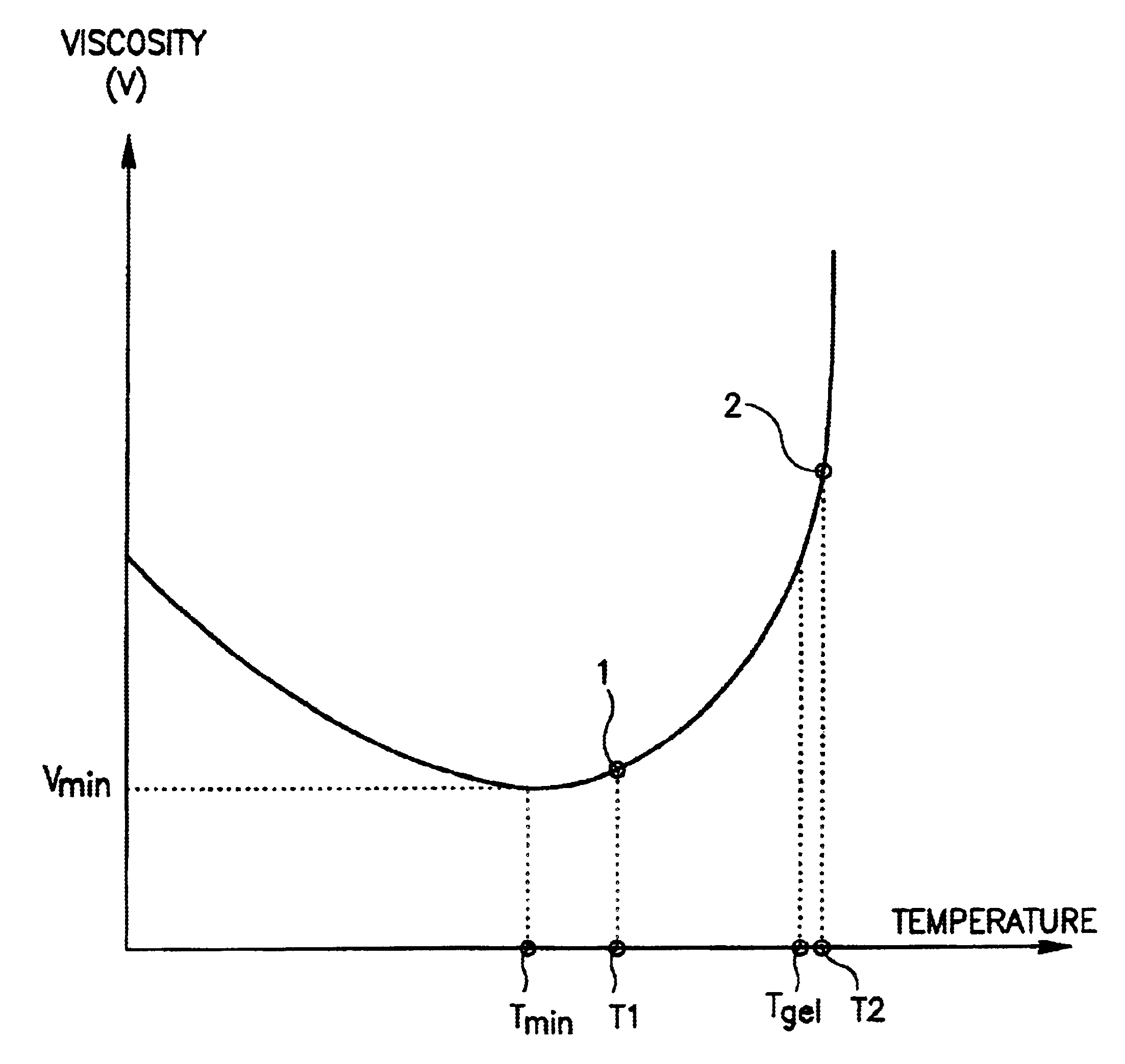

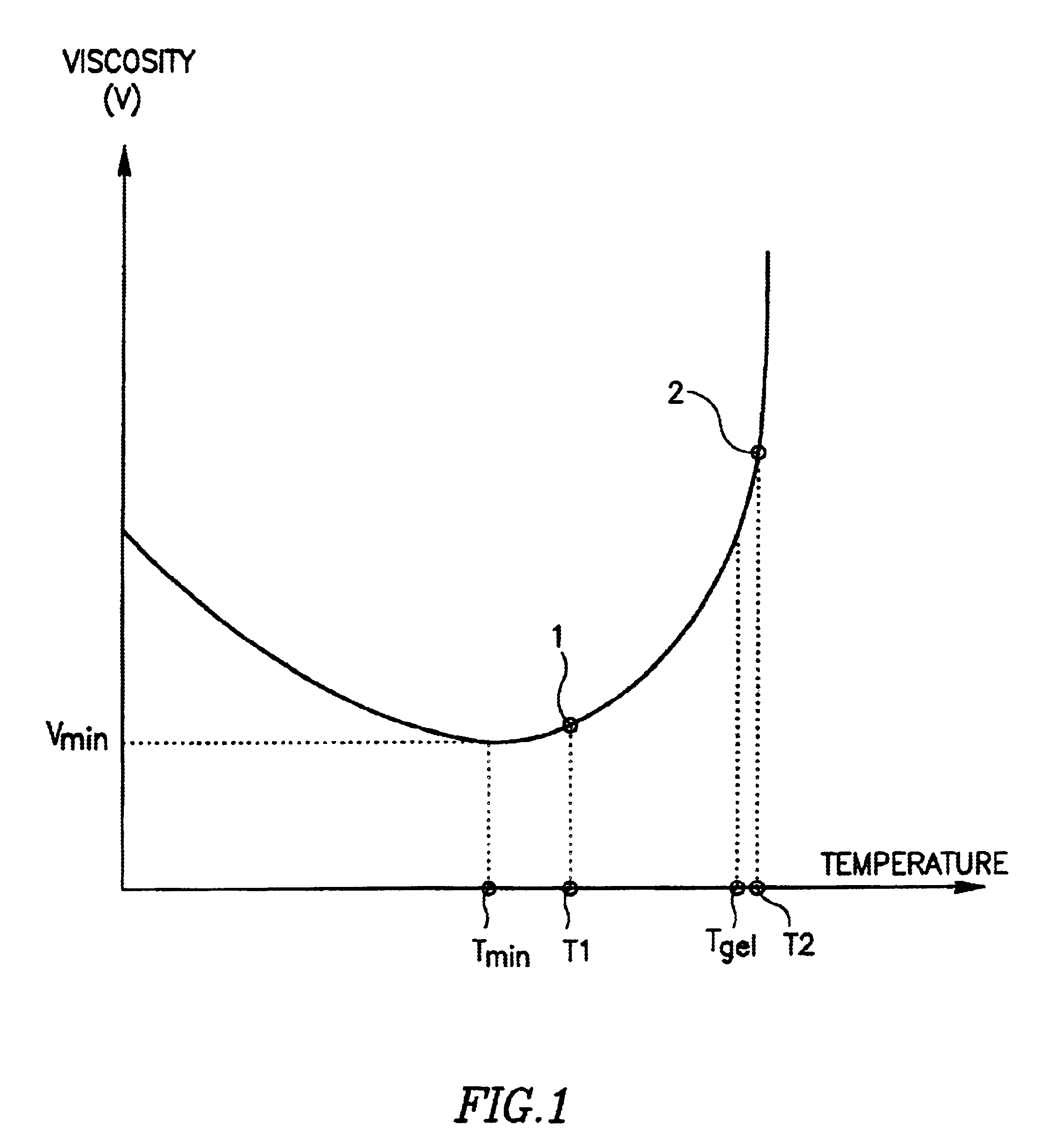

InactiveUS6863859B2Reduce surface tensionHigh strengthAdditive manufacturing apparatusPhotosensitive materialsLower critical solution temperatureWater soluble

The present invention relates to novel polymeric compositions that exhibit Reverse Thermal Gelation (RTG) properties for use as Support Materials (SM) in the manufacture of three-dimensional objects. These polymers are Temperature Sensitive Polymers that respond with a significant change of properties to a small change in temperature. Temperature Sensitive Polymers exhibit cloud point (CP) or lower critical solution temperature (LCST) in aqueous solutions. Water-soluble Temperature Sensitive Polymers are chosen to give low viscosity liquid at low temperature when dissolved in water and by that to permit easy dispensing at low temperature. Raising the temperature above their gelation temperature (Tgel) will result in solidification of the composition. At its gel position the material has favorable characteristics as a support and building material. The gel layers have the appropriate toughness and dimensional stability to support the model layers during the building process. After the building process is completed the gel can be cooled down to a temperature below its Tgel so the gel can liquefy and be removed easily by rinsing with water.

Owner:STRATASYS LTD

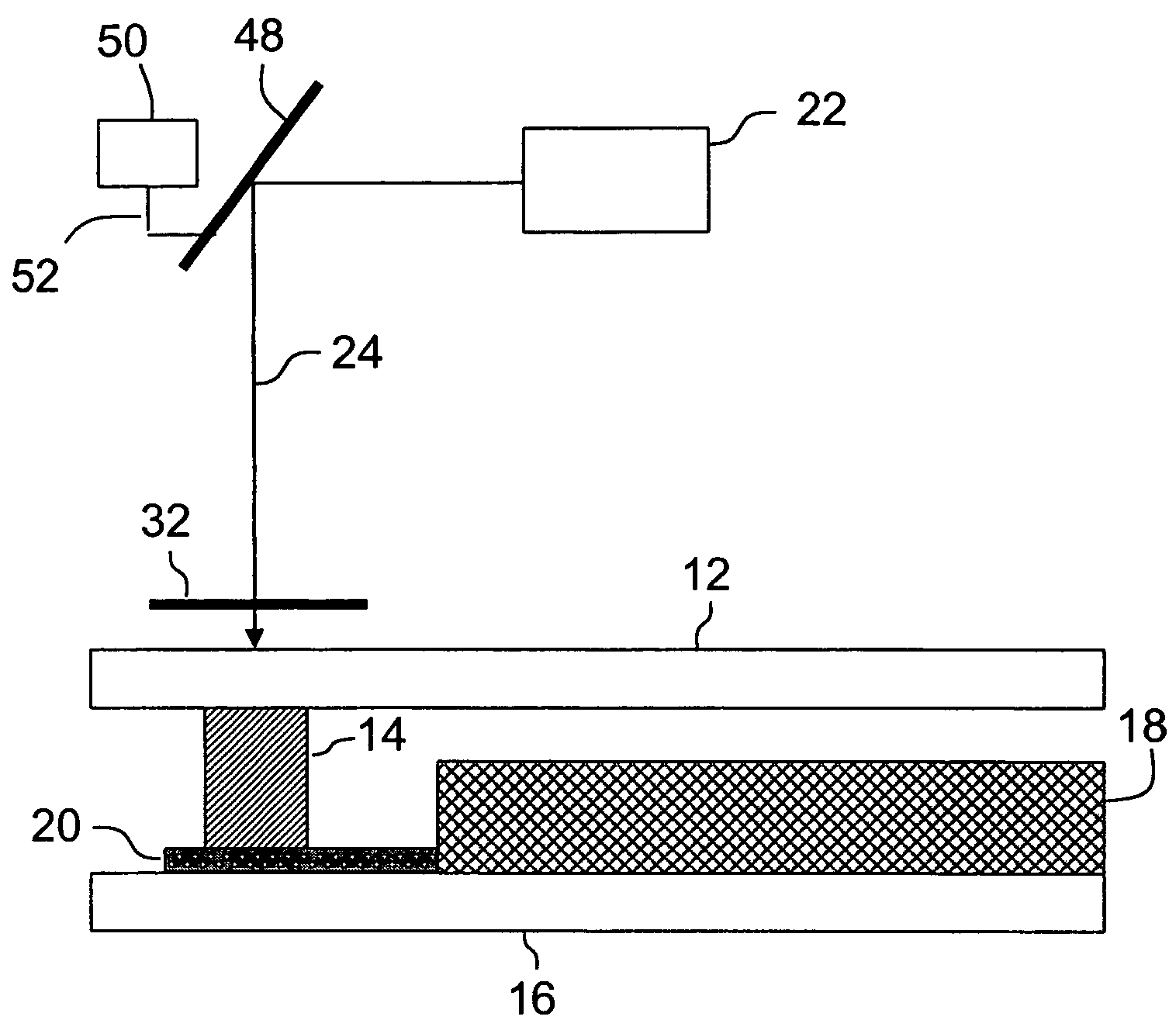

Method of making a glass envelope

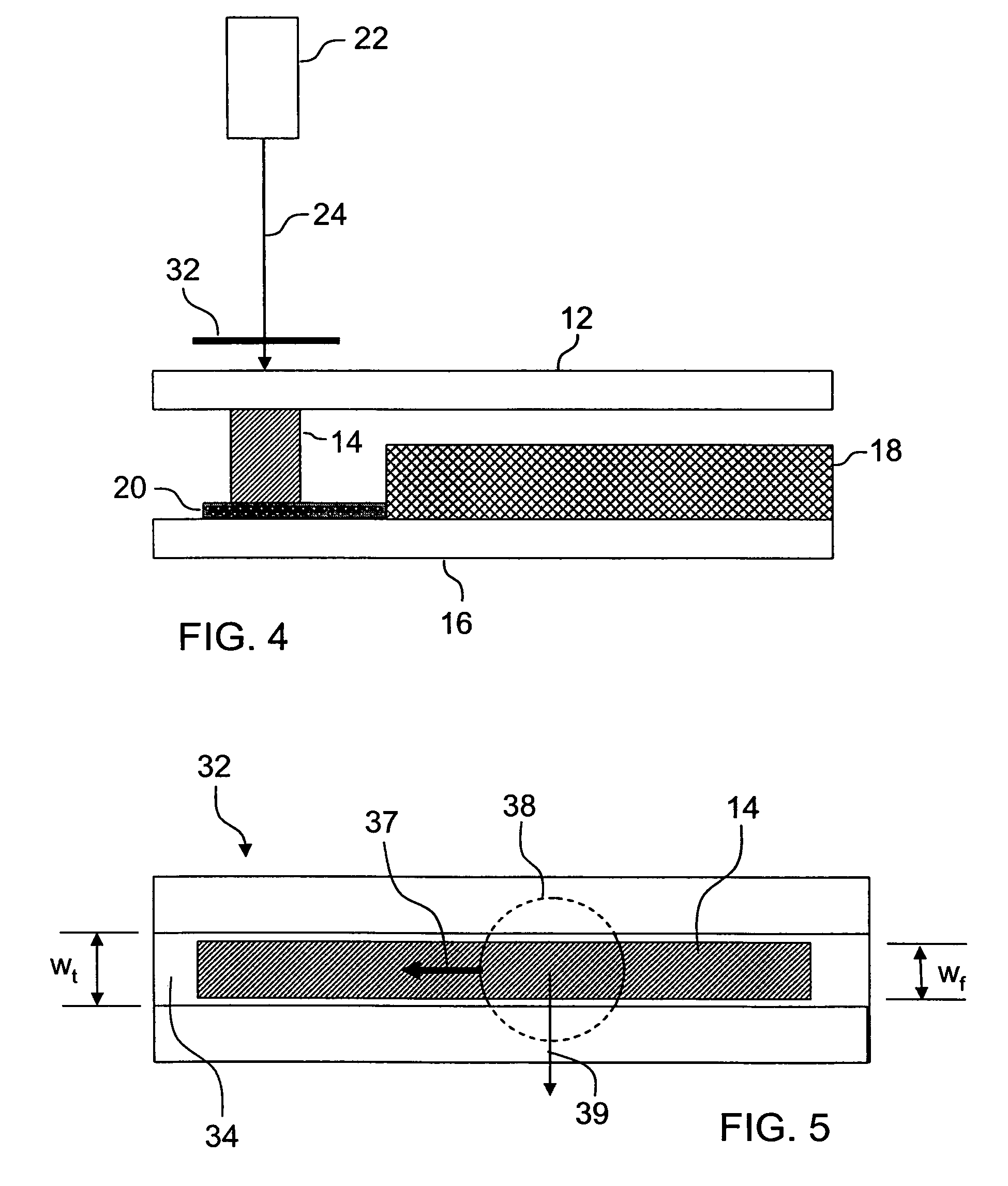

InactiveUS20070128967A1Easy to understandElectroluminescent light sourcesSolid-state devicesFritLight beam

A method of minimizing stress in an OLED device laser sealing process using an elongated laser beam. A laser beam having an intensity distribution which decreases as a function of distance from the longitudinal axis of the beam is passed through a mask to create an elongated beam having a length-wise intensity distribution which decreases as a function of distance from the axis of the beam and a substantially constant width-wise intensity distribution. The elongated beam is traversed over a line of frit disposed between two substrates. The tails of the length-wise intensity distribution provide for a slow cool down of the frit as the beam traverses the line of frit.

Owner:CORNING INC

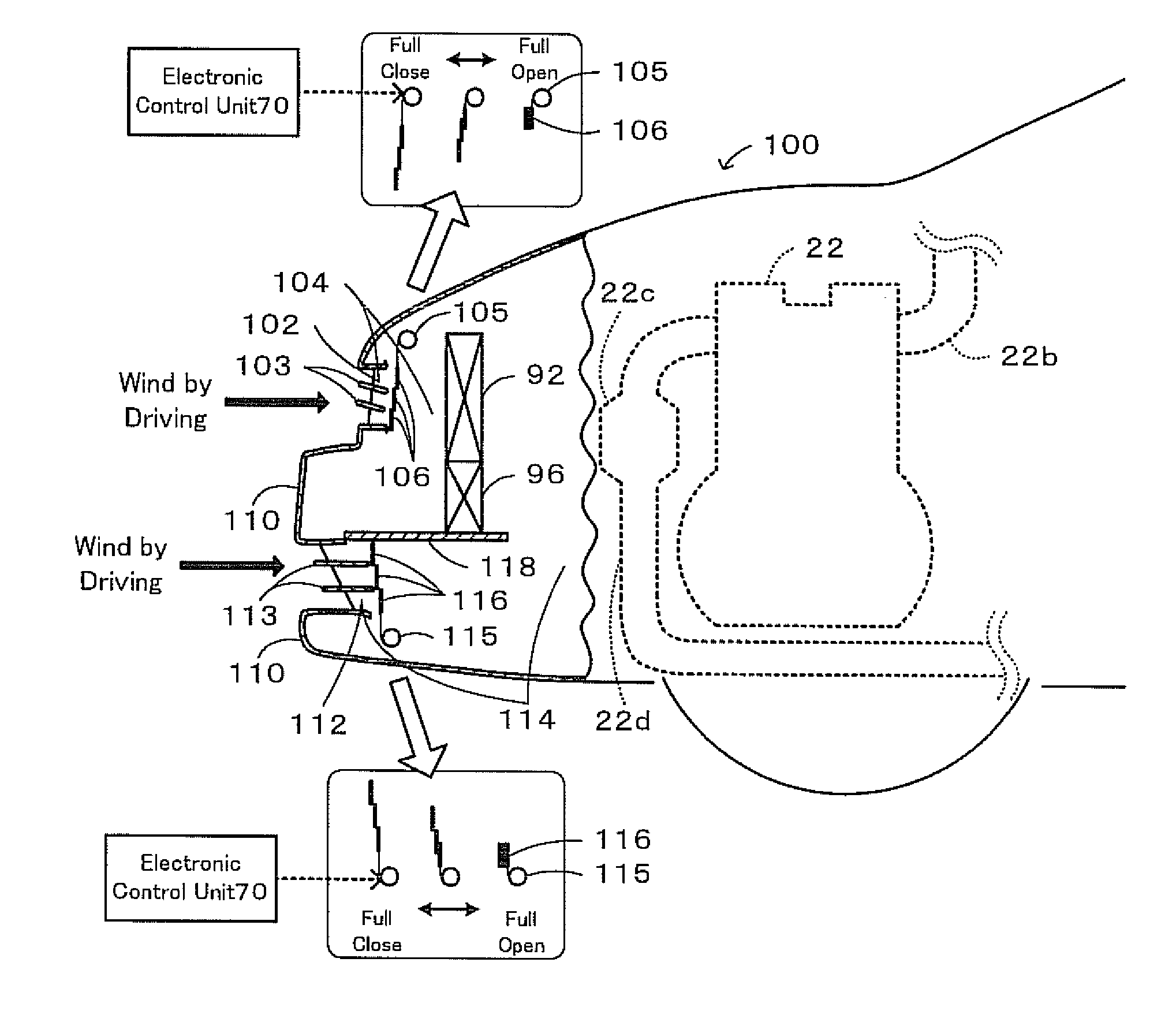

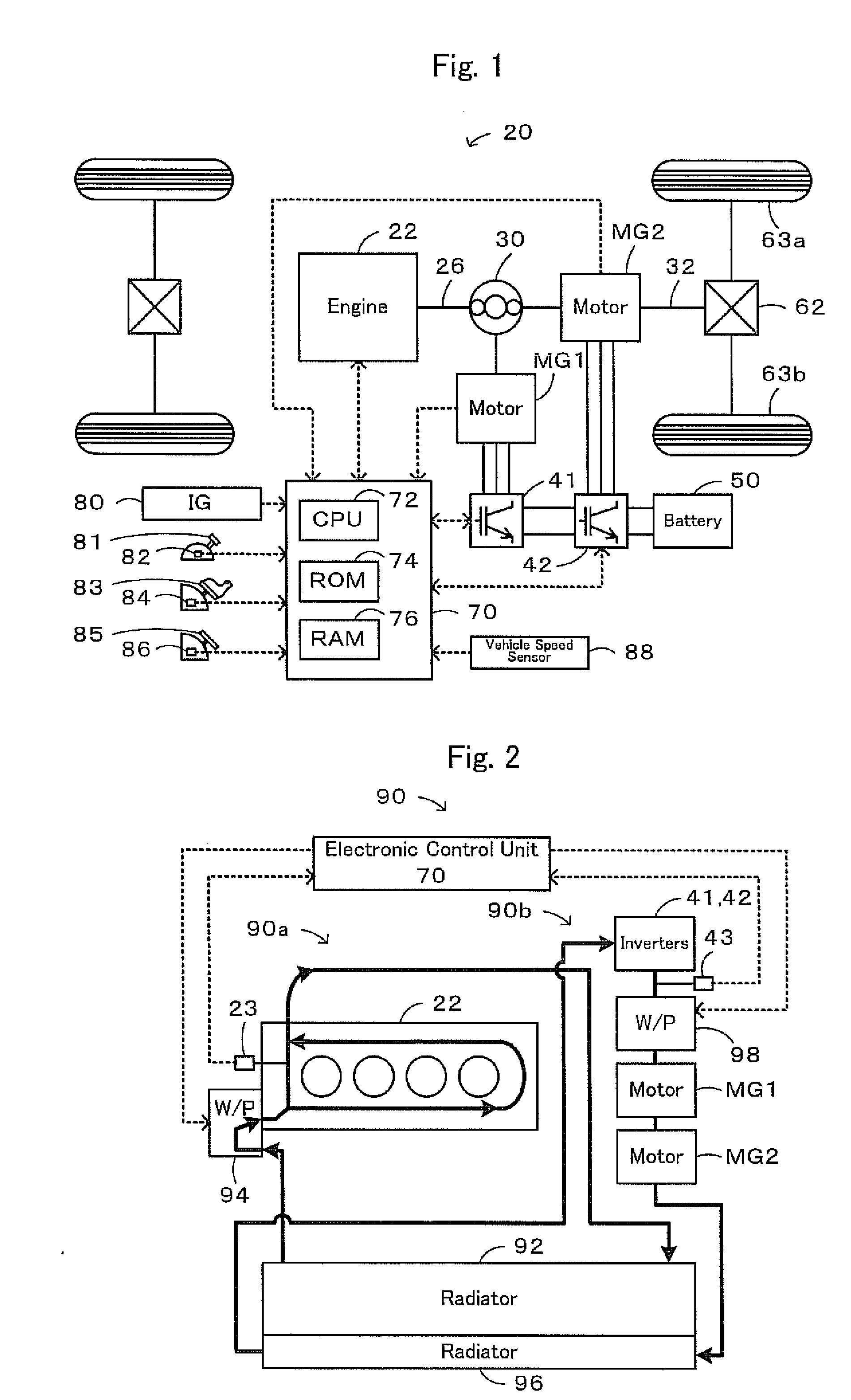

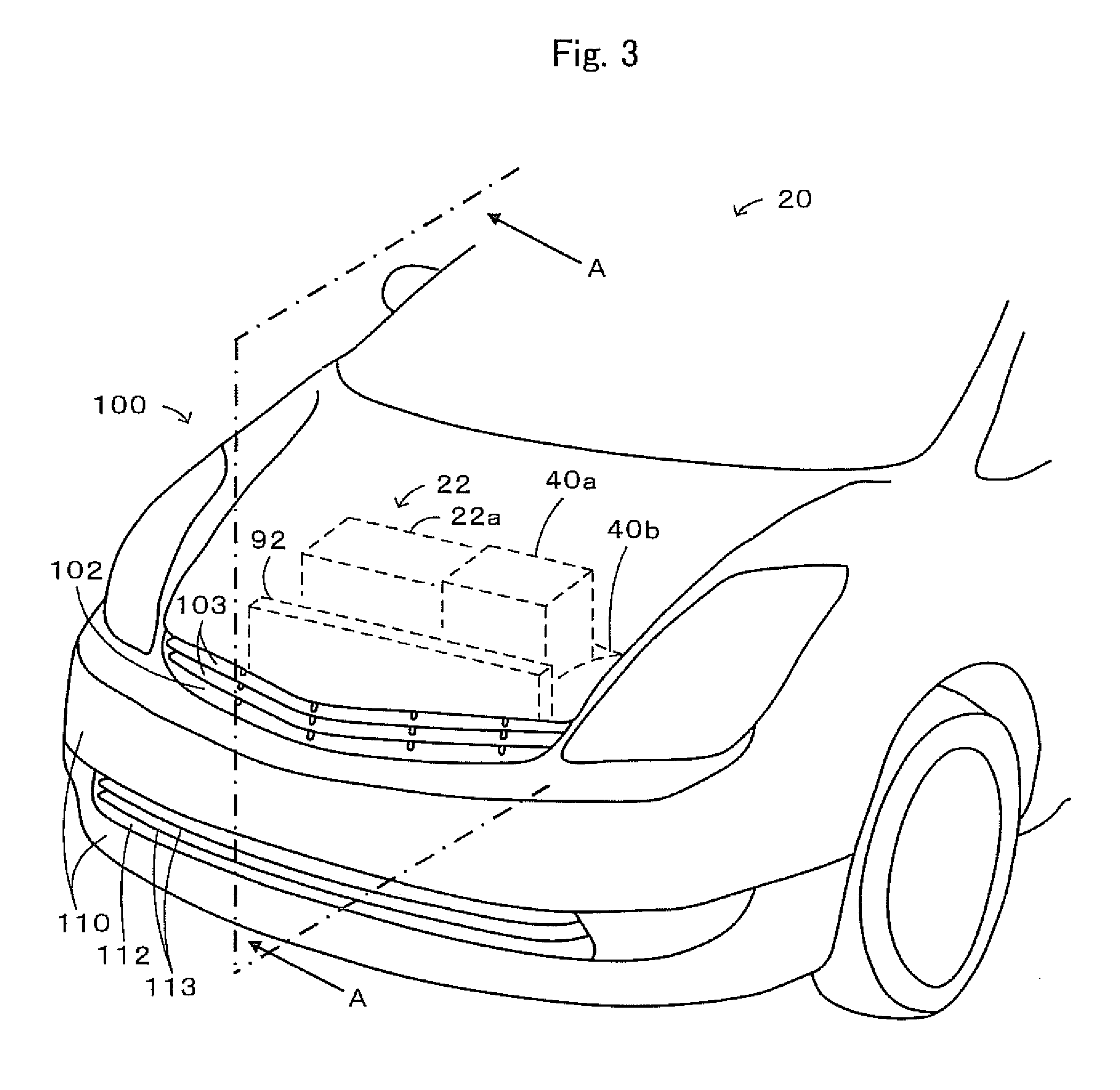

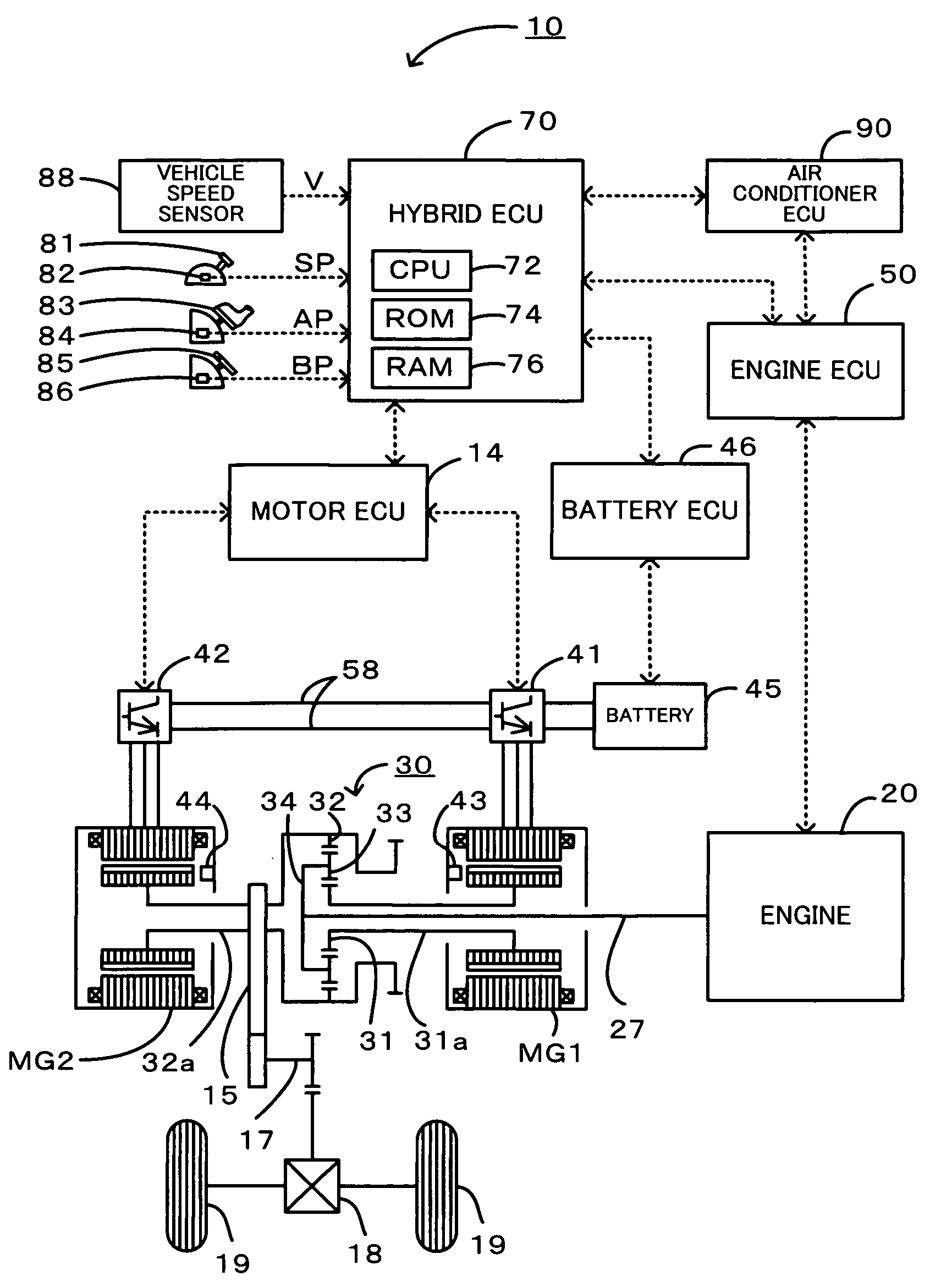

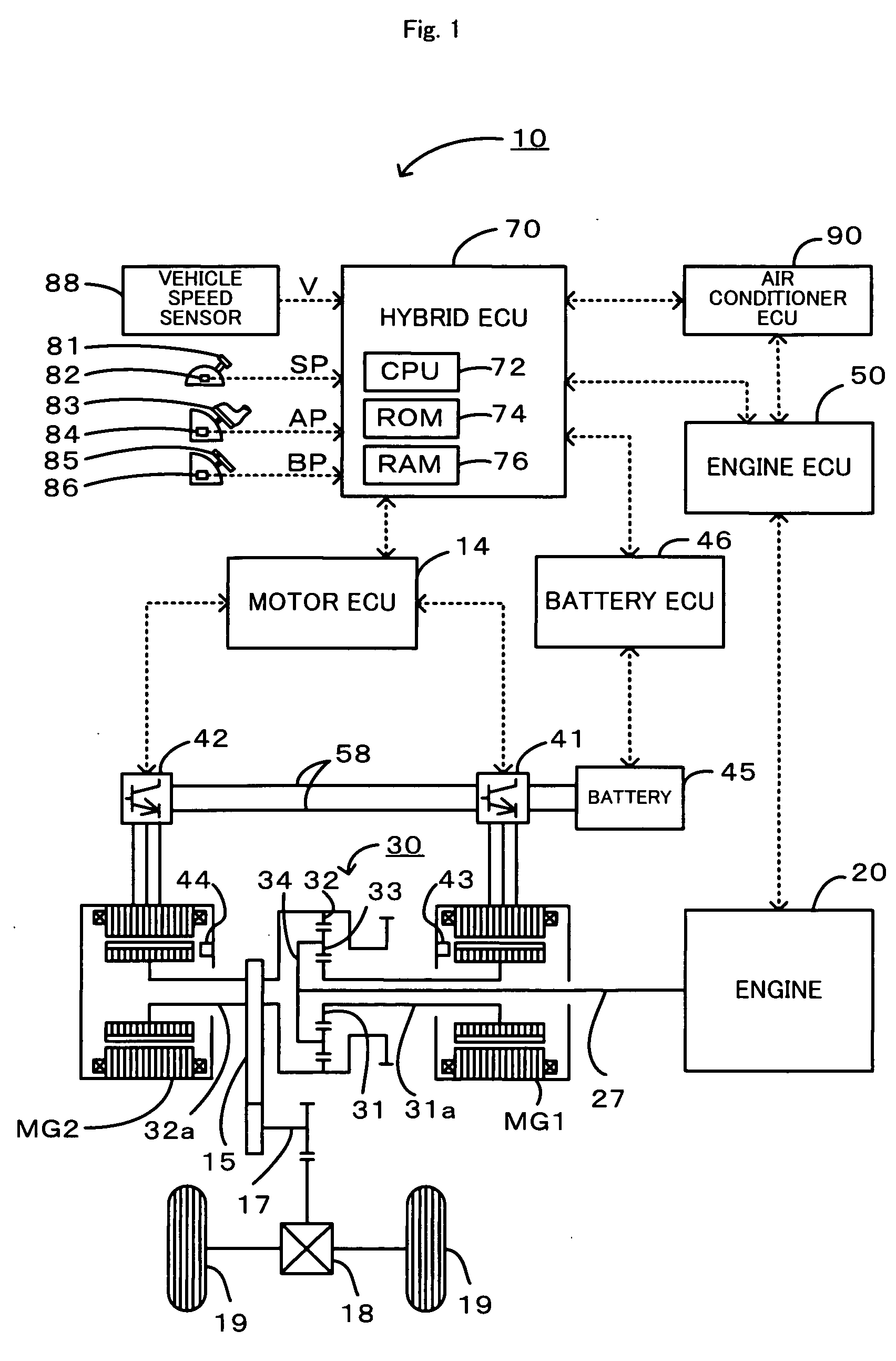

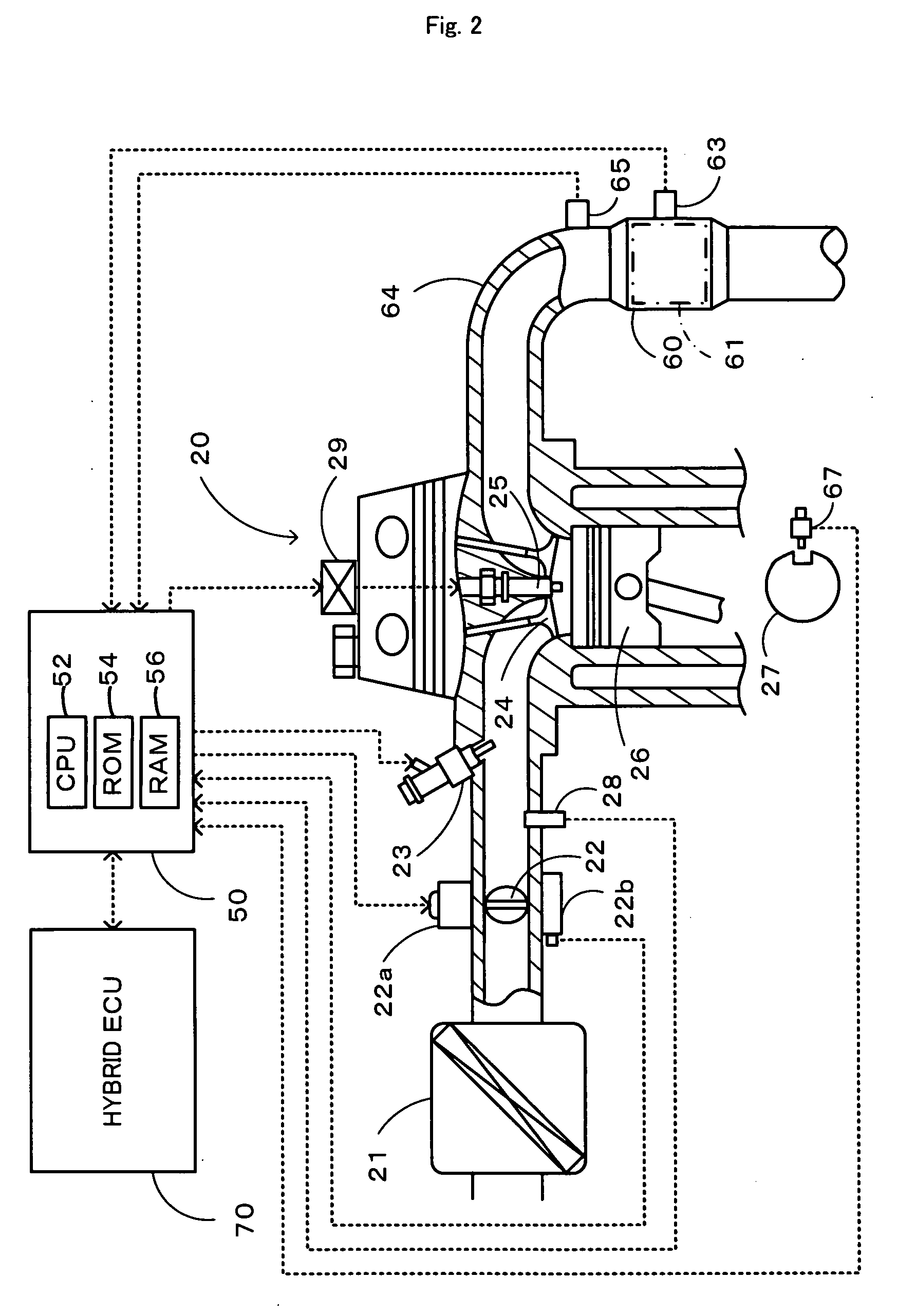

Motor vehicle and control method of motor vehicle

ActiveUS20100147611A1Adequate heat dissipationIncrease volumeCoolant flow controlElectric propulsion mountingMobile vehicleCooling down

A motor vehicle is equipped with an outside air introduction assembly 104 functioning to introduce the outside air into a radiator 92 in an engine cooling system during driving, as well as with an outside air introduction assembly 114 functioning to introduce the outside air into an engine 22 during driving. The motor vehicle is also equipped with shutter plates 106 capable of regulating the amount of the outside air to be introduced by the outside air introduction assembly 104, as well as with shutter plates 116 capable of regulating the amount of the outside air to be introduced by the outside air introduction assembly 114. The shutter plates 106 and the shutter plates 116 are individually actuated and controlled to increase the amount of the outside air to be introduced by the outside air introduction assembly 104 and the amount of the outside air to be introduced by the outside air introduction assembly 114 with an increase of temperature of cooling water detected as a cooling water temperature Twe in the engine cooling system. Such actuation and control assures the adequate cooling performances to cool down the cooling water by the radiator 92 and to cool down the engine 22.

Owner:TOYOTA JIDOSHA KK

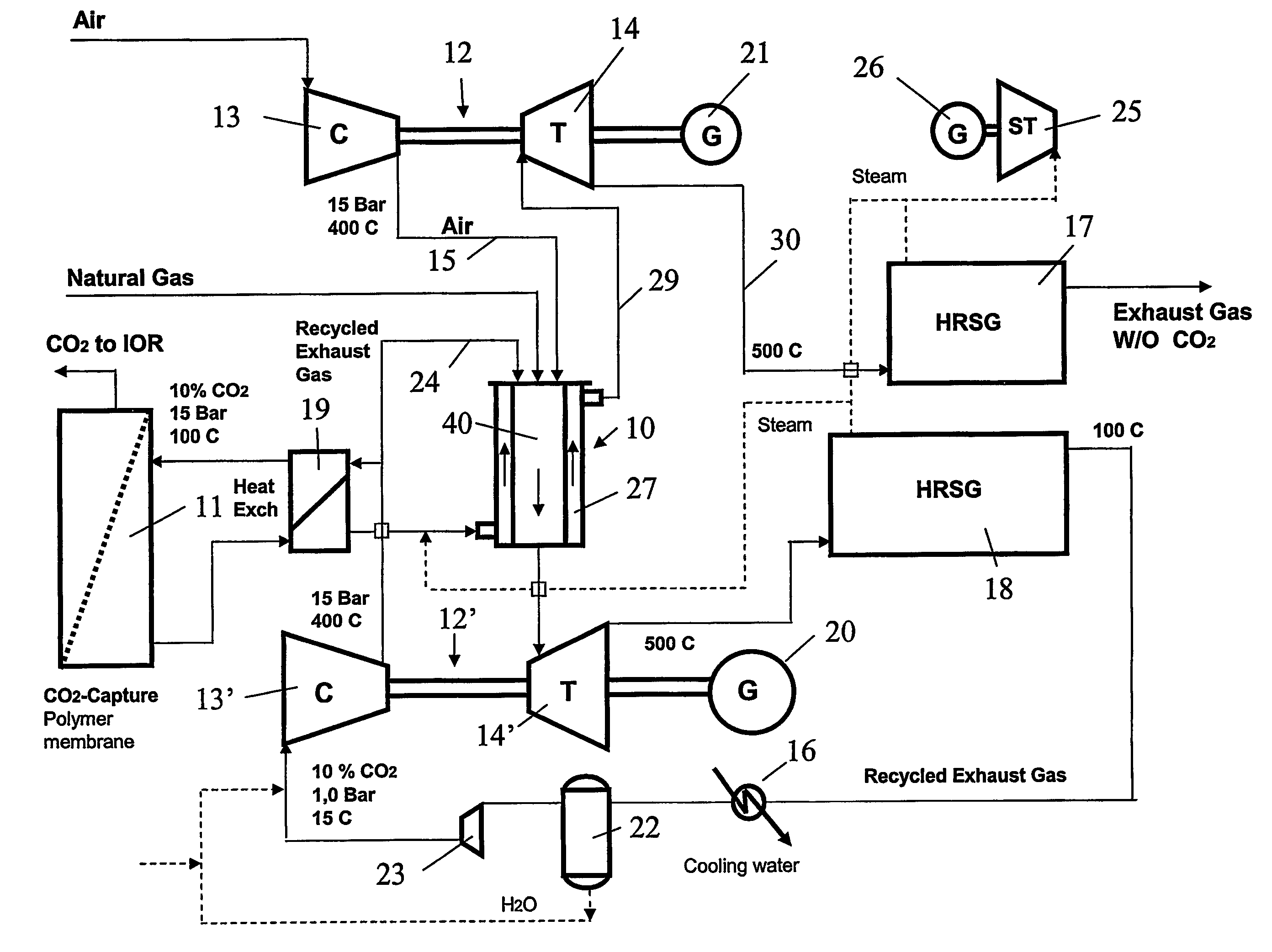

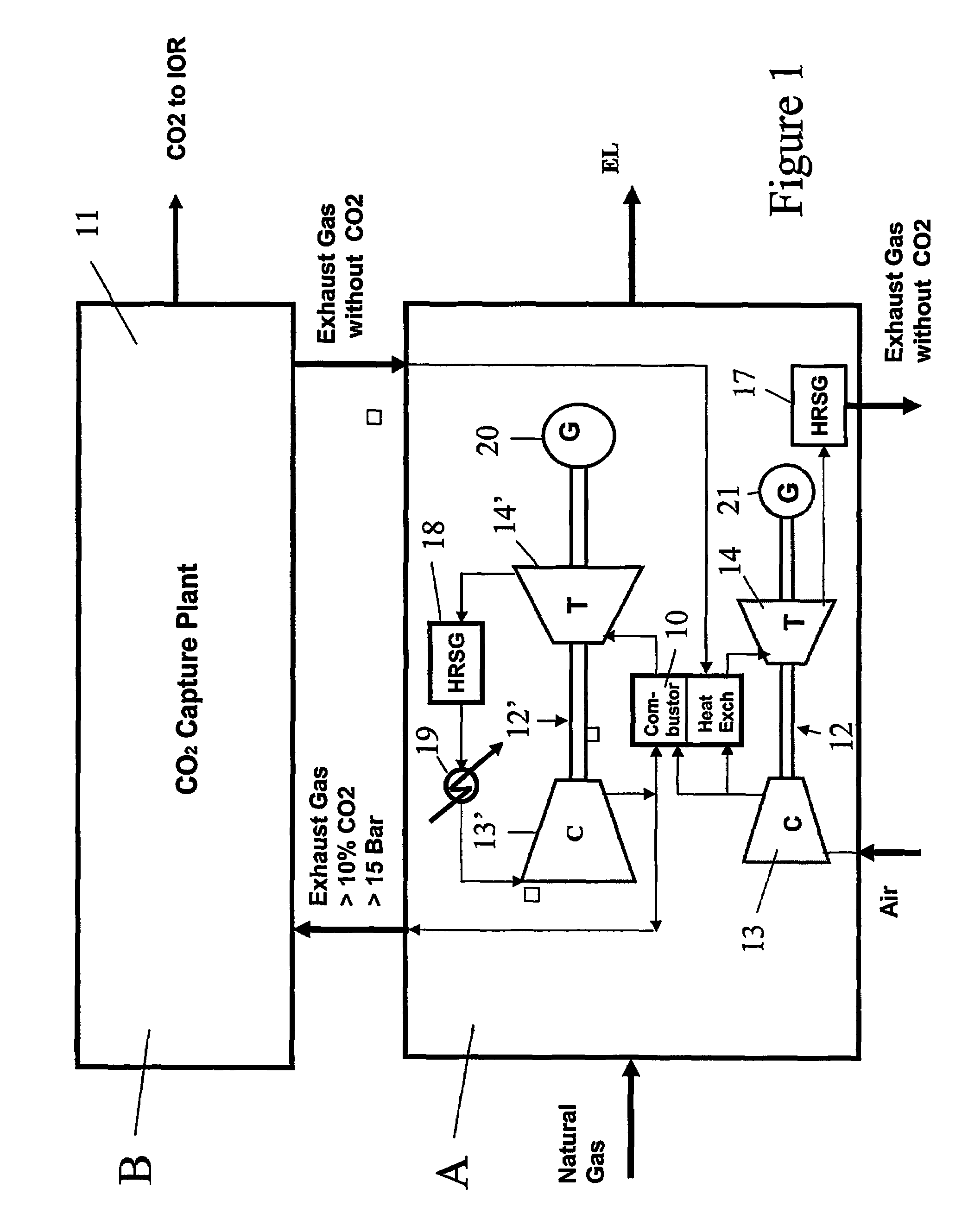

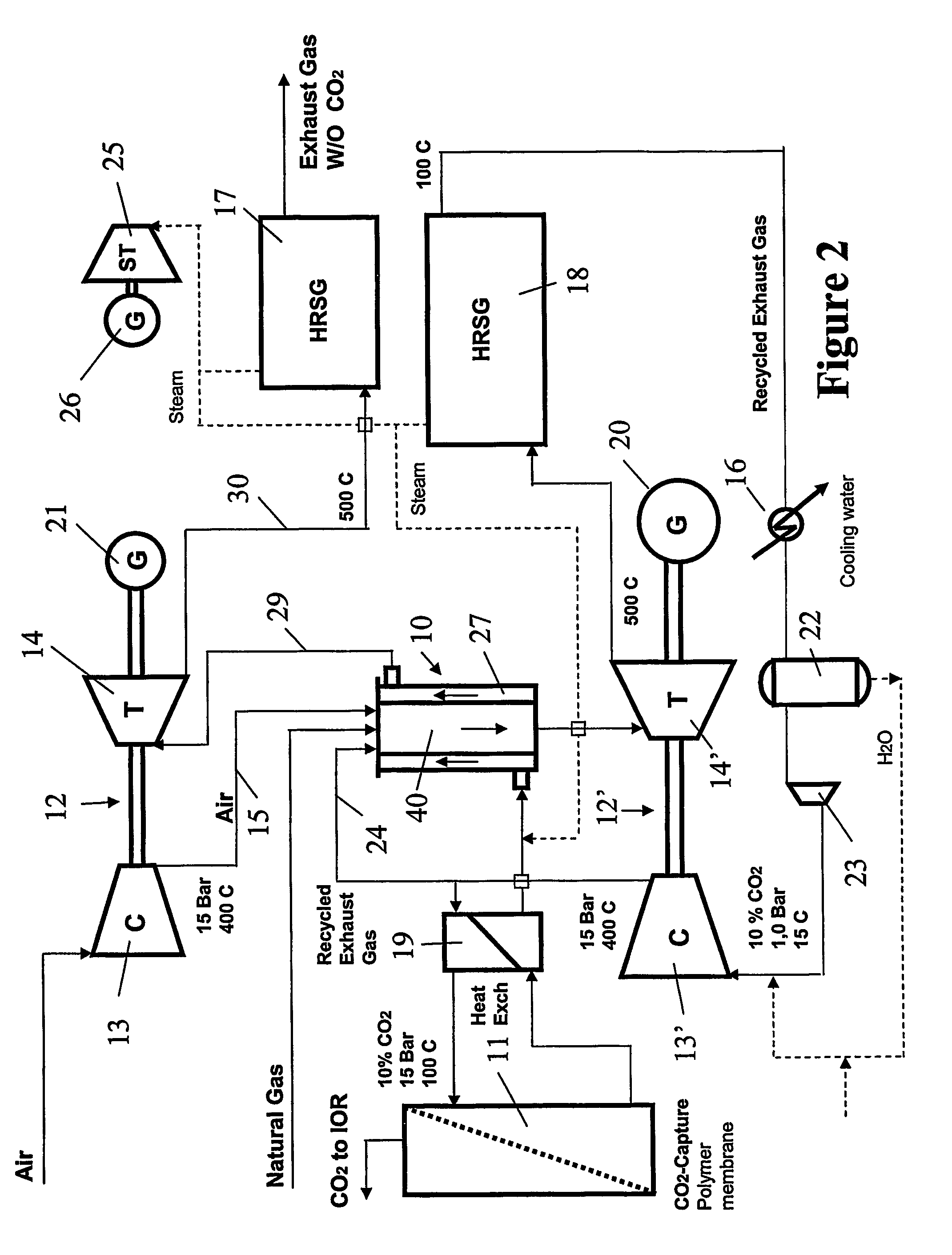

Efficient combined cycle power plant with CO2 capture and a combustor arrangement with separate flows

ActiveUS7490472B2Favourable and improved heat transferMore energyTurbine/propulsion engine coolingDispersed particle separationPower stationCombustor

The invention relates to a method for inter alia to increase the energy and cost efficiency of a gas power plant or a thermal heat plant with CO2 capturing. The power plant comprises gas turbine plants (12,12′) comprising compressor units (13,13′) and turbine units (14,14′) and further comprises a combustor (10). The combustor (10) is working in principle with to separate gas part streams where one gas part stream flows internally through the flame tube (40) of the combustor (10), while the other gas part stream is flowing along the exterior of the flame tube (40). The first gas part stream comprises additional air and re-circulated, un-cleaned flue gas from the combustor (10), said gases being combusted together with fuel inside the flame tube (40). The second gas part stream comprises cleaned flue gas which is heated up at the exterior of the flame tube (40) while the flame tube (40) is cooled down. The invention comprises also a power plant, a combustor and a CO2 capture plant.

Owner:STATOIL ASA PETRO SA (NO)

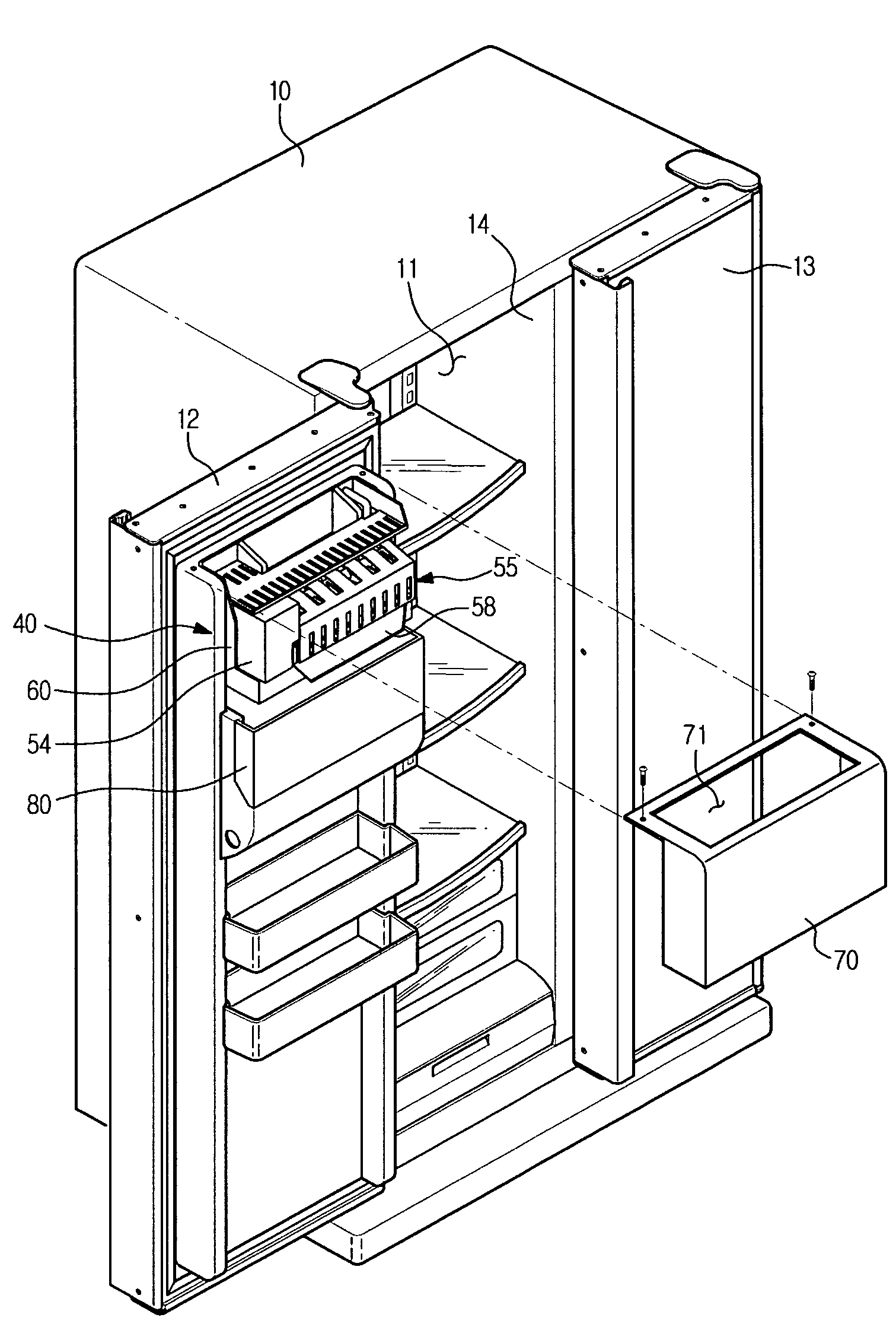

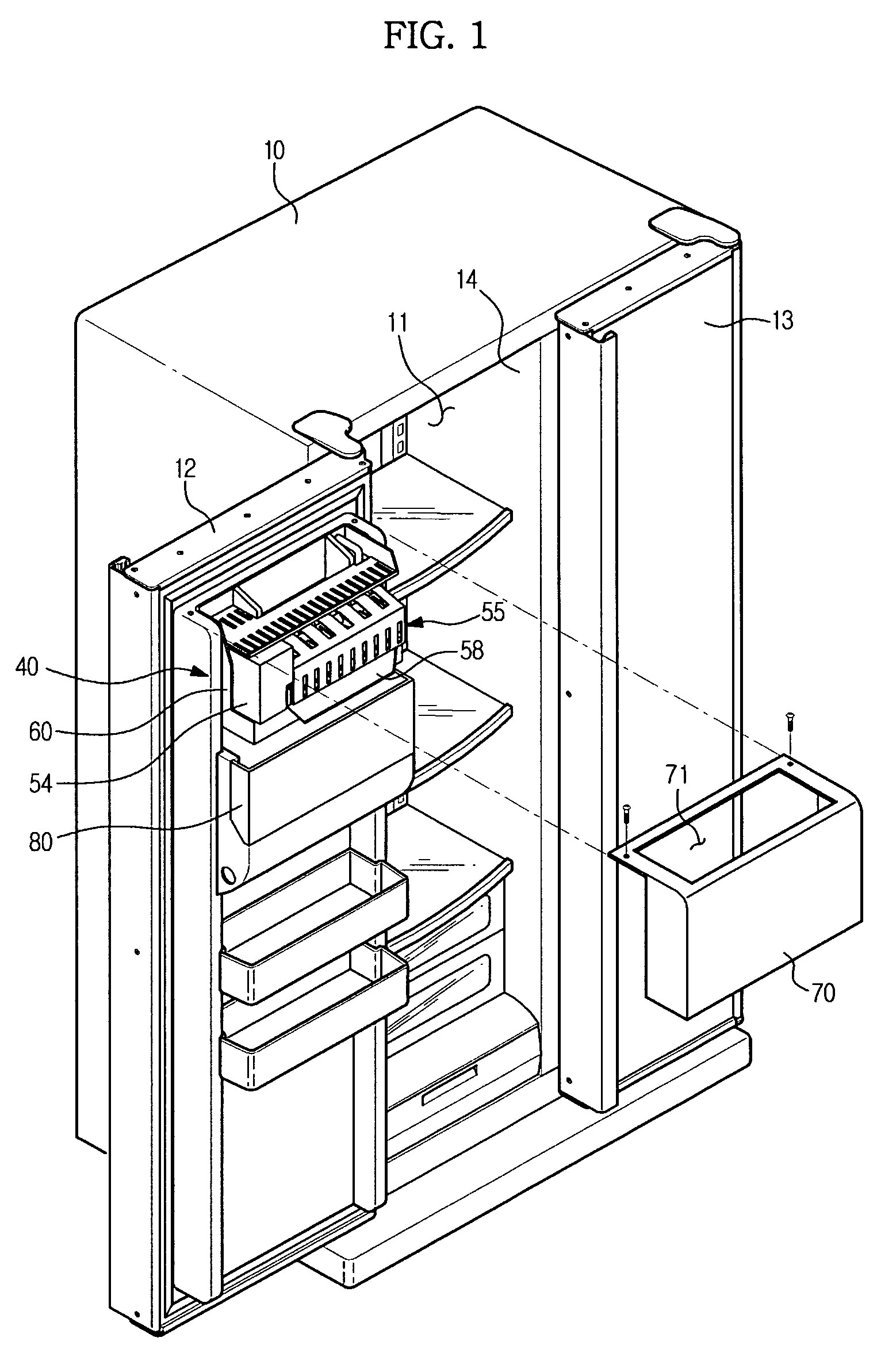

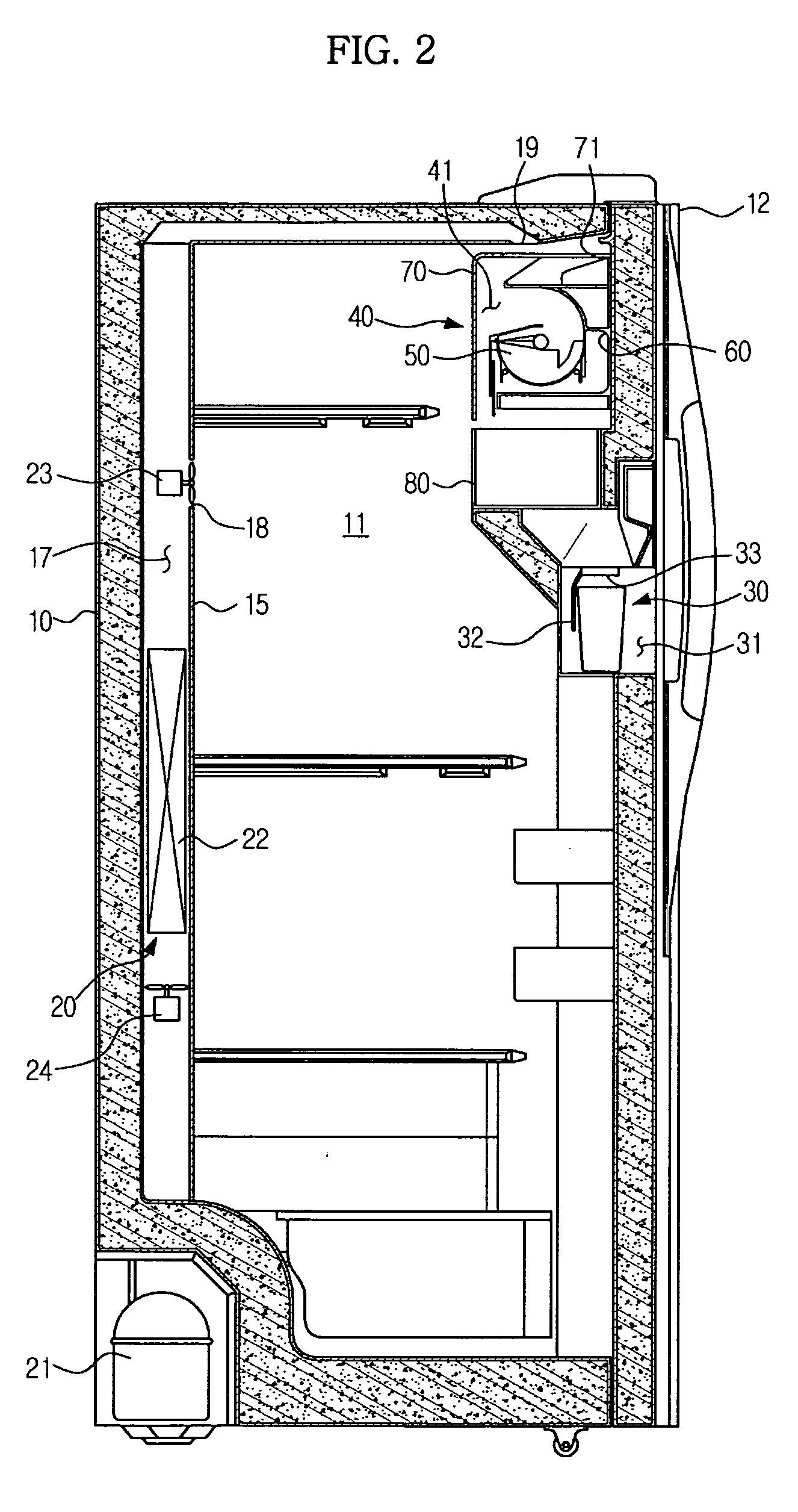

Ice maker and refrigerator having the same

InactiveUS20080295539A1Shorten ice making timeQuality improvementLighting and heating apparatusIce productionEngineeringCooling down

A refrigerator includes a refrigerator main body having a storage chamber, a door coupled to the refrigerator main body to be opened or closed, a cool air supplying device which generates cool air, an ice maker including an ice making tray having ice making cells to produce ice and a cool air guide member installed in the door, coupled to the ice making tray and having a cool air line that guides the cool air supplied from the cool air supplying device to flow around the ice making tray. The cool air line disposed on the cool air guide member to supply the ice making tray guides the cool air supplied from the cool air supplying device to move along the surrounding of the ice making tray, thereby uniformly cooling down the ice making tray.

Owner:SAMSUNG ELECTRONICS CO LTD

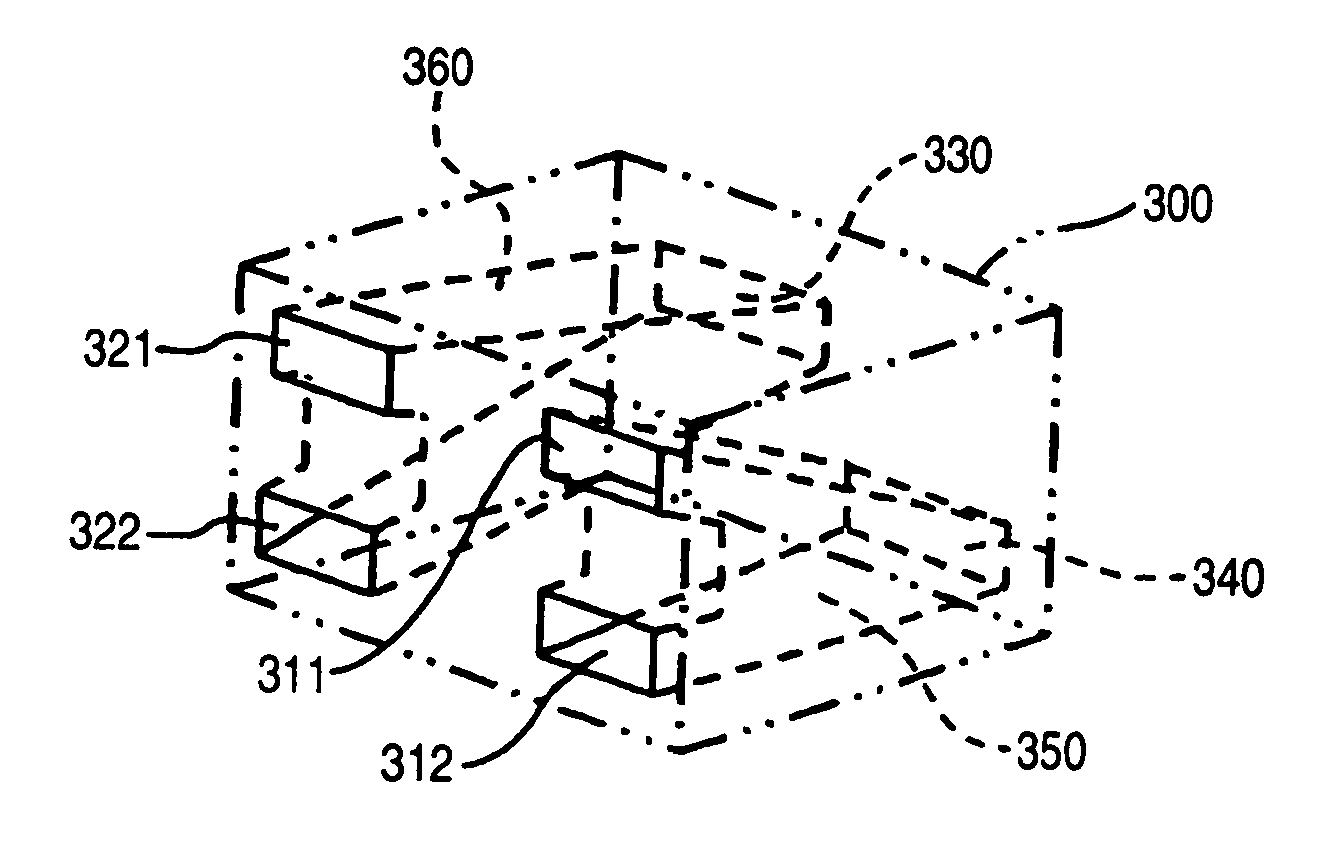

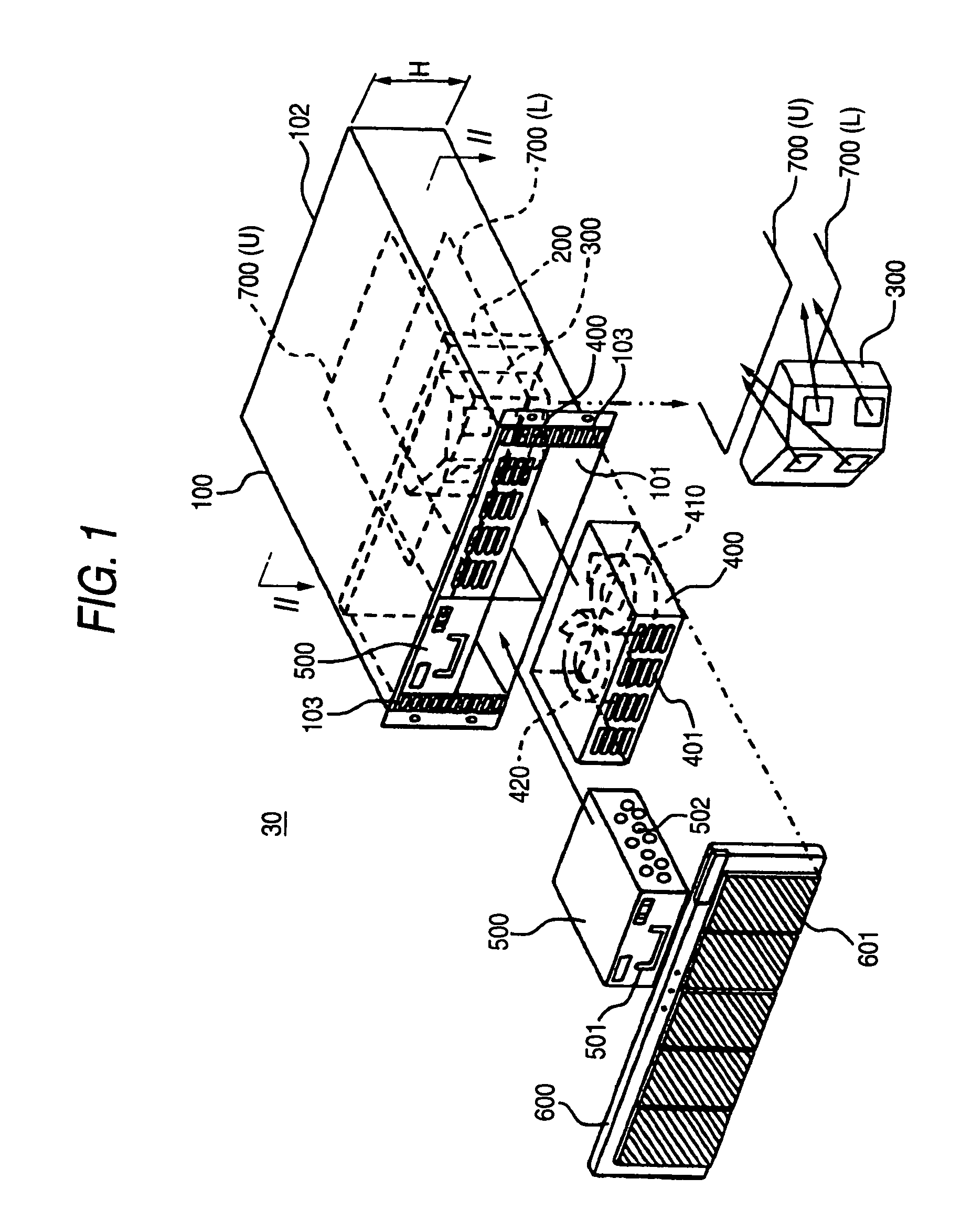

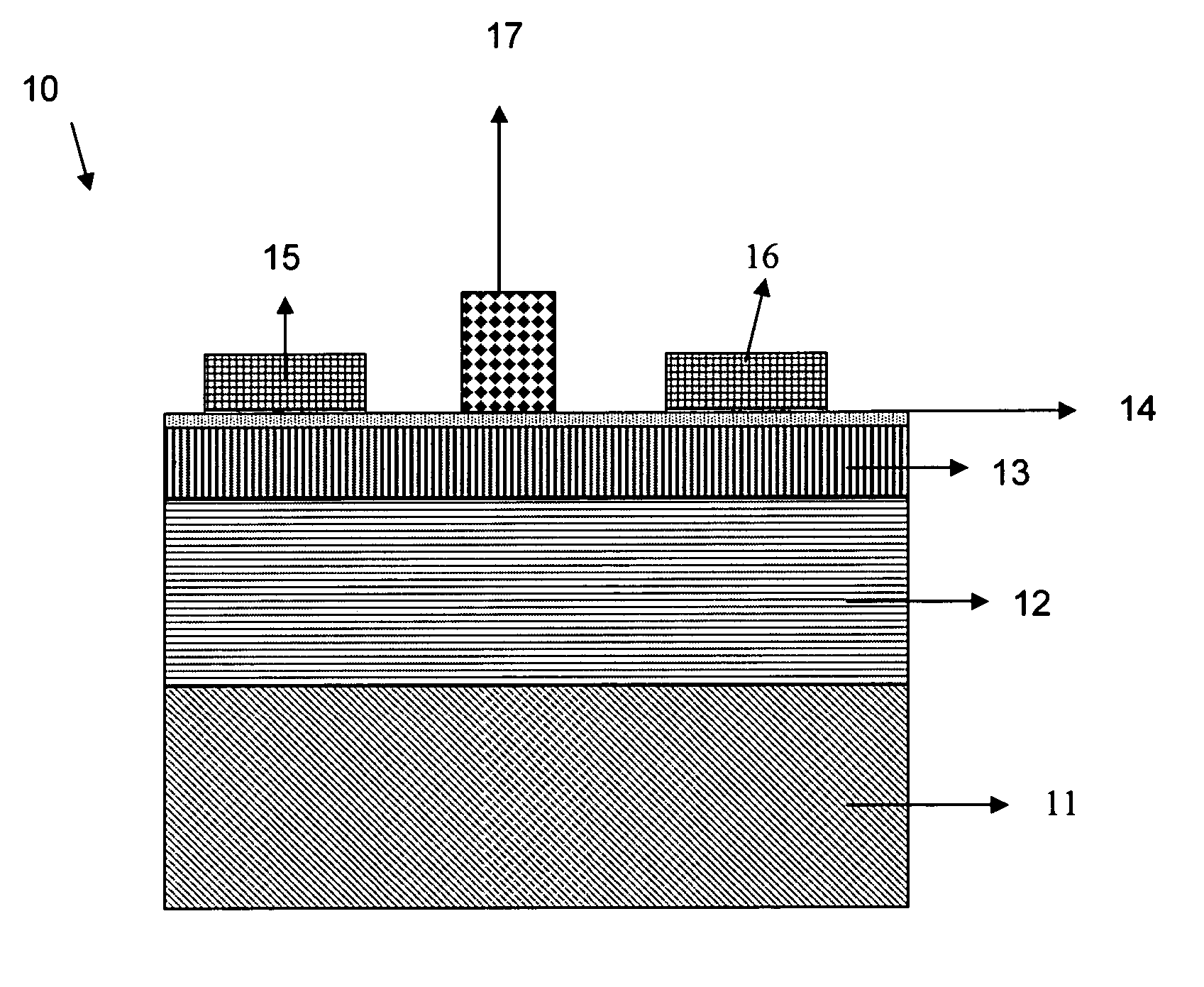

Electronic equipment

InactiveUS7042722B2Improve reliabilityEfficient use ofDigital data processing detailsReducing physical parameters of carriersComputer moduleEngineering

An object is to effectively cool down an electronic equipment which is face with height limitations and tends to readily increase in heat generation amount to thereby provide the reliability required. The interior of a chassis of a control unit is partitioned by a back board into a front side space and a rear side space. In the rear side space, two control modules are attached so that these are stacked up and down, while two fan modules and a single duct member are attached in the front side space. Each fan module has two fans as built therein. A cooling air stream or “wind” from each fan flows into the lower-side control module through the duct member and others, whereas a cooling wind from the other fan flows into the upper-side control module. Even when either one of the fan modules goes down during operation, it is still possible by using the remaining fan module to cool down the both control modules.

Owner:HITACHI LTD

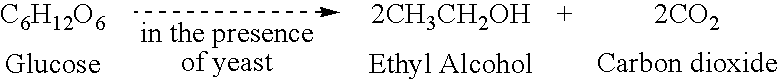

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

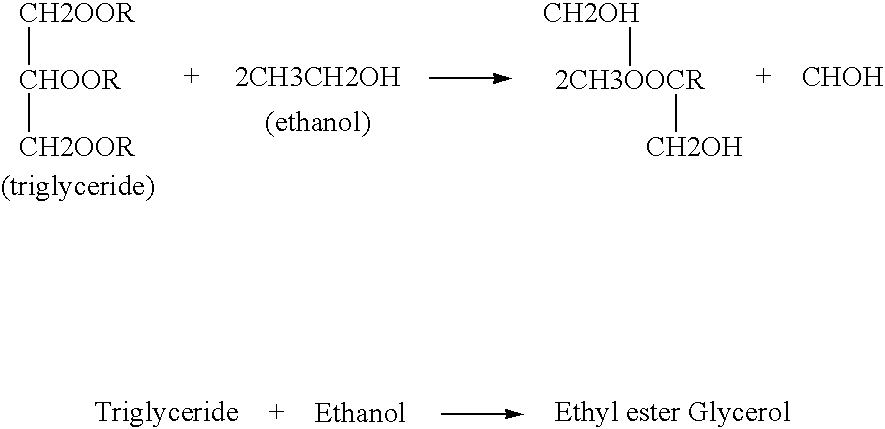

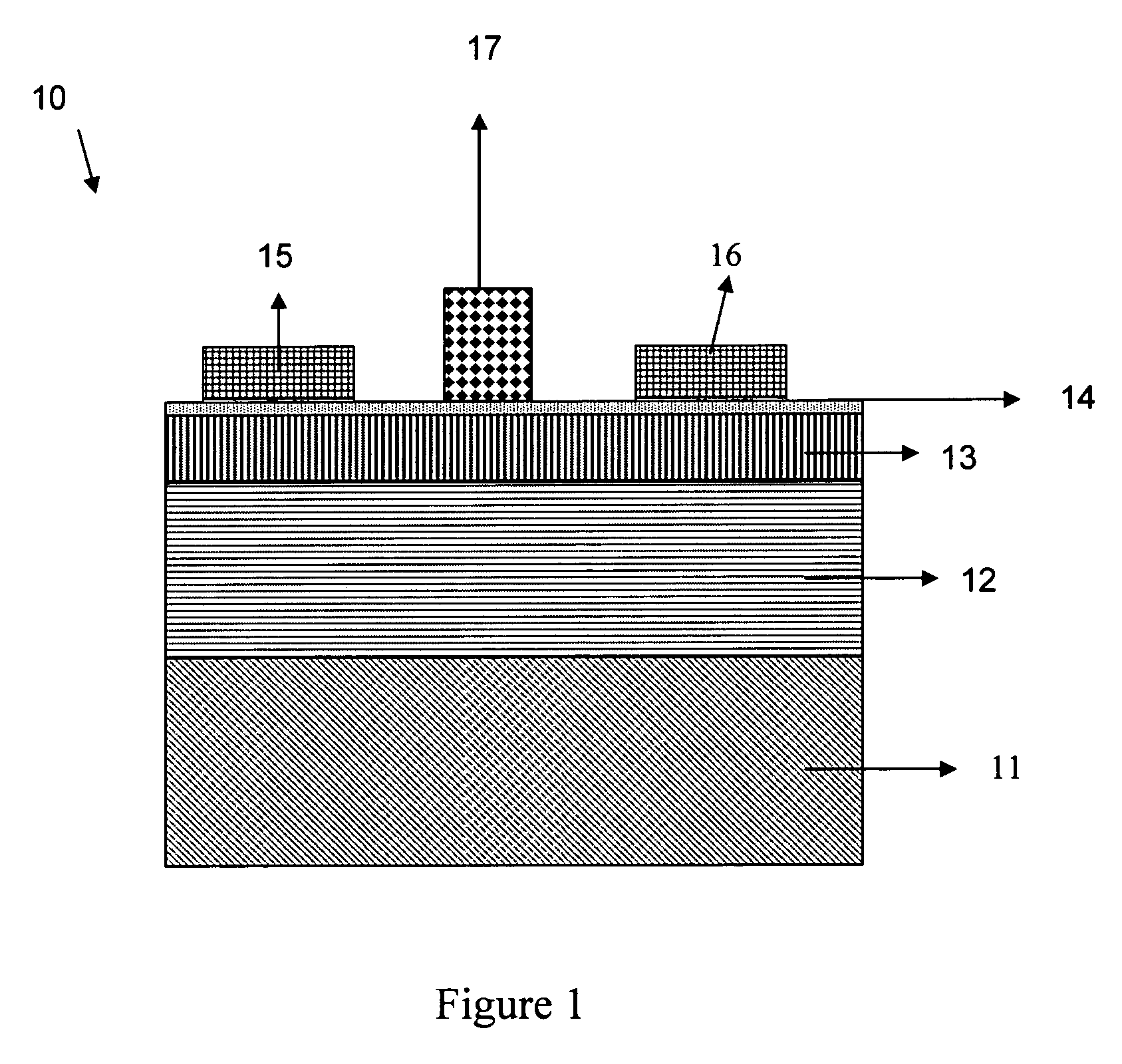

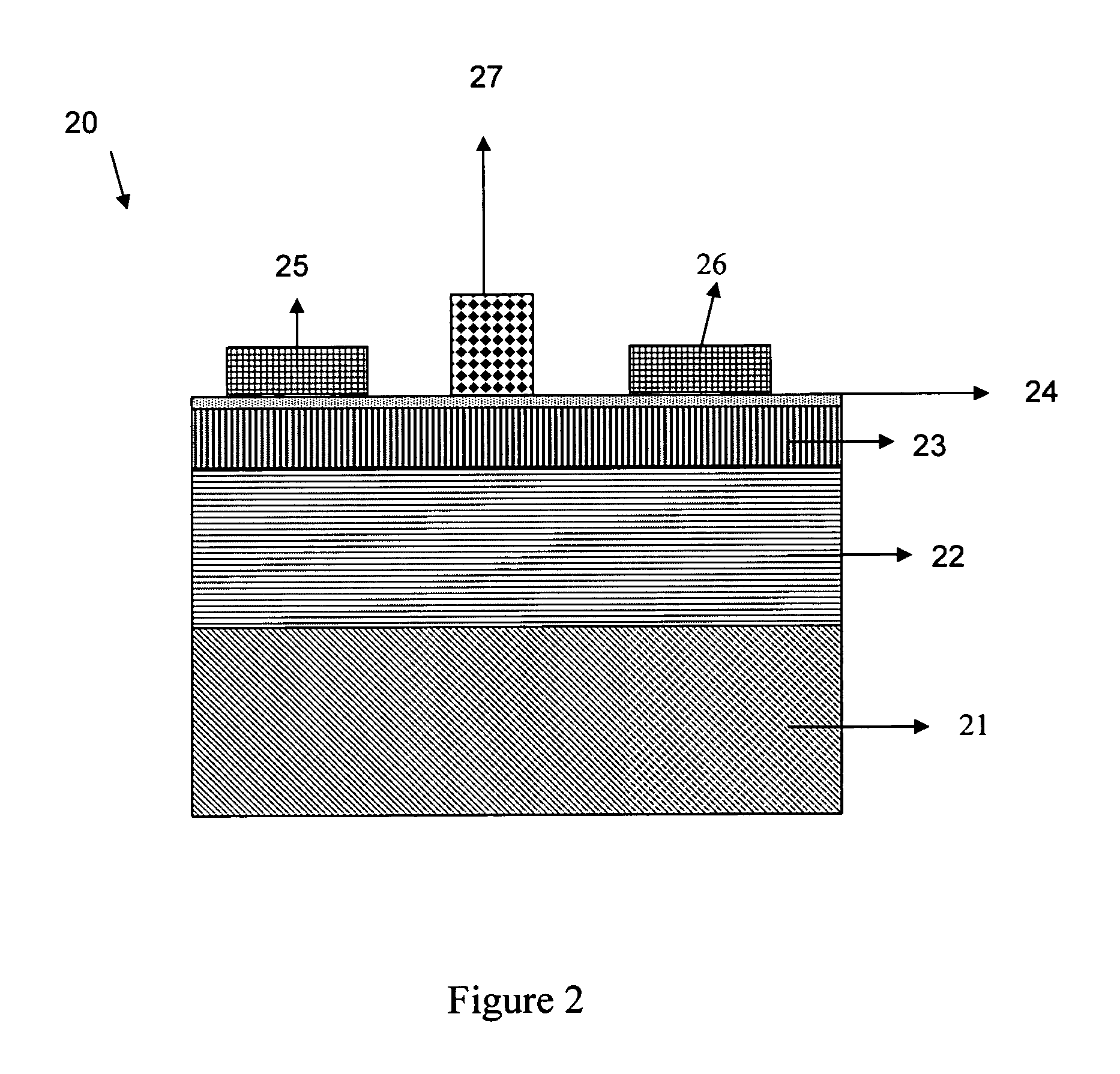

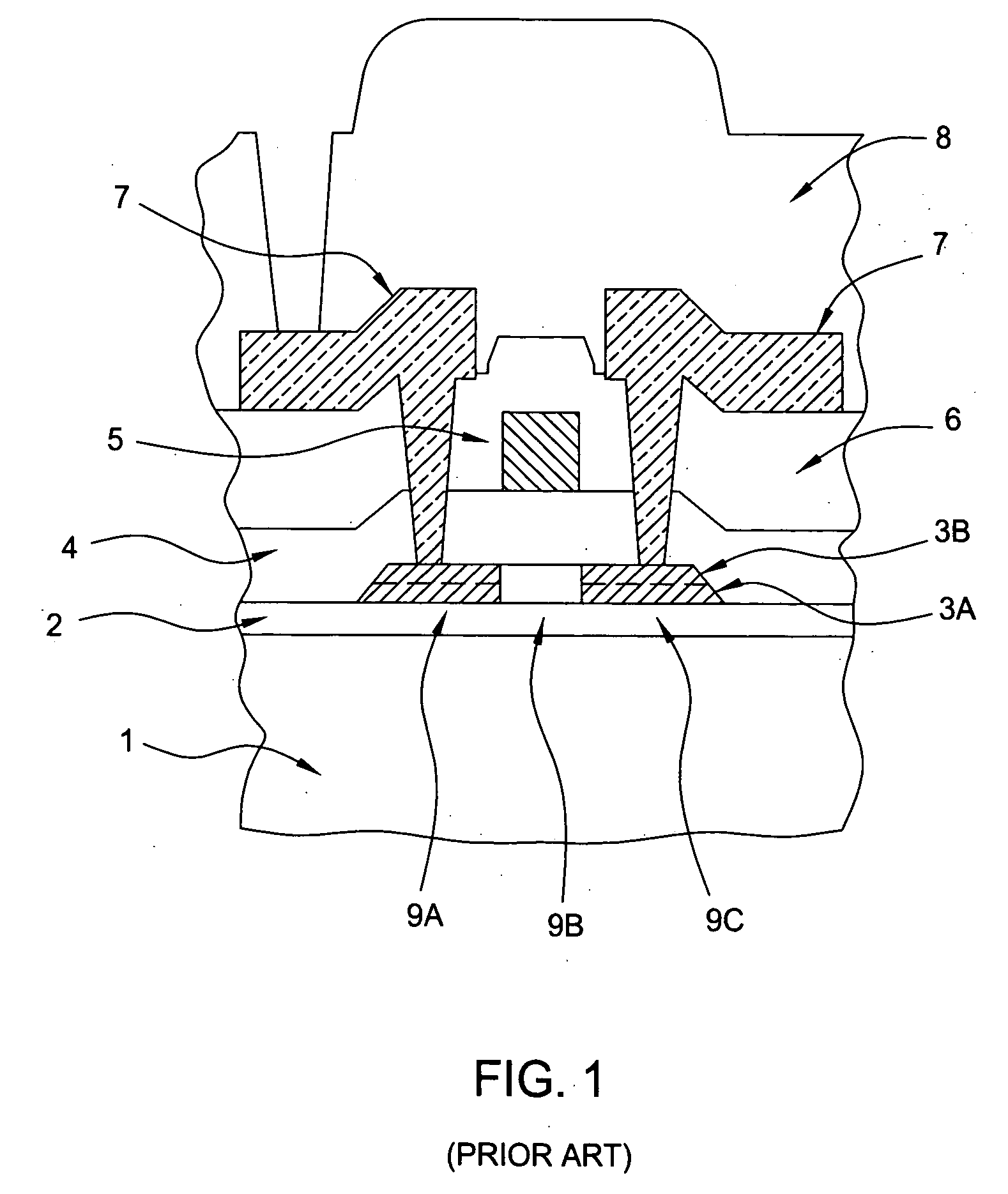

AlGaN/GaN high electron mobility transistor devices

ActiveUS20060006414A1Avoid crackingReduce the appearance of cracksSolid-state devicesSemiconductor/solid-state device manufacturingMESFETCooling down

The present invention recites a new method for manufacturing Group III-N field-effect devices, such as HEMT, MOSHFET, MISHFET devices or MESFET devices, grown by Metal-Organic Vapor Phase Expitaxy, with higher performance (power), by covering the surface with a thin SiN layer on the top AlGaN layer, in the reactor where the growth takes place at high temperature, prior cooling down the structure and loading the sample out of the reactor, as well as a method to produce some HEMT transistors on those heterostructures, by depositing the contact on the surface without any removal of the SiN layer by MOCVD. The present invention recites also a device.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

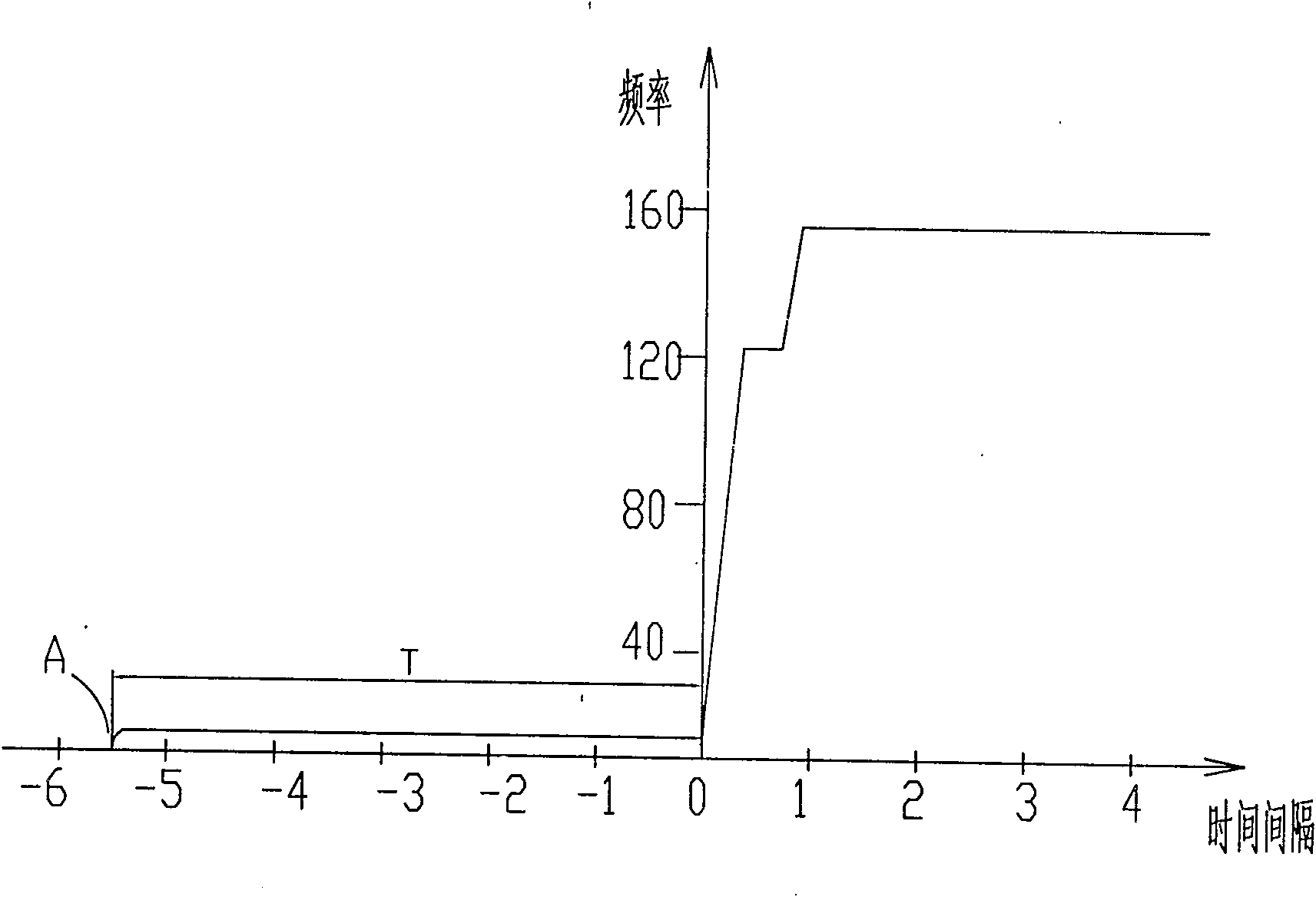

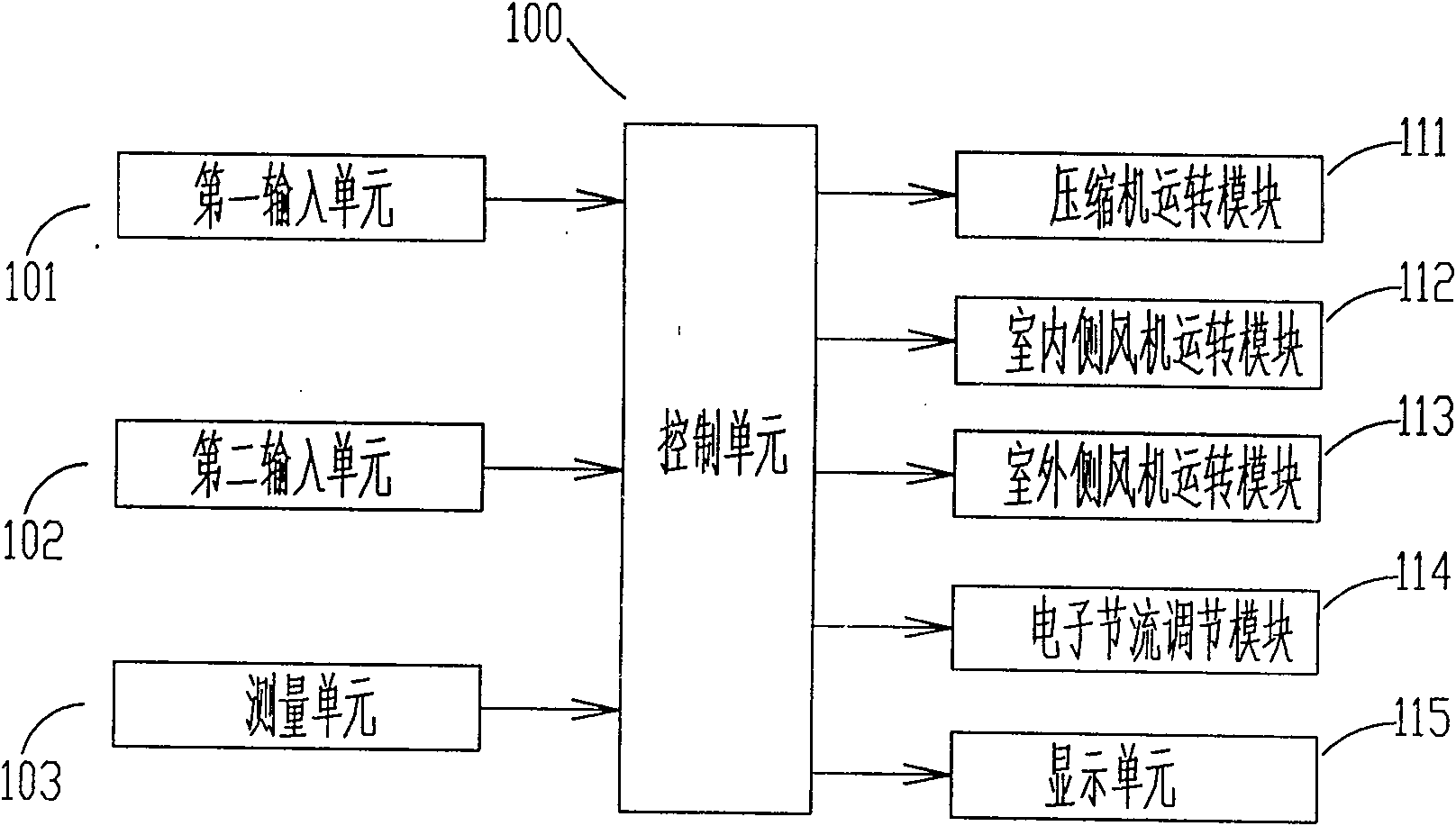

Control method for improving comfortability of frequency conversion air conditioner wind-discharging temperature

ActiveCN101586866AReduce waiting timeImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusFrequency conversionCooling down

A control method for improving comfortability of frequency conversion air conditioner wind-discharging temperature is characterized in that before opening the refrigeration / heat-production of the frequency conversion air conditioner, the frequency conversion air conditioner runs in a precooling / preheating mode, by means of alterring an operation frequency of a compressor and an operation frequency of a fan of an outdoor heat excharger. The control method includes the following steps: opening the precooling / preheating mode; the compressor operates at a first rotary speed during a first period; the fan of the outdoor heat excharger operates at a second rotary speed during the first period; opening the refrigeration / heat-production mode, the fans of the compressor and the outdoor heat excharger operate at a normal rotary speed. The first rotary speed is a speed having a frequency number of 0-37.5Hz, the second rotary speed is a speed having a frequency number of 0-30Hz. By means of the invention, it is capable of ensuring a temperature of an air outlet of an indoor set of the air conditioner to be a user setting temperature stably, so as to reduce a time for cool-down of the air conditioner.

Owner:MIDEA GRP CO LTD

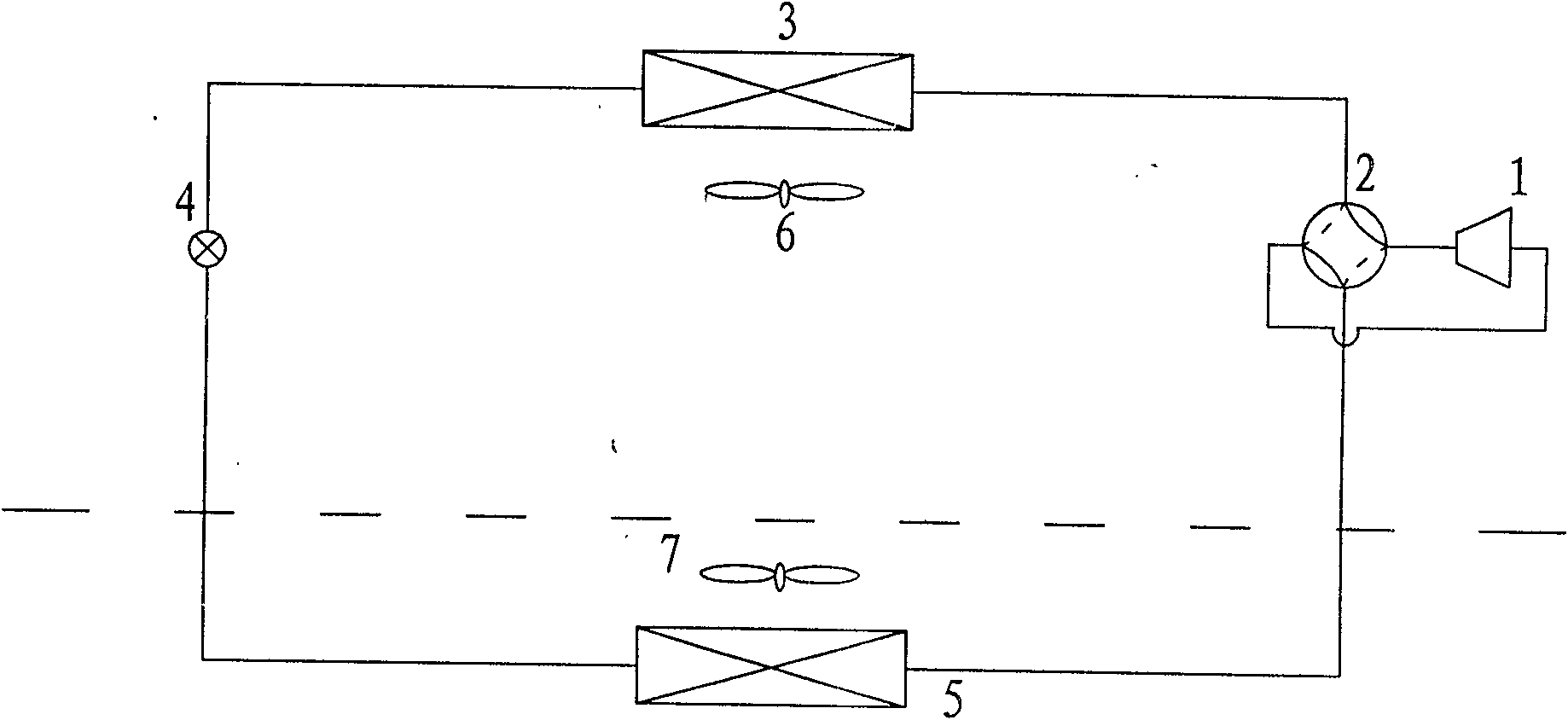

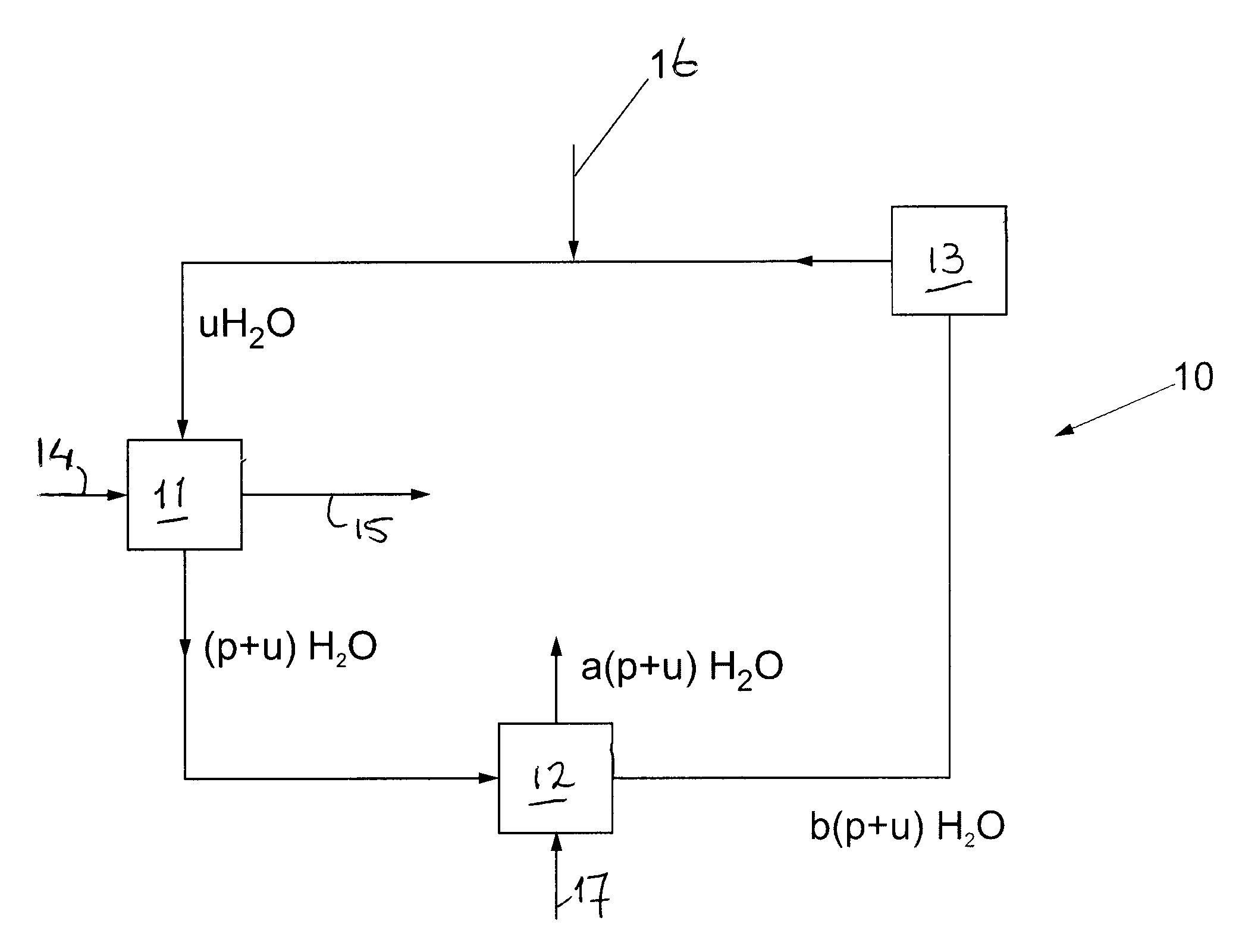

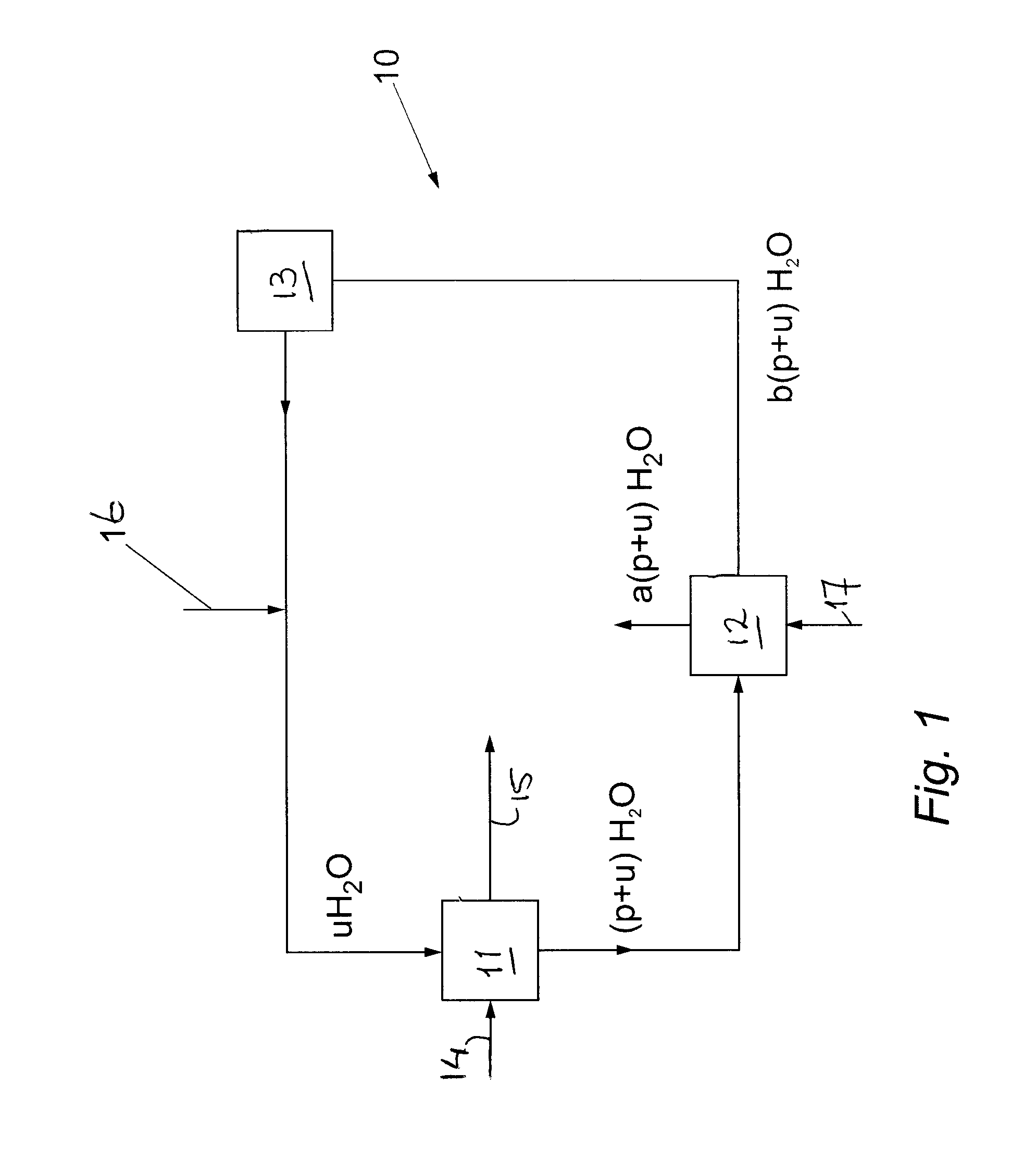

Process for cooling down a hot flue gas stream

InactiveUS7655071B2Reduce water consumptionConserve waterMethane captureCarbon compoundsFlue gasEvaporation

A process for cooling down a hot flue gas stream comprising water vapour and carbon dioxide, the process including: (a) heat exchange between the hot flue gas stream and a cooling water stream so that the hot flue gas stream is cooled to a cooled down gas stream at a temperature at which at least part of the water vapour therein has condensed and the cooling water stream increases in temperature; (b) combining the condensed water vapour and the cooling water stream to produce a combined water stream; (c) separation of the cooled down gas stream from the combined water stream; (d) cooling the combined water stream by contact with air from the atmosphere and by evaporation of a portion of the combined water stream; (e) using at least part of any non-evaporated and cooled water of the combined water stream as at least part of the cooling water stream for cooling the hot flue gas stream in step (a); and (f) storing any non-evaporated and cooled water of the combined water stream that is not used in step (e) and using the stored water later as at least part of the cooling water stream in step (a).

Owner:SHELL OIL CO

Clear coating composition having improved early hardness and water resistance

InactiveUS6472493B1Improve efficiencyRemove blemishesLiquid surface applicatorsPolyurea/polyurethane coatingsPolyesterOrganic fluid

A fast hardening clear coating composition for repairing a clearcoat / colorcoat finish of a vehicle, which composition is capable of being wet sanded, buffed or polished to a high gloss finish on the same day of application, comprising a film forming binder and an organic liquid carrier, where the binder contains a hydroxyl component comprising a hydroxyl-containing acrylic polymer and a hydroxyl-terminated polyester oligomer, and an organic polyisocyanate crosslinking component, at least portion of which comprises a trimer of isophorone diisocyanate, where the composition further contains, as a combined curing catalyst, at least one dialkyl tin aliphatic carboxylate, at least one tertiary aliphatic mono or diamine, and at least one aliphatic carboxylic acid, in an effective amount such that the clear coating composition on curing at ambient temperatures is in a water spot free and sufficiently hard state for sanding or buffing within about 4 hours after application or on cool down when baked under normal conditions.

Owner:AXALTA COATING SYST IP CO LLC

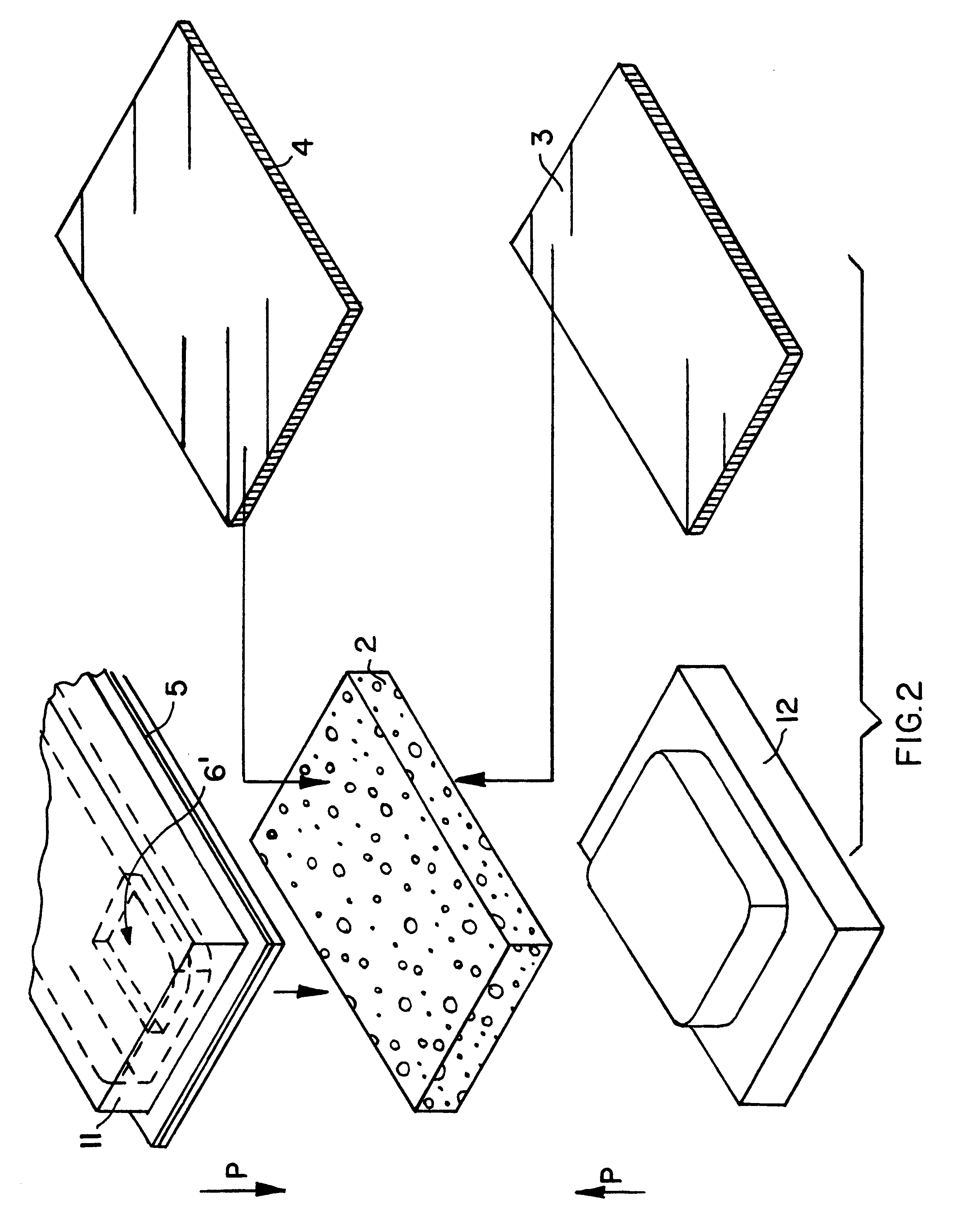

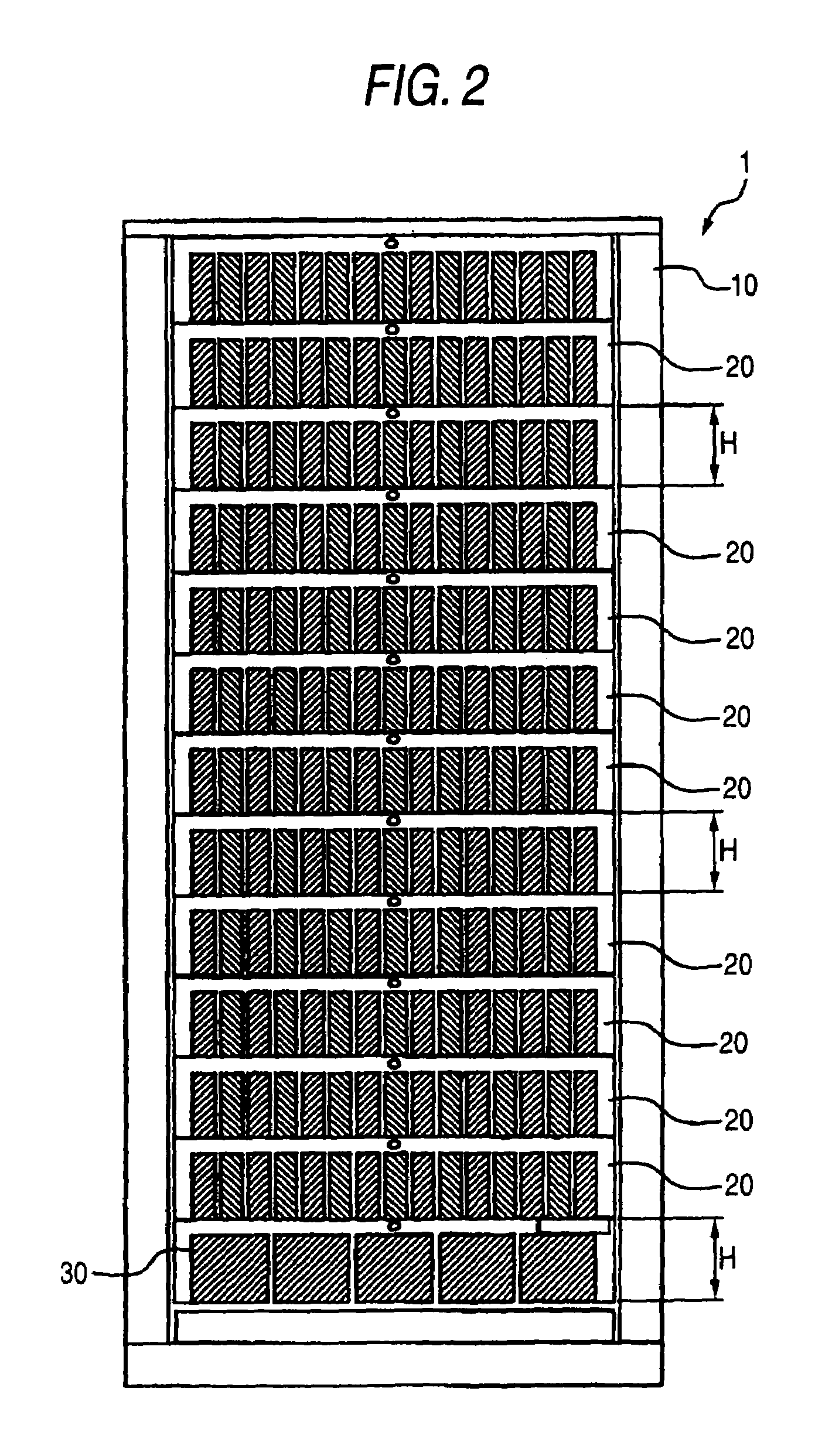

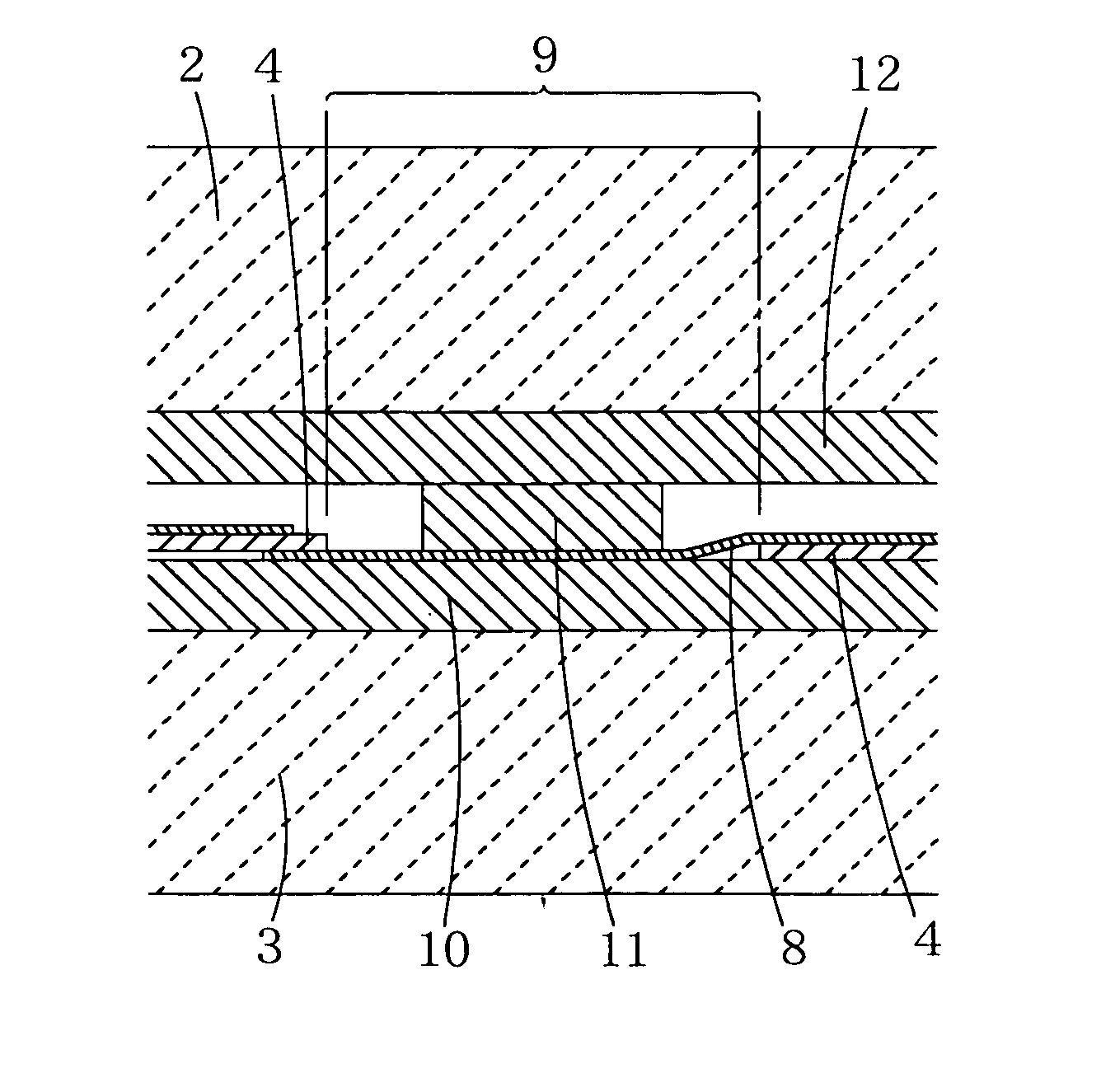

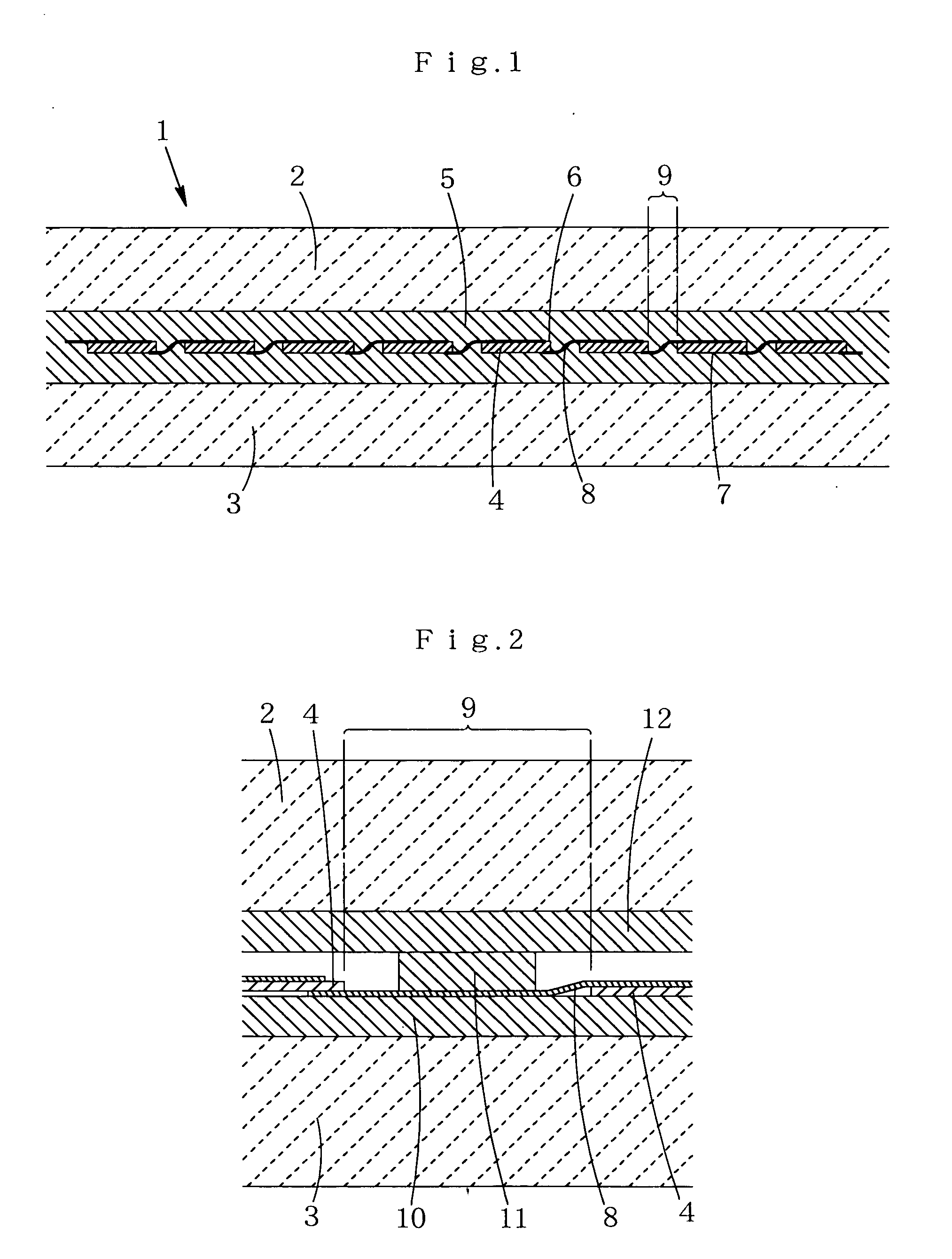

Solar battery module manufacturing method

ActiveUS20050274410A1Control generationEffectively inhibit flowingPV power plantsSolid-state devicesEngineeringCooling down

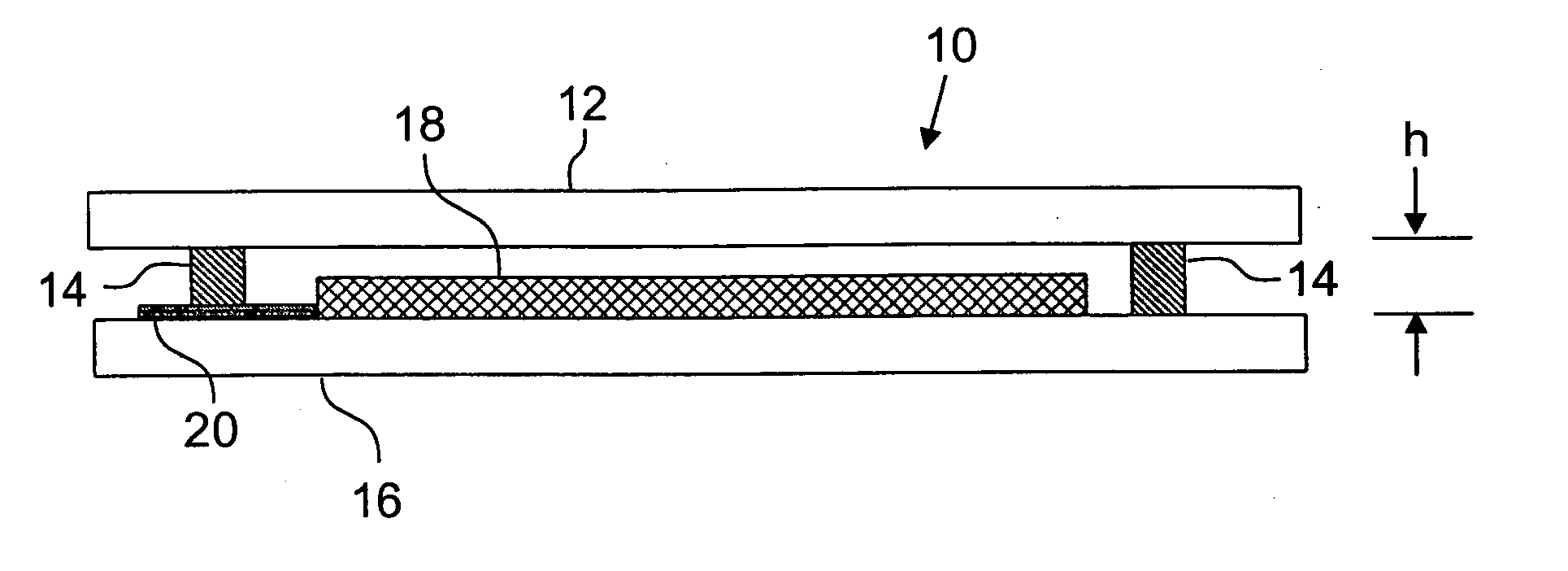

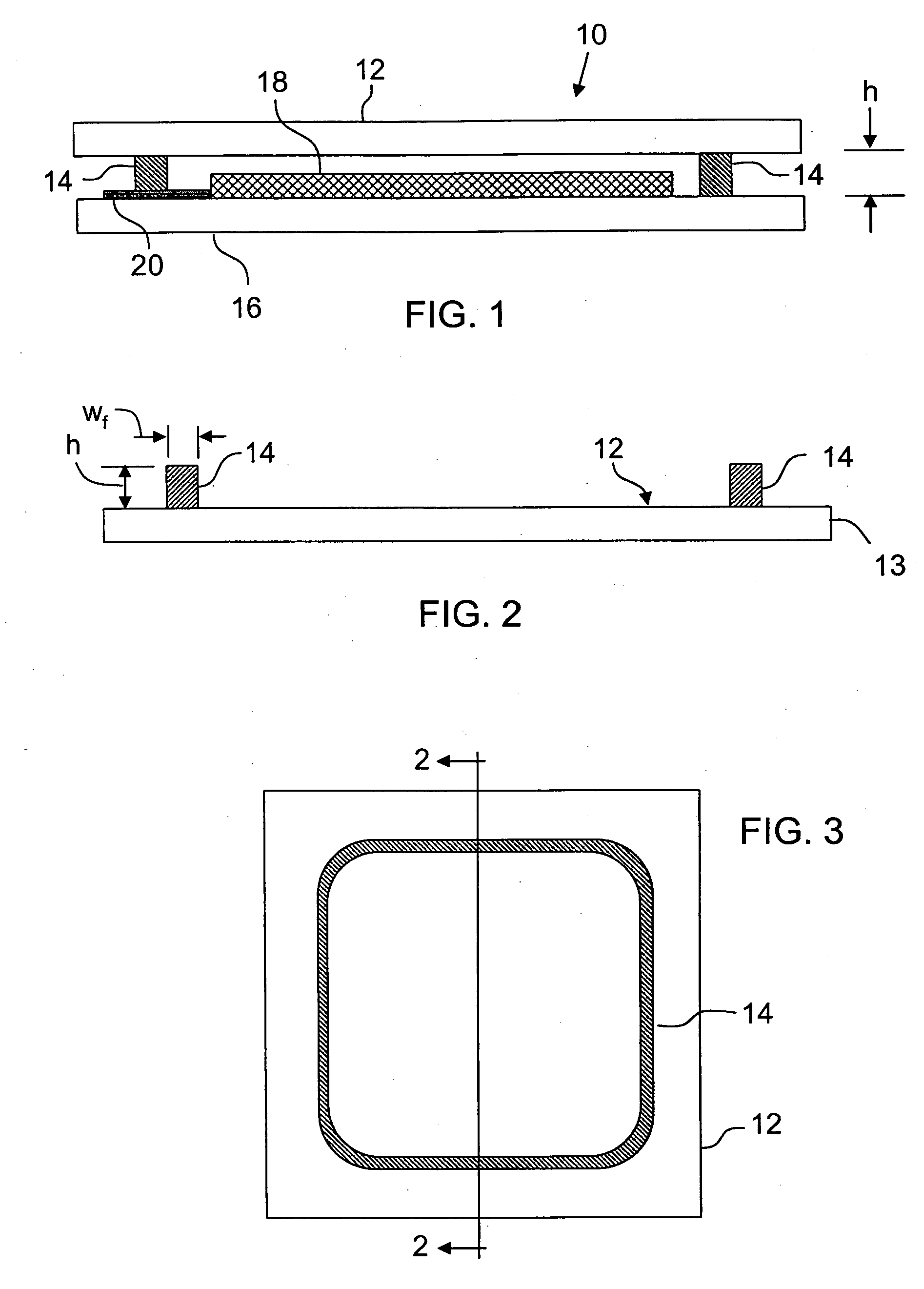

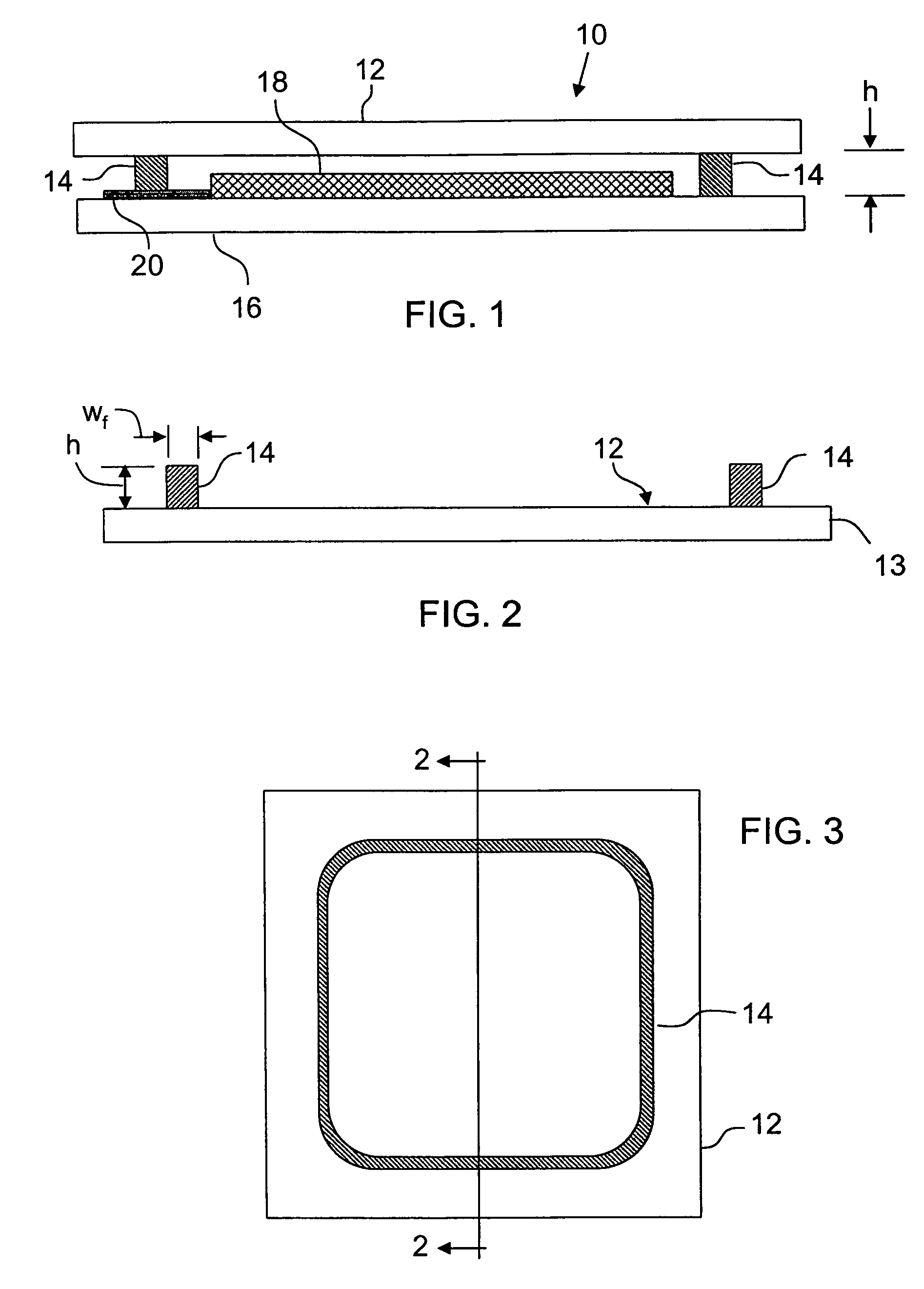

Provided is a process of producing a solar battery module 1 including plural solar battery cells 4 sealed by a resin 5 between a transparent panel 2 of the light reception surface side and a back face panel 3, which is characterized by arranging plural solar battery cells 4 at a prescribed interval and mutually connecting them to each other by a conductor 8; arranging a first sealing resin sheet 12 substantially covering the entire surface of the transparent panel 2 of the light reception surface side between the transparent panel 2 of the light reception surface side and the solar battery cells 4; arranging a second sealing resin sheet 10 substantially covering the entire surface of the back face panel 3 between the back face panel 3 and the solar battery cells 4; arranging sealing resin sheet pieces 18, 19 which are thicker than the solar battery cells 4 at a space 9 between the solar battery cells 4 so as to be sandwiched by the first sealing resin sheet 12 and the second sealing resin sheet 10; discharging air between the transparent panel 2 of the light reception surface side and the back face panel 3; and heating the resin 5 for melting and then cooling down it for sealing. According to this, when the plural solar battery cells 4 are arranged and sealed by the resin 5, breakage of the solar battery cells 4 can be prevented from occurring.

Owner:NAKAJIMA GLASS

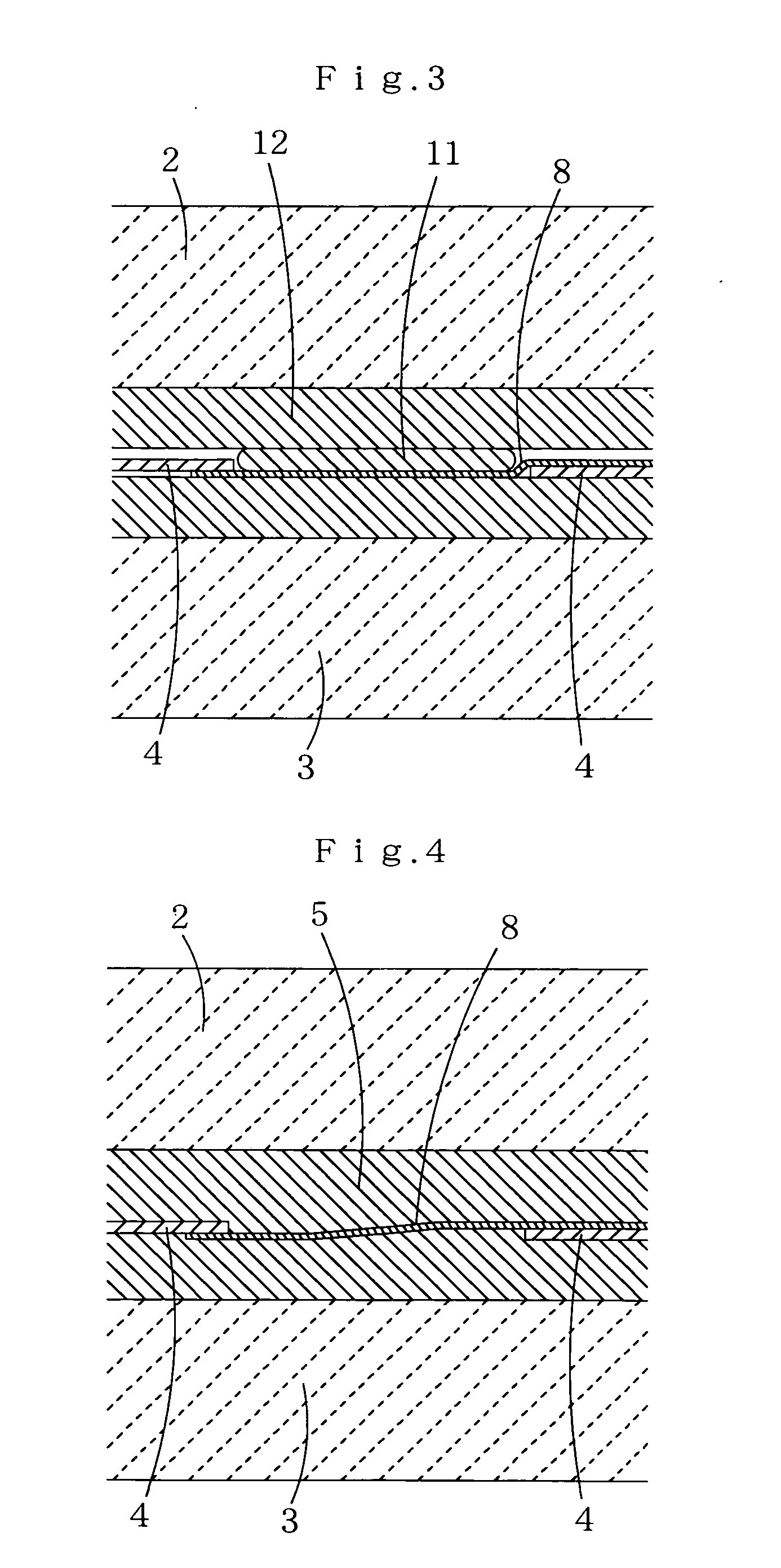

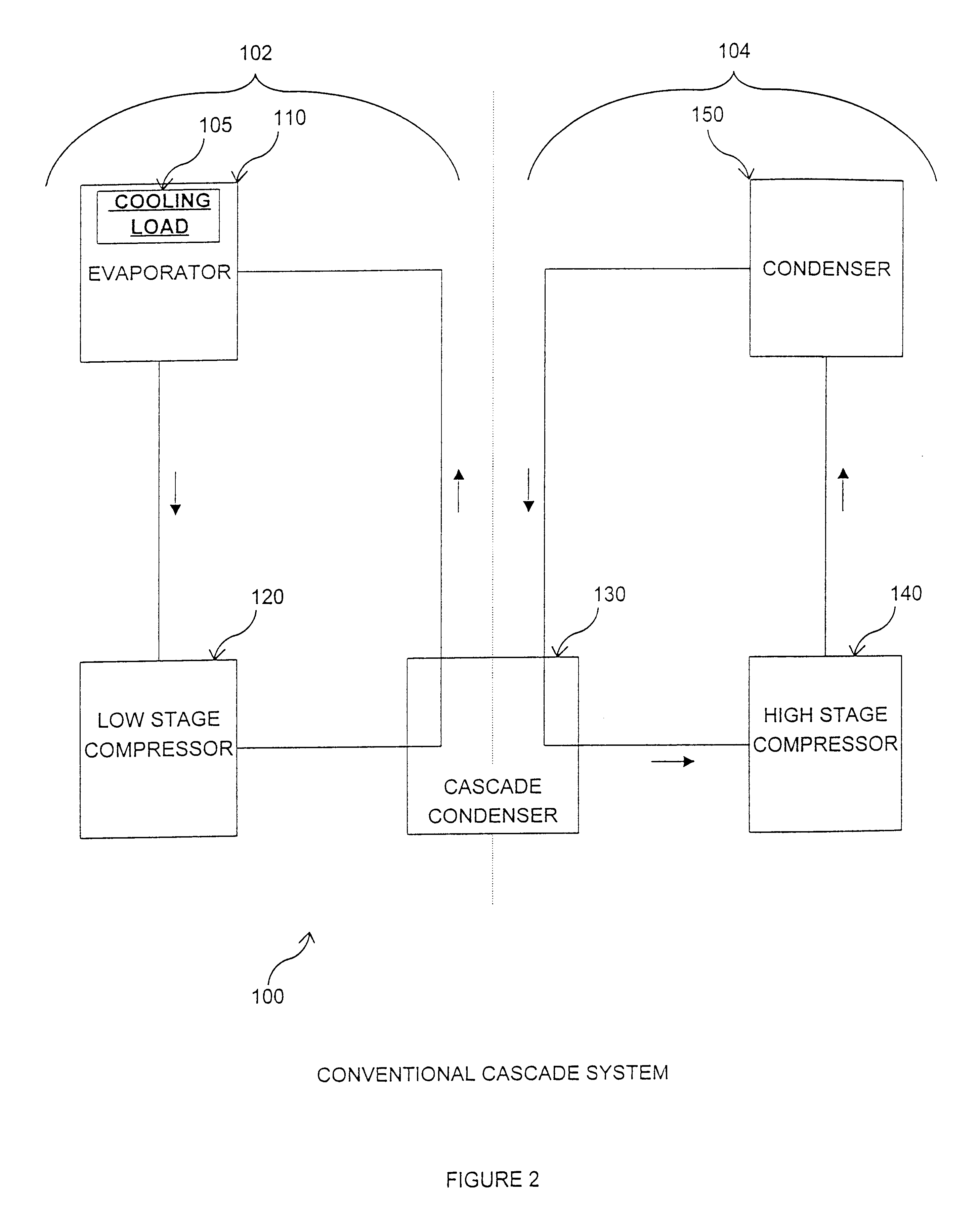

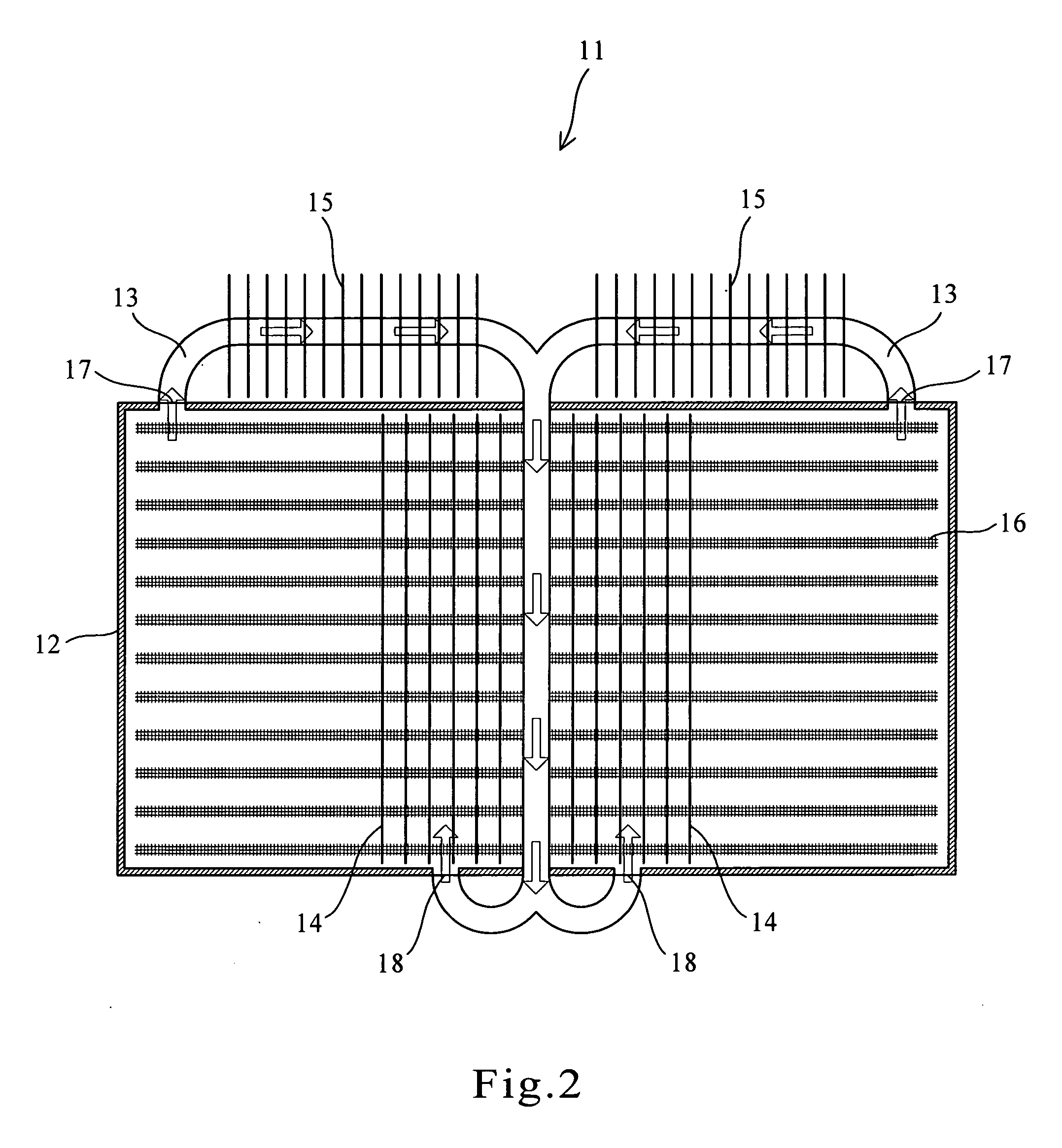

Environmental test chamber fast cool down and heat up system

InactiveUS6460355B1Improve energy efficiencyLow calorie contentWeather/light/corrosion resistanceCompression machines with several evaporatorsNuclear engineeringCooling down

An environmental test chamber provides a fast cool down to a temperature of about -125° F. and a fast heat up of an element under test.

Owner:TRIESKEY GUY T

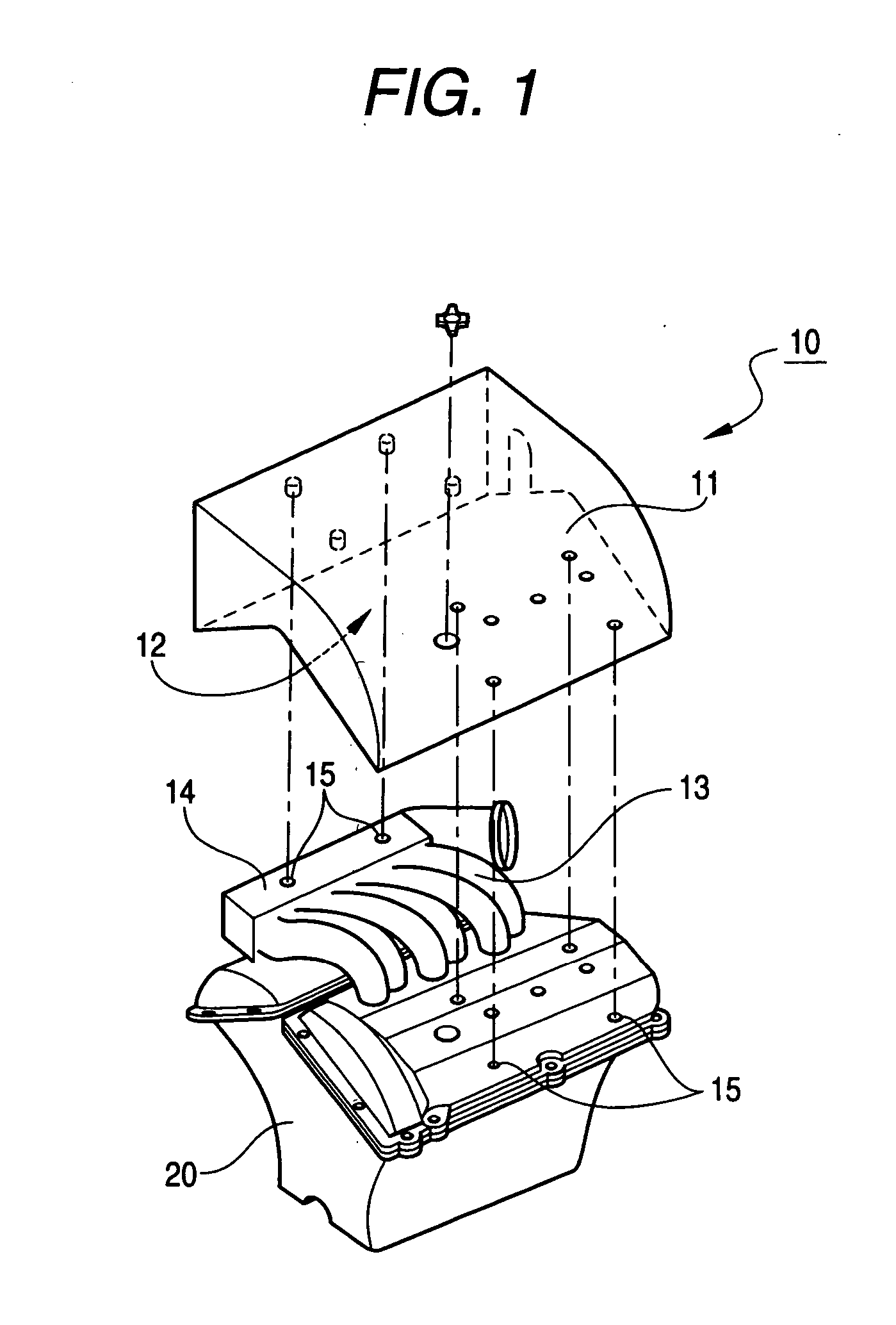

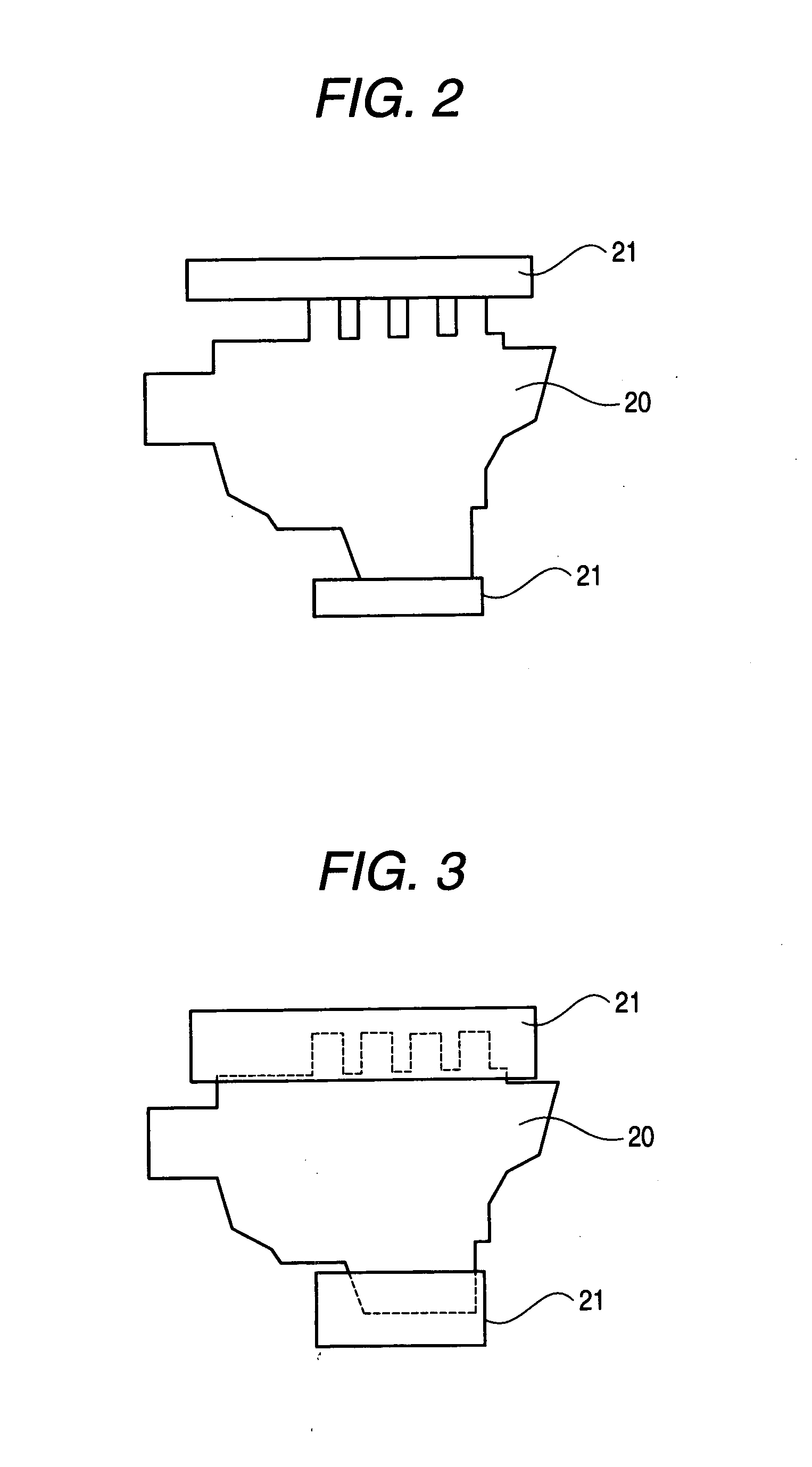

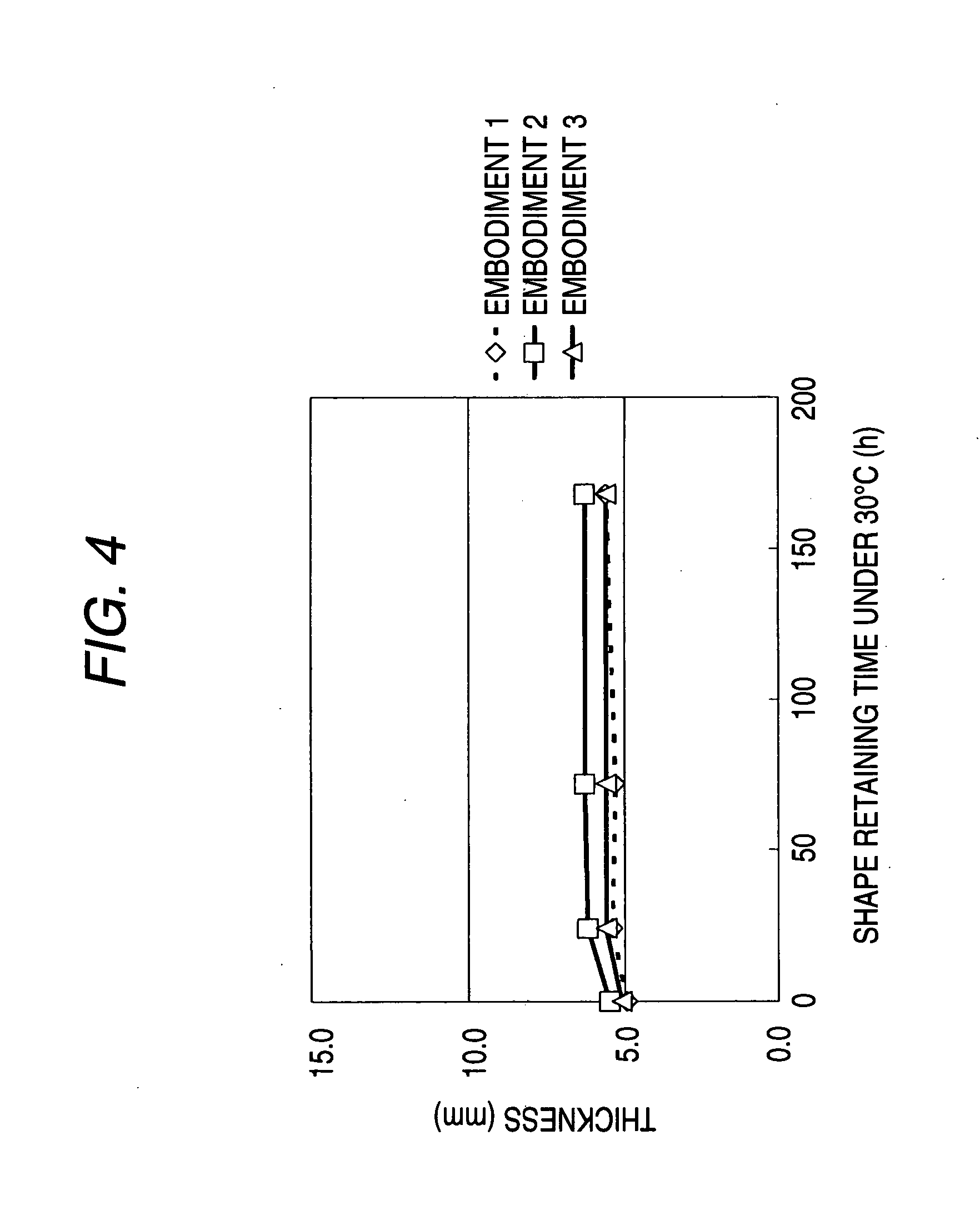

Shape memory foam material

InactiveUS20040164499A1Excellent mounting property and soundproof performanceImprove insulation effectEngine sealsMachines/enginesSurface layerRoom temperature

A shape memory foam material is obtained by impregnating a base foam material in a thermoplastic substance, heating and compressing the same at a temperature the same as or higher than the softening temperature of a thermoplastic substance as well as less than the softening temperature of the base foam material, cooling down while retaining the compressed state, and releasing the pressure after the cooling operation. The compressed state of the shape memory foam material is retained in a room temperature by a hardened product of a thermoplastic substance existing at least in the surface layer part thereof. The compressed state is released by softening the hardened product by heating. Moreover, a soundproof cover for an automobile engine is obtained using this shape memory foam.

Owner:NICHIAS CORP

Storage battery temperature regulator having thermoelectric transducer, and vehicle including the storage battery temperature regulator

InactiveUS7061208B2Batteries circuit arrangementsThermoelectric device with peltier/seeback effectTransducerEngineering

A temperature regulator efficiently regulates a temperature of a storage battery. The regulator includes a thermoelectric transducer having a first face and a second face. The first face is thermally coupled with one or plural storage batteries, and the second face is thermally coupled with a thermal action accelerating medium that accelerates thermal action on the second face. The first face and the second face do two jobs contradictory to each other, i.e., heat dissipation and heat absorption, responsive to a polarity in exciting the battery. This structure allows the temperature regulator to cool down and warm up the storage battery.

Owner:PANASONIC CORP

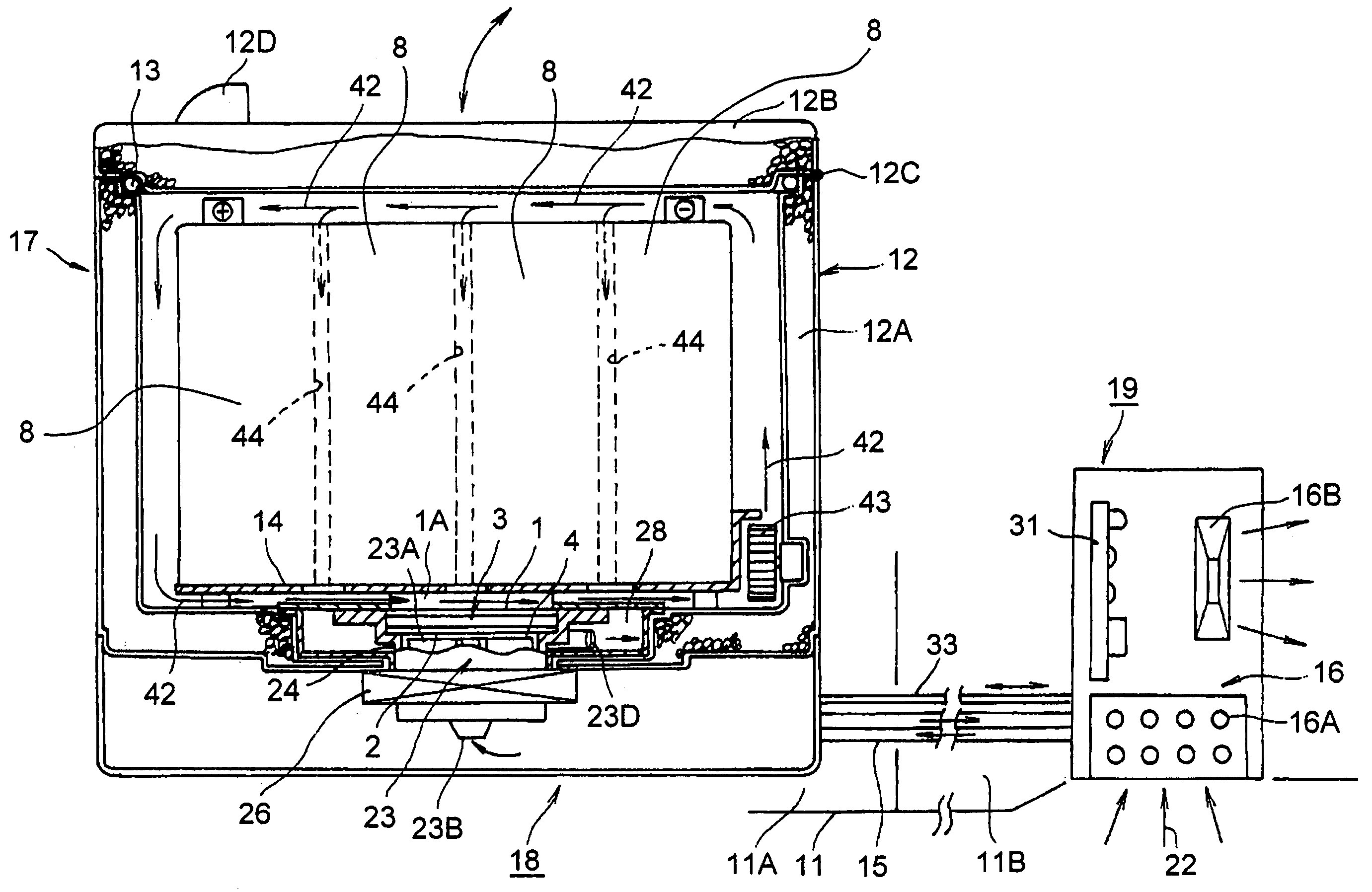

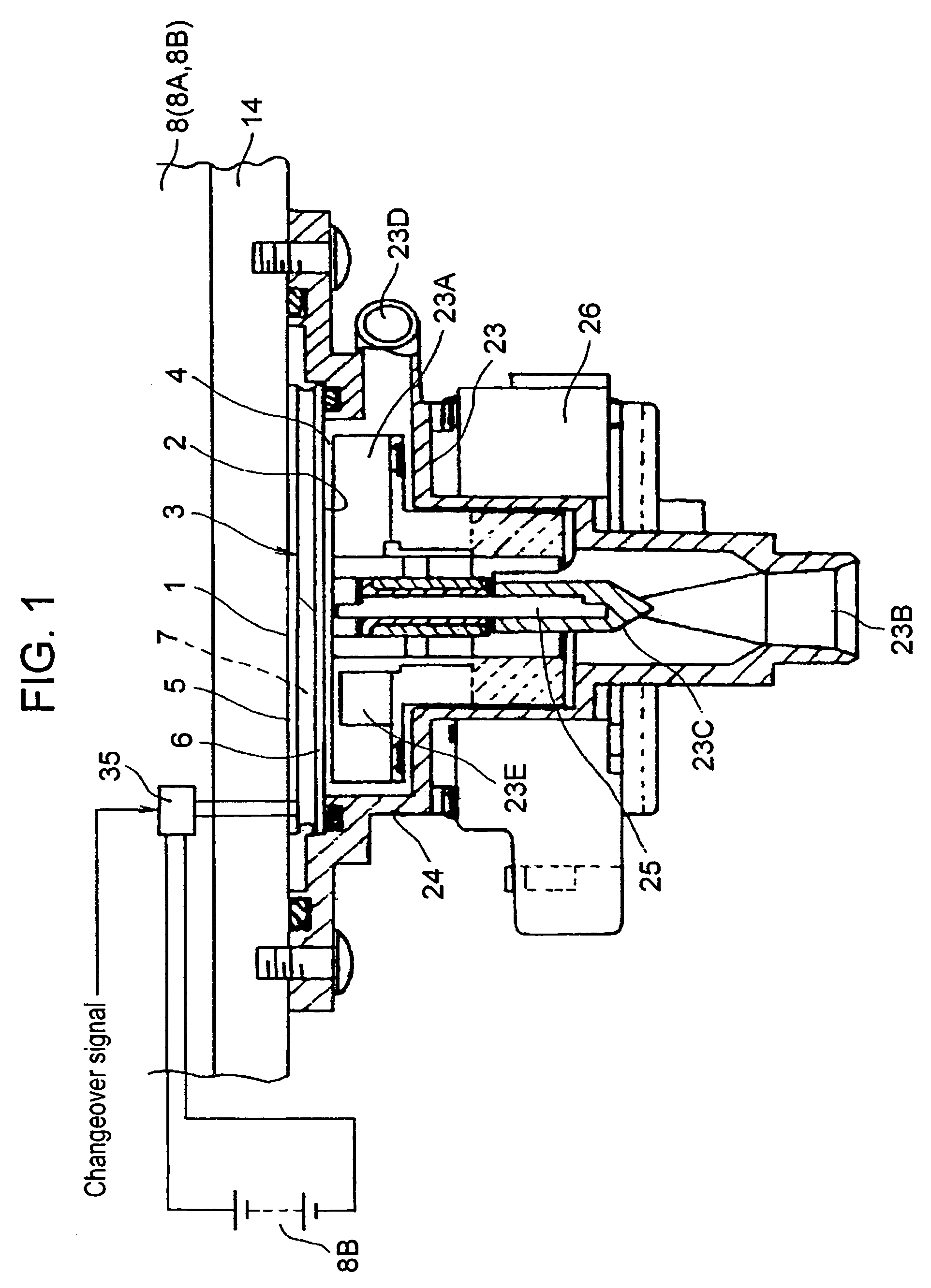

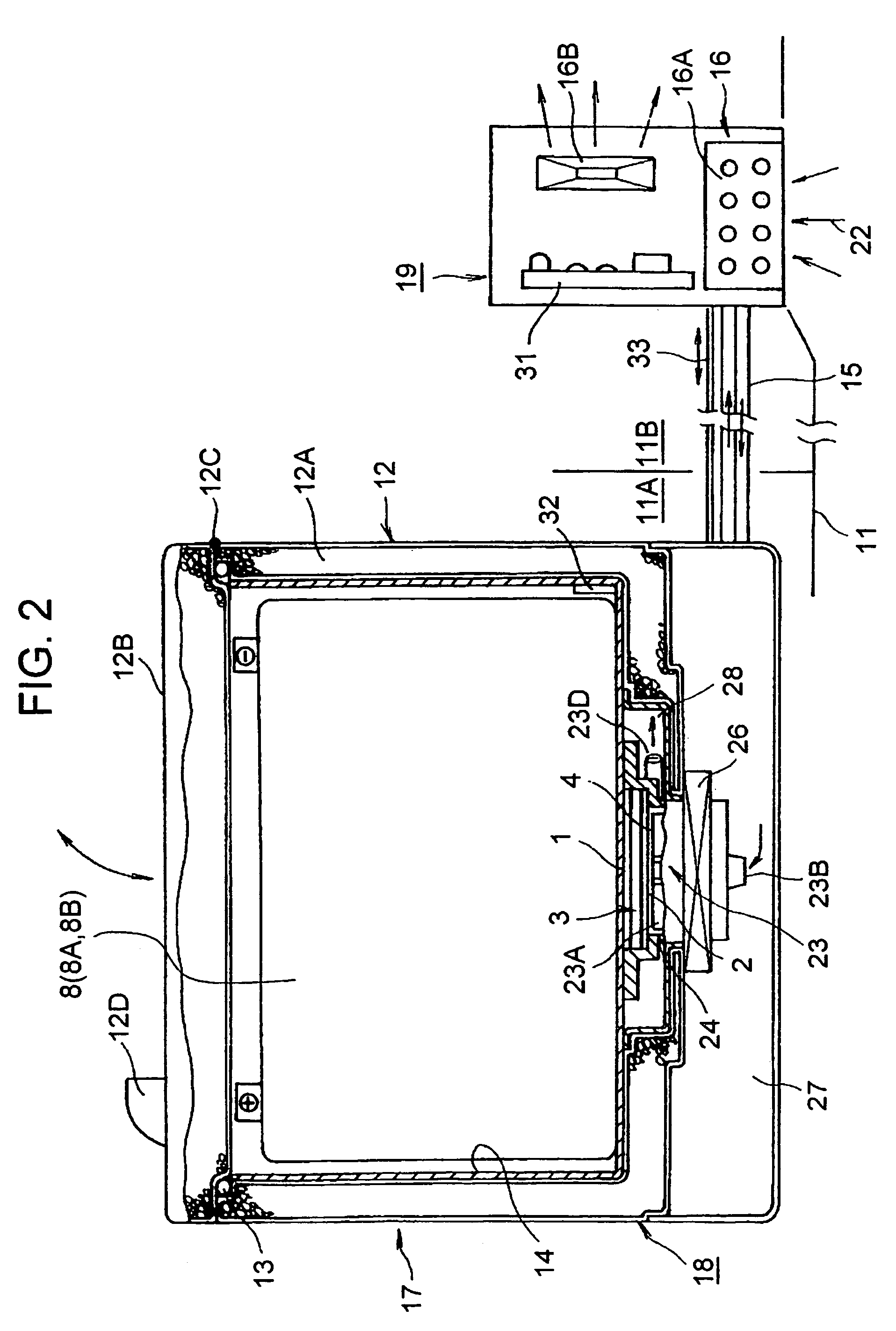

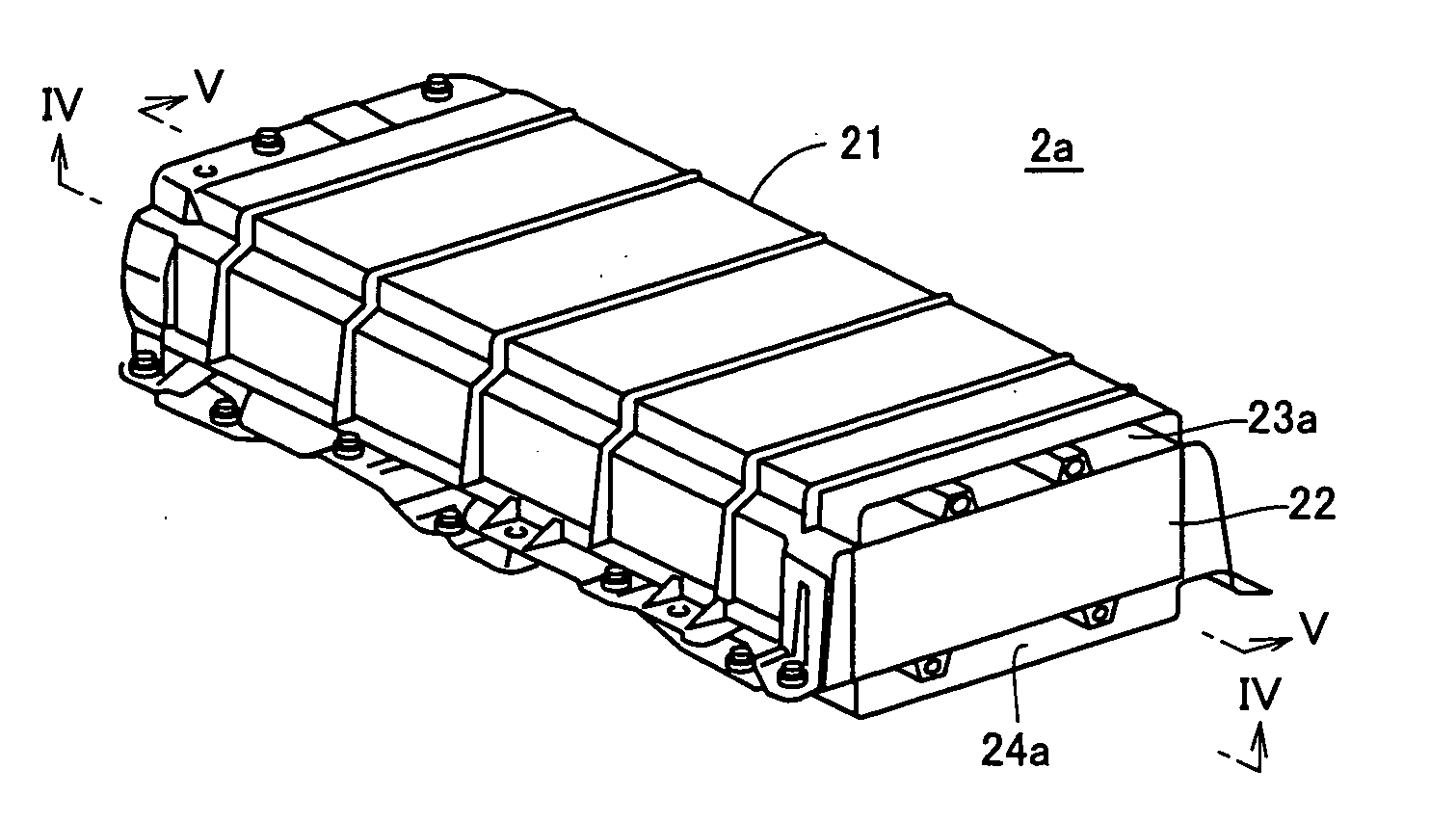

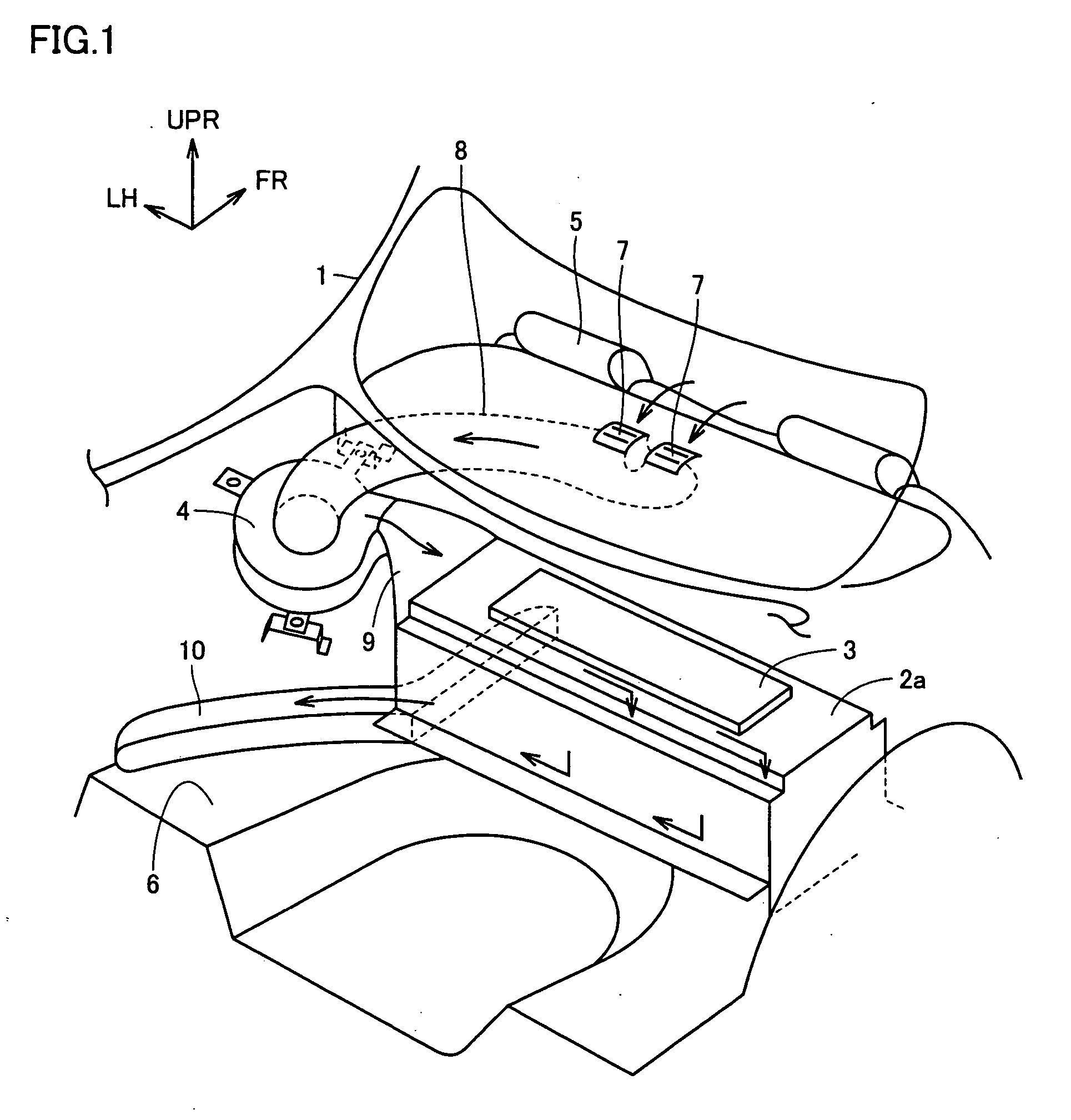

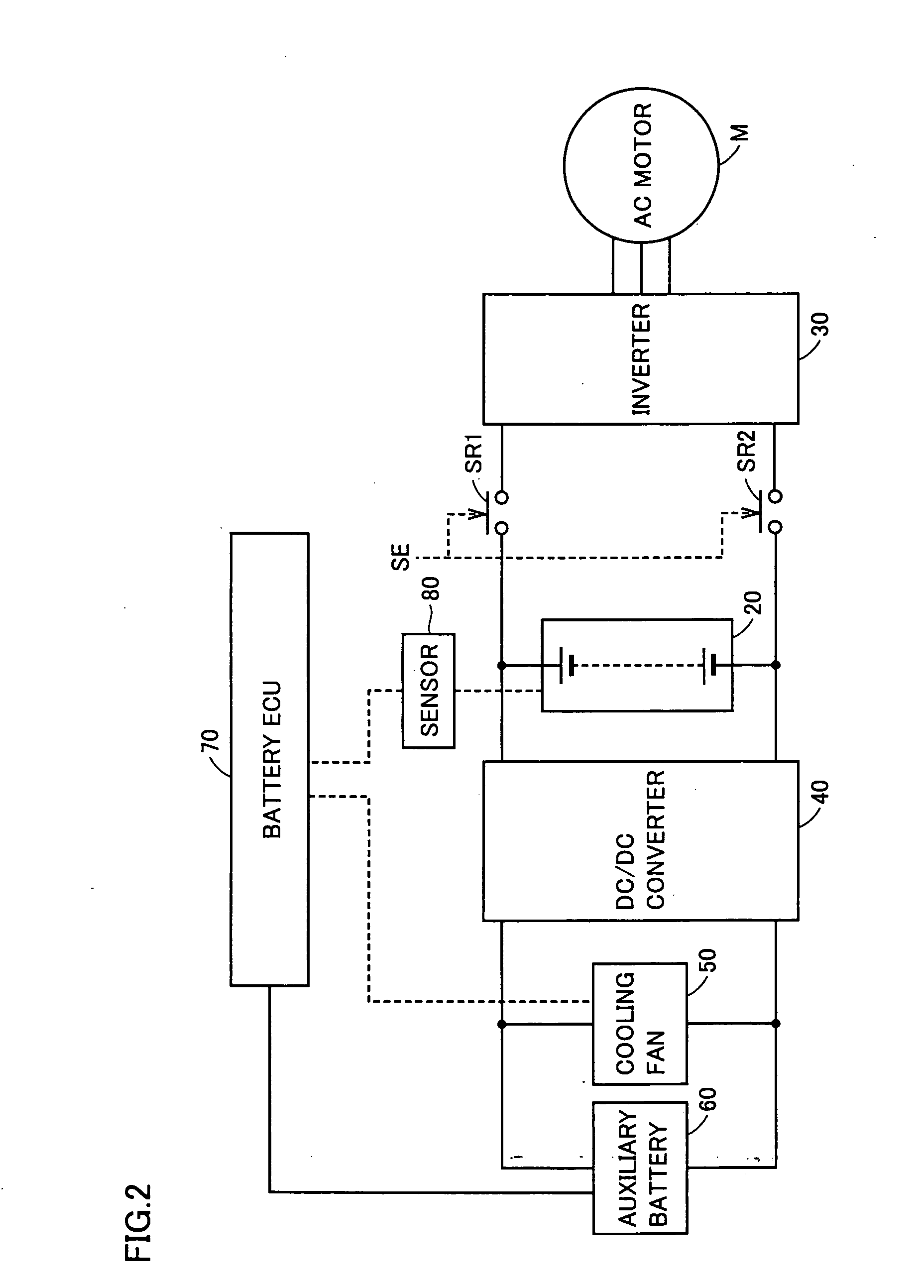

Power supply unit compactly accommodating components and having uniform battery characteristic

InactiveUS20050285563A1Satisfies needIncrease volumeBatteries circuit arrangementsAir coolingEngineeringAir conditioning

A component box has a shape of a substantially flat plate, and is stacked along a direction UPR toward the ceiling of a vehicle with its center placed at a central portion of a casing for a battery pack. Cooling wind which has been used for air-conditioning inside the vehicle and supplied from a cooling fan to the battery pack is supplied to a coolant introducing space located on an upper side of a module, passes through a gap between adjacent battery groups to flow down to a lower side of the battery groups, and then is emitted from a coolant lead-out space located at a lower side of the module out of the battery pack. Since the component box is in contact with a cooling wind passage with the casing therebetween, the component box in contact with the cooling wind via the casing is cooled down simultaneously with the cooling of the module. Since the component box is placed with its center positioned at the central portion of the battery pack, variations in temperature among batteries can be suppressed.

Owner:TOYOTA JIDOSHA KK

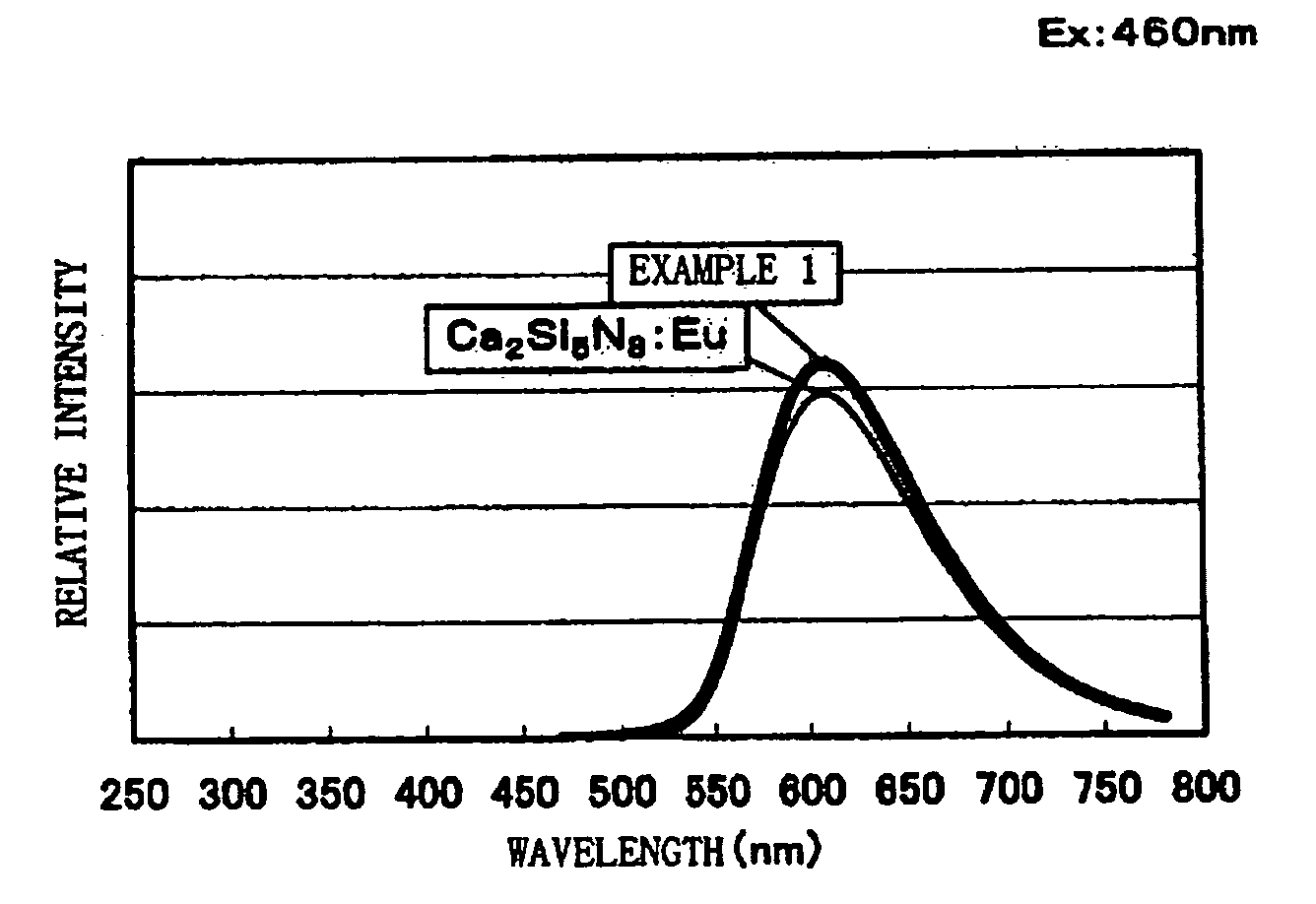

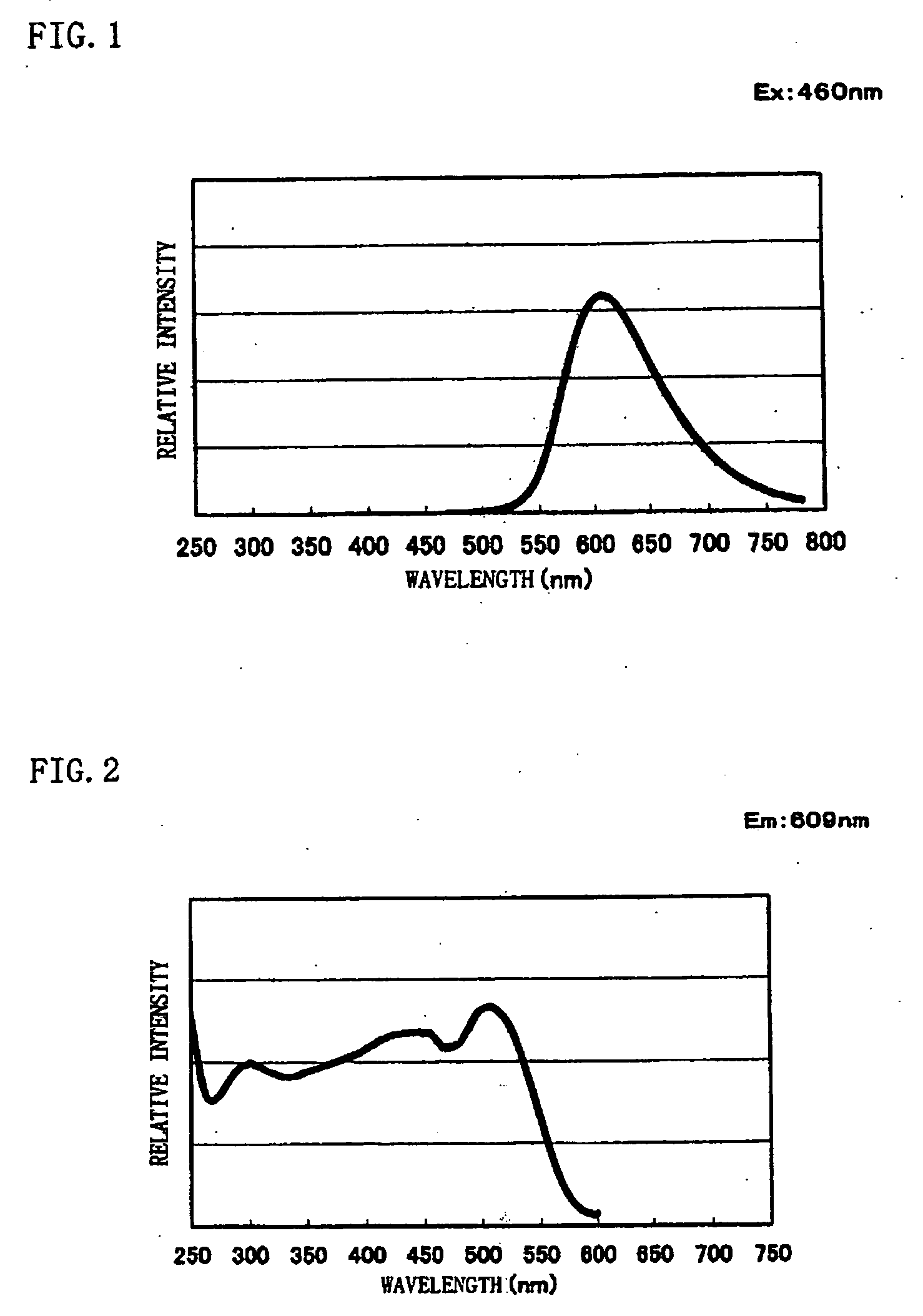

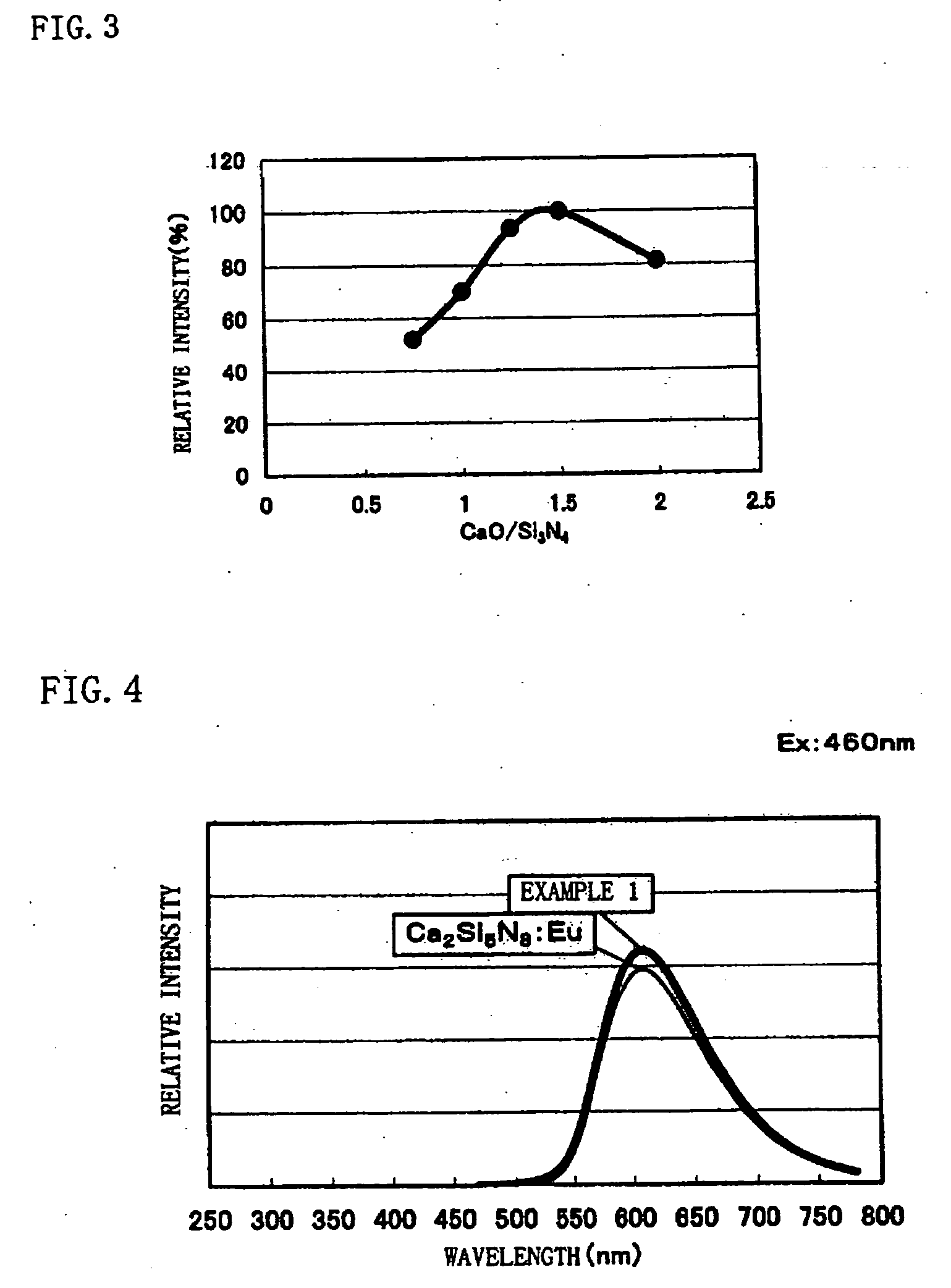

Phosphor and production method of the same and light source and LED using the phosphor

InactiveUS20050253500A1Long life-timeEasy to produceDischarge tube luminescnet screensElectroluminescent light sourcesFluorescencePhosphor

A phosphor with high efficiency having an excitation band corresponding to light of the ultraviolet-visible (300 to 550 nm) wavelength region emitted from a light emitting element which emits blue or ultraviolet light is provided. Commercially available CaO [3N], Si3N4 [3N], and Eu2O3 [3N] are prepared, respective materials are weighed and mixed to have a mol ratio of CaO:Si3N4:Eu2O3=1.4775:1:0.01125, and then the mixture is heated to 1600° C. by a heating rate of 15° C. / min under a nitrogen atmosphere and retained and fired at 1600° C. for three hours. Thereafter, the raw materials are cooled down from 1600° C. to 200° C. for an hour to thereby produce a phosphor having a composition formula Ca1.58Si3O1.63N4.35:Eu0.024.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

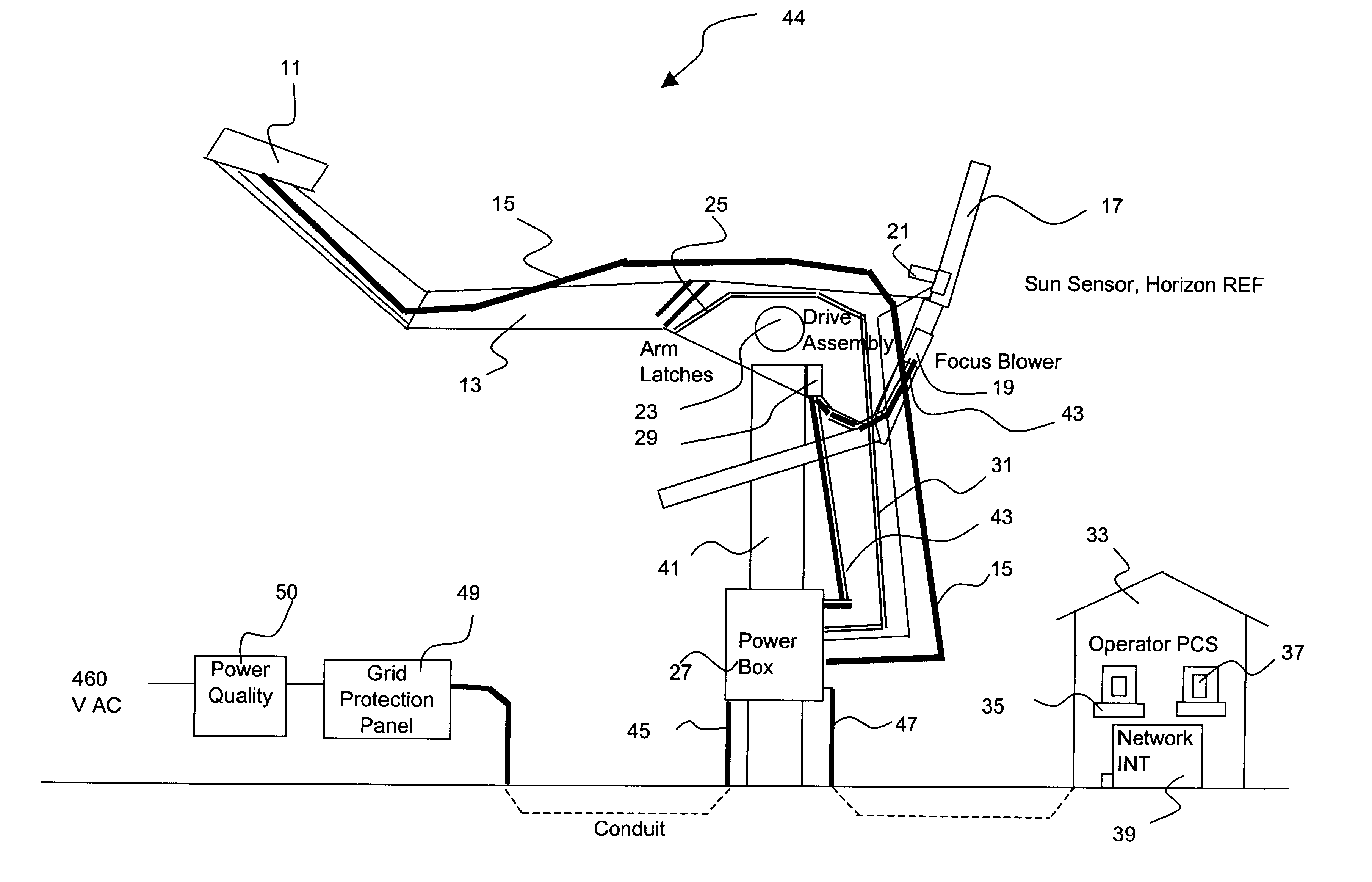

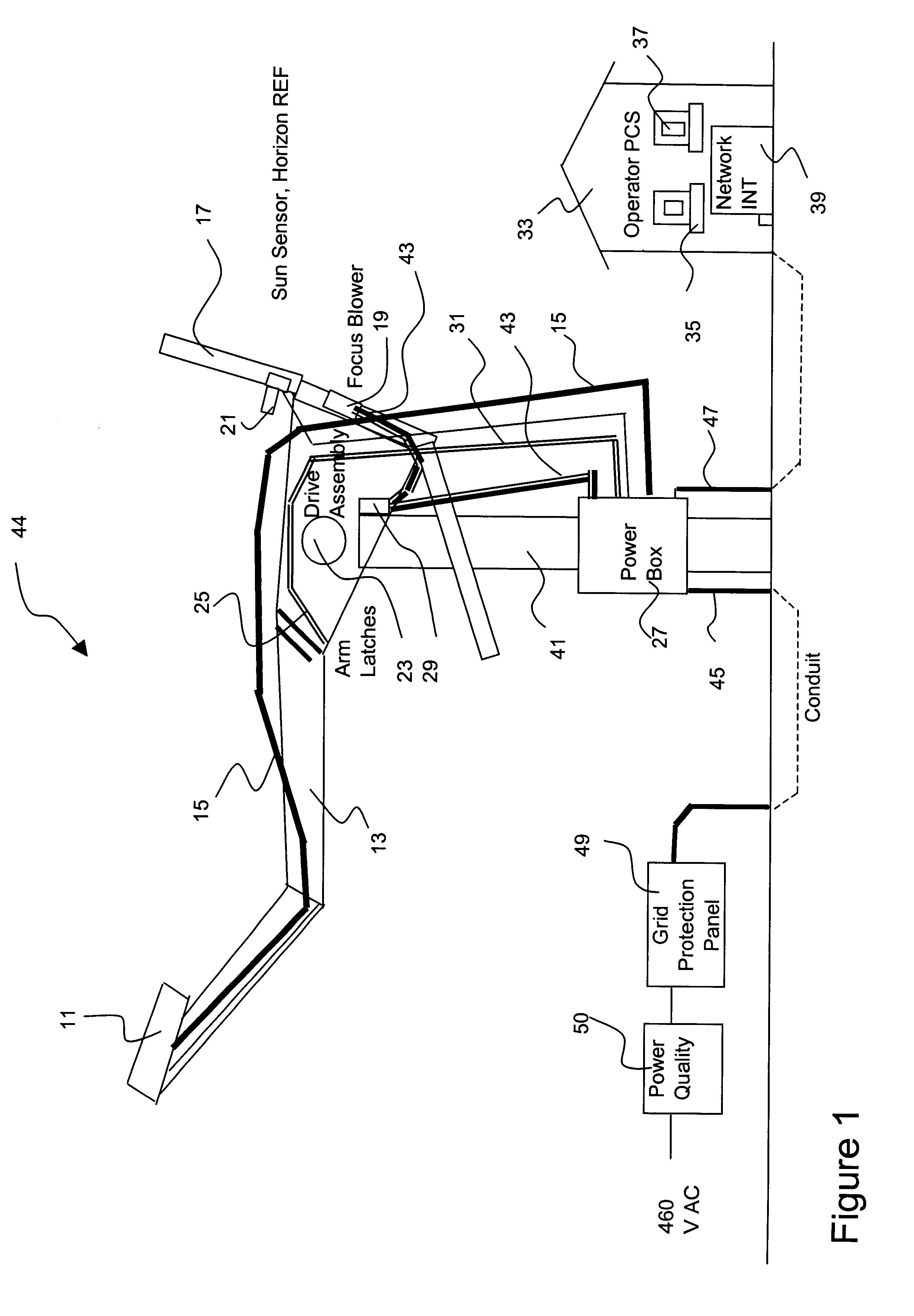

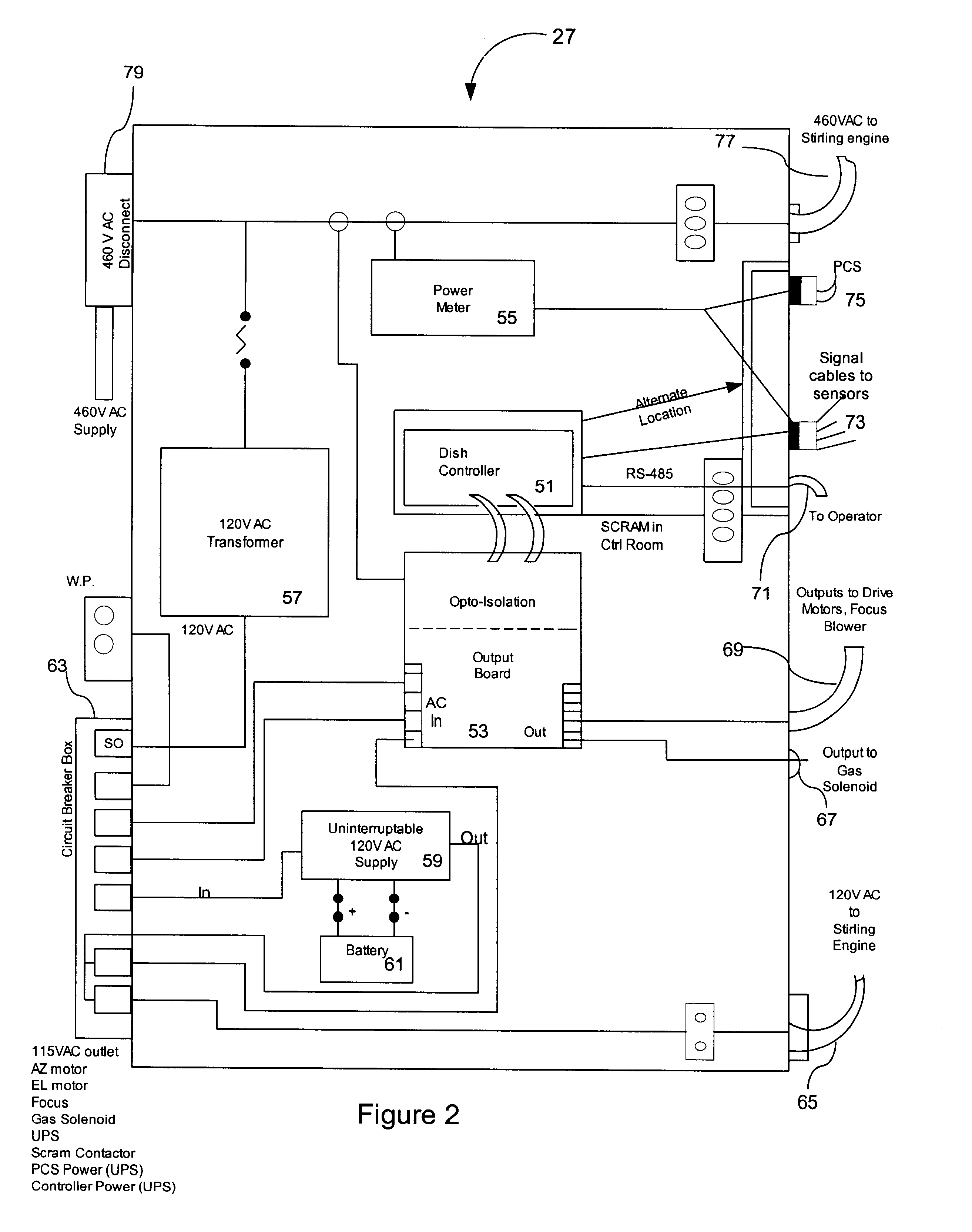

Method and system for controlling operation of an energy conversion device

A method and system is described for controlling a solar collector. A microprocessor receives inputs from one or more sensors in the system and determines the level of operation of an energy conversion device. If the level of operation reaches a predetermined setpoint below a maximum level at which the device is to operate, a variable focus solar concentrator is defocused to reduce energy input into the energy conversion device. When the system cools down and operates at a second predetermined level, lower than the first predetermined level, the concentrator is then refocused to increase the power input to the energy conversion device.

Owner:LEIDOS

Air shroud for dissipating heat from an electronic component

ActiveUS7310228B2Components is relatively effectiveDissipating heat from an electronic componentDigital data processing detailsSemiconductor/solid-state device detailsWorking temperatureEngineering

A air shroud for dissipating heat from an electronic component is composed of a air shroud of a roughly U-shaped cross section, whose left and right sides are formed into a first and a second opening, respectively. A passage is formed between the first and second openings, enabling air to flow along a specific direction. A flexible thin piece is fixed inside the air shroud which covers a specific electronic component on a circuit board, and the flexible thin piece is touched with a surface of the electronic component. The fast-flowing air flows quickly along the passage, so as to effectively cool down a working temperature of the specific electronic component, thereby increasing a lifetime of usage of the specific electronic component.

Owner:SUPER MICRO COMP

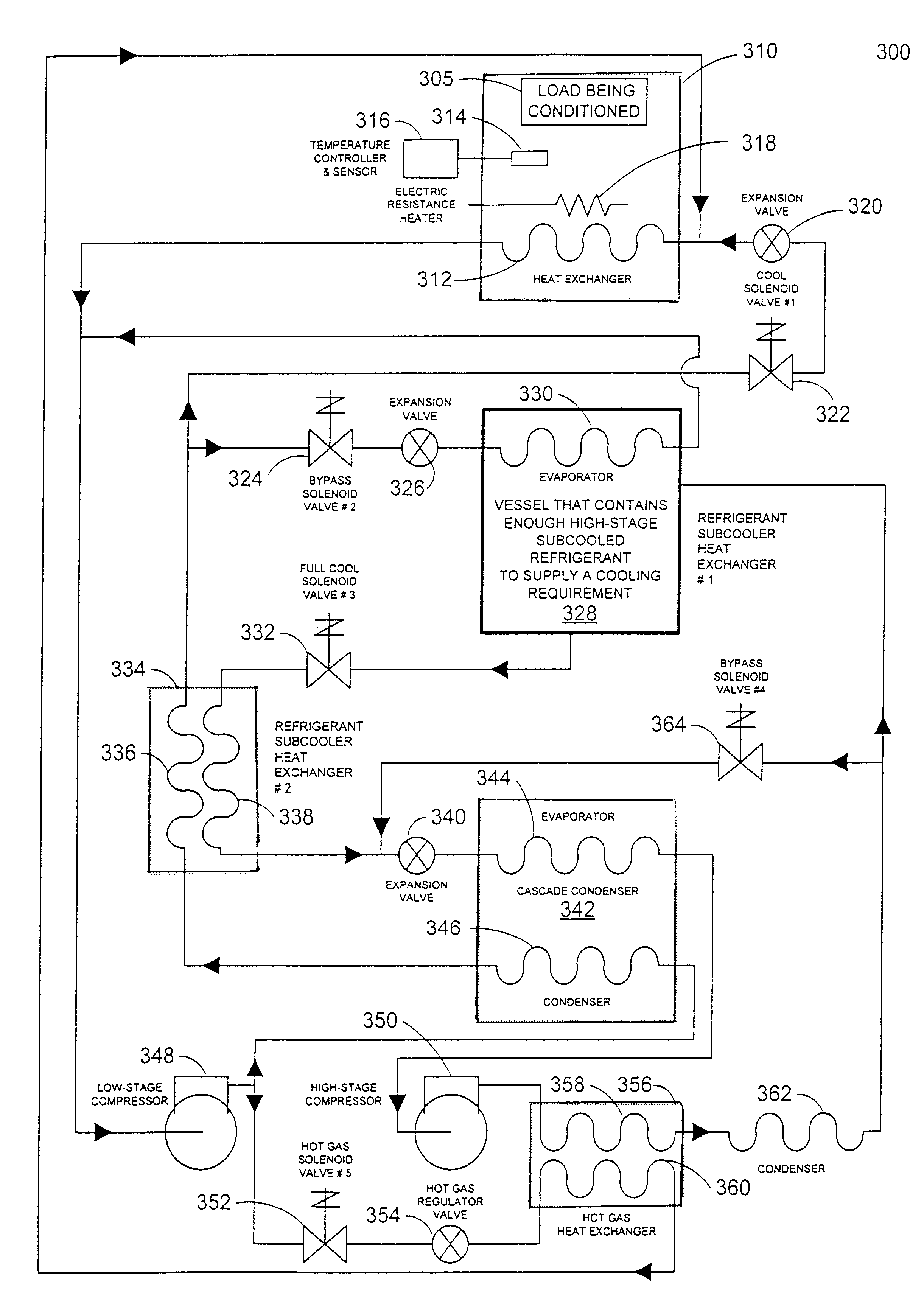

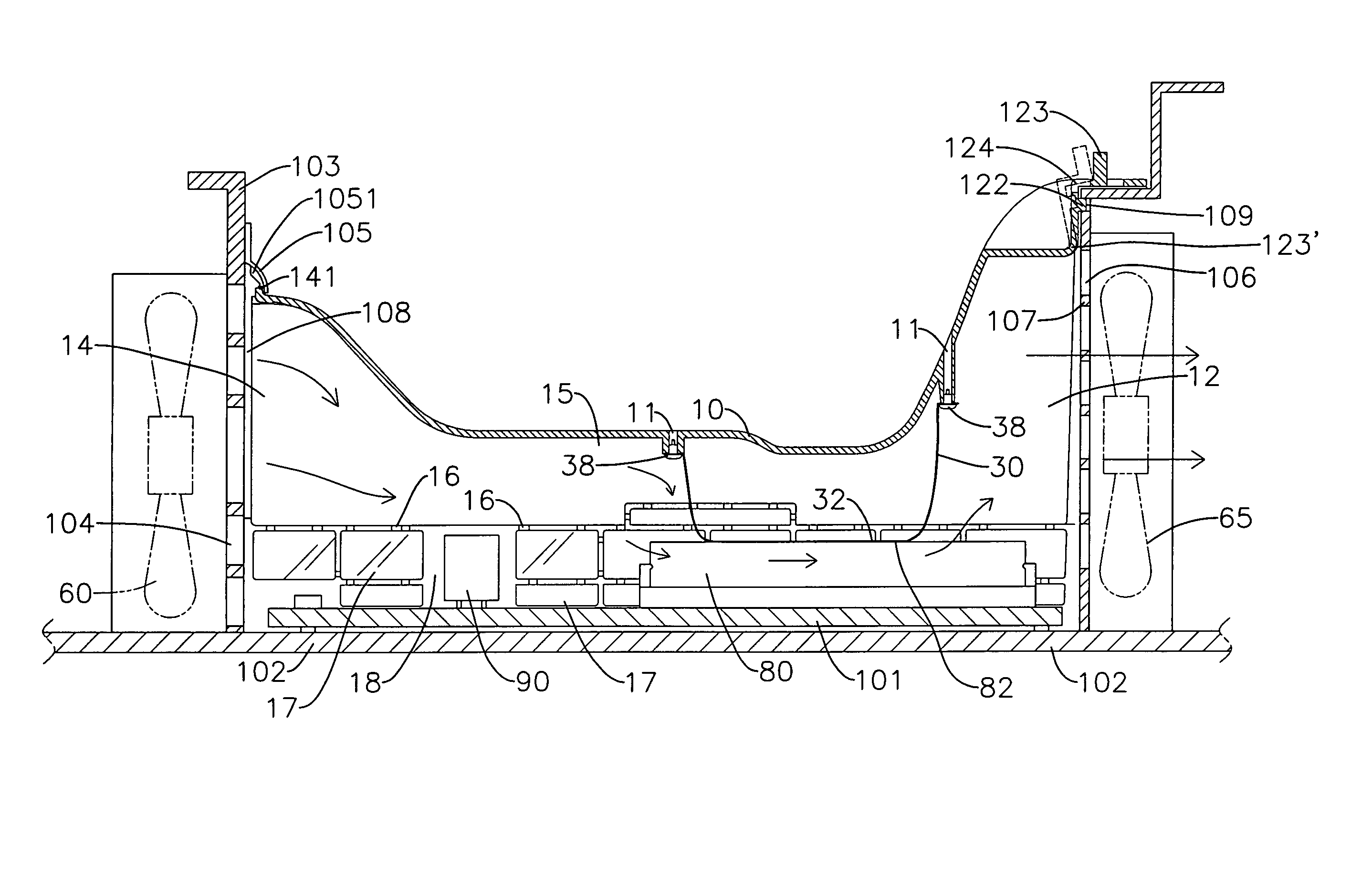

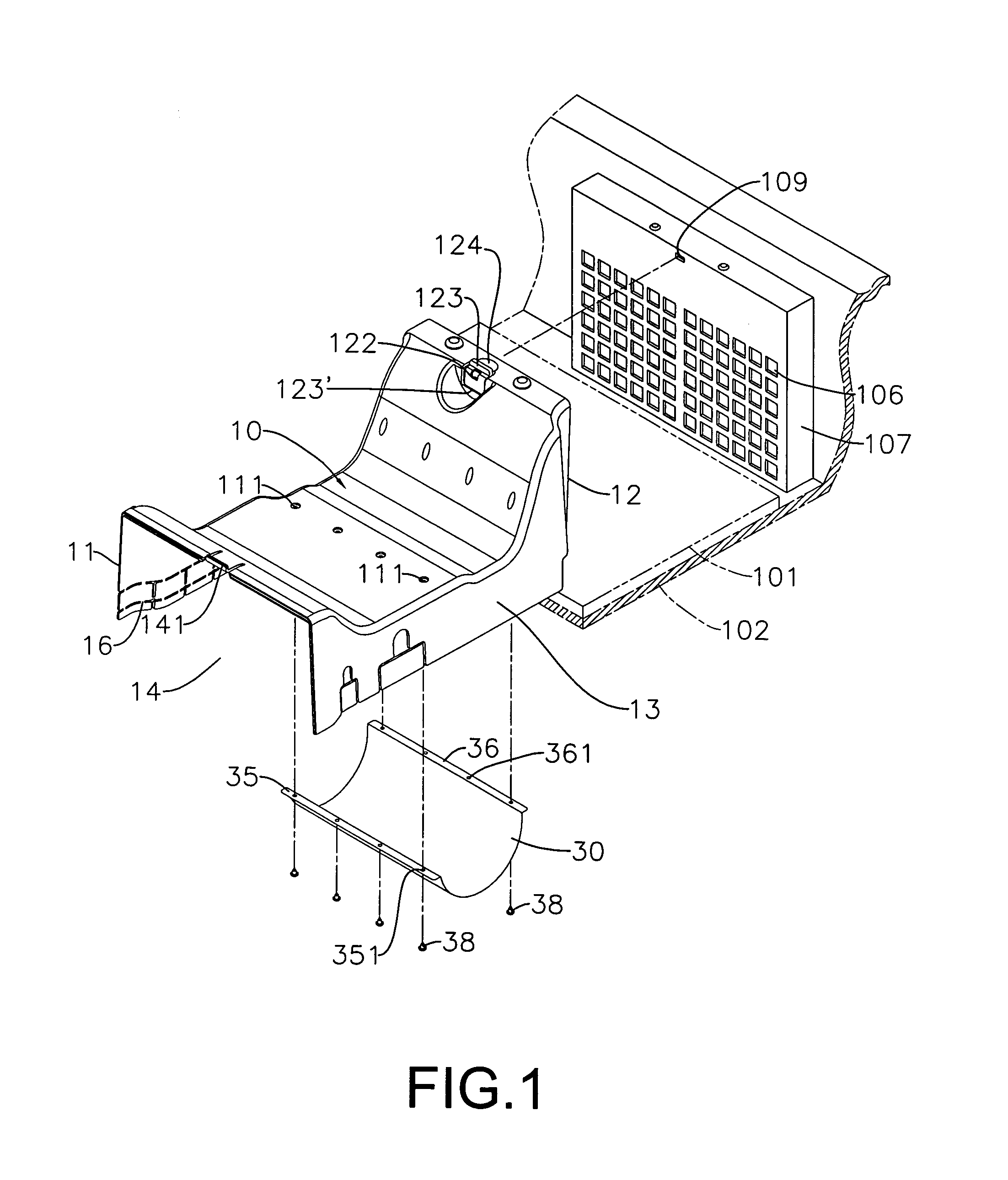

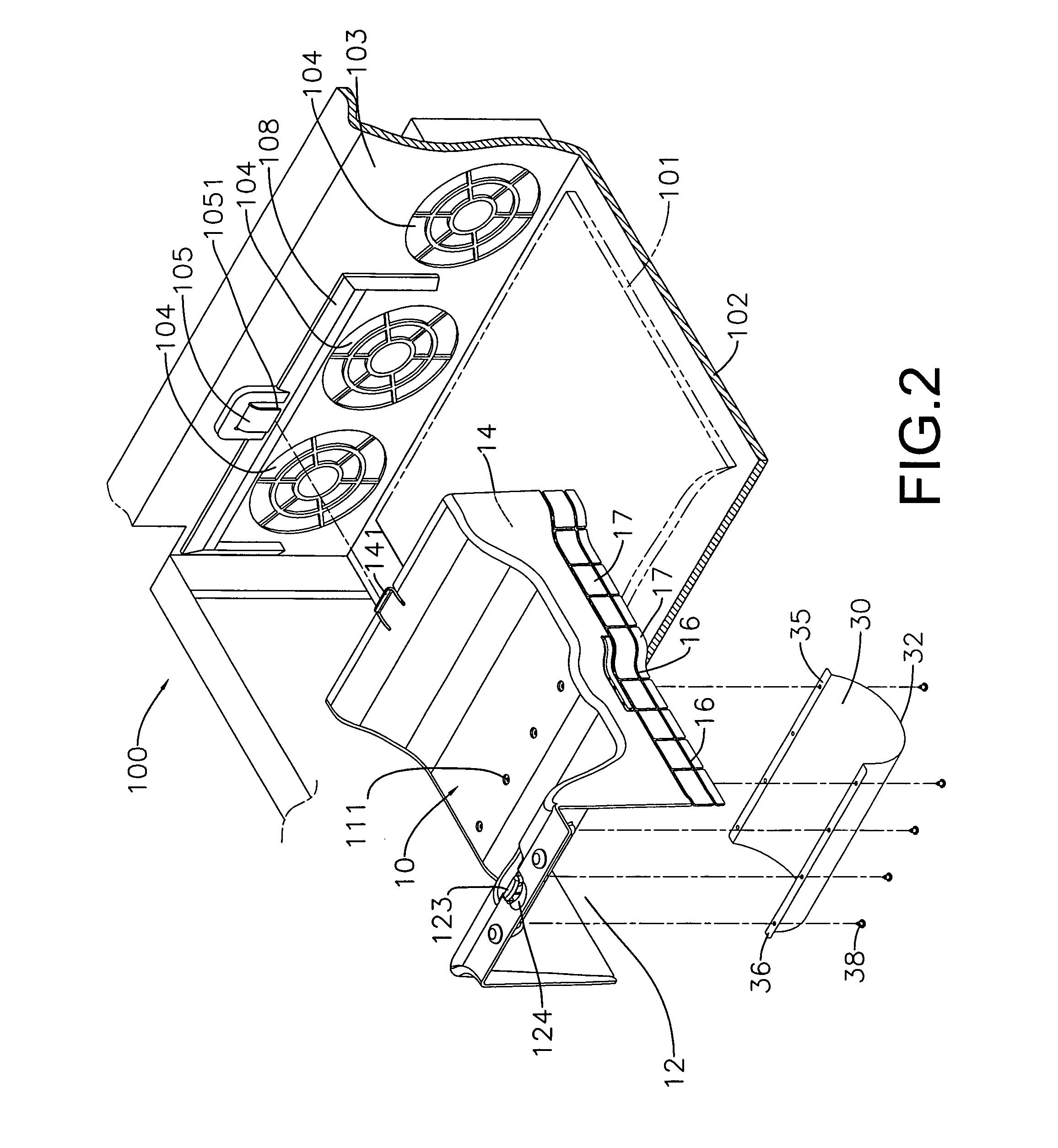

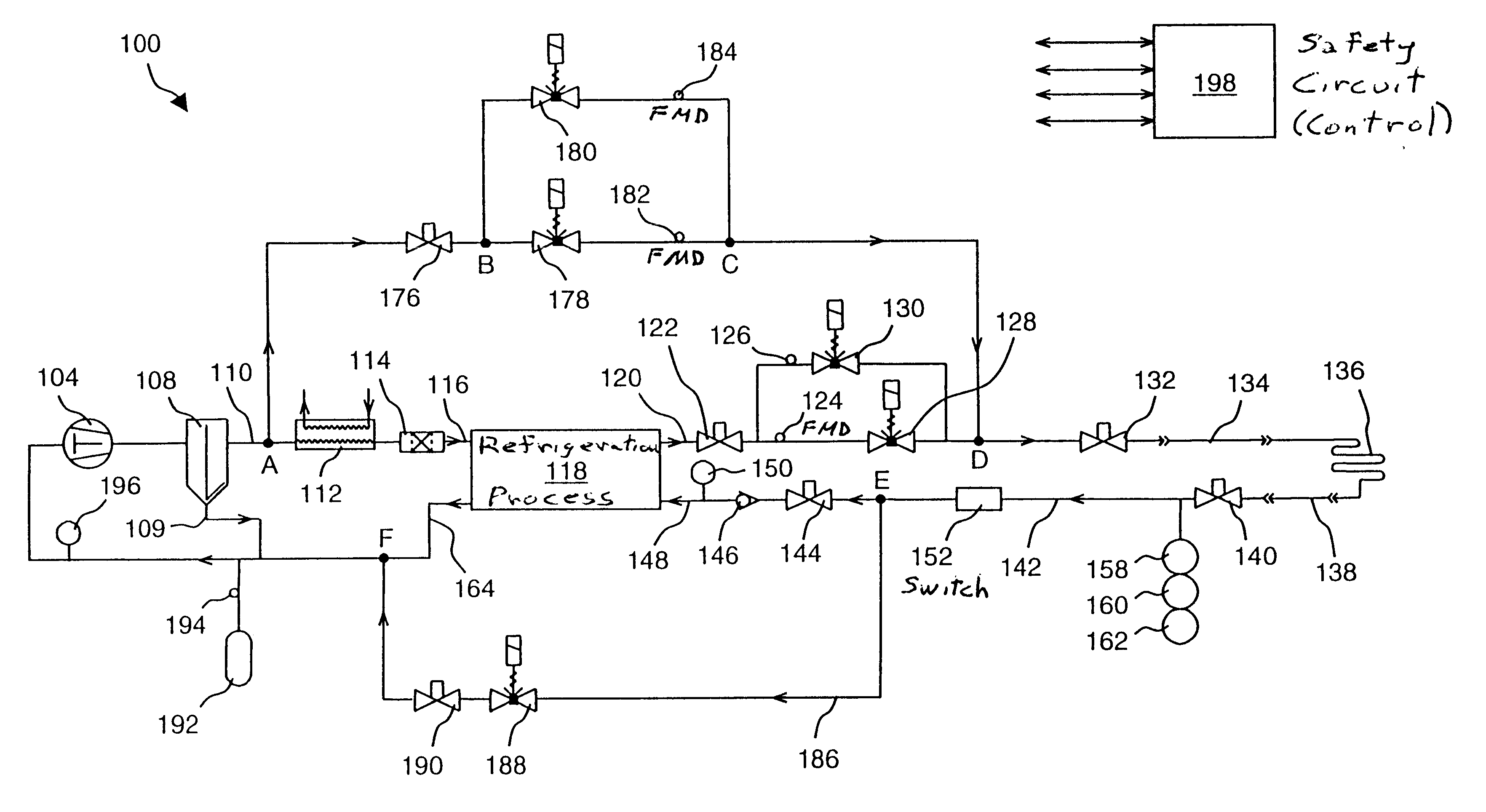

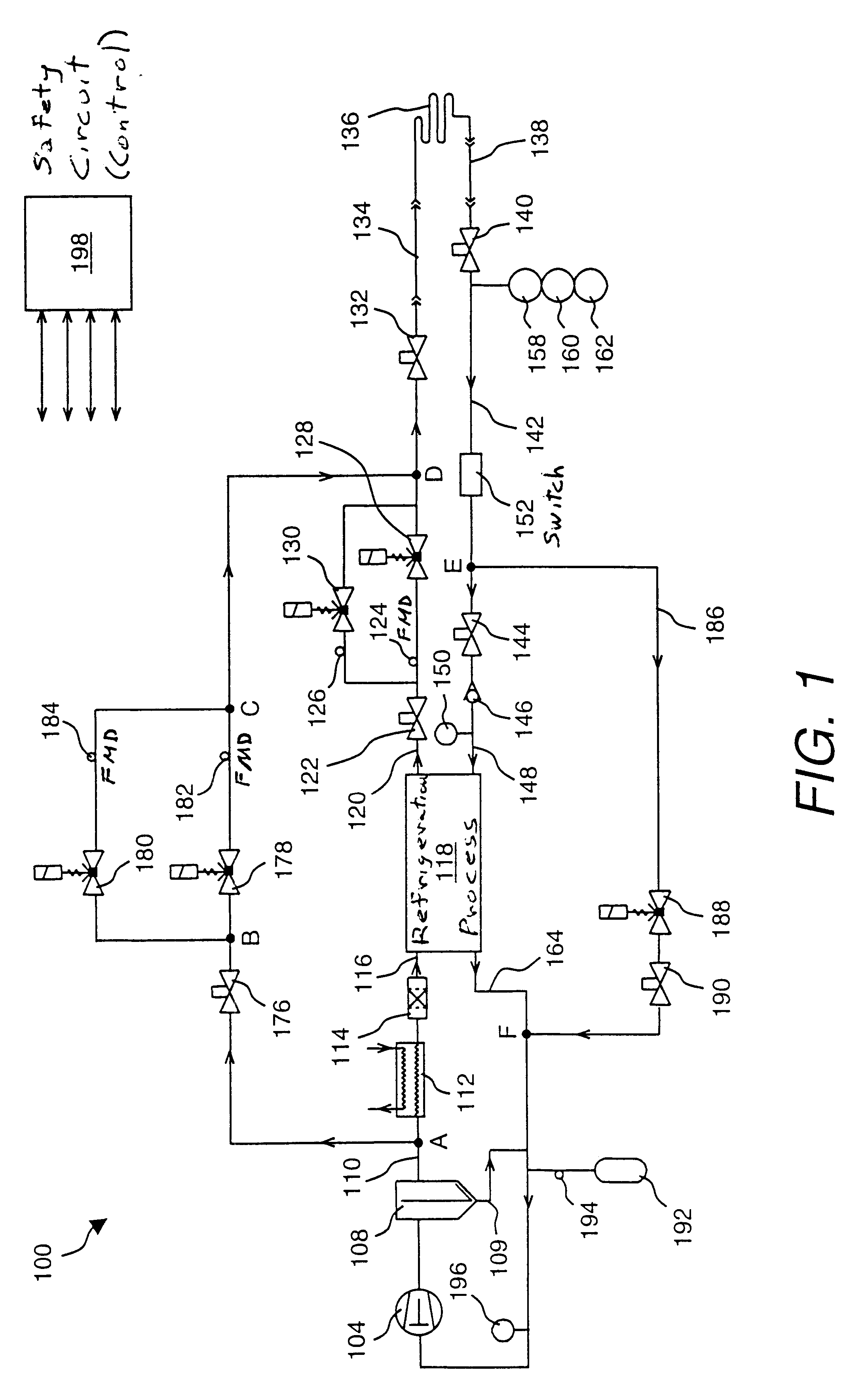

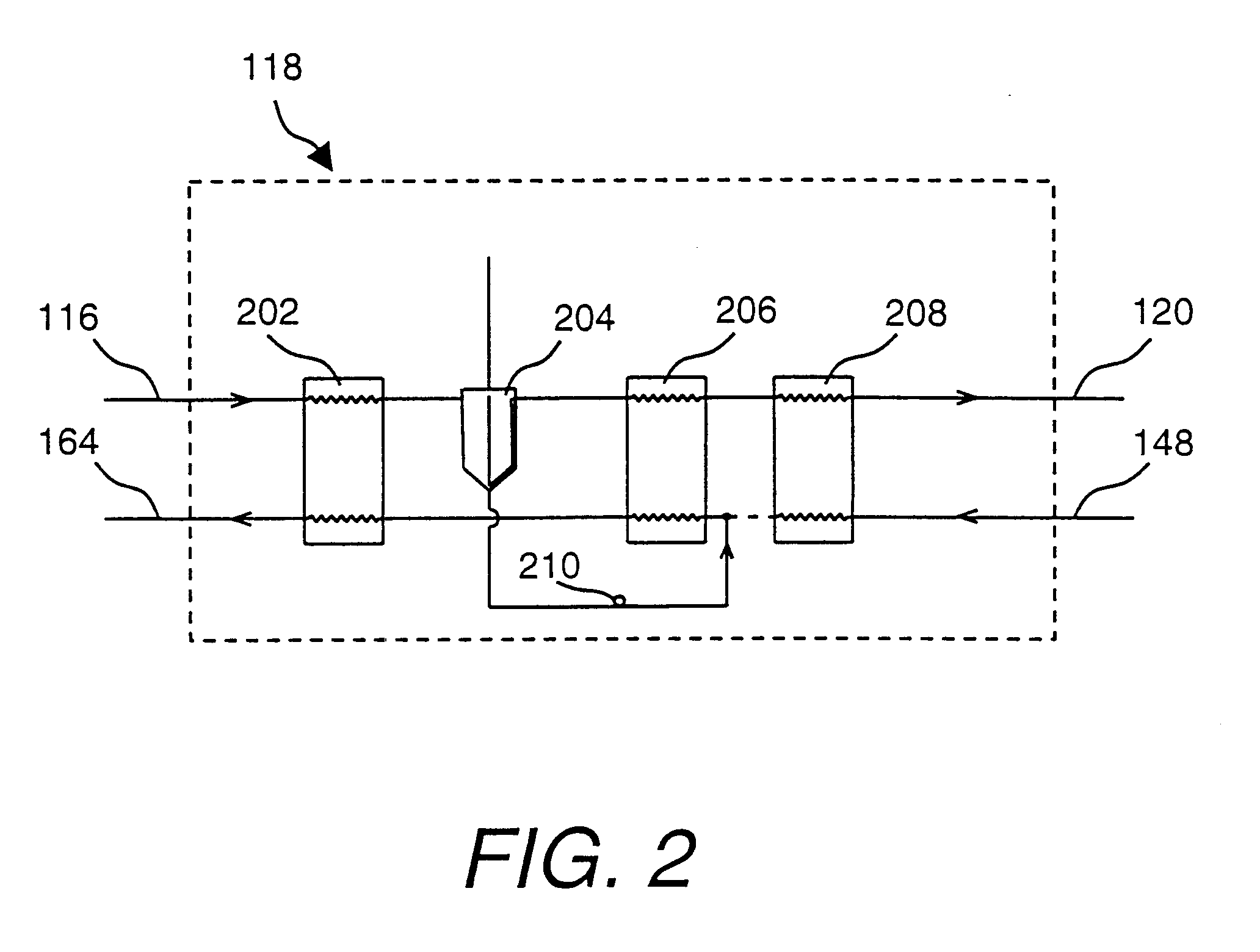

Very low temperature refrigeration system with controlled cool down and warm up rates and long term heating capabilities

InactiveUS6574978B2Prevent overloadShort maintenance periodMechanical apparatusCompression machinesRecovery periodEngineering

Heating / defrost constructions of a very low temperature refrigeration system having a defrost supply circuit and a defrost return bypass circuit optimizing the heating / defrost cycle, preventing overload (excessive pressure) of its refrigeration process and protecting components from damaging temperatures. The defrost cycle operates continuously, when required, and provides a shorter recovery period between heating / defrost and cooling operating modes. The rate of the temperature change during cool down or warm up is controlled in an open loop fashion by controlled refrigerant flow in bypass circuits.

Owner:EDWARDS VACUUM LLC

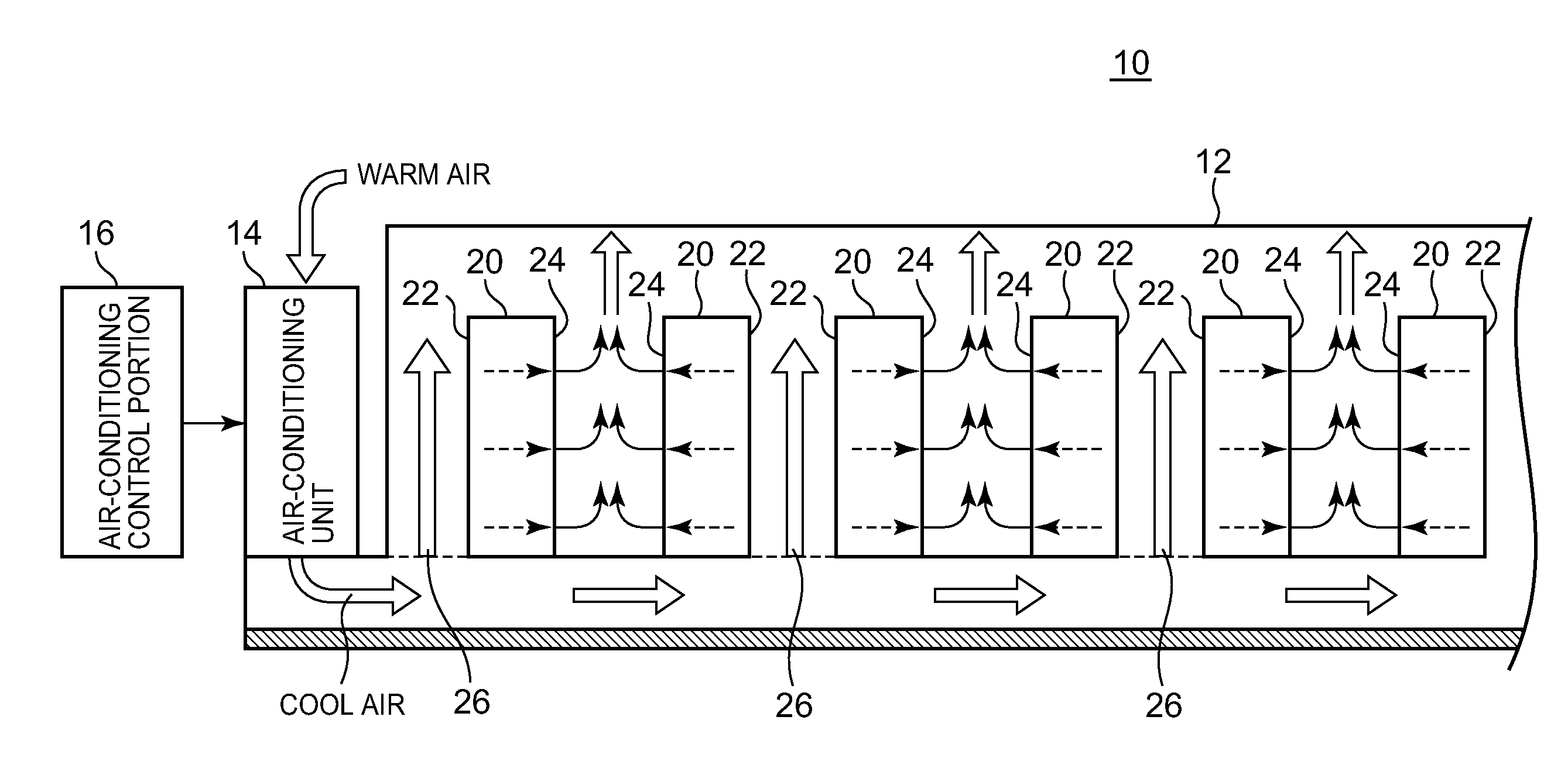

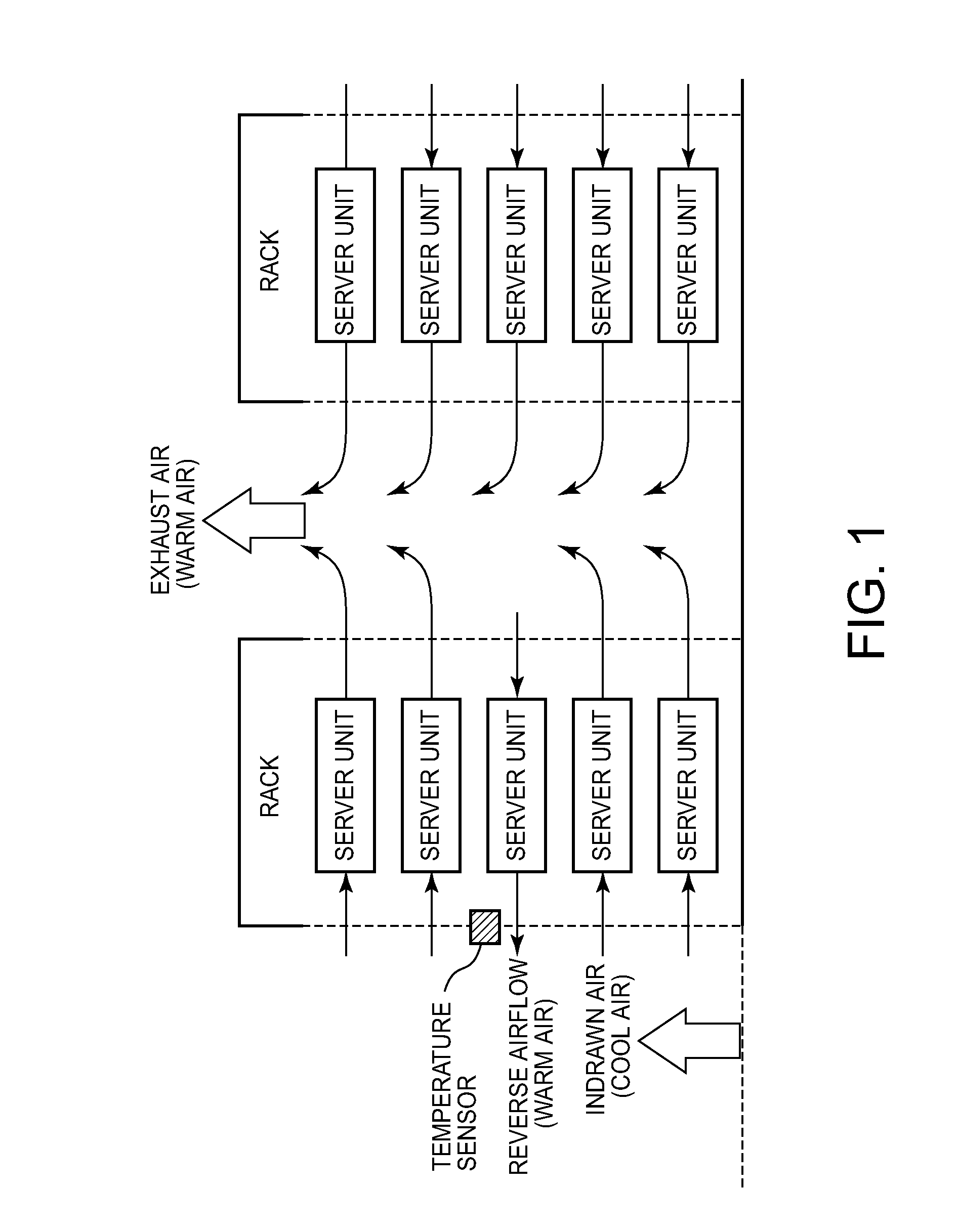

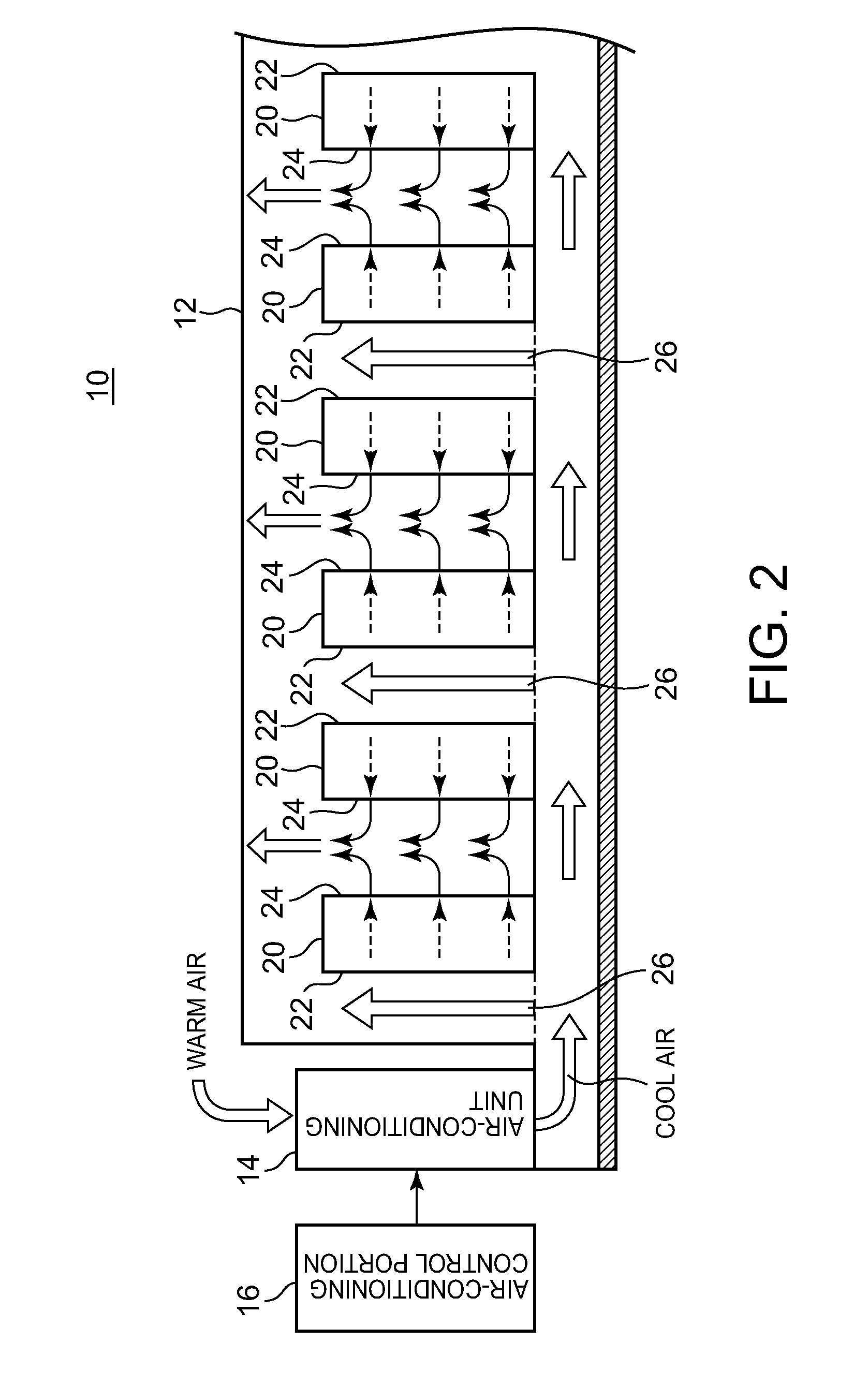

Control device, control method, and control program

Provision of a control device, method and program capable of performing a suitable temperature control in a room having an equipment installed therein. A control device controls air-conditioning of a room having installed therein a plurality of pieces of equipment each being capable of drawing outside air to thereby cool down an interior of the equipment. A storage portion is capable of storing therein operating information that represents as to whether it is abnormal or not if each piece of equipment is put into a non-operating state. A temperature measurement portion is capable of measuring a temperature of the air drawn by each piece of equipment. A detection portion is capable of measuring a flow speed of the air drawn by each piece of equipment. A control portion is configured to control the air-conditioning based on the measurement result of the temperature or the flow speed of the air drawn by each piece of equipment.

Owner:IBM CORP

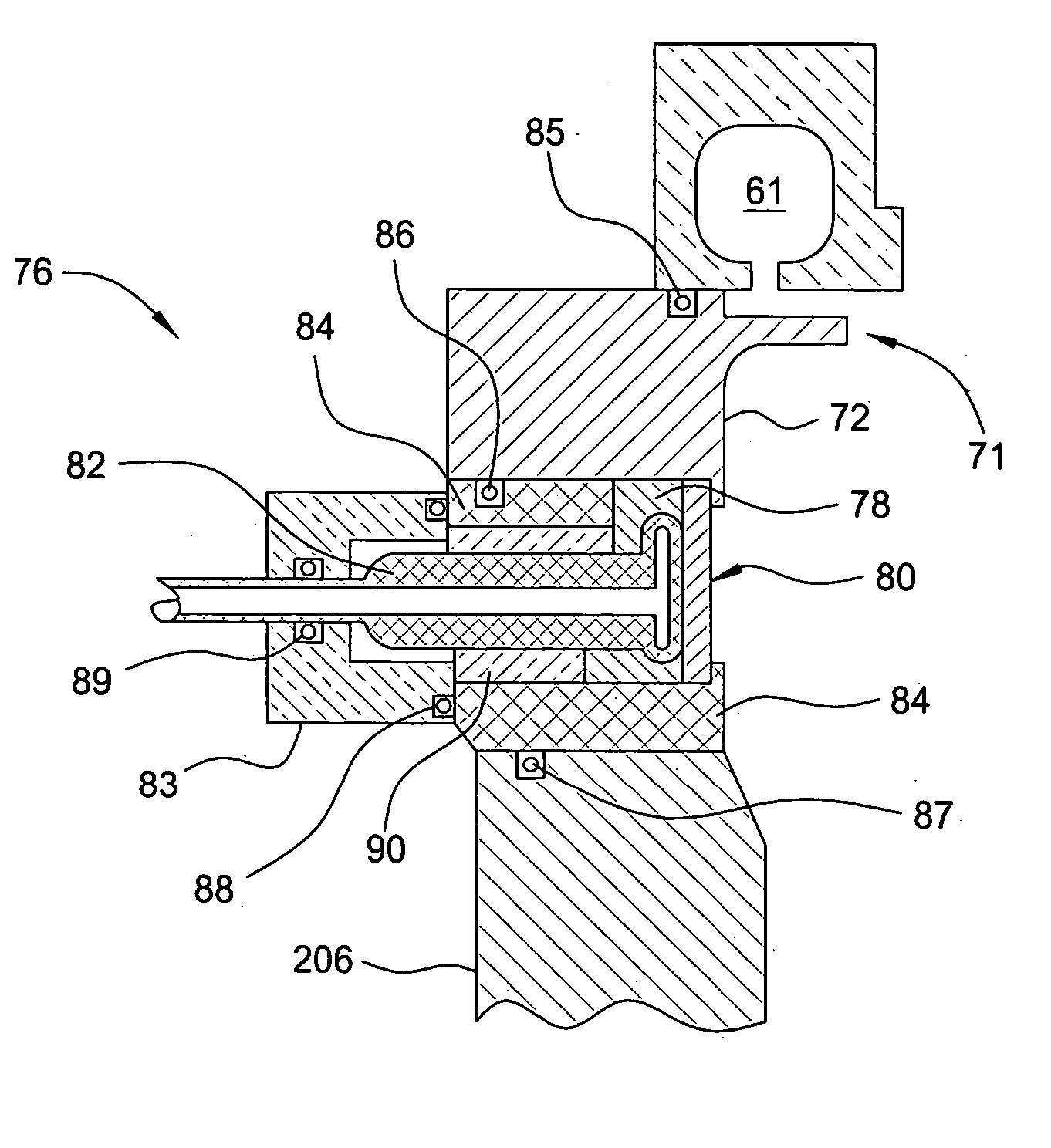

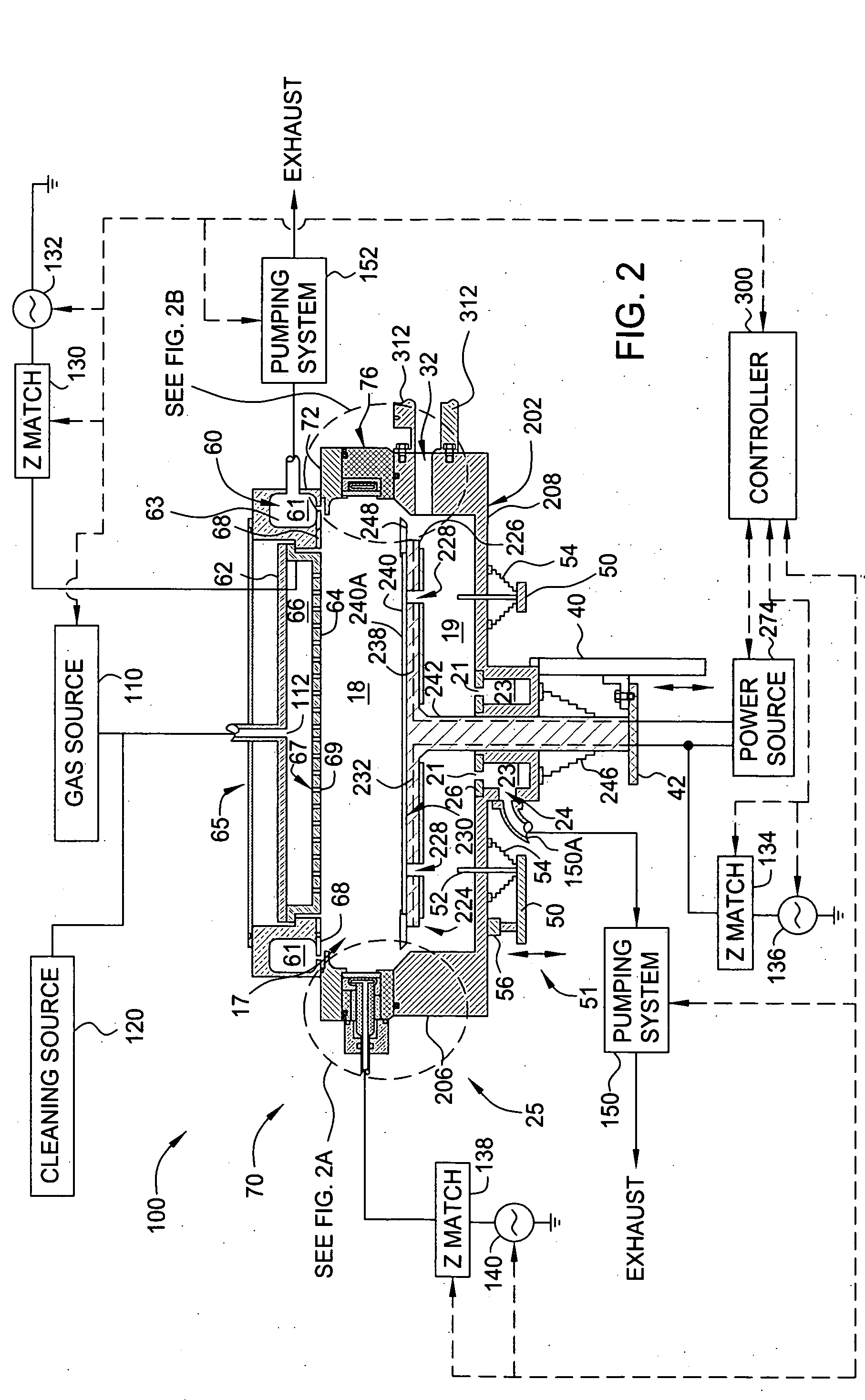

Multi-layer high quality gate dielectric for low-temperature poly-silicon TFTs

InactiveUS20060105114A1Quality improvementSolid state diffusion coatingChemical vapor deposition coatingCapacitanceEngineering

A method and apparatus that is useful for forming a high quality gate dielectric layer in MOS TFT devices using a high density plasma oxidation (HDPO) process. The HDPO process forms a good interface and then a second layer, which has good bulk electrical properties, is deposited at a higher deposition rate over the HDPO layer. In one embodiment a thin HDPO process layer is formed over the channel, source and drain regions to form a high quality dielectric interface and then one or more dielectric layers are deposited on the HDPO layer to form a high quality gate dielectric layer. The HDPO process generally entails using an inductively and / or capacitively coupled RF energy transmitting device to generate and control the plasma generated over the surface of the substrate and injecting a gas containing an oxidizing source to grow the interfacial layer. A second dielectric layer may then be deposited on the surface of the substrate using a CVD or plasma enhanced CVD deposition process. Aspects of the present invention also provide a cluster tool that contains at least one specialized plasma processing chamber that is capable of depositing a high quality gate dielectric layer. The cluster tool is advantageous because it supports both the pre-processing steps, such as, preheating the substrate, pre-cleaning the surface of the substrate prior to processing, and cool down after processing, all in a single controlled environment.

Owner:APPLIED MATERIALS INC

Electronic engine control device, vehicle equipped with electronic engine control device, and electronic engine control method

InactiveUS20050262827A1Maximum preventionImprove fuel consumption rateHybrid vehiclesElectrical controlLow loadHigh load

On the premise that a target torque of an engine is equal to 0, that observed catalyst temperature is in a specified temperature range causing deterioration of the catalyst, and that the engine runs idle without a fuel cut regardless of fulfillment of preset fuel cut conditions, the control procedure of the invention determines whether a predetermined engine stop condition is fulfilled (step S300). Upon fulfillment of the predetermined engine stop condition, the control procedure subsequently determines whether a high load is applied to an exhaust catalyst (step S320). The engine runs idle (step S310) when a high load is applied to the exhaust catalyst. The relatively low-temperature exhaust gas from the engine in the idling state forcibly cools down the exhaust catalyst. This prevents the exhaust catalyst from being kept at high temperature. When a low load is applied to the exhaust catalyst at step S320, on the other hand, the engine is stopped (step S330). The stop of the engine cuts off the air flow through the exhaust catalyst. The exhaust catalyst is thus not exposed to the lean exhaust atmosphere and does not significantly deteriorate even at high temperature.

Owner:TOYOTA JIDOSHA KK

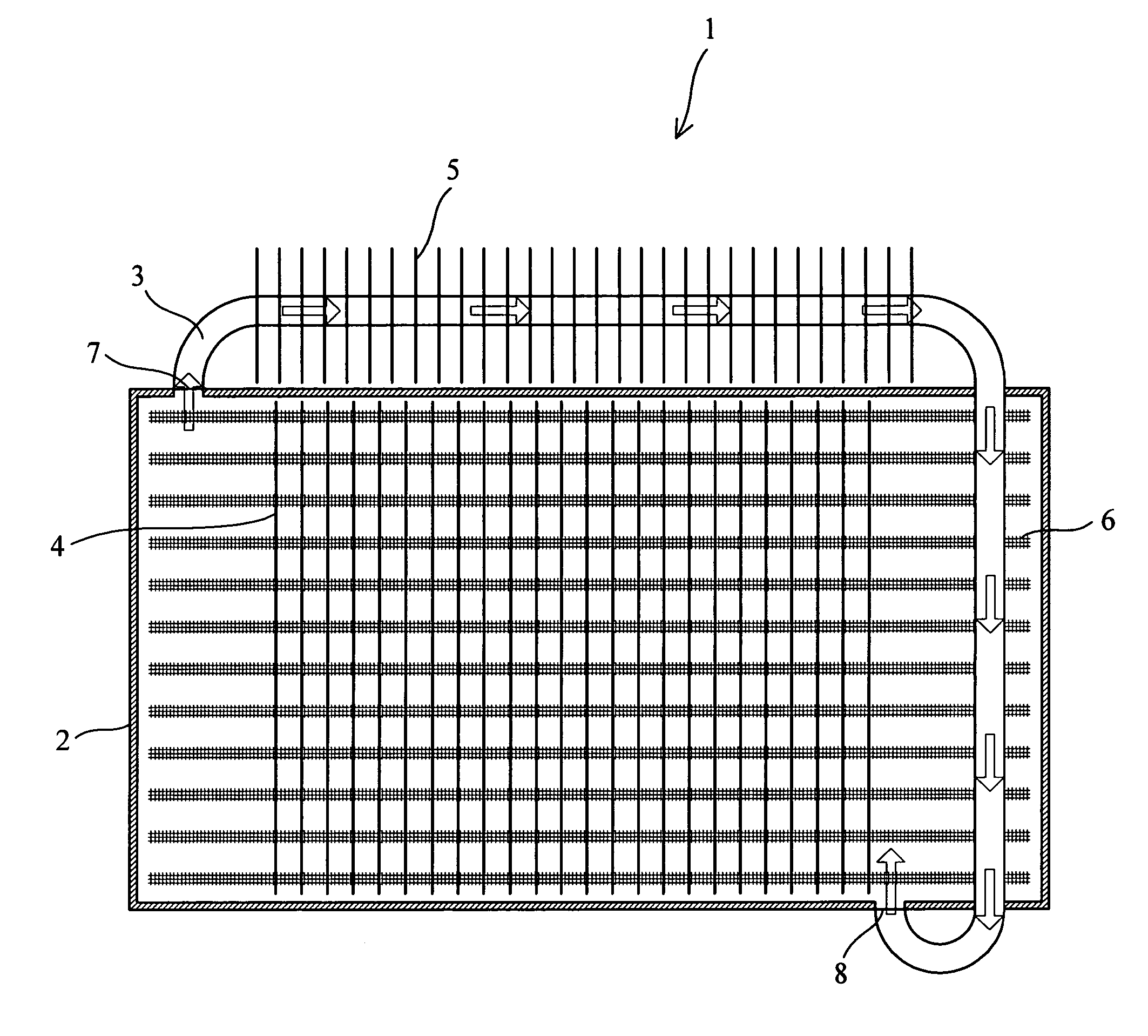

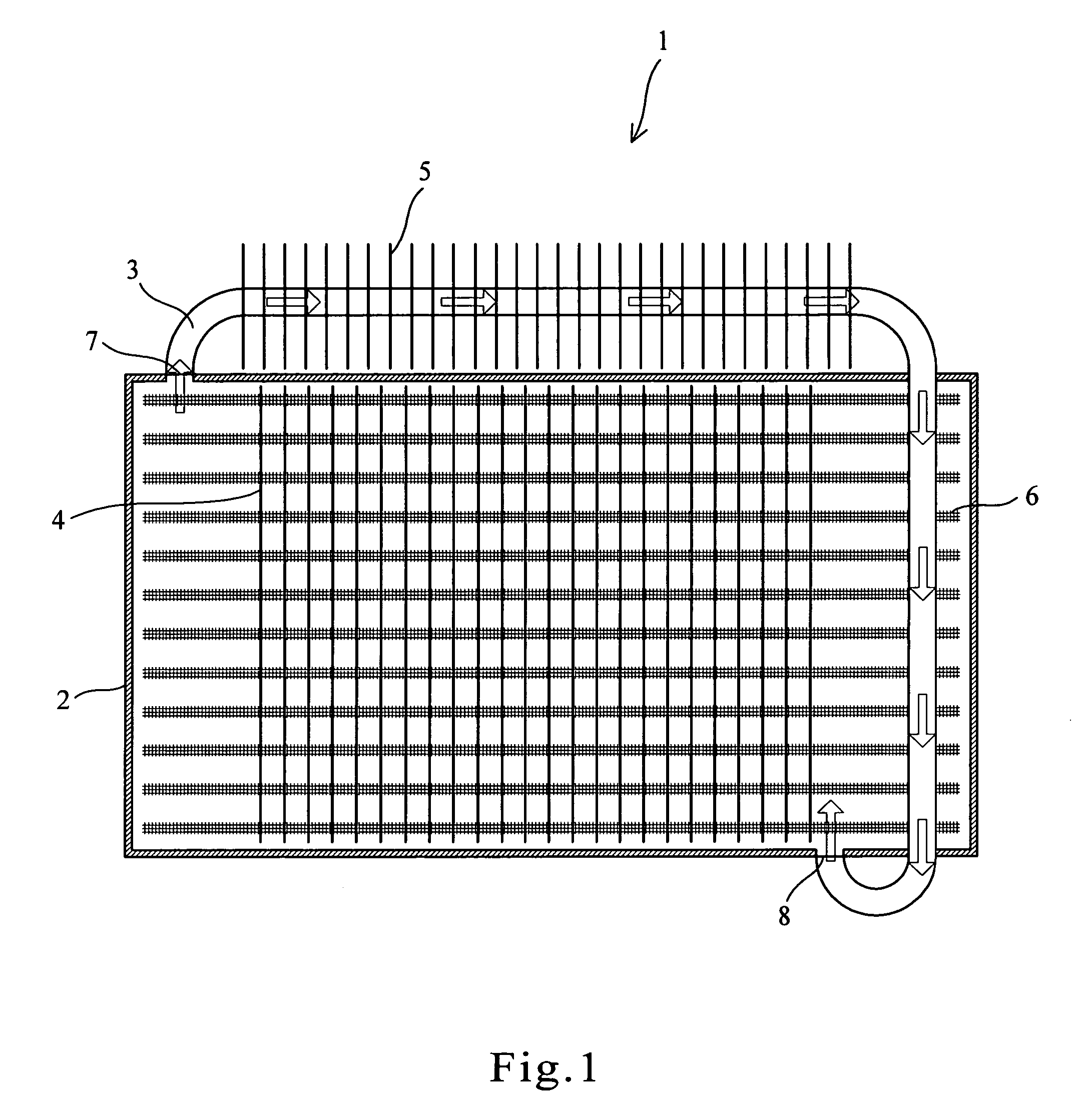

Closed-loop cycling type heat-dissipation apparatus

InactiveUS20060018093A1Improve heat transfer efficiencyLow inner temperatureModifications for standard racks/cabinetsClosed loopEngineering

This invention provides a closed-loop cycling type heat-dissipation apparatus, including at least one metal conduit and plural heat-dissipation fins. Hot air in a housing of a screen module is channeled into the metal conduit through an upper exit of the housing. Heat-dissipation fins attached onto the metal conduit then make heat exchange with atmosphere. The heat of the hot air is dissipated to atmosphere by thermal convection or thermal radiation of surfaces of the heat-dissipation fins. The hot air is cooled down and then channeled into the housing of the screen module through a lower entrance thereof. A closed-loop heat-dissipation cycle is formed. Inner temperature of the housing and temperature difference between inner part and outer part of the housing are effectively lowered. The present apparatus can provide a capability sufficient for heat-dissipation while without the aid of other baggage. The heat-dissipation is relied on nature heat-dissipation cycle in a system and without thermal convection between air in the system and atmosphere.

Owner:METAL INDS RES & DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com